Well cementation cement sheath integrity simulation and evaluation tester

A technology for cementing and simulation evaluation, applied in the field of oil drilling, can solve the problems such as the inability to quantitatively analyze and measure the change of the anti-channeling strength of the cementing sheath, the complex and large test device, and the difficulty in understanding problems, and achieve intuitive and reliable performance and low cost. Inexpensive and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

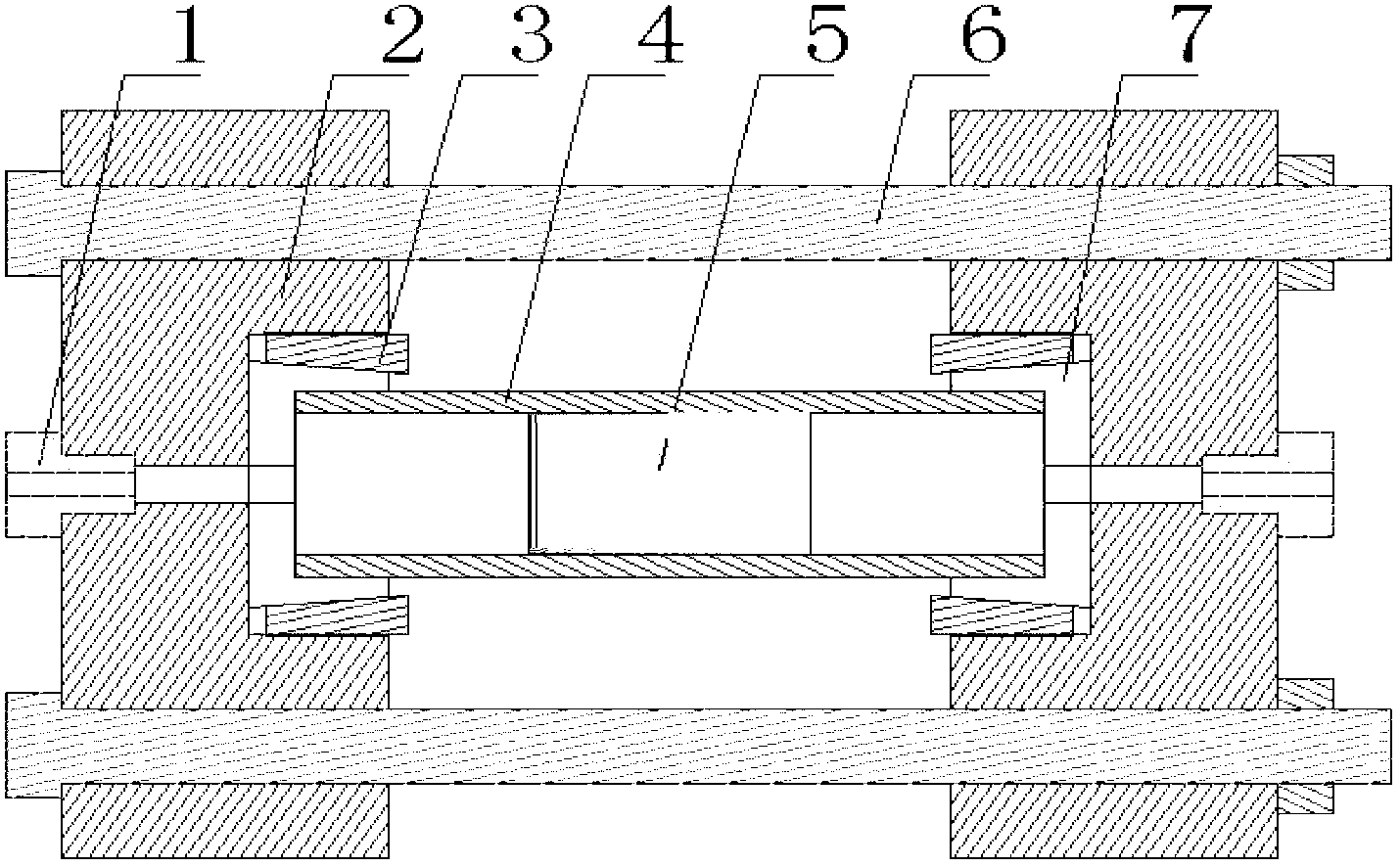

[0030] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

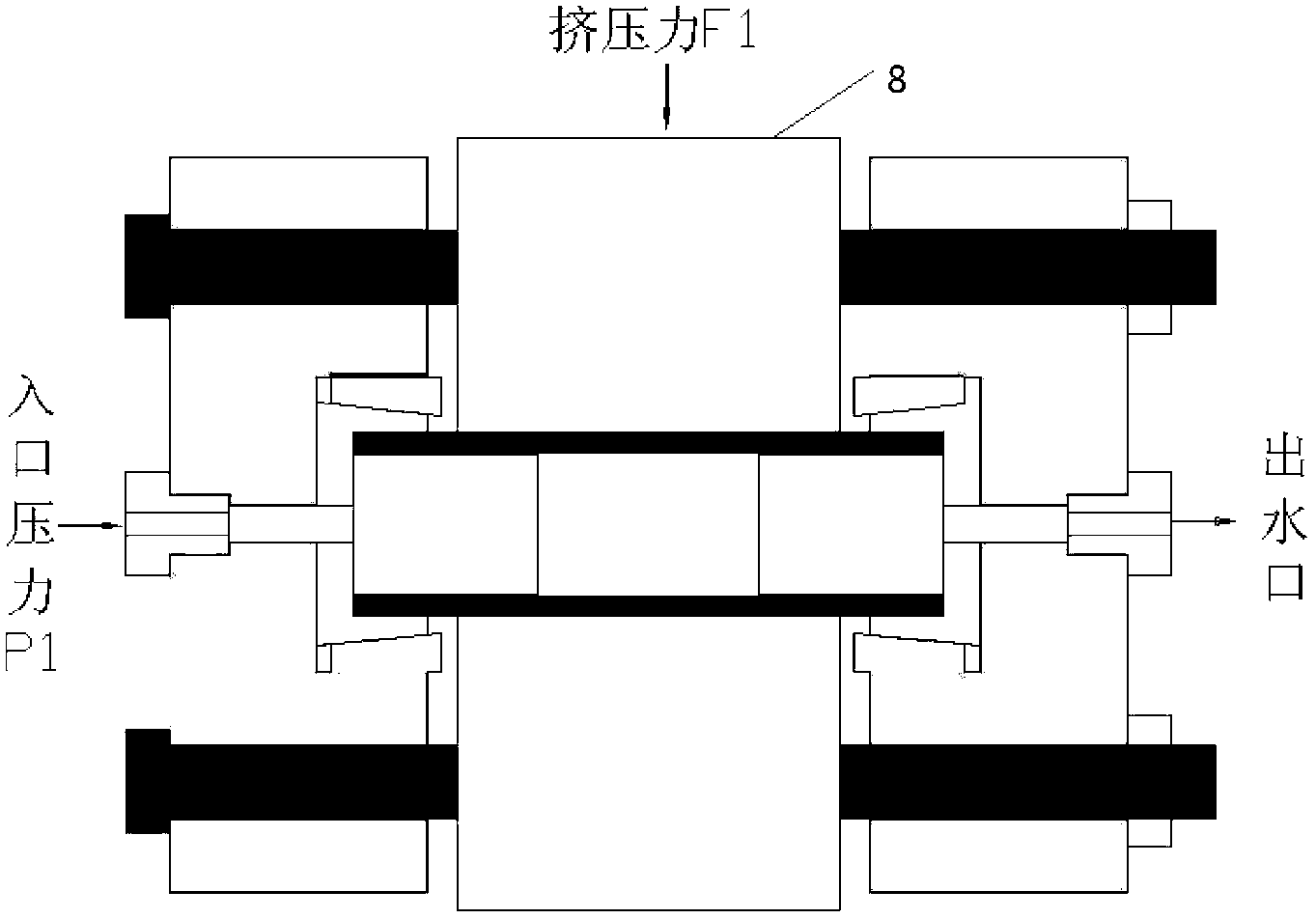

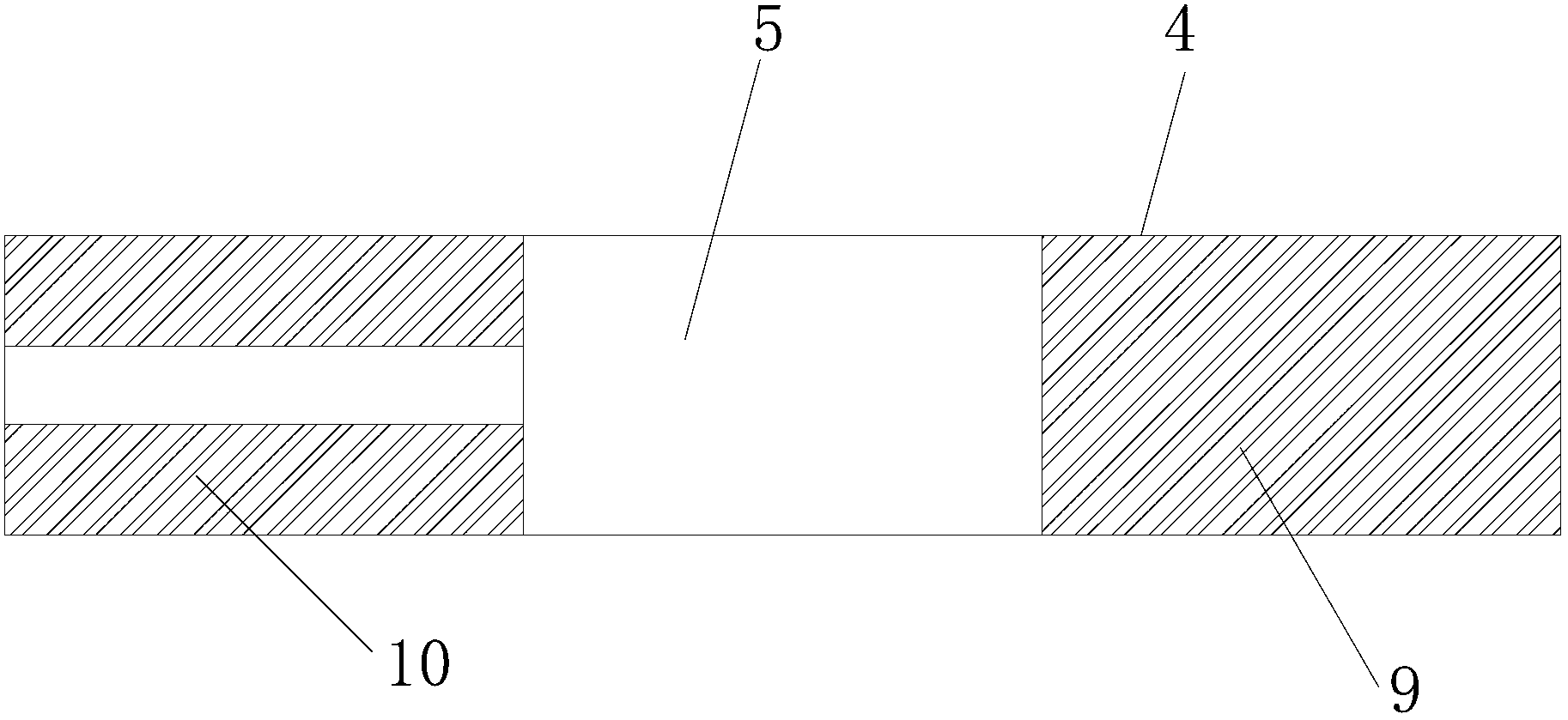

[0031]Referring to the accompanying drawings, a cementing cement sheath integrity simulation evaluation tester includes a pressure joint 1, the pressure joint 1 is arranged on the compression packing 2, and the compression ring 3 is connected with the compression disc through a screw thread 2 connection, and the trapezoidal rubber sealing ring 7 is fixed on the compression disc 2 and the steel pipe 4, and the steel pipe 4 equipped with the cement solidification body test sample 5 is clamped and connected as a whole through the screw nut connection assembly 6 The trapezoidal rubber sealing ring 7 ensures the hydraulic sealing performance of the steel pipe 4 in the cementing cement sheath mechanical performance simulation tester through the axial compression of the two compression discs and the lateral force gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com