Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2346results about "Calcium/strontium/barium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

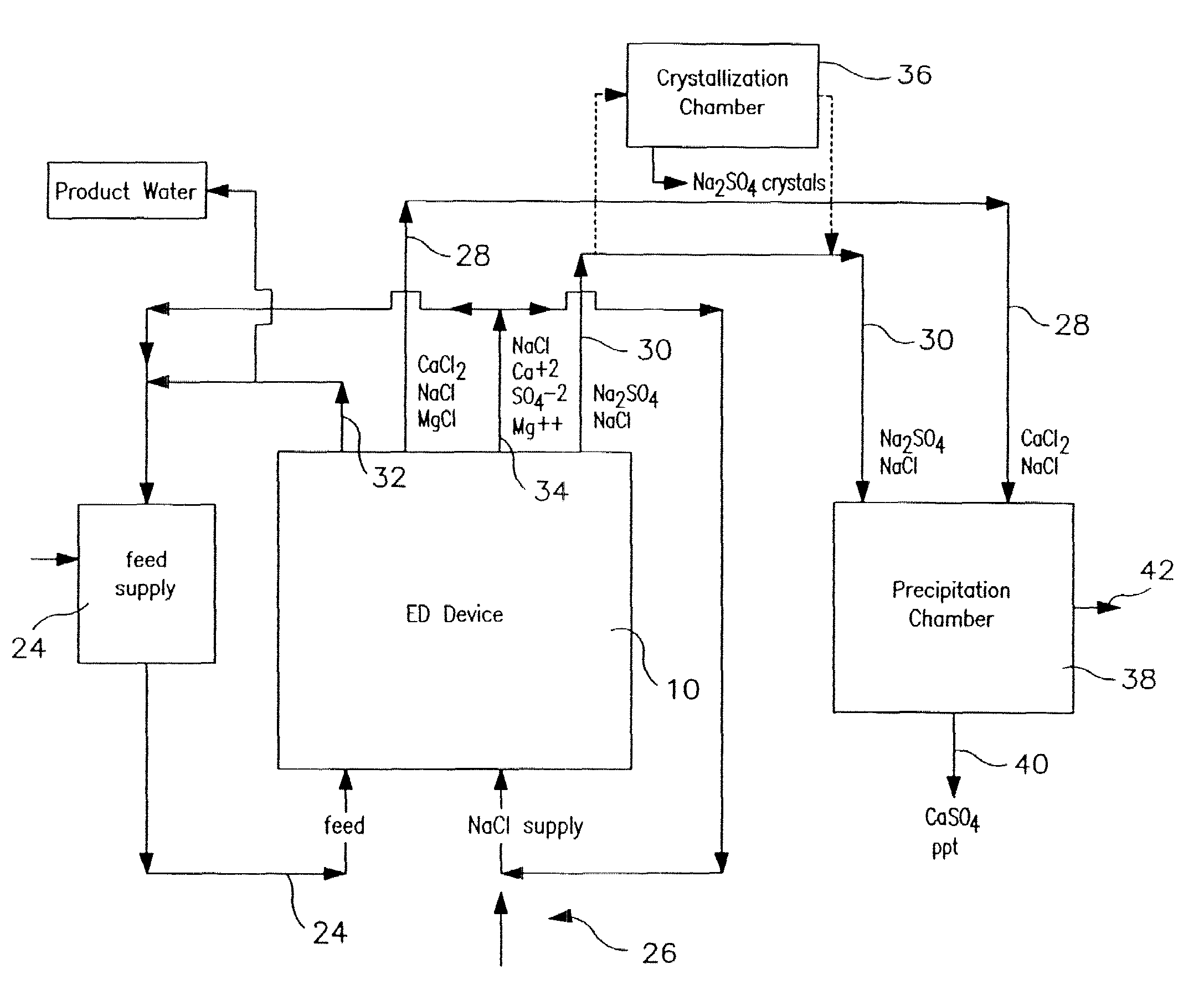

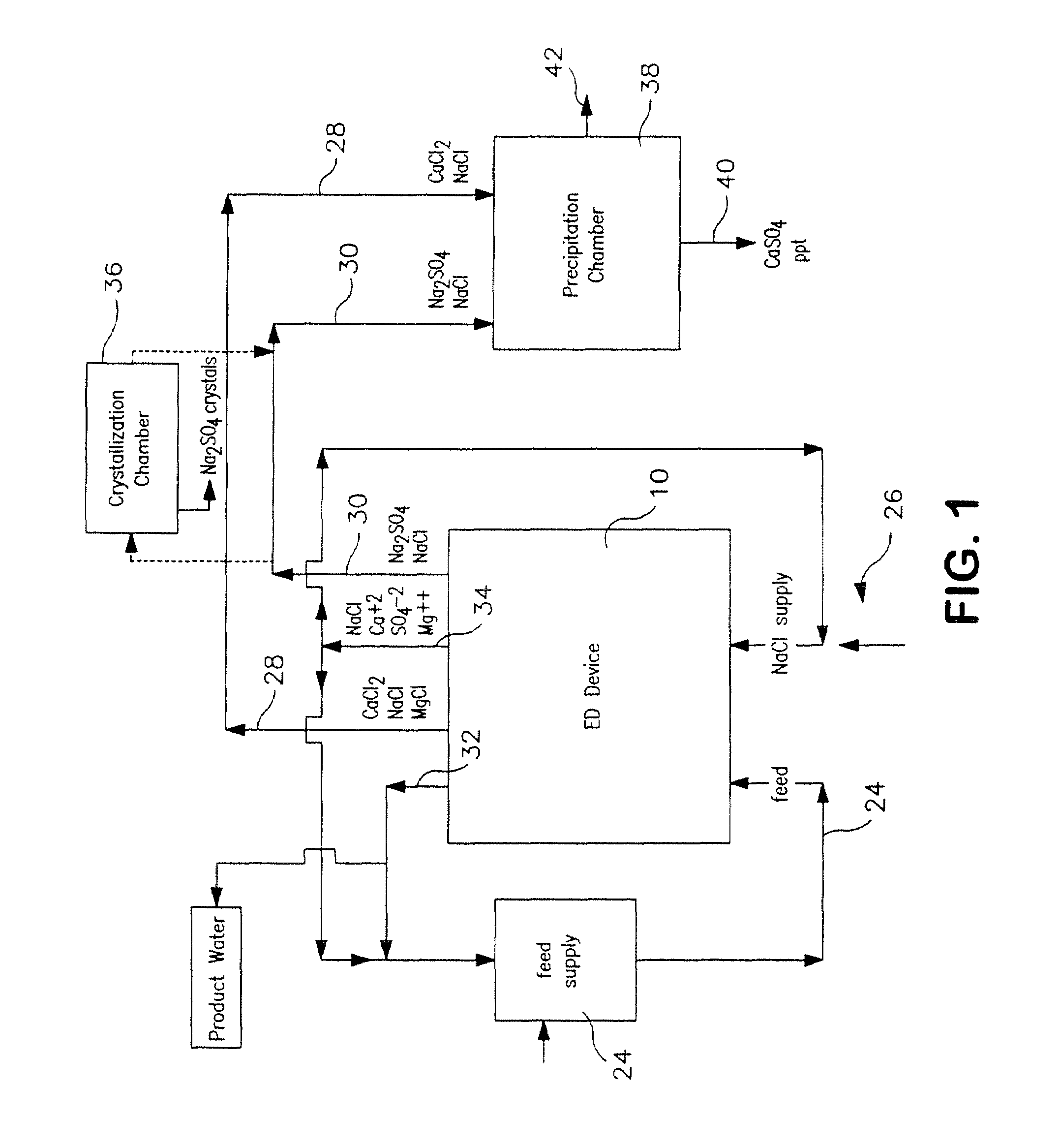

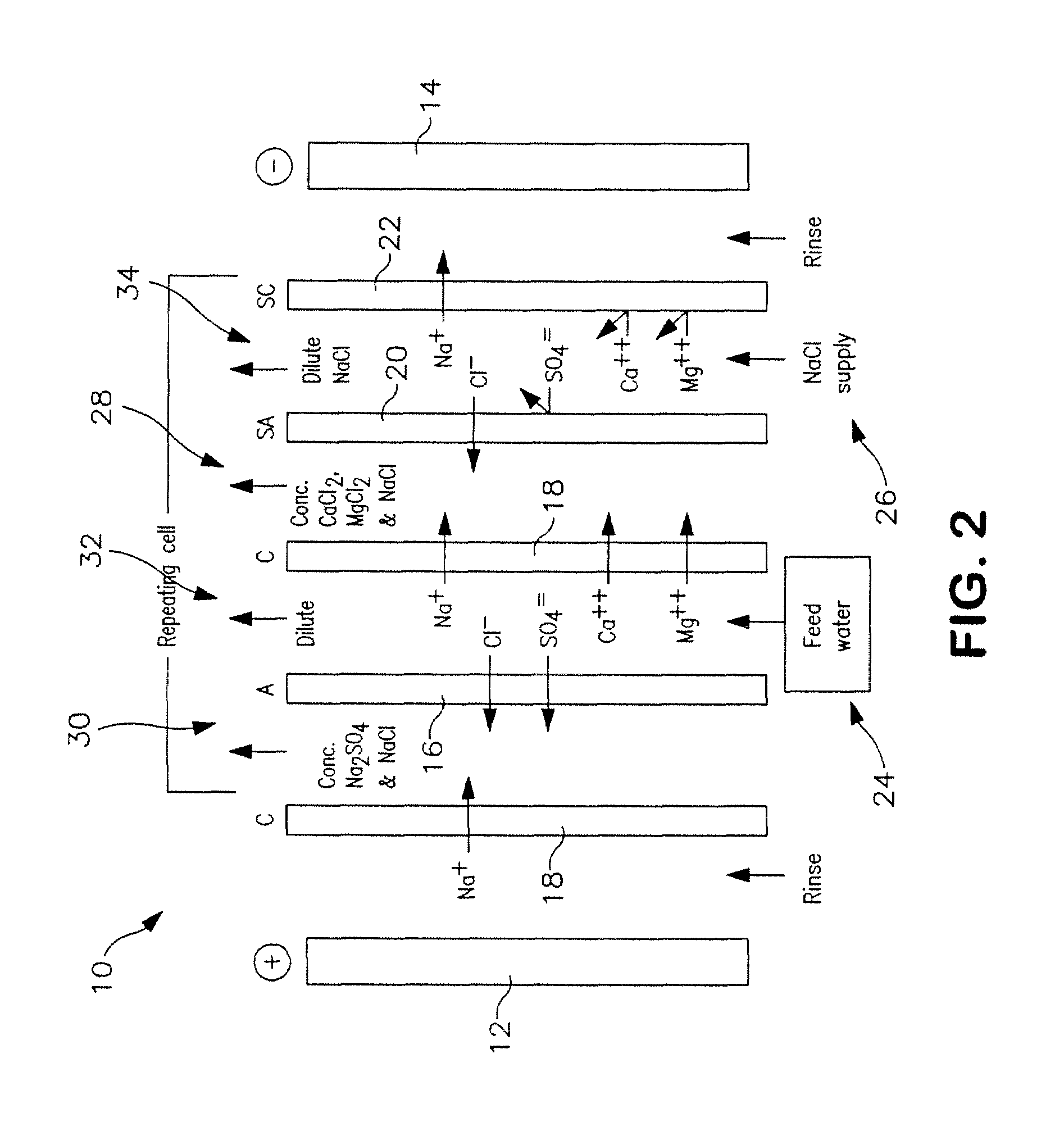

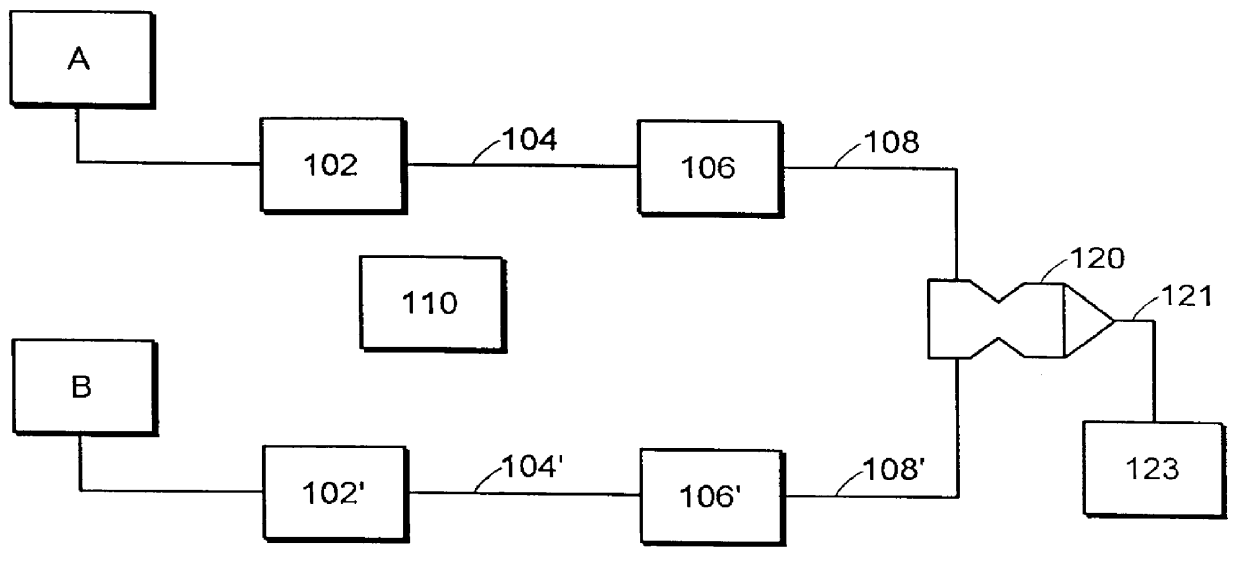

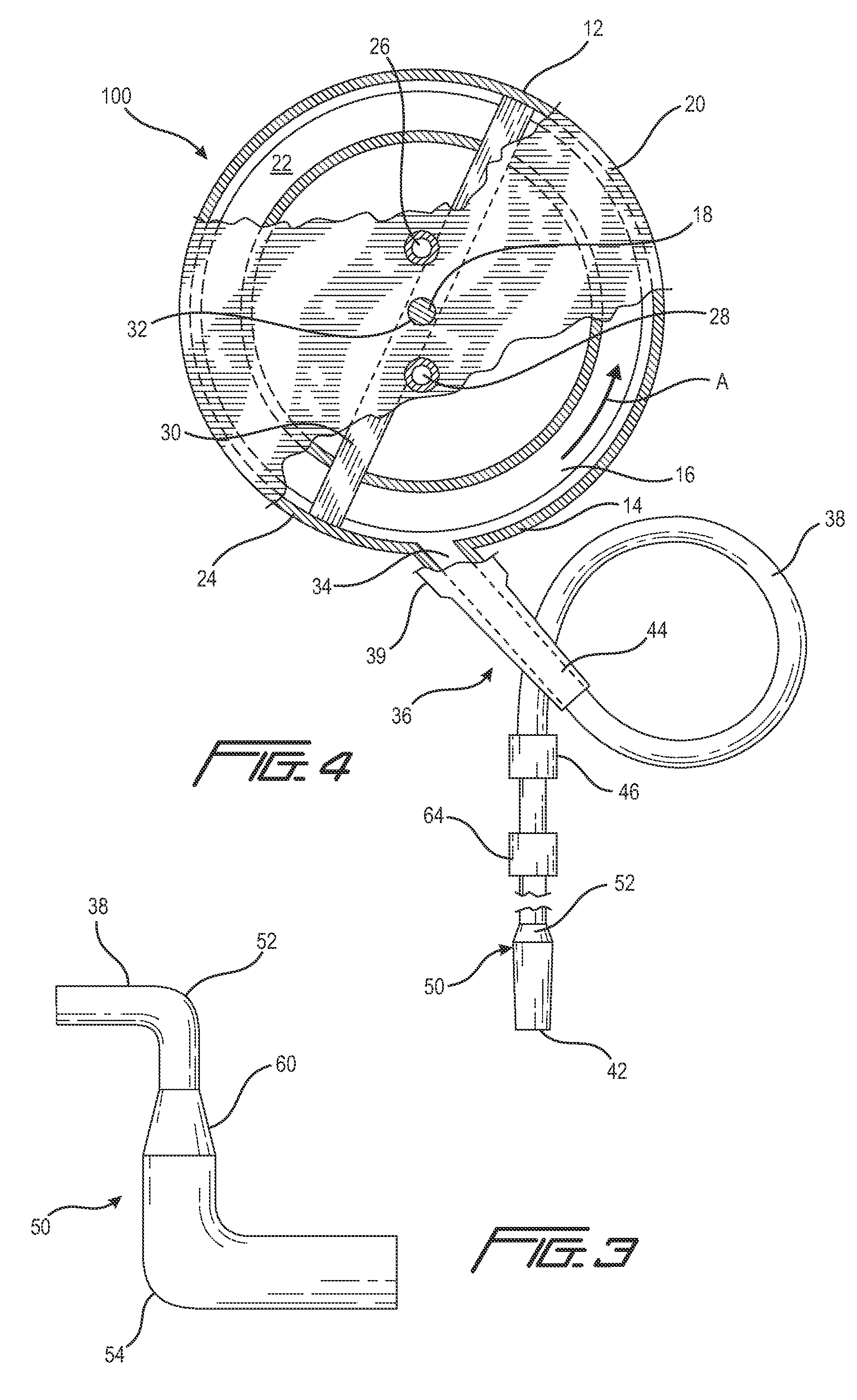

Water desalination process and apparatus

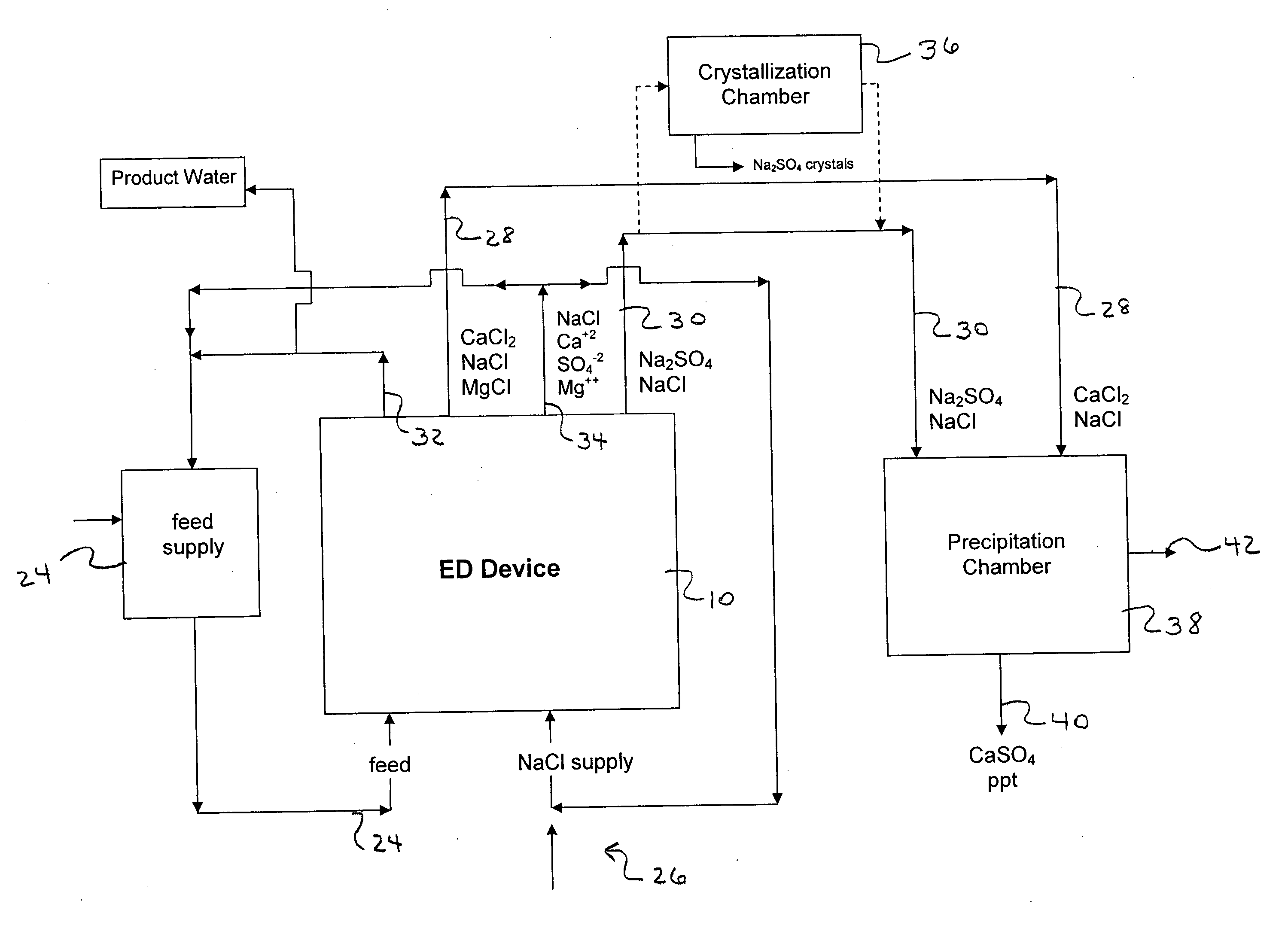

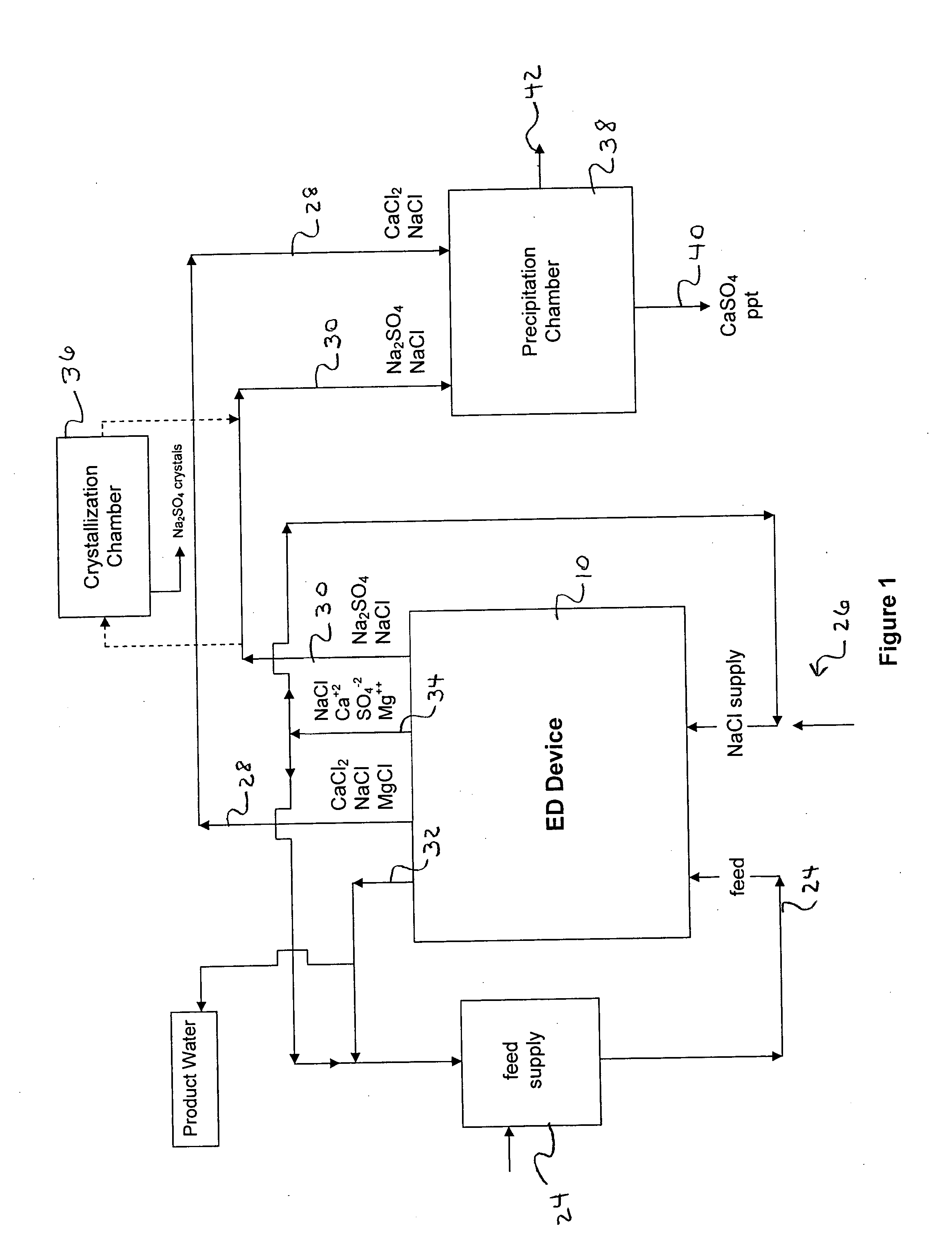

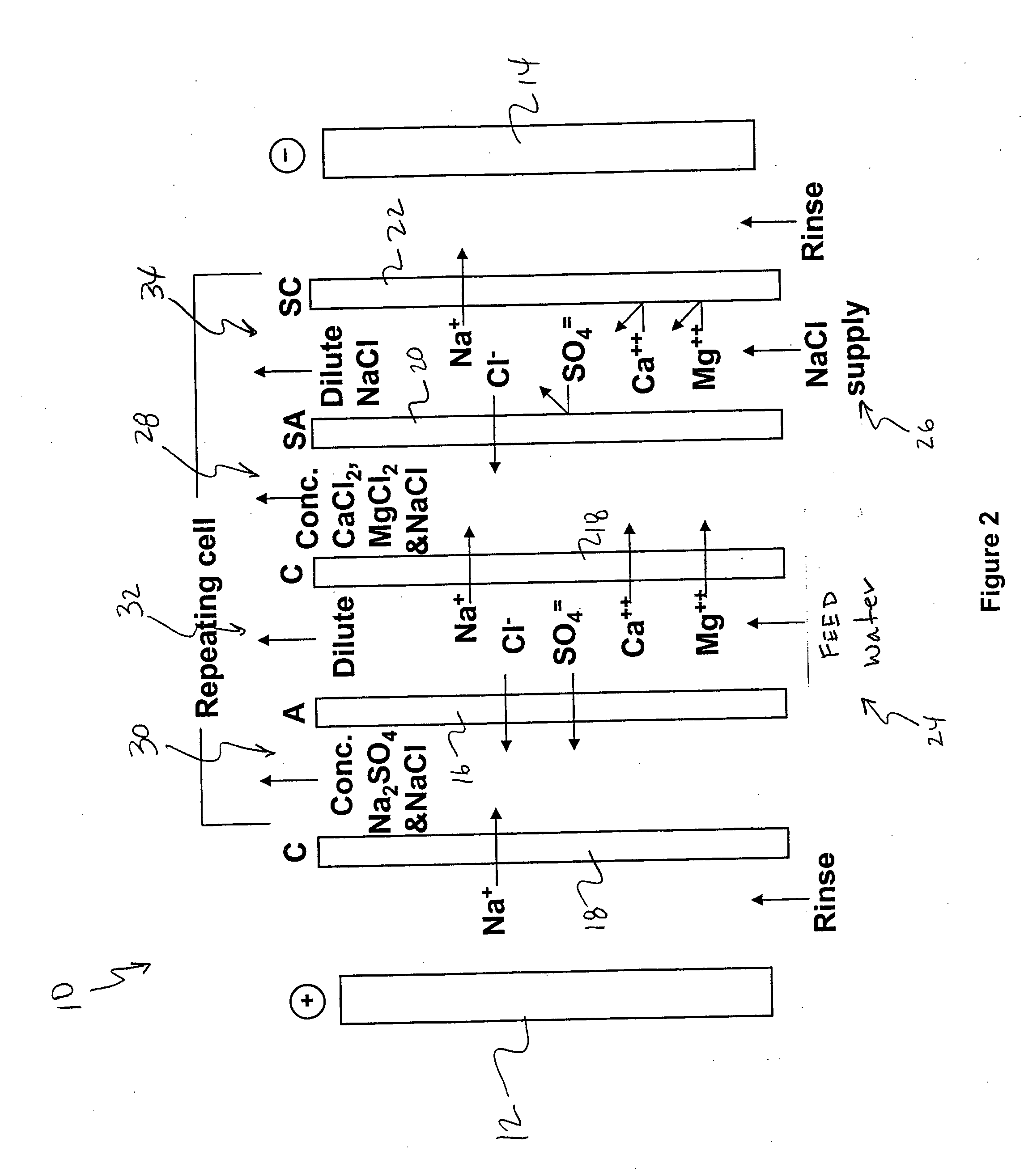

ActiveUS20060060532A1Electrolysis componentsGeneral water supply conservationSolubilityWater desalination

