Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309 results about "Violin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

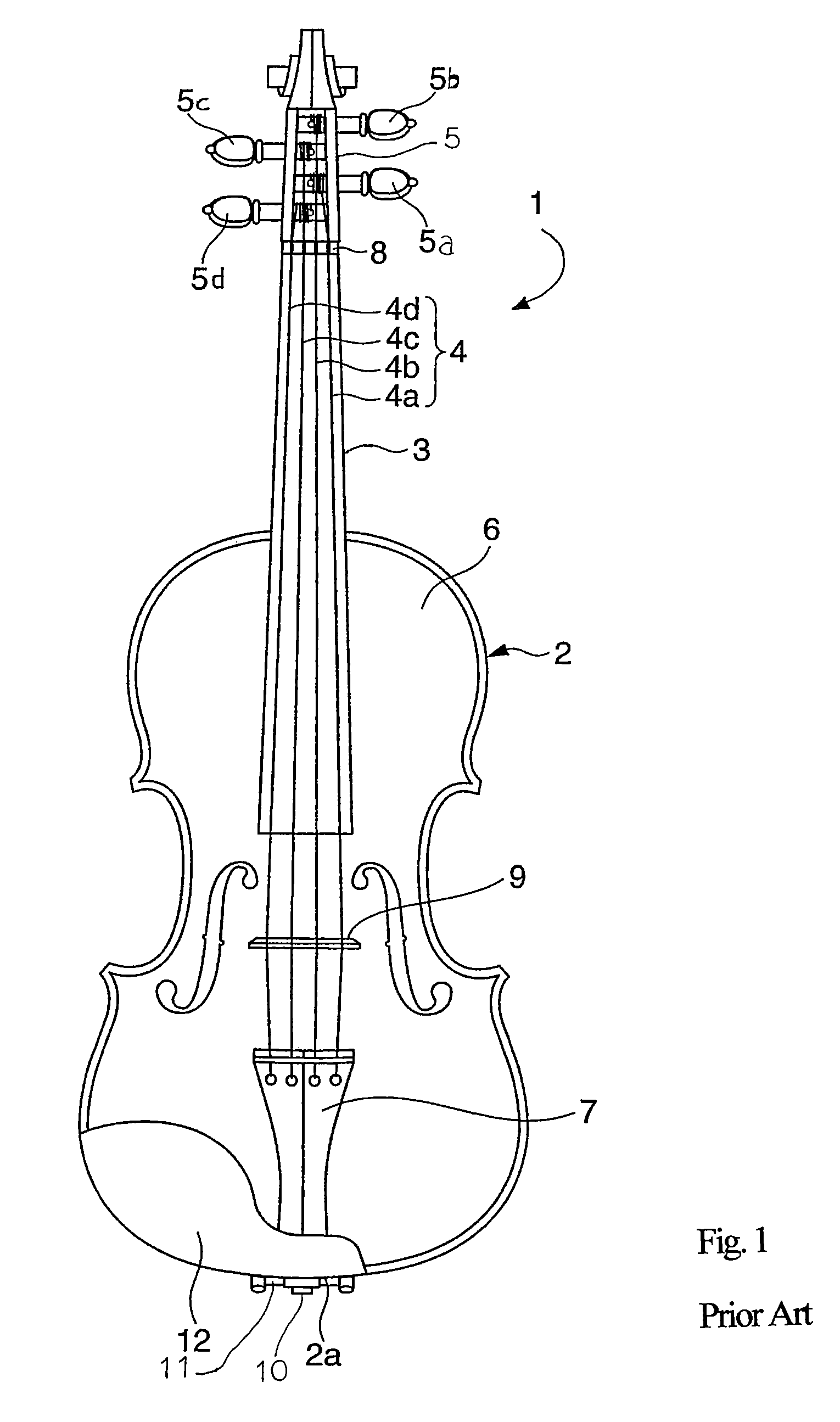

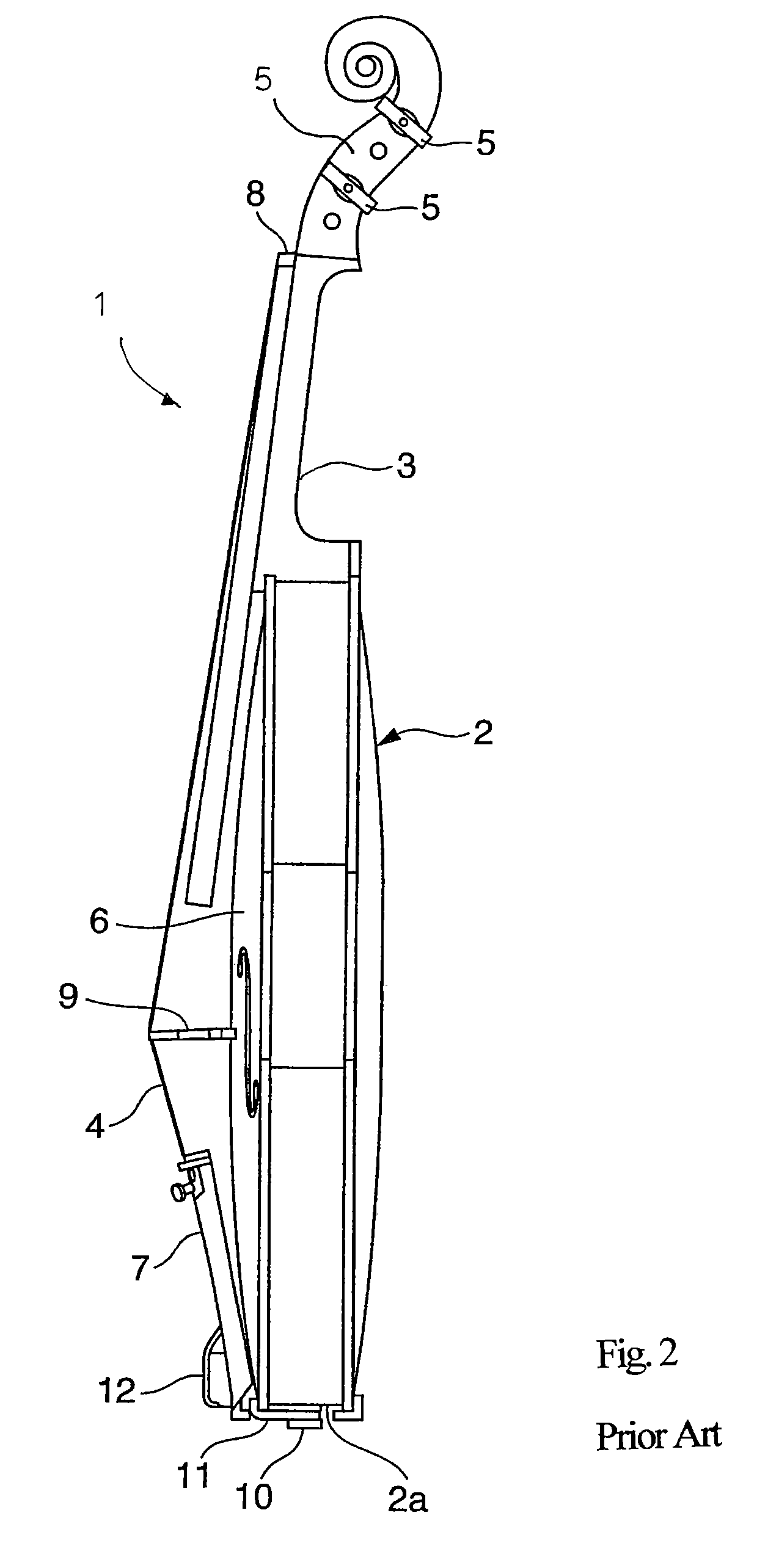

The violin, sometimes known as a fiddle, is a wooden string instrument in the violin family. Most violins have a hollow wooden body. It is the smallest and highest-pitched instrument in the family in regular use. Smaller violin-type instruments exist, including the violino piccolo and the kit violin, but these are virtually unused. The violin typically has four strings, usually tuned in perfect fifths with notes G3, D4, A4, E5, and is most commonly played by drawing a bow across its strings, though it can also be played by plucking the strings with the fingers (pizzicato) and by striking the strings with the wooden side of the bow (col legno).

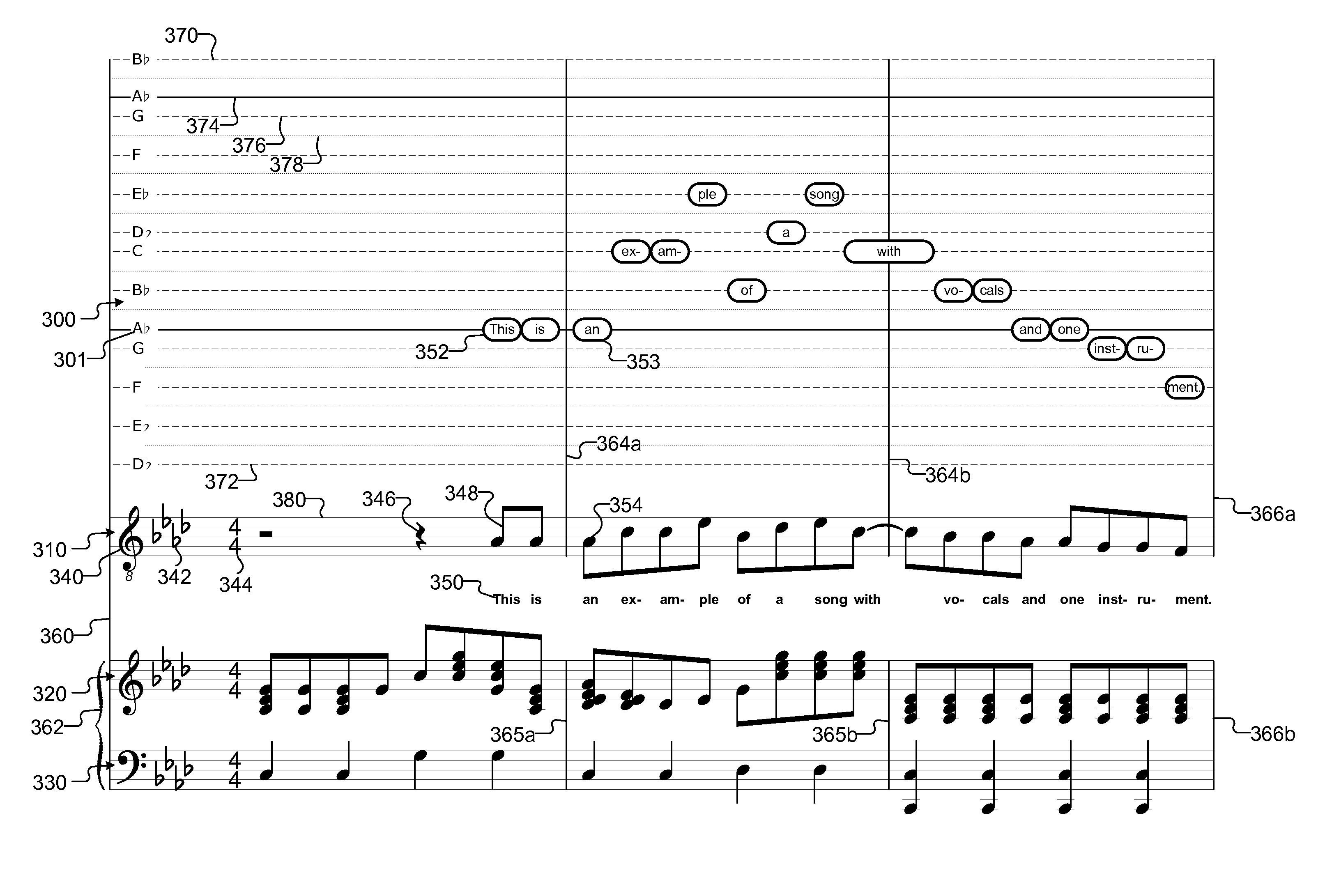

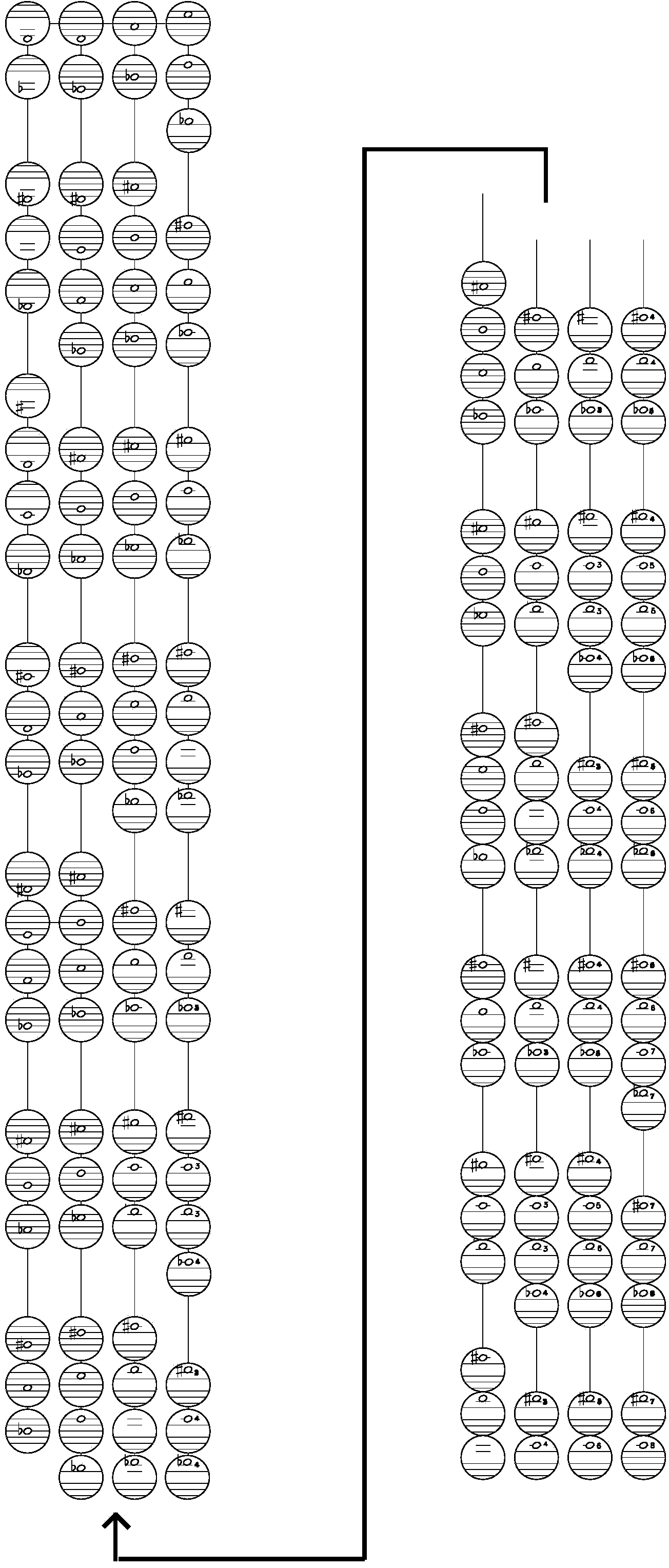

Method and apparatus for musical training

A method and apparatus for providing musical training is disclosed. The method / apparatus allows a user to practice voice lessons, ear training lessons, songs, and / or various musical instruments that rely on good pitch perception (such as a violin or a brass instrument). The method / apparatus displays a sequence of music notes to the user via a combination of conventional music staffs (such as a grand staff) and instances of a pitch-based representation. The method / apparatus also displays the accuracy of the user in hitting notes, the quality of his / her tone if supported, changes to his / her vocal range if desired, and tracks the user's practice history. The method / apparatus further provides features such as automatic vocal range detection, adjustment of lessons to a user's vocal range, and a display method that makes changes to the pitches of music notes clear during musical key / scale changes.

Owner:EROL NESET ARDA

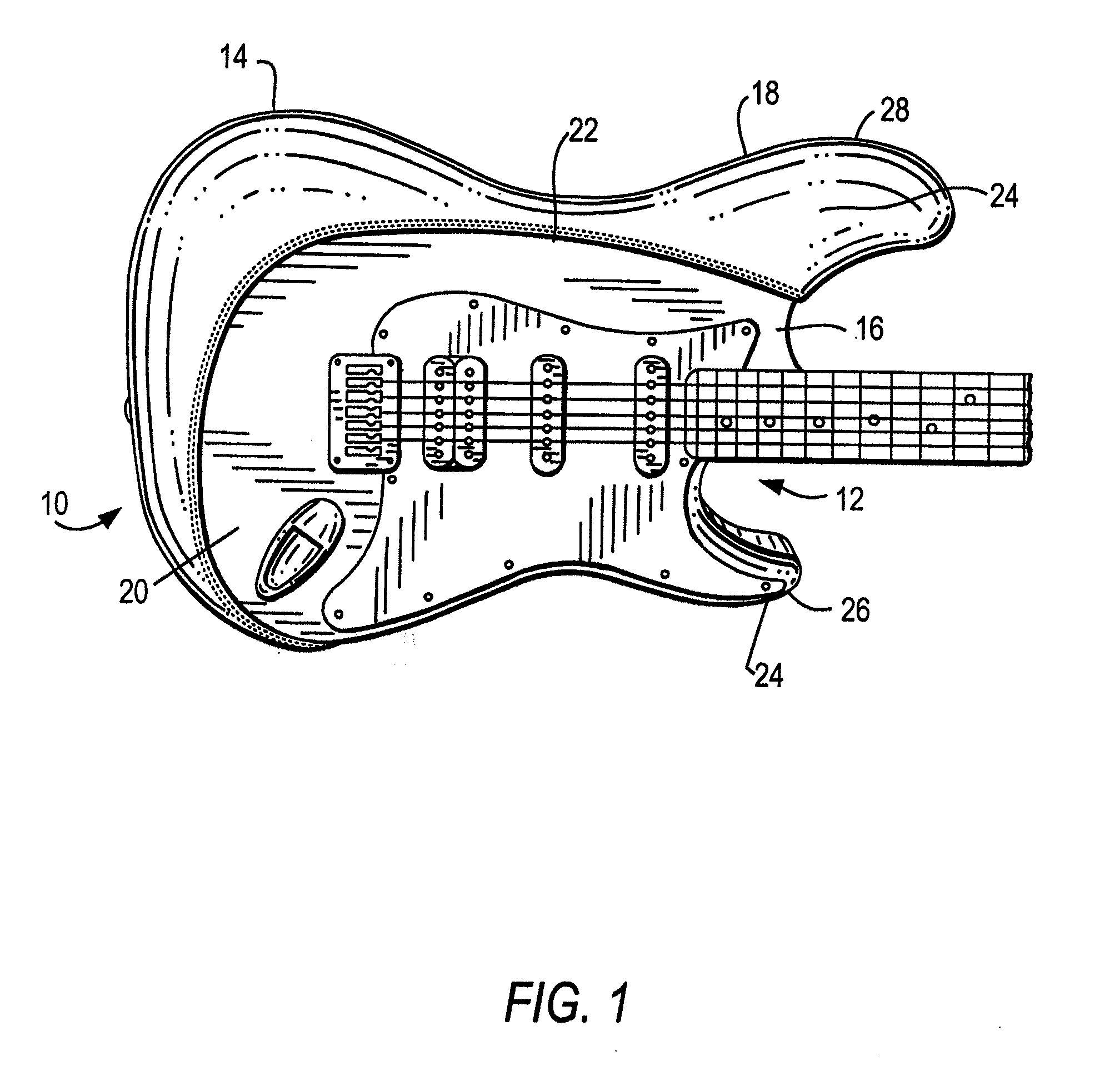

Musical instrument

ActiveUS20080028920A1Quality improvementEasy to implementElectrophonic musical instrumentsMusical toneSpeech sound

A musical device is disclosed that generates note tones, influences the sound of notes that are generated independently and performs a variety of user defined or user controlled activities. These activities include but are not limited to producing musical notes, determining, influencing or changing the sound, quality, voice, volume or other characteristics of a note, activating and coordinating the replay of stored loops, recording, editing and playing user created pieces previously produced and controlling peripheral devices such as lighting. The musical device uses a combination of strings and frets to locate notes on a fingerboard that a user may activate. The notes correspond to locations on the fingerboard. As a result, the invention includes a system to generate a sound corresponding to a note selected and activated according to preselected parameters such as the voice (e.g., trumpet, violin). A user's intent to play a particular note is preferably confirmed by a system of sensors corresponding to each note position that confirms a user's intent to play a particular note. The musical device also includes one or more switches that activate functions, loops or voices corresponding to note positions on the fingerboard.

Owner:ZIVIX

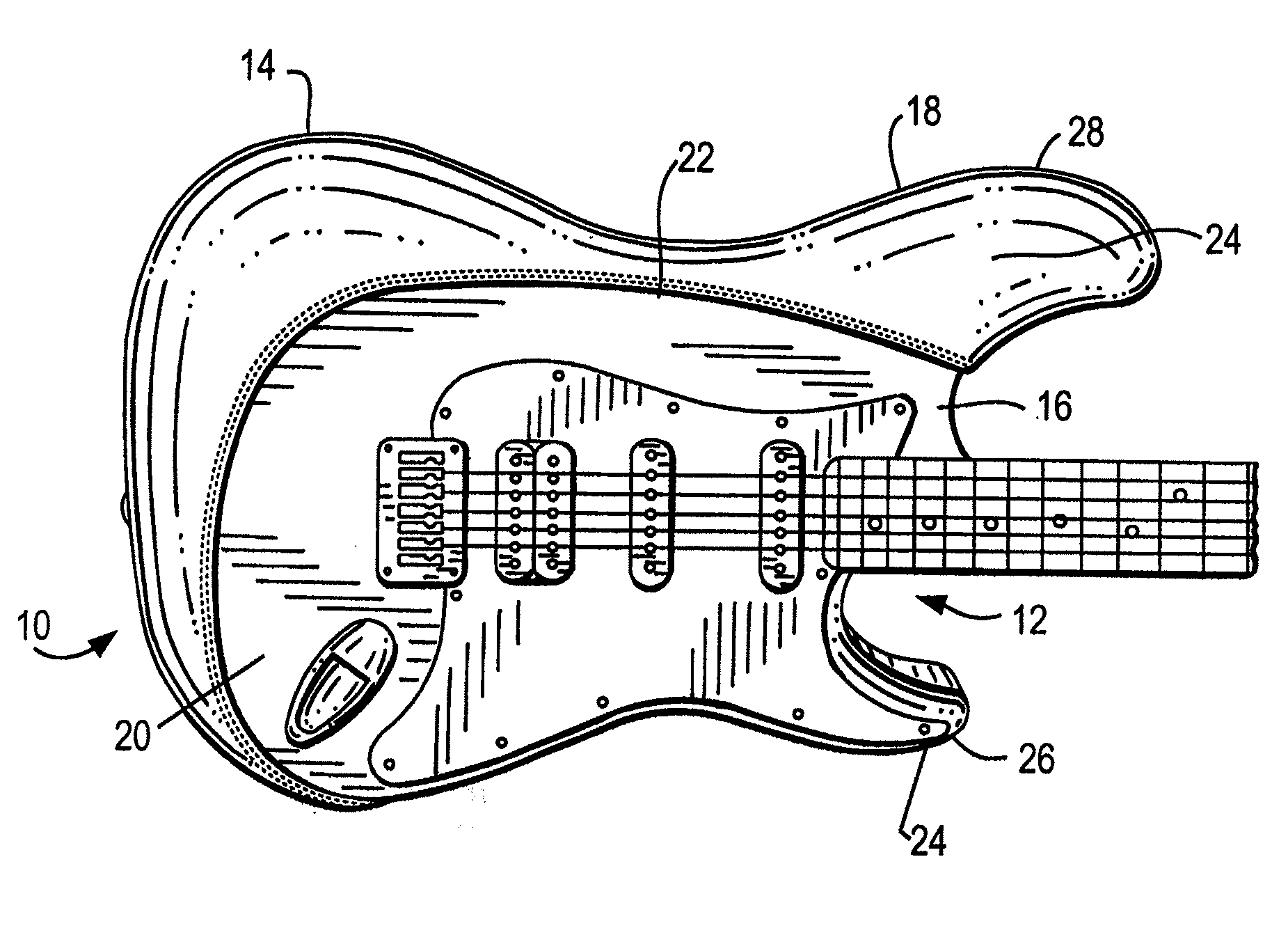

Musical instrument

ActiveUS7598449B2Quality improvementEasy to implementElectrophonic musical instrumentsMusical toneSpeech sound

A musical device is disclosed that generates note tones, influences the sound of notes that are generated independently and performs a variety of user defined or user controlled activities. These activities include but are not limited to producing musical notes, determining, influencing or changing the sound, quality, voice, volume or other characteristics of a note, activating and coordinating the replay of stored loops, recording, editing and playing user created pieces previously produced and controlling peripheral devices such as lighting. The musical device uses a combination of strings and frets to locate notes on a fingerboard that a user may activate. The notes correspond to locations on the fingerboard. As a result, the invention includes a system to generate a sound corresponding to a note selected and activated according to preselected parameters such as the voice (e.g., trumpet, violin). A user's intent to play a particular note is preferably confirmed by a system of sensors corresponding to each note position that confirms a user's intent to play a particular note. The musical device also includes one or more switches that activate functions, loops or voices corresponding to note positions on the fingerboard.

Owner:ZIVIX

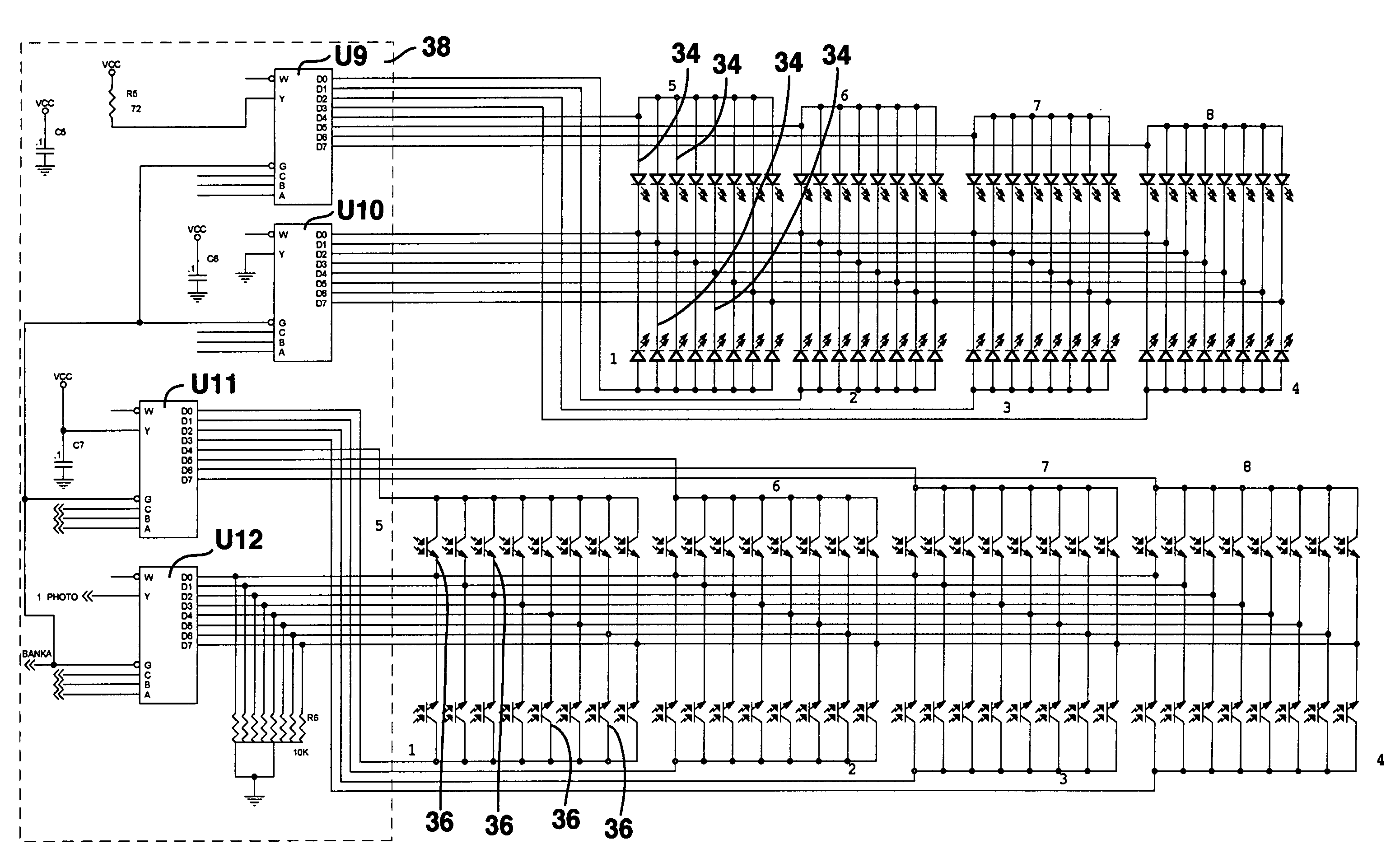

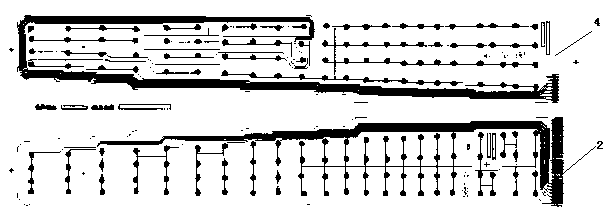

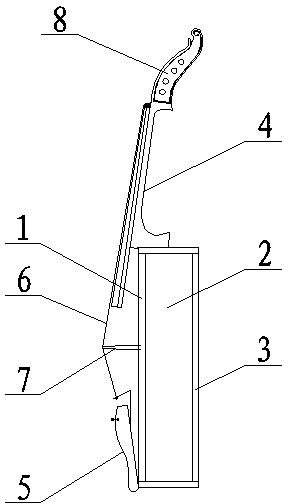

Electronic musical instrument simulation learning tool

The invention relates to an electronic musical instrument simulation learning tool. A bottom circuit 2, a baffle 3 and a top circuit 4 are made of three-layered fpc plate flexible circuit material; through pressing keys on the bottom circuit 2 and the top circuit 4, circuit connectors are contacted with a switch through baffle key holes 20, signals are processed to digital signals via a usb interface 6 to be inputted to a multimedia computer, the digital signals are converted to sounds corresponding to a digital musical instrument music score, sounds including those of a violin, a piano, a harmonica, an erhu and the like can be played, 88keys, the three-layered fpc keyboard circuit boards 2 and 4, and the baffle 3 are pressed downwardly and fixed on the surface of a finger board 1 through bolts 8 and bolt holes 23, the keys are distributed corresponding to the sound positions of the bowstring musical instrument, and three parts of software, terminal simulation hardware and a simulation blanket are included.

