Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208 results about "Partial hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

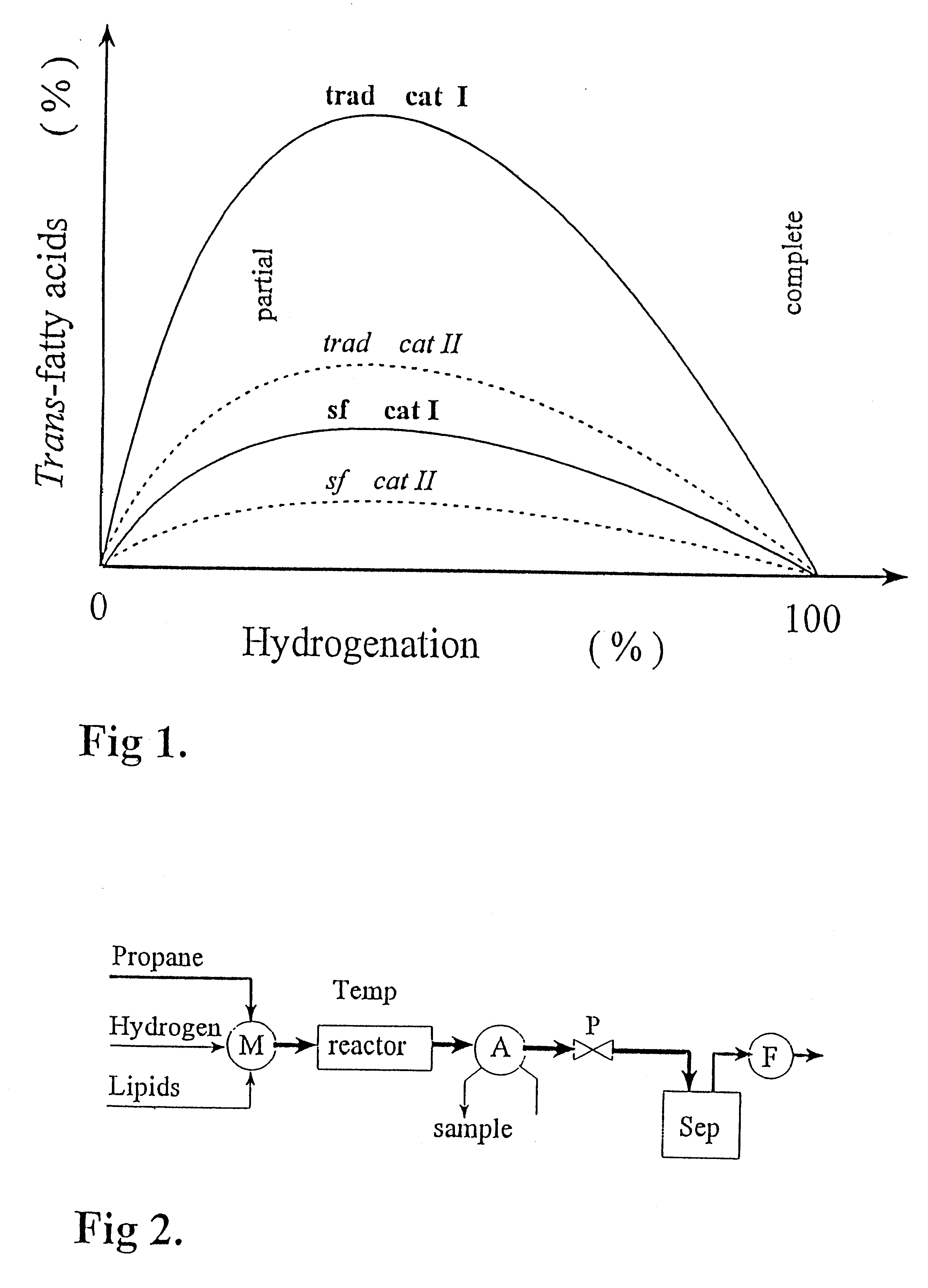

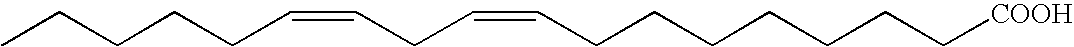

Hydrogenation, complete or partial, is a chemical process in which hydrogen is added to liquid oils to turn them into a solid form. Partially hydrogenated fat molecules have trans fats, and they may be the worst type of fat you can consume.

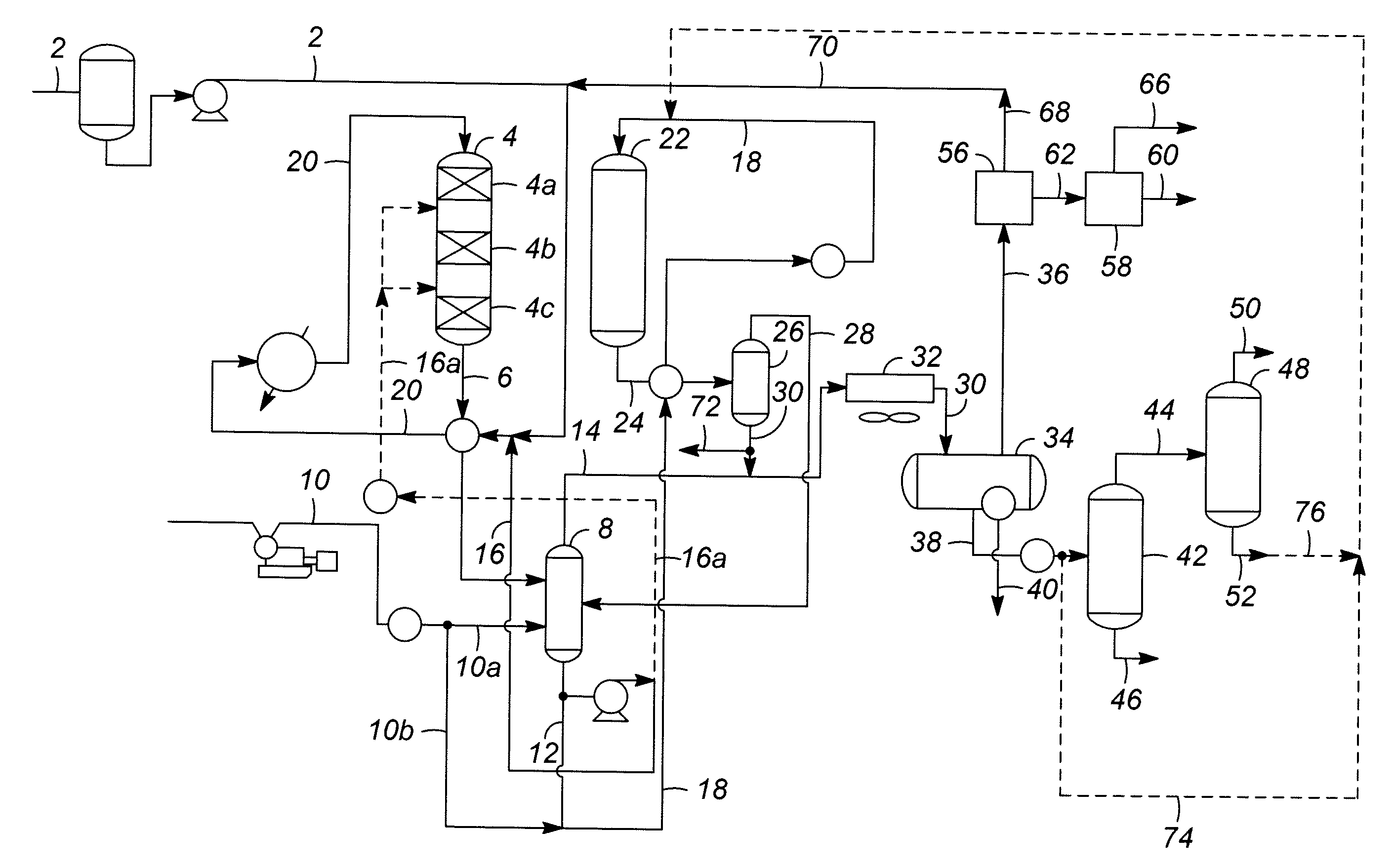

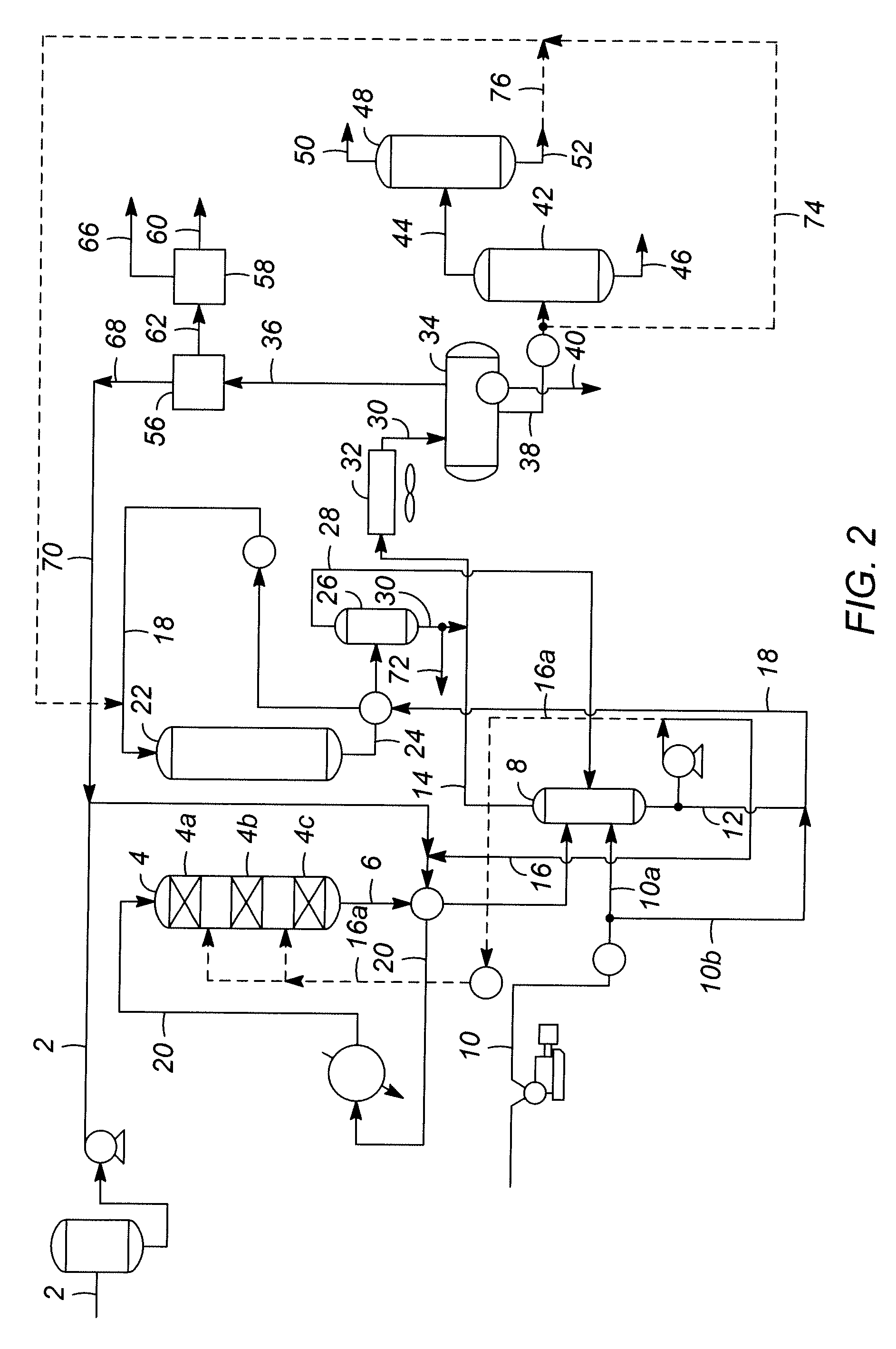

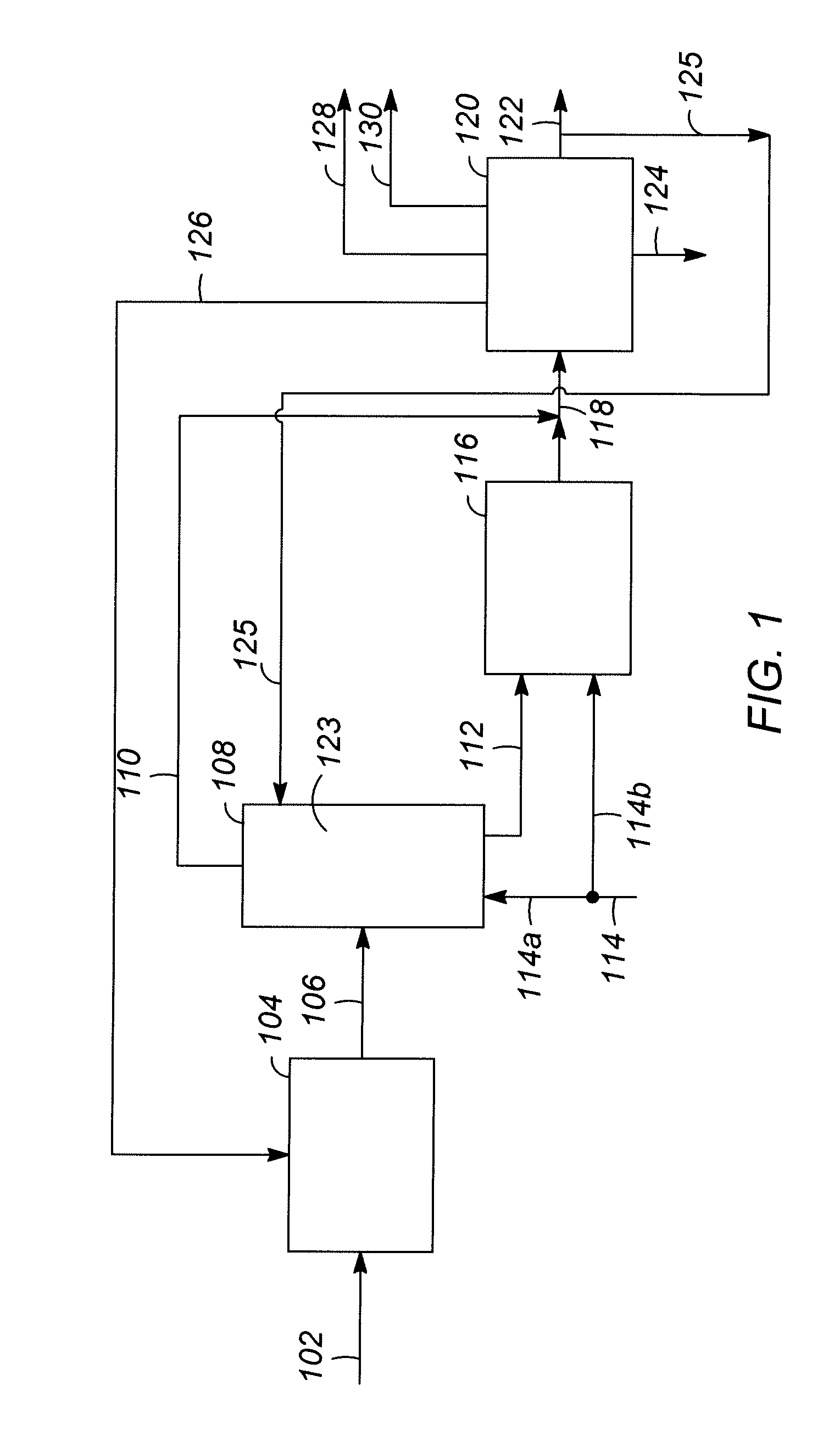

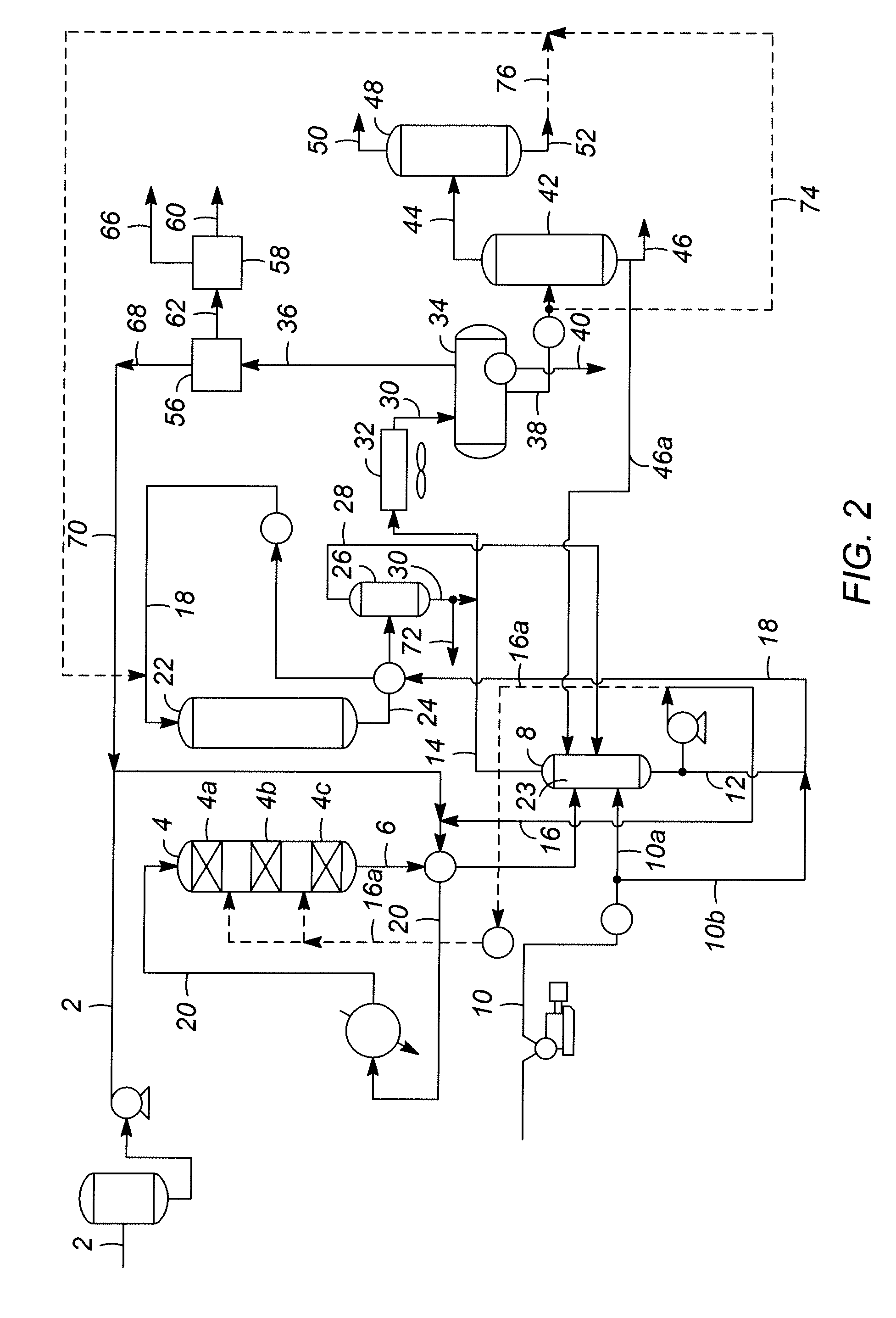

Production of Diesel Fuel from Biorenewable Feedstocks

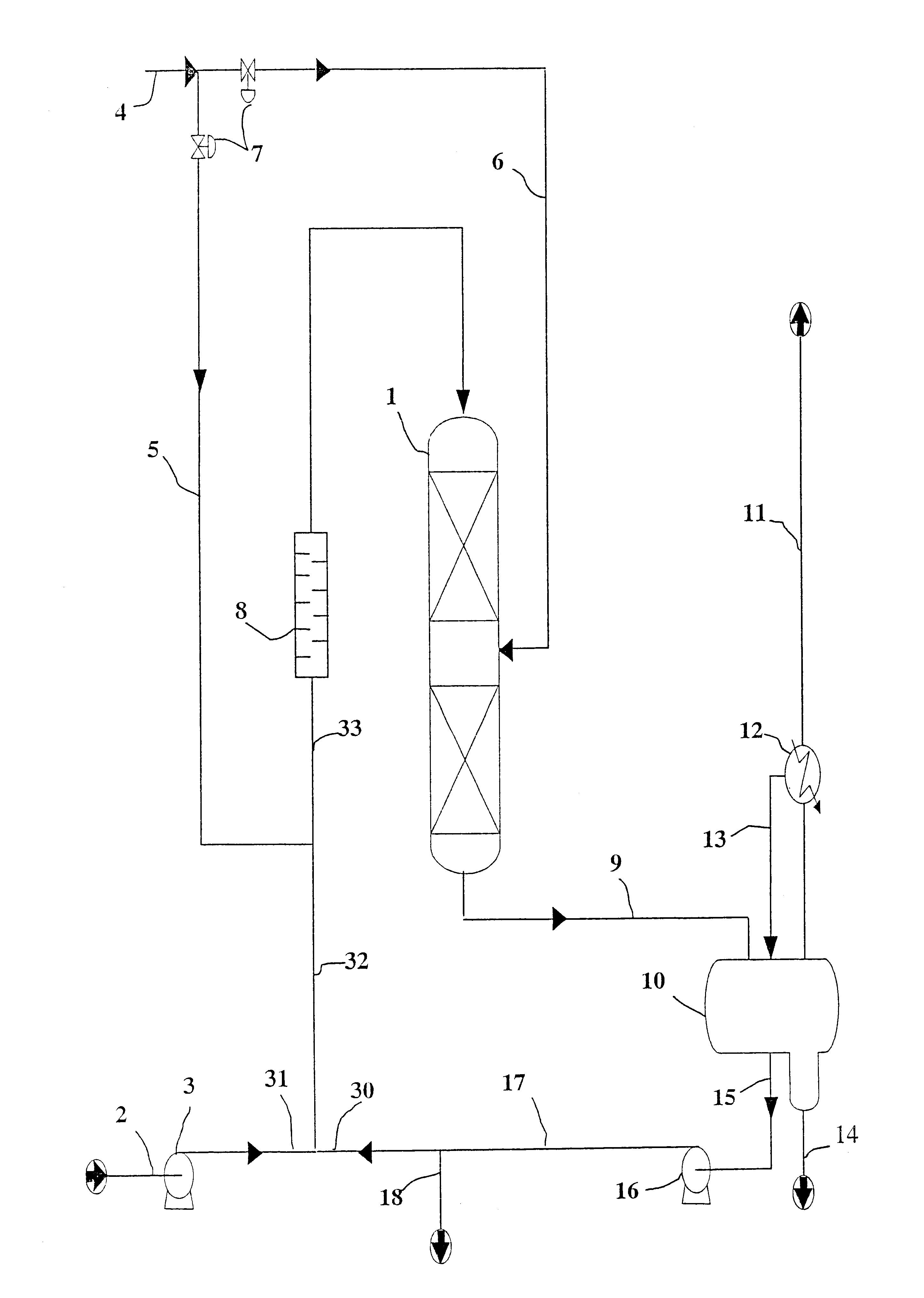

ActiveUS20090077866A1Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationSolubilityHydrogen

