Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

618 results about "Dry sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

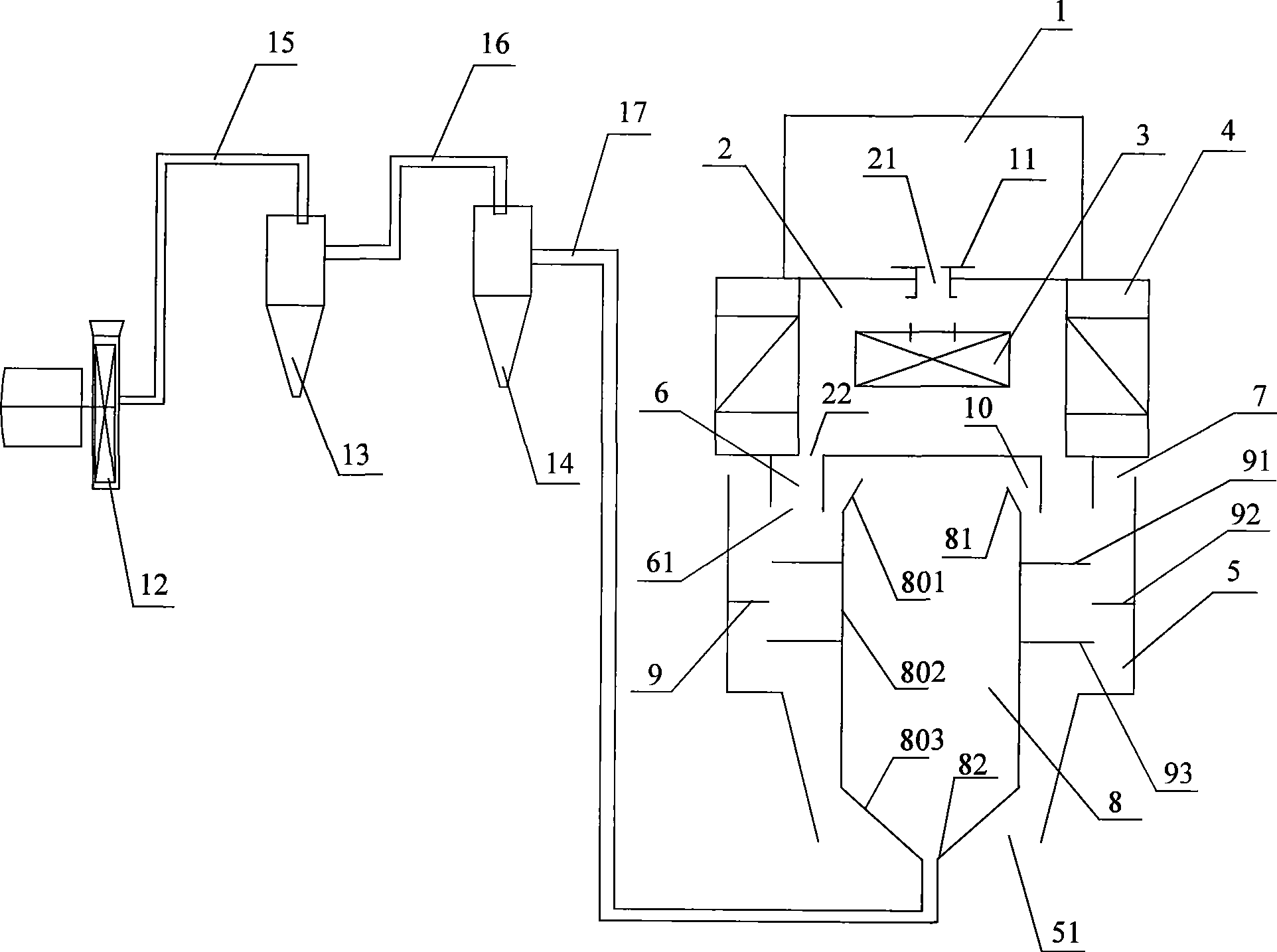

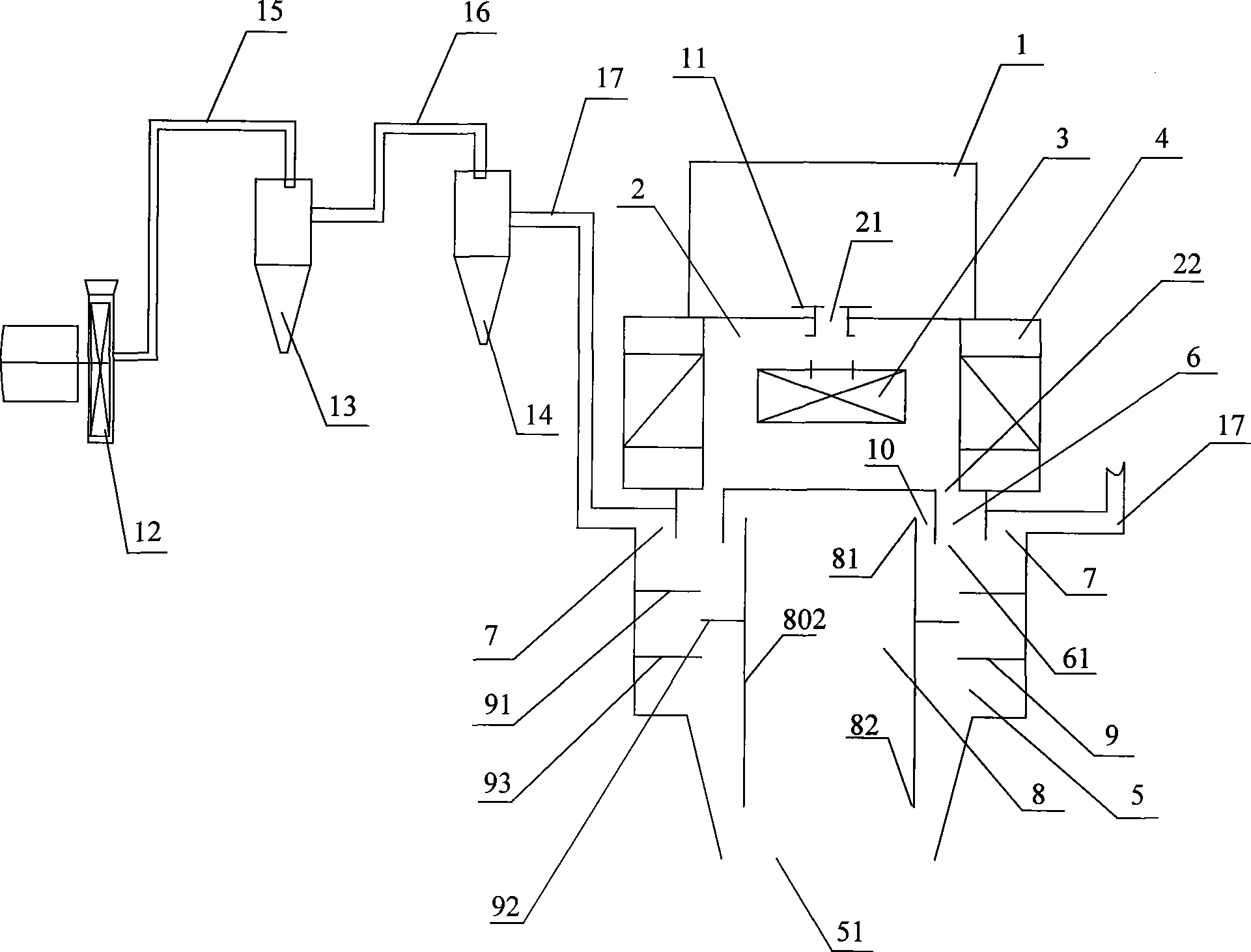

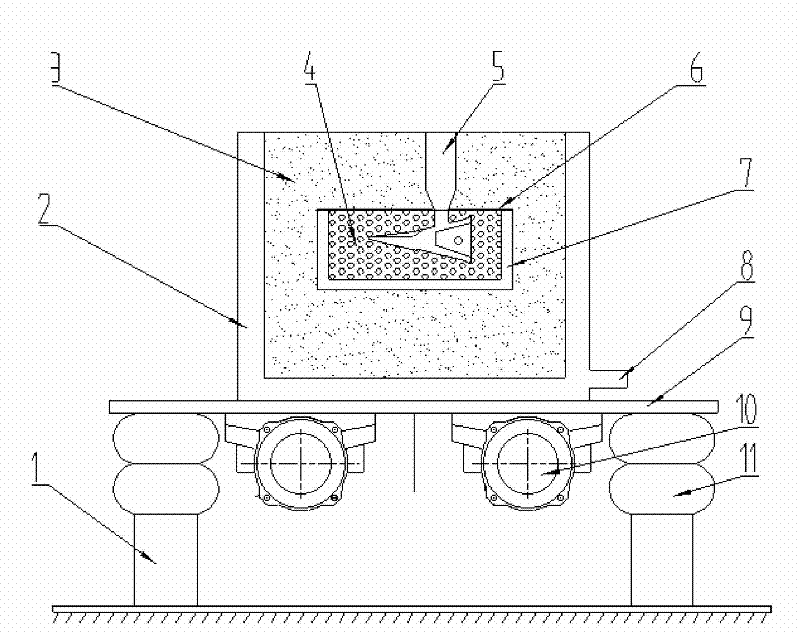

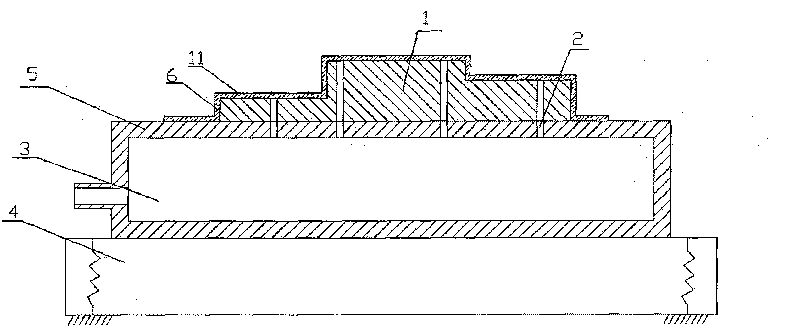

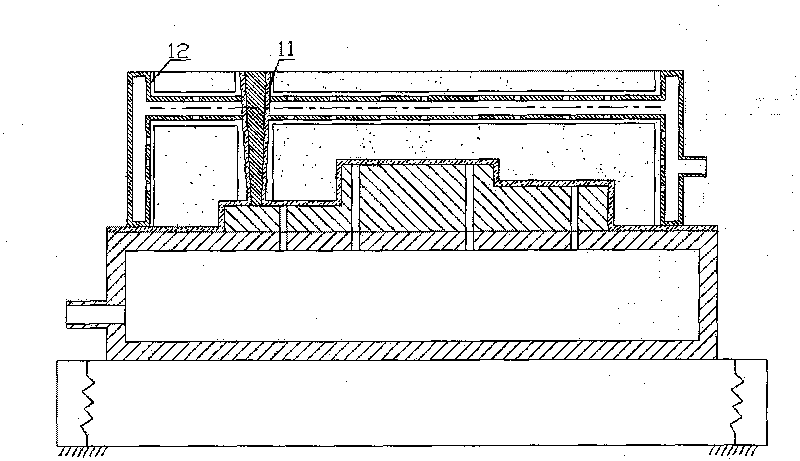

Dry-type sand making method and dry-type sand making machine thereof

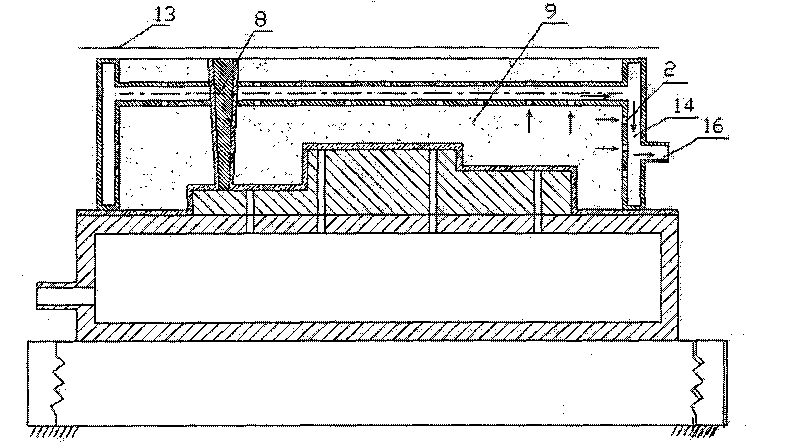

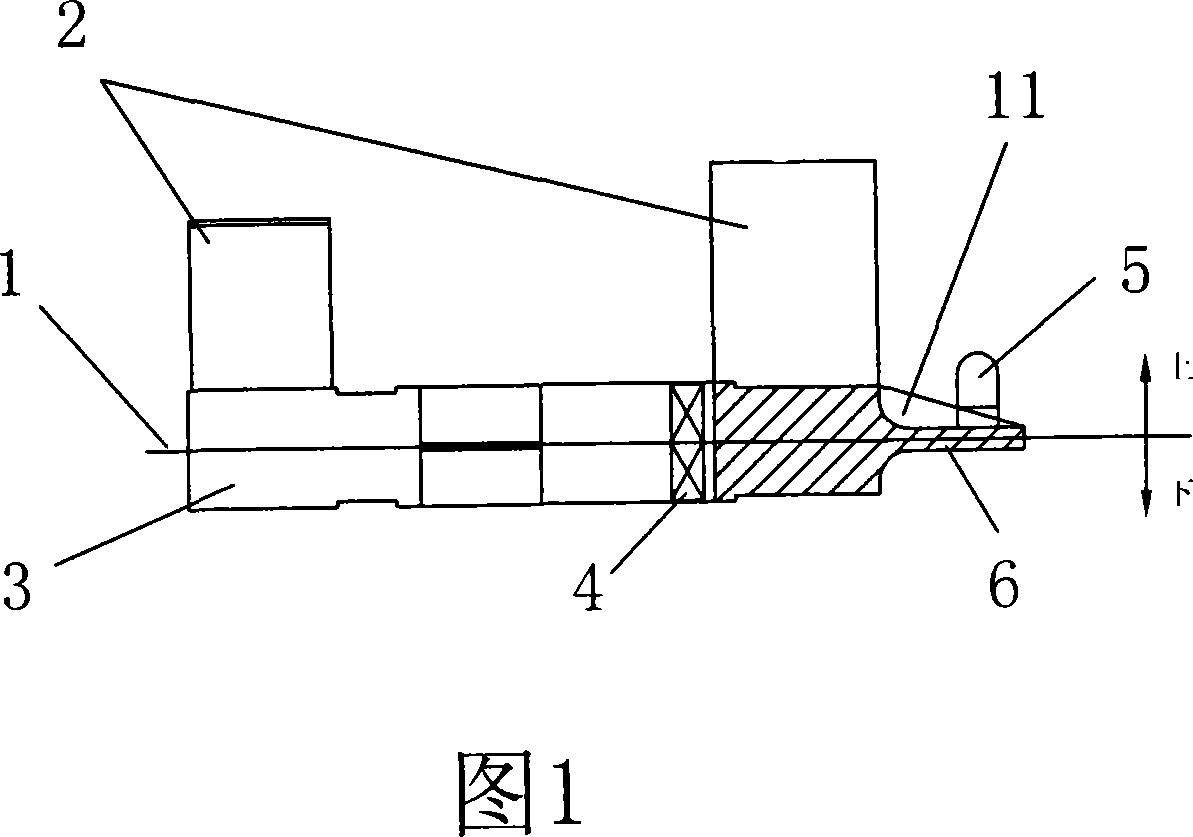

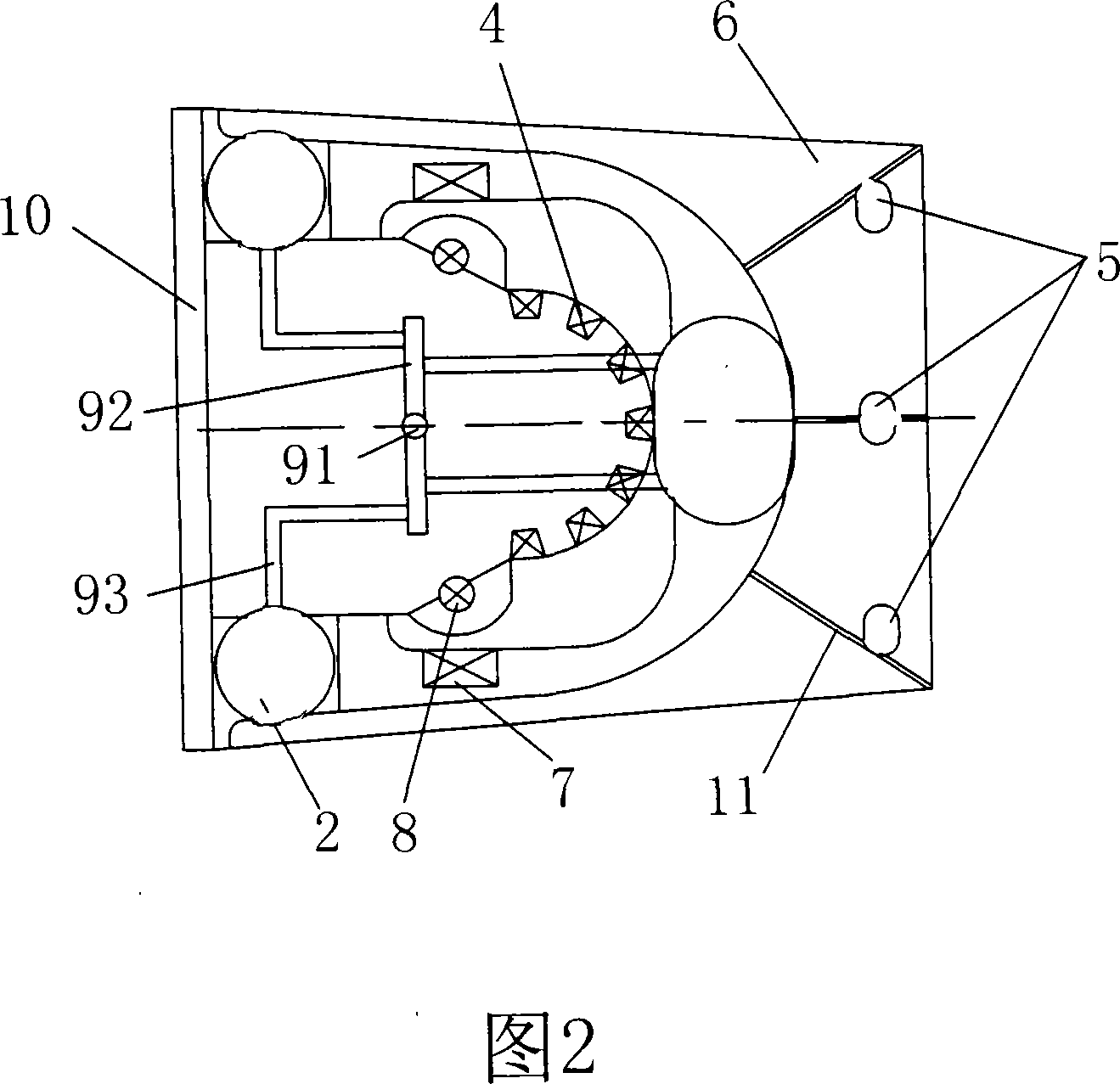

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

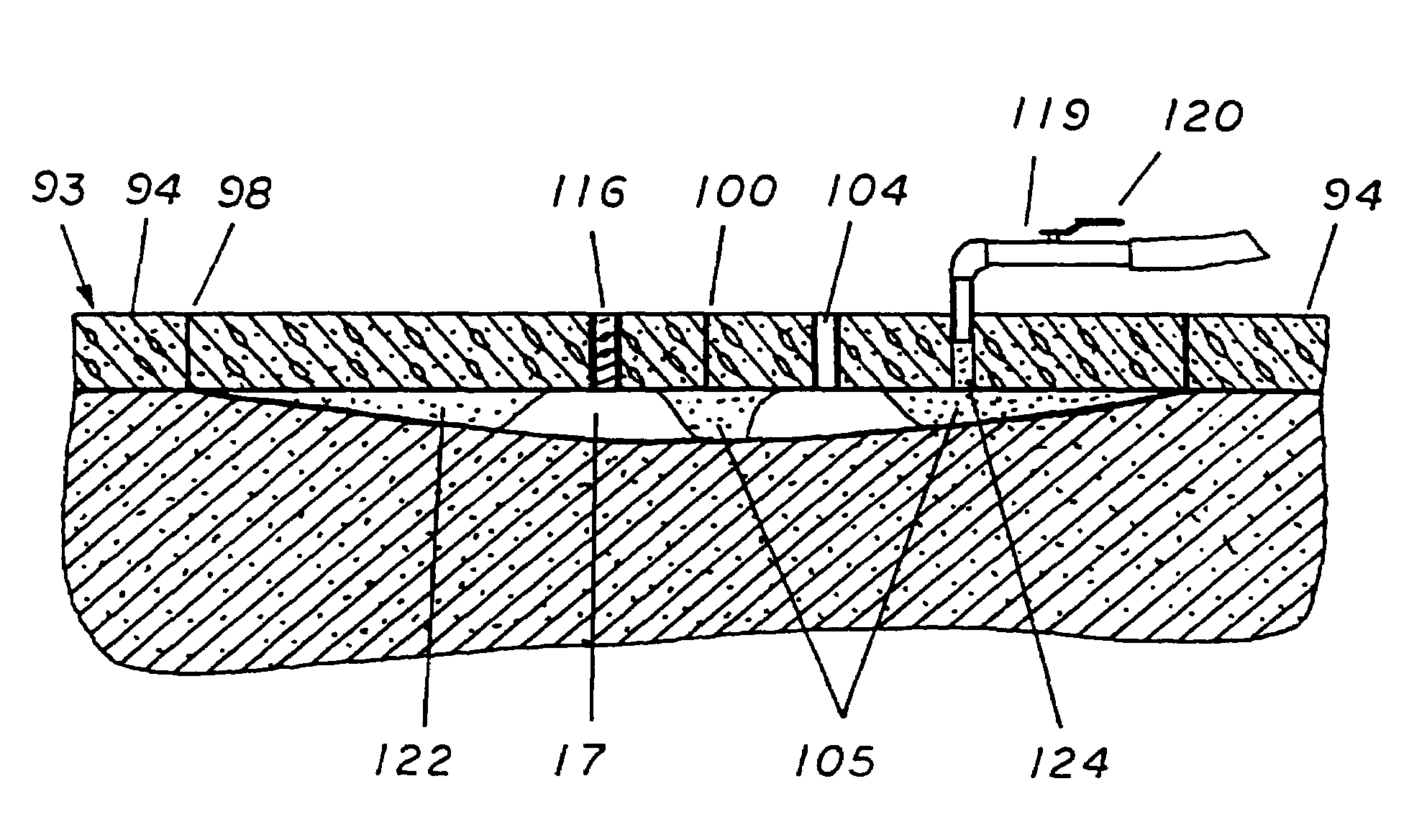

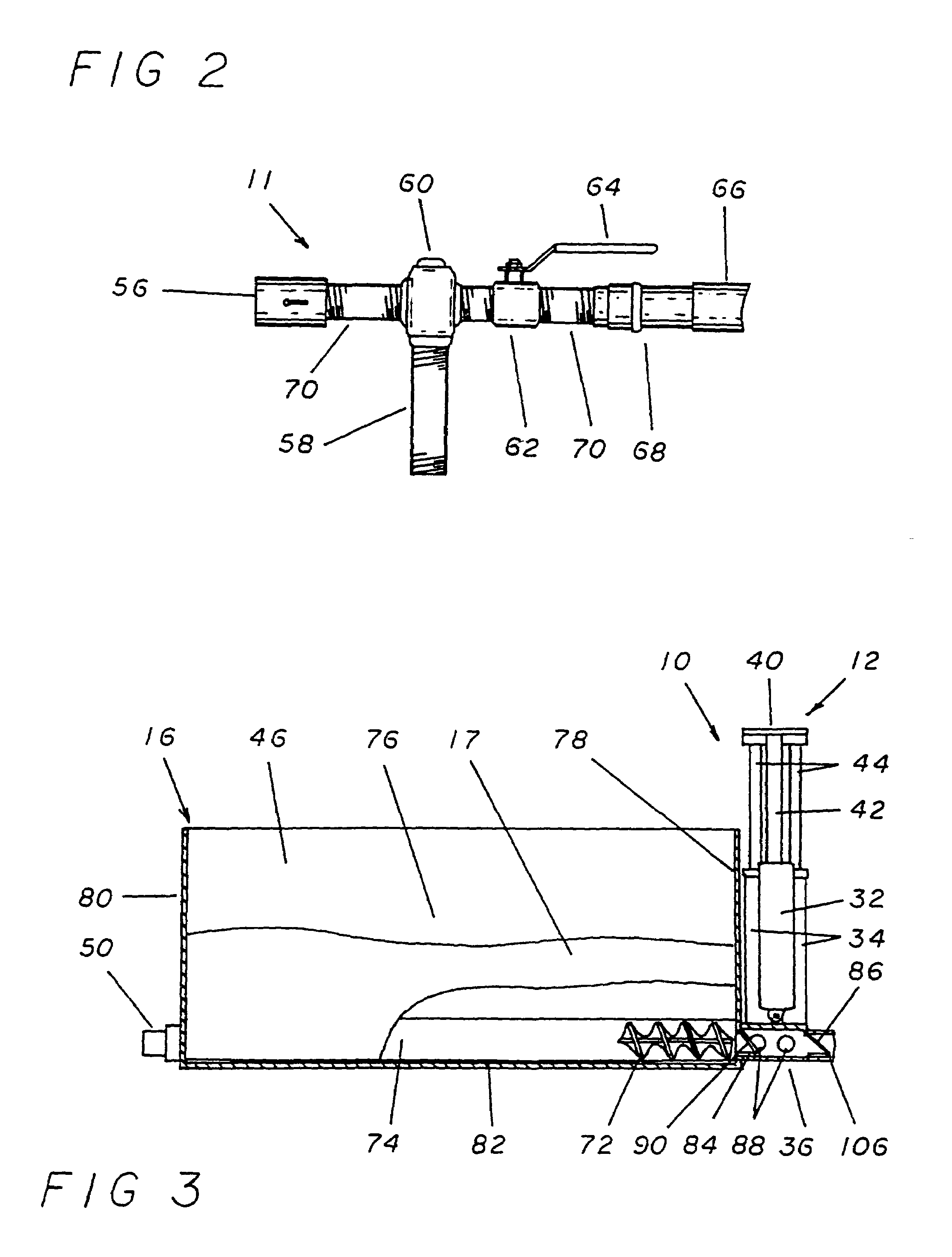

Method of repairing damaged concrete slabs

A method of repairing concrete slabs that have become uneven and dangerous is provided that employs lime sludge that is injected under pressure into the space between the lower surface of the damaged concrete slab and the underlying ground to raise that slab back into a level orientation. Once this has been accomplished, any remaining space below the slab is filled in with well dried sand blown in under pressure.

Owner:ASPLIN CHARLES LEE

Dry-mixed mortar station

InactiveCN101462310AGood construction performanceQuality improvementMixing operation control apparatusSold ingredients supply apparatusDry sandDelivery system

The invention discloses a dry mortar mixing station, which consists of a sand conveying system, a drying system, a dust removing system, a dry sand hoisting-sieving and storing system, a powder storage system, a mixture metering and conveying system, a stirring system, and a finished product storing, conveying and packaging system. The dry mortar mixing station has good metering precision and efficient production capability; and the produced dry mixed mortar has superior construction performance and quality, is environment-friendly, can meet various construction works, and can adapt to different requirements of various novel building materials on mortar.

Owner:徐州天地重型机械制造有限公司

Method for lost foam casting of composite two-liquor bimetallic hammerhead of crusher