Owner:张胜祥

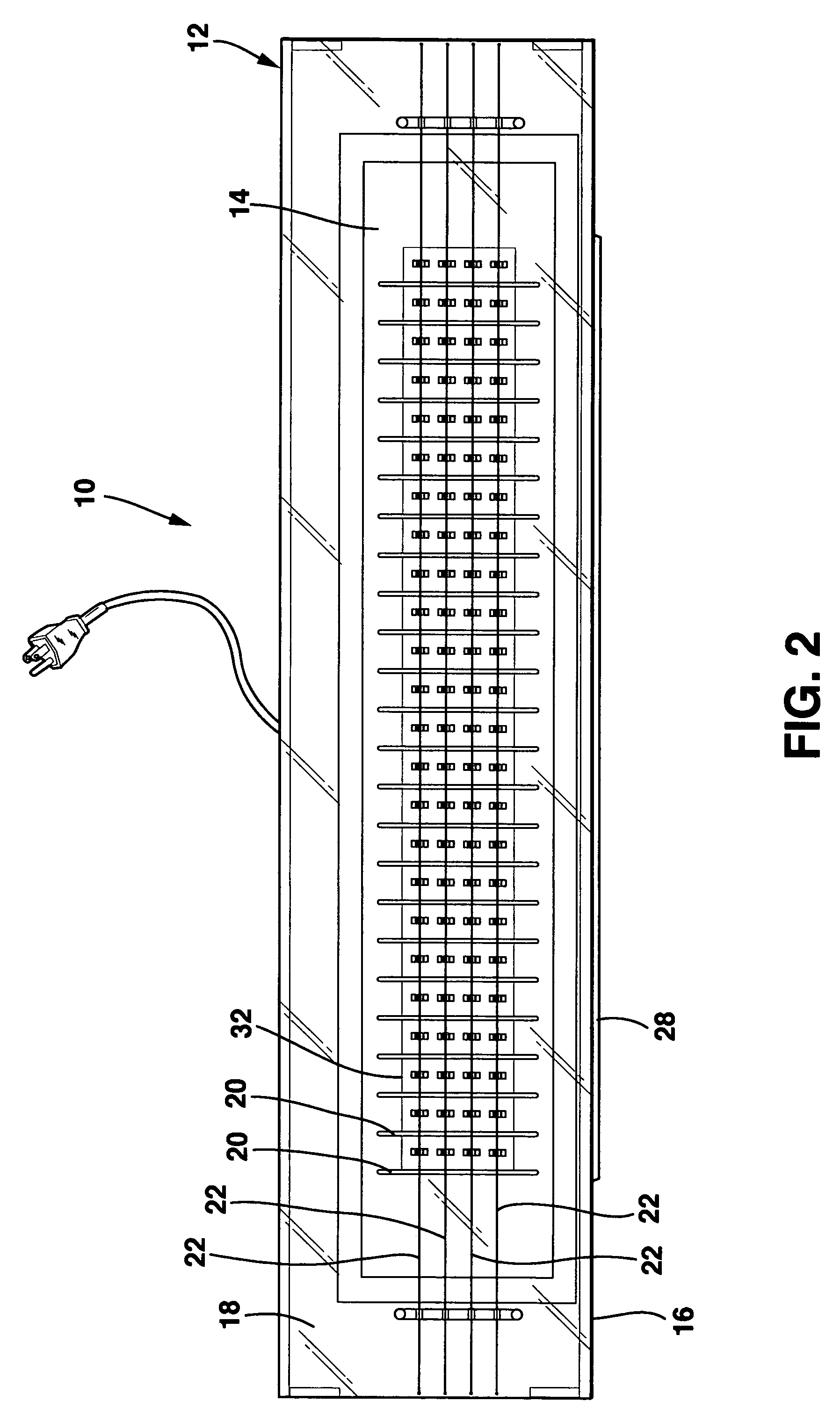

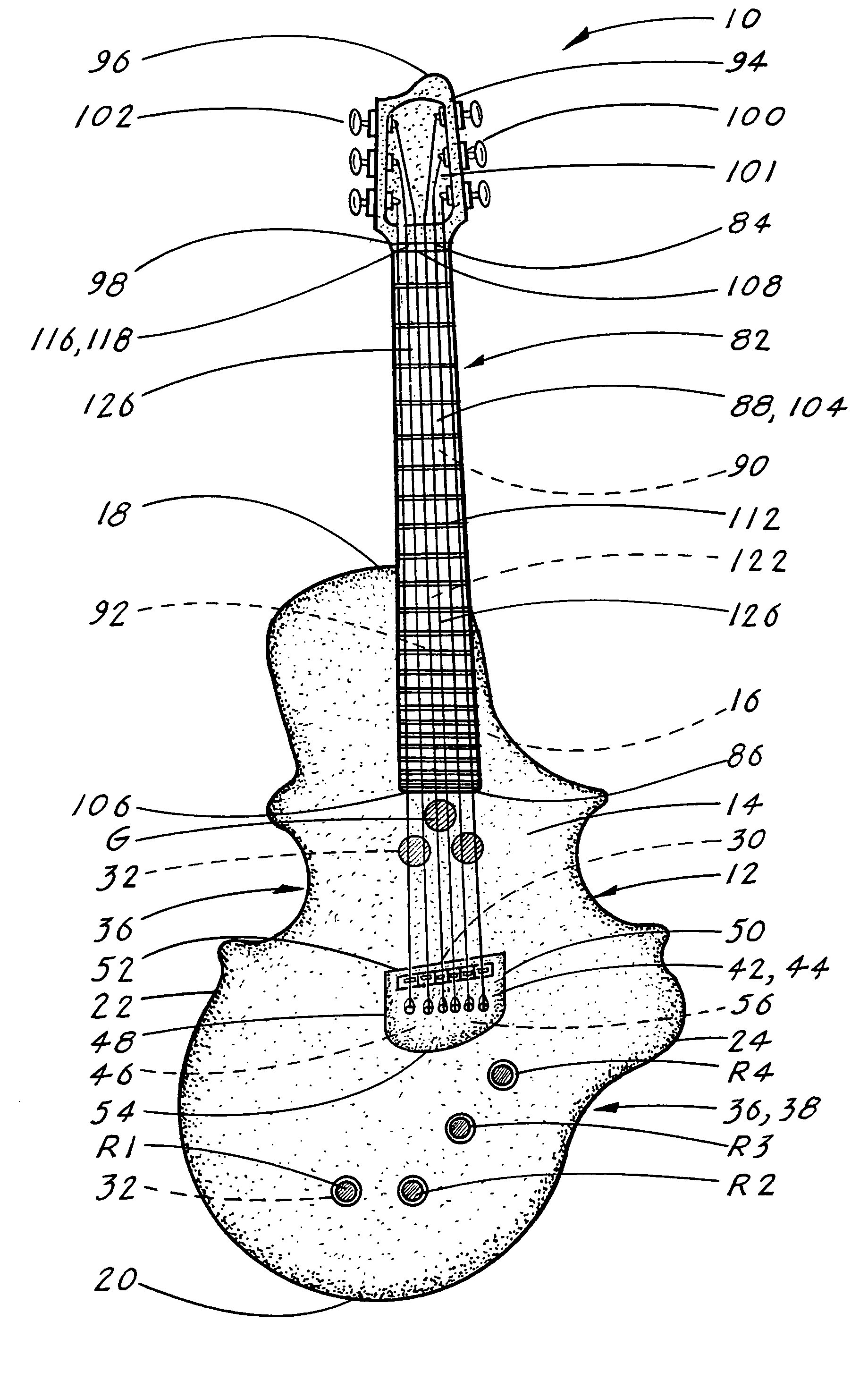

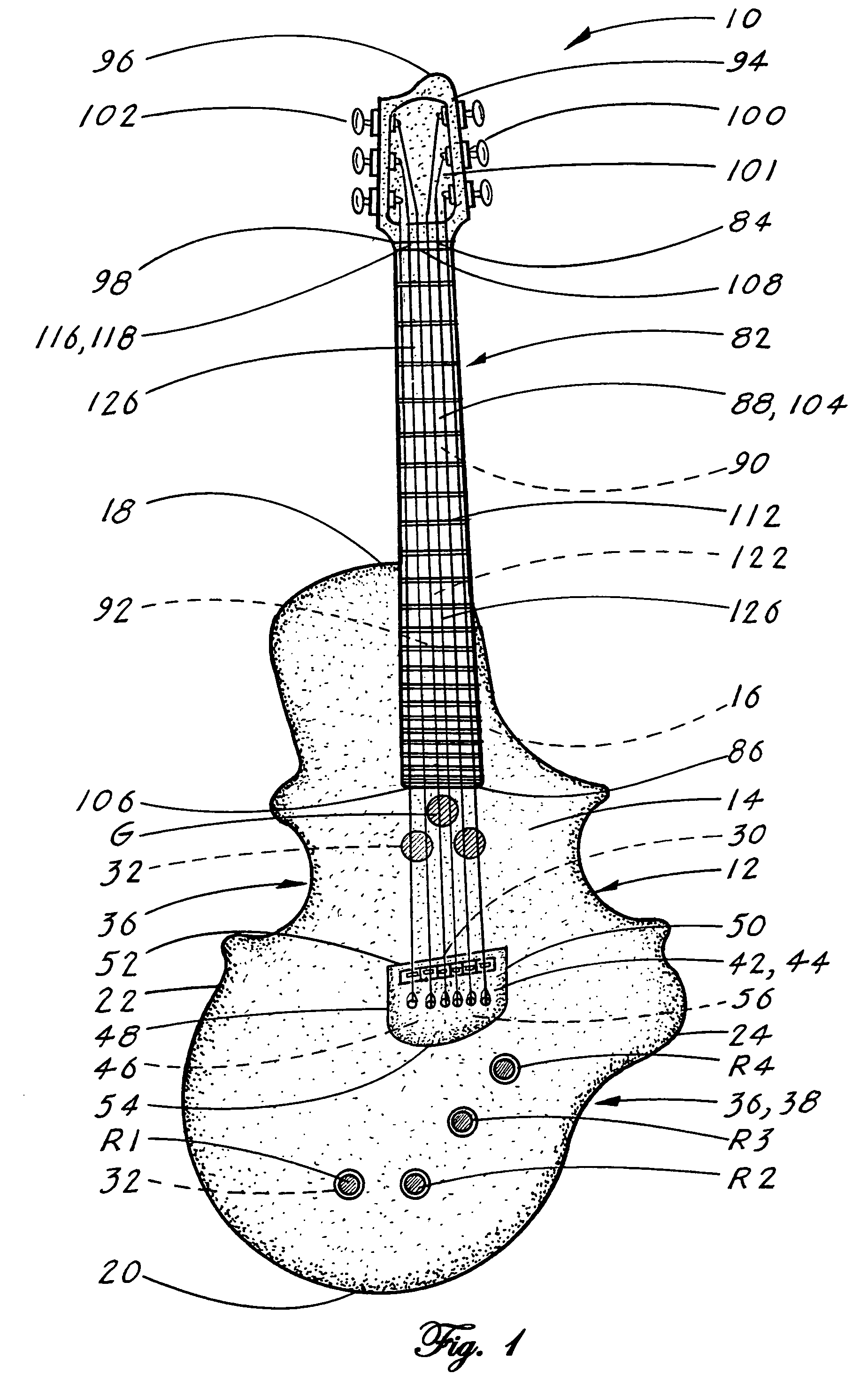

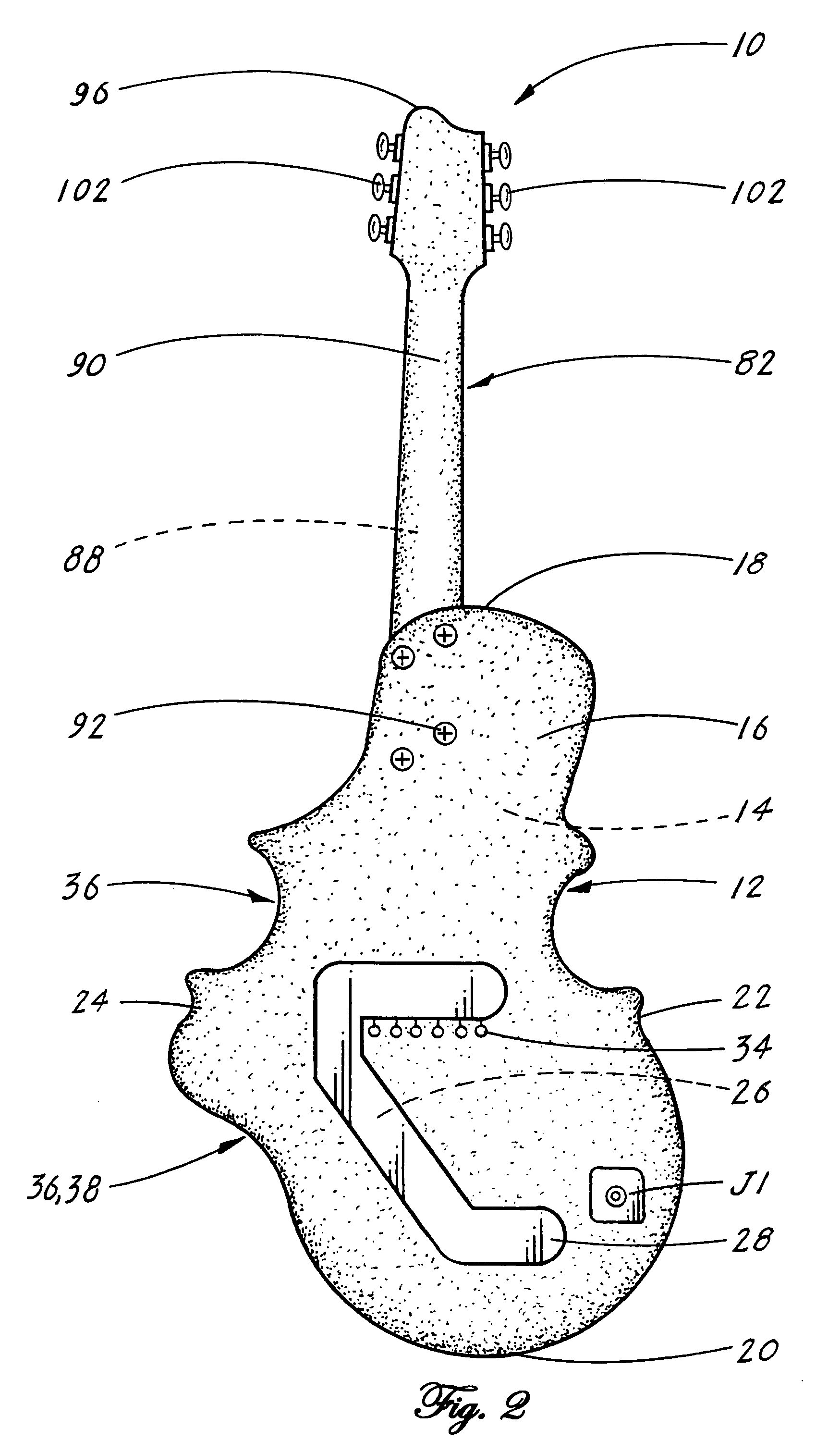

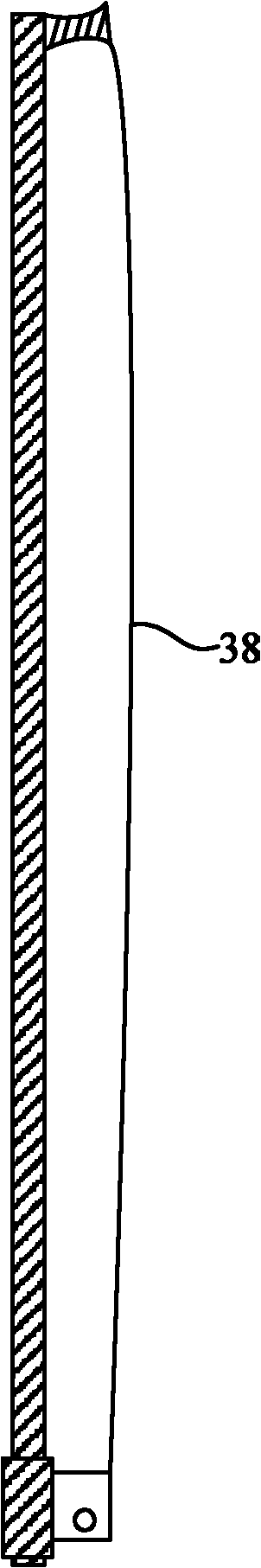

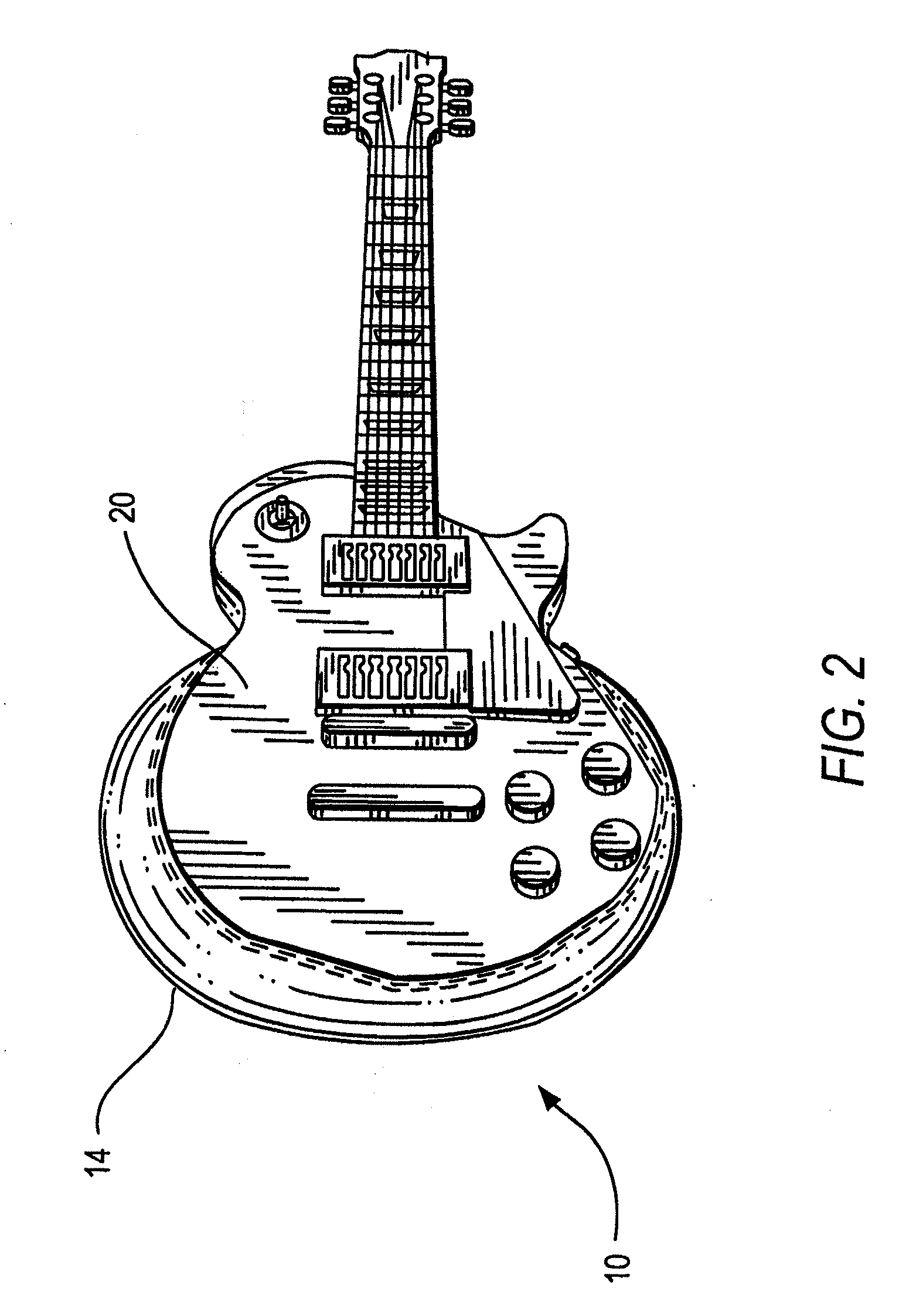

Guitar and violin hybrid instrument

A guitar and violin hybrid instrument (10) comprising either a solid or hollow body (12). The body (12) has an upper surface (14), a lower surface (16), an upper end (18), a lower end (20), a left half (22), and a right half (24). Located on the body's (12) lower section is a leg contour (38) that provides a comfortable leg support. On the lower surface (16) is an electronics cavity (26) for housing an electronics circuit (130). Located on the body's (12) upper surface (14) is a plurality of magnetic pickups (G), control knobs for the operating the electronics circuit (130) and a bridge (42). Located on the bridge's (42) upper surface (44) is a plurality of piezoelectric pickups (Y). A neck (82) extends from the body's upper end (18). Attached to the neck's (82) upper surface (88) is a fretboard (104) on which a multiplicity of frets (112) are distributed. Located at the neck's (82) outer end (84) is a headstock (94) which has a plurality of tuning pegs (102) for adjusting the tension of a plurality of strings (126) that extend from the bridge (42), across the body (12) and over the magnetic pickups (G) to the tuning pegs (102).

Owner:WILSON JONATHAN E

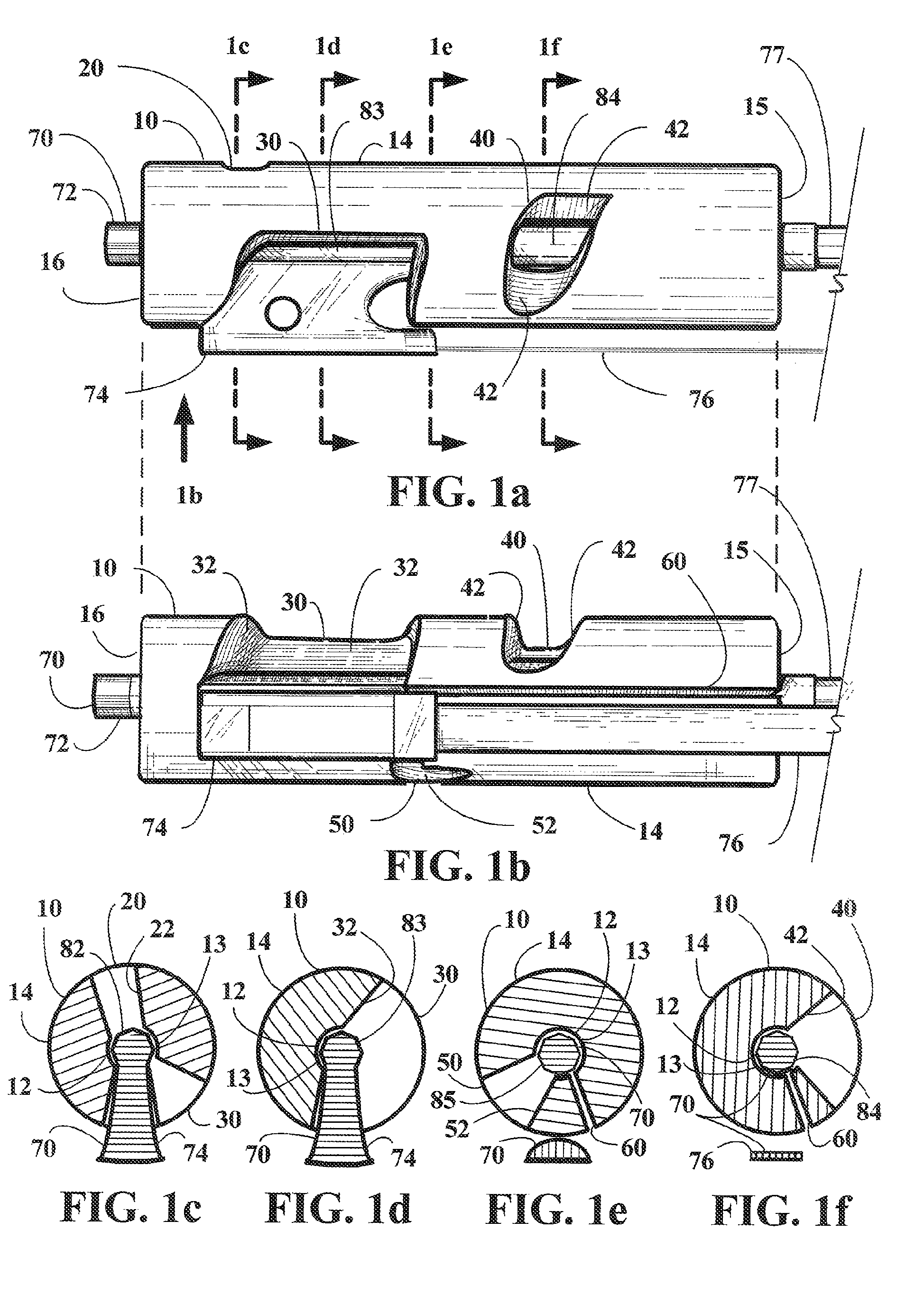

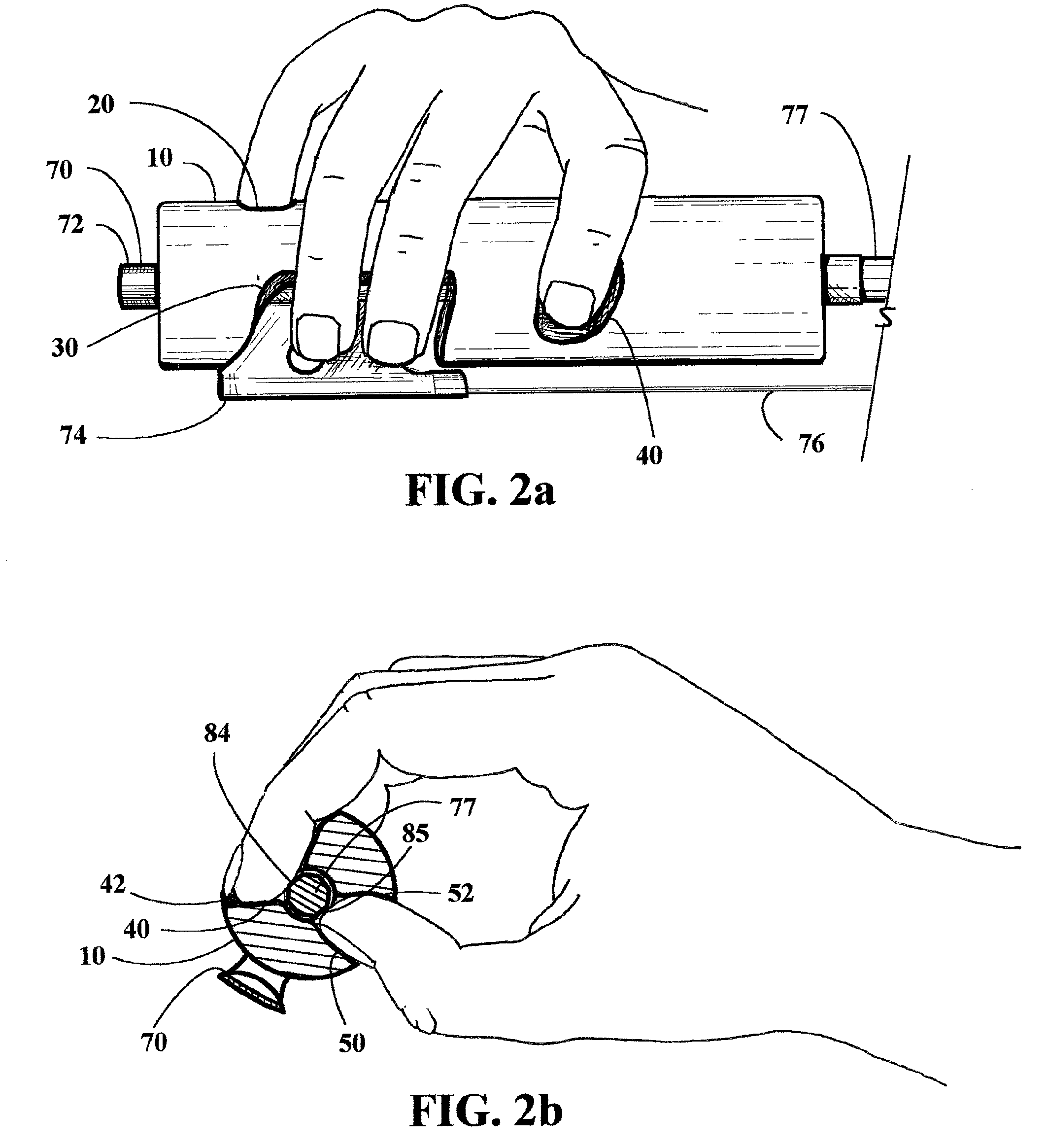

Violin and viola teaching aid

Violin or viola teaching aids are disclosed that are suitable to be attached to either a violin or viola bow. The aids with elongated raised ridges provide a tactile indication of the proper placement of the right hand on a bow. An embodiment is disclosed that has a cylindrical shape with a hollow passageway that fits over the stick of a bow. A plurality of holes provide lateral openings into the hollow passageway. The rims of the holes provide a tactile indication of the location in which the fingers and thumb are to contact the bow. Embodiments are disclosed that are comprised of resilient sponge rubber.

