Novel EVA adhesive film

A kind of adhesive film, a new type of technology, applied in the direction of adhesives, film/sheet adhesives, electronic equipment, etc., can solve the problems of battery chip fragmentation, poor creep resistance, poor heat resistance, etc., to ensure service life, High photoelectric conversion efficiency and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

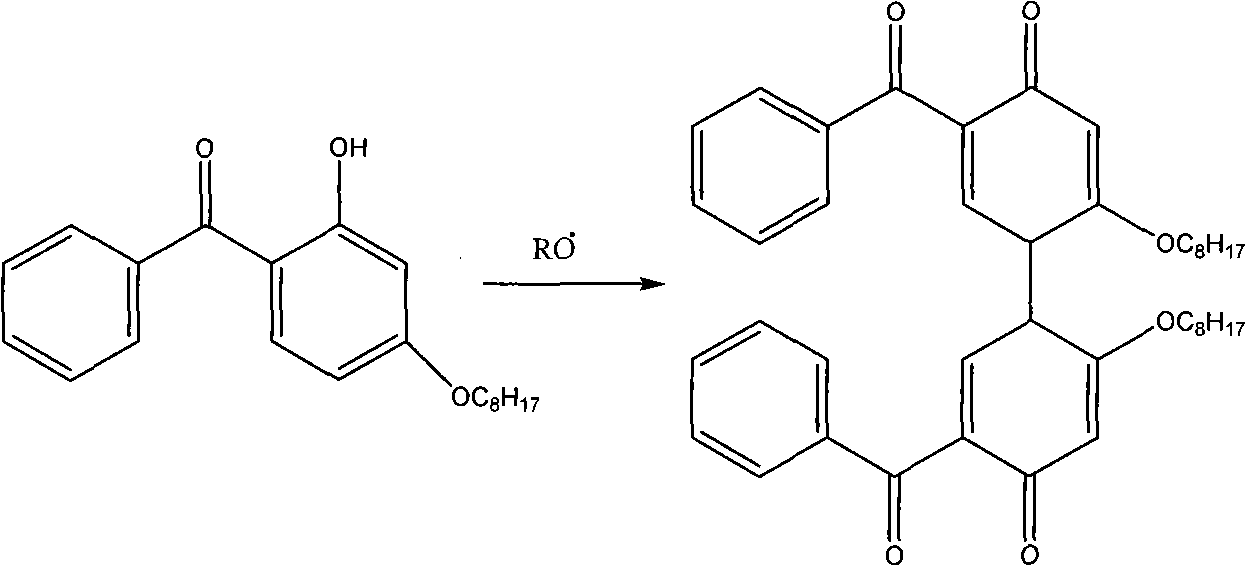

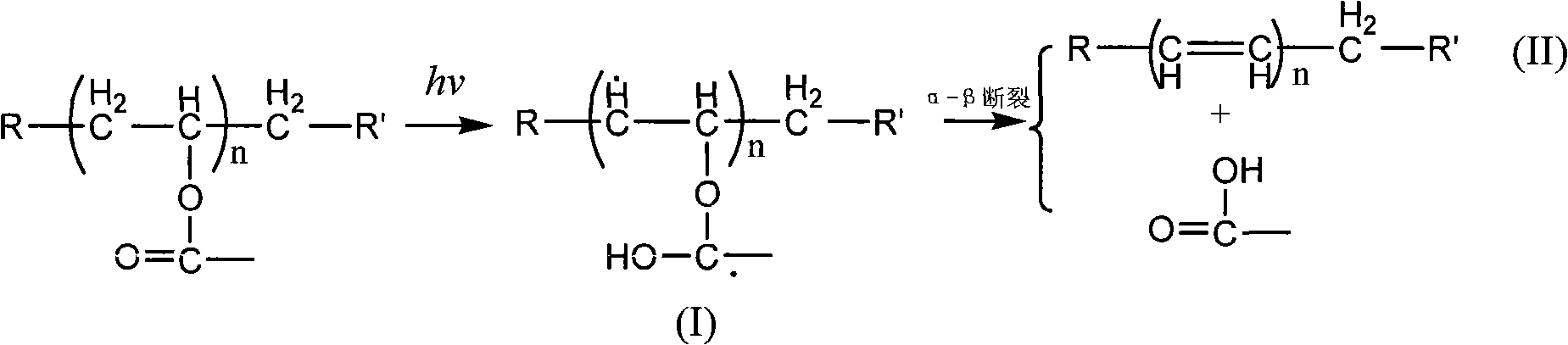

Method used

Image

Examples

Embodiment 1

[0033]In terms of parts by mass, 0.1 part of hindered amine light stabilizer bis(1,2,2,6,6-five Methyl-4-piperidinyl) sebacate / methyl-1,2,2,6,6-pentamethyl-4-piperidinyl sebacate compound (mass ratio 1:1, Beijing Tiangang Co., Ltd.), 0.2 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-tris Oxyzine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite compound (mass ratio 1:2, developed by Tianda Tianhai Technology Co., Ltd.), 1.5 parts of crosslinking curing agent o, o-tert-amyl-o-(2-ethylhexyl)-mono-peroxycarbonate (Guangzhou Liben (Julong) Rubber Raw Material Trading Co., Ltd.), 0.4 Parts of tackifier γ-aminopropyltriethoxysilane (Nanjing Lipai Chemical Co., Ltd.), and mix well. The mixture is blended and extruded in an extruder, and the temperature is controlled at 90°C. The extruded product is cast, cooled, cut, and coiled to obtain the EVA film S-1.

Embodiment 2