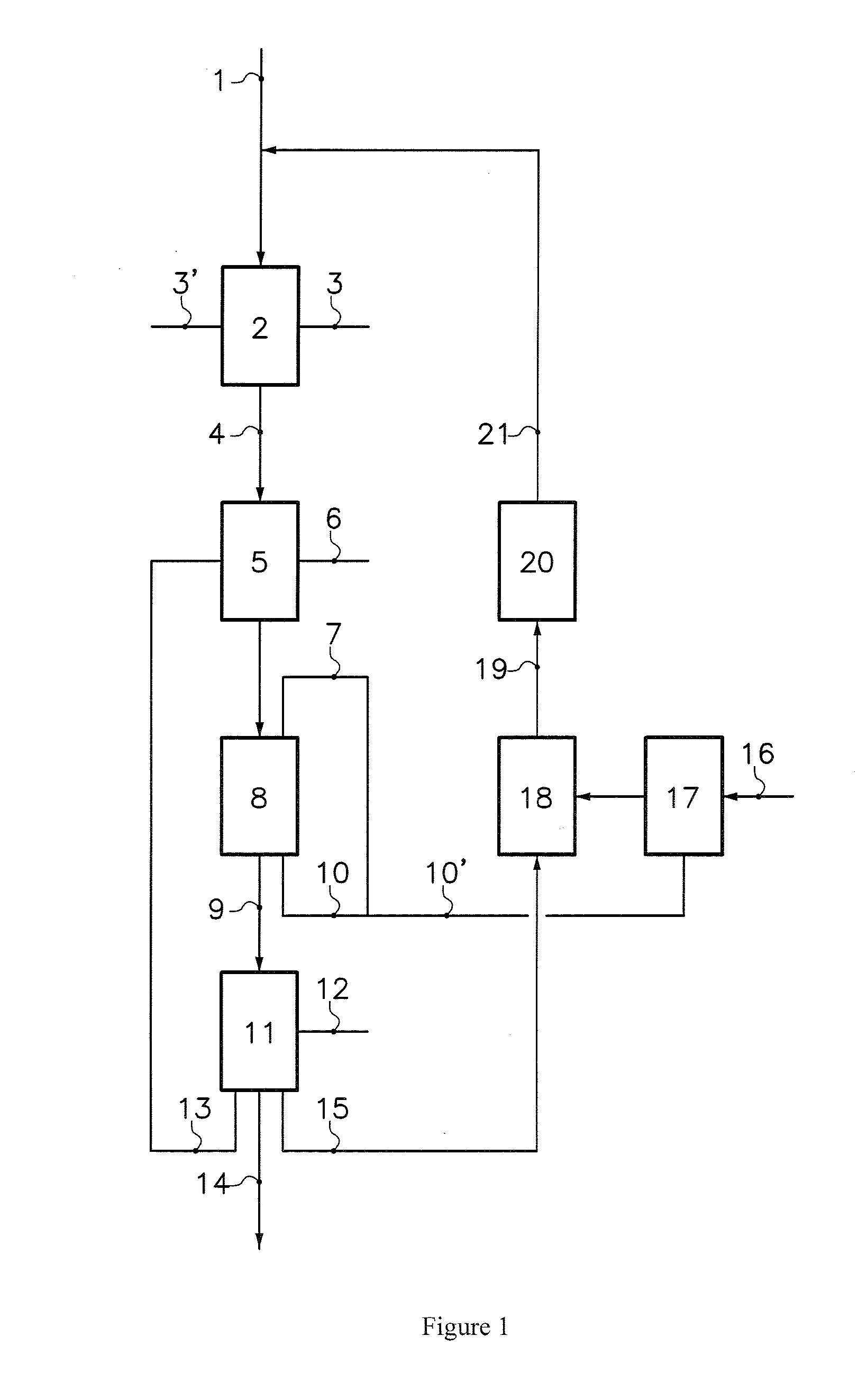

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

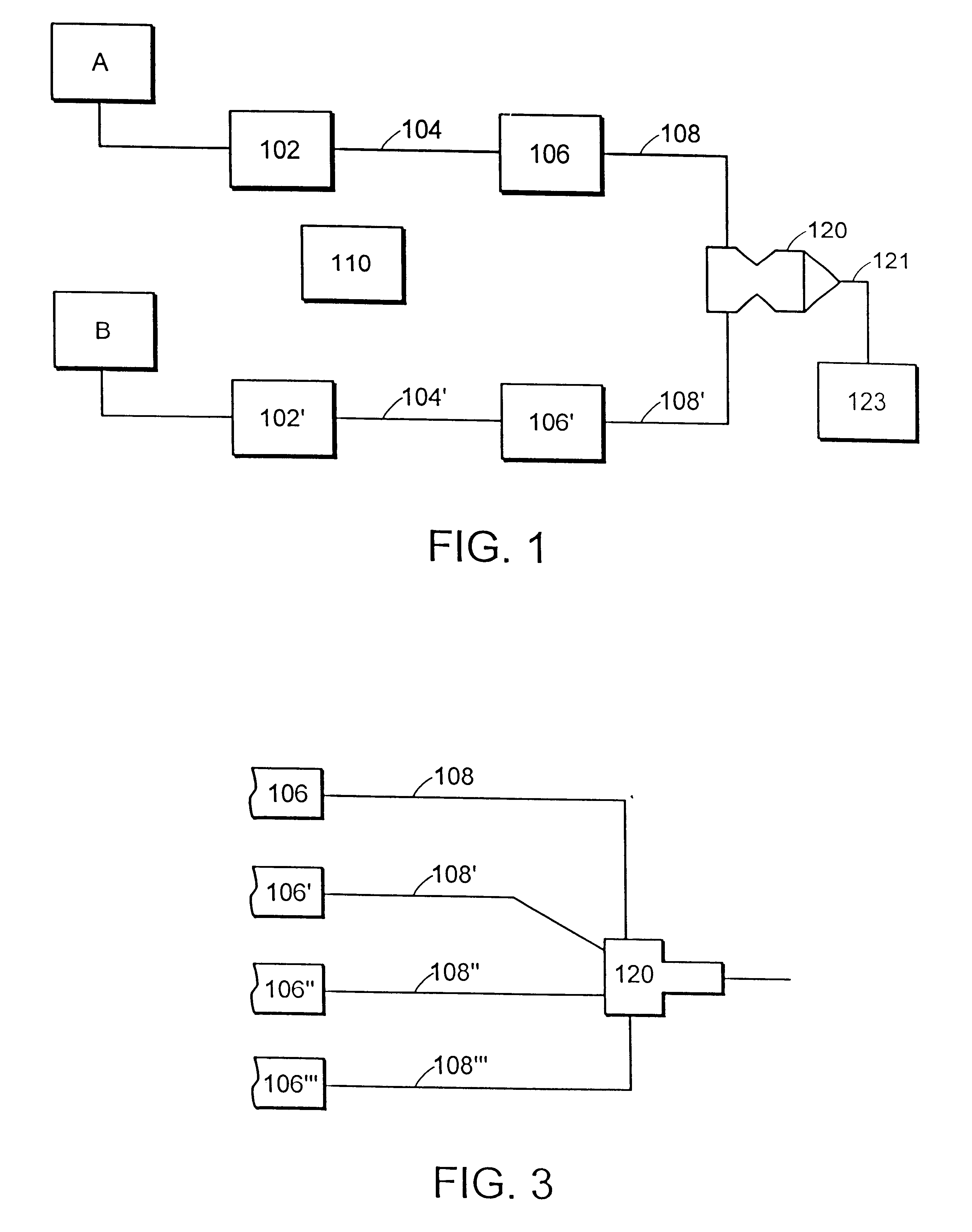

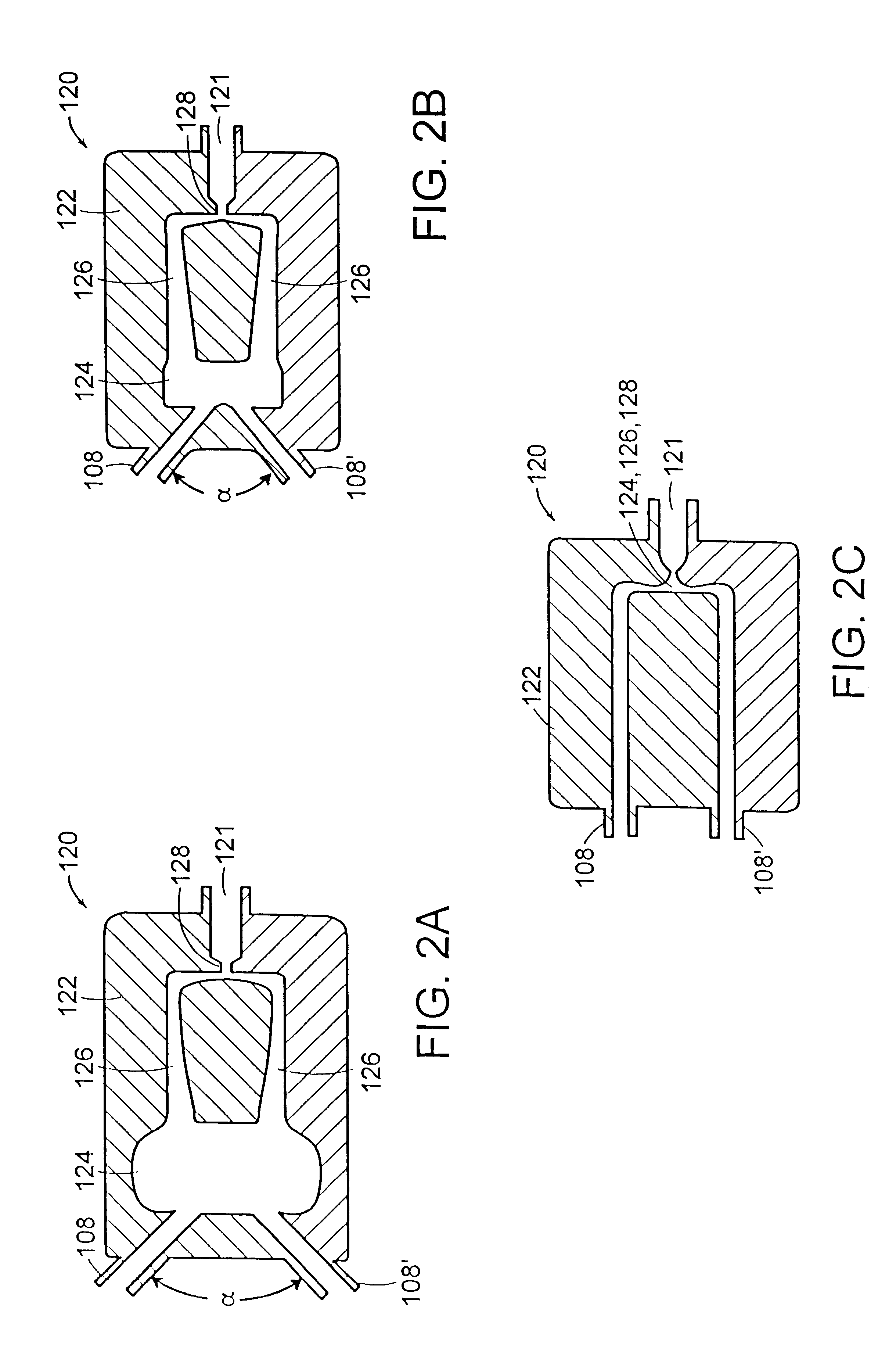

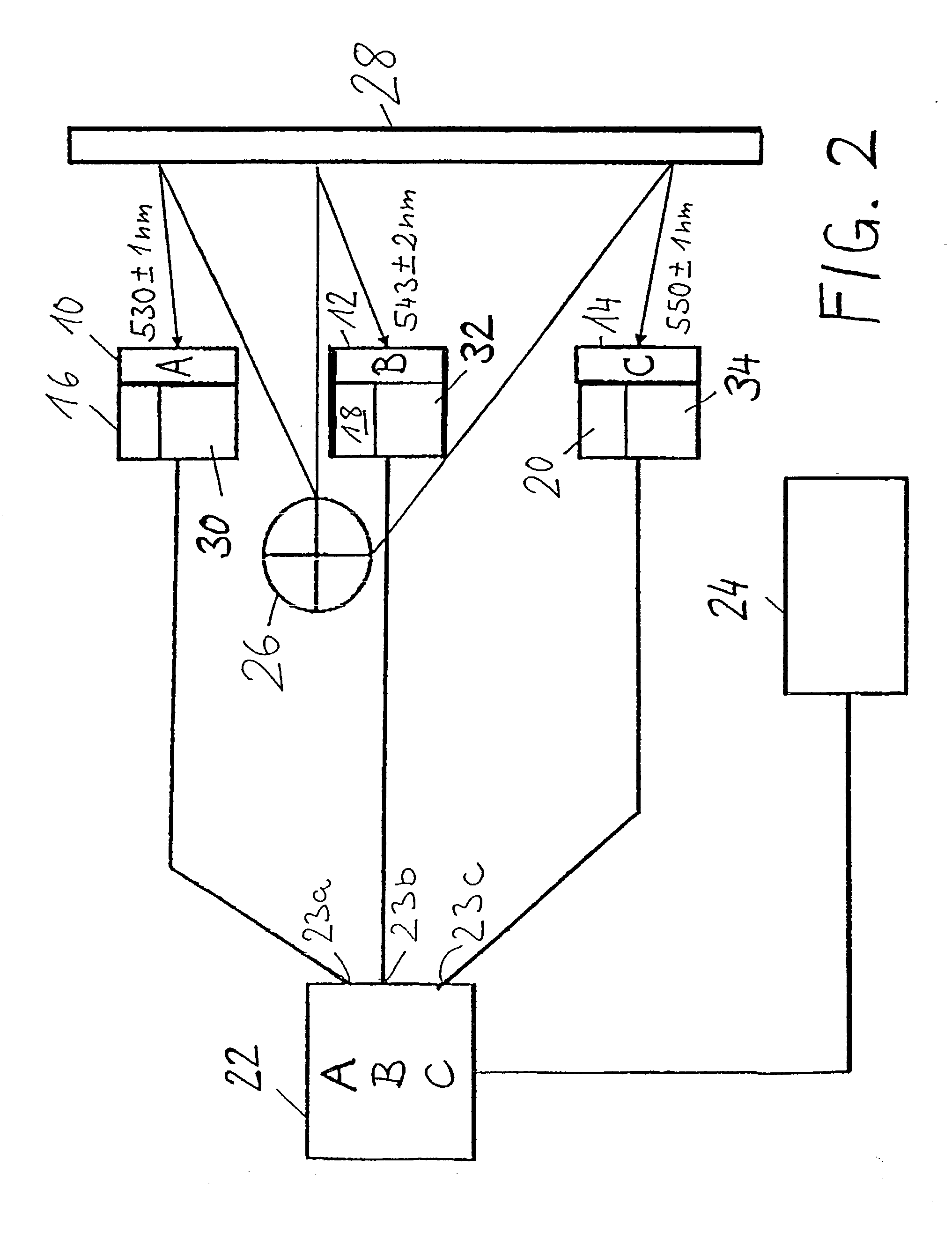

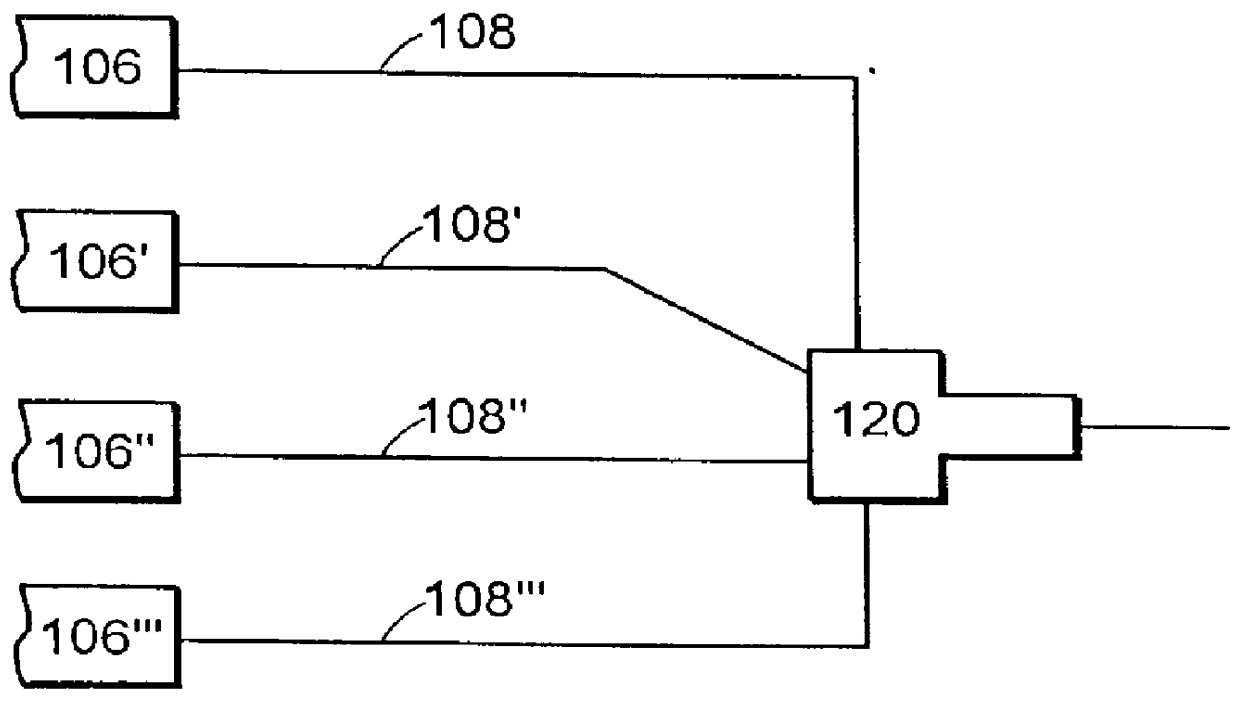

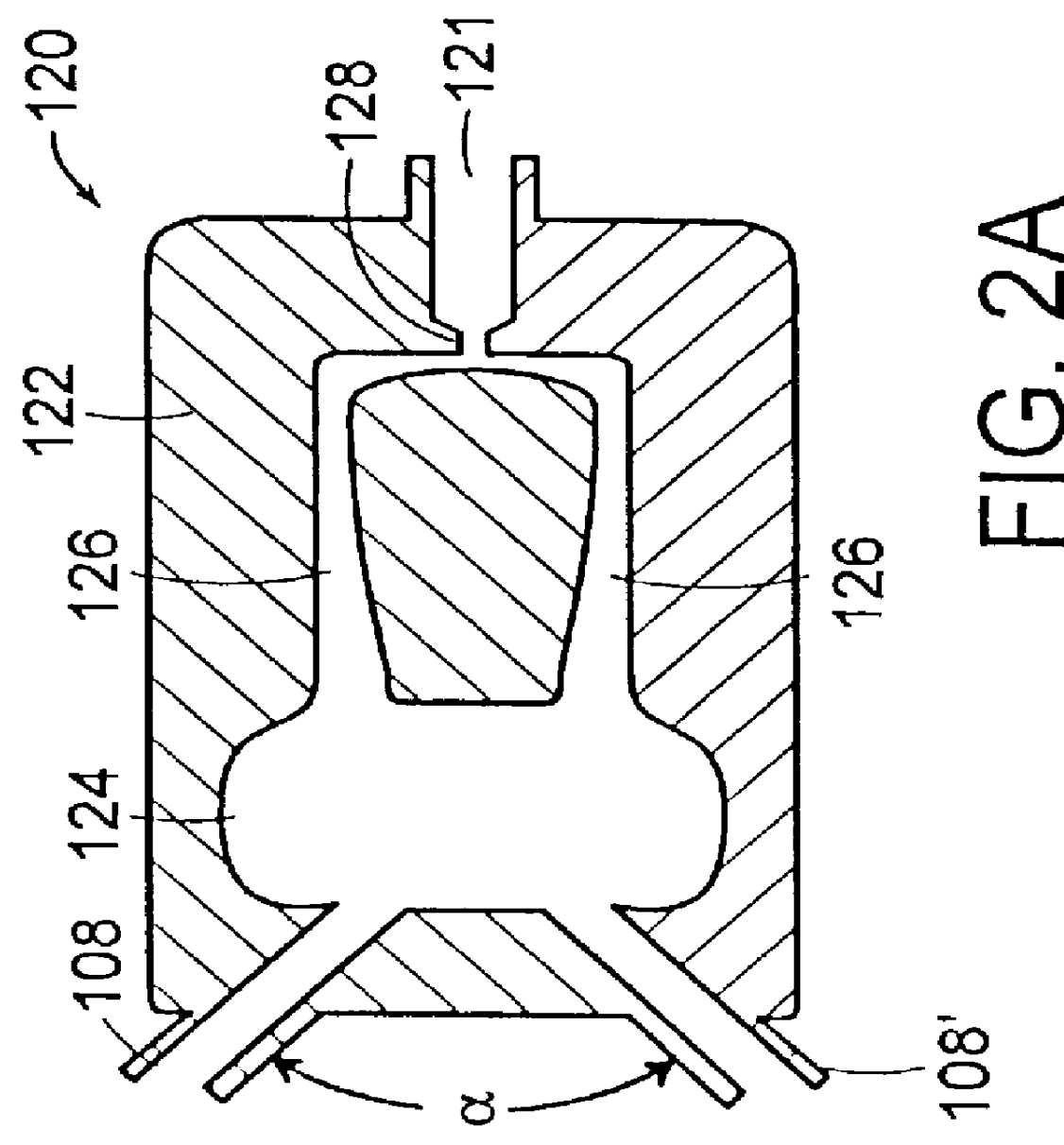

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

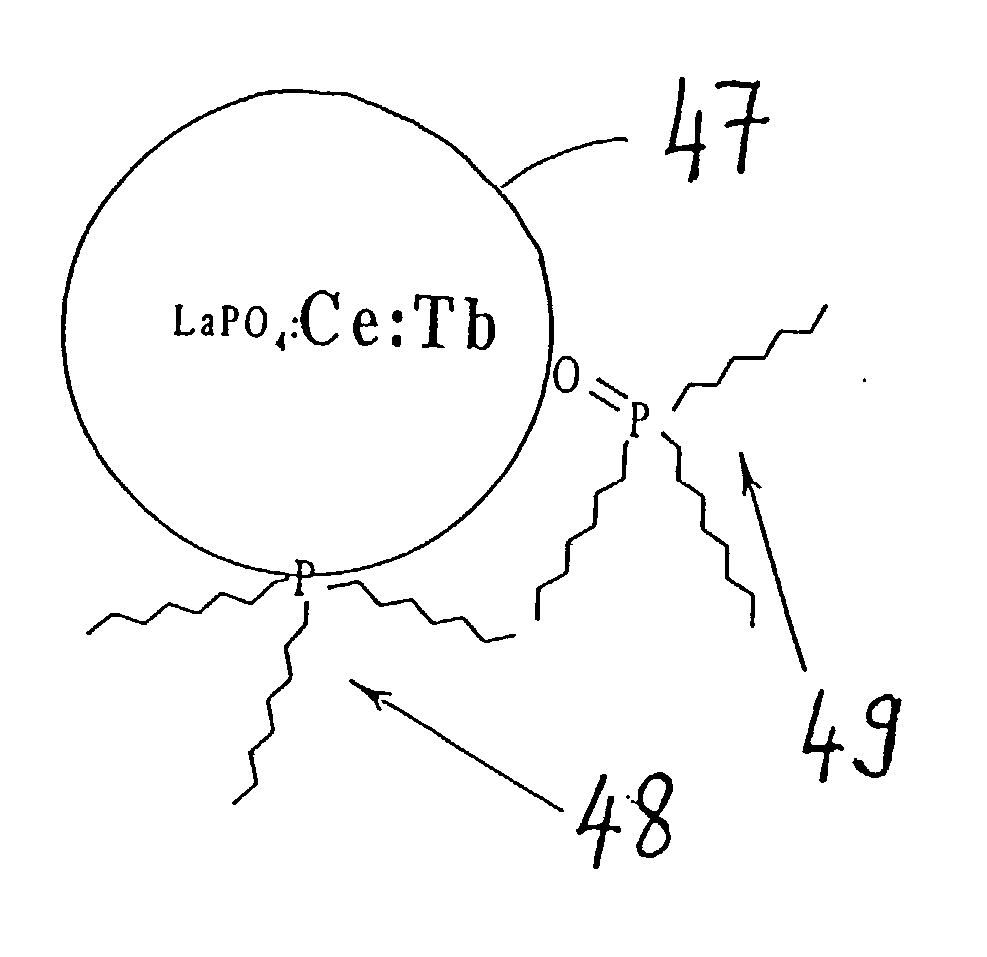

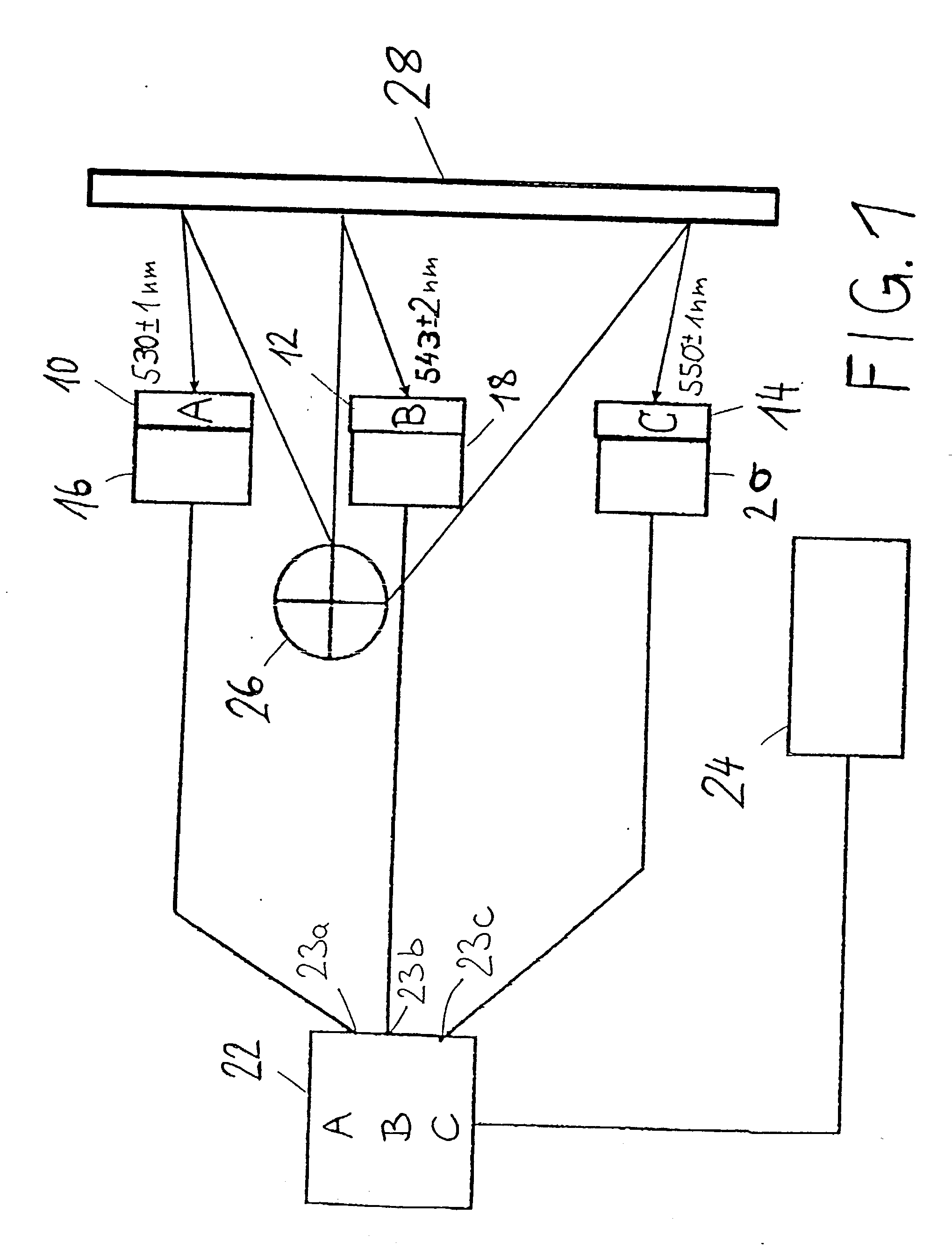

Synthesis of nanoparticles

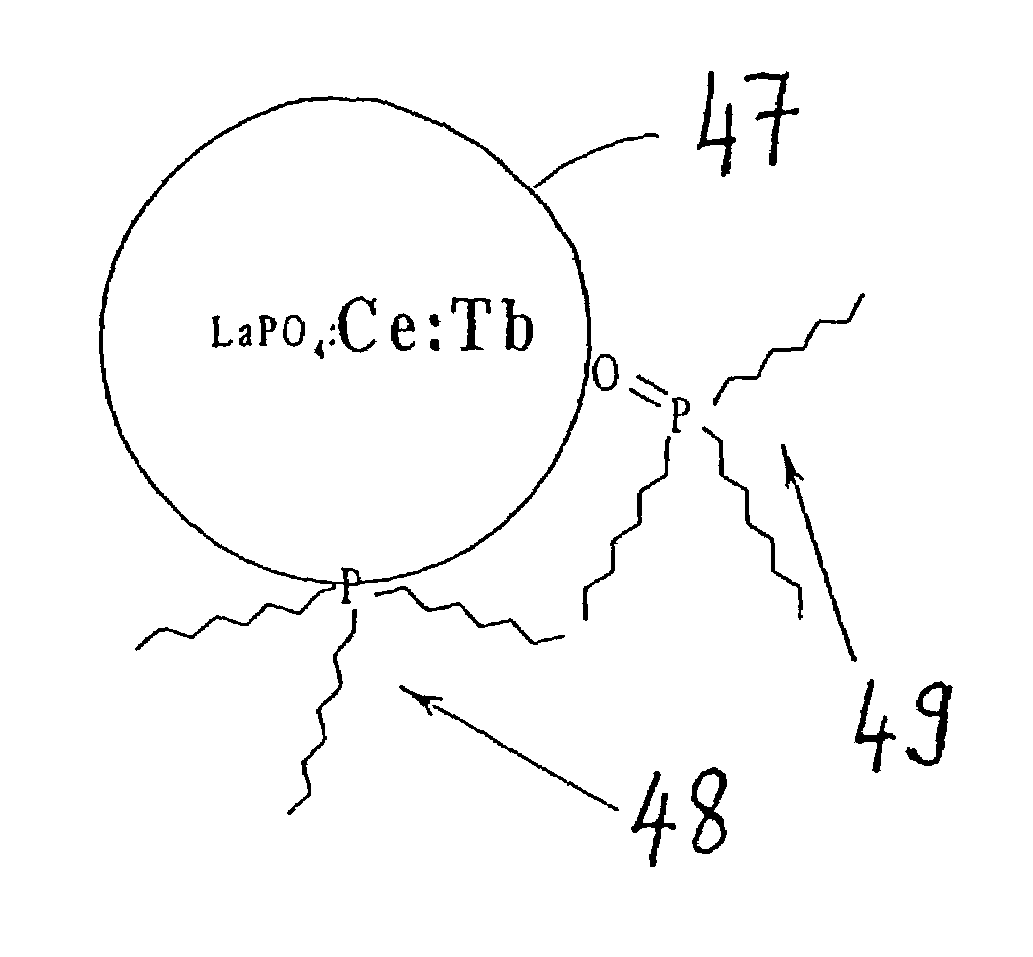

InactiveUS20030032192A1High sensitivityIncreasing efficiency of collectorOptical radiation measurementMaterial nanotechnologyDopantOrganic solvent

The present invention relates to methods for the preparation of inorganic nanoparticles capable of fluorescence, wherein the nanoparticles consist of a host material that comprises at least one dopant. The synthesis of the invention in organic solvents allows to gain a considerably higher yield compared to the prior art synthesis in water. All kinds of objects can advantageously be marked and reliably authenticated by using an automated method on the basis of a characteristic emission. Further, the size distribution of the prepared nanoparticles is narrower which renders a subsequent size-selected separation process superfluous.

