Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about How to "High folding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

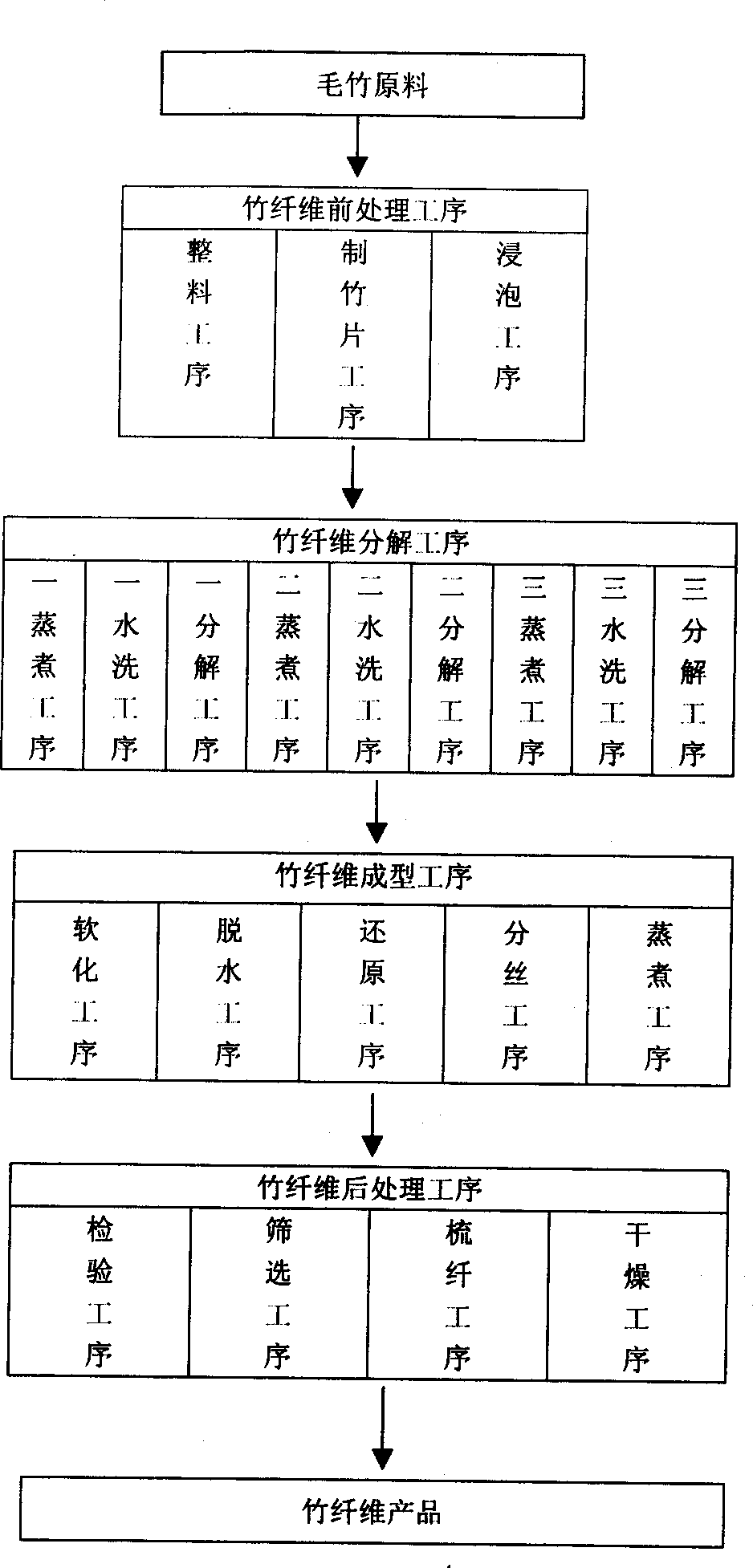

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

Surface sizing solution, and surface sizing solution used sized paper

The invention provides a surface sizing solution used in the papermaking field. The surface sizing solution contains a product and water, the product is obtained after a cross-linking reaction of nano fibrillated cellulose, starch and a cross-linking agent, the nano fibrillated cellulose is single microfibrils of cellulose having a length of 100-2000nm and a diameter of 3-200nm obtained through defibrating cellulose raw materials, wherein bone dry mass parts of the nano fibrillated cellulose, the starch and the cross-linking agent are 0.1-10, 85-99.75 and 0.15-5 respectively. The invention also provides a sized paper made by using the surface sizing solution. The surface sizing surface containing the nano fibrillated cellulose is coated on the surface of paper to realize enforcing and toughening effects in order to effectively improve the flexibility resistance of the sized paper.

Owner:GOLD EAST PAPER JIANGSU

Method for preparing polyurethane surface sizing agent

InactiveCN101768243AImprove adhesionGood film formingWater-repelling agents additionPaper/cardboardEmulsionOrganic solvent

The invention discloses a method for preparing a novel polyurethane surface sizing agent. Diisocyanate and polyglycol are first uniformly blended and then added with a moderate amount of catalyst to react, so that polyurethane prepolymer is obtained; hydrophilic chain extender is then added to react with the polyurethane prepolymer; the temperature is reduced, organic base is added to regulate to the pH value, deionized water is added under high-speed shearing, and after emulsification, polyurethane emulsion is obtained; and the temperature is increased, vinyl monomer is added in the polyurethane emulsion, and initiator is used to initiate polymerization, so that the modified aqueous polyurethane emulsion surface sizing agent is prepared. The invention can completely eliminate the adverse affection of small-molecular emulsifier and organic solvent on the application performance of sizing agent product and environment protection, and replaces internal sizing.

Owner:SHAANXI UNIV OF SCI & TECH

Production method of high-performance latex paper

InactiveCN102191725AImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensile strength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

