Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5485 results about "Coal tar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used on the hair/scalp to treat dandruff and other scaly, itchy skin conditions (psoriasis or seborrheic dermatitis).

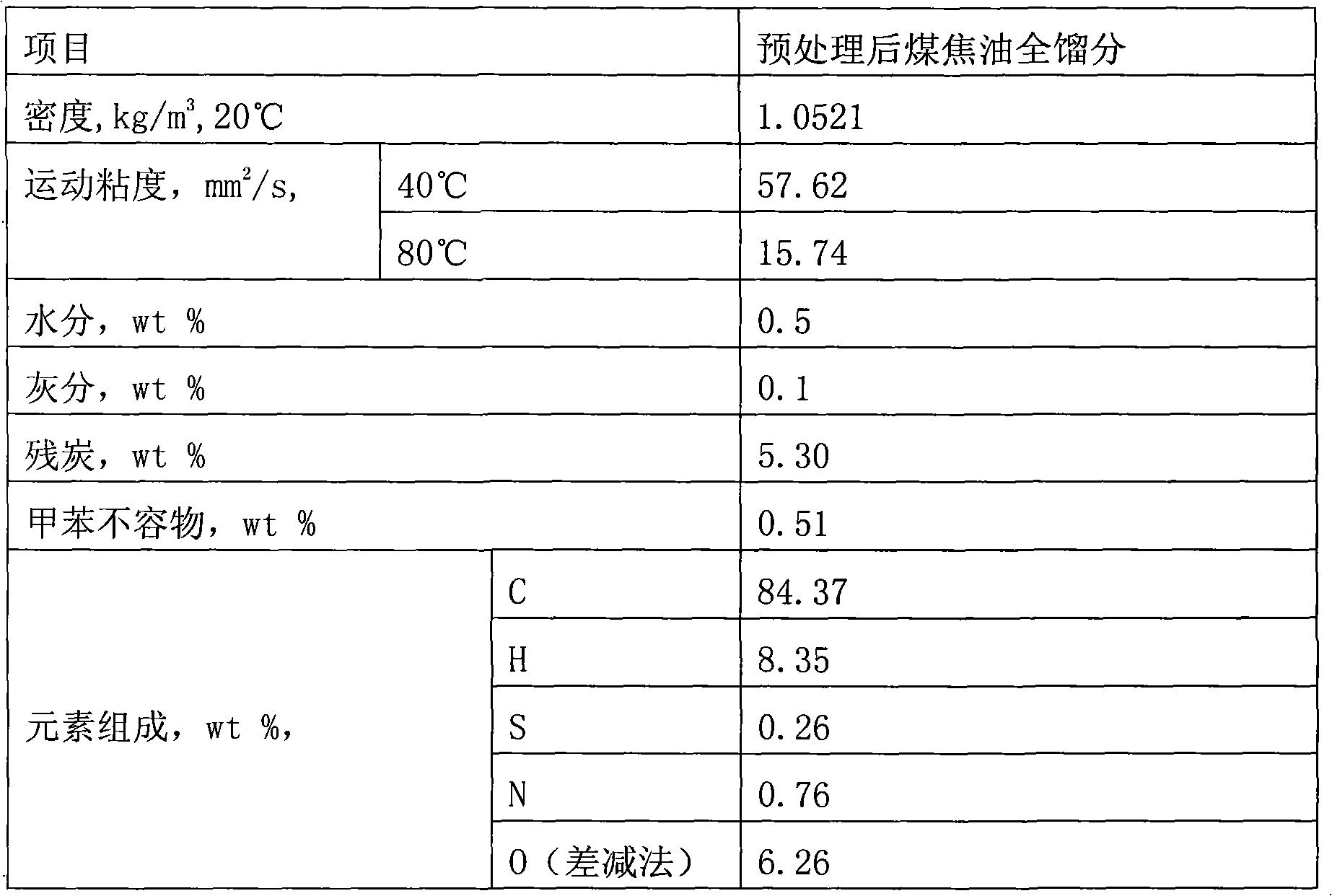

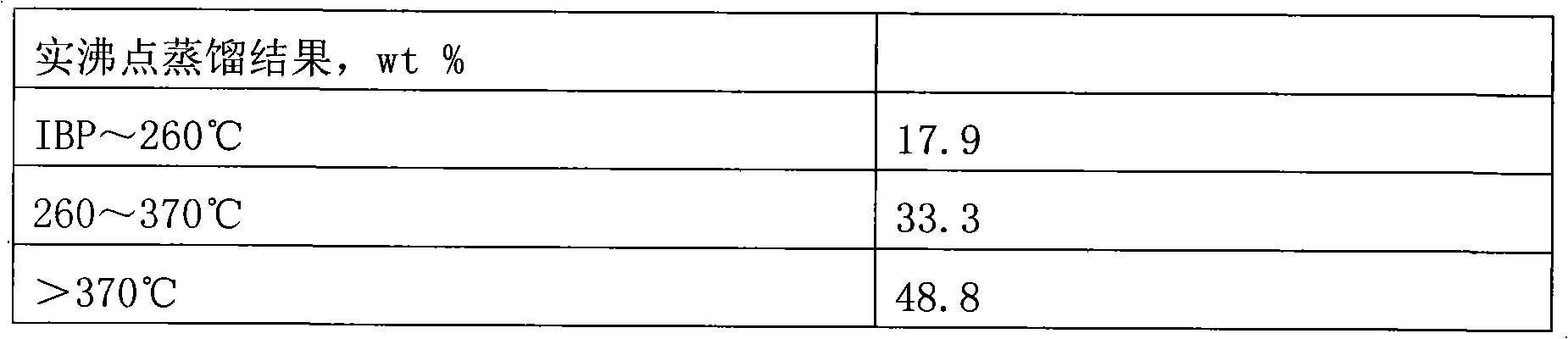

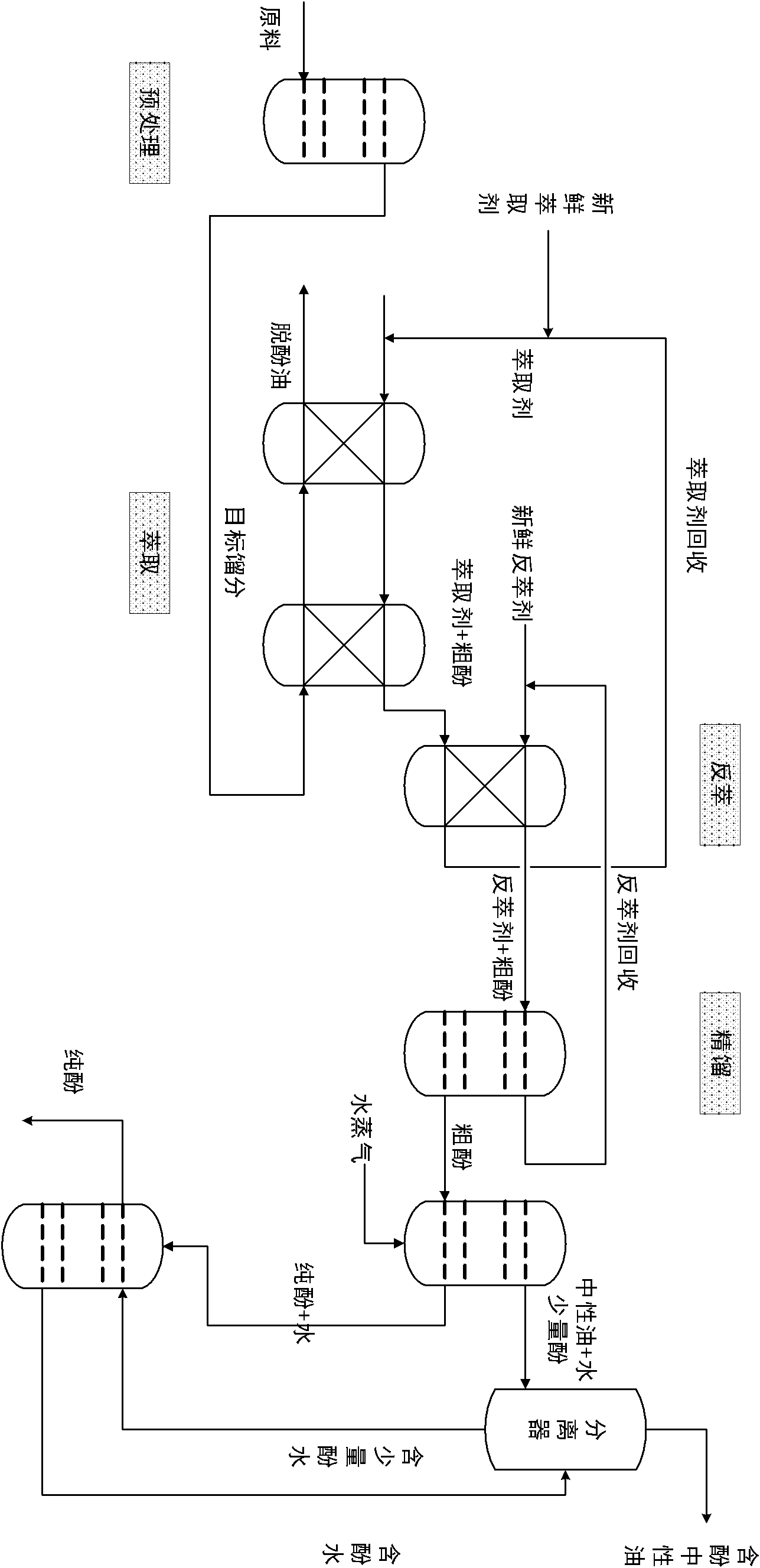

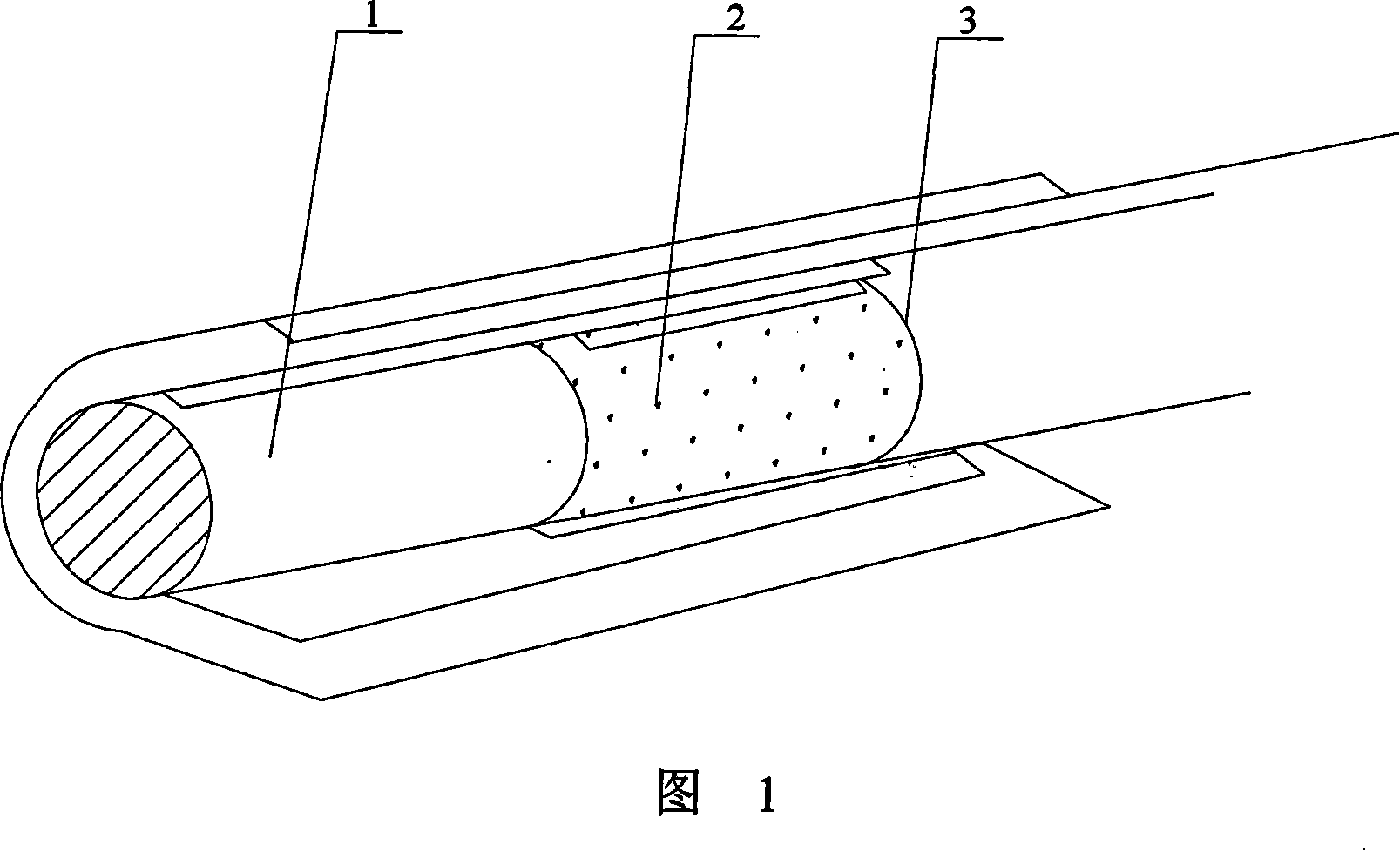

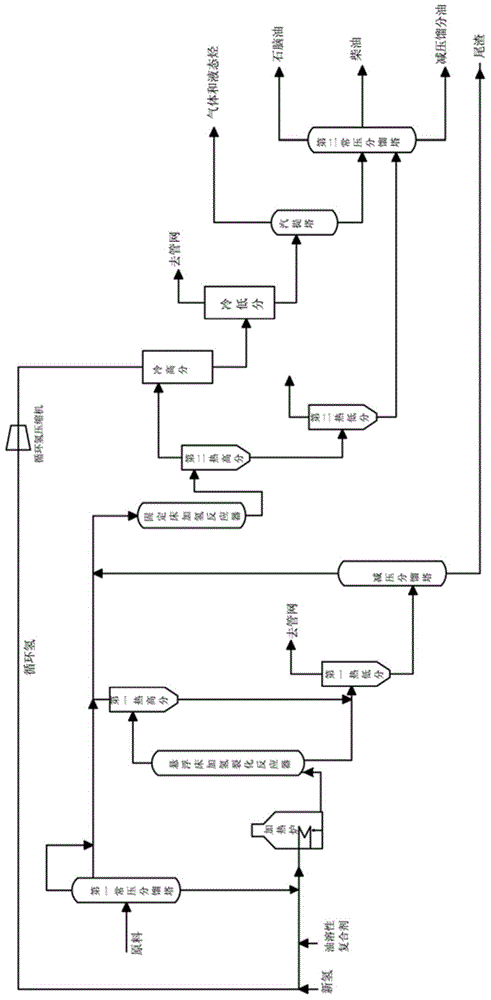

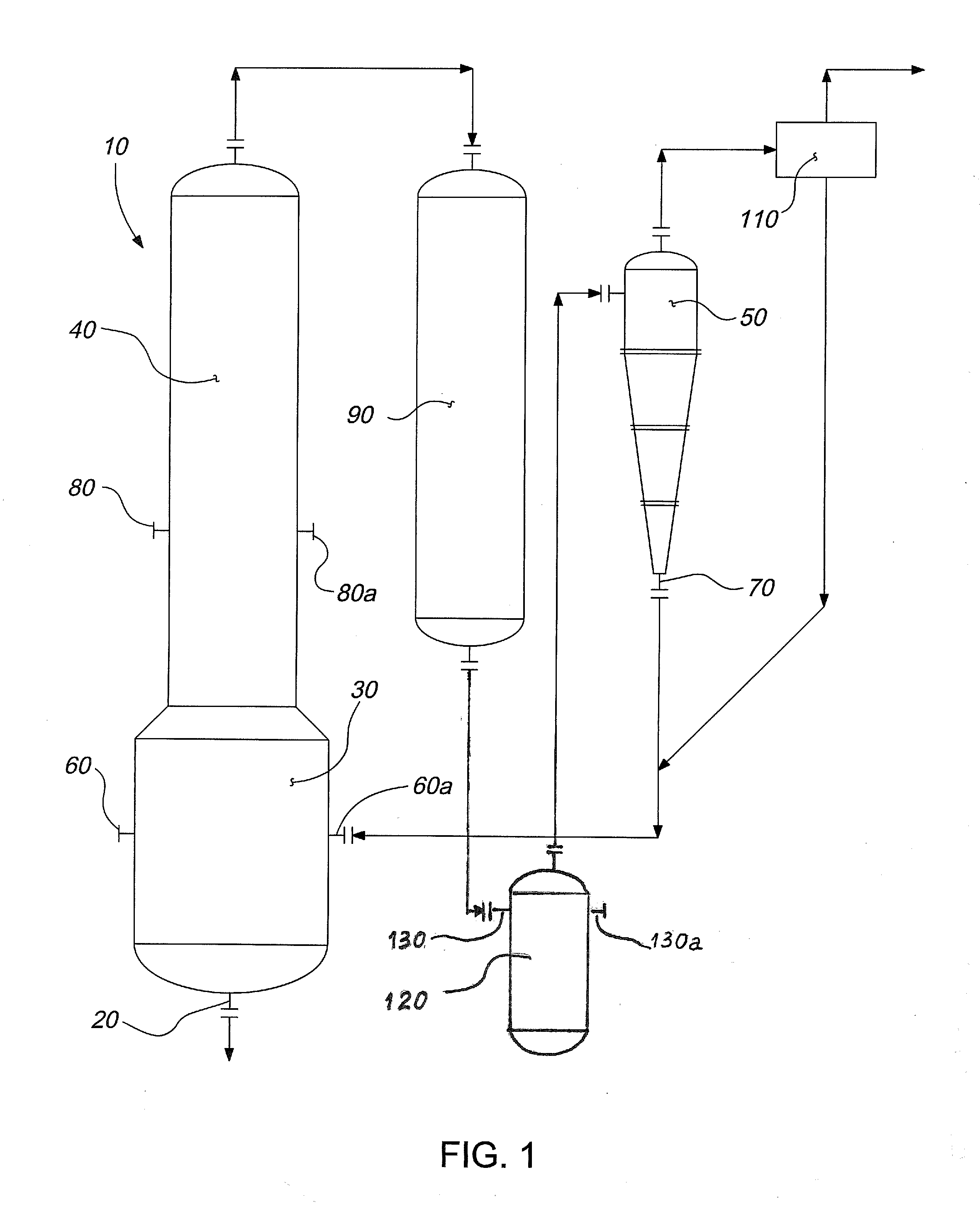

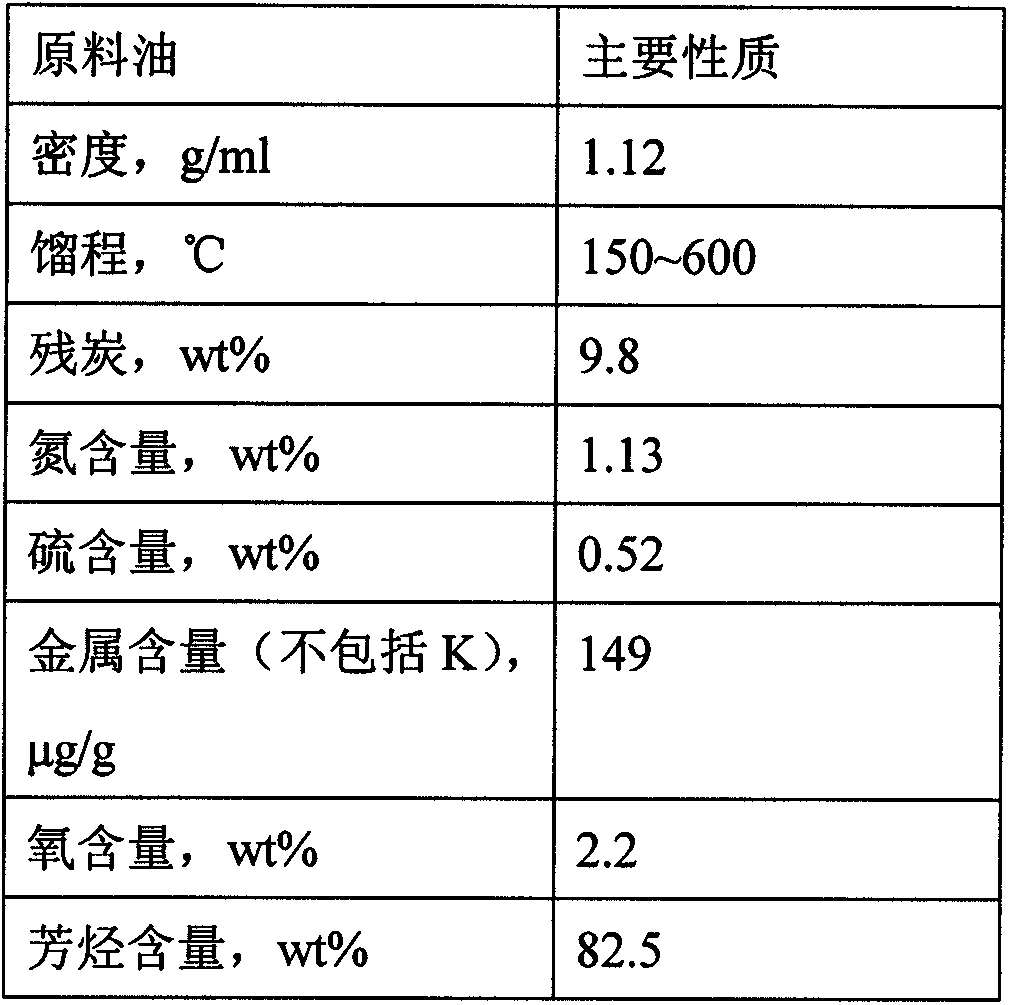

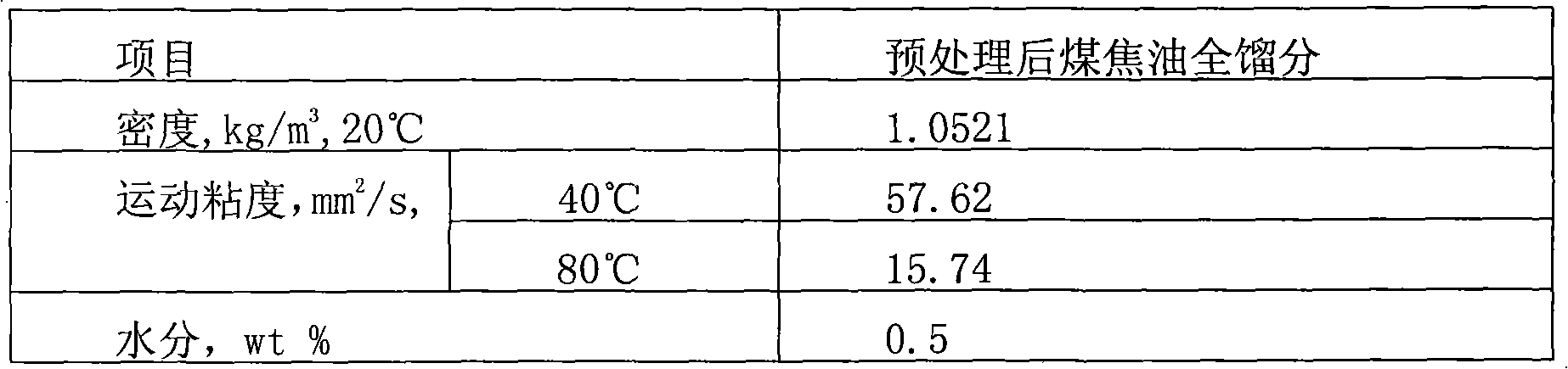

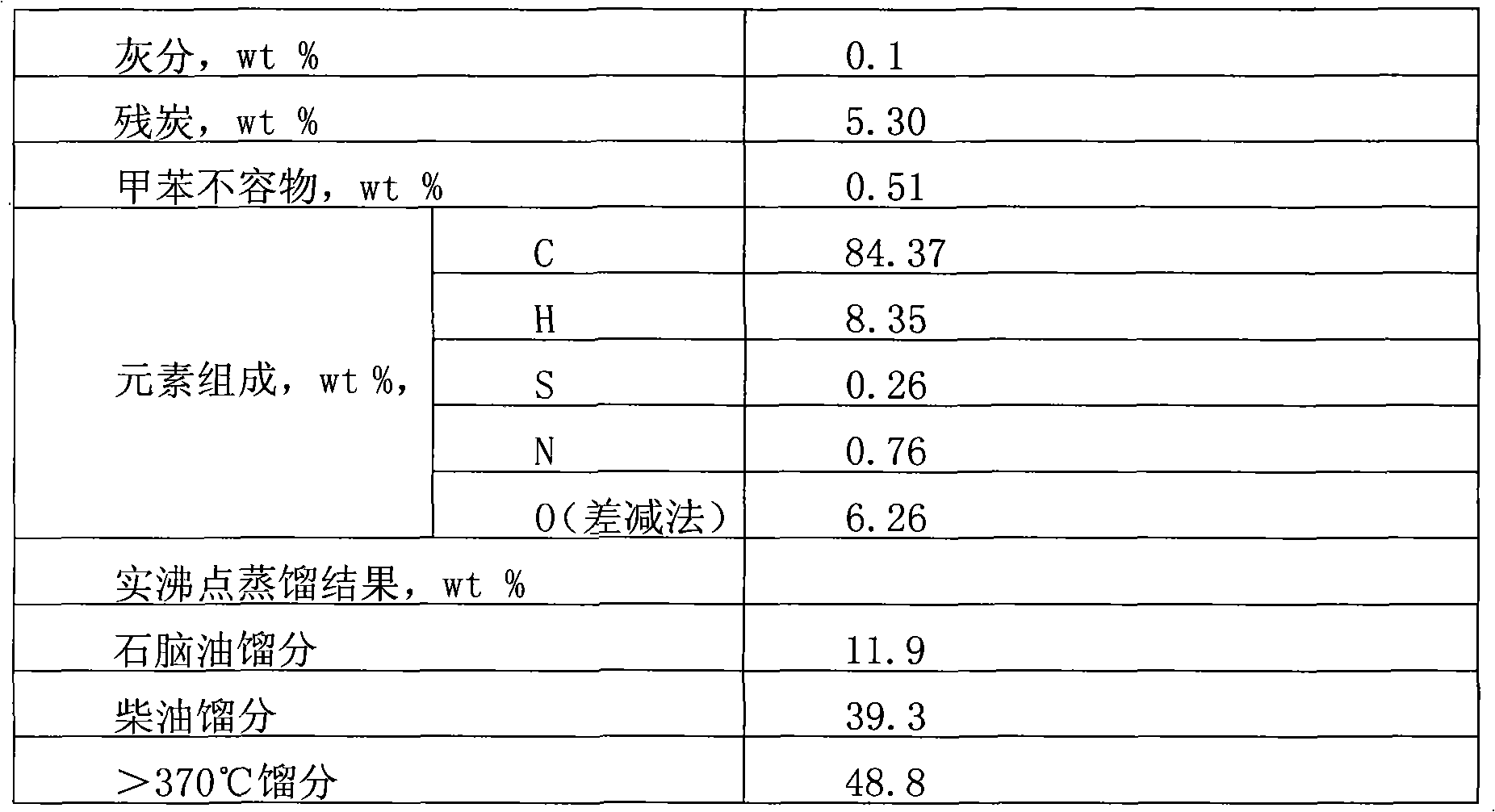

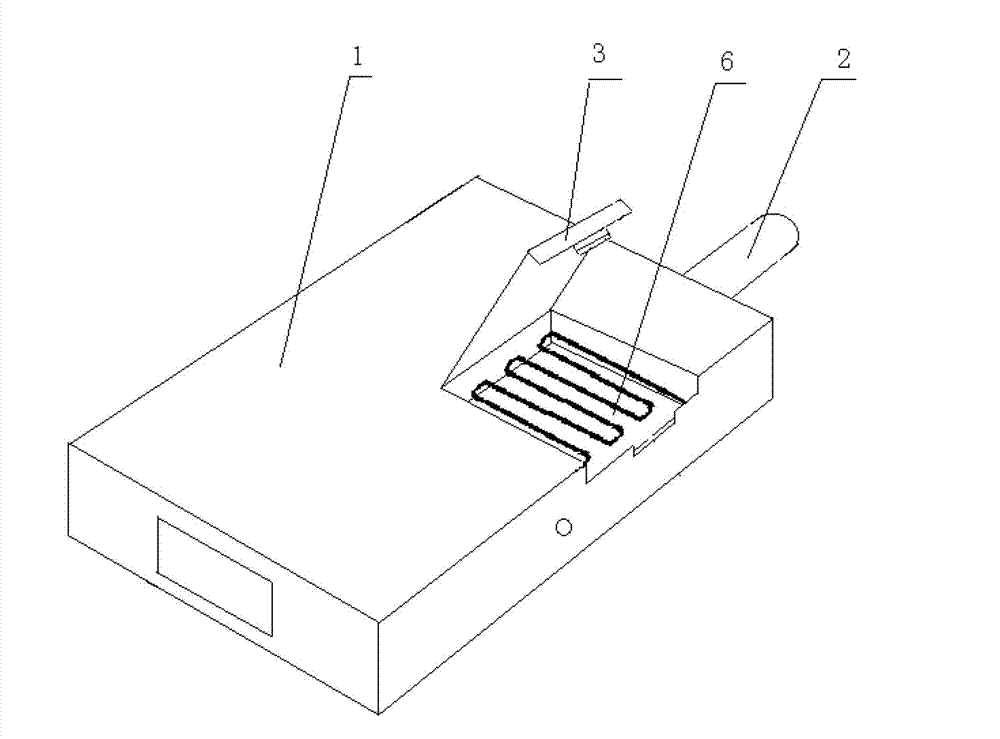

Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

ActiveCN101885982ATo achieve the purpose of recyclingImprove utilization efficiencyTreatment with hydrotreatment processesFuel oilBULK ACTIVE INGREDIENT

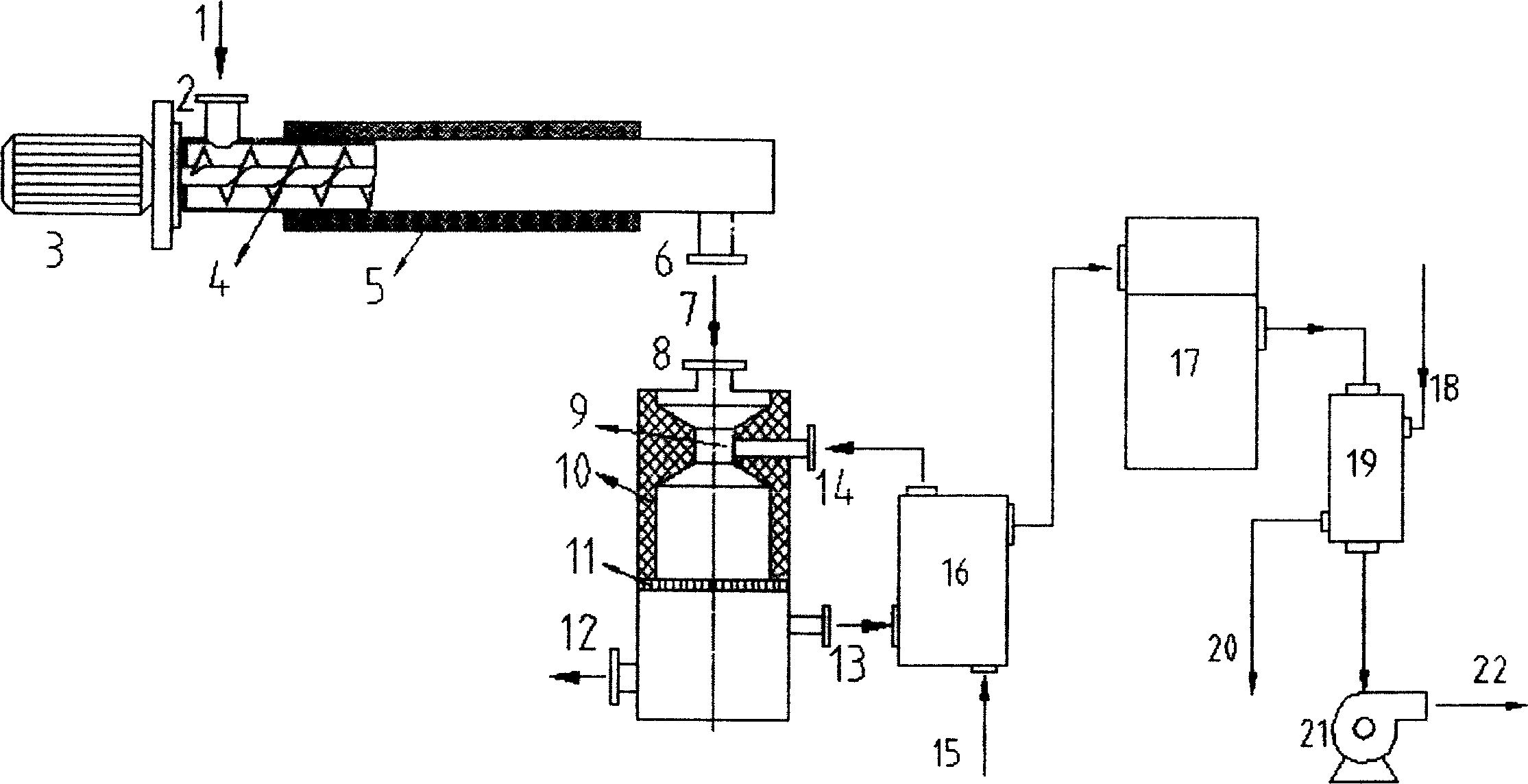

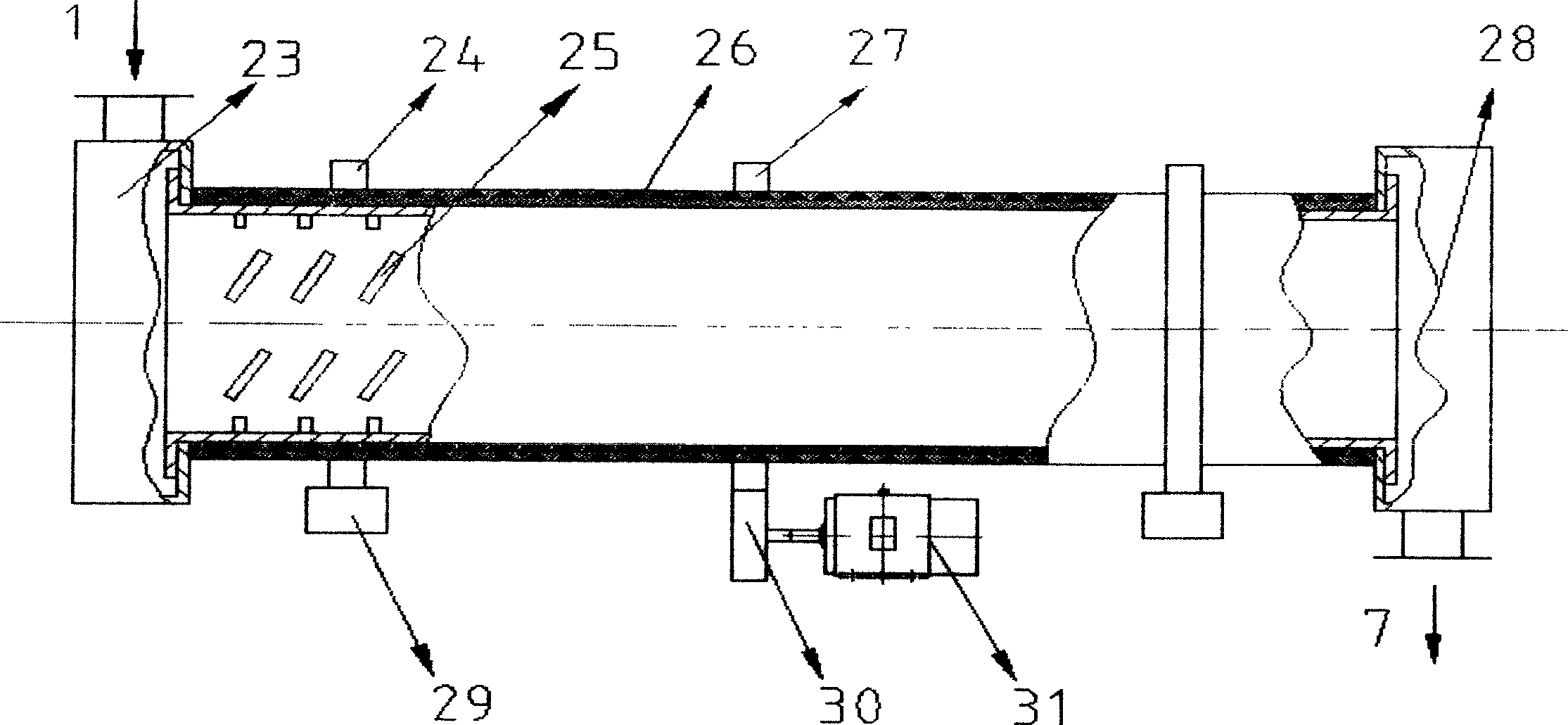

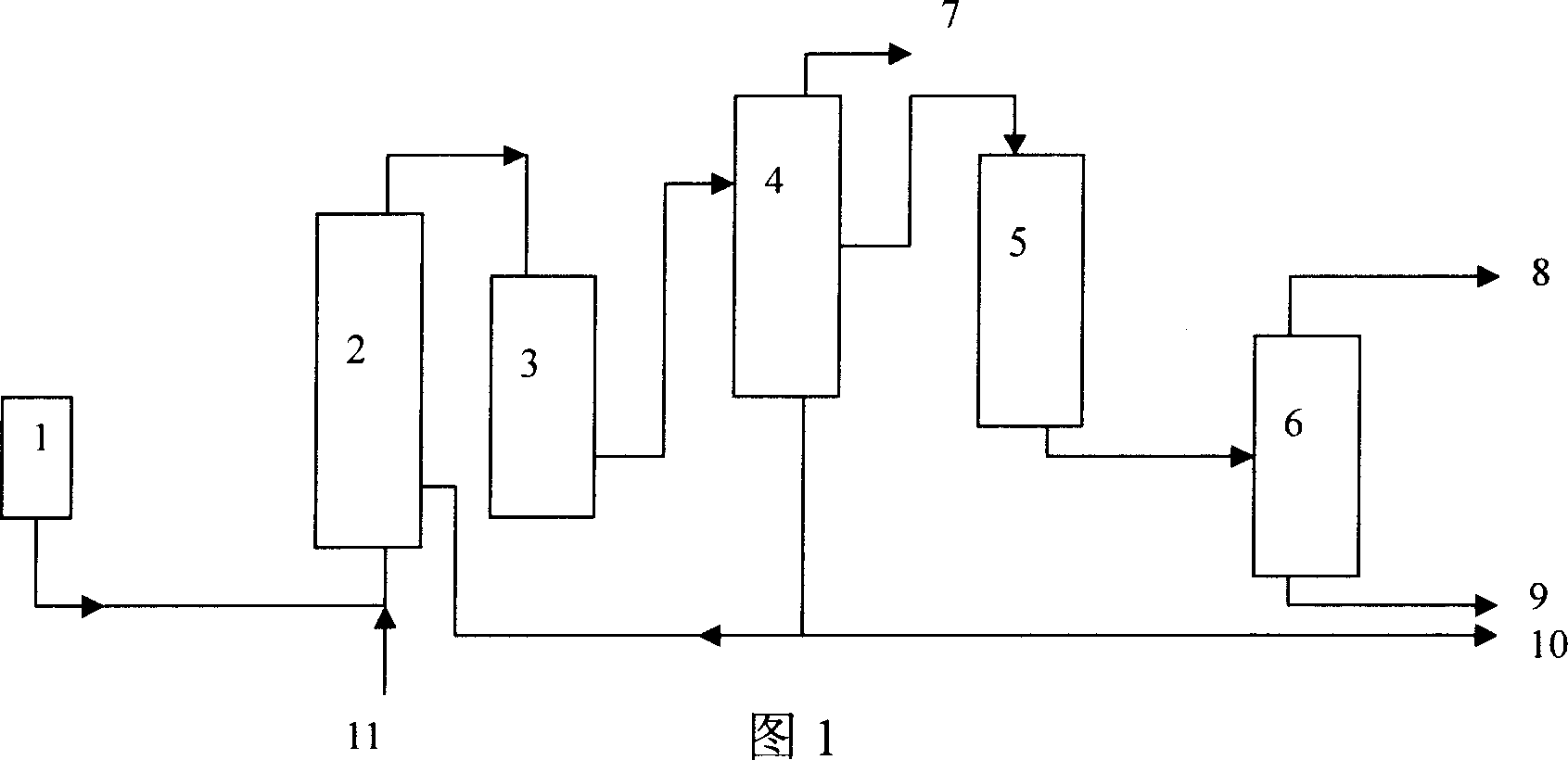

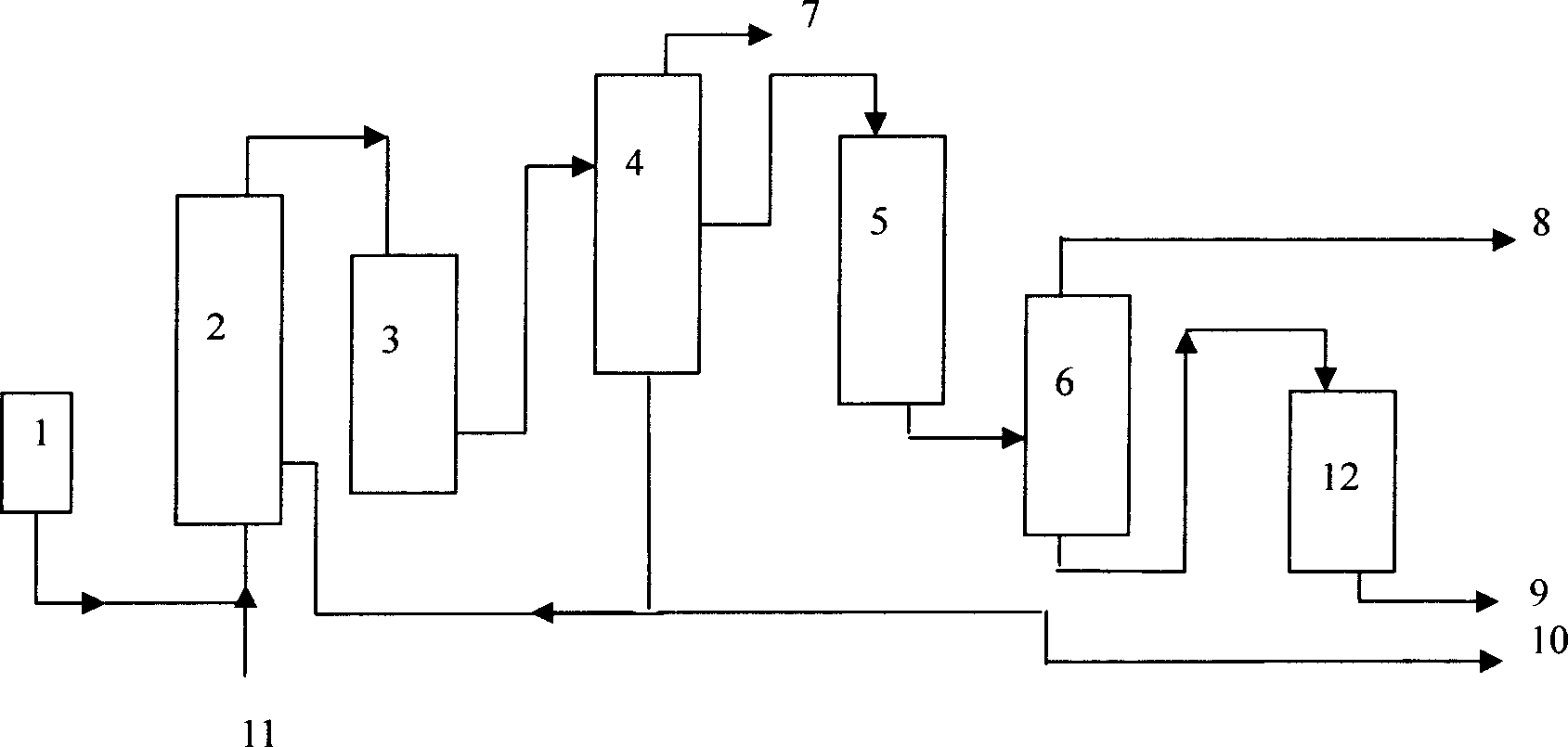

The invention relates to a hydrogenation method for a coal tar suspension bed of a heterogeneous catalyst. The method comprises processes of coal tar raw material pretreatment and distillatory separation, coal tar heavy fraction suspension bed hydrogenation cracking and conventional light fraction oil extraction, wherein the suspension bed hydrogenation reaction temperature is between 320 and 480DEG C, the reaction pressure is 8 to 19MPa, the volume air speed is 0.3 to 3.0h<-1>, the hydrogen oil volume ratio is 500 to 2,000, the catalyst is a powdery granular coal tar suspension bed hydrogenation catalyst of a single metal active ingredient containing molybdenum, nickel, cobalt, tungsten or iron or a composite multi-metal active ingredient, the adding amount of the catalyst is based on the ratio of the metal quantity of the active ingredient to the weight of the coal tar raw materials of 0.1: 100-4: 100, most of tail oil containing the catalyst after lightweight oil is separated froma hydrogenation reaction product is directly circulated to a hydrogenation bed reactor, a small part of tail oil is subjected to catalyst removal treatment and then circulated to the hydrogenation bed reactor to be subjected to further lightweight treatment, and the heavy oil is totally or furthest circulated. The method fulfills the purposes of maximum production of the lightweight oil in the coal tar and cyclic utilization of the catalyst, and greatly improves the utilization efficiency of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

