Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1086 results about "Vinyltriethoxysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

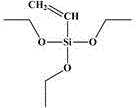

Vinyltriethoxysilane is an organosilicon compound with the formula (C₂H₅O)₃SiCH=CH₂. It is a colorless liquid. The compound is bifunctional, featuring both a vinyl group and hydrolytically sensitive ethoxysilyl groups. As such it is a crosslinking agent.

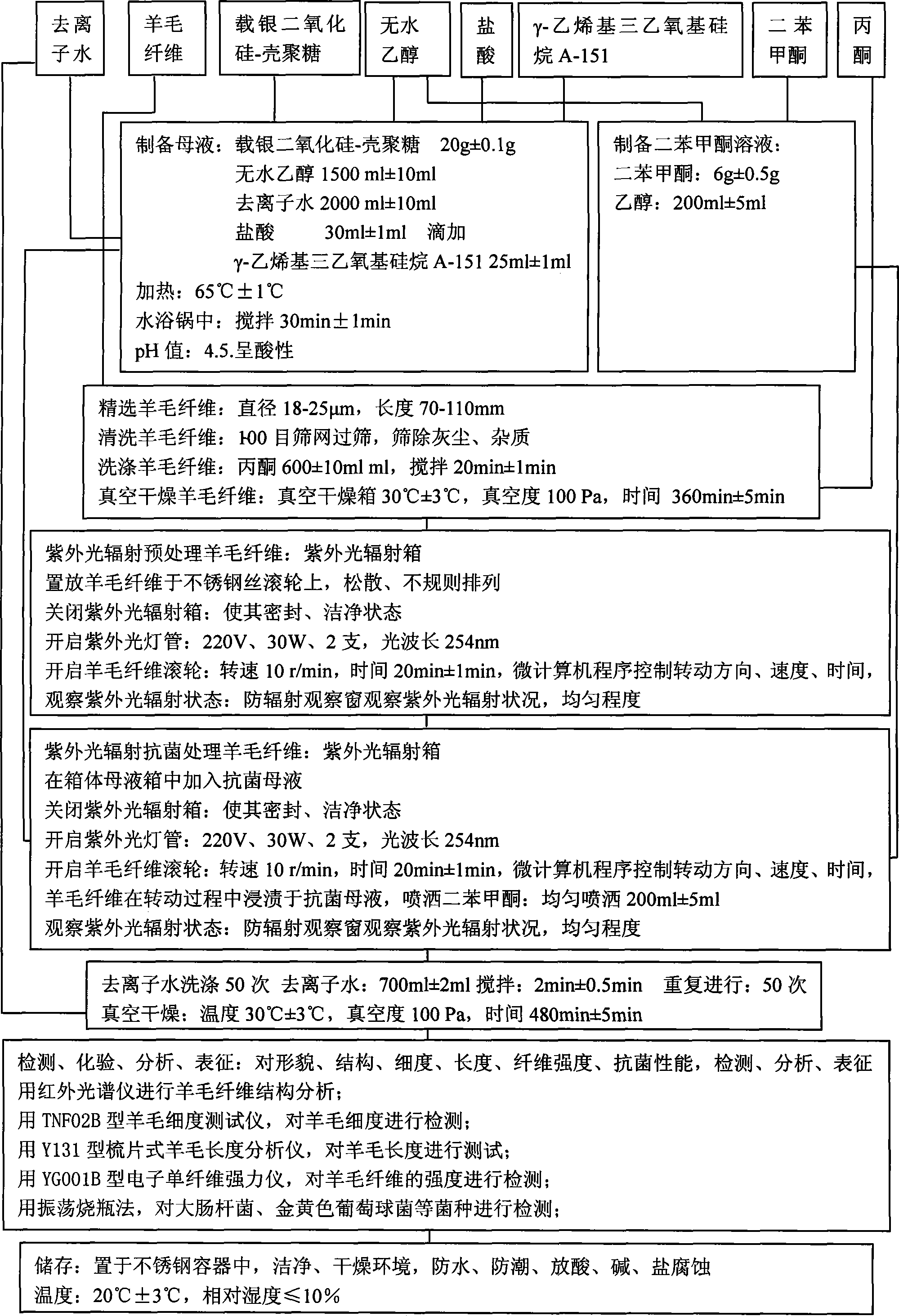

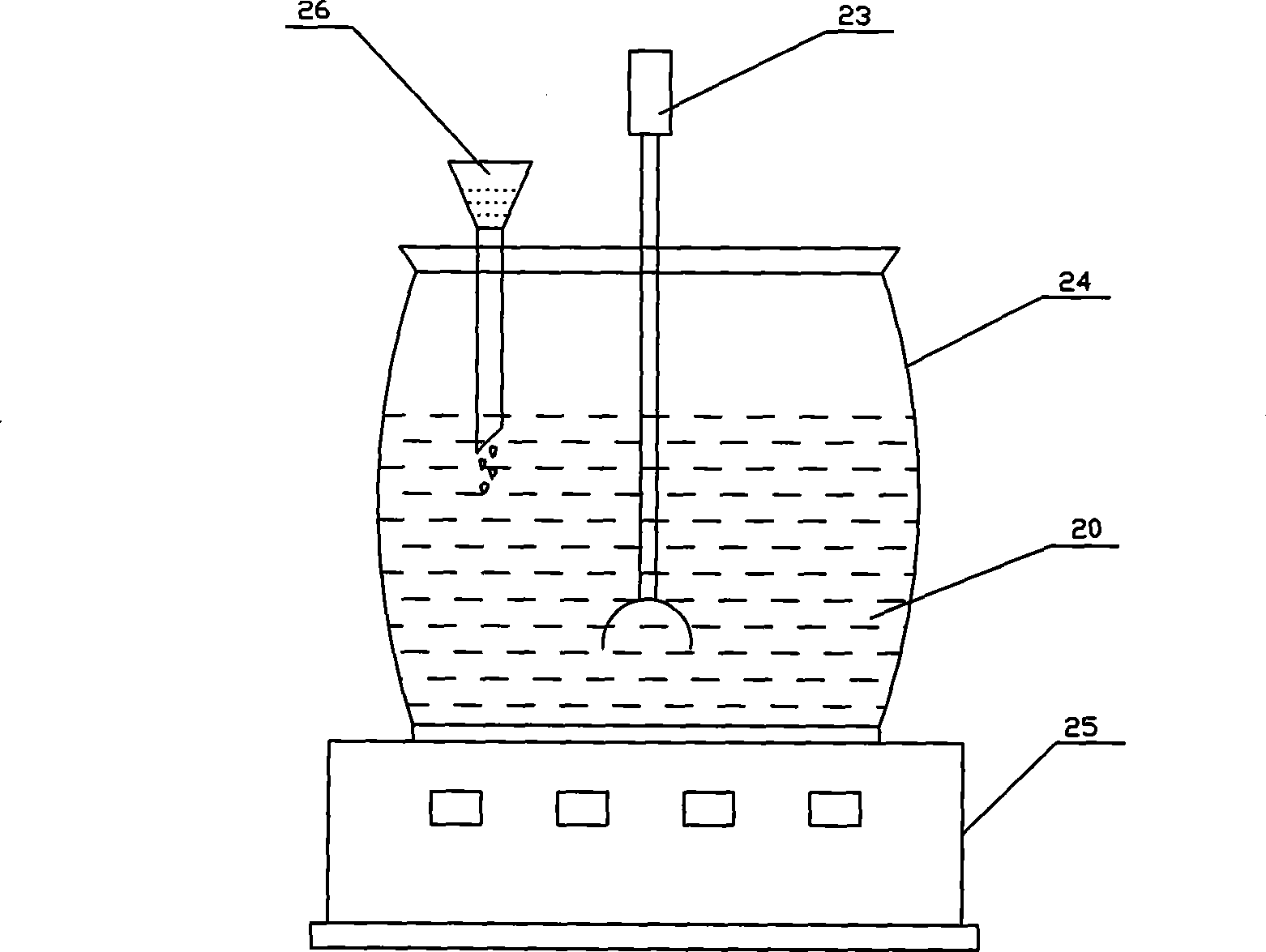

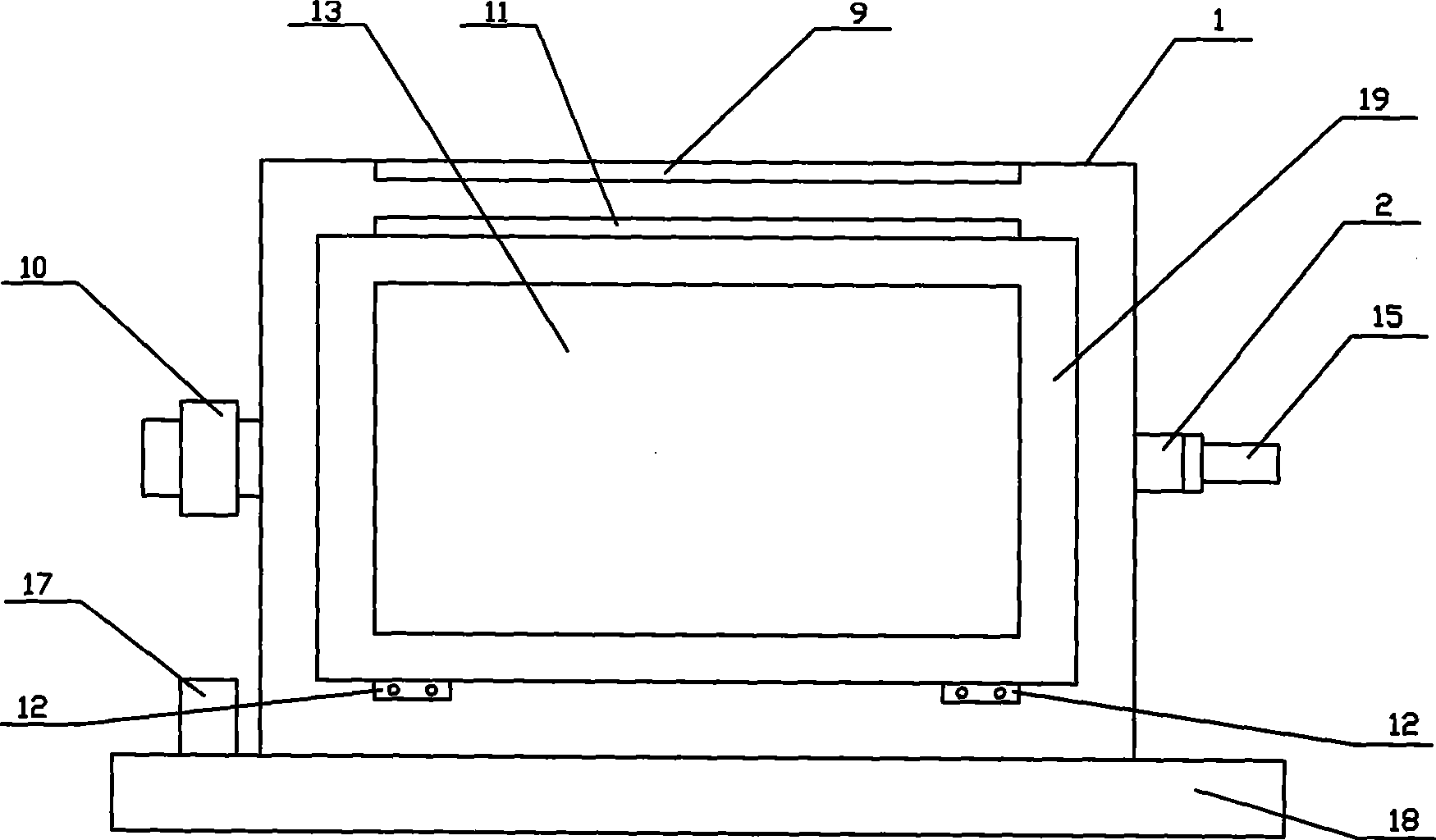

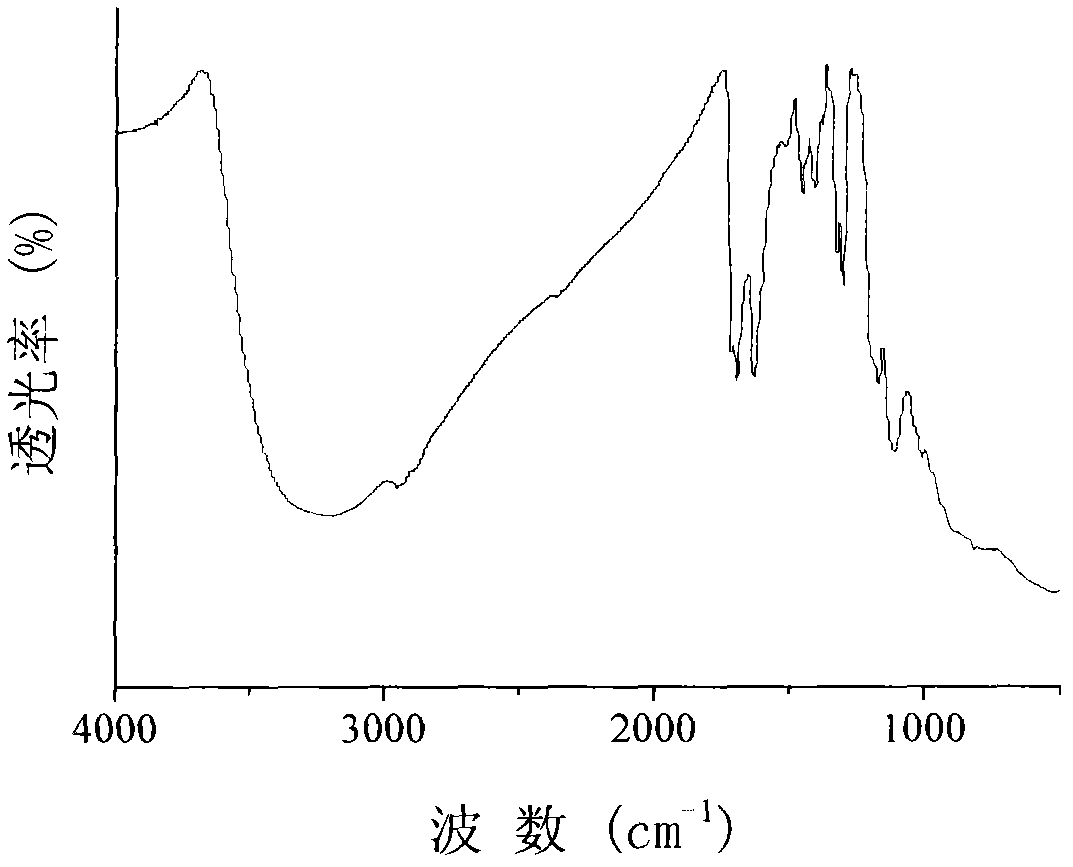

Antibacterial processing method for wool fiber

InactiveCN101413208AImprove durabilityEasy to manufacturePhysical treatmentAnimal fibresPre irradiationChemical reaction

The invention relates to an antibacterial treatment method for wool fiber, which comprises the following steps: an organic-inorganic composite antibacterial agent, namely silver-bearing silicon dioxide-chitosan is taken as an antibacterial agent and prepared into a pentabasic antibacterial mother liquor with anhydrous alcohol, deionized water, a diluted hydrochloric acid, a dispering / coupling agent and gamma-vinyltriethoxysilane A-151; the wool fiber is subjected to pre-irradiation of the ultraviolet light, and then immersed into the antibacterial mother liquor for secondary irradiation; and the wool fiber and the silver-bearing silicon dioxide-chitosan composite antibacterial agent generate chemical reaction under the action of a light trigger benzophenone and are combined by means of valence linkage to form an antibacterial film with the thickness of 200 nanometers. The antibacterial treatment method improves the persistence of antibacterial functions of the wool fiber, and the antibacterial rate of the wool fiber is still 98.6 percent after being washed for 50 times. Moreover, the antibacterial treatment method has short process flow, small number of equipment used, quick antibacterial speed, high efficiency and good effect, is easy to prepare the mother liquor, is particularly suitable for performing antibacterial treatment on the wool fiber and pashm fiber, and improves the efficiency by 90 percent compared with the prior antibacterial technology.

Owner:TAIYUAN UNIV OF TECH

Method for modifying nano titanium dioxide sol by utilizing silane coupling agent

InactiveCN102031022ASimple processMild reaction conditionsPigment treatment with organosilicon compoundsSilanesPollution

The invention discloses a method for modifying nano titanium dioxide sol by utilizing a silane coupling agent. The method comprises: mixing 20-70 parts by weight of absolute ethyl alcohol, 10-25 parts by weight of deionized water and 5-25 parts by weight of hydrochloric acid at room temperature; adding the mixture to the mixed liquor of 100 parts by weight of butyl titanate and 20-70 parts by weight of absolute ethyl alcohol at the addition speed controlled at 0.4-0.6g / min; stirring the mixture for 0.5-1.5 hours, then adding 1-20 parts by weight of silane coupling agent, and stirring the mixture for 