Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286results about "Thiosulfates/dithionites/polythionites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium thiosulfate-containing pharmaceutical compositions

Provided herein are pharmaceutically acceptable sodium thiosulfate and pharmaceutical compositions thereof. Also provided herein are methods for determining the total non-purgable organic carbon in a sodium thiosulfate-containing sample. Further provided herein are methods for producing pharmaceutically acceptable sodium thiosulfate. Still further provided herein are methods of treatment comprising the administration of pharmaceutically acceptable sodium thiosulfate.

Owner:HOPE MEDICAL ENTERPRISES HOPE PHARMA

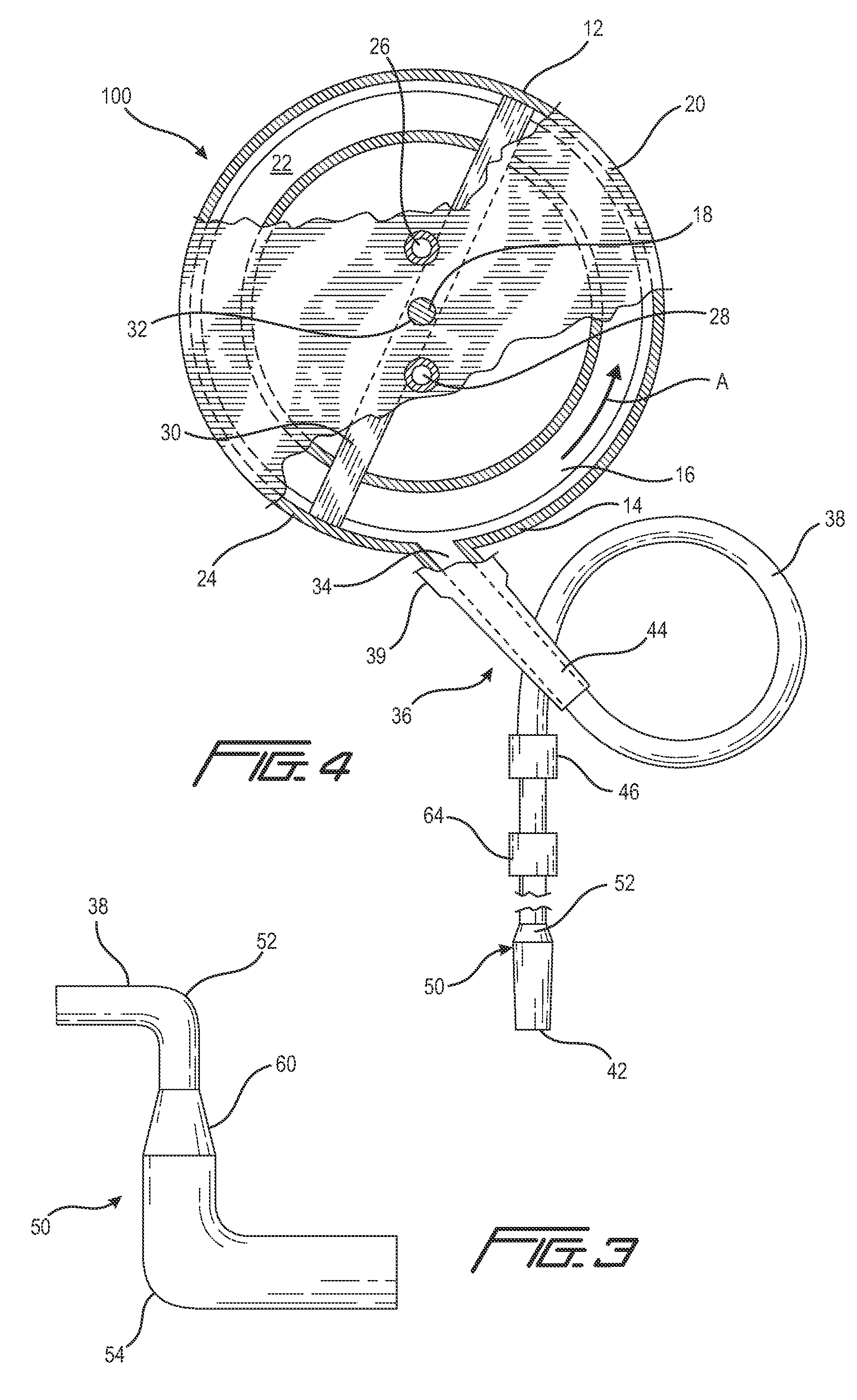

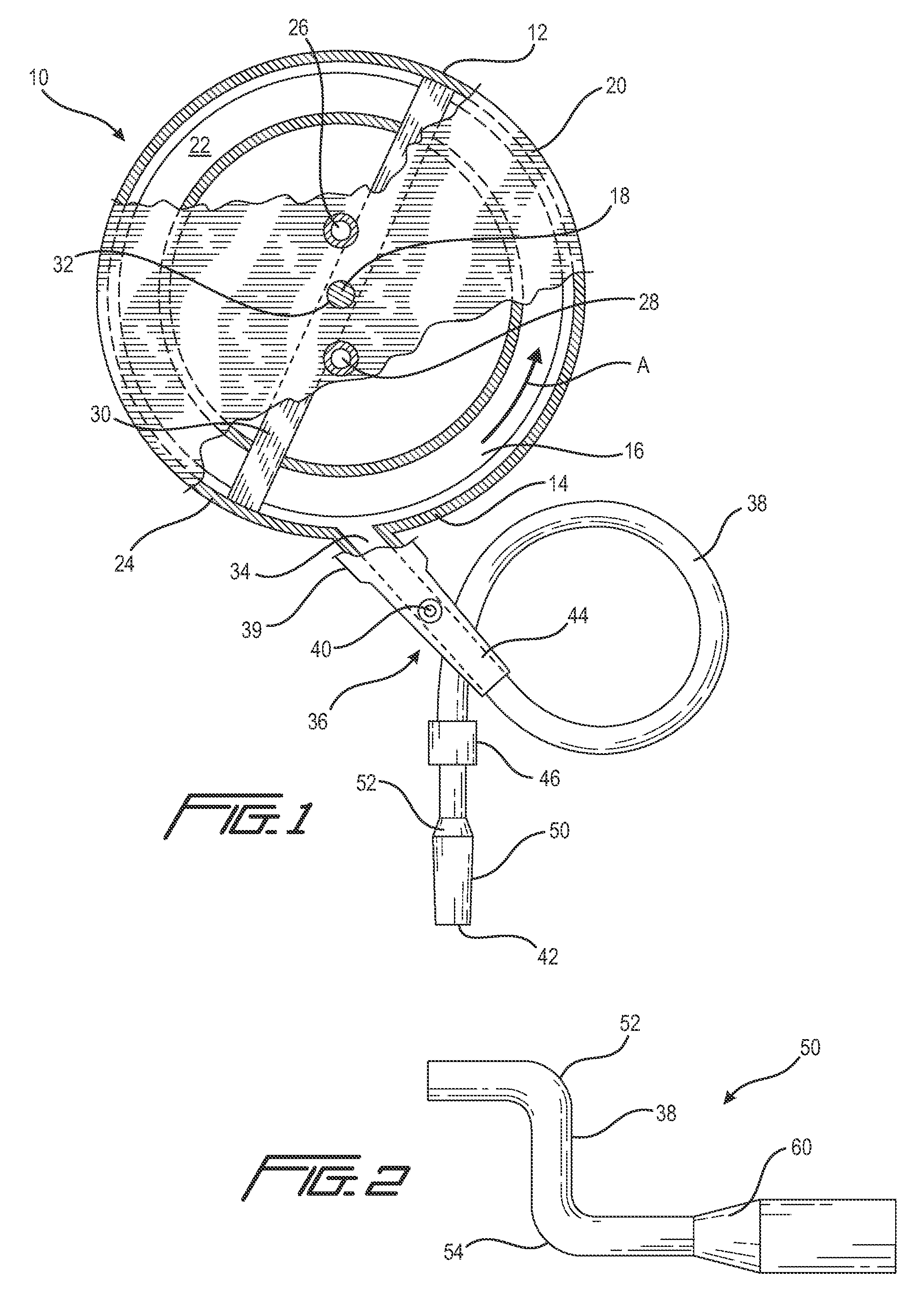

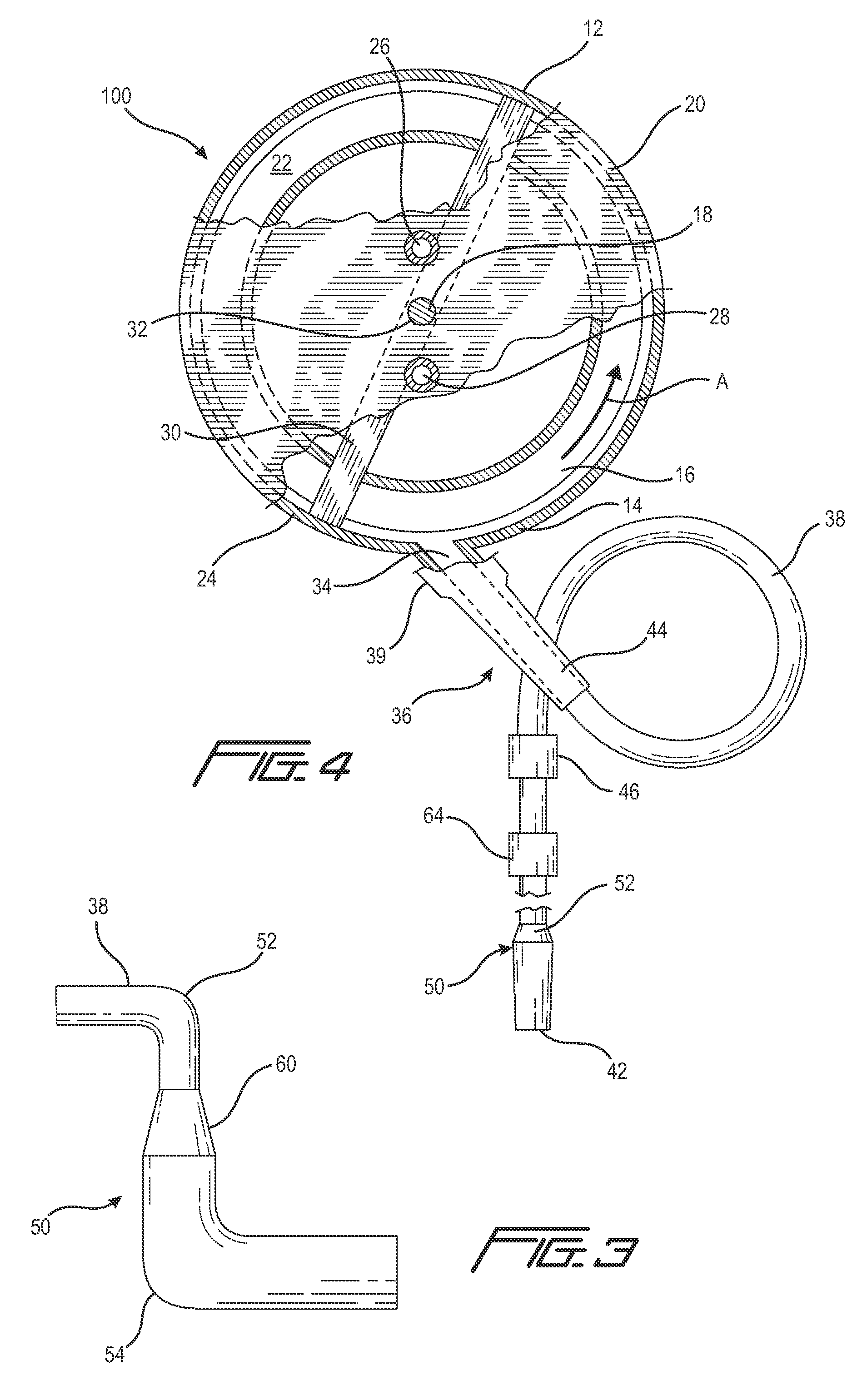

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

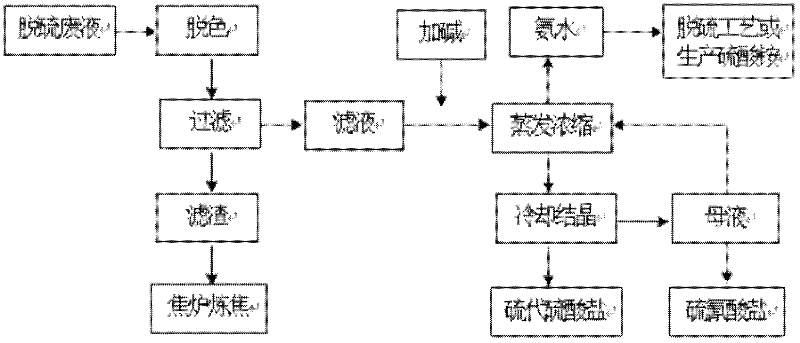

Method for treating desulfurization waste liquid of wet oxidation method

ActiveCN102295379AReduce manufacturing costNot easily decomposed by heatThiosulfates/dithionites/polythionitesThiocyanic acidSodium thiocyanateEvaporation

A method for treating desulfurization waste liquid of a wet oxidation method. The method comprises the following steps: firstly adding a decolorant into desulfurization waste liquid for decolorizing treatment, filtering after decolorization, adding alkali into the filtrate, controlling the PH to be 8-9, performing evaporation concentration under a condition with a negative pressure, condensing the evaporated ammonia gas and water vapor to obtain concentrated ammonia liquor which can be returned to the system for recycle or be used to produce ammonium sulfate, performing fractional crystallization of the concentrated desulfurization liquid to respectively obtain high-purity sodium thiocyanate and sodium hyposulfite. The invention has a simple process, and stable operations, and effectively solves the problem of difficult HPF desulfurization waste liquid treatment in coking enterprises; the method not only reduces the discharge of the waste liquid, but also recovers a lot of chemical products with economic value, and the method has quite significant economic benefits and environmental benefits.

