Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

823 results about "Mechanical pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

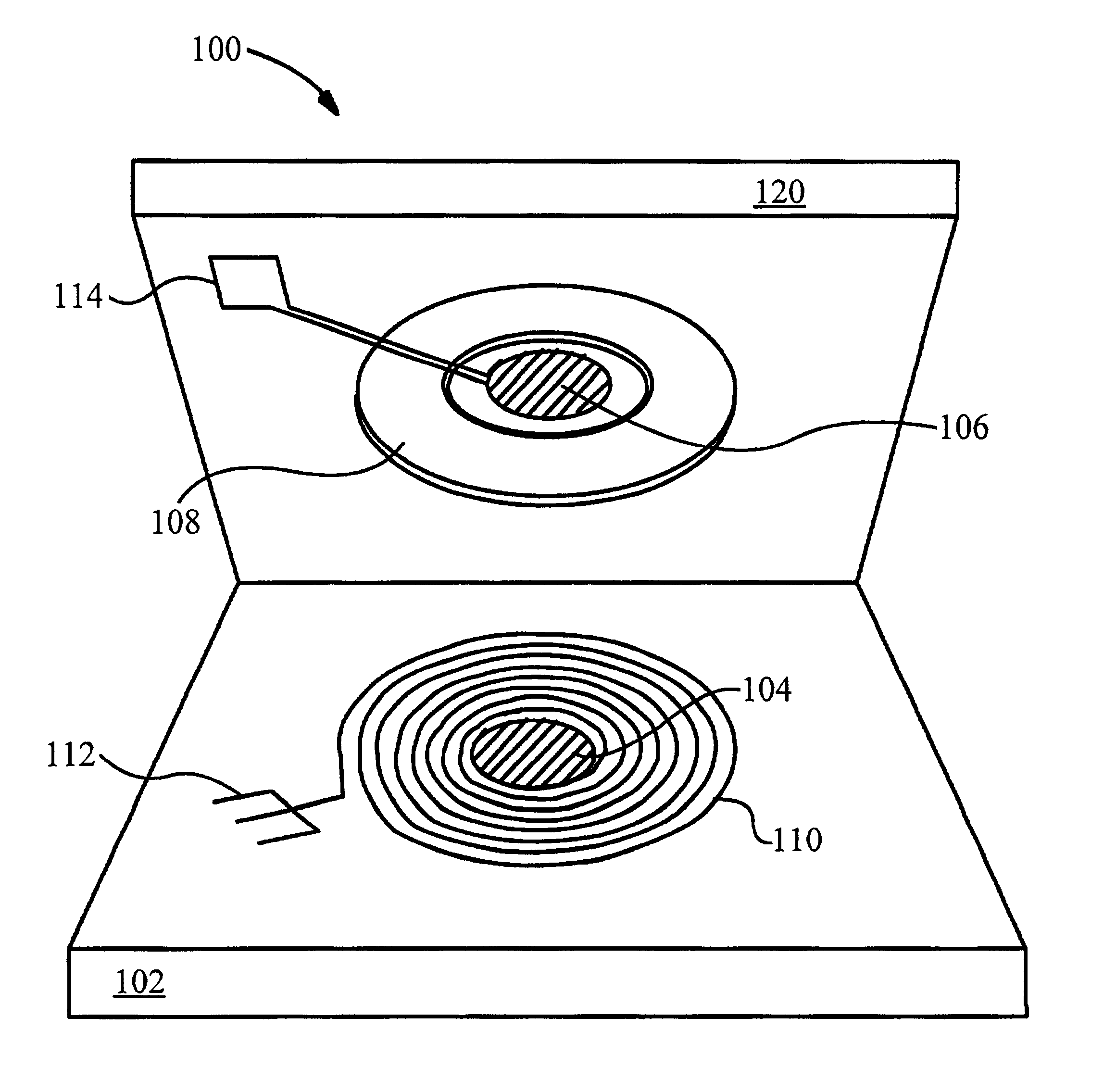

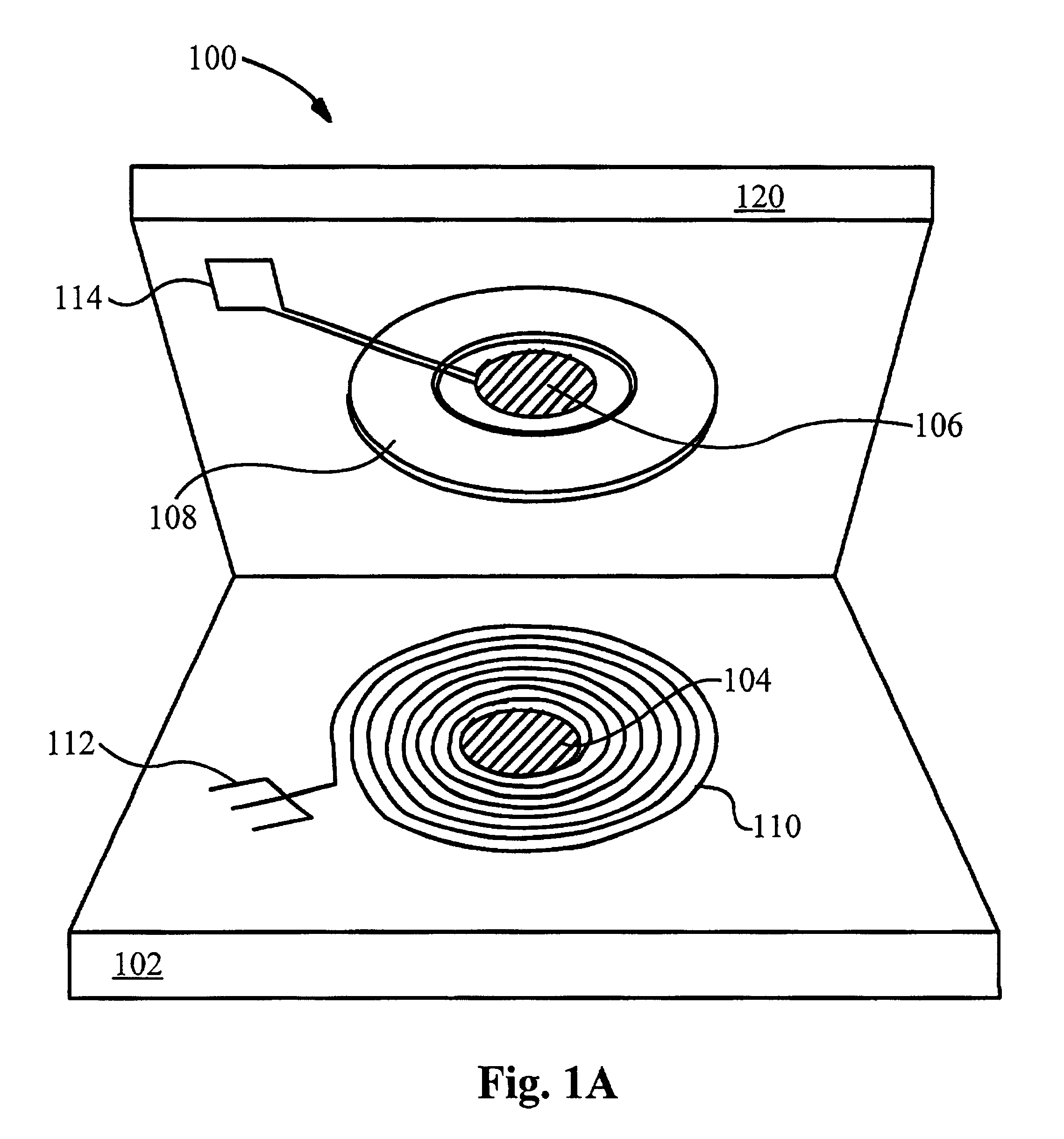

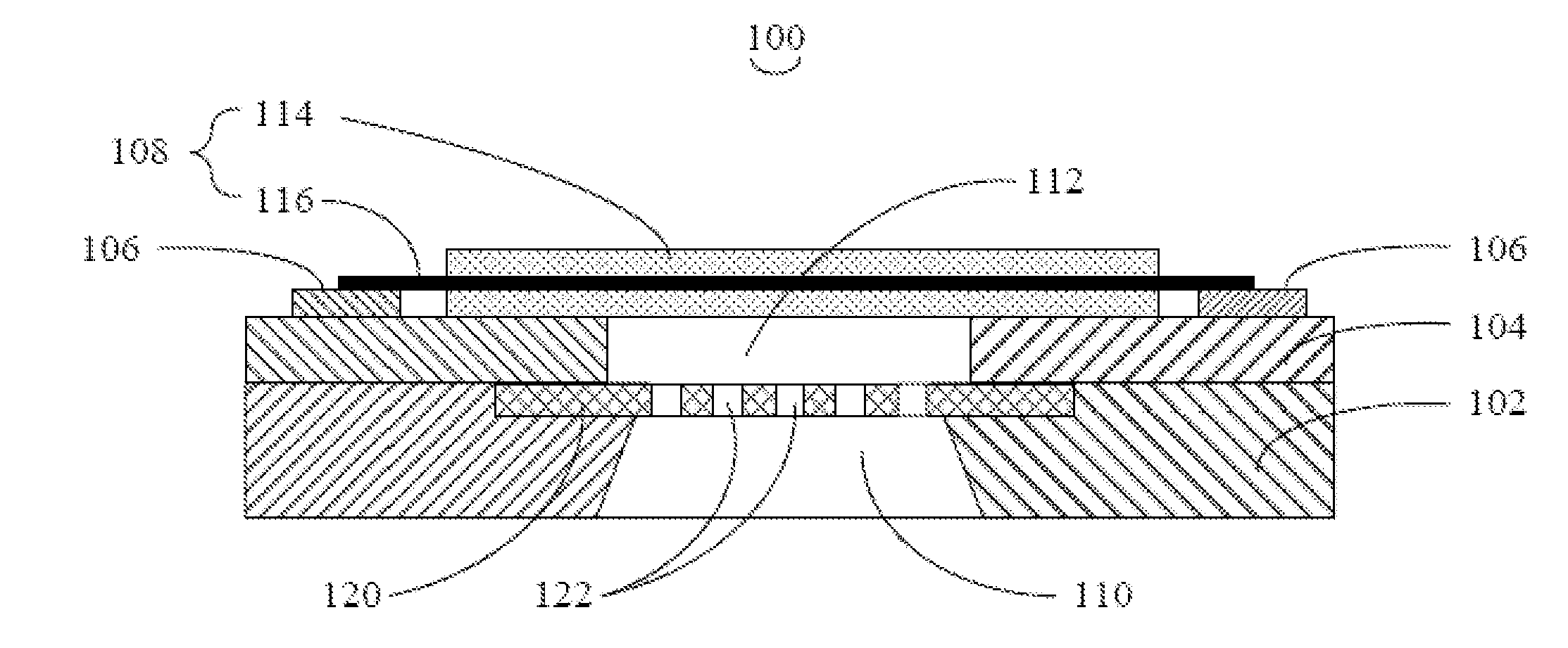

Implantable continuous intraocular pressure sensor

InactiveUS6939299B1Worn safely and comfortably and convenientlyPerson identificationTonometersIntraocular pressureSpiral inductor

An implantable miniaturized pressure sensor integrates a capacitor and an inductor in one small chip, forming a resonant LC circuit having a Q value of 10 or greater. The capacitor has an upper capacitor plate and a lower capacitor plate disposed proximate thereof. The upper and lower capacitor plates are connected to one or more spiral inductor coils. The sensor is micromachined from silicon to form a thin and robust membrane disposed on top of the upper capacitor plate. The sensor is hermetically sealed and the membrane is deflected relative to the upper capacitor plate by an external fluid, gas, or mechanical pressure. The resonant frequency of the sensor can be remotely monitored and continuously measured with an external detector pick up coil disposed proximate the sensor. The sensor can be smaller than 2×2×0.5 mm and is particularly useful for intraocular applications.

Owner:IOSENSOR

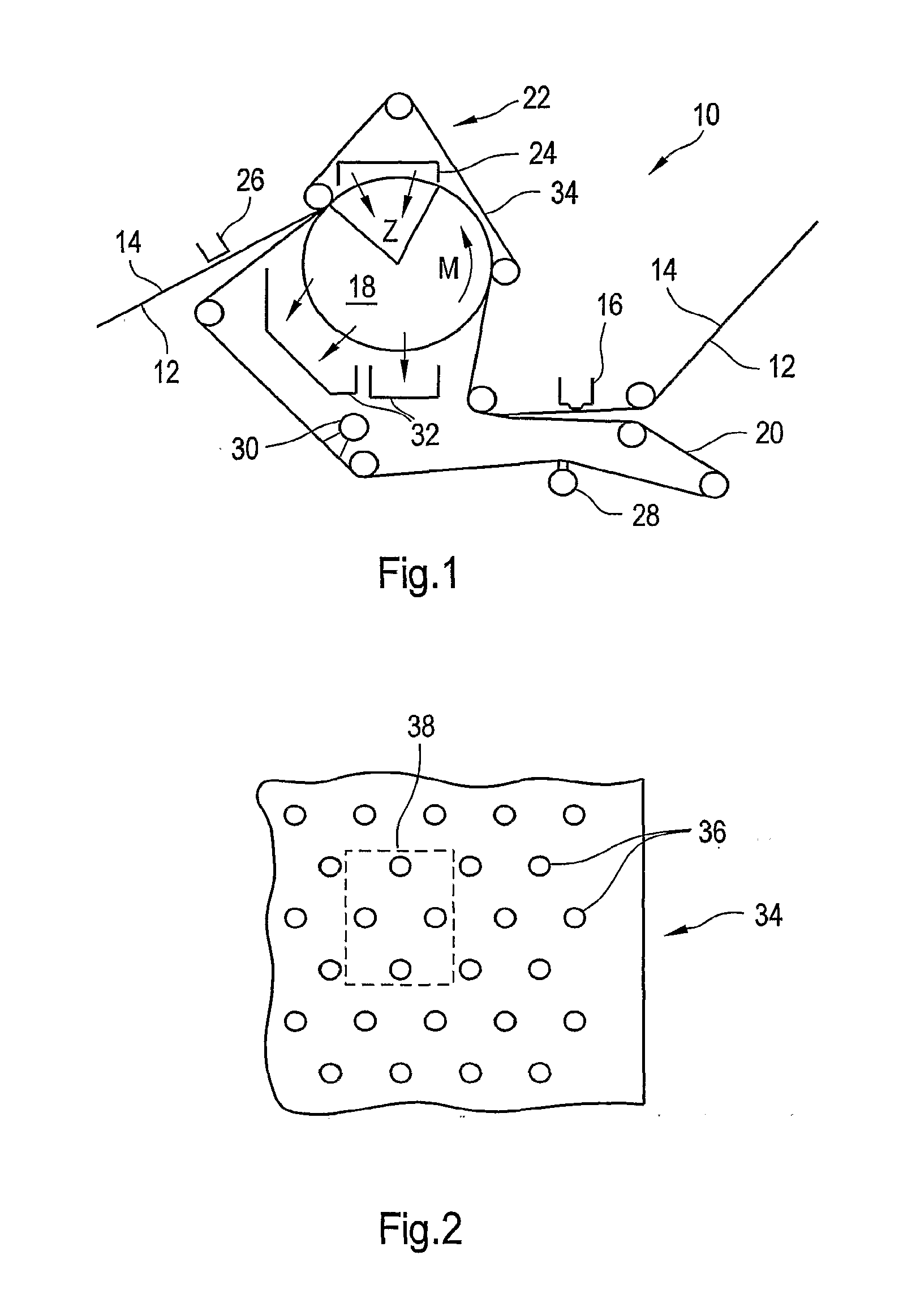

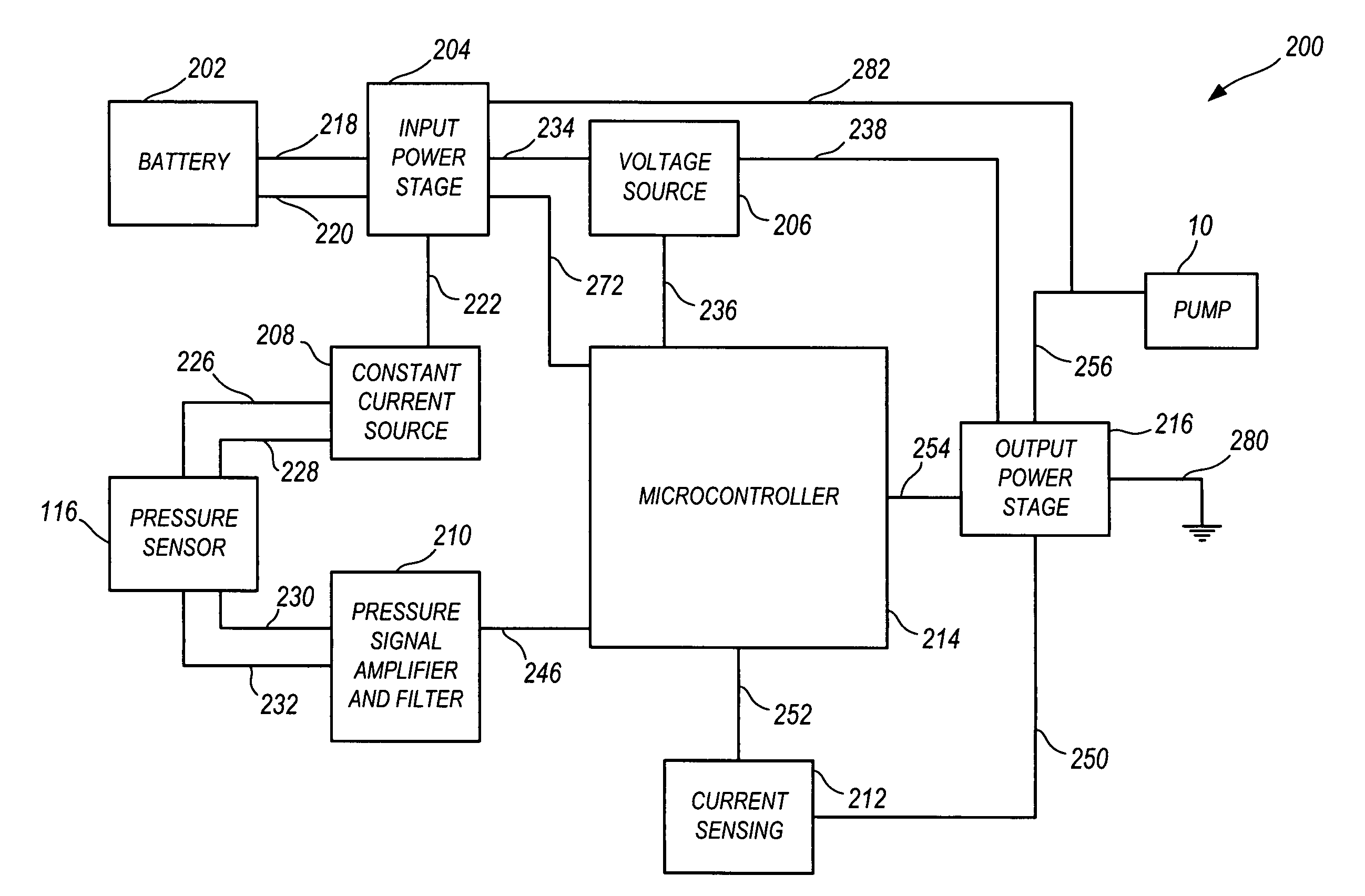

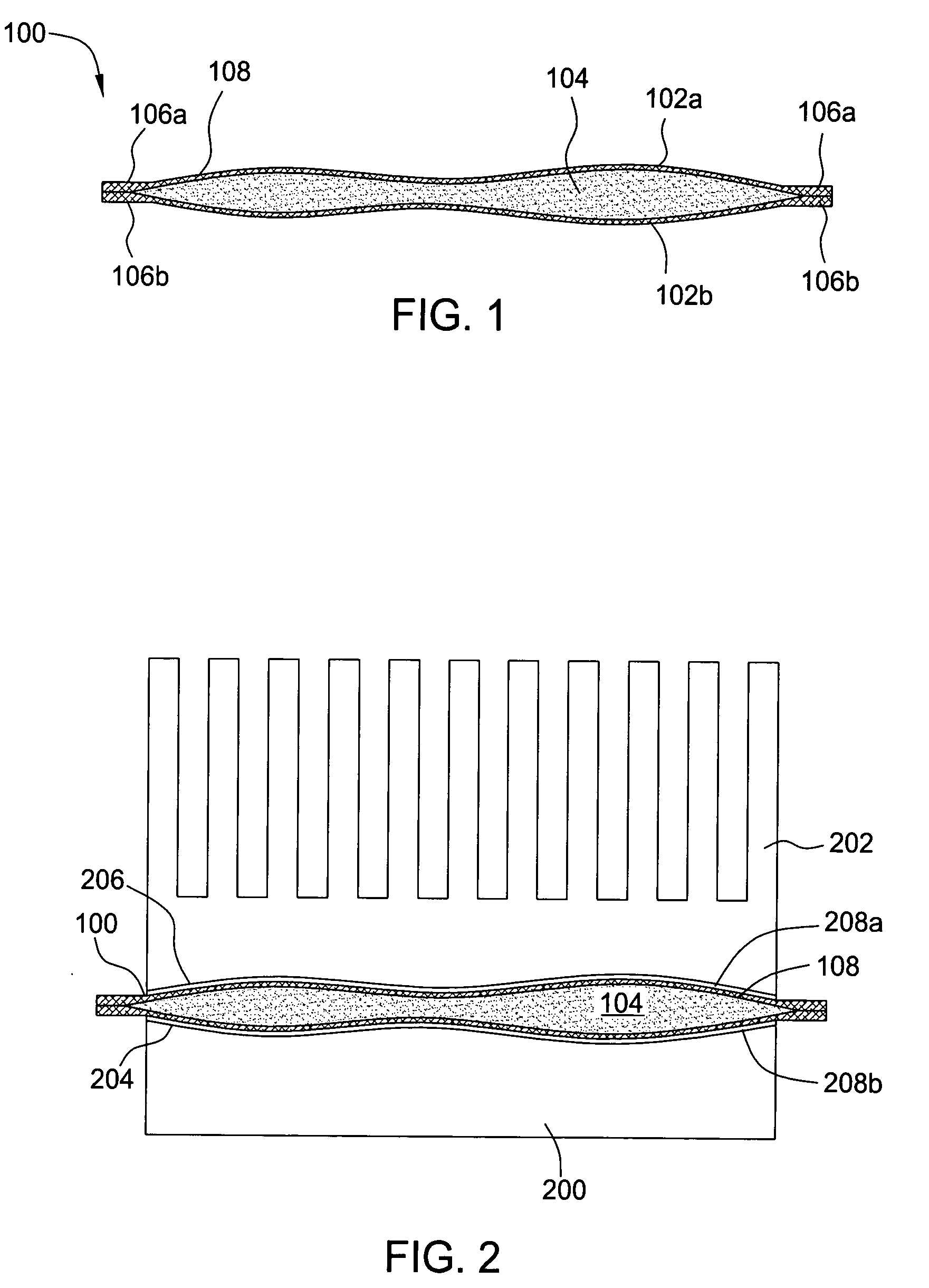

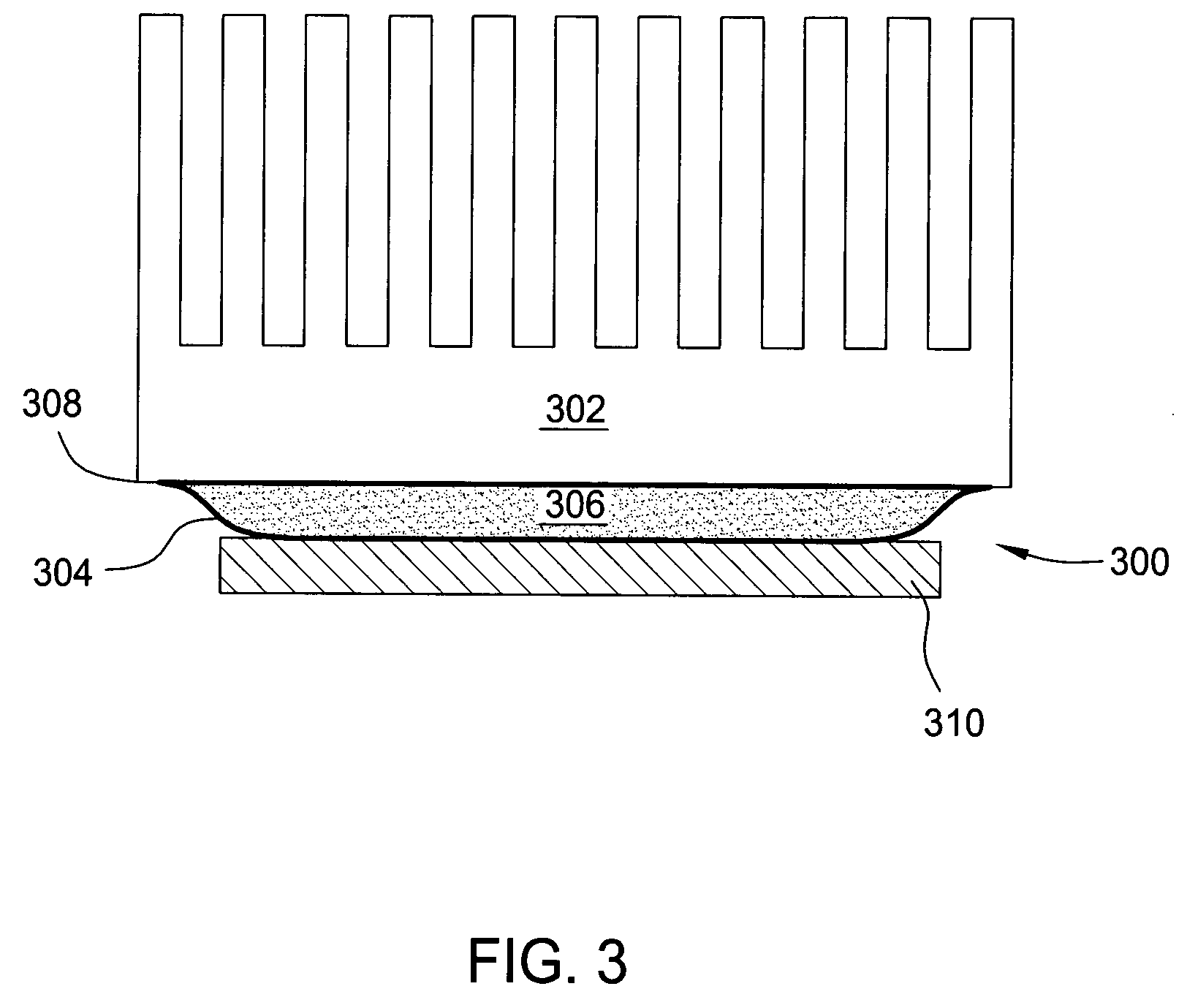

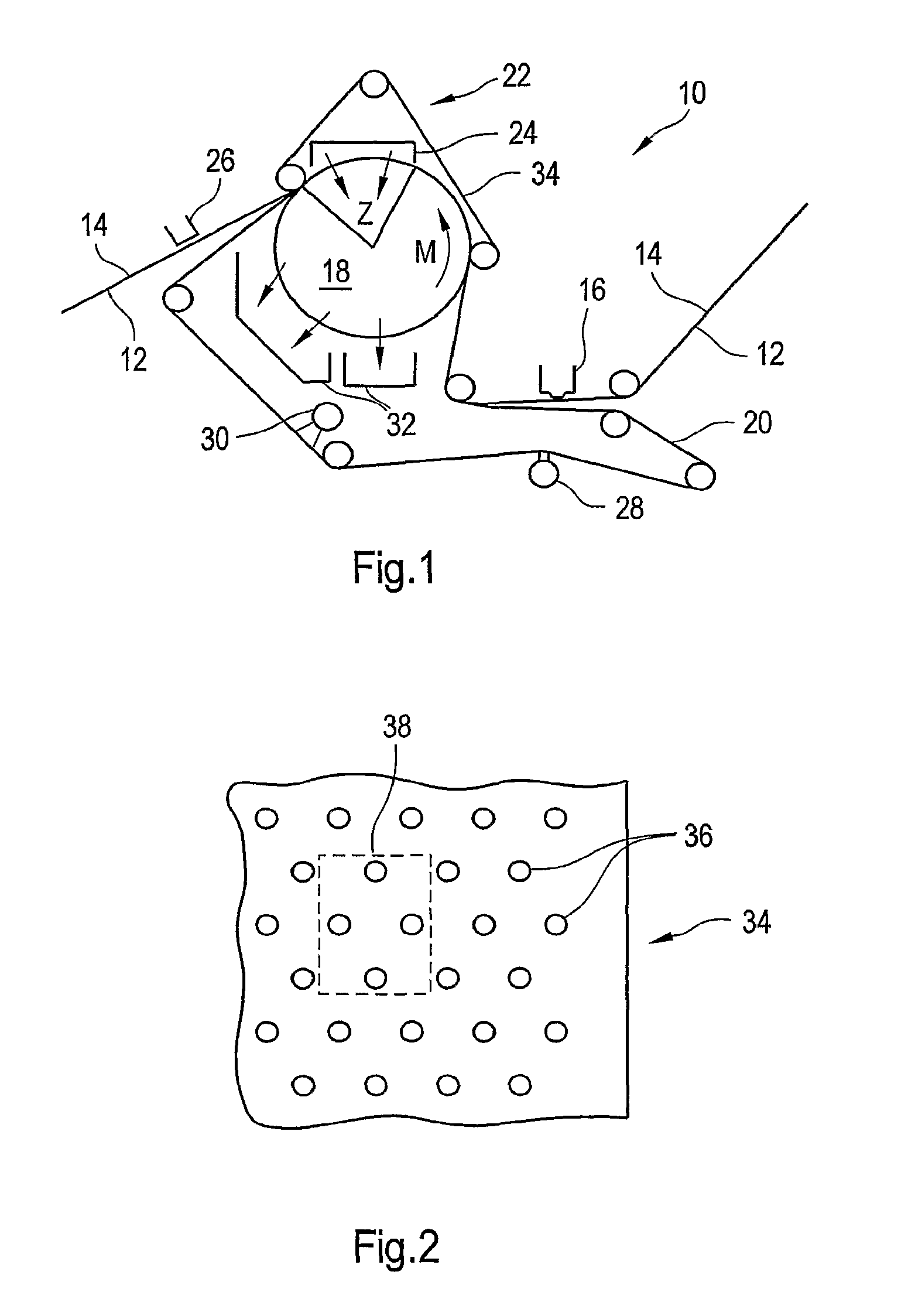

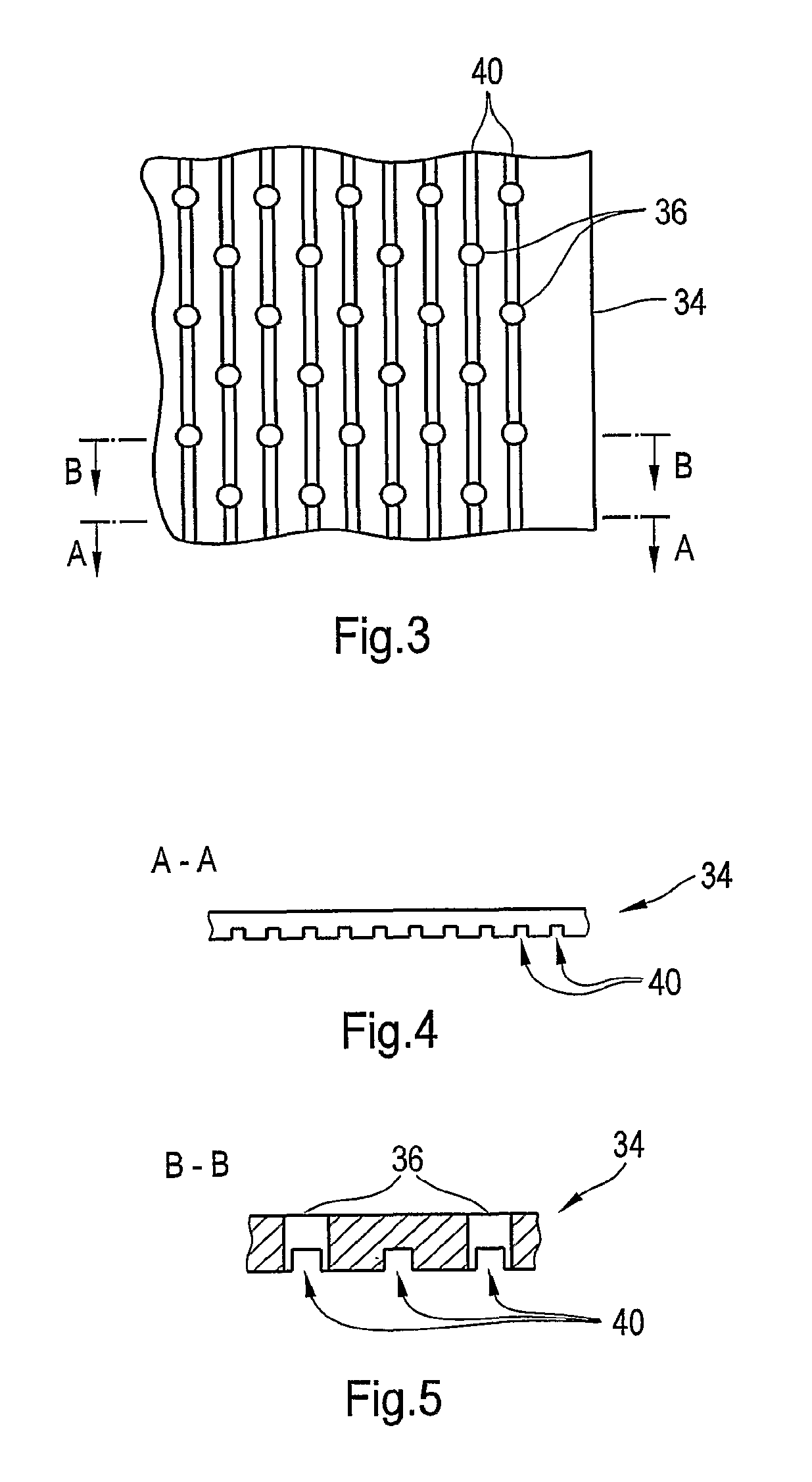

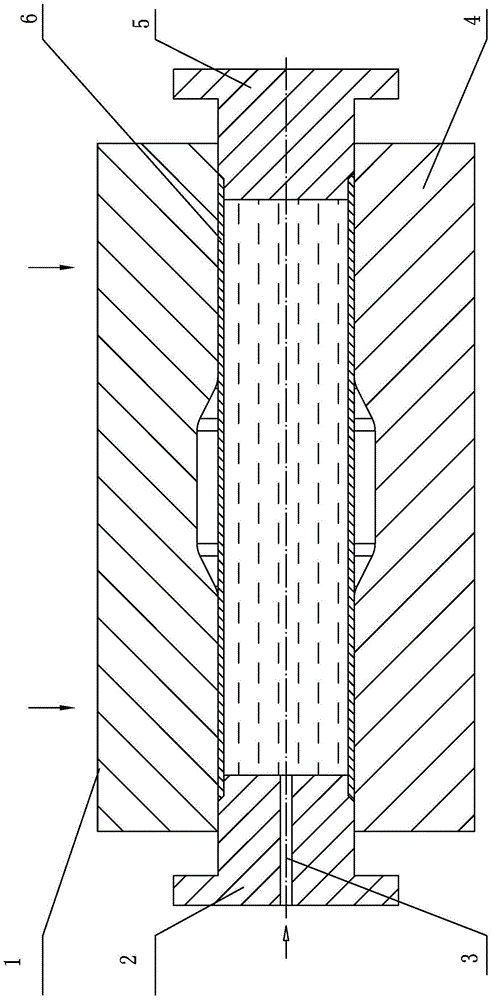

Press section and permeable belt in a paper machine

InactiveUS20100170651A1Large tensionIncrease the opening areaPress sectionDifferential pressureMechanical pressure

A pressing arrangement including at least one first fabric and second fabric both being permeable. A paper web is disposed between the first fabric and the second fabric. A pressure producing element is in contact with the first fabric. A support surface of a supporting structure is in contact with the second fabric. A differential pressure is provided between the first fabric and the support surface that acts on the first fabric, the paper web, and the second fabric, whereby the paper web is subjected to mechanical pressure and experiences a predetermined hydraulic pressure so as to cause water to be drained from the paper web. The pressing arrangement is structured and arranged to allow air to flow in a direction from the first fabric through the paper web and through the second fabric.

