Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1425 results about "Softened water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Softened water is basically hard water with the calcium and magnesium removed. The most popular and least expensive way to soften water is using salt to eliminate the minerals in the water. Hard water going through the softening process ends up with just one ion in the water and that ion is salt.

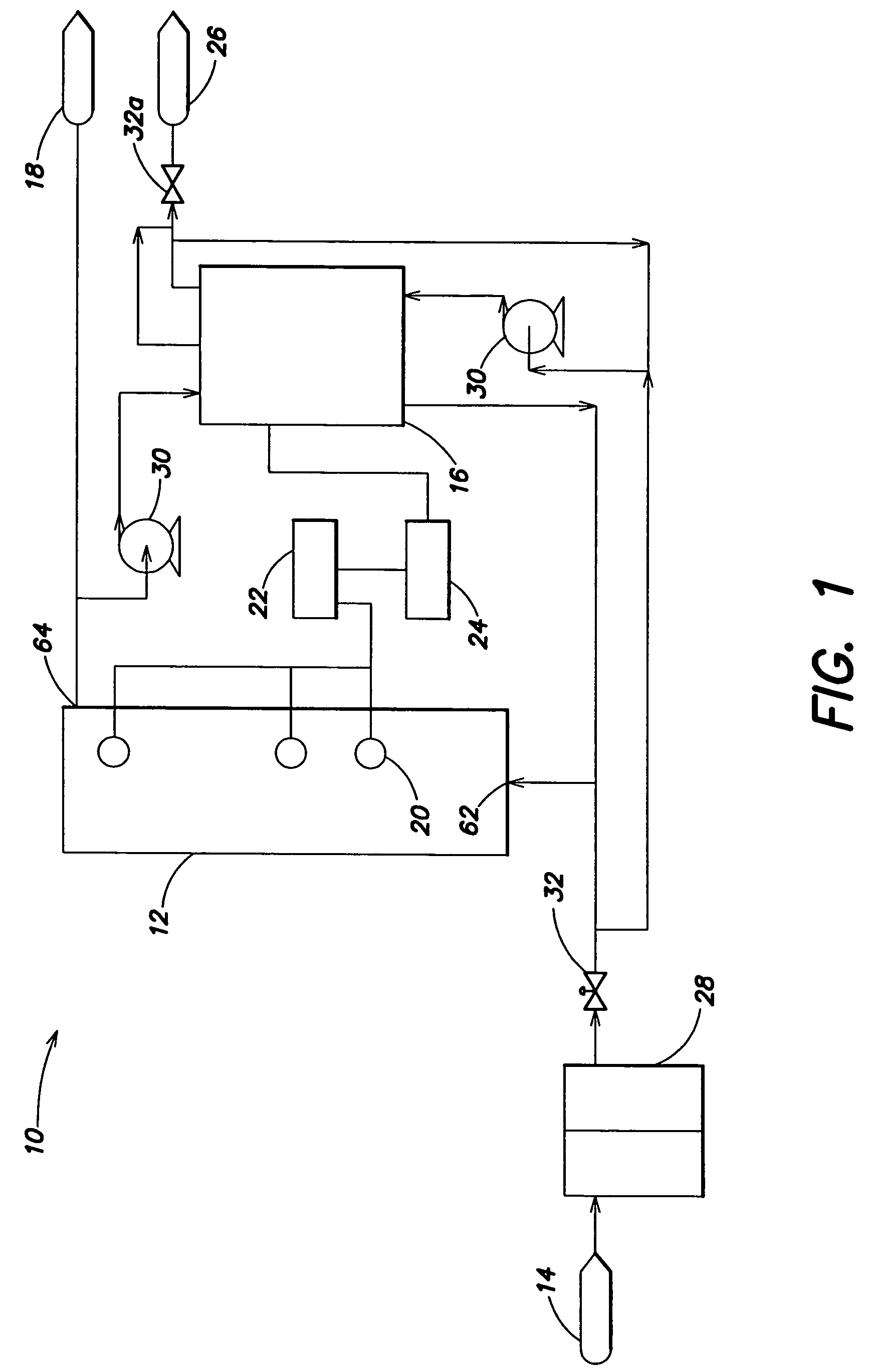

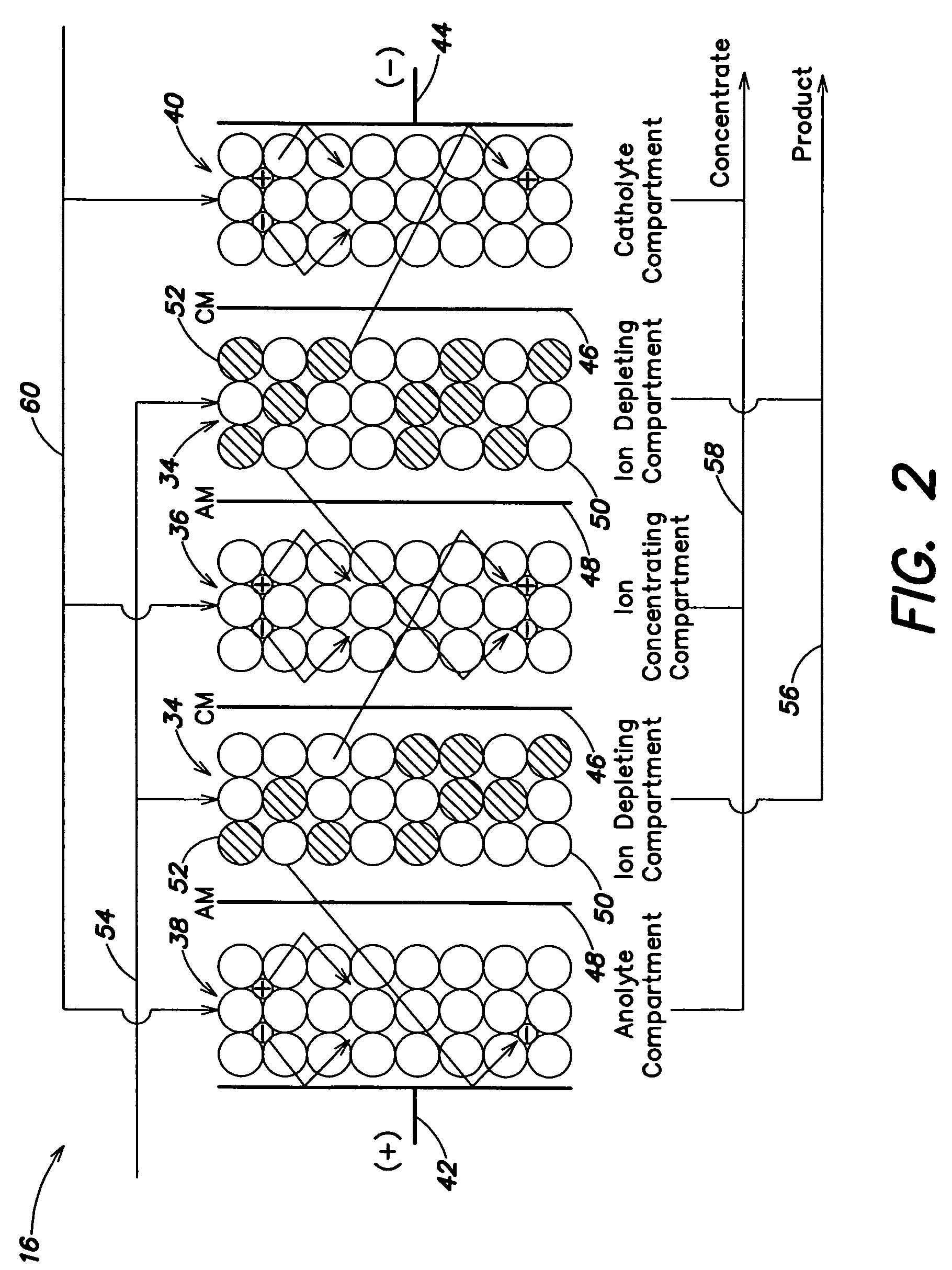

Water treatment system and method

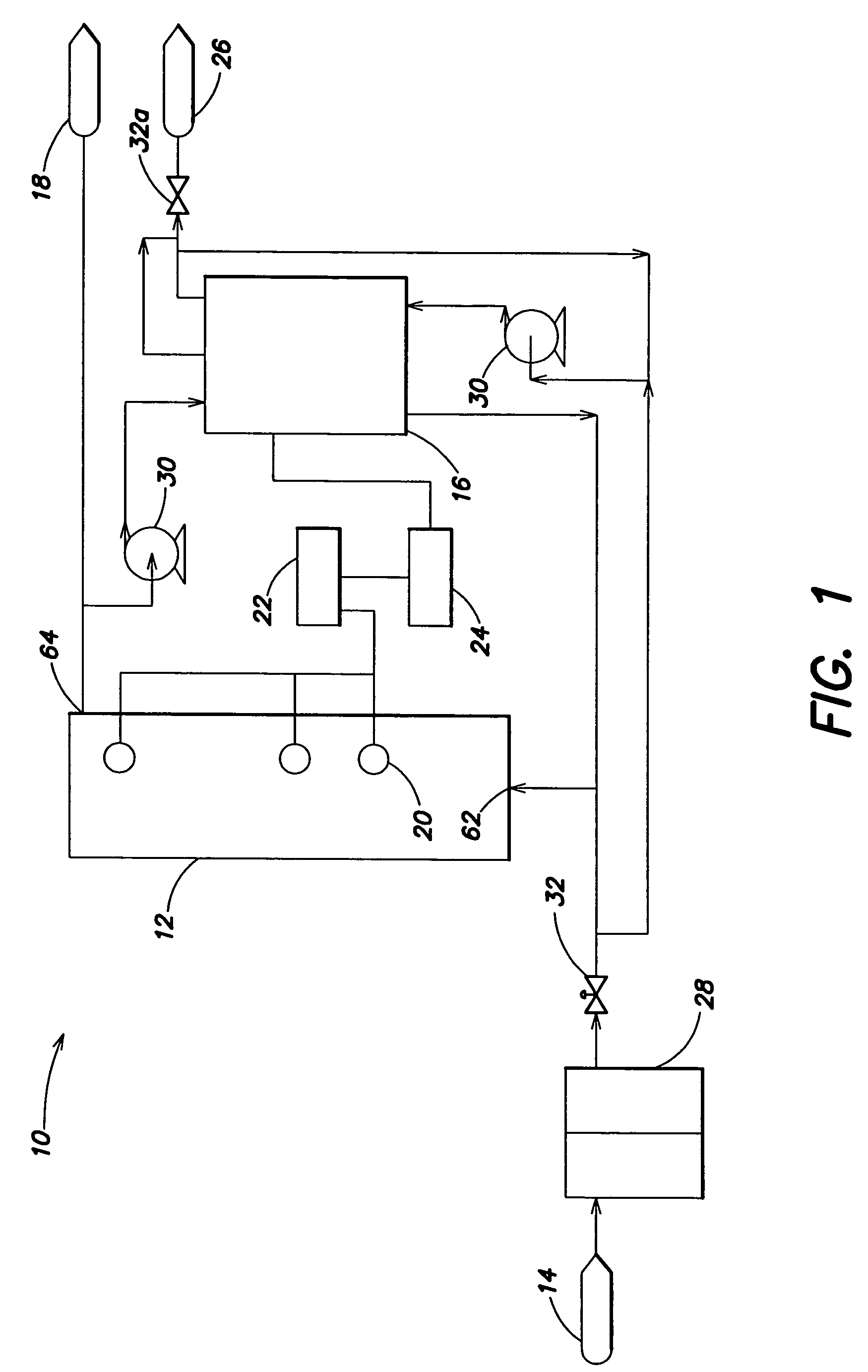

ActiveUS20050103722A1Water treatment parameter controlIon-exchange column/bed processesWater treatment systemWater source

