Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Make up for the lack of" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

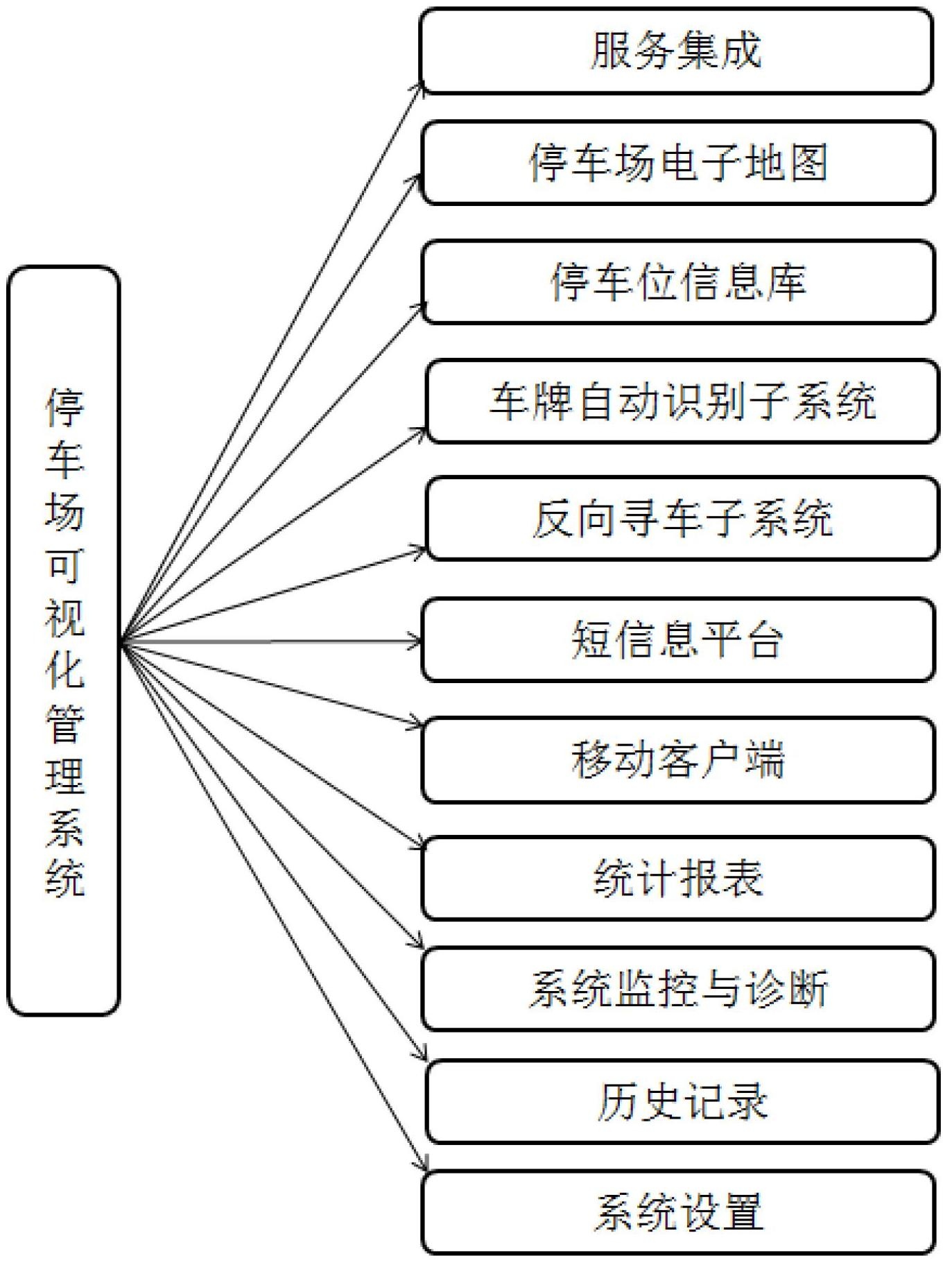

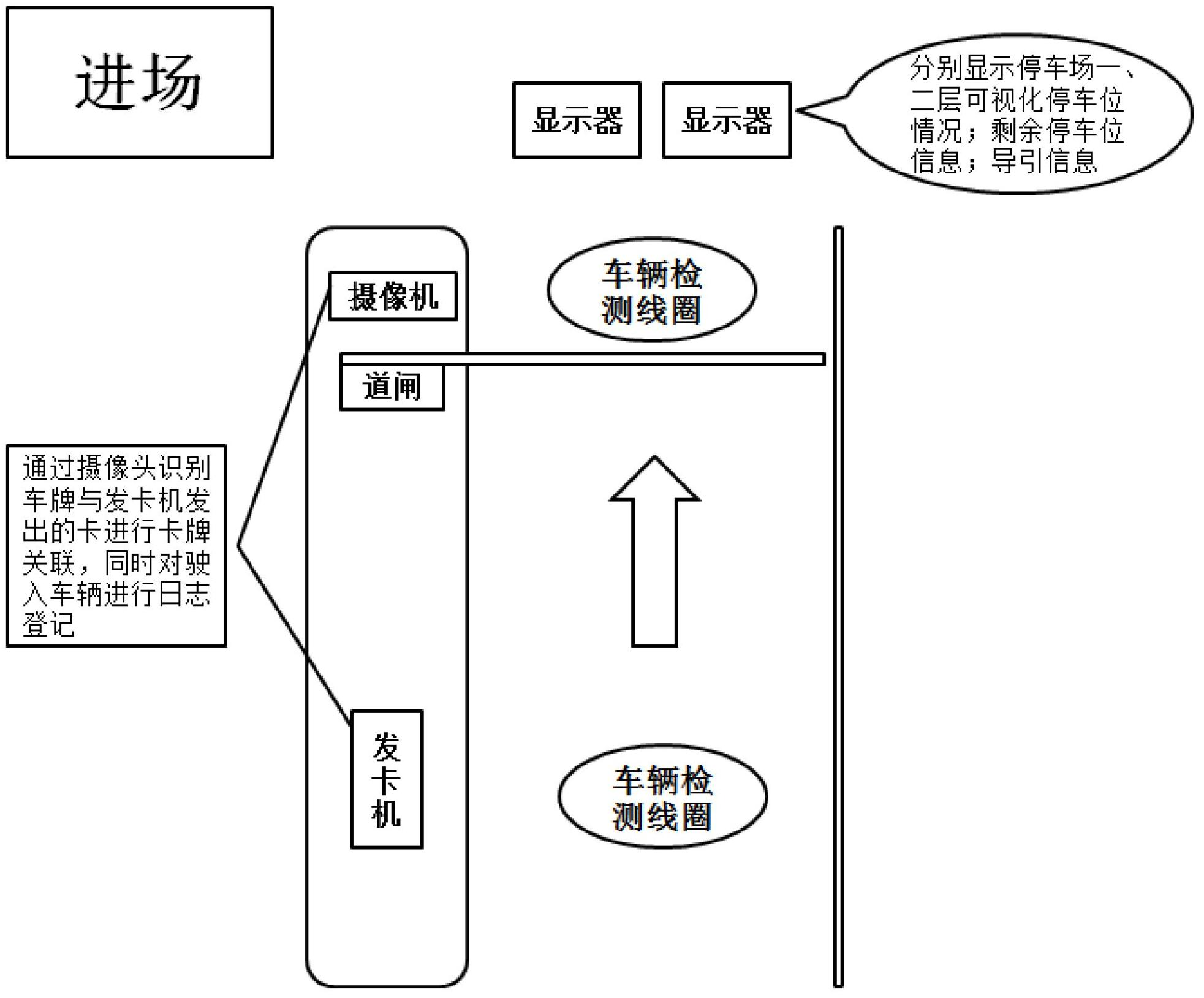

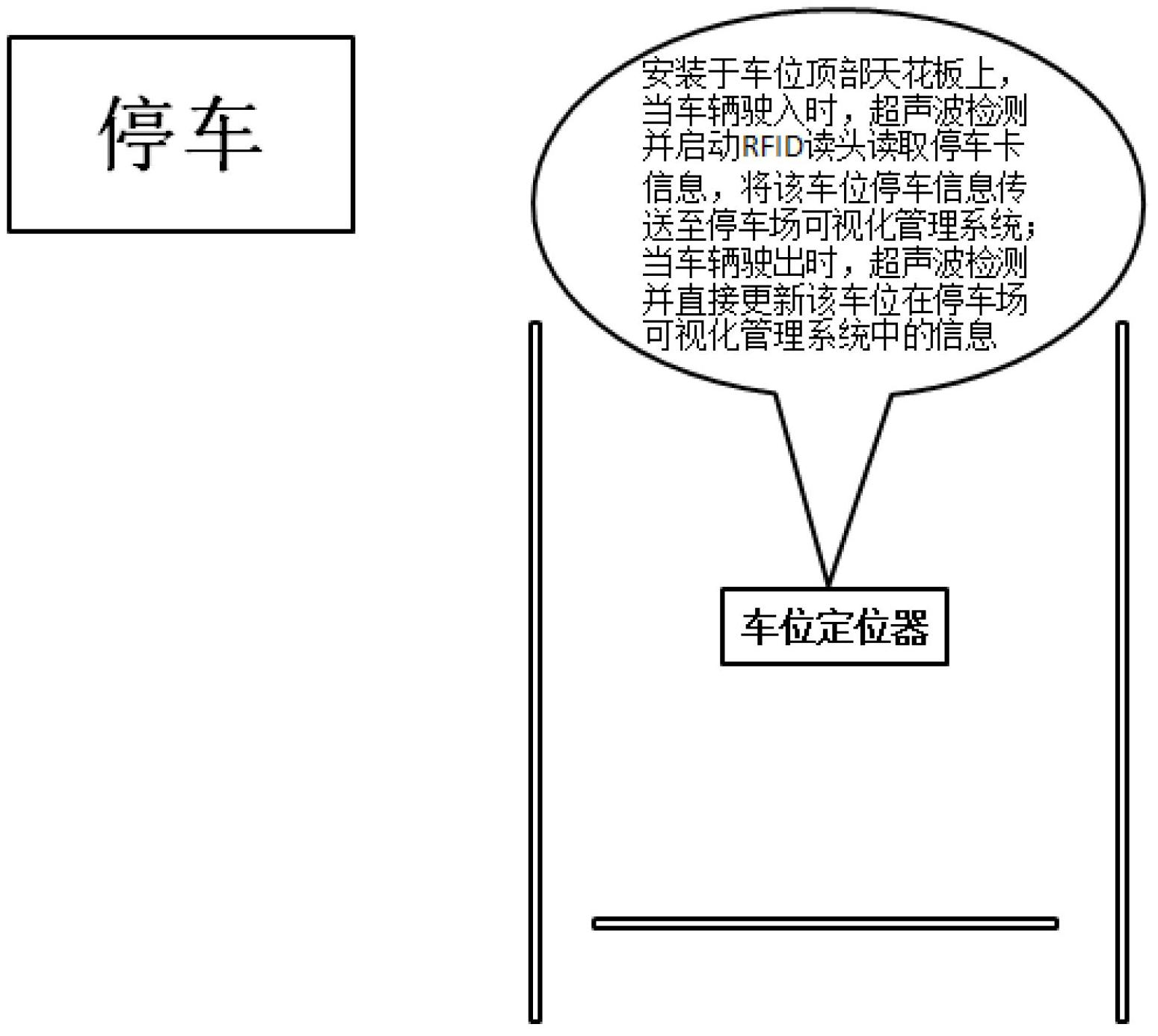

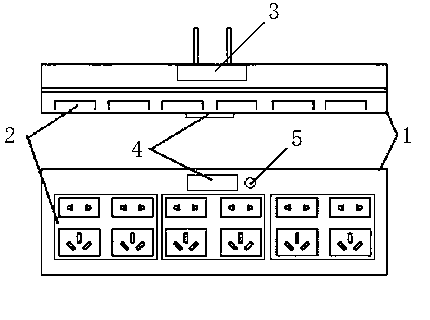

Intelligent guiding and car locating system for parking lot

InactiveCN102646342AImprove service qualityConvenient parkingIndication of parksing free spacesParking areaApplication server

The invention discloses an intelligent guiding and car locating system for a parking lot. The intelligent guiding and car locating system comprises a vehicle detecting coil, an automatic card sender, a license plate identifying camera, position identifiers, a vehicle guide display screen, an application server, a database server, an intelligent searching terminal, and a parking lot visible management system. The devices are communicated with one another by accessing a router through a wired network. When a car owner drives a car into the parking lot, the intelligent guiding and car locating system guides and indicates the car owner to find a parking space conveniently and rapidly. Meanwhile, parking cards are bound with license plates, so that a vehicle parking position is recorded by the position identifier mounted above each parking space. When the car owner finds the car, the parking space can be found by inputting a license plate number through the intelligent searching terminal or slotting the parking card, and an optical car taking route is obtained simultaneously.

Owner:SHANGHAI MARITIME UNIVERSITY

Ultra-large-capacity intelligent express cabinet

InactiveCN106204951ARealize individual weighingAchieve re-useApparatus for meter-controlled dispensingIndividual entry/exit registersWeight changeComputer module

The invention discloses an ultra-large-capacity intelligent express cabinet. A weighing device is arranged under express row cabinets so that each row of express row cabinet can be independently weighed; the increased weight of the express row cabinets is acquired through a weight change acquisition module when cabinet doors are opened in single time, and the increased weight and depositing information is bound and stored; meanwhile, an express single cabinet space information judgment module is arranged so that a plurality of pieces of expresses can be stored in one express single cabinet and residual space express single cabinets are reutilized, and the problem that the quantity of express single cabinets of an existing express cabinet is made up; meanwhile, an access control module is controlled according to the weight change acquisition module to manage and control the opening and closing of an express taking room outlet; the access control module ensures that a receiver can smoothly take away the expresses only if the receiver takes the expresses meeting the weight of the own expresses, so that the express single cabinets can contain the plurality of expresses and phenomena of incorrectly taking and taking by mistakes do not occur, and furthermore, the space is extremely saved and the utilization rate of a cabinet body is improved; and the anti-theft aim is realized.