0-24 hours; and heating the mixture to 70-85 DEG C and stirring the mixture to react for 0.5-2.0 hour, thus preparing the nano titanium dioxide sol modified by the silane coupling agent, wherein the silane coupling agent is gamma-methacryloxy propyl trimethoxy silane, ethenyl trimethoxy silane or ethenyl triethoxy silane. The method has the characteristics of simple process, mild reaction conditions, no pollution, wider application prospect and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of polyacrylate emulsion containing silicon, fluorine and phosphate group

The invention relates to a preparation method of polyacrylate emulsion containing silicon, fluorine and a phosphate group. The polyacrylate emulsion is widely applied in the fields of leather, paper and architectural decoration and finishing paint due to excellent caking property, film-forming property and mechanical properties. According to the preparation method provided by the invention, butyl acrylate, methyl methacrylate, styrene, hydroxypropyl methacrylate, vinyl triethoxy silane, phosphate functional monomer and dedecafluoroheptyl methacrylate are taken as polymerization monomers, lauryl sodium sulphate and fatty alcohol-polyoxyethylene ether are taken as emulsifiers, peroxysulphate is taken as an initiator, and a pre-emulsification seeded emulsion polymerization process is adopted for preparing the polyacrylate emulsion. According to the polyacrylate emulsion obtained by adopting the preparation method provided by the invention, fluorine, silicon and the phosphate group are introduced into a molecular structure, flame retardance, low temperature resistance, corrosion resistance, water resistance, anti-scouring property, mechanical properties and adhesiveness with materials such as metal and cement of a polymer emulsion film are obviously improved, and the obtained polyacrylate emulsion can be applied to leather, textile, metal antirust paints and decorative finish paints for an internal wall and an external wall of a building material and has good development prospect.

Owner:南京紫鸿生物科技有限公司 +1

In situ moisture generation and use of polyfunctional alcohols for crosslinking of silane-functionalized resins

InactiveUS8460770B2Improve propertiesReduce rateSynthetic resin layered productsSpecial surfacesSilanesStrong acids

Polymer compositions comprise a (i) silane-functionalized polymer, e.g., a polyethylene grafted with vinyl triethoxy silane, (H) polyfunctional alcohol e.g., α,α,α′,α′˜tetramethyl-I,3-benzenediethanol and, optionally, (iii) acid, e.g., an alkylated aryl disulfonic acid. The use of polyfunctional alcohols in the absence of a strong acid yields a light-crosslinking of the silane-functionalized polymer and this, in turn, provides a polymer melt with improved extensional properties such as elongational viscosity and melt strength. The use of a polyfunctional alcohol in combination with a blocked strong acid provides a slow rate of crosslinking during melt processing and a high degree of ultimate crosslinking after the polymer composition has been shaped or molded.