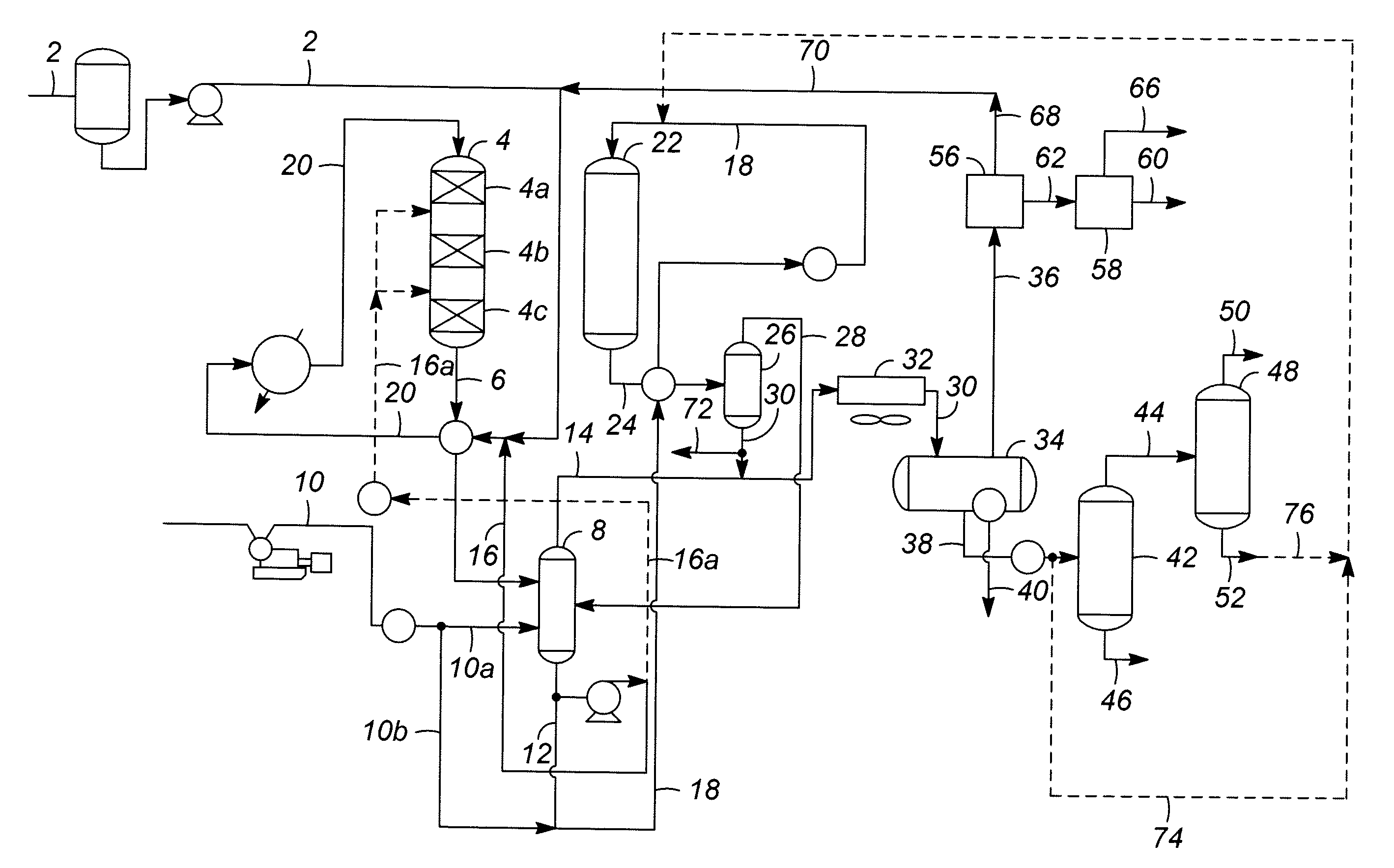

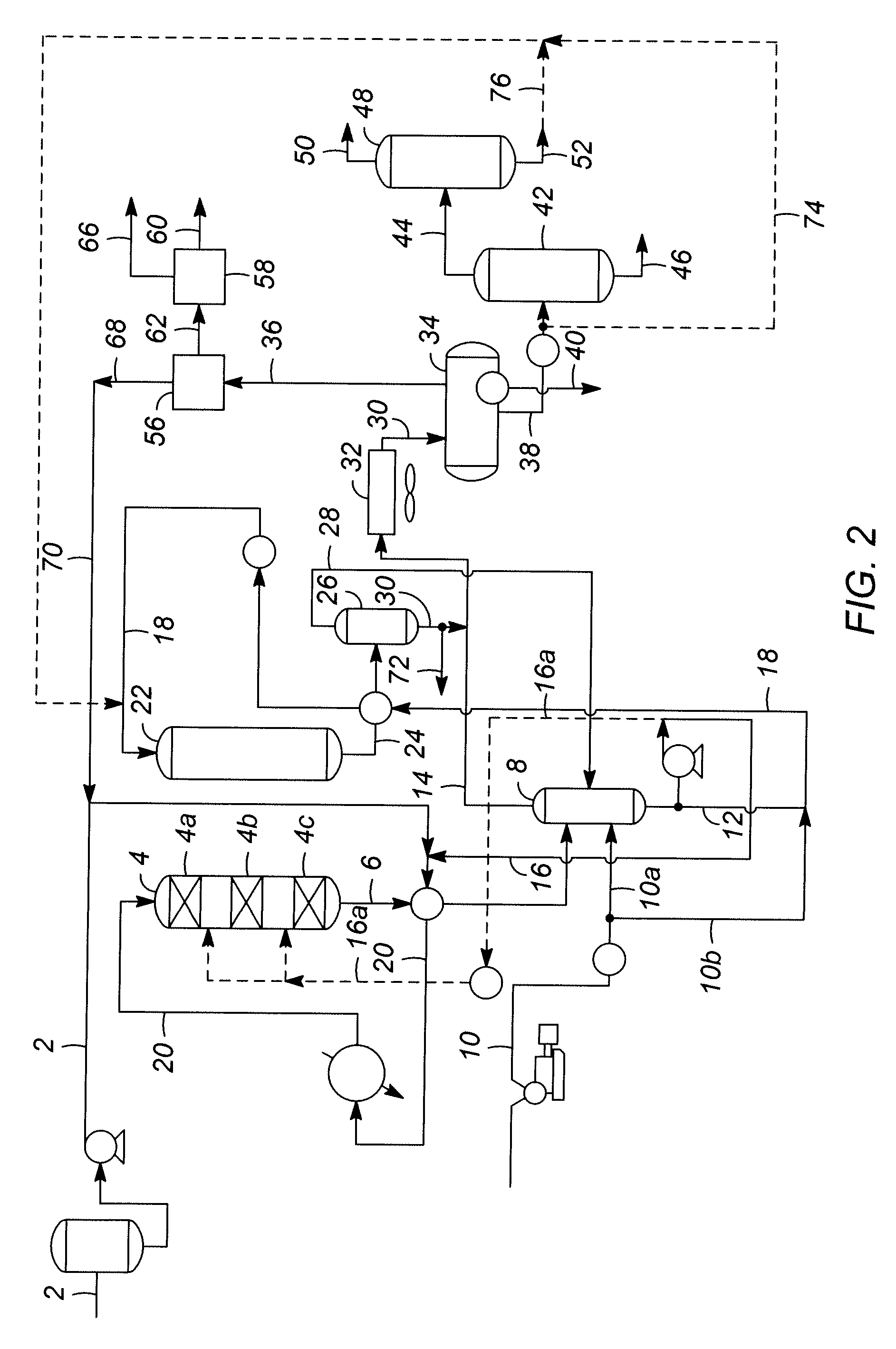

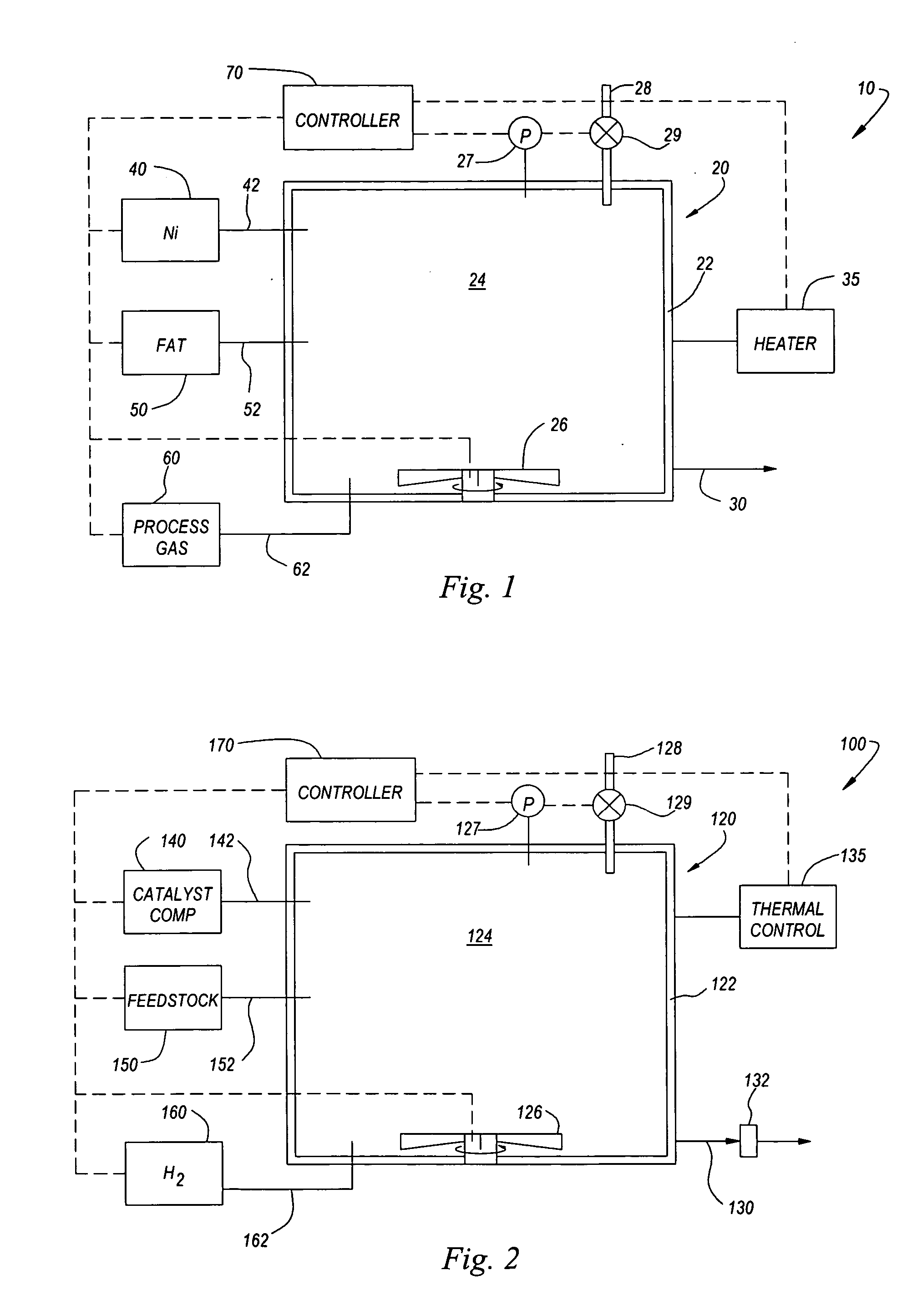

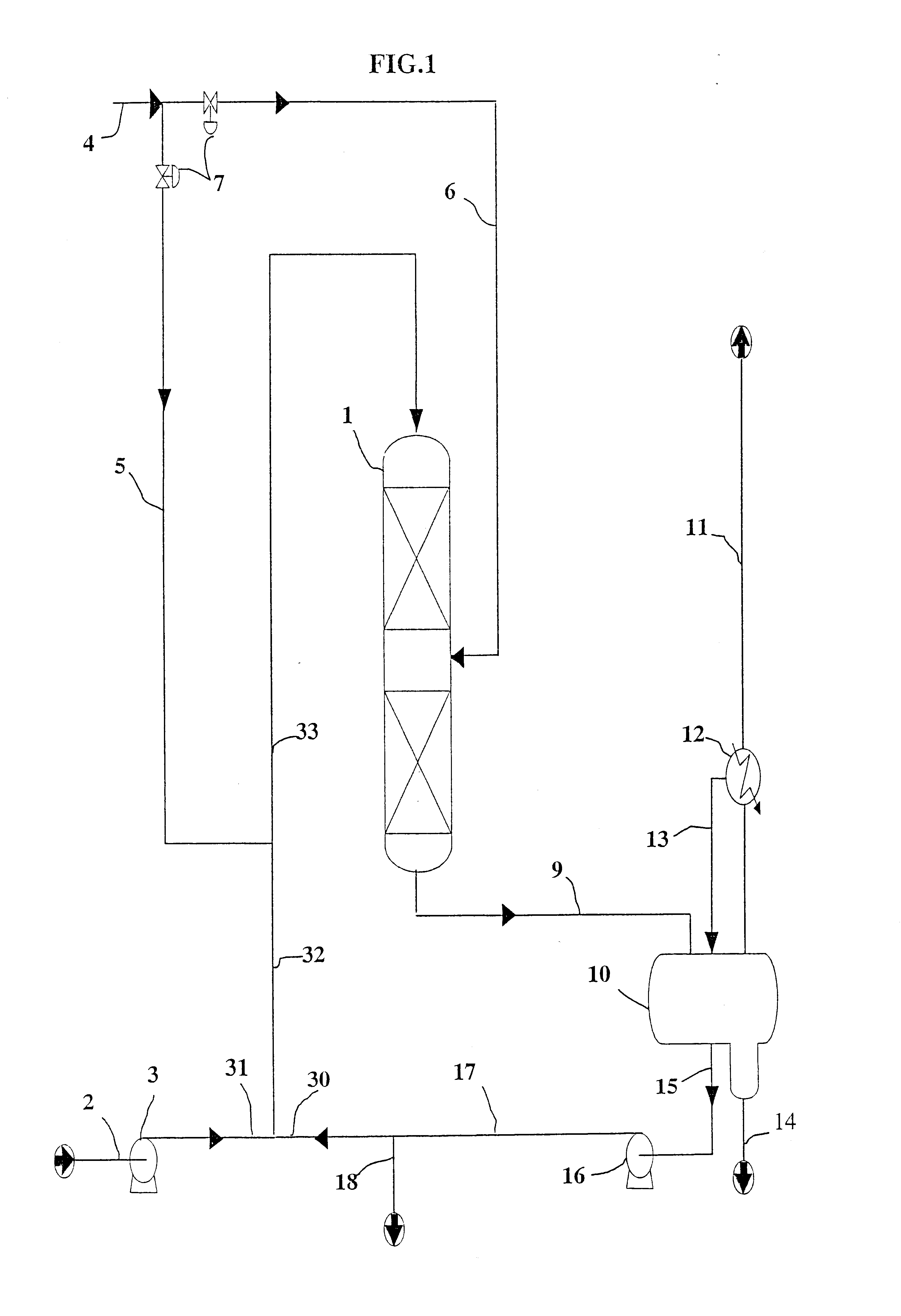

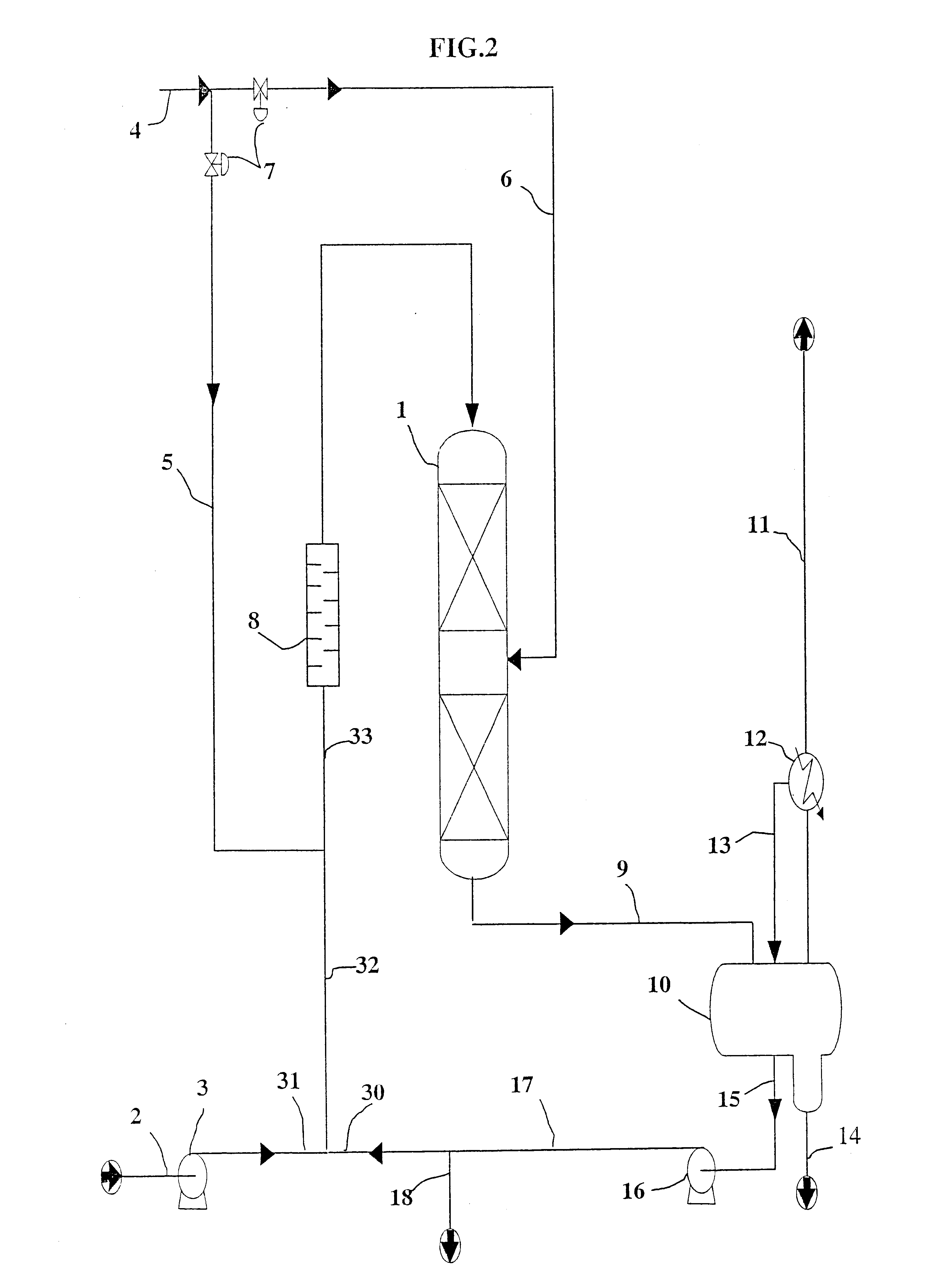

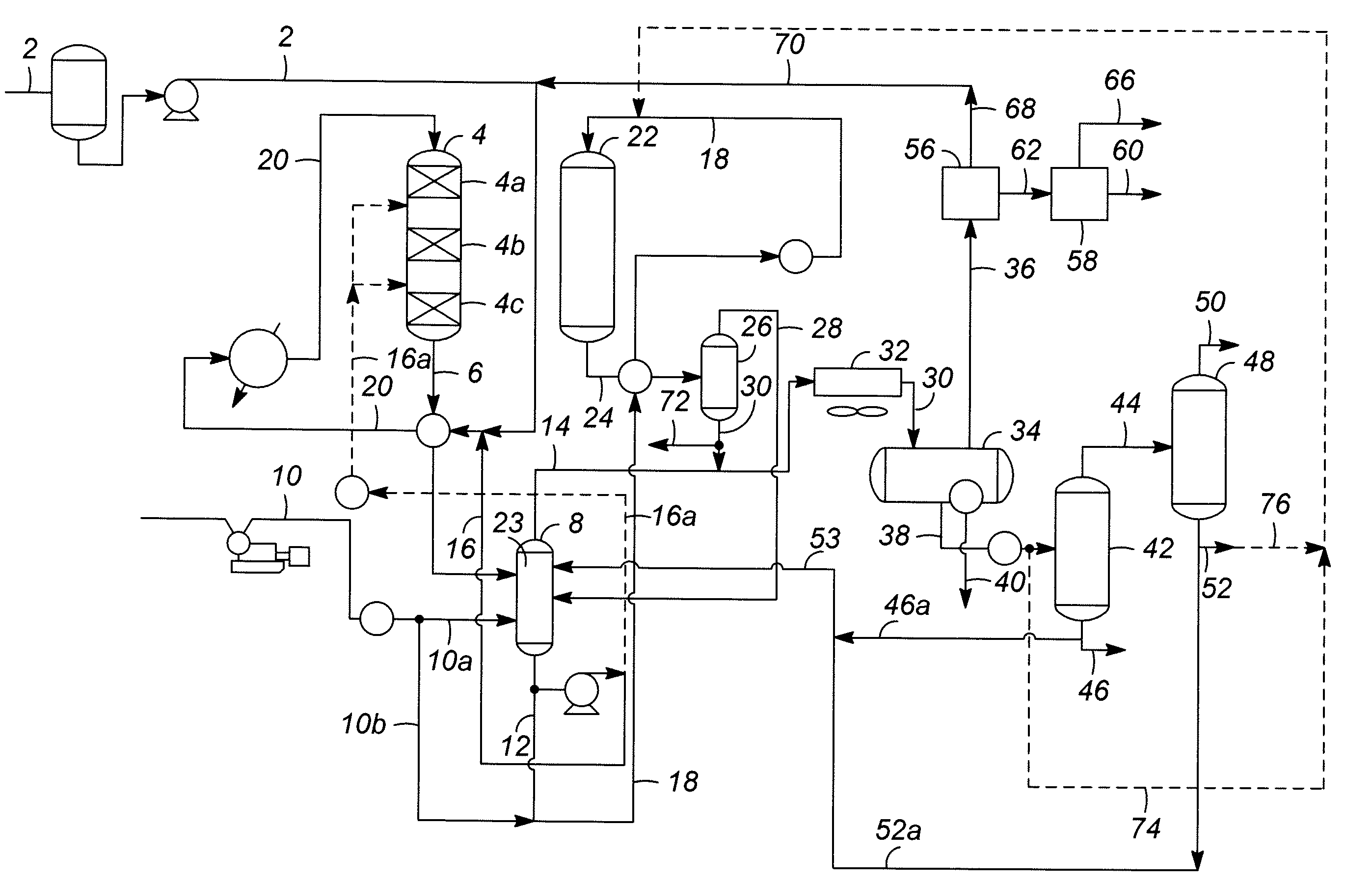

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant oils and animal oils, fats, and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating, decarbonylating, and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel or diesel boiling range fuel blending component. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture.

