Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1157 results about "Pressure generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

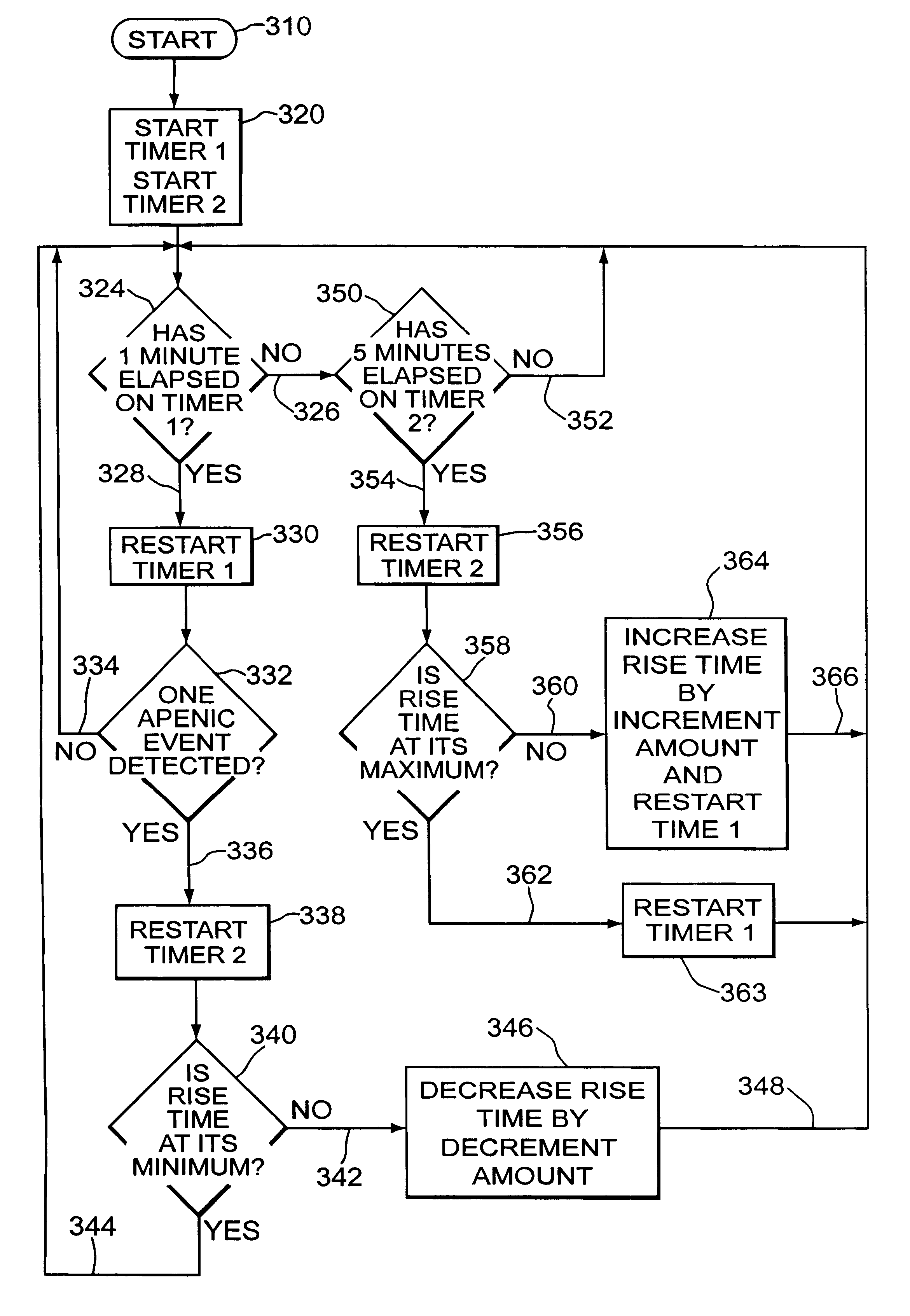

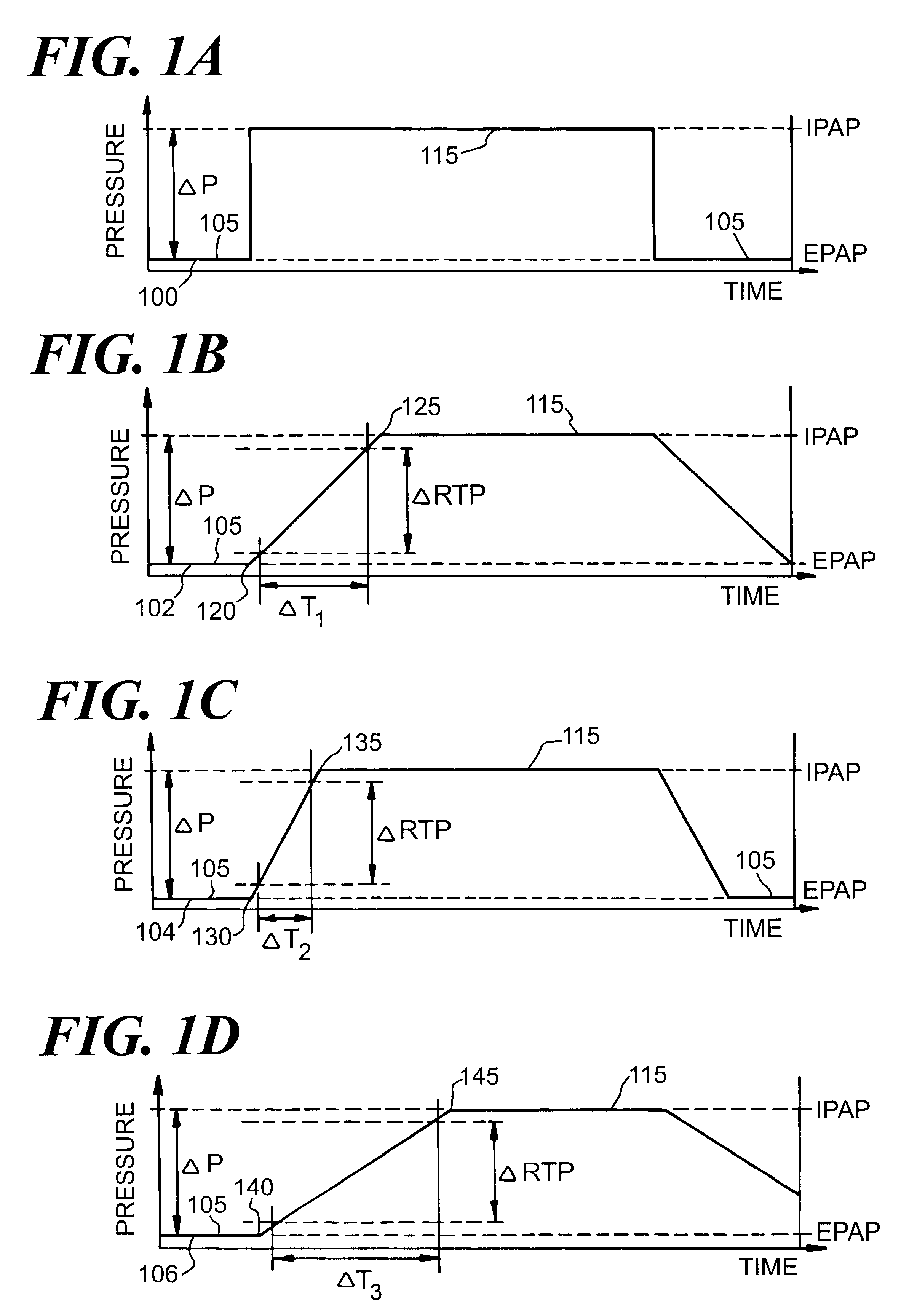

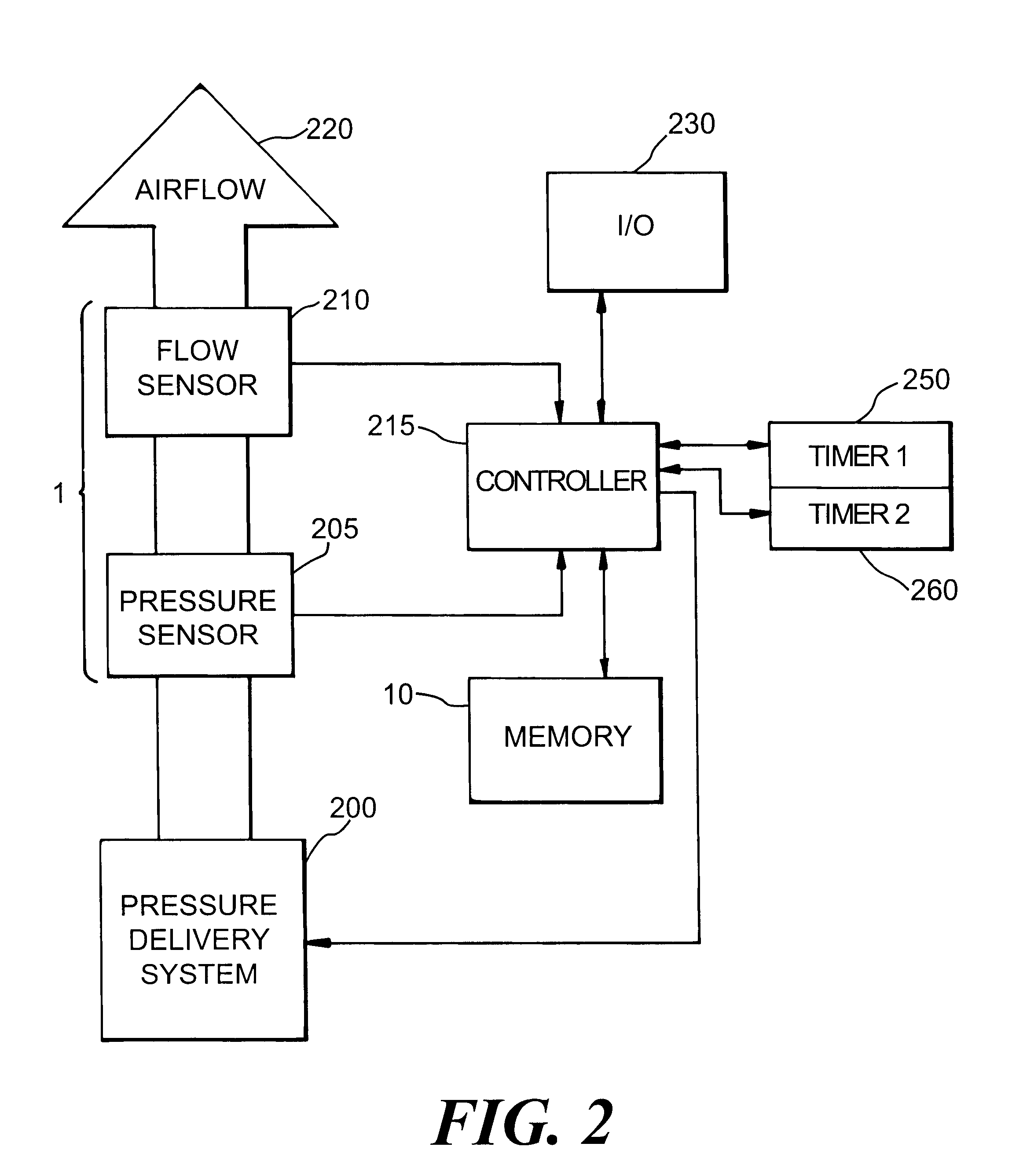

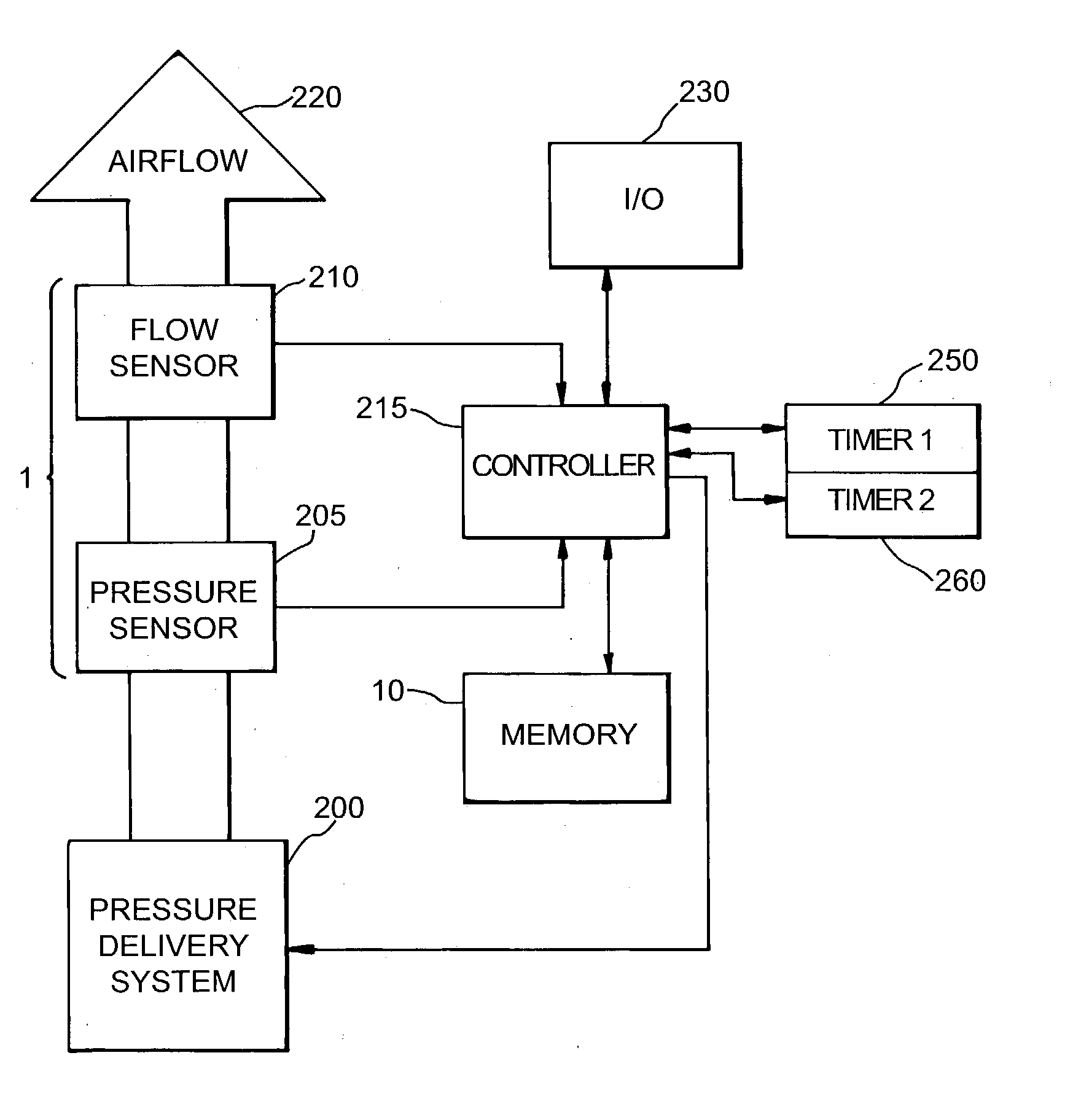

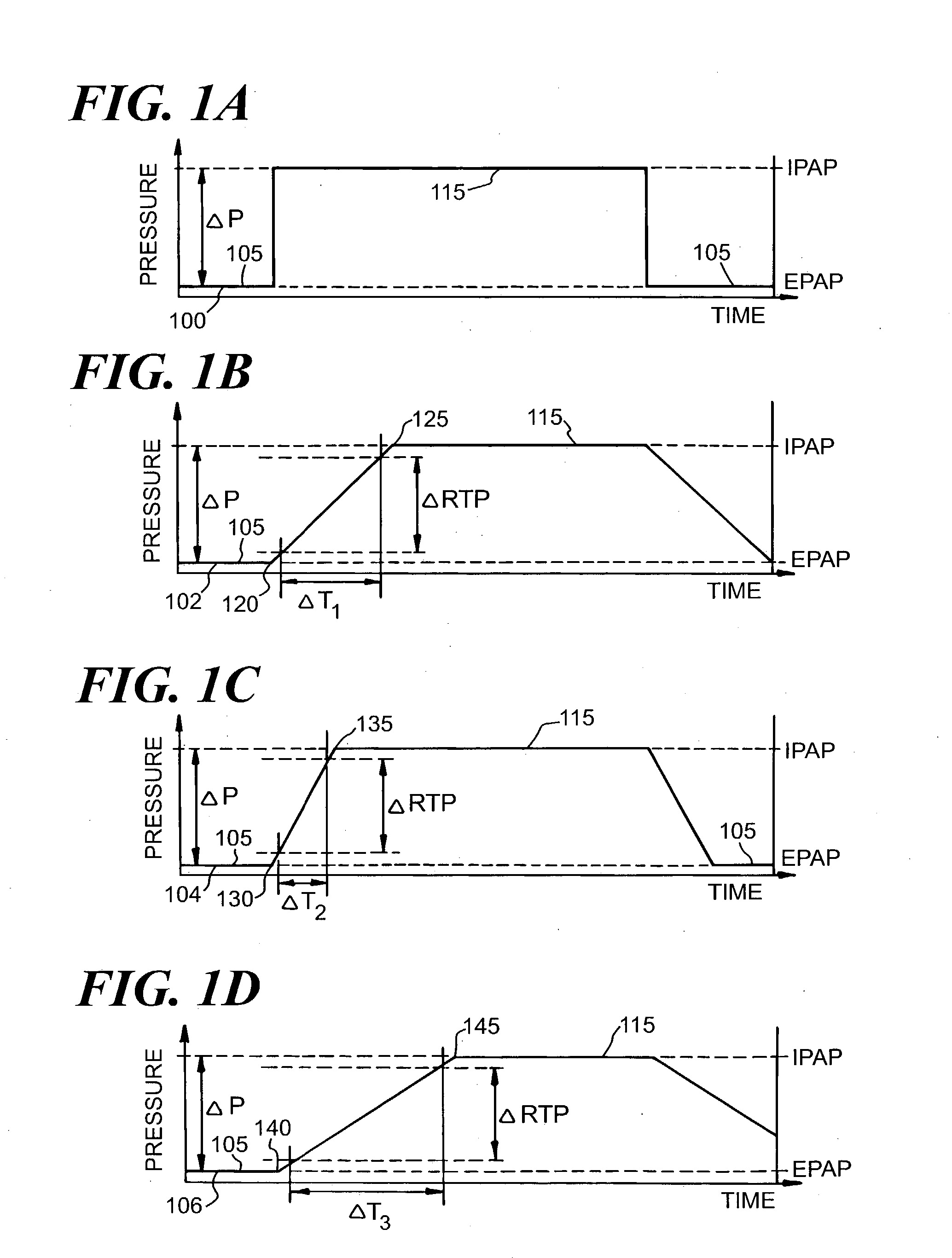

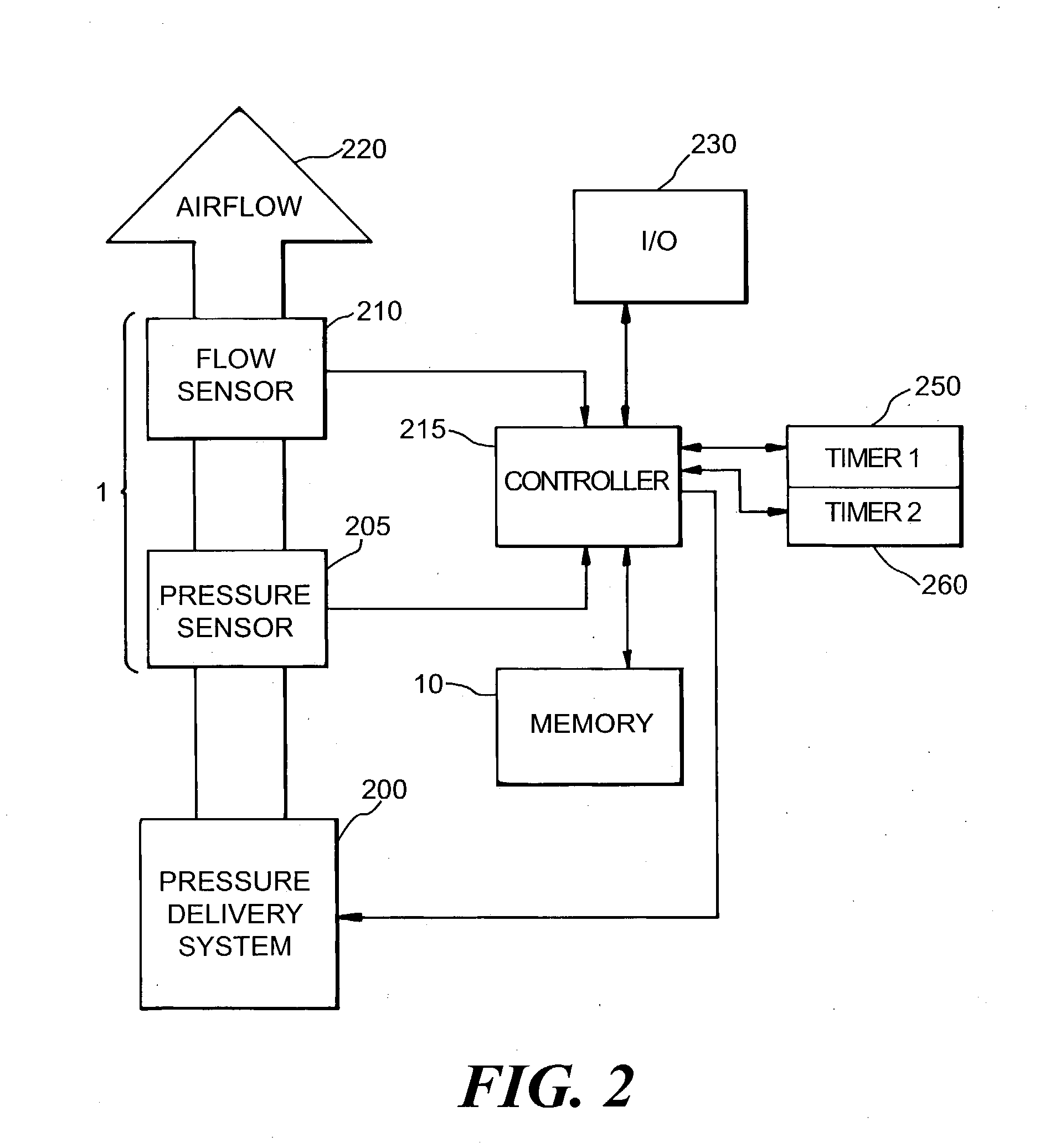

Automatic rise time adjustment for bi-level pressure support system

InactiveUS6532960B1Operating means/releasing devices for valvesRespiratory masksNon-invasive ventilationTreatment effect

An apparatus and method for a bi-level positive airway pressure support in which the rise time from the expiratory positive airway pressure to the inspiratory positive airway pressure is automatically controlled by the pressure support system. The pressure support system includes a sensor, a control system, and a pressure generating system. The sensor monitors the patient's respiration to detect respiratory events, such as an apnea, hyponea or other disturbance, and the control system responds to the sensor information to adjust the rise time from the expiratory positive airway pressure to the inspiratory positive airway pressure gas pressure to maximize patient comfort and pressure support treatment effectiveness.

Owner:RIC INVESTMENTS LLC

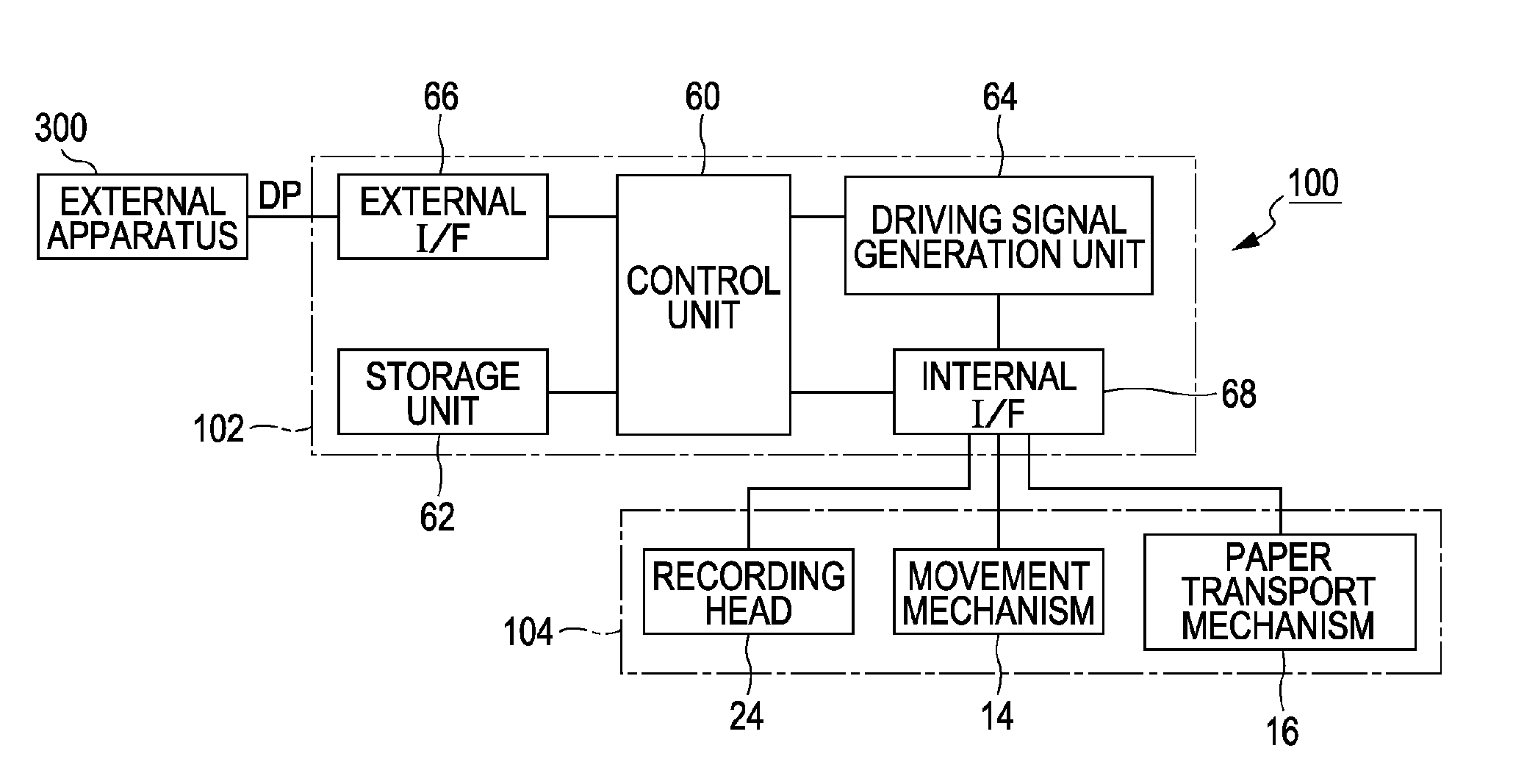

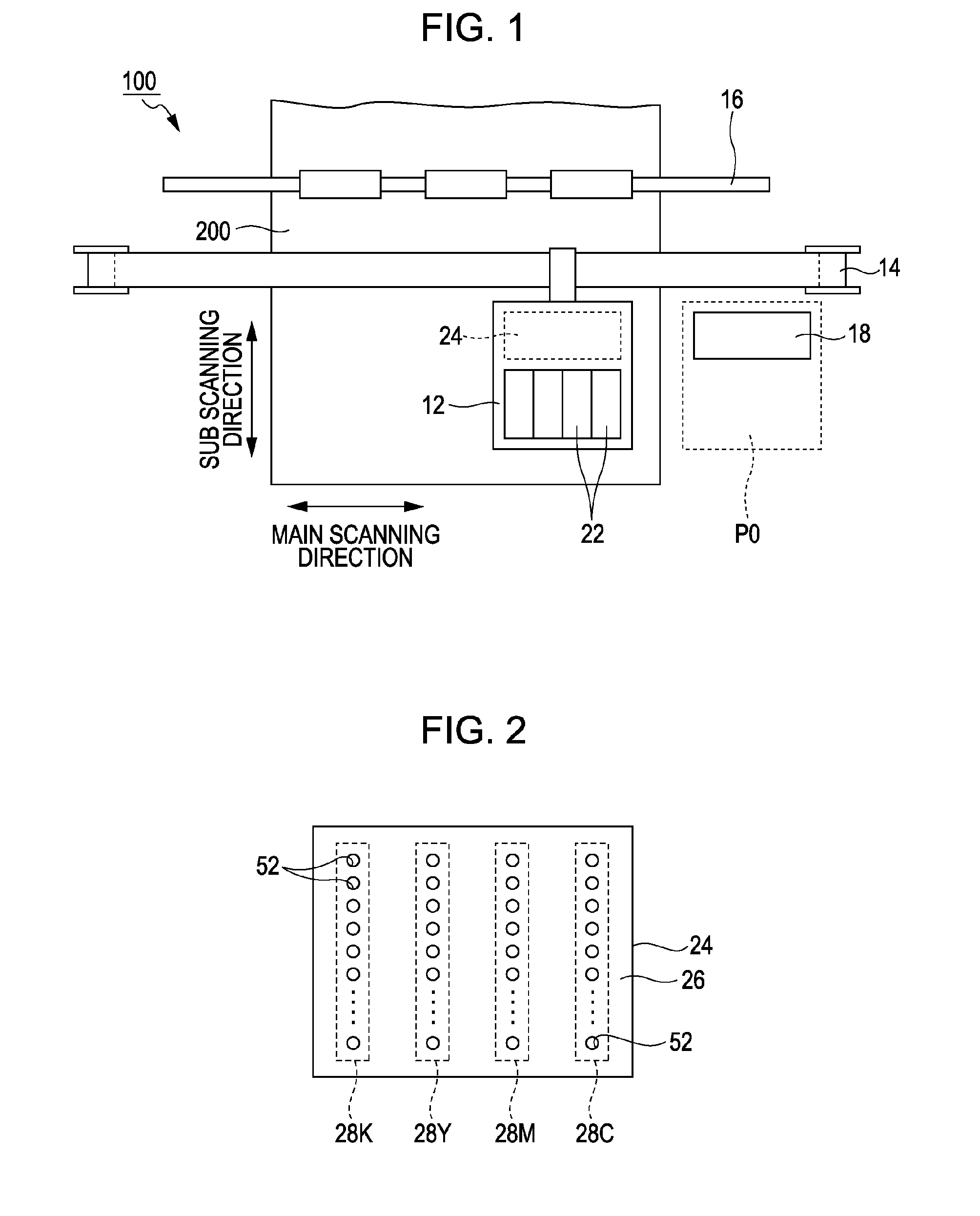

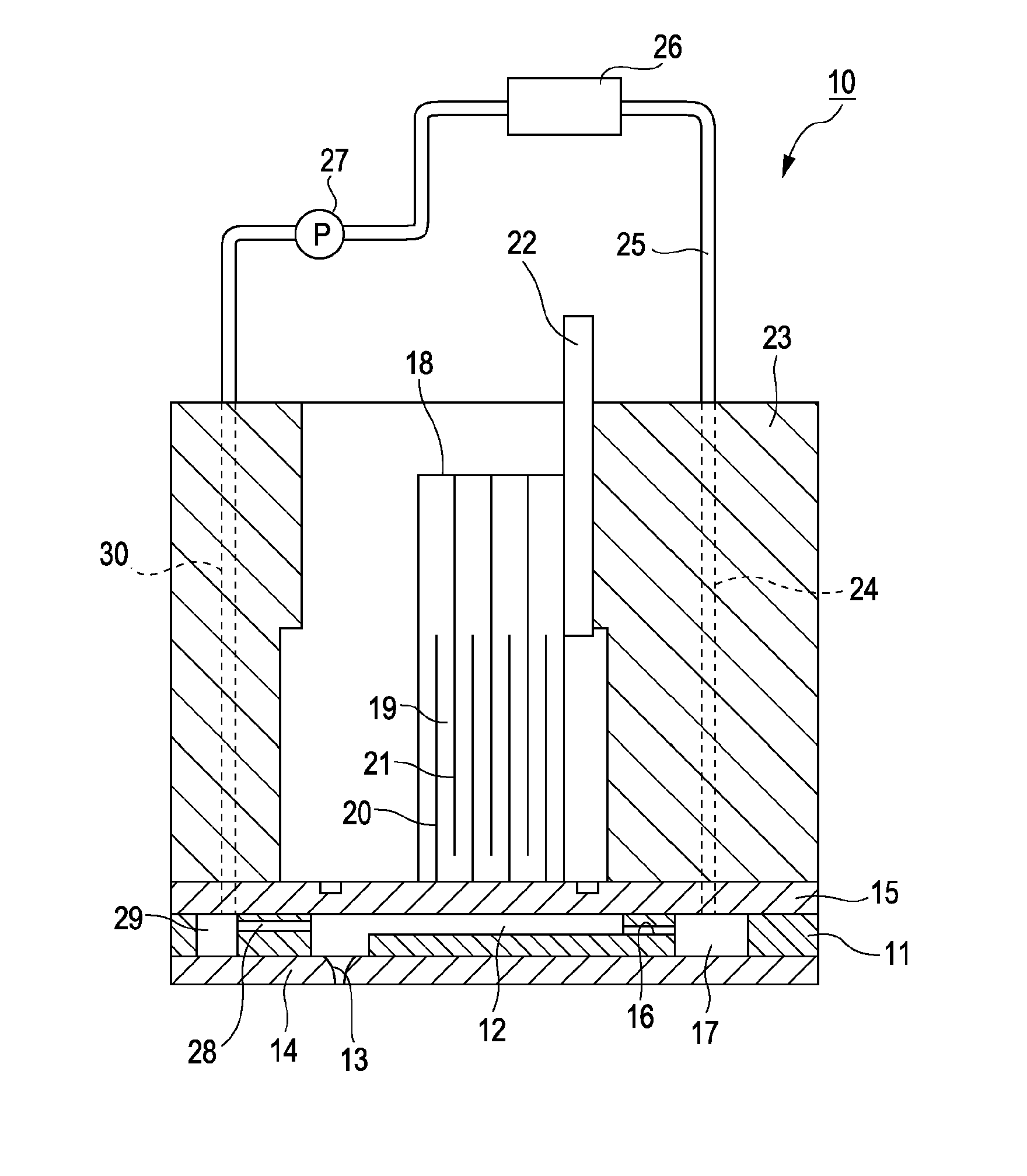

Manufacturing method of ink jet head

InactiveUS6139761ADistanceSimple processRecording apparatusSemiconductor/solid-state device manufacturingPressure generationSilicon oxide

A manufacturing method for an ink jet head having an ink ejection pressure generation element for generating energy for ejecting ink, and an ink supply port for supplying the ink to an ink jet head, including the steps of preparing a silicon substrate; forming, on a surface of the silicon substrate, the ink ejection pressure generation element and silicon oxide film or silicon nitride film; forming anti-etching mask for forming an ink supply port on a back side of the silicon substrate; removing silicon on the back side of the silicon substrate at a position corresponding to the ink supply port portion through anisotropic etching; forming an ink ejection portion on a surface of the silicon substrate; and removing the silicon oxide film or silicon nitride film from the surface of the silicon substrate of the ink supply port portion.