Owner:DOW GLOBAL TECH LLC

Mud resistance and slump loss resistance type high-performance polycarboxylic acid water reducer and preparation method thereof

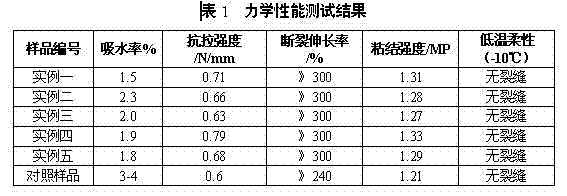

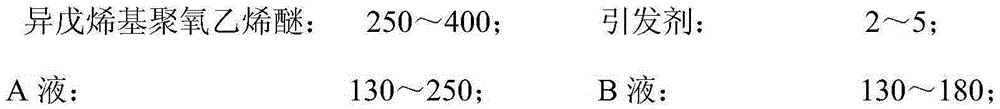

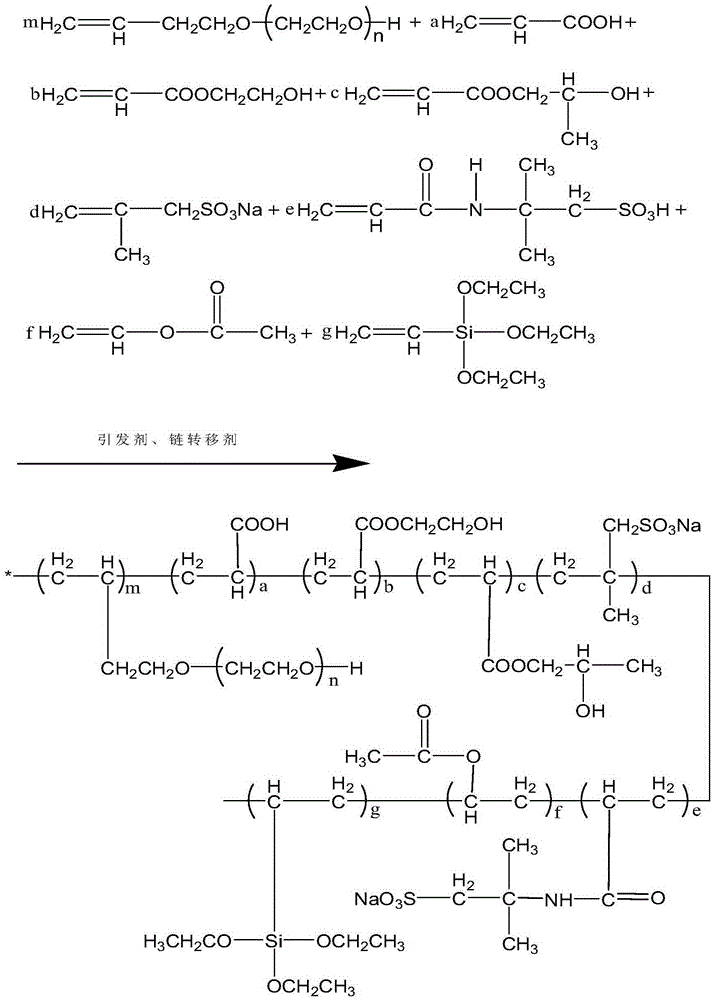

The invention discloses a mud resistance and slump loss resistance type high-performance polycarboxylic acid water reducer and a preparation method thereof. The water reducer comprises isopentenyl polyoxyethylene ether, an initiator, a solution A and a solution B, wherein the solution A comprises acrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, sodium methylacrylsulfonate, 2-acrylamido-2-methylpropanesulfonic acid, vinyl acetate, vinyltriethoxysilane and water; and the solution comprises a chain transferring agent, a reducing agent and water. The high-performance polycarboxylic acid water reducer is obtained through scientific proportioning and multi-time test. The water reducer has high water reducing rate and good slump loss resistance, solves the problem of adaptability of polycarboxylic acid water reducers to concrete raw materials, and can realize a good slump loss resistance effect and reduce the slump loss of concrete when the water reducer is especially applied in case of concrete raw materials with large mud content; and the preparation method of the water reducer has the advantages of simple operation, convenient preparation, low cost, and suitableness for industrial large-scale production.

Owner:四川恒泽建材有限公司

Wear-resistant and heatproof modified polyurethane rubber cable material

InactiveCN105602238AImprove performanceGood wear resistance and heat resistancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl alcohol

The invention discloses a wear-resistant and heatproof modified polyurethane rubber cable material which comprises the following raw materials: modified polyurethane, acrylate rubber, ethylene-propylene-diene monomer, nitrile butadiene rubber, epoxy resin, polyether glycol, toluene diisocynate, polyvinyl alcohol, diisobutyltin dilaurate, polyvinyl chloride, hydroxyl-terminated polybutadiene, hydroxyl-terminated polyalcohol, isocyanate, vinyltriethoxysilane, dibutyltin dilaurate, silicone oil, a carbon nanotube, organic modified montmorillonoid, nano alumina powder, talc powder, bamboo carbon fiber, chlorinated paraffin, silicon dioxide, zinc oxide, stearic acid, nano aluminum hydroxide, a flame retardant, an anti-aging agent, a plasticizer, an antioxidant and an accelerant. The modified polyurethane rubber cable material disclosed by the invention has excellent wear-resistant and heatproof properties.

Owner:ANHUI DUJIANG CABLE GROUP

Plastic-wooden composite tray and preparation method thereof

The invention discloses a plastic-wooden composite tray which is prepared from the raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of copolymerization polypropylene, 30-40 parts of modified wood meal, 40-50 parts of plastic renewable material, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of n-butyl methacrylate, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of triethoxyvinylsilane, 0.3-0.4 part of antioxidant 1010, 0.4-0.6 part of anti-aging agent MB, 8-10 parts of foaming modifier, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of TPE (Thermoplastic Polyurethane Elastomer), 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of glass fiber and 3-4 parts of semi-reinforced carbon black. The plastic-wooden composite tray produced by using the preparation method has the advantages of excellent mechanical property, capability of being sawed, planed and nailed, good durability, high repeated usage rate, capability of being recycled, resistance to insect biting, acid and alkaline resistance, aging resistance, and low water absorption and low deformation rate.

Owner:芜湖太平洋塑胶有限公司

Capacitor thin film with homo-polypropylene as substrate and preparation method thereof

InactiveCN103102587AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor thin film with homo-polypropylene as a substrate and a preparation method of the capacitor thin film. The composition raw materials of the thin film in parts by weight are as follows: 20-30 parts of LDPE (Low Density Polyethylene), 30-40 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of dicyclopentadienyl iron, 0.9-1.1 parts of poly-4-methyl-1-pentene, 0.5-0.7 part of permanent white, 9-11 parts of nano-clay, 2.0-2.5 parts of catechol, 1.2-1.6 parts of di(ethylene glycol) benzoate, 1.3-1.8 parts of dibutyl phthalate, 4-6 parts of calcium stearate, 1.5-2.0 parts of vinyl triethoxy silane, and 2.5-3.0 parts of modified tree ash. The thin film provided by the invention is manufactured by taking the homo-polypropylene as a main raw material and the low density polyethylene as an auxiliary raw material, and enabling a plurality of auxiliary additives and the homo-polypropylene as well as the low density polyethylene to be subjected to mixed extrusion, film blowing sizing, and cutting; the preparation method is simple; simultaneously, the diatomite, the nano-clay and the modified tree ash are added into the raw materials to enhance barrier property and air tightness of the thin film; and the thin film has the characteristics of good pressure resistance, good impact resistance, heat seal strength, and good heat seal performance.

Owner:TONGLING YIHENGDA ELECTRONICS

Preparation method of nuclear shell structure high-silicon silicone acrylic emulsion used for building exterior wall

InactiveCN101781390AHigh silicon contentImprove smoothness and beautyCoatingsSODIUM DODECYL BENZENE SULFONATEDodecylbenzenesulfonic acid

The invention discloses a preparation method of nuclear shell structure high-silicon silicone acrylic emulsion used for building exterior walls. Firstly, the invention uses octavinyl cyclotetrasiloxane, octamethylcyclotetra siloxane, dodecylbenzene sulfonic acid, sodium dodecyl benzene sulfonate, emulsifier 0P-10 and deionized water to prepare unsaturated organo-siloxane low polymer emulsion; theorgano-siloxane low polymer emulsion, acrylate monomer mixture, initiator A, emulsifier, pH value regulator, molecular weight regulator and deionized water are adopted to polymerize nuclear emulsion;and finally, silicon acrylic nuclear emulsion, deionized water, anion / non-ion emulsifier, acrylate monomer mixture, VTES coupling agent and initiator B are adopted to polymerize nuclear emulsion to prepare high-silicon silicone acrylic emulsion. The method of the invention effectively inhibits organosilicon self-polymerization, so that the silicone acrylic emulsion of the invention has high silicon content and stable storage, has the properties of favorable weather resistance, smudge resistance, water resistance and the like, has high gloss and beautiful degree and can satisfy the requirements of high-grade buildings on exterior wall paint.

Owner:TIANJIN URBAN CONSTR COLLEGE

Weather-proof polyolefin wire cable material and preparation method thereof

InactiveCN104109276AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsEpoxyPolyolefin

The invention discloses a weather-proof polyolefin wire cable material and a preparation method thereof, the cable material comprises the raw material by weight: 60-80 parts of LDPE, 15-25 parts of EVA, 10-15 parts of SEBS, 14-18 parts of magnesium hydroxide, 2-4 parts of stearic acid, 1-2 parts of zinc oxide, 5-10 parts of zinc borate, 1-2 parts of lead sulfate tribasic, 1-2 parts of vinyltriethoxysilane, 4-8 parts of octyl epoxy stearate, 0.5-1 part of light stabilizing agent GW-4800.5, 1-1.5 parts of anti-oxidant 215, 0.5-1 part of dibutyltin dilaurate, 0.5-1 part of dicumyl peroxide, 20-25 part of aluminum silicon black, 10-15 parts of nano barite, 5-10 parts of nano diatomite and 4-8 parts of composite filling material. The polyolefin cable material has excellent flame retardation performance, physical and mechanical properties and weatherability, can be widely used in electric power cable, communication cable, control cable, optical cable , subway cable, insulation or sheath, electronic wire, automobile and the like, and has the advantages of environmental protection and durable performance.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