Owner:武汉三车科技有限公司

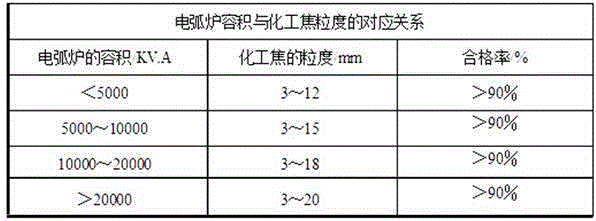

Coke oven coking method for improving ratio of long flame coal for chemical coke

ActiveCN104087328AHigh yieldMeet the requirements of chemical cokeSpecial form destructive distillationChemical industryAdhesive

The invention relates to a coke oven coking method for improving a ratio of long flame coal for chemical coke. The method comprises the following steps: a, performing secondary crushing on long flame coal, and mixing the long flame coal with an adhesive in a storage warehouse; b, performing pre-grinding on the long flame coal mixed with the adhesive, feeding the coal into a coal blending chamber, improving a ratio of the long flame coal mixed with the adhesive to 80 percent, adjusting a gas-fat coal ratio with high adhesiveness to 20 percent, and feeding the coal into a crusher for crushing after mixing; c, performing primary water injection on the prepared mixed coal, crushing the coal in a crusher chamber, performing secondary water injection on the crushed mixed coal, feeding coking coal into a charging car for tamping, so that the coking coal is smashed into a dense coal cake, and feeding the coal into a carbonization chamber for performing high-temperature dry distillation; and d, performing high-temperature dry distillation on the coking coal, performing coke quenching by adopting a dry method, and finally naturally cooling to obtain the chemical coke product. According to the method, low-cost smelting and chemical industry carbon materials can be produced, and the gap that smelting and chemical industry carbon materials are deficient is overcome.

Owner:新疆新鑫新能源化工有限公司

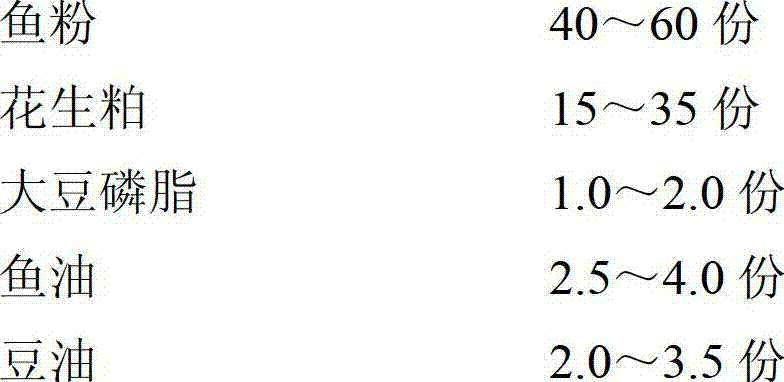

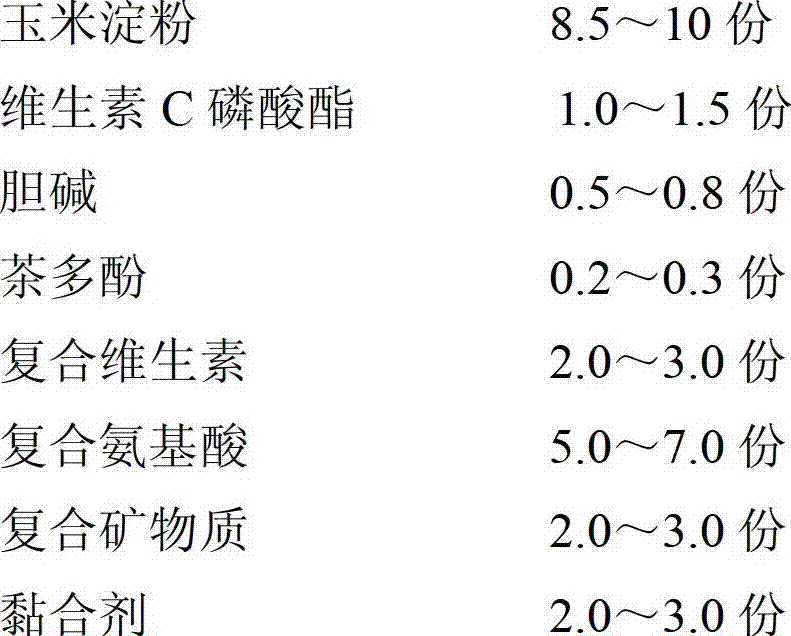

Basic bait formulation for Nibea albiflora

The invention relates to a basic bait formulation for Nibea albiflora. The basic bait formulation for the Nibea albiflora is characterized by comprising fish meal, peanut meal, soybean phospholipid, fish oil, soybean oil, corn starch, vitamin C phosphate, choline, tea polyphenol, composite vitamin, composite amino acid, a composite mineral substance and a bonding agent. Compared with the prior art, the fish meal and the peanut meal are taken as main raw materials and various beneficial components are added, so that the problems that amino acids are unbalanced as well as lysine, methionine and threonine are short in the peanut meal can be effectively solved; the amino acids are balanced by adding synthetic amino acids or other protein feeds, so that all nutritional requirements can be supplied to the Nibea albiflora; multiple effective antibacterial substances including the tea polyphenol are added into the feed to prevent the feed from going mouldy and deteriorating, so that artificial breeding is facilitated; the bait is good in feed attractant effect, has a higher food coefficient than natural bait and is relatively applicable to livestock and aquatic feeds; and the peanut meal is low in cost, so that compared with the feed in the prior art, the bait provided by the invention saves cost and is high in economic benefit.

Owner:ZHEJIANG OCEAN UNIV

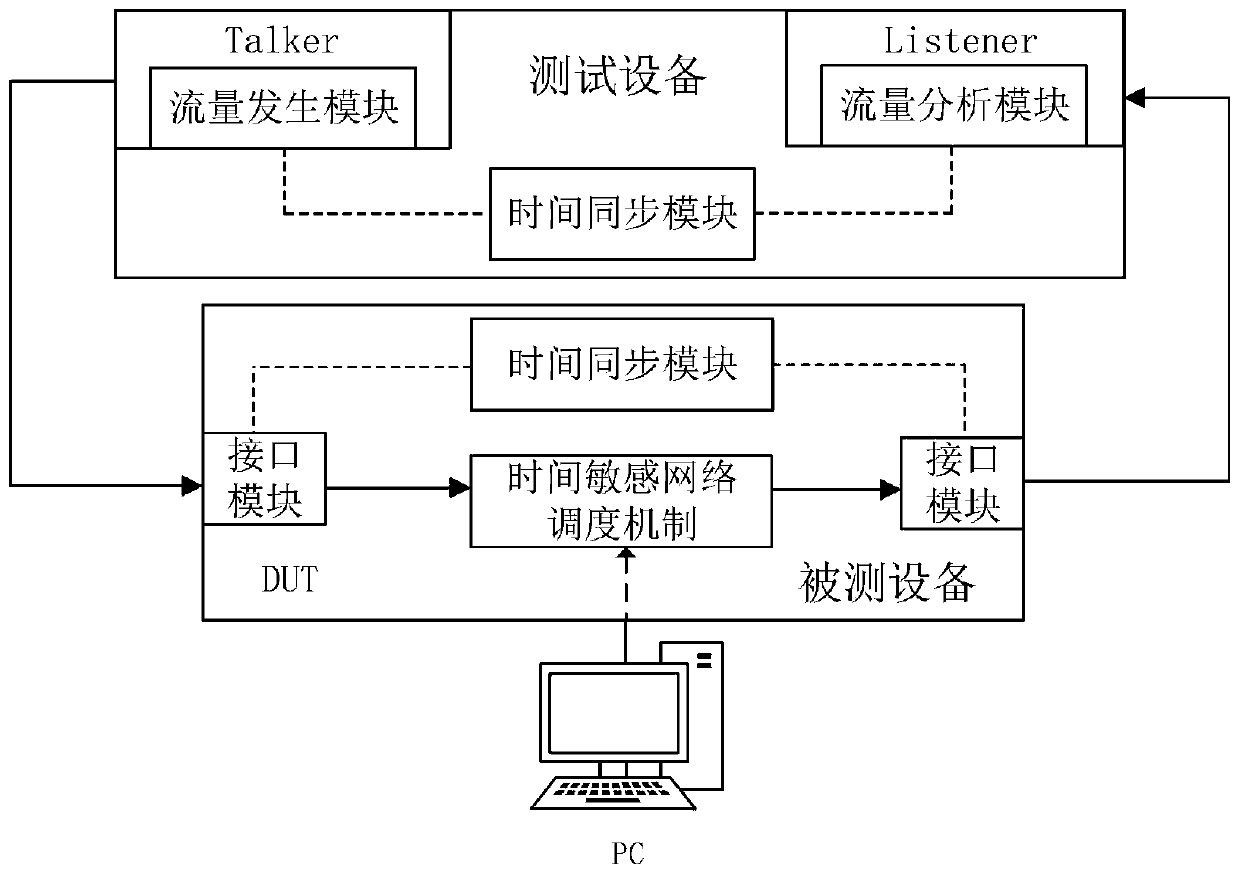

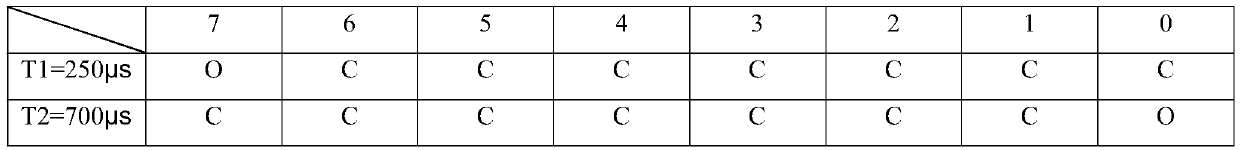

Test method for time-sensitive network data frame scheduling

The invention relates to a test method for time-sensitive network data frame scheduling, and belongs to the technical field of communication. The method comprises the following steps: a network topology structure of test equipment and DUT is built; on the premise that time synchronization between the equipment is completed, Talker sends test data to the DUT, the test data is forwarded to Listner after being scheduled by a time sensitive network, and the test equipment extracts a flow characteristic analysis scheduling sequence. The method is used for testing a gating function, a time sequencefunction, a scheduling precision and gating precision of the scheduled time sensitive network, and verifying whether a time sensitive network scheduling mechanism is correctly realized by the DUT or not.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

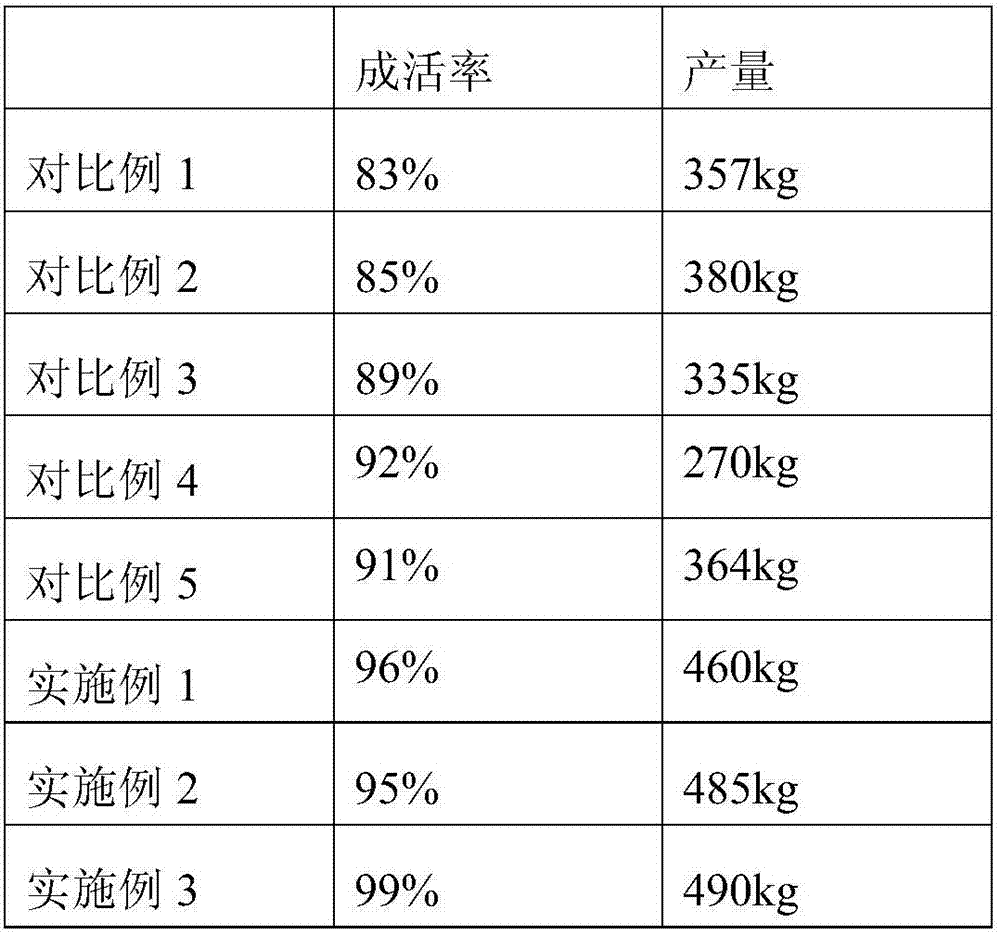

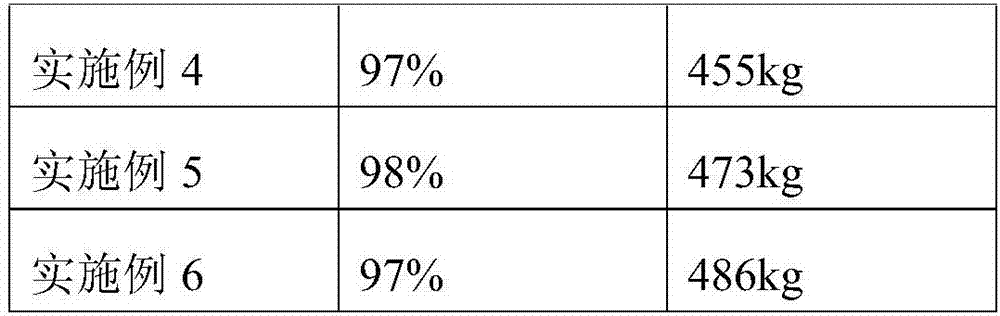

Method for cultivating selenium-enriched tilapia

InactiveCN106818560APromote growthPromote absorptionFodderClimate change adaptationBenthic algaeTilapia

The invention discloses a method for cultivating selenium-enriched tilapia. The method comprises a step (1) of preparing selenium-enriched spirulina seed liquid; a step (2) of performing culture pond management: deeply ploughing soil at the bottom of a culture pond for 20-30 cm, spraying natural botanical fungiticide according to an amount of 6-12 kg / 100 m2, performing insolation for 15-20 days, injecting pond water with a depth of 1-1.5 m into the culture pond, placing benthic algae attaching substrate at the bottom of the pond, applying selenium-enriched spirulina seed liquid according to an amount of 600-1200 g / 100 m2, and culturing selenium-enriched spirulina for 12-18 days at a culture pond water temperature of 25-35 DEG C; and a step (3) of performing feeding management. By adoption of technical means, the selenium-enriched tilapia can be cultivated efficiently, the content of selenium element of tilapia is effectively increased while the yield of the tilapia is improved, and the method can be popularized in a large area for a long term and have wide market application values.

