Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "No porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

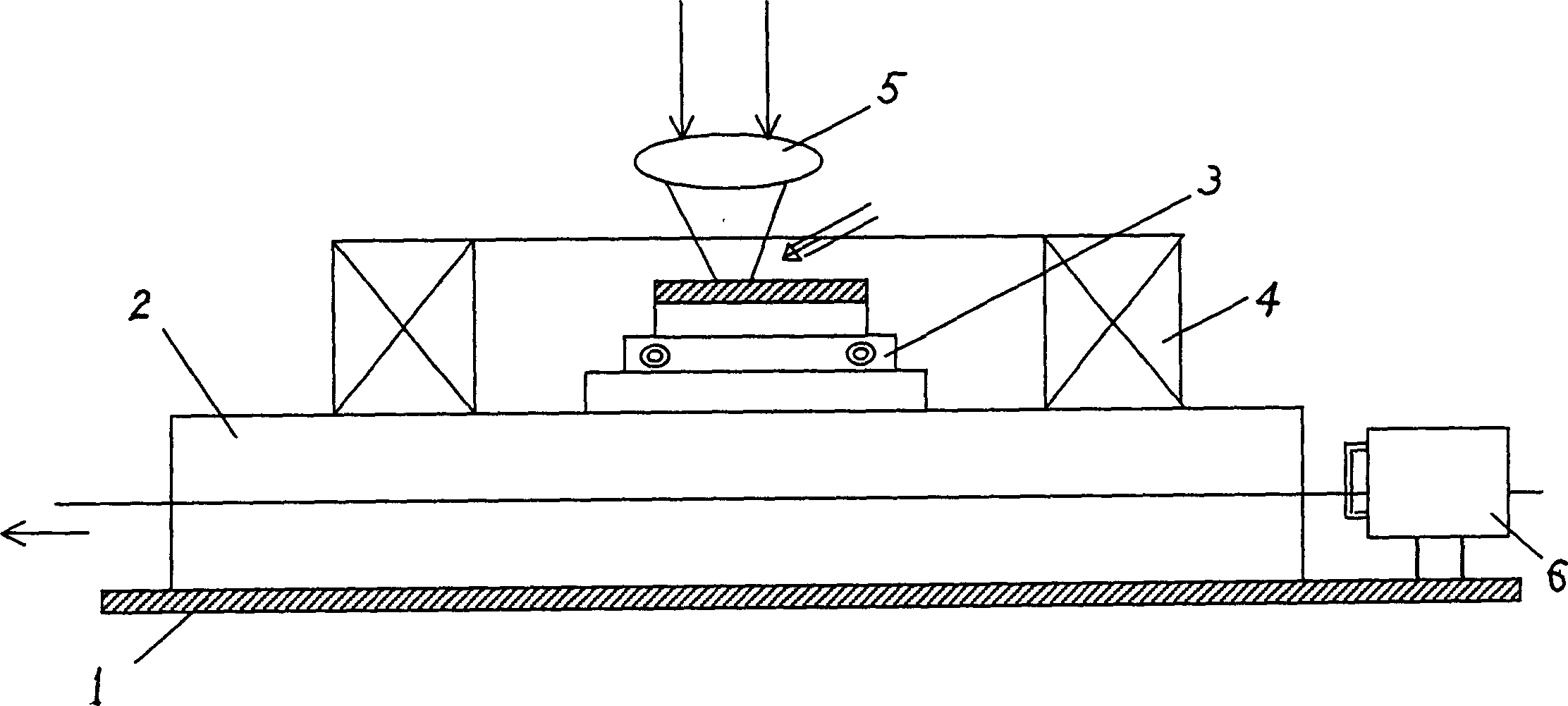

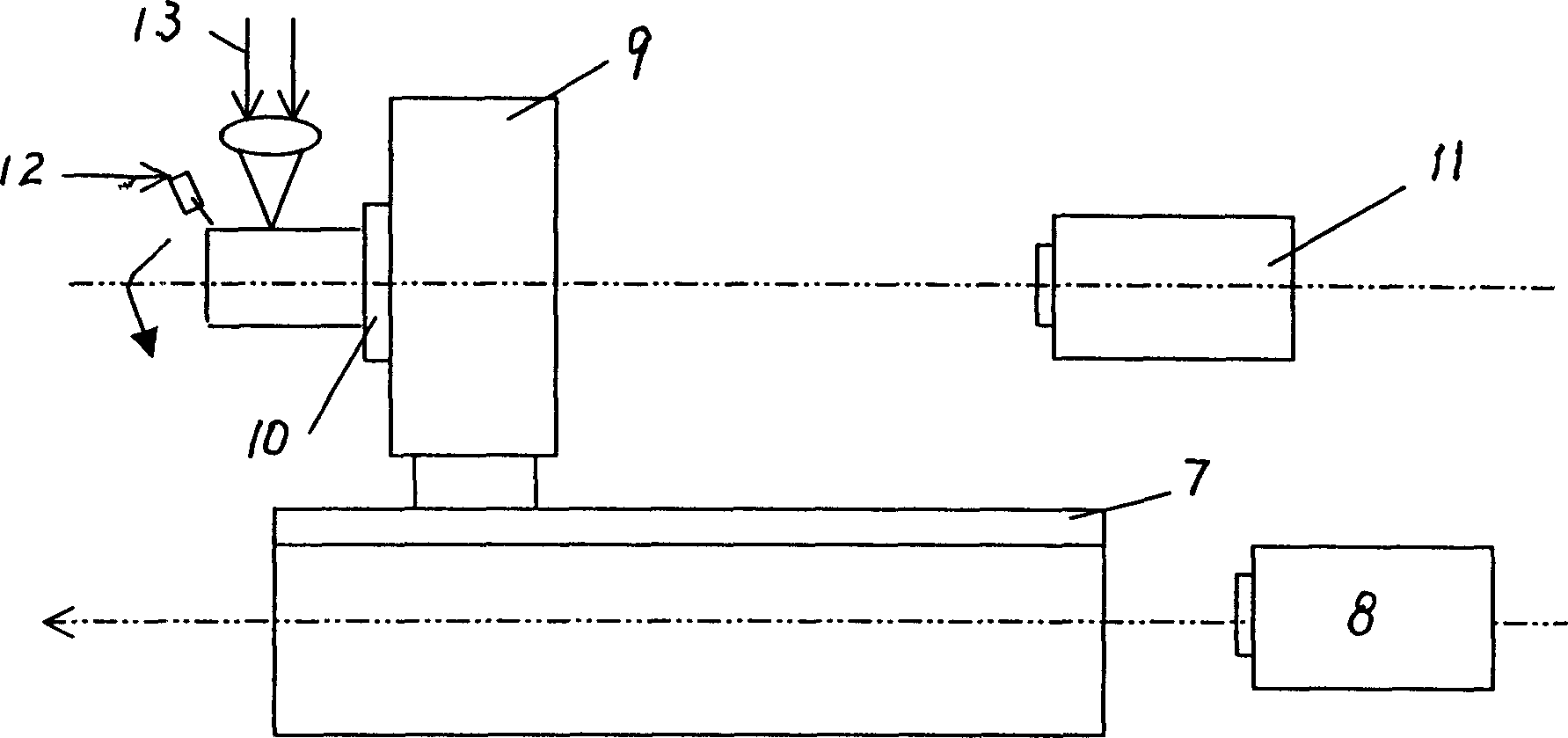

Laser-induction hybrid melting direct forming method and device

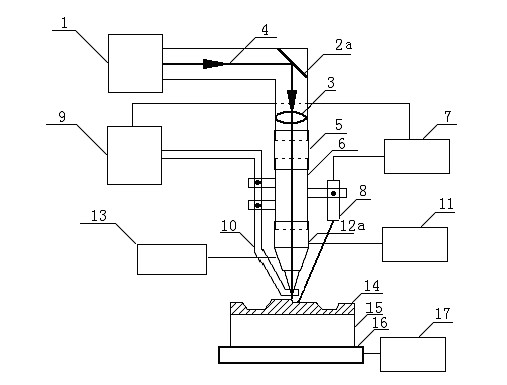

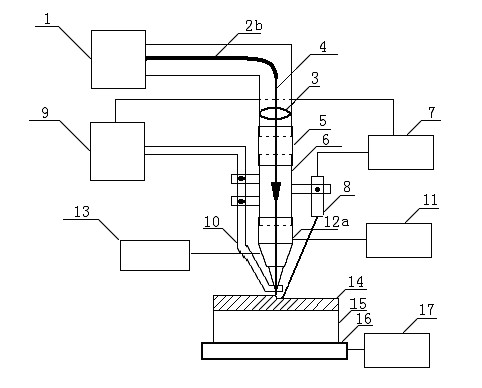

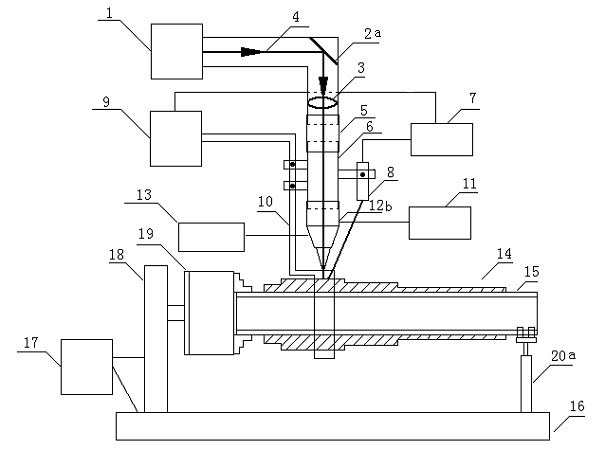

The invention discloses a laser-induction hybrid melting direct forming method and device. The laser-induction hybrid melting direct forming method comprises the following steps of: generating a three-dimensional model of a part through CAD (Computer-Aided Design) software, and then slicing the three-dimensional model and generating a G code to drive a numerical control system and a base body to move; and melting synchronously fed metal or metal / ceramic hybrid powder through a high-power laser beam and an induction heat source, and depositing the three-dimensional part in a designed shape layer by layer, wherein a temperature controller is used for monitoring and controlling the temperature of the base body in the processing process. The device for realizing the laser-induction hybrid melting direct forming method comprises a laser, a light path system, an induction heating and temperature control system, a powder feed system and the numerical control system. The device can be used for directly generating large and medium size three-dimensional parts on various metal base bodies, has the advantages of high processing efficiency, compact part structure, fine crystalline grain, excellent mechanical property, less residual stress without deformation or cracking phenomenon, high processing flexibility without tools and moulds, high material utilization ratio, cleanness without pollution and capability of designing the components of a metal-ceramic hybrid layer as required and even changing the components in a gradient manner.