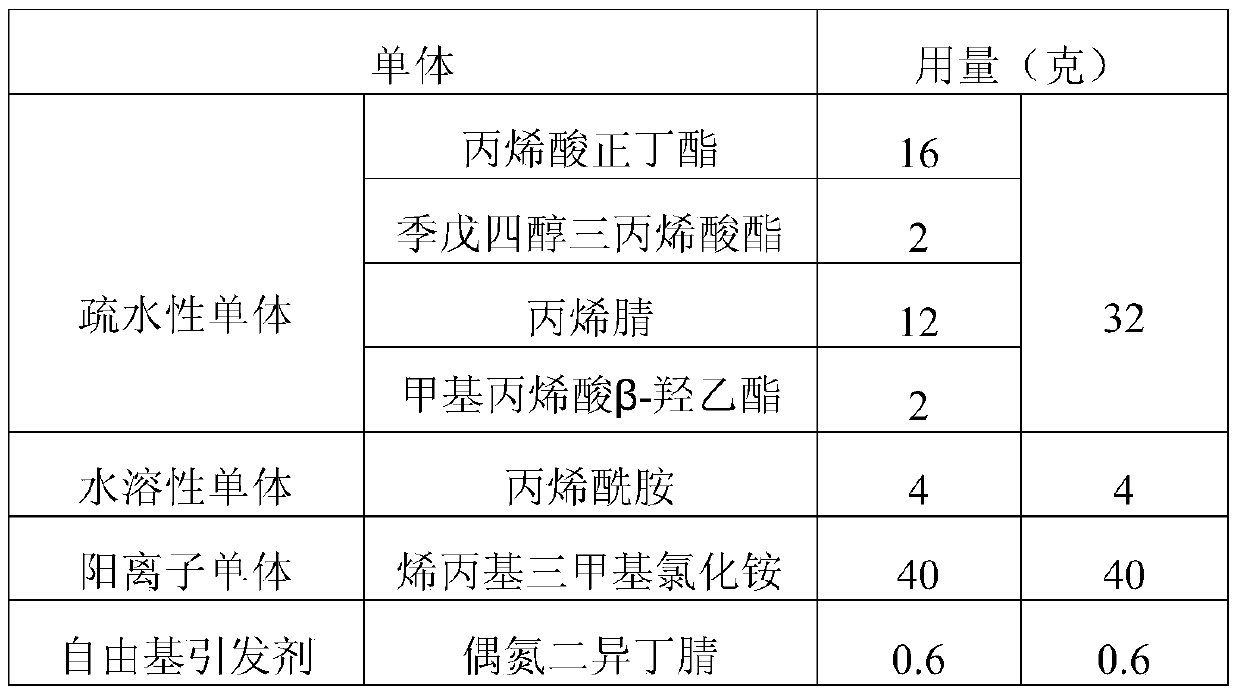

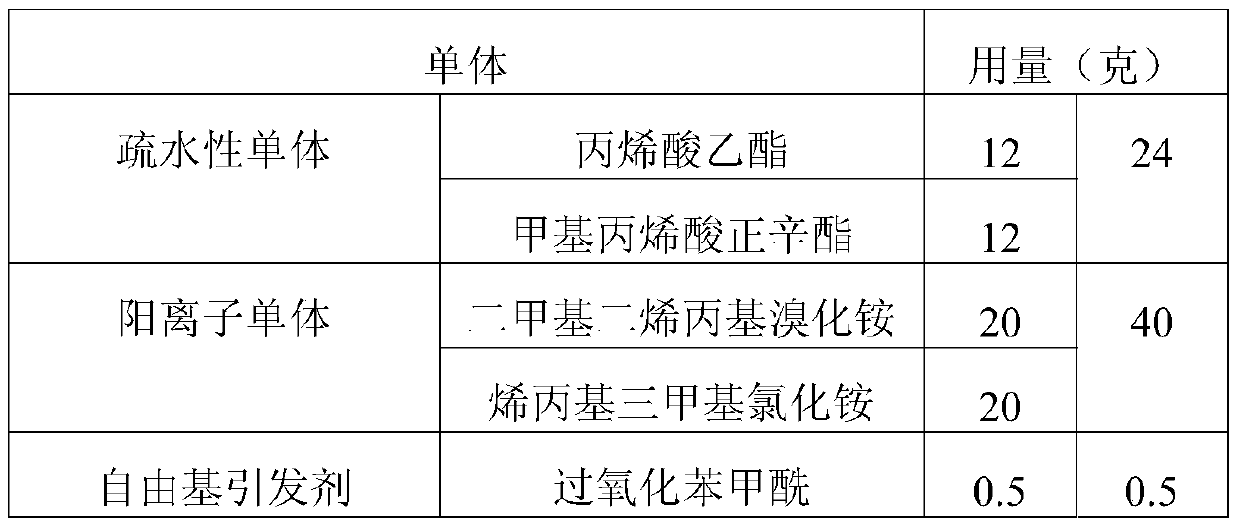

Cationic flocculant and preparation method thereof

InactiveCN105504163AGood electrostatic attractionHigh affinityWater contaminantsWater/sewage treatment by flocculation/precipitationCyclohexanonePersulfate

The invention discloses a cationic flocculant and a preparation method thereof. The cationic flocculant is prepared by carrying out polymerization reaction on reaction monomers comprising a cationic monomer and a hydrophobic monomer under the action of a free-radical initiator, wherein the cationic monomer comprises one or combination of more of acryloyloxyethyl alkyl quaternary ammonium salts and / or allyl alkyl quaternary ammonium salts; the hydrophobic monomer comprises one or combination of more of styrene, acrylonitrile, vinyl acetate, vinyltrimethoxysilane, vinyltriethoxysilane and acrylate; and the free-radical initiator comprises one or combination of more of azodiisobutyronitrile, azodiisohexyl cyanide, azodiisobutylamidine hydrochloride, cyclohexanone peroxide, benzoperoxide and persulfate. The flocculant can adsorb anionic dyes, has favorable affinity with electrically neutral organic matters or organic matters with a small amount of anions, and has excellent flocculating settling effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

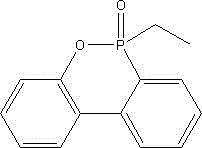

Phosphorus-containing flame retardant based on polyhedral oligomeric silsesquioxane (POSS) and preparation method of phosphorus-containing flame retardant

The invention discloses a phosphorus-containing flame retardant based on polyhedral oligomeric silsesquioxane (POSS) and a preparation method of the phosphorus-containing flame retardant. The flame retardant is prepared by carrying out hydrogenated addition and acid-catalyzed hydrolysis condensation reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and DOPO derivatives thereof and vinyltriethoxysilane (VTES); the flame retardant has the advantages of high phosphorus content, high flame-retardant efficiency, good heat resistance and little influence on mechanical property of a material; the flame retardant is used for products such as high temperature vulcanized silicone rubber and room temperature vulcanized silicone rubber, and also can be used as a temperature-resistant flame retardant of a thermoplastic polymer material; meanwhile, the flame retardant is high in phosphorus content; by adding a small amount of flame retardant, an excellent flame-retardant effect can be realized; a unique POSS structure belongs to a semi-inorganic organosilicone material, so the heat resistance of the flame retardant is improved.

Owner:SHANDONG SHIP TECH RES INST

Tipping paper and production method thereof

InactiveCN103741551AGood yellowing resistanceImprove toughnessSpecial paperPaper/cardboardSodium metasilicateSilanes

Tipping paper is prepared from the following raw materials in parts by weight: 60-70 parts of softwood pulp, 100-120 parts of hardwood pulp, 2-3 parts of trimethoxy(methyl)silane, 3-4 parts of triethoxyvinylsilane, 1-2 parts of sodium metasilicate, 1-2 parts of ethanol, 2-3 parts of polyvinyl acetate emulsion, 1-2 parts of sodium carbonate, 1-2 parts of an anti-oxidation agent 168, 3-4 parts of meerschaum powder, 2-3 parts of vermiculite powder, 1-2 parts of sodium tripolyphosphate, 1-2 parts of sodium carboxymethylcellulose, 1-2 parts of sodium persulfate and 1-2 parts of grape seed oil. The technological effects comprise that by adding the anti-oxidation agent into the raw materials, the tipping paper is increased in yellowing resistance, and also is substantially prolonged in storage time; and also, by adding ester materials into the raw materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

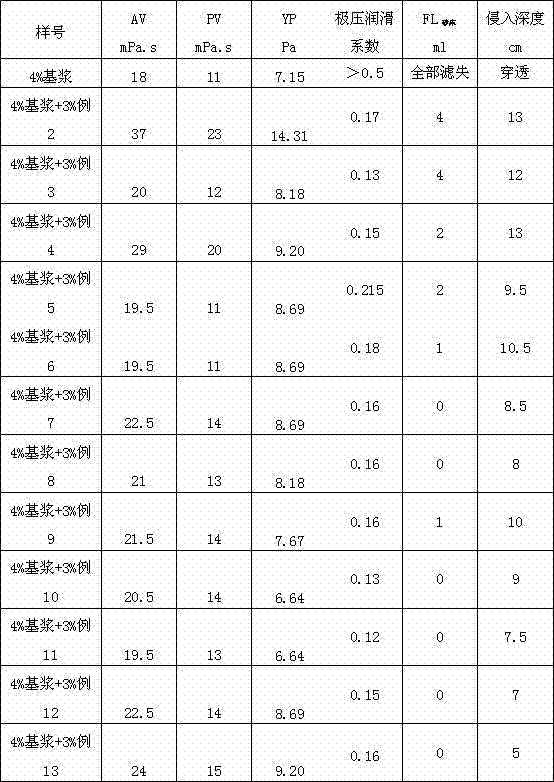

Temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method

InactiveCN103937471AEffective blockingDoes not affect rheological parametersDrilling compositionSodium bisulfateVegetable fibers

The invention relates to a temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method, the drill-feeding plugging agent comprises the following components by weight: 30-80 parts of vegetable fiber, 10-40 parts of mineral fiber, 10-40 parts of fruit shell, 0-10 parts of powdered steatile, and 3-10 parts of silicon-based gel deformation particles. The silicon-based gel deformation particles enable emulsification and dispersion of 1.4-2.5 parts of vinyltriethoxysilane monomer according to weight to an aqueous solution composed of 18-24 parts of acrylamide, 0.0025-0.005 parts of N,N'-methylene bisacrylamide, 0.7-1.25 parts of OP-10 and 0.1-0.17 parts of sodium dodecyl benzene sulfonate, 0.003 parts of disodium ethylene diamine tetraacetate, 0.009-0.12 parts of ammonium persulfate and 0.009-0.012 parts of sodium bisulfate, a process of micellar copolymerization is carried out, a polymer is dried, granulated and crushed to obtain the silicon-based gel deformation particles with average particle size of 80-200 meshes; easy-leakage highly-permeable stratum and micro crack are effectively plugged, rheological parameter of the drilling fluid is not influenced, frictional resistance coefficient of the drilling fluid is reduced, a storage layer is protected, and the drill-feeding plugging agent is suitable for plugging the easy-leakage stratum and the storage layer.

Owner:中国石油天然气股份有限公司冀东油田分公司钻采工艺研究院

High-wear-resistant antibacterial acrylate paint

InactiveCN106366899AImprove wear resistanceGood solvent resistanceFireproof paintsAntifouling/underwater paintsWear resistantUnsaturated polyester

The invention discloses high-wear-resistant antibacterial acrylate paint. The high-wear-resistant antibacterial acrylate paint is prepared from the raw materials: an aqueous acrylate emulsion, alkyd resin, organosilicon modified unsaturated polyester resin, silica sol, cellulose acetate butyrate, polyvinyl pyrrolidone, modified nano-titania, calcium carbonate whiskers, octadecyl trimethyl ammonium chloride modified montmorillonite, hollow glass beads, zinc oxide, ethylene glycol mono-n-propyl ether, di-propanediol butyl ether, triethylene glycol monoethyl ether, an anti-settling agent, a humectant, an antifoamer, per-methoxylation melamine resin, 3,5-dimethyl-2-aminobenzoic acid, trimethylaniline, a leveling agent, vinyl triethoxysilane and deionized water. The high-wear-resistant antibacterial acrylate paint provided by the invention is high in hardness, good in wear resistance, excellent in antibacterial performance and long in service life.