Owner:UOP LLC

Hydrogenated and partially hydrogenated heat-bodied oils and uses thereof

Owner:ARCHER DANIELS MIDLAND CO

Production of diesel fuel from biorenewable feedstocks

ActiveUS7999142B2Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationSolubilityHydrogen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant oils and animal oils, fats, and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating, decarbonylating, and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel or diesel boiling range fuel blending component. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture.

Owner:UOP LLC

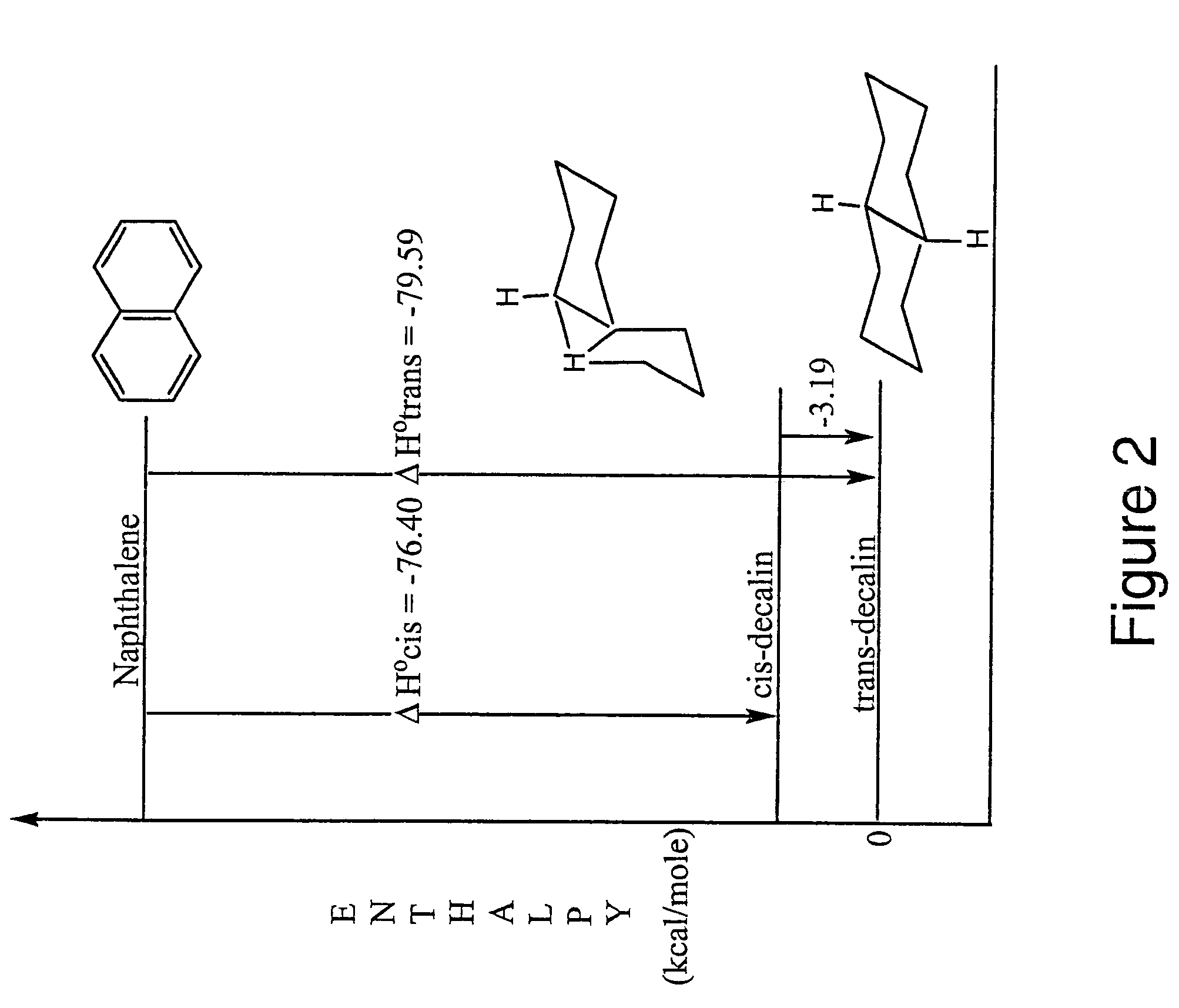

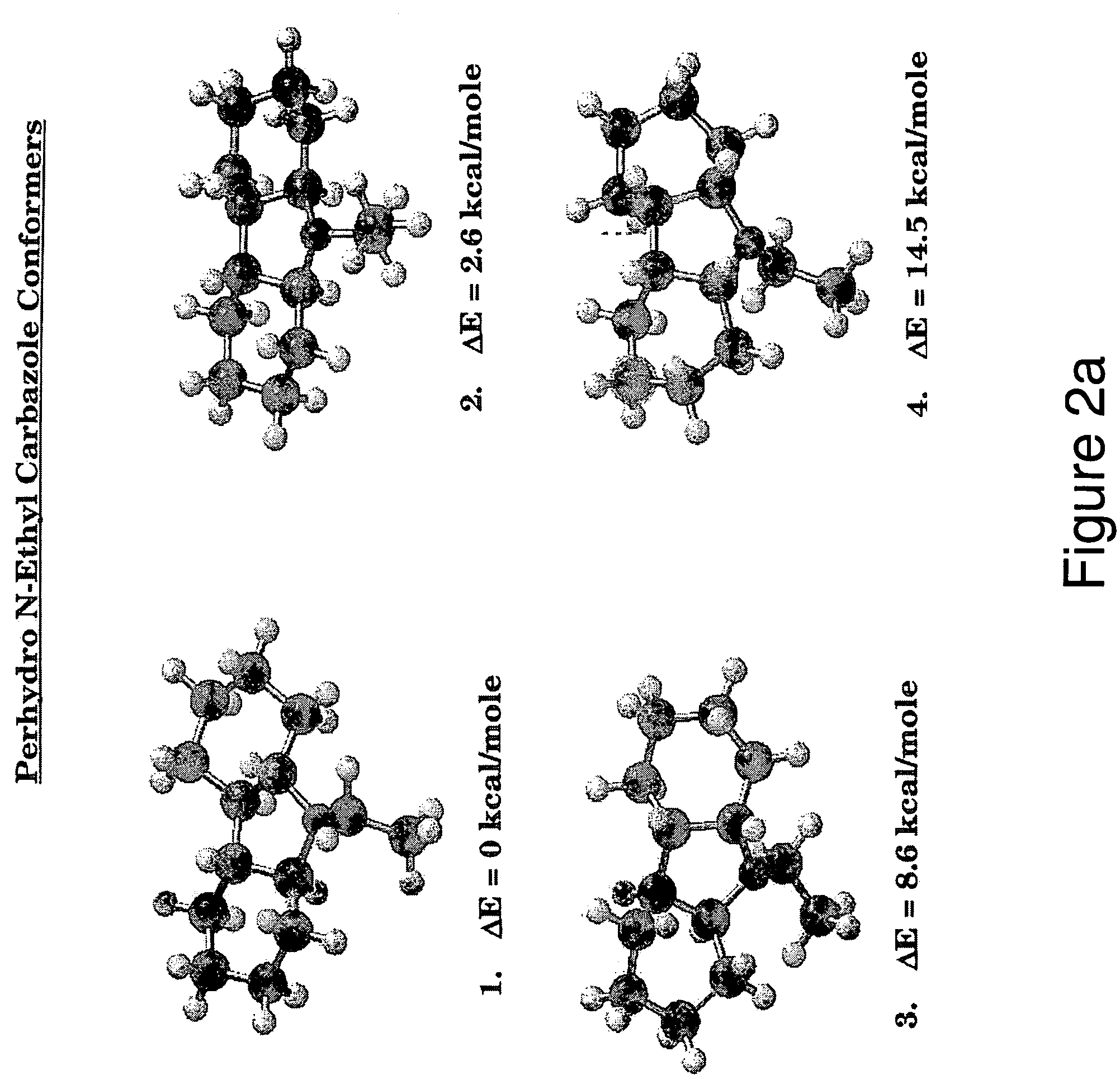

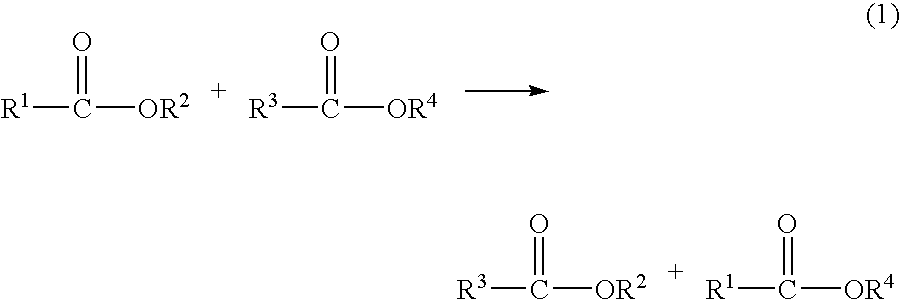

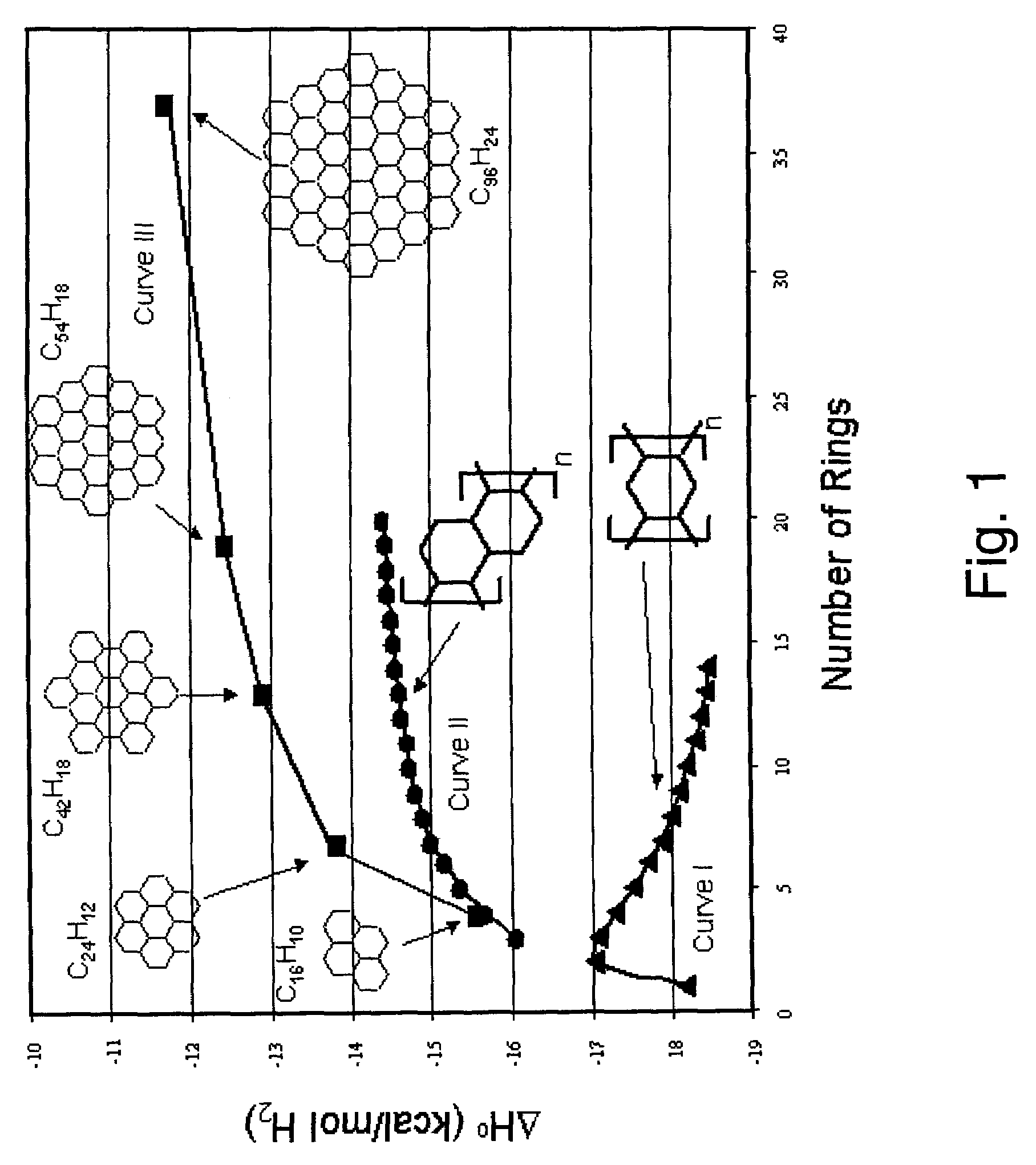

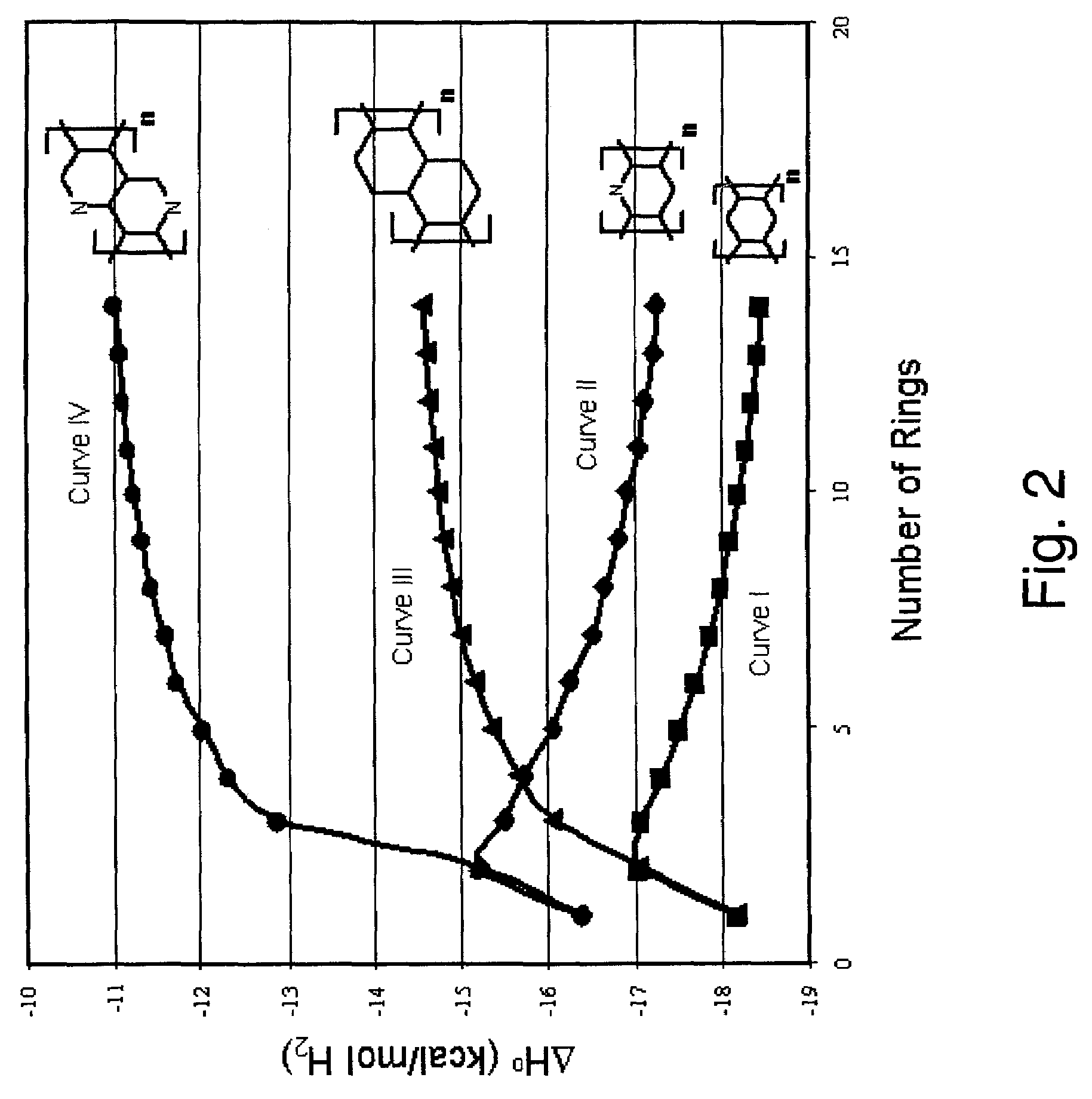

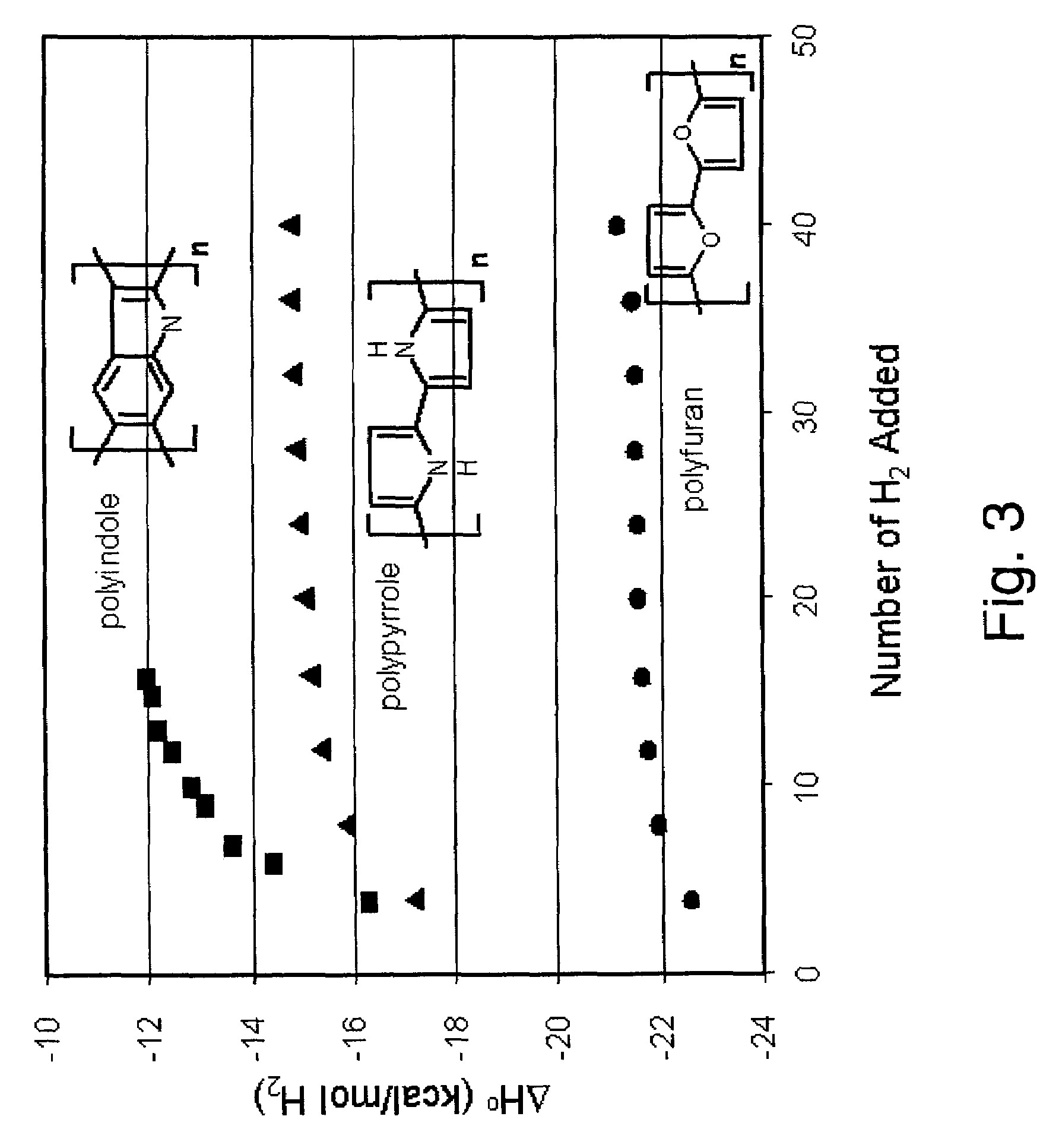

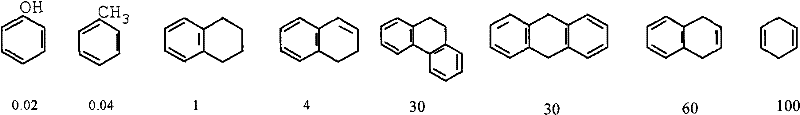

Hydrogen storage by reversible hydrogenation of pi-conjugated substrates

ActiveUS20050002857A1Less energy expenditureEasy to separateCatalytic naphtha reformingVariable capacity gas holdersPartial hydrogenationDehydrogenation

Processes are provided for the storage and release of hydrogen by means of a substantially reversible catalytic hydrogenation of extended pi-conjugated substrates which include large polycyclic aromatic hydrocarbons, polycyclic aromatic hydrocarbons with nitrogen heteroatoms, polycyclic aromatic hydrocarbons with oxygen heteroatoms, polycyclic aromatic hydrocarbons with alkyl, alkoxy, nitrile, ketone, ether or polyether substituents, pi-conjugated molecules comprising 5 membered rings, pi-conjugated molecules comprising six and five membered rings with nitrogen or oxygen hetero atoms, and extended pi-conjugated organic polymers. The hydrogen, contained in the at least partially hydrogenated form of the extended pi-conjugated system, can be facilely released for use by a catalytic dehydrogenation of the latter in the presence of a dehydrogenation catalyst which can be effected by lowering the hydrogen gas pressure, generally to pressures greater than 0.1 bar or raising the temperature to less than 250° C. or less, or by a combination of these two process parameters.