Owner:HUAZHONG UNIV OF SCI & TECH

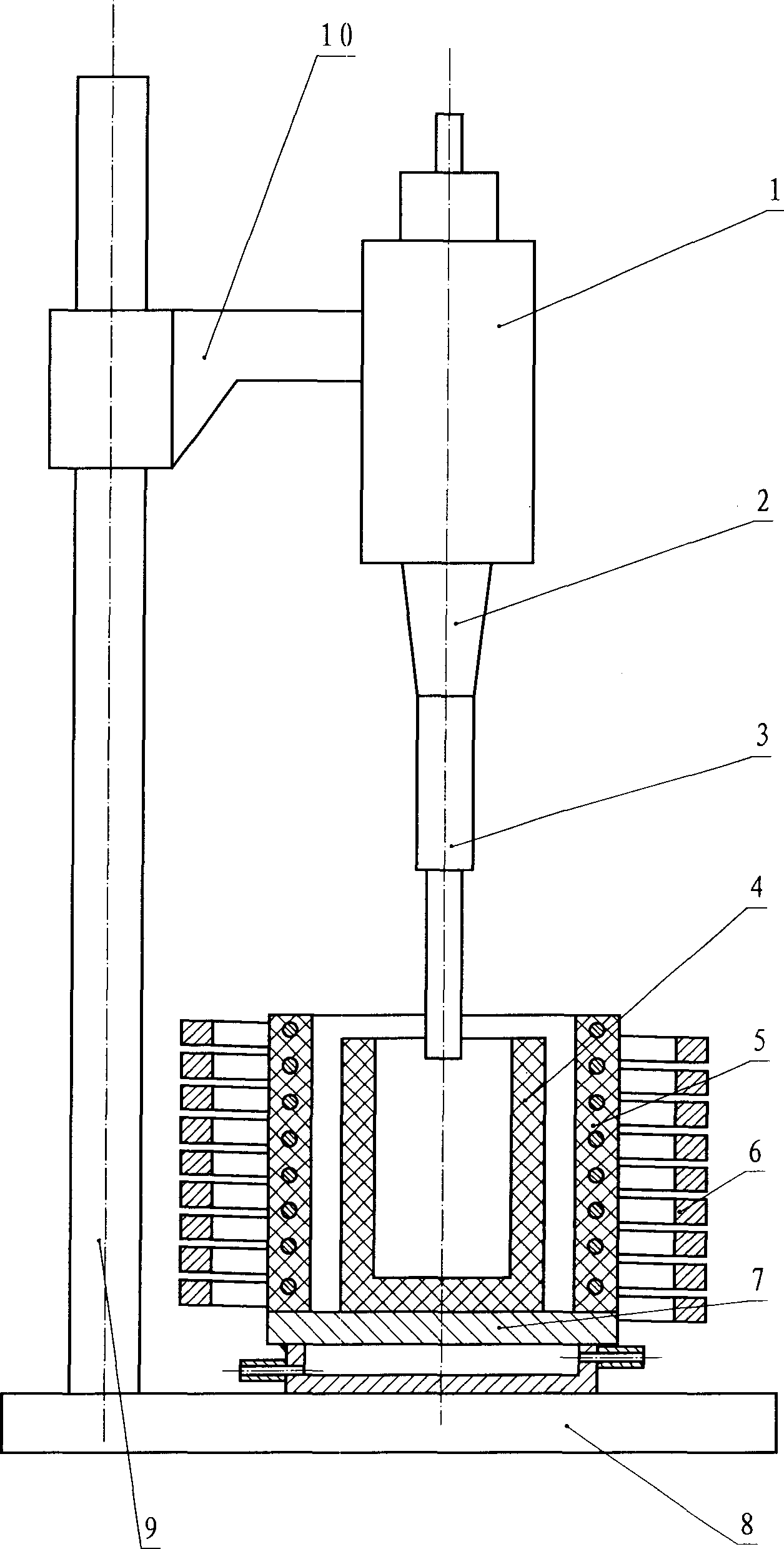

Method for preparing nanocystalline ingot casting by magnetic field and ultrasonic combined treatment of metal melt and dedicated apparatus therefor

It is a method for preparation and the special device of nanocrystalline ingotting from metallic fondant treated jointly by magnetic field and supersonic wave, solving the present technique problem of complex device, high cost, and difficulty to prepare large-scale nanometer material and so on. The invented method is as the following steps: melting and heating the matched raw material, deairing the metallic fuse-elements, pouring rapidly the deaired metallic fuse-elements into preheated crucible, heating upwards the liquidus curve, applying electromagnetic mixing and ultrasonic vibration, chilling until it freezes totally, then the block-shaped nanocrystalline ingotting being prepared; the special device that applied joint treatment of electromagnetic mixing and ultrasonic vibration having a holding furnace, which is equipped with a crucible, the special being characterized in that outboard of the holding furnace is equipped with magnetic field generator, over the crucible there is a ultrasonic transducer, and bottom of the crucible is equipped with a chiller.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

