Cationic flocculant and preparation method thereof

A cationic flocculant and cationic monomer technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of incomplete flocculation and direct reuse standards and other problems, to achieve the effect of complete flocculation effect, fast flocculation speed and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

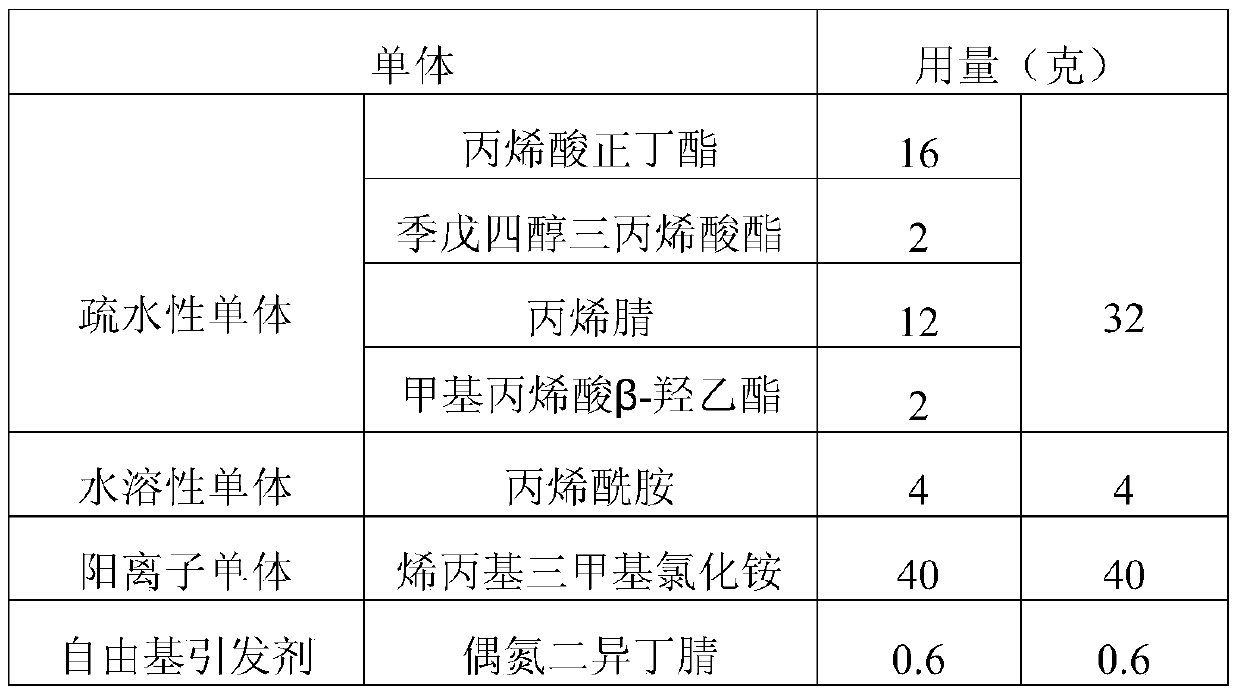

[0041] This embodiment provides a cationic flocculant. The raw material composition of the cationic flocculation is shown in Table 1.

[0042] Table 1 Raw material composition of cationic flocculant

[0043]

[0044] The preparation method of this cationic flocculant comprises the following steps:

[0045] Add 80g of ethanol and all monomers (hydrophobic monomers, water-soluble monomers and cationic monomers) into the three-necked flask, stir and mix evenly, raise the temperature to 70°C, and add 0.4g of azobisisobutyronitrile, keep warm for 2h An additional 0.2 g of azobisisobutyronitrile was added, and then the temperature was raised to 80° C. to continue the reaction for 7 hours to complete the polymerization reaction, and the temperature was lowered to obtain a cationic flocculant.

