Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Lixiviant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lixiviant is a liquid medium used in hydrometallurgy to selectively extract the desired metal from the ore or mineral. It assists in rapid and complete leaching. The metal can be recovered from it in a concentrated form after leaching.

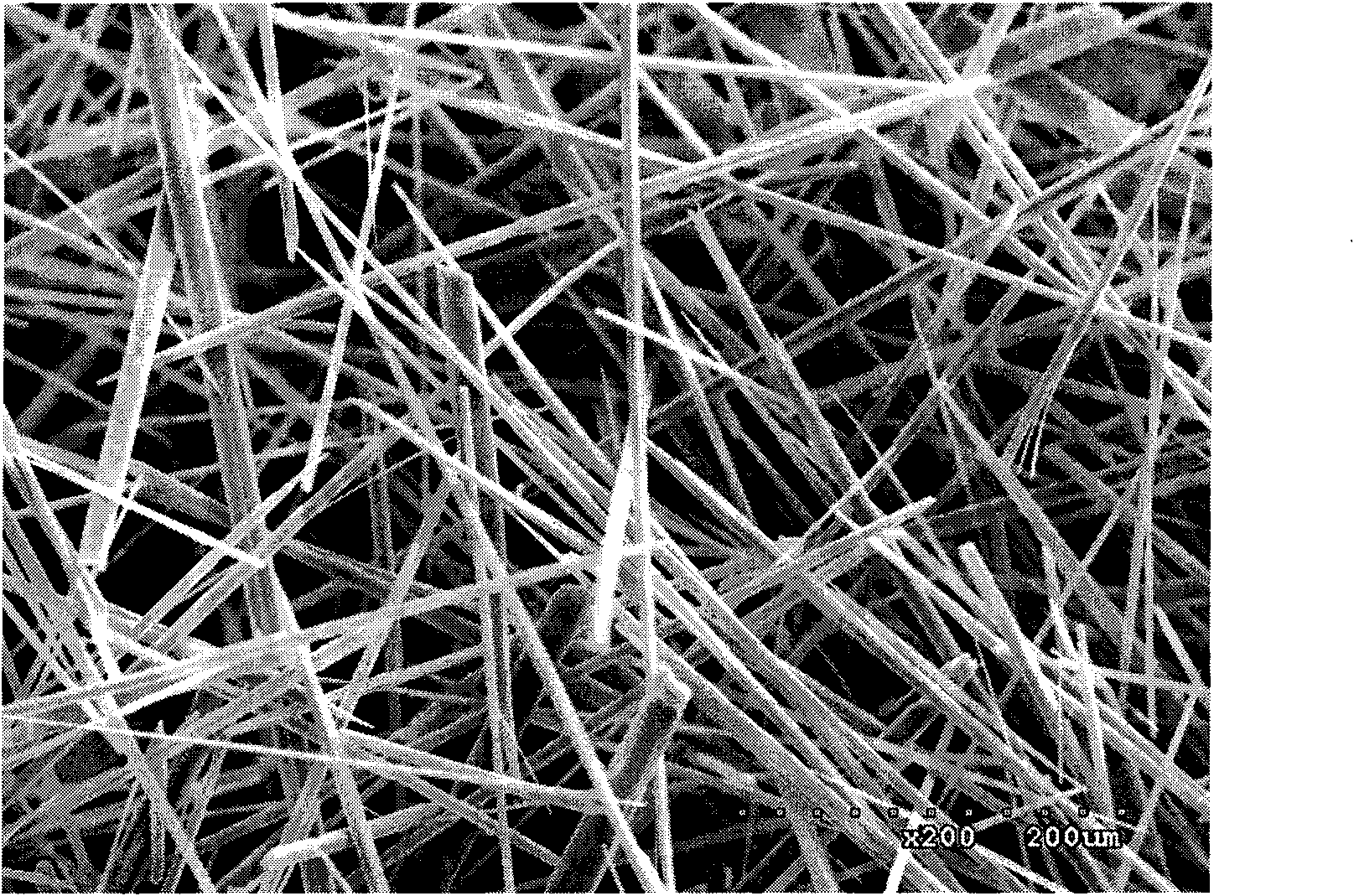

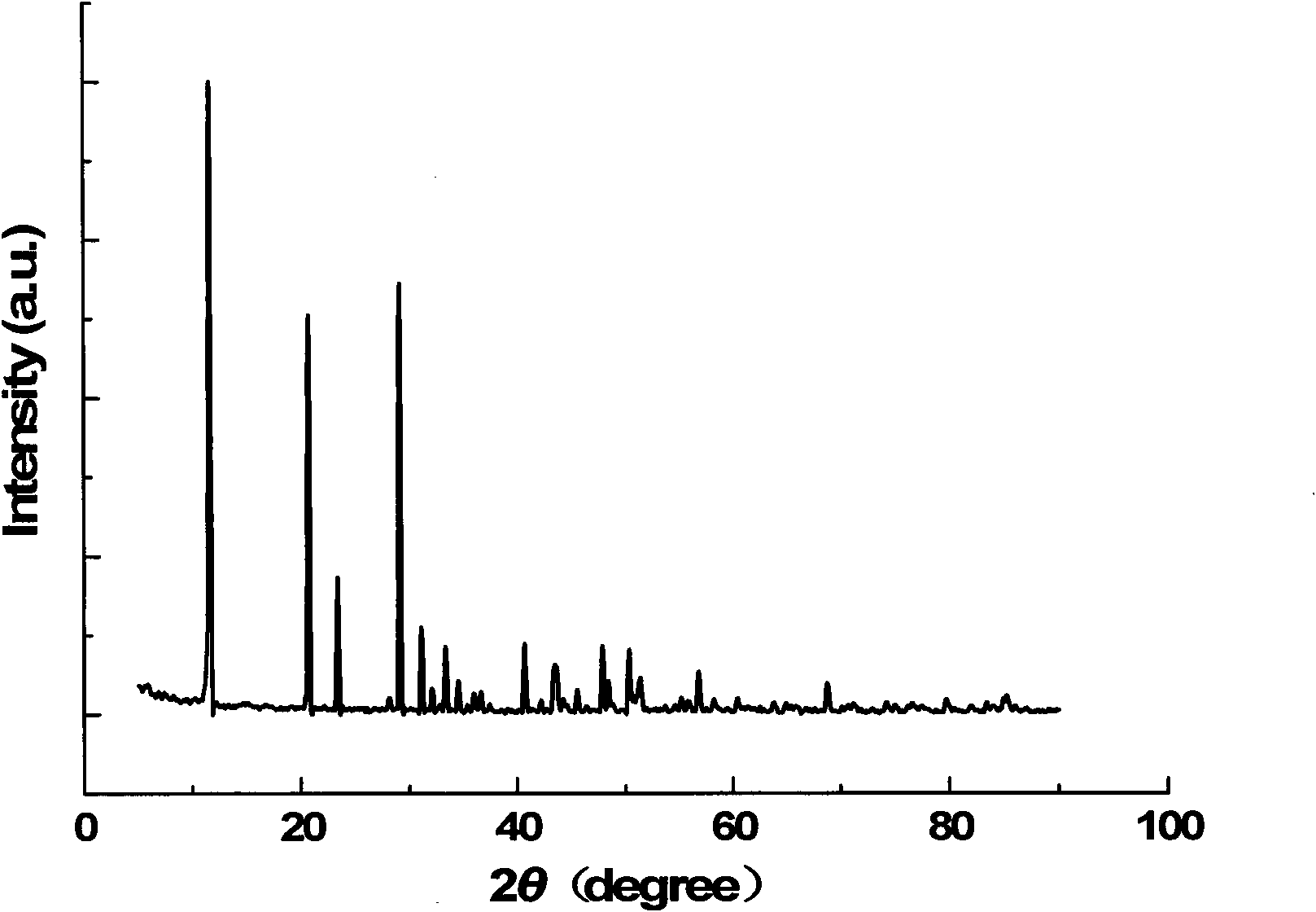

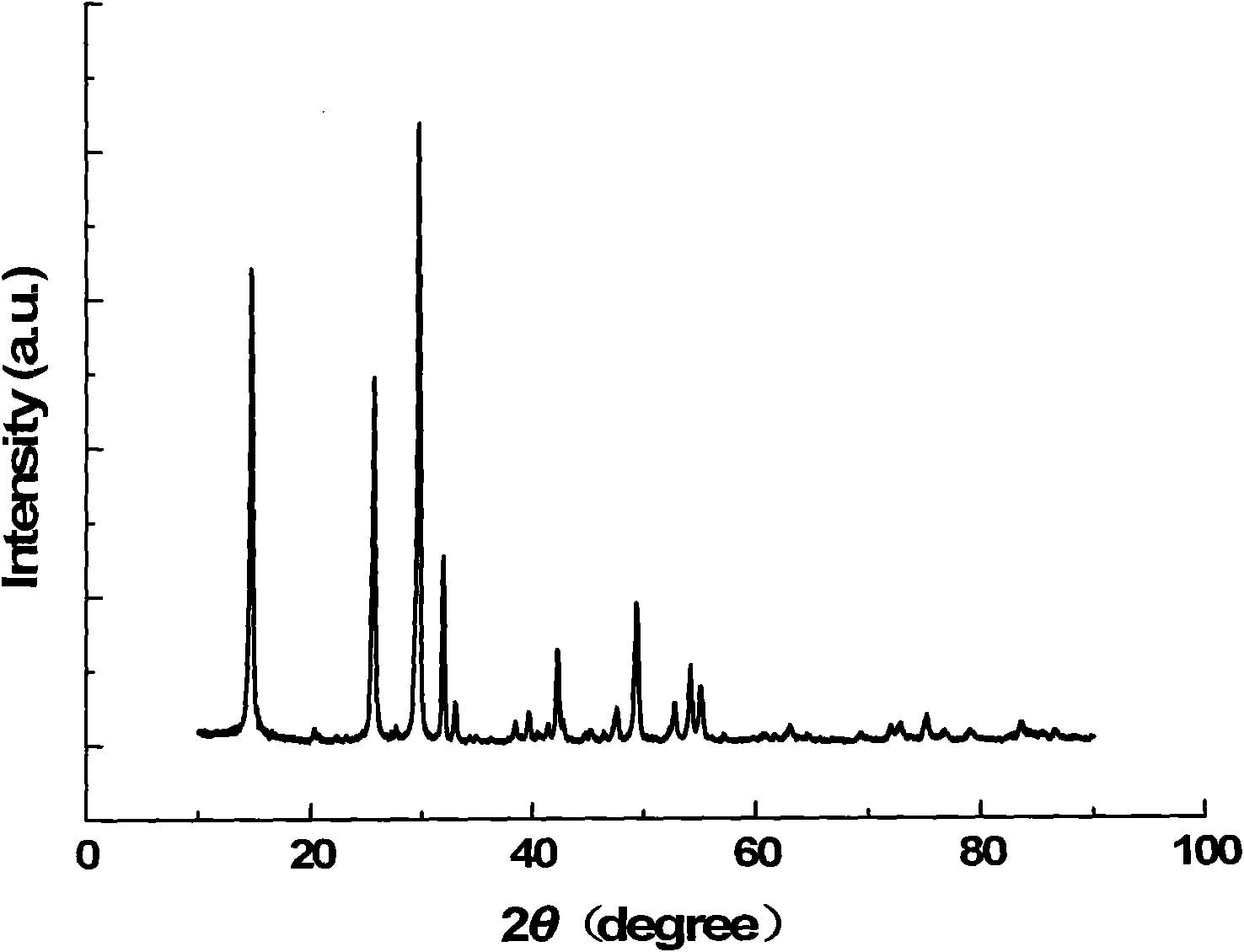

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

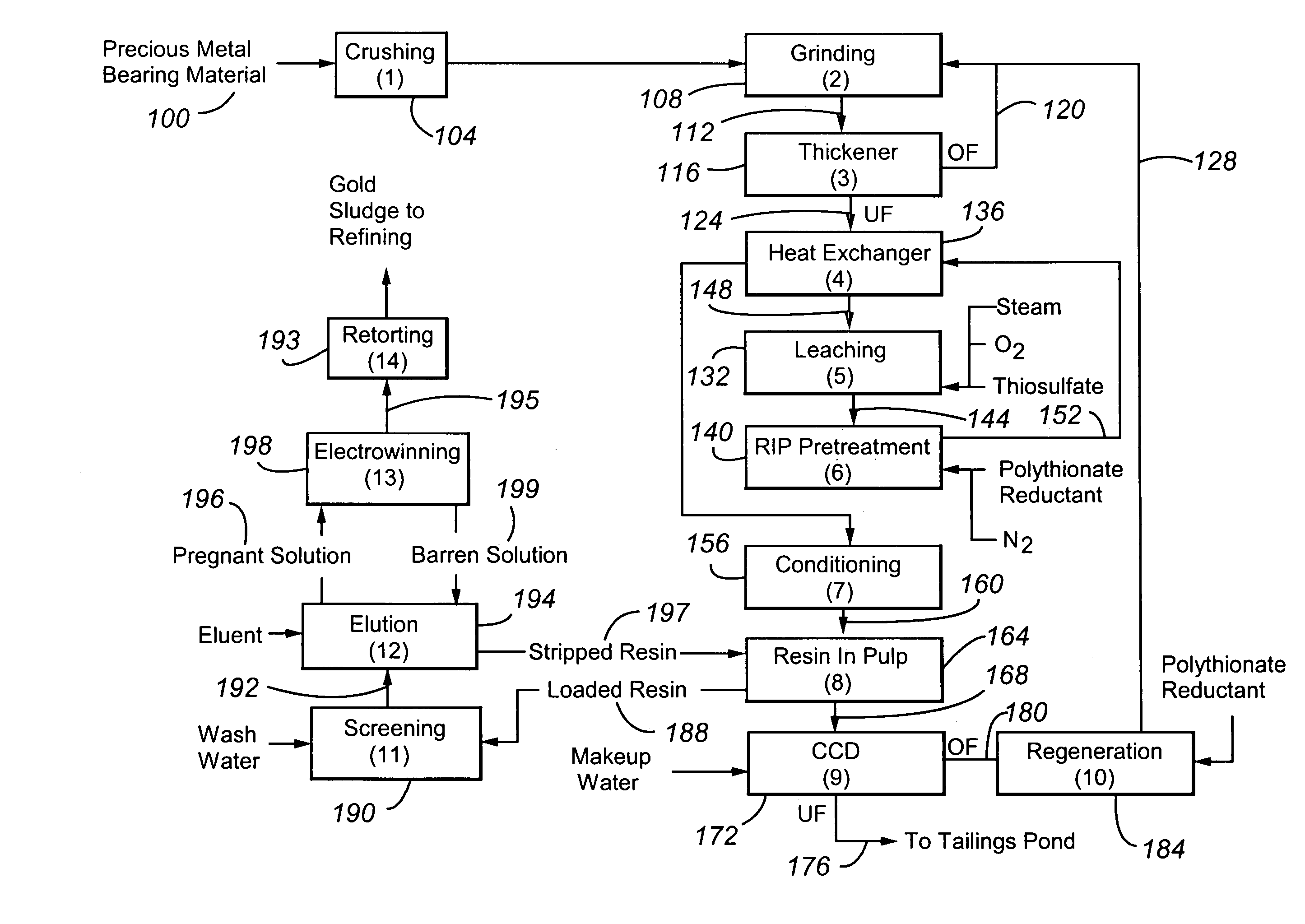

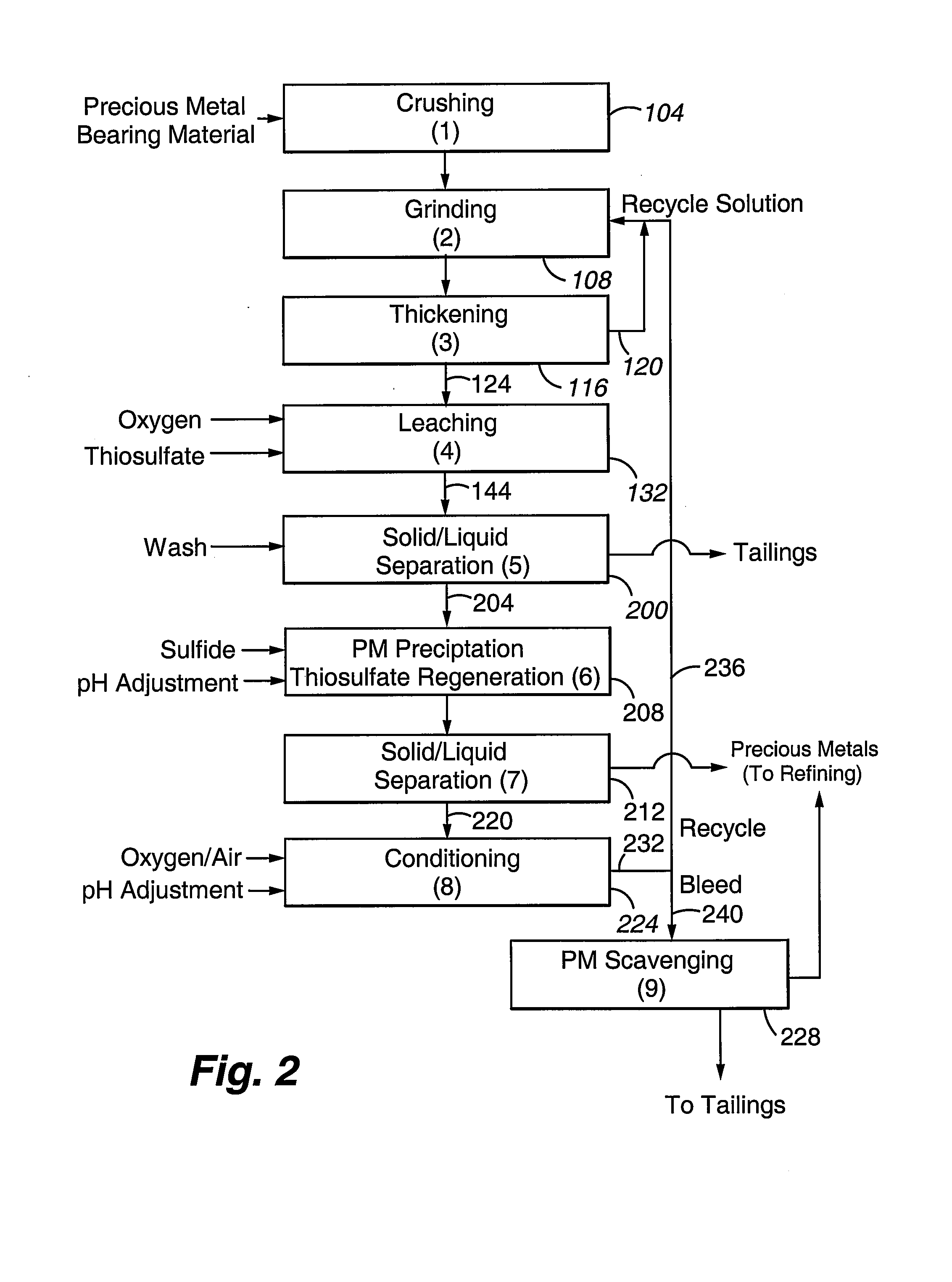

Method for thiosulfate leaching of precious metal-containing materials

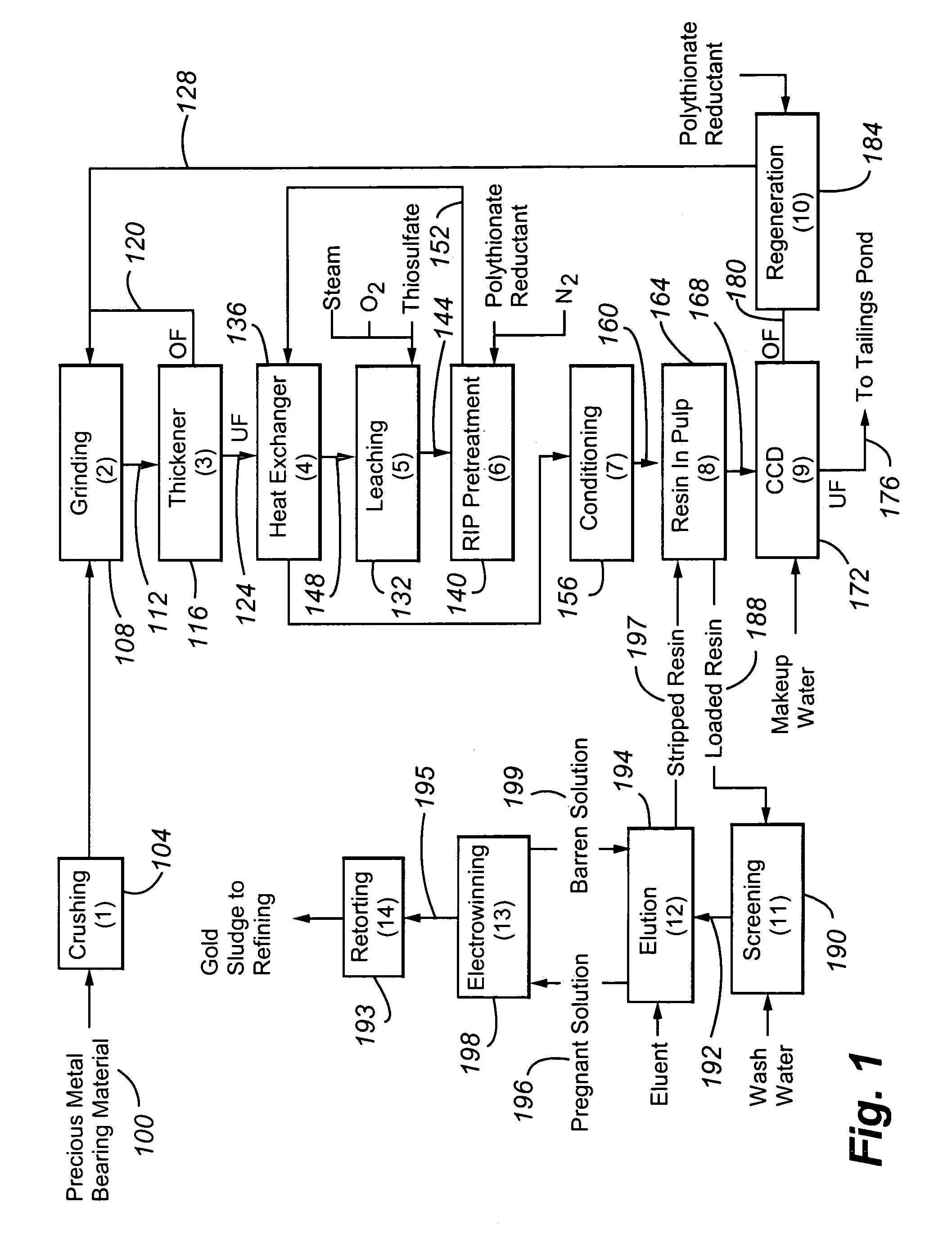

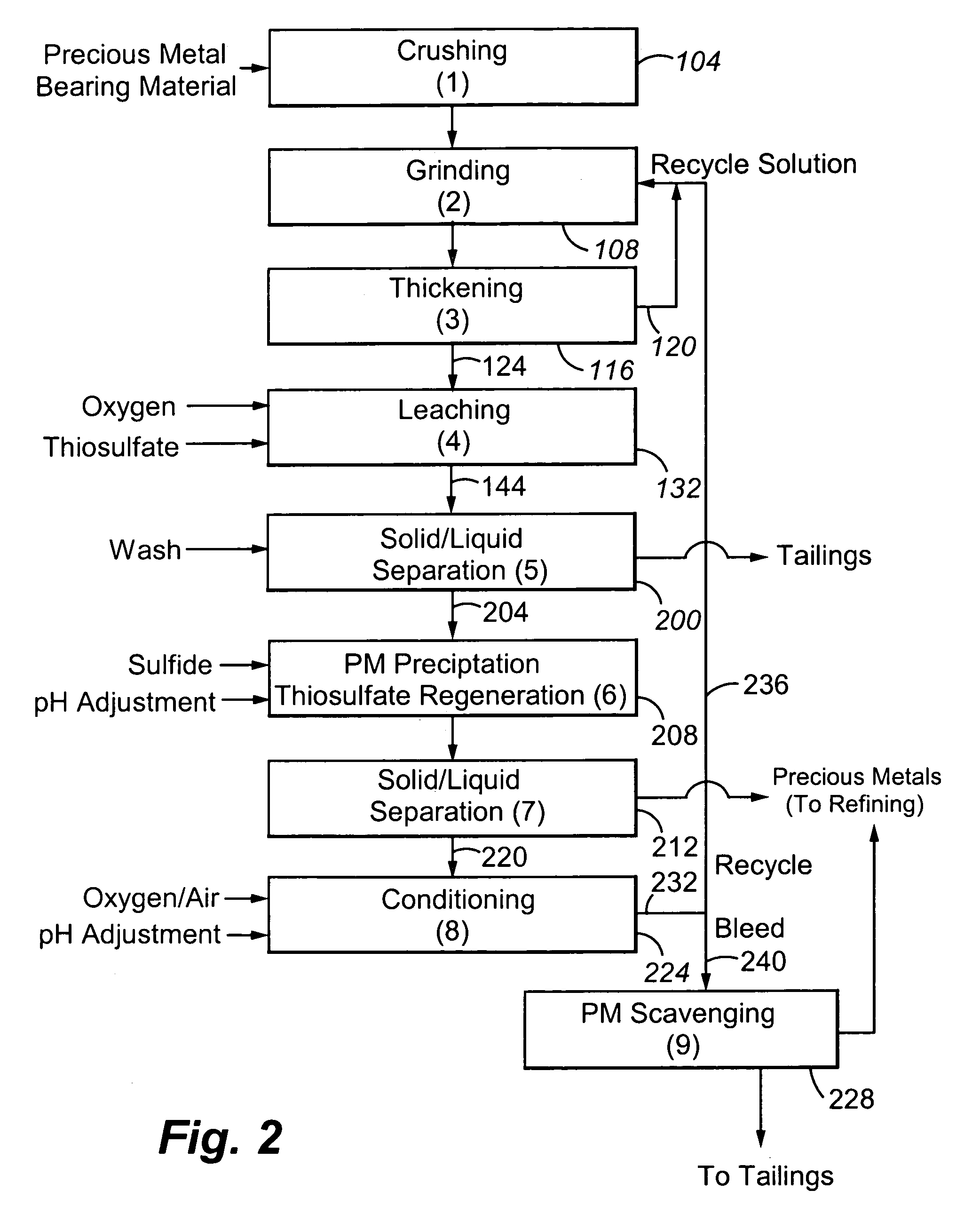

InactiveUS7066983B2Improve precious metal loading capacityQuantity minimizationSolvent extractionGold compoundsLixiviantThio-