InactiveCN102873308ASimple production processImprove efficiencyFoundry mouldsFoundry coresThermal insulationDry sand

The invention discloses a method for lost foam casting of a composite two-liquor bimetallic hammerhead of a crusher. The method includes: embedding a crusher hammerhead molded body made of foam plastics into dry sand of a sand box, and vacuumizing; then respectively preparing high-chromium iron casting liquor and carbon steel casting liquor; after melting down and deoxidizing the two kinds of metallic casting liquor, performing carbon steel pouring (1300-1400 DEG C) prior to high-chromium iron pouring (1550-1650 DEG C), and rapidly covering high-chromium iron liquor by thermal insulation agents after pouring is completed; subjecting a molded crusher hammerhead casting to thermal treatment at the temperature of 900-1000 DEG C, then rapidly discharging the casting and cooling the casting in air; and tempering at the temperature of 250-300 DEG C finally.

Owner:XI AN JIAOTONG UNIV

Lost wax shell-based negative pressure dry sand and iron shot chilling vibrational casting process method

InactiveCN102240778AHigh strengthReduce the number of hanging coatsFoundry mouldsFoundry coresWaxHigh density

The invention discloses a lost wax shell-based negative pressure dry sand and iron shot chilling vibrational composite casting process method. The method is characterized by comprising the following steps of: feeding a shell manufactured by a lost wax process into a chilling sand box; loading steel shots in the gap between the shell and the chilling sand box; feeding the chilling sand box into a sand box with a vacuumized negative pressure model; fully filling dry sand between the chilling sand box and the sand box with the vacuumized negative pressure model; paving a plastic film; placing a pouring cup; and pouring under the simultaneous vacuumizing and vibrating condition. By the method, the strength of molding sand is high, a chilling effect is good, the process characteristics of lost foam casting and hot investment casting are combined, the defect of foam-gasified carbon special for the lost foam casting is overcome, the chilling effect of the iron shots is fully exerted, the pouring is performed under the vibration condition, and alloy grains are refined, so that wear-resisting castings have higher density, hardness and wear resistance.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

Preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of external wall

The invention discloses a preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of an external wall. The preparation method is characterized in that the anti-cracking mortar comprises the following components in percentage by mass: 40-80% of building phosphogypsum, 20-50% of dried sand, 0-20% of cement, 0-5% of fly ash, 0-0.2% of a high-performance plasticizer, 0-0.2% of a thixotropic agent, 0.1-0.3% of a water-retaining agent, 0.01-0.4% of a gypsum retarder, 0-3% of a micromolecular polymer and 0-0.25% of anti-cracking fiber. According to the preparation method, the building phosphogypsum prepared by washing and calcining industrial byproduct phosphogypsum is used as a cementing material, so that the problems that a cement-based material is easy to shrink, hollow and crack are solved; through full use of the characteristics of fast setting and hardening, good volume stability and low own ratio of compressive strength to flexural strength of a gypsum material, the anti-cracking mortar, of which the ratio of the compressive strength to the flexural strength is lower than 2.5, the operable time is 1-2h, the final setting time is shorter than 3h, the insulation board bonding strength is higher than 0.10MPa and breakage occurs inside an insulation board, is prepared. The anti-cracking mortar is applied to the interior insulation of the external wall and low in cost, reduces the environment pollution, and is simple in production process, low in energy consumption and good in product performance; compared with other insulation board crack resisting products, the anti-cracking mortar has higher market competitiveness and is strong in practicality.

Owner:四川华邦保和涂料有限公司

Method for eliminating carbon defects by adopting high-performance coating, negative-pressure firing, vacant shell pouring and quick airflow cooling in lost foam casting

