Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1441 results about "Bleach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bleach is the generic name for any chemical product which is used industrially and domestically to clean, to lighten hair color and to remove stains. It often refers, specifically, to a dilute solution of sodium hypochlorite, also called "liquid bleach".

Photobleach speckle and laundry detergent compositions containing it

InactiveUS20030087790A1Little and no stainingLittle or no stainingOrganic detergent compounding agentsDetergent dyesParticulatesBleach

A speckle composition for use in particulate laundry detergent compositions comprising a porous granular carrier, and at least 0.01 wt % photobleach, preferably at least 0.05 wt %, more preferably at least 0.1 wt %, based on the active ingredient the composition being layered with a finely divided high carrying capacity particulate material and / or a water-soluble material. The most preferred photobleach is a blend of Zn and Al sulphonated phthalocyanine.

Owner:HENKEL IP & HOLDING GMBH

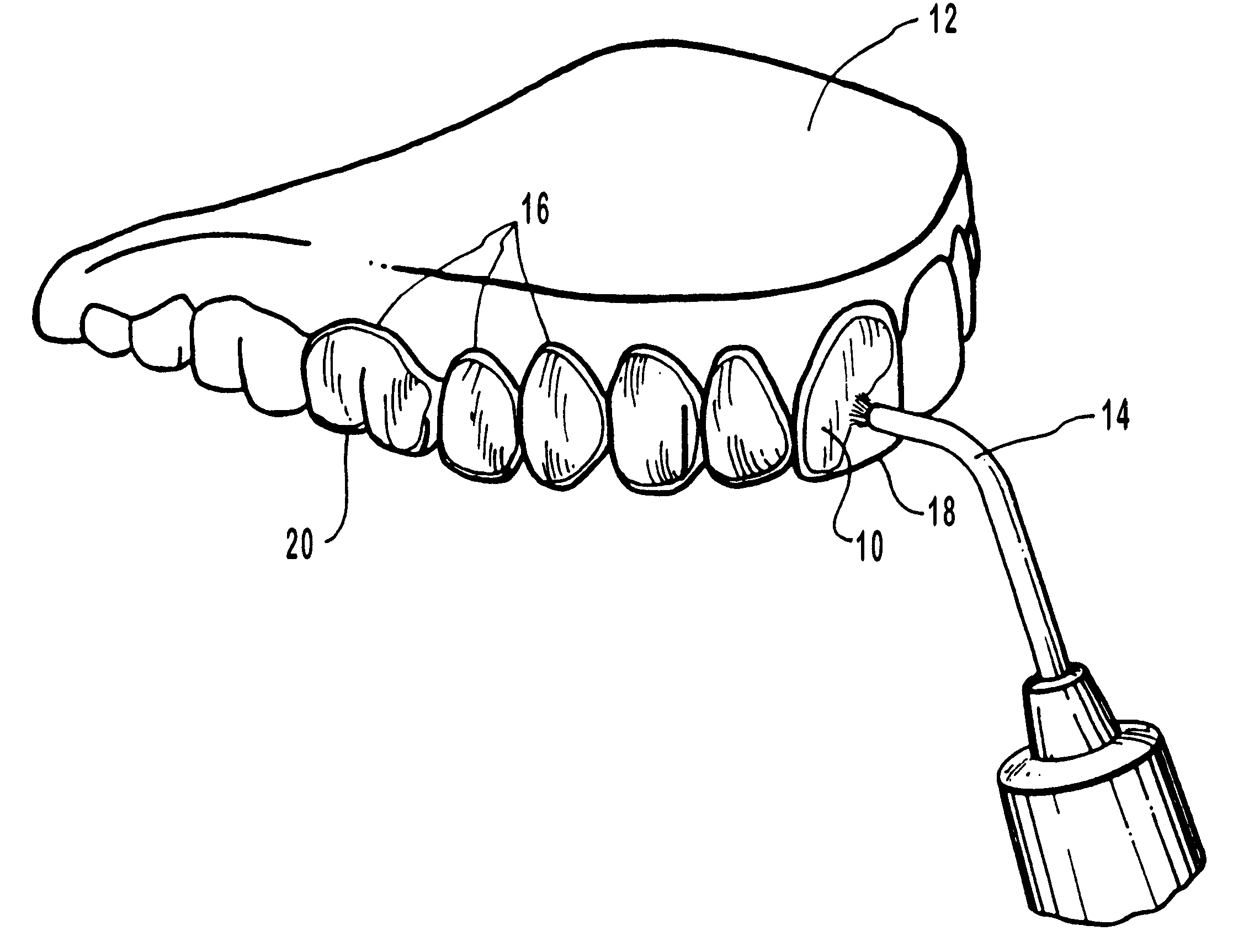

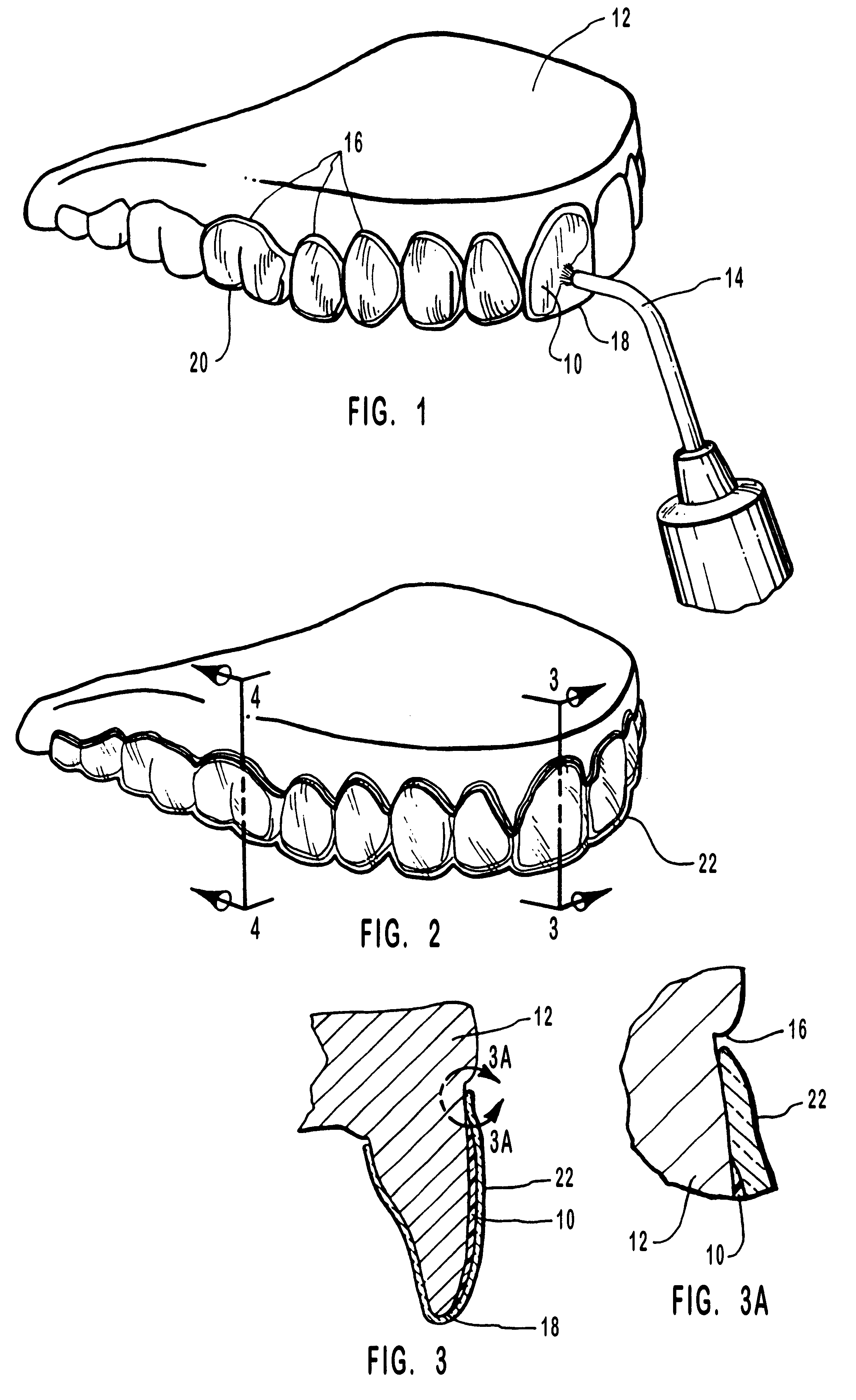

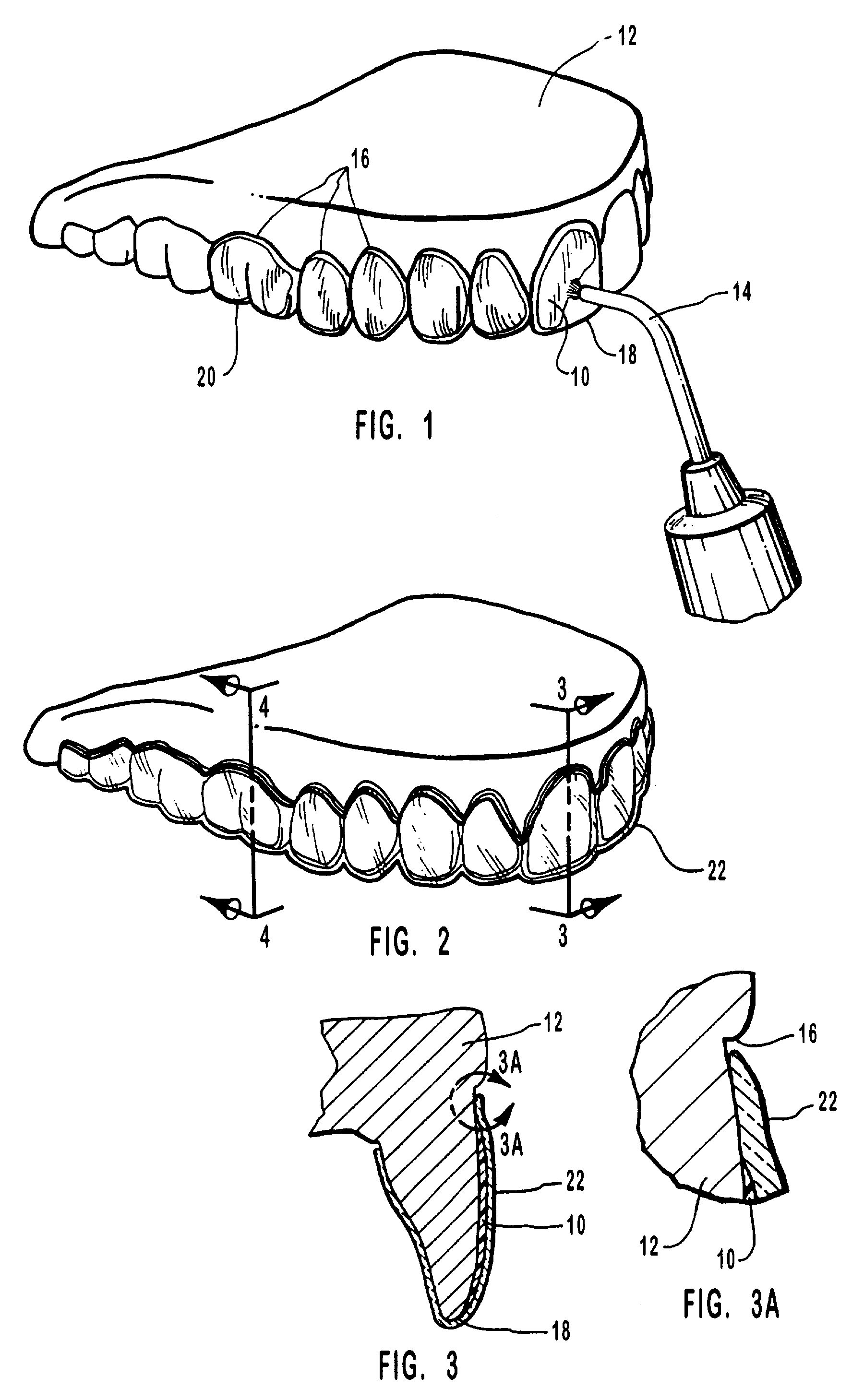

Methods for bleaching, opacifying and desensitizing teeth

InactiveUS6368576B1Trend downReduce sensitivityCosmetic preparationsTeeth fillingPotassium nitrateCarbamide peroxide

Owner:ULTRADENT PROD INC

One-part dental compositions and methods for bleaching and desensitizing teeth

InactiveUS6309625B1Reduce sensitivityTrend downCosmetic preparationsGum massagePotassium nitrateMedicine