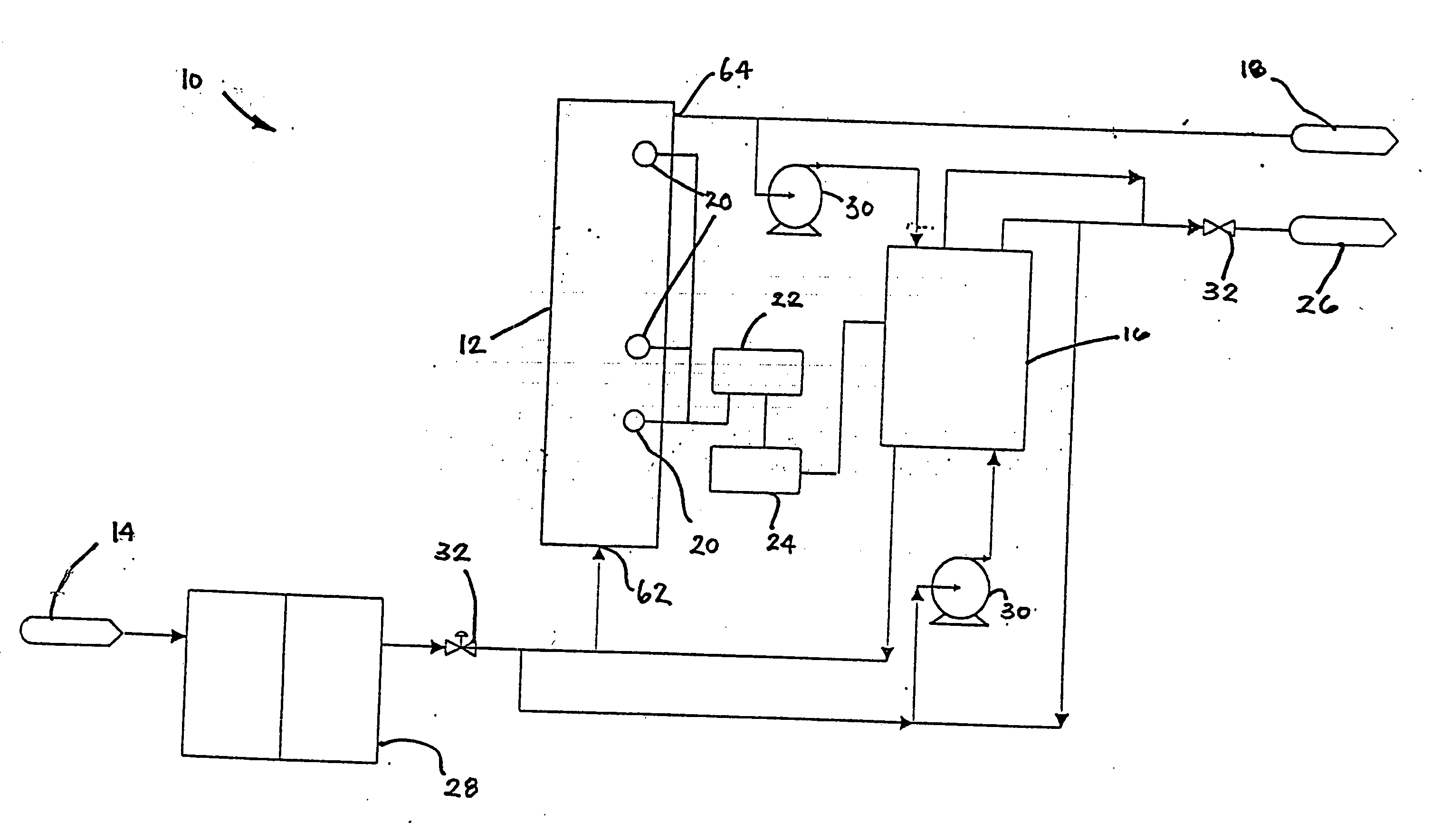

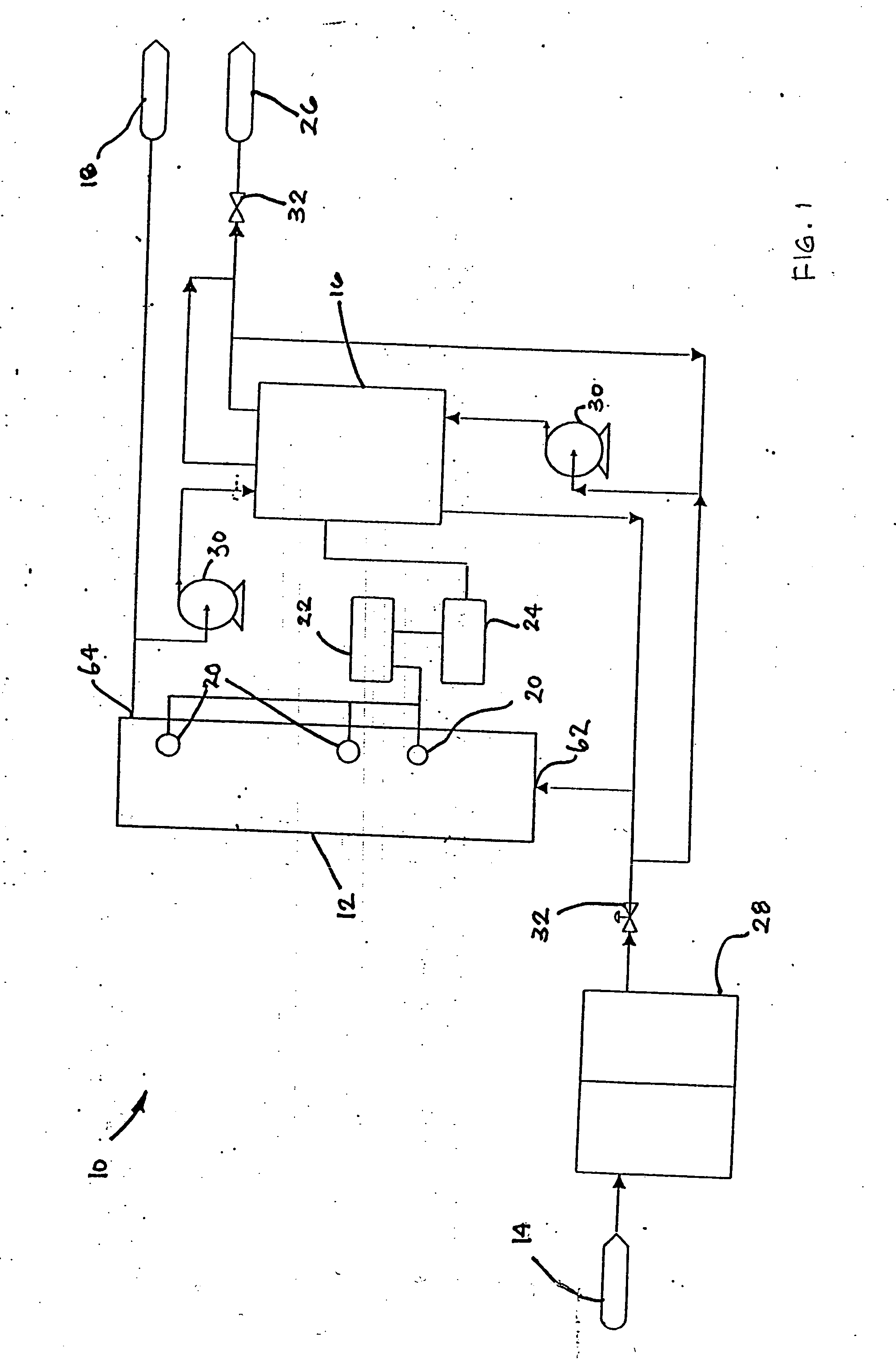

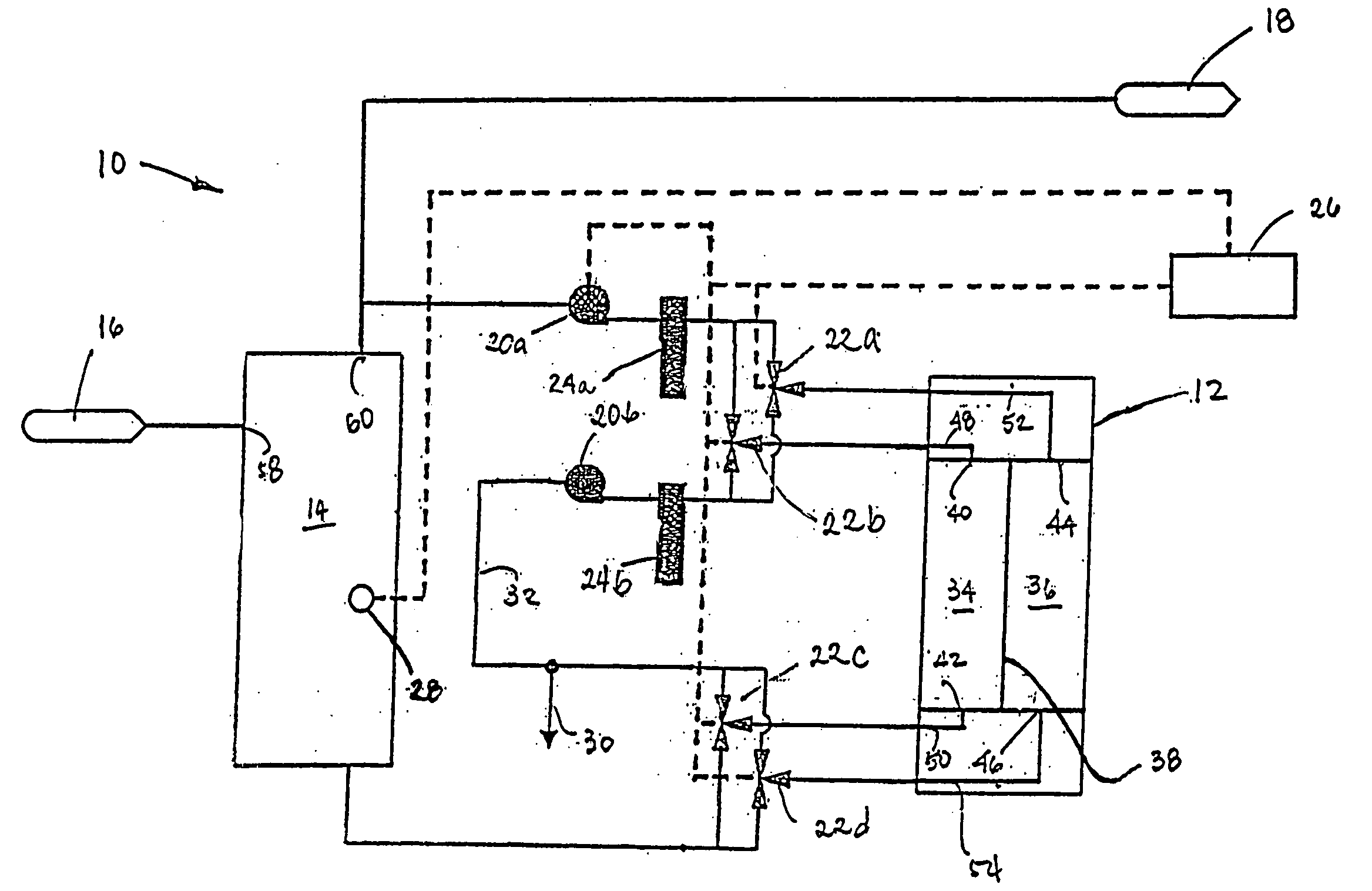

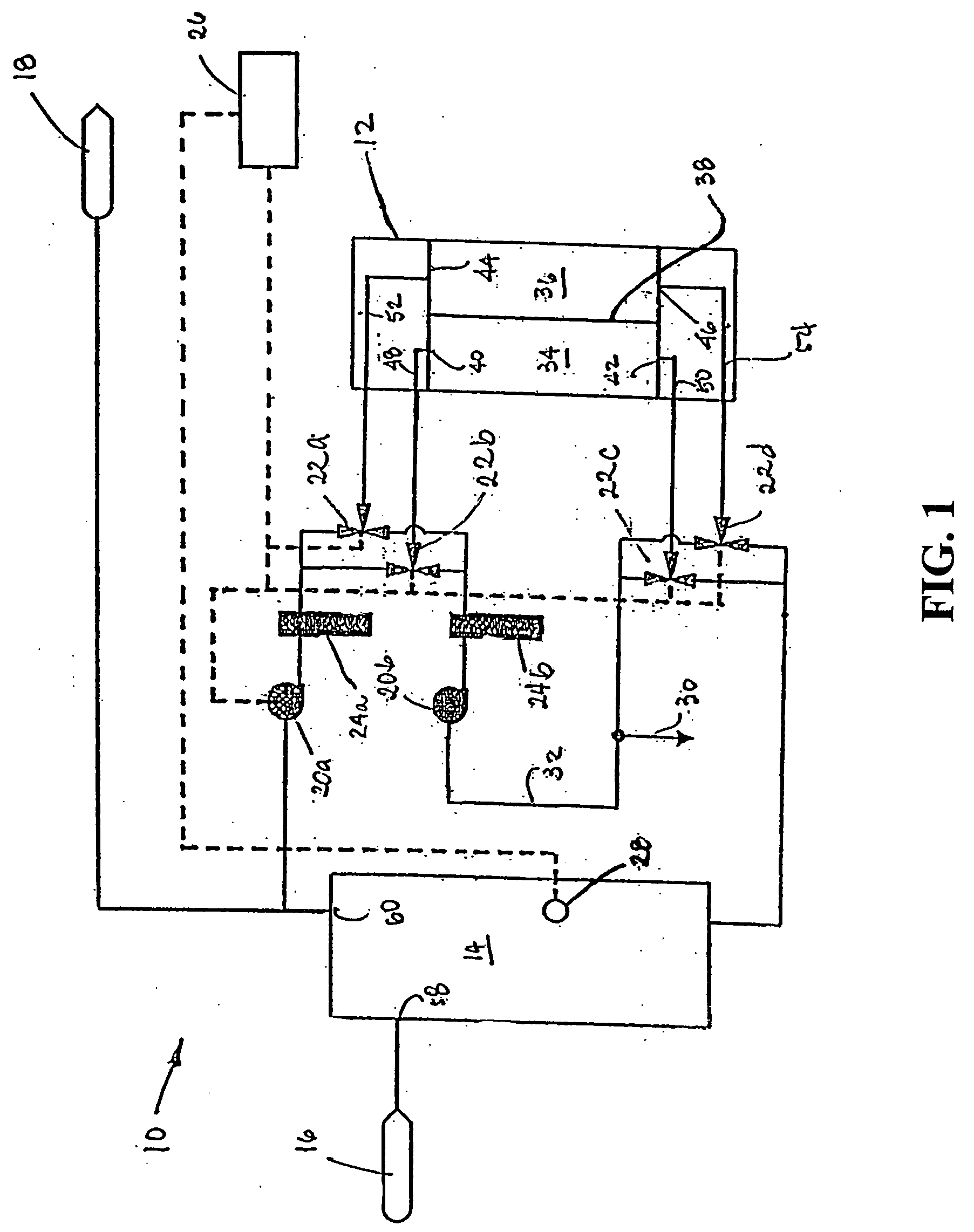

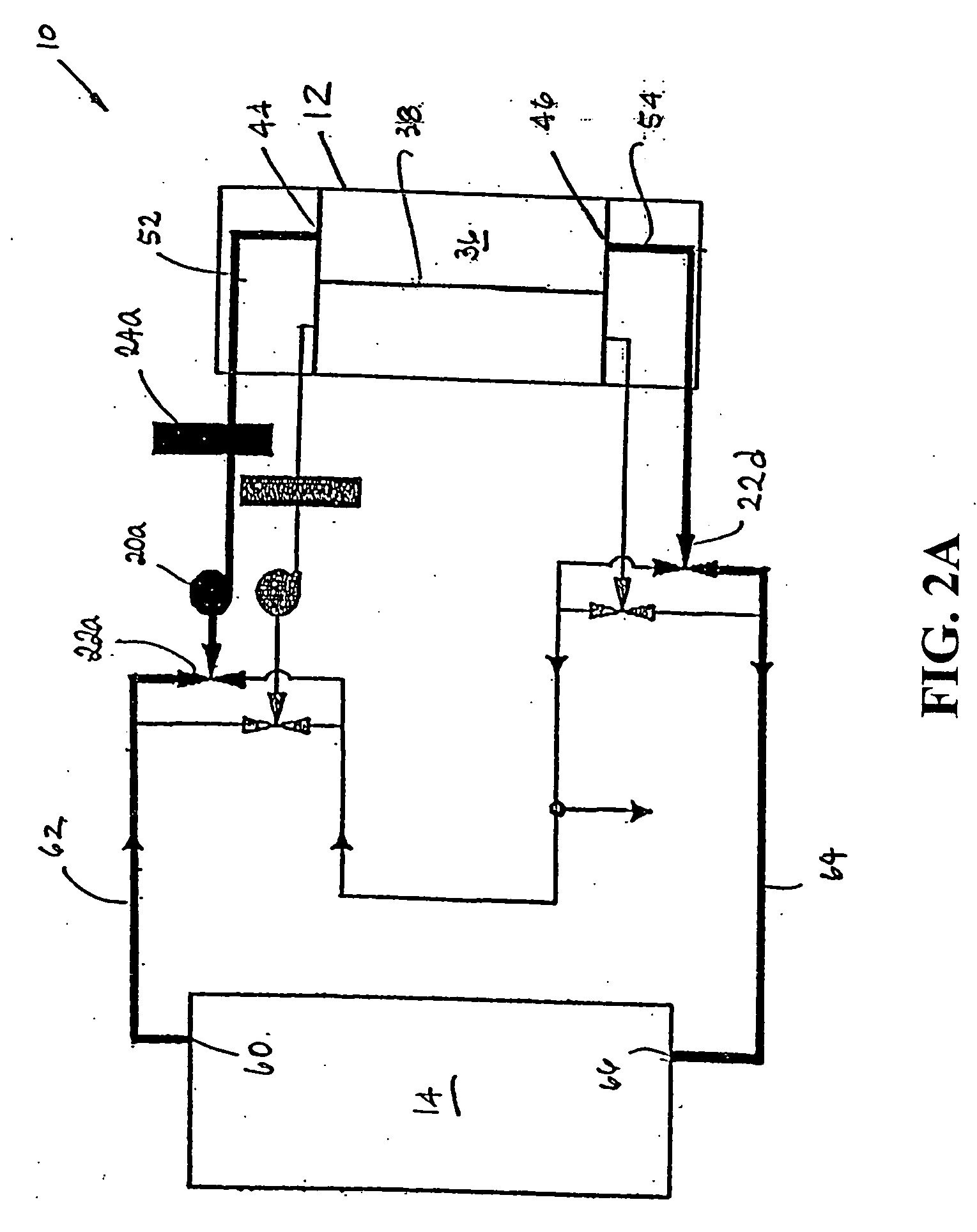

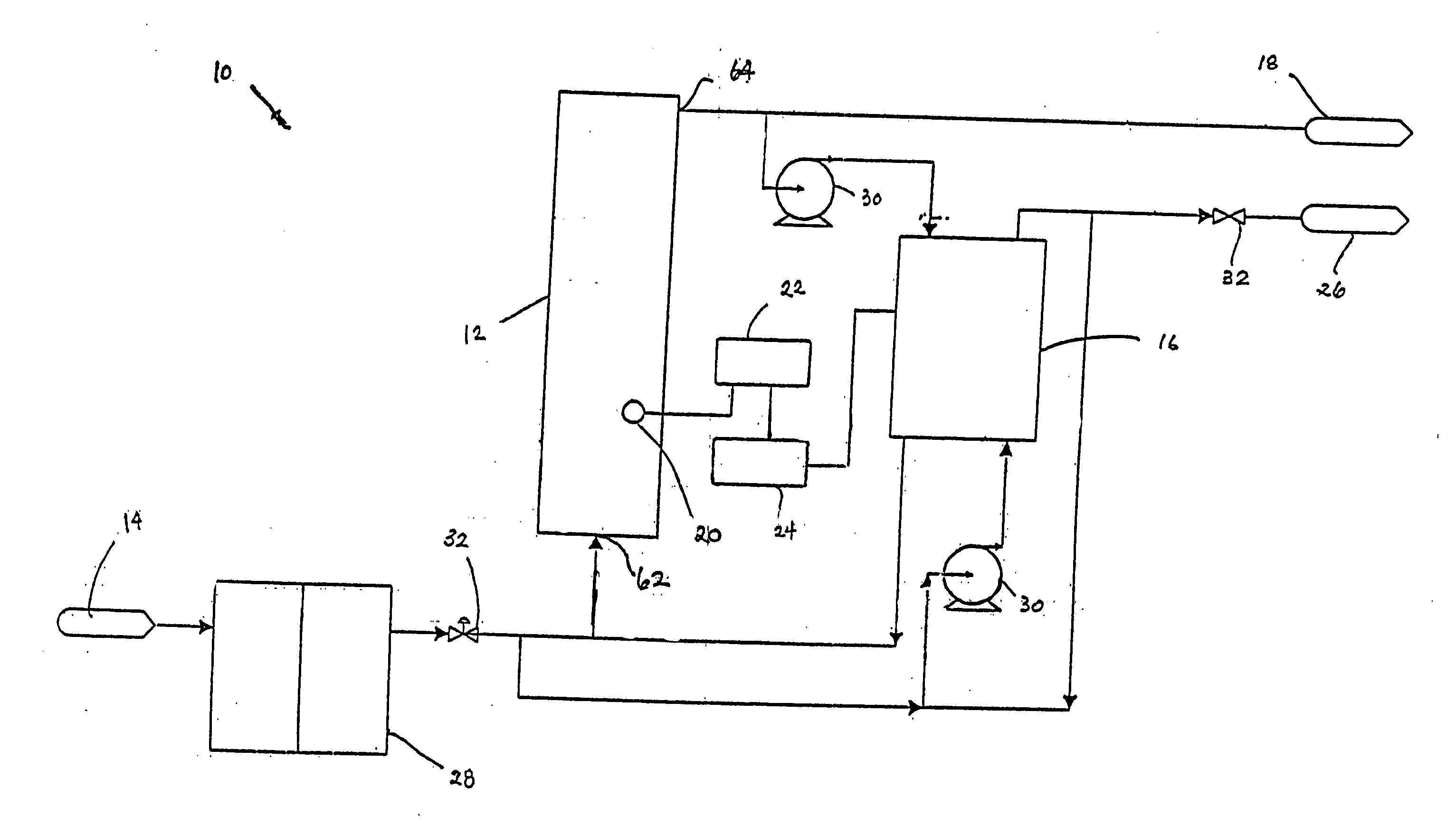

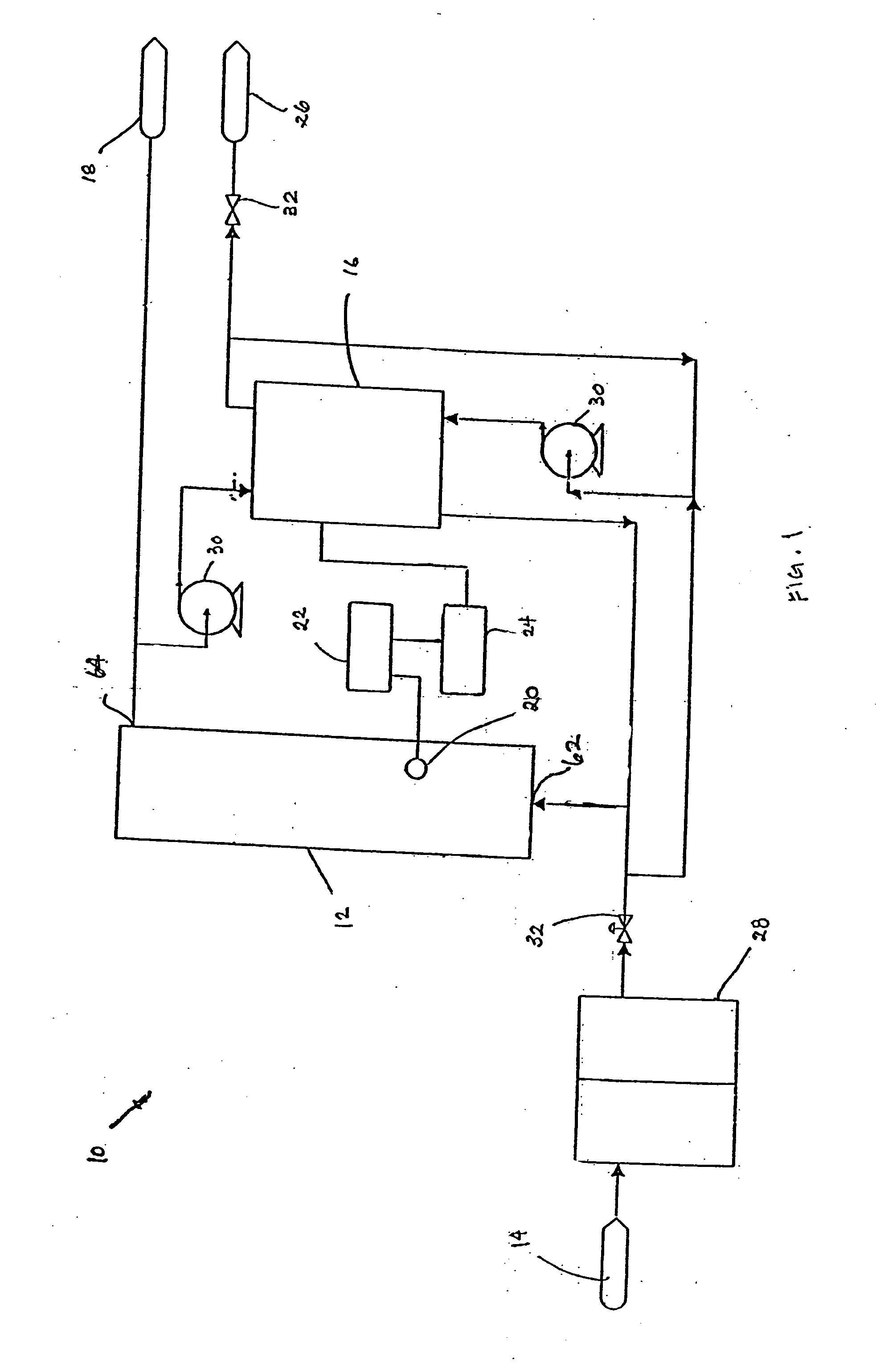

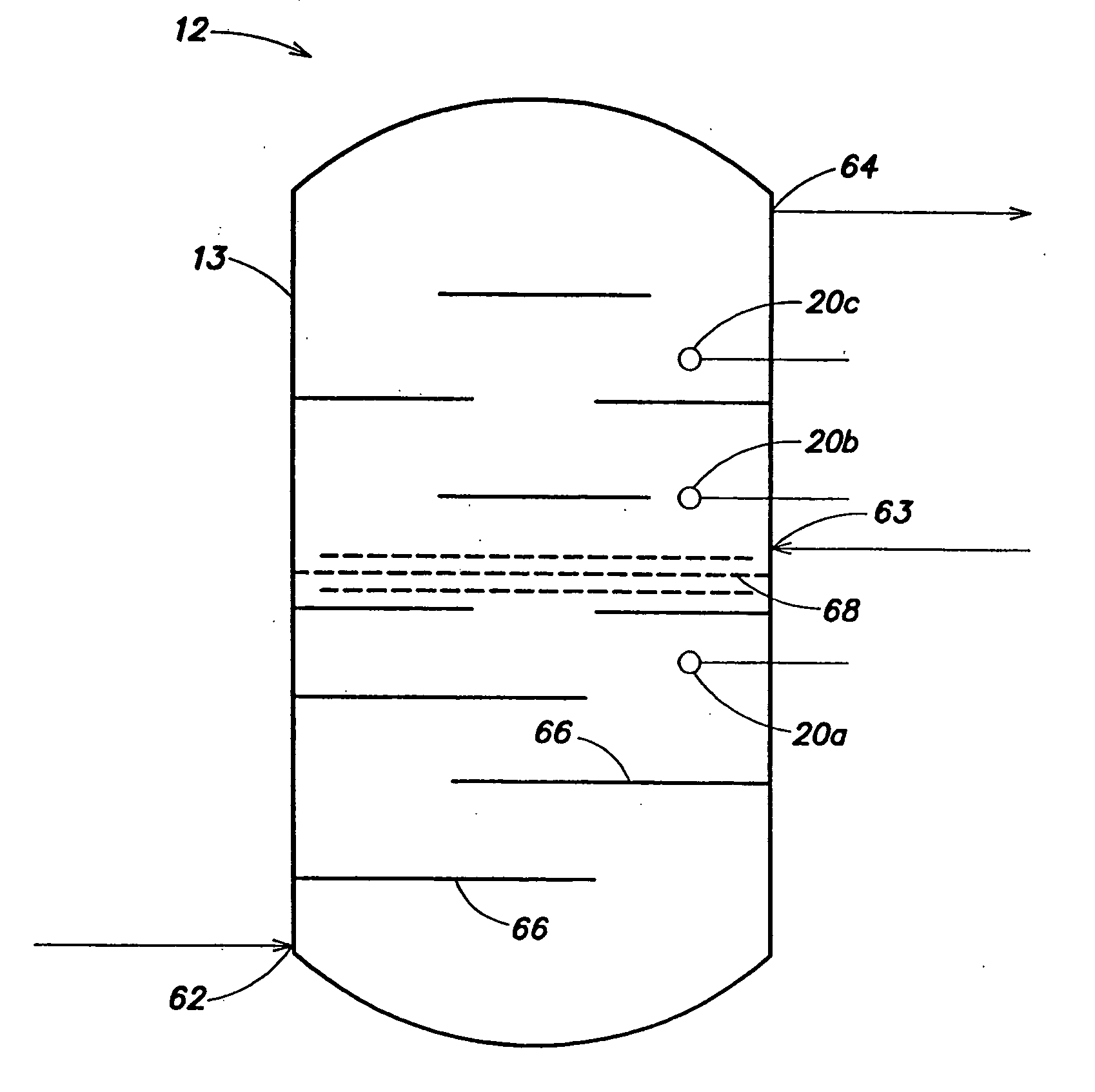

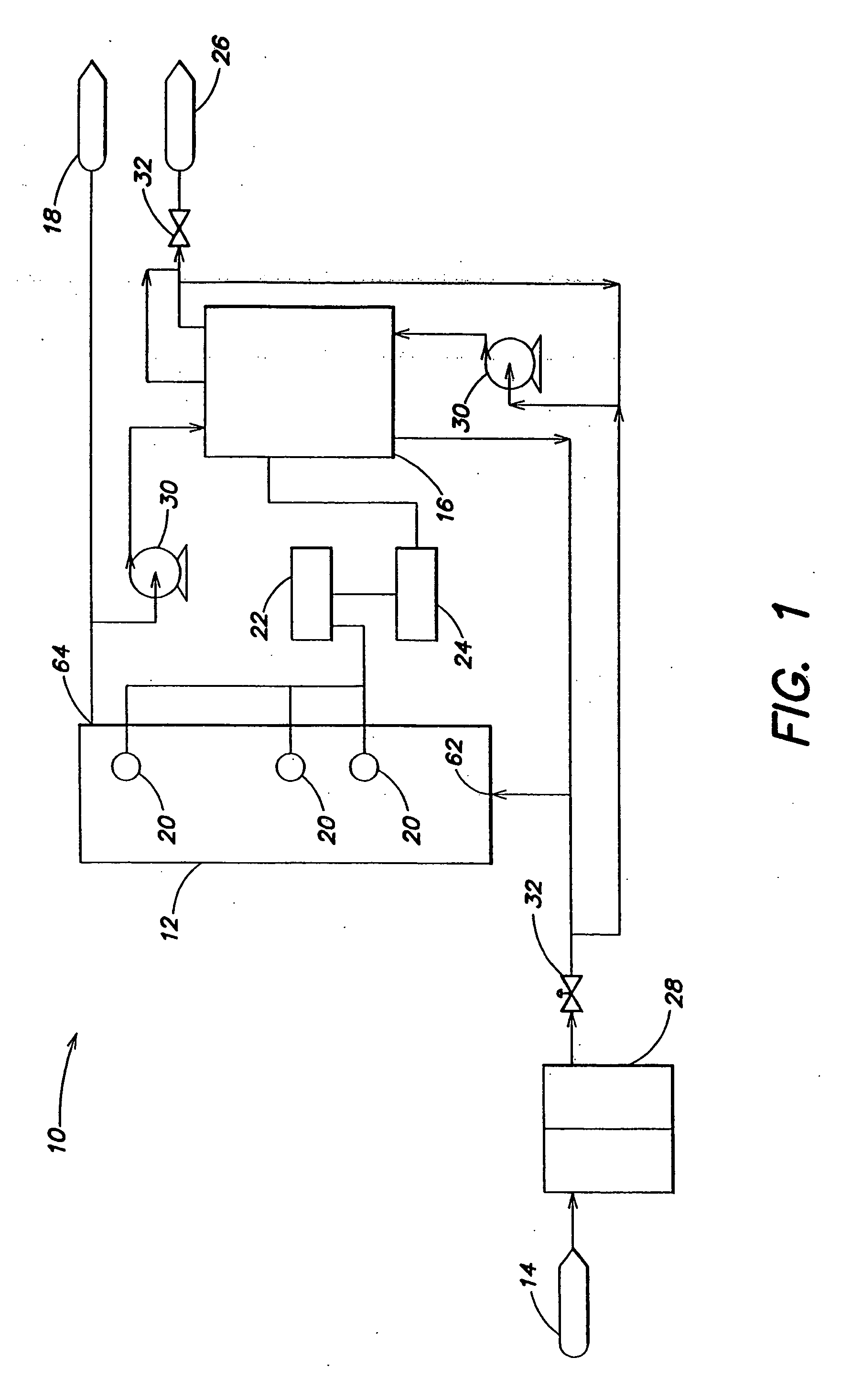

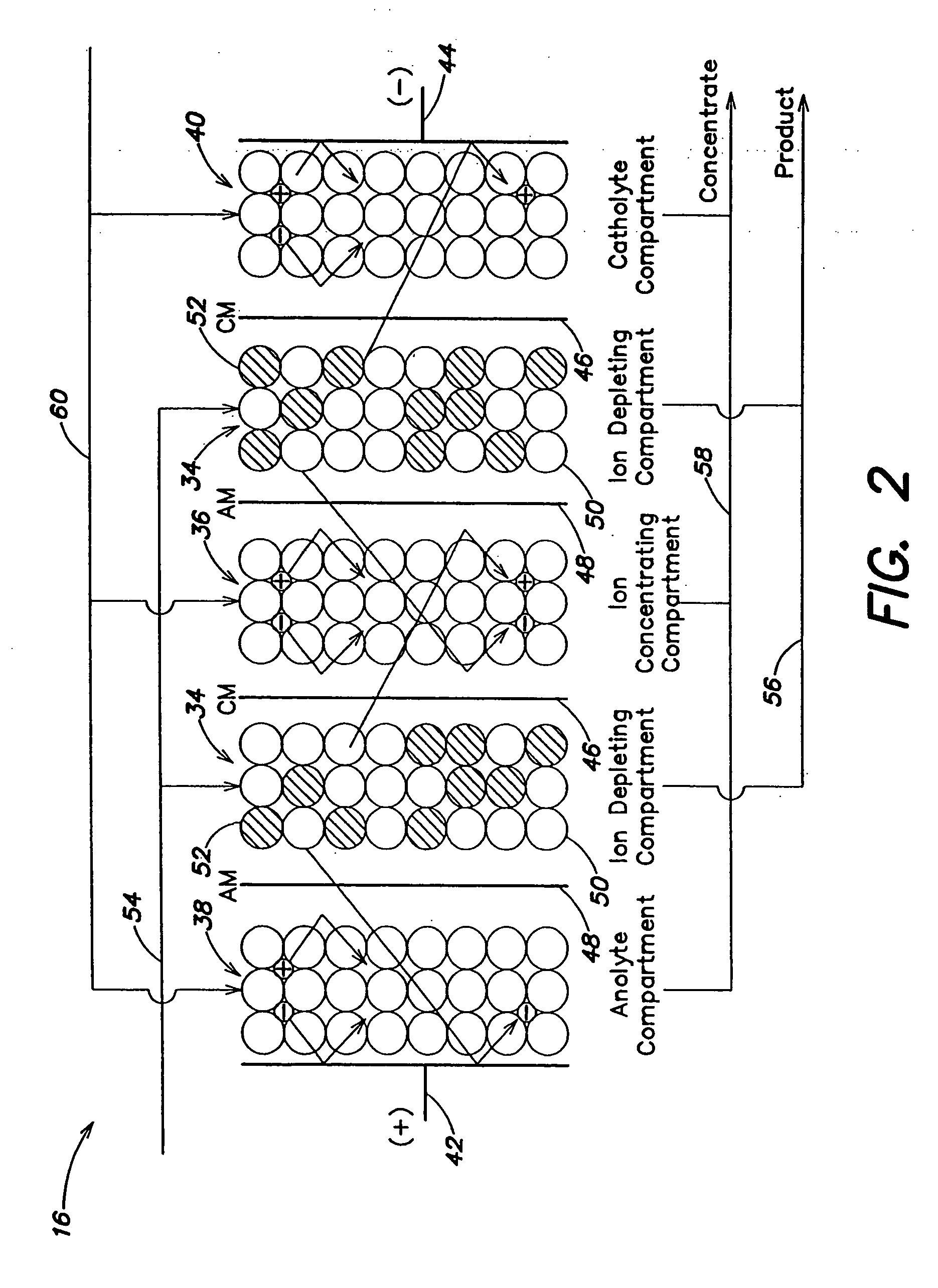

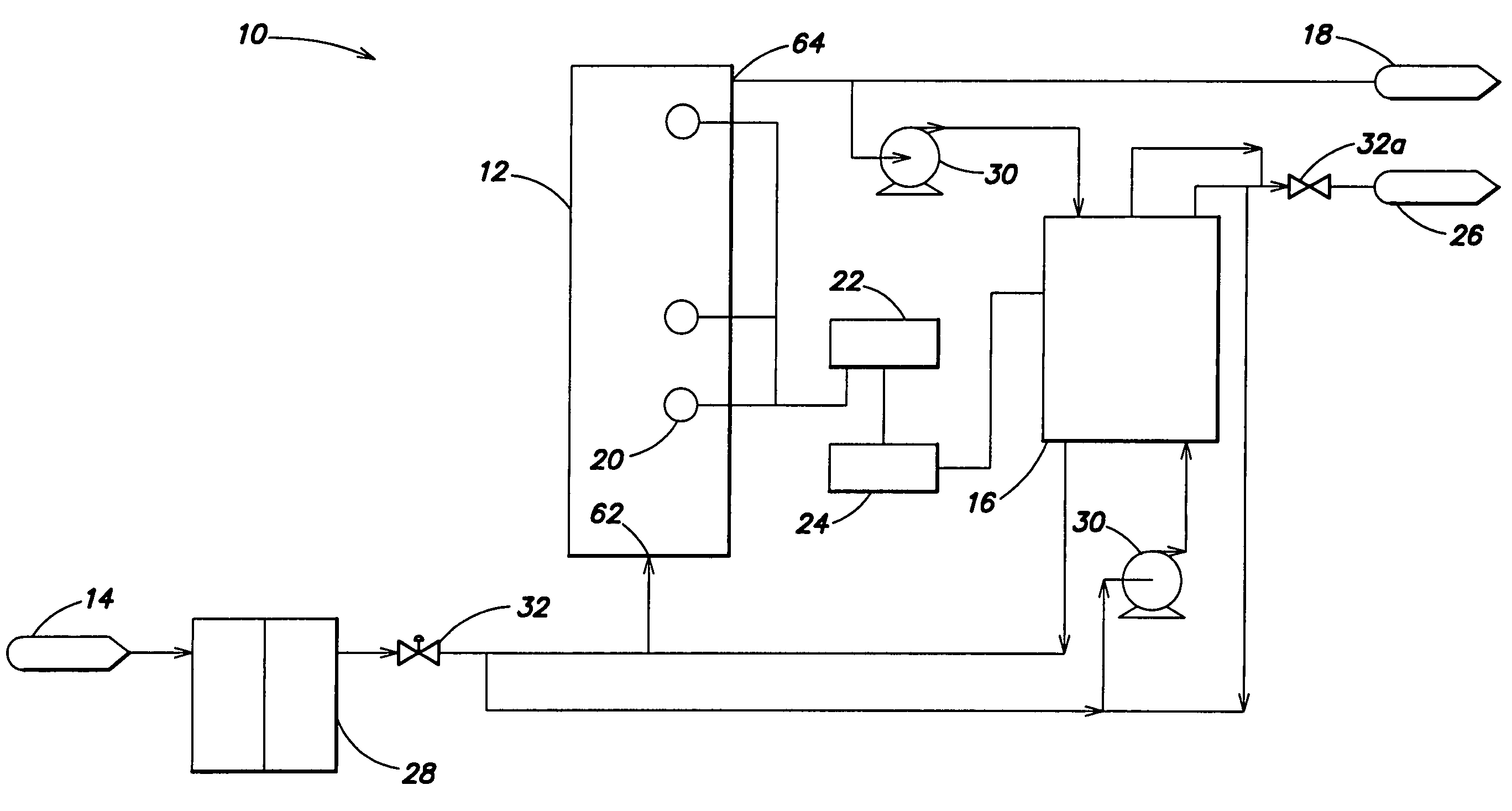

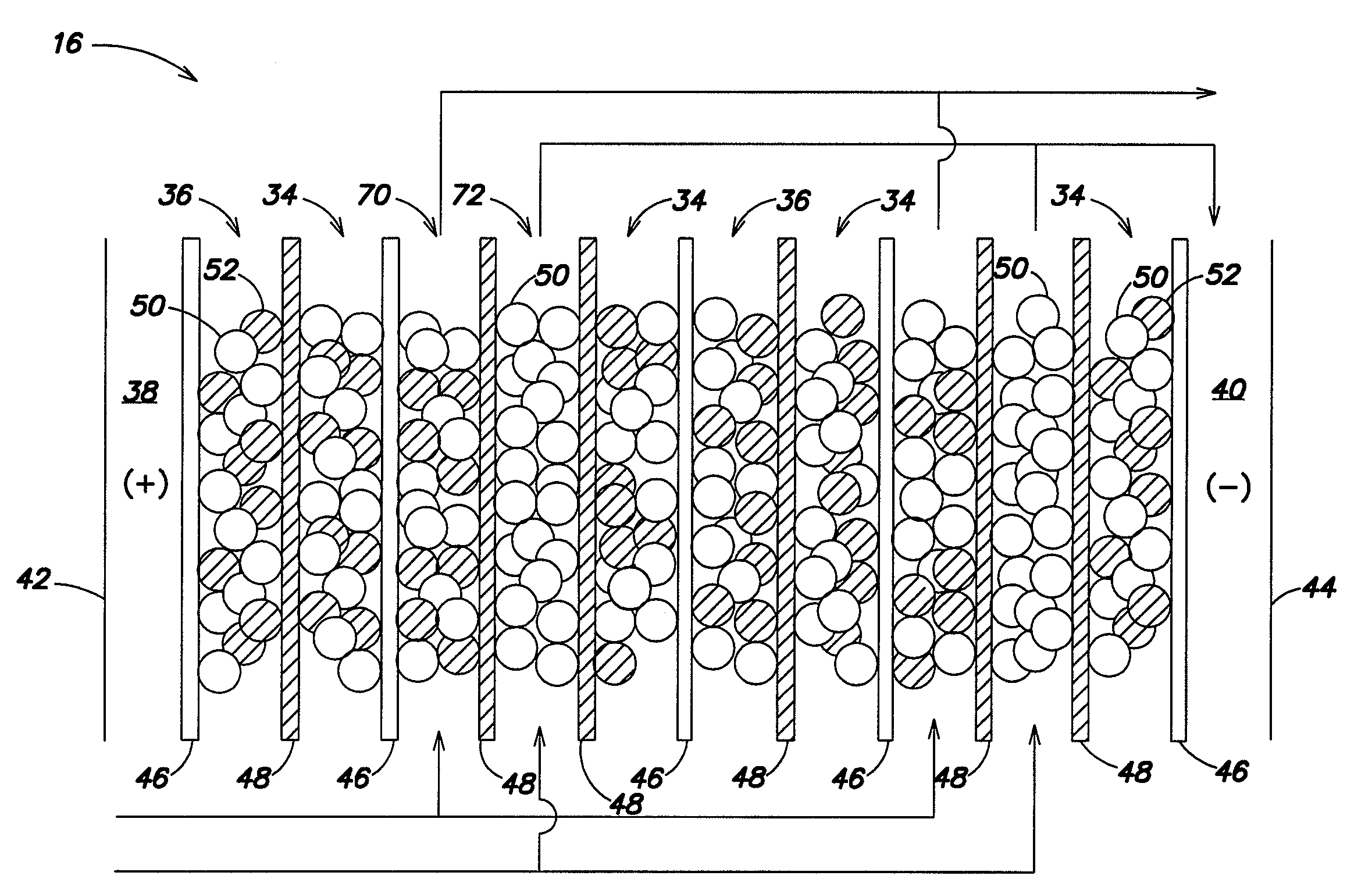

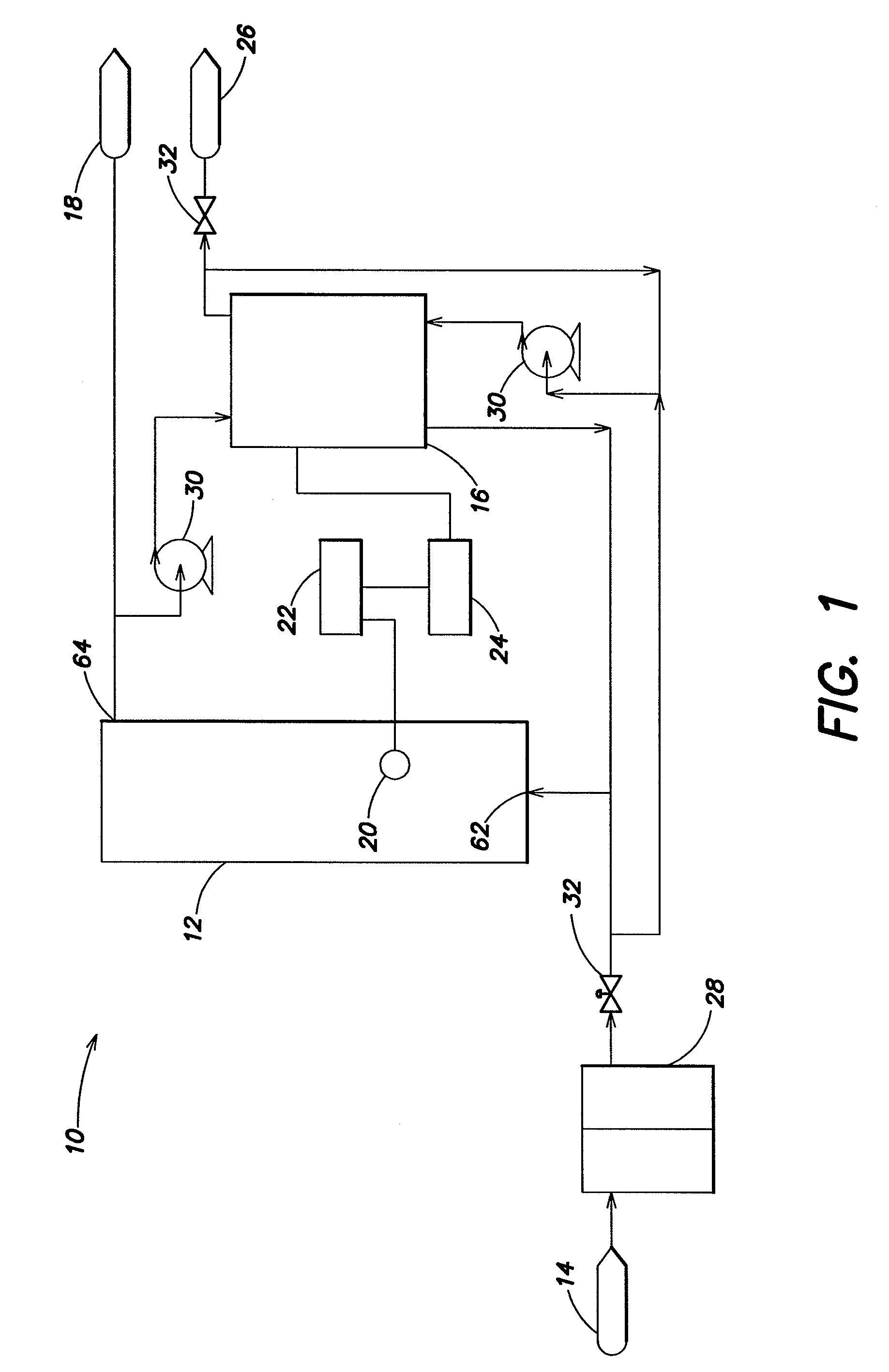

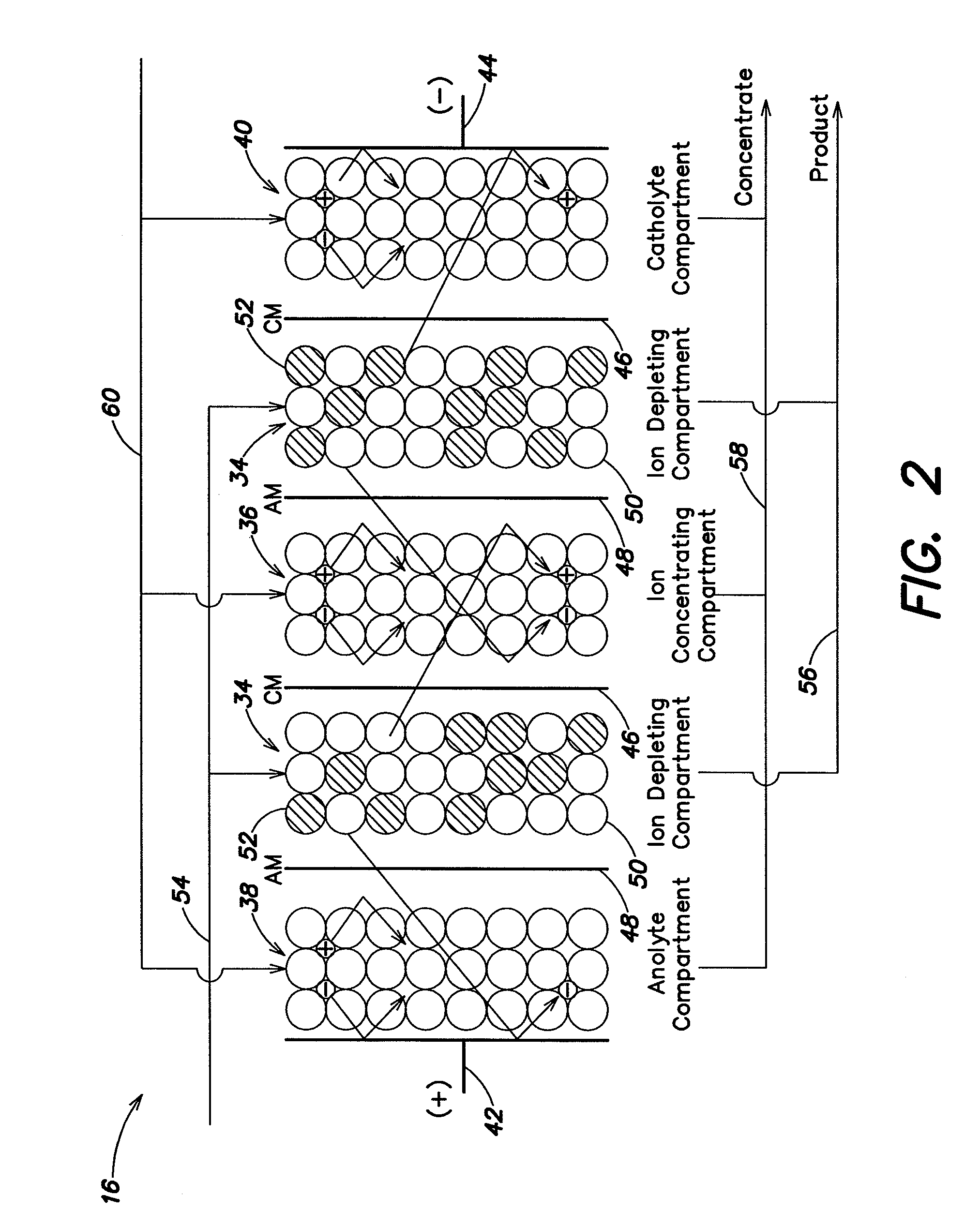

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

ActiveUS20050103622A1Improve water purification abilitySludge treatmentVolume/mass flow measurementWater treatment systemSoftened water

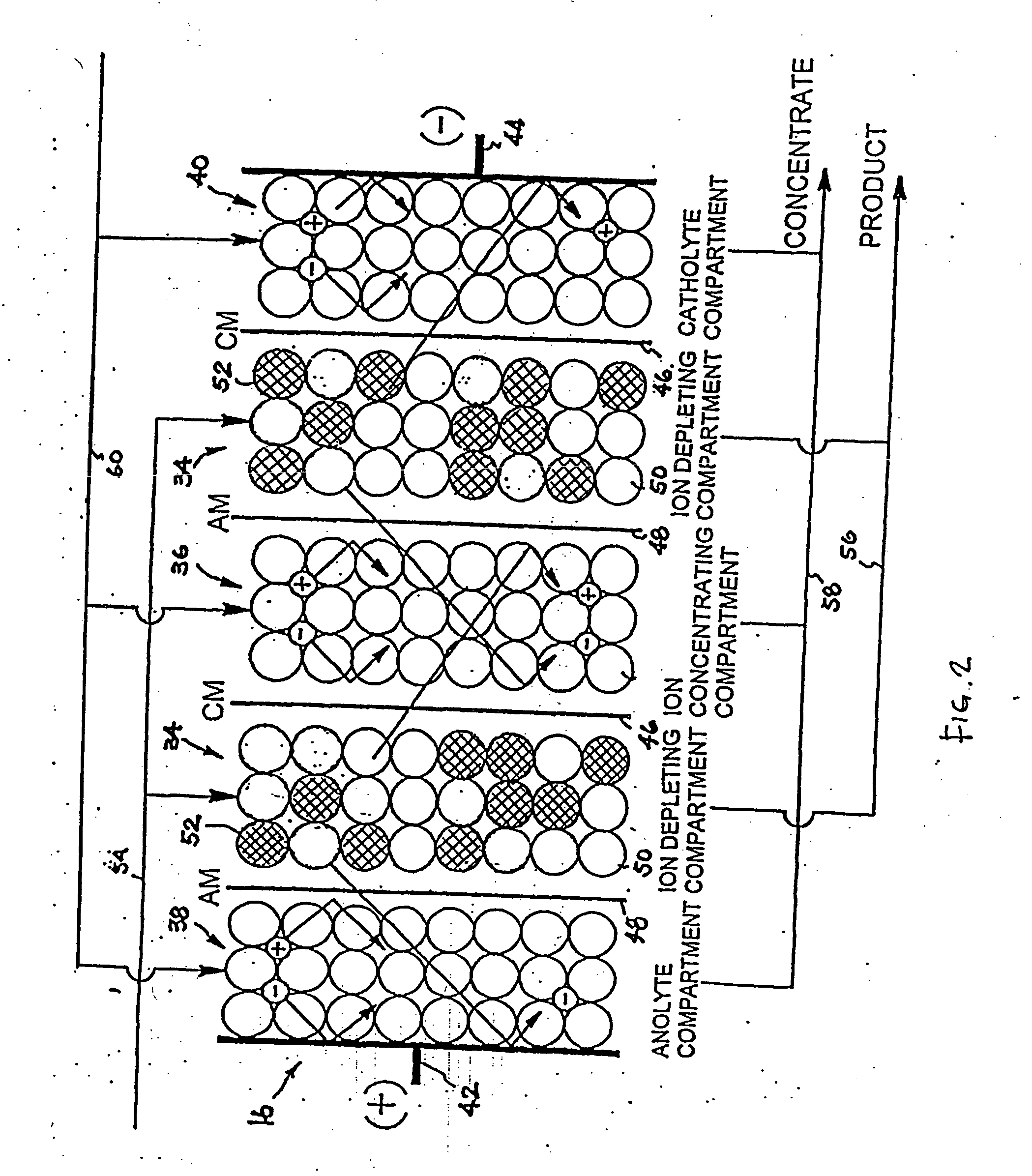

A treatment system provides treated or softened water to a point of use by removing at least a portion of any undesirable species contained in water from a water source. The treatment system can be operated to reduce the likelihood of formation of any scale that can be generated during normal operation of an electrochemical device. The formation of scale in the treatment system, including its wetted components, may be inhibited by reversing or substituting the flowing liquid having hardness-causing species with another liquid having a low tendency to produce scale, such as a low LSI water. Various arrangements of components in the treatment system can be flushed by directing the valves and the pumps of the system to displace liquid having hardness-causing species with a liquid that has little or no tendency to form scale.

