Double-resonance girder type micro mechanical pressure sensor

A vibrating beam type micro-mechanical pressure technology, which is applied in the measurement of fluid pressure, measurement of fluid pressure through electromagnetic elements, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of difficult processing, high production cost, and actual temperature There are problems such as deviation, so as to reduce the difficulty of production, improve the yield and improve the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with a specific embodiment and accompanying drawings.

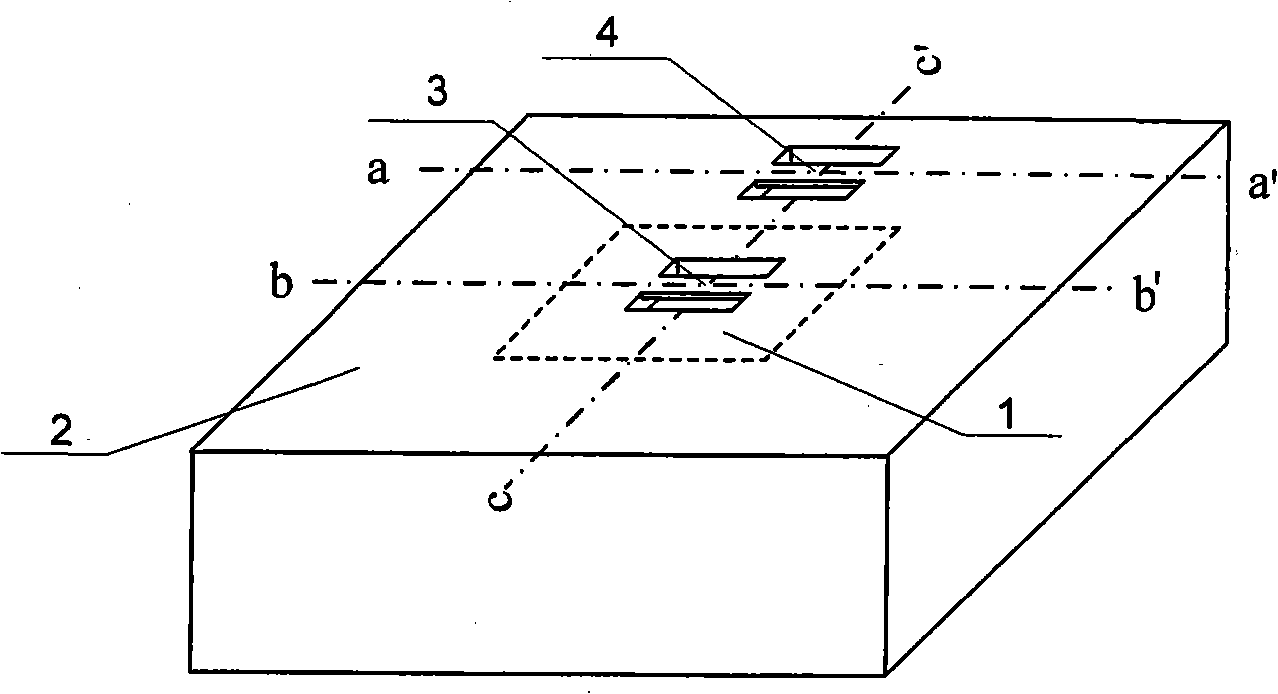

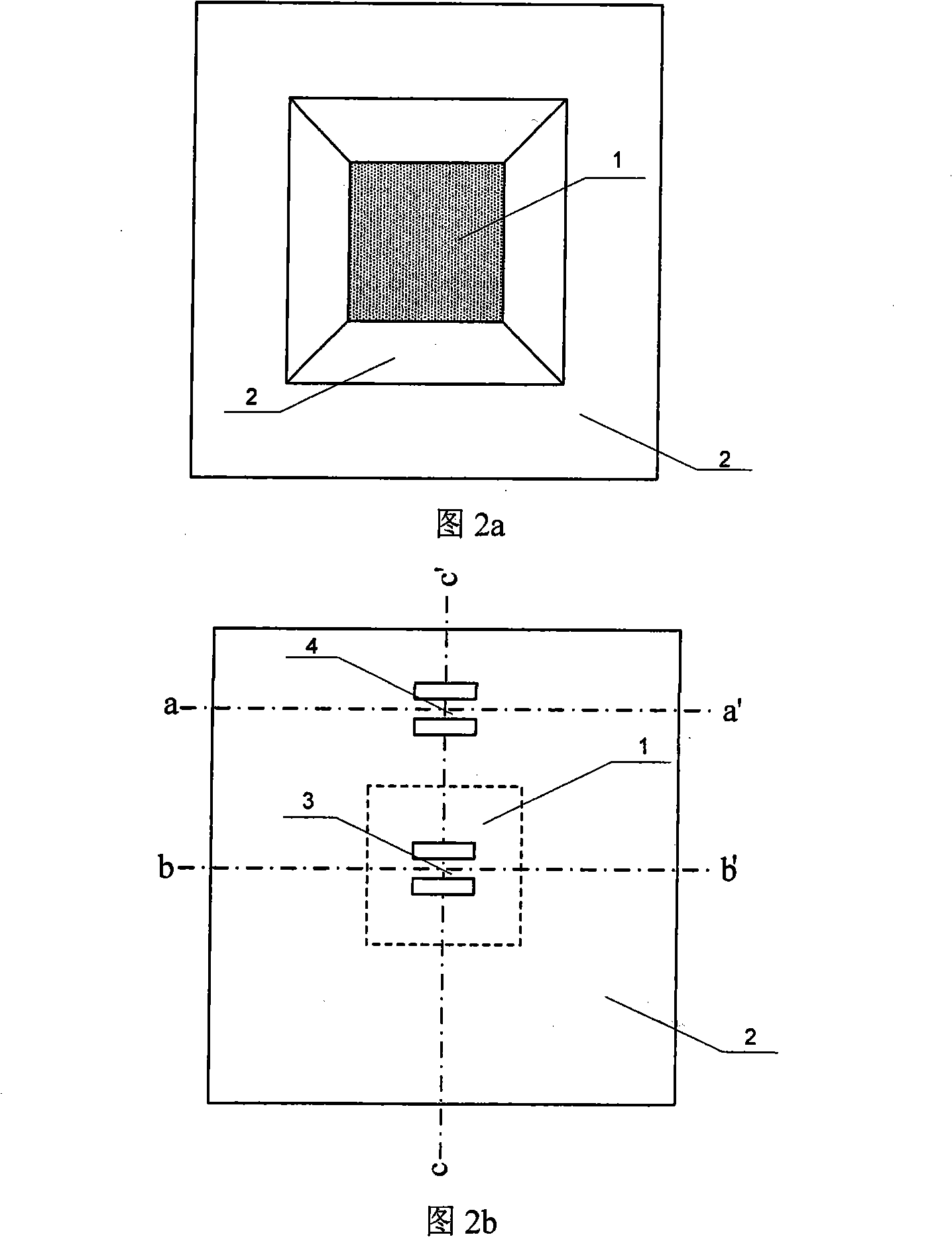

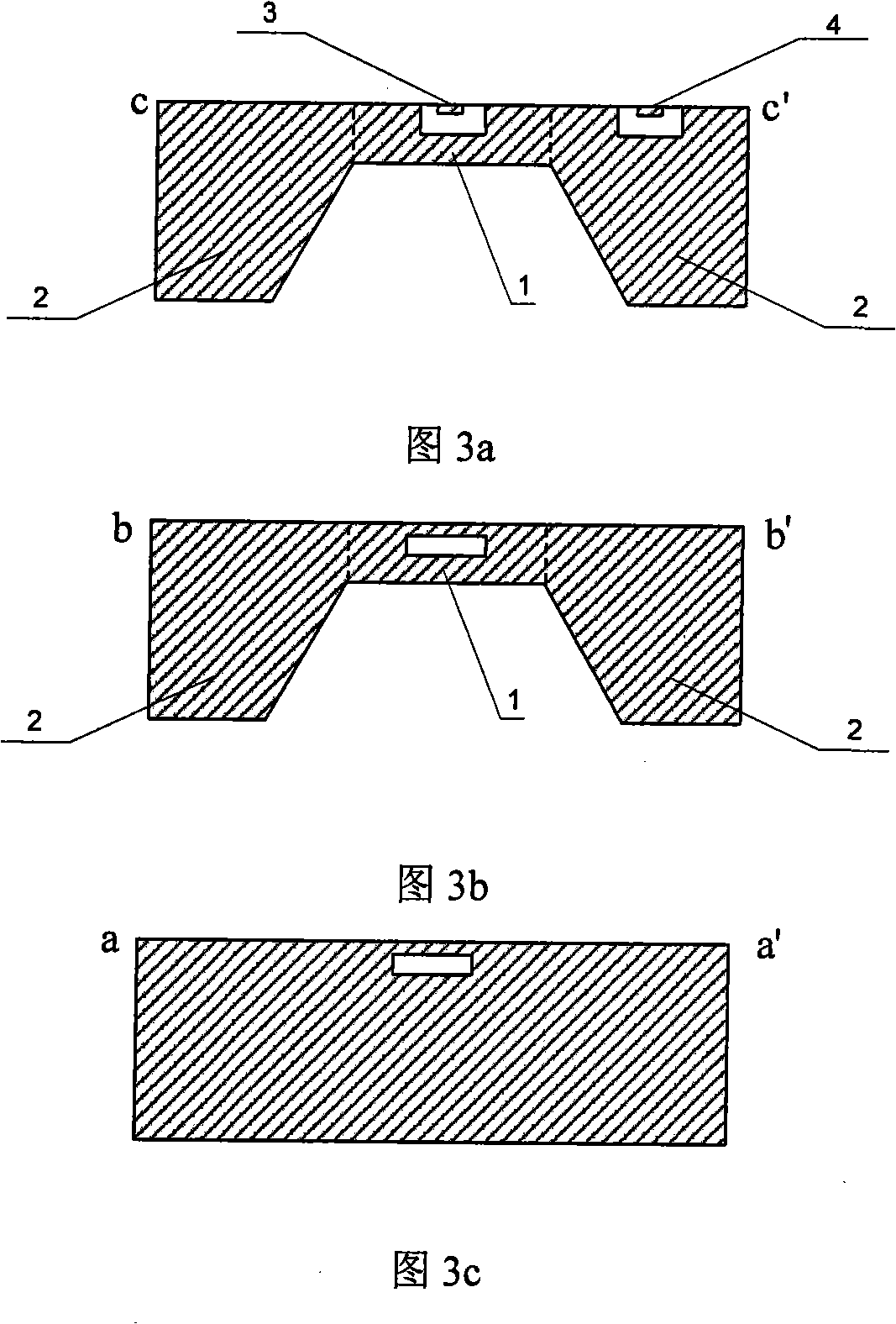

[0026] Such as figure 1 , figure 2 , image 3 As shown, a double-resonant beam micromechanical pressure sensor of this embodiment includes four parts: a pressure-sensitive diaphragm 1, a non-pressure-sensitive area 2, a resonant working beam 3 and a resonant compensation beam 4; the materials used in each part are the same Consistent, it can be silicon, or silicon nitride, or quartz, or metal tungsten, or permanent elastic alloy and other materials. The size of the square diaphragm is much larger than the thickness in the side length direction; the non-pressure-sensitive area 2 is located around the pressure-sensitive diaphragm 1 and is a structure with holes in the middle. The aperture of the diaphragm 1 is exactly the same, starting from the thickness position that is flat with the lower surface of the pressure-sensitive diaphragm 1, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com