Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3960 results about "Asbestos" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asbestos (pronounced: /æsˈbɛstəs/ or /æsˈbɛstɒs/) is a term used to refer to six naturally occurring silicate minerals. All are composed of long and thin fibrous crystals, each fiber being composed of many microscopic 'fibrils' that can be released into the atmosphere by abrasion and other processes. Asbestos is a well known health hazard, and use of it as a building material is now banned in many countries. Inhalation of the fibres can lead to various lung conditions, including asbestosis and cancer.

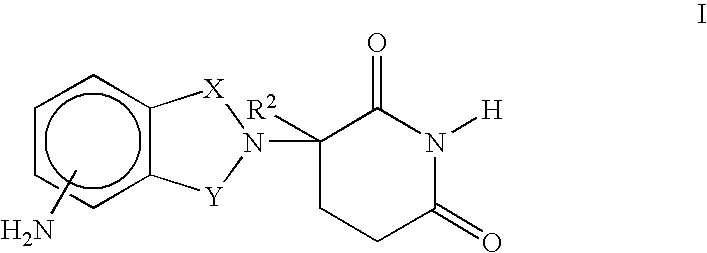

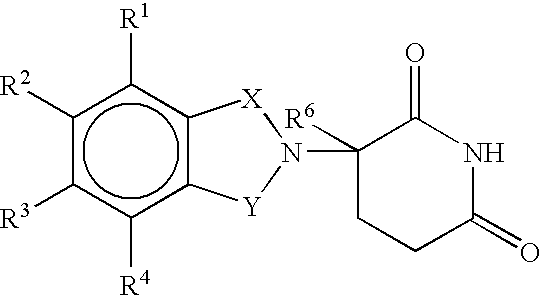

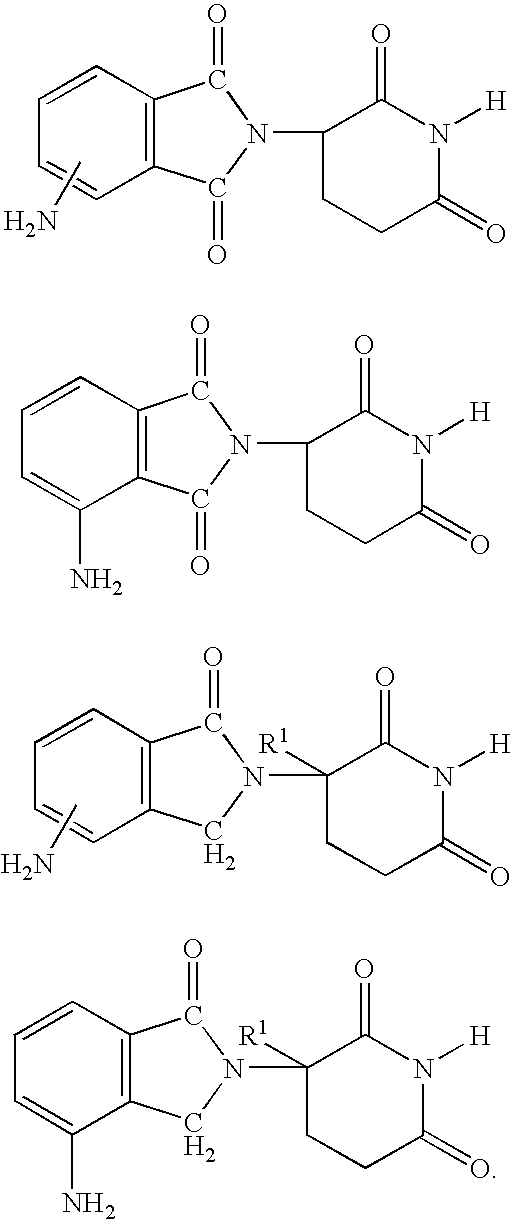

Methods of using and compositions comprising immunomodulatory compounds for the treatment and management of asbestos-related diseases and disorders

Methods of treating, preventing and managing an asbestos-related disease or disorder are disclosed. Specific embodiments encompass the administration of an immunomodulatory compound, or a pharmaceutically acceptable salt, solvate, hydrate, stereoisomer, clathrate, or prodrug thereof, alone or in combination with a second active agent and / or chemotherapy, surgery, or radiation therapy. Pharmaceutical compositions, single unit dosage forms, and kits suitable for use in the methods of the invention are also disclosed.

Owner:CELGENE CORP

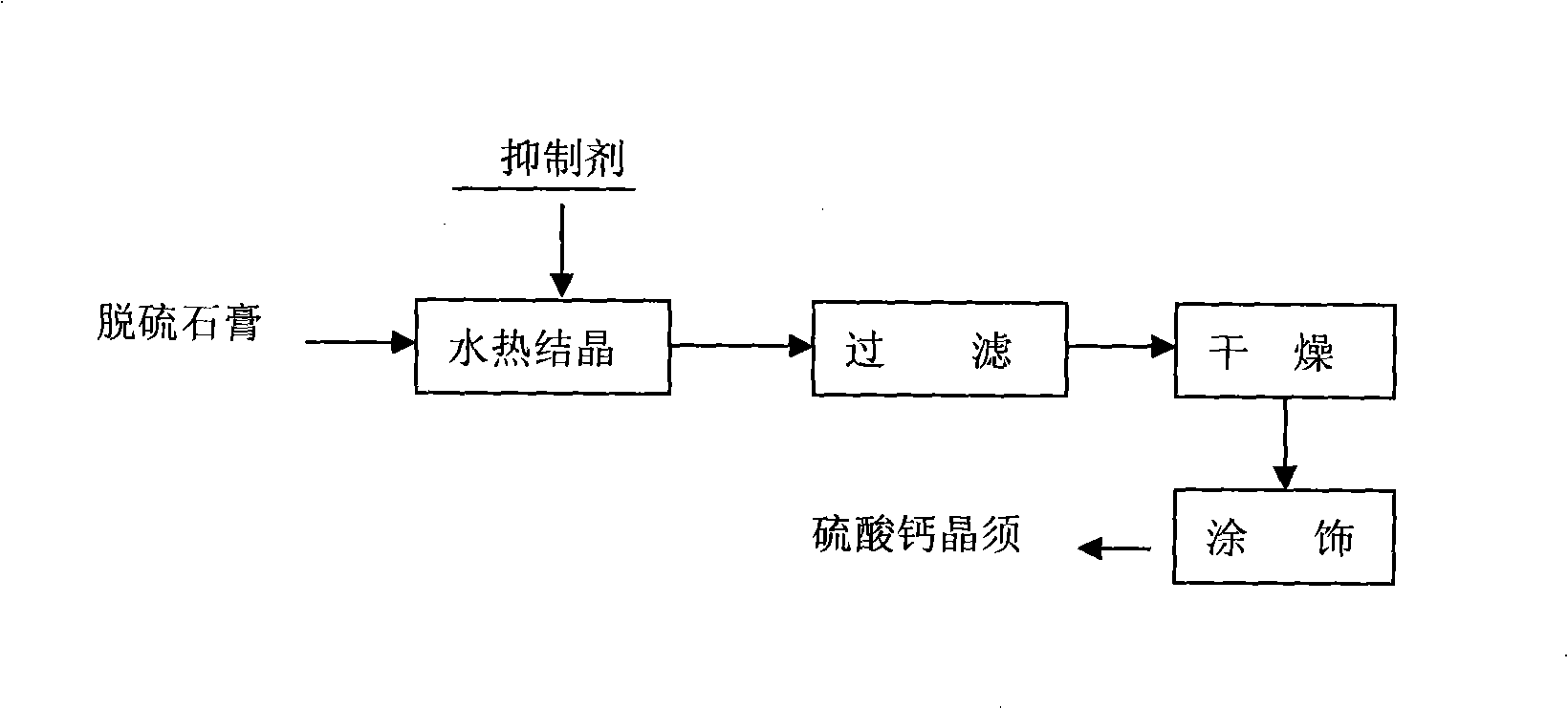

Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

InactiveCN101311337AReduce environmental problemsMitigation resourcesPolycrystalline material growthFrom normal temperature solutionsGlass fiberSulfate

The invention discloses a method for using flue gas desulfurization gypsum to prepare calcium sulfate whisker, comprising process steps of size mixing, high-temperature crystallization, drying and coating, etc. The method utilizes the flue gas desulfurization gypsum as the raw material, which has low production cost, short technological process and saves natural gypsum mine and effectively relieves the environmental pollution problem of the flue gas desulfurization gypsum. The product purity can be up to more than 98 percent, which can be used as filler with medium intensity or as friction material, building material or insulating material, and the like, instead of asbestos. The product can also partly replace organic macromolecular compounds such as glass fiber, resin, rubber and plastic, and the like, and has good describability.