[0035] In terms of parts by mass, 0.01 part of hindered amine light stabilizer bis(1,2,2,6,6-5 Methyl-4-piperidinyl) sebacate / methyl-1,2,2,6,6-pentamethyl-4-piperidinyl sebacate compound (mass ratio 1:1, Beijing Tiangang Co., Ltd.), 5 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxyl-2,6-dimethylbenzyl)-1,3,5-tris Oxyzine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite compound (mass ratio 1:2, developed by Tianda Tianhai Technology Co., Ltd.), 1.5 parts of crosslinking curing agent 2,5-dimethyl-2,5-bis(benzoylperoxy)-hexane (Shanghai Yanjia Plastic Chemical Co., Ltd.), 0.4 parts of tackifier γ- Aminopropyltriethoxysilane (Nanjing Lipai Chemical Co., Ltd.), the mixture is blended and extruded in the extruder, the temperature is controlled at 90 ° C, and the extruded product is cast, cooled, cut, and coiled. , that is, to the EVA film S-2.

Embodiment 3

[0037] In parts by mass, 100 parts of VA content is 33% ethylene-vinyl acetate copolymer (U.S. DuPont), add 5 parts of hindered amine light stabilizer bis(1,2,2,6,6-5 Methyl-4-piperidinyl) sebacate / methyl-1,2,2,6,6-pentamethyl-4-piperidinyl sebacate compound (mass ratio 1:1, Beijing Tiangang Co., Ltd.), 0.1 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-tris Oxyzine-2,4,6-(1H,3H,5H)-trione / tris(2,4-di-tert-butylphenyl)phosphite compound (mass ratio 1:2, developed by Tianda Tianhai Technology Co., Ltd.), 1.5 parts of cross-linking curing agent 2,5-dimethylhexane-2,5-di-tert-butyl peroxide (Taixing Reagent Chemical Factory), 0.01 parts of tackifier γ-aminopropyl tri Ethoxysilane (Nanjing Lipai Chemical Co., Ltd.), and mix well. The mixture is blended and extruded in an extruder, and the temperature is controlled at 90°C. The extruded product is cast, cooled, cut, and coiled to obtain the EVA film S-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com