Owner:黄怀勇

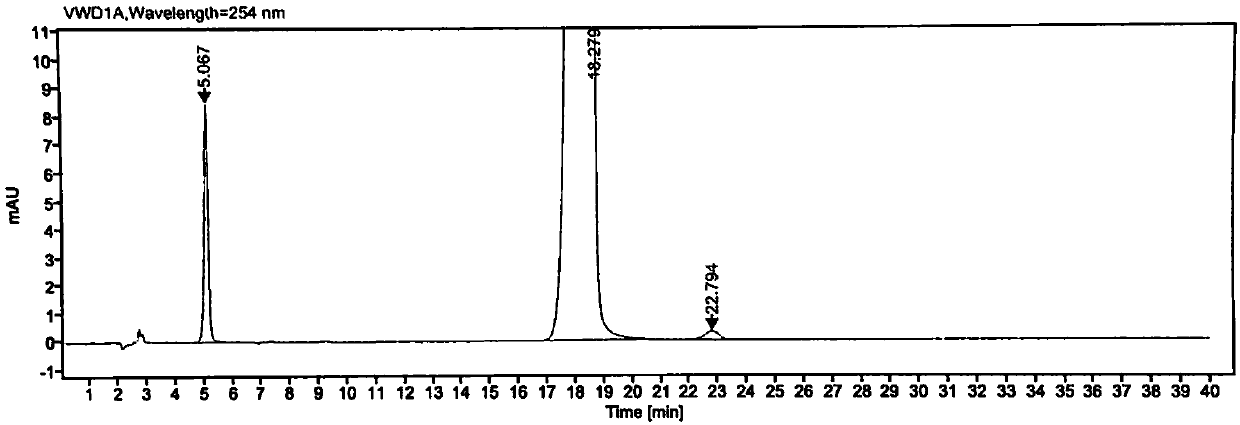

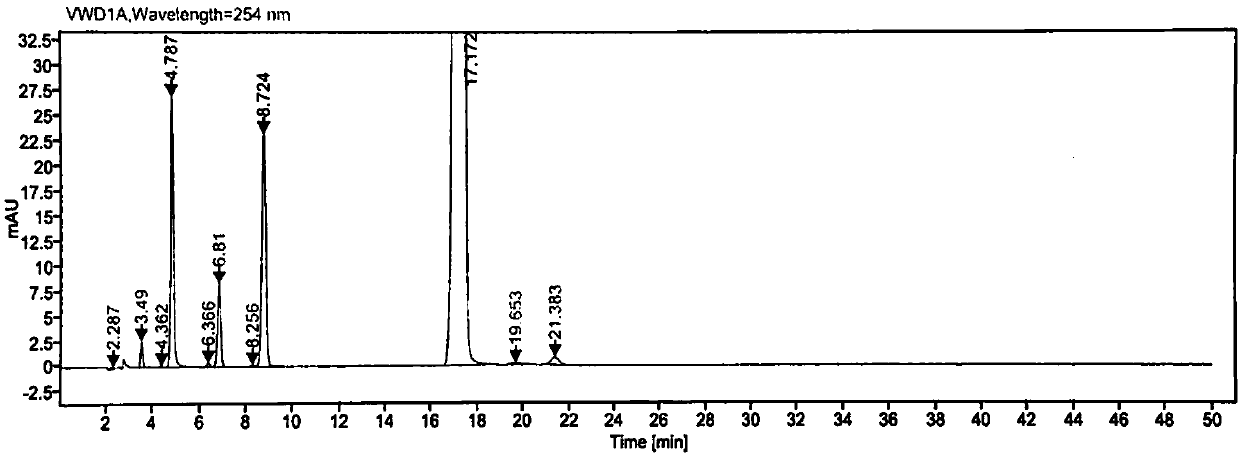

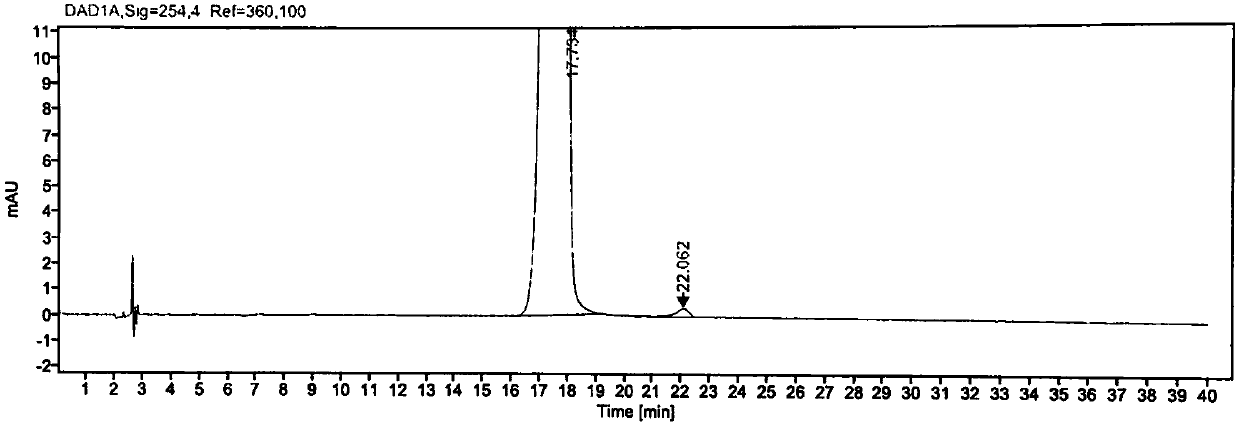

High-performance liquid chromatography method for clopidol related substances

ActiveCN107907607AImprove separation efficiencyFast analysisComponent separationChemistryWavelength range

The invention belongs to the technical field of medicine analysis and particularly relates to a high-performance liquid chromatography method for clopidol related substances. The method includes: taking octadecyl silane serves as a stationary phase, taking mixed liquid of phosphate buffer (or acetate or borate) with pH of 3.0-8.0 and methyl alcohol (or acetonitrile or tetrahydrofuran) as a mobilephase, injecting into a high-performance liquid chromatograph under conditions that column temperature is 20-60 DEG C, sample injection quantity is 5-50microlitre and flow velocity is 0.5-2mL / min, andperforming sample analysis in a wavelength range of 200-380nm. The high-performance liquid chromatography method is high in separation efficiency, quick in analysis and high in detection sensitivity,clopidol quality is controlled by detection of the content of impurities in clopidol, and accordingly product stability and quality can be better controlled.

Owner:JIANGSU TIANHE PHARMA CO LTD

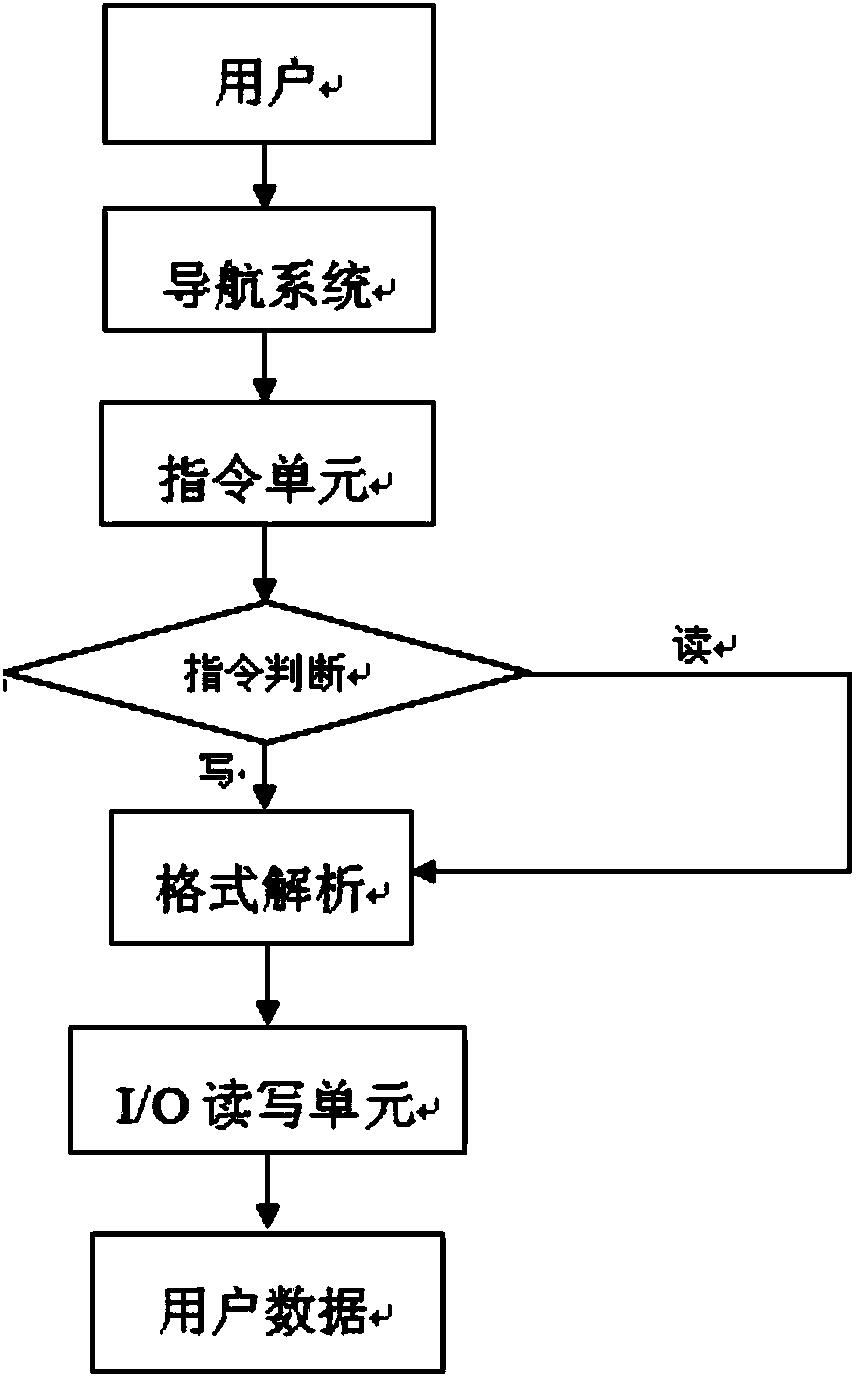

Self-identification method of GPS user data format

ActiveCN103530353AMake up for the lack ofDoes not affect functionInstruments for road network navigationSpecial data processing applicationsEmbedded databaseData integrity

The invention relates to a self-identification method of a GPS user data format. In order to achieve the data integrity and consistency aims, an embedded database will be adopted in a GPS to store user data; in order to generate and analyze a user data structure, a data format description method is adopted, and the self-identification method is based on the fact that the user data format can be organized according to the certain format to enable a machine to easily analyze and generate the user data structure; the user data format is organized according to the characteristics of the user data structure, format information is described, and then data compatibility checking on data is carried out. The self-identification method has the advantages that the data added and changed by a user in an old GPS version are effectively retained, the already retained old user data can also be used in updated or refreshed GPS software, and various functions of the GPS are not influenced. The GPS software is intelligent and user-friendly, and the shortcoming of user data losses on the user when the GPS is refreshed and upgraded is overcome.

