Slurry bed reactor and uses thereof

A slurry bed and reactor technology, which is applied to slurry bed reactors and their application fields, can solve the problems of complex equipment, low production efficiency, and heavy equipment, and achieves the advantages of reducing circulation circulation, uniform distribution, and improving filtration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

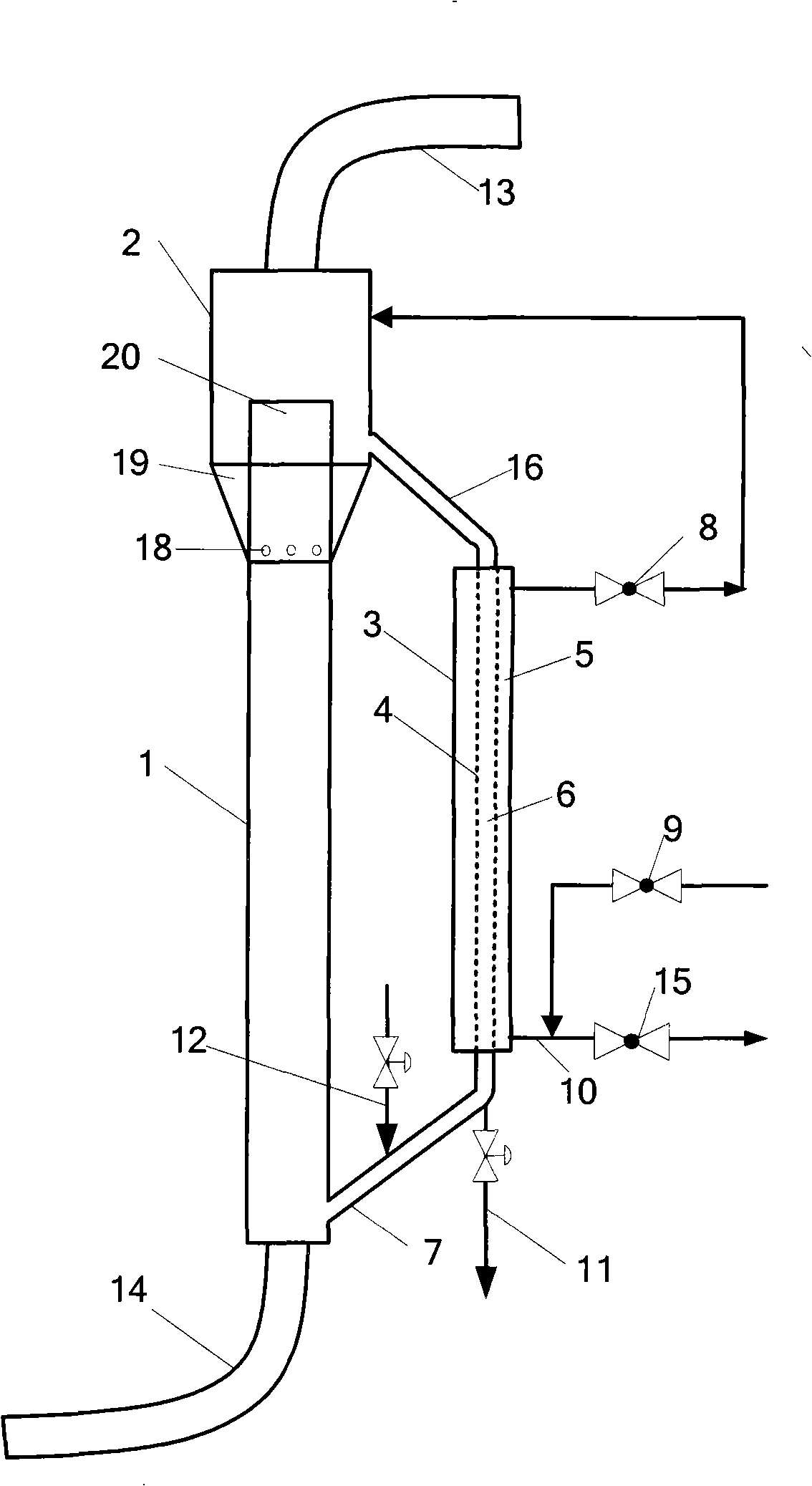

[0061] Use as attached figure 1 In the shown reactor, the flow disturbance zone 20 and the steady flow zone 19 are separated by a cylindrical baffle, and the bottom of the steady flow zone 19 communicates with the reaction zone through the opening at the bottom of the baffle. where the size of the reaction zone is 70×3200mm; the diameter of the expansion section of the settlement zone is 150mm, and the height is 1000mm; the size of the cylindrical baffle is 70×700mm, there are 6 openings at the bottom of the baffle 12 holes; the outer tube size of the downcomer is 70×2000mm, the inner filter tube is made of metal microporous membrane, and the size of the filter tube is 30×1800mm, average pore size 1.0μm.