Owner:NORTHEASTERN UNIV

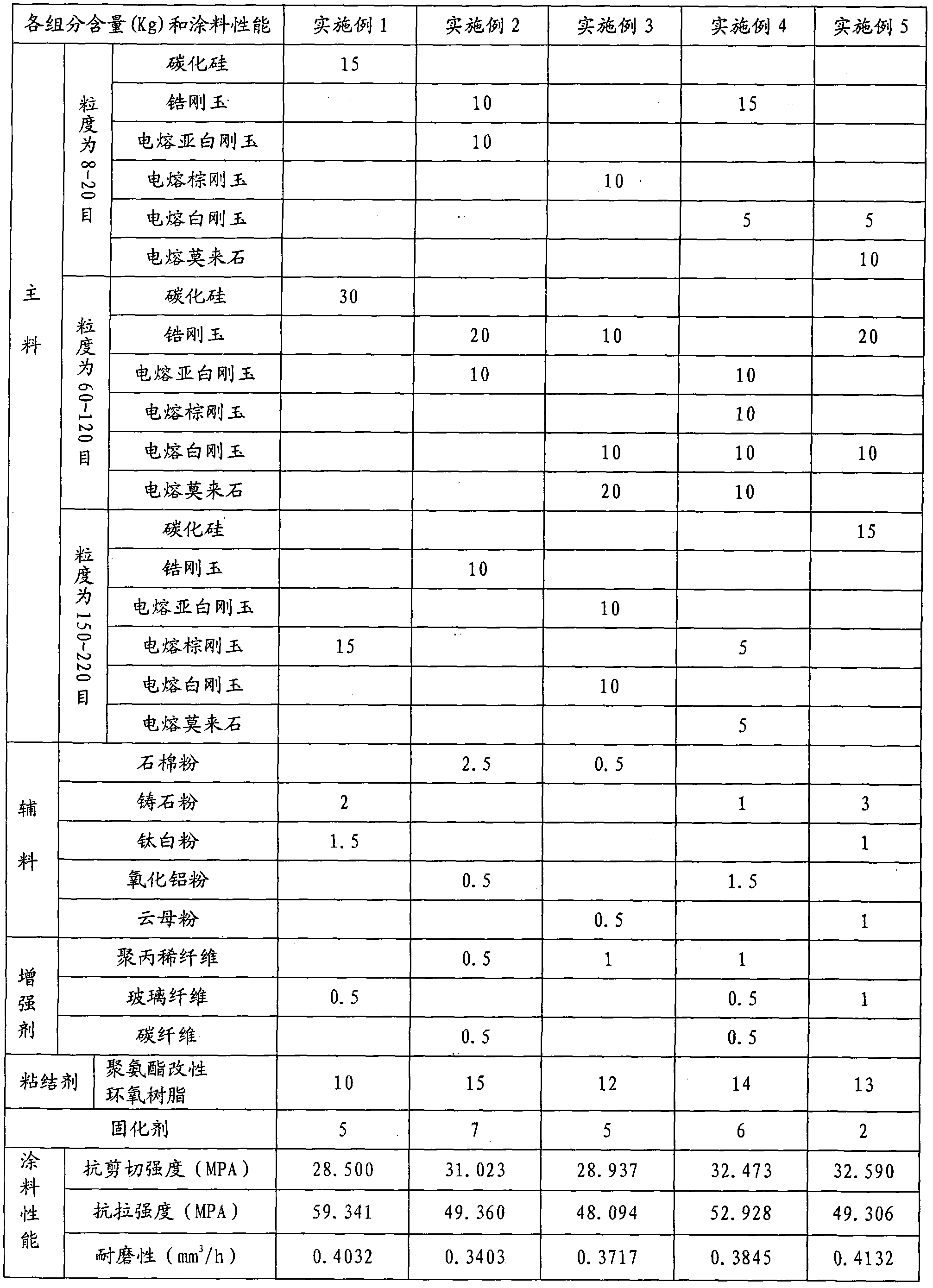

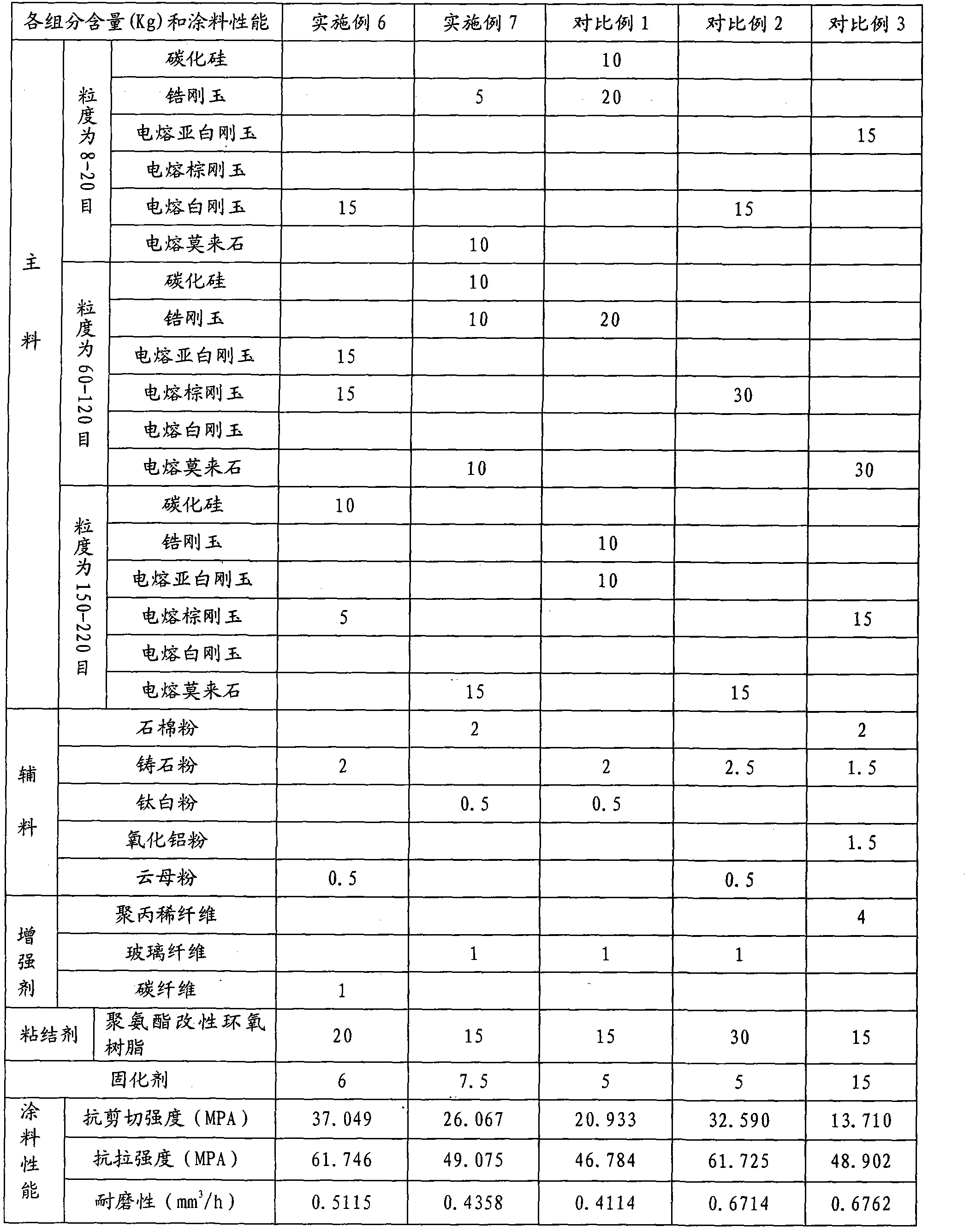

Polymer wear-resistance coating material

ActiveCN102040901AReduce operating costsReduce labor intensityEpoxy resin coatingsEpoxyCarbon fibers

The invention relates to a polymer wear-resistance coating material, which is a coating material consisting of a component A and a component B, wherein the component B is a solidifier, and the weight part of the component B is 2 to 10 percent of that of the component A; the component A consists of 40 to 80 weight parts of a main ingredient which is one or more mixed in random ratio of silicon carbide, fused zirconia alumina, fused sub-white corundum, fused brown aluminium oxide, fused white corundum and fused mullite, 1 to 5 weight parts of an auxiliary material which is one or more mixed in a random ratio of asbestos powder, glass-ceramic powder, titanium white, aluminium oxide powder and mica powder, 0.5 to 2 weight parts of reinforcing agent which is one ore more mixed in a random ratio of polypropylene fibers, glass fibers and carbon fibers, and 10 to 20 weight parts of a bonding agent which is polyurethane modified epoxy resin. The construction and use of the coating material are convenient and quick, the bonding strength of the coating material is high and the use cost of the coating material is low; and the coating material has high wear resistance, corrosion resistance and air corrosion resistance.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

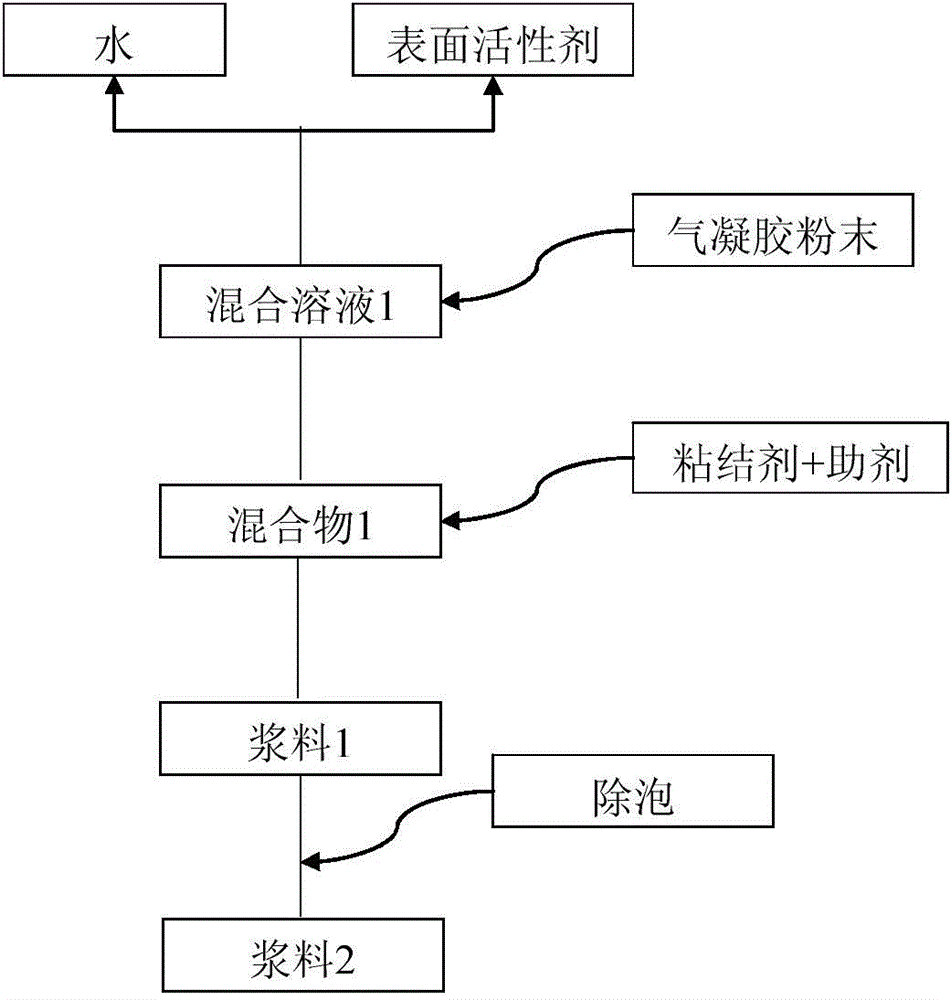

Aqueous slurry material containing silicon dioxide aerosol, preparation method and application thereof

The invention discloses an aqueous slurry material containing silicon dioxide aerosol, a preparation method and an application thereof. The aqueous slurry material is a stable dispersion system formed by uniformly mixing silicon dioxide aerosol powder, a surfactant, a bonding agent and water. The preparation method includes following steps: mixing water with the surfactant uniformly, adding the aerosol powder and mixing the mixture uniformly to obtain a suspension liquid, and adding the bonding agent and adding or not adding an additive, and uniformly mixing the mixture to obtain the aqueous slurry material. The aqueous slurry material is free of asbestos and other harmful fiber materials, is convenient to transport and construct, is free of cutting and can be easily controlled in thickness of a produced heat-insulating material, can be used through an optimized construction scheme freely, is simple in preparation process and low in cost, and is suitable for large-scale industrial production. The aqueous slurry material can be used for coating the surface of a base material and can form a coating after drying, which is flat in surface, is excellent in heat-insulating performance and is strong in bonding force, and also can be mixed with other structural materials to prepare an aqueous composite material.