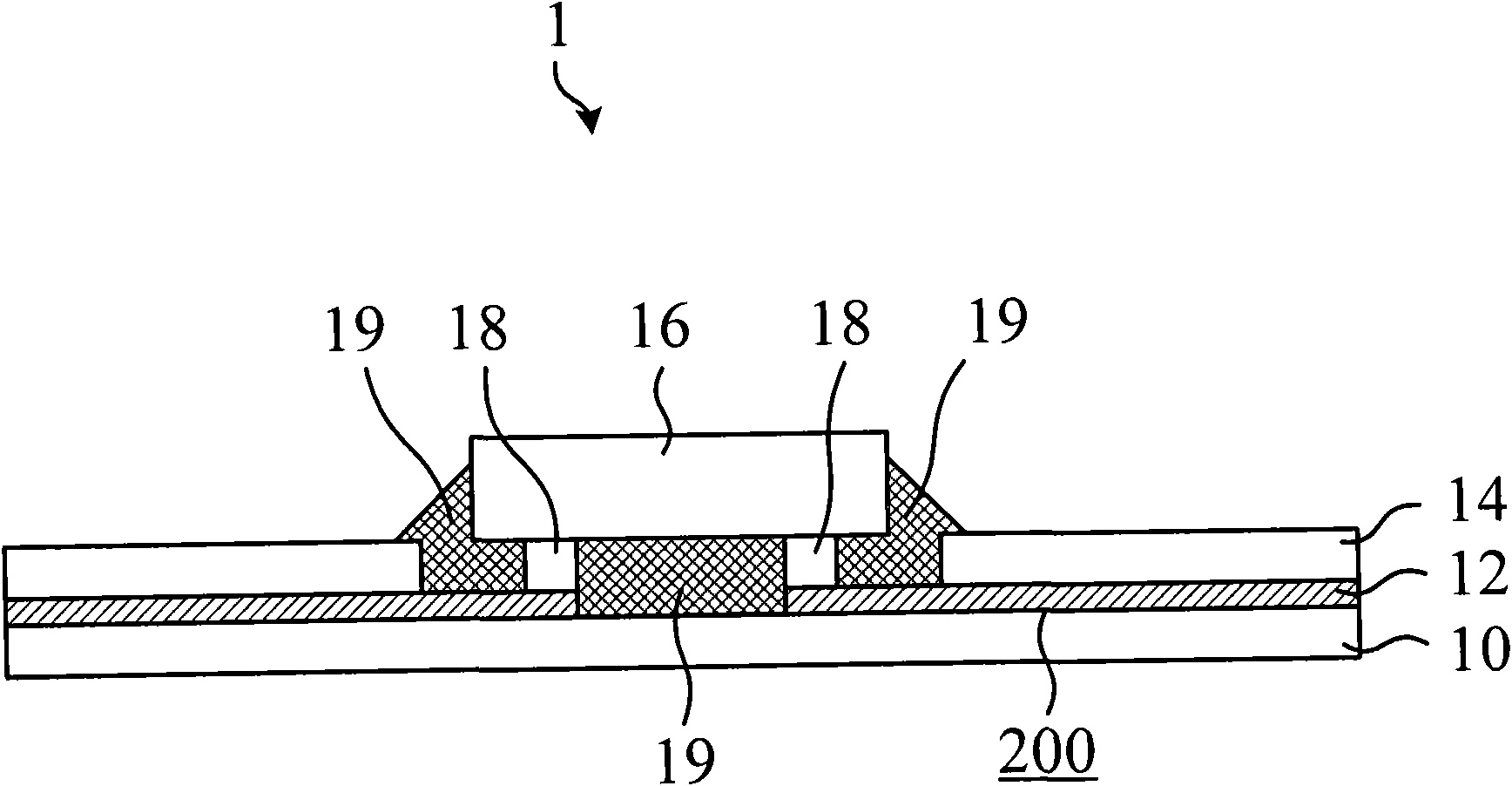

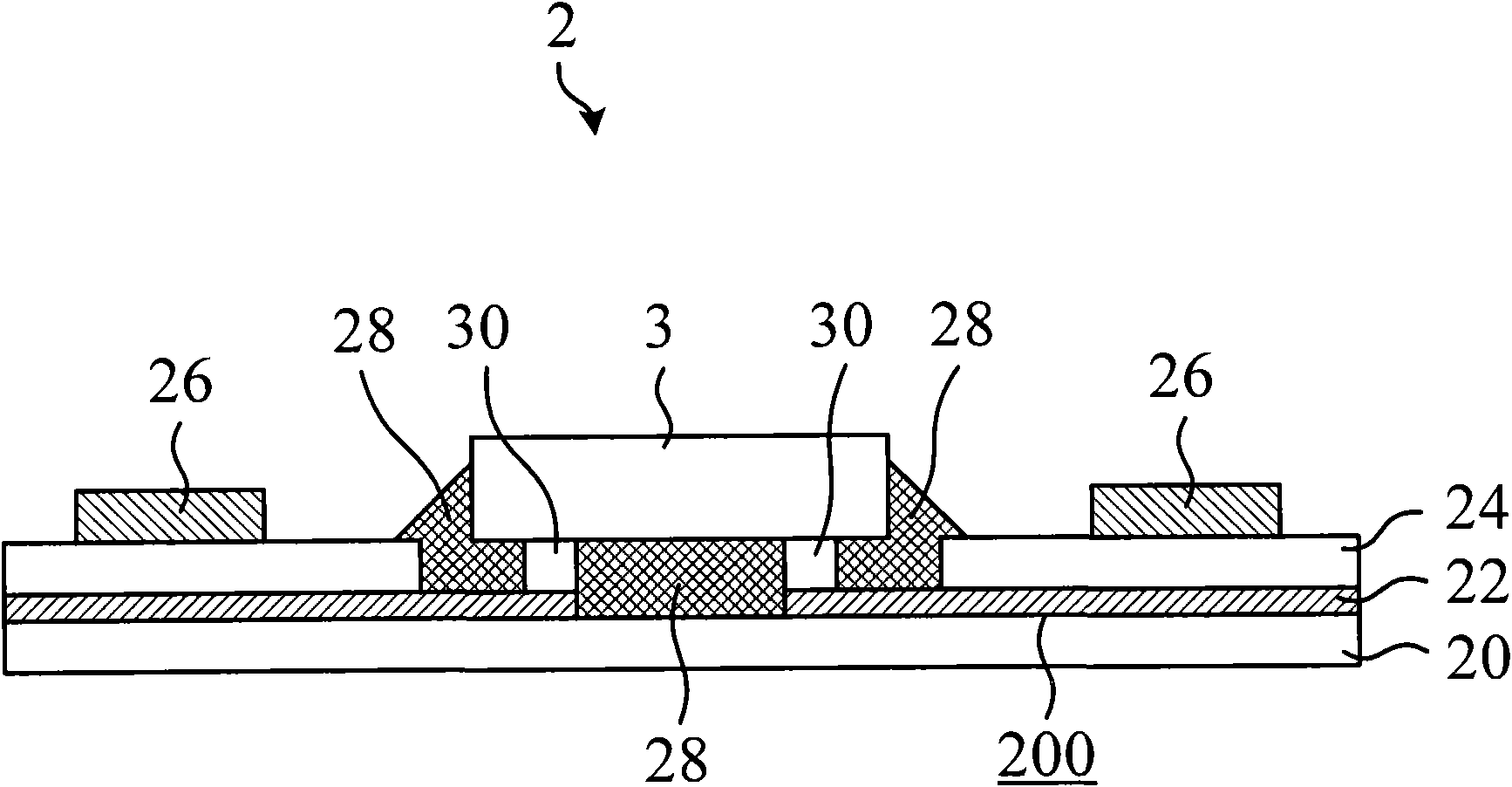

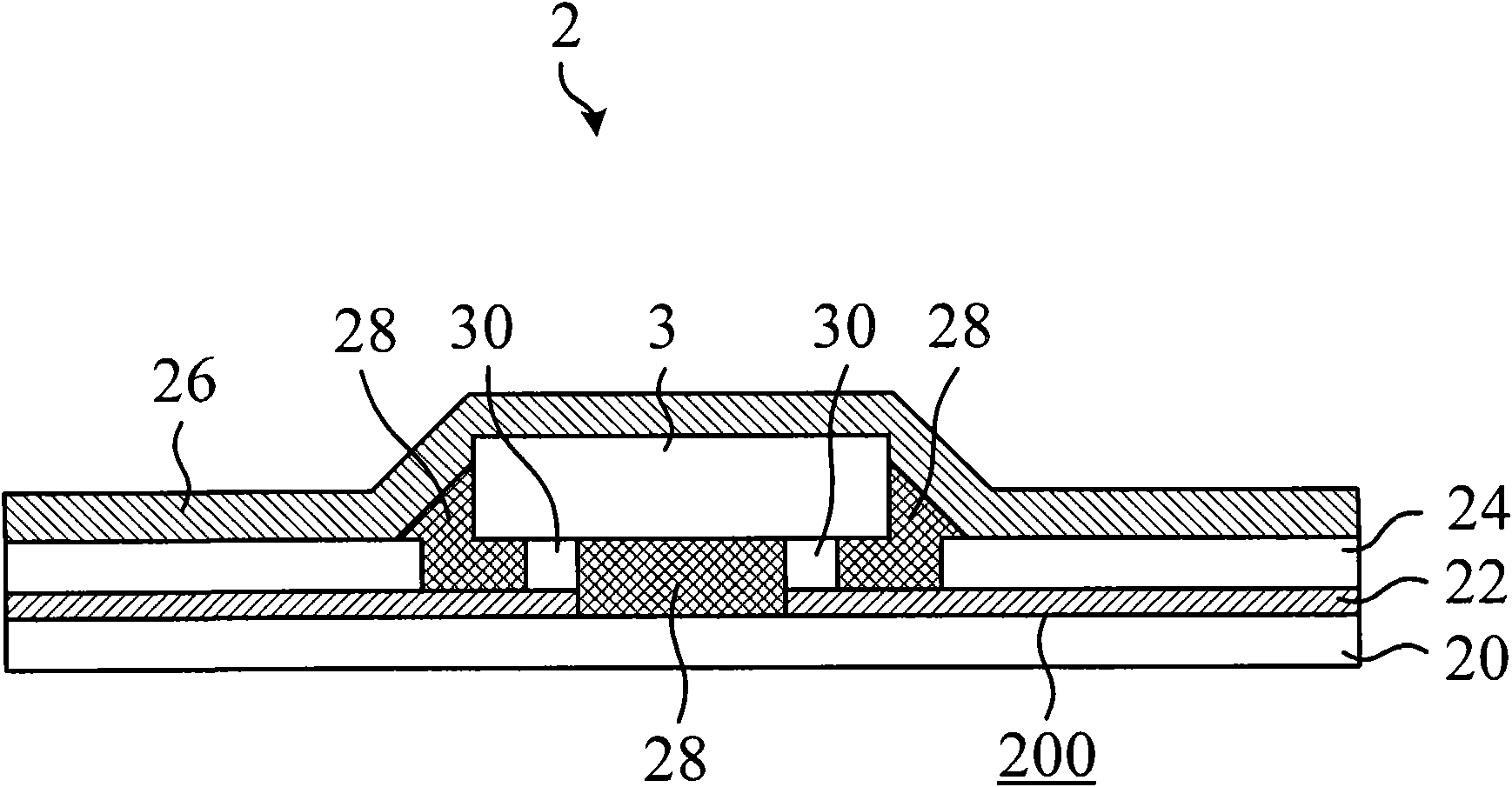

Chip on film packaging structure and chip on film packaging method

ActiveCN101626010AHigh folding resistanceSemiconductor/solid-state device detailsSolid-state devicesState of artChip on film

The invention discloses a chip on film packaging structure, which comprises a flexible substrate, a lead layer, an insulating layer and an elastic layer. The flexible substrate has a surface; the lead layer is formed on the surface and is provided with a plurality of leads; the insulating layer is formed on the lead layer; and the elastic layer is formed on the insulating layer and corresponds to at least one of the leads. When the flexible substrate is bent under the action of an external force, the elastic layer can buffer the deformation of the corresponding lead. Therefore, the rupture, caused by over deformation, of the corresponding lead can be avoided. The invention also provides a chip on film packaging method, which can improve the folding endurance of the chip on film packaging structure so as to solve the problem of the prior art.

Owner:RAYDIUM SEMICON

Method for preparing organosilicon modified paper sheet humidifying strong agent

InactiveCN101302731AImprove wet strengthImprove surface water resistanceReinforcing agents additionCross-linkEpoxy

The invention discloses a preparation method of a paper wet strengthening agent that is modified by organic silicon, which comprises the following steps: firstly combines the raw materials of dibasic acid and polyhydric amine into a polyamine intermediate compound of daiamid. A certain amount of the polyamine intermediate compound of daiamid, epoxy chloropropane and an organosilane coupling agent are taken to react under certain temperature so as to achieve certain viscosity, and the reaction is halted by adding acid, thus obtaining the paper wet strengthening agent that is modified by organic silicon. The preparation method of the paper wet strengthening agent that is modified by organic silicon can reduce the usage of the epoxy chloropropane and lower the organic chlorine content in discharged substances; the cross-linked product greatly increases molecular weight and active crosslinking points of molecular chain sections. The product of the paper wet strengthening agent that is modified by organic silicon achieves greatly raised retention degree, can improve not only the wet strength of paper but also the paper physical performance such as folding resistance, tensile strength and dry strength, etc., and the superficial water-proof performance of paper can be greatly raised if the paper wet strengthening agent is coated on the surface of paper.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing antibacterial paper on the basis of interlayer self-assembling technology

InactiveCN102587196AIncreased tensile indexHigh folding resistanceNon-fibrous pulp additionPaper/cardboardCelluloseFiber

The invention discloses a method for preparing antibacterial paper on the basis of an interlayer self-assembling technology. In the method, cationic polyelectrolyte chitosan biguanide hydrochloride (CGH) with an antibacterial function, and anionic polyelectrolyte carboxymethyl cellulose sodium (CMC) are alternately deposited on the surface of a bleached kraft hardwood fiber to prepare a layered ordered self-assembled multilayer ultrathin film, which can improve the strength property of a paper sheet while endowing the paper sheet with a good antibacterial performance. Through the change of the environment and the technical conditions of an interlayer self-assembling