Production of non-metallic material calcium-sulfate whiskers

A technology of calcium sulfate whiskers and non-metallic materials, which is applied to the growth of polycrystalline materials, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of complicated experimental steps, difficult industrialization and the like, and achieves low production costs. , The effect of solving pollution and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

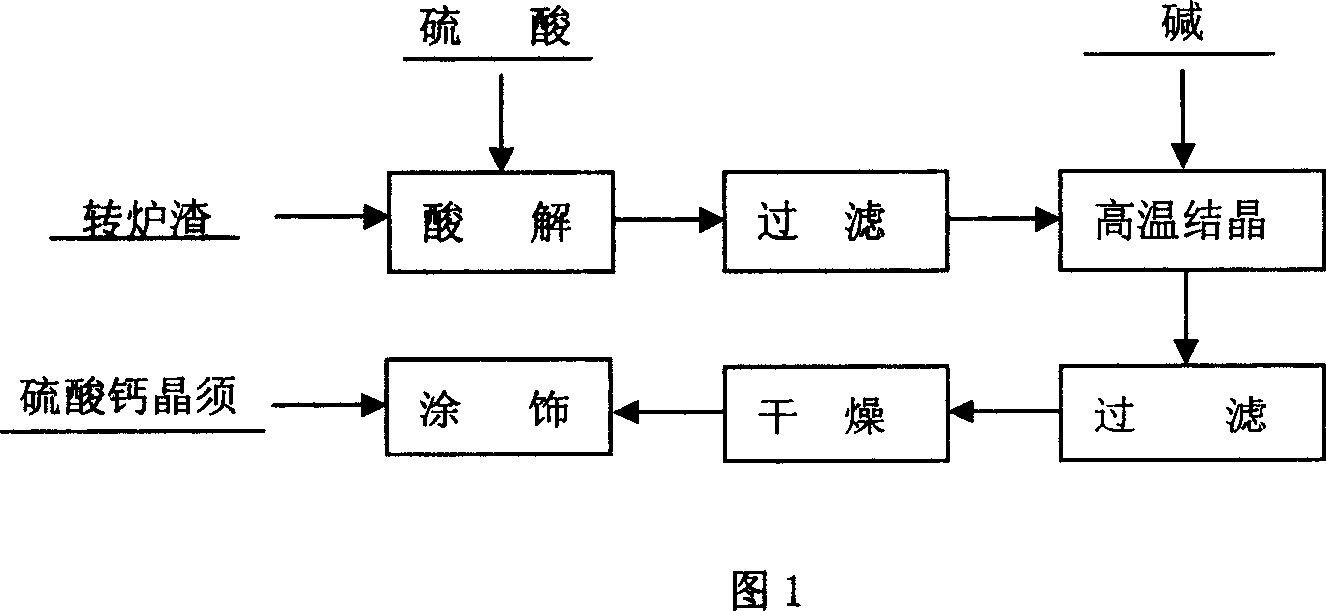

Image

Examples

Embodiment 1

[0025] Selection: 40g of converter slag with a particle size of 0.074mm is used as raw material (the components of converter slag are shown in Table 1) and 240g of 10% sulfuric acid are reacted, the reaction temperature is 50°C, and the reaction time is 40min; after filtration and separation, the liquid phase is used to prepare ferric sulfate Mixture with magnesium sulfate, etc., the solid phase is calcium sulfate containing silicon dioxide; mix calcium sulfate with water at a ratio of 5:1 according to the solid-liquid ratio, adjust the pH value to 5 with calcium oxide; suspend the prepared calcium sulfate The liquid is put into the reaction kettle, under the condition that the temperature is 120°C, the pressure is 0.3MPa and the stirring speed is controlled at 50 rev / min, it is kept for 480min, filtered and washed; Under the condition of 120min, the holding time is 120min to obtain calcium sulfate whiskers; the calcium sulfate whiskers are surface-modified and dispersed by pol...

Embodiment 2

[0031] Selection: 40g of converter slag with a particle size of 0.09mm is used as raw material (the components of converter slag are shown in Table 2) and 160g of 15% sulfuric acid are reacted, the reaction temperature is 90°C, and the reaction time is 40min; after filtration and separation, the liquid phase is used to prepare iron oxide , the solid phase is calcium sulfate, the calcium sulfate is mixed with water at a ratio of 0.4 according to the solid-liquid ratio, and the pH value is adjusted to 6 with calcium oxide; the prepared calcium sulfate suspension is put into the reaction kettle, and the temperature is 150°C , under the condition that the pressure is 0.6MPa and the stirring speed is controlled as 100 rev / min, it is incubated for 240min, filtered and washed; the washed calcium sulfate whiskers are kept at a temperature of 100°C for 120min to obtain calcium sulfate Whiskers: use polyvinyl alcohol to modify and disperse the calcium sulfate whiskers on the surface, the...

Embodiment 3

[0037] Selection: use 40g of converter slag with a particle size of 0.074mm as raw material (the composition of converter slag is shown in Table 1) and react with 160g of 20% sulfuric acid, the reaction temperature is 70°C, and the reaction time is 40min; after filtration and separation, the liquid phase is used to prepare iron oxide , the solid phase is calcium sulfate, the calcium sulfate is mixed with water at a ratio of 0.6 according to the solid-liquid ratio, and the pH value is adjusted to 7 with calcium oxide; , under the condition that the pressure is 0.8MPa and the stirring speed is controlled as 200 rev / min, it is incubated for 300min, filtered and washed; the washed calcium sulfate whiskers are kept at a temperature of 140°C for 60min to obtain calcium sulfate Whiskers: use polyvinyl alcohol to modify and disperse the calcium sulfate whiskers on the surface, the dosage of the modifier is 0.5%, and finally obtain anhydrous calcium sulfate whiskers; the length of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com