Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5239 results about "Carvacryl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified release formulations containing drug-ion exchange resin complexes

ActiveUS20070215511A1Reduction of undesirable tasteConvenient coatingPowder deliverySmall article dispensingDrugPlasticizer

A coated drug-ion exchange resin complex comprising a core composed of a drug complexed with a pharmaceutically acceptable ion-exchange resin is provided. The drug-ion exchange resin complex is in admixture with a release retardant. The coating is a polyvinyl acetate polymer and a plasticizer. Methods of making and products containing this coated complex are described.

Owner:TRIS PHARMA

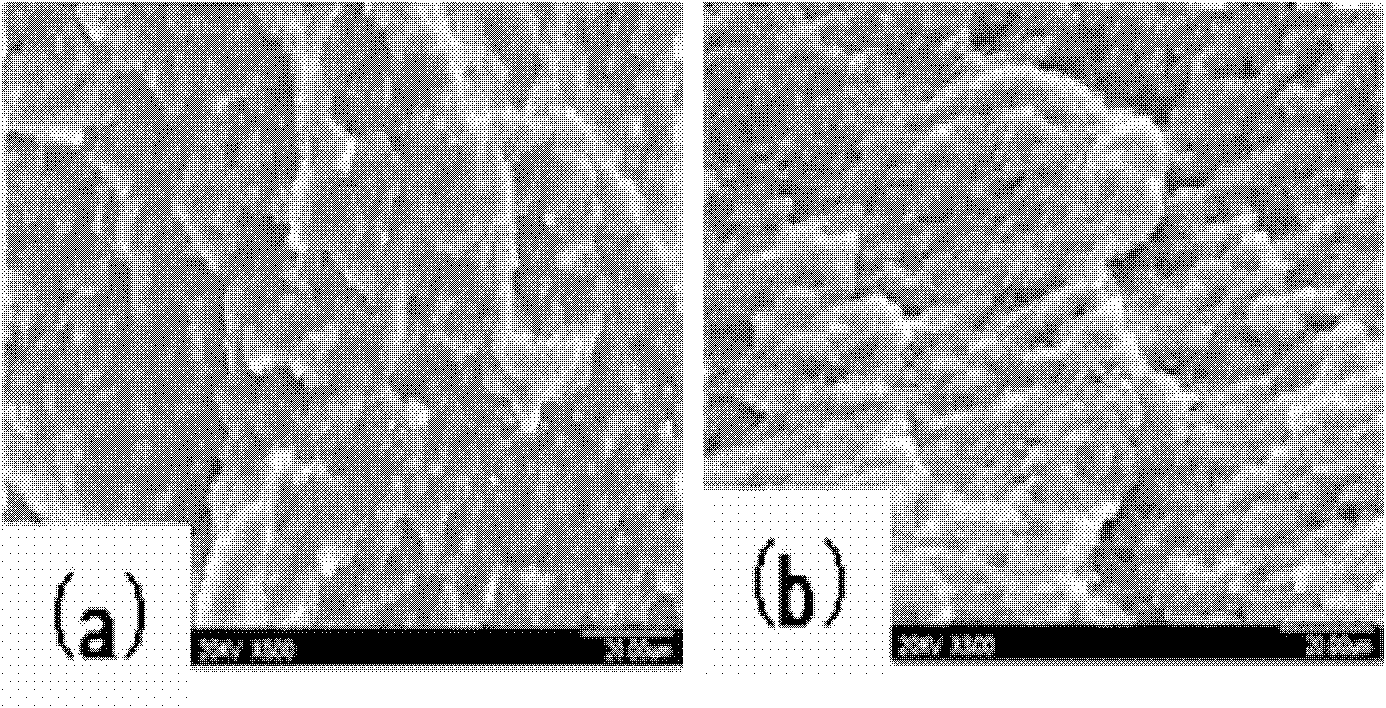

Cementitious article and method for preparing the same

ActiveUS20100247937A1Solid waste managementSynthetic resin layered productsAcetic acidPolymer science