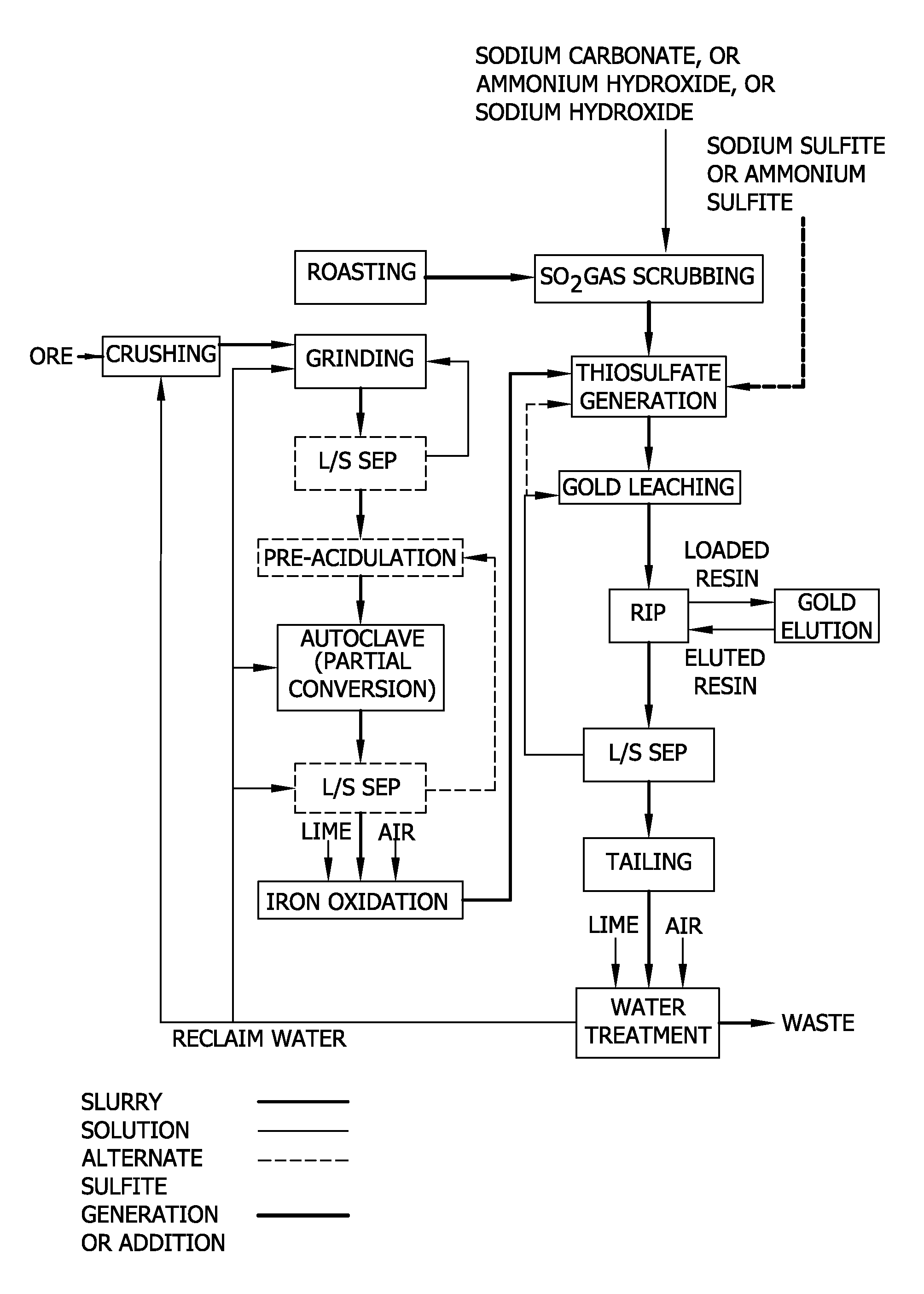

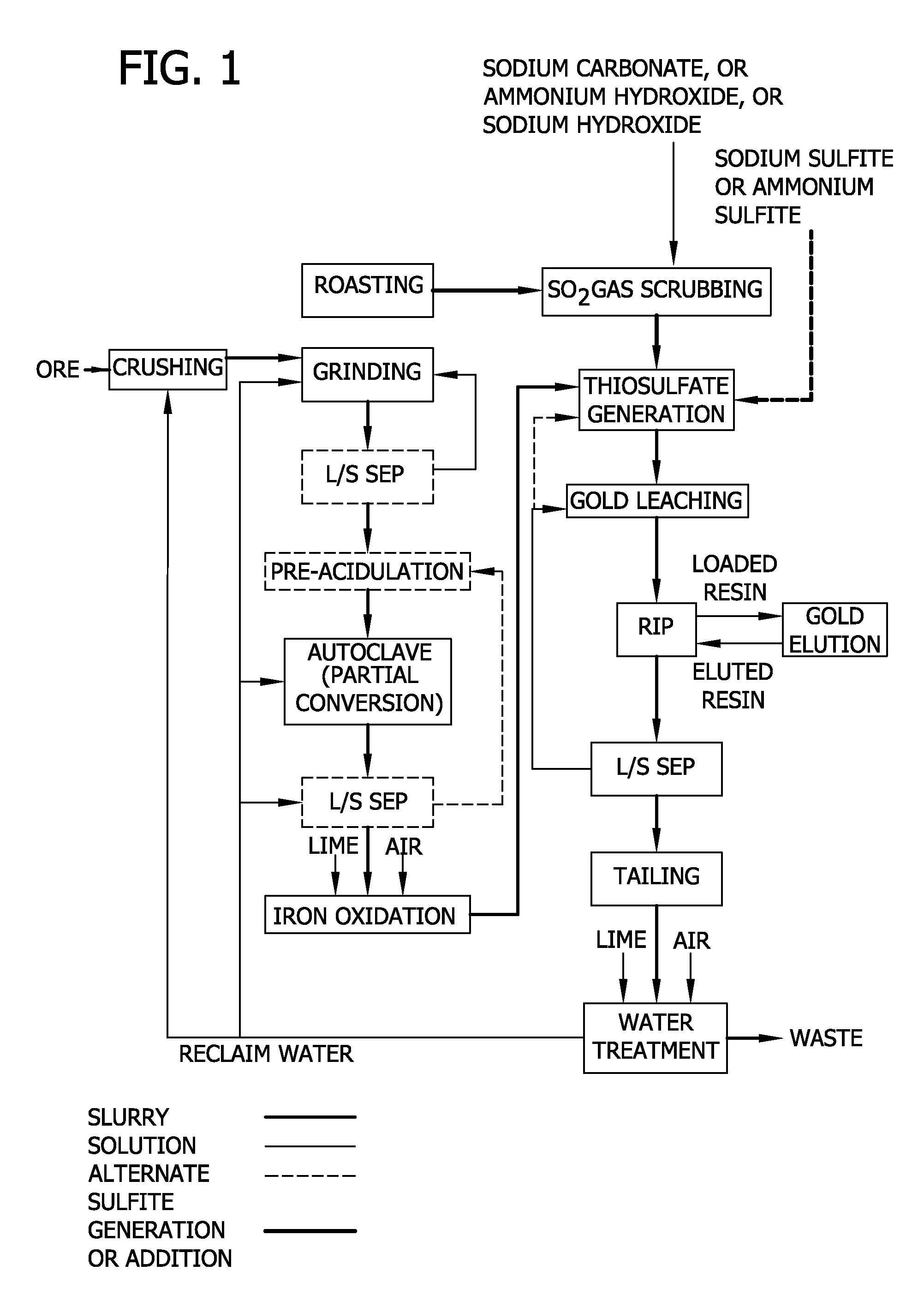

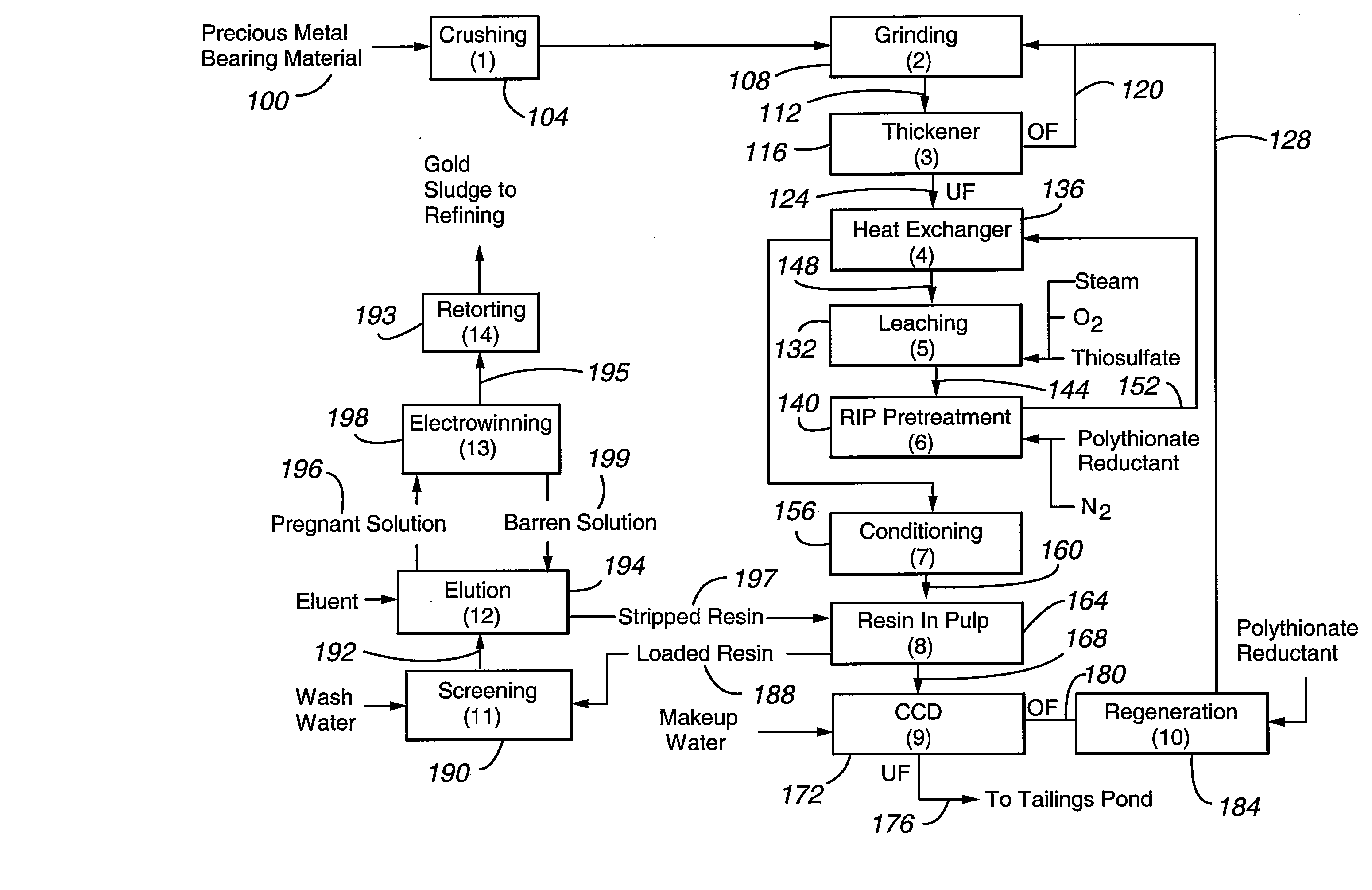

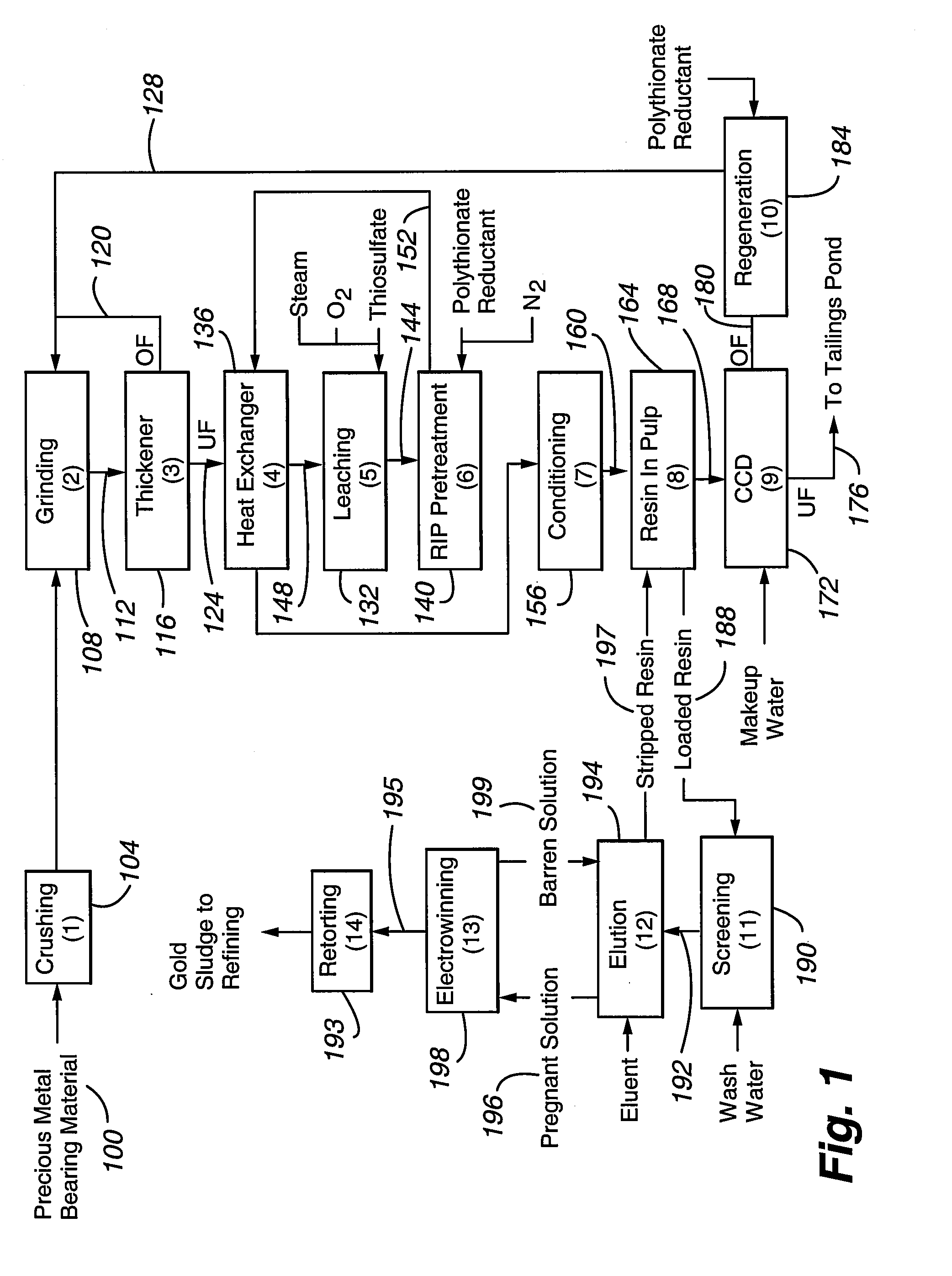

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ lixiviants that include at most only small amounts of copper and / or ammonia and operate at a relatively low pH, reduction of polythionates, inert atmospheres to control polythionate production, and electrolytic solutions which provide relatively high rates of precious metal recovery.

Owner:PLACER DOME TECHN SERVICES

Method for thiosulfate leaching of precious metal-containing materials

InactiveUS7544232B2Avoid the needLow costCopper sulfidesProcess efficiency improvementLixiviantRefractory

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ heap leaching or lixiviants that include one or more blinding agents.

Owner:PLACER DOME TECHN SERVICES

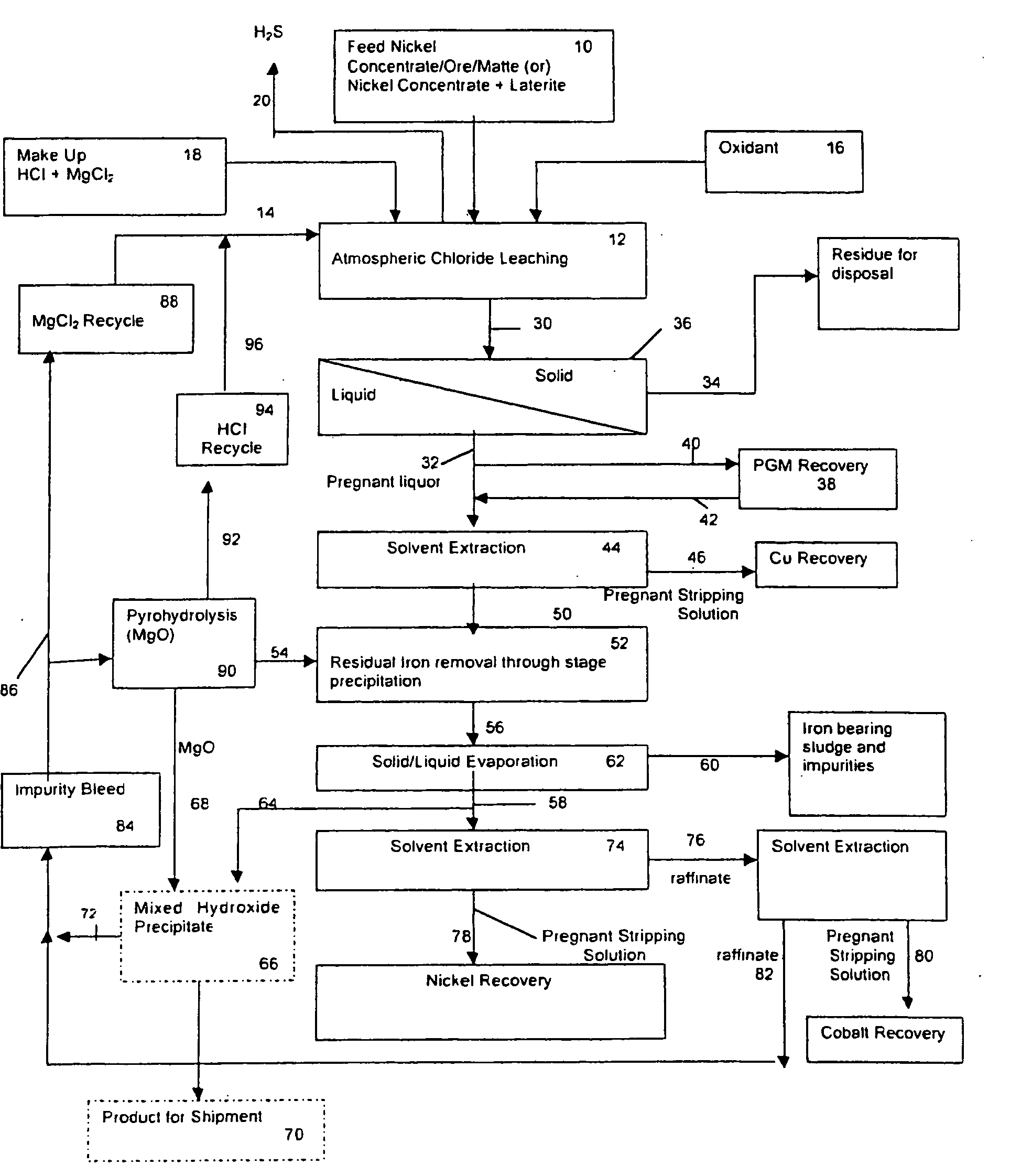

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20090013829A1Simple gas/liquidReduce the amount requiredSolid sorbent liquid separationGold compoundsLixiviantSulfide