Owner:SHOUGANG CORPORATION

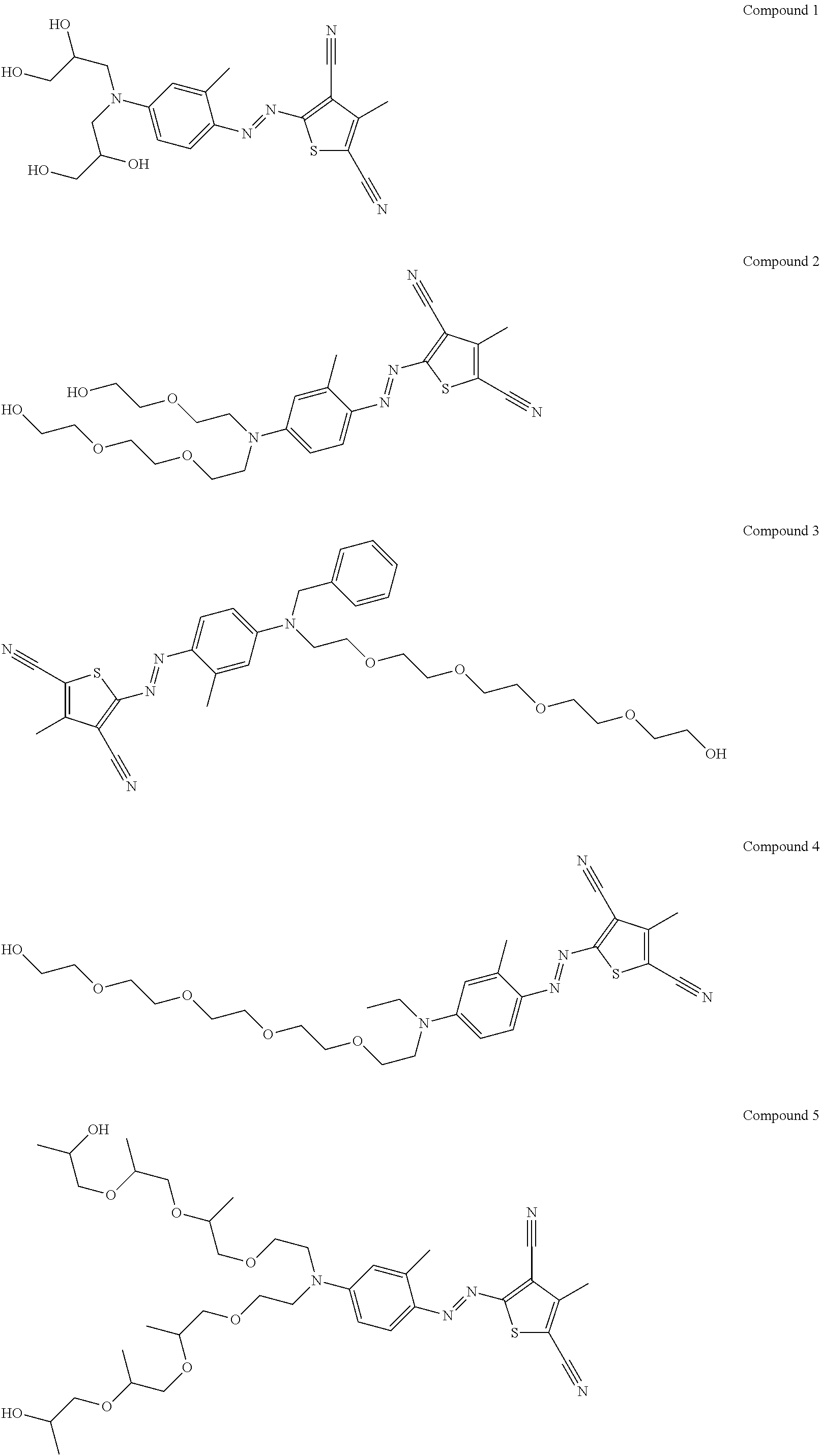

Production of silver sulfate grains using organo-sulfate or organo-sulfonate additives

ActiveUS7261867B1Uniform morphologyUniform sizePigmenting treatmentCosmetic preparationsOrganic sulfonic acidSulfonate

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble organo-sulfate or organo-sulfonate additive compound, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain size of less than 50 micrometers.

Owner:EASTMAN KODAK CO

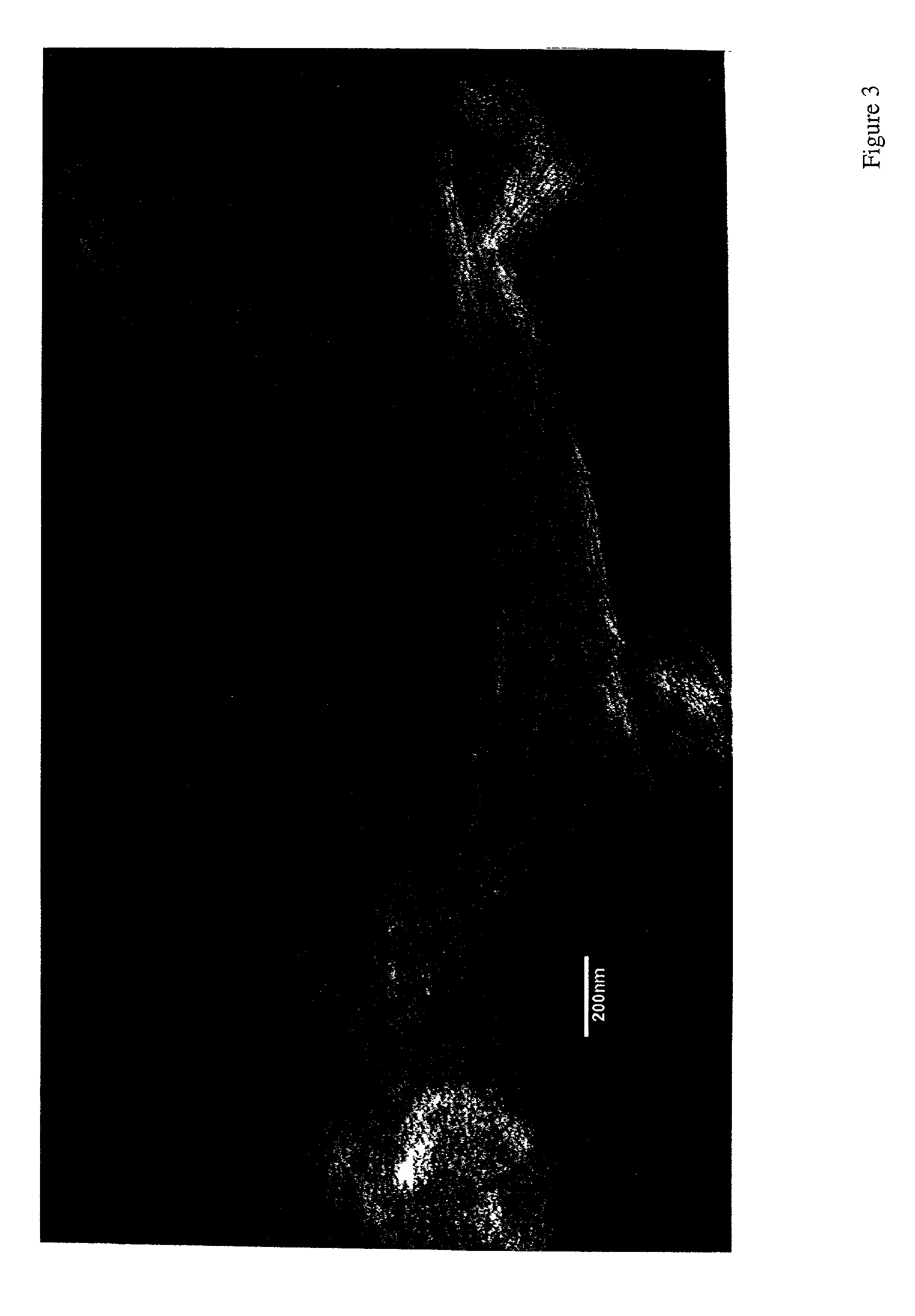

Methods for manufacturing functionalized inorganic oxides and polymers incorporating same

InactiveUS20070167562A1Improve propertiesHigh strengthGroup 4/14 element organic compoundsSilicaNanoparticleFilling materials

Inorganic oxide substrates are functionalized with silicon-free organic functionalizing agents. The organic functionalizing agent has a bonding functional group for bonding to the substrate and a functionalizing moiety that is not bonded to the substrate for imparting a desired functionality to the substrate. The functionalized inorganic oxide substrates are manufactured by selecting a functionalizing agent and reaction conditions that allows the bonding functional group to bond to the inorganic material while leaving the functionalizing moiety available for providing the desired functionality. The functionalized inorganic oxides can be used as filler materials in polymers or to manufacture a supported nanoparticle catalyst.