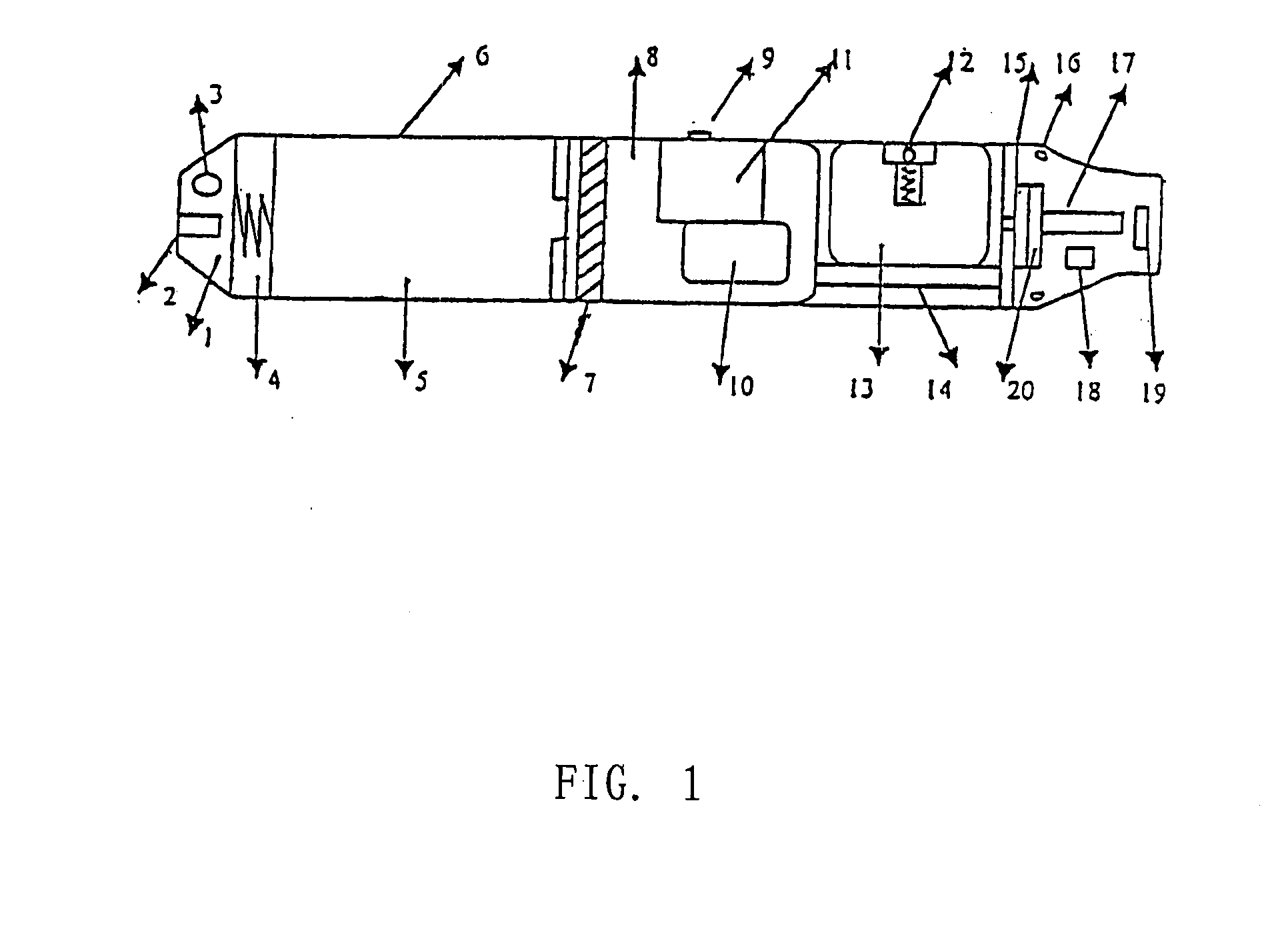

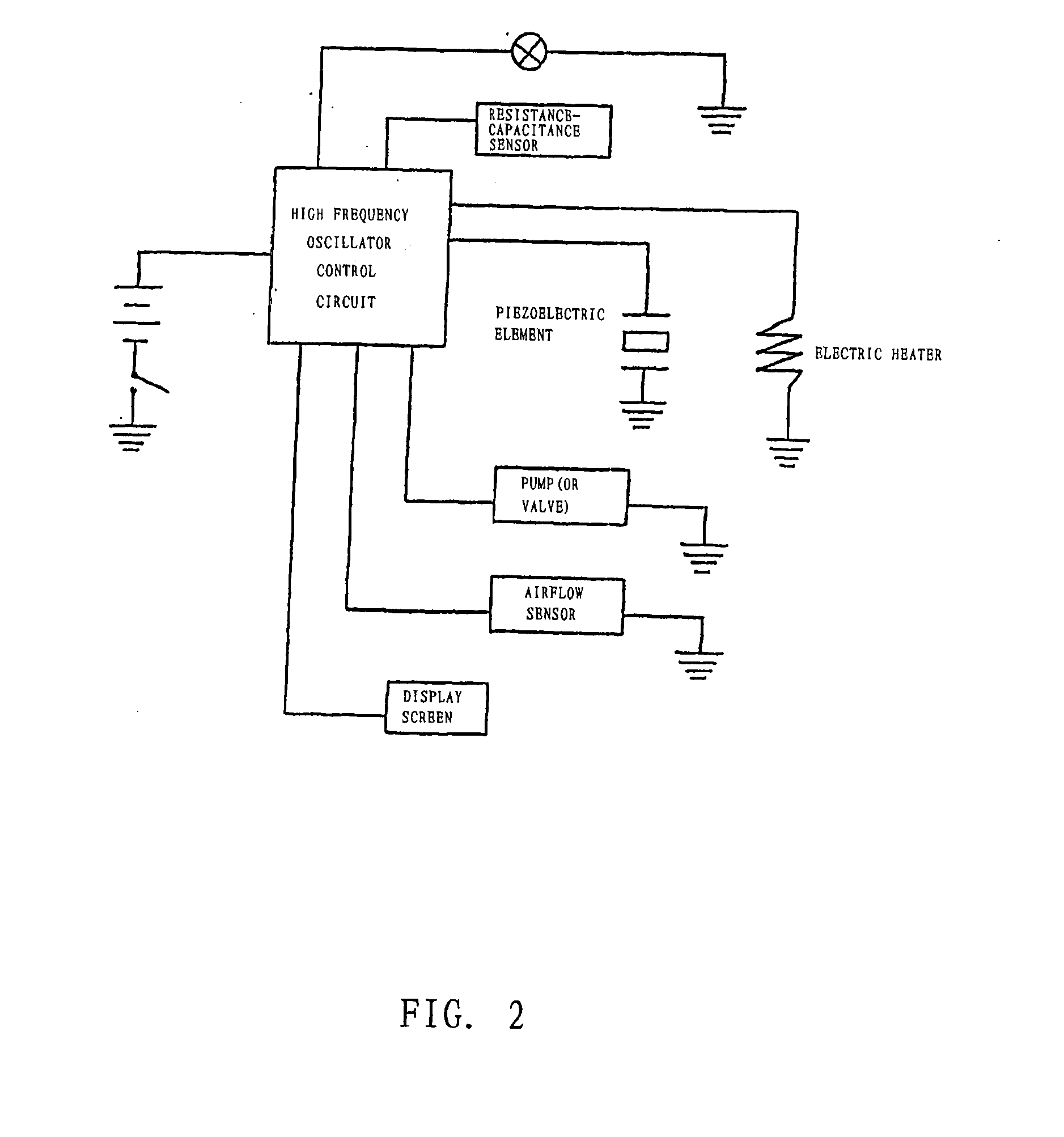

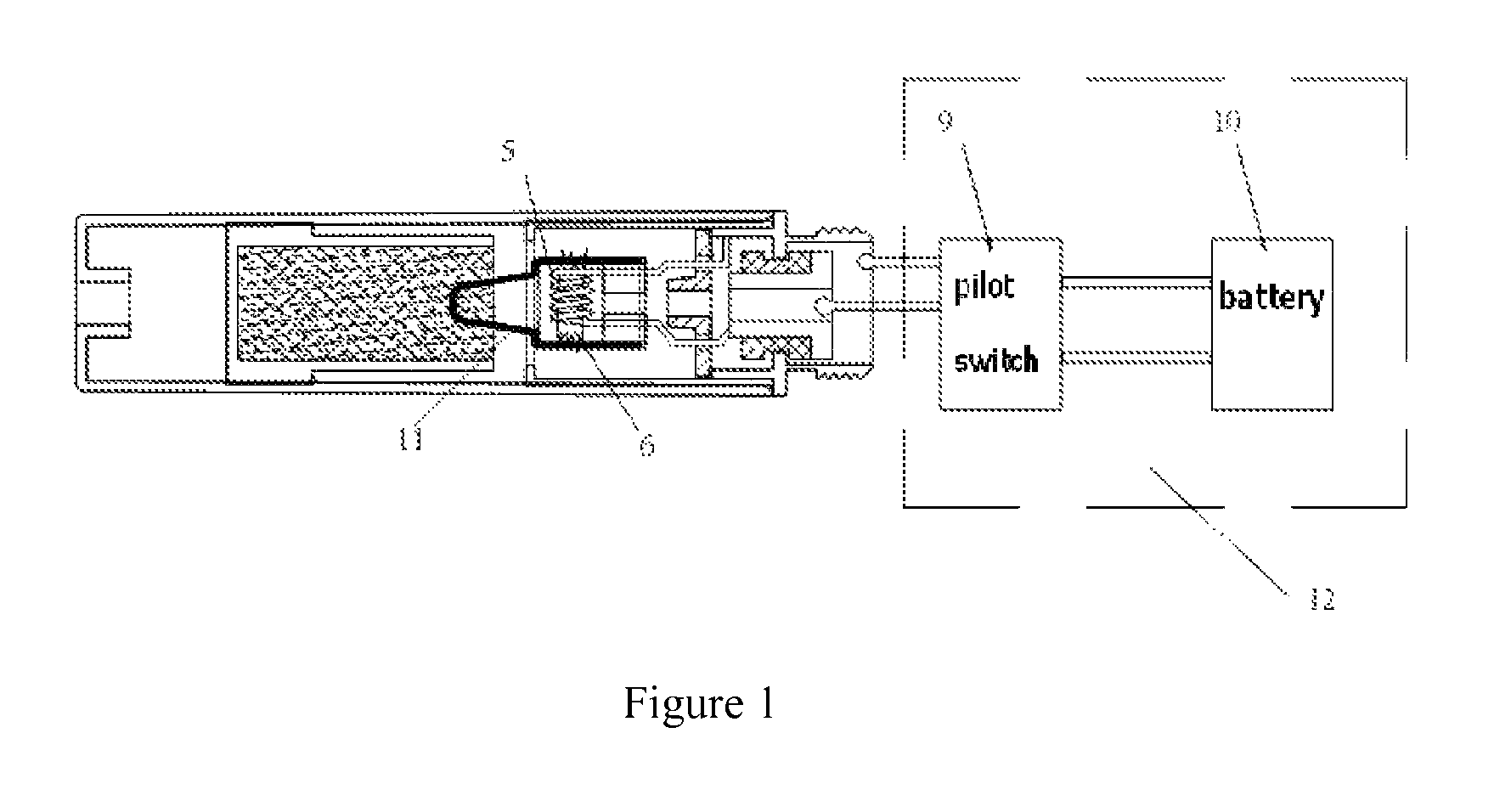

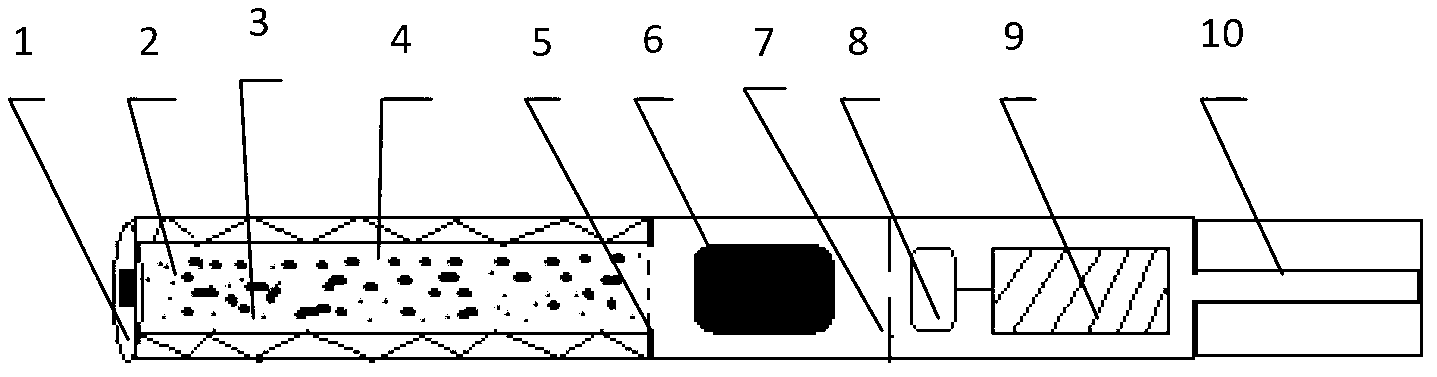

Flameless electronic atomizing cigarette

ActiveUS20120090630A1Reduce cancer riskBatteries circuit arrangementsTobacco treatmentTarVaporization