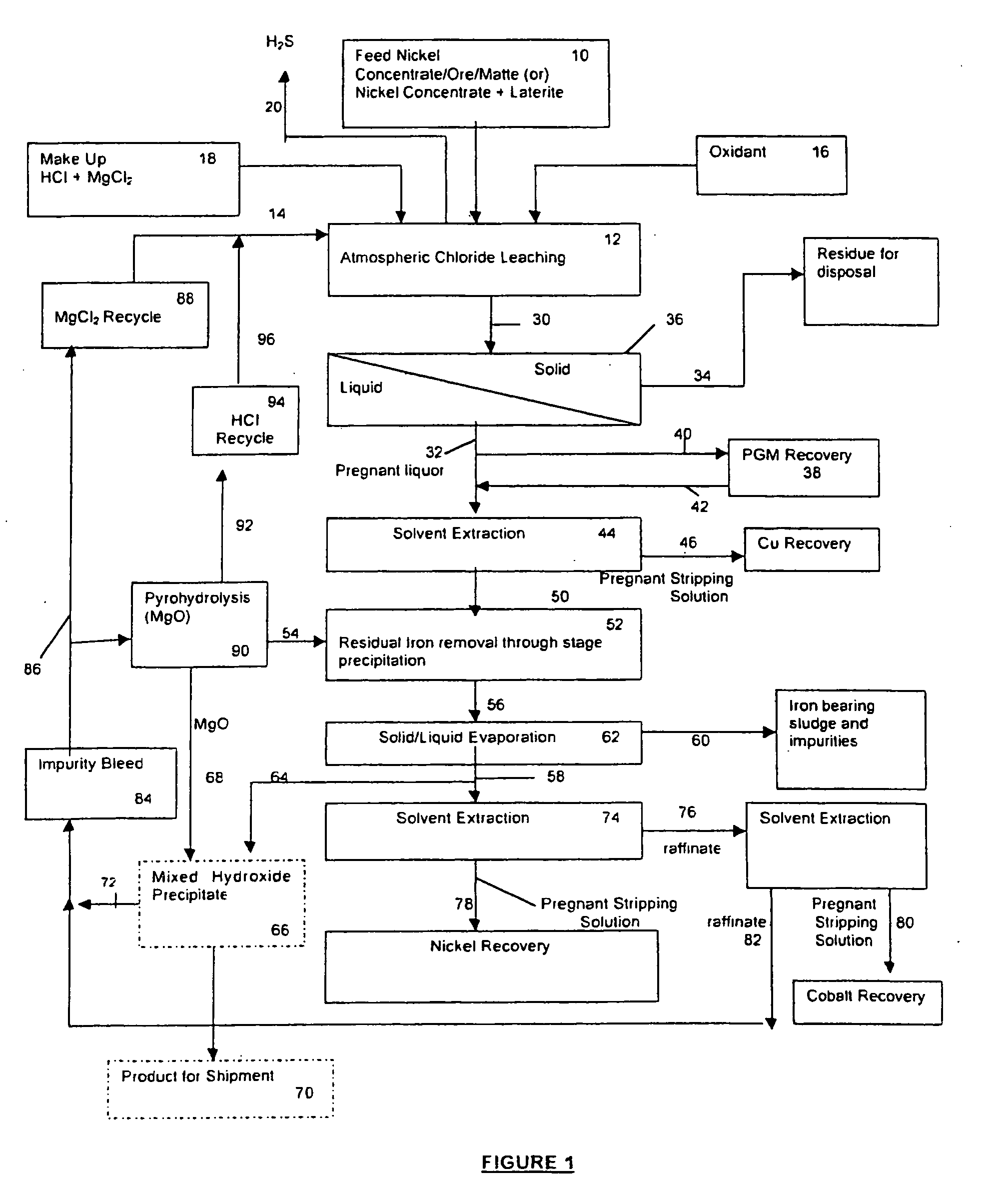

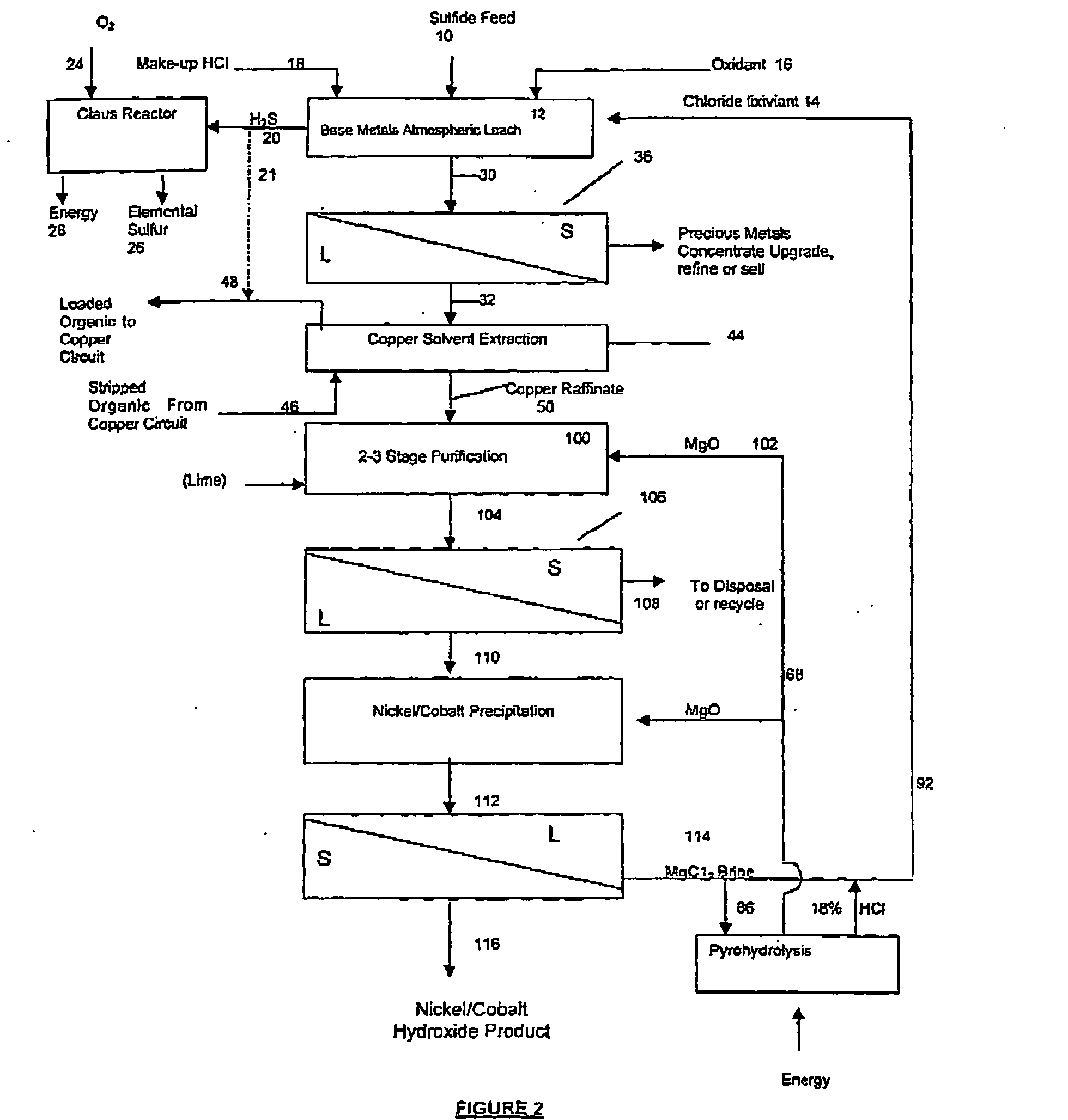

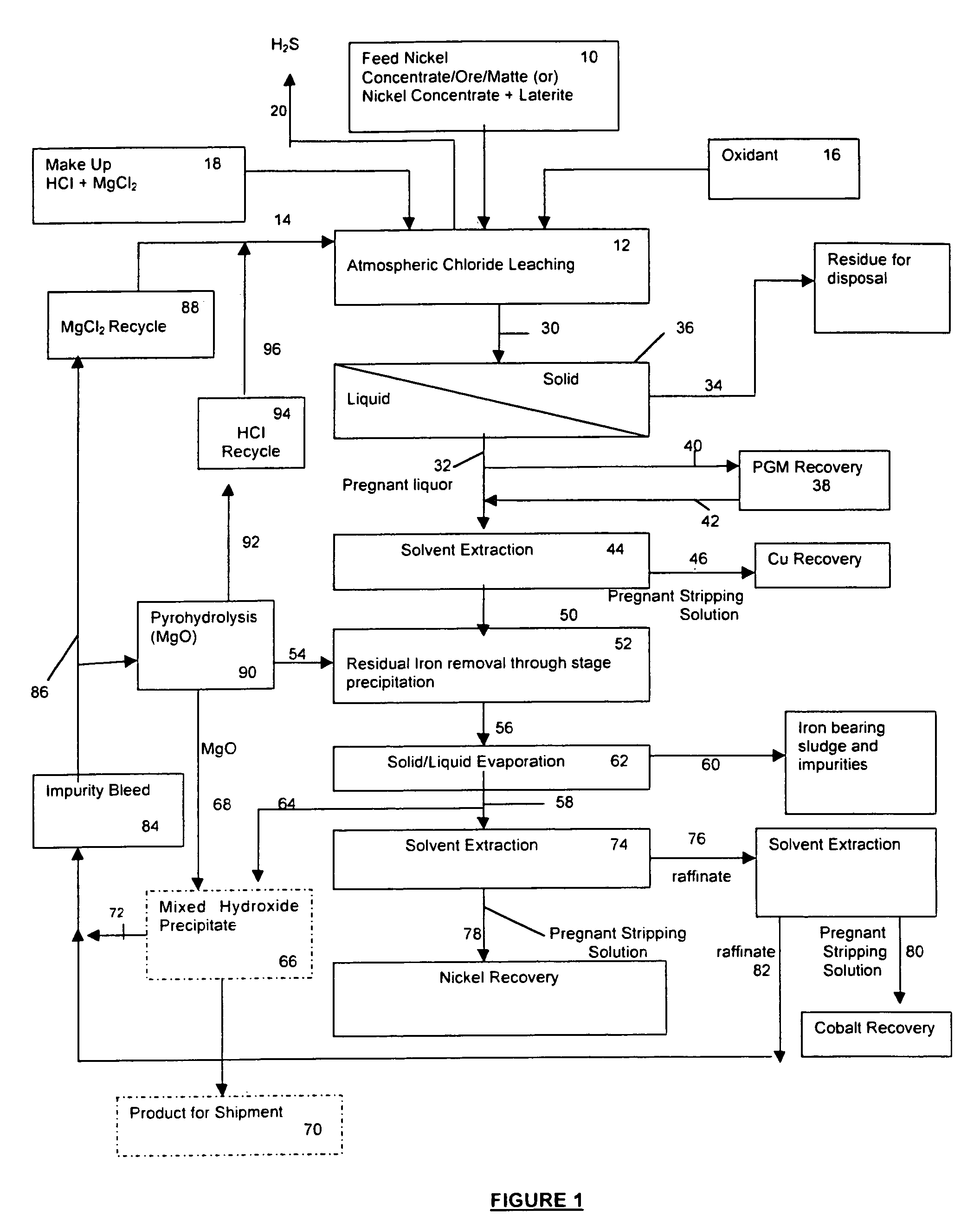

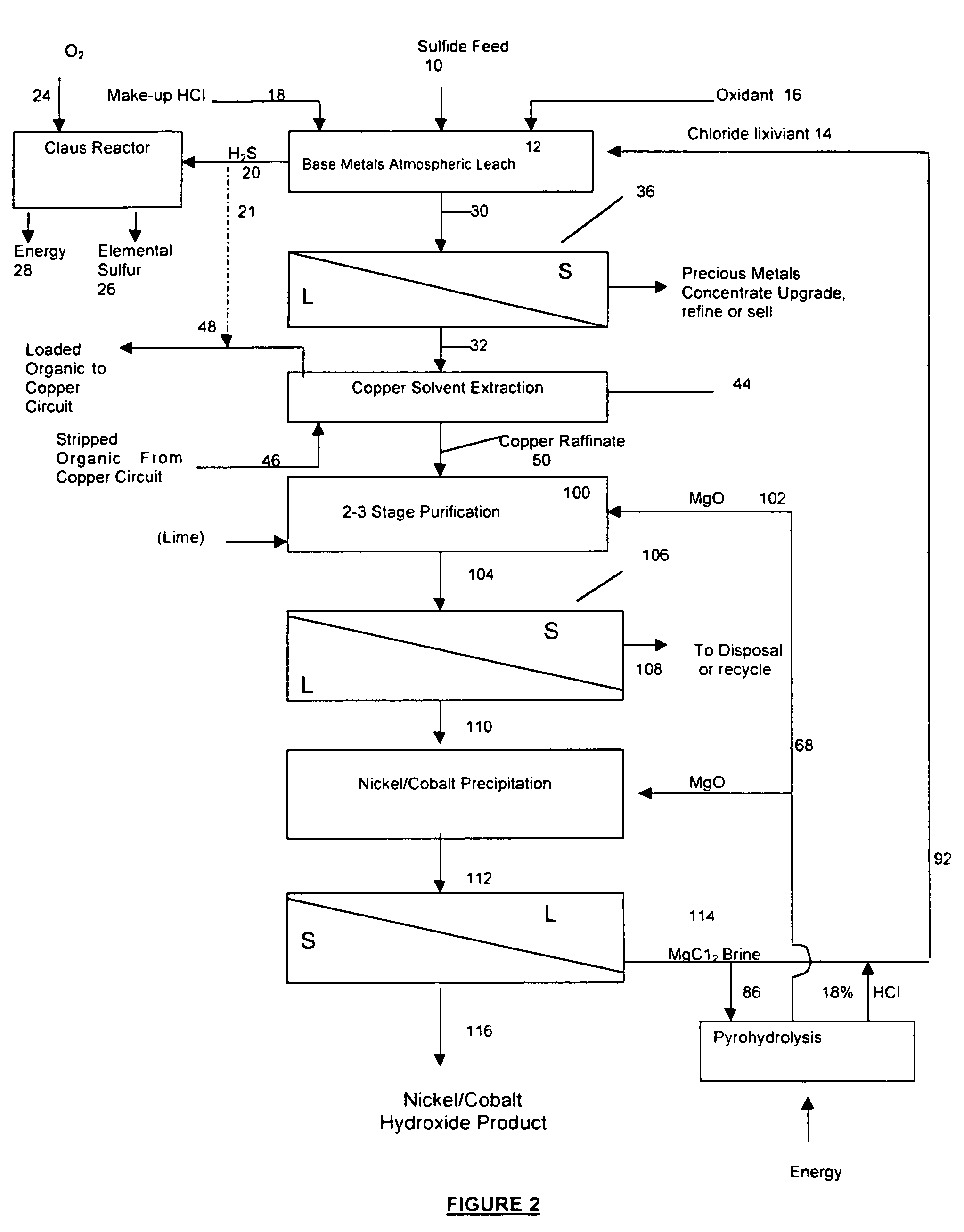

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated

Owner:JAGUAR NICKEL INC

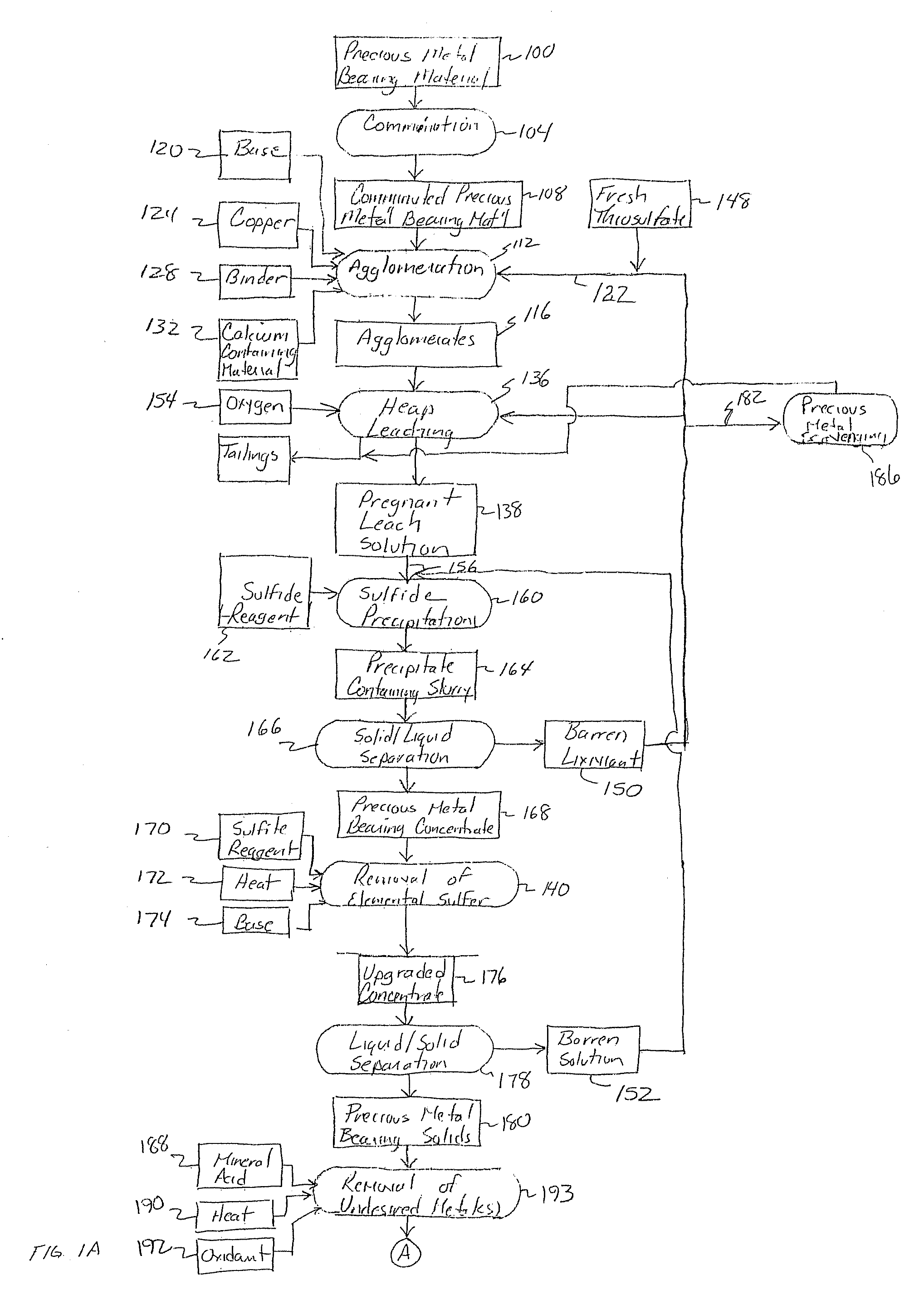

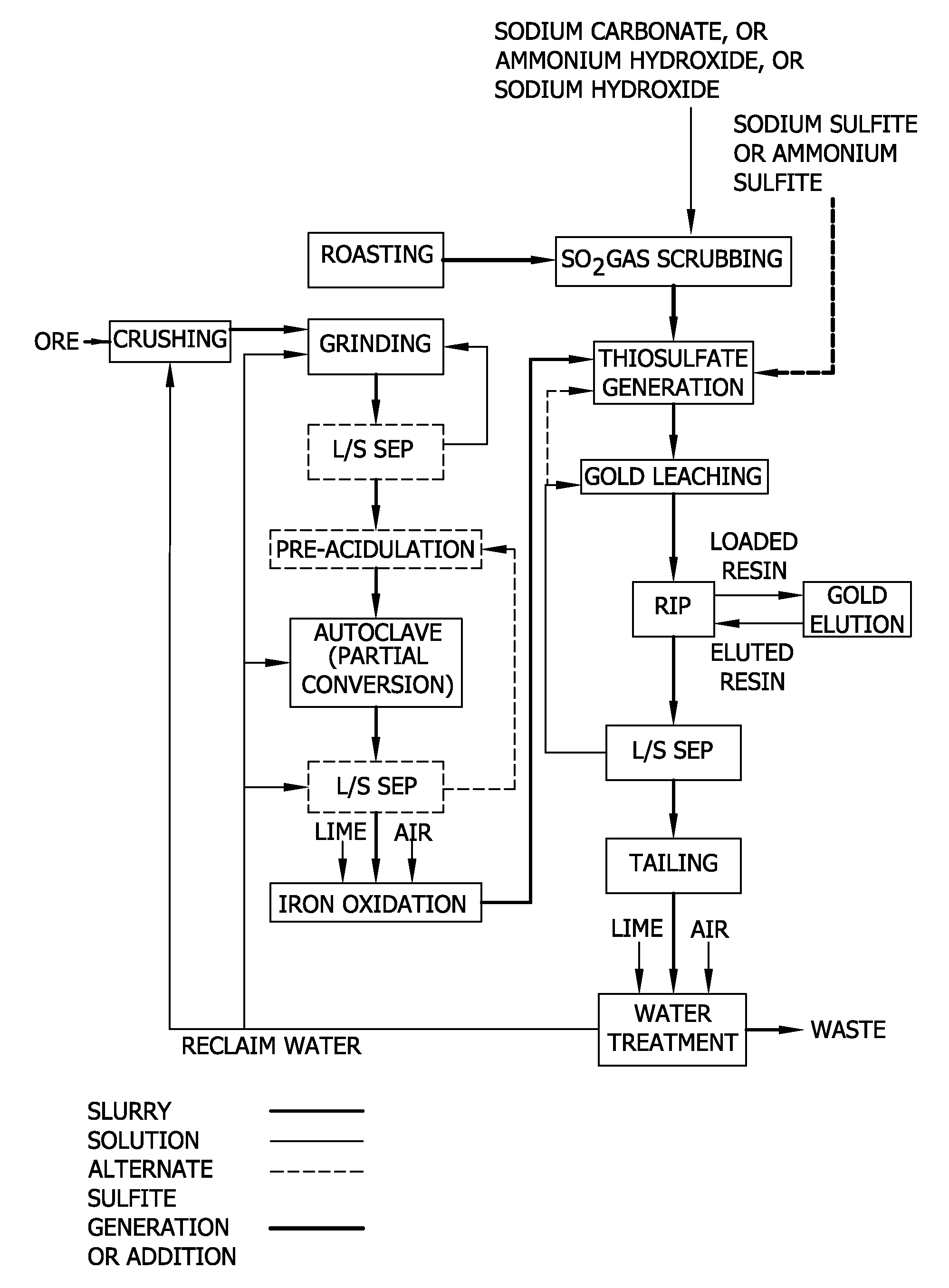

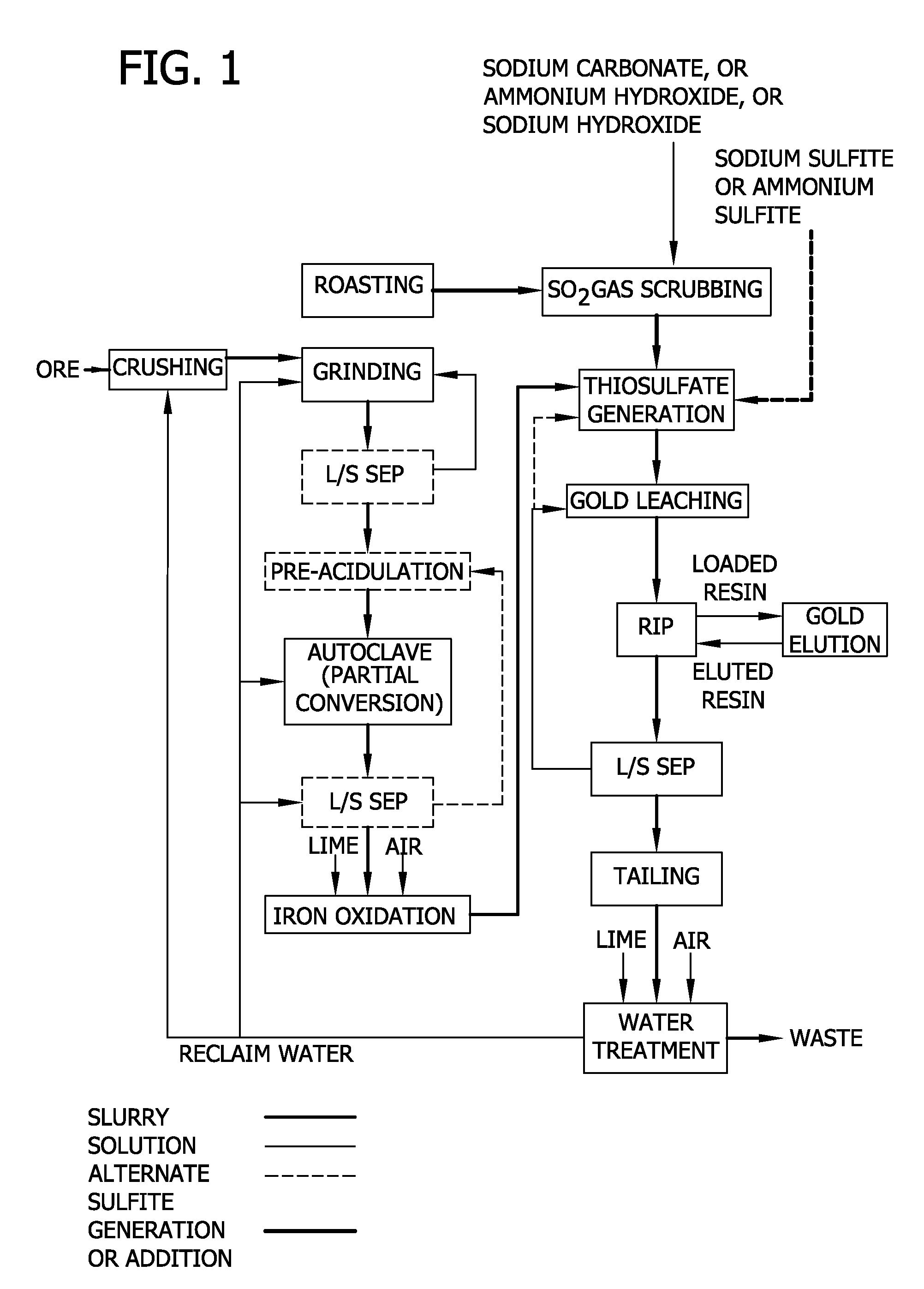

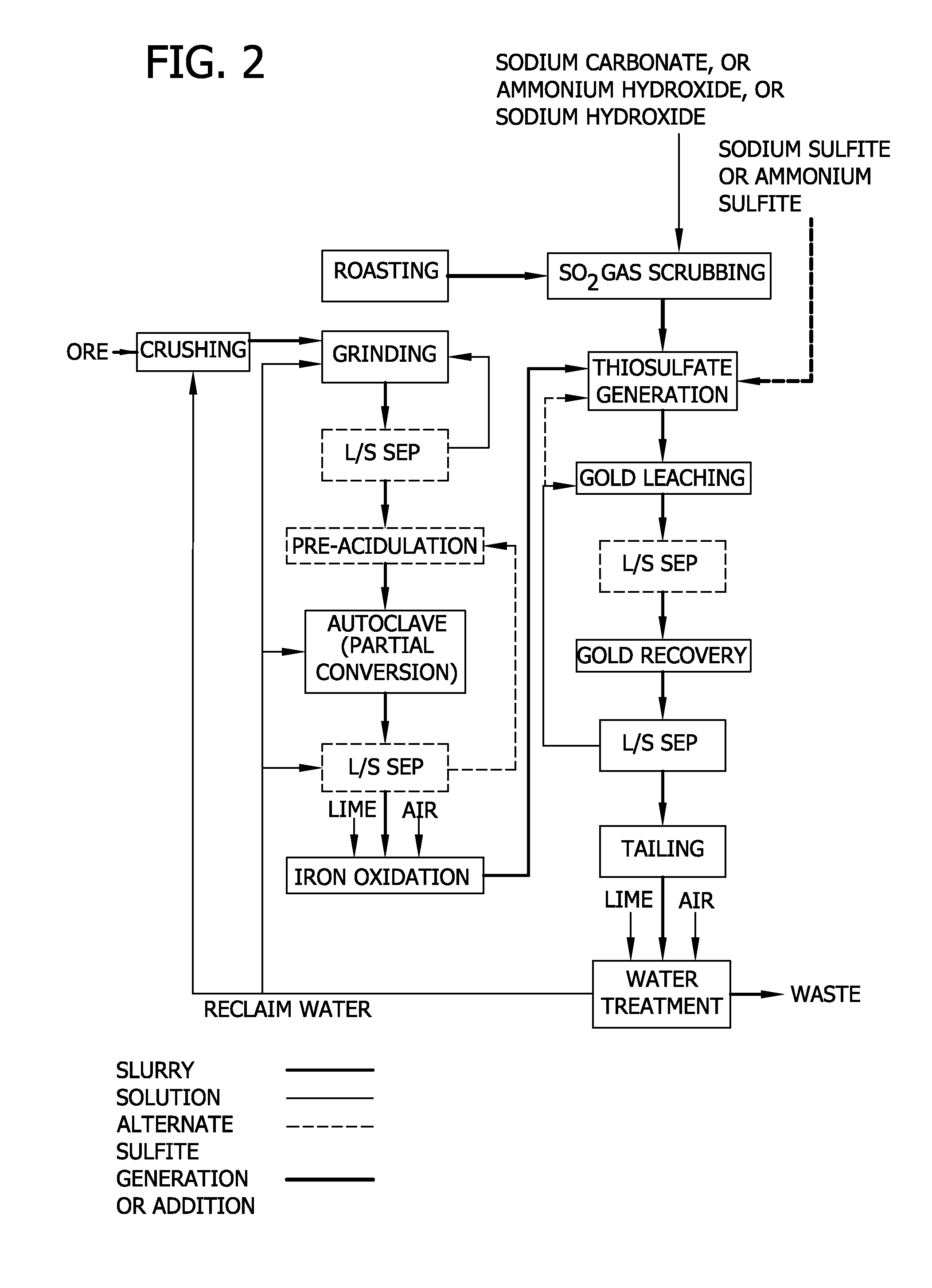

Thiosulfate generation in situ in precious metal recovery

Precious metal recovery by thiosulfate leaching where thiosulfate lixiviant is generated in situ employing elemental sulfur generated from partial oxidation of sulfidic precious metal-bearing feed and / or employing reactants from processing effluent.

Owner:BARRICK GOLD

Process for the recovery of value metals from base metal sulfide ores

InactiveUS7736606B2Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationLixiviantSulfide

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

Method for thiosulfate leaching of precious metal-containing materials

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ lixiviants that include at most only small amounts of copper and / or ammonia and operate at a relatively low pH, reduction of polythionates, inert atmospheres to control polythionate production, and electrolytic solutions which provide relatively high rates of precious metal recovery.

Owner:PLACER DOME TECHN SERVICES

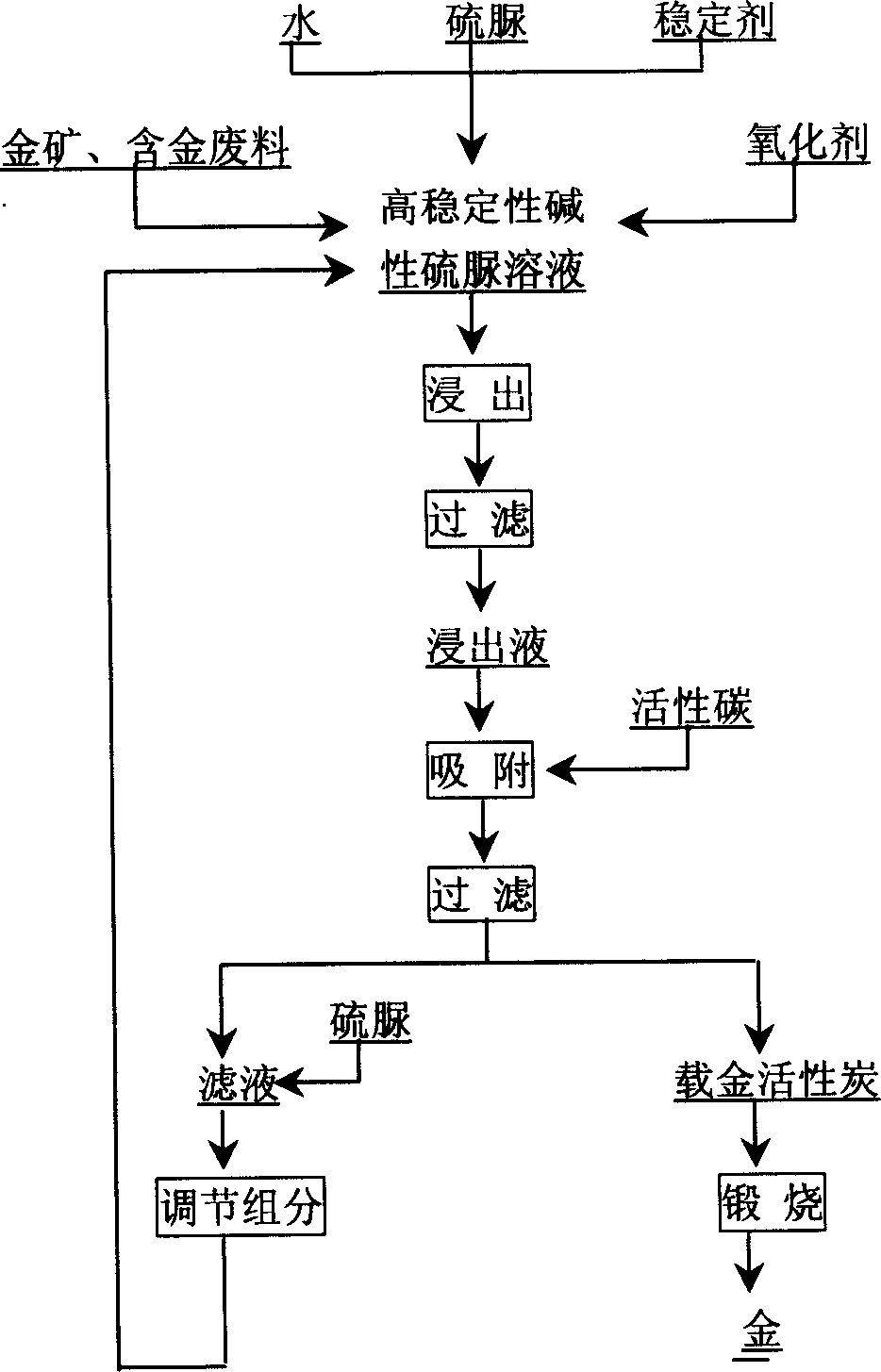

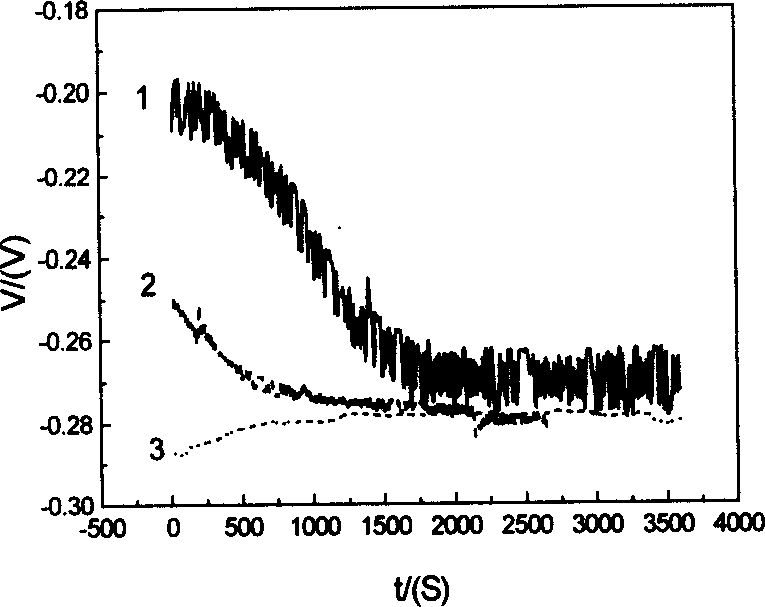

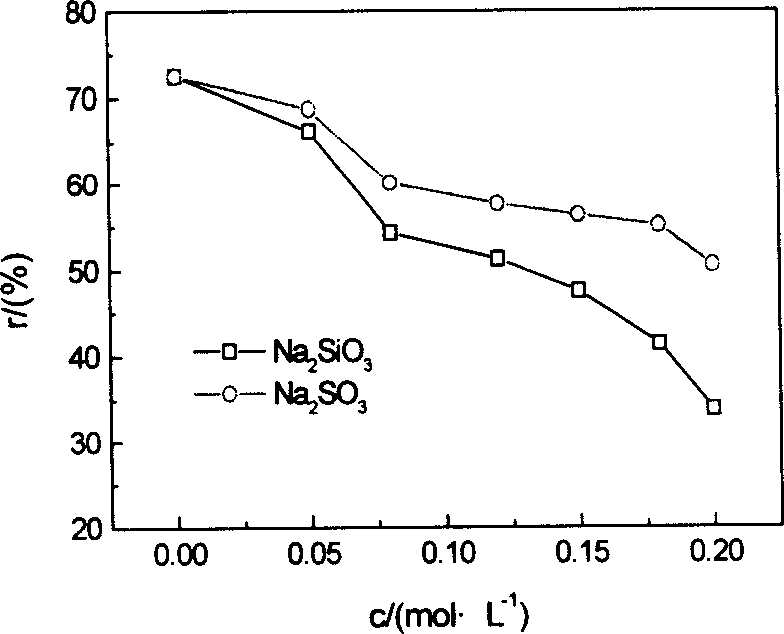

Stable alkali thiourea system and its selective immersion gold method

This invention is stable alkaline thiourea system and its selective dunking gold method. the materials are gold mine of low sulfur content, calcine or gold contain abatement. Cyanogens lixiviant is alkaline thiourea, stabilizer is sodium sulphite or sodium silicate, they constitute high stability alkaline thiourea system, and bland oxidizing agent is potassium ferricyanide with moderate electric potential during sunking process. Alkaline thiourea stability problem is solved radically, reagents used in this invention is nontoxic, gold dissolving is fast, the reaction only needs 3~4 hours, dunking gold rate is 80%. There is selectivity in gold dissolving, associated metal or basic metal as Fe, Co, Ni, Cu, Ag of waste gold matter is not easy corrode in alkaline condition. Gold recovery from dunking solution is convenient. There is almost no corruption to equipment comparing to acid solution, equipment design and run requirement is low.