Owner:HEADWATERS TECH INNOVATION GRP

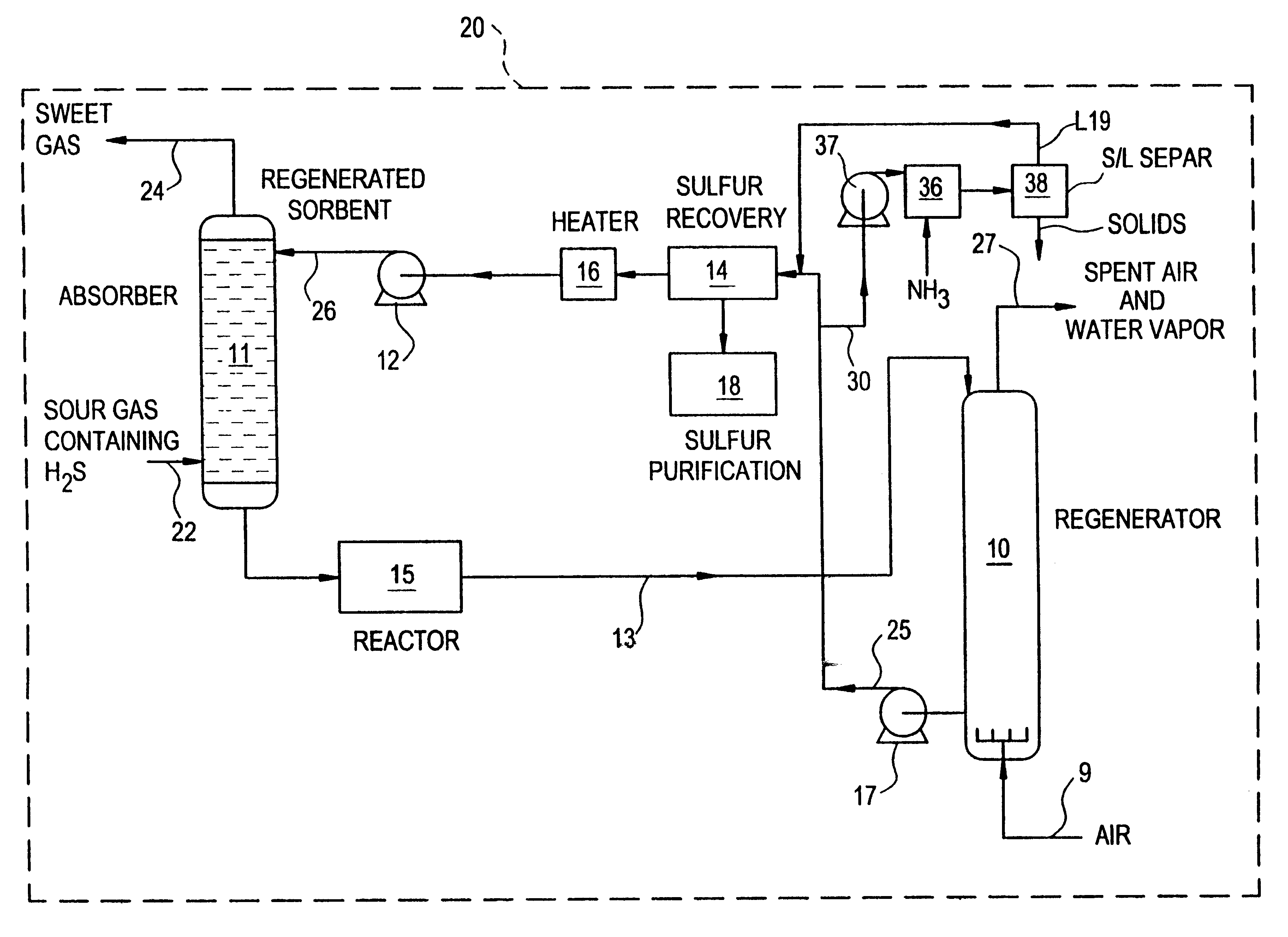

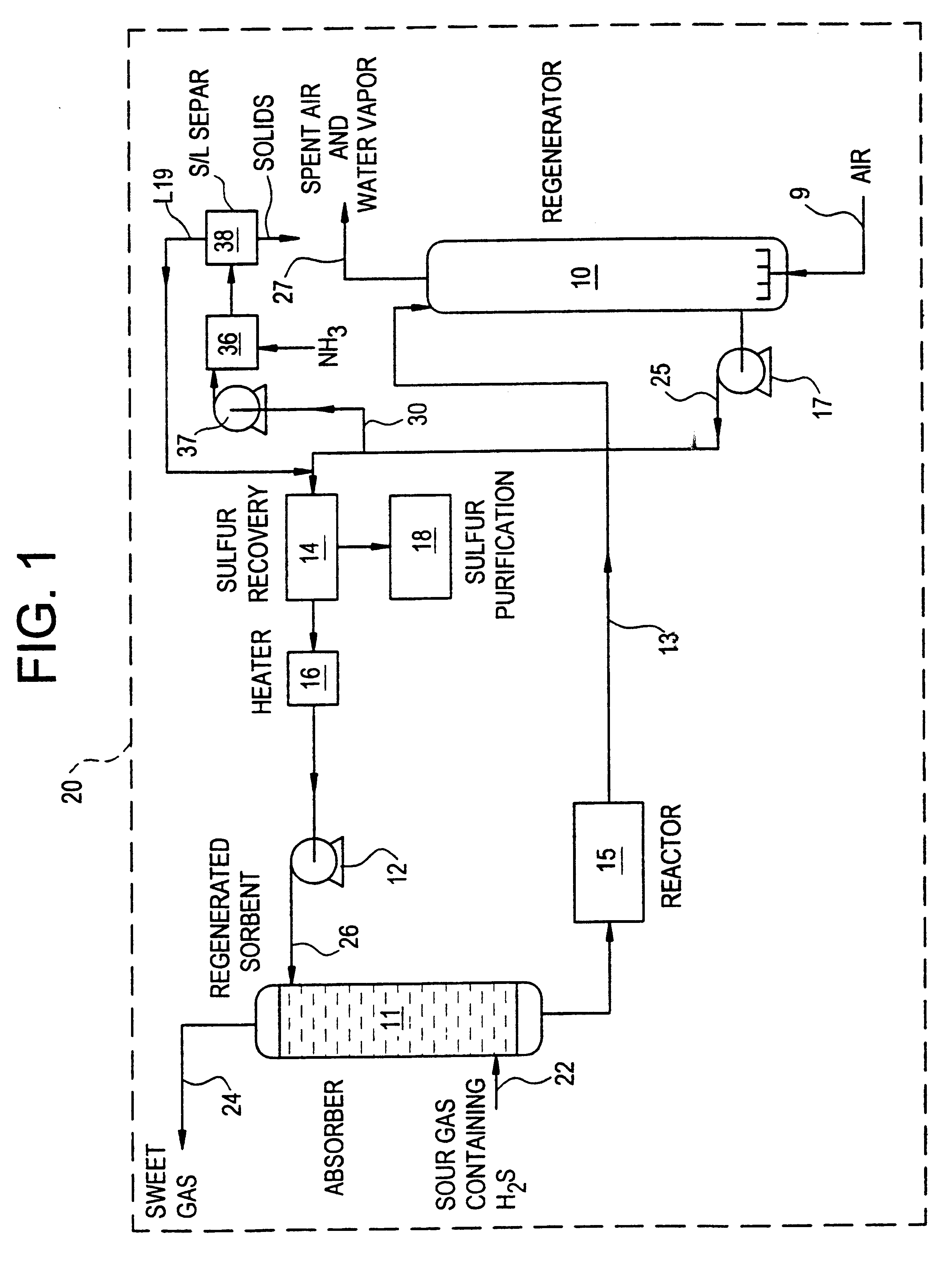

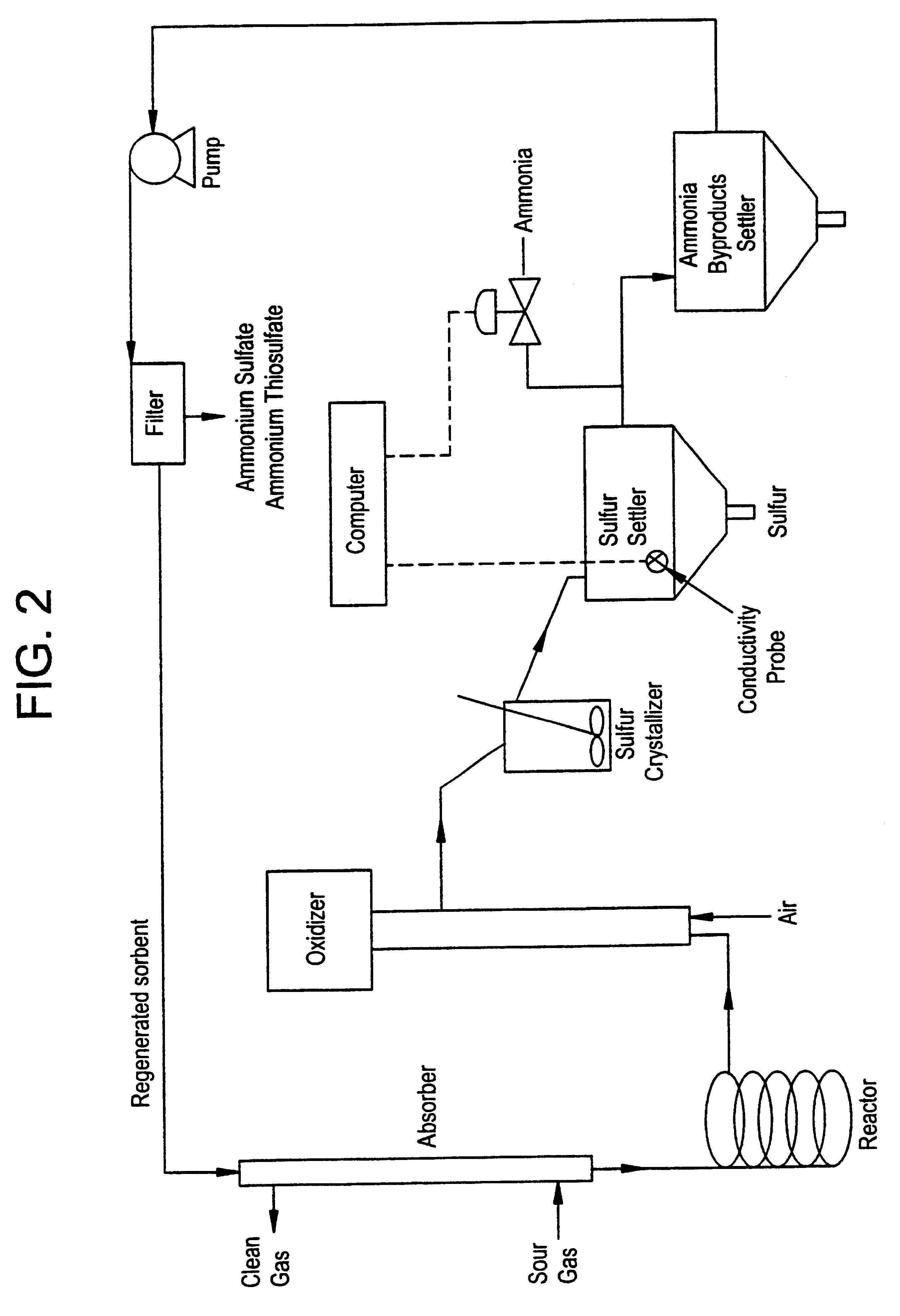

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

Precipitated aragonite and a process for producing it

InactiveUS20010033820A1Less expensiveEfficient and less-expensiveCalcium/strontium/barium carbonatesInorganic/elemental detergent compounding agentsParticulatesAragonite

Disclosed is a novel form of particulate precipitated aragonite, a novel process for producing it and compositions containing it.

Owner:3P TECH

Photocatalytic powder and polymer composition

InactiveUS6683023B2Good effectClean environmentPigmenting treatmentOrganic-compounds/hydrides/coordination-complexes catalystsShell moldingSlurry

Owner:RESONAC HOLDINGS CORPORATION

Photocatalytic powder, photocatalytic slurry, and polymer composition, coating agent, photocatalytic functional molded article and photocatalytic functional structure using the powder

InactiveUS20010046944A1Good effectClean environmentPigmenting treatmentOther chemical processesShell moldingSlurry

An object of the present invention is to provide a photocatalytic powder containing titanium dioxide fine particles containing an anionically active substance, where the electrokinetic potential of the fine particle is from about -100 to 0 mV in an aqueous environment at pH 5. Another object of the present invention is to provide a photocatalytic slurry containing the powder, and a polymer composition, a coating agent, a photocatalytic functional molded article and a photocatalytic functional structure using the powder.

Owner:SHOWA DENKO KK

Method for processing secondary salt in desulphurization waste liquid

InactiveCN103058442AHigh salt contentNo emissionsThiosulfates/dithionites/polythionitesThiocyanic acidInorganic saltsWastewater

The invention relates to a method for processing secondary salt in desulphurization waste liquid, comprising the following steps: a, carrying out pre-treatment on the desulphurization waste liquid, and removing the impurities in the desulphurization waste liquid; b, conveying the desulphurization waste liquid to a de-coloring kettle via a centrifugal pump; c, after atomizing via the nozzle of a spray dryer, drying the desulphurization waste liquid, so that Na2S2O3, Na2SO4 and NaCNS secondary salts can be separated by a manner of solid salts, and recycling the secondary salts which are adopted as inorganic salts to realize the discharge without wastewater. The method for processing the secondary salt in the desulphurization waste liquid disclosed by the invention can rationally process the waste liquid which is produced in the desulphurization step in gas production factories and has a high content of the secondary salt, realizes the discharge without wastewater, effectively recycles the waste heat of systems, realizes the reuse of the heat, reduces the production cost, has simple process and has performance of environmental-friendliness.

Owner:甘肃银光聚银化工有限公司

Method of separating multi-ammonium compound salt

InactiveCN101012065ANon-flammableNon-explosiveThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium compoundsWastewater

The invention discloses a separating method of multi-ammonia composite salt, which comprises the following steps: separating ammonia thiocyanate under low temperature (0-25 deg.c); enriching ammonium thiosulfate and ammonium sulfate under middle temperature (40-65 deg.c); separating ammonium sulfate under high temperature (80-90 deg.c); separating enriched ammonium thiosulfate at 20-40 deg.c; dissolving, crystallizing and separating solid from liquid for several times under different temperature to separate ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate one by one.

Owner:苏州久王环保科技股份有限公司

Cathode material for lithium secondary battery and manufacturing method thereof

ActiveUS7799301B2Excellent characteristicsImprove sinterabilityThiosulfates/dithionites/polythionitesConductive materialLithium carbonatePhosphoric acid

Owner:JX NIPPON MINING & METALS CORP

Method of improving yield of chlorine dioxide generation processes

InactiveUS20020037248A1Preventing decrease of overall process yieldReduced pHOther chemical processesThiosulfates/dithionites/polythionitesGeneration processChlorine dioxide

A greater yield of chlorine dioxide from a chlorine dioxide generating process is obtained by providing acidic or acidity-generating components in the product chlorine dioxide solution to provide a chlorine dioxide solution having a pH below about 5.5.