Owner:EVOQUA WATER TECH LLC

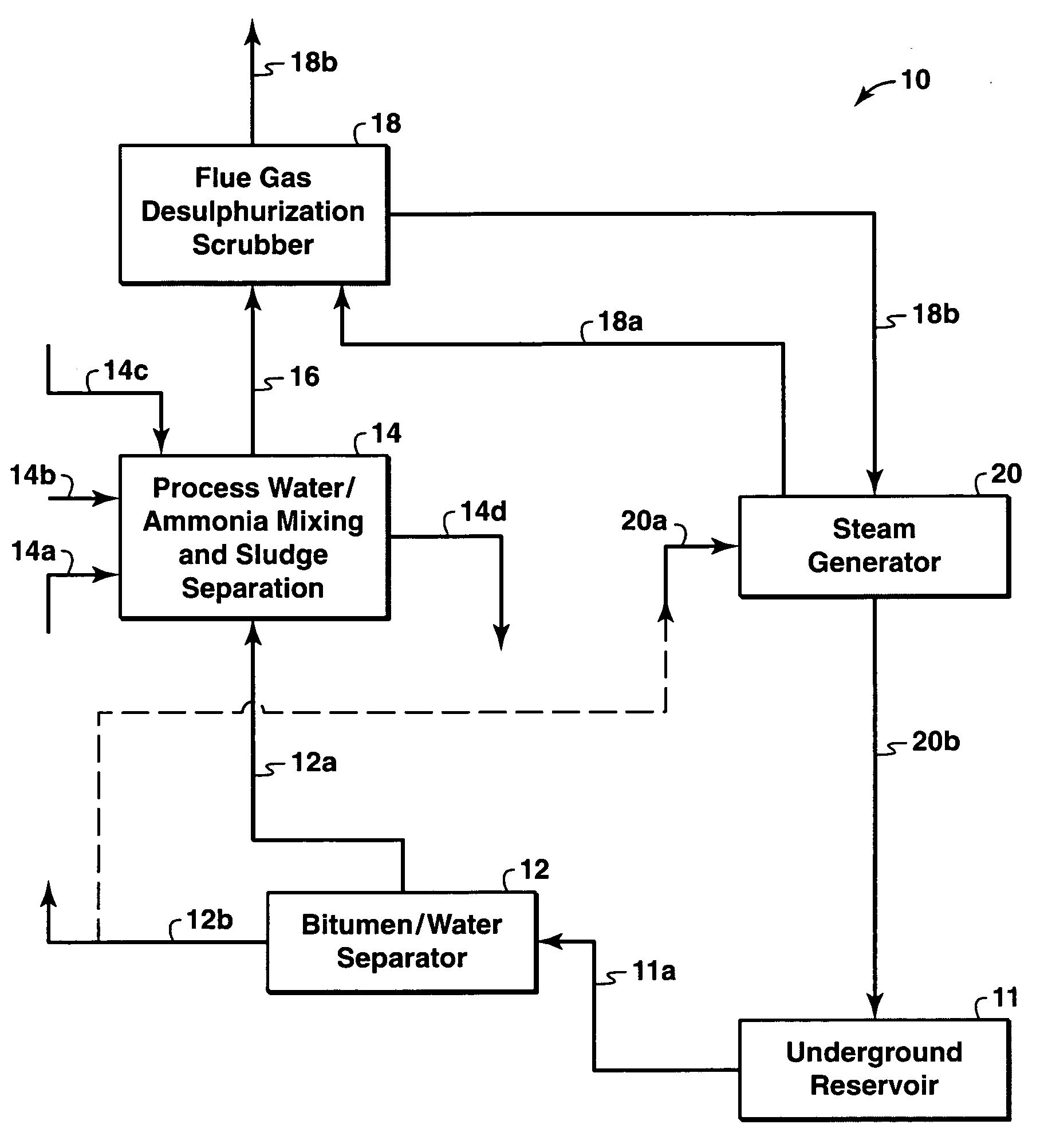

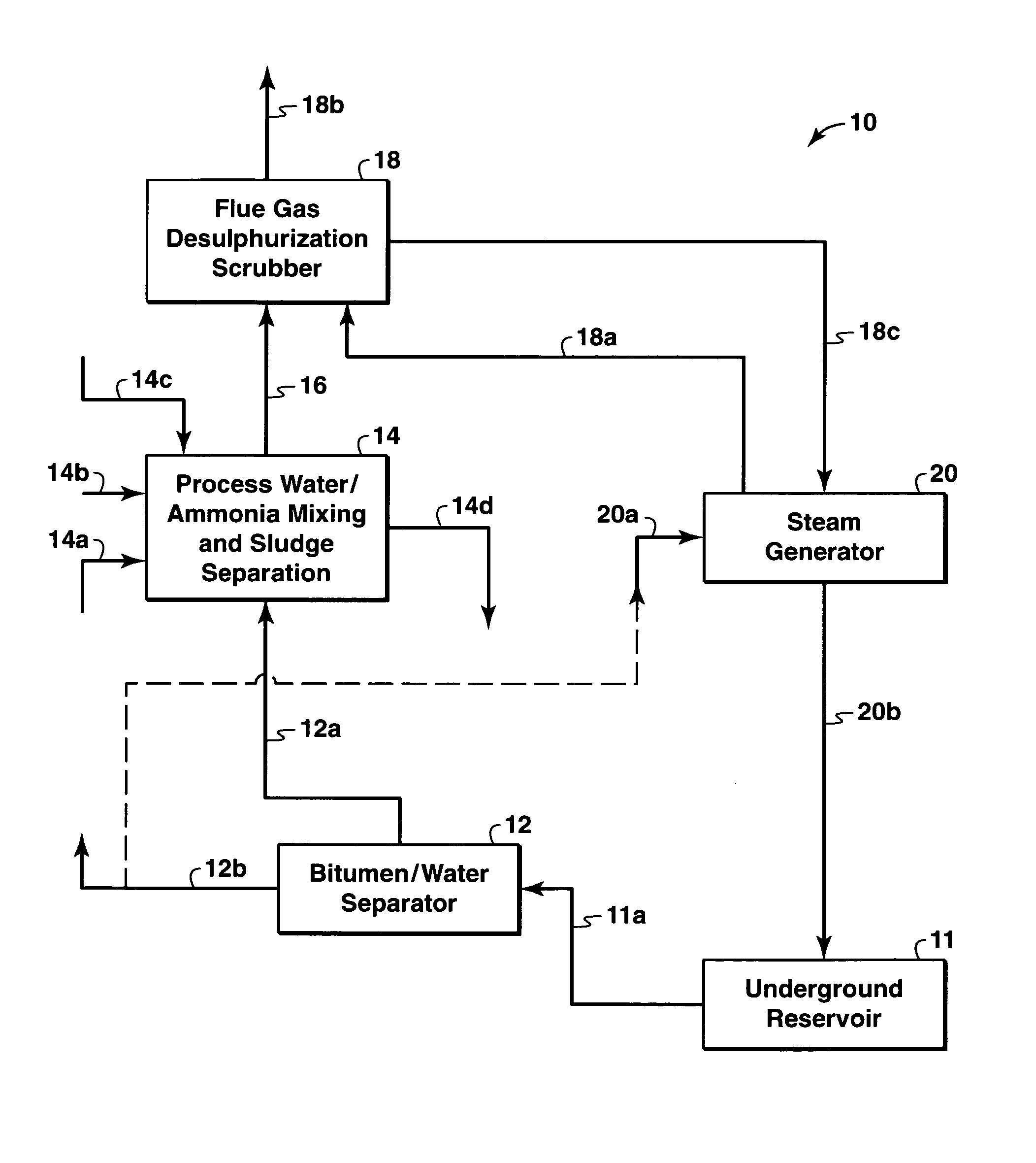

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

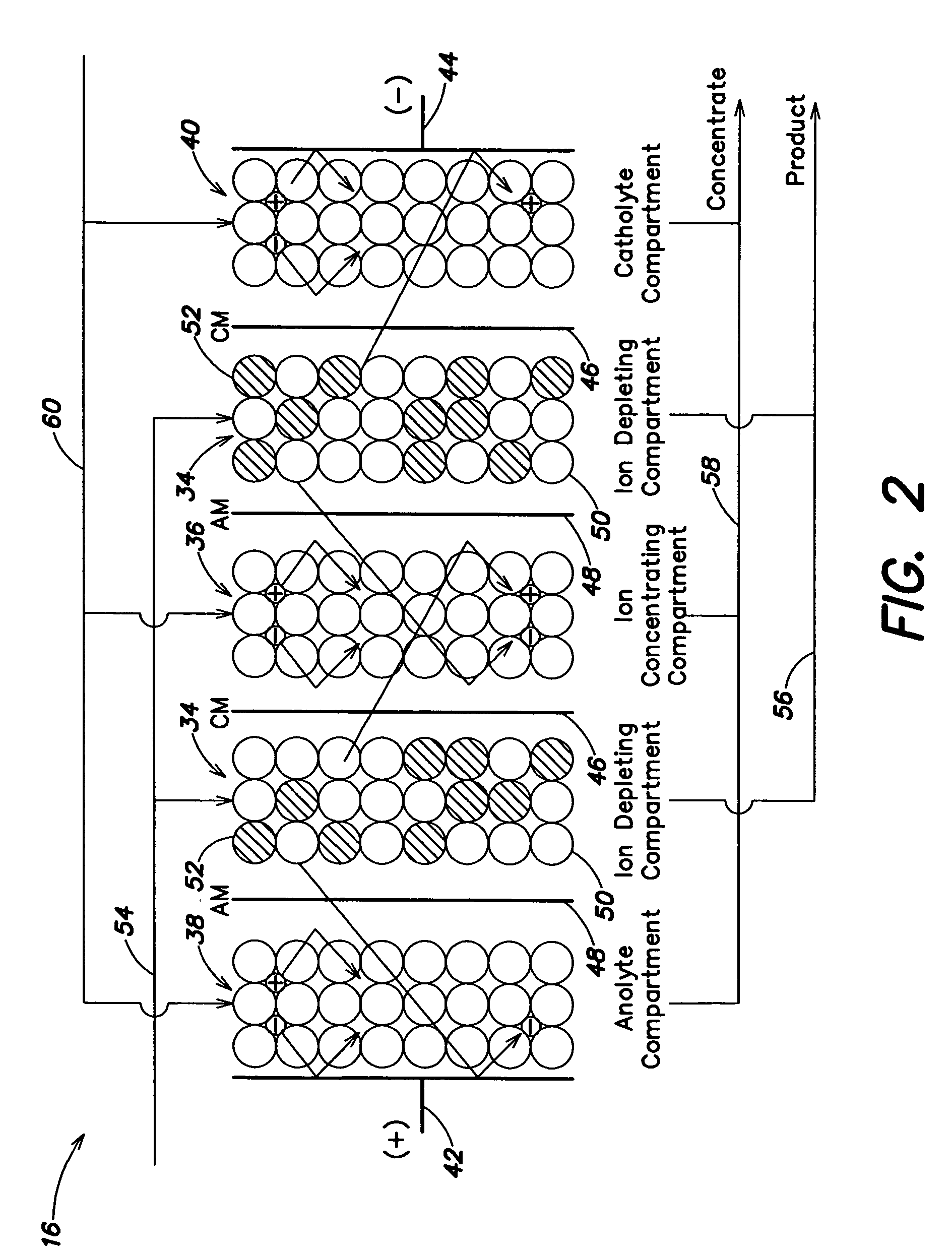

Water treatment system and method

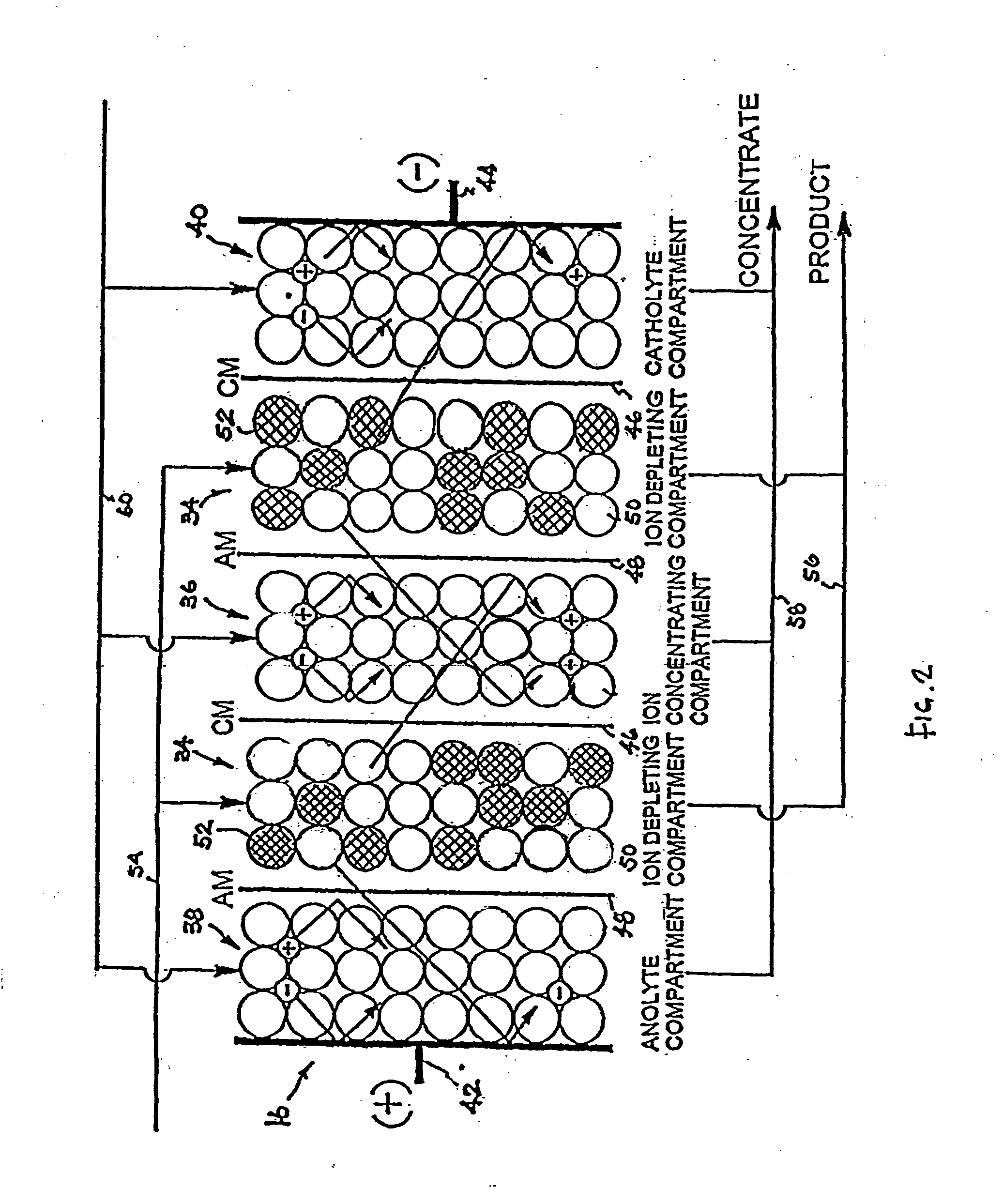

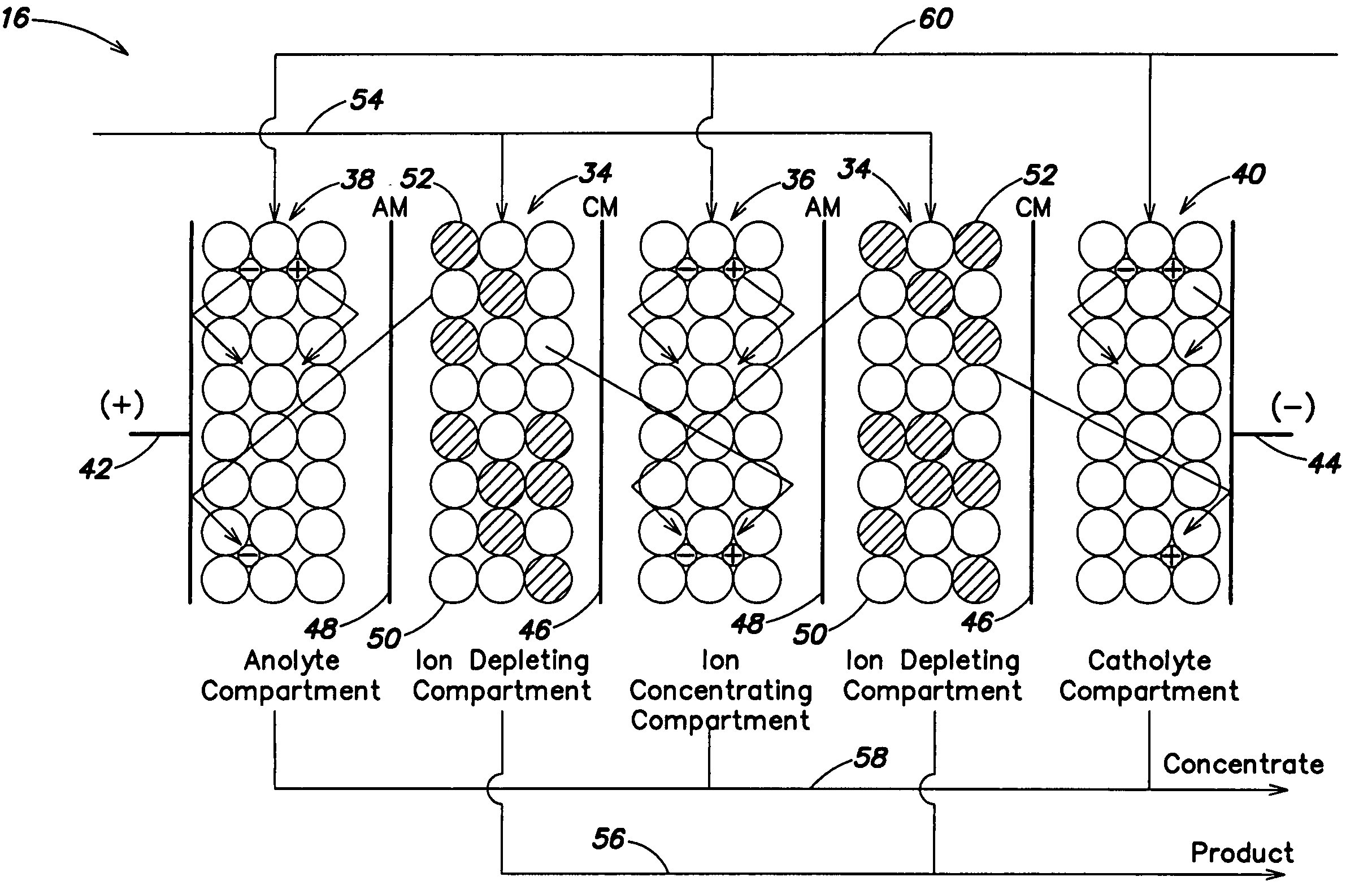

ActiveUS20050103630A1Inhibit migrationPromote migrationSludge treatmentVolume/mass flow measurementWater sourceSoftened water

The present invention is directed to a water treatment or purification system and method for providing treated water in industrial, commercial and residential applications. The treatment system provides treated or softened water to a point of use by removing at least a portion of any hardness-causing species contained in water from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system includes an electrochemical device, such as an electrodeionization device, that can have at least one compartment that generates and traps hydrogen ions which can be used in another compartment of the electrochemical device such as, an electrode compartment, to reduce or at least dissolve any scale. Other applications of the system would be in the treatment and processing of foods and beverages, sugars, various industries such as the chemical, pharmaceutical, waste water treatment and power generating industries.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

ActiveUS20050103644A1Facilitate water treatmentSludge treatmentVolume/mass flow measurementWater treatment systemWaste stream