Owner:ANHUI JINDUN PAINT

High-strength multifunctional plugging agent

InactiveCN110105935AImprove the development effectImprove adhesionDrilling compositionMicron scaleSilanes

The invention discloses a high-strength multifunctional plugging agent. The plugging agent comprises, by mass, 100 parts of a structural forming agent, 0.001-15 parts of a curing agent, 0.001-10 partsof an interface adhesion agent, 0.001-200 parts of a nano filler and 0.001-30 parts of a diluent, wherein the structural forming agent comprises one or two of unsaturated polyester and vinyl resin; the curing agent comprises one or more of peroxide, persulfide and azo compounds; the interface adhesion agent comprises vinyl triethoxy silane or vinyl trimethoxy silane; the nano filler comprises oneor more of nanoscale or micron-scale carbonate, silicate and sulfate. During use, the structural forming agent, the curing agent, the interface adhesion agent, the nano filler and the diluent are mixed and react to generate liquid gel; the liquid gel is injected to a target plugged zone position and is solidified to form the high-strength multifunctional plugging agent. The plugging agent is stable in performance, good in residence property, high in adhesion force, high in elasticity modulus and high in compressive strength, and has a wide application range and good effects in oil and gas field drilling and production operation.

Owner:陕西鼎和源瑞环境工程有限公司

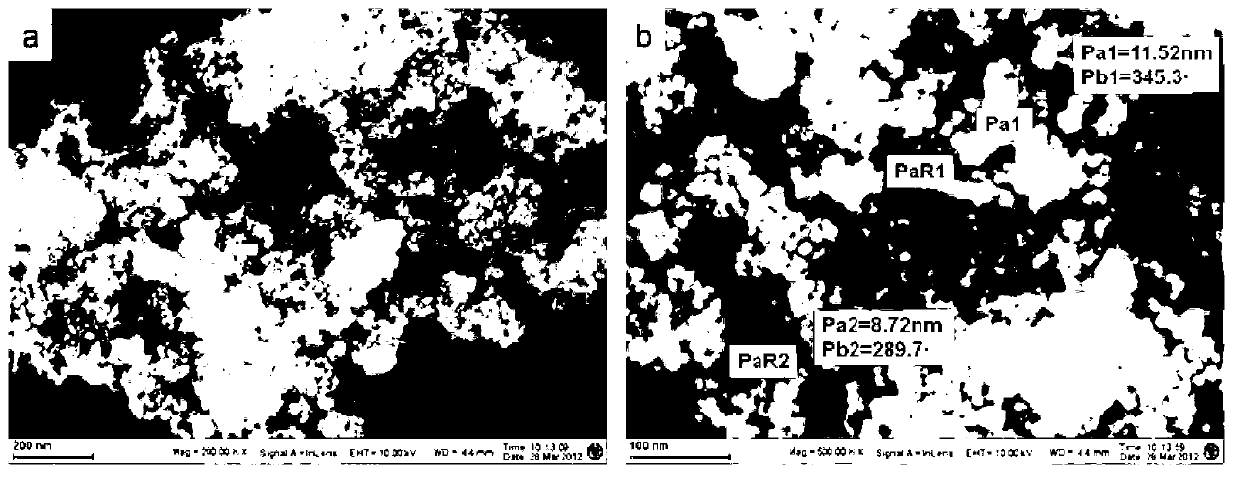

Preparation method of porous magnetic polystyrene microspheres

ActiveCN102964539AEasy to shapeEvenly distributedOrganic/organic-metallic materials magnetismCross-linkBenzoyl peroxide

The invention discloses a preparation method of porous magnetic polystyrene microspheres. The method comprises steps of: (1) adding dry Fe3O4 magnetic nanoparticles into an aqueous ethanol solution, treating with ultrasonic, adding vinyltriethoxysilane, transferring into a reactor together, stirring under a constant temperature and a nitrogen atmosphere for aging, and then washing, drying under vacuum and grinding the obtained product into powder; (2) mixing the powder obtained in the step (1) and benzoyl peroxide, and then adding into styrene containing a pore forming agent and a cross-linking agent for the ultrasonic treating; (3) dissolving polyvinylpyrrolidone and sodium dodecyl sulfate into water by using the ultrasonic; and (4) adding the liquid obtained in the step (2) into the liquid obtained in the step (3), treating with the ultrasonic, pouring the obtained mixture into a reactor, heating for condensation reflux to obtain a suspension liquid, separating with magnet, washing with ethanol, re-separating with the magnet, re-washing with pure water, drying under vacuum and grinding to obtain claybank powdery product, extracting with a soxhlet way, and drying under vacuum to obtain the finish product.