Owner:苏州同玄新材料有限公司

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

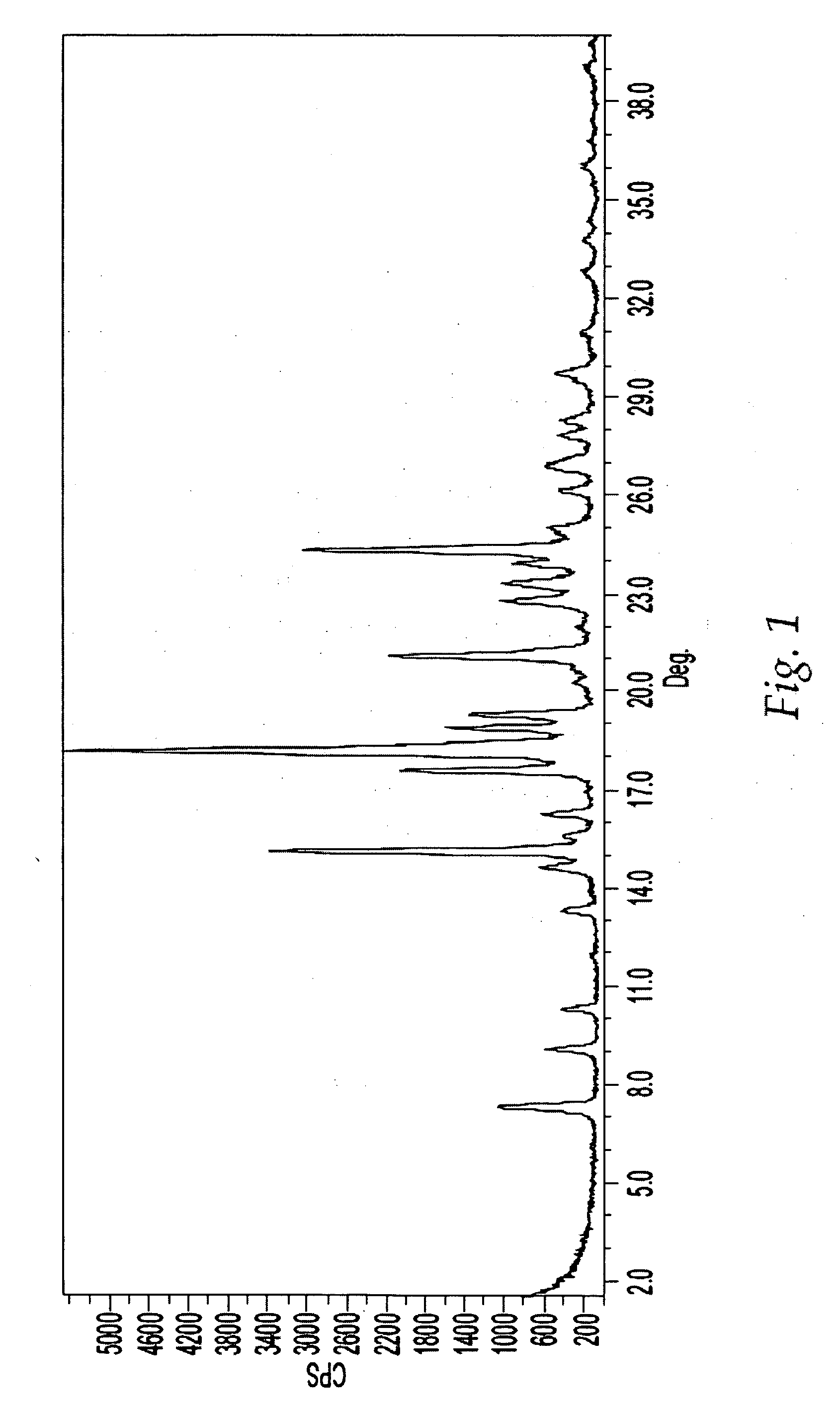

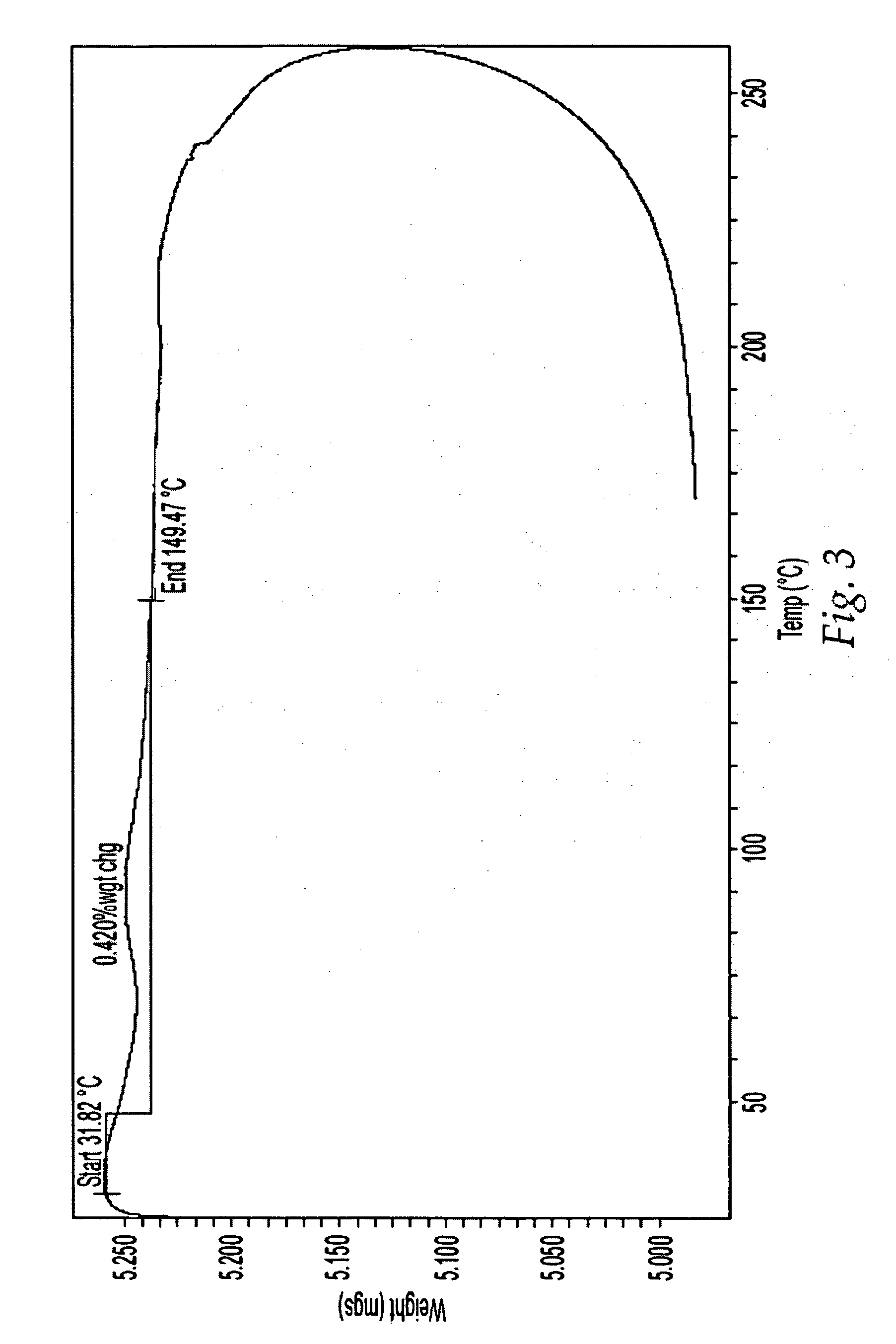

Solid forms of a JNK inhibitor

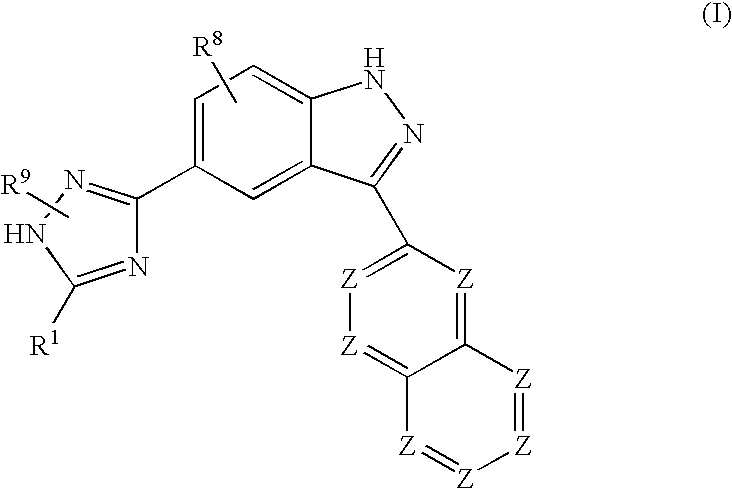

The present invention provides solid forms of Compound (I), pharmaceutical compositions thereof, and methods for the treatment or prevention of diseases including, but not limited to a liver disease, cancer, a cardiovascular disease, a metabolic disease, a renal disease, an autoimmune condition, an inflammatory condition, macular degeneration, pain and related syndromes, disease-related wasting, an asbestos-related condition, pulmonary hypertension, ischemia / reperfusion injury, central nervous system (CNS) injury / damage or a disease treatable or preventable by the inhibition of JNK. In particular, the invention relates to certain novel crystal forms of the compound 1-(5-(1H-1,2,4-triazol-5-yl)(1H-indazol-3-yl))-3-(2-piperidylethoxy)benzene.

Owner:CELGENE CORP

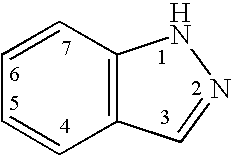

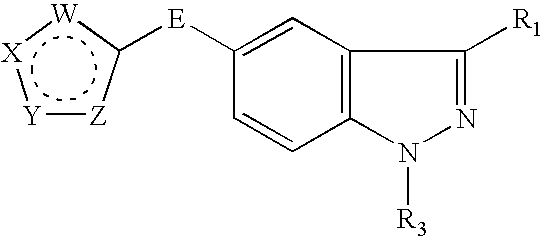

Indazole compounds and methods of use thereof

InactiveUS20060004043A1Modulating levelUseful in treatmentAntibacterial agentsBiocideAutoimmune conditionProtein kinase A signaling

This invention is directed to Indazole Compounds or pharmaceutically acceptable salts, solvates and hydrates thereof. The Indazole Compounds have utility in the treatment or prevention of a wide range of diseases and disorders that are responsive to the inhibition, modulation or regulation of kinases, such as inflammatory diseases, abnormal angiogenesis and diseases related thereto, cancer, atherosclerosis, a cardiovascular disease, a renal disease, an autoimmune condition, macular degeneration, disease-related wasting, an asbestos-related condition, pulmonary hypertension, diabetes, obesity, pain and others. Thus, methods of treating or preventing such diseases and disorders are also disclosed, as are pharmaceutical compositions comprising one or more of the Indazole Compounds. This invention is based, in part, upon the discovery of a novel class of 5-triazolyl substituted indazole molecules that have potent activity with respect to the modulation of protein kinases. Thus, the invention encompasses orally active molecules as well as parenterally active molecules which can be used at lower doses or serum concentrations for treating diseses or disorders associated with protein kinase signal transduction.