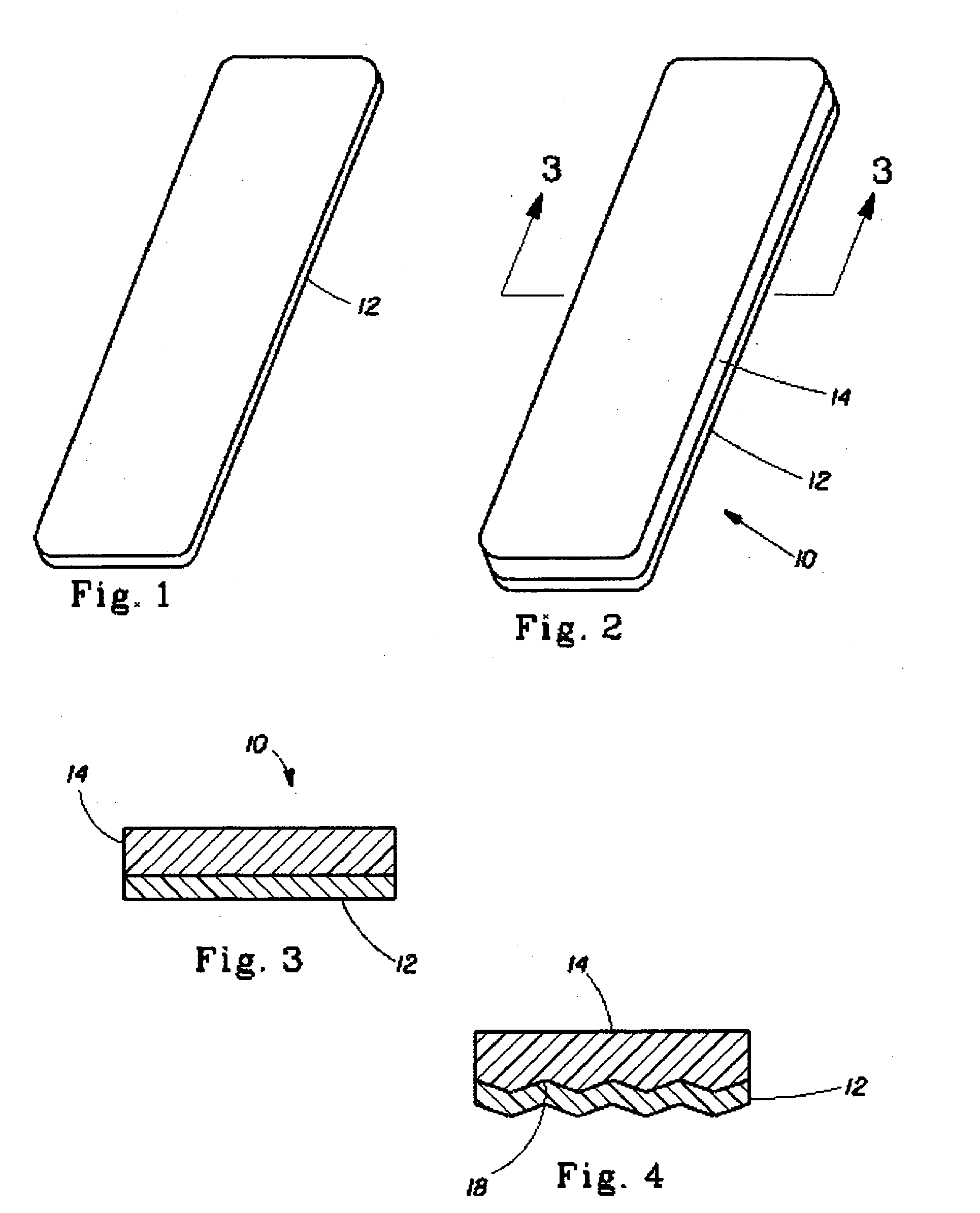

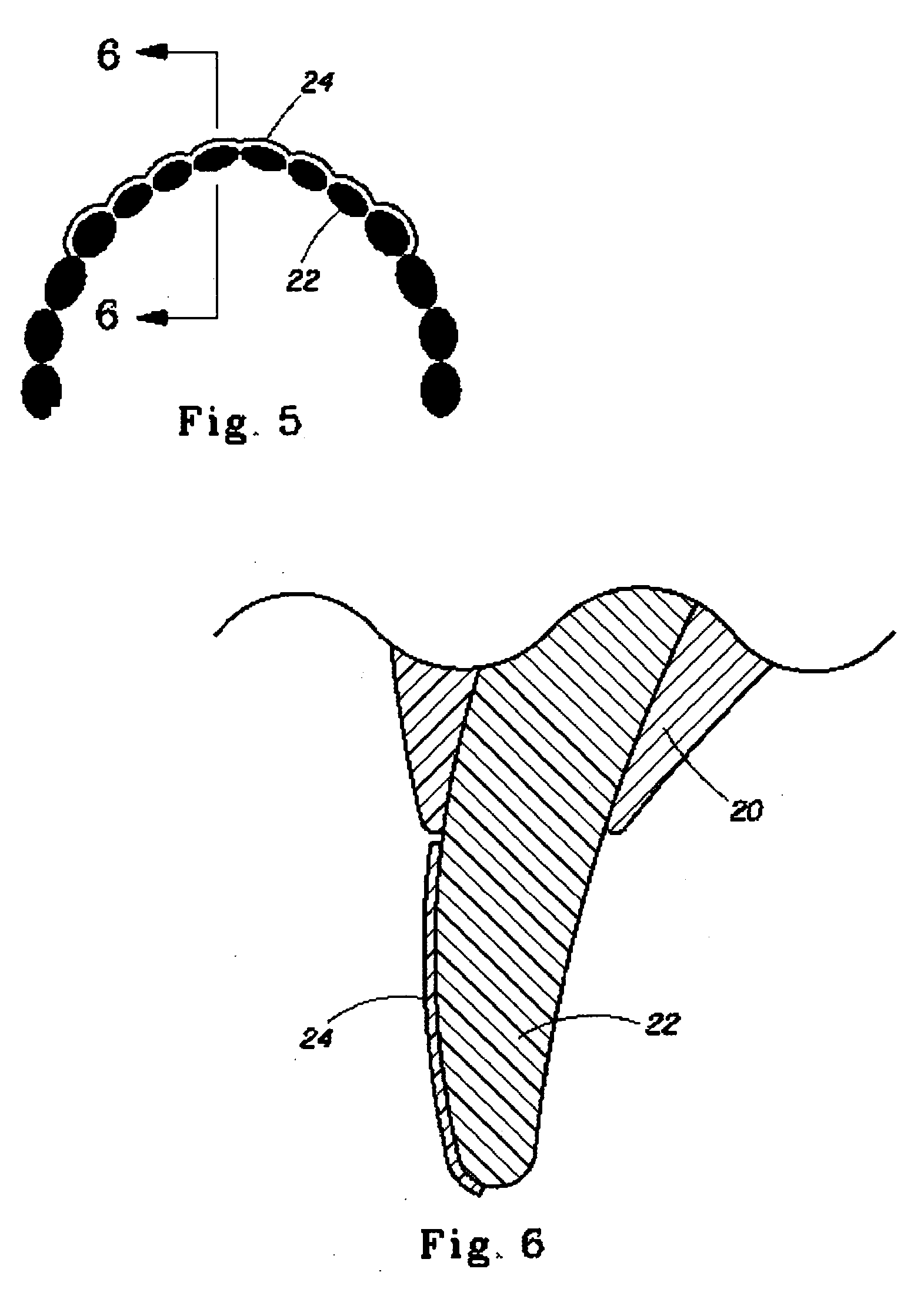

Composition and methods that include potassium nitrate for whitening and / or reducing tooth sensitivity. The dental compositions may optionally include a dental bleaching agent, such as hydrogen peroxide or carbamide peroxide. The dental compositions may be applied directly to the person's teeth, or they may be loaded into a comfortable fitting, flexible, thin-walled dental tray and placed over the person's teeth. In that case, the dental compositions will include a tackifying agent, such as carboxypolymethylene, dispersed within a solvent, which assists the composition in retaining the dental tray over the person's teeth as a result of the adhesive properties of the dental composition rather than due to mechanical interlocking of the tray over the person's teeth. The dental compositions may further include anticariogenic and antimicrobial agents.