Owner:VOITH PATENT GMBH

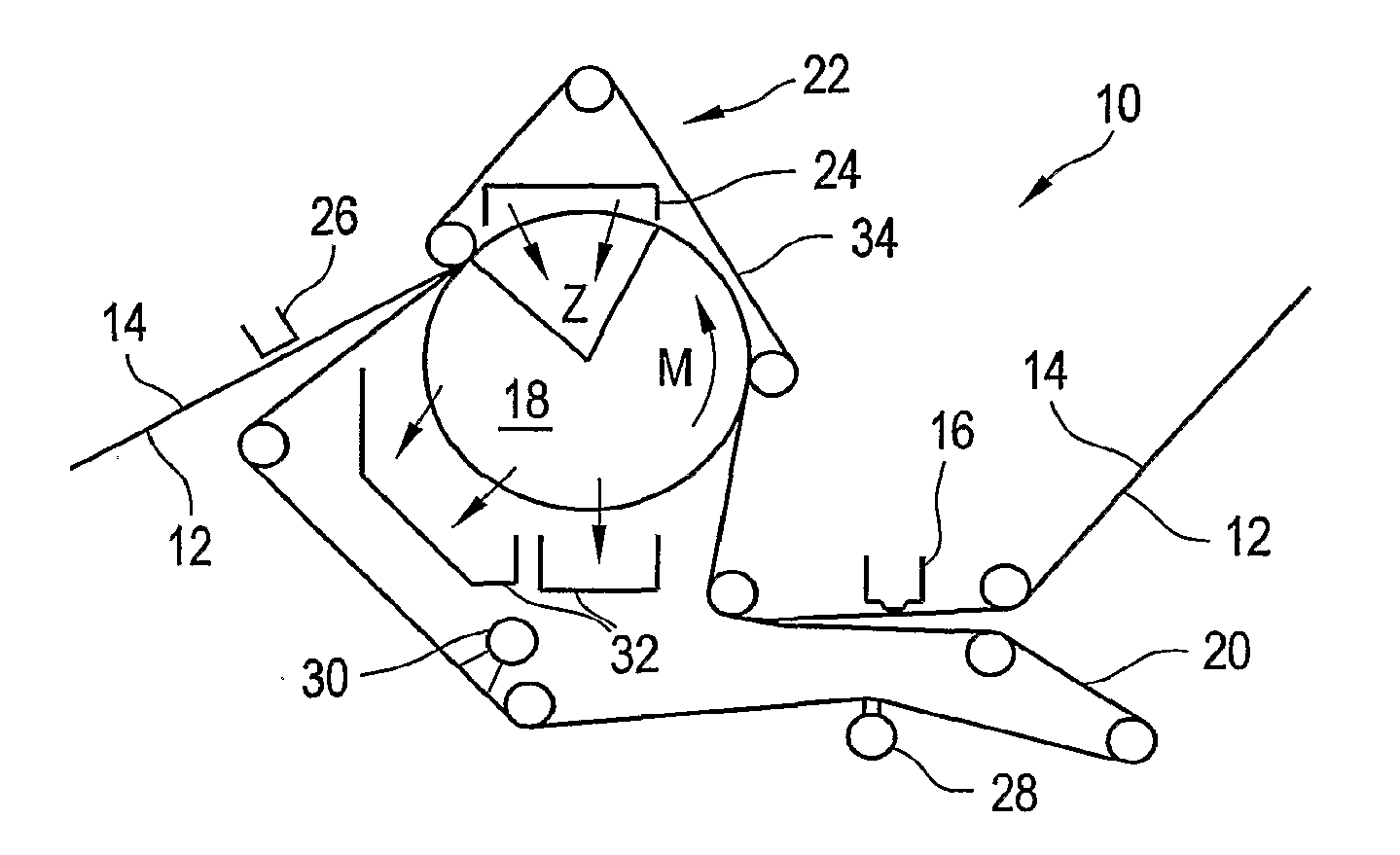

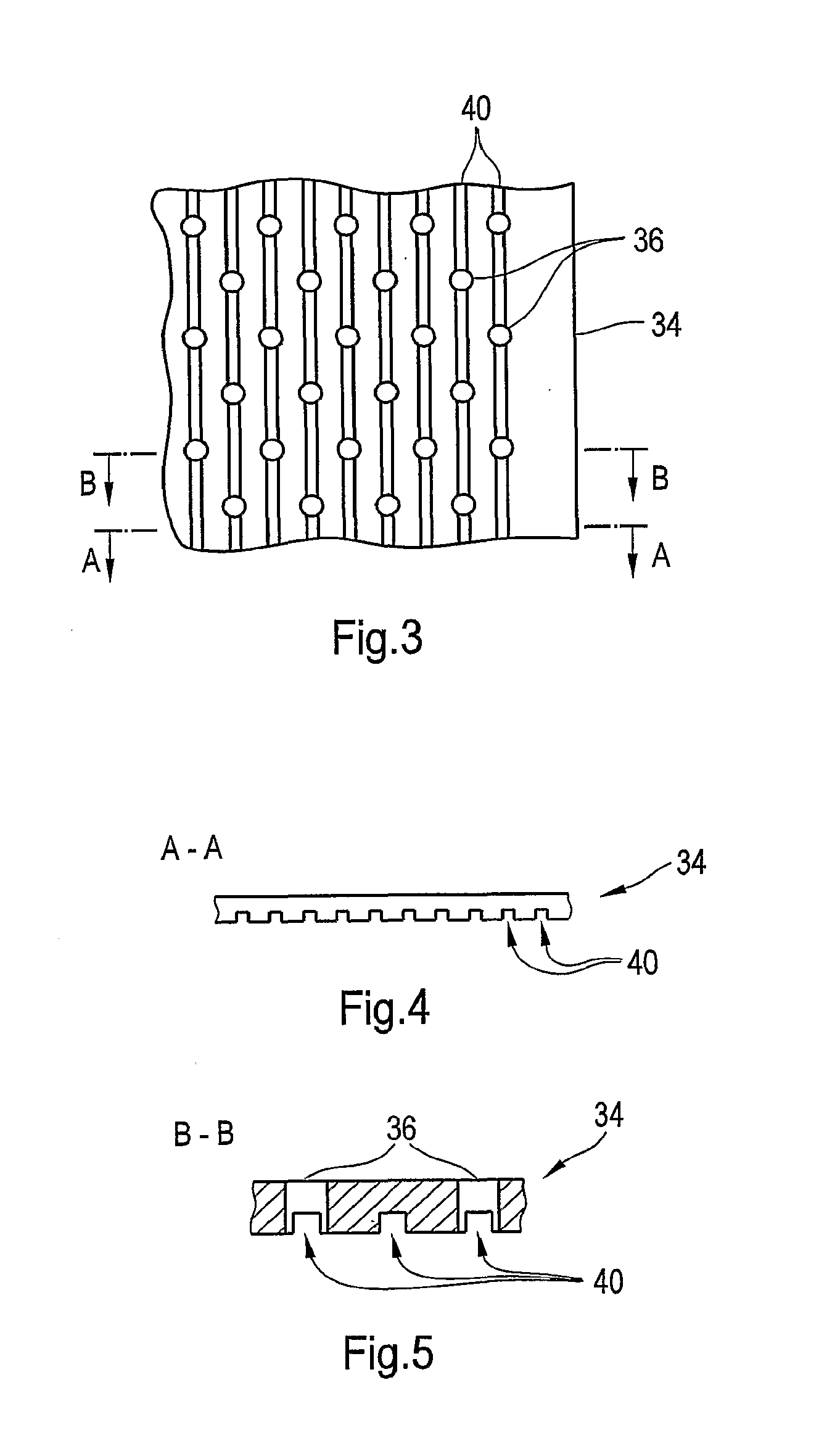

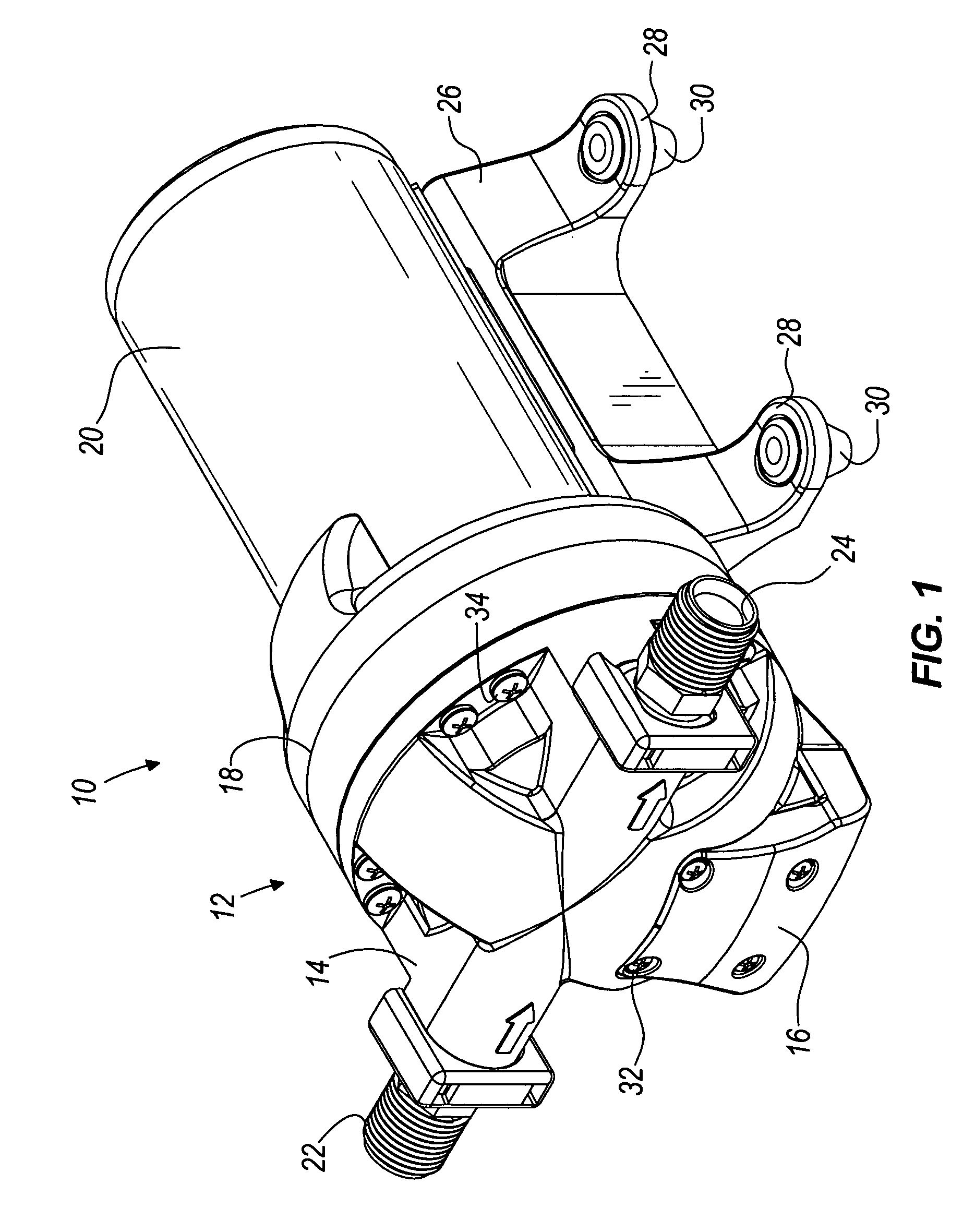

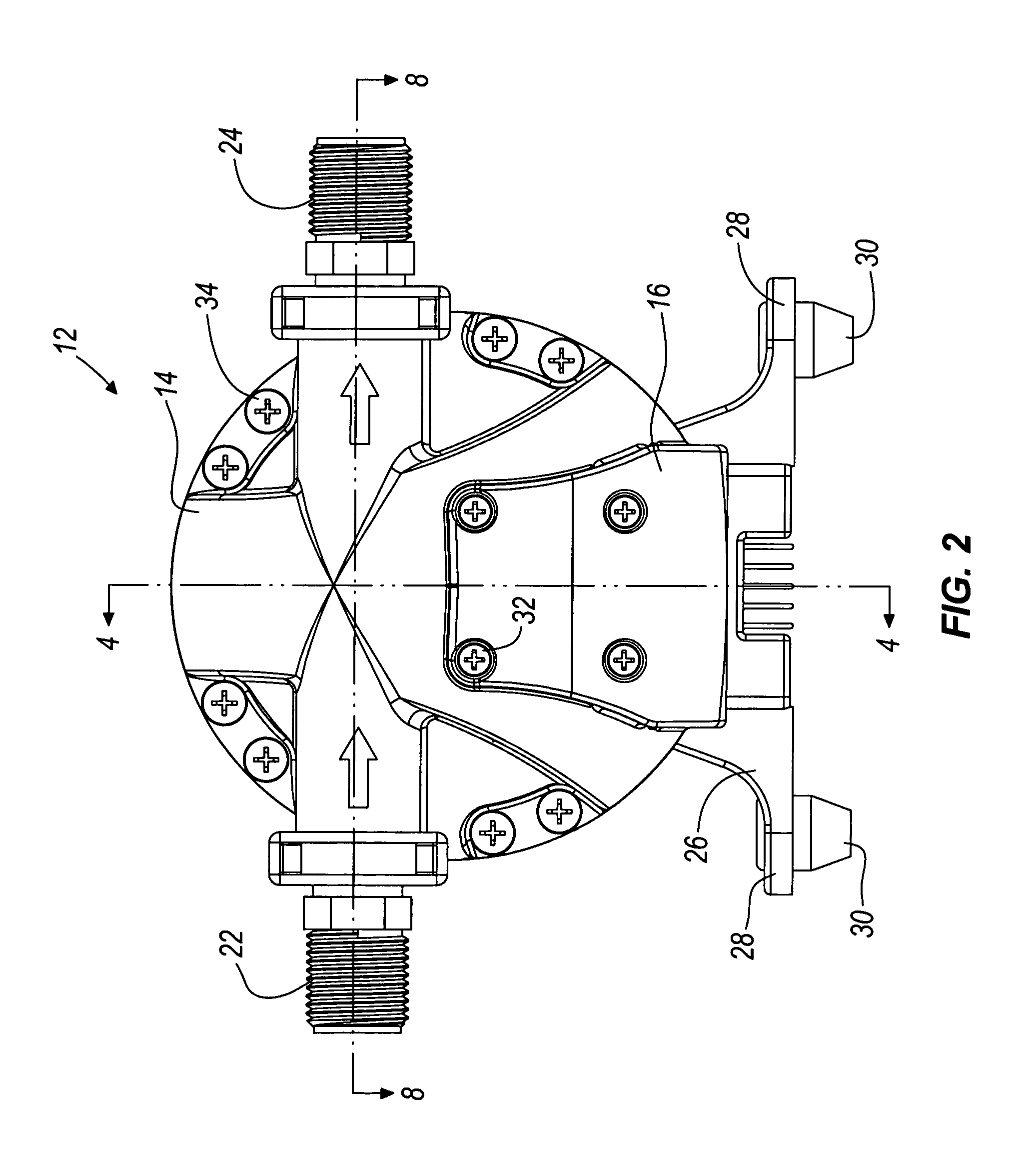

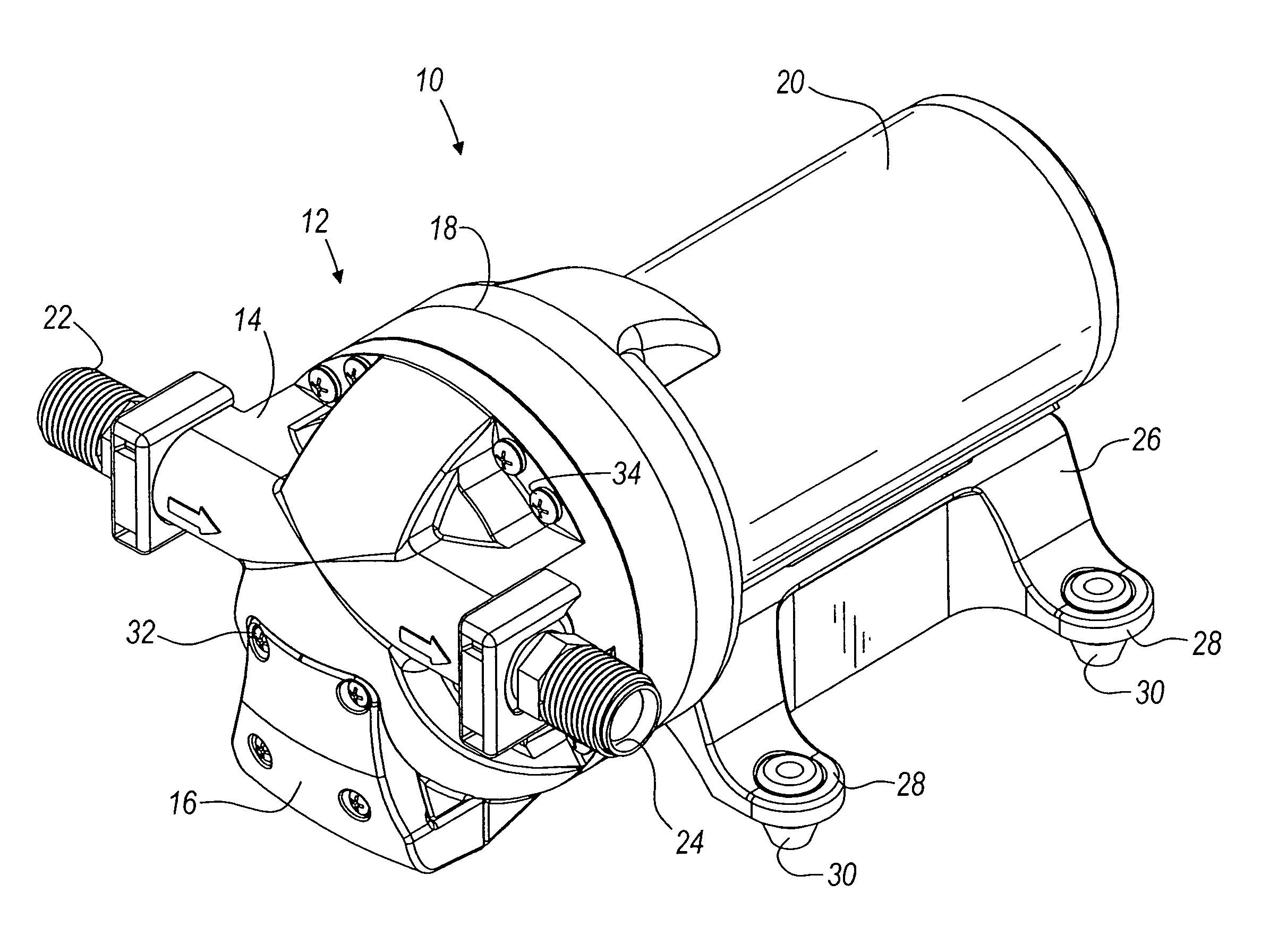

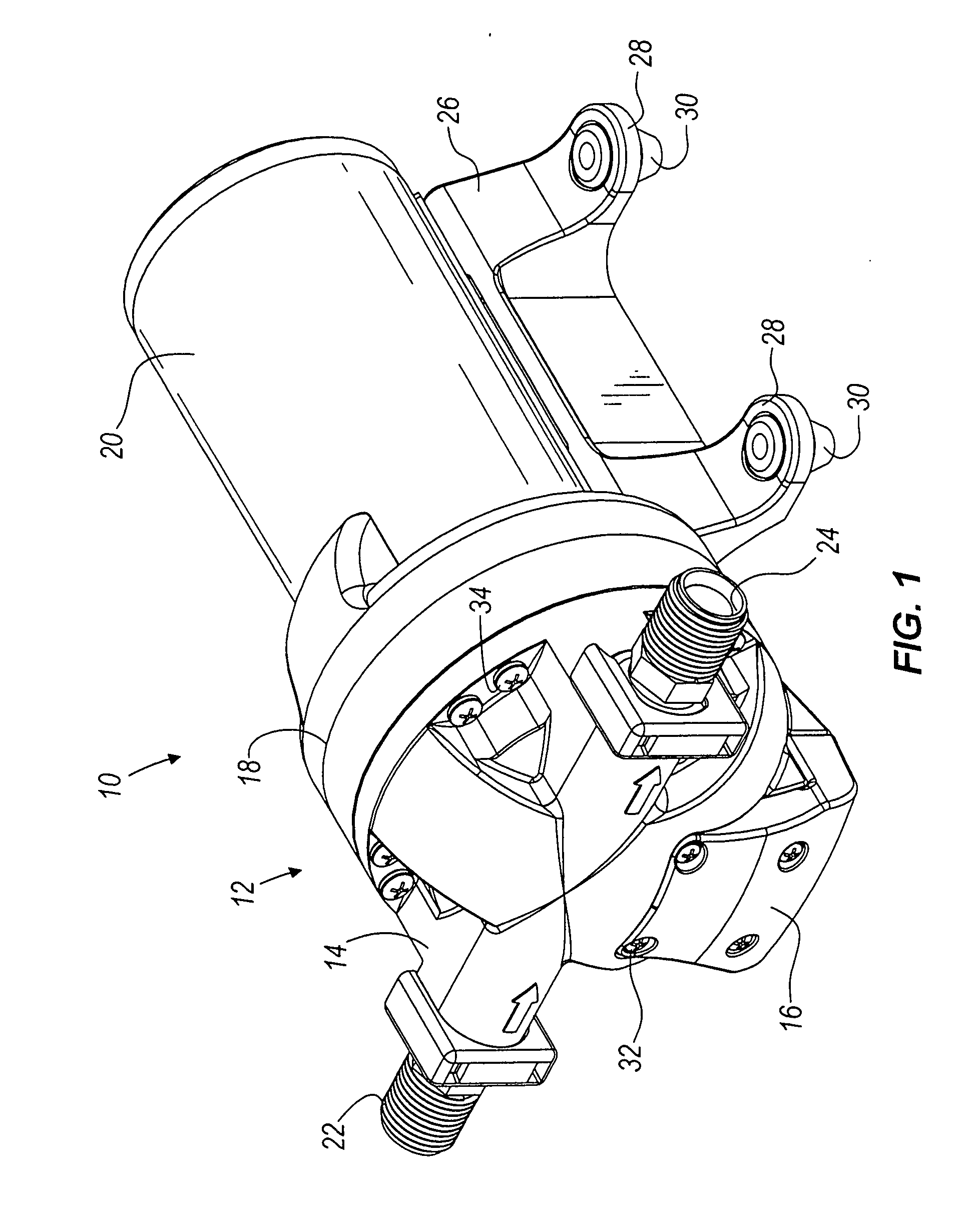

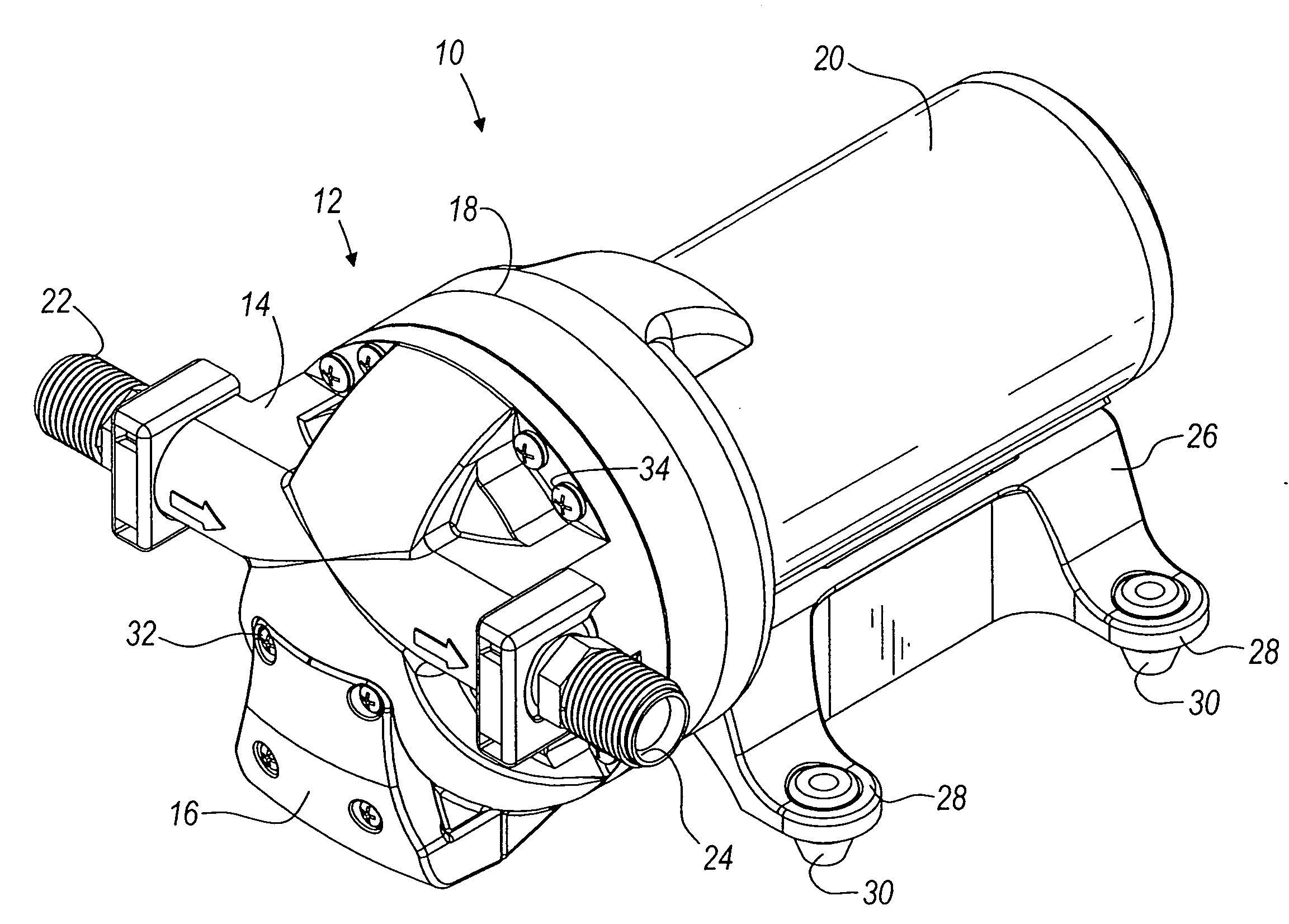

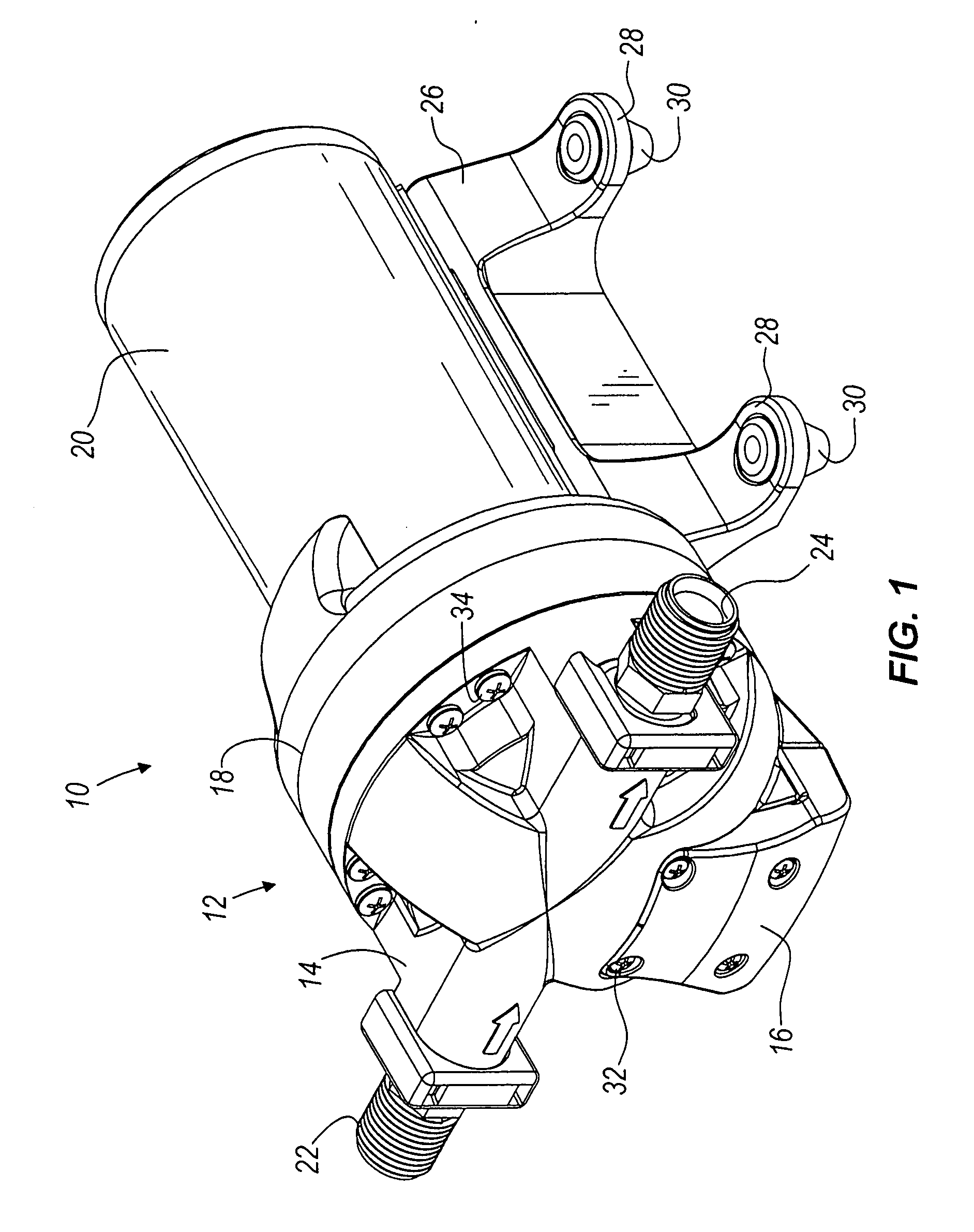

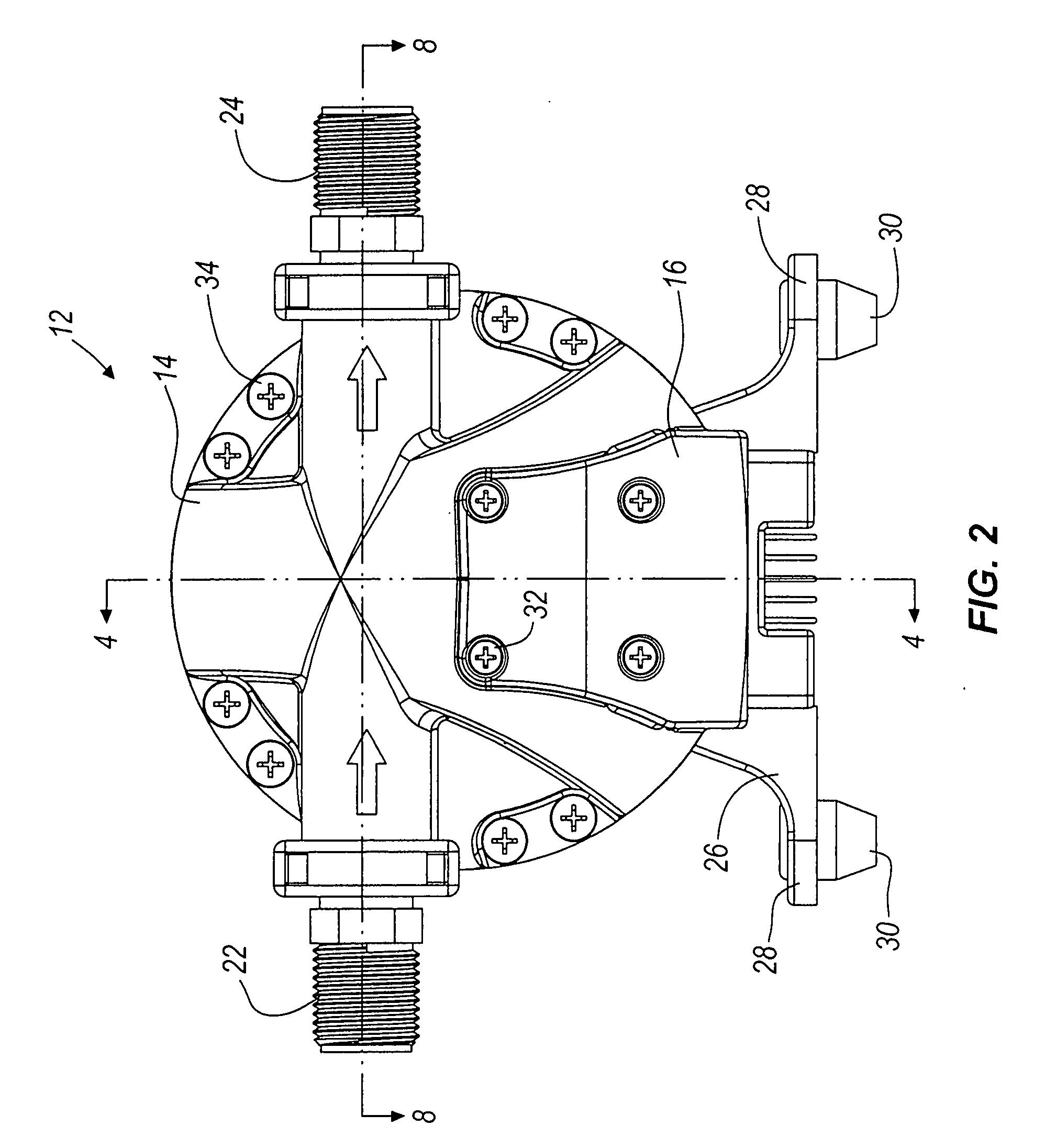

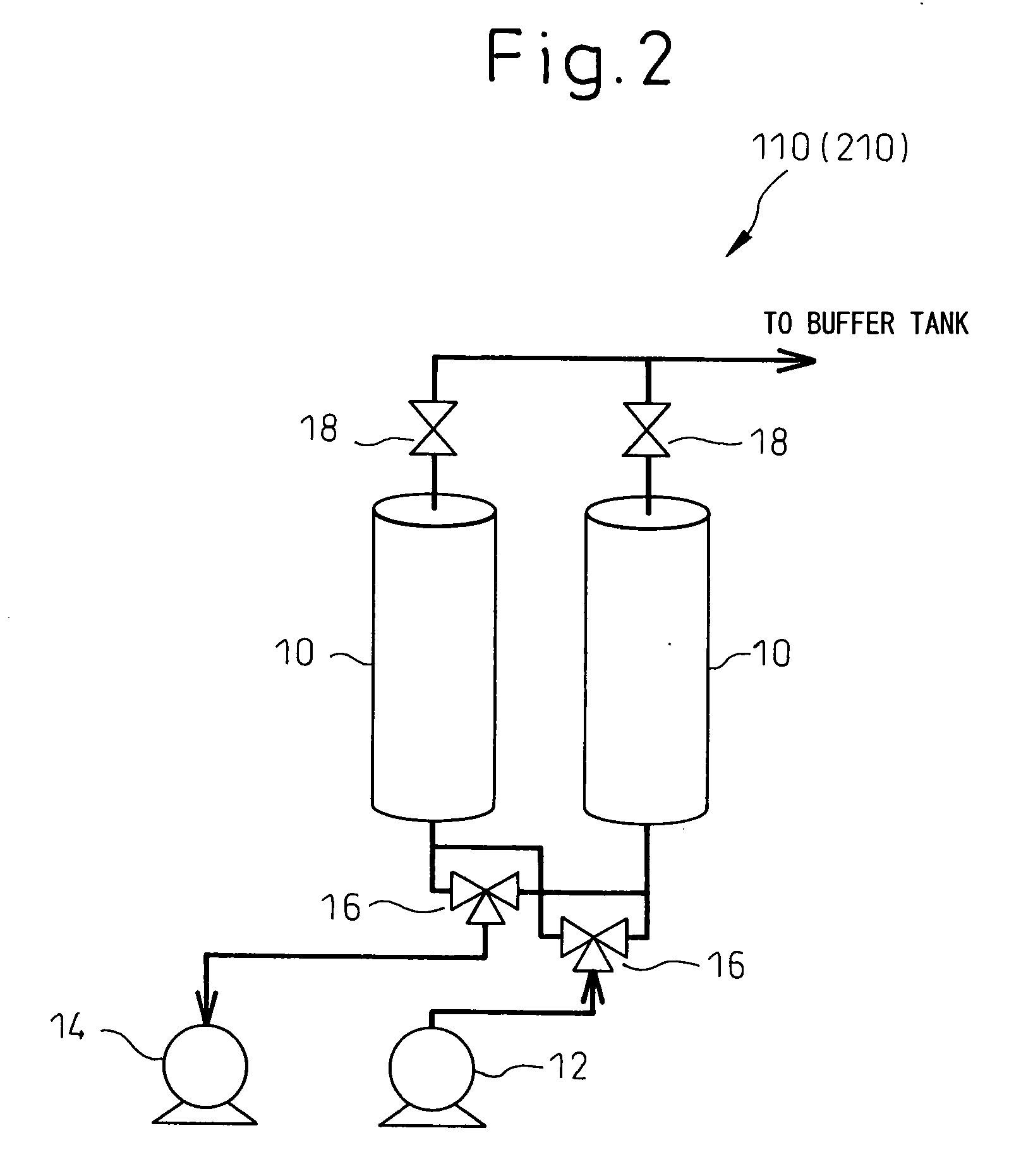

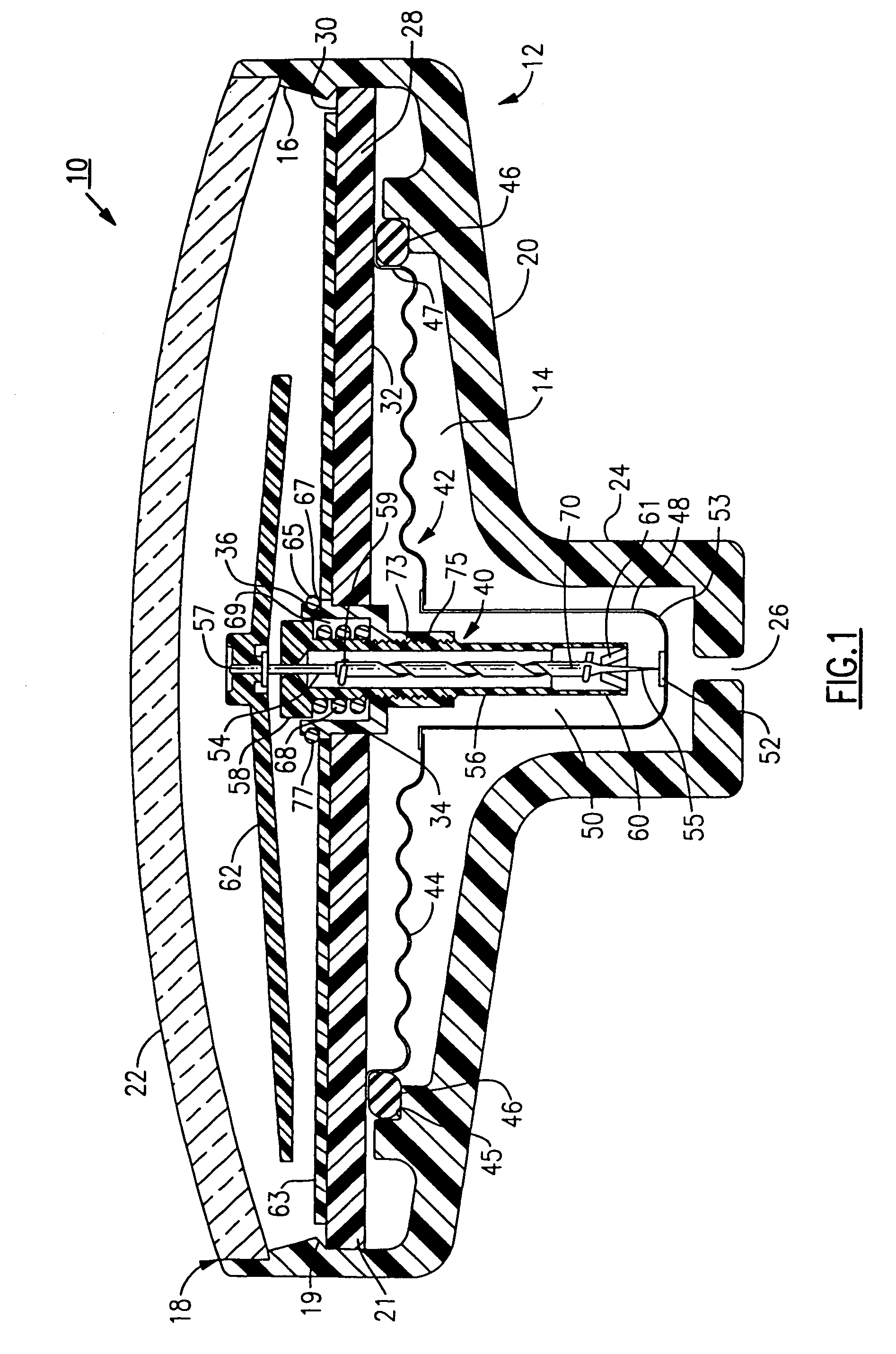

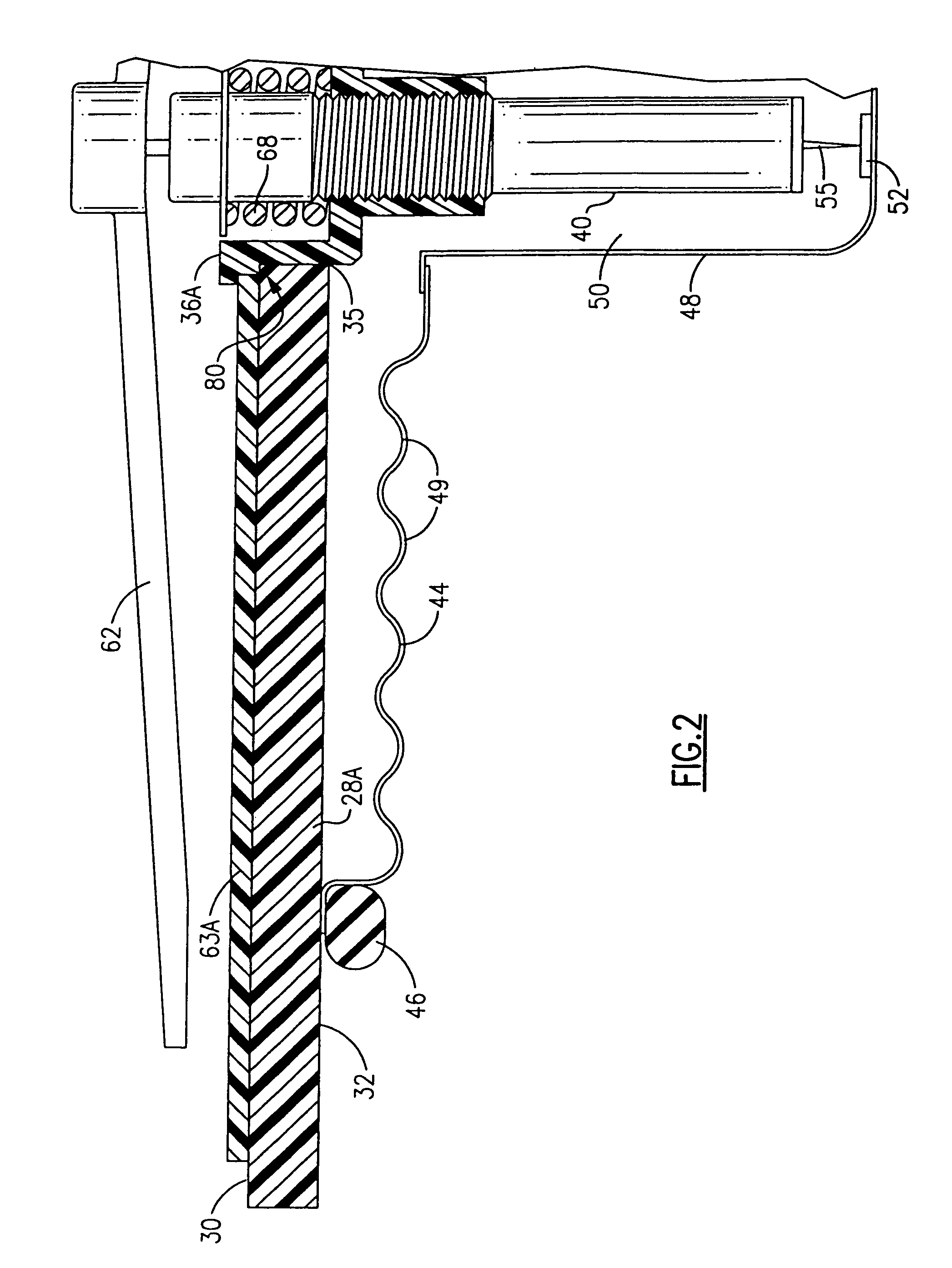

Pump and pump control circuit apparatus and method

InactiveUS7083392B2Large range of motionReduce diaphragm stressFluid parameterFlexible member pumpsMicrocontrollerControl system

A method and apparatus for a pump and a pump control system. The apparatus includes pistons integrally formed in a diaphragm and coupled to the diaphragm by convolutes. The convolutes have a bottom surface angled with respect to a top surface of the pistons. The apparatus also includes an outlet port positioned tangentially with respect to the perimeter of an outlet chamber. The apparatus further includes a non-mechanical pressure sensor and a temperature sensor coupled to a pump control system. For the method of the invention, the microcontroller provides a pulse-width modulation control signal to an output power stage in order to selectively control the power provided to the pump. The control signal is based on the pressure within the pump, the current being provided to the pump, the voltage level of the battery, and the temperature of the pump.

Owner:SHURFLO

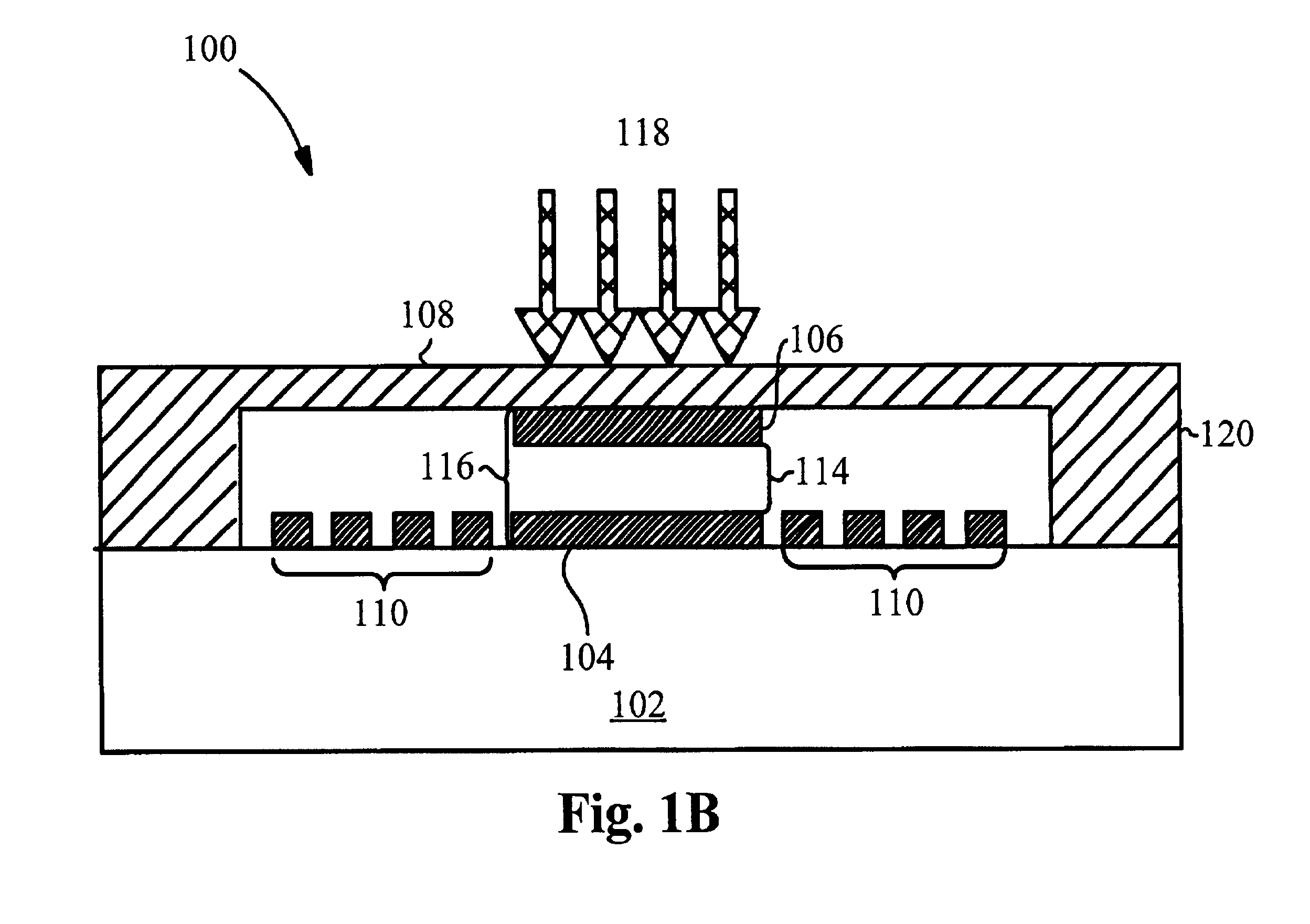

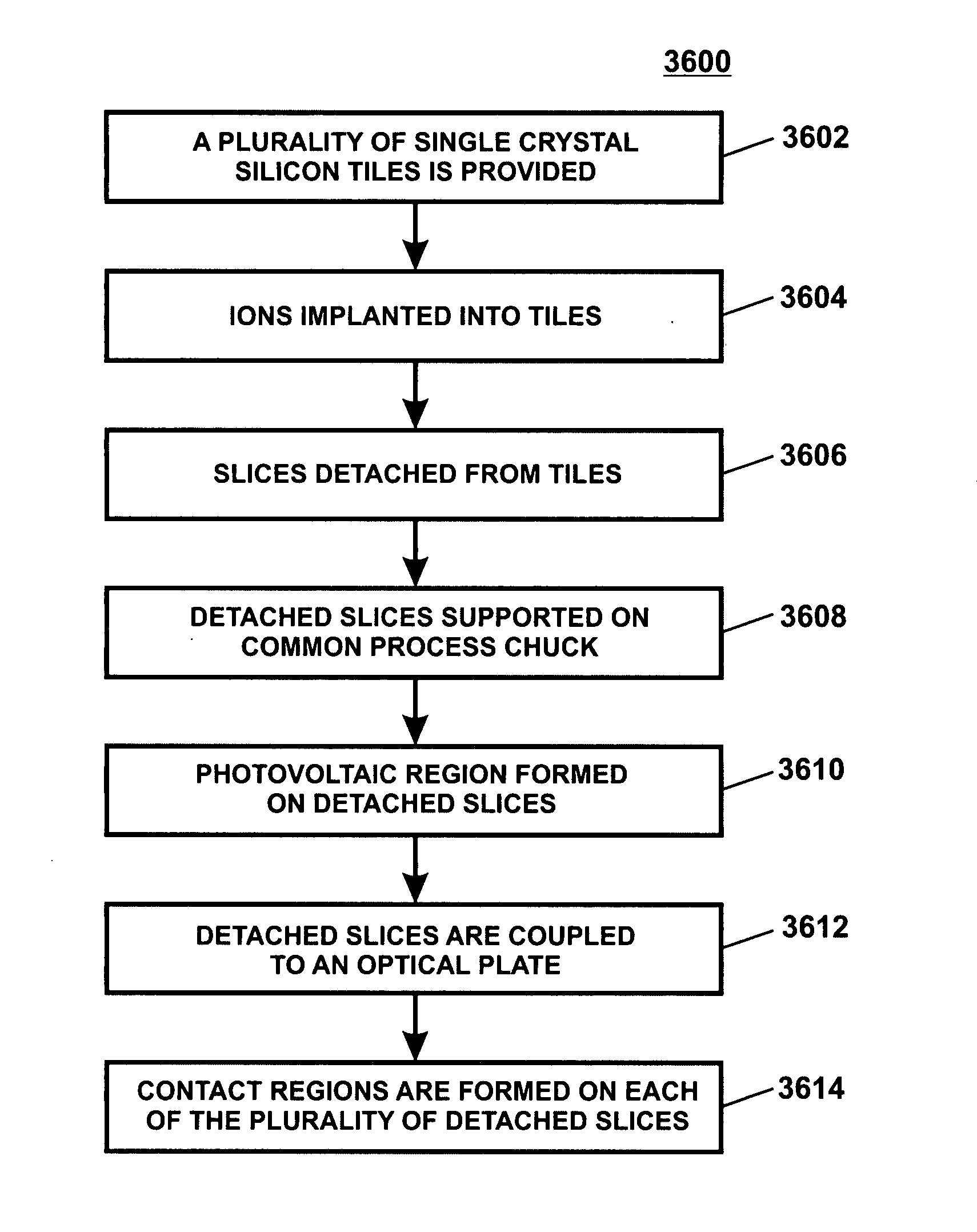

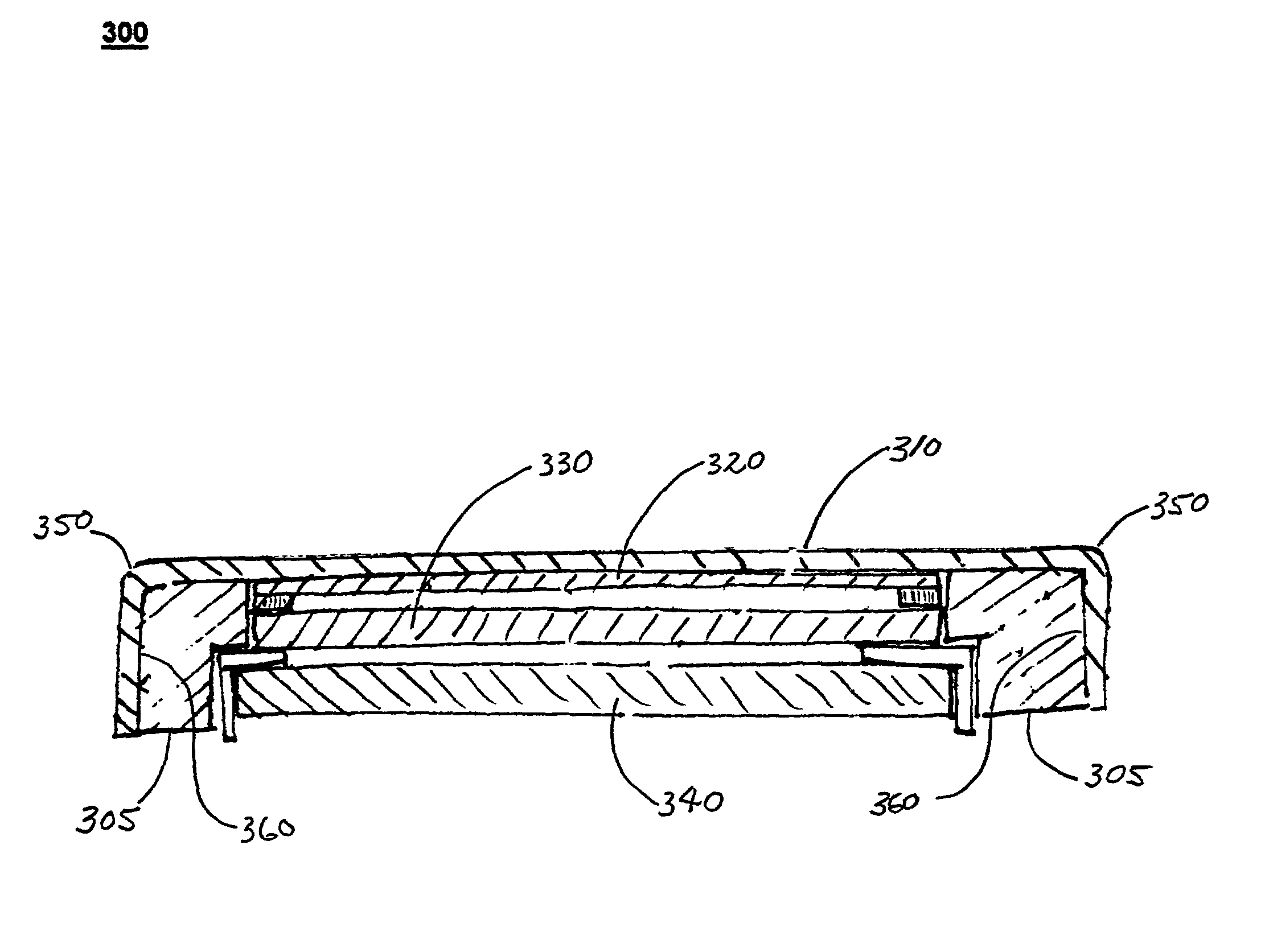

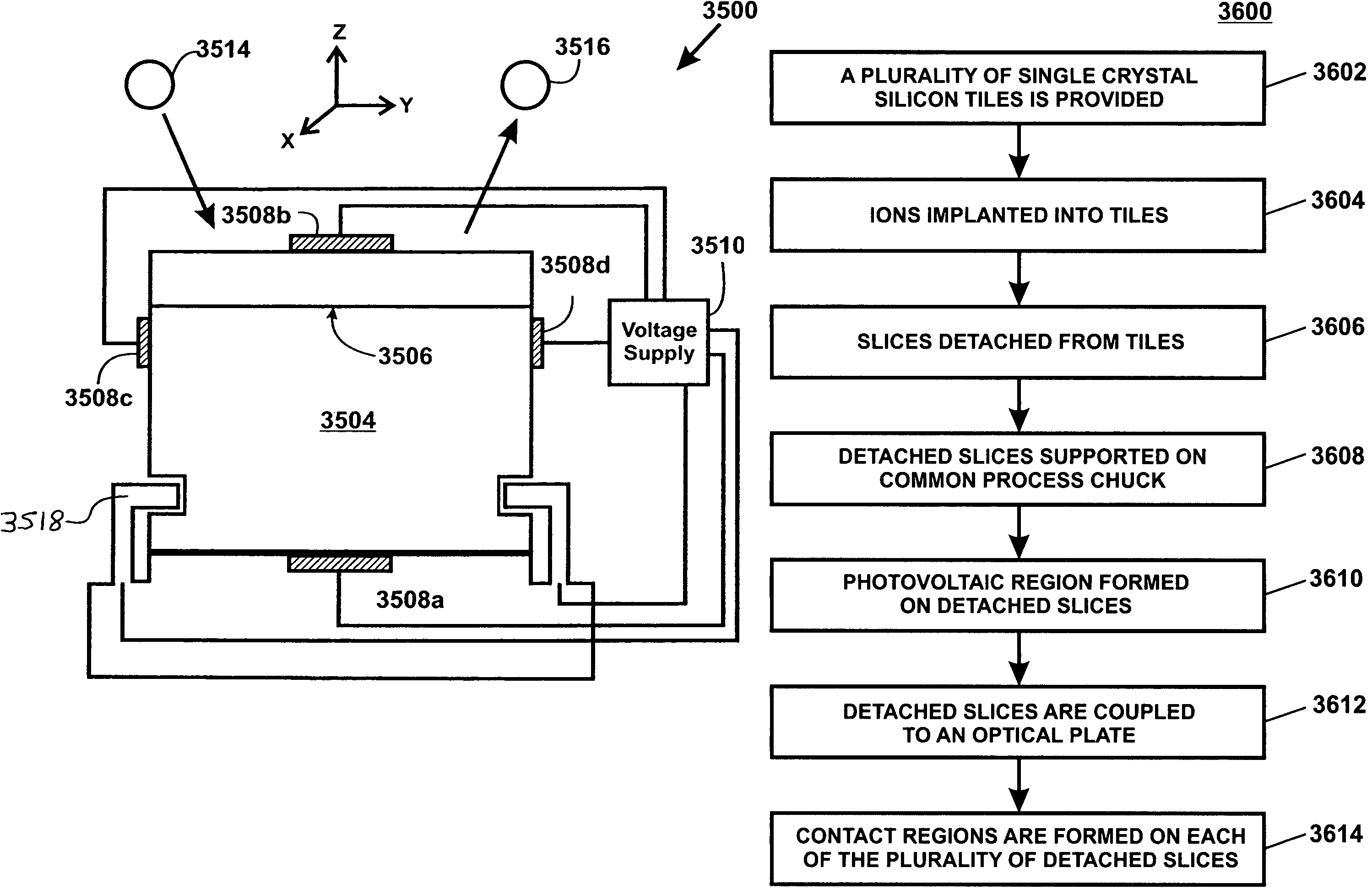

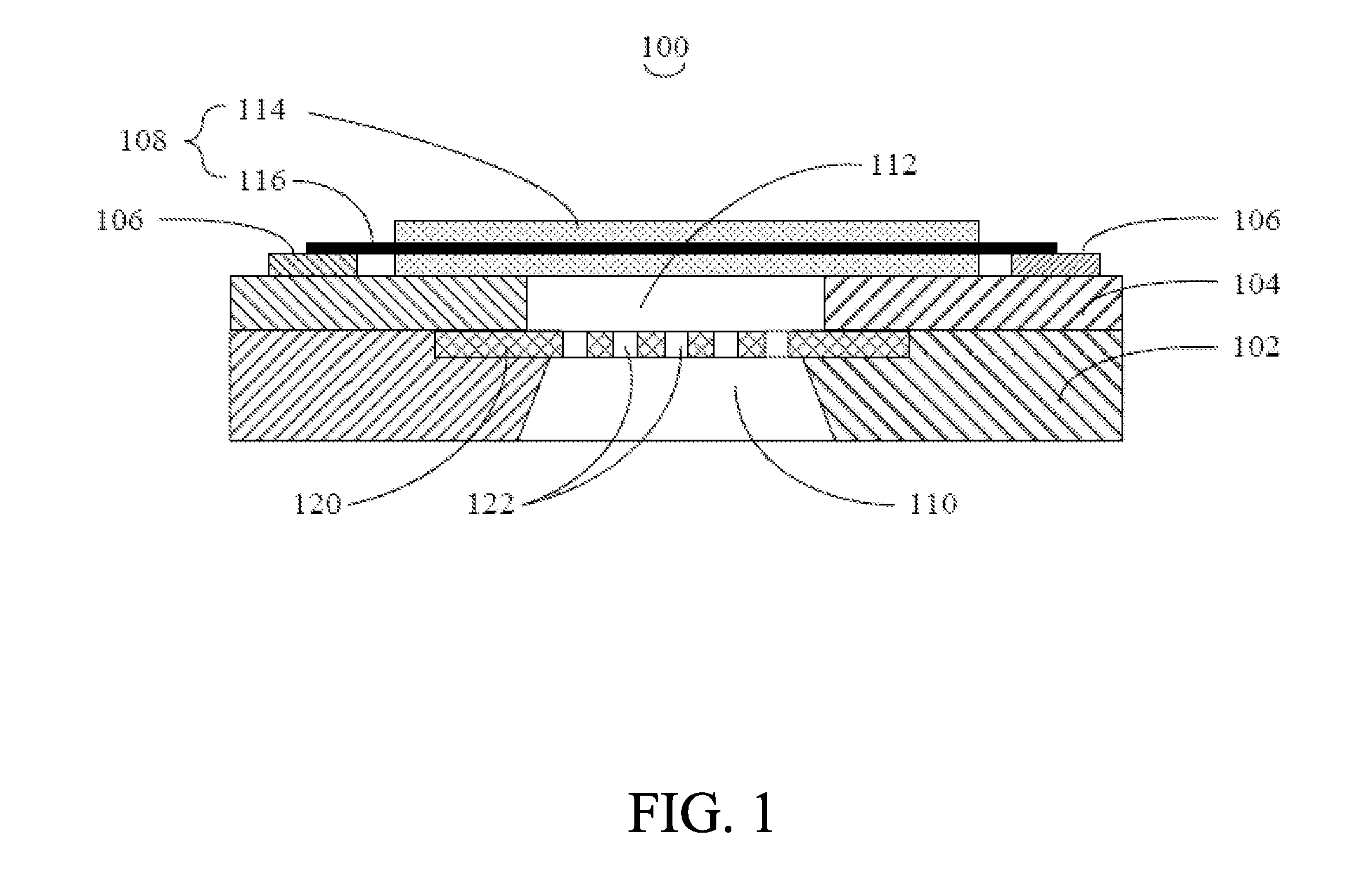

Method and structure for fabricating solar cells using a layer transfer process

InactiveUS20080160661A1Quality improvementEfficient powerSemiconductor/solid-state device manufacturingSemiconductor devicesMechanical pressureSolar cell

A reusable silicon substrate device for use with layer transfer process. The device has a reusable substrate having a surface region, a cleave region, and a total thickness of material. The total thickness of material is at least N times greater than a first thickness of material to be removed. In a specific embodiment, the first thickness of material to be removed is between the surface region and the cleave region, whereupon N is an integer greater than about ten. The device also has a chuck member adapted to hold a handle substrate member in place. The chuck member is configured to hold the handle substrate in manner to facilitate bonding the handle substrate to the first thickness of material to be removed. In a preferred embodiment, the device has a mechanical pressure device operably coupled to the chuck member. The mechanical pressure device is adapted to provide a force to cause bonding of the handle substrate to the first thickness of material to be removed.