Owner:CANON KK

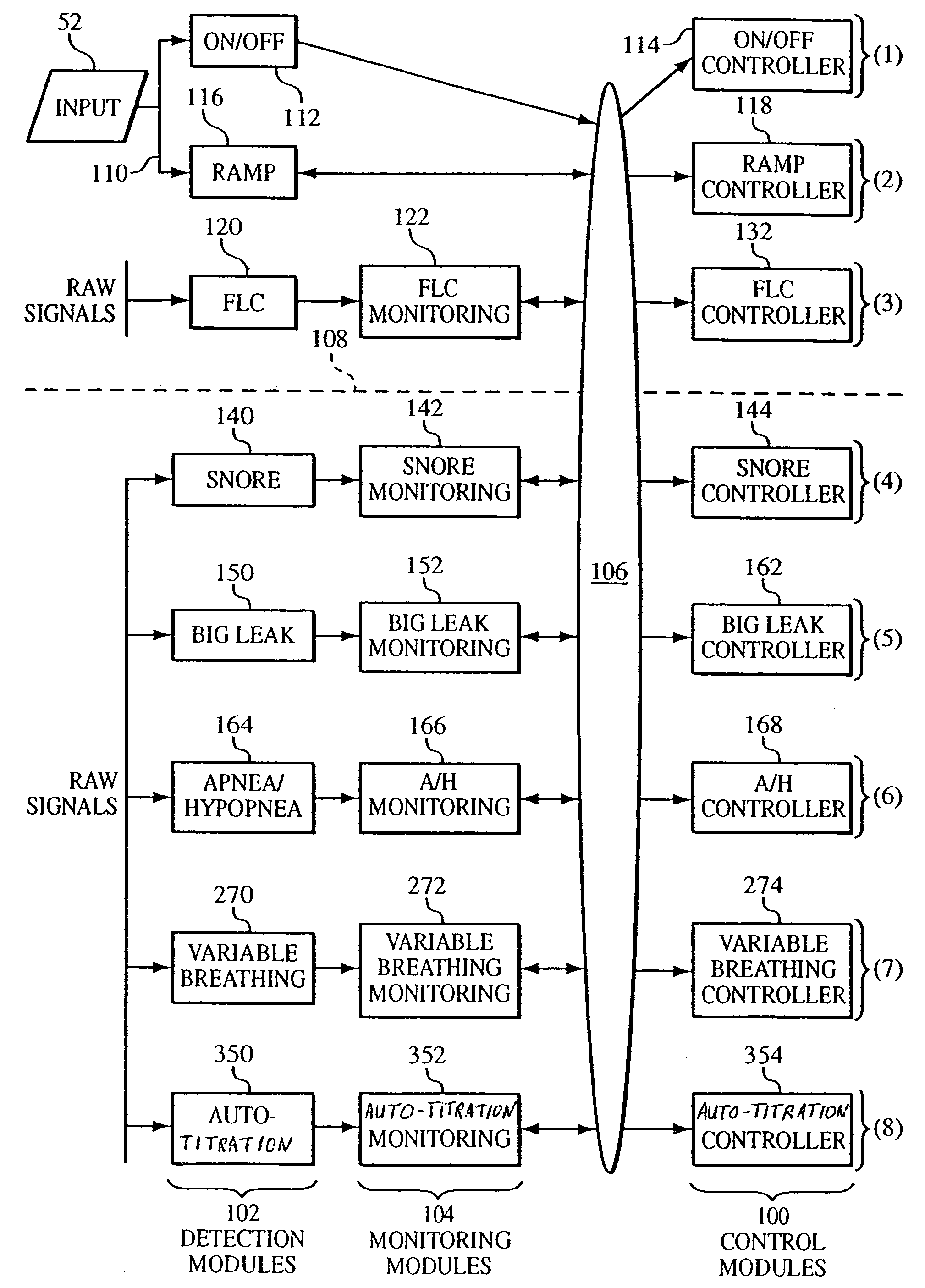

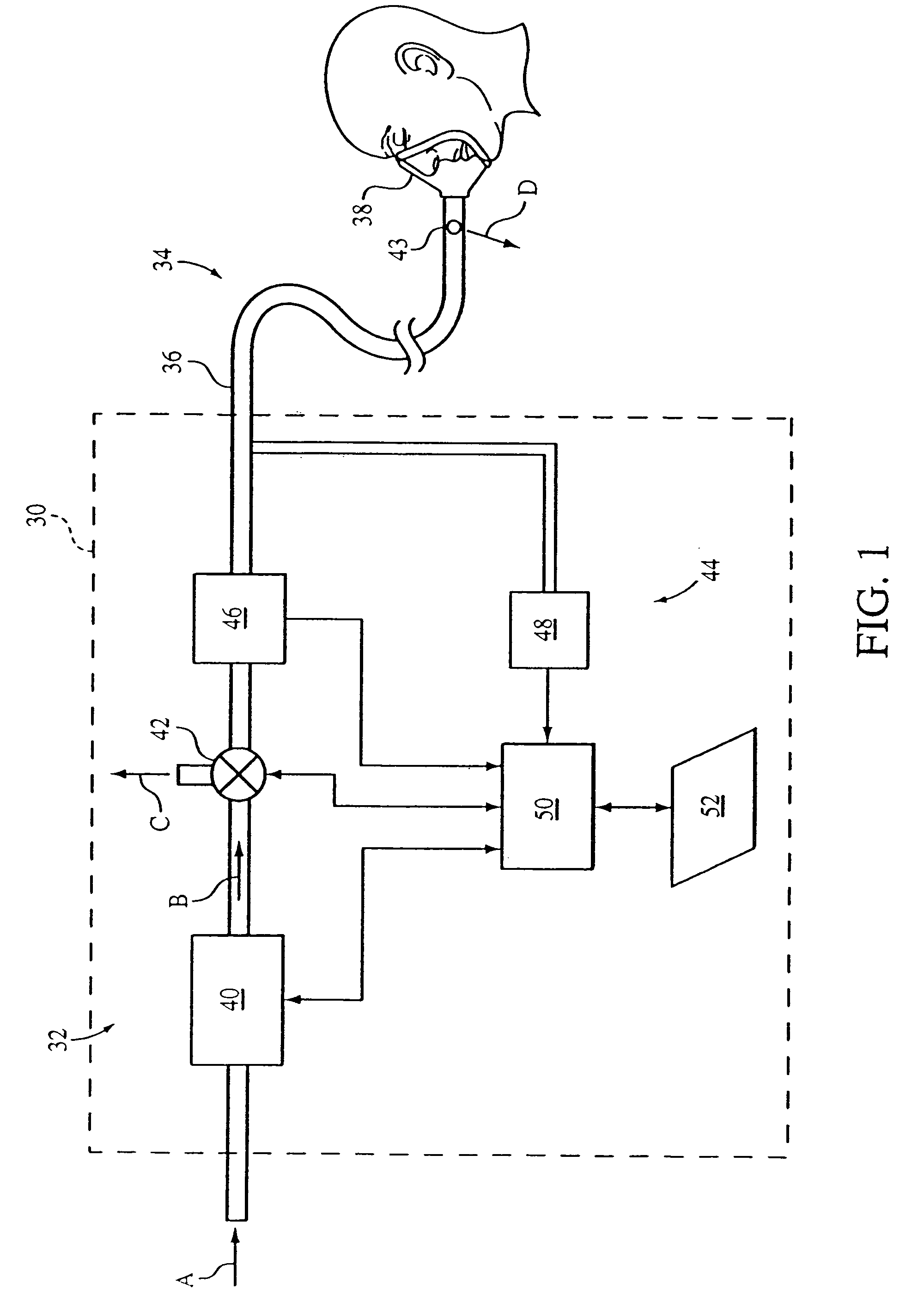

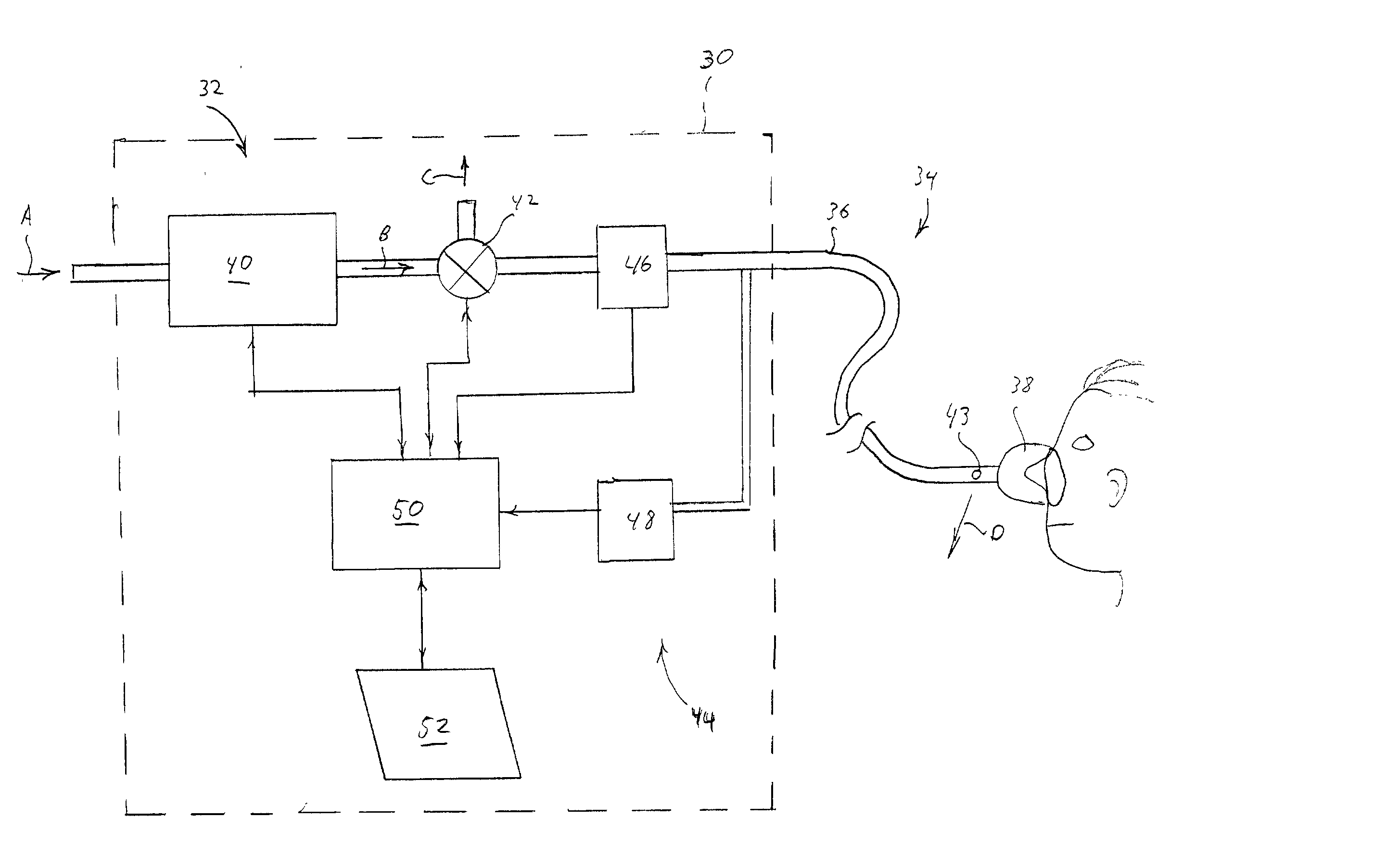

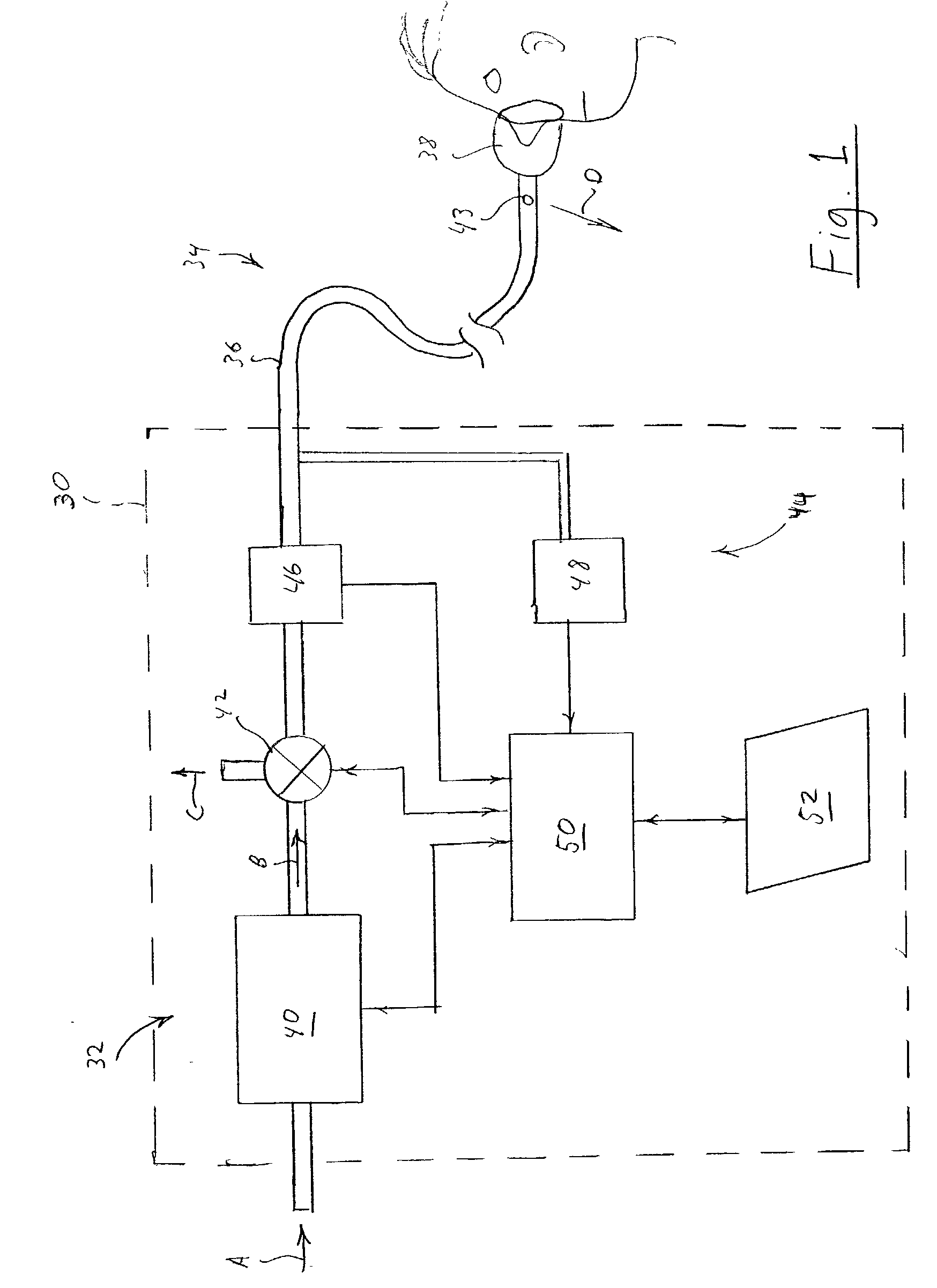

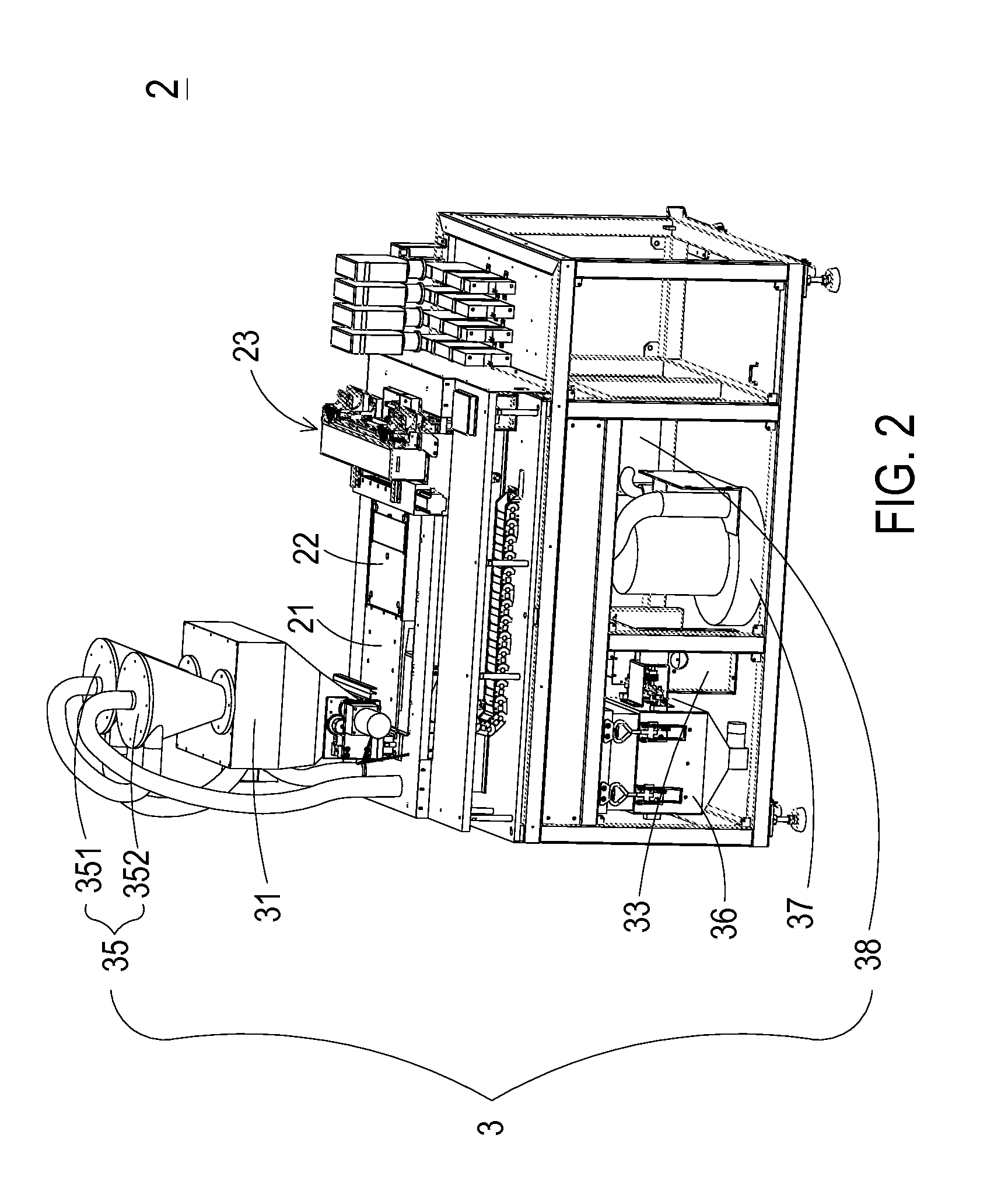

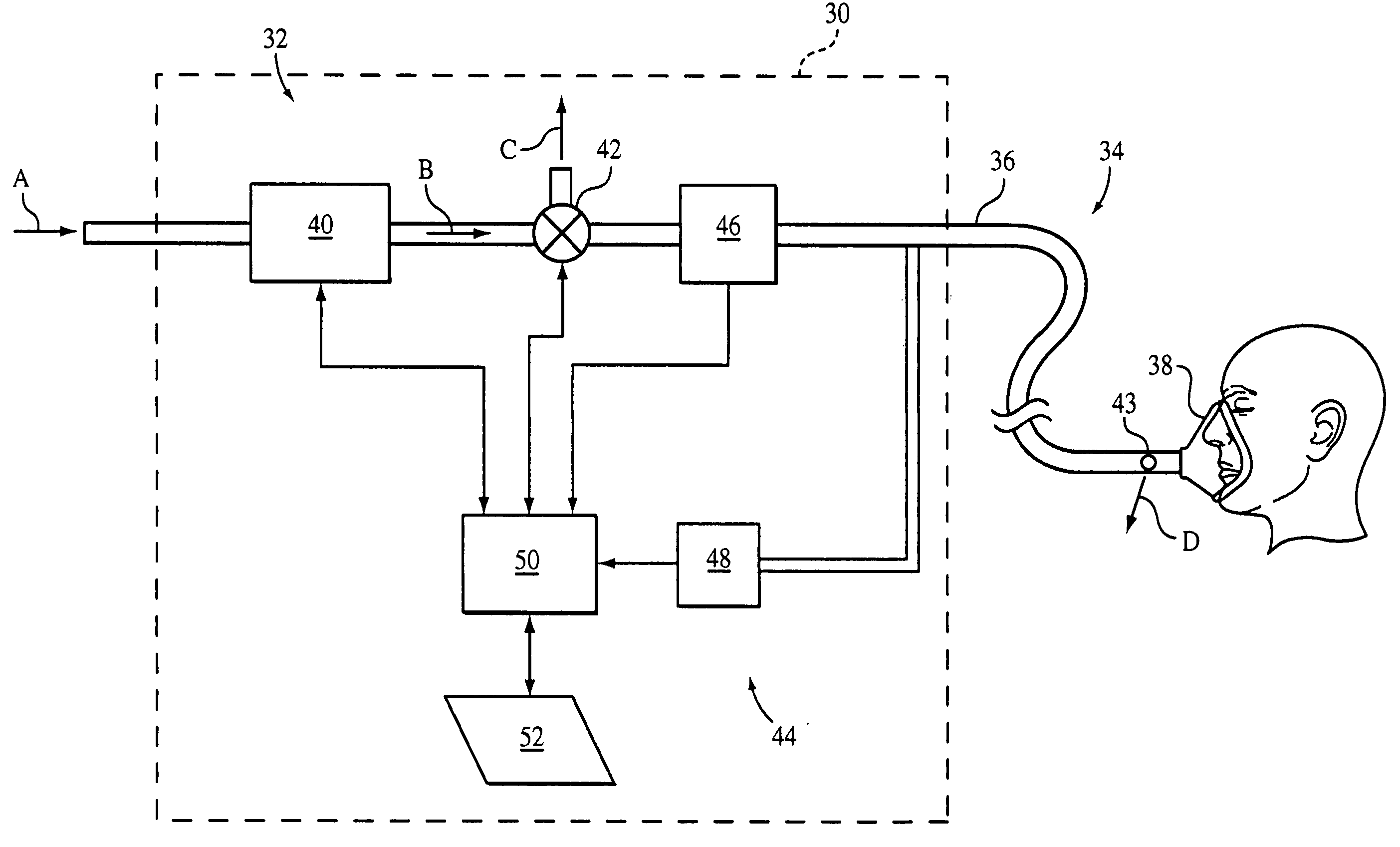

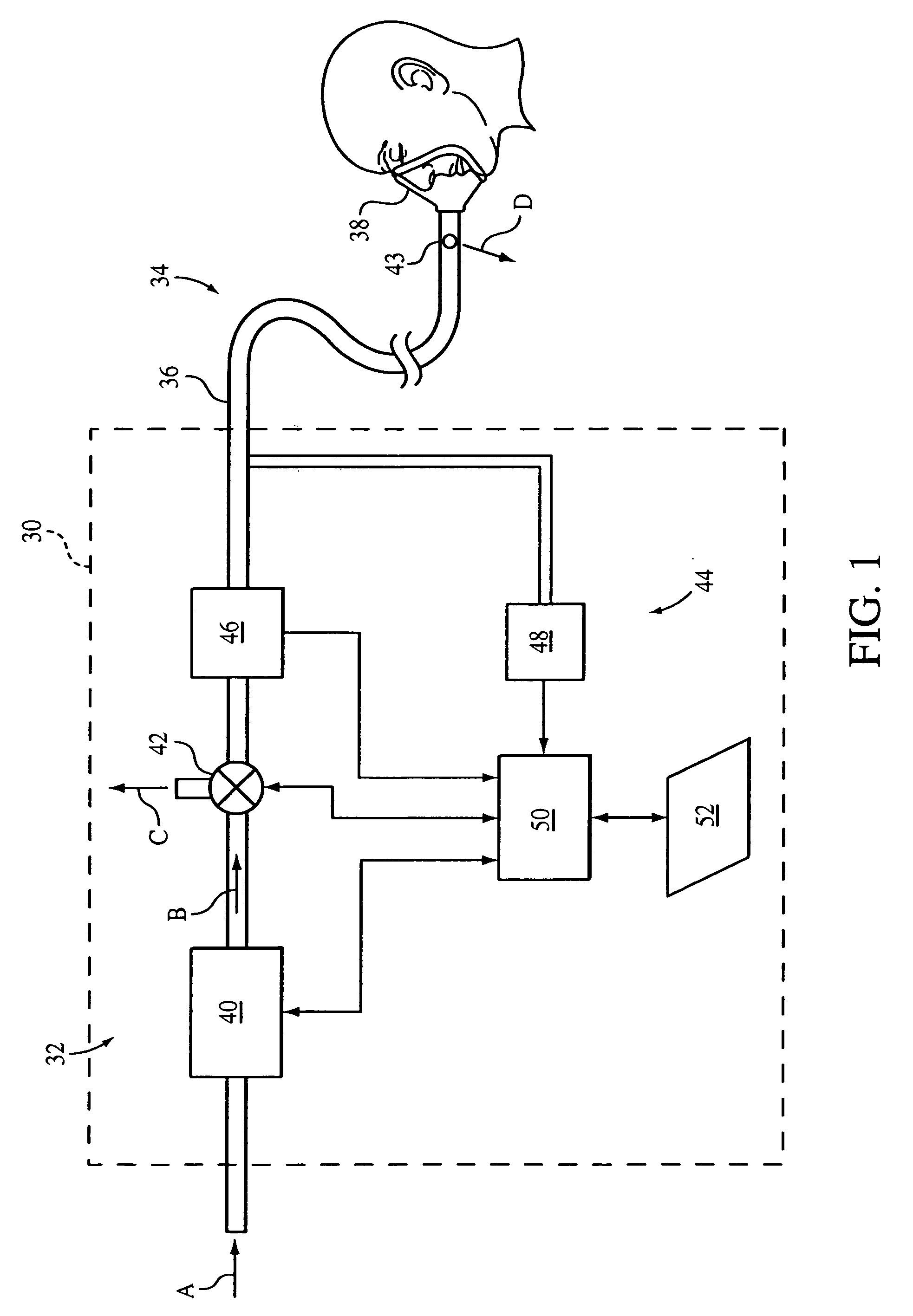

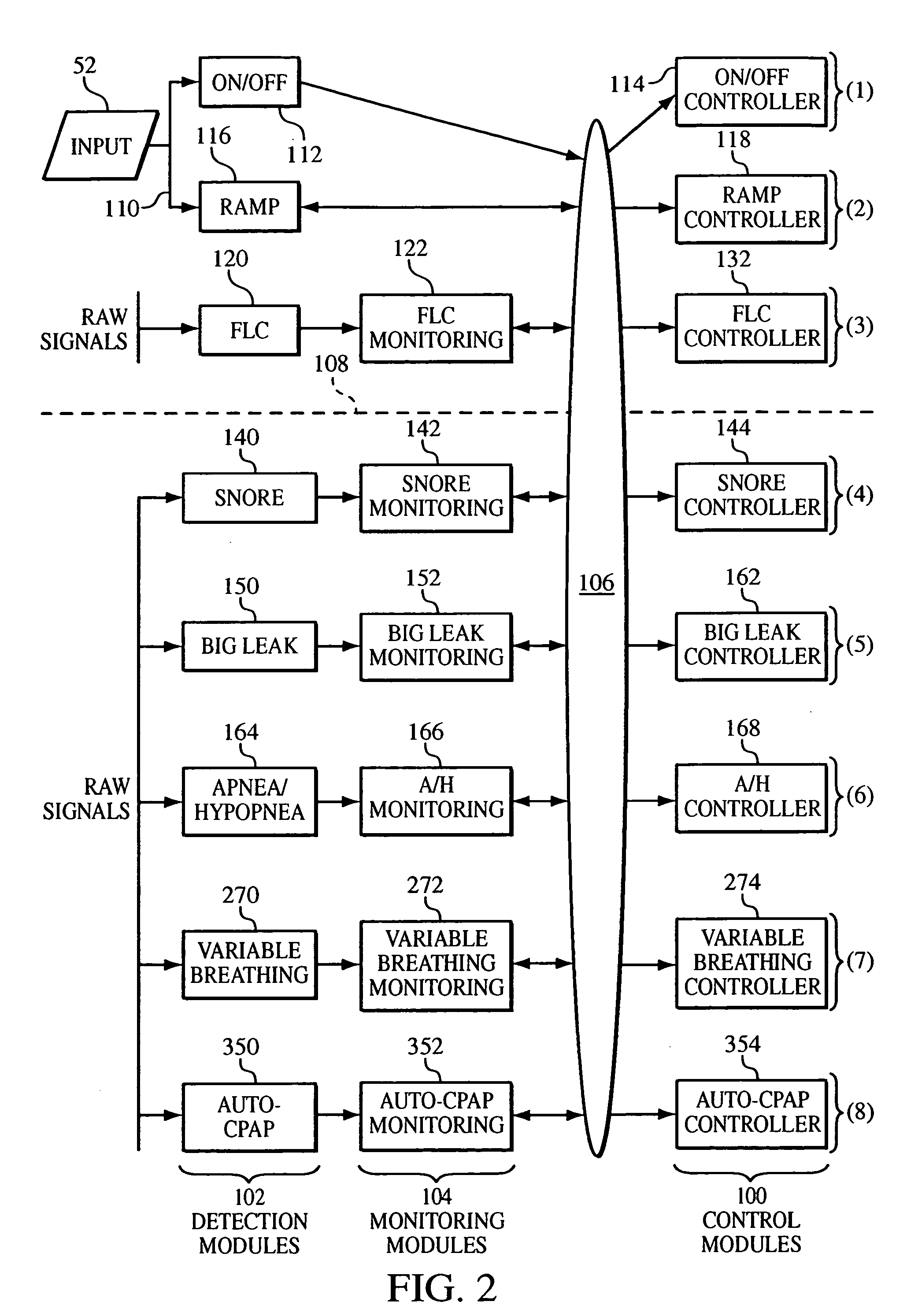

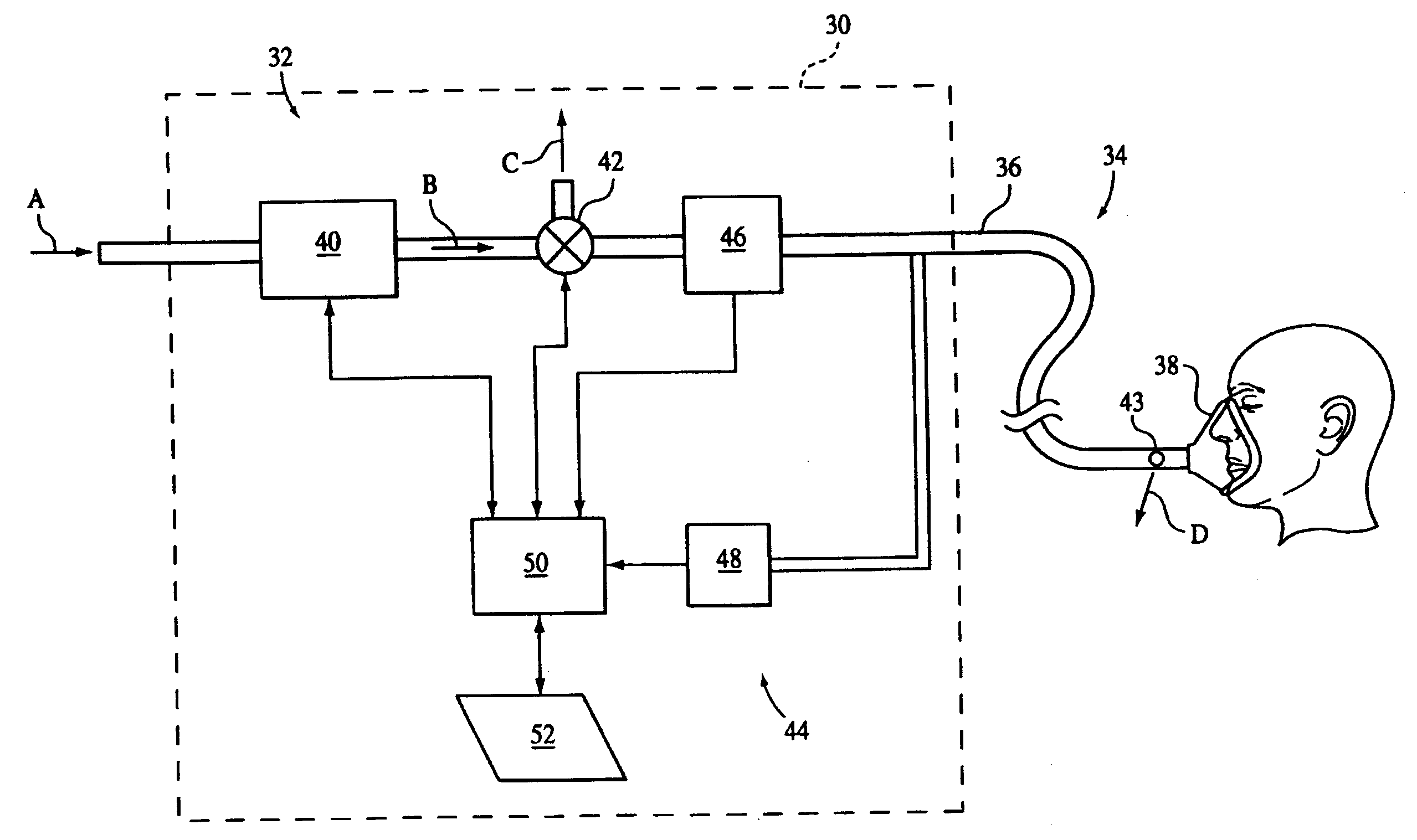

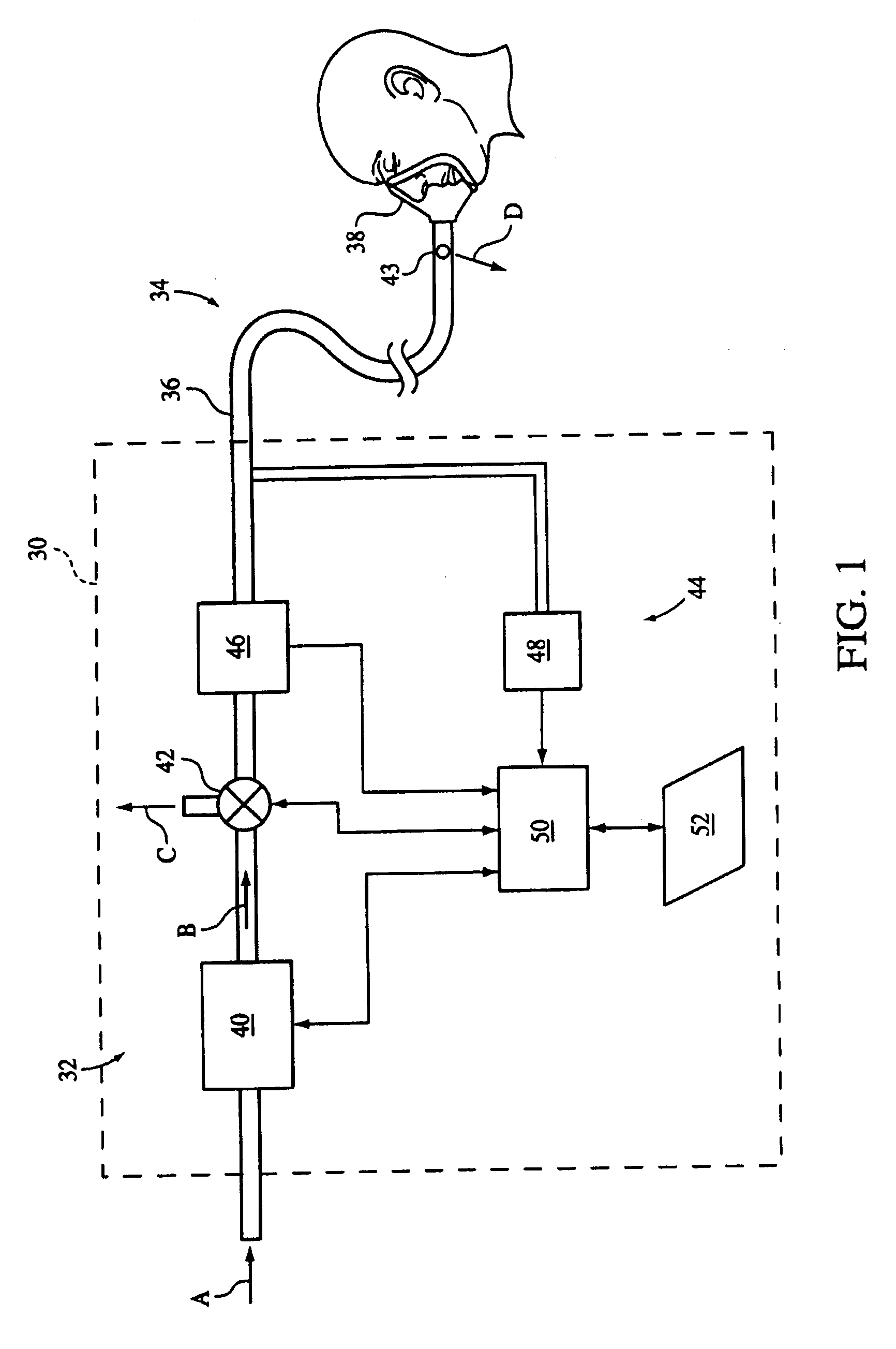

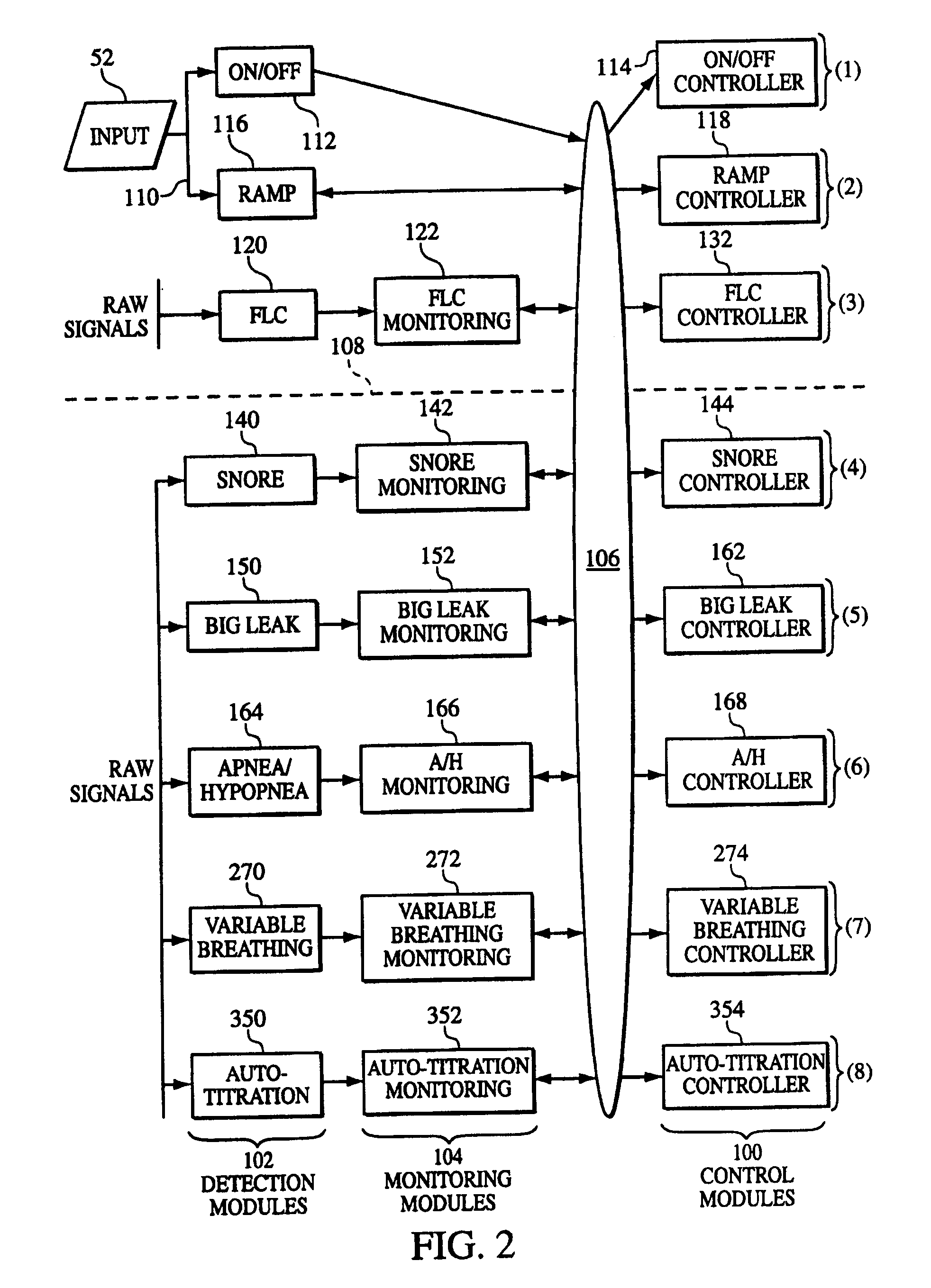

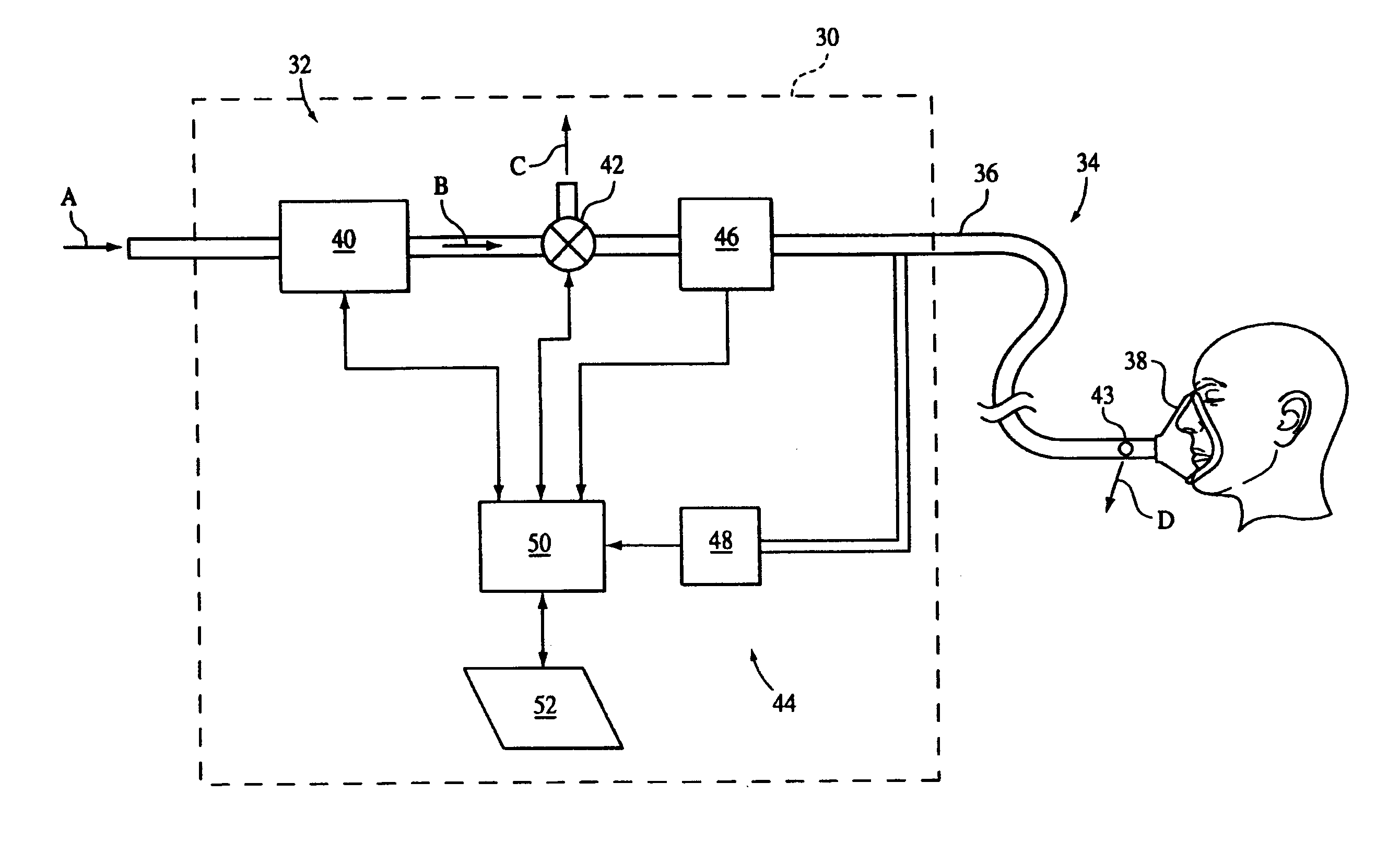

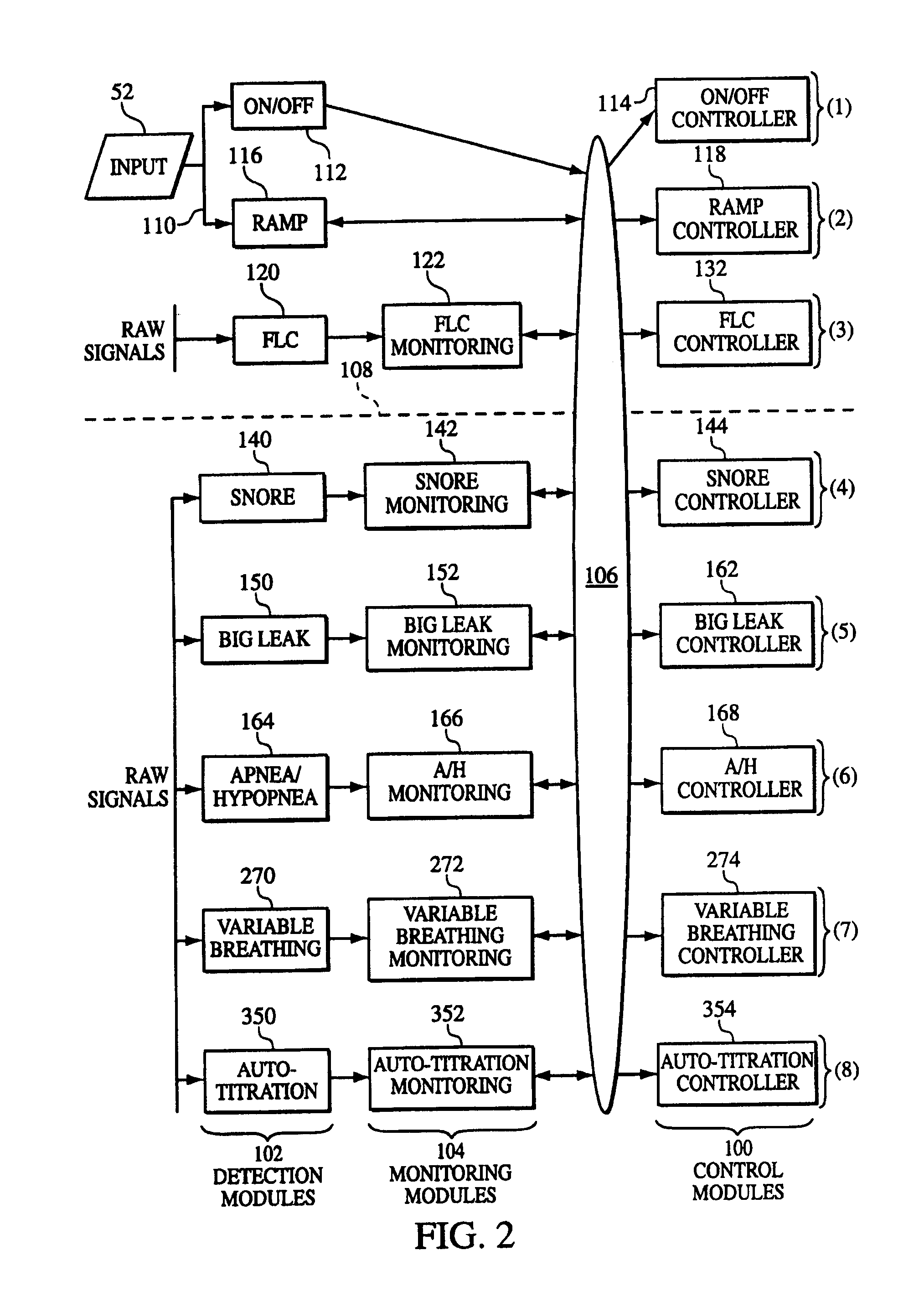

Auto-titration bi-level pressure support system and method of using same

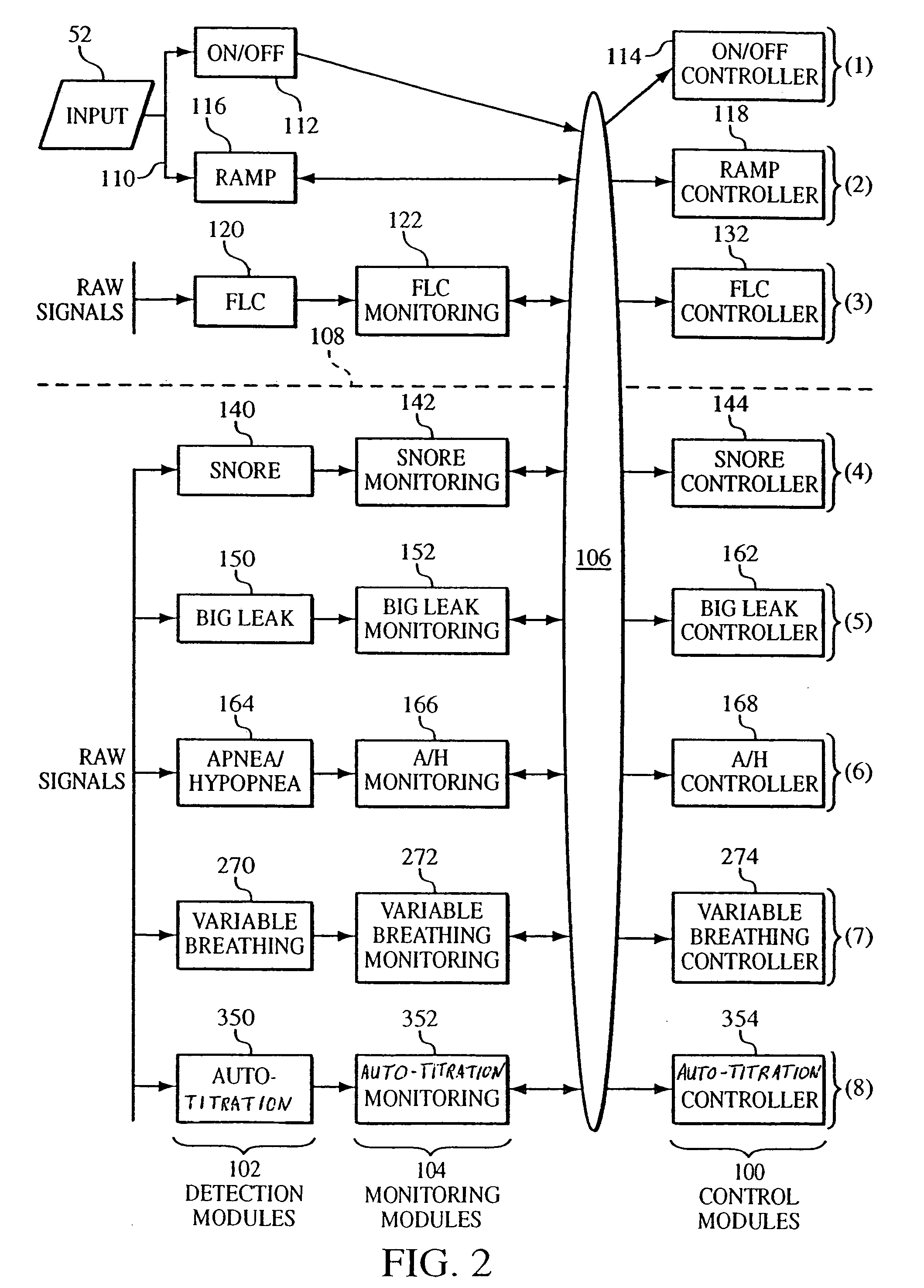

ActiveUS20060000475A1Overcomes shortcomingRespiratorsOperating means/releasing devices for valvesDuring expirationPatient comfort

A bi-level pressure support system and method of treating disordered breathing that optimizes the pressure delivered to the patient during inspiration and expiration to treat the disordered breathing while minimizing the delivered pressure for patient comfort. The pressure generating system generates a flow of breathing gas at an inspiratory positive airway pressure (IPAP) during inspiration and at an expiratory positive airway pressure (EPAP) during expirations. A controller monitor at least one of the following conditions: (1) snoring, (2) apneas, (3) hypopneas, or (4) a big leak in the pressure support system and adjusts the IPAP and the EPAP independently based on the occurrence of any one of these conditions.