Owner:ULTRADENT PROD INC

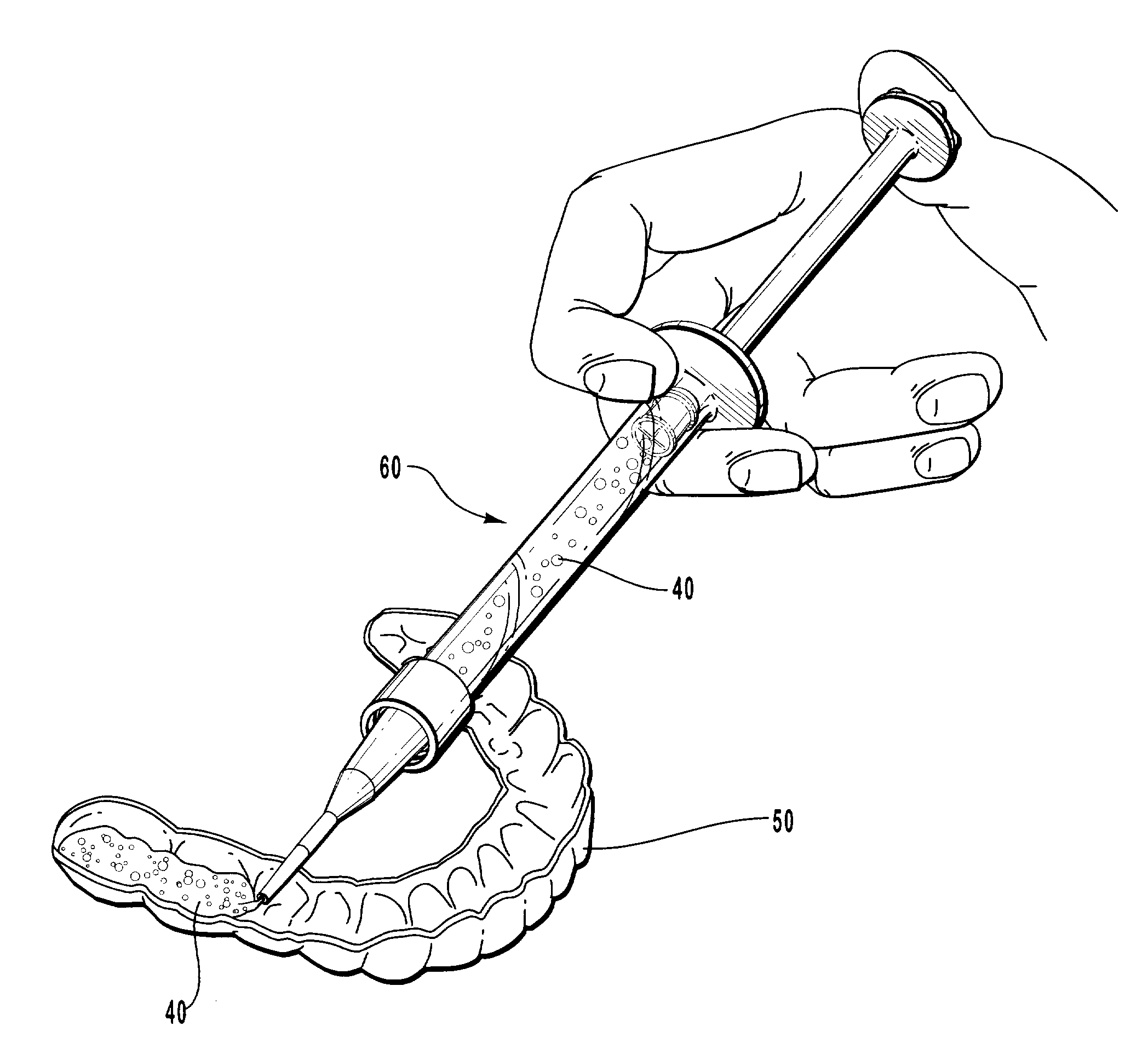

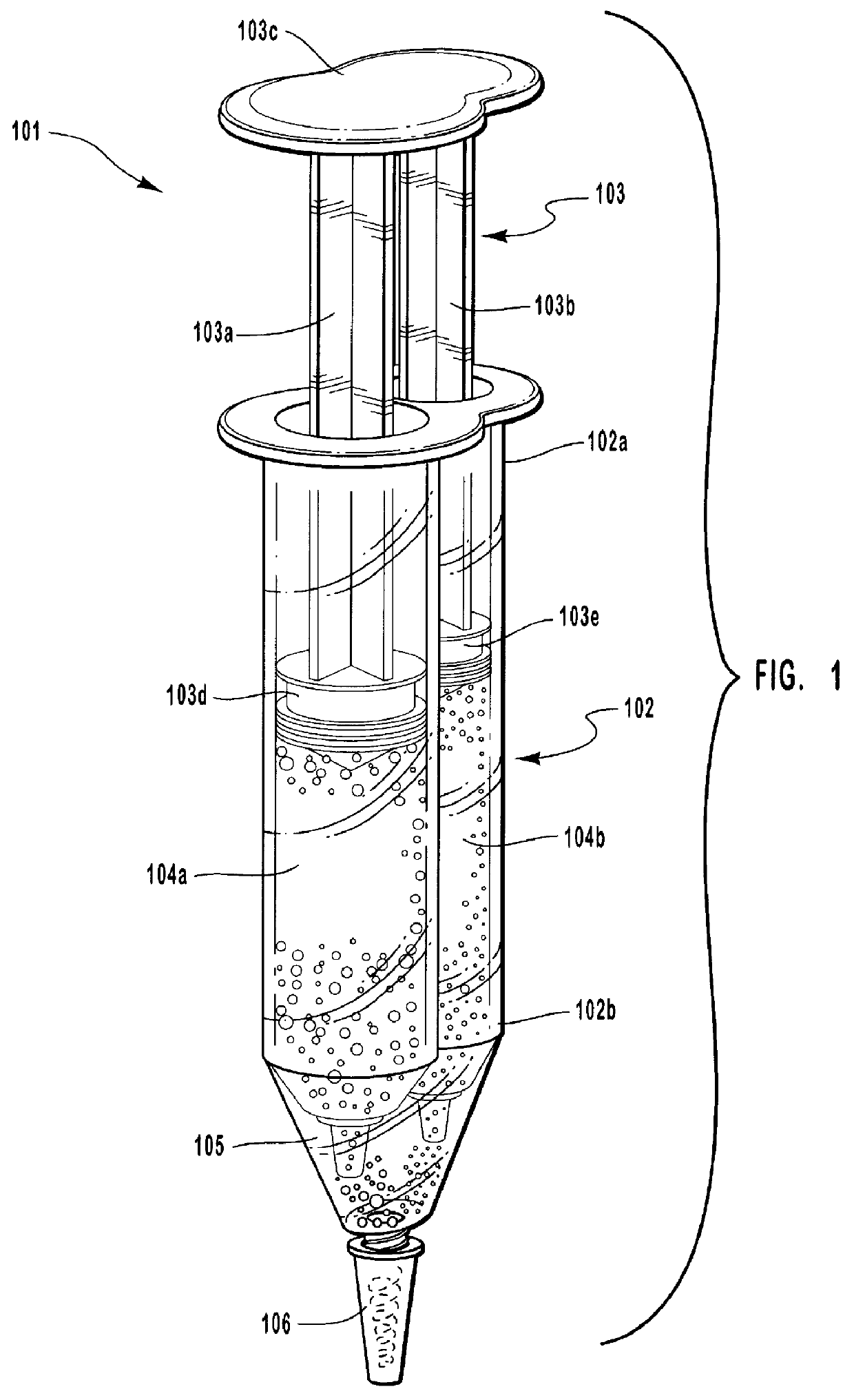

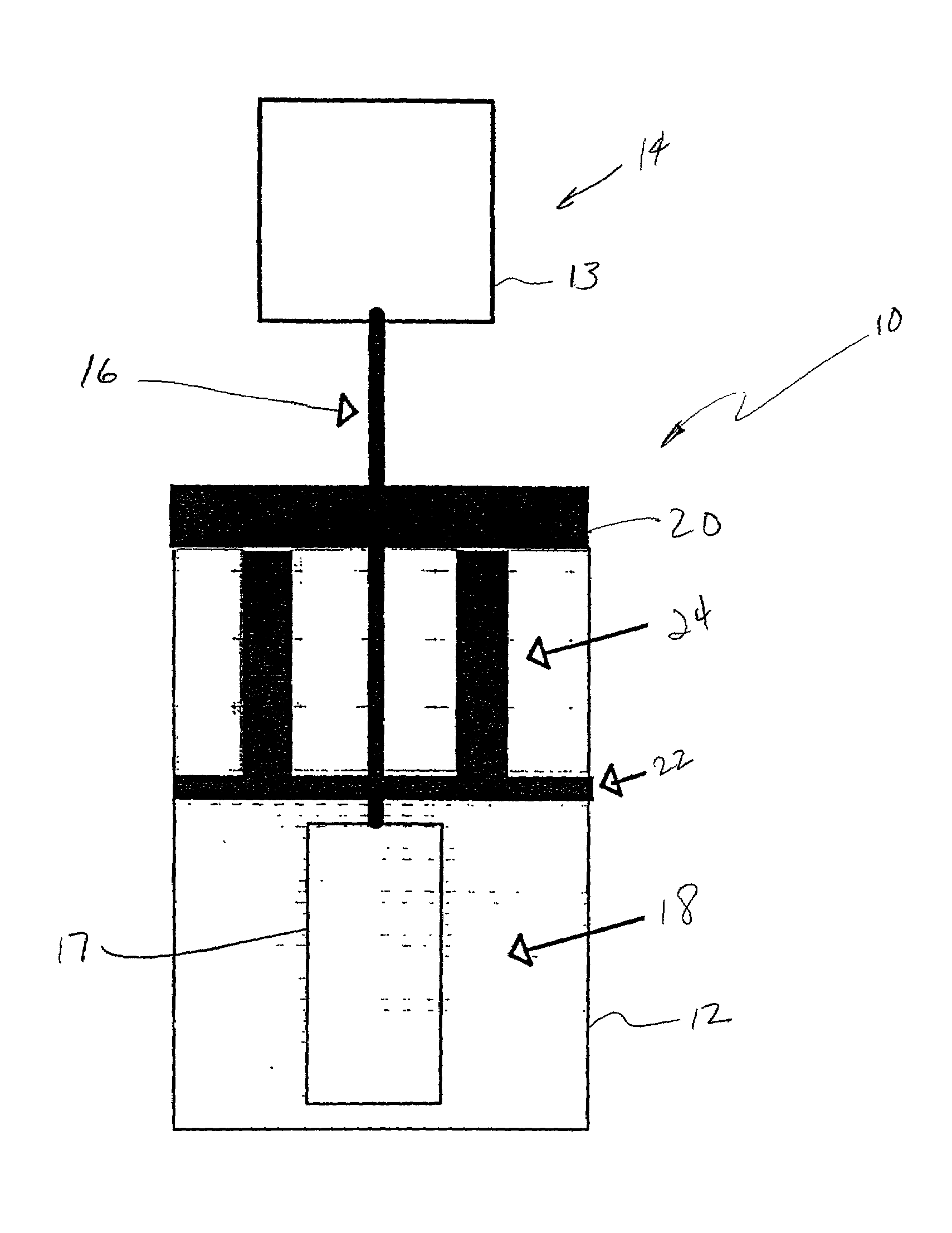

Binary energizer and peroxide delivery system for dental bleaching

A dental bleach storage, mixing and delivery device and related method are disclosed. The device includes a barrel with at least two chambers. The chambers store components that when mixed can form a dental bleach or whitener. A plunger is provided that can be reciprocated within the barrel to force such components from their chambers. A mixing tip is provided for the end of the barrel. The components may be forced through the mixing tip which thoroughly mixes them together. The resulting bleach or whitener is applied to a patient's teeth where oxygen ions released from the bleach or whitener and will whiten the patient's teeth.

Owner:CAO GROUP

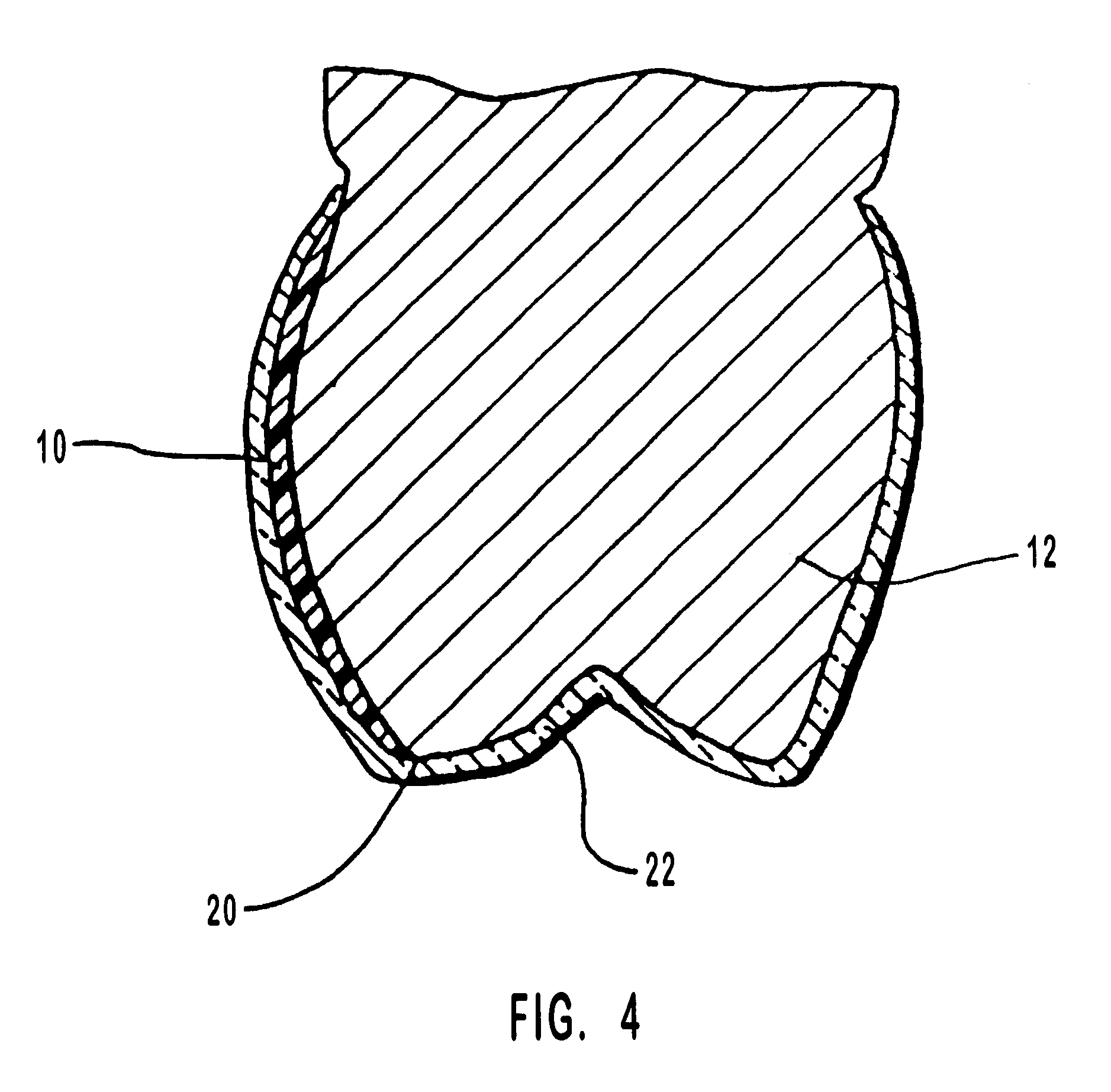

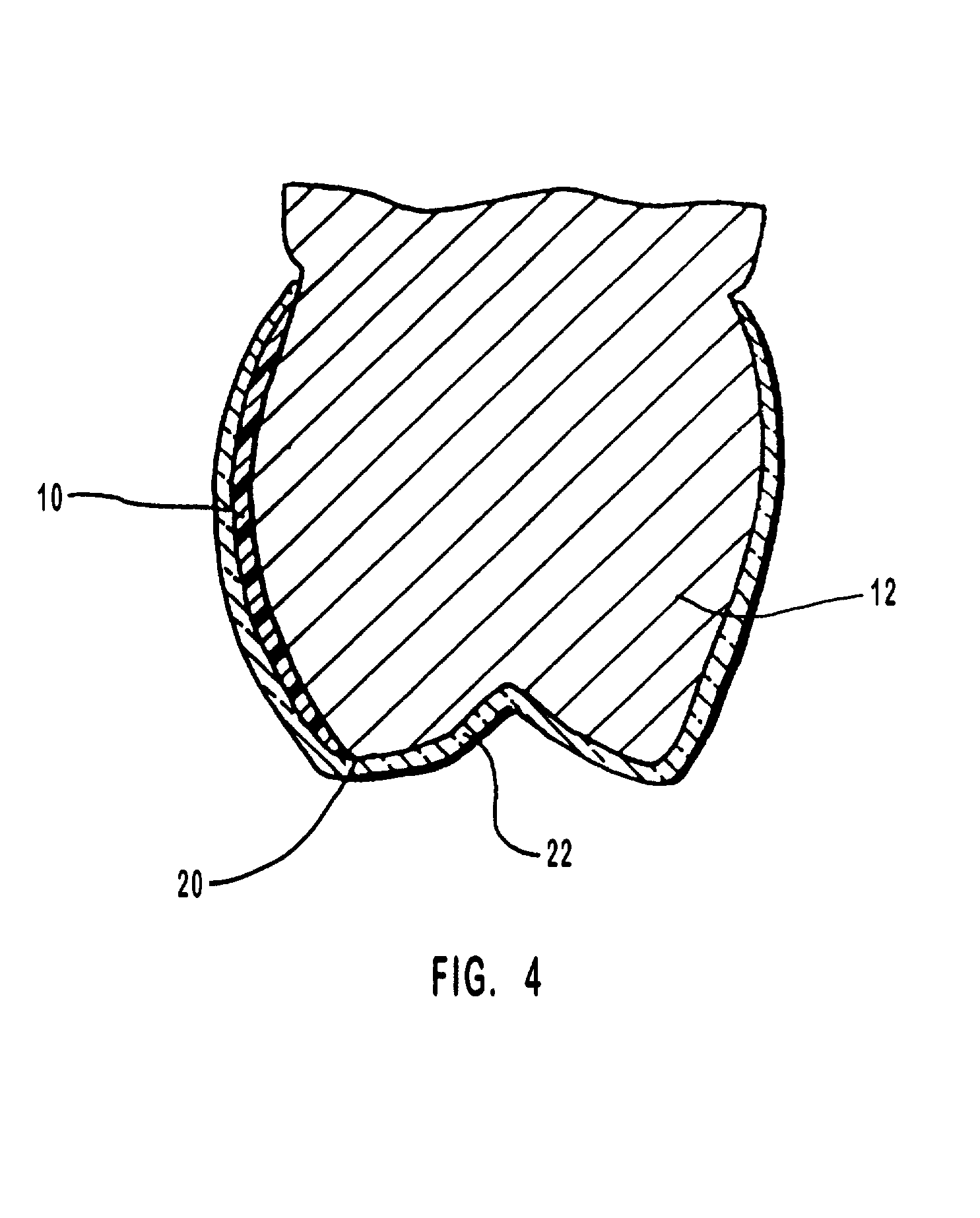

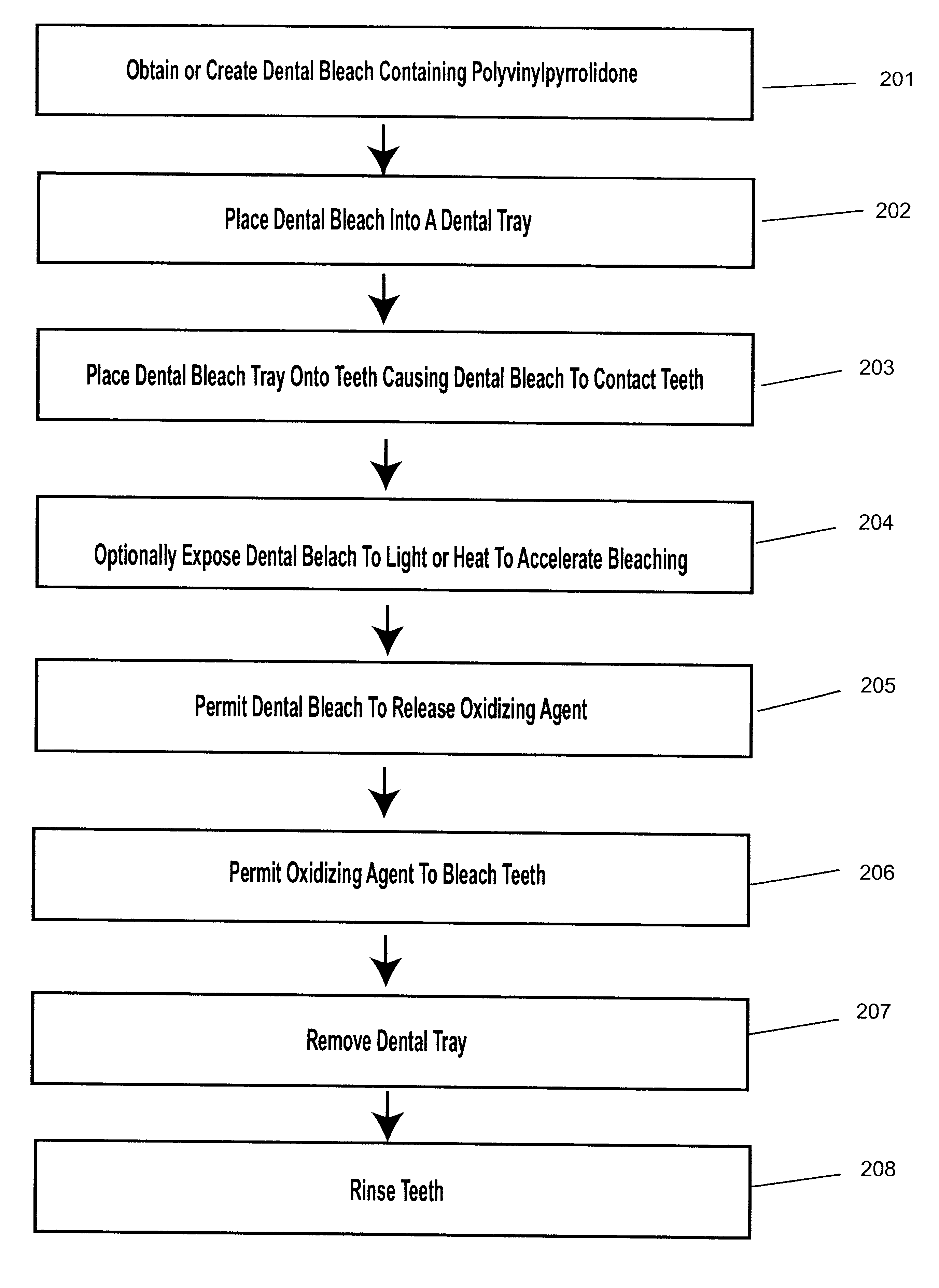

Enamel-safe tooth bleach and method for use

InactiveUS6500408B2High viscositySignificant interferenceBiocideCosmetic preparationsBleachTeeth Bleaching

