Method for conversion of low-hydrogen heavy oil to light fractions by hydrogenation with hydrogen-supplying hydrocarbons

A technology for supplying hydrogen hydrocarbons and hydrogen content, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of high cracking reaction probability, low heat transfer agent efficiency, and low reaction heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

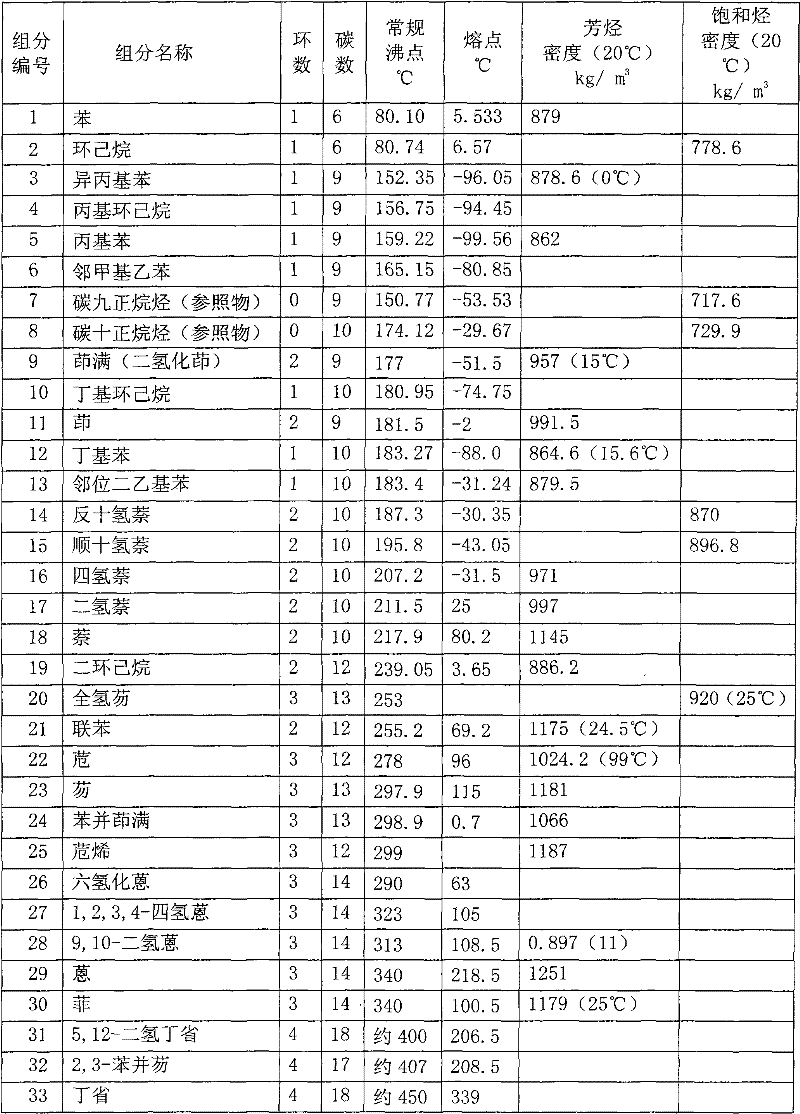

[0367] This embodiment illustrates the present invention by taking the low-temperature coal tar whose byproduct properties are as shown in Table 2 of the large-scale vertical furnace blue charcoal production plant of Sinosteel Group Anshan Thermal Energy Research Institute and Hubei Huanggang Huaxing Metallurgical Kiln Co., Ltd. as an example.

[0368] Taking the processing of 500,000 tons / year low-temperature coal tar as an example, about 75,000 tons / year of coal-based heavy oil with a conventional boiling point higher than 482°C and coal tar light fraction with a conventional boiling point lower than 482°C are obtained by fractionating low-temperature coal tar.

[0369] Coal tar light fractions with a conventional boiling point lower than 482°C enter the coal tar light fraction hydrotreating process HPU1. The process conditions of the hydrogenation unit are shown in Table 3 to Table 7. The oil produced by separation and hydrofinishing is obtained from gas, liquefied petroleum ...

Embodiment 2

[0375] Based on Example 1, the light distillate oil less than 370°C in the hydrogenation reaction product of the suspended bed or bubbling bed enters the coal tar distillate oil hydrotreating process HPU1 for joint processing to produce gas, liquefied gas, naphtha, diesel components, Hydrofined tail oil, etc. Distillate oil with a normal boiling point greater than 370°C in the suspension bed or bubbling bed hydrogenation reaction product enters the suspension bed or bubbling bed hydrogenation reaction process HPU21 for cyclic cracking.

[0376] Compared with Example 1, the upgrading process of the light oil produced by suspension bed hydrocracking and the hydrotreating process HPU1 of coal tar distillate oil are combined, which simplifies the process.

Embodiment 3

[0378] Based on Example 2, the light oil final boiling point of the oil produced by suspension bed hydrocracking is increased, that is, the light fraction oil with a conventional boiling point less than 450°C in the suspension bed or bubbling bed hydrogenation reaction product enters the aforementioned coal tar fraction Oil hydrorefining process HPU1 combined processing to produce gas, liquefied gas, naphtha, diesel components, hydrorefined tail oil, etc.

[0379] Compared with Example 2, the hydrogenation load of HPU1 in the hydrofinishing process is increased, the proportion of solvent oil in the raw material oil of HPU21 in the suspension bed hydrocracking process is increased, and the hydrogenation load of the suspension bed hydrocracking process is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com