Owner:CENT SOUTH UNIV

Process of leaching precious metals

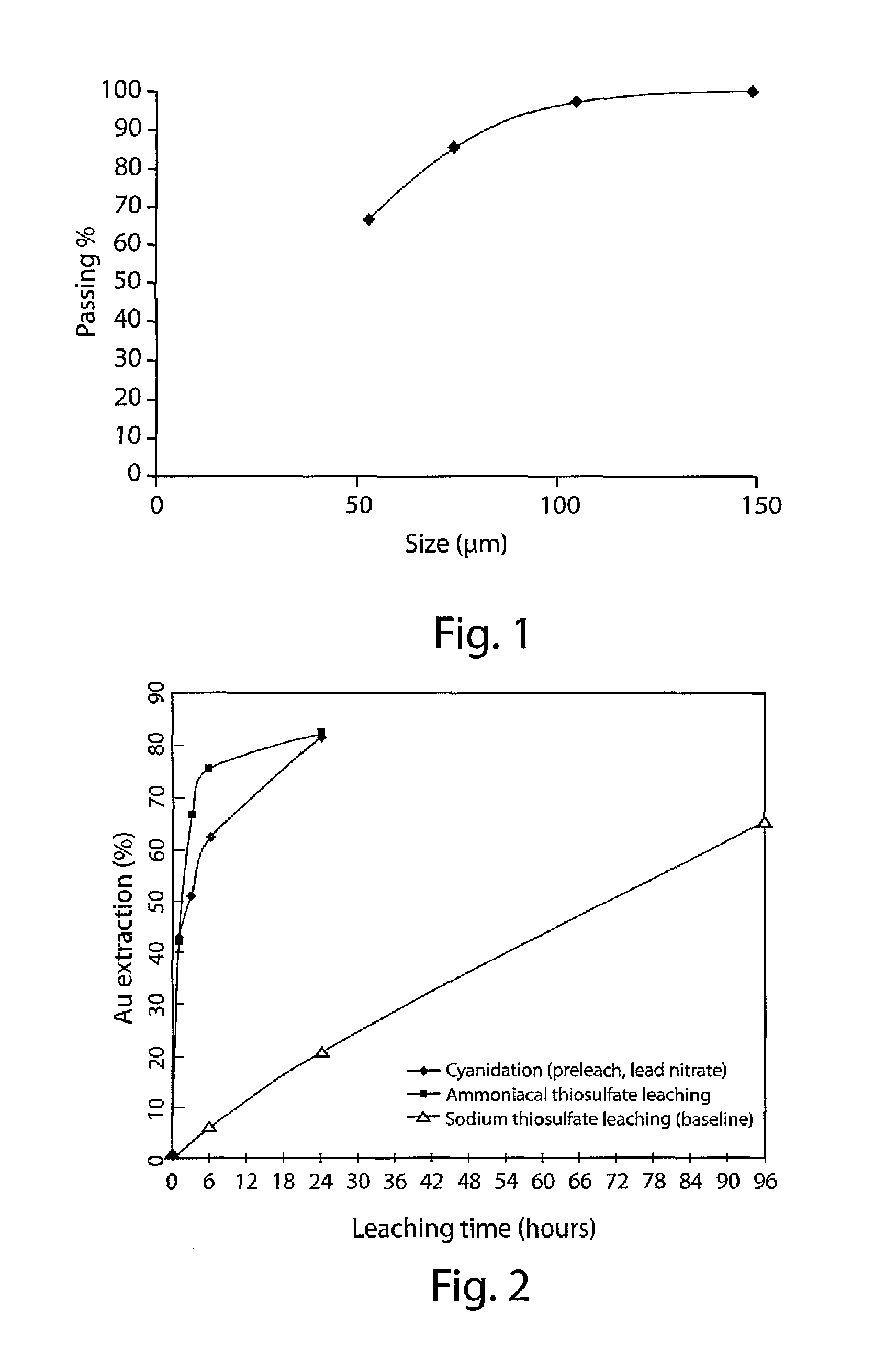

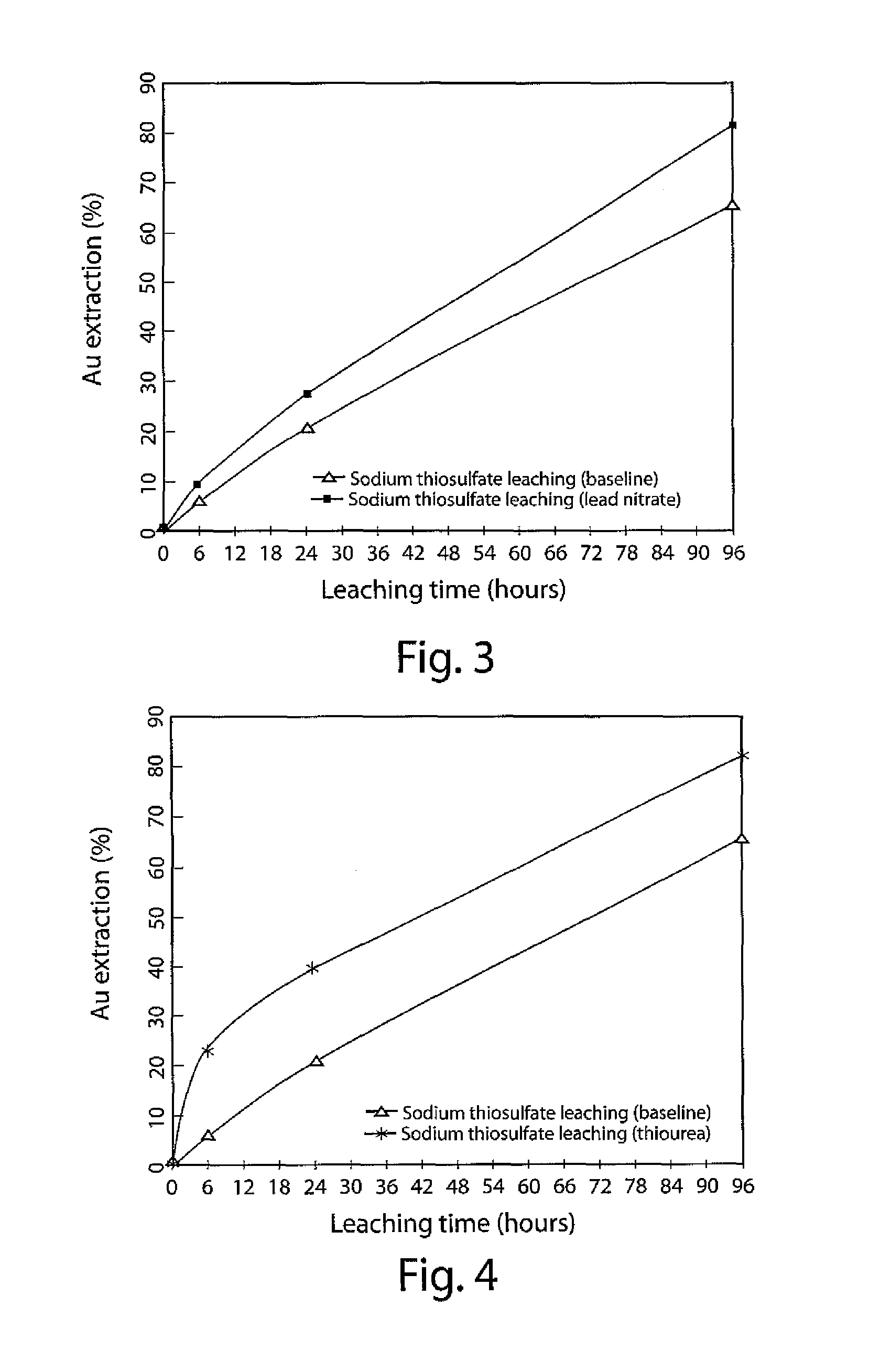

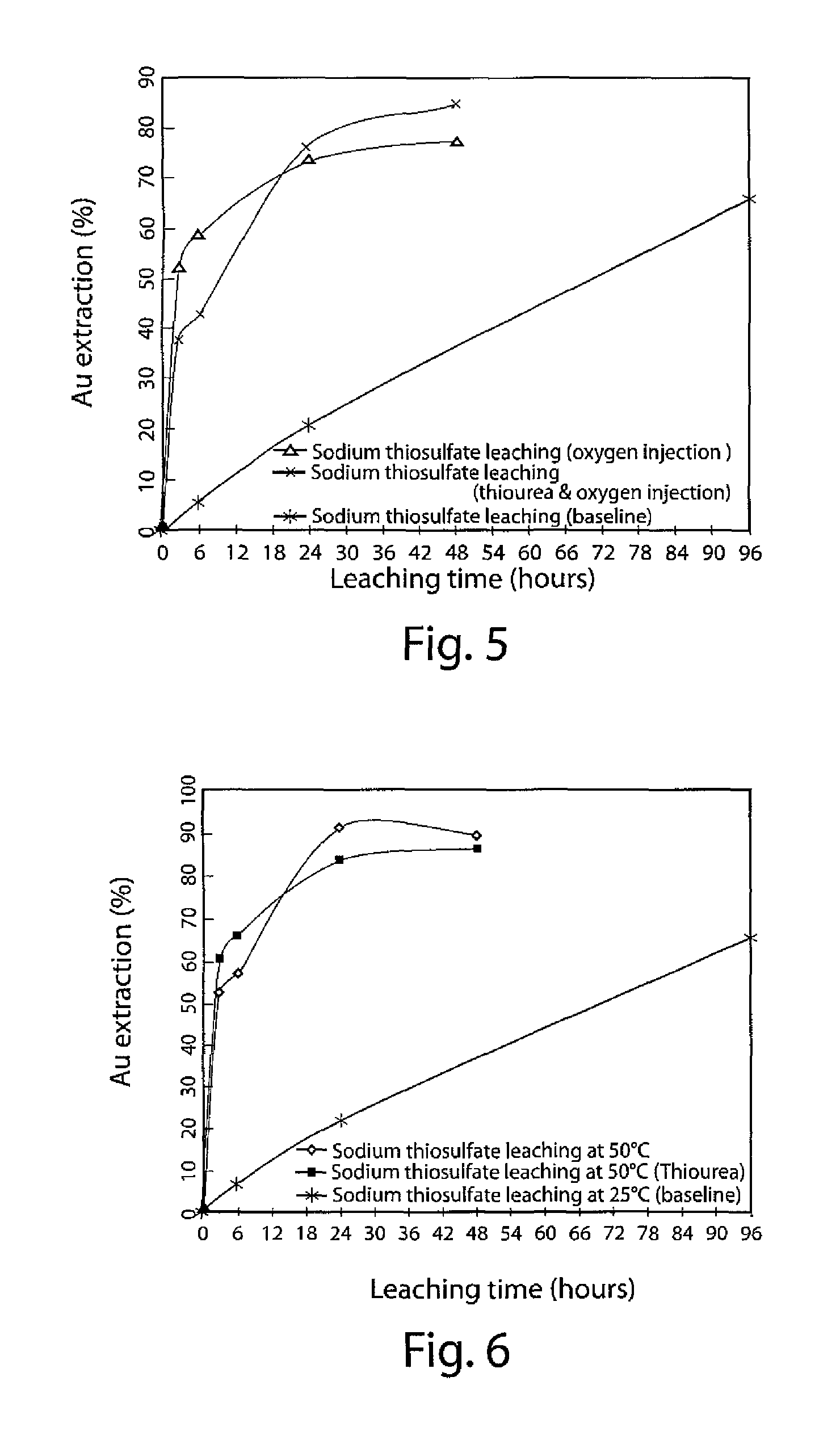

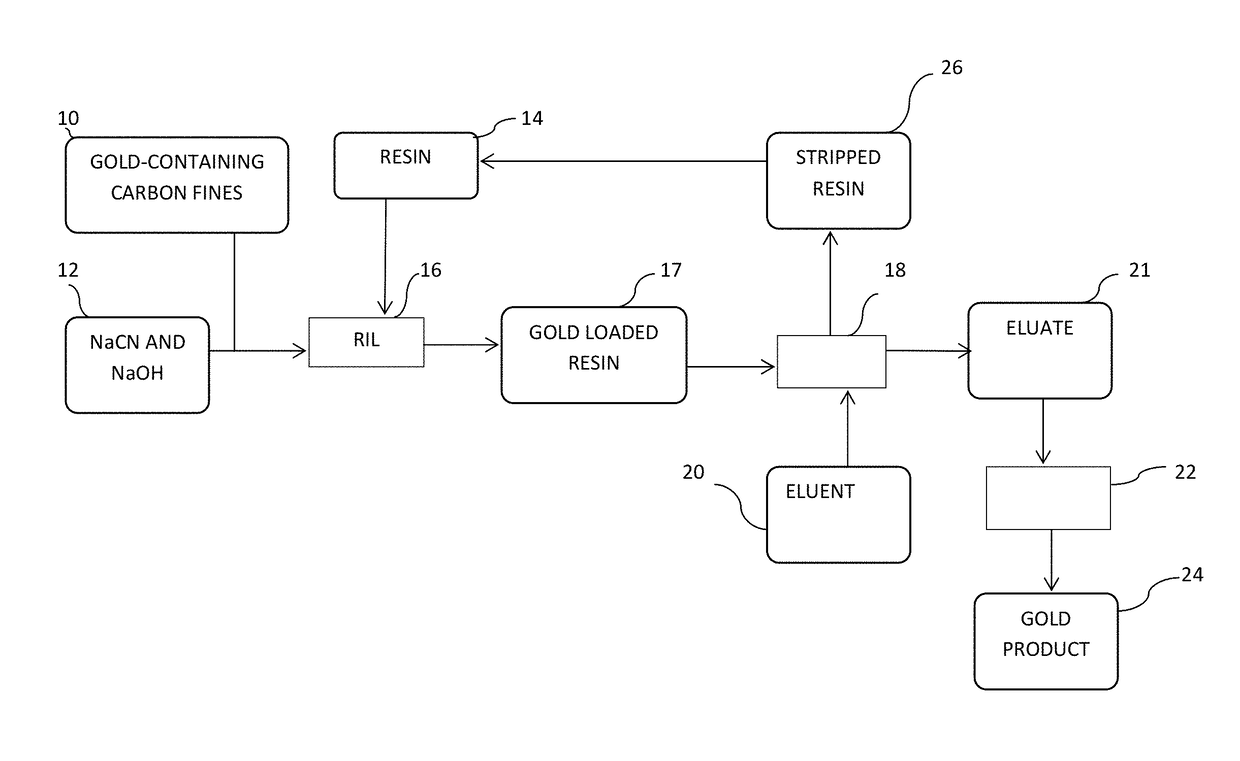

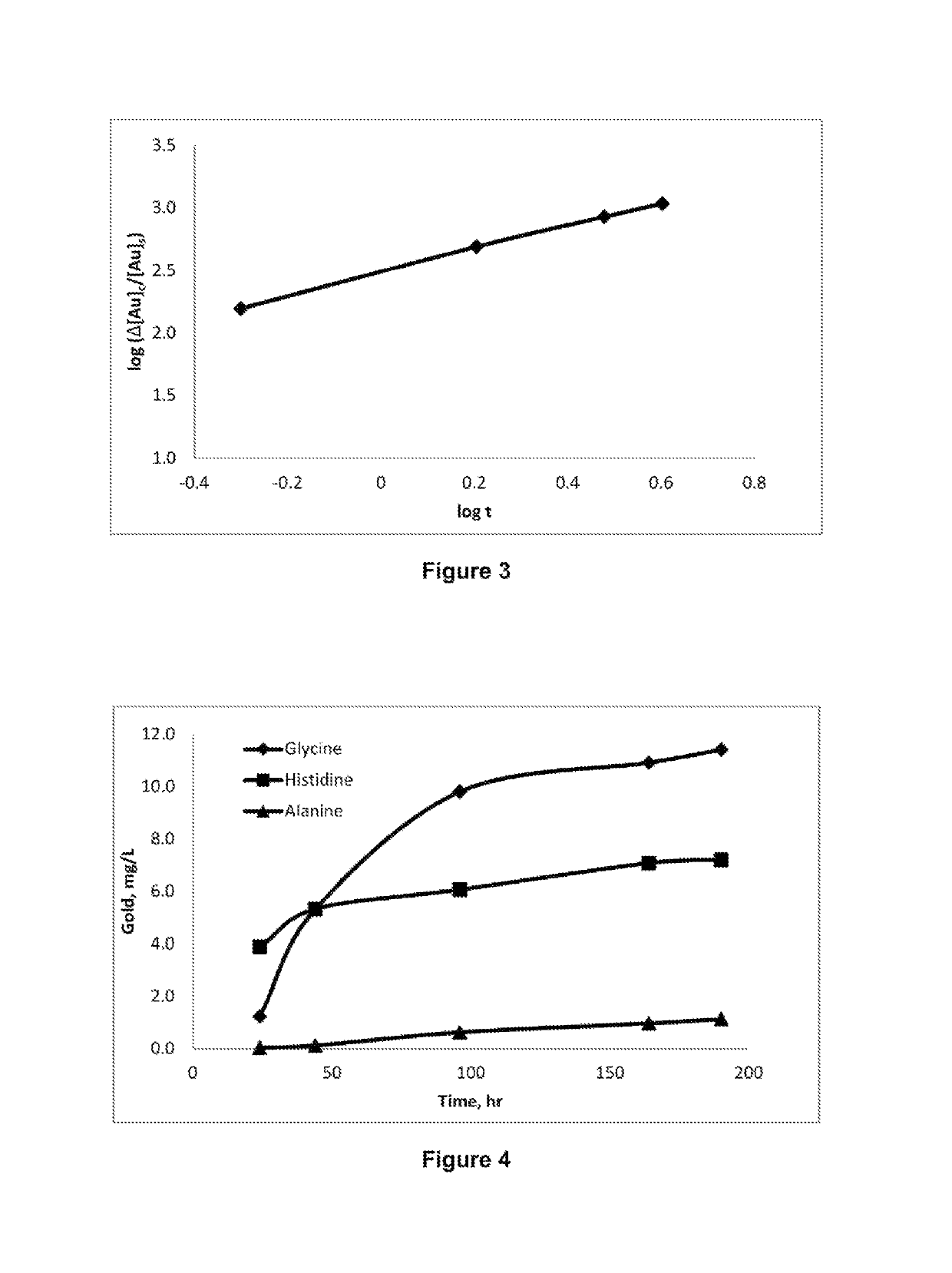

ActiveUS20140212346A1Increase concentrationReduce usageProcess efficiency improvementLixiviantLead nitrate

The invention relates to modifications of a non-ammoniacal thiosulfate process of leaching precious metals (e.g. gold or silver) from precious metal-containing ores. The process involves leaching the ore with an aqueous lixiviant containing a soluble thiosulfate other than ammonium thiosulfate, a copper compound and an organic compound that serves as a copper ligand (i.e. a ligand-forming compound). Four modifications of this process are effective for increasing the amount of precious metal that can be extracted, reducing the consumption of materials, or for improving the rate of extraction. These four process, which may be used singly or in any combination, include (a) additions of soluble lead (e.g. as lead nitrate), (b) additions of thiourea, (c) increases in dissolved oxygen, and (d) increases of temperature at ambient pressure. This avoids the use environmentally harmful chemicals and allows for extraction from a variety of ores, e.g., containing substantial amounts of sulfides and / or quartz.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

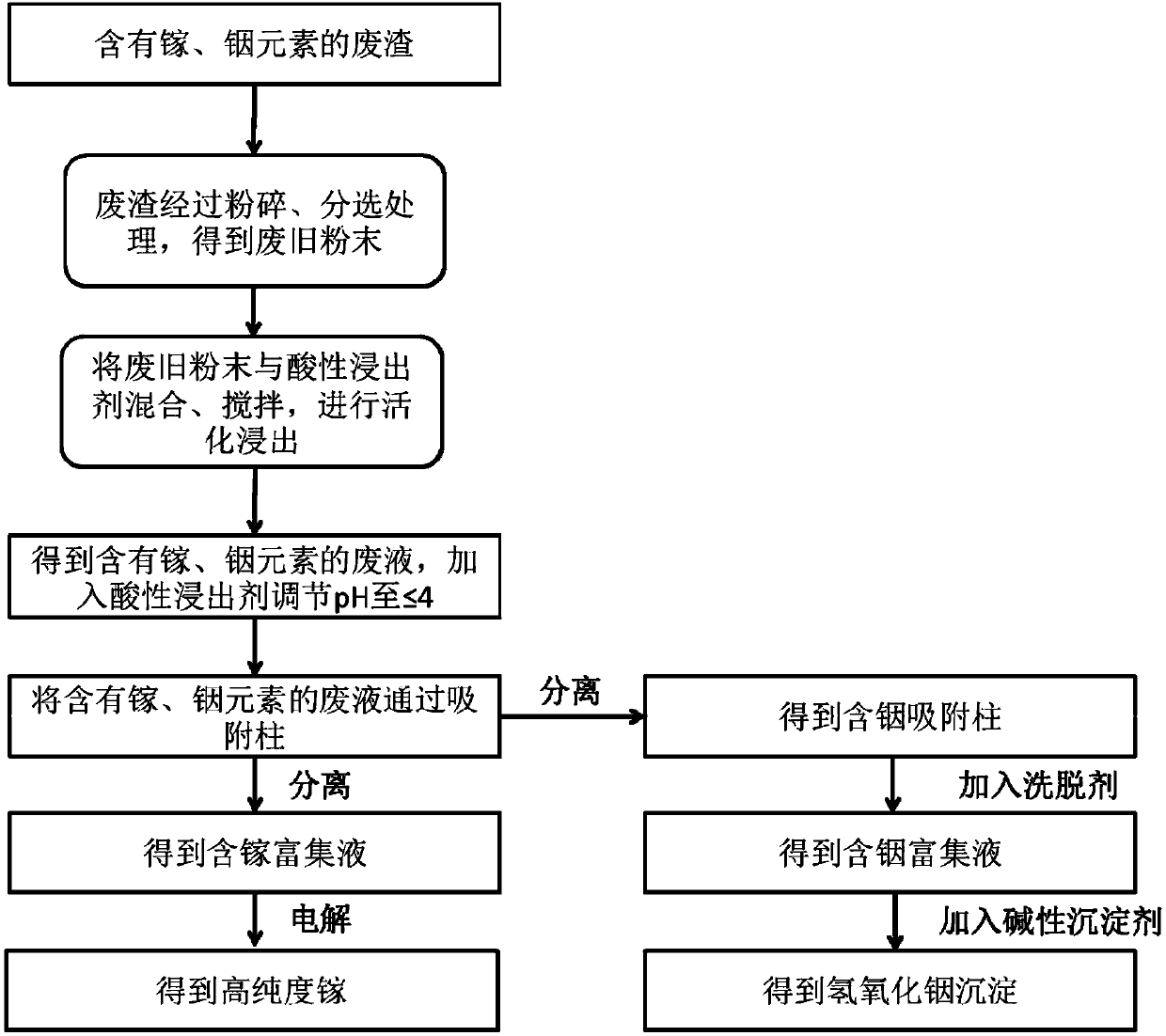

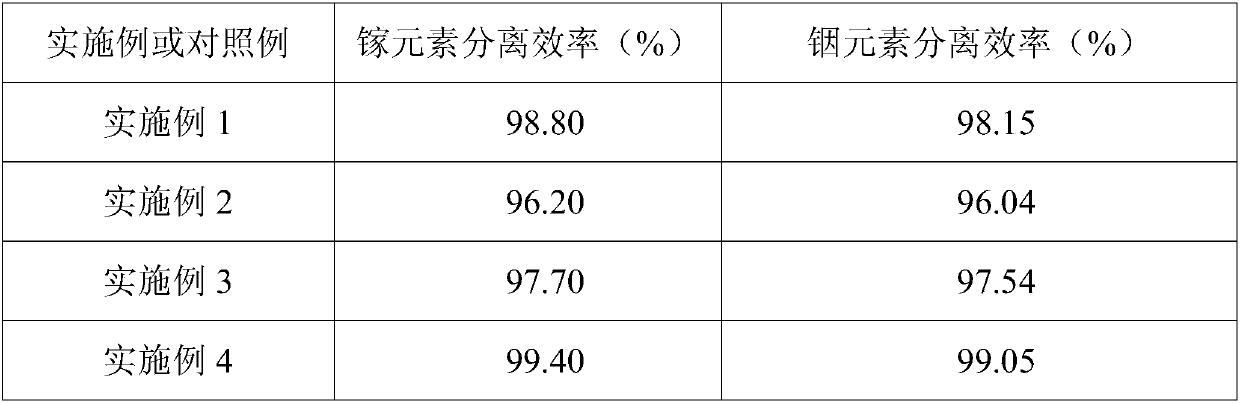

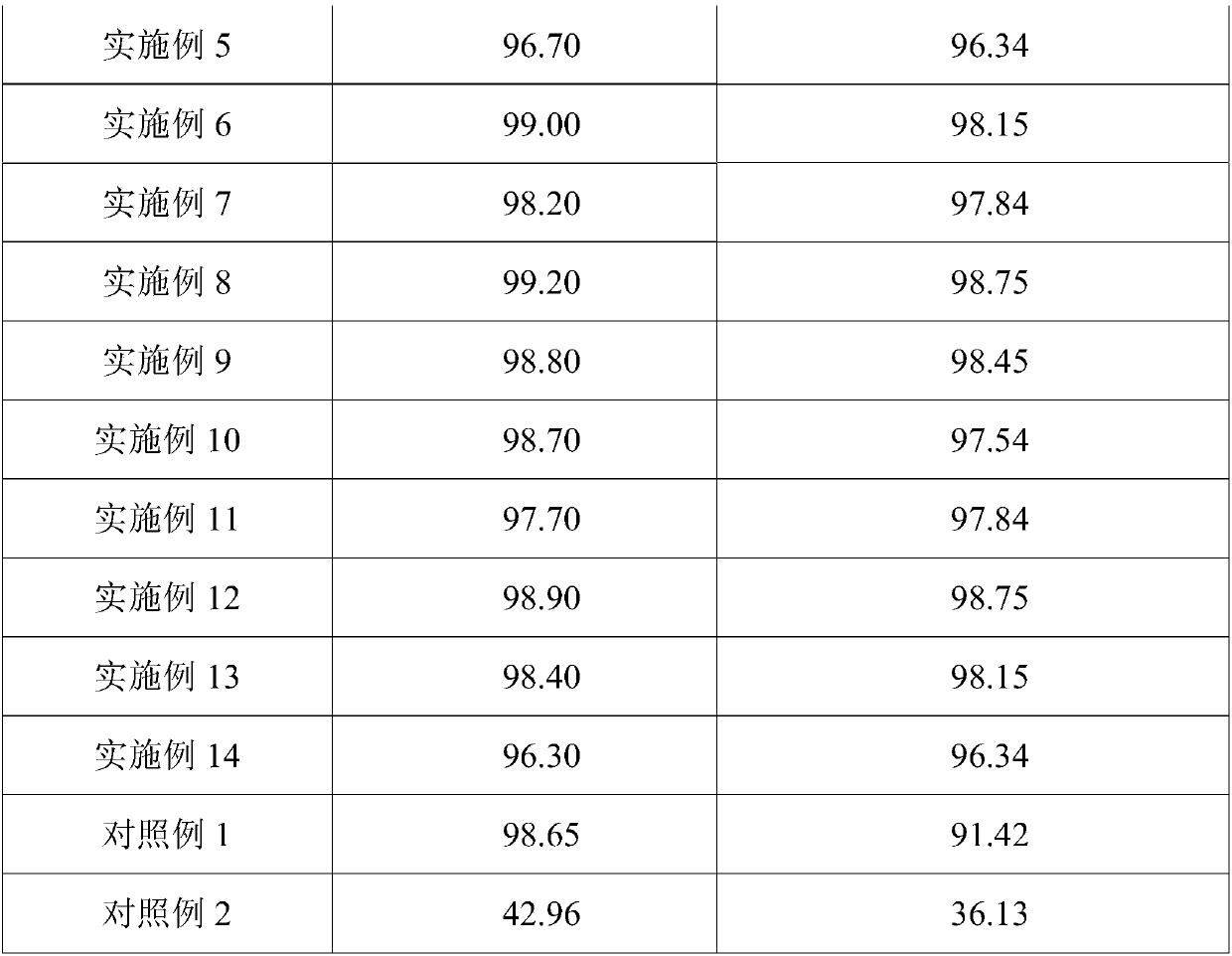

Method for recovering gallium and indium elements from waste residue containing gallium and indium elements

InactiveCN109897960AIncrease concentrationEfficient leachingPhotography auxillary processesProcess efficiency improvementIndium(III) hydroxideLixiviant

The invention relates to a method for recovering gallium and indium elements from waste residue containing the gallium and indium elements. The method includes the following steps that (1), the wasteresidue containing the gallium and indium elements and an acid lixiviant are mixed, activated leaching treatment is carried out, and waste liquor containing the gallium and indium elements is obtainedafter treatment; and (2) the acid lixiviant is added to the waste liquor containing the gallium and indium elements obtained in the step (1) to adjust the pH value to be less than or equal to 4, thenthe waste liquor containing the gallium and indium elements passes through an adsorption column, an indium-containing adsorption column and gallium-containing enrichment liquid are obtained, the indium-containing adsorption column is washed through an eluent to obtain indium-containing enrichment liquid, an alkaline precipitator is added into the indium-containing enrichment liquid to obtain indium hydroxide precipitates, and the gallium-containing enrichment liquid is electrolyzed to obtain elemental gallium. The method for recovering the gallium and indium elements from the waste residue containing the gallium and indium elements can adapt to a wider range of the pH change, the flow change and the temperature change, the separation efficiency and purity are high, and 96% or above of thegallium and indium elements can be separated from the waste residue.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