Owner:FONTEM VENTURES

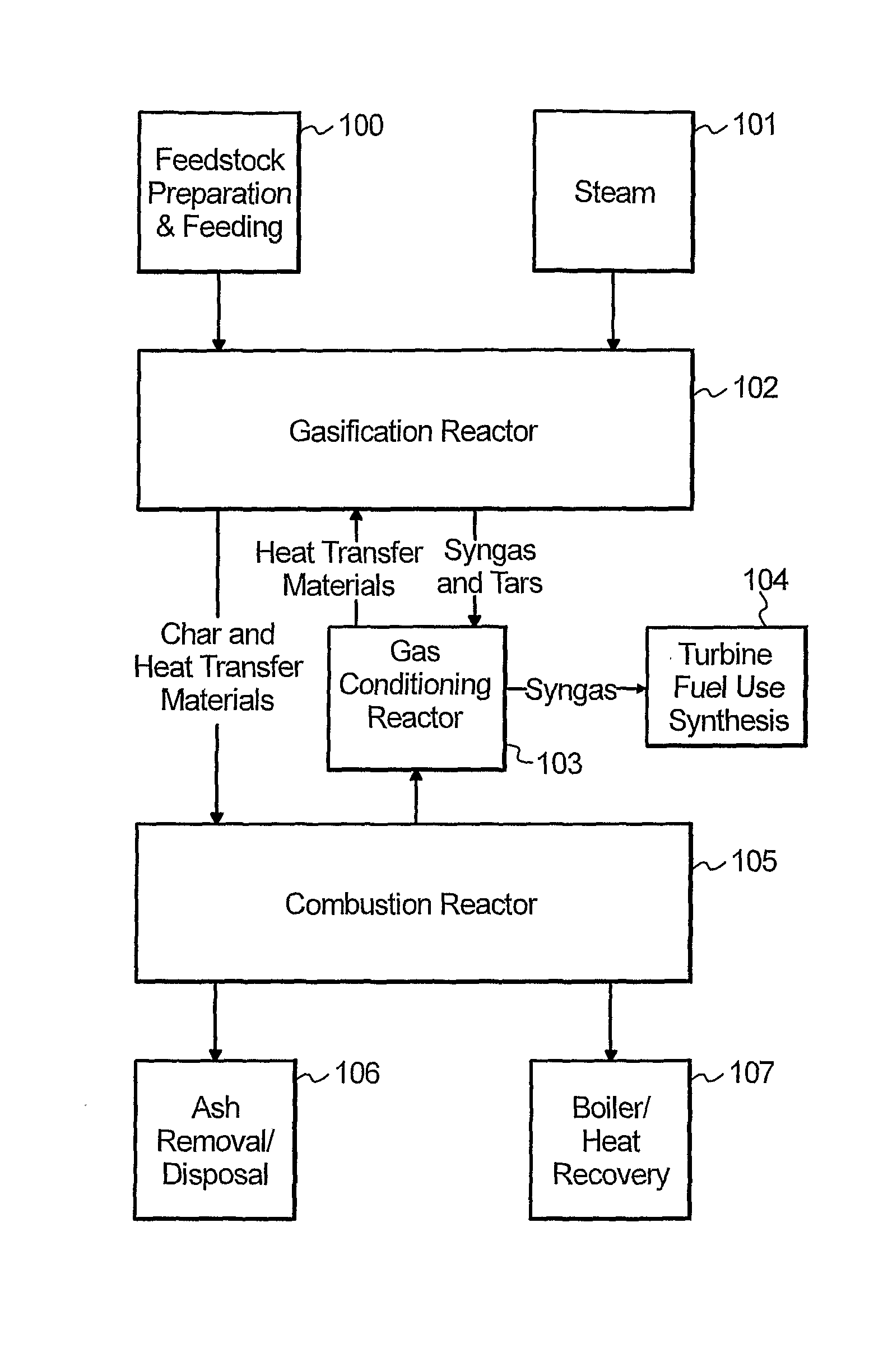

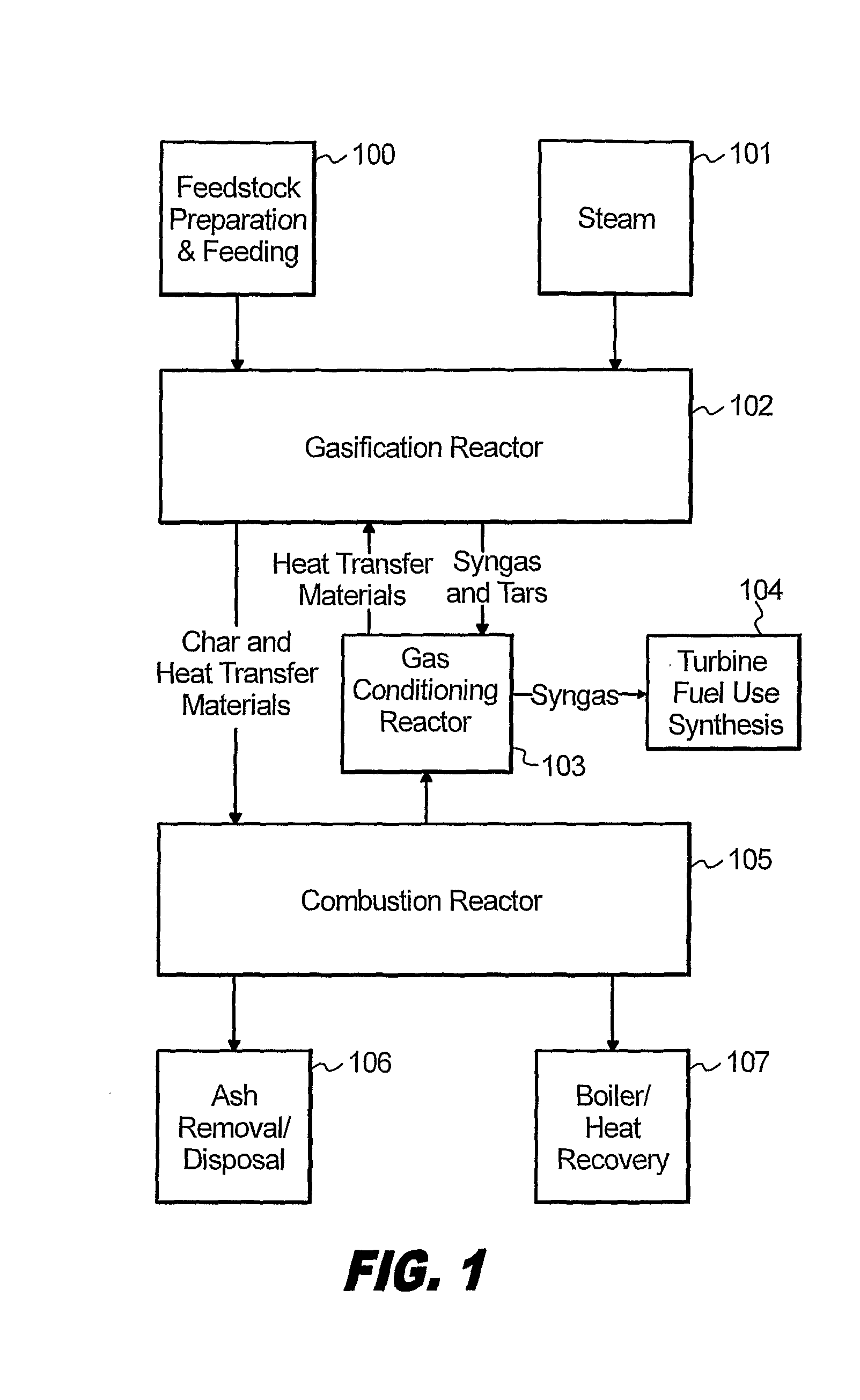

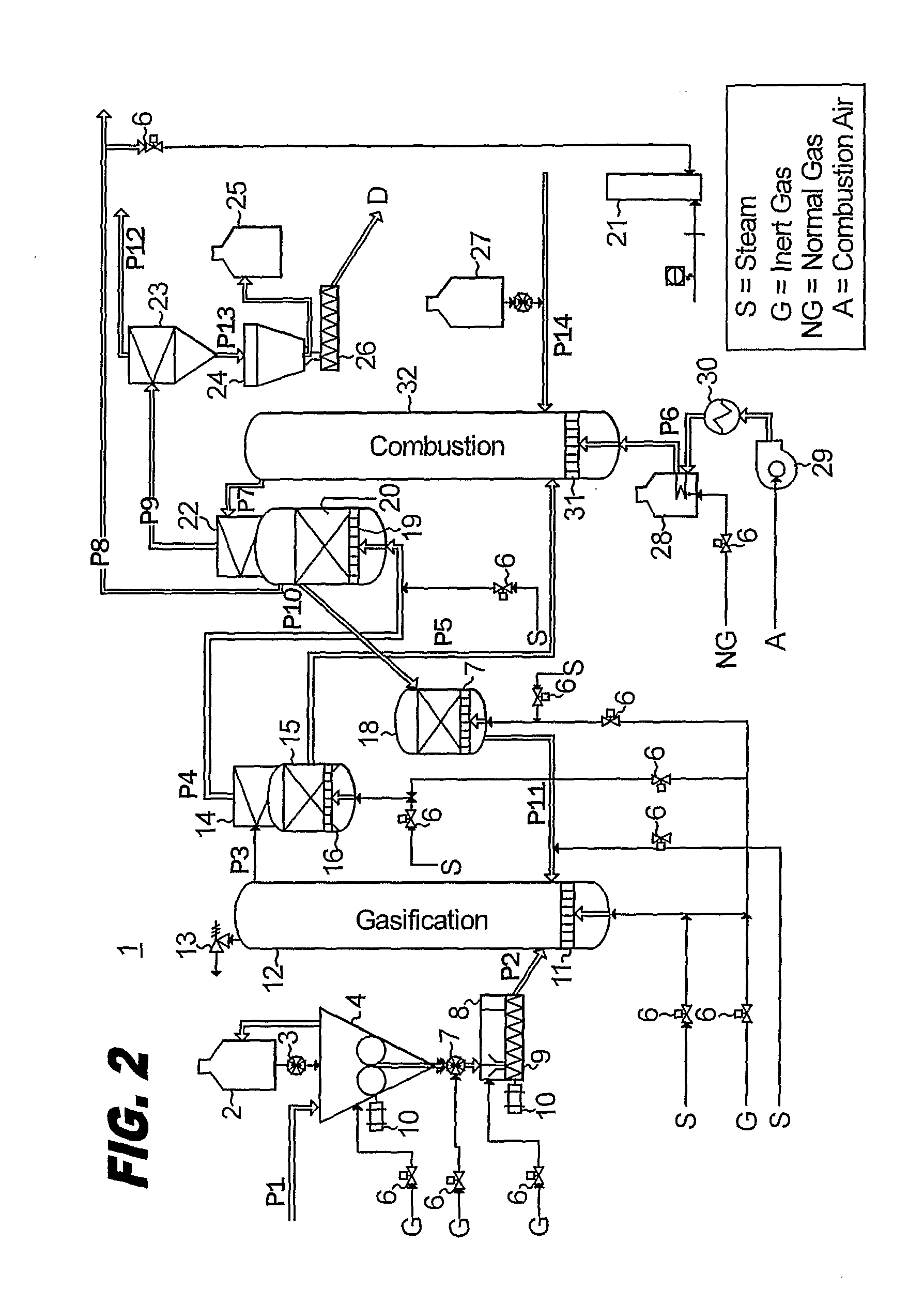

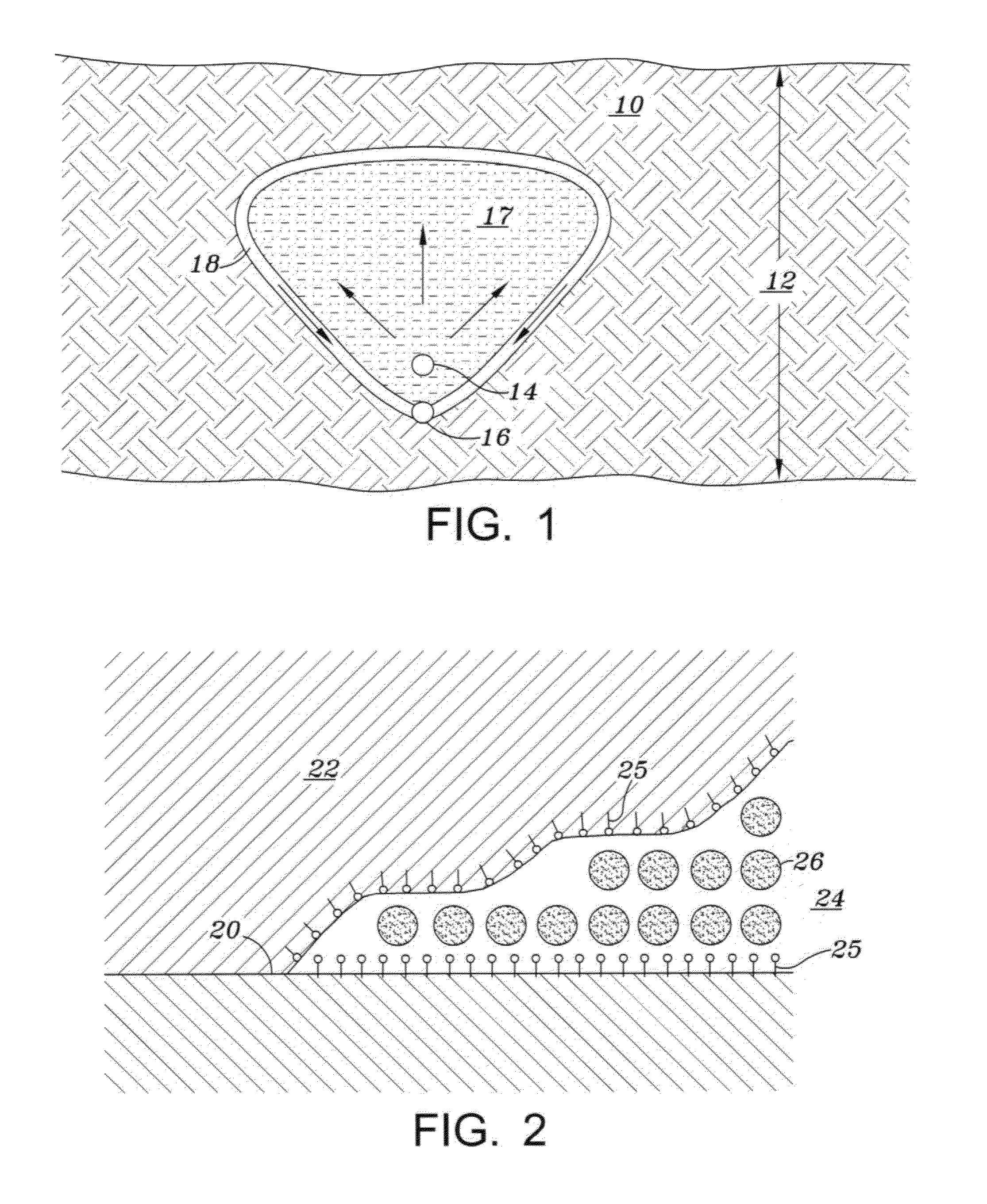

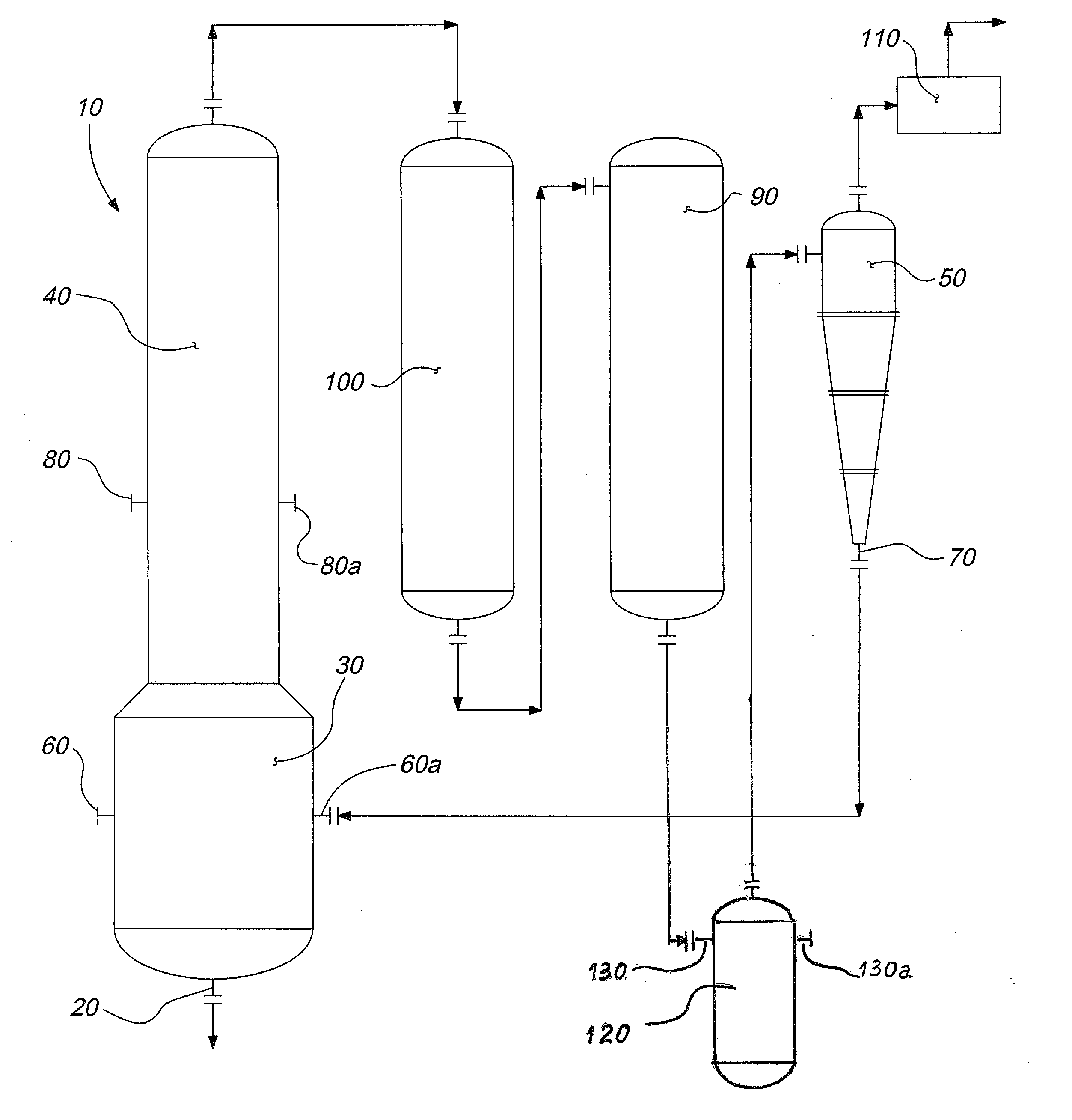

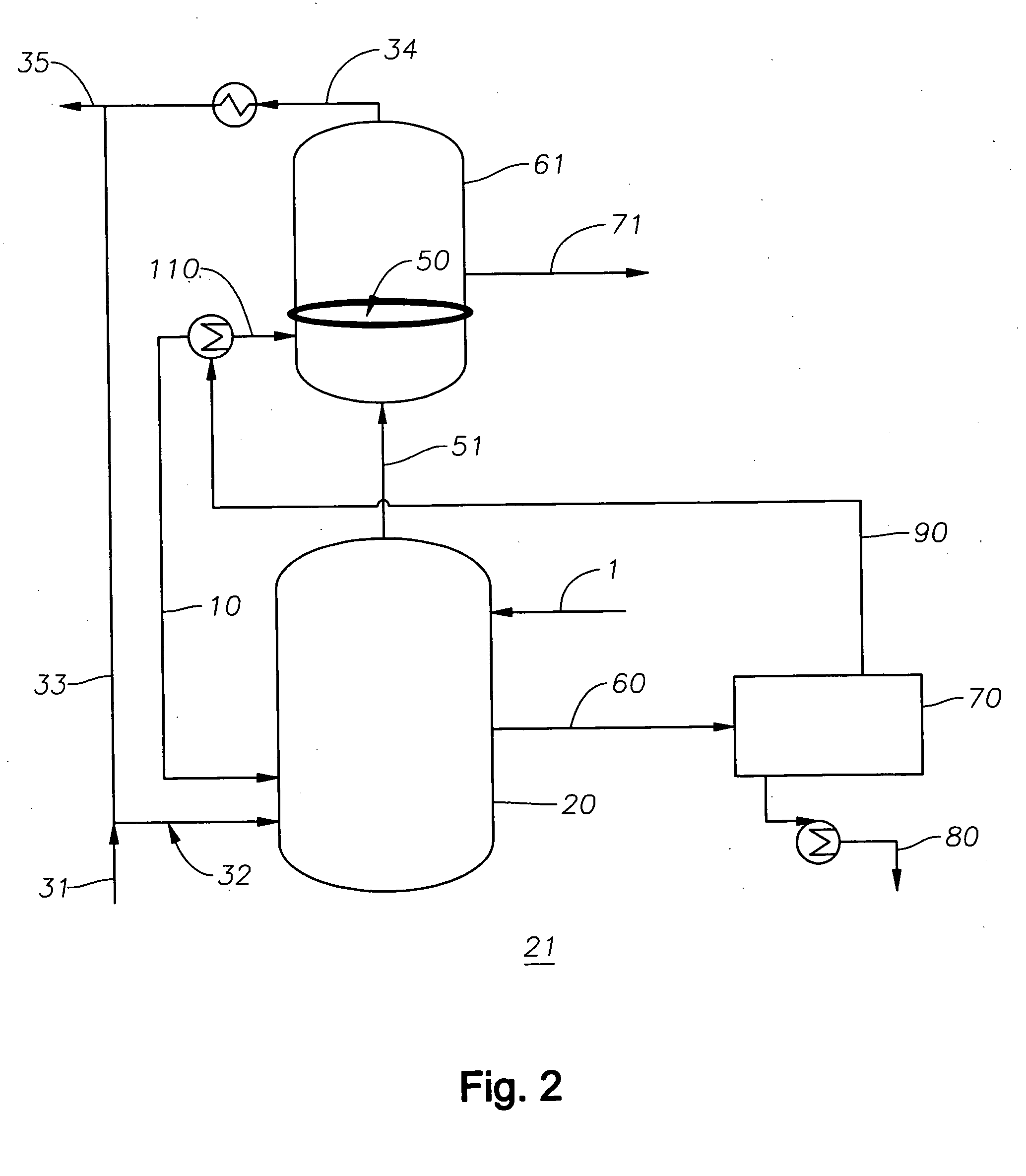

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

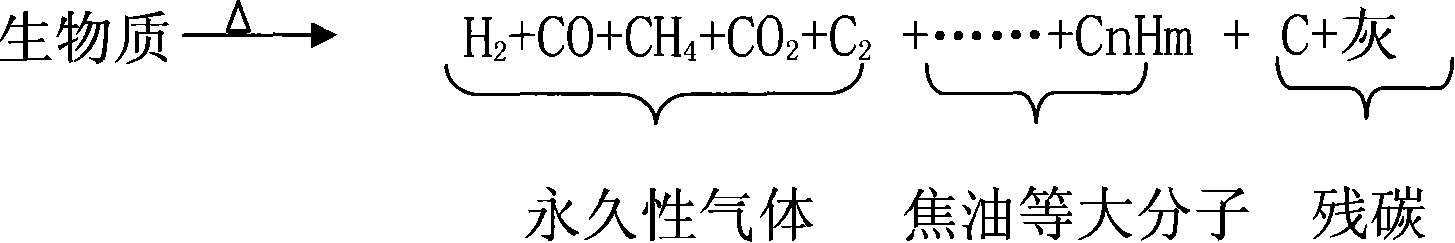

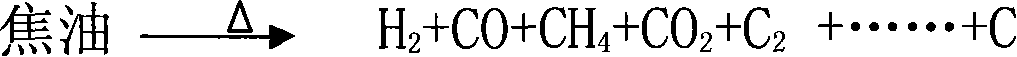

Low-tar biomass gasifying method and apparatus

InactiveCN1710023AWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

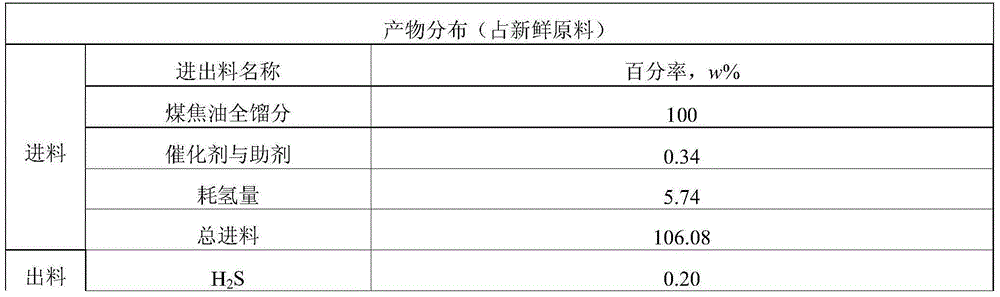

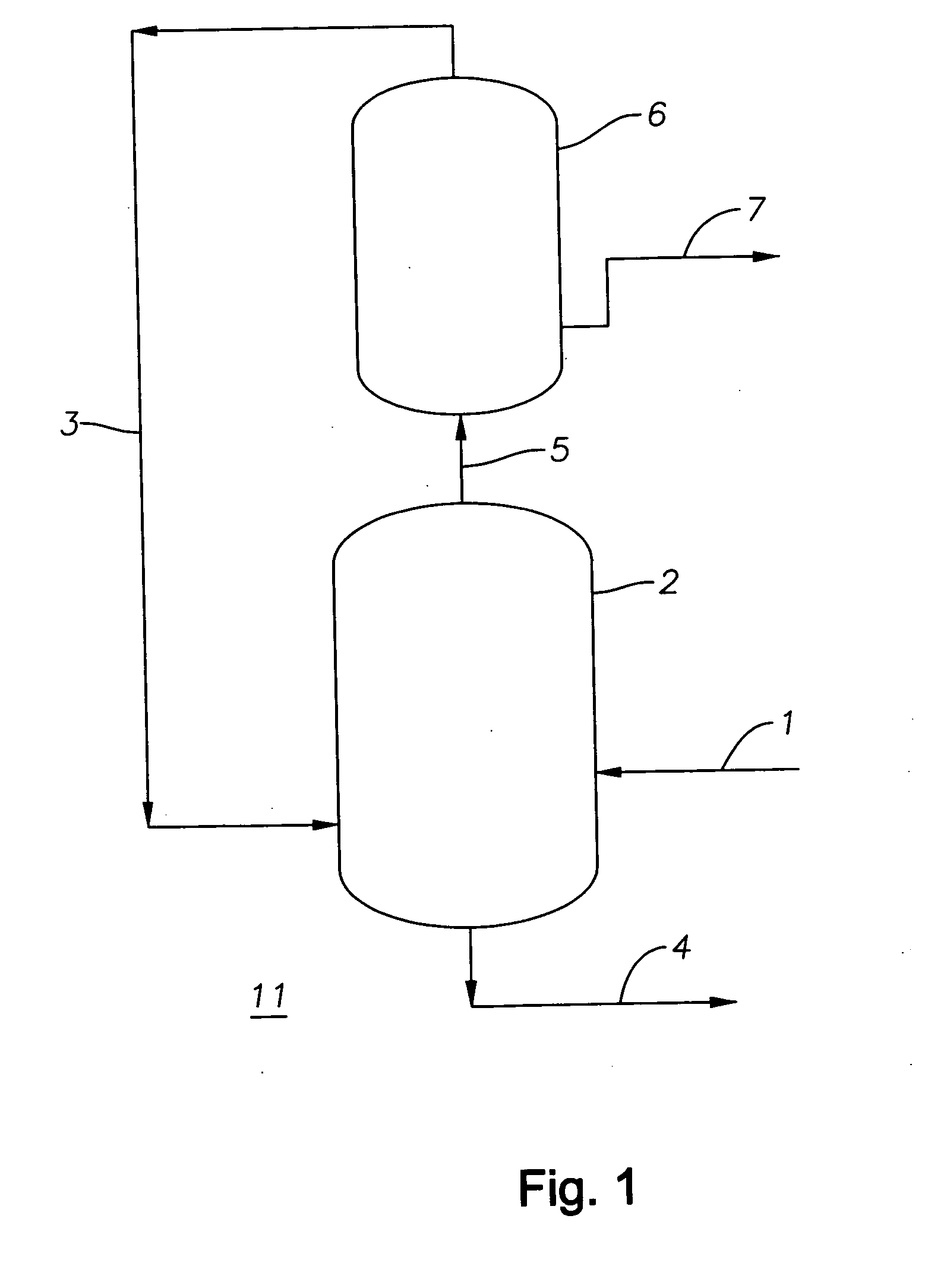

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

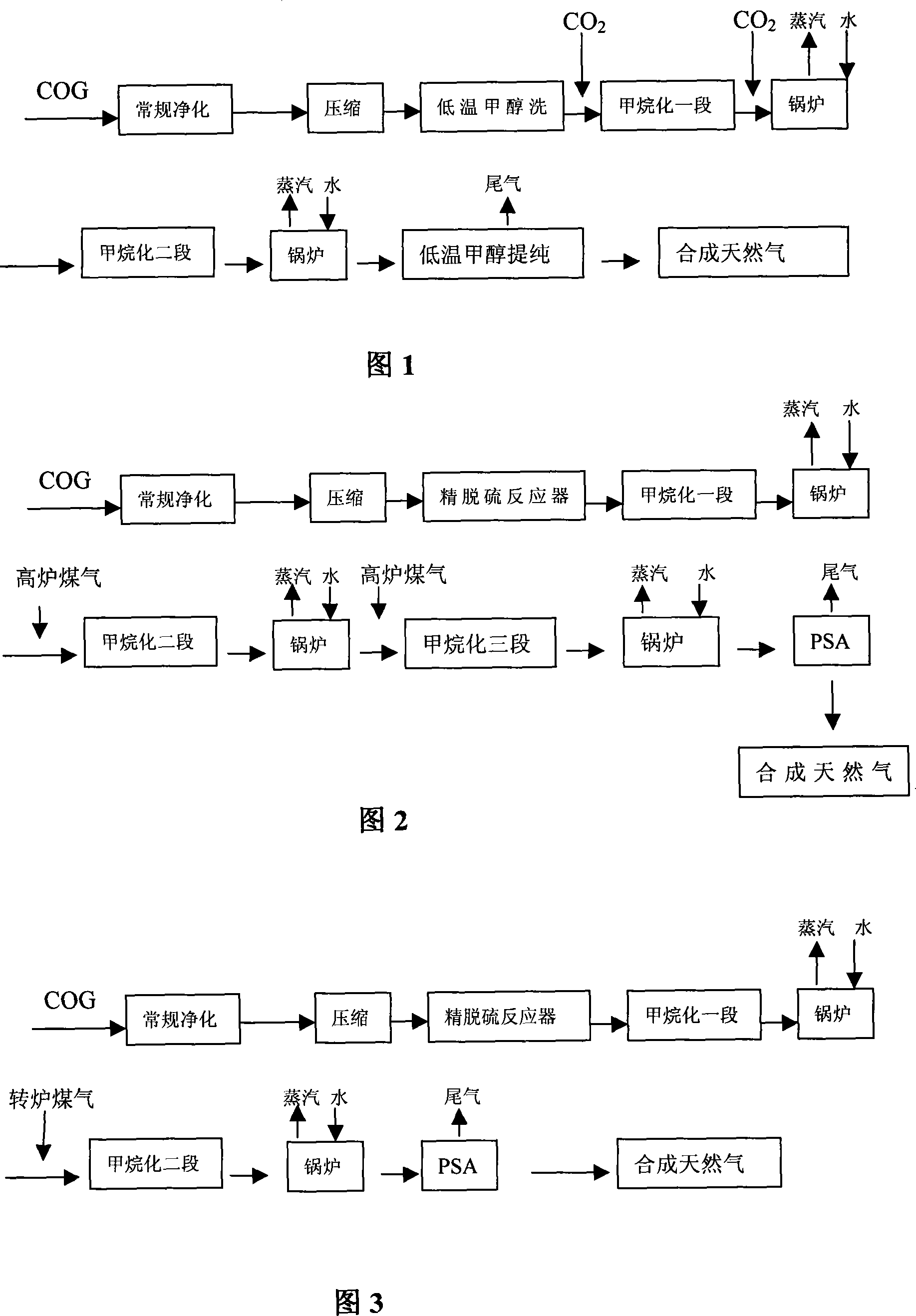

Method and device for synthesizing natural gas by using coke oven gas

A method for synthesizing and producing natural gas by hydrogen of coal gas and its synthesizer are disclosed. The process is carried out by purifying tar, crude removing sulfur, ammonia, benzene and naphthalene, compressing to 0.5-5.0 MPa, removing sulfur impurities, supplementing carbon 5-20 wt%, and methanation reacting to obtain final product. It saves energy resources and has no environmental pollution.

Owner:张文慧 +1

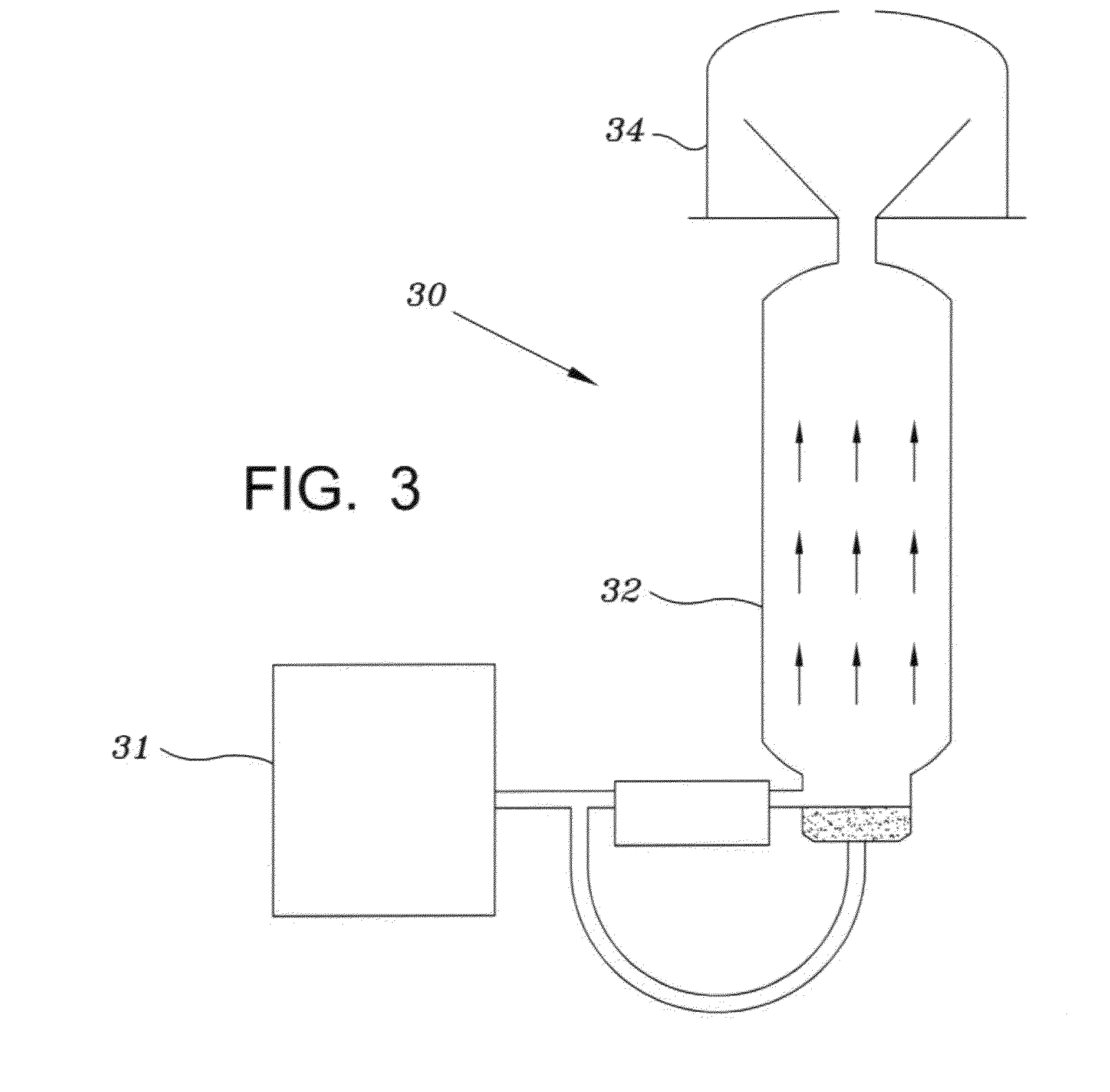

Method for Recovering Hydrocarbon from Tar Sand Using Nanofluid

InactiveUS20120255887A1Facilitated releaseFluid removalLiquid hydrocarbon mixture productionTarSlurry

Method for recovery of bitumen from tar sand is provided. An aqueous fluid containing a wetting agent and nanoparticles is injected into a first horizontal well at a temperature above reservoir temperature. Bitumen is released from sand grains and flows into a second horizontal well, where it is transported to surface. In a surface treatment facility, a slurry of tar sand is formed and surfactant and nanoparticles are added to the slurry.

Owner:FTS INT SERVICES

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

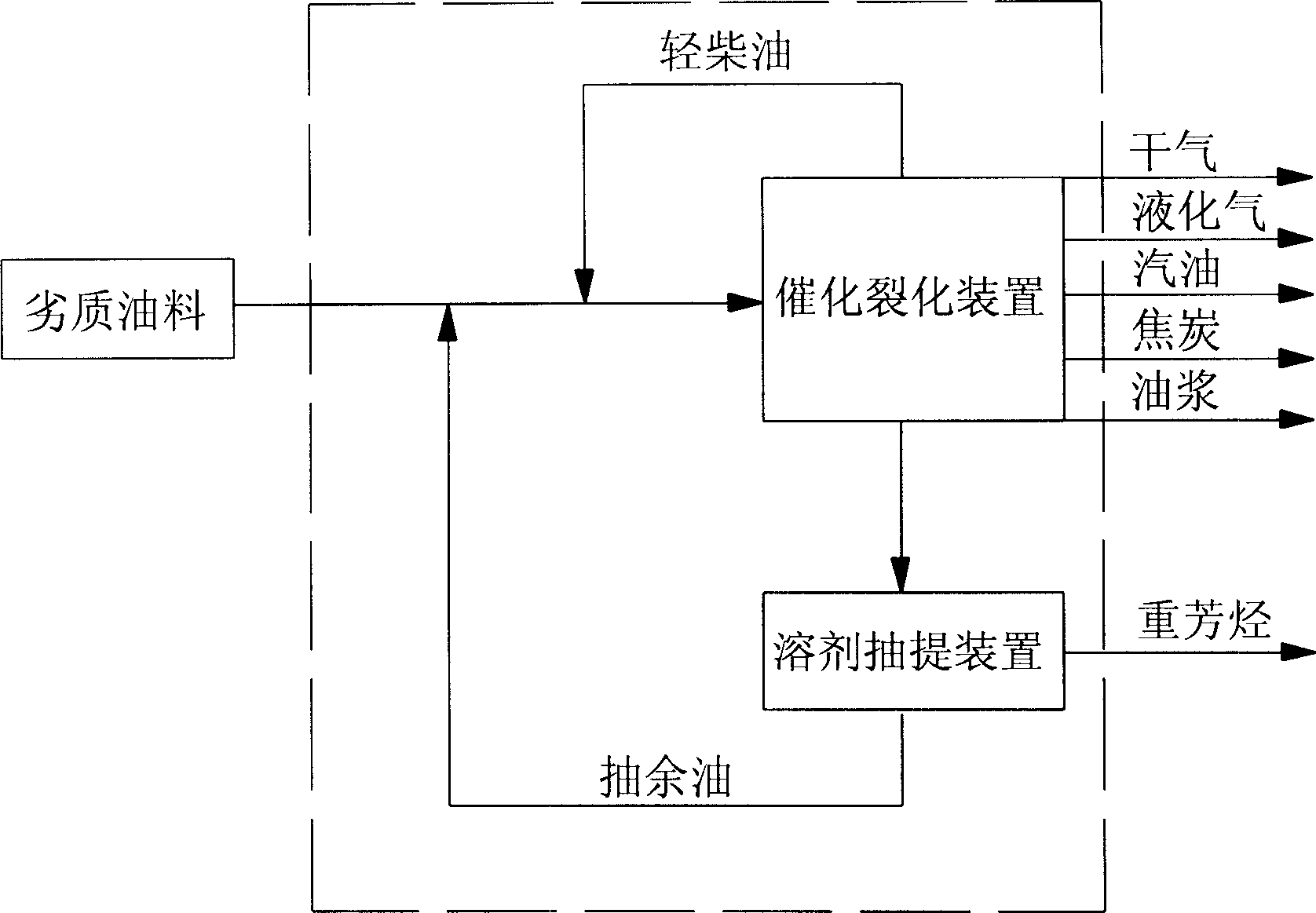

Catalyzing and cracking process of inferior oil

InactiveCN1746265AHigh yieldReduce unit consumptionCatalytic crackingHydrocarbon oils refiningResidual oilSolvent

A catalytic and cracking process of inferior oil is characterized by catalytic cracking the inferior oil to obtain light diesel fuel cut fraction, returning it to catalytic cracker to recycle, extracting the obtained heavy diesel fuel cut fraction from solvent, extracting residual oil and returning to catalytic cracker to recycle. It has higher recovery rate, better quality and more yield of product. It can be used for various inferior fuel heavy oils, catalytic raw materials, shale oil and coal tar.