Owner:AIR PROD & CHEM INC

Polyketone Plasticizers

InactiveUS20080242895A1Remove colorEasy to separateOrganic compound preparationCarbonyl compound preparation by oxidationPolymer sciencePlasticizer

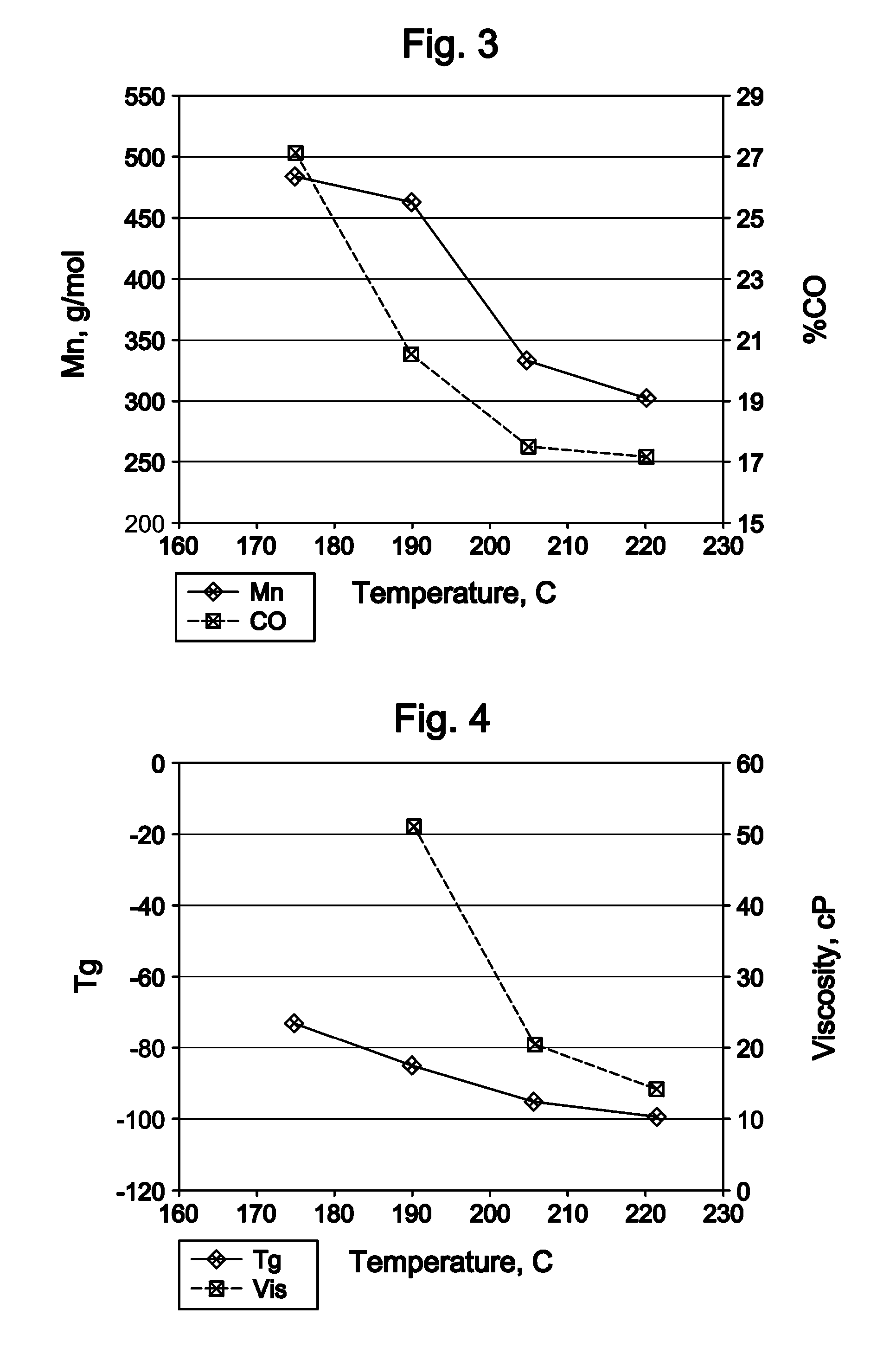

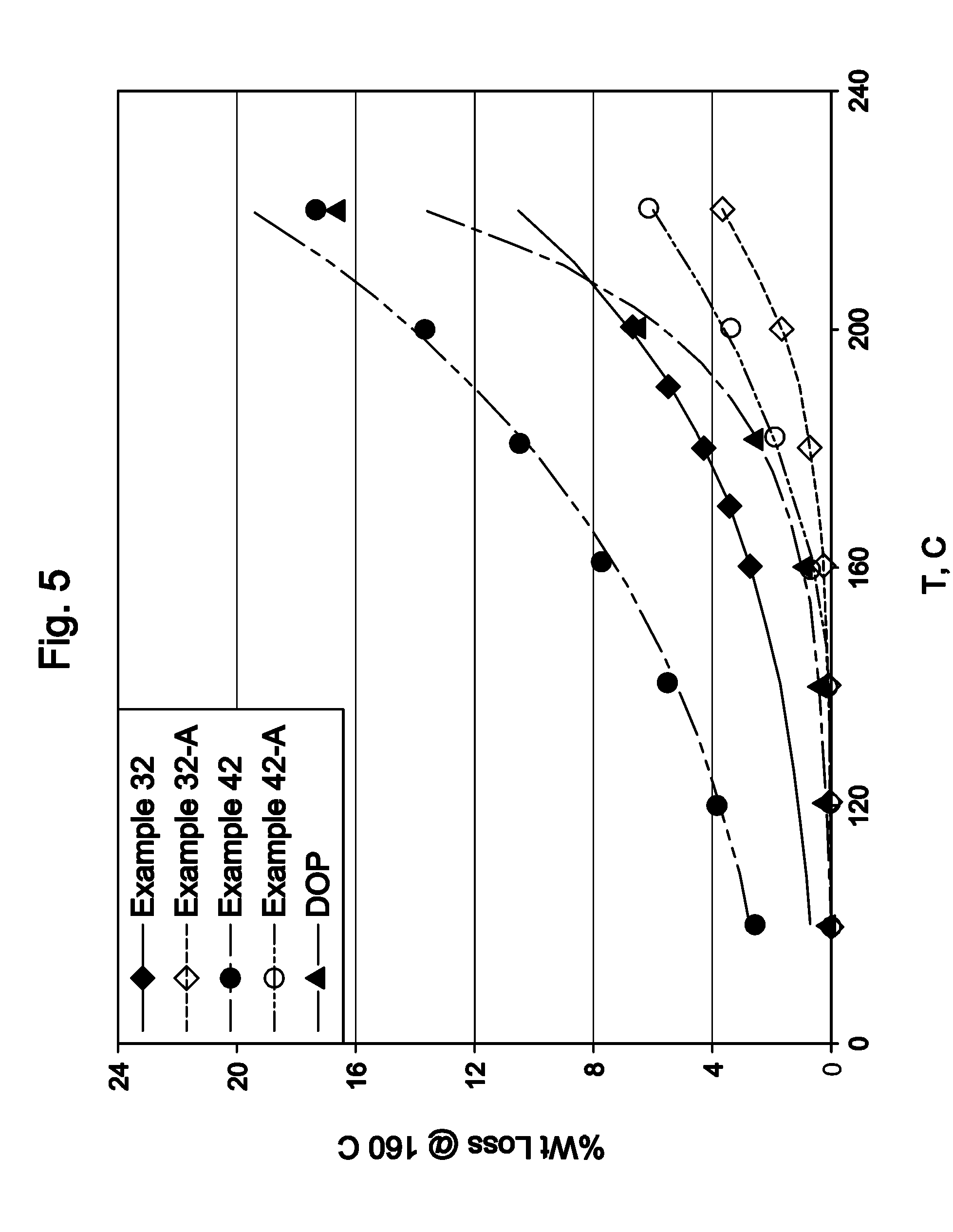

The invention relates to polyketone compounds and the at least partially hydrogenated products thereof, the use of said polyketone compounds and / or the at least partially hydrogenated products thereof as plasticizers, processes of making polyketone compounds and the at least partially hydrogenated products thereof, compositions comprising the polyketone compounds and / or the at least partially hydrogenated products thereof, and to articles formed from products of the invention.

Owner:EXXONMOBIL CHEM PAT INC

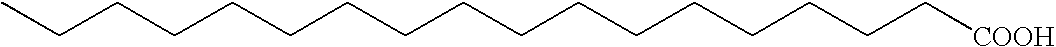

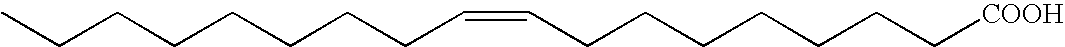

Elimination of trans-unsaturated fatty acid compounds by selective adsorption with zeolites

InactiveUS6229032B1Low yieldLow costFatty oils/acids recovery from wasteFatty acid hydrogenationPartial hydrogenationDouble bond

A novel process for the selective elimination of fatty acid compounds containing carbon-carbon double bonds in trans configuration from a substrate containing cis- and trans-isomers of said fatty acid compounds, by selective adsorption by a microporous zeolite material is disclosed. The pore size and shape of usable zeolite materials enable differentiation between cis- and trans-isomers of unsaturated fatty acid chains. The zeolite materials used have a selectivity ratio alphatrans / cis higher than 1.00; this ratio is defined based on the elution properties of cis and trans double bond containing fatty acid methylesters dissolved in n-hexane during a column chromatography experiment with the zeolite material as the stationary phase and n-hexane as the mobile phase. Besides selective adsorption of trans-unsaturated fatty acid compounds, simultaneous or subsequent total or partial hydrogenation of the double bonds in said compounds can be carried out while using the same or similar zeolite material, containing finely dispersed catalytic active metals. The majority of these catalytic active sites must be inside the pores.

Owner:K U LEUVEN RES & DEV

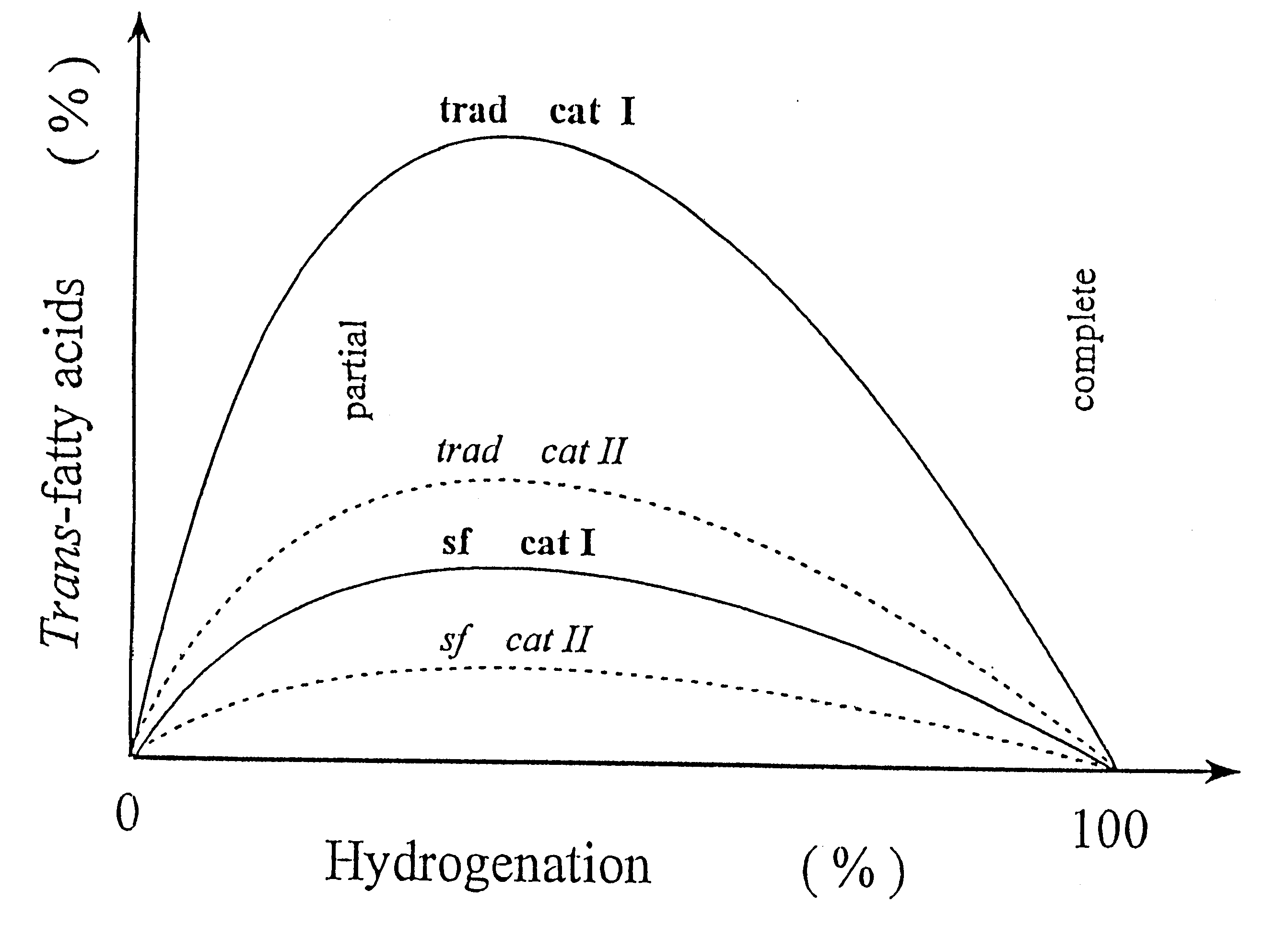

Low trans-fatty acid fat compositions; low-temperature hydrogenation, e.g., of edible oils

InactiveUS20050027136A1Fatty acid hydrogenationOrganic compound preparationPartial hydrogenationHydrogenation reaction

The present disclosure provides low trans-fatty acid fat compositions, methods of hydrogenating unsaturated feedstocks (e.g., oils), and hydrogenation catalyst compositions. One exemplary method involves producing an activated catalyst composition by heating a nickel-based catalyst to a first temperature of at least about 100° C. in the presence of hydrogen and a fat component. An unsaturated feedstock may be contacted with the activated catalyst composition and hydrogenated by sustaining a hydrogenation reaction at a second temperature of no greater than about 70° C. Some specific implementations of the invention permit the production of partially hydrogenated seed oils with low trans-fatty acid contents.