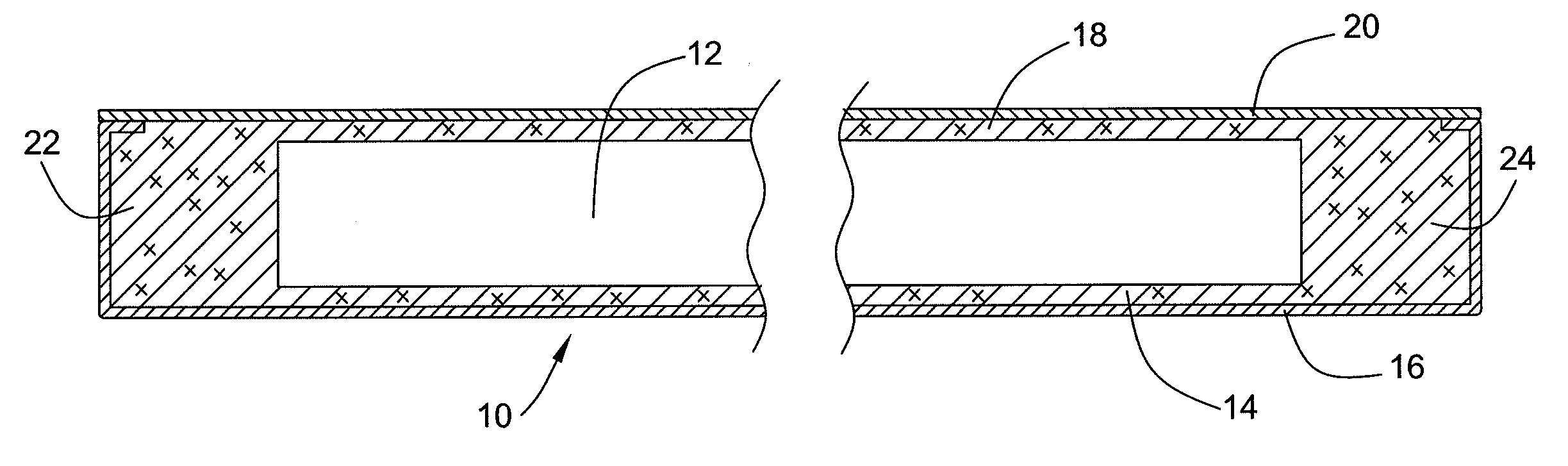

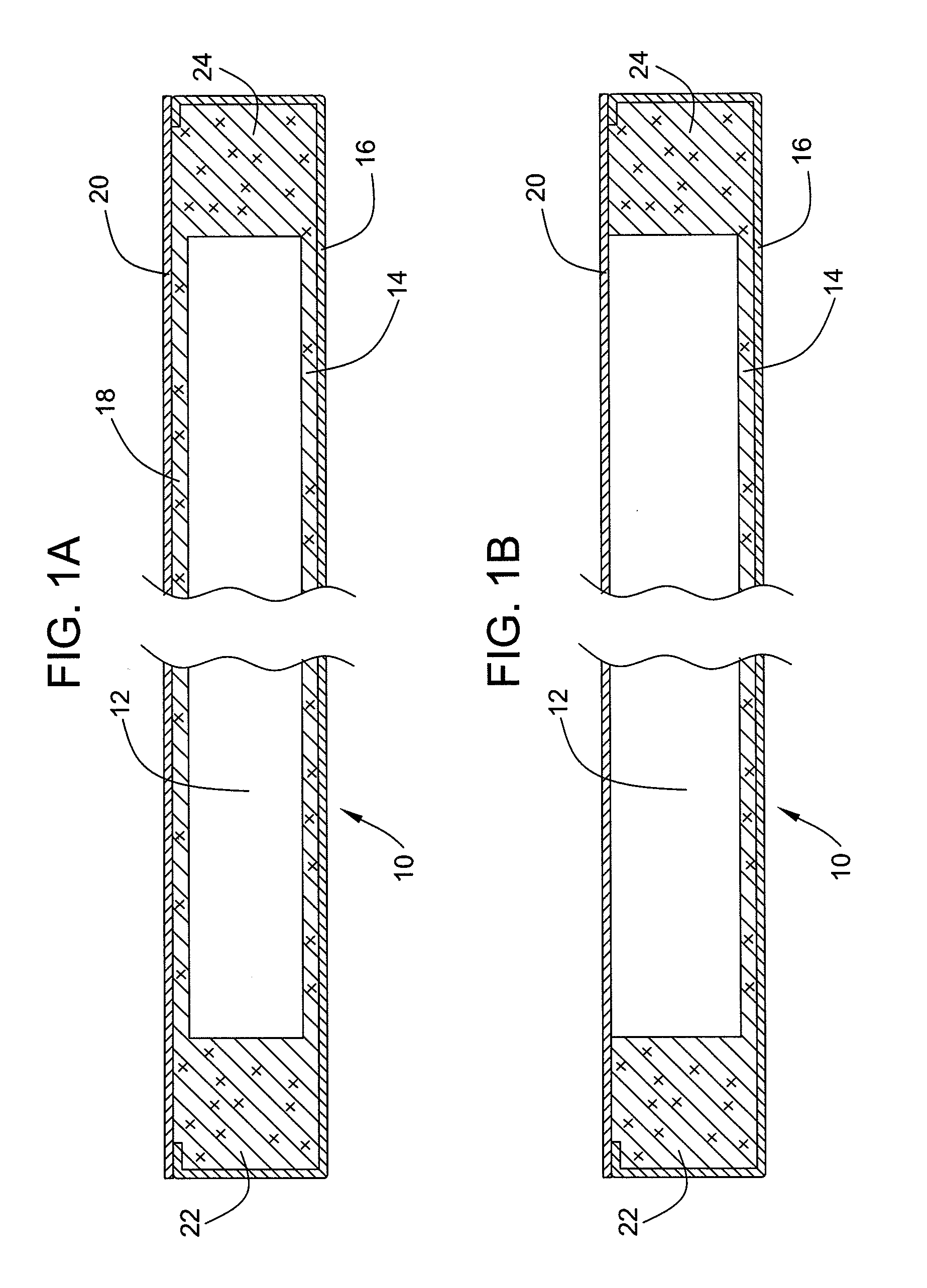

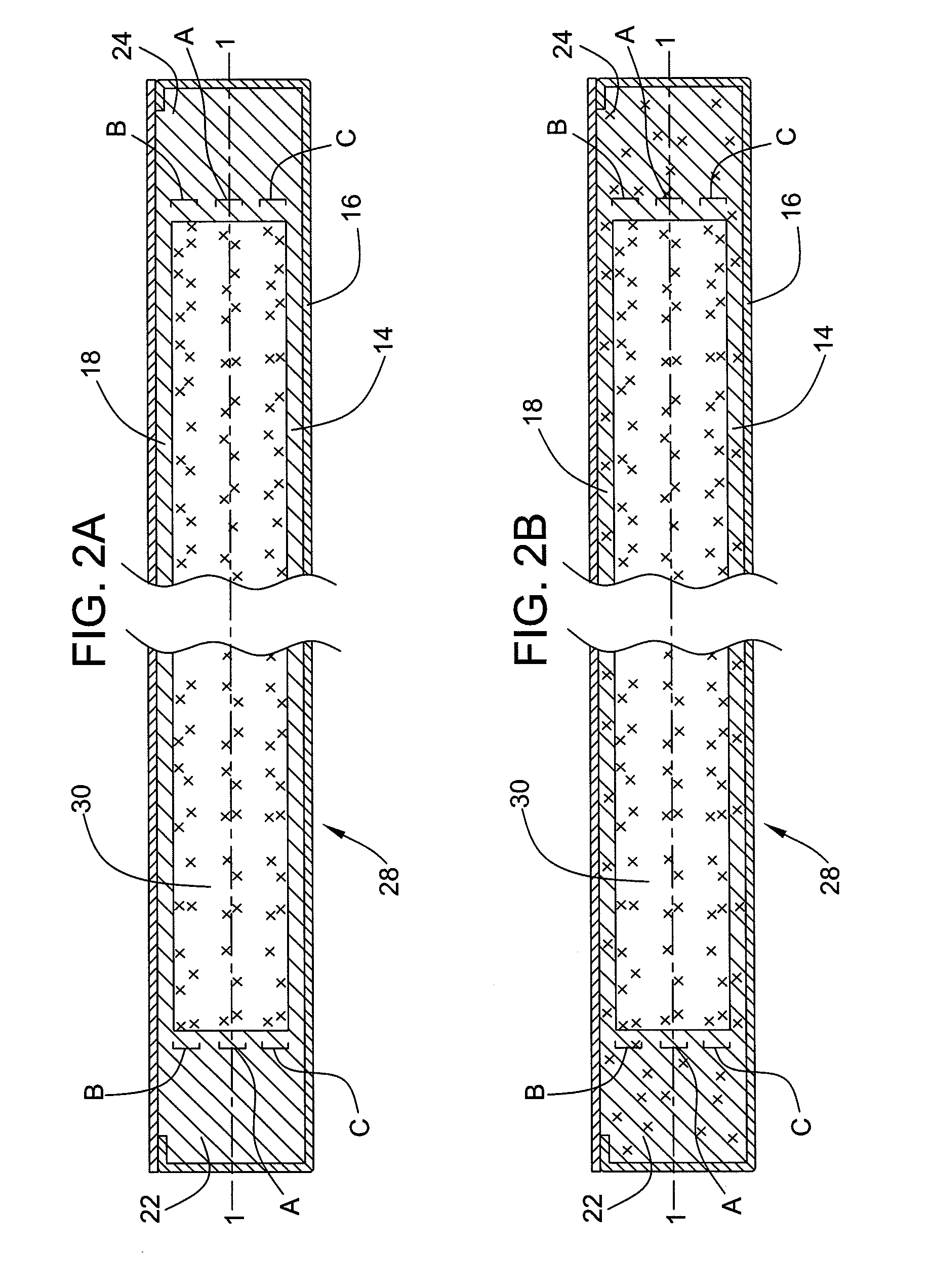

A cementitious article and a method of making a cementitious article are disclosed. The cementitious article comprises a cementitious component that comprises a polyvinyl acetate type polymer, a monobasic phosphate, and optionally boric acid. Cementitious articles, such as board, are prepared such that the polyvinyl acetate type polymer, the monobasic phosphate, and optionally boric acid can be present in the cementitious core, and / or in dense layers if present. The concentration of the polyvinyl acetate type polymer, monobasic phosphate, and optionally boric acid in the cementitious article can increase from a central region A to peripheral regions B and C, respectively. In some embodiments, the polyvinyl acetate type polymer is a polyvinyl alcohol and the monobasic phosphate is monoammonium phosphate.

Owner:UNITED STATES GYPSUM CO

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

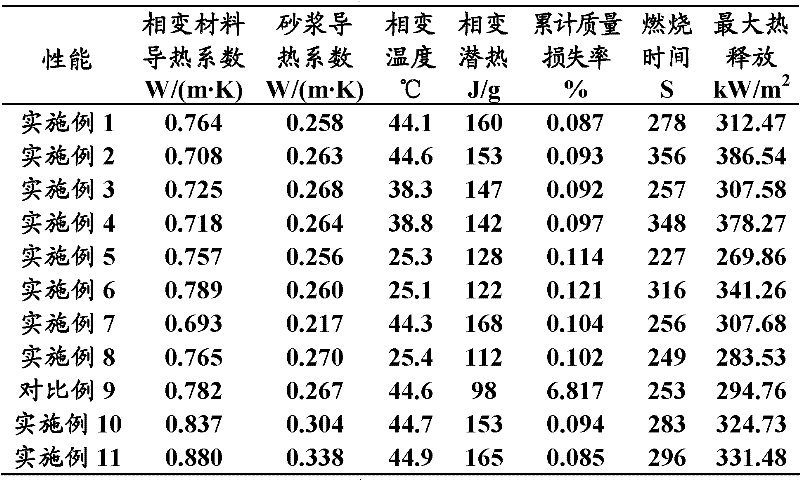

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

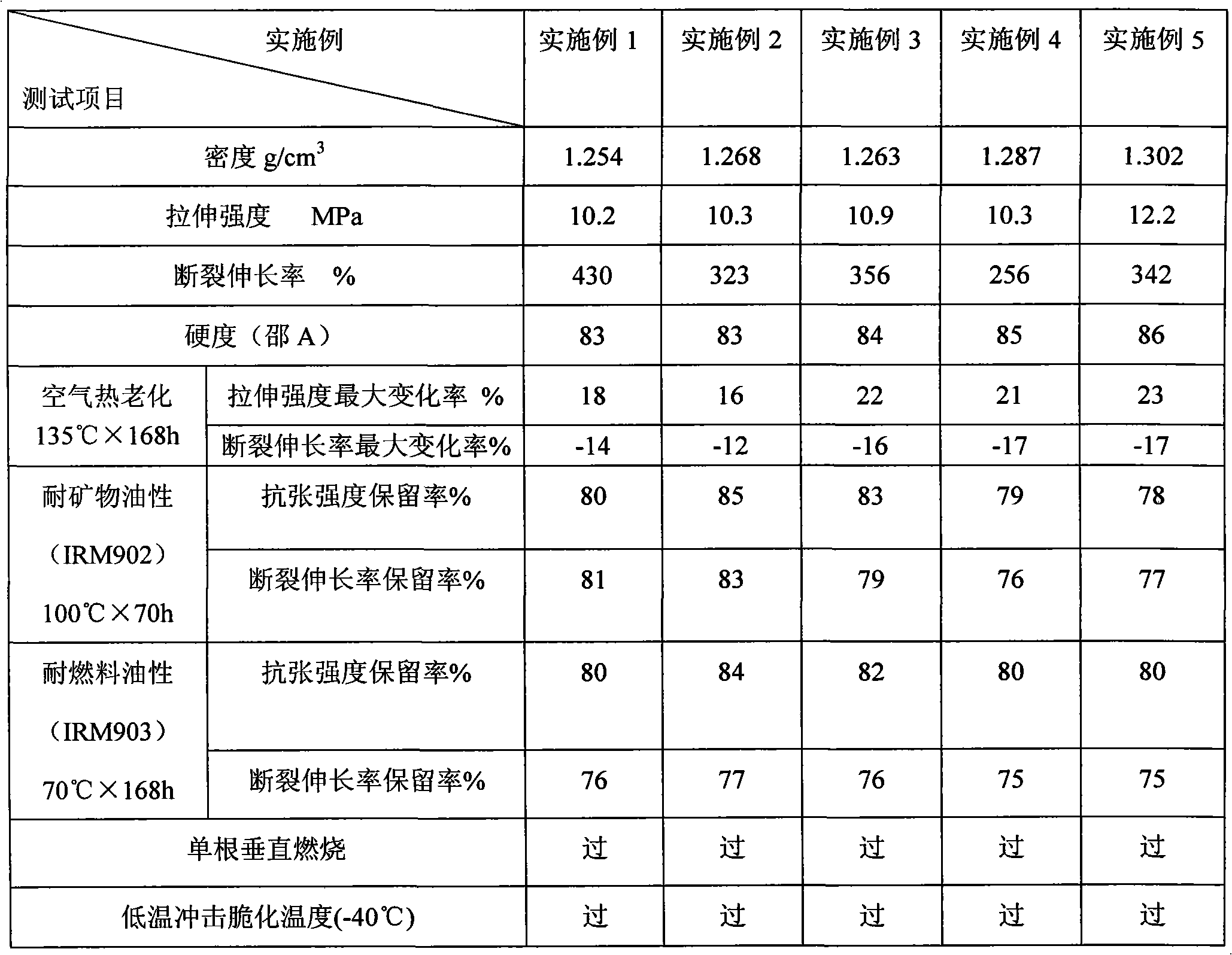

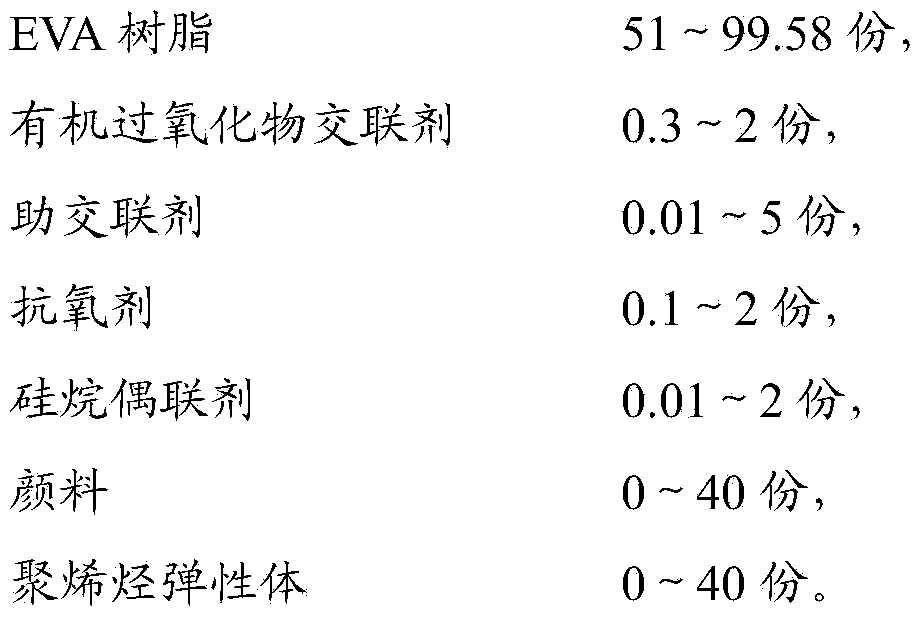

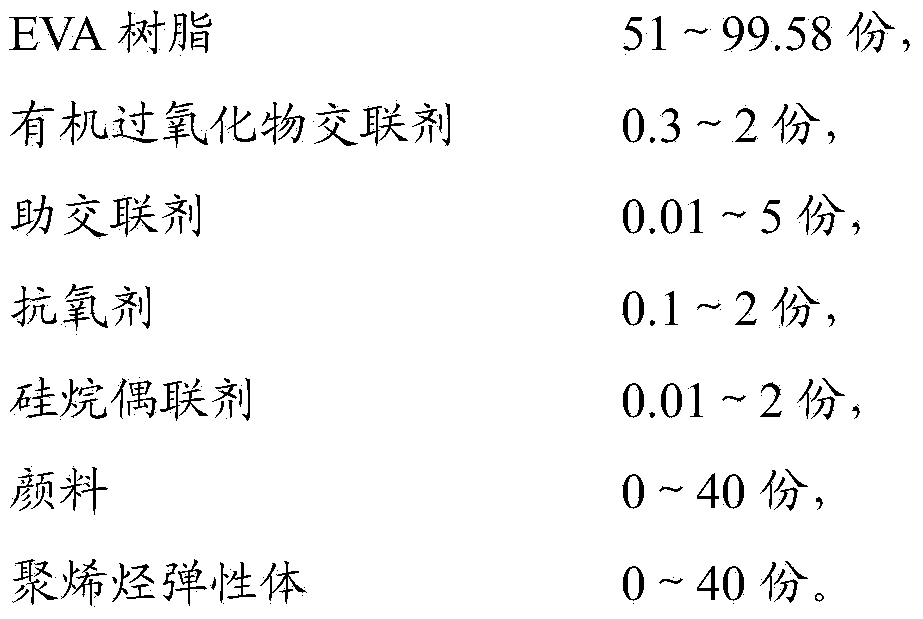

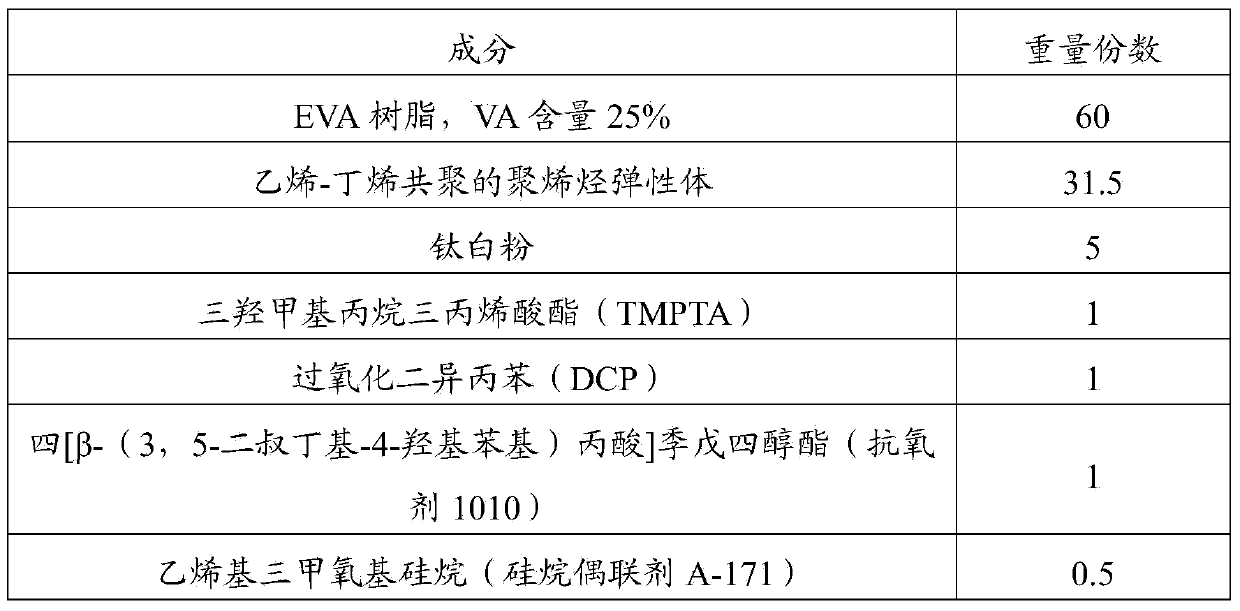

Radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film and preparation method thereof