Owner:SUPERIOR PLUS INCOME FUND +1

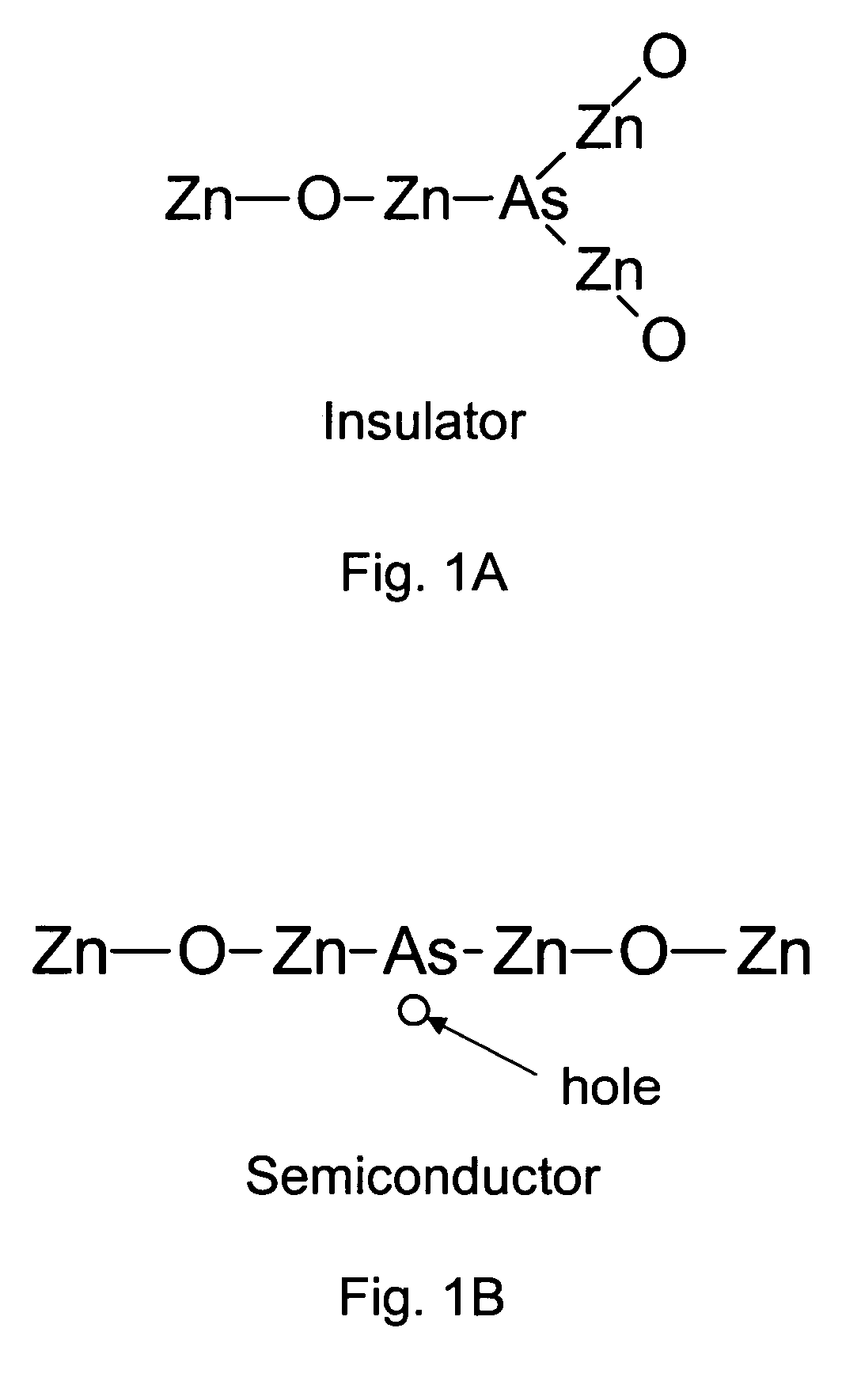

Low dielectric constant group II-VI insulator

InactiveUS7691353B2Laser detailsSemiconductor/solid-state device detailsDopantDielectric permittivity

Low dielectric constant group II-VI compounds, such as zinc oxide, and fabrication methods are disclosed. Low dielectric constant insulator materials are fabricated by doping zinc oxide with at least one mole % p-type dopant ion. Low dielectric constant zinc oxide insulator materials are fabricated by doping zinc oxide with silicon having a concentration of at least 1017 atoms / cm3. Low dielectric zinc oxide insulator materials are fabricated by doping zinc oxide with a dopant ion having a concentration of at least about 1018 atoms / cm3, followed by heating to a temperature which converts the zinc oxide to an insulator. The temperature varies depending upon the choice of dopant. For arsenic, the temperature is at least about 450° C.; for antimony, the temperature is at least about 650° C. The dielectric constant of zinc oxide semiconductor is lowered by doping zinc oxide with a dopant ion at a concentration at least about 1018 to about 1019 atoms / cm3.

