Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

709 results about "Waste stream" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste stream. Waste stream: The total flow of solid waste from homes, businesses, institutions, and manufacturing plants that is recycled, burned, or disposed of in landfills; or segments of that total flow, such as the "residential waste stream" or the "recyclable waste stream.

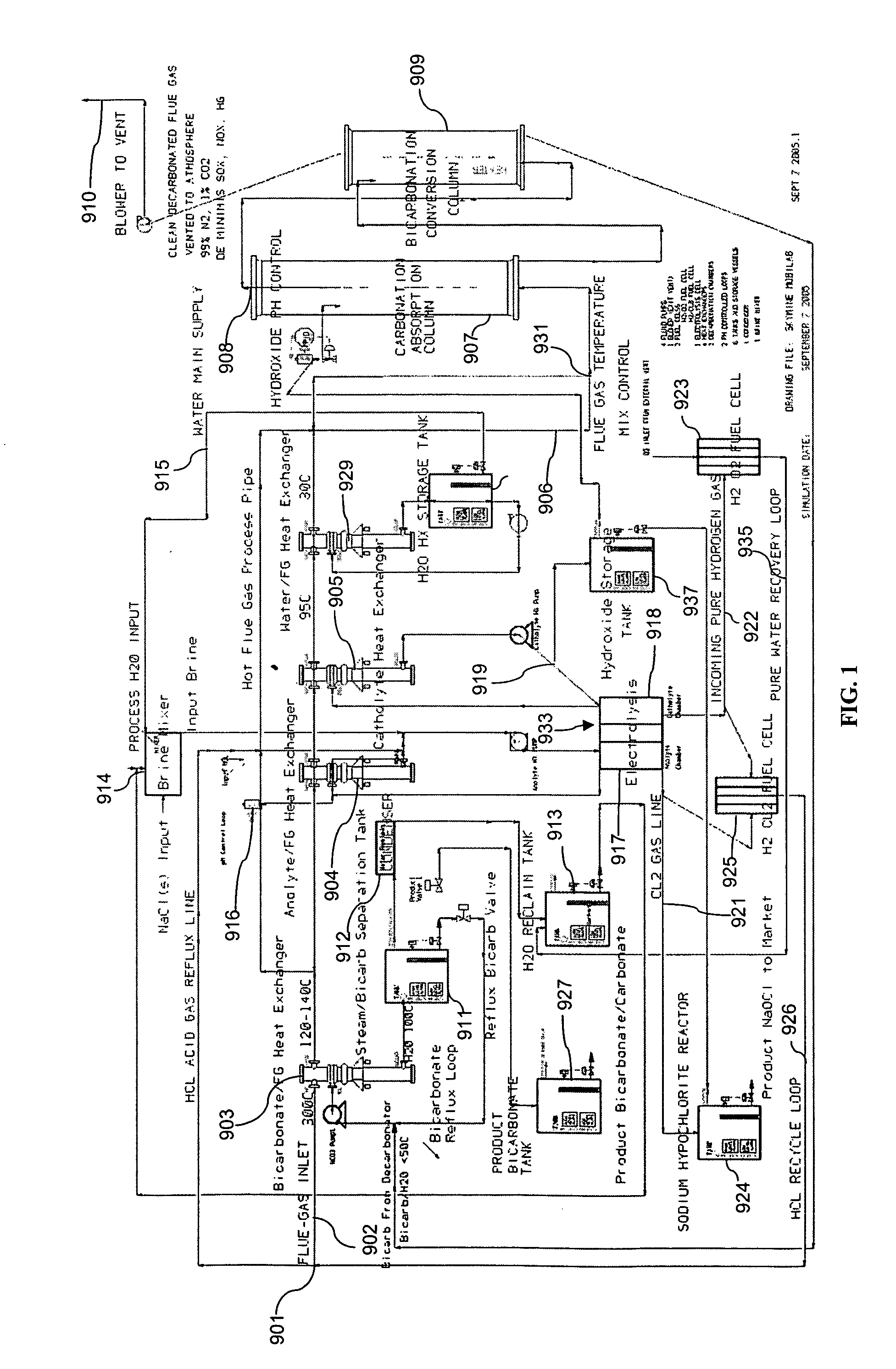

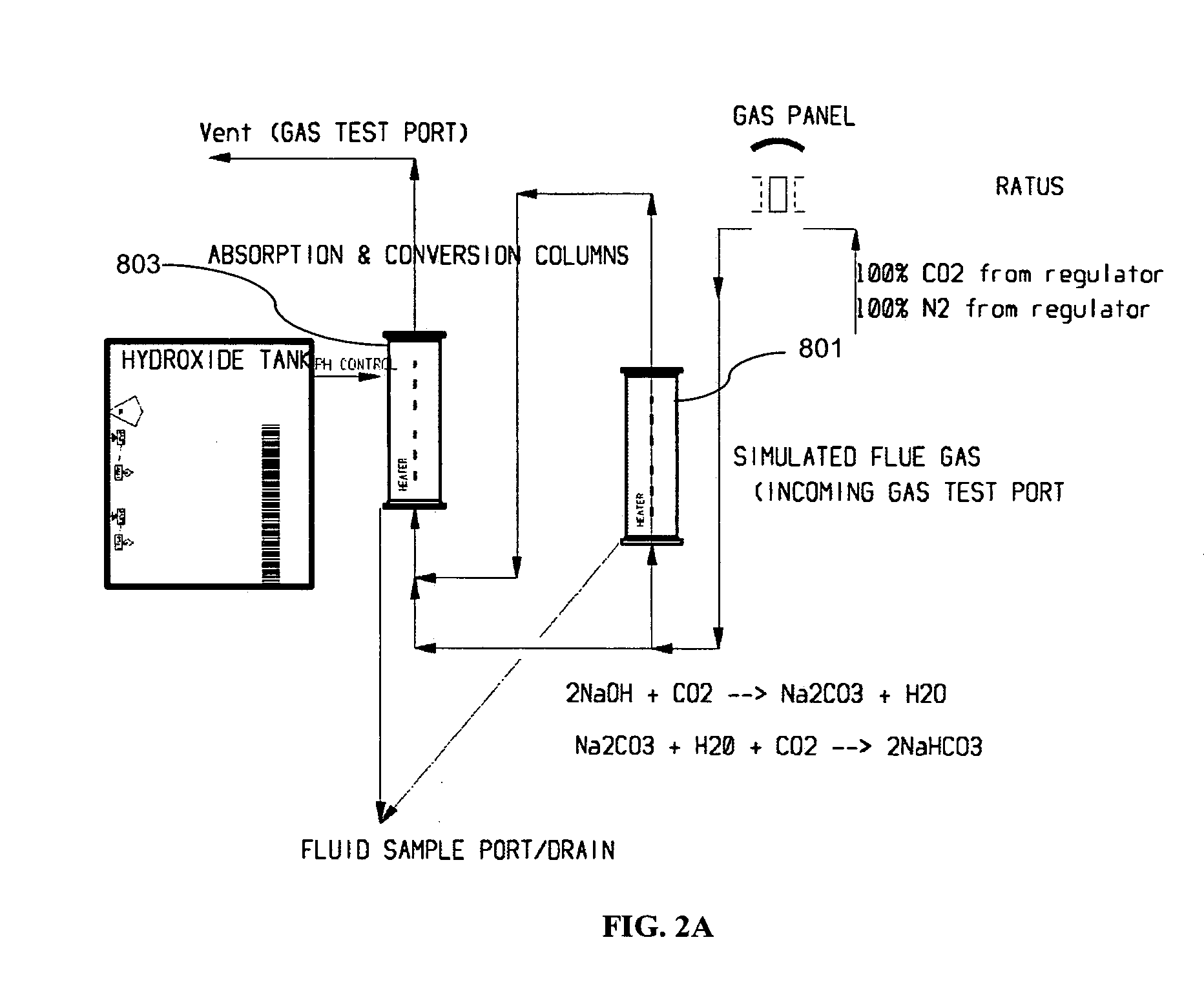

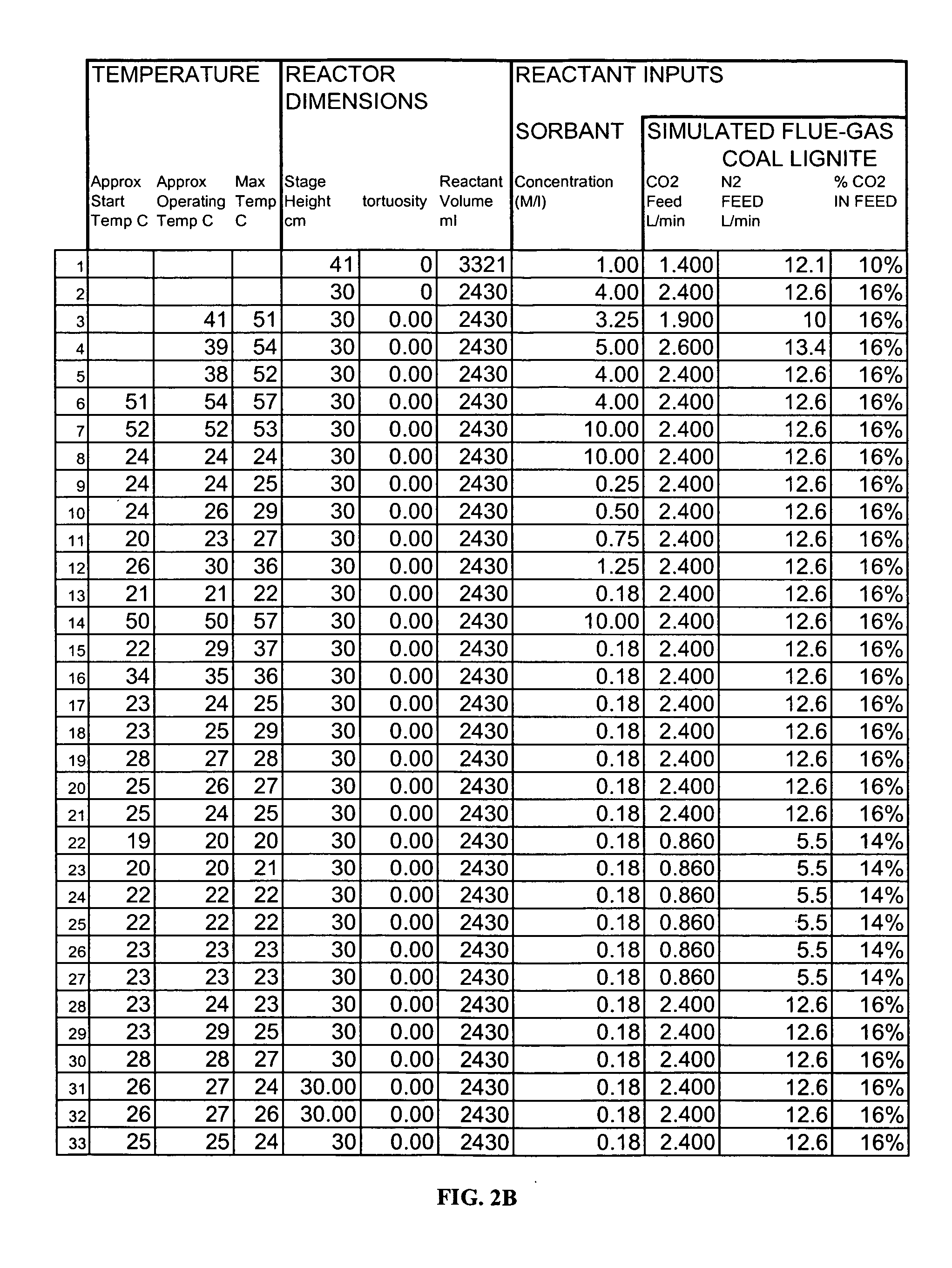

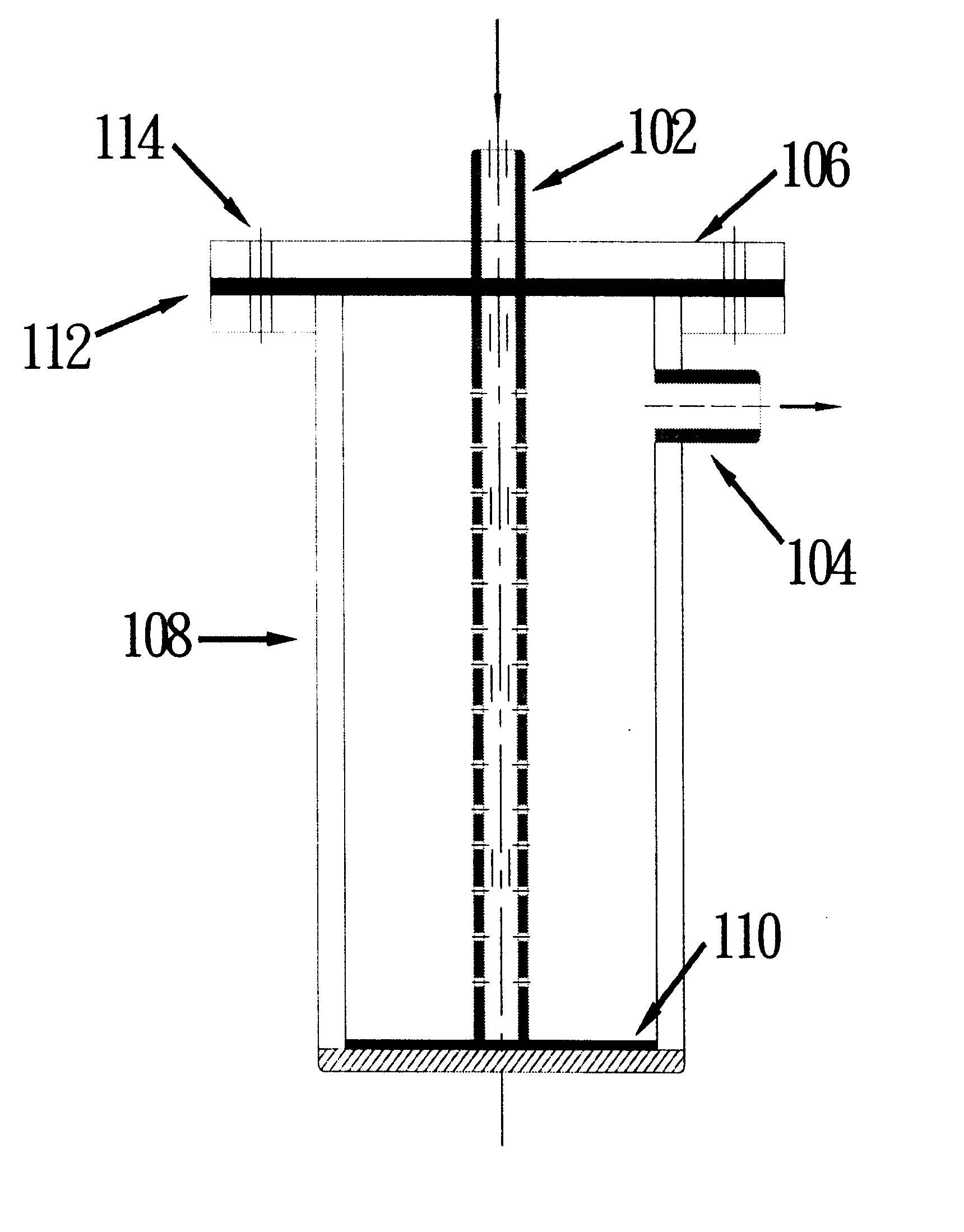

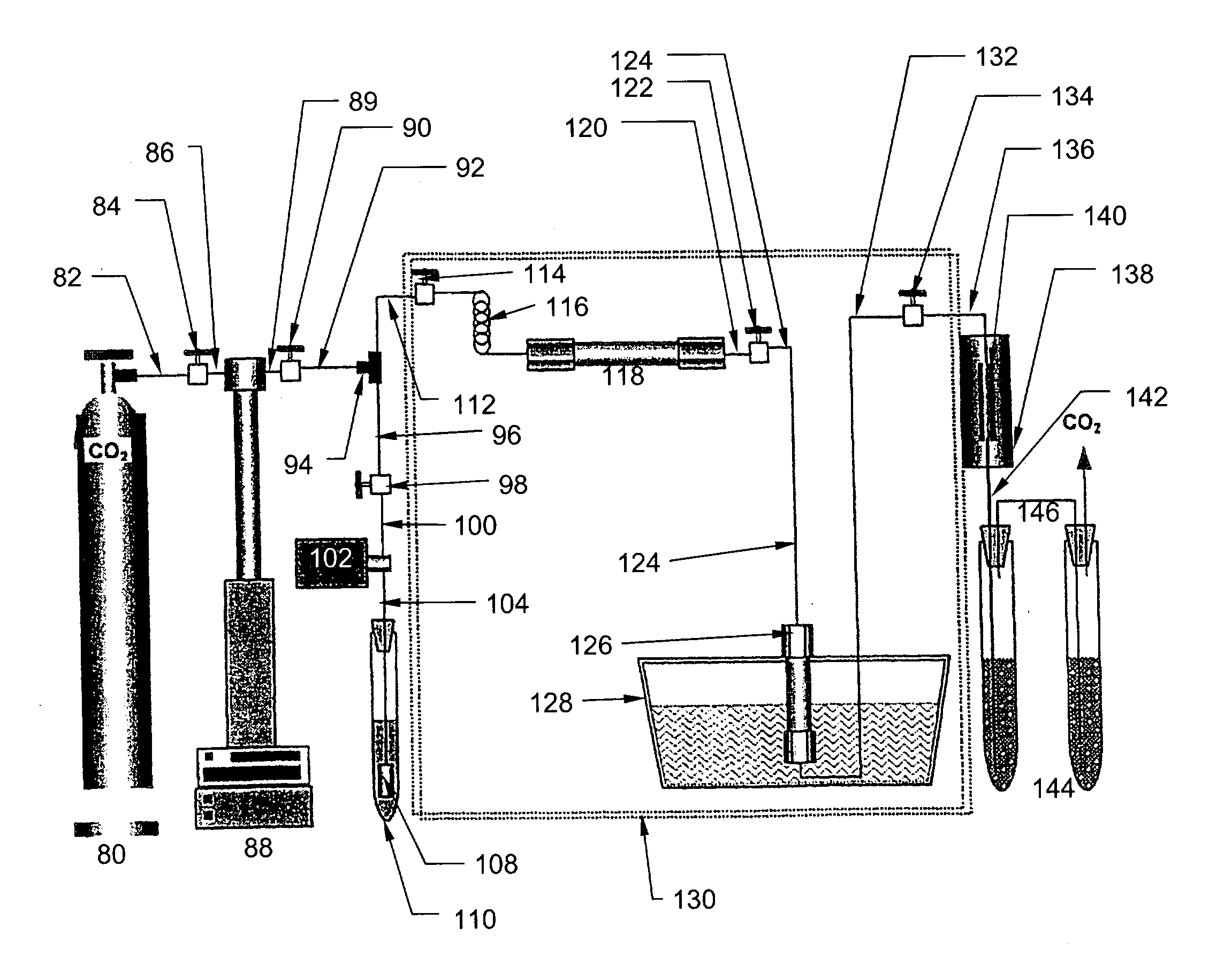

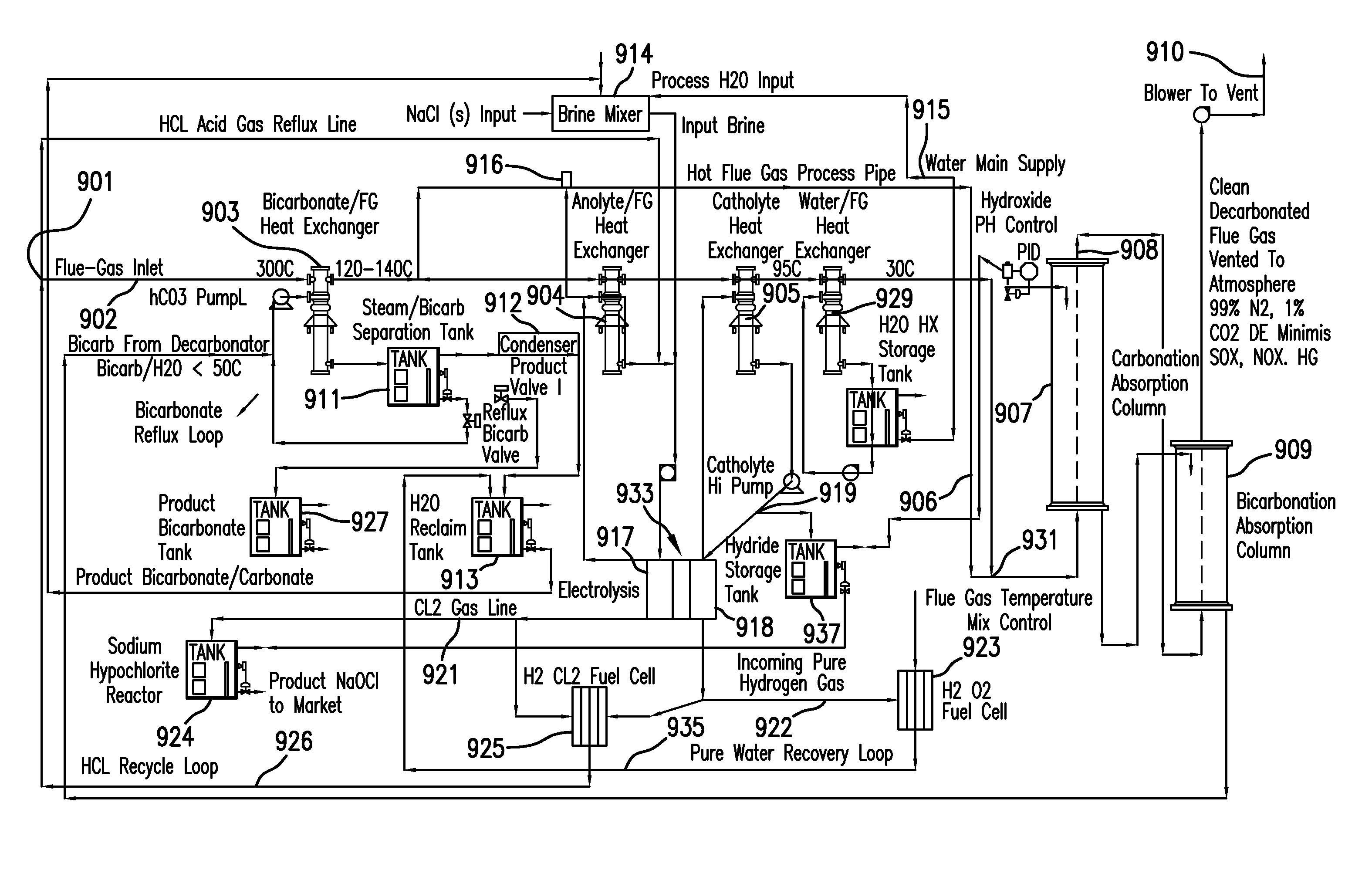

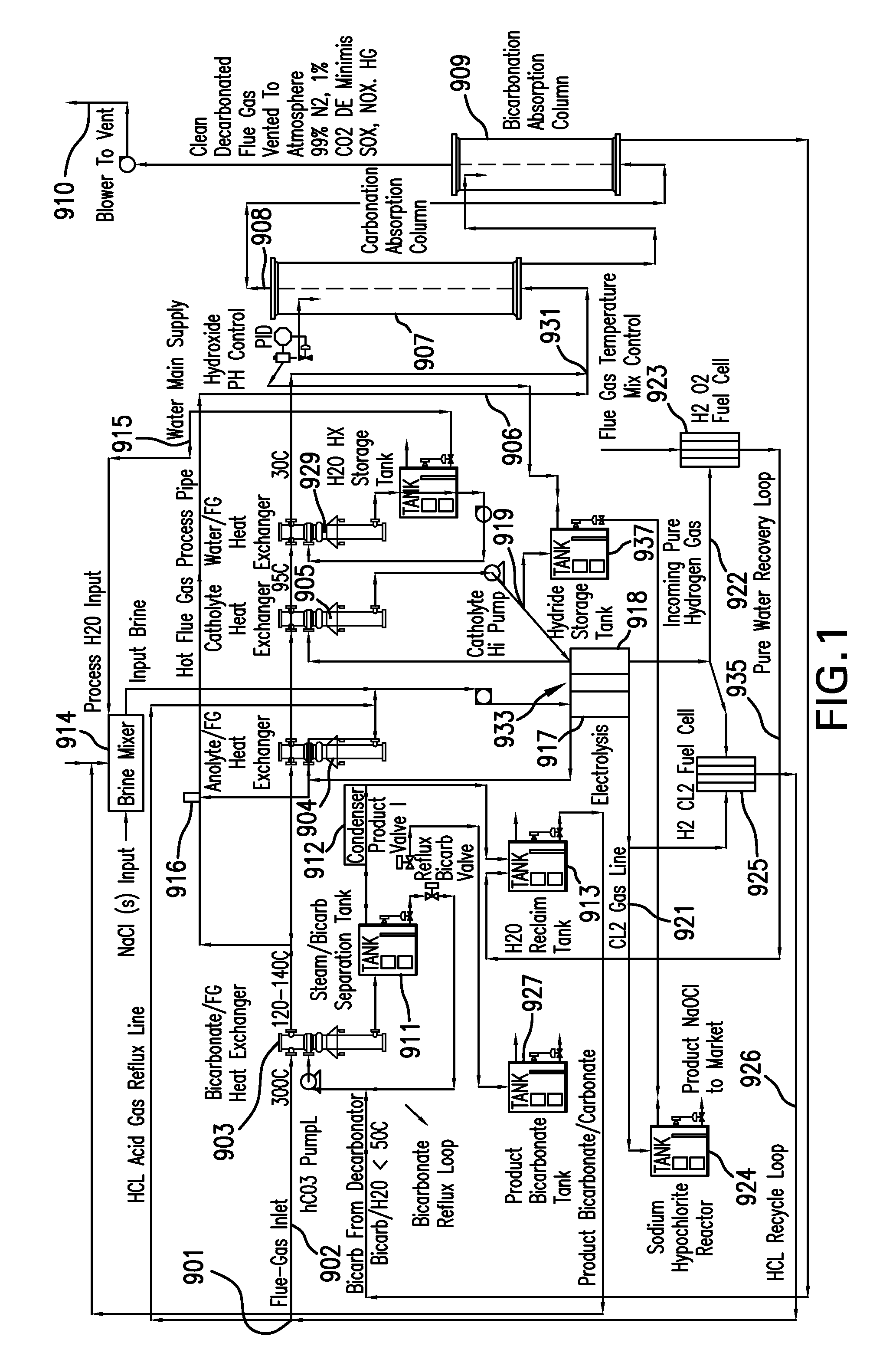

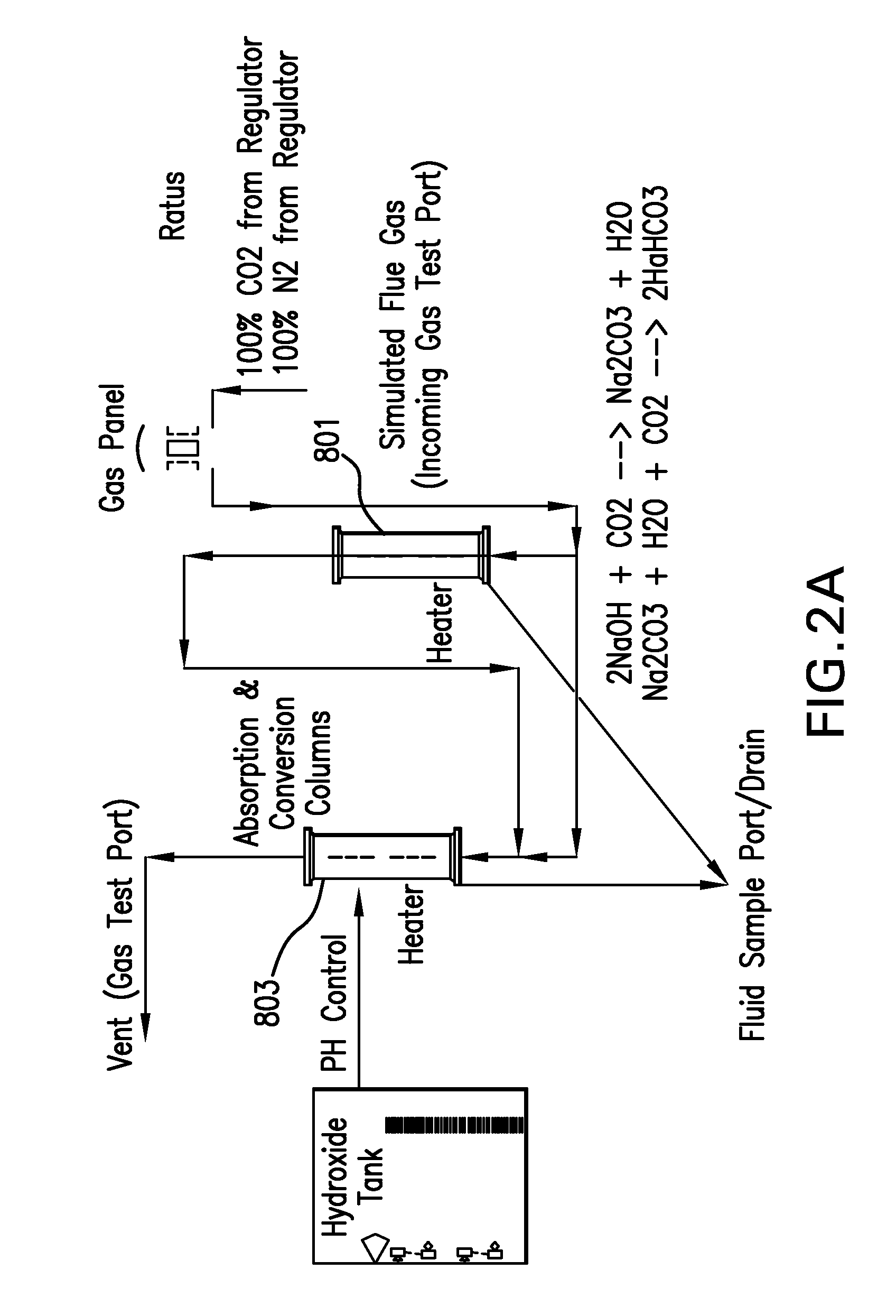

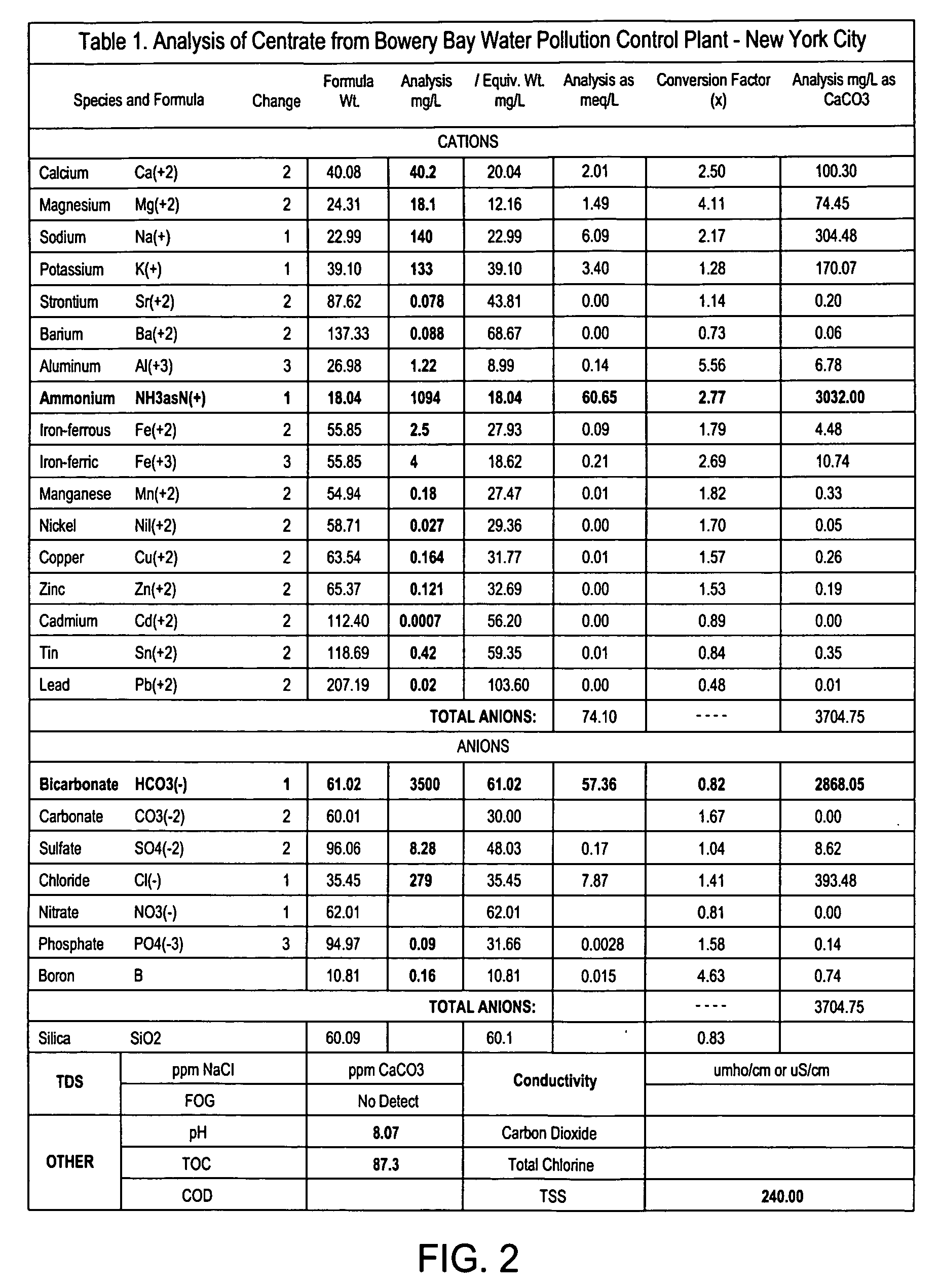

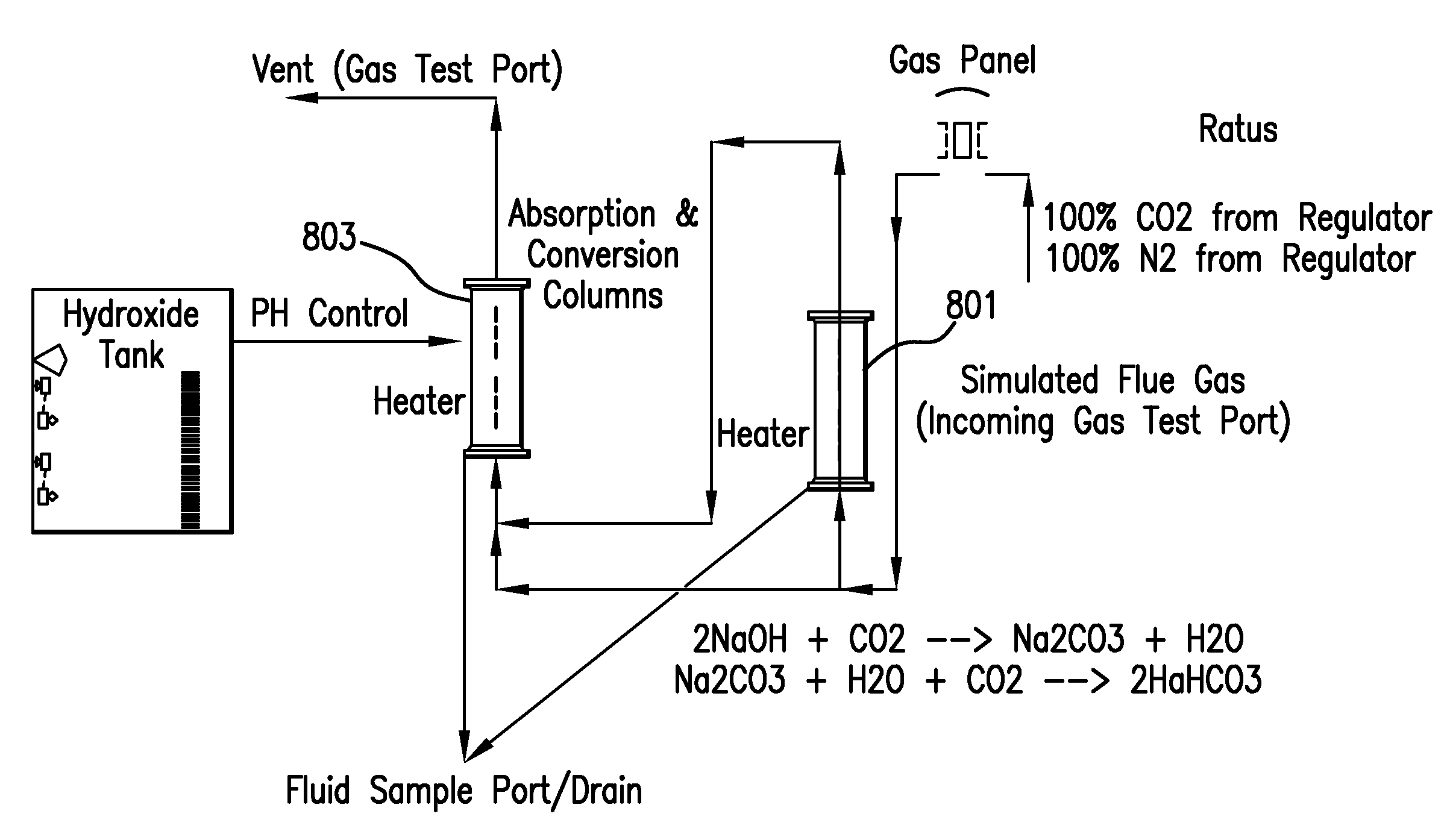

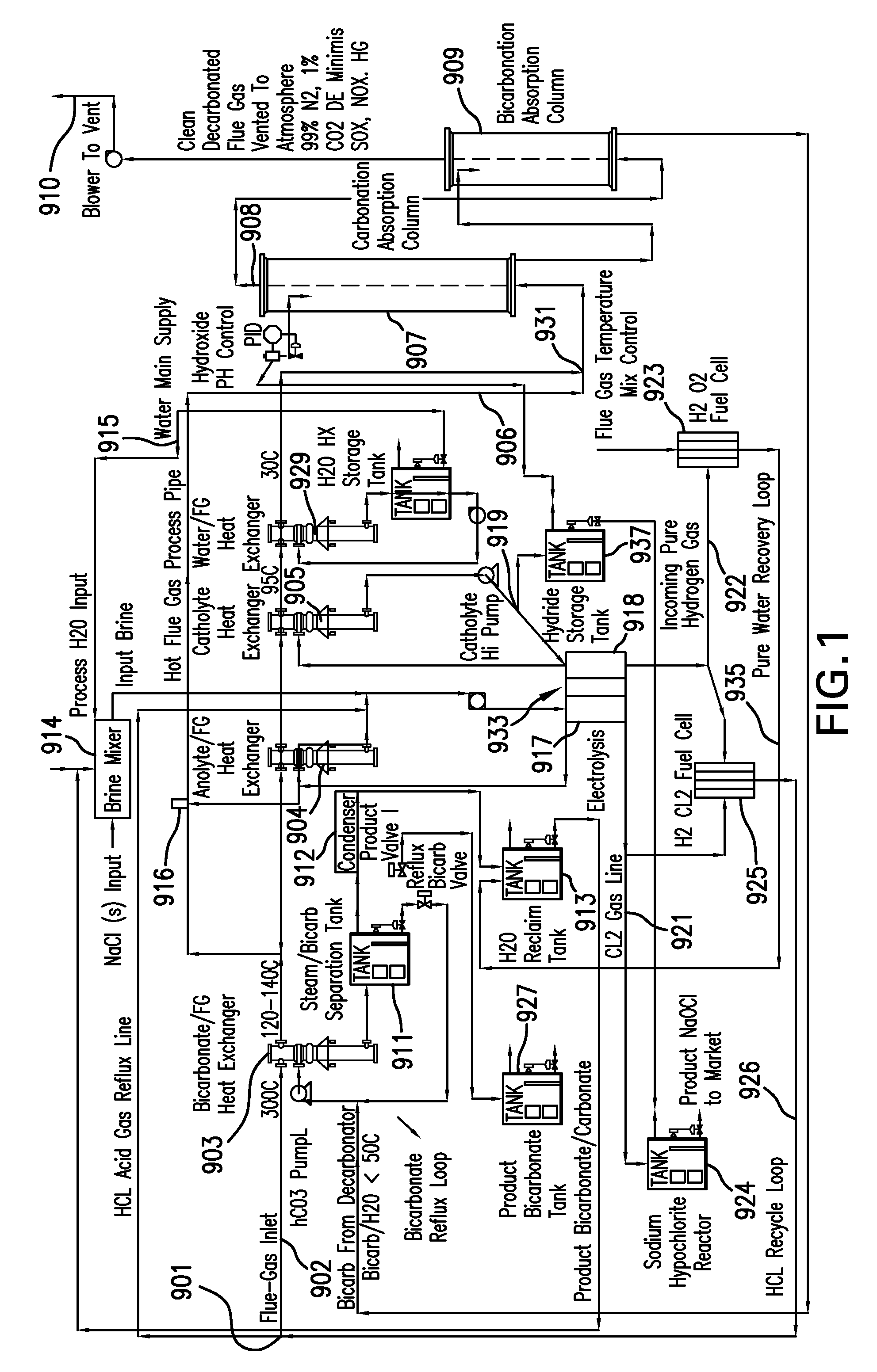

Removing carbon dioxide from waste streams through co-generation of carbonate and/or bicarbonate minerals