ActiveCN103804774AGood dimensional stabilityImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyolefin

The invention discloses a radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film which comprises the following components in parts by weight: 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer. The invention also discloses a preparation method of the radiation pre-crosslinked EVA resin film, which comprises the steps of sufficiently mixing 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer, and adding into an extruder; extruding and forming a film through a T-shaped flat mould; rolling and radiating to obtain the radiation pre-crosslinked EVA resin film. Since the film is partially crosslinked before use, the dimensional stability and heat resistance of the film are remarkably improved, thus the film is suitable for large-scale popularization and application.

Owner:SHANGHAI HIUV NEW MATERIALS

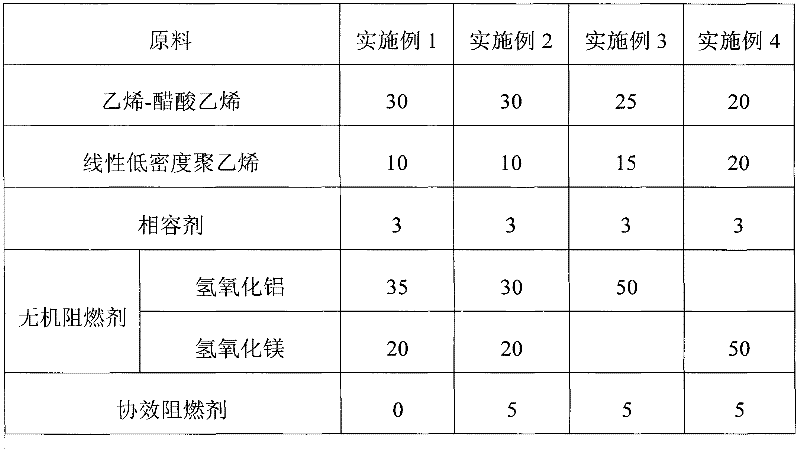

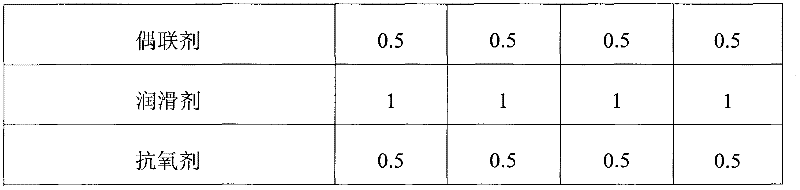

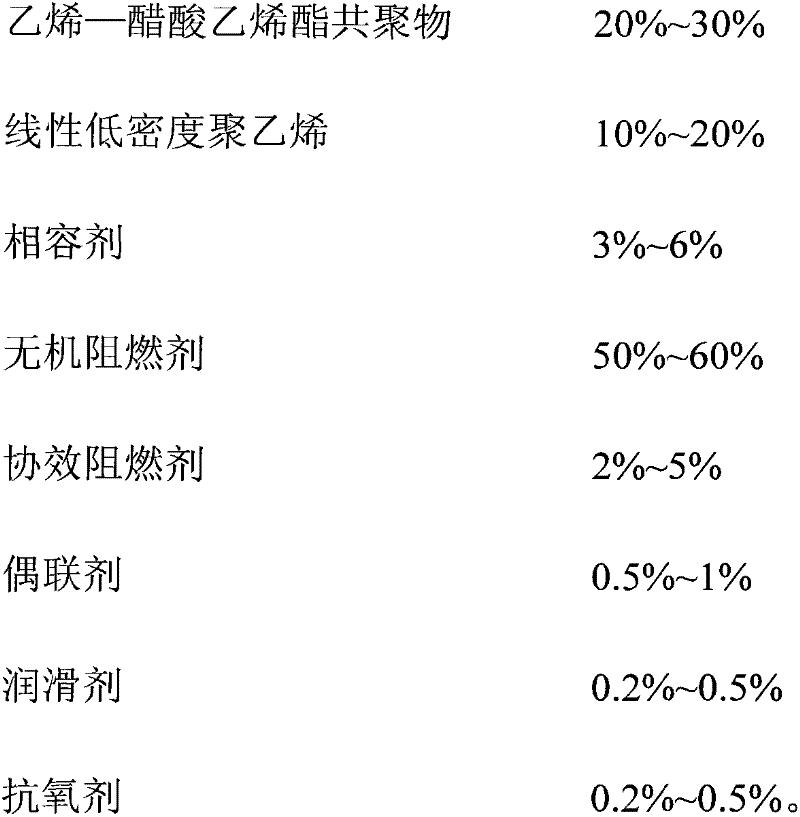

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

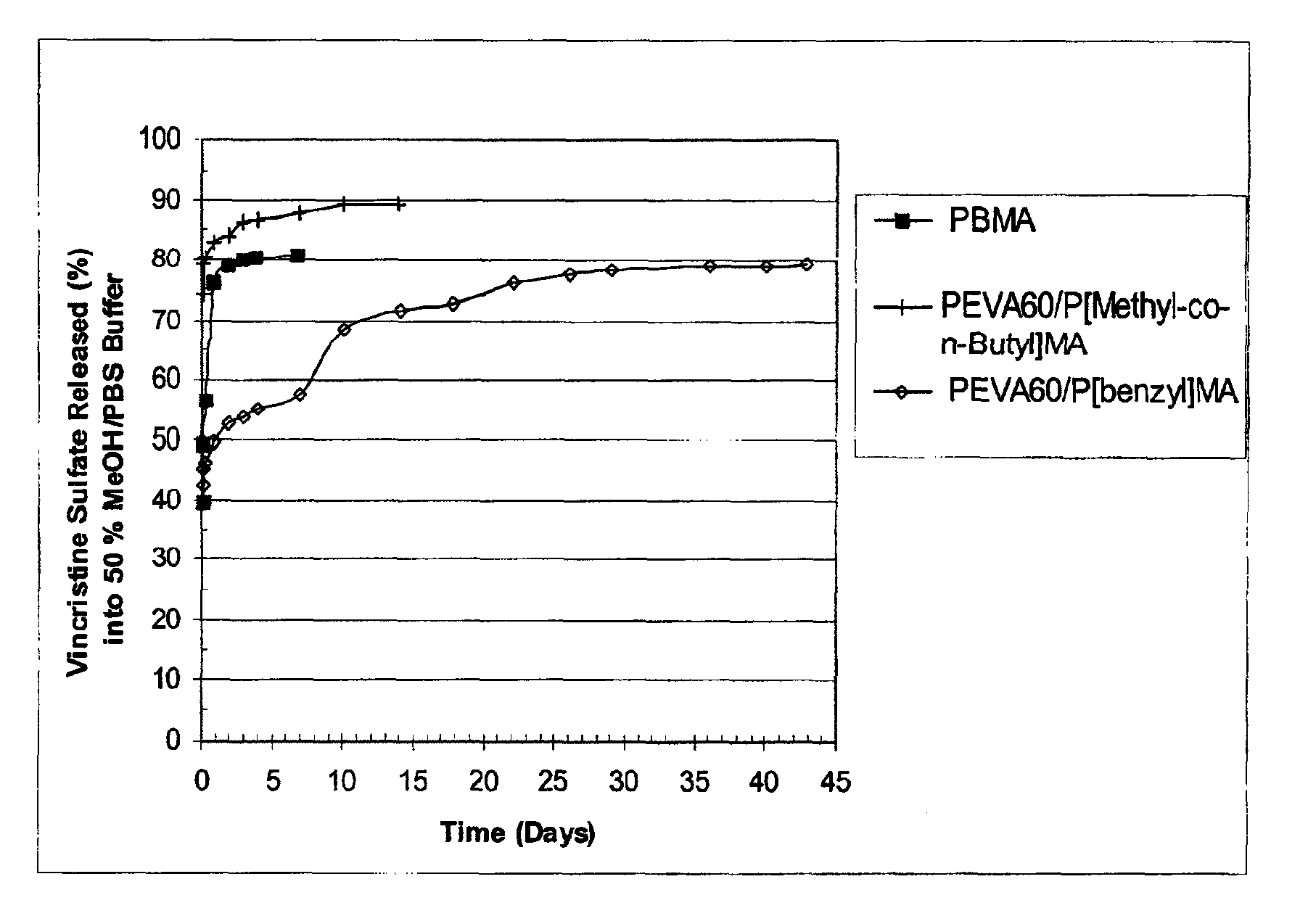

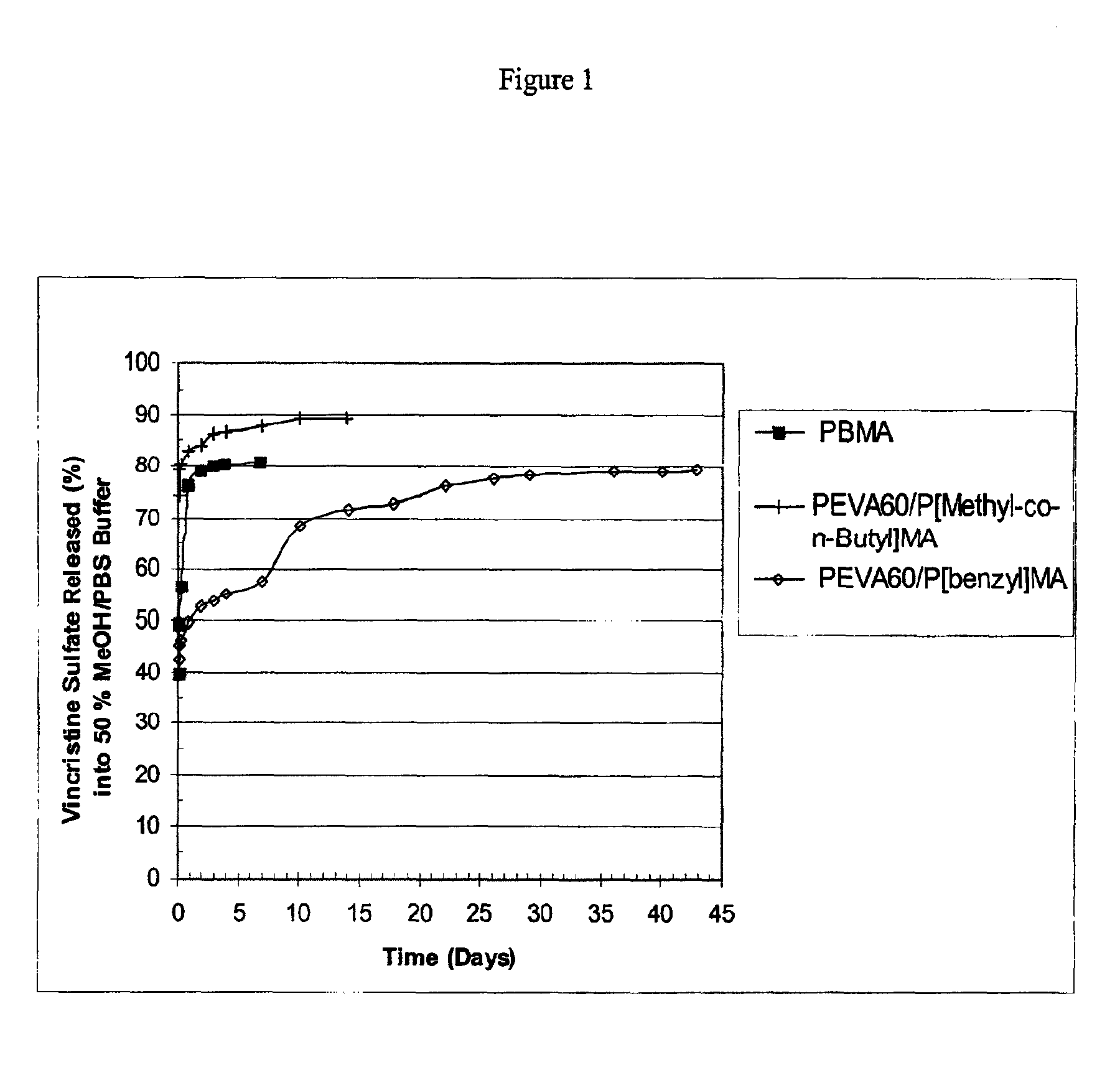

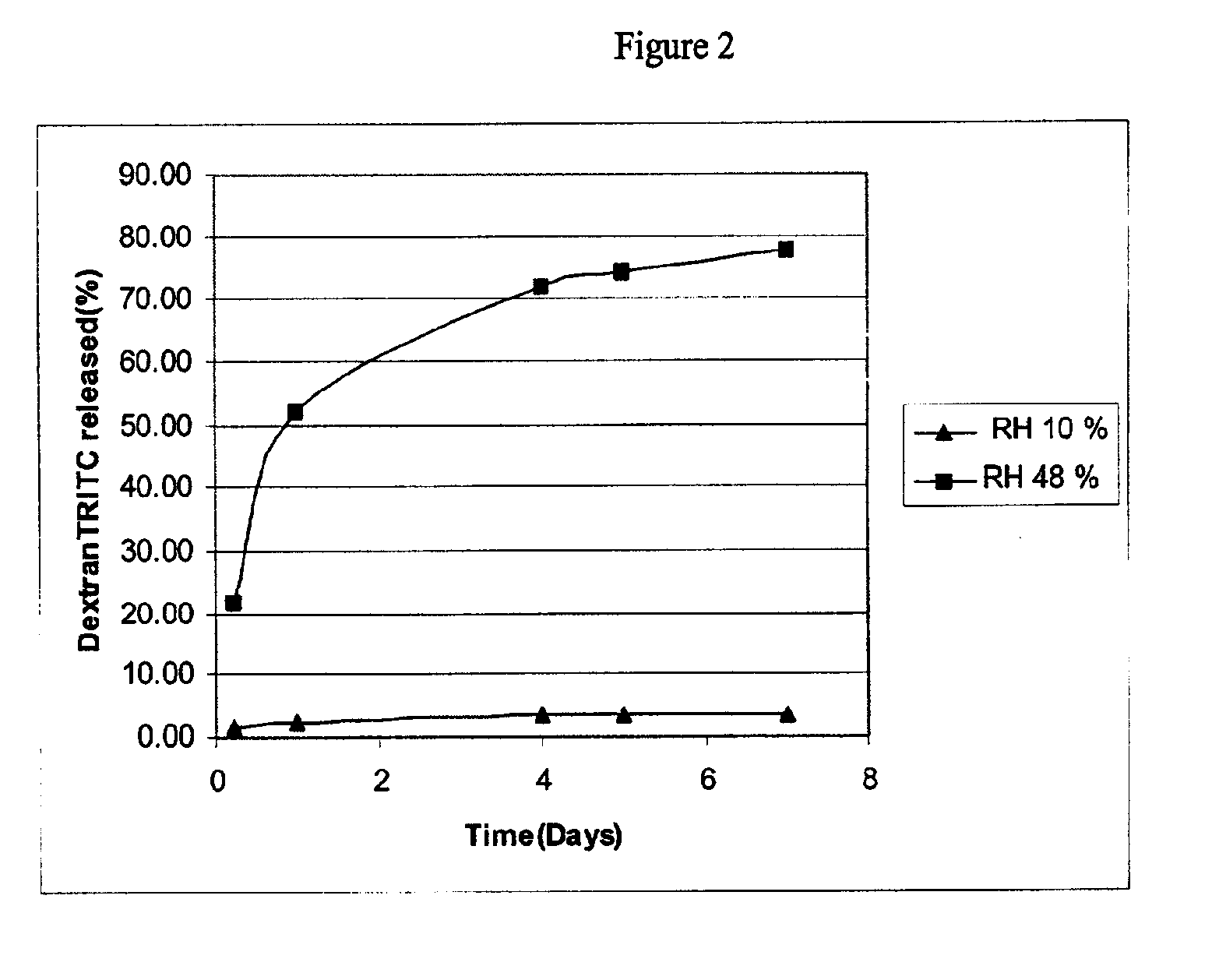