Owner:DUBELL SHOCKLEY GEORGEANN

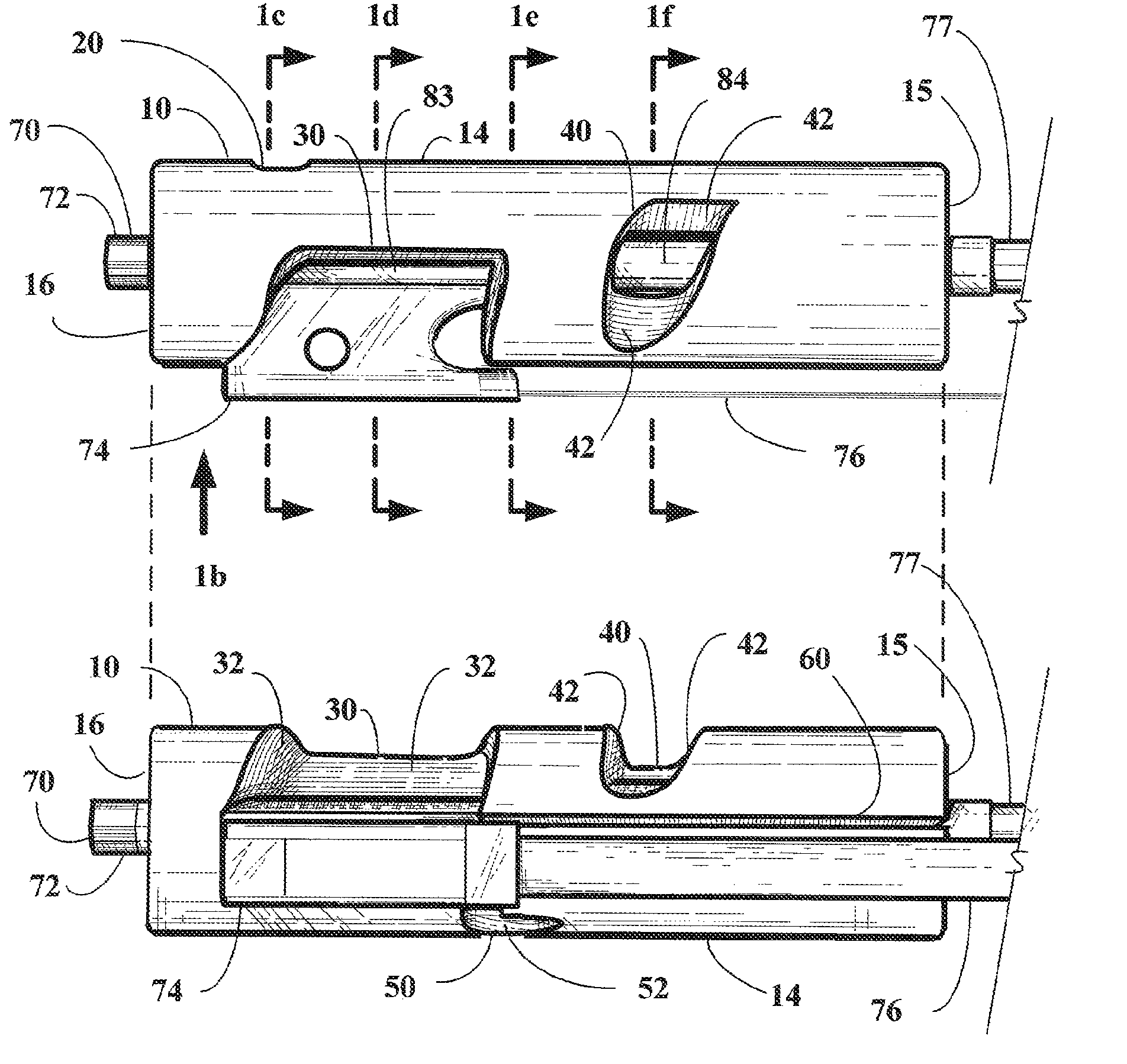

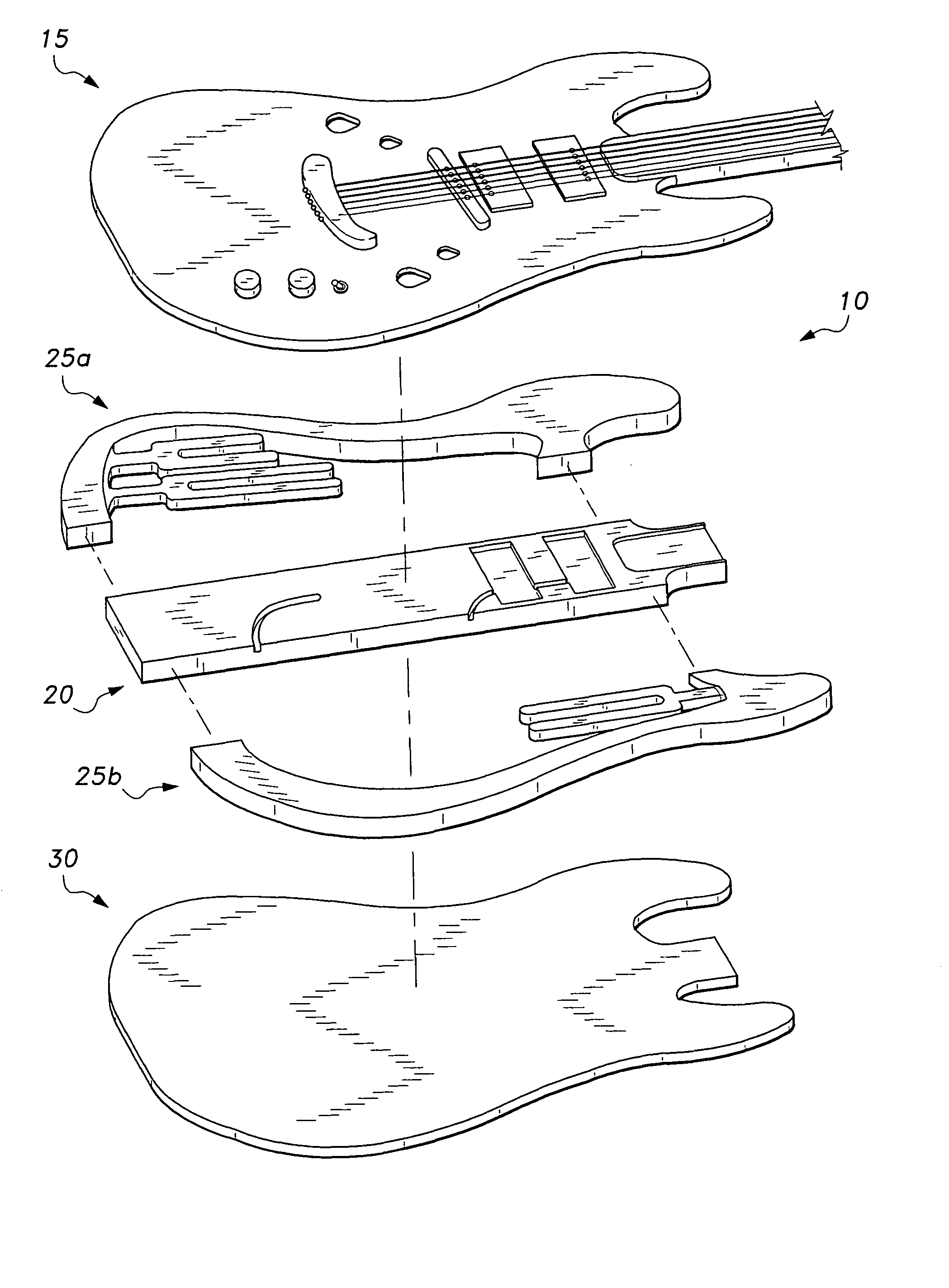

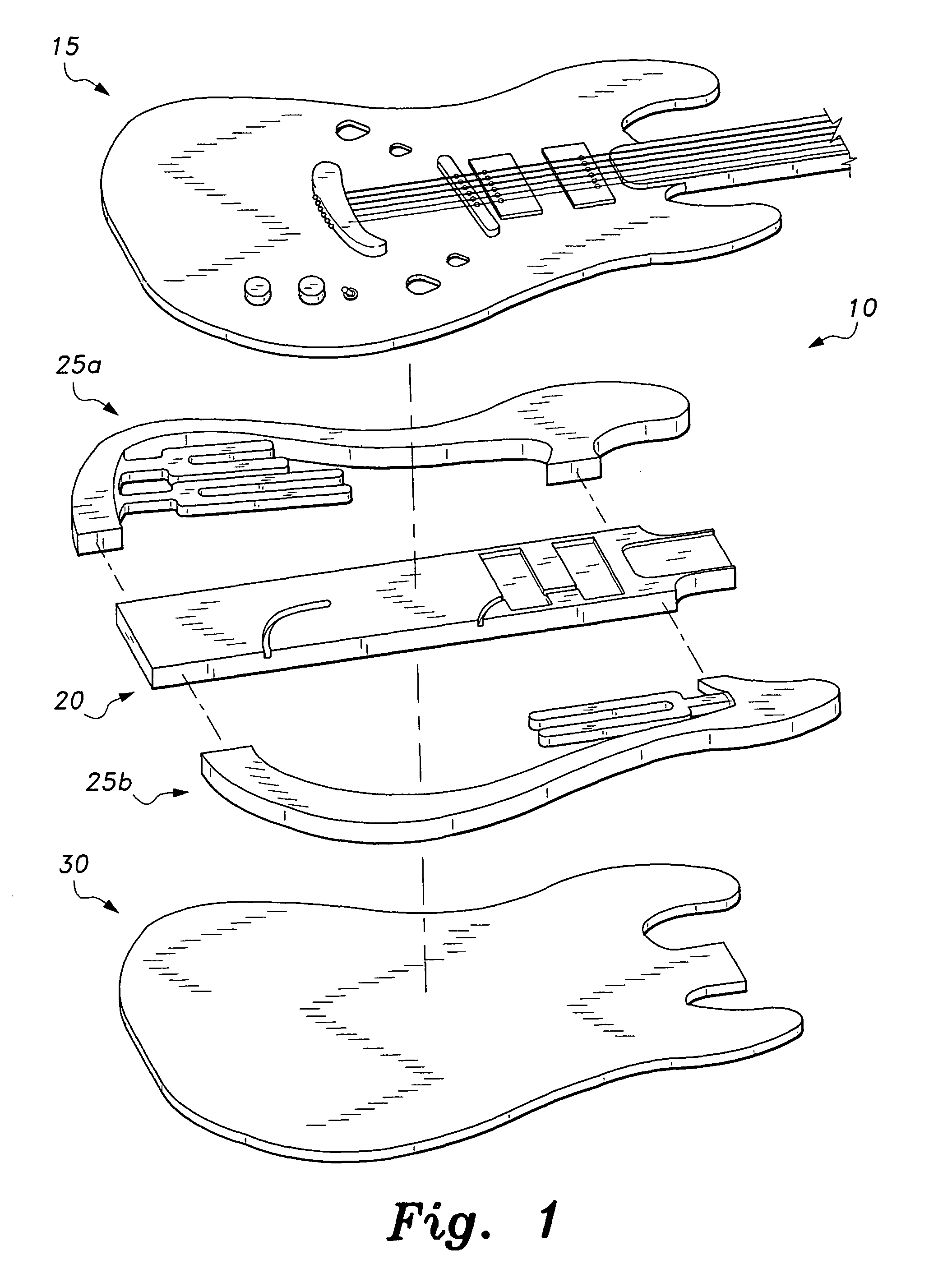

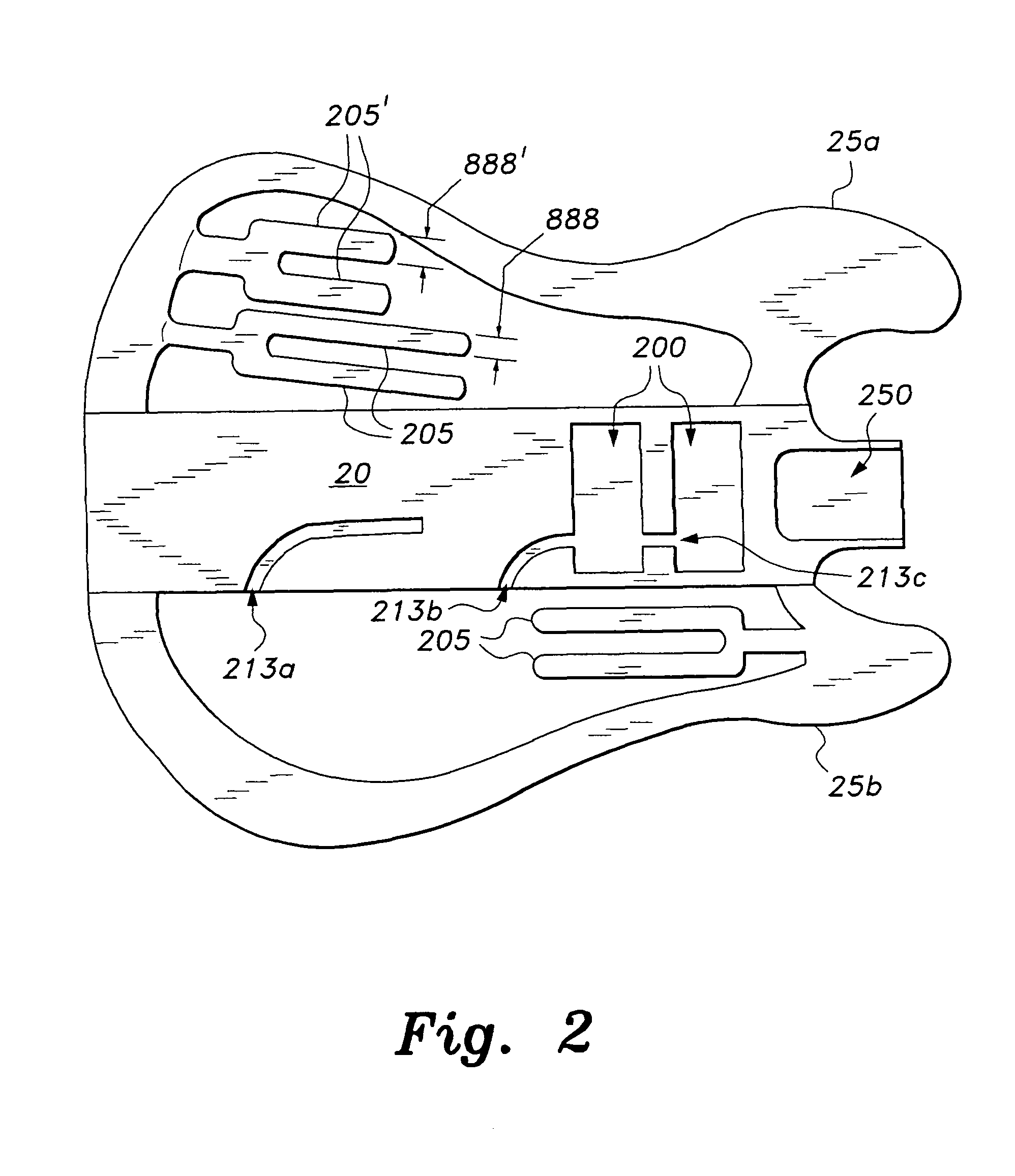

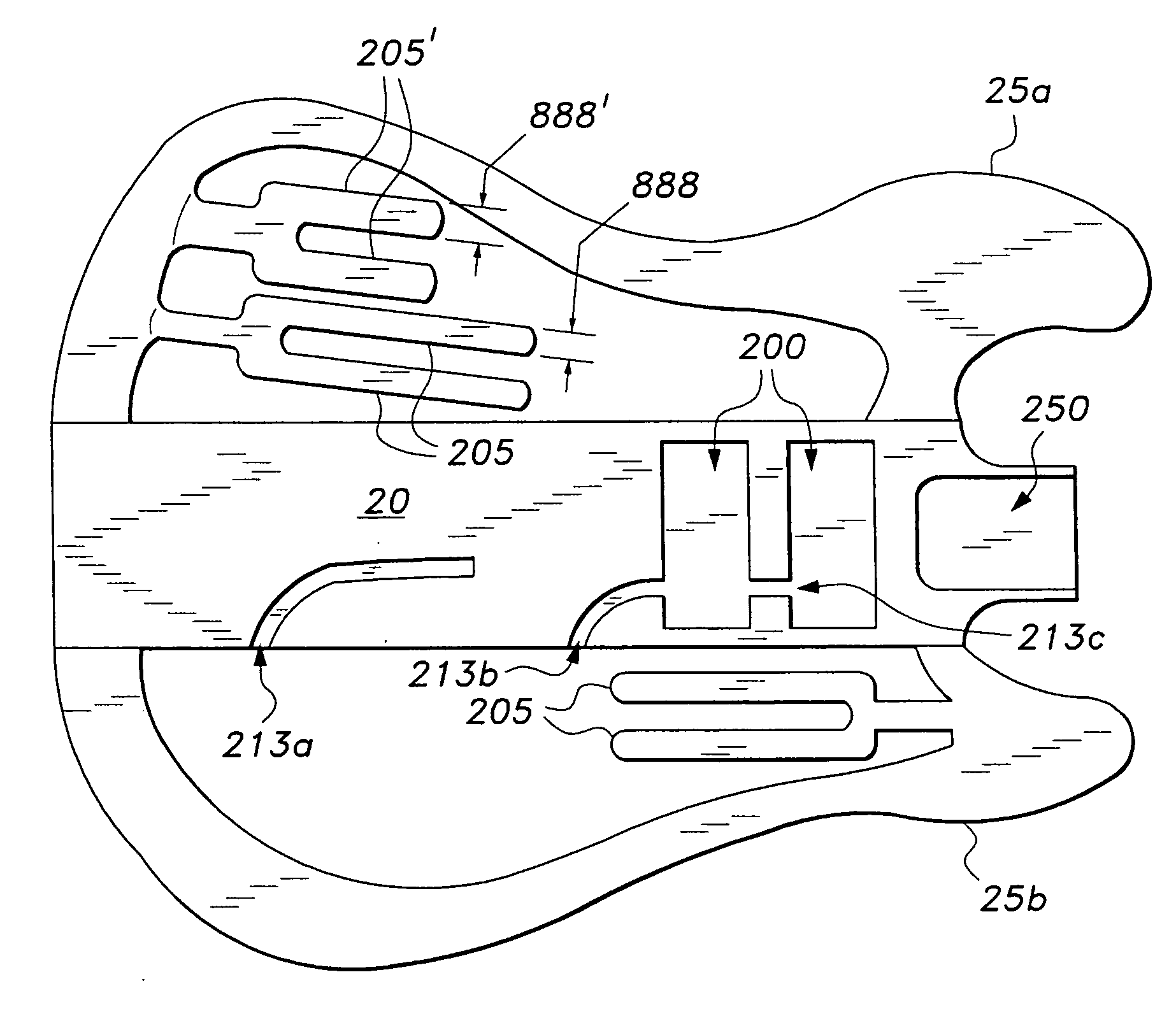

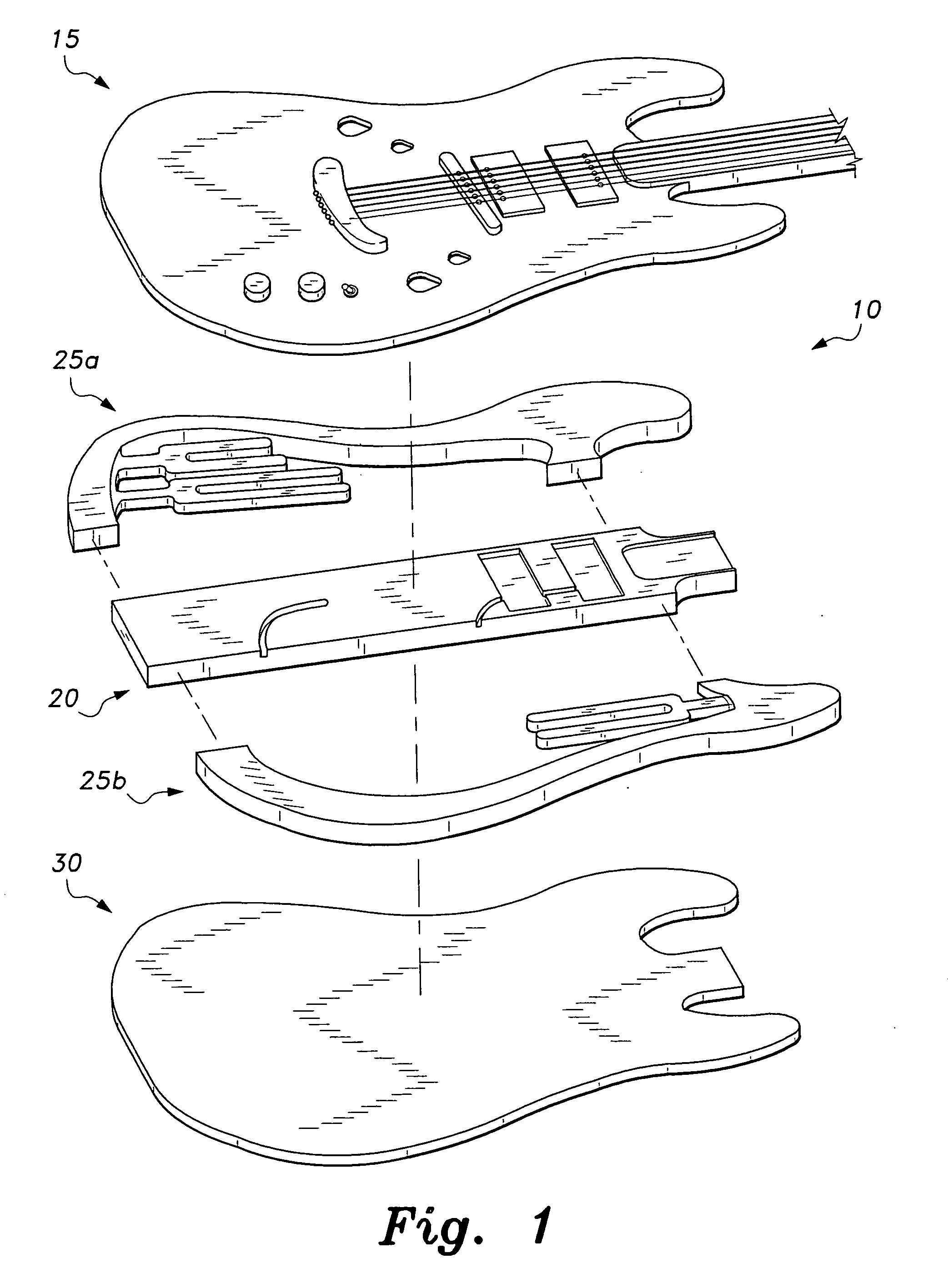

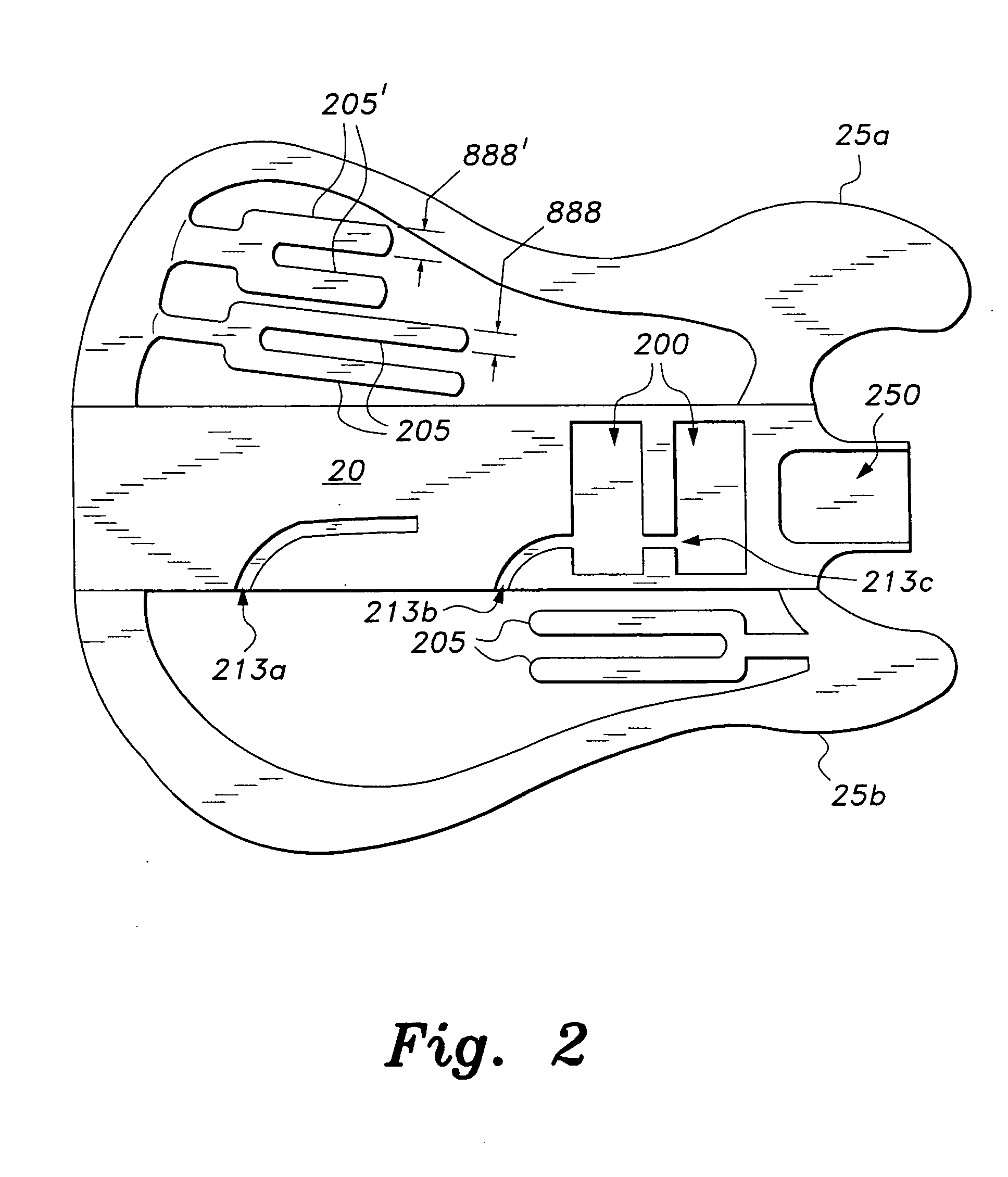

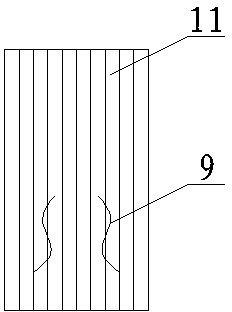

Semi-hollow body for stringed instruments

The semi-hollow body for stringed instruments includes a plurality of resonance-enhancing baffle pairs, each resonance-enhancing baffle pair having a bifurcated prong shape, similar to a tuning fork. The resonance-enhancing baffle pairs extend from an interior peripheral area of the instrument body and create various combinations of baffled and un-baffled regions in a resonance chamber of the semi-hollow body. A solid, central core region separates an upper resonance chamber from a lower resonance chamber. Alternatively, individual resonance enhancing baffles shaped like reeds are disposed inside the instrument body. The semi-hollow body for stringed instruments can be adapted for guitars, violins, mandolins, ukuleles, or the like, and provides a rich, resonant tone to the instrument while avoiding acoustic feedback problems associated with hollow body instruments. Front and back plates cover front and back portions of the body to give it a solid body look and feel.