Owner:SHENYANG MXNAVI CO LTD

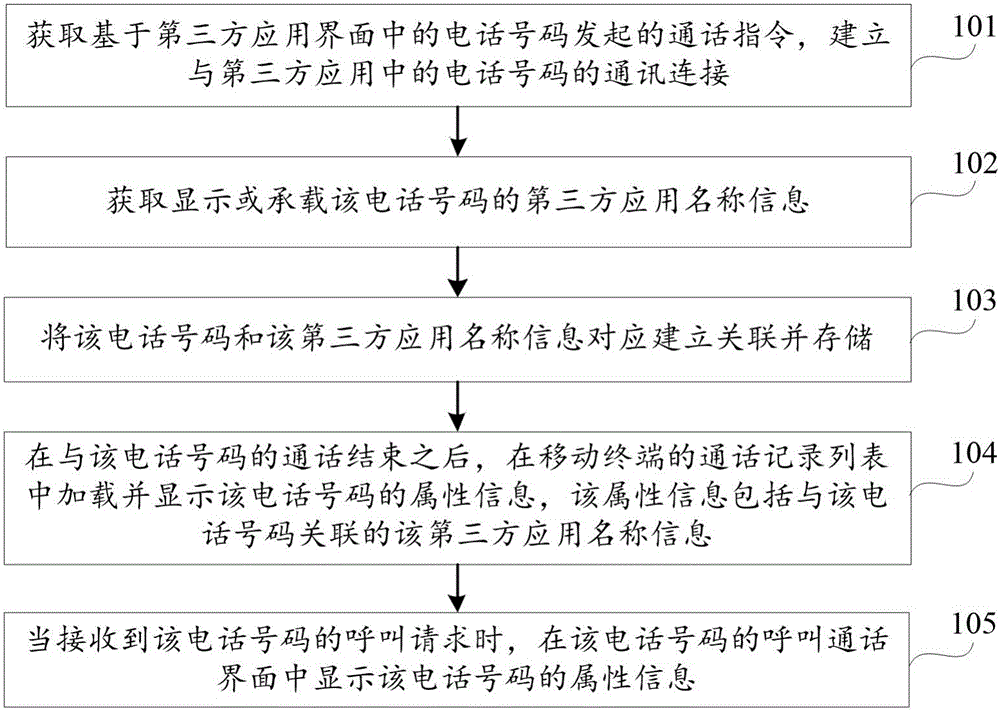

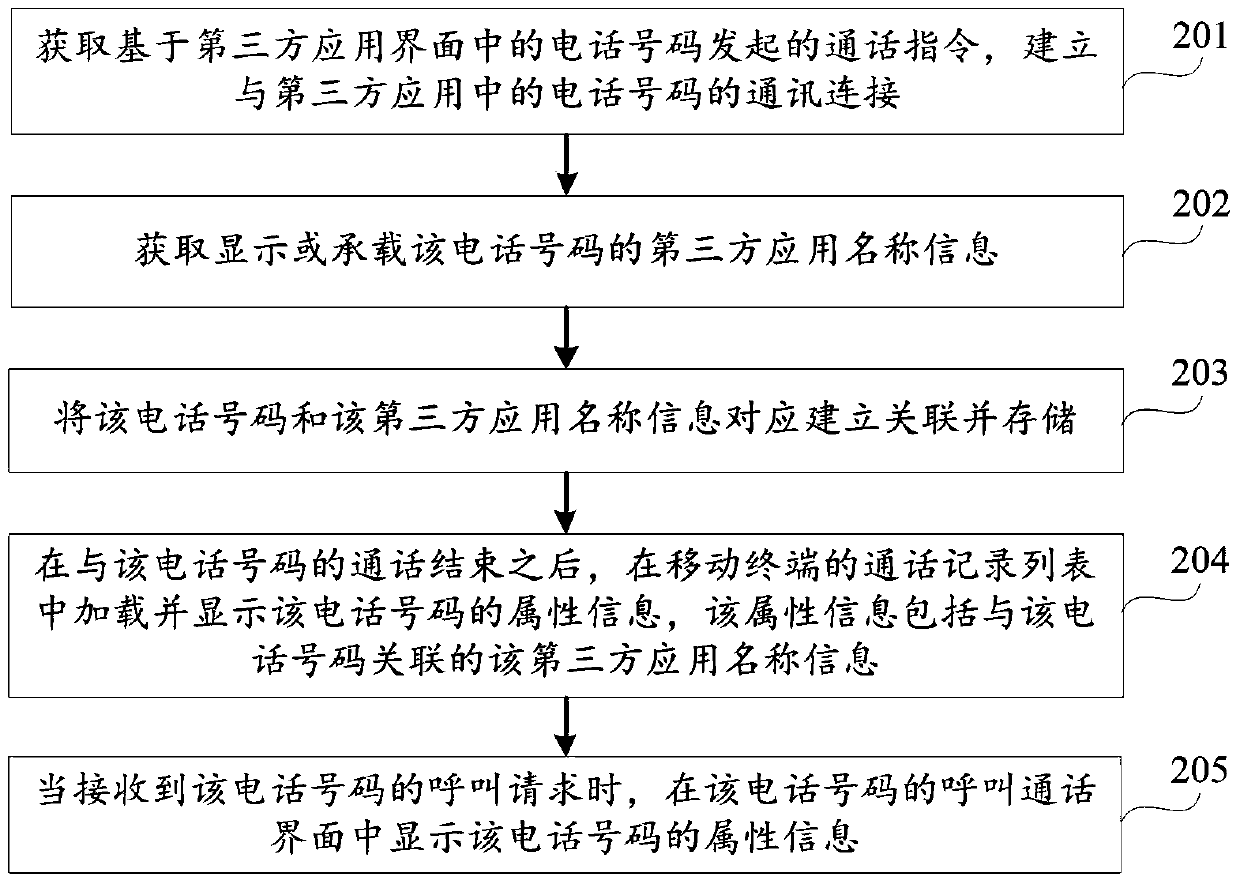

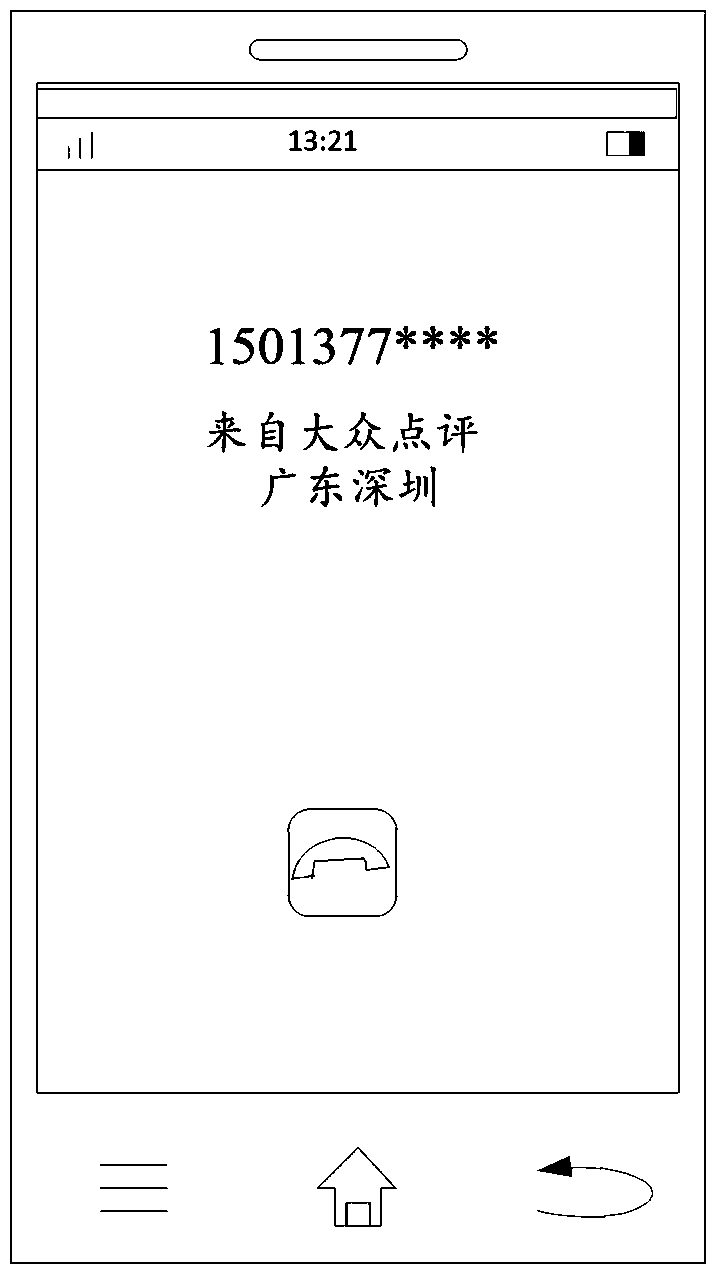

Phone number attribute information display method and device

ActiveCN107438129AMake up for the lack ofCalling susbscriber number recording/indicationCommunication interfaceThird party

The present invention discloses a phone number attribute information display method and device and belongs to the mobile terminal technical field. The method includes the following steps that: a call communication instruction initialed based on a phone number in a third-party application interface is obtained, and a communication connection with the phone number in the third-party application is established; third-party application name information for displaying or carrying the phone number is obtained; the phone number and the third-party application name information are correspondingly associated and are stored; and after call communication with the phone number is finished, the attribute information of the phone number is loaded and displayed in a call record list, wherein the attribute information contains the third-party application name information associated with the phone number; and when the call request of the phone number is received, the attribute information of the phone number is displayed in a call communication interface. According to the method and device of the present invention, the attribute information containing the third-party application name information is displayed, so that a user can be informed of the source of the phone number, and a defect that a number database does not cover the phone number can be eliminated.

Owner:TENCENT TECH (SHENZHEN) CO LTD

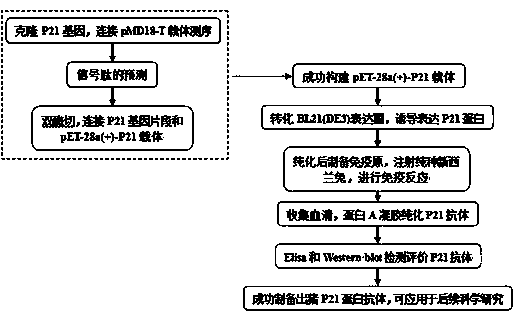

Porcine P21 protein antibody as well as preparation method and application thereof

InactiveCN103880953AMake up for the lack ofSerum immunoglobulinsImmunoglobulins against animals/humansBiochemistryProtein antibody

The invention discloses a porcine P21 protein antibody as well as a preparation method and an application thereof. Porcine P21 protein obtained through expression and purification is used for preparing an immunogen to immunize a purebred New Zealand rabbit so as to prepare a rabbit anti-pig P21 protein antibody; and the prepared rabbit anti-pig P21 protein antibody is capable of well recognizing the P21 protein of a pig and a mouse, while a commercially available anti-human P21 antibody is only capable of limitedly recognizing the P21 protein of the mouse. The porcine P21 protein antibody prepared in the invention fills up the blank in deficiency of a porcine specific antibody and provides materials for a scientific research of porcine genetic breeding.

Owner:SOUTH CHINA AGRI UNIV

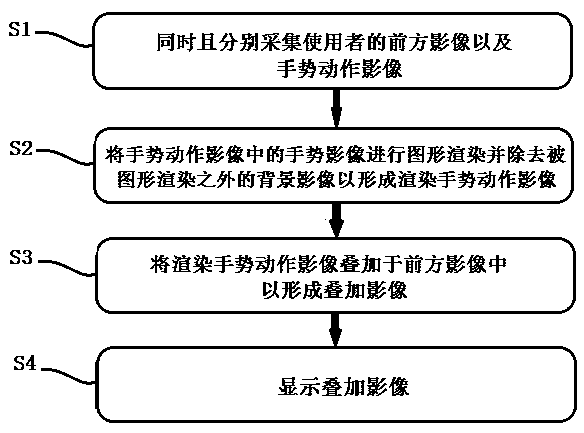

Pair of augmented reality experience glasses with virtual image superposition and imaging method thereof

InactiveCN110244837AMake up for the lack ofGuaranteed viewing effectInput/output for user-computer interactionGraph readingUses eyeglassesGraphics

The invention discloses a pair of augmented reality experience glasses with virtual image superposition and an imaging method thereof. The pair of experience glasses comprises a reality image acquisition unit, a gesture acquisition unit, an image processing unit, an image display unit and an optical lens which are arranged on a glasses body, the real image acquisition unit, the gesture acquisition unit and the image display unit are all electrically connected with the image processing unit; the image processing unit performs graphic rendering on a gesture image in the gesture action image acquired by the gesture acquisition unit and then superposes the gesture image in a front image acquired by the real image acquisition unit to form a superposed image, and the superposed image is identified by eyes of a user through the image display unit and the optical lens; according to the technical scheme, the brightness, the contrast ratio, the gain, the white balance and the color measurement display effect of the acquired front image can be adjusted, and the virtual image can be superposed and covered in the front image, so that the synchronous combination of the virtual image and the real image is realized.

Owner:BEIJING SWEET TECH CO LTD

Method for cultivating Longji pepper

InactiveCN107960283AImprove germination ratePromote germinationBiocideSeed and root treatmentSprouted SeedsPre treatment

The invention discloses a method for cultivating Longji pepper. The method includes the following steps of (1) seed pretreatment, wherein pepper seeds are rubbed, then exposed to the sun for 1 day, soaked in a pretreatment solution for 30-45 minutes, spread on a wet gauze cloth, covered with a layer of wet gauze cloth, and irrigated withan active liquid once every other day for continuous 2 timesto obtain sprouted seeds; (2) seedling management, wherein the sprouted seeds are evenly spread on a seedbed, covered with a layer of nutrient soil with a thickness of 0.3-0.6cm, and then covered witha layer of dried straw on the nutrition soil, and seedlings are grown for 20 days; (3) field planting and management, wherein the pepper seedlings planted in a mode that two plants share 1 hole at aplant spacing of 30-50 cm*20-30 cm, and a water-fertility integration technology is used for drop irrigation of a liquid fertilizer on the pepper seedlings. The Longji pepper seeds cultivated by the method have high germination rate, easy survival of seedlings and broad market promotion value.

Owner:桂林国农生态农业科技有限公司

Probenazole production process

ActiveCN101712677BReduce pollutionMake up for the lack ofOrganic chemistryPhosphorus pentasulfideEthyl acetate

Owner:JIANGSU NOON CROP SCI CO LTD

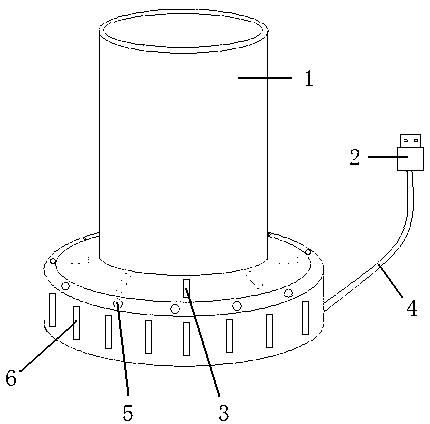

Pen container with USB (universal serial bus) ports

InactiveCN103317922AMake up for the lack ofSimple structureWriting accessoriesElectronic equipmentPower output

The invention discloses a pen container with USB (universal serial bus) ports. The pen container comprises a pen container base and a plug, at least five USB ports are arranged on the pen container base, a power output line connected with the plug is arranged on the pen container base, and the plug is a plug of the USB ports. The pen container with the USB ports is simple in structure and safe and convenient to operate, and the circumstance that a computer has few USB ports is made up; the attractive and elegant pen container can also contain several electronic equipment with USB interfaces and pens, so that another novel use is developed for the pen container.

Owner:张人益

Manufacturing method of violin type electroacoustic musical instrument

PendingCN113990273ASave forest resourcesMake up for the scarcity of raw materialsElectrophonic musical instrumentsStringed musical instrumentsViolinTimbre

The invention discloses a manufacturing method of a violin type electro-acoustic musical instrument. The manufacturing method comprises the following steps of designing the shape of a product; carrying out injection molding, carrying out injection molding on a polymer synthetic material in a mold to obtain a white blank of the musical instrument; paint spraying, according to requirements of the market and customers, spraying the white blank into a required color appearance; drying, the sprayed door blank being placed in a drying oven heated to 30 DEG C, the adsorption force of the color being enhanced, and a musical instrument body being formed; installing a sound pick-up, arranging the sound pick-up with signal conversion and amplification functions on the guitar body; assembling accessories to form a finished product; testing and adjusting the timbre quality; and packaging finished products. The method is advantaged in that the method is energy-saving and environment-friendly, forest resources are protected, production cost is reduced, productivity is improved, and the tone quality of the traditional violin type electroacoustic musical instrument can be well restored by adopting the body made of the polymer synthetic material.