Owner:ZENO MATERIALS LLC

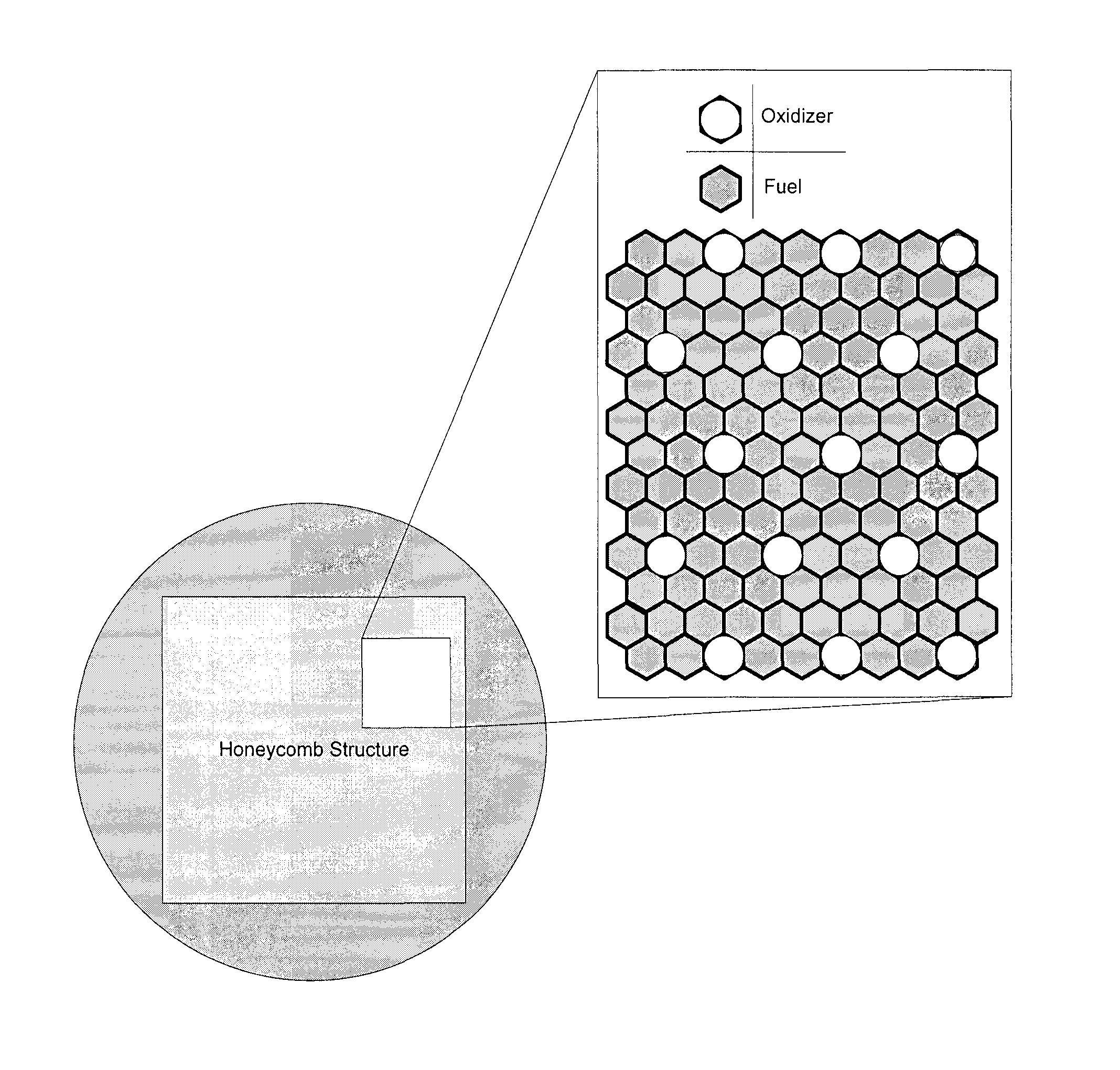

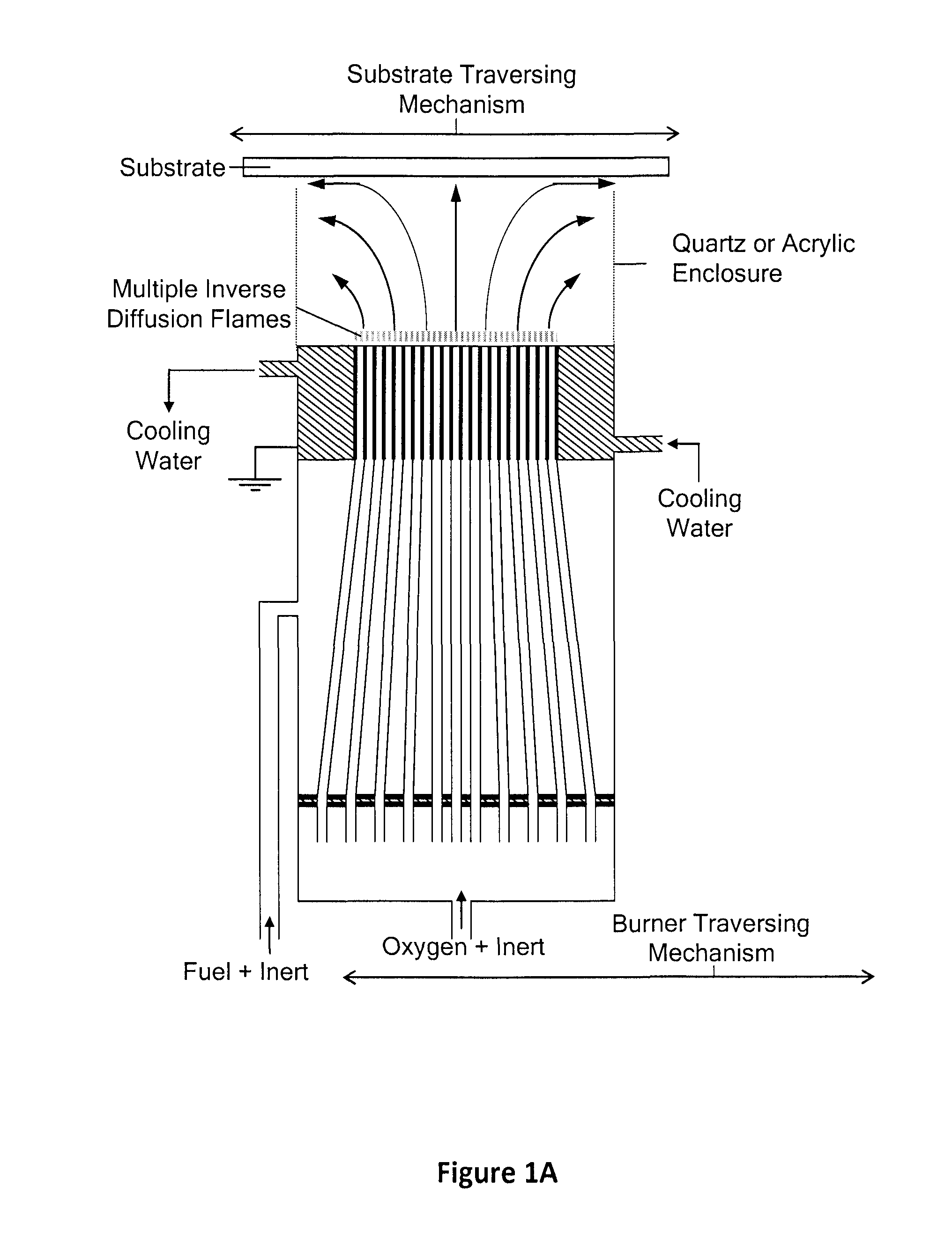

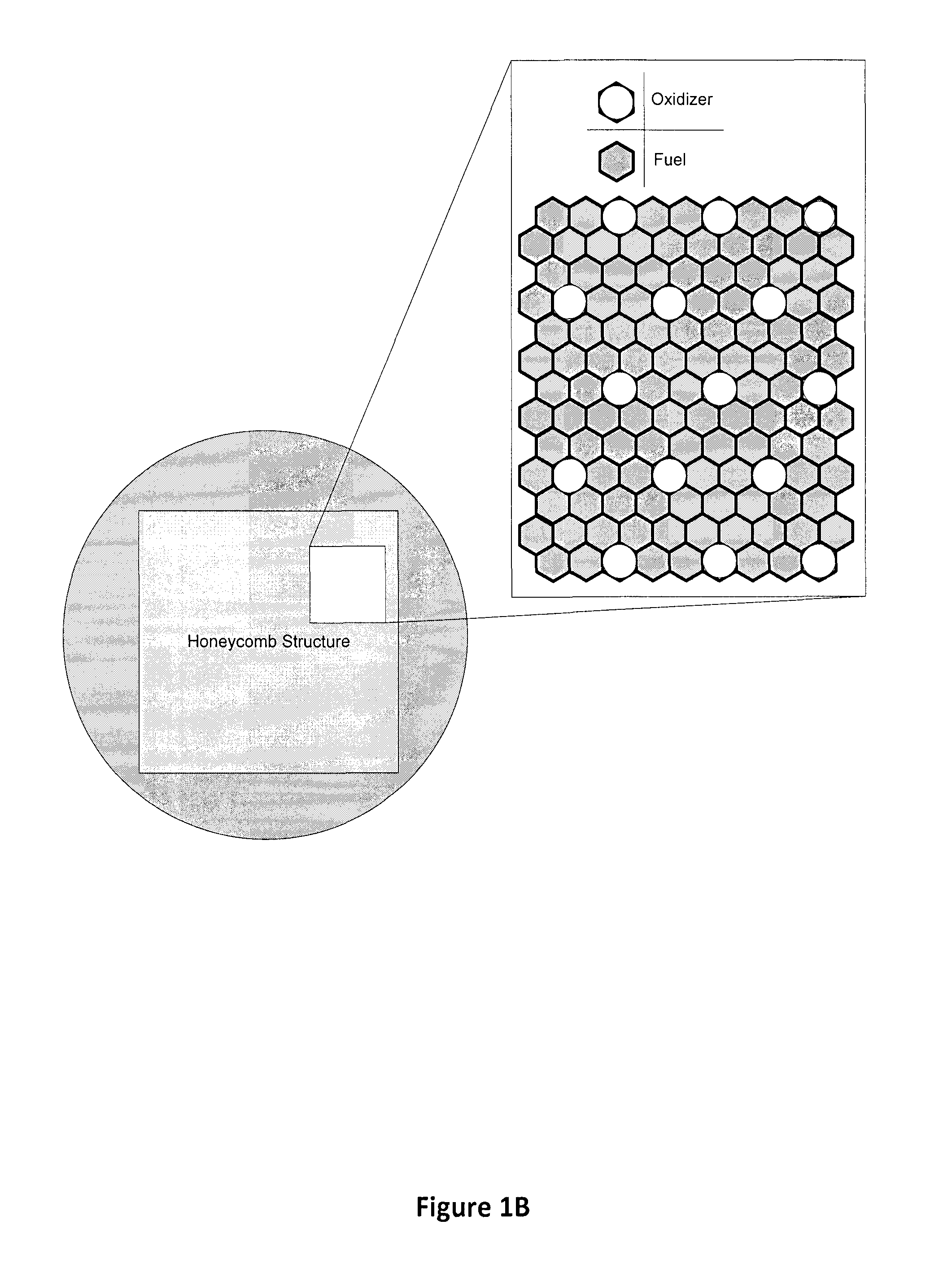

Scalable Multiple-Inverse Diffusion Flame Burner for Synthesis and Processing of Carbon-Based and Other Nanostructured Materials and Films and Fuels

ActiveUS20140054505A1Efficient hydrogen extractionImprove hydrogen permeabilityCyanogen compoundsThiosulfates/dithionites/polythionitesDiffusion flameNanostructured materials

Owner:RUTGERS THE STATE UNIV

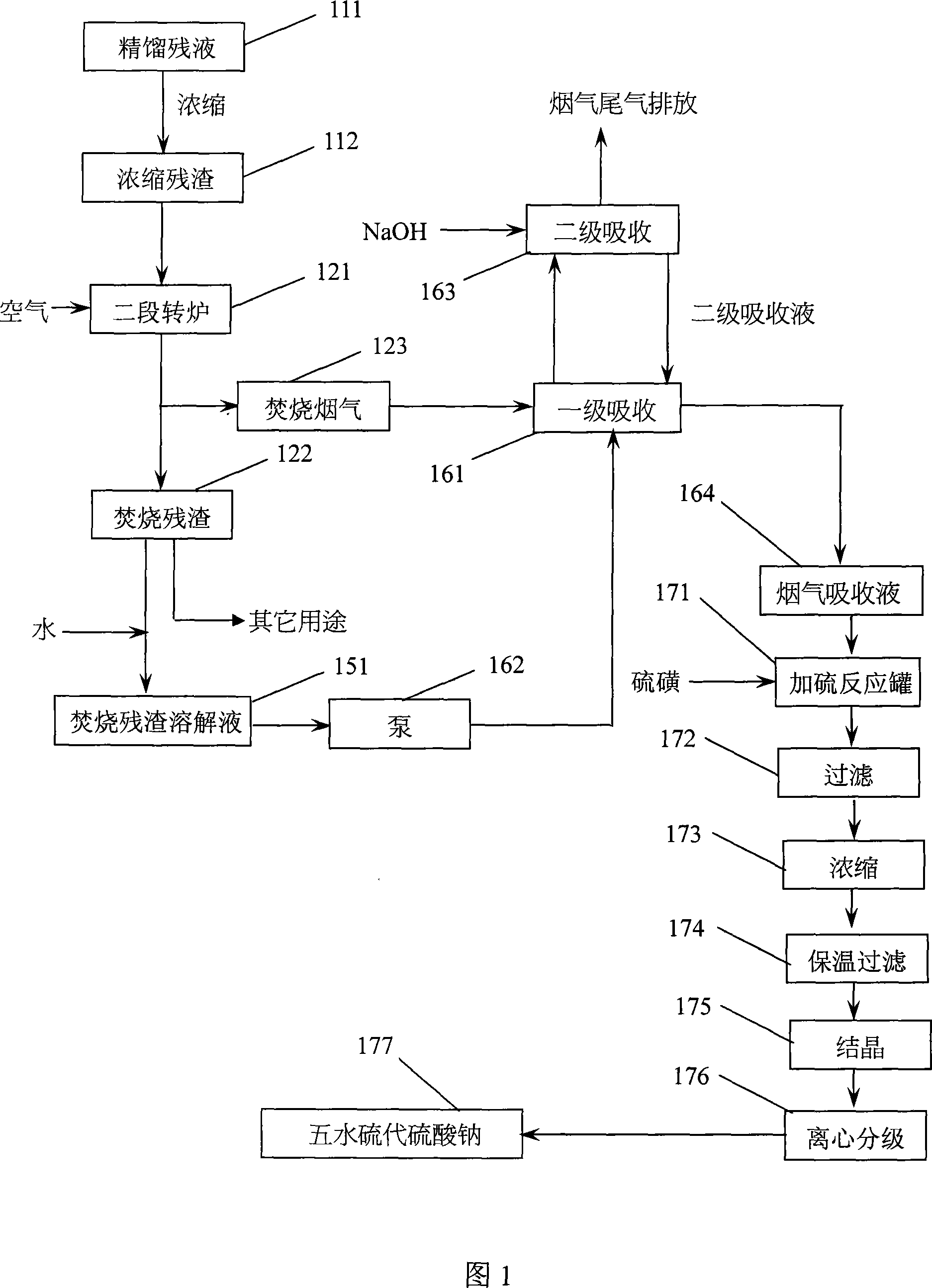

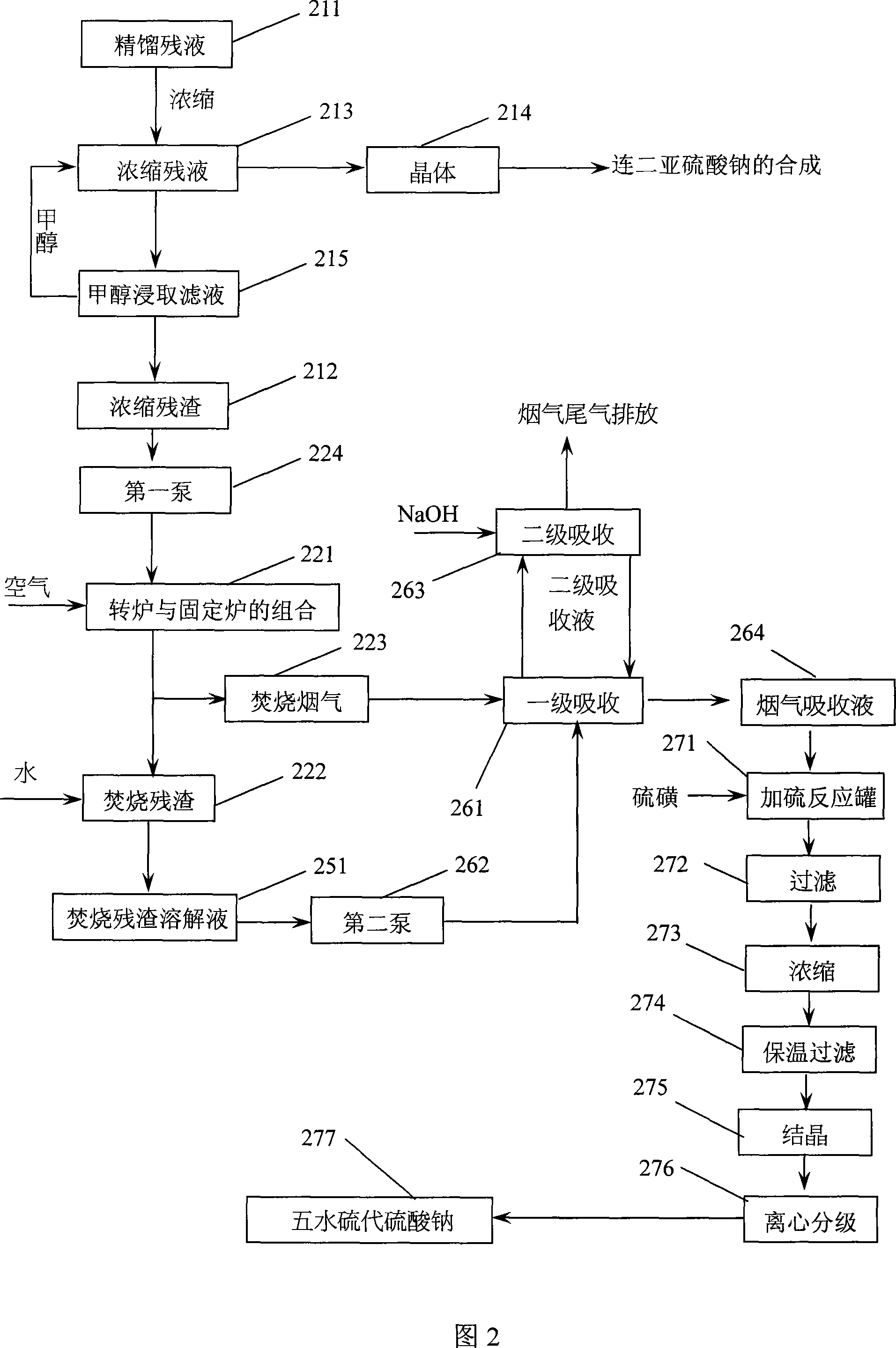

Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

InactiveCN101081715AEliminate secondary pollutionRecycling resourcesThiosulfates/dithionites/polythionitesDispersed particle separationDithionous acidSulfite salt

The present invention is process of treating mother liquid residue from sodium formate method to produce sodium hyosulfate and after being rectified to recover methanol. The process includes the following steps: 1. concentrating to obtain concentrated residue with or without sodium formate recovery; 2. incinerating the concentrated residue in a converter or one combined furnace to obtain incinerated clinker; 3. discharging high temperature clinker; 4. dissolving the clinker to form water solution; 5. absorbing SO2 from the incinerating fume with the water solution; and 6. adding sulfur to the absorbed solution to prepare sodium thiosulfate. The process can eliminate pollutant while producing sodium thiosulfate as chemical material.

Owner:GUANGDONG ZHONGCHENG CHEM INC LTD

Method for treating sulfides in waste streams

ActiveUS20170073257A1Non toxicWaste water treatment from quariesWater treatment compoundsWaste streamWastewater

A method for treating sulfide in an aqueous fluid comprises contacting the fluid with an oxidizer in the presence of a sulfur dye or sulfurized vat dye. In one embodiment, the method comprises treating sulfide contaminated water by contacting the contaminated water with air in the presence of a sulfur dye or a sulfurized vat dye. The method is useful for remediating industrial, agricultural, and municipal waste water.

Owner:BILL ARCHER LLC

Mesostructured transition aluminas

InactiveUS20030052047A1Easy to implementRefining with metalsMolecular sieve catalystsPtru catalystEngineering

Mesoporous crystalline alumina compositions and process for the preparation thereof are described. The compositions are useful as catalysts and absorbents.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Preparation method of analytically pure sodium thiosulfate

InactiveCN101891159AThe process steps are simpleControllableThiosulfates/dithionites/polythionitesAlkalinitySulfite salt

The invention relates to a preparation method of analytically pure sodium thiosulfate, comprising the following steps: (1) placing distilled water and sodium sulfite into a stainless steel reactor, heating for dissolving, heating the mixed solution until boiling, slowly adding sulphur powder to the stainless steel reactor, enabling the reacted mixture to boil for 2-3 hours until the solution does not show alkalinity, stopping heating, standing for 5-6 hours, and filtering to obtain solution A; and (2) heating and concentrating the solution A into 22-33 degree Be, cooling to obtain crystals, moving the crystals into a vacuum drier to dry at 30-35 DEG C, and taking out to obtain the finished product. In the method, the analytically pure sodium thiosulfate is obtained by synthetic reaction of the sodium sulfite and the sulphur powder, thus having simple process steps, easily controlled operation and high production efficiency; and the obtained sodium thiosulfate has low impurity content, thus the product can be widely applied to the market.