Owner:CENT FUR ANGEWANDTE NANOTECH

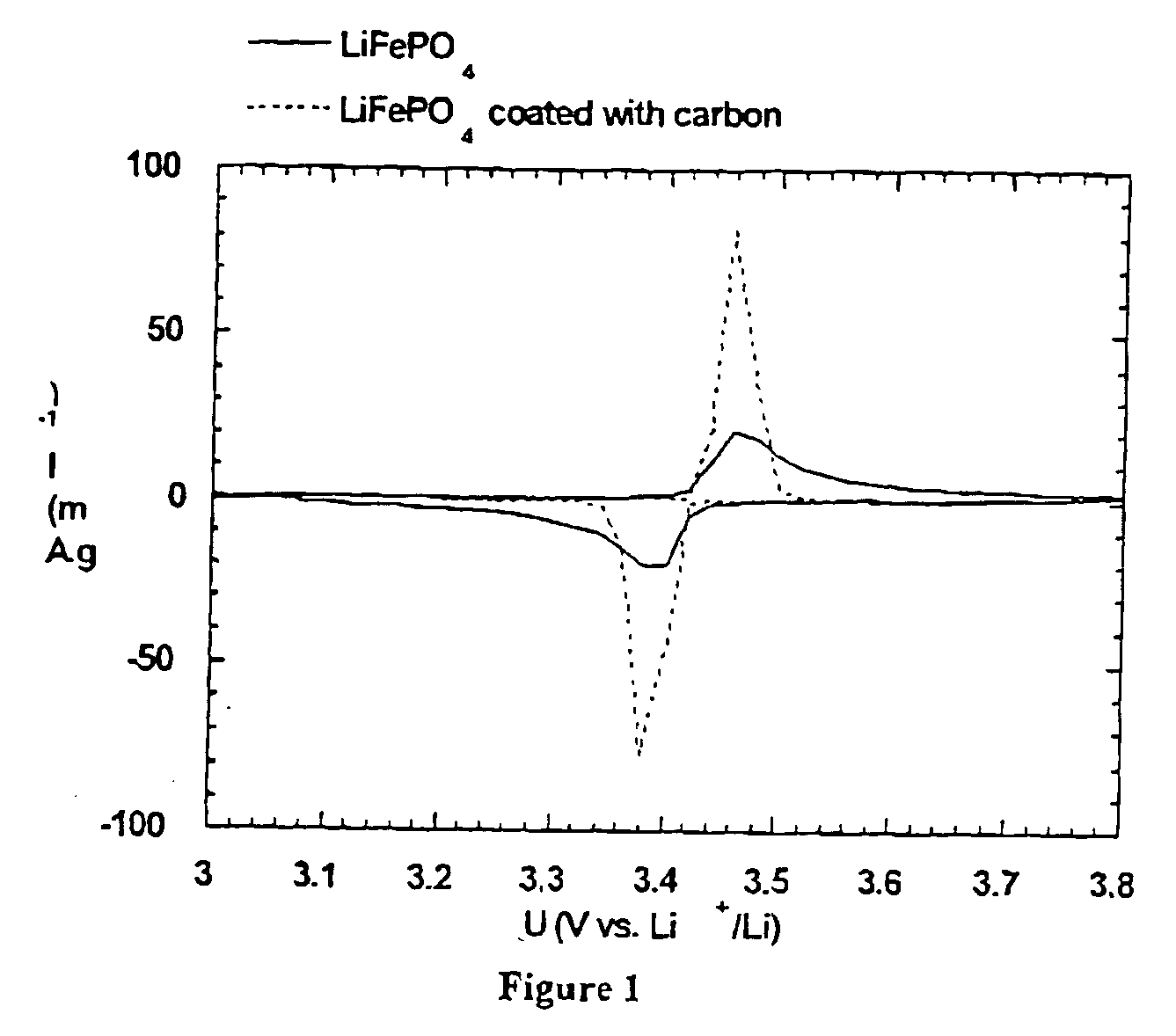

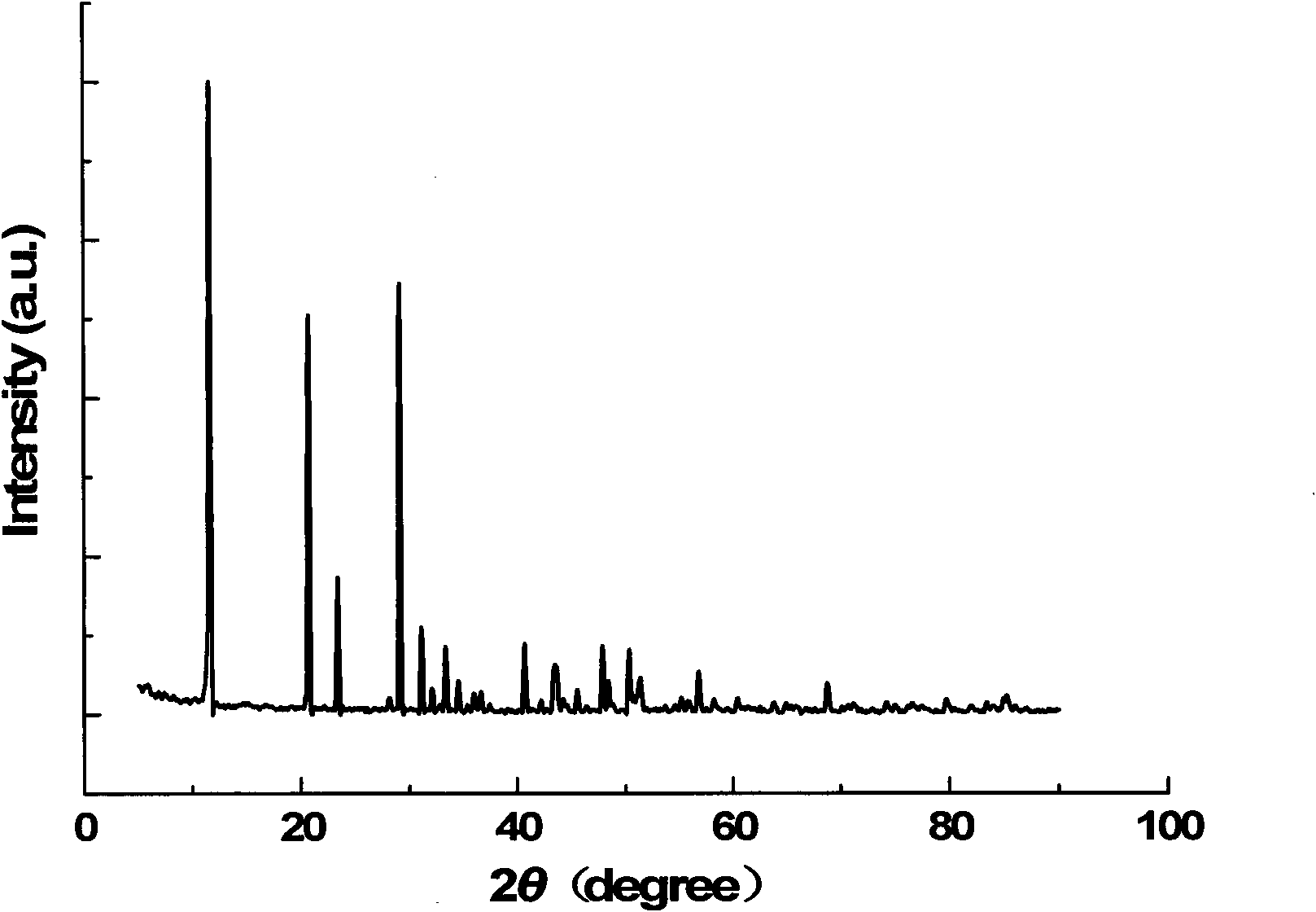

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

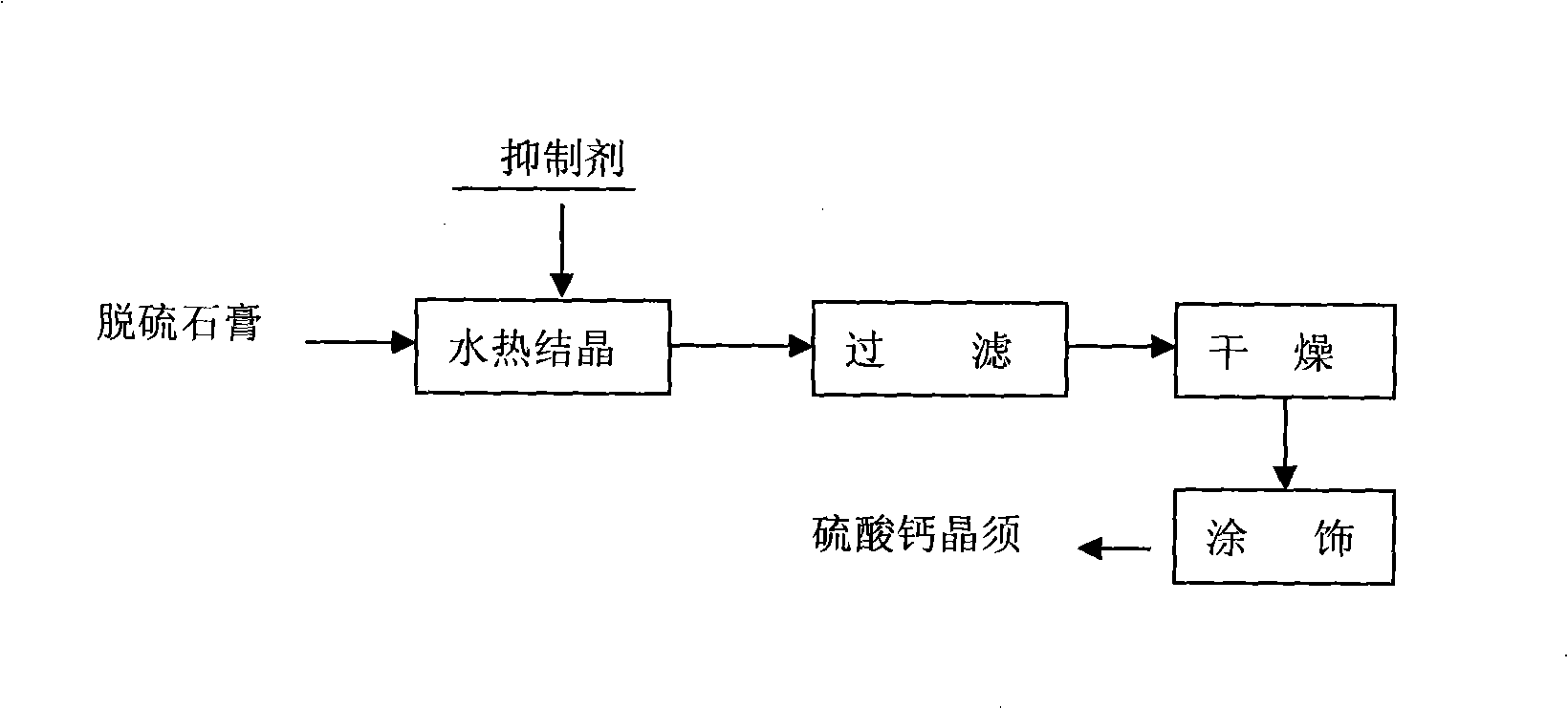

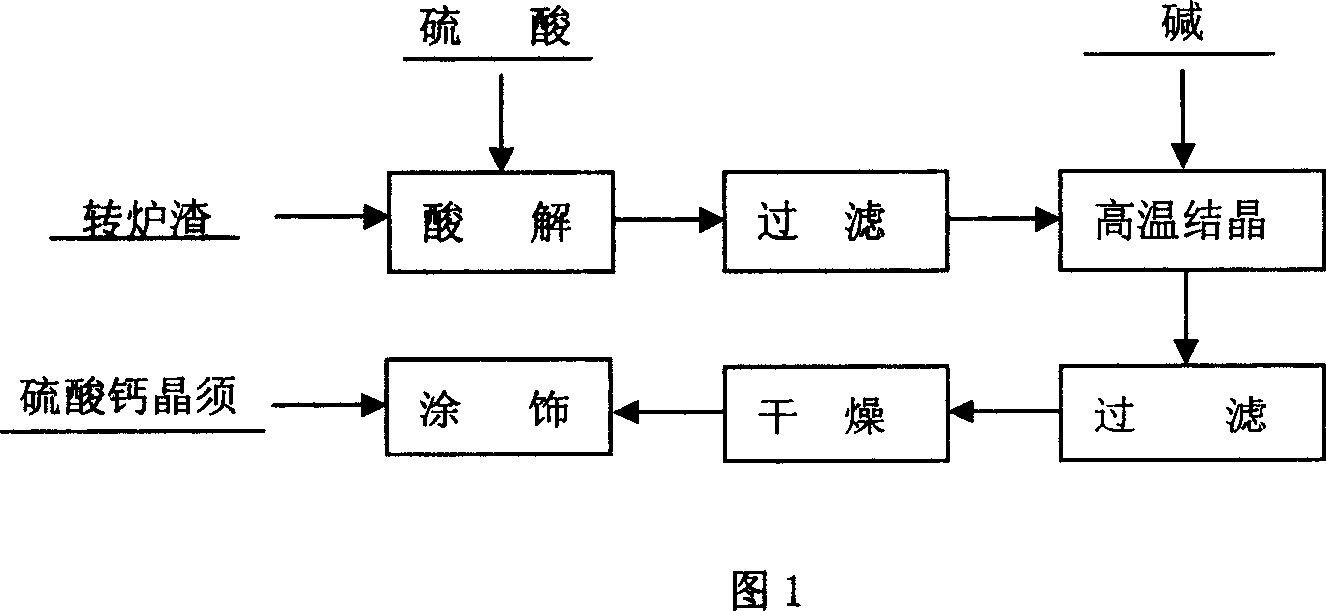

Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

InactiveCN101311337AReduce environmental problemsMitigation resourcesPolycrystalline material growthFrom normal temperature solutionsGlass fiberSulfate

The invention discloses a method for using flue gas desulfurization gypsum to prepare calcium sulfate whisker, comprising process steps of size mixing, high-temperature crystallization, drying and coating, etc. The method utilizes the flue gas desulfurization gypsum as the raw material, which has low production cost, short technological process and saves natural gypsum mine and effectively relieves the environmental pollution problem of the flue gas desulfurization gypsum. The product purity can be up to more than 98 percent, which can be used as filler with medium intensity or as friction material, building material or insulating material, and the like, instead of asbestos. The product can also partly replace organic macromolecular compounds such as glass fiber, resin, rubber and plastic, and the like, and has good describability.