Owner:RIC INVESTMENTS LLC

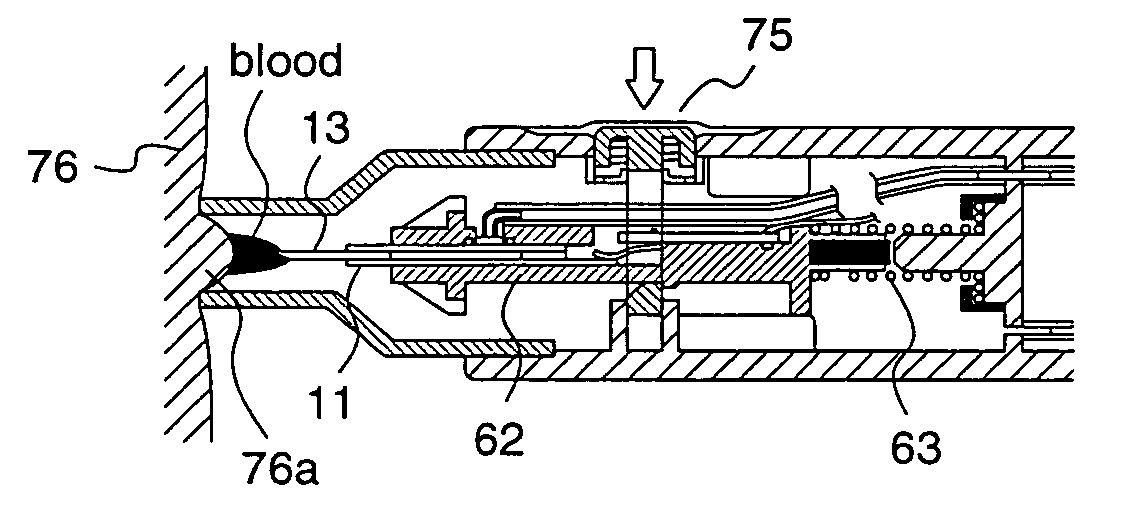

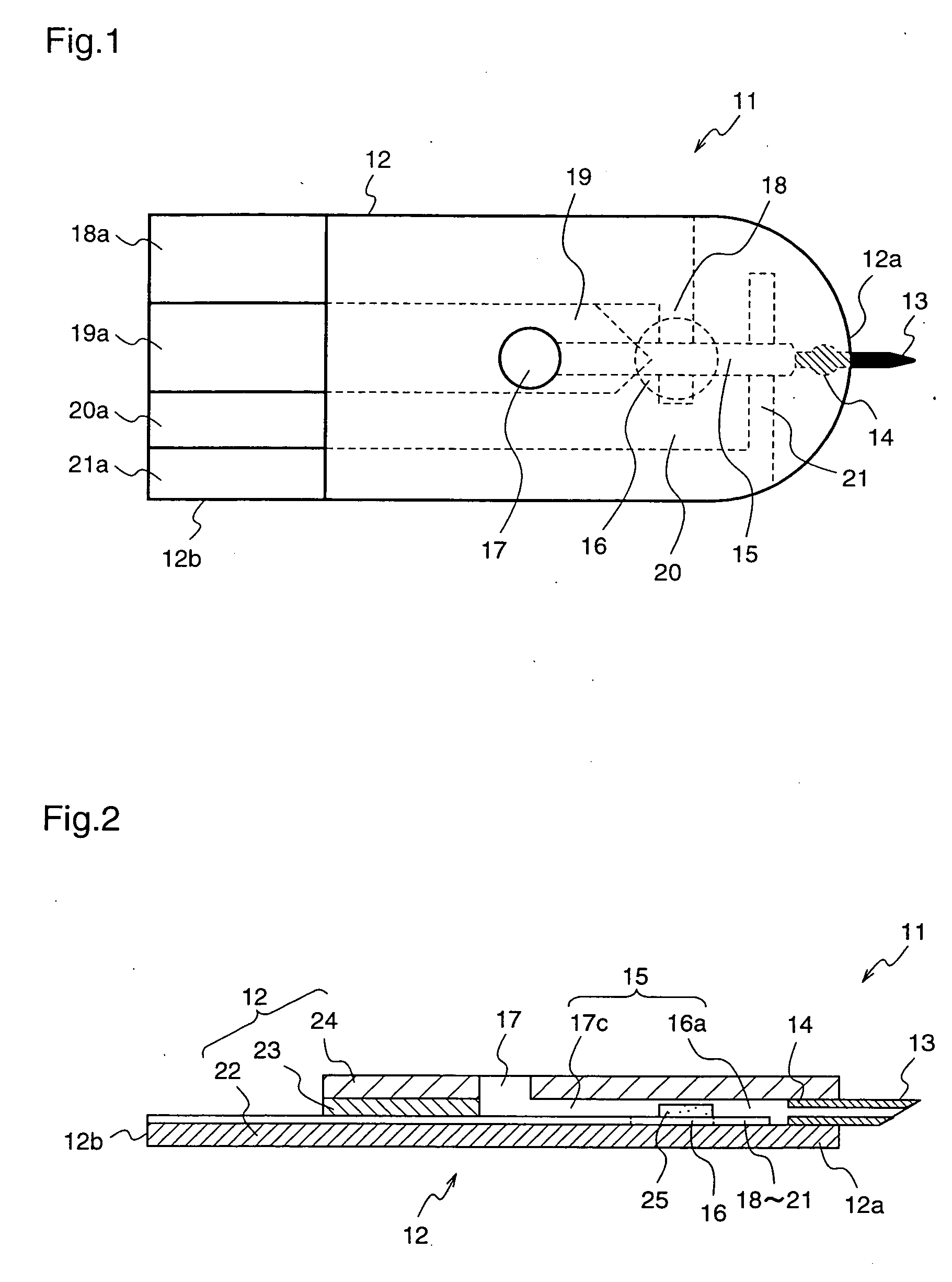

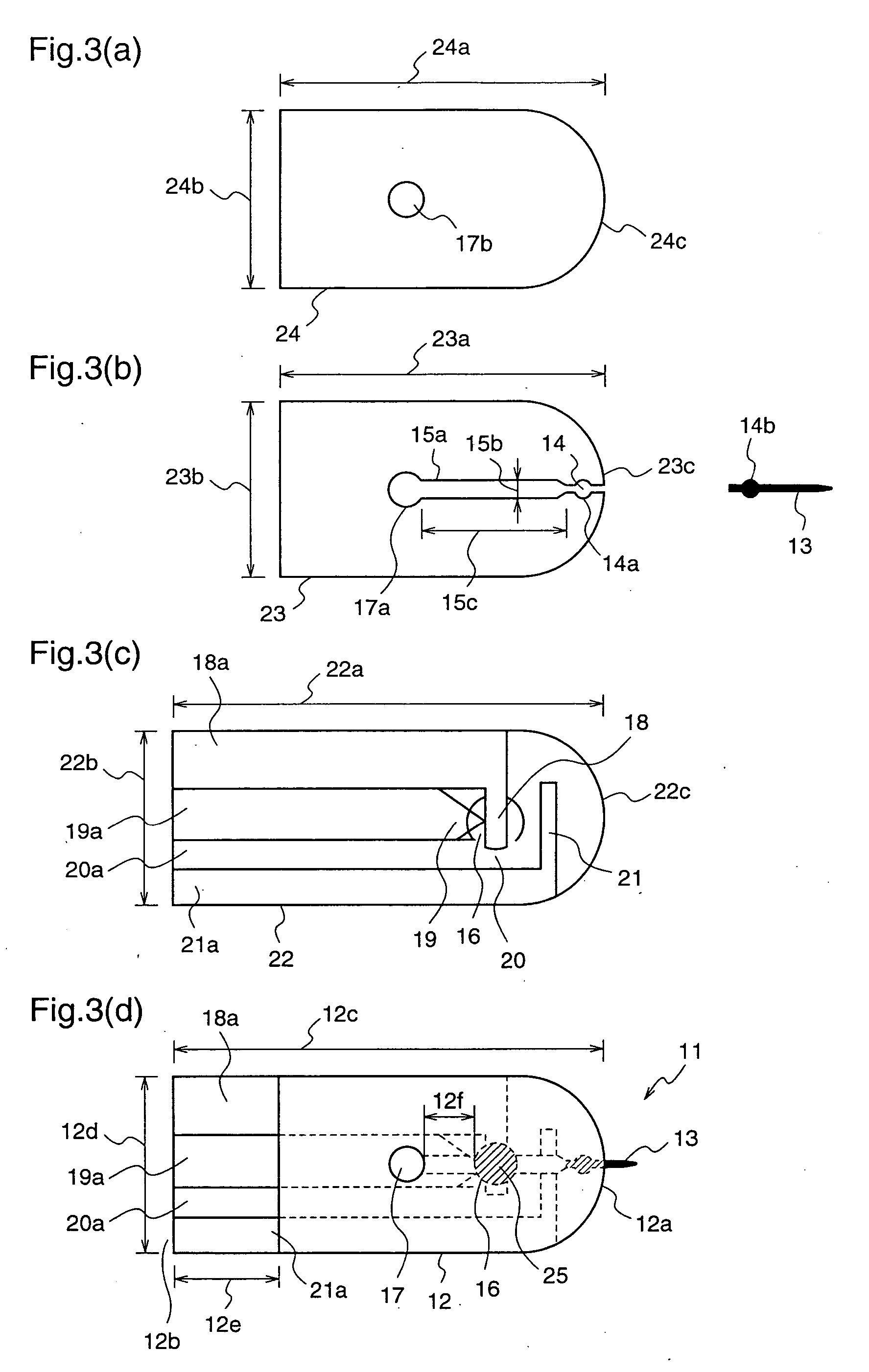

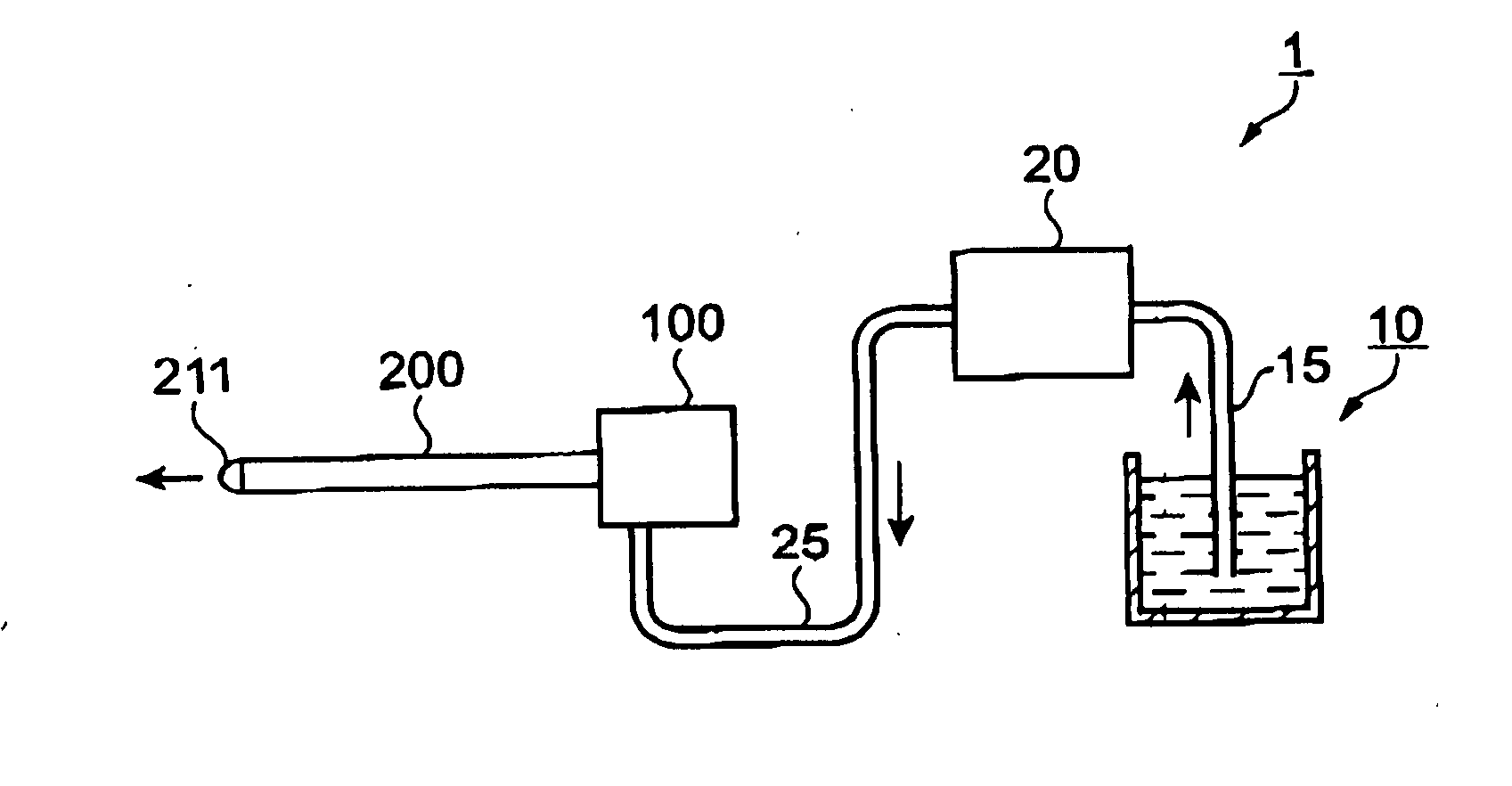

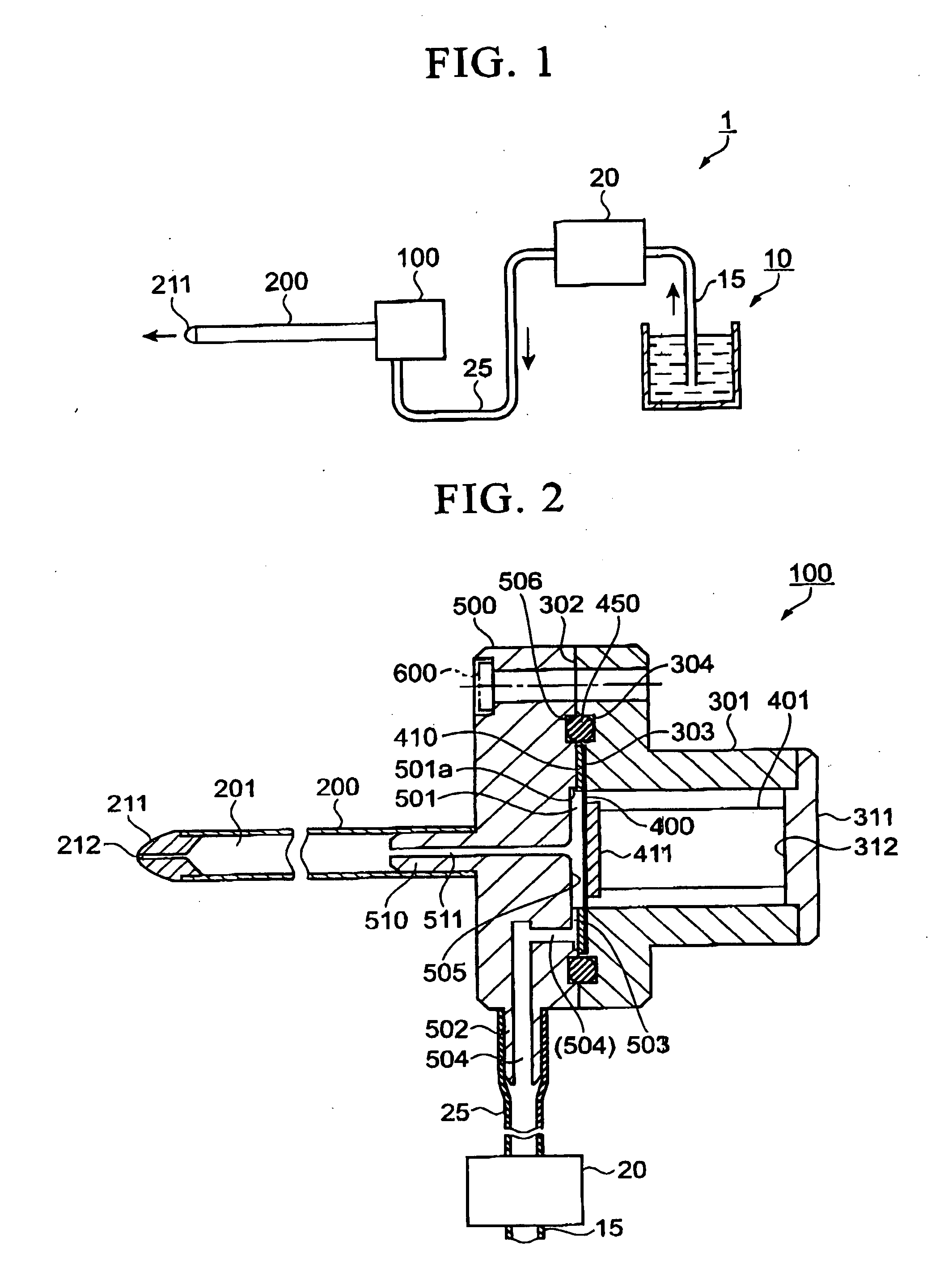

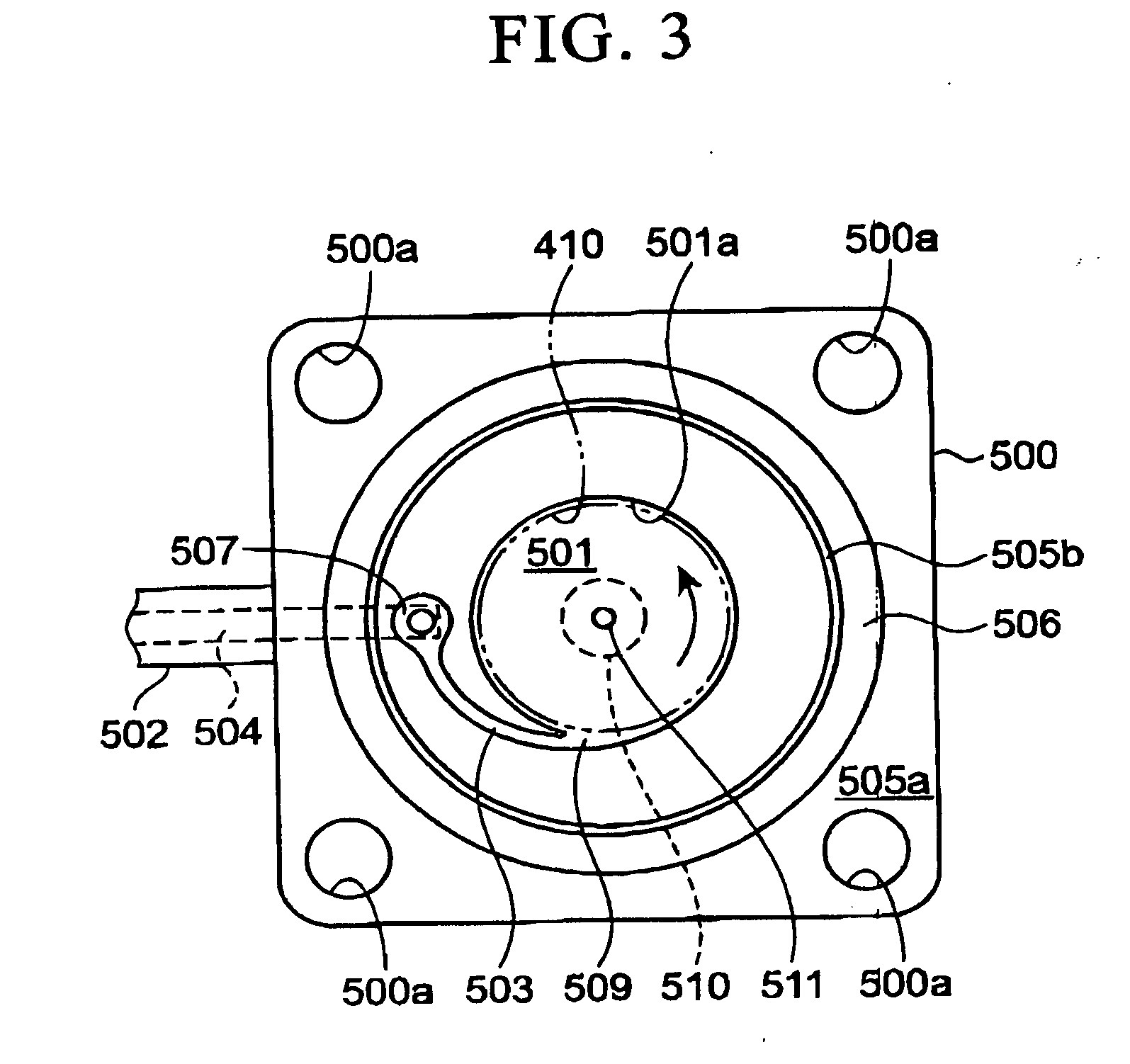

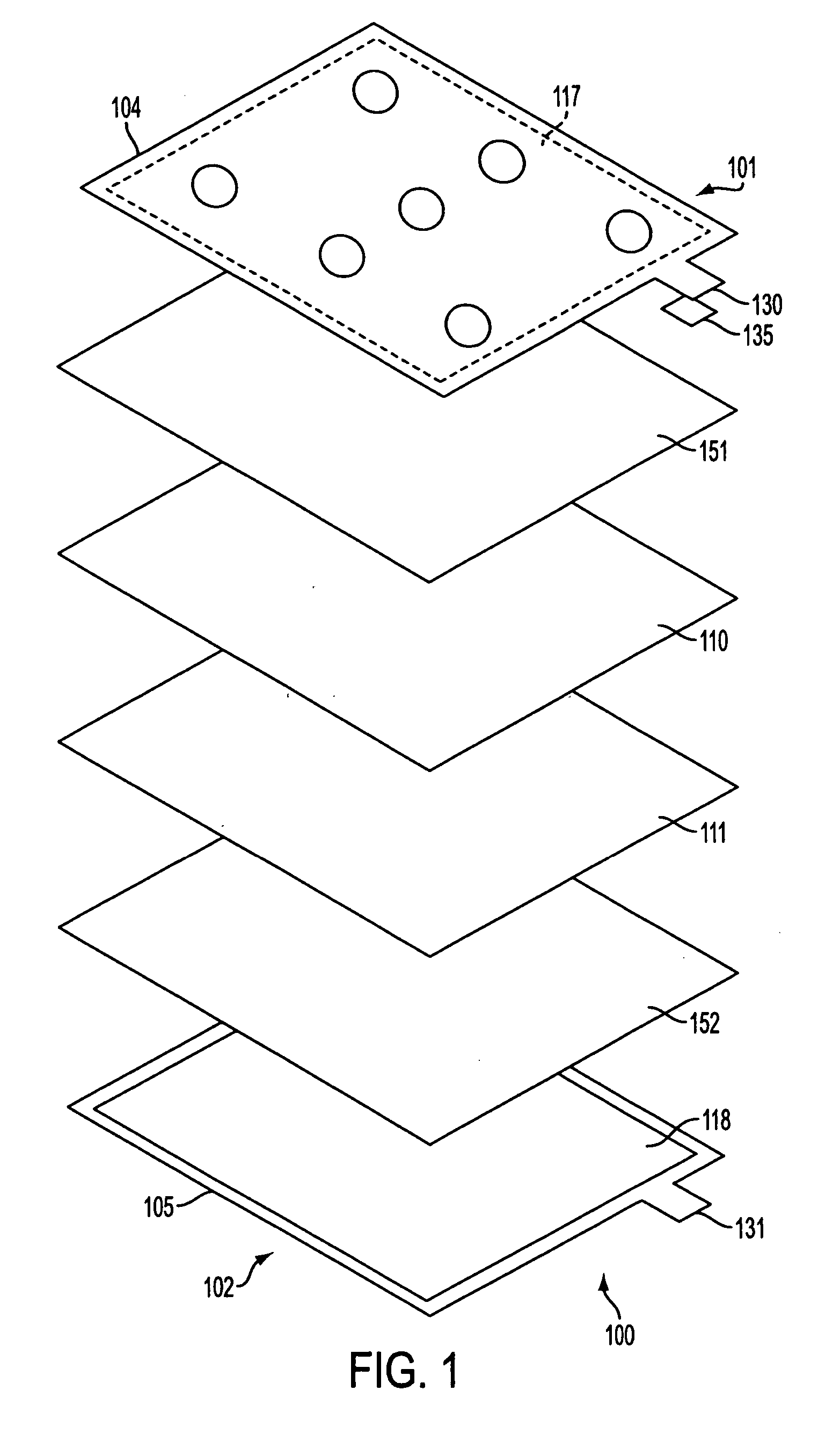

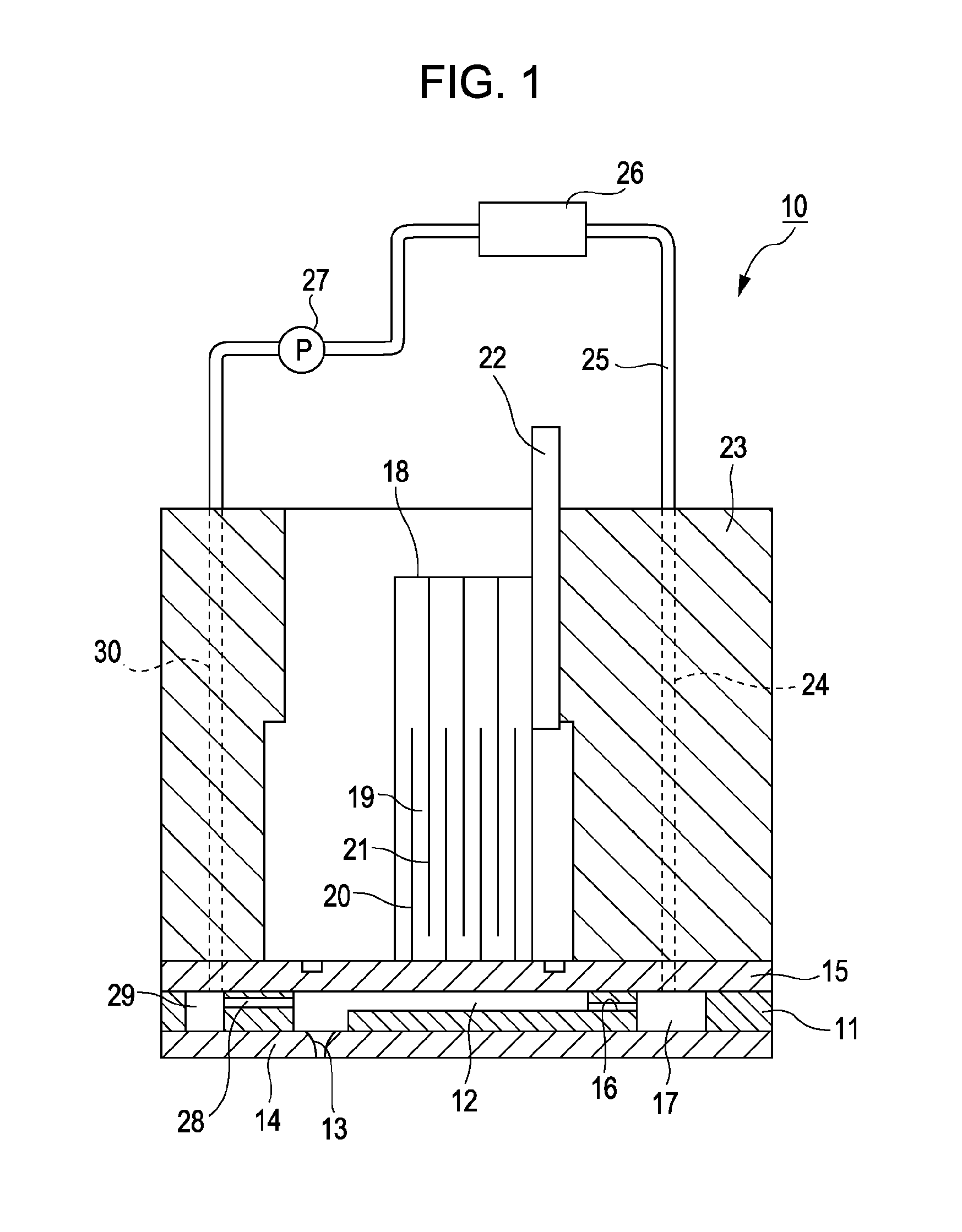

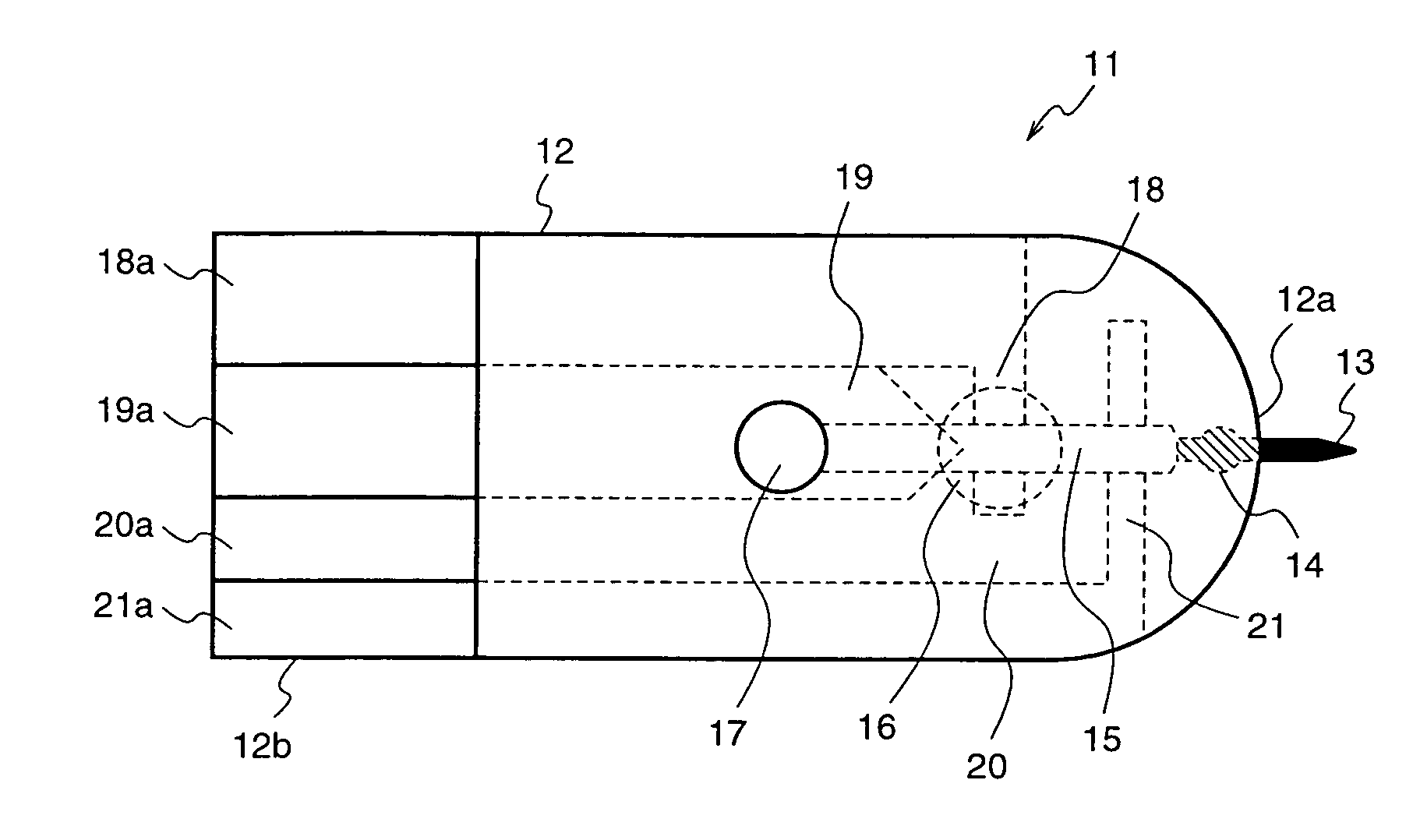

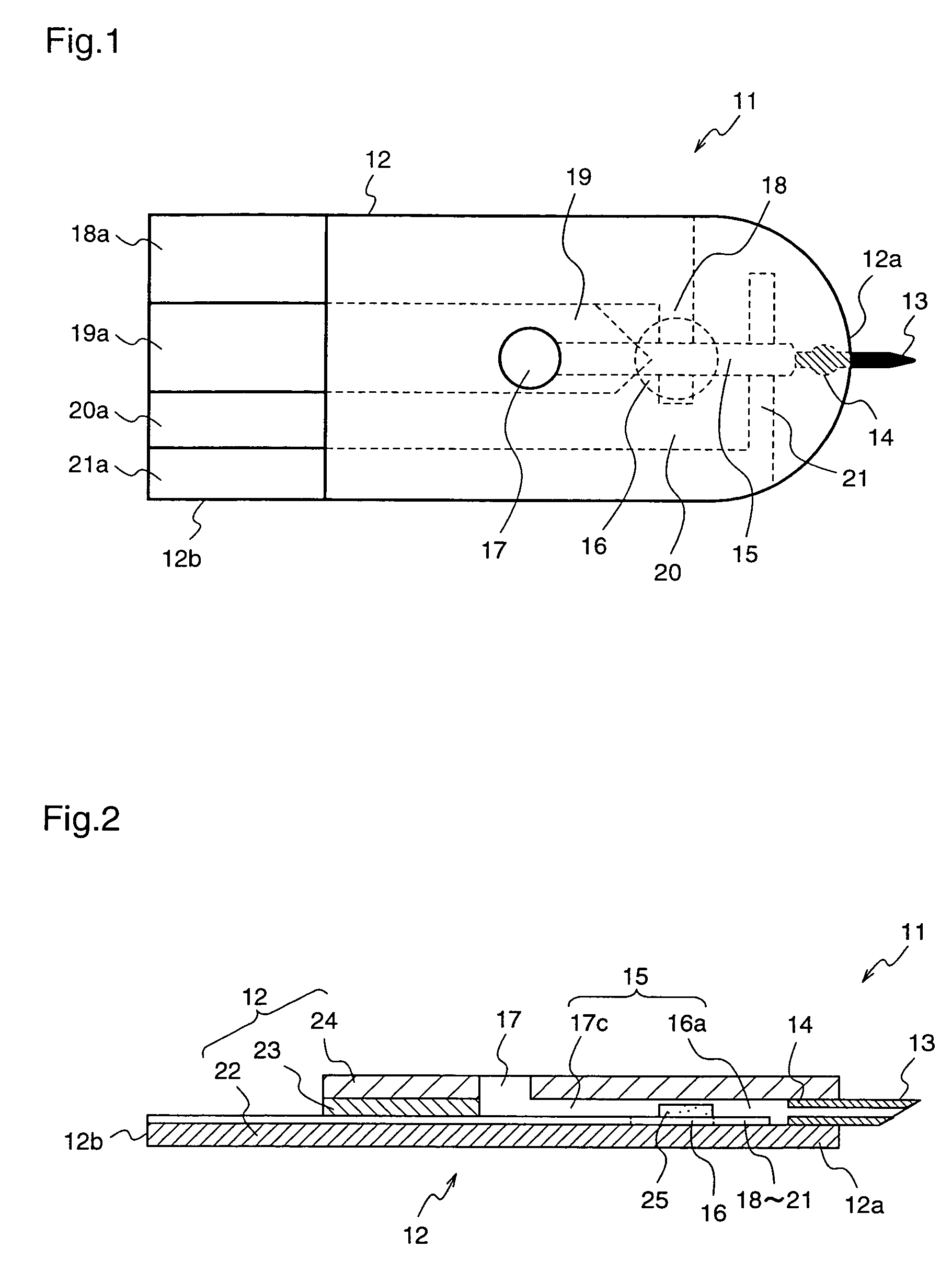

Blood sensor, blood testing apparatus, and method for controlling blood testing apparatus

A blood sensor comprises a base (12), a detection part (16) disposed on the base (12), a blood collection needle (13) disposed at a front end (12a) of the base (12), a negative pressure generation part (17) for applying negative pressure to a portion of the blood collection needle (13), and a supply path (15) for supplying blood collected by the blood collection needle (13) to a detection part (16).

Owner:PHC HLDG CORP

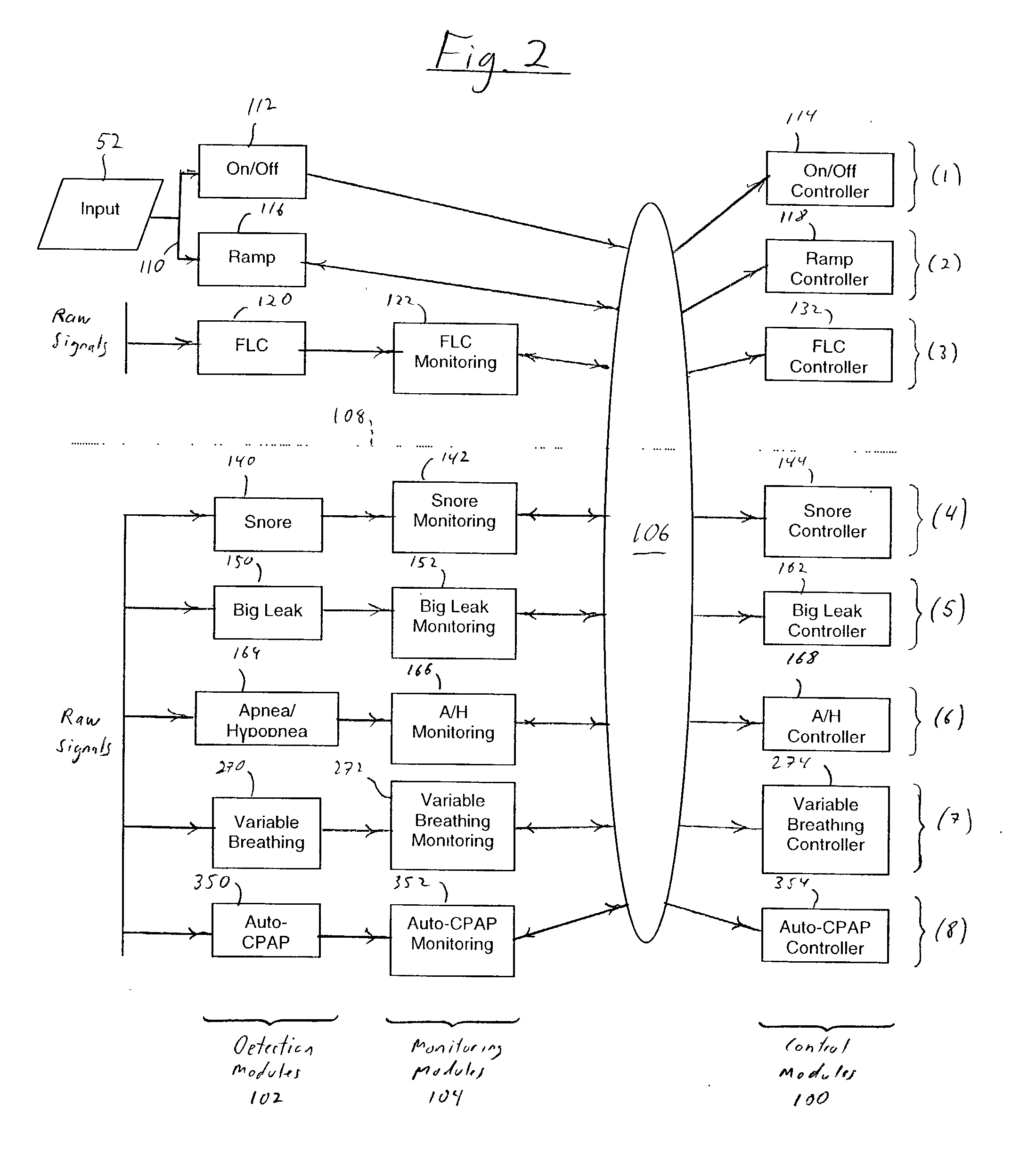

Auto-titration pressure support system and method of using same

InactiveUS20030111079A1Increase pressureRespiratorsOperating means/releasing devices for valvesStress minimizationControl layer

A pressure support system and method of treating disordered breathing that optimizes the pressure delivered to the patient to treat the disordered breathing while minimizing the delivered pressure for patient comfort. The controller in the pressure support system operates as a set of prioritized control layers, wherein each control layer competes for control of the pressure generating system to implement a unique pressure control process. The pressure support system also controls the pressure provided to the patient based on the variability of the monitored data and a trend analysis of this data, including an indication the skewness of the patient's inspiratory waveform.

Owner:RIC INVESTMENTS LLC

Drug infusion device

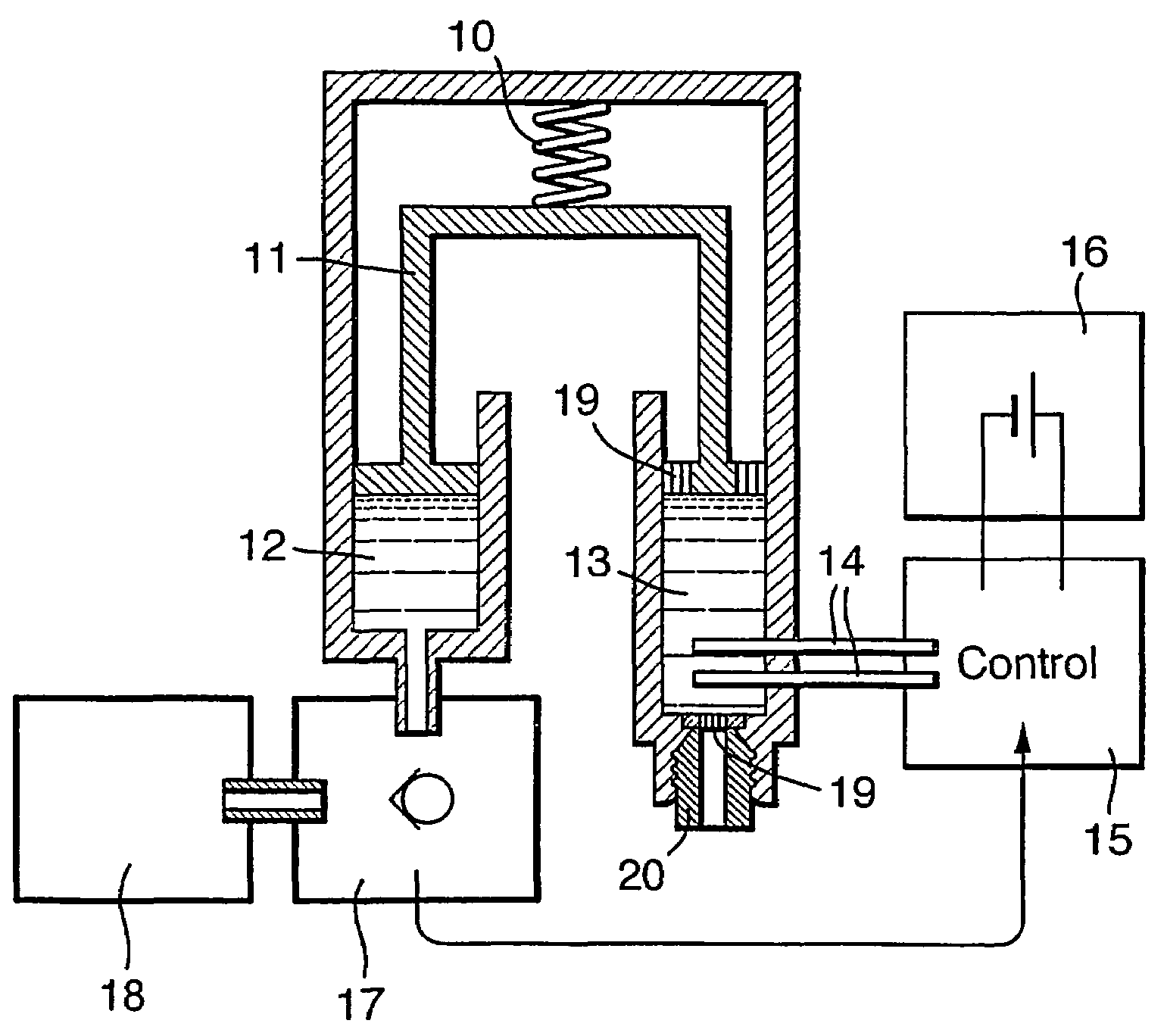