Owner:TIANJIN CHEM REAGENT RES INST

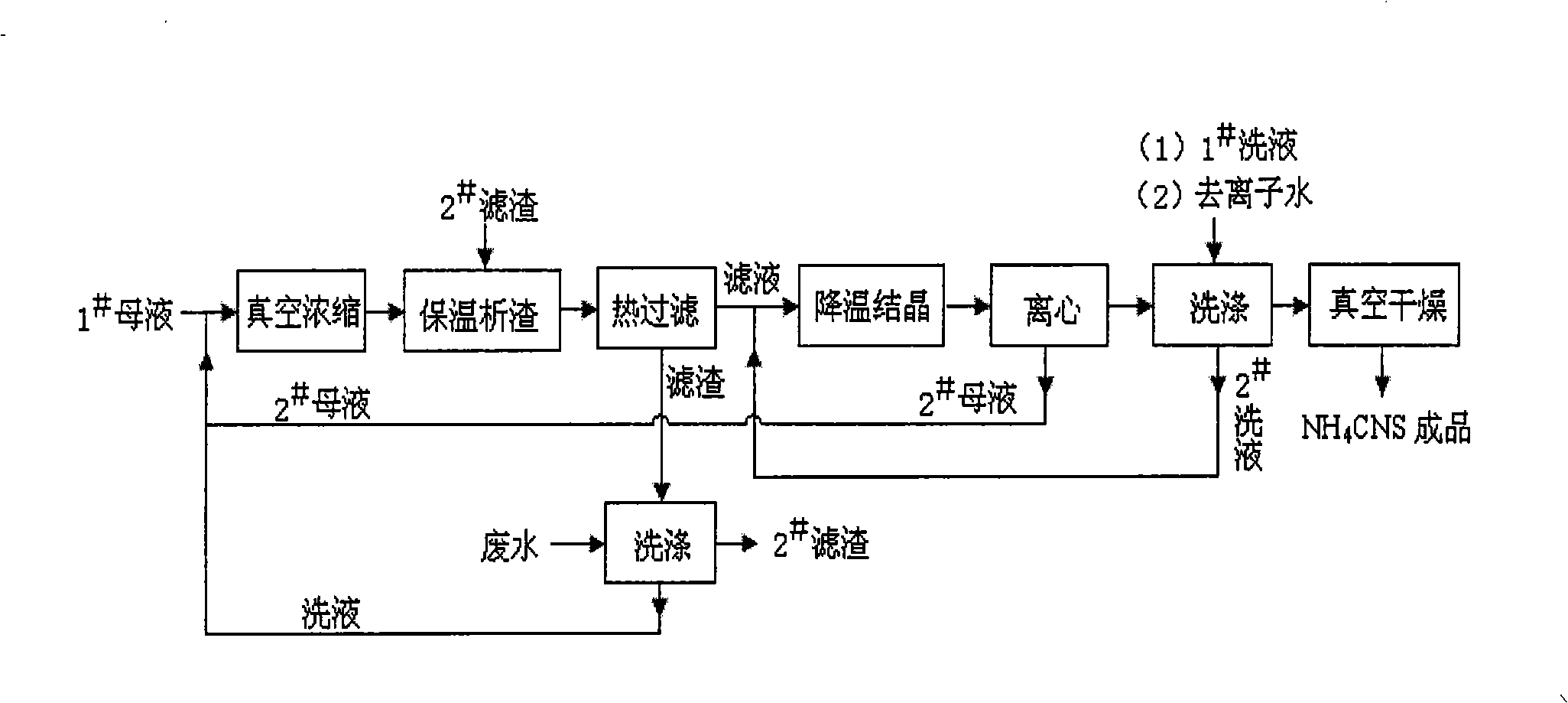

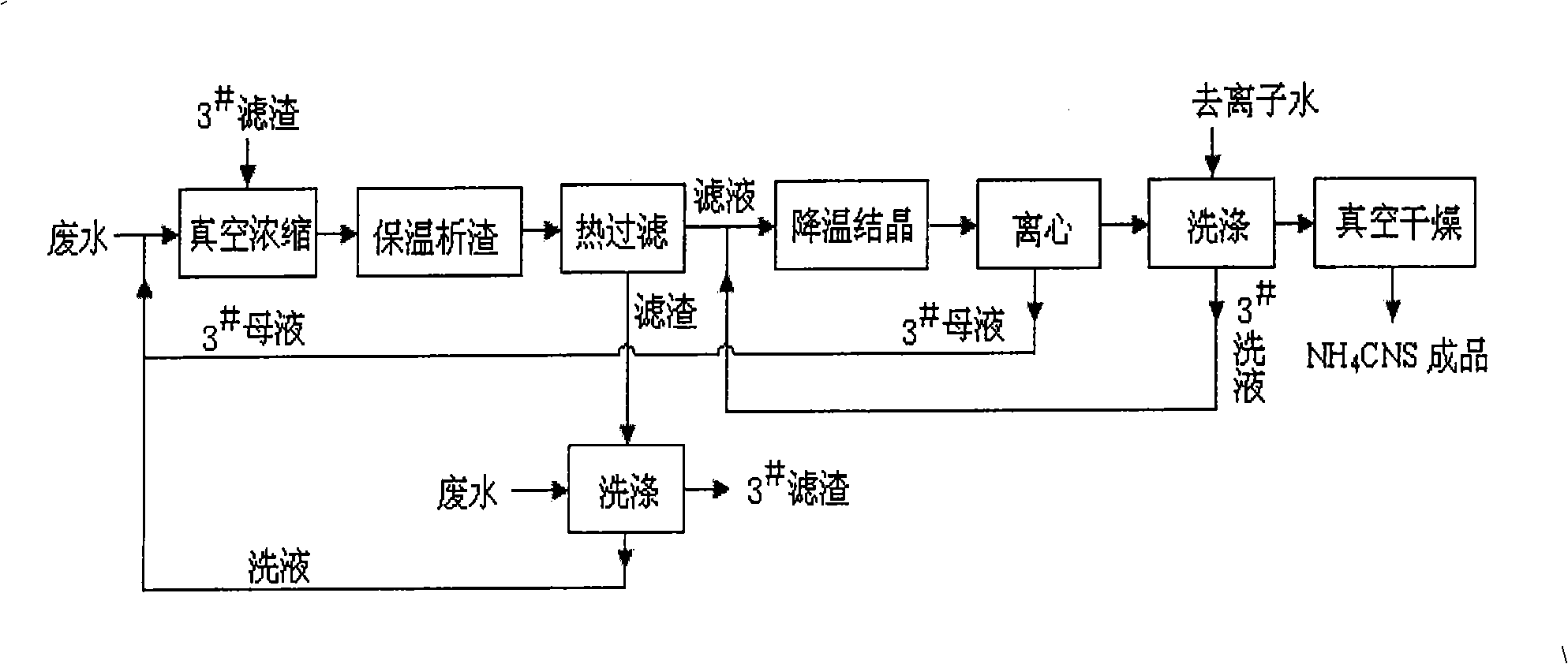

Process for recycling inorganic salt from wastewater for desulfurization and decyanation of coke oven gas

ActiveCN101402461AHigh recovery rateEasy to operateThiosulfates/dithionites/polythionitesThiocyanic acidCatalytic oxidationNo production

The invention provides a process for reclaiming inorganic salt from wastewater in the desulphurization and decyanation of coal gas of a coke furnace. The process aims at reclaiming ammonium thiocyanate (NH4CNS), ammonium thiosulfate ((NH4)2S2O3) and ammonium sulphate ((NH4)2SO4) from wastewater produced by a liquid-phase catalytic oxidation, desulphurization and decyanation process taking ammonia as an alkaline resource. In particular, the process comprises that the wastewater and a mother solution with the ratio of NH4CNS to (NH4)2S2O3 more than or equal to 1.0 (wt) and the ratio of NH4CNS to (NH4)2S2O3 less than 1.0 (wt) are separated to obtain finished products of NH4CNS, (NH4)2S2O3 and (NH4)2SO4 through a targeted process. The process is easy to operate and control parameter, has high salt reclaiming rate and high product quality, reaches the aim that the wastewater can be fully treated and has no production of three wastes, and has good economic and social benefits.