Owner:NORTHEASTERN UNIV

Water desalination process and apparatus

ActiveUS7459088B2Electrolysis componentsGeneral water supply conservationWater desalinationSolubility

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

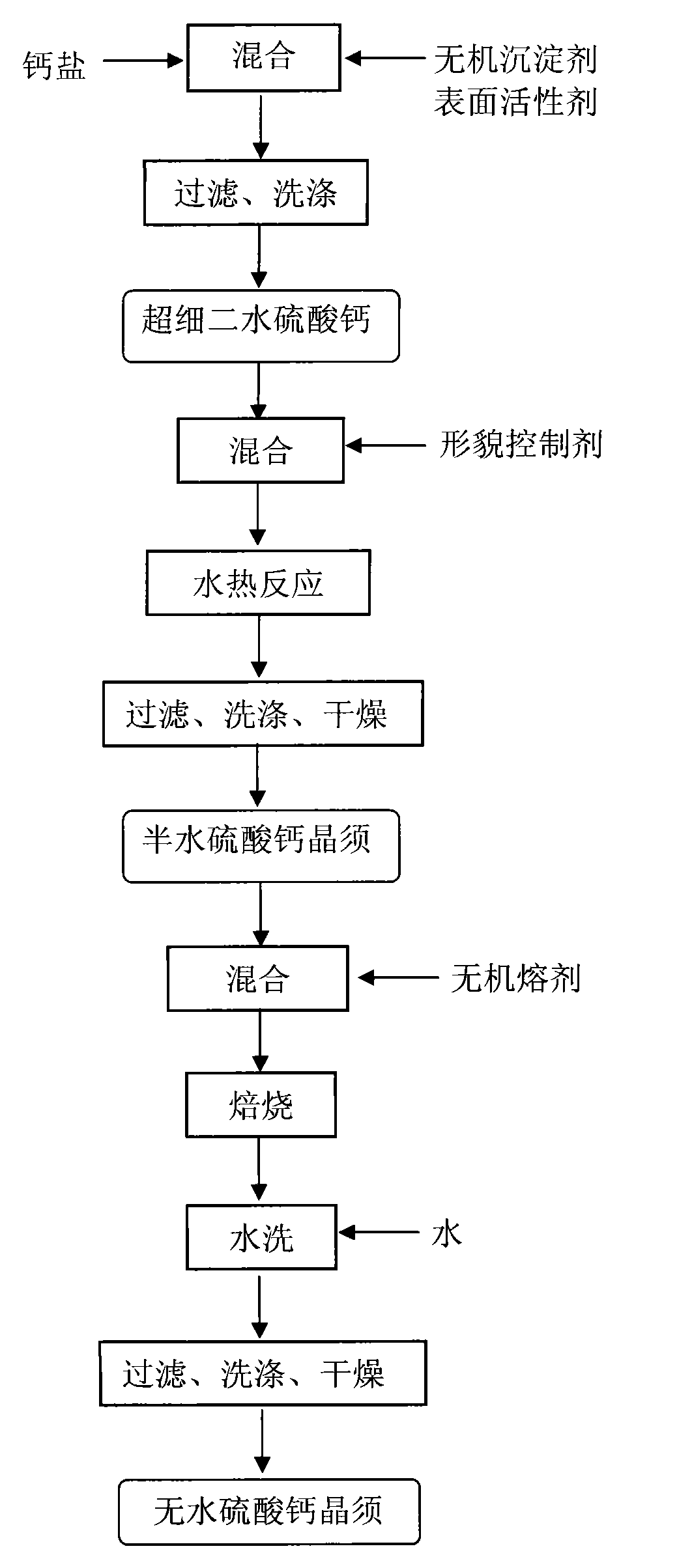

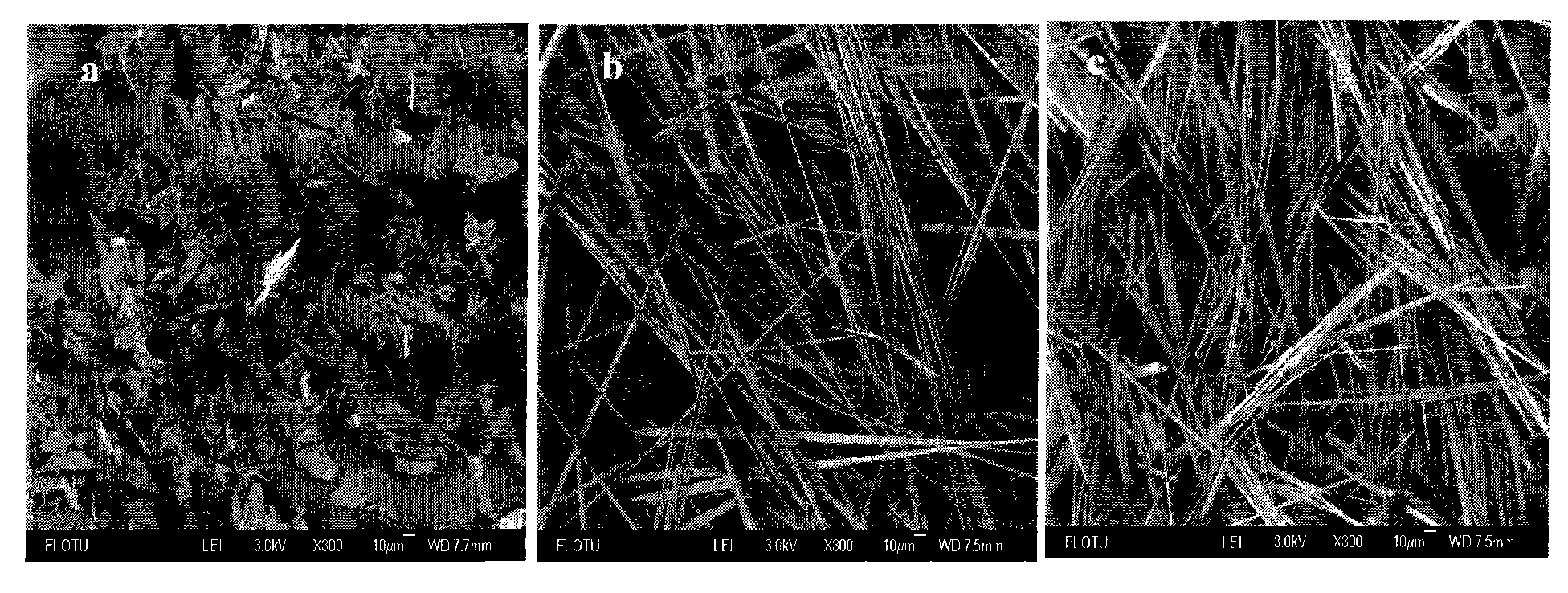

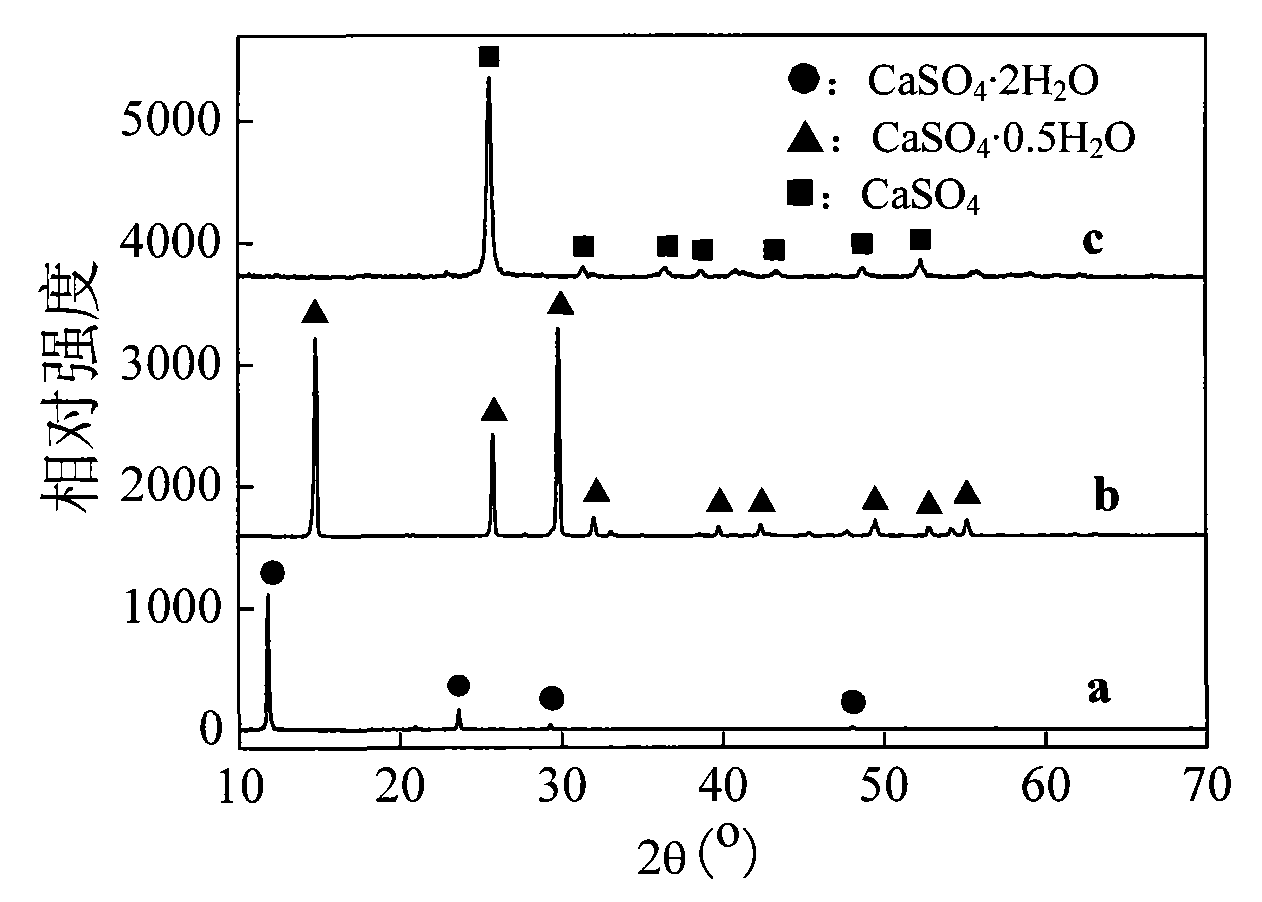

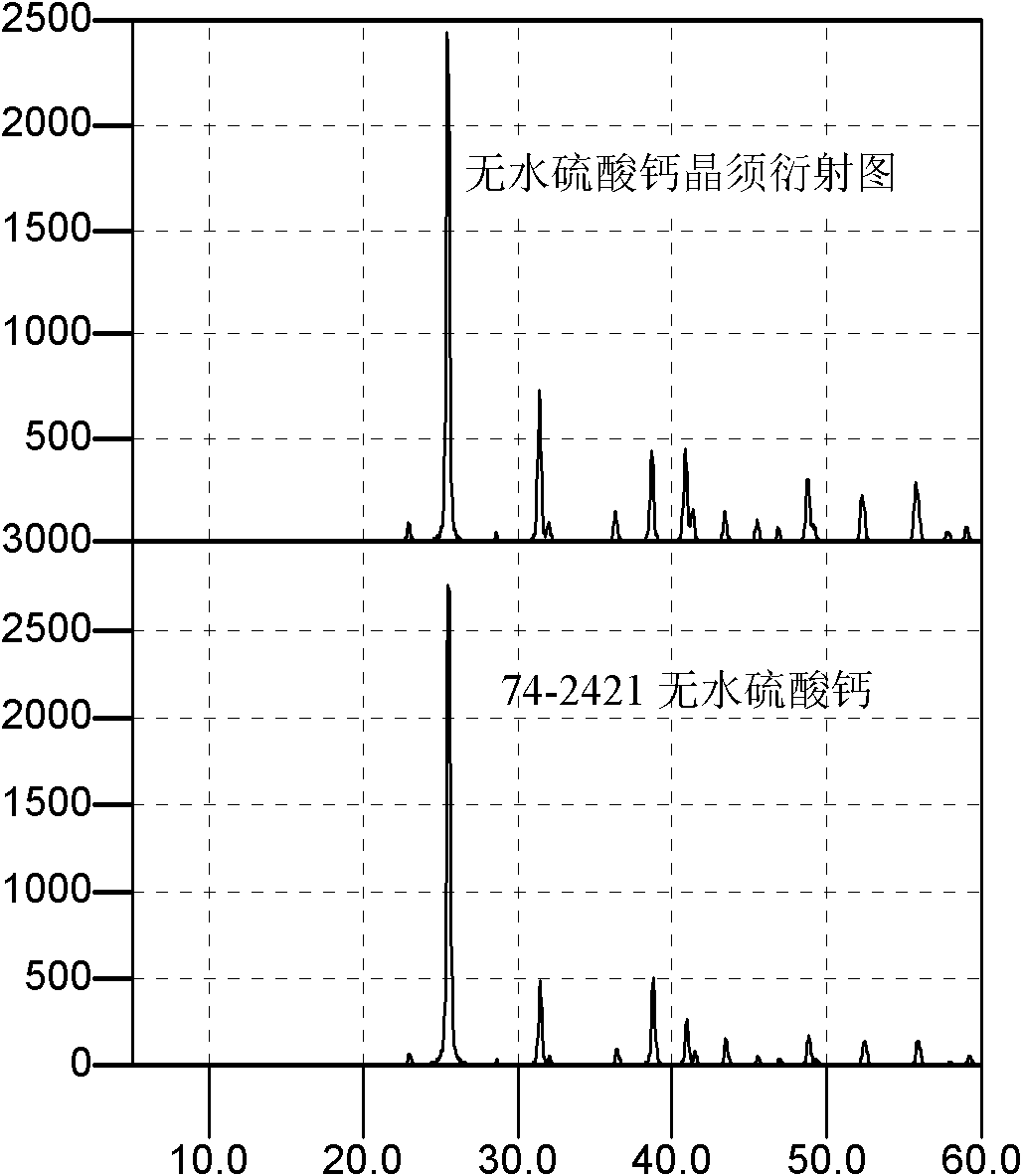

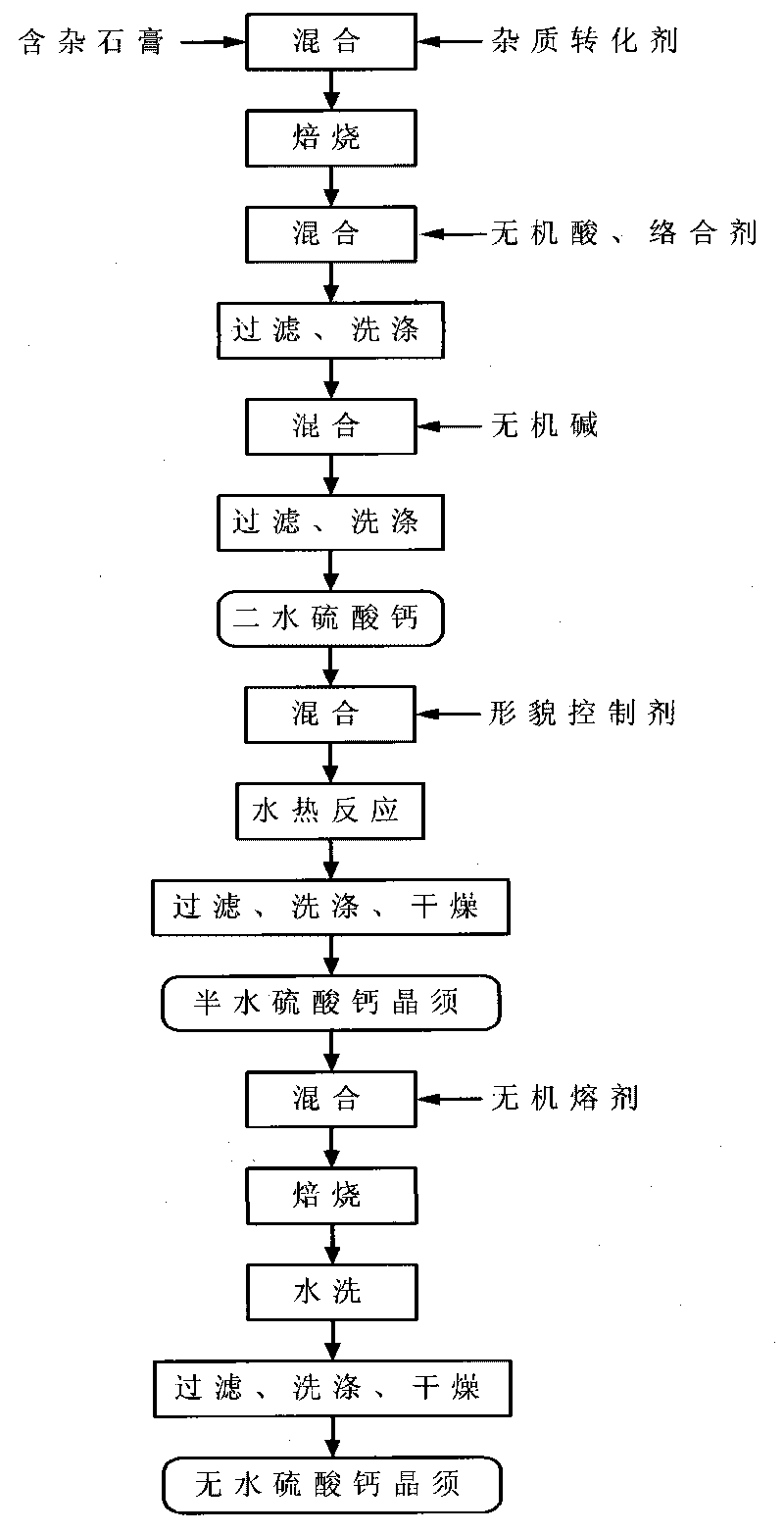

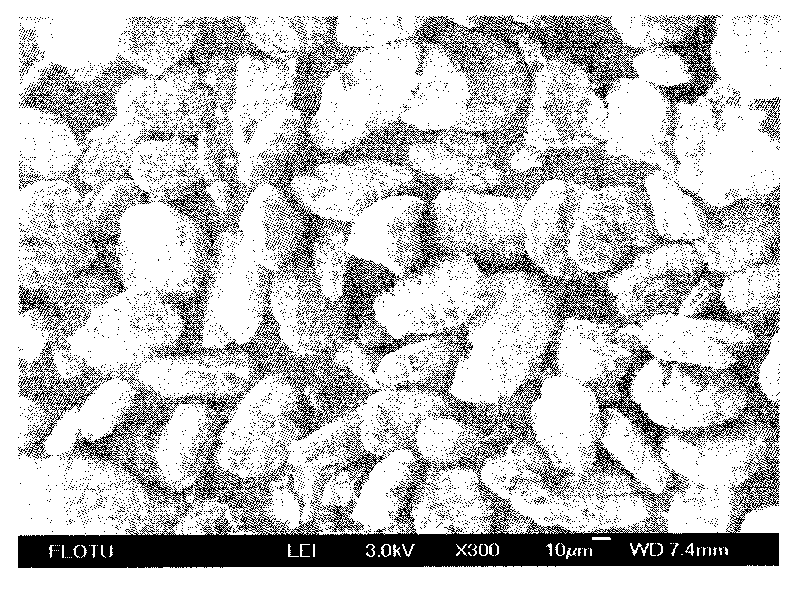

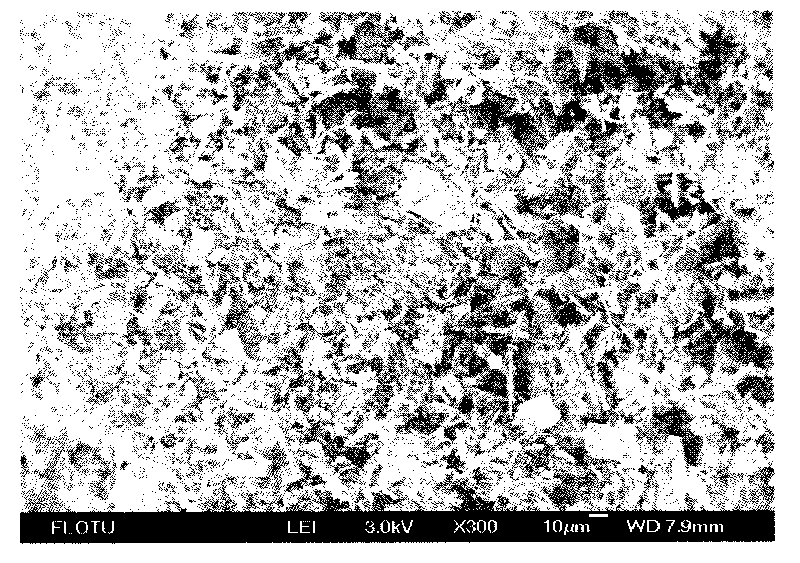

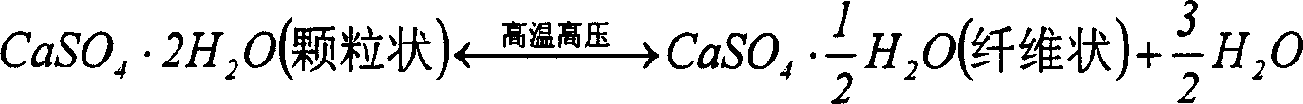

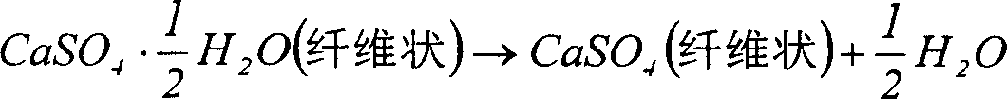

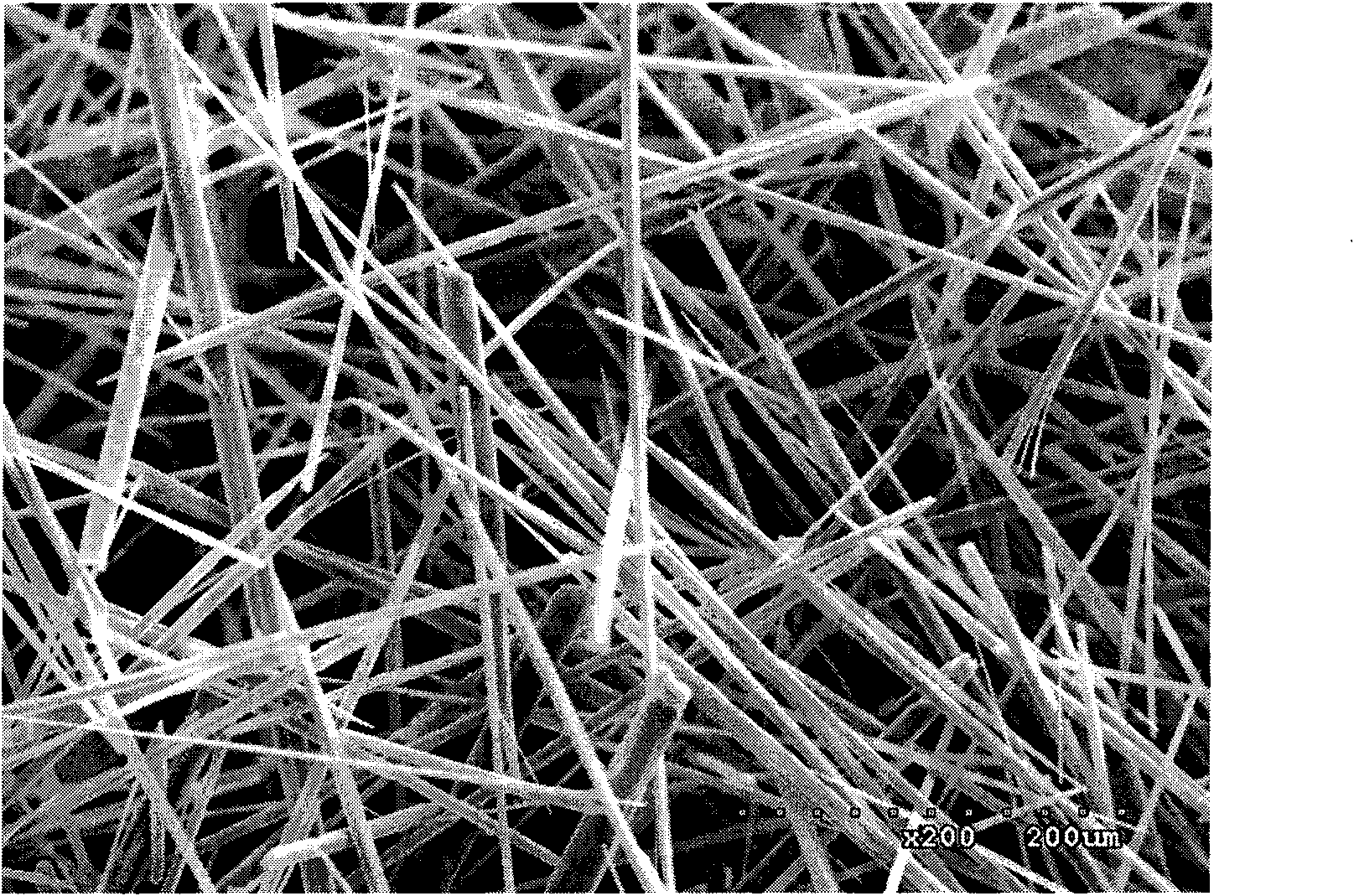

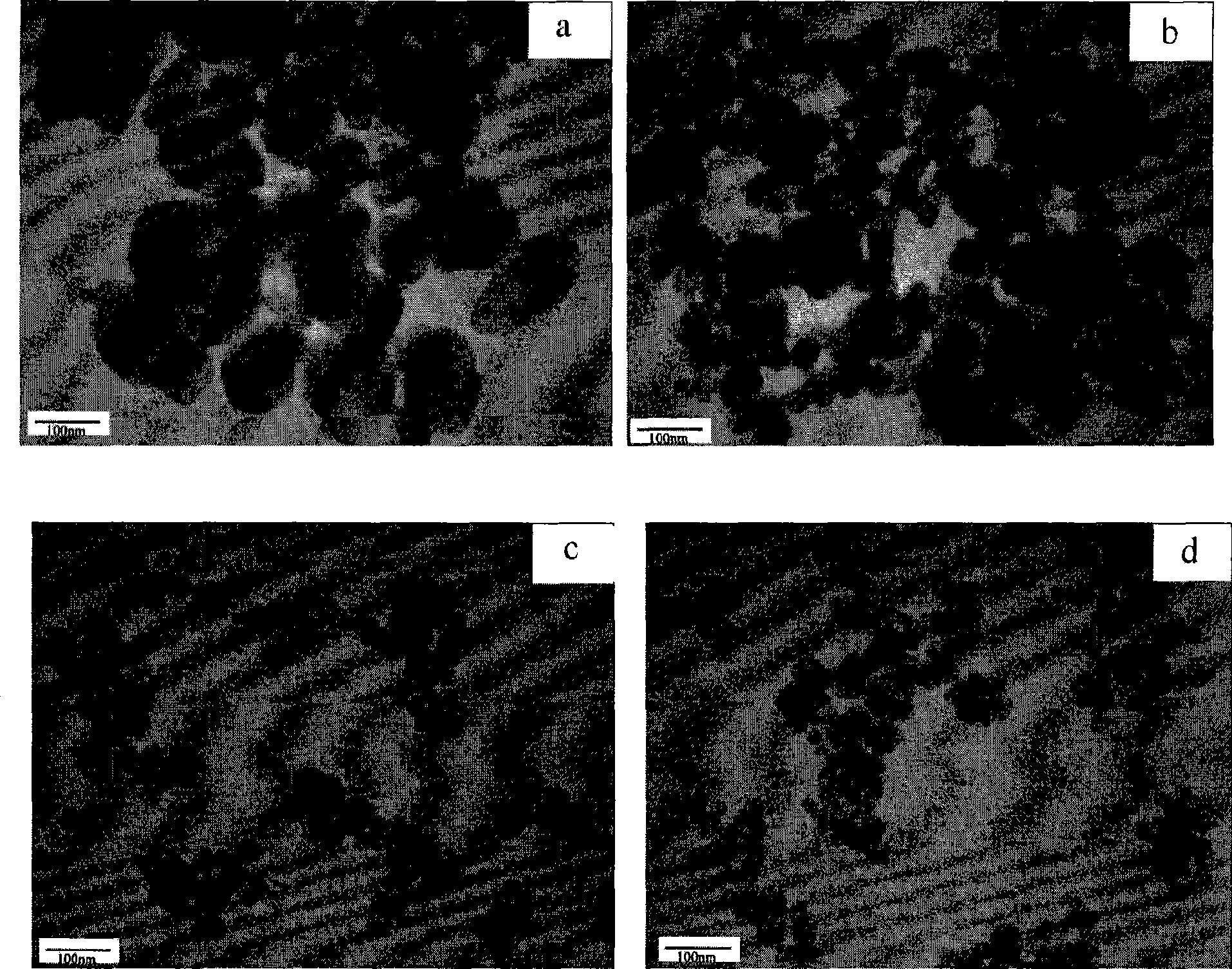

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

Use of multiple stream high pressure mixer/reactor

InactiveUS6159442AHigh strengthMaintain good propertiesCalcium/strontium/barium carbonatesPressurized chemical processStream flowHigh pressure

Owner:MICROFLUIDICS INT

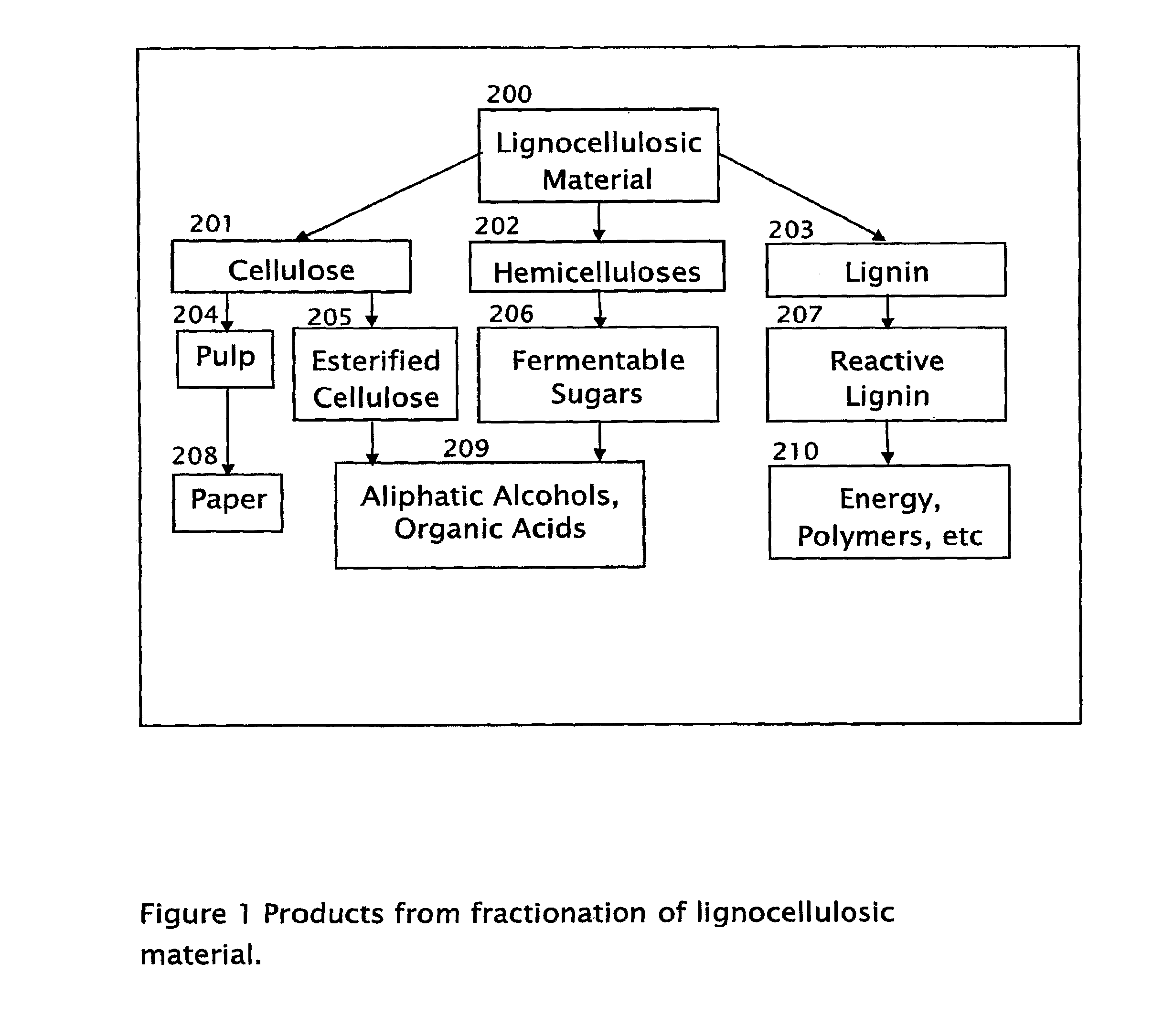

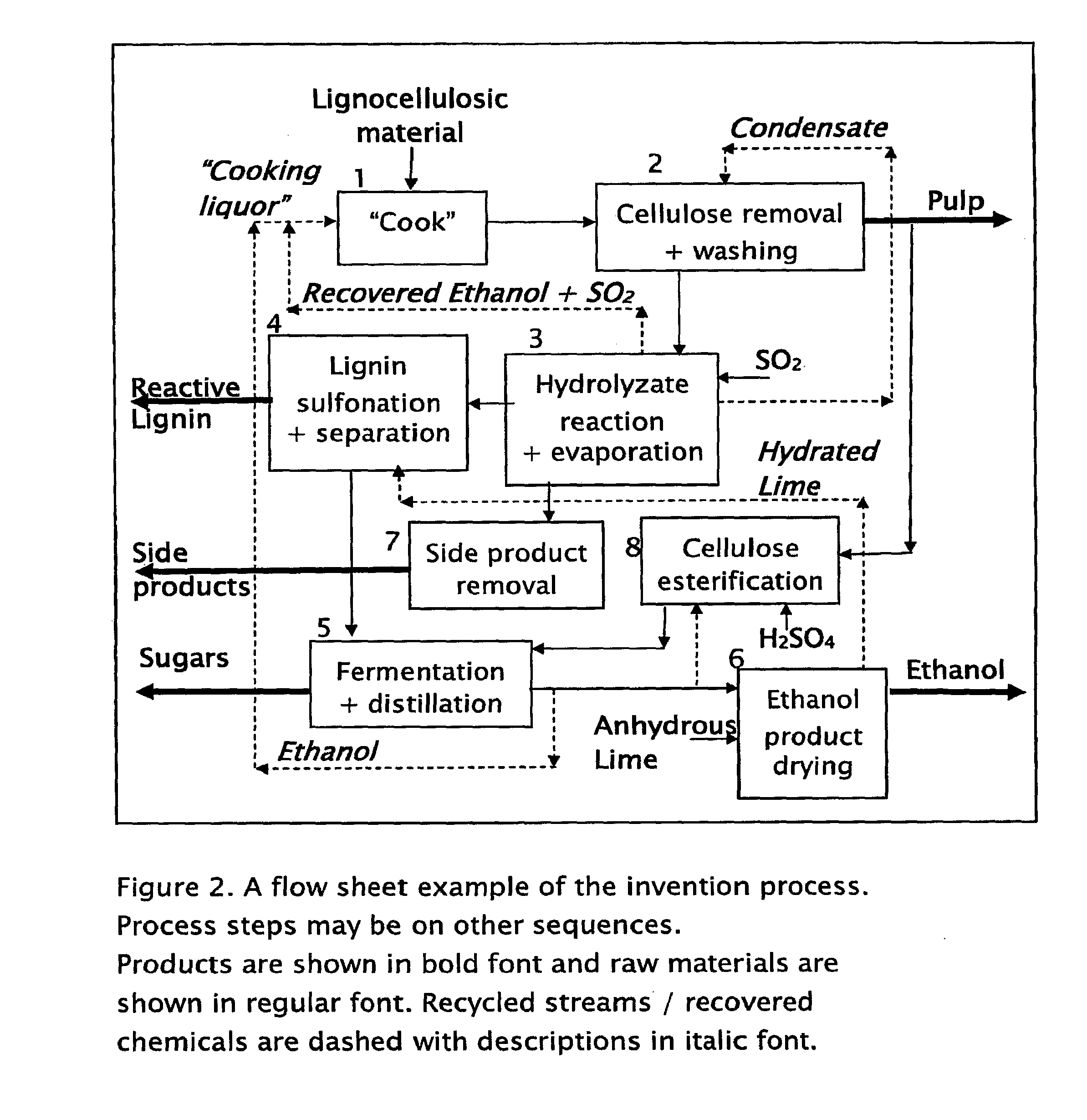

Process for the stepwise treatment of lignocellulosic material to produce reactive chemical feedstocks

InactiveUS20110003352A1Using liquid separation agentCalcium/strontium/barium sulfatesSulfonateLignosulfonates

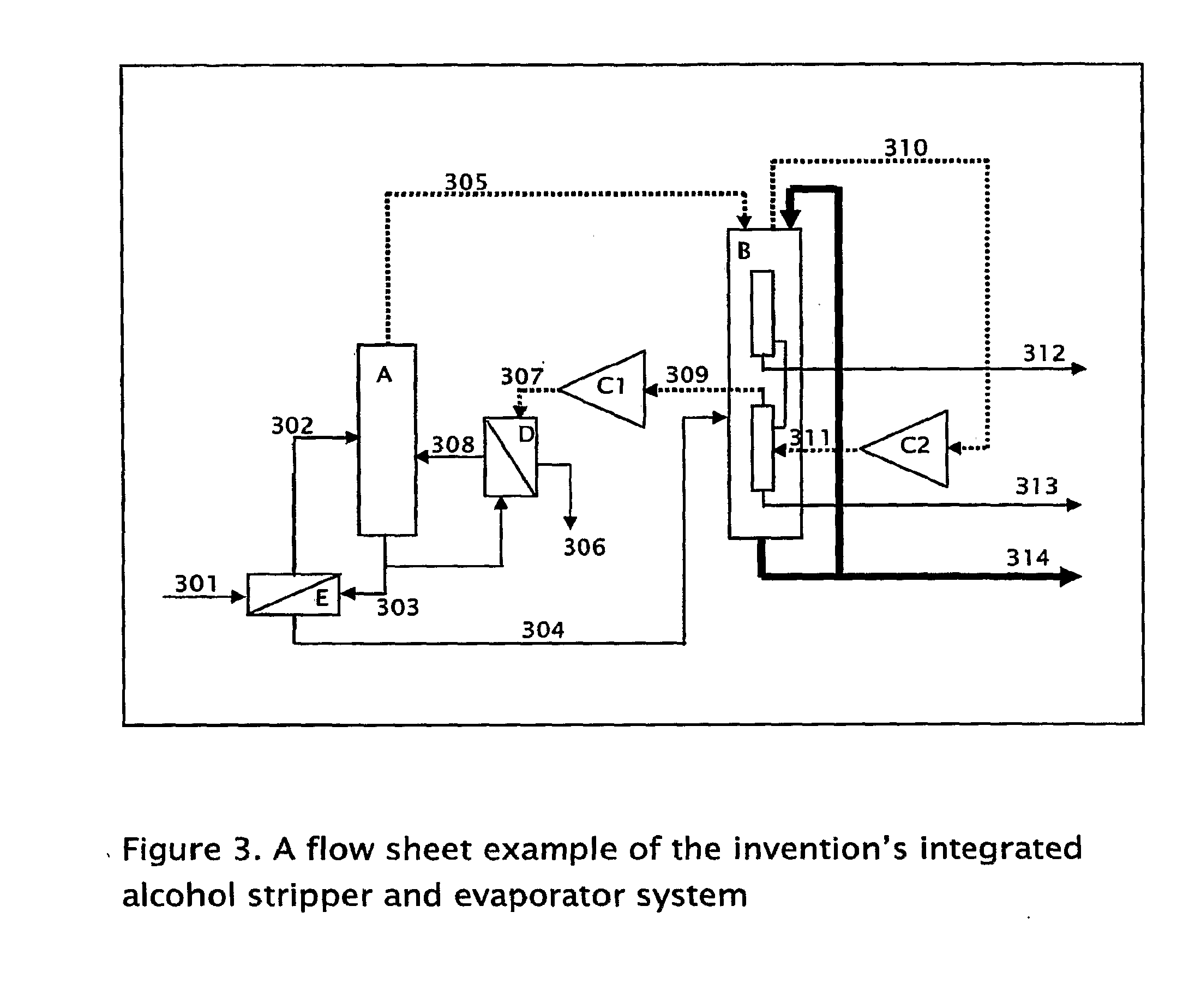