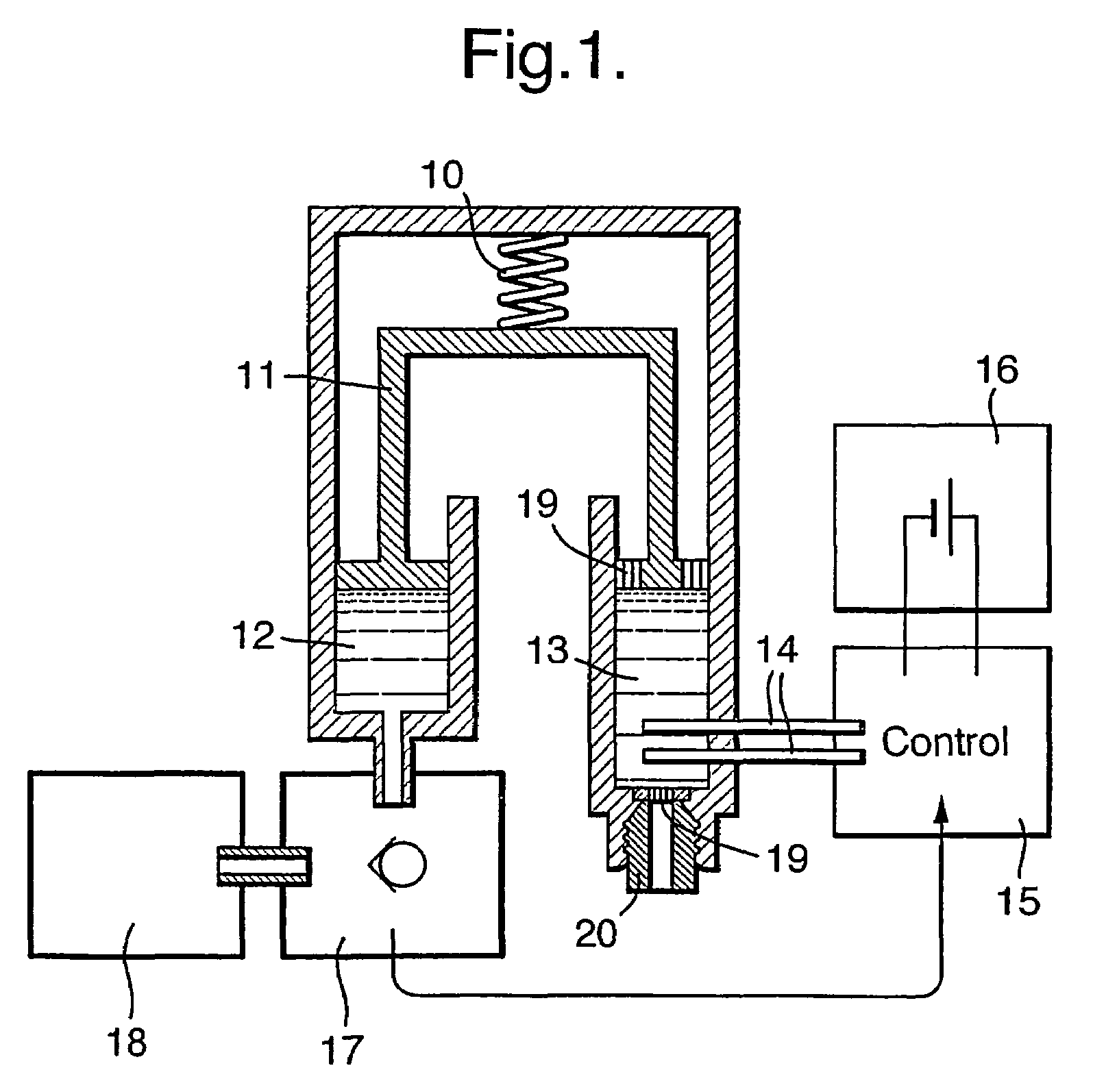

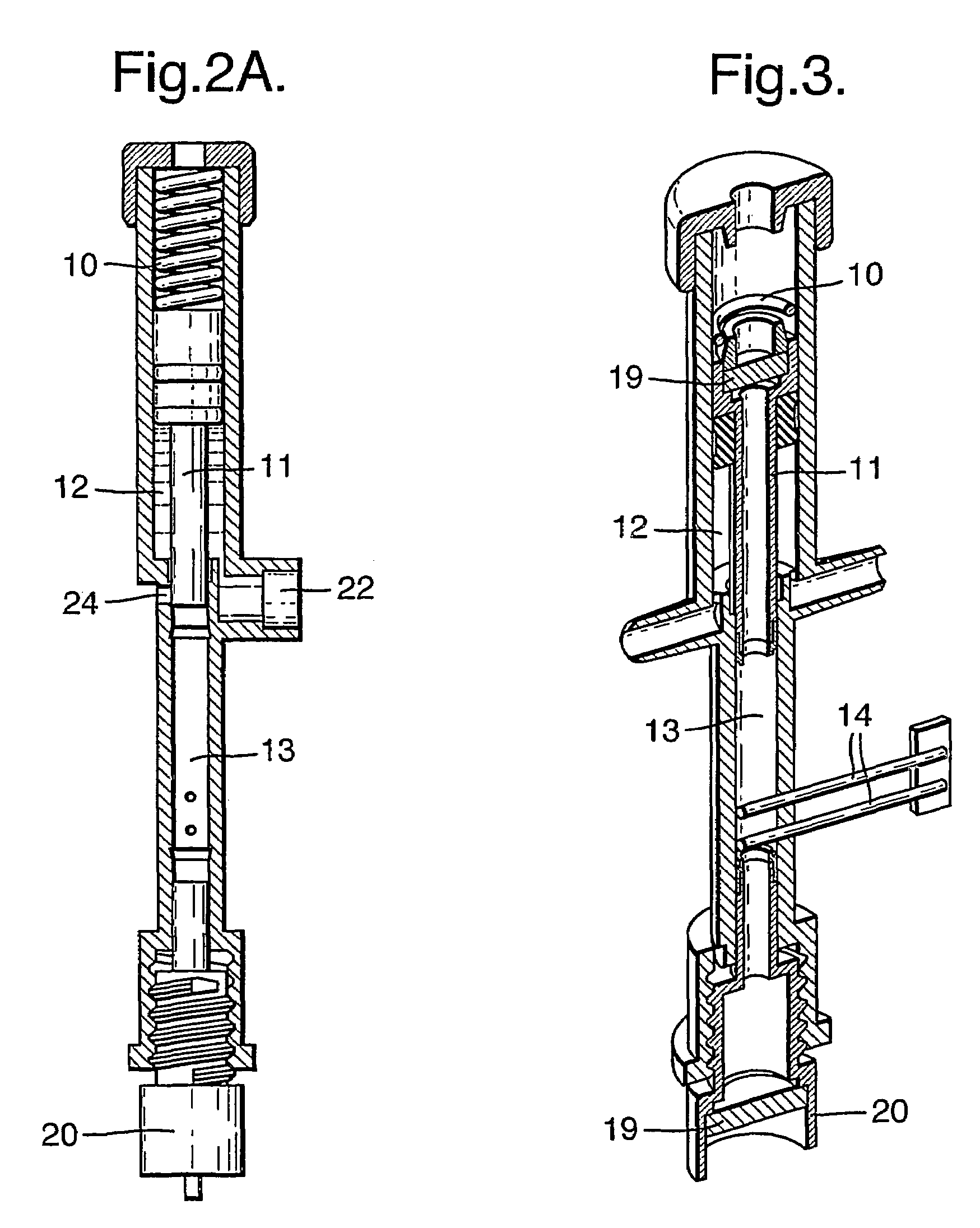

ActiveUS7524304B2Stable and constant infusion deviceFriction effect is negligibleAutomatic syringesPharmaceutical delivery mechanismDrug reservoirMedication infusion

The invention provides a drug delivery infusion device comprising an injection means (18) in fluid connection with a drug reservoir chamber (12) and pressure-generation means (10) coupled to both the drug reservoir (12) and to a liquid-filled control chamber (13), wherein the coupling is such that the liquid-filled control chamber (13) serves to constrain the motion of the pressure-generation means (10), thereby controlling the drug infusion rate, wherein the liquid-filled control chamber (13) is associated with means for controlled depletion of the liquid therein whereby depletion of the volume of liquid in the control chamber enables the pressure-generation means to drive the drug in the reservoir chamber therefrom for infusion thereof.

Owner:UNITED THERAPEUTICS CORP

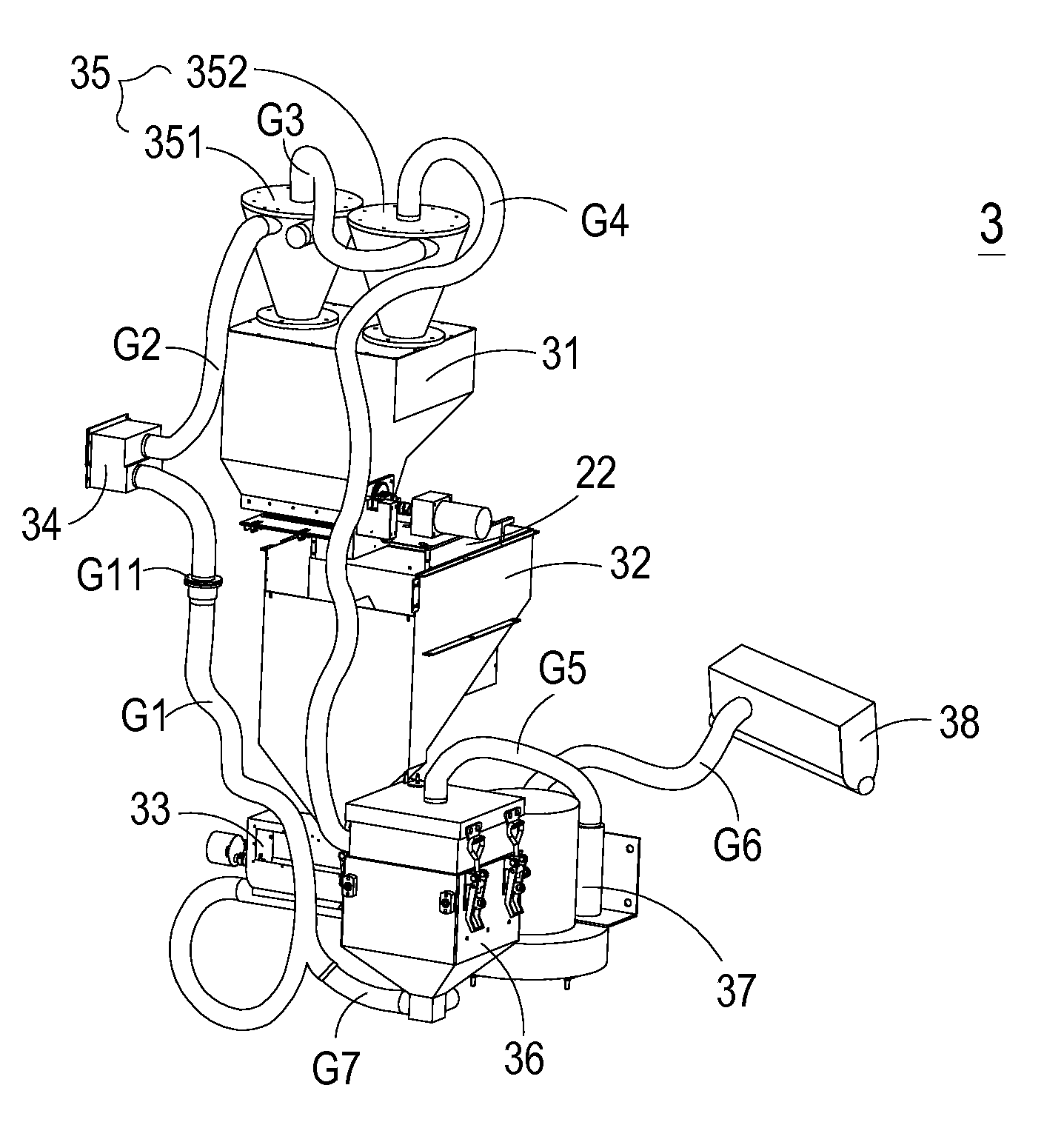

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

Auto-titration pressure support system and method of using same

InactiveUS20040187870A1Increase pressureRespiratorsOperating means/releasing devices for valvesStress minimizationControl layer

A pressure support system and method of treating disordered breathing that optimizes the pressure delivered to the patient to treat the disordered breathing while minimizing the delivered pressure for patient comfort. The controller in the pressure support system operates as a set of prioritized control layers, wherein each control layer competes for control of the pressure generating system to implement a unique pressure control process. The pressure support system also controls the pressure provided to the patient based on the variability of the monitored data and a trend analysis of this data, including an indication of the skewness of the patient's inspiratory waveform.