Owner:BHAGWAT SHRIPAD S +10

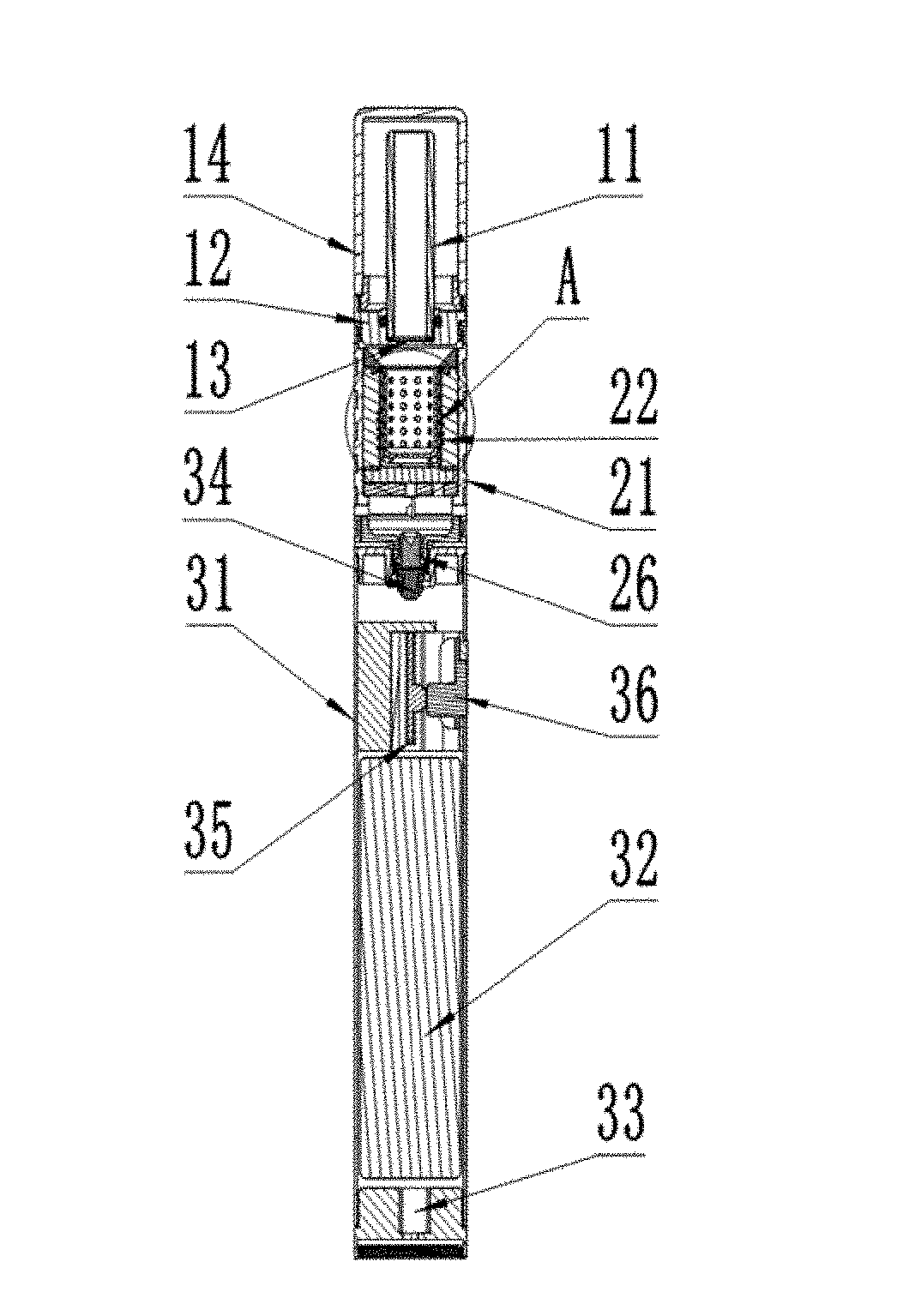

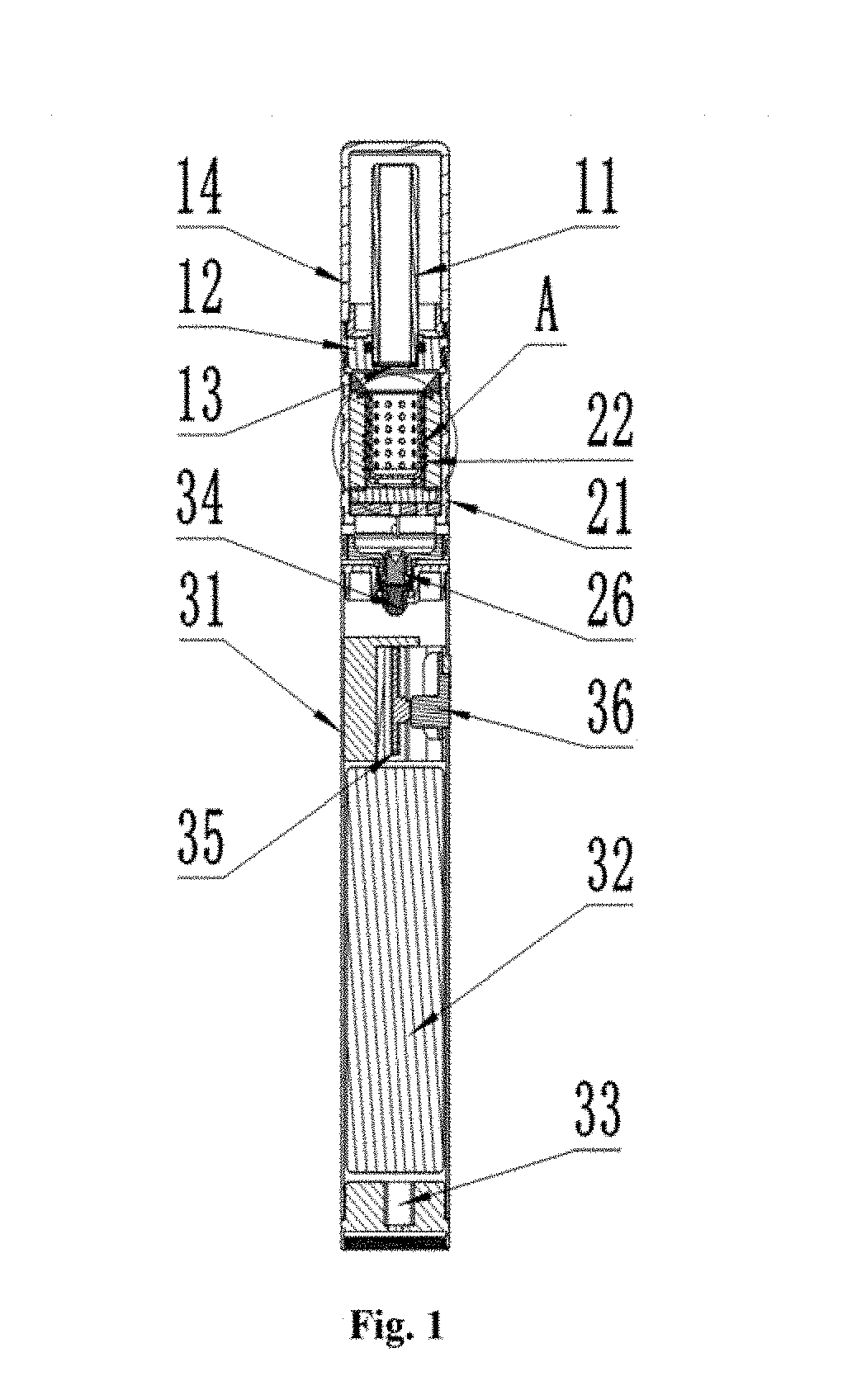

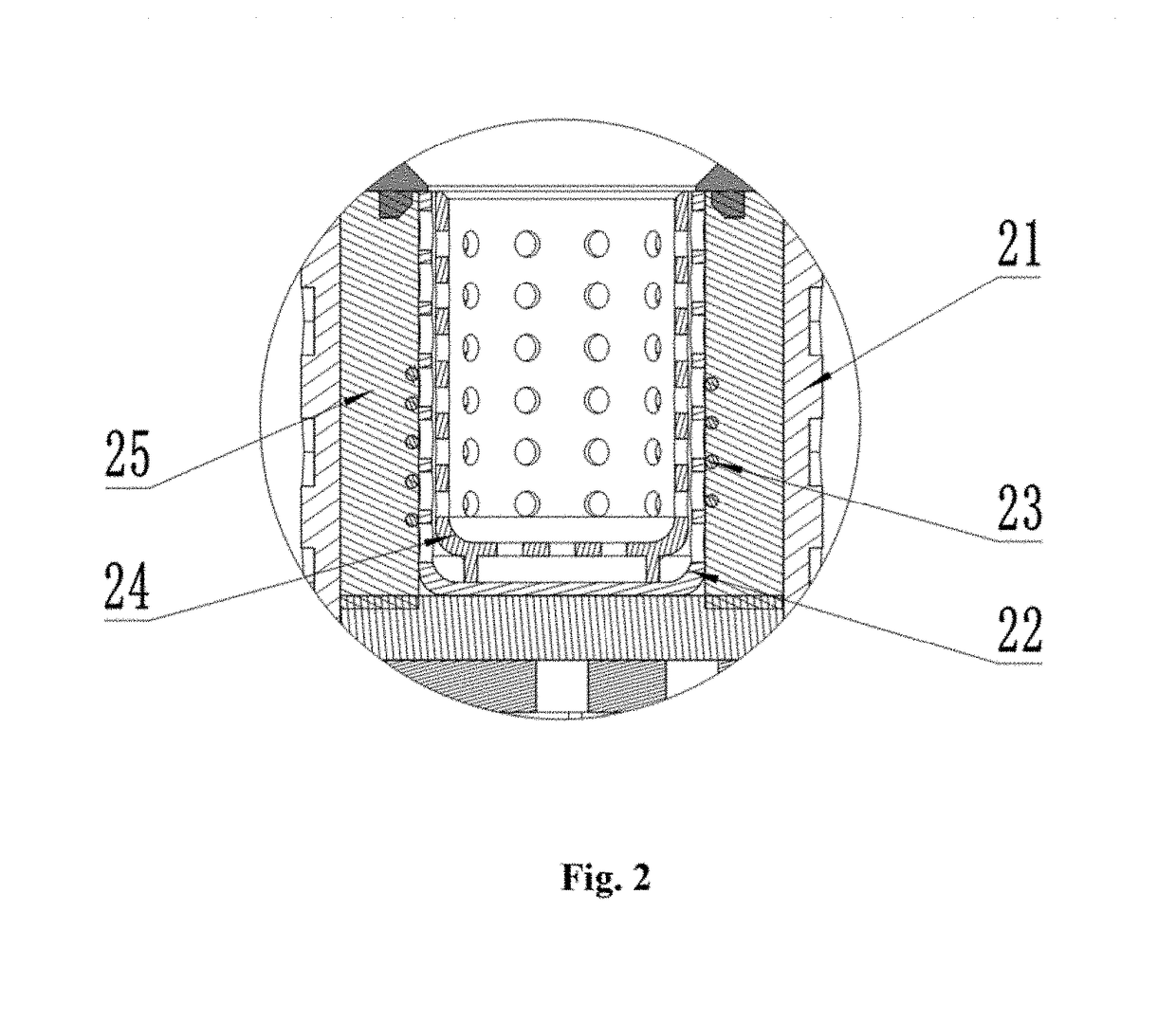

Annular stereoscopic-heating electronic cigarette with replaceable inner container

InactiveUS20170215474A1Evenly heatedProlonging smoking timeProgramme controlTobacco pipesNickel cadmiumEngineering

This invention provides an annular stereoscopic-heating electronic cigarette with replaceable inner container, comprising: a cylindrical electronic cigarette body; the electronic cigarette body comprises a smoke-filtering member, an annual stereoscopic-heating member and a heat-controlling member; wherein: the annual stereoscopic-heating member comprises an annual stereoscopic-heating casing, and an openwork member for conducting heat. A nickel cadmium (Ni-Cd) heating coil is spirally wind around and firmly contacts the exterior surface of the open member. A replaceable shredded tobacco inner container is sleeved within the openwork member. The exterior of the Ni-Cd heating coil and the bottom of the openwork member are respectively wrapped around by an asbestos heat-insulating layer. A short-circuit contactor is set at the bottom of the annular stereoscopic-heating casing and connects to the Ni-Cd beating coil.

Owner:LRIDER TECH CO LTD

Methods of vitrifying waste with low melting high lithia glass compositions

InactiveUS6258994B1Reduce pointsReduce the temperatureSludge treatmentSolid waste disposalAlkali metal oxideRadioactive agent

The invention relates to methods of vitrifying waste and for lowering the melting point of glass forming systems by including lithia formers in the glass forming composition in significant amounts, typically from about 0.16 wt % to about 11 wt %, based on the total glass forming oxides. The lithia is typically included as a replacement for alkali oxide glass formers that would normally be present in a particular glass forming system. Replacement can occur on a mole percent or weight percent basis, and typically results in a composition wherein lithia forms about 10 wt % to about 100 wt % of the alkali oxide glass formers present in the composition. The present invention also relates to the high lithia glass compositions formed by these methods. The invention is useful for stabilization of numerous types of waste materials, including aqueous waste streams, sludge solids, mixtures of aqueous supernate and sludge solids, combinations of spent filter aids from waste water treatment and waste sludges, supernate alone, incinerator ash, incinerator offgas blowdown, or combinations thereof, geological mine tailings and sludges, asbestos, inorganic filter media, cement waste forms in need of remediation, spent or partially spent ion exchange resins or zeolites, contaminated soils, lead paint, etc. The decrease in melting point achieved by the present invention desirably prevents volatilization of hazardous or radioactive species during vitrification.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

Automotiv non-asbestos high strength braking friction disk, and its prodn. method

InactiveCN1563735AImprove heat resistanceEnhancement effect is goodFriction liningHeat resistanceMetal fibers

The wearing piece of non-asbestos high srength material applies the high molecular compound, phenolic ressin as the agglomerant. The metal fiber or organic fiber is strengthen component. The stuffing applies regulator with frictional properties and barium sulfate, black lead, alumina as accessory ingredient. The production possesses excellent characteristic of physical chemical and mechanical and thermo-stability.

Owner:APPLIED PHYSICS INST OF GUANGXI ACADEMY OF SCI

Ceramic base/NAO composite friction material and preparation method thereof

The invention relates to an oxide ceramic base / NAO composite friction material used in a brake of a medium or high-grade car and a preparation method thereof. In the composite friction material, mixed fibers comprise aramid fibers, potassium titanate fibers and silicon, magnesium and calcium oxide ceramic fibers; aedelforsite or mineral fibers and copper fibers are used as the enhancement and conduction fibers; phenolic resin is used as the organic bonding agent; pure oxide ceramics, such as Al2O3, ZrO2, MgO, CaO and the like, are used as the abrasives; solid lubricant, sulfide, graphite coke and the like are used as the abrasion resistant lubricants; and sodium bicarbonate is used as the blowing agent and pairing antioxidant, and barium sulfate inorganic filler is used as the function and toughening filler. The ceramic base / NAO organic friction material mainly maintains the unique performance of the asbestos friction material, remakably lowers the noise, reduces the abrasion possibility, and is beneficial to prolonging the service life of a brake disc, there by being a novel green (less-dust) low-noise environmentally-friendly friction material.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

Friction material for brakes

Owner:FEDERAL MOGUL PROD INC(US)