ActiveUS20060185985A1Improve ecologic efficiency of processEcologic efficiencyCalcium/strontium/barium carbonatesElectrolysis componentsElectrolysisWaste stream

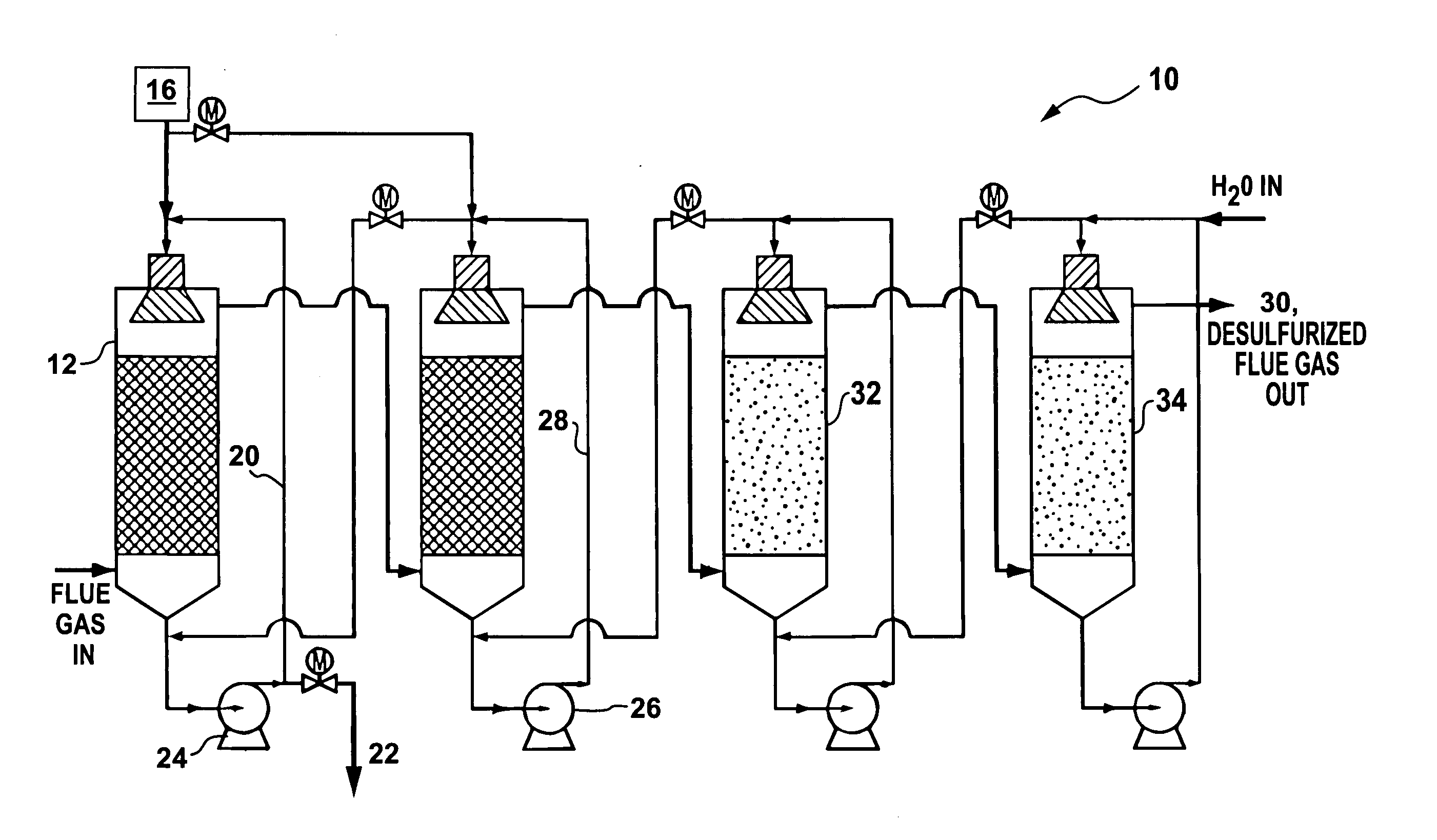

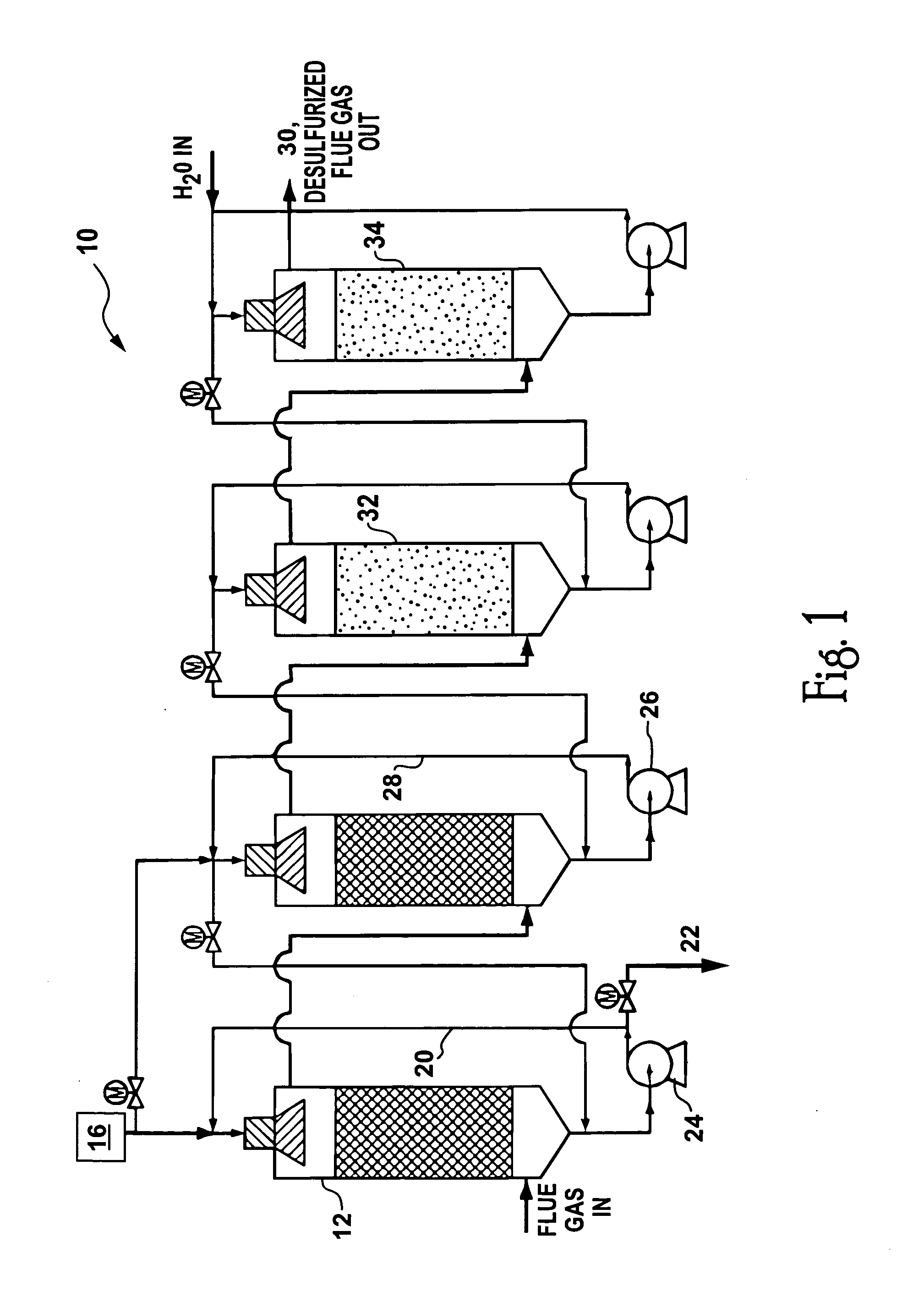

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

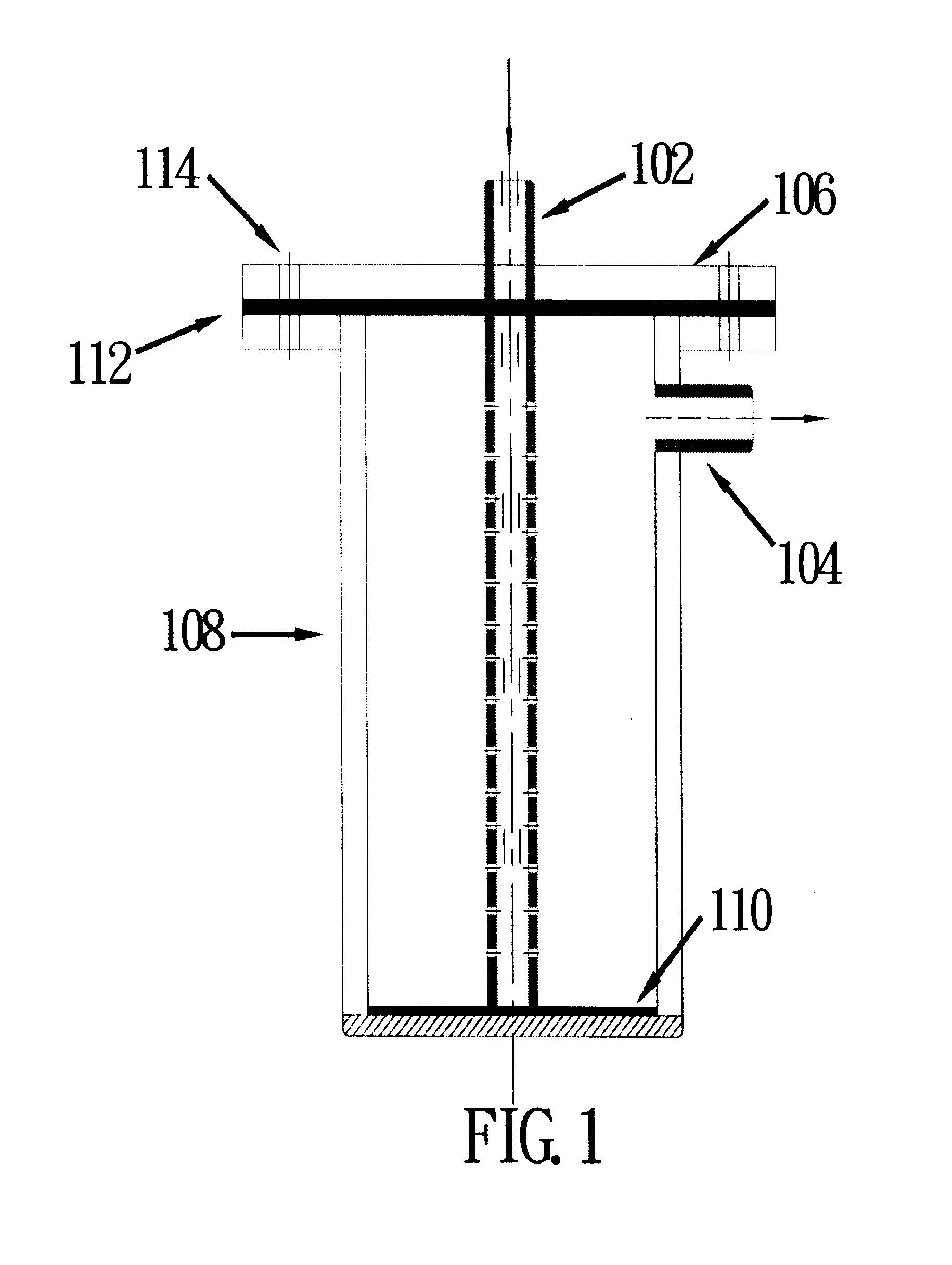

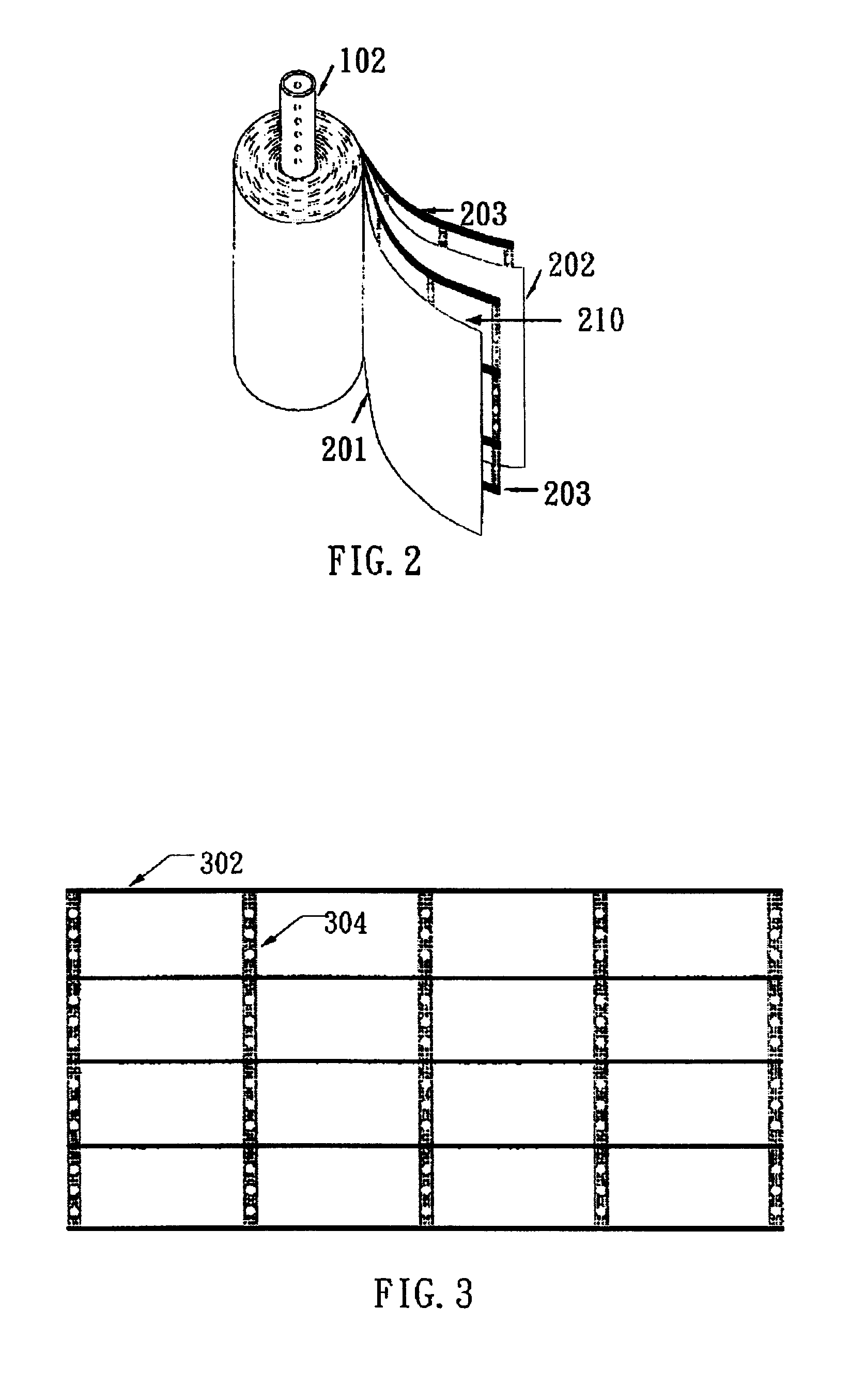

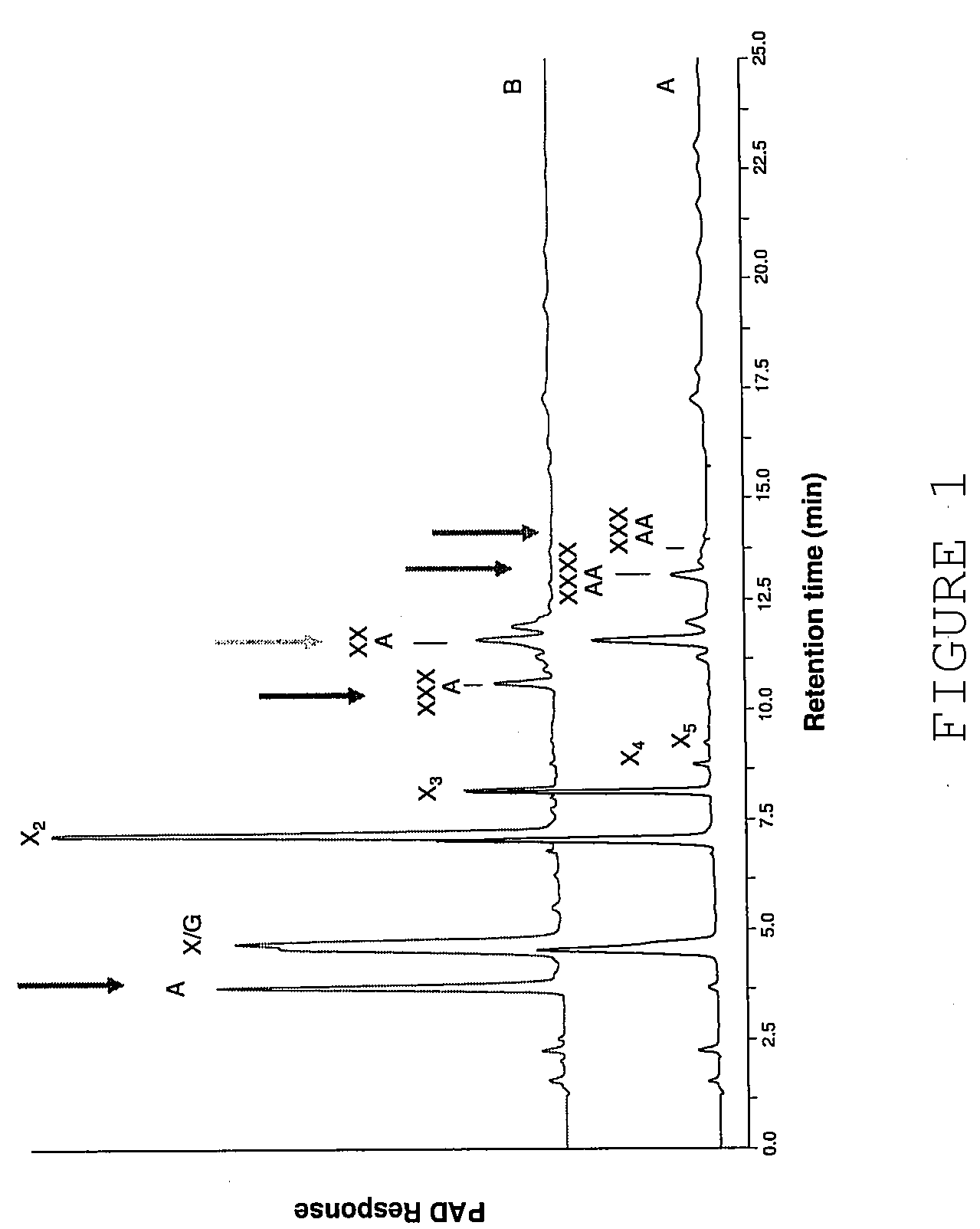

Replaceable flow-through capacitors for removing charged species from liquids

InactiveUS6462935B1Material nanotechnologyWater treatment parameter controlCapacitanceCapacitive deionization

A free-standing flow-through capacitor (FTC) is constructed by concentrically winding two electrodes and two dividers into a hollow-center roll. A liquid-feeding pipe is inserted to the central opening for delivering fluids to the FTC. Nanoparticles of hydrated iron compound with Fe3O4 as the main component or its composite powders are used as the active materials for the electrodes. With channels crated by the dividers assembled in the roll, fluids injected from the feed pipe are confined inside the FTC, and flow outwardly and transversely through the entire length of the electrodes. Under an application of a low DC voltage to the electrodes, charged species are adsorbed and removed from the treated liquids as soon as they are in contact with the electrodes. Capacitive deionization using FTC of the present invention is applicable to waste-streams reduction, water purification and desalination at low costs and easy operation.

Owner:SHIUE LIH REN

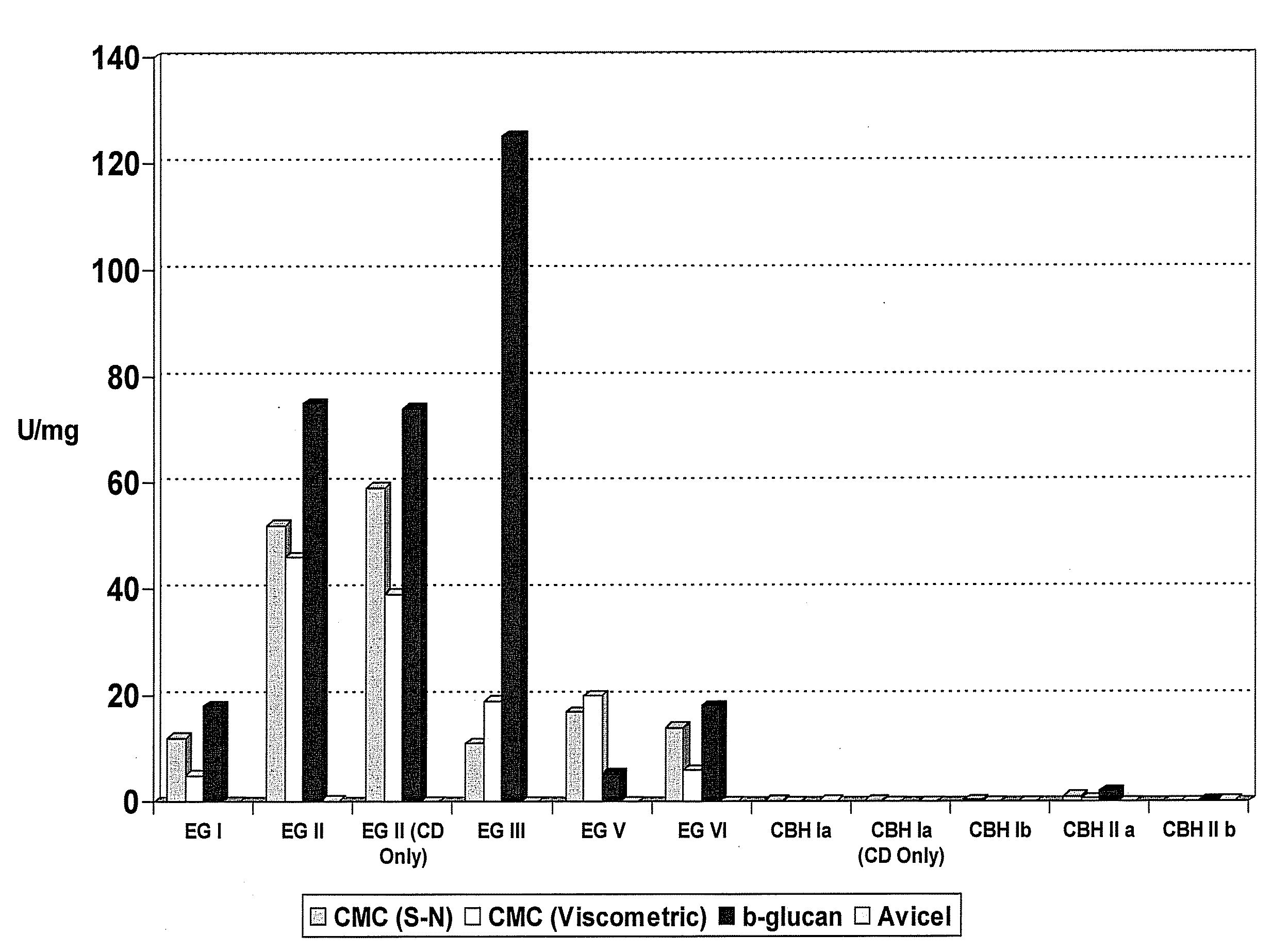

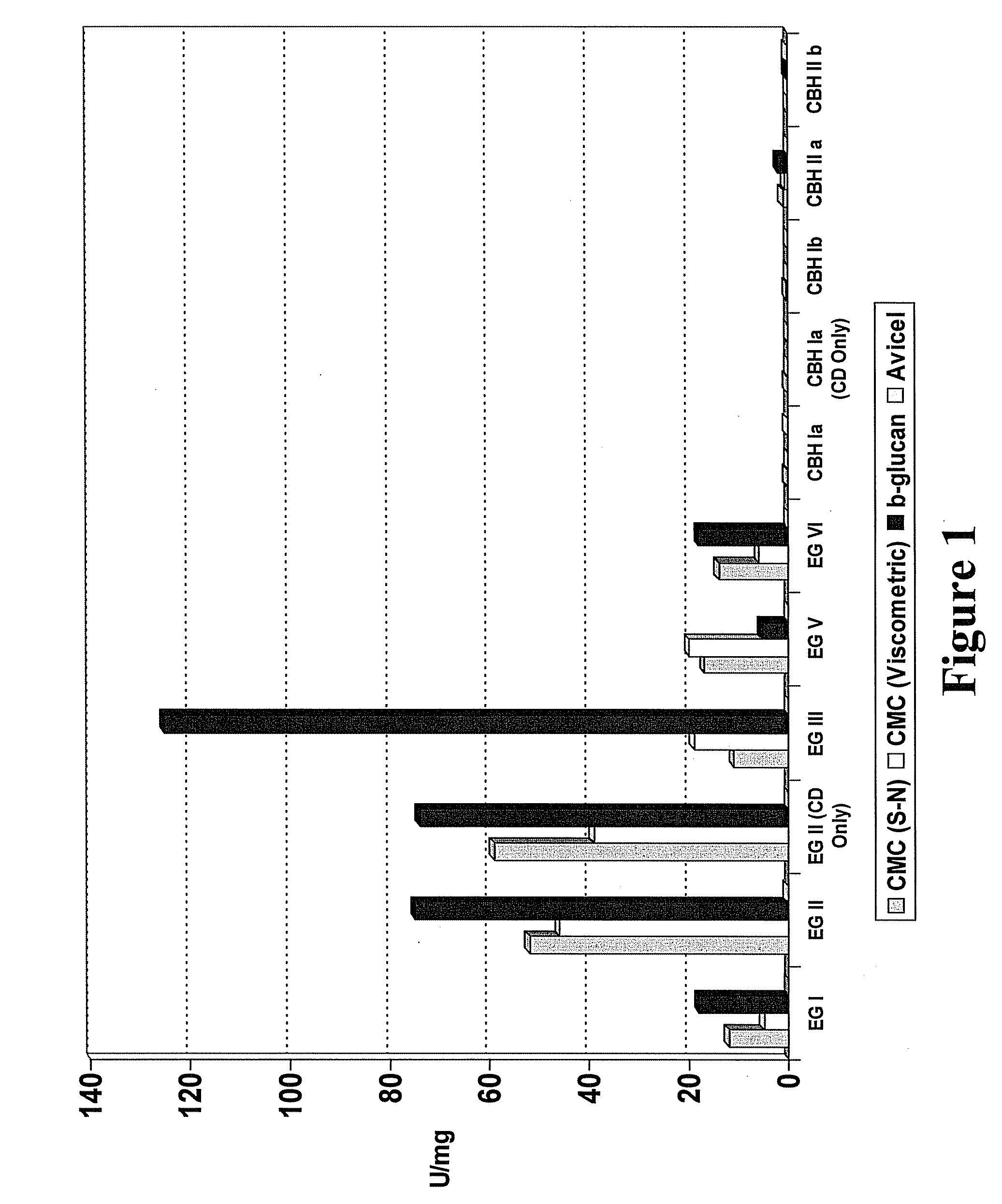

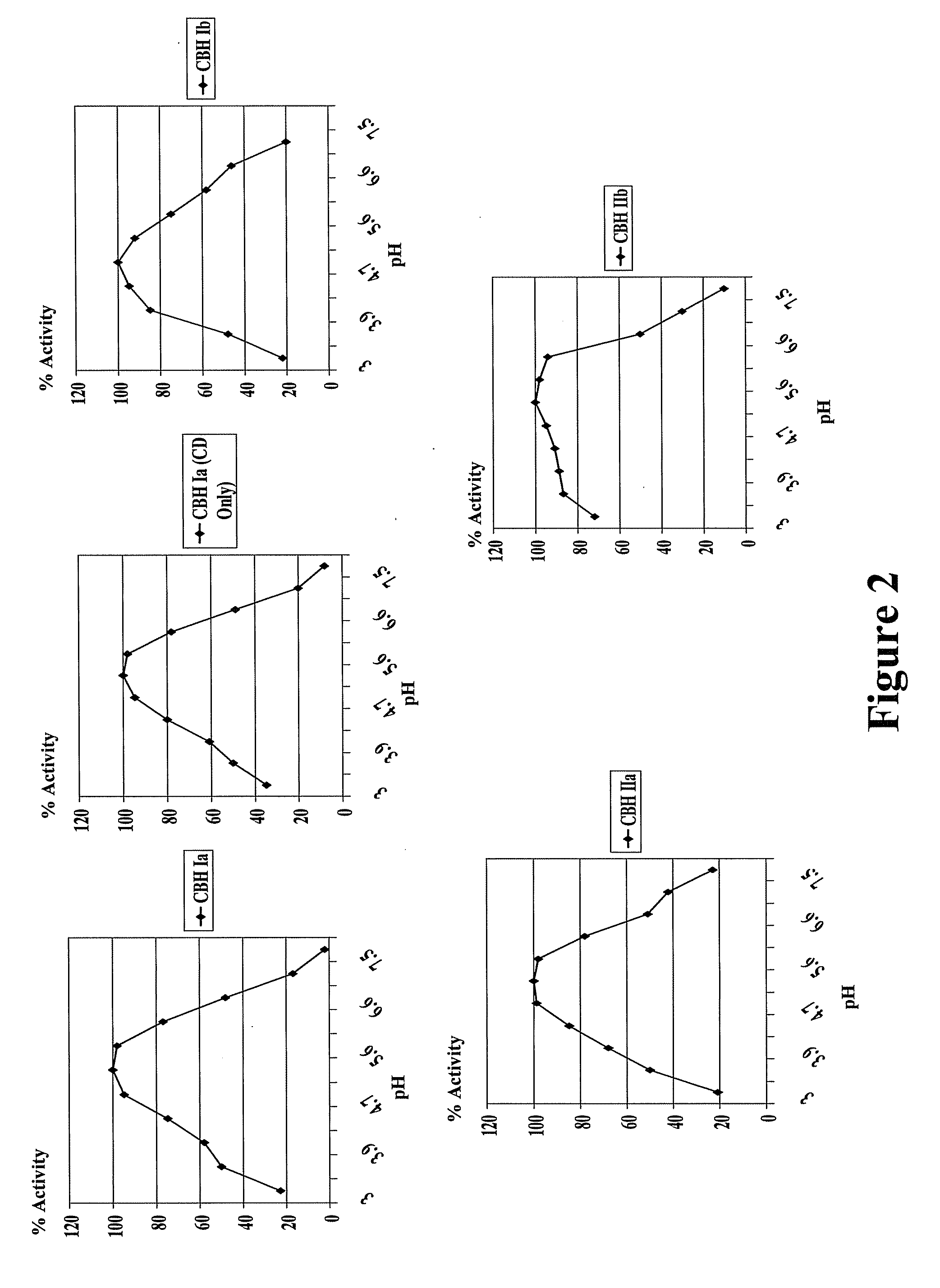

Novel Fungal Enzymes

This invention relates to novel enzymes and novel methods for producing the same. More specifically this invention relates to a variety of fungal enzymes. Nucleic acid molecules encoding such enzymes, compositions, recombinant and genetically modified host cells, and methods of use are described. The invention also relates to a method to convert lignocellulosic biomass to fermentable sugars with enzymes that degrade the lignocellulosic material and novel combinations of enzymes, including those that provide a synergistic release of sugars from plant biomass. The invention also relates to a method to release cellular content by degradation of cell walls. The invention also relates to methods to use the novel enzymes and compositions of such enzymes in a variety of other processes, including washing of clothing, detergent processes, biorefining, deinking and biobleaching of paper and pulp, and treatment of waste streams.

