Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10363results about How to "Improve separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

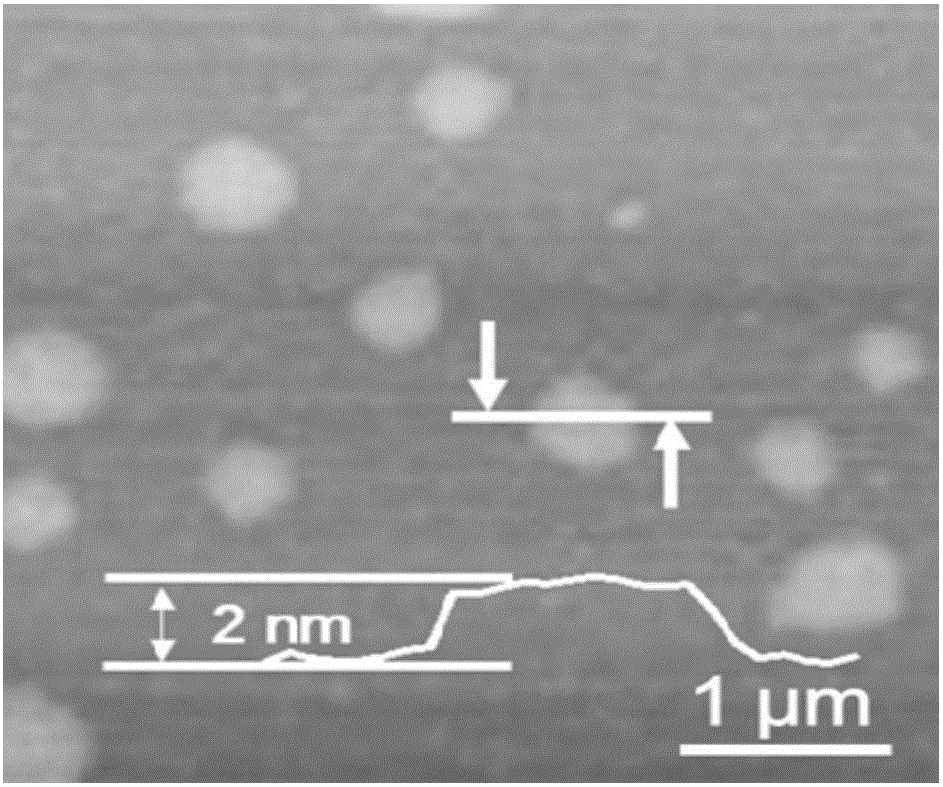

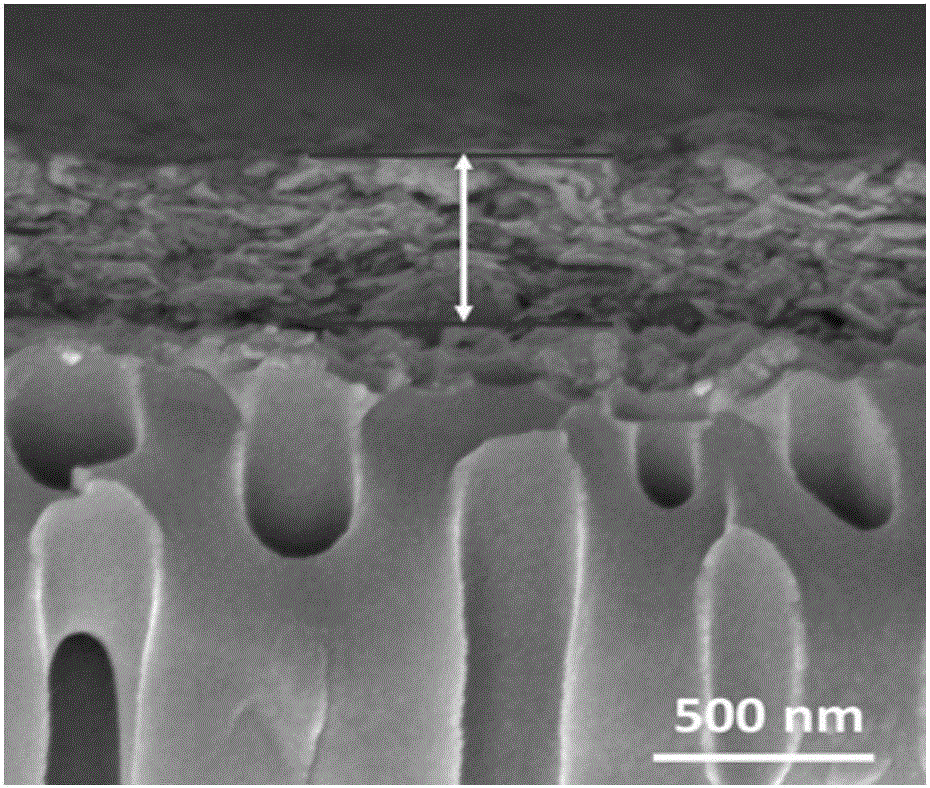

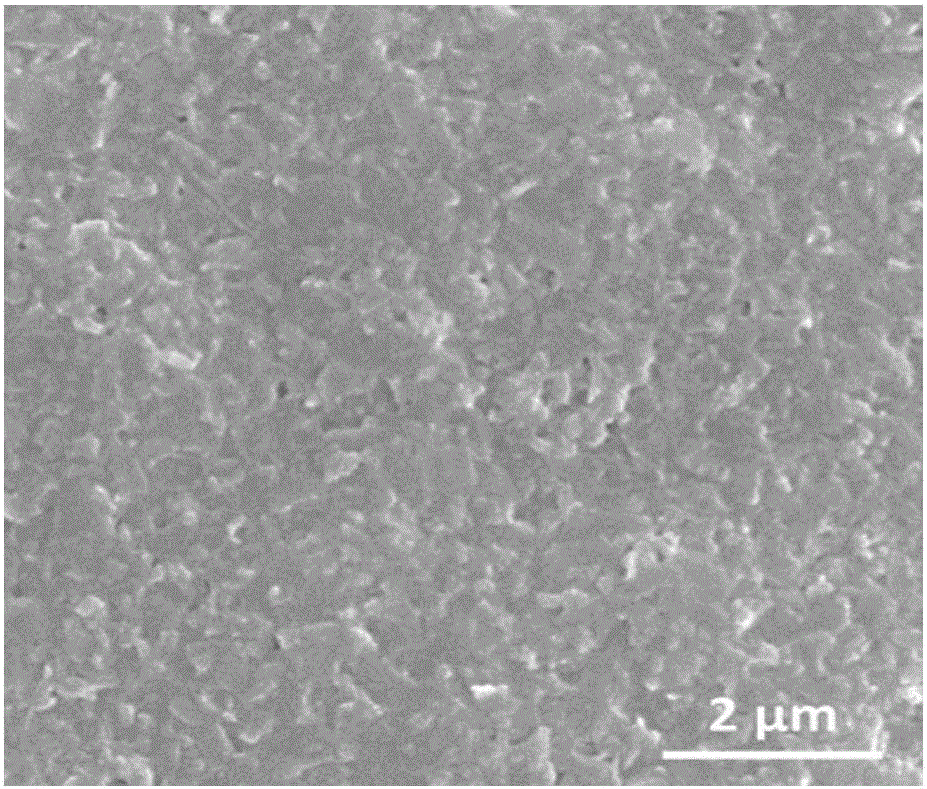

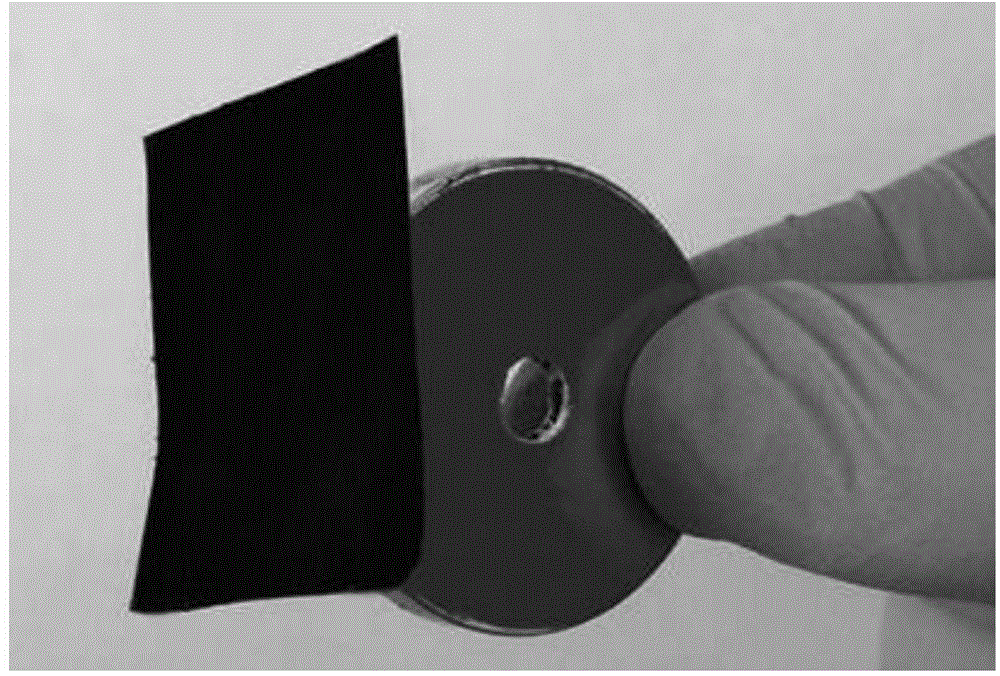

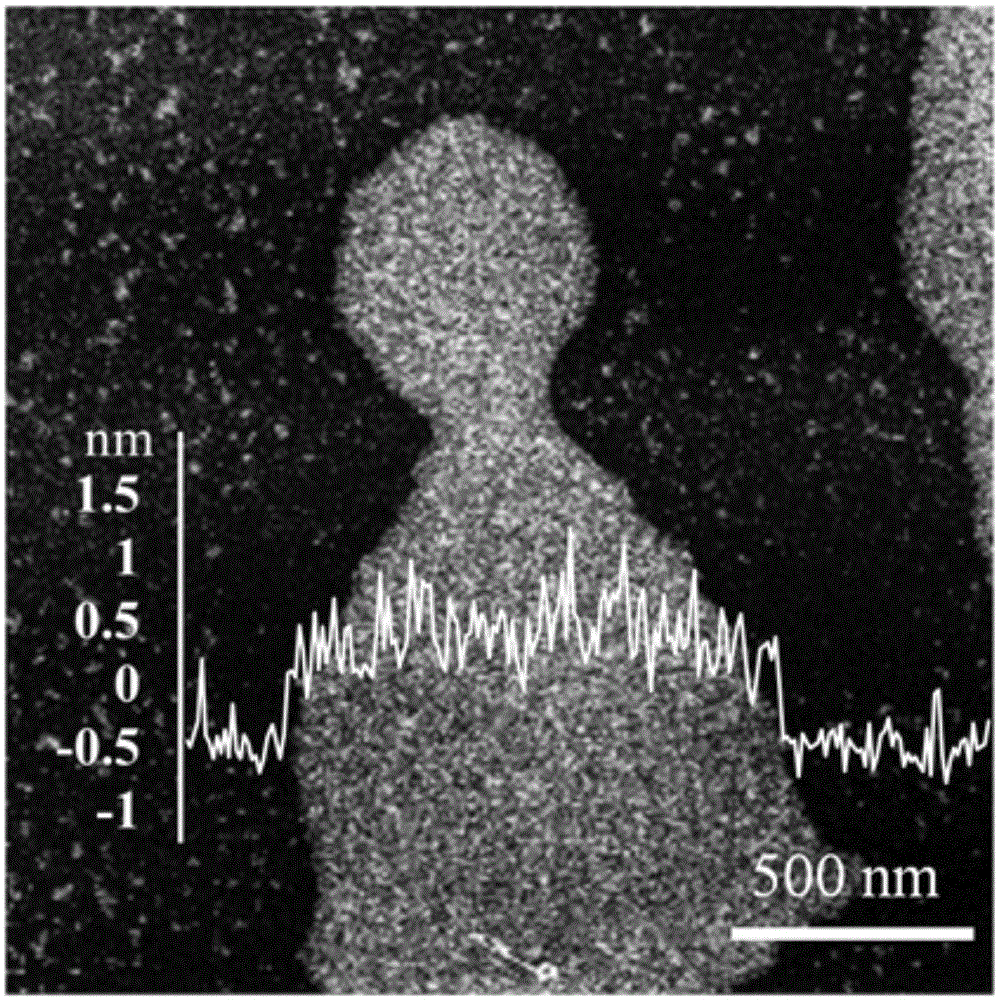

High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

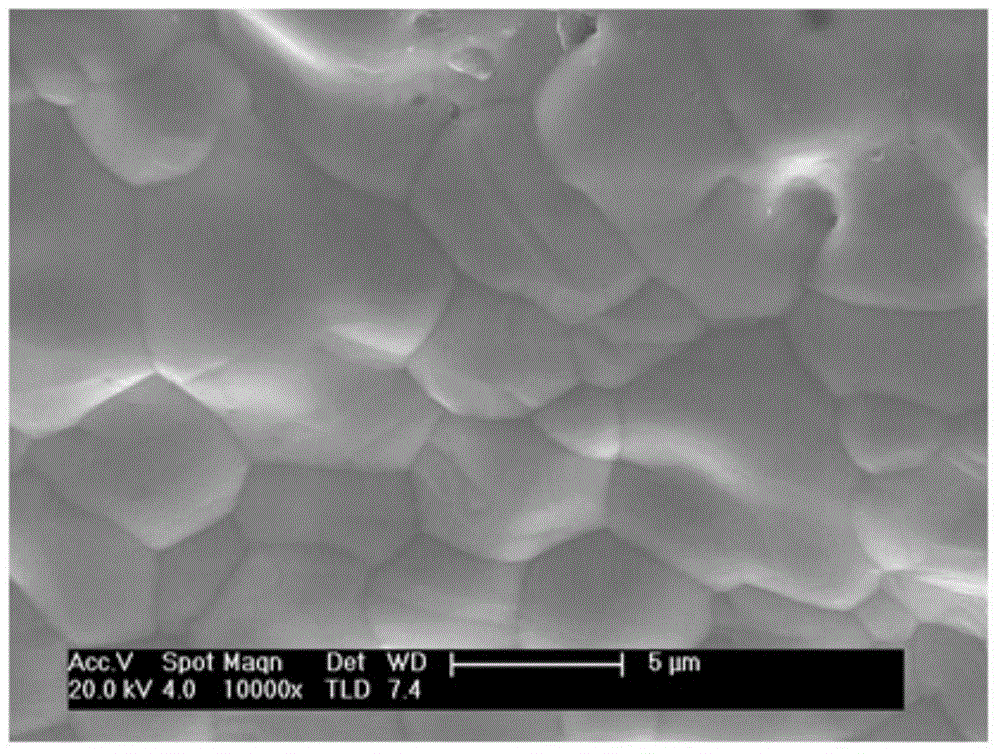

ActiveCN106178979AIncrease water fluxHigh selectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous substrateCentrifugation

The invention belongs to the technical field of membrane preparation and water purification and discloses a high-performance two-dimensional layered Ti3C2-MXene membrane, a preparation method thereof and an application of the Ti3C2-MXene membrane in water treatment. The method comprises steps as follows: (1), Ti3AlC2 powder and an HF solution are mixed, stirred for a reaction, centrifugally washed and dried, and Ti3C2 powder is obtained; (2), the Ti3C2 powder and a solvent are mixed, stirred for the reaction, washed and dried, and treated powder is obtained; (3), the treated powder is dissolved in the solvent and subjected to ultrasonic treatment and centrifugation, a liquid supernatant is taken and dried, and a two-dimensional nanosheet is obtained; (4), a solution is prepared from the two-dimensional nanosheet and deposited on a porous substrate with a nano self-assembly technology, and the high-performance two-dimensional layered Ti3C2-MXene membrane is obtained. The membrane has ultrahigh water flux, higher selectivity and good mechanical property and stability; the method is simple, low in energy consumption and cost, good in repeatability and wide in applicability.

Owner:SOUTH CHINA UNIV OF TECH

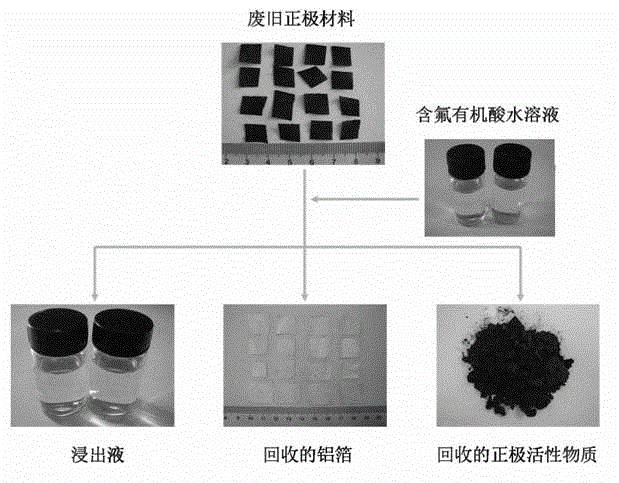

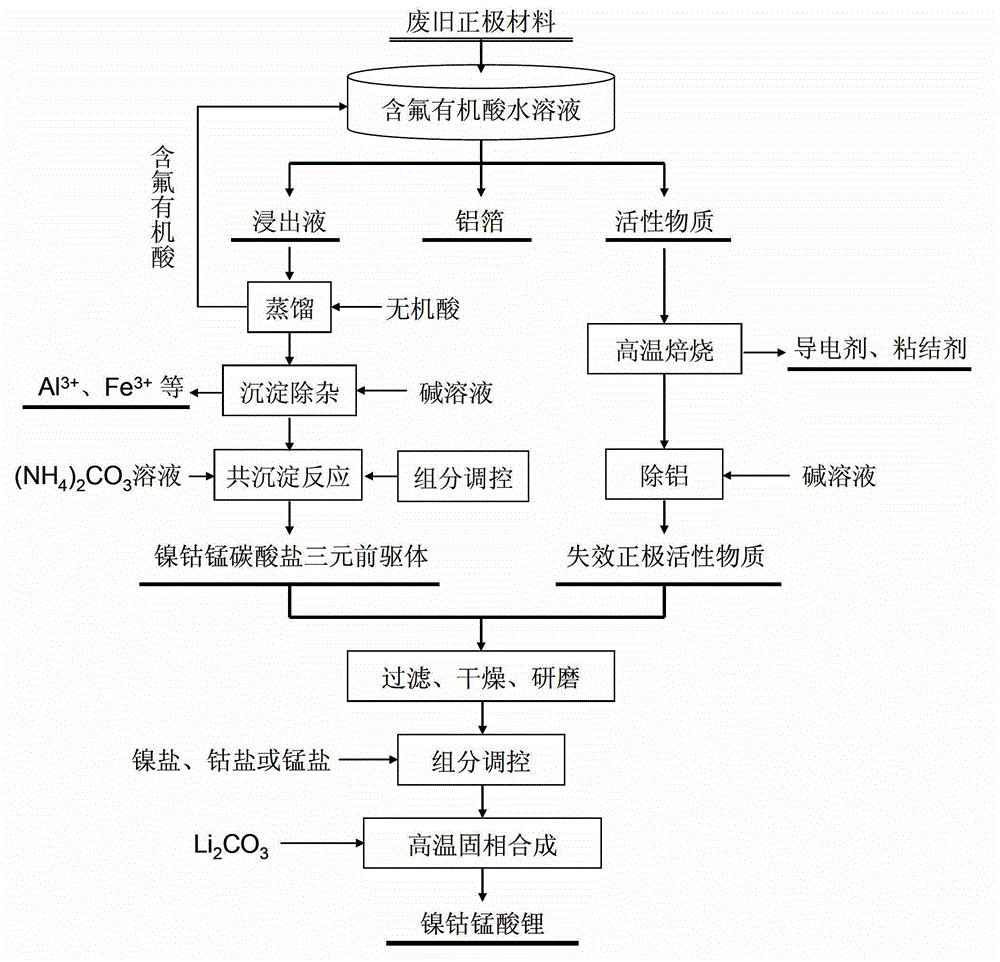

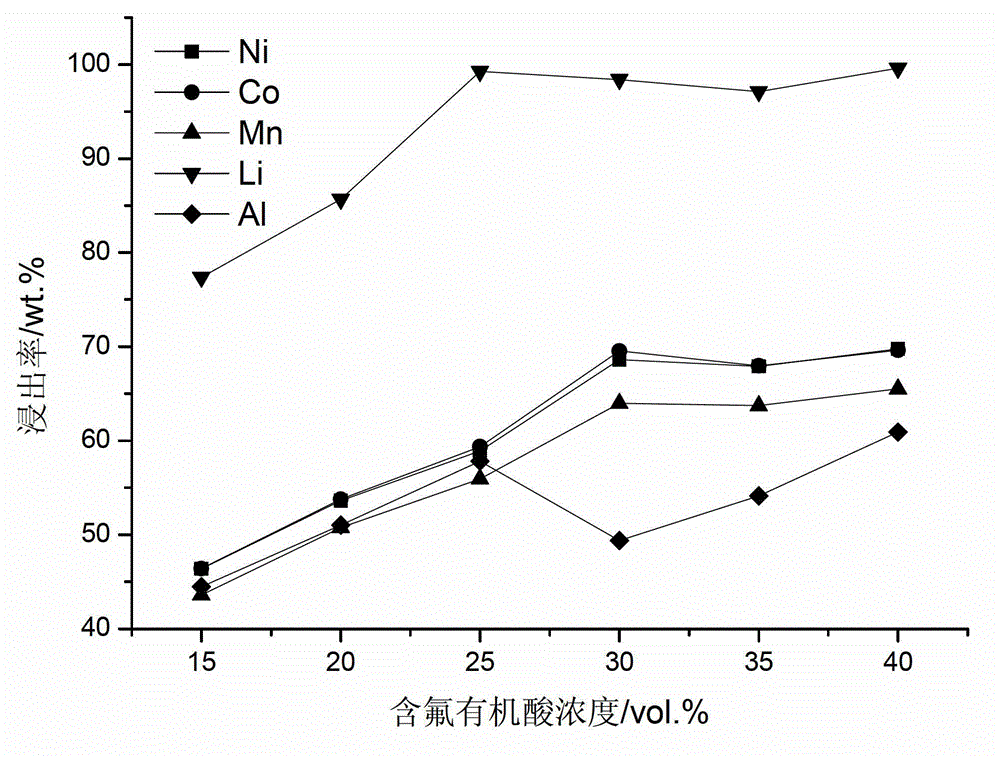

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

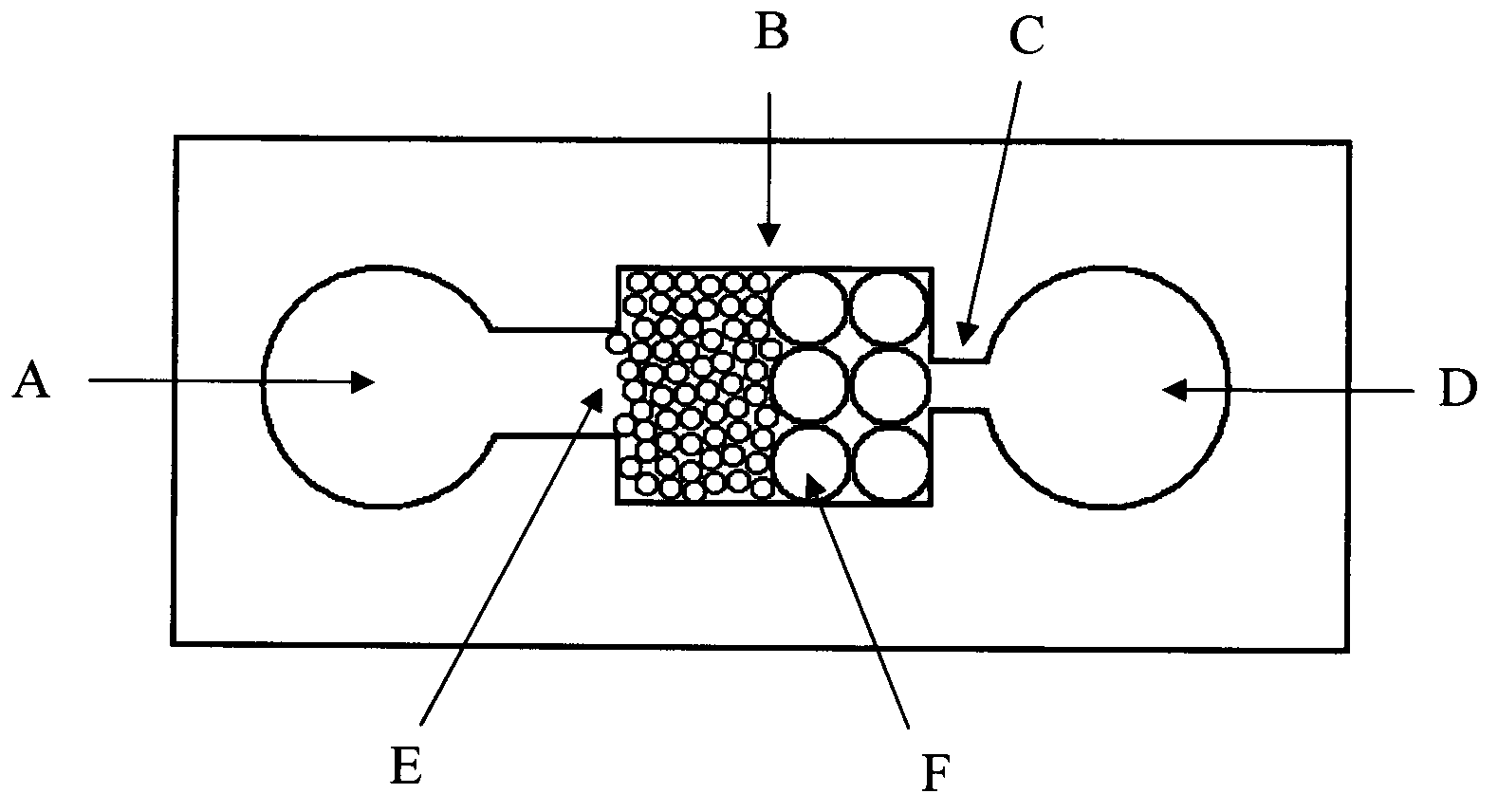

Micro-fluidic serum extracting chip

InactiveCN103285949ASimple and efficient operationImprove separation efficiencyPreparing sample for investigationLaboratory glasswaresMicro fluidicChemistry

The invention aims to provide a micro-fluidic serum extracting chip. The chip is formed by a blood sample introduction pool, a micro channel, a serum separation chamber and a sample collecting pool, wherein the interior of the serum separation chamber is filled with two kinds of micro balls with different hole diameters. The operating principle of the chip is as follows: the whole blood is added from a sample introduction port, the blood sample flows through the serum separation chamber along the micro channel under the action of surface tension or certain negative pressure, hemocytes are intercepted by a micro ball structure, and the serum flows out from ventages among the micro balls, and finally enters the sample collecting pool. The chip provided by the invention can be used for rapidly extracting the serum on line, the operation is simple and convenient, the separation efficiency is high, and the further integration with other operation units is easy to realize.