Owner:SILICON GENERAL CORPORATION

Dental bleaching compositions containing sucralose

Dental bleaching compositions that include sucralose. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous such as a mixture of propylene glycol and silica fume. Anhydrous propylene glycol and / or anhydrous glycerin are especially useful in order to maintain the desired degree of hydration of the perborate being used. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

Dental bleaching compositions containing sucralose

InactiveUS6322774B1Effectively disguise the bitter taste of such agents over timeAccurate quantityCosmetic preparationsImpression capsFlavouring agentGlycerol

Dental bleaching compositions that include sucralose as a non-nutritive sweetener. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous, such as a mixture of a liquid or solvent carrier and a tackifying agent. Propylene glycol and / or glycerin are especially useful liquid or solvent carriers. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are preferably sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

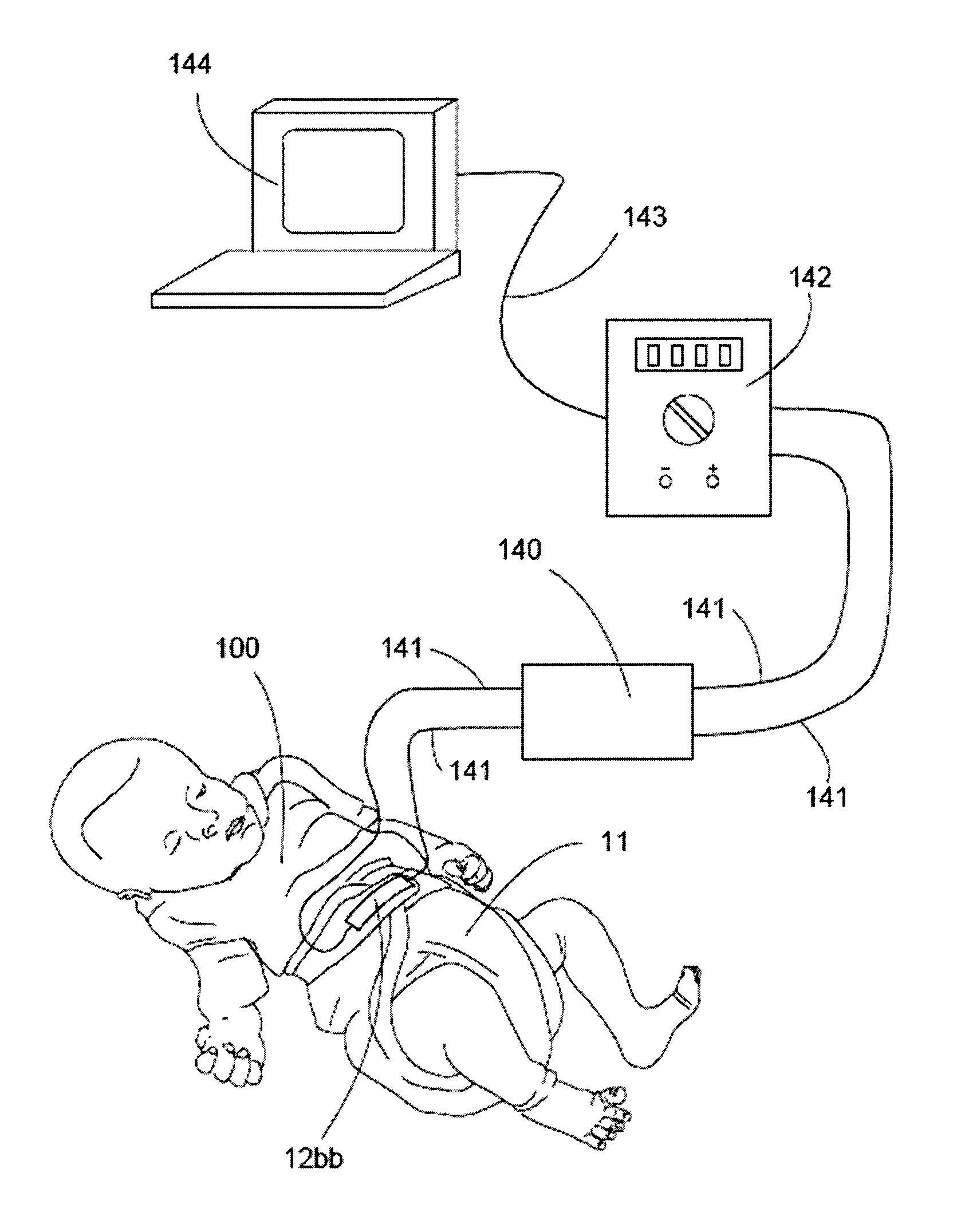

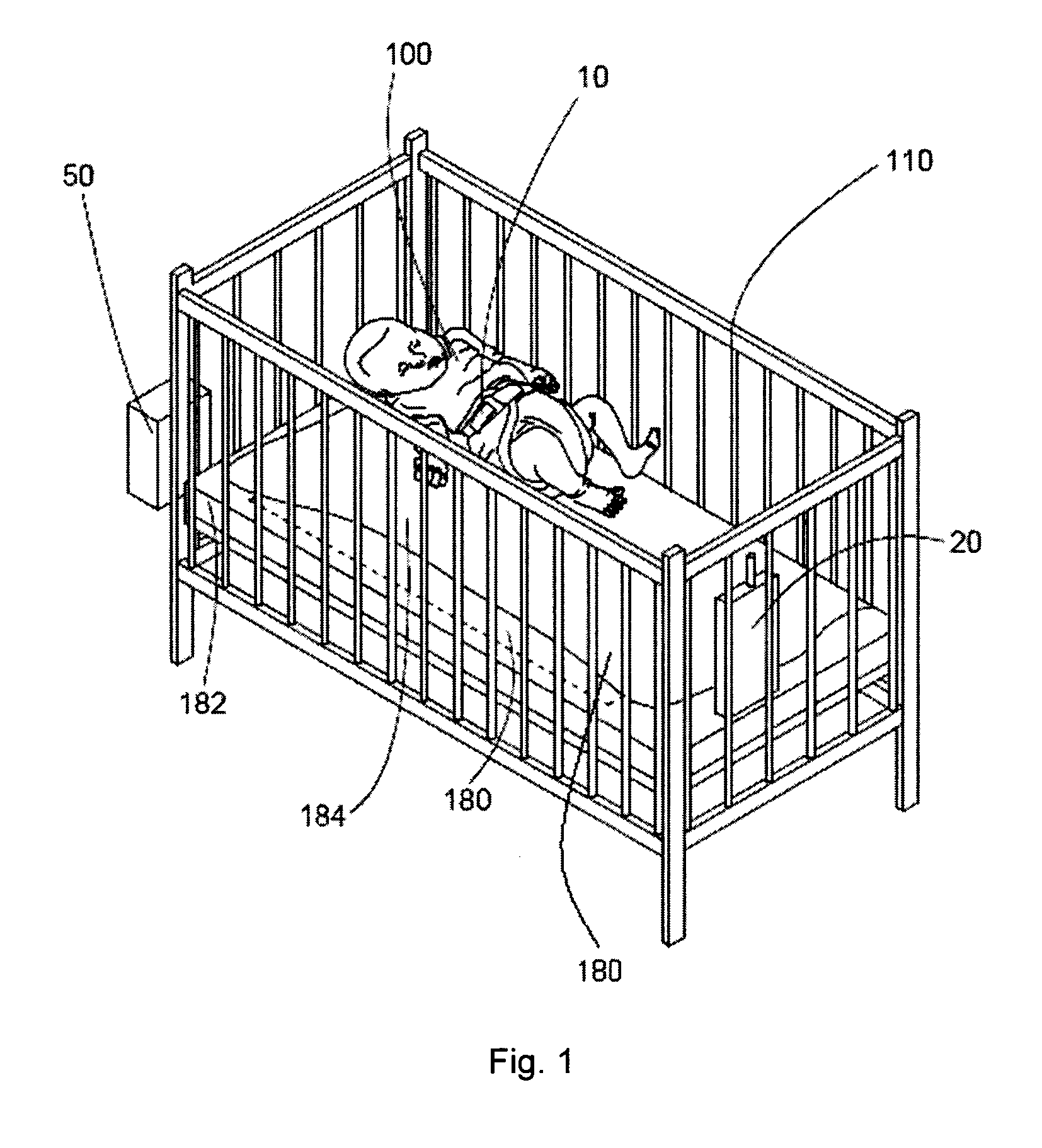

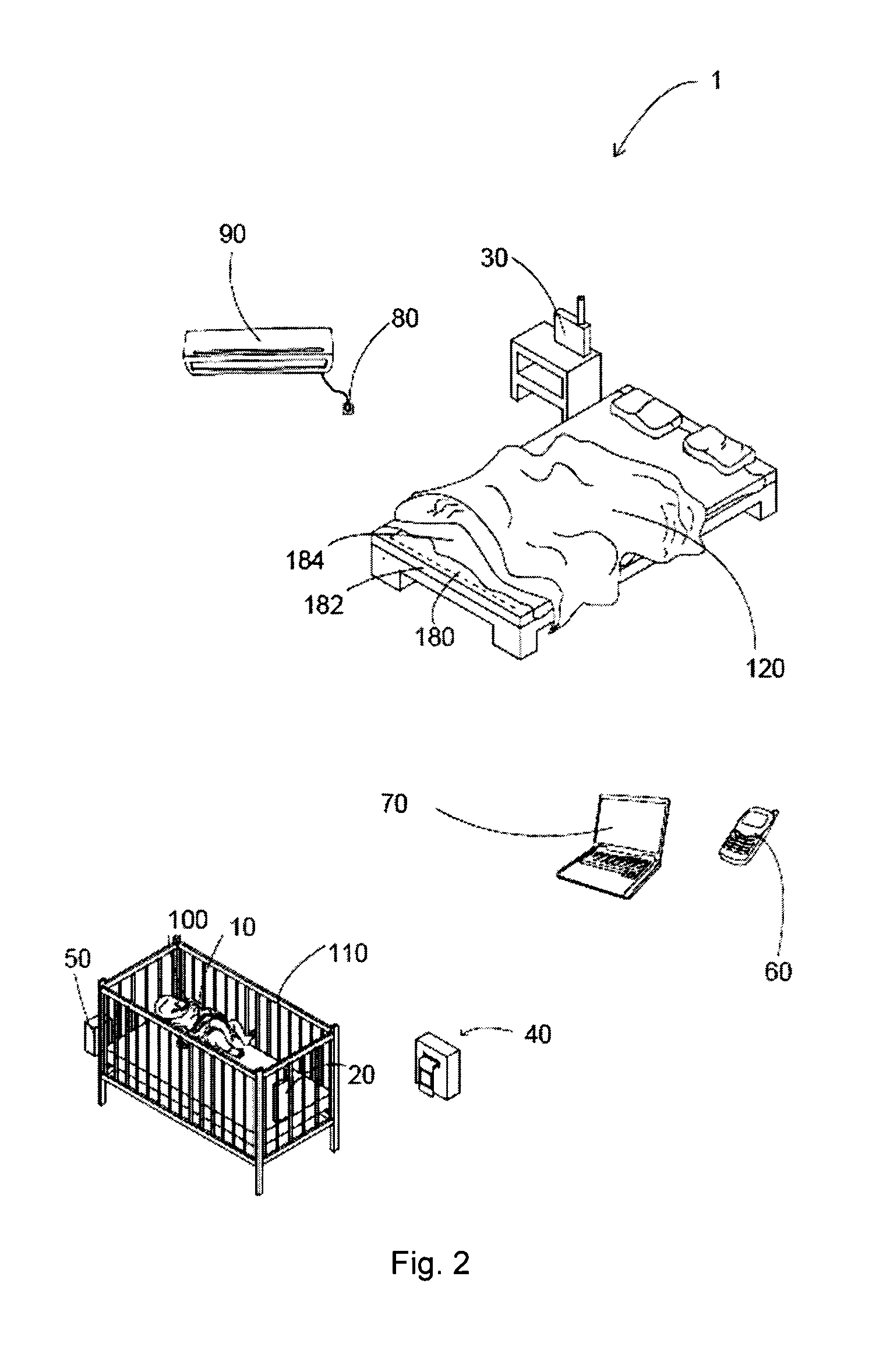

Monitoring physiological condition of a subject

InactiveUS20130165809A1Cheap, non invasive, accurate, small and disposableImprove securityRespiratory organ evaluationTelemetric patient monitoringResistive sensorsElectrical resistance and conductance

A system for monitoring breathing of a subject, the system comprising: (a) a wearable subject unit comprising: an elastic resistive sensor positionable such that breathing motion of the subject applies mechanical pressure to said elastic resistive sensor, wherein said elastic resistive sensor is configured to change its resistance responsive to the mechanical pressure, and a transmitter configured to wirelessly transmit a signal based on the change in resistance of the elastic resistive sensor; and (b) a platform unit comprising a receiver and being positionable in wireless transmission range with said subject unit, said platform unit configured to receive said signal from said subject unit and to issue an advisory signal indicative of the breathing of the subject.