Bioactive agent release coating and controlled humidity method

A coating composition in the form of a one or multi-part system, and method of applying such a composition under conditions of controlled humidity, for use in coating device surfaces to control and / or improve their ability to release bioactive agents in aqueous systems. The coating composition is particularly adapted for use with medical devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a first polymer component such as polyalkyl(meth)acrylate, polyaryl(meth)acrylate, polyaralkyl(meth)acrylate, or polyaryloxyalkyl(meth)acrylate and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

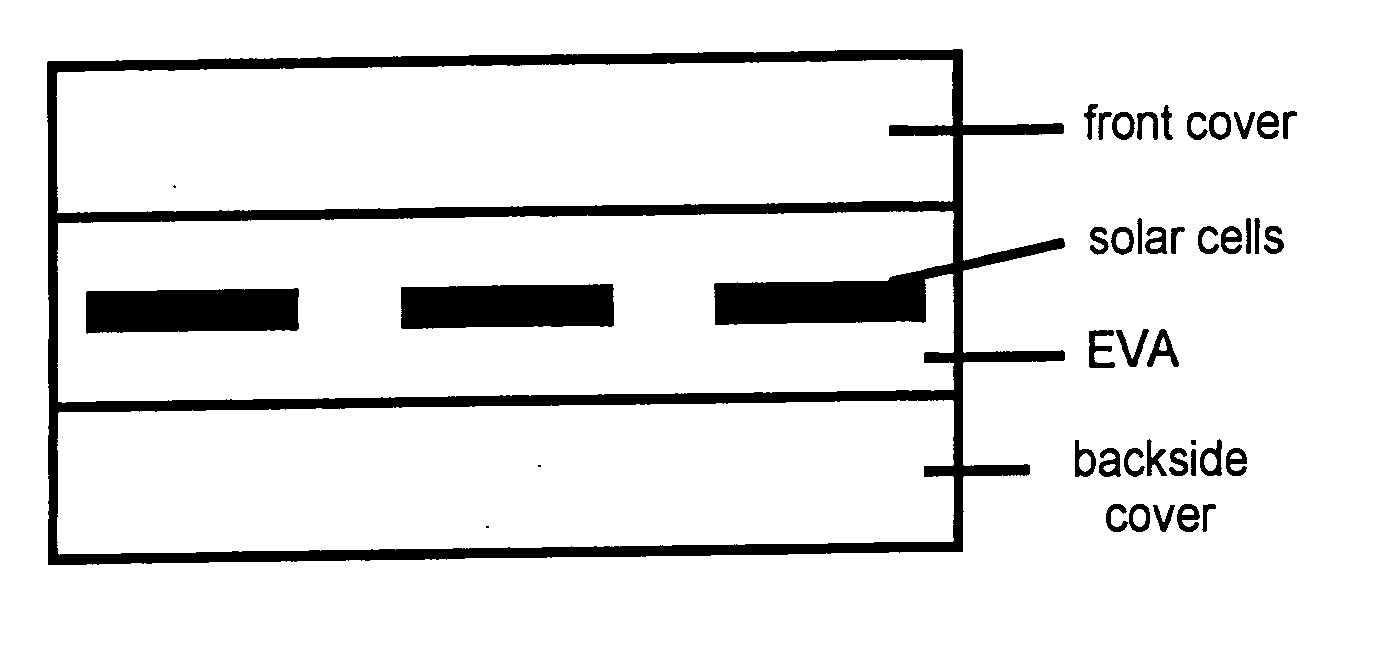

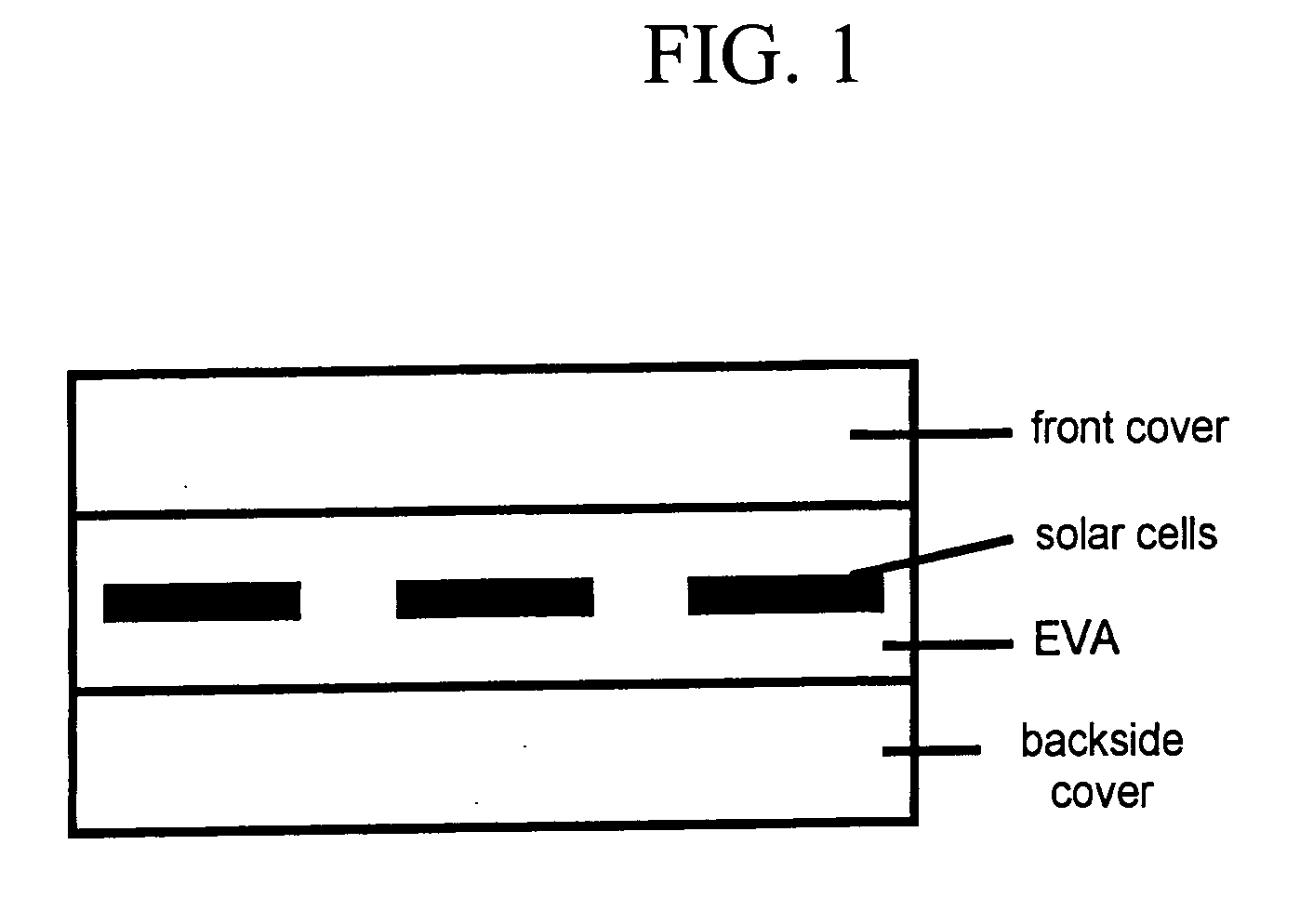

White coated polyester film, process for production thereof and use thereof as a backside cover in solar modules

ActiveUS20100215902A1Good adhesion valueLow yellowness indexArtificial filament physical treatmentFilm/foil adhesivesChemistryPolyester

A white coated polyester film is provided which has excellent adhesion to the ethylene-vinyl acetate (EVA) typically used as an encapsulation material in solar modules. The good adhesion properties are achieved with a polymeric coating which includes at least one polyurethane and a crosslinker.