Owner:DANISCO US INC

Adsorption process for continuous purification of high value gas feeds

Using a high pressure rotary adsorbent wheel, a high value compressed gas feed can be purified by concentrating the impurity such as water, condensing it out, before final purification. Instead of exhausting gas from the system, the effluent can be put back into the feed at a point prior to condensation of the high value gas feed, and therefore the entire feed is purified without any high value gas feed going into a waste stream.

Owner:UOP LLC

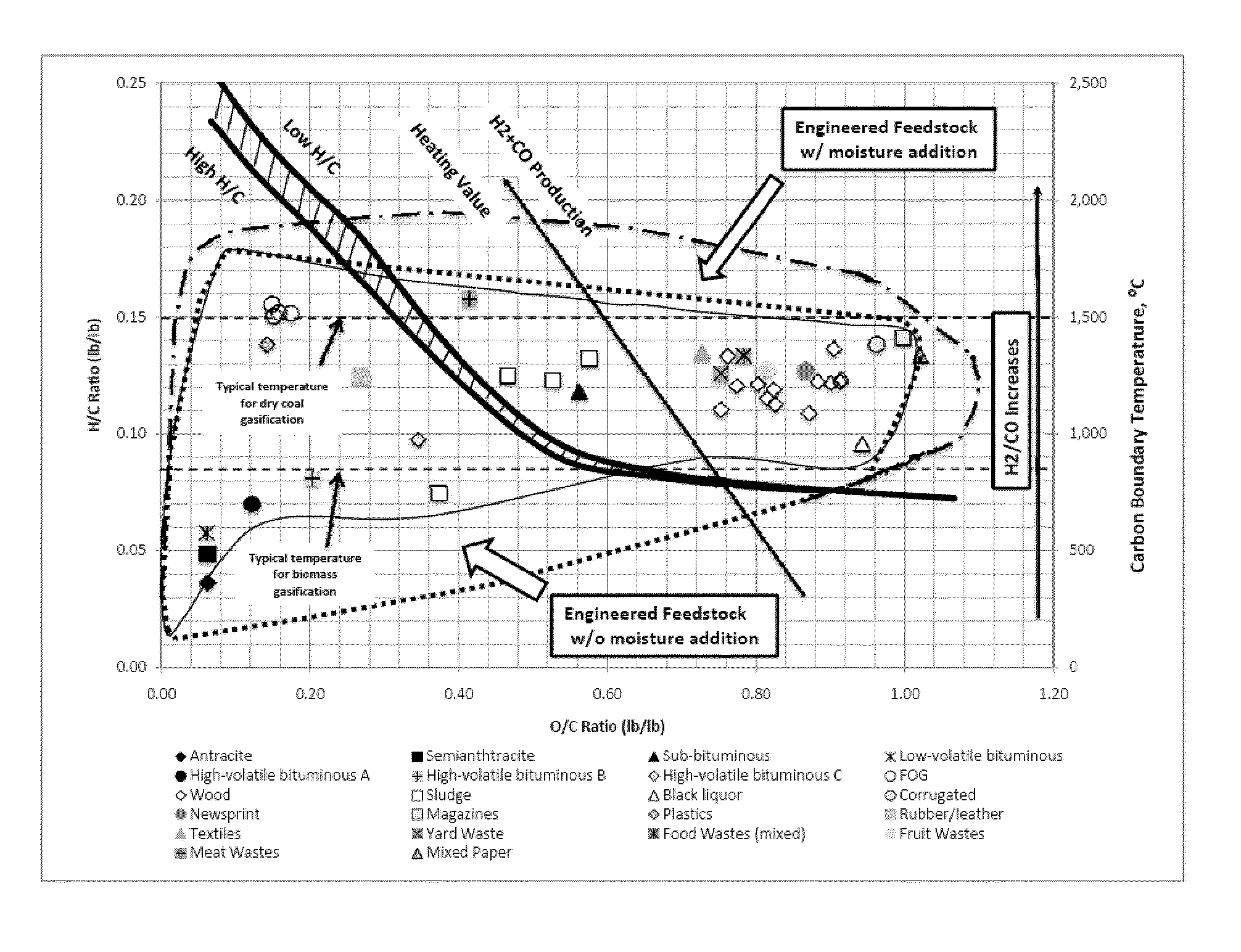

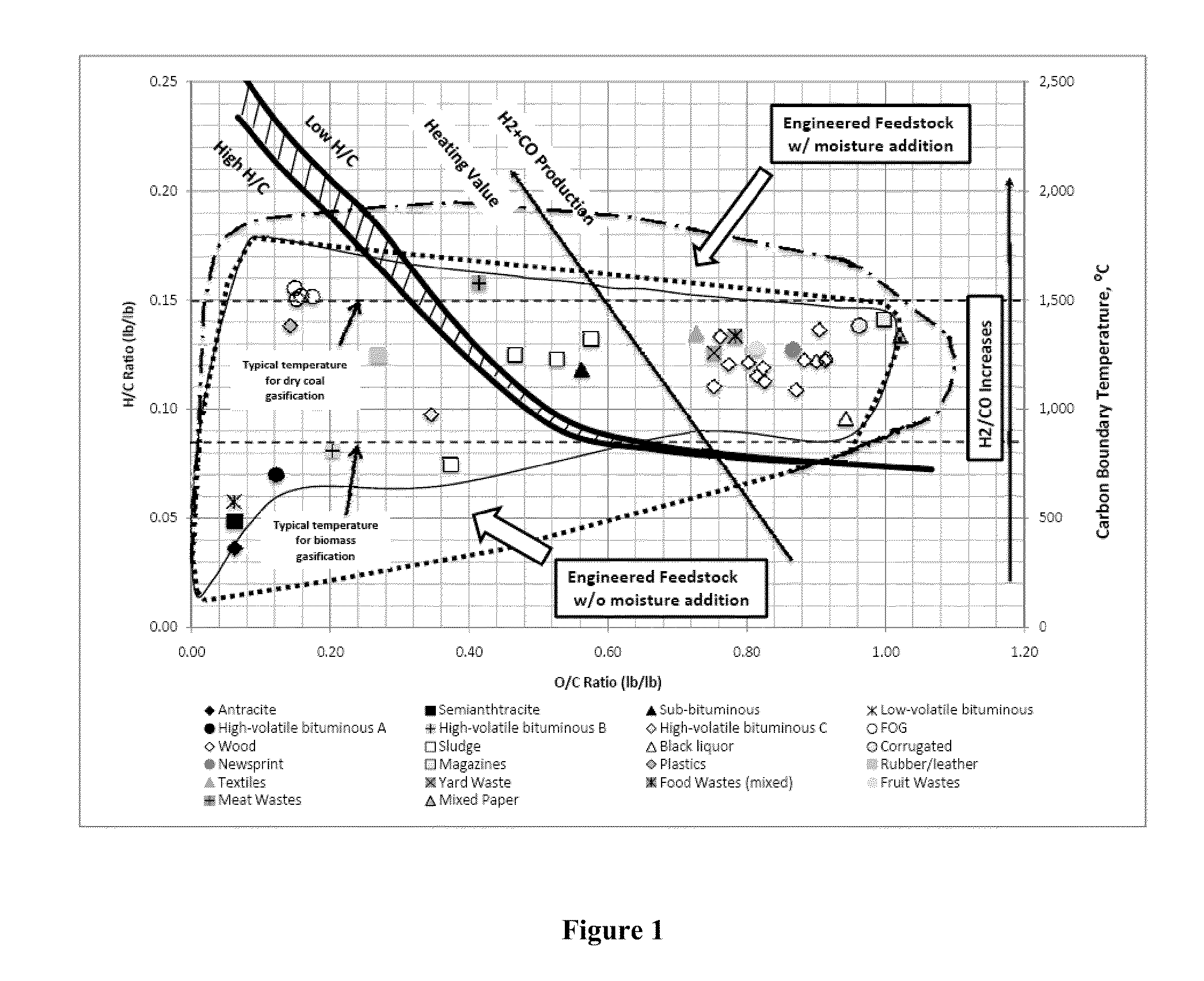

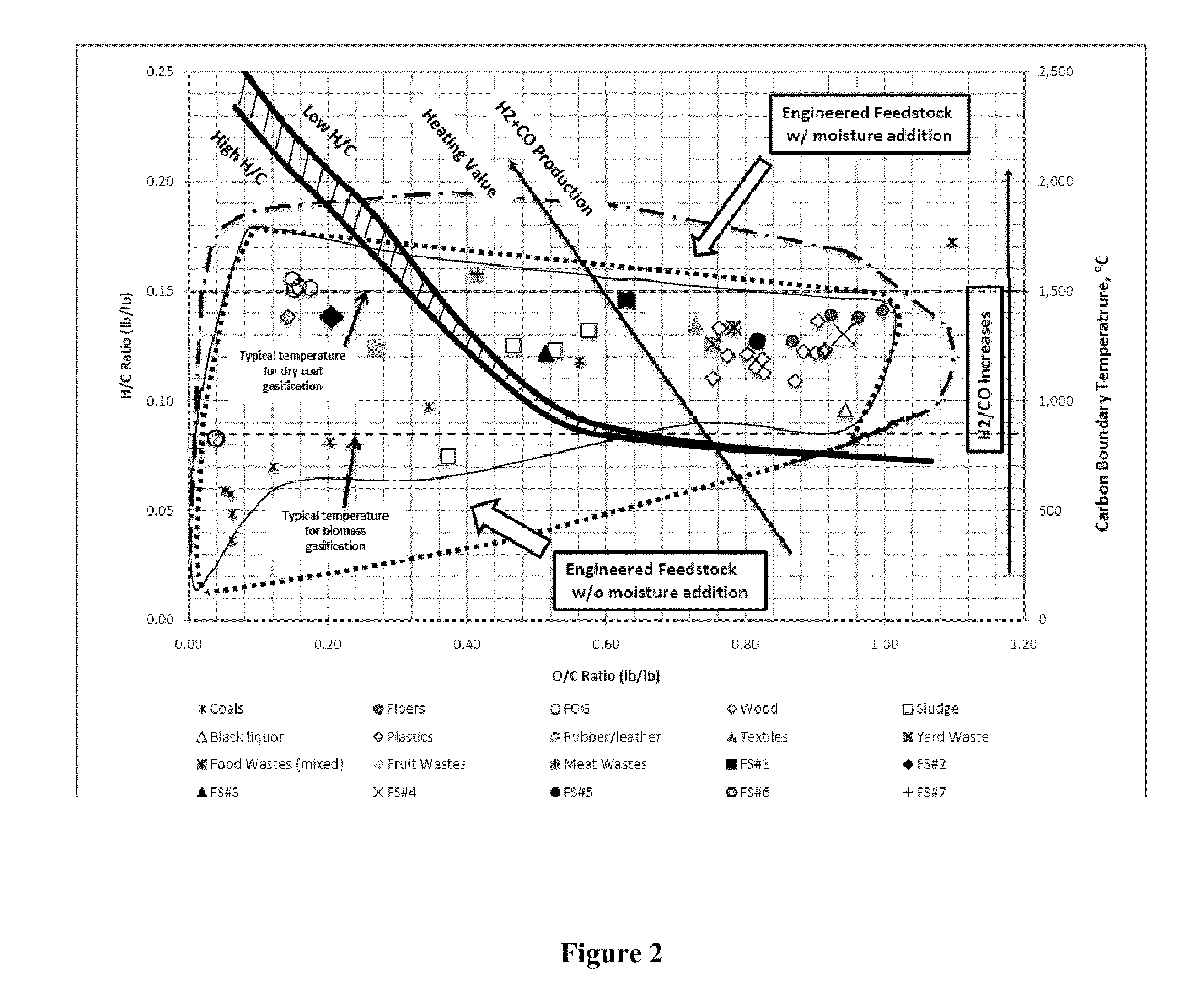

Sorbent containing engineered fuel feed stock

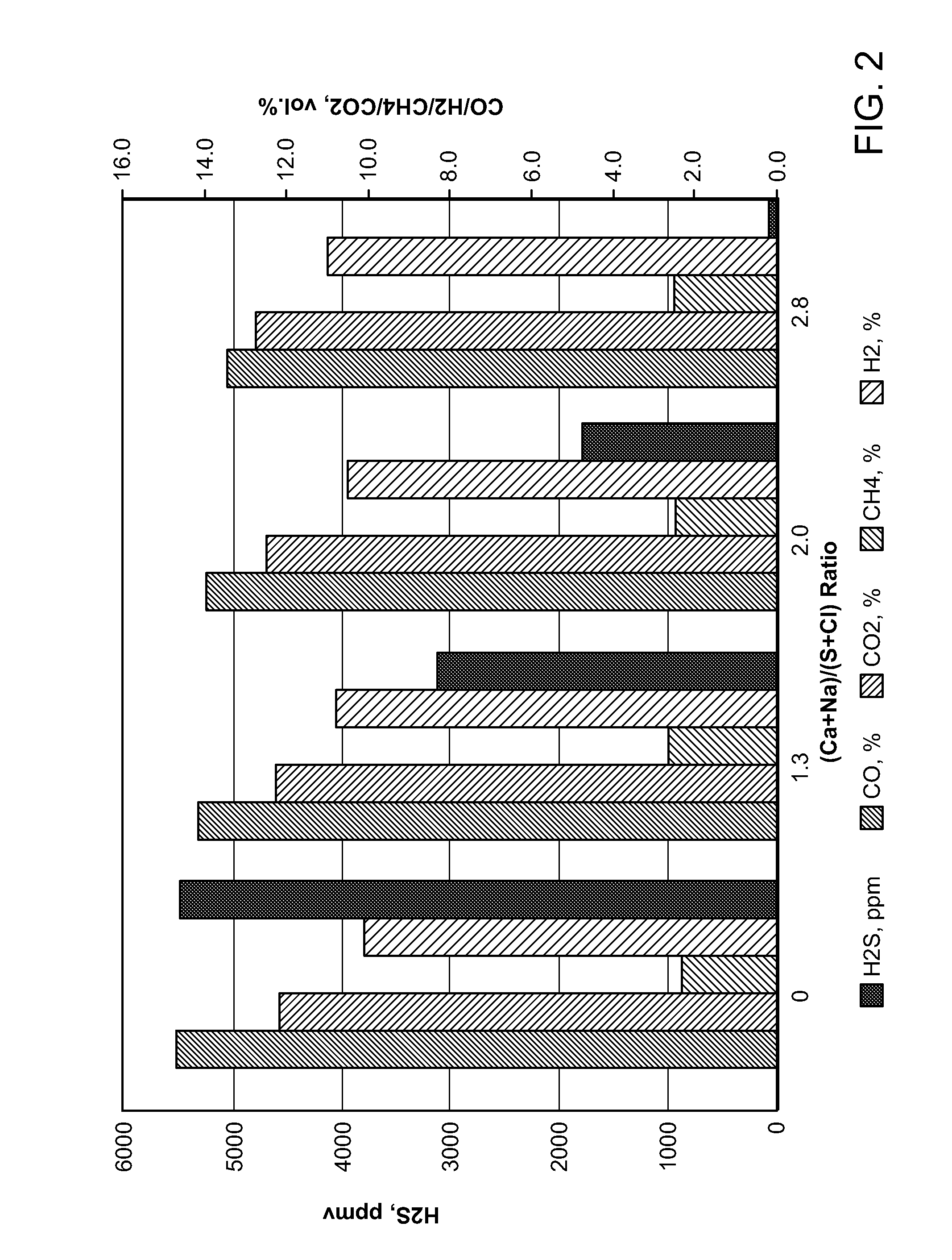

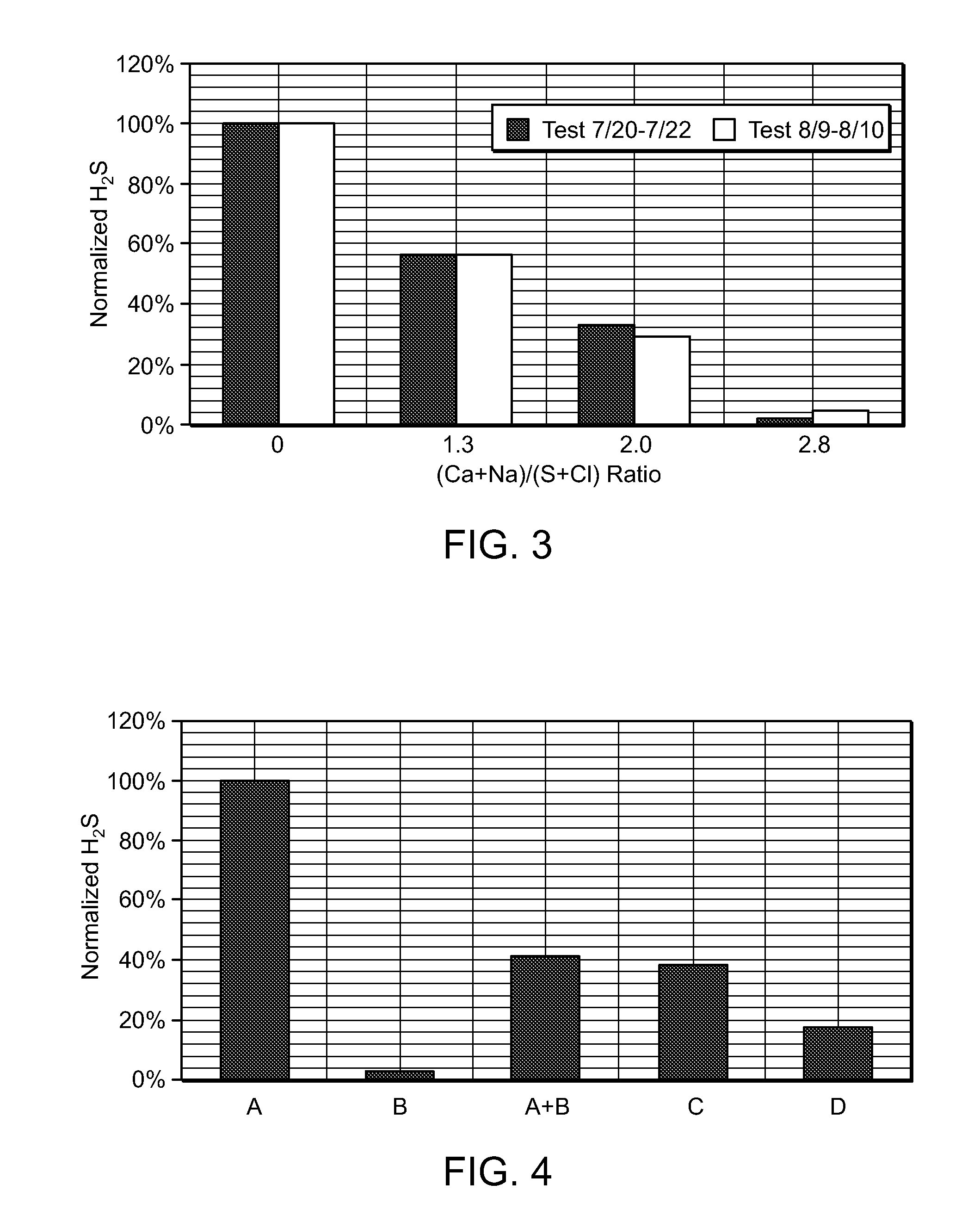

ActiveUS20110099890A1Less-harmful emissionEmission reductionSolid fuel pretreatmentBiofuelsPower stationCombustion

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, methods of making the fuel feed stocks, methods of producing energy from the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles and contain a sorbent. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels. In addition, one or more sorbents can be added to the feed stocks in order to reduce the amount of a variety of pollutants present in traditional fuel and feed stocks, including, but not limited, sulfur and chlorine. Further, these feed stocks with added sorbent can mitigate corrosion, improve fuel conversion, extend power generating plant lifetime, reduce ash slagging, and reduced operating temperature.