Owner:DIGISENSE

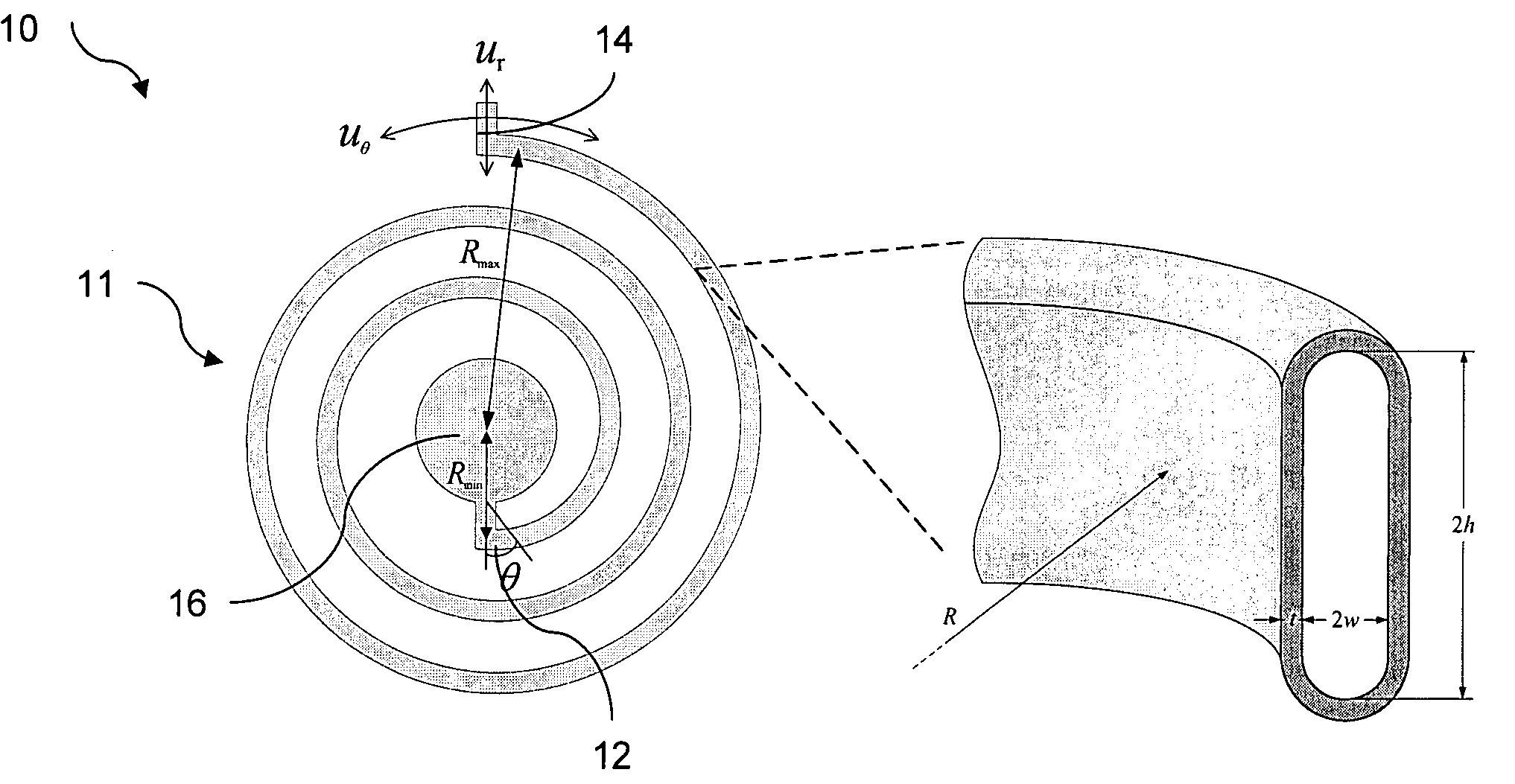

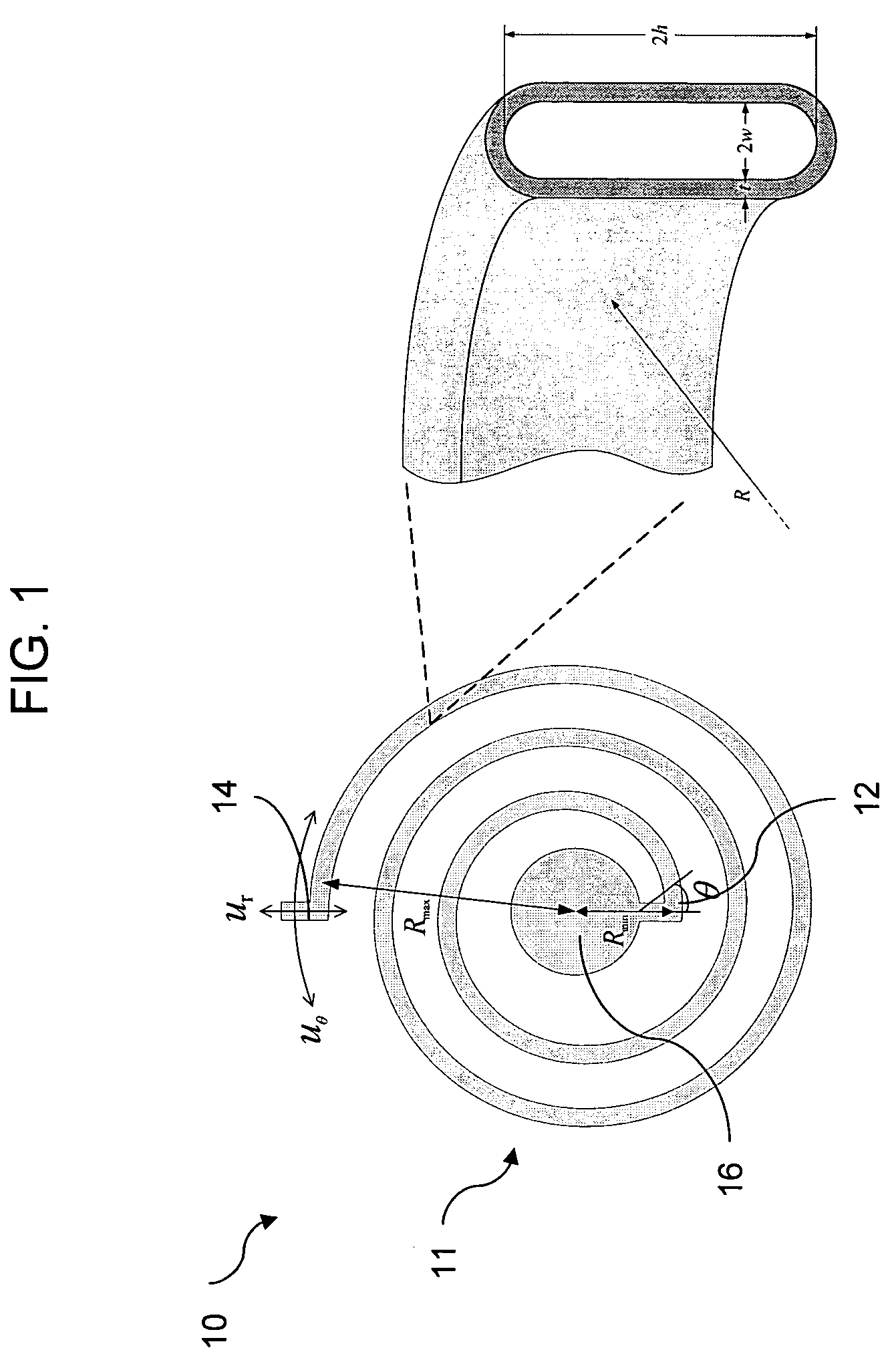

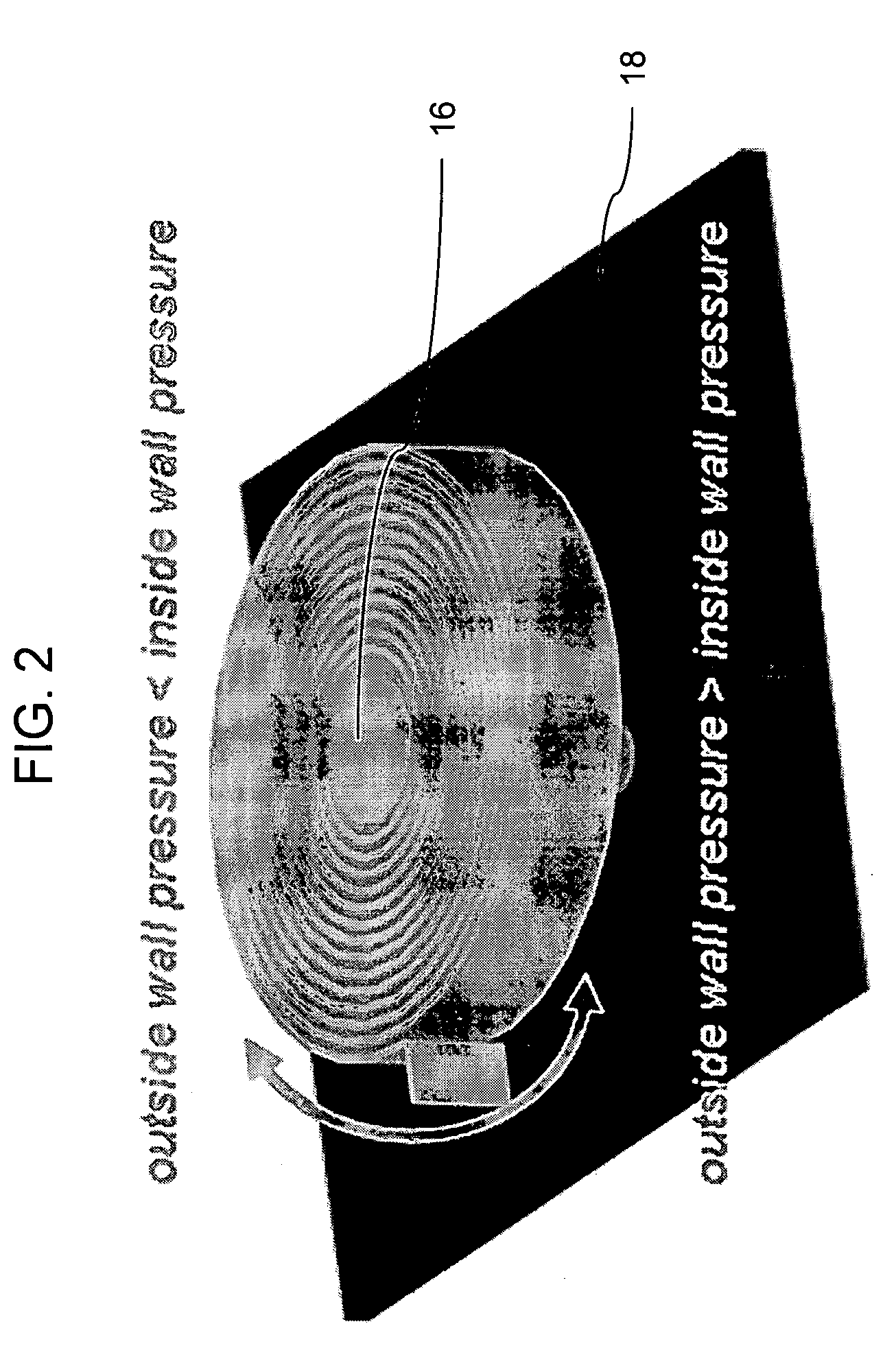

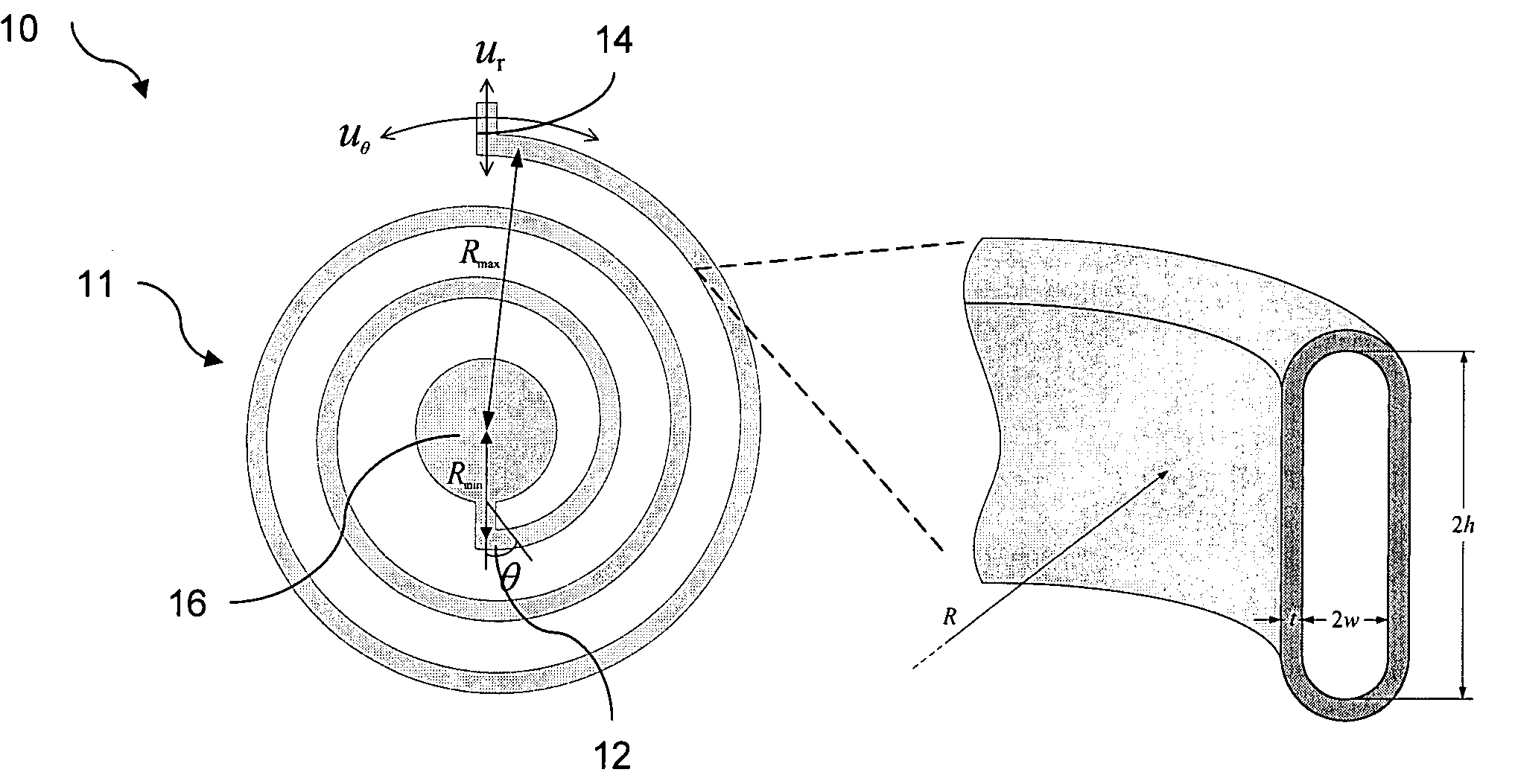

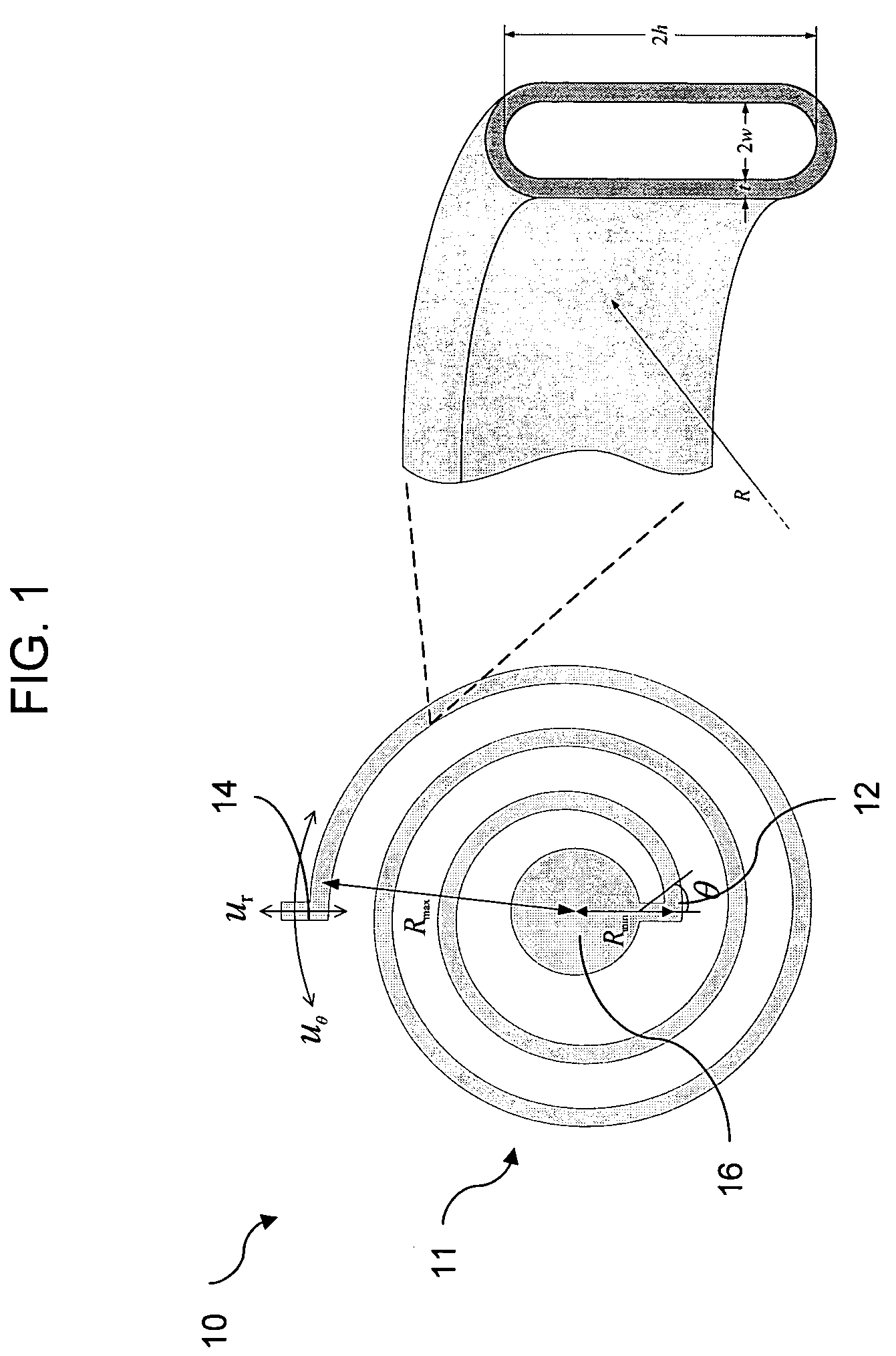

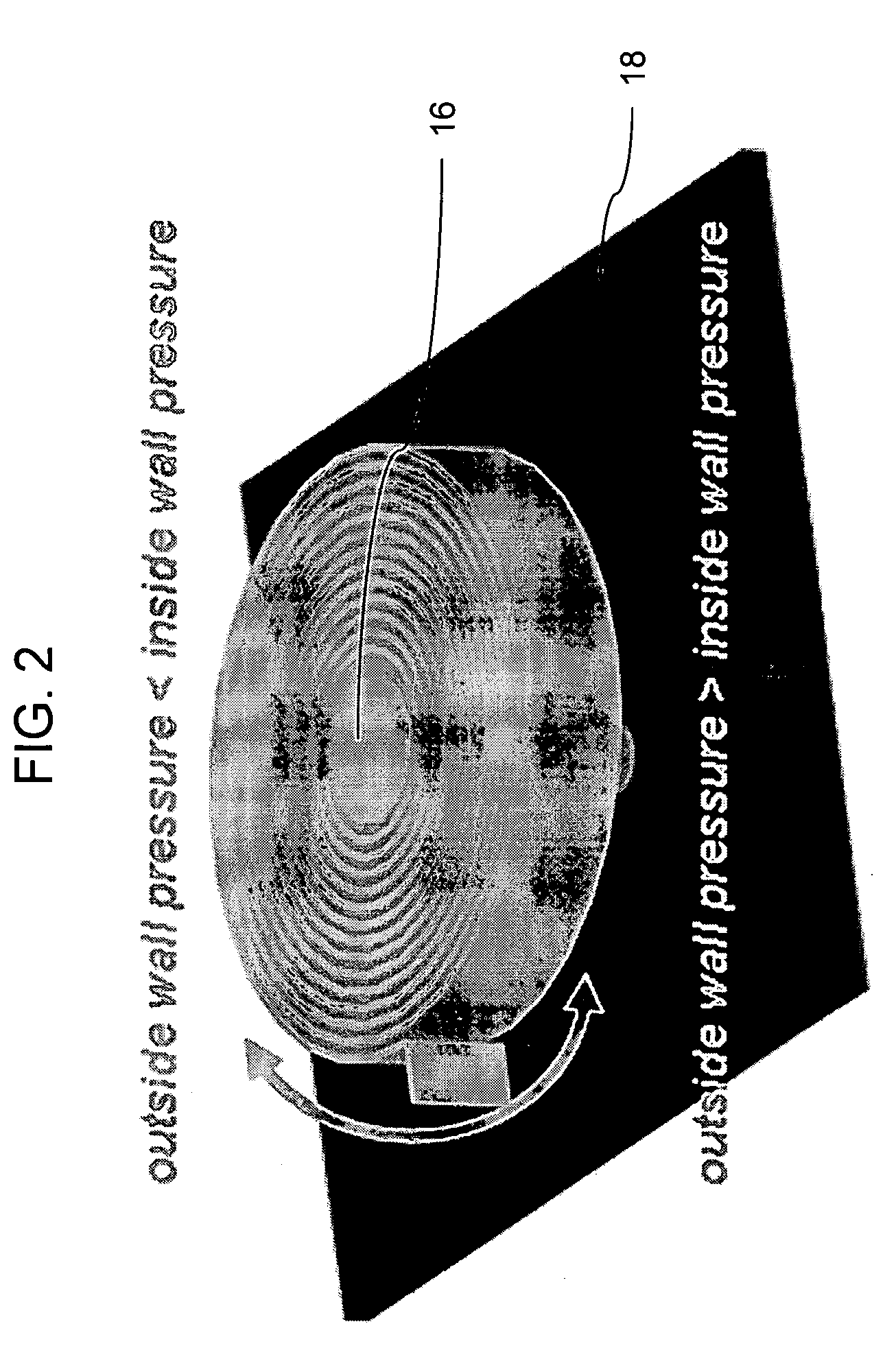

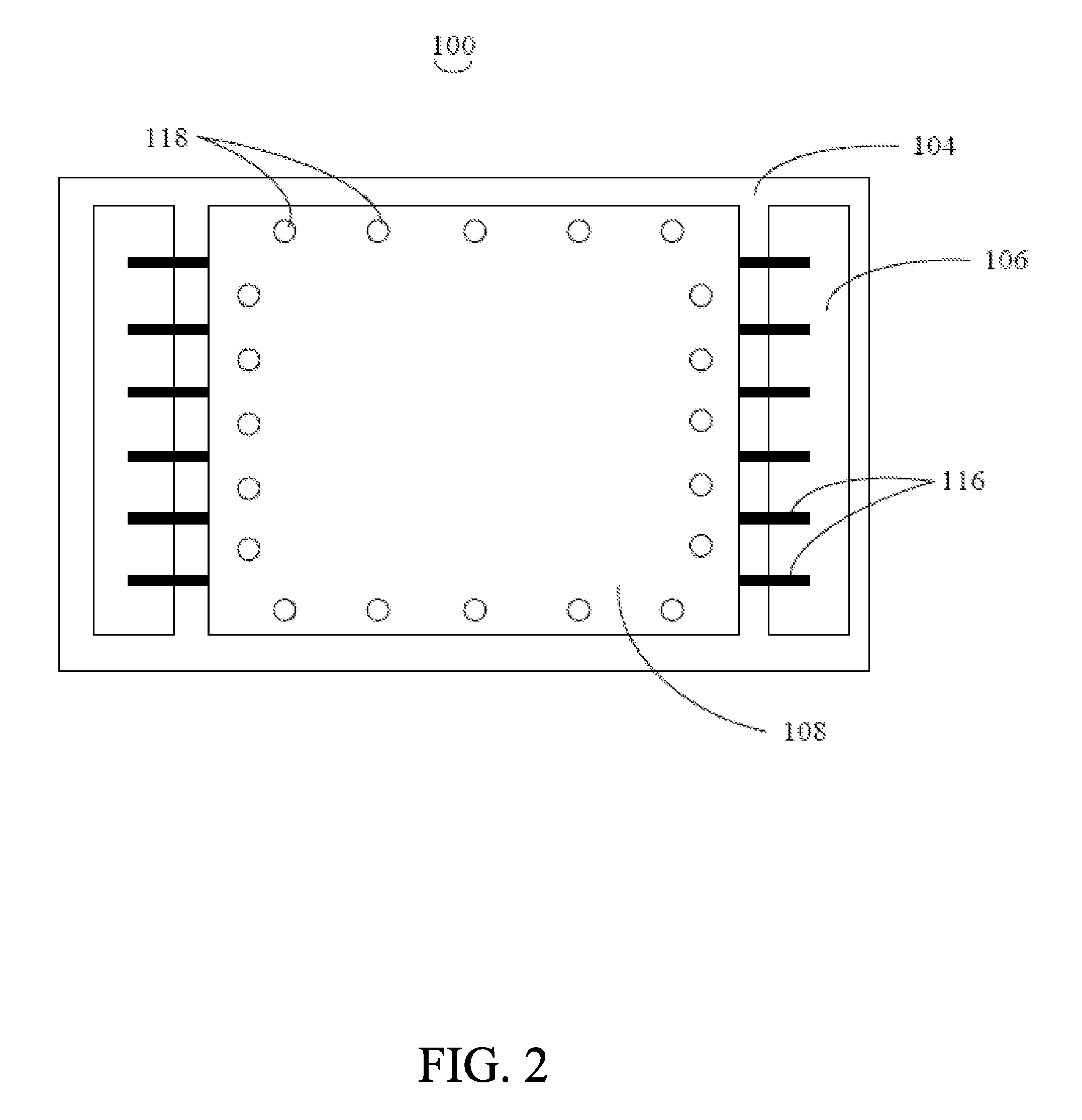

Implantable mechanical pressure sensor and method of manufacturing the same

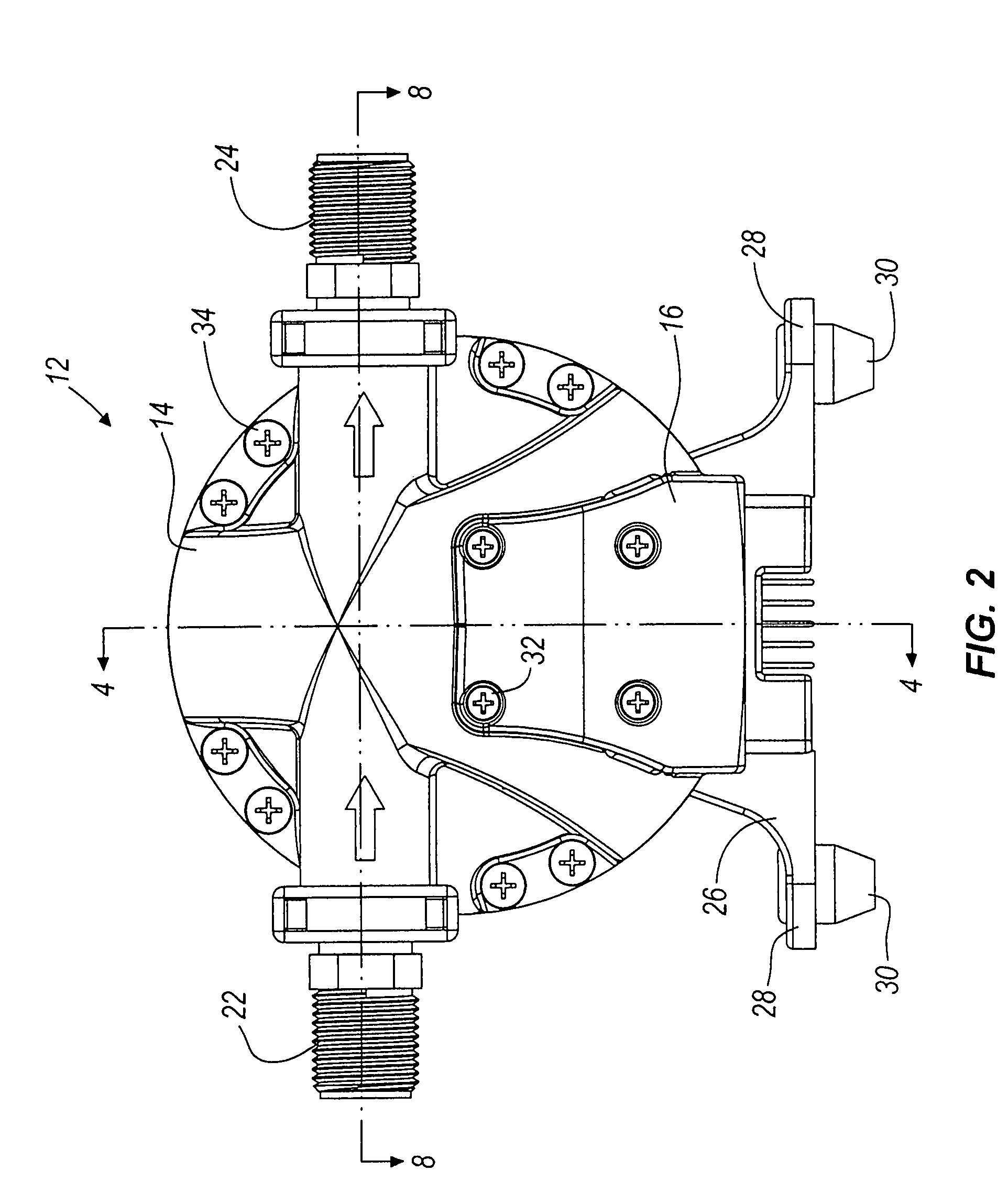

InactiveUS7252006B2Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsIn planeGlaucoma

A biocompatible, mechanical, micromachined pressure sensor and methods of manufacturing such a pressure sensor are provided. The pressure sensor of the current invention includes a high-aspect-ratio curved-tube structure fabricated through a one-layer parylene process. The pressure sensor of the current invention requires zero power consumption and indicates the pressure variation by changes of the in situ in-plane motion of the sensor, which can be gauged externally by a direct and convenient optical observation. In one embodiment, the pressure sensor of the current invention has been shown to work as an IOP sensor for eye implantation where the intraocular in-plane motion of the sensor can be recorded from outside of the eye, such that the intraocular pressure in glaucoma patients can be constantly monitored.

Owner:CALIFORNIA INST OF TECH

Pump and pump control circuit apparatus and method

InactiveUS20080181786A1Large range of motionRelieve pressureFluid parameterFlexible member pumpsMicrocontrollerControl system

A method and apparatus for a pump and a pump control system. The apparatus includes pistons integrally formed in a diaphragm and coupled to the diaphragm by convolutes. The convolutes have a bottom surface angled with respect to a top surface of the pistons. The apparatus also includes an outlet port positioned tangentially with respect to the perimeter of an outlet chamber. The apparatus further includes a non-mechanical pressure sensor and a temperature sensor coupled to a pump control system. For the method of the invention, the microcontroller provides a pulse-width modulation control signal to an output power stage in order to selectively control the power provided to the pump. The control signal is based on the pressure within the pump, the current being provided to the pump, the voltage level of the battery, and the temperature of the pump.