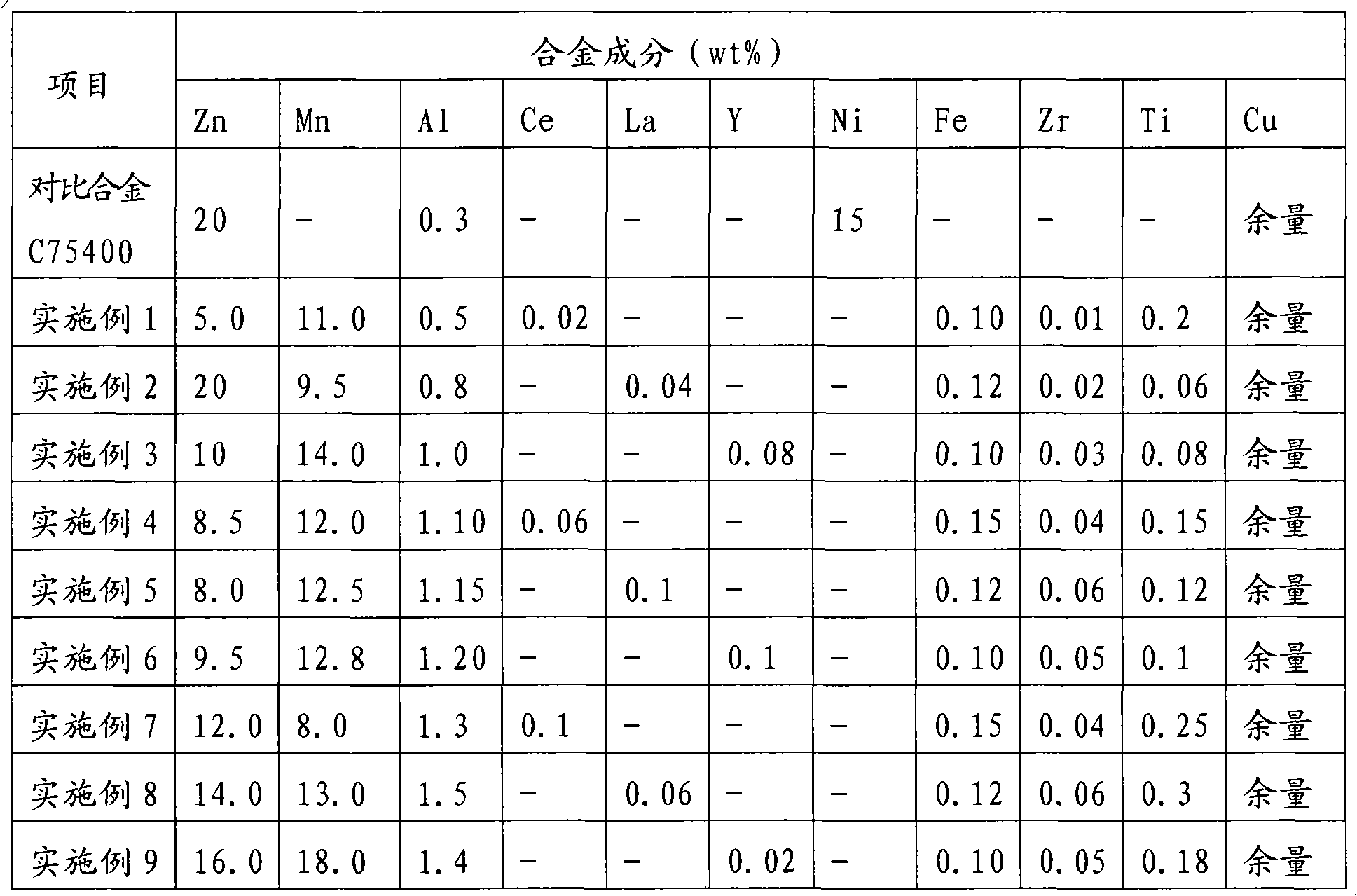

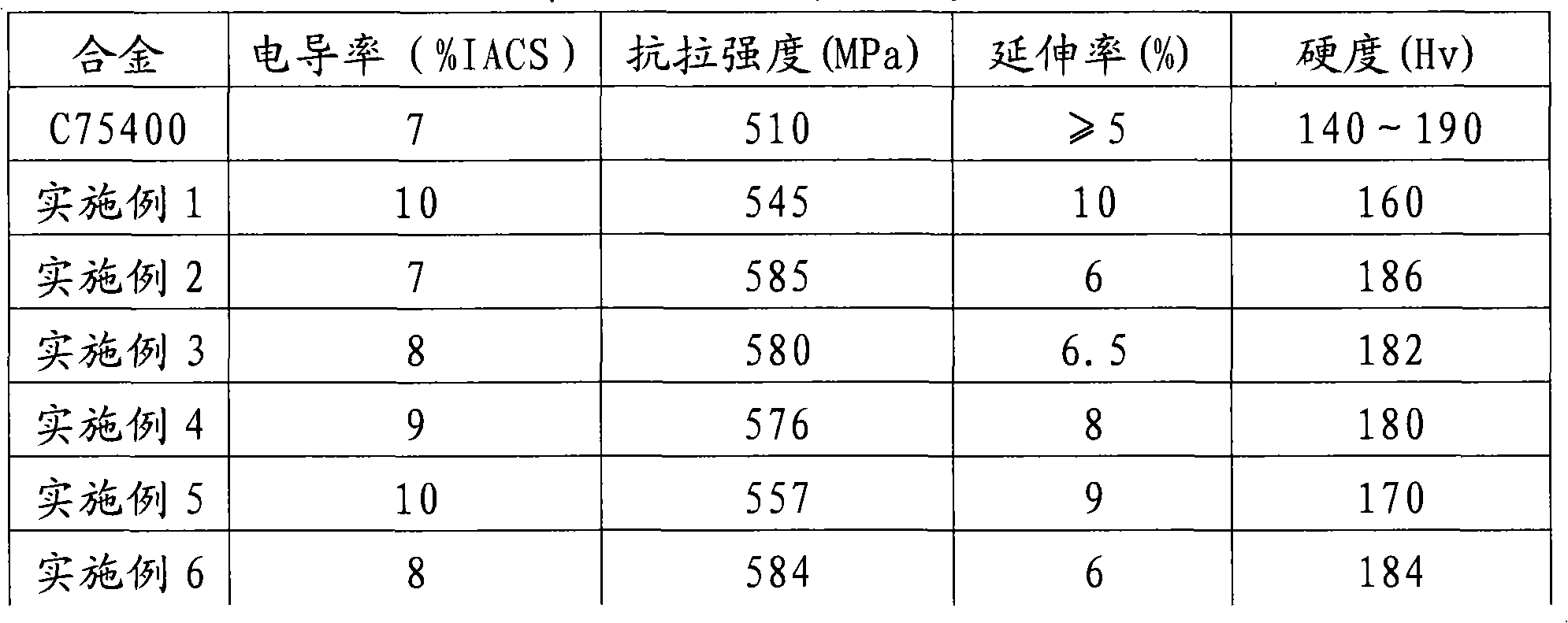

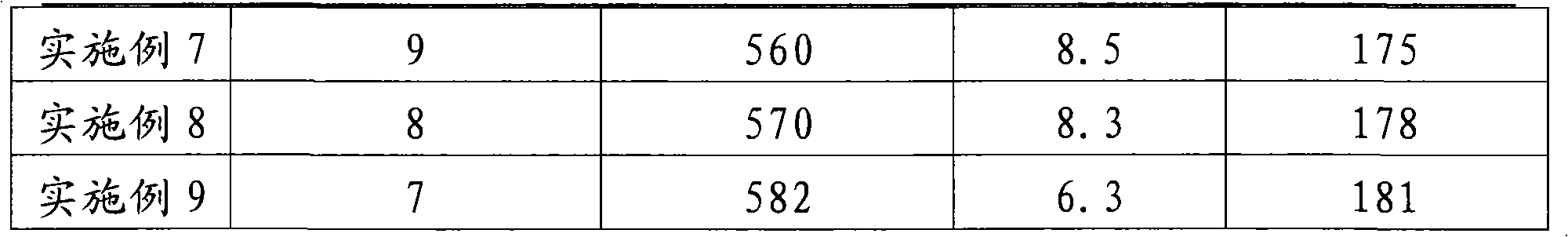

Nickel-free white copper alloy containing rare earth additional elements and method for manufacturing plates made of same

The invention discloses nickel-free white copper alloy containing rare earth additional elements and a method for processing plates made of the same. The nickel-free white copper alloy comprises the following components in percentage by weight: 0.02 to 0.1 percent of rare earth elements, 5 to 20 percent of zinc, 8 to 18 percent of manganese, 0.5 to 2.0 percent aluminum, 0 to 0.5 percent of iron, 0 to 0.5 percent of titanium, 0 to 0.1 percent of zirconium and the balance of copper. An alloy processing method comprises the following major technological processes of: alloy smelting and casting, hot rolling, thermal annealing, cold rolling and the like. The method is characterized in that: copper, zinc, manganese and aluminum are taken as main alloy elements; rare earth elements such as lanthanum, cerium and iridium as well as trace elements such as iron, zirconium and titanium are added in an alloy smelting process; and a human-friendly and environmental-friendly nickel-free white copper alloy plate is manufactured by the technological methods of high-temperature alloying, degassing, impurity removing, casting, cast ingot hot rolling, thermal annealing, cold rolling, finished product annealing and the like.

Owner:JIANGXI UNIV OF SCI & TECH

Graphite base with protective coating layer and preparation method thereof

InactiveCN101775590ANo porosityMitigate Thermal MismatchChemical vapor deposition coatingReaction chamberGraphite

The invention provides a graphite base with a protective coating layer and a preparation method thereof. The invention prepares a silicon carbide coating layer on the surface of the porous graphite base through combining the in-situ chemical gas-phase reaction permeation and the chemical gas-phase deposition two-step method. The preparation method is carried out according to the following steps: placing the a base body of the graphite base in a reaction chamber, introducing SiCl4 gas and H2 gas into the reaction chamber according to the volume ratio that SiCl4 / H2 equals to 1 / 5 to 50 under the condition of the reaction chamber temperature between 1300 and 1600 DEG C and the vacuum between 200 and 500 Pa, wherein the hydrogen flow rate is between 200 and 1000 ml / min, the gas introduction time is between 0.5 and 2 hours, and a primary SiC coating layer is permeated on the base body of the graphite base through the in-situ gas-phase reaction; and then b, introducing CH3SiCl3 gas and H2 gas into the reaction chamber according to the volume ratio that CH3SiCl3 / H2 equals to 1 / 5 to 100, controlling the hydrogen flow rate to be in a range between 200 and 1000 ml / m and the gas introduction time between 1 and 50 hours, and depositing a secondary SiC coating layer outside the surface of the primary SiC coating layer after schizolysis.

Owner:刘锡潜 +1

Additive for electrolytic copper foil, electrolytic copper foil manufacturing process and electrolytic copper foil

ActiveCN102181889AIncrease the areaGood thickness uniformityElectroforming processesCopper foilCellulose

Owner:惠州联合铜箔电子材料有限公司

Preparation method of chemical nickeling phosphorus alloy film

InactiveCN1912180AUniform and dense thicknessNo porosityLiquid/solution decomposition chemical coatingPhosphorous acidChemical plating

The invention relate to a chemical plating nickel phosphor alloy coating manufacturing method. It includes oil removing, rust removing, activating, chemical plating, and post treatment. Its bath uses secondary phosphorous acid as reducer, nickel sulfate as main salt, adds complexing agent, buffering agent, stabilizing agent, etc. It optimizes bath constituent and chemical plating technological parameter by homogeneous design and single factor test method to form active surface, reduce nickel phosphor alloy coating at certain chemical plating condition. The invention has the advantages of safe, reliable, even coating, long useful life, cathodic protection function for copper alloy screw propeller, lowering marine life defilement.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

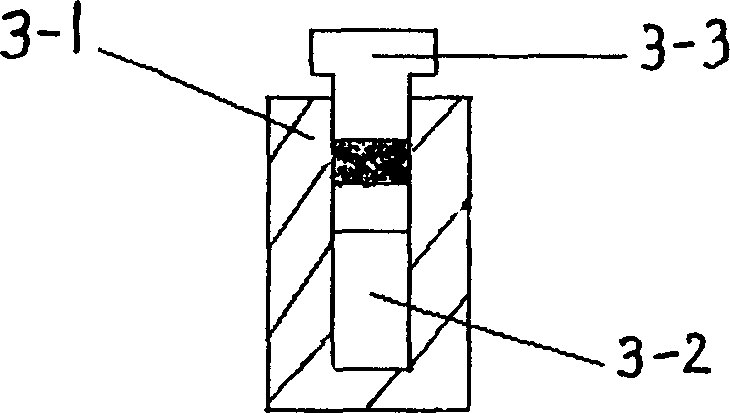

Method and its device for preparing cutter by laser coating composite ceramic layer

InactiveCN1554803AQuality improvementNo porosityMetallic material coating processesLaser beam welding apparatusFiberHeat-affected zone

The present invention relates to method and apparatus for making cutter with laser coated composite ceramic layer, belongs to the field of ceramic coating on metal surface, and aims at lowering cutter manufacturing cost while prolonging the service life of cutter. The cutter making process includes applying hard alloy powder to the surface of cutter base, applying mechanical pressure, preheating, and laser treating after or while applying the hard alloy powder. The cutter made may be chemical fiber cutter, milling cutter or trimming cutter. One of the cutter making apparatus includes bench, special fixture, electromagnetic coil and laser processing system. The other cutter making apparatus includes bench, chuck, powder blowing feeder and laser processing system. The present invention has high coating quality, less heat deformation, high production efficiency and other advantages.