Owner:JINNENG SCI & TECH

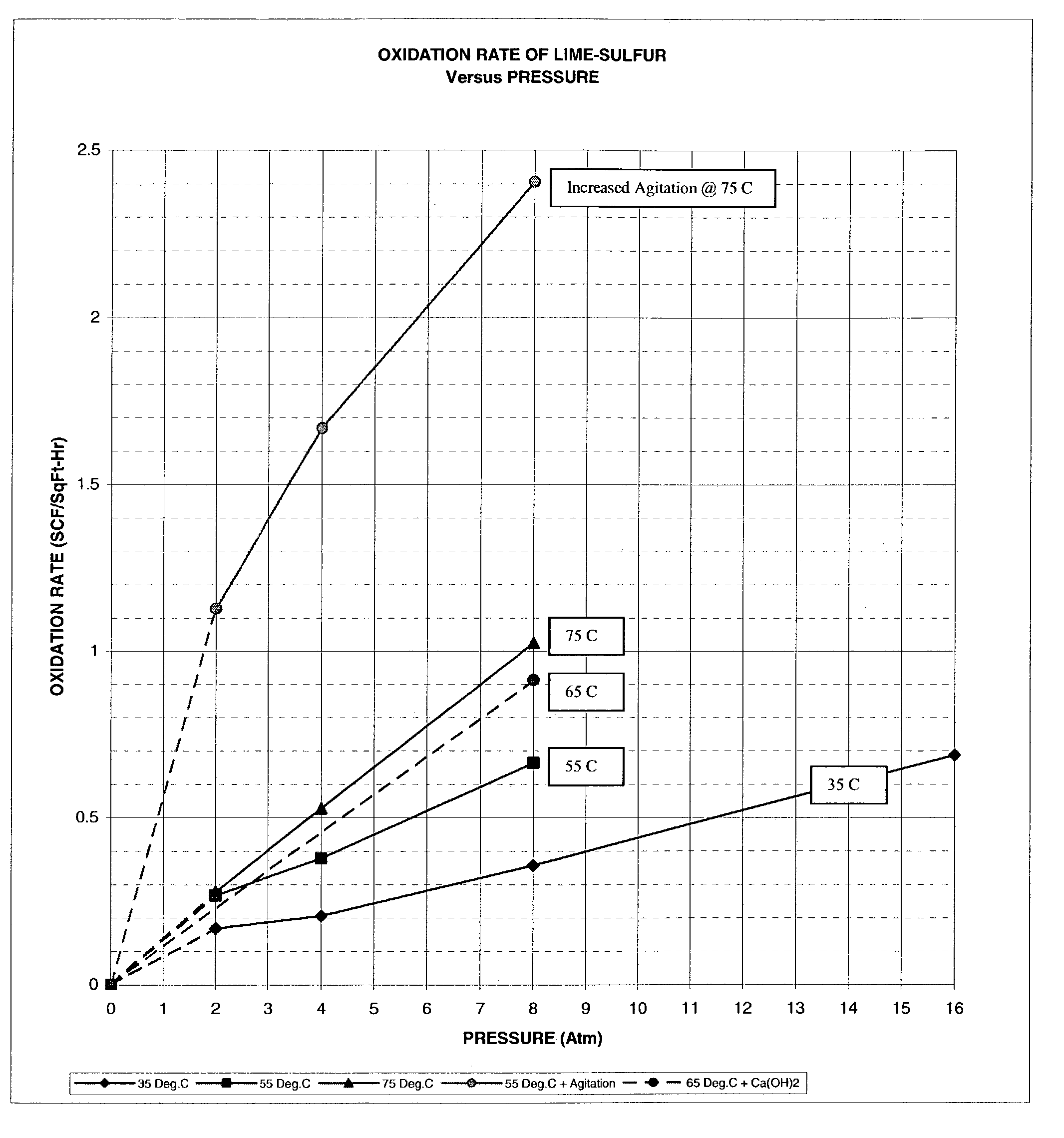

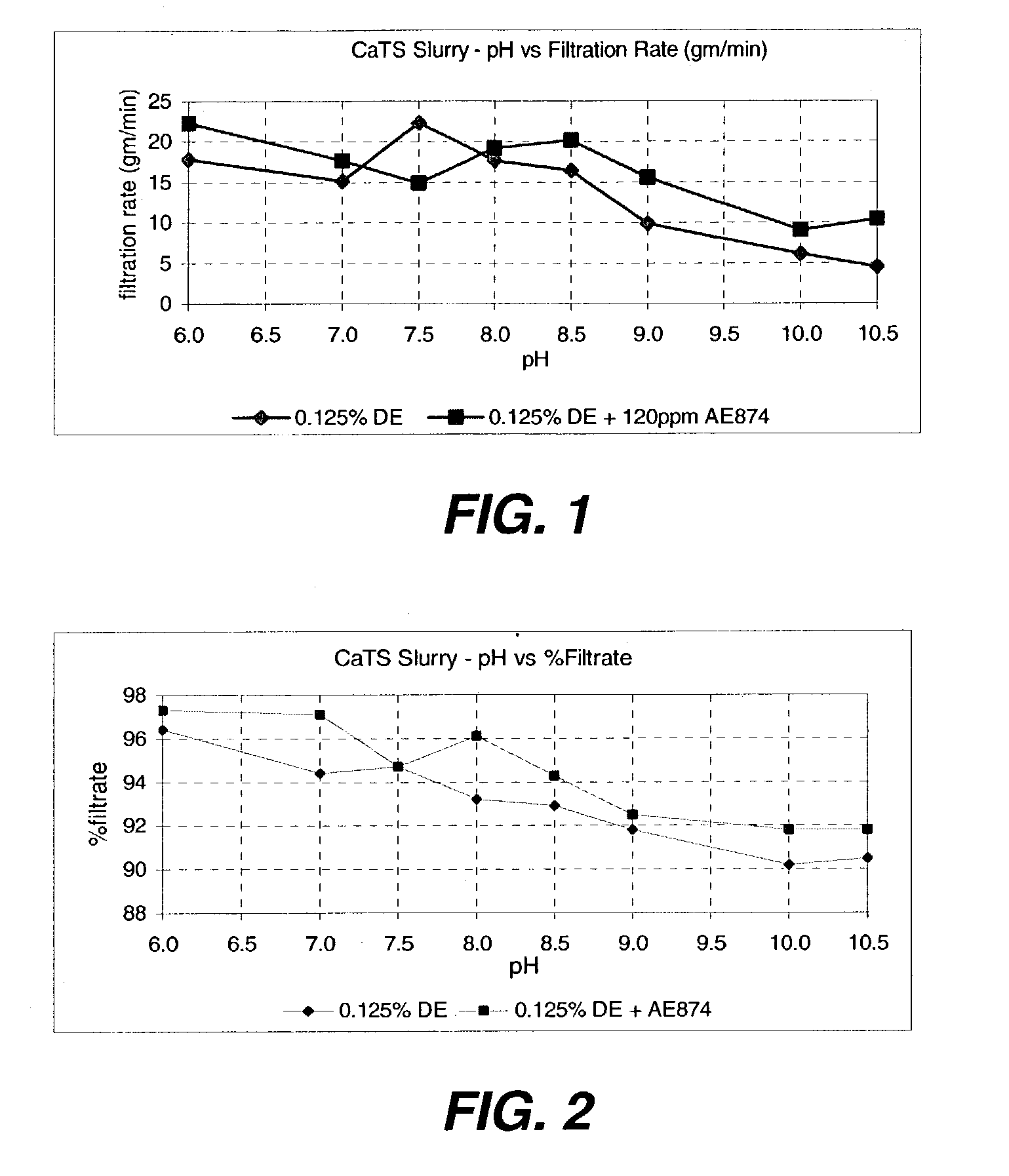

Process for preparing calcium thiosulfate solution

InactiveUS6984368B2Thiosulfates/dithionites/polythionitesMagnesium/calcium/strontium/barium sulfides/polysulfidesParticulatesSulfur

An efficient process to produce calcium thiosulfate (CaS2O3) from lime, sulfur and oxygen is described. By selecting appropriate process conditions such as mole ratios of lime to sulfur, temperature and pressure of the reaction process and the oxidation conditions, including rate and duration, the concentration of byproducts in the resulting suspension can be reduced to about 2% by weight or less. The solid particulate dispersion in the suspension tends to form a slimy solid suspension that is hard to filter if not treated properly. The suspension then can be acidified and treated with a flocculent. This agglomerates the solids into a floc that filters with ease. The resulting calcium thiosulfate is a clear liquid with concentrations achievable up to 29%.

Owner:TESSENDERLO KERLEY INC

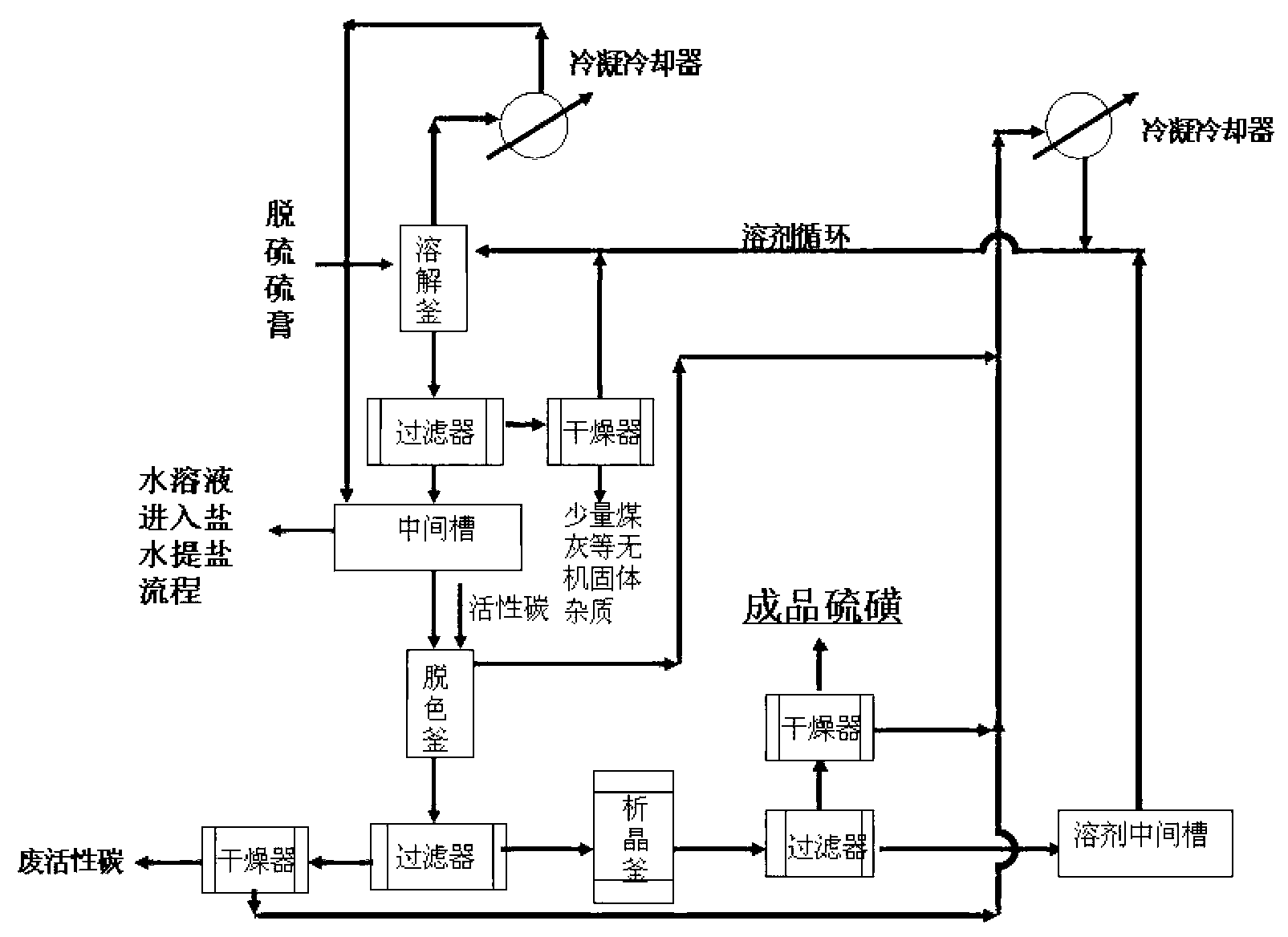

Production technique for extracting ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

InactiveCN101850952ASolving Recycling ProblemsEmission reductionThiosulfates/dithionites/polythionitesThiocyanic acidOrganic solventEconomic benefits

The invention discloses a production technique for extracting ammonium thiosulfate and ammonium thiocyanate from a desulfurization waste liquor, which comprises the following steps: settling, filtering, decoloring, concentrating, crystallizing, separating, drying a sulfur-containing waste liquor generated in a desulfurization production process of HPF in a coke-oven plant, and finally, recovering ammonium thiocyanate and ammonium thiosulfate by using a mixed organic solvent. The invention is a production technique for comprehensively treating waste water generated in the prior HPF desulfurization technique, and the mixed organic solvent is used for separating ammonium thiocyanate and ammonium thiosulfate. The invention effectively solves the problem of waste water recovery in the desulfurization process, reduces discharge and environmental pollution of waste water, recovers important chemical raw materials (ammonium thiocyanate and ammonium thiosulfate), and can increase the economic benefit.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

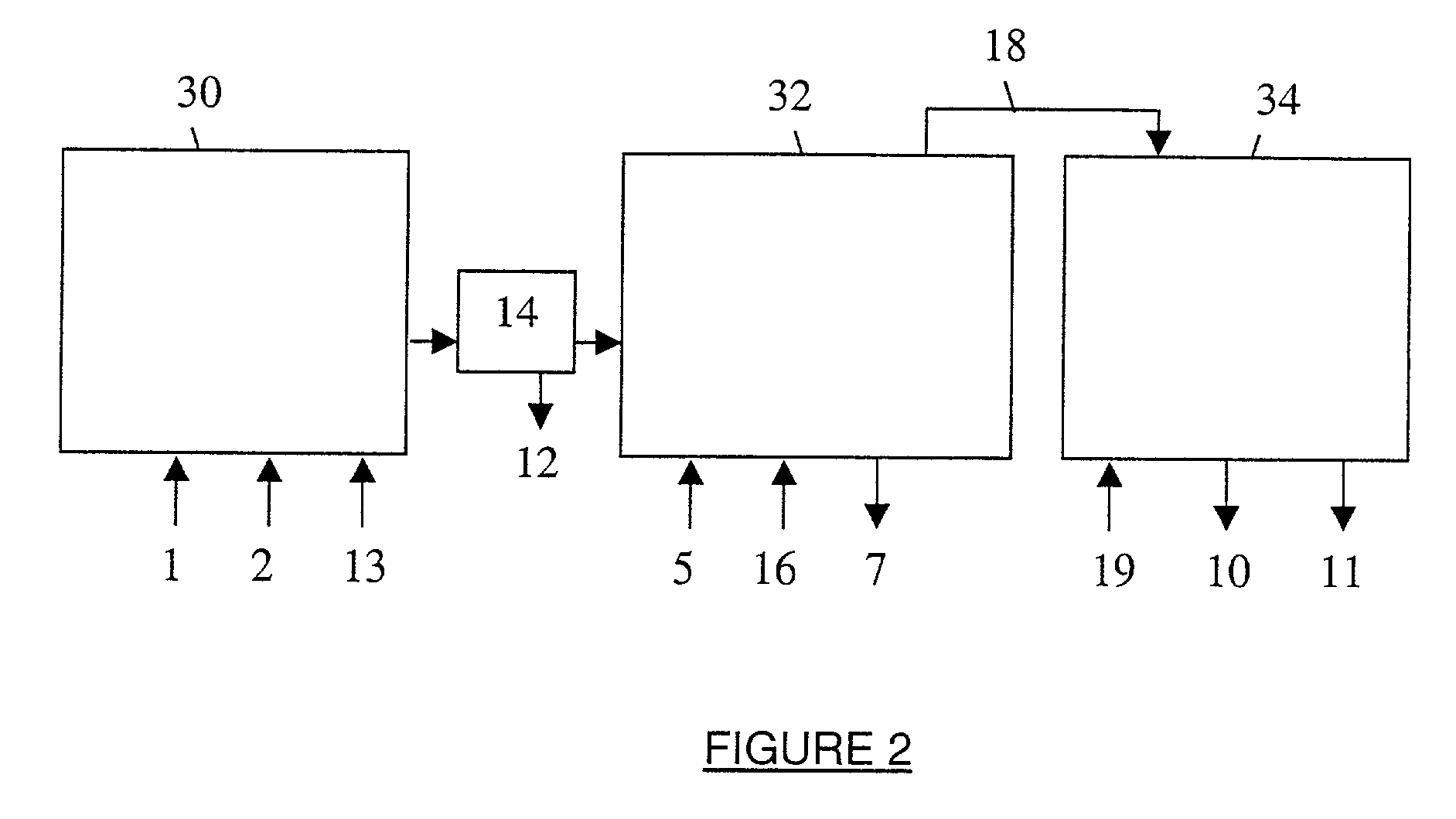

Process for production of ammonium thiosulphate

InactiveUS20030223930A1Speed up the processThiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

A process for continuous production of ammonium thiosulphate, (NH4)2S2O3 (ATS) from NH3, H2S and SO2 comprising steps of: (a) partial condensation in a partial condenser 4 of a first gaseous or partial liquid feed stream comprising H2O, H2S and NH3 with a molar H2S:NH3 ratio <0.4; (b) passing the aqueous condensate comprising NH4HS and NH3 from the partial condenser 4 to a reactor 9 in which said condensate is contacted with a third feed gas stream 7 comprising H2S and with an aqueous solution 10 comprising NH4HSO3 and (NH4)2SO3 under formation of an aqueous solution of (NH4) 2S2O3; (c) passing the gas stream comprising NH3 and H2S from the partial condenser 4 to a mixing device 13 in which said gas stream is completely dissolved in the water drained off from the aerosol filter 25; (d) passing a second feed gas stream 20 comprising approximately 2 / 3 mole SO2 per mole of NH3 contained in the first feed stream to a SO2 absorber 21 and the aerosol filter 25; (e) passing the aqueous solution produced in mixing device 13 to the SO2 absorber 21; (f) passing the off gas from the absorber 21 to the aerosol filter 25 and (g) adding to the aerosol filter 25 a balance amount of water required for obtaining approximately 40-65 wt % (NH4)2S2O3 in the aqueous of solution of (NH4)2S2O3 being withdrawn from the reactor 9.