Owner:AYERS JEFFREY L

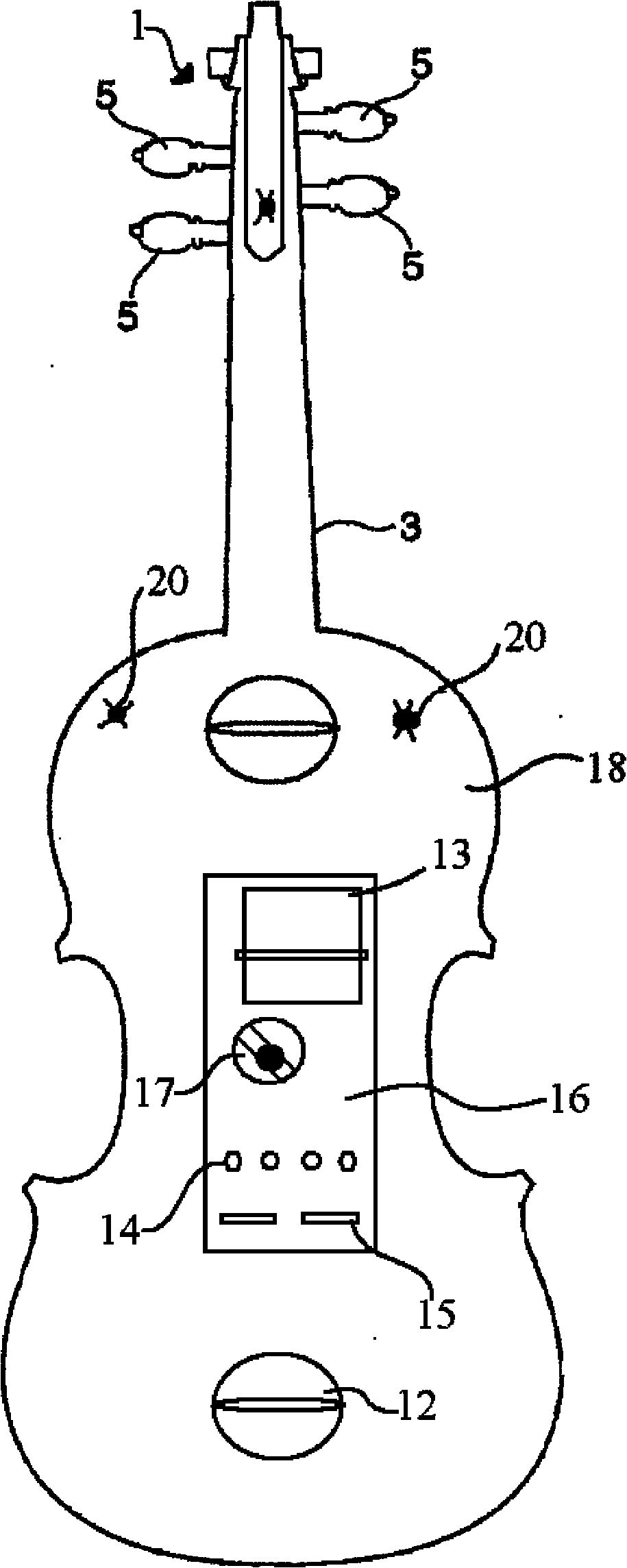

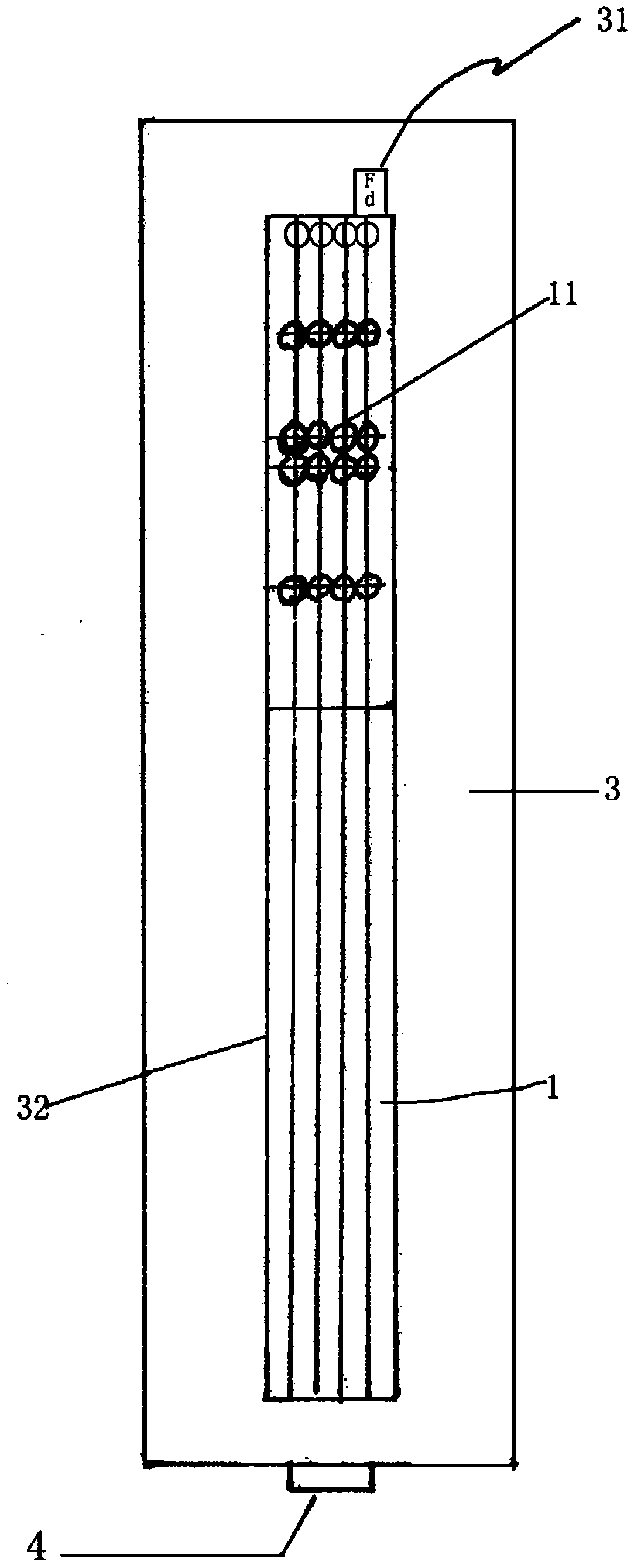

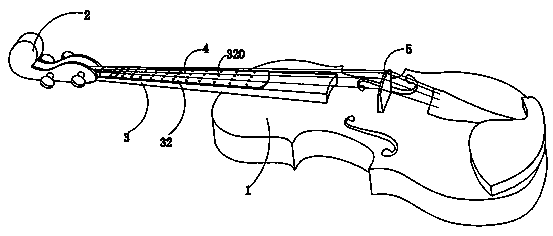

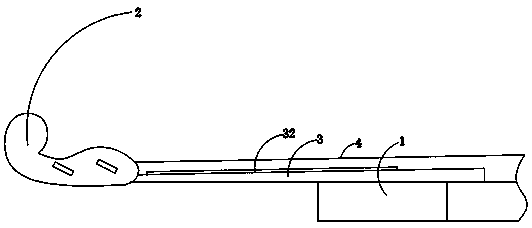

Digital stringed instrument controlled by microcomputer

InactiveCN102129798ACorrect bow postureCorrectionElectrophonic musical instrumentsViolinsMicrocomputerElectricity

The invention discloses a digital stringed instrument controlled by a microcomputer, which comprises a bow, an instrument head and an instrument body connected to the instrument head, wherein the instrument head comprises a tuning peg and a finger board; the instrument body comprises a panel, a side plate and a rear plate; a tying string board is arranged on the panel; the tying string board and the tuning peg are connected by strings; a finger board sensor used for distinguishing the correct intonation position on the surface of the finger board is arranged on the surface of the finger board; the finger board sensor is electrically connected to a control device; at least four correlation sensors which are used for sensing the route, angle, speed or pressure of the bow on the strings are arranged on the panel; the correlation sensors are electrically connected to the control device; and the four correlation sensors are distributed in a quadrilateral manner. The digital stringed instrument controlled by the microcomputer can be used for monitoring in real time and prompting a stringed instrument player to keep a correct instrument-holding posture and the information such as the intonation generated by the left hand and the route, speed and force for bowing by using the right hand, and the like, so a beginner can quickly master the important points in learning playing violin, namely the correct intonation and bowing way, while the interest of the beginner is promoted in learning process.

Owner:程矛

Method for processing instrument panel such as violin

The invention relates to a method for processing the faceplates of fiddle musical instruments, and is characterized by the following steps: (1) the faceplate material of coniferous wood for making the faceplates of the fiddle musical instruments is put into water at a temperature of 15DEG C-25DEG C for soaking for 1-24 hours, so that the percentage of moisture of the wood reaches saturation; (2) the faceplate material with the percentage of moisture in saturation is put into a freezing chamber at 0DEG C-40DEG C for freezing for 10-60 minutes; (3) the frozen faceplate material is thawed at a temperature of 5DEG C-40DEG C; and (4) the thawed faceplate material is aired for 7-10 days and then is used for making musical instruments. The invention solves the problems as follows: the prior common faceplate material of coniferous wood for making the faceplates of the fiddle musical instruments is not aired enough after being cut down, so that the timbre is poor; although the price is low and the international low-class fiddle market is occupied, the economic benefit is poor; and the precious forest resource of the country is wasted.

Owner:许铁云

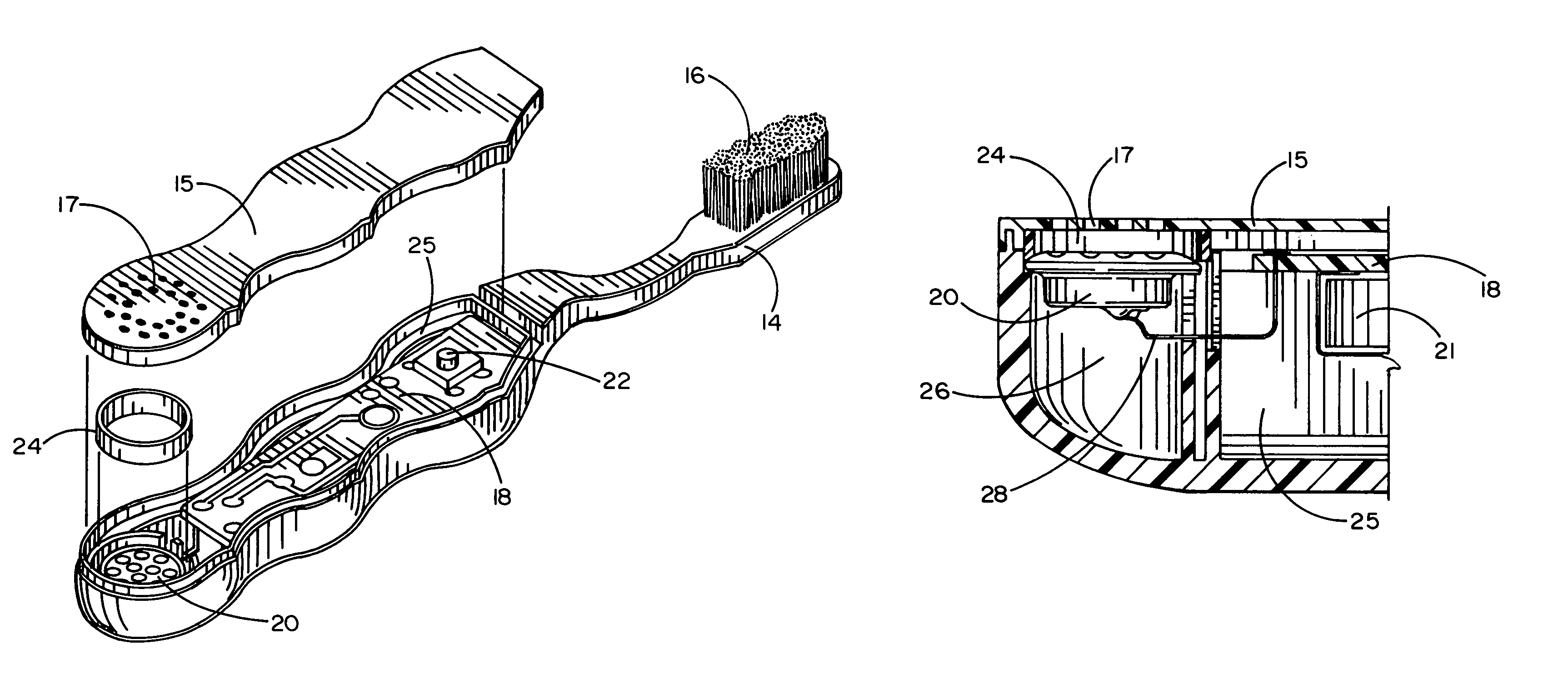

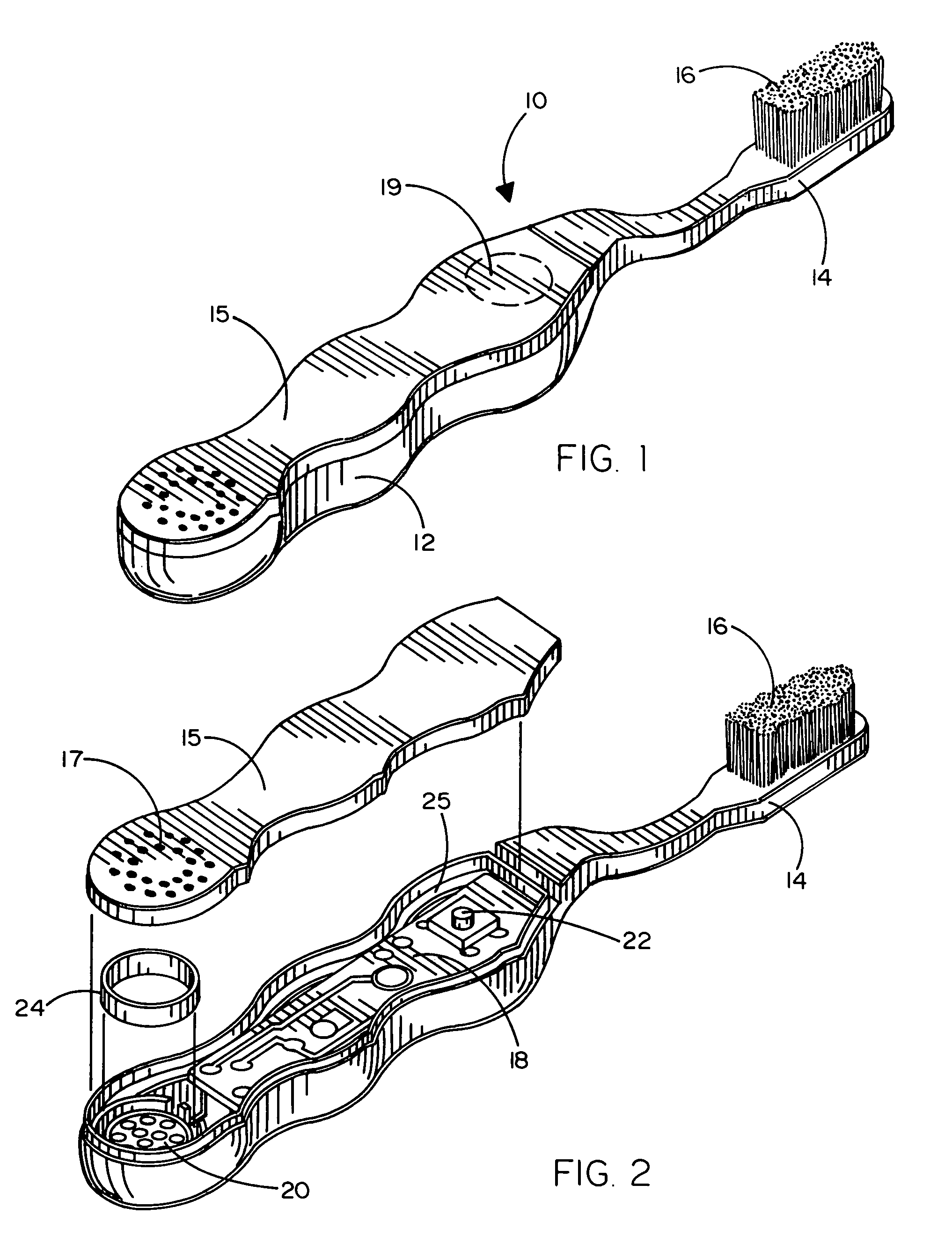

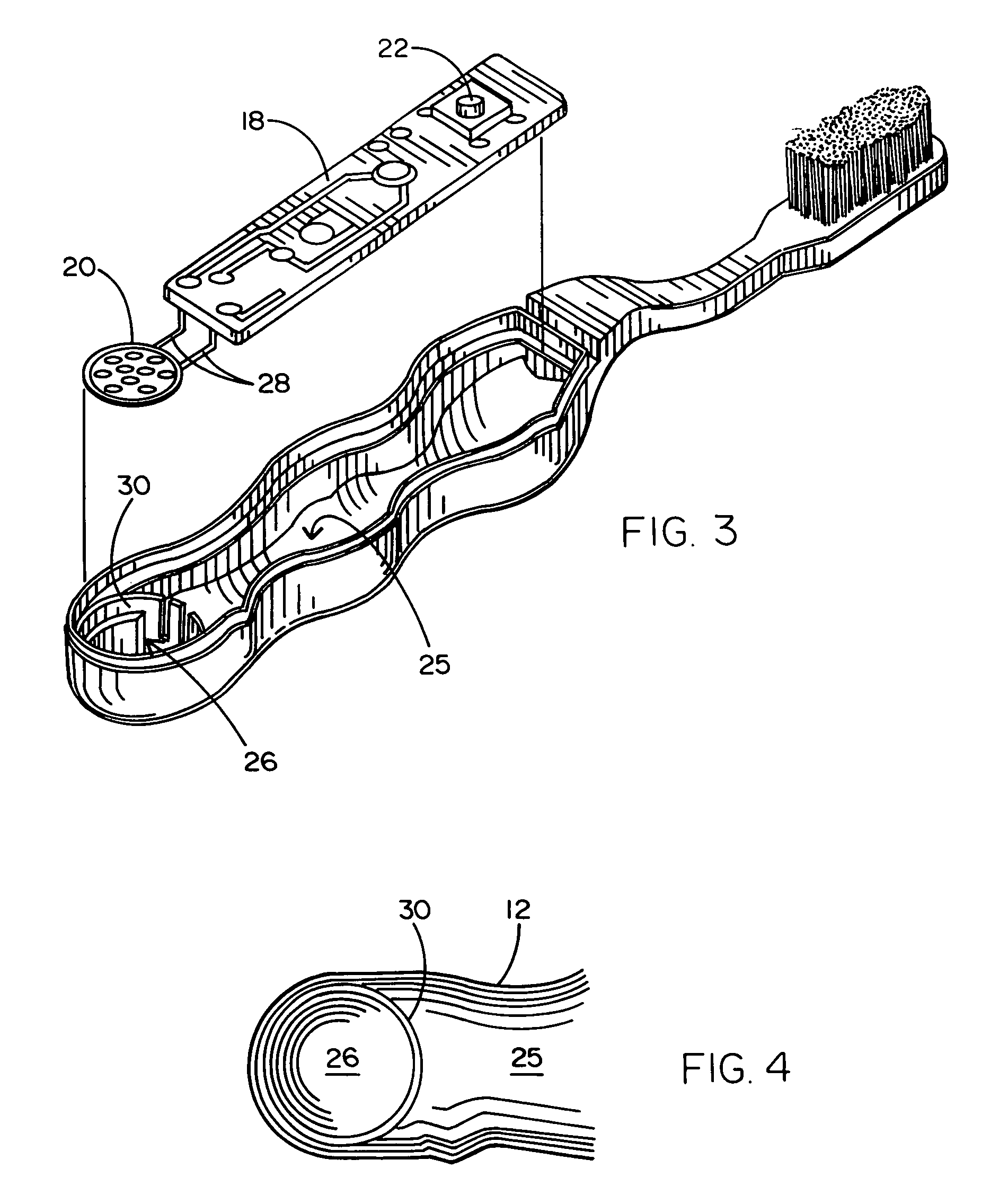

Child's music-playing toothbrush configured for attractive display of graphics and improved sound quality

A music-playing toothbrush having a hollow handle housing containing suitable solid state electronic components for selectively playing a musical tune with improved sound quality. The sound quality is expressly addressed in the handle design with an interior sealed speaker enclosure configured to direct the sound toward the listener with little internal leakage and with an undulating violin-like cavity shape that suppresses internal standing waves. Moreover, the handle provides a relatively large, relatively flat, substantially uninterrupted surface for receiving attractive and motivational graphics such as licensed cartoon characters, which may be compatible with the musical selection.

Owner:WORLD TREND

Semi-hollow body for stringed instruments

The semi-hollow body for stringed instruments includes a plurality of resonance-enhancing baffle pairs, each resonance-enhancing baffle pair having a bifurcated prong shape, similar to a tuning fork. The resonance-enhancing baffle pairs extend from an interior peripheral area of the instrument body and create various combinations of baffled and un-baffled regions in a resonance chamber of the semi-hollow body. A solid, central core region separates an upper resonance chamber from a lower resonance chamber. Alternatively, individual resonance enhancing baffles shaped like reeds are disposed inside the instrument body. The semi-hollow body for stringed instruments can be adapted for guitars, violins, mandolins, ukuleles, or the like, and provides a rich, resonant tone to the instrument while avoiding acoustic feedback problems associated with hollow body instruments. Front and back plates cover front and back portions of the body to give it a solid body look and feel.

Owner:AYERS JEFFREY L

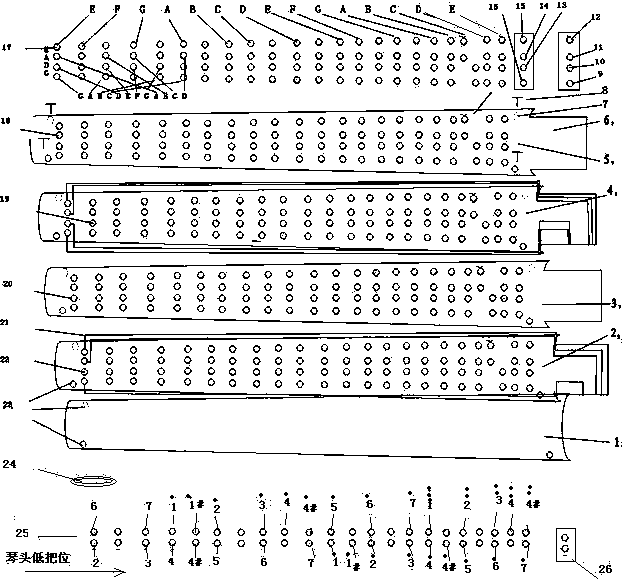

Violin finger exercise device

A violin finger exercise device comprises a fixed panel and a movable panel, wherein the fixed panel is made of a transparent material, and a finger position picture of including a C major (a minor) and temporary rising and lowering tones on the basis of the C major (a minor); the movable panel can move relative to the fixed panel in parallel and is provided with a continuous modulation finger position picture. The movable panel is moved so that different sections of the continuous modulation finger position picture can be correspondingly overlapped with the lower portion of the transparent fixed panel, and accordingly a learner can clearly see the overlapped condition of the upper layer finger position picture and the lower layer finger position picture and learn about the mutual relationship of finger positions after modulation. The fixed panel is labeled in a musical notation mode, and the exercise process sequentially includes training of notes of a music score, training of notes of the violin finger exercise device and training of fingering positions and is a process of looking for positions according to the pictures. Compared with the prior art, the violin finger exercise device requires very clear and simple conceptual work, is easy to master by a learner and accordingly can improve learning efficiency.

Owner:韩盟

Cover for playable device

InactiveUS20100122755A1Versatile in appearanceInexpensive and convenient customizationFlexible coversWrappersEngineeringViolin

This invention relates to a cover for a playable device, such as an instrument, a musical instrument, for example a guitar, a bass, a violin, a viola, or a cello, peripherals designed to resemble instruments, controllers designed to resemble instruments and / or toys. The cover can be form-fitted on a playable device leaving a playing area of the playable device fully exposed, such that the cover can be used while the playable device is being played or is merely being stored. The cover may protection from damage during use and storage. In some embodiments, the cover may be used to customize a playable device.

Owner:POST LAWRENCE S

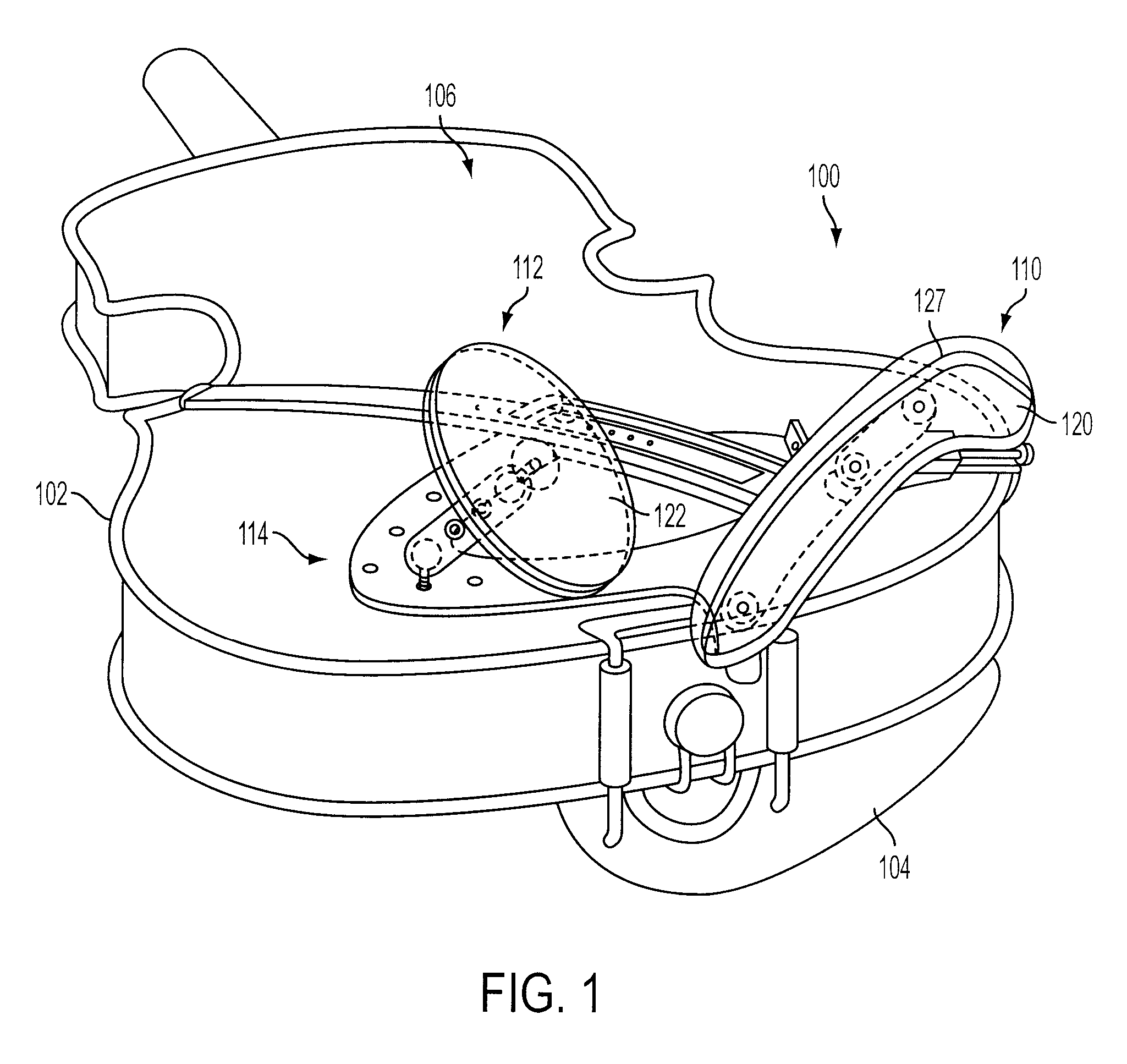

Instrument support

An instrument support may be used to support an instrument, such as a violin or a viola, against collar-bone / shoulder and chest regions of a player. The instrument support may include a collar-bone rest and a chest rest, providing a dual plane design. The rests may be adjustable to adjust the location on the back of the instrument and to adjust the heights and angles with respect to the instrument to suit the anatomical differences between players.