Owner:苏州扬清芯片科技有限公司

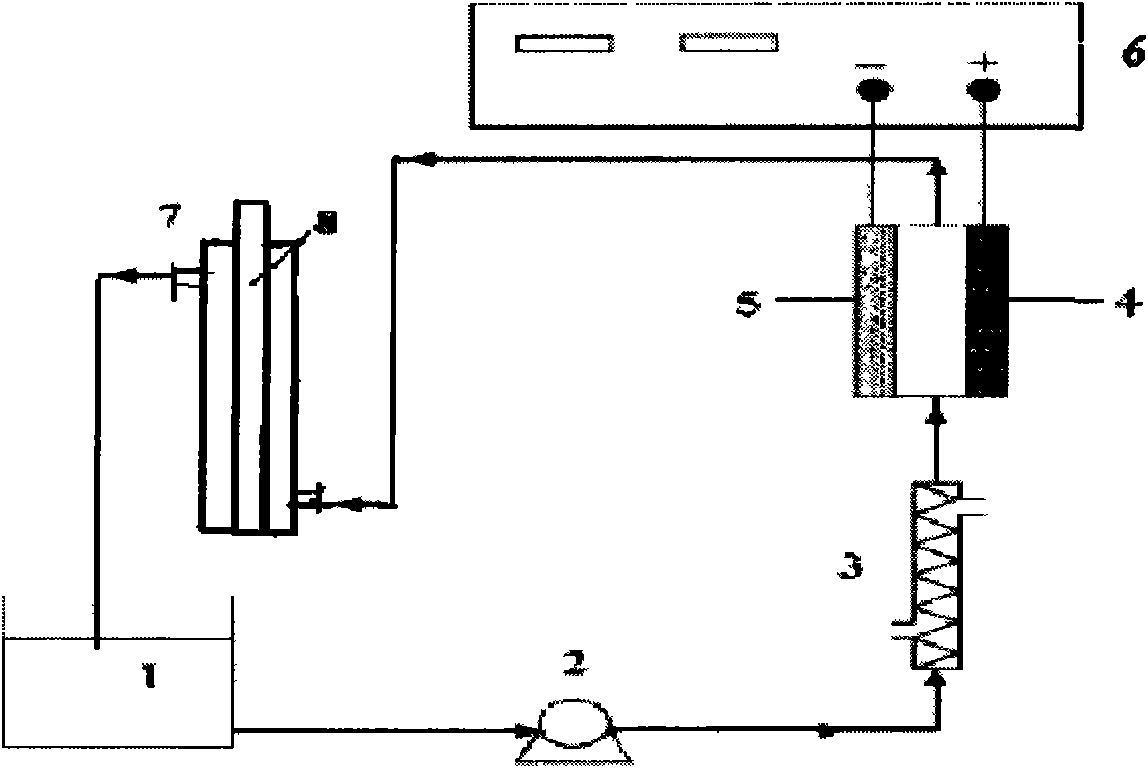

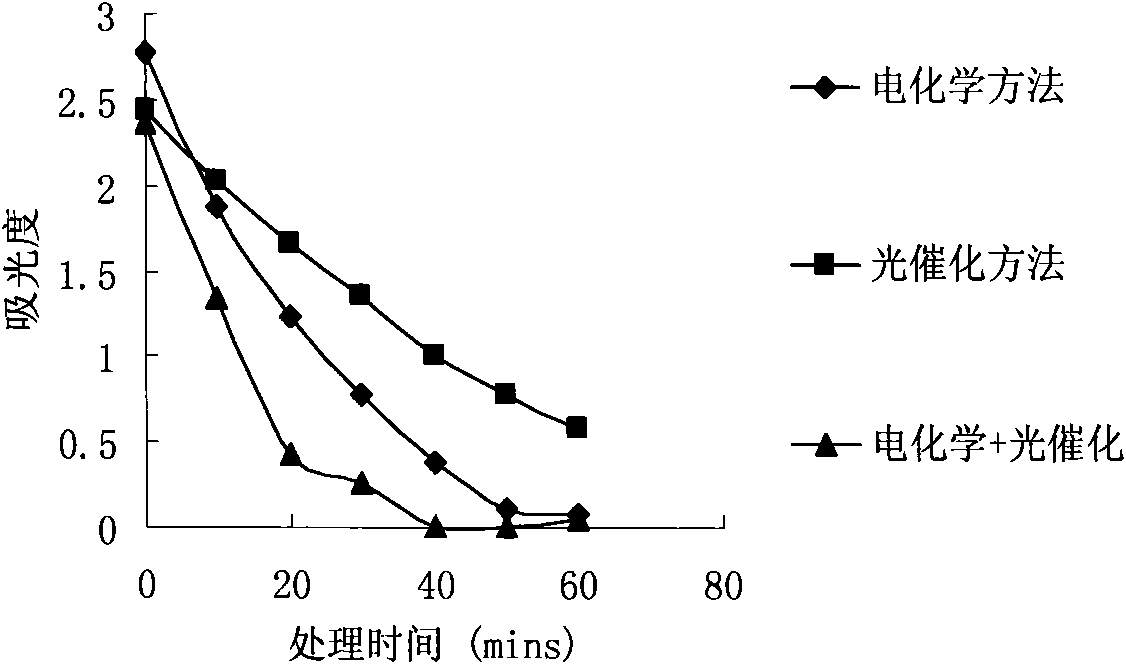

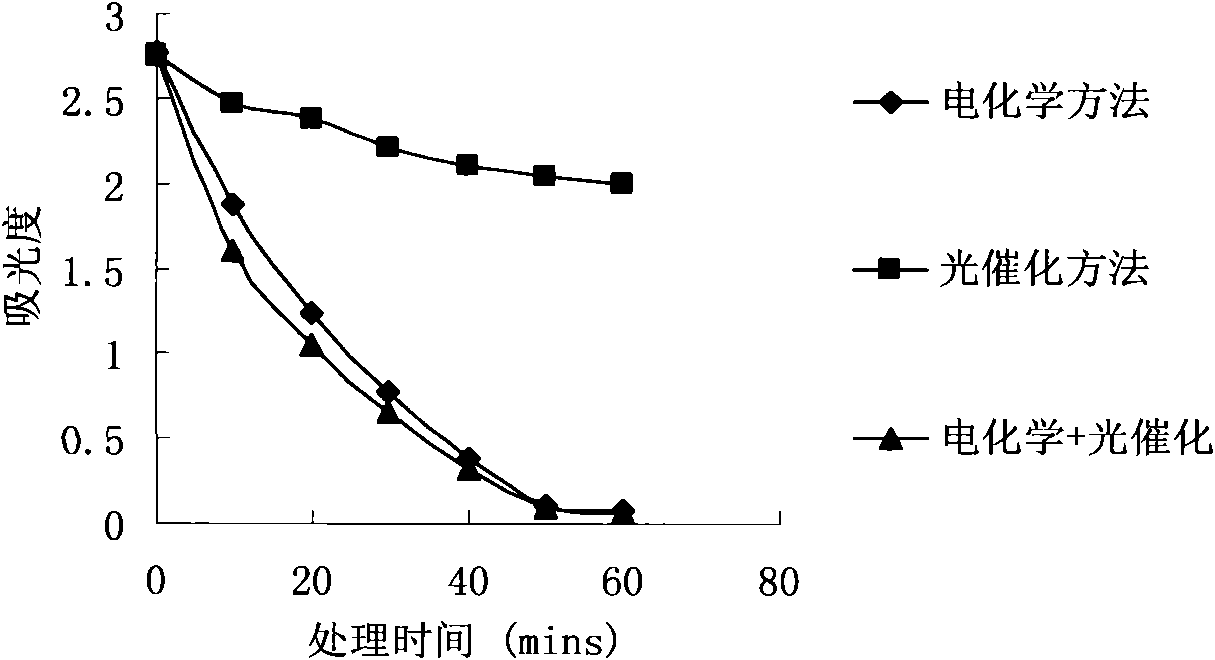

Wastewater treatment method and device combining electrochemical degradation and photocatalysis oxidation technologies

InactiveCN101555082AImprove separation efficiencyImprove current efficiencyWater/sewage treatment by irradiationMultistage water/sewage treatmentEnvironmental chemistryElectrochemical degradation

The invention relates to a wastewater treatment method and device combining electrochemical degradation and photocatalysis oxidation technologies taking a diamond film electrode as the anode. The device comprises a flowing electrolytic bath and a photocatalytic reactor. Contaminants have electrocatalytic oxidation at the anode of the flowing electrolytic bath and are electrolyzed to separate out water and then enter the photocatalytic reactor for further degradation. The combination of two technologies can improve the current efficiency reduction caused by oxygen analyzing reaction in an electrochemistry part because oxygen analyzed by the electrochemistry part is a favorable trapping agent of photoelectrons of a photocatalysis part, can improve the separation efficiency of the photoelectrons and cavities and improve the catalytic degradation of the photocatalysis part. Meanwhile, by opening or closing various parts of the device, proper operational modes can be selected according to the kinds and the concentration of wastewater, such as an independent electrochemistry method, an independent photocatalysis method, an electrochemistry and photocatalysis combined method and other different operational modes.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

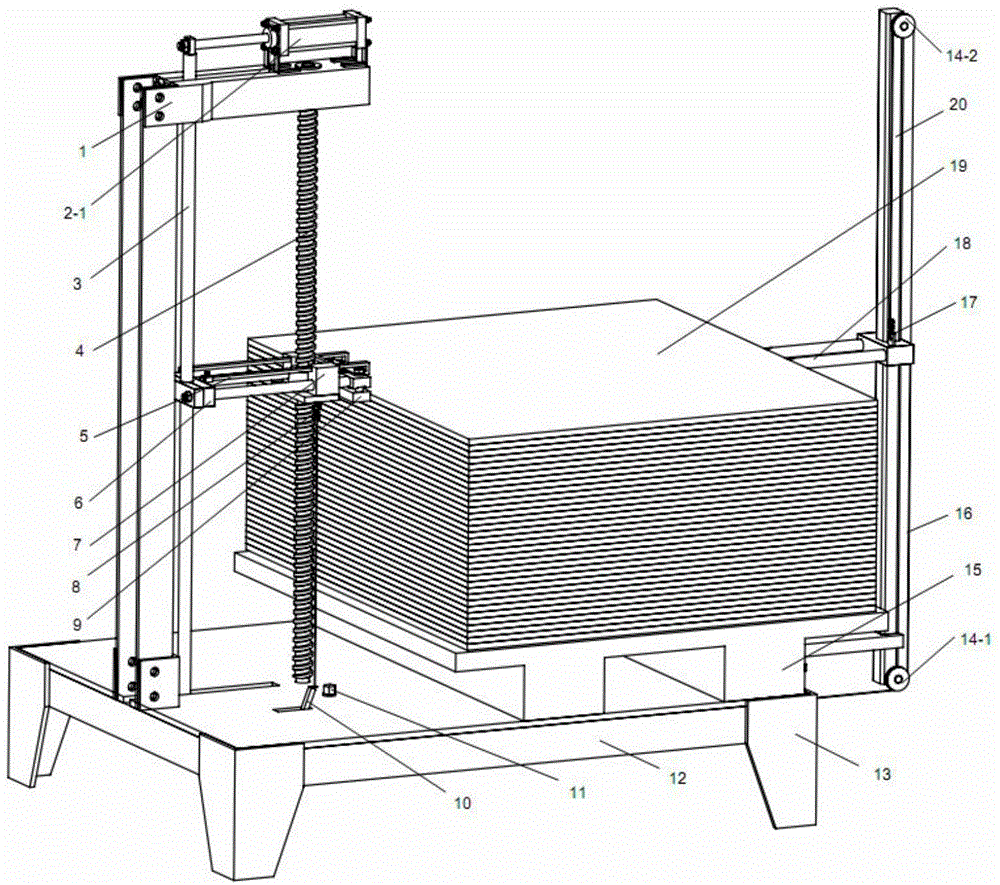

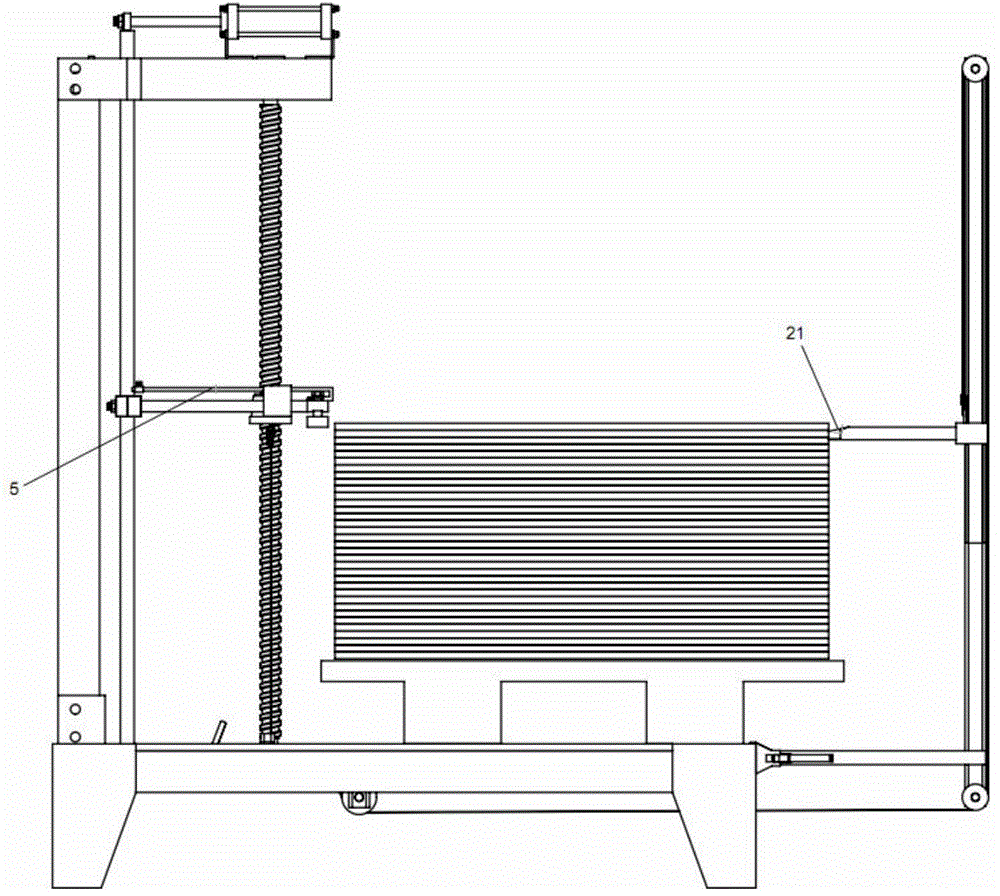

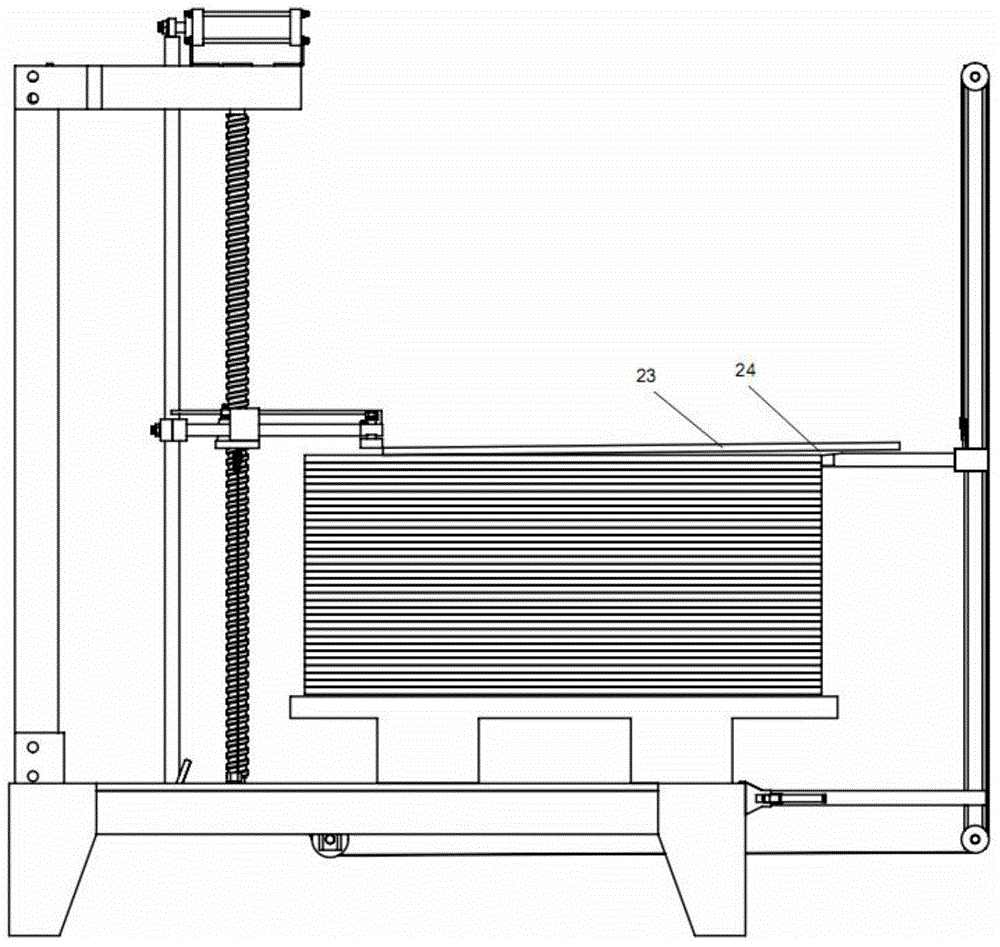

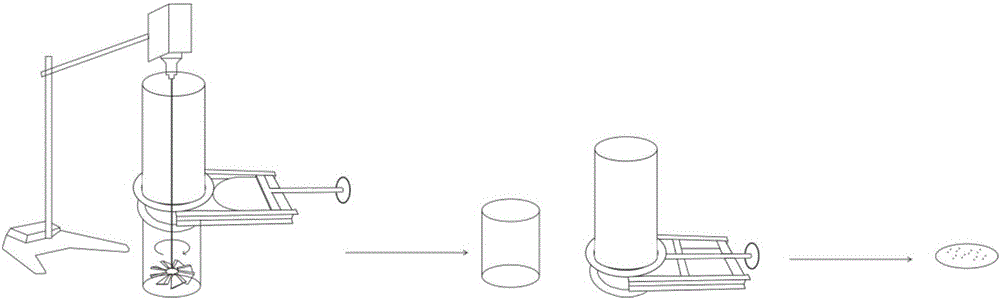

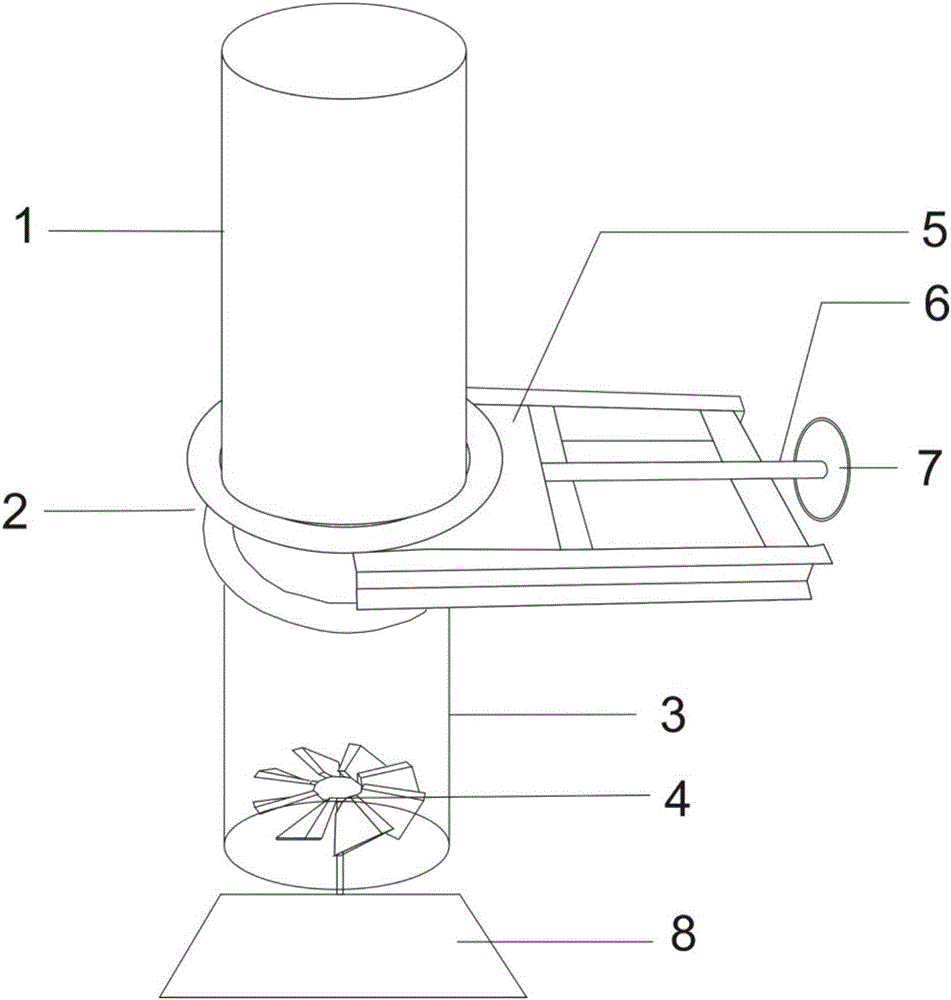

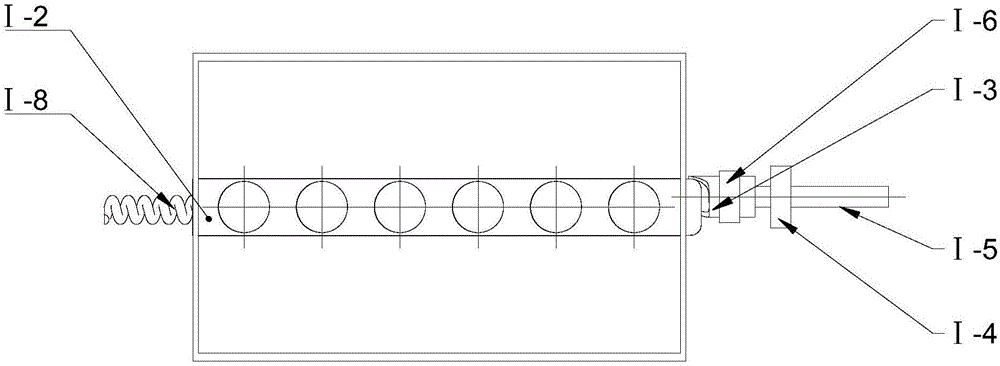

Separation device for detaching and stacking stamped sheet metal

A separation device for detaching and stacking stamped sheet metal comprises a driving mechanism, a pushing mechanism, a lifting mechanism, a separating mechanism and a sheet metal supporting base. The sheet metal supporting base is used for supporting the other mechanisms and stacking the sheet metal. The pushing mechanism allows a pushing assembly to slide linearly in the horizontal guide direction of a guide support through a vertical slide rod connected with a cylinder so that the effect of pushing out the sheet metal on the top layer can be achieved. The lifting mechanism controls the guide support to rise and fall by adjusting the number of rotation circles of a screw so that a push block can always keep aligned with the sheet metal on the top layer when starting to work. The separating mechanism is connected to the lifting mechanism when a steel wire rope is wound around a pulley so that the separating mechanism can synchronously rise and fall together with the lifting mechanism under the influences of the gravity of the separating mechanism. A separating rod can prevent the sheet metal on the top layer from absorbing the sheet metal on the lower layer and sliding together with the sheet metal on the top layer, and a separating inclined block makes a gap formed between the sheet metal on the top layer and a sheet metal stack. The intermittent movement of the pushing mechanism and the lifting mechanism is achieved through double ratchets by means of the driving device. The separation device is easy to operate, high in efficiency, good in separation effect, high in flexibility and wide in applicability.