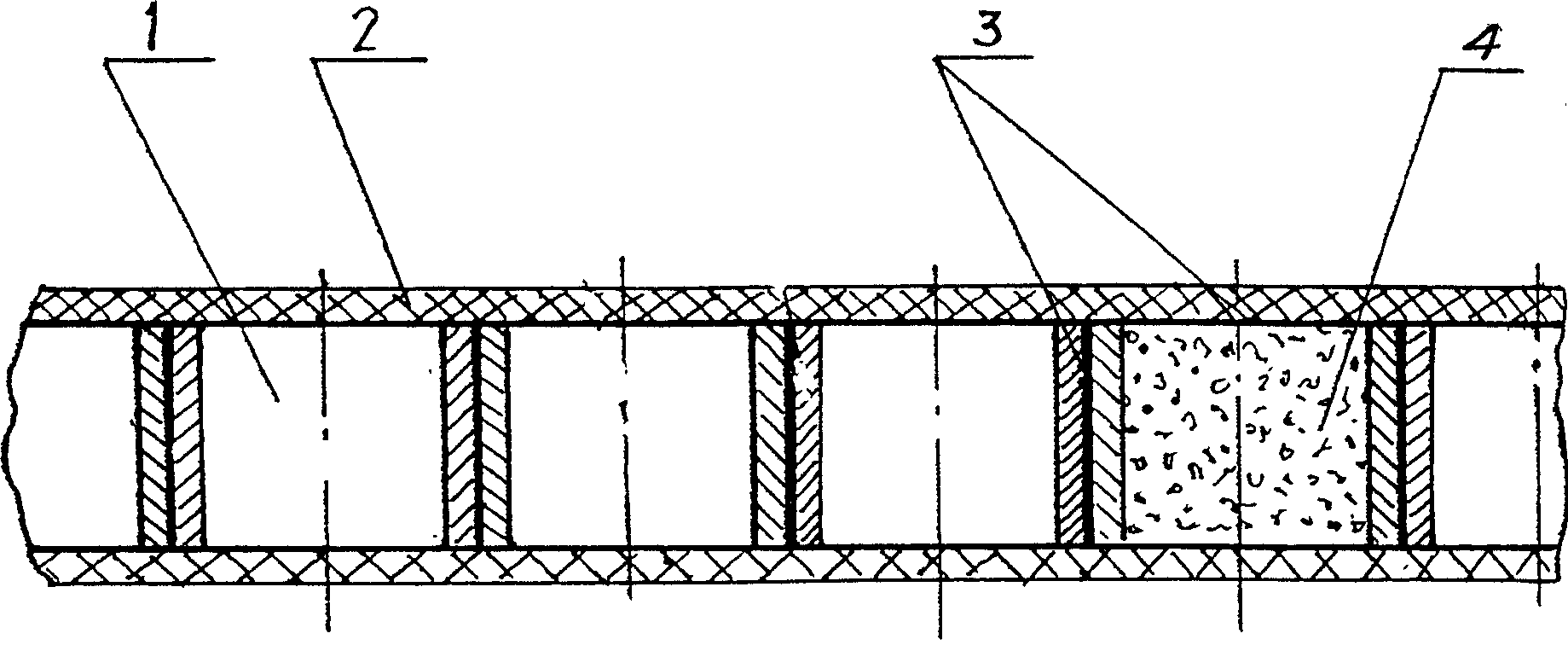

Non-asbestos static sealing materials and products thereof

InactiveCN1844291AEliminate micro gapsIncrease the compression ratioOther chemical processesFiberGraphite

The invention provides a packing material containing no asbestos and its preparing process, wherein the material is prepared from binders, mica, vermiculite, graphite, organic fiber and inorganic fiber, silicon dioxide, porcelain clay, barium sulfate, anti-aging agent, preservative agent and vulcanizing auxiliary agent through calendaring formation.

Owner:长春蓝天密封技术开发有限公司

Magnesium-alloy metal-type casting coating and preparation method thereof

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

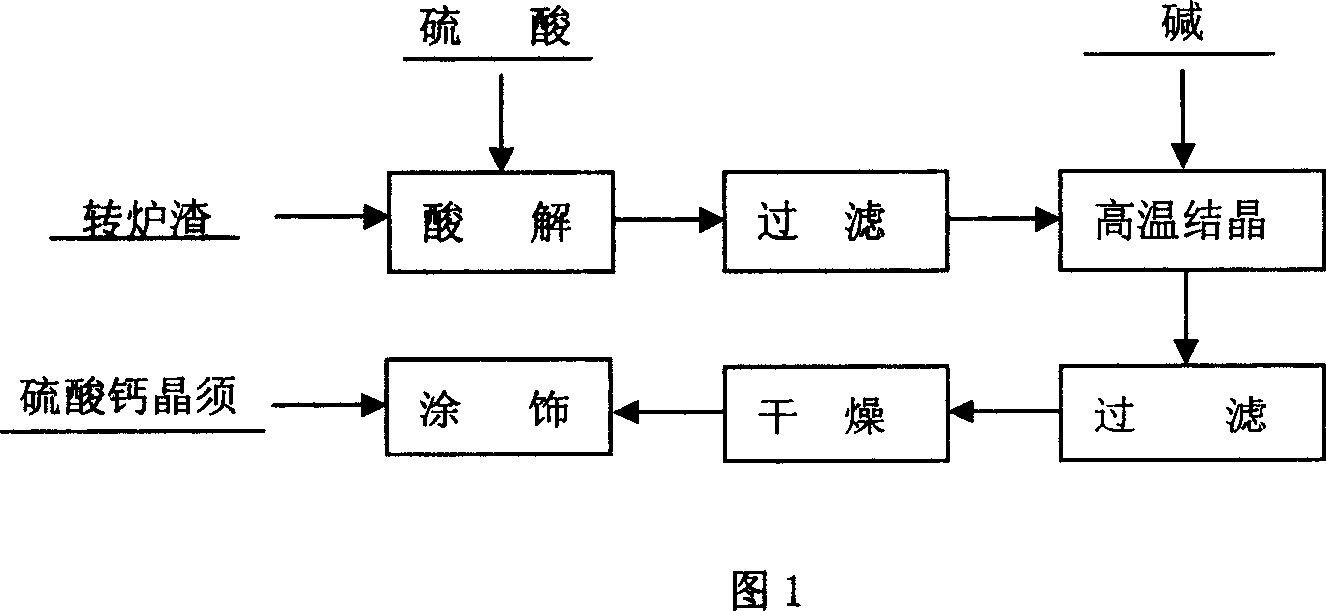

Production of non-metallic material calcium-sulfate whiskers

InactiveCN101029415AAvoid pollutionShort processPolycrystalline material growthFrom normal temperature solutionsGlass fiberSlag

Production of non-metallic calcium sulfate whiskers is carried out by taking converter slag as raw materials, grinding, leaching out sulfuric acid, filtering to obtain calcium sulfate suspended solution, synthesizing by high-temperature crystallizing method, separating and drying to obtain the final product. The purity is above 98%. It's cheap, has better quality and short process flow path. It can be used as filler, friction material, building material or thermal-insulating material and used to substitute glass fiber.

Owner:NORTHEASTERN UNIV

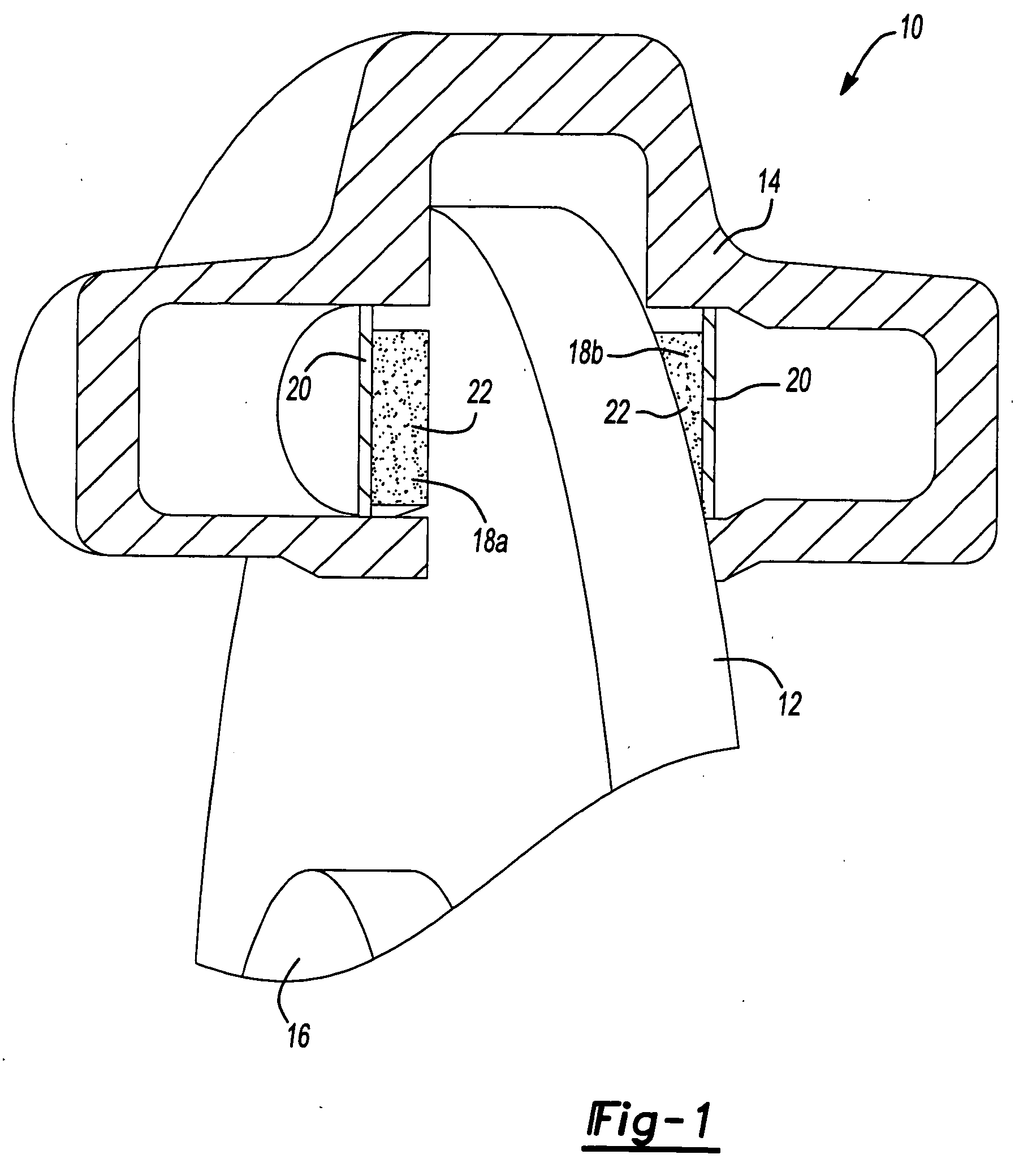

Copper-free non-asbestos organic friction material

A braking element generally including a friction material having one of iron fibers, aluminum, zinc, tin and combinations thereof. An amount of the iron fibers in the friction material is in a range between about 1 v % to about 10 v %. An amount of one of the aluminum, the zinc, the tin and the combinations thereof is in a range between about 1 v % to about 5 v %. The friction material is free of elemental copper. As the friction material wears, elemental copper is not released into the environment.

Owner:AKEBONO CORP (NORTH AMERICA)

Low-abrasion environment-friendly composite ceramic-based friction material

ActiveCN101619202ANo brake noiseReduce wear rateOther chemical processesFriction liningComposite ceramicBoron nitride

The invention discloses a low-abrasion environment-friendly composite ceramic-based friction material which comprises the following components in percentage by weight: 5 to 7 phenolic resin, 5 to 9 nitrile rubber, 2 to 5 aramid fiber, 2 to 6 silicon carbide, 15 to 20 ceramic fiber, 3 to 5 zirconia, 8 to 10 artificial graphite, 3 to 10 molybdenum disulphide, 5 to 15 zirconium silicate, 1 to 3 aluminum oxide, 8 to 10 potassium titanate whiskers, 5 to 15 precipitated barium sulfate, 1 to 3 magnesium oxide, 1 to 3 petroleum coke, 3 to 5 friction powder, 8 to 10 vermiculite and 4 to 9 boron nitride. The invention has the advantages that the friction material manufactured by using the components and the blending ratio has the advantages of no asbestos and brake noise, low wear rate, stable high-temperature brake performance, stable speed reduction brake, lower cost than the similar imported products, and the like.