Owner:CARGILL INC

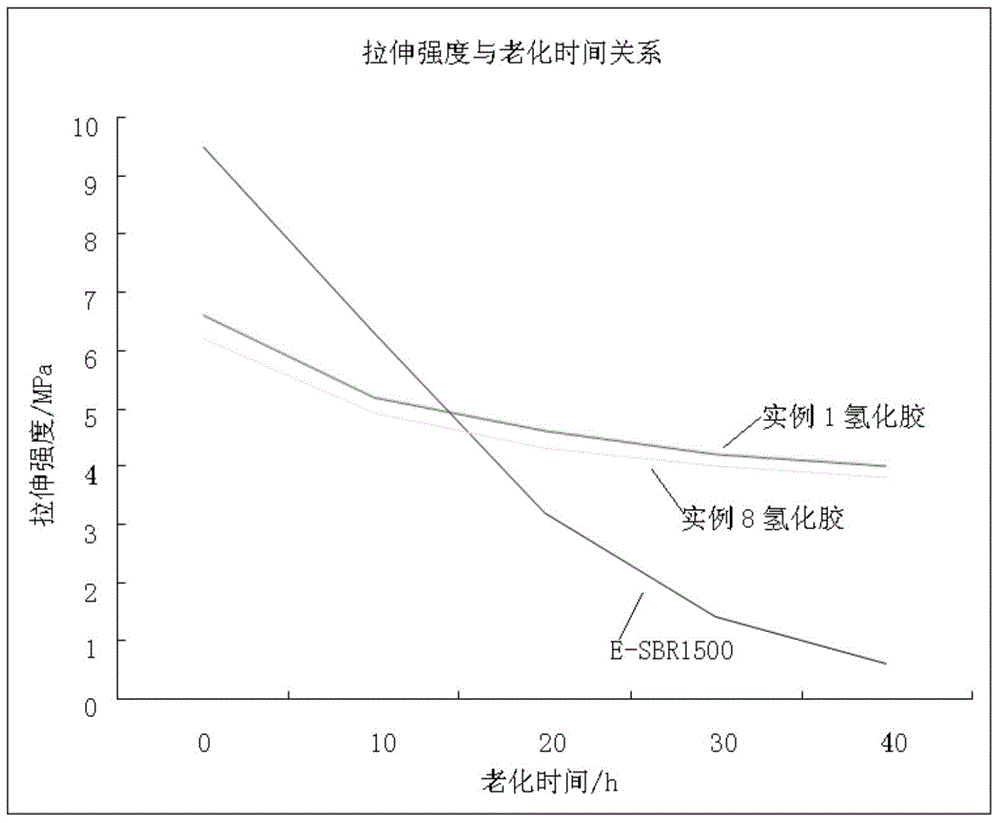

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

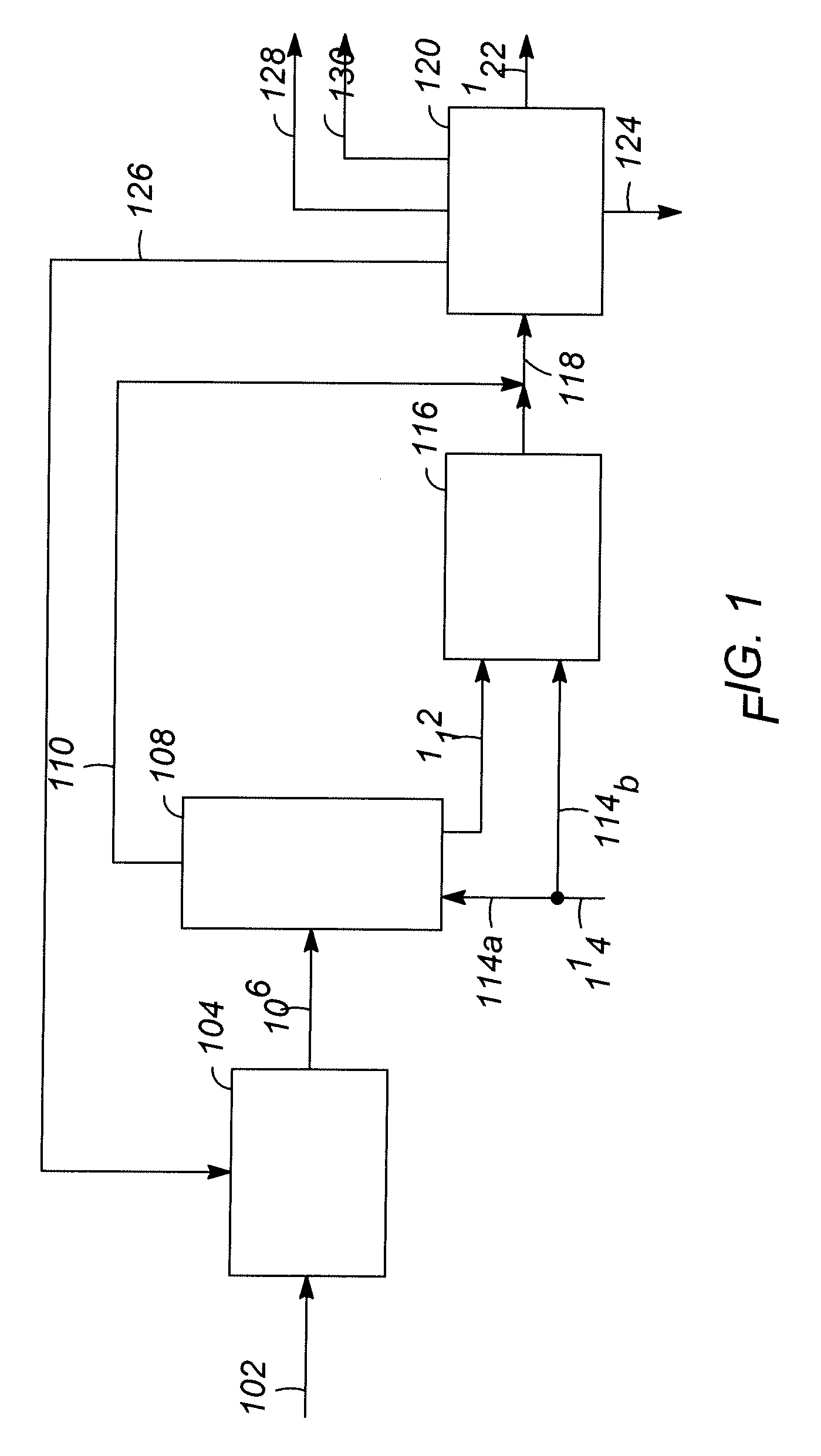

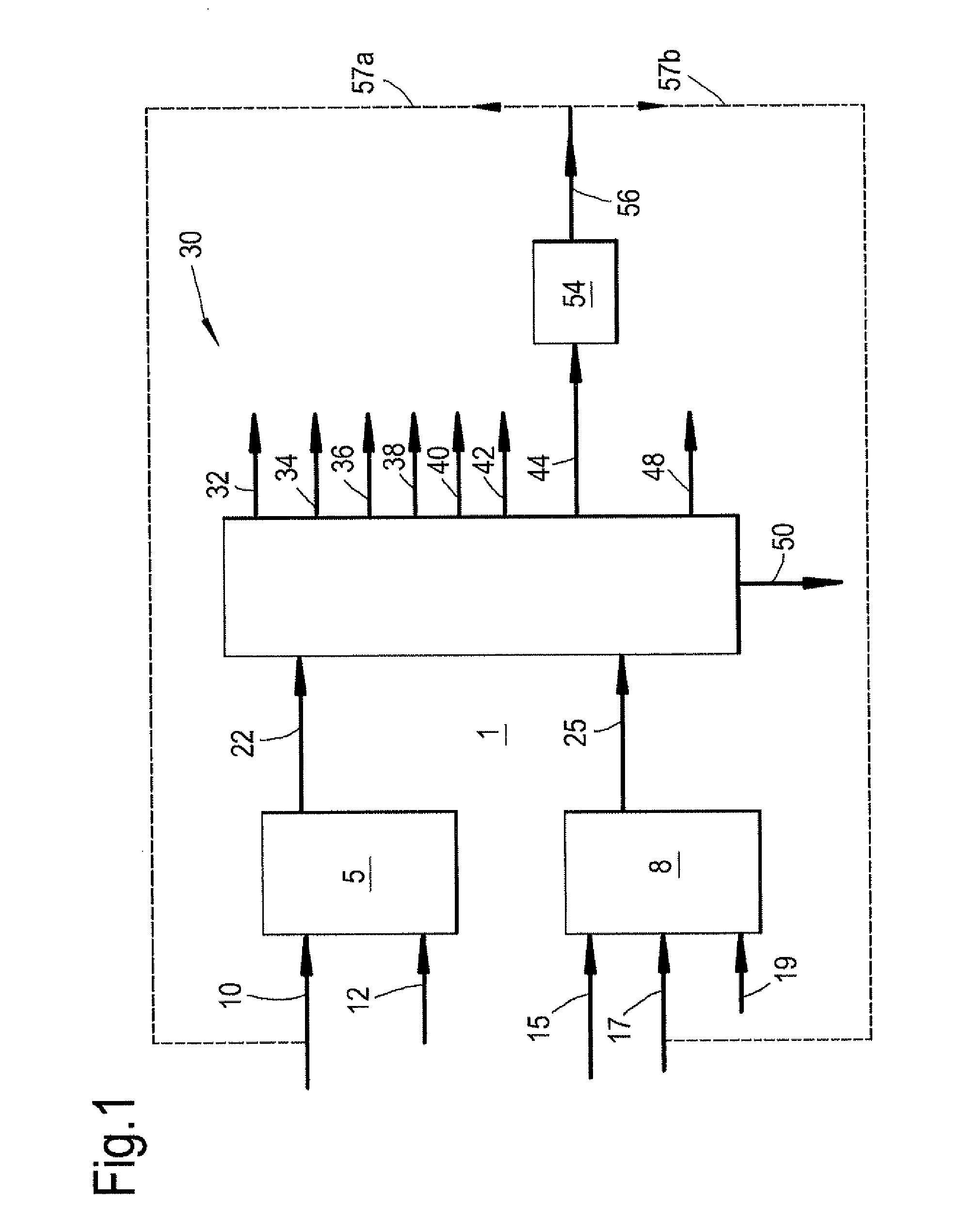

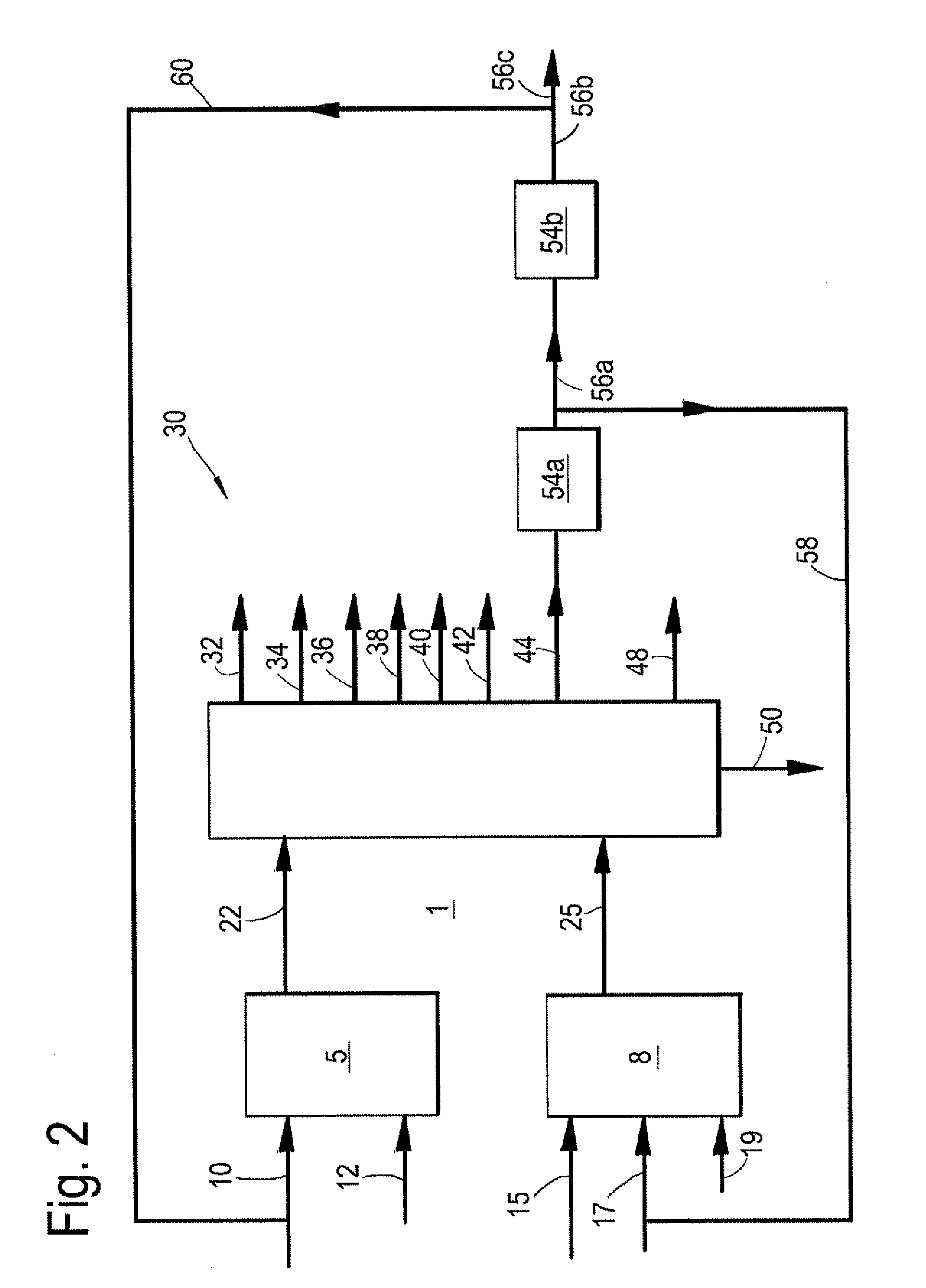

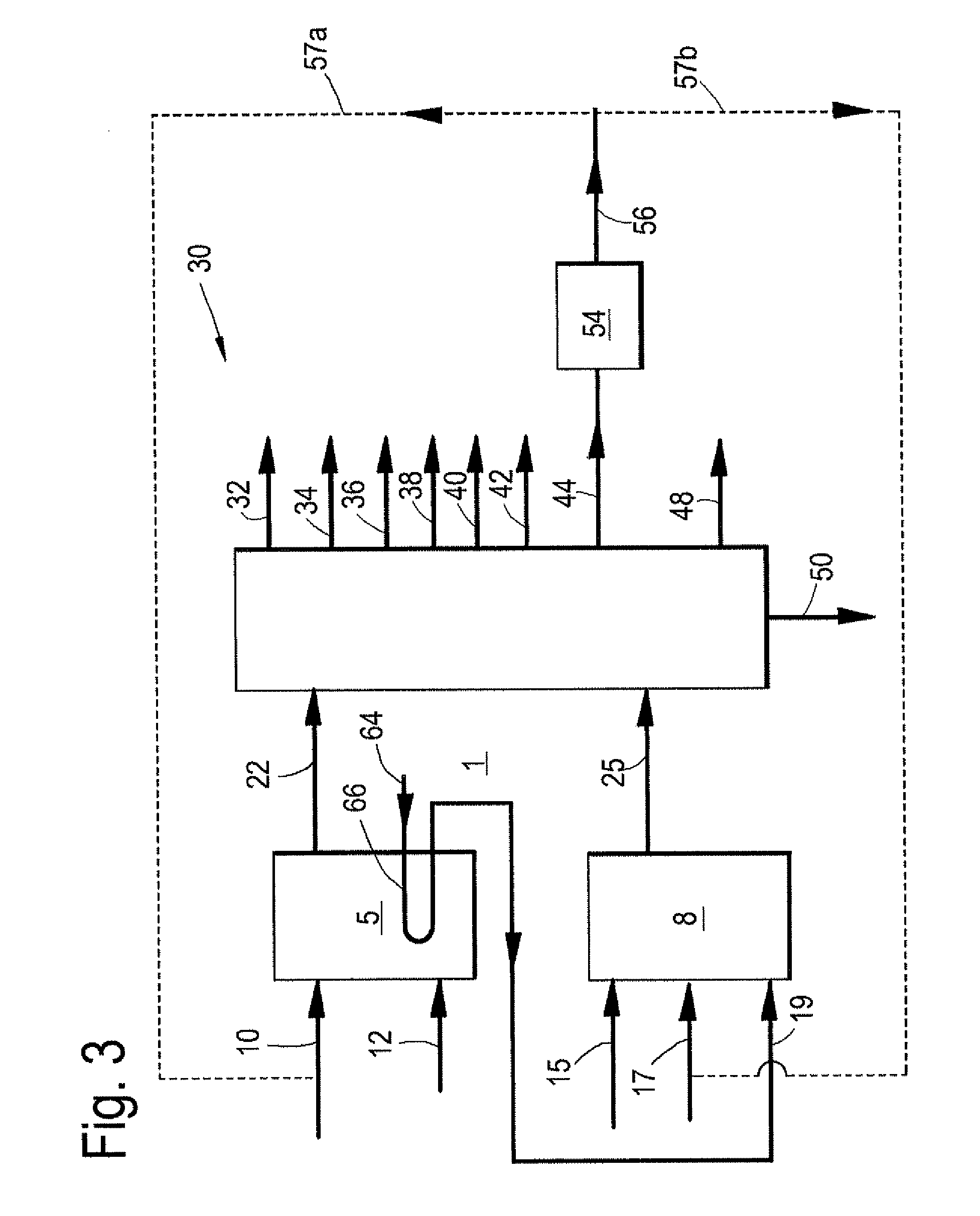

Process and integrated system for the preparation of a lower olefin product

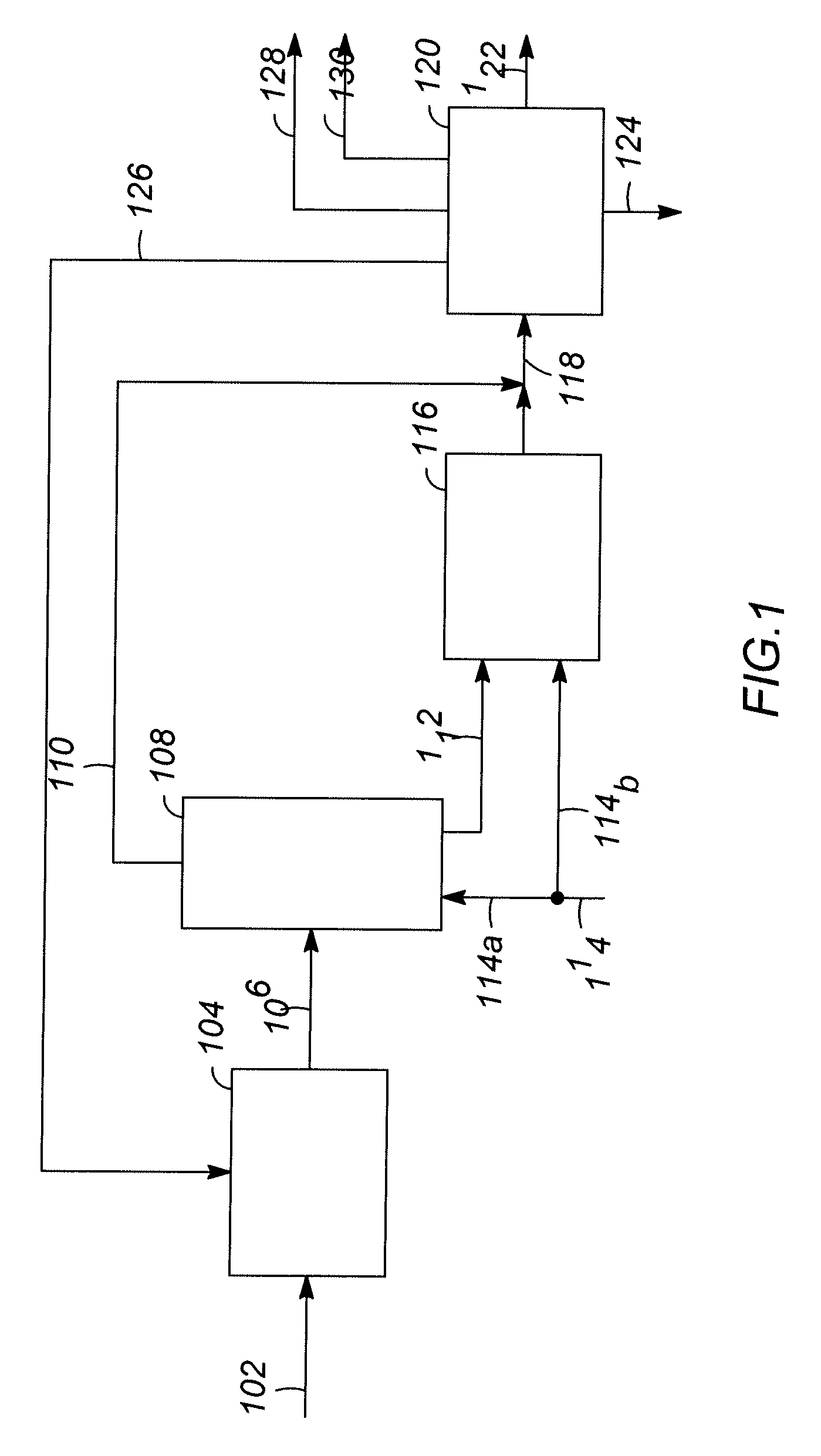

InactiveUS20110112344A1High conversion of feedstockOptimize allocationThermal non-catalytic crackingHydrogenChemistryEffluent

A process for the preparation of an olefin product comprising ethylene and / or propylene, which process comprises the steps ofa) cracking a paraffin feedstock comprising C2-C5 paraffins under cracking conditions in a cracking zone to obtain a cracker effluent comprising olefins;b) converting an oxygenate feedstock in an oxygenate-to-olefins conversion system, comprising a reaction zone in which an oxygenate feedstock is contacted with an oxygenate conversion catalyst under oxygenate conversion conditions, to obtain a conversion effluent comprising ethylene and / or propylene;c) combining at least part of the cracker effluent and at least part of the conversion effluent to obtain a combined effluent, and separating an olefin product stream comprising ethylene and / or propylene from the combined effluent, wherein the cracker effluent and / or the conversion effluent comprises a C4 portion comprising unsaturates, and wherein the process further comprises at least partially hydrogenating at least part of the C4 portion, to obtain an at least partially hydrogenated C4 feedstock; and recycling at least part of the at least partially hydrogenated C4 feedstock as recycle feedstock to step a) and / or step b), and an integrated system for performing the process.