Owner:GUANGXI UNIV

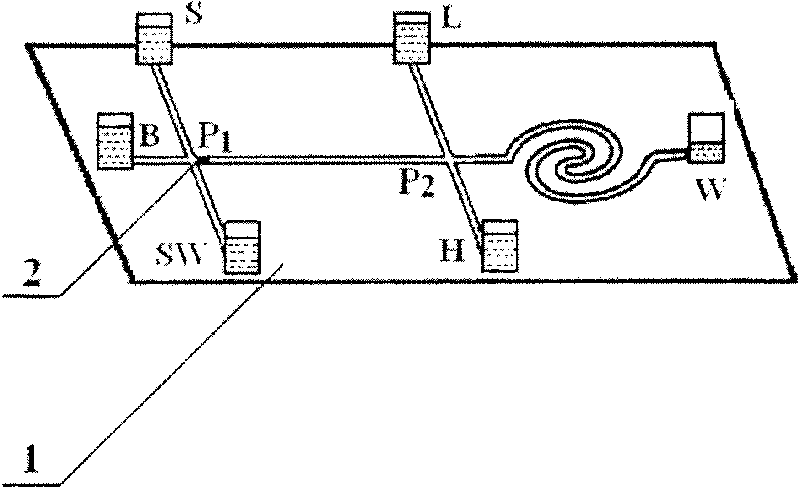

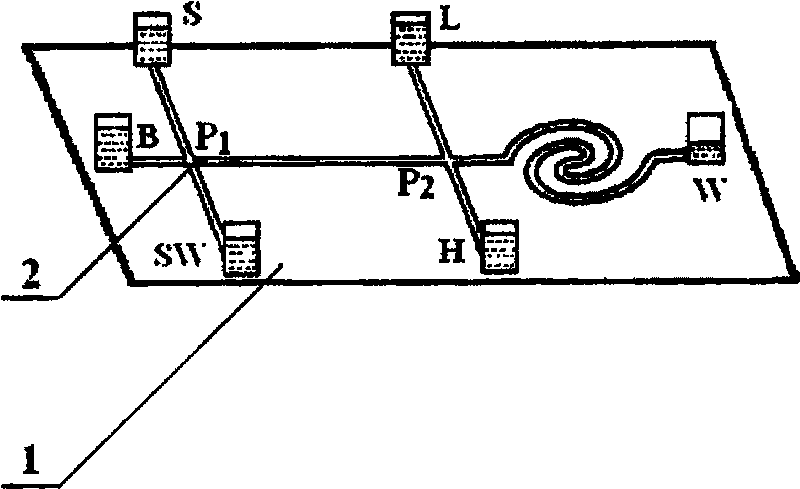

Microfluidic chip for capillary electrophoresis separation and chemiluminescence detection

InactiveCN101692047AImprove separation efficiencyHigh sensitivityChemiluminescene/bioluminescenceDispersed particle separationCapillary electrophoresisElectrophoresis

The invention discloses a microfluidic assay chip integrated capillary electrophoresis separation with chemiluminescence detection. The microfluidic chip consists of a buffer solution storage tank, a sample liquid storage tank, a sample waste liquid tank, a waste liquid tank, a sheath flow storage tank, a sample introduction channel, a separation channel, a sheath flow channel and a detection channel. A terminal of the separation channel and a starting point of the detection channel are communicated with the sheath flow channel. A chemiluminescence reagent enters the detection channel through the sheath flow channel; and when compositions to be assayed after the capillary electrophoresis separation of the chip meets the chemiluminescence reagent at a connecting point of the separation channel and the detection channel, the compositions are mixed with chemiluminescence reagent in the detection channel and then undergo luminous reaction. The inside of the separation channel is provided with a microporous plug to prevent the chemiluminescence reagent from flowing backwards into the separation channel under the driving of pressure difference so as not to influence electrophoresis separation. The microfluidic assay chip has the characteristics of high separation efficiency, high detection sensitivity, simple structure, small volume, light weight, convenient operation and the like, and is ideal to prepare a portable micro total separation system.

Owner:ZHEJIANG UNIV

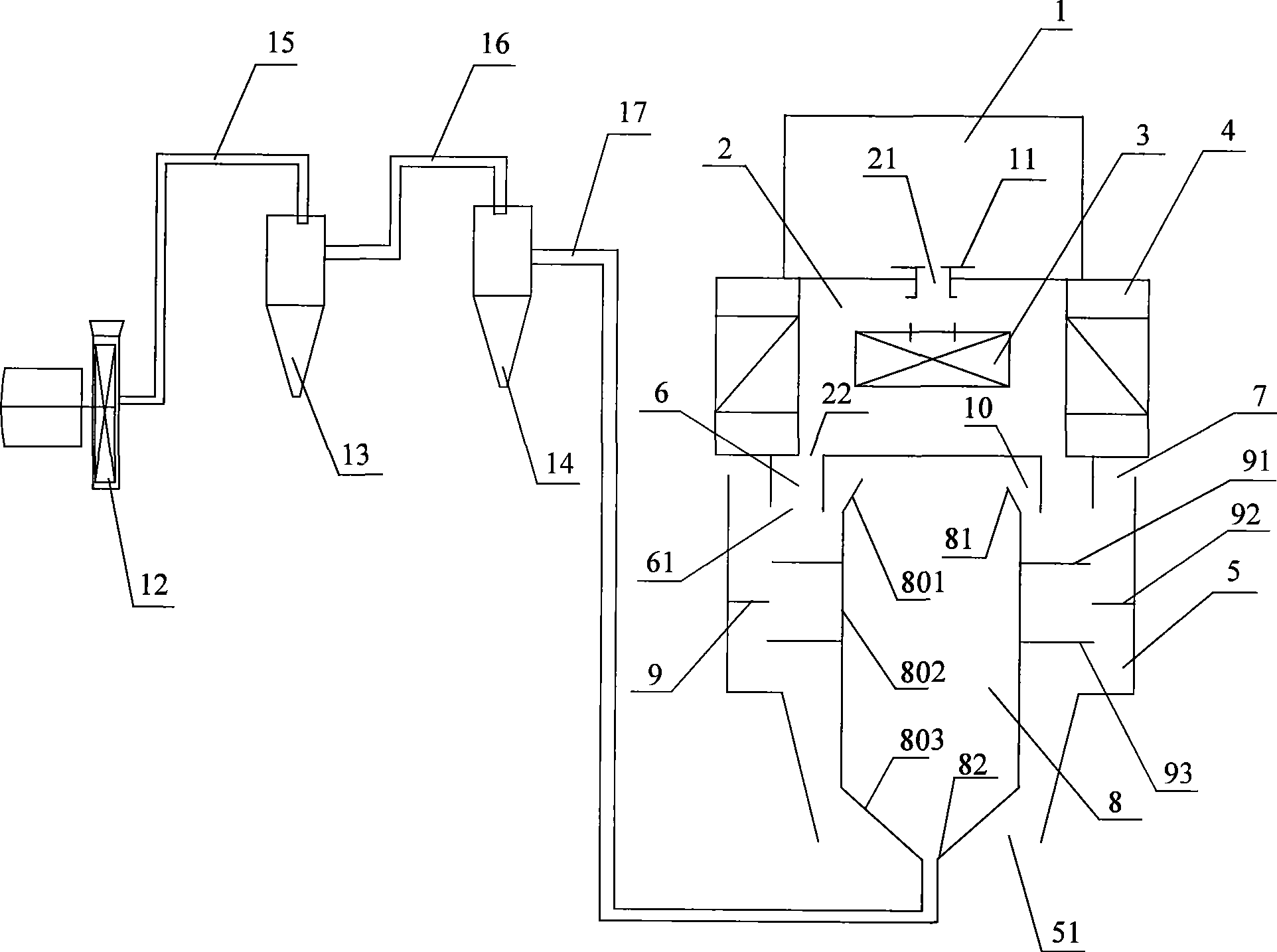

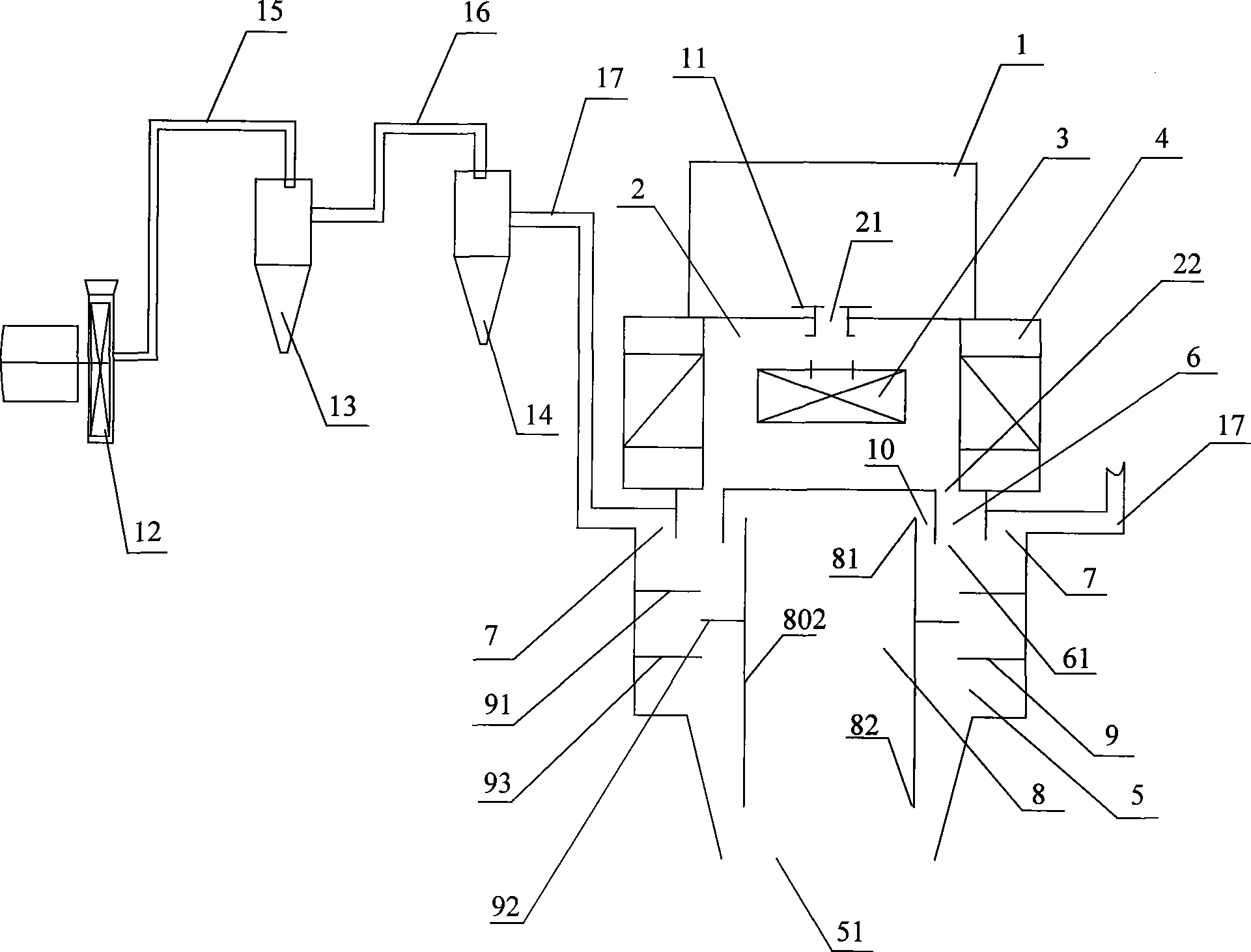

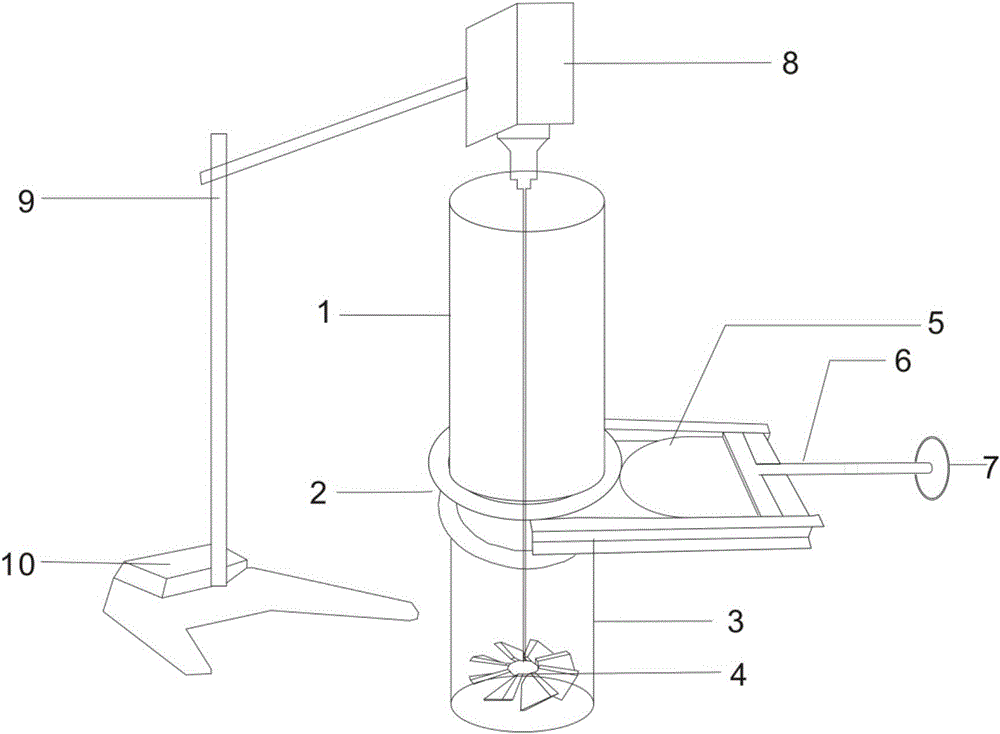

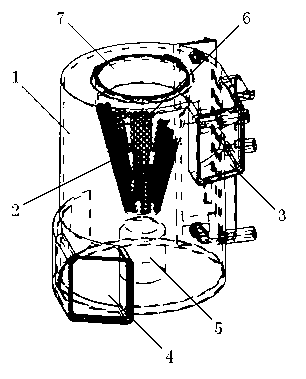

Dry-type sand making method and dry-type sand making machine thereof

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

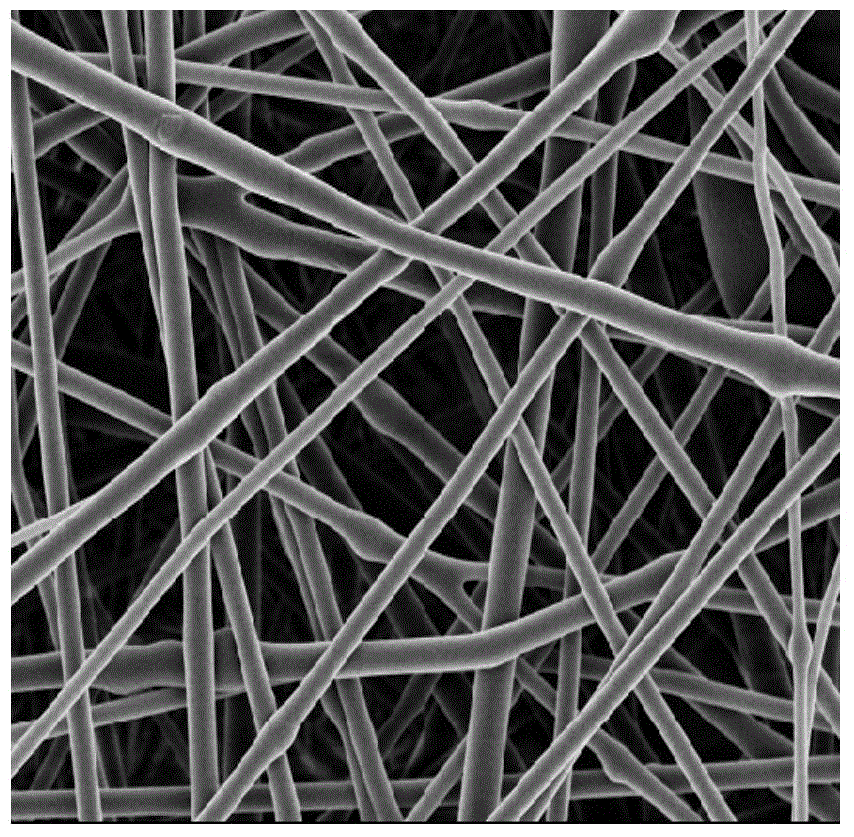

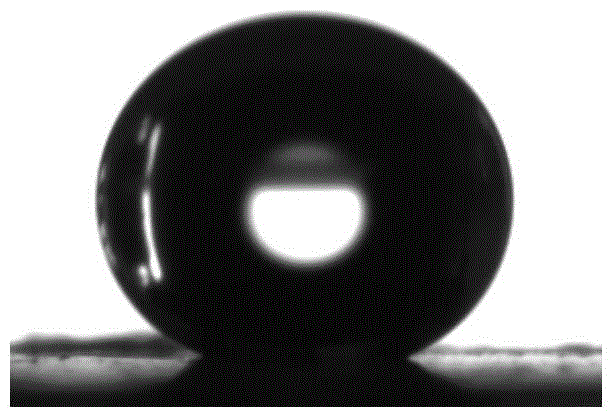

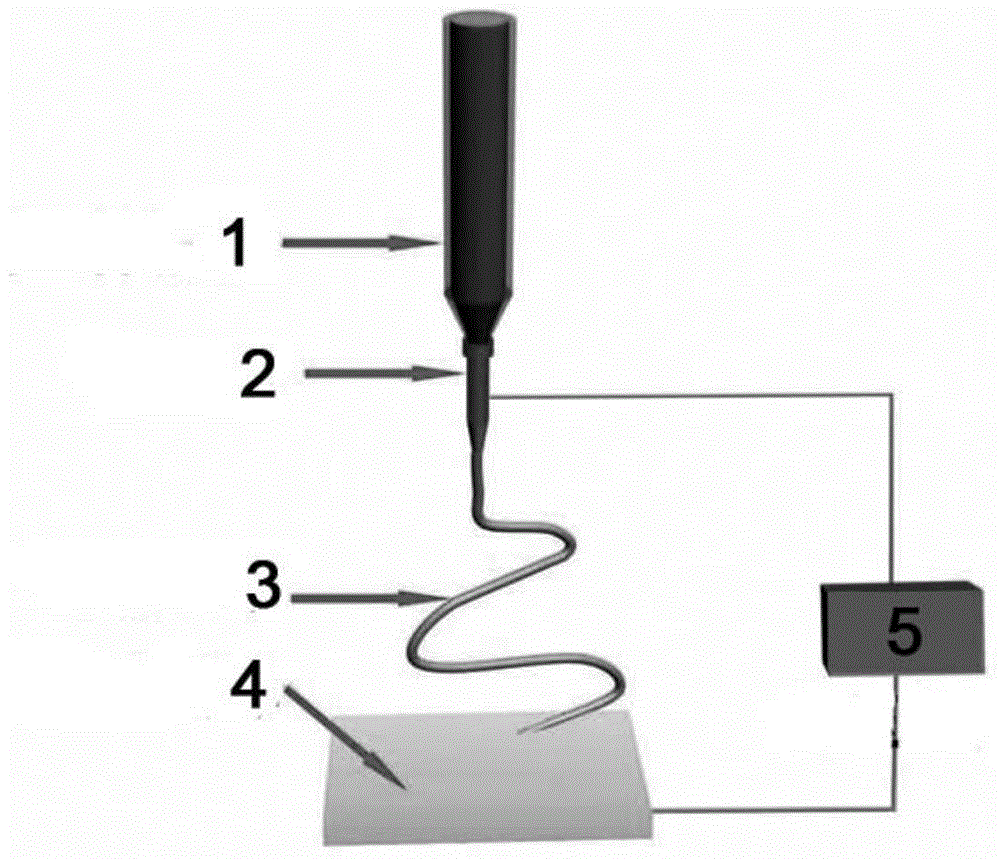

Hydrophobic film with self-cleaning function, preparation method thereof and application thereof

ActiveCN105002656AHigh porosityWith self-cleaning functionSemi-permeable membranesFilament/thread formingPorosityFiber

The invention relates to a hydrophobic film, and specifically relates to a hydrophobic film with a self-cleaning function, and a preparation method thereof and an application thereof. The hydrophobic film is a polymer nanofiber film prepared through an electrospinning fiber technique, the surface of the hydrophobic film is subjected to nanocrystallization modification to improve the surface hydrophobicity, and the contact angle between the hydrophobic film and water is 140-180 DEG. According to the invention, the electrospinning fiber technique and the surface nanocrystallization technique are combined, the preparation technology is simple, and the prepared hydrophobic film has the self-cleaning function and a high porosity factor, and can be applied to fields of air purifying filters, film distillation and oil-water separation and the like.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

Stabilization of Porous Morphologies for High Performance Carbon Molecular Sieve Hollow Fiber Membranes