Owner:HALDOR TOPSOE AS

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

Method for the production of alpha-alane

ActiveUS20050222445A1Reduce impurityHydrogenThiosulfates/dithionites/polythionitesCyclododecatrienePolydimethyl siloxane

A method of forming alpha-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbomylene, norbomadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof. Ether is removed from the crystallization solution to crystallize the alpha-alane.

Owner:NORTHROP GRUMMAN SYST CORP

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

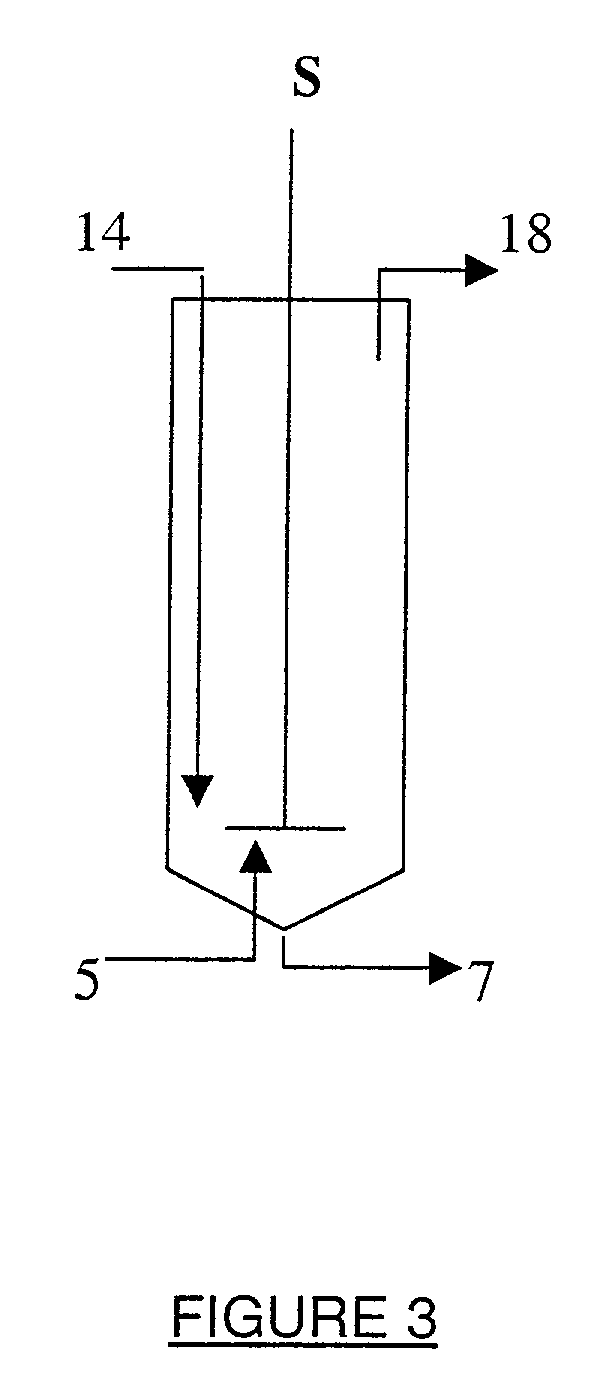

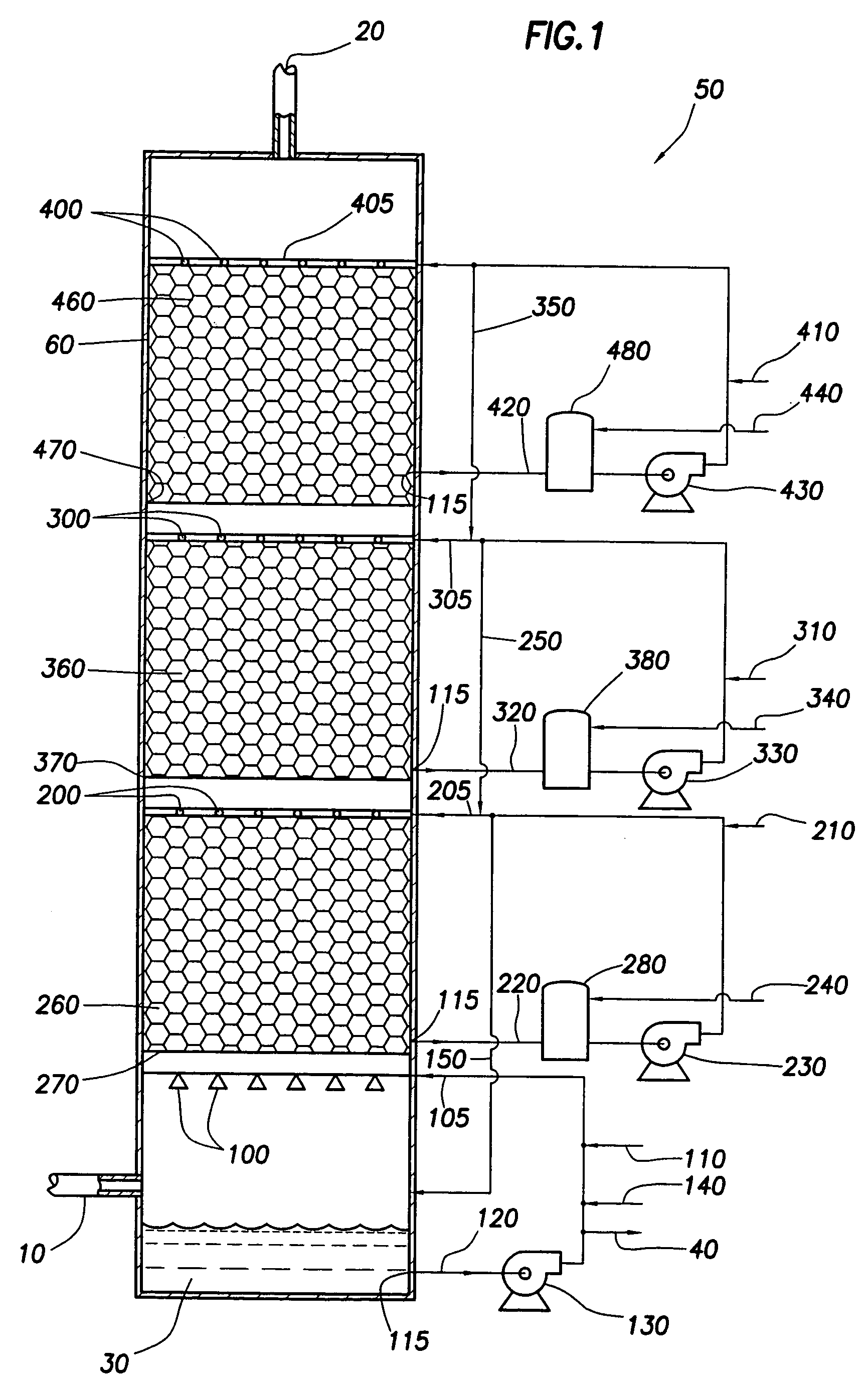

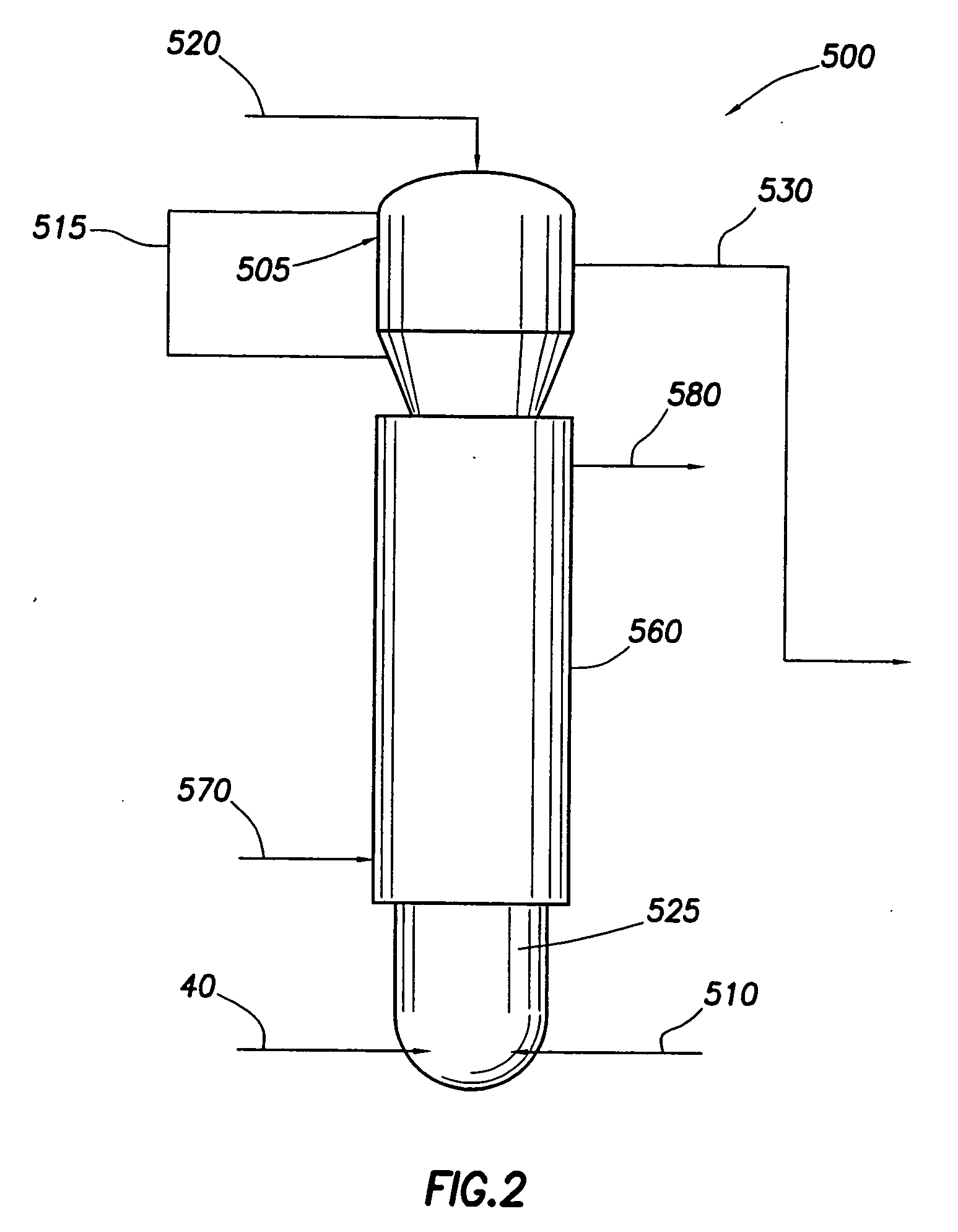

Process and apparatus for scrubbing sulfur dioxide from flue gas and conversion to fertilizer

A method for removing sulfur dioxide from flue gas and forming ammonium salts is described, along with a method for conversion of the ammonium salts into thiosulfate. Also described are an apparatus for absorbing sulfur dioxide from flue gas and an apparatus for converting ammonium salts into thiosulfate. The apparatus for absorbing sulfur dioxide from flue gas includes a multistage scrubber. The apparatus for converting ammonium salts into thiosulfate includes a fluidized bed reactor.

Owner:CANKAR

Cleaning method

ActiveUS20110107527A1Efficient removalOrganic detergent compounding agentsOrganic chemistryBleachCleaning methods

Owner:THE PROCTER & GAMBLE COMPANY

Hydrogen sulfide abatement in molten sulfur

InactiveUS6887447B2Thiosulfates/dithionites/polythionitesSulfur preparation/purificationDicarboxylic acidKetone

The present invention provides a method for inhibiting the evolution of H2S from sulfhydryl compounds in molten sulfur by using scavenging agents such as anhydrides and polymers thereof, conjugated ketones, carbonates, epoxides, monoesters and diesters of unsaturated dicarboxylic acids and polymers of these esters, and the like and mixtures thereof. In one embodiment, it is preferred that the scavenging agent is in liquid form at contact temperature with the molten sulfur. In another embodiment, the scavenging agent may be atomized into the vapor space over the molten sulfur to contact the sulfur with the agent.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com