Owner:MITSUBISHI POLYESTER FILM +1

Modified rubber powder and its prepn and use

InactiveCN1974621ALow costReduce noiseNon-macromolecular adhesive additivesOther chemical processesRubber materialChemical reaction

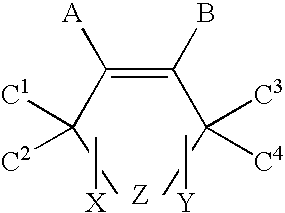

The present invention relates to modified rubber powder and its preparation process and use. Structurally, the modified rubber powder has alkyl group, alkenyl group, hydroxyl group, carboxyl group, nitrile group or amino group in the side chain or has side chain connected via double bond reaction to butadiene, polystyrene, vinyl acetate, acrylate, acrylonitrile or other compound. The modified rubber powder has the structural features of rubber retained and thus excellent mechanical performance, physical and chemical performance and machining performance. The introduction of functional group to the side chain results in obviously raised compatibility with other rubber material, plastic and other polymer material, easy grafting reaction and functional group chemical reaction for further modification. In addition, the performances may be regulated via altering the sort and amount of the introduced functional groups.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

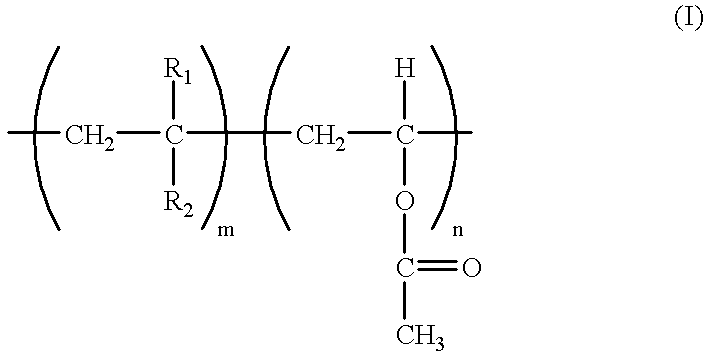

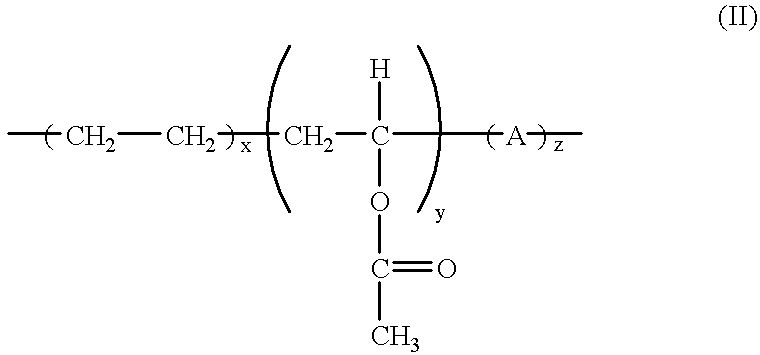

Gel polymer electrolyte of vinyl acetate

InactiveUS6268088B1Enhanced interactionImprove ionic conductivityOrganic electrolyte cellsSolid electrolyte cellsSolventFluid electrolytes

A gel polymer electrolyte according to the present invention comprises a polymer selected from the group consisting of vinyl acetate copolymer, poly(ethylene / vinylacetate / carbon oxide: EVACM), and poly(ethylene / vinylacetate / maleic acid anhydride: EVAMA); an inorganic filler; and a liquid electrolyte that a lithium salt is dissolved in an aprotic solvent. It is preferable that the polymer material in a gel polymer electrolyte according to the present invention is in the range of 20 to 30% by weight, the inorganic material filler is in the range of 5 to 20% by weight, and the liquid electrolyte is in the range of 60 to 80 % by weight. As a specific functional group which has a high compatibility with a liquid electrolyte in the present invention is contained in the polymer material, a lithium ion becomes to move with ease in electrolyte, and the ionic conductivity is over 0.5 mS / cm which is the demand level of a gel polymer electrolyte. Also, it provides the gel polymer electrolyte material with a high film formability, a good property of containing an electrolyte, a good adhesion, and a good mechanical strength.

Owner:CHEIL IND INC

Soft low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

InactiveCN101817952ABright surfaceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses a soft low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable material comprises the following components (based on by mass part ratio): 80-90 parts of copolymer of ethylene-vinylacetate, 10-20 parts of linear low-density polyethylene, 65-130 parts of an inorganic fire retardant through surface treatment, 10-30 parts of high-effective flame retardant synergist, 10-20 parts of high molecular compatilizer, 0.9-1.5 parts of antioxidant and 1-2 parts of processing aid. The preparation method comprises the steps of resin blending extrusion; surface treatment of the inorganic fire retardant; batching, mixing, extrusion, granulation and the like. Compared with the prior art, the invention has the characteristics of predominant flame retardation (an oxygen index up to 36), excellent toughness, excellent bending resistance, low density (density is only 1.28g / cm<3>), low smoke, low corrosion, low toxicity, environmental protection, good processability, bright surface of extrudates and the like.

Owner:XI AN JIAOTONG UNIV +1

Ethylene-vinyl acetate copolymer packaging thin film

InactiveCN102391568AEnhanced network structureImprove moisture resistancePhotovoltaic energy generationSemiconductor devicesPolymer scienceNetwork structure

The invention discloses an ethylene-vinyl acetate copolymer packaging thin film, which is used for packaging solar cell components. The thin film is prepared from the following raw materials in part by weight: 100 parts of an ethylene-vinyl acetate copolymer, 0.1 to 2.0 parts of crosslinking agent, 0.1 to 10.0 parts of aid crosslinking agent and a proper amount of aid. The ethylene-vinyl acetate copolymer contains 25 to 33 percent of vinylacetate, and the ratio of the amount of the aid crosslinking agent and the crosslinking agent is 1:10 to 10:1. In the invention, the introduction of the aid improves the network structure of crosslinked resin, improves crosslinking efficiency, greatly reduces the dosage and residue of the crosslinking agent greatly and avoids aging phenomenon caused by residual crosslinking agent, and the prepared thin film has higher dampness and heat resistance, high ultraviolet resistance, high thermal-oxidative aging resistance and the like and has long service life.

Owner:DONGFANG TURBINE CO LTD

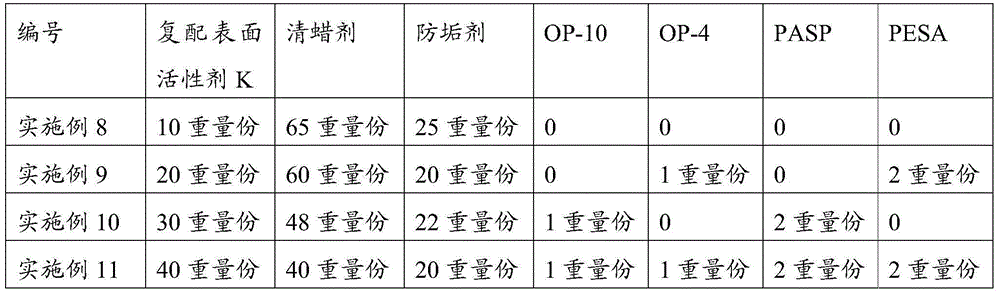

A soluble antiscale wax control ball

ActiveCN105441051ASolubleImprove wax removal effectDrilling compositionCarvacryl acetateCleansing Agents

A soluble antiscale wax control ball is disclosed. The soluble antiscale wax control ball comprises surfactants, wax cleaning agents and an antiscale agent RX-613. The surfactants comprise sodium alkylbenzenethiosulphonate, Ninol and polyoxyethylene alkyl ether. The wax cleaning agents comprise ethylene-vinyl acetate copolymer and polyethylene. The soluble antiscale wax control ball is advantaged by being soluble and having functions of preventing scaling and wax precipitation of pipelines, being capable of not blocking pipelines, and the like. The soluble antiscale wax control ball can dissolve old scale into crude oil and can prevent crude oil components from scaling onto walls of pipelines, and therefore problems of mechanical wax-cleaning antiscale balls at present, such as pipeline blockage and high running costs, which are caused by pipeline transfiguration, and the like are overcome. Experiment research shows that the soluble antiscale wax control ball can achieve wax-cleaning effects of rubber balls in site and has multiple functions comprising chemical wax cleaning and scale prevention, the comprehensive wax cleaning rate is 85.2%, and the antiscale rate is 82.18%.