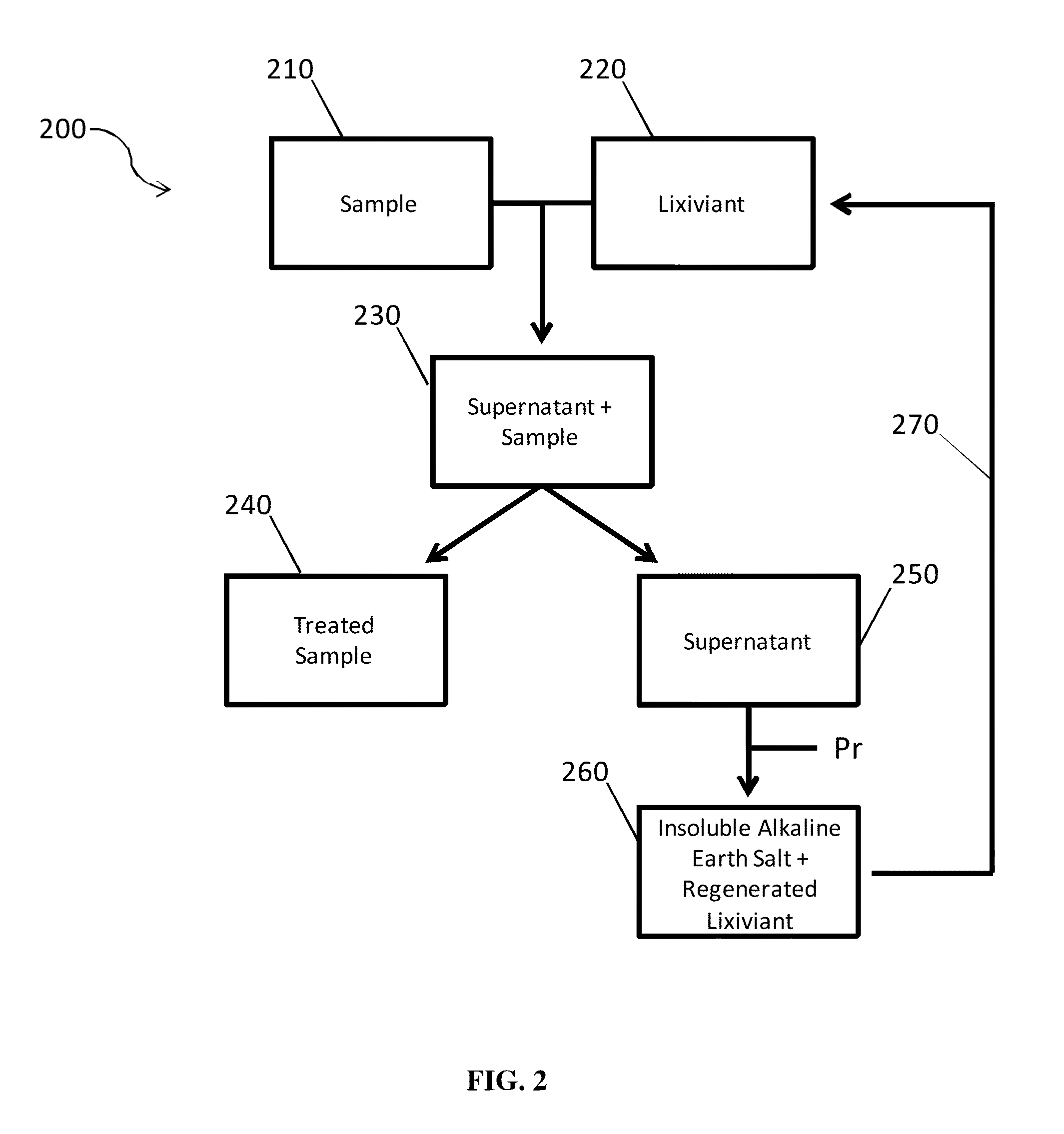

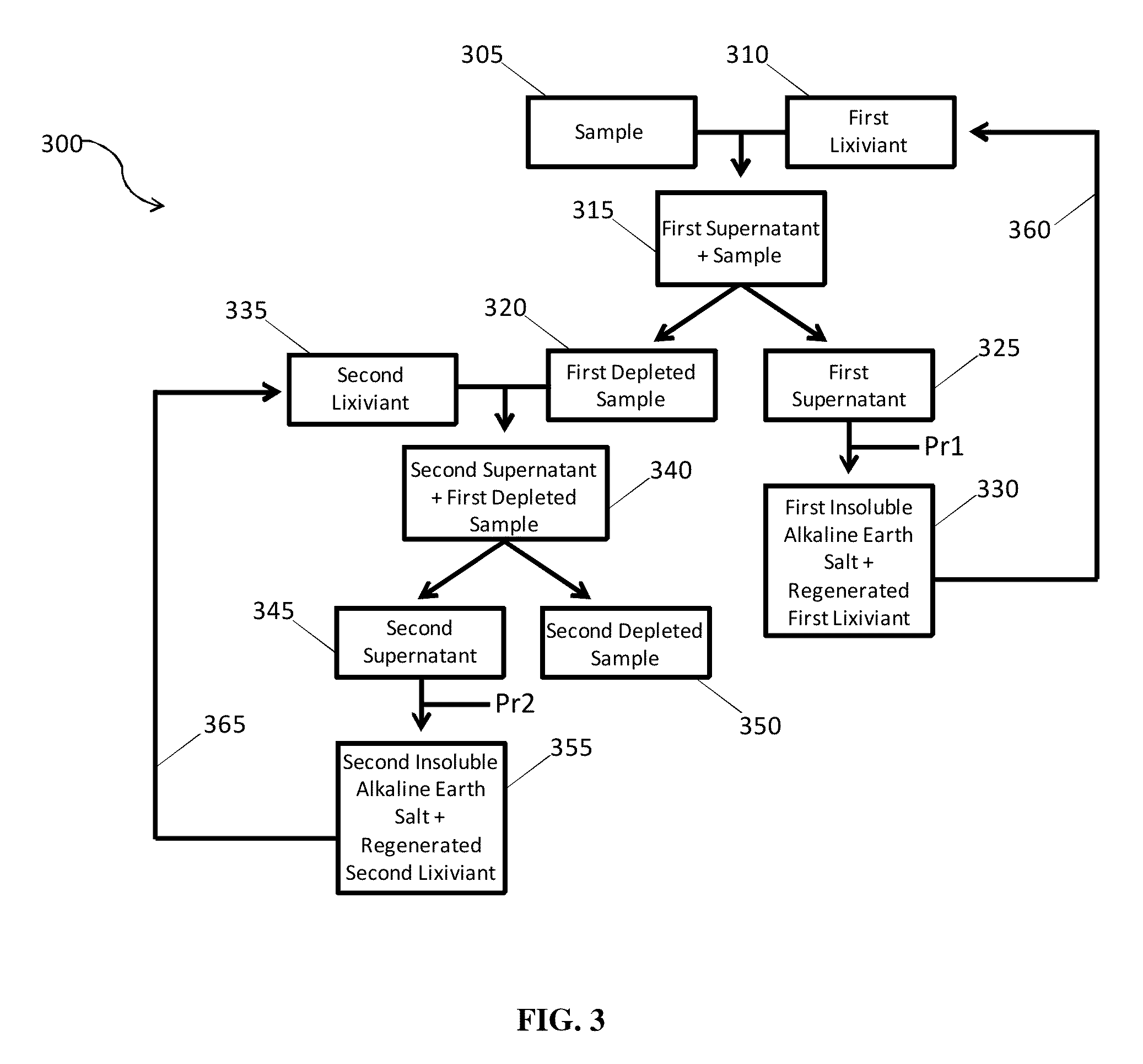

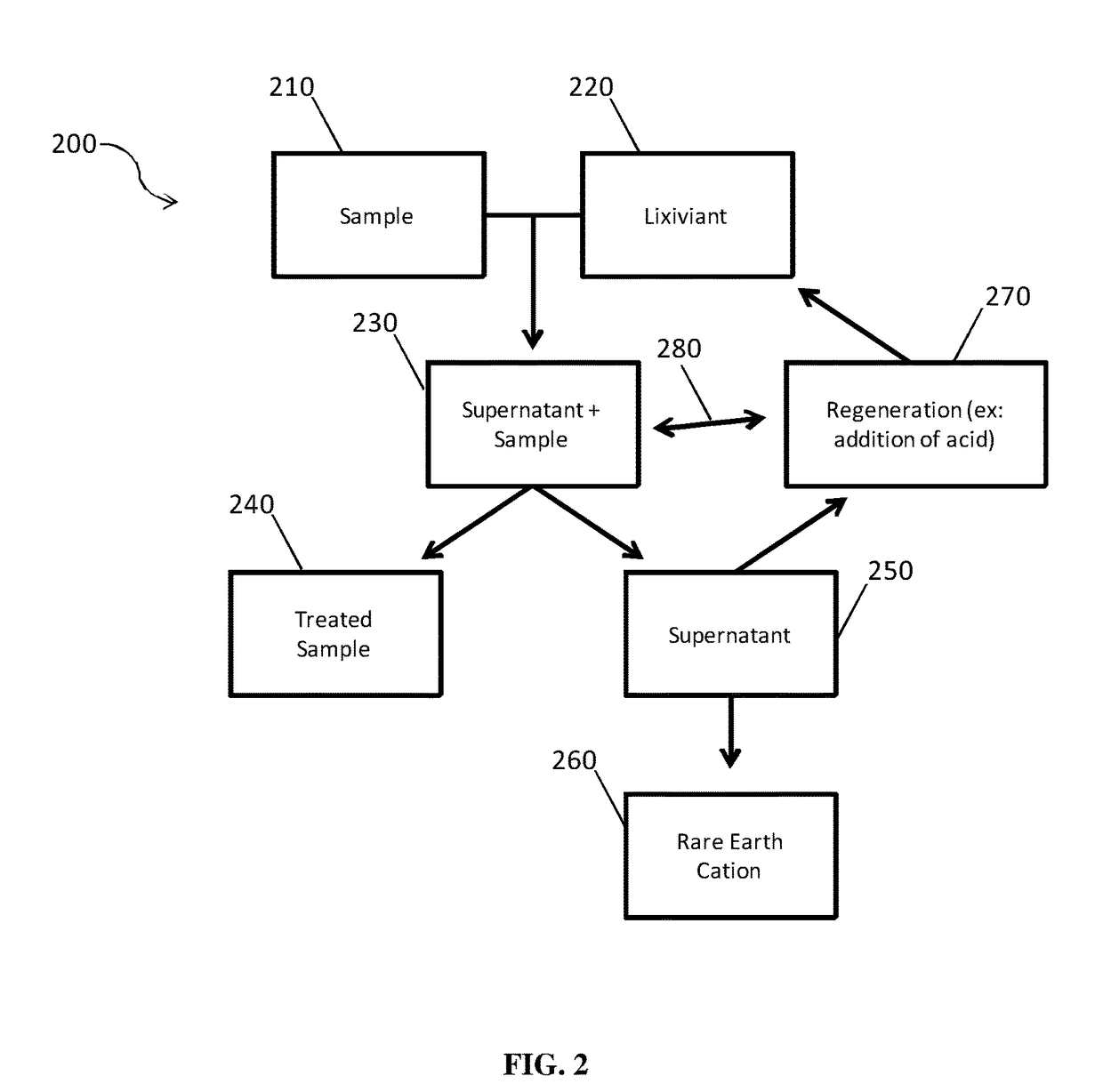

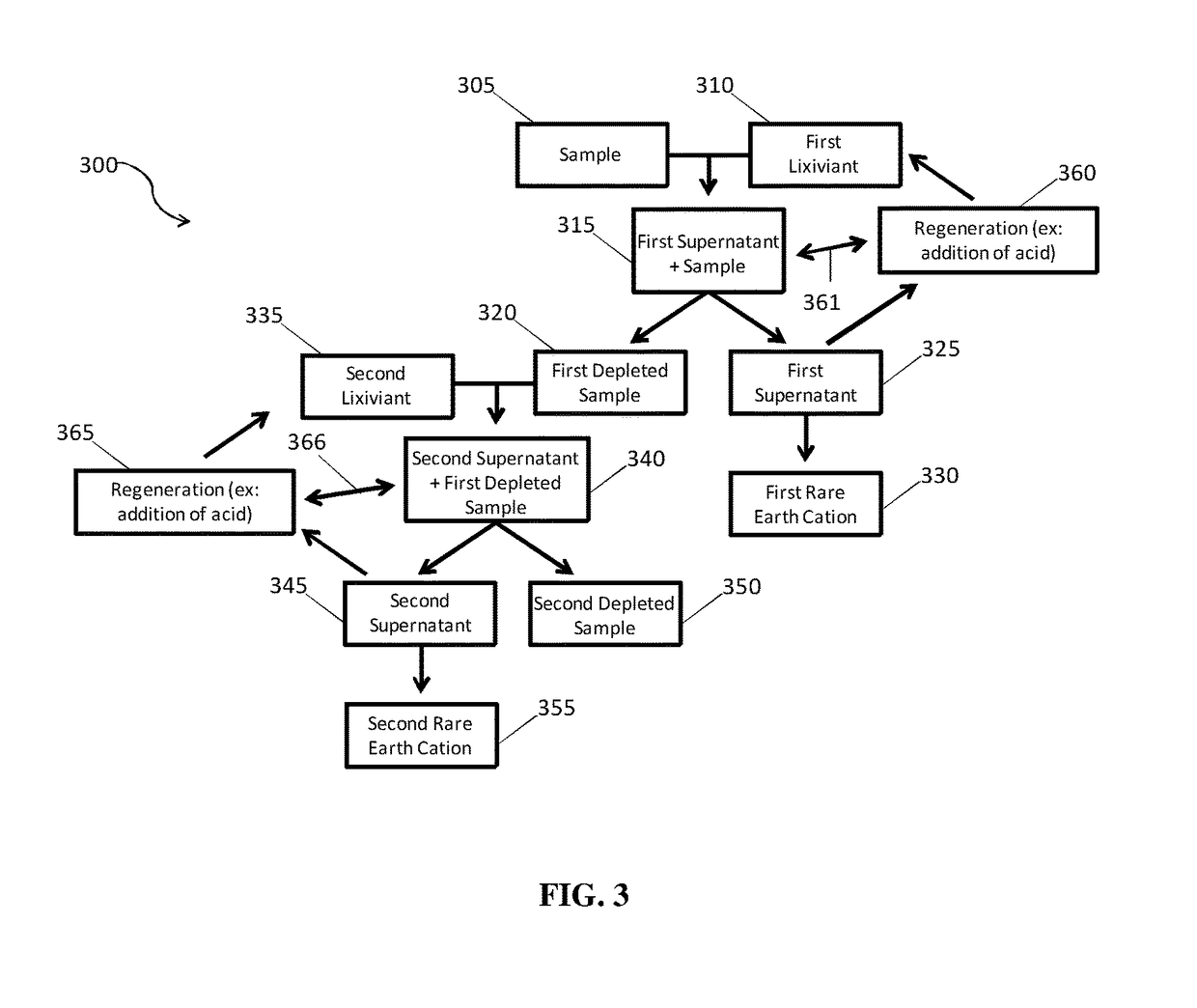

Refining agents for alkaline earth production

Hydrometallurgical systems, methods, and compositions are described in which organic amine-based lixiviants are utilized in the selective recovery of alkaline earth elements. The lixiviant can be regenerated and recycled for use in subsequent iterations of the process. Multiple alkaline earth elements can be recovered from a sample in parallel or in serial applications of the disclosed methods.

Owner:LIXIVIA

Thiosulfate generation in situ in precious metal recovery

Owner:BARRICK GOLD

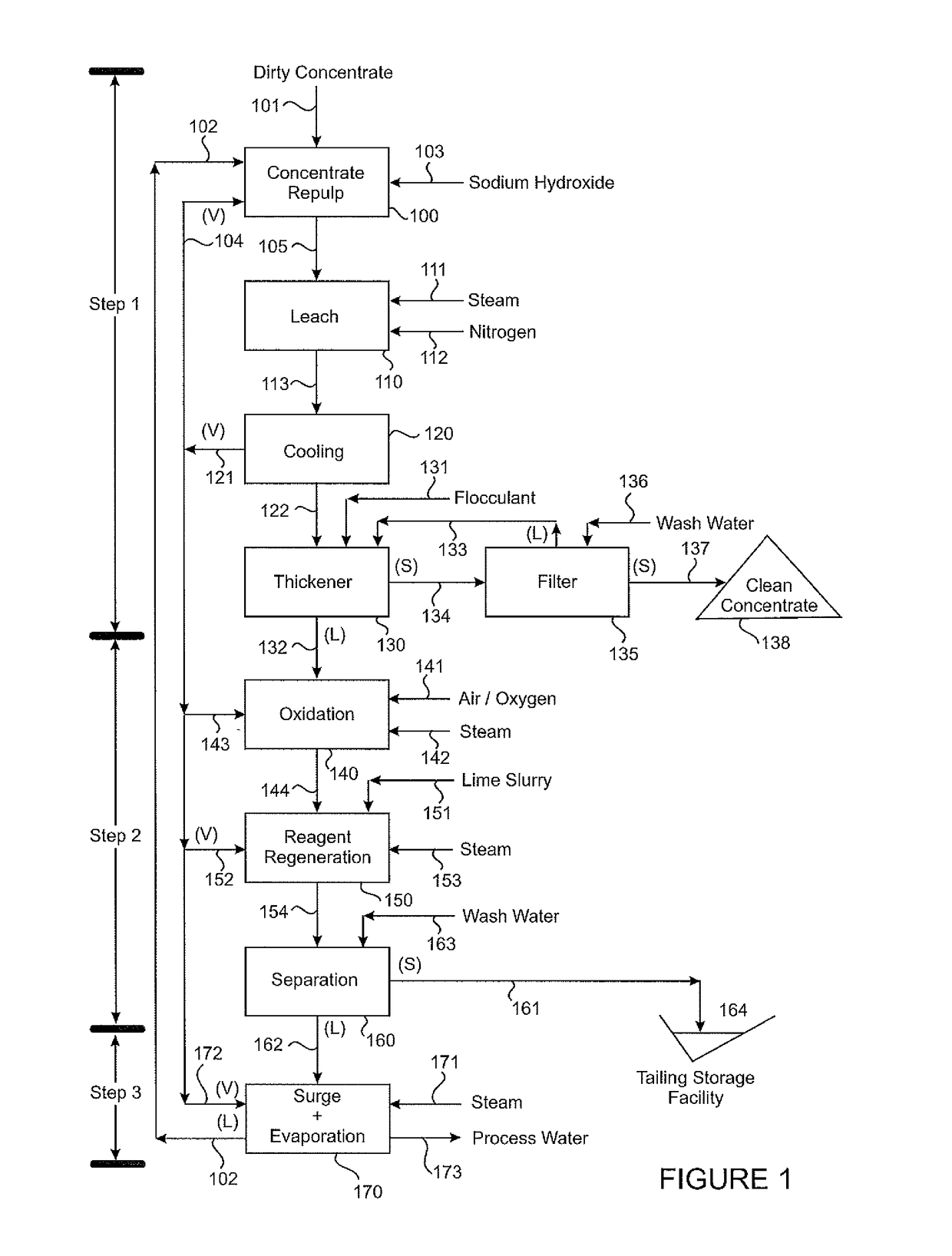

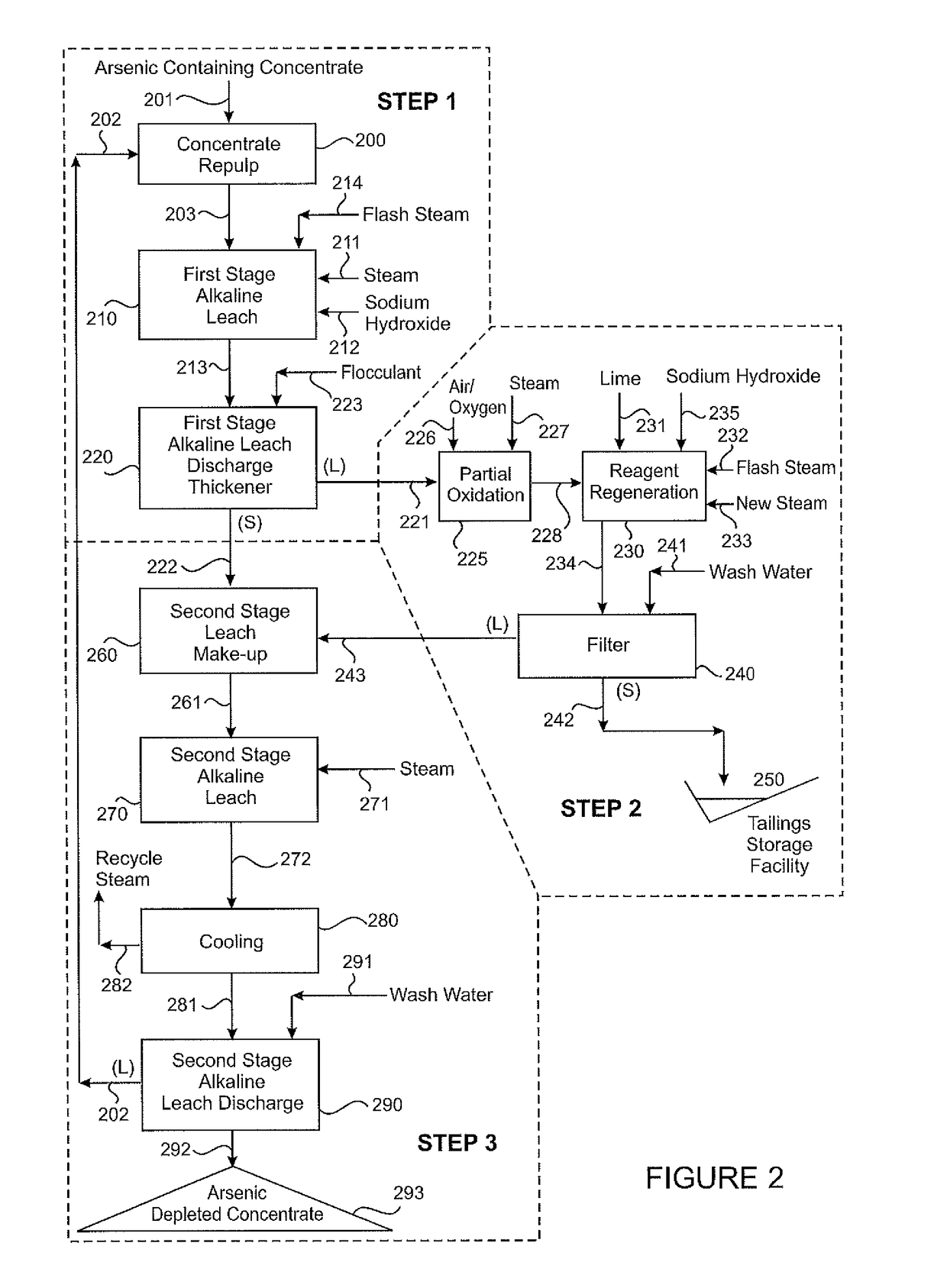

Purification of copper concentrate by removal of arsenic and antimony with concomitant regeneration and recycle of lixiviant

A hydrometallurgical process for the removal of arsenic and antimony from a so-called “dirty” copper concentrate (101) is described. The process comprises the following steps: Step 1: repulping (100) the “dirty” copper concentrate with an alkaline lixiviant (102, 103), and subjecting the “dirty” copper concentrate to an alkaline leaching process (“the Leach”) in a Leach reactor (110). The arsenic and antimony are dissolved in the Leach to produce a “clean” copper concentrate (138) and leach discharge liquor (132). Step 2: subjecting the Leach discharge liquor (132) to a lime treatment step (151) in order to regenerate (150) the alkaline lixiviant as well as precipitate an impurity rich precipitate (161) containing arsenic and antimony. Then the impurity rich precipitate (161) is separated (160) from the regenerated alkaline lixiviant (162). The impurity rich precipitate is washed and disposed of in an environmentally safe condition. Step 3: recycling the regenerated alkaline lixiviant (162) to the Leach in Step 1, and so employing the recycled alkaline lixiviant (102) in the further extraction of arsenic and antimony from incoming “dirty” copper concentrate (101).