Owner:THE PORTABENE

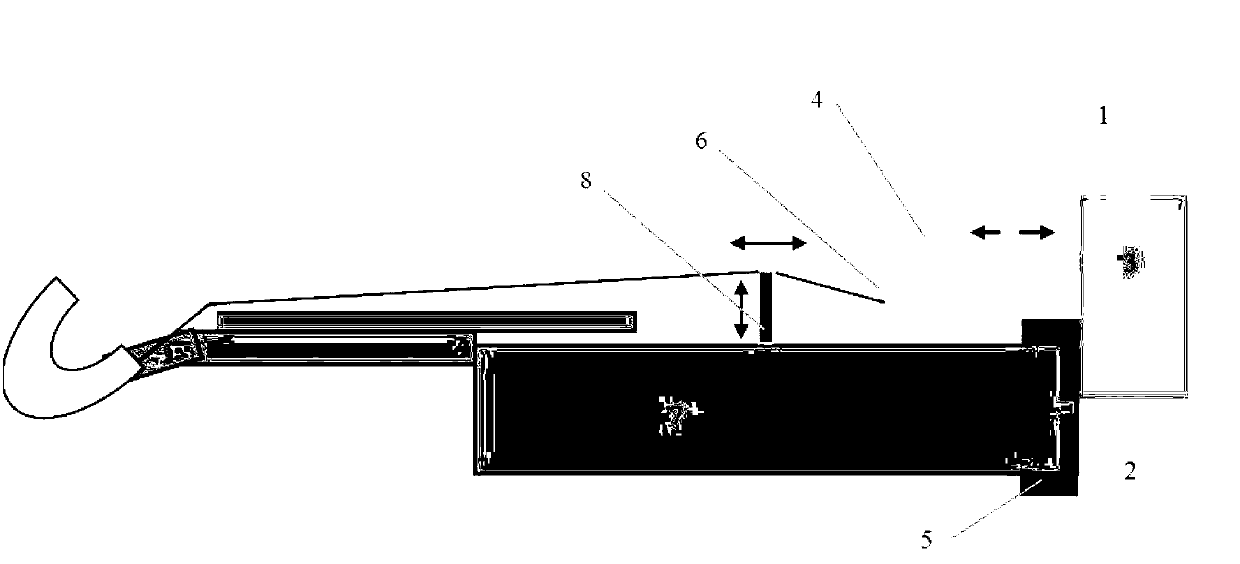

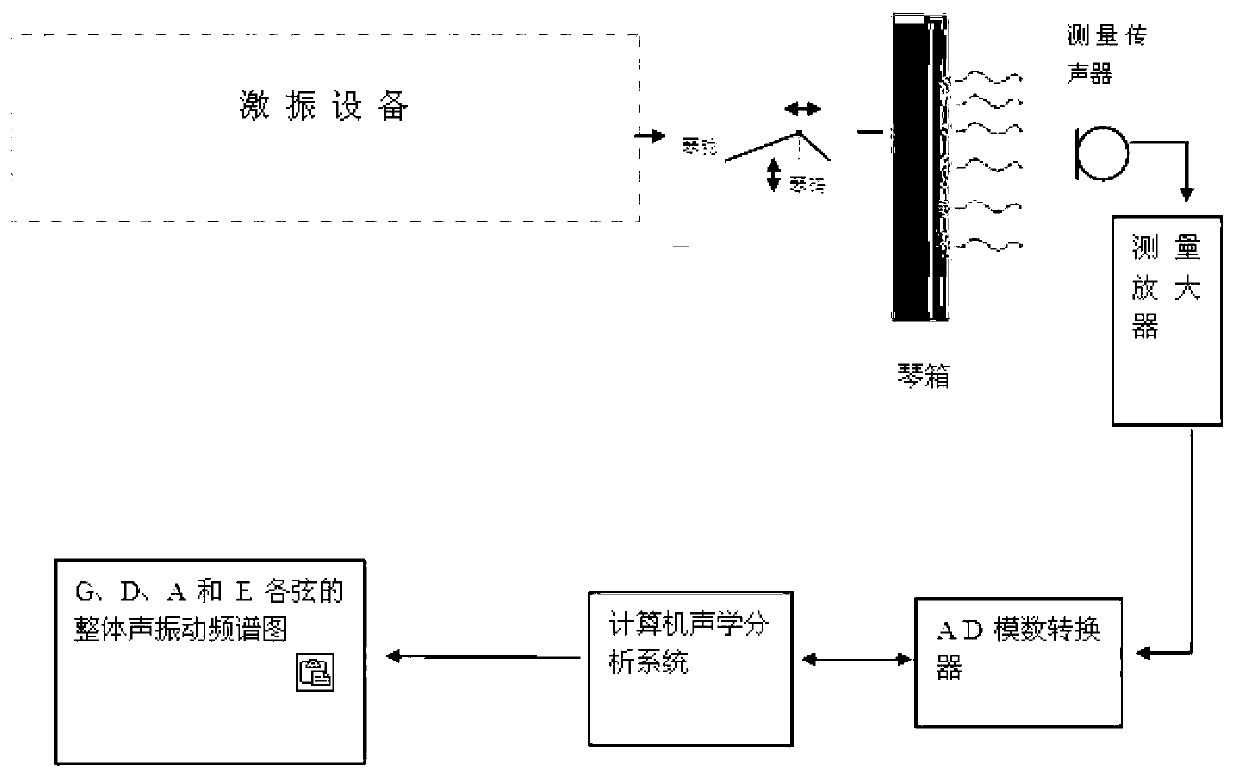

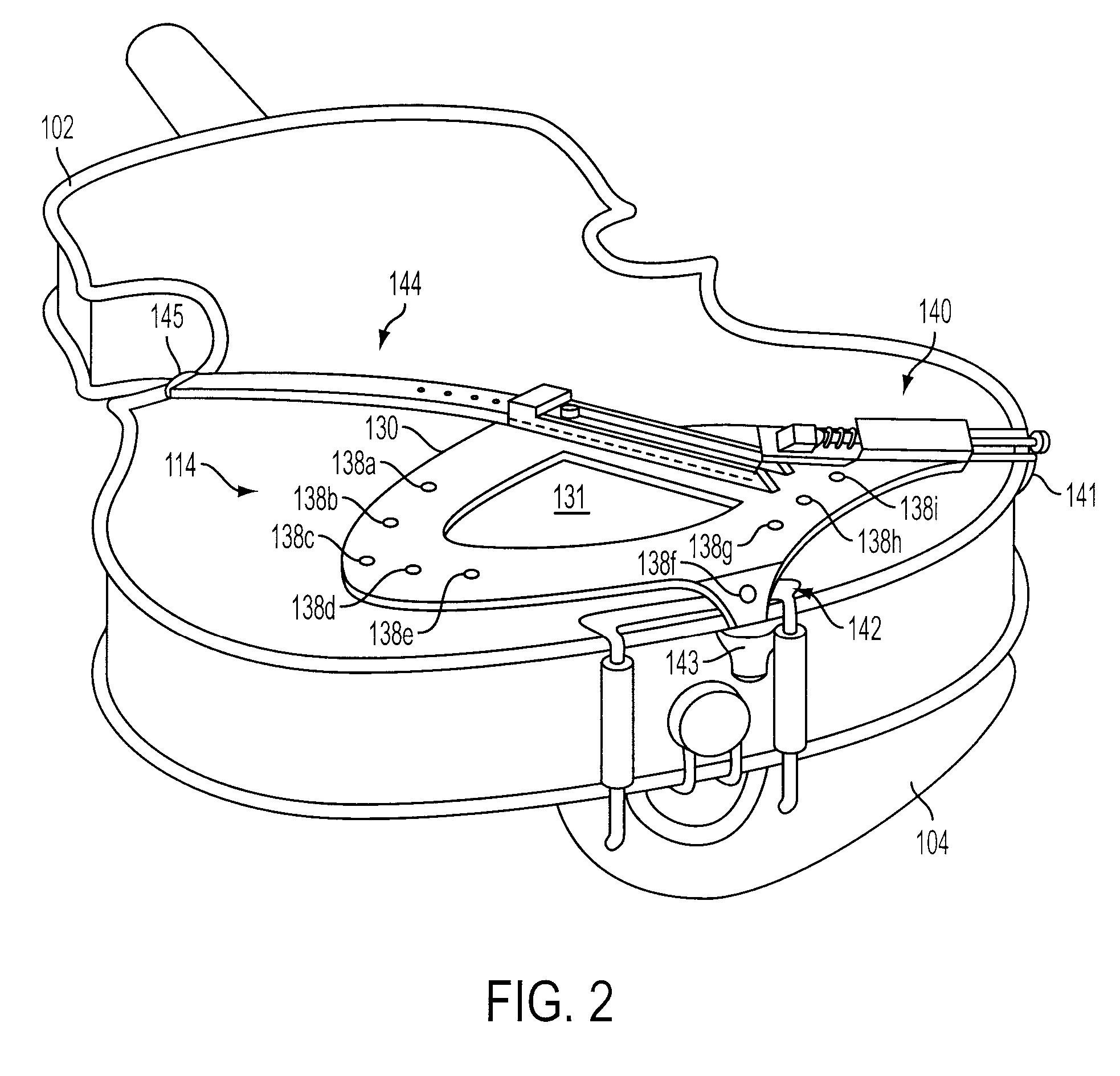

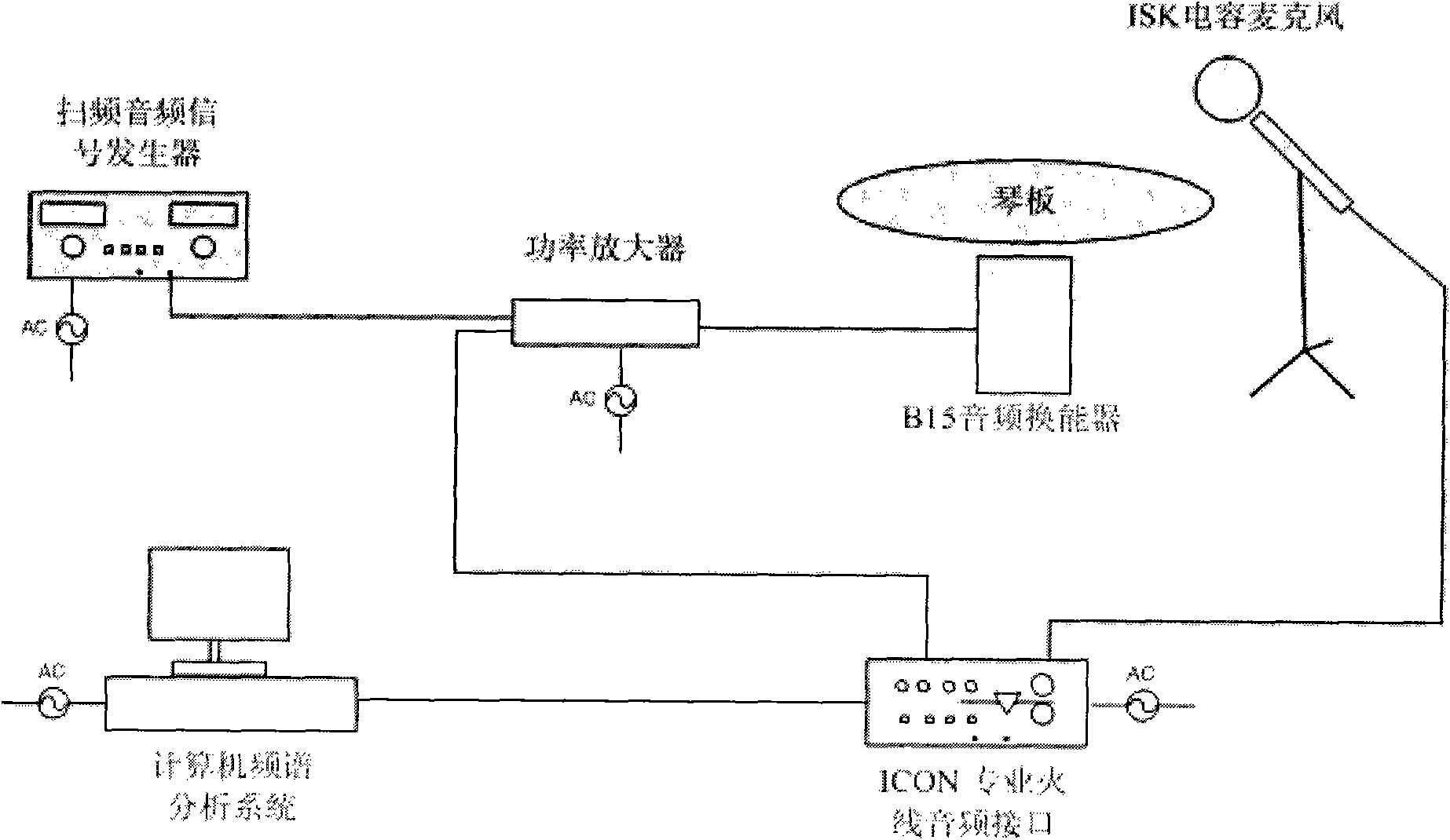

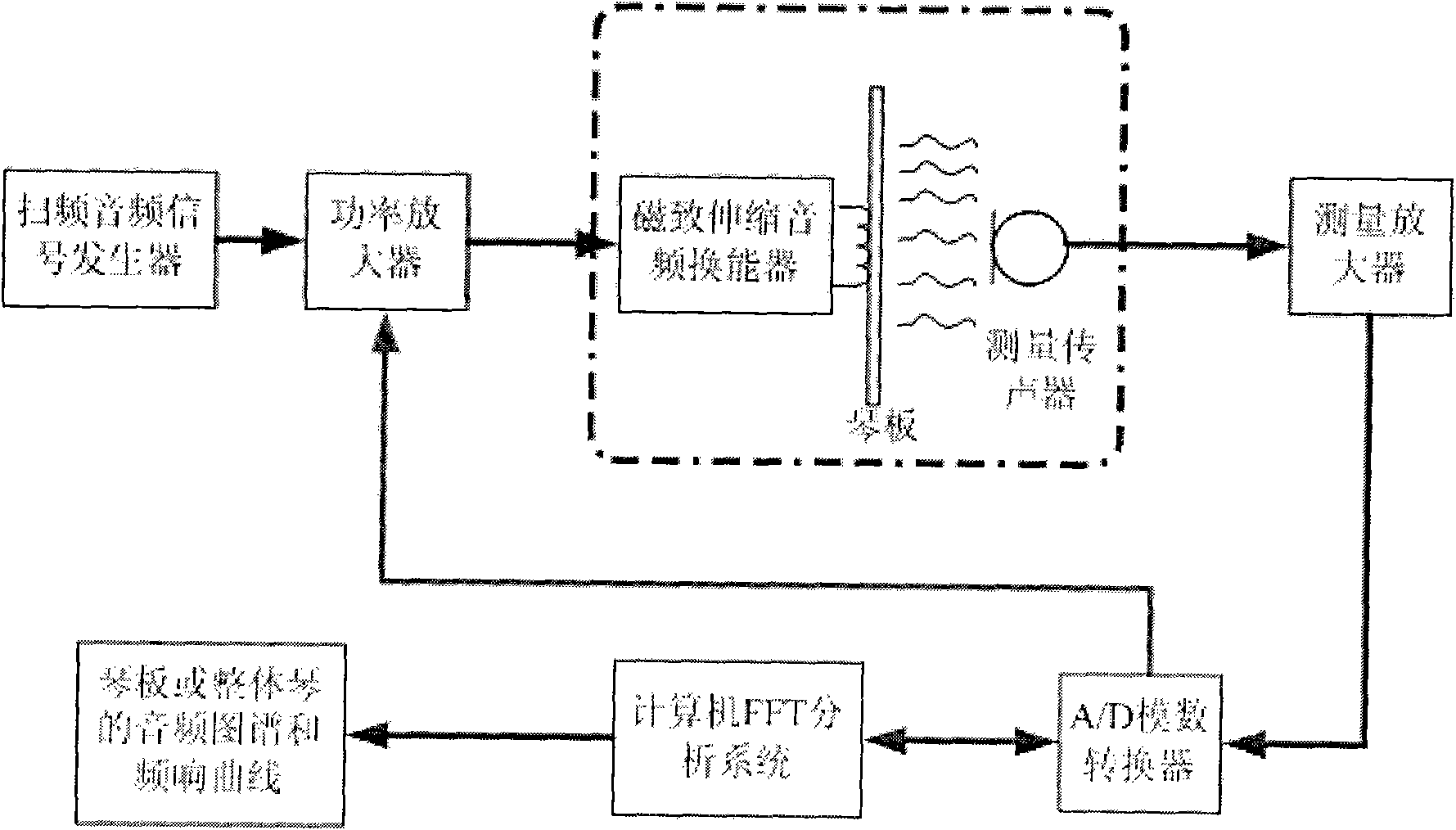

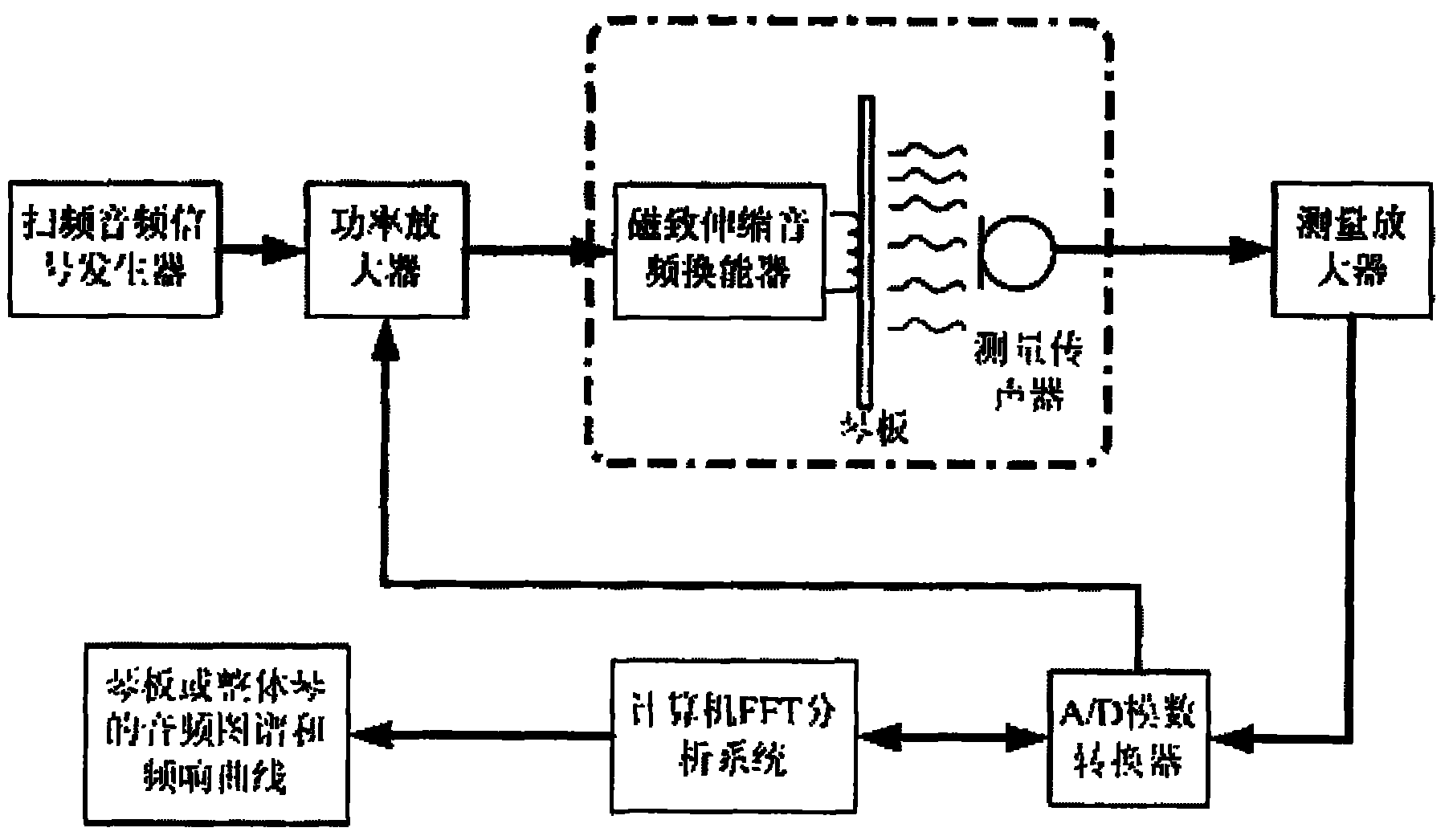

Vibration excitation equipment for entire acoustic vibration of violin and system and method for measuring frequency spectrum

InactiveCN103344324AHigh precisionImprove scienceSubsonic/sonic/ultrasonic wave measurementFrequency spectrumVoice frequency

The invention discloses vibration excitation equipment for the entire acoustic vibration of a violin and a system and method for measuring a frequency spectrum. The vibration excitation equipment comprises a voice frequency signal generator, a power amplifier, a giant magnetostrictive transducer, a string pulling arm and a violin case attaching clamp. According to the measuring method, the method that strings are pulled by the giant magnetostrictive transducer to excite the vibration of violin bridges is introduced, firstly, the giant magnetostrictive transducer and the string pulling arm respectively pull the G string, the D string, the A string and the E string and excite the vibration of a violin case under the control of voice frequency signals, and then a spectrogram is generated by means of acoustic measurement and a computer spectral analysis technique. The vibration excitation equipment for the entire acoustic vibration of the violin and the system and method for measuring the frequency spectrum simulate the motion states, such as the torsional pendulum vibration in the horizontal direction and the alternate vibration in the perpendicular direction, of the violin when the violin is played and the violin bridges are pulled under the vibration of the violin strings, the measuring environment is similar to the actual playing state of the violin, and the accuracy and scientificity of the frequency spectrum measurement result are improved. Meanwhile, feasible technological approaches are offered to tone adjustment, acoustical quality objective evaluation and the like in the manufacturing processes of the violin.

Owner:SHANXI UNIV

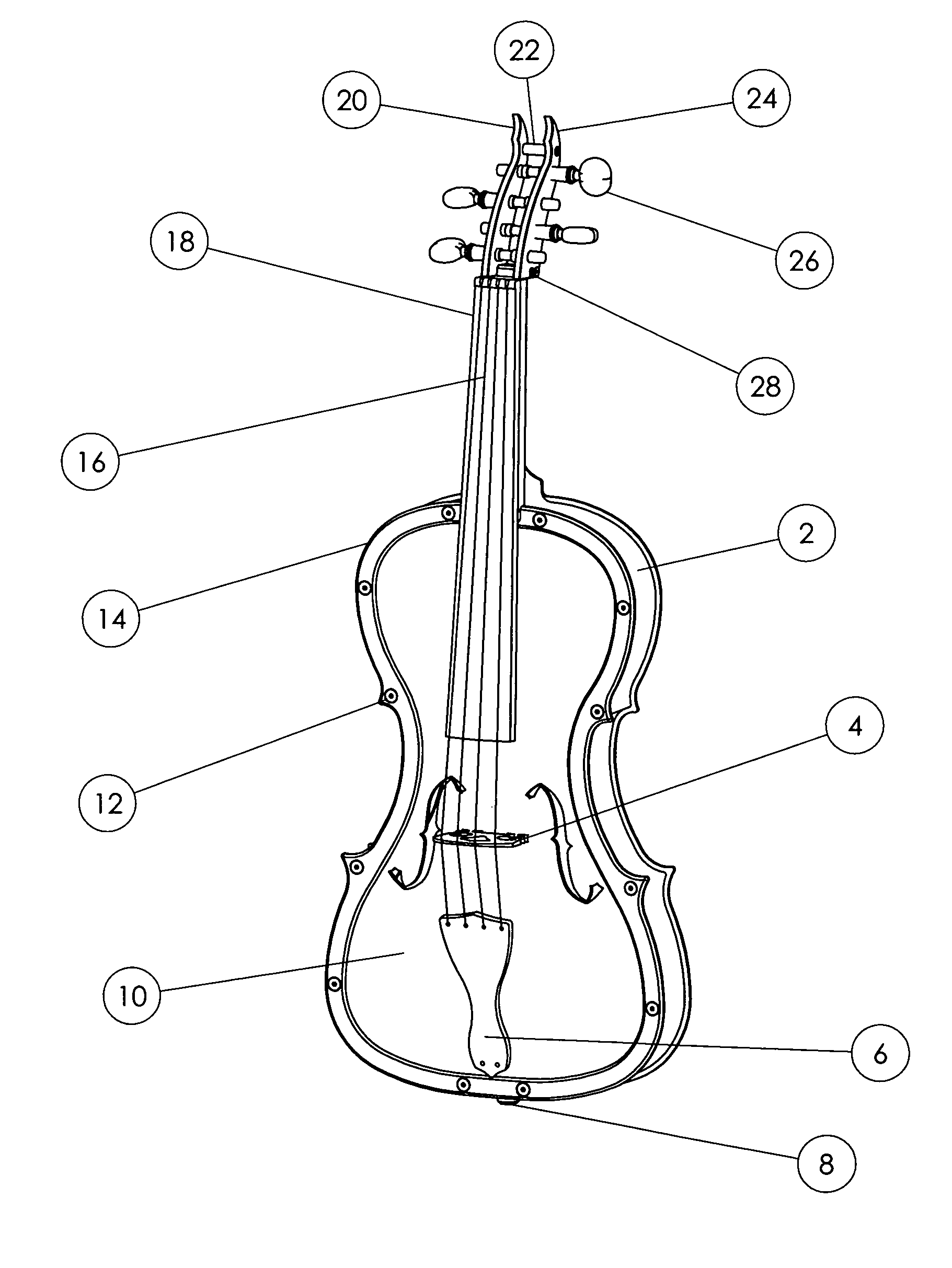

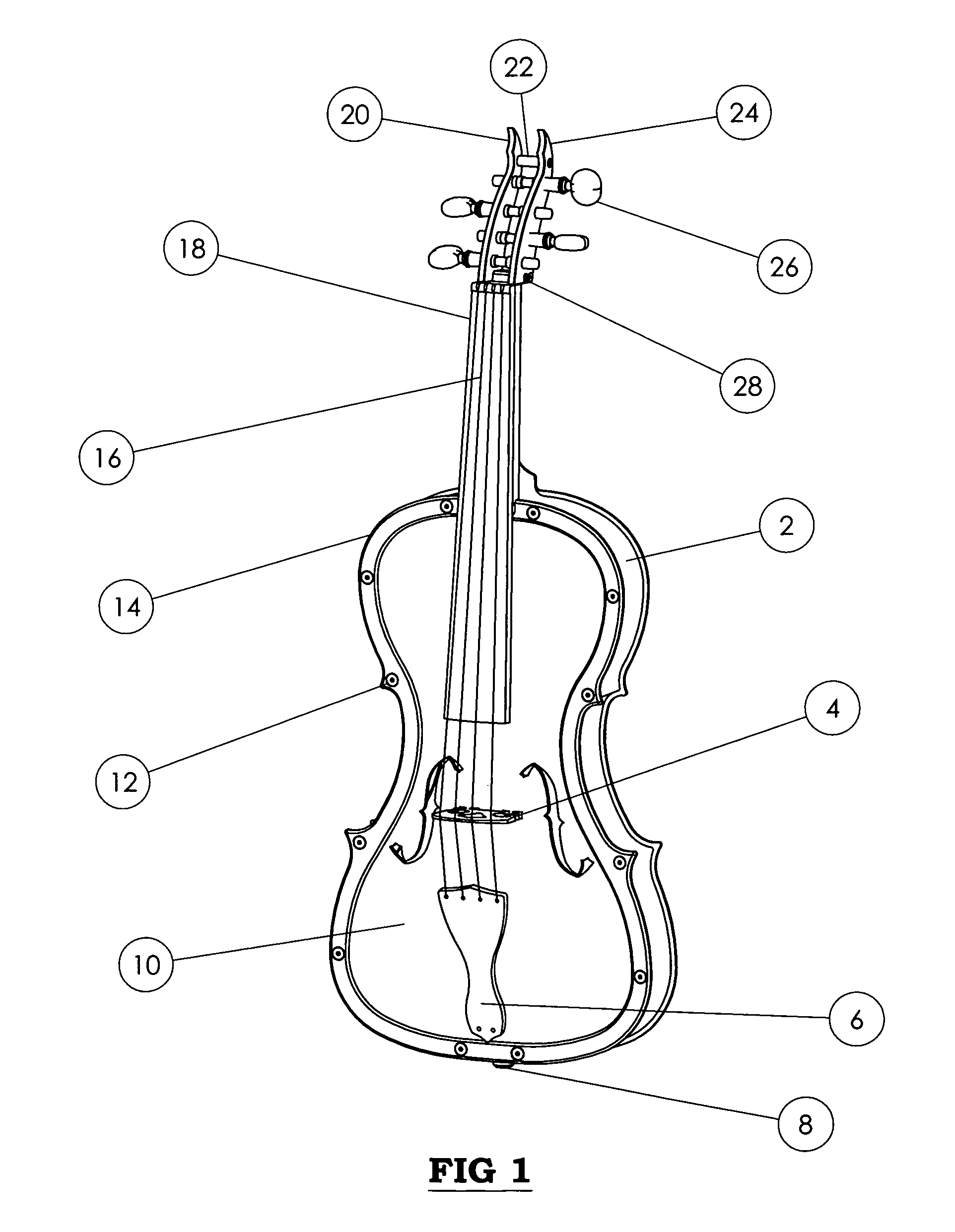

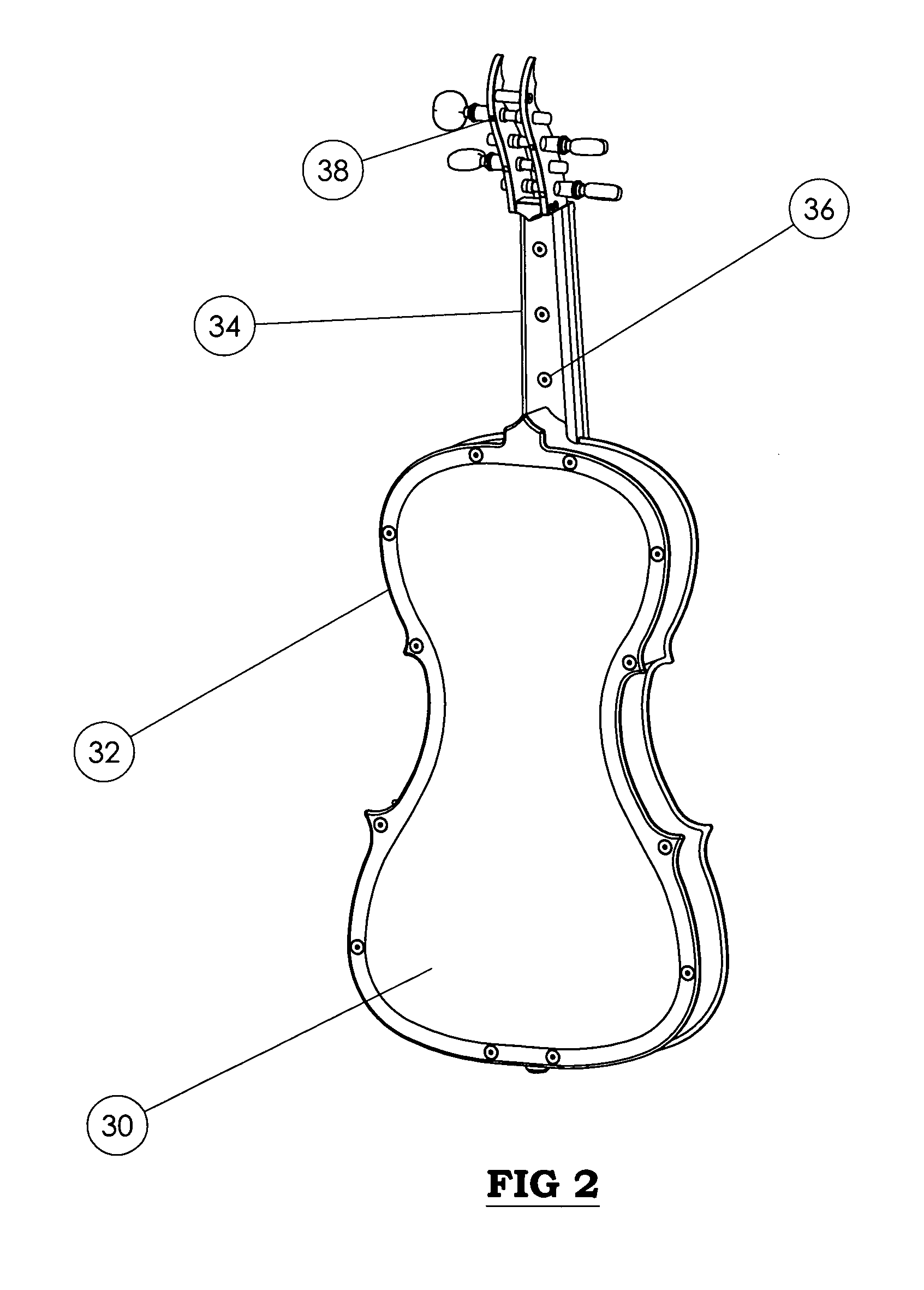

Combined metal and composite violin construction

A new method for construction of a violin or instrument of the violin family comprising a combination of light weight metal and composite materials. Components are joined using fasteners whenever possible to simplify assembly and disassembly. The results of this method are enhanced environmental stability, durability, and serviceability over existing violin designs.