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

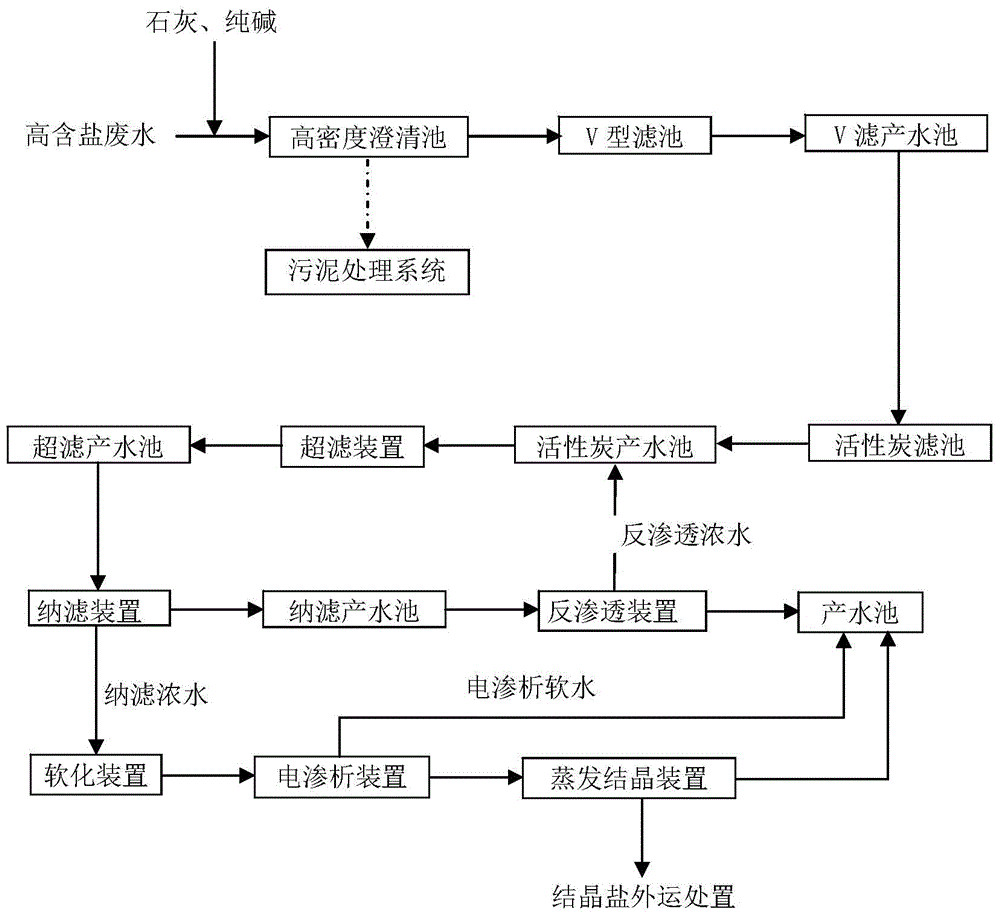

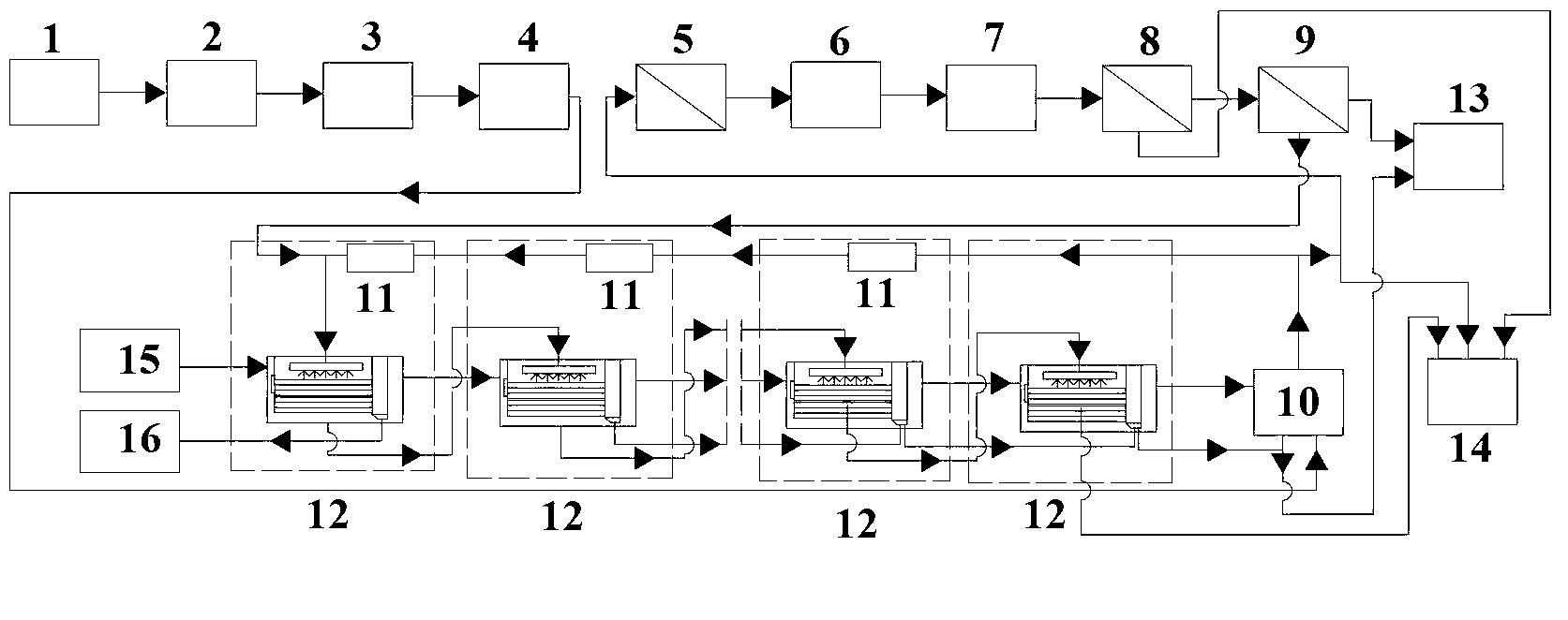

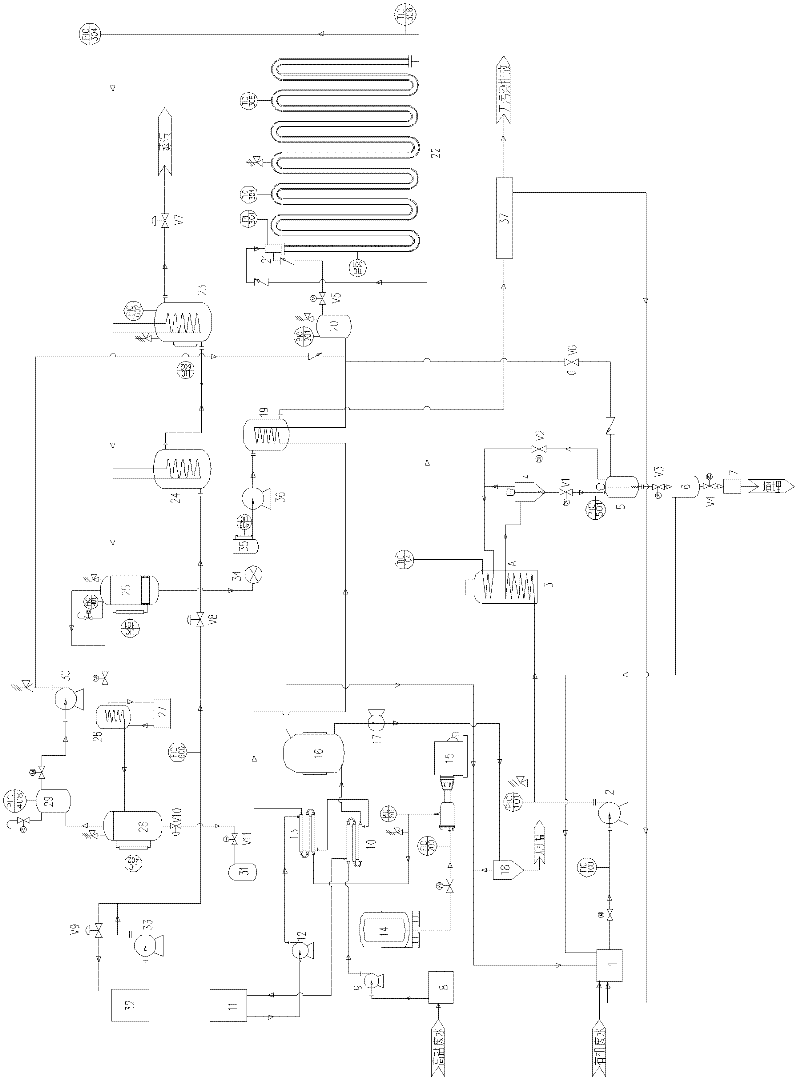

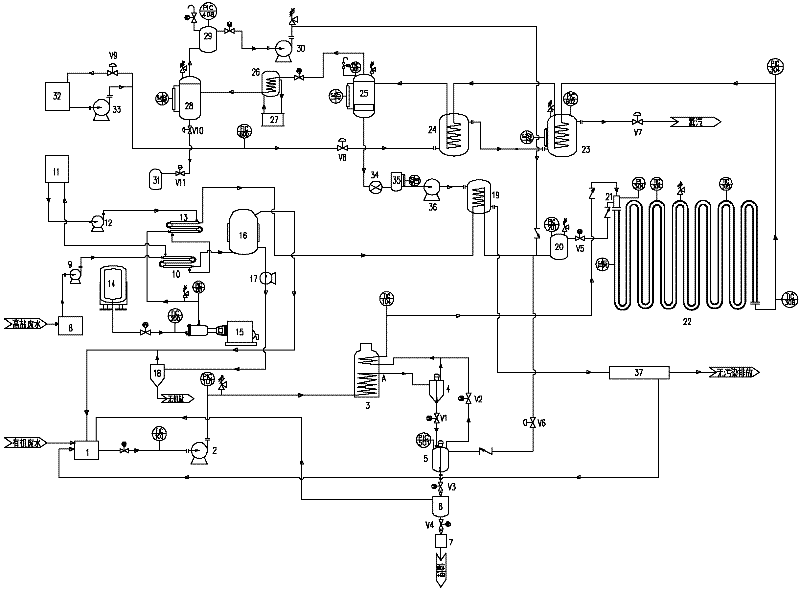

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

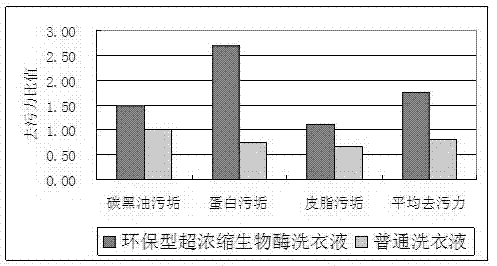

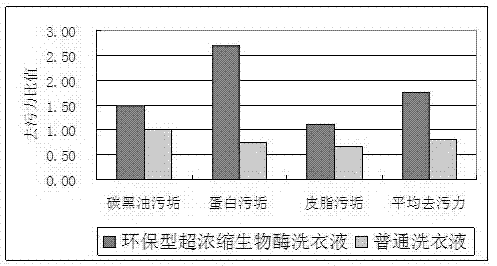

Environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and preparation method thereof

ActiveCN102242022ANo pollution in the processReduce consumptionNon-ionic surface-active compoundsDetergent mixture composition preparationHydrotropePhosphate

The invention relates to a detergent for daily use, and specifically relates to an environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and a preparation method thereof. The prepared product in the invention is mobile liquid with low viscosity, contains no phosphates, fluorescent brightening agents or alkylphenol polyoxyethylene, and has no pollution to environment. The production process for the product is simple; preparation and mass production of the product are easy; the product can be widely used for washing of various fabrics and clothing and is both applicable to hand wash and machine wash. The environment-friendly type hyperconcentration biological enzyme liquid laundry detergent comprises, by weight, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether sodium sulfate-70, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether-9, 0.5 to 30 parts of sodium alkylbenzene sulfonate-60, 0.2 to 15 parts of triethanolamine, 0.1 to 10 parts of sodium citrate, 0 to 5 parts of citric acid, 0 to 5 parts of aliphatic acid, 0.02 to 8 parts of biological enzyme, 0.1 to 20 parts of an enzyme stabilizer, 0.5 to 30 parts of a solvent, 0 to 15 parts of a hydrotropic agent, 0 to 5 parts of a bactericide, 0.001 to 5 parts of an antiseptic, 0 to 3 parts of essence and 1.0 to 40 parts of softened water.

Owner:上海开米科技有限公司

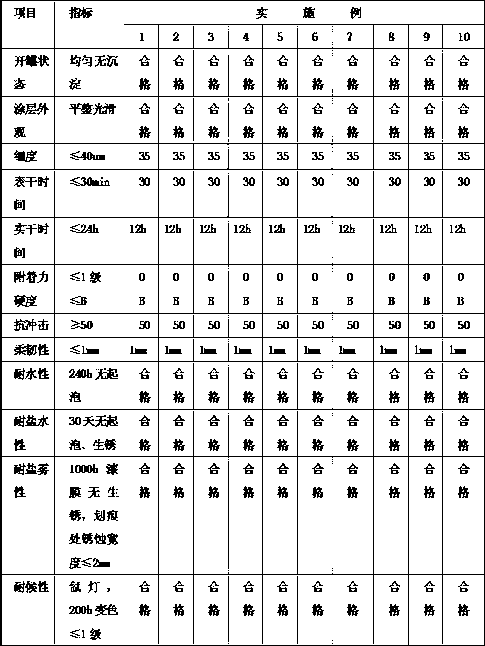

Aqueous high-performance monocomponent primer-topcoat anti-corrosion coating

The invention discloses an aqueous high-performance monocomponent primer-topcoat anti-corrosion coating, comprising aqueous modified acrylic acid emulsion, coloring pigment, antirust pigment, filling material, film forming auxiliary agent, thickening anti-settling agent, softened water, anti-flash rust agent, and auxiliary additive. The coating disclosed herein has excellent salt mist resistance, can resist salt mist for more than 1000h and resist weather for more than 200h, and has the characteristics of rapid drying, low content of VOC, no environmental pollution, and no harm to constructers' health. The coating disclosed therein is convenient for using, can be applied in high pressure airless spraying and ordinary air spraying, the thickness of single coating wet film can reach 200 mum without sagging or cracking, and the coating disclosed herein is widely suitable for anti-corrosion protection of locomotive, container, automobile, ship, bridge, iron tower, storage tank, pipeline and other steel structures.

Owner:中山大桥化工企业集团中山智亨实业发展有限公司

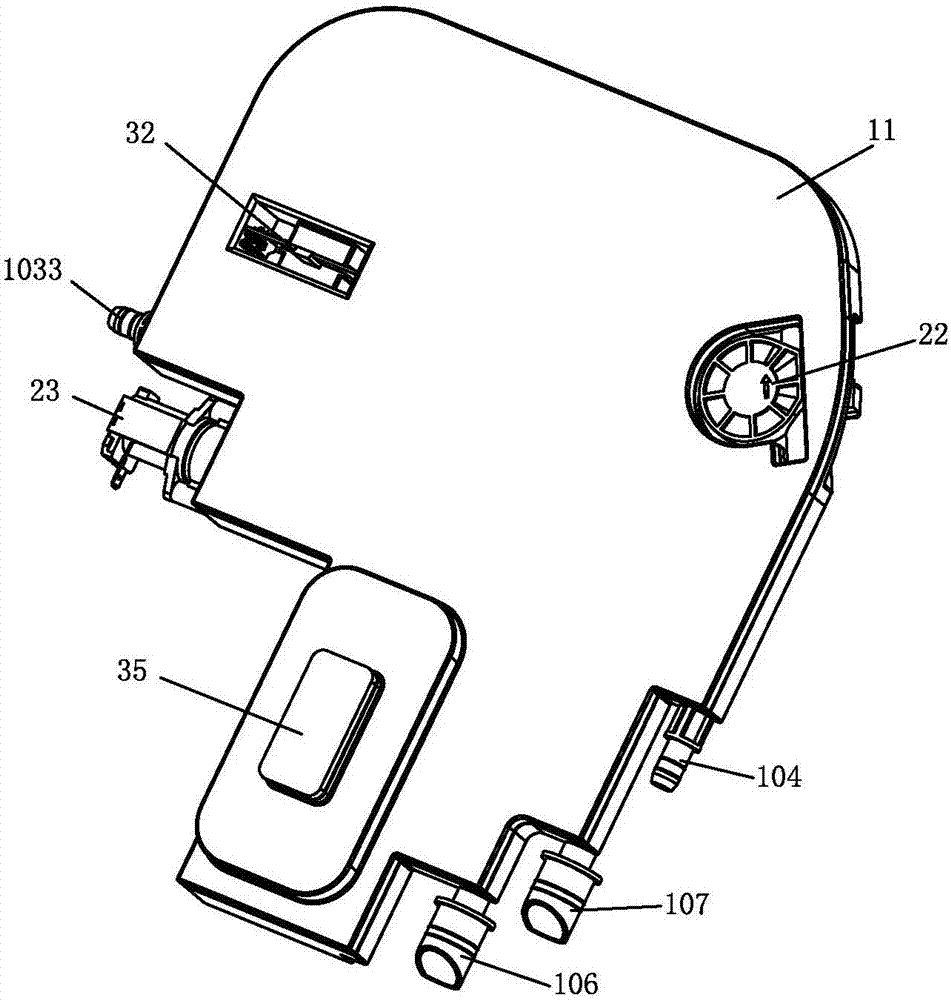

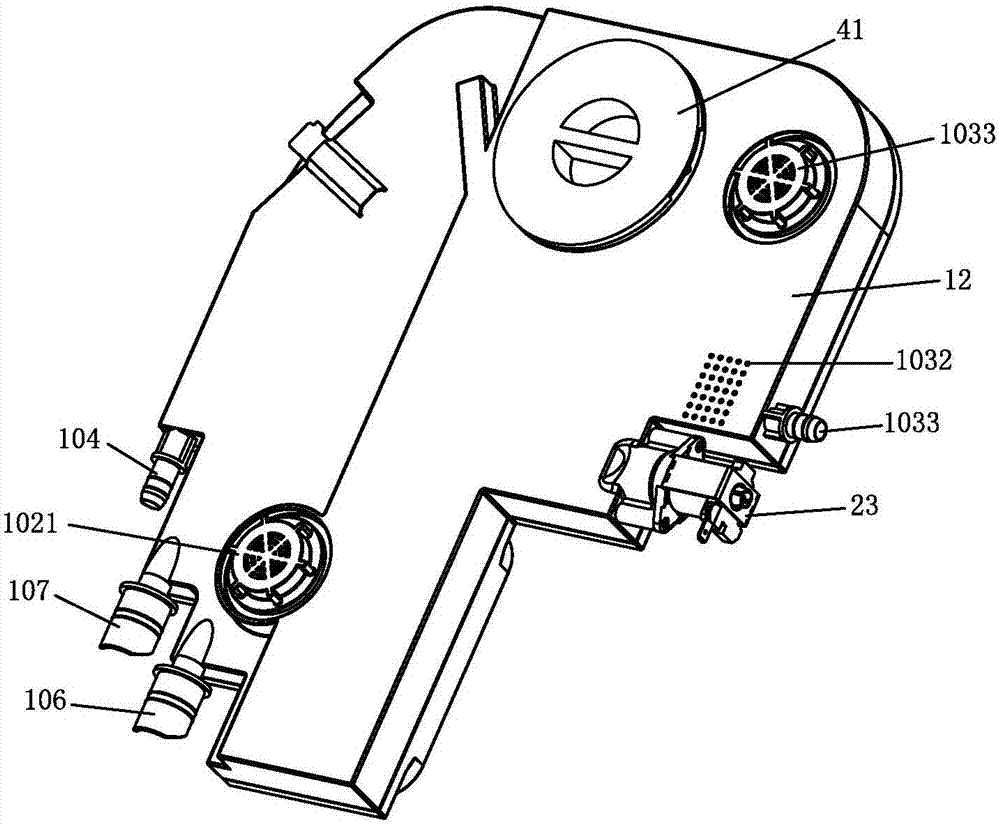

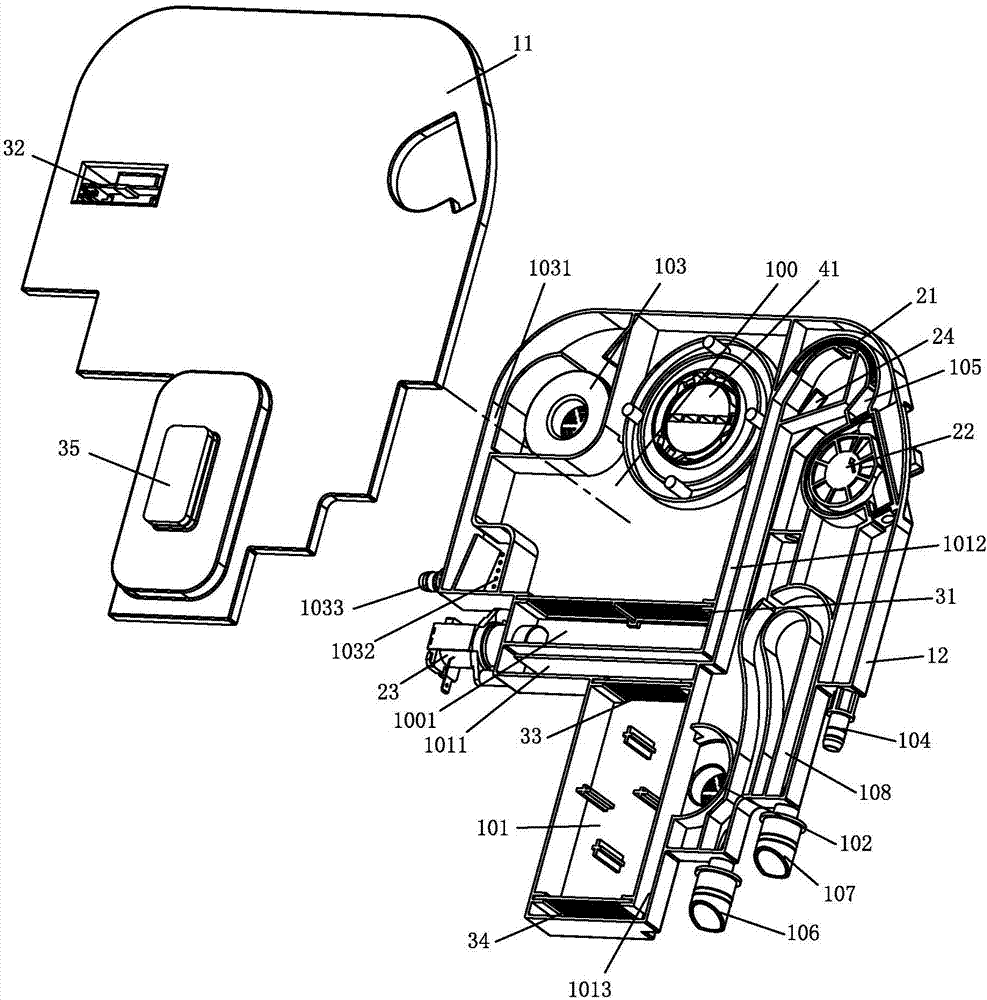

Respirator and softener assembly for dish washing machine

PendingCN106963318ASolve the problem of too small to install a water softenerSave spaceTableware washing/rinsing machine detailsSoftened waterEngineering

The invention relates to a respirator and softener assembly for a dish washing machine. The assembly comprises a body composed of an upper respirator and softener piece and a lower respirator and softener, a salt cavity and a resin cavity are formed in the body and adjacent to each other in a spaced mode, a water inlet device interface is arranged at the position, corresponding to a softened water outlet end of the resin cavity, on the body, and a respirator interface is arranged at the position, corresponding to the salt cavity, on the body. By means of the innovated design, the respirator, the water inlet device and a water softener are integrated to form the respirator and softener assembly, space is greatly saved, the respirator and softener assembly can be vertically installed in the dish washing machine, and the problem that the bottom spaces of a water tank dish washing machine, a table type dish washing machine, a drawer dish washing machine, a small dish washing machine and the like are small and accordingly water softeners cannot be installed is solved.

Owner:中山市吉相电器有限公司

Aqueous acrylic modified epoxy ester primer-topcoat integrated anticorrosive baking finish

InactiveCN101864236AHigh hardnessHigh mechanical strengthAnti-corrosive paintsEpoxyWater dispersible

The invention discloses aqueous acrylic modified epoxy ester primer-topcoat integrated anticorrosive baking finish. The baking finish consists of the following components in part by weight: 45 to 65 parts of aqueous acrylic modified epoxy ester resin, 2 to 20 parts of amino resin, 5 to 35 parts of pigment, 0 to 15 parts of filler, 1 to 3 parts of water dispersible dryer, 0.1 to 0.55 part of pH regulator, 5 to 15 parts of softened water, 0.2 to 0.4 part of dispersant, 0.3 to 0.5 part of wetting agent, 0.15 to 0.25 part of flatting agent, 0.3 to 0.5 part of antifoaming agent, and 0.2 to 0.3 part of preservative and mildew preventive. Without organic solvent, the baking finish is safe, energy-saving and free from pollution; the pencil hardness reaches 2H, the coating performance is stable, the film-coating mechanical strength is high, the positive and negative impact resistance can reach 5Kg.cm, and the flexibility can reach 1mm; the baking finish can integrate antirust and anticorrosive functions, can be used as primer or topcoat, reduces the construction process, is simple and quick to operate, can be sprayed or dip-coated, and can be quickly cured; a coated film does not become yellow; and the baking finish meets the development direction of aqueous anticorrosive paint.