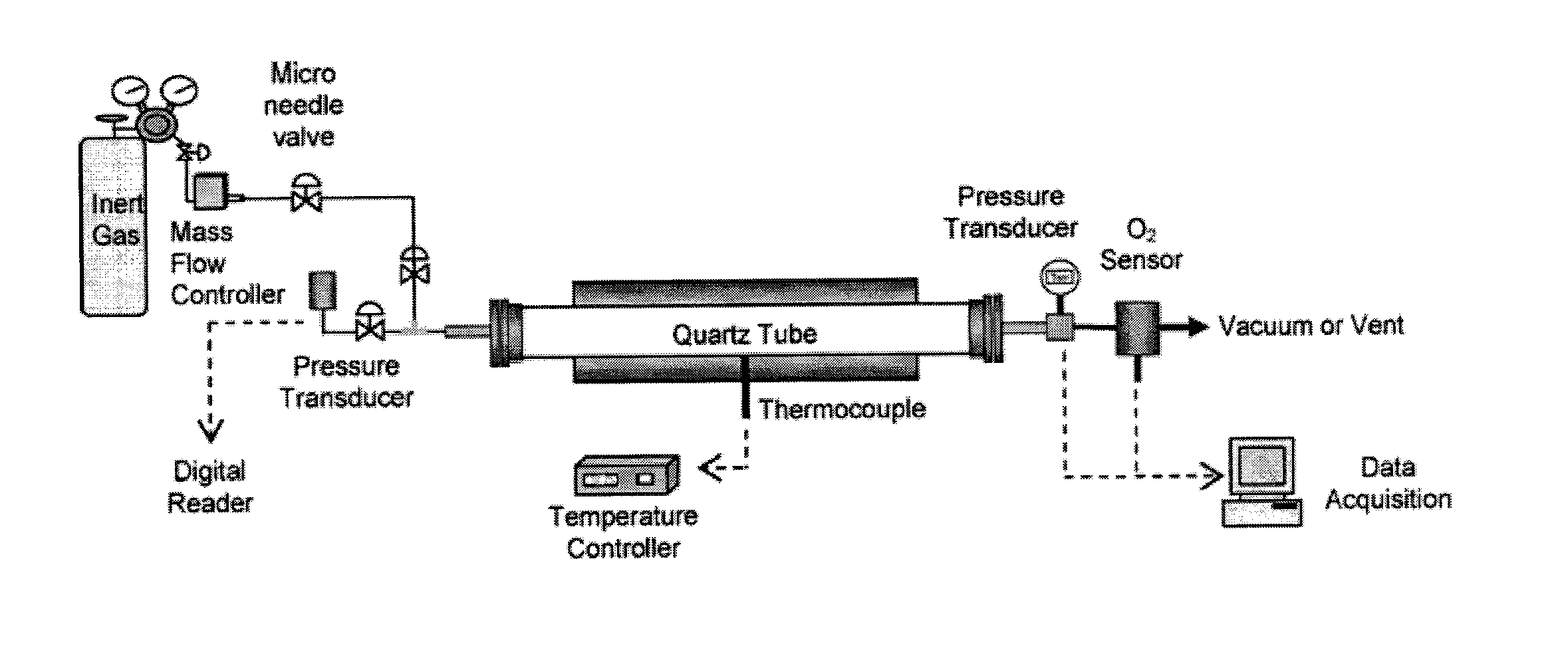

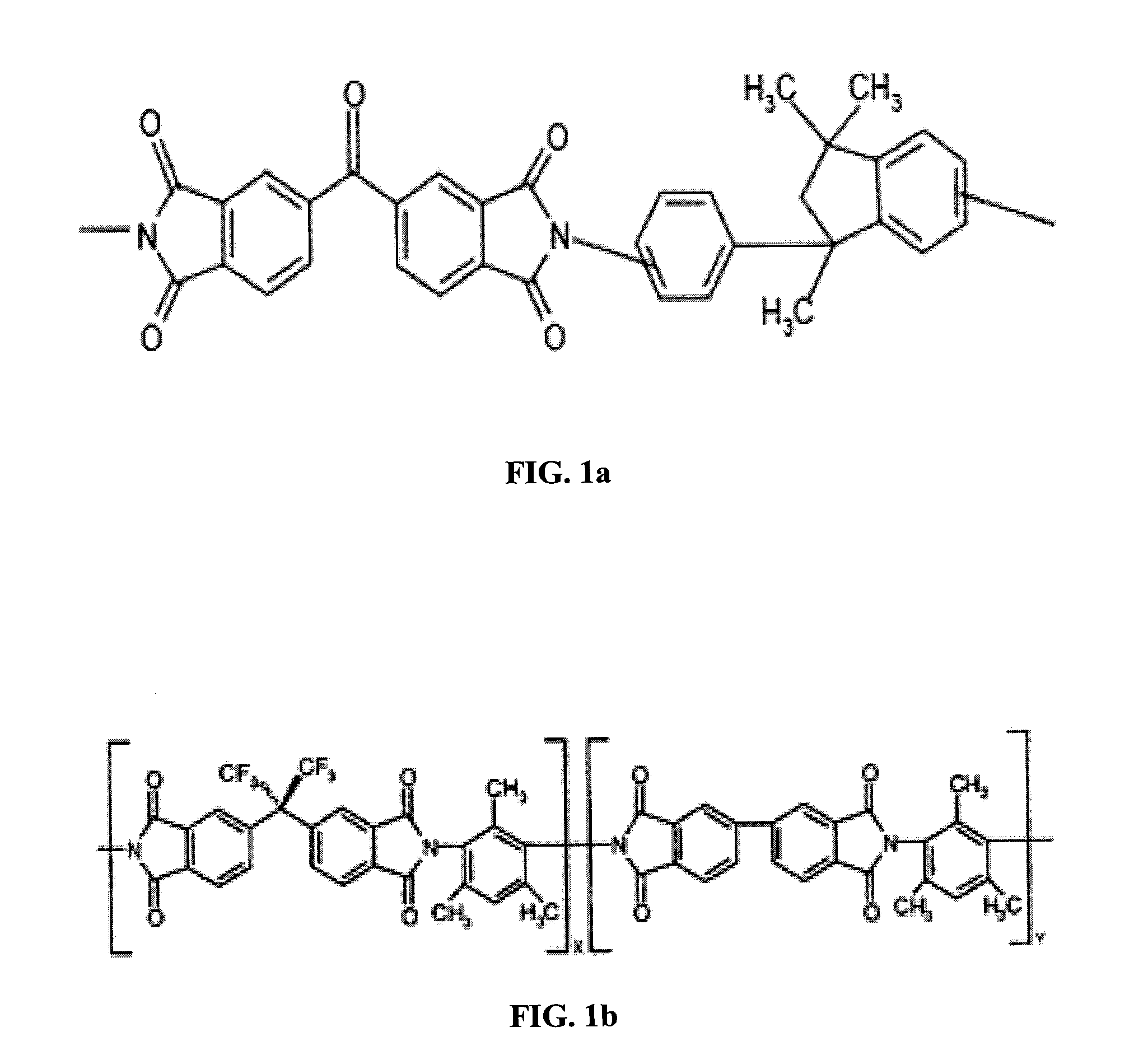

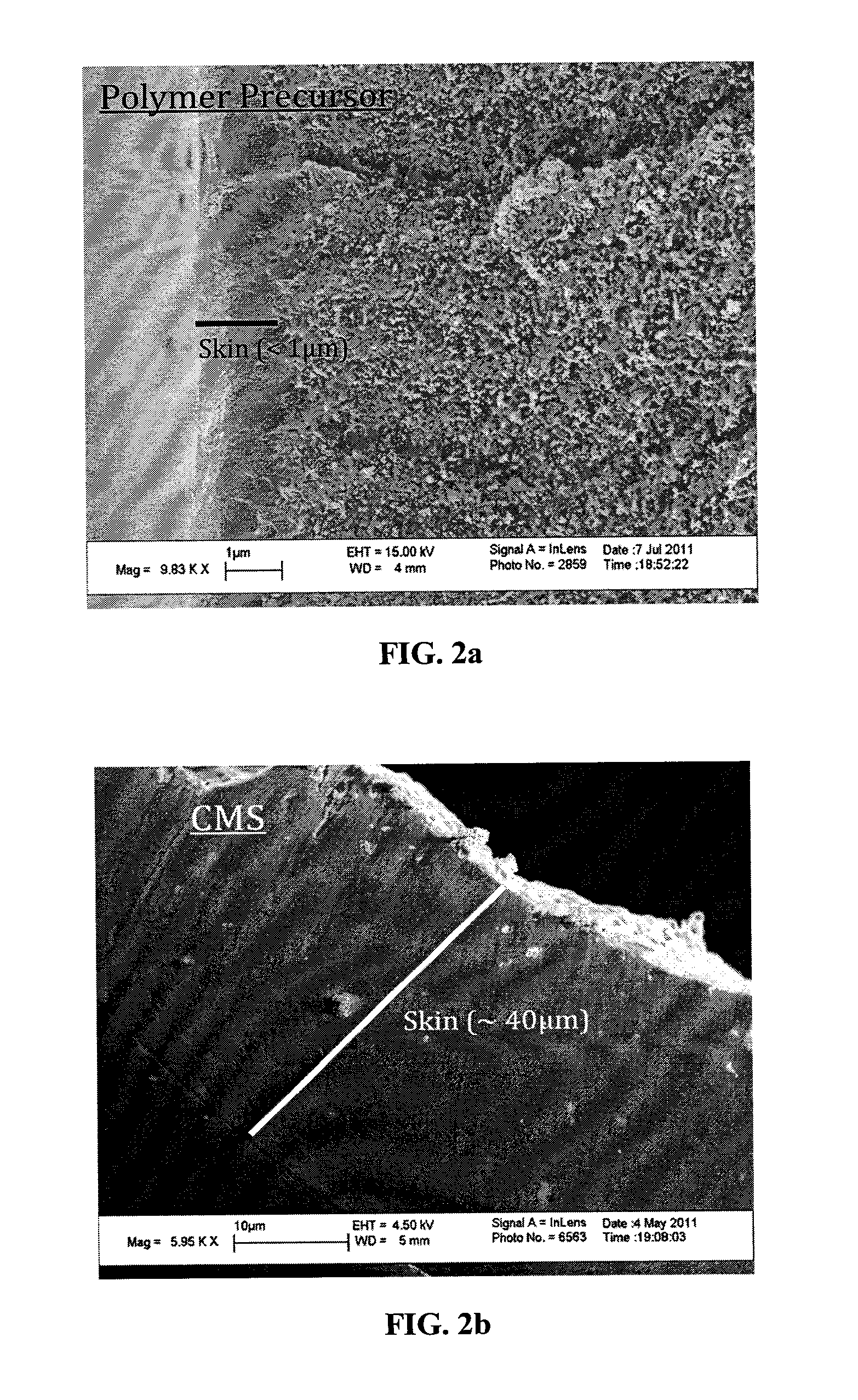

ActiveUS20130152793A1Improve separation efficiencyReducing and eliminating conventional dropSemi-permeable membranesMembranesImideMolecular sieve

Carbon molecular sieves (CMS) membranes having improved thermal and / or mechanical properties are disclosed herein. In one embodiment, a carbon molecular sieve membrane for separating a first and one or more second gases from a feed mixture of the first gas and one or more second gases comprises a hollow filamentary carbon core and a thermally stabilized polymer precursor disposed on at least an outer portion of the core. In some embodiments, the thermally stabilized polymer precursor is created by the process of placing in a reaction vessel the carbon molecular sieve membrane comprising an unmodified aromatic imide polymer, filling the reaction vessel with a modifying agent, and changing the temperature of the reaction vessel at a temperature ramp up rate and ramp down rate for a period of time so that the modifying agent alters the unmodified aromatic imide polymer to form a thermally stabilized polymer precursor.

Owner:AIR LIQUIDE ADVANCED TECH U S +1

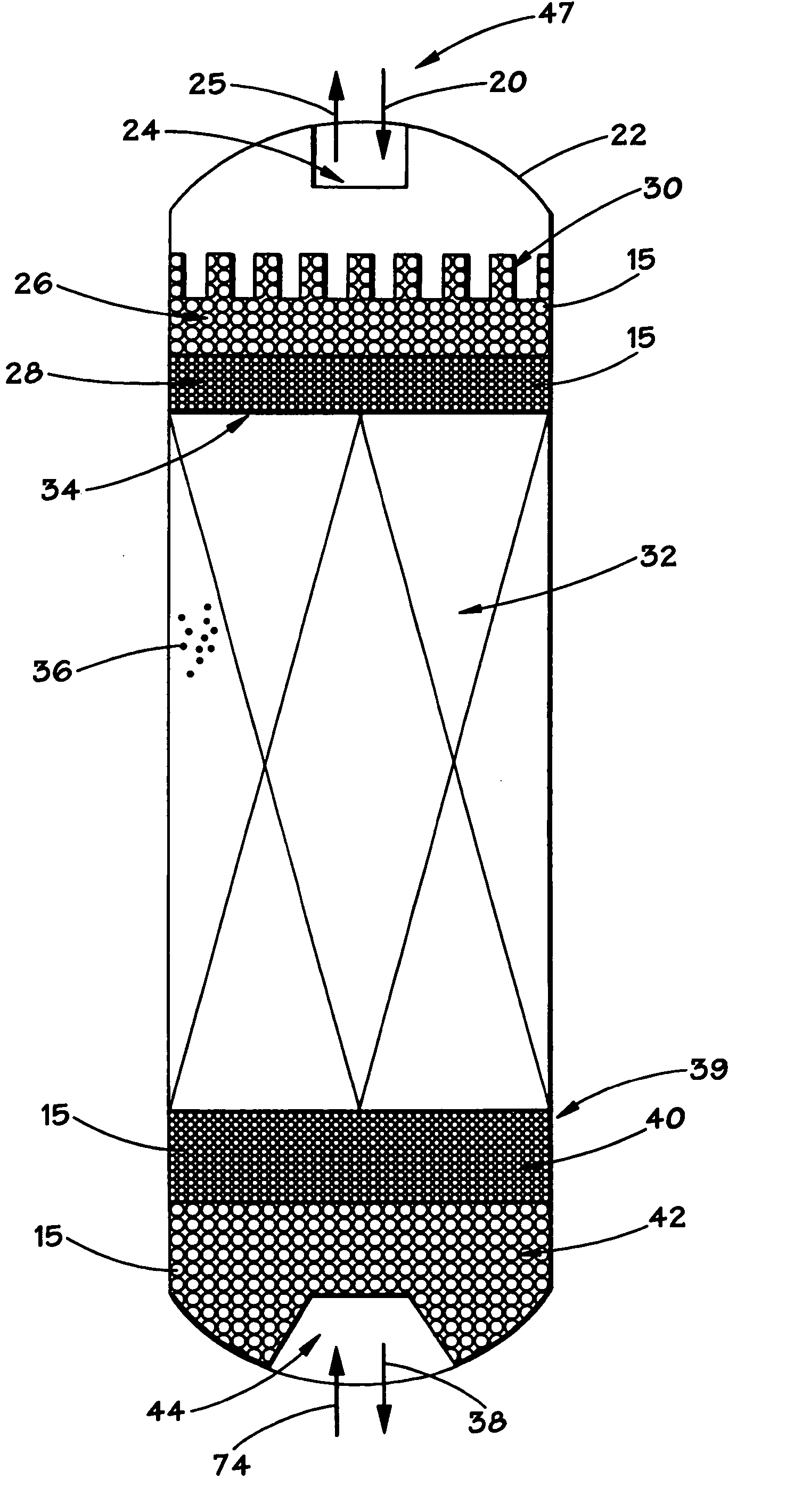

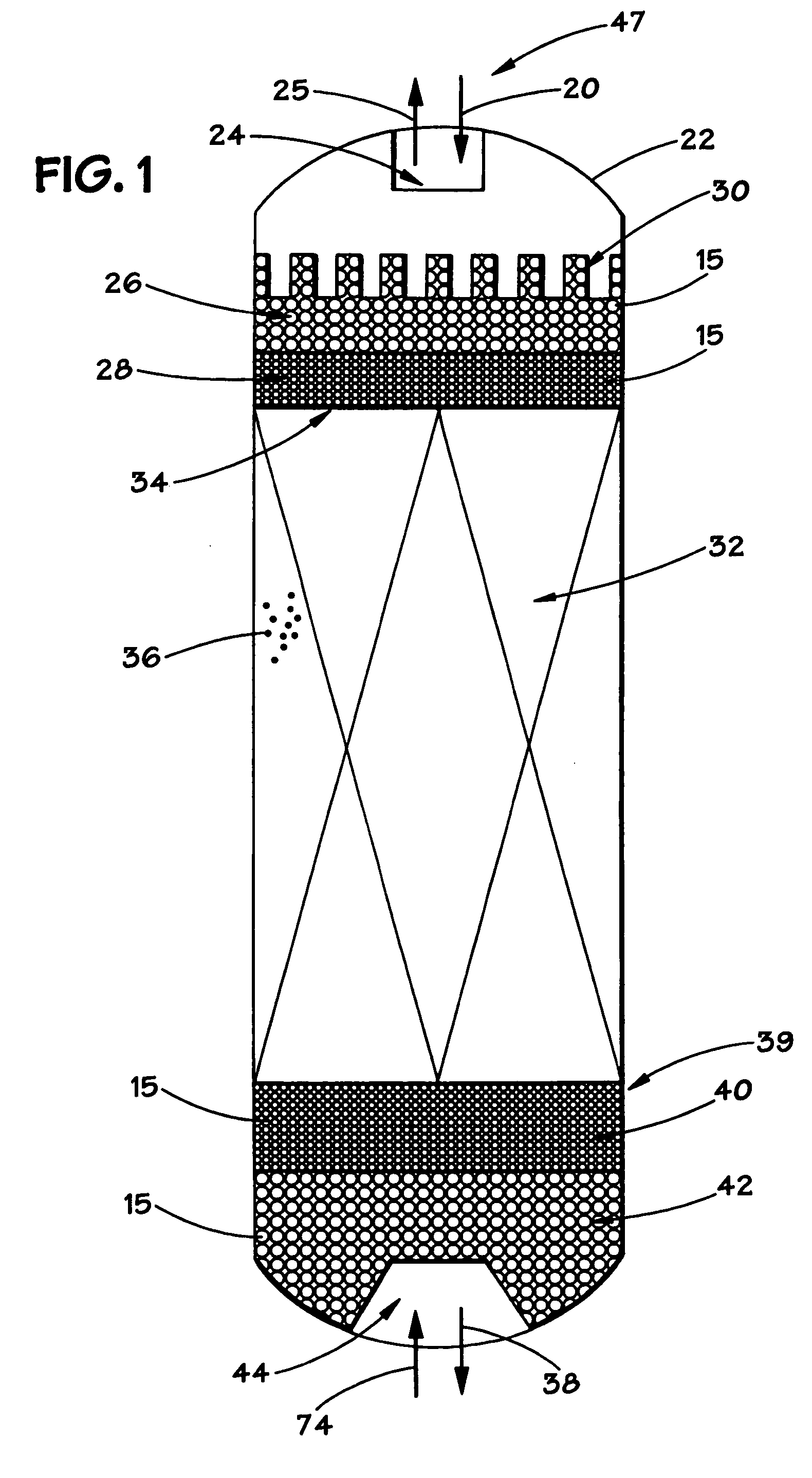

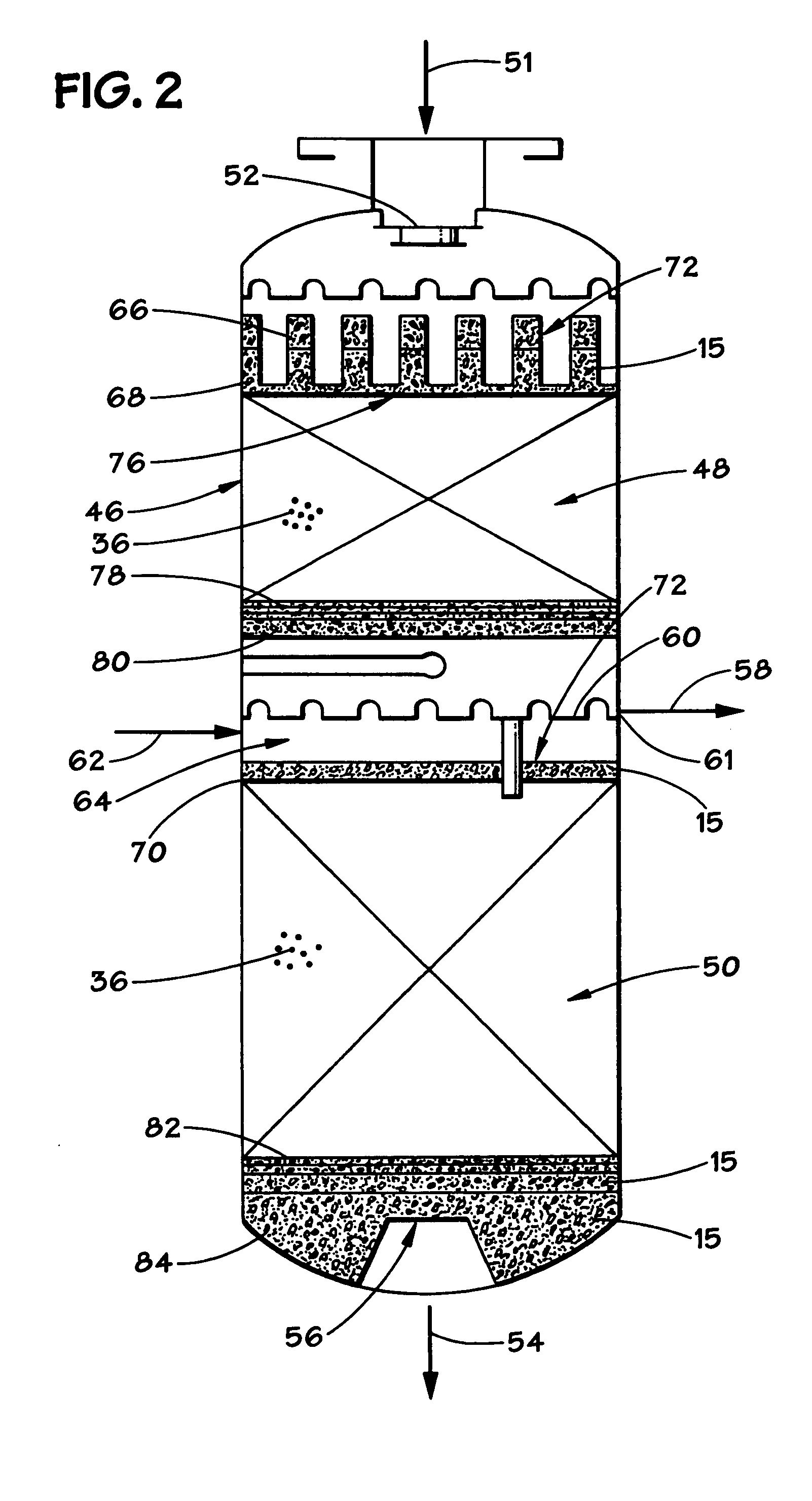

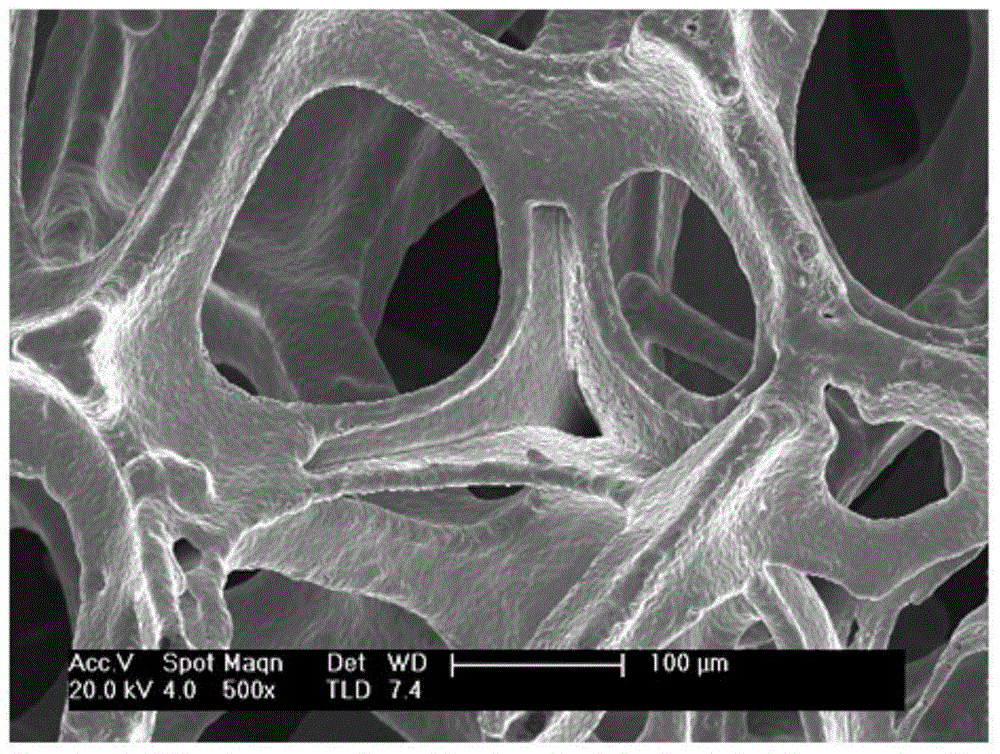

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

Preparation method of graphene/g-C3N4 compound photocatalyst

InactiveCN103769187AHigh degree of oxidationIncrease the areaPhysical/chemical process catalystsDecompositionHigh energy

The invention relates to a preparation method of a graphene / g-C3N4 compound photocatalyst, and adopts a high temperature decomposition method to prepare the graphene / g-C3N4 compound photocatalyst. The method comprises the following steps of (1) preparing g-C3N4 powder by adopting concentrated hydrochloric acid melamine through high temperature decomposition; (2) synthesizing high specific surface area graphite oxide by adopting an improved Hummers method, stripping the graphite oxide in an ultrasound manner, removing the graphene with the low oxidation degree through centrifugation, finally extracting a supernatant liquid, drying, and preparing polarity graphene oxide powder; and (3) uniformly mixing the prepared graphene oxide powder and the g-C3N4 through a high energy ball grinder to dissolve in hydrazine hydrate, and preparing the graphene / g-C3N4 compound photocatalyst with a high photocatalytic activity. The preparation method provided by the invention has the advantages that a raw material is cheap, the technology is simple and convenient and the like, and the prepared compound photocatalyst has the wide application prospect on the fields such as wastewater treatment and gas purification.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

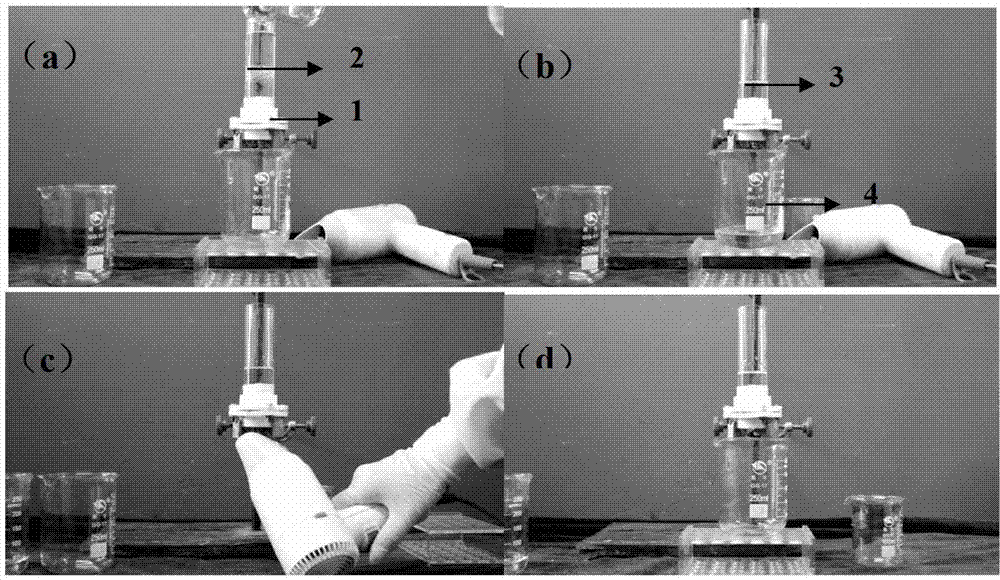

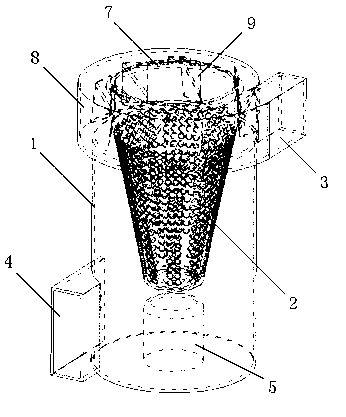

Micro-plastic separation method and device

ActiveCN106363835AImprove separation efficiencyShort processing timeSemi-permeable membranesPlastic recyclingFreeze-dryingVolumetric Mass Density

The invention belongs to the technical field of solid waste treatment and relates to a micro-plastic separation method and device. The micro-plastic separation method comprises the steps that (1) settlings of field natural water are collected; (2) the settlings of the field natural water is subjected to low-temperature drying and freeze-drying, and samples to be treated are obtained; (3) after a density solution is added into the samples to be treated, sufficient stirring is conducted until the samples to be treated are completely suspended in the density solution, and a non-sediment layer and a sediment layer are formed from top to bottom after still standing; and (4) the non-sediment layer is extracted and passes through a filter film, liquid passing through the filter film is repeatedly used, and objects isolated by the filter film include but limited to micro-plastic particles in the settlings of the field natural water. The provided micro-plastic pollutant separation method and device are capable of rapidly and effectively separating and extracting the micro-plastic particles in settlings of water such as rivers and lakes.