Owner:NANJING FORESTRY UNIV

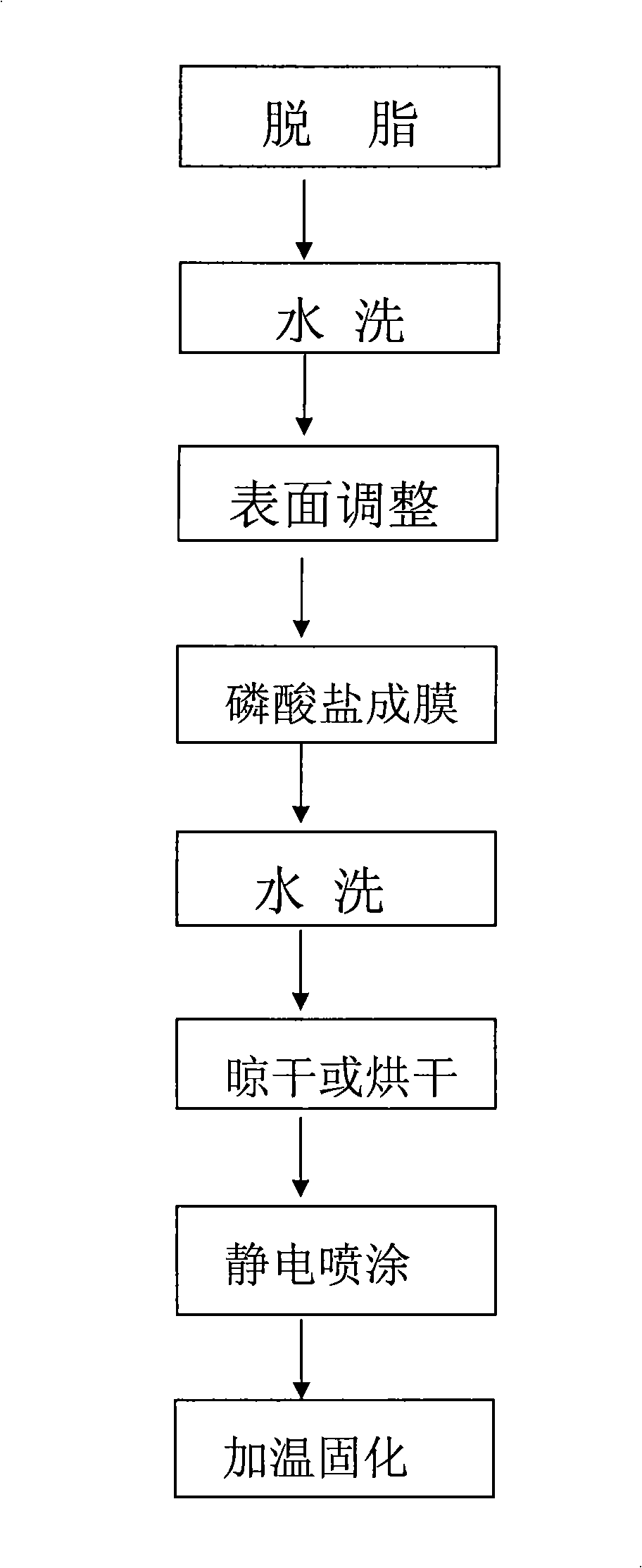

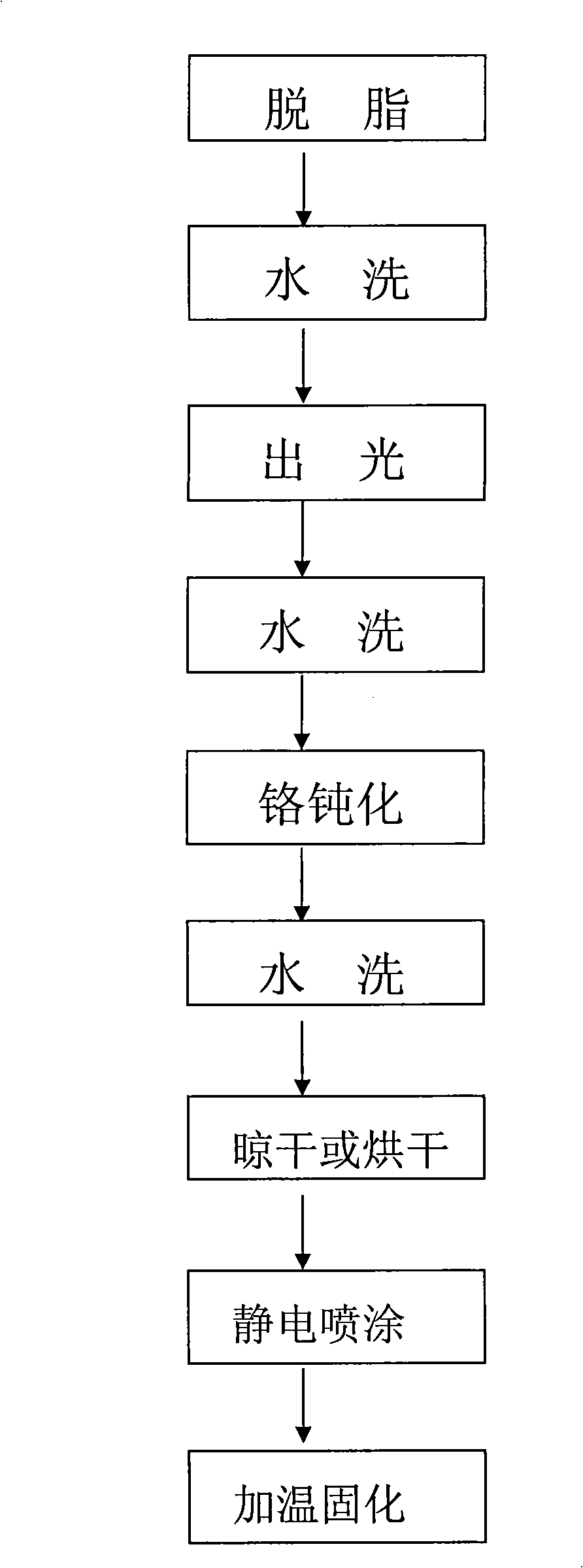

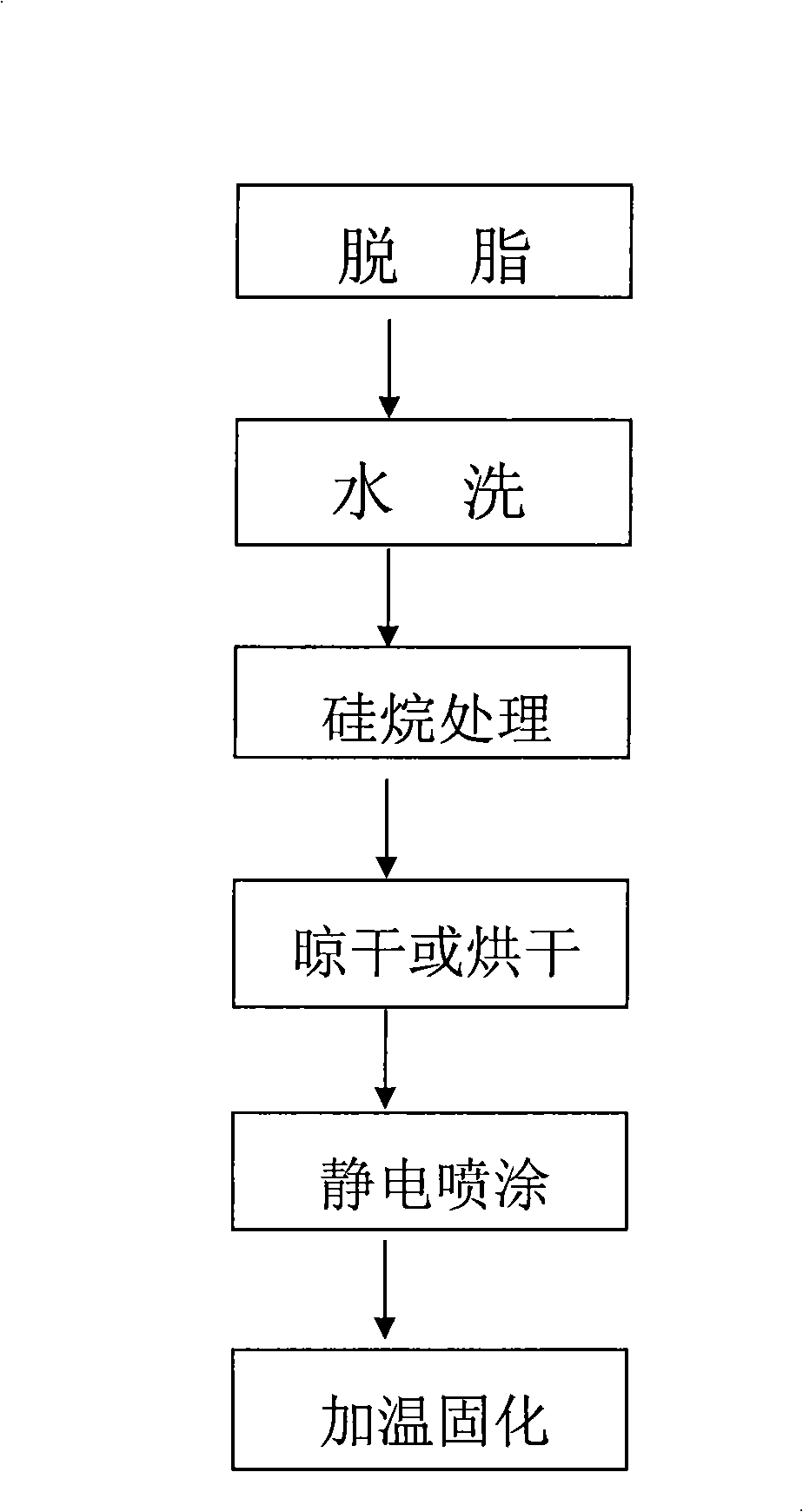

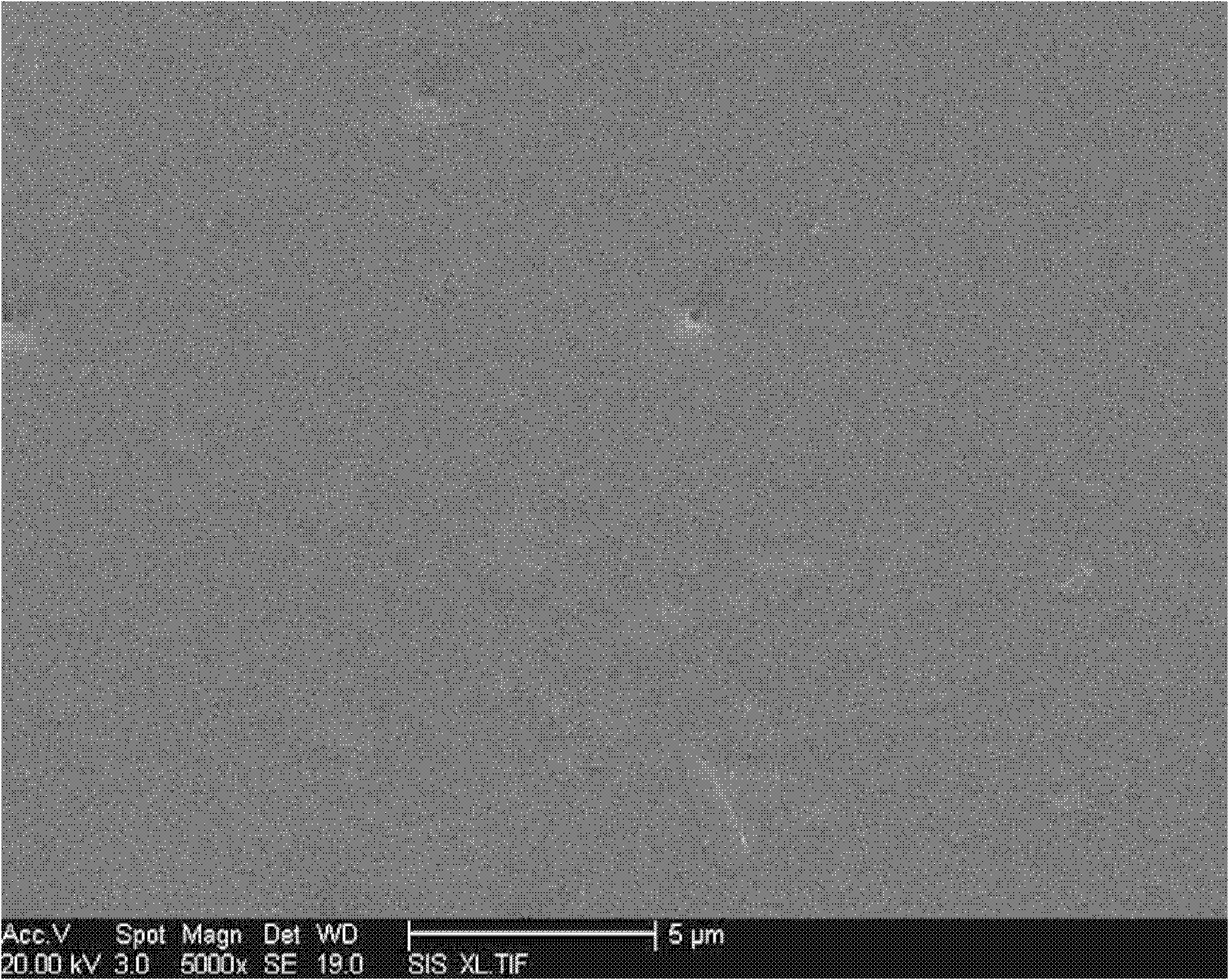

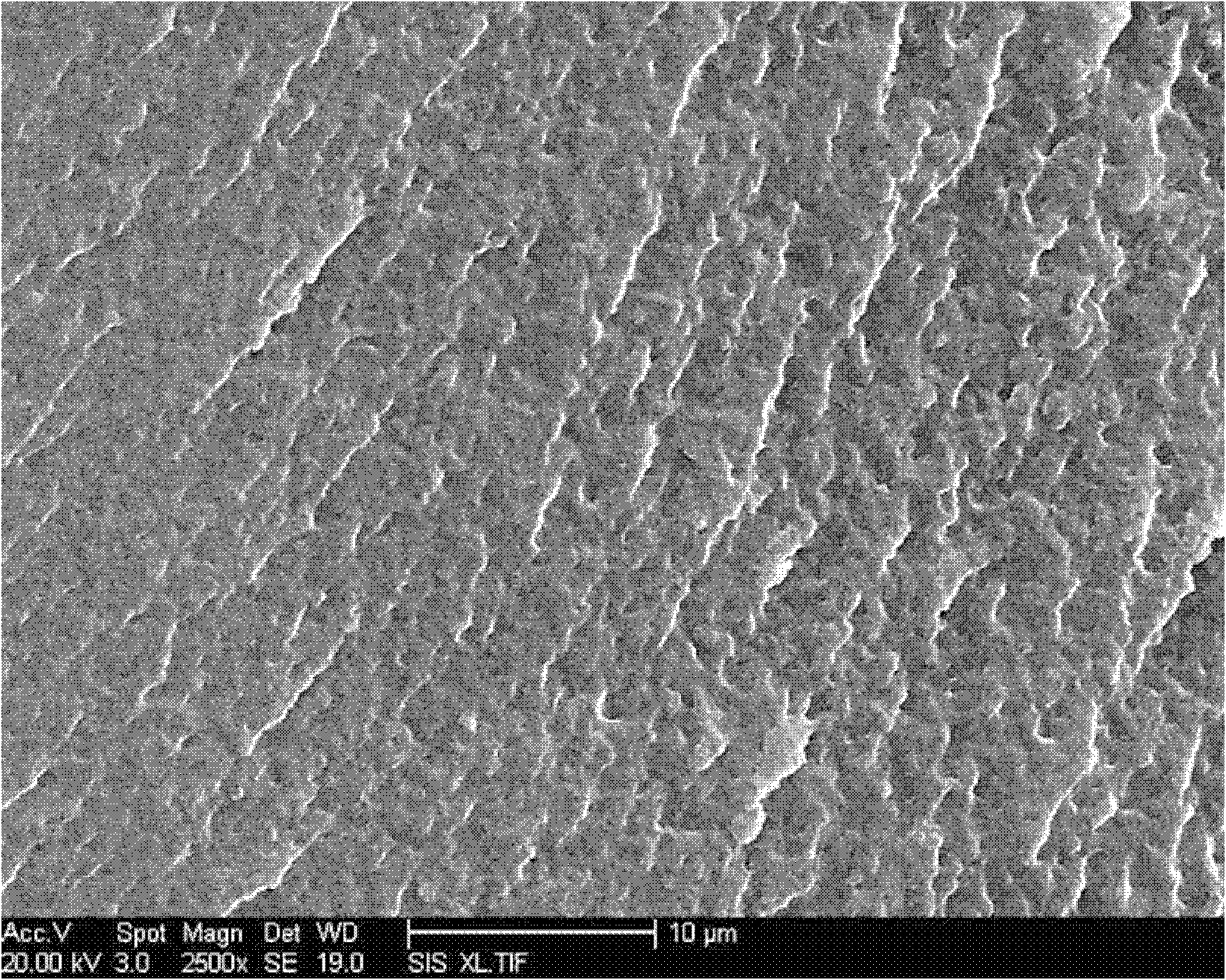

Silane treatment technique before electrostatic powder spraying of metal

The invention provides a silane treating process method before coating metal electrostatic powder, which can be particularly applied to the metal electrostatic powder coating industry. The invention also provides an environment-friendly, energy-saving and high-efficient silane agent. The weight proportion of the main components of the agent is as follows: vinyl triethoxy silane 1% to 3%, 3-aminopropyl triethoxysilane 1% to 2%, propyl triethoxy silane 0% to 1%, isocyan-acid propyl triethoxy silane 0.5% to 1.5%, ethanol 4% to 8%, and acetic acid 0.4% to 1.2%, and the rest being deionized water. The treatment method can save energy, can be used without heating, does not contain heavy metal and phosphorus which are harmful to the environment, does not produce sediment during the treatment process with stable groove liquid, can be used continuously through filling, can simultaneously treat a plurality of substrates such as iron pieces, galvanized parts, aluminum parts and aluminum alloys, and can obviously improve the adhesion between the powder coatings and the metal substrates.

Owner:武汉材保表面新材料有限公司

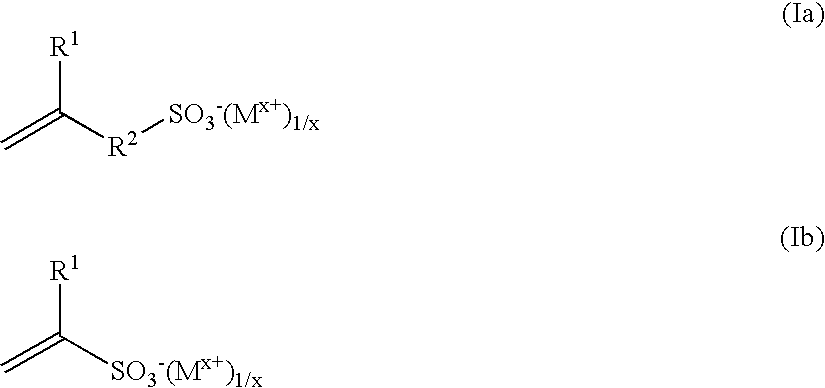

Copolymer based on olefinic sulphonic acids

A copolymer based on olefinic sulphonic acids as monomer component a) and an organosilicone-containing compound as reactive component b) is proposed, for which in particular 2-acrylamido-2-methylpropanesulphonic acid (AMPS®) is suitable as component a) and vinyltrimethoxysilane, vinyltriethoxysilane and trichlorosilane as component b). This copolymer, which may have a molecular weight of from 5,000 to 5,000,000 g / mol, may also comprise further reaction components c) and d) in addition to the two main components for which further reaction components (meth)acrylamides or vinyl ethers are suitable. These copolymers, which are obtainable in particular by precipitation or gel polymerizations, are used in particular in applications in construction chemistry and here especially as water retention agents and fluid loss additives in drilling fluids and for well cementing. The novel copolymers are distinguished by pronounced thermal stability, which is displayed especially under difficult pressure conditions and at high salinities.

Owner:BASF CONSTR POLYMERS

Hydrophobic-surface treatment agent and preparation method thereof

InactiveCN103224511AHigh yieldLower surface energyGroup 4/14 element organic compoundsSilanesSynthesis methods

The invention discloses a hydrophobic-surface treatment agent and a preparation method thereof. The preparation method comprises adding 1,1,1,3,5,5,5-heptamethyltrisiloxane and a catalyst into a reactor under 35-65 DEG C, adding vinyl trimethoxysilane or vinyl triethoxysilane in drops, after the reaction, adding active carbon for adsorption processing, filtering, and distilling filtrate under a reduced pressure to obtain the hydrophobic-surface treatment agent. According to the invention, the 1,1,1,3,5,5,5-heptamethyltrisiloxane with high-activity silicon-hydrogen bonds and the vinyl silane with double bonds are used as raw materials, a high-yield hydrosilylation reaction is utilized, and the product is prepared by a one-step synthesis method. The agent is high in reaction activity of function groups, low in surface energy, mild and controllable in reaction conditions, high in product yield and low in production cost.

Owner:DONGHUA UNIV

Method for preparing antibacterial fiber membrane

ActiveCN105839295AUniform pore sizeExcellent stable membrane fluxHollow filament manufactureElectro-spinningYarnCellulose diacetate

The invention discloses a method for preparing an antibacterial fiber membrane. The method comprises the following steps: preparing a complex antibacterial agent by using N-(4-hydroxy-3-methoxybenzyl)acrylamide, 2-hydroxypropyl methacrylate, N, N- (dimethylamino)ethyl methacrylate, and vinyltriethoxysilane-modified nano zinc oxide; adding polyacrylonitrile, cellulose diacetate and glucose to a mixed solvent to obtain a mixed solution; adding the complex antibacterial agent, poly vinyl alcohol, laponite, silver ion loaded zeolite molecular sieve, nano titanium dioxide, alumina sol, calcium chloride and dilauryl thiodipropionate to water to be uniformly mixed, adding the mixed solution and then conducting electrostatic spinning to obtain a raw yarn, putting the raw yarn in water to be soaked and dried. The method for preparing the antibacterial fiber membrane provided by the invention has the advantages of simple process, mild conditions, good antibacterial properties, excellent stain resistance, high mechanical strength and toughness, and long service life.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Extra-weather-resistant waterborne environment-protective resin and preparation technology thereof