Owner:HUAZHONG UNIV OF SCI & TECH

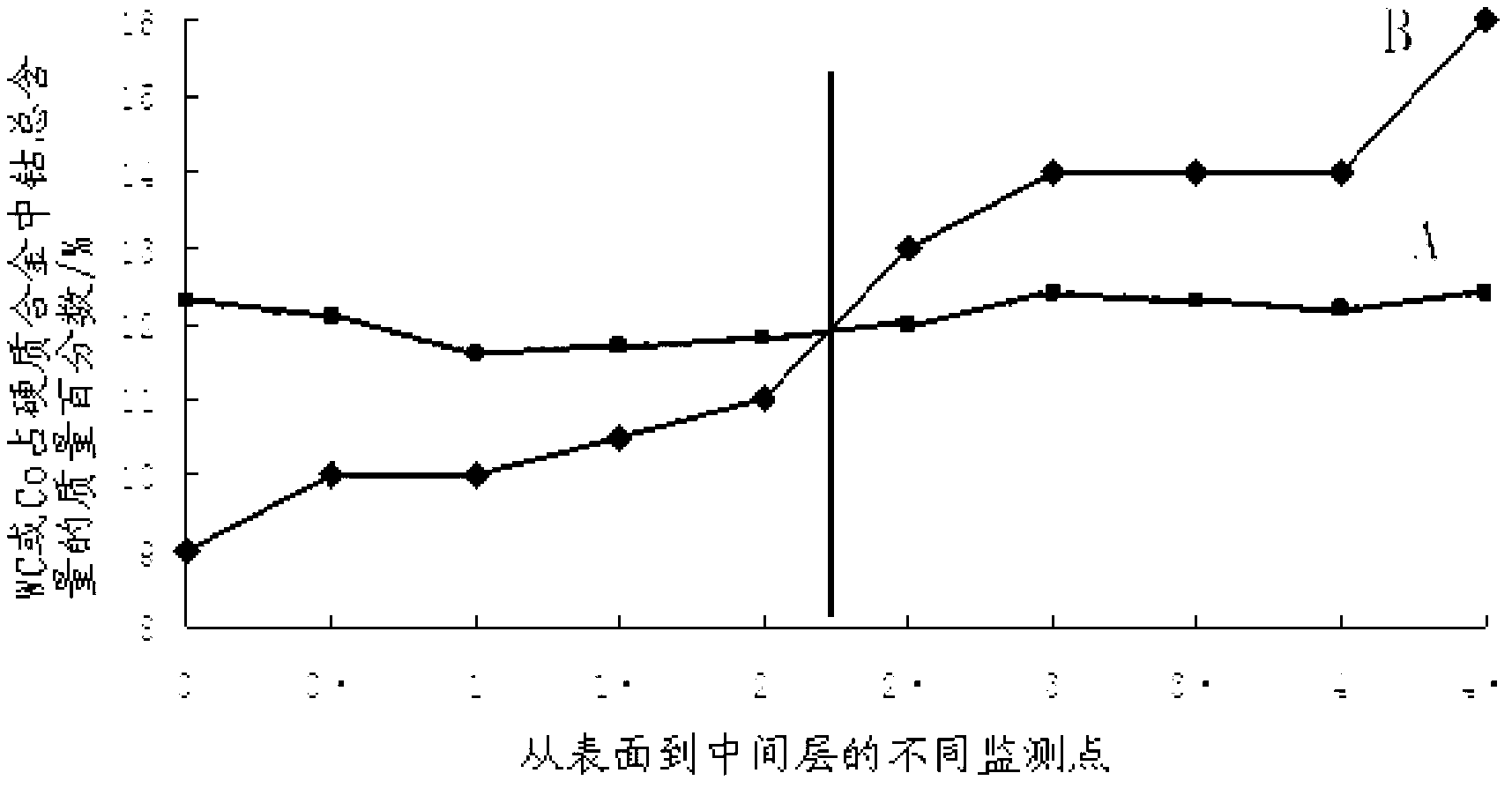

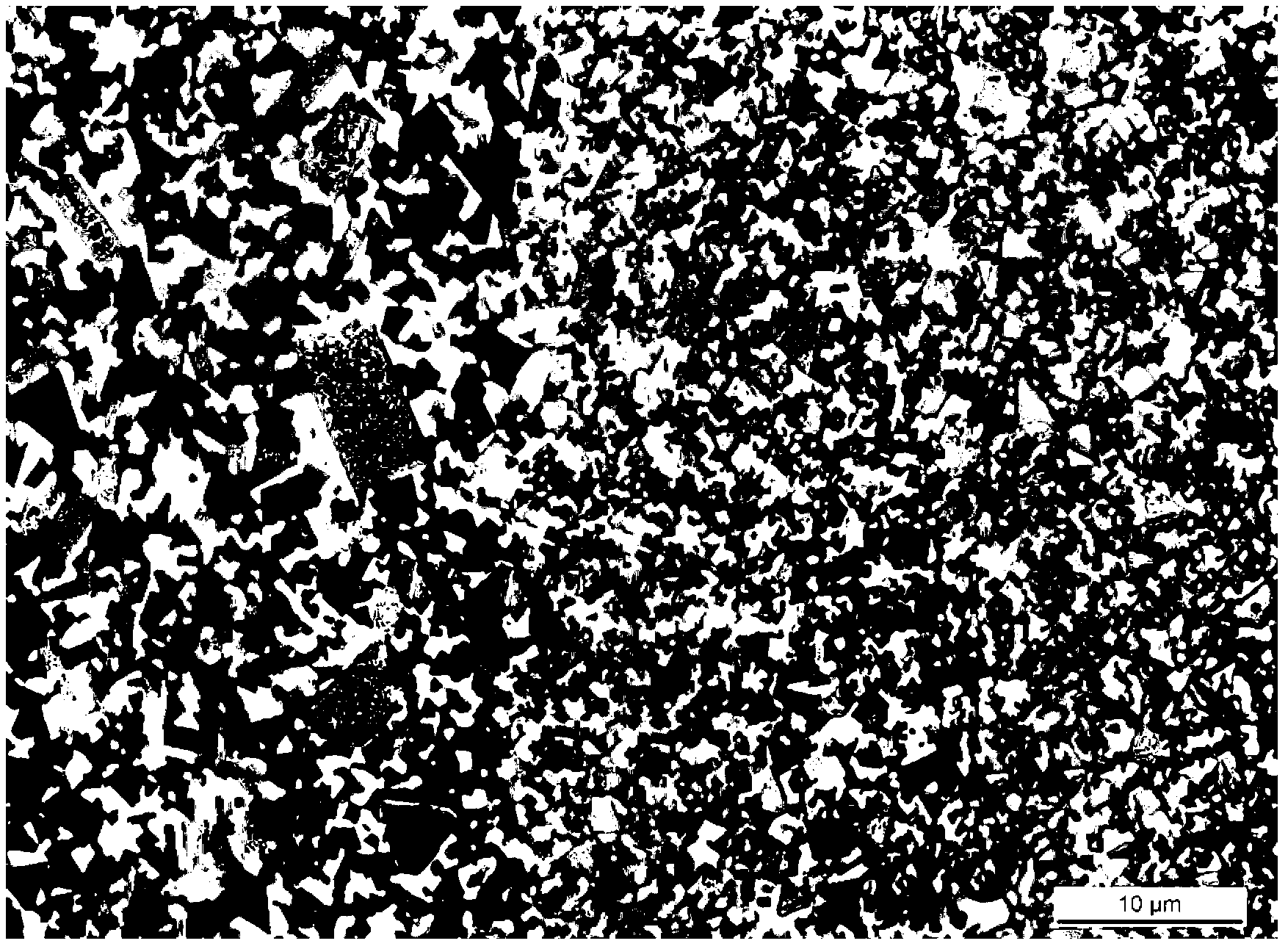

Cemented tungsten carbide alloy material with gradient cobalt content

ActiveCN102703790ANo porosityImprove mechanical propertiesSolid state diffusion coatingAlloyCemented carbide

The invention provides a tungsten carbide-cobalt hard alloy with gradient cobalt content, comprising the following components: 75-90wt% of WC and 6-15wt% of Co, wherein cobalt content is progressively increased from the surface of the hard alloy to the center of the hard alloy. The hard alloy disclosed by the invention has high wearability and high toughness. The invention also provides a preparation method of the tungsten carbide-cobalt hard alloy with the gradient cobalt content.

Owner:SEED TECH CORP LTD

Preparation method of highly-compact nickel-aluminium-based self-lubricating material

The invention discloses a preparation method of a highly-compact nickel-aluminium-based self-lubricating material. The method adopts a combined technology of batch high-energy ball milling and powder metallurgy to prepare a material with a compactness of more than 98%. The invention is especially applicable to mechanical movement self-lubricating part materials working in a corrosive environment at a high temperature.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

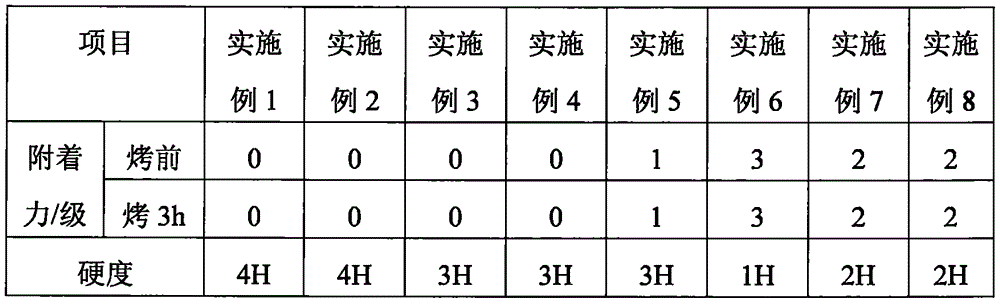

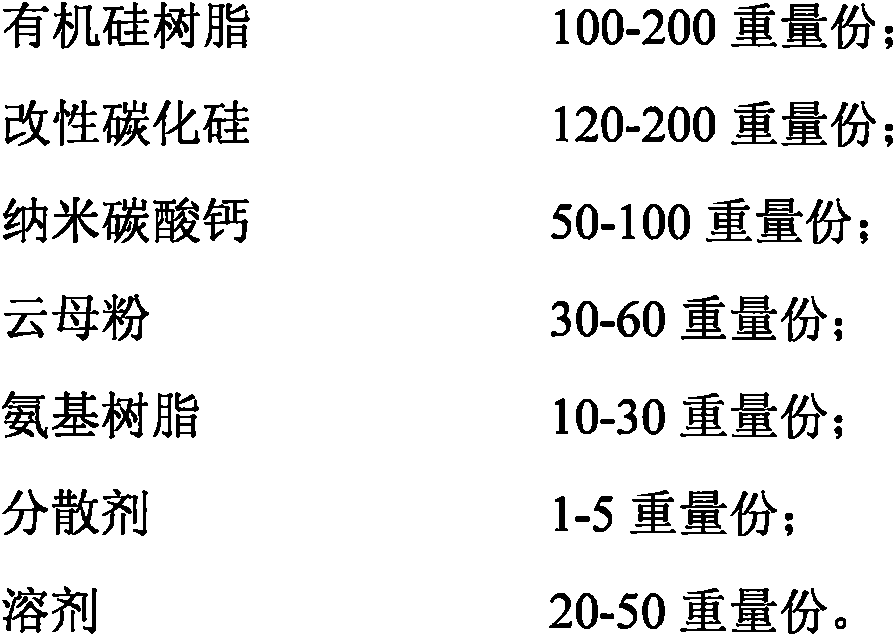

Nonstick pan coating layer, and production method and nonstick pan thereof

ActiveCN105925176AHigh hardnessImprove heat resistanceCooking-vessel materialsAnti-corrosive paintsPorositySolvent

The invention provides a nonstick pan coating layer, and a production method and a nonstick pan thereof. The production method comprises the following steps: mixing organosilicone resin, modified silicon carbide, nanometer calcium carbonate, mica powder, amino resin, a dispersant and a solvent, grinding the obtained mixture, dispersing the ground mixture, and filtering the dispersed mixture to obtain a coating; and spraying the coating on the surface of a metal pan matrix, and baking the sprayed metal pan matrix at 200-300DEG C for 10-30min to obtain the nonstick pan coating layer. The organosilicone resin, saturated modified silicon carbide and the nanometer calcium carbonate are simultaneously applied to the nonstick pan coating layer in order to form the coating layer with excellent performances of above three components. The modified silicon carbide has good thermal stability, corrosion resistance and thermal conduction performance, and guarantees the thermal distribution uniformity of the coating layer; the nanometer calcium carbonate makes the microscopic surface of the organosilicone coating layer be tight and have zero porosity, protects the matrix, and enhances the nonstick effect of the coating layer, and the nanometer calcium carbonate and the modified silicon carbide have synergism, and enhance the hardness and the heat resistance of the nonstick pan coating layer.