Owner:SHURFLO

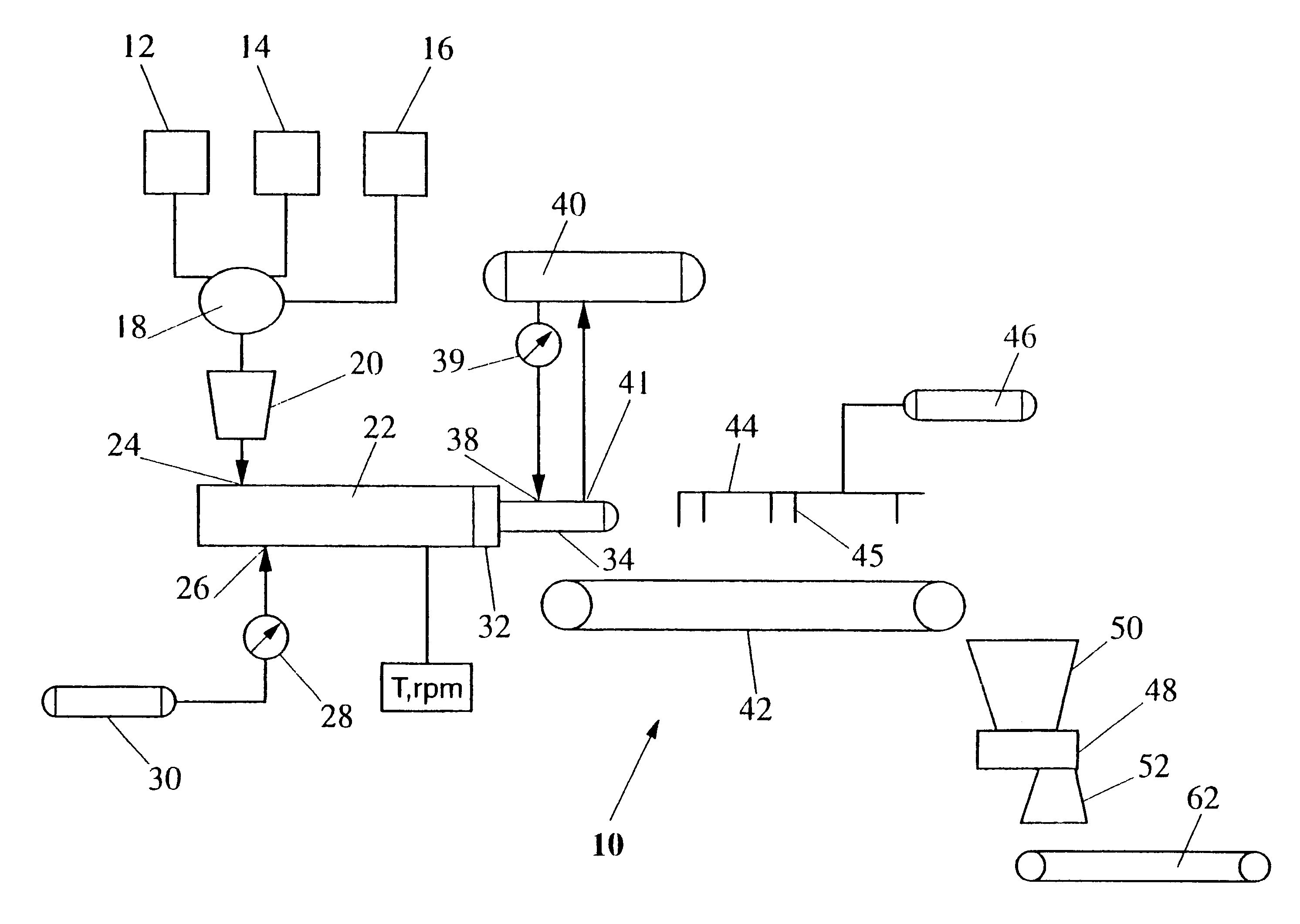

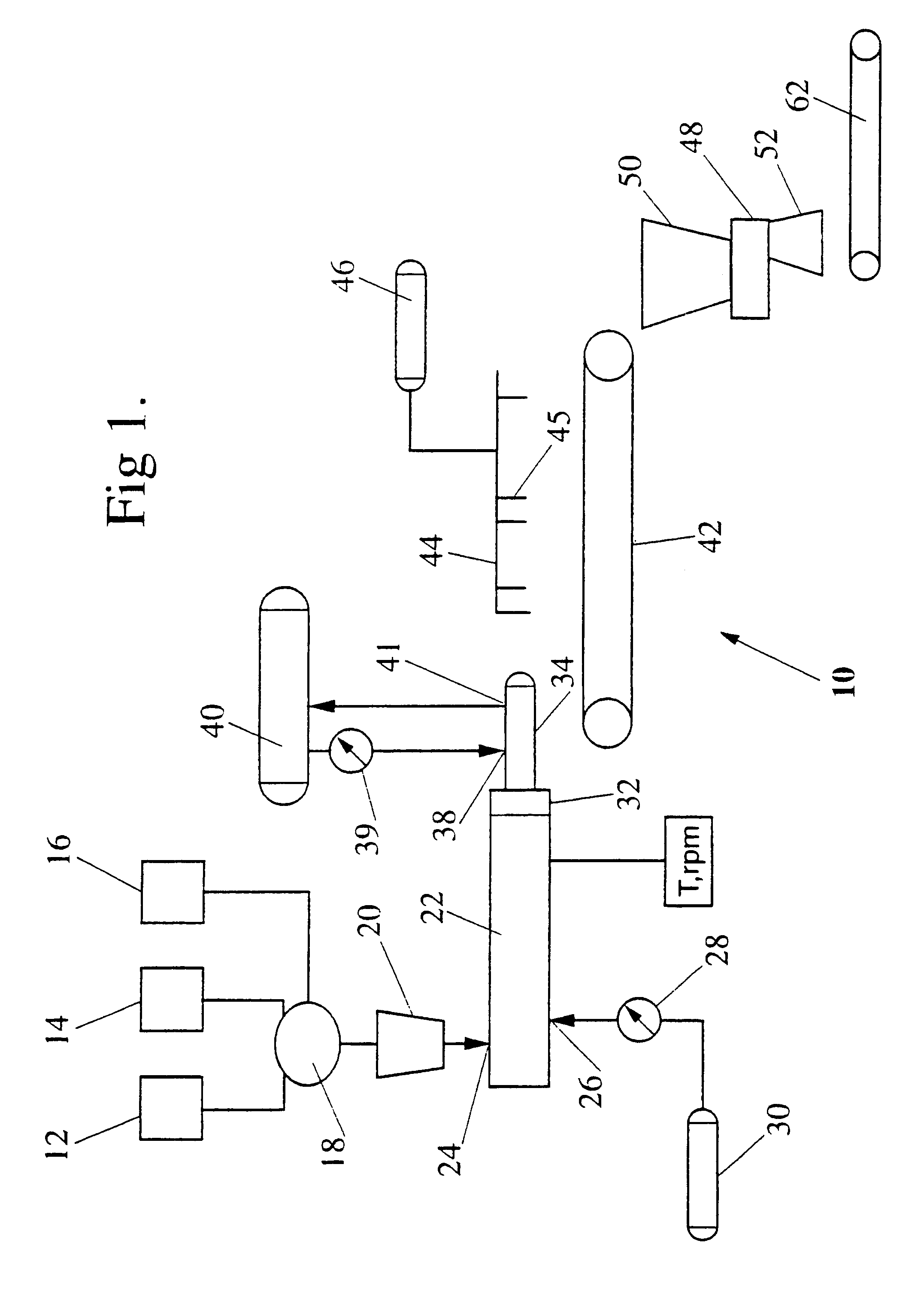

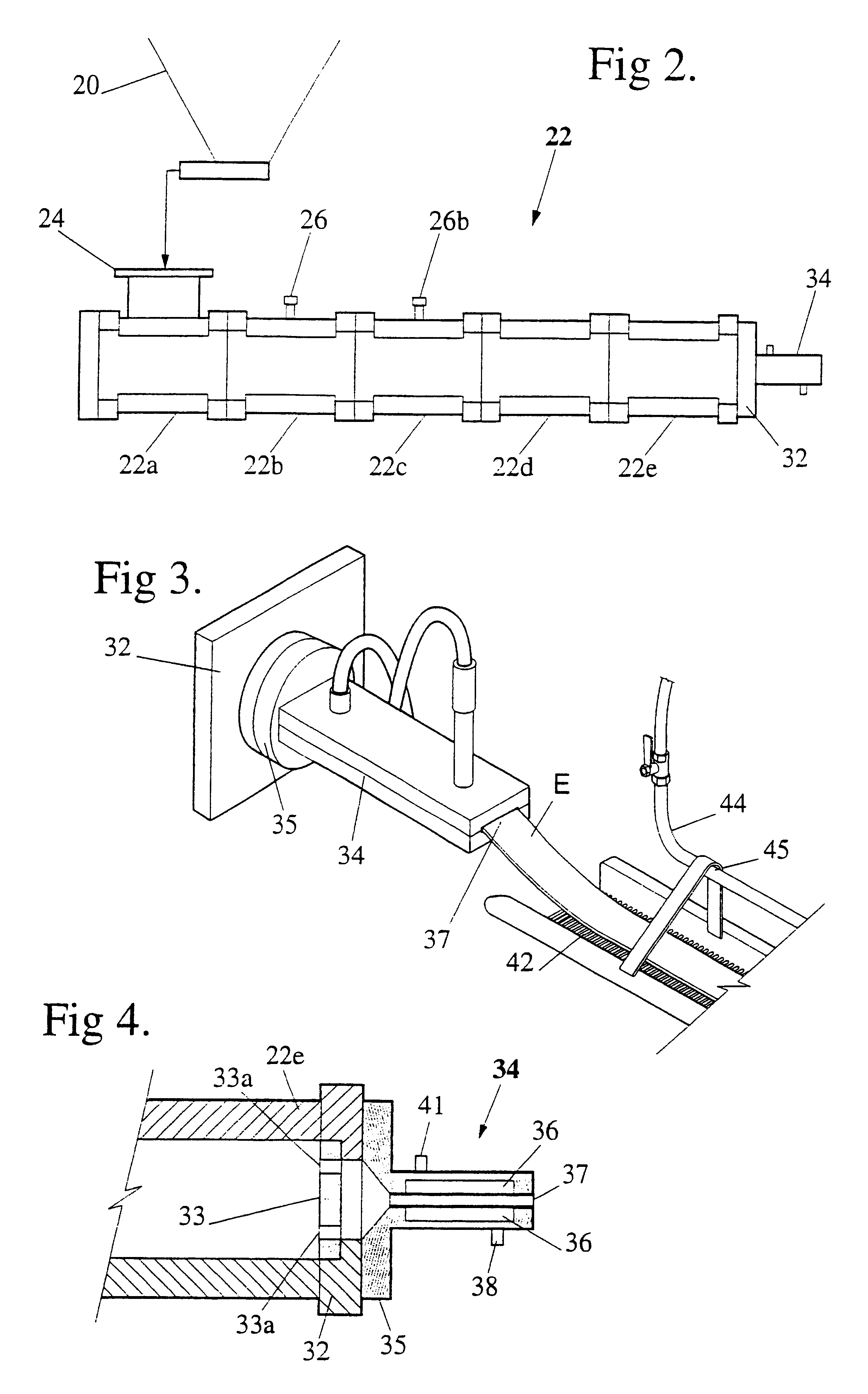

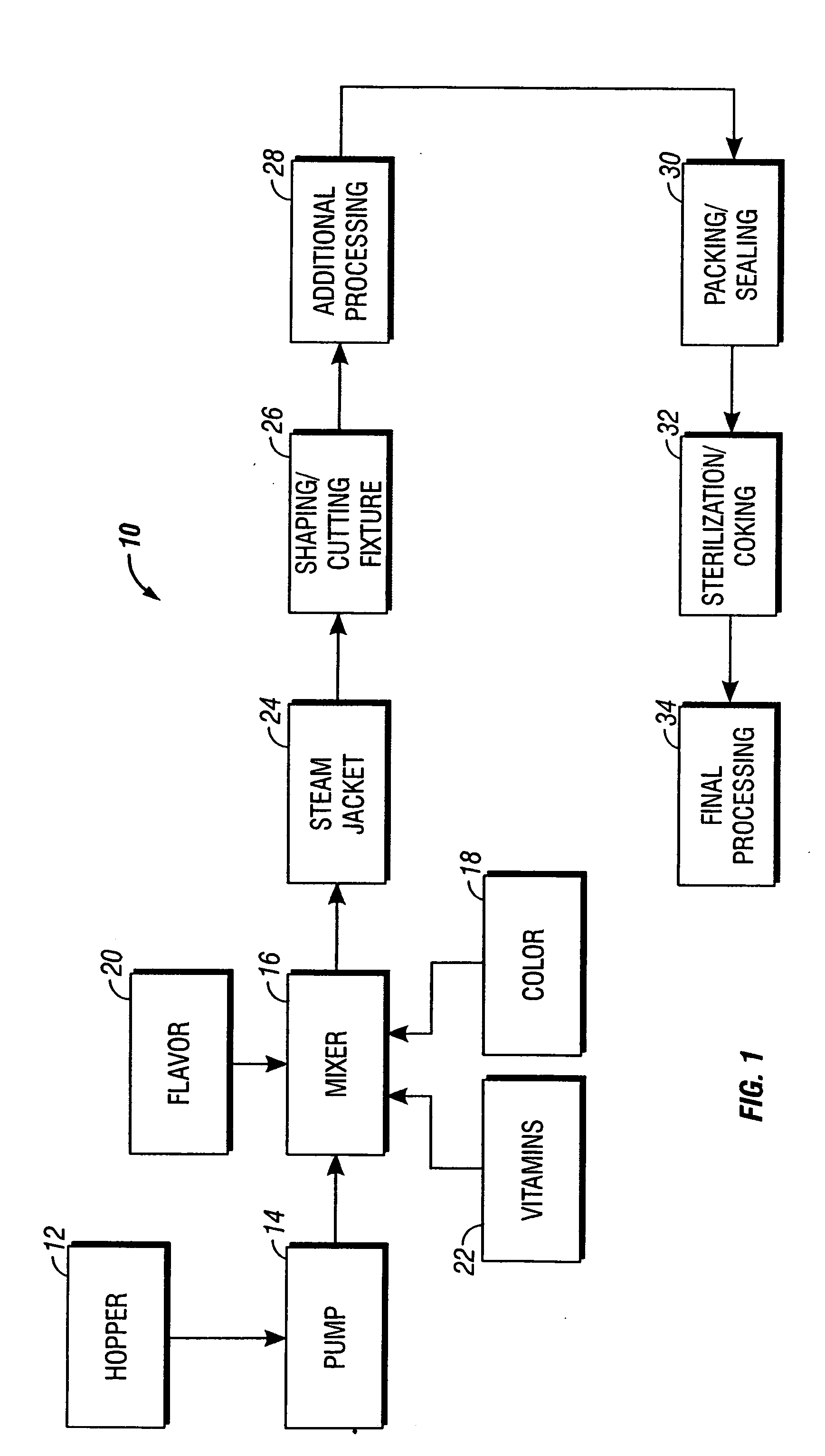

Method and apparatus for the manufacture of meat

InactiveUS6635301B1Proteins working-up by texturisingAnimal feeding stuffMineral bindingTemperature control

A method of manufacturing a texturised proteinaceous meat analogue product, including: subjecting, in a food extruder a mixture containing: about 40 to 95% by weight edible proteinaceous materials selected from the group of predetermined mixtures of defatted soy flour, soy meal, soy concentrate, cereal gluten in vital or starch-containing form and egg white, and up to about 7% by weight of edible mineral binding and cross-linking compounds; to mechanical pressure and added heat sufficient to convert the mixture into a hot, viscous protein lava; extruding the protein lava through and from a temperature controlled cooling die which cools and reduces the viscosity of the protein lava to obtain a cohesive, texturised, extrudate slab or ribbon in which vapour-flashing is substantially inhibited; and subjecting the solidified extrudate slab or ribbon to mechanical shredding in a hammer mill having a cage plate with a plurality of elongate discharge openings and a plurality of hammer bars hinged to discs attached to a rotating shaft, so as to obtain a plurality of extrudate shred that resemble in consistency and texture flaked or shredded meat.

Owner:MARS INC

Pump and pump control circuit apparatus and method

InactiveUS20080152508A1Large range of motionRelieve pressureFluid parameterAC motor controlMicrocontrollerControl system

A method and apparatus for a pump and a pump control system. The apparatus includes pistons integrally formed in a diaphragm and coupled to the diaphragm by convolutes. The convolutes have a bottom surface angled with respect to a top surface of the pistons. The apparatus also includes an outlet port positioned tangentially with respect to the perimeter of an outlet chamber. The apparatus further includes a non-mechanical pressure sensor and a temperature sensor coupled to a pump control system. For the method of the invention, the microcontroller provides a pulse-width modulation control signal to an output power stage in order to selectively control the power provided to the pump. The control signal is based on the pressure within the pump, the current being provided to the pump, the voltage level of the battery, and the temperature of the pump.