Owner:PETROCHINA CO LTD

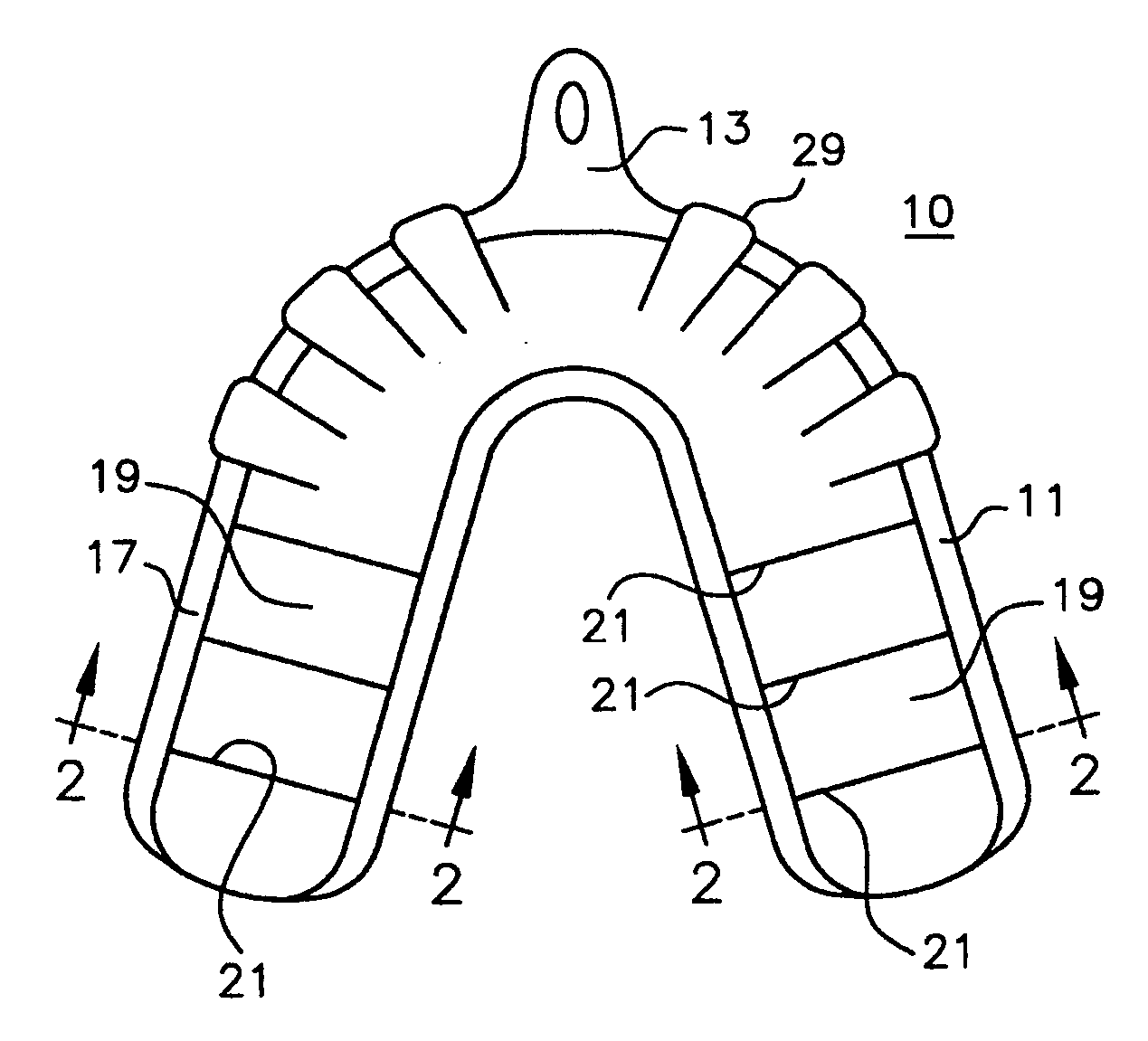

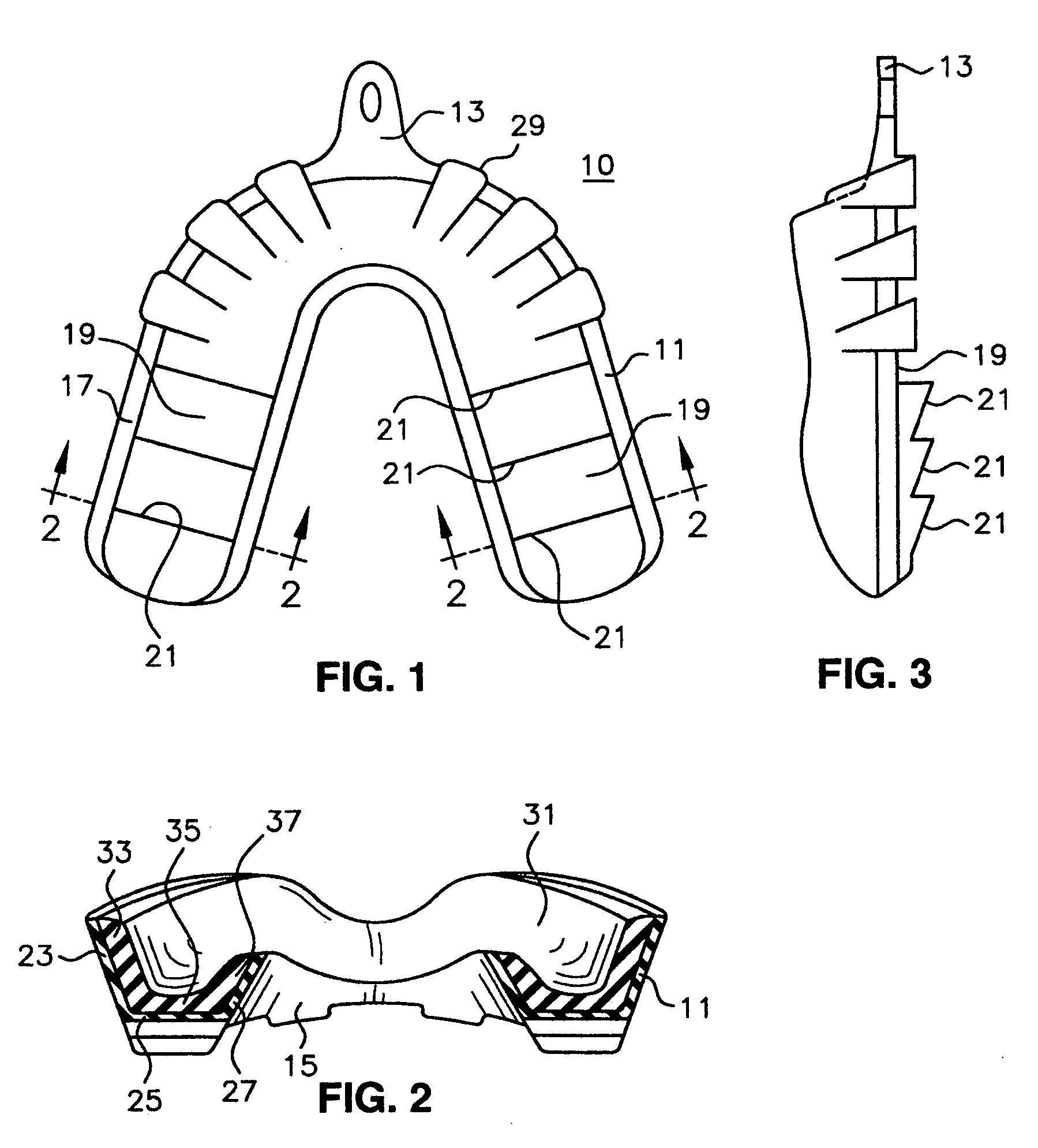

Dual tray athletic mouthguard

A mouthguard for use by athletes, including a dual tray assembly molded together. The first tray is molded from a hard plastic such as an ethylene vinyl acetate copolymer, and has a portion that engage the cusps of the lower jaw molars to prevent the tray from moving backward on impact. A second tray is molded on to the first tray using a soft plastic or gel like material, such as a high percentage vinyl acetate copolymers of ethylene vinyl acetate, that softens at slightly elevated temperatures that a user can easily tolerate. The first time the mouthguard is used, it is heated in warm water, then the user puts it in his or her mouth and bites down to cause the second tray to conform to the upper teeth. When in use, the ridges on the first tray engage the teeth of the lower jaw to prevent movement of the lower jaw on impact.

Owner:SAFE GARD

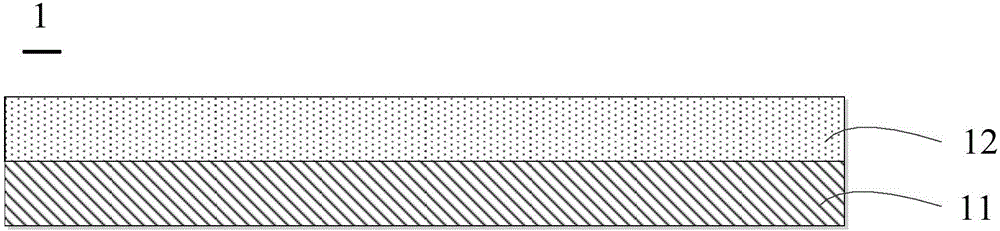

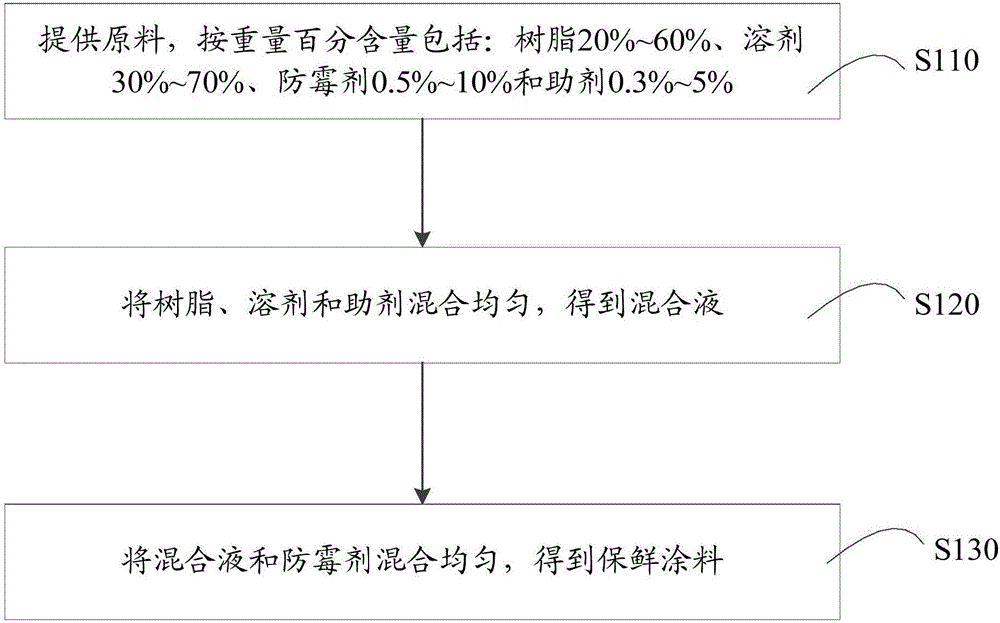

Mildewproof preservative film and preparation method thereof

InactiveCN106634129AIncrease contactNo porosityAntifouling/underwater paintsPaints with biocidesCarvacryl acetateSolvent

The invention discloses a mildewproof preservative film and a preparation method thereof. The mildewproof preservative film comprises a base layer and a mildewproof preservative coating arranged on the base layer, wherein the mildewproof preservative coating is prepared from a mildewproof preservative paint. The mildewproof preservative paint comprises the following components in percentage by weight: 20-60% of resin, 30-70% of solvent, 0.5-10% of mildew preventive and 0.3-5% of aid. The resin is composed of at least one of polyurethane, an acrylate copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyvinylidene chloride, an ethylene-vinyl acetate copolymer, a polyvinyl acetate copolymer and a vinyl acetate-butyl ester copolymer; and the solvent is composed of at least one of water and ethanol. The mildewproof preservative coating of the mildewproof preservative film has the advantages of compact surface and no void; and by adding the mildew preventive, the mildewproof preservative coating has the favorable effects of keeping the moisture constant and preventing mildewing. The mildewproof preservative film is especially suitable for preserving fruits, bread, tobacco and other foods which have shorter storage period, can easily mildew in a short time and need to be eaten in time.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