Owner:INST OF AQUATIC LIFE ACAD SINICA

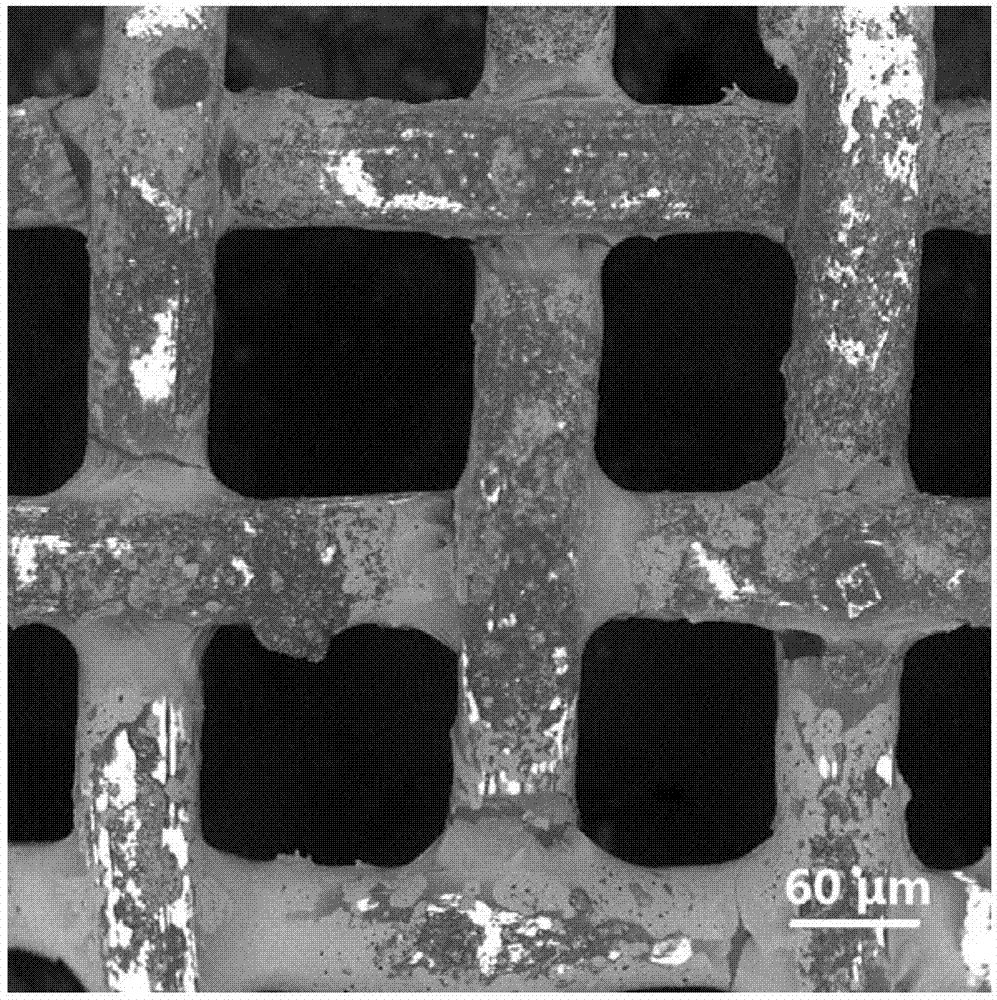

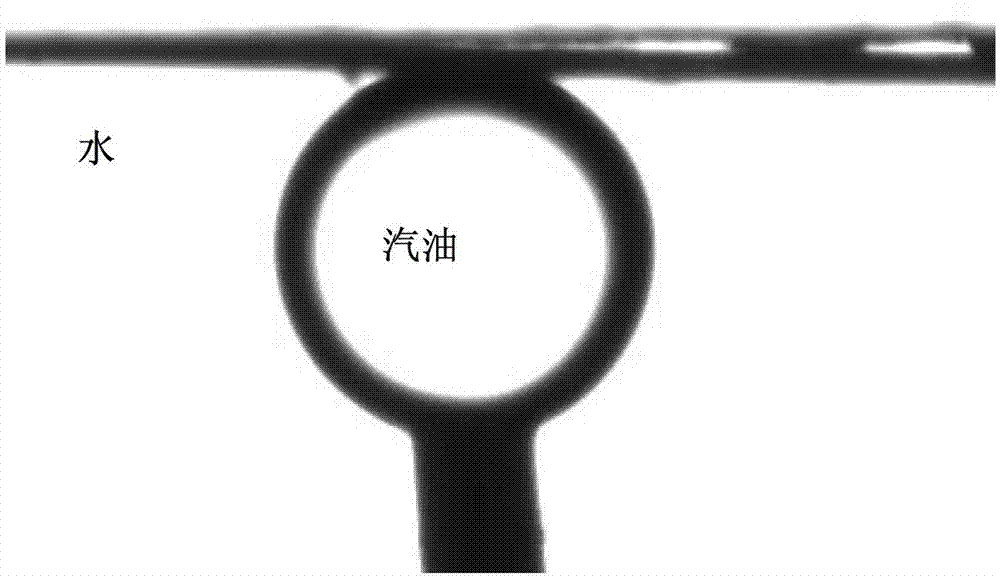

Responsive oil and water separation net film with underwater super lipophobicity property and preparation method thereof

ActiveCN103111096AIncrease speedReduce separation costsLiquid separationCross-linkUltraviolet lights

The invention discloses a responsive oil and water separation net film with an underwater super lipophobicity property and a preparation method thereof. The method comprises the following steps of: (1) dissolving a polymer monomer, a photoinitiator, a cross-linking agent and a thickening agent in water so as to obtain a mixed solution; (2) soaking a fabric net in the mixed solution; and (3) taking out the fabric net, carrying out a polymerization reaction on the soaked fabric net in ultraviolet light the wavelength of which is 365nm so as to obtain a polymer hydrogel coating layer in the fabric net, and then obtain the responsive oil and water separation net film with the underwater super lipophobicity property. The responsive oil and water separation net film with the underwater super lipophobicity property, provided by the invention, has the advantages that the oil-contaminated water can be separated, meanwhile, the temperature and pH dual responsive characteristics are realized, the controllable oil and water separation is realized, a separation device is simplified, and the separation cost is saved.

Owner:TSINGHUA UNIV

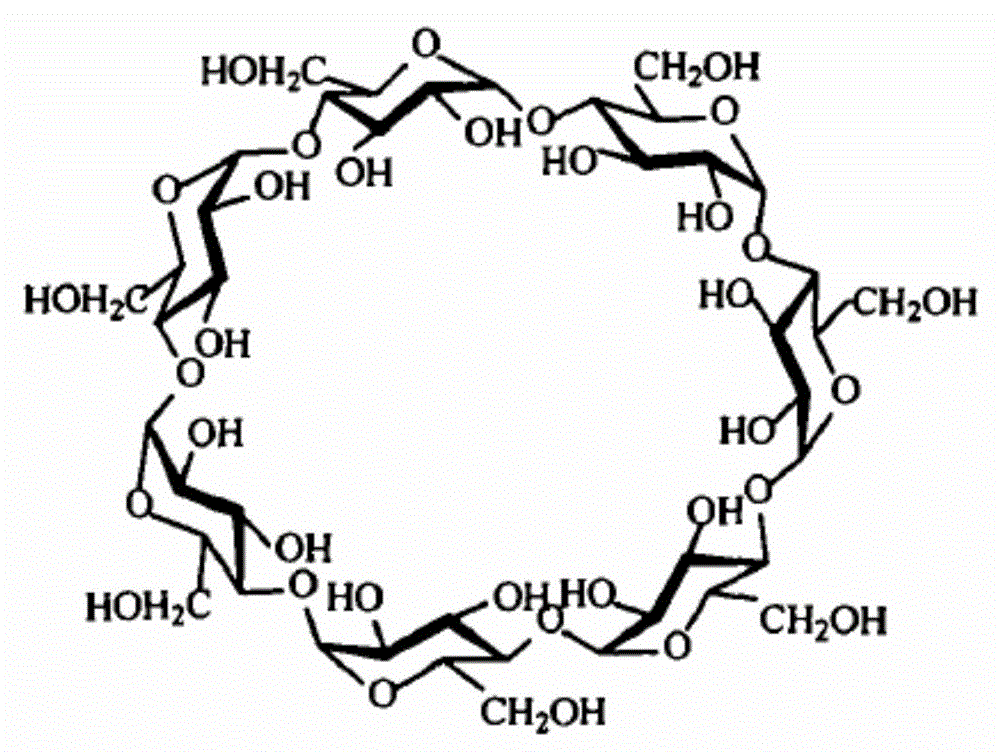

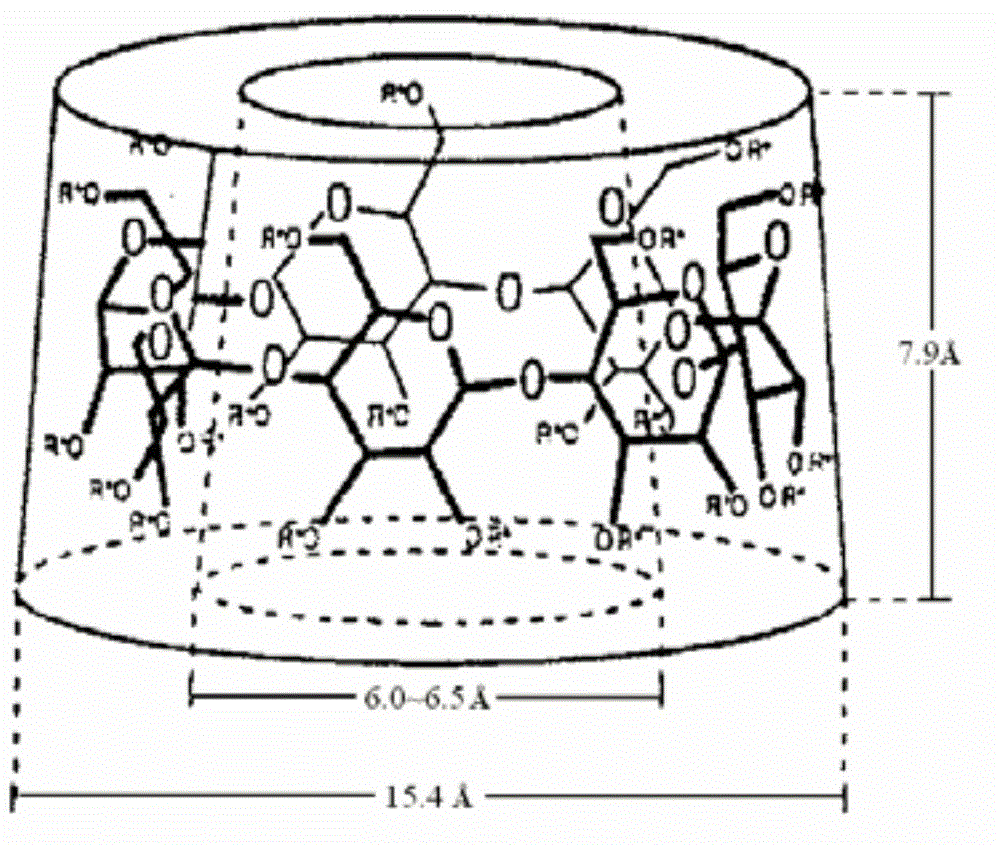

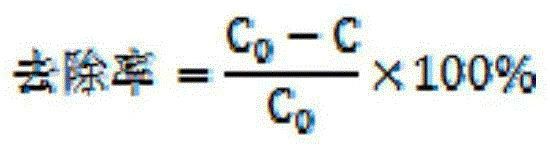

Preparation method of polymer porous membrane for removing water pollutants

ActiveCN104548949AHigh porosityLarge surface area of membrane poresSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkCyclodextrin

The invention relates to the technical field of separation membranes and discloses a preparation method of a polymer porous membrane for removing water pollutants. The preparation method comprises the following steps of blending cyclodextrin and a membrane preparation material, and adding a cross-linking agent into the mixture to fix the cyclodextrin to the membrane material so that repeated use is avoided, cyclodextrin is lost from the polymer porous membrane, a selective separation function of the polymer porous membrane is lost and polymer porous membrane hydrophility is changed. The polymer porous membrane has a substantial capability of adsorption and removal of organic pollutants such as phenols and aromatic amines (aromatic substances) in water, has good heavy metal ion removal effects, has high separation efficiency and low pressure drop, is convenient for regeneration, can be massively produced and used easily, and can be widely used in an ecological protection water purification treatment system and a water treatment system.

Owner:CHINA PETROLEUM & CHEM CORP +1

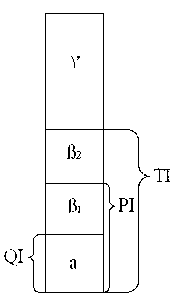

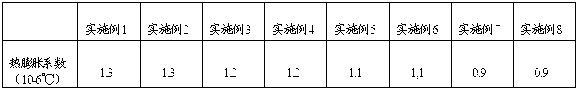

Technology for preparing needle coke raw material from coal-tar pitch

ActiveCN103013566ASuitable for adjusting extraction volumeHigh desulfurization efficiencyWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystCoke

The invention provides a technology for preparing a needle coke raw material from coal-tar pitch. The technology comprises the following steps of 1, fully mixing asphalt and a solvent, and removing insoluble substances in the mixture by a physical separation method, wherein the solvent is a mixture of coal light oil and coal aromatic oil or is a mixture of BTX and coal aromatic oil; a mass ratio of the coal light oil or the BTX to the coal aromatic oil is in a range of (20: 80) to (95: 5); and a mass ratio of the solvent to the asphalt is in a range of 0.5 to 10, 2, feeding a clear liquor without the insoluble substances into a separator, and separating the light solvent from the clear liquor to obtain a heavy fraction having low QI, and 3, carrying out hydrotreatment on the heavy fraction in the presence of a hydrogenation catalyst at a temperature of 300 to 450 DEG C under the pressure of 5 to 20MPa. The needle coke raw material obtained by the technology has low sulfur content and a small expansion coefficient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

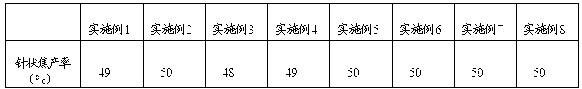

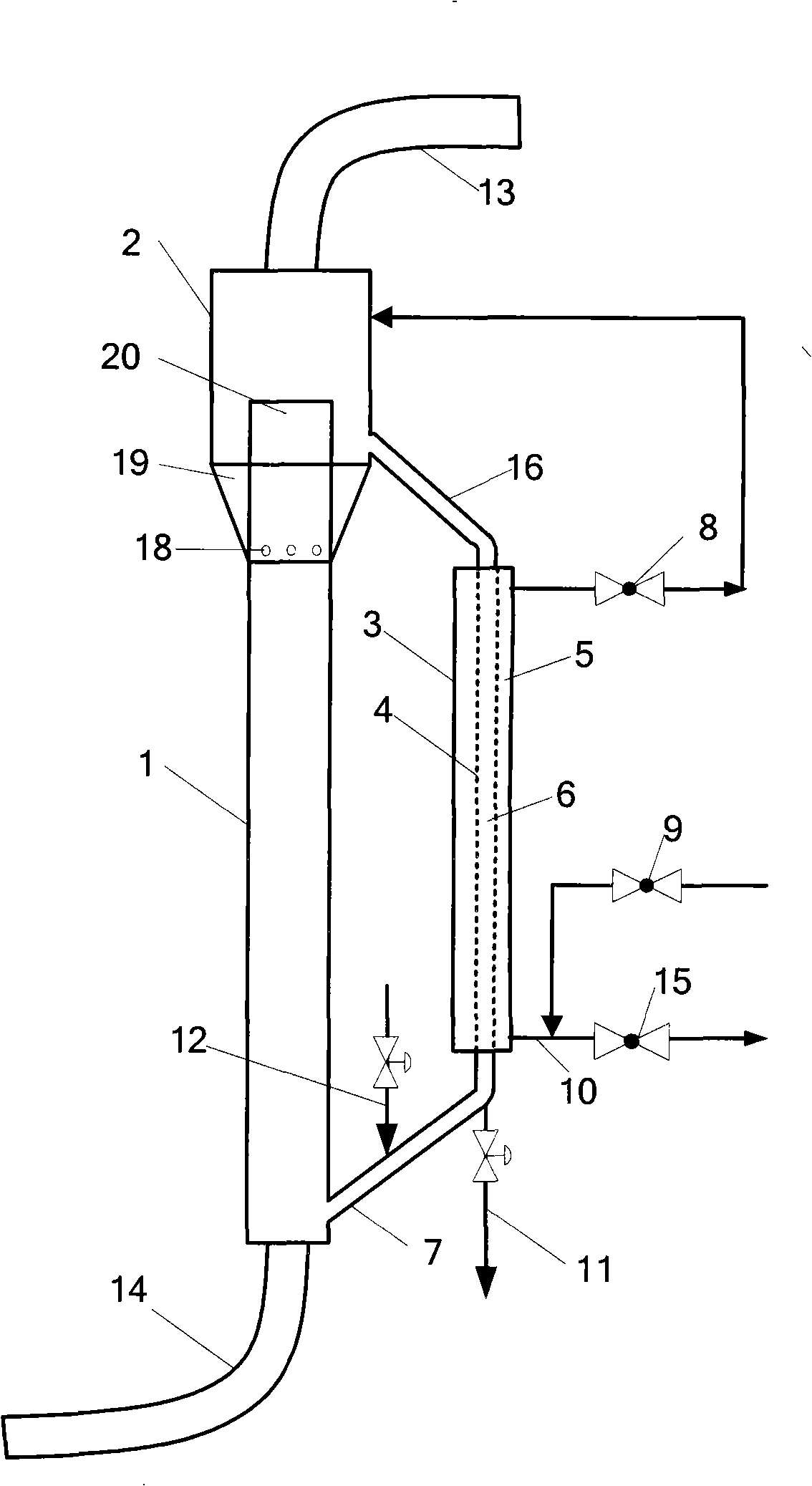

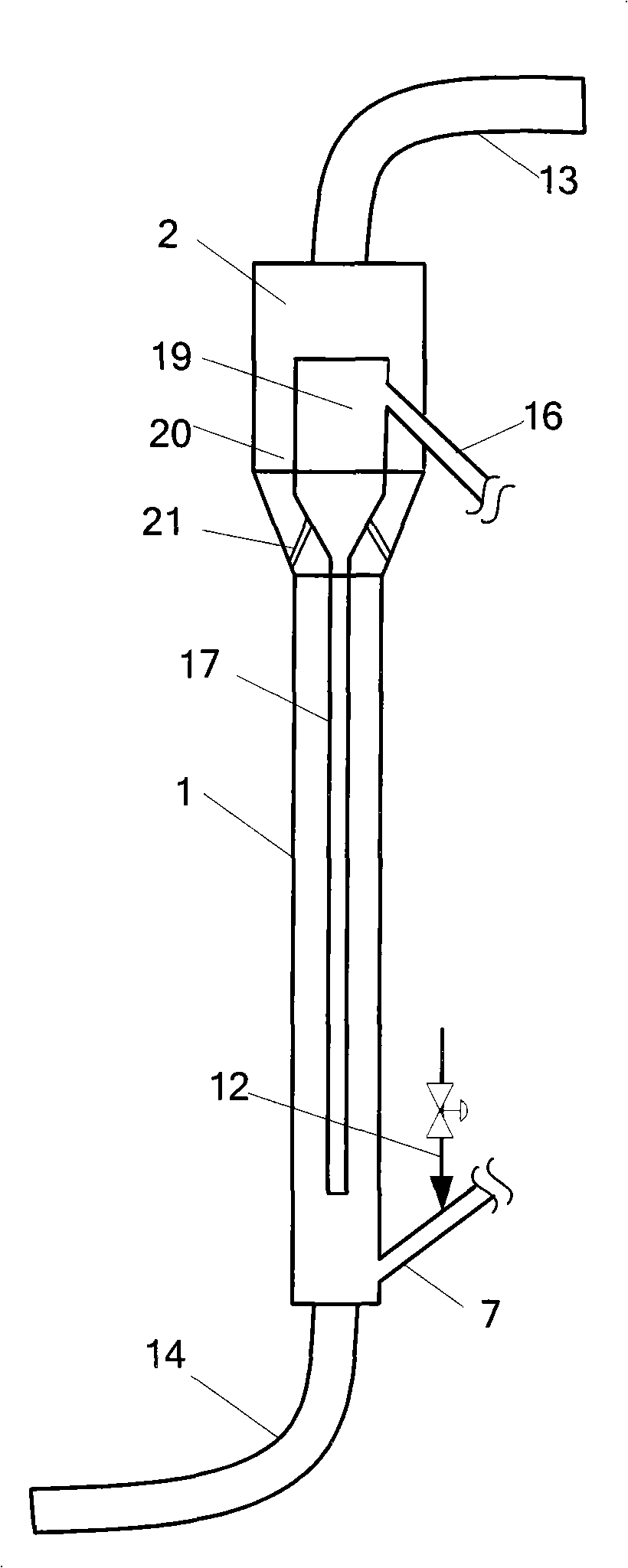

Slurry bed reactor and uses thereof

ActiveCN101314120AEvenly distributedReduce circulation volumeChemical/physical processesLiquid productGas phase

The invention provides a slurry-bed loop reactor, comprising an ascending pipe and at least one downtake pipe 3, wherein, the ascending pipe consists of a reaction zone 1 and a settlement zone 2 with an expanded pipe diameter; an exhaust port 13 is arranged on the top of the settlement zone 2; the inside of each downtake pipe 3 is divided into a filtrate zone 5 and a slurry zone 6 by a filter medium 4, wherein, the filtrate zone 5 is communicated with a liquid discharge port 10; two ends of the slurry zone 6 are communicated with two ends of the ascending pipe 1, so the settlement zone 2 is separated into a steady flow zone 19 and a turbulent flow zone 20, wherein, the upper part of the steady flow zone 19 is communicated with the downtake pipe 3 through a pipeline 16; and the bottom of the steady zone 19 is directly communicated with the reaction zone 1 through an open pore 18 or through a draft tube 17. The slurry-bed loop reactor provided by the invention can realize continuous high-efficiency separation of solid catalyst particles, a liquid product and reacting gas, realize continuous discharging of a gas phase, a liquid phase and a solid phase, reduce turbulence of rising slurry from the reaction zone to settling particles in the settlement zone by separating the settlement zone into the turbulent flow zone and the steady flow zone, improve the separation efficiency of the settlement zone, and reduce the filtering load of the downtake pipe, thereby improving the treating capacity and the separation efficiency of the whole reactor, and prolonging the backsurge period.