Owner:邓先樑 +4

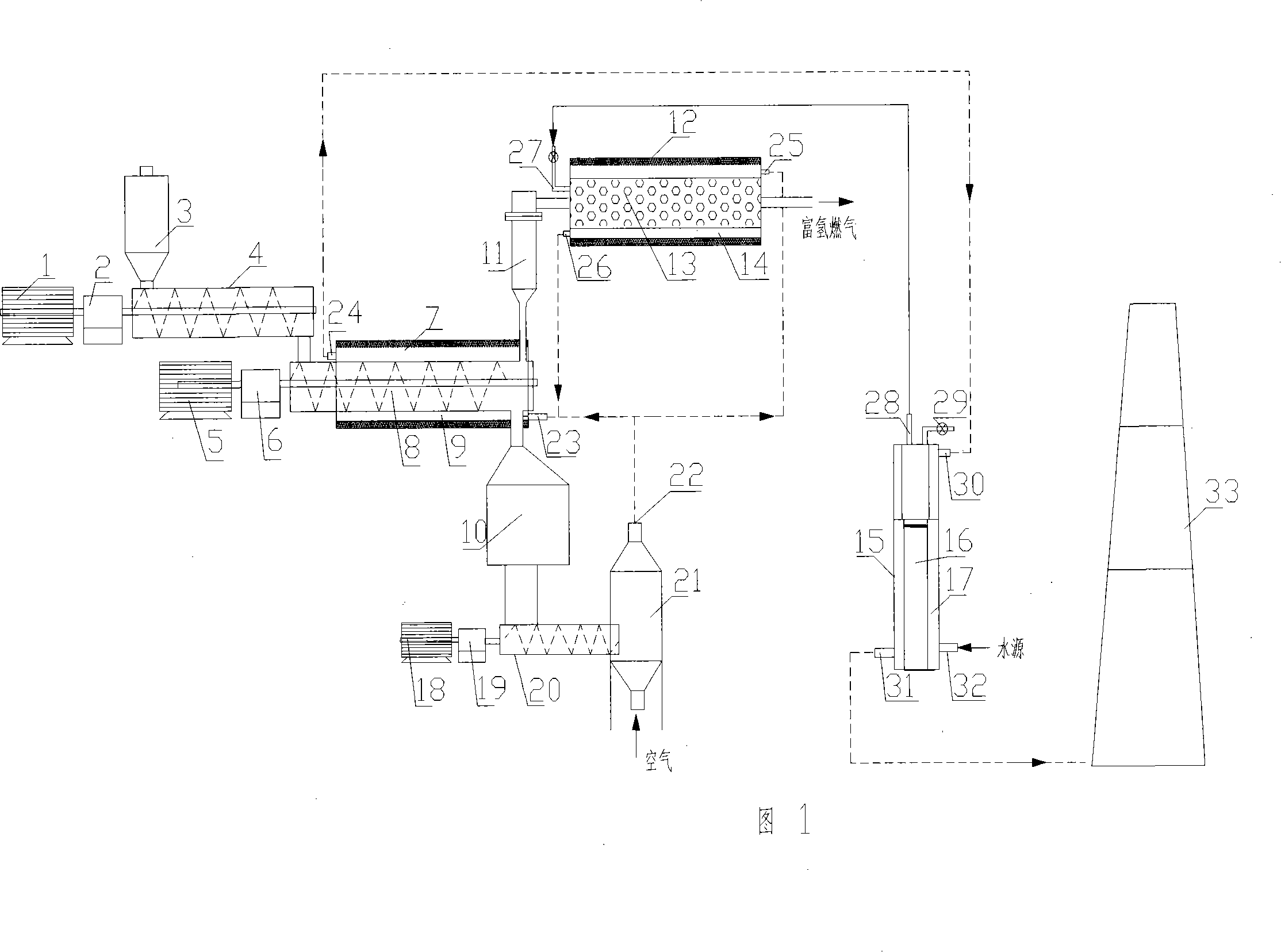

Method and device for preparing biomass hydrogen-rich combustion gas

InactiveCN101100621AReduce material requirementsReduce control requirementsHydrogenGaseous fuelsWater vaporGas phase

Production of biomass hydrogen-enriching fuel gas is carried out by thermal cracking for biomass raw materials at 550-650 deg. C under isolated air, converting it into gas-phase product and residual carbon, separating residual carbon from gas-phase product, transferring out of reacting system, burning to obtain heat energy, cracking at 800-950 deg. C and reforming into hydrogen, methane and other light hydrocarbons. It combines bitter spar catalyst and steam; it can eliminate tar, decrease methane content and increase hydrogen content. Hydrogen content reaches to 30%-55 wt%.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

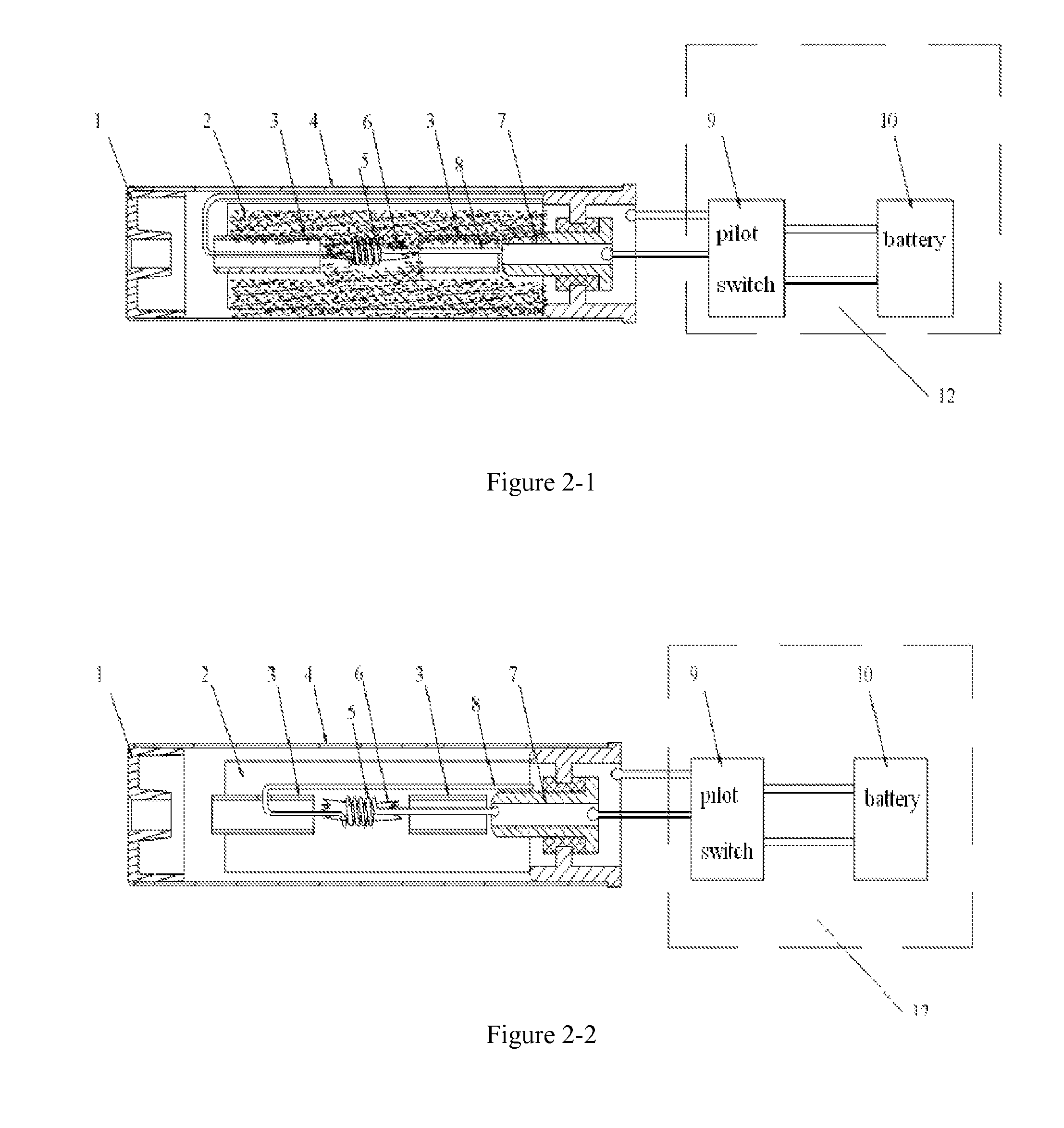

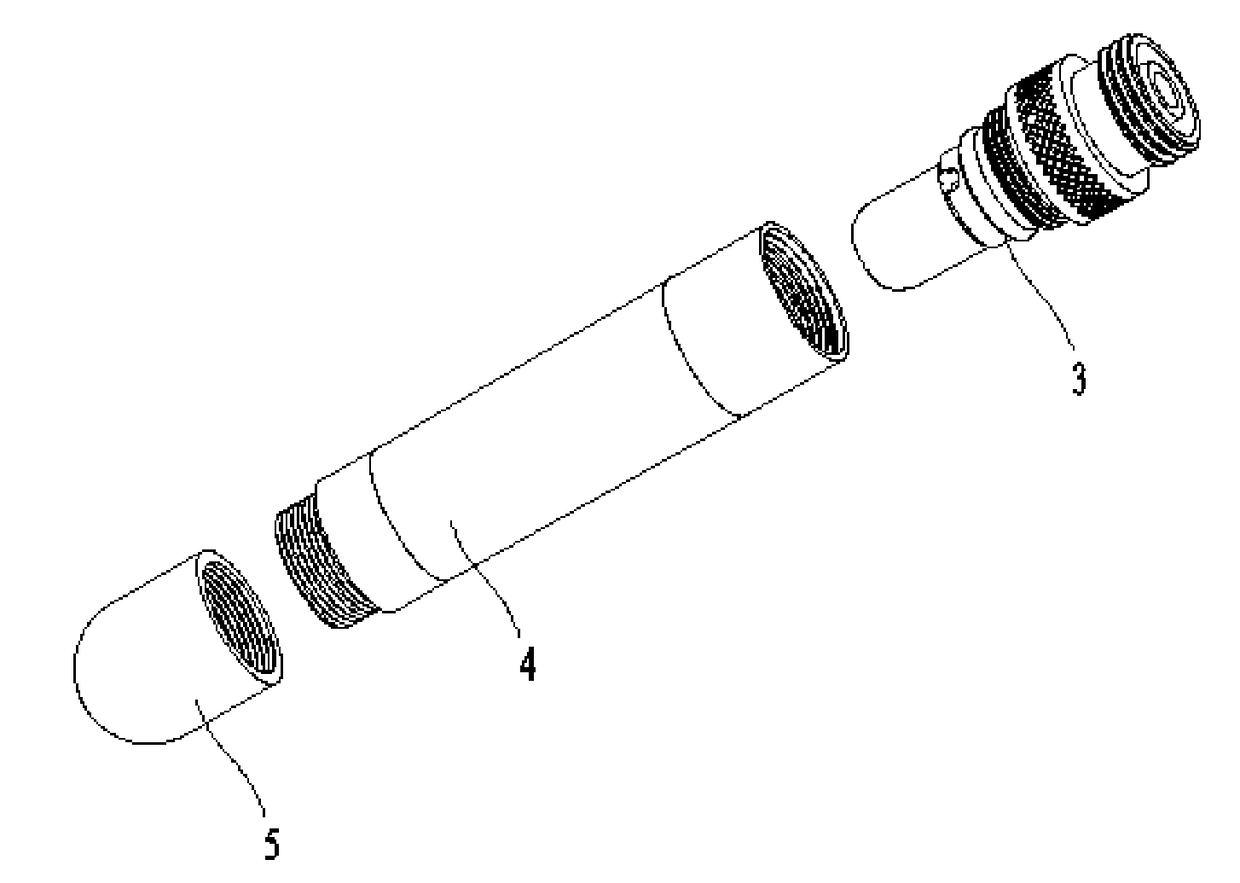

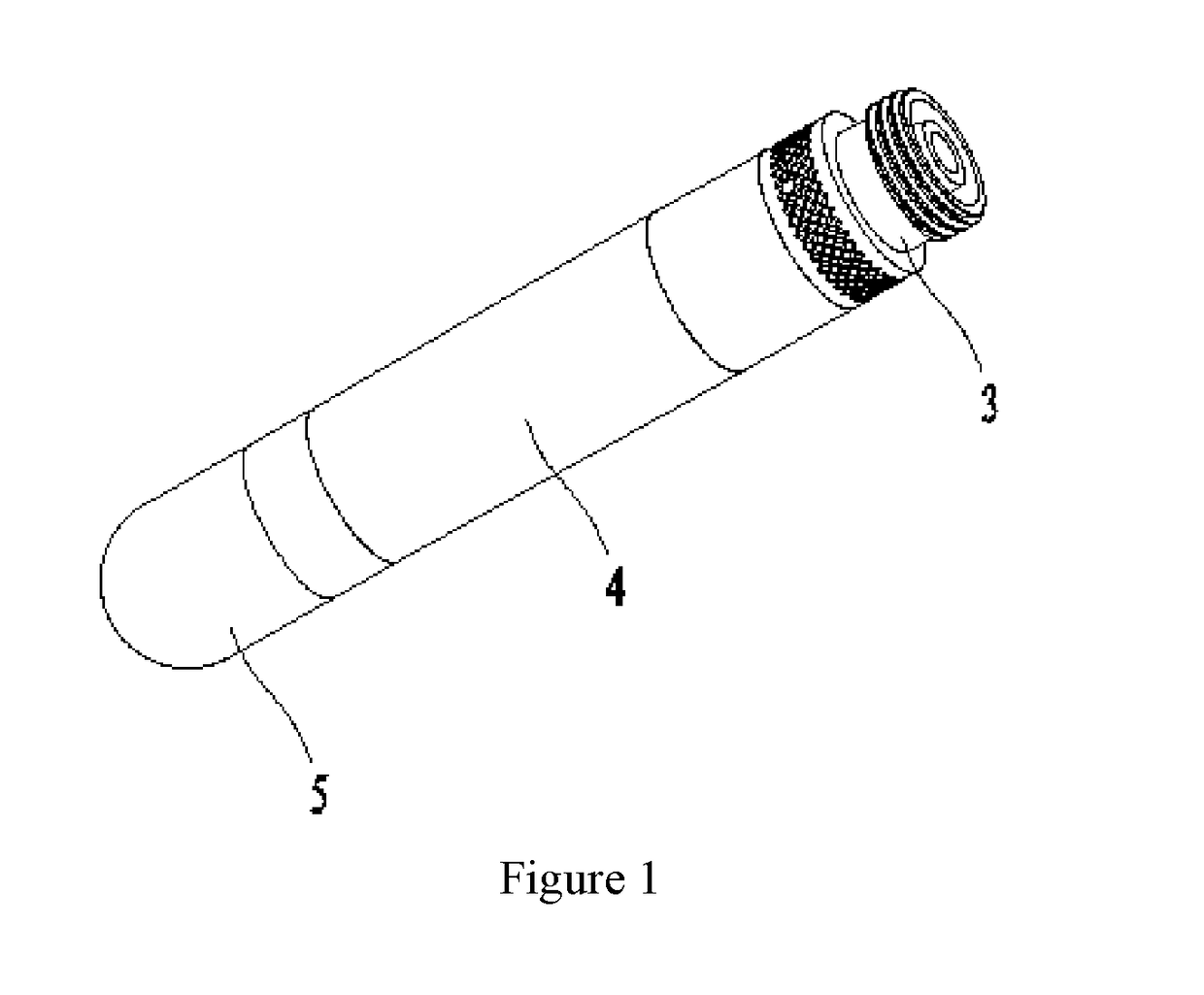

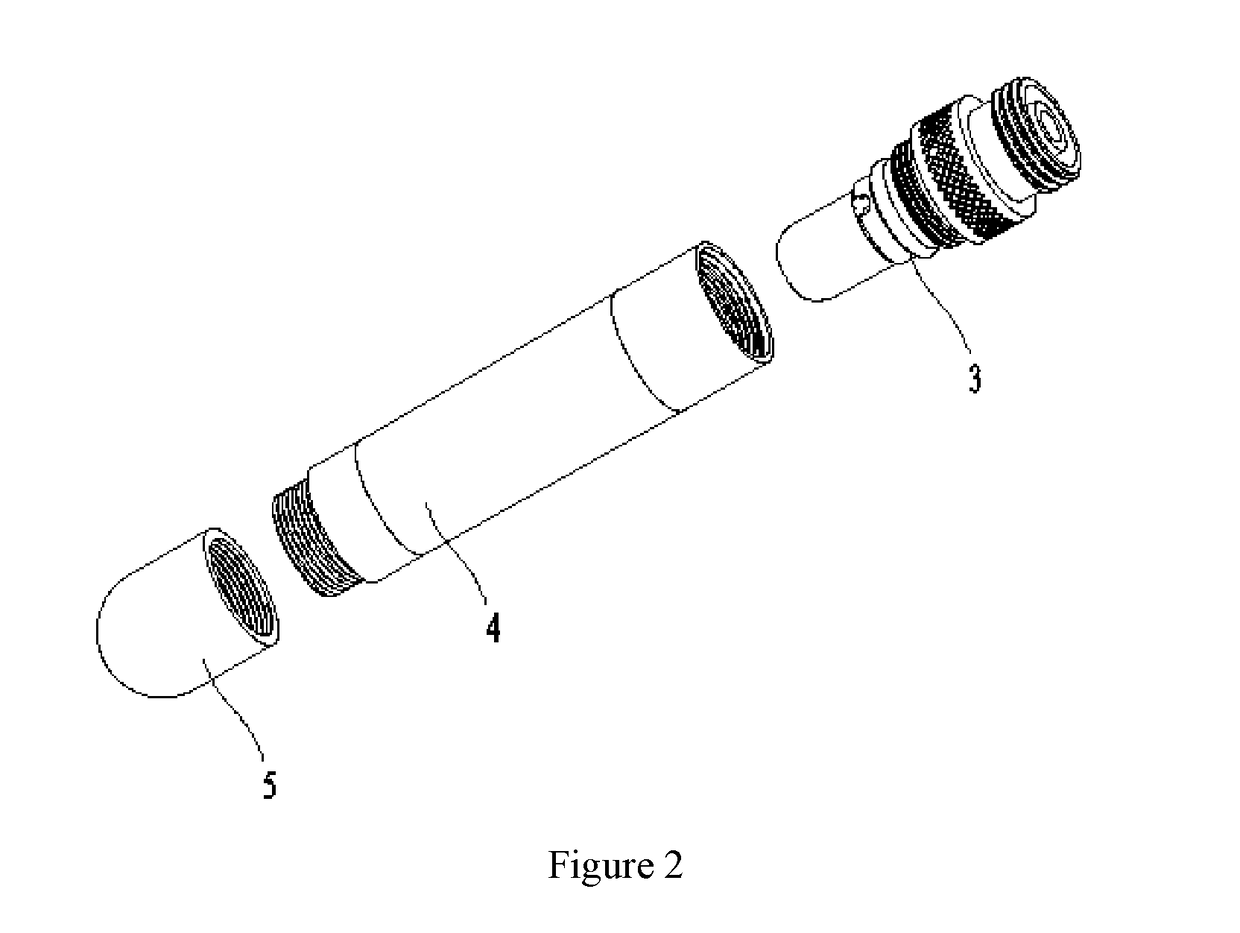

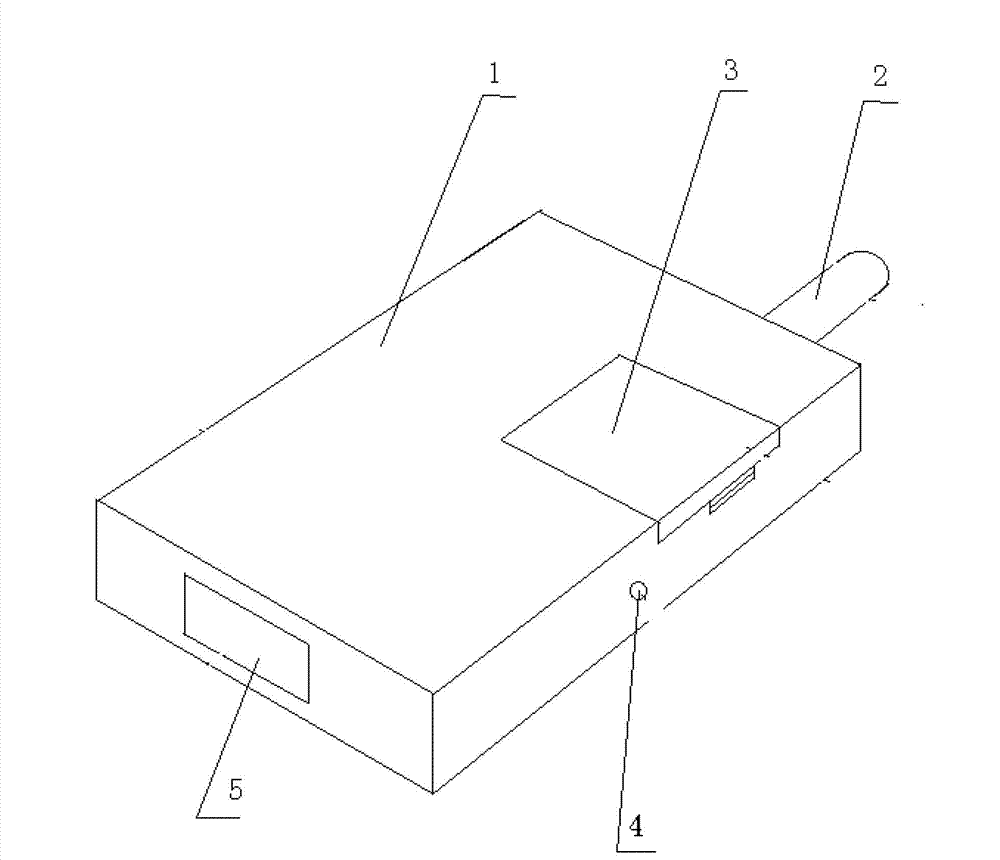

Electronic cigarette atomization device

An electronic cigarette atomization device is built in a disposable electronic cigarette or disposable smoke capsule electronic cigarette. The electronic cigarette atomization device comprises a tar storage (2) between the smoke capsule shell (4) of the electronic cigarette and a hollow tubular bracket (3), a smoking channel corresponding to the hollow tubular bracket (3), and a heating element (5) electrically connected to a battery (10) of the electronic cigarette at outlet of the tar storage in the channel. The heating element (5) and the axis of the hollow tubular bracket (3) form an angle of 10-90°, connection wires (8) at two ends of the heating element (5) are provided between the hollow tubular bracket (3) and the smoke capsule shell (4), electrically connected to the battery (10).