A method for the fractionation of lignocellulosic materials into reactive chemical feedstock in a batch or semi continuous process by the stepwise treatment with aqueous aliphatic alcohols in the presence of sulfur dioxide or acid. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, or converted to esterified cellulose, cooking chemicals are reused, lignin is separated in the forms of reactive native lignin and reactive lignosulfonates and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. In an integrated vapor compression stripper and evaporator system, aliphatic alcohol is removed from a liquid stream and the resulting stream is concentrated for further processing.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC +1

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

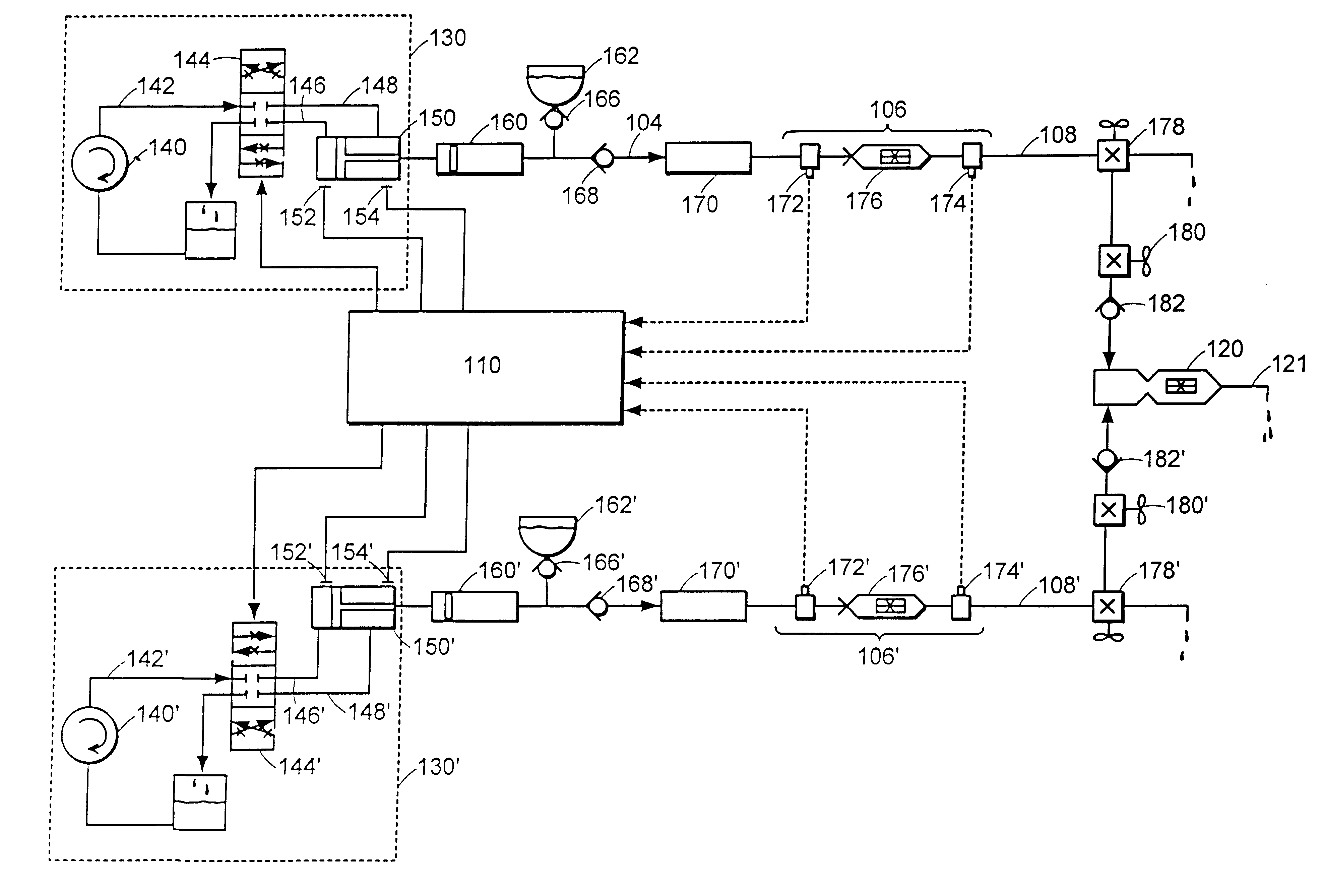

Process for producing sodium bicarbonate for flue gas desulphurization

InactiveUS20100290967A1Electrolysis componentsVolume/mass flow measurementSodium bicarbonateFlue gas

Process for producing sodium bicarbonate for purifying flue gases, according to which an aqueous solution containing sodium sulfate is subjected to electrodialysis to produce a sodium hydroxide solution and a sodium bisulfate solution, the sodium hydroxide solution being carbonated in order to obtain sodium bicarbonate.