Owner:SHELL OIL CO

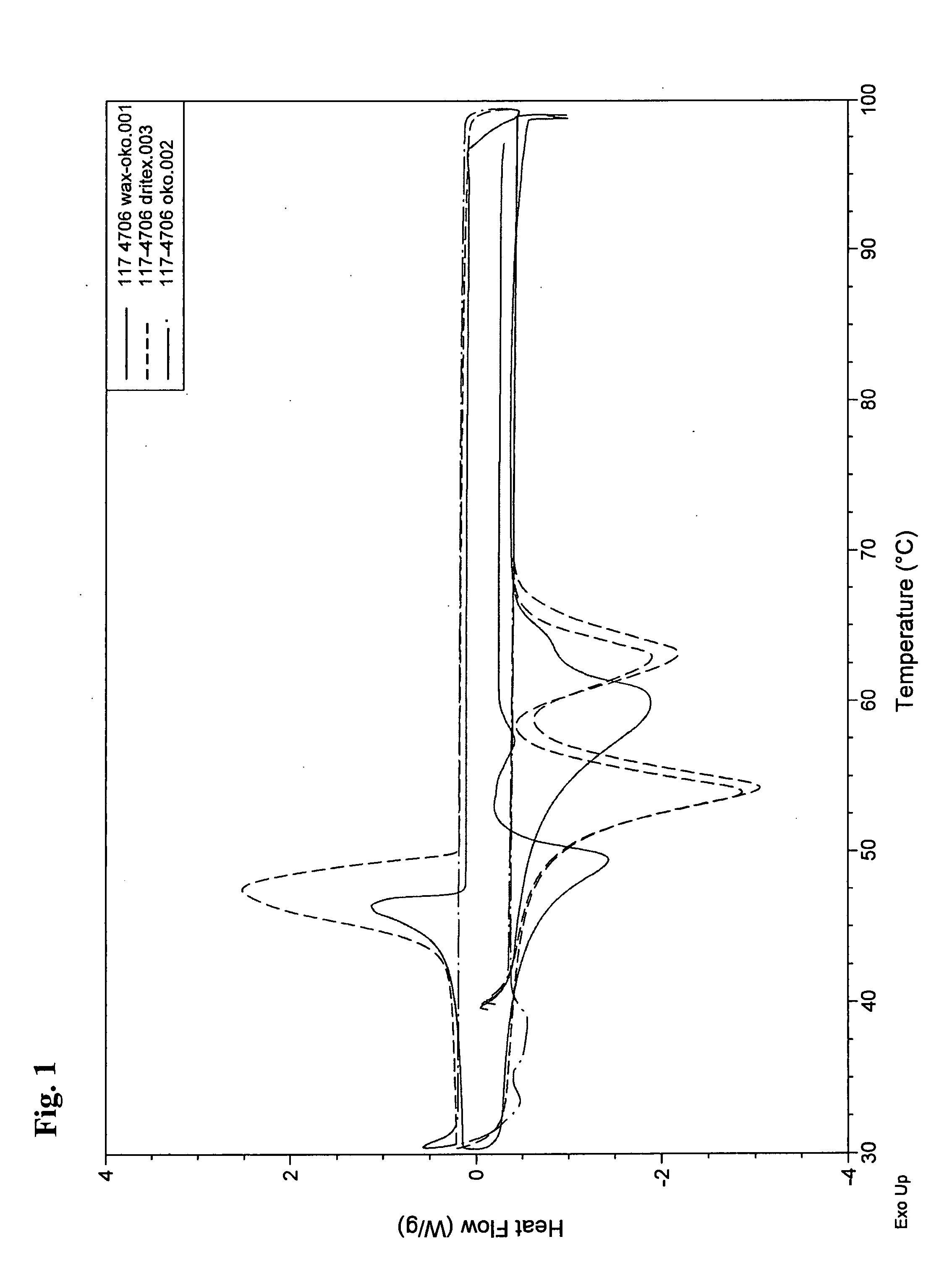

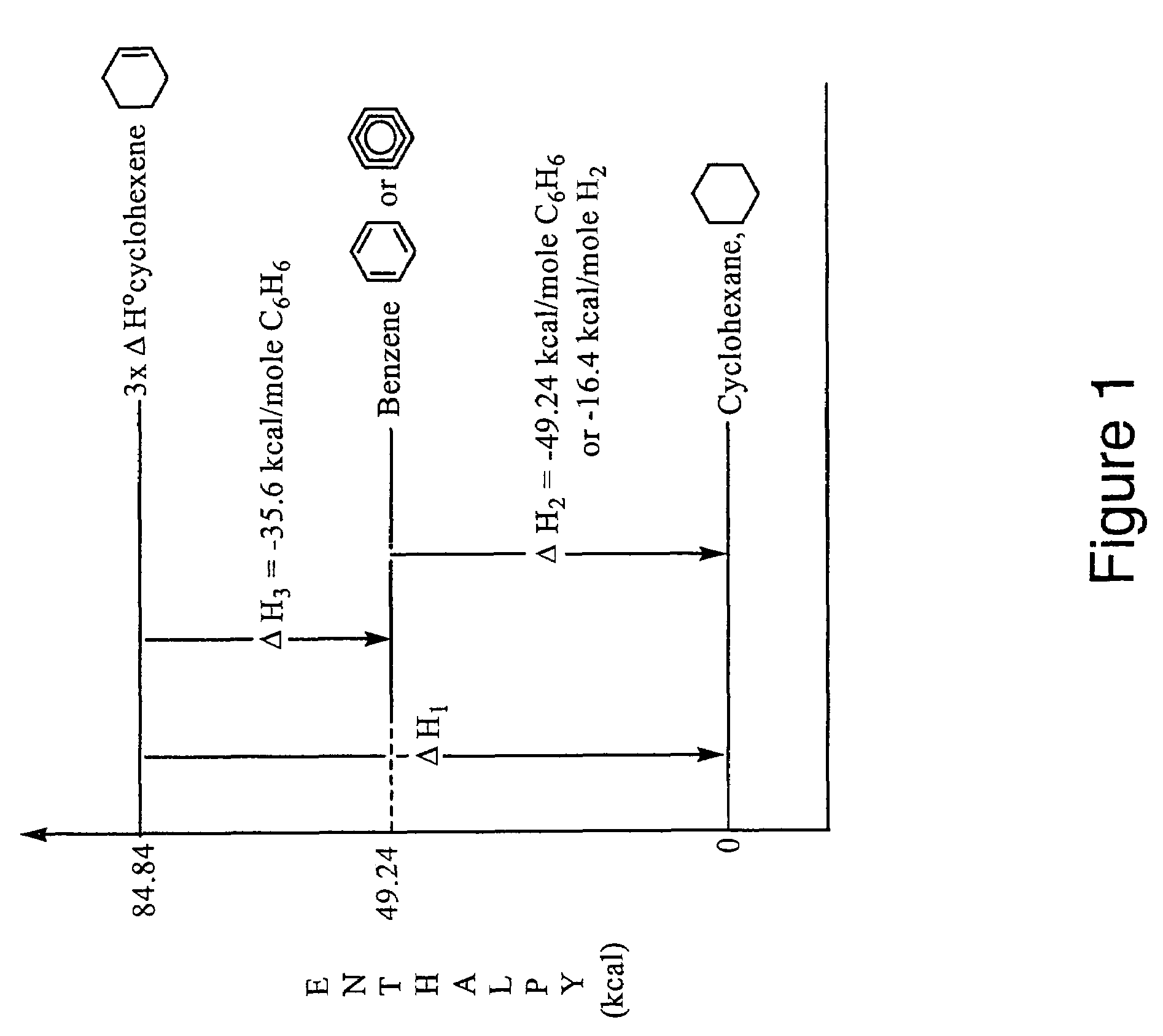

Partially hydrogenated fatty substances with a low content of trans fatty acids

A partially hydrogenated fatty substance produced by partial hydrogenation of a substrate, such as vegetable, animal or marine oil, said partially hydrogenated substance having a low content of trans fatty acids. When the hydrogenation degree is below 30% the trans-fatty acid concentration can be expressed in the following way: trans<=0.3x(initial IV-IV) in %. of the total amount of fatty acids, wherein IV refers to iodine value. When the hydrogenation degree is between 30 and 70% the trans-fatty acid concentration can be expressed with: trans<=0.09xinitial IV in % of the total amount of fatty acids. The partial hydrogenation is performed by a process in which the substrate, hydrogen gas and a solvent are mixed, and the whole mixture is brought into a supercritical or near-critical state. This substantially homogeneous super-critical or near-critical solution is led over the catalyst, whereby the reaction products formed, i.e. the hydrogenated substrates, will also be a part of the substantially homogeneous super-critical or near-critical solution.

Owner:POUL MOLLER LEDELSES OG INGENIORRADGIVNING APS

Hydrogen storage by reversible hydrogenation of pi-conjugated substrates

InactiveUS7351395B1Easily reversibleNot volatileMultiple metal hydridesHydrogen productionPartial hydrogenationDehydrogenation

Processes are provided for the storage and release of hydrogen by means of a substantially reversible catalytic hydrogenation of extended pi-conjugated substrates which include large polycyclic aromatic hydrocarbons, polycyclic aromatic hydrocarbons with nitrogen heteroatoms, polycyclic aromatic hydrocarbons with oxygen heteroatoms, polycyclic aromatic hydrocarbons with alkyl, alkoxy, nitrile, ketone, ether or polyether substituents, pi-conjugated molecules comprising 5 membered rings, pi-conjugated molecules comprising six and five membered rings with nitrogen or oxygen hetero atoms, and extended pi-conjugated organic polymers. The hydrogen, contained in the at least partially hydrogenated form of the extended pi-conjugated system, can be facilely released for use by a catalytic dehydrogenation of the latter in the presence of a dehydrogenation catalyst which can be effected by lowering the hydrogen gas pressure, generally to pressures greater than 0.1 bar or raising the temperature to less than 250° C. or less, or by a combination of these two process parameters.

Owner:AIR PROD & CHEM INC

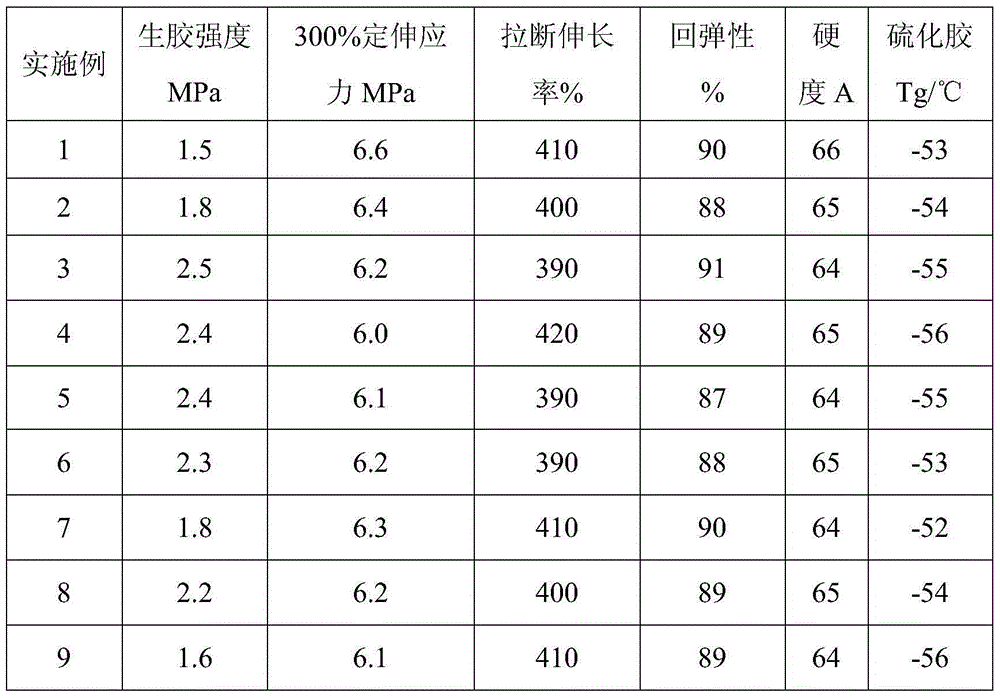

Hydrogenated polystyrene-b-styrene/butadiene/isoprene random copolymer as well as preparation method and application thereof

The invention discloses a hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer as well as a preparation method and application thereof. The hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer is obtained by hydrogenating a mixed polymer consisting of Sn-b-BSmIR, (Sn-b-BSmI)2Si(CH3)2, (Sn-b-BSmI)3SiCH3 and (Sn-b-BSmI)4Si. The preparation method comprises the following steps: preparing a polystyrene block at first, then grafting a styrene / butadiene / isoprene random copolymer block to the polystyrene block, further coupling by using a compound coupling agent, and finally performing partial hydrogenation to obtain the hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer. The preparation method is simple and low in cost, and the prepared hydrogenated polystyrene-b-styrene / butadiene / isoprene random copolymer is good in mechanical property and ageing resistance and has vulcanizable double bonds; and after the random copolymer is vulcanized, the prepared vulcanized rubber has very good elasticity, keeps relatively good rigidity and strength, is good in ageing resistance, and is suitable for outdoor sealing materials.

Owner:CHINA PETROLEUM & CHEM CORP

Hydrogenated and partially hydrogenated heat-bodied oils and uses thereof

Owner:ARCHER DANIELS MIDLAND CO

Hydrogen storage by reversible hydrogenation of pi-conjugated substrates

InactiveUS7101530B2Easily reversibleNot volatileMultiple metal hydridesHydrogen productionPartial hydrogenationDehydrogenation

Processes are provided for the storage and release of hydrogen by means of a substantially reversible catalytic hydrogenation of extended pi-conjugated substrates which include large polycyclic aromatic hydrocarbons, polycyclic aromatic hydrocarbons with nitrogen heteroatoms, polycyclic aromatic hydrocarbons with oxygen heteroatoms, polycyclic aromatic hydrocarbons with alkyl, alkoxy, ketone, ether or polyether substituents, pi-conjugated molecules comprising 5 membered rings, pi-conjugated molecules comprising six and five membered rings with nitrogen or oxygen hetero atoms, and extended pi-conjugated organic polymers. The hydrogen, contained in the at least partially hydrogenated form of the extended pi-conjugated system, can be facilely released for use by a catalytic dehydrogenation of the latter in the presence of a dehydrogenation catalyst which can be effected by lowering the hydrogen gas pressure, generally to pressures greater than 0.1 bar or raising the temperature to less than 250° C. or less, or by a combination of these two process parameters.

Owner:AIR PROD & CHEM INC

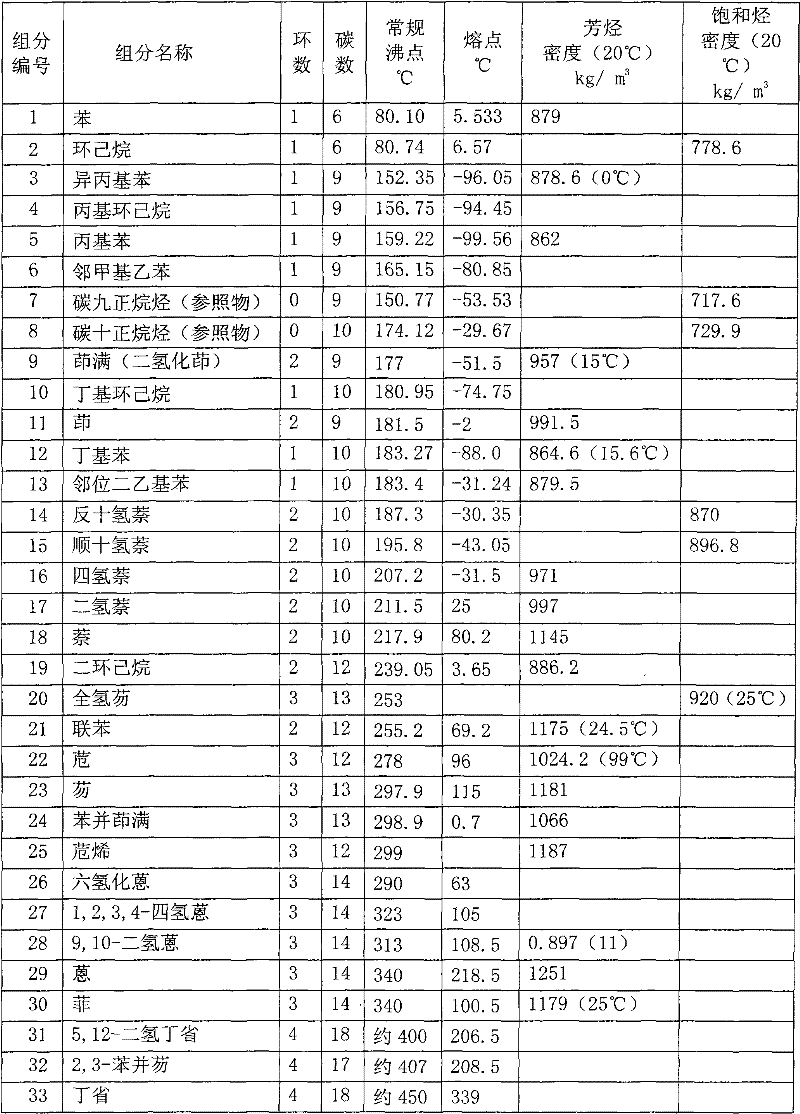

Method for conversion of low-hydrogen heavy oil to light fractions by hydrogenation with hydrogen-supplying hydrocarbons

ActiveCN102585897AImprove efficiencyShort reaction timeTreatment with hydrotreatment processesLiquid productPartial hydrogenation

The invention relates to a method for conversion of low-hydrogen heavy oil to light fractions by hydrogenation with hydrogen-supplying hydrocarbons, which is a process for conversion of heavy oil such as coal pitch by hydrogenation with hydrogen-supplying hydrocarbon stream enriched in hydrogen-supplying hydrocarbons. The method has the effects of inhibiting condensation coking speed, increasing liquid product yield in the process of conversion of coal tar heavy oil to light fractions, improving product quality, reducing reaction temperature increase and enhancing stability and safety of device operation. The hydrogen-supplying hydrocarbon stream can be hydrogenation reaction effluents in partial hydrogenation saturation process of bicyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbons or oil products enriched in partial saturated aromatic hydrocarbons obtained in the separation process of bicyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbons. The precursor substance of hydrogen-supplying solvent oil is coal tar fractions with boiling points of 350-450 DEG C, and the hydrogen-supplying solvent oil mainly comprises hydrocarbon components with ordinary boiling points of 350-450 DEG C. The combination of the method for conversion of coal tar heavy oil to light fractions by hydrogenation and method for conversion of coal tar light fractions by hydrogenation constitutes a novel combined process for conversion of full-range fractions of coal tar by hydrogenation.

Owner:洛阳瑞华新能源技术发展有限公司

Acid-resistant non-dairy creamer and preparation method thereof

ActiveCN101919454ARaw materials are simpleSolve the problem of acid intoleranceEdible oils/fatsMonoglycerideVegetable oil

The invention discloses acid-resistant non-dairy creamer and a preparation method thereof, and the acid-resistant non-dairy creamer comprises the following components by weight percent: 20-35% of partially hydrogenated vegetable oil, 5-15% of starch sodium octenylsuccinate, 0.3-0.7% of monoglyceride, 0.3-0.7% of sodium stearoyl lactylate, 0.2-0.4% of silicon dioxide and the balance of glucose syrup. A product can solve the difficult problem that the non-dairy creamer in the prior art has no acid resistance, simplify the application method of the non-dairy creamer in the prior art, reduce the uncertainty of the process, reduce auxiliary supplementary materials required during applications and expand the range of the applications.

Owner:JIAHE FOODS IND CO LTD

Plant lipid cream and production method thereof

InactiveCN101647496AFine foamImprove the decorative effectEdible oils/fats production/working-upDispersitySucrose

The invention discloses a plant lipid cream and production method thereof. The plant lipid cream is prepared by the steps that proteolytic enzyme is utilized to restrict hydrolyzed soy separation, soas to obtain soy proteolysis solution; the soy proteolysis solution is mixed with partially hydrogenated plant oil, sucrose, starch syrup, sodium alginate tech grade, carrageenan, microcrystalline cellulose, phosphate, edible emulsifier; and then filtering, aqueous phase material preparation, oil phase material preparation, mixing, blending, secondary homogeneity, aging, filling and packing are carried out sequentially. The invention modifies enzymolysis of isolated soy protein, dissolubility, dispersity and emulsibility are obviously improved, and the functional characteristic is close to casein, thus substituting application of nutrose in plant lipid cream; plant raw materials are adopted, raw material cost is reduced, thus having positive significance on nutrition and health care function; the product has favourable mouthfeel and flavour; and the production method of the invention is based on plant lipid cream similarity processing technology, utilizes biological enzyme technology and has wide applicability.

Owner:GUANGDONG IND TECHN COLLEGE

Polyol made from partialy hydrogenated, fully epoxidized natural oils

InactiveUS20110065821A1Low densityResistant to yellowingFatty acid hydrogenationFatty acid oxidationVegetable oilGram

A method is disclosed for making a polyol comprising: fully-epoxidizing a partially hydrogenated vegetable oil to obtain a fully-epoxidized vegetable oil derivative having an iodine value less than 4 g I2 / 100 gram, an EOC of from 4.0 to 5.7% and a Gardner color value of 2 or less; and then reacting the fully-epoxidized vegetable oil derivative with a ring opener to form a polyol having a hydroxyl number from 40 to 80 mg KOH / gram, a number average molecular weight of at least 1500 Daltons, a dynamic viscosity less than 10 pascal-seconds, and an EOC below 3.0 wt %.

Owner:CARGILL INC

Process for hydrogenating cuts containing hydrocarbons, in particular unsaturated molecules containing at least two double bonds or at least one triple bond

Hydrogenation of a liquid cut containing hydrocarbons, in particular unsaturated molecules containing at least two double bonds or at least one triple bond, is described wherein the unsaturated molecules are at least partially hydrogenated to less unsaturated molecules containing at least one double bond, in at least one reactor comprising at least two distinct beds of at least one hydrogenation catalyst, and wherein a gas phase containing hydrogen is introduced, a portion thereof being mixed with said cut upstream of the first catalyst bed and a portion thereof being introduced upstream of the subsequent beds contained in said reactor.

Owner:INST FR DU PETROLE

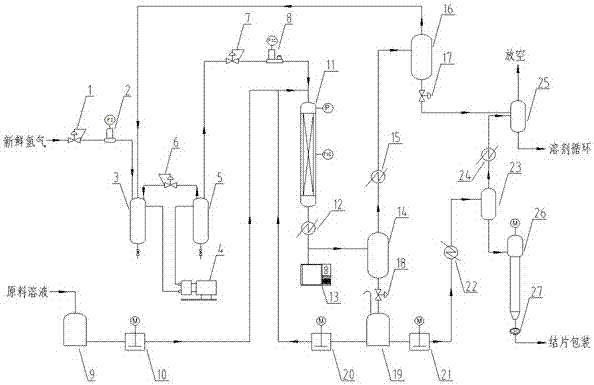

Continuous preparation method of hydrogenated bisphenol A

ActiveCN106866365AIncrease process linksRaise the ratioPreparation by hydrogenationHydroxy compound separation/purificationCyclic processHydrogenation reaction

The invention relates to a continuous preparation method of hydrogenated bisphenol A. The method comprises the following steps: carrying out a hydrogenation reaction on a prepared bisphenol A raw material in a fixed bed hydrogenation reactor under the action of a precious metal supported hydrogenation catalyst, returning the obtained hydrogenation products to the reactor according to a certain proportion in order to carry out cycle hydrogenation in order to control the ratio of the cis-trans structure in the hydrogenation product, and carrying out gas-liquid separation, normal pressure solvent removal, reduced pressure byproduct removal and sheeting treatment on the extracted partial hydrogenation products to obtain the final hydrogenated bisphenol A product, and recycling separated hydrogen and solvent. The method has the advantages of simple process flow, high controllability of the reaction process, realization of continuous preparation of the hydrogenation products, stable performances of the target product, and increase of the cis-trans isomer ratio in the hydrogenation products through the partial cycling process of the hydrogenation products, and allows the converstion rate of the hydrogenation reaction to reach 100%, the selectivity to be more than 95%, the purity of the product to be more than 97% and the cis-trans isomer ratio to reach 60%.