Owner:ALCHEMIDES +2

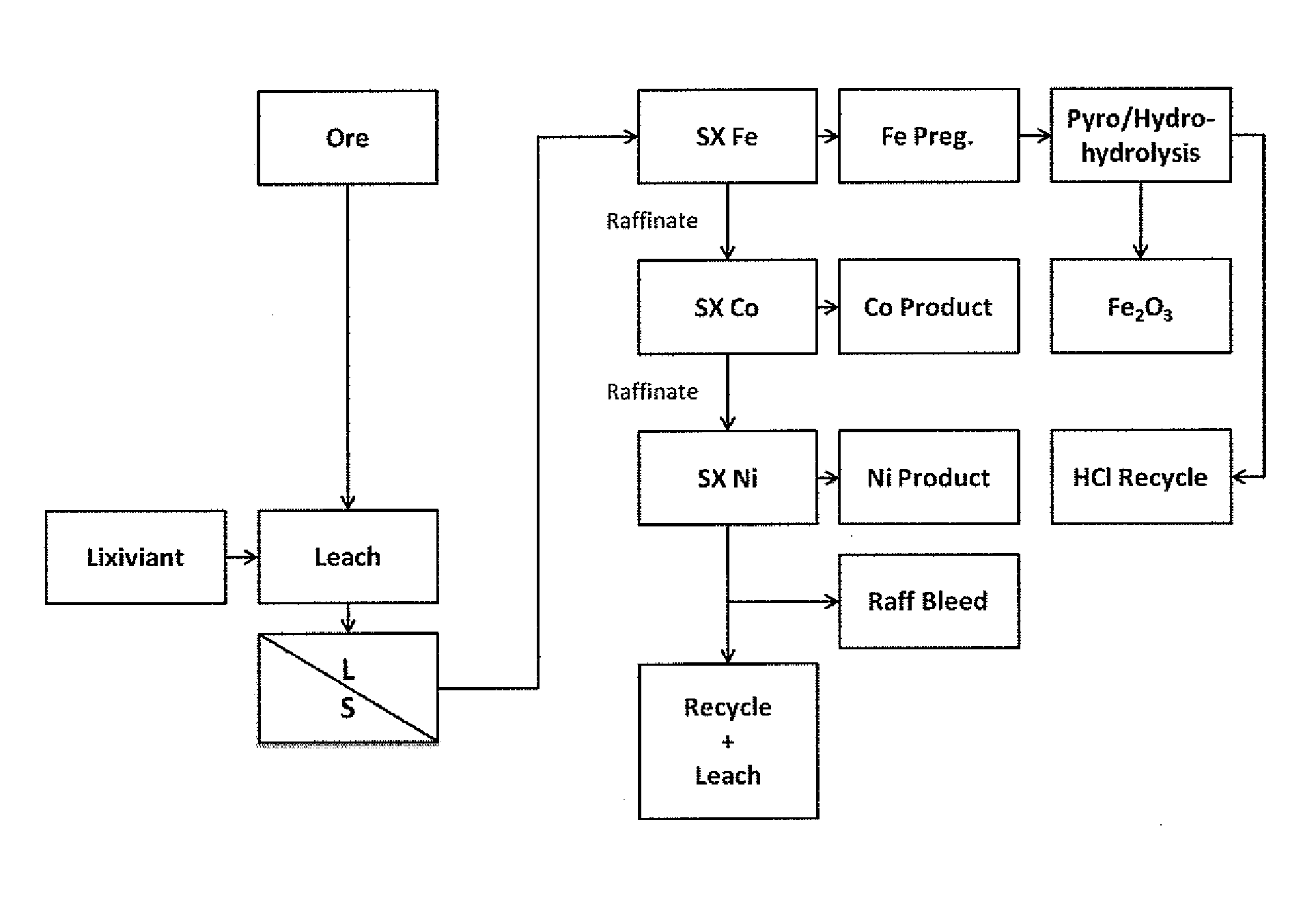

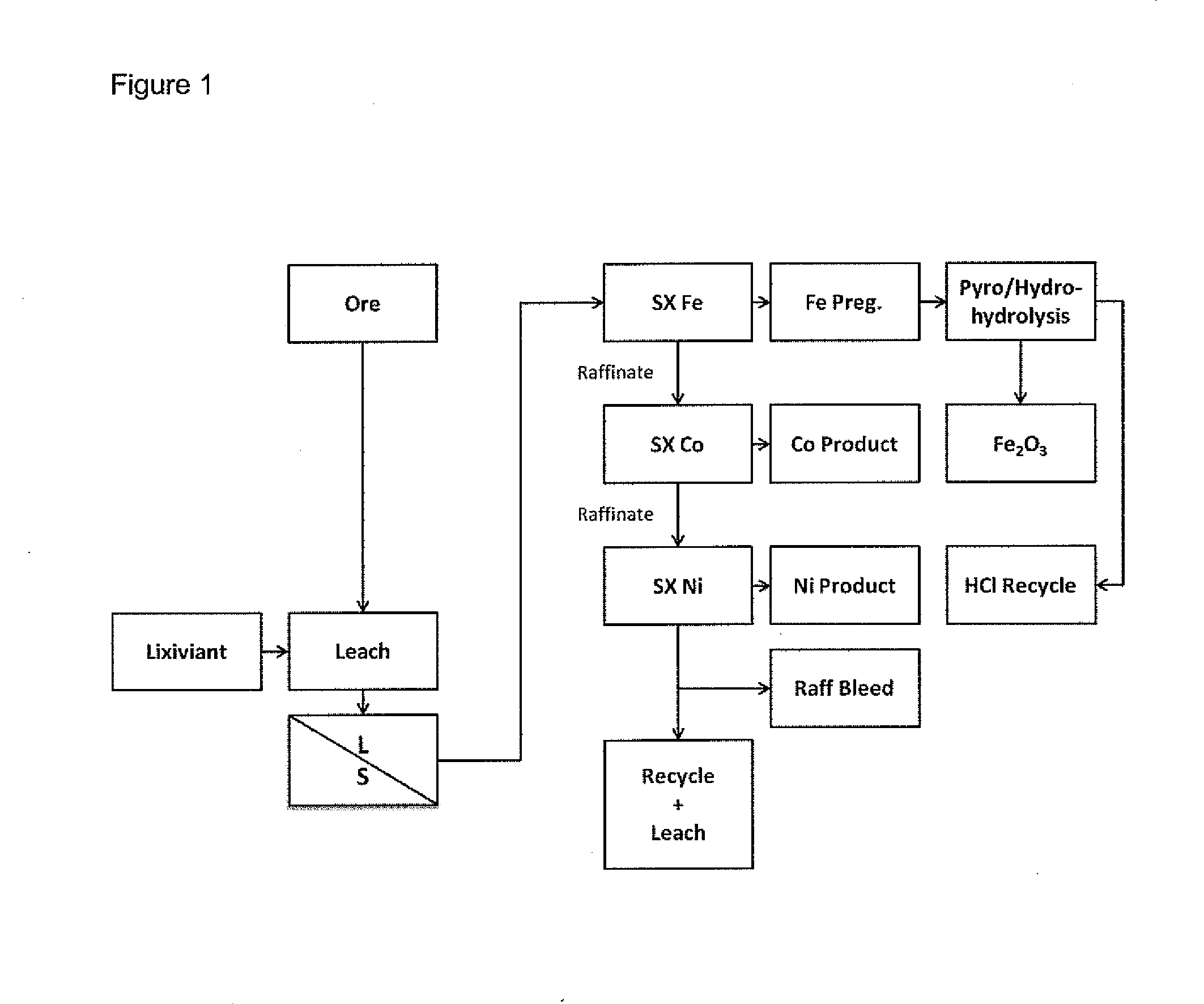

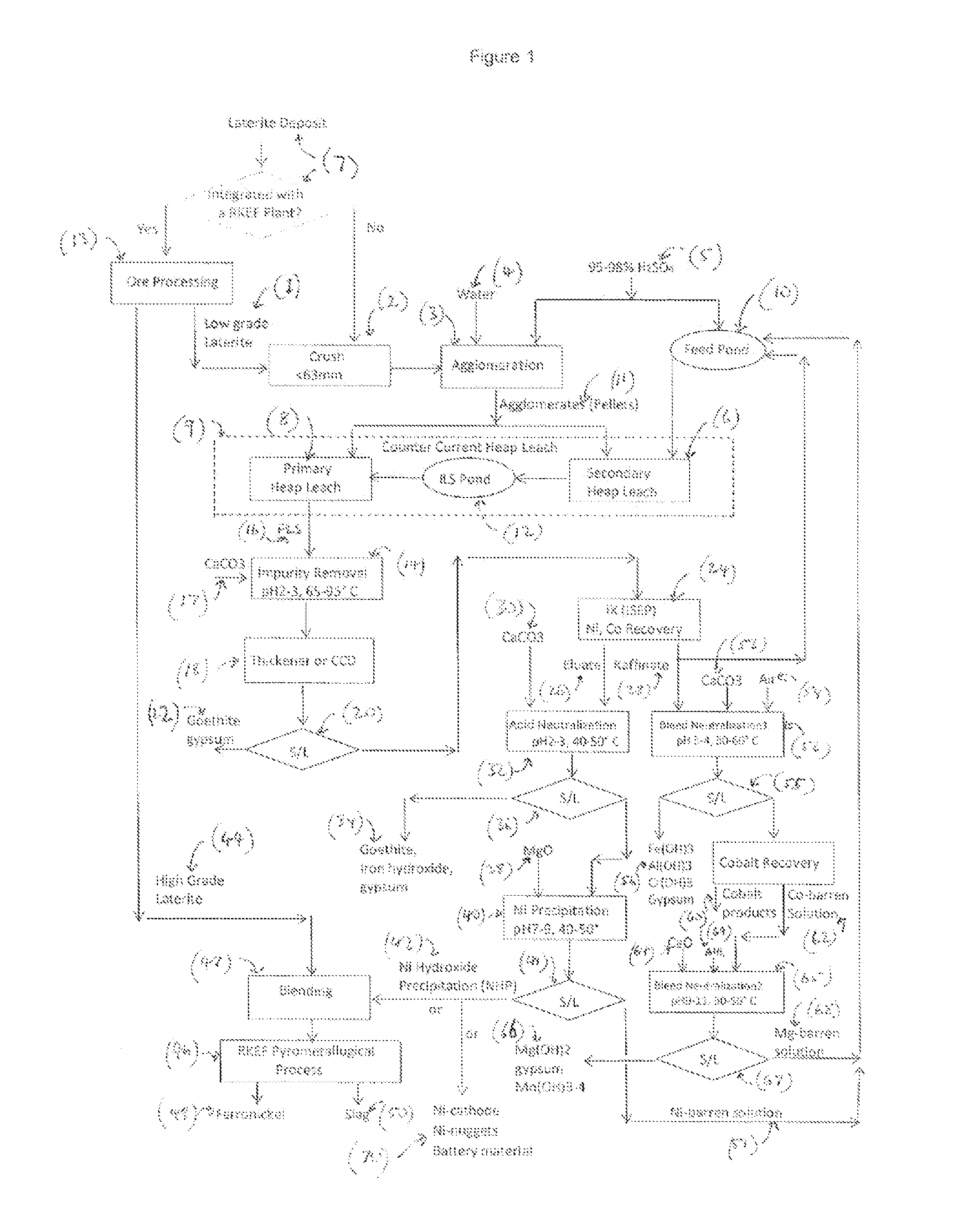

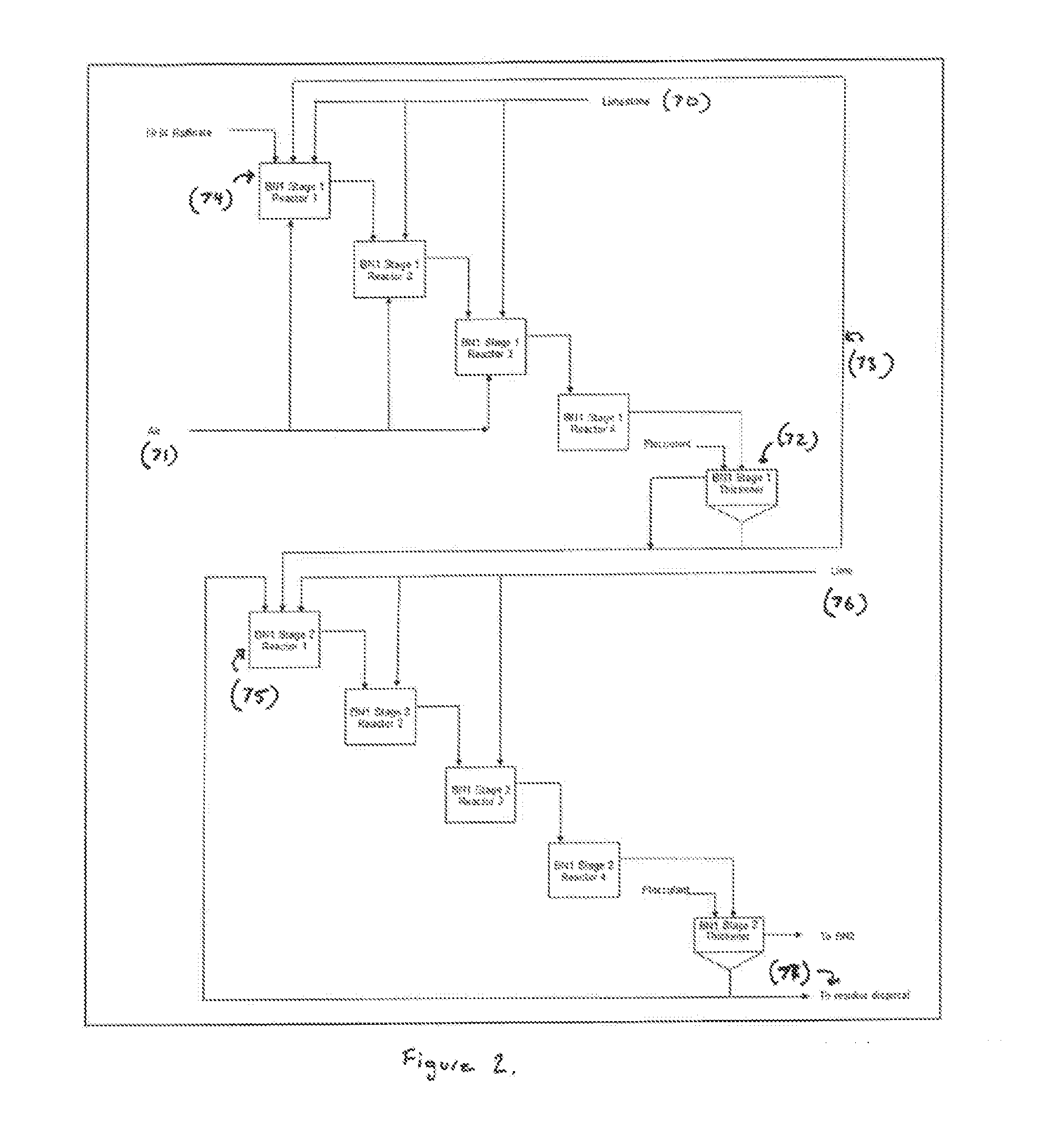

Separation of iron from value metals in leaching of laterite ores

ActiveUS20130149219A1Solvent extractionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsLixiviantKetone

The invention provides a process for the leaching of a laterite ore, concentrate, tailings or waste rock for the recovery of value metals, at least one value metal being nickel. The laterite ore or concentrate is subjected to a leaching step with a lixiviant comprising hydrochloric acid to leach nickel from the laterite ore, followed by a liquid / solids separation step. The liquid obtained is subject to solvent extraction with a dialkyl ketone, to obtain a solution rich in iron and a raffinate. Separation of iron from cobalt and nickel is obtained.

Owner:ORF TECH INC

Method for reducing and lixiviating zinc containing material by sulfur dioxide

The invention discloses a method for reducing and lixiviating zinc containing material by sulfur dioxide. The method comprises the following steps: adding the zinc containing material into an acid lixiviant to lixiviate the zinc containing material by the acid lixiviant; in the process of lixiviating, introducing sulfur dioxide through the mixture of the acid lixiviant and the zinc containing material to realize reduction and lixiviation by sulfur dioxide. The method in the embodiment of the invention achieves the advantages of high zinc and ferrum lixiviation rate, low slag rate and high adaptability to raw materials, i.e. the method is suitable for processing various zinc containing materials; the method can reduce the possibility that organics and foreign ions enter the system, achieves the advantages of no elemental sulfur and high lead / silver enrichment degree, also can optimize the subsequent technical flow and reduce equipment investment and energy consumption.

Owner:YUNNAN HUALIAN ZINC & INDIUM

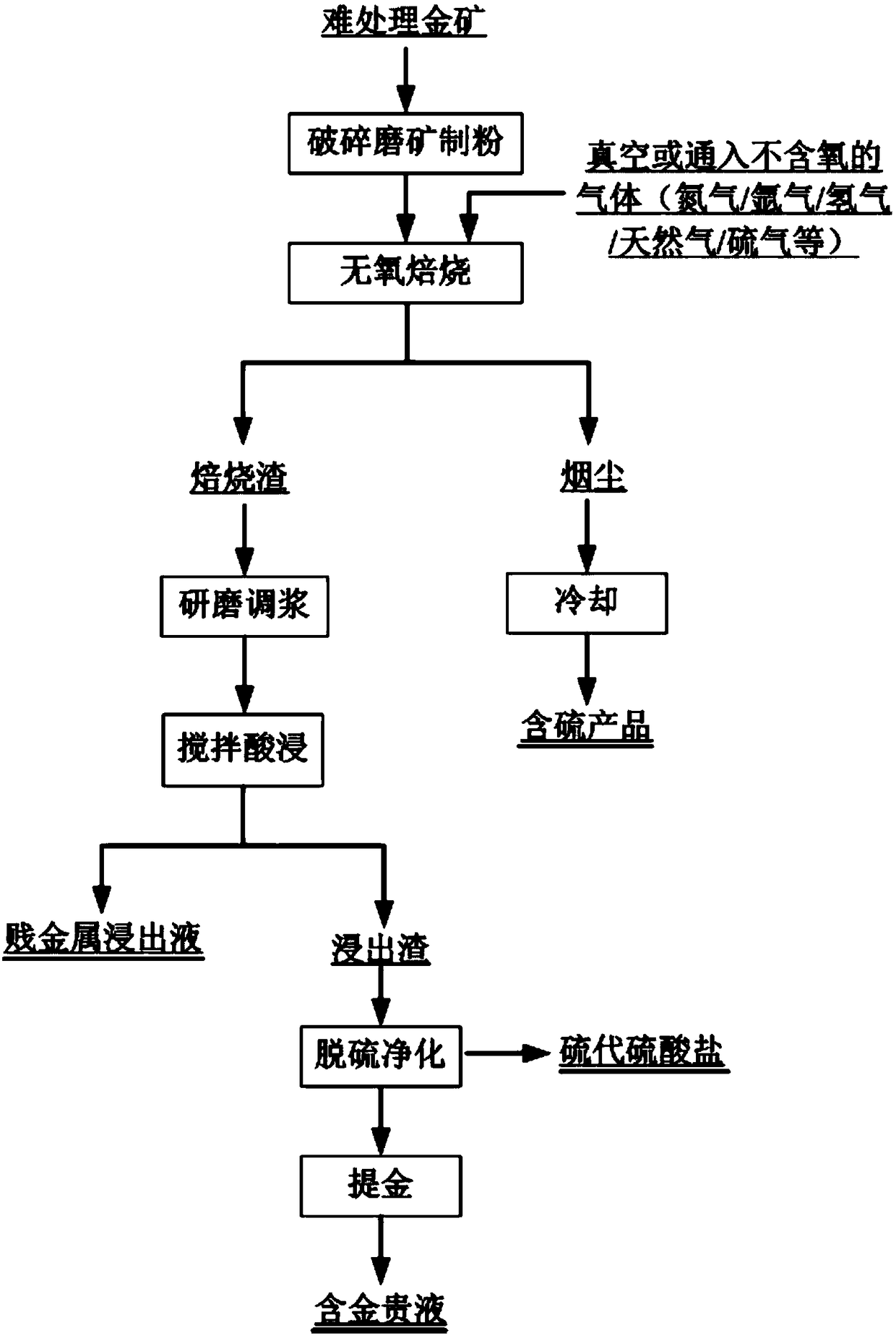

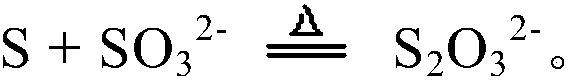

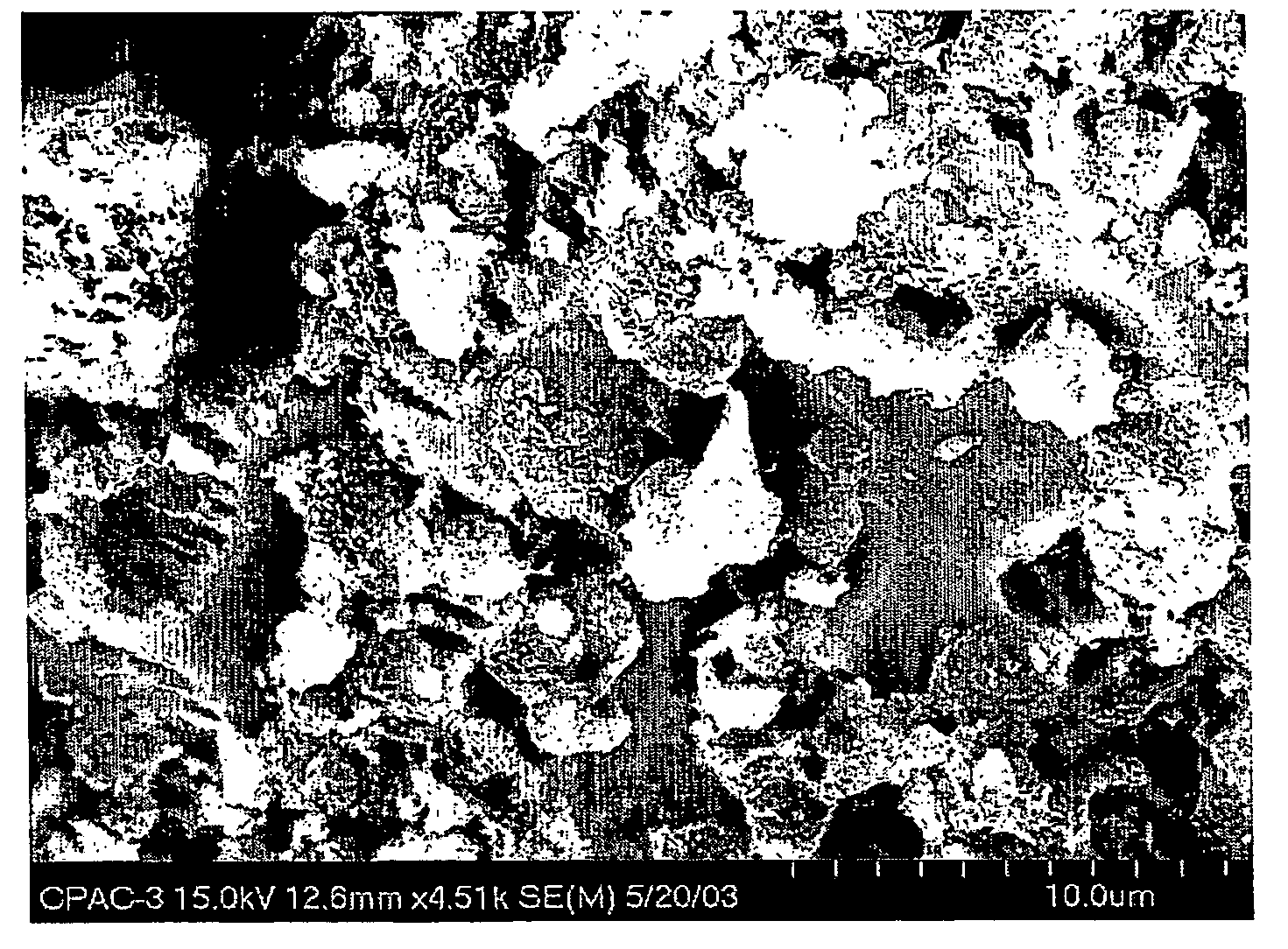

Grinding and leaching pretreatment process of refractory gold ore

InactiveCN108913875ALow cost and environmentally friendlyImprove solubilityThiosulfates/dithionites/polythionitesProcess efficiency improvementLixiviantSlag

The invention relates to a grinding and leaching pretreatment process of refractory gold ore. The process is mainly used for combined pretreatment of anaerobic roasting and mechanical activated leaching on the refractory gold ore. The process specifically comprises the following steps that S1, the gold ore is broken, and subjected to ball milling and powdering, and gold ore powder is obtained; S2,the obtained gold ore powder is placed in gas atmosphere without oxygen or vacuum to be roasted, and after roasting, roasting slag and smoke are obtained; S3, the roasting slag is subjected to grinding and pulp mixing, slurry is placed in a reaction kettle to be subjected to temperature control and stirring leaching, and a base metal leaching agent and leaching slag are obtained; S4, the leachingslag is subjected to desulfuration purification; S5, a gold lixiviant is used for carrying out gold extraction on purifying slag. The advantages of a roasting method and a mechanical activated leaching method are combined, and the beneficial effects of being high in raw material adaptability, gentle in operation condition, low in equipment requirement, obvious in environment and economic benefitand the like are achieved.

Owner:NORTHEASTERN UNIV

Catalyzed dissolution of copper from sulfur-containing copper minerals

Leaching of copper from minerals containing sulfur and copper is hampered by the formation of sulfur on the surface of the mineral during conventional processing. An improved method for extracting copper from a sulfur-containing copper mineral is provided, comprising adding a lixiviant and a silica-containing or titanium-containing compound to a sulfur-containing copper mineral.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Chloride process for the leaching of gold

A process for the extraction of gold from a gold-bearing ore or concentrate, comprising the steps of leaching the gold-bearing ore or concentrate with a lixiviant of hydrochloric acid and magnesium chloride at atmospheric pressure at a temperature of at least 90° C. and an Eh of at least 900 mV. After a liquid / solids separation step, the solution obtained is subjected to an organic solvent extraction step using an oxime to obtain a solution of organic solvent containing gold, which is stripped with sodium thiosulphate to recover gold. The extraction may be operated to extract gold with or without iron. Materials used in the process may be recycled. The process avoids environmental and other hazards associated with the use of cyanide to extract gold.