Owner:上海东音乐器有限公司

Method and device for displaying attribute information of telephone number

ActiveCN107438129BMake up for the lack ofCalling susbscriber number recording/indicationCommunication interfaceThird party

The present invention discloses a phone number attribute information display method and device and belongs to the mobile terminal technical field. The method includes the following steps that: a call communication instruction initialed based on a phone number in a third-party application interface is obtained, and a communication connection with the phone number in the third-party application is established; third-party application name information for displaying or carrying the phone number is obtained; the phone number and the third-party application name information are correspondingly associated and are stored; and after call communication with the phone number is finished, the attribute information of the phone number is loaded and displayed in a call record list, wherein the attribute information contains the third-party application name information associated with the phone number; and when the call request of the phone number is received, the attribute information of the phone number is displayed in a call communication interface. According to the method and device of the present invention, the attribute information containing the third-party application name information is displayed, so that a user can be informed of the source of the phone number, and a defect that a number database does not cover the phone number can be eliminated.

Owner:TENCENT TECH (SHENZHEN) CO LTD

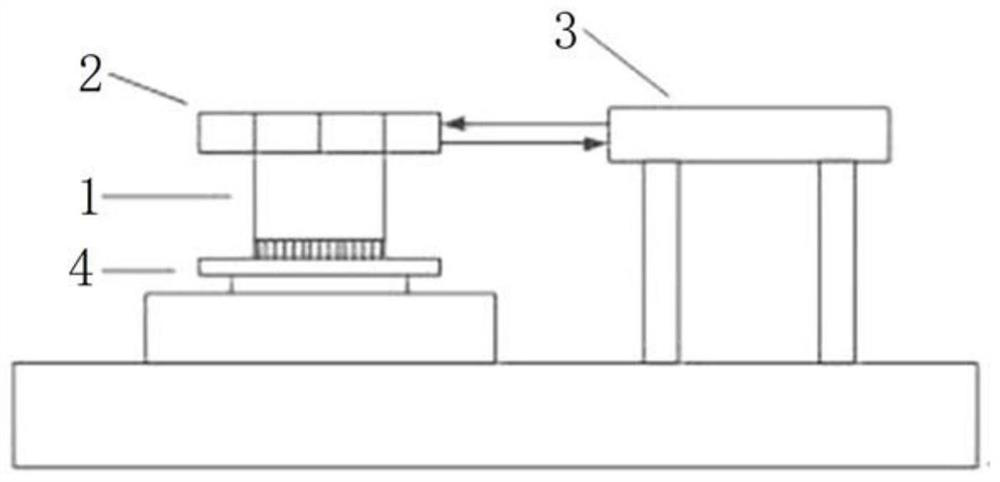

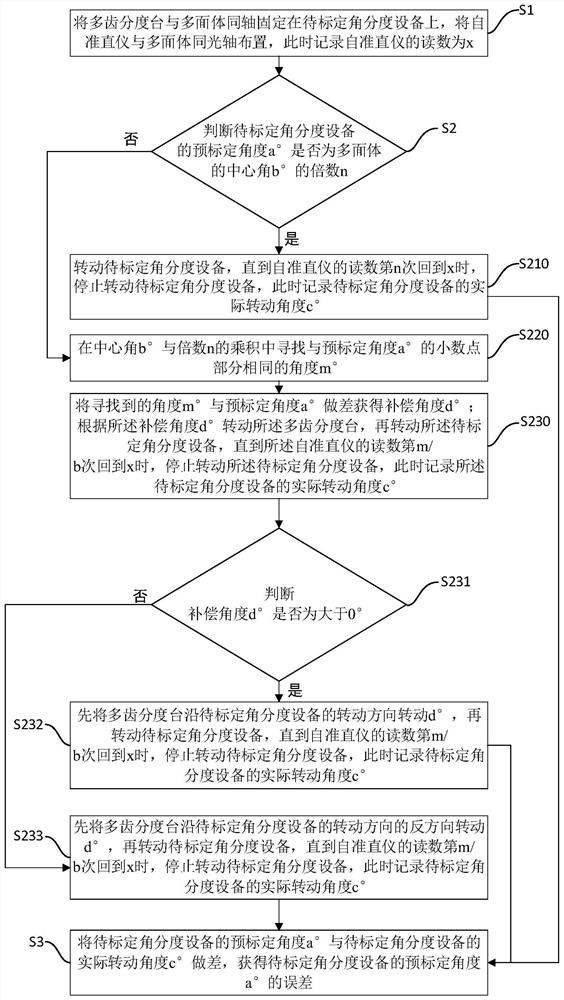

Angle Calibration Method

ActiveCN111060030BMake up for the lack ofImprove calibration accuracyUsing optical meansComputer graphics (images)Autocollimator

The invention discloses an angle calibration method. The position of an angle indexing device is calibrated by combining a multi-tooth indexing table with a polyhedron and cooperating with an autocollimator. Each pre-calibrated position of the angle indexing device corresponds to a pre-calibration For the angle, use the multi-tooth indexing table to calibrate the integer part of the pre-calibrated angle, and use the polyhedron to calibrate the fractional part of the pre-calibrated angle. The present invention realizes the multi-position accuracy calibration of the angle indexing equipment through the combination of the multi-tooth indexing table and the polyhedron and the autocollimator, which makes up for the shortcomings of only using the multi-tooth indexing table or the polyhedron to calibrate the small number of positions. It has low requirements on the environment, high calibration accuracy and simple operation.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

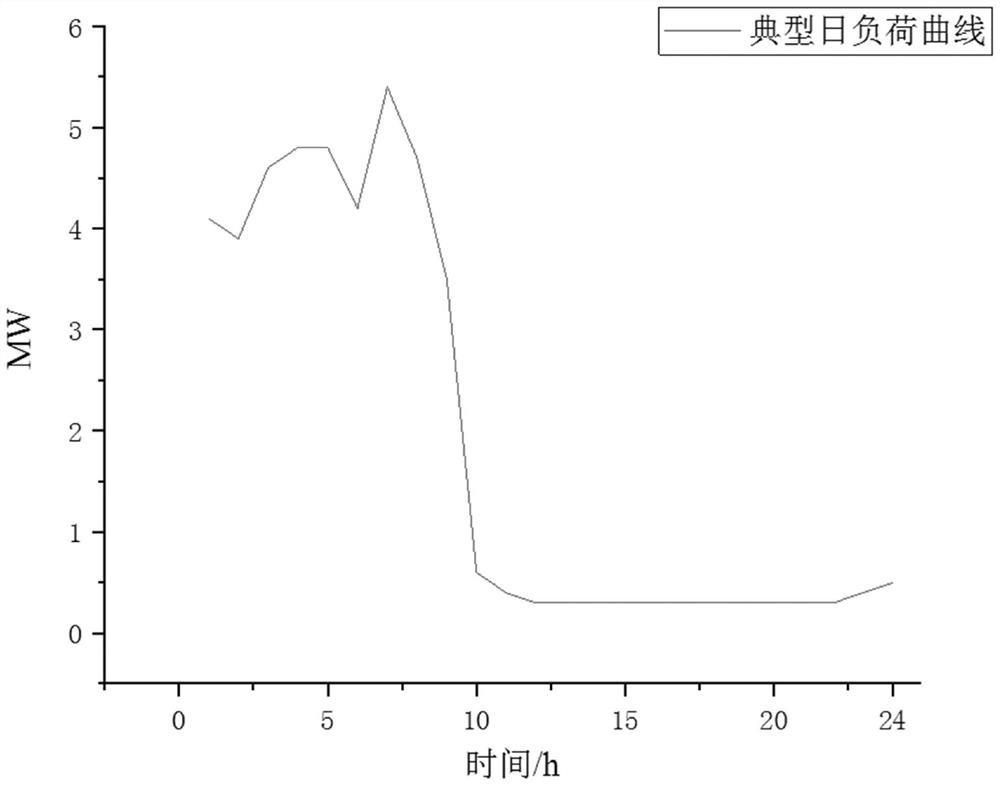

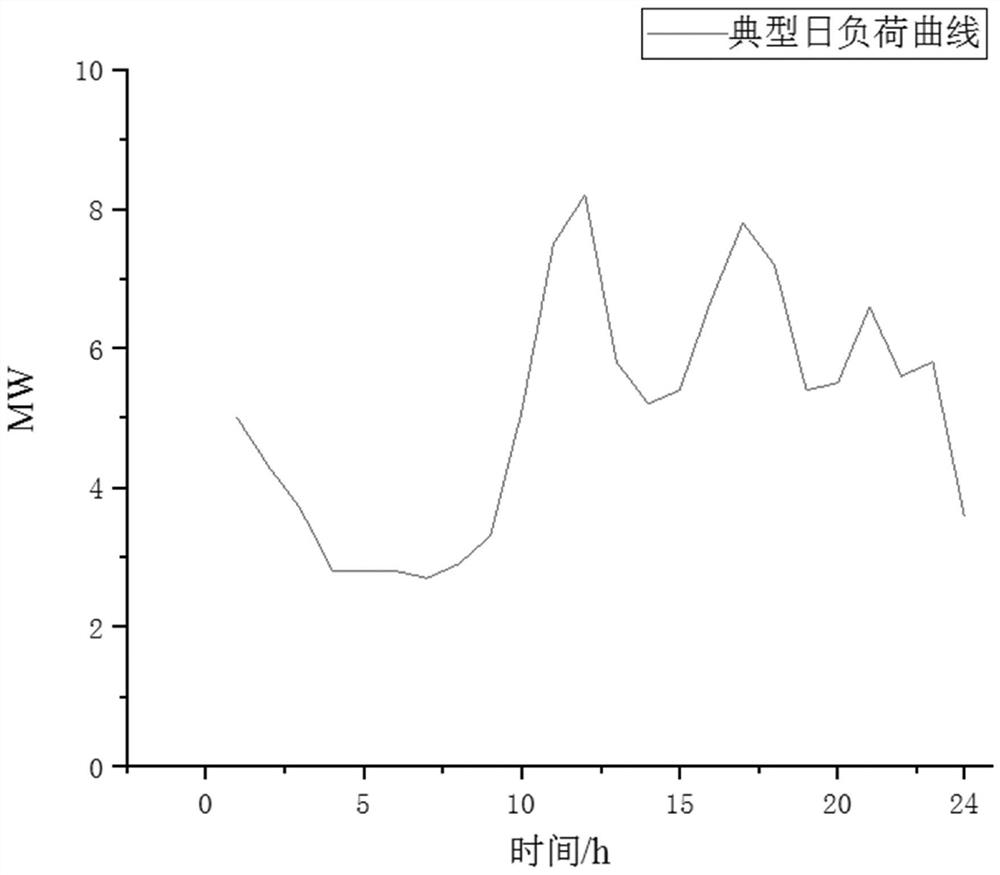

Two-part electricity price pricing analysis method

InactiveCN111985978AMeet needsMake up for the lack ofMarket predictionsMarket data gatheringElectricity pricePower grid

The invention discloses a two-part electricity price pricing analysis method. The method comprises the steps of obtaining power grid data information of a to-be-analyzed area; classifying the electricity users in the to-be-analyzed area; constructing a user electricity price function; calculating a user utility income function of each category of users; constructing an electricity selling enterprise user utility income objective function by taking the maximum user utility income of all users as a target; constructing constraint conditions of the electricity selling enterprise user utility income objective function by taking nonnegative electricity selling enterprise user income, incentive compatibility and supply and demand balance as principles; and solving the objective function to obtain the final electricity price of the users. The method accurately and visually reflects the apportionment of the power supply cost and the formulation of the two-part electricity price of an electricity selling enterprise, better meets the actual requirements of user evaluation and electricity price formulation planning, is clear in calculation process and clear in physical significance, can effectively distinguish the user types, and makes up for the deficiency of user information loss. The method is scientific, reasonable and good in implementation.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Farming method of feeding snail with papaya

InactiveCN106888996AIncrease dissolved oxygen contentImprove survival rateClimate change adaptationAnimal feeding stuffOxygenSalinity

The invention discloses a farming method of feeding snail with papaya. The method comprises the steps that 1, the management of the culture pond: oxygenate agent is sprayed in the dosage of 30-50 g / m2 into the pond every 2 days, and the level of the dissolved oxygen is larger than or equal to 3.5 mg / L; 2, the management of unicellular algae culture: the pH value of the pond water is regulated to 7.5-8.2, the salinity is 15-20%o, unicellular algae solution is sprayed in the dosage of 200-280 g / mu, the unicellular algae is cultivated for 20-30 days; 3, the management of stocking: the snails are stocked for 165-185 days, China cipangopaludina with a weight range of 3-5 g and a stocking density of 65-80 stocking / m2 are stocked, every night 0.2-0.5 kg / 100m2 papaya pulp is fed in a casting mode, every 2-3 days 0.5-0.8 kg / 100m2 fodder is fed. The farmed snails are easy to survive, high in yield and good in taste, with extensive promotional value.

Owner:陆川县一品养殖专业合作社

Peach patch of fruits and vegetables, and method of processing the same

Owner:CHENGDU UNIV

Coke oven coking method for increasing the proportion of long-flame coal used in chemical coke

ActiveCN104087328BMeet the requirementsLow costSpecial form destructive distillationChemical industryCoal briquette

The invention relates to a coke oven coking method for improving a ratio of long flame coal for chemical coke. The method comprises the following steps: a, performing secondary crushing on long flame coal, and mixing the long flame coal with an adhesive in a storage warehouse; b, performing pre-grinding on the long flame coal mixed with the adhesive, feeding the coal into a coal blending chamber, improving a ratio of the long flame coal mixed with the adhesive to 80 percent, adjusting a gas-fat coal ratio with high adhesiveness to 20 percent, and feeding the coal into a crusher for crushing after mixing; c, performing primary water injection on the prepared mixed coal, crushing the coal in a crusher chamber, performing secondary water injection on the crushed mixed coal, feeding coking coal into a charging car for tamping, so that the coking coal is smashed into a dense coal cake, and feeding the coal into a carbonization chamber for performing high-temperature dry distillation; and d, performing high-temperature dry distillation on the coking coal, performing coke quenching by adopting a dry method, and finally naturally cooling to obtain the chemical coke product. According to the method, low-cost smelting and chemical industry carbon materials can be produced, and the gap that smelting and chemical industry carbon materials are deficient is overcome.