Owner:威海新元科盛新材料有限公司

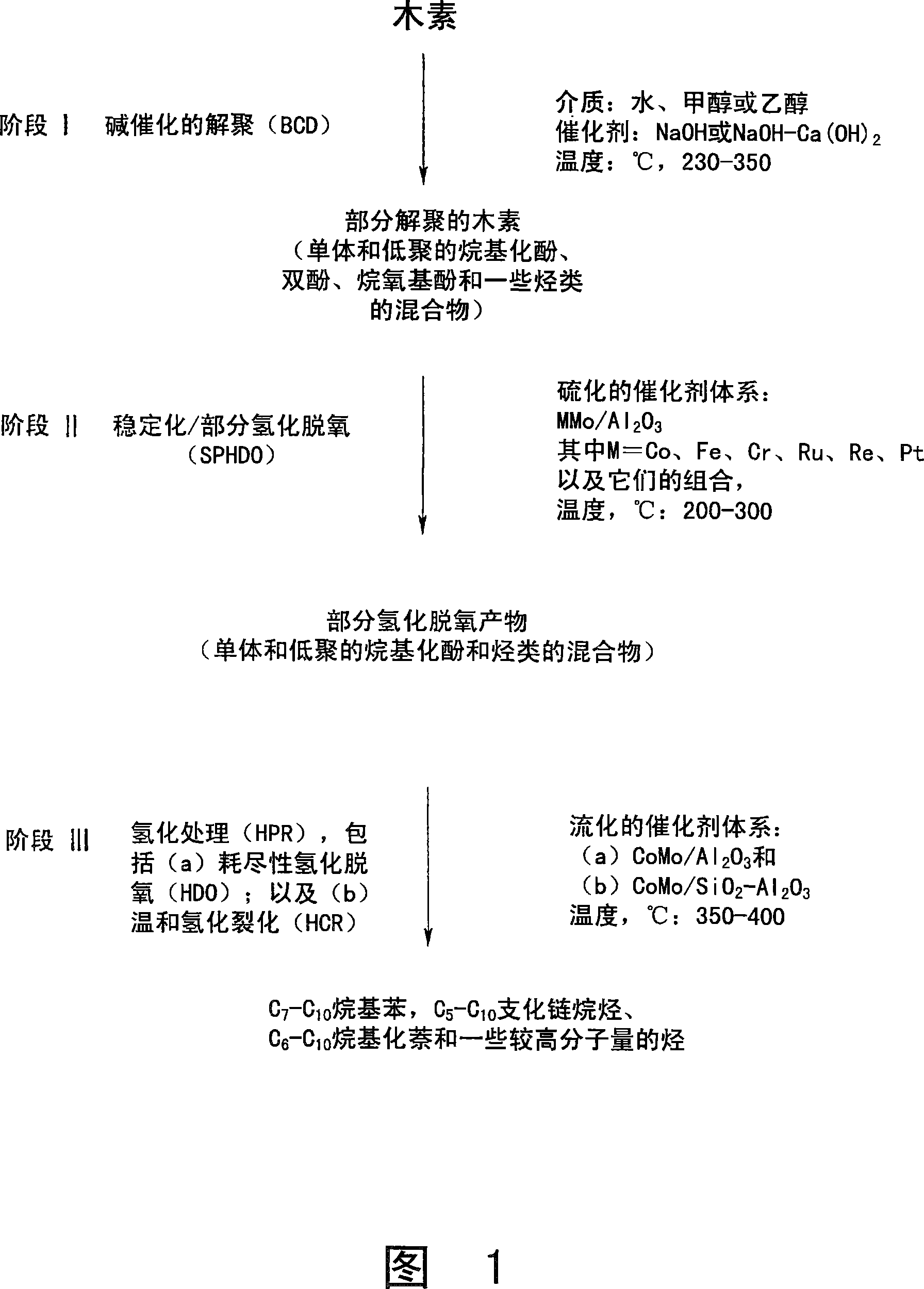

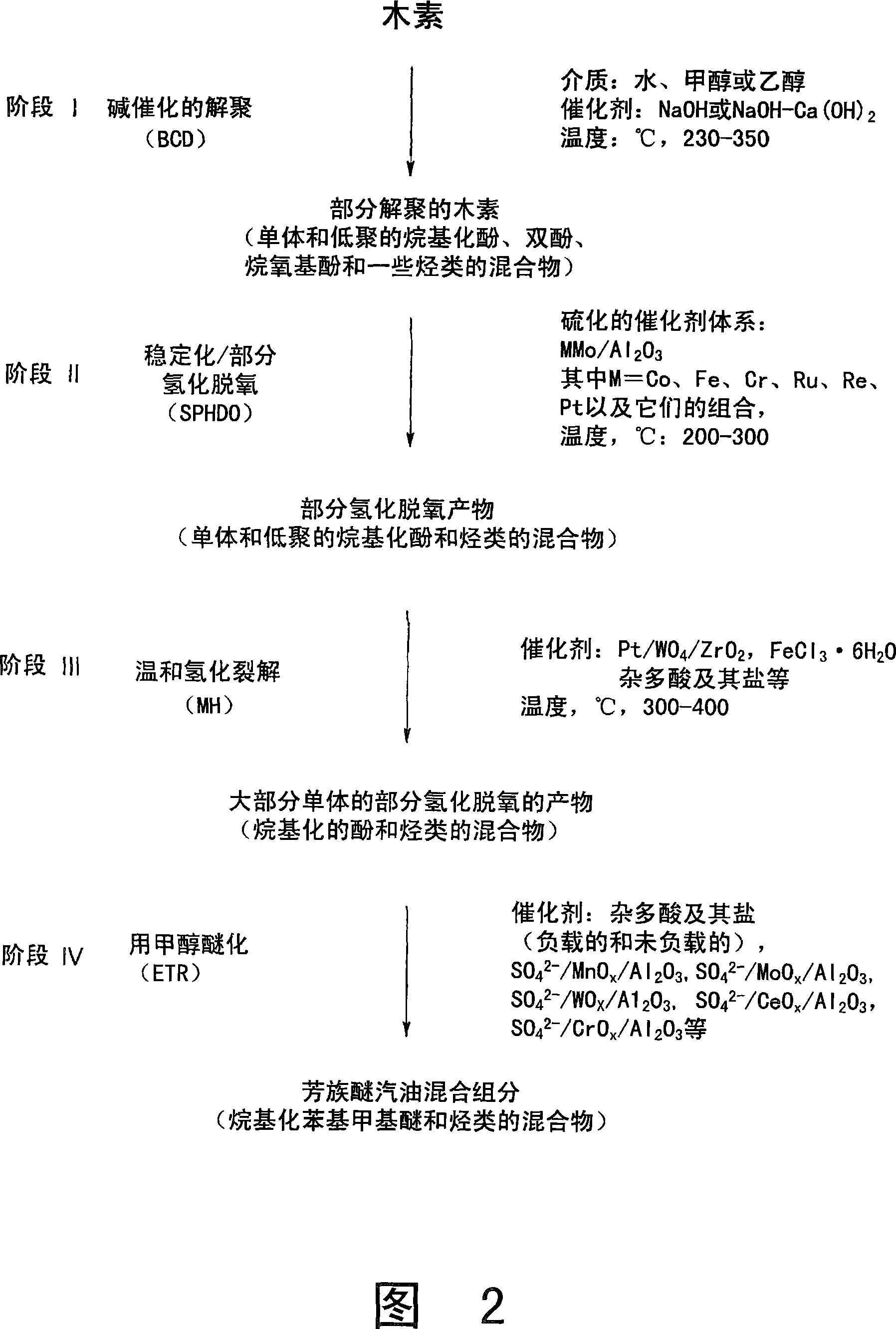

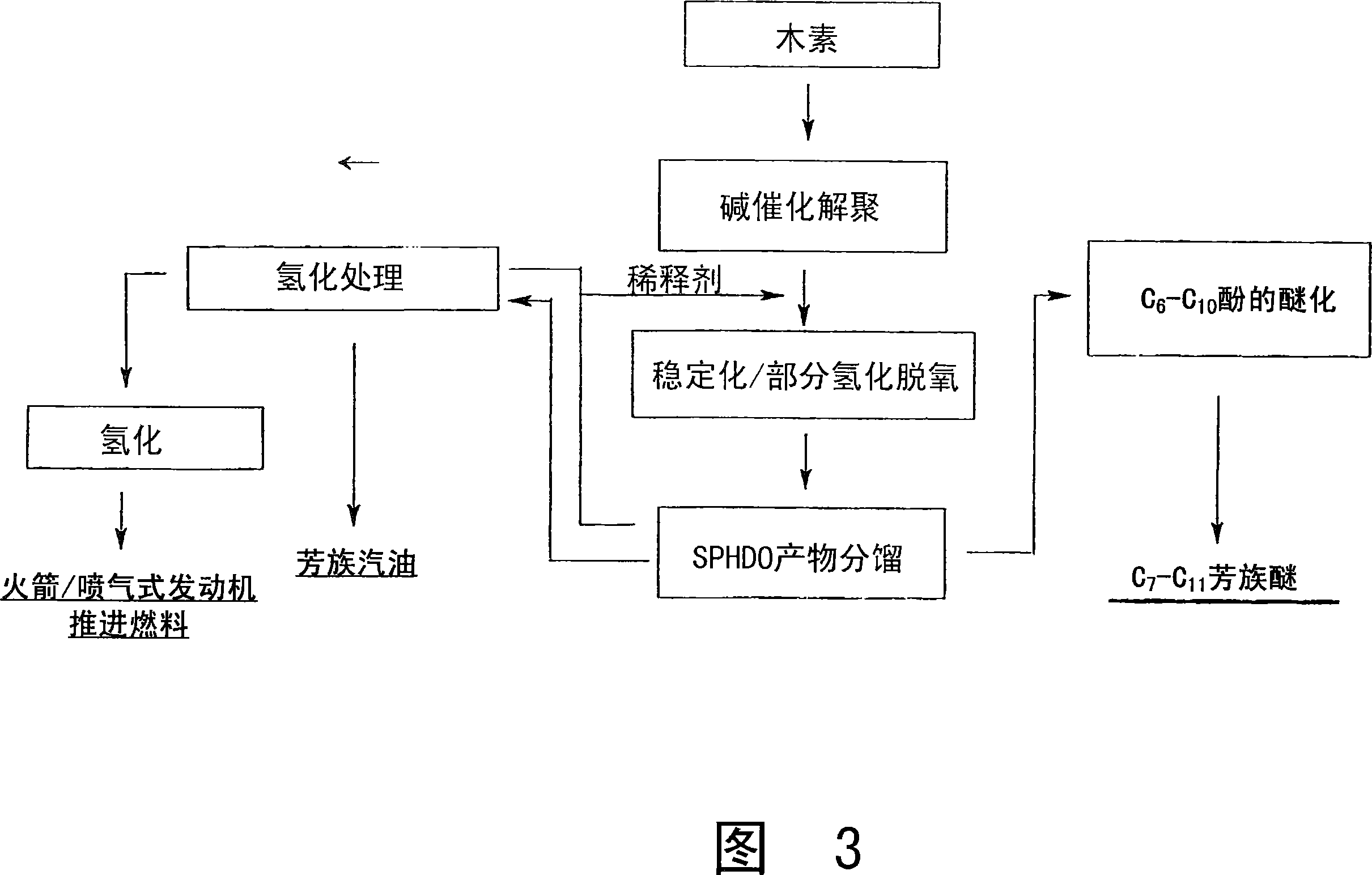

Processes for catalytic conversion of lignin to liquid bio-fuels

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio- fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a refining step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

Method for producing 1-octene

InactiveUS7030286B2High purityHigh yieldOrganic compound preparationOrganic chemistry methods1-OcteneOctene

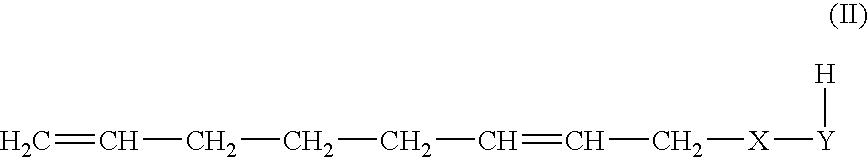

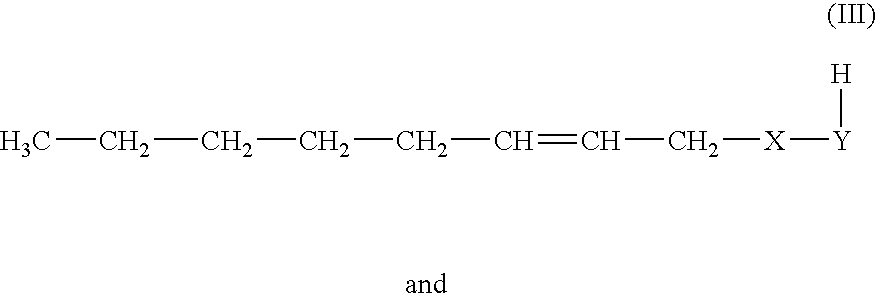

The invention relates to a process for preparing 1-octene by reacting 1,3-butadiene with a telogen of the formula H—X—Y—H, where X is O, N, S or P and Y is C, N or Si and X and Y bear, depending on their valence, further substituents, in the presence of a telomerization catalyst to form a telomer of the formula H2C═CH—CH2—CH2—CH2—CH═CH—CH2—X—Y—H, partially hydrogenating the telomer to form a 1-substituted 2-octene of the formula H3C—CH2—CH2—CH2—CH2—CH═CH—CH2—X—Y—H and dissociating the 1-substituted 2-octene to give 1-octene.

Owner:OXENO OLEFINCHEMIE GMBH

Titanium hydride hydrogen storage emulsion explosive

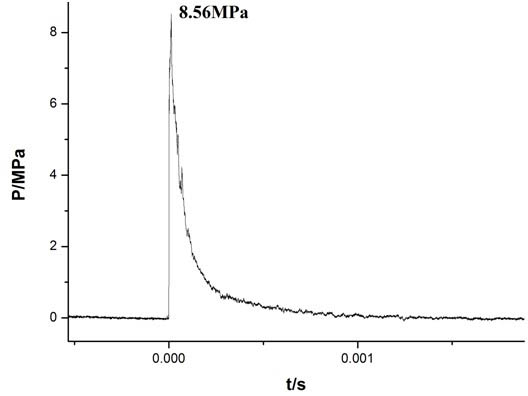

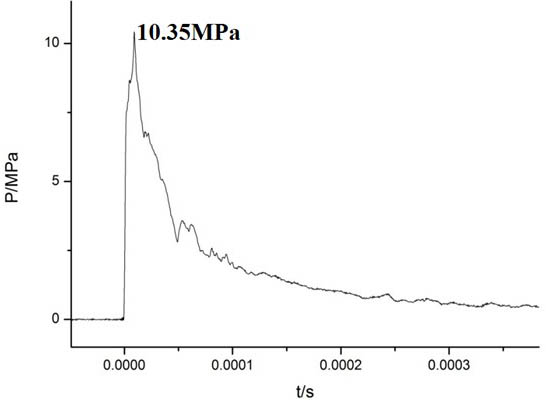

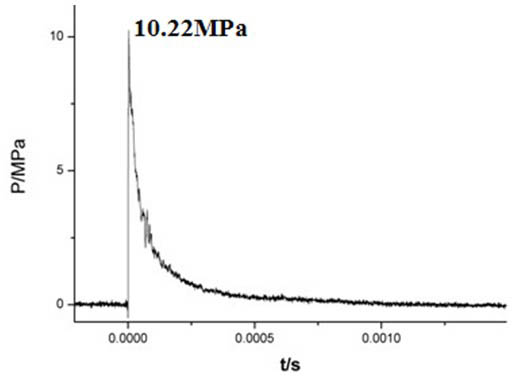

InactiveCN102432408AEvenly distributedPlay a foaming effectNon-explosive/non-thermic compositionsDetonationChemical reaction

The invention, belonging to the technical field of explosive preparation, particularly relates to an emulsion explosive prepared by using hydrogen storage materials. The explosive comprises an emulsion base and a sensitizing agent, wherein, the sensitizing agent is titanium hydride, the weight of the sensitizing agent accounts for 0.6-8 % of the total weight of the titanium hydride hydrogen storage emulsion explosive, and the purity of titanium hydride is no less than 95 %. During the detonation process, partial titanium hydride reacts with water in the emulsion base to release a little hydrogen, thus a certain foaming effect on the emulsion base is achieved, and the emulsion base is allowed to detonate, so that titanium hydride plays a role as the sensitizing agent. Simultaneously, the rest titanium hydride is subject to thermal decomposition under the effect of high temperature generated by the reaction between emulsion base and hydrogen bubbles to rapidly release hydrogen, and hydrogen continues participating the detonation reaction with the emulsion base to allow the output energy to contain the energy released by the emulsion base and titanium hydride together. The titanium hydride hydrogen storage emulsion explosive disclosed herein has the characteristics of low output explosion pressure, large impulse, long decay time, and high energy.

Owner:UNIV OF SCI & TECH OF CHINA

Production of Diesel Fuel from Renewable Feedstocks

A process has been developed for producing diesel fuel from renewable feedstocks such as plant oils and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel fuel. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture. A diesel range stream or a naphtha range stream, or a mixture of the two streams is used as a rectification agent in the selective hot high pressure hydrogen stripper to decrease the amount of product carried in the overhead.

Owner:UOP LLC

Aromatic candle with skin care effect and preparation method thereof

The invention relates to an aromatic candle with a skin care effect and a preparation method thereof. The aromatic candle is characterized by comprising the following raw materials in part by weight: 150 to 300 parts of partially hydrogenated glyceride, 100 to 300 parts of triglyceride, and 1 to 8 parts of natural essential oil. The preparation method comprises the following steps: mixing the raw materials; heating the mixture to a temperature of between 50 and 100 DEG C; stirring the mixture evenly; pouring an emulsion after mixing into a candle forming die; and cooling the formed emulsion and then demoulding the formed candle to obtain a finished product of the aromatic candle with the skin care effect. Because the aromatic candle is added with the essential oil which has the skin care effect, the wax oil after a candle is burnt has the skin care effect by daubing the wax oil on a skin.

Owner:NINGBO KWUNGS WISDOM ART & DESIGN

Shortening system

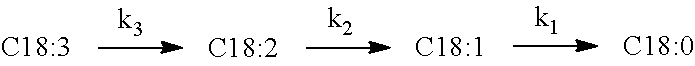

InactiveUS20090220653A1Improve sensory propertiesGreat tasteFatty acid hydrogenationEdible oils/fats ingredientsGeometric isomerVegetable oil

A shortening system, such as a spray shortening system; for instance, a shortening system containing unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil or canola oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of conserved trans monoglyceride and / or diglyceride, advantageously a monoglyceride or a mono- and diglyceride that is mostly monoglyceride, based on a highly unsaturated ‘oil, such as a highly unsaturated vegetable oil, e.g., canola or soybean oil,’ which has been selectively and partially hydrogenated so as to result in conservation of the geometric isomer of the C18:1 ester, namely the C18:1t or elaidic ester, as well as to methods for making and using such a shortening system, products from the use of such a shortening system, and the monoglyceride and / or diglyceride constituent of the shortening system, and methods for making and uses thereof.