Owner:CHINA PETROLEUM & CHEM CORP +1

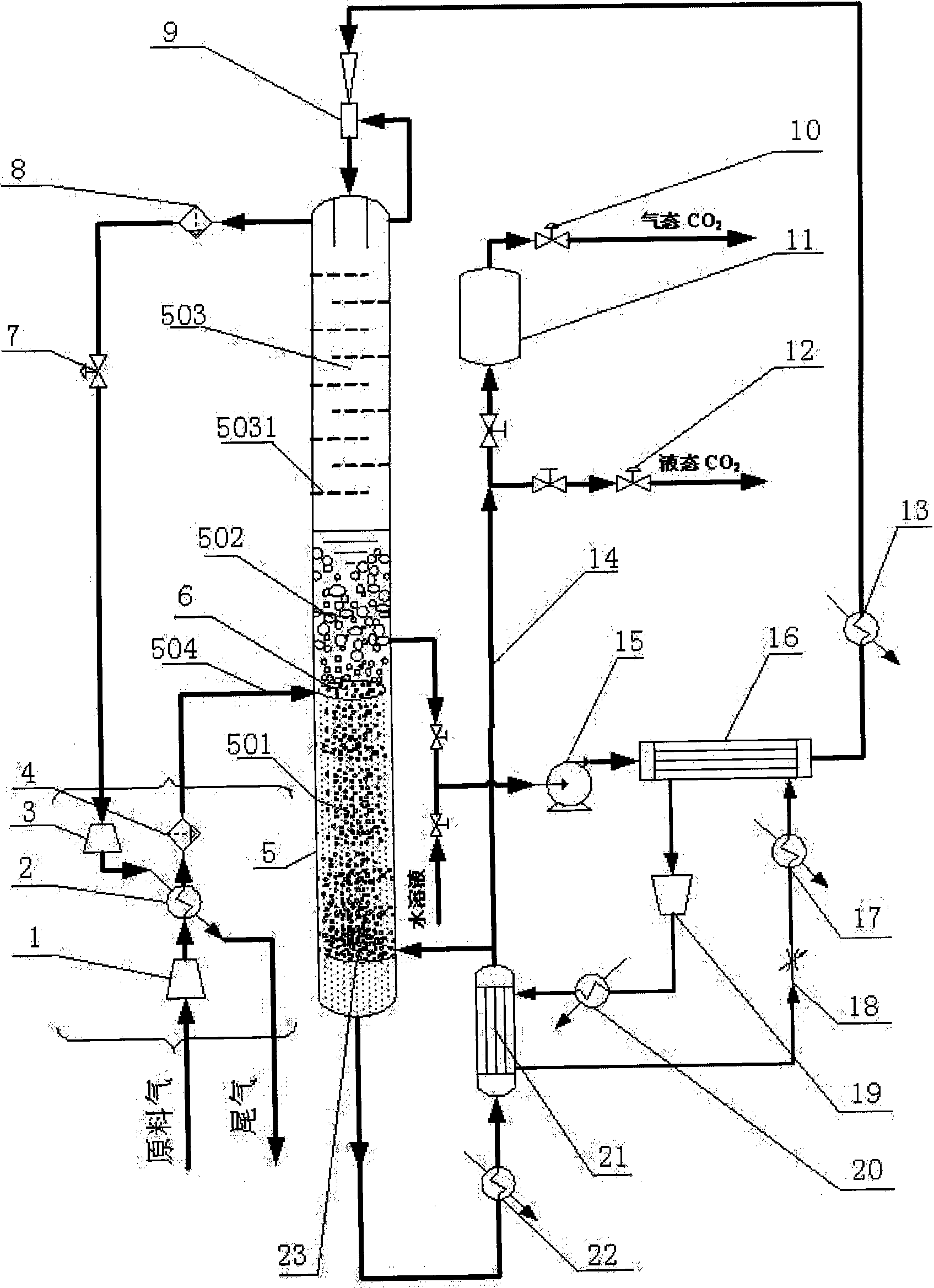

Carbon dioxide industrial-scale separation and purification system and method in mixture gas by hydrate method

ActiveCN101456556AIncrease concentrationIncrease separation rateProductsCarbon compoundsCollection systemFractionation

The invention discloses a system and a method for industrially separating and purifying CO2 in mixed gas by a hydrate method. The system consists of a feed gas pretreatment system, a hydrate separation tower, a micro-bubble jet-loop reaction system, a column bottom hydrate decomposition system, a CO2 product collection system, a hydrate formation and decomposition heat comprehensive utilization system and a tail gas energy recovery system. The method integrates hydrate bubbling reaction technology, spraying reaction technology and micro-bubble jet reaction technology, adopts CO2 reflux displacement fractionation technology to improve the concentration of the CO2 in a hydrate phase, has simple separation technology and device and high separation rate and efficiency, comprehensively utilizes the formation heat and decomposition heat of the hydrate during refrigeration cycle, simultaneously recovers compression work of tail gas and cold energy for feed gas pretreatment, and has low energy consumption and cost during separation. The system and the method can be applied to industrial and continuous separation and purification of the CO2 in the mixed gas such as flue gas (CO2 / N2), IGCC synthetic gas (CO2 / H2), biomass synthetic gas (CO2 / H2), natural gas (CO2 / CH4), coalbed gas and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

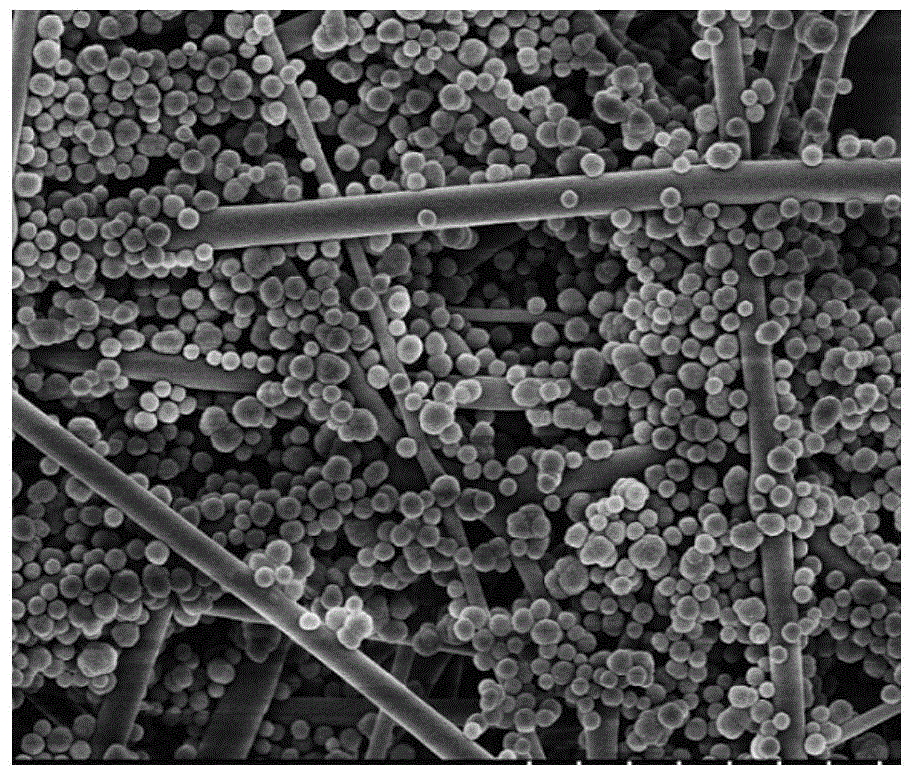

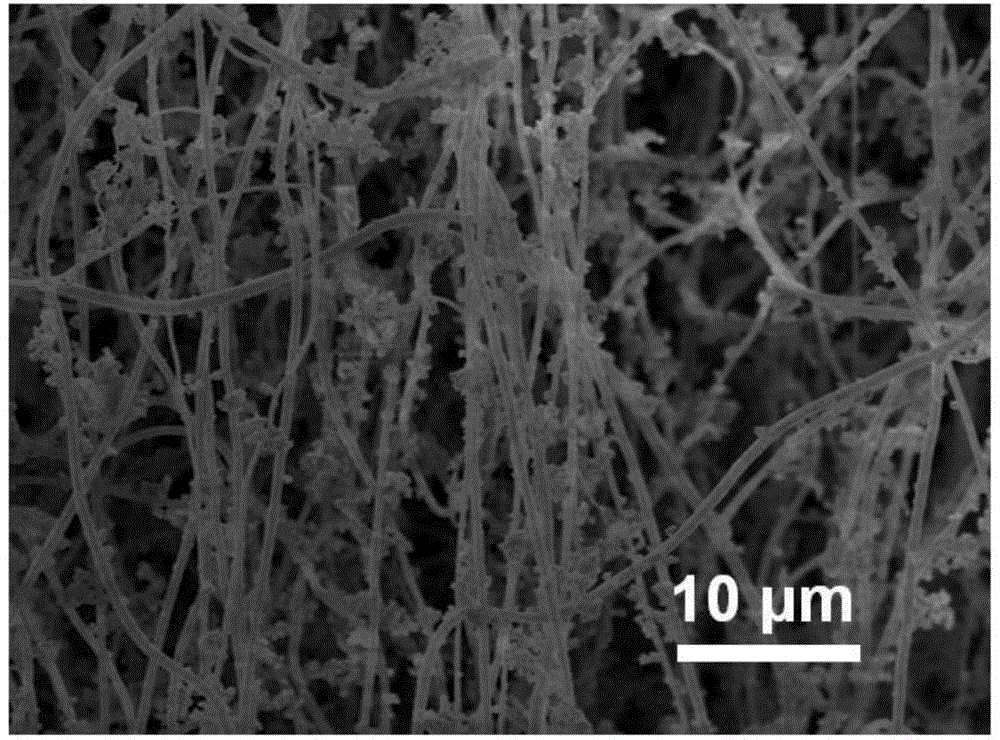

Magnetic response type high-efficiency oil-water separation fiber membrane and preparation method thereof

InactiveCN104436760AResponsiveMagnetic field responsiveLiquid repellent fibresNon-woven fabricsFiberMicro nano

The invention discloses a magnetic response type high-efficiency oil-water separation fiber membrane and a preparation method thereof, and belongs to the field of functional micro-nano fiber materials. The magnetic response type high-efficiency oil-water separation fiber membrane disclosed by the invention is prepared by the following steps: dissolving hydrophobic polymers, such as polyvinylidene fluoride, polyurethane or polycaprolactone, as main raw materials into an organic solvent to form a polymer solution; preparing a non-woven fiber membrane material prepared from micro-nano structure fibers by adopting an electrospinning method; forming a sticky polydopamine membrane through polymerization of polydopamine in an alkaline solution, and firmly attaching magnetic nanoparticles onto the surface of an electrospinning fiber membrane by adopting the sticky polydopamine membrane, so as to prepare the magnetic response type high-efficiency oil-water separation fiber membrane. The fiber membrane disclosed by the invention has a super-hydrophobic / super-oleophilic property in air, and has an excellent adsorptive property on a plurality of common oils; the preparation method of the high-efficiency oil-water separation fiber membrane, disclosed by the invention, is simple, low in energy consumption, and high in efficiency,and can be widely applied to the fields such as remote controllable efficient separation of oily wastewater, and the magnetic responsiveness is realized.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

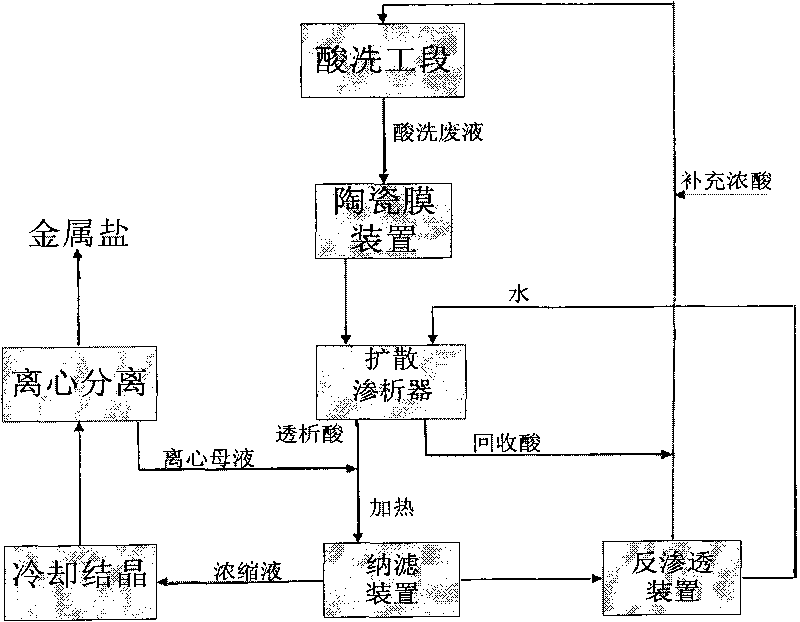

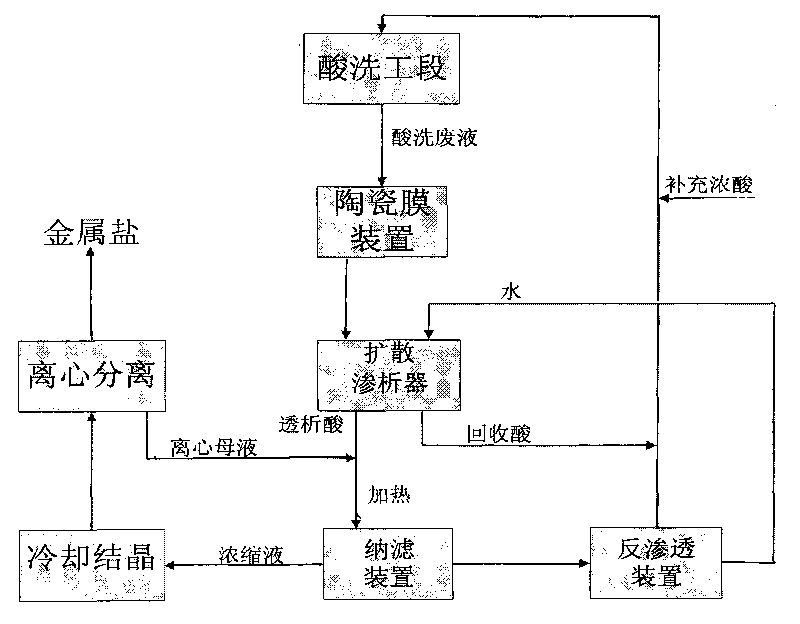

Process for recovering heavy metallic salt and inorganic acid in pickling waste liquid

ActiveCN101759250AOptimizing the integration processReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLiquid wasteIron salts

The invention relates to a process for separating and recovering heavy metallic salt and inorganic acid in pickling waste liquid by a membrane method, which comprises the following concrete steps: filtering and removing solid suspended substances in pickling waste liquid through an inorganic ceramic membrane; separating acid from salt in the ceramic membrane penetrating liquid through diffusion dialysis; and heating the dialysis liquid of a diffusion dialyzer, then introducing the dialysis liquid into a nanofiltration membrane, and cooling and crystallizing the concentrated liquid of a nanofiltration device and then centrifuging the crystal of the concentrated liquid to obtain iron salt, wherein the penetrating liquid of the nanofiltration device passes through a reverse osmosis membrane device, the concentrated liquid of the reverse osmosis device returns to a pickling section, and the water discharged from the reverse osmosis device enters a diffusion dialysis section for recycling. The invention has the characteristics that the pickling waste liquid is completely used as resources, the recovery process is simple, the recovery ratio of metallic salt and acid is high, and water is recycled. The process of the invention can be coupled with various pickling sections to realize continuous and stable automated operation, and the supplemented acid amount can be quantitatively controlled according to the acid amount consumed by the crystallized metallic salt.

Owner:NANJING UNIV OF TECH +1

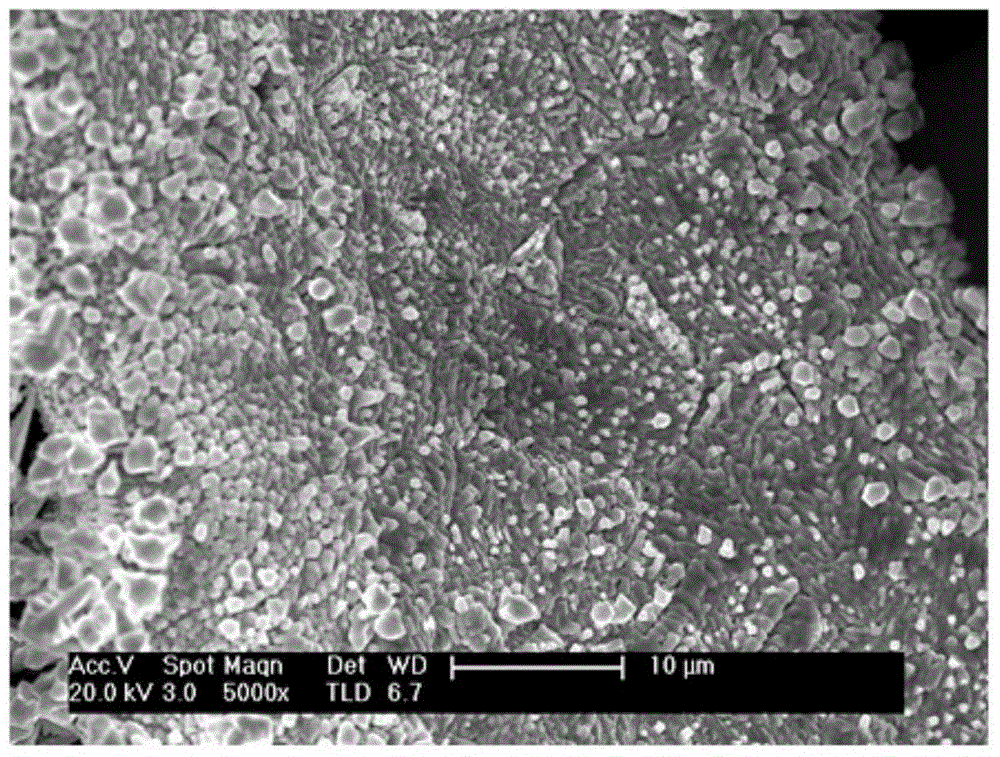

Adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and preparation method and application thereof

ActiveCN105148744AHighly corrosiveStrong mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAir atmosphereThin membrane

The invention belongs to the technical field of separating film materials, and discloses an adjustable and controllable ultrathin two-dimensional nano g-C3N4 film, and a preparation method and application thereof. The preparation method comprises the following steps of performing heat treatment on dicyandiamide or cyanurtriamide under an inert atmosphere to obtain caked g-C3N4; pulverizing the caked g-C3N4 and calcining under an air atmosphere to obtain g-C3N4 powder; dispersing the g-C3N4 powder in solvent to obtain g-C3N4 two-dimensional nanosheet solution; adding electrolyte solution for modifying; depositing a g-C3N4 two-dimensional nanosheet on a porous carrier of which the pore diameter is greater than 200 nanometers to form a two-dimensional g-C3N4 ultrathin film; and drying to remove the solvent so as to obtain the adjustable and controllable ultrathin two-dimensional nano g-C3N4 film loaded on the porous carrier. The g-C3N4 film is high in water permeability and high in separation efficiency, and has a wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