Embodiment 2

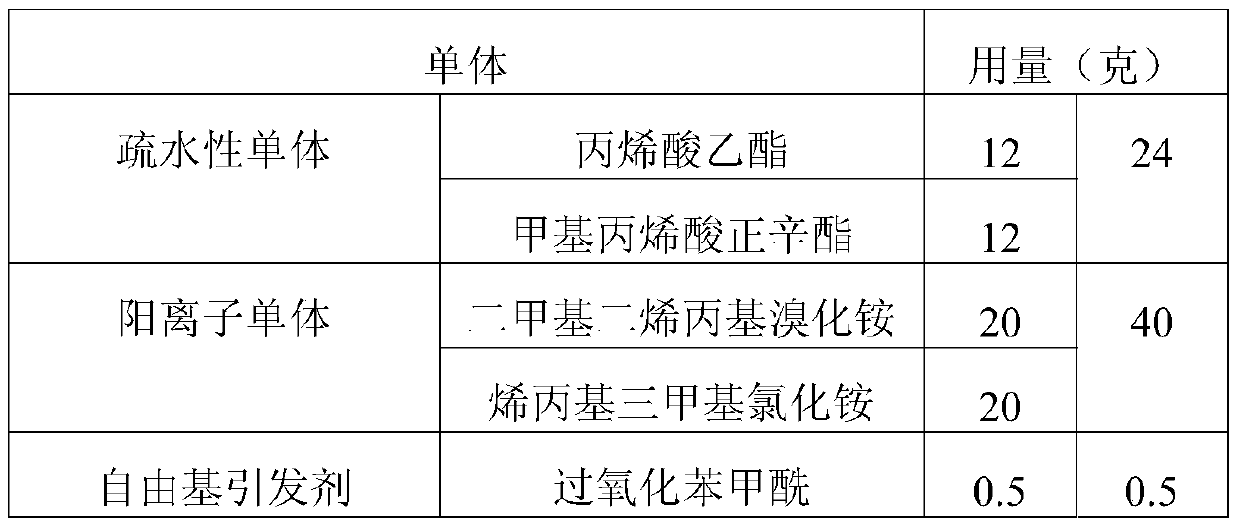

[0047] This embodiment provides a cationic flocculant. The raw material composition of the cationic flocculation is shown in Table 2.

[0048] The preparation method of this cationic flocculant comprises the following steps:

[0049] Add 40g ethanol, 30g n-propanol and 20g dimethyl diallyl ammonium bromide, 20g allyl trimethyl ammonium chloride, 4g ethyl acrylate, 4g n-octyl methacrylate to the three-necked flask, stir and mix Evenly, heat up to 85°C, and add 0.3g benzoyl peroxide, keep warm for 30min and start to add dropwise the mixed solution of 8g ethyl acrylate, 8g n-octyl methacrylate and 10g n-propanol (2h dropwise), drop After the addition, 0.2 g of benzoyl peroxide was added, and then the temperature was raised to 90° C. to continue the reaction for 5 hours to complete the polymerization reaction, and the temperature was lowered to obtain a cationic flocculant.

[0050] Table 2 Raw material composition of cationic flocculant

[0051]

Embodiment 3

[0053] This embodiment provides a cationic flocculant, and the raw material composition of the flocculant is shown in Table 3.

[0054] Table 3 Raw material composition of cationic flocculant

[0055]

[0056] The preparation method of this cationic flocculant comprises the following steps:

[0057] (1) Add 80g of water, 10g of hexadecyldimethylallyl ammonium chloride, 40g of acryloyloxyethyltrimethylammonium chloride, 2.5g of methyl methacrylate, 0.5g of ethylene into the reaction vessel Triethoxysilane, 4g styrene, 1g diethylene glycol diacrylate, stirred and heated to 75°C;

[0058] (2) After the temperature rises to 75°C, add 0.2g potassium persulfate and 0.2g sodium bisulfite to the reaction vessel, polymerize at this temperature for 30-45min, and then drop the remaining 17.5g methyl Methyl acrylate, 1.5g vinyltriethoxysilane, 12g styrene and 3g diethylene glycol diacrylate were added dropwise within 2 hours; after the dropwise addition, a free radical initiator (0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com