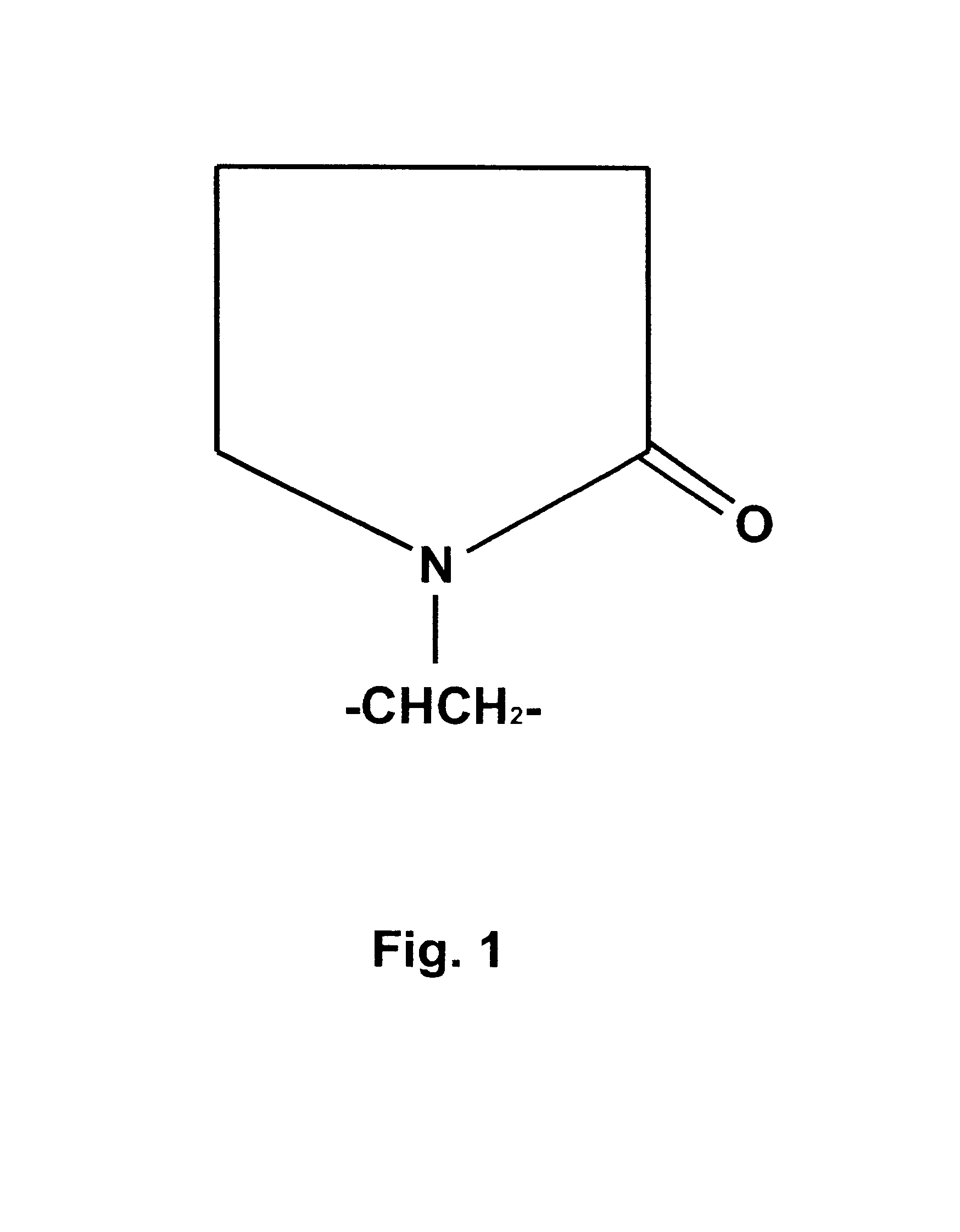

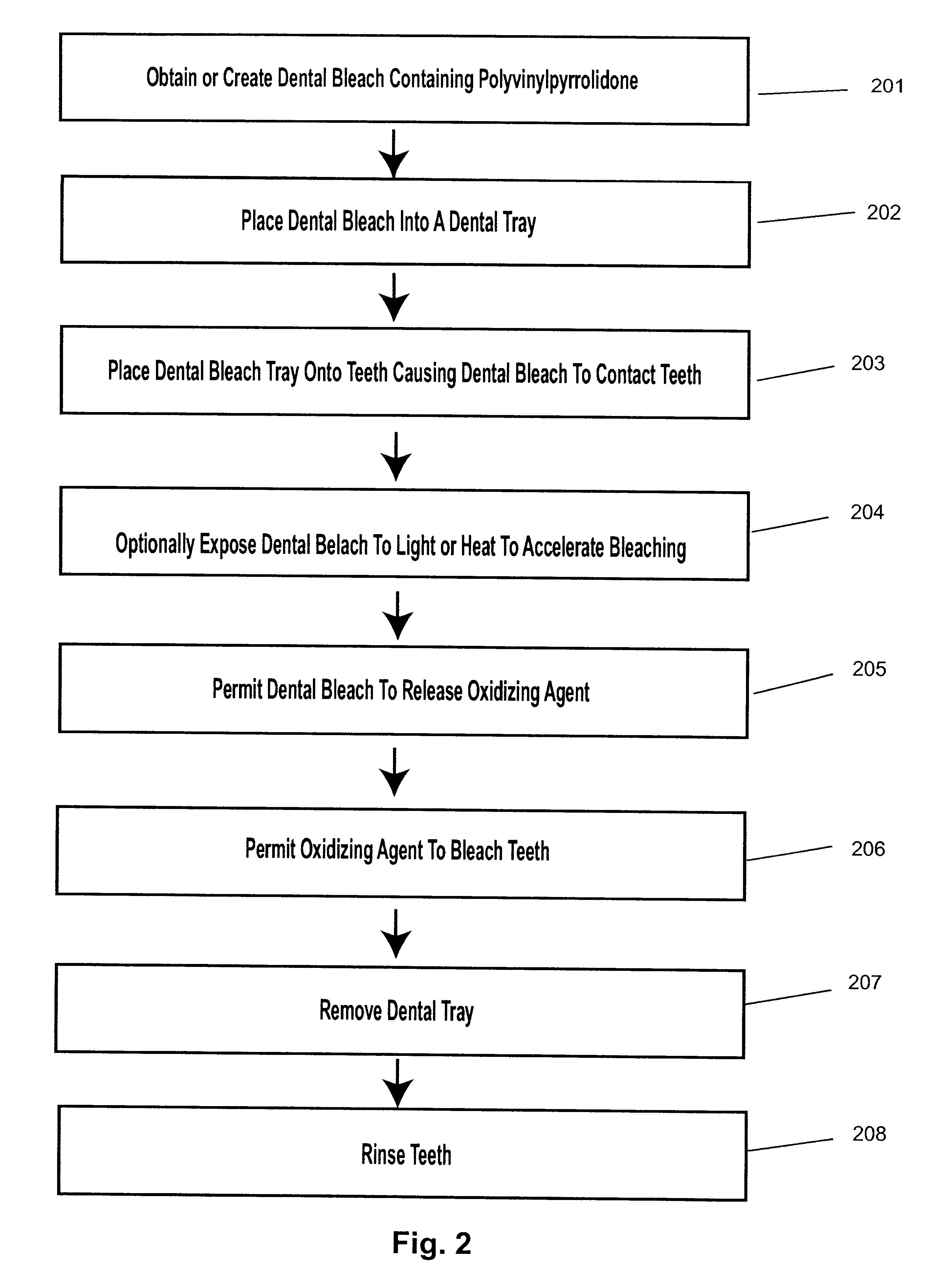

A dental bleach that includes a bleaching agent and a thickening agent. The bleaching agent is typically a peroxide and the thickening agent is polyvinylpyrrolidone. A viscous or sticky dental bleach results. Optionally, a basic agent, light or heat may be added to accelerate bleaching. Bleaching may take place with the use of a dental tray. Bleach may be placed into the dental tray from a single barrel, double barrel or multi-barrel syringe containing the components of the bleach. Bleach may be placed against a flexible strip which is placed onto teeth to be bleached.

Owner:ULTRADENT PROD INC

Light or heat activated dental bleaching compositions

InactiveUS6387353B1Solve the lack of lifePromote decompositionCosmetic preparationsImpression capsBleachBiological activation

Dental bleaching compositions are made with a bleaching agent and a stable radiant-energy absorbing compound that acts as a bleaching agent activator. The dental bleaching compositions of the present invention can be one-part, pre-mixed compositions that do not require mixing at the time of treating a patient's teeth but which remain stable over time. The bleaching agent may consist of hydrogen peroxide, either in aqueous form or complexed with urea (carbamide peroxide) or sodium perborate. The bleaching agent activator includes hydrocarbons that are stable in the presence of the bleaching agent, which do not prematurely accelerate liberation of the bleaching agent, but which allow for selective activation of the bleaching agent by irradiation of the bleaching composition with radiant energy. The bleaching composition may optionally include a neutralizing agent to adjust the pH, a carrier to help provide proper consistency and potency, and a stabilizing agent to maintain maximum potency of the bleaching agent over time. The bleaching composition may also include a thickening agent to achieve a selected viscosity. The dental bleaching compositions may be adapted to be loaded into and delivered from a syringe.

Owner:ULTRADENT PROD INC

Emulsion composition for delivery of bleaching agents to teeth

InactiveUS20050137109A1Safe and effective amountCosmetic preparationsToilet preparationsEmulsionMedicine

The present invention relates to a composition for whitening teeth comprising: a safe and effective amount of an aqueous phase; a safe and effective amount of a bleaching agent; a safe and effective amount of an inert hydrophobic phase; and a safe and effective amount of an emulsifier; wherein the inert hydrophobic phase is in predominant proportion relative to the aqueous phase present in the composition. In another embodiment the present invention also relates to an oral care delivery system comprising: an integral carrier and a safe and effective amount of the above composition. In one embodiment the delivery system comprises: a first layer of a strip of material; a second layer comprising the present composition, whereby the bleaching agent is releasably associated with the strip of material.

Owner:THE PROCTER & GAMBLE COMPANY

Dental bleaching compositions containing sucralose

Dental bleaching compositions that include sucralose. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous such as a mixture of propylene glycol and silica fume. Anhydrous propylene glycol and / or anhydrous glycerin are especially useful in order to maintain the desired degree of hydration of the perborate being used. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

Laundry detergent compositions in the form of an article

InactiveUS20110028374A1Organic detergent compounding agentsNon-surface-active detergent compositionsWater dispersiblePlasticizer

A laundry additive article comprises surfactant, water-soluble and / or water-dispersible film-forming polymer, plasticizer, bleach, suds suppressor and Remaining Water. The article is in the form of a first flexible porous dissolvable solid structure having a dry density and having a Percent open cell content.