Owner:AS DE DANSKE SUKKERFABRIKKER

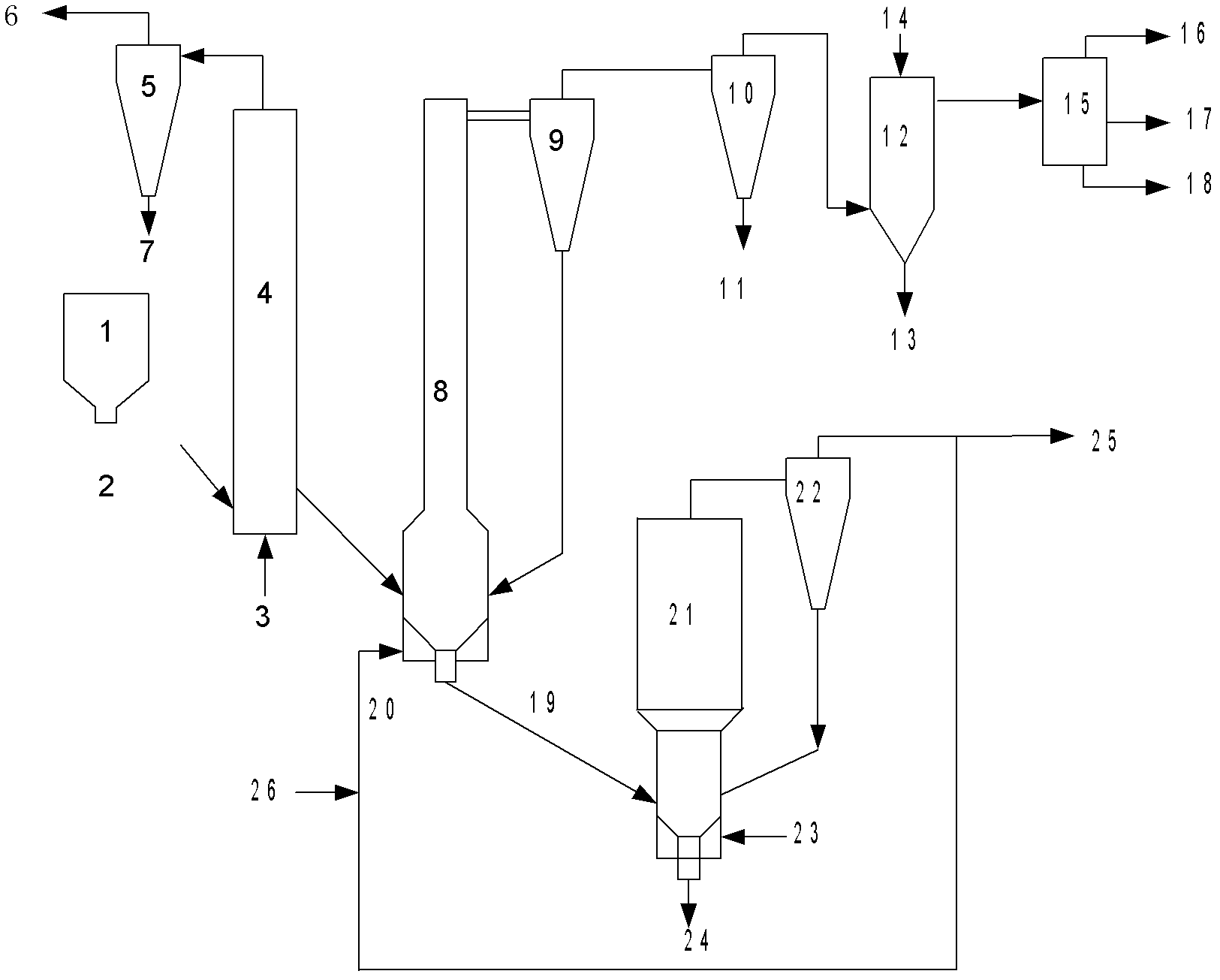

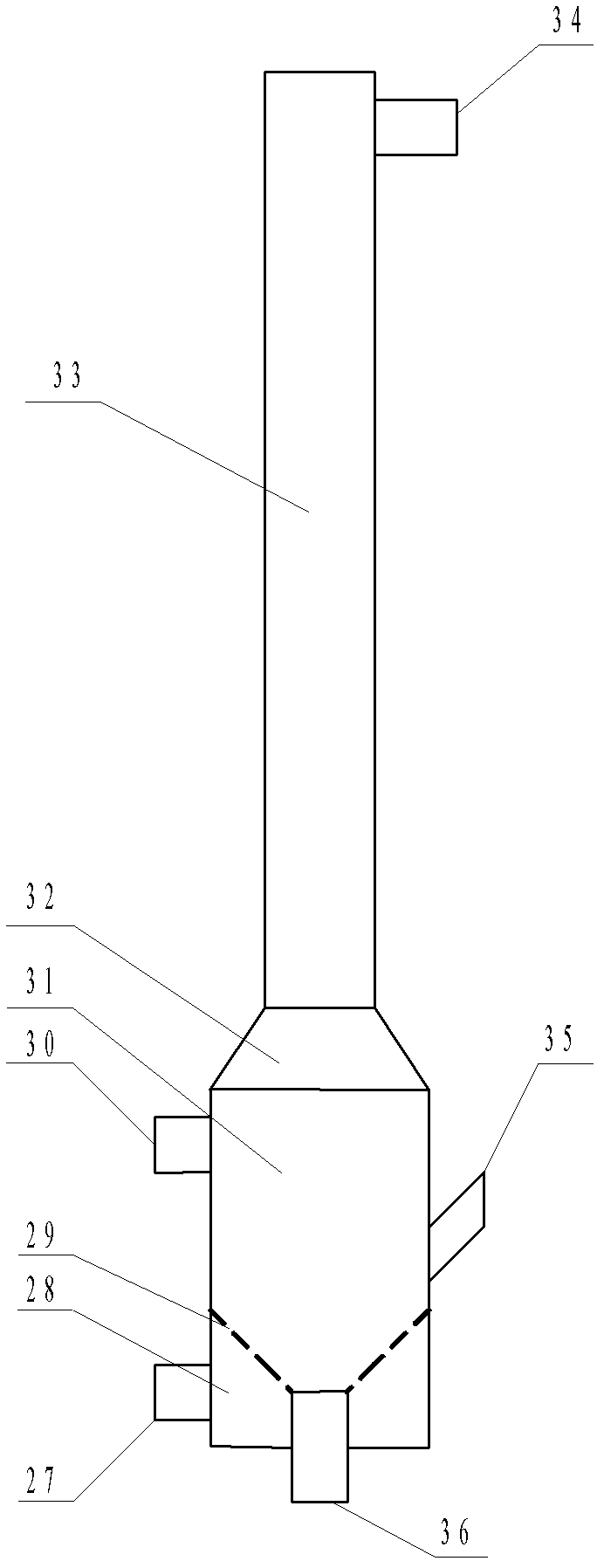

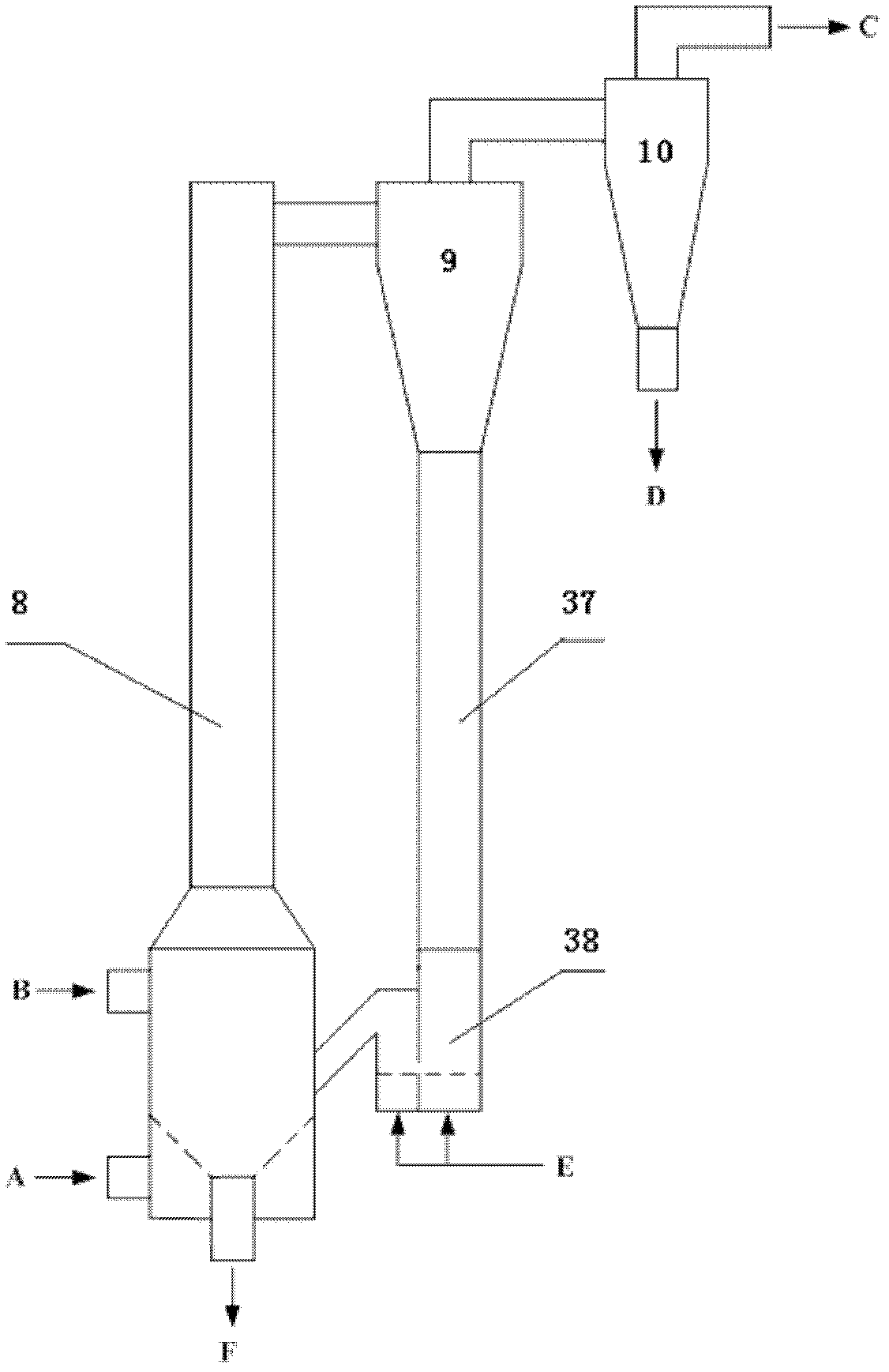

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

InactiveCN103160299AExtended stayHigh solid contentDirect heating destructive distillationSpecial form destructive distillationPartial hydrogenationHydrogen atmosphere

The invention provides a fluidized bed low-temperature destructive distillation system and a low-temperature destructive distillation method of low-rank coal. According to the method, a mixed gas of hot coal gas produced by a gasification furnace and circulation cold coal gas is adopted as a hot carrier and a fluidizing gas of a destructive distillation reaction. A hydrogen atmosphere of coal gas can provide a partial hydrogenation effect, such that obtained tar has the advantages of high light component content, good quality, high thermal efficiency, and high yield. Also, with the method, a two-stage low-temperature destructive distillation reactor is adopted, such that the retention time of solid particles in the reactor is increased, destructive distillation effect is improved, high solid content in the bed can be maintained, and operation stability can be maintained. The invention also provides a low-temperature destructive distillation reactor. The low-temperature destructive distillation reactor is the two-stage low-temperature destructive distillation reactor, such that the retention time of solid particles in the reactor is increased, and destructive distillation effect is improved. With the two-stage low-temperature destructive distillation reactor, high solid content in the bed can be maintained, and operation stability can be maintained.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Hydrogen storage system materials and methods including hydrides and hydroxides

InactiveUS20050191234A1Alkali/alkaline-earth/beryllium/magnesium hydridesMultiple metal hydridesPartial hydrogenationHydrogen storage system

In one aspect, the present invention provides a system for methods of producing and releasing hydrogen from hydrogen storage compositions having a hydrogenated state and a dehydrogenated state. In the hydrogenated state, such a composition comprises a hydride and a hydroxide. In a dehydrogenated state, the composition comprises an oxide. A first reaction is conducted between a portion of the hydride and water to generate heat sufficient to cause a second hydrogen production reaction between a remaining portion of the hydride and the hydroxide.

Owner:GM GLOBAL TECH OPERATIONS LLC

Viscosity index improvers for lubricating oil compositions

ActiveUS20050003974A1Efficient modificationSolid fuelsLiquid carbonaceous fuelsViscosity indexIsoprene

A polymer suitable for use as a viscosity index improver for lubricating oil compositions, which is at least one, at least partially hydrogenated linear or star-shaped random copolymer of isoprene and butadiene, in which at least 70 wt. % of the butadiene is incorporated into the polymer as 1,4 units and the weight ratio of isoprene addition product to butadiene addition product in the copolymer is in a range of from about 90:10 to about 70:30.

Owner:INFINEUM INT LTD

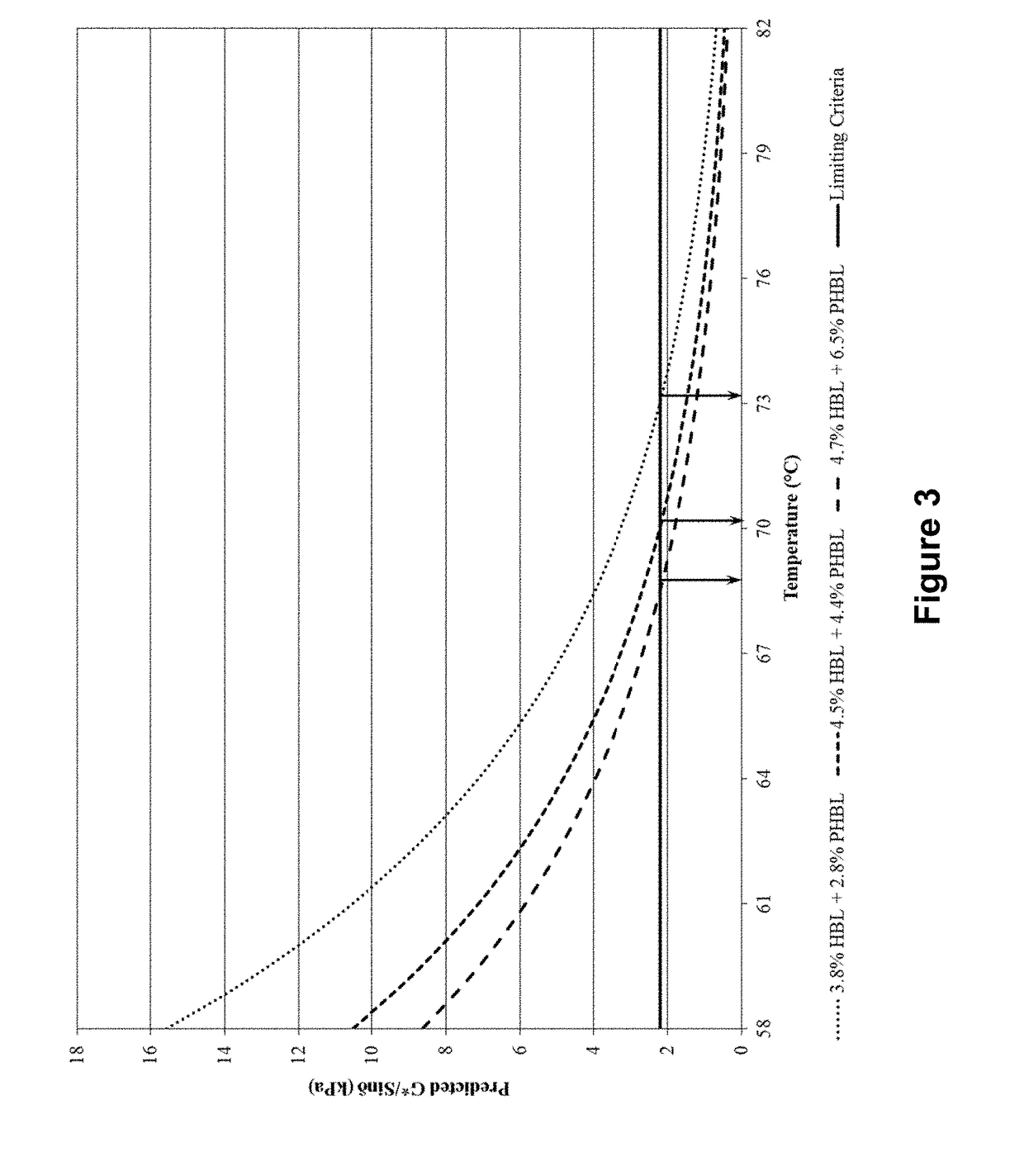

Rejuvenation of vacuum tower bottoms through bio-derived materials

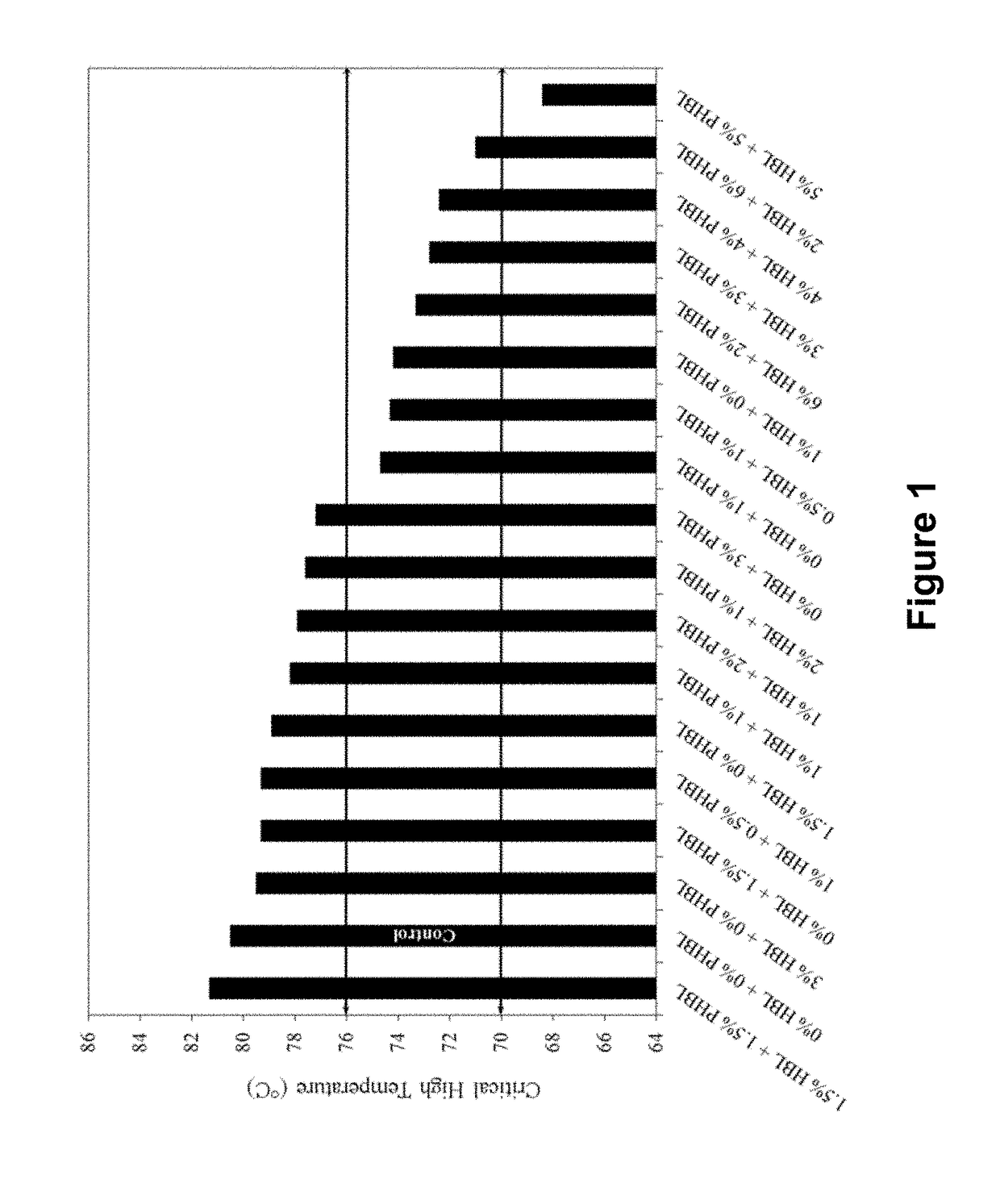

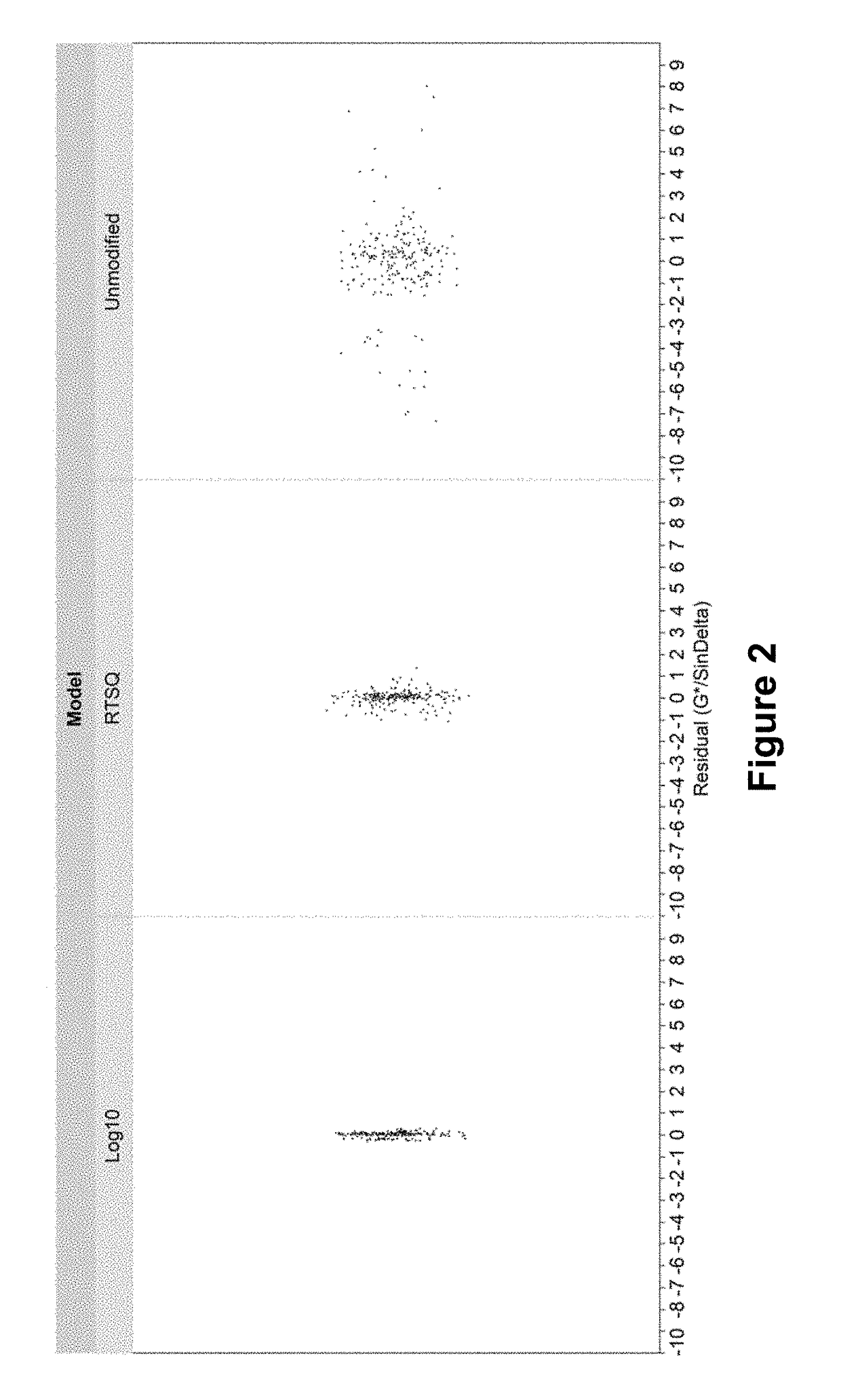

ActiveUS20170247542A1Improve low temperature performanceReduce stiffnessIn situ pavingsClimate change adaptationShear stiffnessTower

The present invention relates to an asphalt product. The asphalt product includes an asphalt binder and a bio-oil blend comprising a mixture of a non-hydrogenated bio-oil and a partially hydrogenated bio-oil, where the bio-oil blend is mixed with the asphalt binder to form an asphalt product having a shear stiffness of 0.20 kPa to 11,000 kPa at a temperature ranging from 25° C. to 85° C. and / or a viscosity of 0.15 Pa·s to 1.50 Pa·s at a temperature ranging from 120° C. to 165° C. The present invention further relates to methods of producing an asphalt product and methods of applying an asphalt product to a surface.

Owner:IOWA STATE UNIV RES FOUND

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com