Owner:ORF TECH INC

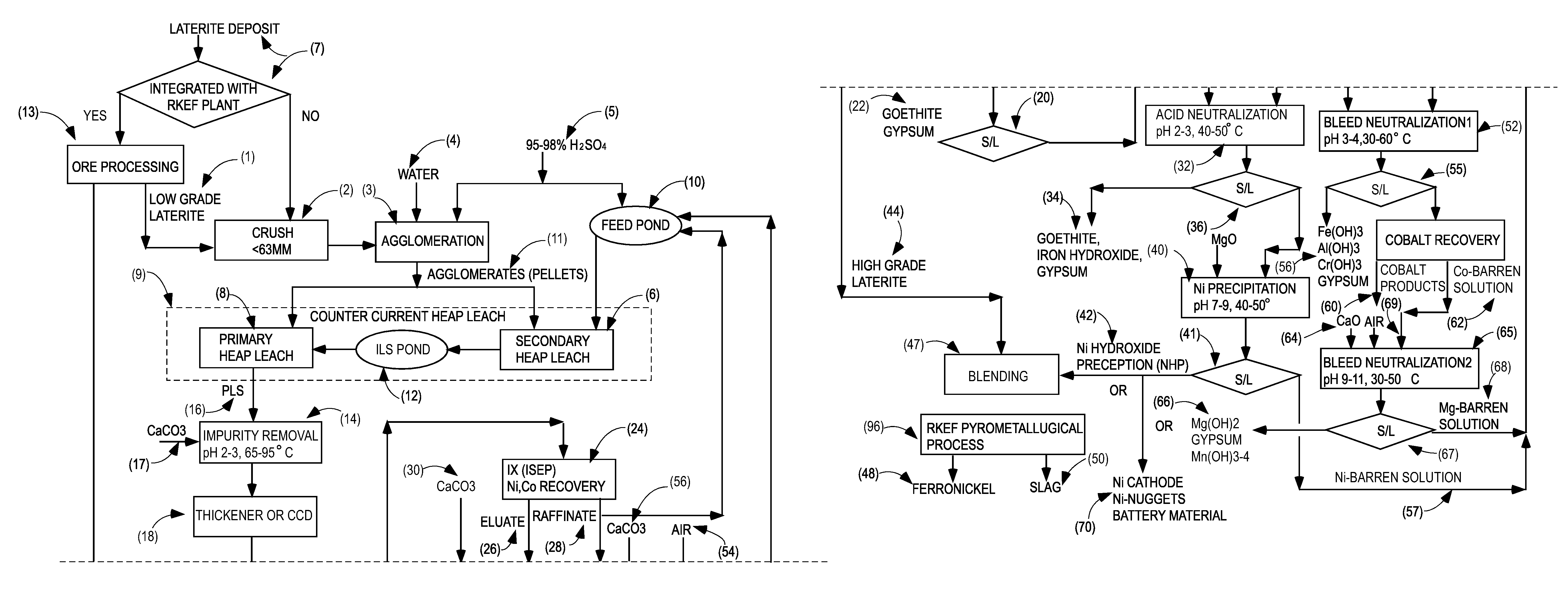

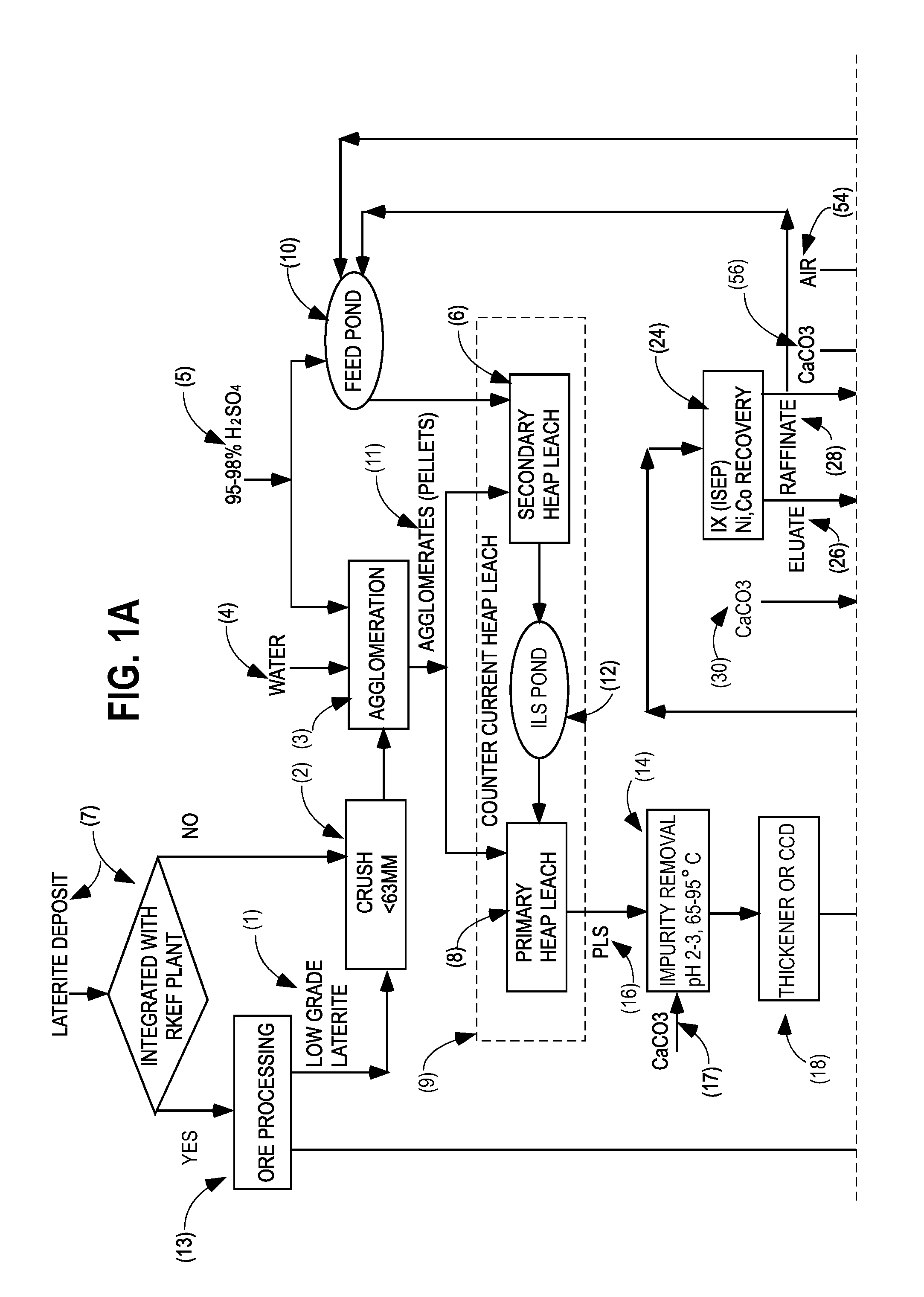

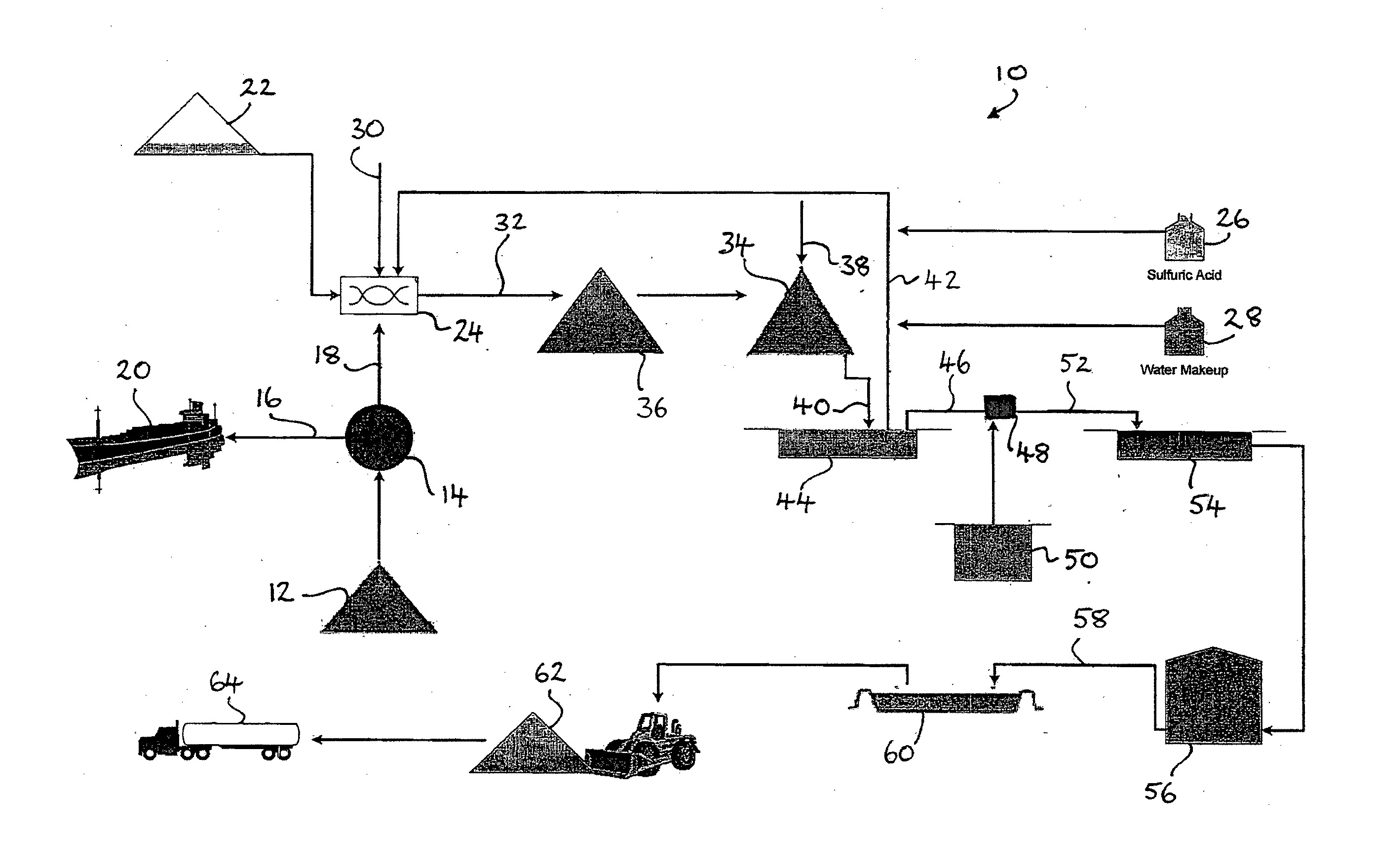

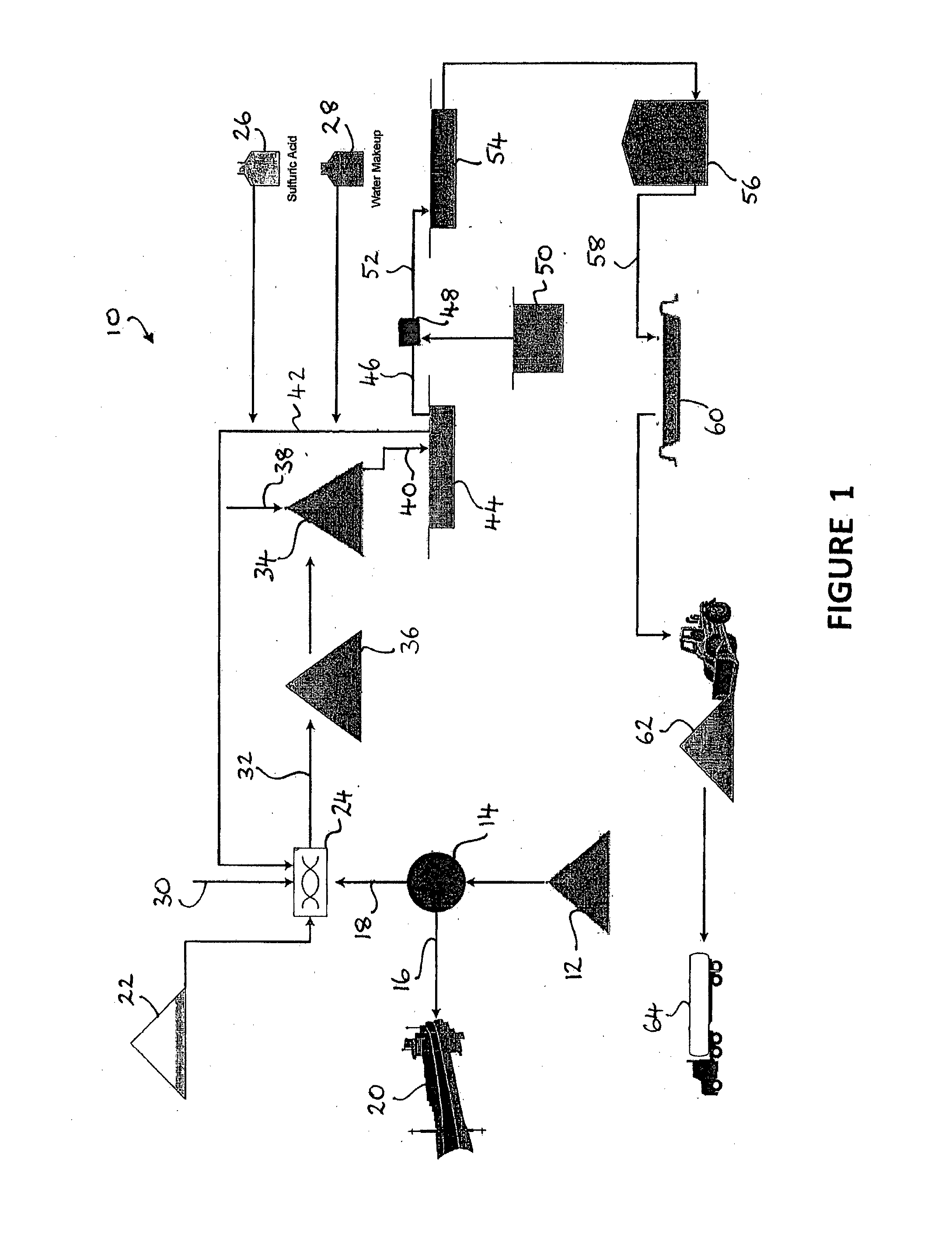

An improved process for heap leaching of nickeliferous oxidic ores

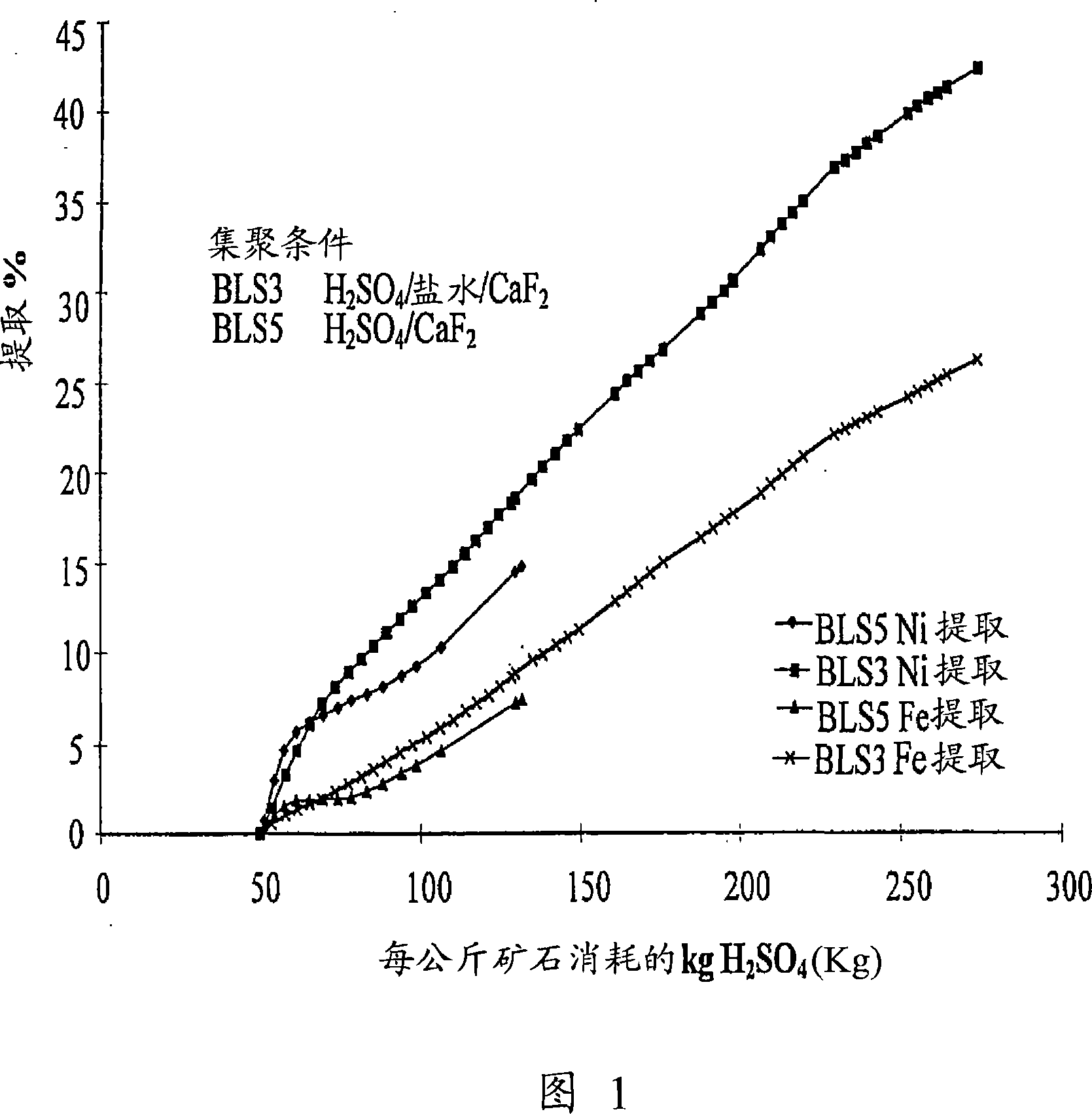

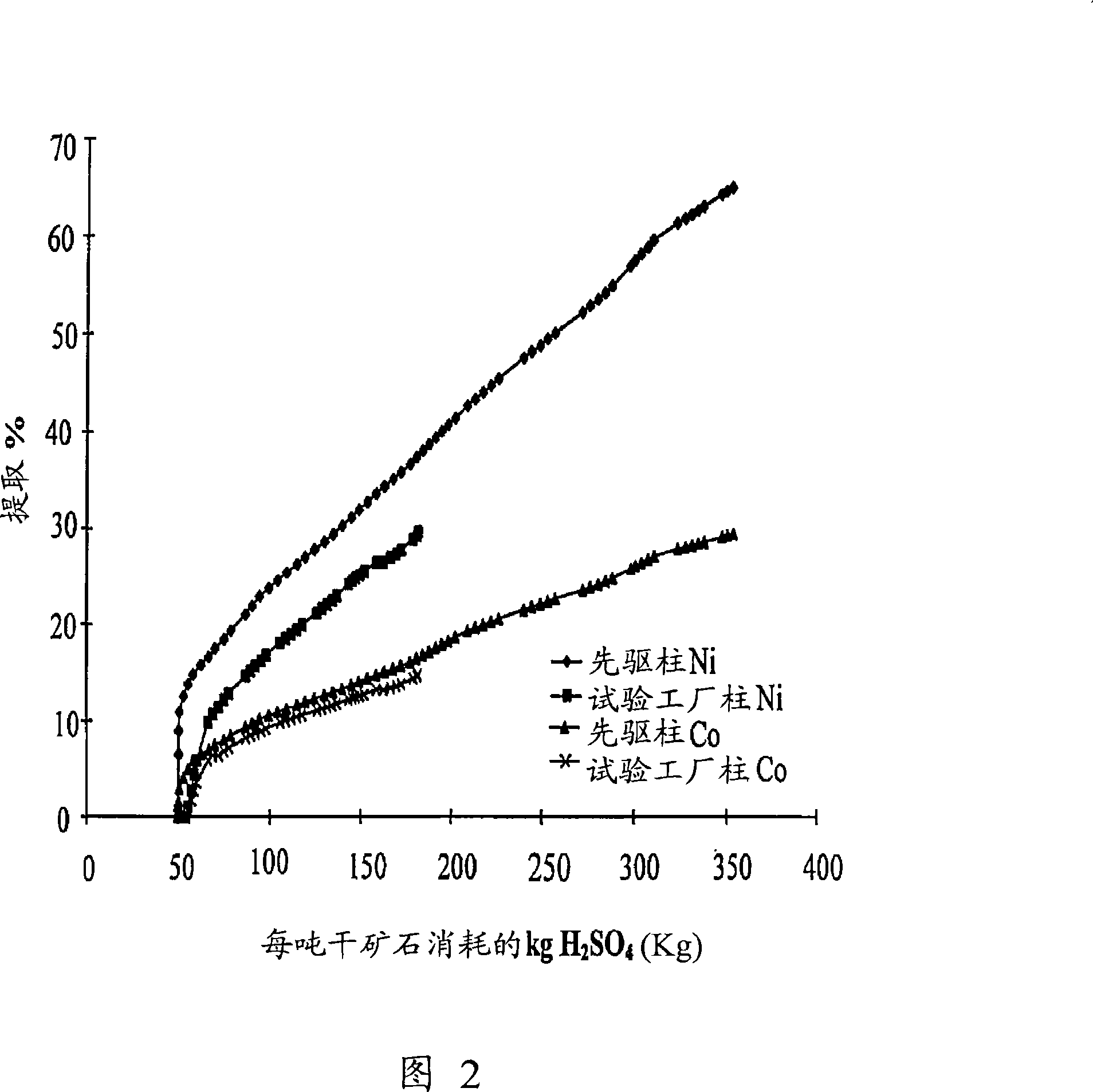

A process for the recovery of nickel and cobalt from a nickeliferous oxidic ore by heap leaching, the process including the steps of: a) forming the nickeliferous oxidic ore into one or more heaps; b) leaching the ore heap with a leach solution in a leach step wherein the leach solution includes an acid supplemented hypersaline water as the lixiviant, the hypersaline water having a total dissolved solids concentration greater than 30 g / l; and c) recovering the nickel and cobalt from the resultant heap leachate.

Owner:BHP BILLITON SSM TECH PTY LTD

Process of leaching precious metals

ActiveUS9150942B2Increase concentrationAccelerate the rate of precious metal extractionProcess efficiency improvementLixiviantLead nitrate

The invention relates to modifications of a non-ammoniacal thiosulfate process of leaching precious metals (e.g. gold or silver) from precious metal-containing ores. The process involves leaching the ore with an aqueous lixiviant containing a soluble thiosulfate other than ammonium thiosulfate, a copper compound and an organic compound that serves as a copper ligand (i.e. a ligand-forming compound). Four modifications of this process are effective for increasing the amount of precious metal that can be extracted, reducing the consumption of materials, or for improving the rate of extraction. These four process, which may be used singly or in any combination, include (a) additions of soluble lead (e.g. as lead nitrate), (b) additions of thiourea, (c) increases in dissolved oxygen, and (d) increases of temperature at ambient pressure. This avoids the use environmentally harmful chemicals and allows for extraction from a variety of ores, e.g., containing substantial amounts of sulfides and / or quartz.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

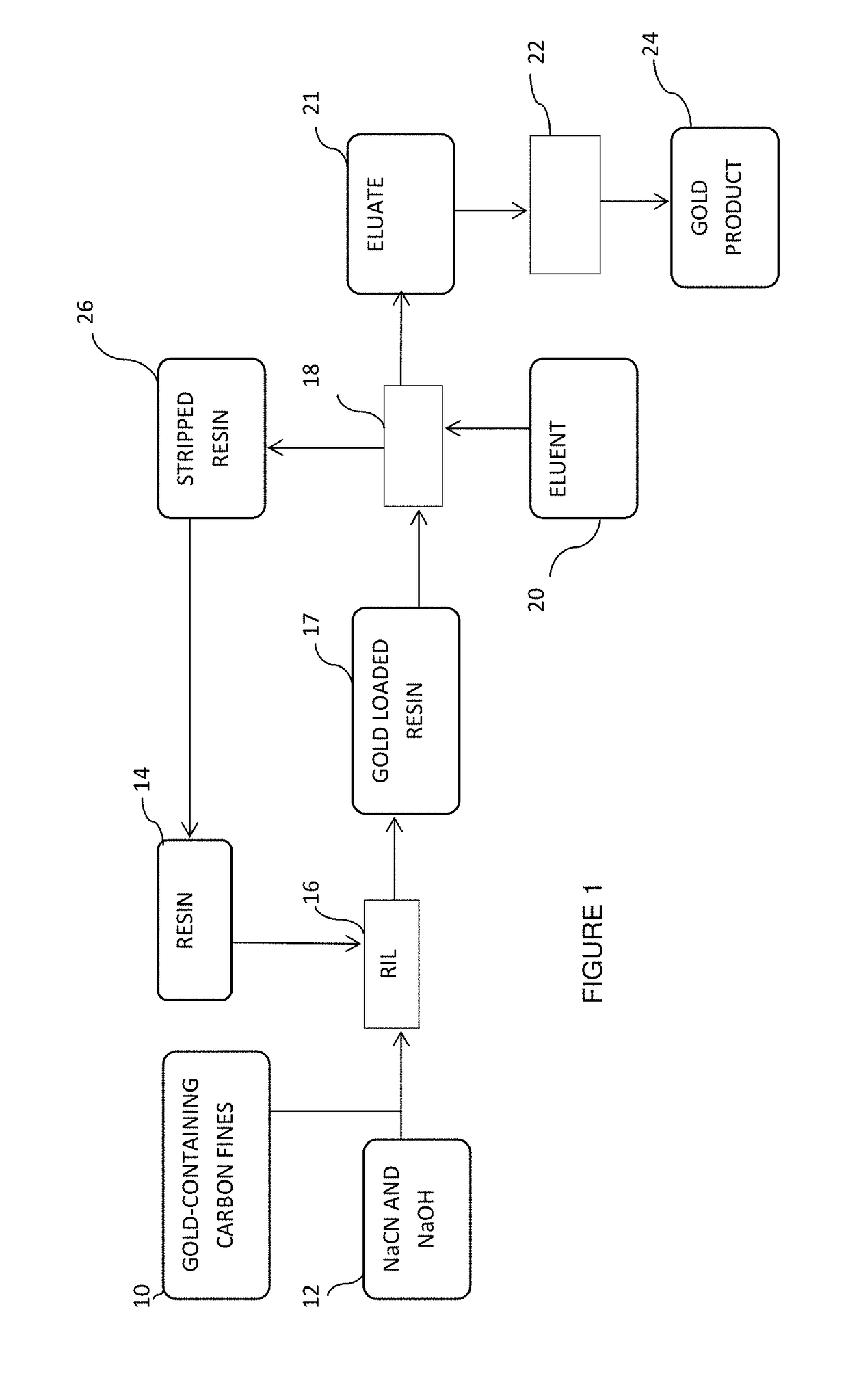

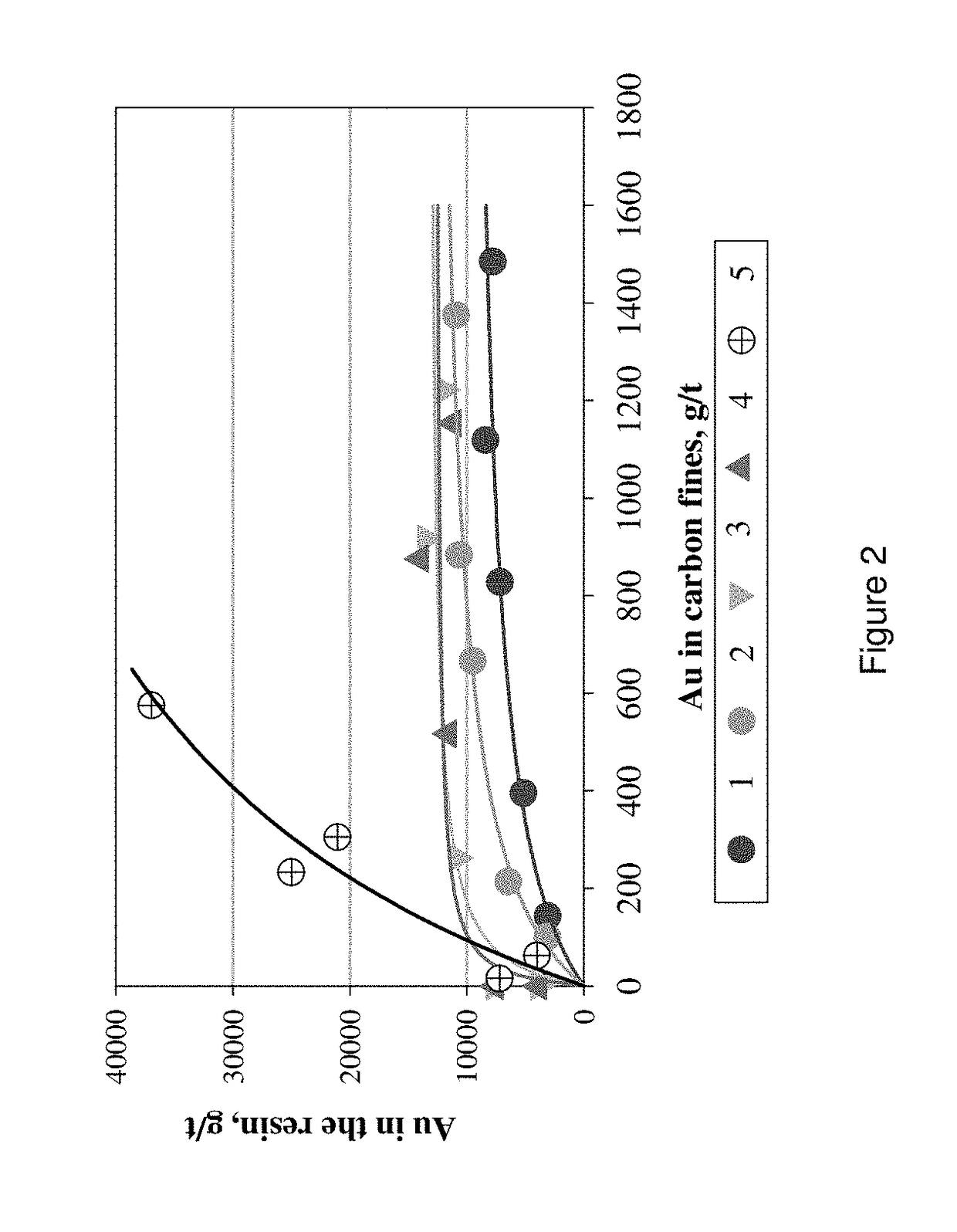

Gold recovery from carbon

A method of recovering gold from carbon fines in a resin-in-leach process wherein the fines are contacted with an ion exchange resin, in the presence of a suitable lixiviant, to load gold onto the resin, eluting the gold from the resin using a suitable eluent and recovering the gold from a resulting eluate.