Owner:HUNAN XIANGJIANG PAINT GRP

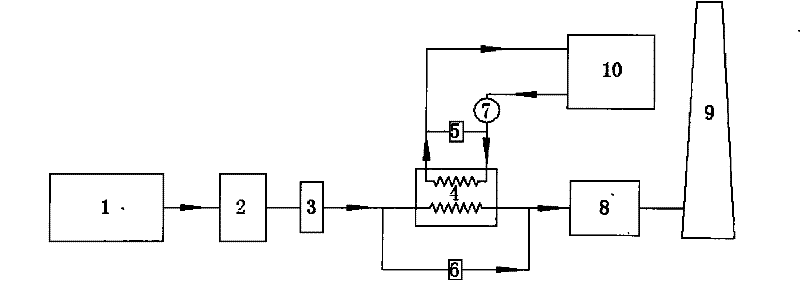

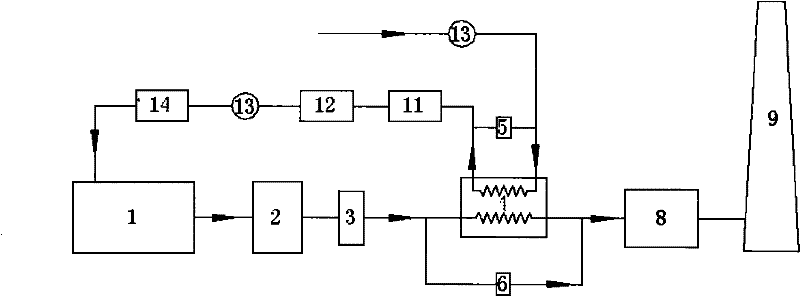

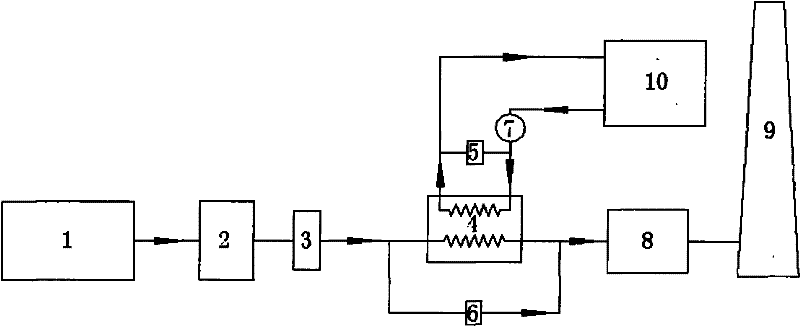

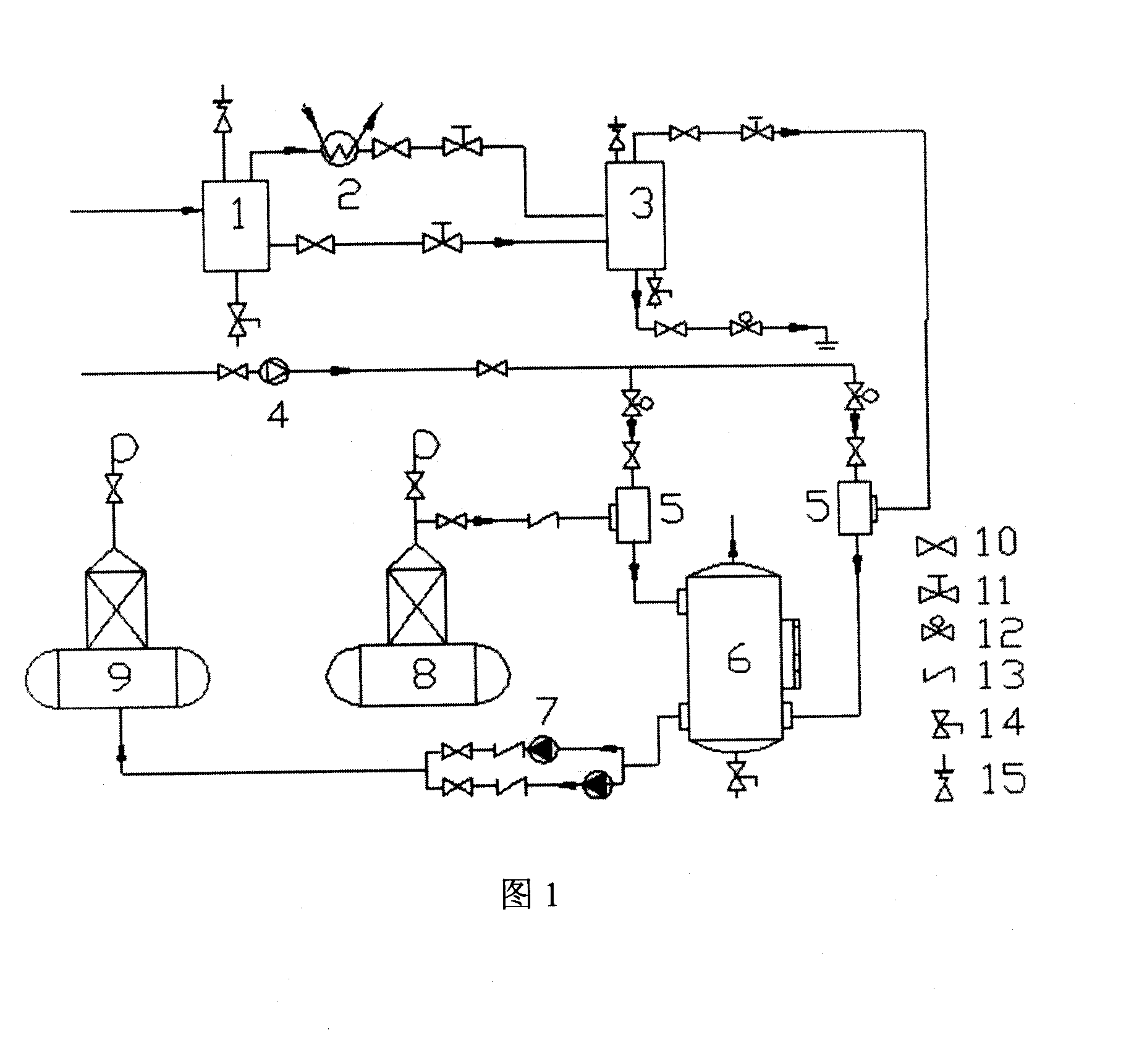

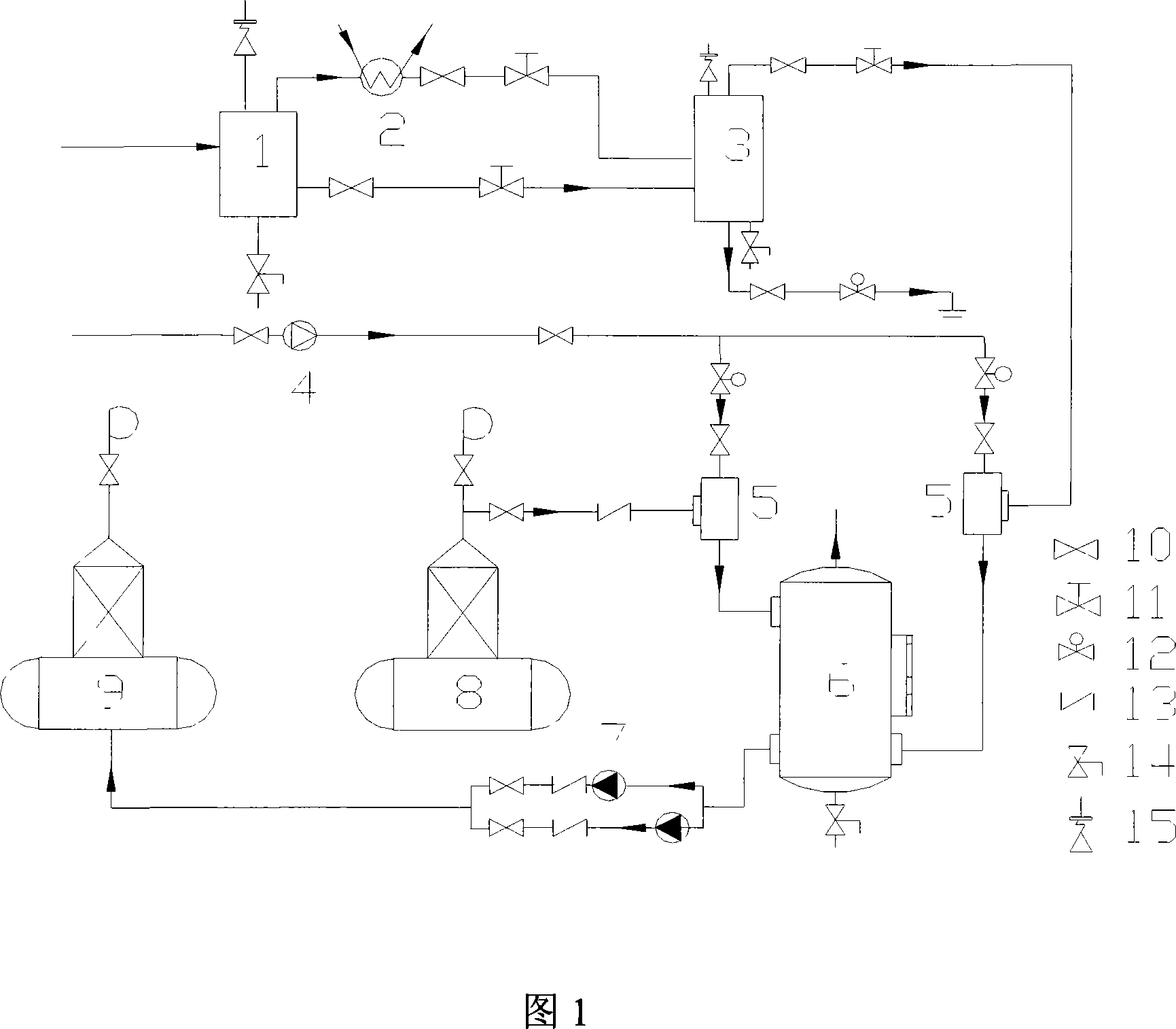

Method for recovery and utilization of waste heat from low temperature flue gas

InactiveCN102269401AReduce heatIncreasing energy efficiencyHot-water central heatingThermal energyBoiler feedwater pump

The invention discloses a method for recovering and utilizing waste heat from low-temperature flue gas. An air-water heat exchanger (4) is connected in series or in parallel in the flue at the rear of the induced draft fan or booster fan (3) of the existing boiler or kiln (1). The inlet port of the hot side of the air-water heat exchanger is connected with the induced draft fan or booster fan (3), the outlet port of the hot side is connected with the desulfurization absorption tower (8) or the chimney (9), and the inlet port of the cold side is circulated with the heat user The outlet pipe or condensate pipe of the water or boiler softened water system is connected, the cold side outlet is connected with the hot user circulating water supply or the boiler feed water pump, and a waterway is connected between the hot side outlet pipe and the cold side inlet pipe of the air-water heat exchanger A bypass pipe, and a waterway bypass regulating valve (5) is arranged on the pipe; a flue gas bypass pipe between the induced draft fan or booster fan and the desulfurization absorption tower (8), and a flue gas bypass pipe A flue bypass regulating valve (6) is arranged on it. By connecting a gas-water heat exchanger in series or in parallel in the flue behind the induced draft fan of the boiler or kiln, the purpose of saving heat energy can be achieved.

Owner:LUOYANG BLUE SEA INDAL

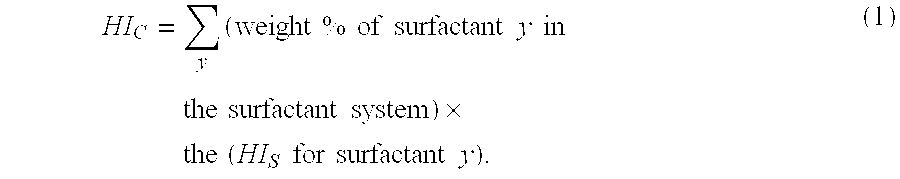

Compositions for cleaning with softened water

InactiveUS20050256020A1Material nanotechnologyNon-surface-active detergent compositionsSoftened waterSURFACTANT BLEND

Owner:THE PROCTER & GAMBLE COMPANY

Seawater desalting method

ActiveCN102849887APrevent scalingAvoid pollutionGeneral water supply conservationSeawater treatmentSoftened waterDistillation

The invention belongs to the technical field of desalting of seawater, and relates to a seawater desalting method. The seawater desalting method comprises the following steps of: charging filtering water which is obtained by the pretreatment of seawater into a heat exchanger of a heat discharge section of a seawater desalting system for condensing the steam and recovering the heat energy of the heat discharge section to obtain the heat-exchanged warm seawater with higher temperature; transporting the warm seawater into an ultrafiltration device by a low-pressure pump, transporting the ultrafiltration produced water into a nanofiltration device by a high-pressure device, selectively removing the scaled ions in seawater to obtain nanofiltration softened water, and inputting into a reverse osmosis device through the high-pressure pump to obtain reverse osmosis produced water and reverse osmosis concentrated water; recovering the energy of the reverse osmosis concentrated water to be directly taken as the charged water of a heat recovering section of an MED (multi effect distillation) device or an MSF (multi stage flash) device; mixing the desalting produced water and the reverse osmosis produced water through the MED device or the MSF device to be taken as drinking water; and recovering the energy of nanofiltration concentrated water, and mixing with the concentrated water to be discharged or comprehensively utilized. The method is simple in technology, low in energy consumption, high in desalting efficiency, good in effect, simple in device structure, reliable in principle, stable in production process, and environment-friendly.

Owner:OCEAN UNIV OF CHINA

Preparation method of aroma rapeseed oil

ActiveCN102936531AStrong fragranceRetain nutrientsFatty-oils/fats refiningFatty-oils/fats productionScreening proceduresAdditive ingredient

The invention discloses a preparation method of aroma rapeseed oil, wherein the preparation method comprises the following main procedures: selecting rapeseeds, removing impurities, and removing macadam and clods, wherein the impurity content is smaller than 0.1% and the rapeseed content in the screen underflow is smaller than 0.5% after the screening procedure; frying the rapeseeds at 140-145 DEG C; squeezing the rapeseeds through a squeezer and controlling the thickness of an oil cake to be smaller than 1.5mm to obtain crude oil; primarily deslagging the squeezed crude oil through an oil clarifying box, and pumping the crude oil in a blade filter to be filtered, wherein the insoluble impurity in the filtered crude oil is smaller than 0.2%; obtaining clean crude oil, controlling the operation temperature at 65-70 DEG C and controlling the water temperature at 70-75 DEG C to perform hydration degumming; washing the clean crude oil twice by virtue of softened water, drying and dewatering at vapor pressure of 4-5 Mpa; stirring the clean crude oil at a rotating speed of 30 r / min (revolutions per minute), and cooling until the oil temperature is lower than 80 DEG C; and filtering the clean crude oil in a frame filter to obtain the aroma rapeseed oil. The prepared rapeseed oil generates full-bodied fragrance, and the nutrition ingredients and physiological active ingredients in the rapeseed oil are kept to the maximum.

Owner:YUNNAN ZHENWEI GREASE

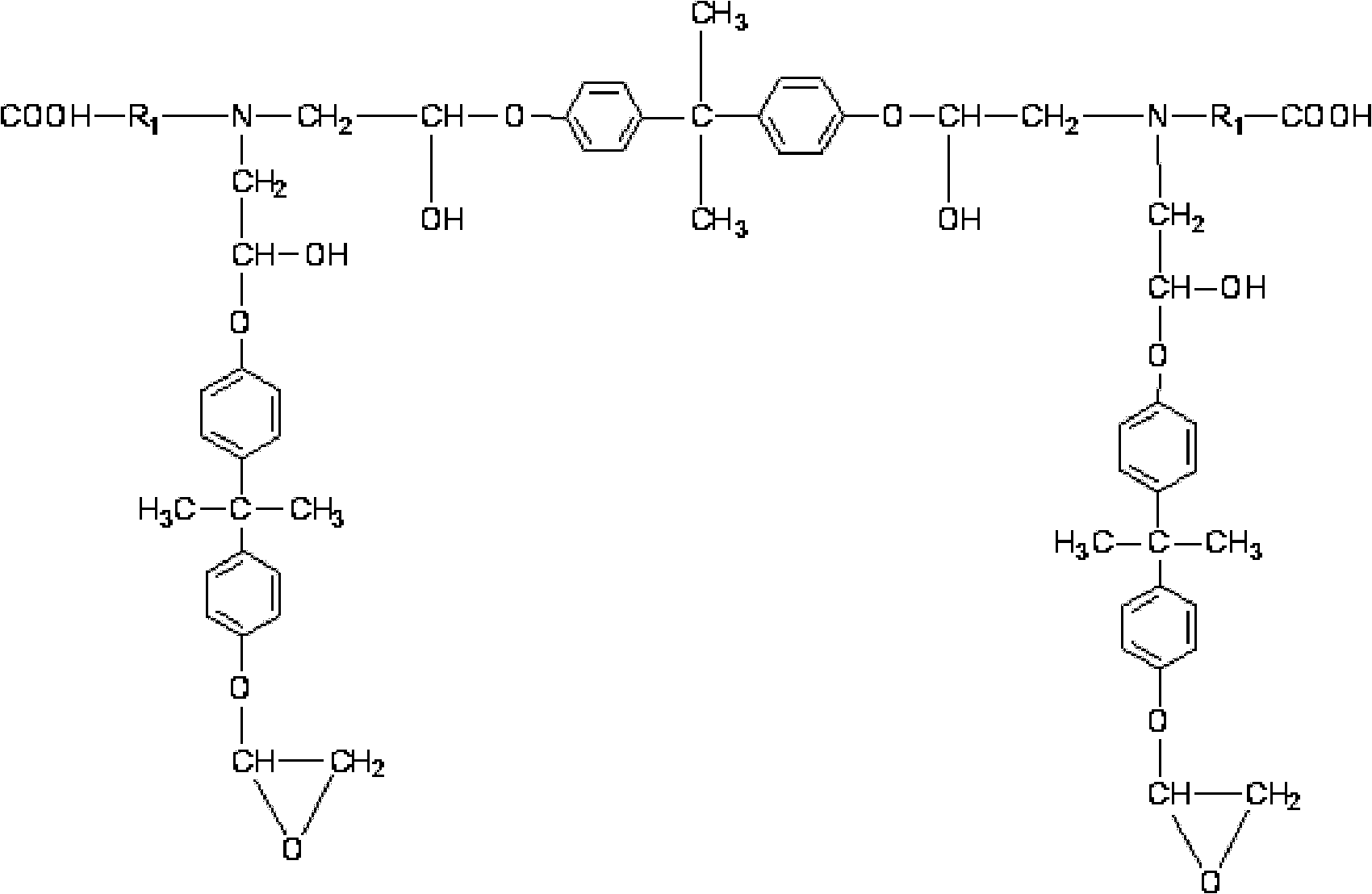

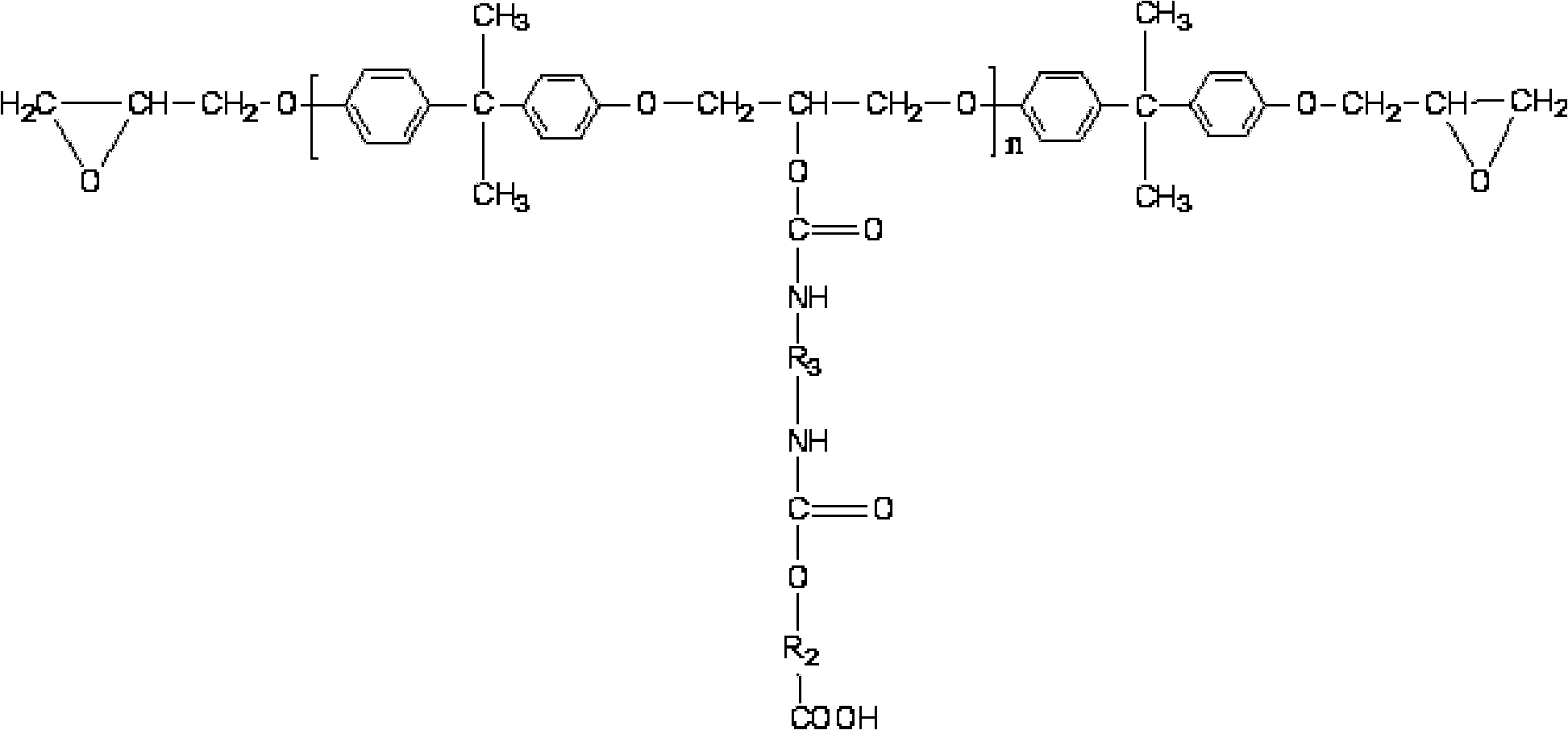

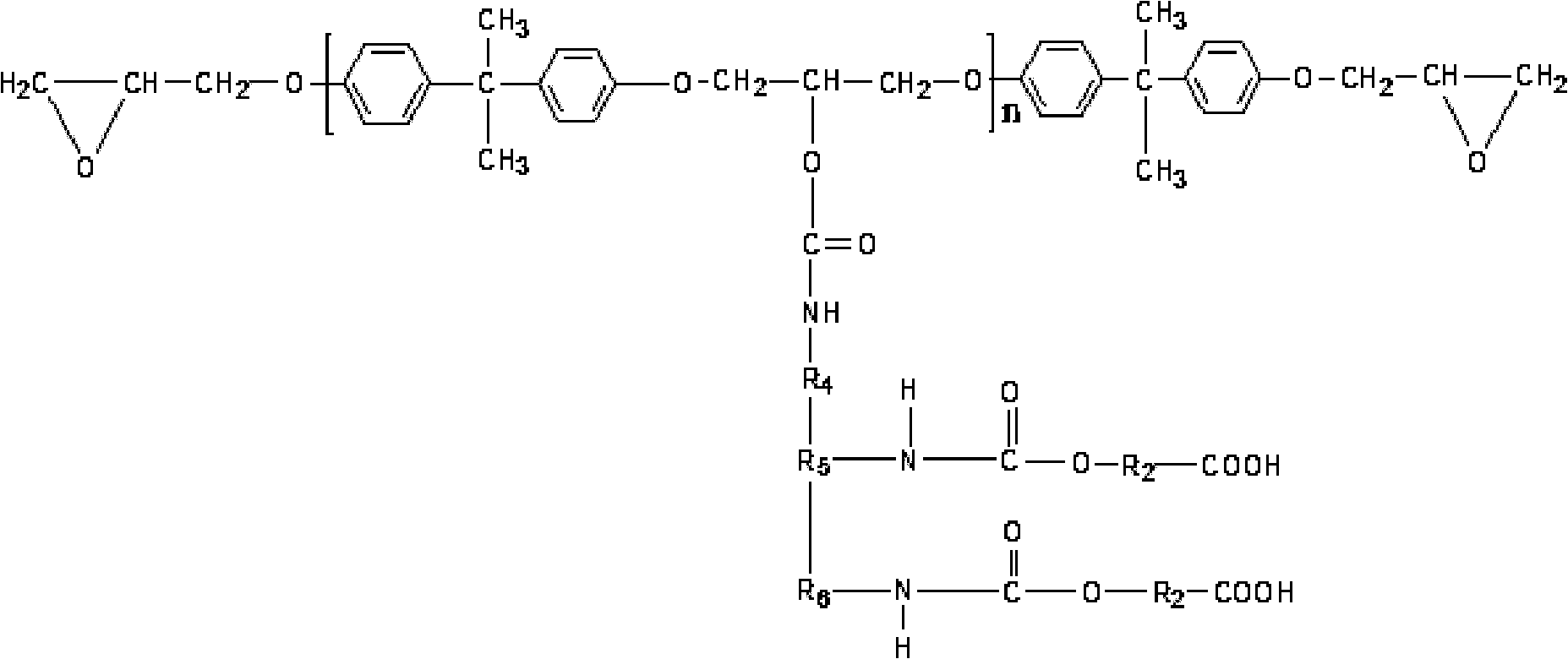

Antirust emulsion of self-crosslinked interpenetrating net polymer and its production

InactiveCN101029115AImprove stabilityExcellent calcium ion stabilityAnti-corrosive paintsCross-linkEpoxy

A self-cross-linked interpenetrating network polymer antirust emulsion and its production are disclosed. The emulsion consists of epoxy resin 2-50 proportion, unsaturated hydrocarbon monomer mixture 20-80 proportion, olefine hydroxyl-acid 0.5-8 proportion, functional organic silane 0.5-25 proportion, functional organic fluoride monomer 0.5-20 proportion, cross-linking agent 0.1-1.2 proportion, neutralizing agent 0.5-1.5 proportion, emulsifying agent 1-8 proportion, chain transfer agent 0.05-0.6 proportion, pH regulator 0.2-0.6 proportion, initiating agent 0.3-0.8 proportion, softened water 90-150 proportion and cross-linking curing agent 0.2-5 proportion. The process is carried out by dosing in the first, second and third reactors, mixing in the third reactor and discharging to obtain final product. It has excellent weather and water resistances, better anti-corrosive performance and storage stability.