Owner:HART SAMUEL ALLEN

Instrument support

An instrument support may be used to support an instrument, such as a violin or a viola, against collar-bone / shoulder and chest regions of a player. The instrument support may include a collar-bone rest and a chest rest, providing a dual plane design. The rests may be adjustable to adjust the location on the back of the instrument and to adjust the heights and angles with respect to the instrument to suit the anatomical differences between players.

Owner:THE PORTABENE

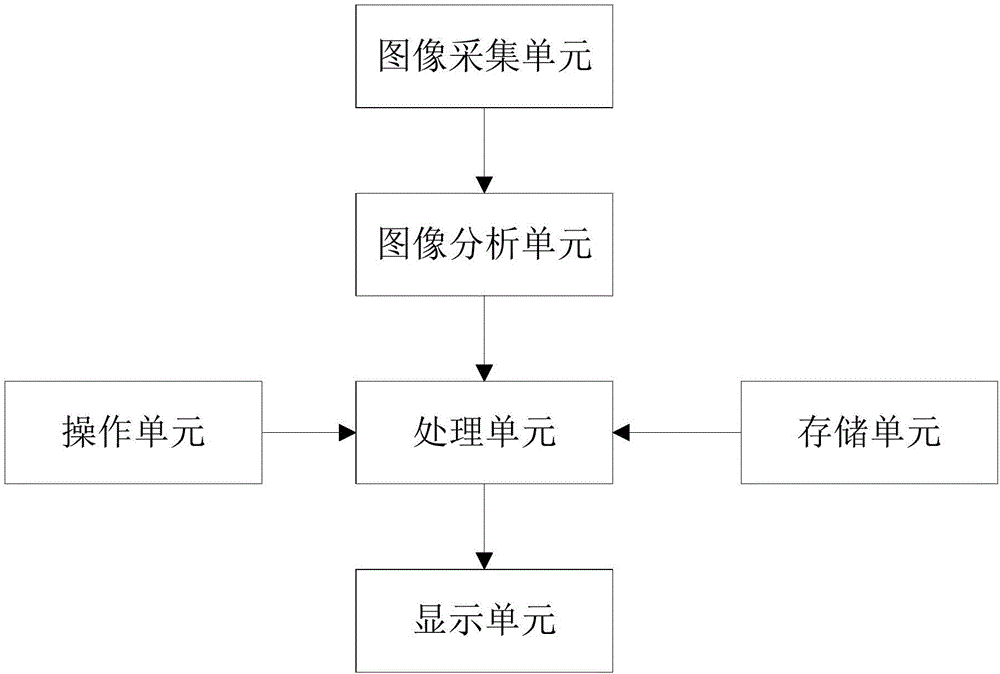

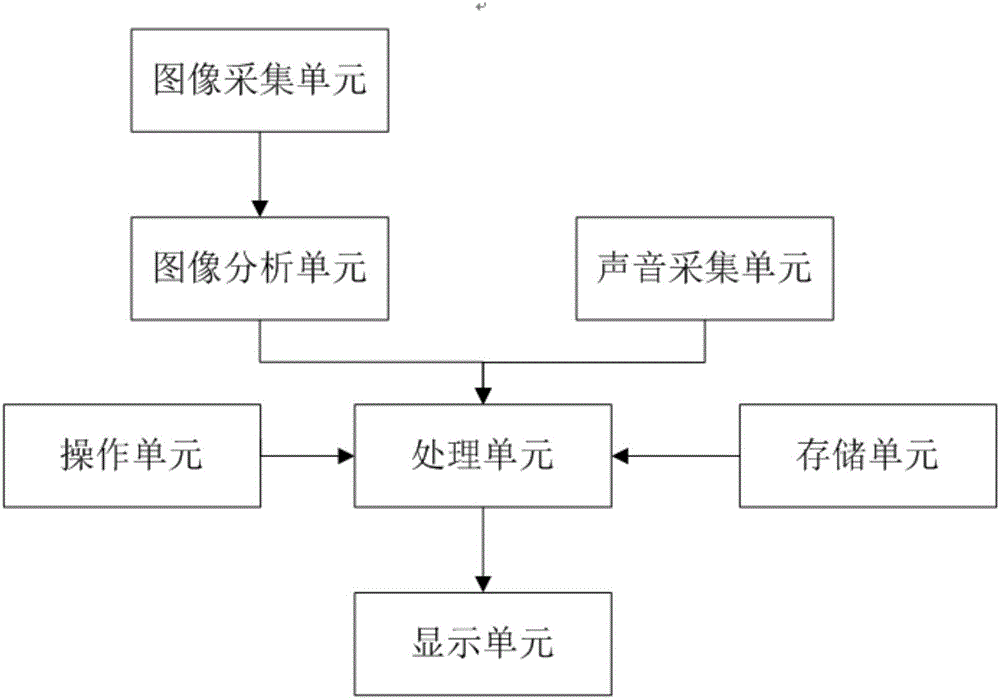

Violin supplementary learning experience system based on augmented reality (AR)

The invention discloses a violin supplementary learning experience system based on augmented reality (AR). The system comprises an image acquisition unit, an image analysis unit, a storage unit, an operation unit, a processing unit and a display unit, wherein the image acquisition unit is used for acquiring a video image that a current user holds a violin fingerboard in real time; the video image also contains fingernails of a hand holding a violin; the image analysis unit is used for analyzing an image of the current violin, identifying regions of a counter and a finger plate of the current violin and identifying and locating four strings of the violin; the storage unit stores a music score as well as virtual animation elements for finger pressing action and fiddle bow operation, which correspond to a syllable and a musical note; the processing unit is used for displaying on the display unit according to counter and finger plate regions of the current violin and the four located strings of the violin and setting a region for displaying the animation elements; and the processing unit calls a corresponding music score in the storage unit and the virtual animation elements for the corresponding pressing action and fiddle bow operation and displaying the virtual animation elements in the display region.

Owner:DALIAN VINCENT SOFTWARE TECH

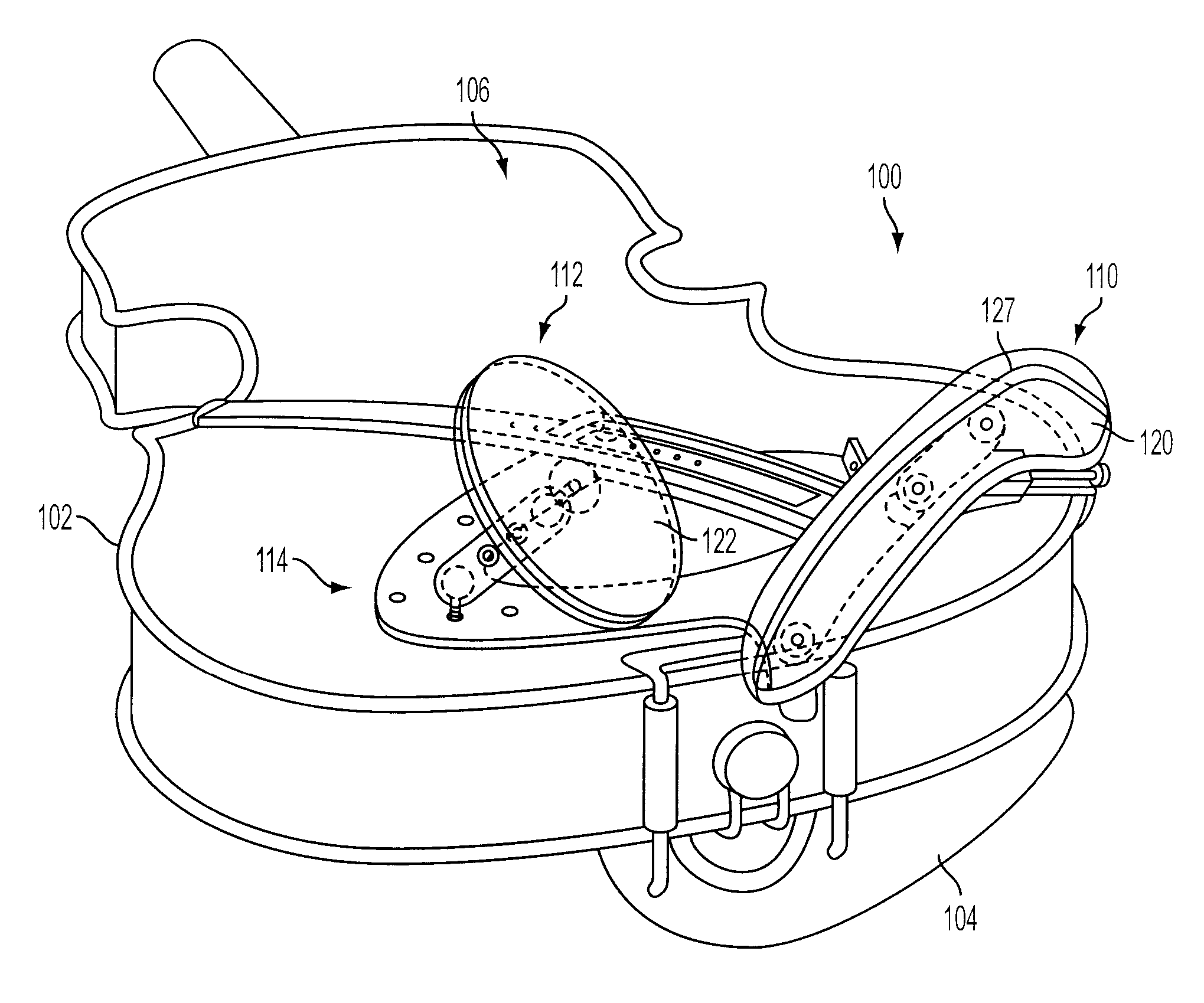

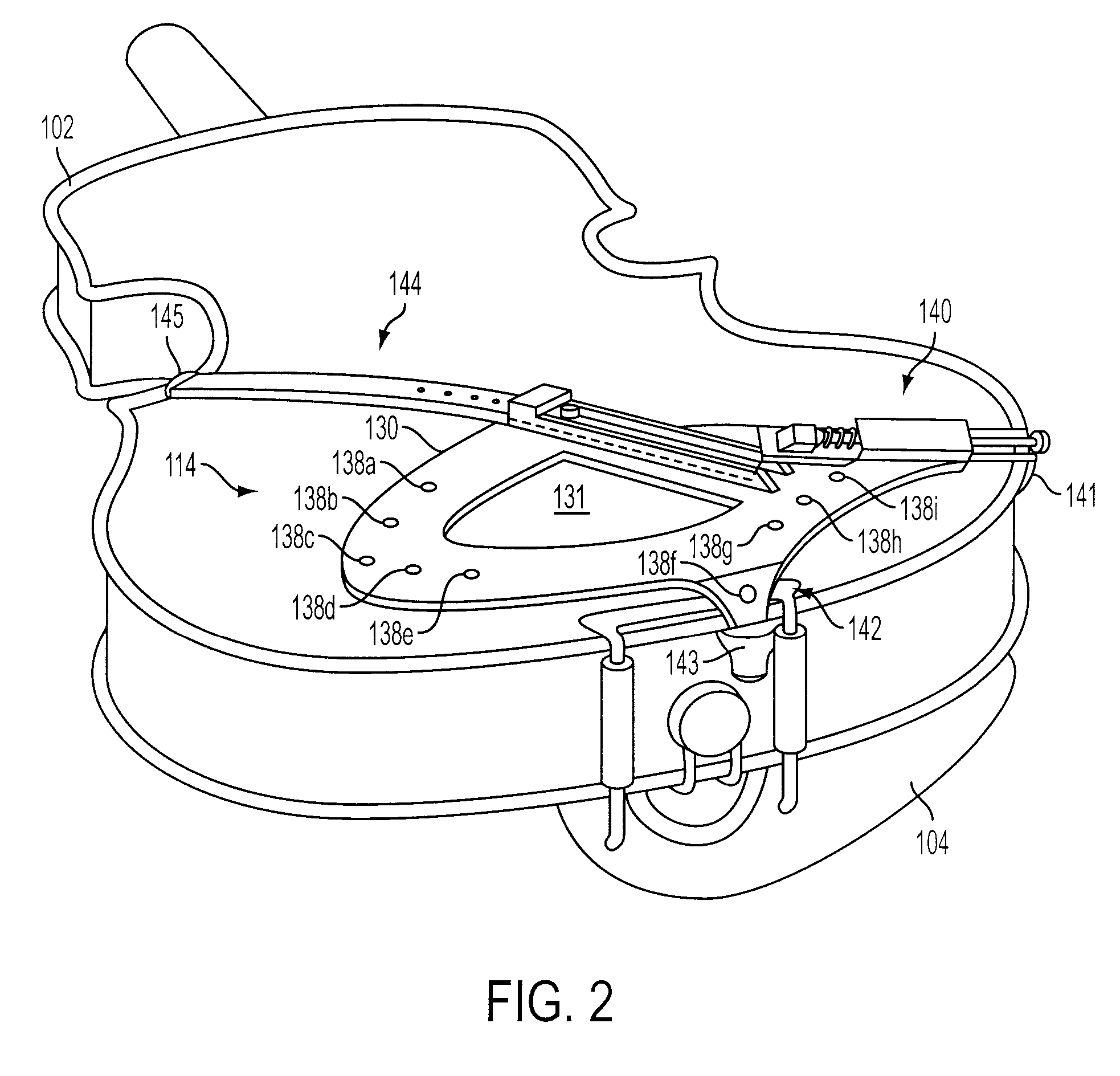

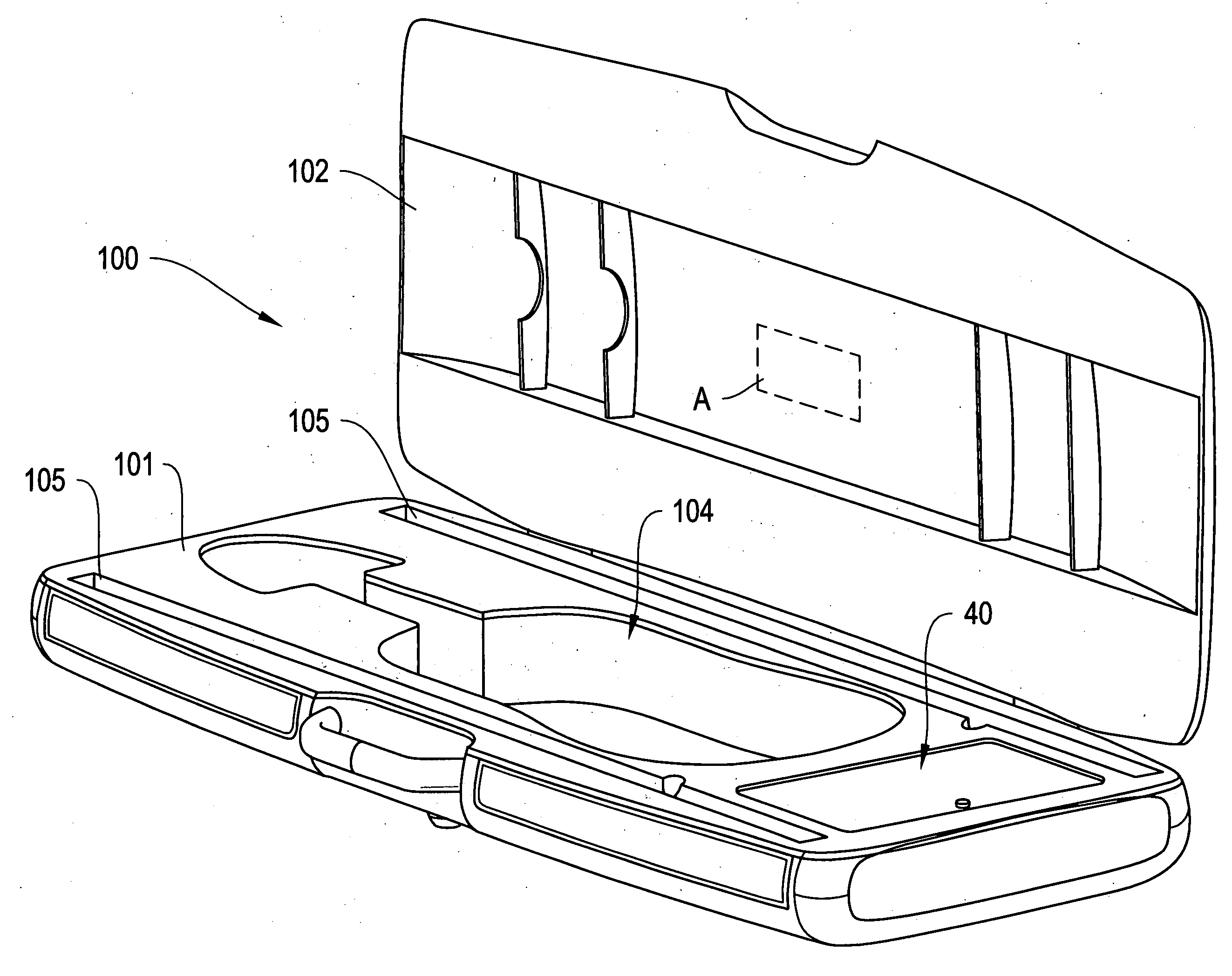

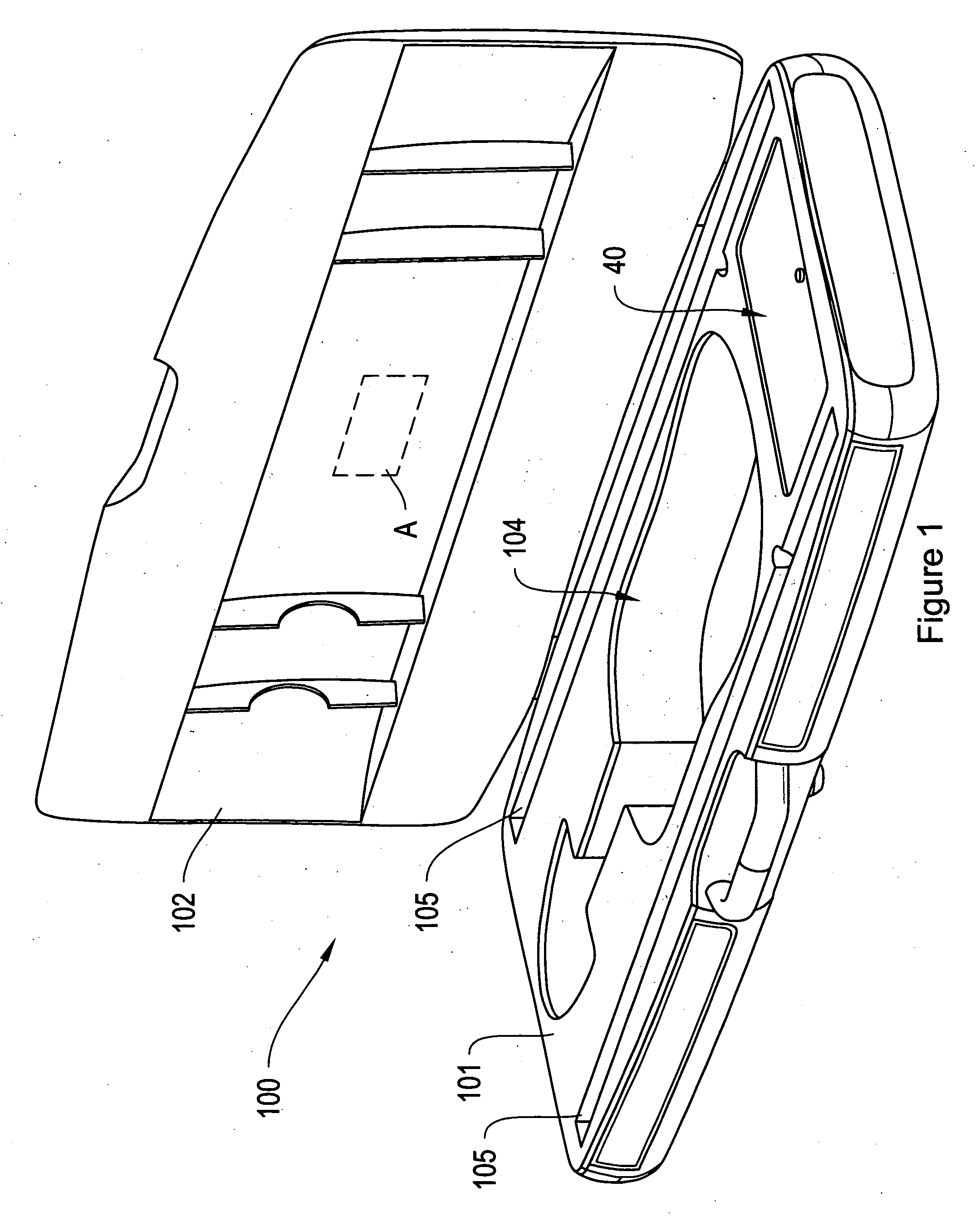

Safe instrument case and protection devices

InactiveUS20100170811A1Potential damageNo damageOther accessoriesContainer/bottle contructionWireless transmissionEngineering

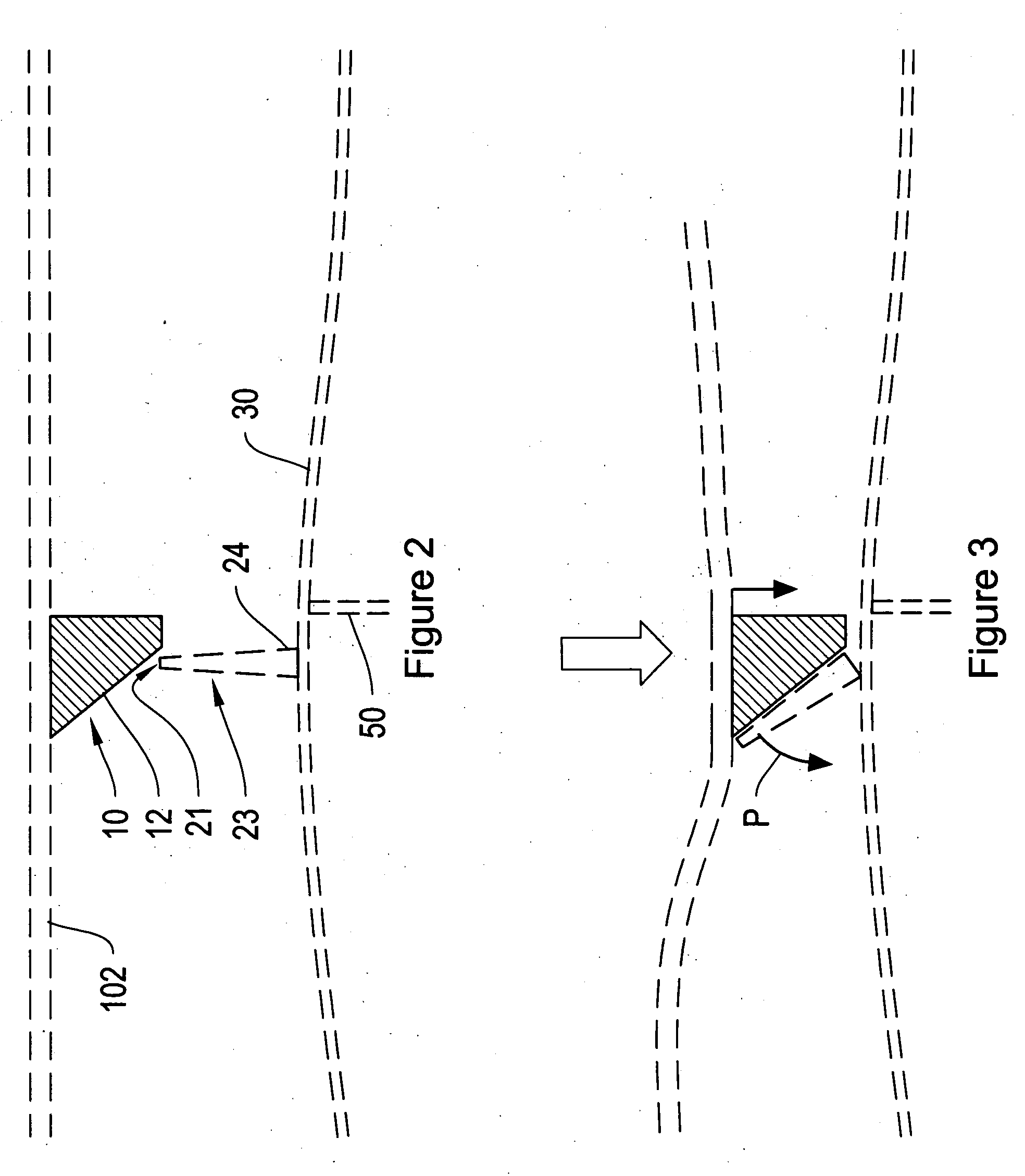

A violin or viola case alleviates potential damage pathways by including one or more protective features. In one aspect, a safety device knocks down the bridge upon the occurrence of crushing contact, impact with the lid of the case or sharp movement. The safety device may be part of the case, or may be provided as an add-on attachment for an existing case. By harnessing the shock or movement to collapse the bridge when trauma to an instrument case occurs, the instrument experiences a low-impact, broad area slap against the top by the face of the bridge as it is knocked down, and collapse of the thin vertical bridge leaves free space between the instrument and the case to prevent damage upon further impact or movement. A well secures the bow in a protected recess away from the instrument. The case in another or further aspect includes parametric monitor, or monitor and control, that detects and records environmental parameters and out-of limit conditions such as temperature, humidity and impact that may affect instrument integrity. The parameters are monitored, values logged, and records displayed, preferably effecting wireless transmission of records and alarm conditions. A method of safe transport includes providing an instrument with a sacrificial bridge and transporting in a case fitted with a bridge knock-down instrument protector.