InactiveCN101690976AEliminate carbon defectsGrain refinementFoundry mouldsFoundry coresDry sandPlastic film

The invention discloses a method for eliminating carbon defects by adopting a high-performance coating, negative-pressure firing, vacant shell pouring and quick airflow cooling in lost foam casting. The process comprises the following steps: placing a mould into a sand box; filling dry sand into the sand box; sealing the upper surface of a sand layer with a plastic thin film; starting a vacuum pump, igniting and gasifying the foam mould from a pouring gate under a negative pressure condition so as to form an intact vacant shell cavity, wherein over 95 percent of carbon is discharged out of the molding sand box; pouring molten iron and steel; lifting or cutting the sealing thin film on the top surface of the sand box when the molten iron and steel is in a temperature area where a liquid phase and a solid phase coexist, and then sucking cold airflow into the sand box so as to quickly cool a cast piece; and after stopping the pouring, continuing extracting air for 3 to 6 minutes, and then stopping the vacuum pump. The method can realize the elimination of the carbon defects of the cast piece, grain refinement, and easy falling-off of the coating by discharging and reducing carbon and pouring the vacant shell in the lost foam casting, makes the cast piece have bright and clean surface to comprehensively improve the quality of the cast piece, saves energy and reduce consumption, is high in efficiency and benefit and is applied to industrialized mass production.

Owner:刘玉满 +1

Tube imbedding casting process to form bent cast hole

InactiveCN101020225AEasy to operateIncrease success rateFoundry mouldsFoundry coresDry sandSteel tube

The present invention relates to casting method, and is especially tube imbedding casting process to form bent cast hole. The process includes the following steps: setting steel tube filled with dry sand inside mold cavity and fixing in sand core; closing the mold and pouring molten iron into the mold cavity to form the casting; and eliminating dry sand from the steel tube. The process is simple and effective.