Owner:CHONGQING HONGYU FRICTION PROD

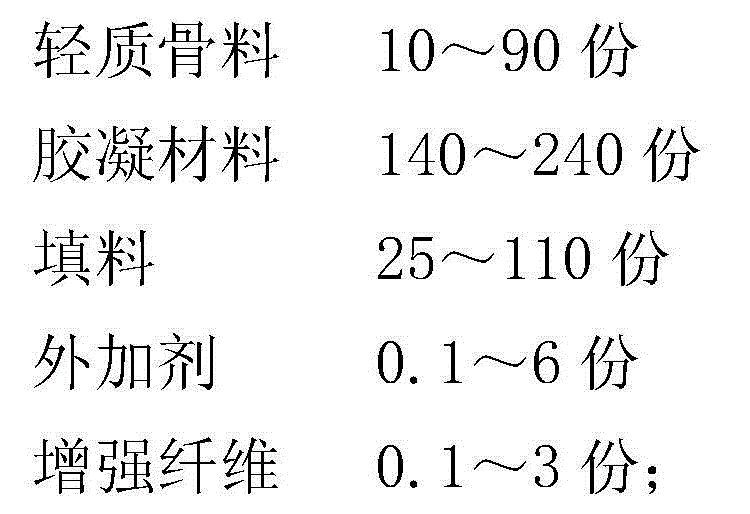

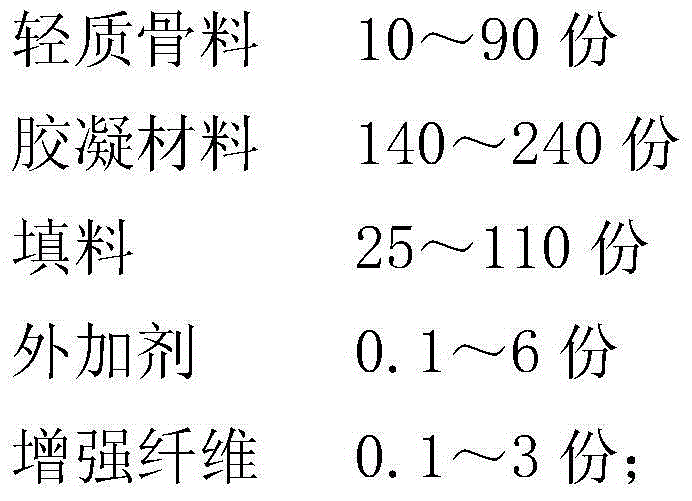

Fireproof decorative board base material

The invention provides a fireproof decorative board base material. The fireproof decorative board base material comprises 10 to 90 parts of lightweight aggregate, 140 to 240 parts of gel material, 25 to 110 parts of filler, 0.1 to 6 parts of additives and 0.1 to 3 parts of reinforced fibers; the lightweight aggregate comprises 10 to 60 parts of perlite; the gel material consists of an organic gel material and an inorganic gel material; additives are one or combination of more of water reducing agent, early strength agent, accelerating agent, defoaming agent, air entraining agent, water repellent, curing agent, dispersing agent, coupling agent, flame retardant and smoke inhibitor; the reinforced fibers are one of asbestos, paper pulp, polypropylene fibers, fluorine resin fibers and glass fibers. Compared with the prior art, the fireproof decorative board base material has the beneficial effects that the base material which is high in strength, high in fireproof grade, small in density and likely to composite with an aluminum foil is provided, the base material is composited with the aluminum foil to form a decorative board, and a novel solution is provided for the decoration of an outer wall.

Owner:SNTO TECH GRP

Mixed casting molding sand and preparation method thereof

The invention discloses a mixed casting molding sand and a preparation method thereof. The preparation method mainly comprises: performing dry mixing of component raw materials including quartz sand, attapulgite, wax, asbestos, a furan resin, a phenolic resin, bentonite and potassium dichromate by certain weight parts; and adding water, mixing, placing sand, molding, casting, cooling and separating to obtain finished product. The preparation method of the invention is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of an aluminum sand piece is made smooth by strictly controlling the particle size of quartz sand, and the breathability is high.

Owner:邹平县永通金属材料有限公司

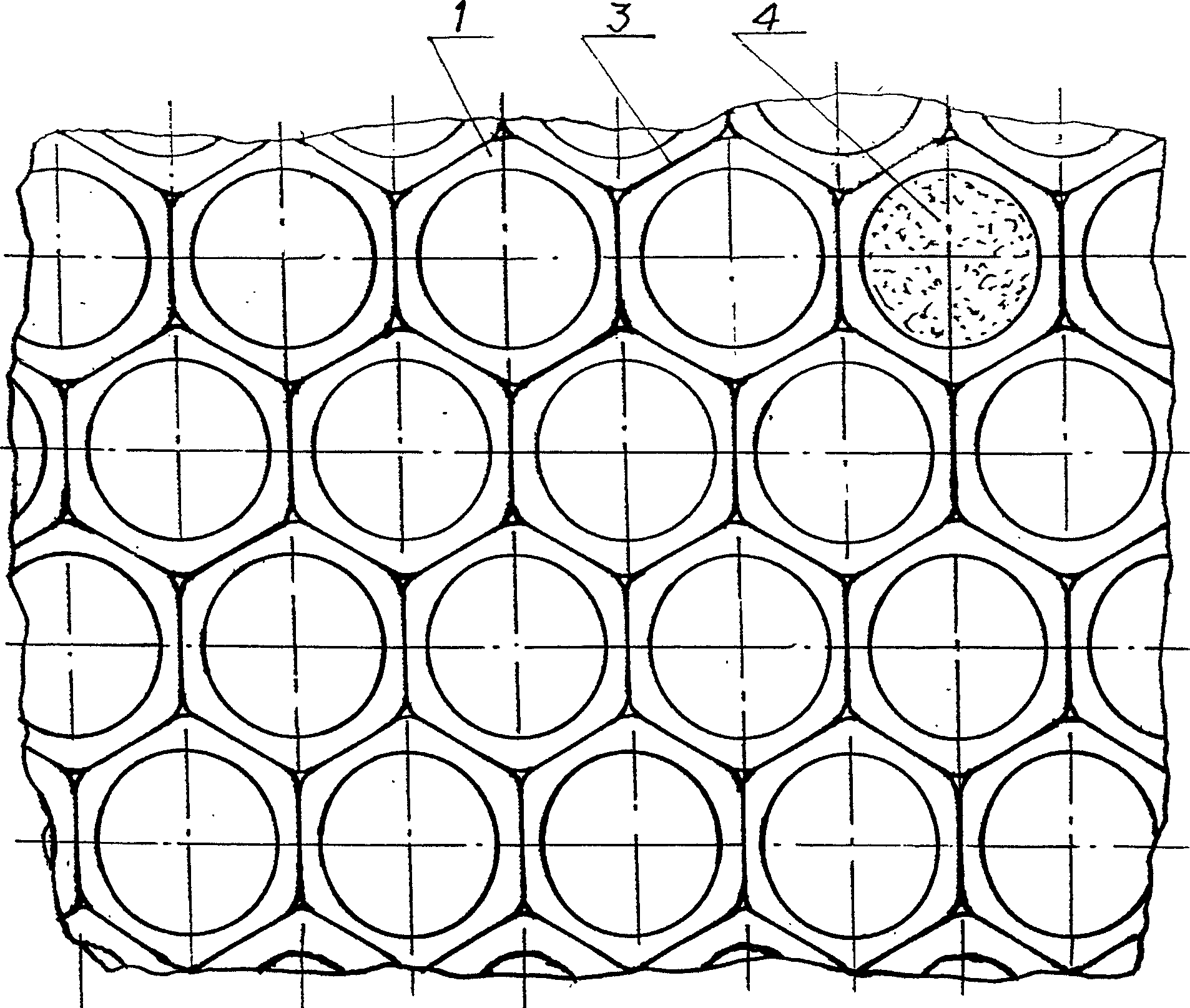

Non-asbestos friction material

ActiveUS20080156226A1Improve braking effectAvoid problemsOther chemical processesFriction liningHeavy metal compoundGraphite

A non-asbestos friction material not containing a heavy metal and a heavy metallic compound as the blending ingredients of the friction material is provided with graphite and coke in total from 5 to 25 vol % in volume of friction material. A volume ratio of the graphite / coke is preferably from 2 / 1 to 7 / 1. An average particle size of the coke is preferably from 150 to 400 μm.

Owner:AKEBONO BRAKE IND CO LTD

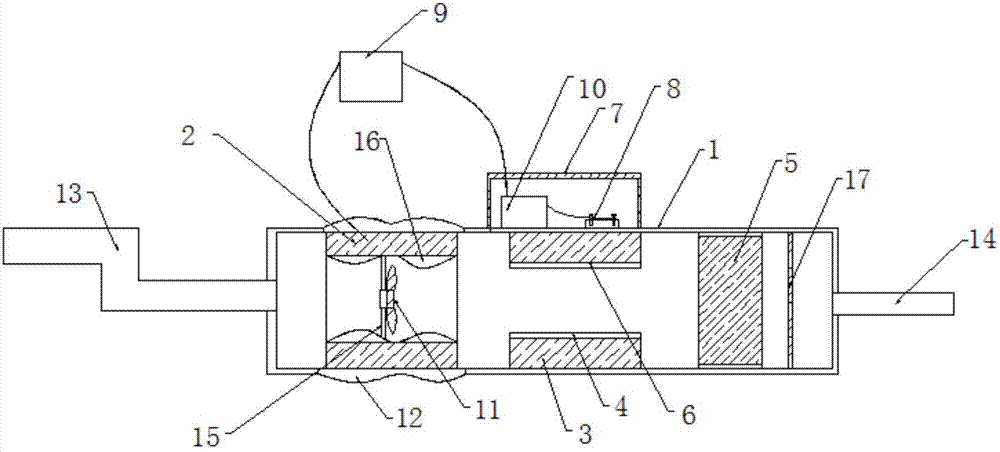

Vehicle tail gas purifying device

InactiveCN107387203AReduce consumptionImprove spoiler effectInternal combustion piston enginesExhaust apparatusElectricityActivated carbon filtration

The invention discloses a vehicle tail gas purifying device. The vehicle tail gas purifying device comprises a main body; a temperature difference generator, an asbestos filter cylinder and an activated carbon filter screen are mounted in an inner cavity of the main body in sequence from left to right in a tail gas feeding direction; a relative fixed base is arranged between the temperature difference generator and the asbestos filter cylinder; an electrostatic dust removing anode plate and an electrostatic dust removing cathode plate are respectively mounted on the relative fixed base; a turbulent fan is fixedly mounted on the inner wall of the temperature difference generator through a fixed frame; heat collecting plates are respectively arranged on the inner walls of two opposite sides of the temperature difference generator; an equipment box is fixedly welded in the middle position of the outer side of the top of the main body; a transformer and a protection switch are fixedly mounted in an inner cavity of the equipment box; and the temperature difference generator is connected with an accumulator through an intelligent charger. The vehicle tail gas purifying device is skillful in concept, uses vehicle tail gas afterheat for generating electricity, fully uses resources, can purify and decompose vehicle tail gas, and reduces environmental pollution by the vehicle tail gas.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

T91 water wall tube row welding technology

ActiveCN104801834AImprove medium and high temperature strengthStrong anti-porosityArc welding apparatusMaterials preparationHydrogen

The invention relates to a T91 water wall tube row welding technology. The welding technology comprises the steps of (1) cleaning before welding; (2) welding material preparation: preparing welding wires and flux, and performing baking before flux use, wherein the baking temperature is in a range of 250 DEG C to 400 DEG C, and the baking time ranges from 0.5h to 3h; (3) spot welding before welding: using R317 welding wires to flat steel and T91tube electric welding, wherein the welding strips are needed to be baked; (4) preheating before welding: performing preheating before welding to enable all portions of materials to be welded to be uniform in heating; (5) tube row welding: performing welding in the condition of the 300A-320A welding current, 26V-27V welding voltage and 80mm / min-90mm / min and performing coverage with asbestos immediately after front welding seams are welded; (6) hydrogen removal after welding; (7) detection; (8) thermal treatment. The welding technology is simple and convenient to operate, covering through insulation cotton is performed after welding, and accordingly, cracks due to rapid cooling can be prevented.