Owner:RIC INVESTMENTS LLC

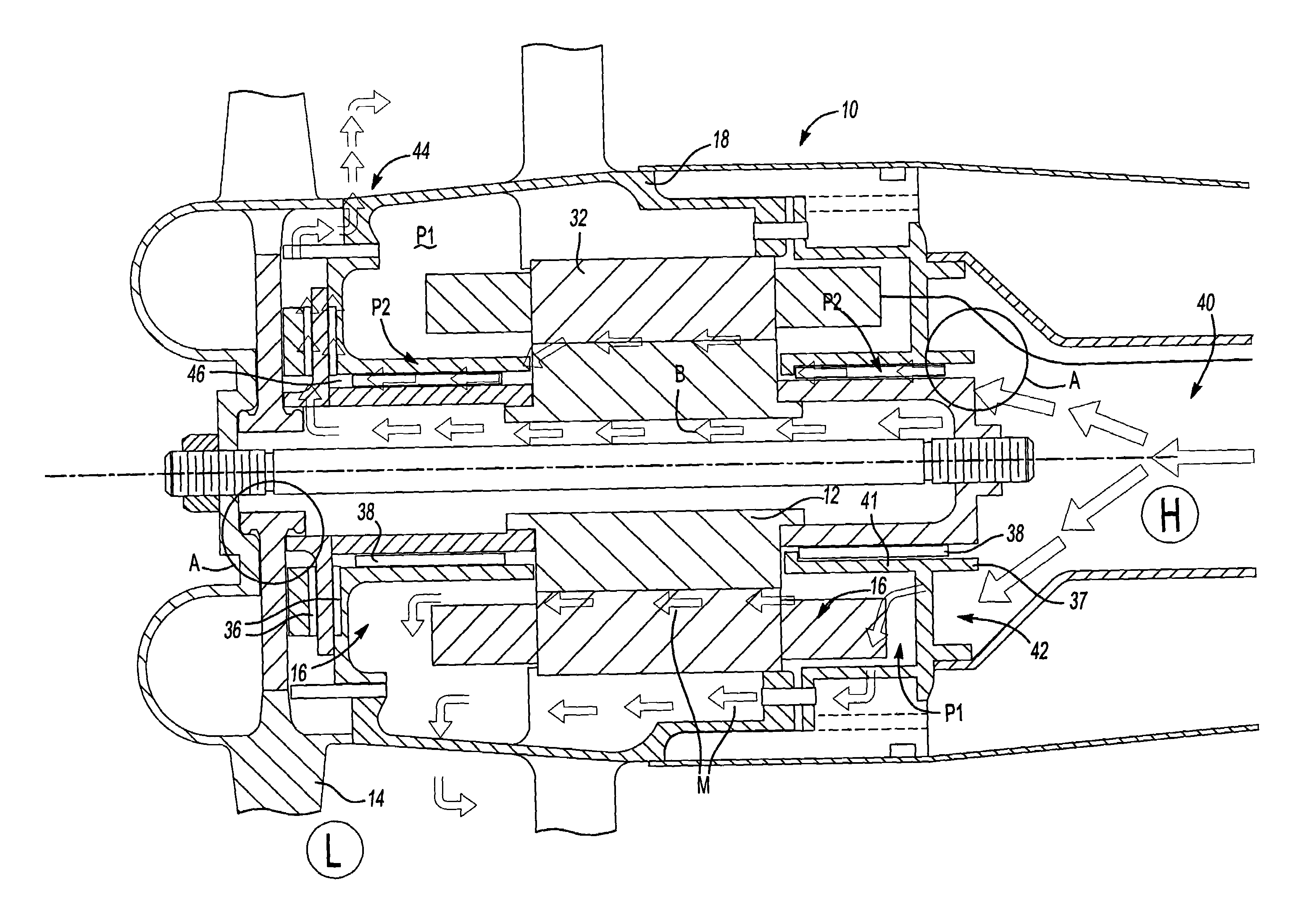

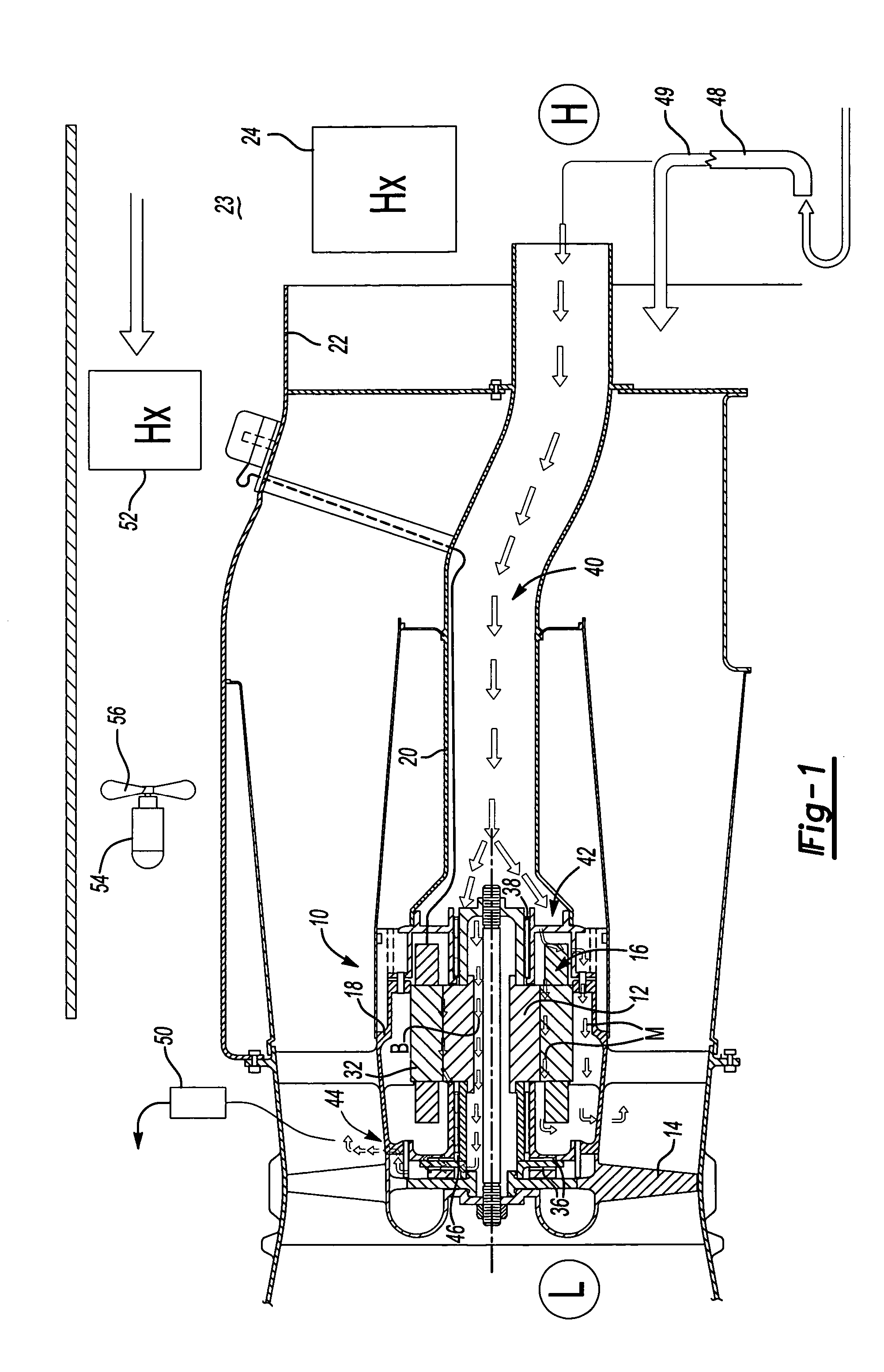

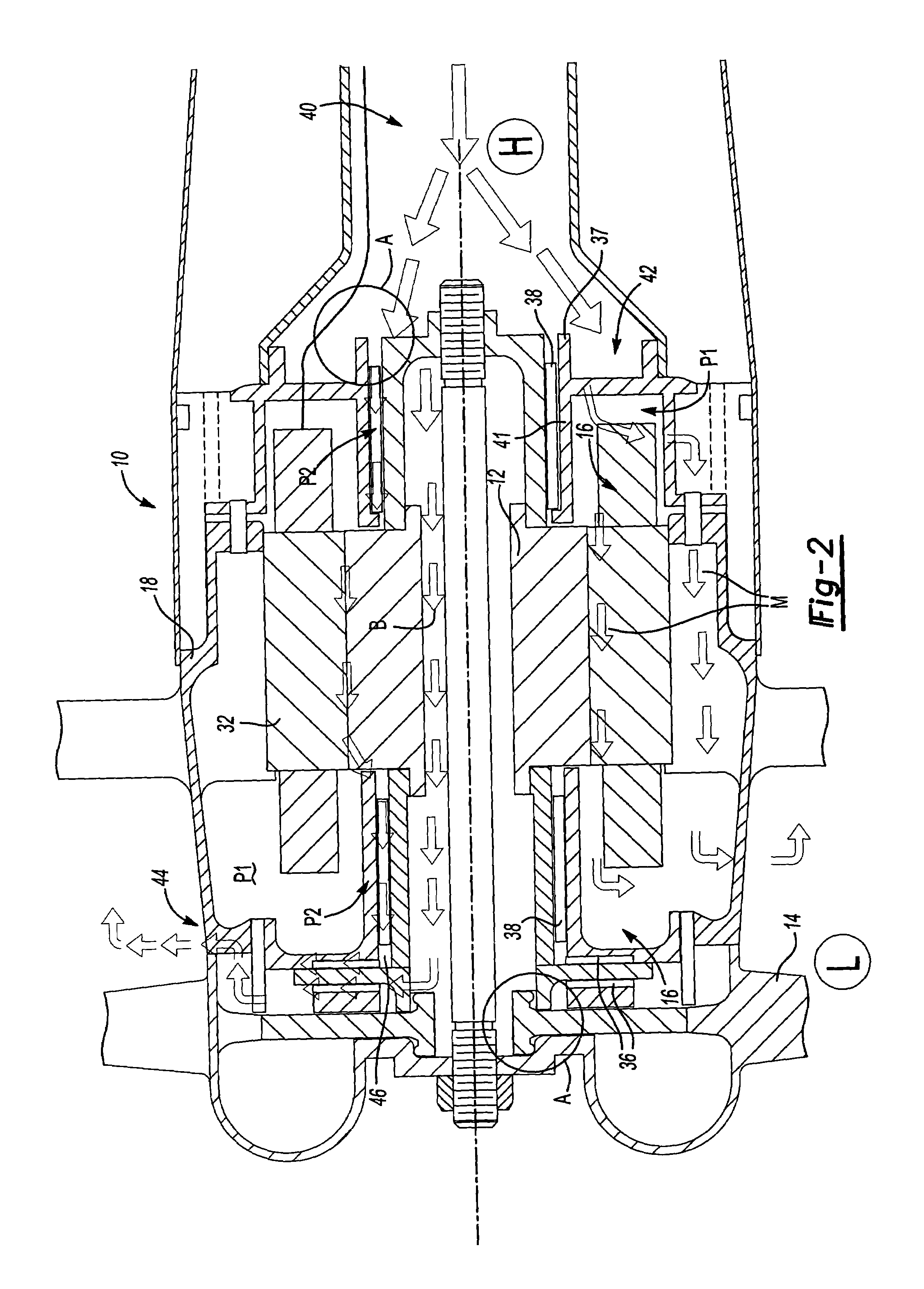

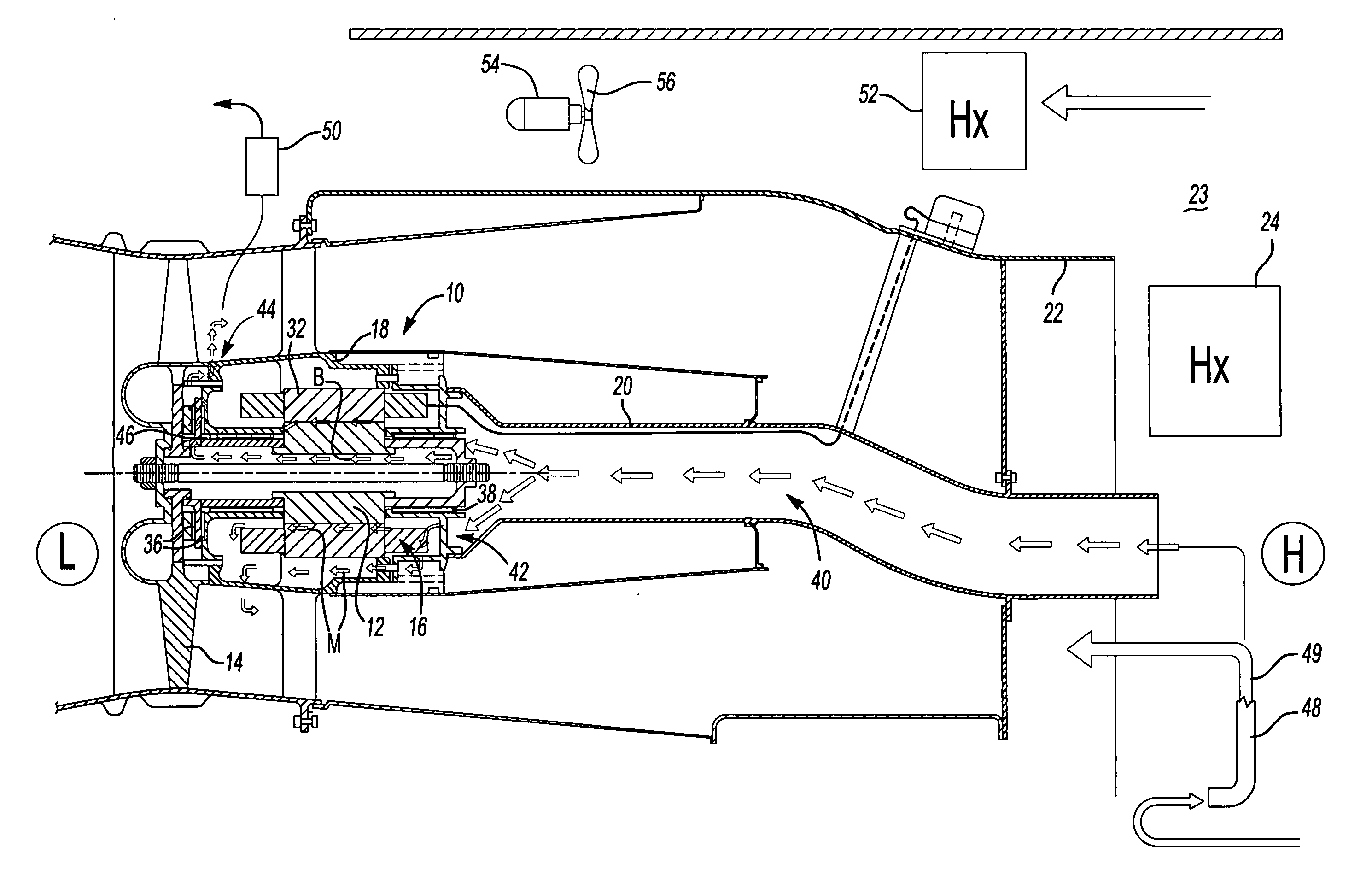

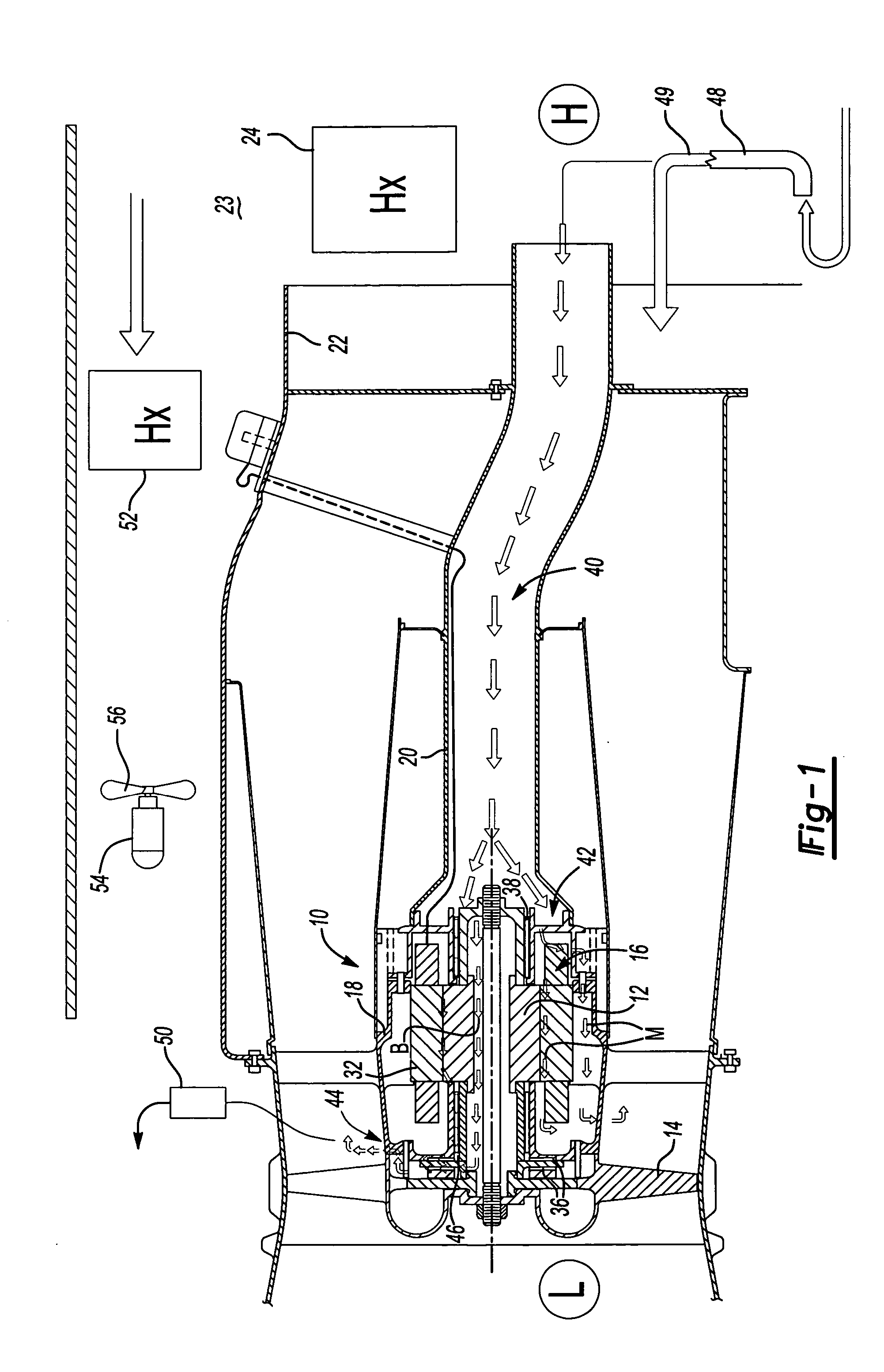

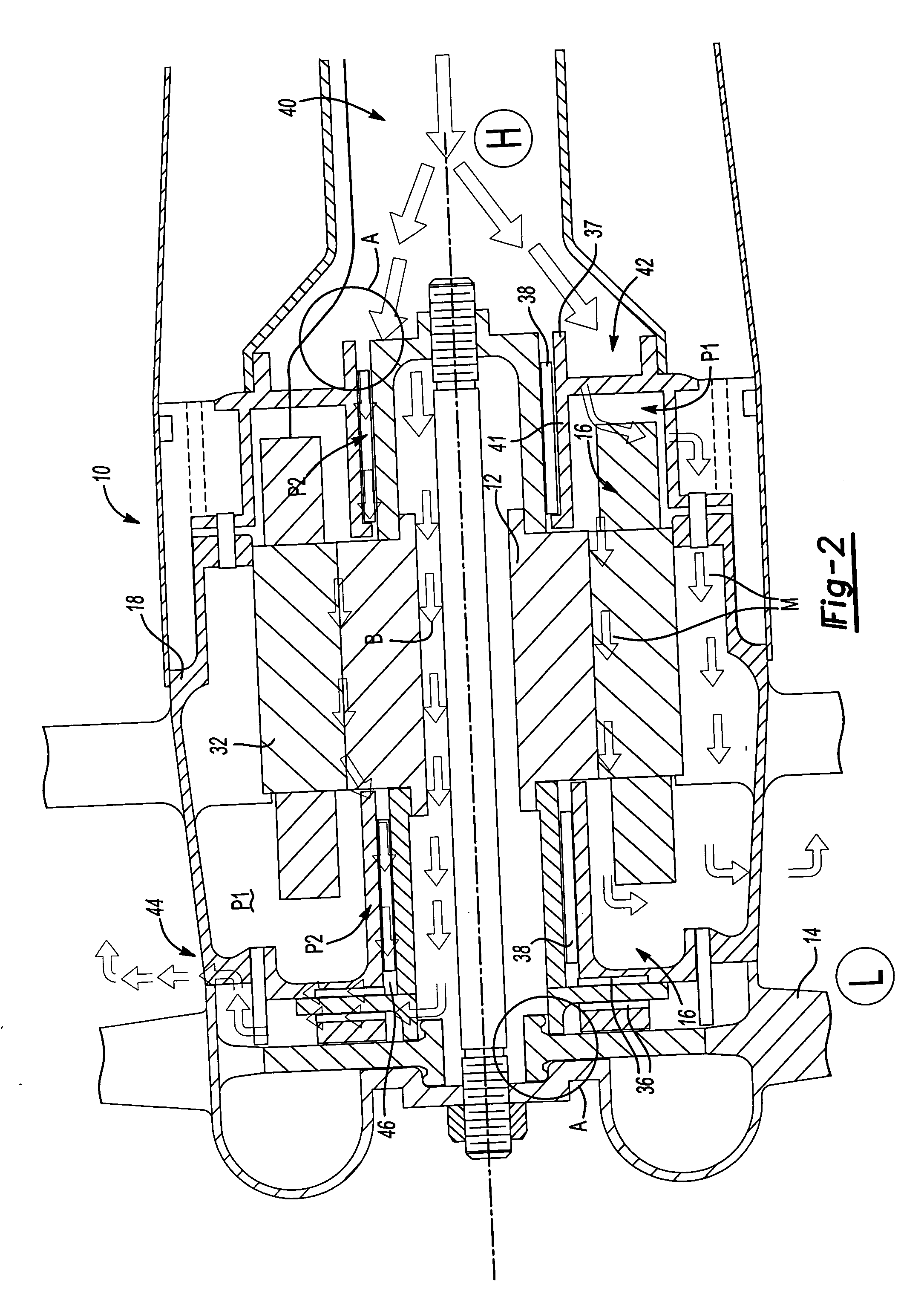

Integral motor and air bearing cooling path

ActiveUS7394175B2Reduce complexityLow costPump componentsMechanical energy handlingPressure generationAir bearing

Owner:HAMILTON SUNDSTRAND CORP

Auto-Titration Bi-Level Pressure Support System and Method of Using Same

InactiveUS20080041382A1Reduce pressureIncrease pressureChemical protectionHeat protectionHypopneaPhysical medicine and rehabilitation

Owner:PHILIPS RS NORTH AMERICA LLC

Auto-Titration Bi-Level Pressure Support System and Method of Using Same

InactiveUS20080041383A1Overcomes shortcomingChemical protectionOperating means/releasing devices for valvesHypopneaPhysical medicine and rehabilitation

Owner:PHILIPS RS NORTH AMERICA LLC

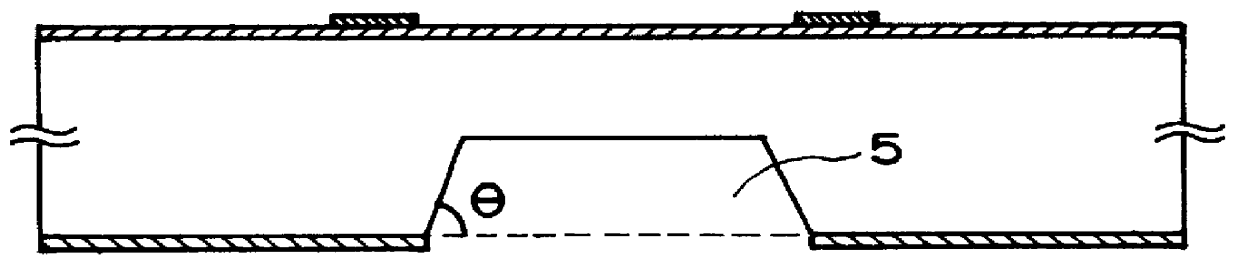

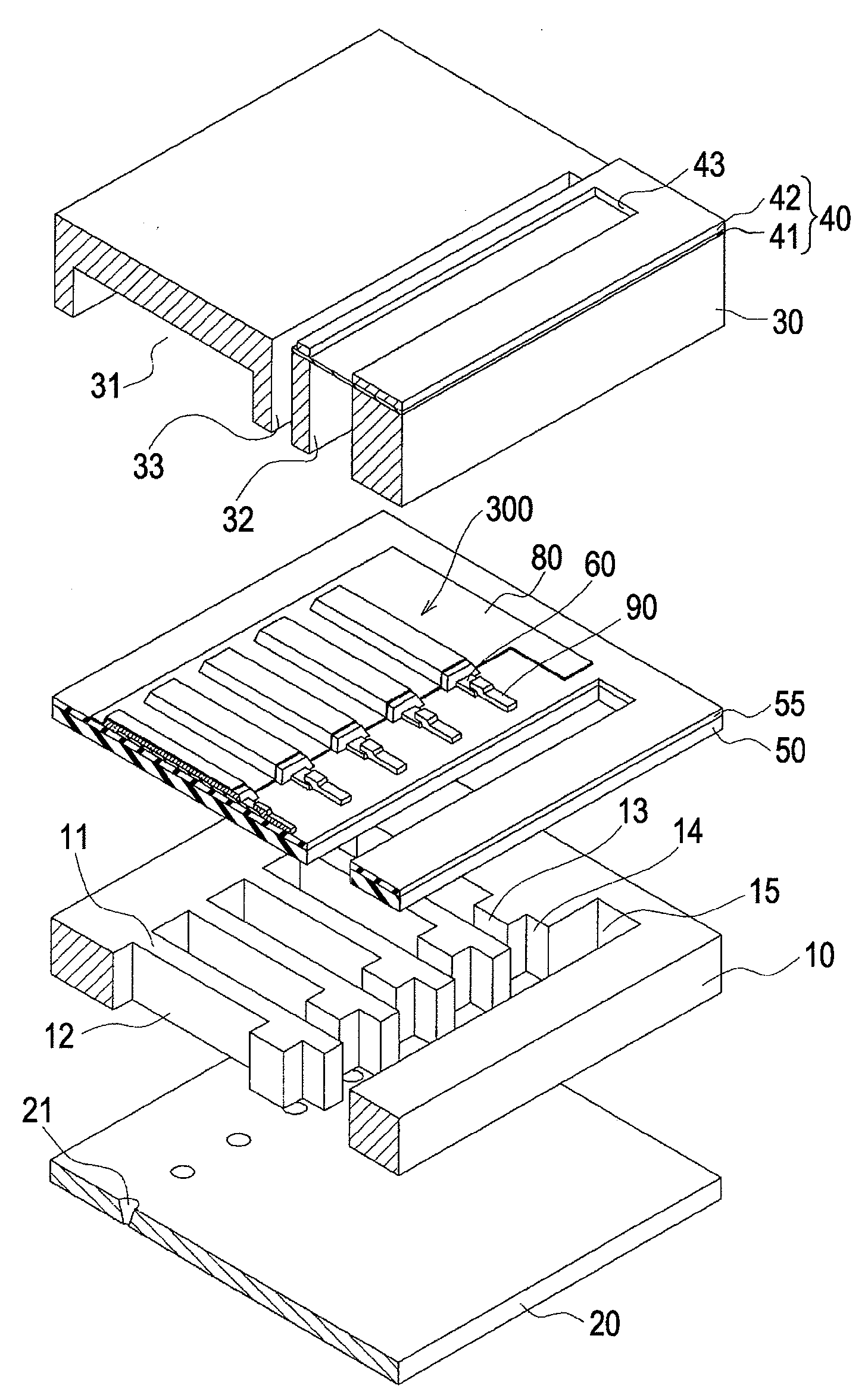

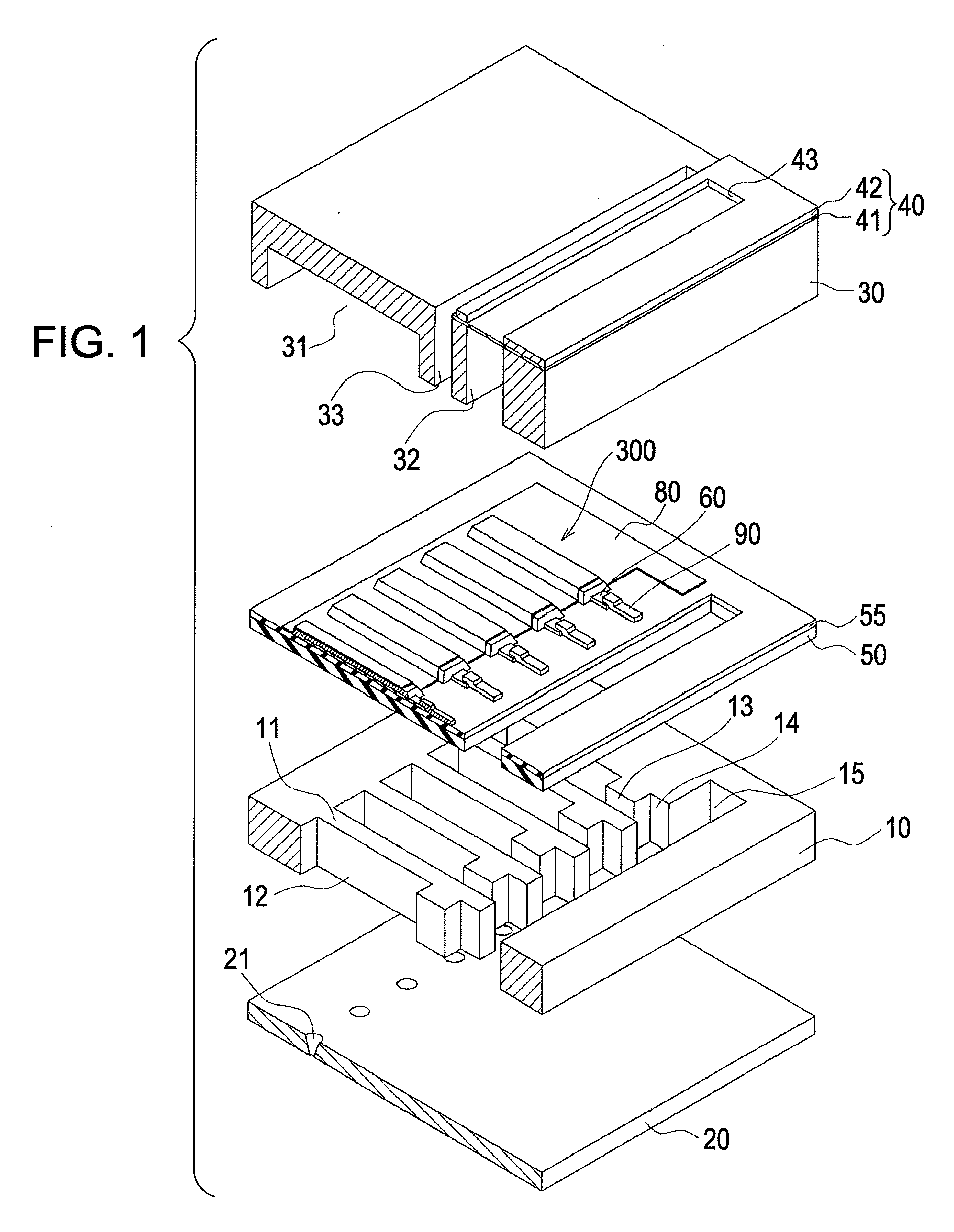

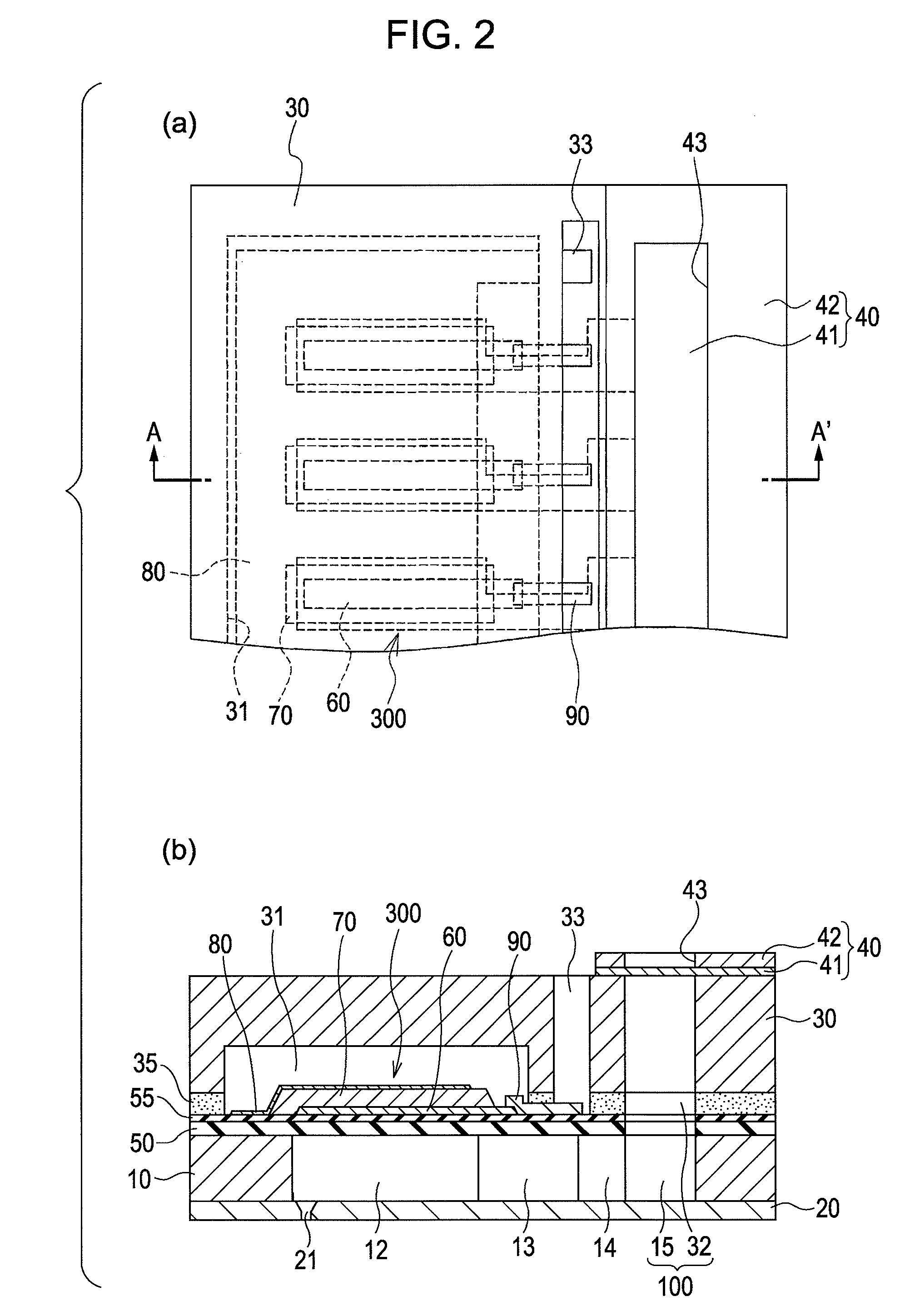

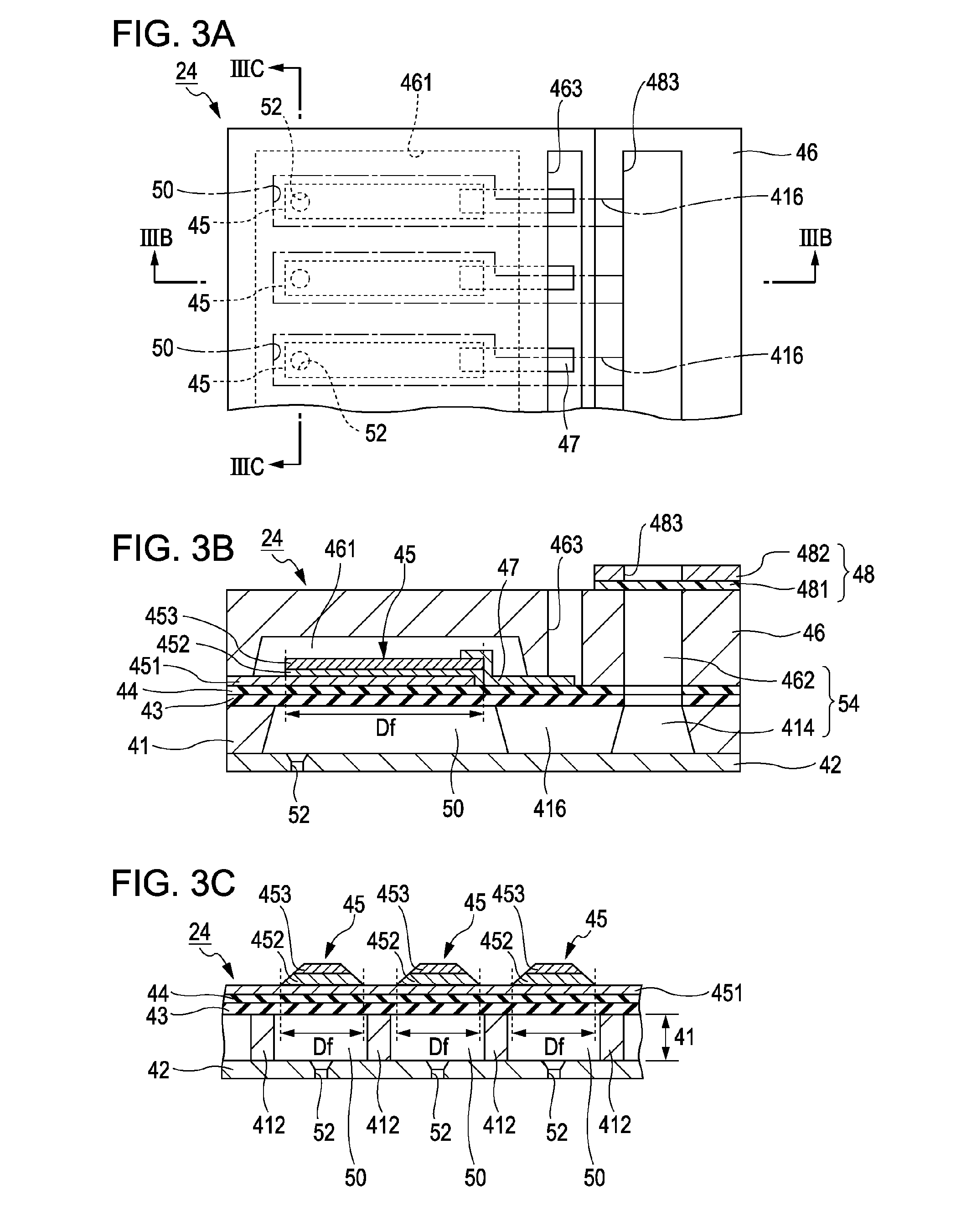

Liquid jet head and a liquid jet apparatus

ActiveUS20090284568A1Preventing piezoelectric elements from being brokenAvoid layeringPrintingLiquid jetPressure generation

A lower electrode 60 in a region opposite each of pressure generation chambers 12 is formed to have a width smaller than the width of the corresponding pressure generation chamber 12, and an upper surface and an end surface of the lower electrode 60 in a region corresponding to each of the pressure generation chambers 12 is covered with a piezoelectric material layer 70. An end surface of the piezoelectric material layer 70 forms a slope surface sloping downward toward the outside, an upper surface and an end surface of the piezoelectric material layer 70 in the region opposite each of the pressure generation chambers 12 are covered with an upper electrode 80, and a distance D1 between the upper surface of the lower electrode 60 and the upper surface of the piezoelectric material layer 70 and a distance D2 between the end surface of the lower electrode and the end surface of the piezoelectric material layer 70 satisfy the relationship D2≧D1.

Owner:SEIKO EPSON CORP

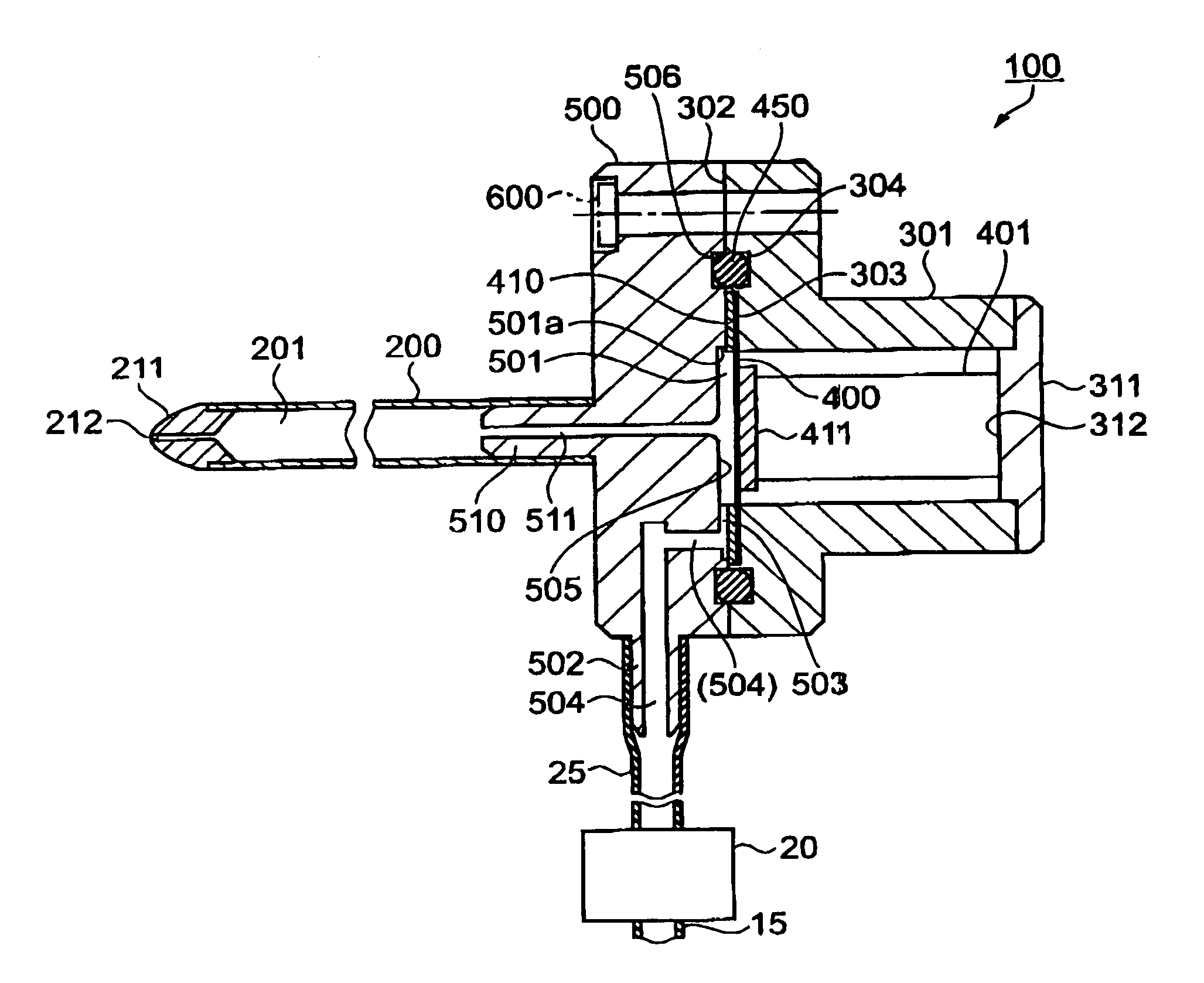

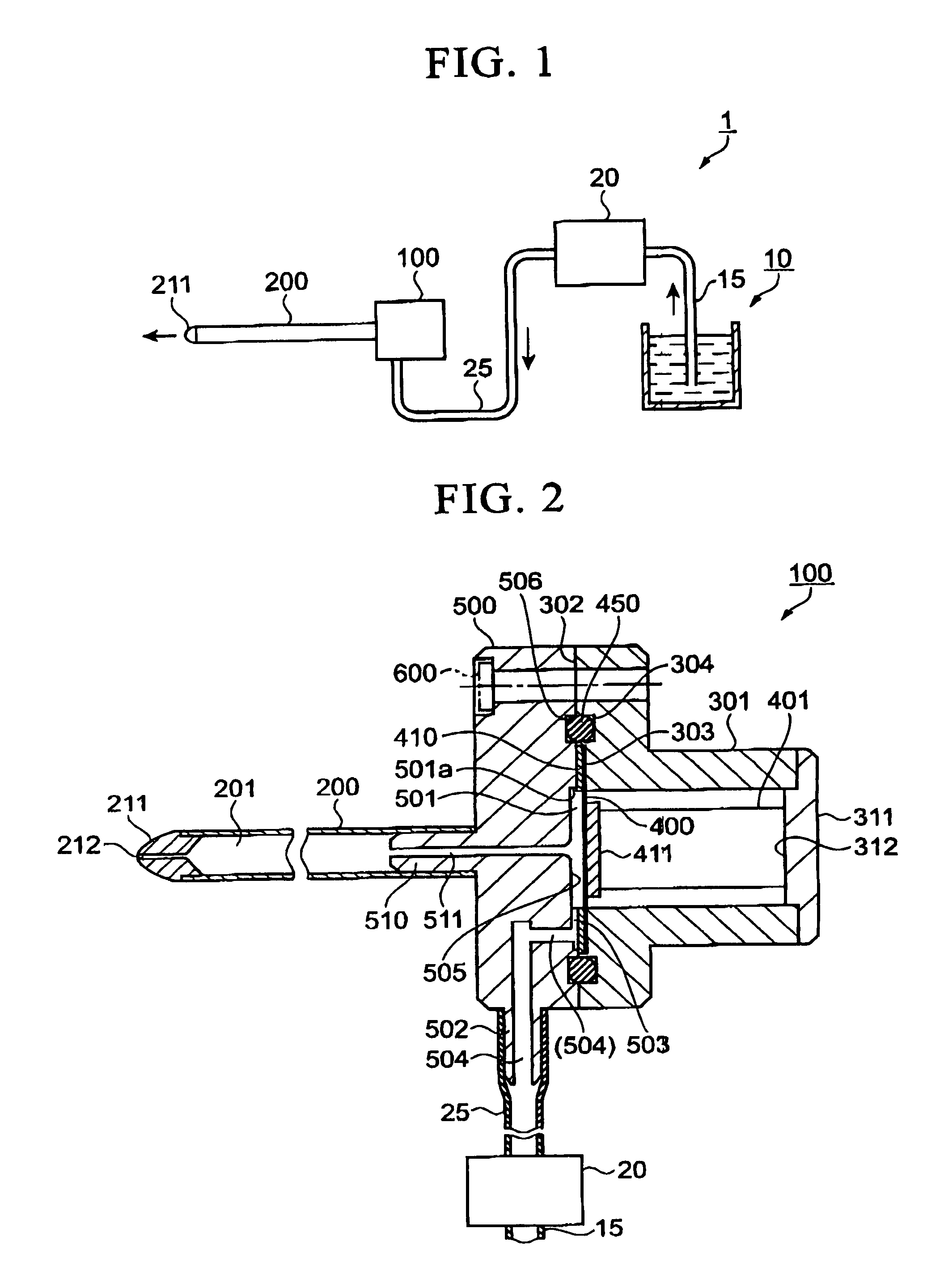

Fluid injection device

ActiveUS20080086077A1Prevent liquid leakageRise of pressure is not hinderedCannulasDispensing apparatusPressure generationEngineering

A fluid injection device includes: a pulse generation section that includes a fluid chamber whose volume is changeable, and an inlet flow passage and an outlet flow passage that are connected to the fluid chamber; a first connection flow passage connected to the outlet flow passage, having an end portion; a second connection flow passage connected to the inlet flow passage; a fluid injection opening formed at the end portion of the first connection flow passage, having a diameter smaller than the diameter of the outlet flow passage; a connection flow passage tube including the first connection flow passage and having rigidity adequate to transmit pules of fluid flowing from the fluid chamber to the fluid injection opening; and a pressure generation section that supplies fluid to the inlet flow passage.