Owner:TIANSHUI SPARK MACHINE TOOL

Preparation method of phosphorus building gypsum base light self-leveling mortar

The invention discloses phosphorus building gypsum base light self-leveling mortar. The phosphorus building gypsum base light self-leveling mortar is characterized by being prepared from the followingcomponents in percentage by mass: 70 to 90 percent of phosphorus building gypsum, 0 to 20 percent of dried sand, 0 to 20 percent of cement, 0 to 5 percent of coal ash, 5 to 20 percent of lightweightaggregate, 0 to 15 percent of active excitant, 0 to 3 percent of water repellent, 0.1 to 1 percent of high-performance plasticizer, 0 to 0.2 percent of sedimentation-resistant assistant, 0 to 0.2 percent of flocculation assistant, 0.01 to 0.4 percent of calcium sulphate retarder, 0 to 3 percent of high-molecular polymer and 0.05 to 0.3 percent of high-performance de-foaming agent. The prepared light self-leveling mortar is less than or equal to 1,000Kg / m<3> in unit weight, is larger than or equal to 10MPa in pressure resistance. The production process is easy, is low in energy consumption, andis high production performance; the light self-leveling mortar is particularly suitable for indoor thick layer leveling projects, has certain insulation, heat insulation and sound insulation functions, contributes to lowering environmental pollution, is simple in production process, is low in energy consumption and has high performance; compared with other self-leveling mortar products, the phosphorus building gypsum base light self-leveling mortar has higher market competitivity and high practicability.

Owner:四川华邦保和涂料有限公司

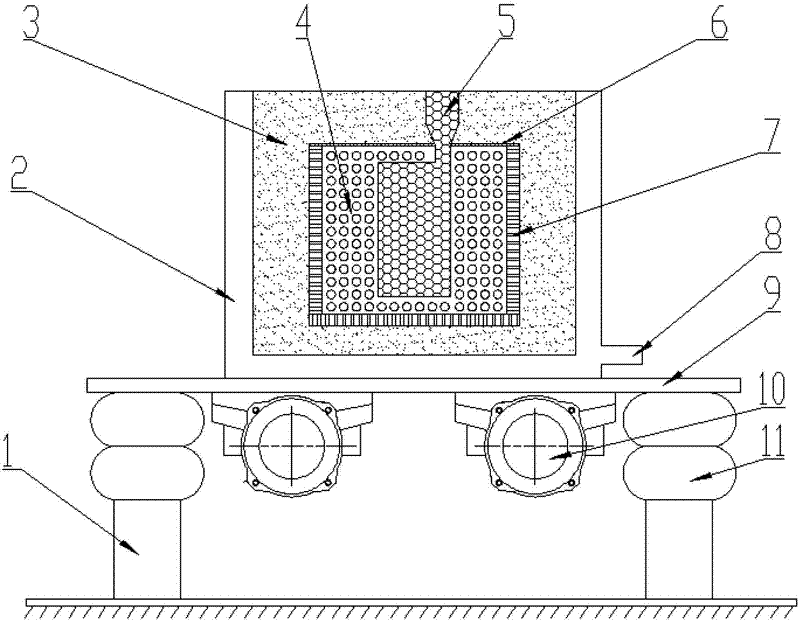

Vacuum sealed molding casting method production process for front bridge and rear bridge of automobile

InactiveCN101722298ALow investment costReduce labor intensityFoundry mouldsFoundry coresVacuum pumpingSurface layer

The invention relates to a vacuum sealed molding casting method production process for a front bridge and a rear bridge of an automobile. The front bridge and the rear bridge of the automobile are characterized by being produced by the following steps that: (1) a model is provided with a longitudinal air hole by which the model is divided into an upper half body and a lower half body; (2) the upper half body of the model is flatly placed on an air exhaust box, a film is roasted to be soft and then covered on the surface layer of the model, and after air exhaust, the film is closely adhered to the model and a top plate; (3) the film, covered on the circumference of the gating and risering model, is jointed with an in gate in the half body of the model, the film on the model is sprayed with a coating, and then a sand box is covered, the sand box is filled with dry sand, a vibrating table is started to tamp the dry sand, the surface of the sand layer is scraped to be smooth, and an upper opening is covered by a sealing cover; (4) the dry sand is agglomerated and hardened by vacuum pumping, the air exhaust box stops air exhaust, but the sand box is continuously vacuumized, the sand box is lifted up, the upper half body models is taken out, the gating and risering model is drawn out, and the upper sand box is formed; (5) the lower half body of the model repeats the steps to form the lower sand box; and (6) the bottom surfaces, where the mould cavities of the half body models are formed, of the upper sand box and the lower sand box are closed, and the molten metal is poured in from the gating and risering, and after cooling, the blanks of the front bridge and the rear bridge of the automobile are produced. The products produced by the process are high in accuracy and low in cost.

Owner:薛立华

Vacuum solid type cast penetrated method for preparing particle reinforced metal-base surface composite material

The invention relates to a v-epc cast-penetrating process for manufacturing metallic matrix surface composites with particle reinforced. According to structure of parts, foam material is cut or directly produced to a vaporable mode by foaming technology; reinforced particle is prepared into a precast block corresponding to a hard wearing surface shape required by the composites; the precast block is fixed on a surface of the foam material mode required to be alloyed; then embedding the mode into dry sand and pouring molten metal in a state of negative pressure after consolidating, wherein the negative pressure generated by vacuumizing can pump out gas generated by evaporating the foam plastic and gelatinize during pouring, meanwhile cavity filling performance of the molten metal can be increased by vacuum sealing technology to facilitate the molten metal infiltrating in the particle, thereby, a thicker and more compact composite layer can be obtained, and the prepared metallic matrix surface composites with tungsten carbide particle reinforced has higher surface quality and volume fraction of a strengthening body, more even strengthening body distribution as well as excellent impact wear resistance. The method of the invention is applicable to composite cast with low requirement, as well as to composite cast in complex shape with high technology requirement.

Owner:KUNMING UNIV OF SCI & TECH

Method for casting large main-bearing seat

The invention is concerned with molding method for large tape of headstock seat, relating to workout molding technology, make wood mould, make sand casting, close box, molding, cooling and clear casting. Workout molding technology to produce headstock seat by plot out the plane of mould and make wood mould according to the process demand and locate the wood mould on the mould plane. Make casting mould and set cold iron and close box to dry sand casting. Melt casting mould liquid and during the melting process, blow inert gas and feed the wire. Pour the casting, keep temperature and carry heat treatment by routine method. This method takes exothermic risers with same number of moulds to replace the existing micro - particle riser, and this saves the pouring amount of melting liquid and avoids the limitation of shrinkage of the shaped cold iron when it is on the surface of bearing hole. When during the pouring, it forms the anaerobic condition to enhance the purity of steel water and the produce of impurity between two oxidations and the dissection capability of thick part of casting is satisfied.

Owner:SHANGHAI HULIN HEAVY IND +1

Shell casting method through contraction and then gasification of high-performance coating foam and mold sample of evanescent mode

InactiveCN102672103AStrong enoughSufficient dimensional accuracyFoundry mouldsFoundry coresSurface finishInvestment casting

The invention discloses a shell casting method through contraction and then gasification of high-performance coating foam and a mold sample of an evanescent mode. The method comprises the following steps of: manufacturing the mold sample; preparing an inner-layer coating and an outer-layer coating; spreading the coatings; drying the coatings; performing reduction and contraction; performing gasification and evanescence; and packing and casting, wherein the inner-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with 180-220 meshes and water; and the outer-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with thickness being 70-100 meshes and180-220 meshes in half and water; According to the method, the mold sample has sufficient strength, dimensional accuracy and surface smoothness; carbon defects such as recarburization, slag inclusion, air holes, cockles and carbon black caused by the foam mold sample can be eliminated; the method is applicable in casting the evanescent mode with any steel; the situation that 5-10 layers of coatings are coated, and 5-10 layers of dry sand are spread when in investment casting does not needed; roasting at the temperature of 1000 DEG C in a kiln is unnecessary; and the process is simple, has low cost, and has energy conservation and emission reduction.