Owner:THE PROCTER & GAMBLE COMPANY

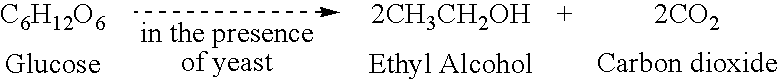

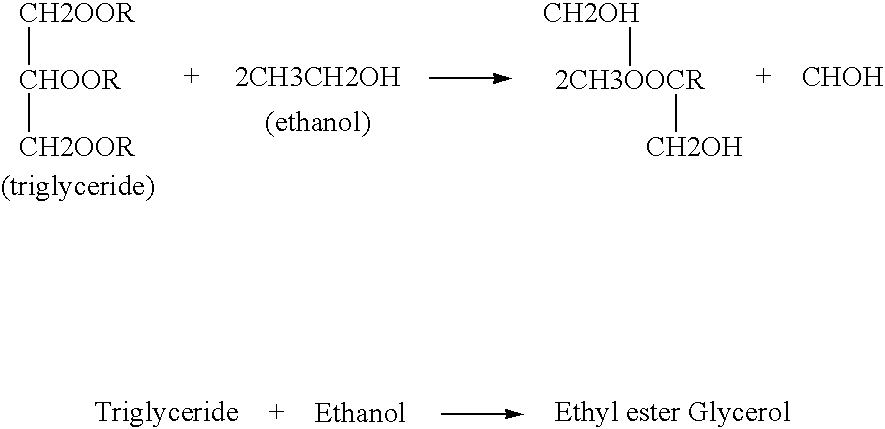

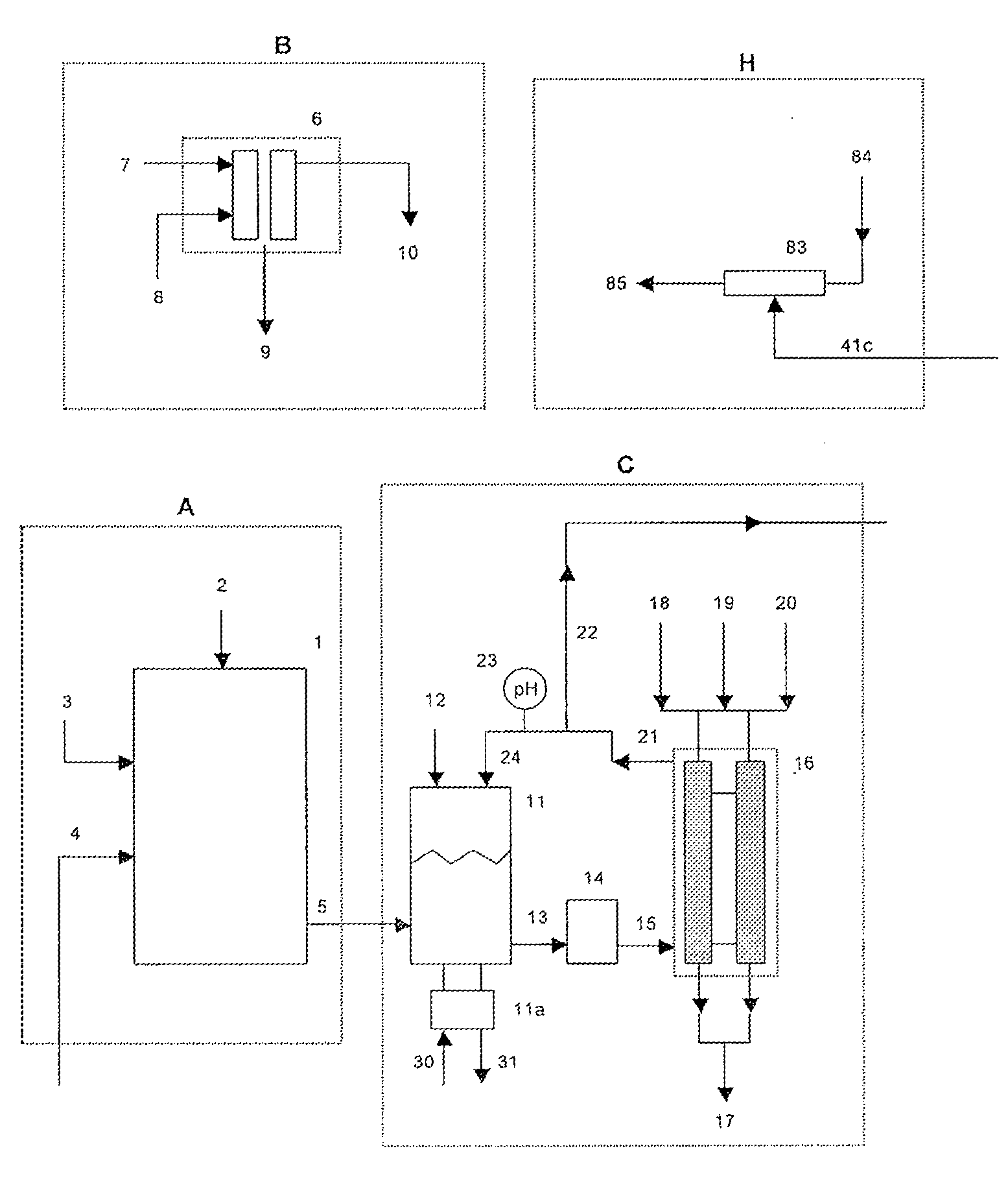

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

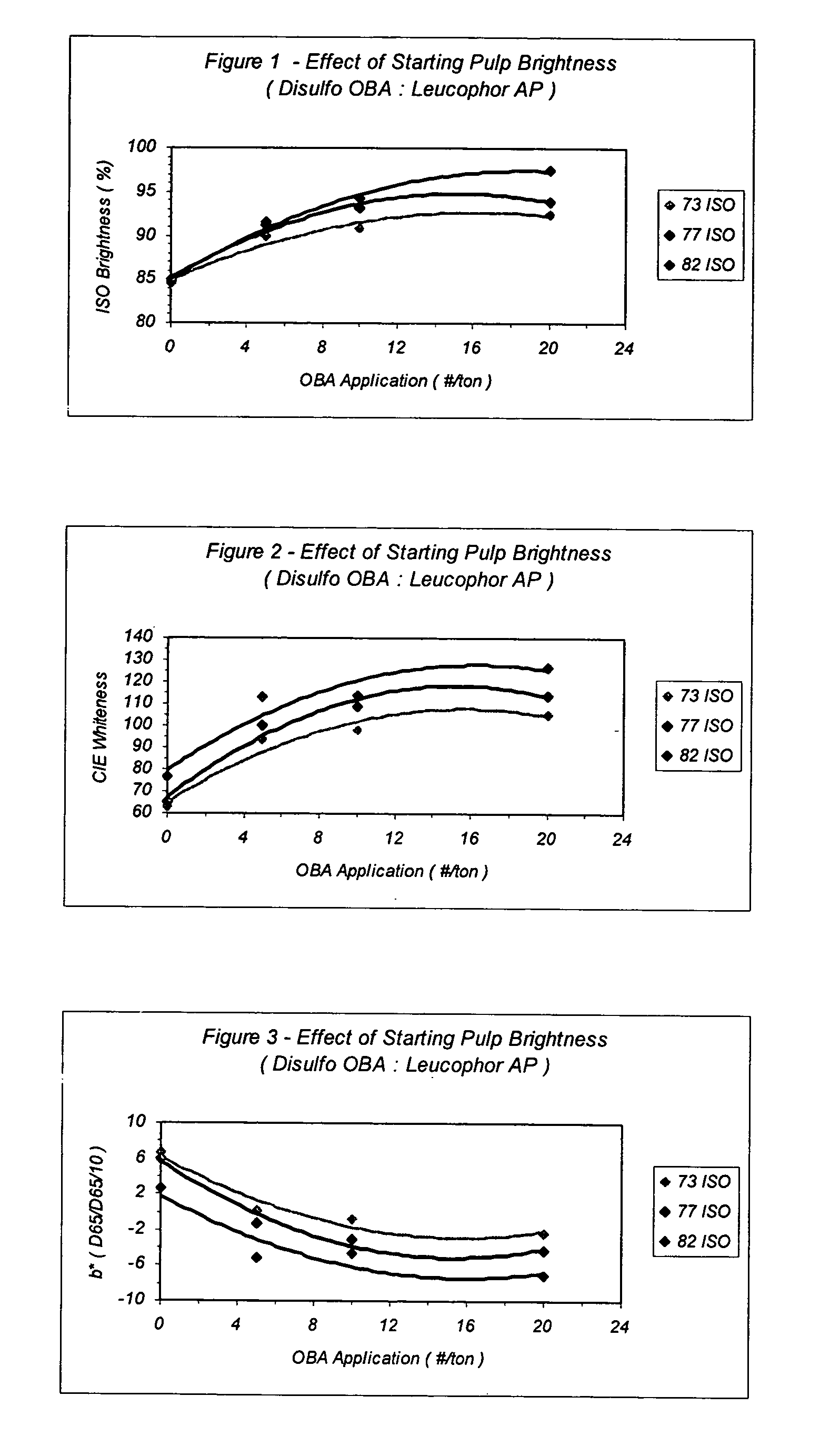

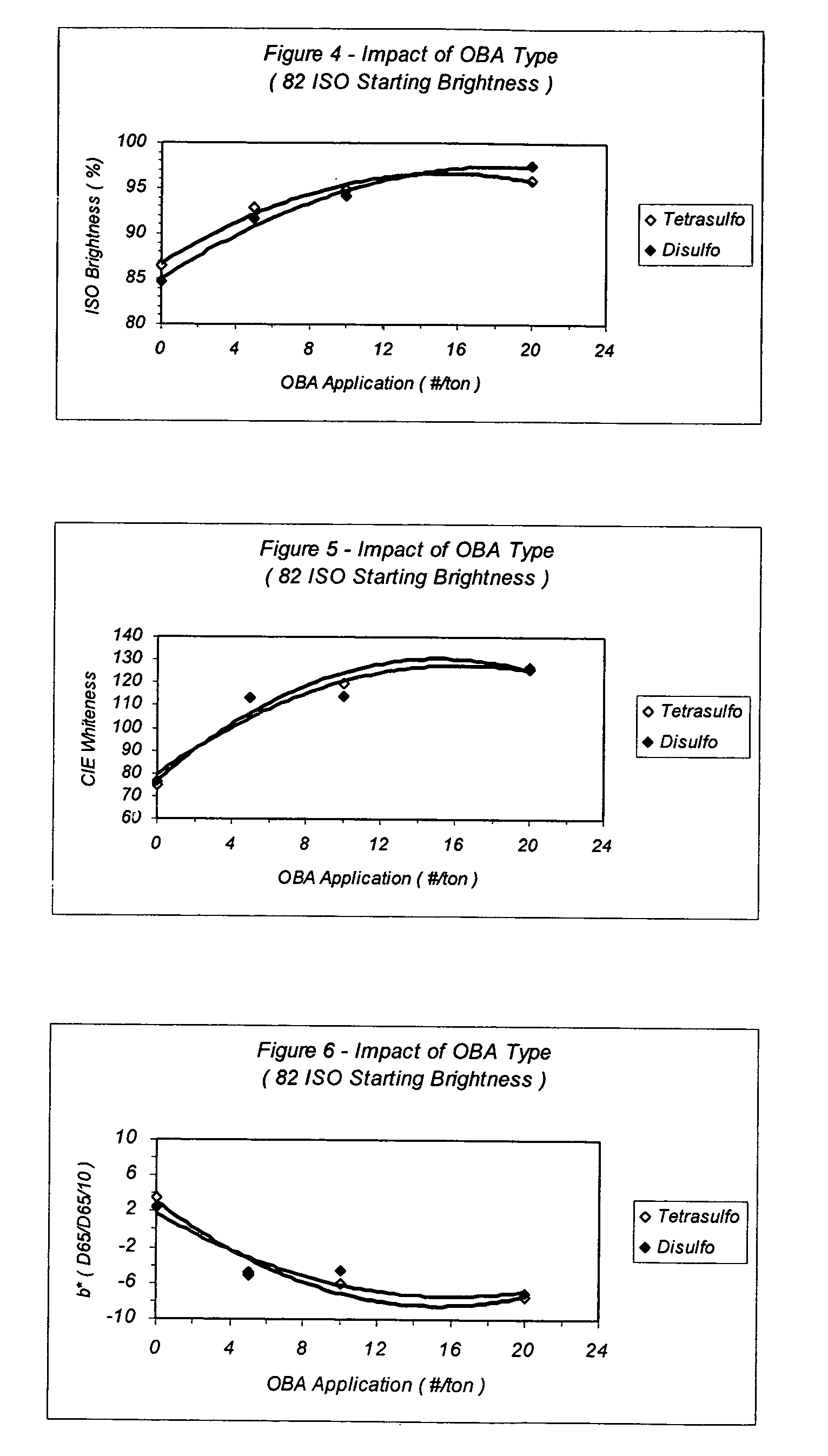

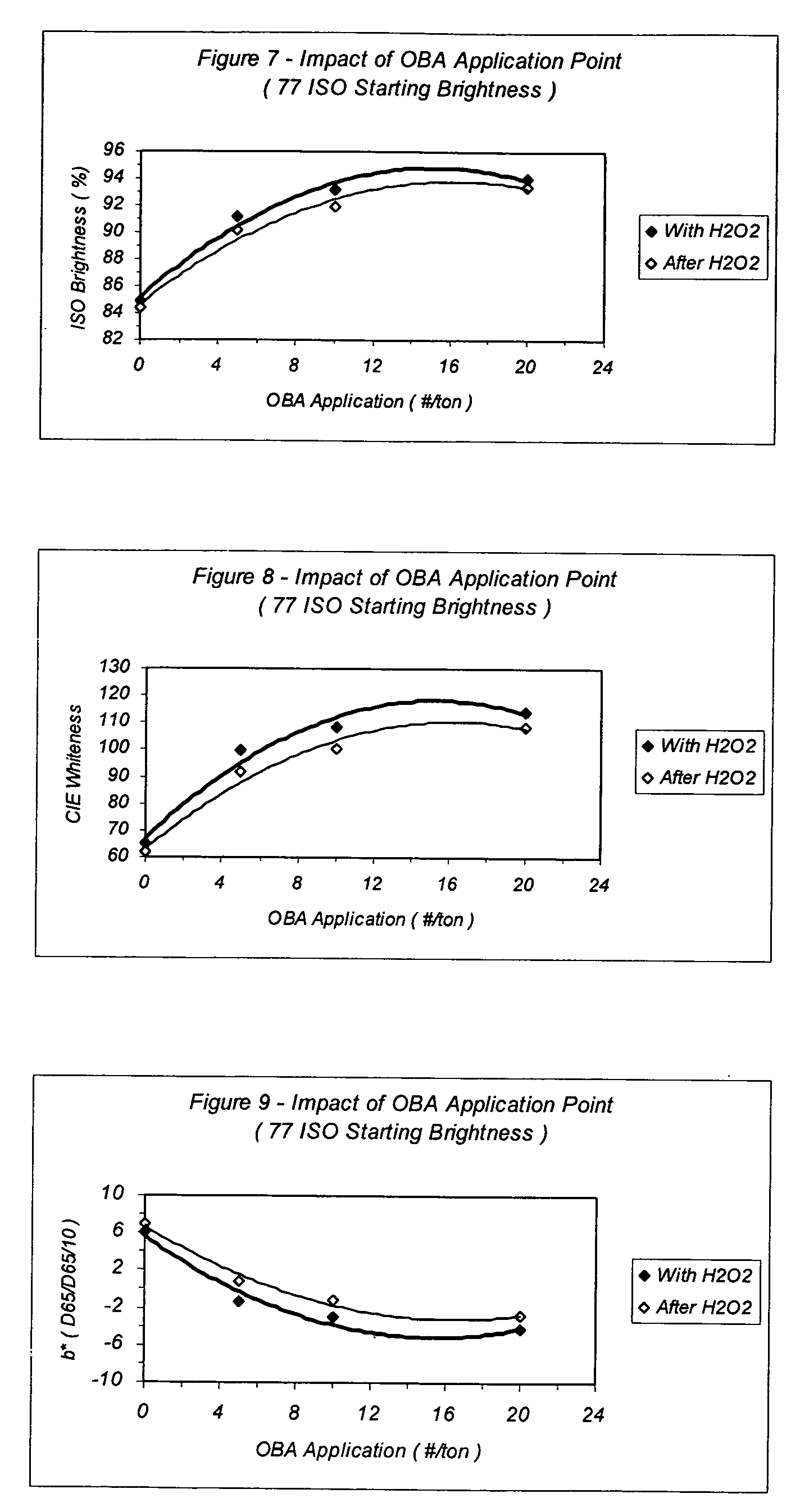

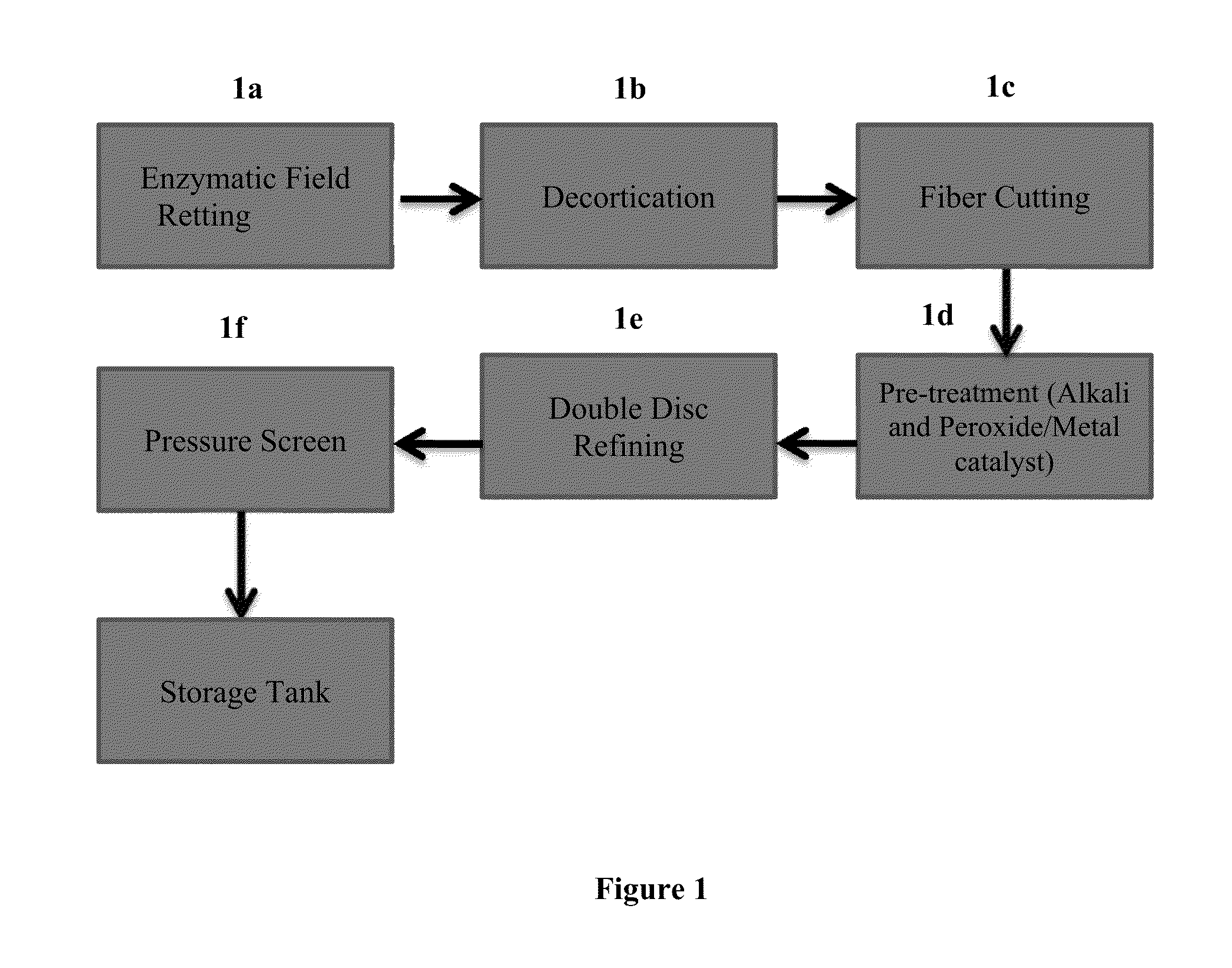

Process for manufacturing pulp, paper and paperboard products

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

Bleaching device using electro-optical and chemical means namely in the medical and dental field

A complete bleaching unit is made up of an electrochemical system, finding its application in particular in the dental and medical fields, allowing, thanks to the creation of an electrophoretic field, a strong, fast penetration and directing the bleaching agents, their removal under the same conditions together with the molecules responsible for coloration and an effective and controlled penetration of the stabilizing agents for the apatite crystal, basic component of the tooth, such as fluorine. Also thanks to its light-based optical system, the invention provides that the activation of the photosensitive bleaching products by decreasing the heat effect while increasing the photonic effect thanks to a selection of wavelength in the range of 400-500 nm and, finally, thanks to an electro-optical unit, the control of the evolution of coloration by objective spectrocolorimetry-based methods.

Owner:DURET

Detergent compositions

InactiveUS20060205628A1Easy to cleanSame levelNon-ionic surface-active compoundsDetergent mixture composition preparationBleachSURFACTANT BLEND

Owner:NOVOZYMES AS

Bleaching composition

PCT No. PCT / US97 / 04957 Sec. 371 Date Mar. 24, 1999 Sec. 102(e) Date Mar. 24, 1999 PCT Filed Mar. 25, 1997 PCT Pub. No. WO97 / 36989 PCT Pub. Date Oct. 9, 1997Bleach compositions comprising a percarbonate bleach and an amino tricarboxylic acid exhibit a reduced tendency to deposit calcium carbonate insolubles on substrates being bleached. Laundry compositions comprising percarbonate bleach and methyl glycine diacetic acid are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Modified soy proteins in personal care compositions