Owner:COPPIARDI MARCO LUIGI

Cat toy with music string component

InactiveUS6883465B2Stimulating playful activityPromoting healthy interactionToysOther apparatusTasselEngineering

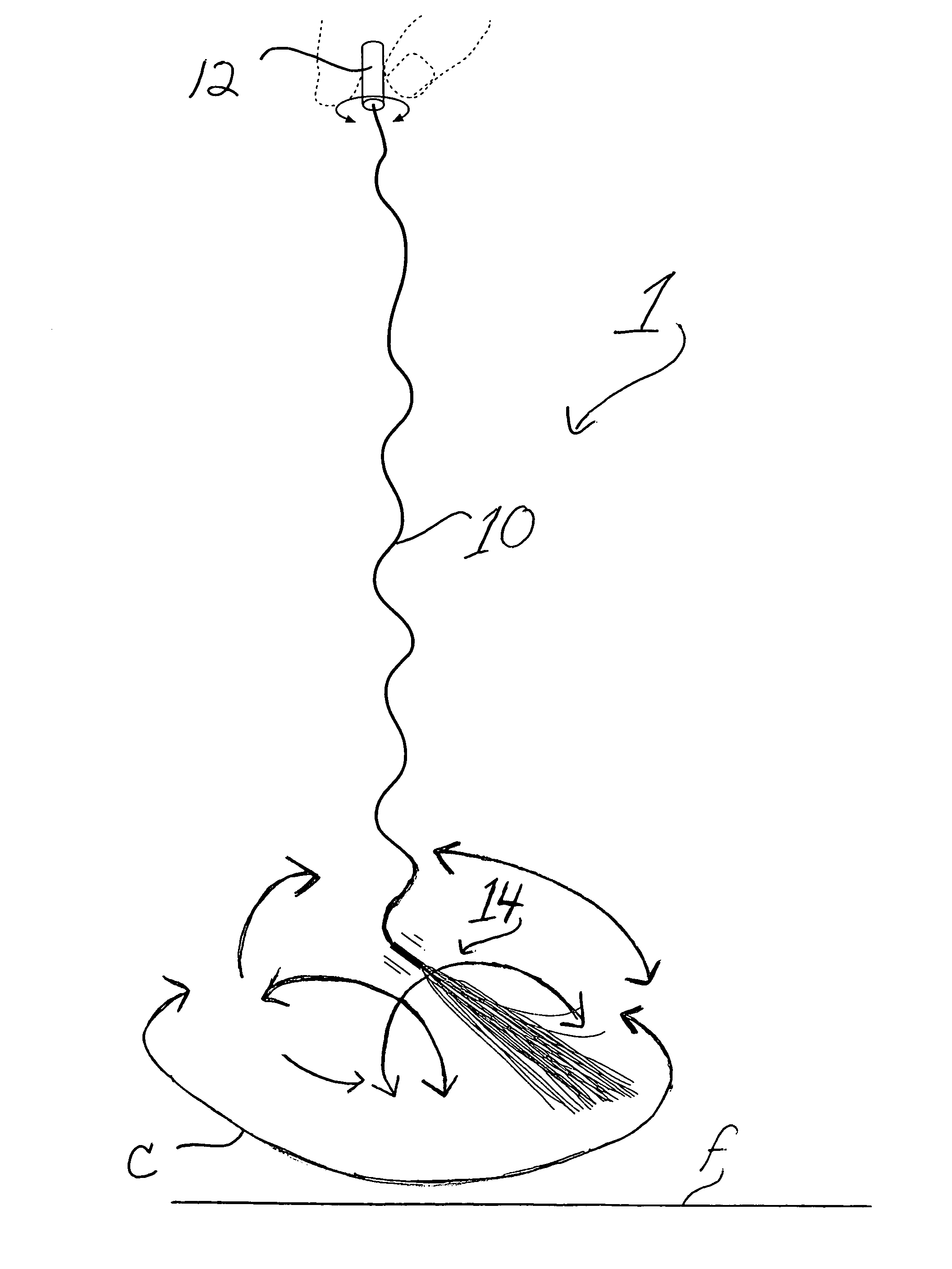

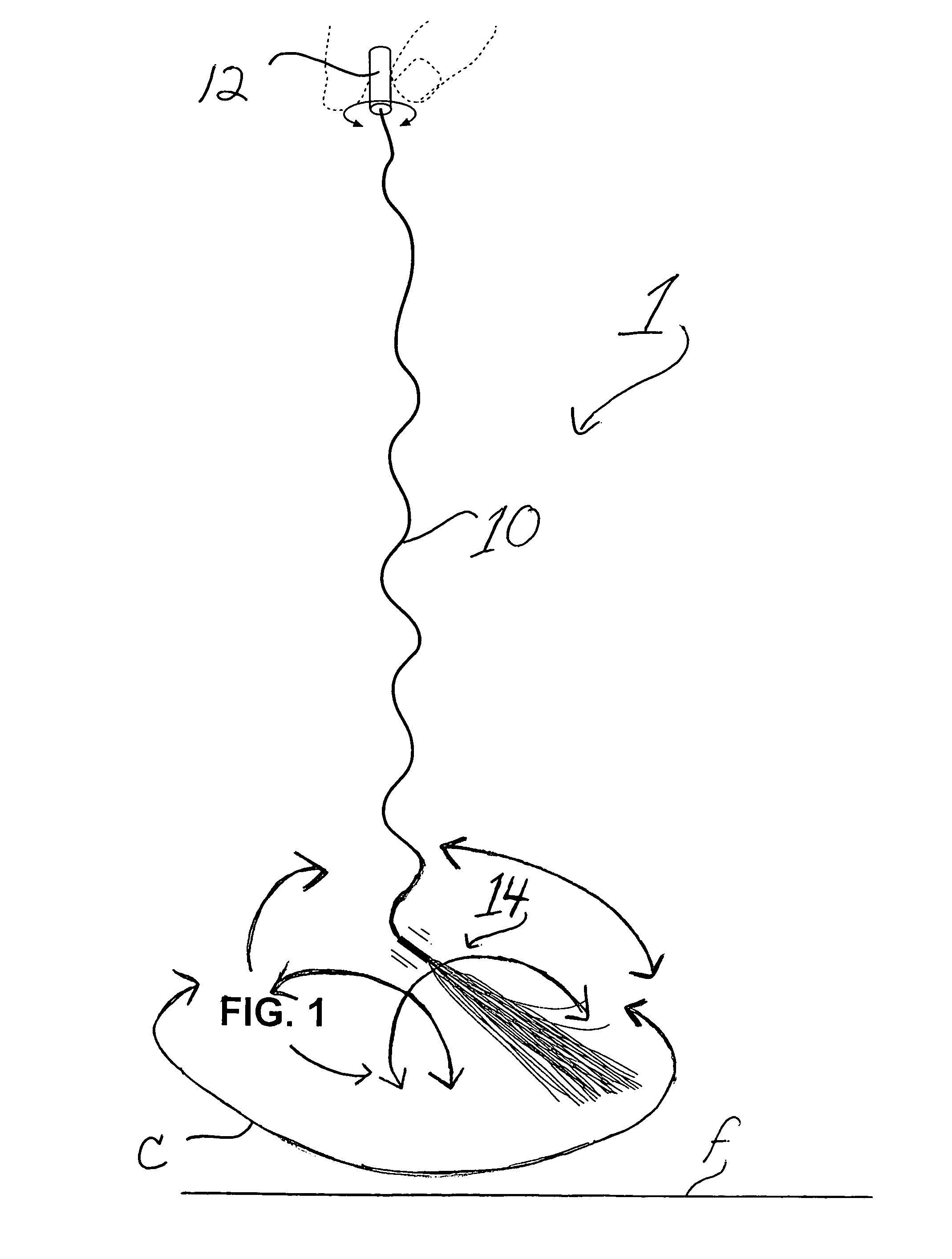

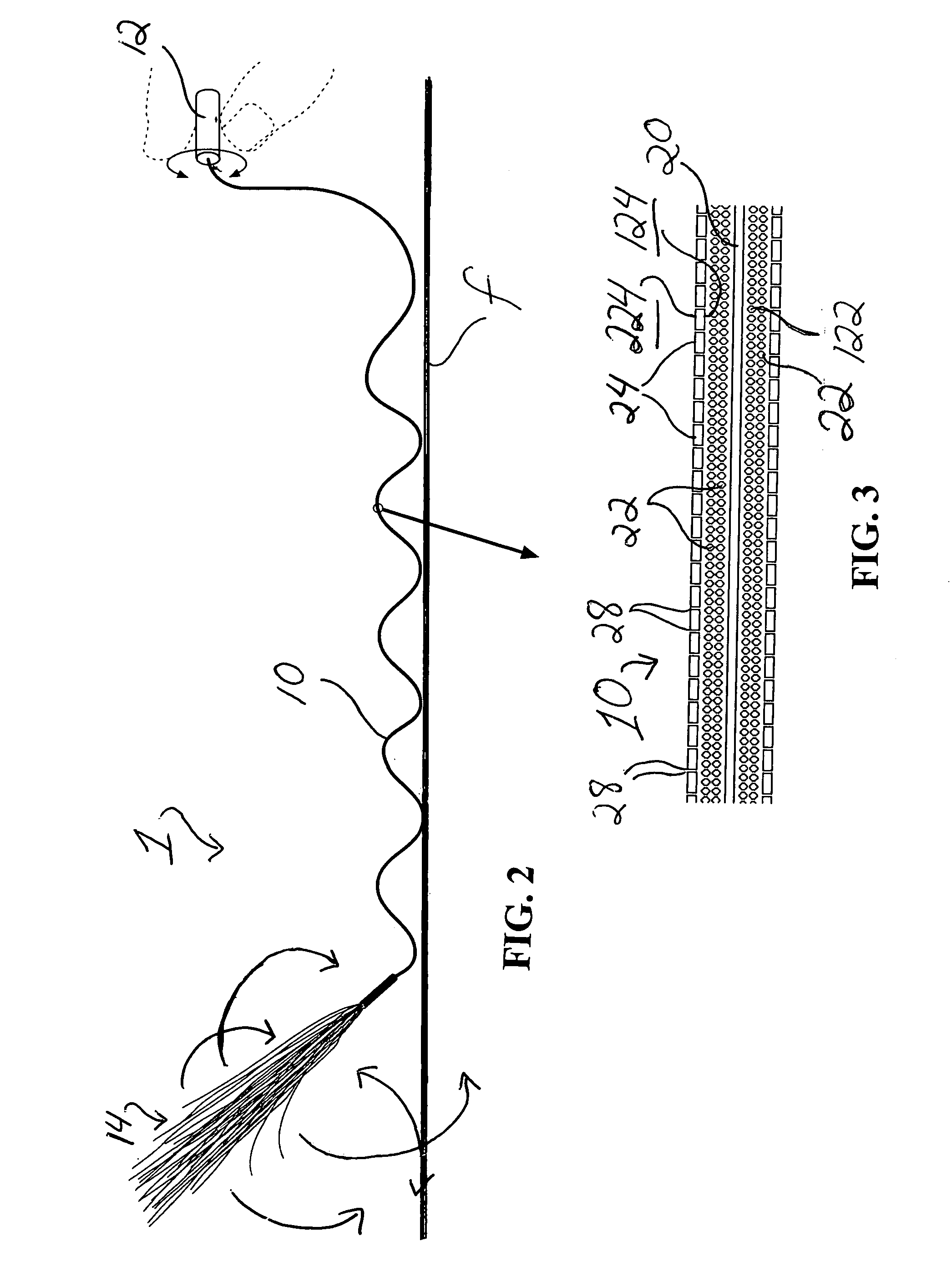

A stringed cat toy to encourage playful activity and exercise in cats and healthy interaction between cat owners and their pets. The cat toy comprises an elongated music string with a small handle securely connected at one end and an object which is attractive to cats secured at the opposite end. The preferred cat toy string is selected from a group of composite strings used for instruments such as the cello, bass or violin, which are of low tensile strength and are designed for low-frequency vibration on the order of about 100 Hertz or less. The dynamic properties of the composite string facilitate interesting movements of the attractor, preferably a horse hair tassel, when the handle is rotated. The motion of the attractor appears to be a life-like and erratic movement that simulates prey and stimulates natural predatory instincts within the cat to encourage the animal to leap at the object. Such playful activity both exercises the cat and promotes beneficial interaction between cat and owner.

Owner:TELFORD STEVE +1

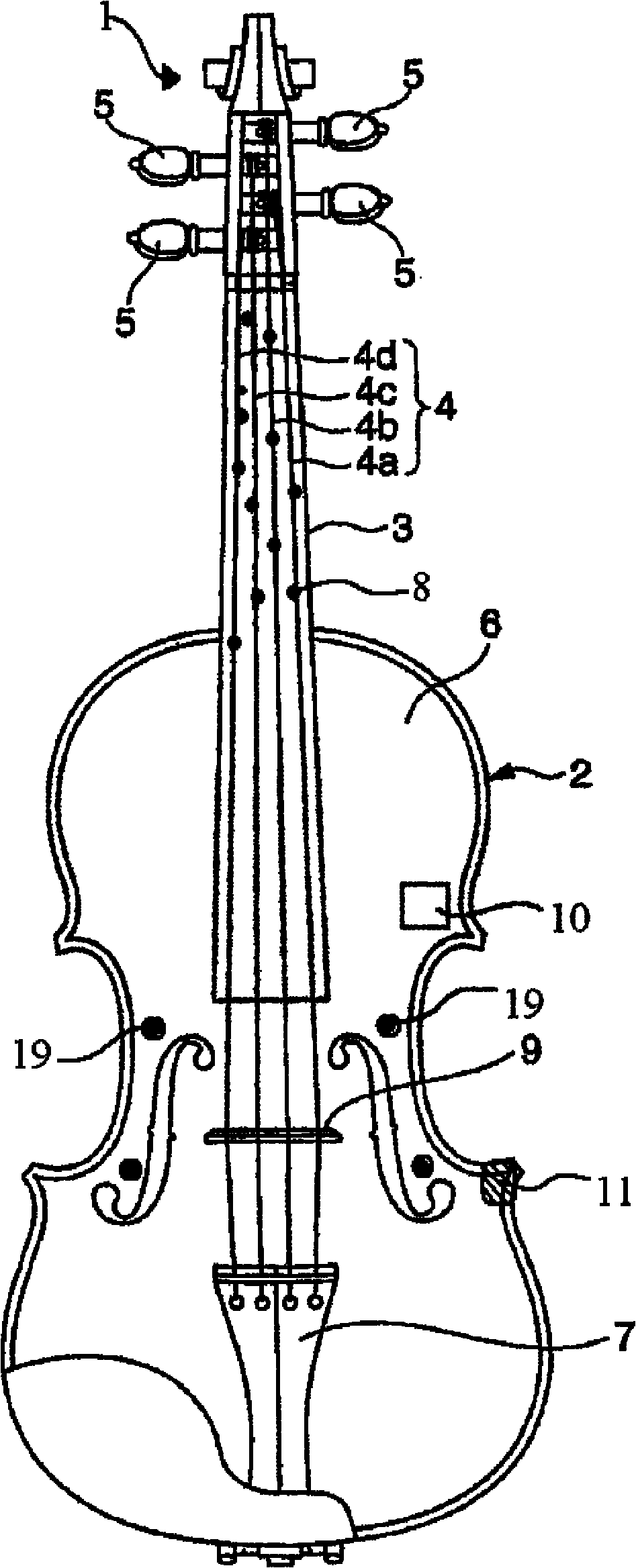

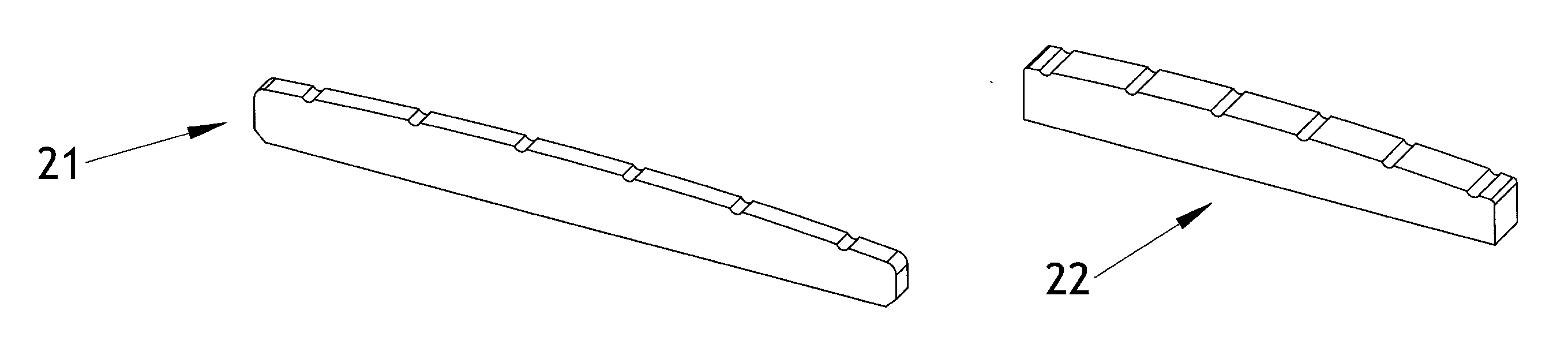

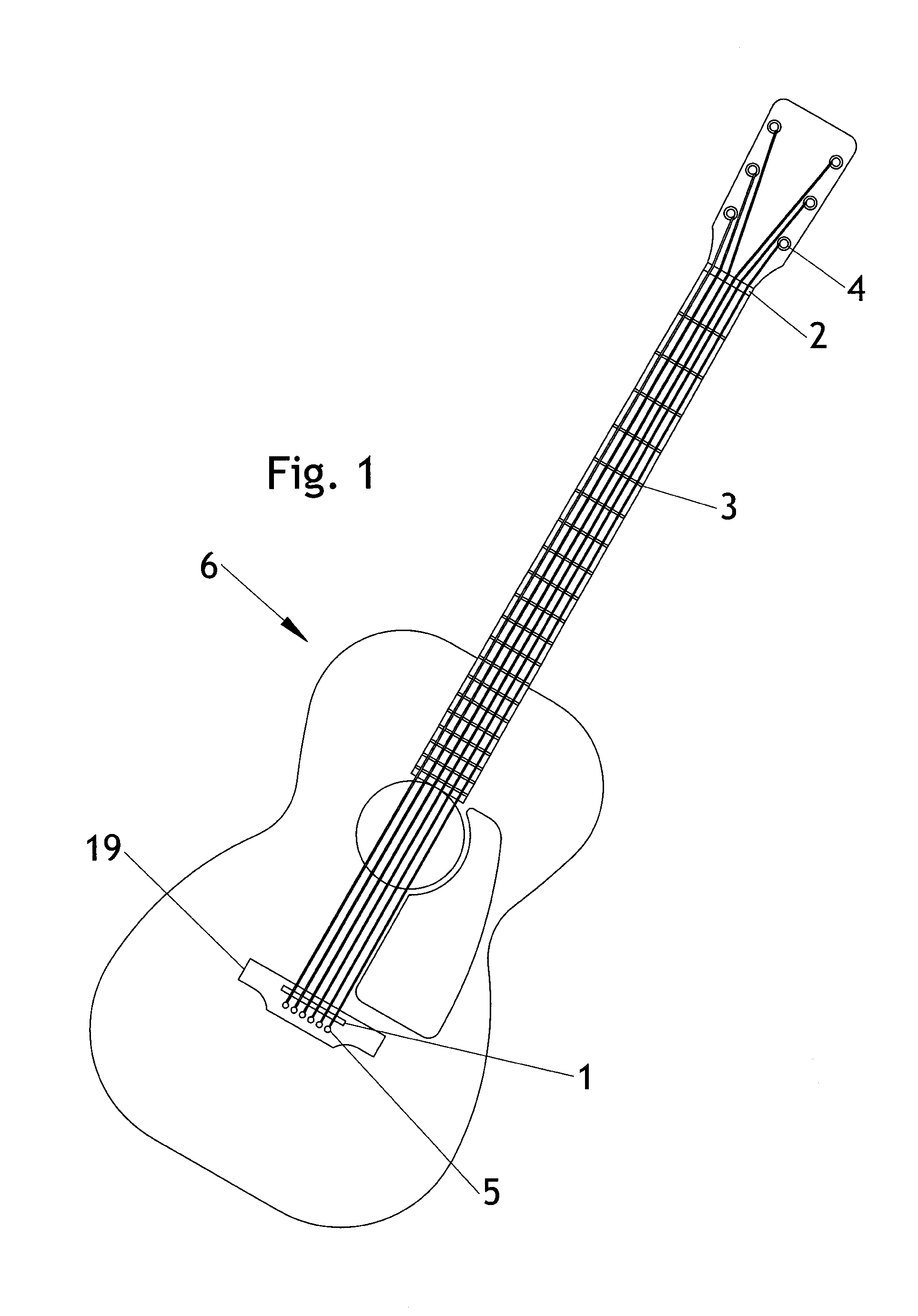

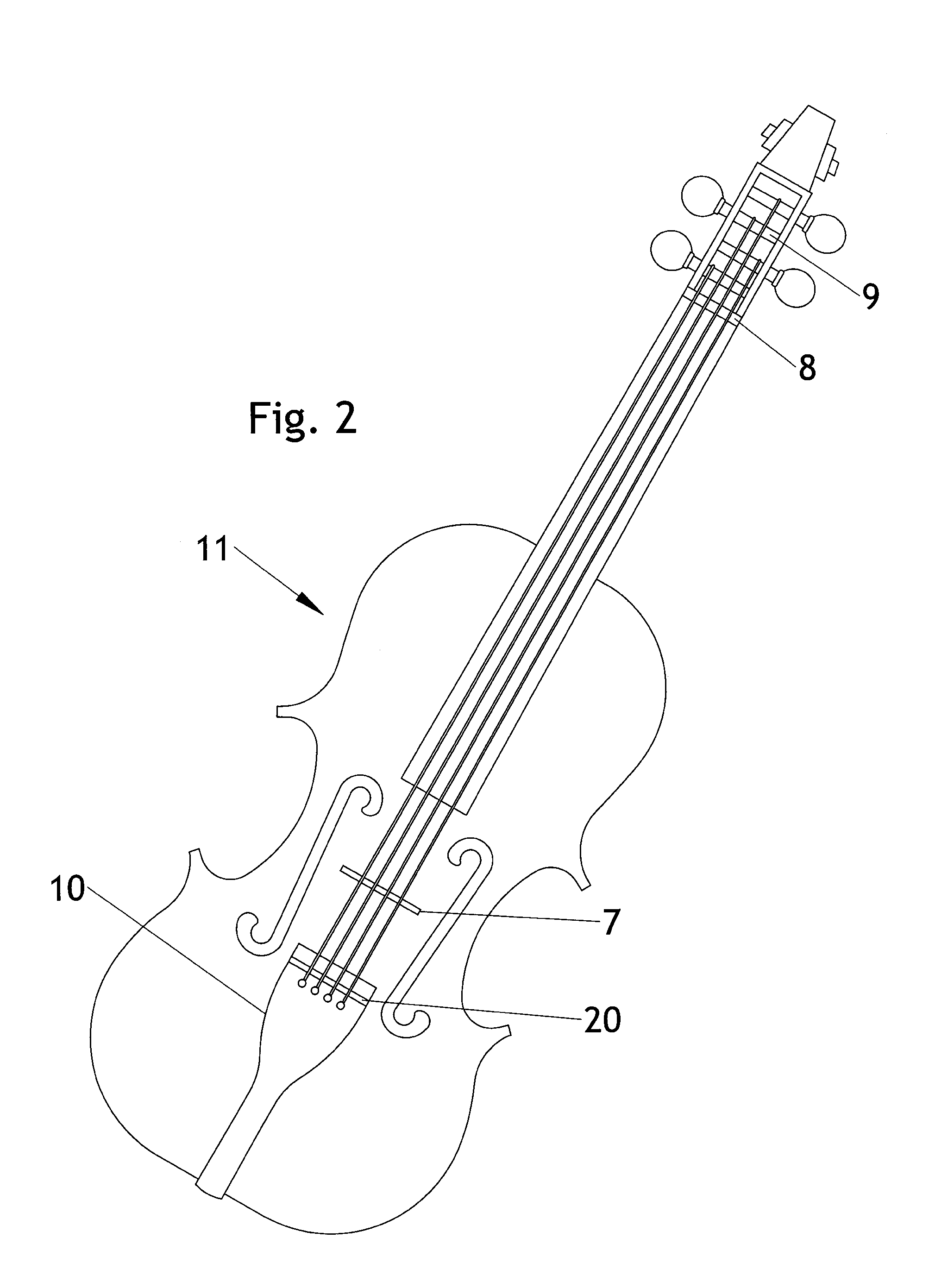

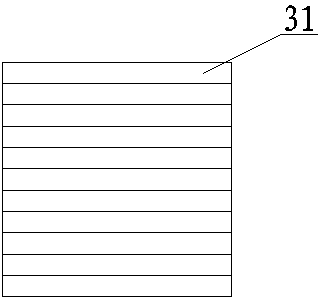

Pyrolytic carbon components for stringed instruments

Pyrocarbon components have been found to create richer, clearer sound when employed as bridges (19), saddles (1), nuts (2), frets (3), tuning heads (4), pegs (9) and other components which contact the strings in guitars (6, 16), violins (11) and like stringed musical instruments. Bridges / saddles and nuts of stringed instruments produce a marked difference in the sound when pyrocarbon components are used compared with currently used materials. There is a significant increase in sound volume for a given intensity of string movement, along with richer harmonics and a clearer, less muddy sound. The crystalline structure of pyrolytic carbon minimizes the damping of string vibration as it is transferred to the sound-amplifying portion of acoustic instruments, producing a rich, pleasing and higher volume sound. The useful life of strings is increased in contact with pyrolytic carbon components before they go “dead” or break.

Owner:OBBLIGATO

Violin table tone setting and case assembling tone tuning method and special device

InactiveCN101789237AImprove intuitive effectAcoustic quality is easy to controlStringed musical instrumentsSound qualityAnalog-to-digital converter

The invention discloses a violin table tone setting and case assembling tone tuning method and a special device. The special device for the violin table tone setting and case assembling tone tuning comprises an audio swept-signal generator, a power amplifier, a magneto striction audio transducer, a measurement microphone, a measurement amplifier, an analog-digital converter, a special frequency spectrum analysis software and a computer. The violin table tone setting and case assembling tone tuning method is directly started with timber vibration sounding angle, utilizes the audio transduction technology and the computer frequency spectrum analysis technology to respectively generate the frequency response curve of a panel, back panel and a case of a standard violin and a new violin, and sets the tone of the new violin to an expected sounding state through the comparison analysis. The method greatly improves the Doctor Huggis violin table tone setting method, and the computer frequency spectrum analysis technology and the audio transduction technology are applied to the violin tone setting and the case assembling tone setting links. Compared with the traditional tone setting method, the method has the advantages of good intuition and easy control of sound quality.

Owner:王宏伟

Method of manufacturing violin by using carbon fiber composites

The invention discloses a method of manufacturing a violin by using carbon fiber composites. A violin mold is designed to be an opened-type molding mold, and the violin mold comprises a violin covering mold for manufacturing a violin panel and a violin main body mold used for manufacturing a violin head, a violin neck, a side board and a back board. The violin mold is manufactured through working procedures of preparation of molds, material cutting, laying, combination and bagging, tidying, hot-pressing and solidification, demolding after leaving an oven, finishing and the like. The carbon fiber violin imitates acoustical effect of wood, and is manufactured through the advantages of good designability, strong intensity, high molding amount, light and hard characters of the carbon fiber composites. The carbon fiber violin uses domestic carbon fibers, and is not limited by resources, the panel and the back board use different structural design through imitation of wood acoustics effects, and reinforcement processing is conducted on the violin neck and a violin box. The violin has the advantages of being graceful in tone, not prone to deforming, not prone to being affected by moisture, and not prone to cracking and the like, completely subverting the traditional musical instrument industry, enabling the violin to show new brilliance, and exploiting a new way for the manufacturing of musical instruments.

Owner:LIANYUNGANG SHENYING CARBON BIKE CO LTD

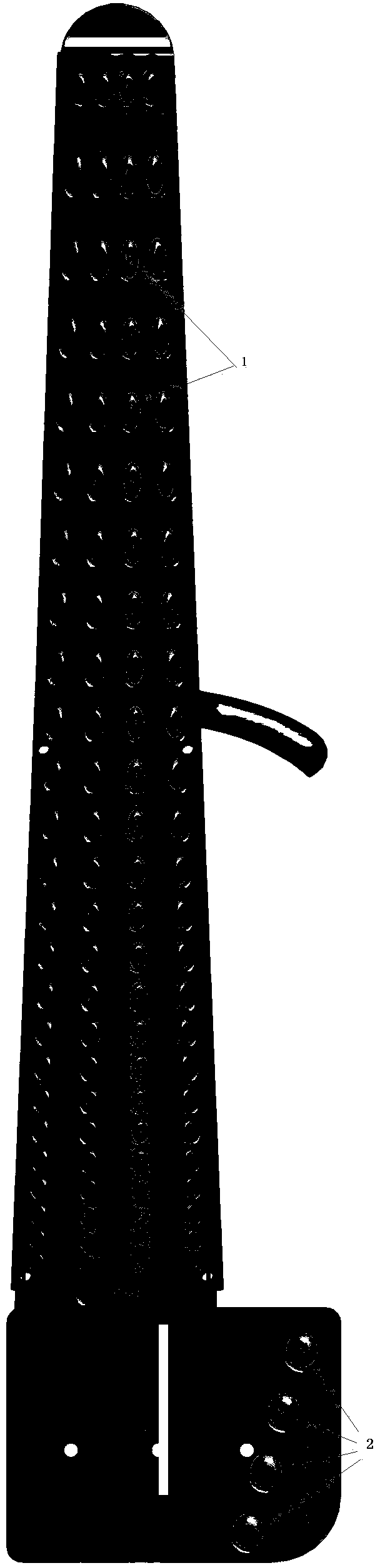

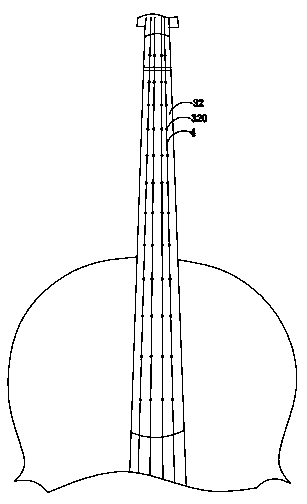

Violin instrument

InactiveCN104200801AEasy to findShorten the period of extensive explorationElectrophonic musical instrumentsMusicElectricityViolin

The invention provides a violin instrument. The violin instrument comprises a violin head, a violin neck, a finger board, a violin body, strings, a bridge and a nut, wherein the bridge and the nut are used for supporting the strings; a plurality of first electric contacts which correspond to intonations are accurately marked on a surface, which is close to the strings, of the finger board; the strings are conductive strings which can be in contact with the first electric contacts so that a turn-on circuit can be formed; the finger board is also provided with an electronic device which is serially connected between the first electric contacts and the conductive strings; and a circuit of the electronic device is turned on when the first electric contacts are in contact with the conductive strings.

Owner:王择儒

Manufacturing technology for bamboo violin

The invention relates to manufacturing technology for a bamboo violin. A violin face board, a violin base board, violin side boards and a violin head are made of bamboo. The bamboo is easy to take and the bamboo violin is convenient to manufacture, low in cost, capable of effectively reducing wood resource consumption and protecting natural environment, good in sound effect and long in service life.