Owner:刘翔 +1

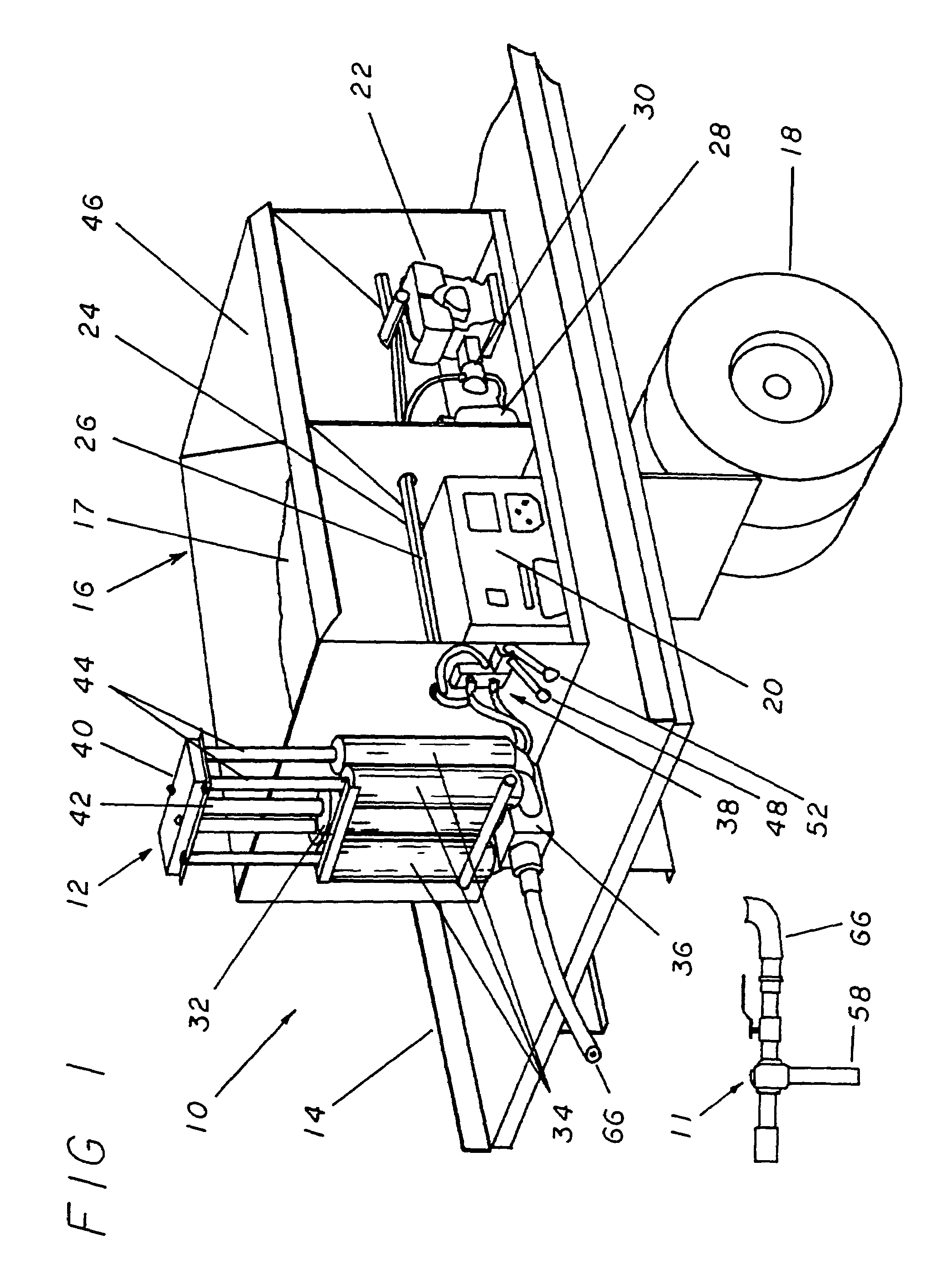

Slab leveling system and method

InactiveUS8186907B1Economical and efficient operationImprove portabilityRoads maintainenceDry sandEngineering

A system for leveling a slab by raising and filling in voids under the slab. A mixture of compressed air and well dried sand is pumped through hose to a gun nozzle. The slab to be leveled is supplied with at least one hole for receiving the gun nozzle in a fluid tight connection. The compressed air is used to lift the slab while the sand is used to fill the void and keep the slab in a level position. The operator may supply successive burst of pressure to lift the slab as needed, while adjusting the air and sand flow. Finally, the gun nozzle is removed from the hole which is then patched thus, completing the repair of the damaged slab.

Owner:ASPLIN CHARLES LEE

Negative-pressure molding process of casting refractory material product

InactiveCN101823122AEmission reductionReduce lossesFoundry mouldsFoundry coresSurface layerSuction stress

The invention discloses a negative-pressure molding process of a casting refractory material product, comprising the following steps: 1. placing a model on a template with an exhaust chamber, wherein, the model is equipped with air vents; coating a thin film on a model surface layer, and sticking the thin film on the model surface layer by vacuum suction; and spraying zircon powder paint on the model outer surface coated with the thin film; 2. placing a sand box on the template surrounding the model, wherein, the side wall of the sand box is equipped with a filtering air tube; filling dry sand into the sand box, slightly shocking, coating a back film to close the sand box, and sucking the sand box in a negative pressure condition so as to harden a casting mould; 3. removing the vacuum status of an exhaust chamber in step 1, lifting the box and drawing to finish casting box; 4. reserving a casting head and an exhaust vent on an upper box consistent with the casting box of the casting mould, filling up dry sand, sealing the thin film and then sucking an inner cavity in a negative pressure condition; and 5. closing the upper box and the casting box to form an overall casting mould with the casting head and the cavity; removing the upper box and the casting box at the front of a furnace for direct pouring under a negative pressure status; and after maintaining pressure and solidification, keeping the temperature of a workpiece for 7-12 days to obtain the casting refractory material product.

Owner:HENAN QIANWEI INDAL

Dry powder ceramic tile binding agent

The present invention discloses a drying powder ceramic tile , which consists of the following component with the stated molar ratio: 500 pieces of 425# Porland cement, 500 pieces of drying sand to match a grade above 40 items, 2-3 pieces of intension, 1-3 pieces of water-keeping and 3-5 pieces of cement compound; the intension is calcium formate; the water-keeping is methyl cellulose; the cement compound is polyethylene or the subdivided latex powder. Because the cement compound and the water-keeping increase the felting intension during being used so as to make the anti-flow ability and the water-keeping ability for the cement compound enhanced greatly; the decorating effect for the facing brick is much fixed, perfect; the method solves the problem that the decoration is easy to be fallen off; besides, the thickness of the felting sand slurry decreases to 3-4mm from the original 2cm; the device can not only save the material greatly, but also decrease the weight by the over-heavy sand slurry to the building; besides, the device can decrease the labor intension for the worker and make the construction much faster and more high-efficient.

Owner:山东润东建材有限公司

Casting process method combining steel-shot chilling and vibratory pouring based on disappearing die

InactiveCN102371339ASolve the slow cooling rateImprove toughnessFoundry mouldsFoundry coresVacuum pumpingDry sand

The invention discloses a casting process method combining steel-shot chilling and vibratory pouring based on a disappearing die. The casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die is characterized in that a manufactured foam model is placed into a chilling sand box, steel shots are also placed at the position of a clearance between the foam model and the chilling sand box, then the chilling sand box is placed into a sand box with a vacuum-pumping negative-pressure model, dry sand is filled between the chilling sand box and the sand box with the vacuum-pumping negative-pressure model, a plastic film is laid, a sprue cup is placed, and finally, the operation of pouring is carried out under the condition that the operations of vacuumpumping and vibrating are simultaneously carried out. According to the casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die, the circular use of the steel shots and the sand is realized, the problem of lower cooling speed of a cast in the casting of the disappearing die is thoroughly solved, the problems of bulky crystal grains, uncompacted tissues and the like, which are easy to occur in the casting of a traditional disappearing die, are avoided, the toughness and the compactness of the tissues of the cast are enhanced, the use quantity of alloy elements, such as Cr, Mo and the like, is lowered, the service life of a wear-resisting cast is ensured, the batch production of a product is realized, the rejection rate is reduced, and the manpower cost is lowered.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

Method for preparing icing-resistant copper surface with super hydrophobicity and low adhesiveness

InactiveCN101698939ALow industrial applicationsReduce the amount of condensateVacuum evaporation coatingSputtering coatingPotassium persulfateNano structuring

The invention discloses a method for preparing an icing-resistant copper surface with super hydrophobicity and low adhesiveness, comprising the steps: jetting sand to the copper surface with micron-sized sand pill to construct a micron-sized coarse structure, wherein mesh number of the sand pill is 36-150 meshes, pressure of air flow is 0.2-0.8MPa, and jetting time is 1-5 min; immersing the cleaned and dried sand-jetted copper surface into mixed water solution under 50-90 DEG C, taking off and cleaning with clean water after water bathing for 20-60 min, and drying in a thermostatic oven for 0.5-2 hours under 150-200 DEG C to obtain a micro / nano composite structure at the copper surface, wherein mixed water solution comprises potassium persulfate and potassium hydroxide, the molar concentration of the potassium persulfate is 0.04-0.3 mol / L, and the molar concentration of the potassium hydroxide is 1-4 mol / L; and evaporating and plating the copper plate with micro / nano structure in alcohol solution of fluorosilane to modify the fluorosilane, wherein the evaporating and plating temperature is 200-35 DGE C, time is 1-2 hours, and the weight percent of the weight of the fluorosilane to that of the alcohol solution in the alcohol solution of fluorosilane is 1-4%.