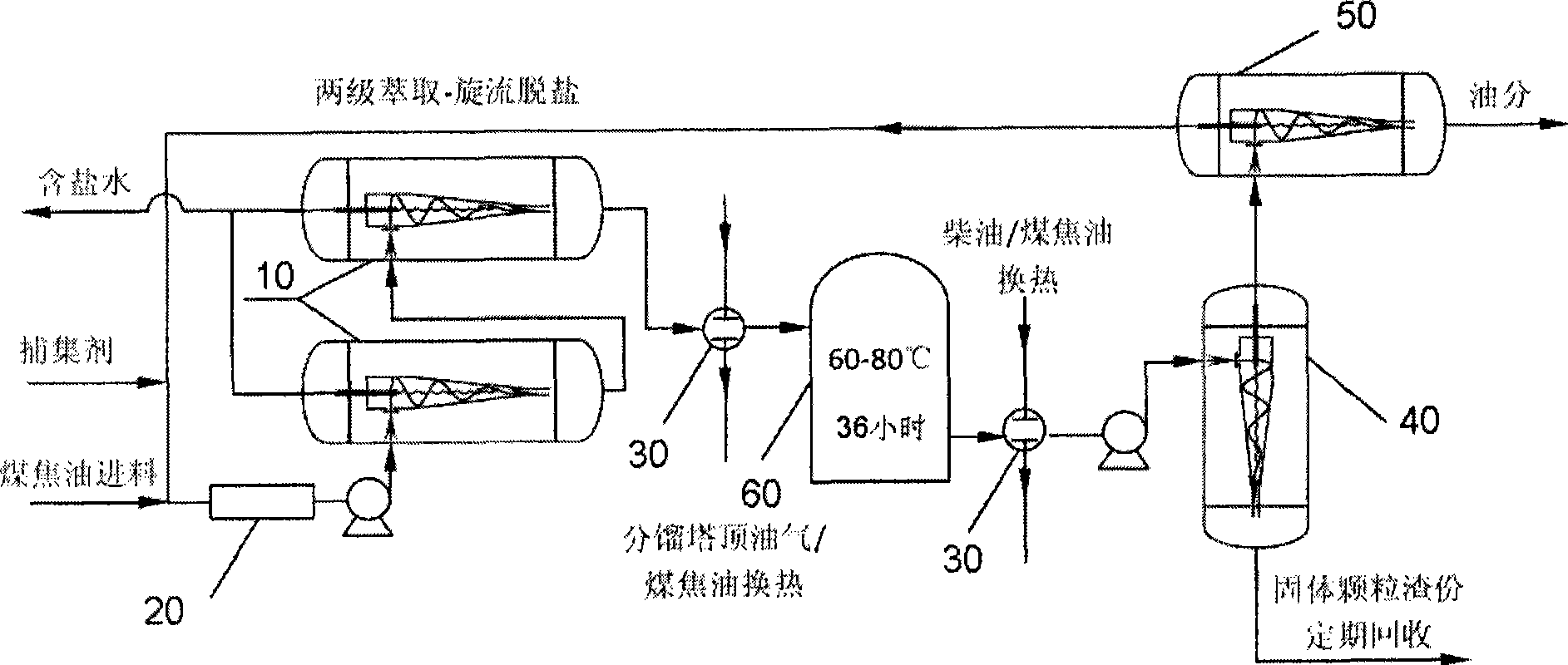

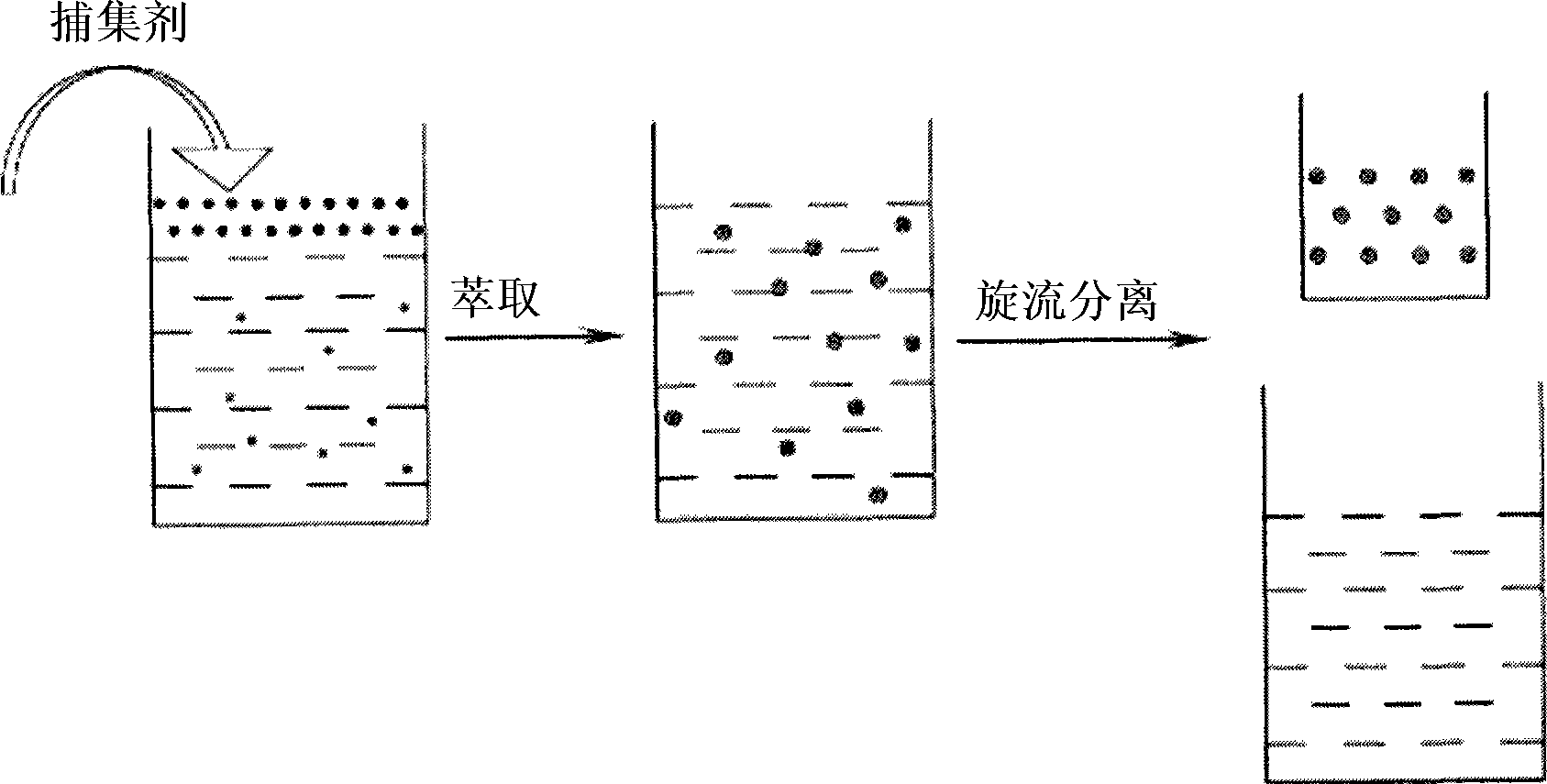

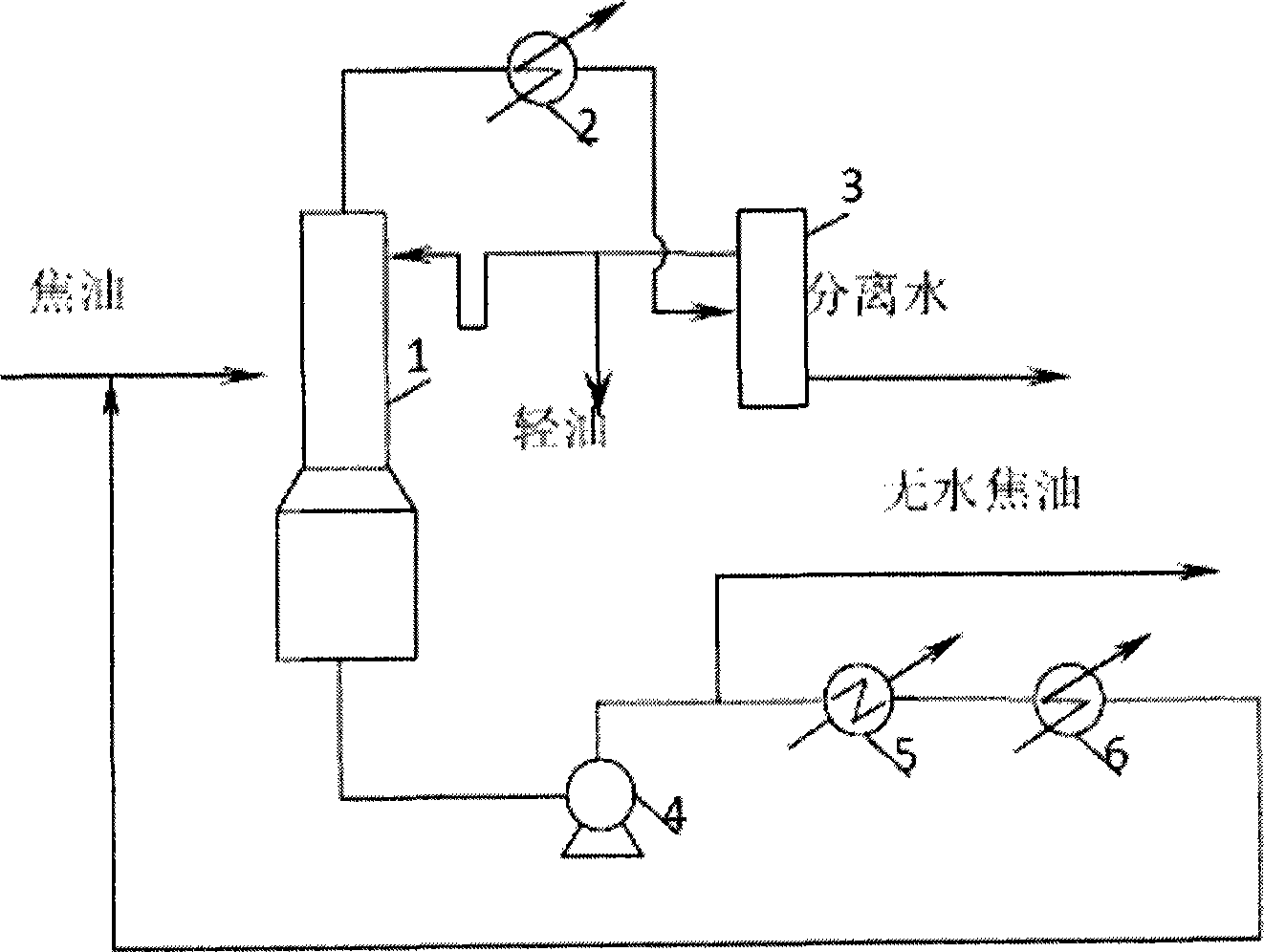

Coal tar coupled rotational flow purification method and apparatus

ActiveCN101475818AReduce heat consumptionReduce resistanceTar working-up by water removalTar working-up by solvent extractionPurification methodsPhysical chemistry

The invention relates to a method and a device for purifying coal tar through coupling rotational flow, wherein the method for purifying the coal tar through coupling rotational flow comprises the following steps: (a) mixing coal tar feed with a trapping agent sufficiently so as to extract out saline matters dispersed in the coal tar; (b) performing liquid-liquid rotational flow separation on thecoal tar in which the dispersed saline matters are extracted out for separating out the saline matters so as to obtain desalinated coal tar; (c) keeping stand and depositing the desalinated coal tar so as to remove the moisture therein and obtain dehydrated coal tar; (d) performing solid-liquid rotational flow separation on the dehydrated coal tar so as to remove solid particles therein and obtain the coal tar without the solid particles; and (e) performing micro rotational flow separation on the coal tar without the solid particles so as to remove the micro moisture therein. The invention also provides a device for purifying the coal tar through the coupling rotational flow.

Owner:EAST CHINA UNIV OF SCI & TECH

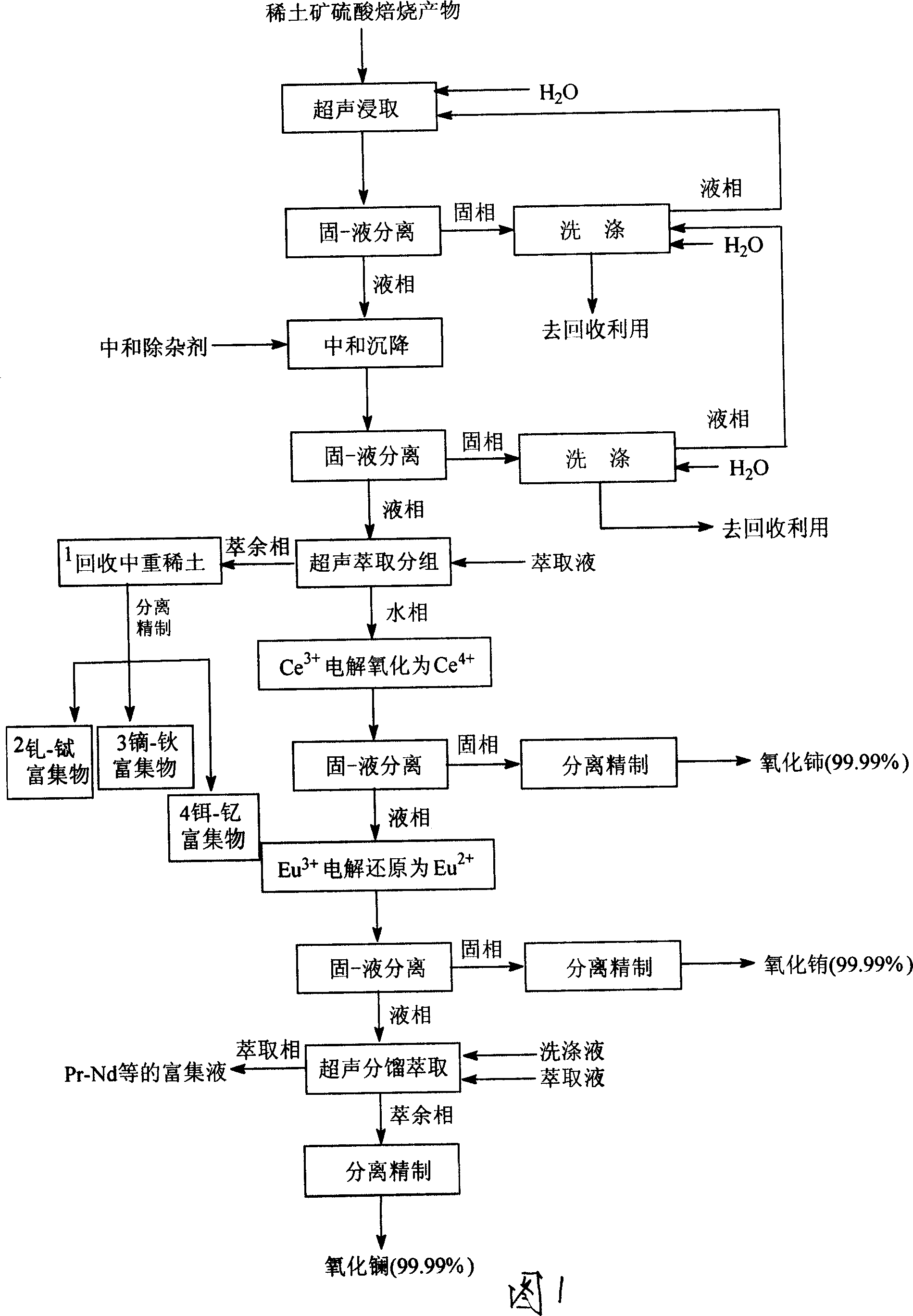

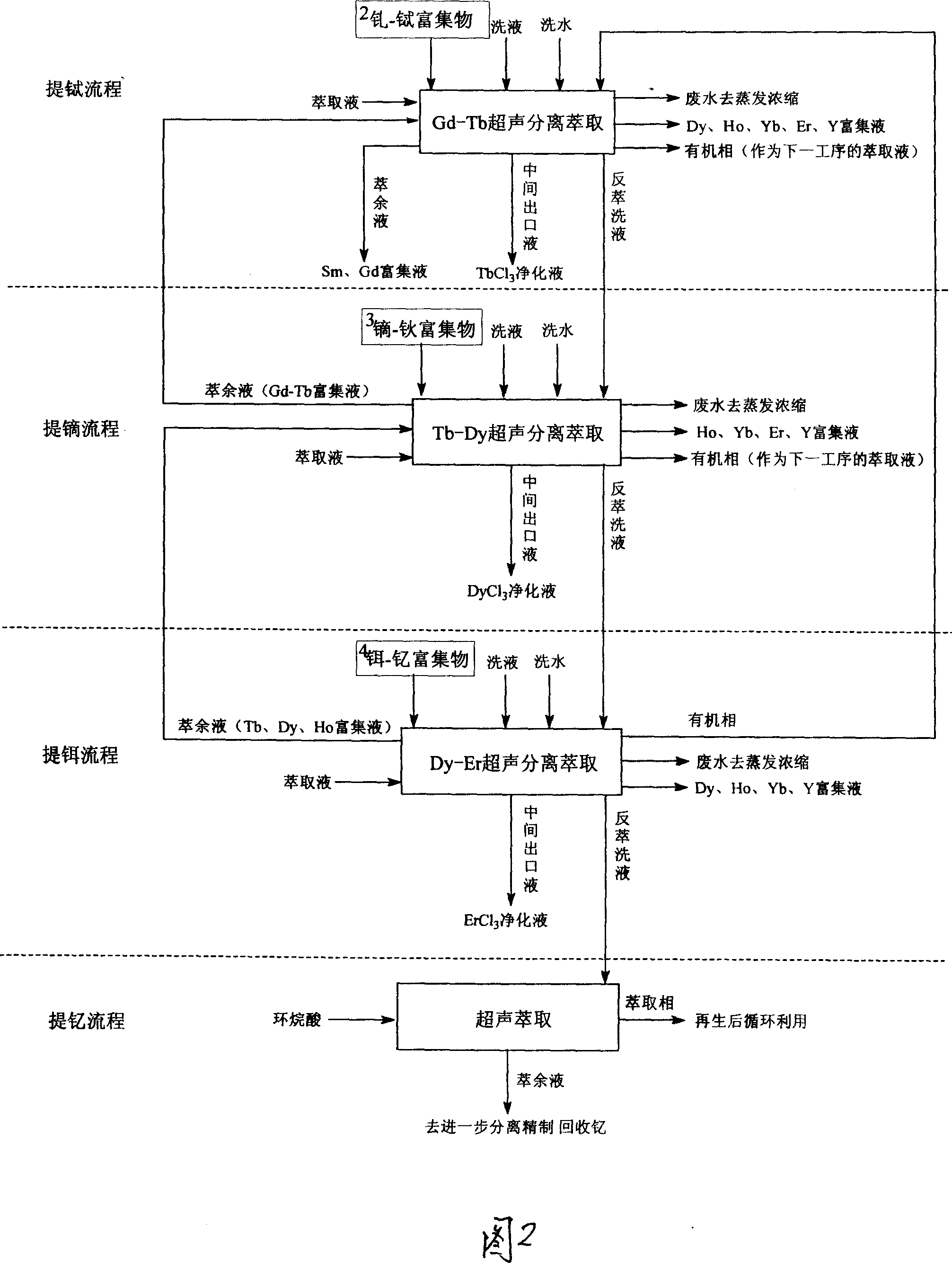

Method for separating highly-pure rare-earth oxide from sulphating roasting rare earth mine

InactiveCN101012499AHigh recovery rateAvoid generatingProcess efficiency improvementElectrochemical responseChemical treatment

The invention discloses a full-separating method of high-purity rare earth oxide from rare earth rare earth ore reinforced and sintered by sulfuric acid, which is characterized by the following: producing La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3 and Y2O3 through ultrasonic extracting-electrochemical quantivalence-changing synthetic separating technique; oxidizing Ce3+ into Ce4+; reducing Eu3+ into Eu2+ t oseparate from other tervalent rare earths.

Owner:YANGZHOU UNIV +2

Magnetism/metal/fluorescence composite silicon dioxide nano particle and preparation method thereof

InactiveCN101125968AGood biocompatibilityGood chemical stabilityInorganic pigment treatmentLayered productsFluorescenceMicrosphere

The invention relates to magnetic / metal / fluorescence compound silicon dioxide nanometer particle and preparation method thereof, pertaining to nanometer material technical field. The nanometer particle is covered with an internal magnetic core, a metal layer and a lighting layer in sequence from interior to exterior; the internal magnetic core consists of organosilicon covering 6-1,000 ferrite nanometer particles; the metal layer is of a connection shell layer made of Ag or Au; the lighting layer is of SiO2 layer doped with organic lighting dye. The preparation method comprises steps of preparation of ferrite nanometer particles, laying silicon dioxide and metal layer to the internal magnetic core through inorganic silicon resource and organic silicon resource, secondary organic silicon layer coating and the coating of the layer doped with organic lighting dye. The nanometer particle of the invention has high lighting intensity and can dramatically improve detection sensitivity when being applied in biological marker, has rapid response in magnetic field, which improves separating rate; during preparation course, the control of magnetic matter content, diameter of particle and silicon dioxide shell layer through adjustment of reaction conditions.

Owner:JILIN UNIV

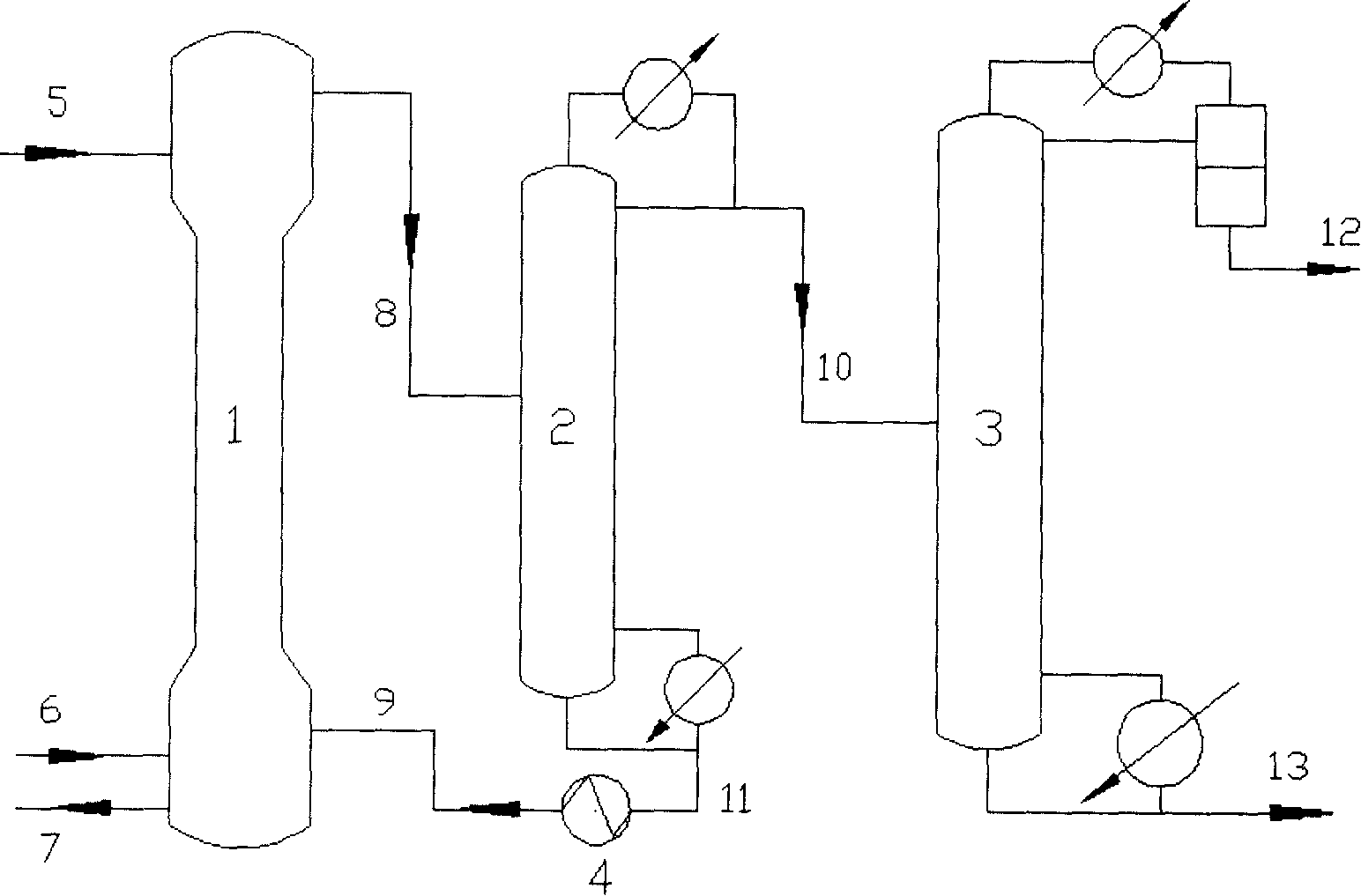

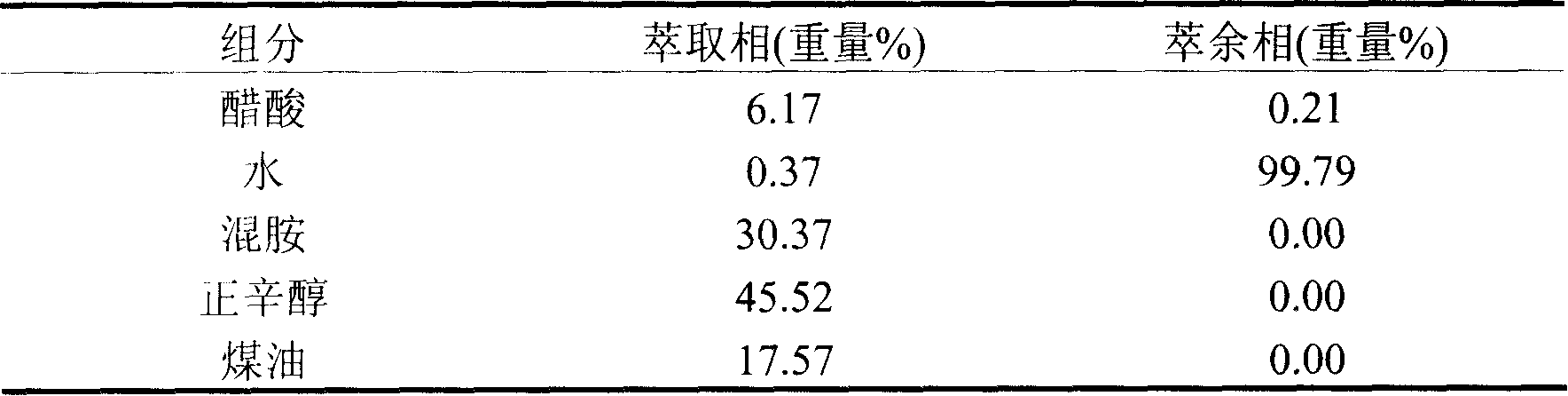

Method for recycling acetic acid in dilute acetic acid

ActiveCN101172941AImprove separation efficiencyIncreased acetic acid contentLiquid solutions solvent extractionCarboxylic compound separation/purificationBenzeneButyl acetate

The invention relates to a method for recycling acetic acid from diluted acetic acid, and aims at solving the problem that the recycling of acetic acid in the hydrolysis of furfural and methyl acetate as well as the Fischer-Tropsch combined production is difficult. The invention comprises the steps as follows: a) diluted acetic acid is extracted by a pulse filling extracting tower, the extractionphase containing extracting agent, the acetic acid and little water for the tower top is acquired, and the residual extraction phase of water containing micro acetic acid from the tower kettle is acquired; b) the extraction phase in an extracting agent recycling tower is conveyed; c) acetic acid 1 is fed into an azeotropic rectifying tower which utilizes one kind of benzene, cyclohexane, ethyl acetate, isopropyl acetate and butyl acetate as the extrainer, two-phase mixture of the extrainer and the water at a phase separator at the top of the tower is acquired, the water is extracted out from the tower top, and the retrainer returns into the tower. The utility model has the technical proposal of producing pure acetic acid at the tower top, solves the problems above, and adapts the industrial productions including recycling of acetic acid from wasted aldehyde water and extracting and refining acetic acid in the methyl acetate hydrolysis technique.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Separation method and culture method for umbilical cord mesenchymal stem cells

ActiveCN103589683AClear chemical compositionAvoid heterogeneous contaminationSkeletal/connective tissue cellsPenicillinPhosphate

The invention relates to a separation method and a culture method for umbilical cord mesenchymal stem cells. The separation method comprises the following steps: thoroughly cleaning umbilical cord tissue of a healthy newborn by using a PBS (phosphate buffer solution) containing streptomycin and penicillin, and removing blood; shearing the umbilical cord into small sections uniform in length, and mechanically separating, bluntly stripping Wharton' s jelly, and removing umbilical arteries and umbilical veins; uniformly shearing the Wharton' s jelly; re-suspending the sheared Wharton' s jelly through an MSCs (mesenchymal stem cells) culture medium, inoculating to a culture dish with laid gelatin, and putting in a CO2 culture box for cultivation; conducting centrifugal separation to obtain tissue blocks and a cell resuspension solution. The culture method comprises the following steps: enwrapping the culture dish, discarding the gelatin, and washing with the PBS; inoculating the separated out tissue blocks and the cell resuspension into the culture dish; performing digestive subculture after cell fusion growth rate reaches 80-90%.