Owner:SOLVAY SA

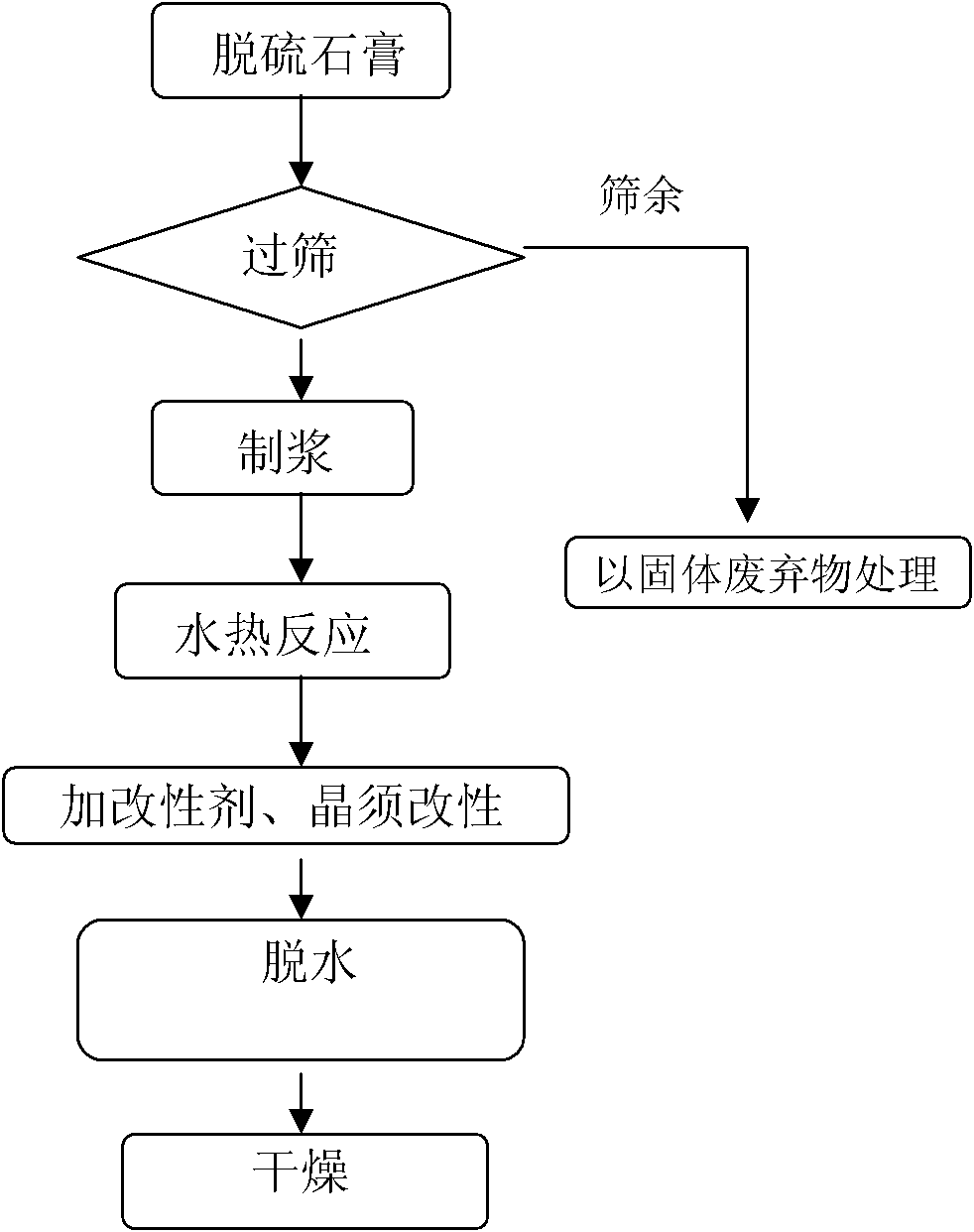

Method for preparing modified calcium sulfate whisker by using desulfurization gypsum

ActiveCN101994153AGood compatibilitySolve the problem of prone to hydration leading to whisker breakagePolycrystalline material growthFrom normal temperature solutionsSulfateMicrometer

The invention discloses a method for preparing a modified calcium sulfate whisker by using desulfurization gypsum, comprising the following steps of sieving, pulping, performing hydro-thermal reaction and whisker surface modification, dewatering and drying, wherein the reaction temperature ranges from 107 DEG C to 180 DEG C, the concentration of desulfurization gypsum and water is 5-33wt% and the drying temperature ranges from 100 DEG C to 300 DEG C, and a modifier which is 0.05-5% of the weight of desulfurization gypsum in the calcium sulfate whisker suspension formed in hydro-thermal reaction. The invention solves the problem that CaSO4.0.5H2O whisker is easy to hydrate in the drying process tocause fracture of the whisker and enhances the compatibility of the calcium sulfate whisker and the high polymer materials. The prepared modified calcium sulfate whisker has a diameter of 0.5-6 micrometers, a length of 30-300 micrometers and a diameter ratio of 15-115 and the contact angle of water on the surface of the modified calcium sulfate whisker ranges from 12 to 140 degrees. The invention has the advantages of good modified effect, simple process, low production cost, the use of the non-toxic modifier and environmental-friendly preparation process.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

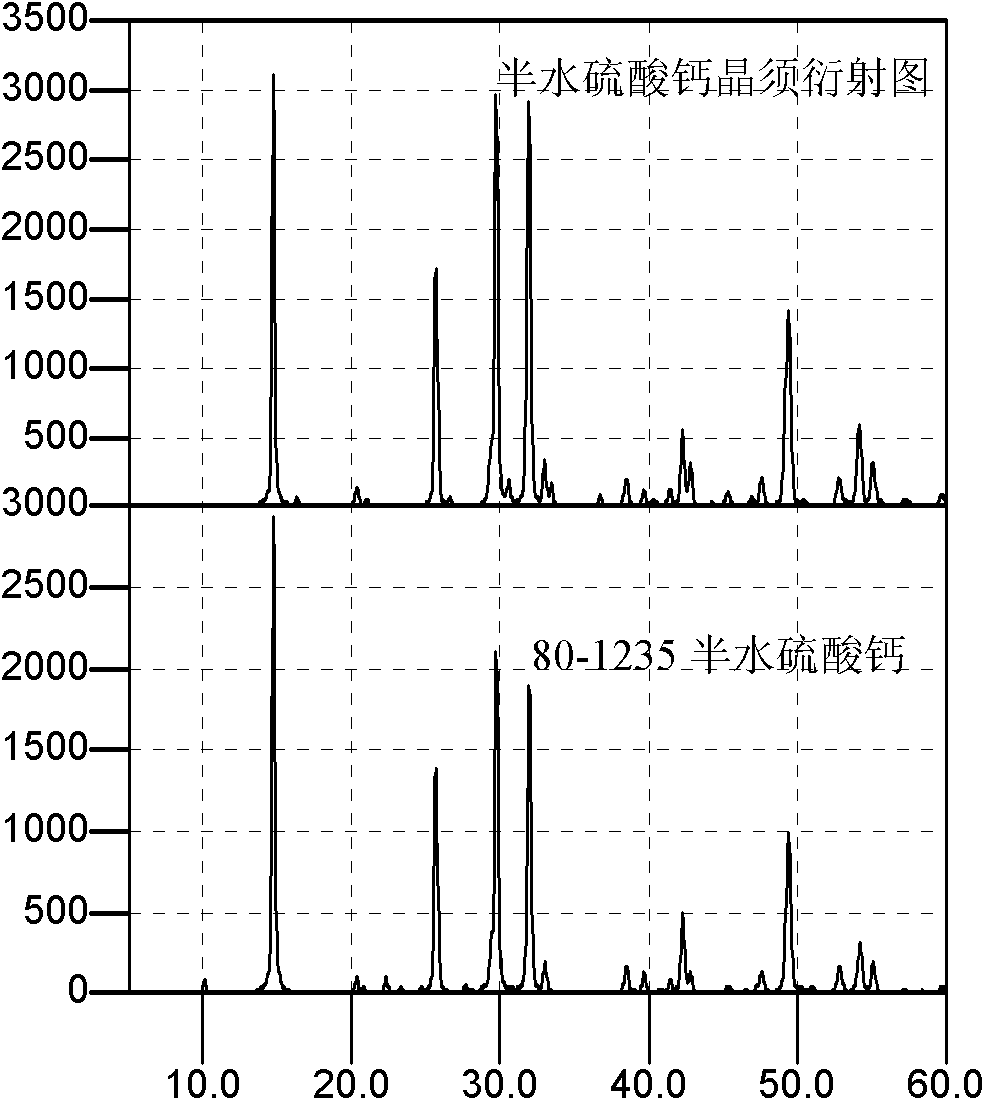

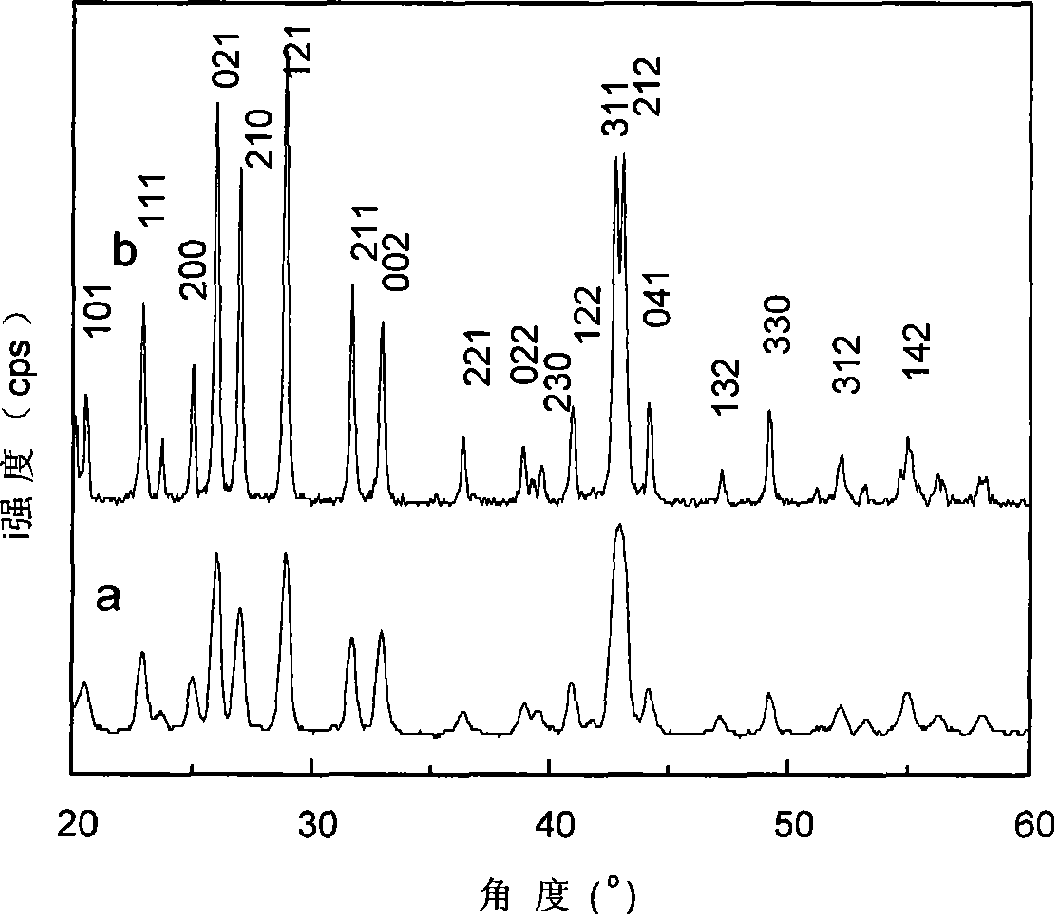

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403AHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

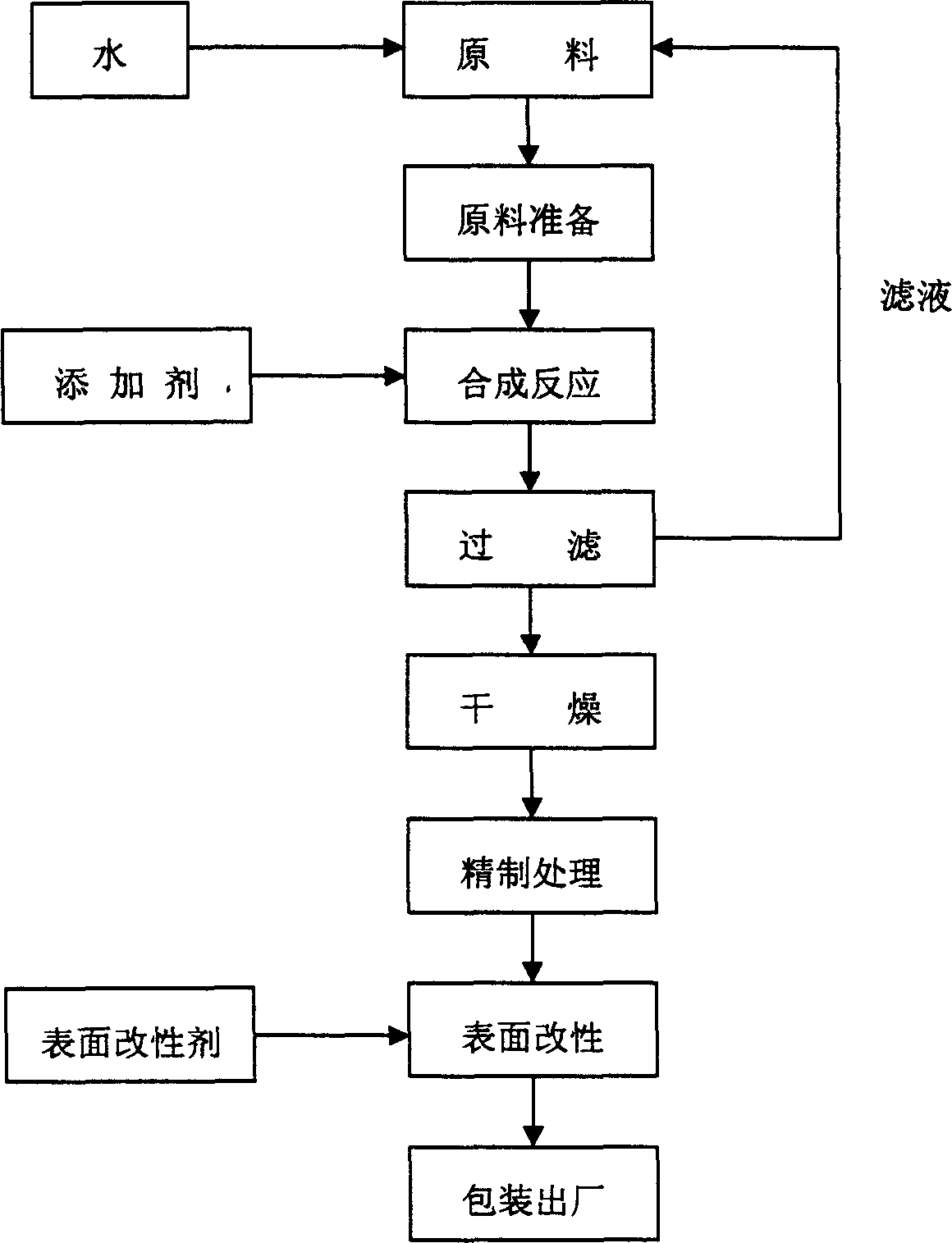

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for production of phosphoric acid and combined production of a-hemihydrate gypsum through dehydrate-hemihydrate wet phosphoric acid technology

ActiveCN103086335AIncrease concentrationHigh recovery rateCalcium/strontium/barium sulfatesPhosphorus compoundsO-Phosphoric AcidSulfate radicals

The invention discloses a method for the production of phosphoric acid and the combined production of a-hemihydrate gypsum through a dehydrate-hemihydrate wet phosphoric acid technology. A dehydrate part production technology is characterized in that the reaction tank temperature is 70-80DEG C, the retention time is 1.5-3h, the free sulfate radical concentration is 1-2%, and the produced wet phosphoric acid concentration omega(P2O5) is 35-39%. A hemihydrate part production technology is characterized in that the reaction tank temperature is 86-94DEG C, the retention time is 1-2h, and the mass concentration of free sulfate radicals is 6-8%. Phosphoric acid produced through the hemihydrate technology has a concentration omega(P2O5) of 10-15% and is used as a recycle acid of the dehydrate part, the crystal water content of the combined-production hemihydrate gypsum is 5-7%, the mass percentage of free P2O5 in gypsum is less than 0.4%, and the crystal form of the produced hemihydrate gypsum is a-hemihydrate gypsum. Compared with the dehydrate technology, the method disclosed in the invention improves the phosphoric acid concentration and improves the phosphorus recovery rate to above 98%, and the combined-production a-hemihydrate gypsum can be directly used as a building gypsum product, so energy consumption saving is realized.