Owner:HARBIN INST OF TECH

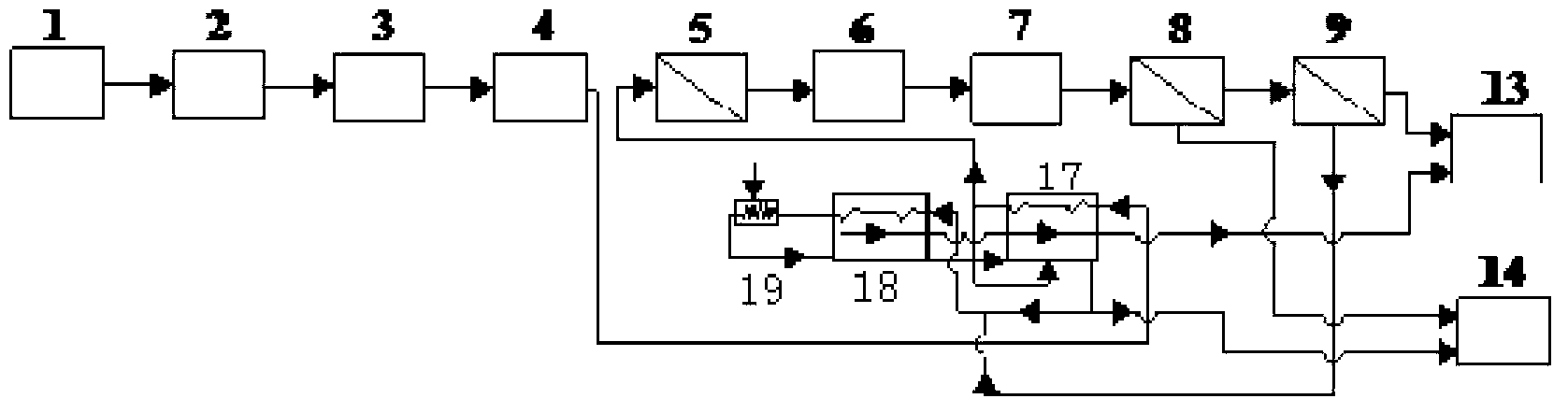

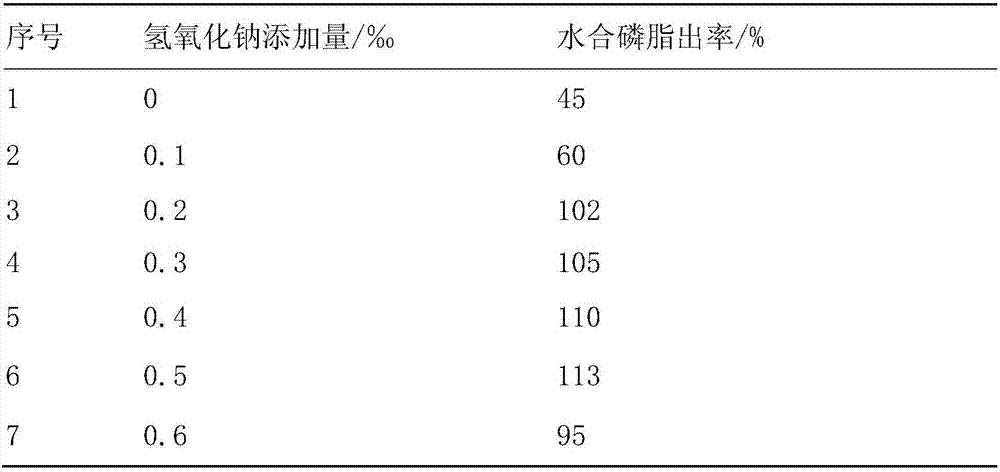

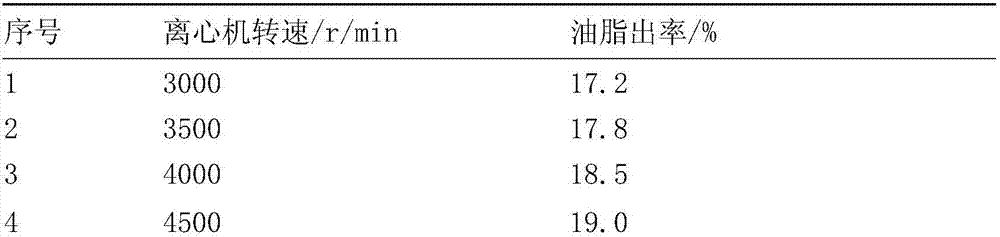

Method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with method

ActiveCN107325125AGood dispersionSmall degree of processingGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsOrganic solventSoftened water

The invention discloses a method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with the method, relates to the field of a treatment method of the soybean oil sediment and aims to solve the problems that with adoption of the conventional soybean phospholipid refining method, organic solvent consumption is high and many residues are produced and are harmful to a human body or the prepared soybean phospholipid is strong in flavor, dark in color and low in quality. According to the method, softened water is added to the soybean oil sediment, then the soybean oil sediment is left to stand for chromatography, heating is performed after chromatography for centrifugal separation, and hydrated phospholipid is obtained. Acetone insoluble substances in the prepared hydrated phospholipid can reach 90% or higher, the phospholipid content is higher, and organic matter residues are avoided.

Owner:山东中阳生物科技有限公司

Ordinary temp. parkerizing liquid

InactiveCN1401820AFast phosphatingFast combinationMetallic material coating processesSoftened waterManganese

An ordinary-temp phosphating liquid for the phosphate treatment of surface of iron and steel contains phosphoric acid (2-4 wt.%), zinc oxide (0.4-0.6 wt.%), zinc nitrate (0.5-1.5 wt.%), nickel nitrate (3-5 wt.%), manganese nitrate (2-4 wt.%), sodium borofluorate (0.2-1 wt.%), sodium chlorate (2-3 wt.%), citric acid (0.5-2 wt.%), and softened water (the rest). Its advantages are high stability, long film-forming time, and high film strength and resistance to corrosion.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

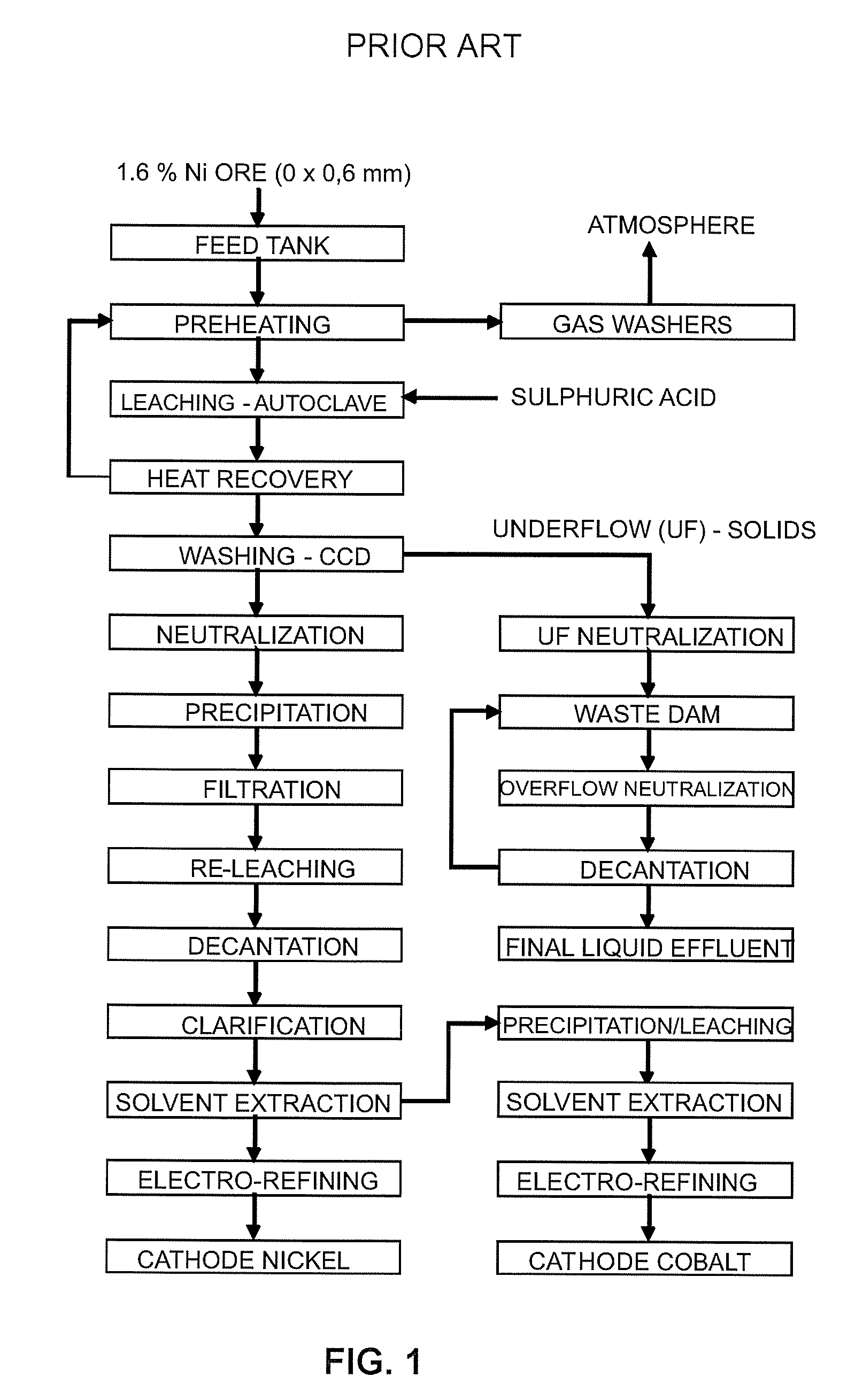

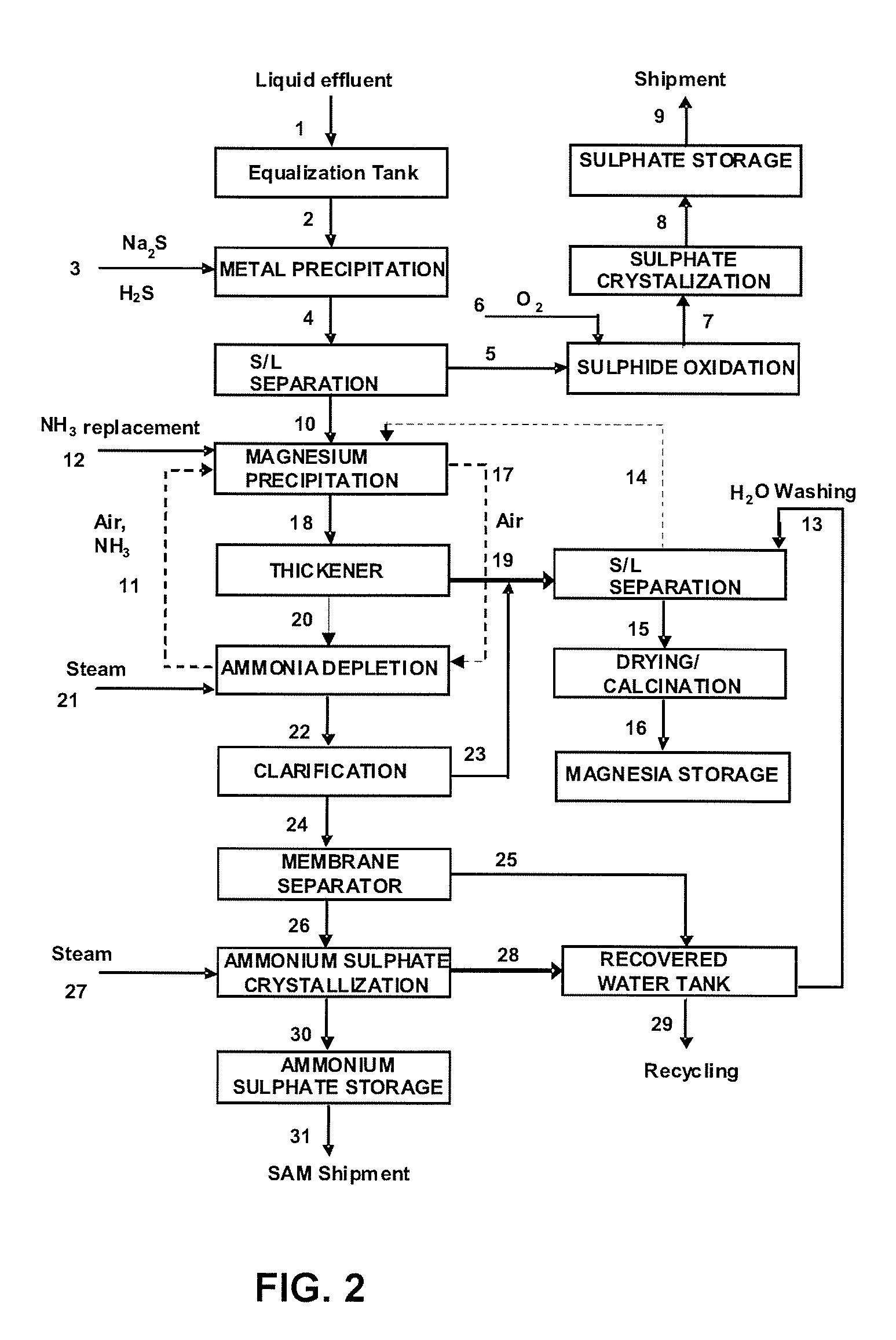

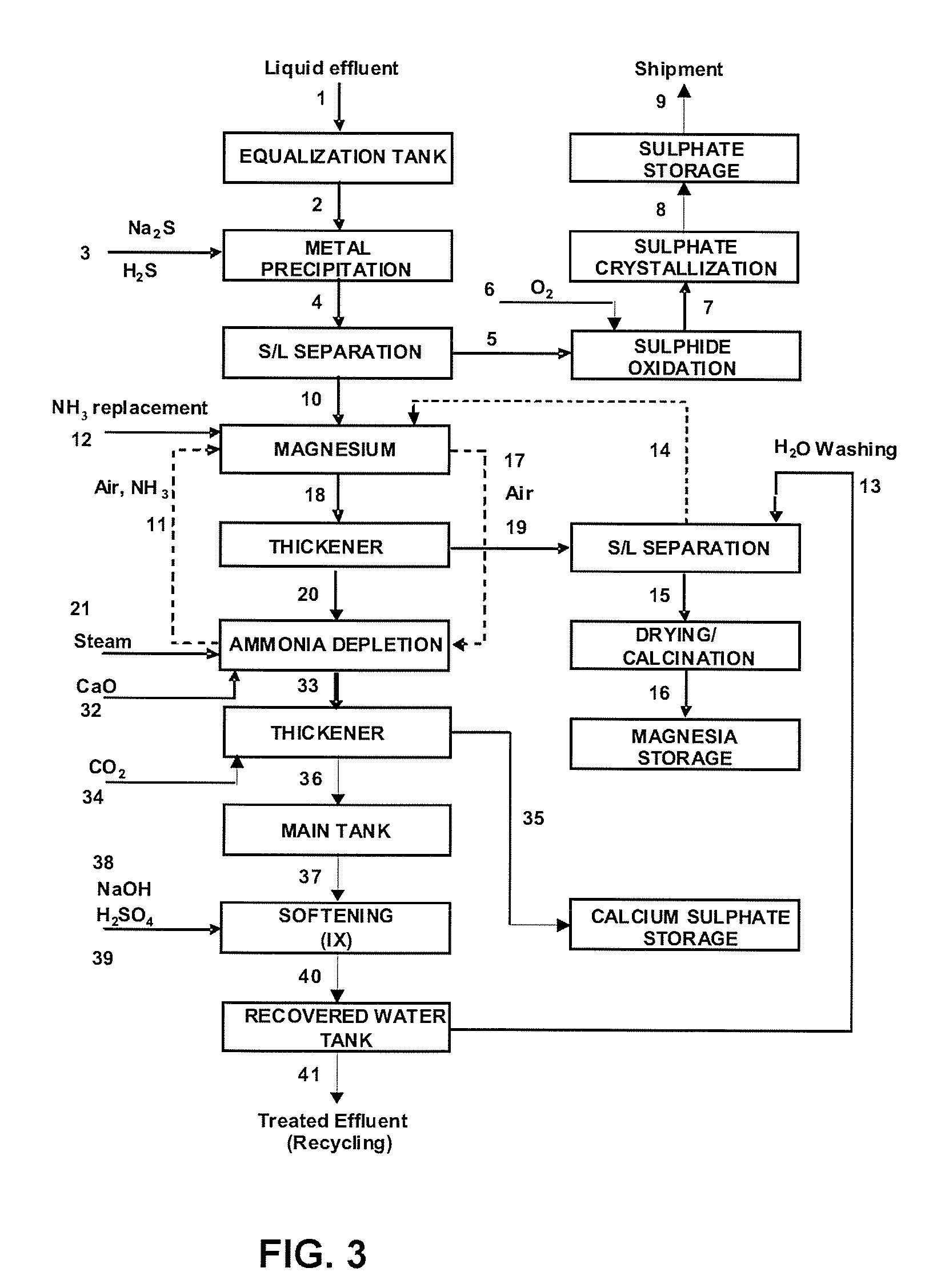

Liquid and solid effluent treatment process

ActiveUS20090180945A1Reduce consumptionReduce environmental impactCobalt ammonia complexesNitrogen compoundsAmmonium sulfateChemistry

A process for recovering metals such as Ni, Co, Mn, Cu, Zn, among others, through precipitation as sulphides, enabling recovery of magnesium in the form of hydroxide, carbonate and oxide and providing recovery of sulphate as gypsum and ammonium sulphate. Liquid phase, after full treatment, comprises recovered water with a quality proper for total reuse in industrial process.This process of liquid and solid effluent treatment is provided with flexibility to process several types of effluents presenting wide variations in their chemical composition. The main steps of this process are: (1) equalization of liquid effluent, (2) precipitation of metals as sulphides, (3) oxidation of metallic sulphides and crystallization as metallic sulphates, (4) precipitation of magnesium as hydroxide and calcination thereof into magnesium oxide (5) recovery of ammonia, (6) preconcentration of the remaining saline solution, (7) evaporation / crystallization of ammonium sulphate, (8) storage of recovered water, (9) partial or total precipitation of sulphate contained in the effluent with quicklime, (10) segregated storage of gypsum and gypsum-magnesium mixture, (11) softening of the remaining solution and (12) storage of softening water.

Owner:VALE CANADA

Surface treating agent and surface treating process of glass fiber filter cloth

ActiveCN102776777AUniform surface colorHigh folding resistanceFibre treatmentDry-cleaning apparatus for textilesGlass fiberPolymer science

The invention relates to a surface treating agent and a surface treating process of a piece of glass fiber filter cloth, belonging to the technical field of the surface treating agent of the glass fiber. The surface treating agent disclosed by the invention comprises 8-15% of PTFE (Polytetrafluoroethylene) dispersing agent, 5-10% of emulsion type high-temperature softening agent, 1-2% of inorganic antistatic agent, 0.5-1% of penetrating agent, 1-2% of silane coupling agent, 0.5-1% of fluorocarbon surfactant and the balance of softened water. The glass fiber filter cloth produced after the treatment of the surface treating agent solves the problems that the corrosion resistance is poor and the air permeability is large in the prior art, and has the advantages that the surface colors are uniform, the flexibility is good, the folding number is large, the air permeability is moderate, and the service life is long.