system, multilayer film structures with different properties can be obtained on the surface of the bleached kraft hardwood fiber, the retention of an antibacterial agent on the fiber is improved, and the antibacterial effect of the paper sheet is enhanced; a layered ordered self-assembled nano-film is prepared by taking a negatively-charged fiber as a matrix and controlling the adsorption process of a reverse-phase ion system,; the preparation method is simple in production process, less in equipment investment and high in adaptability; the prepared antibacterial paper has better antibacterial performance and strength property; and antibacterial requirements of household paper and food packaging paper can be met better.

Owner:ZHEJIANG SCI-TECH UNIV

Organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as preparation method and application thereof

ActiveCN104311716AStrong affinityImprove bindingReinforcing agents additionFunctional monomerChemistry

The invention discloses an organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly adding acrylic acid, hydroxyl-containing vinyl monomer, acrylate, styrene and organic silicon functional monomer into a reactor; adding a water-soluble initiator into the reactor for polymerisation; then cooling to room temperature and adding alkali for neutralizing; finally, slowly adding water into the reactor while stirring at a high speed to disperse so as to obtain the organic silicon modified styrene-acrylate microemulsion reinforcing agent. The organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the advantages of high binding force with paper fibers, good film forming performance and good water resistance and is applied to paper coating. Compared with the common styrene-acrylate emulsion, the organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the following advantages: the surface strength, folding endurance and wet-and-dry strength of the paper can be obviously improved, no organic solvent or surfactant is added in the preparation process, and the organic silicon modified styrene-acrylate microemulsion reinforcing agent is a high-performance environment-friendly paper-making and printing surface coating reinforcement product.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing environment-friendly false proof cover paper

ActiveCN101319475AImprove tear resistanceHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperFiberTear resistance

The invention relates to a method for producing environment-friendly anti-counterfeiting cover paper. In the method, raw fibers with the purity of 100 percent are used to produce base paper; the raw fibers selected comprise the following components in weight portion: 50 to 65 percent of needle oil pulp,10 to 20 percent of silking pulp, and 20 to 30 percent of cotton pulp; the raw fibers are subjected to disintegration by a pulp plate, pulping treatment, blending, pulp conveying, forming by a head box, drying and dehydration and bundling reeling to produce the base paper, and the base paper is orderly subjected to dip dyeing, dip latex, base coating, anti-counterfeiting printing and top coating to produce the anti-counterfeiting cover paper. The cover paper has excellent tearing resistance and folding resistance and good anti-counterfeiting function. The method of the invention has the advantages of simple processing and manufacturing, low production cost and environmental protection, and has the tearing resistance and anti-counterfeiting function. The environment-friendly anti-counterfeiting cover paper is suitable for being manufactured into covers of all certificates, particularly a cover of an environment-friendly anti-counterfeiting passport.