Owner:SHURFLO

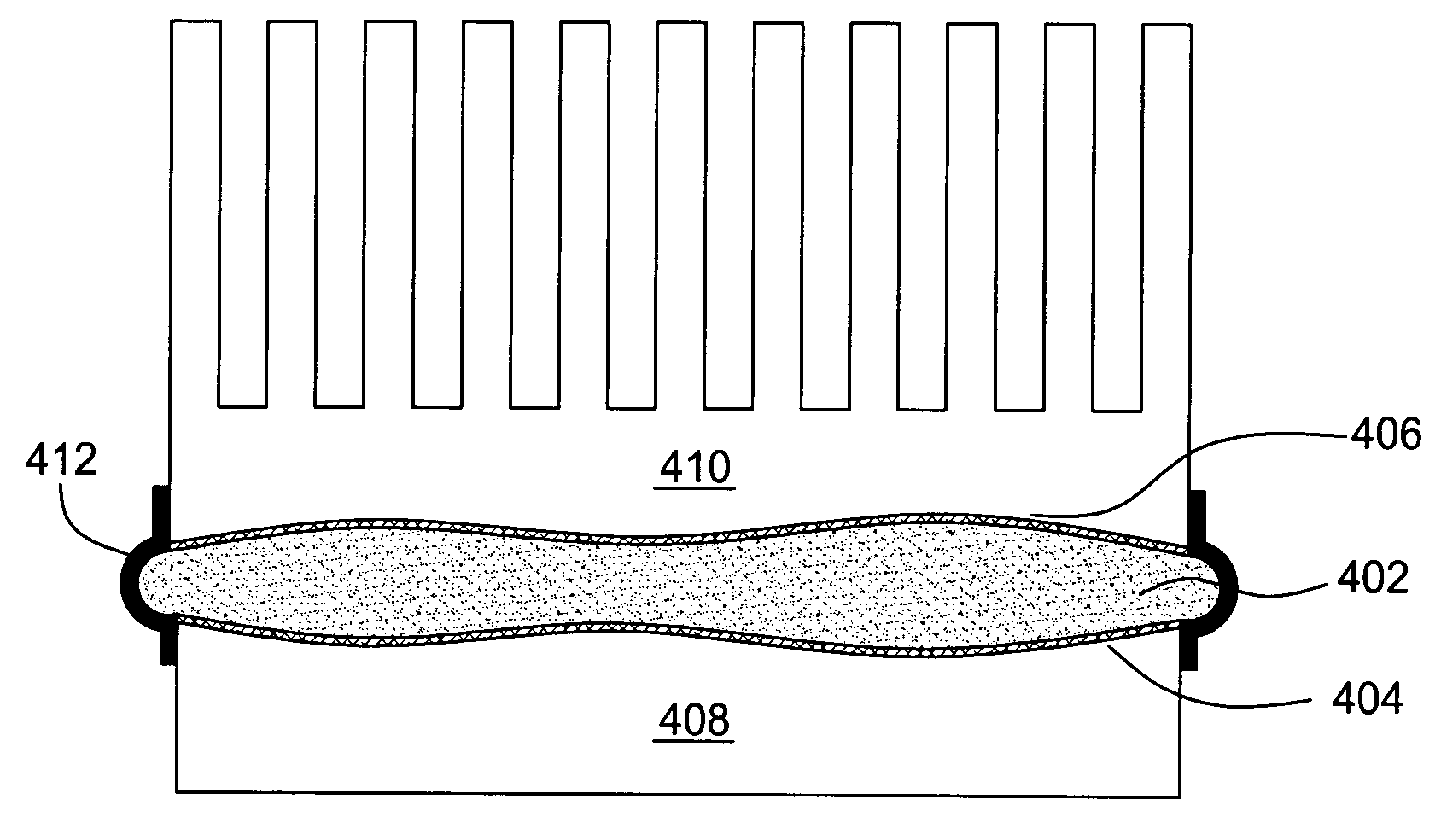

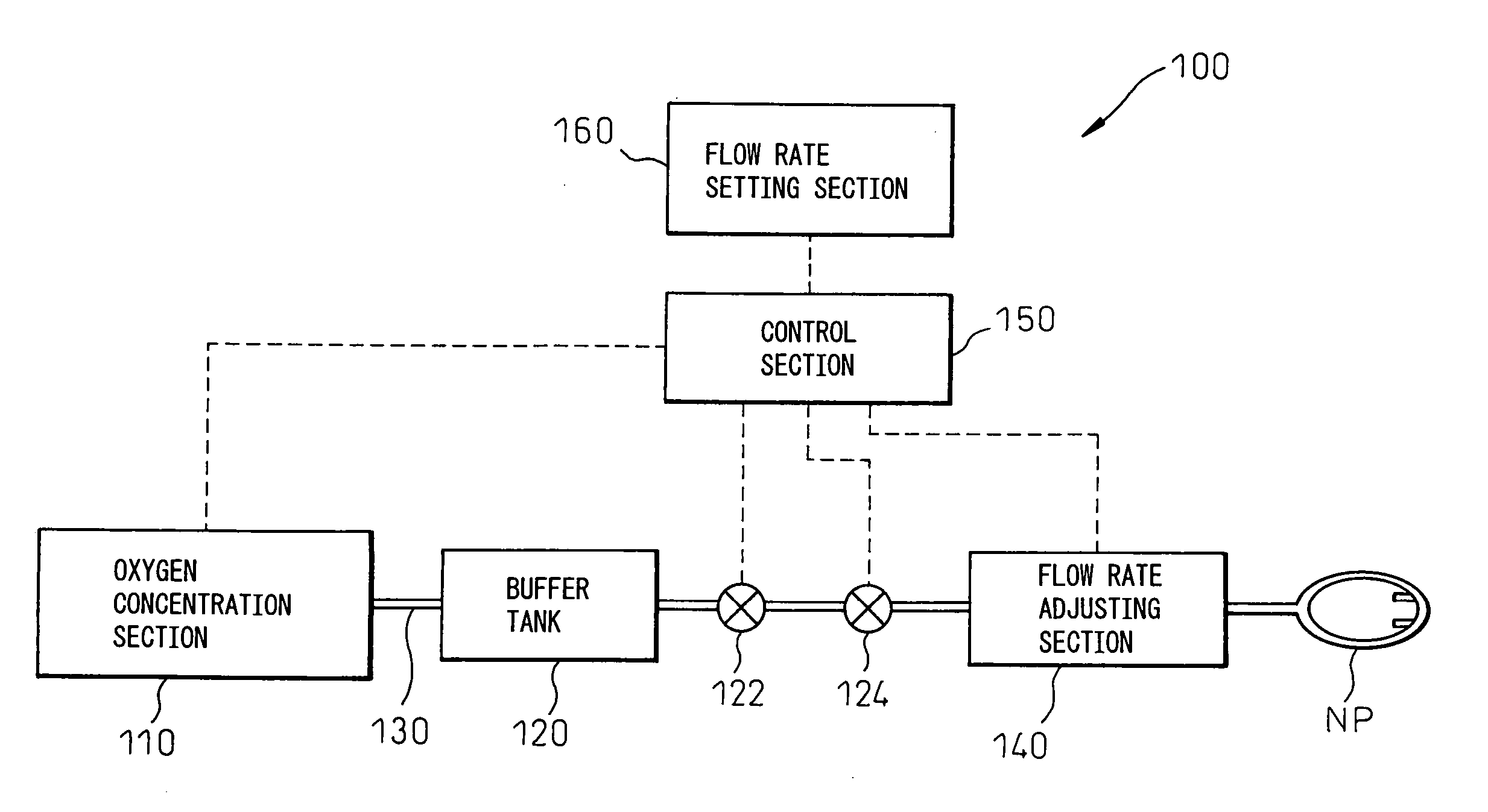

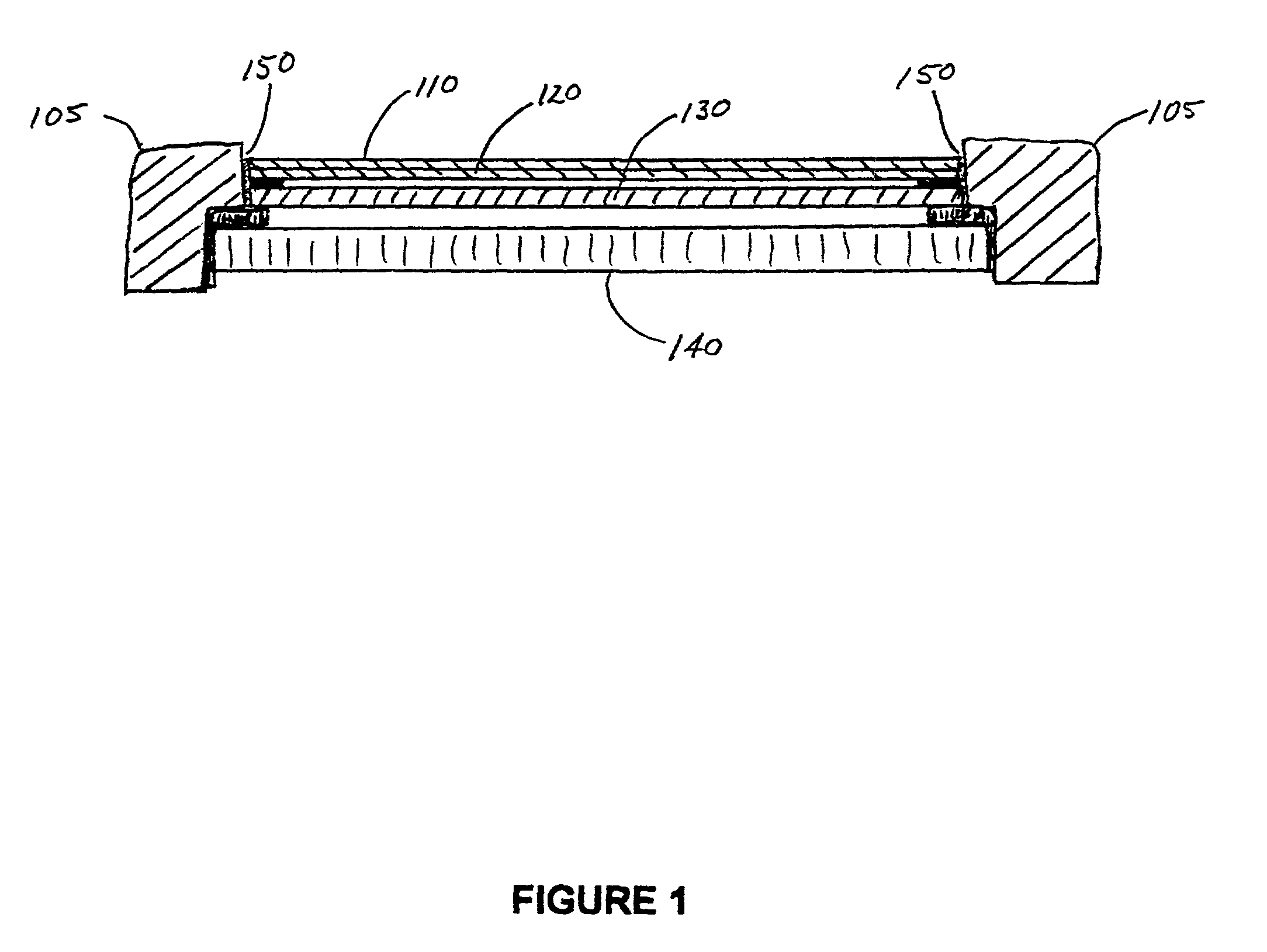

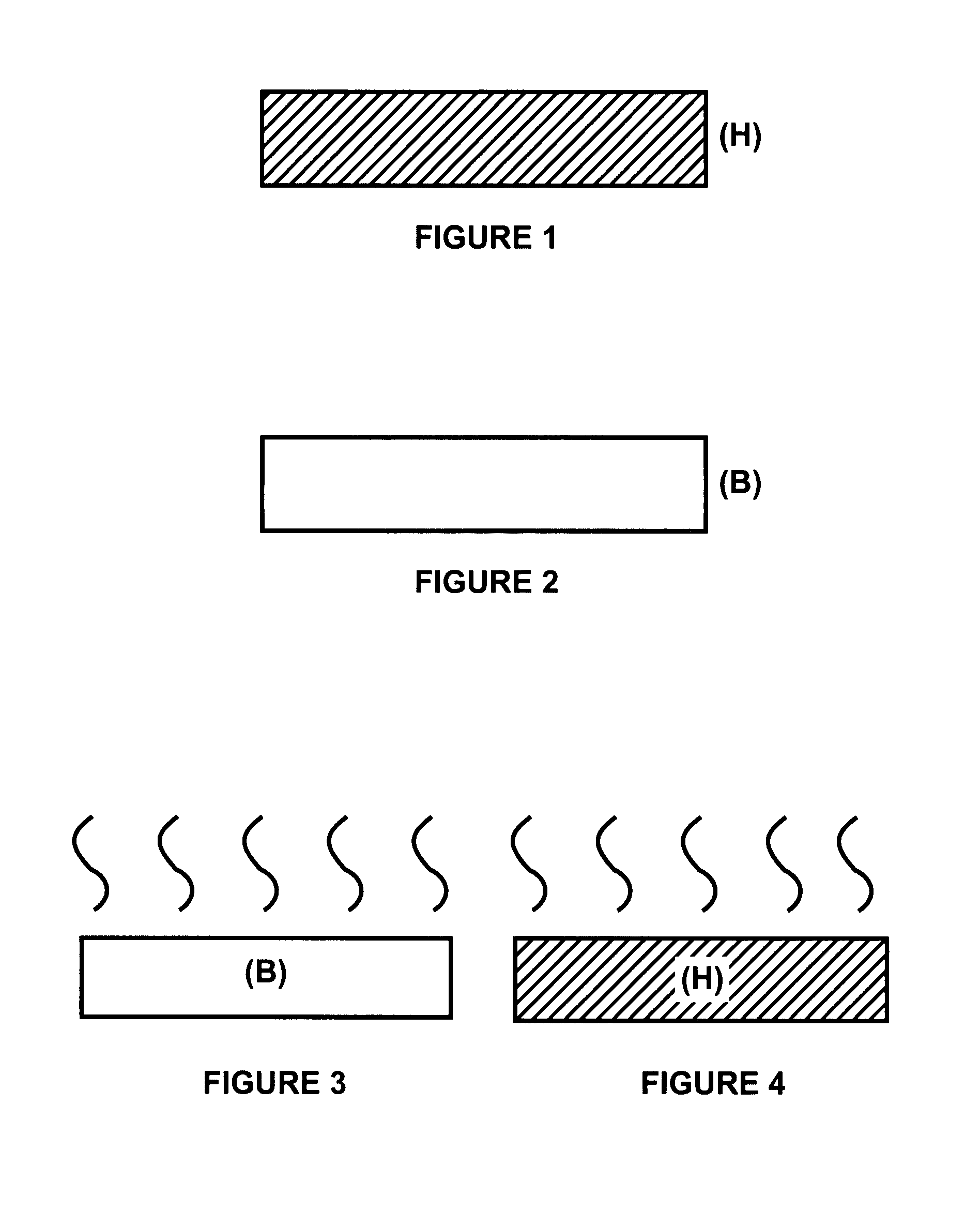

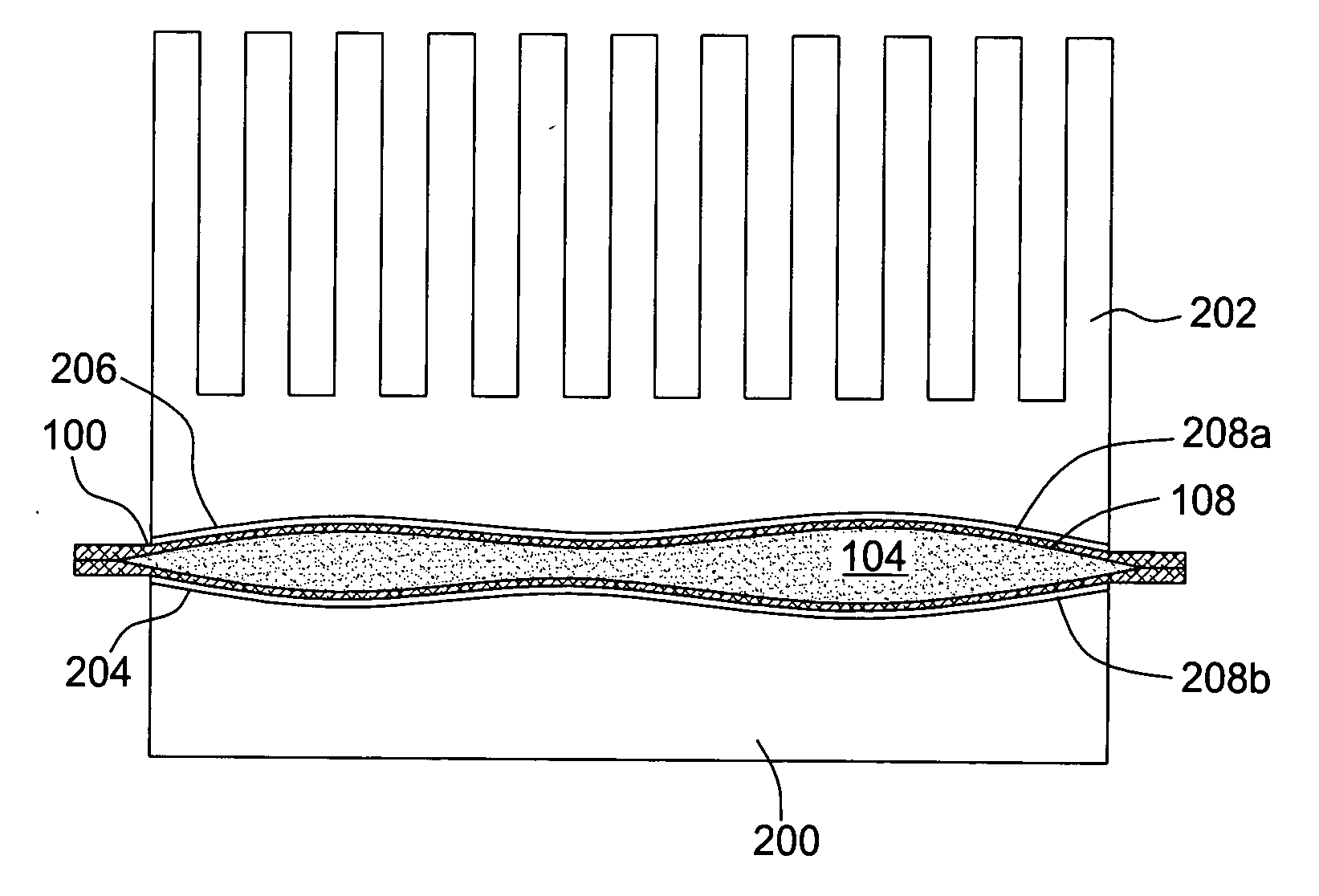

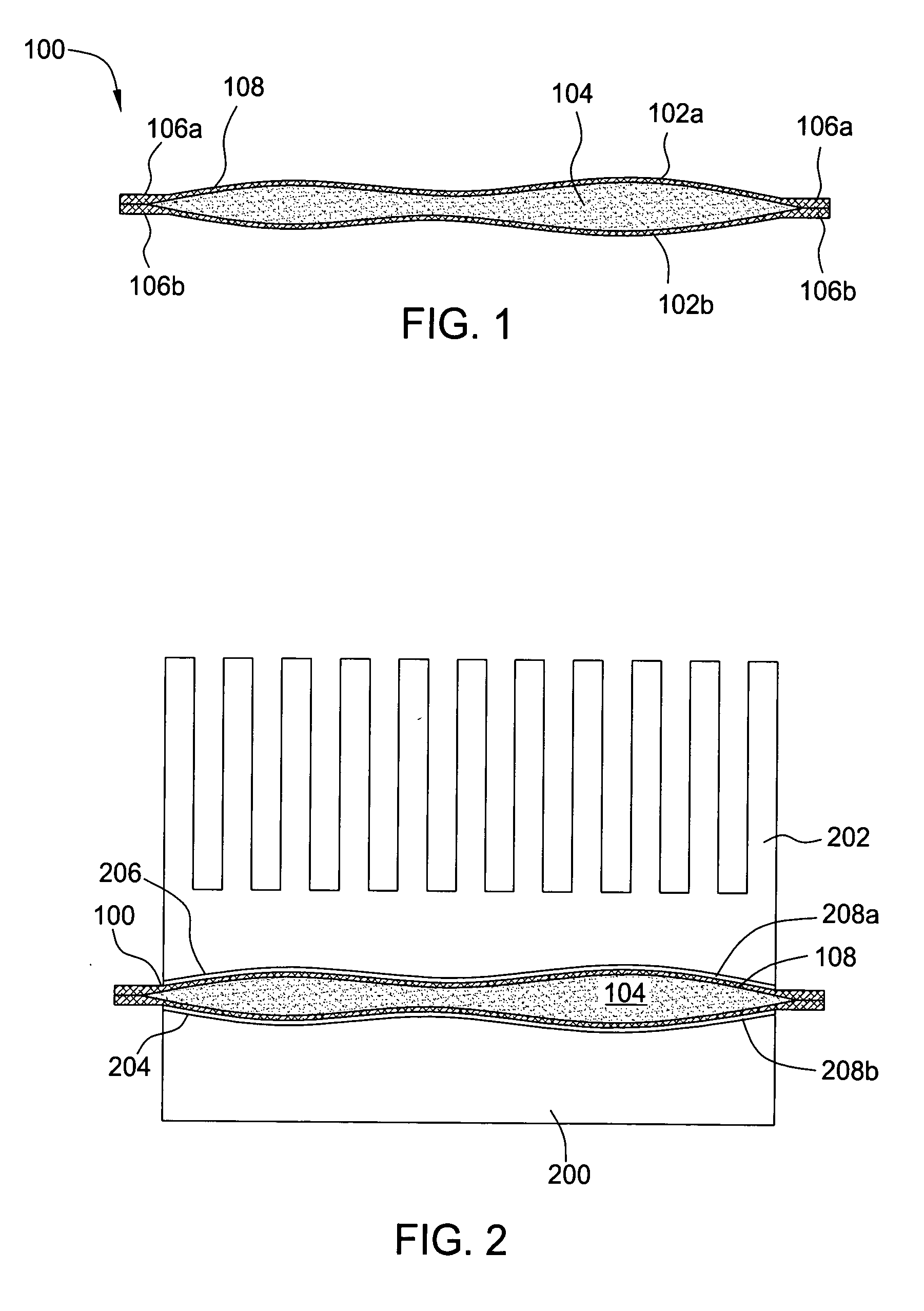

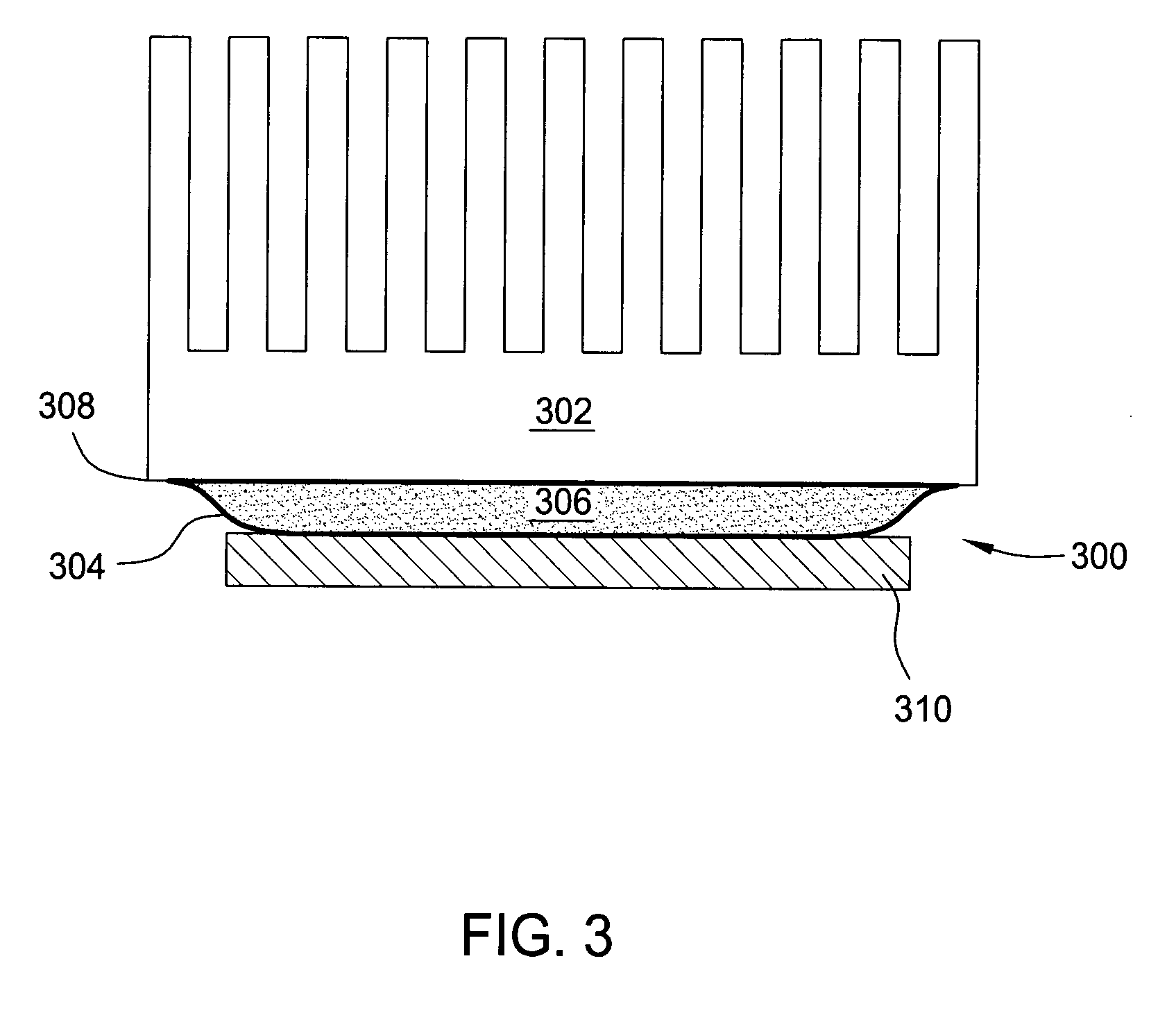

Method and apparatus for chip-cooling

ActiveUS7063127B2Improve heat transfer performanceQuicker and efficient coolingSemiconductor/solid-state device detailsSolid-state devicesMechanical pressureConventional technique

A thermal interface for IC chip cooling is provided. One embodiment of the thermal interface includes a thermally conductive liquid or paste-like metal(s) disposed within a flexible, thermally conductive enclosure. The enclosure is adapted to be placed between an IC chip and a heat sink to enhance heat transfer from the chip to the heat sink, thereby enabling quicker and more efficient cooling of the chip than can be achieved by conventional techniques. In several embodiments, the thermal interface is held in place by mechanical pressure rather than by bonding, which further facilitates inspection and repair of the IC device.

Owner:GLOBALFOUNDRIES U S INC

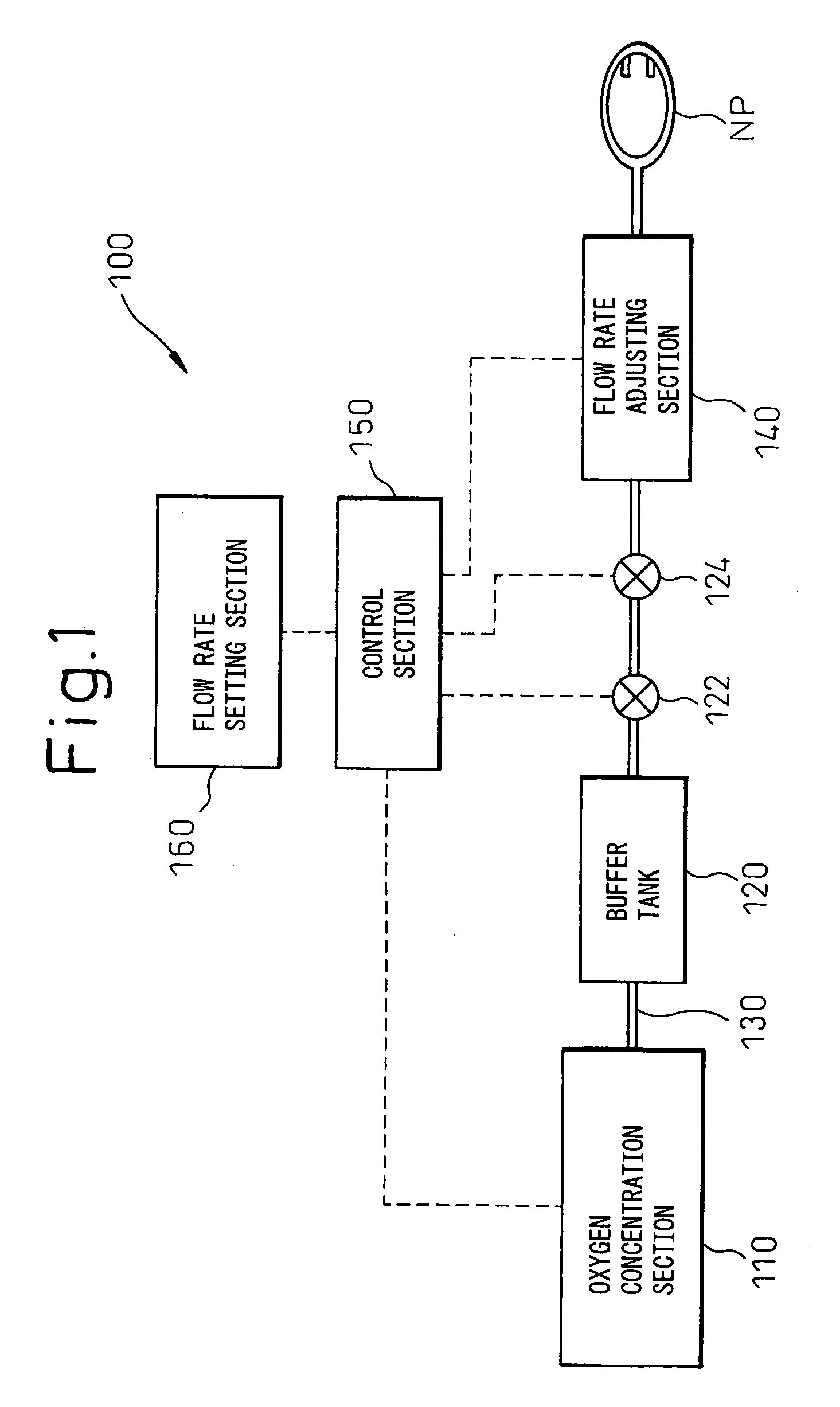

Oxygen concentration apparatus

ActiveUS20070039466A1Accurate measurementReduce weight and sizeGas treatmentMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic sensorProduct gas

An oxygen concentration apparatus (300) according to the present invention has: pressure swing adsorption type oxygen concentration means (310); and a control means (350) that controls switching means (316) that switches between intake of pressurized air into an adsorption column (312) and exhaust from the adsorption column. The switching means is controlled based on pressure in oxygen concentrated gas in the conduit measured by pressure measuring means to adjust a cycle of adsorption and regeneration processes of the oxygen concentration means so that pressure at the upstream of flow rate adjusting means (340) can be controlled and, as a result, the need for a mechanical pressure regulating valve, that has been needed conventionally, can be eliminated. Further, there is also shown a gas supply apparatus that comprises ultrasonic type gas concentration and flow rate measuring means that comprises, in turn, two ultrasonic transducers that is disposed in an opposed manner in the conduit through which product gas flows so that a concentration value measured when the product gas output is stopped is determined to be a product gas concentration.

Owner:TEIJIN LTD

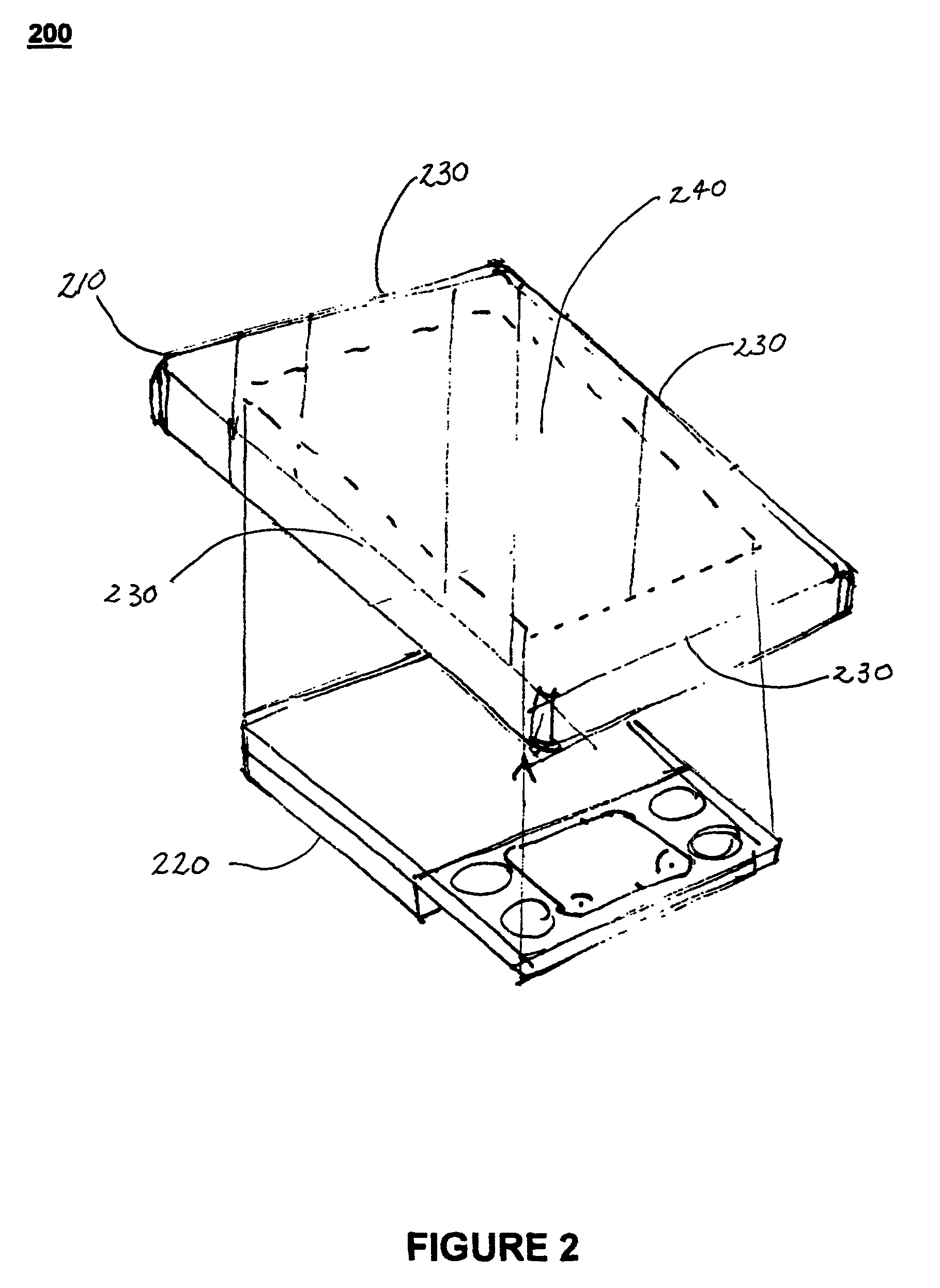

Integrated enclosure/touch screen assembly

InactiveUS8384674B1Moisture and dust free environmentIncreased pressure sensitivityInput/output for user-computer interactionDigital data processing detailsElectrical resistance and conductanceEngineering

An integrated enclosure / touch screen assembly with a soft thermoplastic outer surface coupled directly to a digitizer mechanism. A touch screen assembly consisting of a display mechanism and a resistive digitizer mechanism are enclosed within a single piece cover. The digitizer mechanism consists of a top film and a digitizing element, and the single piece cover is affixed directly to the top film of the digitizer mechanism. The single piece cover has a flat outer surface that is free of any steps or indentations which provides an enclosure that is both dust free and waterproof. The soft thermoplastic material used for the single piece cover will allow activation of the digitizer mechanism by means of mechanical pressure applied to the outer surface of the single piece cover. In one embodiment, the single piece cover is constructed by coupling a soft thermoplastic outer film directly to the top film of the digitizer mechanism by an in mold decoration process. This process forms the flat outer surface for the single piece cover and also may be used to provide various shapes for the outer edges of the cover. In a second embodiment, a touch screen assembly consisting of a display mechanism and a digitizer mechanism are enclosed within a mechanical support mechanism. A soft thermoplastic film is then coupled directly to the top film of the digitizer mechanism and the support mechanism to form a flat outer surface for the entire enclosure that is free of any steps or indentations.

Owner:QUALCOMM INC

Press section and permeable belt in a paper machine

InactiveUS8440055B2Large tensionIncrease the opening areaDrying solid materials with heatDrying solid materials without heatDifferential pressureMechanical pressure

A pressing arrangement including at least one first fabric and second fabric both being permeable. A paper web is disposed between the first fabric and the second fabric. A pressure producing element is in contact with the first fabric. A support surface of a supporting structure is in contact with the second fabric. A differential pressure is provided between the first fabric and the support surface that acts on the first fabric, the paper web, and the second fabric, whereby the paper web is subjected to mechanical pressure and experiences a predetermined hydraulic pressure so as to cause water to be drained from the paper web. The pressing arrangement is structured and arranged to allow air to flow in a direction from the first fabric through the paper web and through the second fabric.

Owner:VOITH PATENT GMBH

Electronic pressure regulating control method of electric pressure cooker

InactiveCN106913201ATo achieve the purpose of maintaining pressureFlexible controlPressure-cookersFailure rateElectronic temperature

A pressure control method of an electronic pressure cooker includes using a temperature sensor to acquire change of the temperature of the cooker according to a relation between the temperature of the cooker and the pressure; converting the change of the temperature into the change of the pressure; and completing control of the pressure of the cooker through a circuit. An electronic temperature sensor is used to replace a mechanical pressure switch, the regulation control is accurate, and the failure rate is low.

Owner:青岛晟通泰电子科技有限公司

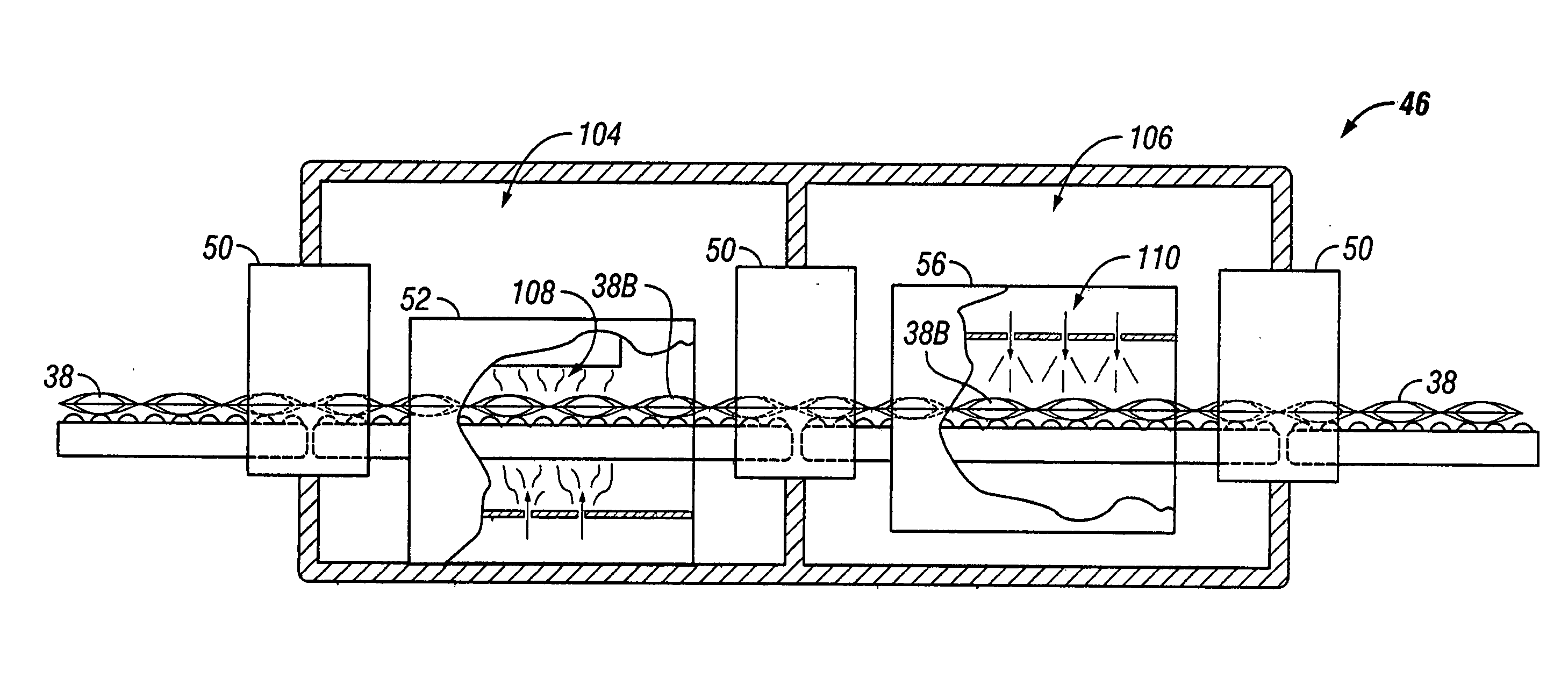

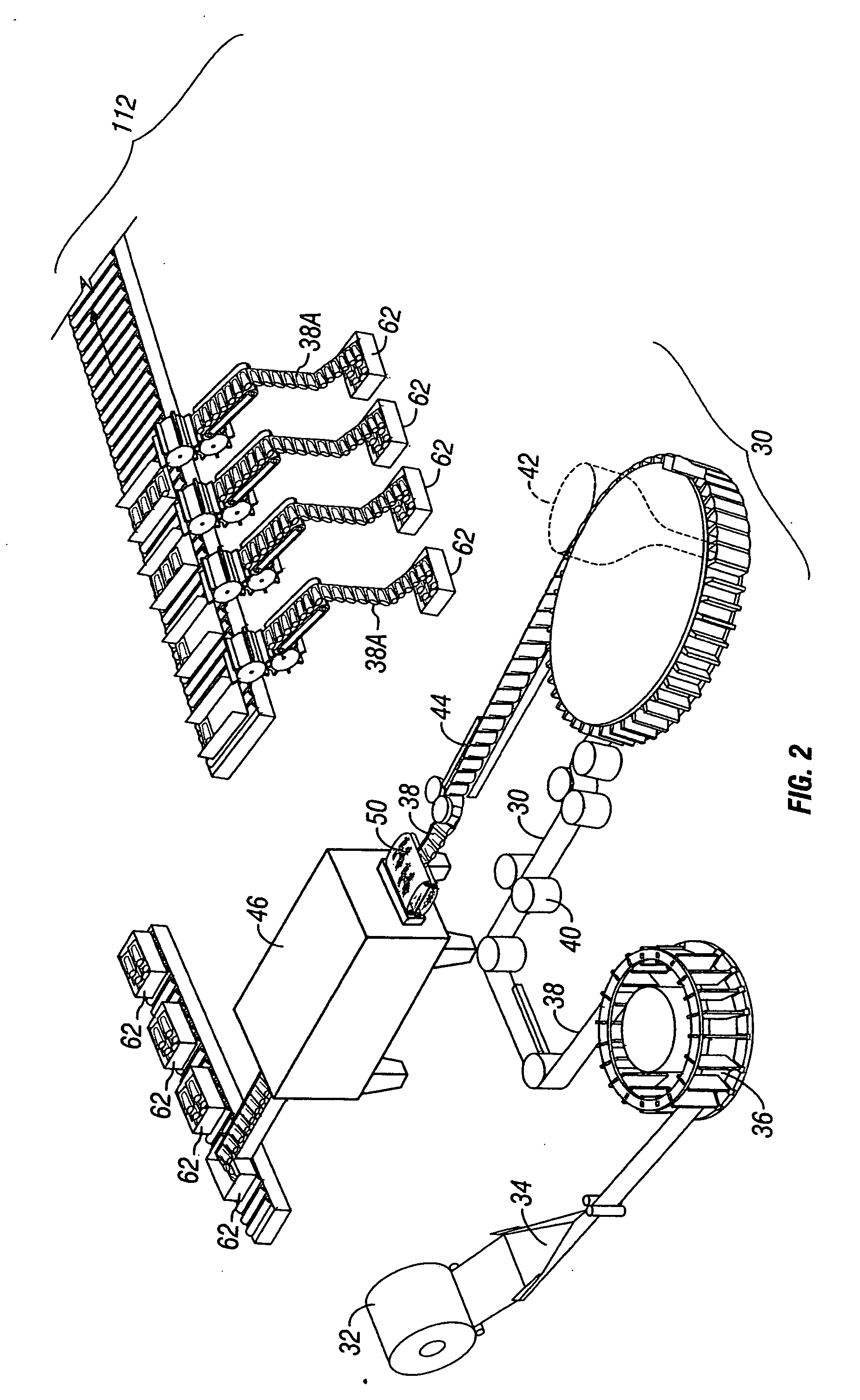

Method and apparatus for continuous processing of packaged products

InactiveUS20050123435A1Increase pressureIncrease temperatureFood preservationPackage sterilisationEngineeringPasteurization

The present invention is directed to a method for the pasteurization and / or sterilization of a continuous web of packages. The method includes the steps of providing a continuous web of individual packages; moving the continuous web through a first mechanical pressure seal into a pressure chamber; applying an increased pressure and temperature; and moving the continuous web through a second mechanical pressure seal out of the pressure chamber. The present invention is also directed to a continuous pressure seal apparatus and an apparatus for the pasteurization and / or sterilization of a continuous web of flexible packages. The apparatus includes a first mechanical continuous feeding pressure seal; a pressure chamber; and a second mechanical continuous feeding pressure seal. The first pressure seal is adjacent to an entry to the pressure chamber and the second pressure seal is adjacent to an exit of the pressure chamber.

Owner:MARS INC

Method and structure for fabricating solar cells using a layer transfer process

InactiveUS7759220B2Easy to disassembleImprove bindingSemiconductor/solid-state device manufacturingSemiconductor devicesSolar cellMechanical pressure

A reusable silicon substrate device for use with layer transfer process. The device has a reusable substrate having a surface region, a cleave region, and a total thickness of material. The total thickness of material is at least N times greater than a first thickness of material to be removed. In a specific embodiment, the first thickness of material to be removed is between the surface region and the cleave region, whereupon N is an integer greater than about ten. The device also has a chuck member adapted to hold a handle substrate member in place. The chuck member is configured to hold the handle substrate in a manner to facilitate bonding the handle substrate to the first thickness of material to be removed. In a preferred embodiment, the device has a mechanical pressure device operably coupled to the chuck member. The mechanical pressure device is adapted to provide a force to cause bonding of the handle substrate to the first thickness of material to be removed.

Owner:SILICON GENERAL CORPORATION

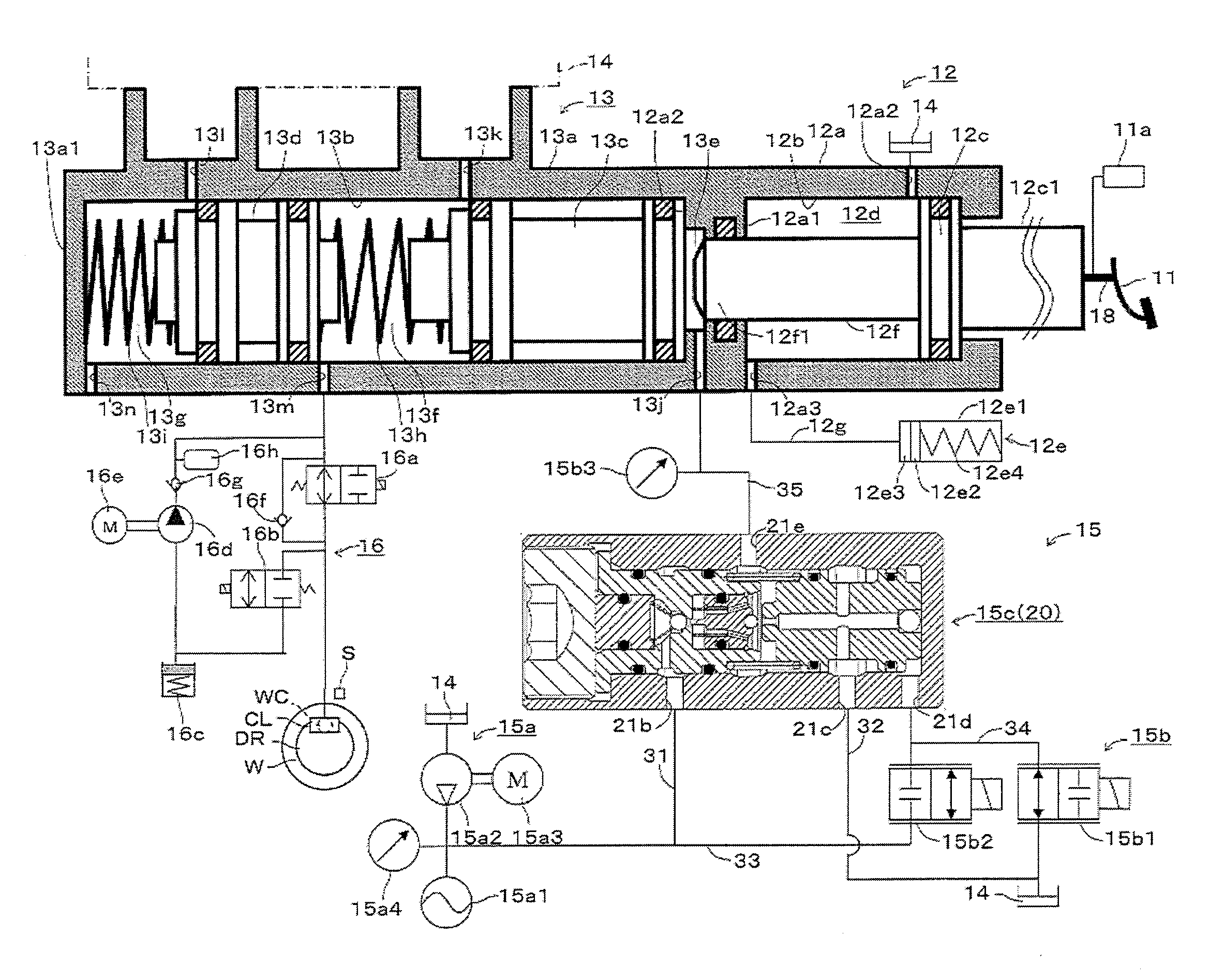

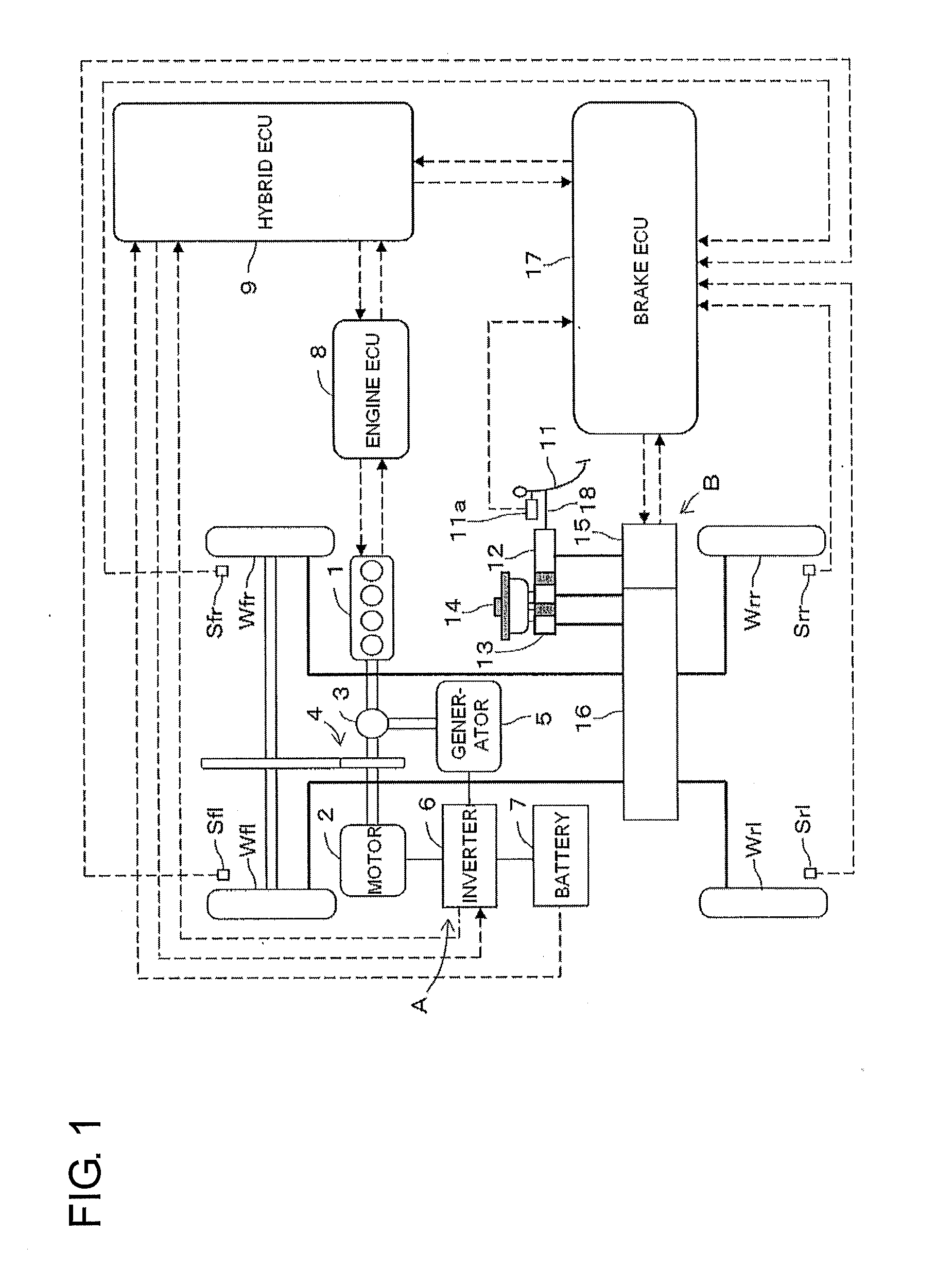

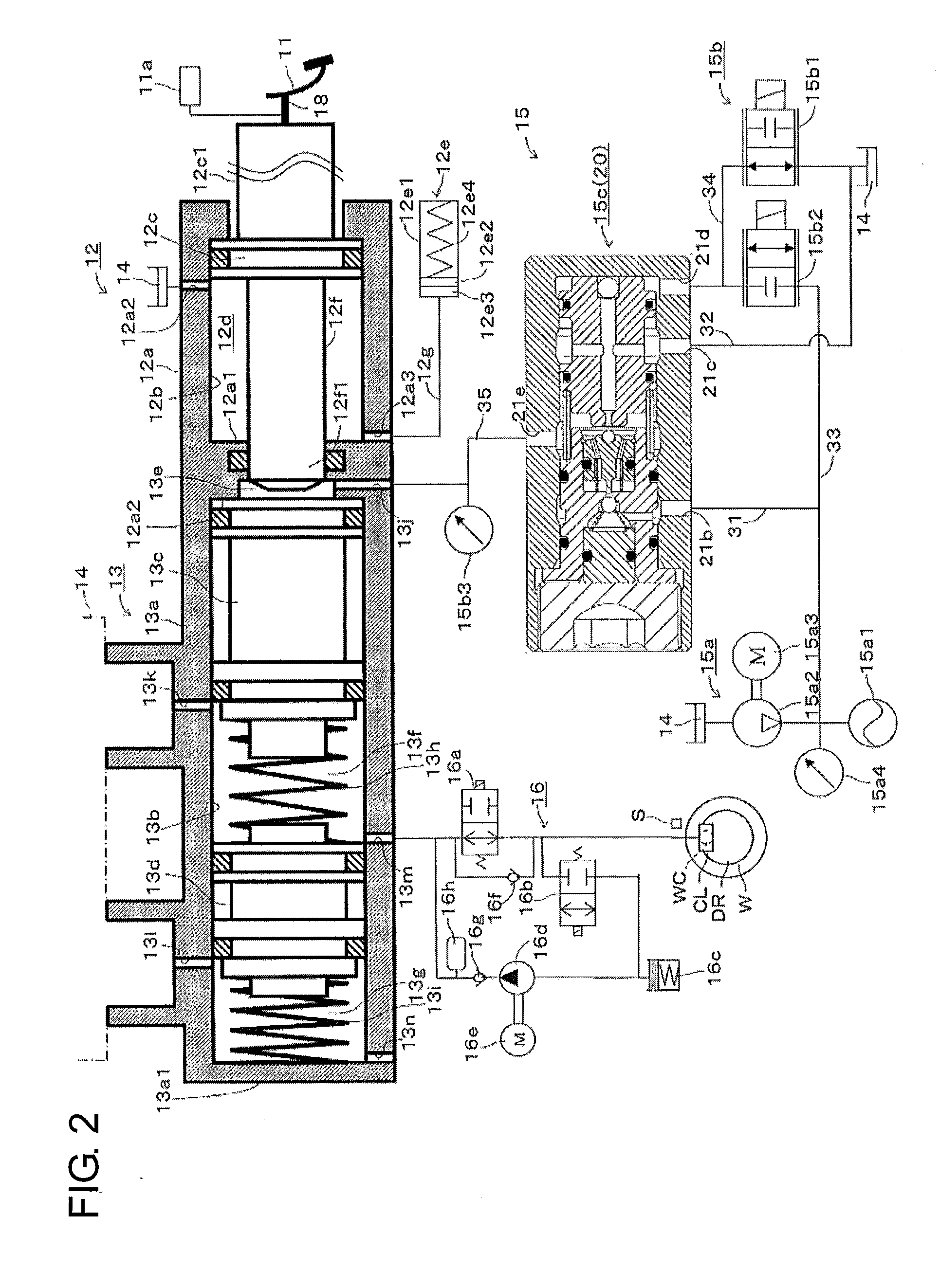

Brake device

InactiveUS20110285199A1Sufficient forceImprove responseBraking action transmissionGas pressure propulsion mountingEngineeringControl valves

A brake device includes: a mechanical pressure regulating part having a high-pressure port, a low-pressure port, a pilot pressure input port, and an output port which outputs fluid pressure corresponding to the pressure supplied to the pilot pressure input port by fluid pressures supplied to both of the high- and low-pressure ports, to a chamber for a master piston; a high-pressure source connected to the high-pressure port and the pilot pressure input port; a low-pressure source connected to the low-pressure port and the pilot pressure input port; and an electrically-operated pilot pressure generating part which includes control valves for controlling flows of the brake fluid between the high-pressure source and the pilot pressure input port, and between the low-pressure source and the pilot pressure input port, respectively, and which outputs desired fluid pressure to the pilot pressure input port by controlling flow of the brake fluid with control valves.