Owner:BEIJING DONGFANG HUAHUI BIOMEDICAL TECH

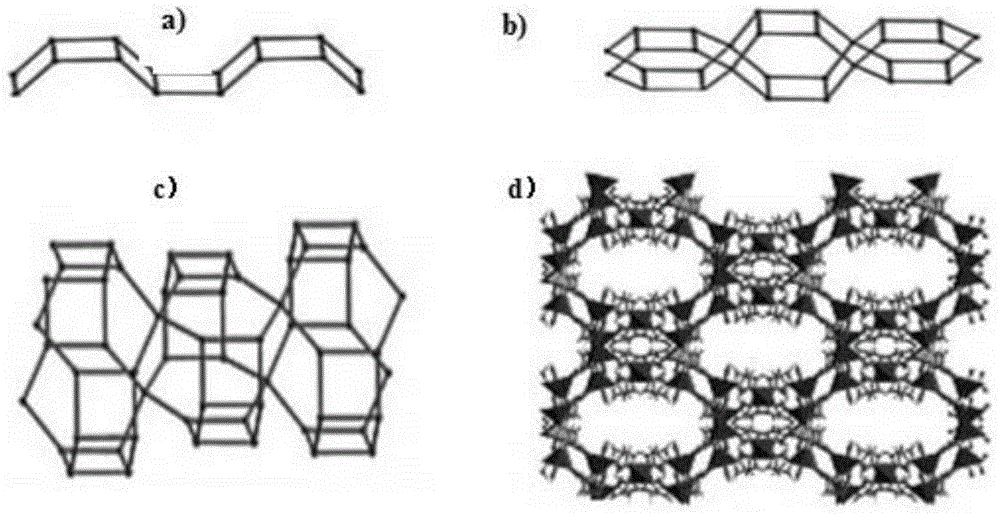

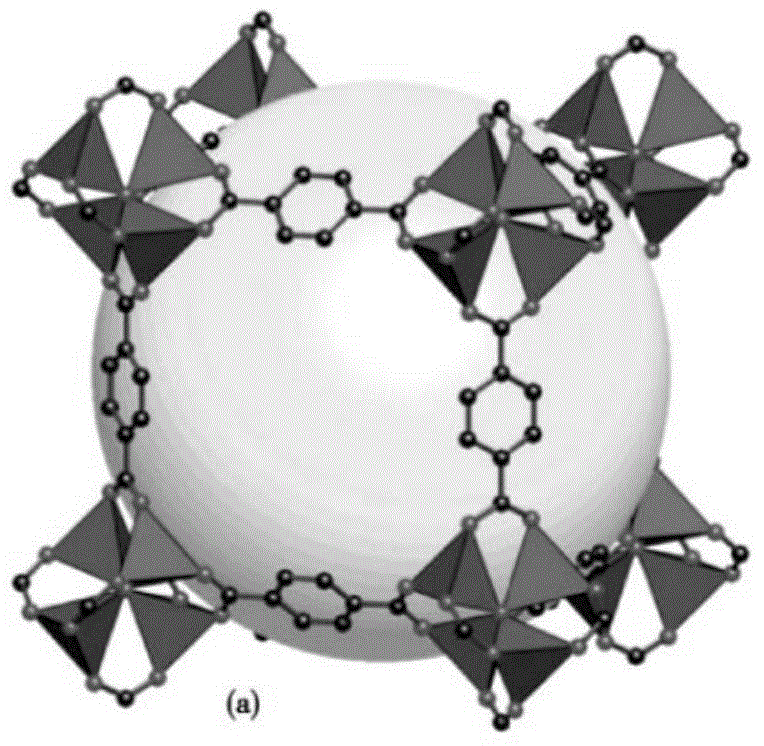

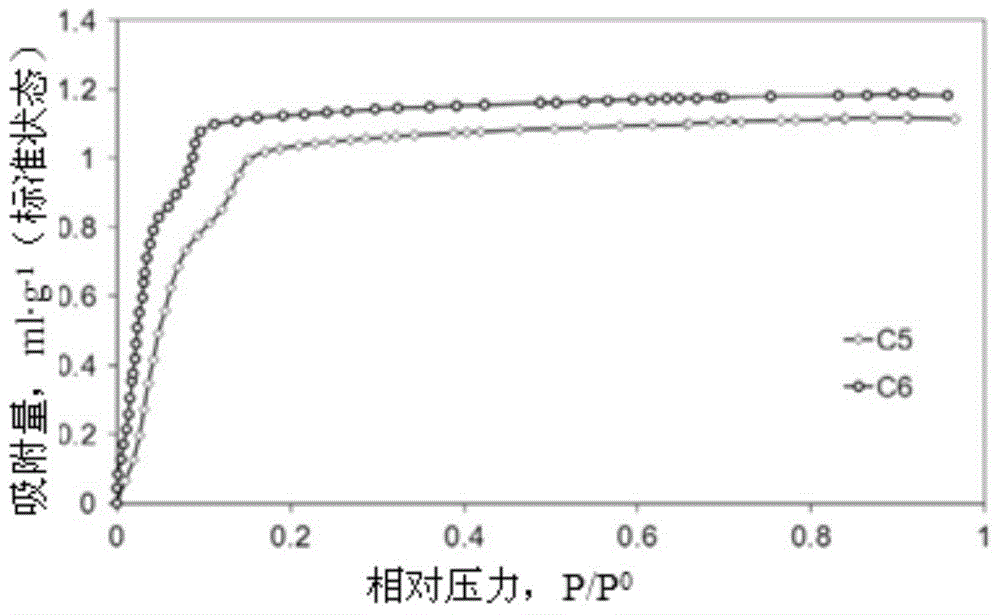

Preparation method of metal-organic framework porous adsorption material for normal paraffin and isoparaffin adsorption separation

InactiveCN104549160AHigh purityReduce transition timeOther chemical processesAdsorption purification/separationN dimethylformamideReaction temperature

The invention relates to a preparation process of a metal-organic framework porous adsorption material for C4-C8 normal paraffin and isoparaffin adsorption separation. According to the preparation method of the synthesized metal-organic framework porous adsorption material, metal ion nitrate and an organic ligand are dissolved according to the mass ratio of 1:1-15 in a mixed solution of N,N-dimethylformamide and N,N-diethyl formamide; stirring is carried out for 0.5-12 h; reaction temperature is controlled to 80-250 DEG C, and reaction time is 12-120 h; and by a hydrothermal synthesis method, the metal-organic framework porous adsorption material is prepared. The material has characteristics as follows: specific surface area is large; pore structure height is ordered; pore size is controllable; surface potential energy is controllable; and adsorption capacity of normal paraffin is large. The material can selectively adsorb normal paraffin from mixed materials of normal paraffin and isoparaffin, has high selectivity and has a wide practical application prospect in normal paraffin and isoparaffin separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

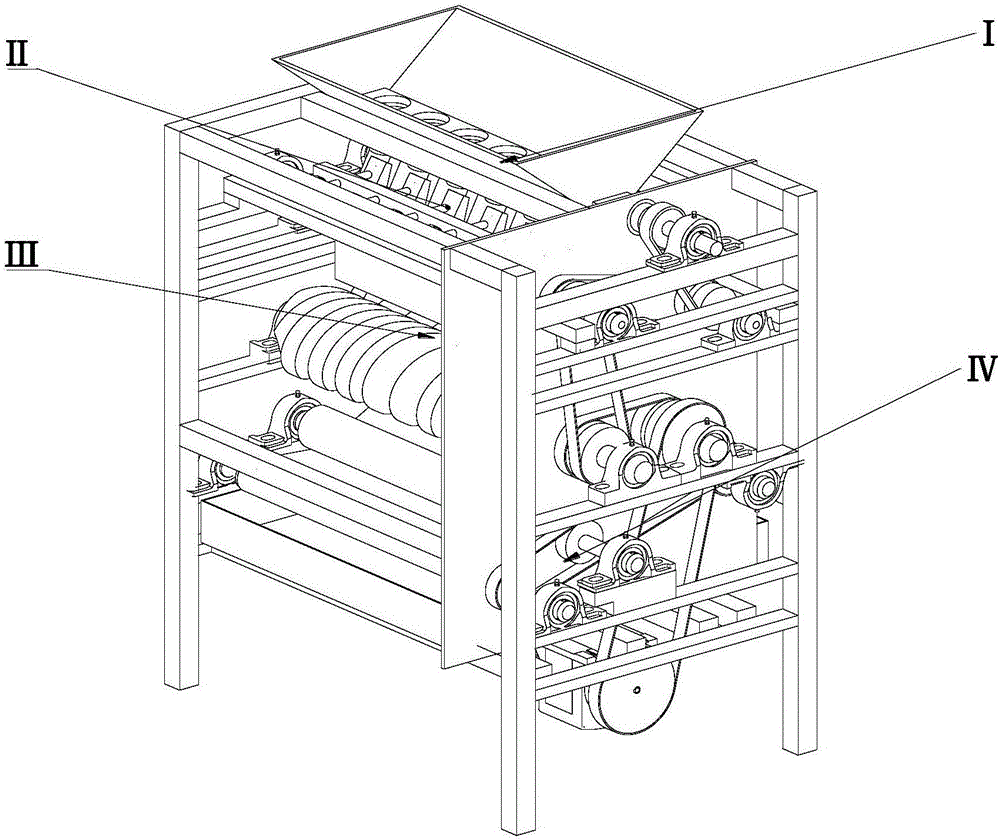

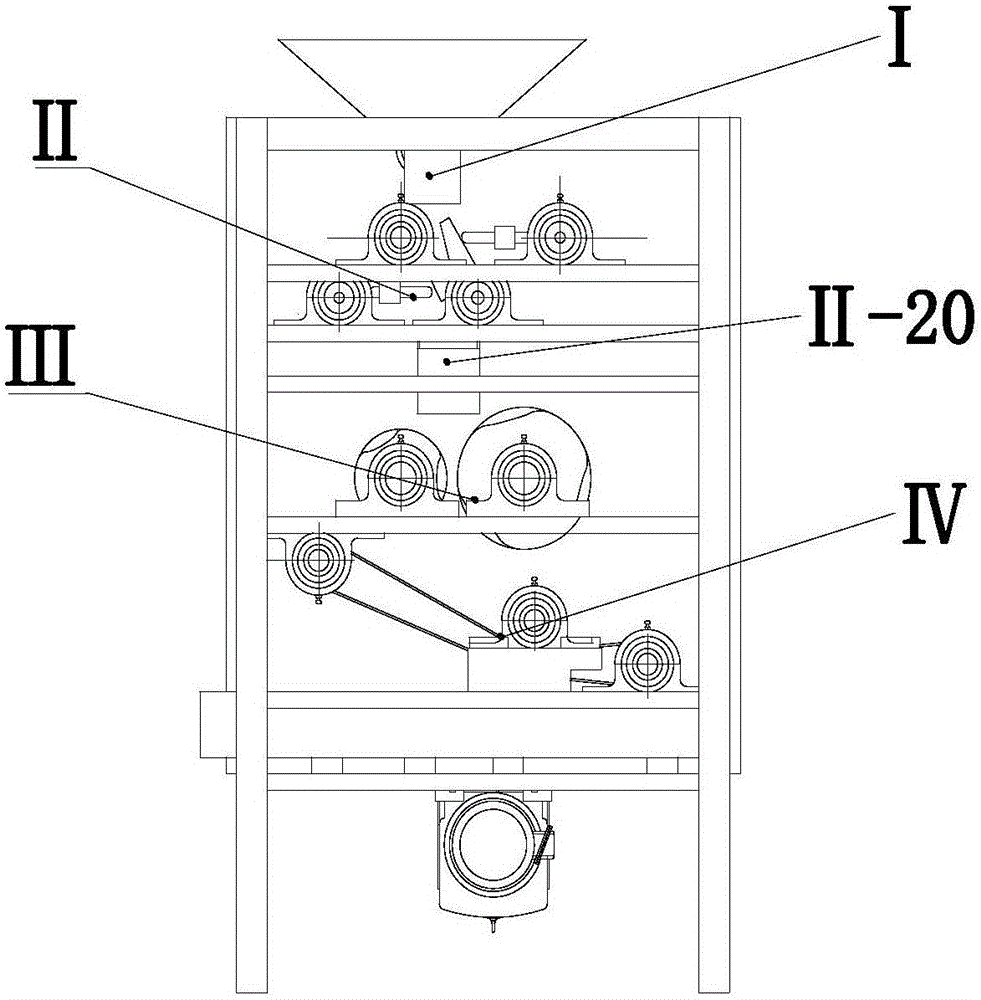

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

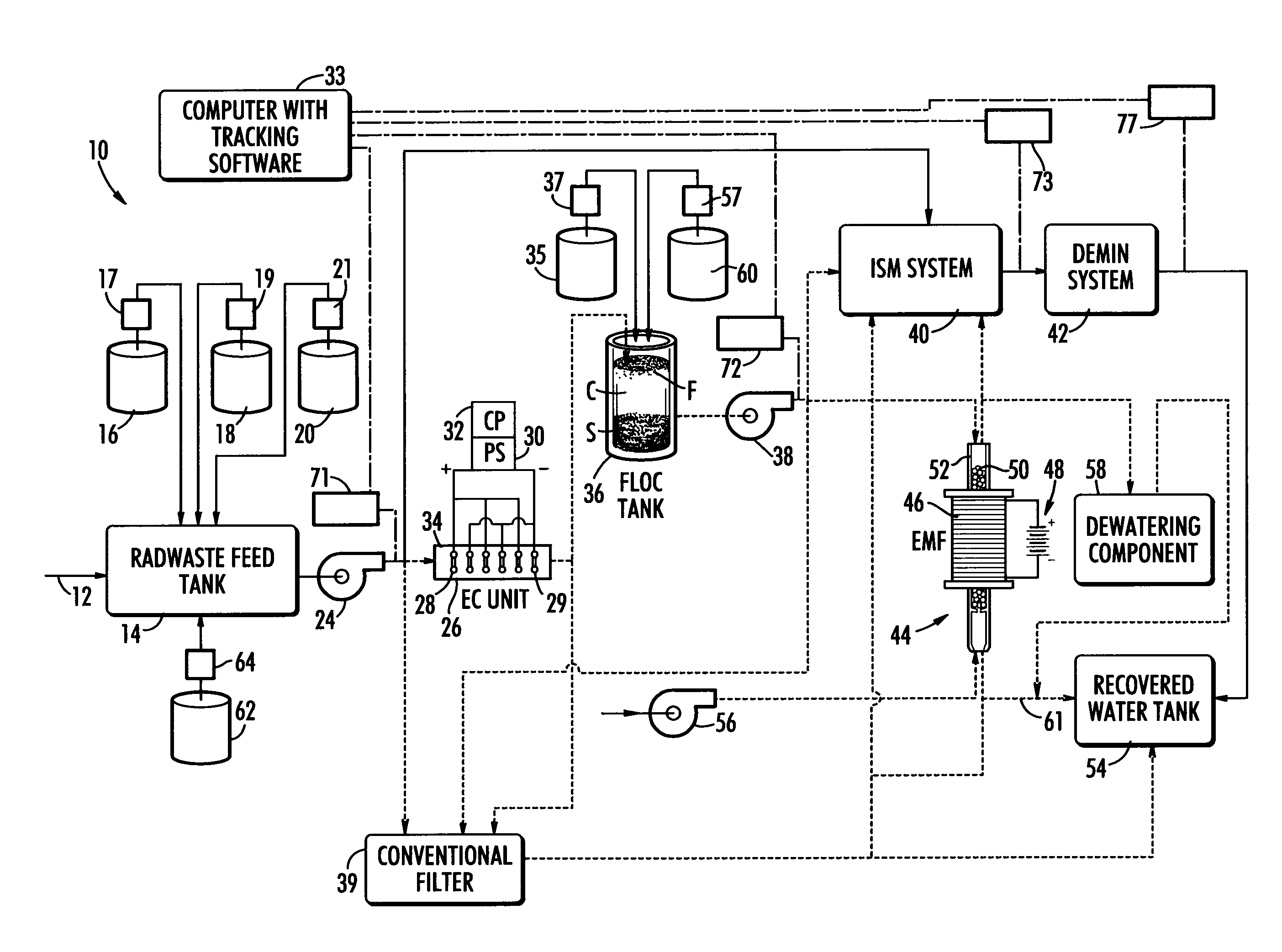

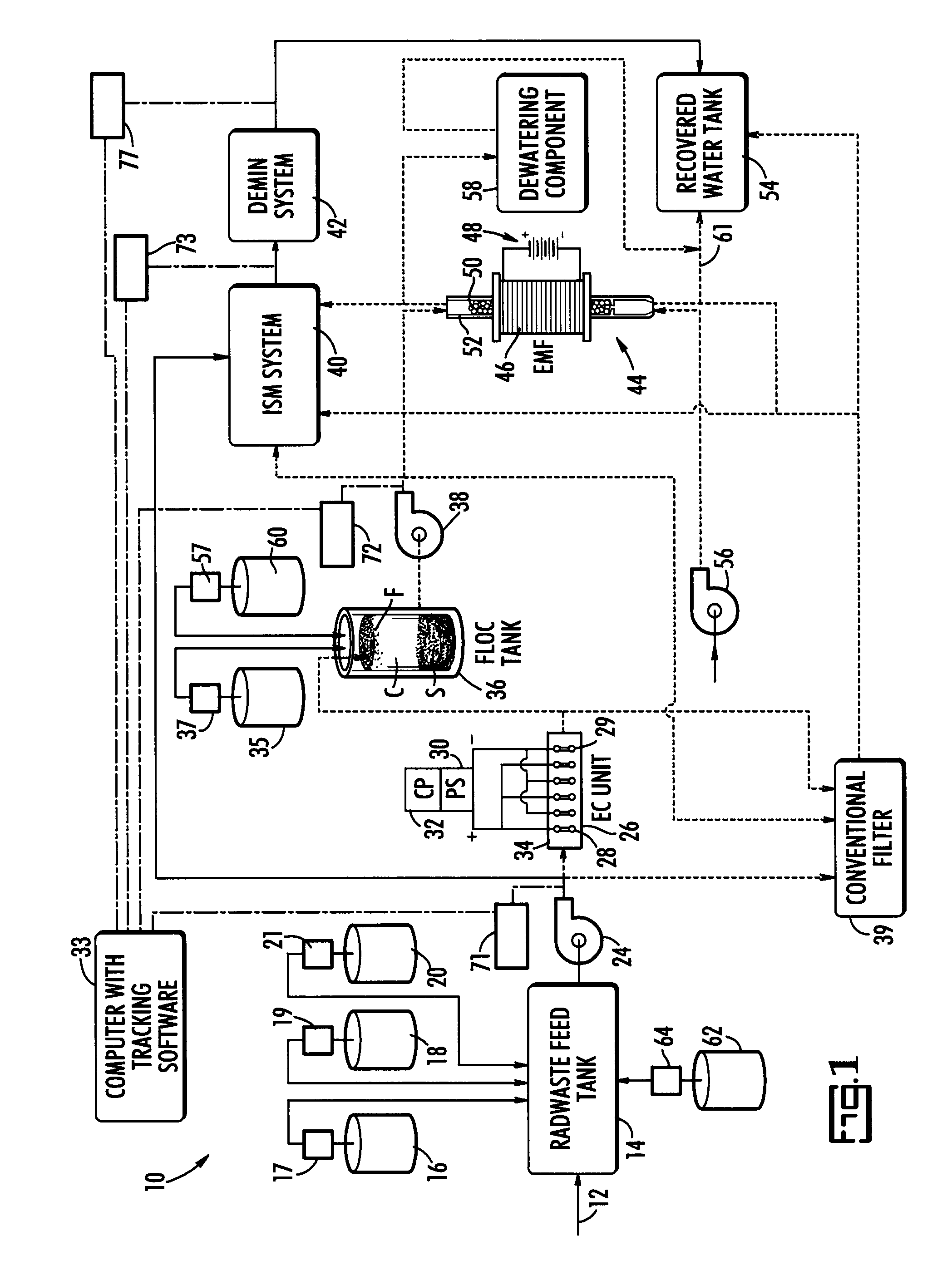

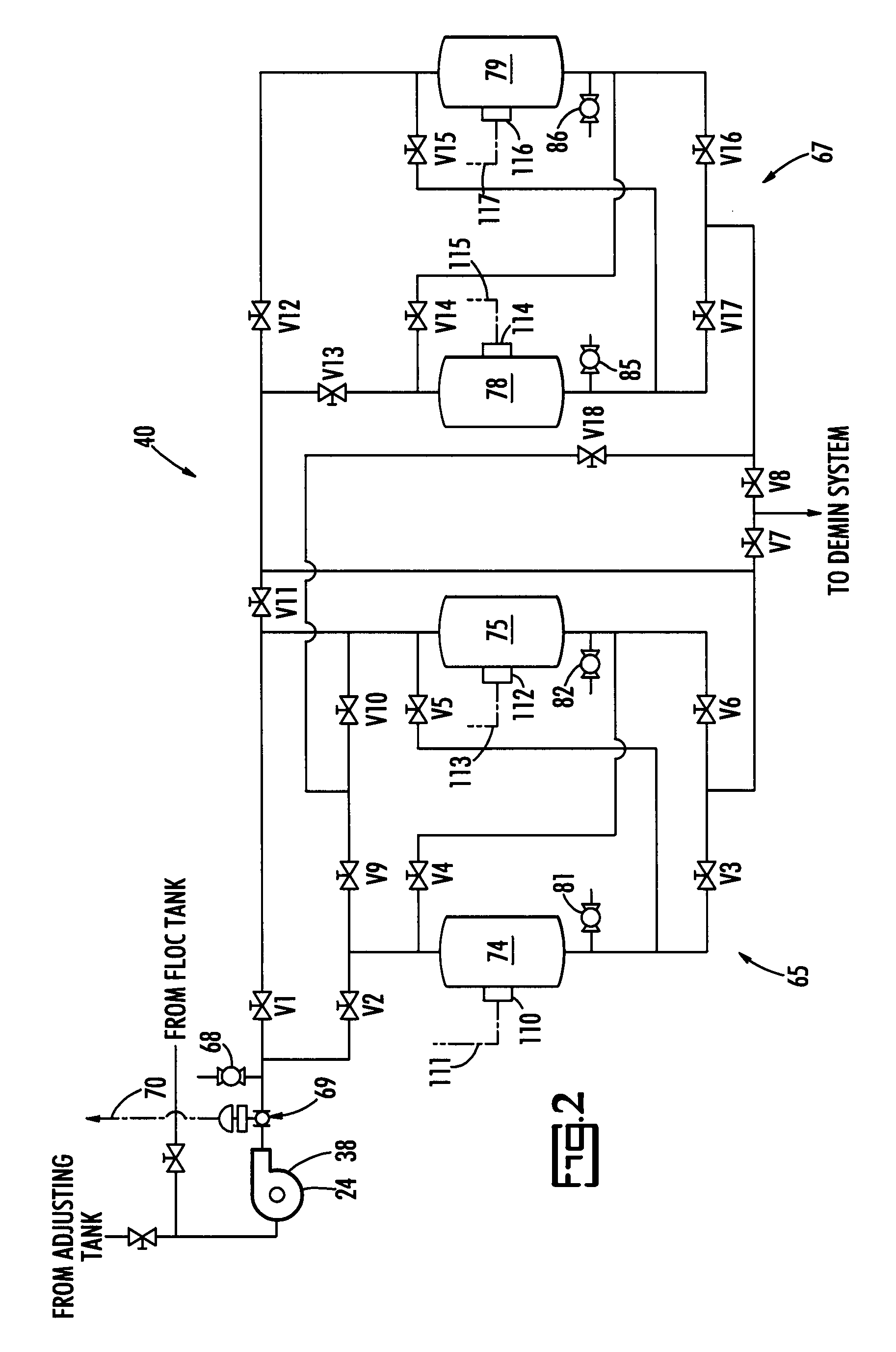

Process and System for Treating Radioactive Waste Water to Prevent Overloading Demineralizer Systems

ActiveUS20090038961A1Easily backflushedAvoid disposition problemsTreatment involving filtrationSolid sorbent liquid separationWastewaterRadioactive waste

A process and system for treating waste water containing contaminants to prevent excessive accumulation on demineralizer media of a driver contaminate capable of such accumulation before another contaminant can reach a predetermined level of accumulation. The waste water is treated upstream of the demineralizer media with removal means for specifically removing the driver contaminant while leaving the other contaminant for subsequent removal by the demineralizer media. The amount of accumulation on the demineralizer media of the other contaminant is monitored, and the supplying of treated waste water to the demineralizer media is terminated when its accumulation reaches the predetermined level.

Owner:ENERGYSOLUTIONS LLC

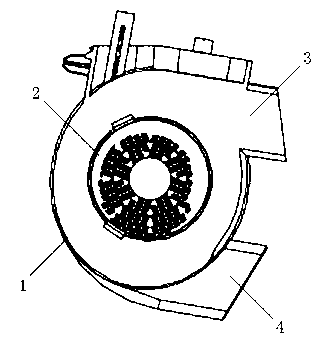

Efficient cyclone separation device for dust remover

InactiveCN103181741AReduce energy lossGreat suctionSuction filtersCycloneElectrical and Electronics engineering

The invention discloses an efficient cyclone separation device for a dust remover, which comprises a barrel body and a filter arranged inside the barrel body, wherein an air inlet communicated with the inside of the barrel is formed on one side of the upper end of the barrel body in tangential direction of the outer wall; the cross section of the outer wall of an air intake way at the upper end of the barrel body, communicated with the air inlet, is helical; and a plurality of air intake guide vanes are evenly arranged inside the air intake way in the circular direction. According to the efficient cyclone separation device for the dust remover, the cross sectional area is gradually reduced from the air inlet to the inside to facilitate the increasement of the tangential speed of the airflow inside the air intake way along with the reduction of the cross sectional area, so as to increase the separation efficiency of an outer eddy side; the air intake guide vanes are arranged inside the air intake way and evenly distributed in the circular direction to facilitate the conversion of the axial speed of the airflow to the tangential speed, reduce the loss of energy of axial downwards speed of an inner eddy and improve the suction power of the dust remover; and therefore, the efficient cyclone separation device for dust remover has the advantages of high efficiency and less power loss and can effectively improve the suction power of a dust remover motor.

Owner:NANJING LG PANDA APPLIANCES

Preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation

ActiveCN104888498ALarge specific surface areaImprove bindingLiquid/solution decomposition chemical coatingLiquid separationNano structuringEtching

The invention provides a preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation. The preparation method comprises the followings steps: firstly, the foamy copper is sequentially put in an ethanol solution and an acetone solution for ultrasonic cleaning and treated with a hydrochloric acid aqueous solution to remove oil stain and oxide skin; for the cleaned foamy copper, a chemical etching or electrochemical deposition method is used to pre-roughen a foamy copper framework so as to improve the membrane-based binding force; then, a dip-coating-sintering method is adopted to obtain a ZnO crystal seed layer on the surface of the framework, and a compact ZnO array nano structure grows in an oriented manner through a chemical bath manner so as to improve the strength and stability of a film layer; finally, fluoridation is performed on the foamy copper to realize the super-hydrophobic super-oleophylic feature and the oil and water separation function. Through the pre-roughening of the foamy copper framework and the compactly arranged zinc oxide nano structure, the strength of the film layer and the membrane-based binding force can be improved, and the damaging and falling behavior of the film layer during oil and water separation by the foamy copper can be reduced, so that the durable oil and water separation capacity of the foamy copper can be improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com