Owner:宁波贝得厨具有限公司

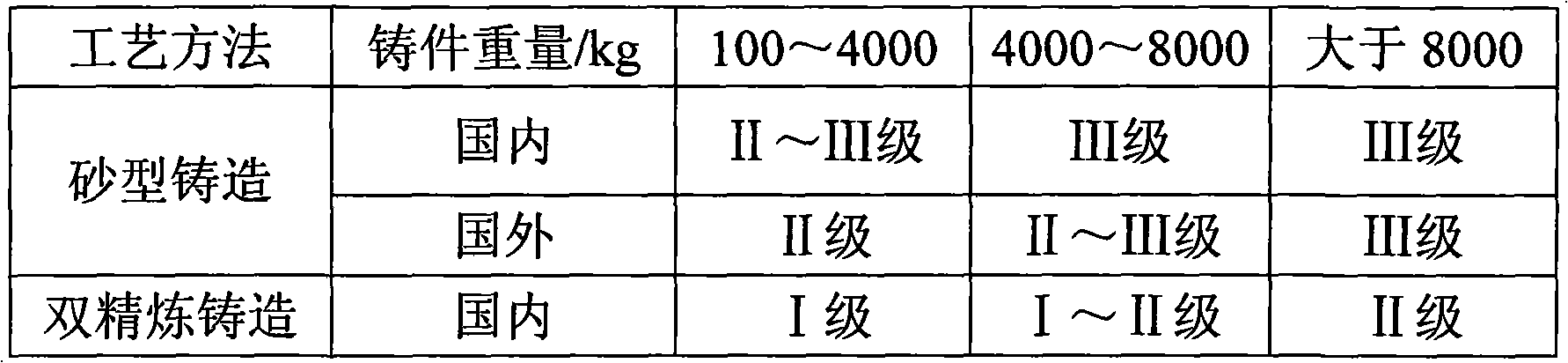

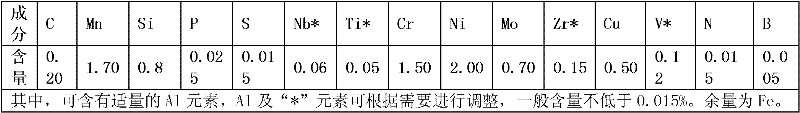

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

High corrosion resistance nickel-tin-phosphorus alloy plating liquid

InactiveCN101191205AFast depositionGood stabilityLiquid/solution decomposition chemical coatingCorrosion resistantSeawater

The invention discloses a high corrosion-resistant nickel-tin-phosphorus alloy plating liquid and is characterized in that: each liter of solution comprises: NiSO4.6H2O of 10 to 45g, NaH2PO2.H2O of 20 to 70g, SnCl4.3H2O of 5 to 30g, CH3COONa of 10 to 50g, complex hydroxycarboxylic complexing agent of 10 to 45g, complex hydroxycarboxylic promoter of 0.060 to 0.600g, Pb2+ or thiourea of 0.001 to 0.008g, the remainder is water. The pH value of the solution is between 4.2 and 5.5. The plating liquid of the invention has quick deposition and good stability; the plating layer has no holes, even thickness, lower corrosion potential and excellent corrosion resistance, and is superior to copper, nickel-phosphorus alloy and stainless steel in sea water; the plating layer has high micro-rigidity and strong abrasion-resistant ability. The invention is widely used in fields such as corrosion resistance of ocean, petrochemical industry, printed circuit boards, electric elements, spaceflight and aviation and so on.