According to the invention, methyl methacrylate (MMA), butyl acrylate (BA), ethyl acrylate (EA), acrylic acid (AA) and methacrylic acid (MAA) and trifluoroethyl methacrylate (TFEMA), vinyltriethoxysilane (KH-151) and styrene (ST) and other functional monomers are used as comonomers; benzoyl peroxide (BPO) is used as a chain initiator, a solution polymerization method is used, and a free radical polymerization is carried out through a special process to synthesize organic fluorine-silicon modified waterborne acrylic resin with excellent performance. The resin is extra-weather-resistant, is applied to a water-based acrylic coating, and has advantages of good gloss retention, exterior durability, good pollution resistance and the like. By the use of the resin, water resistance, solvent resistance and heat resistance of a water-based acrylic resin coating can be improved, and hardness and shock resistance of a paint film can be enhanced. As a coating with superior performance, the product has a wide application prospect.

Owner:沈阳宣伯新材料科技有限公司

Low-temperature-resistant and abrasion-resistant cable

InactiveCN105038257AChanging the crystallization temperatureLower crystallization temperatureRubber insulatorsInsulated cablesPhosphorous acidMelamine phosphate

The invention discloses a low-temperature-resistant and abrasion-resistant cable. The low-temperature-resistant and abrasion-resistant cable comprises a conductive cable core, an inner protective cover and an outer protective cover. The conductive cable core is wrapped by the inner protective cover, and the inner protective cover is wrapped by the outer protective cover. The outer protective cover comprises polymethylvinylphenylsiloxane gum, hydrogenated butadiene-acrylonitrile rubber, solution polymerized styrene-butadiene rubber, methyl fluorine silicone oil, epoxidized soybean oil, dioctyl nylon acid ester, fumed silica, micro gelating capsule red phosphorus, melamine phosphate, dicumyl peroxide, vinyltriethoxysilane, zinc oxide, Ca / Zn compound stabilizer, TX-1 type rare-earth stabilizer, magnesium stearate, antioxygen 1076, phosphorous acid trioctyl ester and silicone powder. The low-temperature-resistant and abrasion-resistant cable is good in low temperature resistance and high in tenacity and abrasion resistance.

Owner:ANHUI RUIKAN SCI CABLE

Hydrophilicity and hydrophobicity adjustable nano SiO2 powder

ActiveCN103450487ARaw materials are easy to getSimple processPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsHydrogenNano sio2

The invention discloses hydrophilicity and hydrophobicity adjustable nano SiO2 powder. The nano SiO2 powder is prepared by the following method: firstly synthesizing vinyl SiO2 particles with tetraethoxysilane, vinyltriethoxysilane and the like by a one-pot method, then using hydrogen-containing silicone oil and allyl polyether as modifying agents to modify the vinyl SiO2 particles step by step via hydrosilylation in the presence of a catalyst, and achieving hydrophilicity and hydrophobicity adjustability by adjusting the amount of hydrogen-containing silicone oil and allyl polyether. The nano SiO2 powder with moderate hydrophilicity and hydrophobicity can be dispersed in solvents with different polarities and can be also used for preparing Pickering emulsion. The method has the beneficial effects that the raw materials used in the method are accessible and the operating steps are simple, so that the method has extensive application prospects in industry.

Owner:YANGZHOU SIXIN NEW MATERIAL TECH CO LTD

High-rigidity steel belt reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN104534192AMeet the processing technology requirementsAvoid breakingRigid pipesPropanoic acidPhosphoric acid

The invention discloses a high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and a preparation method thereof. The high-rigidity steel belt reinforced polyethylene spiral corrugated pipe comprises an inner polyethylene pipe, formed steel belts and an outer polyethylene pipe. The formed steel belts are wound around the outer surface of the inner polyethylene pipe at equal intervals and wrapped by the outer polyethylene pipe. The inner polyethylene pipe and the outer polyethylene pipe respectively comprise, by weight, 80-86 parts of high density polyethylene, 8-10 parts of magnesium hydrate, 4-6 parts of compatilizers, 3-4 parts of dibutyltin dilaurate, 2-4 parts of calcium hypophosphite, 2-3 parts of polyoxyethylene, 5-6 parts of polyethylene-graft-maleic anhydride, 7-9 parts of alkyl phosphoric acid, 3-6 parts of superfine talcum powder, 5-7 parts of lustering agents for plastic, 6-8 parts of aluminium-zirconium coupling agents, 4-5 parts of vinyltriethoxysilane, 4-7 parts of beta (3,5 di-tert-butyl-4-hydroxycyclohexyl phenyl ketone) propionic acid octadecyl ester, 5-8 parts of color master batches and 10-12 parts of assistant master batches. According to the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and the preparation method of the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe, the technology is simple, the production cost is low, pipes are not likely to be fractured, adhesive bonding is firm, the layering problem is not likely to be produced, and using is safe and reliable.