Owner:新疆新鑫新能源化工有限公司

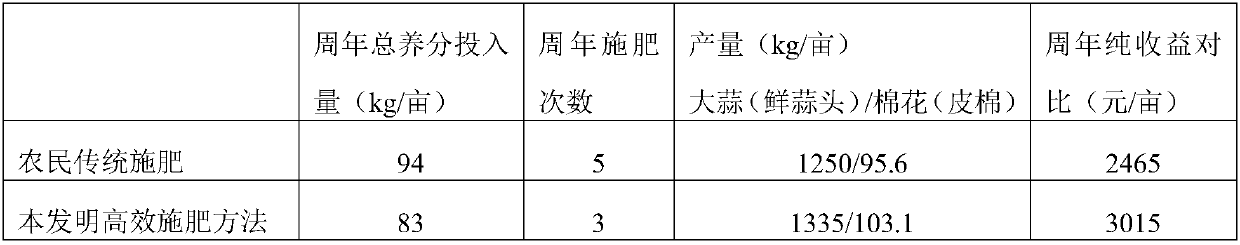

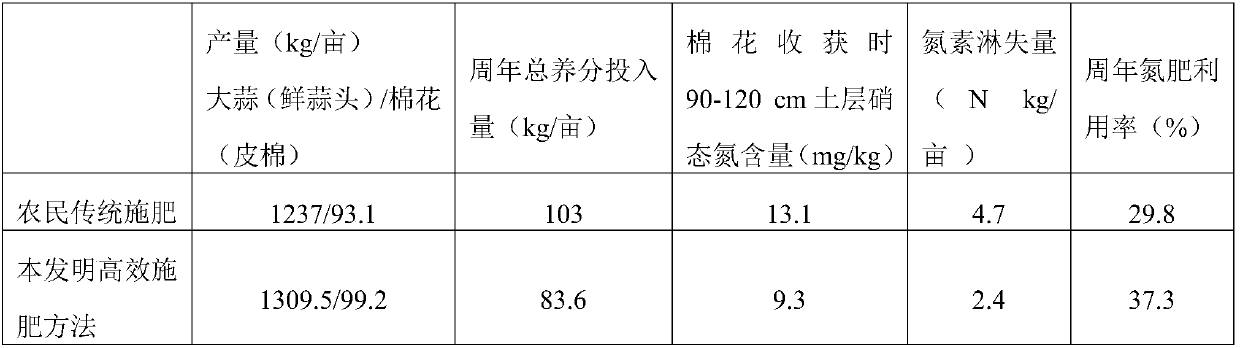

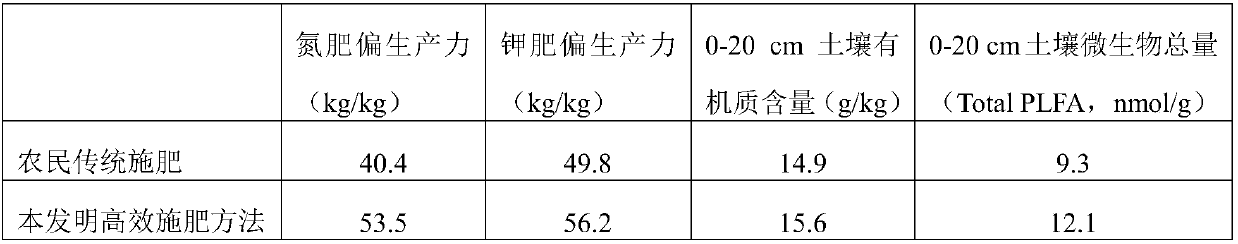

A high-efficiency fertilization method for garlic and cotton rotation resistant to heavy cropping

ActiveCN107258190BReduce churnIncrease the effective concentrationSuperphosphatesAlkali orthophosphate fertiliserContinuous croppingPotassium

The invention relates to an anti-continuous cropping garlic-cotton rotation efficient fertilization method. The method includes: (1) after harvesting of previous crops, taking an organic fertilizer and a polymerized amino acid fertilizer as the base fertilizer, and sowing garlic on from September 25th to October 10th; (2) during the early to middle April of the next year, conducting topdressing of nitrogen and potassium fertilizer from the garlic elongating stage to bolting stage; and (3) transplanting cotton pot seedlings between lines of garlic from the last ten days of April to the beginning of May, harvesting garlic at the last ten days of May, and applying a cotton seedling stage fertilizer during the early to middle June. According to the garlic-cotton rotation efficient fertilization method provided by the invention, polymer polyglutamic acid in the garlic base fertilizer can achieve complexation of nutrient ions in the fertilizer, reduce nutrient loss, and improve the nutrient effective concentration, thus prolonging the fertilizer effect. At the same time, the method can lock in moisture in soil, provides nutrients and moisture to cotton, also provides the basis and guarantee for cotton growth, at the same time increases the diversity of soil organic carbon sources, promotes the recovery of soil microbial diversity, and has anti-continuous cropping effect.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +1

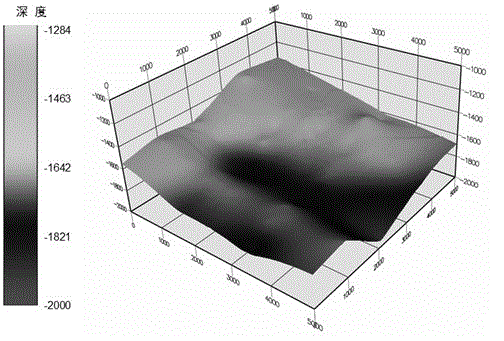

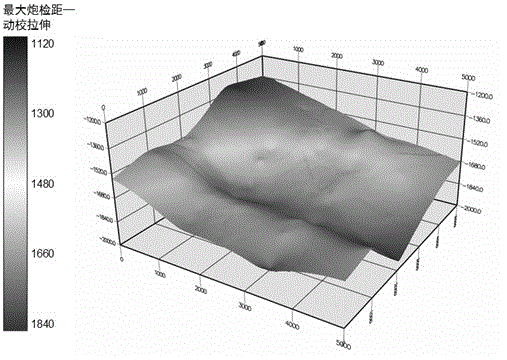

Parameter demonstration method of omnidirectional observation system based on geological model

The invention provides an omnibearing observation system parameter argument method based on a geologic model. The method comprises a step 1, acquiring multiple kinds of geological data, and establishing a work area geological model; a step 2, selecting one layer position in the geological model, and calculating requirements of face elements of physical points on the layer position through adoption of a formula; a step 3, displaying the requirements of the face elements of the physical points on corresponding layer faces in the model; a step 4, selecting one layer position in the geological mode, and calculating the maximum shot-geophone distance requirement of each physical point on the layer position through adoption of a formula; a step 5, displaying the maximum shot-geophone distance requirement of each physical point on the corresponding layer face in the model; and a step 6, determining an observation system parameter satisfying a production need. The method can visually and comprehensively analyze the parameter need of a full area, is relative scientific and reasonable, an argumentation result is relative comprehensive, the deficiency of less argument points in a previous method is made up, and a defect that a previous parameter argument method cannot know the parameter need of the full area is overcome.

Owner:中石化石油工程技术服务有限公司 +1

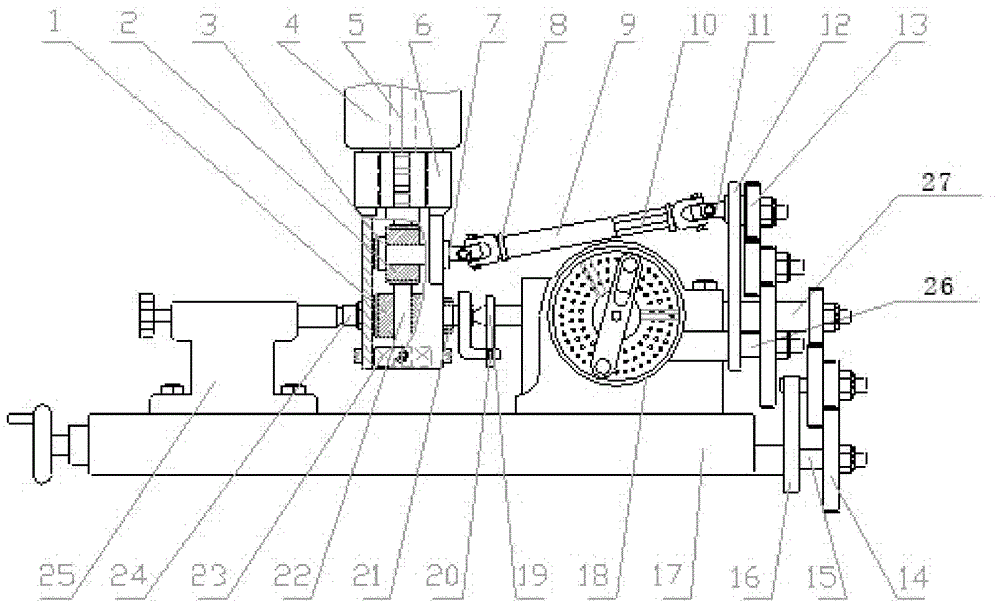

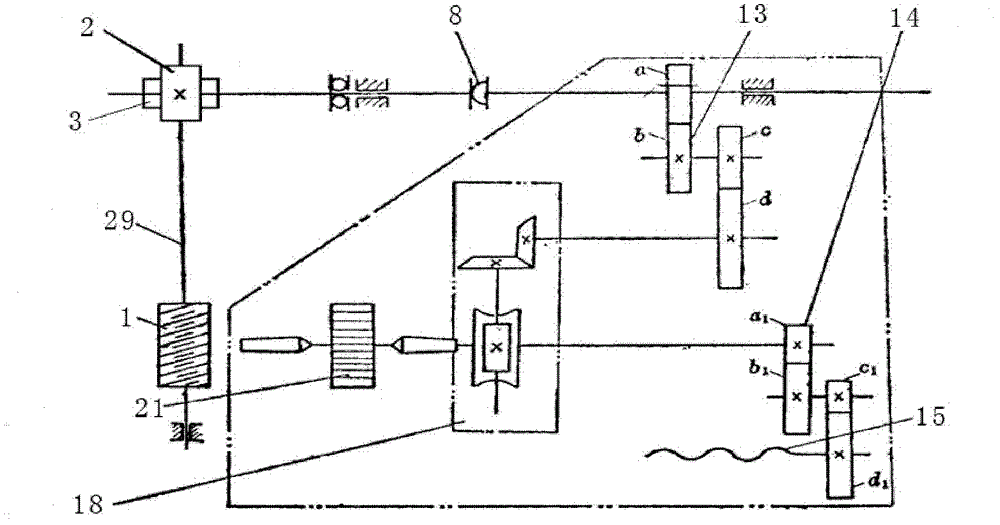

Vertical milling machine for precisely processing gear

The invention provides a vertical milling machine for precisely processing a gear, belonging to the technical field of machining a machine tool. The vertical milling machine for precisely processing the gear comprises a base, a machine body with a guide rail, a lifting platform, a longitudinal work platform, a horizontal work platform, a power system, a speed shifting mechanism, an electric appliance control system and a power output head, wherein the power output head outputs the power to a gear hobber used for milling the gear and a central spindle used for driving a workpiece, the transmission ratio relationship between a main shaft of the milling machine and a processed gear is provided with a strict internal relation transmission chain, so that the accurate transmission between the workpiece and the gear hobber can be realized. The processing of a straight toothed spur gear, an involute spline and a chain wheel can be realized, and after a differential mechanism, the processing of a helical-spur gear can be realized, and a pinion cutter which is small in diameter and has low requirement on the precision of a worm wheel can be processed. The vertical milling machine of the invention solves the difficulty that the precise level can not be achieved by using a disc milling cutter form copying method for the milling machine to process the spur gear, has the advantages of low cost and convenient and rapid assembly and disassembly, and can be used for various common vertical milling machines.

Owner:广东岭南现代高级技工学校

One-plug multiple socket-outlet

InactiveCN103311762AMake up for the lack ofReasonable structural designCoupling device detailsPower switchingPush-button

The invention discloses a one-plug multiple socket-outlet which comprises a socket body. The socket body is provided with more than four socket groups and a plug, a power switch push button is arranged on the socket body, and a power indicating lamp is arranged on the side edge of the switch push button. The one-plug multiple socket-outlet is reasonable in structural design, simple to operate and safe and convenient to use and makes up for the conditions that sockets are few.

Owner:张人益

Semi-artificial practical feed of Locusta migratoria manilensis and production method thereof

InactiveCN102370089BMake up for the lack ofQuality assuranceAnimal feeding stuffAgricultural scienceGrasshopper

The invention discloses a semi-artificial practical feed of Locusta migratoria manilensis which is mainly prepared from wheat bran, corn oil and whole milk powder. The invention also discloses a production method of the semi-artificial practical feed of Locusta migratoria manilensis. The semi-artificial practical feed of Locusta migratoria manilensis provided by the invention can be used as a practical feed of Locusta migratoria manilensis raised artificially and can be used at any time all year round, therefore the defect of the shortage of locusts in seasons without sufficient fresh feed can be overcome; in addition, the quality and survival rate of Locusta migratoria manilensis fed with the semi-artificial practical feed can be better ensured.