Owner:SEIKO EPSON CORP +1

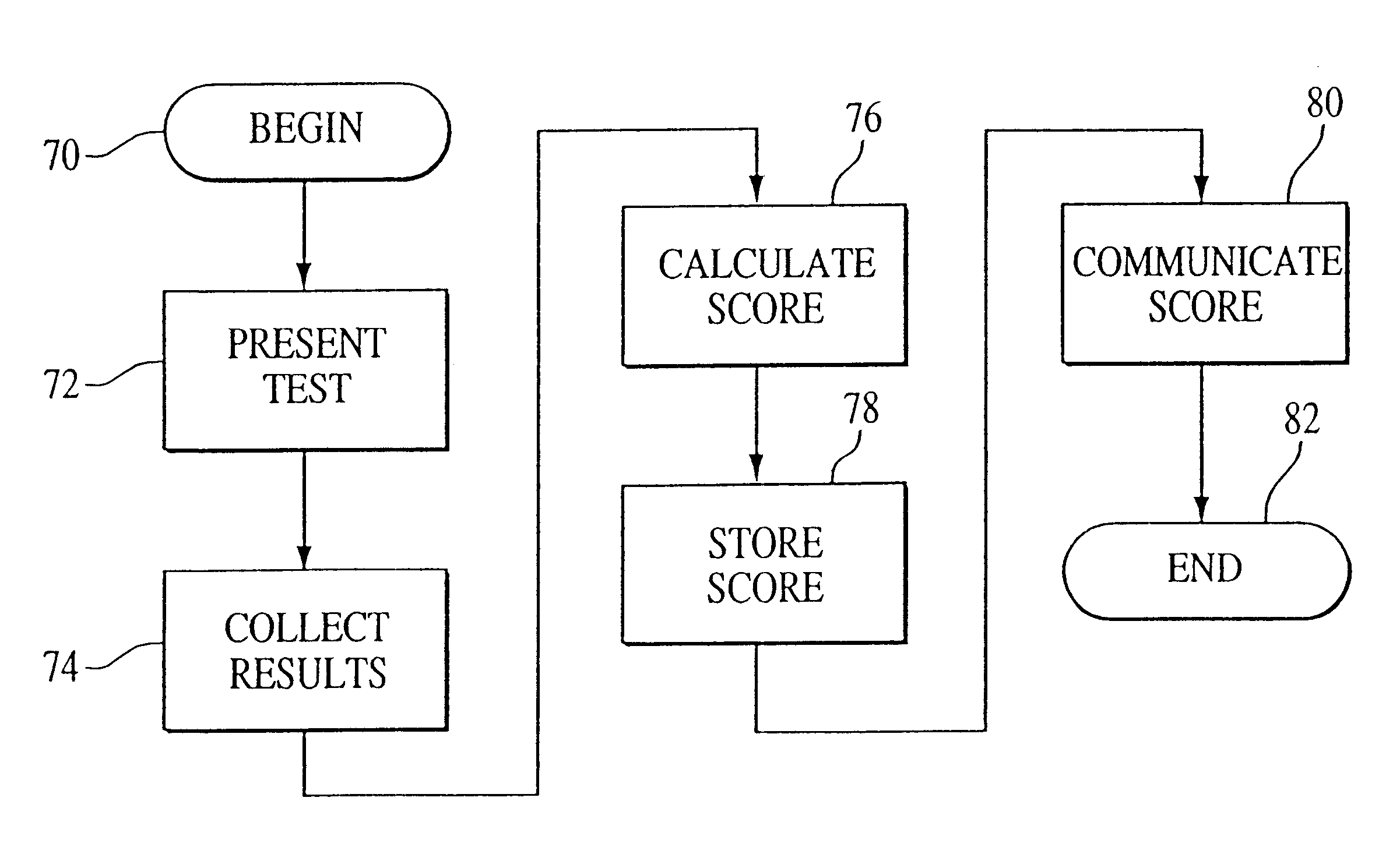

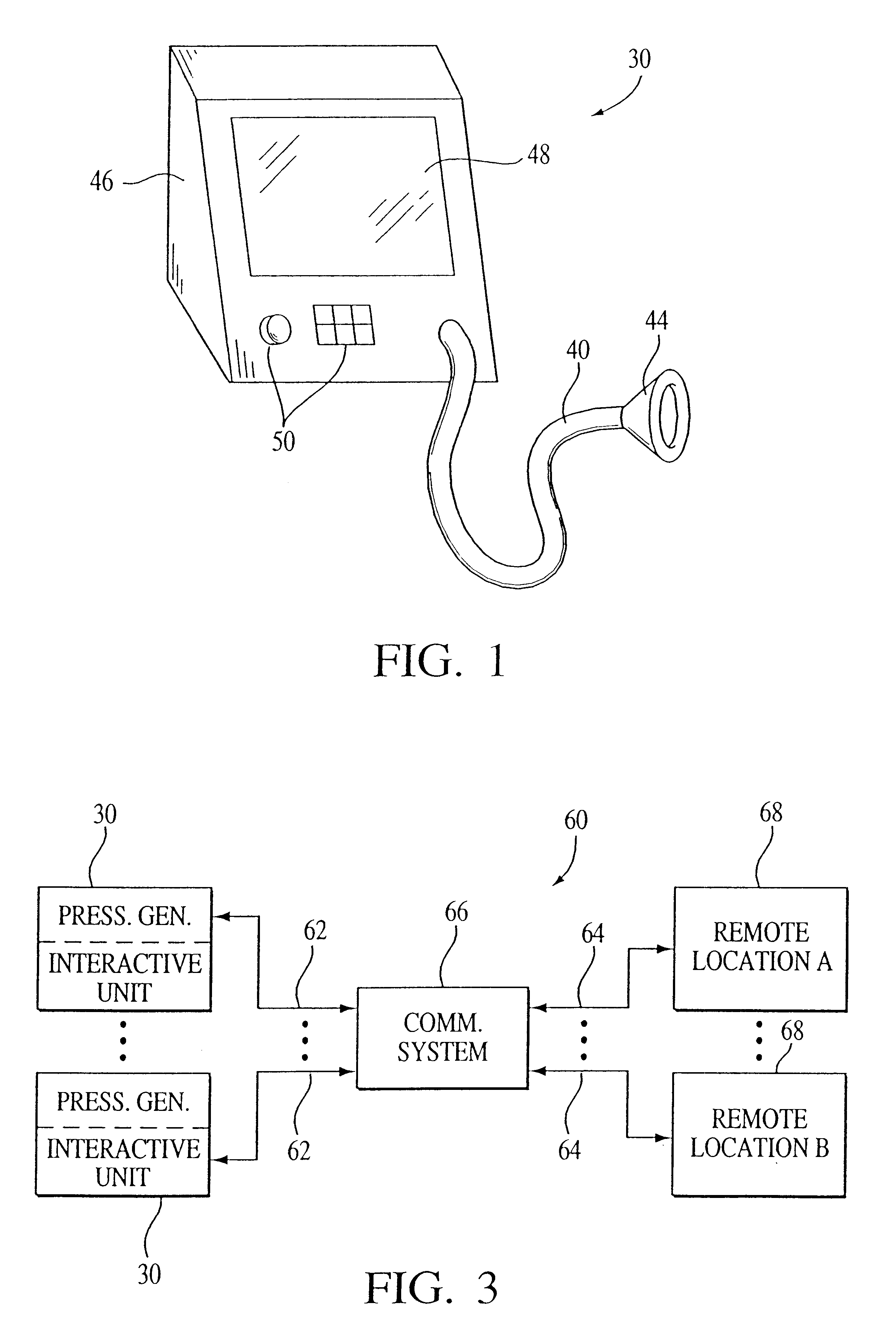

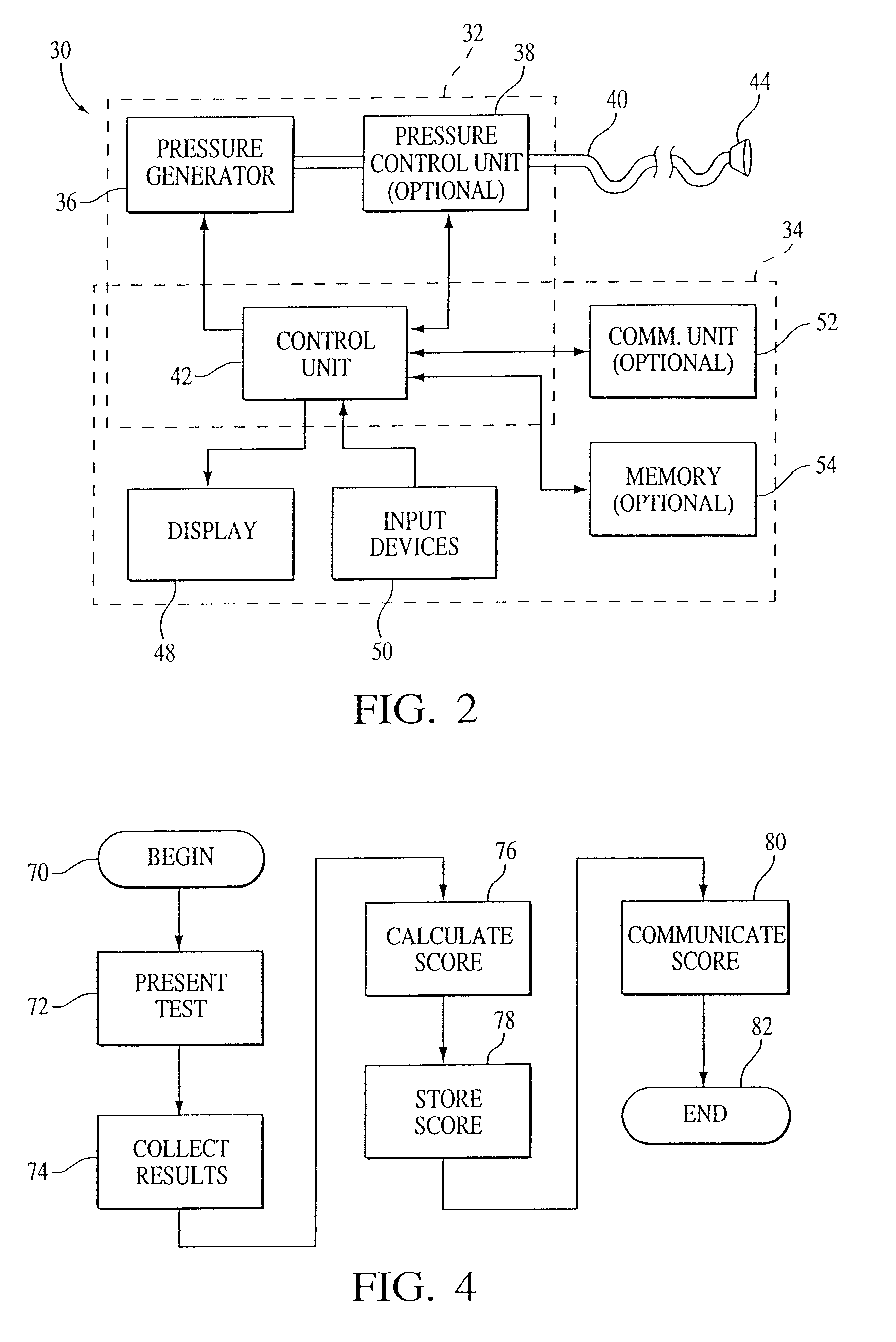

Interactive pressure support system and method

InactiveUS6564797B1Reduces administrative burden and costLess trainingOperating means/releasing devices for valvesRespiratory masksSupporting systemTherapeutic effect

An interactive pressure support system and method employing a pressure generating system that provides a pressure therapy to the pulmonary system of a patient and an interactive system associated with the pressure generating system to enable the patient to interact with the pressure support system, for example, to monitor the effectiveness of the treatment provided by the pressure support system. The interactive system includes an output device that provides first information to the patient, an input device that allows the patient to provide second information that is based on the first information and a control unit that controls the operation of the output device to present the first information and collection of the second information via the input device.

Owner:RIC INVESTMENTS LLC

Integral motor and air bearing cooling path

ActiveUS20060061221A1Low costReduce complexityPump componentsMechanical energy handlingPressure generationAir bearing

A motor is provided including a housing having single and integral motor and bearing cooling inlets. The motor is arranged within the housing and includes a stator and a rotor assembly supported on air bearings. The cooling inlet is in fluid communication with the motor stator and with the air bearings. The motor cooling inlet provides and the bearing cooling inlet provides a uniform pressure on the rotor assembly. The uniform pressures exerted on the rotor assembly produce bearing loads that generally cancel one another. The source of the cooling flow is uncompressed air at low pressure. This may be achieved by providing a vent in the housing that is common to both the motor cooling inlet and the bearing cooling inlet. As a result, journal bearings and seals of substantially the same size may be used.

Owner:HAMILTON SUNDSTRAND CORP

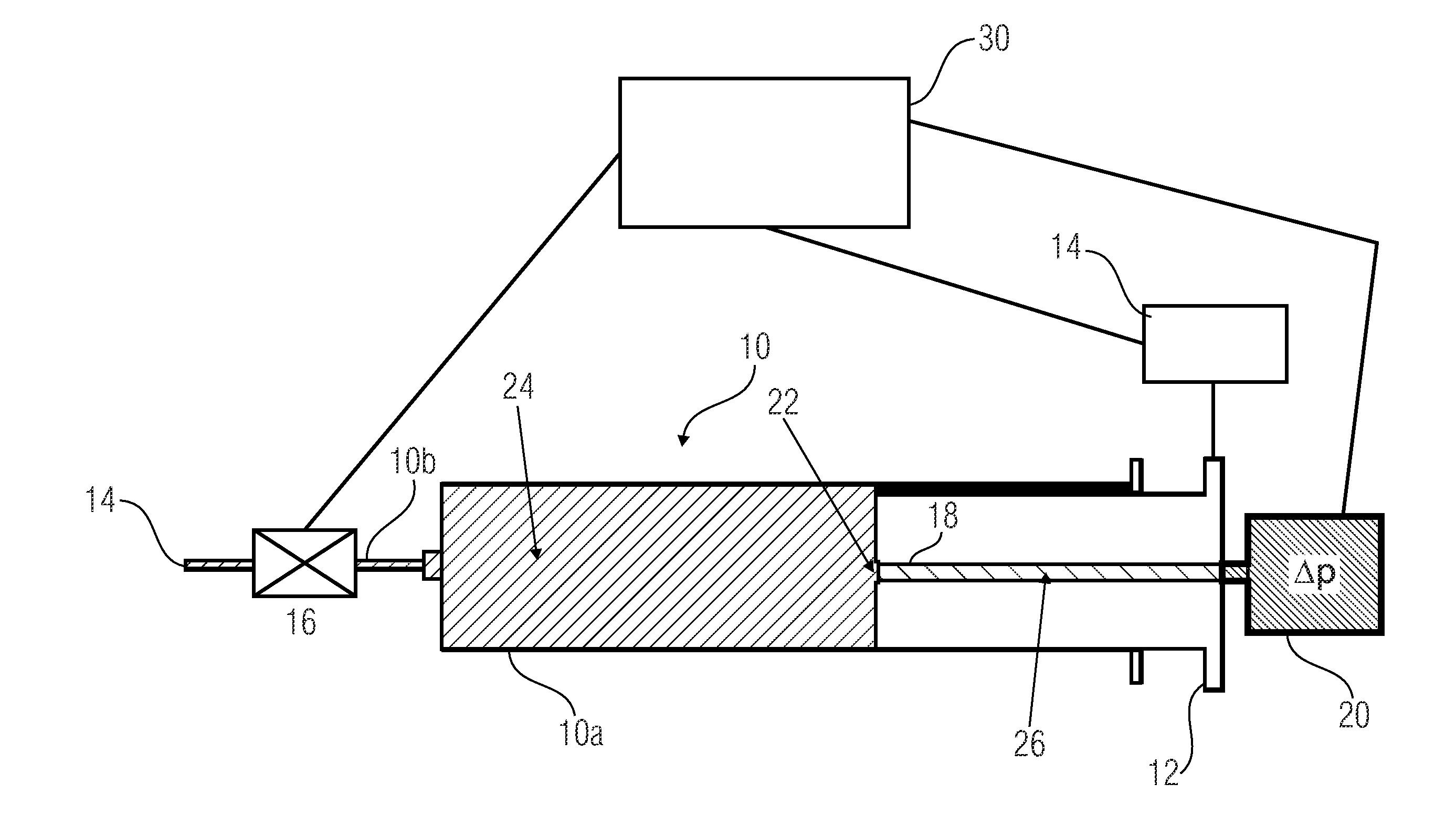

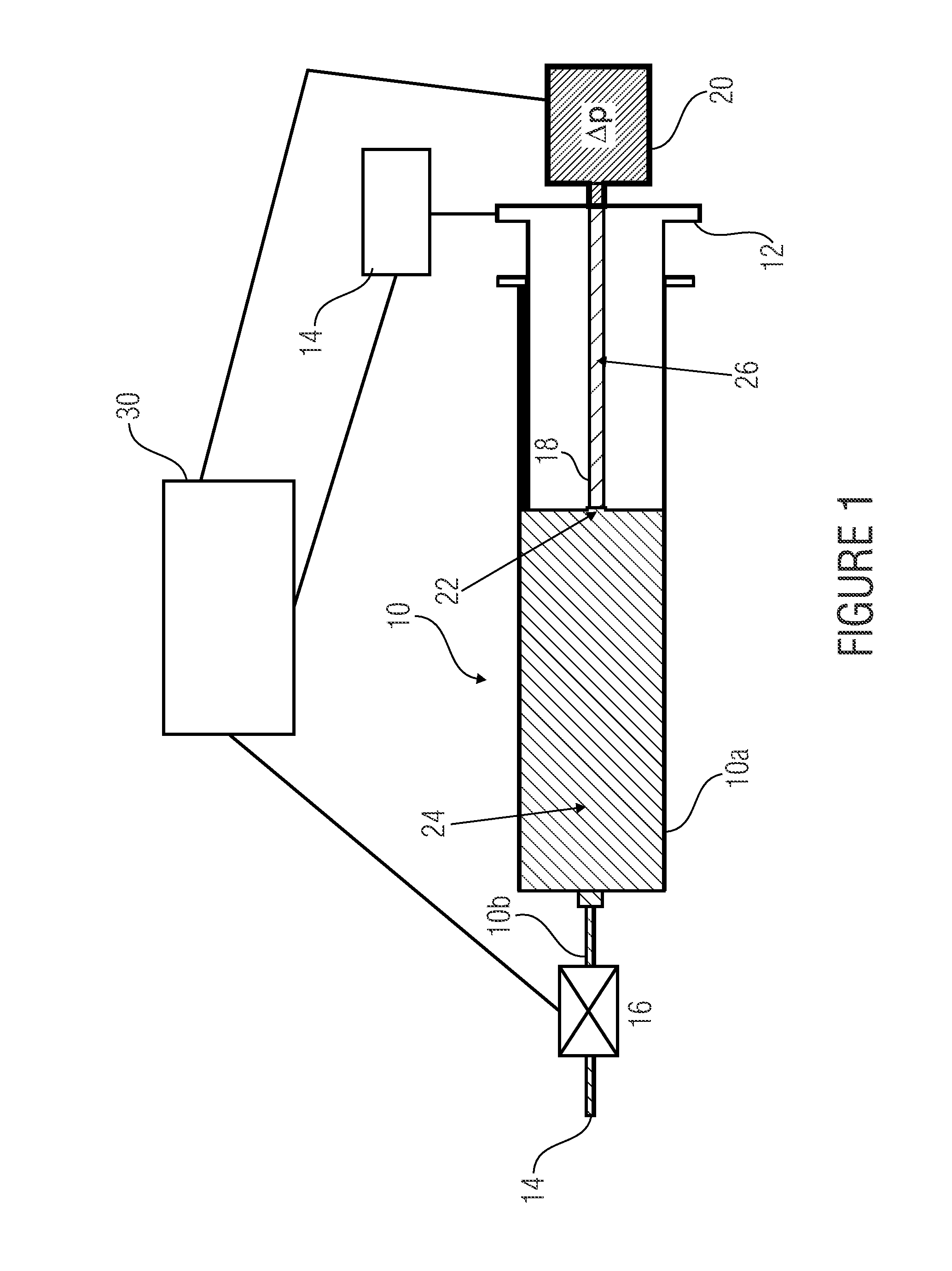

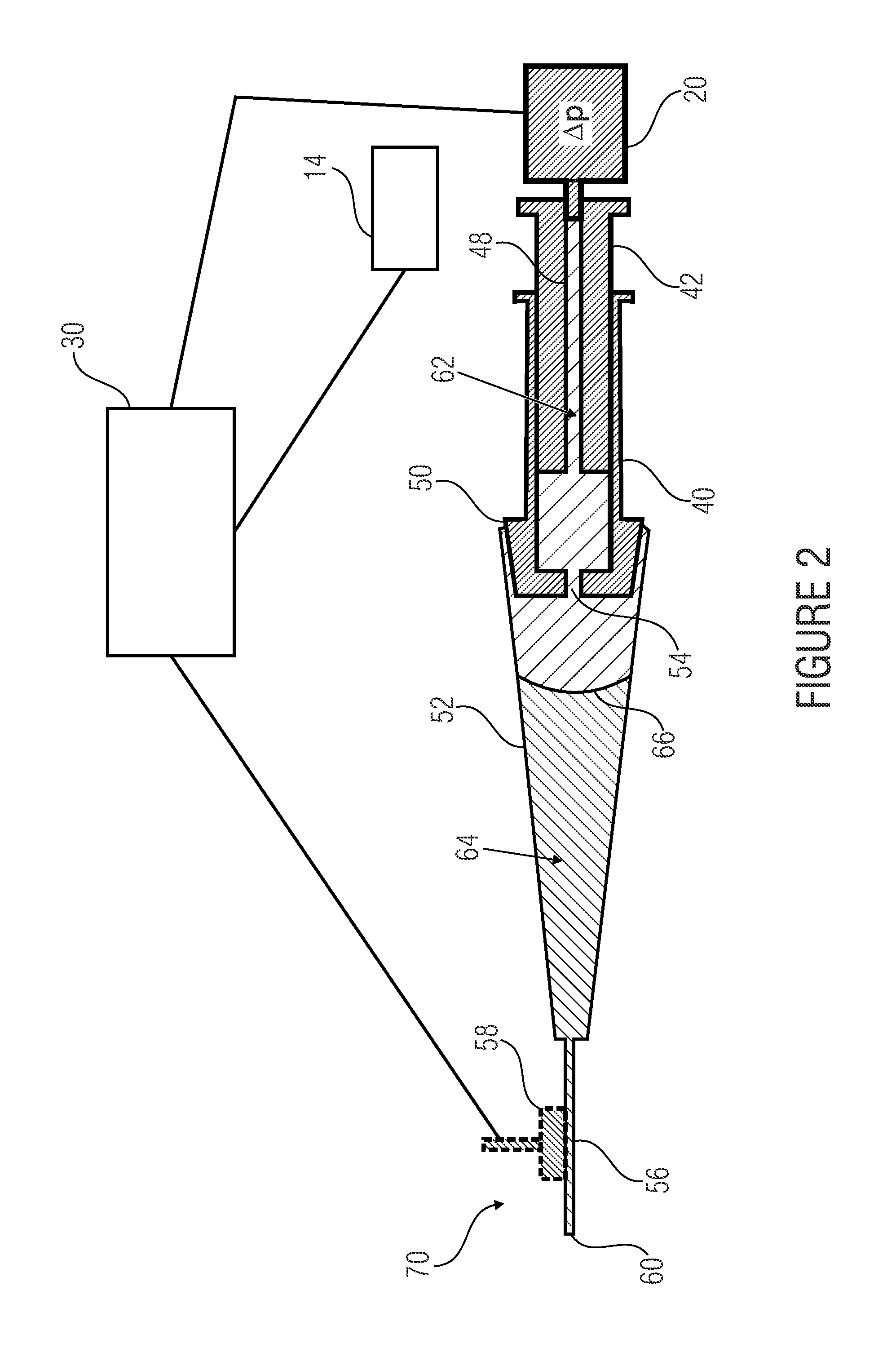

Device and method for dispensing or receiving a liquid volume

ActiveUS20130327787A1Precision and of dosing volumeEasy to set upVolume variation compensation/correction apparatusLiquid transferring devicesPressure generationBiomedical engineering

A device for dispensing or receiving a liquid volume comprises a liquid reservoir having an outlet, a pressure generation means which is implemented to provide a compressible enclosed gas volume of a constant amount of substance with a pressure, wherein the gas volume is in direct or indirect fluidic contact with the liquid in the liquid reservoir, a dosing means coupled to the outlet of the liquid reservoir and operable in order to enable the liquid to pass the outlet, a pressure sensor for measuring a current pressure in the gas volume and for outputting an output signal indicating the current pressure in the gas volume and a controller coupled to the pressure generation means, the dosing means and the pressure sensor. The controller is implemented to control the pressure generation means in order to change the pressure in the gas volume until the output signal of the pressure sensor indicates a first pressure, while the dosing means is not operated so that it prevents liquid from passing the outlet in order to operate the dosing means, depending on the output signal of the pressure sensor, to dispense or receive liquid through the outlet and, during dispensing or receiving liquid through the outlet, to monitor the output signal of the pressure sensor and, depending on the monitored output signal of the pressure sensor, terminate or repeat the operation of the dosing means.

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV +1

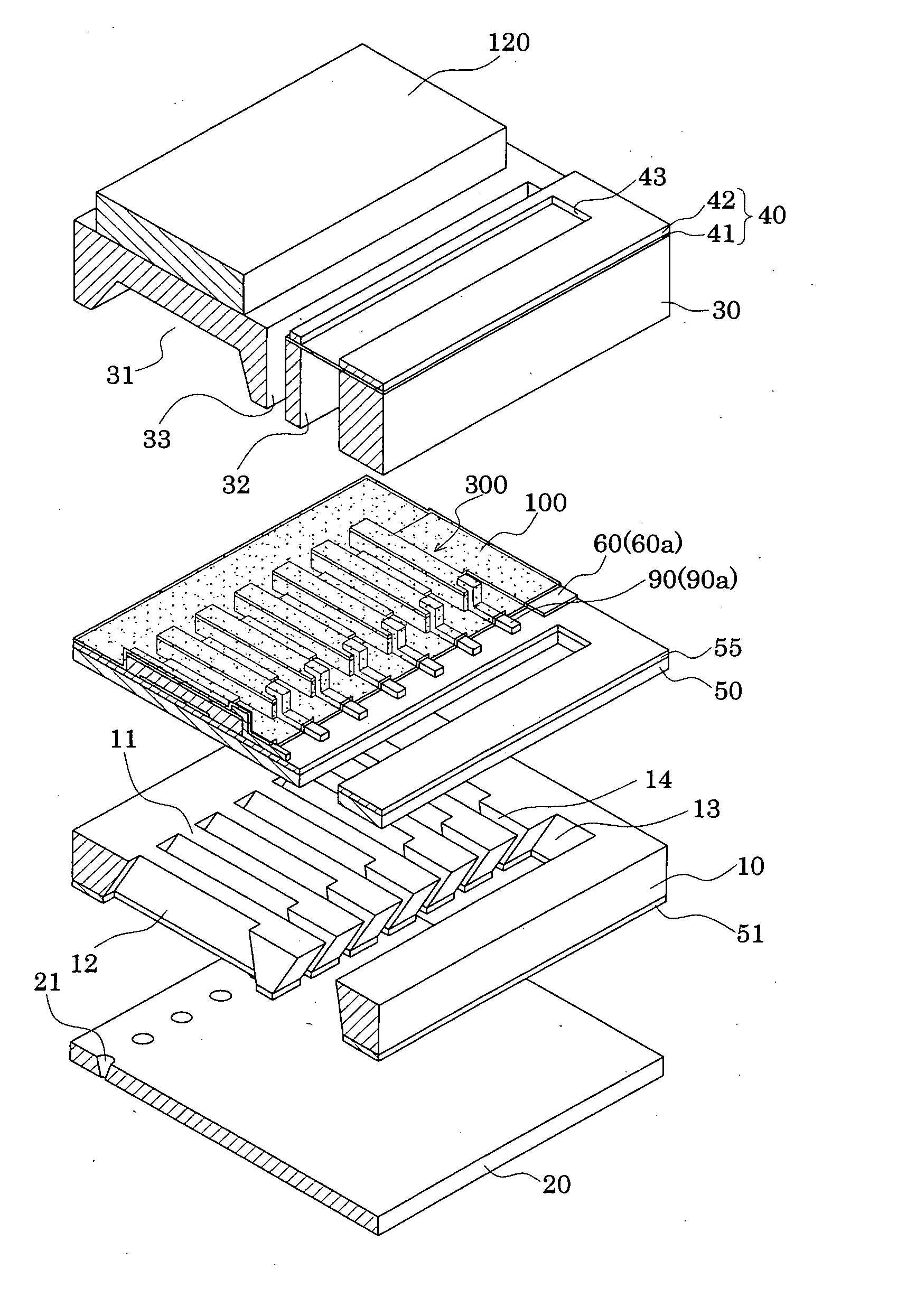

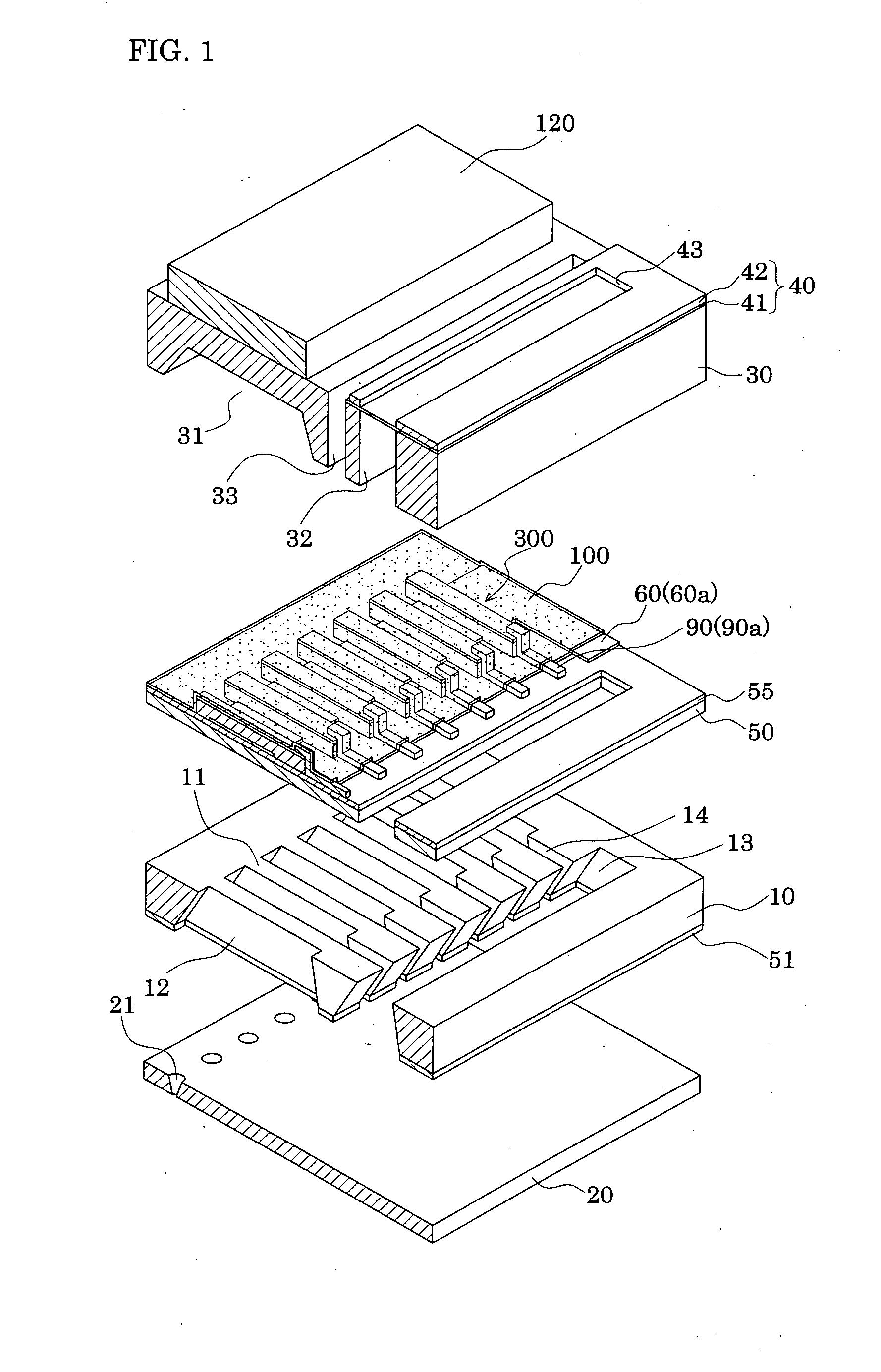

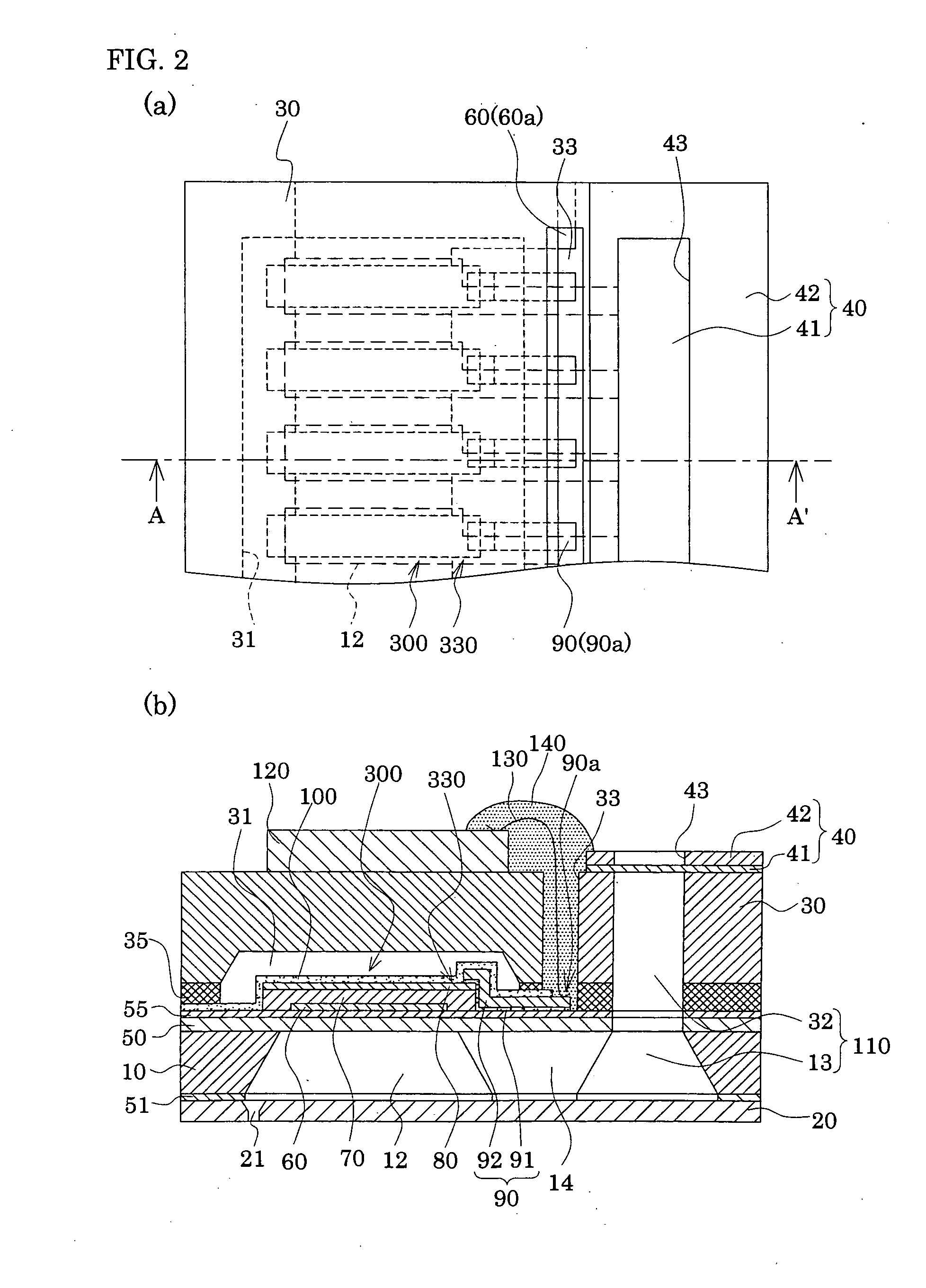

Liquid-jet head and method of producing the same and liquid injection device

There are provided a liquid-jet head which can reliably prevent breakage of piezoelectric elements over a long period of time, and a method for manufacturing the liquid-jet head, as well as a liquid-jet apparatus. Further, there are provided a liquid-jet head which can effectively prevent a drop in the amount of displacement of a vibration plate caused through drive of a piezoelectric element, and a method for manufacturing the liquid-jet head, as well as a liquid-jet apparatus. A liquid-jet head includes a channel substrate 10 which has pressure generation chambers 12 formed therein and communicating nozzle orifices for discharging liquid droplets, and piezoelectric elements 300 each of which is composed of a lower electrode 60, a piezoelectric layer 70, and an upper electrode 80 and which are disposed on one surface of the channel substrate 10 via a vibration plate, wherein at least pattern regions of the respective layers which constitute the piezoelectric elements 300 are covered with an insulating film 100 formed of an inorganic insulating material.