Owner:ADVICS CO LTD

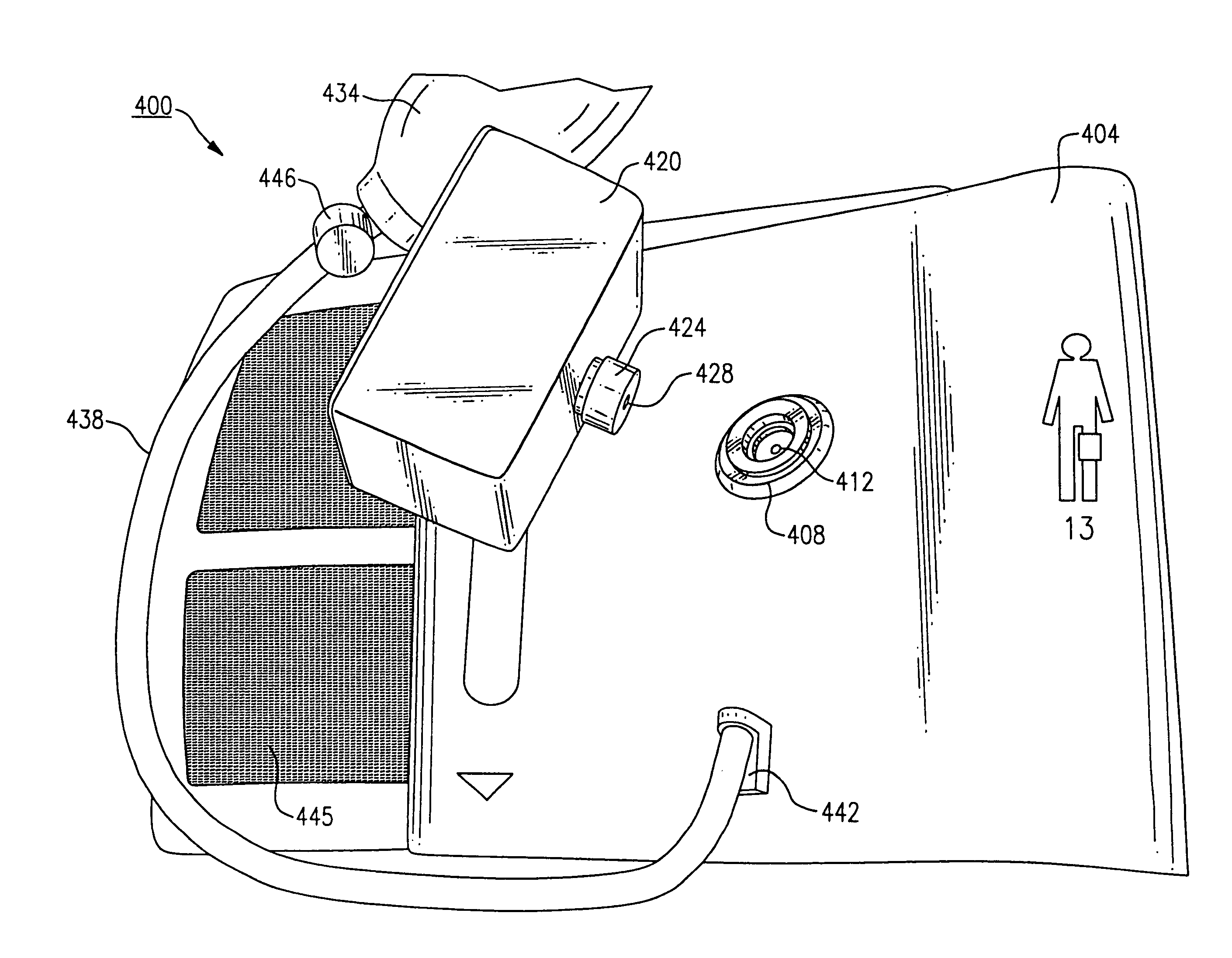

Blood pressure measuring apparatus

InactiveUS7722542B2Blood pressure measurementEasy to carryFluid pressure measurement by electric/magnetic elementsEvaluation of blood vesselsCouplingDisplay device

A blood pressure measuring apparatus includes an inflatable sleeve socket that is capable of receiving an engagement portion of a compact gage housing having either a contained mechanical or an electronic pressure gauge. This coupling permits direct attachment to the sleeve and permitting fluid interconnection between the interior of the sleeve and the contained pressure gauge without requiring any hoses or tubing therebetween. The electronic pressure gauge is responsive to changes in pressure within the inflatable sleeve. The pressure changes can be processed and output to an integral display or can be wirelessly transmitted.

Owner:WELCH ALLYN INC

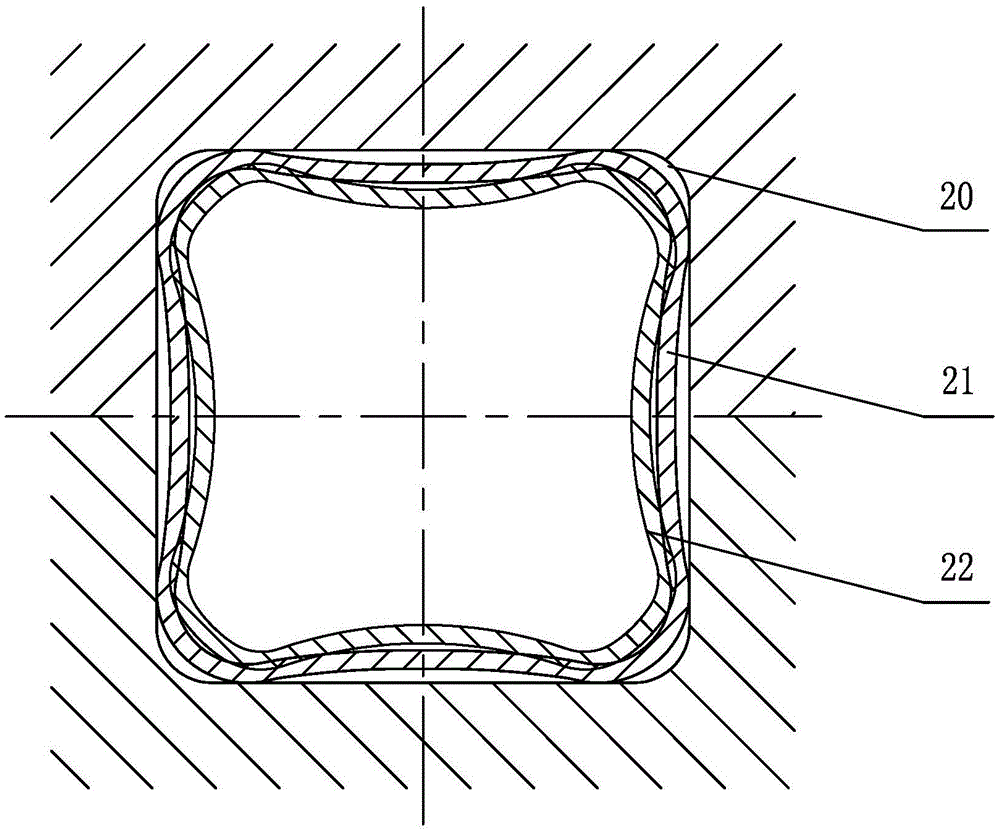

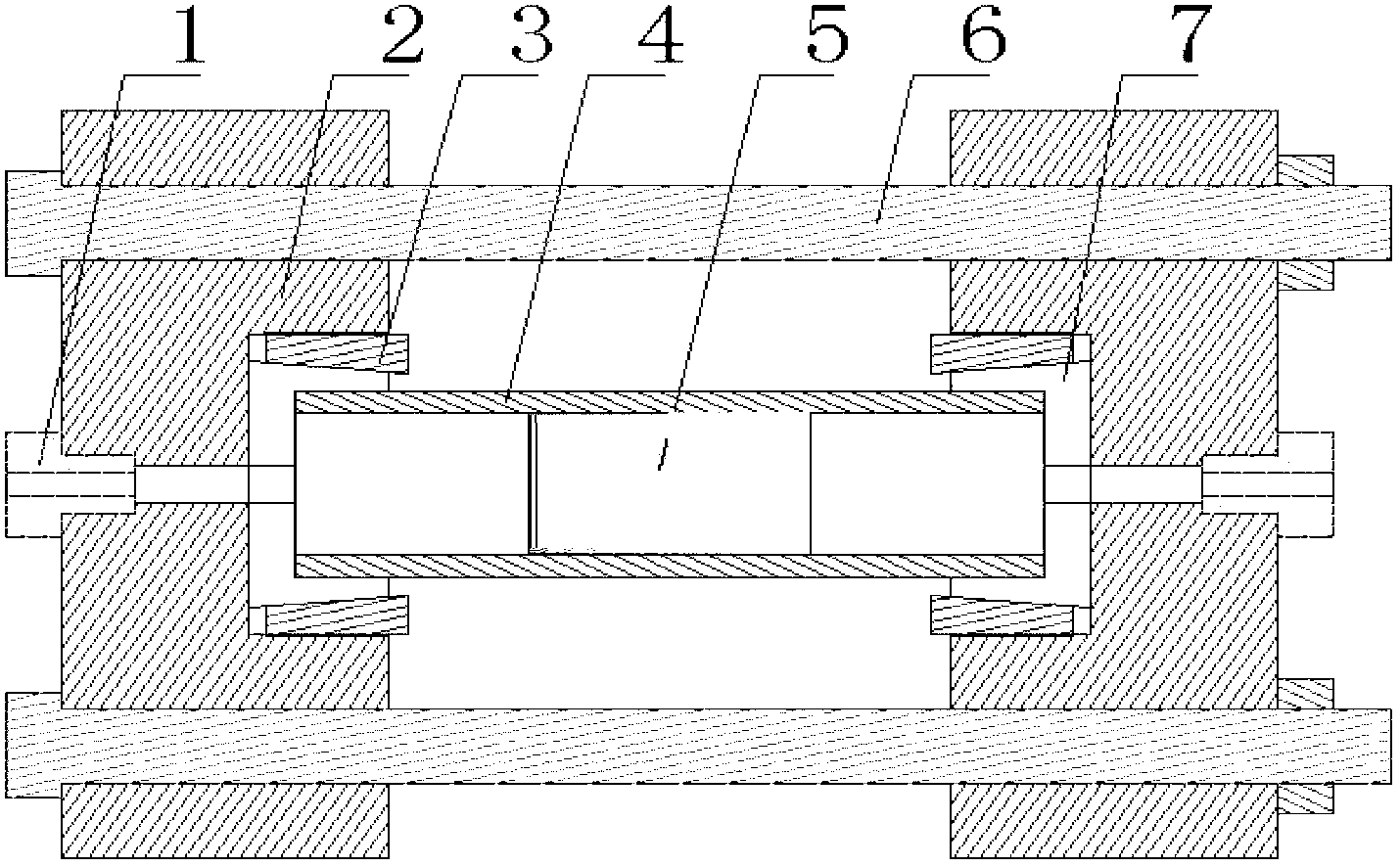

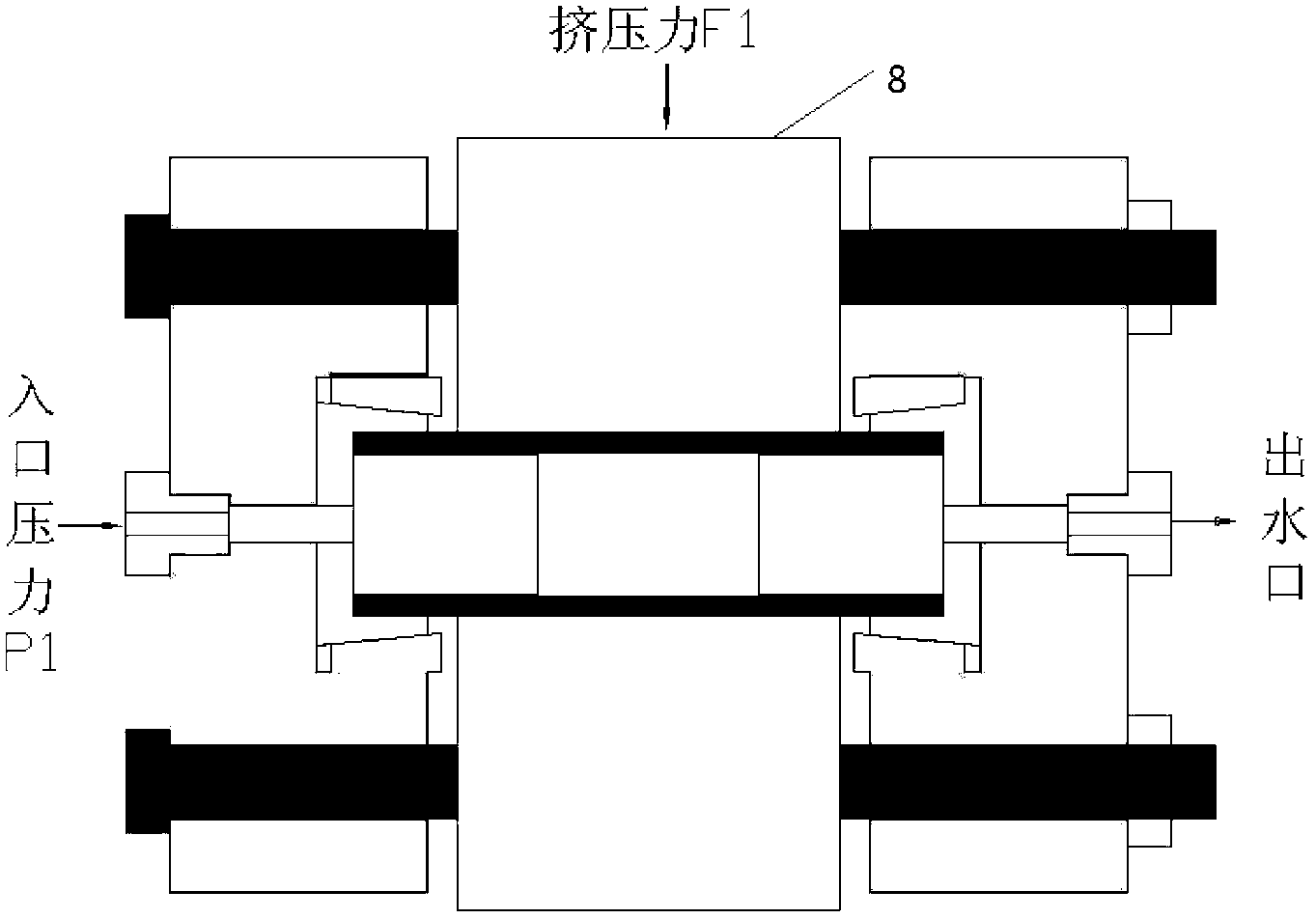

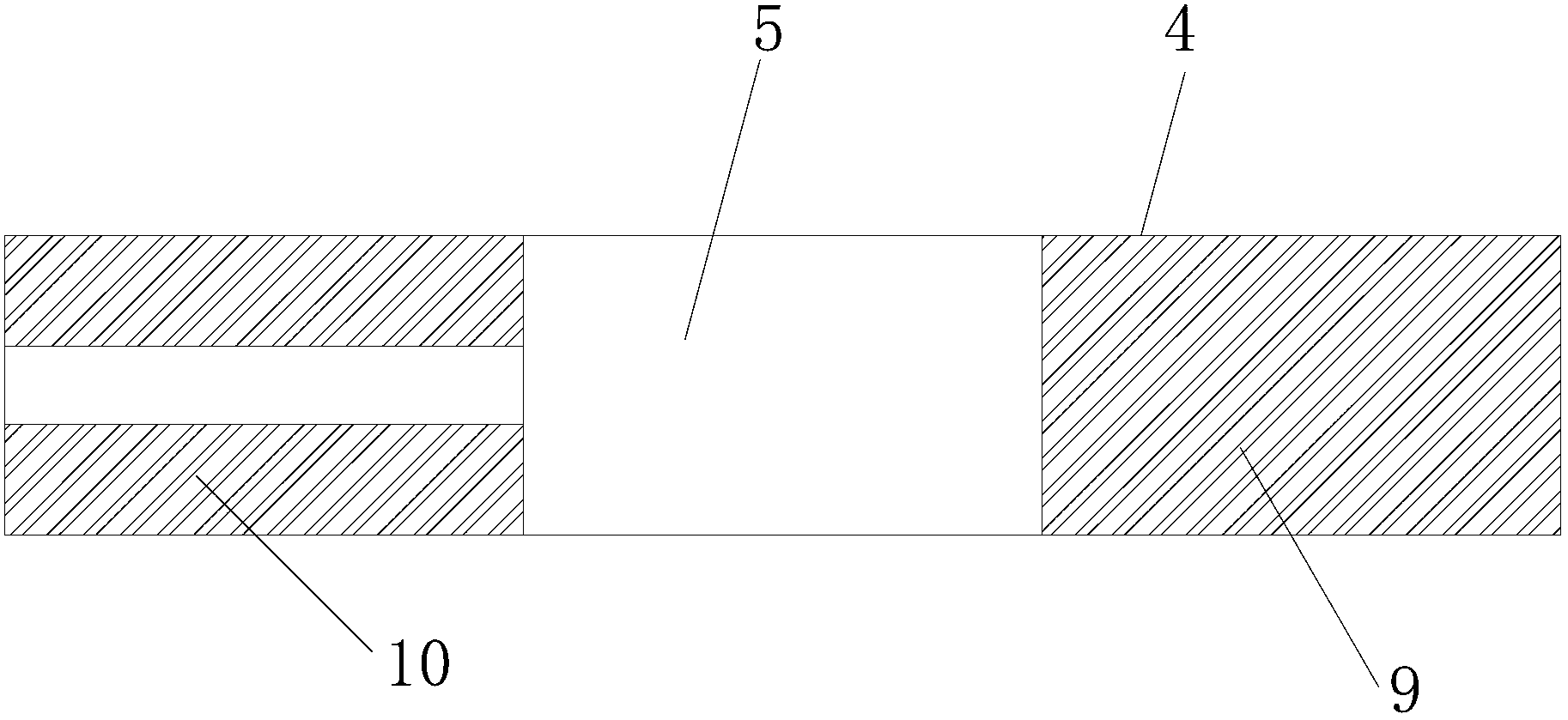

Charging pressing forming method for variable-cross-section special-shaped pipe

The invention discloses a charging pressing forming method for a variable-cross-section special-shaped pipe, and relates to a forming manufacturing method of a metal pipe. The problems that an existing low-internal-pressure forming technology only can form a pipe with the unchangeable section perimeter, and meanwhile, in the internal-high-pressure forming process of an advanced high-strength steel variable-cross-section pipe, the pressure is high, springback is large, and a mold is seriously worn are solved. The forming method comprises the steps that firstly, an upper expansion mold and a lower expansion mold are assembled on a pressure machine; secondly, the upper expansion mold descends to perform mold assembly, a pipe blank is subject to charging, and the pipe blank expands until the pipe blank is attached to the mold; thirdly, the internal pressure of the pipe blank is relieved; fourthly, an upper pressing block and a lower pressing mold are assembled on a pressure machine; fifthly, the upper pressing block descends to perform mold assembly; sixthly, under the joint action of mechanical pressure of the mold and hydraulic pressure of an inner cavity of a variable-cross-section round pipe, mold attaching is carried out, the variable-cross-section round pipe is formed into the variable-cross-section special-shaped pipe, and the forming process is finished; and seventhly, the internal pressure of the variable-cross-section special-shaped pipe is relieved, and the variable-cross-section special-shaped pipe is cut, so that the variable-cross-section special-shaped pipe meeting the design requirement is obtained. The method is used for forming the variable-cross-section special-shaped pipe.

Owner:HARBIN INST OF TECH

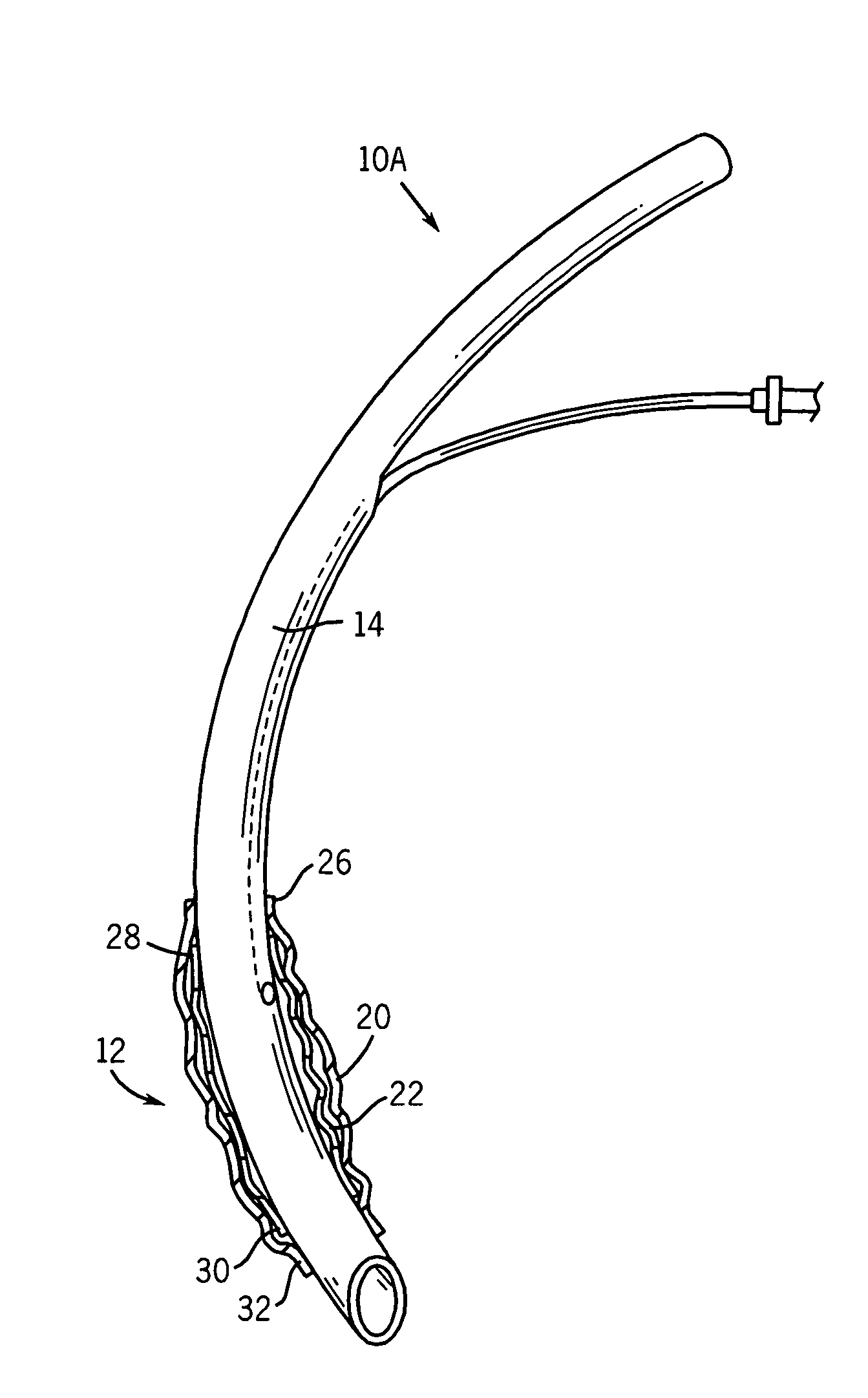

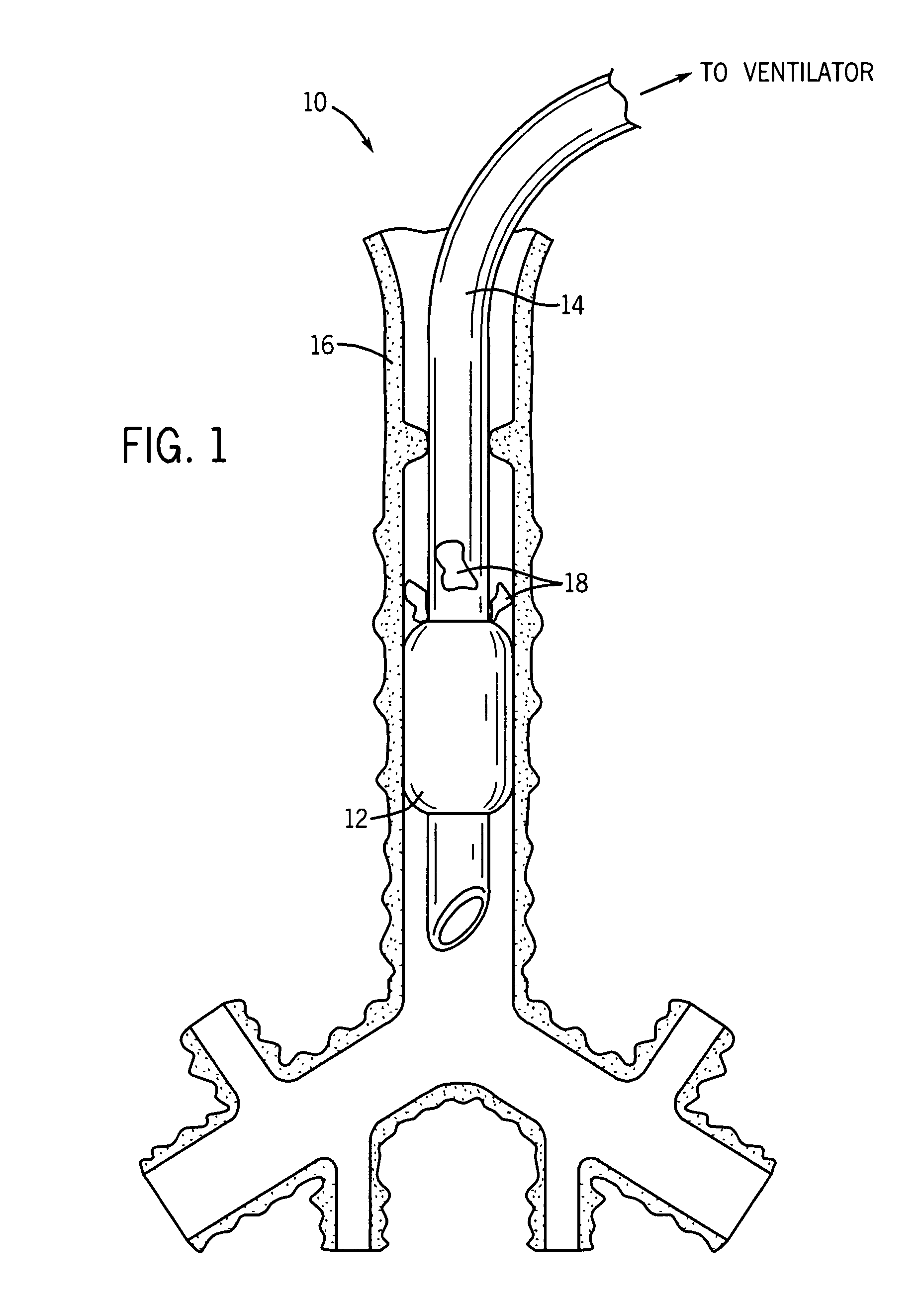

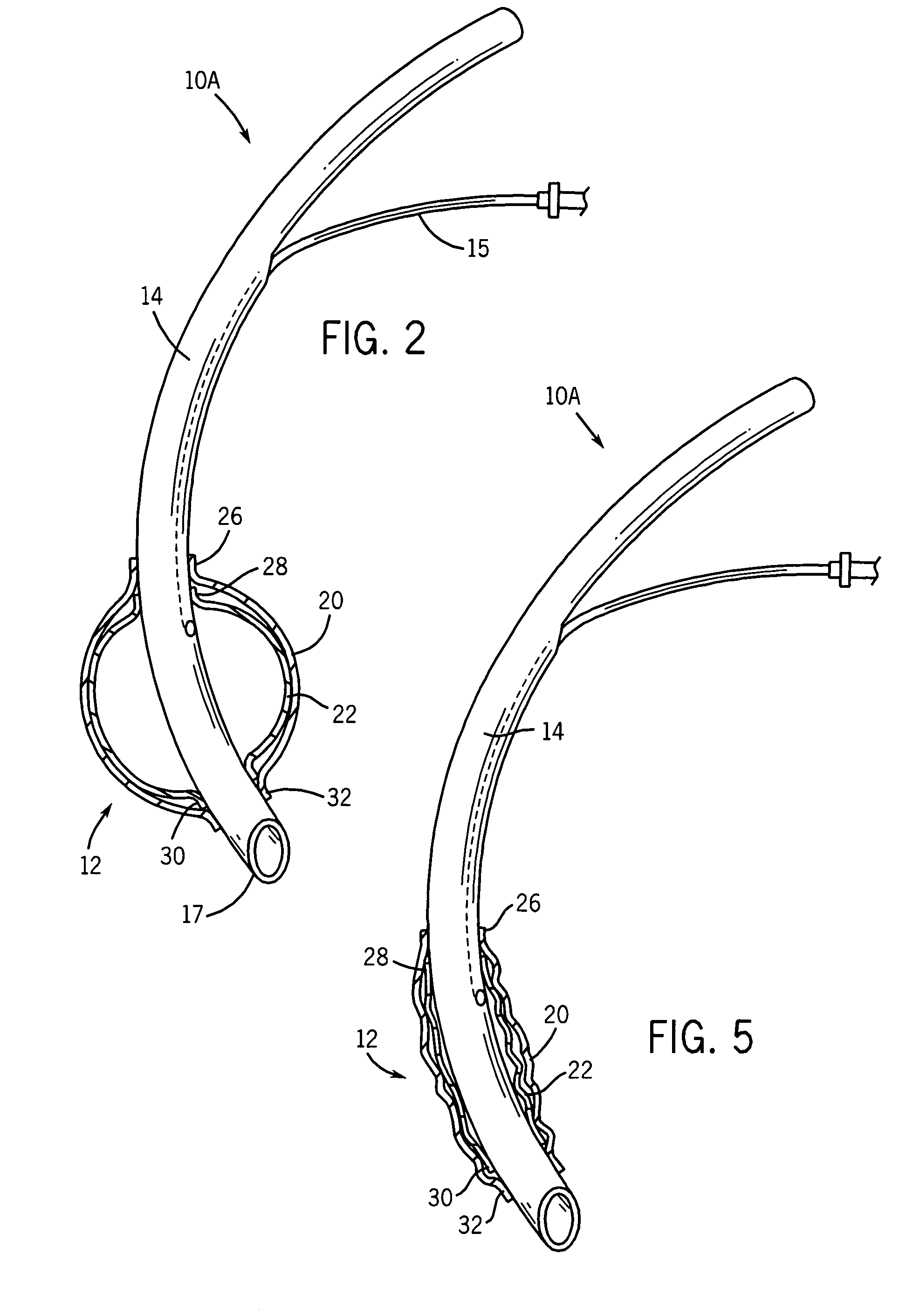

Endotracheal cuff and technique for using the same

A multi-layer inflatable balloon cuff may be adapted to seal a patient's trachea when associated with an endotracheal tube. The outer layer and the inner layer of the balloon cuff may have different material properties that may enhance a cuff's mechanical pressure seal by reducing wrinkles or folds that may form against a patient's tracheal walls.