Owner:KIMSUN TECHHUIZHOU CO LTD

Method of extracting phenolic compound from coal liquefied oil or coal tar

ActiveCN102219649AHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationWater vaporCoal chemical industry

The invention relates to the field of coal chemical industry, and more specifically relates to a method of extracting phenolic compounds from coal liquefied oil or coal tar. The method comprises the following steps: 1) distilling coal liquefied oil or coal tar and cutting to obtain fractions at a temperature of 260 DEG C; 2) mixing an extractant with the obtained fractions and layering the extractant; 3) separating and collecting the extractant layer which contains phenolic compounds; 4) carrying out multistage back extraction on the phenolic compounds so as to obtain a stripping agent-phenol solution and an extractant; 5) separating the stripping agent-phenol solution by rectification, recovering the stripping agent for cyclic utilization, and carrying out separation to obtain crude phenols; 6) removing entrained neutral oil in phenolic compounds by water vapour so as to obtain crude phenol products. The method of extracting phenolic compounds from coal liquefied oil or coal tar provided in the invention avoids the usage of soda acid, exerts no influence on subsequent treating processes, and guarantees high recovery rate and purity of phenols.

Owner:CCTEG CHINA COAL RES INST

Visible heating atomizing cigarette

The invention discloses a visible heating atomizing cigarette which comprises a cigarette body and a cigarette holder. The cigarette body comprises a heating area, an atomizing area and a power source area. The heating area, the atomizing area and the power source area of the cigarette body are sequentially communicated with the cigarette holder through an airflow channel. A case of the heating area is made of heat-insulating transparent materials. Tobacco shreds or remanufactured tobacco leaves are filled in the heating area. Heating wires are arranged between the case and the tobacco shreds. A liquid storing cavity is formed in the atomizing area. The liquid storing cavity is connected with an atomizer in the power source area. The power source area is formed by electrically connecting a battery, a control circuit, a pneumatic inductive switch and the atomizer. When the visible heating atomizing cigarette is burnt and smoked, a user can breathe mixed smoke which is generated after heating of the tobacco shreds and atomizing of fragrance into the mouth through suction, and the sucking effect which is the same as that of a common cigarette is achieved. The visible heating atomizing cigarette has the dual advantages of electronic cigarettes and electrical heating cigarettes and is large in smoke amount, the amount of released harmful ingredients can be reduced greatly, tar cannot be generated, harm of passive smoking and the smoke of side flowing are avoided, and the visible heating atomizing cigarette is an effective substitute of a traditional combustible cigarette.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

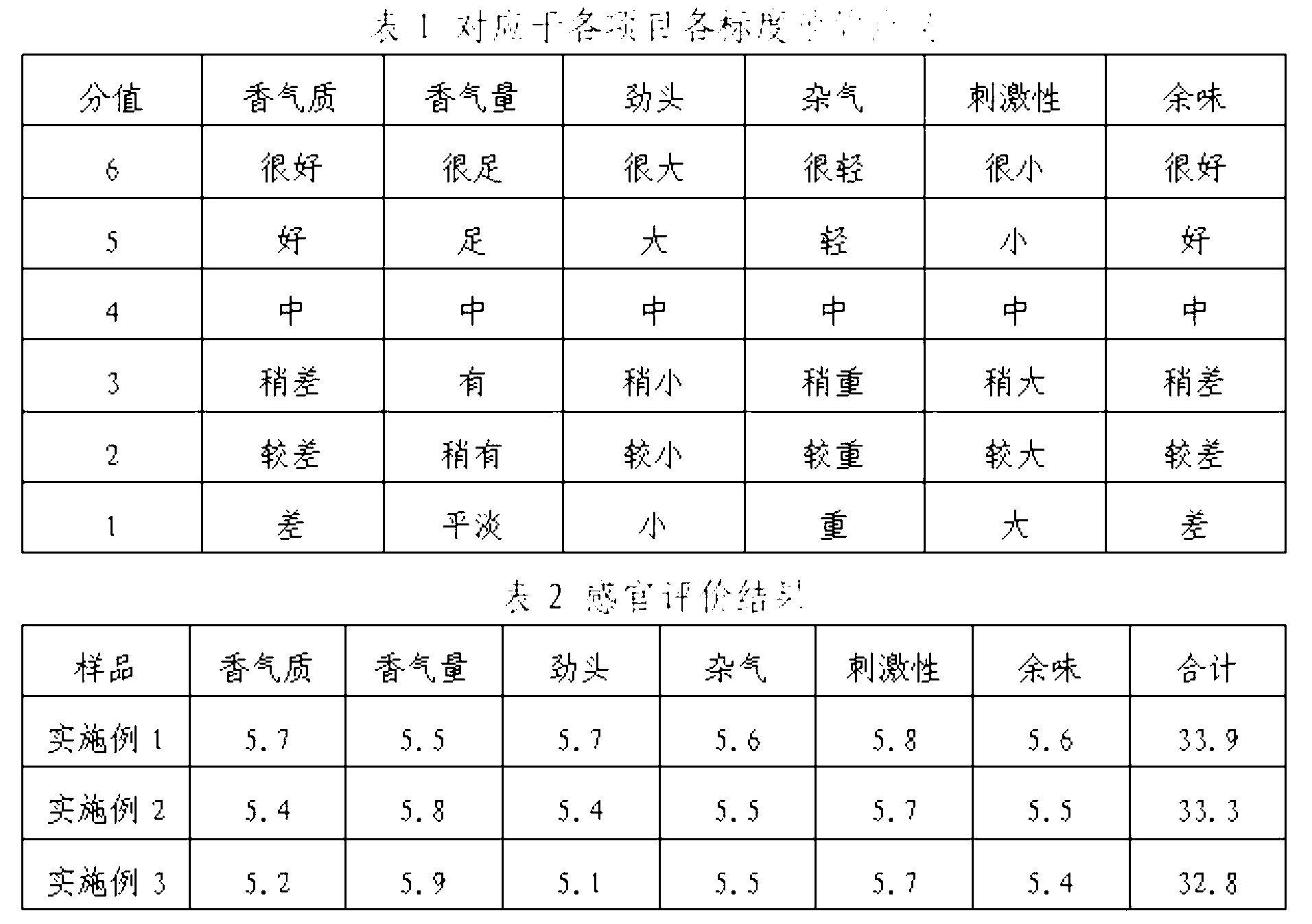

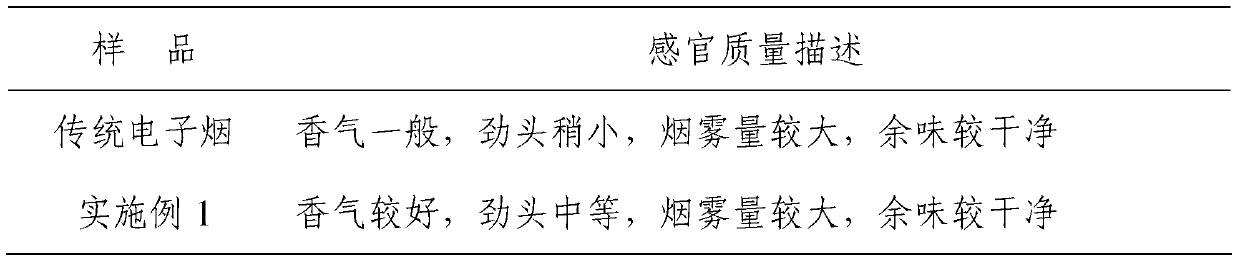

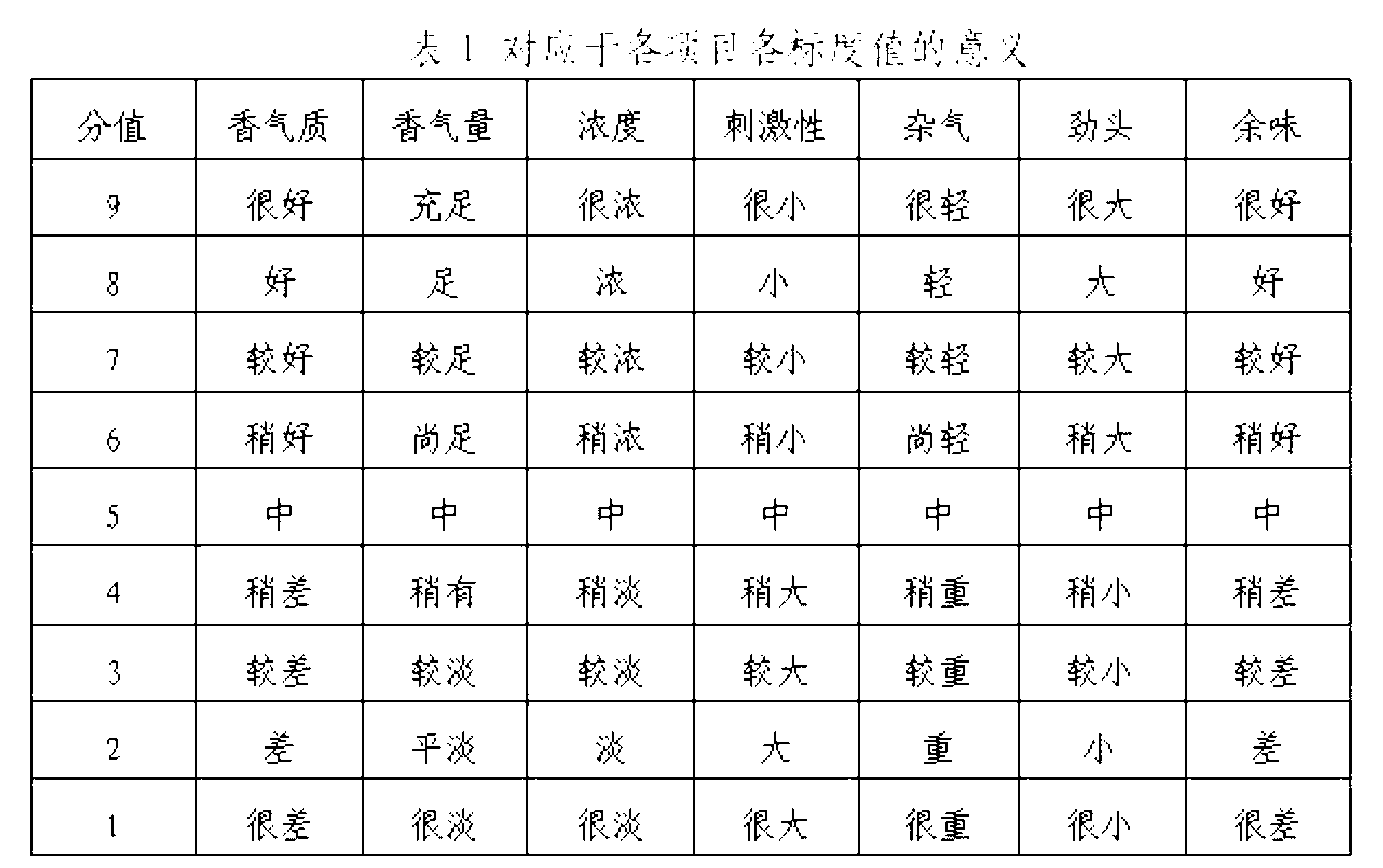

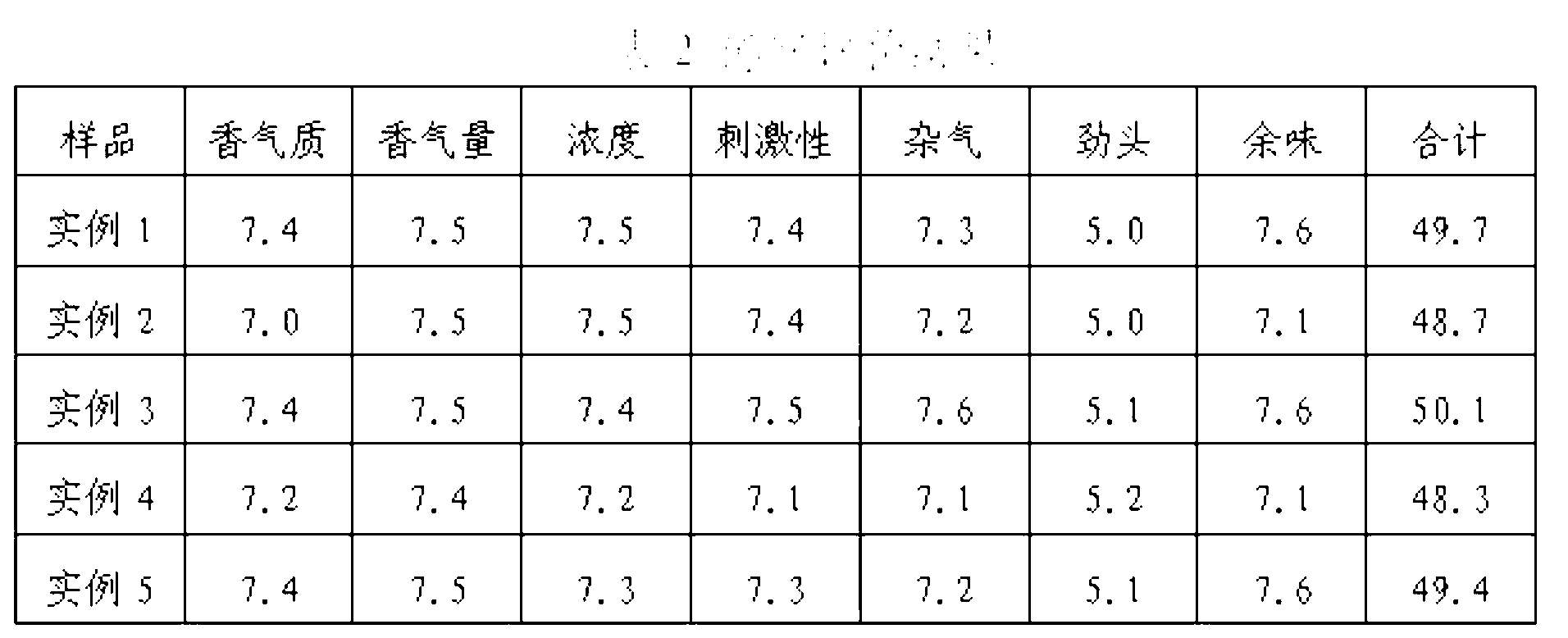

Electronic cigarette liquid capable of effectively improving sensory quality of electronic cigarette

The invention discloses electronic cigarette liquid capable of effectively improving sensory quality of an electronic cigarette, and the electronic cigarette liquid is prepared by uniformly mixing 5 to 10 percent of extract of red-flower Dajinyuan tobacco leaves produced in Yunnan province, 5 to 9 percent of essence for cigarettes, 1 to 5 percent of spice for the cigarettes, 5 to 15 percent of deionized water, 10 to 20 percent of glycerol and balance of propylene glycol. The electronic cigarette liquid is used for atomizing the electronic cigarette, no tar and carbon oxide (CO) is produced, harm on consumers can be greatly reduced, and no harm of second-hand smoking is produced through the application of the product; the extract of the red-flower Dajinyuan tobacco leaves not only provide nicotine, but also provide abundant tobacco characteristic fragrant substances, so that the sensory quality of the electronic cigarette is closer to that of the traditional cigarette; and due to the adoption of the essence and the spice for the cigarette, the fragrance quality and the fragrance quantity of the electronic cigarette can be enhanced, and the satisfactory of the consumers can be improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

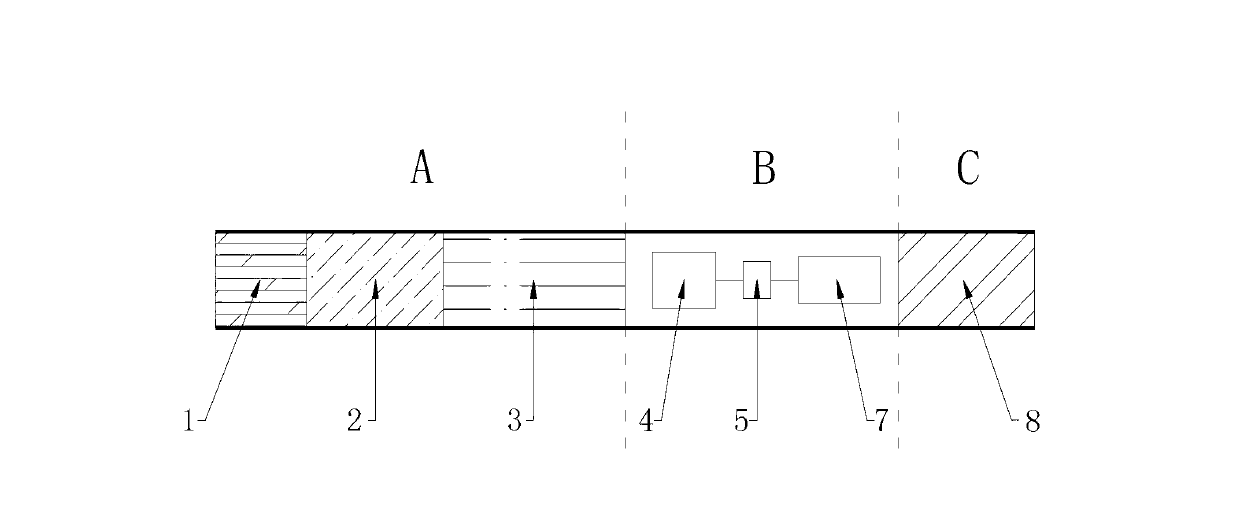

Novel carbon heating electronic cigarette

InactiveCN103271447AImprove the problem of insufficient smoke aromaReduce releaseTobacco devicesPipe TobaccoTar

The invention discloses a novel carbon heating electronic cigarette which is formed by a carbon heating area, an electronic atomization area and a cigarette holder in sequence. The carbon heating area, the electronic atomization area and the cigarette holder are separated one another through breathable partition plates. The carbon heating area is formed by a carbolic matter heat source, an aerosol forming part and a fragrance forming part in sequence. The electronic atomization area is formed by connecting a power supply, an atomizer and a liquid storage cavity electrically. The cigarette holder is a conventional cellulore filter stick. When the novel carbon heating electronic cigarette is sucked, the carbolic matter heat source heats aerosol forming matters and pipe tobacco to form aerosol, sucked airflow triggers a pneumatic inductive switch to be opened, the atomizer works, tobacco liquid in the liquid storage cavity is atomized to form smog, and the smog and the aerosol are sucked into a mouth. The novel carbon heating electronic cigarette integrates advantages of carbon heating type cigarettes and advantages of electronic cigarettes, is novel in appearance and easy to manufacture, does not generate sidestream gas, can meet requirements for cigarette fragrance and nicotine of a consumer, and is low in the content of tar and harmful ingredients.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