Owner:SHANDONG KAILI SPECIAL PAPER

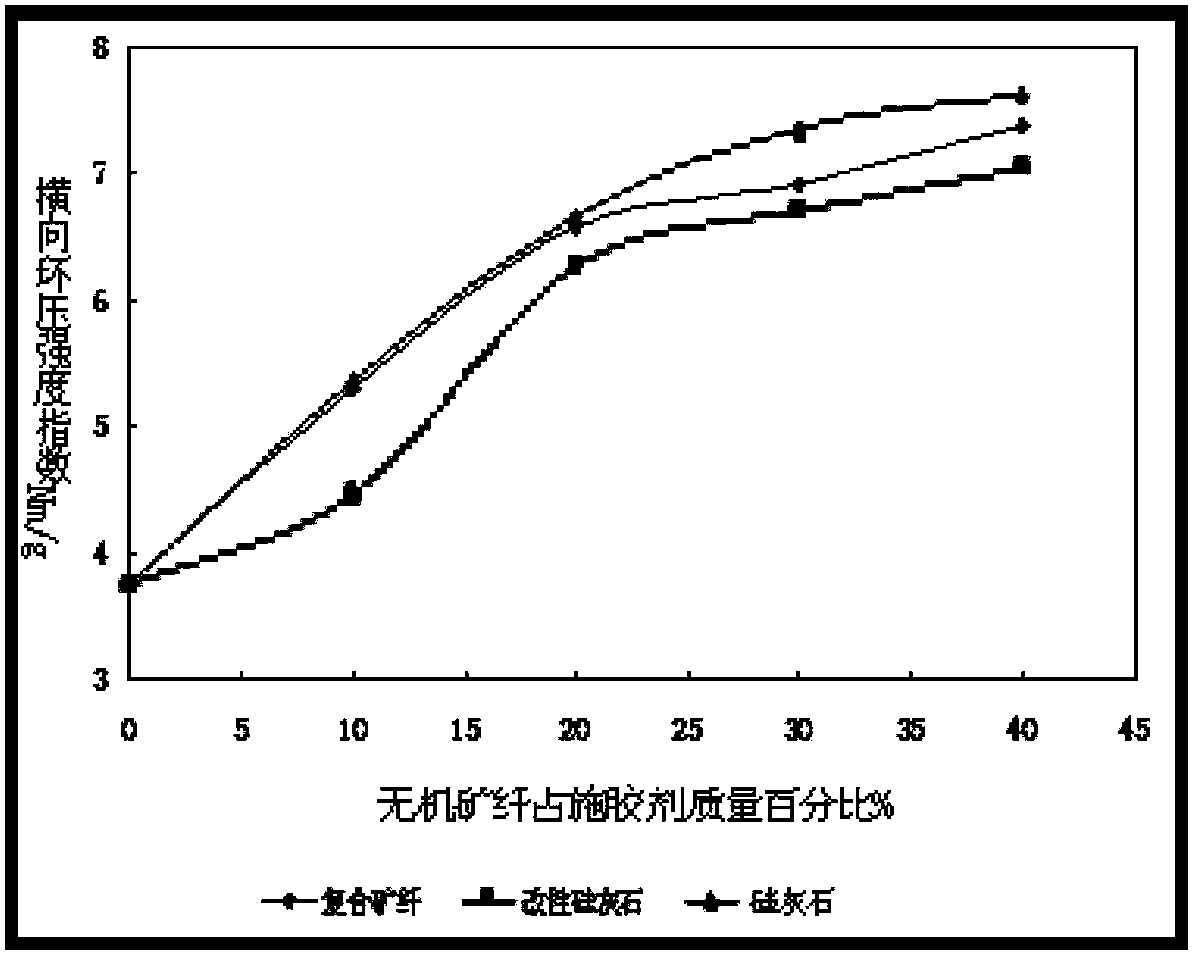

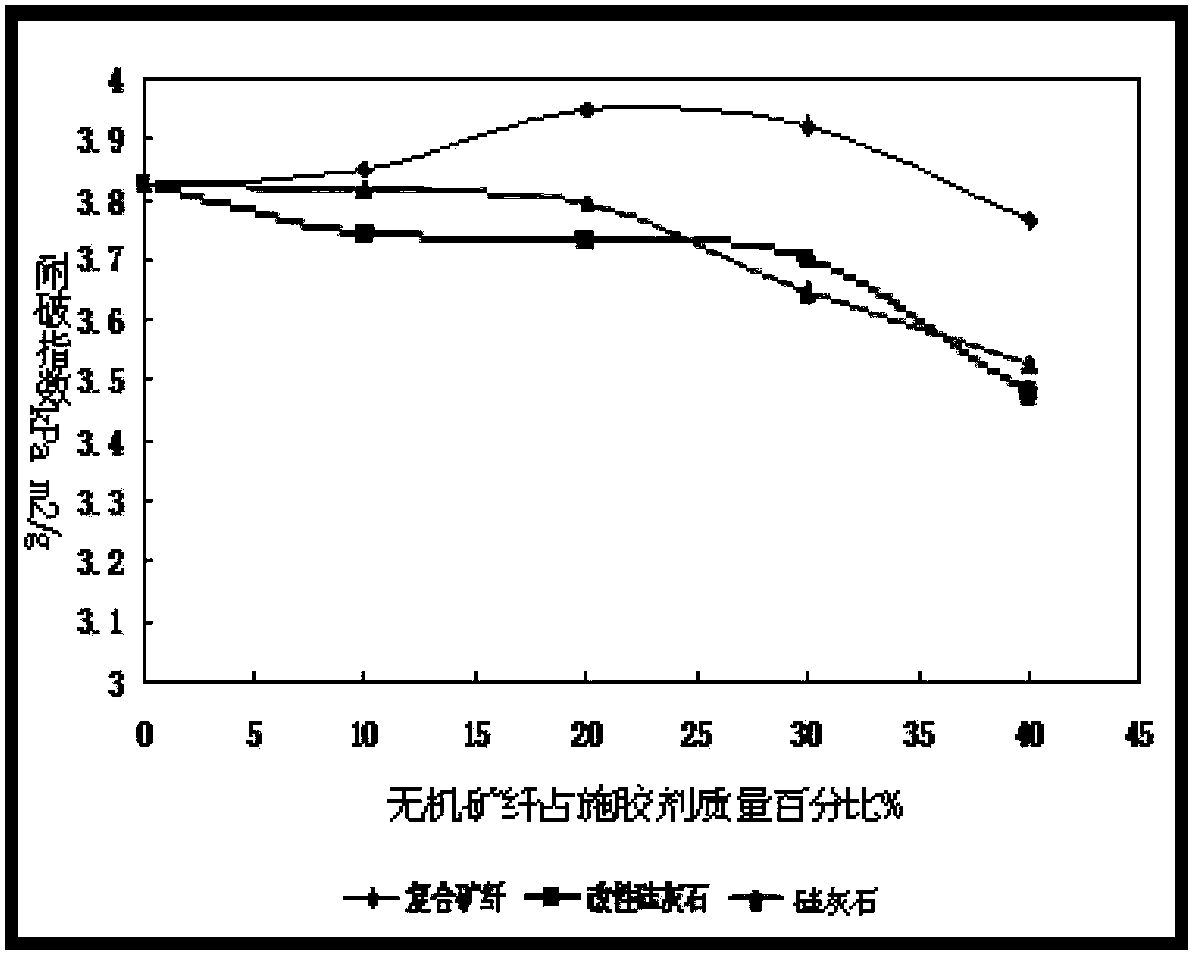

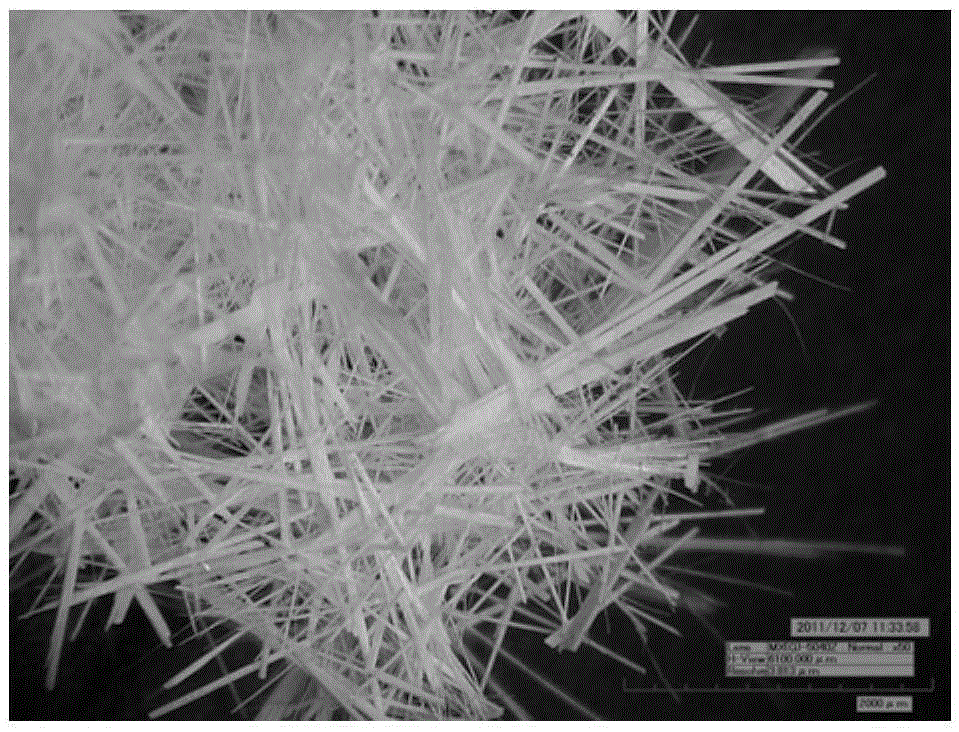

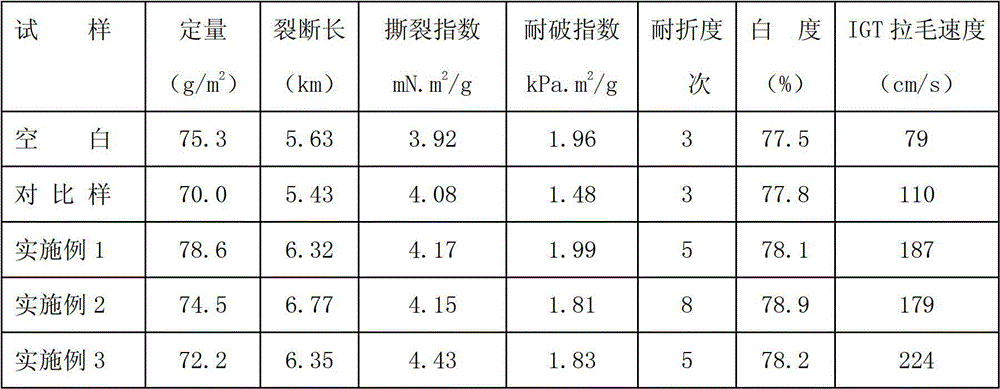

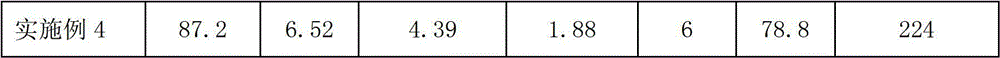

Inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and preparation method thereof

ActiveCN103388286AIncreased ring compressive strengthReduce paper production costsWater-repelling agents additionPapermakingSizing

The invention relates to an inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and a preparation method thereof. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises surface sizing starch and inorganic mineral fibers. The mineral fibers comprise composite mineral fibers, modified wollastonite or wollastonite. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises 5-40wt% of the inorganic mineral fibers. The norganic mineral fiber ring crush strength-improvement surface sizing agent can greatly improve corrugated paper ring crush strength and improve a tensile index and folding strength of a coated paper.

Owner:大连环球矿产股份有限公司

Preparation method of crosslinked grafted modified polyvinyl alcohol surface reinforcing agent

ActiveCN103333352AStability is not affectedImprove surface strengthReinforcing agents additionPaper/cardboardHydrazine compoundSide chain