Owner:SOUTHEAST UNIV

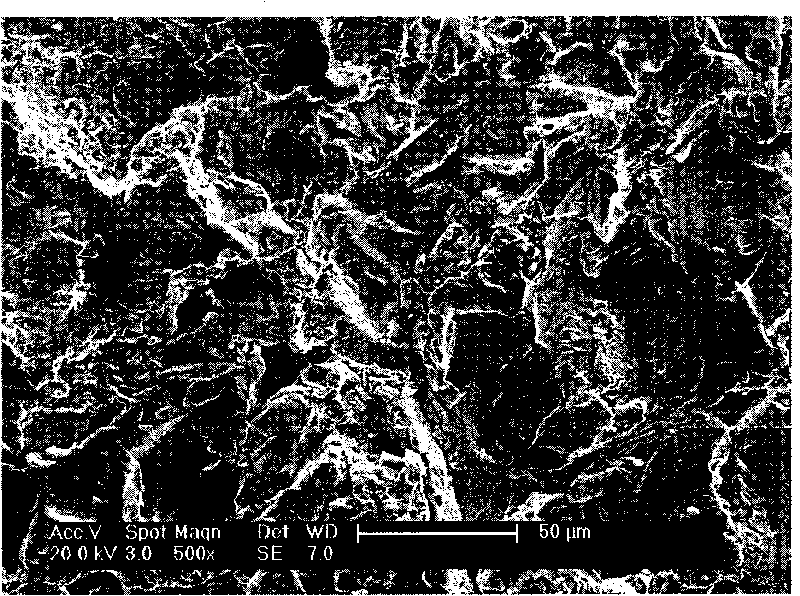

Resin precoated sand prepared from reclaimed sand

ActiveCN103691877AReduce manufacturing costReduce the amount addedFoundry mouldsFoundry coresDry sandThermal expansion

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP +5

Novel technology for casting engine cylinder body by lost foam

InactiveCN102310162ASmall sizeReduce reserved processing volumeFoundry mouldsFoundry coresSmelting processMetallurgy

The invention discloses a novel technology for casting an engine cylinder body by lost foam, and relates to the field of casting technologies. The novel technology is characterized by comprising the following steps of carrying out three-dimensional modeling by three-dimensional software, slitting the three-dimensional model obtained by the previous step into multiple model sheets, preparing molds for preparation of the model sheets, pouring expandable foam beads into the molds, carrying out heating and cooling processes to obtain lost foam model sheets of the engine cylinder body, drying the lost foam model sheets, bonding the dried lost foam model sheets into an integral body according to requirements, bonding a casting system on the bottom of the integral body to obtain a lost foam model, carrying out dip-coating treatment on the surface of the lost foam model by specialized paint 1 to 3 times, putting the lost foam model coated with the specialized paint into a drying room to carry out drying treatment, putting the dried lost foam model into a three-dimensional vibration sand box, adding gradually dry sand into the three-dimensional vibration sand box, covering a film on the surface of the three-dimensional vibration sand box to sealing the three-dimensional vibration sand box, pouring melt obtained by a smelting process into the casting system so that the lost foam model is melted and the melt occupies a space occupied originally by the lost foam model, and cooling the melt to solidification to obtain an engine cylinder body casting. The novel technology improves a qualified rate, saves resources and reduces a cost for enterprises.

Owner:CHUZHOU JINNUO INDAL

Method of casting engine cylinder head with lost foam

InactiveCN102284679APrecise and stable sizeReserved machining allowance is smallFoundry mouldsFoundry coresAdhesiveSmelting process

A method for casting an engine cylinder head with lost foam, which relates to the field of casting technology. The process method is as follows: first, use three-dimensional software to design a model for manufacturing lost foam dies, and manufacture corresponding molds; Inject expandable molding beads, heat and cool to produce individual mold pieces. And dry; the dried mold pieces are bonded as a whole according to the requirements, and the casting system is bonded to obtain the lost foam model; the surface of the lost foam model is dip-coated with a special coating and then dried; the processed lost foam model Put it in the three-dimensional vibrating sand box, after injecting dry sand, cover the surface with a layer of film; inject the smelted solution into the gating system of the lost foam model, the lost foam model is melted, the space is replaced by the solution, and the solution is cooled After solidification, take out the casting from the box. The invention improves production efficiency, reduces labor force, reduces labor cost and manufacturing cost.

Owner:CHUZHOU JINNUO INDAL

Dedicated dust removal device for dry sand-grinding dust removal complete equipment and dust removal method

ActiveCN102000625ARealize the purpose of working around the clockReduce energy consumptionUsing liquid separation agentGrain treatmentsDry sandEngineering

The invention relates to a dedicated dust removal device for dry sand-grinding dust removal complete equipment and a dust removal method. The dedicated dust removal device can effectively remove dust generated by sand grinding, and can substantially reduce energy consumption and noise, and comprises a dust remover and a vibrating screen, wherein a water mist dust pressing suction hood is arranged above the vibrating screen, and the dust suction mouth of the water mist dust pressing suction hood is communicated with the dust remover through a wind suction pipe; and the discharge port of the vibrating screen is provided with an inverted cone-shaped dust suction hood, and a dust suction pipe is arranged in the inverted cone-shaped hood and is communicated with the dust remover. The invention has the advantages that: firstly, the water mist dust pressing, the primary dust removal and the secondary dust removal in the process of sand making can be realized, and the energy consumption and the noise are greatly reduced; secondly, the clean and pure sand is obtained, and the purpose of all-weather operation is realized; and finally, in the application, the water generated when the water mist dust pressing is adopted to suck water dust can be sucked by heat energy generated by the mutual collision between sands in the process of vibrating sand screening, and can be blown by the wind, thereby obtaining dry sand with less water.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Lost foam-shell mold casting vibration and solidification method based on foam mold

InactiveCN102744367ARefine the grain sizeGrain size stabilityFoundry mouldsFoundry coresDry sandPlastic film

The invention relates to a lost foam-shell mold casting vibration and solidification method based on a foam mold, comprising the following steps of: (1) manufacturing the foam mold with a ceramic shell on a surface thereof; (2) after the foam mold is subjected to lost foam mold and baking, putting the foam mold into a bottom-drawing sandbox, filling scattered molded dry sand into the bottom-drying sandbox, closing a vibrating table after vibrating and compacting the scattered dry sand pass through the vibrating table, coating a layer of plastic film on the upper part of the bottom-drawing sandbox, and placing a pouring cup on the upper part of the bottom-drawing sandbox to be poured; and (3) opening a vacuum device and the vibrating table, injecting metal liquid into a ceramic shell through the pouring cup, vibrating and solidifying, closing the vibrating table and the vacuum device after the metal liquid is solidified into a cast completely, and opening the sandbox to perform cleaning. The lost foam-shell mold casting vibration and solidification method based on the foam mold is simple, lower in cost, convenient to operate and environmental-friendly. An effective method with the characteristics of convenience, quickness, low cost, environmental-friendly grain size of refined casts and enhanced performances of the casts is provided for lost foam-shell mold casting enterprises.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Lost foam casting process for casting with good mechanical properties

InactiveCN104690225AReduce generationImprove cooling effectFoundry mouldsFoundry coresNitrogenDry sand

The invention discloses a lost foam casting process for a casting with good mechanical properties. The lost foam casting process comprises the following steps of preparing all main parts from foam material blocks, and bonding all the prepared main parts to prepare a casting model; bonding a pouring gate for the casting model, and coating a refractory material at the outer sides of the casting model and the pouring gate to prepare a final model; placing the final model into a sand box, filling the sand box with dry sand, compacting by using a three-dimensional compacting table, and coating a plastic film on the sand box; uniformly introducing negative-pressure airflow to the sand box from top to bottom until the negative pressure is up to 0.04MPa below zero to 0.08MPa below zero, wherein the negative-pressure airflow is mixed gas of oxygen, nitrogen and carbon dioxide; and pouring molten metal into the region where the final model is arranged in the sand box, gasifying to enable the final model to disappear, replacing the final model with metal, and cooling to obtain the casting. By using the lost foam casting process, generated solid / liquid-phase products can be effectively reduced, molten metal can be prevented from being polluted, the heat radiating effect of metal becomes good, and the mechanical properties of the metal are improved.