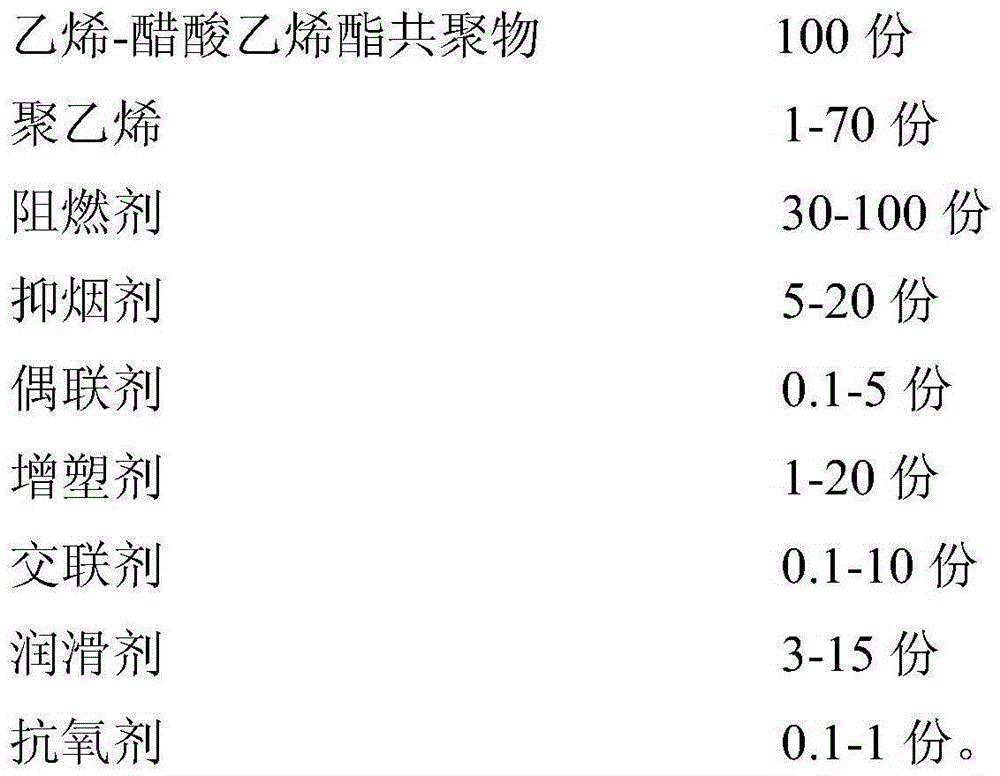

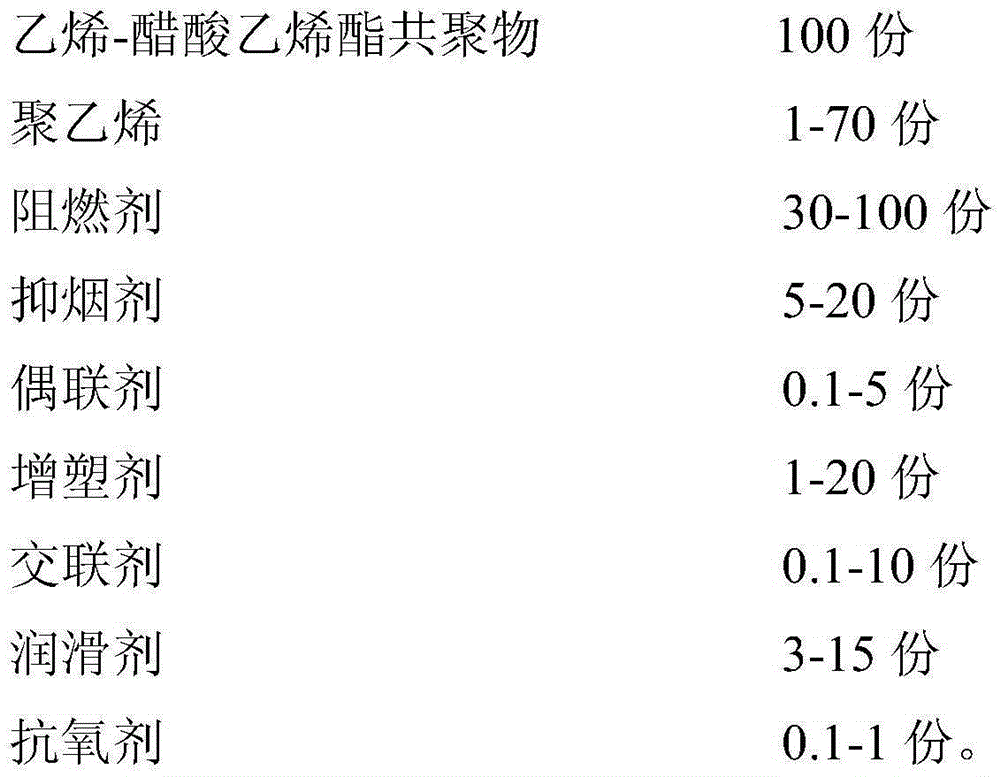

Flexible low-smoke halogen-free flame-retardant wire and cable material and preparation method thereof

InactiveCN105419072ASimple production processLow costPlastic/resin/waxes insulatorsInsulated cablesElastomerThermoplastic

The invention belongs to the technical field of materials and discloses a flexible low-smoke halogen-free flame-retardant wire and cable material and a preparation method thereof. The wire and cable material is prepared by using the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 1 to 70 parts of polyethylene, 30 to 100 parts of flame retardant, 5 to 20 parts of smoke suppressor, 0.1 to 5 parts of coupling agent, 1 to 20 parts of plasticizer, 0.1 to 10 parts of crosslinking agent, 3 to 15 parts of lubricant and 0.1 to 1 part of antioxidant. The wire and cable material disclosed by the invention is a thermoplastic sulfurized elastomer material, can be used for preparing insulating layers and sheath layers of wires and cables, and has the characteristics that no halogen is contained, the flame-retardant effect is good, the smoking amount is low, the surfaces of the insulating layers and sheath layers are smooth and do not stick with one another, the flexibility is good, the mechanical strength is high, the wear resistance is good, the processing fluidity is good, the process is simple and the material can be recycled.

Owner:SOUTH CHINA UNIV OF TECH

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

Irradiation cross-linking low smoke halogen-free fire retardant polyolefin cable material

InactiveCN101286377ALow smoke productionImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention discloses a halogen-free cable material which is irradiation cross-linked, has less smoke and can retard the inflaming of polyolefine, and consists of the following components by mass: 30 to 50 percent of ethylene-vinyl acetate copolymer, 0 to 20 percent of high-density polyethylene, 30 to 60 percent of magnesium hydrate, 0 to 10 percent of red phosphorus, 1 to 5 percent of resin acceptor, 0.1 to 1.5 percent of cross linker, 1 to 5 percent of compatilizer, 0.1 to 1.5 percent of antioxidizer and 0.1 to 1.5 percent of lubricating agent. The halogen-free cable material which is irradiation cross-linked, has less smoke and can retard the inflaming of polyolefine overcomes the harm to the environment and the human bodies when retarding the inflaming of polyolefine material by using traditional halogen-containing flame retardants, has less smoke, innoxiousness, green and environment protection, and can ensure good mechanical performance, flame retarding performance and processing performance.

Owner:ZHEJIANG UNIV

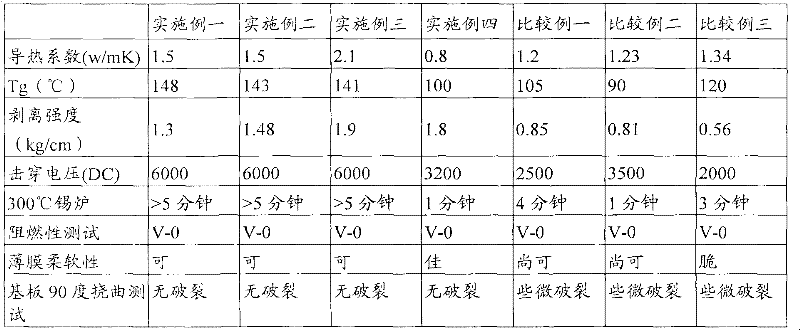

Resin composition

A resin combination mainly comprises: (1) epoxy resin containing silicon atomic compounds; (2) thermoplastic resin; (3) organic elastic powder; (4) a hardener; (5) thermal-conductive inorganic fillers; (6) a phosphorus-containing burning resistant agent; (7) ethylene-vinyl acetate; (8) a catalyst.

Owner:ELITE MATERIAL

Oxygen scavenger compositions

InactiveUS20050139806A1Sufficient viscosityReduce viscosityOther chemical processesSynthetic resin layered productsPolyesterPolyethylene vinyl acetate

The present invention is directed to an oxygen scavenger composition comprising a mixture of (i) a polyester polymer composed of polymer segments containing cycloalkenyl group or functionality; and (ii) an ester type polymer selected from (a)a polyester having a high content of alkylene groups; (b) a polylactone; and (c) a polyvinylacetate having at least about 50 weight percent vinyl acetate mer units therein. The present polymer composition has been found to act as an oxygen scavenger agent under both ambient and refrigerated conditions, to be compatible with conventional film forming packaging materials, to provide compositions exhibiting low tack, and to be capable of being readily processed using conventional film forming equipment.

Owner:HAVENS MARVIN RUSSELL +1

Low-smoke halide-free fireproof polyolefine material and its preparation method and application

A low-smoke and non-halogen poly-olefine material with radiant graft maleic anhydride vinyl-vinyl acetate multi-polymer as compatilizer is prepared by dissolving maleic anhydride 1-5 proportion into acetone, mixing with vinyl-vinyl acetate multi-polymer 100 proportion, volatilizing for acetone, granulating in double-screw extruder, and electronic-ray or gamma-ray radiating by electronic accelerator with 5-30KGy. The compatilizer graft rate is greater than or equal to 1%, it has better poly-olefine material performance, more white fire retardant and no need for anti-smoke agent. It can be used to make poly-olefine thermal shrinkage pipe with VW-1 vertical burning performance according to UL224 standard.

Owner:上海世龙科技有限公司

Environmental-friendly white emulsion

InactiveCN103725229AOptimal temperature timeImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDioxyethylene EtherBenzioc acid

The invention discloses an environmental-friendly white emulsion. The environmental-friendly white emulsion is prepared from the components in percentage by weight: 1.8-2.5 percent of polyvinyl alcohol PVA, 23-27 percent of vinyl acetate VAC, 0.3-0.8 percent of acrylic acid AA, 0.8-1.5 percent of acryl amide AM, 0.1-0.15 percent of ammonium persulfate, an anionic emulsifier A-102, alkyl polyoxyethylene ether LCN-287, a nonionic emulsifier, 5-7 percent of corn starch, a transparent powder, a plasticizer, 2.5-4 percent of diethylene glycol dibenzoate, 0.2-0.3 percent of preservative KSG-201, 0.1-0.2 percent of sodium hydroxide NaOH, 0.3-0.5 percent of methanol, 3-6 percent of functional filler, 0.15-0.3 percent of compound emulsifier and 56-58 percent of water. The environmental-friendly white emulsion is strong in the adhesive force and the adhesive strength, is low in the production cost and is good in the environmental protection performance.