Owner:REPOWER IP LLC

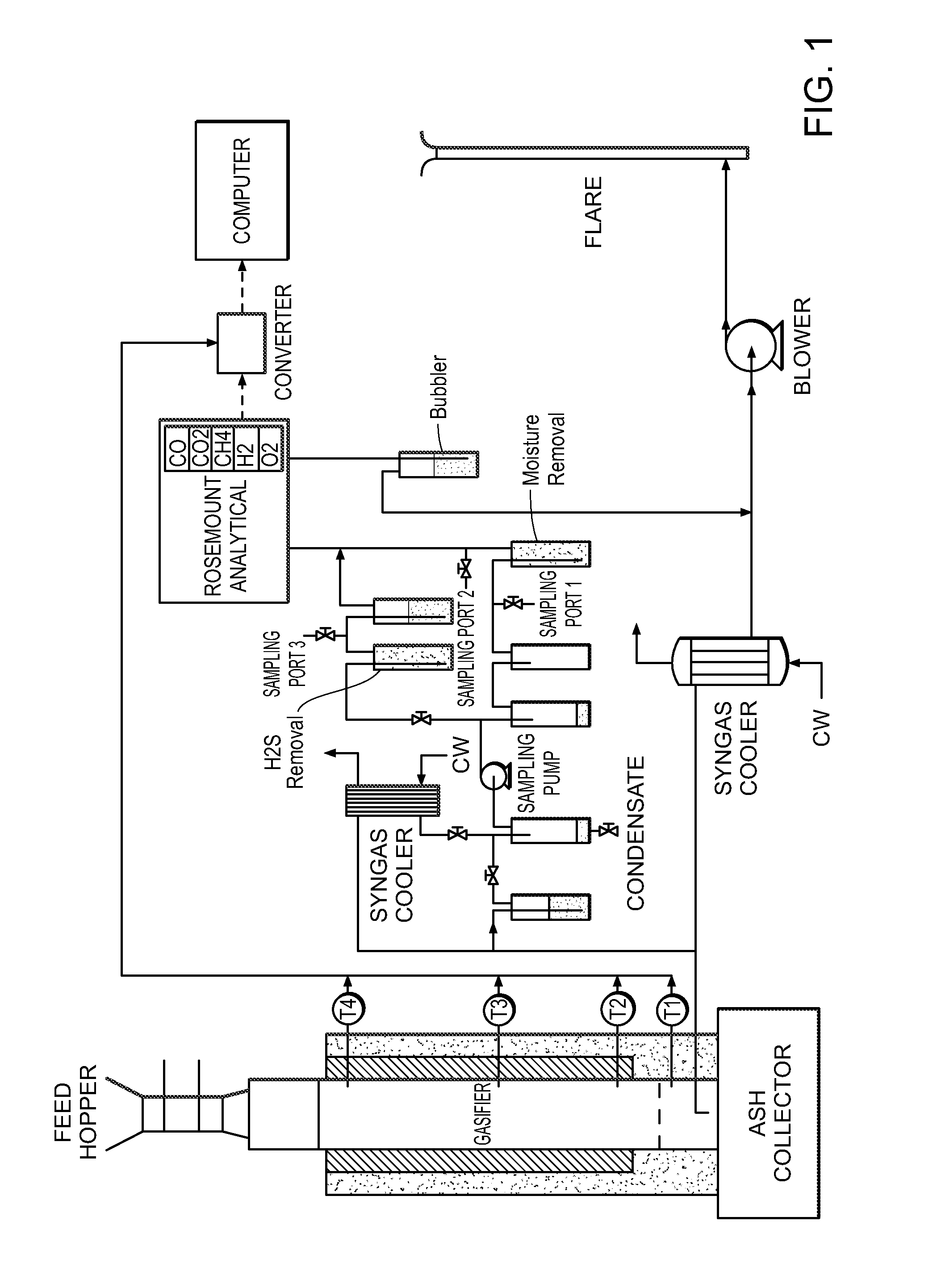

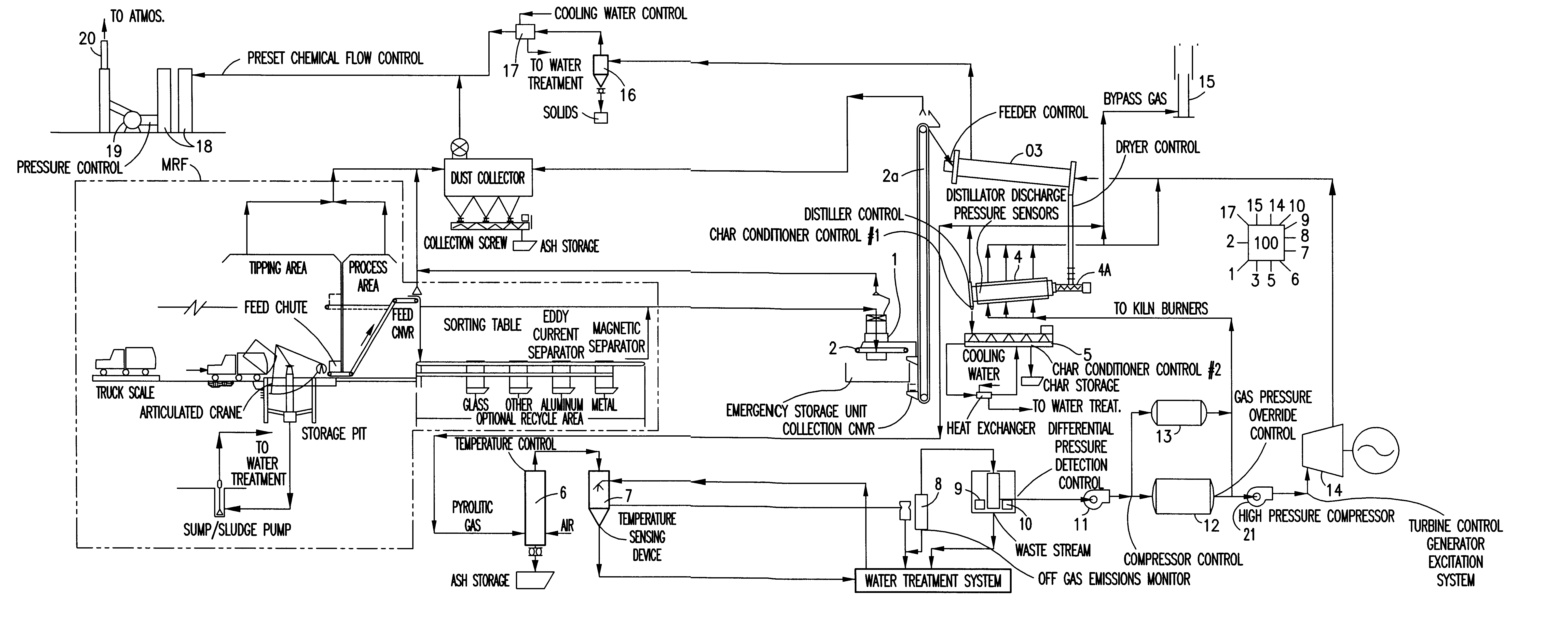

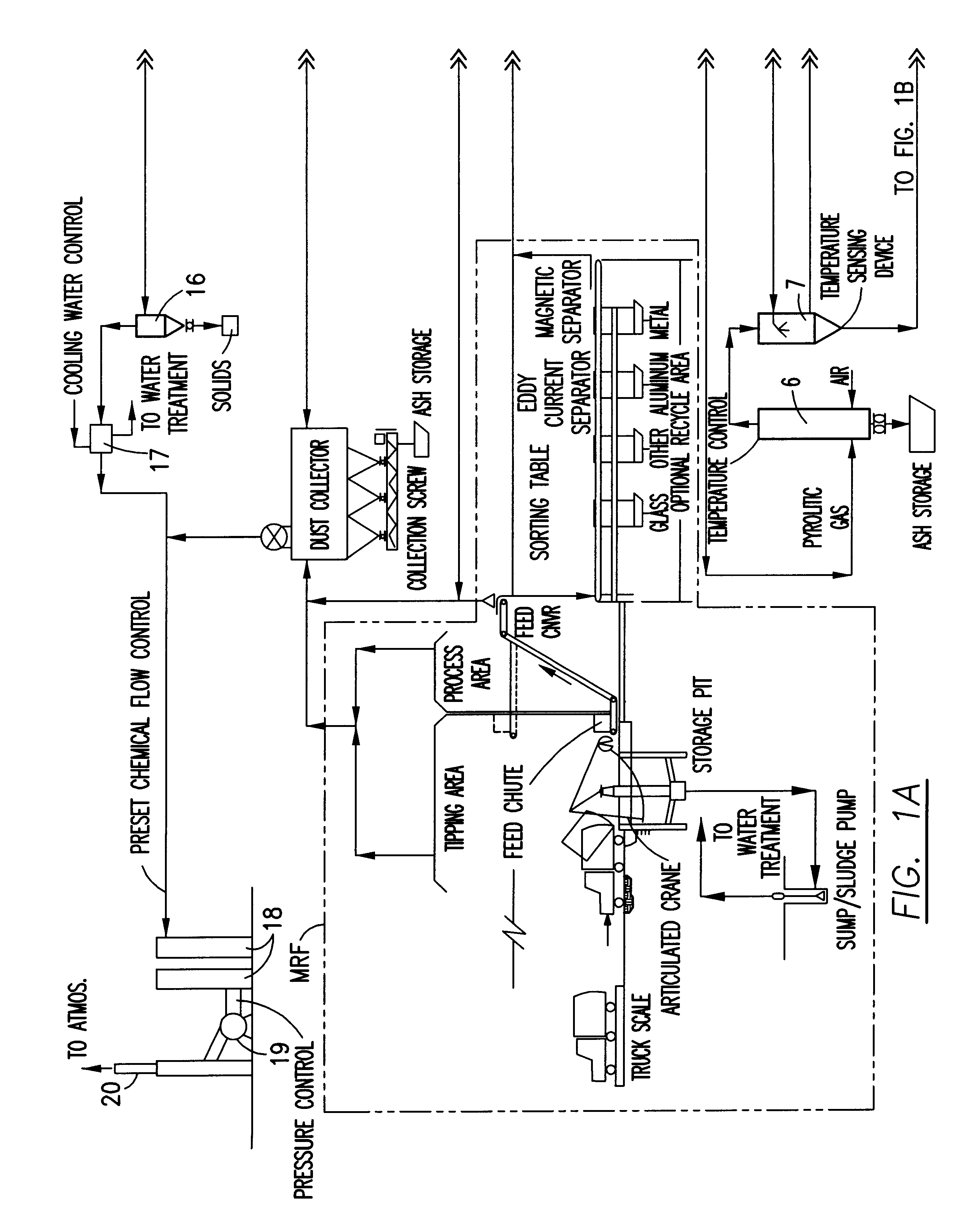

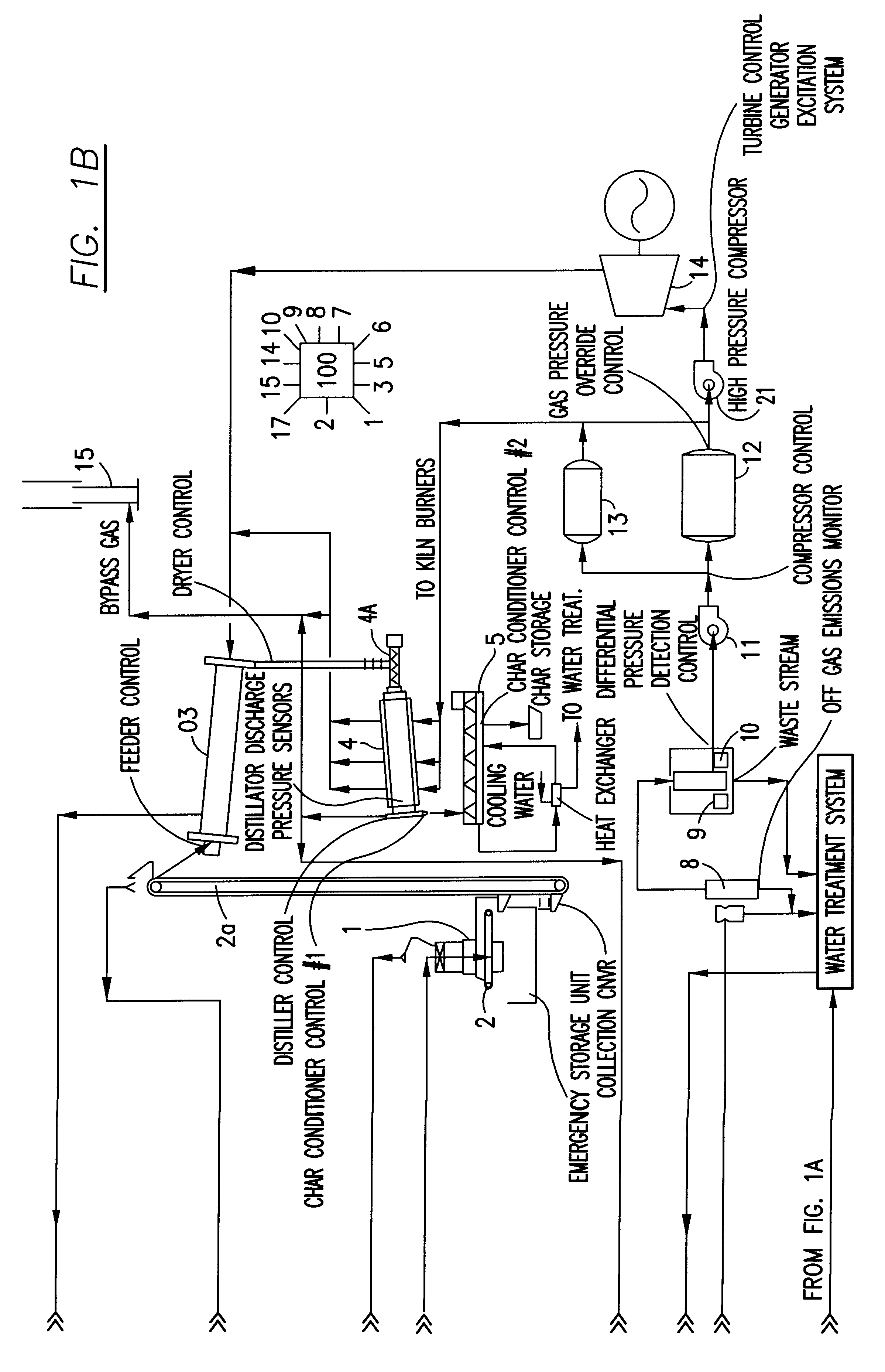

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

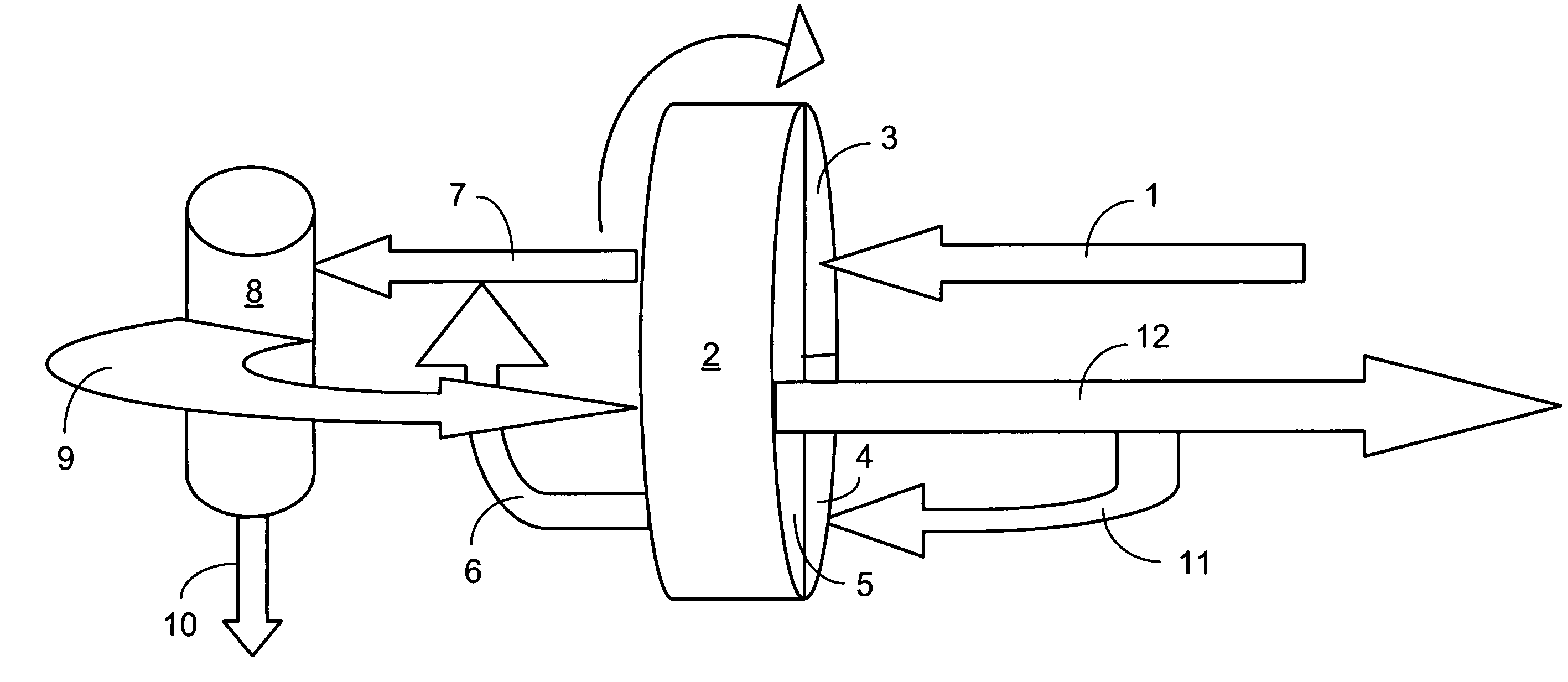

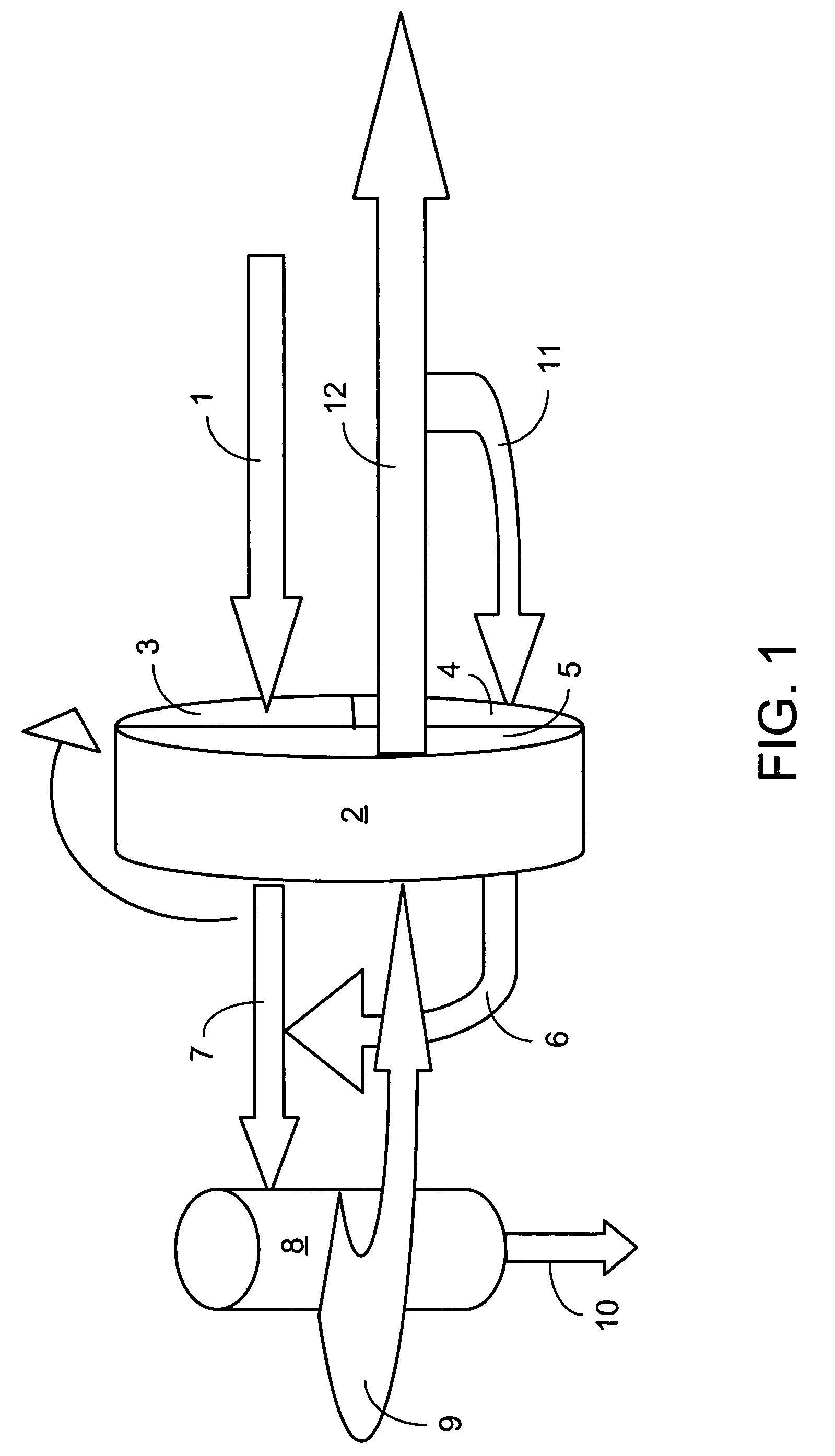

Adsorption process for continuous purification of high value gas feeds

Using a high pressure rotary adsorbent wheel, a high value compressed gas feed can be purified by concentrating the impurity such as water, condensing it out, before final purification. Instead of exhausting gas from the system, the effluent can be put back into the feed at a point prior to condensation of the high value gas feed, and therefore the entire feed is purified without any high value gas feed going into a waste stream.

Owner:UOP LLC

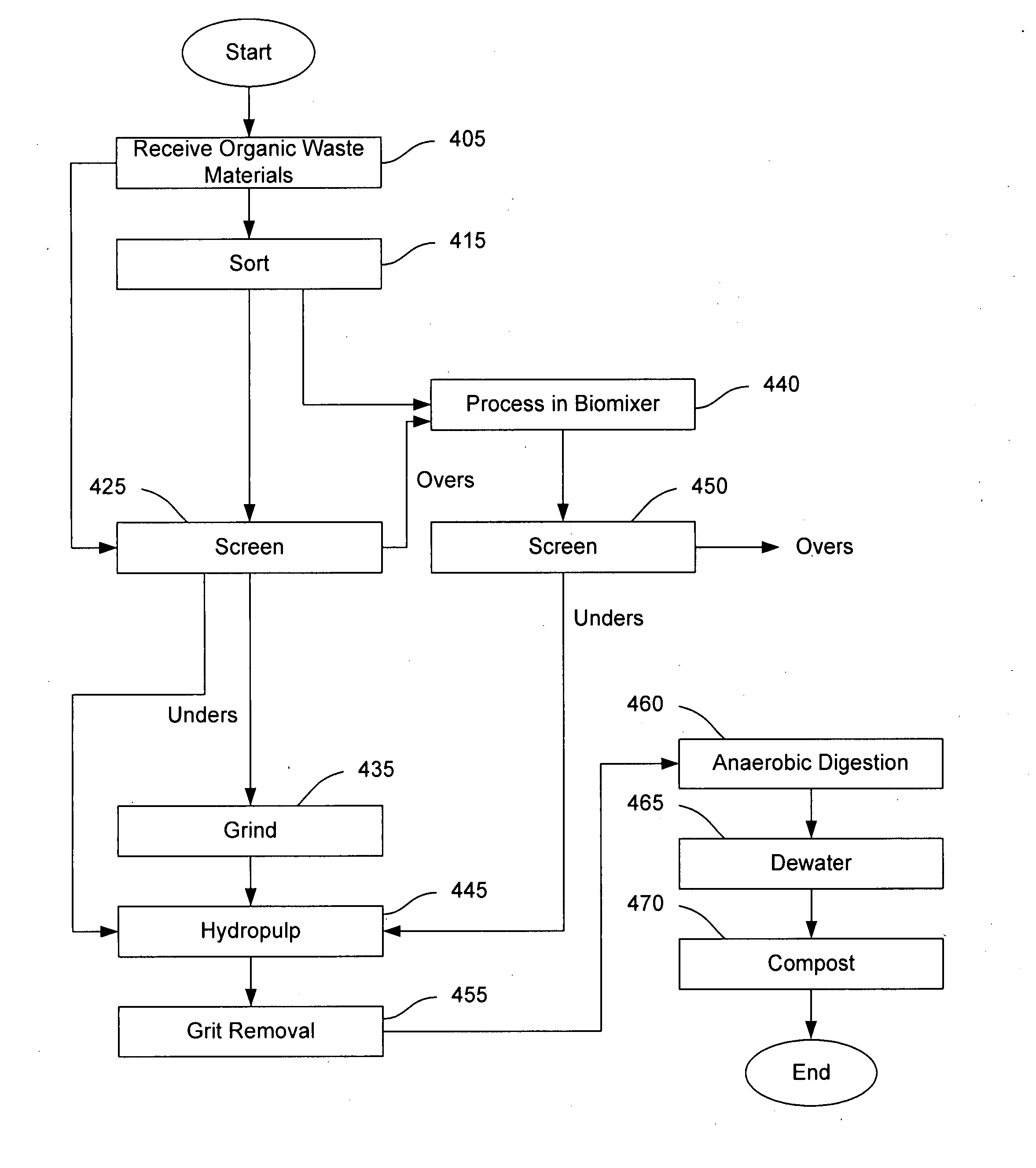

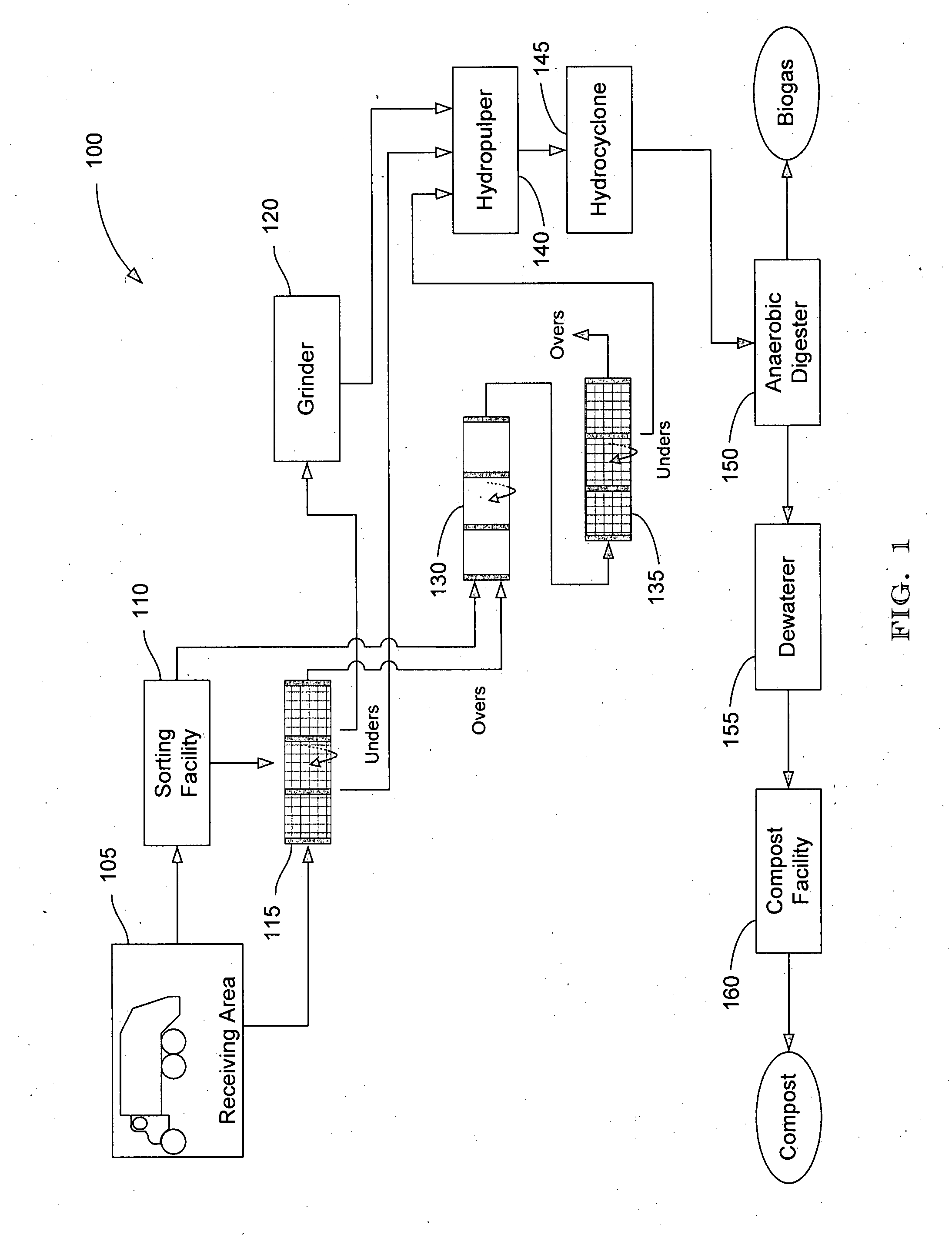

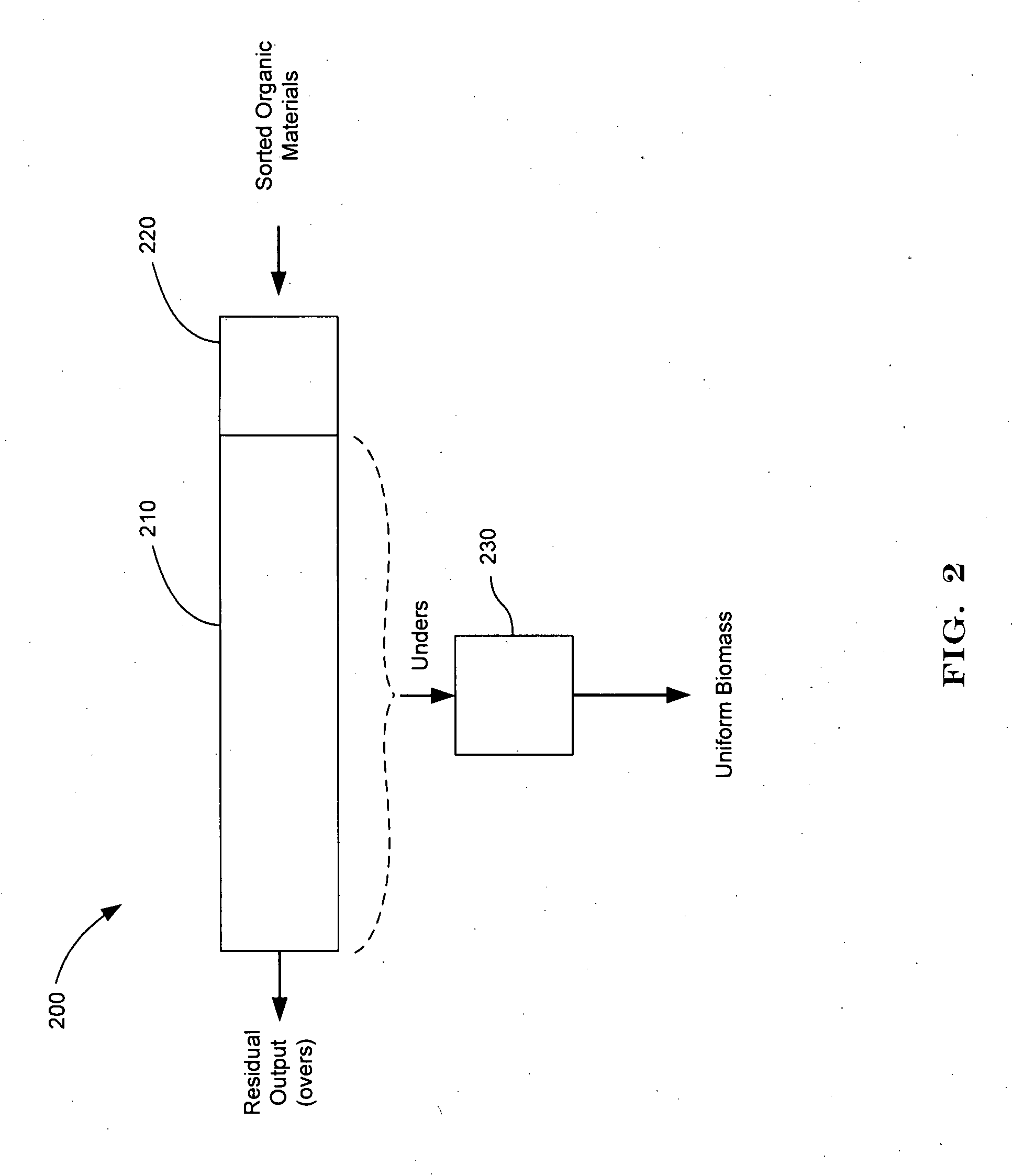

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

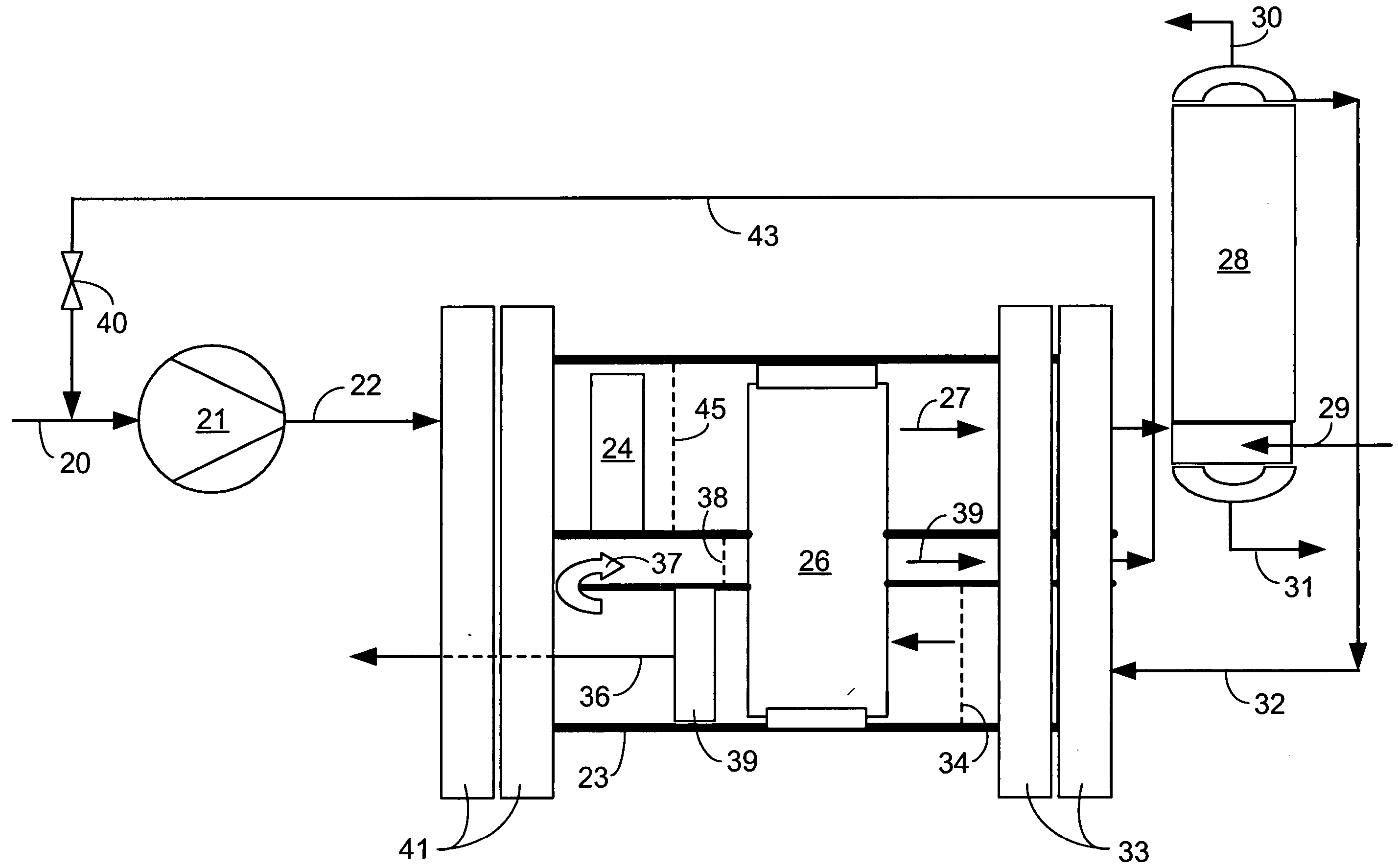

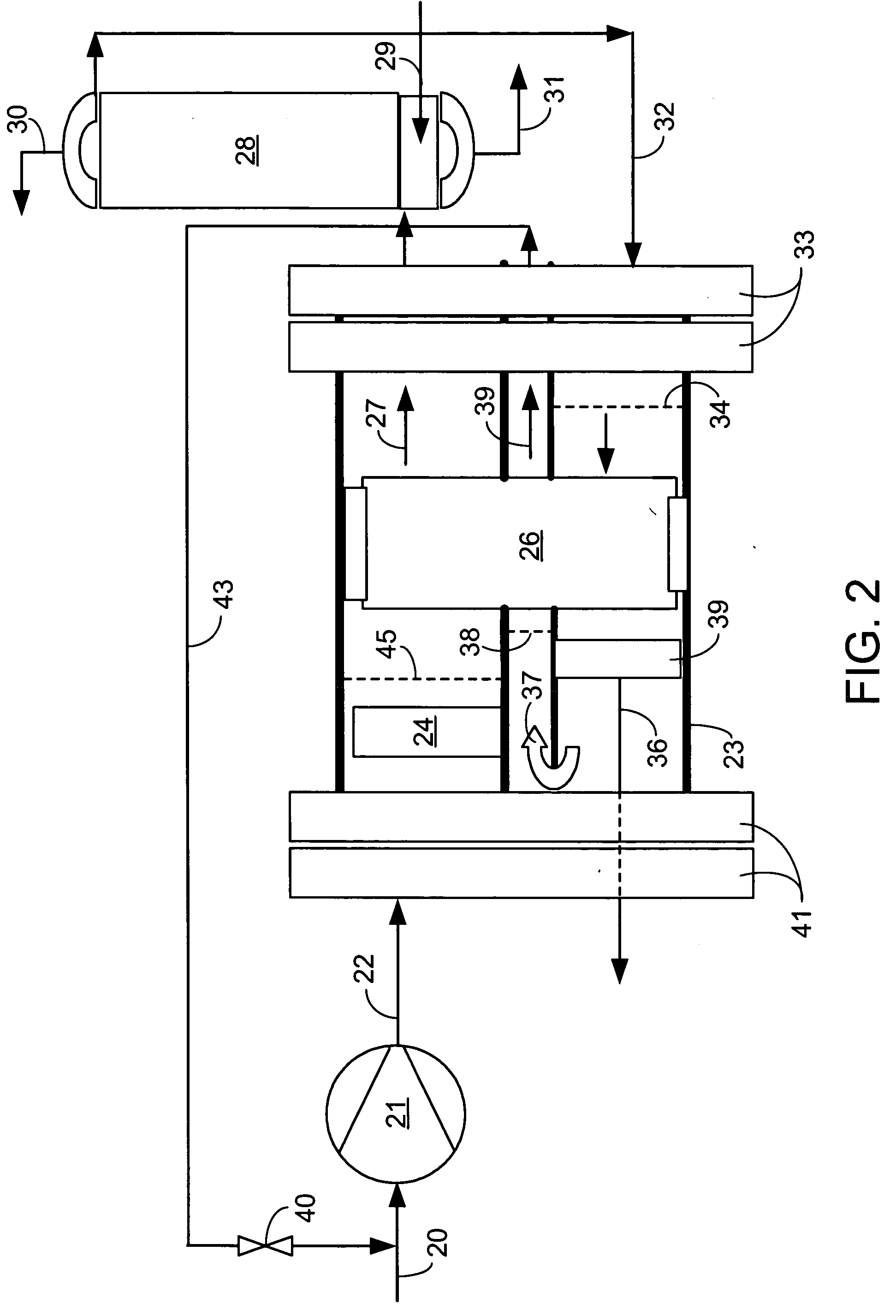

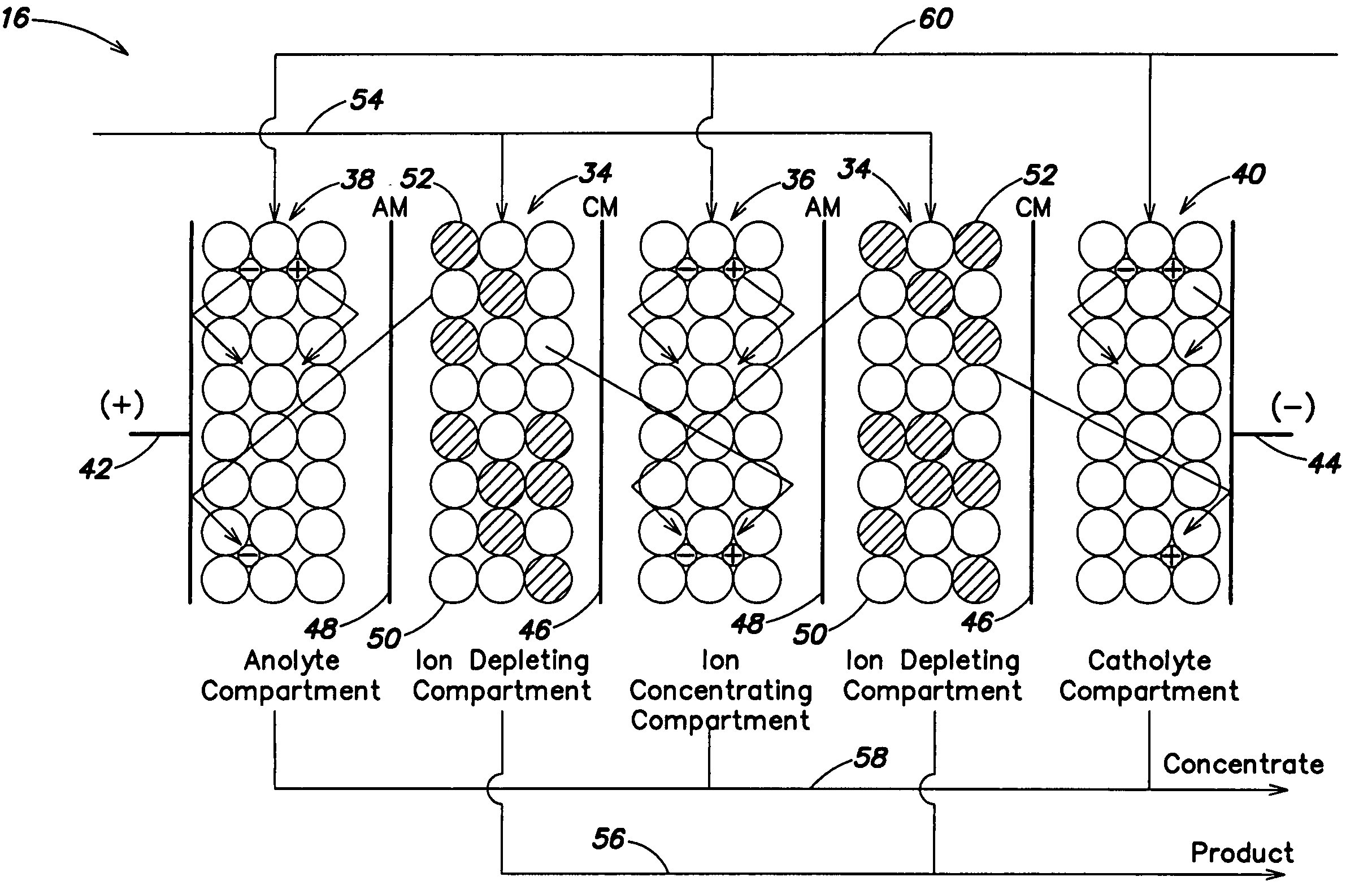

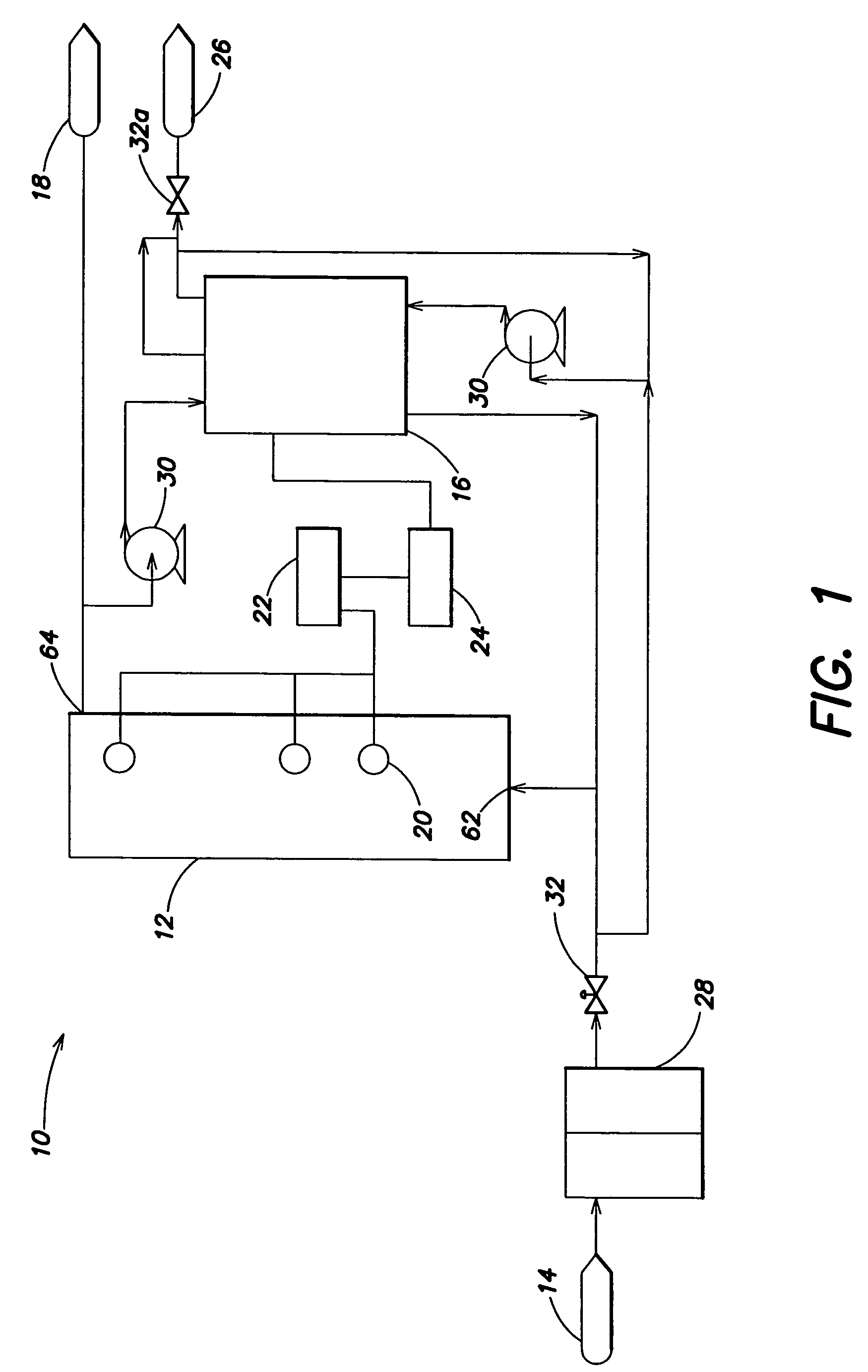

Water treatment system and method

ActiveUS20050103644A1Facilitate water treatmentSludge treatmentVolume/mass flow measurementWater treatment systemWaste stream