Owner:QINGDAO DAYUN MACHINERY

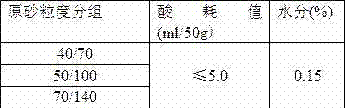

High-performance shrinkage-free cement-based grouting material prepared by manufactured sand and preparation method of cement-based grouting material

The invention relates to a high-performance shrinkage-free cement-based grouting material prepared by manufactured sand, which comprises the following raw materials by weight percentage: 50-60% of manufactured sand, 30-40% of ordinary portland cement, 3-6% of fly ash, 1-5% of slag powder, 0.02-0.04% of fiber, 0.1-0.14% of heavy material and 3-5% of light material. A preparation method of the cement-based grouting material comprises the following steps of manufactured sand treatment: selecting sand within three gradation ranges produced by a dry sand manufacturing system for standby, proportionally compounding and mixing components in the light material and the heavy material to obtain a mixture A, and proportionally mixing the manufactured sand, the ordinary portland cement, the fly ash, the slag powder, the fiber and the mixture A to obtain the cement-based grouting material. The cement-based grouting material has the advantages of low cost, good flowability, high uniformity, plastic micro-expansion without shrinkage, early strength, high strength and the like.

Owner:经纬建材有限公司

Lost foam casting process for engine cylinder block and head

InactiveCN104985119AReduce consumptionImprove working environment conditionsFoundry mouldsFoundry coresHigh volume manufacturingDry sand

The invention discloses a lost foam casting process for an engine cylinder block and head. The process comprises the following specific steps of making of models: first selecting foaming materials and filling cavities of metal molds with the foaming materials after the foaming materials are pre-foamed and cured, heating the foaming materials to expand the foaming materials again, filling the cavities of the metal molds withfoaming materials, and demolding the foaming materials after the foaming materials are cooled to obtain foam plastic models; model assembling and surface treatment: bonding the foam plastic models to obtain a model cluster and dipping and coating the model cluster with a refractory coating; sand filling and shaping: putting the model cluster obtained in the previous step into a sand box, adding dry quartz sand to the sand box while vibrating the sand box after culturing and fixing sand, and sealing and vacuumizing the sand box; pouring displacement: injecting liquid metal into the model cluster, and displacing the liquid metal and the foam plastic models to finally form a cast; and cooling and cleaning: cooling the sand box and the cast, naturally separating the cast from dry sand so as to obtain a cast finished product. The cast manufactured by the lost foam casting process disclosed by the invention has the advantages of good quality, low cost, unlimited material, various sizes and high precision and can be manufactured on a large scale.

Owner:上柴动力海安有限公司

Preparation method of anti-shrinkage autoclaved aerated concrete block dry powder masonry mortar

The invention provides a preparation method of novel anti-shrinkage dry powder masonry mortar special for autoclaved aerated concrete blocks, and the components and ratios are: 15%-20% of anhydrite, 25%-35% of portland cement, 5%-16% of lime powder, 33%-54% of dry sand (20-40 meshes), 0.6%-0.8% of redispersable latex powder, 0.3%-0.5% of cellulose ether, and 0.4%-0.6% of calcium formate. The dry shrinkage value of the dry powder mortar is adjusted by adding cement and gypsum, and thus is close to a dry shrinkage value of an autoclaved aerated concrete block; the dry shrinkage value of a material for bonding the mortar is close to the dry shrinkage value of the autoclaved aerated concrete block; the synchronization of the shrinkage and the expansion overcomes quality accidents of empty drum, sun crack, and even shedding of masonry and floated coats caused by excessively rapid water loss of walls; and the invention has good value for popularization and application.

Owner:汤建新 +1

Lost foam casting (LFC) method without roasting by using precise paraffin wax model sample and high-performance coating shell mould

InactiveCN102632196AGood coating performanceGuaranteed StrengthFoundry mouldsFoundry coresParaffin waxPhysical chemistry

The invention discloses a lost foam casting (LFC) method without roasting by using a precise paraffin wax model sample and a high-performance coating shell mould, comprising the following steps of: (1) manufacturing the paraffin wax model sample; (2) preparing a coating; (3) coating the coating and drying; (4) dewaxing the shell mould and recovering; (5) boxing the shell mould and filling sand; (6) burning out the residual wax under a negative pressure; and (7) pouring molten metal. The LFC method without roasting by using a precise paraffin wax model sample and a high-performance coating shell mould disclosed by the invention is simple in process, low in cost, less in energy consumption, high in efficiency, and more stable in casting quality; and silica sol having the same weight with Guilin No. 5 is added in the coating on an inner layer, so that the coating property of the coating on the wax model can be obviously improved, thus ensuring finish degree, and the coating is suitable for castings with various different materials. The coating on an outer layer is low in cost after being compounded of coarse and fine quartz sand and powder, the procedure of scattering dry sand layer by layer is cancelled, and the strength, stiffness and air permeability of the coating are ensured. Test detection indicates that the coating on the inner layer or the coating on the outer layer has a normal-temperature strength of greater than 1.5 MPa and the air permeability of 1.3 cm<2> / Pa.min after being dried, has strength being greater than 1.35 MPa and air permeability being 1.5 cm<2> / Pa.min after being roasted for 10 minutes at 1000 DEG C.

Owner:刘玉满 +1

Method of casting thin wall water chamber for high power diesel engine

ActiveCN101011723AUniform wall thicknessQuality improvementFoundry mouldsFoundry coresDry sandEngineering

The invention relates to the casting for the thin wall cooling water jacket of a big power diesel engine, starting with cutting with the foam block, sticking cooling water jacket mold and pouring system, spraying the shroud, using sand mold to make the inside support for the cooling water jacket, setting the integrated cooling water jacket and pouring system in the enclosed sand box with the support parts placed inside the cooling water jacket, using dry sand to complement the enclosed sand box, sealing the enclosed san box and extracting the air to negative pressure, casting iron melt, keeping the temperature of the casting piece and slowing cooling down to indoor temperature, cleaning the casting piece for inspection. Cooling water jacket make in this having deformation ratio less than 1mm, without preserving processing margin and defect after processing.

Owner:HUDONG HEAVY MACHINERY

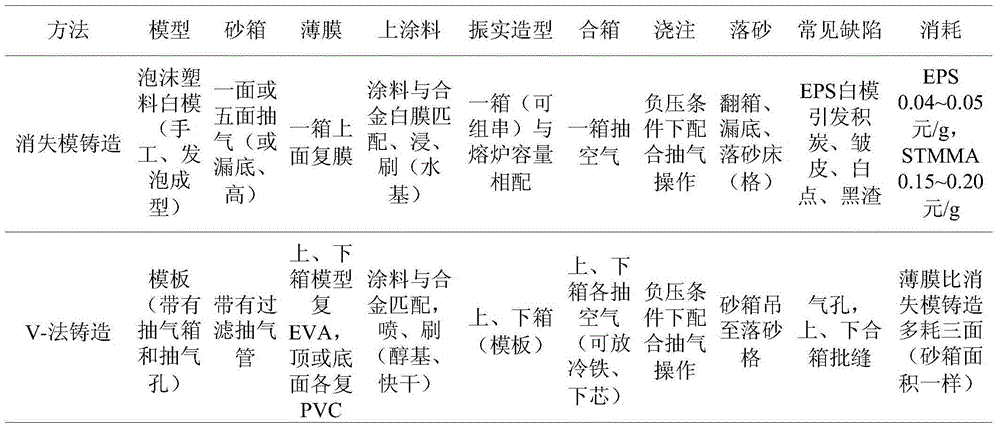

V-method casting process

The invention discloses a V-method casting process which comprises the following steps: directly connecting an air hole in EVA with the size of 0.10-0.20mm with a vacuum pipe of an exhaust chamber; vacuumizing a softened plastic film by virtue of the air hole in the mold; placing a negative pressure sand box on the mold; filling the sand box with dry sand; covering a layer of sealing films on the top of the sand mold, and connecting a pouring basin with a top sprue, wherein only the sand needs to be flattened on the lower mold before laminating; vacuumizing the sand box, releasing the vacuum in the mold exhaust chamber, introducing compressed air for blowback, and separating the sand mold from the mold; producing the lower mold by using the same method; closing the upper mold and the lower mold, and preparing to perform pouring. According to the V-method casting process disclosed by the invention, the defects of unreasonable ratio, complicated operation process, low reliability and the like in the prior art can be overcome, and the advantages of reasonable ratio, simple operation process and low reliability are realized.

Owner:LIUZHOU ZHENGLONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com