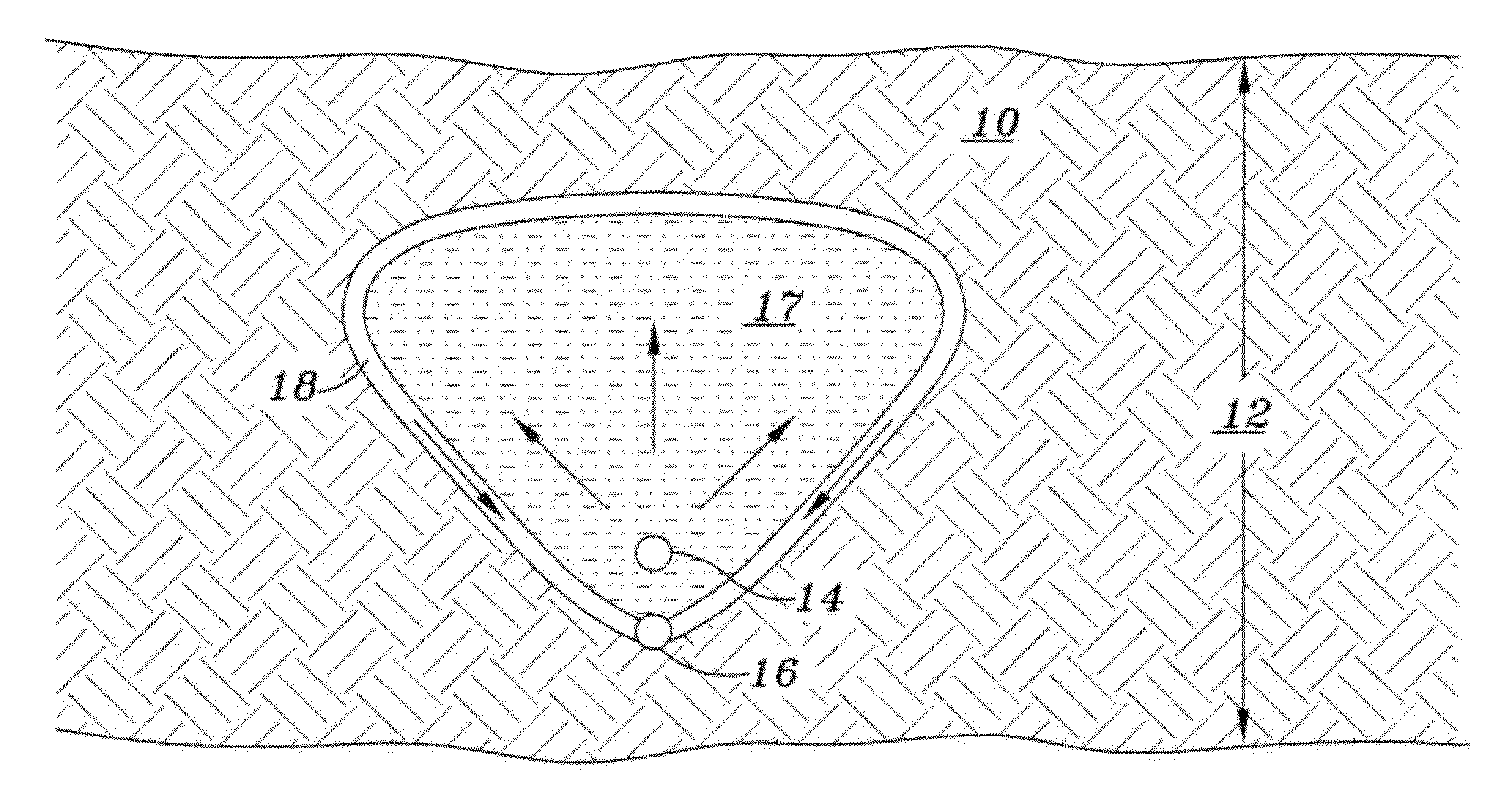

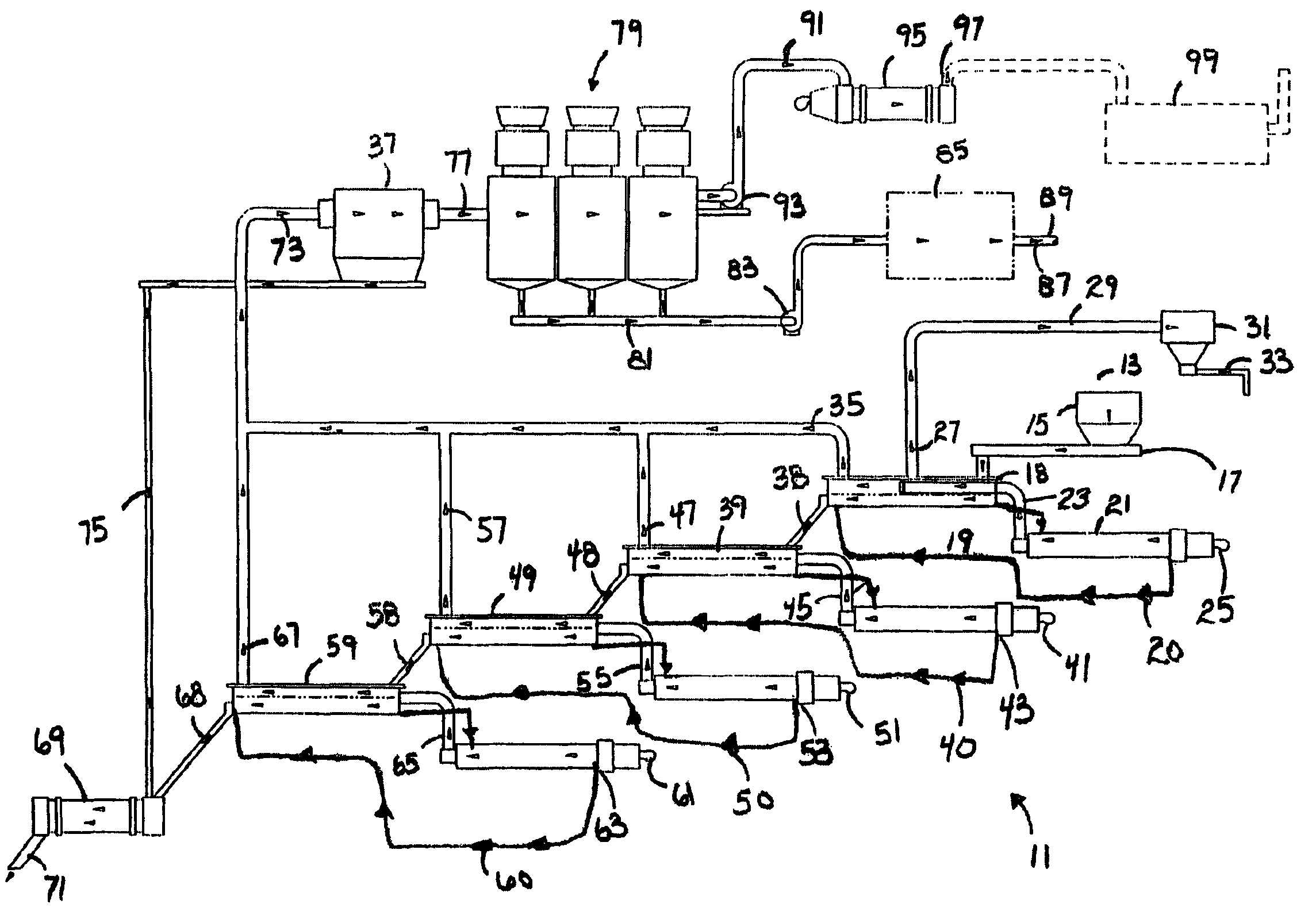

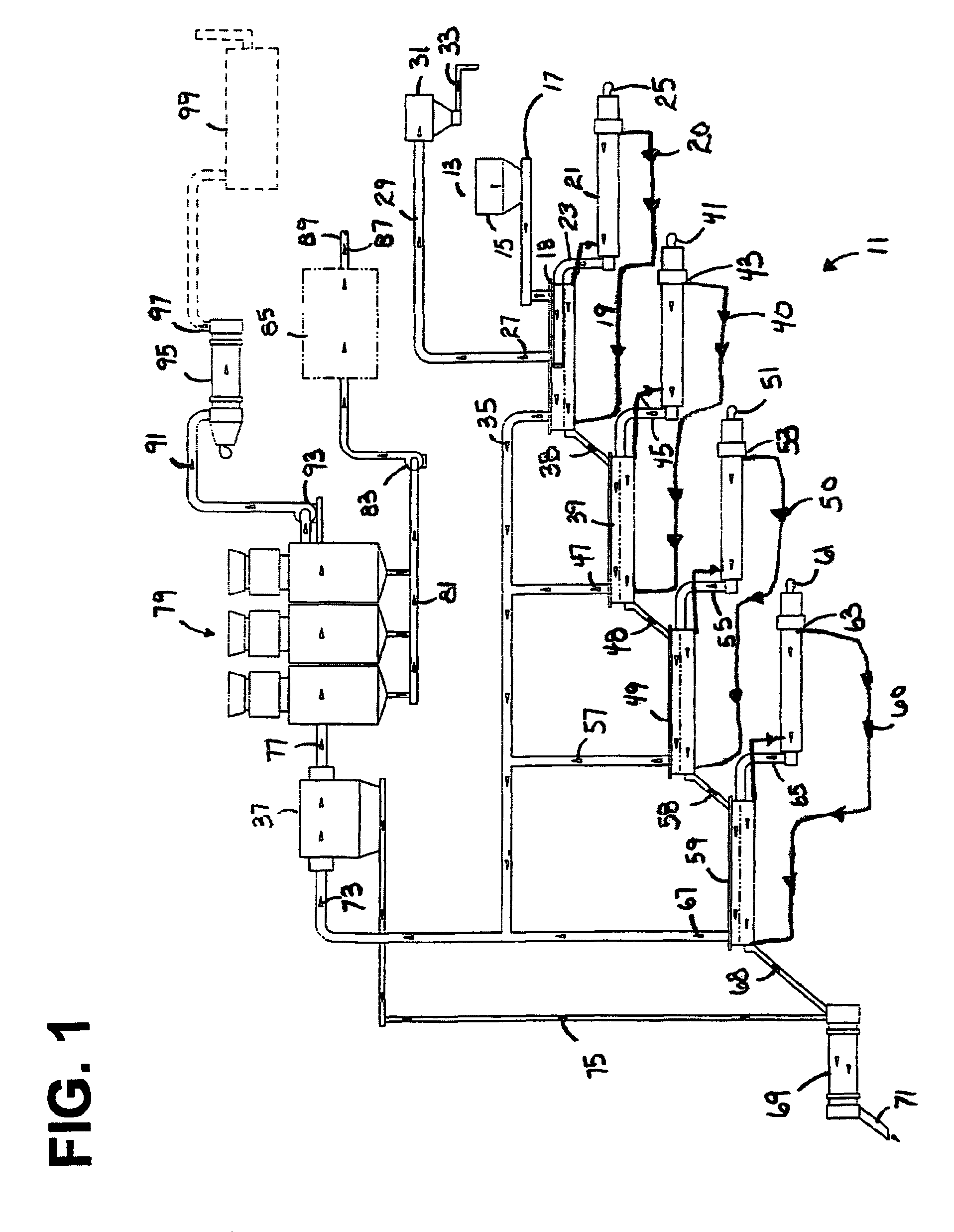

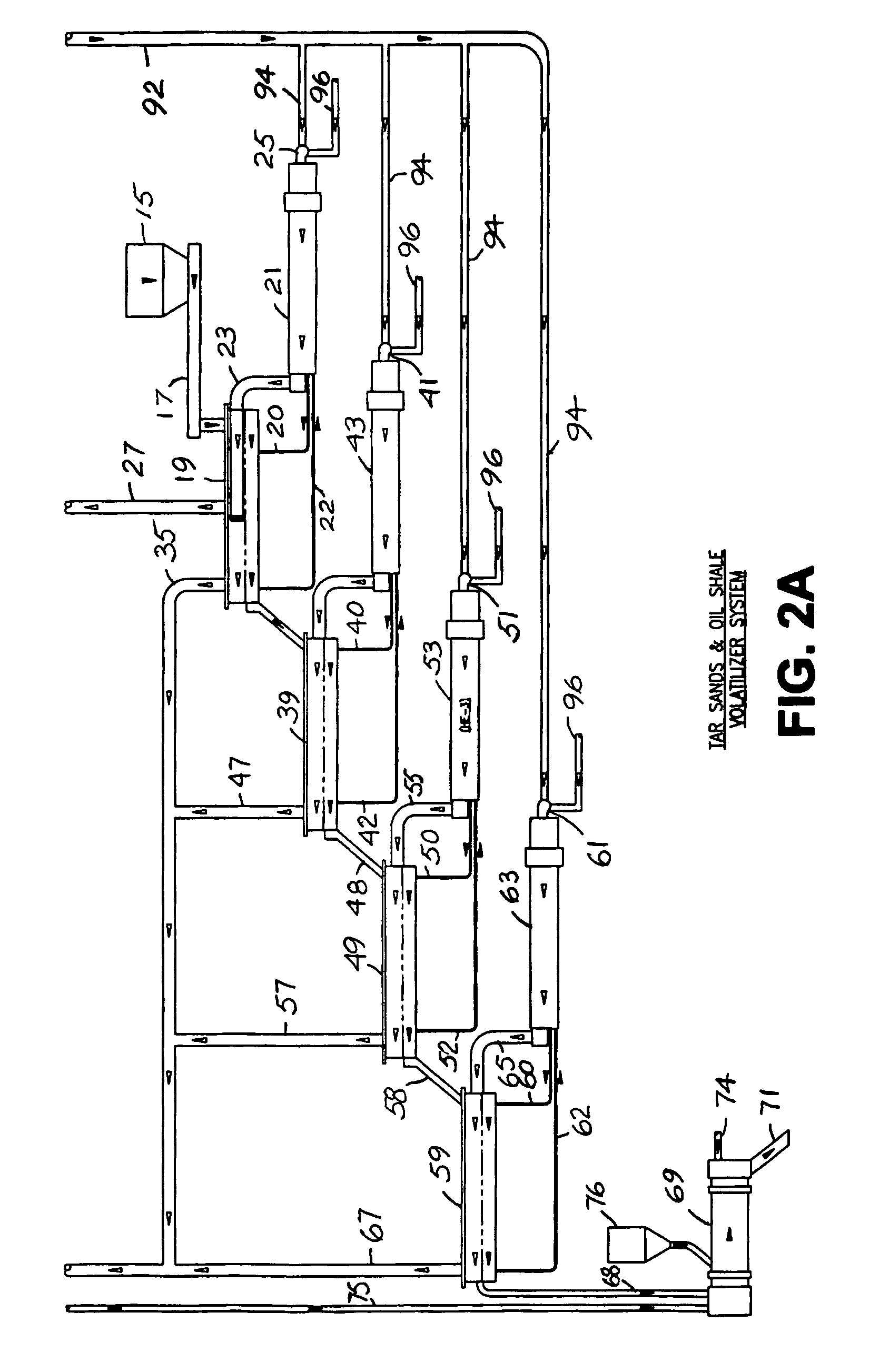

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

Filtering material for cigarette filter tip and its preparation method

ActiveCN101103845AEasy to shapeConducive to the manufacture of cigarettesTobacco preparationTobacco treatmentEconomic benefitsTar

The invention discloses a filter material for cigarette filter and the preparation method. Based on the expanded cabo particles from <The Preparation Method of an Expanded Cabo Particles and Relevant Equipment> (Application No.: 200710065892.3), the expanded cabo particles are extracted, shaped and selected as so to become the required filter material. The filter material utilizes the waste in the cigarette production, which not only has significant economic benefits, but also is not necessary to be recycled, and will not cause the abrasion of equipment and affect the sensory quality of cigarette. The filter material is uniformly arranged on the filter tows so as to make a composite filter; as the composite is applicable to the cigarette, the smell of the cigarette will be more clear and soft, and the tar and nicotine content in the smoke gas can be reduced effectively. The invention has the advantages that: the operation is simple; the effect is remarkable, therefore the invention has a good applicable prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

Atomization assembly and electronic cigarette

InactiveUS20170143040A1Easy to disassemblePromote sheddingOhmic-resistance waterproof/air-tight sealsTobacco devicesTarCoal tar

The present invention discloses an atomization assembly and an electronic cigarette. An atomization assembly comprises a transparent atomization sleeve. One end of the atomization sleeve is connected to a connection column, and the other end of the atomization sleeve is detachably connected to an atomization core configured to atomize smoke tar. A vent-pipe with two ends being inserted into the connection column and the atomization core respectively is sheathed in the atomization sleeve, and a first oil storage container for storing the smoke tar is formed between the atomization sleeve and the vent-pipe. The following advantageous effects can be achieved: the user can disassemble the suction nozzle cover at regular time to clean the liquid smoke stored in the oil storage container; besides, it is convenient to change the atomization core, to view the residual smoke tar and to add the smoke tar.

Owner:HUIZHOU KIMREE TECH

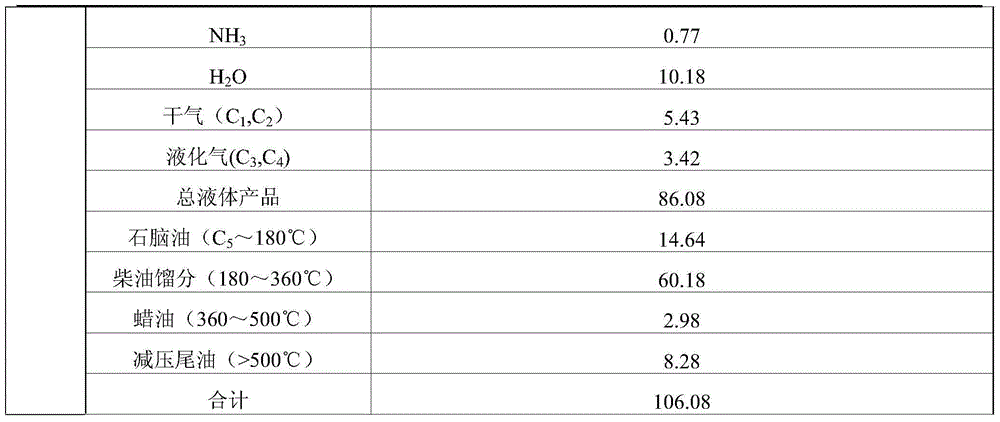

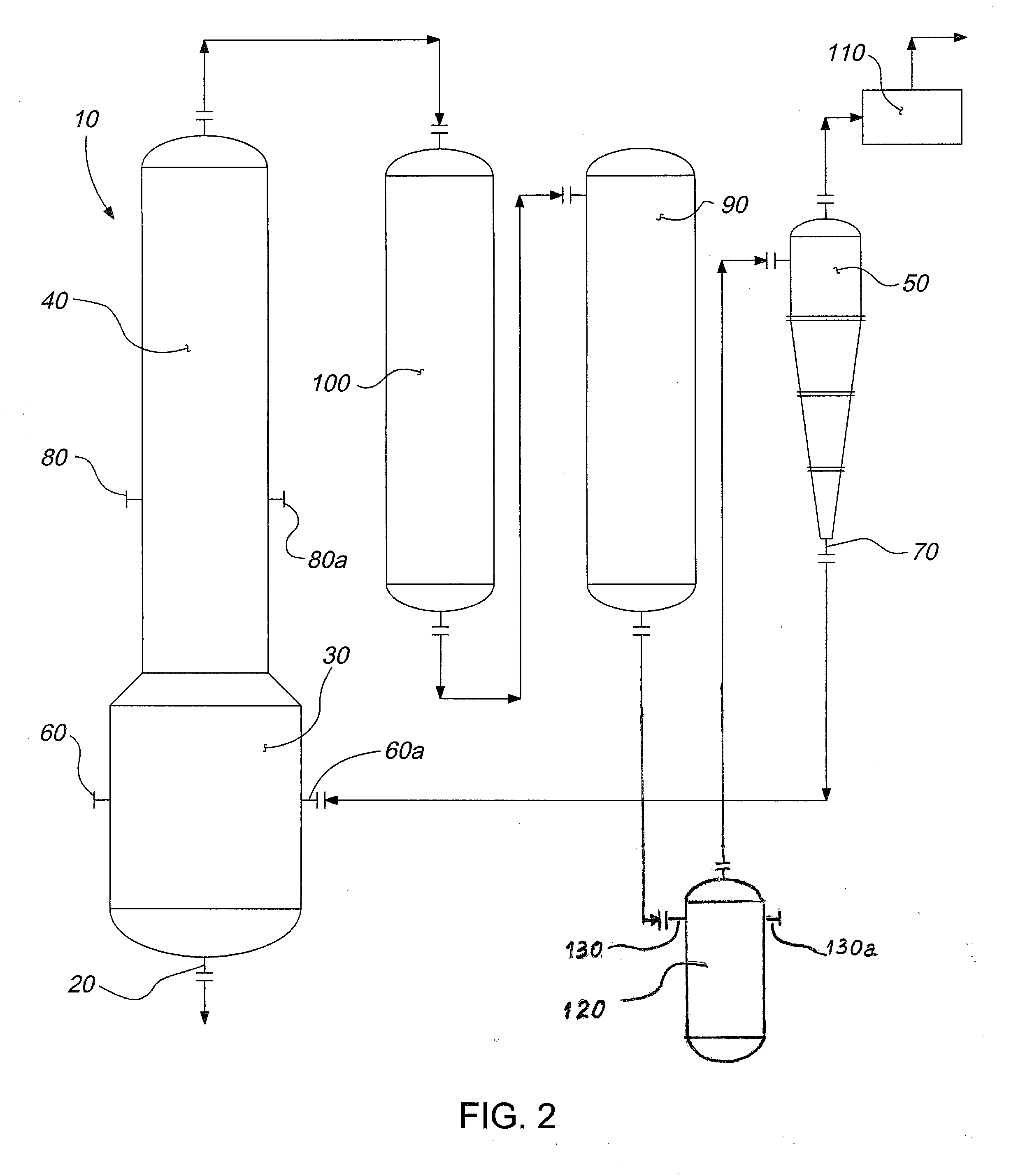

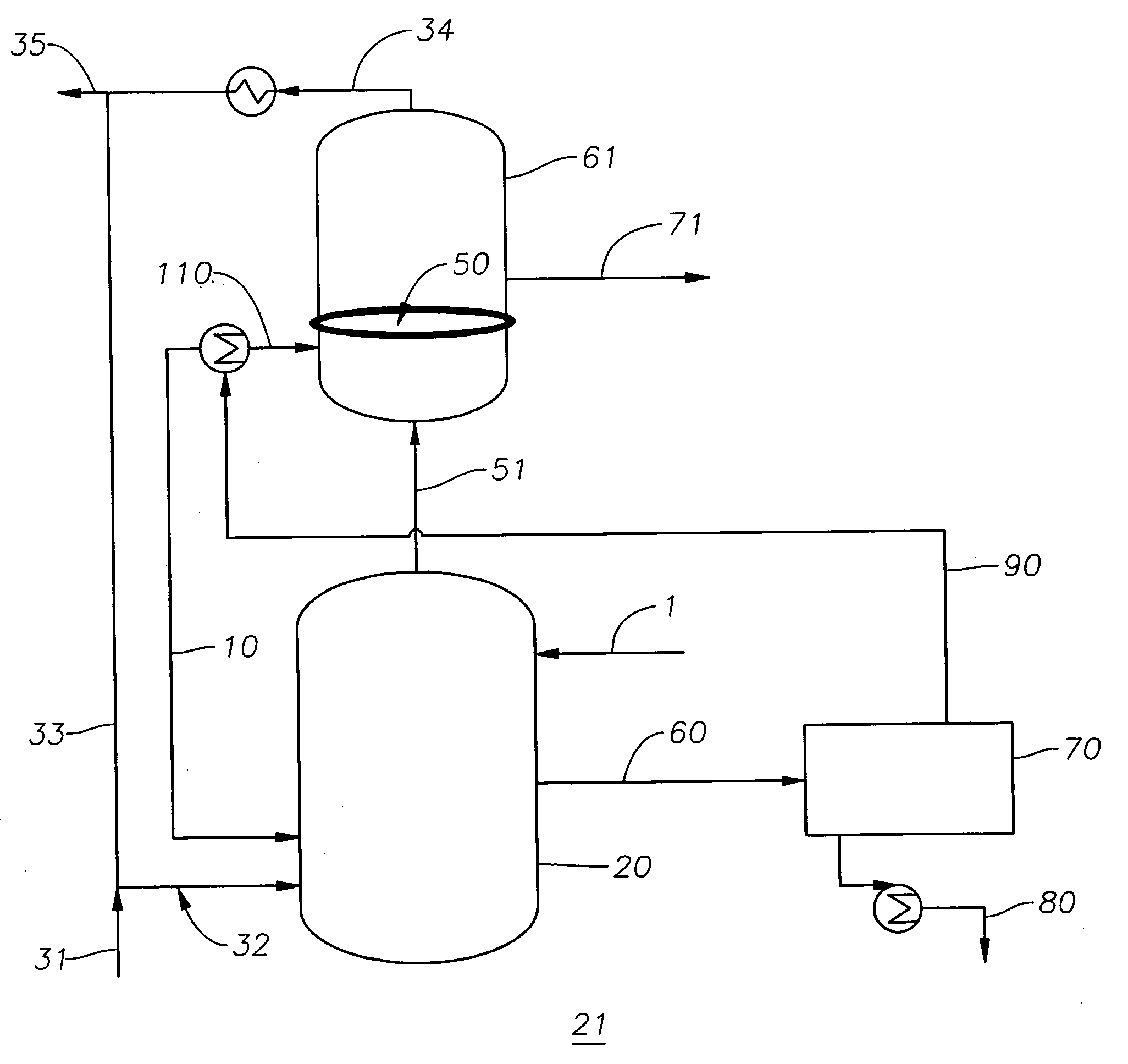

Combination method for hydrocracking of coal tar whole-fraction suspended bed and hydro-upgrading of fixed bed

ActiveCN104946306AImprove propertiesHigh yieldTreatment with hydrotreatment processesReaction temperatureFixed bed

The invention provides a combination method for hydrocracking of a coal tar whole-fraction suspended bed and hydro-upgrading of a fixed bed. In the method disclosed by the invention, a slurry-bed hydrocracking reactor is a circulating reactor, an adopted catalyst is a high-activity oil-soluble dispersible compound, and the adopted catalysts are a supported hydrorefining catalyst and a hydrocracking catalyst. In the process, the adopted reaction pressure is 12-20 MPa, the volume ratio of hydrogen to oil is 500-1200 Nm<3> / m<3>, the reaction temperature is 350-450 DEG C, and the volume space velocity is 0.3-1.5 / h. In the process, when coal tar whole-fractions are treated, the yields of naphtha, diesel oil and vacuum gas oil are 85-90 wt % higher than the yield of distillate oil, the yield of unconverted tail oil is less than 10 wt %, the obtained naphtha and diesel oil conform to the national V quality standards, and the vacuum gas oil can be used as a raw material of a catalytic cracking device or a raw material for producing base oil of low-freezing-point special lubricating oil.

Owner:INNER MONGOLIA SHENGYUAN TECH CO LTD

Process for preparing needle coke

The invention provides a method for preparing needle coke. The method is as follows: after delayed coking treatment of fraction or residual oil which are rich in arene through a certain temperature rise formula, green coke obtained is calcined, and the needle coke with high intermediate phase content and developed needle structure are prepared. The petroleum raw materials used comprise mixture of one type or a plurality of types among virgin wax oil, coked wax oil, catalytic cracking clarified oil, ethylene tar, coal tar, dense oil, residual oil and other hydrocarbon-enriched substances. The delayed coking temperature rise formula is characterized in that: intermediate phases generated can be driven to grow fully and are flushed by air flow with enough flow rate before solidification, thereby the granularity of the needle coke prepared is large (the content of coke breeze is not more than 25 weight percent) and the needle coke can be used for large-scale steel-making electric furnaces. When the method is used for an industrial device, people only need to adjust the prior temperature rise formula according to the characteristics of the raw materials and the technological flow.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Gasification system and process with staged slurry addition

A system and process for gasifying carbonaceous feedstock with staged slurry addition in order to prevent the formation of tar that causes deposition problems. Dry solid carbonaceous material is partially combusted, then pyrolysed along with a first slurry stream comprising carbonaceous material in two separate reactor sections, thereby producing mixture products comprising synthesis gas. The second slurry stream comprising particulate carbonaceous material is fed to a drying unit downstream of a heat recovery zone along with the mixture product exiting the heat recovery zone. The resulting final temperature of the second stage mixture products and dried particulate carbonaceous material is between 450° F. and 550° F., a temperature range that is typically not conducive to the emission of heavy molecular-weight tar species.