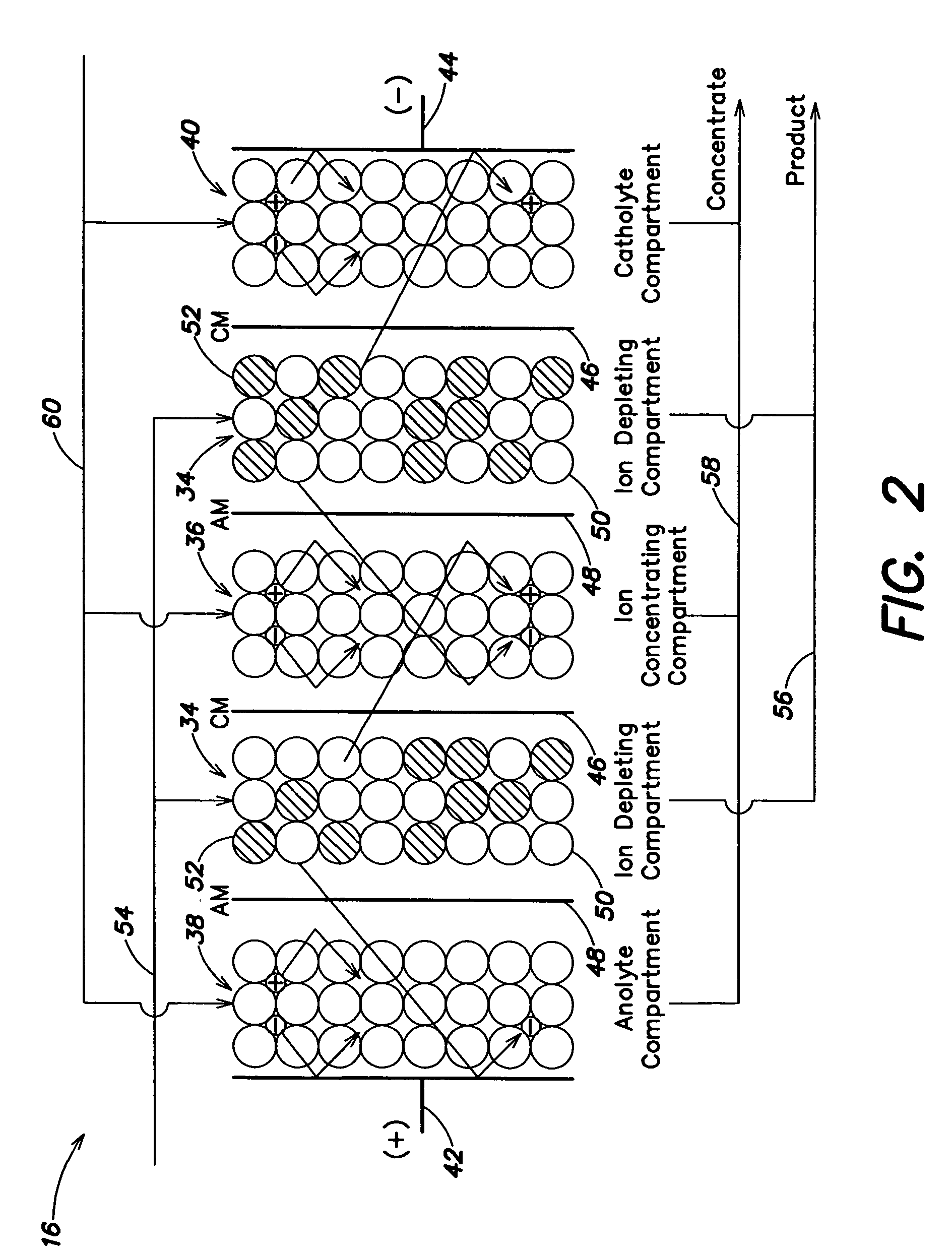

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

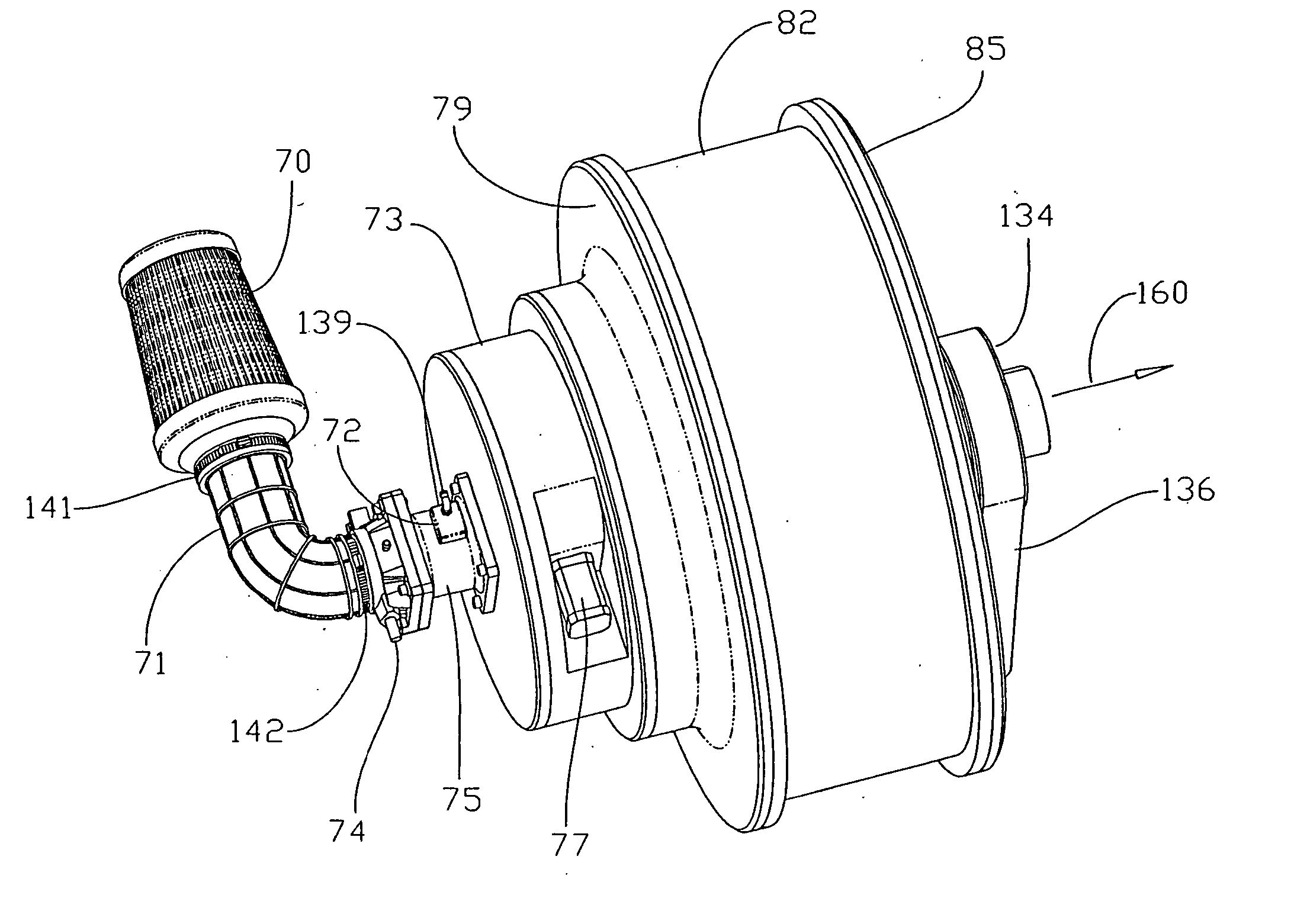

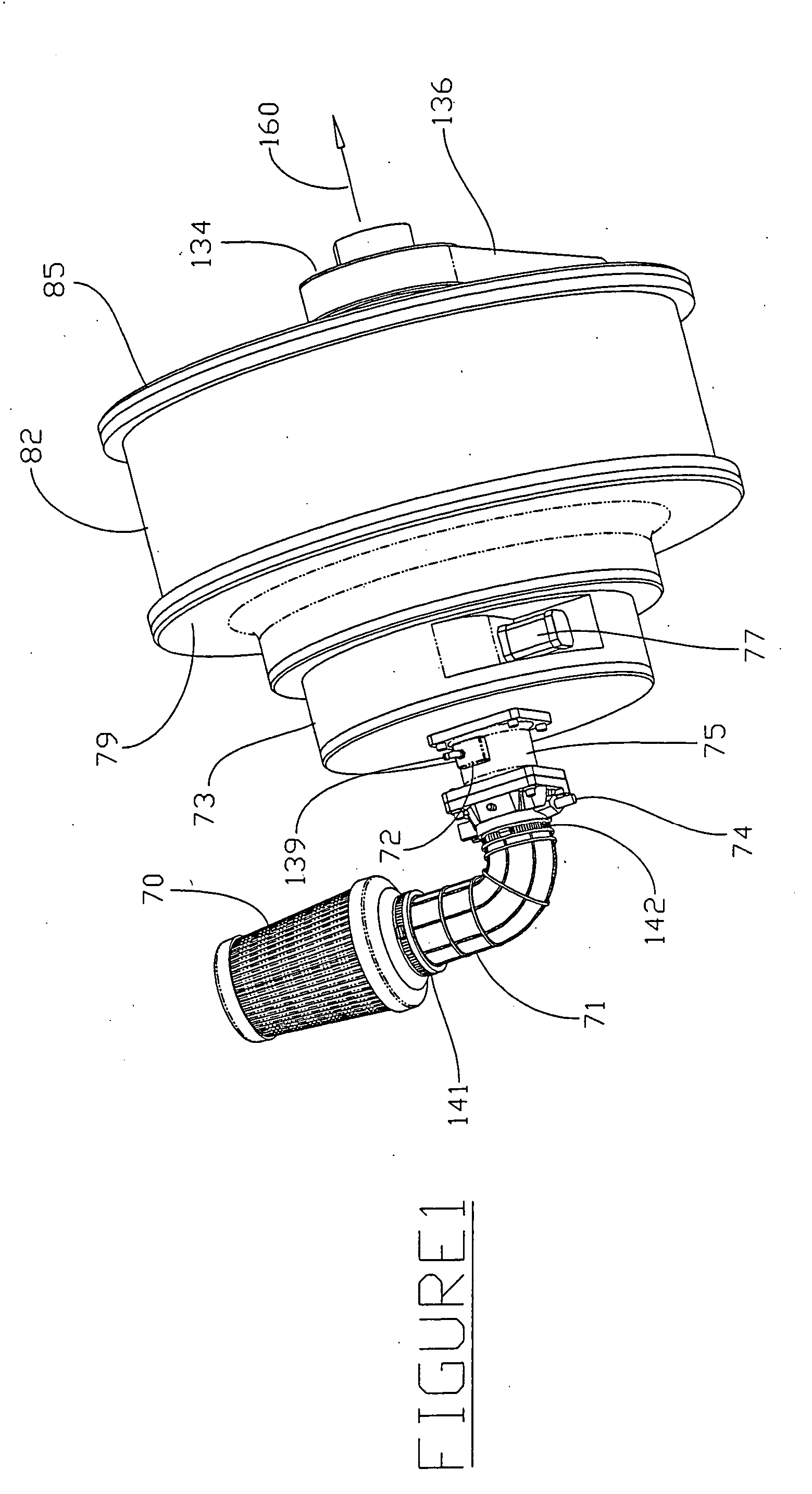

Method and apparatus for treating waste streams

InactiveUS6716360B2Overcome problemsUrea derivatives preparationSludge treatment by oxidationSufficient timeWaste stream

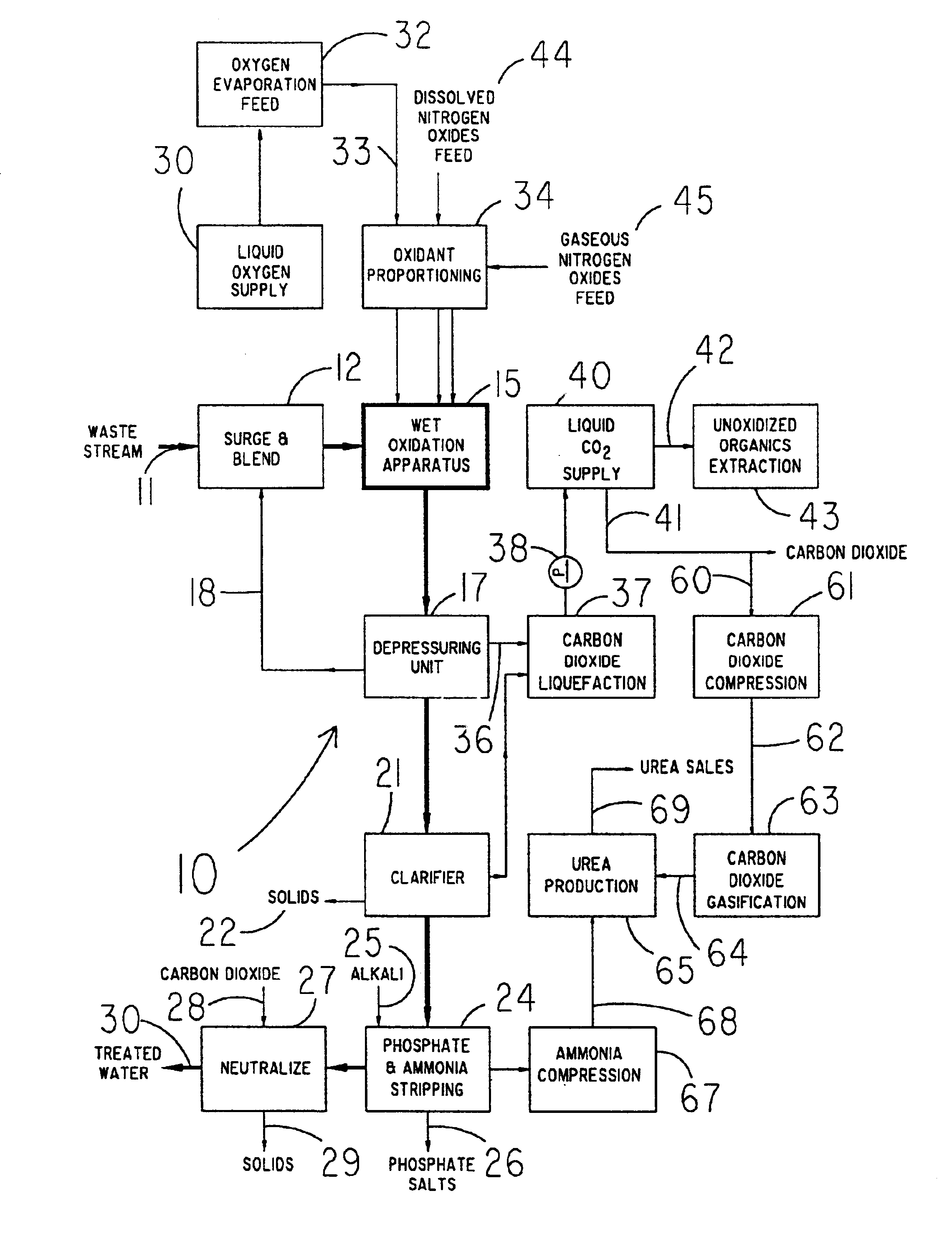

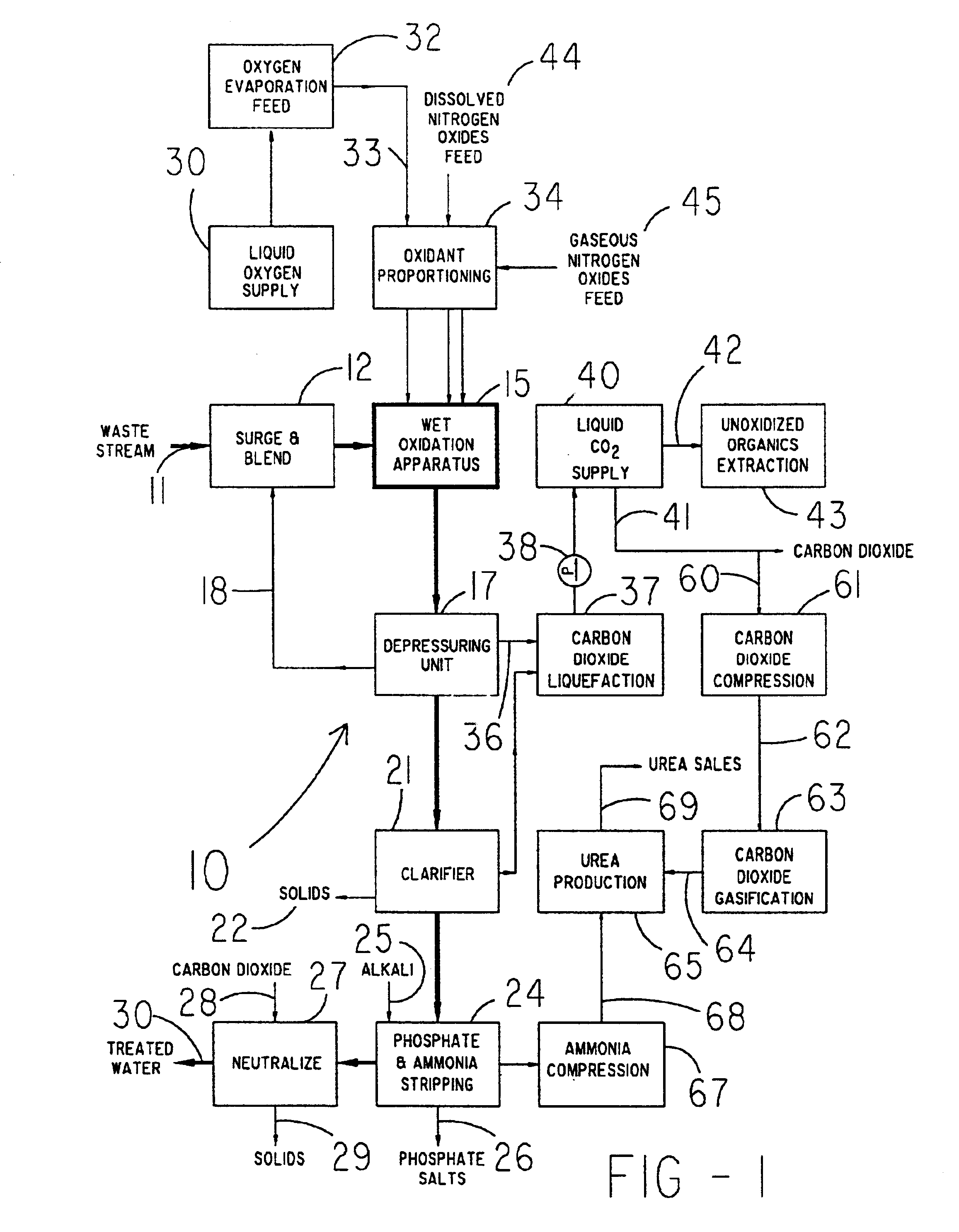

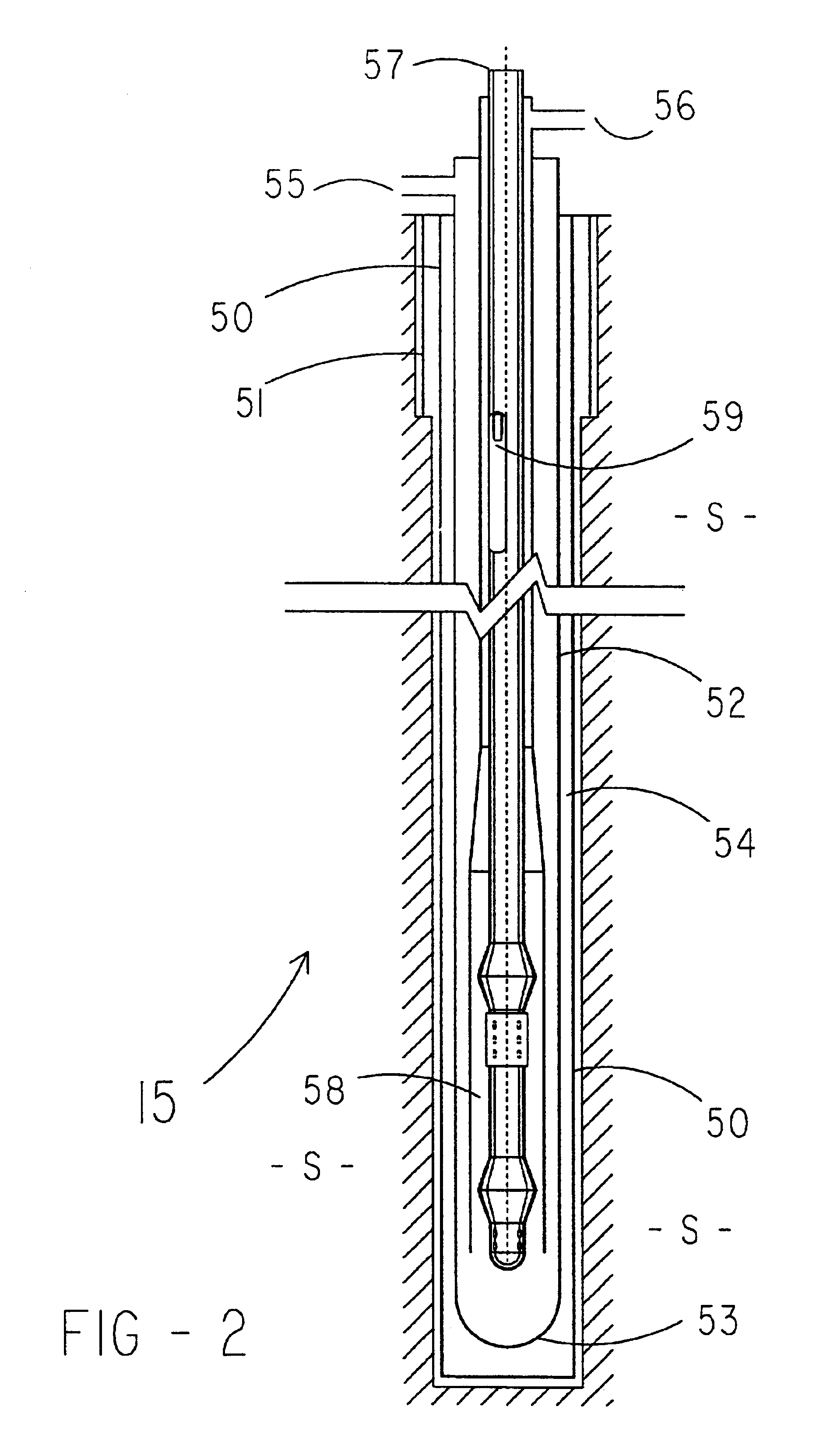

A method for treating a waste stream, the method including the steps of providing a waste stream that includes waste solids suspended in water, feeding the waste stream to the top of a hydraulic downdraft column, conducting the waste stream to the bottom of the hydraulic downdraft column, conducting the waste steam to a first reaction zone, introducing nitrogen-containing oxides into the first reaction zone so that the waste stream is contacted with the nitrogen-containing oxides, conducting the waste stream up a hydraulic updraft column into a second reaction zone, where the second reaction zone is configured to provide sufficient time so that a reaction between the nitrogen-containing oxides and waste solids can take place and substantially consume the nitrogen-containing oxides, introducing oxygen gas into the waste steam after the nitrogen-containing oxides are substantially consumed, thereby providing a second reactant that reacts with waste solids suspended within the stream, conducting the stream to the top of the hydraulic updraft column.

Owner:EAU VIRON

Novel Fungal Enzymes

InactiveUS20090280105A1Easy to cleanOrganic active ingredientsNon-fibrous pulp additionCelluloseWaste stream

This invention relates to novel enzymes and novel methods for producing the same. More specifically this invention relates to a variety of fungal enzymes. Nucleic acid molecules encoding such enzymes, compositions, recombinant and genetically modified host cells, and methods of use are described. The invention also relates to a method to convert lignocellulosic biomass to fermentable sugars with enzymes that degrade the lignocellulosic material and novel combinations of enzymes, including those that provide a synergistic release of sugars from plant biomass. The invention also relates to methods to use the novel enzymes and compositions of such enzymes in a variety of other processes, including washing of clothing, detergent processes, deinking and biobleaching of paper and pulp, and treatment of waste streams.

Owner:DANISCO US INC

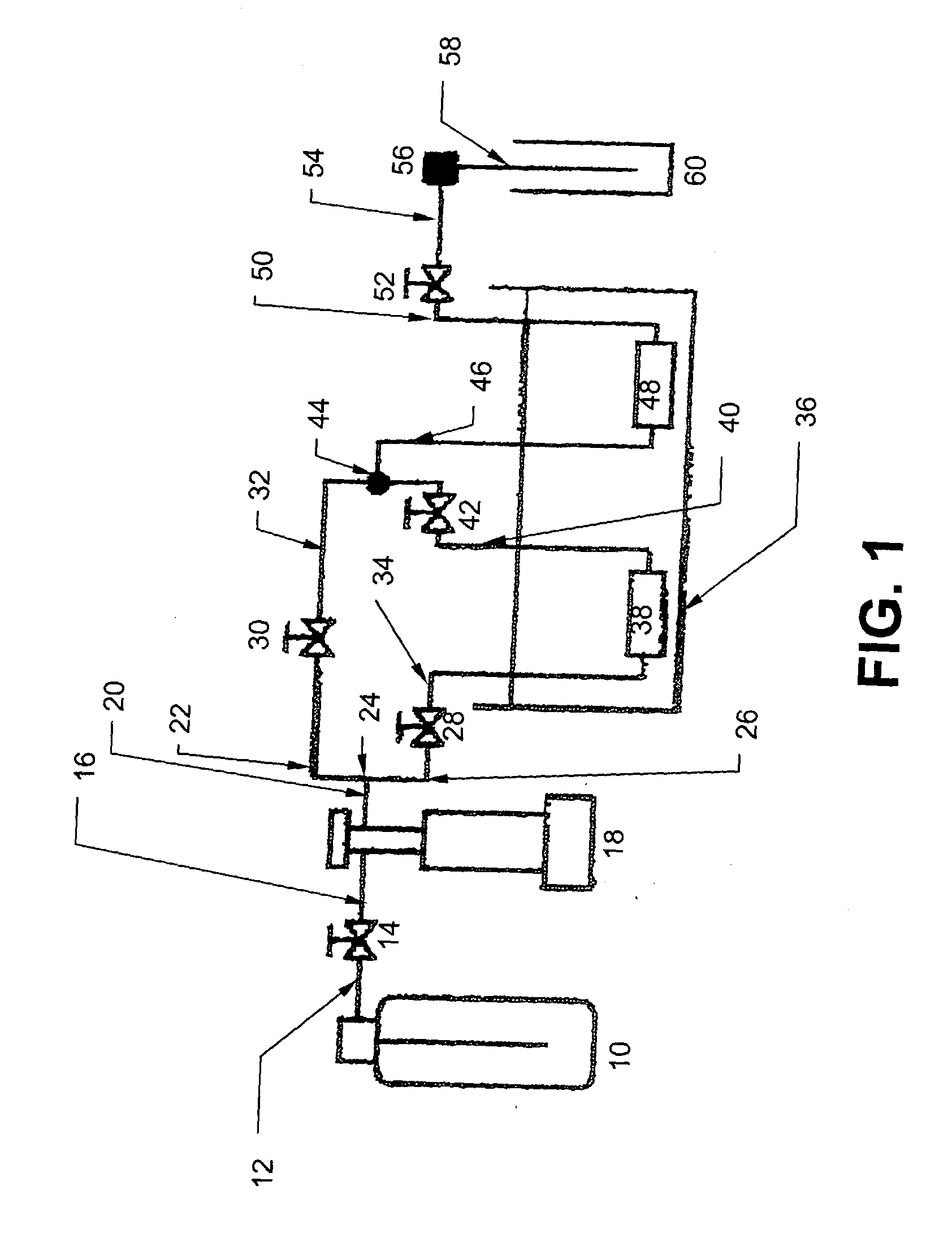

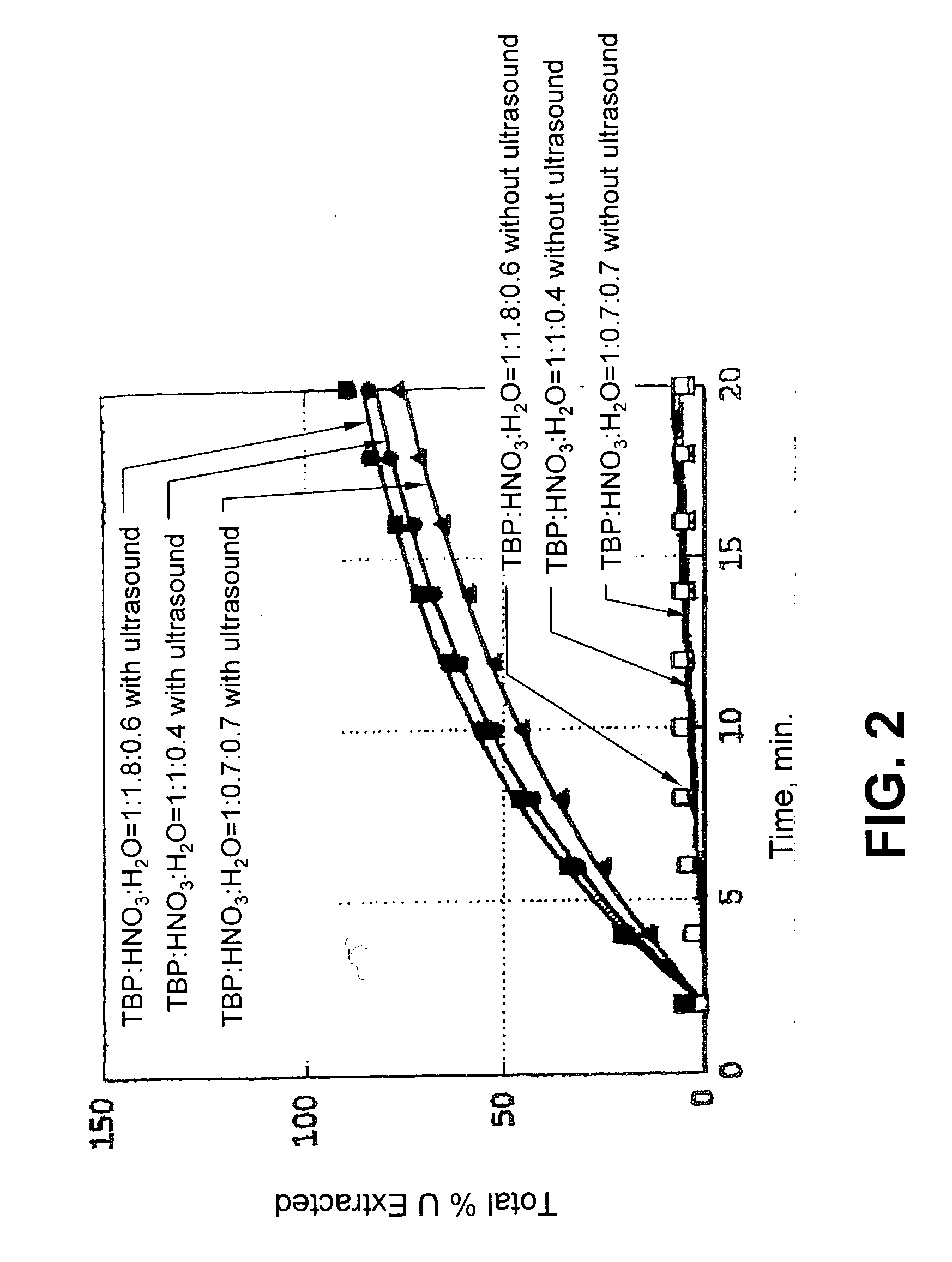

Ultrasound enhanced process for extracting metal species in supercritical fluids

InactiveUS20030183043A1Enhances rate and efficiencyReduce probabilitySolid sorbent liquid separationGold compoundsUranium oxidePresent method

Improved methods for the extraction or dissolution of metals, metalloids or their oxides, especially lanthanides, actinides, uranium or their oxides, into supercritical solvents containing an extractant are disclosed. The disclosed embodiments specifically include enhancing the extraction or dissolution efficiency with ultrasound. The present methods allow the direct, efficient dissolution of UO2 or other uranium oxides without generating any waste stream or by-products.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST +1