Owner:TYCO HEALTHCARE GRP LP

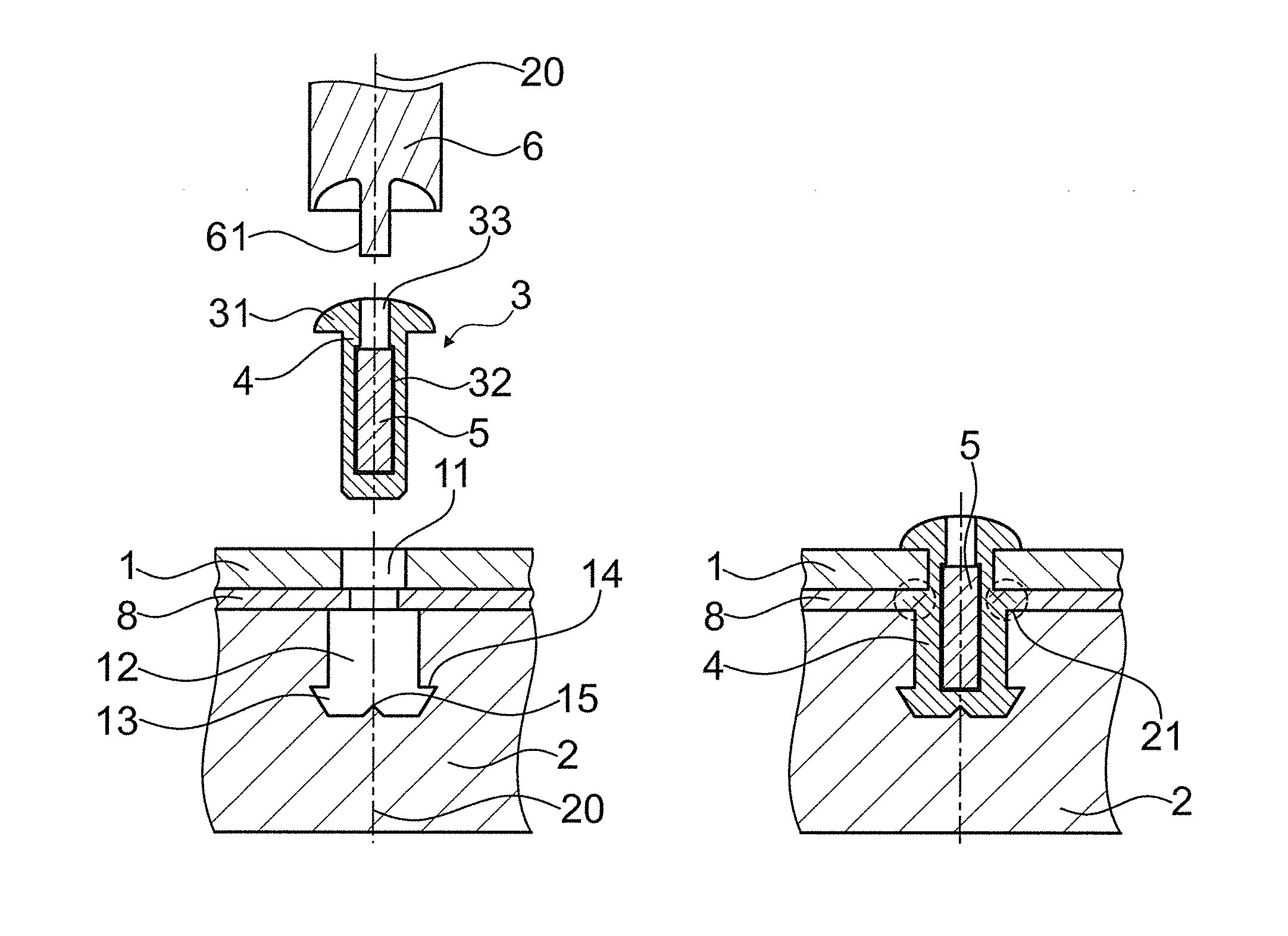

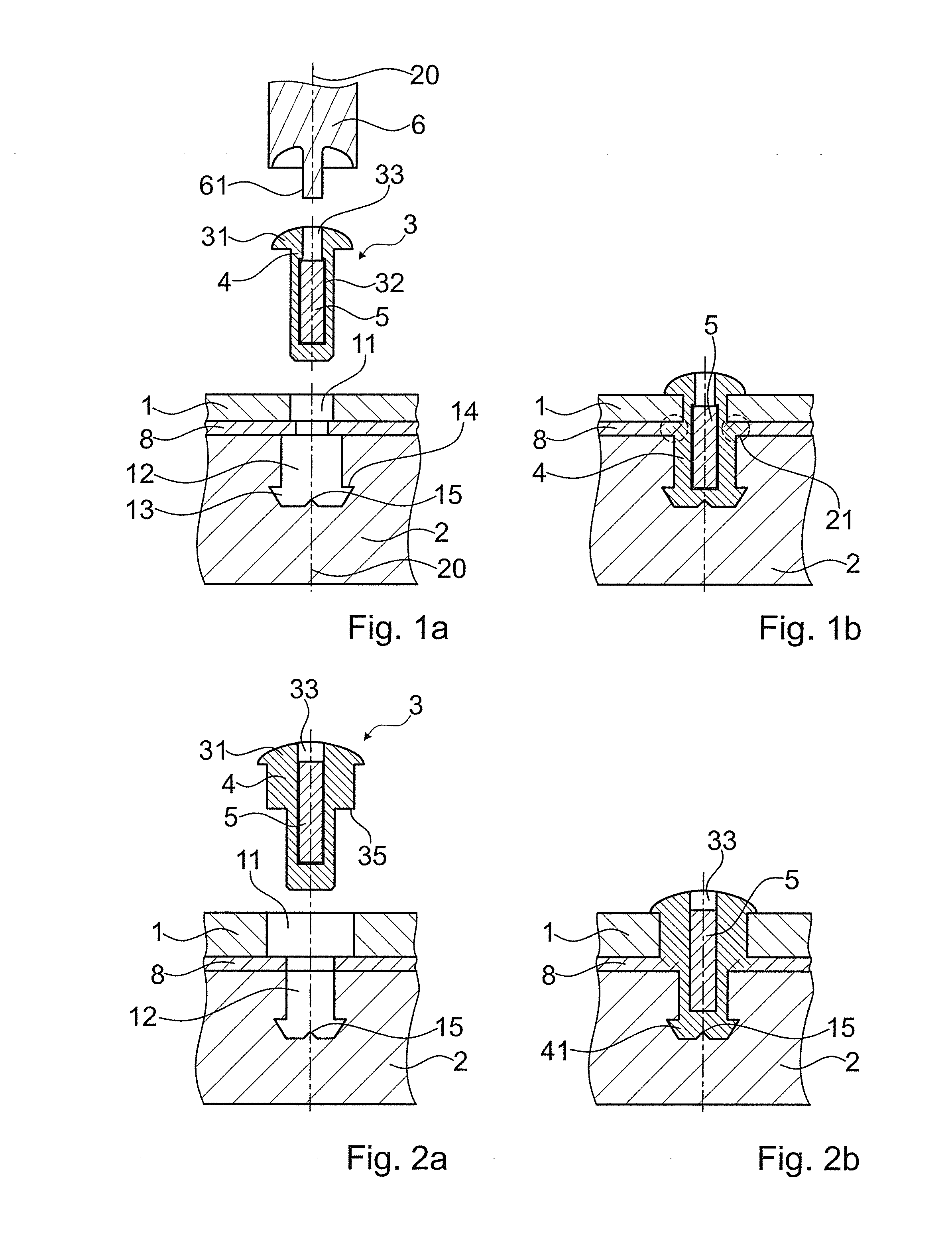

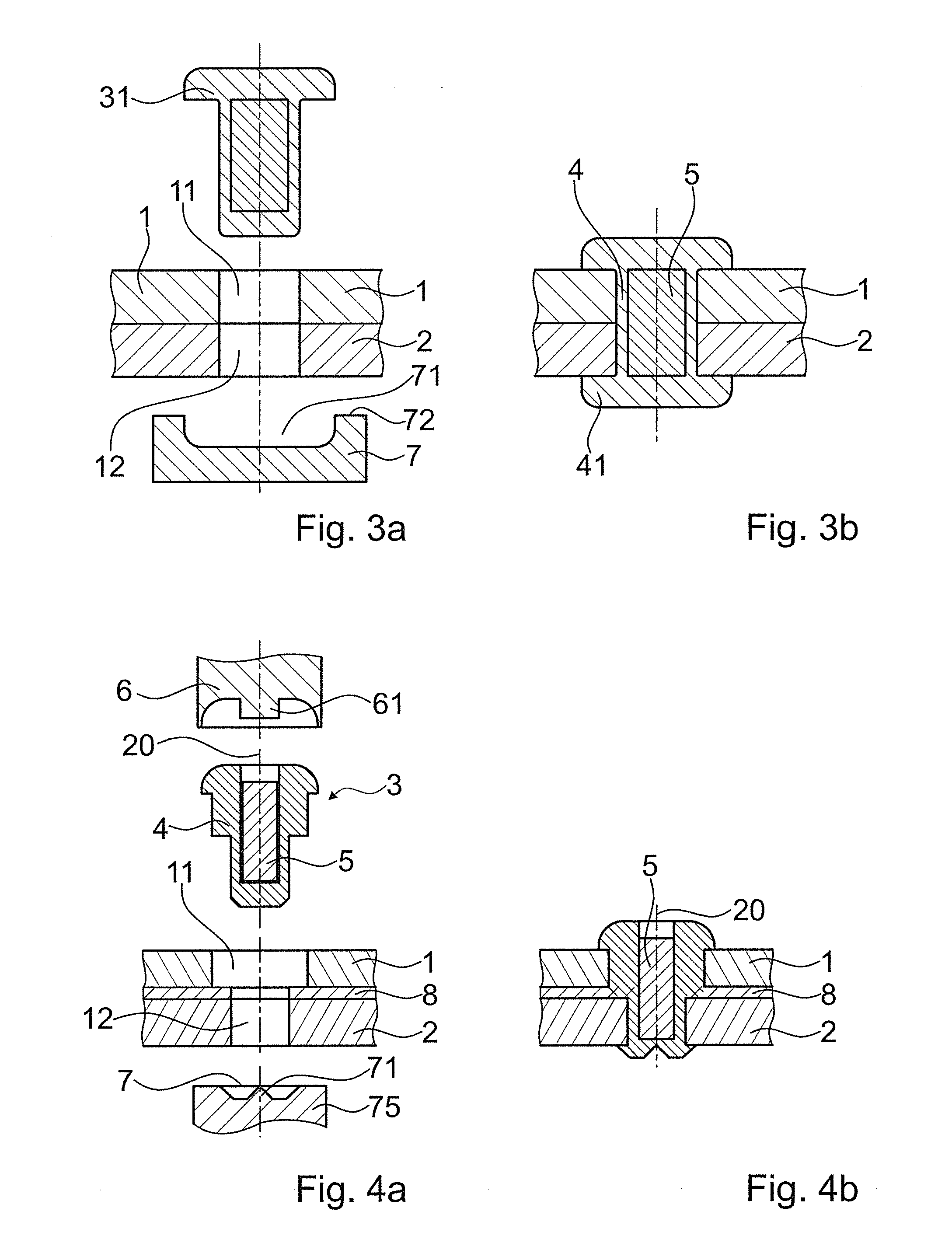

Bonding objects together

ActiveUS20160341234A1Improve shear resistanceImprove ductilityMaterial gluingSheet joiningEngineeringMechanical pressure

A method of bonding a connector to a first object includes providing the connector, the connector being separate from the first object and including a thermoplastic material; arranging the first object and the connector relative to one another so that the connector reaches from a proximal side of the object through a first opening in the object; generating and applying vibrations and mechanical pressure to the connector until a flow portion of the thermoplastic material is liquefied and caused to flow sideways radially into an open space; and removing the source of the vibrations and causing the liquefied thermoplastic material to re-solidify, resulting in the connector with a foot portion, a head portion, and a shaft portion between the foot portion and the head portion. The shaft portion extends along an axis through the first opening, and secures the connector to the first object.

Owner:WOODWELDING

Implantable mechanical pressure sensor and method of manufacturing the same

InactiveUS20050268722A1Fluid pressure measurement using elastically-deformable gaugesCatheterIn planeParylene

A biocompatible, mechanical, micromachined pressure sensor and methods of manufacturing such a pressure sensor are provided. The pressure sensor of the current invention comprises a high-aspect-ratio curved-tube structure fabricated through a one-layer parylene process. The pressure sensor of the current invention requires zero power consumption and indicates the pressure variation by changes of the in situ in-plane motion of the sensor, which can be gauged externally by a direct and convenient optical observation. In one embodiment, the pressure sensor of the current invention has been shown to work as an IOP sensor for eye implantation where the intraocular in-plane motion of the sensor can be recorded from outside of the eye, such that the intraocular pressure in glaucoma patients can be constantly monitored.

Owner:CALIFORNIA INST OF TECH

Method and apparatus for chip-cooling

ActiveUS20050061474A1Improve heat transfer performanceQuicker and efficient coolingSemiconductor/solid-state device detailsSolid-state devicesMechanical pressureIc devices

The present invention is a thermal interface for IC chip cooling. One embodiment of the invention comprises a thermally conductive liquid or paste-like metal(s) disposed within a flexible, thermally conductive enclosure. The enclosure is adapted to be placed between an IC chip and a heat sink to enhance heat transfer from the chip to the heat sink, thereby enabling quicker and more efficient cooling of the chip than can be achieved by conventional techniques. In several embodiments, the thermal interface is held in place by mechanical pressure rather than by bonding, which further facilitates inspection and repair of the IC device.

Owner:GLOBALFOUNDRIES US INC

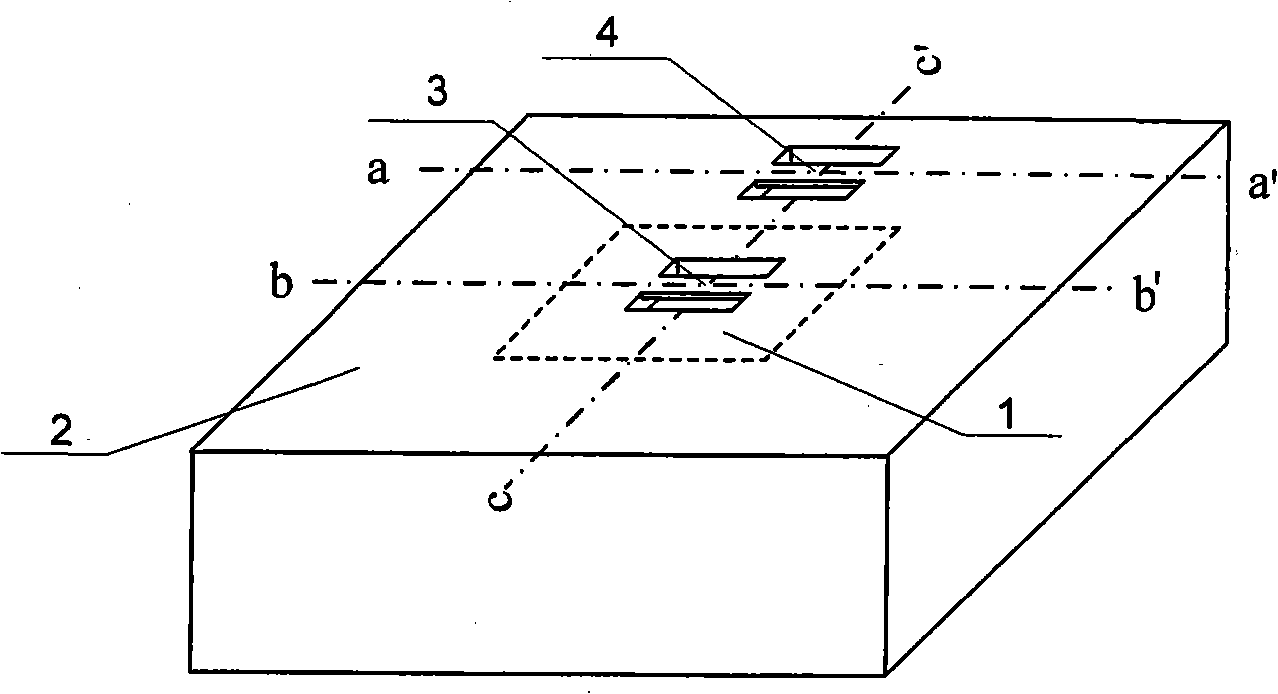

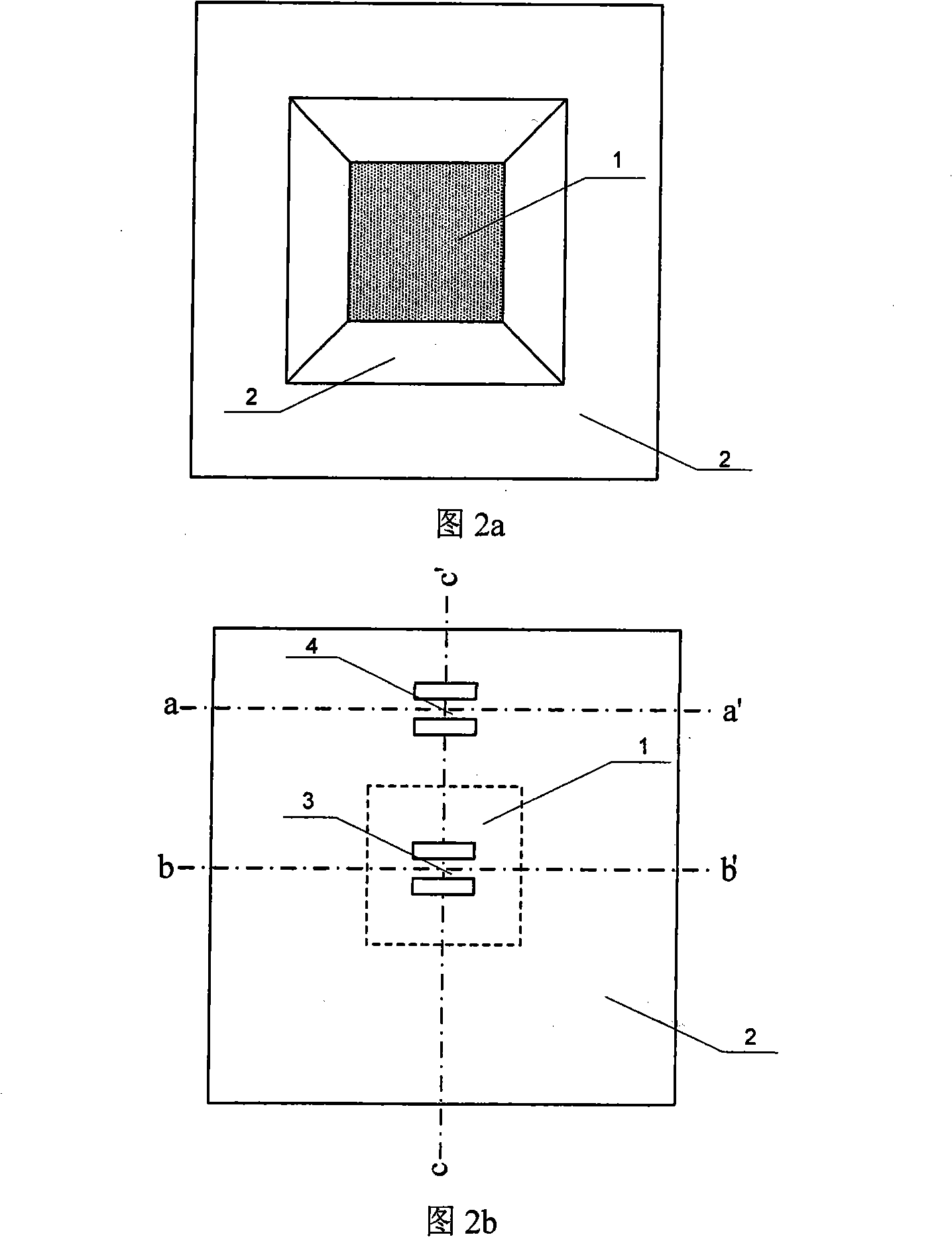

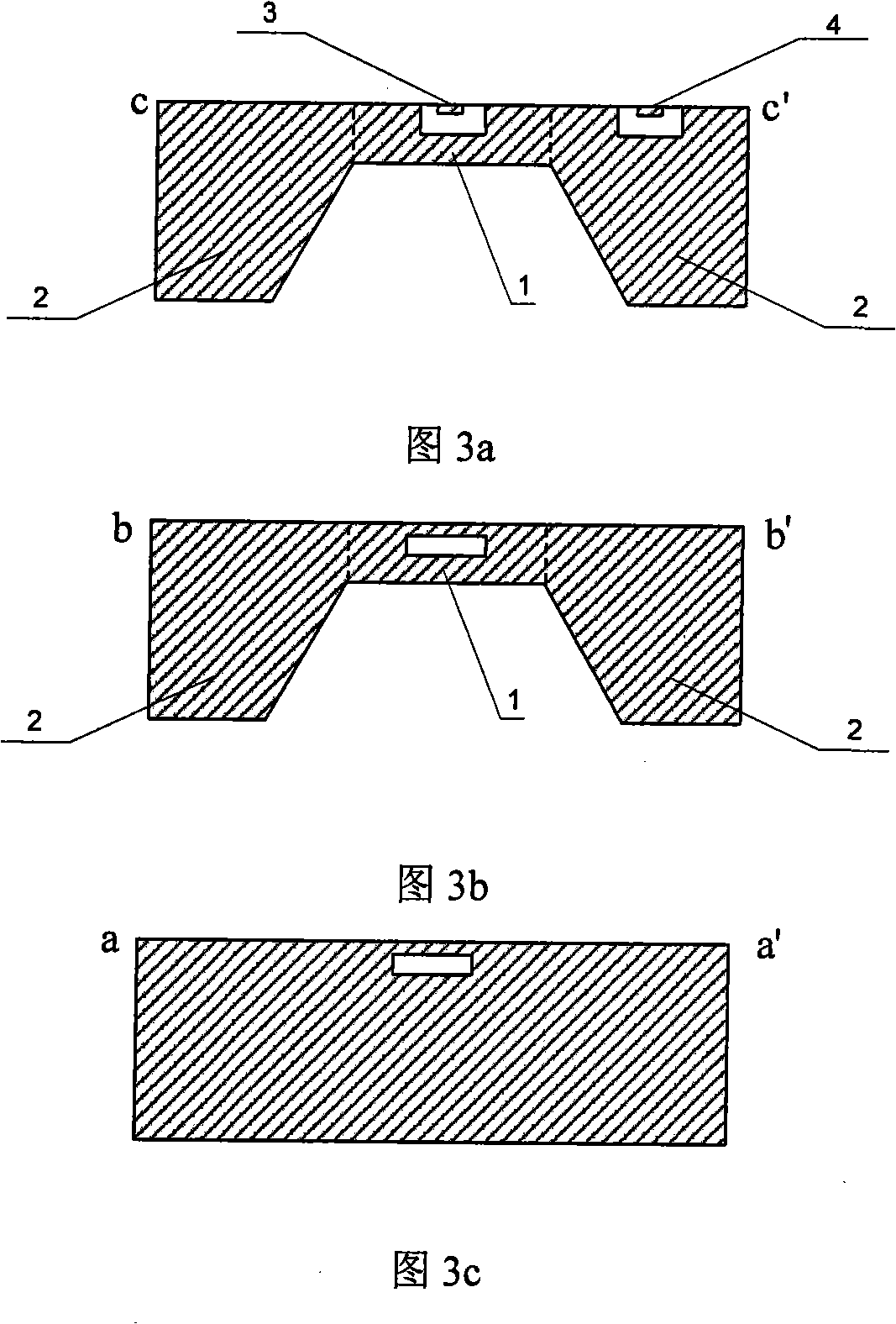

Double-resonance girder type micro mechanical pressure sensor

InactiveCN101281071ASimple structureReduce manufacturing difficultyTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPressure generationResonance

A bi-resonant beam micromachine pressure sensor mainly comprises sensing membrane, non-sensing area, resonant working beam and resonant compensating beam; the centre of the structure is rectangular sensing membrane for sensing the tested pressure to generate corresponding deformation; the peripheral part of the sensing membrane is non-sensing area which does not sense the tested pressure; periphery of the sensing membrane is clamped in the inner wall of the non-sensing area; both ends of the resonant working beam are clamped at the centre of upper surface of the sensing membrane to sense the tested pressure so as to change the resonance frequency and obtain the corresponding tested pressure valve through testing the resonance frequency by the closed loop system; both ends of the resonant compensating beam are clamped in the upper surface of the non-sensing area and are parallel to the resonant working beam and have the same physical dimension with the resonant working beam; the resonant compensating beam does not sense the tested pressure and only senses the temperature the same with the resonant working beam and other environmental factors; executing difference by using the resonance frequency of the resonant working beam and the resonance frequency of the resonant compensating beam is able to remove the change of the resonance frequency of the resonant working beam caused by temperature and other environmental factors so as to improve the measuring precision and stability of the sensor.

Owner:BEIHANG UNIV

Dental bleaching compositions incorporating perborates

InactiveUS6409993B1Improve performanceAccurate quantityCosmetic preparationsTeeth fillingBleachSodium Perborate Monohydrate

Dental bleaching compositions that include perborate bleaching agents, such as sodium perborate monohydrate. The bleaching agent is dispersed within a sticky and viscous carrier such as a mixture of propylene glycol and silica fume. Anhydrous propylene glycol and / or anhydrous glycerin are especially useful in order to maintain the desired degree of hydration of the perborate being used. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

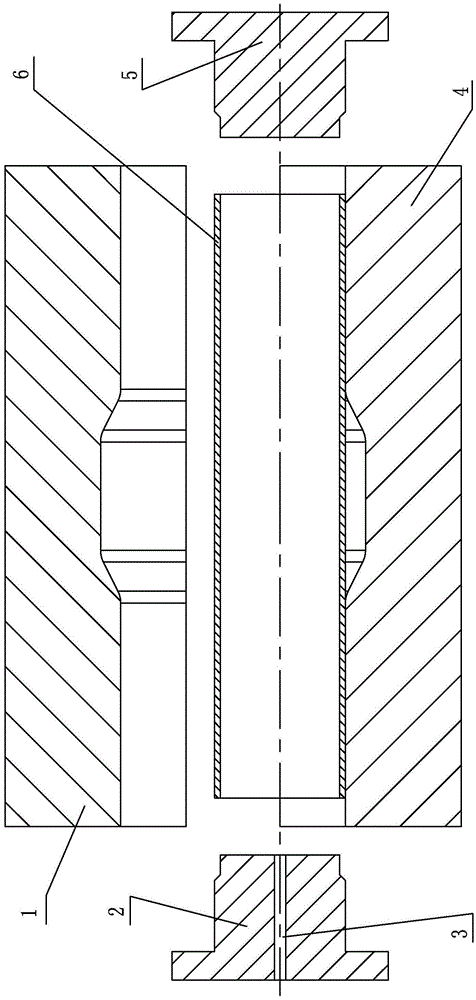

Well cementation cement sheath integrity simulation and evaluation tester

A well cementation cement sheath integrity simulation and evaluation tester includes pressing joints, wherein the pressing joints are arranged on compress packings; screwing compression rings are connected with compress discs through screw threads, and fix trapezoid rubber seal rings onto the compress discs and a steel tube; the steel tube containing a well cementation cement solidified body test sample is clamped tightly by screw rod and screw nut connecting assemblies and connected with the screw rod and screw nut connecting assemblies into a whole; pressing blocks and a mechanical pressure device are connected together to exert mechanical extrusion force to simulate the process that underground pressure variation causes damage and micro cracks to an oil well cement sheath; the pressing joints and a fluid pressing device are connected, so as to exert fluid pressure, simulate fluid pressure of the formation fluid on the well cementation cement sheath, and test and evaluate anti-channeling strength of the well cementation cement sheath; cured samples are placed in the well cementation cement sheath mechanical property simulation tester for test and analysis; and the tester can detect variation situations of the anti-channeling strength of the well cementation cement sheath under different conditions, so that impacting ductility and packing reliability of the well cementation cement sheath can be evaluated accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

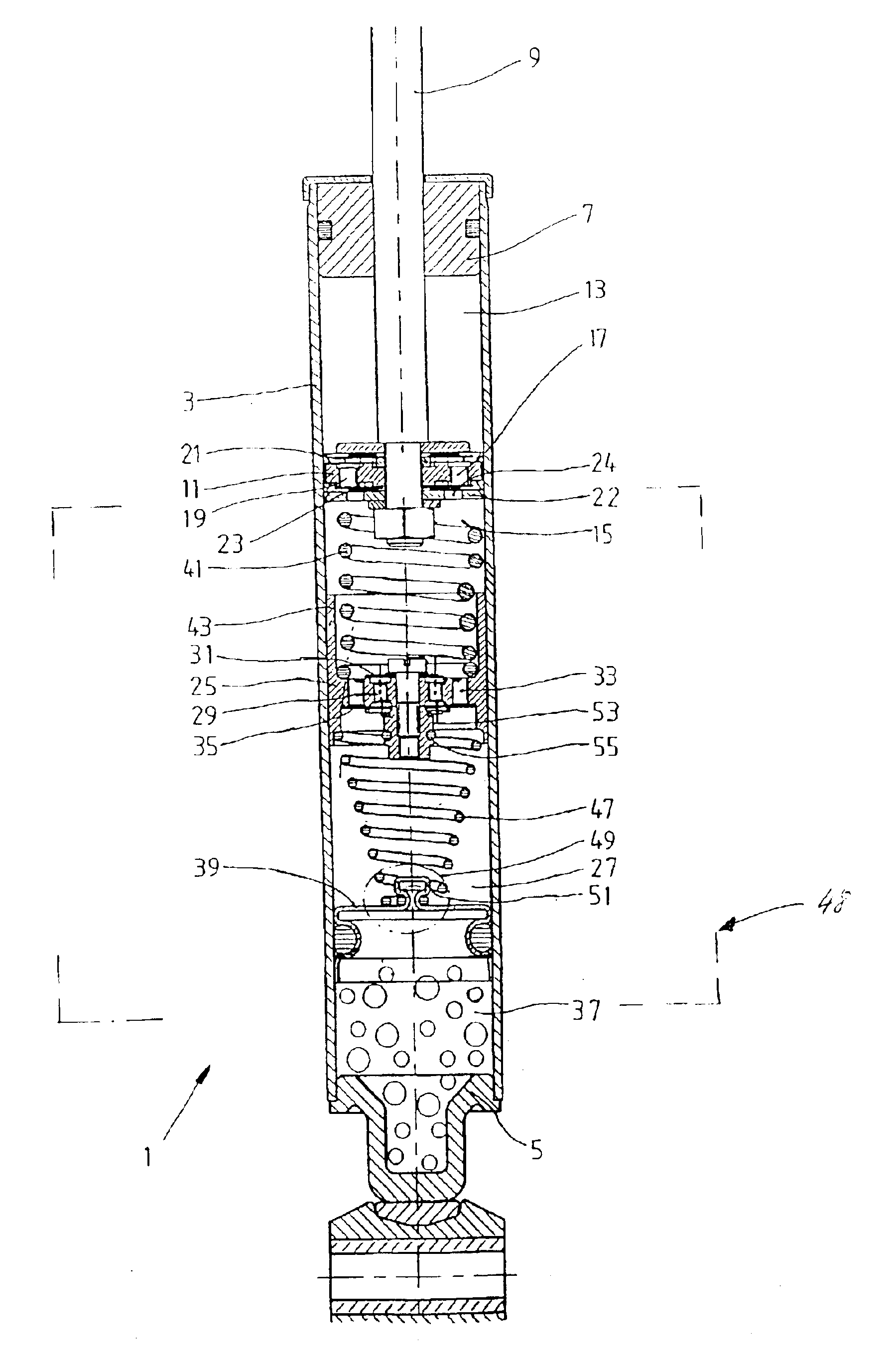

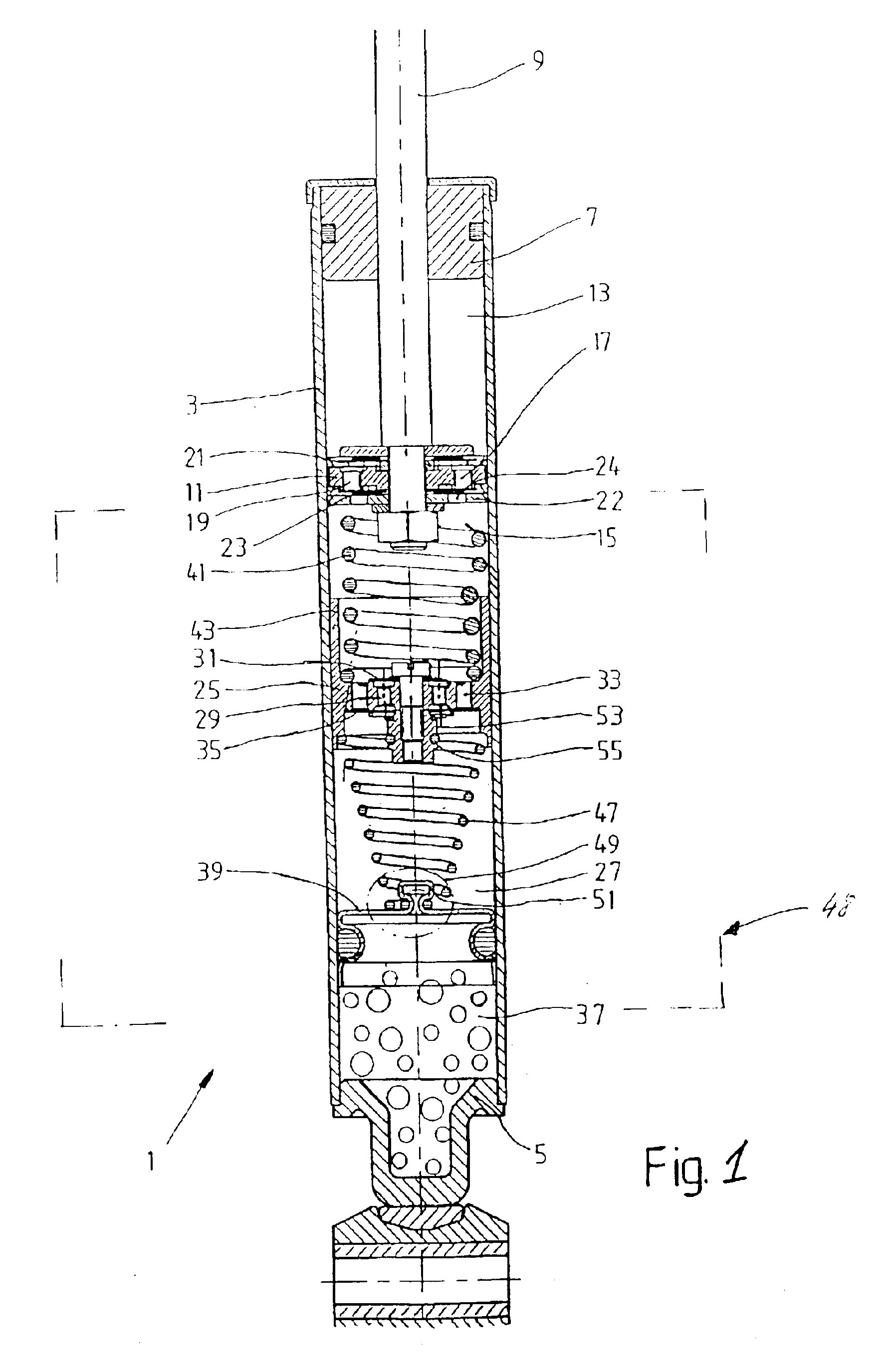

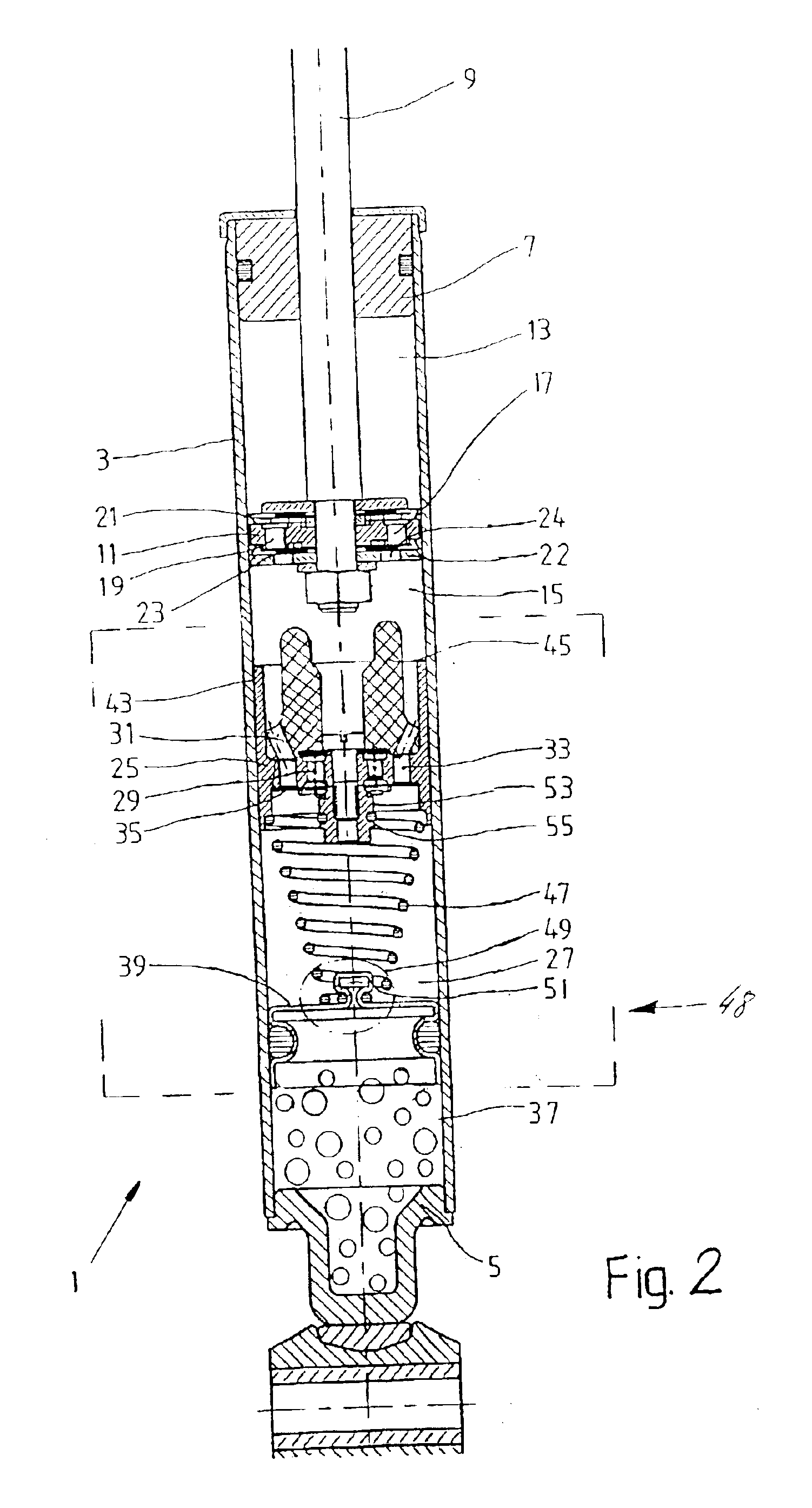

Vibration damper with a hydraulic pressure stop

A vibration damper with a hydraulic-mechanical pressure stop includes a cylinder filled with damping medium; a piston rod movable in and out of the cylinder, a first piston fixed to the piston rod with freedom of axial movement, a second piston spaced from the first piston, a transfer spring in the second working space for moving the second piston toward the third working space in response to movement of the first piston toward the second working space; and a disk valve which allows damping medium to flow from the third working space through the second piston to the second working space as the second piston moves toward the third working space. The first piston divides the cylinder into a first and a second working space where the piston rod extends through the first working space. The second piston separates the second working space from a third working space.

Owner:ZF SACHS AG

Micro-electro-mechanical pressure sensor

ActiveUS20090013792A1Fluid pressure measurement by electric/magnetic elementsElectricityVibrating membrane

The present micro-electro-mechanical pressure sensor includes a substrate, a dielectric isolation layer, at least two electrodes, and a vibrating membrane. The substrate includes an acoustic cavity. The dielectric isolation layer is formed on the substrate, and the dielectric isolation layer includes a through hole corresponding to the acoustic cavity. The at least two electrodes are separately formed on the dielectric isolation layer. The vibrating membrane covers the through hole, and the vibrating membrane includes at least one carbon nanotube structure with two opposite ends. The two opposite ends of the carbon nanotube are respectively connected to at least a given one of the at least two electrodes.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com