The invention relates to a preparation method of a crosslinked grafted modified polyvinyl alcohol surface reinforcing agent. The method comprises the steps of: evenly mixing polyvinyl alcohol with water to obtain a polyvinyl alcohol water solution; increasing the temperature of the water solution, adding ketone carboxyl-containing vinyl monomer, cationic monomer, long side chain radical-containing vinyl monomer, self-crosslinking monomer, and other types of vinyl monomers, to obtain a vinyl monomer / polyvinyl alcohol mixture solution; evenly mixing water with a water-soluble initiator to obtain an initiator water solution; dropwise adding the initiator water solution into the mixture solution, increasing the temperature of the system, reacting until no acrylic ester monomer smell exists; cooling the temperature of the system to room temperature, regulating the pH value with alkali, adding hydrazine or the derivatives thereof to be stirred evenly, thus obtaining the crosslinked grafted modified polyvinyl alcohol surface reinforcing agent. The stability of the system cannot be influenced by adopting the preparation method; the crosslinked grafted modified polyvinyl alcohol surface reinforcing agent is used for paper surface reinforcing agent, the surface strength, water resistance, tensile strength, folding strength and the like of paper can be greatly improved, and the film forming property can be enhanced.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

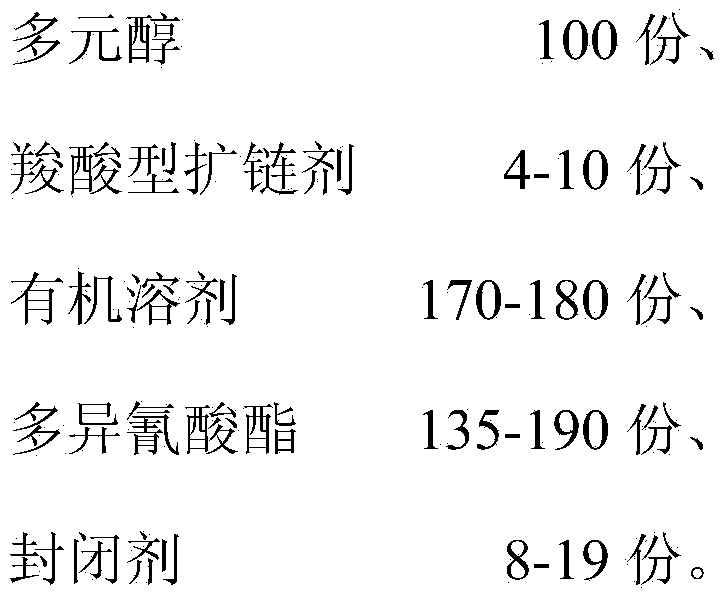

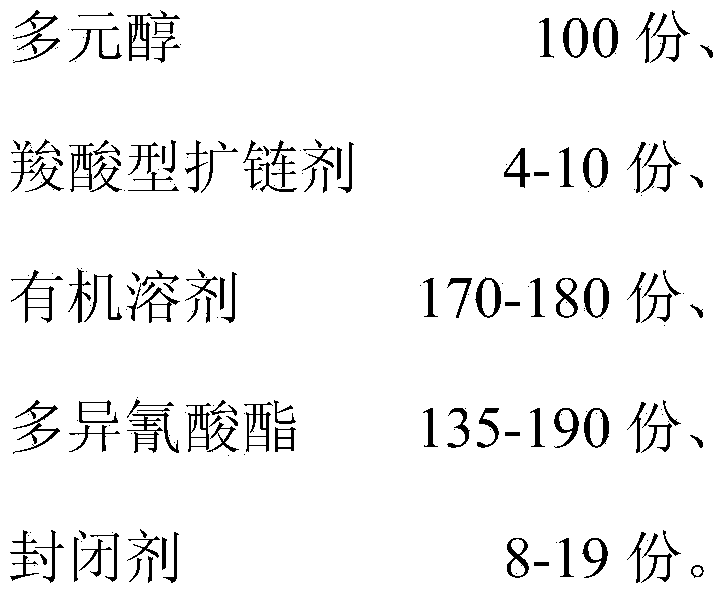

Preparation method of closed water-based polyurethane modified PAE (polyarylether) wet strength agent

InactiveCN103524708AIncreased dry tensile indexIncreased wet tensile indexReinforcing agents additionWater basedDistillation