Owner:江苏凤灵乐器有限公司

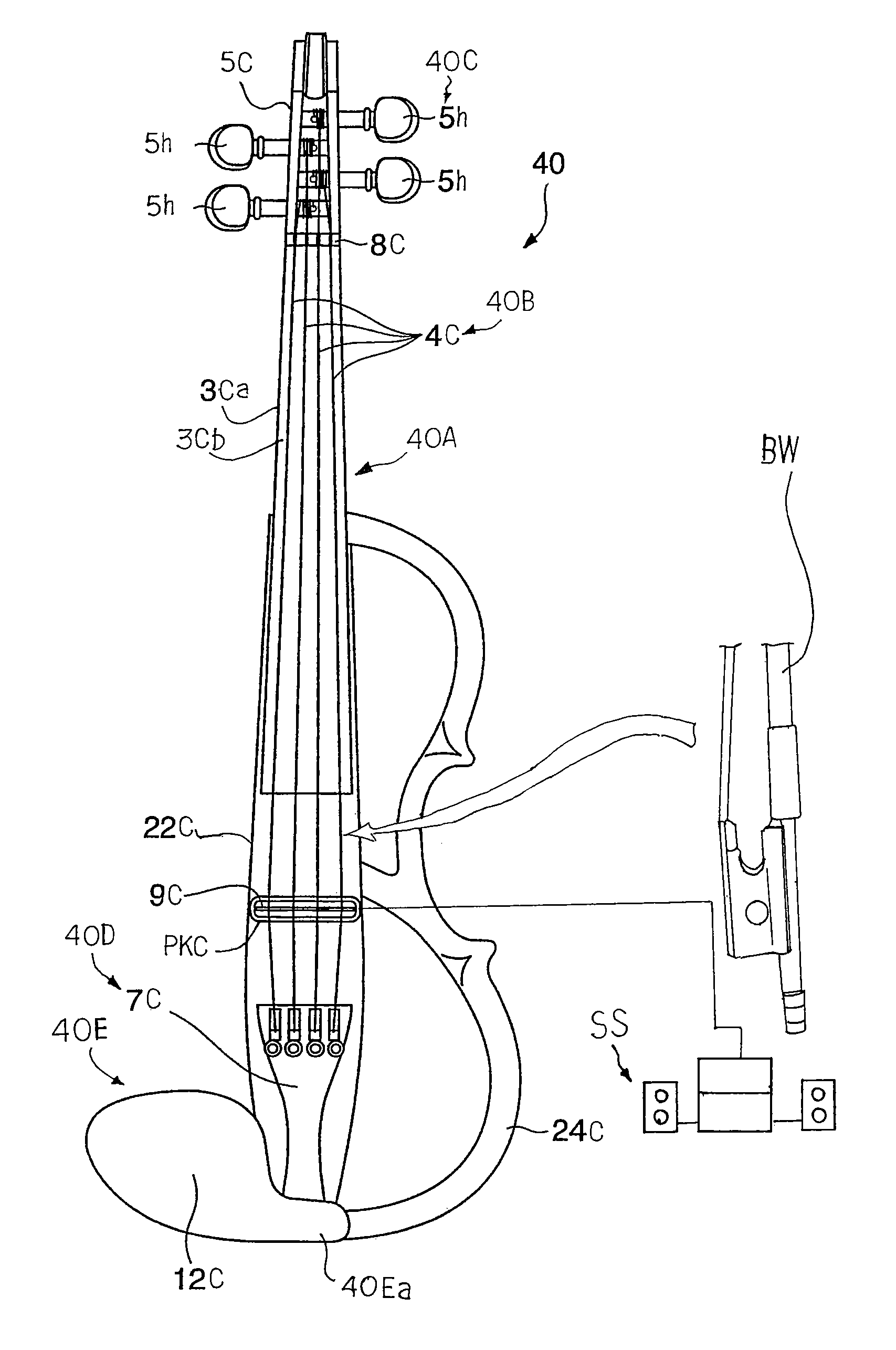

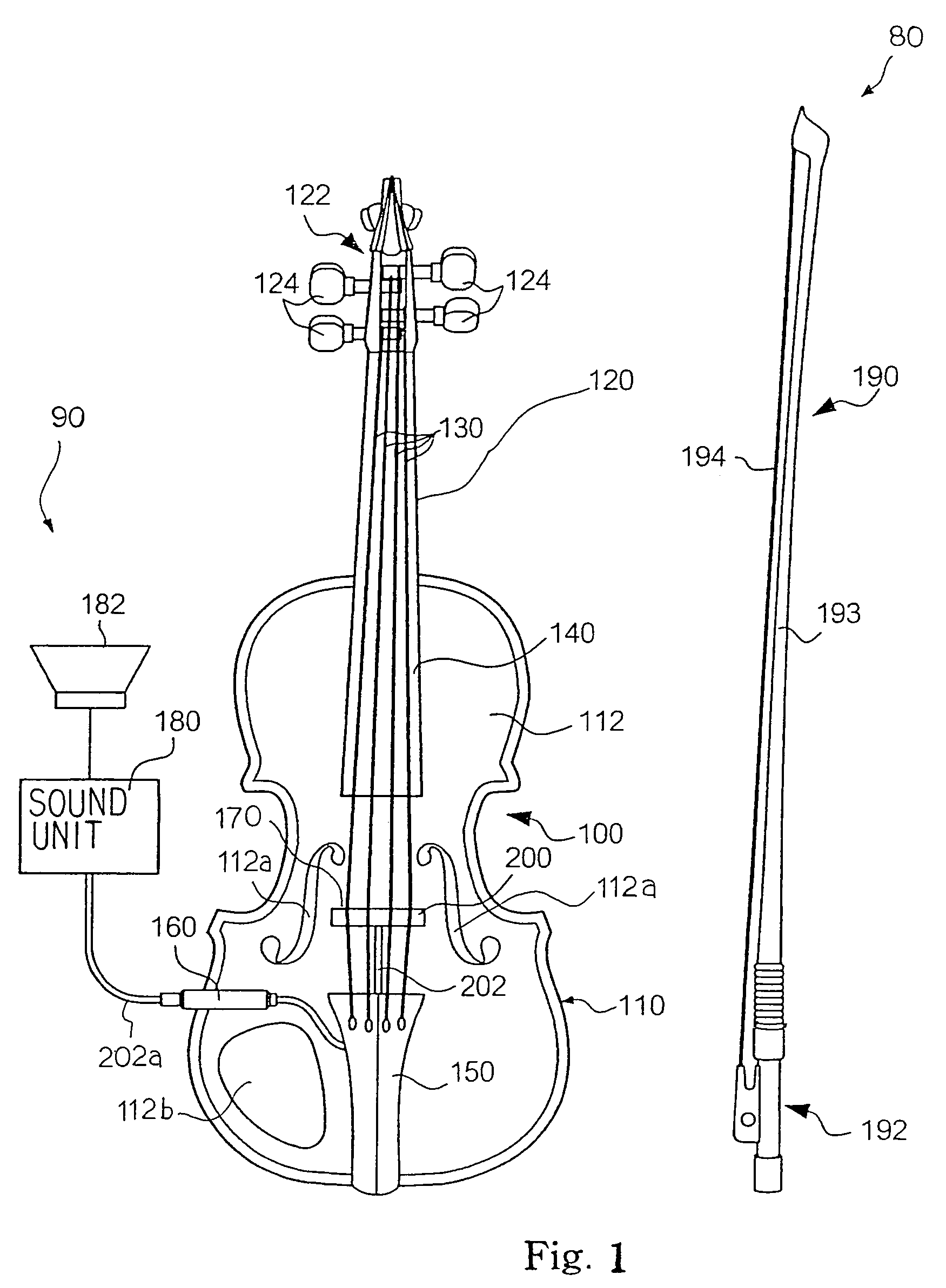

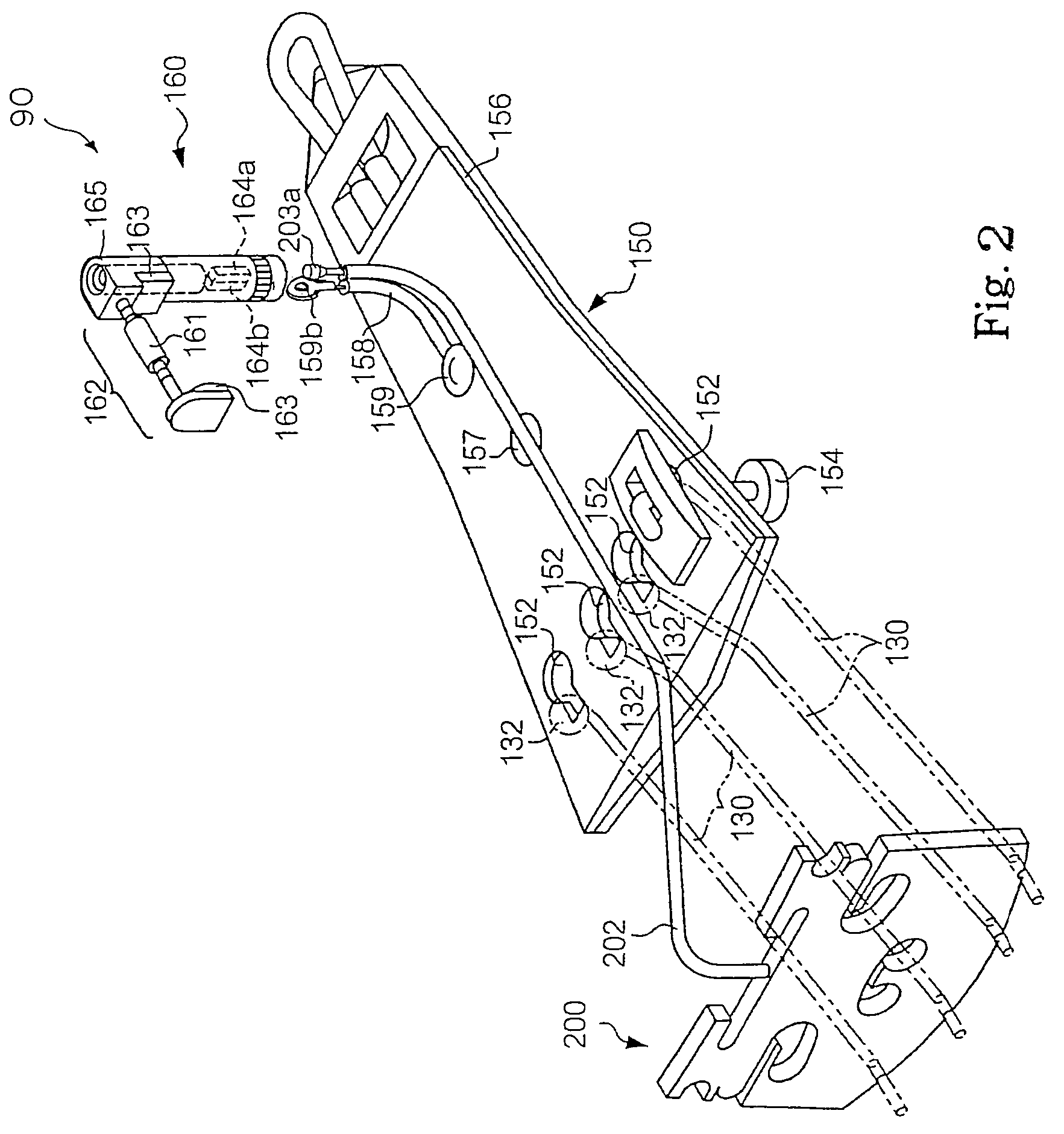

Stringed musical instrument and structure of tailpiece unit used therein

An electric violin has strings stretched over an instrument body, and the strings are anchored to a tailpiece, which in turn is connected to a tail wire to the instrument body; a saddle plate is bolted to the instrument body, and the tail wire is connected to the saddle plate by means of bolts; and the electric violin further has a blindfold extending from a chinrest, and the blindfold prevents the tail wire, saddle plate and bolts from eyes of users so that the electric violin does not give the antique impression of acoustic violin to the users without sacrifice of durability of the connection between the tail wire and the instrument body.

Owner:YAMAHA CORP

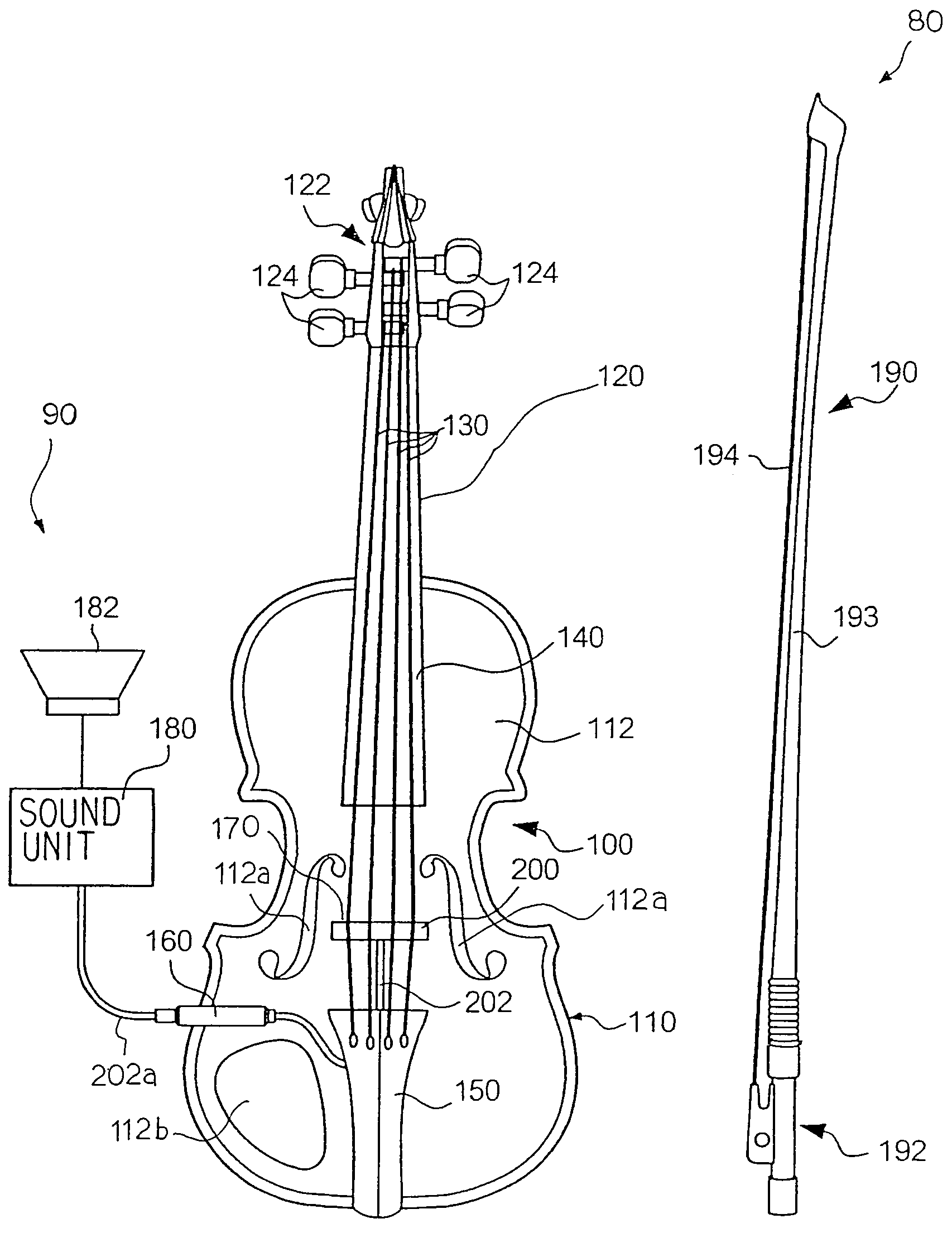

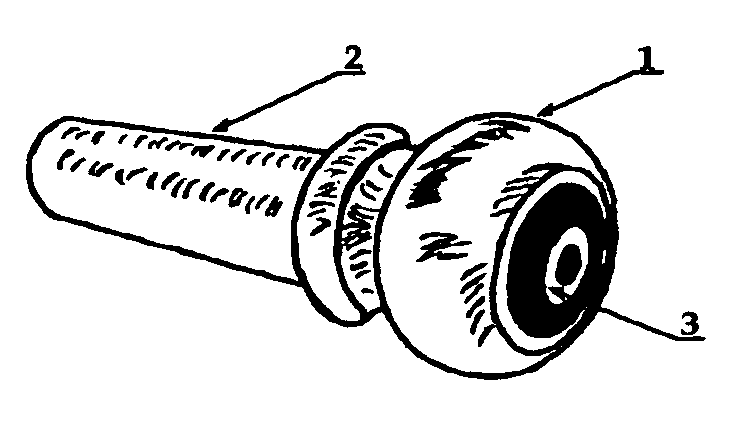

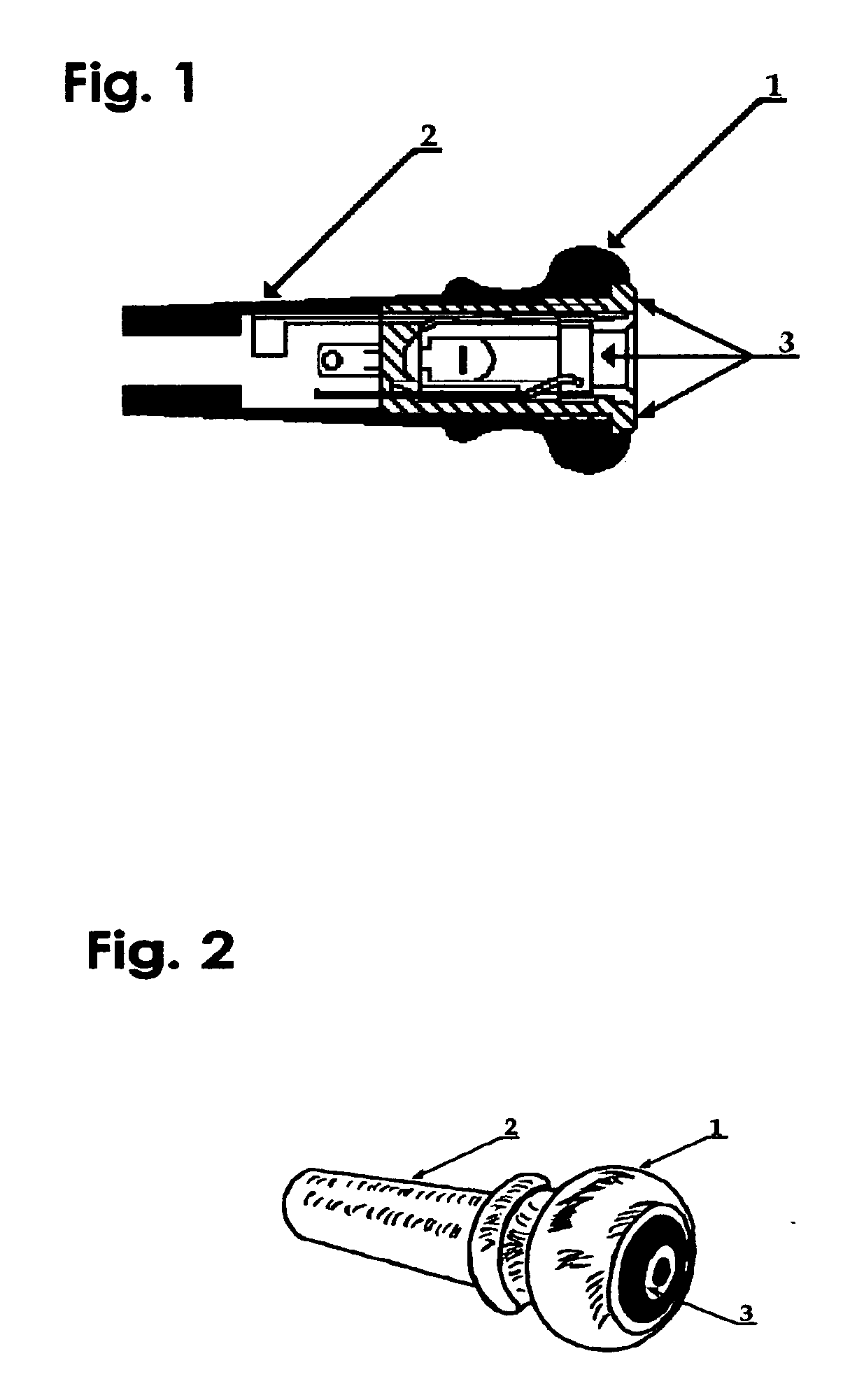

Stringed musical instrument equipped with pickup embedded in bridge and bridge used therein

ActiveUS7138577B2Improve fidelityElectrophonic musical instrumentsStringed musical instrumentsElectricityEngineering

An electric acoustic violin is a combination of an acoustic violin and an electric system, and the electric system includes a pickup unit for converting the vibrations of the strings to an electric signal; and a hollow space is formed in the bridge for receiving the pickup unit so that the vibrations are transferred from the strings through the bridge to the pickup unit, whereby the pickup unit faithfully converts the vibrations to the electric signal without any influence of the tension exerted on the bridge by the strings.

Owner:YAMAHA CORP

Augmented reality and performance evaluation-based violin learning experience assisting system

The invention discloses an augmented reality and performance evaluation-based violin learning experience assisting system comprising an image collection unit, an image analysis unit, a storage unit, an operation unit, a processing unit and a display unit, wherein the image collection unit is used for collecting video images of a current user holding a violin fingerboard in real time, fingernails of hands holding a violin are also displayed in the video images, the image analysis unit is used for analyzing images of the current violin, a contour and a fingerplate zone of the current violin are identified, four violin strings of the violin are identified and positioned, the storage unit is used for storing music scores as well as virtual animation elements of pressing movements and violin bow movements corresponding to syllables and notes, the operation unit is used for displaying the contour and the fingerplate zone of the current violin and the four positioned violin strings of the violin in the display unit and setting an animation element display area, and the processing unit is used for calling a corresponding music score and virtual animation elements of corresponding pressing movements and violin bow movements and then displaying the same in the animation element display area.

Owner:DALIAN VINCENT SOFTWARE TECH

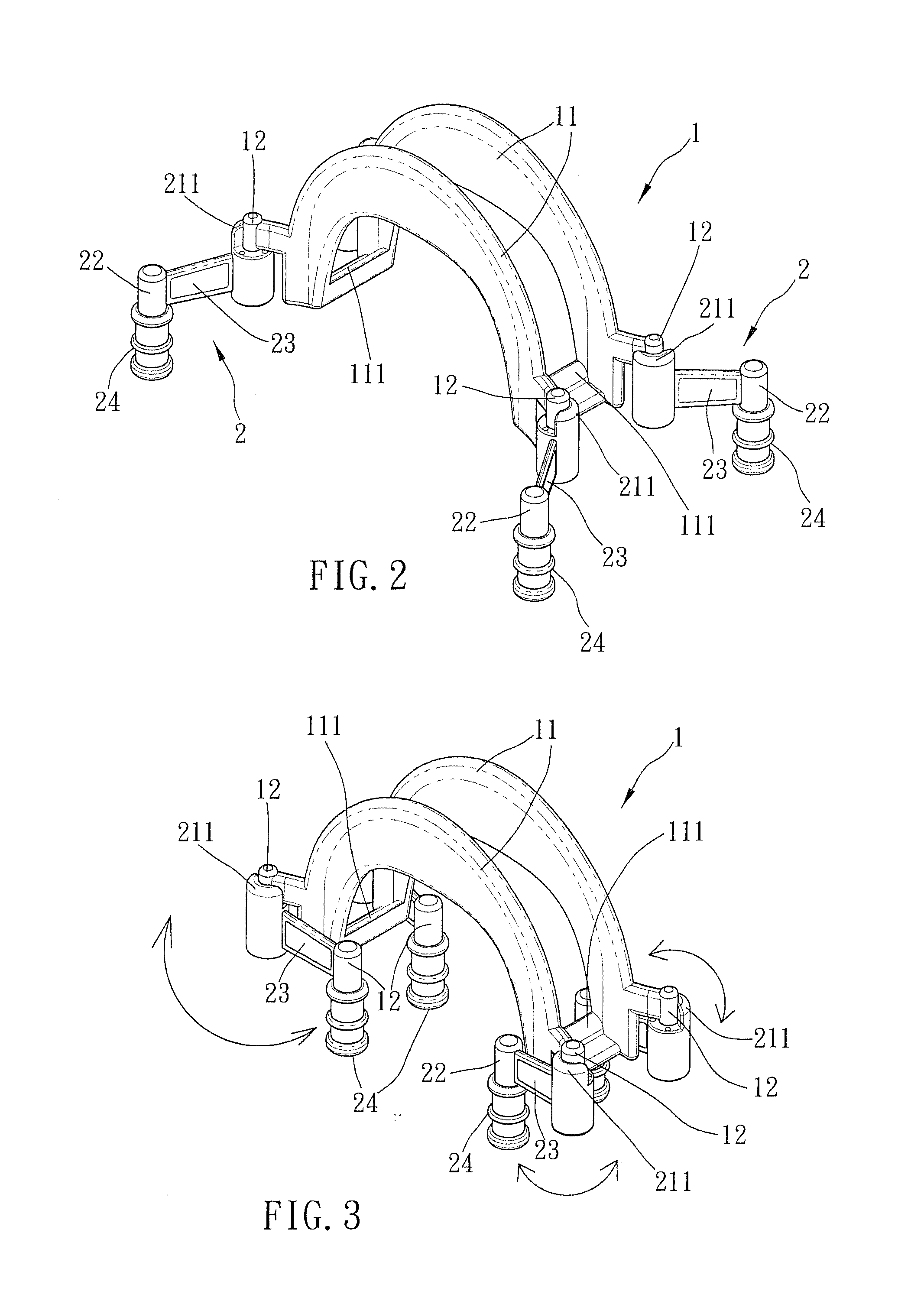

Musical instrument training aid

A musical instrument training aid for attaching to a violin / cello to support a bow playing the violin / cello is disclosed to include a bridgelike base member having two pairs of pivot shafts at the two ends, four suspension arms respectively pivotally coupled to the pivot shafts, and four anchoring boots respectively capped on the legs of said suspension arms and adapted for securing the suspension arms and the bridgelike base to the waist of the violin / cello.

Owner:CHEN KUAN HUNG

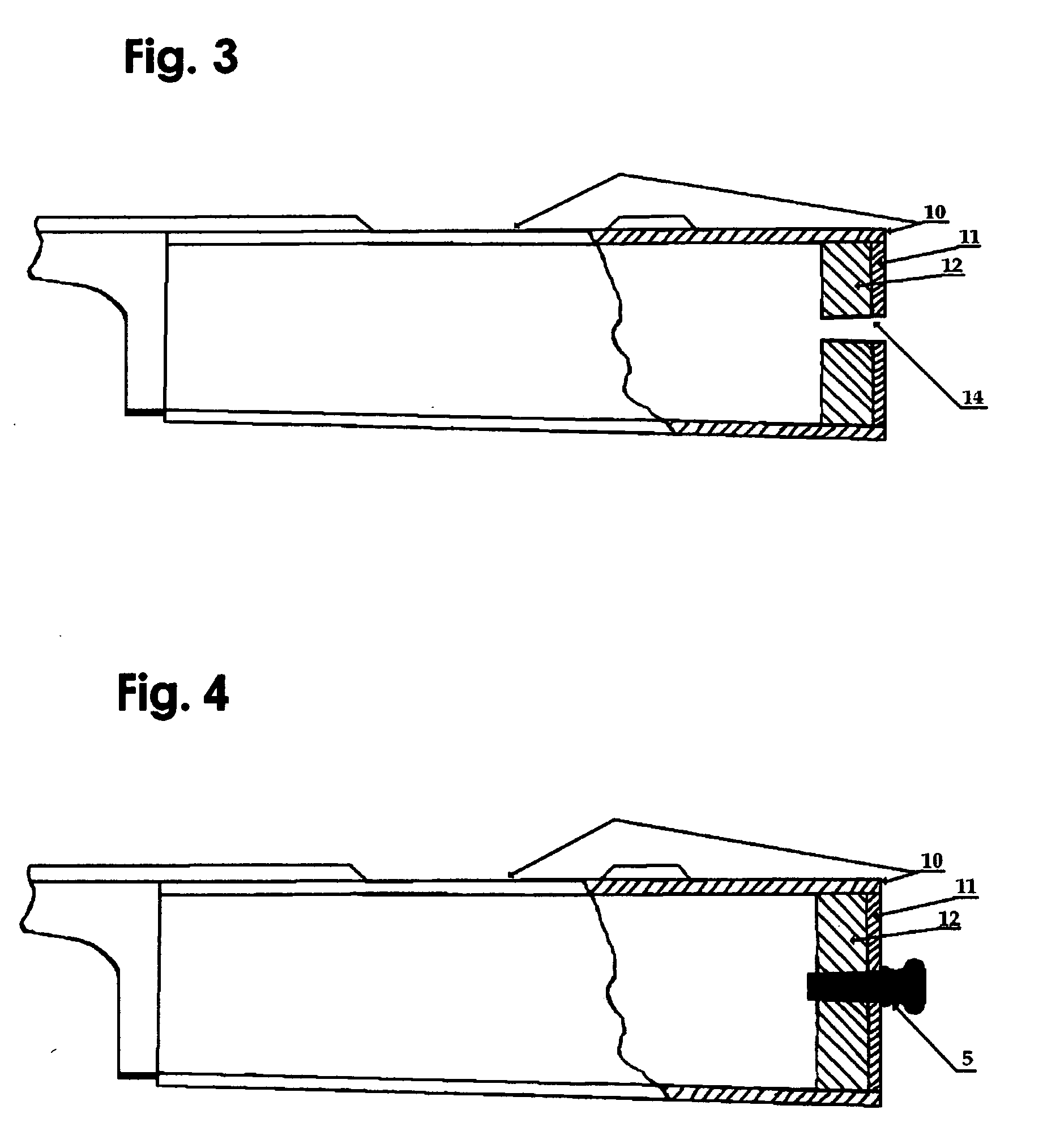

Combination end pin and output jack for musical instruments

InactiveUS20060278059A1Maintain integrityMaintaining valueElectrophonic musical instrumentsStringed musical instrumentsEngineeringViolin

An end pin / electrical output jack assembly which can be fitted (with no modification to the instrument) to acoustic guitars, mandolins, violins, and other musical instruments which are equipped with a traditional tapered pin type of end pin inserted into a tapered hole in the instrument. Also the use of a tapered hole to receive and / or retain an electrical output jack assembly or a combination end pin and output jack on / in a musical instrument.

Owner:GIPSON HOWARD KEITH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com