Owner:LUMMUS TECH INC

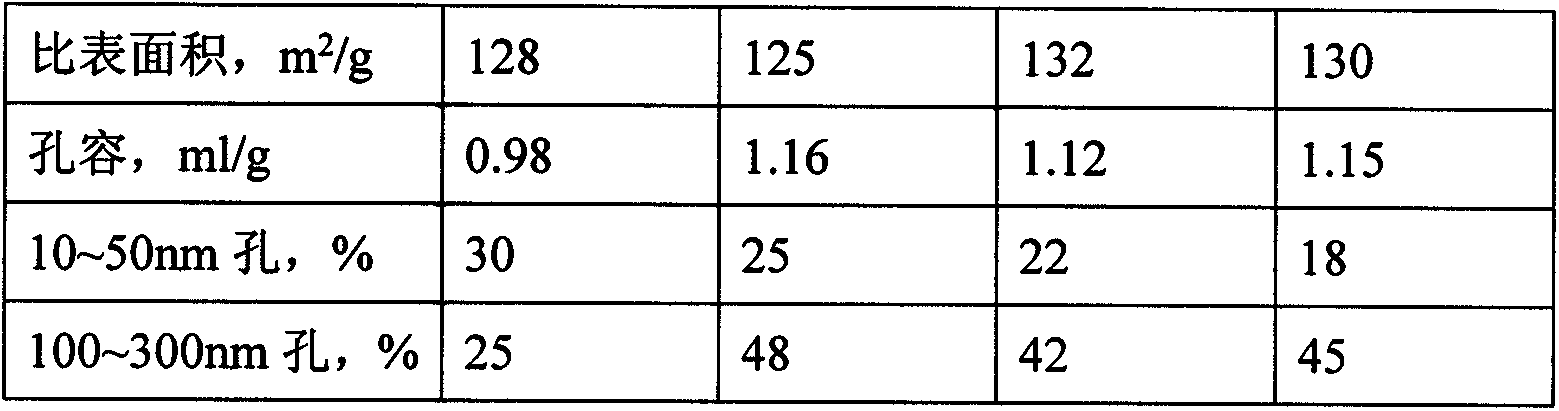

Protective agent of coal tar hydrogenation catalyst and preparation method of protective agent

ActiveCN103706408ASmall pressure dropHigh activityCatalyst protectionHydrocarbon oil crackingPotassiumMetal impurities

The invention discloses a protective agent of a coal tar hydrogenation catalyst and a preparation method of the protective agent. The protective agent is composed of three parts, namely carriers, active components and assistants, wherein the carriers include aluminium oxide and zirconium oxide in common; the active components include oxides of molybdenum, nickel or tungsten in common and account for 1-10% of total mass of the catalyst; the assistants include potassium and phosphorus in common, and account for 0.5-6% of total mass of the catalyst, and the balance is the carriers. The preparation method comprises preparation of the carrier and preparation of the protective agent. The protective agent has the advantages that the carrier comprises fine holes and thick holes, of which the apertures are relatively concentrated, wherein the thick holes are beneficial to containing metal impurities and carbon residue; a pressure drop of a catalyst bed is reduced, the hydrogenation catalyst is protected, removal of metal impurities such as vanadium is facilitated by the thin holes, the demetallization activity of the protective agent is properly improved, and different pore volumes and hole distribution of carriers can be prepared by adjusting the ratio of two pore forming materials. In addition, the preparation method of the protective agent is simple in technology, and convenient and stable to fabricate.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

Compound coal tar hydrogenation catalyst and preparation method thereof

ActiveCN101927167AReduce manufacturing costReduce use costHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsLow activityIron sulfide

The invention relates to a compound coal tar hydrogenation catalyst and a preparation method thereof. The catalyst comprises a high-activity component of water-soluble salts of molybdenum, nickel, cobalt or tungsten and comprises a low-activity component of iron oxide ore or iron sulfide ore, wherein the mass ratio of the metals in the high-activity component to the metals in the low-activity component is 1:1,000 to 1:10; iron accounts for more than or equal to 40 weight percent of the ore; and water accounts for less than 2 weight percent of the catalyst. The catalyst is used for the coal tar hydrocracking technical process in a suspension bed, has higher hydrogenation activity and the lightweight oil yield of over 94 percent, and can be recycled; the preparation and use cost of the catalyst can be greatly reduced, the consumption of the catalyst is reduced in the process, the coke deposition of the reaction system is avoided simultaneously and the operation cycle is prolonged.

Owner:CCTEG CHINA COAL RES INST

Process for upgrading tar

ActiveUS20080099371A1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionDistillationTar

A feedstream comprising tar is feed to a solvent deasphalter wherein it is contacted with a deasphalting solvent or fluid to produce a composition comprising a mixture or slurry of solvent containing a soluble portion of the tar, and a heavy tar fraction comprising the insoluble portion of the tar. These fractions may be separated in the deasphalter apparatus, such as by gravity settling wherein the heavy tar fraction is taken off as bottoms, and the solvent-soluble fraction taken as overflow or overheads with the solvent. The overflow or overheads is sent to a solvent recovery unit, such as a distillation apparatus, wherein solvent is recovered as overheads and a deasphalted tar fraction is taken off as a sidestream or bottoms. The solvent or a portion thereof, recovered as overheads, may be then be recycled to the solvent deasphalter, or in a preferred embodiment, at least a portion of the solvent is steam cracked to produce a product comprising light olefins.

Owner:EXXONMOBIL CHEM PAT INC

Electronic cigarette liquid prepared from strong-flavor tobacco

The invention discloses an electronic cigarette liquid prepared from strong-flavor tobacco. The liquid is made by mixing 10% to 30% of strong-flavor tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. The strong-flavor tobacco leaf extract is selected from the group consisting of strong-flavor flue-cured tobacco leaf extract in Henan, Anhui, Guangxi, Guangdong and Hunan, or the mixtures thereof. The electronic cigarette liquid takes the strong-flavor tobacco leaf extract as a main component, so that the smell and the taste of electronic cigarettes are closer to the traditional cigarette. The electronic cigarette liquid is used for atomization of the electronic cigarettes without production of tar or carbon dioxide, so that the harm to consumers is greatly reduced and the harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Hydrotreated hydrocarbon tar, fuel oil composition, and process for making

InactiveUS20140174980A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansBoiling pointTar

Provided is a hydrocarbon tar. The tar has 75 wt % or more of aromatics of 10 carbons to 75 carbons based on the total weight of the tar. The aromatics exhibit 40% to 80% aromaticity. The tar has a boiling point of from 300° F. to 1350° F. There is also a fuel oil composition having the tar therein. There are also processes for making the hydrocarbon tar.

Owner:EXXONMOBIL CHEM PAT INC

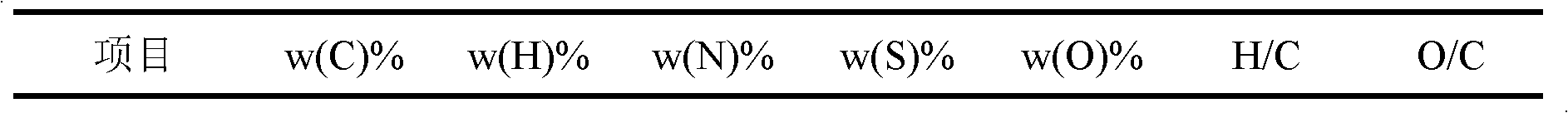

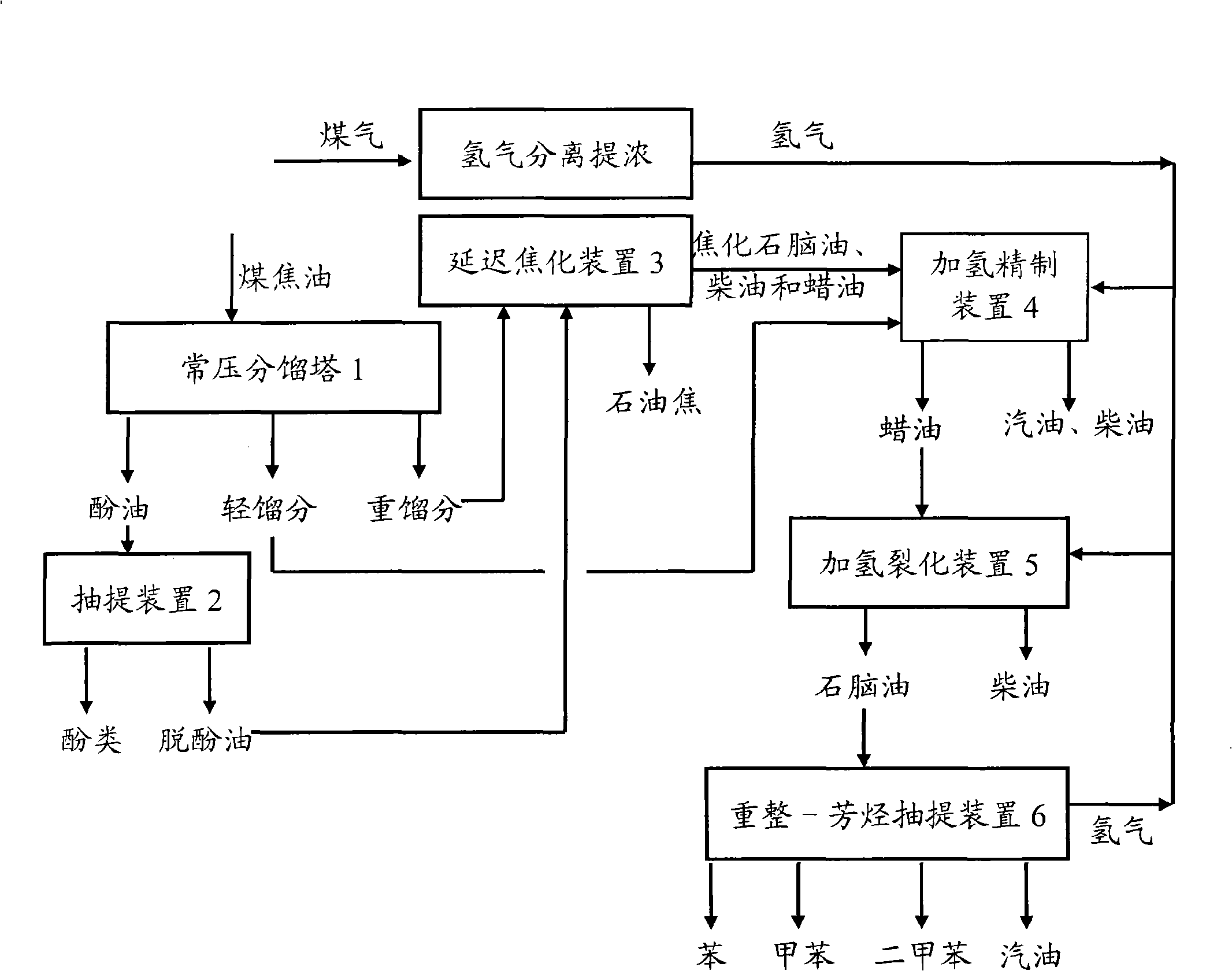

Medium and low temperature coal tar deep processing method

InactiveCN101538482AImprove performanceEfficient use ofThermal non-catalytic crackingCatalytic naphtha reformingCatalytic reformingFractionation

The invention discloses a medium and low temperature coal tar deep processing method. Medium and low temperature coke material is pretreated and fractionated to obtain light fraction, carbolic oil and heavy fraction, dephenolization treatment is carried out on the carbolic oil to obtain phenols product and dephenolized oil, the dephenolized oil and the above heavy fraction carry out pyrogenetic reaction jointly to obtain various carbonized products, wherein carbonized naphtha, at least one of carbonized diesel oil and carbonized wax oil is mixed with the light fraction obtained by material fractionation to carry out hydrofining and hydrocracking reaction, hydrogenated naphtha obtained by hydrocracking carries out catalytic reforming-aromatics extraction to obtain benzene, toluol, xylene, solvent oil and other products. Compared with the prior art, gasoline fraction and diesel oil fraction obtained by the inventive method are clean and stable in properties. In addition, the invention can produce a plurality of chemical products with high added value, truly realizes the effective utilization of medium and low temperature coal tar, and greatly improves the service life of devices.

Owner:胜帮科技股份有限公司

Cigarette device not burning when heated

The invention provides a cigarette device not burning when heated. The cigarette device comprises an outer shell, a controller and a heating mechanism, wherein the controller is arranged in the outer shell, the heating mechanism is connected with the controller, a containing cavity is formed between the heating mechanism and the outer shell, solid-state tobacco is arranged in the containing cavity, an opening part corresponding to the containing cavity is formed in the outer shell, the opening part can be opened and closed, a smoking port and an air inlet opened to the containing cavity are formed in the outer shell, the air inlet, the containing cavity and the smoking port are communicated with each other to form an air inlet channel, an airflow sensor is arranged in the air inlet channel, and the airflow channel is connected with the controller. According to the cigarette device not burning when heated, passive smoking is avoided due to the fact that the solid-state tobacco does not burn when heated to a certain temperature; and smoke produced after the solid-state tobacco is heated does not contain hazardous substances produced by cleavage reaction caused by burning or tar which can cause great harm to human body.

Owner:SHANGHAI TOBACCO GRP CO LTD

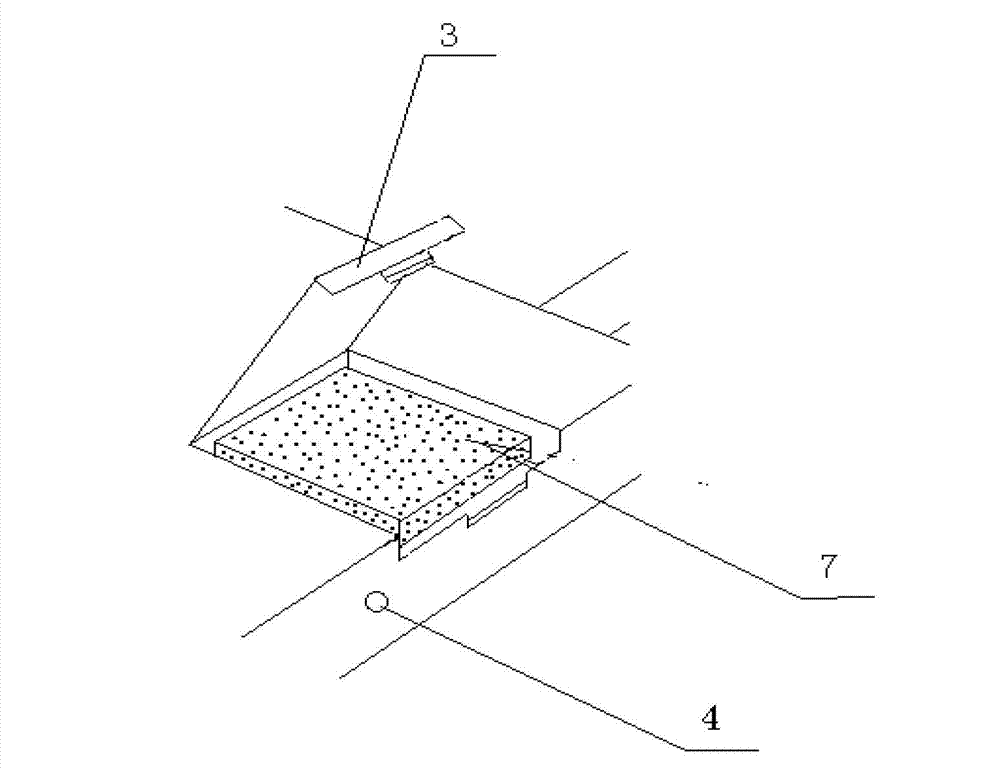

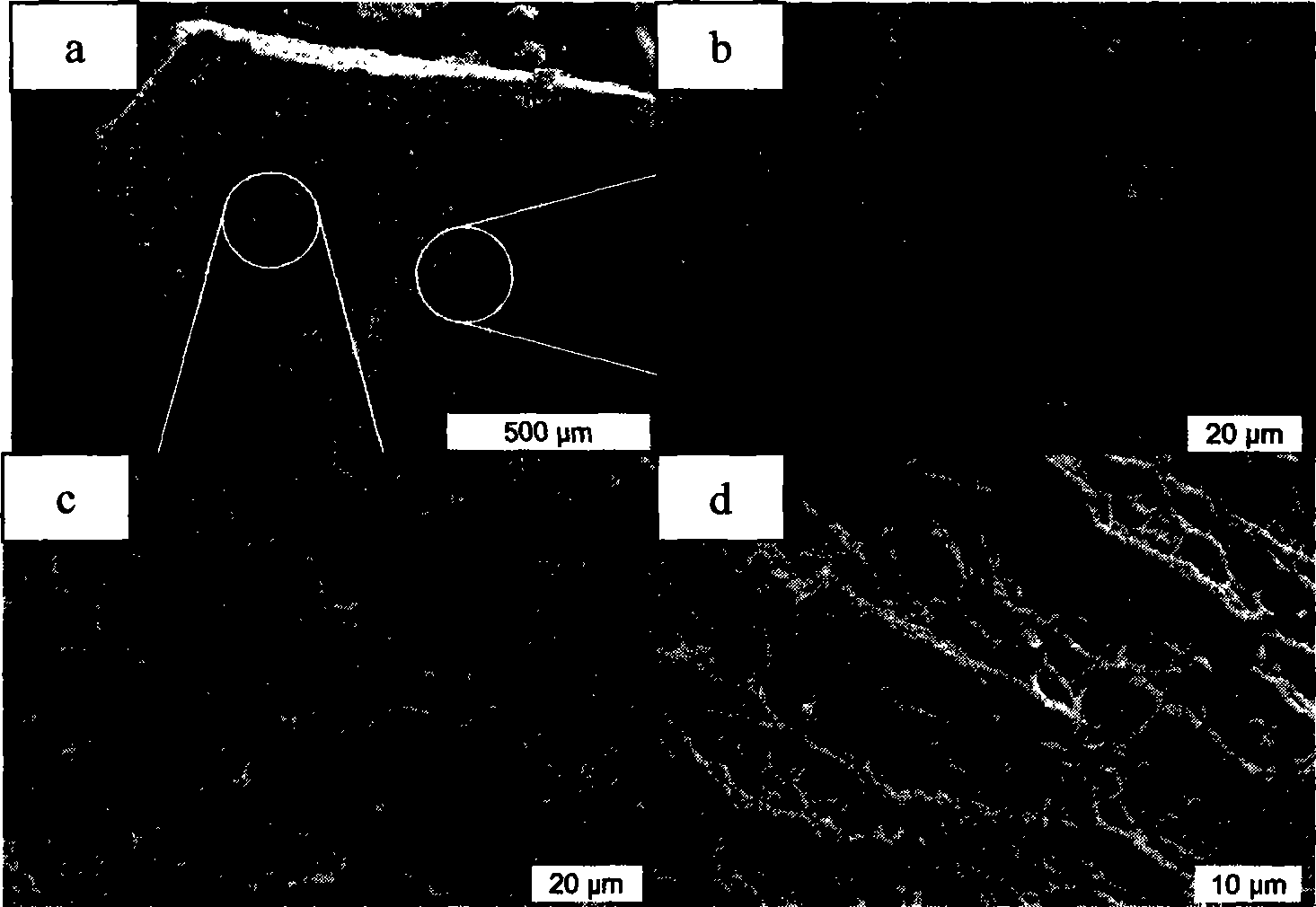

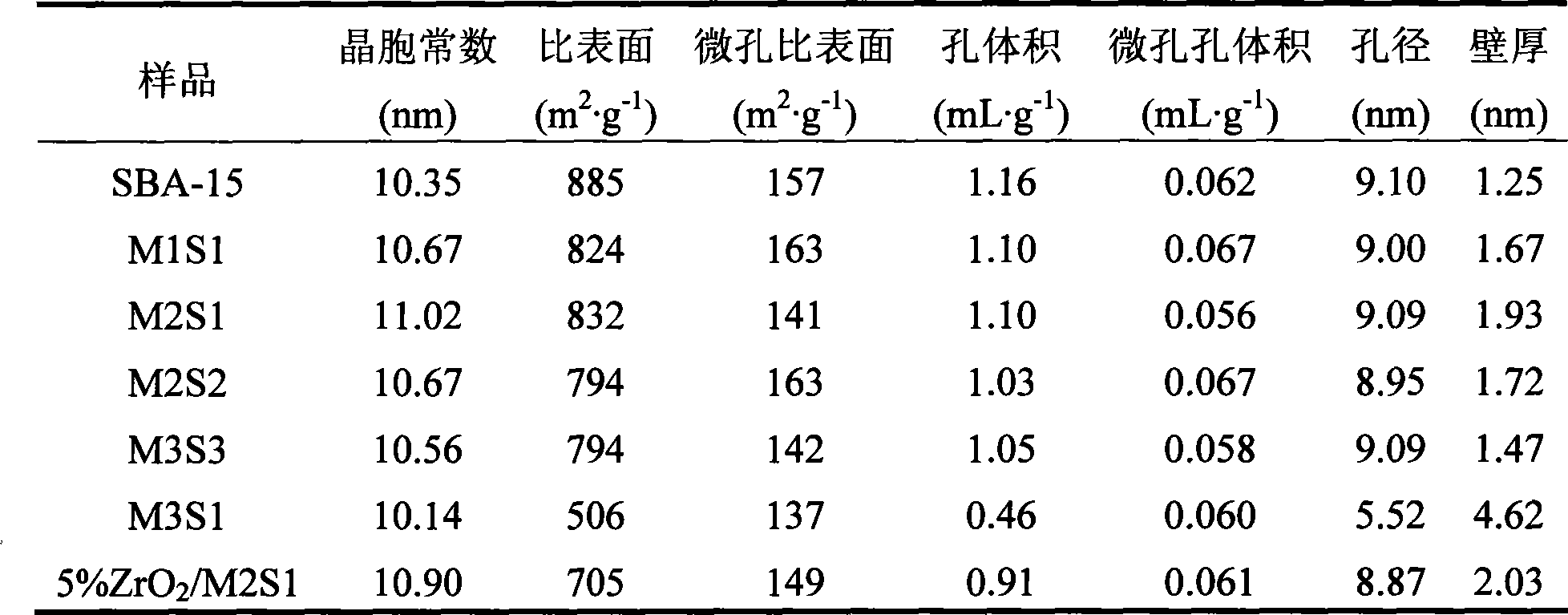

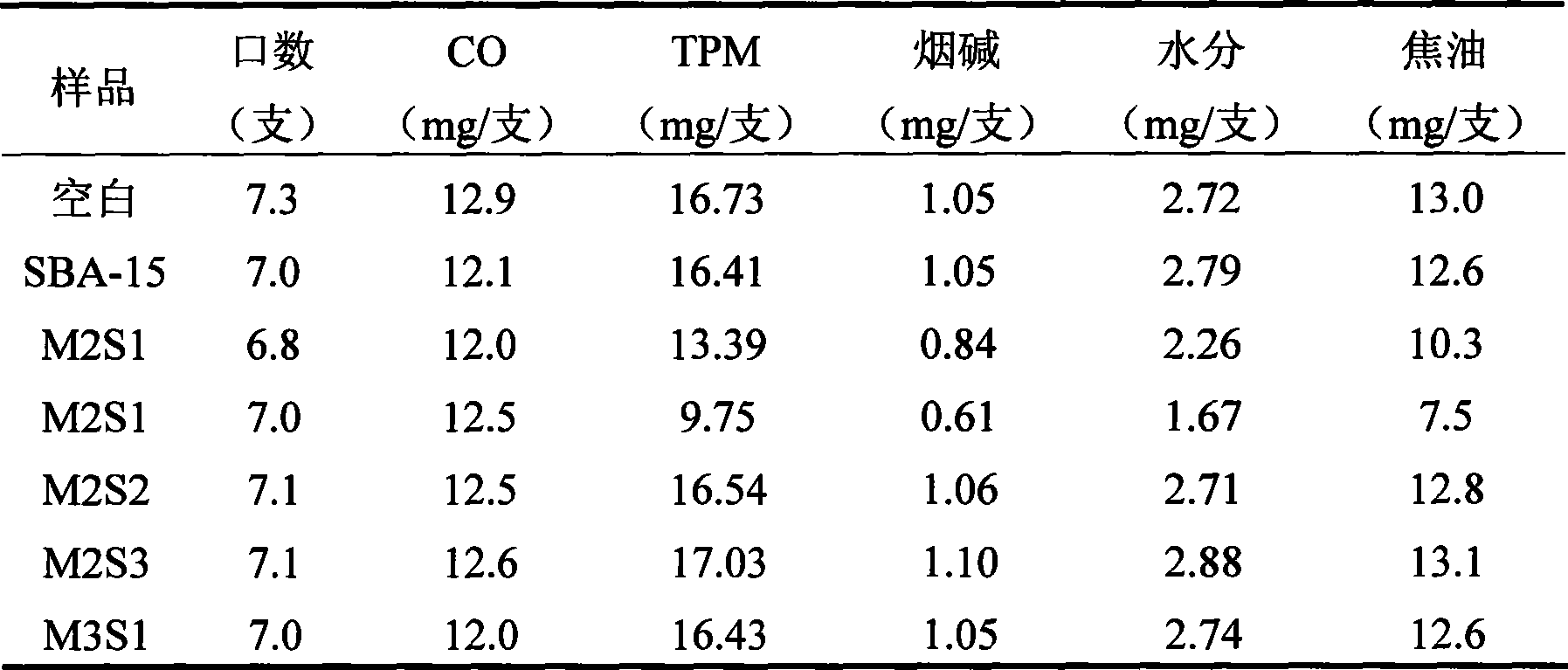

Novel mesoporous material for absorbing granule phase substance, coke tar, phenol and amine nitrite in mainstream flue gas of tobacco

InactiveCN101433818ANo change in microscopic morphologyNo change in macroscopic appearanceTobacco smoke filtersSilicon compoundsParticulatesToxicant

The invention discloses a novel mesoporous material for adsorbing tar, phenol and special nitrosamine in tobacco and so on, in mainstream smoke of the tobacco. The mesoporous material with high adsorption property is used as an addition material for filter tips of cigarettes; and the mesoporous material is a mesoporous molecular sieve with a three-dimensional mesh microstructure and monolithic appearance such as SBA-15,or is a SBA-15 mesoporous molecular sieve material which is plated with a liquid film or is modified by metal oxides such as zirconia and is provided with the three-dimensional mesh microstructure and the monolithic appearance. The invention adopts a more convenient and effective method to develop the SBA-15 mesoporous molecular sieve material with the three-dimensional mesh microstructure and the monolithic appearance and modify the surface / a surface layer, has good performance of intercepting environmental toxins such as interception particulate phase matters and phenol in smoke, has the characteristics of saving energy, saving time, and reducing environmental pollution during the preparation, can also reduce cost, and has remarkable economic benefit and social benefit.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com