Owner:SEIKO EPSON CORP

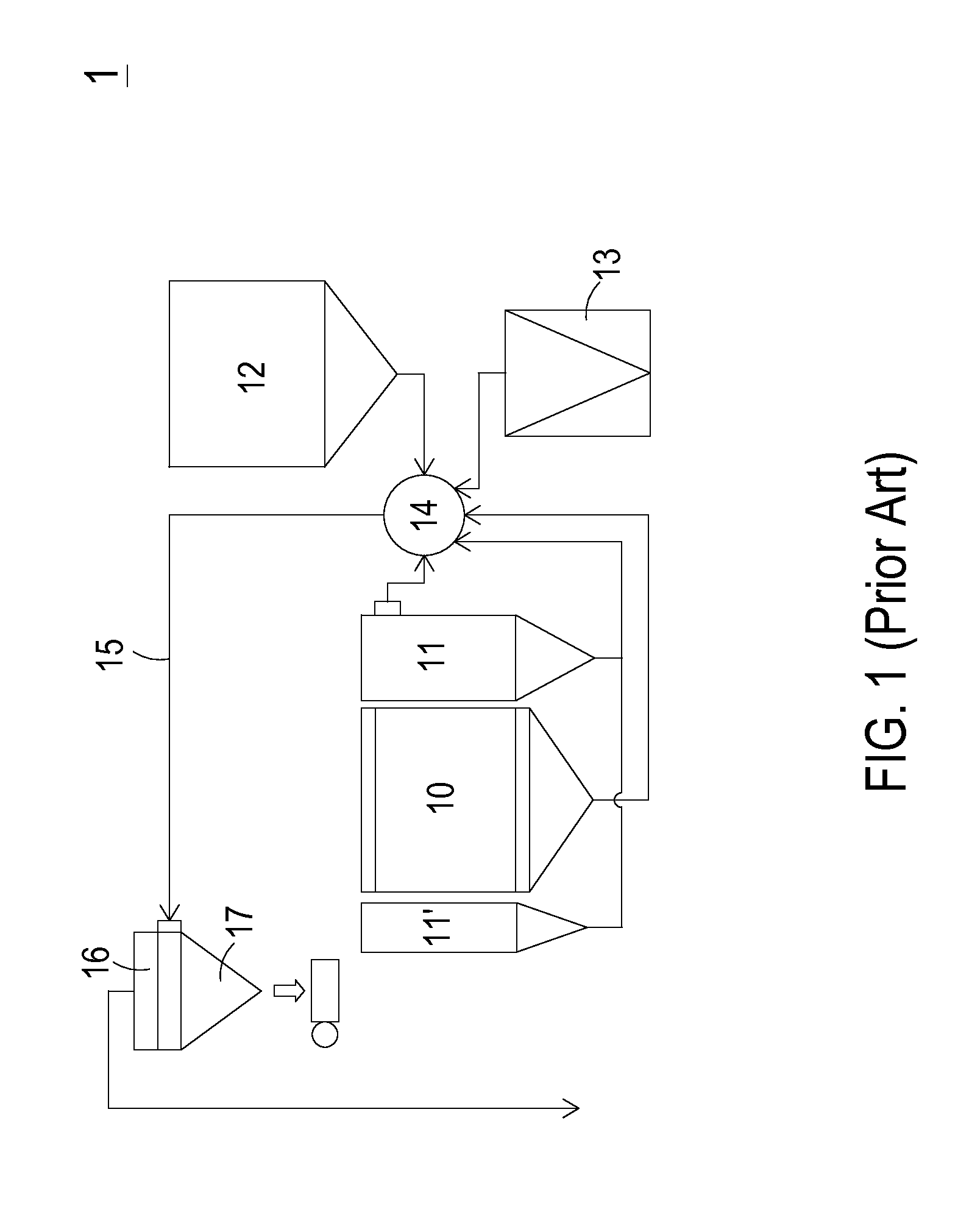

Multi-cell battery charge control

InactiveUS20050084754A1Secondary cells charging/dischargingNon-aqueous electrolyte accumulator electrodesPressure generationBattery charge

Embodiments of the present invention provide a method and system for controlling a multi-cell battery. In one embodiment of the present invention, a stack of bipolar wafer cells may be connected in series. Each cell may have an area that may be expandable in response to pressure. Such an area may be aligned with a corresponding area of at least one adjacent cell. The invention further includes a trigger mechanism that may be responsive to a force created by pressure generated in a cell in the stack of bipolar cells.

Owner:ELECTRO ENERGY

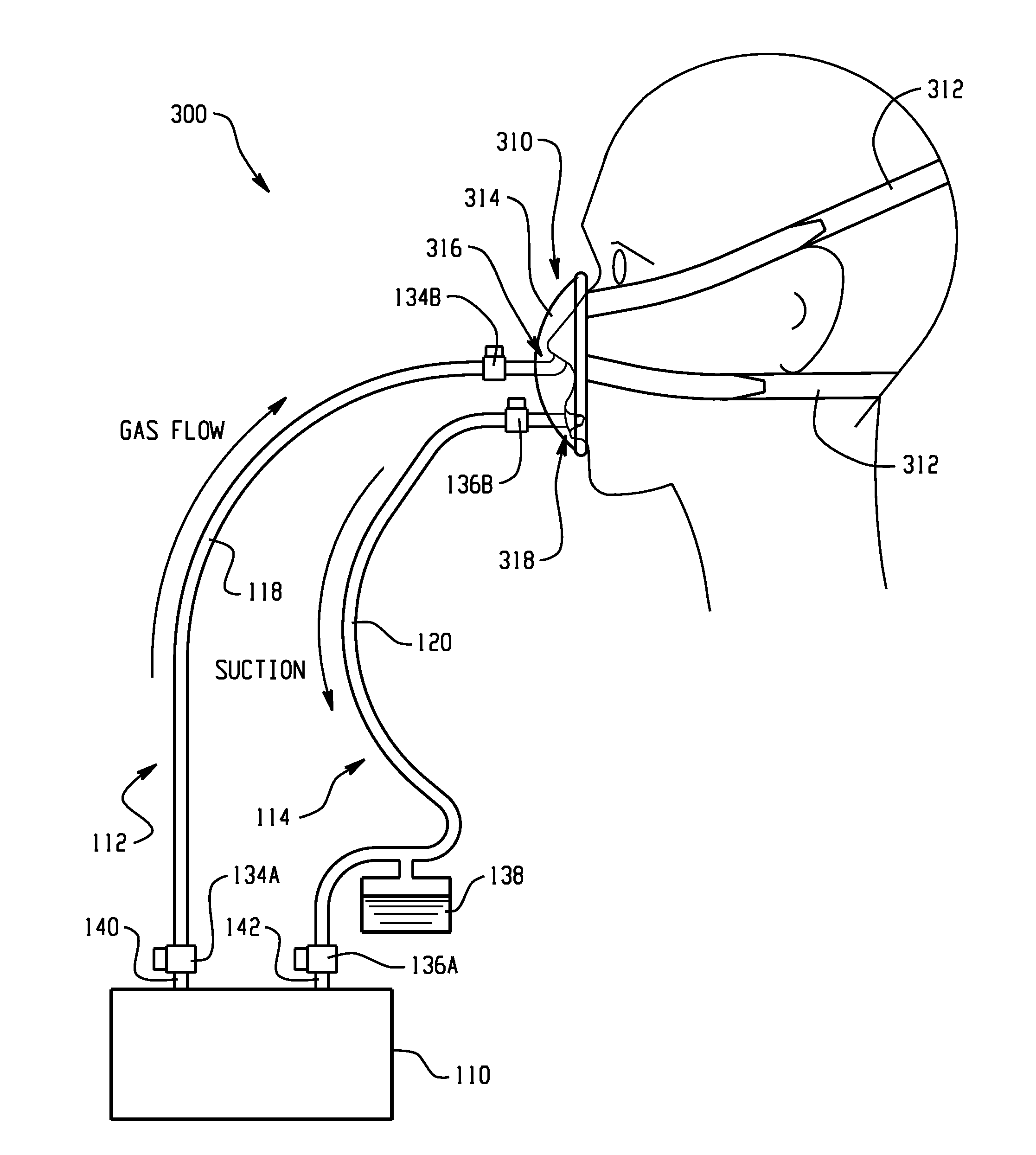

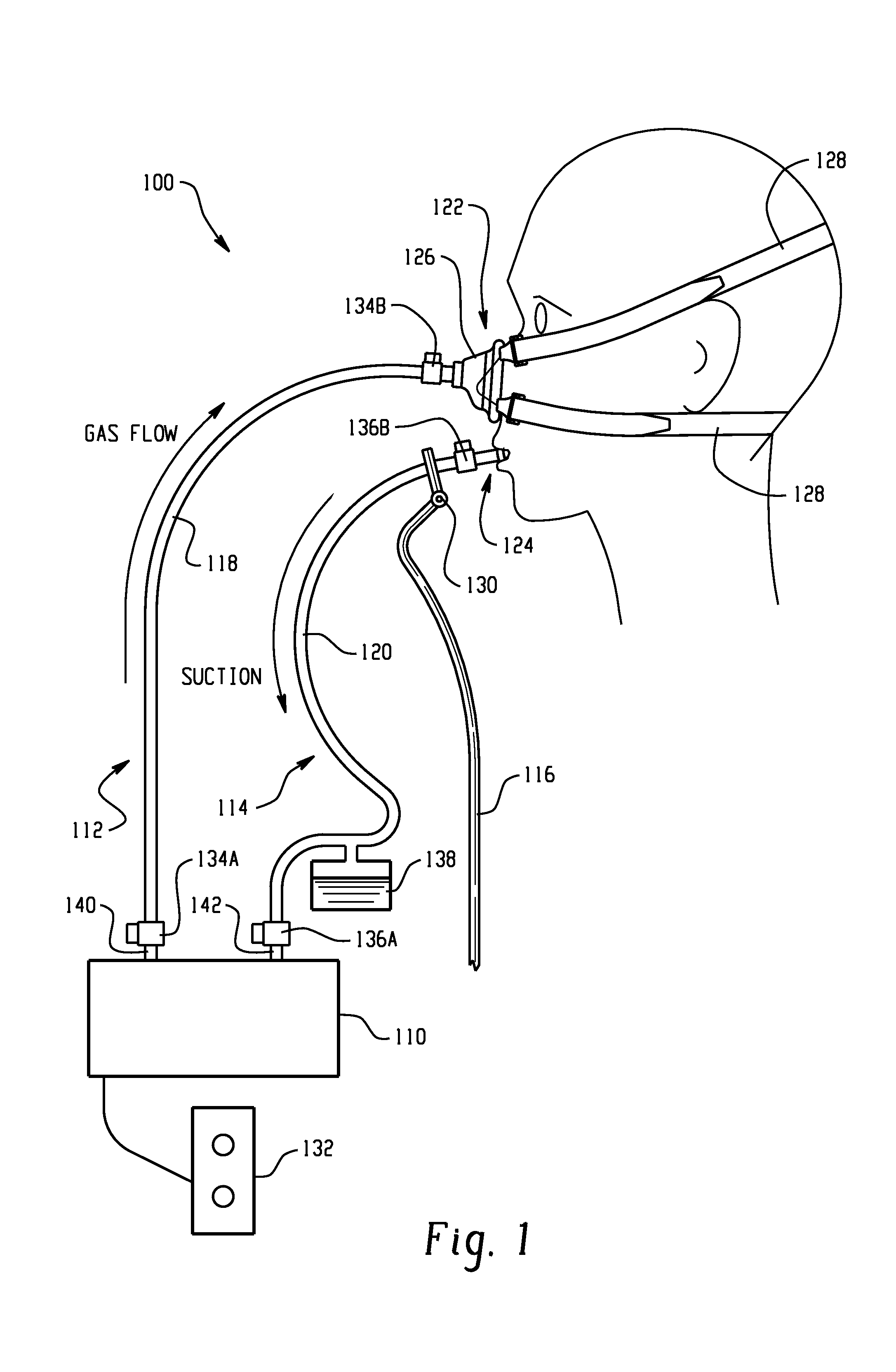

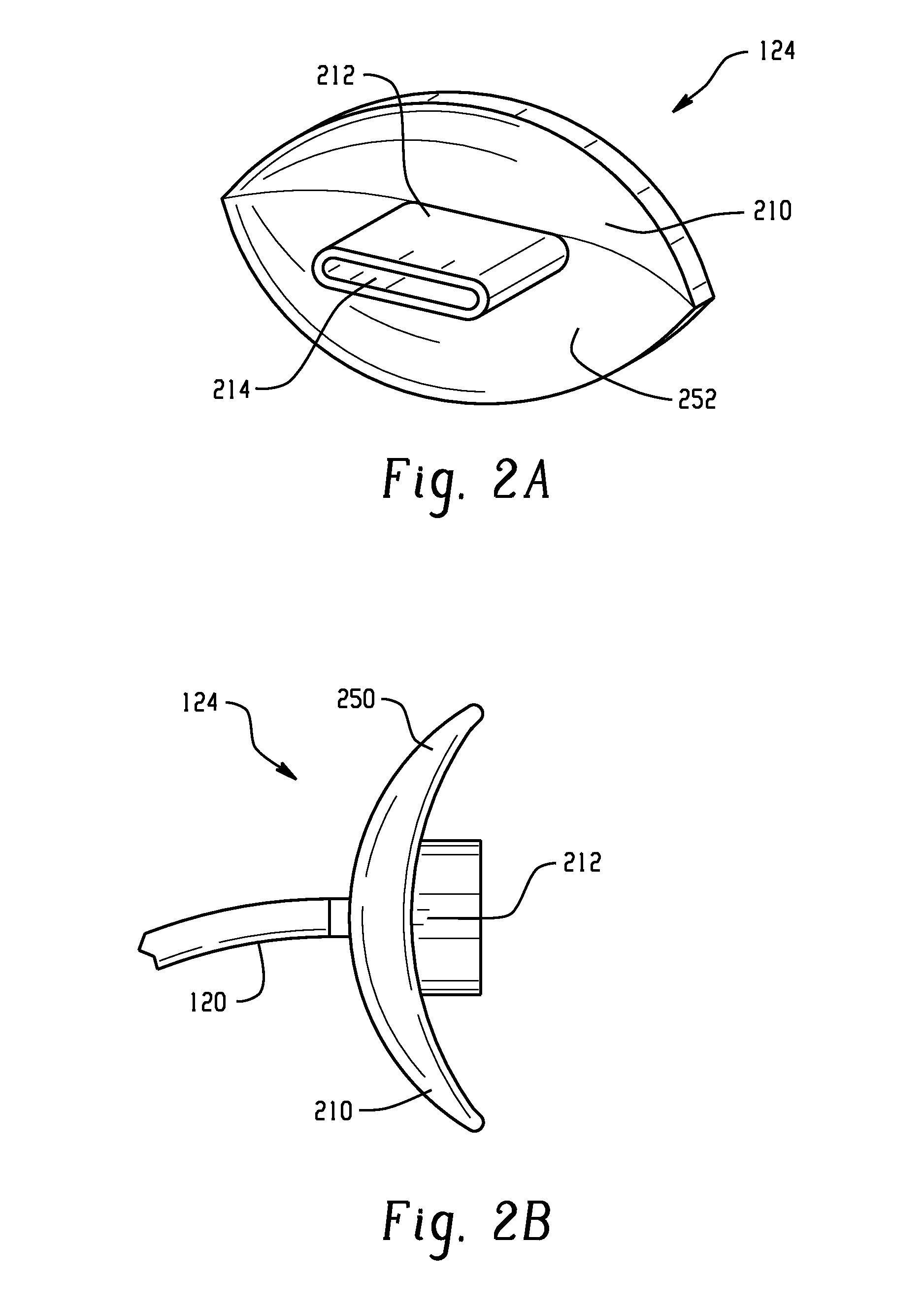

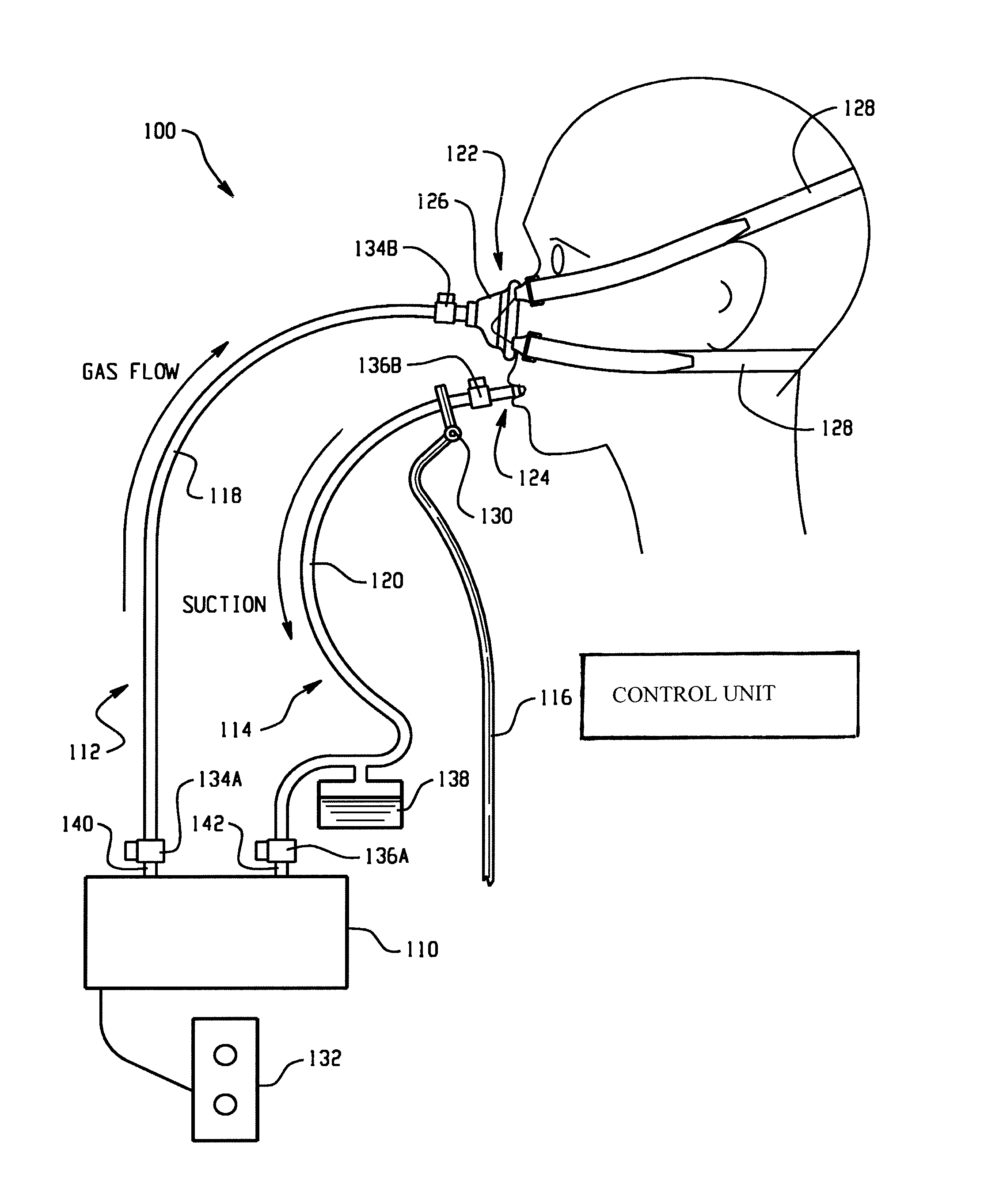

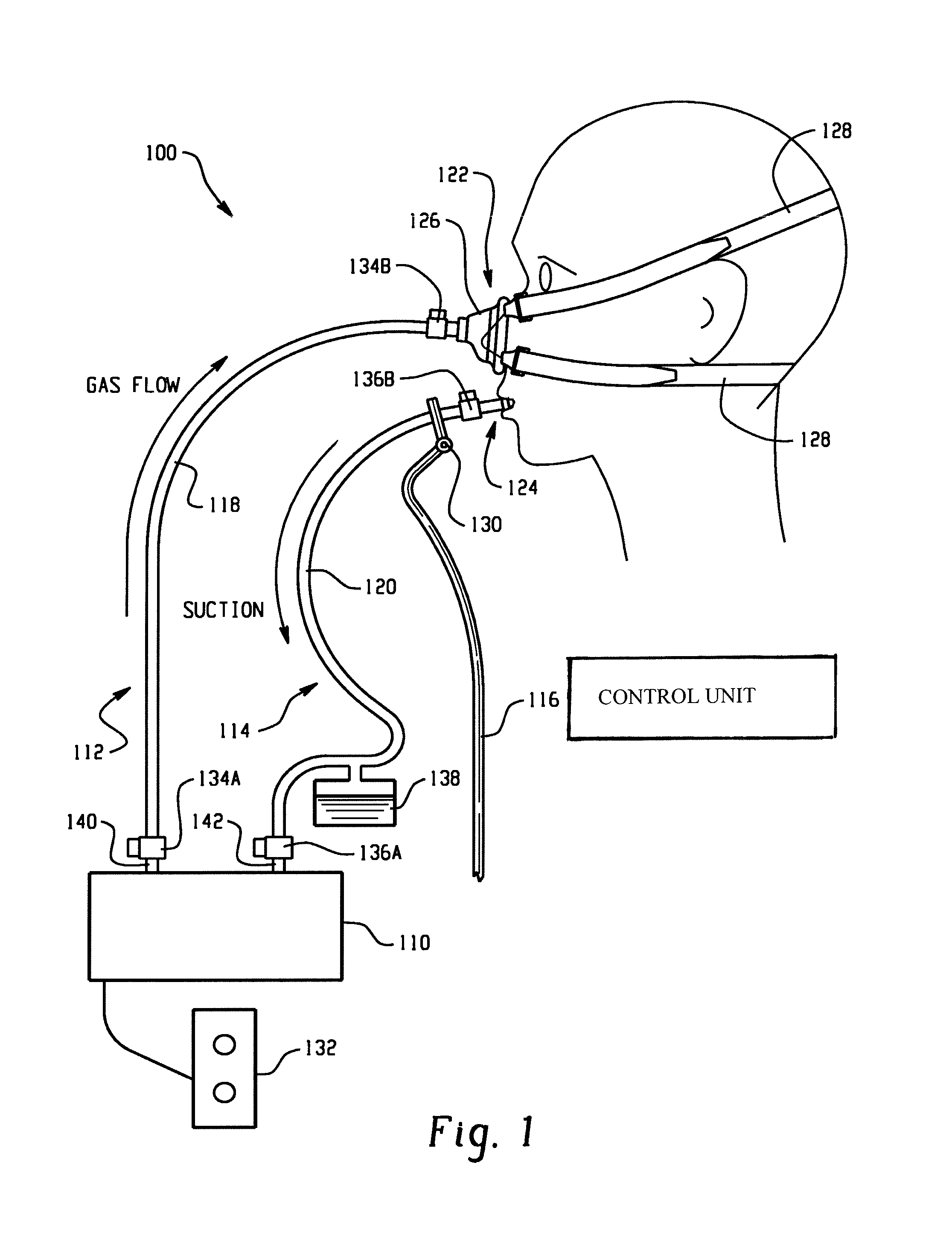

Combination lung ventilation and mucus clearance apparatus and method

ActiveUS20100122699A1Improves patient comfortImproves device efficacyOperating means/releasing devices for valvesBreathing filtersPressure generationActivity daily

A medical device and method for combination lung ventilation and mucus clearance of a patient is disclosed. The medical device may be configured to provide lung ventilation with intermittent, on-demand mucus clearance, freeing the patient's mouth for activities of daily living such as when the patient is awake; and, in another configuration, the device can provide lung ventilation with automated mucus clearance, such as when the patient is sedated or asleep. The medical device may comprise a pressure generation source, a ventilation portion, and a mucus clearance portion. The mucus clearance portion may be separable from or separate from the ventilation portion such that the medical device is capable of maintaining lung ventilation with the mouth interface removed from the patient.

Owner:METROHEALTH VENTURES LLC

Liquid ejecting apparatus and control method thereof

InactiveUS20120249638A1Reduce residual vibrationReduce impactOther printing apparatusResidual vibrationPressure generation

A liquid ejecting apparatus includes: a liquid ejecting head, having a pressure chamber filled with a liquid, and a pressure generation element that causes the pressure of the liquid within the pressure chamber to fluctuate that ejects the liquid from a nozzle based on the pressure fluctuation in the liquid within the pressure chamber; a driving waveform generation unit that generates a driving waveform for ejects the liquid; a control unit that causes the liquid ejecting head to execute a flushing operation that discharges the liquid within the pressure chamber; and a residual vibration detection unit that detects a residual vibration in the liquid within the pressure chamber. The control unit calculates a characteristic value in accordance with a characteristic of the liquid based on the residual vibration produced by the flushing operation, and corrects the driving waveform based on the characteristic value.

Owner:SEIKO EPSON CORP

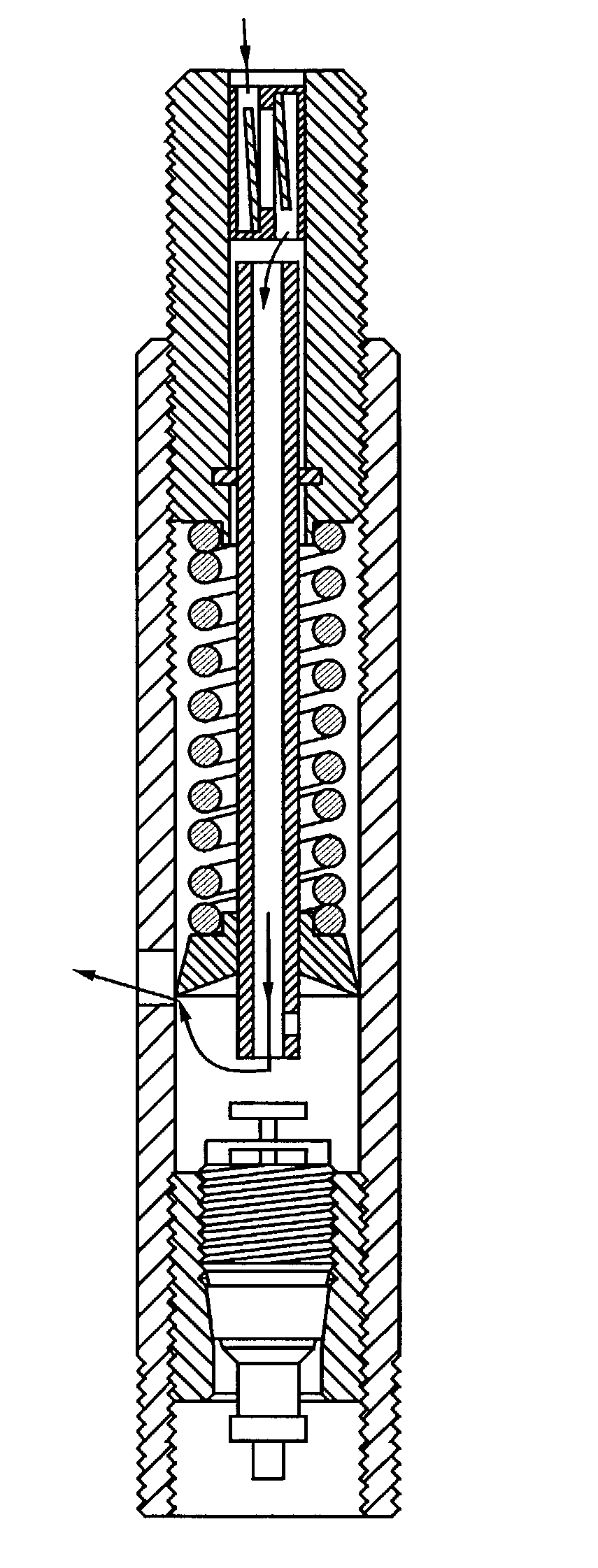

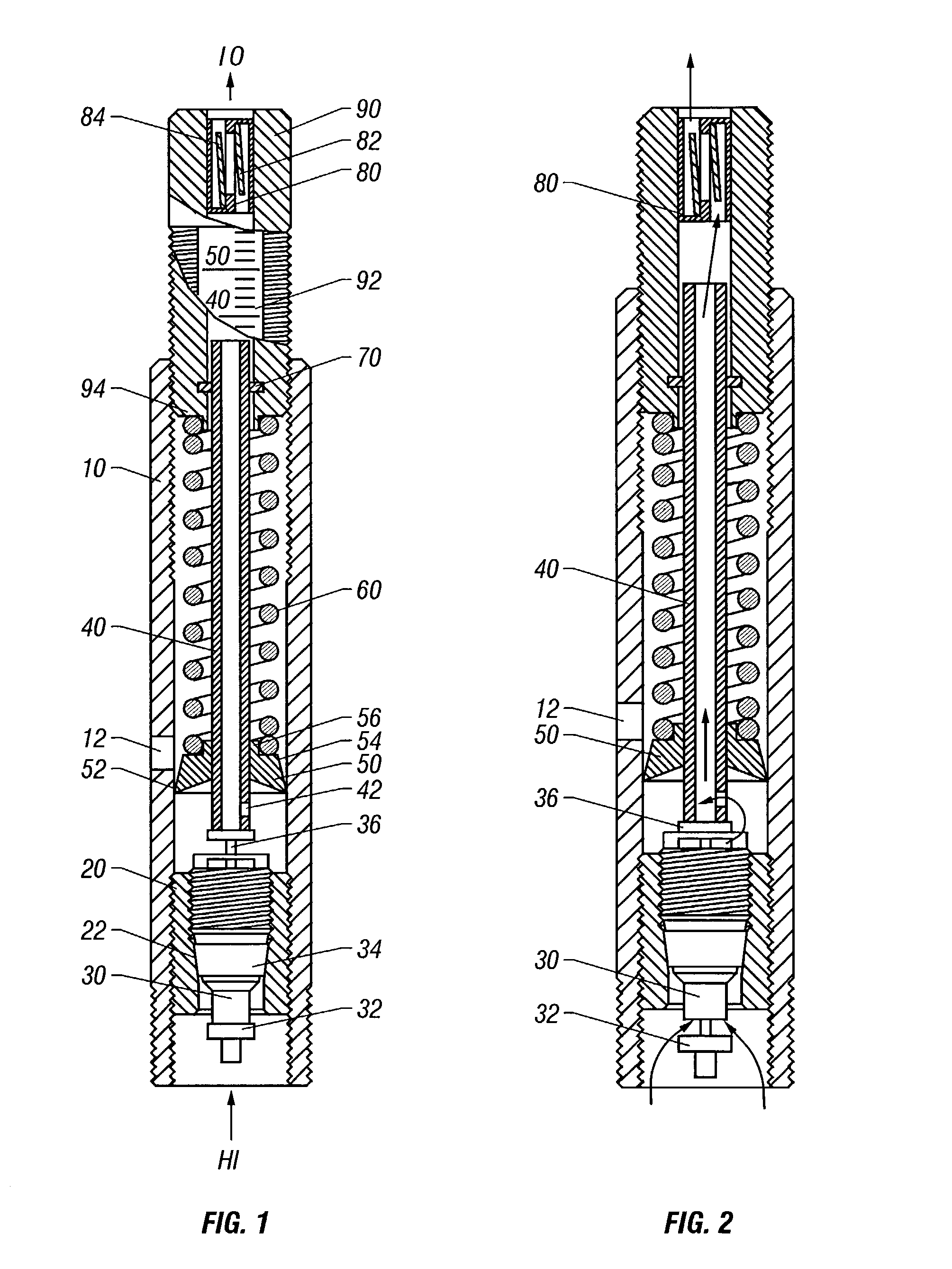

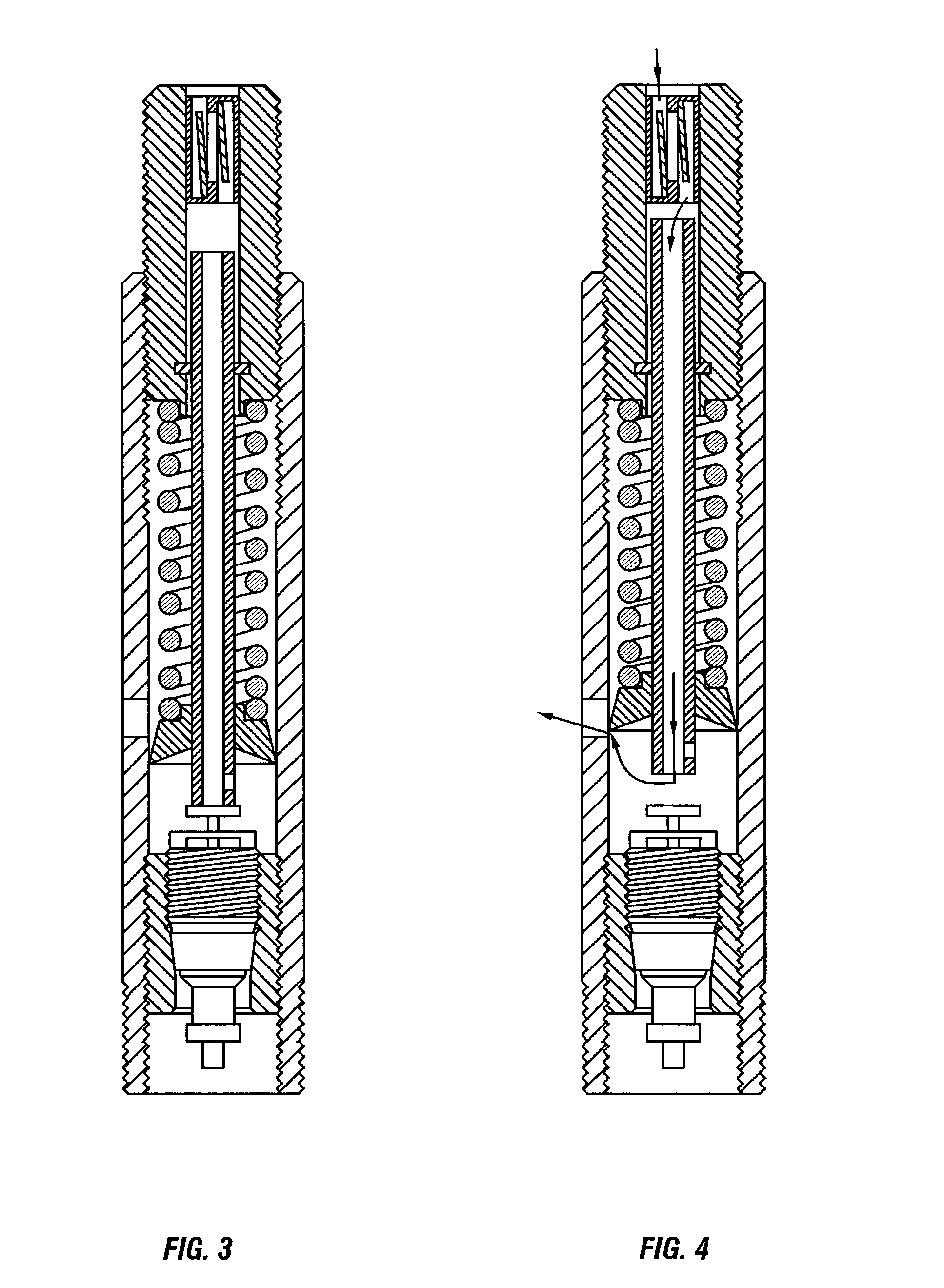

Pressure regulator and method of use

InactiveUS7032611B1Operating means/releasing devices for valvesCheck valvesPressure generationPressure sense

A pressure regulating device for connecting a pressure source to an inflatable object comprises: a hollow casing; a valve system positioned inside the hollow casing; a fluid inlet connected to the valve system; a fluid outlet; a fluid conduit positioned inside the hollow casing between the fluid inlet and the fluid outlet; a pressure-sensing structure attached to the conduit and being movable inside the hollow casing and attached to the pressure sensing structure; a pressure-generating structure disposed inside the hollow casing and attached to the pressure-sensing structure. The pressure-generating structure can exert a bias force upon the pressure-sensing structure in proportion to a desired pressure in the inflatable object. The pressure regulator can inflate the object when the initial pressure inside the inflatable object is lower than the desired pressure and automatically terminates inflation when the pressure inside the object reaches the desired pressure.

