Lost wax shell-based negative pressure dry sand and iron shot chilling vibrational casting process method

A process method and chilling technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of non-compact structure, coarse grain, slow cooling speed, etc., to achieve fine alloy grain and good wear resistance performance, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

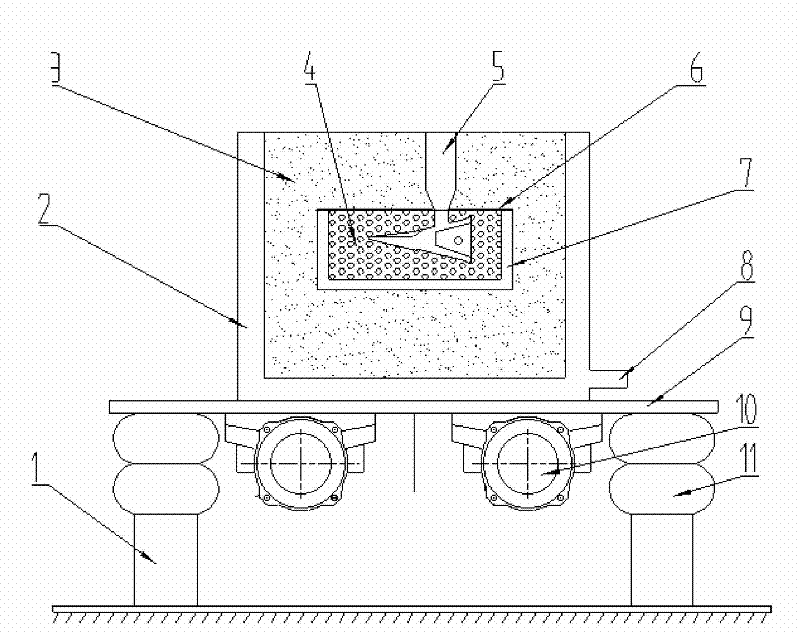

[0025] combine figure 1 As shown, the vibratory composite casting process based on negative pressure dry sand and iron shot chilling based on the lost wax shell, its specific steps are:

[0026] (1) Make a paraffin model, dip it in paint, and spray the first layer of sand;

[0027] (2) After the model in step (1) is dried, dip it in the crystalline aluminum chloride solution, spray the back sand, and dry it in a ventilated place in the city for about 1 hour;

[0028] (3) Repeat step (2) two to three times;

[0029] (4) Put the model in step (3) into the steam kettle, remove the paraffin, and dry it to become an empty shell 5;

[0030] (5) Put the empty shell 5 made by the lost wax process into the quenching sand box 7, the surrounding space is 150-230mm, and put 40-60mm into the space between the casting body empty shell and the chilling sand box. Steel shot 4 (the upper opening of the quenching sand box is covered with asbestos cloth 6);

[0031] (6) Add 300-450mm dry san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com