Owner:JIANGSU GREENLEAVES BOILER

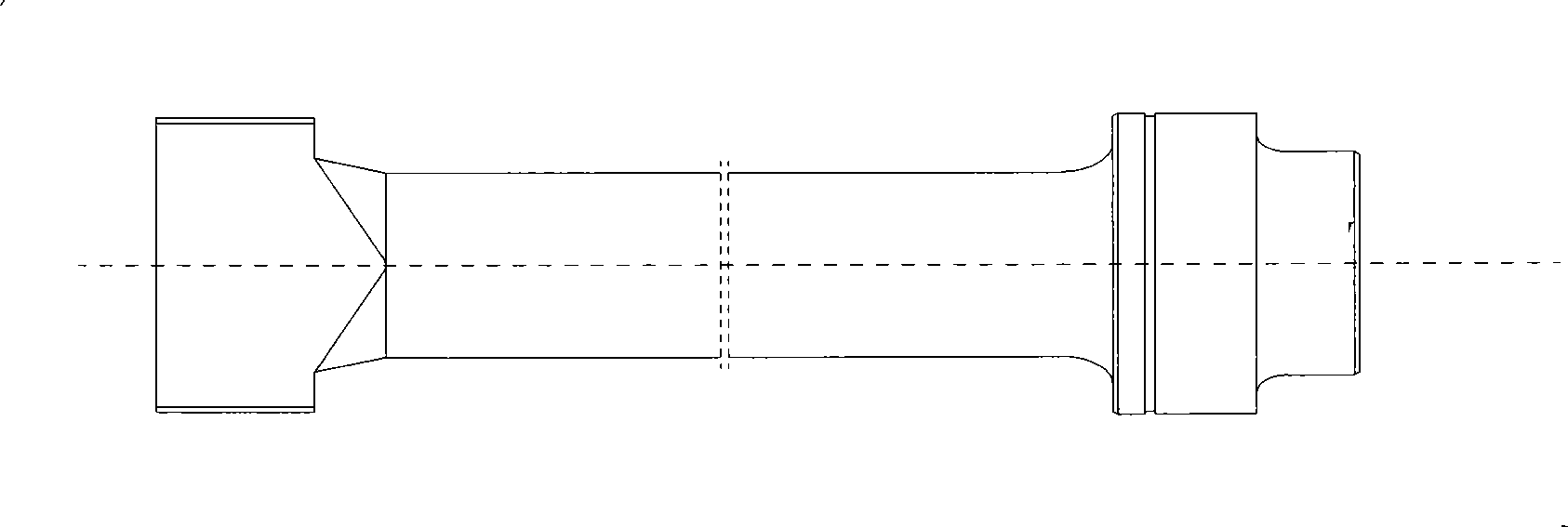

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

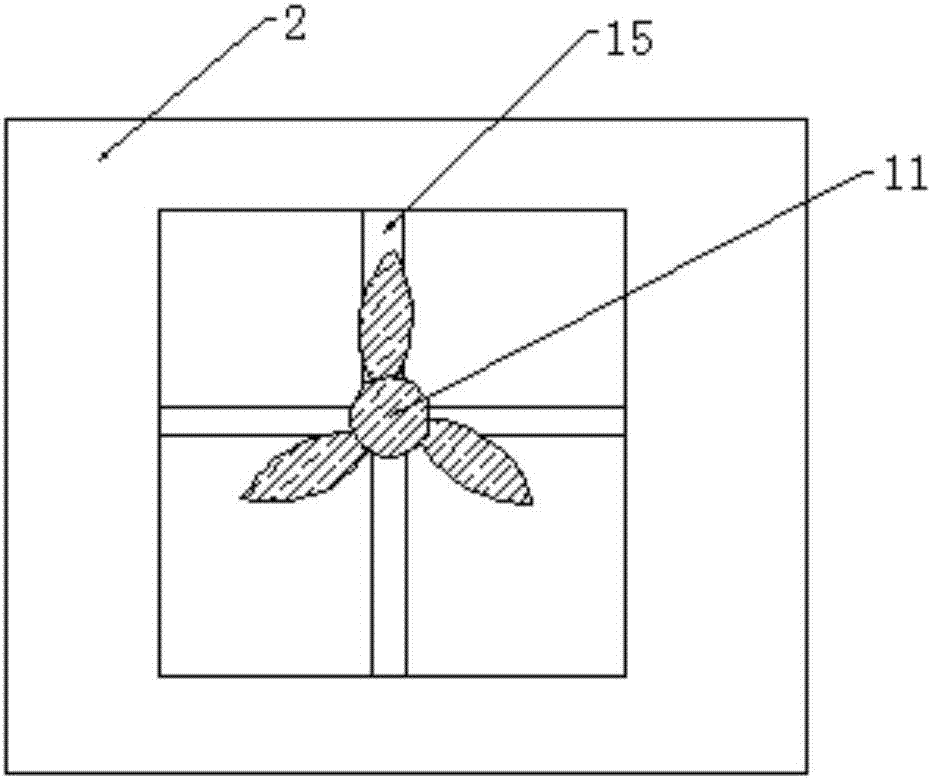

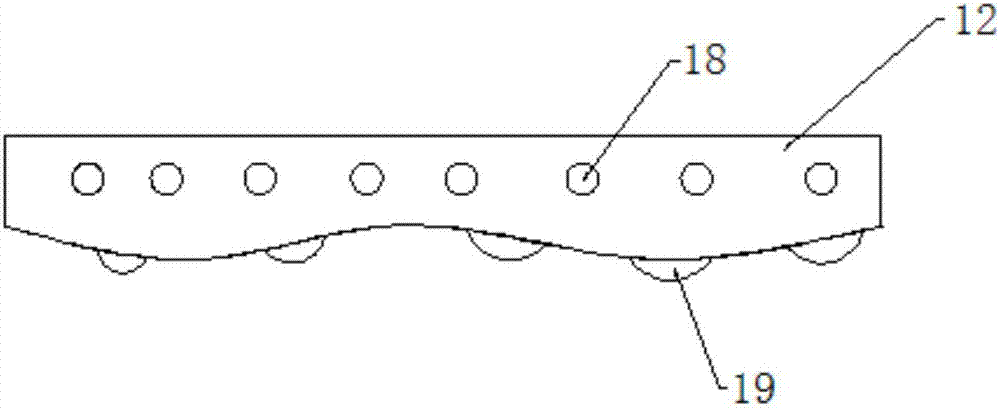

Sludge aerobic composting reactor

InactiveCN101148373AClimate change adaptationSewage/sludge fertilisersVacuum extractorSludge compost

The present invention relates to aerobic sludge compost reactor, and is especially one kind of aerobic sludge compost reactor for utilizing high water content sludge. Technologically, the aerobic sludge compost reactor consists of one air controlling system, one stirring system, one fermentation tank system and one heating and temperature controlling system. The fermentation tank system consists of one inner tank and one outer tank, and has sludge inlet, compost outlet, sewage discharge port and manually controlled sewage discharging unit. The air controlling system comprising blower and vacuumizing machine is connected to the fermentation tank through pipeline. The stirring system consists of motor, link rod and stirring blades. The heating and temperature controlling system consists of ceramic casing, asbestos, temperature inductor and control circuit. The present invention has convenient use, low cost, no environmental pollution and other advantages.

Owner:FUJIAN NORMAL UNIV

Bamboo-made wallboard

InactiveCN1743598AReduce weightEasy constructionConstruction materialLayered productsFiberWood shavings

A bamboo wall board is composed of bamboo tubes with adhesive peripheral faces, in which, the outer shapes of multiple bamboo tubes are the same, they are orthohexagonal post, die-square or cylindrical and an adhesive agent for connecting bamboo tubes is set at the contact places of the peripheral faces, the tubes are filled with fillers of bamboo bits, wood flour, wood shavings, fibers, crushed plant stovers, cement slurry, gypsum powder or foamed plastics, all of which are doped with adhesives. The bamboo wallboard is adhered with coats of bamboo boards, wood plywood, fiberboard, plastics, metallic board, gypsum boards or asbestos boards.

Owner:天津市朗明通信科技有限公司

Method for ecologically breeding black-bone chickens in medlar garden

InactiveCN101606508AFull of nutritionImprove qualityBird housingsHorticultureReticulateGallus gallus gallus

The invention relates to a method for ecologically breeding black-bone chickens in a medlar garden, comprising the following steps: 1. medlar garden construction: the growth of garden nursery stocks takes more than one year, strong stocks have no pest infection, row spacings of planted plants are 1 m*2 m, 333 plants are planted in per mu, forage grass or / and vegetables, i.e. lucernes, small rapes, small Chinese cabbage, and the like are interplanted among rows of medlar plants, a net-shaped iron-wire protective guard with the height of 1.5 m is constructed around the medlar garden, and movable water tanks and forage tanks are placed in the medlar garden; 2. simple chicken house construction: a finished chicken house is in a steel bar pipe frame and asbestos tile structure, a roof structure is in a monoclinic way, the height of circumferential asbestos tiles is 1.5 meters, the upper part of the chicken house is provided with a steel plate net, and the chicken house is internally provided with the forage tanks and drinking bowls in a matching way; 3. brooding, grazing and manual forage supplement: chicks are collected to be brooded for 4-5 weeks and then bred in the medlar garden for 8-10 weeks without original temperature, and two batches of the black-bone chickens are grazed and bred every year; 4. breeding density: the number of each batch of the black-bone chickens which are averagely bred on the earth per mu is properly controlled between 100 and 150; and 5. a breeding way: an all-in and all-out breeding way is carried out for the same batch of the black-bone chickens.

Owner:GANSU AGRI & FORESTRY RES INSTOF MOUNTAIN GROUP

Resin casting molding sand and preparation method thereof

ActiveCN102380575AEasy to prepareReasonable formulaFoundry mouldsFoundry coresDry mixingPotassium dichromate

The invention discloses resin casting molding sand and a preparation method thereof. The method mainly comprises: performing dry mixing of component raw materials including quartz sand, straw ash, tung oil, asbestos, a furan resin, a phenolic resin, kaoline and potassium dichromate by certain weight parts; and adding water, mixing, placing sand after mixing, molding, casting, cooling and separating to obtain a finished product. The preparation method is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of the aluminum sand is made smooth by strictly controlling the particle size of the quartz sand, and the breathability is high.