Owner:WENGFU (GRP) CO LTD

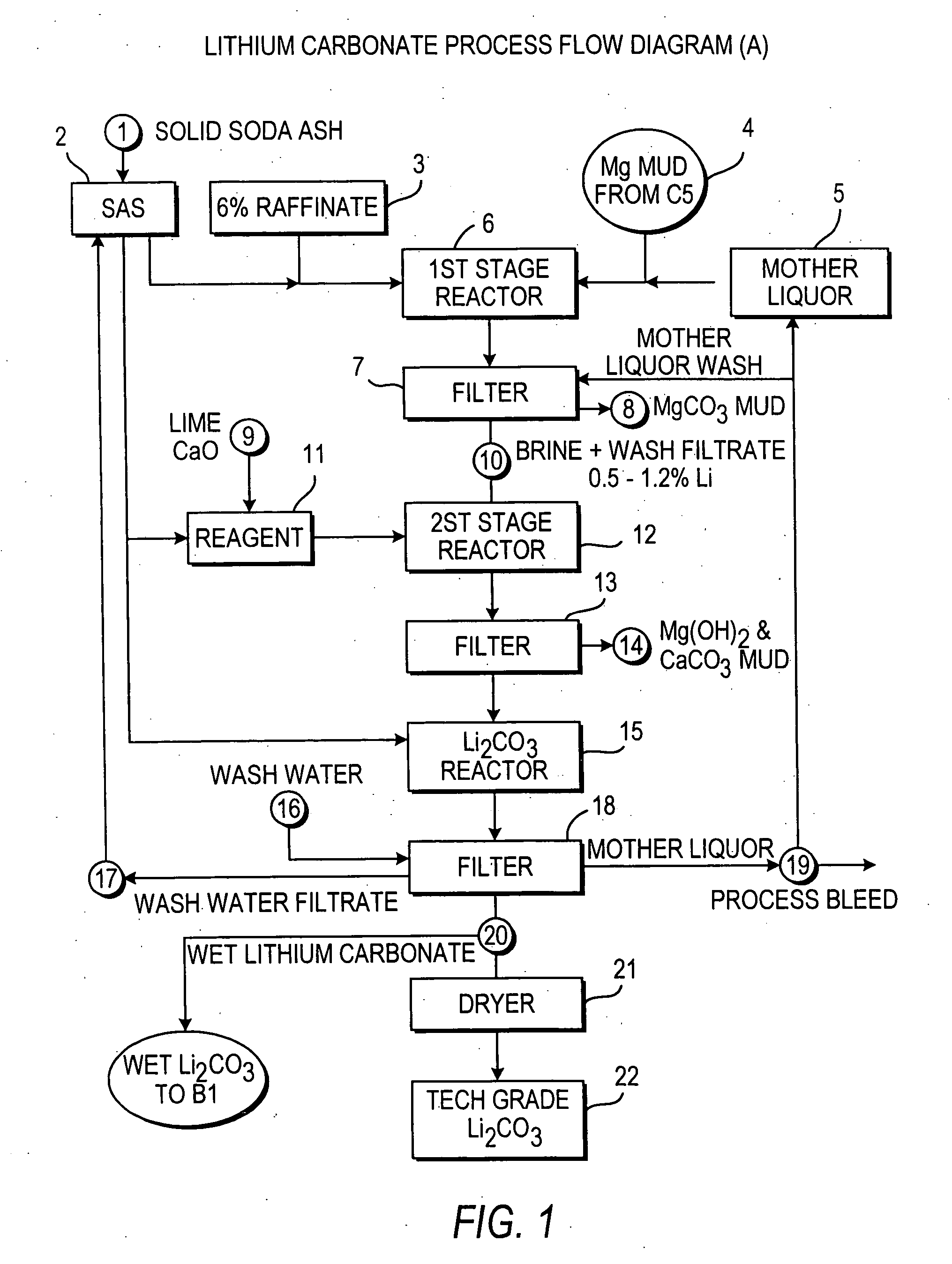

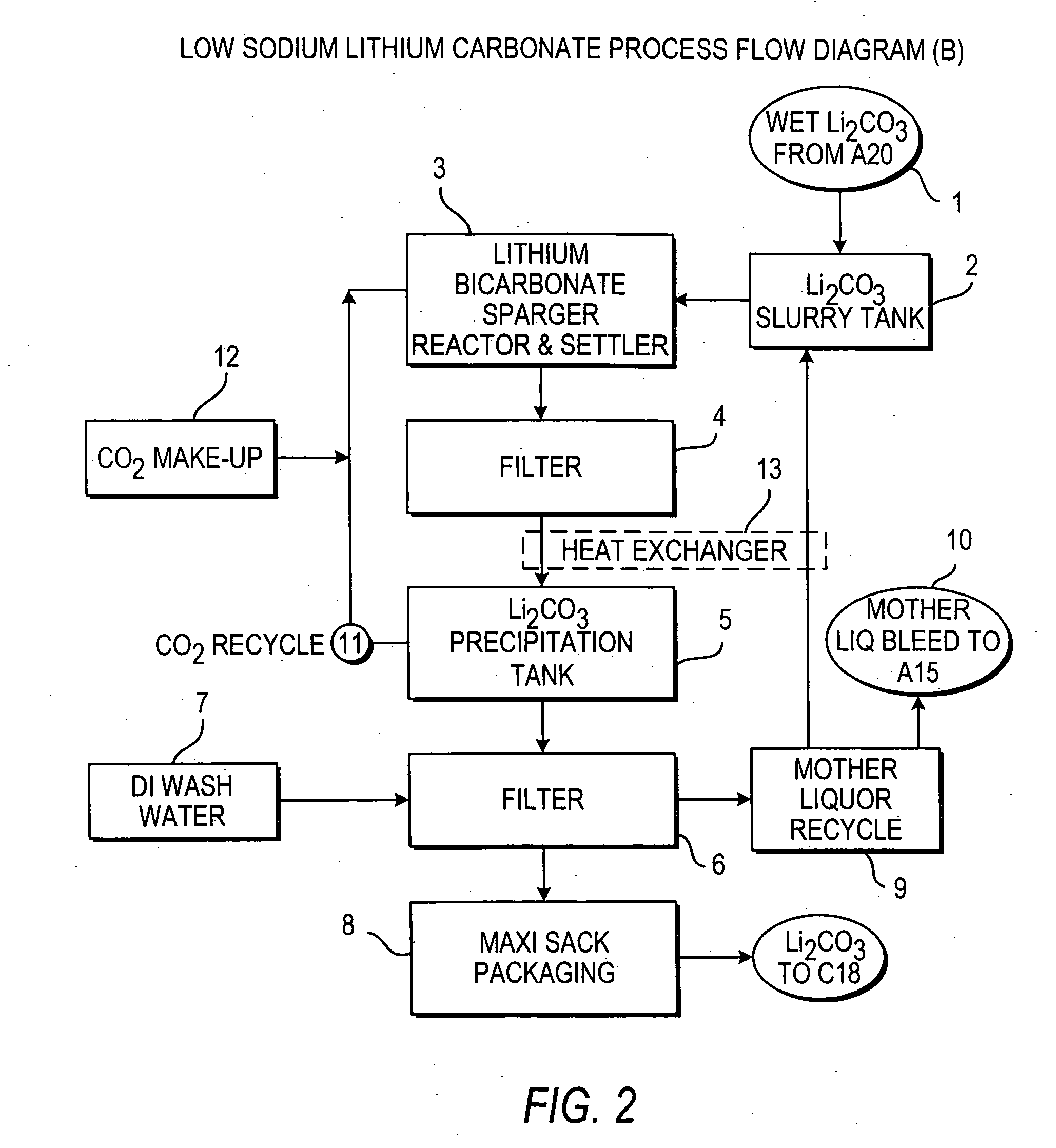

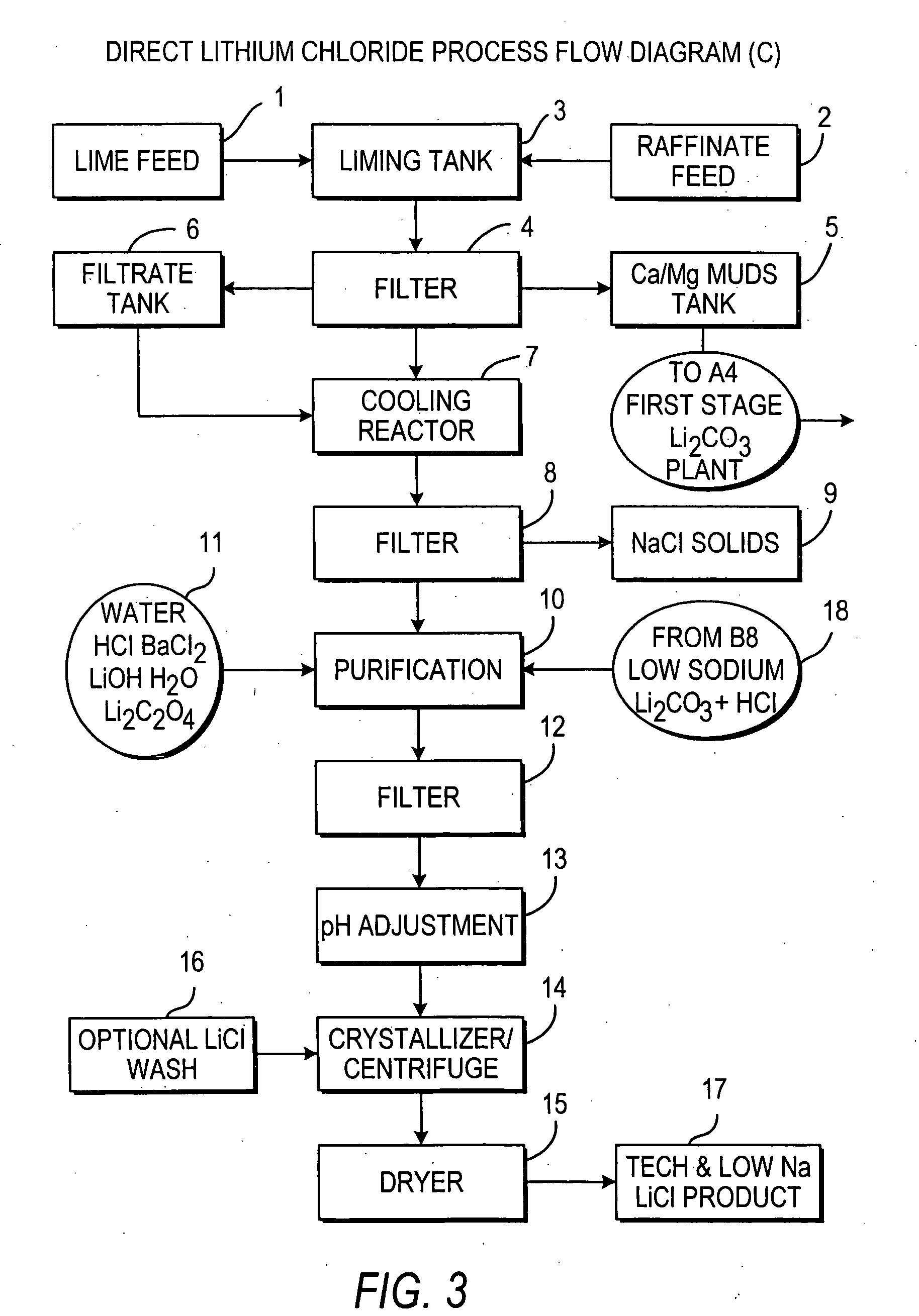

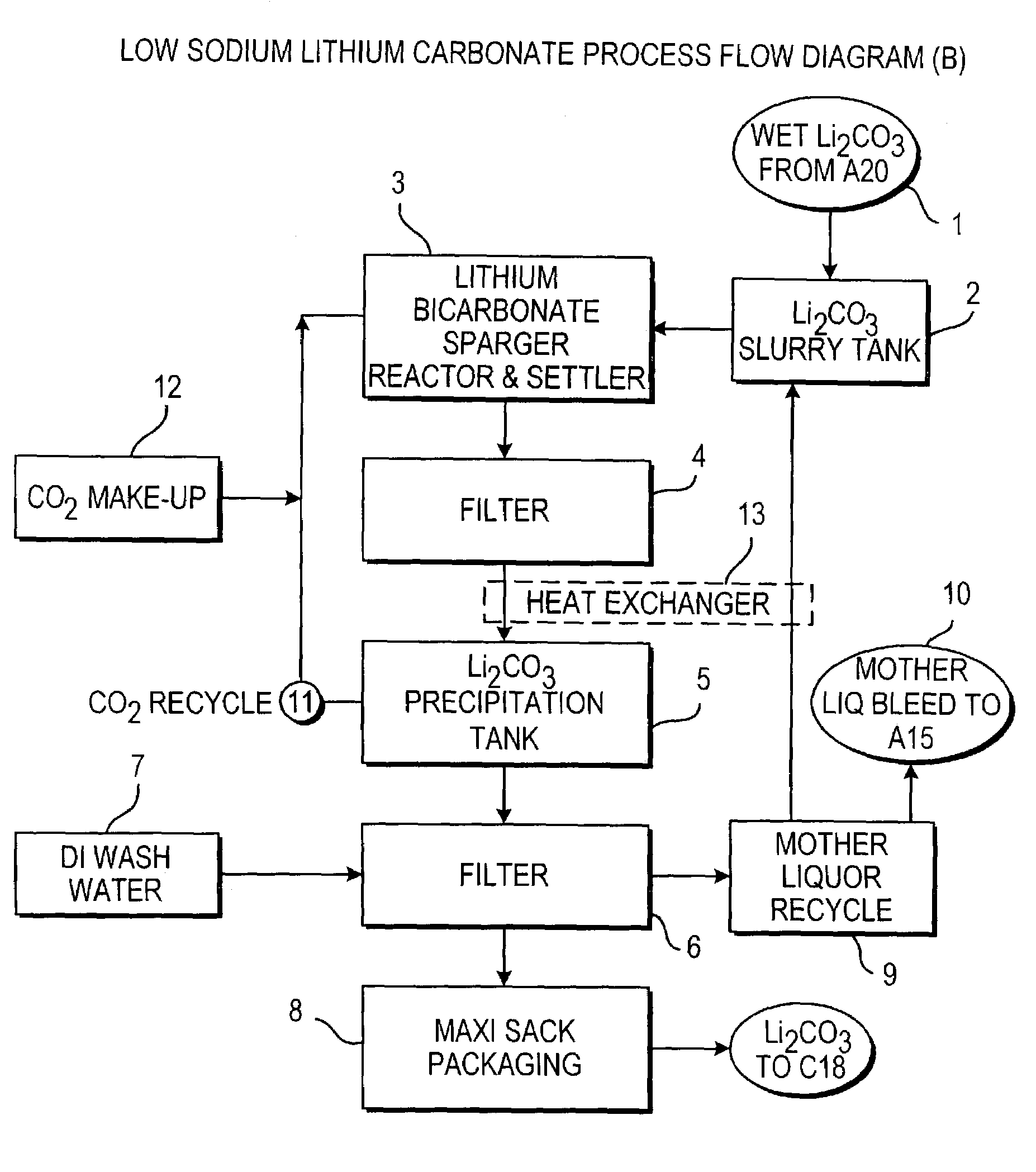

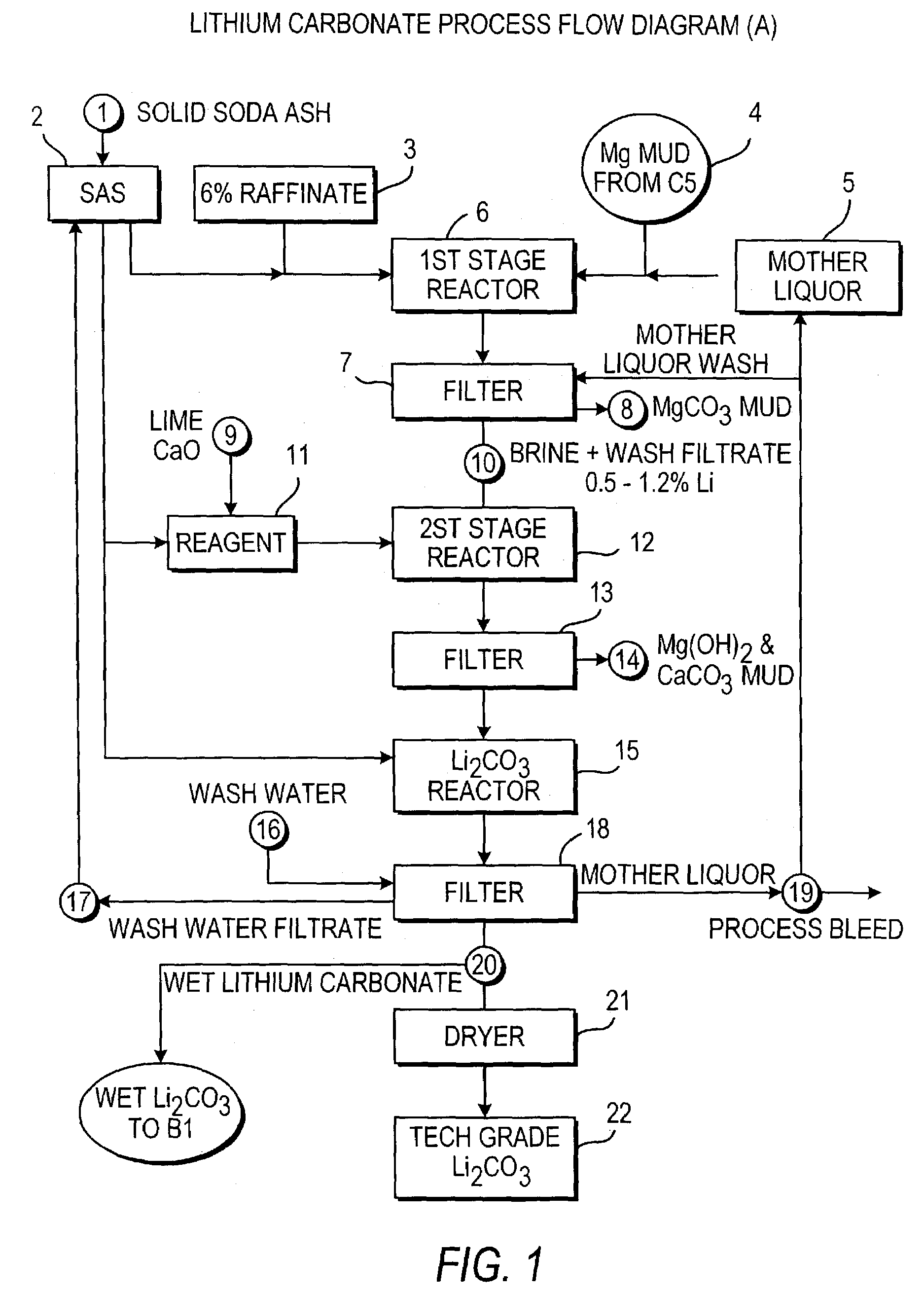

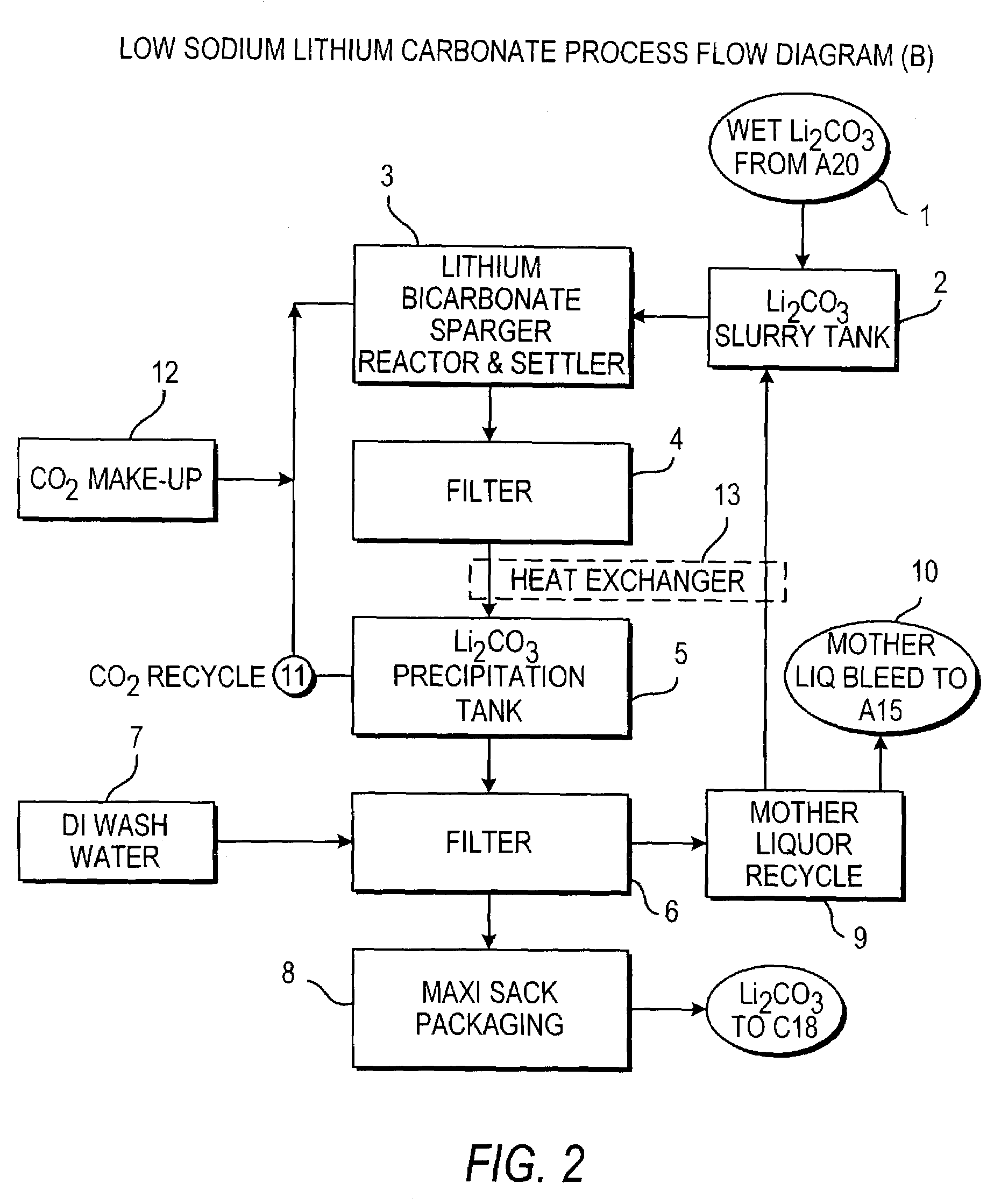

Production of lithium compounds directly from lithium containing brines

InactiveUS20060115396A1Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:BORYTA DANIEL ALFRED +2

Process for manufacturing ultra low consistency alpha- and beta- blend stucco

InactiveUS20080069762A1Cheap methodAid in reactivityCalcium/strontium/barium sulfatesFluidized bedSlurry

A process is disclosed for making a blend of alpha- and beta-stucco including a slurry calcination step to produce alpha calcium sulfate hemihydrate followed by a fluidized bed calcination step to produce beta calcium sulfate hemihydrate. The process starts with 50-75% gypsum-containing solids slurry, and then steam calcines the slurry in a first reactor to form partially calcined gypsum slurry which contains calcium sulfate dihydrate and alpha calcium sulfate hemihydrate. The partially calcined slurry is then dewatered. Then the filter cake is fed into a kettle to complete the calcination process by converting the calcium sulfate dihydrate of the filter cake material into beta calcium sulfate hemihydrate.

Owner:UNITED STATES GYPSUM CO

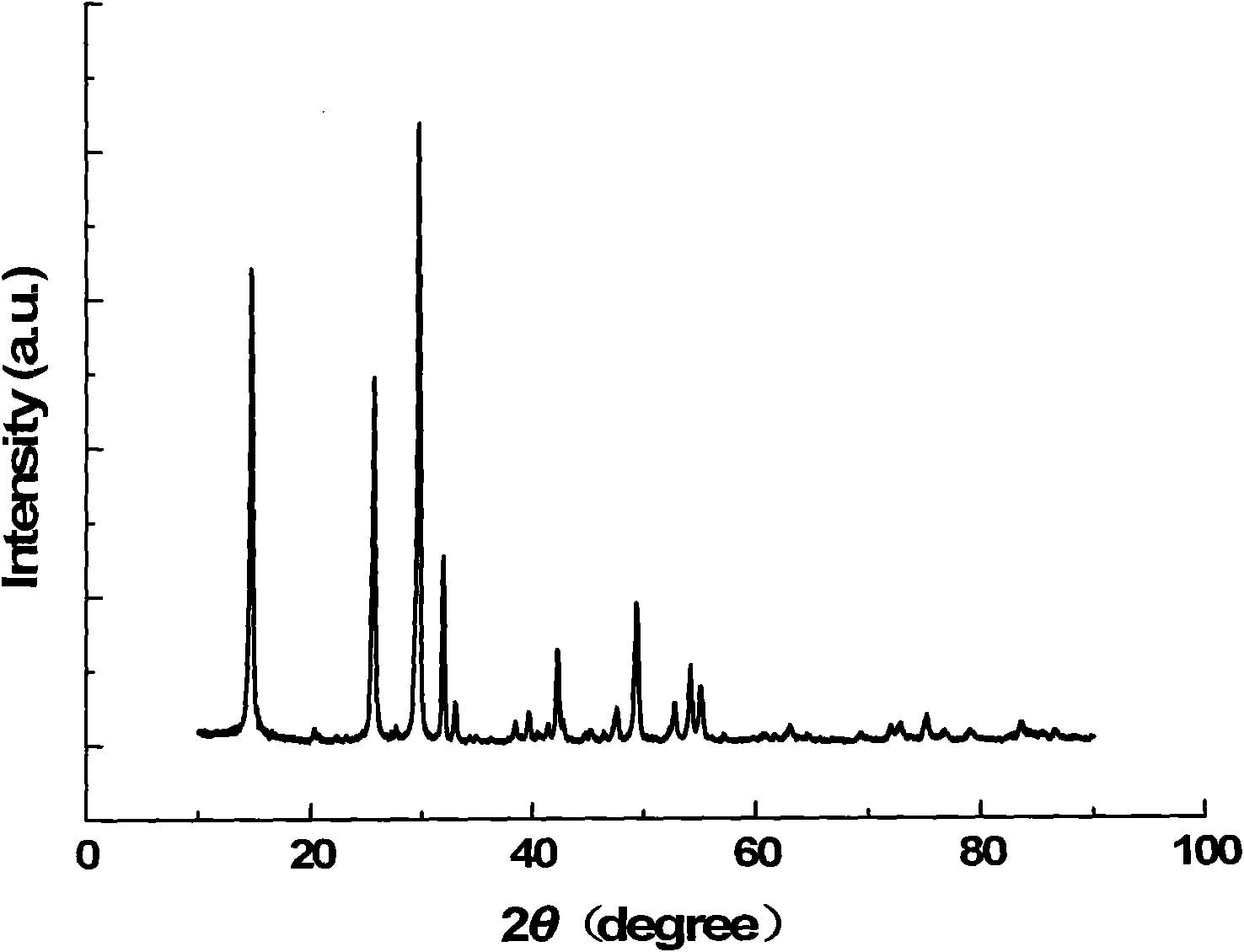

Production of lithium compounds directly from lithium containing brines

InactiveUS7157065B2Reduce in quantityPromote absorptionCalcium/strontium/barium carbonatesChemical/physical/physico-chemical processesSlurryLithium compound

A continuous process for directly preparing high purity lithium carbonate from lithium containing brines by preparing a brine containing about 6.0 wt % lithium and further containing other ions naturally occurring in brines; adding mother liquor containing carbonate to precipitate magnesium; adding a solution of CaO and sodium carbonate to remove calcium and any residual magnesium; precipitating lithium carbonate from the purified brine by adding soda ash solution; filtering to obtain solid lithium carbonate; preparing an aqueous slurry of the lithium carbonate and introducing carbon dioxide gas at a temperature from at least minus 10 to +40° C.; passing the lithium bicarbonate solution through a filter to clarify the solution; introducing said filtered lithium bicarbonate solution into a reactor and adjusting the temperature of the solution to from 60–100° C. to precipitate ultra-pure lithium carbonate.