The invention provides a preparation method of a sealed water-based polyurethane modified PAE (polyarylether) wet strength agent, which comprises the following steps: carrying out vacuum dehydration on polyalcohol and carboxylic acid chain extender, adding organic solvent and polyisocyanate, reacting in a nitrogen atmosphere to obtain NCO-terminated polyurethane prepolymer, and adding a closing agent to react until the -NCO content is zero to obtain a closed polyurethane prepolymer; mixing polyethylene polyamine, dibasic acid and catalyst to carry out polycondensation reaction, removing the generated water by distillation, cooling to 120-140 DEG C, and adding hot water to obtain a polyamide-imide solution; and sequentially adding water and the closed polyurethane prepolymer into the polyamide-imide solution, dissolving by stirring, adding epoxy chloropropane to react, adding a terminator when the system viscosity reaches 40-100 cps, and regulating the pH value of the system to 3.0-5.0. Compared with the traditional PAE wet strength agent, after the wet strength agent provided by the invention is applied to paper, the dry tensile index, wet tensile index, wet strength retention and folding strength are enhanced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

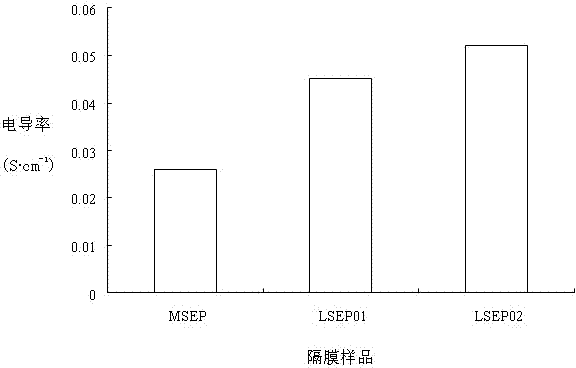

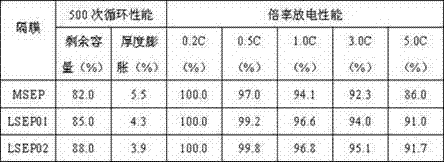

Coating for power lithium battery diaphragm, power lithium battery diaphragm and preparation thereof

ActiveCN102433745AHigh liquid absorptionHigh tensile strengthCell component detailsNatural fibresNano siliconN dimethylformamide

The invention provides a coating for a power lithium battery diaphragm, a power lithium battery diaphragm and preparation thereof. The coating for the power lithium battery diaphragm which takes wet nonwoven cloth as a base material is characterized by comprising 5-20% (wt) chlorinated polyvinylidene fluoride, 10-20% (wt) glycerol, 60-80% (wt) N, N-dimethylformamide, 2.5-5% (wt) sodium hypochlorite and 2.5-5% (wt) nano-silicon carbide whiskers. A method for preparing the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material is characterized bycomprising the following specific steps of: proportionally dissolving chlorinated polyvinylidene fluoride in the mixed solution of glycerol, sodium hypochlorite and N, N-dimethylformamide to form thick transparent fluid; adding the nano-silicon carbide whiskers to the thick transparent fluid and stirring the same until the whiskers are completely homogenized and dispersed, thereby obtaining the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material. The coating is capable of obviously improving the absorbency, electrical properties, high temperature shrinkage resistance and tensile strength of the power lithium battery diaphragm.

Owner:CHINA HAISUM ENG

Production technology of kraft vermicelli case board paper

InactiveCN105696395AHigh strengthIncrease the lengthPulp beating methodsPaper recyclingEnvironmental resistanceSurface layer

The invention discloses a production technology of kraft vermicelli case board paper. The production technology comprises the steps that recycled waste paper materials are screened, the recycled waste paper with low ash content is selected for pulping with softwood pulp, preliminary pulping is conducted through the processes of repulping, purifying, screening and the like, the fiber strength is emphatically improving in the grading and beating processes, longer fibers are screened to serve as surface layer pulp, the fiber beating degree is improved on the condition that the fiber strength is not damaged, and the fiber bonding strength is improved through the fiber arrangement mode on a net portion so as to improve the surface strength, toughness and folding strength of finished paper; by means of the measures of surface sizing, after-drying moisture precise control and finished paper coating, the product has the better explosion-proof line quality advantage and is more environmentally friendly, and the market share of the product is bound to be increased.

Owner:JIANGSU LEE & MAN PAPER MFG

Production method for high-bulk grey board

ActiveCN102691233AImprove stiffnessHigh folding resistanceSpecial paperPaper/cardboardPulp (paper)Manufacturing engineering

The invention discloses a production method for a high-bulk grey board. The production method is characterized in that when pulp required for a surface lining and a bottom lining is prepared, mechanical pulp is added into deinked pulp for preparing the surface lining and mixed waste paper pulp for preparing the bottom lining respectively in a pulp mixing process. compared with the grey board processed by a traditional method, the high-bulk grey board processed by the production method provided by the invention has the advantages as follows: the gram weight is low on the premises that the thicknesses are equal and the product performances are ensured, conversely, the thickness is 12 percent lager than that of the traditional grey board on the premise of equal gram weights; and as the gram weight of the high-bulk grey board is low under the condition of equal thicknesses, so that the consumption of paper pulp is reduced, the consumption of corresponding fiber resource is reduced, and meanwhile the energy consumption during transport is also reduced, so as to correspondingly reduce the emission of carbon dioxide and facilitate the environment protection and resource protection.

Owner:SHANDONG BOHUI PAPER INDUSTRY CO LTD

Surface sizing enhancer

InactiveCN103103877AImprove qualityHigh folding resistanceWater-repelling agents additionSulfateCross linker

The invention relates to a surface sizing enhancer which is characterized by comprising the following components in parts by weight: 930-950 parts of ferrous sulfate, 2-12 parts of a combined polymer, 6-12 parts of a cationic monomer, 8-16 parts of a crosslinking agent and 6-12 parts of an initiator. The surface sizing enhancer has the beneficial effects that the surface sizing enhancer can replace partial pasty starch and can comprehensively improve the quality of paper; according to requirements of different pieces of paper, by a pasting process, 15-30 percent of starch can be replaced; compared with the conventional surface sizing enhancer, the surface sizing enhancer has the advantages that the water resistance is greatly improved; and furthermore, the annular pressure of the paper, the breakage resistance and the humidity breakage property are obviously improved. Various macromolecule copolymers are used as ligand polymers and are mixed and crosslinked with the original starch to form a whole; and during surface sizing, coating can be effectively prevented from inwards penetrating into the paper, off-machine curing is performed without influence of the environment, and a phenomenon that the paper is wetted and deforms can be well solved.

Owner:天津市奥东化工有限公司

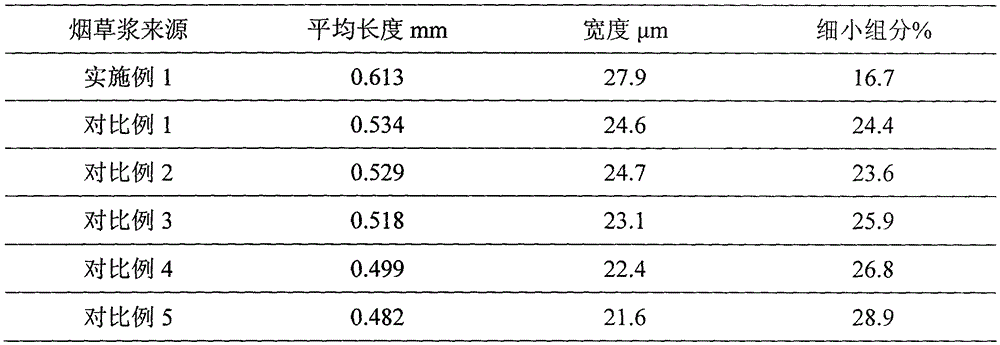

Method for preparing tobacco pulp from regenerated tobacco

InactiveCN105595400AReduce energy consumption for refiningImprove running performanceTobacco preparationFiberSolvent

The invention discloses a method for preparing tobacco pulp from regenerated tobacco. The method includes the following steps that 1, the tobacco raw material is extracted and then subjected to solid-liquid separation, and an aqueous solvent is added into tobacco filter residues obtained after solid-liquid separation, wherein the aqueous solvent contains salt and alkali and a nonionic surfactant; 2, the tobacco filter residues are fed into a pulping machine for defibering; 3, a complex enzyme preparation is added into the filter residues obtained after defibering for enzymolysis; 4, after enzymolysis is completed, pulping continues till the needed pulping degree is obtained, and the tobacco pulp is obtained. In the method for preparing the tobacco pulp, the pulp forming characteristic of the tobacco is effectively improved by organically combining the physical action, the enzyme preparation and the chemical reagent according to the specificity of the tobacco raw material, so that the effects of improving the papermaking property of the tobacco pulp and increasing the physical indexes of the regenerated tobacco are achieved, and meanwhile the interior quality of the regenerated tobacco is improved.