Owner:张欣杨

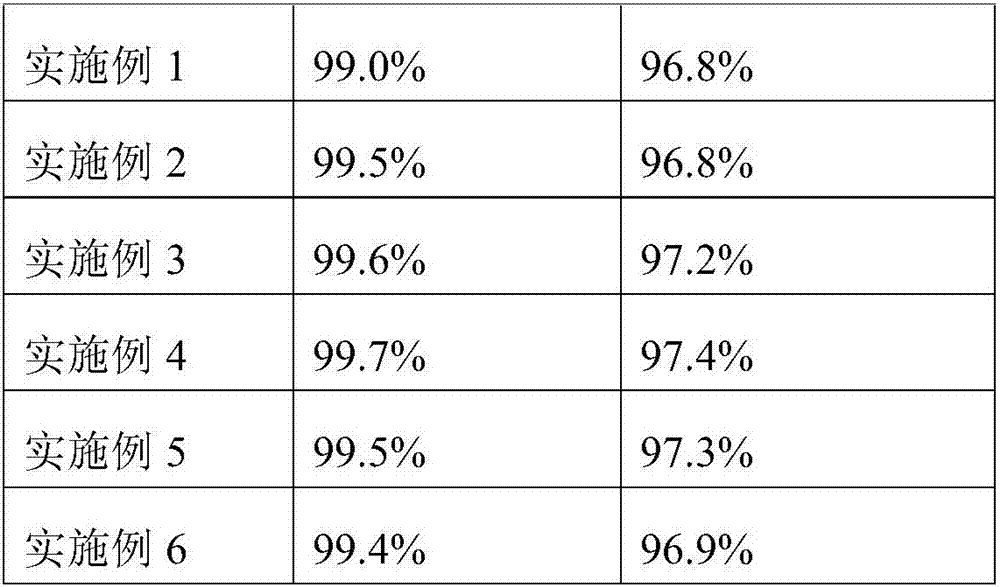

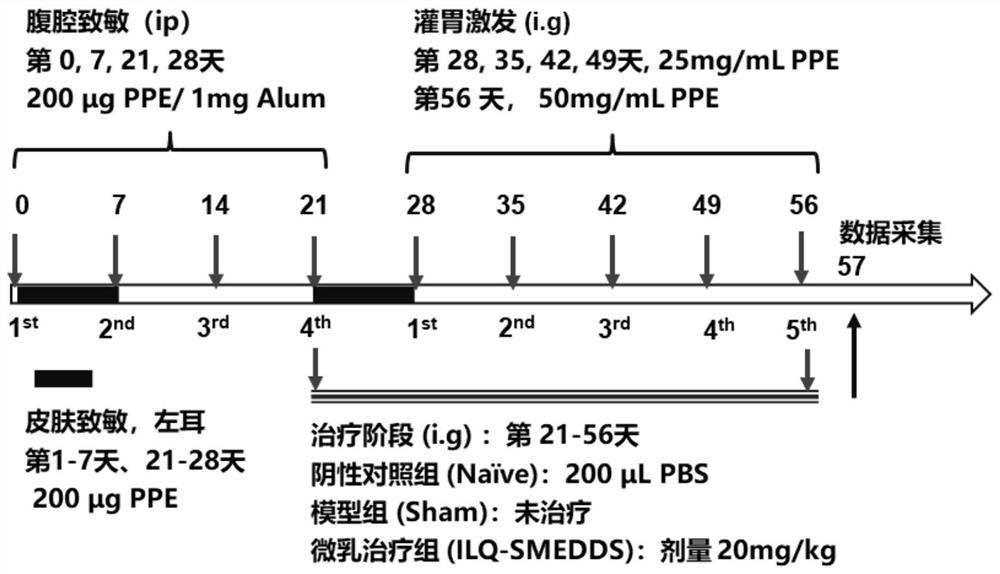

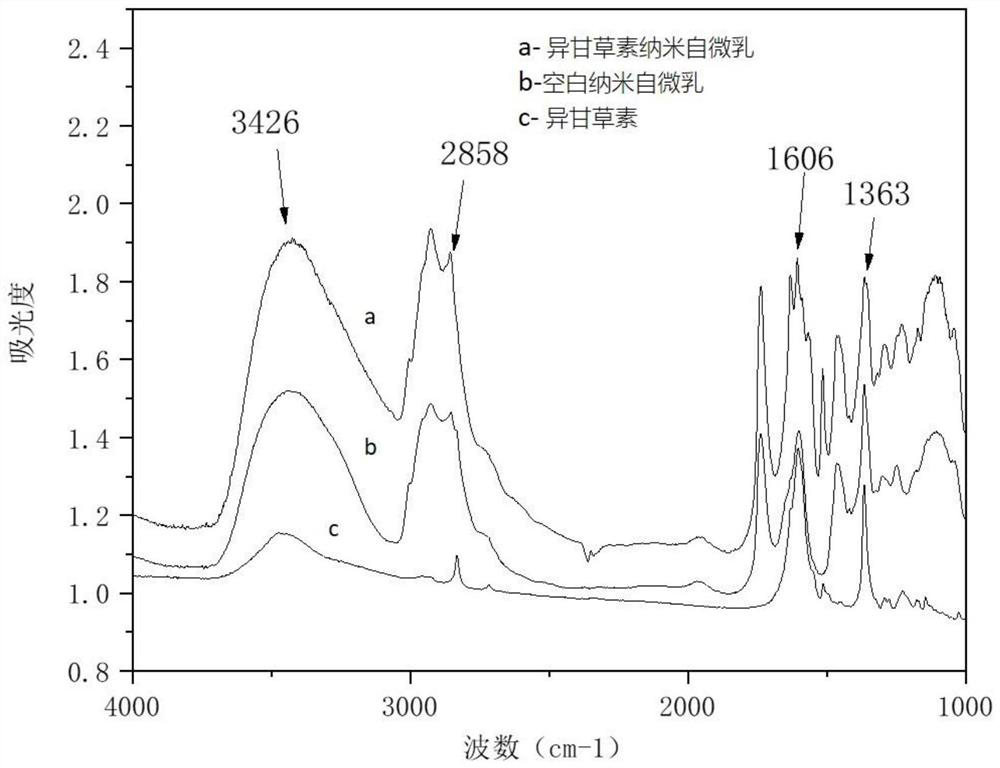

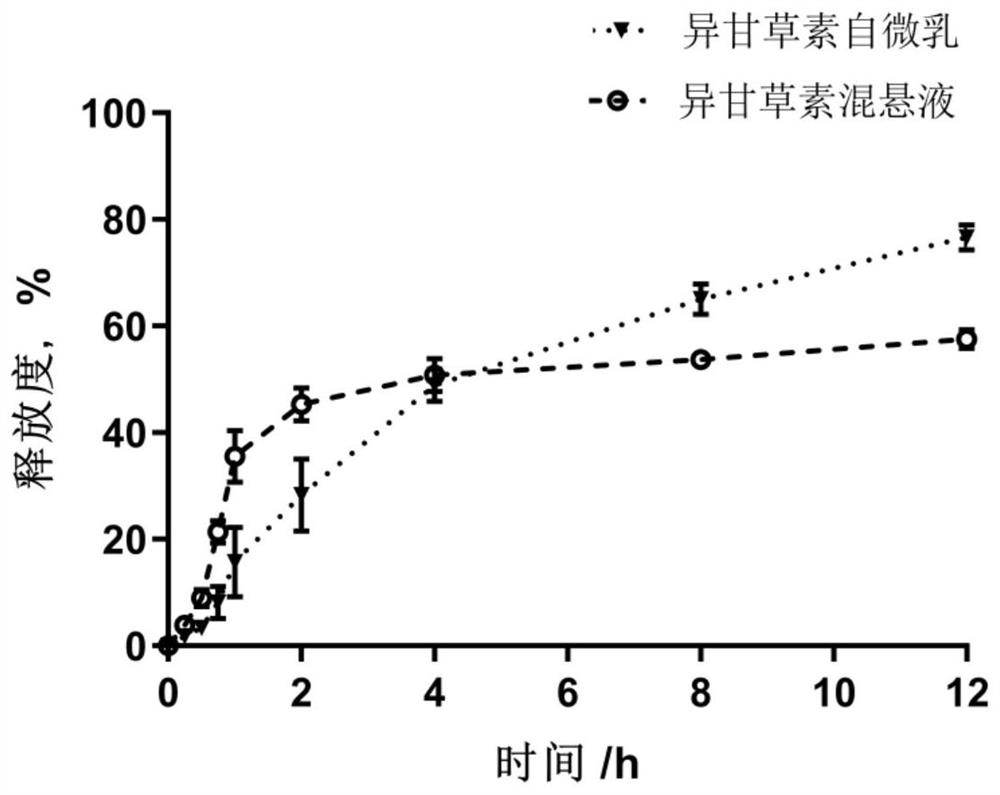

Isoliquiritigenin self-microemulsion, preparation method and application thereof, and application of isoliquiritigenin self-microemulsion to EOE model mice

ActiveCN113813229AImprove solubilityEasy to prepareCompounds screening/testingDigestive systemIsoliquiritigeninActive agent

The invention belongs to the technical field of medicines, and particularly relates to an isoliquiritigenin self-microemulsion, a preparation method and application thereof and an application of the isoliquiritigenin self-microemulsion to EOE model mice. The isoliquiritigenin self-microemulsion comprises a surfactant, a cosurfactant, an oil phase and isoliquiritigenin, wherein the surfactant is selected from Tween 80 and polyoxyethylated castor oil, the mass ratio of Tween 80 to polyoxyethylated castor oil is 7: (2-4), the cosurfactant is PEG400 and 1, 2-propylene glycol, the mass ratio of the PEG400 to the 1, 2-propylene glycol is 1: (0.5-1.5), the oil phase is selected from ethyl oleate, the mass ratio of the oil phase to the surfactant to the cosurfactant is (2-4): (5-7): 1, and the isoliquiritigenin reaches a saturated state in the isoliquiritigenin self-microemulsion. The isoliquiritigenin self-microemulsion is used for treating eosinophilic esophagitis, and is applied to EOE model mice. The solubility of the isoliquiritigenin in the isoliquiritigenin self-microemulsion is obviously improved, besides, the preparation method does not change the physical and chemical properties of the isoliquiritigenin, and the preparation method is simple and convenient to popularize.