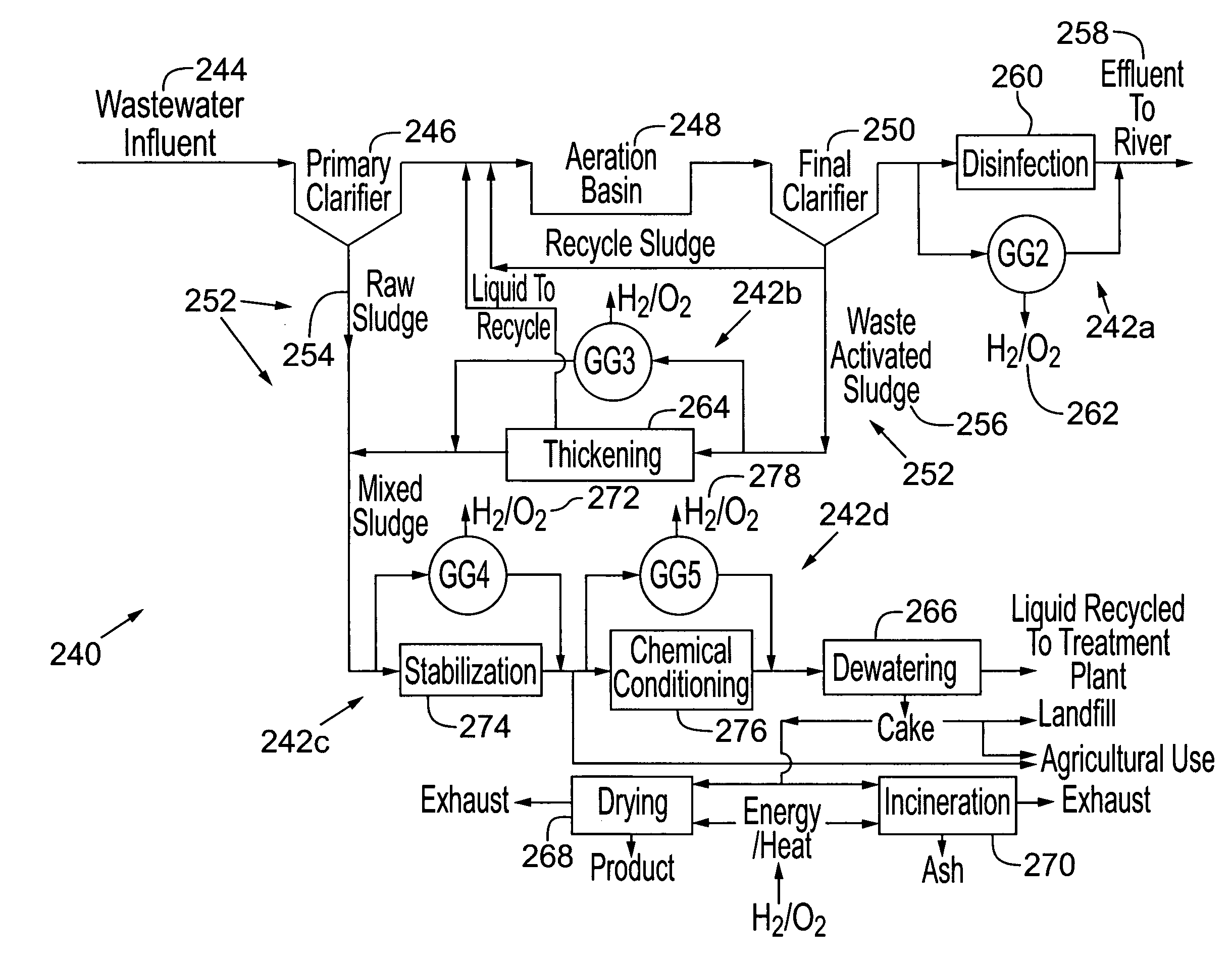

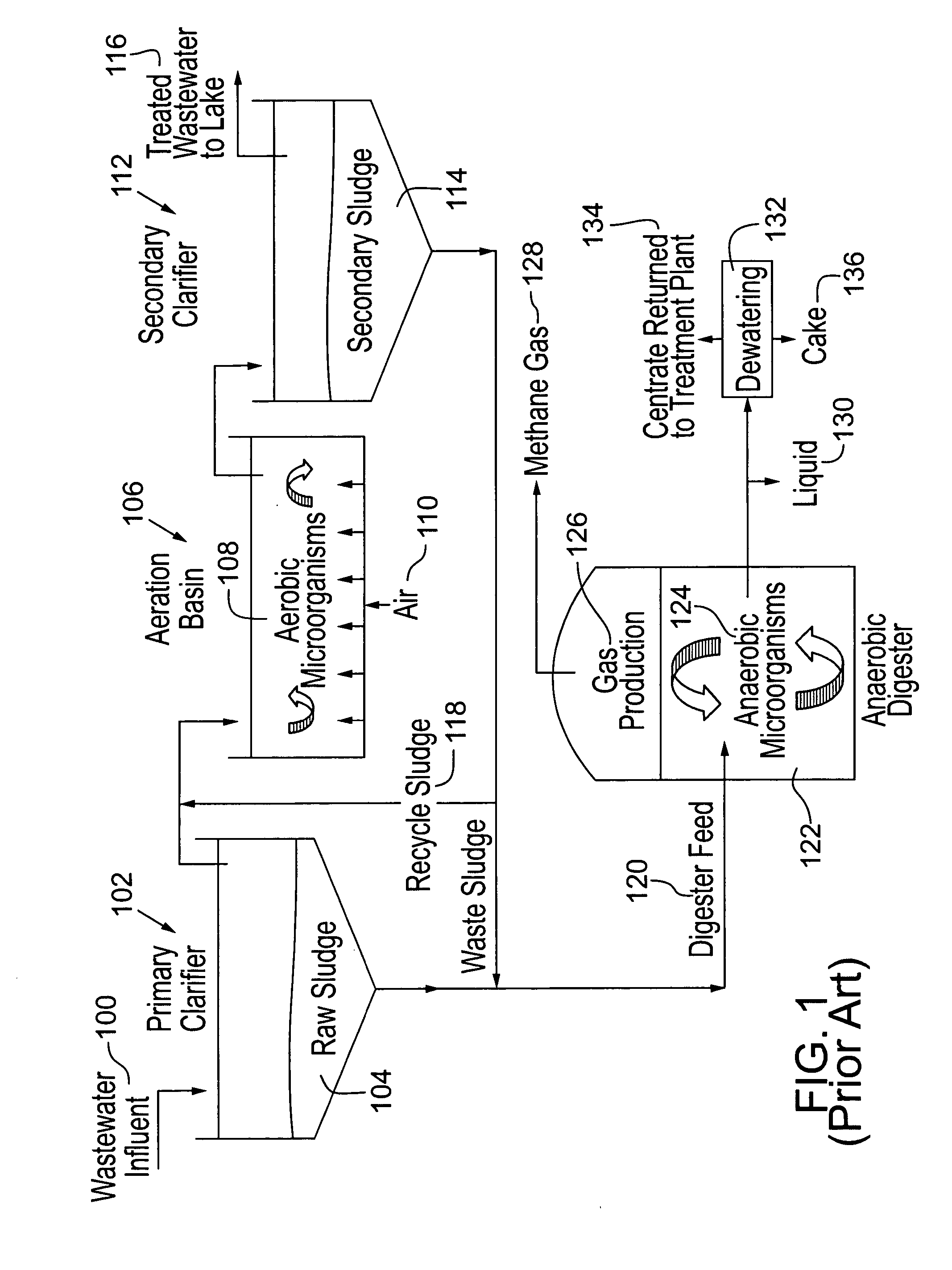

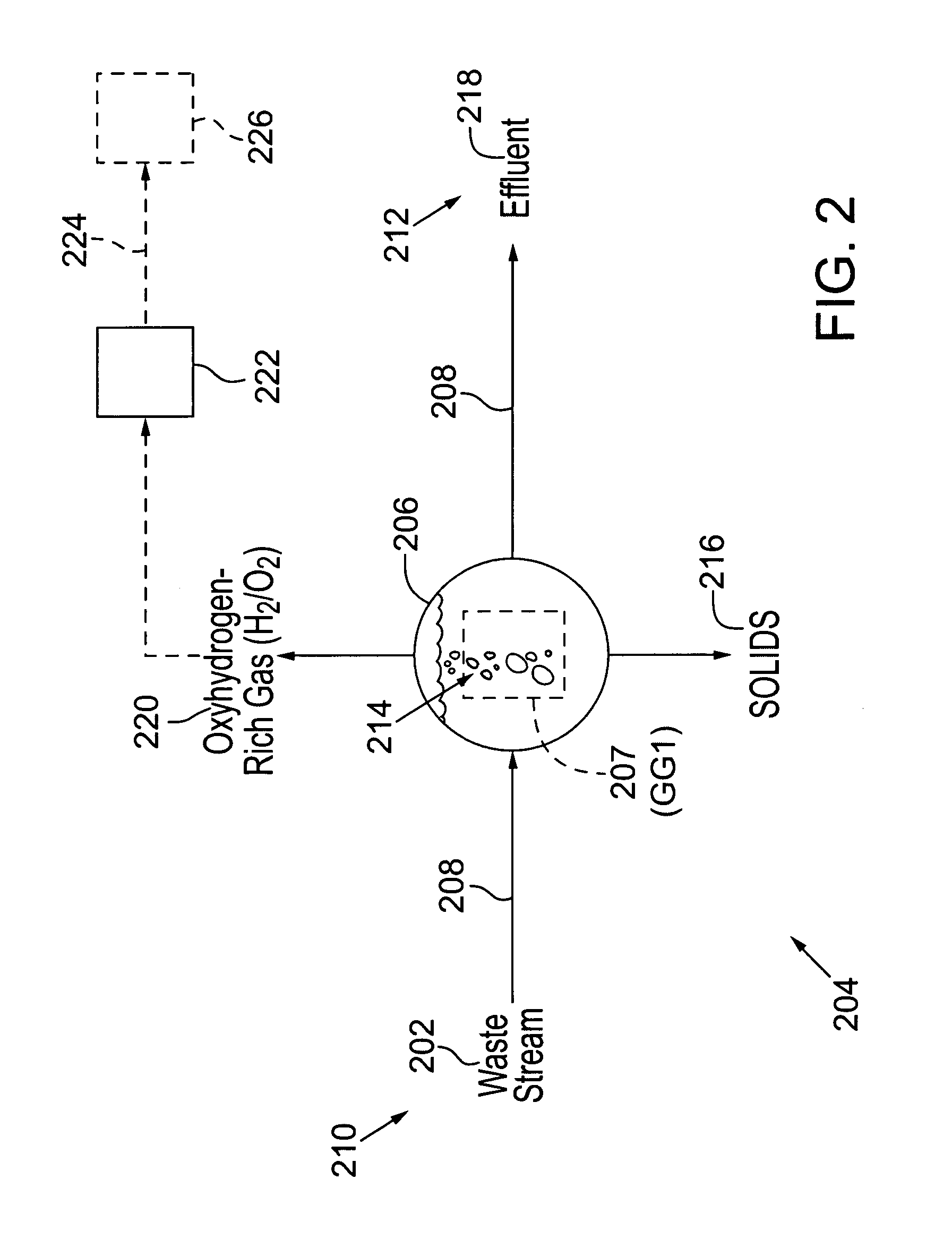

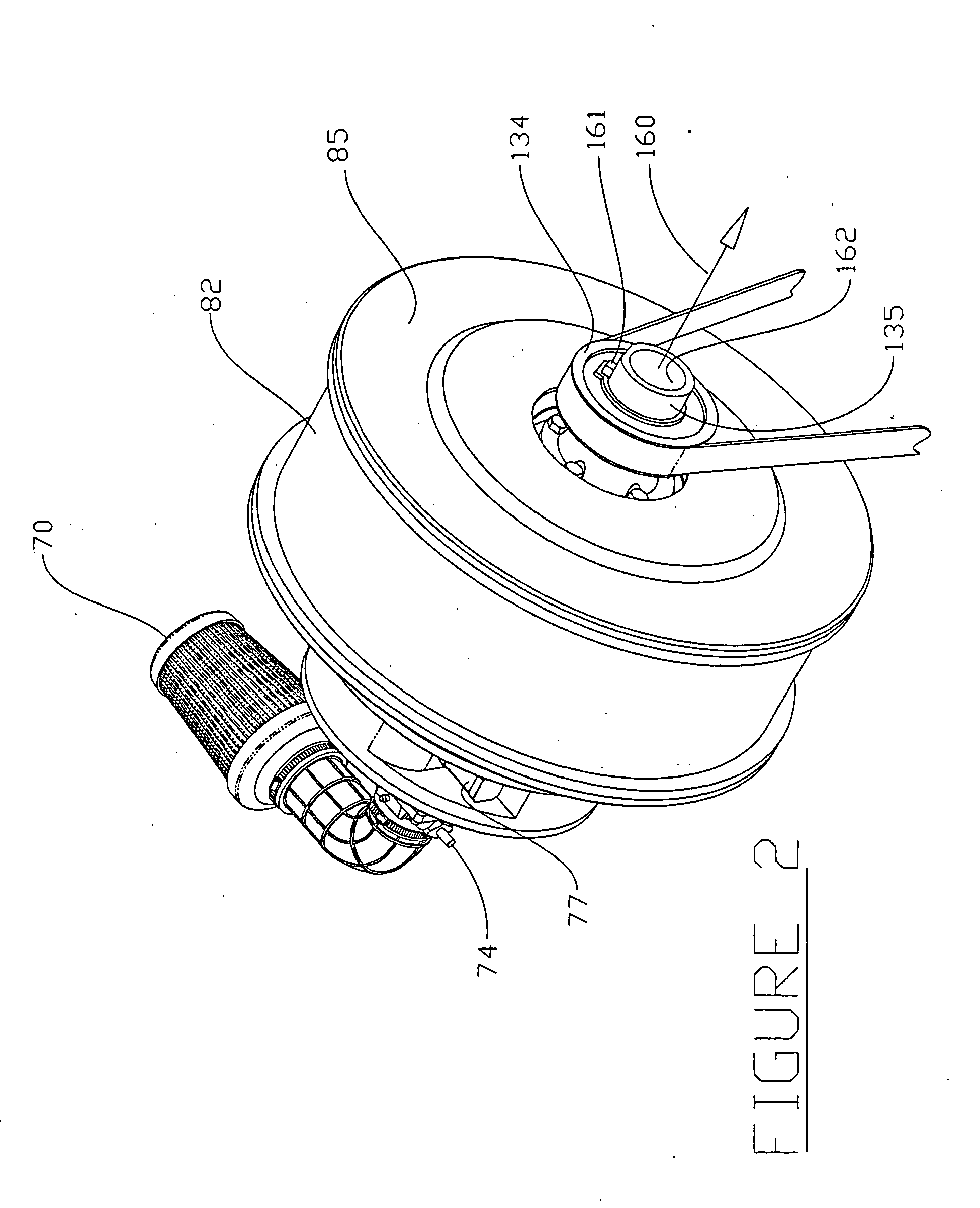

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

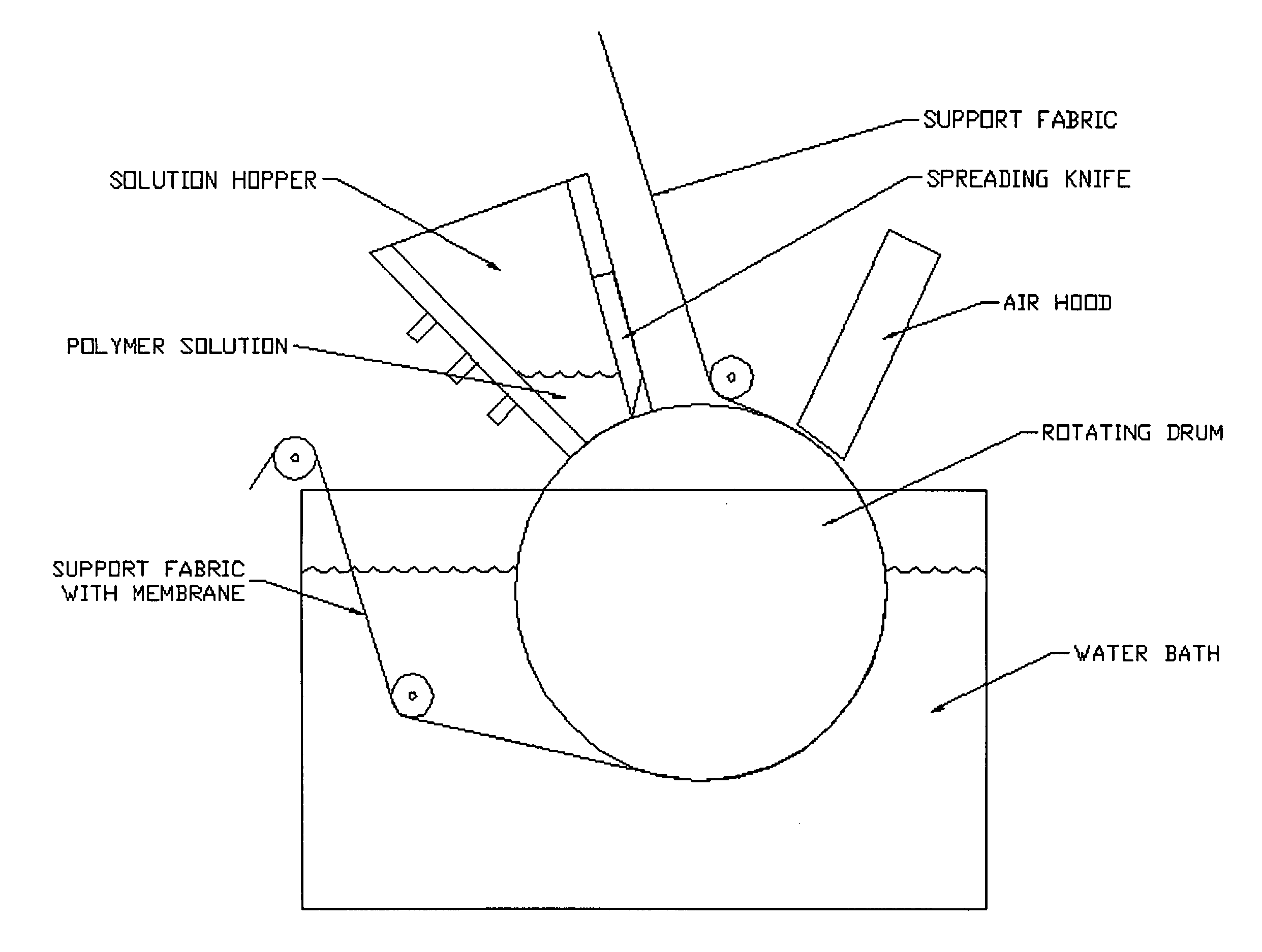

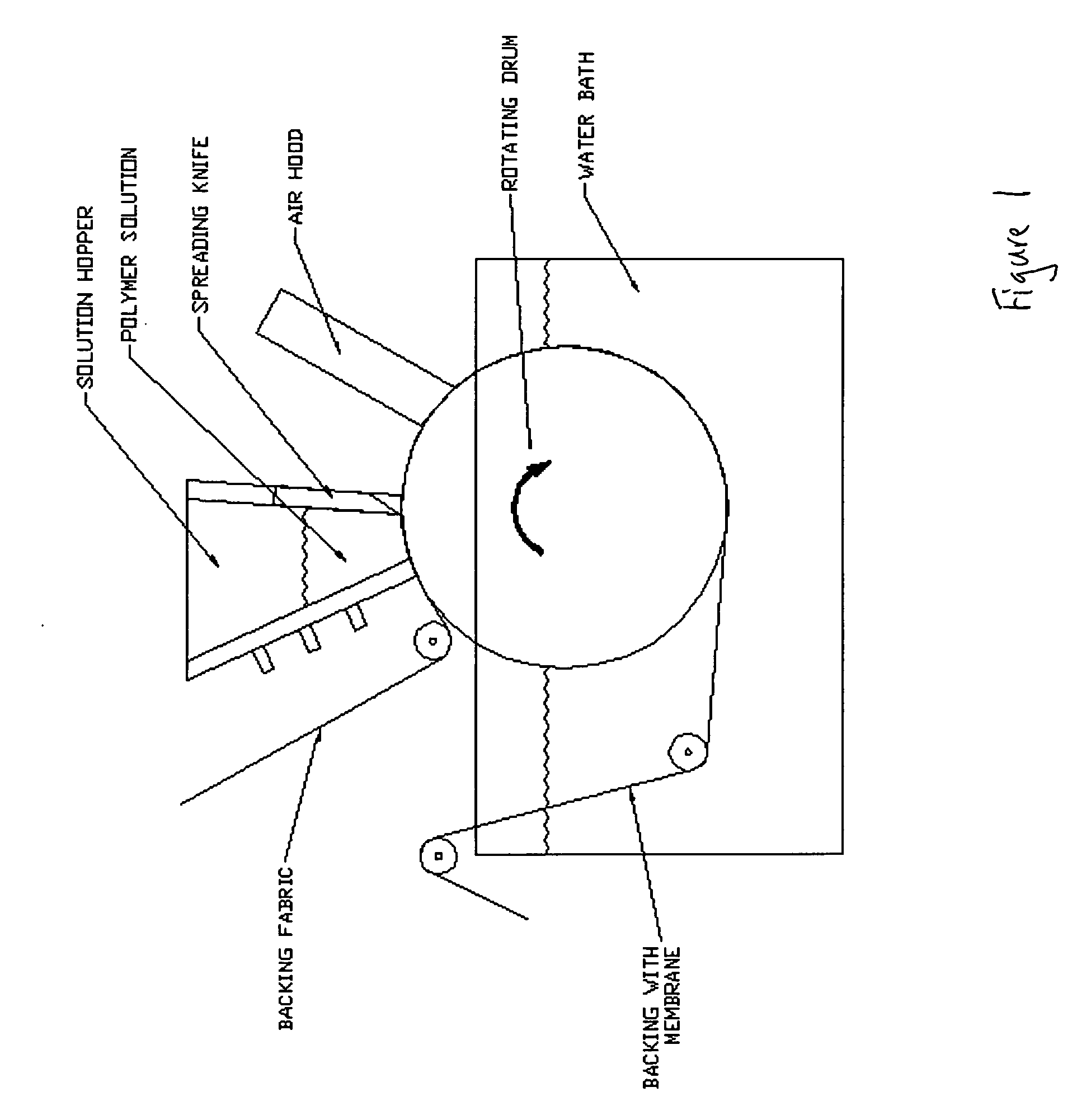

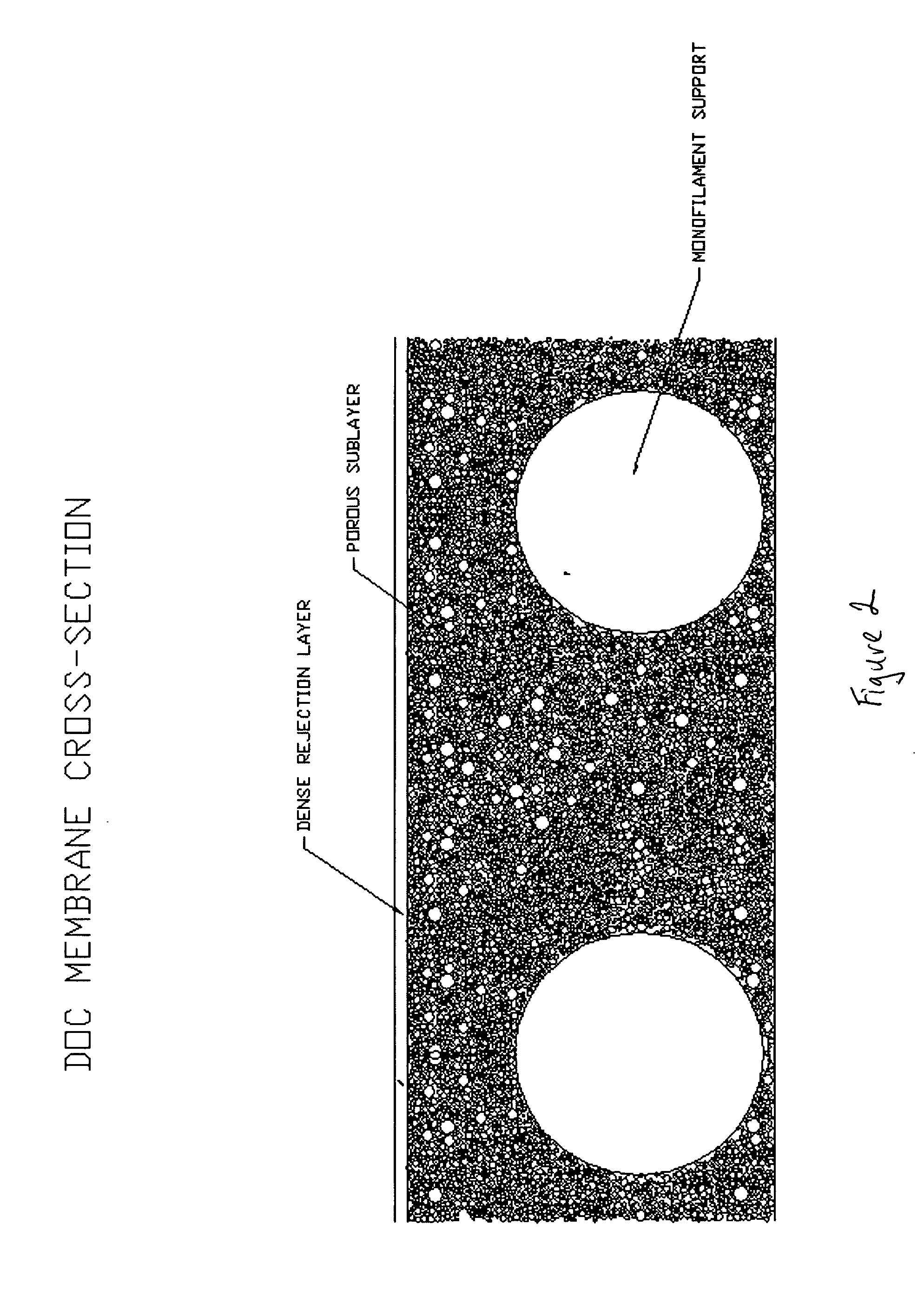

Asymmetric forward osmosis membranes

InactiveUS20060226067A1Lower resistanceHigh titer reductionSemi-permeable membranesMembranesFiltration membraneWaste stream

There is disclosed a membrane formulation having high flux for forward osmosis applications. There is disclosed a forward osmosis filtration membrane having a salt rejection 99+% or greater, and comprising an asymmetric hydrophobic porous backing and cellulosic fibers. The membranes of the present invention find use in a variety of applications including osmotic-driven water purification and filtration, desalination of sea water, purification of contaminated aqueous waste streams, and the like. Specifically, there is disclosed a forward osmosis filtration membrane having a skin layer for salt rejection and a porous scaffold layer having a woven or non-woven mesh embedded within it.

Owner:HYDRATION SYST

Removing carbon dioxide from waste streams through co-generation of carbonate and/or bicarbonate minerals

ActiveUS7727374B2Calcium/strontium/barium carbonatesPhotography auxillary processesElectrolysisWaste stream

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

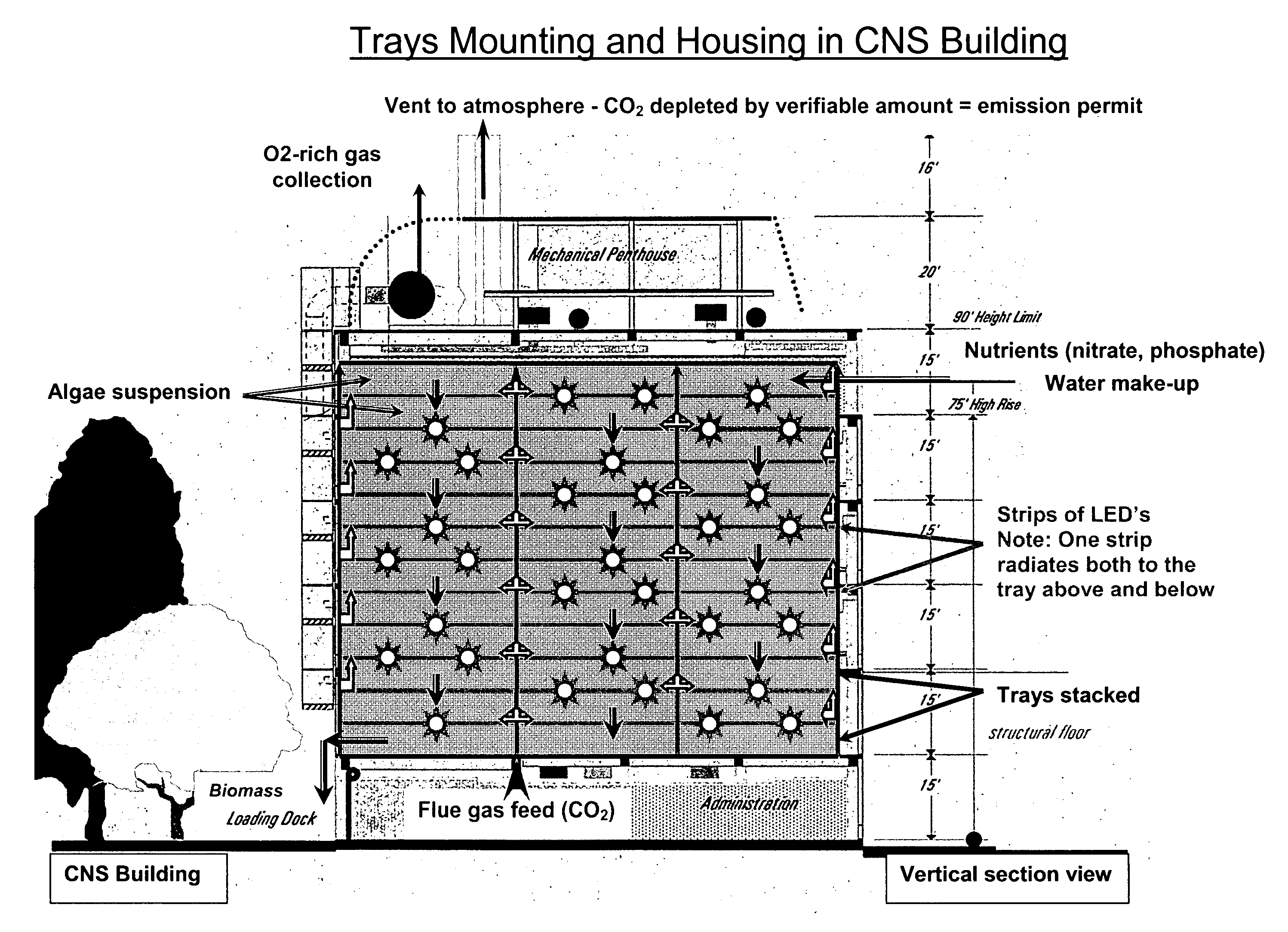

Carbon Neutralization System (CNS) for CO2 sequestering

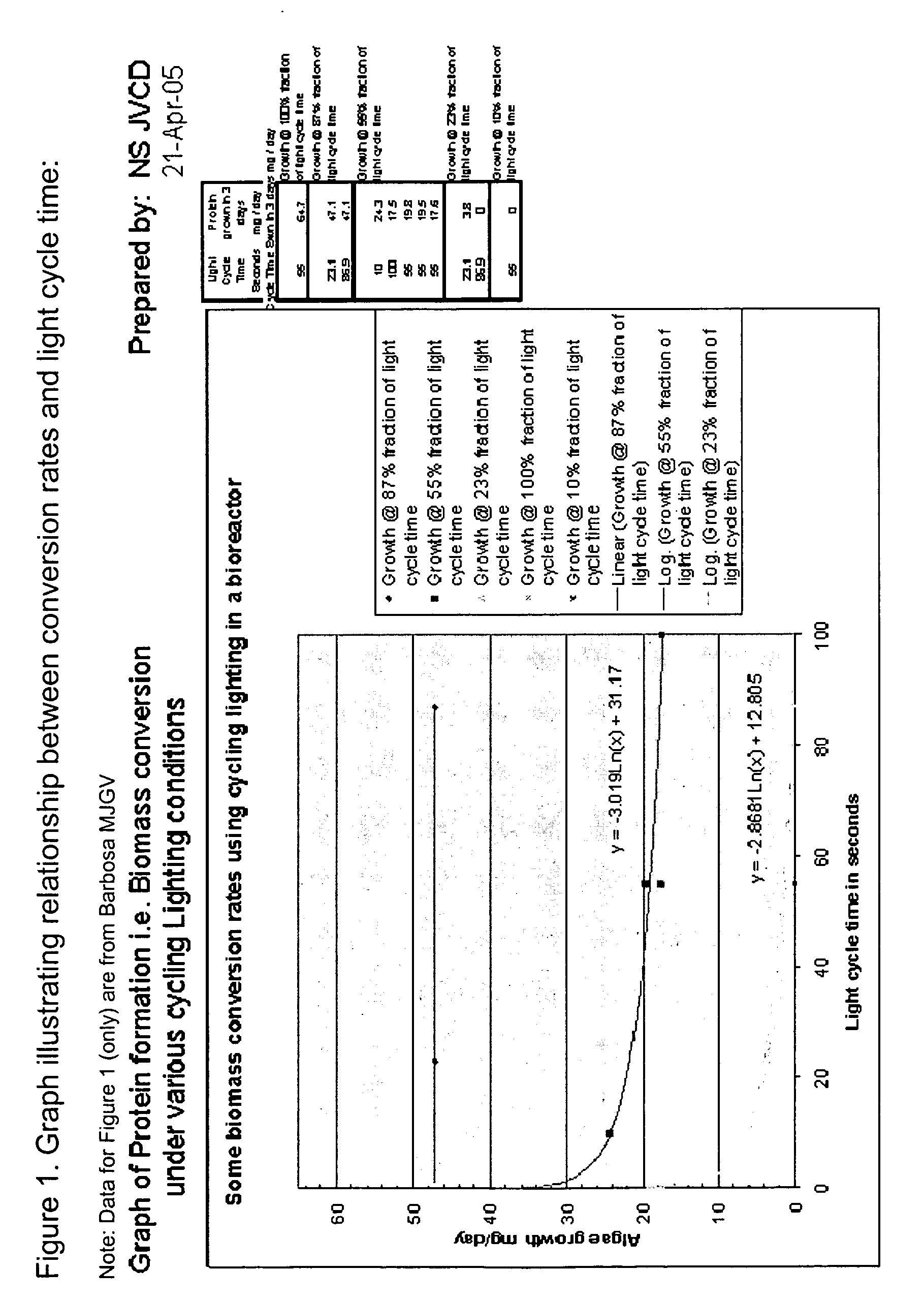

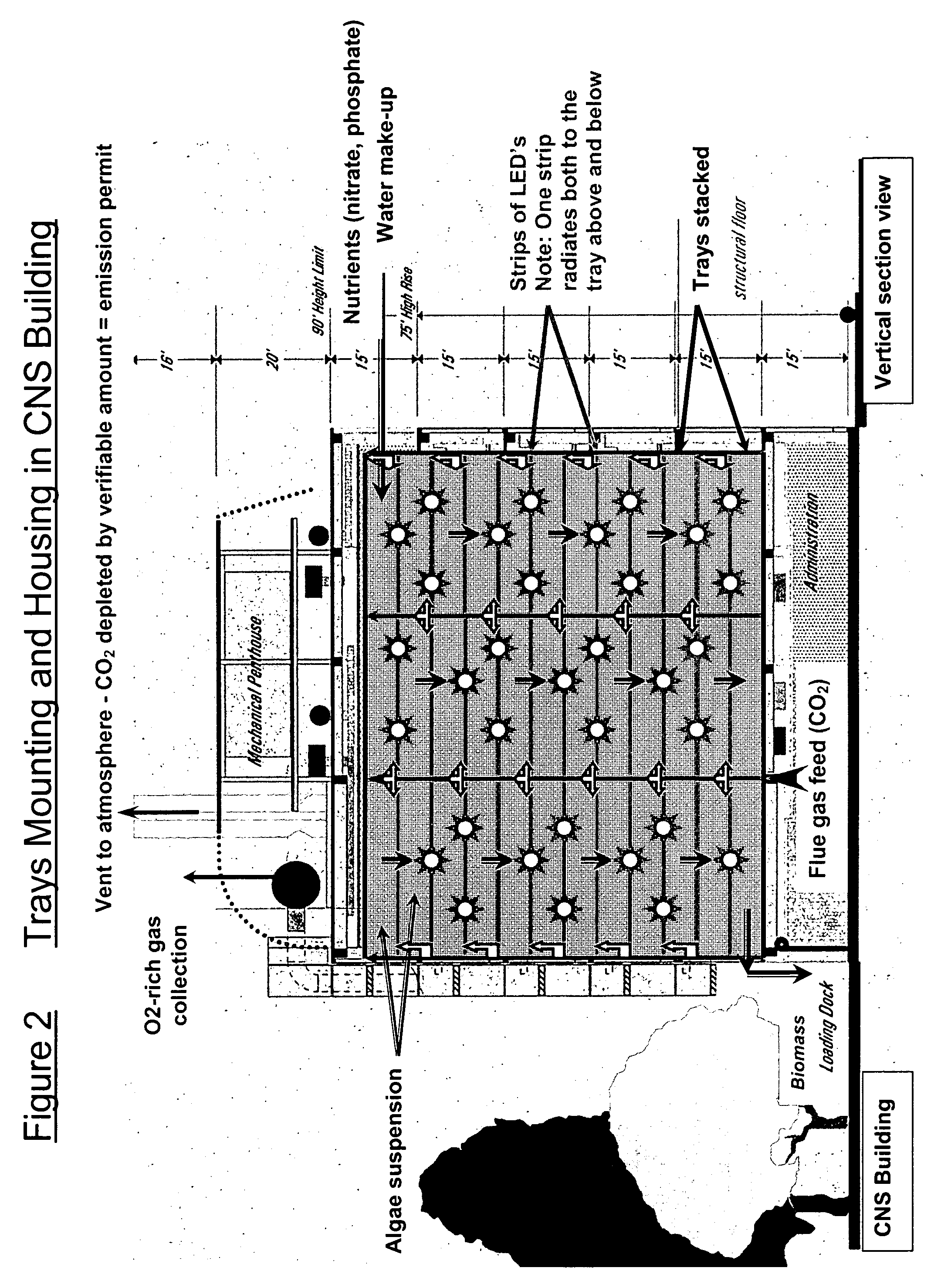

InactiveUS20070092962A1Reduce energy costsSave energyBioreactor/fermenter combinationsBiological substance pretreatmentsWaste streamPhotobioreactor

A device and method for carbon dioxide sequestering involving the use of a photo-bioreactor with Light Emitting Diodes (LED's) for the cost-effective photo-fixation of carbon dioxide (CO2). This device and method is useful for removing undesirable carbon dioxide from waste streams.