Owner:GUANGZHOU YIJIANG CHEM CO LTD

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

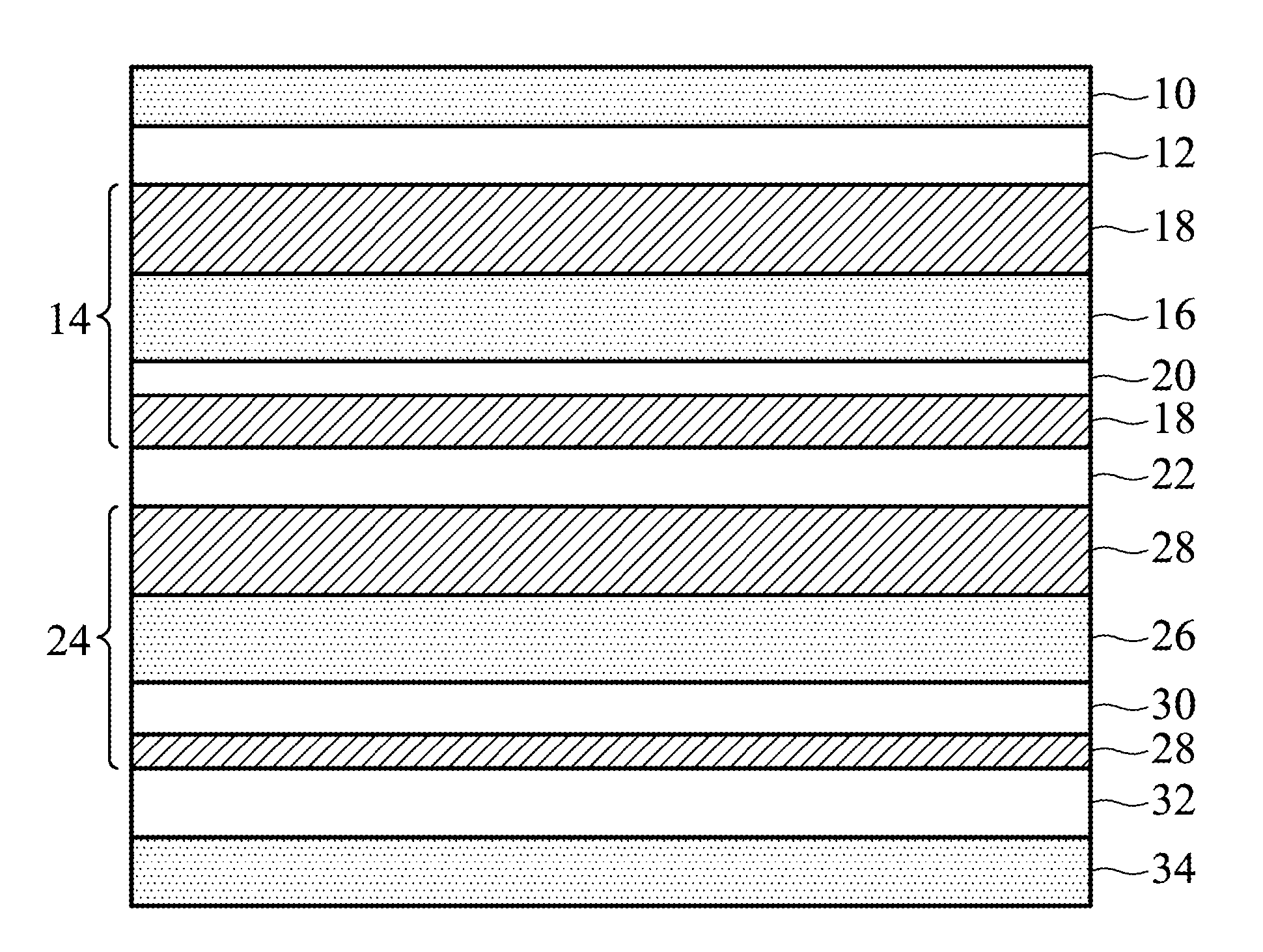

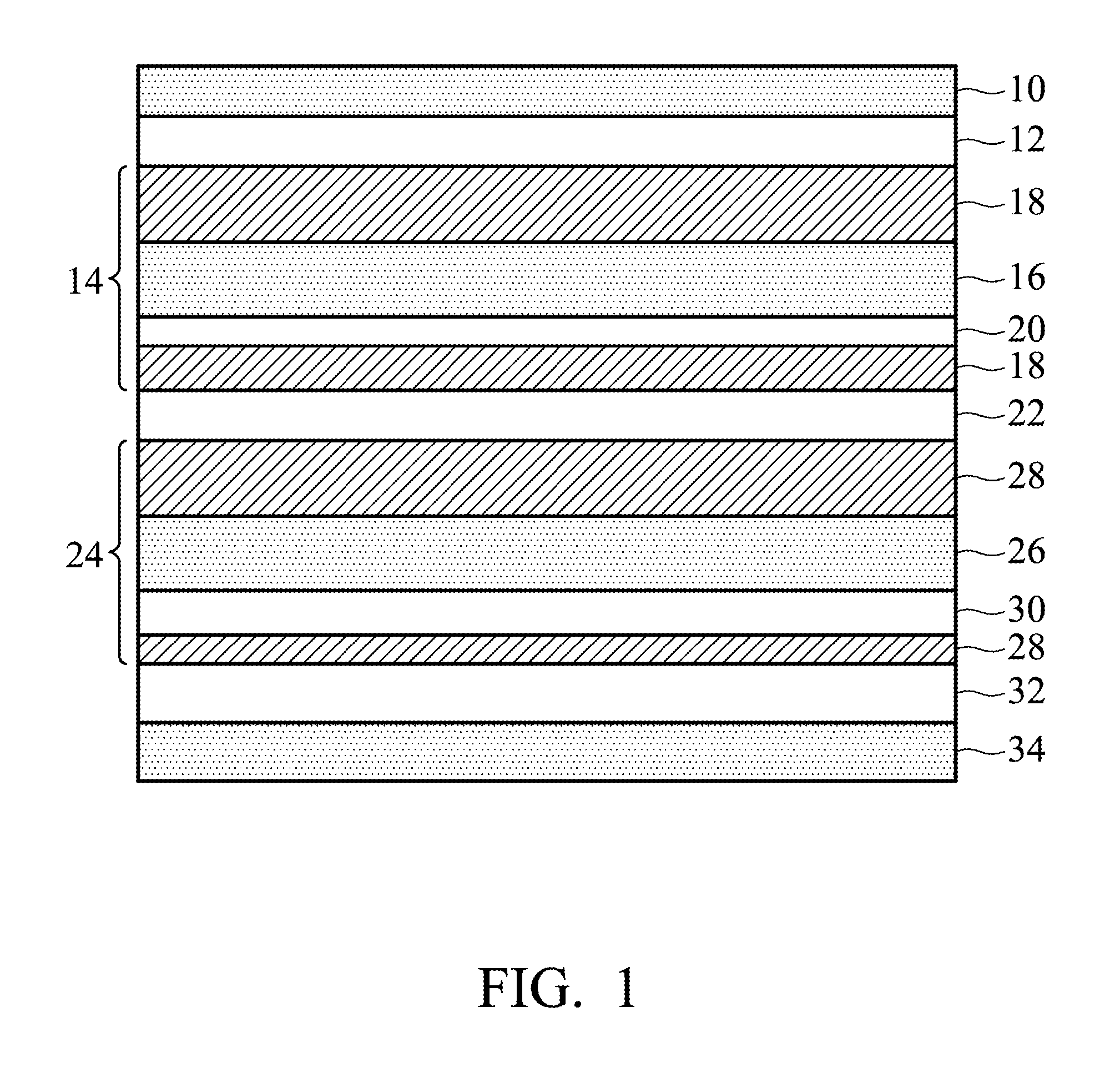

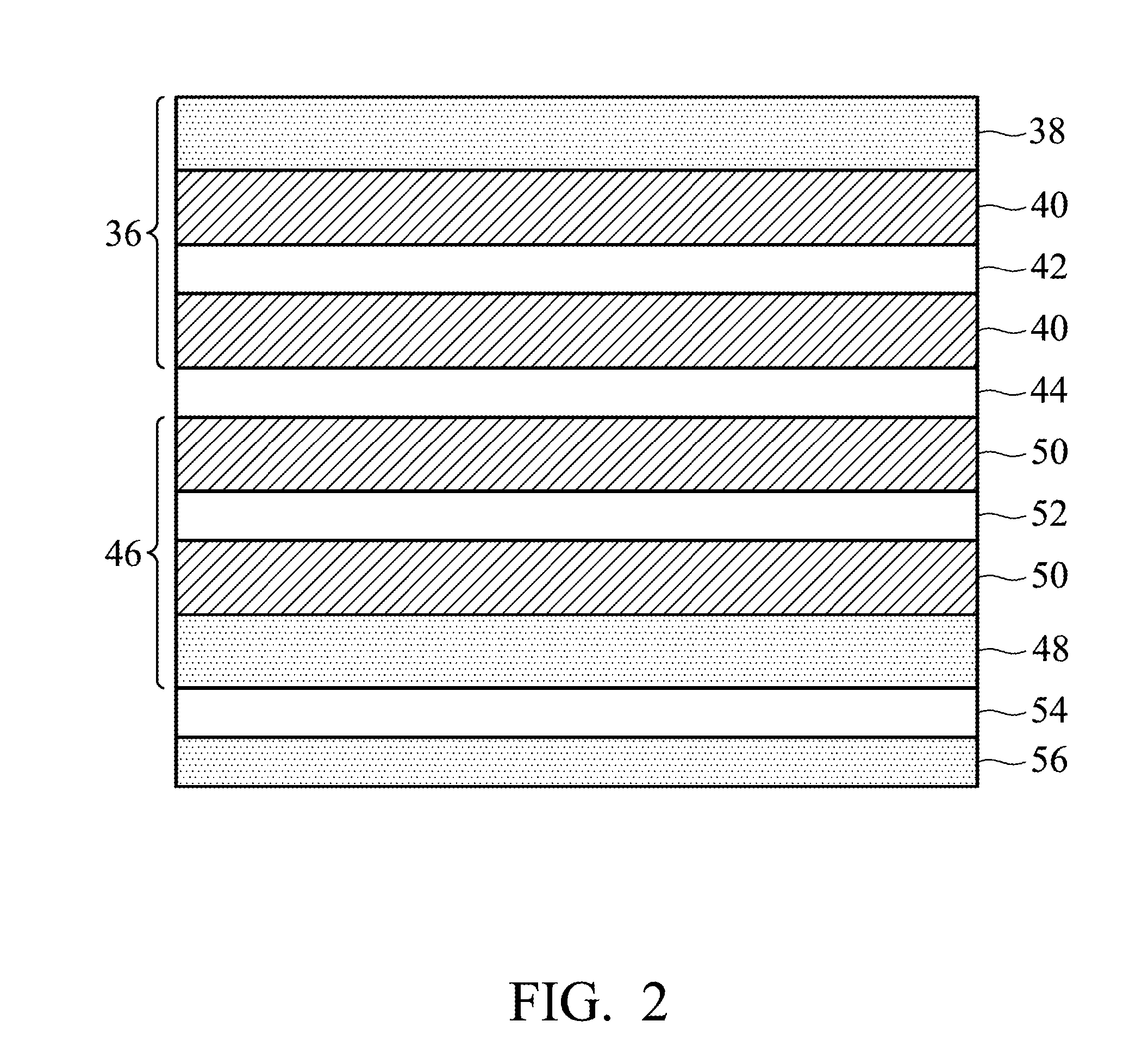

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and preparation method thereof

InactiveCN103756579AImprove barrier propertiesImprove hydrolysis resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantAging resistance

The invention discloses an EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and a preparation method thereof. The glue film is prepared from the following raw materials in parts by weight: 100 parts of an EVA copolymer, 0.5-5 parts of a crosslinking agent, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of an ultraviolet absorber, 0.05-0.5 part of a light stabilizer, 0.1-3 parts of a silane coupling agent and 0.01-55 parts of a water resistant. The preparation method comprises the following steps: plastifying and extruding; stretching; drawing; rolling and the like. The glue film disclosed by the invention has the beneficial effects that the EVA glue film obtained by the invention has good gas-water barrier property and hydrolysis resistance as well as better damp-heat aging resistance.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material and preparation method thereof

ActiveCN102731891AMitigates melt fractureHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material. The material is characterized in that: the material is prepared from raw materials of: substrate resin, a fire retardant, a lubricating agent, and an anti-oxidant. The substrate resin is composed of metallocene linear low-density polyethylene (MLLDPE), an ethylene-vinyl acetate polymer, and an interface compatibilizing agent. The preparation method comprises the steps that: the raw materials are well mixed in a high-speed mixing machine; the mixture is subjected to mixed extrusion under a processing temperature of 125-145 DEG C on a same-direction double-screw extruder; and the material is subjected to hot-cut granulation, such that a finished product is obtained. Compared with a traditional thermoplastic halogen-free low-smoke flame-retardant polyolefin cable material, the cable material provided by the invention has good oil resistance. When the cable material is soaked in mineral oil, the change rates in tensile strength and breaking elongation are low.

Owner:中广核三角洲(江苏)塑化有限公司 +1

High temperature resistant soft low-smoke no-halogen flame-proof polyolefine cable material

ActiveCN101397380AGood flexibilityHigh limiting oxygen indexLiquid organic insulatorsInsulated cablesPolyolefinCarvacryl acetate

The invention discloses a high temperature resistant flexible low-smoke zero-halogen flame-retardant polyolefin compound. The material formula thereof consists of the following materials: an ethylene-vinyl acetate copolymer, a propylene-ethylene copolymer, an interfacial compatilizer, a flame retardant, an antioxidant silane coupling agent and a lubricant, wherein, the Shore A hardness of the ethylene-vinyl acetate copolymer is less than 75, the weight content of the vinyl acetate in the raw material monomer is 30 percent to 70 percent, the Shore A hardness of the propylene-ethylene copolymer is less than 90, and the Shore A hardness of the interfacial compatilizer is less than 80. The invention can meet the high temperature resistant conditions of an aging test (135 DEG C 168h), and has the advantage of low cost.

Owner:中广核三角洲(江苏)塑化有限公司

Energy-saving type concrete crack repairing agent

The invention discloses an energy-saving type concrete crack repairing agent which comprises the following components in parts by weight: 12-18 parts of sand, 5-10 parts of a quartz powder, 20-35 parts of ordinary portland cement, 10-18 parts of sulphoaluminate cement, 6-12 parts of sodium silicate, 5-9 parts of a polyvinyl acetate emulsion powder, 3-7 parts of silica fume, 7-10 parts of a slag powder, 6-9 parts of fly ash, 8-10 parts of an expansive agent, 0.4-0.6 part of a polycarboxylic acid type high-efficiency water-reducing agent, and 0.2-0.4 part of polypropylene fiber. The concrete repairing agent has high bonding strength, and significantly improves the binding force between a new concrete interface and an old concrete interface; the concrete repairing agent is short in congealing curing time, fast in development of strength after congealing, and suitable for rapid repairing; the concrete repairing agent has the advantages of environmental protection, no toxicity, no smell, harmlessness to human bodies, single-component construction, and no pollution to the environment; and the concrete repairing agent can be used for repairing of concrete cracks, holes, honeycombs and pock marks, and drawing repairing of seams of face bricks and mosaic.

Owner:HUNAN CONSTR ENG GRP COR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com