Owner:HENAN UNIV OF CHINESE MEDICINE

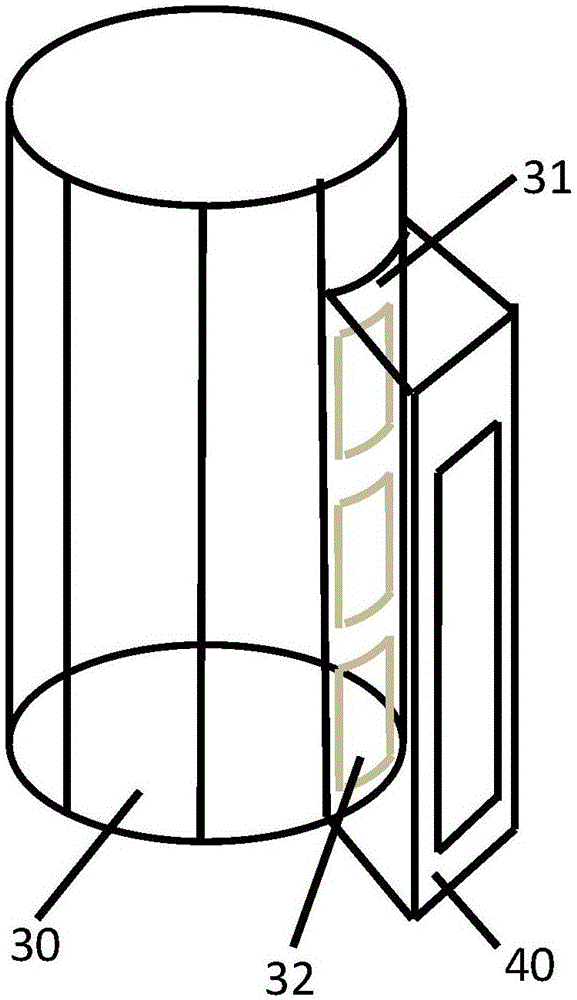

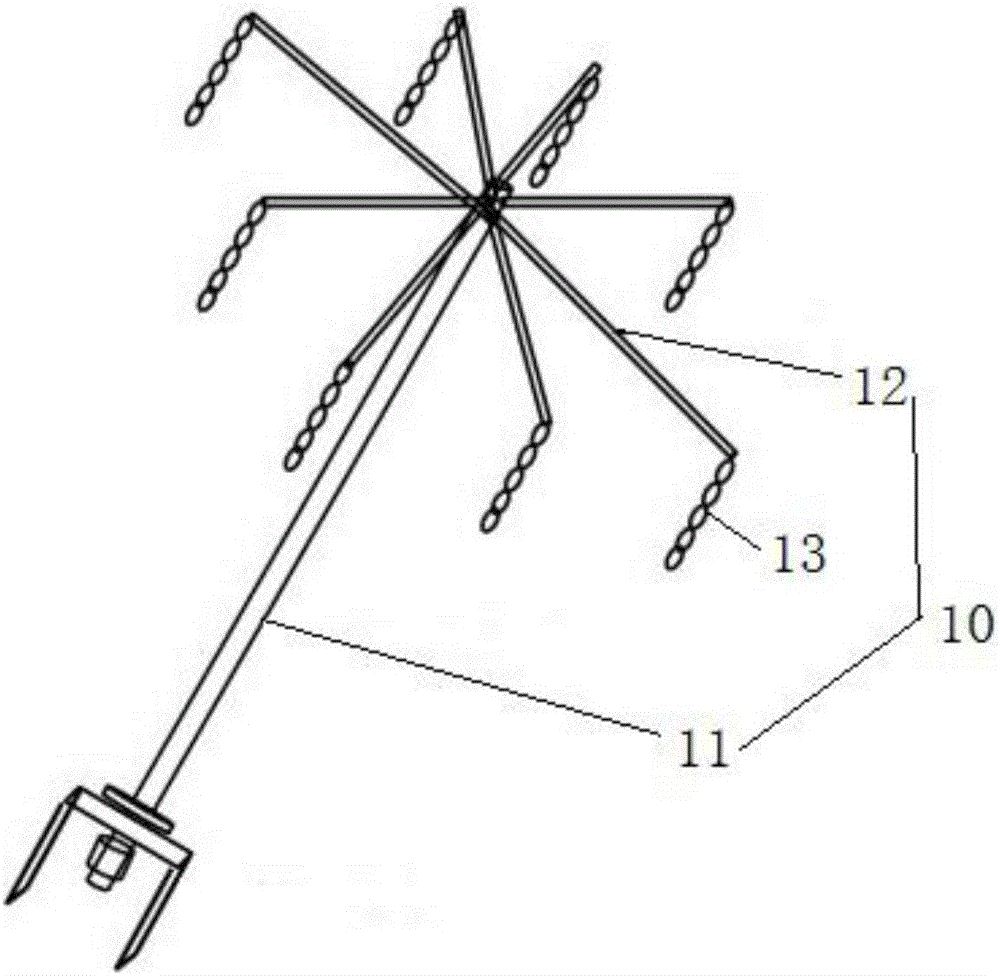

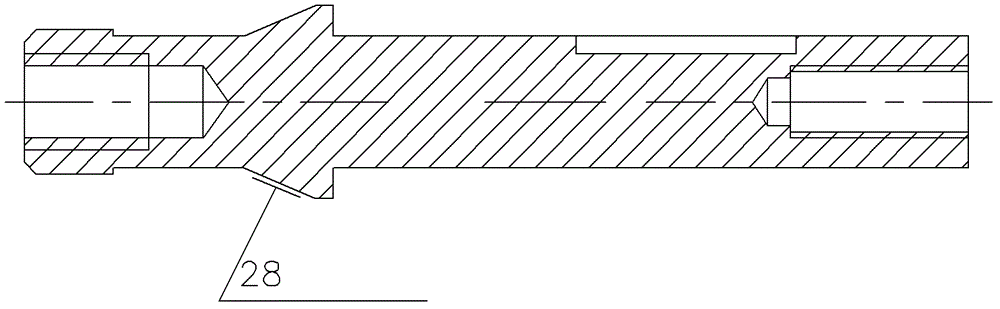

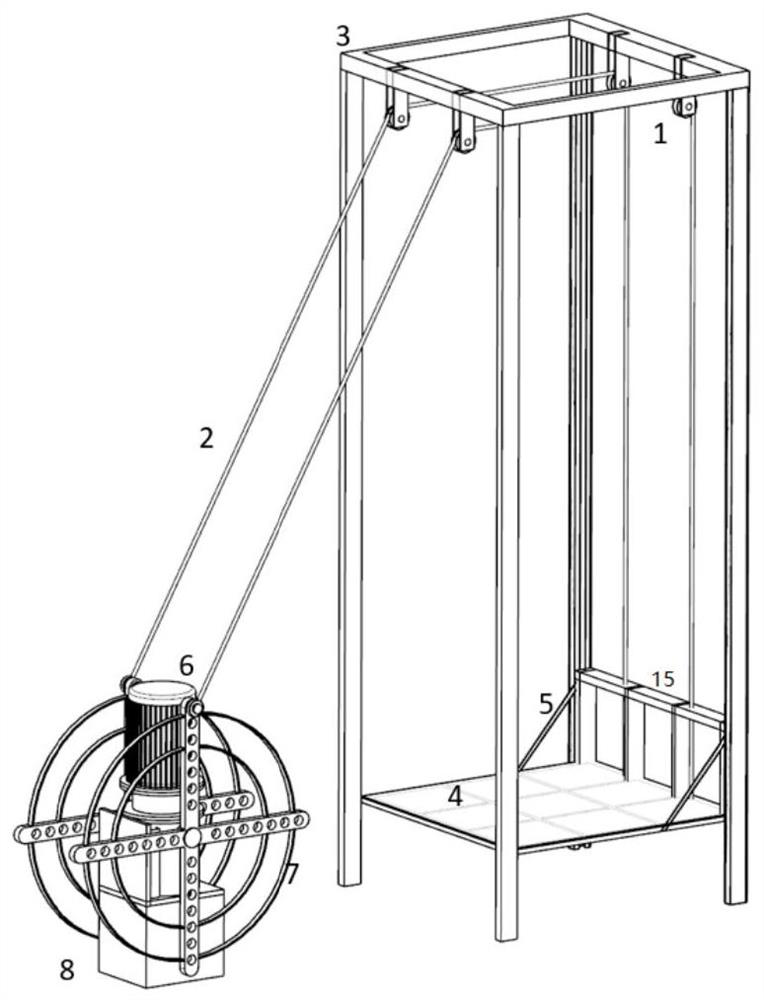

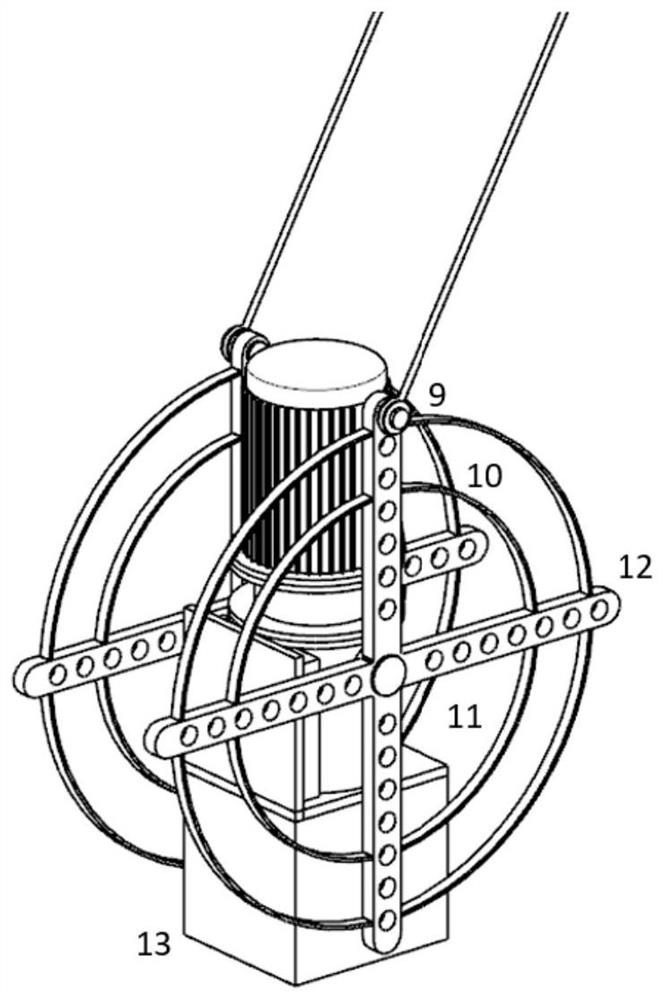

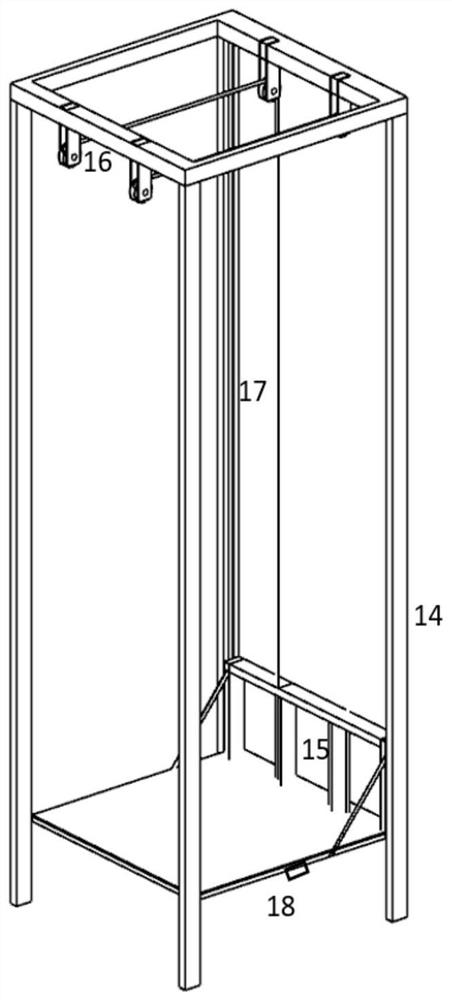

Simple system for simulating fluctuating motion of ocean conditions

The invention aims to provide a simple system for simulating fluctuating motion under ocean conditions, the simple system comprises a power input part and a power output part, the power input part comprises a high-power motor 6, a gear reducer 8, a crank mechanism 7 and a base 13, and the power output part comprises an integral frame 3, a motion platform 4, a triangular rib 5, a support structure 15, four stainless steel pulleys 1 and a traction rope 2. The invention aims to provide a motion system which is wide in research working condition, convenient in instrument mounting and free of other interference on an experiment body, and is used for real-time measuring of parameters such as liquid level of a reactor liquid container, impact load on a side wall surface, flow of a simple loop and pressure drop under the condition of reproducing fluctuation. The system is low in cost, convenient to build and simple to operate.

Owner:HARBIN ENG UNIV

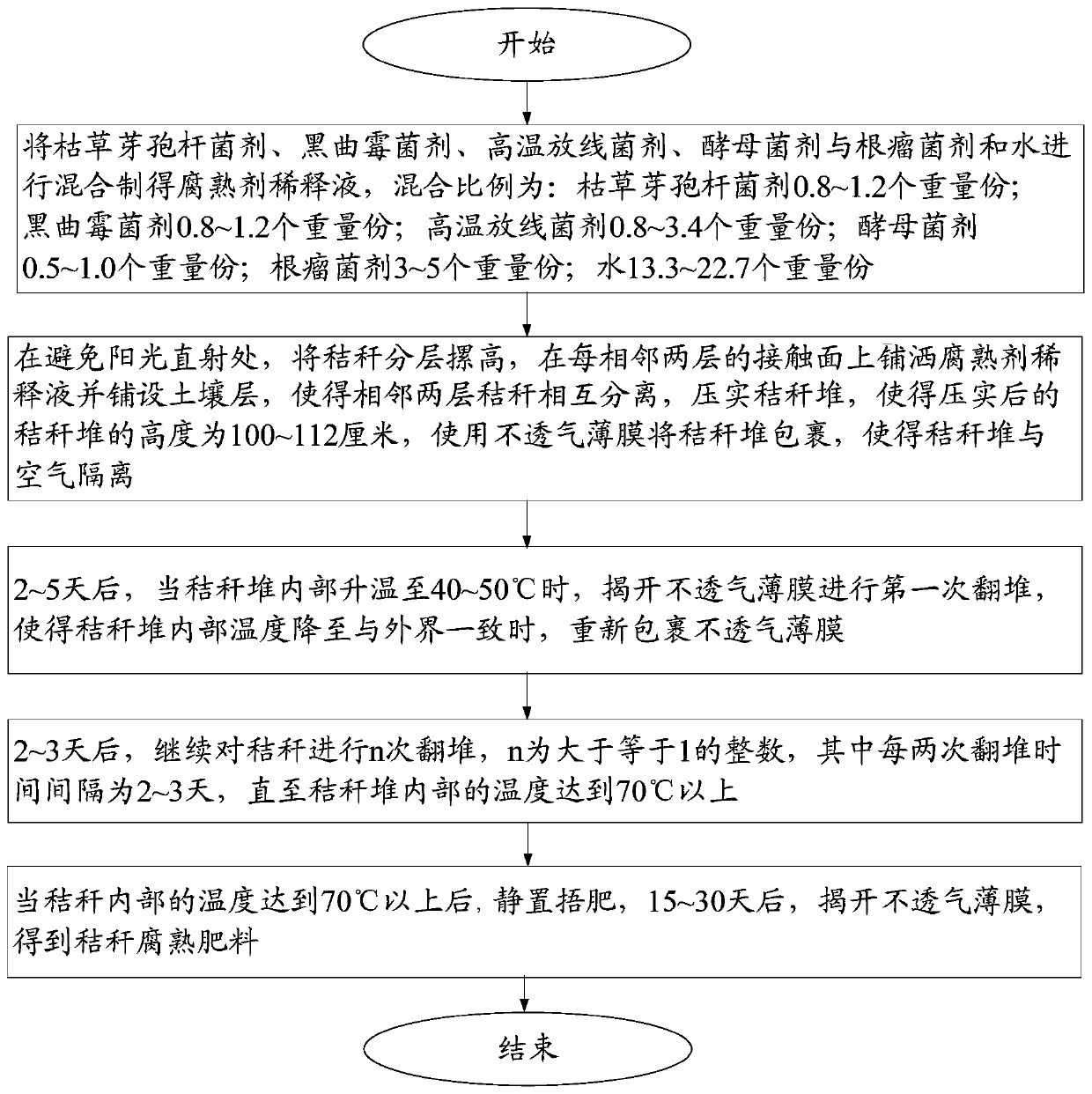

A kind of production method of straw decomposed fertilizer of leguminous crops

ActiveCN105936600BMake up for the lack ofAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationLegume cropsAspergillus niger

The present invention provides a production method of a leguminous crops straw decomposing fertilizer. The method comprises the steps of: mixing by weight 0.8-1.2 parts of Bacillus subtilis agent, 0.8-1.2 parts of Aspergillus niger agent, 0.8-3.4 parts of thermophilic actinomycetes agent, 0.5-1.0 part of saccharomycetes agent, 3-5 parts of rhizobium agent and 13.3-22.7 parts of water to obtain a decomposition agent diluent. The production method of the leguminous crop straw decomposing fertilizer provided by the invention can transform straw into fertilizer for effective usage, and uses of biological agents in the whole process to effectively avoid the pollution to the environment; besides, the prepared straw composting fertilizer is rich in nitrogen, phosphorus and potassium, can be applied directly to legume crops, and can reduce the application amount of chemical fertilizer.

Owner:金禾佳农(北京)生物技术有限公司

Super large capacity smart express cabinet

InactiveCN106204951BRealize individual weighingAchieve re-useApparatus for meter-controlled dispensingIndividual entry/exit registersComputer moduleComputer science

The invention discloses an ultra-large-capacity intelligent express cabinet. A weighing device is arranged under express row cabinets so that each row of express row cabinet can be independently weighed; the increased weight of the express row cabinets is acquired through a weight change acquisition module when cabinet doors are opened in single time, and the increased weight and depositing information is bound and stored; meanwhile, an express single cabinet space information judgment module is arranged so that a plurality of pieces of expresses can be stored in one express single cabinet and residual space express single cabinets are reutilized, and the problem that the quantity of express single cabinets of an existing express cabinet is made up; meanwhile, an access control module is controlled according to the weight change acquisition module to manage and control the opening and closing of an express taking room outlet; the access control module ensures that a receiver can smoothly take away the expresses only if the receiver takes the expresses meeting the weight of the own expresses, so that the express single cabinets can contain the plurality of expresses and phenomena of incorrectly taking and taking by mistakes do not occur, and furthermore, the space is extremely saved and the utilization rate of a cabinet body is improved; and the anti-theft aim is realized.

Owner:武汉三车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com