[0062] The composition of the catalyst is: containing 20.3% by weight of Co 2 o 3 , 76.1 wt% SiO 2 , 3.6% by weight of MgO. The preparation method is to contain Co(NO 3 ) 3 and Mg(NO 3 ) 2 solution impregnated SiO 2 The microsphere carrier is left to stand ...

Embodiment 2

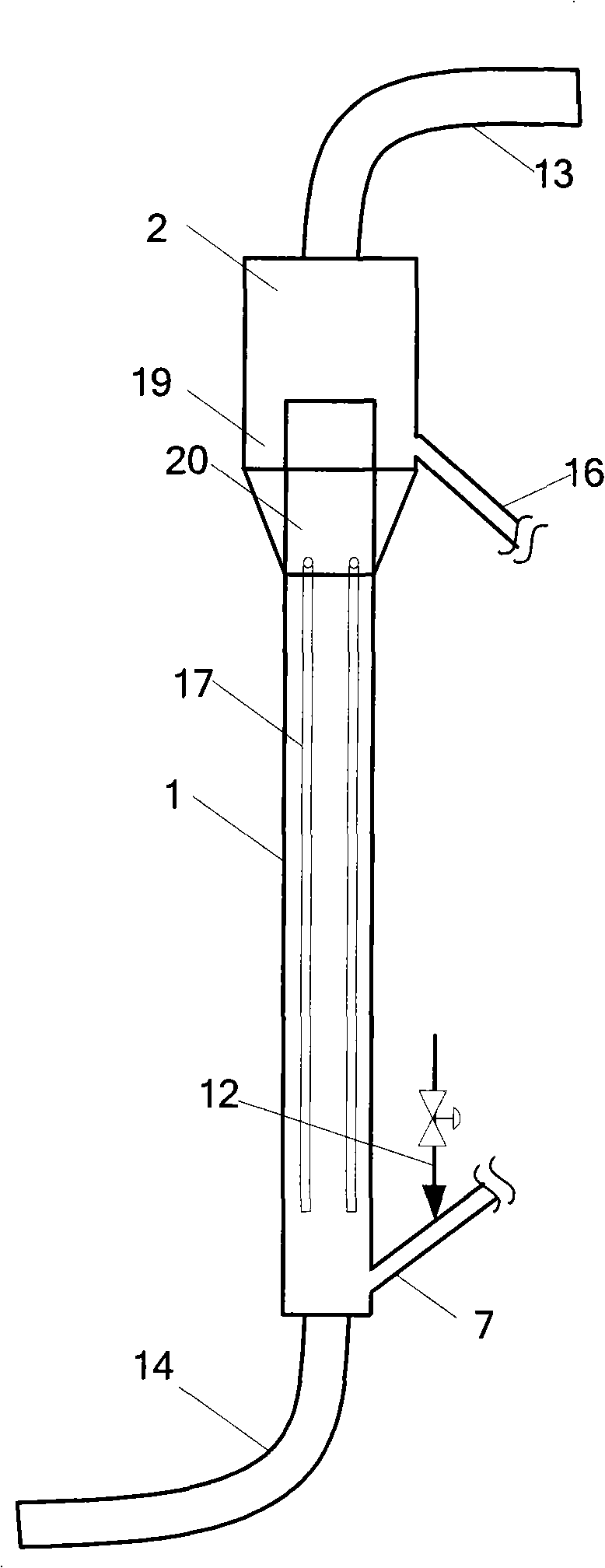

[0066] Use as attached figure 2 In the shown reactor, the disturbed flow zone 20 and the steady flow zone 19 are separated by a cylindrical baffle, and the bottom of the steady flow zone 19 communicates with the lower part of the reaction zone through a draft tube 17 . where the size of the reaction zone is 280×3600mm; the diameter of the expanded section of the settlement zone is 450mm, and the height is 1000mm; the size of the cylindrical baffle is 280×700mm, 6 diversion tubes in total, the sizes are 12×3000mm and 12×1500mm, staggered arrangement; the outer tube size of the downcomer is 280×2000mm, the inner filter tube is made of metal microporous membrane, with an average pore size of 0.2μm, such as Figure 6 The 7 wires shown are connected in parallel, and the size of each wire is 30×1000mm.