Owner:SAUDI ARABIAN OIL CO

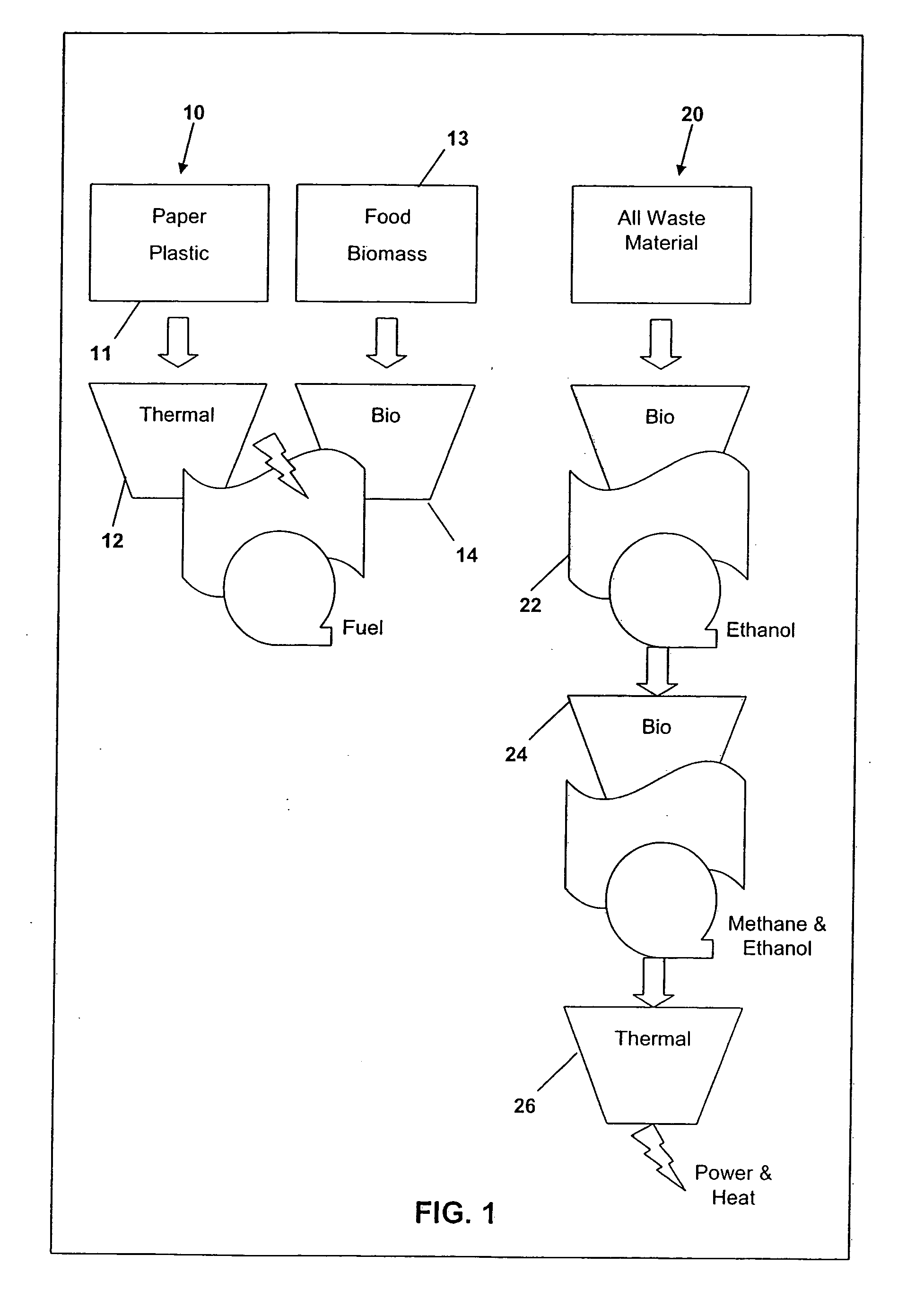

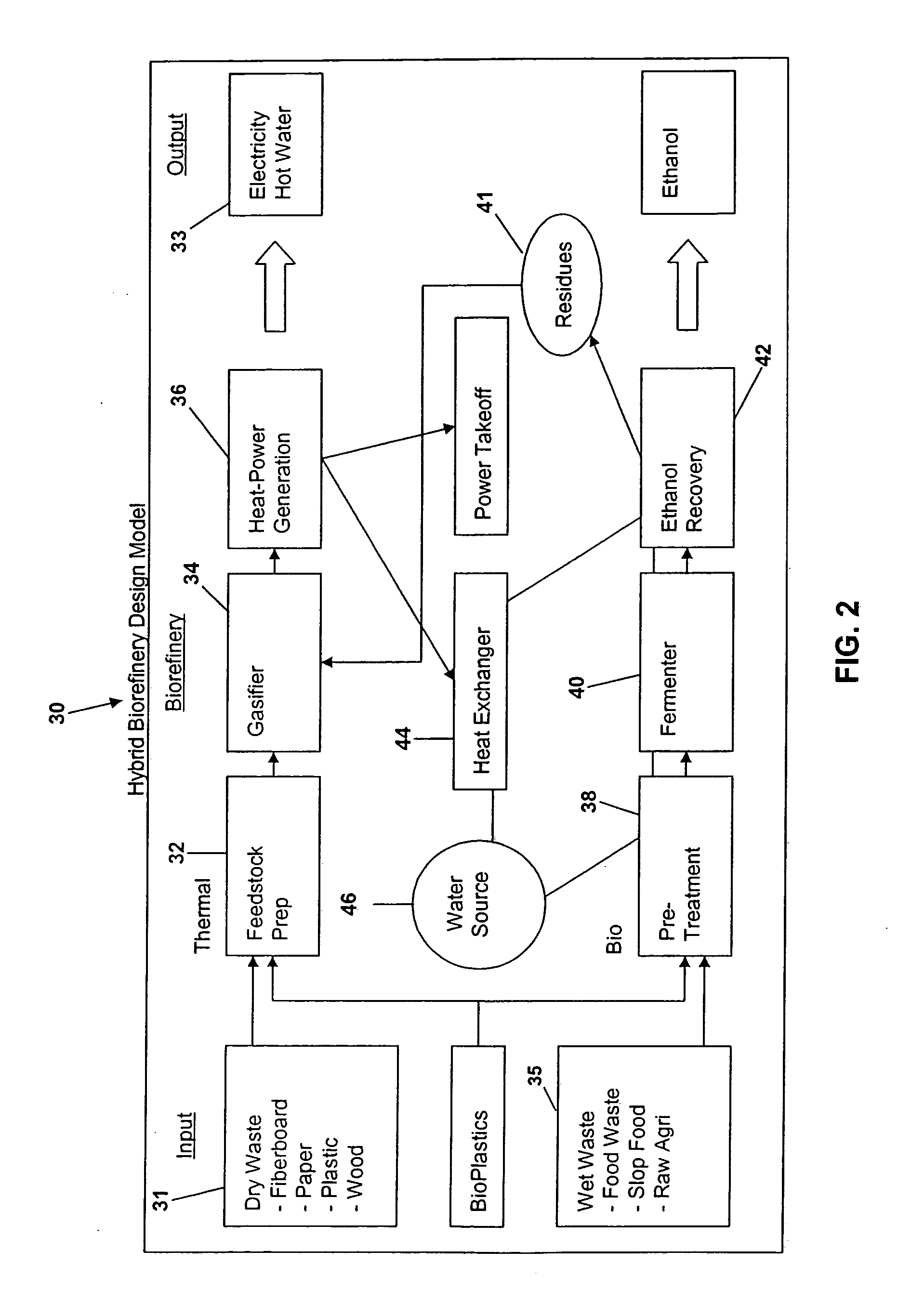

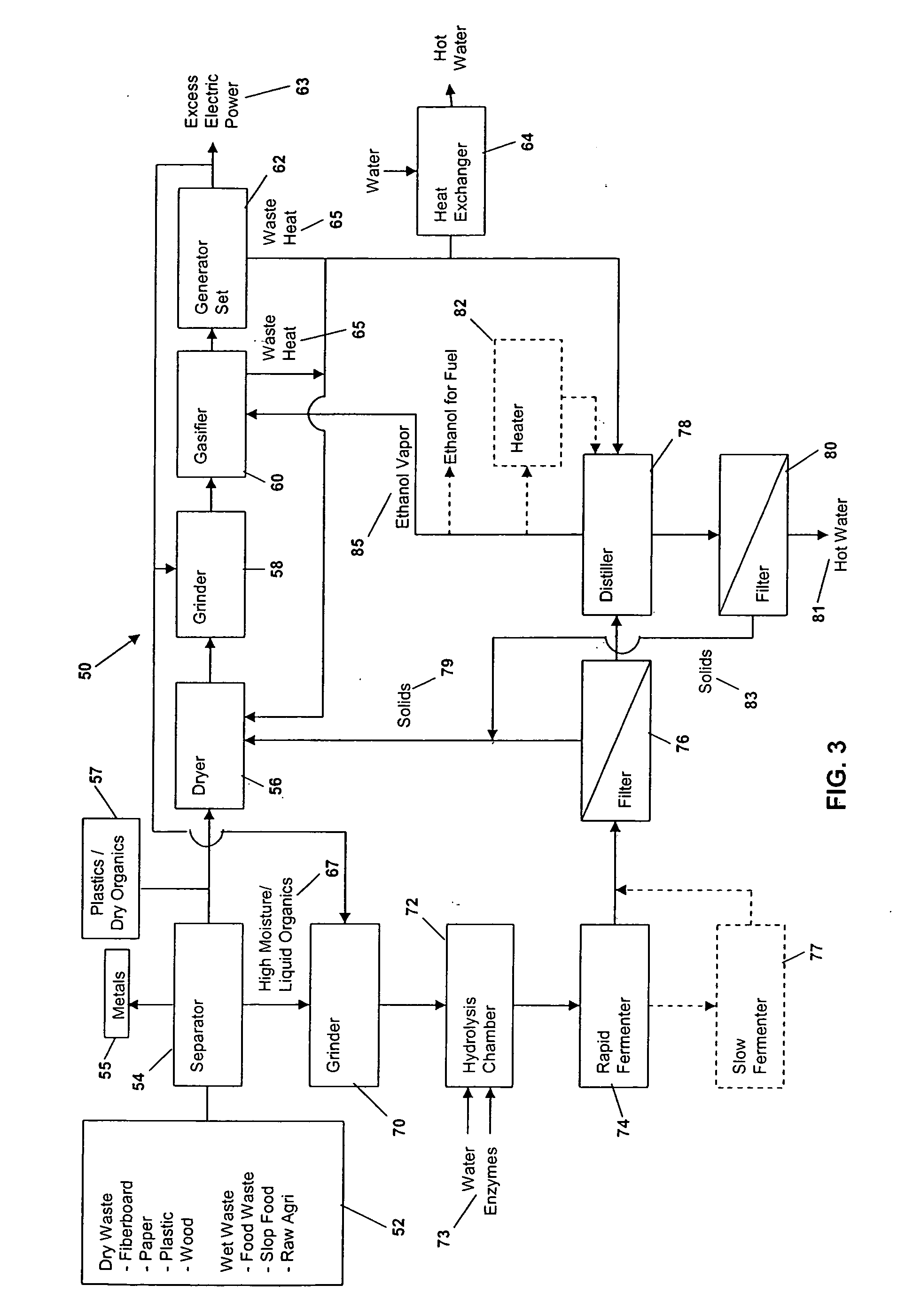

Integrated thermochemical and biocatalytic energy production system

InactiveUS20070117195A1Readily susceptibleEnergy costBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationWaste stream

A method and apparatus for treating organic wastes is provided. Organic wastes are separated into high and low moisture content organic waste streams. The low moisture content organic waste stream is subjected to a gasification process and generates a producer gas. The high moisture content organic waste is subjected to a fermentation process and produces a mixture of ethanol and water. Waste heat from the gasification process is subjected to a distillation column. Vapors recovered from the distillation column are mixed in a hydrous vapor form with the producer gas and produce fuel that can be used as an energy source.

Owner:PURDUE RES FOUND INC

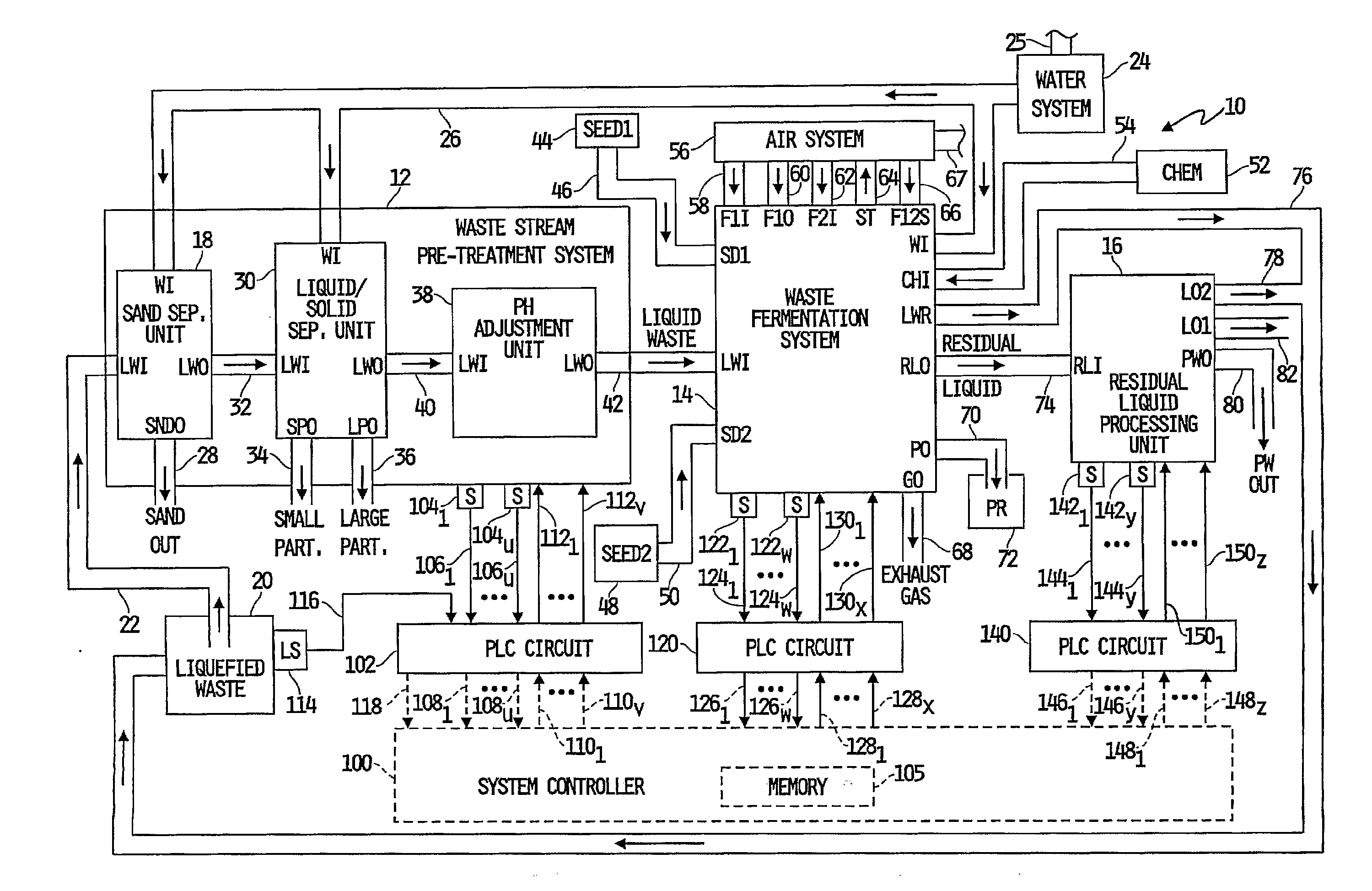

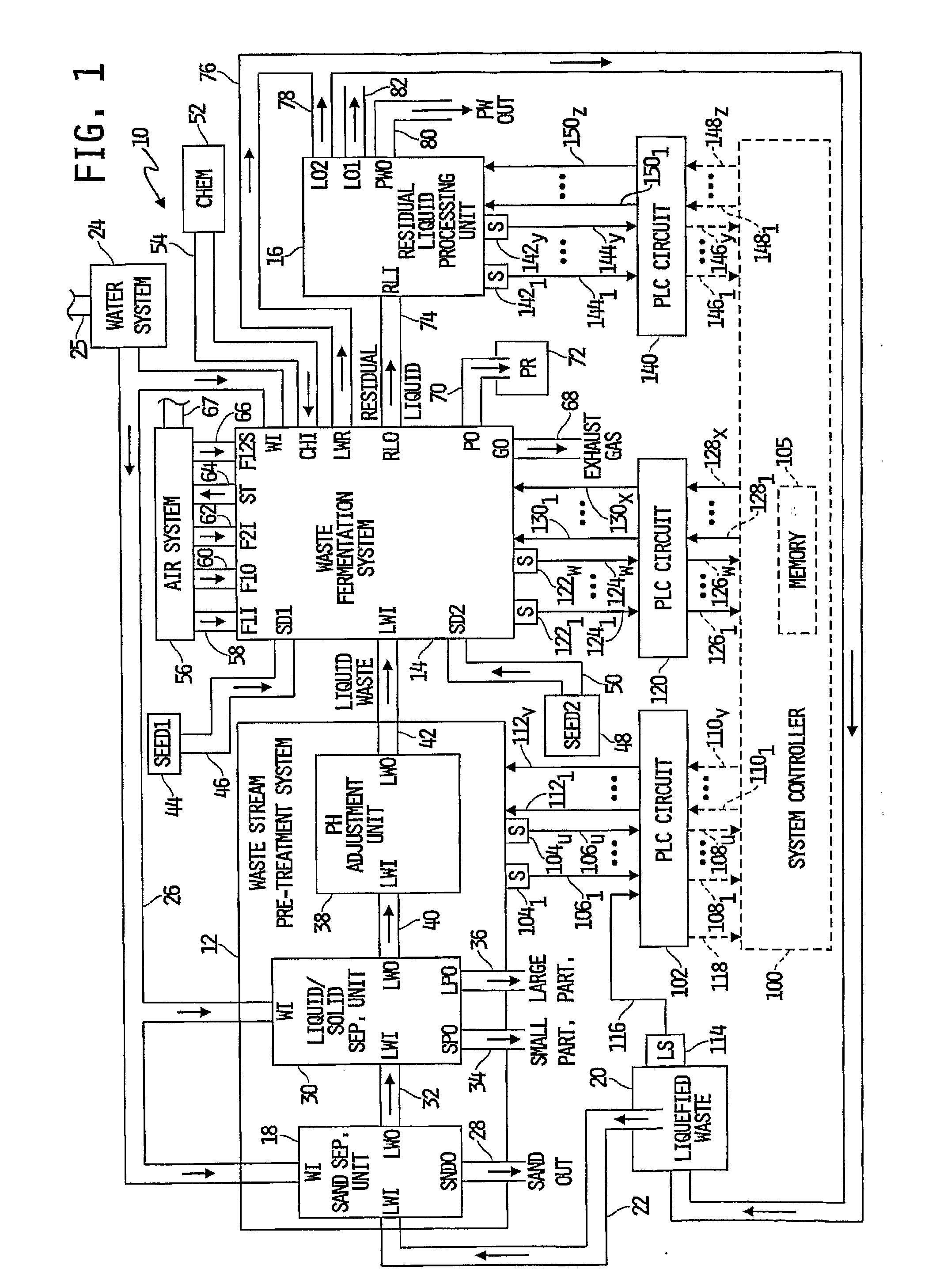

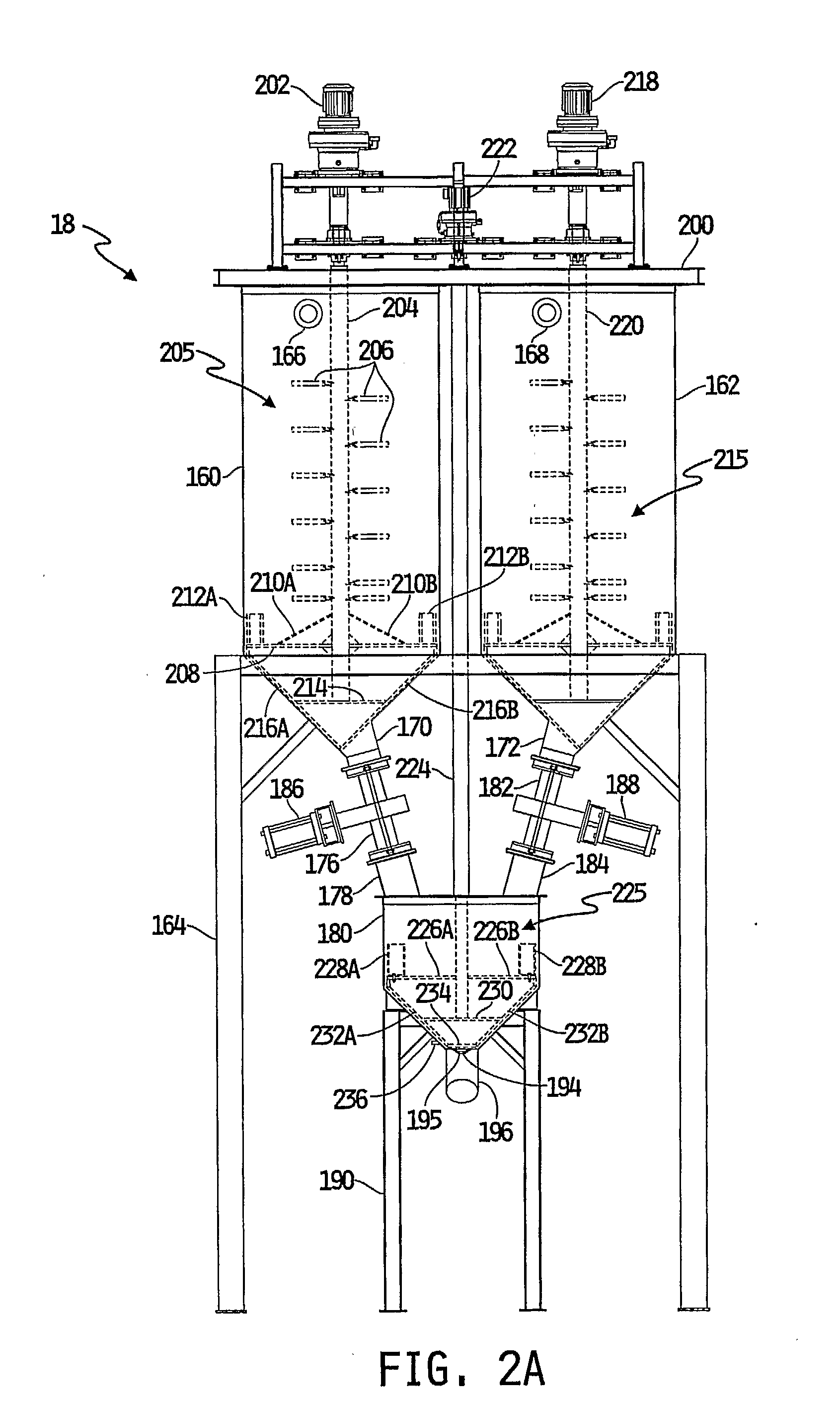

System for the treating biomaterial waste streams

InactiveUS20070175825A1Animal corpse fertilisersExcrement fertilisersWaste streamEnvironmental engineering

A process for treating a biomaterial waste stream is described. The process may form part of a waste fermentation system. The treating process can degrade at least a portion of the biomaterial waste stream into other components or materials. These other components or materials may be reintroduced into a fermentation process as a nutrient for a fermenting organism.

Owner:BIOMASS PROCESSING TECH

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:SOLAR REACTOR TECH

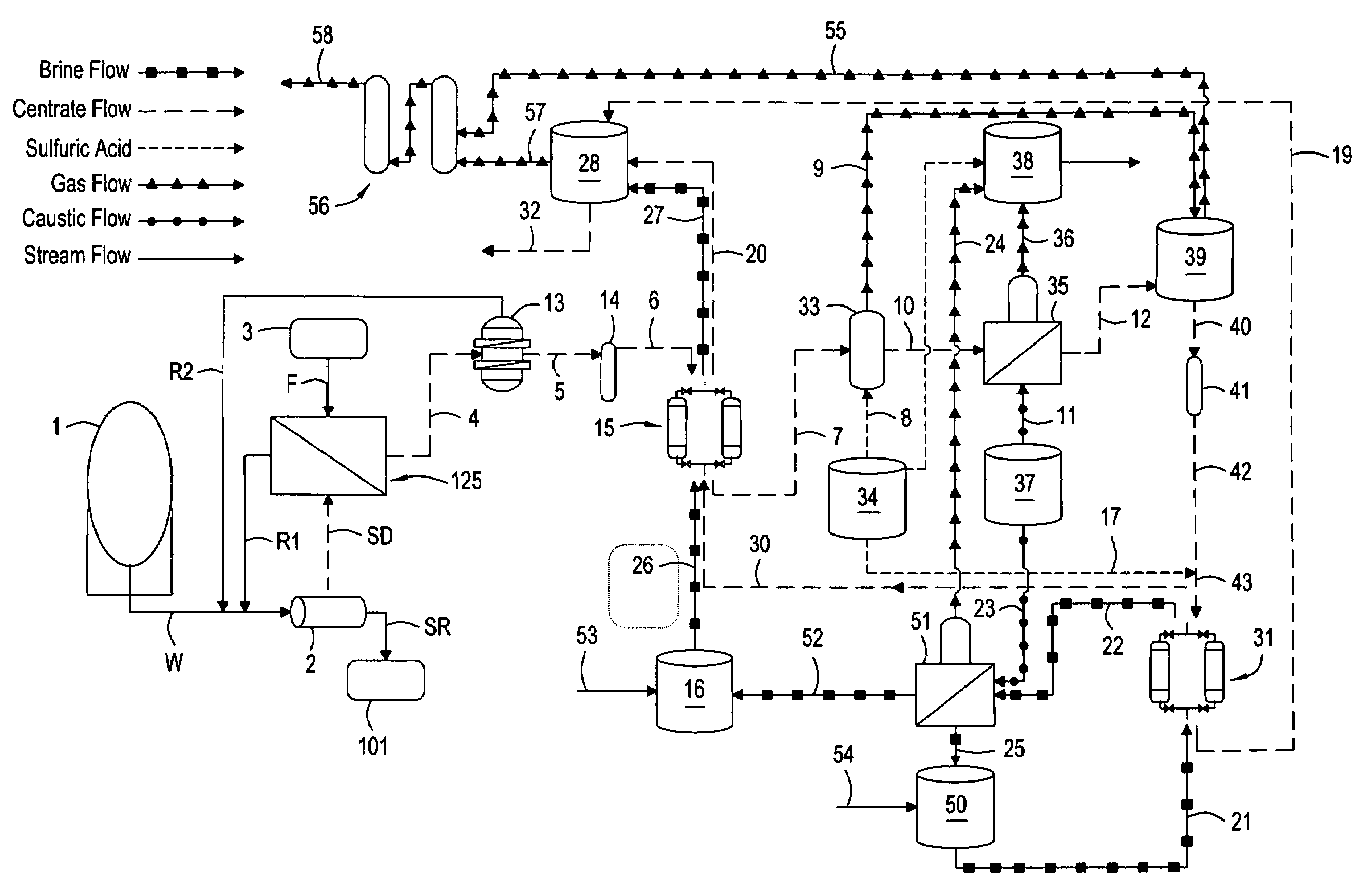

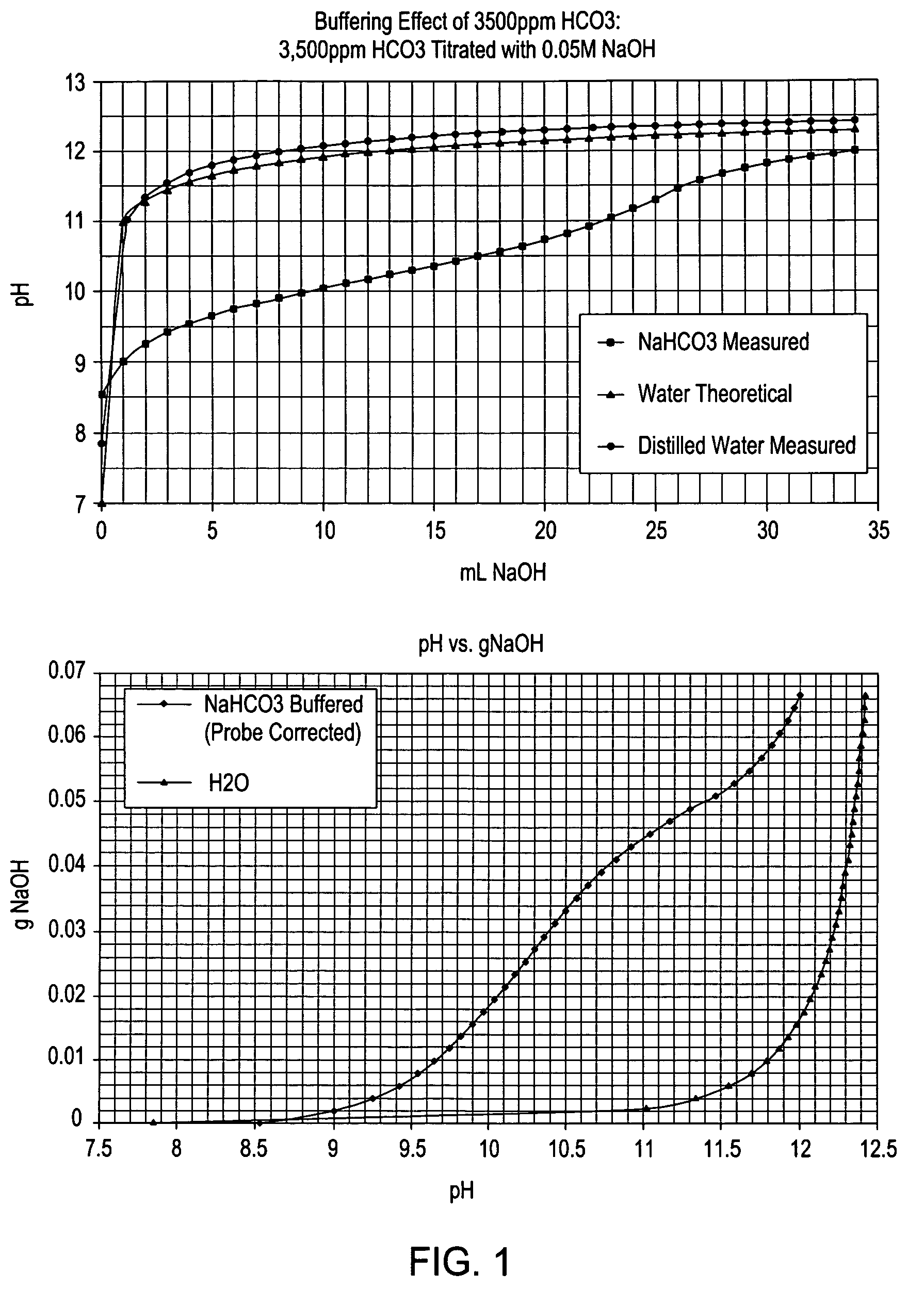

Ammonia recovery process

InactiveUS20080053909A1Effective and efficient ammonia recovery processEfficient and effective processIon-exchanger regenerationSolid sorbent liquid separationWaste streamAmmonia

Embodiments include a method and apparatus for cost-effective and efficient ammonia recovery from a waste stream. In some embodiments, ammonia is recovered after bicarbonate buffer removal from the waste stream via addition of an acid.

Owner:FASSBENDER ALEXANDER G

Removing Carbon Dioxide From Waste Streams Through Co-Generation of Carbonate and/or Bicarbonate Minerals

ActiveUS20090127127A1Prevent returnChloride preparationCalcium/strontium/barium chloridesDicarbonateElectrolysis

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

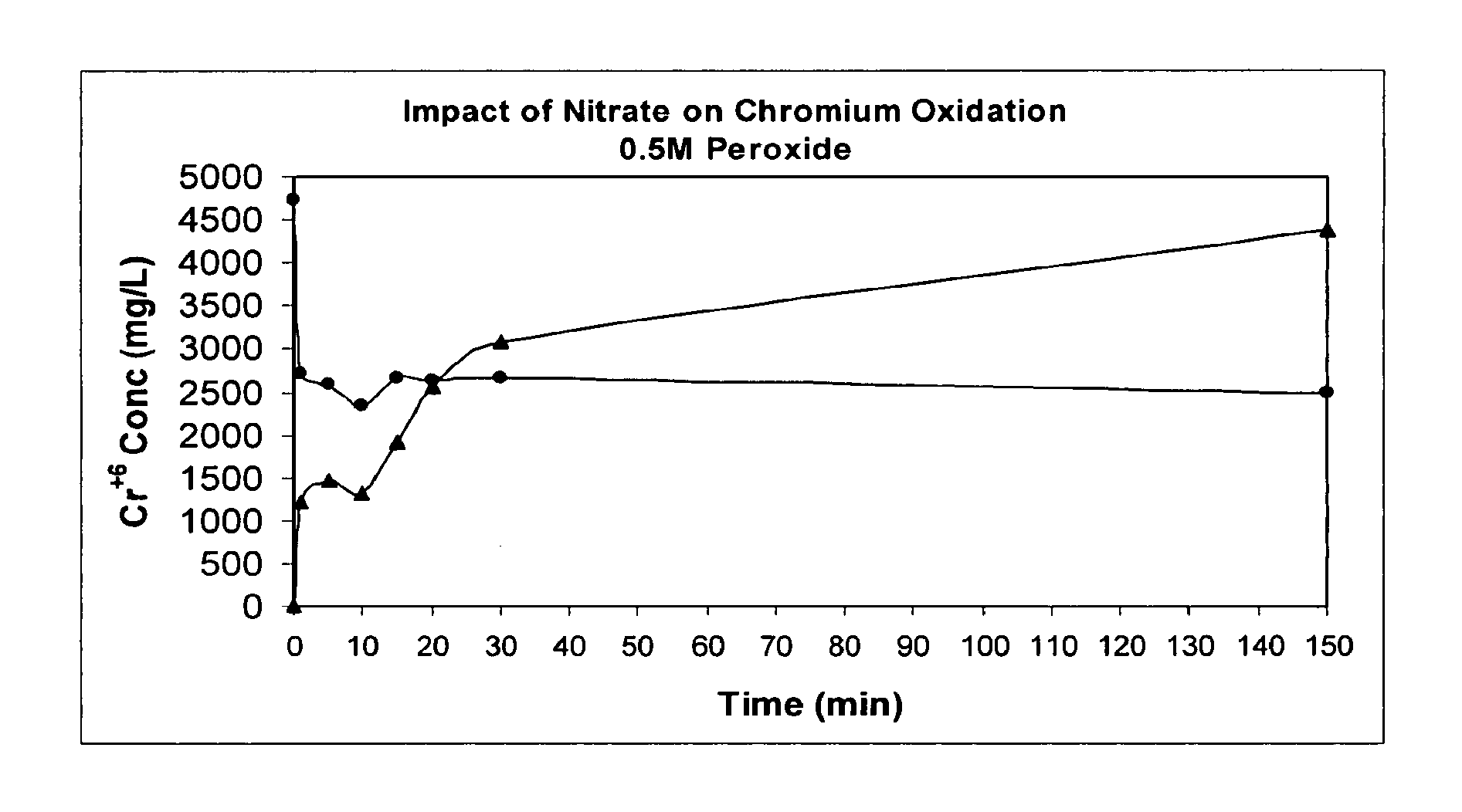

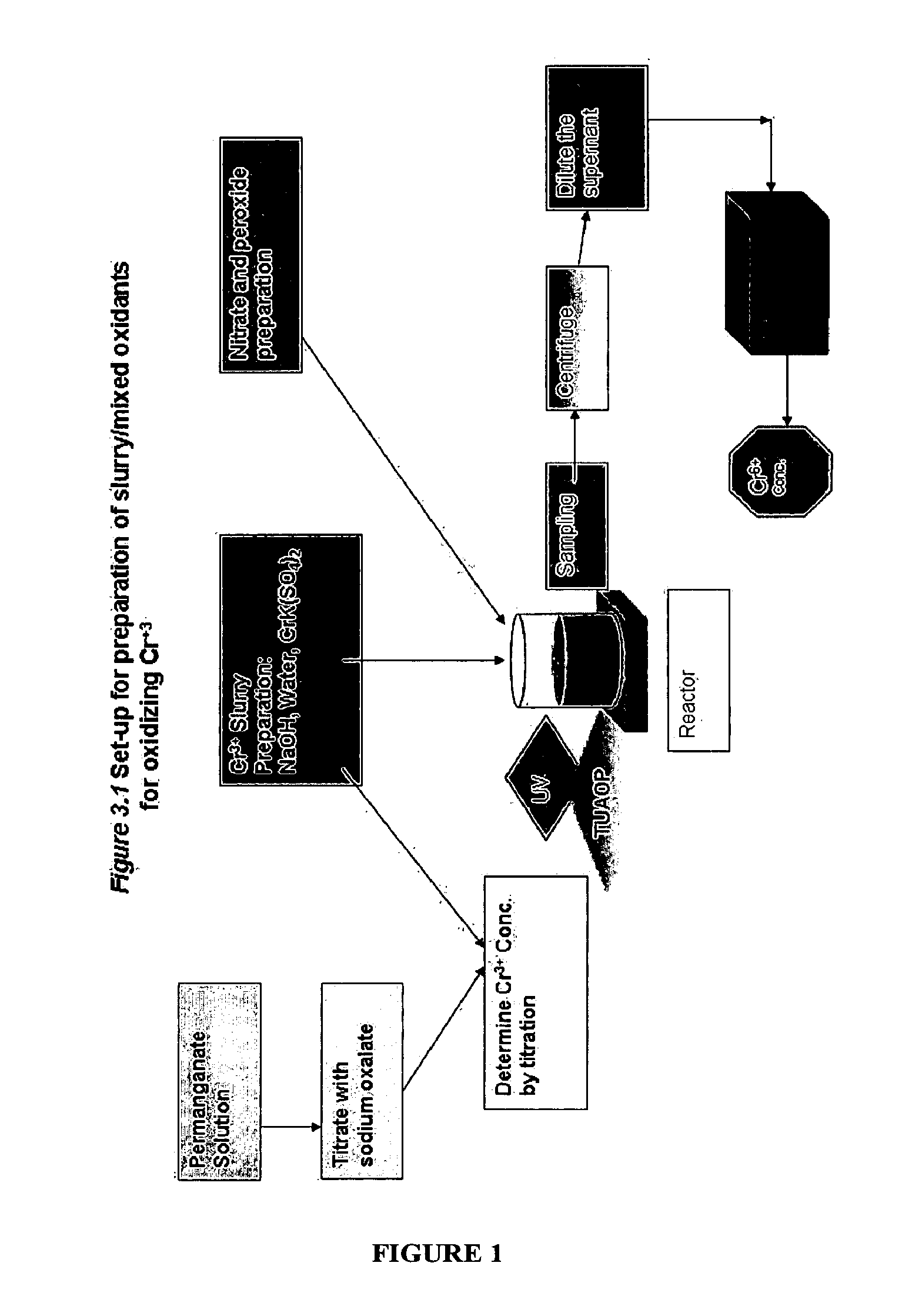

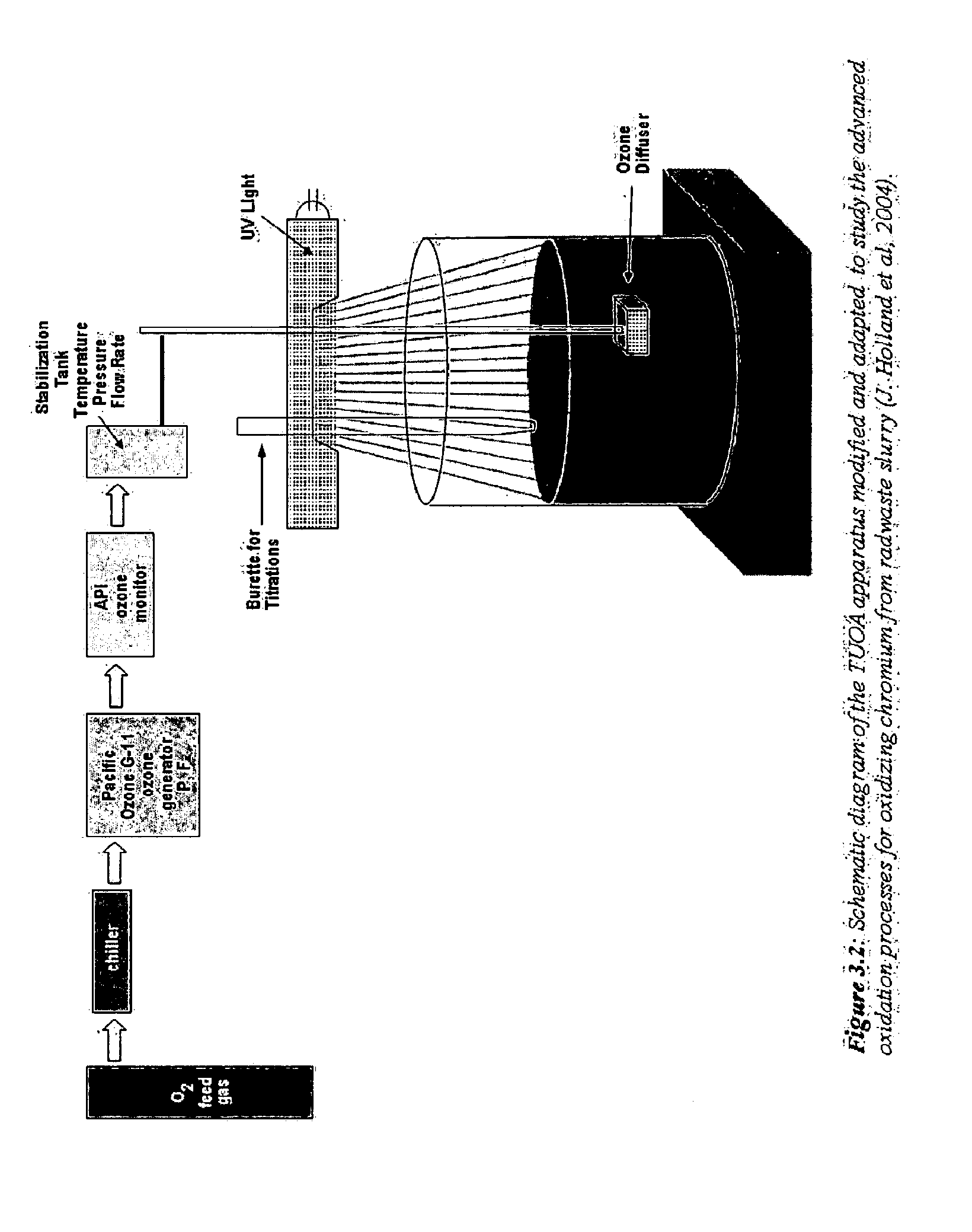

Oxidative Treatment Method

InactiveUS20100320156A1Quickly and efficiently decomposeEffective treatmentWater/sewage treatment by irradiationDecorative surface effectsElectrolysisWaste stream

The present invention provides a method for oxidizing a substance (e.g., in a waste stream, drinking water, a paper pulp slurry, or on a surface), which uses free radicals and reactive species generated from multiple oxidants. The method comprises combining peroxynitrite or peroxynitrous acid and at least one additional oxidizing agent for a period of time sufficient to oxidize the substance of interest. The peroxynitrite or peroxynitrous acid preferably is formed by irradiation of nitrate ion and / or nitric acid (e.g., with UV or gamma rays). The yield of free radicals and reactive species, which are the intermediate species that perform the oxidation may be increased by addition of a catalysts, electromagnetic radiation, sonic waves, and / or electrolysis.