Personal care compositions comprising a modified soy protein as an active ingredient are described. The modified soy proteins of the instant invention include soy proteins modified by treatment with a reducing agent and subsequently reacted with a carboxylic acid anhydride; soy proteins modified by treatment with a reducing agent, reacted with a carboxylic acid anhydride and subsequently oxidized; soy proteins modified by reaction with a hydroxy alkyl acrylate; soy proteins modified with ionic monomers such as epoxide, acrylate, and chlorohydrin; and soy proteins modified by reaction with an alkyl acrylimidoglycolate. The compositions may be in the form of skin care, skin cleansing, or anti-wrinkle products, shampoos, make-up, conditioners, lotions, aerosols, gels, mousses, dyes, or bleaches.

Owner:SOLAE LLC

Two-part dental bleaching systems having improved gel stability and methods for bleaching teeth using such systems

InactiveUS6503485B1Maintain bleaching potencyHigh concentrationCosmetic preparationsGum massageParticulatesAlkaline earth metal

Dental bleaching systems that include a bleaching component and a neutralizing component which, when mixed together, yield a mixed composition having a desired bleaching activity and viscosity. The bleaching composition includes a suitable bleaching agent, such as aqueous hydrogen peroxide, in a concentration of about 3% to about 95% by weight of the bleaching composition component. The neutralizing component includes a particulate base dispersed within a stable gel that includes at least one polymeric thickening agent. The neutralizing component is substantially water-free to prevent destruction of the gelling capability of the thickening agent by the base. The particulate base may include oxides, hydroxides or carbonates of alkali metals or alkaline earth metals. Maintaining the bleaching agent and neutralizing agent in separate components provides increased stability during storage and transport.

Owner:ULTRADENT PROD INC

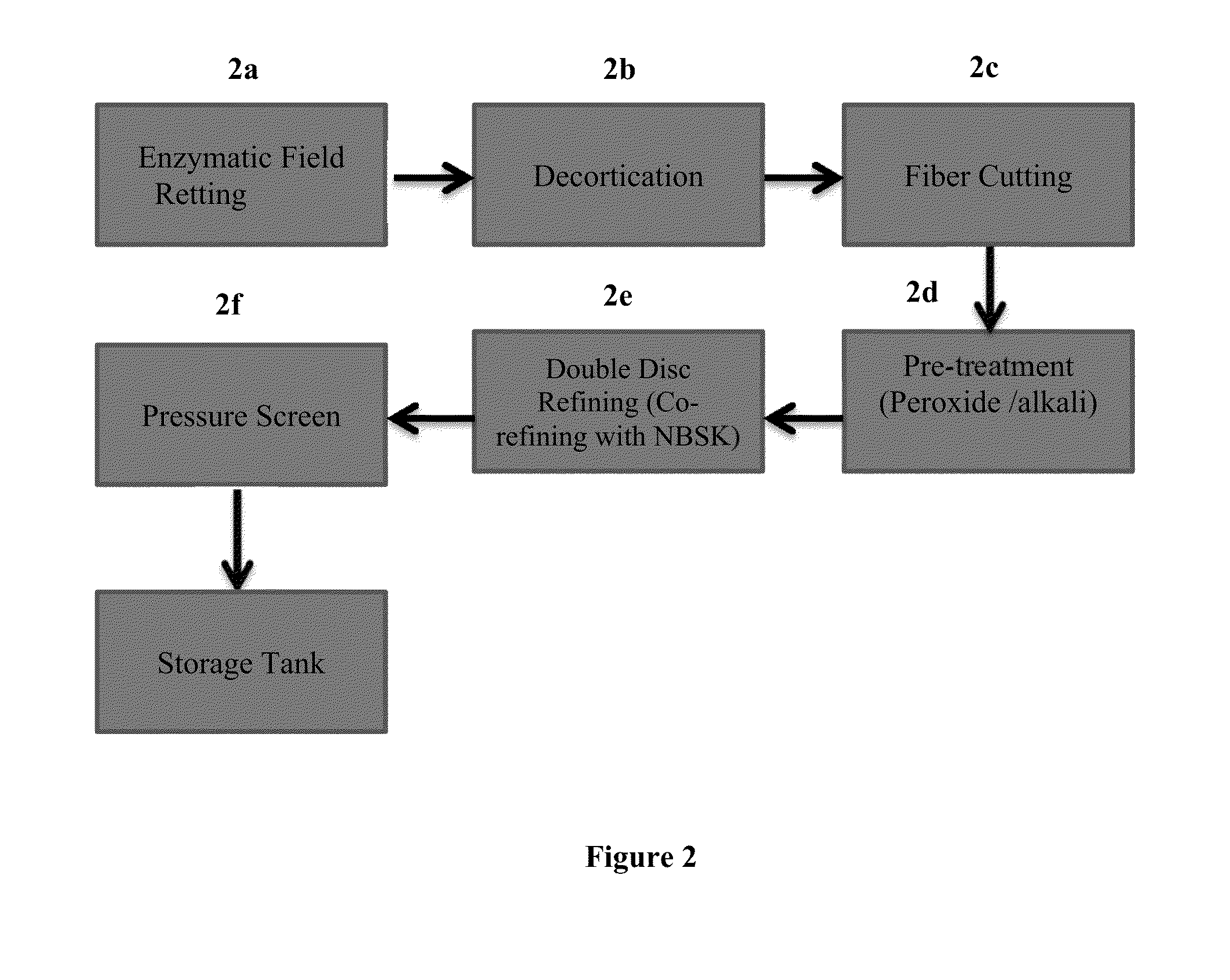

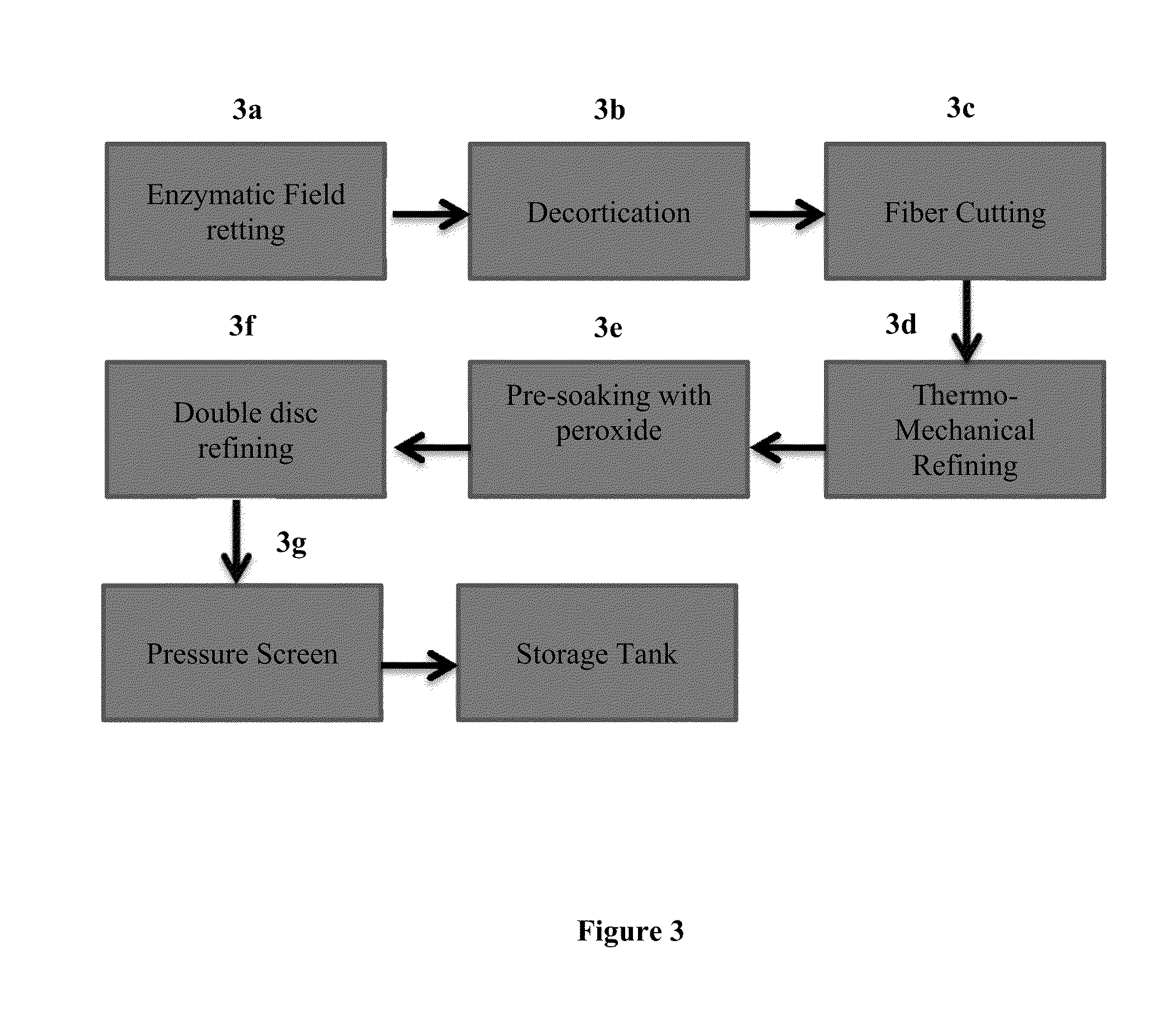

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS20160130762A1Reduce manufacturing costLose weightNon-fibrous pulp additionPaper after-treatmentCelluloseBleach

A method to prepare, pulp, and bleach cannabis bast and hurd fibers to allow for the fiber to be incorporated into absorbent cellulosic structures on a wet-laid paper machine while keeping the pectin within the fibers. The wet laid paper machine can use the ATMOS, NTT, ETAD, TAD, or UCTAD method to produce the absorbent cellulosic structure. Absorbent cellulosic structures are produced with the cannabis bast and hurd fibers or with the bast fibers alone with the hurd fibers being combined with paper mill sludge or dust to form a fuel pellet.