[0067] 160 liters of slurry containing solid particles is preliminarily introduced into the reactor, the particle size range of the slurry is 1-100 μm, and the superfic...

Embodiment 3

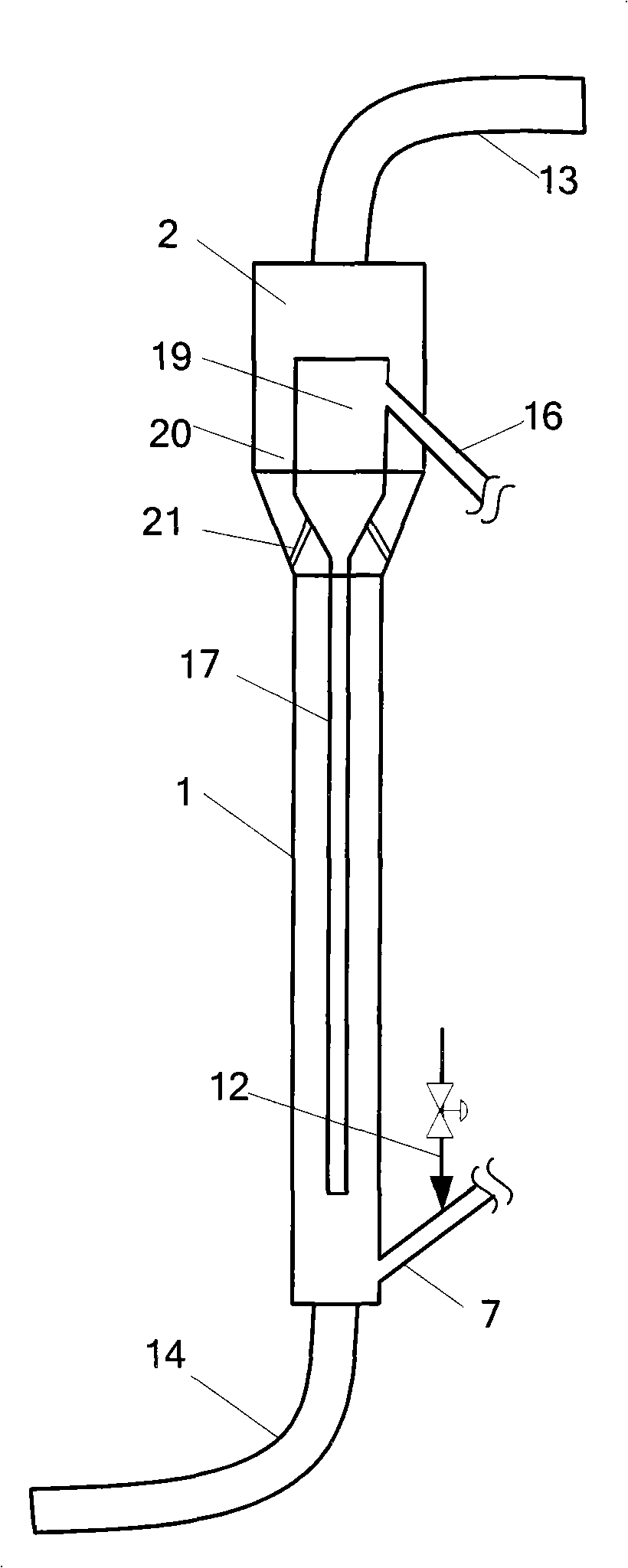

[0070] Use as attached image 3 In the shown reactor, the disturbed flow zone 20 and the steady flow zone 19 are separated by a conical cylindrical baffle, and the conical cylindrical baffle is fixed on the inner wall of the riser through a bracket 21. The bottom of the steady flow zone 19 communicates with the lower part of the reaction zone through the guide tube 17 . where the size of the reaction zone is 280×3600mm; the diameter of the expansion section of the settlement zone is 450mm, and the height is 1500mm; 150×750mm, the size of the guide tube is 40×2800mm; the size of the outer tube of the downcomer is 100×1200mm, the inner filter tube is made of metal microporous membrane with an average pore size of 1 μm, such as Figure 6 The 7 wires shown are connected in parallel, and the size of each wire is 30×1000mm.

[0071] Introduce 160 liters of slurry containing solid particles into the reactor in advance. The particle size range in the slurry is 1 to 100 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com