Owner:SHENG XIAYANG

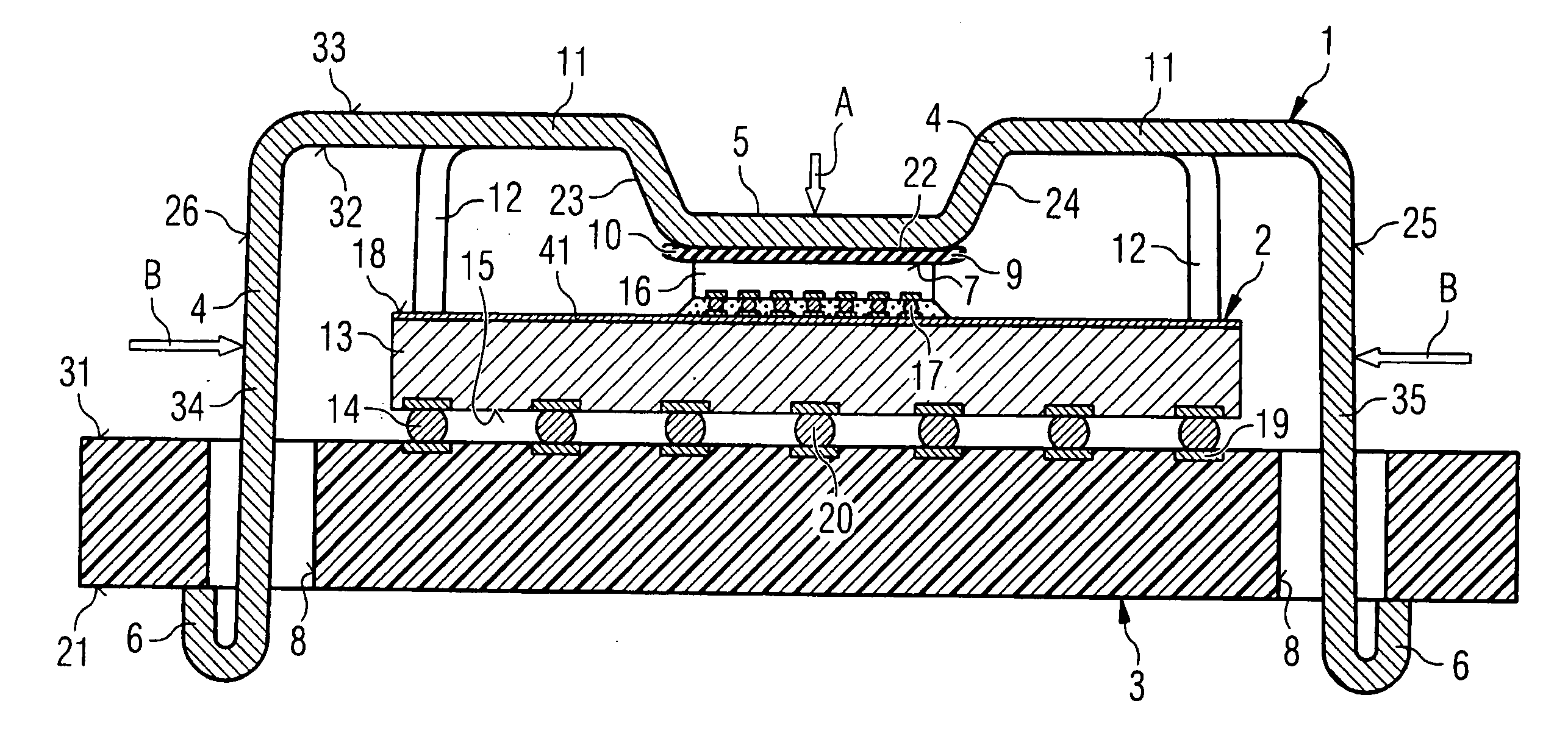

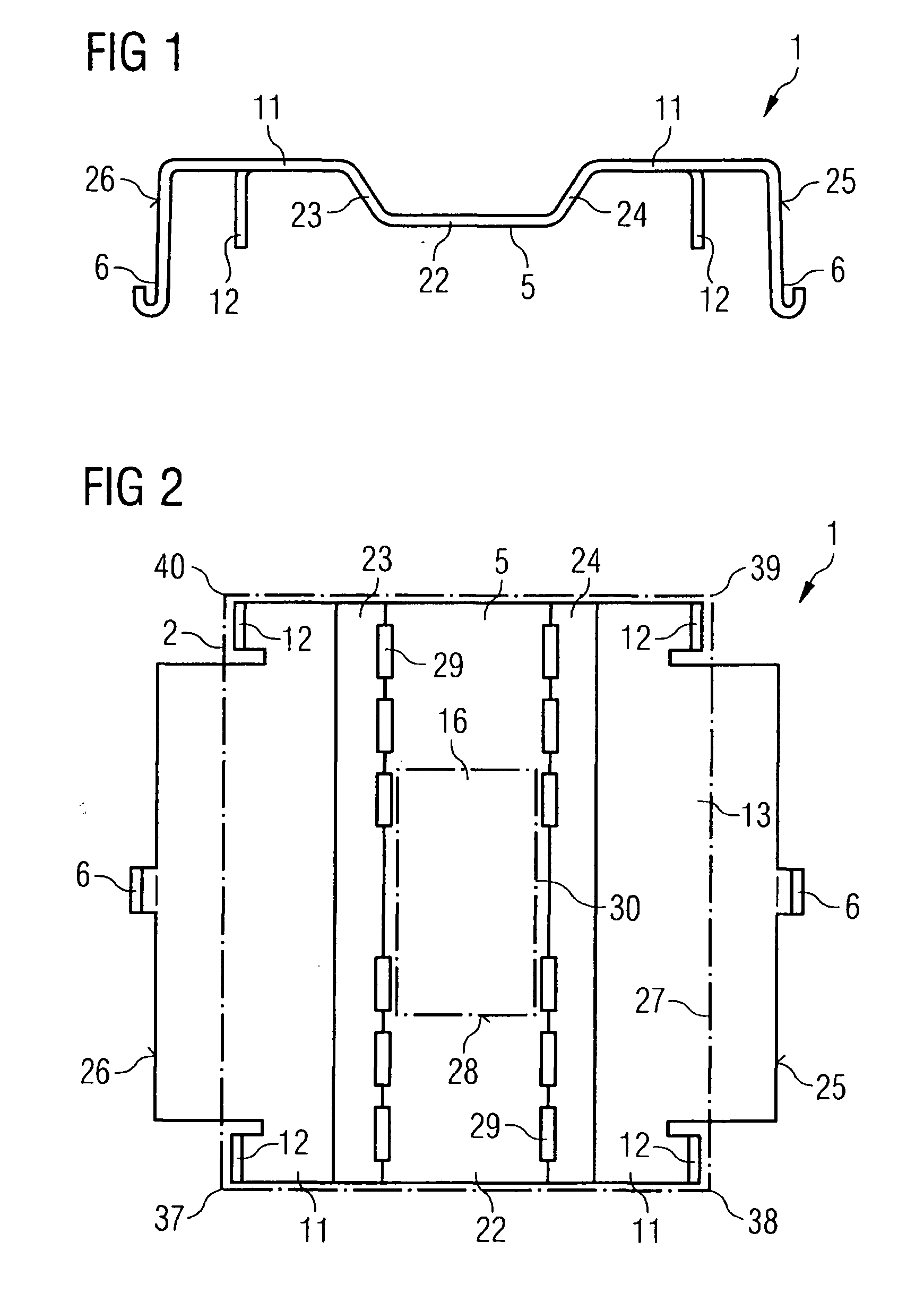

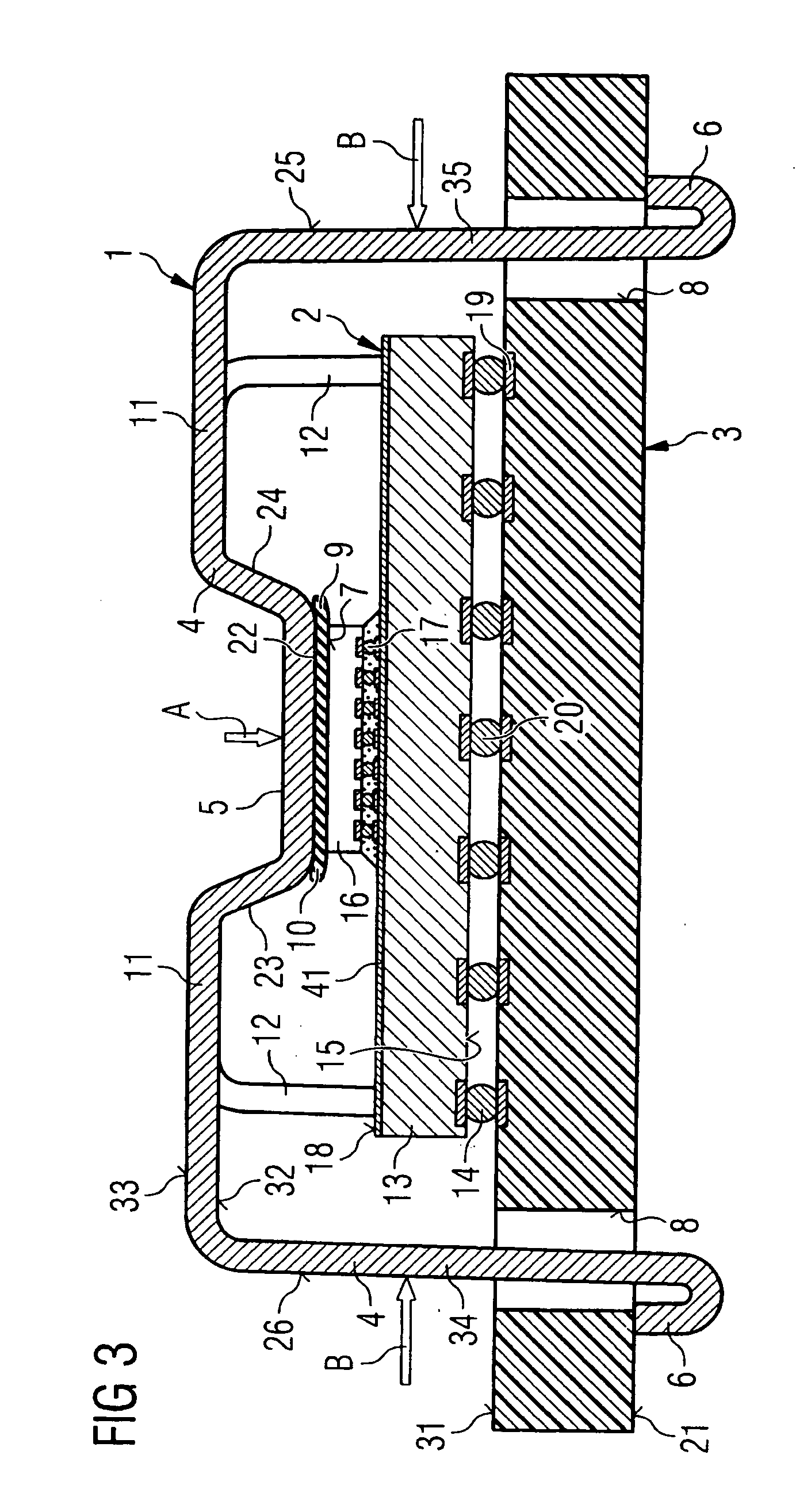

Heat sink for surface-mounted semiconductor devices

InactiveUS20060158857A1Semiconductor/solid-state device detailsSolid-state devicesPressure generationInter layer

A heat sink is arranged on a main circuit board of an electronic module. The heat sink includes a three-dimensionally structured thermally conductive plate with a press-on region and with snap-action hooks. The snap-action hooks are arranged approximately at right angles with respect to the press-on region and are resiliently connected to the press-on region. The snap-action hooks are latched into place, with pressure generation of the press-on region onto a rear side of a surface-mountable semiconductor device, into corresponding passage openings of the circuit board. A plastically deformable thermal composition is disposed between the rear side of the semiconductor device and the press-on region of the heat sink so as to form an intermediate layer therebetween to provide compensation for the thickness tolerances of the semiconductor device.

Owner:INFINEON TECH AG

Automatic slope adjustment for bi-levelpressure support system

InactiveUS20030127097A1Operating means/releasing devices for valvesRespiratory masksSupporting systemPositive pressure

An apparatus and method for a bi-level positive airway pressure support in which the rise time from the expiratory positive airway pressure to the inspiratory positive airway pressure is automatically controlled by the pressure support system. The pressure support system includes a sensor, a control system, and a pressure generating system. The sensor monitors the patient's respiration to detect respiratory events, such as an apnea, hyponea or other disturbance, and the control system responds to the sensor information to adjust the rise time from the expiratory positive airway pressure to the inspiratory positive airway pressure gas pressure to maximize patient comfort and pressure support treatment effectiveness.

Owner:RIC INVESTMENTS LLC

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20130233939A1Favorable ejection characteristicDeterioration of characteristicInking apparatusMovable spraying apparatusPressure generationEngineering

A ink jet type recording head which circulates ink between a first manifold and a second manifold via a pressure generation chamber is provided, the flow path member has a first and second bypass flow paths which connect the first and second manifolds, respectively in two locations of one end side and the other end side of a nozzle row on the outside of the nozzle row on which the nozzle openings are formed, and a relationship between a flow path resistance R of the first and second bypass flow paths, and a flow path resistance r of a flow path portion including the pressure generation chamber which connects the first and second manifolds is R<r / N (wherein, N is the number of all nozzle openings).

Owner:SEIKO EPSON CORP

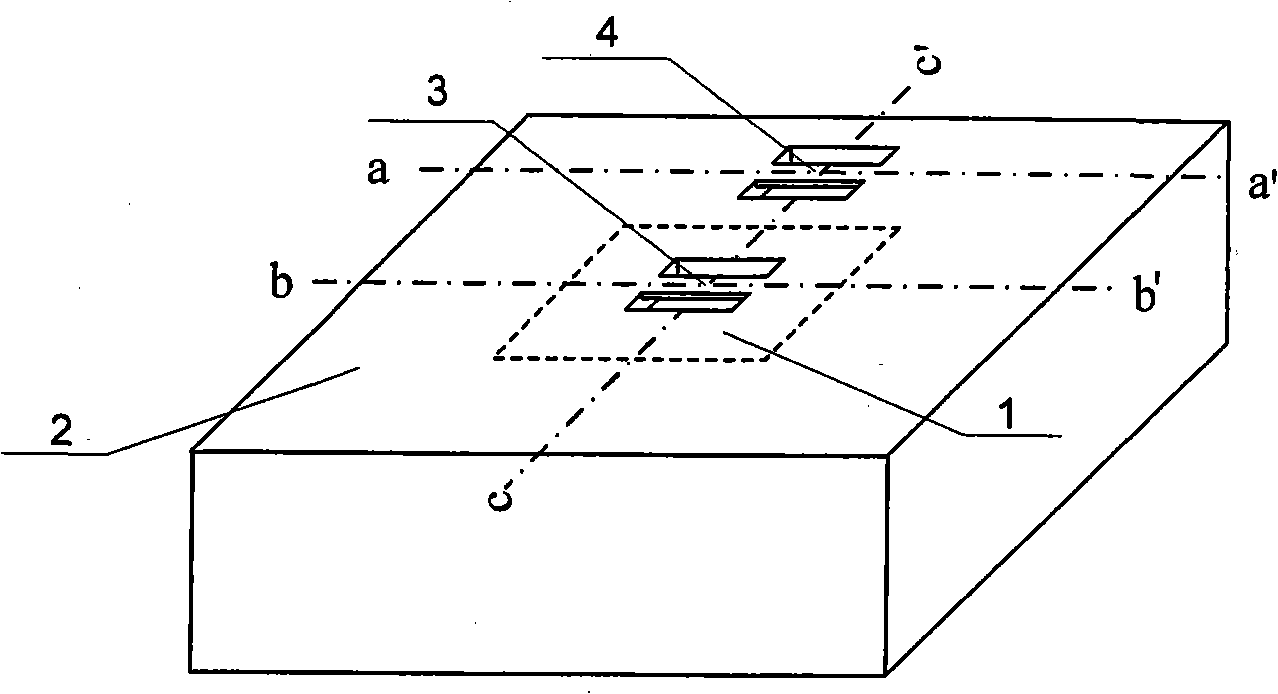

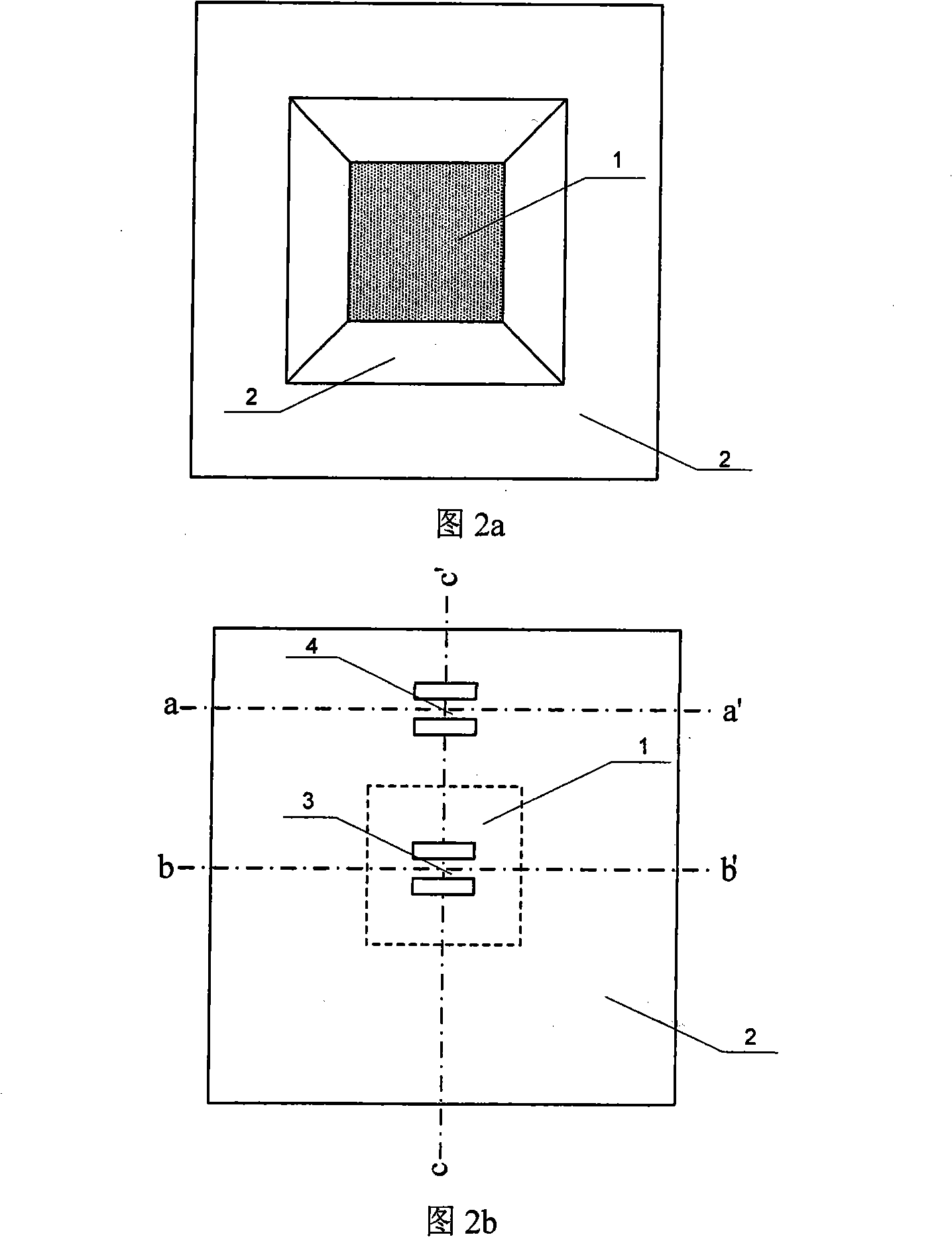

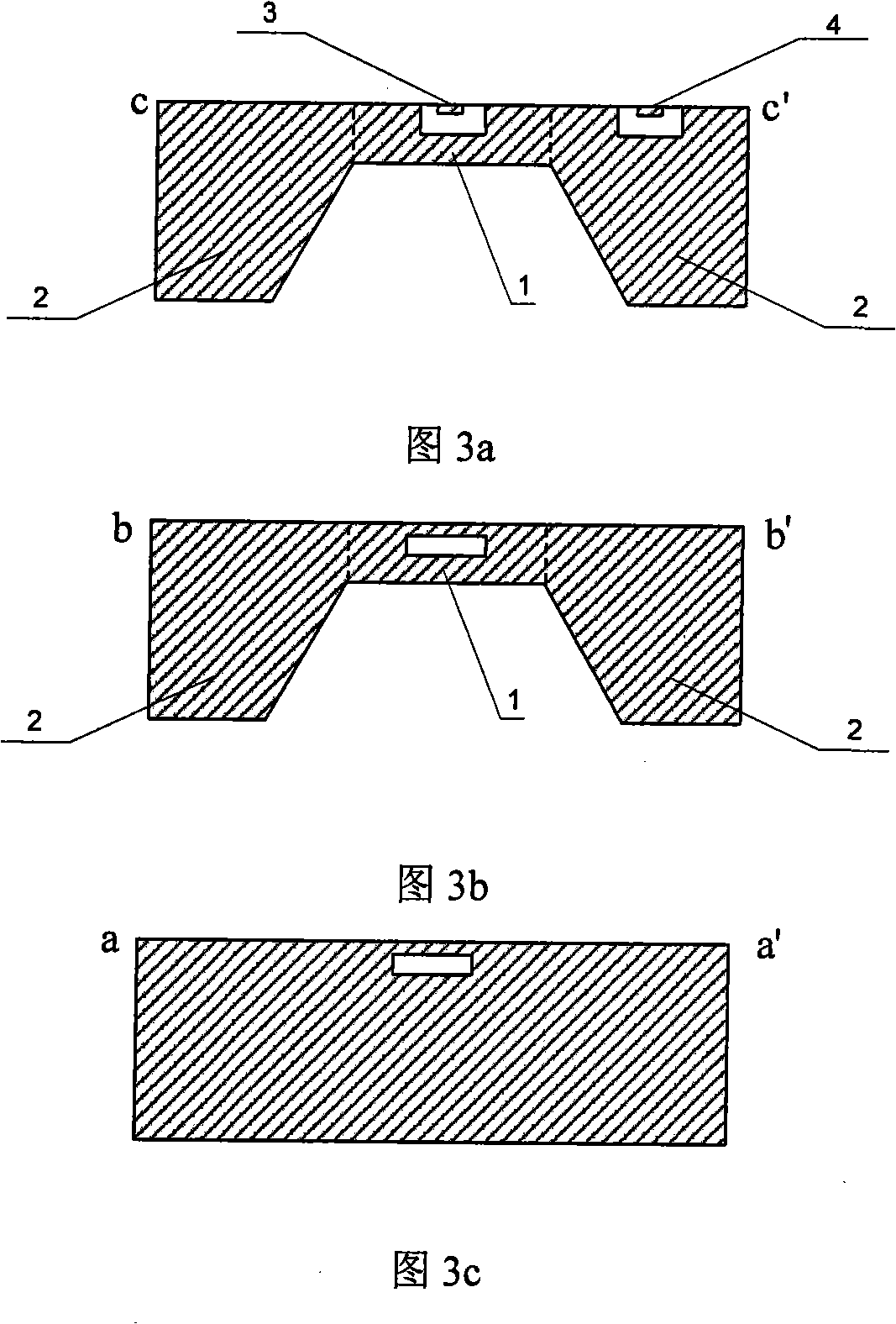

Double-resonance girder type micro mechanical pressure sensor

InactiveCN101281071ASimple structureReduce manufacturing difficultyTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPressure generationResonance

A bi-resonant beam micromachine pressure sensor mainly comprises sensing membrane, non-sensing area, resonant working beam and resonant compensating beam; the centre of the structure is rectangular sensing membrane for sensing the tested pressure to generate corresponding deformation; the peripheral part of the sensing membrane is non-sensing area which does not sense the tested pressure; periphery of the sensing membrane is clamped in the inner wall of the non-sensing area; both ends of the resonant working beam are clamped at the centre of upper surface of the sensing membrane to sense the tested pressure so as to change the resonance frequency and obtain the corresponding tested pressure valve through testing the resonance frequency by the closed loop system; both ends of the resonant compensating beam are clamped in the upper surface of the non-sensing area and are parallel to the resonant working beam and have the same physical dimension with the resonant working beam; the resonant compensating beam does not sense the tested pressure and only senses the temperature the same with the resonant working beam and other environmental factors; executing difference by using the resonance frequency of the resonant working beam and the resonance frequency of the resonant compensating beam is able to remove the change of the resonance frequency of the resonant working beam caused by temperature and other environmental factors so as to improve the measuring precision and stability of the sensor.

Owner:BEIHANG UNIV

Blood sensor, blood testing apparatus, and method for controlling blood testing apparatus

A blood sensor including a base (12), a detection part (16) disposed on the base (12), a blood collection needle (13) disposed at a front end (12a) of the base (12), a negative pressure generation part (17) for applying negative pressure to a portion of the blood collection needle (13), and a supply path (15) for supplying blood collected by the blood collection needle (13) to a detection part (16).

Owner:PHC HLDG CORP

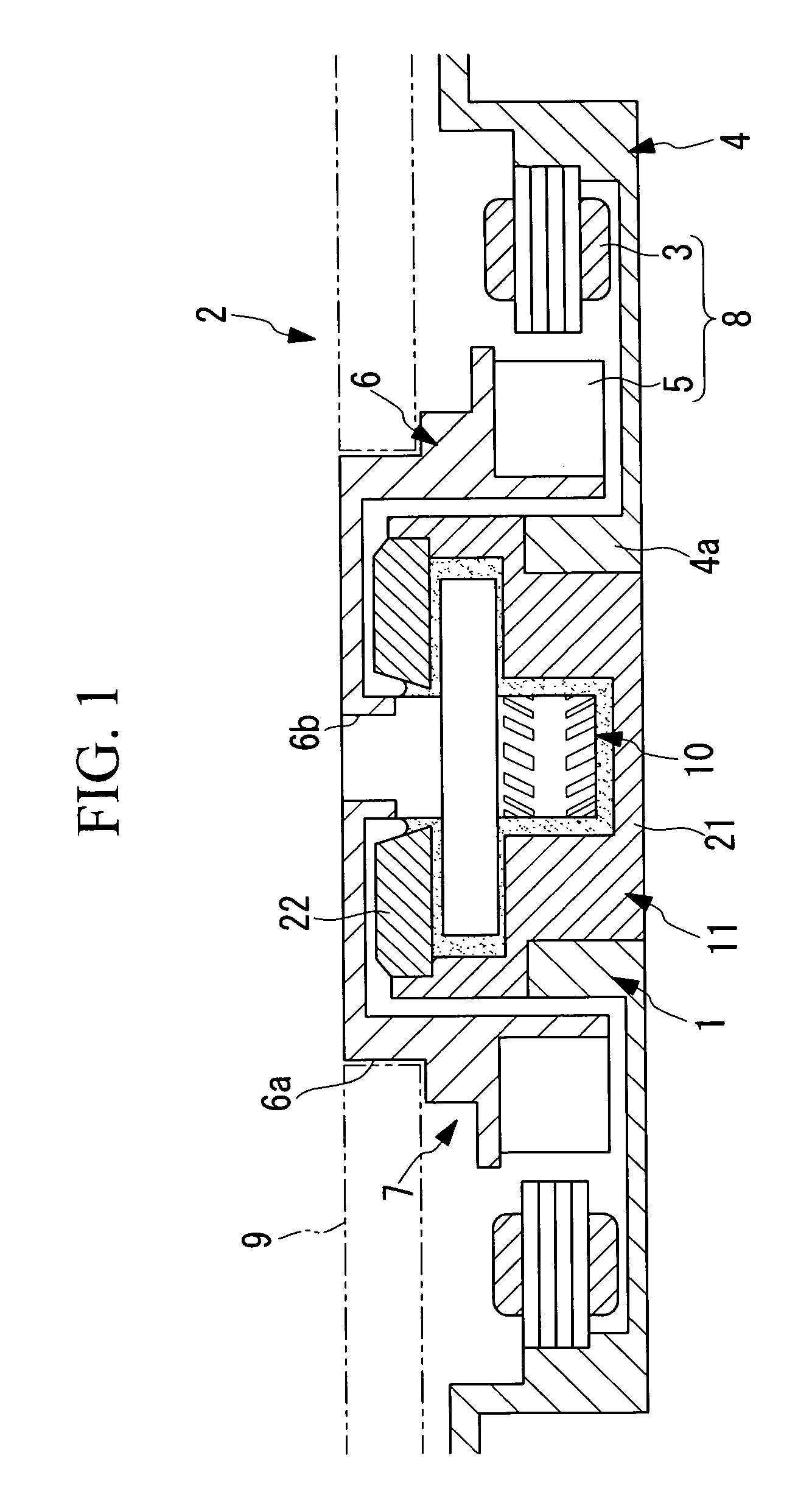

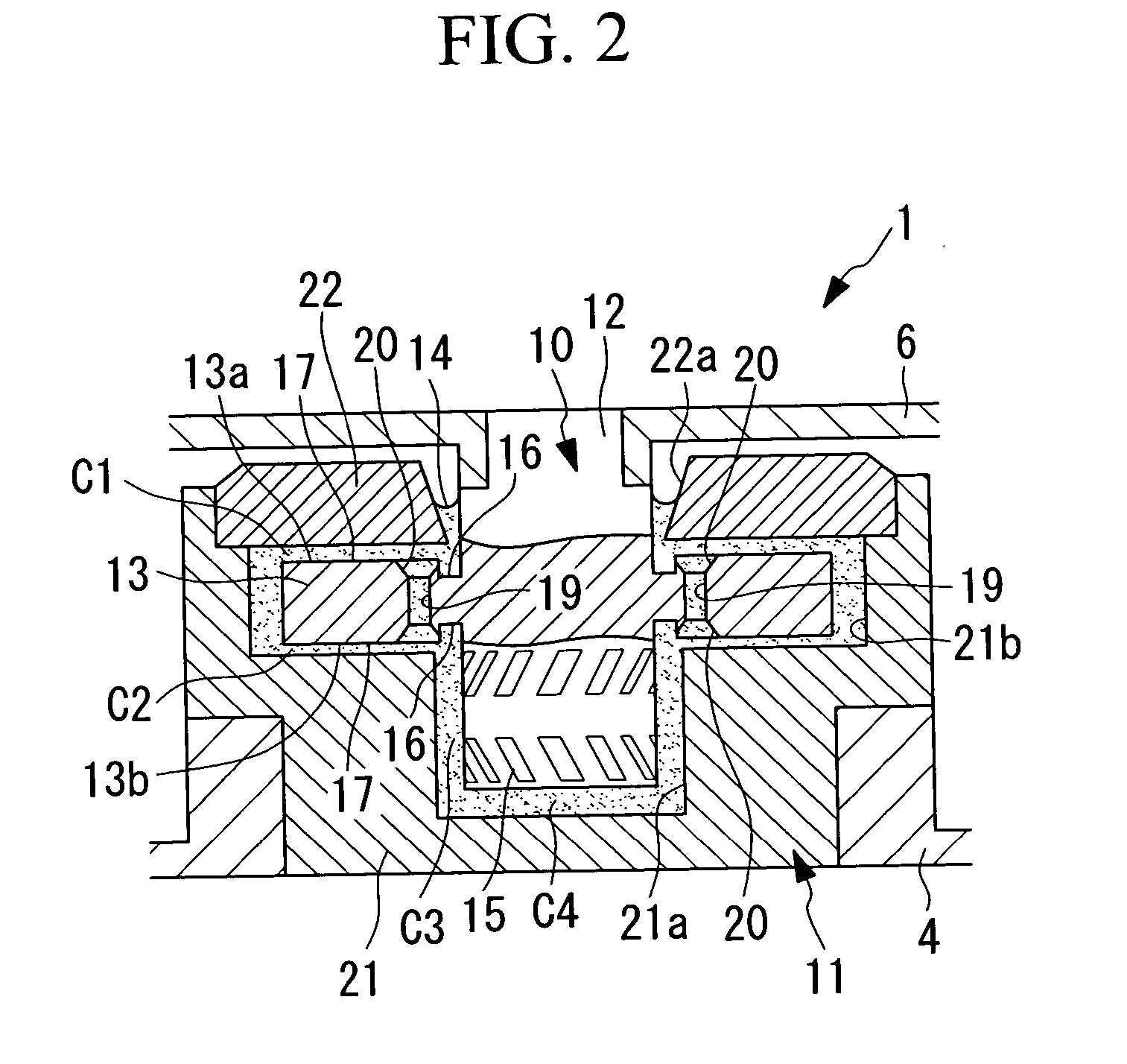

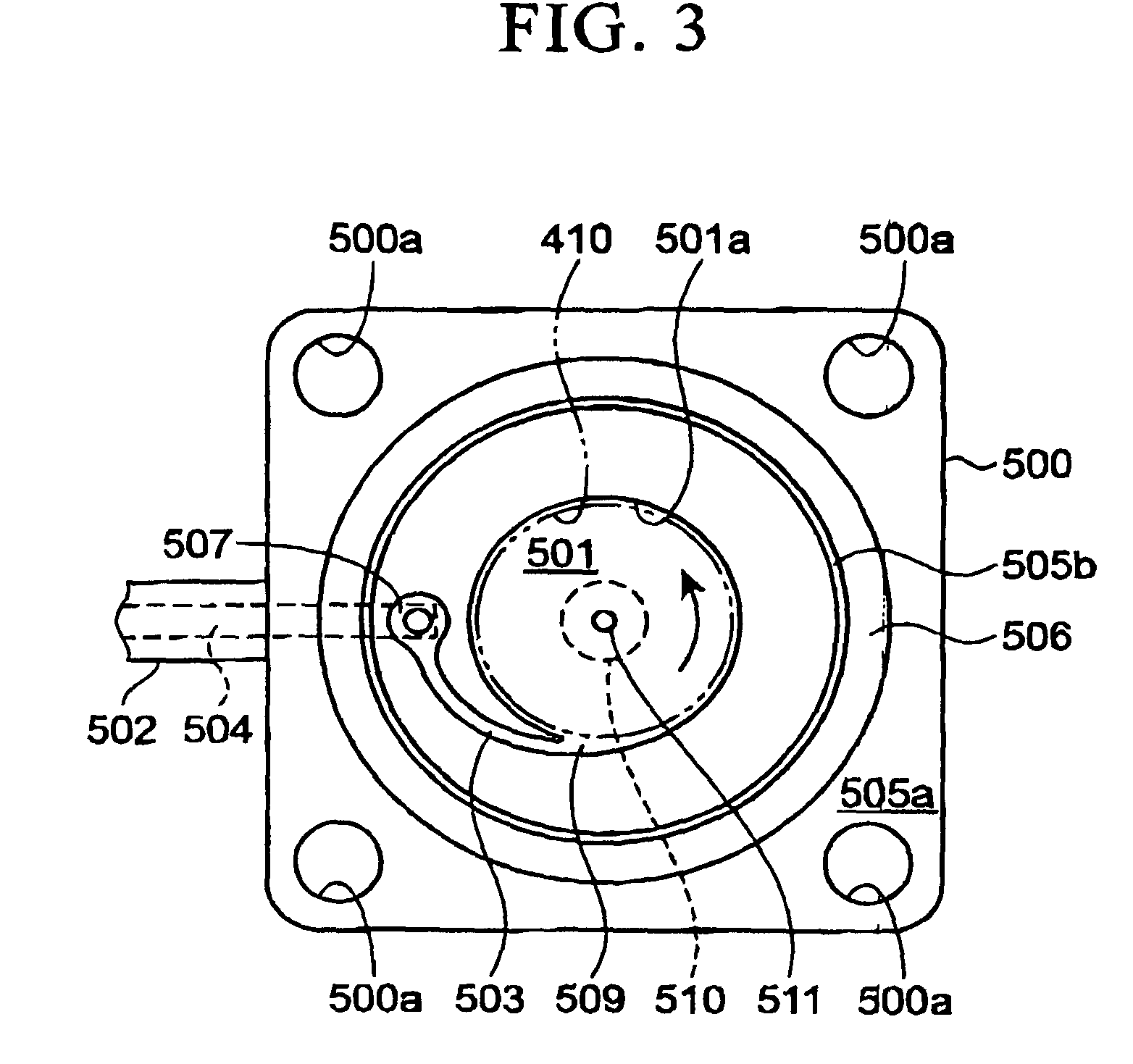

Fluid dynamic pressure bearing, motor, and recording medium driving device

InactiveUS20070177832A1Avoid mistakesAvoid bubblingShaftsRecord information storagePressure generationWorking fluid

The generation of bubbles can be suppressed by enabling a stable supply of working fluid to a dynamic pressure generating groove, and oscillation at the time of rotation and leakage of working fluid can be prevented effectively by efficiently releasing any bubbles generated. There is provided a fluid dynamic pressure bearing 1 provided with an annular dynamic pressure generating face 17 made by forming a dynamic pressure generating groove, which draws a working fluid 14 toward a midway position in the radial direction from the inside and outside of a thrust bearing plate 13 in the radial direction, when a shaft 10 and a housing 11 are rotated relative to each other about the axis, on thickness direction end faces 13a, 13b of the thrust bearing plate 13, or on an inner surface of the housing 11, and an inner groove section 16, which is located on an inner peripheral side thereof and that is depressed more than the dynamic pressure generating face 17 in the thickness direction, on the end faces 13a, 13b. Moreover there is provided a through hole 19 which passes through the thrust bearing plate 13 in the thickness direction so as to open to the dynamic pressure generating face 17, and there is provided a communicating cavity 20 which connects the opening portion of the through hole 19 and the inner groove section 16.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Environmental Mechanical Test Apparatus

InactiveUS20090314107A1Weather/light/corrosion resistanceEarth material testingPressure generationTest sample

An environmental mechanical test apparatus includes a pressure generation source and an isolation cylinder in fluid communication with the pressure generation source. The test apparatus further includes a pressure containment cell configured to receive a test specimen, an environmental chamber disposed about the pressure containment cell, and a load frame operably associated with the pressure containment cell. The pressure containment cell is in fluid communication with the pressure generation source and the isolation cylinder and includes a viewing window.

Owner:SCHLUMBERGER TECH CORP

Combination lung ventilation and mucus clearance apparatus and method

ActiveUS8844530B2Avoid bacterial contaminationReduce riskTracheal tubesOperating means/releasing devices for valvesPressure generationIntensive care medicine

A medical device and method for combination lung ventilation and mucus clearance of a patient is disclosed. The medical device may be configured to provide lung ventilation with intermittent, on-demand mucus clearance, freeing the patient's mouth for activities of daily living such as when the patient is awake; and, in another configuration, the device can provide lung ventilation with automated mucus clearance, such as when the patient is sedated or asleep. The medical device may comprise a pressure generation source, a ventilation portion, and a mucus clearance portion. The mucus clearance portion may be separable from or separate from the ventilation portion such that the medical device is capable of maintaining lung ventilation with the mouth interface removed from the patient.

Owner:MHS CARE INNOVATION LLC

Fluid injection device

ActiveUS7901374B2Easy constructionImprove reliabilityCannulasDispensing apparatusPressure generationEngineering

A fluid injection device includes: a pulse generation section that includes a fluid chamber whose volume is changeable, and an inlet flow passage and an outlet flow passage that are connected to the fluid chamber; a first connection flow passage connected to the outlet flow passage, having an end portion; a second connection flow passage connected to the inlet flow passage; a fluid injection opening formed at the end portion of the first connection flow passage, having a diameter smaller than the diameter of the outlet flow passage; a connection flow passage tube including the first connection flow passage and having rigidity adequate to transmit pulses of fluid flowing from the fluid chamber to the fluid injection opening; and a pressure generation section that supplies fluid to the inlet flow passage.

Owner:SEIKO EPSON CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com