Owner:SICHUAN FIBERGLASS GRP

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

Water treatment system and method

InactiveUS20060157422A1Sludge treatmentLiquid separation by electricityWater treatment systemWater source

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

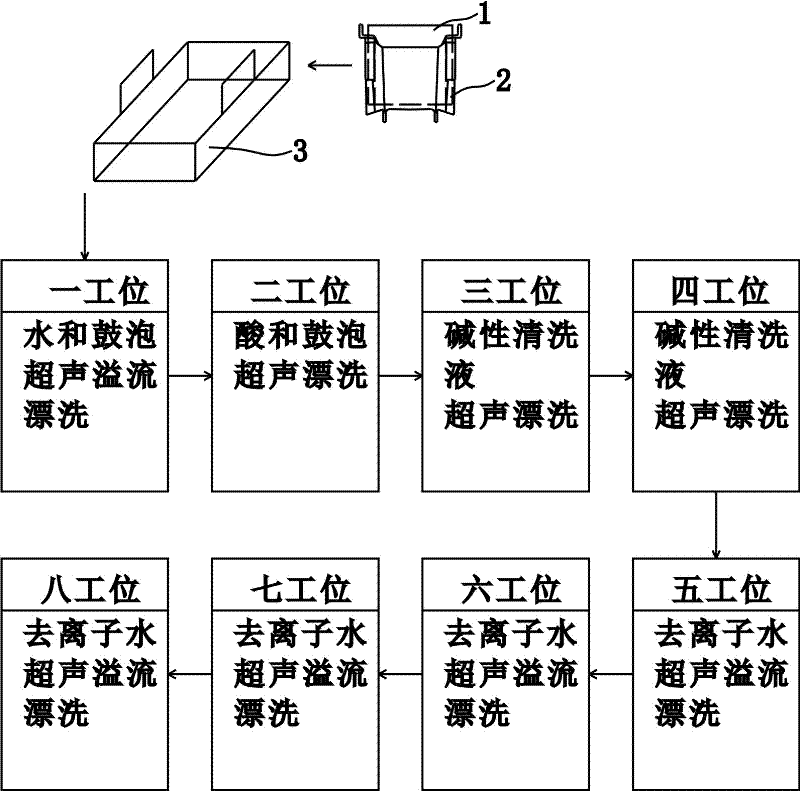

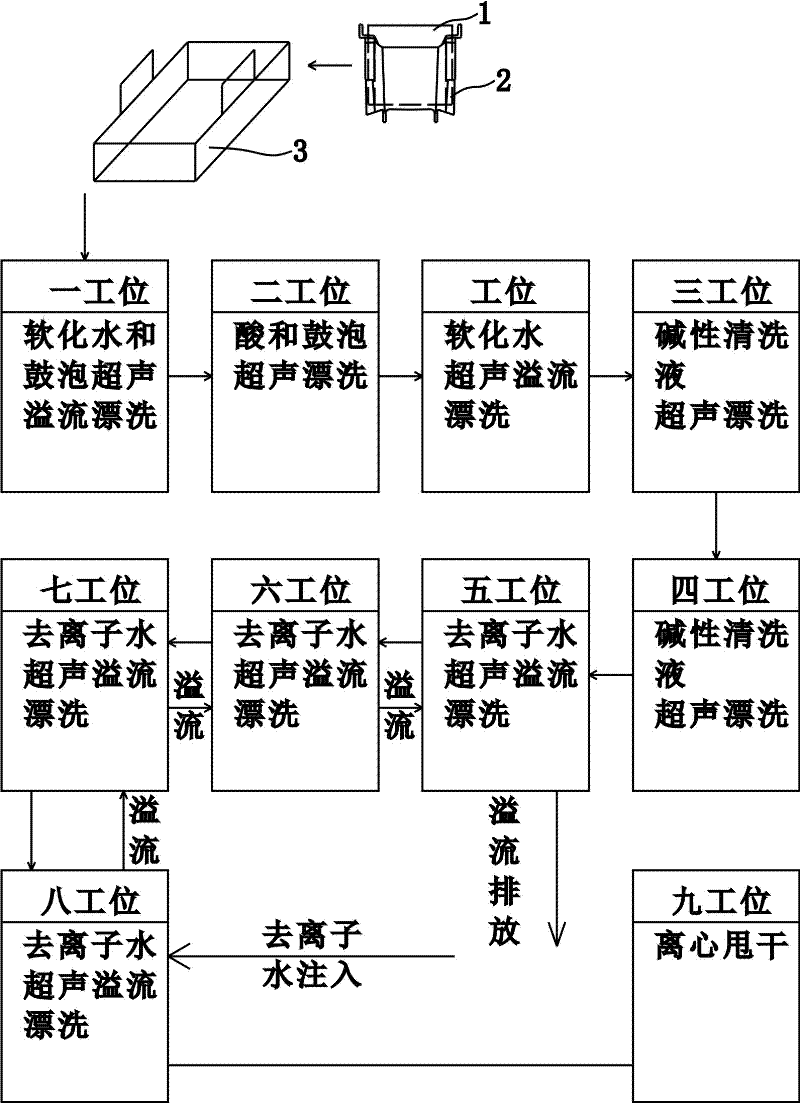

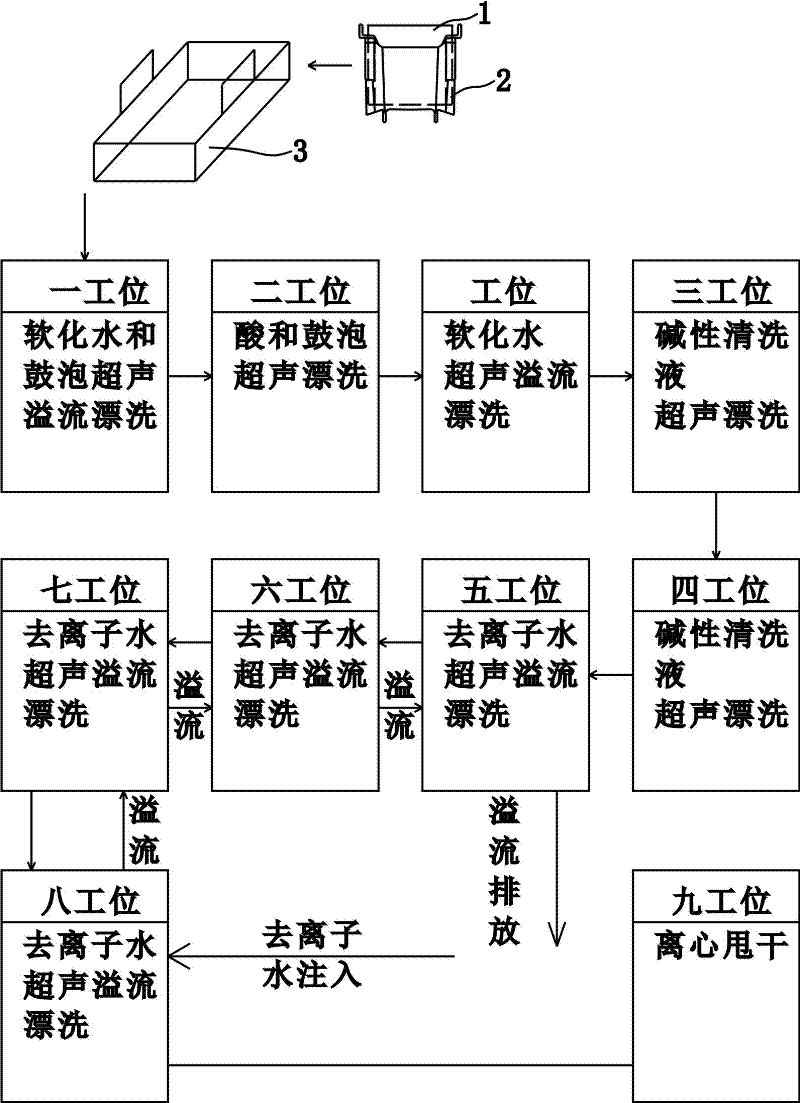

Cut/ground silicon wafer surface cleaning method

InactiveCN102412172ASolving and overcoming easy-to-produceAddress and overcome reactivitySemiconductor/solid-state device manufacturingCleaning using liquidsSurface cleaningSoftened water

The invention discloses a cut / ground silicon wafer surface cleaning method. A silicon wafer and a silicon wafer carrier are sequentially immersed into the following stations and cleaned in corresponding processes: ultrasonic overflow rinsing in a first station cleaning tank with softened water and bubbles and the like. The cut / ground silicon wafer surface cleaning method overcomes the problem of easy acid-alkali neutralization reaction, so that the PH value and concentration of the alkaline cleaner of a third station and a fourth station can be kept constant, and thereby the dirt-removing capability of the alkaline cleaner can be persistently effective. The cut / ground silicon wafers cleaned by the method have high surface cleanliness, good repeatability and a consistent color; the oxidation phenomena of mottling, bluing and blacking are prevented, and the acceptance rate of the cleaned silicon wafers is high; meanwhile, the cleaner does not need to be added in the effective period of cleaning capacity specified by the process, the cut / ground silicon wafer surface cleaning method is easy to operate, however, the effective service period of the cleaner is doubled, and the cleaning cost is greatly reduced; and the cleaning quality and the economic benefit are remarkably increased.

Owner:沈利军

Nanometer acrylic acid microemulsion, water-thinned heat reflecting and isolating paint and their production process

InactiveCN1361186AWill not polluteImprove densification performanceFireproof paintsOrganic solventEmulsion

The present invention is one kind of nano acrylic acid microemulsion, water-thinned heart reflecting and isolating paint with the nano acrylic acid microemulsion and their prodcution process. The present invention aims at solving the technological problems of available paint, which contains great amount of organic solvent to pollute environment and has poor heat reflecting and isoalting performance. The water-thinned heat reflecting and isolating paint consists of nano acrlic acid microemulsion, conventional acrylic acid emulsion, pigment, filler, infrared ray reflector, assistant, pH regulator, densifier and softened water. The paint contains no organic solvent and has excellent heat reflecting and isolating performance.

Owner:耿世斋

Production technology of double-faced cotton fabric

ActiveCN101713153AExcellent water and oil repellencyDoes not affect the positive effectDyeing processVegetal fibresSoftened waterAdhesive

The invention relates to a production technology of a double-faced cotton fabric. The production technology comprises the following steps: 1. drying the dyed or whitened double-faced cotton fabric to prepare grey cloth for standby; 2. mixing 10wt% of adhesive WSF, 3wt% of water and oil repellent AFF300 %, 1.76wt% of thickener FN and 85.24wt% of softened water evenly to prepare printing paste; 3. coating the printing paste on one side of the grey cloth, sending to a printing machine to perform coating layer printing treatment, sending to a dryer for drying; 4. sending the dried grey cloth to a tentering and forming machine for curing treatment; and 5. adding 30g of hydrophilc agent RWS per 1L of water in the groove of the stentering forming machine, after the curing treatment, and sending the grey cloth to the tentering and forming machine again to perform tentering and forming and hydrophilic finishing treatments. The production technology of the invention can be used to ensure that the front of the fabric has interface structure with complimentary geometry and shows good water repellent and oil repellent properties; and the back of the fabric has hydrophilic and moisture transmission performances under the premise of not affecting the properties of the front of the fabric.

Owner:QINGDAO JIFA GROUP

Water treatment system and method

Owner:EVOQUA WATER TECH LLC

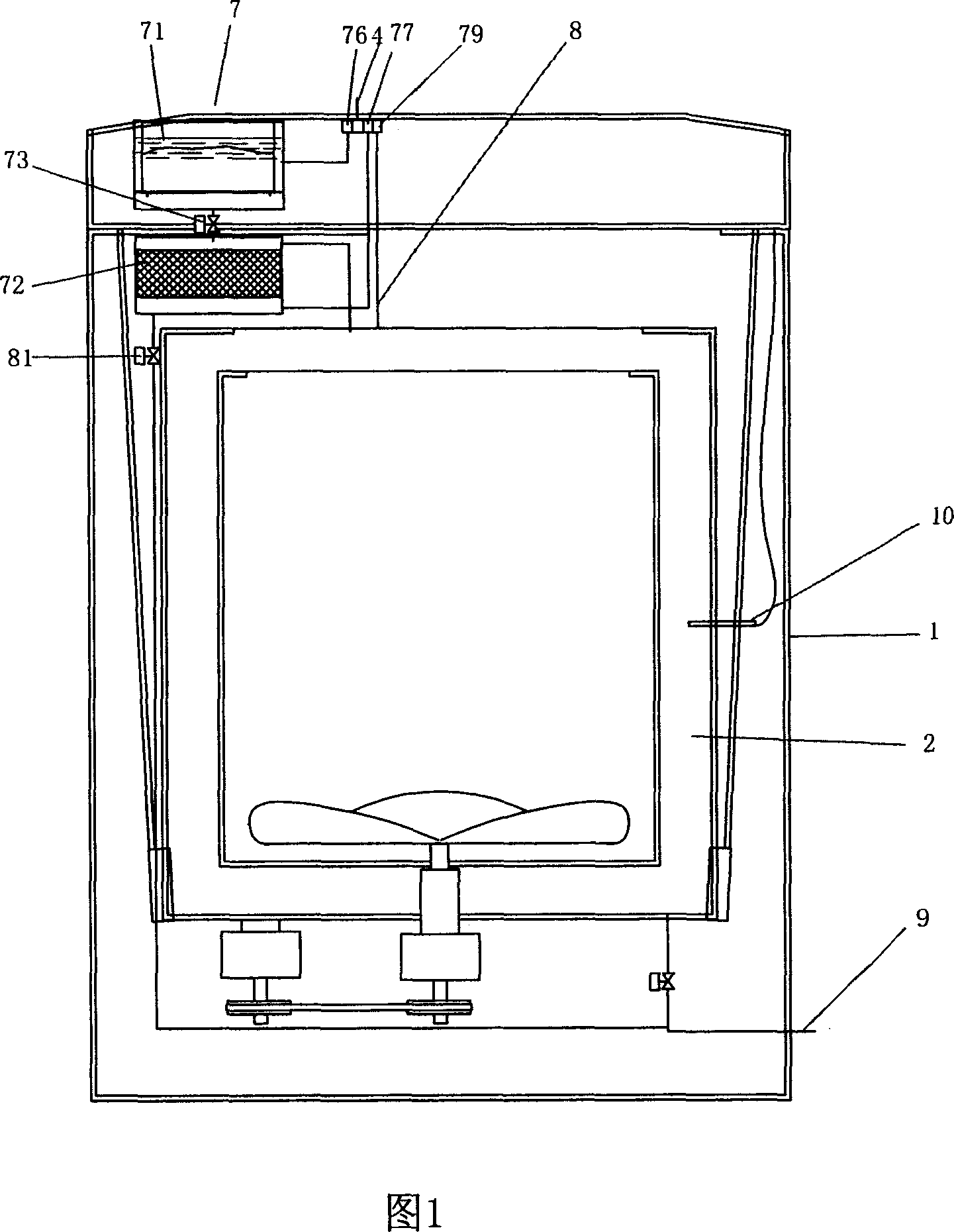

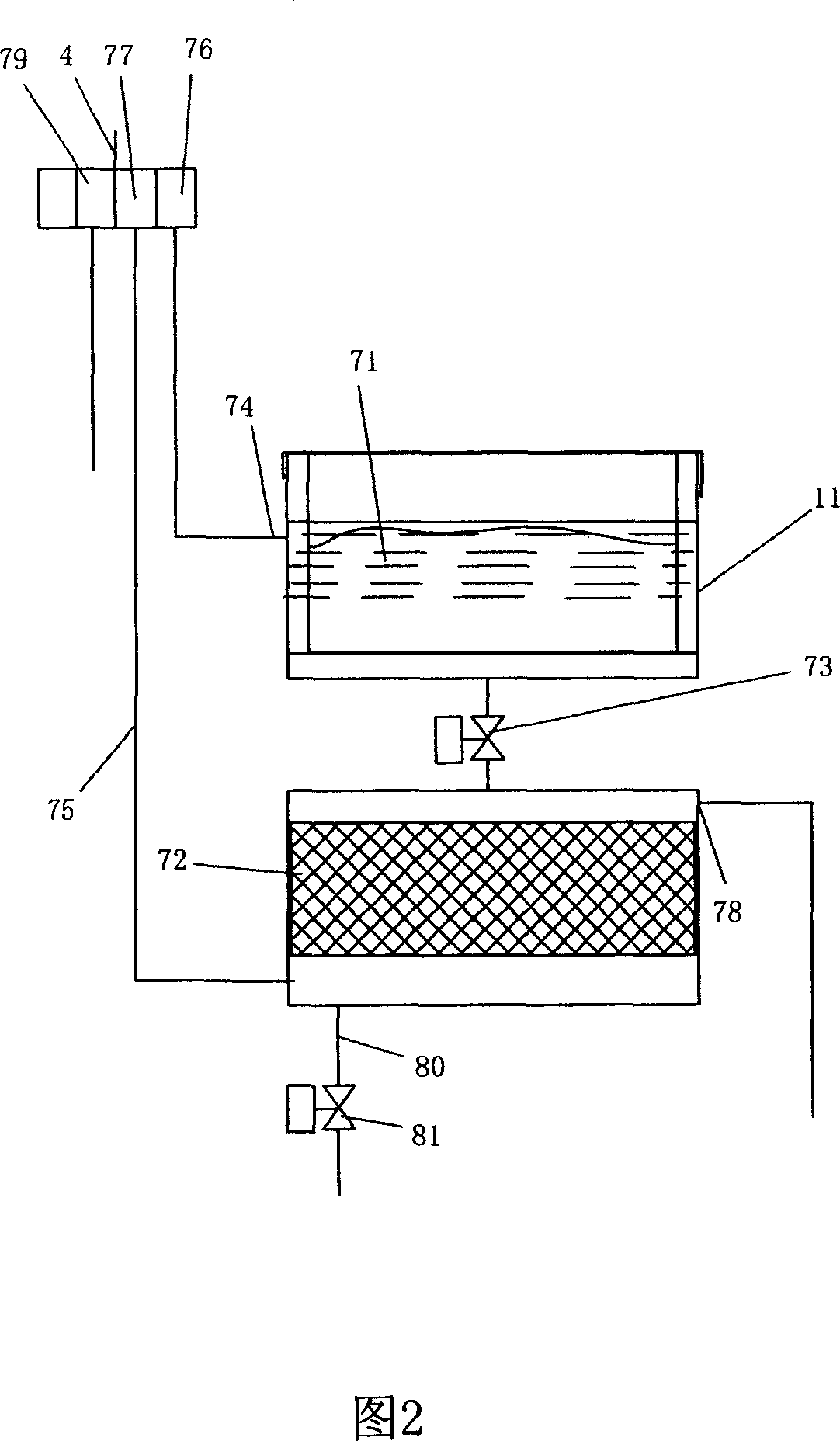

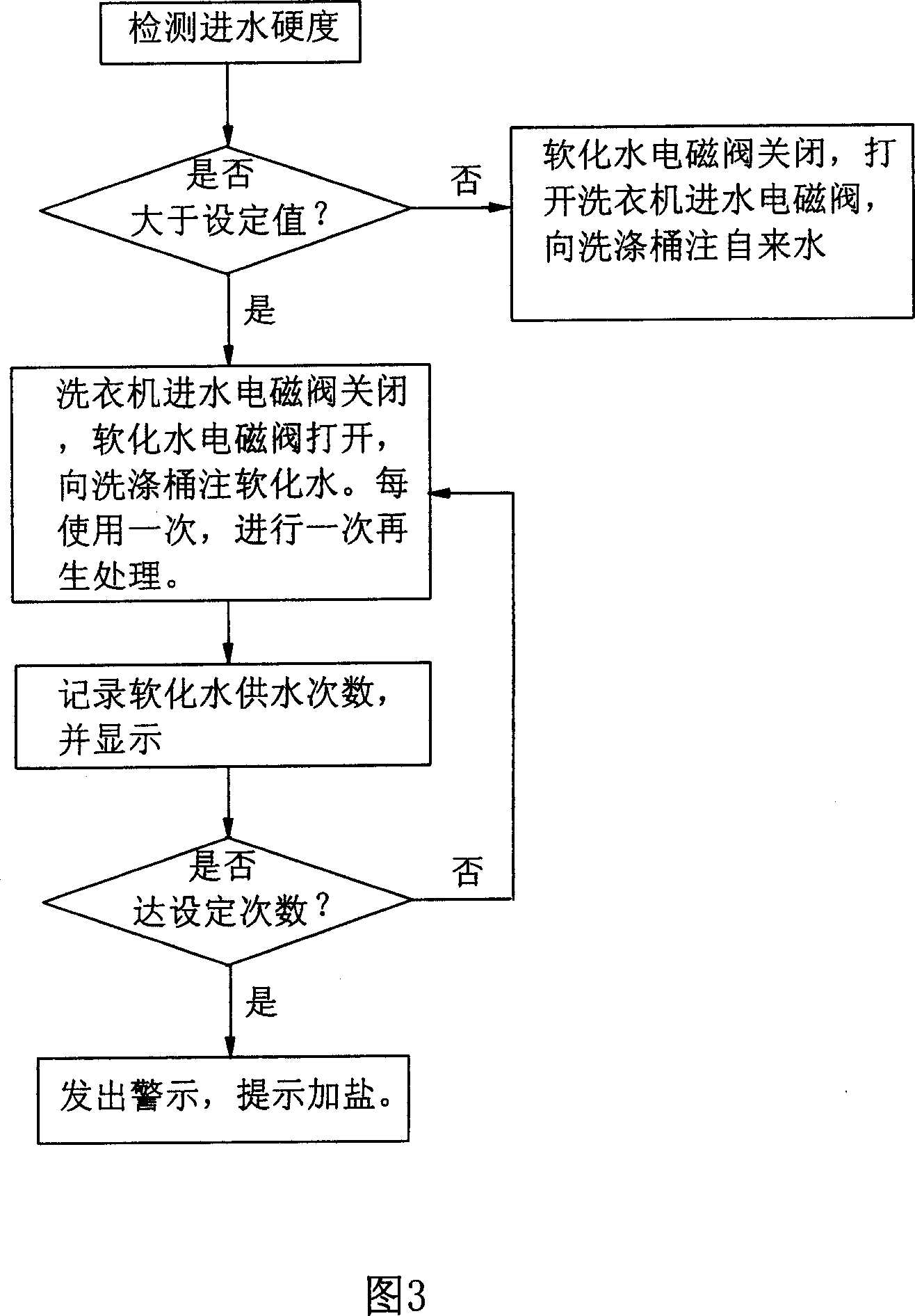

Washer with hardness controller and water hardness controlling method

ActiveCN101029445AAvoid wastingEnsure softening qualityOther washing machinesWater/sewage treatment by ion-exchangeSoftened waterWater quality

A method for controlling water hardness of washer is used for automatic washer with ion-exchange resin water softener and controller. The process is carried out by inspecting water hardness by inspector, controlling softened-water electromagnetic valve, softened-water discharge electromagnetic valve and water-intake pipe electromagnetic valve turnoff / turn-on, passing running-water into washing drum or passing into washing drum by water softener, ion-exchange resin salt brine reclaim treating, recording treating time by controller, accumulating, displaying, storing, alarming while reaching accumulation end to a certain value, reminding users to add into salt and judging running-water hardness. It saves resources and has better softened water quality.

Owner:HAIER GRP CORP +1

Water borne epoxy intermediate paint

ActiveCN102093805AImprove mechanical propertiesImprove salt spray resistanceEpoxy resin coatingsEpoxyCompound a

The invention discloses water borne epoxy intermediate paint. The intermediate paint comprises a component A and a component B, and the weight ratio of the component A to the component B is between 0.5 and 10, wherein the component A comprises the following ingredients in percentage by weight: 23-55 percent of water borne epoxy resin curing agent, 0.1-1 percent of wetting dispersant, 1-5 percent of antirust pigment, 5-10 percent of tinting pigment, 1-5 percent of filler, 1-2 percent of film forming auxiliary, 0.1-1 percent of defoaming agent, 0.1-0.5 percent of flatting agent, 0.01-0.5 percent of antiseptic, 0.5-2 percent of rust inhibitor, 0.01-0.1 percent of rheology modifier and 36.09-49.9 percent of softened water; and the component B comprises the following ingredients in percentage by weight: 10-30 percent of self-emulsified water borne epoxy resin and 70-90 percent of softened water. By compounding a self-emulsified epoxy resin emulsion and a self-emulsified water borne epoxy resin curing agent, the mechanical performance and the salt mist resistance of the paint can be improved, and the environmentally friendly requirement can be fulfilled.

Owner:武汉海源九天新材料有限公司 +2

Boiler low grade residual heat combined reclamation method and device

InactiveCN101165399ASelf-utilizationAchieving joint recyclingLiquid degasificationFeed-water heatersRecovery methodWater storage tank

This invention relates to a waste heat combined recovery method of power station boiler and its device composition. It mainly recovers the sewage of boiler, the waste heat and cleaning water of the discharged gas from high pressure deaerator. The device includes flash tank, jet type mixed heater, degas water storage tank, frequency converting pump, softening water pump, pipeline and valve. Softened water is used as working medium. It condenses the flash steam and discharged gas from high pressure deaerator through jet type mixed heater. In the degas water storage tank, the air in the discharged gas from high pressure deaerator is removed. The heat water in the water storage tank is transported into the low pressure deaerator through frequency converting pump. Thus, it fulfills the self-using of recovered heat. This invention only brings in softened water from outside and does not change the original thermal system.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Quinoa plant protein beverage and preparation method thereof

InactiveCN105725006AIncrease profitHigh in nutrientsSugar food ingredientsFood ingredient as thickening agentSoftened waterPolydextrose

The invention relates to a quinoa plant protein beverage, relates to a preparation method of the beverage, and belongs to the technical field of food beverages.The quinoa plant protein beverage is prepared from a quinoa product, polydextrose, a stabilizer, a sweetening agent and softened water; the quinoa product is a quinoa concentrated solution and / or quinoa powder and / or a quinoa fermentation solution, and the protein content in the quinoa plant protein beverage is not lower than 1.0 g / 100 g.Multiple modes of combining ultrasonic cleaning, enzymolysis, microwave assisted ultrasonic extraction and hot water extraction are adopted, the raw material utilization ratio and nutrient content of quinoa are effectively increased, and the quality is effectively improved; the food safety of the product is effectively guaranteed.A preserved strain lactobacillus plantarum CGMCC NO.11763 is adopted, the quinoa concentrated solution is partially fermented, the taste of the quinoa plant protein beverage is enriched, the digestion and absorption rate is increased, and probiotic factors are supplemented.

Owner:北京农品堂食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com