Owner:TIANJIN UNIV

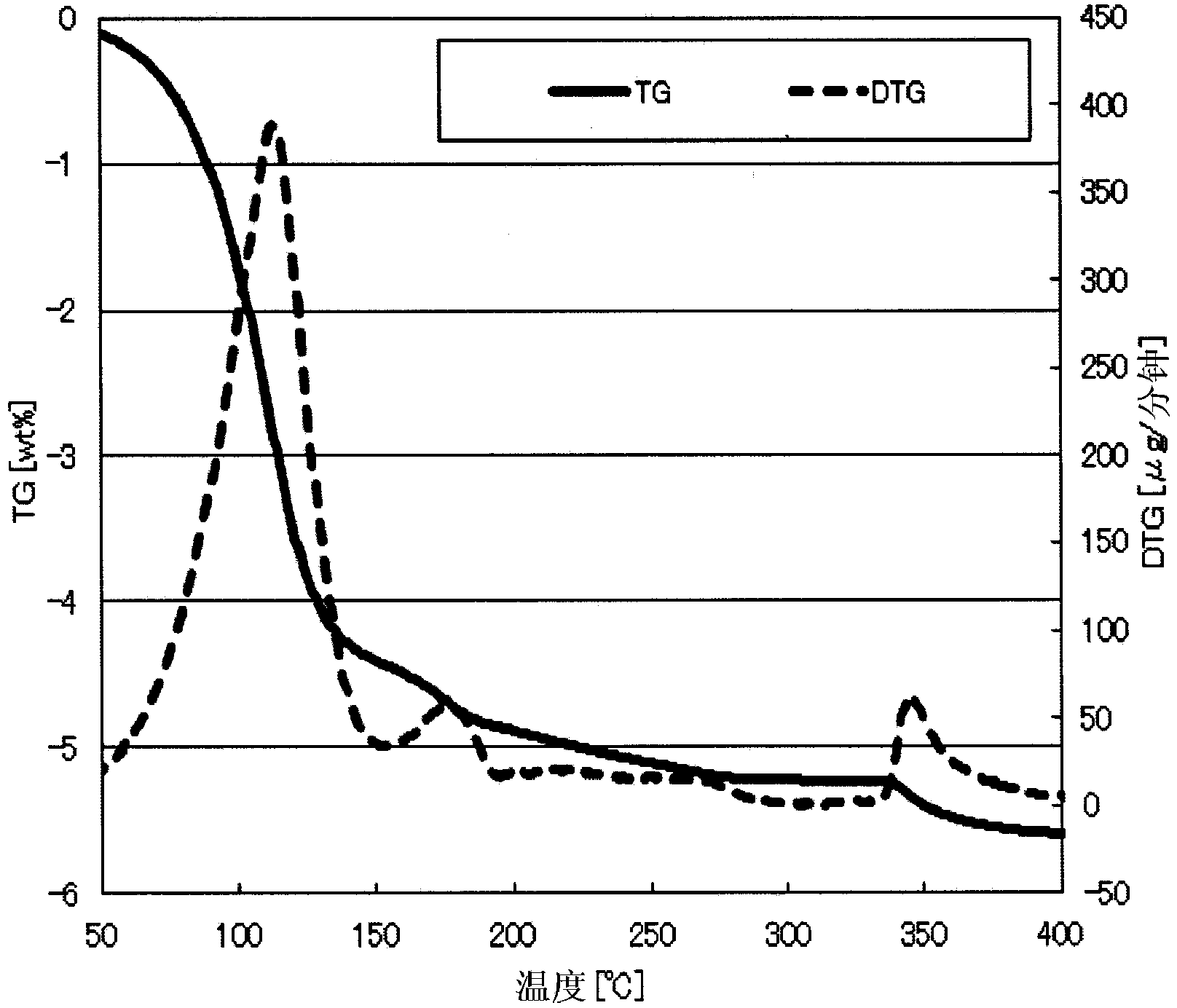

Bonding material and bonding method in which said bonding material is used

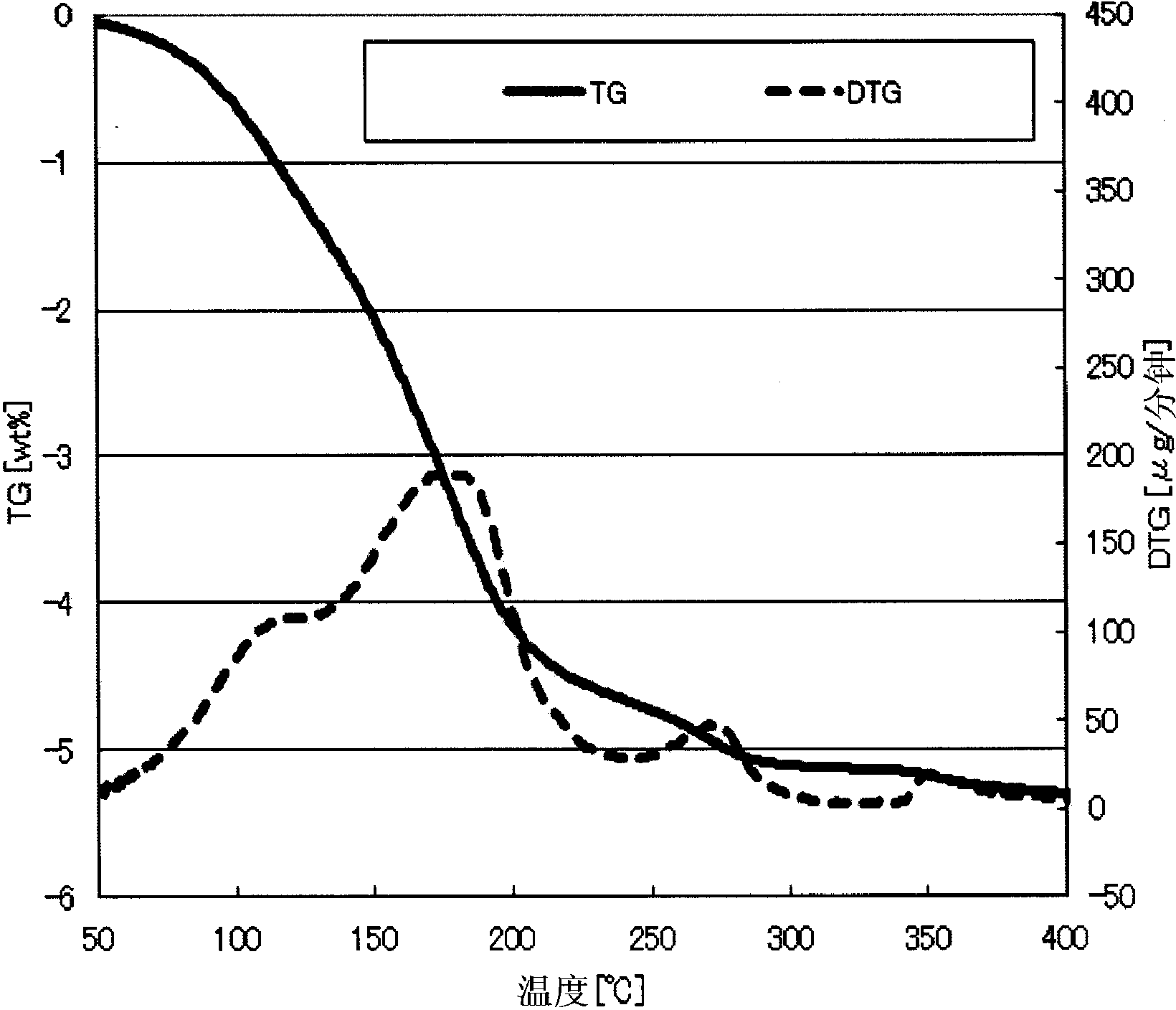

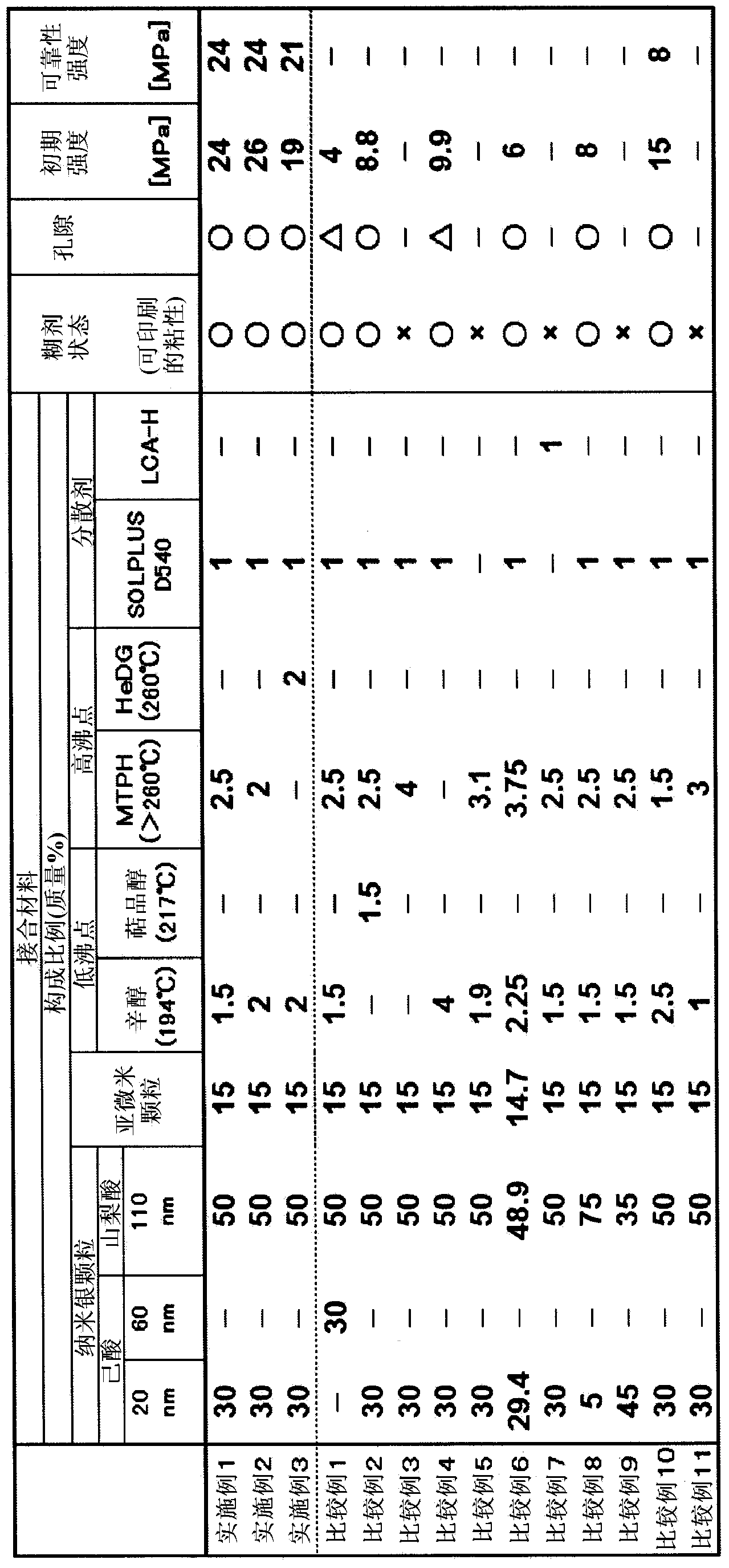

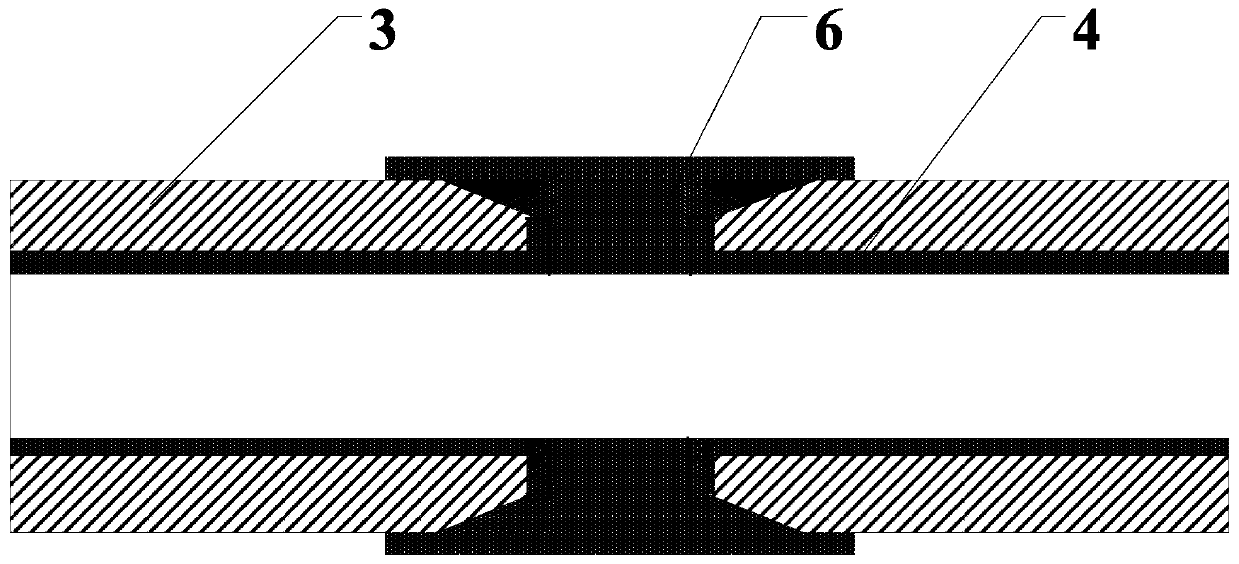

InactiveCN104066534AImprove reliabilityIncrease contentTransportation and packagingWelding/cutting media/materialsIn planeCarbon number

The purpose of the present invention is to enable highly-reliable bonding of bonding surfaces to be carried out such that the occurrence of uneven drying at the center and ends of the bonding surfaces, which occurs in-plane on a bonding layer in a desolvation process of a preliminary drying step, is reduced, thereby ensuring that the bonding surfaces do not detach even if repeatedly exposed to heat shock after bonding. This bonding material, which solves the aforementioned problem, is characterized by being covered by organic matter with a carbon number of six or less, comprising main silver particles, and covered by organic matter with a carbon number of six or less, comprising nano silver particles having an average primary particle size of 10 to 30 nm, and sub silver particles. The bonding material is further characterized by containing nano silver particles with an average primary diameter of 100 to 200 nm, two types of solvents with different boiling points, and a dispersant.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Steel normal-temperature blackening solution composite film-forming accelerator, steel normal-temperature blackening solution and preparation method of steel normal-temperature blackening solution

InactiveCN102899650ASimple preparation processReduce manufacturing costMetallic material coating processesComposite filmPhosphate

The invention discloses a steel normal-temperature blackening solution composite film-forming accelerator which comprises the following components in parts by weight: 1-3 parts of calcium nitrate, 4-8 parts of cobalt nitrate, 2.5-5 parts of sodium borate and 0.3-0.6 part of metanitrobenzene sulfonic acid. The adhesive force and corrosion resistance of a blackening film are obviously improved, and the film-forming speed is also increased. The invention also discloses a steel normal-temperature blackening solution. The steel normal-temperature blackening solution takes water as a solvent, has a pH value of 2-3 and comprises the main components of 2-8 g / L copper sulfate, 3-6.5 g / L selenium dioxide, 2-10 g / L potassium dihydrogen phosphate, 2-6 g / L zinc nitrate, 1-3 g / L nickel sulfate, 2-6 g / L composite film-forming accelerator, 3-8 g / L urea and 0.5-8 g / L complexing agent. The invention also discloses a preparation method of the steel normal-temperature blackening solution. The blackening film of the prepared blackening solution has firm adhesive force, high corrosion resistance and less sediment.

Owner:田康

Split type die for press machine, manufacturing method and forging cutting teeth thereof

InactiveCN101408030AHigh dimensional accuracyIncrease productivitySoil-shifting machines/dredgersForging/hammering/pressing machinesEngineeringMechanical property

The invention discloses a split type mould used for a press, a manufacturing method and a forging bucket tooth thereof, which utilizes the split type mould to solve the technical problem of demoulding. The adopted mould is divided into an upper separated body and a lower separated body, the upper separated body consists of a punch head upper cover and a punch head embedded at the lower end of the punch head upper cover; the lower separated body is formed by that an outer sleeve is fixedly connected on a backing plate and internally installed with a tube mold of the separated body, and a disconnecting square sleeve is installed at the upper part inside the tube mold; and an ejector rod is installed in the central hole of the backing plate. The manufacturing method comprises the following steps: the punch head is utilized for hammering the blank so as to carry out foring compression in the tube mold, the punch head moves upwards when the press returns to the original position, the disconnecting square sleeve prevents the forging bucket tooth form moving so as to disconnect the punch head and the forging bucket tooth, the ejector rod ejects the forging bucket tooth and the tube mold of the separated body upwards, the tube mold is divided into two blocks along the outer sleeve, and the forging bucket tooth carries out demoulding automatically. The invention solves the problem of the automatic demoulding of the bucket tooth by foring compression; the mechanical property and the wear-resisting property of the forging bucket tooth are improved by more than 30 percent compared with that of a casting bucket tooth, especially when being used in severe conditions such as mines and the like, the forging bucket tooth has more superior performances.