Owner:FIRST QUALITY TISSUE

Emulsified compositions for bleaching or dyeing the hair and method of bleaching or dyeing the hair using these emulsified compostions

InactiveUS20060042023A1Reduced irritating odorReduce an irritating odor of ammoniaCosmetic preparationsHair cosmeticsIrritationBleach

It becomes possible to provide ammonia-containing hair bleaches or hairdyes which are highly safe and cause less hair damage, skin inflammation and irritation, and have no or reduced irritating odor of ammonia, and a method for bleaching or dyeing hair with the use of the hair bleaches or hairdyes by decreasing an average diameter of emulsified particles of emulsified compositions of ammonia-containing hair bleaches or hairdyes enough to reduce an irritating odor of ammonia.

Owner:ARIMINO

Biocompatible tissue for therapeutic use and method of making same

InactiveUS6933103B1ConservingDead animal preservationMammal material medical ingredientsBleachSodium hydroxide

A biocompatible graft material and a method for making the same are disclosed. The method of making the graft material involves freezing and subsequently thawing a donated tissue sample in a bleach solution. The tissue is then washed in a detergent solution, treated with antimicrobial agents, and soaked in a hypertonic solution. The tissue is thereafter treated with sodium hydroxide and later hydrogen peroxide to yield the desired biocompatible graft material.

Owner:BRENNEN MEDICAL

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20060013778A1Avoid allergiesLonger contact/coating periodCosmetic preparationsGum massageZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

Encapsulated flavor and fragrance

The present invention provides solid complexes of urea and flavor and fragrance chemicals as well as methods of providing the complexes. The complexes are advantageously incorporated in powdered detergent and bleach products. The urea complexes protect the flavor or fragrance molecules from chemical reaction with other elements of the products. When added to water the urea complex is quickly removed from the flavor or fragrance molecule thereby delivering the material at the desired time.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Corrosion inhibitor system for mildly acidic to ph neutral halogen bleach-containing cleaning compositions

A cleaning composition with a corrosion inhibitor system and an active halogen-based bleaching system and aqueous solution is described for inhibiting corrosion of metal surfaces to which the composition is applied, especially when the cleaning composition is not rinsed from the treated metal surface prior to drying of the composition on the metal surface. The corrosion inhibitor is at least an alkyl phosphonate compound, wherein the alkyl group has 6 or more carbon atoms, and salts thereof. The bleaching system includes one or more sources of hypohalous acid or hypohalite ion, such as a stabilized hypochlorite solution, in particular a mixture of N-chlorosulfamate salts.

Owner:SC JOHNSON & SON INC

Method for treating aluminum electrolysis waste cathode carbon block using acid and alkali combination method

A method for treating aluminum electrolytic waste cathode carbon blocks by an acid and alkali combination method is characterized by comprising the following steps: (1) aluminum electrolytic waste cathode is added to concentrated basic solution for reaction; a filtered solid phase is obtained by filtering and is added to concentrated acid for reaction; and carbon powder is obtained after filtration; (2) filtrates are mixed and dropwise added with the concentrated basic solution, the pH value thereof is adjusted to 9, the obtained mixture is kept standing and filtered to obtain cryolite; (3) the filtrate is added with saturated bleach solution, kept standing and filtered to obtain calcium fluoride; (4) the fourth filtrates is heated, evaporated and crystallized to obtain sodium chloride solid. With the purposes of waste utilization and environmental protection, the method successfully provides the process for treating aluminum electrolytic waste cathode by the acid and alkali method, which causes the waste cathode to not be the conventional waste and pollutant and to become artificial mineral resources. The method solves the problem of waste utilization in aluminum electrolysis industry, improves benefit, and improves the comprehensive level of the aluminum electrolysis industry of China.