Owner:MINTEK

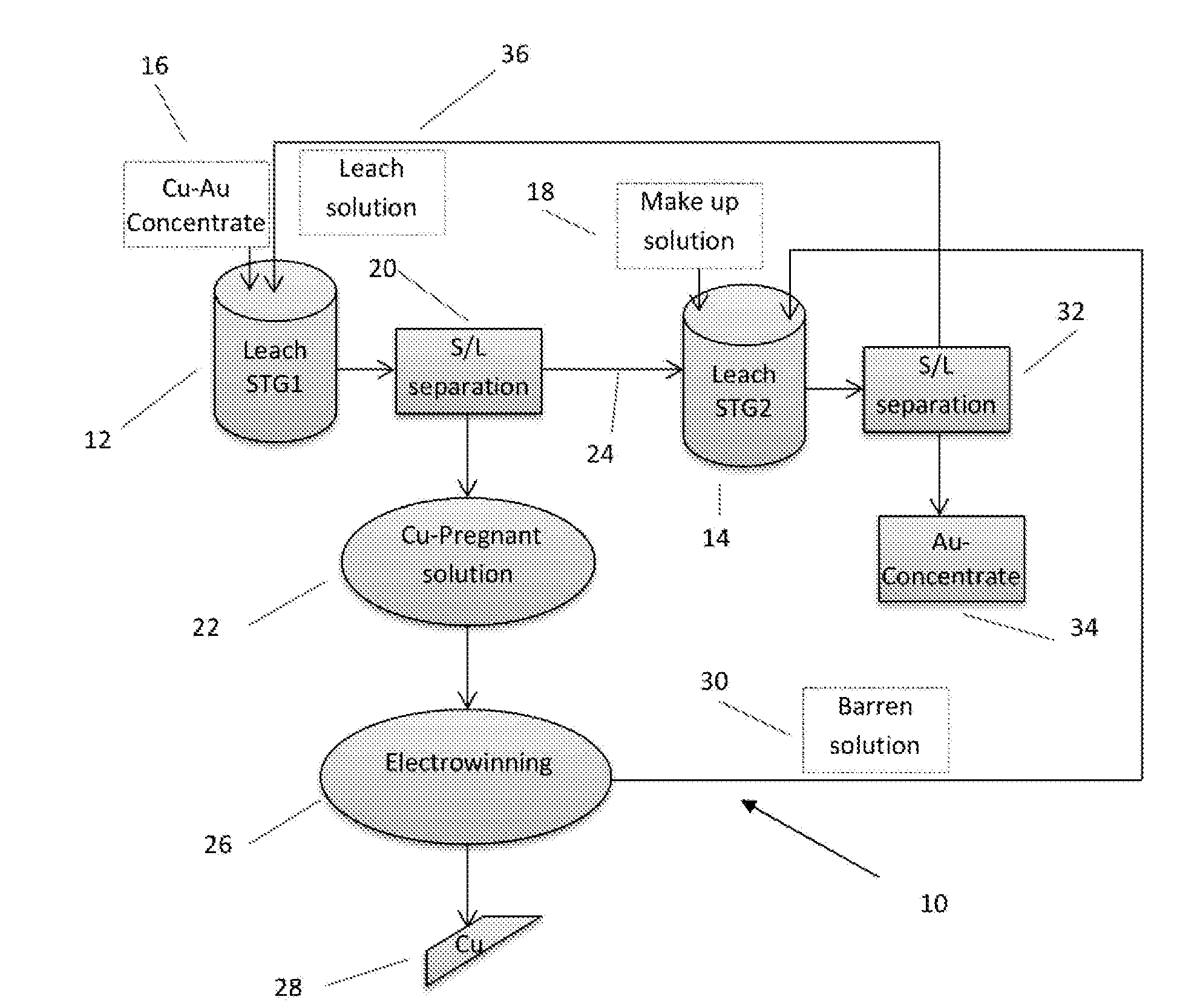

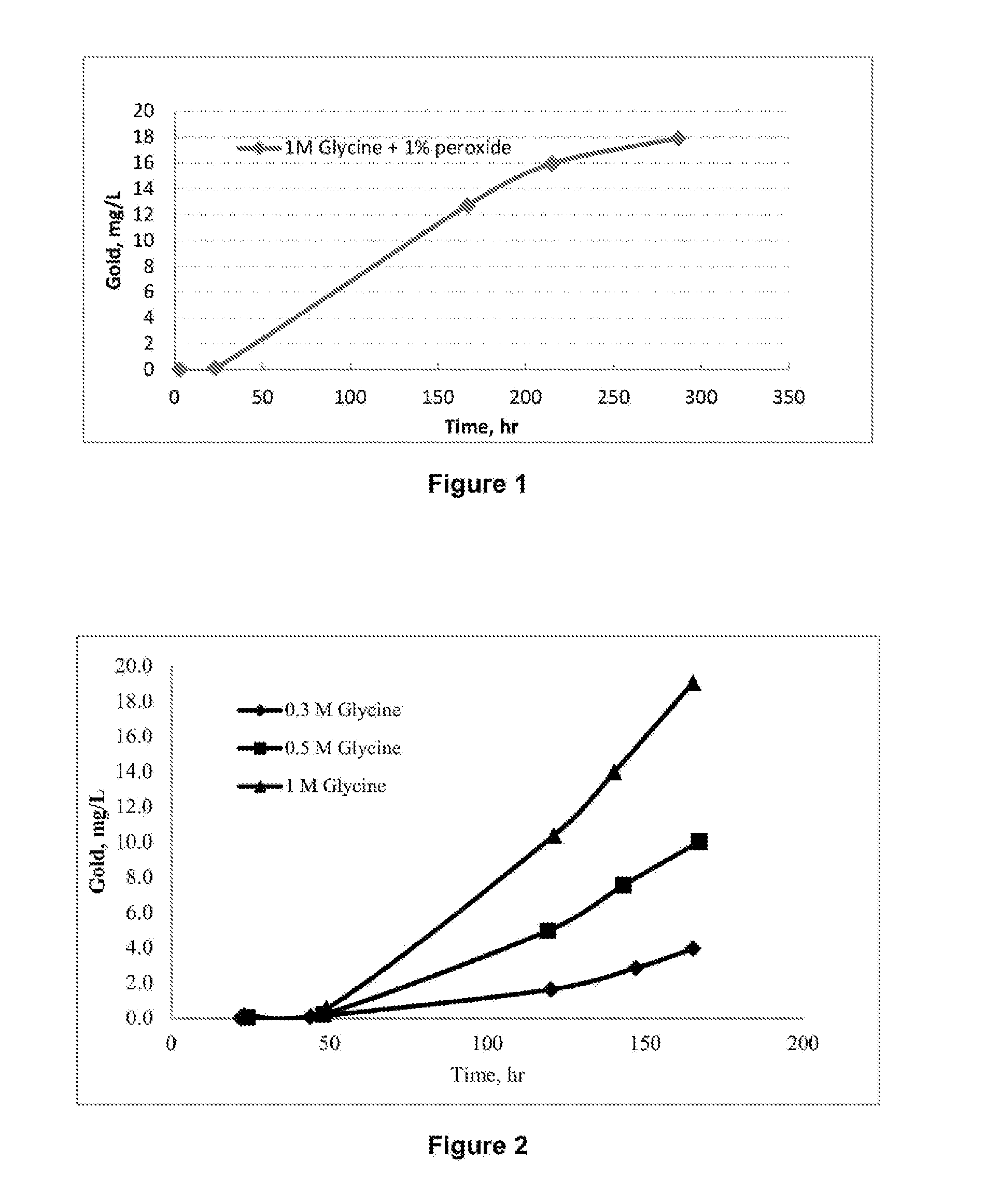

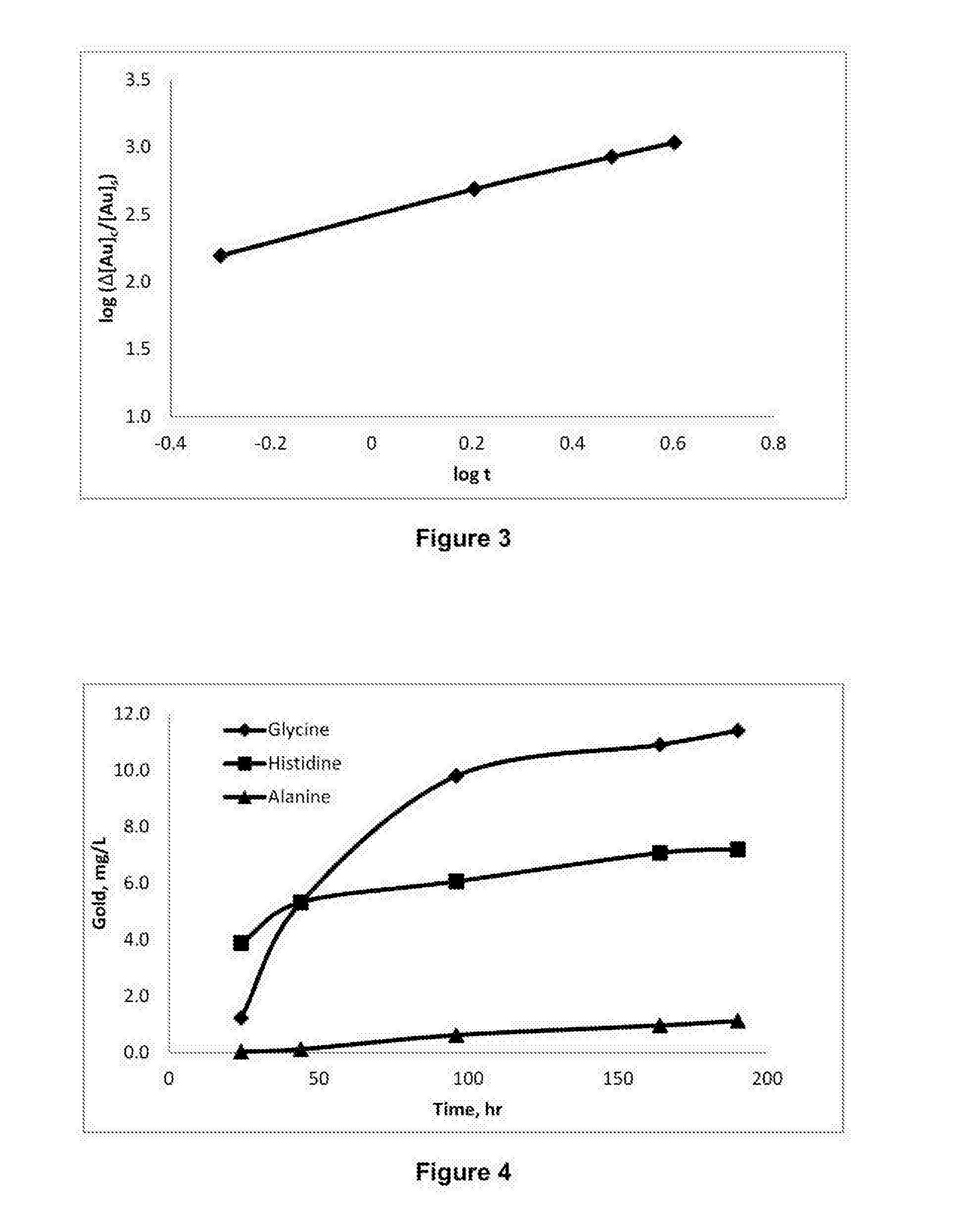

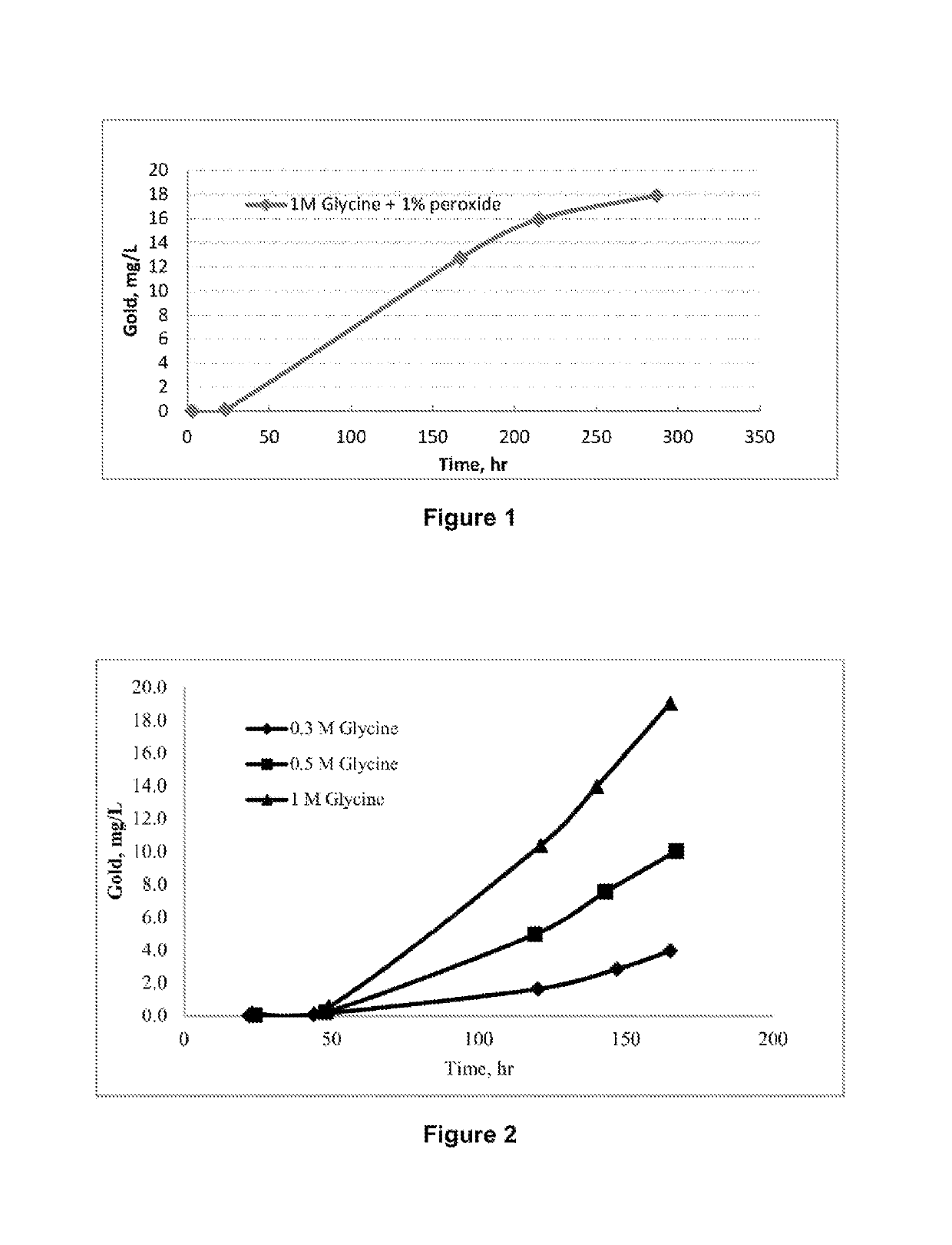

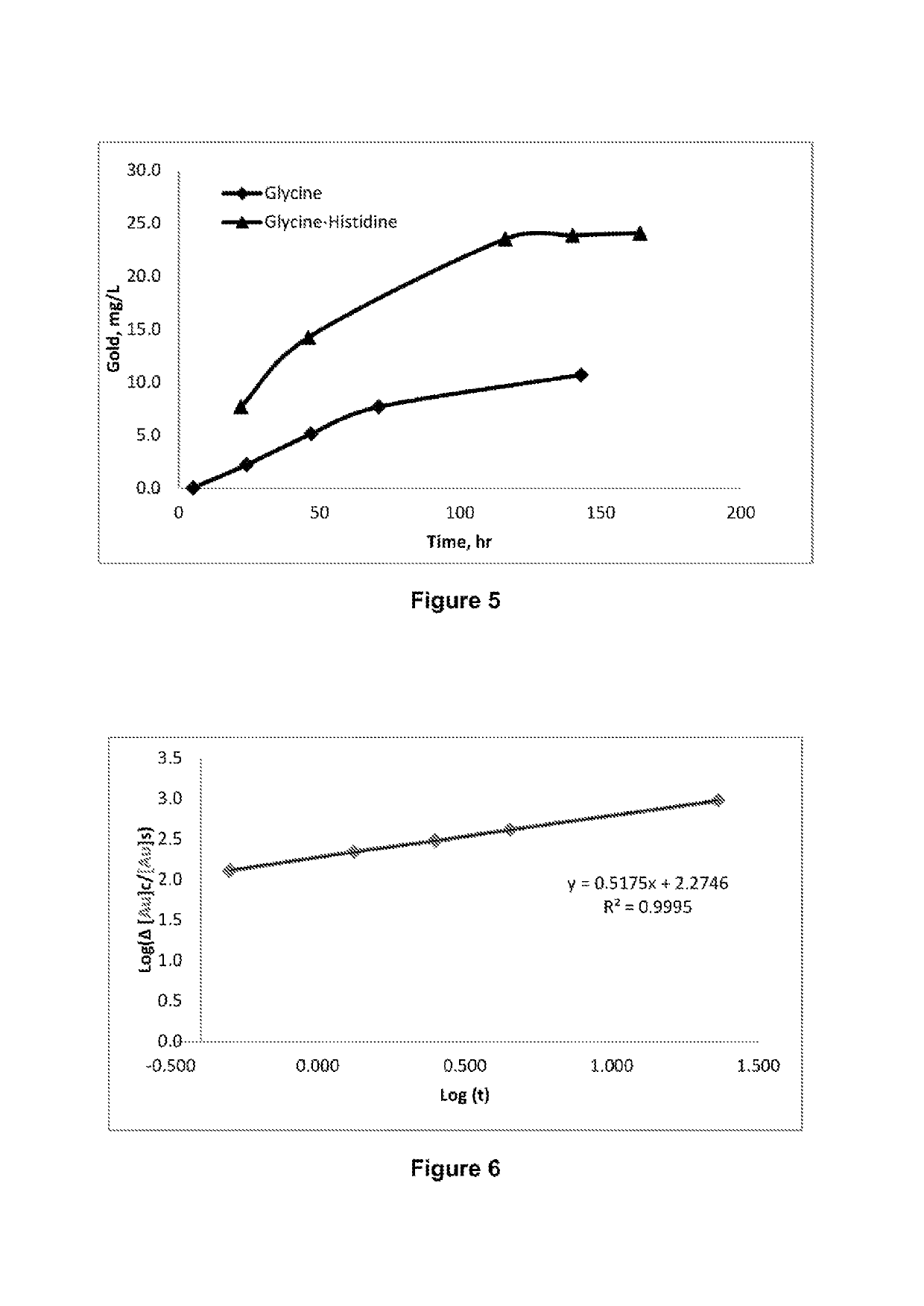

A process for copper and/or precious metal recovery

ActiveUS20160194734A1High dissolution rateOrganic chemistryOther chemical processesLixiviantMetal leaching

A process for recovery of metal comprising copper and / or a precious metal from a metal containing material, including the steps of: leaching the metal containing material with an alkaline lixiviant and an amino acid or derivative thereof in order to produce a metal containing leachate; and extracting the metal from the leachate.

Owner:MINING & PROCESS SOLUTIONS PTY LTD

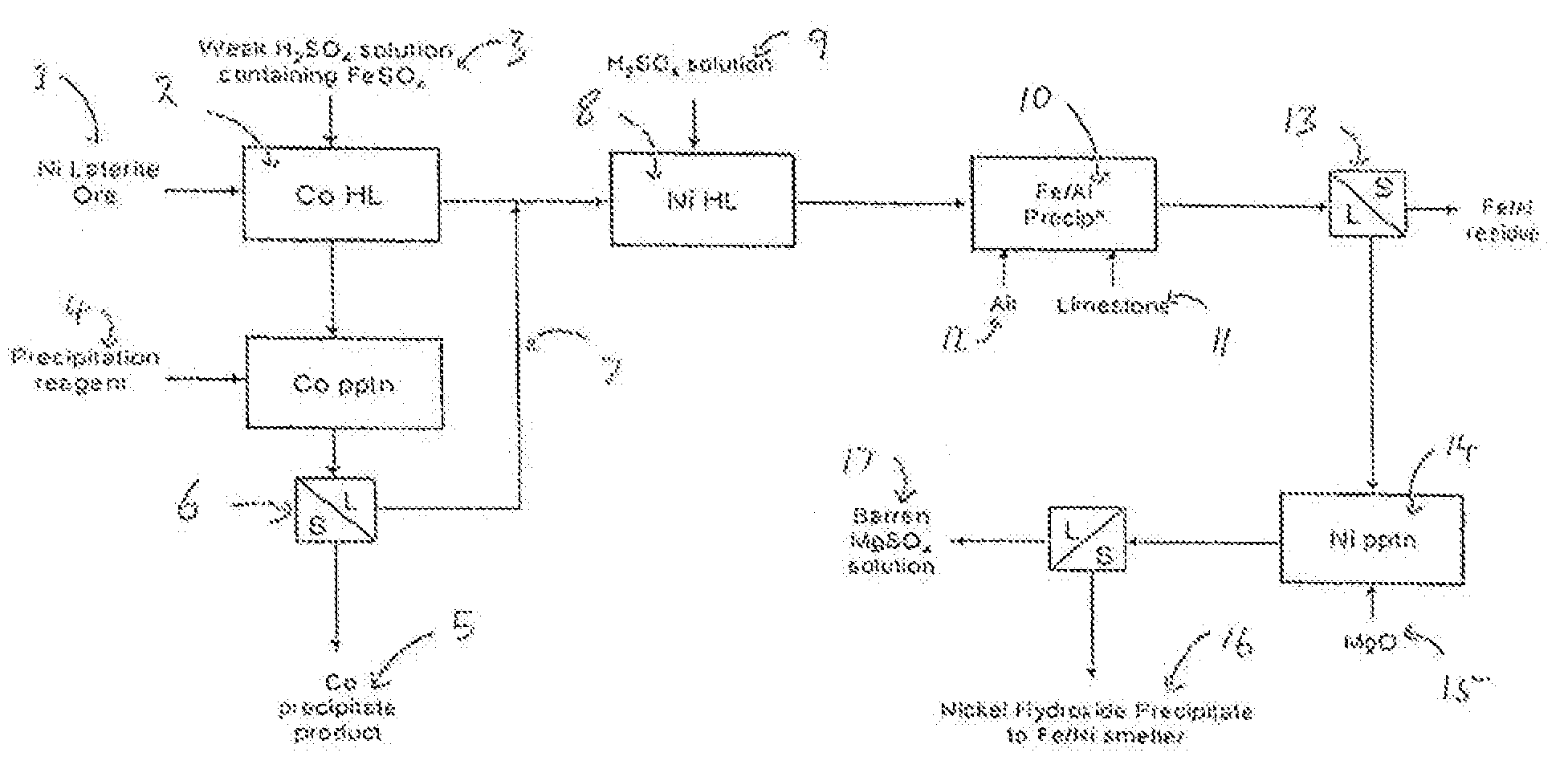

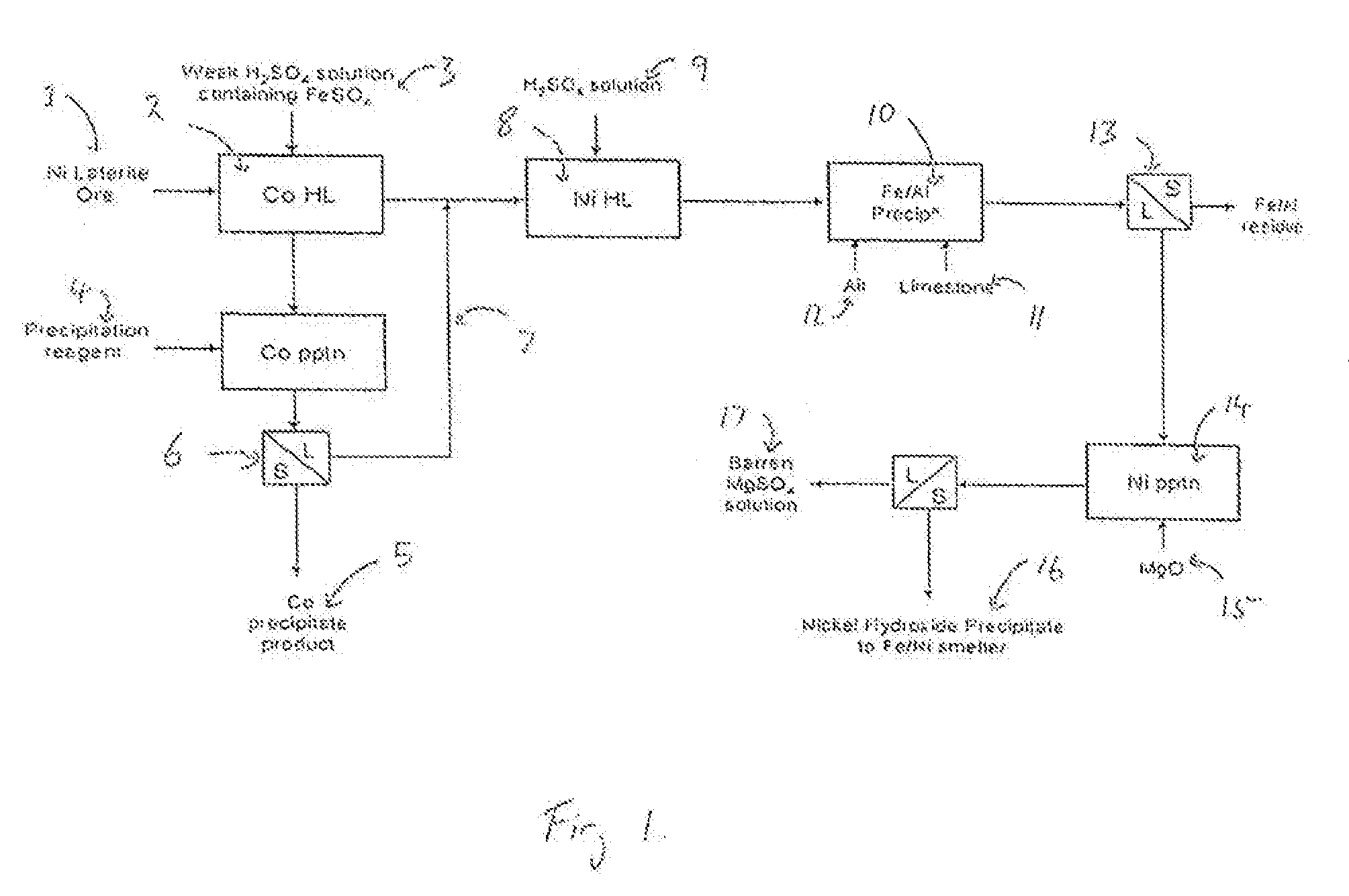

Selectively leaching cobalt from lateritic ores

A heap leach process for the recovery of nickel and cobalt from a lateritic ore, said process including the steps of leaching and / or agglomerating the ore with a lixiviant that includes ferrous ions, wherein the lixiviant is able to liberate cobalt from the cobalt containing minerals within the ore in preference to nickel, to produce a cobalt rich pregnant leach solution relatively free of nickel.

Owner:CERRO MATOSO

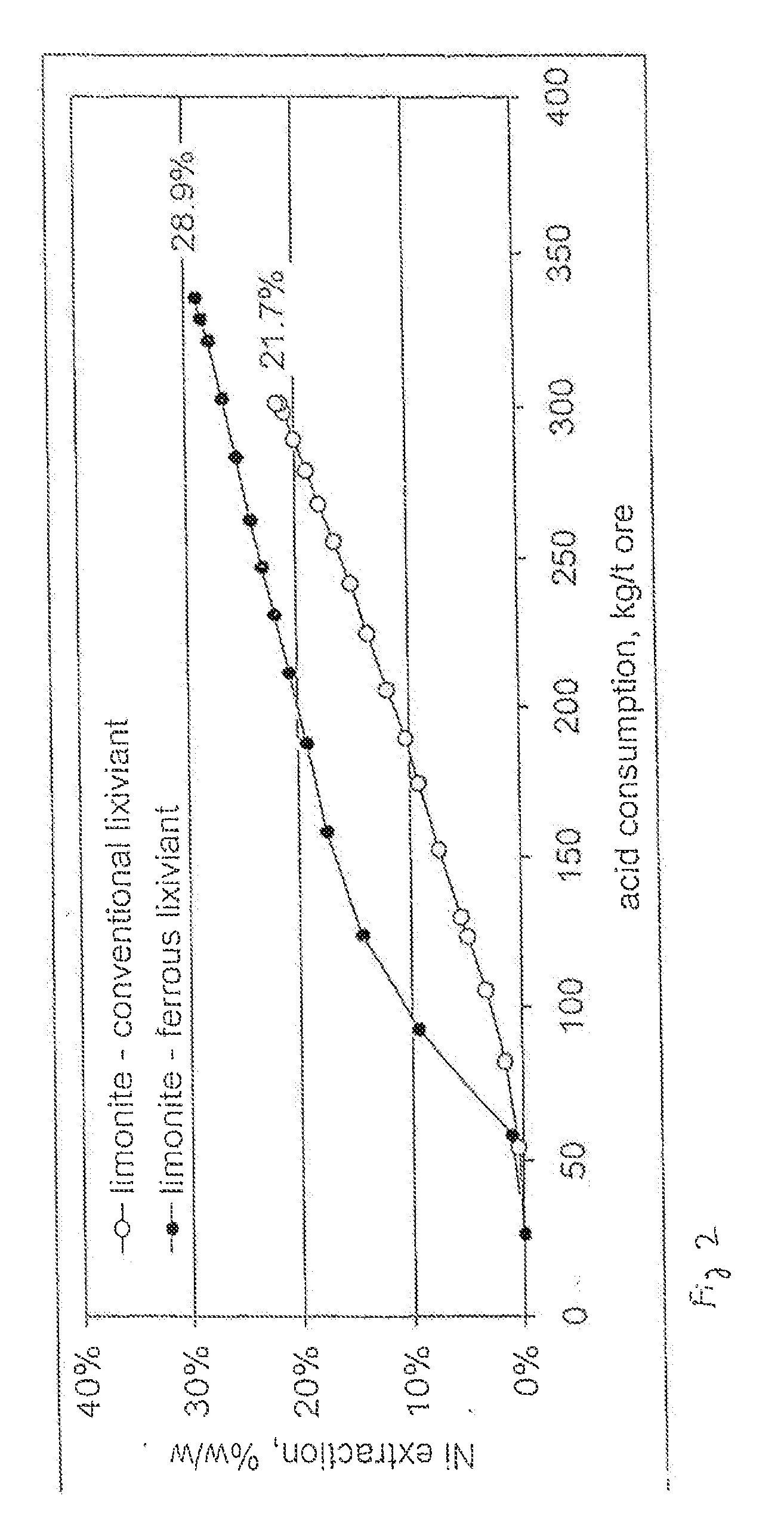

Lixiviant for rare earth production

Hydrometallurgical compositions are described in which organic amine-based lixiviants and organic amine-based pre-lixiviants are utilized in the selective recovery of rare earth elements. The lixiviant species can be regenerated in situ, permitting the organic amine to be used in substoichiometric amounts.

Owner:LIXIVIA

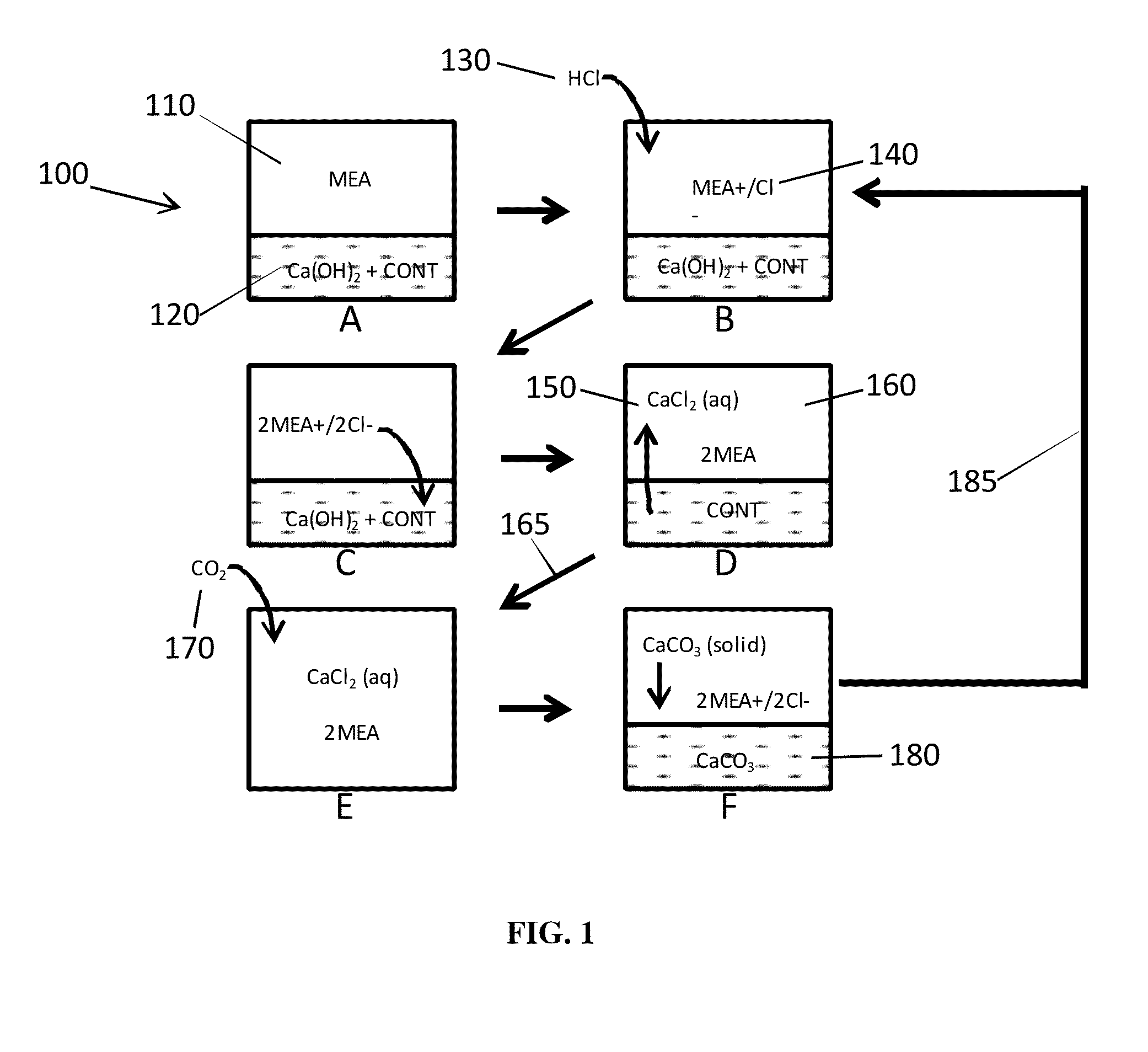

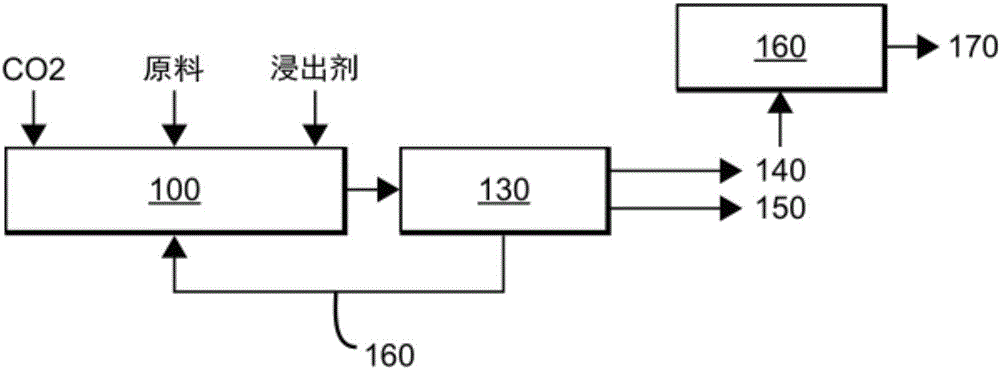

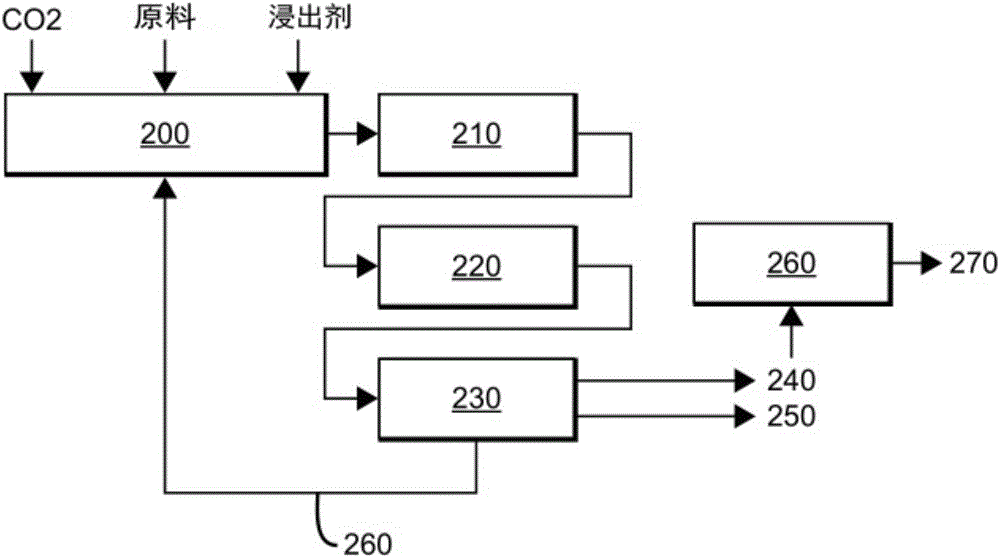

Methods for producing alkaline earth carbonates

Hydrometallurgical systems, methods, and compositions are described in which amine-based lixiviants are utilized in substoichiometric amounts to recover alkaline earths from raw or waste materials. The lixiviant can be regenerated and recycled for use in subsequent iterations of the process or returned to a reactor in a continuous process. Extraction of the alkaline earth from the raw material and precipitation of the extracted alkaline earth is performed in the same reactor and essentially simultaneously.

Owner:LIXIVIA

Production of High Grade Nickel Product

InactiveUS20150000466A1Eliminate the problemFrom normal temperature solutionsLiquid separation by electricityPregnant leach solutionElectrolysis

A process for the production of a high grade nickel product including the steps of: a) providing at least one heap of a nickeliferous lateritic ore and leaching that heap with a suitable lixiviant, preferably sulfuric acid solution, to produce a nickel rich pregnant leach solution (PLS); b) subjecting the PLS to an impurity removal step to precipitate ferric iron, and preferably partially precipitate aluminium and chromium as hydroxides; and c) recovering a high grade nickel product from the PLS preferably by either nickel ion exchange, solvent extraction, electrowinning, conventional multi-stage neutralization, pyrohydrolysis or sulfidation.

Owner:CERRO MATOSO

Process for copper and/or precious metal recovery

Owner:MINING & PROCESS SOLUTIONS PTY LTD

Production of high grade nickel product

Owner:CERRO MATOSO

Heap leaching of manganese-containing ores

ActiveUS20130309151A1Reducing of liabilityReduce pollutionProcess efficiency improvementRhenium compoundsPregnant leach solutionLixiviant

A method for the heap leaching of manganese-containing ores, the method characterised by the steps of: (i) beneficiating the manganese-containing ore and separating into a coarse fraction and a fine ore fraction; (ii) combining the fine ore fraction with a sulfide ore material to produce a combined ore fraction; (iii) stacking the combined ore fraction to form at least one heap; and (iv) applying a lixiviant to the heap to produce a pregnant leach solution (PLS) containing dissolved manganese values, wherein the lixiviant is added to the or each heap in the presence of soluble iron.

Owner:AUVEX RESOURCES PTY LTD

Chloride process for the leaching of gold

A process for the extraction of gold from a gold-bearing ore or concentrate, comprising the steps of leaching the gold-bearing ore or concentrate with a lixiviant of hydrochloric acid and magnesium chloride at atmospheric pressure at a temperature of at least 90° C. and an Eh of at least 900 mV. After a liquid / solids separation step, the solution obtained is subjected to an organic solvent extraction step using an oxime to obtain a solution of organic solvent containing gold, which is stripped with sodium thiosulphate to recover gold. The extraction may be operated to extract gold with or without iron. Materials used in the process may be recycled. The process avoids environmental and other hazards associated with the use of cyanide to extract gold.

Owner:ORF TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com