Owner:陈宏毅

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

Chlorinated polythylene fire retardant jacket compositions

ActiveCN101289563ANo foamingNo porosityInsulated cablesInsulated conductorsRare earthChlorinated polyethylene

The invention discloses a chlorinated polyethylene flame-retardant sheath material compound. The flame-retardant sheath material compound comprises compositions with the following weight portions: 100 portions of chlorinated polyethylene, 5 to 8 portions of rare earth complex stabilizer REC-LS, 25 to 30 portions of high-performance complex flame retardant HZR-2, 3 to 5 portions of thiadiazole derivative curing agent, and 1.5 to 2 portions of aldehyde-amine condensate accelerant. A cable obtained by the invention has more comprehensive performance, good mechanical property, ozone-resistant and chemical-resistant performance, flame resistance and oil resistance, high temperature-resistant class, and free color matching.

Owner:四川川东电缆有限责任公司

High-pressure grouting leaking stoppage method for settlement joint of building

ActiveCN107060116AImprove repair efficiencyCost-effectiveBuilding repairsBuilding insulationsStructure and functionEngineering

The invention provides a high-pressure grouting leaking stoppage method for a settlement joint of a building. According to the high-pressure grouting leaking stoppage method for the settlement joint of the building, high complementary between polyurethane modified epoxy resin grouting fluid and acrylamide grouting fluid on core properties is utilized, outer side protection is formed by making use of the polyurethane modified epoxy resin grouting fluid, inner side expansion filler is formed by making use of the acrylamide grouting fluid based on the outer side protection, so that advantages are used to complement to each other, strengths are combined together, advantages are enhanced and disadvantages are avoided, rapid grouting leaking stoppage of the settlement joint of the building is achieved, the leaking stoppage quality is improved, the endurance of leaking stoppage is improved without damaging the original structure and functions of the building, and requirements for development of buildings in the present stage are satisfied.

Owner:天津德砼防腐防水工程有限公司

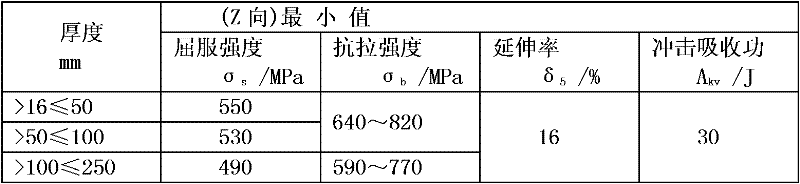

Bimetal metallurgical composite pipe and manufacturing method thereof

The invention discloses a bimetal metallurgical composite pipe and a manufacturing method thereof. The manufacturing method comprises the following steps of manufacturing a pipe blank of the bimetal metallurgical composite pipe by adopting a vacuum water-cooling die casting technology, specifically inner metal and outer metal are metallurgically combined in a high-temperature diffusion mode, and the two ends of the pipe blank are covered by the inner metal; carrying out hot rolling forming on the obtained pipe blank of the bimetallic metallurgical composite pipe so as to enable the pipe diameter and the wall thickness of the bimetallic metallurgical composite pipe to meet the preset standard and make the inner metal meet the preset thickness requirement; and carrying out quenching and tempering treatment on the whole hot-rolled bimetallic metallurgical composite pipe to make the outer metal meet the preset strength requirement, and completing the manufacturing of the bimetallic metallurgical composite pipe. According to the method, the high strength of an oil pipe column is ensured, and meanwhile, the integrity of corrosion resistance of the inner wall is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for manufacturing metal laser melting additive

InactiveCN107876771AImprove pass rateReduce manufacturing costAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser additive manufacturing

The invention provides a method for manufacturing metal laser melting additive. After each layer of laser additive is manufactured and machined, a single-layer laser solidification area is traversed and scanned by adopting a nondestructive inspection method, the defect feature is recognized and positioned, the containing region is simplified, the defect area is removed by adopting a machining method, and finally the cutting area is repaired through the additive remanufacturing method. Each layer of additive manufacturing is subjected to laser melting, scanning flaw detection, mechanical removal and additive remanufacturing, so that the multi-layer machining is carried out in a reciprocating manner, and the complex metal parts without pores and cracks are manufactured.

Owner:DALIAN UNIV

Method for overlaying glass die by plasma

ActiveCN101913019AImprove welding efficiencyIncrease profitArc welding apparatusPlasma welding apparatusFree coolingWear resistance

The invention discloses a method for overlaying a glass die by plasma. The method comprises the following steps of: (1) reheating; (2) prefabricating a glass die for overlaying; (3) setting an overlaying parameter; (4) arranging the position of an overlaying gun and overlaying; (5) insulating heat; and (6) heating the glass die and naturally cooling. The overlaying efficiency of the glass die is improved, and nickel-base powder overlaid to the glass die is not easy to fall off, thus the utilization ratio of the nickel-base powder is higher. The glass die overlaid by the method has better uniformity and has no pores on the surface. In the overlaying process, the invention solves the problem that the glass die is extremely easy to have an oxidation layer, is beneficial to improving the oxidation resistance and the wear resistance of the glass die and guarantees the quality stability of the glass die.

Owner:CHANGSHU JINGGONG MOLD MFG

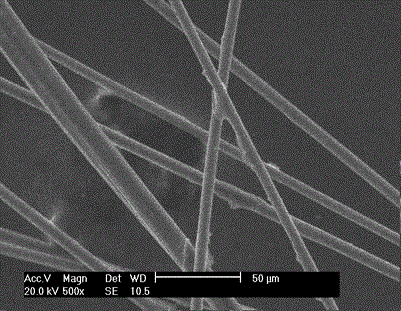

Carbon fiber surface coating treatment method

InactiveCN106835684AImprove surface roughnessImprove interfacial adhesionCarbon fibresHeat resistant fibresCarbon fibersMetallic materials

The invention belongs to the technical field of non-metal material surface treatment and particularly relates to a carbon fiber surface coating treatment method. The method includes the steps that firstly, fiber pretreatment is conducted, wherein surface adhesive removal is conducted on carbon fibers through the burning method, then a nitric acid solution or a sodium hydroxide solution is used for roughening the carbon fibers obtained after surface adhesive removal, and the roughened carbon fibers are placed in an acetic acid solution for activation; secondly, tetraethoxysilane, a cosolvent, water and a catalyst are mixed, the pH is adjusted, the materials are evenly stirred and stand still, and a sol solution is prepared; thirdly, the pretreated carbon fibers are soaked in the sol solution, heat preservation and vibration are conducted, and the carbon fibers with the surfaces coated with compact SiO2 coatings are obtained. The preparation method solves the problems that existing carbon fiber coating treatment methods are harsh in experiment condition, complex in operation and high in equipment requirement, and is simple in process route, low in production cost and free of pollution, and raw materials are easy to obtain.

Owner:KUNMING UNIV OF SCI & TECH

Electroslag fusion casting manufacturing method for annular plate of hydraulic generator

ActiveCN102416463AAchieve the purpose of near-net shape in melting and castingHigh dimensional accuracyManufacturing technologySlag

The invention discloses an electroslag fusion casting manufacturing method for an annular plate of a hydraulic generator. The method is characterized by comprising the following steps of: 1) controlling slag systems and slag amount; 2) igniting; 3) selecting a crystallizer; 4) rotating the crystallizer by using a control system; 5) selecting power supply parameters; 6) controlling casting alloy components after fusion casting; and 7) selecting a casting thermal processing process. A near-net-shape forming annular plate manufacturing technology is provided for producing annular anti-tear steel plates for hydraulic generator seat rings, top covers and bottom rings at present; a rotatable crystallizer is used for electroslag fusion casting formation, so that technical requirements on production of the annular plate are met; and the produced annular plate has high laminated tearing resistance, higher fatigue resistance and higher crack generation and expansion resistance, and the quality and the performance of the annular plate are not lower than those of a specially-forged product which is made of the same material as that of the annular plate.

Owner:沈阳市盛华特种铸造有限公司

Two-layered flexible substrate, and copper electrolyte for producing same

InactiveCN102348835ANo porosityPolycrystalline material growthFrom normal temperature solutionsChip on filmThiourea

Disclosed is a two-layered flexible substrate which has excellent bending endurance, and furthermore, wherein Kirkendall voids do not arise even if a chip-on-film lead section is tin plated and heat treatment is performed. The disclosed two-layered flexible substrate is provided with a copper layer using a copper electrolyte on one or both faces of an insulating film, and is characterized by the copper crystal grains forming the aforementioned copper layer having a grain size of at least 1 [mu]m and no more than the thickness of the copper layer, and by X-ray diffraction of the aforementioned copper layer having a ratio of the (200) peak strength to the sum of the main six peak strengths { (200) peak strength / ( sum of (111), (200), (220), (311), (400), and (331) peak strengths) } of at least 0.4. Furthermore, the copper electrolyte for forming the aforementioned copper layer is characterized by including as an additive at least one of chloride ions, thiourea, a thiourea derivative, and thiosulfuric acid.

Owner:JX NIPPON MINING & METALS CORP

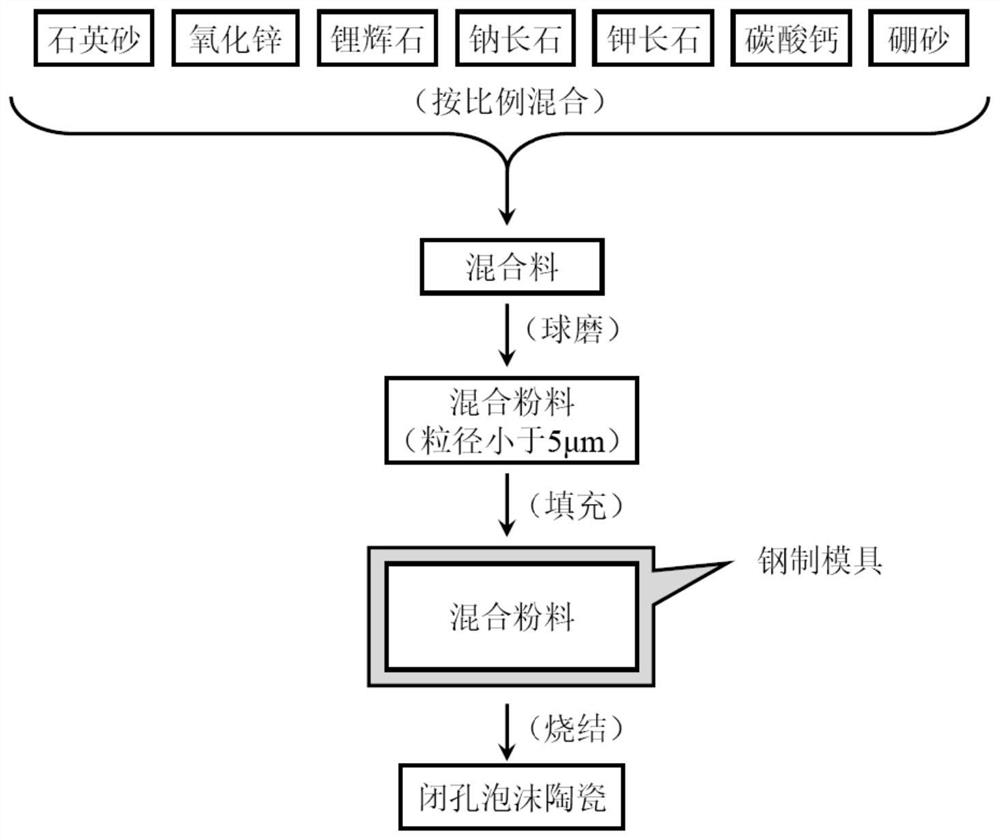

Ultra-light fully-closed-cell foamed ceramic with compact surface and low-temperature firing method of ultra-light fully-closed-cell foamed ceramic