Owner:宁夏夏盛实业集团有限公司

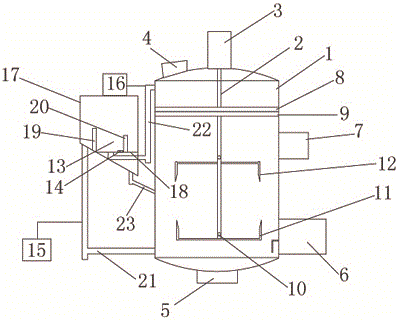

Preparation method and material stirring device of self-adhesion type medical paper

ActiveCN106012679AFlexible control of air permeabilityHigh folding resistanceSpecial paperTransportation and packagingMeasuring instrumentSlurry

The invention discloses a preparation method and material stirring device of self-adhesion type medical paper. The method includes the steps that softwood pulp and hardwood pulp serve as raw materials, and the self-adhesion type medical paper is prepared through the steps of crushing, stirring, purifying and drying and post-processing. The stirring device comprises a shell and a stirring mechanism arranged in the shell, and the outer side of the shell is provided with a cycle mechanism. Multiple indexes such as air permeability, strength and folding strength of the self-adhesion type medical paper prepared from the method meet the use requirements of the modern medical industry at the same time, by means of the stirring device, a pulping pool can be omitted, equipment cost is reduced, the loss of pulp in the process from the pulping pool to a pulp mixing pool is avoided radically, and cost is saved; in addition, by means of a beating degree measuring instrument (6) of the stirring device, monitoring of the beating degree in the production process is achieved, and production is optimized; through the cycle structure of secondary pulping, the application space of the device can be expanded, and pulp meeting different requirements can be obtained according to different production requirements.

Owner:ZHEJIANG KAIFENG NEW MATERIAL CO LTD

Preparation method of cotton pulp for high-strength paper

ActiveCN102174757AProtection strengthEmission reductionPulp bleachingPulping with inorganic basesFiberAcetic acid

The invention relates to a preparation method of cotton pulp for high-strength paper. In the preparation method, a material sorting process, a cotton opening process, an impurity removal process, an alkali preparation process, a dipping process, a steaming and bleaching process, a pre-desanding process, a pre-pulping process, a concentration process, a post-desanding process, a post-pulping process and a pulp copying process are performed on cotton linter to obtain the cotton pulp. The alkali preparation and dipping processes comprise the following steps of: controlling the alkali preparationtemperature to be between 30 and 40 DEG C; adding 2 to 3.5 percent of NaOH, 0.1 to 0.2 percent of anthraquinone, 2.5 to 3.5 percent of boiling agent and 2 to 3 percent of peracetic acid according to oven dry stock amount to obtain alkali liquor, wherein the alkali liquor proportion is 1:(4.5-5.5); and performing penetration mixing on the alkali liquor and the cotton linter from which impurities are removed. By the method, pulp fibers have high folding strength, high breaking length and high whiteness, pollution to the environment is reduced, and fluorescent substances are removed in the firstheat preservation process.

Owner:山东银鹰股份有限公司

Liner paper for environment protection cigarette

InactiveCN1888308ANo smellNo toxicityFlexible coversCoatings with pigmentsPulp and paper industryPrinting ink

The present invention relates to an internal lining paper for environment-protecting cigarette. It is made up by coating water printing ink on the surface of raw paper. The smoothness of raw paper is greater than on equal to 1000S, unit area paper weight is 60-80g / sq.m, water content is less than 35g / sq.m, thickness is 0.05-0.07 mm and the dose of water printing ink (by solid content) is 4-7g / sq.m. The procedures for coating printing ink are successively as follows: placing paper, leveling, tensioning, coating, drying, calendaring and rolling up.

Owner:CHANGDE FURONG INDAL DEV

Surface modification method for calcium sulfate whiskers

InactiveCN105350084AReduce the burden onHigh hardnessPolycrystalline material growthAfter-treatment detailsAnhydrous Calcium SulfateWater processing

The invention discloses a surface modification method for calcium sulfate whiskers. The surface modification method comprises steps: anhydrous calcium sulfate whiskers are prepared; a surface modifier solution is prepared; the calcium sulfate whiskers are added slowly into the surface modifier solution with stirring, slow stirring is carried out, and a reaction is carried out; the modified anhydrous calcium sulfate whiskers are subjected to impurity removal processing. The method is simple, the steps are few, raw materials are saved, water processing burden is reduced, the anhydrous calcium sulfate whisker product has good performance, and tensile strength, the tear resistance, the folding strength and the pop strength are high. The solution synthesis method is employed, a calcium-containing industrial tail liquid is reacted with sulfuric acid, calcium sulfate whiskers are prepared, the cleaning utilization problem of calcium ions in the waste liquid is solved, which facilitates to achieve cyclic utilization of raw materials and resources are saved. The yield of the prepared calcium sulfate whiskers is high, the crystal form is structured and the length-to-diameter ratio is high.

Owner:SHANDONG UNIV OF SCI & TECH +1

Preparation method and application of oxidized starch

InactiveCN102718878AComply with clean and environmentally friendly production requirementsImprove smoothnessWater-repelling agents additionPaper coatingBursting strengthFiber

The invention provides oxidized starch, a preparation method thereof and application. The preparation method of the oxidized starch includes the steps: (1) under the condition of mixing, spraying catalyst solution into the starch, spraying oxidants and increasing the temperature to reach 30-50 DEG C; (2) after mixing the starch every 15 minutes within an hour, spraying residual oxidants to react for 4-8 hours; and (3) cooling the starch, adding neutralizers until the pH (potential of hydrogen) of a system is 6-8, crushing the starch, and screening the starch by a screen with 90-120 meshes to obtain the oxidized starch. The weight of the sprayed oxidants accounts for 30-60wt% of the overall weight of oxidants, catalysts are sodium hydroxide or potassium hydroxide, and the oxidants are hydrogen peroxide. The oxidized starch can be used for gluing the surface of paper, continuous and uniform films are formed on the surface of a paper sheet, oil resistance and scratch resistance of the paper sheet can be improved, and smoothness and glossiness of the paper sheet are improved. When the oxidized starch is used for internal sizing, paste can be uniformly and adsorbed on fibers, and the bursting strength and the folding resistance of the paper are improved.

Owner:新乡市东升新材料有限公司 +1

Preparation method for dampproof quick-drying surface sizing agent

InactiveCN107034730AReduce dosageHigh bonding strengthWater-repelling agents additionFiltrationPolyethylene glycol

The invention discloses a preparation method of a moisture-proof and quick-drying surface sizing agent, which belongs to the technical field of papermaking auxiliary preparation. In the present invention, chitosan is firstly added to sodium hydroxide solution to soak and swell, then chloroacetic acid solution is added to stir and react, the product is collected and filtered by suction to obtain a filter cake, and the filter cake is washed to obtain carboxymethyl chitosan, and then stearic acid , silane coupling agent, etc., and anhydrous ethanol are stirred to obtain a mixed solution, which is heated and reacted with carboxymethyl chitosan and water, and the product is collected and then heated and reacted with polydimethylsiloxane, polyethylene glycol, etc. , and finally cool naturally to get the moisture-proof and quick-drying surface sizing agent. The moisture-proof and quick-drying surface sizing agent prepared by the present invention has the advantages of good sizing effect, good moisture-proof performance, and fast drying speed, and can effectively improve the sizing effect. The various strength properties of the final paper can be improved, and the moisture-proof and water-resistant capabilities of the paper can be improved, which has a good application prospect.