Owner:ROCKWOOD LITHIUM INC

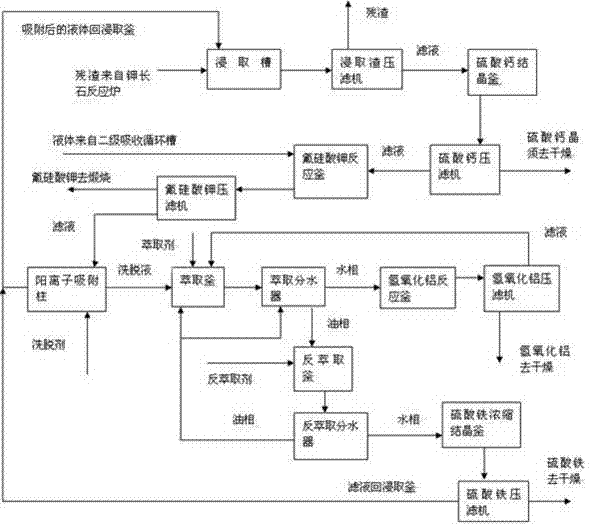

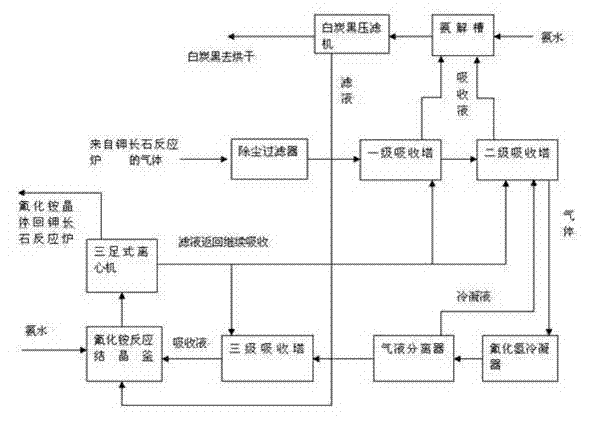

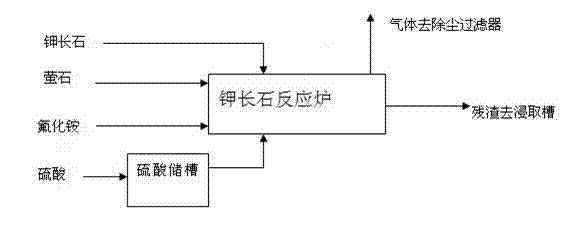

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

Synthesis of nanoparticles

Owner:CENT FUR ANGEWANDTE NANOTECH

Calcium sulphate-based composition and methods of making same

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

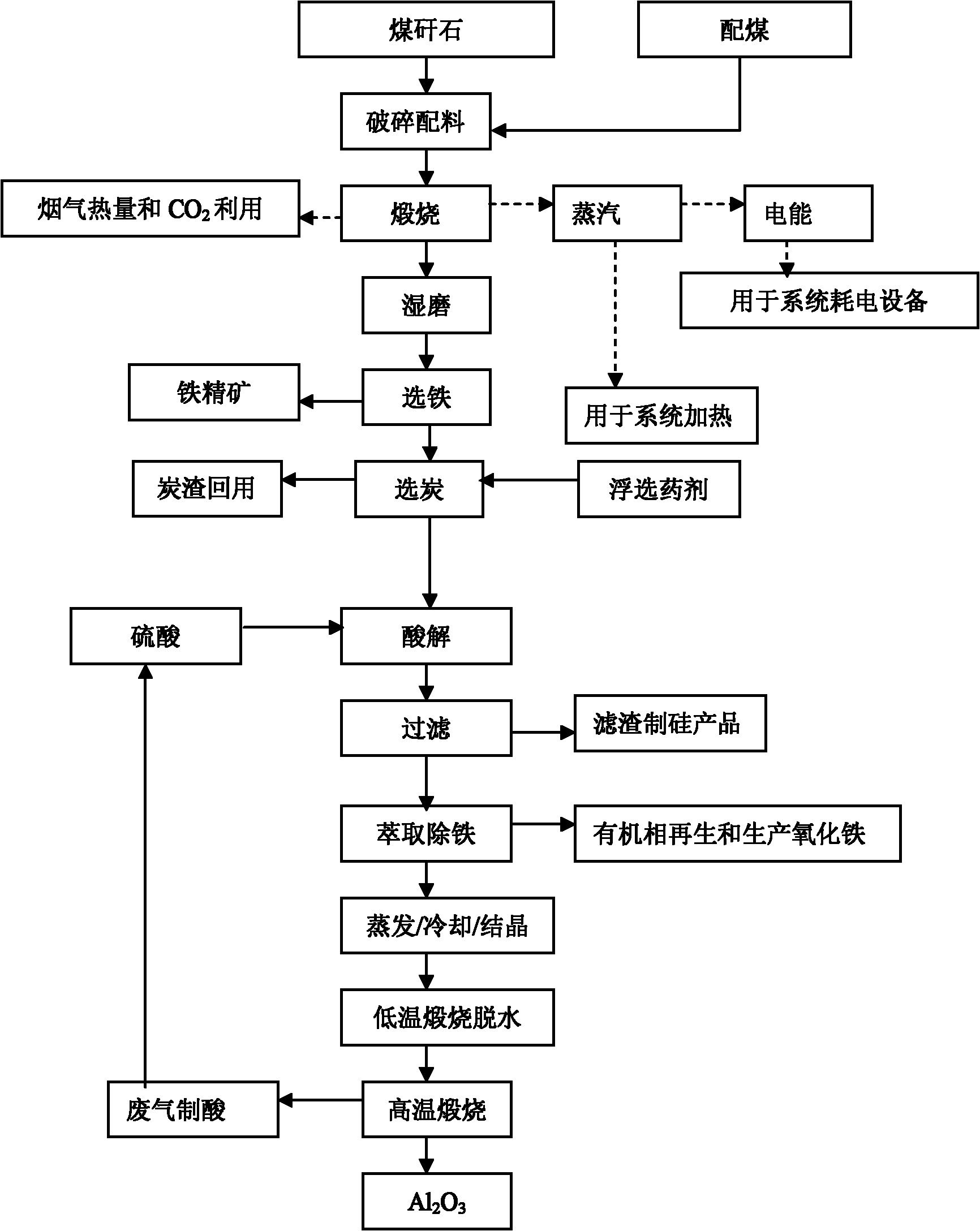

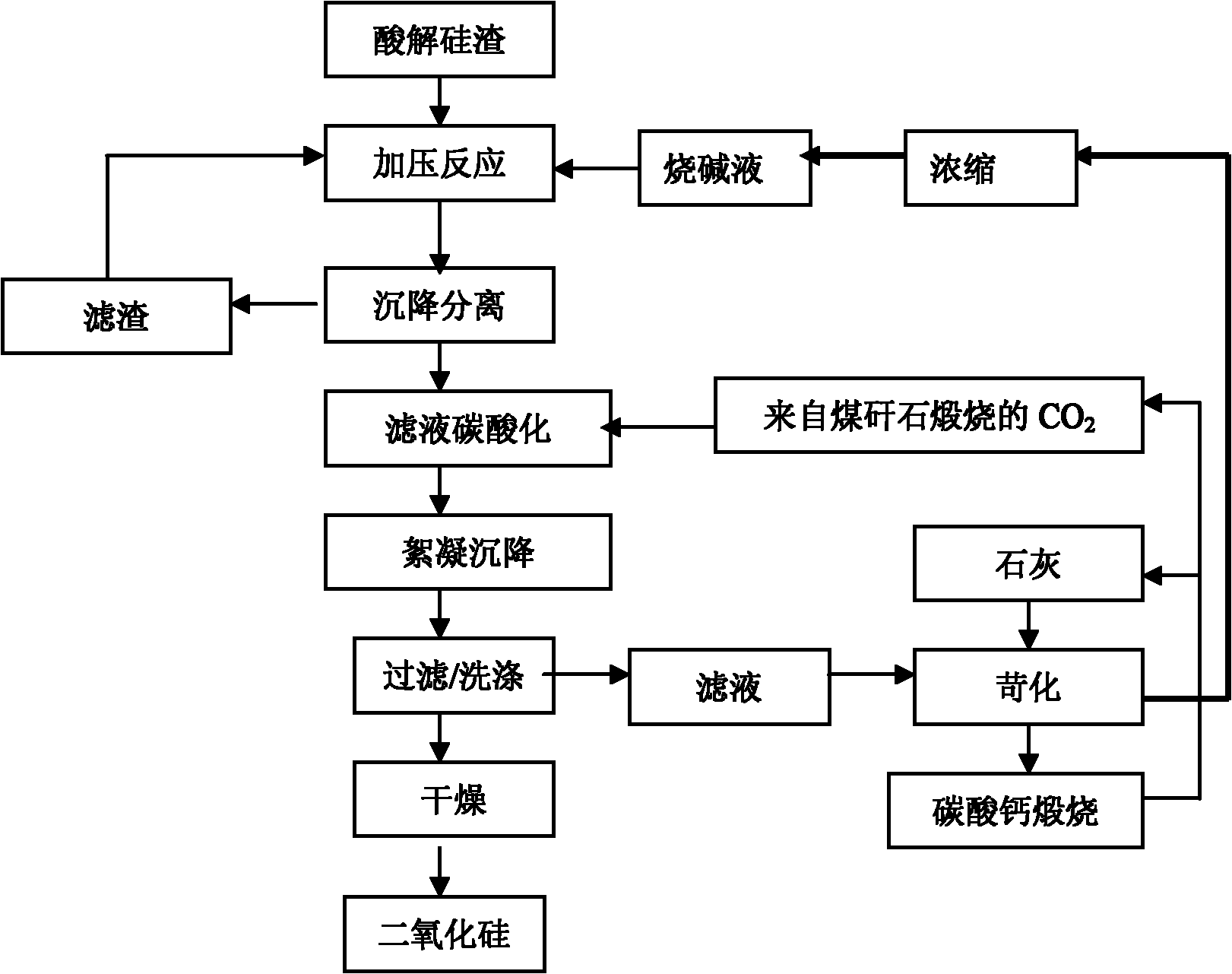

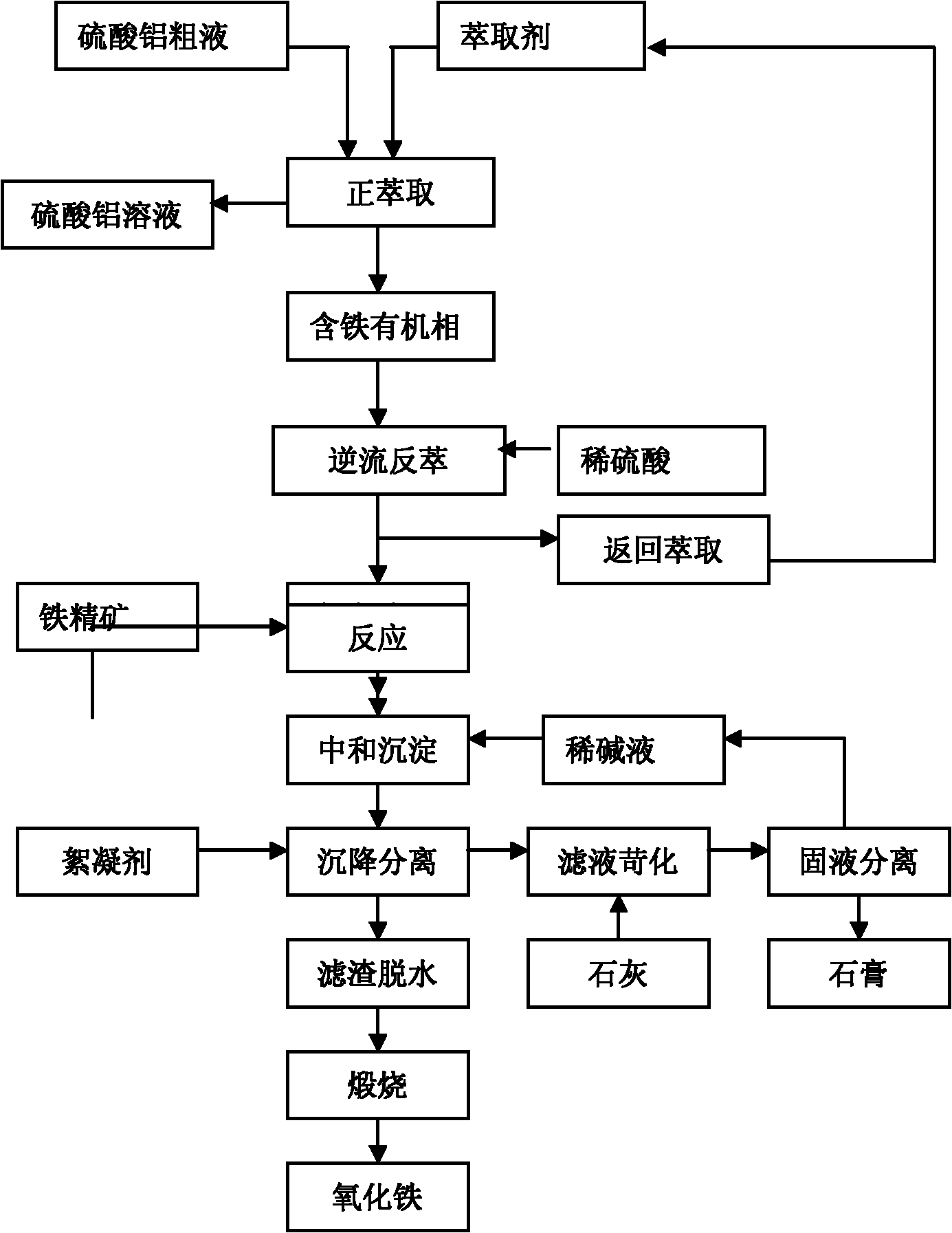

Method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes

InactiveCN101913632AEfficient use ofMeet steamSilicaCalcium/strontium/barium sulfatesBiological activationCoal blending

The invention relates to a method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes. Coal blending is carried out according to heating value conditions after the gangue is pretreated, gangue activation is achieved while calcination generation is carried out, and the produced electricity and steam are supplied for a system to use; the aluminum oxide is extracted from the ashes by an acid method, the monox is extracted by an alkaline method, and the ferric oxide is extracted by comprehensive utilization of by-products; and acid, alkaline, lime, an extractant andCO2 which are required by each craft link are recycled inside the system. The invention has the beneficial effects that gangue reclamation is implemented by using the method; the energy and the chemical components in the gangue are fully utilized; the discharge amounts of greenhouse gases and waste ashes are greatly reduced, and the economic benefit of the system is improved; and the method is a novel technology of gangue greening and high added-value utilization, and has obvious competitive advantage.

Owner:KUNMING UNIV OF SCI & TECH +1

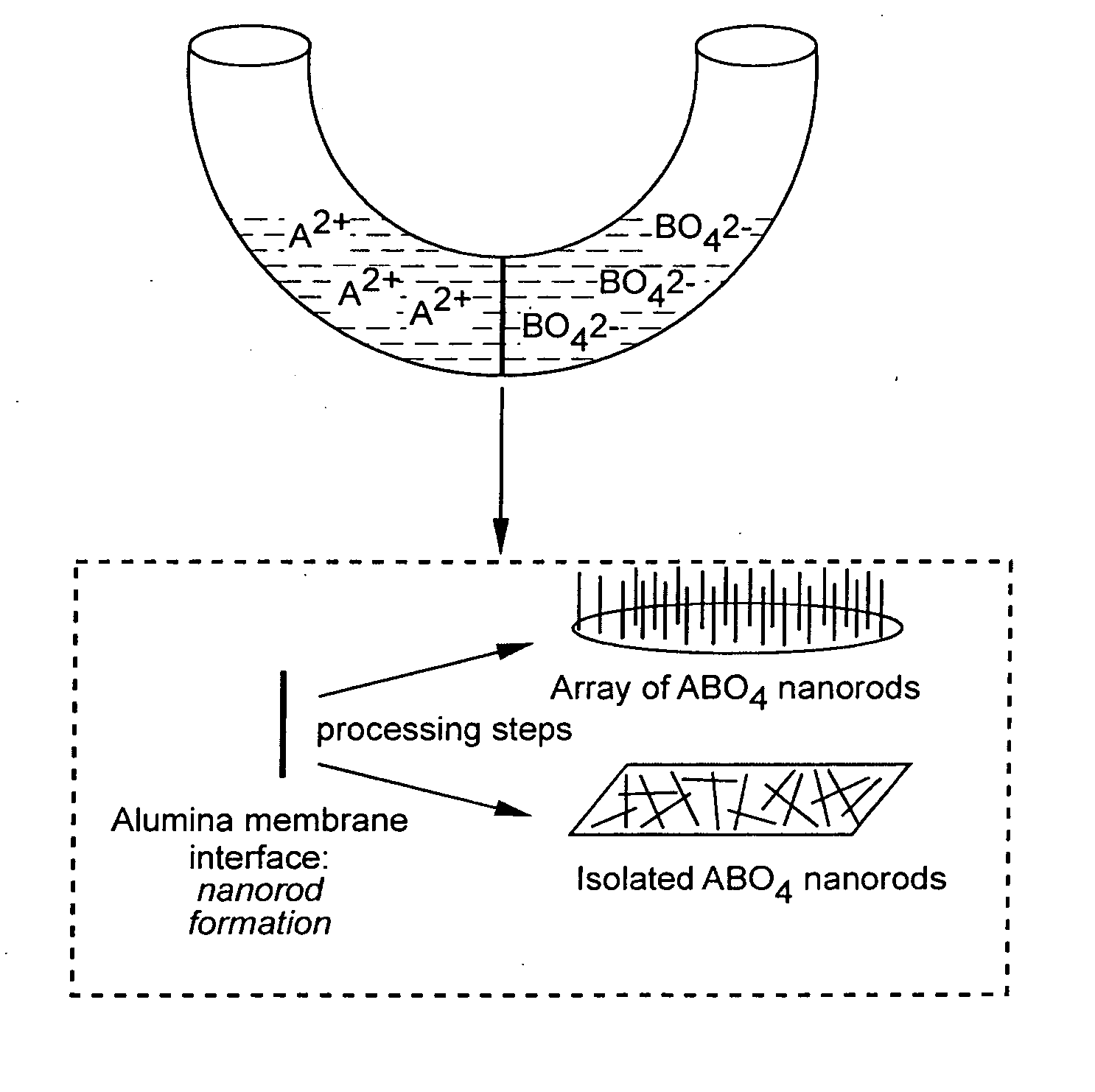

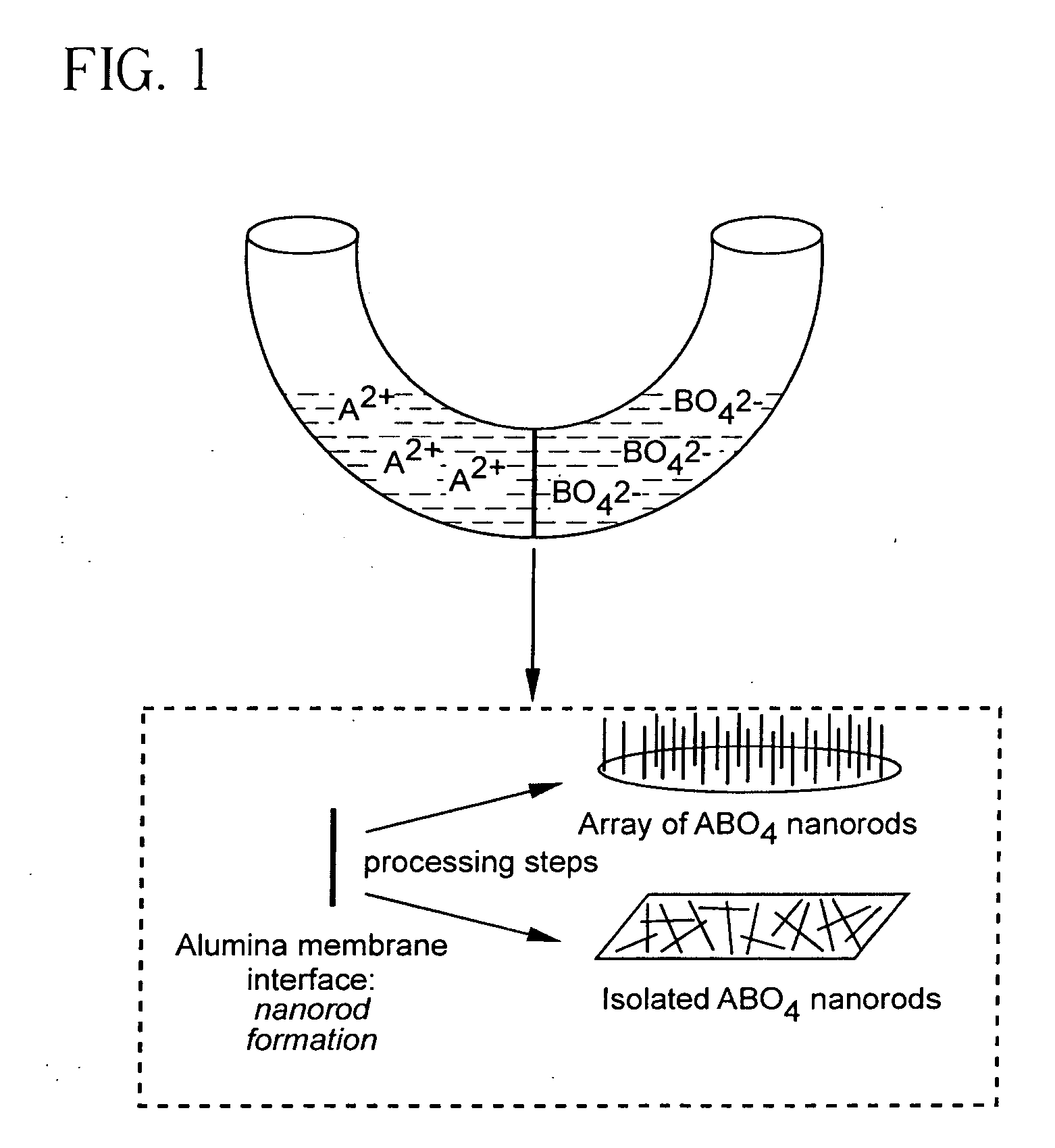

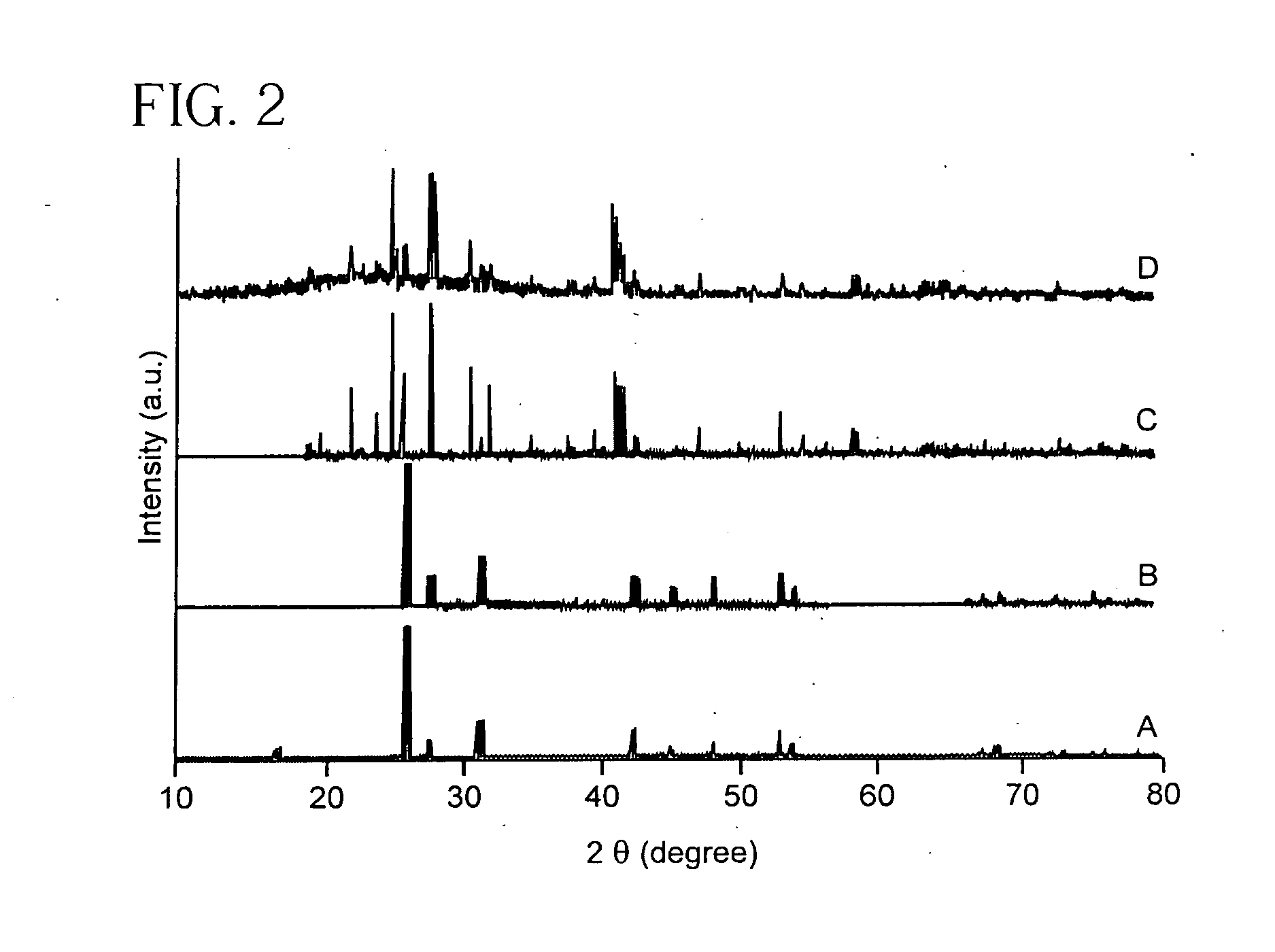

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

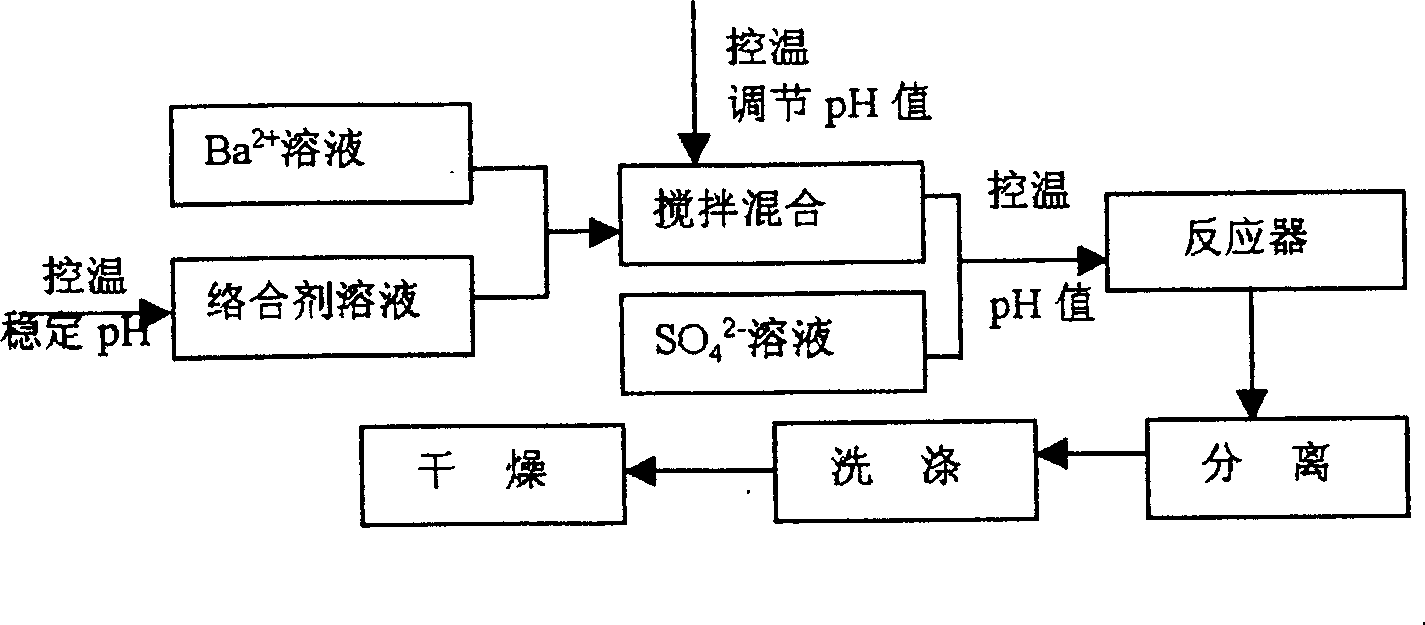

Prepn of nano barium sulfate

InactiveCN1398789AStable operating conditionsGood resolubility and dispersibilityMaterial nanotechnologyCalcium/strontium/barium sulfatesSal ammoniacSulfate radicals

The present invention belongs to the field of chemical technology and is especially a complexing process of preparing nanometer BaSO4. The process includes two main steps of complexing reaction and deposition reaction. Specifically. Ba2+ ion solution and EDTA complexing agent solution produce complexing reaction in a reactor to produce complex solution with certain stability and ammonia water being used for regulating system pH value. The complex solution is made to react with sulfate radical solution while stirring to prepare nanometer level BaSO4 particles as precipitate. The nanometer level BaSO4 product is hexagonal crystal and blue in color, and has grain size of 20-40 nm and average grain size of 25 nm. The process is stable in operation, and the product has high quality and dispersivity.

Owner:ZHONGBEI UNIV

Production of non-metallic material calcium-sulfate whiskers

InactiveCN101029415AAvoid pollutionShort processPolycrystalline material growthFrom normal temperature solutionsGlass fiberSlag

Production of non-metallic calcium sulfate whiskers is carried out by taking converter slag as raw materials, grinding, leaching out sulfuric acid, filtering to obtain calcium sulfate suspended solution, synthesizing by high-temperature crystallizing method, separating and drying to obtain the final product. The purity is above 98%. It's cheap, has better quality and short process flow path. It can be used as filler, friction material, building material or thermal-insulating material and used to substitute glass fiber.

Owner:NORTHEASTERN UNIV

Method for preparing nano barium sulfate with controllable particle size distribution

InactiveCN101423239APrecise control of particle sizeInhibit growthCalcium/strontium/barium sulfatesEmulsionSlurry

The invention provides a preparation method of nano barium sulfate with the controllable particle size distribution. The preparation method takes BaCl2 and Na2SO4 as raw materials, respectively prepares two types of solution and then simultaneously adds the two types of solution into a rotary liquid membrane reactor with the high-speed rotation at the same flow rate for carrying out nucleation reaction, and centrifugal washing and drying are carried out to the obtained slurry to obtain the nano BaSO4 with the particle size of 30-120nm and the narrower particle size distribution. The purpose of precisely controlling the particle size of the product can be achieved by regulating and controlling the rotational speed, the gap and other operation parameters of the reactor, thereby being capable of preparing the BaSO4 with the particle size of 30-40nm. The method combines the advantages of a micro-reactor and a high gravity reactor and simultaneously avoids the shortcomings of the micro-emulsion method, the complex method and the like, thereby having small reaction space and high preparation speed and being capable of meeting the requirements on the industrial preparation of the nano BaSO4.

Owner:BEIJING UNIV OF CHEM TECH

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

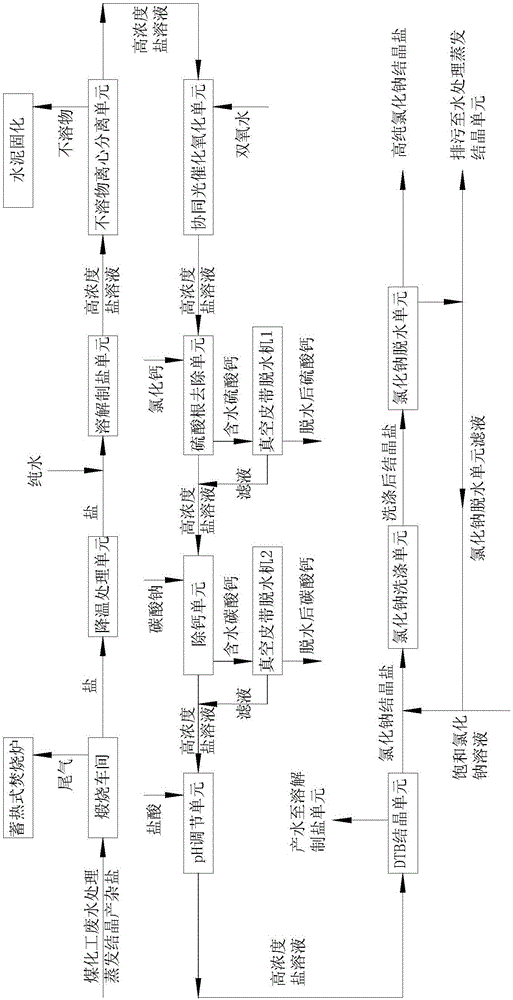

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com