Owner:HANGZHOU TONGYU IND

Polyethylene cable material and preparation method thereof

InactiveCN103351518AImprove mechanical propertiesHigh temperature resistantPlastic/resin/waxes insulatorsInsulated cablesMonoglycerideSlag

The invention provides a polyethylene cable material and a preparation method thereof. The coating is characterized by comprising the following raw materials by weight parts: 45-50 parts of linear low-density polyethylene, 2-3 parts of PPS, 4-5 parts of stearic acid monoglyceride, 1-2 parts of nano-clay brick slag powder, 16-19 parts of general purpose polystyrene, 2-3 parts of polyisobutylene, 1-2 parts of ABS high crumb rubber, 4-5 parts of microcrystalline wax, 3-4 parts of rapeseed oil, 32-35 parts of sepiolite powder, 23-26 parts of vermiculite powder, 12-14 parts of celestine powder, 1-2 parts of magnesium oxide, 1-2 parts of zinc oxide, 2-3 parts of zinc stearate, 1-2 parts of an accelerator TETD, 3-5 parts of methyl trimethoxy silane, 2-3 parts of vinyltriethoxysilane, 2-3 parts of ethyl acrylate, 8-10 parts of high wear resistant carbon black N 330 and 6-8 parts of modified diatomite. The cable material provided by the invention is high in mechanical property, high temperature resistance, high in flame retardant, and low-smoke and nontoxic during combustion.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

Method for synthesizing modified manganese dioxide nanometer material compound acrylic ester type oil-absorptive resin

InactiveCN102807646AHigh oil absorption rateImprove thermal stabilityMicrowave radiometryBenzoyl peroxide

Disclosed is a method for synthesizing modified manganese dioxide nanometer material compound acrylic ester type oil-absorptive resin. The method includes modifying analytically pure manganese dioxide by vinyltriethoxysilane, modifying prepared manganese dioxde nanowires by cetyl trimethyl ammonium bromide so that manganese nanometer materials are of hydrophobicity; utilizing butyl methacrylate and butyl acrylate as oil-absorptive resin as main monomer, utilizing poval, N, N'-methylene bisacrylamide, benzoyl peroxide and ethyl acetate as dispersing agent, crosslinking agent, trigger and pore-forming agent of a polymerizing reaction system, and synthesizing modified manganese dioxide nanometer material compound acrylic ester type oil-absorptive resin by means of microwave radiation. The oil absorption ratio of the acrylic ester type oil-absorptive resin synthetized by the method to halohydrocarbon such as carbon tetrachloride is 20-40% higher than that of conventional acrylic ester type high-oil-absorption resin, and thermal stability is improved largely.

Owner:YANSHAN UNIV

Artemisinin molecule imprinting polymer on surface of porous microsphere silica gel as well as preparation and application methods thereof

InactiveCN101845126AAdsorptiveSelectiveOrganic chemistryBulk chemical productionCross-linkPolymer science

The invention relates to an artemisinin molecule imprinting polymer on the surface of porous microsphere silica gel. The artemisinin molecule imprinting polymer is prepared by adopting the steps of: selecting the porous microsphere silica gel as a basal material, taking vinyl triethoxysilane as a coupling agent, artemisinin as a template molecule, methacrylate and acrylamide as functional monomers, ethylene glycol dimethacrylate as a cross-linking agent and azodiisobutyronitrile as an initiating agent, preparing a polymer and removing the artemisinin in the polymer. The invention also provides a preparation method and an application method of the artemisinin molecule imprinting polymer on the surface of the porous microsphere silica gel. The artemisinin molecule imprinting polymer on the surface of the porous microsphere silica gel can separate the artemisinin from other structural analogues, such as artemether, and the like under normal pressure and temperature and supercritical conditions, is especially suitable for supercritical conditions and has specific adsorption property, selectivity and favorable mechanical stability; and the preparation method is simple, convenient and suitable for large-scale popularization and application.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of three dimensional printing rapid forming inorganic powder material

InactiveCN104310948AEasy to operateSmall median diameterClaywaresVinyltriethoxysilaneRoom temperature

The invention discloses a preparation method of a three dimensional printing rapid forming inorganic powder material, and the method is characterized in that: adding 8%-22% by mass of vinyltriethoxysilane and 78%-92% by mass of an inorganic powder material into a grinding machine, starting the grinding machine for grinding for 4-6h in 200 rpm / min speed at room temperature to obtain a preprocessed inorganic powder material; then adding 85%-96% by mass of preprocessed inorganic powder material and 4%-15% of EVA (ethylene vinyl-acetate copolymer) hot melt adhesive powder into the grinding machine, starting the grinding machine for grinding for 4-6h in 200 rpm / min speed at room temperature to obtain the three dimensional printing rapid forming inorganic powder material, The method has the advantages of being simple in preparation process, easy to control, low in production cost, and easy in industrial production. The material can be directly formed by heating at 140 to 180 DEG C and under the pressure in the 2MPa-6MPa range without spraying of an adhesive, and the forming operation is simple.

Owner:UNIV OF JINAN

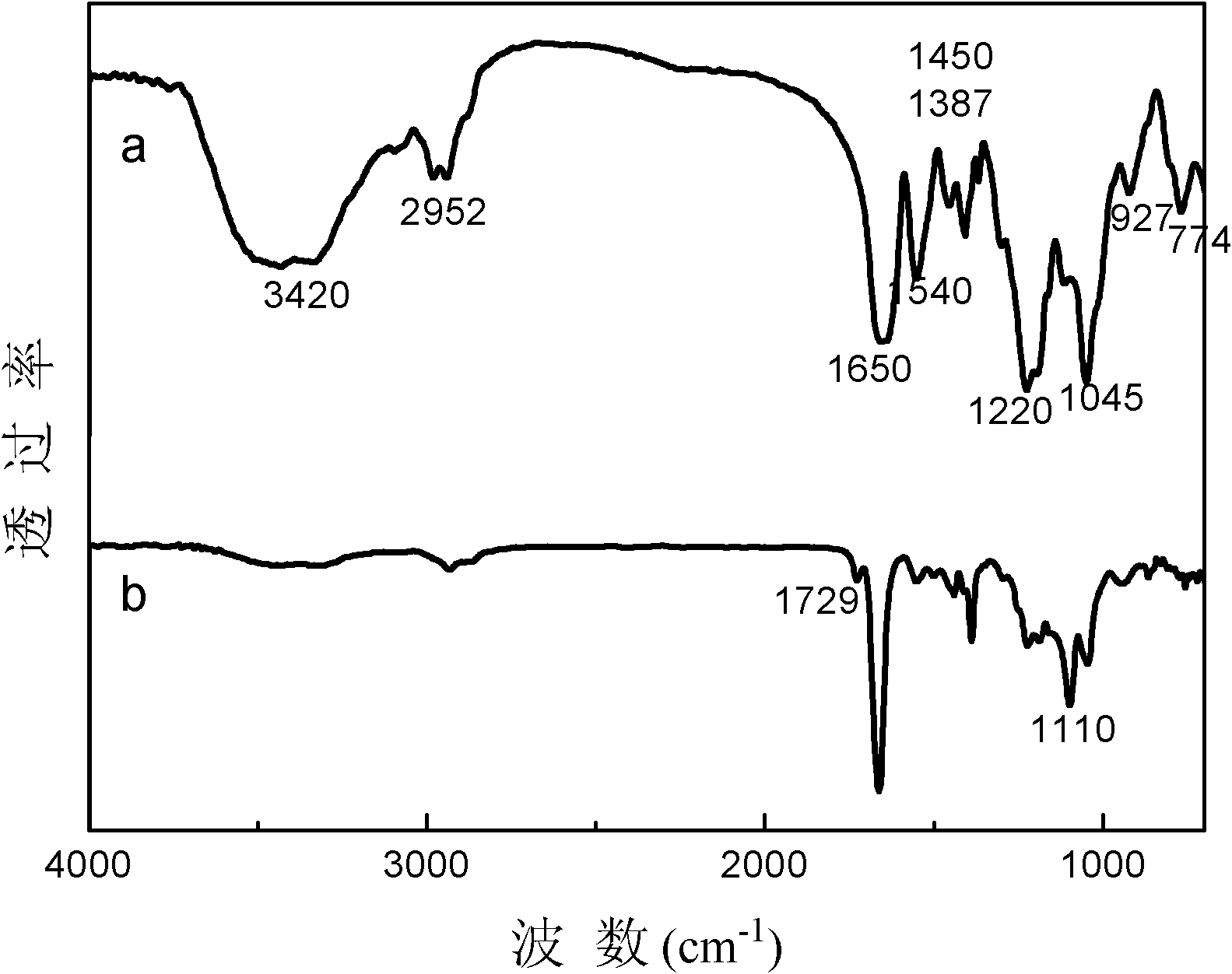

Preparation method of interpenetrating network structure p(liamps)-based single ion transport gel polymer electrolyte film

InactiveCN102276860AIncrease the number of transfersGood dimensional stabilityCell component detailsCross-linkMethacrylate

The invention relates to a preparation method of a gel polymer dielectric film by conveying an interpenetrating network structure P (LiAMPS) single ion, which belongs to a preparation method of polymer electrolyte films. The present invention solves the problems of low transport numbers and dimension stability of the present gel polymer electrolyte ions. The invention employs 2-acrylamide-2-methyl propanesulfonic acid lithium (LiAMPS) and vinyltriethoxysilane free radical polymerization to obtain a linear polymer P (LiAMPS-co-VTES), P (LiAMPS-co-VTES) containing an ethoxy functional group enables hydrolysis and polycondensation to form a net structure, simultaneously a cross-linking agent monomer polyethylene glycol dimethyl methacrylate is performed a free radical polymerization to form another net structure. The invention is capable of raising the dimension stability of the polymer electrolyte. Through heat weightlessness analysis, the polymer electrolyte films have good heat stability, the initial weightless temperature of the films is more than 200 DEG C, so that the requirement of lithium ion battery can be satisfied.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com