Owner:CHANGZHOU UNIV

Method for preparing powdery amphoteric guar gum derivative

ActiveCN101871180AImprove conversion rateMild reaction conditionsReinforcing agents additionPaper/cardboardPolymer scienceOrganic solvent

The invention discloses a method for preparing powdery amphoteric guar gum derivative having high degree of substitution, which adopts a semidry method and completes the cationization and anionized reactions of guar gum in a same reactor at the same time. The method comprises the following steps of: preparing sodium hydroxide into solution by using an alcohol / water mixture; spraying the solution into guar gum raw powder; adding a powdery quaternized reagent into the alkaline guar gum with stirring; and reacting the mixture with a carboxyalkylation reagent to obtain the product. The method has the advantages of completing the cationization and anionized reactions of the guar gum in the same reactor at the same time, no need for the separation and purification of intermediate products, directly performing subsequent reactions, fully utilizing reaction heat in a synthesis process, reducing energy consumption and solving the problems of high cost, difficult post treatment and low product degree of substitution of modified guar gum prepared by an aqueous method or an organic solvent method in the prior art along with characteristics of the semi-dry method.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Preparation method of modified PAE wet strength agent

InactiveCN101949110AHigh strengthHigh folding resistanceReinforcing agents additionPolymer sciencePtru catalyst

The invention relates to a preparation method of a modified PAE wet strength agent, comprising the following steps of synthesizing polyamide used as an intermediate: reacting 1-1.2 percent of dicarboxylic acid with 0.005-0.02 percent of polyethylene polyamine for 2-10h under the action of a catalyst at the temperature of 140-200 DEG C; reacting 1 percent of the polyamide with 0.2-1 percent of chloroepoxy propane for 2-6h at the temperature of 40-80 DEG C with a pH value of 8-10; adding polymine and hexamethylene tetramine into the PAE, and continuously reacting for 0.5-1.5h; adding hydrogen peroxide after finishing the reaction, wherein the weight ratio of the PAE to the polymine to the hydrogen peroxide is 1:0.002-0.2:0.005-0.02, and the pH value is 2-5. The invention has the advantages that polyamide epichlorohydrin modified by a PEI crosslinking agent is used as a wet strength agent for papermaking, and the wet strength agent can be kept for a longer time without generating bubbles and flocculation and can enable a paper to have stronger wet strength and stronger folding endurance.

Owner:天津市奥东化工有限公司

Wear-resistant flame retardation wallpaper raw paper and making method thereof

InactiveCN105908561AImprove brushing effectTightly boundVegetable material additionWax additionWear resistantGas phase

The invention discloses a wear-resistant flame retardation wallpaper raw paper. Present technologies and present formulas are improved, meerschaum powder-antimony oxide-chlorinated paraffin is adopted as a flame retardant and is modified, H. and OH. free radicals in the chain reaction and for keeping combustion in a paper combustion reaction gas phase are captured to change the reaction mode in the gas phase, the heat release amount of the reaction is reduced to quench flame, and nanometer calcium carbonate is added to raw materials after being organically modified to improve the brush ability of raw paper and make the raw paper be closely combined with a decoration layer and not shed. The flame retardation property of the flame retardation wallpaper raw paper meets GB / T14656-93 requirements, the tearability, the folding strength, the ring crush strength and the tensile strength are improved, and wallpaper produced by using the raw paper has the advantages of environmental protection, no pollution, wear resistance, difficult shedding, full utilization of the moisture absorption, ventilation, bacteriostasis, anti-bacterium, warmness in winter, coolness in summer and humidity adjustment characteristics of bamboo charcoal fibers to purify and adjust air, and avoiding of damages of harmful materials to the health of human bodies.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Novel packaging paper

InactiveCN105133432AWide range of raw materialsMild responseFlexible coversWrappersGlass fiberEngineering

The invention discloses novel packaging paper, which is prepared from the following components by weight: glycerin, corn starch, glass fibers, cunninghamia lanceolata powder and bentonite. According to the present invention, the novel packaging paper has advantages of wide raw materials, mild reaction, no toxicity, environmental protection and the like, and the green chemistry concept in the modern requirement is met; compared with the general packing paper, the produced packaging paper of the present invention has high tensile strength and high folding resistance, and is suitable for a variety of occasions; and the produced packaging paper has high printing adaptability, is suitable for a variety of surface printing, and further has characteristics of extremely high tensile resistance, complete degradation, and significant bacterial inhibition effect.

Owner:HEFEI LONGFA PACKING CO LTD

Surface sizing agent and method for preparing same

ActiveCN101161931AImprove binding abilityGood surface strength and folding resistanceWater-repelling agents additionPaper/cardboardSurface strengthSynthetic polymer

The invention discloses a surface sizing agent which is soap-free emulsion of polymers with the following general formula I: (general formula I) wherein, R is selected from a saturated fatty alcohol group with carbon numbers of 1-18; X is selected from any one in Na<+>, K<+>, NH4<+>, etc; n is 10-1000. The sizing agent is a novel synthetic polymer surface sizing agent for paper, so surface sizing capability of paper can be greatly improved, binding fastness of paper and ink can be improved, surface strength of paper can be improved, etc.; besides, the invention also has the advantages that: few crust is provided during using process, cleaning is convenient, folding resistance of finished product is increased, wet strength is high, etc. The invention also discloses a preparation method of the sizing agent.

Owner:CHINA BANKNOTE PRINTING & MINTING

VOC-free water-based epoxy polyurethane surface sizing enhancer and preparation method thereof

InactiveCN104328711AImproves paper strength propertiesGood adhesionPaper coatingReinforcing agents additionFunctional monomerChemistry

The invention discloses a VOC-free water-based epoxy polyurethane surface sizing enhancer which is composed of the following materials, by weight, 12-75 parts of vinyl monomer, 8-35 parts of polymer polyol, 2.5-20 parts of a polyisocyanate compound, 0.12-0.75 part of trimethylol propane, 3-18 parts of a hydrophilic chain extender, 0-0.18 parts of a catalyst, 0.8-5 parts of vinyl monomer containing activated hydrogen, 0.12-2.5 parts of an initiator and 5-57 parts of a monomer mixture, wherein the monomer mixture contains 4-35 parts of vinyl monomer and 1-22 parts of functional monomer containing epoxy groups. The invention also discloses a preparation method of the VOC-free water-based epoxy polyurethane surface sizing enhancer. By the use of the enhancer, a surface sizing agent with good adhesion property and film-forming property can be obtained. During the preparation process of the enhancer, there is no organic solvent. The preparation process is simple, safe, environmentally friendly and pollution-free.

Owner:SHAANXI UNIV OF SCI & TECH

High-strength high-temperature resistant oil filter paper and preparation method thereof

InactiveCN102912678AImprove high temperature resistanceHigh strengthNon-macromolecular organic additionPaper/cardboardFiberBursting strength

The invention discloses high-strength high-temperature resistant oil filter paper and a preparation method of the high-strength high-temperature resistant oil filter paper. The high-strength high-temperature resistant oil filter paper is prepared from the following materials in parts by weight: 50-60 parts of softwood pulp, 20-30 parts of polybenzimidazole fibre, 20-30 parts of high silica glass fibre, 2-5 parts of modified sepiolite, 1-3 parts of lithopone, 2-4 parts of activated clay, 1-2 parts of nanometer titania, 0.5-0.8 parts of decabromodiphenyl ether, 2-3 parts of cationic polyacrylate latex, 0.5-1 part of glycerol triglyceride acid, 0.4-0.8 parts of diethanol amide, 0.5-1 part of vinyltriethoxysilane, 0.4-0.8 parts of sodium laurylsulfate and 2-5 parts of dialdehyde starch. The filter paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com