Owner:托普工业(江苏)有限公司

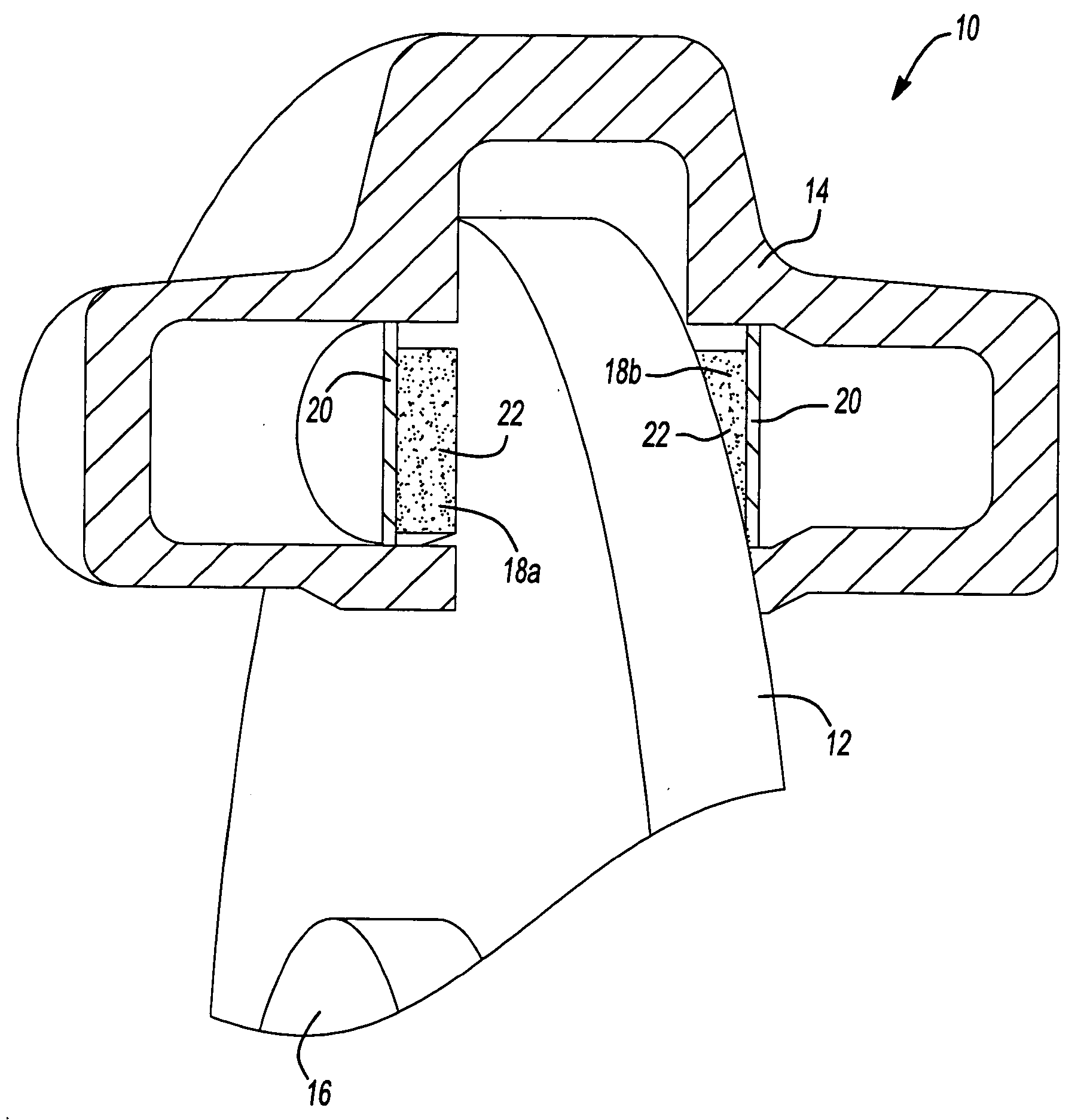

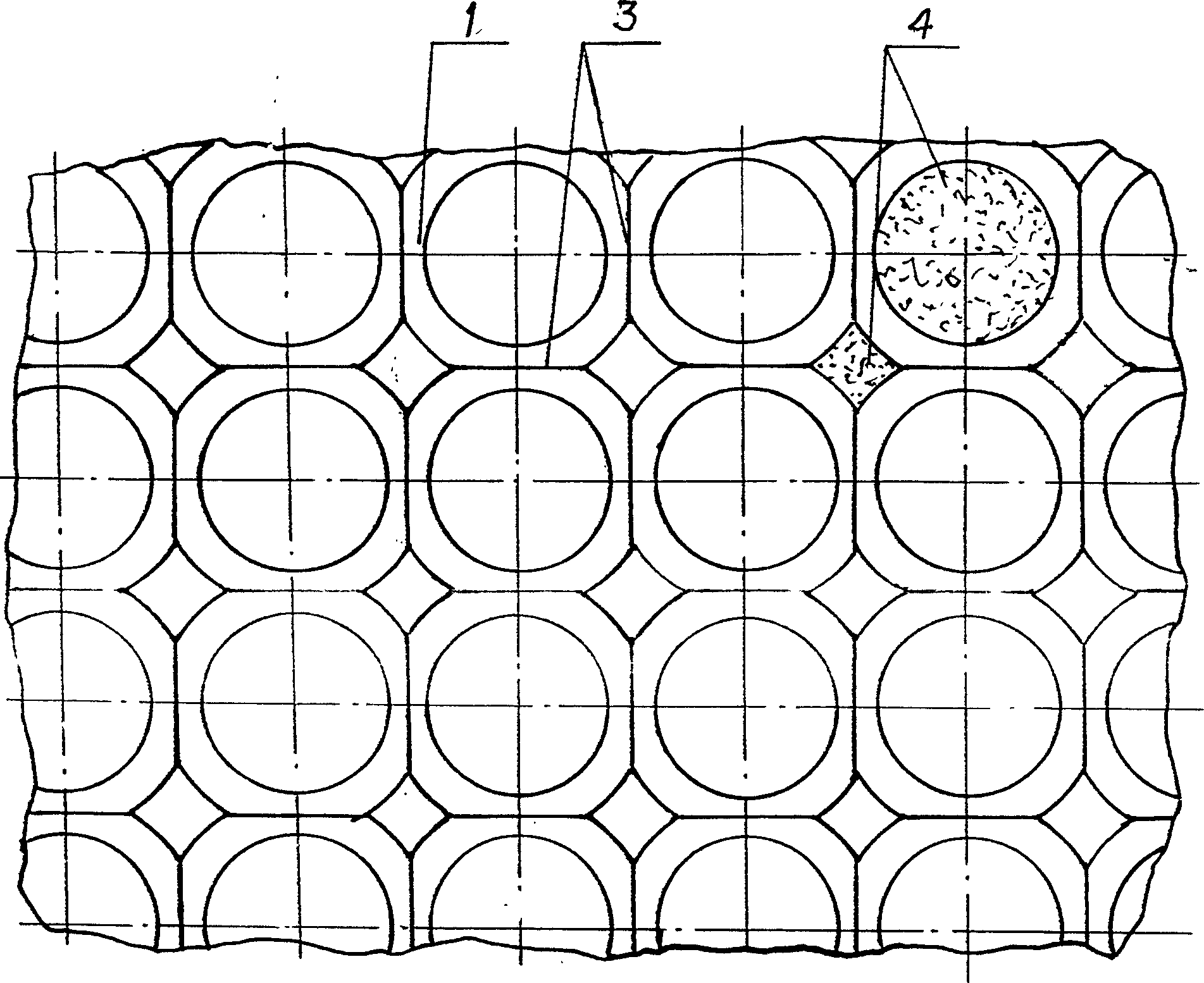

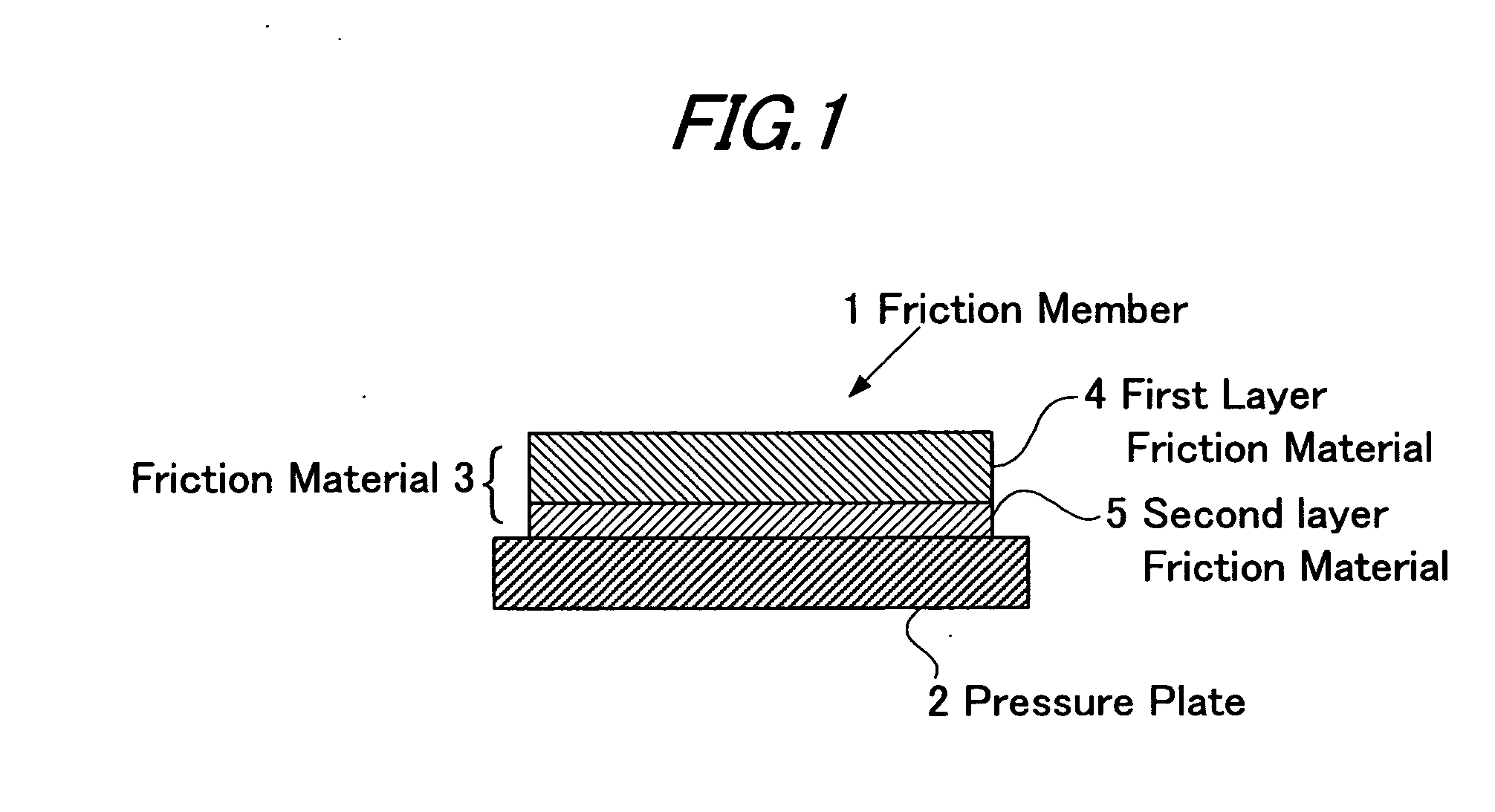

Non-asbestos friction member

A friction material containing a thermosetting resin binder, reinforcing fibers, and a friction modifier are integrally formed with a pressure plate. The friction material has a first layer friction material on a side of a friction surface and a second layer friction material on a side of the pressure plate. A pre-mix containing an elastomer and a cross-linker is blended in the second layer friction material. The premix preferably contains fibers, and the premix preferably contains 10 to 97 vol % of an elastomer blended therewith.

Owner:AKEBONO BRAKE IND CO LTD

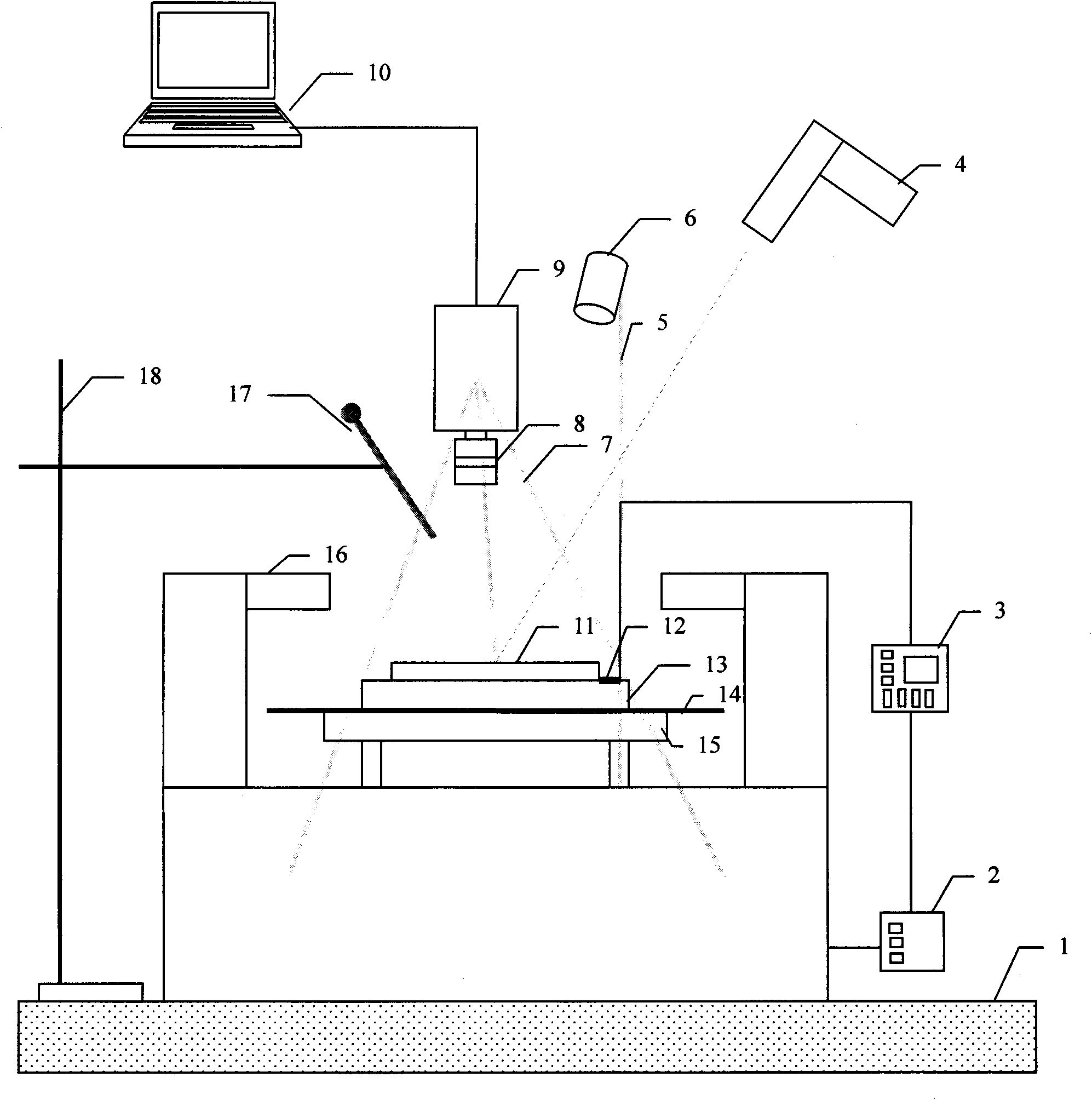

Method and device of measuring material thermal shock property

ActiveCN101666733AAccurate recordStable and reliable measurement environmentStrength propertiesStructural deformationWire gauze

The invention relates to a method and a device of measuring material thermal shock property, which belongs to the technical field of engineering materials, structural deformation and mechanics experiment. The measuring device comprises an air cushion precision optical platform, a temperature controlled switch, a PID temperature controller, an infrared radiation thermometer, an LED lamp bracket, anLED lamp, an A-frame, a lens, a high speed camera, a computer, a test piece, a thermoelectric pair, alumina ceramics, asbestos wire gauze, a heating furnace, a thermal insulation shield, a burette and a stand. The invention combines heating equipment and an optical photographic apparatus, masterly utilizes a digital image cross-correlation method and provides the method and the device of measuring material thermal shock property. The invention has novel train of thought, compact structure and complete system, and can realize quantitative analysis and measurement on the material thermal shockproperty.

Owner:TSINGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com