Owner:TULANE EDUCATIONAL FUND

Method of processing waste product into fuel

InactiveUS20050142250A1Efficient conversionControlled and adjustable resistanceMilk preparationSolid fuelsWaste streamWaste product

Fuels used may be derived from existing waste streams such as animal wastes and streams of discarded or unwanted animal byproducts generated at animal slaughterhouses. A method of processing organic waste products into fuel includes homogenizing the waste products. The waste products are heated and pressurized. Water is removed from the waste products. Selected constituent of the waste products are separated from the waste products into a waste stream. The waste stream is blended with a fuel to form a bio-fuel mixture.

Owner:STONE MICHAEL

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS8349034B2Less-harmful emissionEmission reductionMechanical working/deformationBiofuelsWaste streamEngineering

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

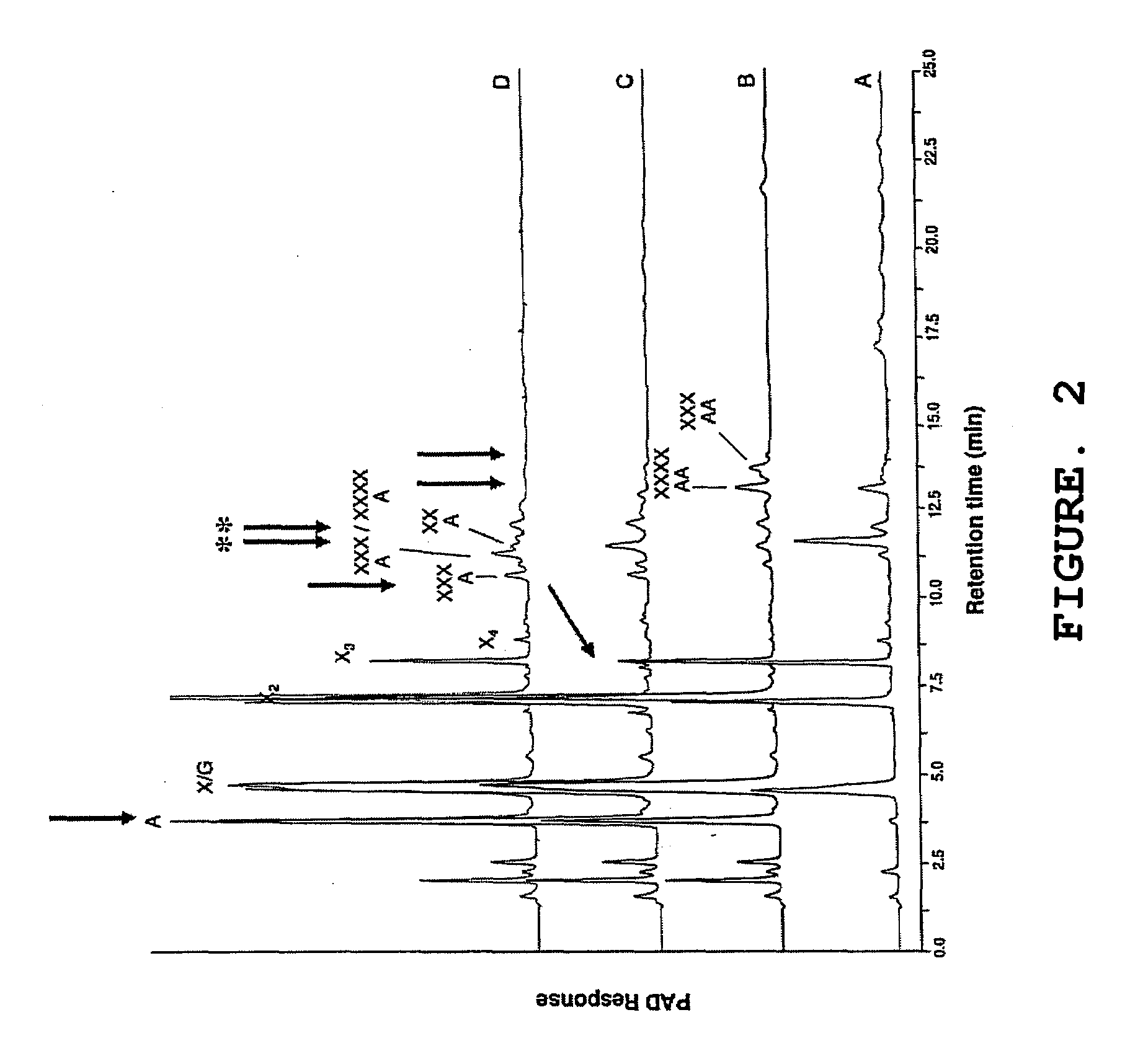

System for waste water treatment

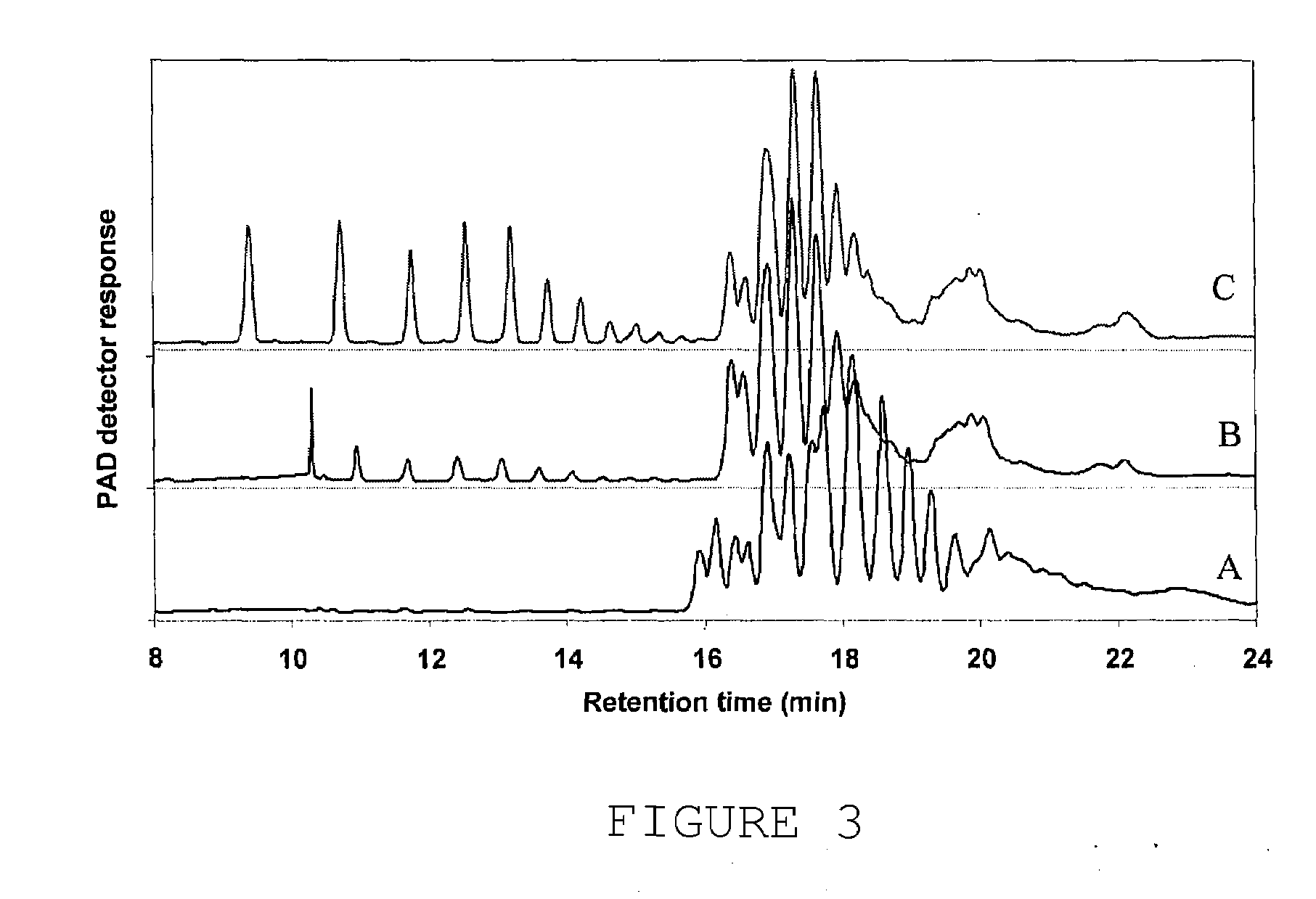

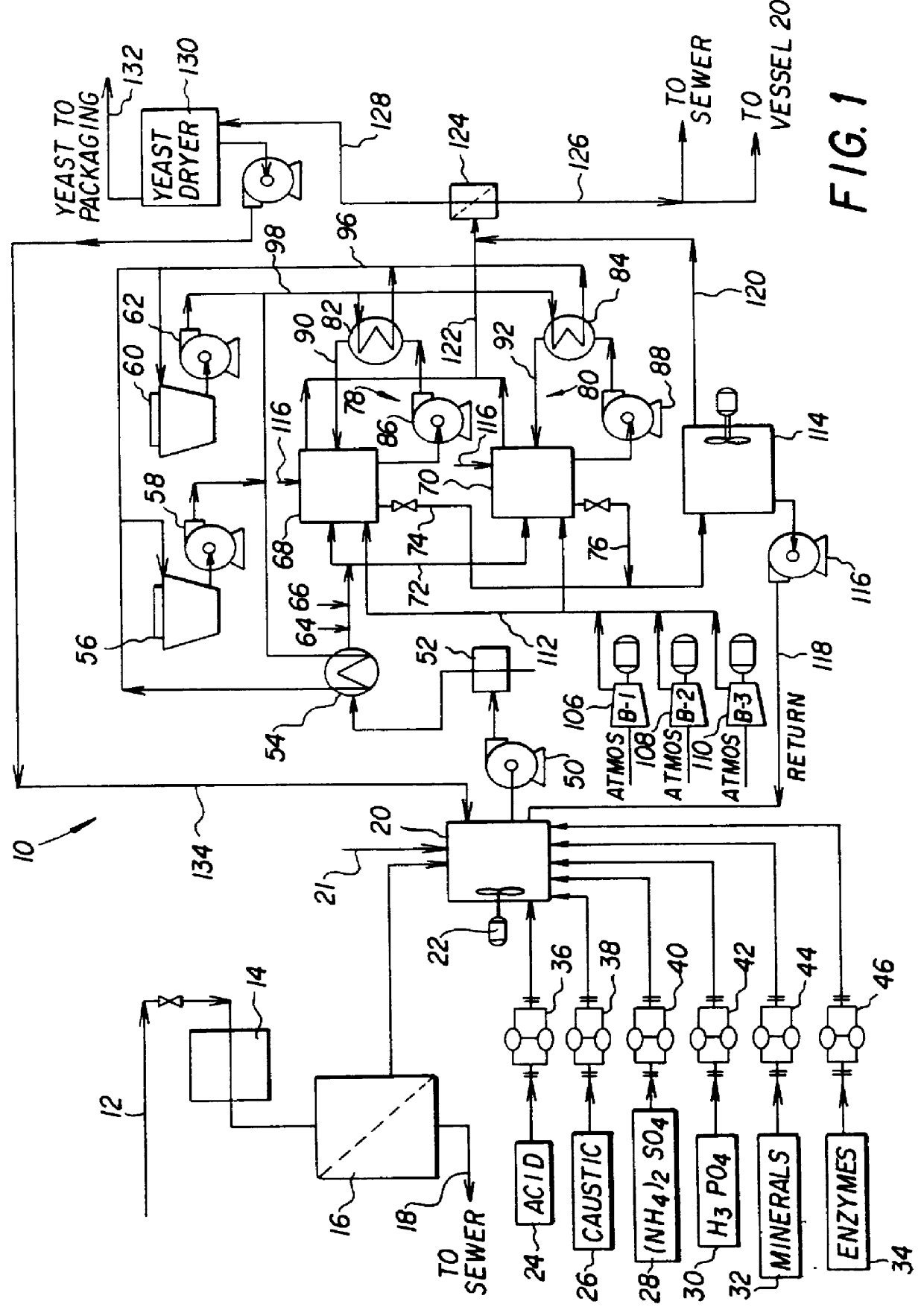

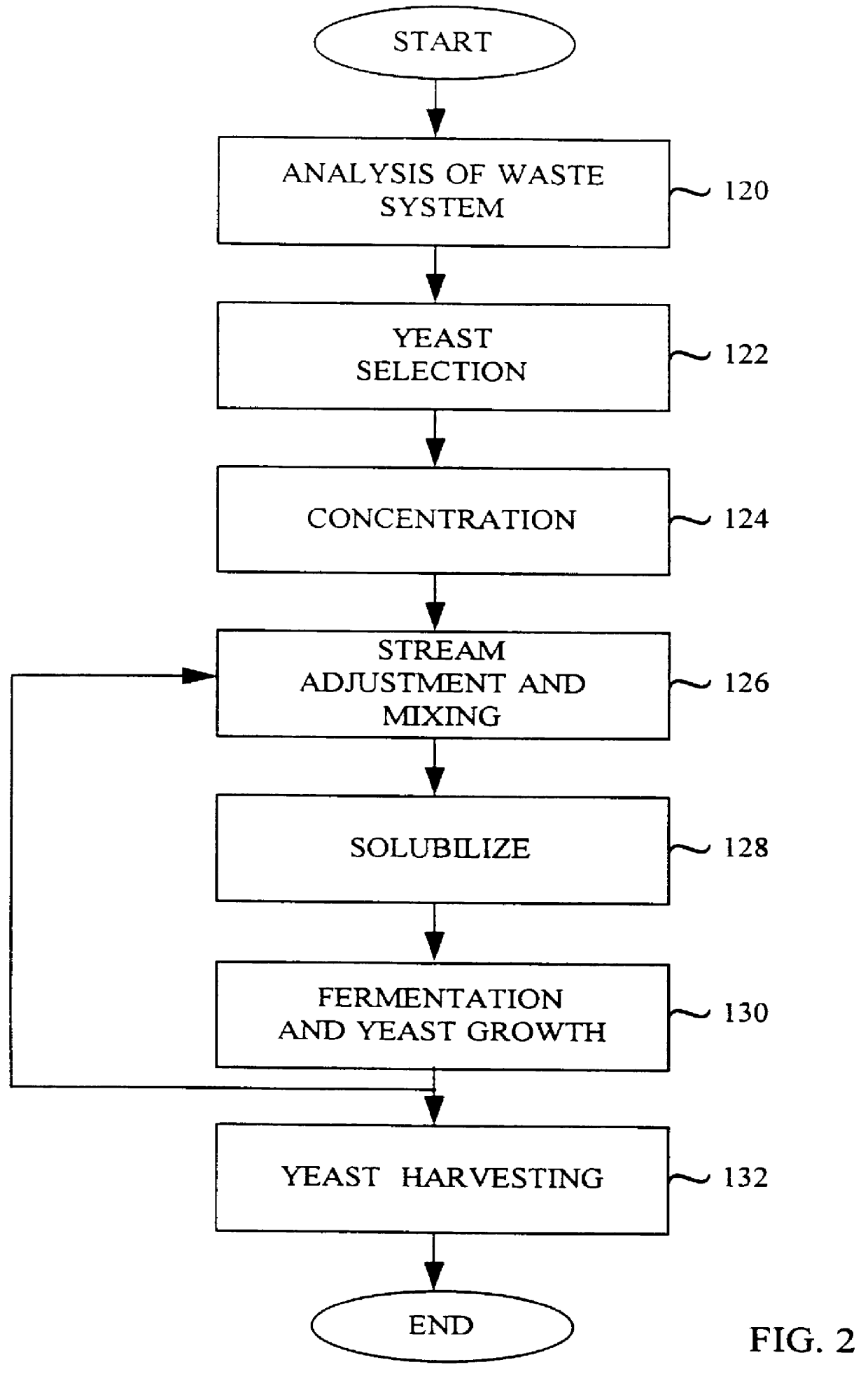

InactiveUS6036854AQuantity minimizationIncreasing predictability and controllabilityOther chemical processesSolid sorbent liquid separationWaste streamSimple sugar

A process and system for waste water treatment including a concentration means positioned at the front of the treatment system in order to concentrate the starches and sugars contained in a waste stream. In a mixing vessel, the concentrate stream is treated with a variety of additives in order to increase consumption of the biological components and to produce a stream having a predictable and predetermined level of soluble starches. The waste stream is solubilized by subjecting the stream to heat and enzyme treatment such that the starches and complex sugars are converted to simple sugars. In a fermentation vessel, a carefully selected yeast strain is introduced into the waste stream and permitted to feed on the sugars. The operating conditions in the vessel (e.g. pH, temperature, oxygen supply, and mineral supply) are carefully controlled to enhance consumption of the biological components in the waste stream. The final product is a marketable grade yeast and a clean water stream for environmentally safe disposal.

Owner:SHANE AGRA CORP

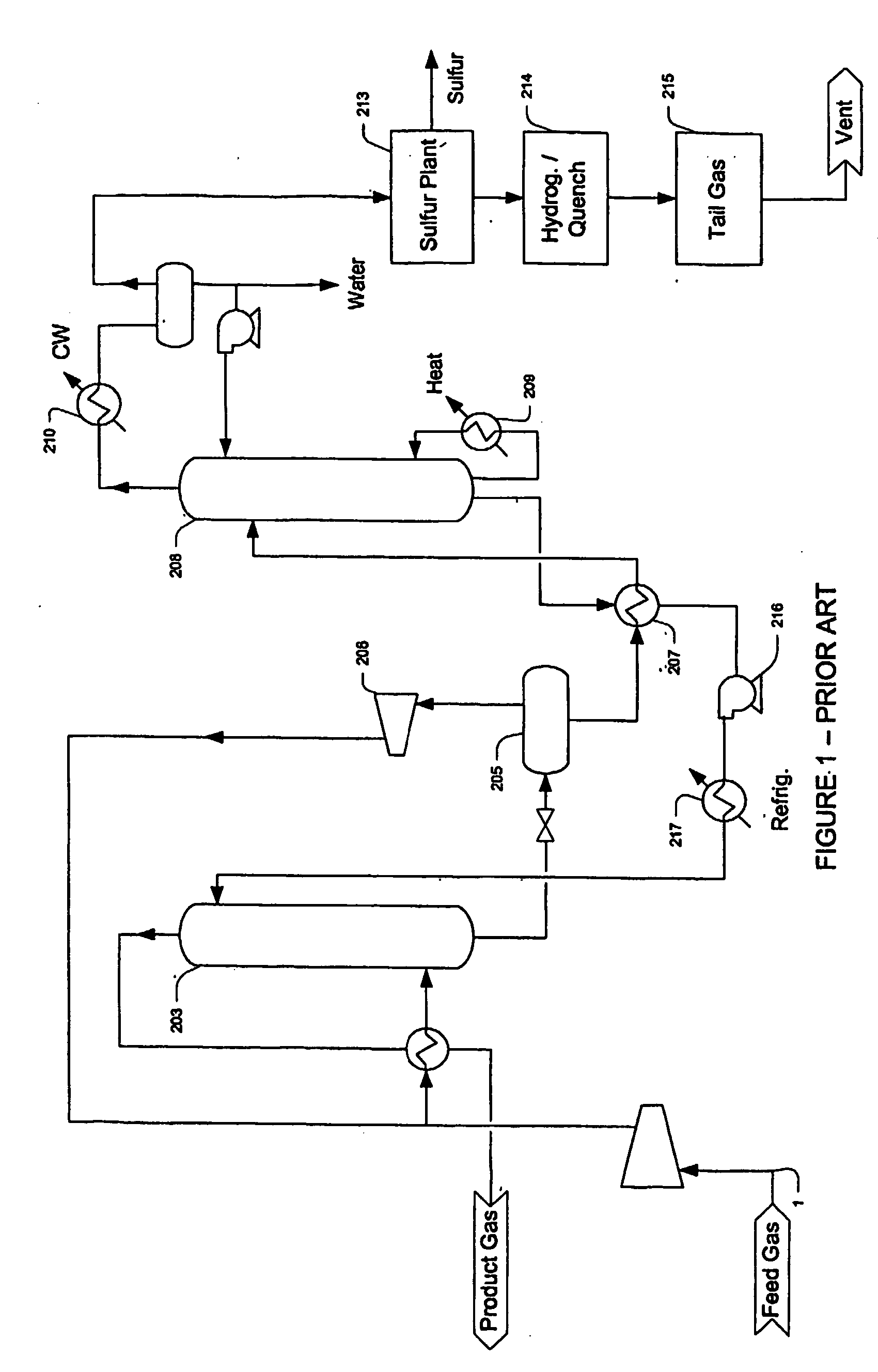

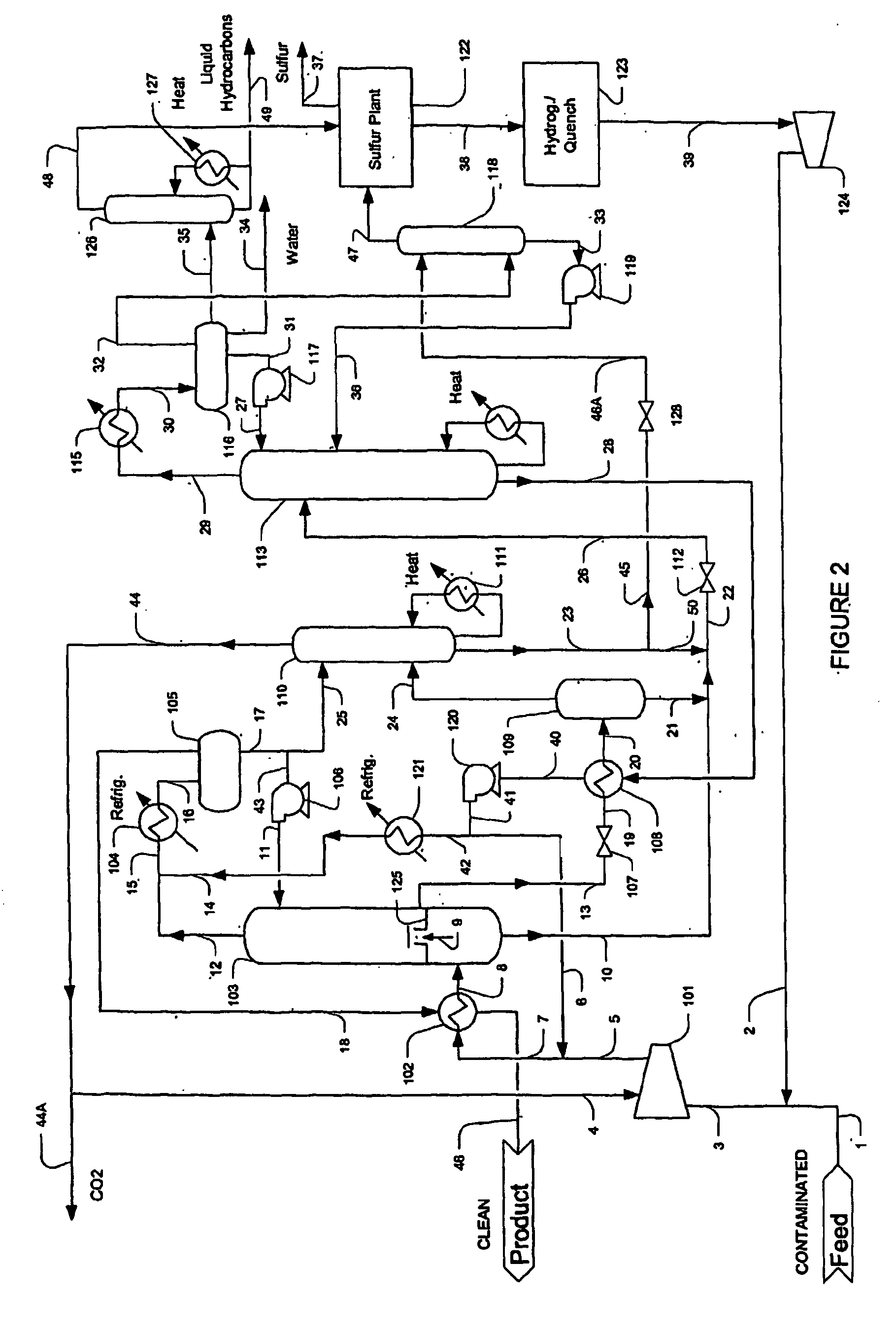

Configurations and methods for acid gas and contaminant removal with near zero emission

InactiveUS20060150812A1Reduce temperature riseEnhance selective absorptionProductsLiquid degasificationWaste streamHydrocotyle bowlesioides

A gas (1) comprising hydrogen sulfide, carbon dioxide, and hydrocarbon contaminants is treated in a plant (FIG. 2) in a configuration in which waste streams are recycled to extinction. In especially preferred aspects of contemplated methods and configurations, hydrogen sulfide and other sulfurous components are converted to a sulfur product (37), carbon dioxide (44A) is separated at a purity sufficient for enhanced oil recovery or sale, and hydrocarbon contaminants are purified to a marketable hydrocarbon product (49).

Owner:FLUOR TECH CORP

Methods of vitrifying waste with low melting high lithia glass compositions

InactiveUS6258994B1Reduce pointsReduce the temperatureSludge treatmentSolid waste disposalAlkali metal oxideRadioactive agent

The invention relates to methods of vitrifying waste and for lowering the melting point of glass forming systems by including lithia formers in the glass forming composition in significant amounts, typically from about 0.16 wt % to about 11 wt %, based on the total glass forming oxides. The lithia is typically included as a replacement for alkali oxide glass formers that would normally be present in a particular glass forming system. Replacement can occur on a mole percent or weight percent basis, and typically results in a composition wherein lithia forms about 10 wt % to about 100 wt % of the alkali oxide glass formers present in the composition. The present invention also relates to the high lithia glass compositions formed by these methods. The invention is useful for stabilization of numerous types of waste materials, including aqueous waste streams, sludge solids, mixtures of aqueous supernate and sludge solids, combinations of spent filter aids from waste water treatment and waste sludges, supernate alone, incinerator ash, incinerator offgas blowdown, or combinations thereof, geological mine tailings and sludges, asbestos, inorganic filter media, cement waste forms in need of remediation, spent or partially spent ion exchange resins or zeolites, contaminated soils, lead paint, etc. The decrease in melting point achieved by the present invention desirably prevents volatilization of hazardous or radioactive species during vitrification.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

Composition for odor control

ActiveUS20050115895A1Promote growthInhibition productionSpecific water treatment objectivesWater contaminantsSpecific enzymeWaste stream

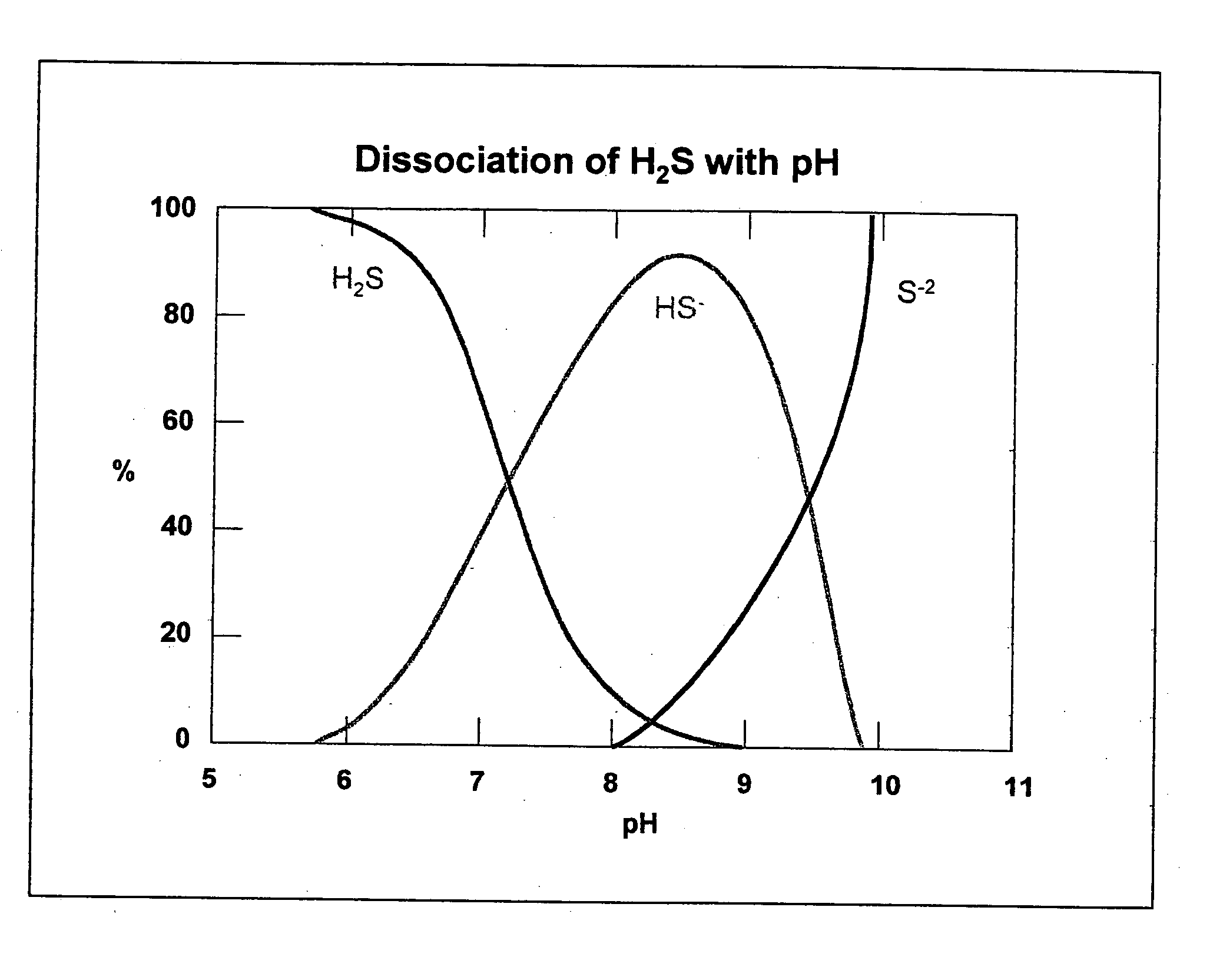

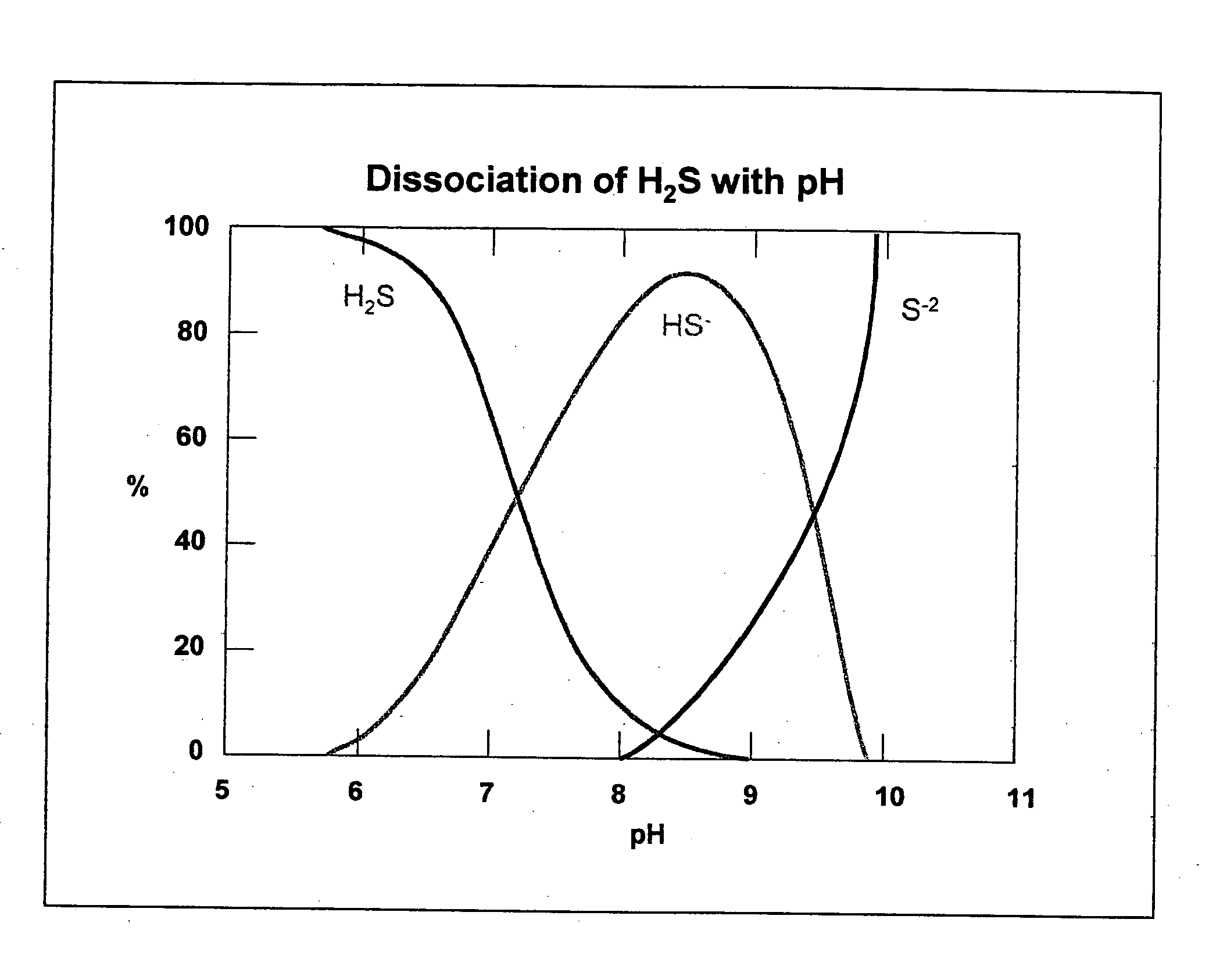

A synergistic composition is provided for controlling odor from waste products. The composition comprises a combination of nitrate salt, sulfide-consuming compound, pH-elevating compound, sulfide-oxidizing, nitrate-reducing bacteria, and sulfide-oxidizing enzyme. The method includes adding a sufficient amount of the composition to a waste stream to provide sufficient sulfide-consuming compound to effect immediate removal of sulfide. The composition incorporates a pH elevating compound, which both decreases the amount of gaseous H2S and puts the aqueous phase into a pH range where naturally occurring bacteria can more easily metabolize the sulfide. The composition also includes one or more nitrate salts which will accomplish longer term prevention of odors. Specific bacteria are incorporated into the formulation to insure that the nitrate has the right type and amount of bacteria present to prevent formation of and / or consume sulfide. Specific enzymes are incorporated into the formulation to promote oxidation of sulfide.

Owner:EVOQUA WATER TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com