ActiveCN113121257AImprove insulation effectImprove sound insulationCeramicwareFoaming agentHeat conservation

The invention discloses ultralight fully-closed-cell foamed ceramic with a compact surface. According to the invention, quartz sand is taken as a main material, calcium carbonate is taken as a foaming agent, borax is taken as a fluxing agent and zinc oxide, albite, potassium feldspar and spodumene are taken as conditioning agents; and a sintering temperature is 740 to 800 DEG C. The invention further discloses a low-temperature firing method of the ultralight fully-closed-cell foamed ceramic. The preparation technology disclosed by the invention has the remarkable advantages of simple process, low sintering temperature, short sintering time and the like, so the manufacturing cost of the method is far lower than the manufacturing cost of existing preparation technology. Besides, different from foamed ceramic prepared in the prior art, the interior of the ultralight fully-closed-cell foamed ceramic with the compact surface is of a porous structure, pores are independent from one another and do not communicate with each other, the surface is continuous and compact and free of pores, the heat preservation and sound insulation effects of the foamed ceramic can be remarkably improved, the foamed ceramic has excellent waterproof and moisture-proof performance, and the reliability of a product is obviously improved.

Owner:YANTAI UNIV

Preparation method of metal preservative layer

InactiveCN104674200AUniform and dense thicknessNo porosityLiquid/solution decomposition chemical coatingChemical platingBuffering agent

The invention relates to a preparation method of a chemical nickel-plating phosphorus alloy clad layer on the surface of a copper alloy for preventing seawater corrosion and sea biological defile. The method comprises the following five technical processes: deoiling; derusting; activating; carrying out chemical plating; and carrying out post-treatment. In the plating solution of the metal preservative layer, sodium hypophosphite is used as a reducing agent, nickel sulfate is used as a main salt, and a complexing agent, a buffering agent, a stabilizer and the like are added. The components of the plating solution and the chemical plating process parameters are optimized by using a uniform design technique and a single factor experiment method, so that an active surface can be formed. Chemical reduction-deposition is carried out on the nickel phosphorus alloy clad layer under a certain chemical plating condition. By adopting the preparation method provided by the invention, the chemical plating process is safe and stable, the clad layer is uniform, and the prepared clad layer is long in service life, smooth in surface and small in noise, and has a cathode protective effect on a copper alloy propeller matrix and is capable of reducing sea biological defile.

Owner:于洪洲

High antiwear concrete conveying pipe and production method thereof

InactiveCN101323934AImprove anti-wear performanceImproves wall thickness uniformityMaterials scienceCasting

The invention discloses a concrete delivery pipe with high-wearing feature. According to mass percentage, the following materials are adopted: 0.15 to 0.4 percent of C, 0.1 to 2.0 percent of Si, 1.6 to 3.0 percent of Mn, 0.3 to 2.0 percent of Cr, 0 to 0.5 percent of Mo, 0.02 to 0.1percent of V, 0.01 to 0.06 percent of Ti, 0 to 0.03 percent of Ni, 0 to 0.5 percent of Cu, 0.02 to 0.06 percent of Nb, 0.01 to 0.05 percent of Al, 0.0005 to 0.005 percent of B, 0.02 to 0.06 percent of Re, 0 to 0.02 percent of N, 0 to 0.035 percent of S, 0 to 0.035 percent of P and the rest being Fe, and then the steps of smelting, centrifugal casting, hot rolling, controlled cooling, etc. are carried out to the materials. The production process of the invention is simple and short; the produced delivery pipe has martensite and bainite metallographic structure with high-wearing feature and a service life 4 to 20 times higher than No.20 seamless pipe.

Owner:CHENGDU TIANYUAN XINTAI COMPOSITE MATERIAL

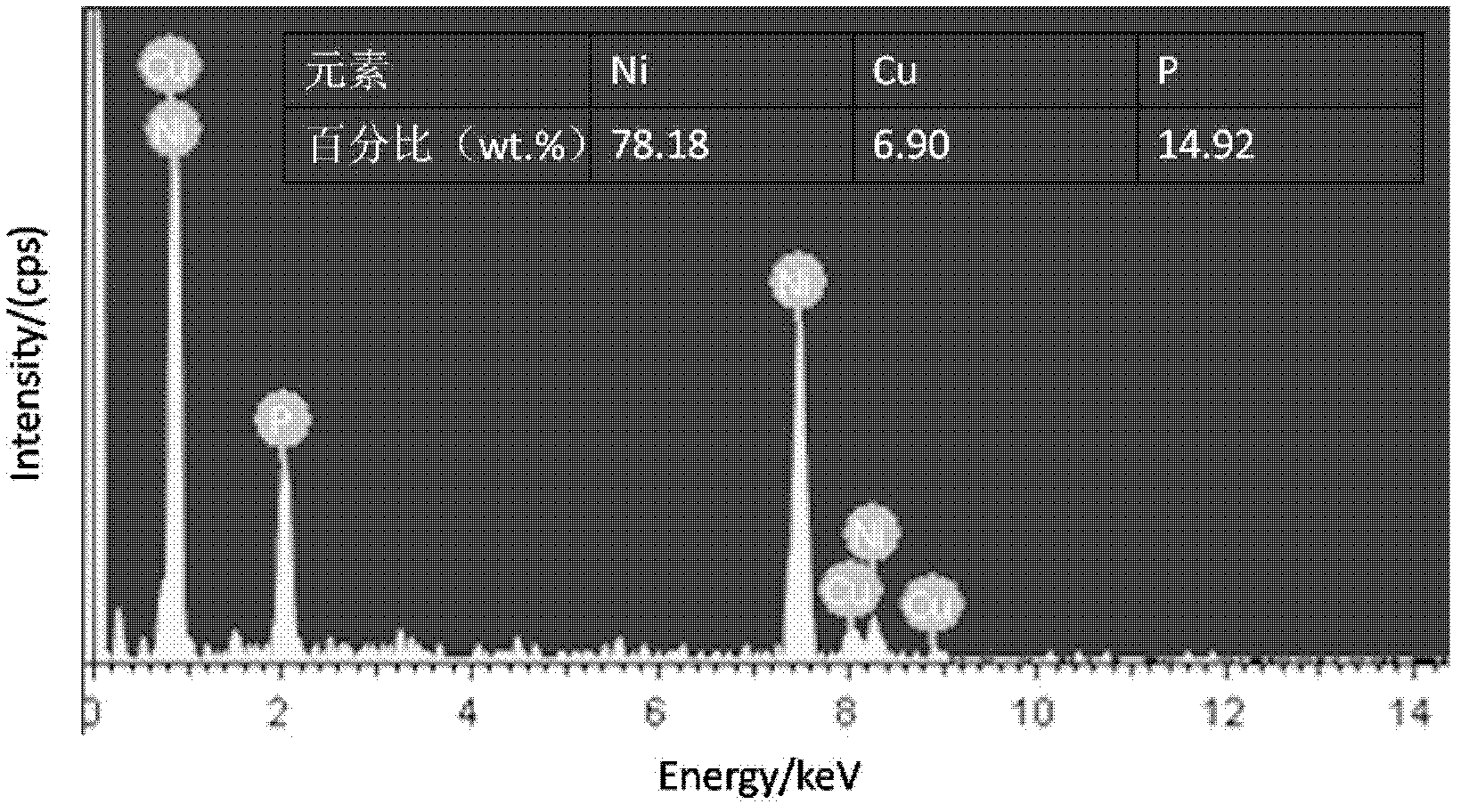

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576AReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

Graphite mixed sand

InactiveCN102085560ASmall coefficient of thermal expansionHigh refractorinessFoundry mouldsFoundry coresSodium BentoniteMullite

The invention discloses graphite mixed sand, which comprises amorphous graphite ores. The graphite mixed sand is characterized by comprising the following components in percentage by weight: 40 to 45 percent of amorphous graphite sand, 30 to 45 percent of magnesium oxide sand, and 10 to 25 percent of mullite sand. The grain diameters of the amorphous graphite sand, the magnesium oxide sand and the mullite sand are generally between 80 and 120 meshes. The graphite mixed sand provided by the invention has small thermal expansion coefficient, high fire resistance, high hardness and stable thermo-chemical performance. The mullite sand for replacing bentonite is favorable for improving the air permeability of the graphite mixed sand. The graphite mixed sand product is mainly used for melted film casting, gypsum filler V method molding and vacuum suction casting, so that the internal crystalline phase tissues of the metal liquid are uniform during condensing, segregation and pores are not produced, and various mechanical properties of metal castings are improved.

Owner:大连核心铸造技术工程研究所

Welding process of hydrogenation reaction kettle cylinder body

InactiveCN101579783AImprove fusion qualityAvoid Weld CrackingNon-electric welding apparatusHydrogenation reactionCarbon steel

The invention discloses a welding process of a hydrogenation reaction kettle cylinder body which is used for producing various chemical raw materials with a method of continuous hydrogenation. A plate resulted from compounding common carbon steel and stainless steel with the explosive technology is welded and processed into a cylinder shape, thereby overcoming phenomena such as easily-occurring welding cracks, and the like, which are caused by different material properties of the carbon steel and the stainless steel and by the welding among great-thickness carbon steels; and the production cost of the reaction kettle is greatly reduced. The hydrogenation reaction kettle cylinder body produced according to the welding process is widely applied in chemical engineering, pharmaceutical and other industries for producing sorbierite, xylitol, maltose, furfuryl alcohol, and the like.

Owner:倪加明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com