Owner:NORTHEASTERN UNIV +1

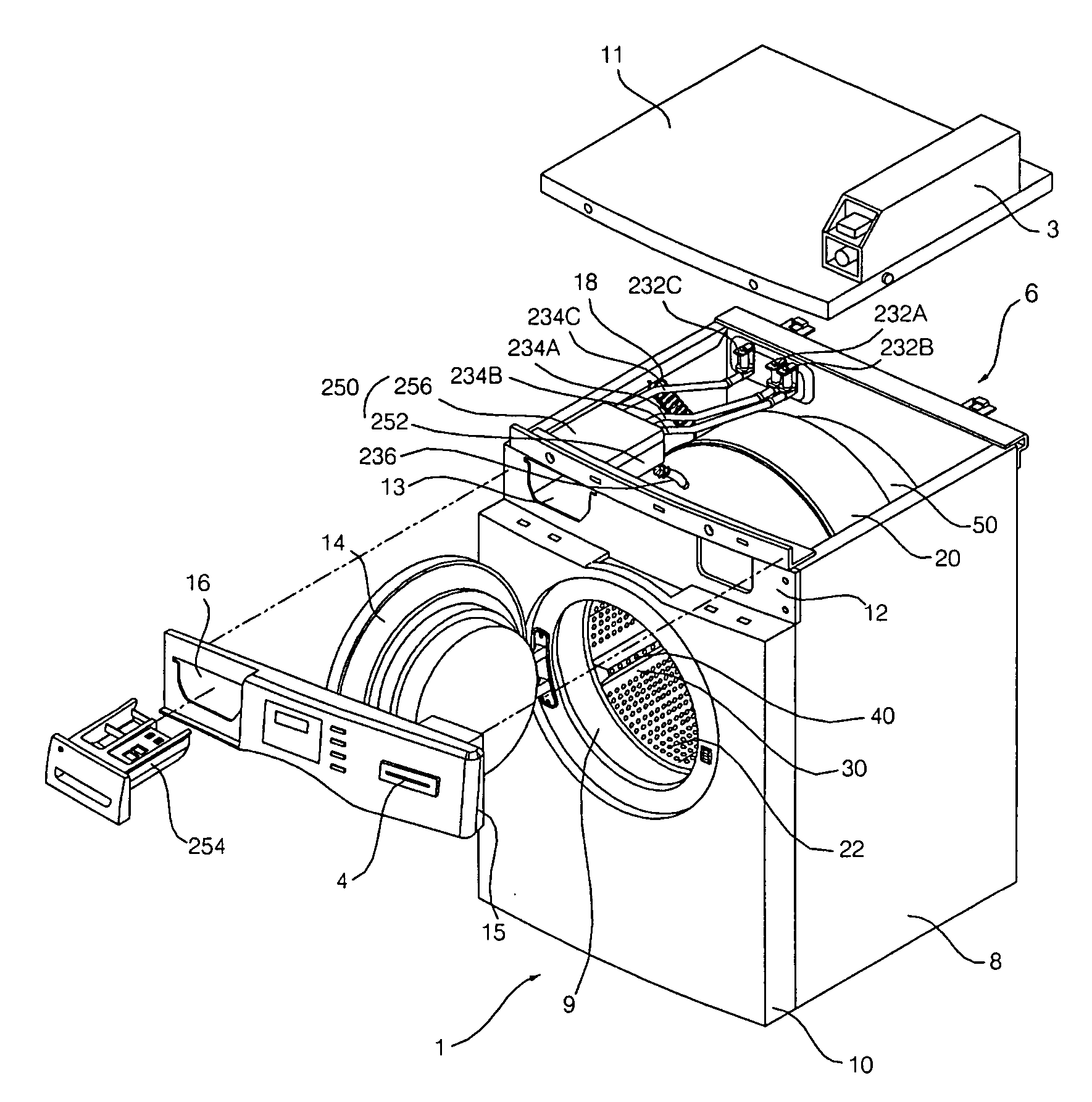

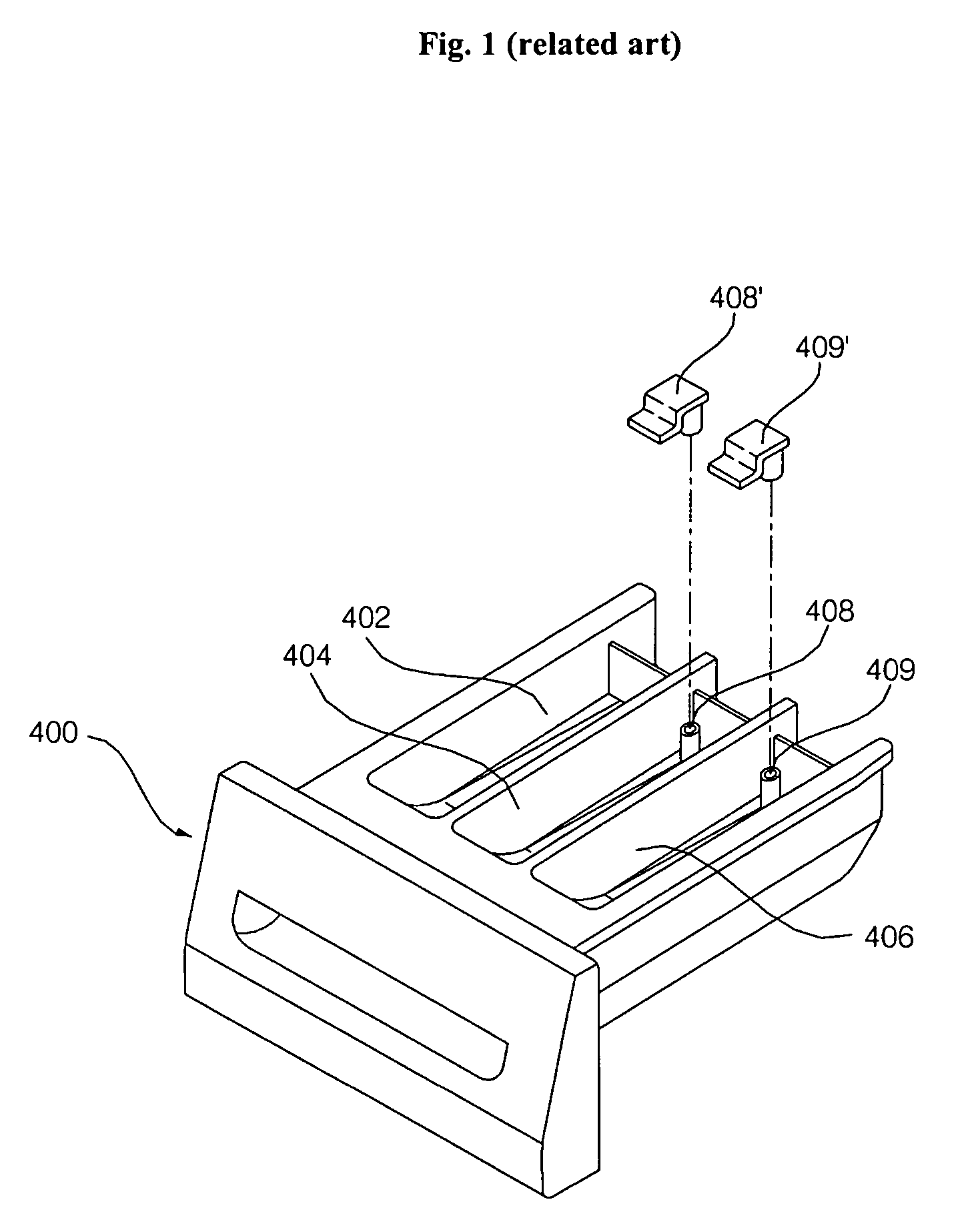

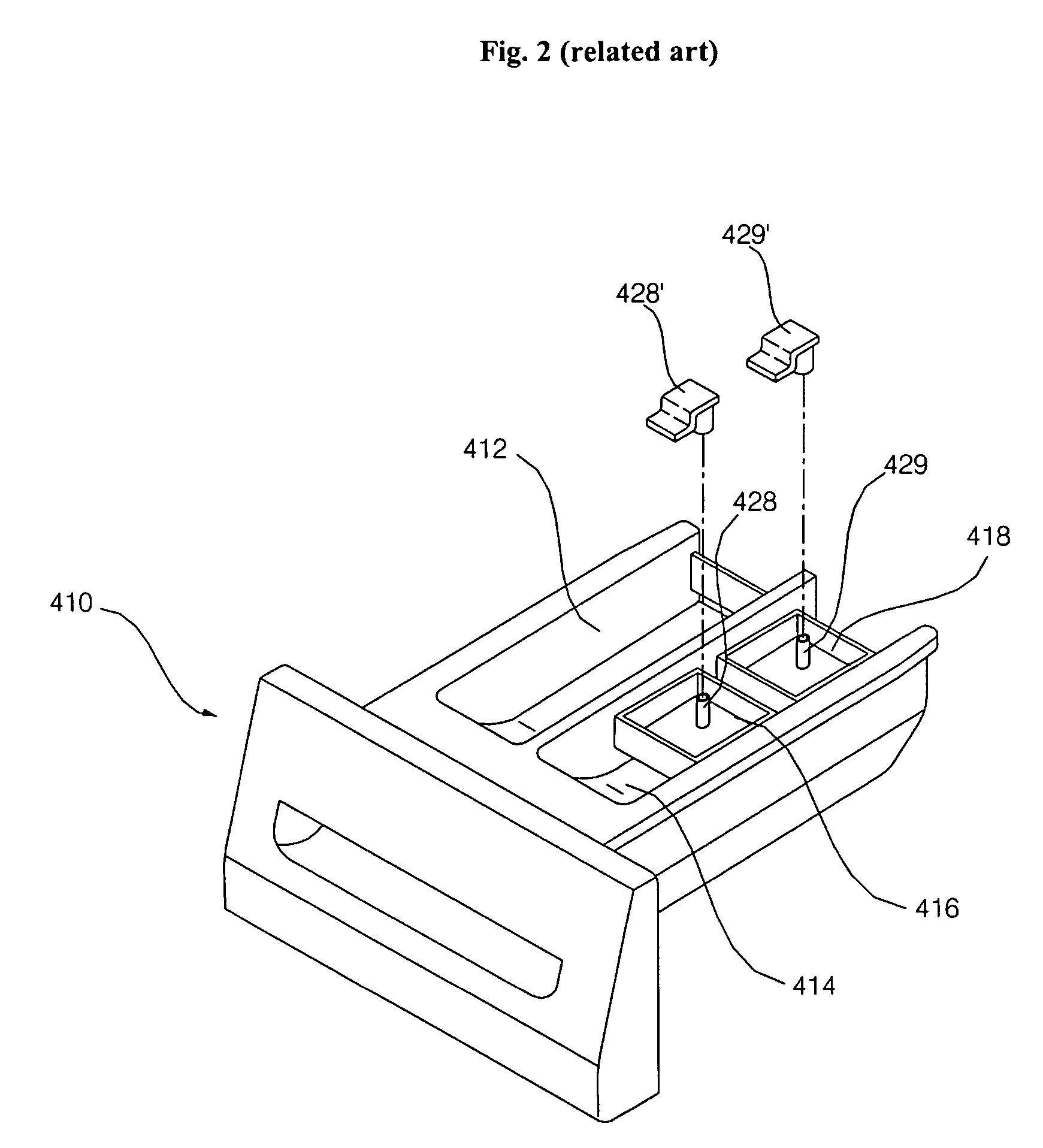

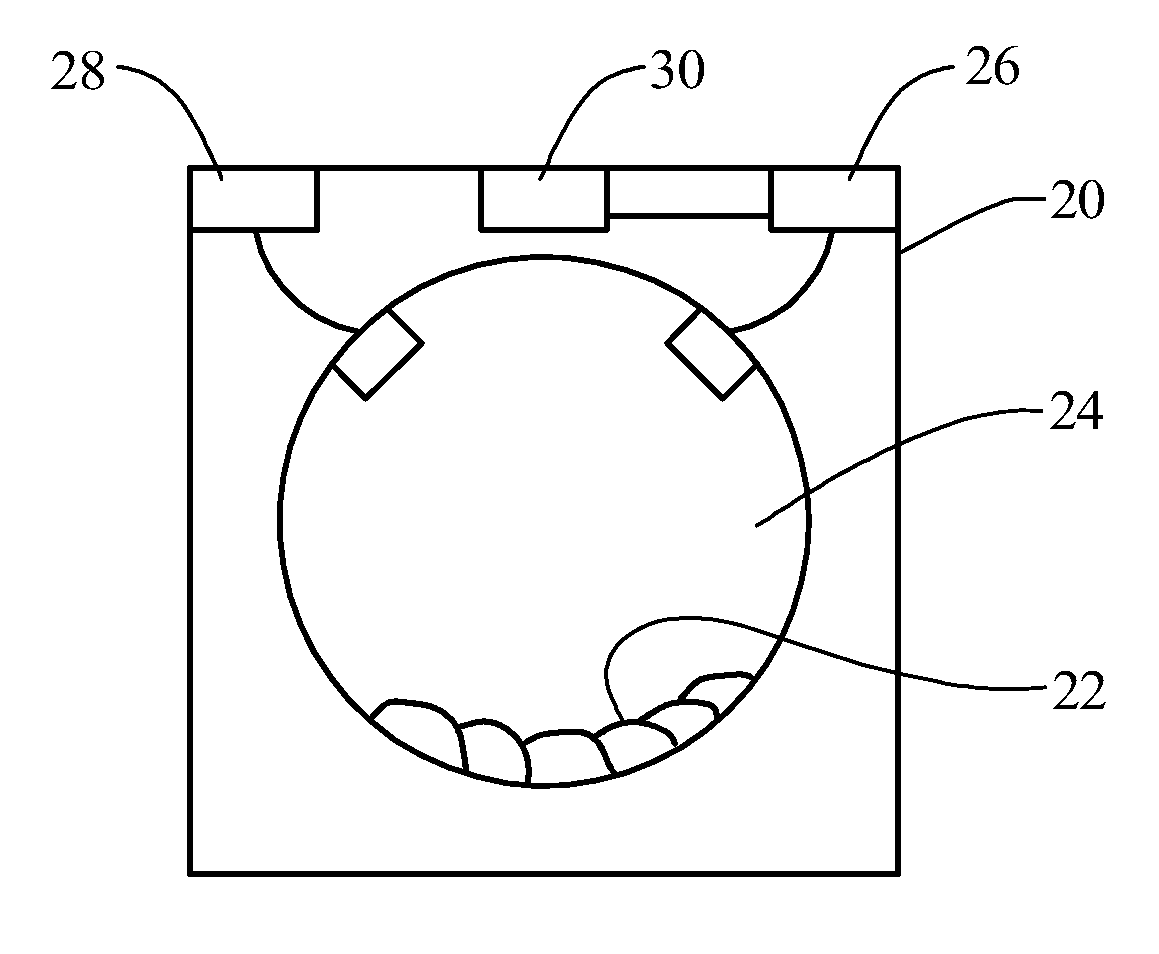

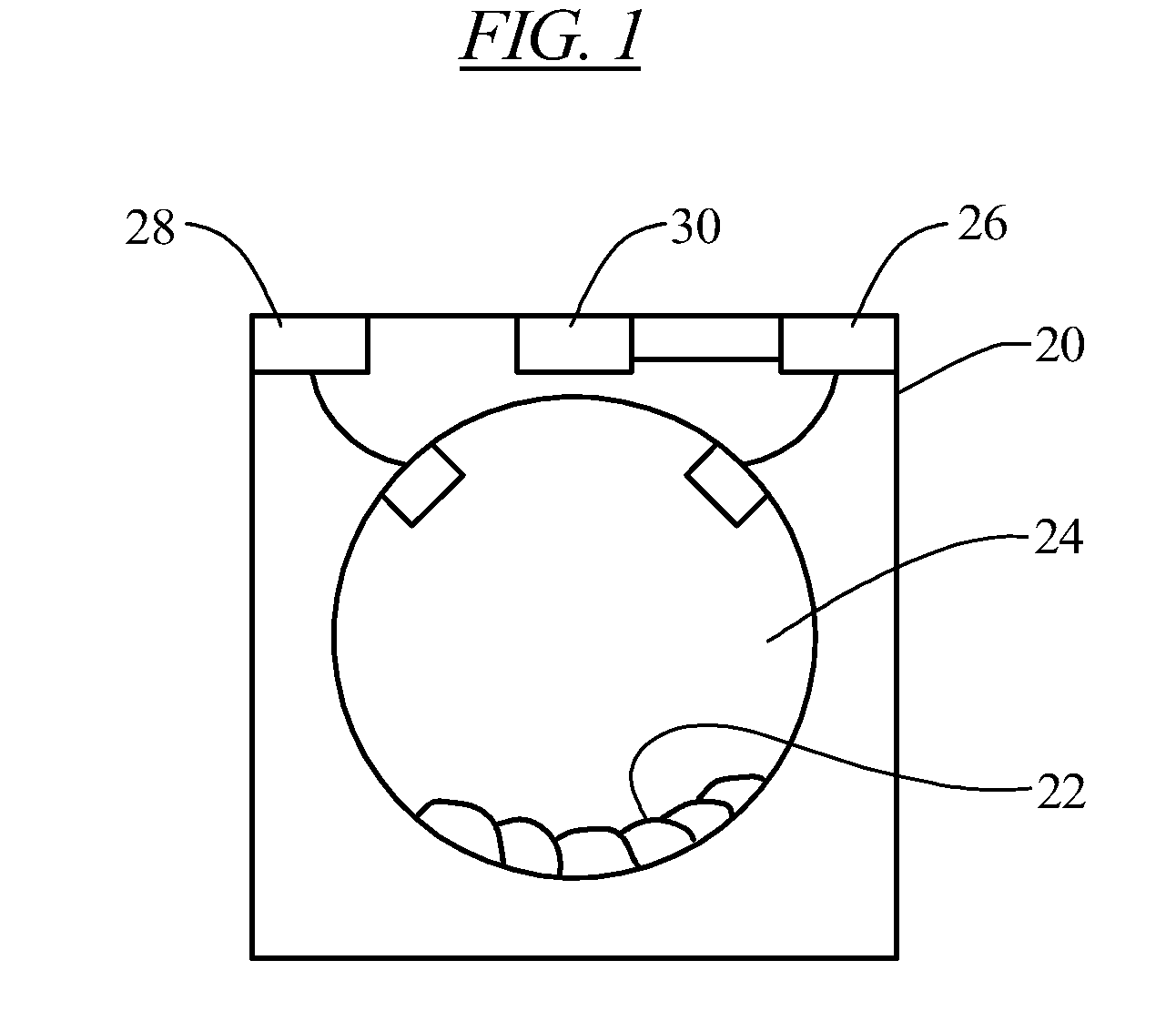

Detergent supplying apparatus of washing machine

InactiveUS20070056330A1Simple structureEasy to cleanOther washing machinesTextiles and paperBleachProcess engineering

Provided is a detergent supplying apparatus of a washing machine. The apparatus includes a drawer provided with a bleach / softener supplying part for housing and supplying bleach and softener, and a detergent supplying part for housing and supplying detergent; and a drawer cap combined to the drawer to cover an upper surface of the bleach / softener supplying part, and provided with a bleach input port and a softener input port, respectively.

Owner:LG ELECTRONICS INC

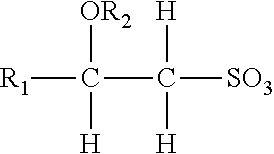

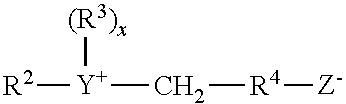

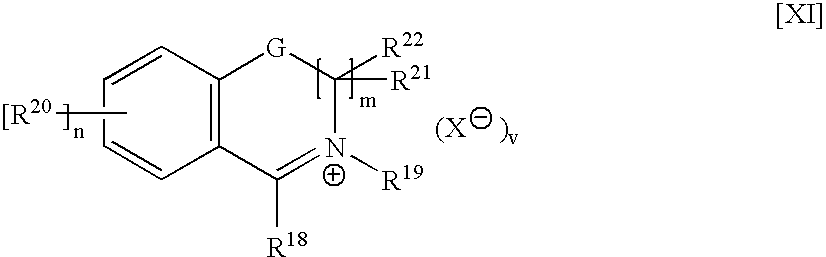

Fast-acting formulation components, compositions and laundry methods employing same

InactiveUS20050256017A1Improve bleaching effectImproved color safetyNon-surface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsAziridineBleach

The present invention relates to formulation components, such as organic catalyst compounds designed with time-controlled bleaching to increase color safety, compositions and laundry methods employing such organic catalyst compounds. More particularly, this invention relates to organic catalysts compounds such as quaternary imine bleach boosting compounds, quaternary oxaziridinium bleaching species, modified amines and amine oxides, imines, and / or oxaziridines, compositions and laundry methods employing such organic catalyst compounds.

Owner:THE PROCTER & GAMBLE COMPANY

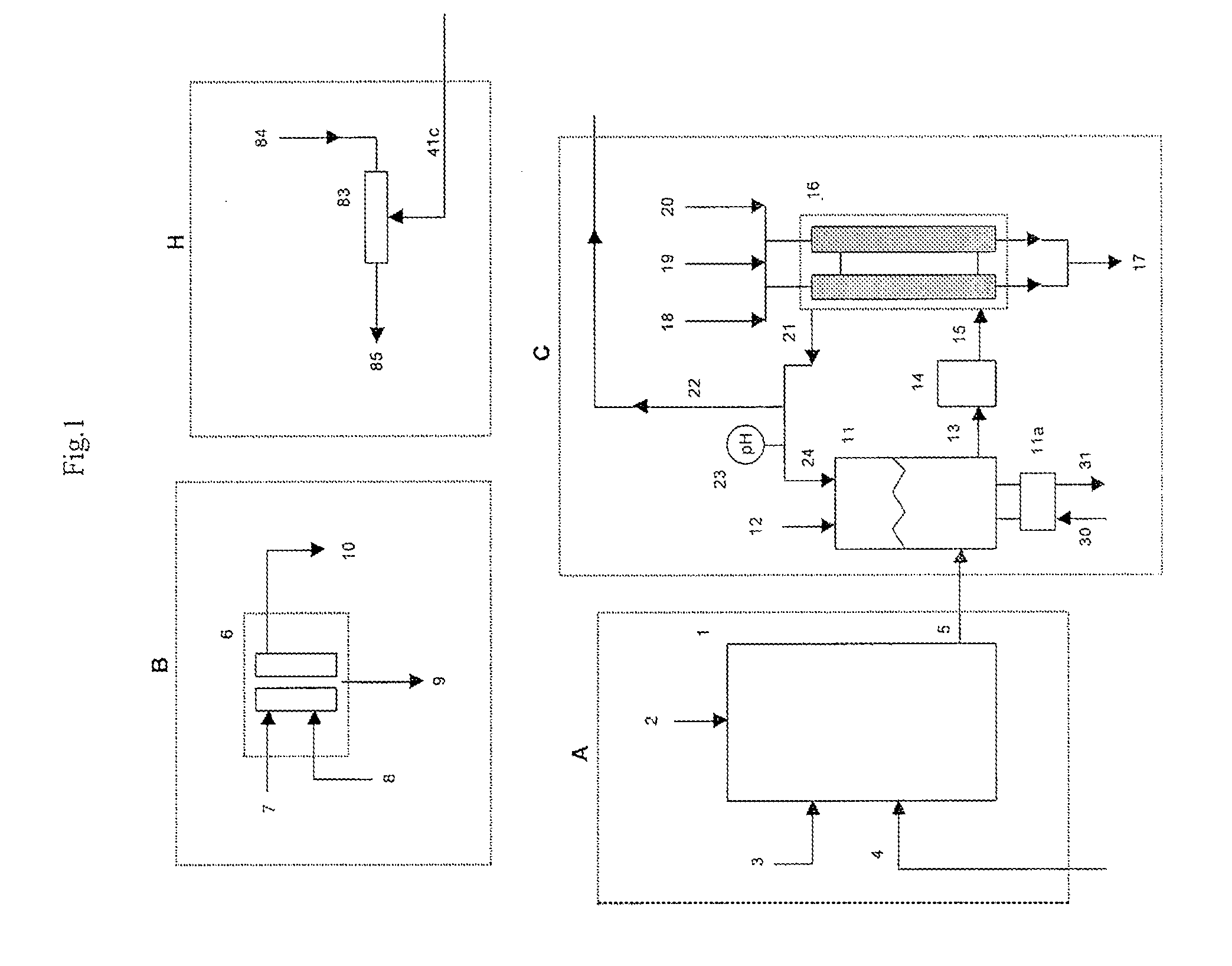

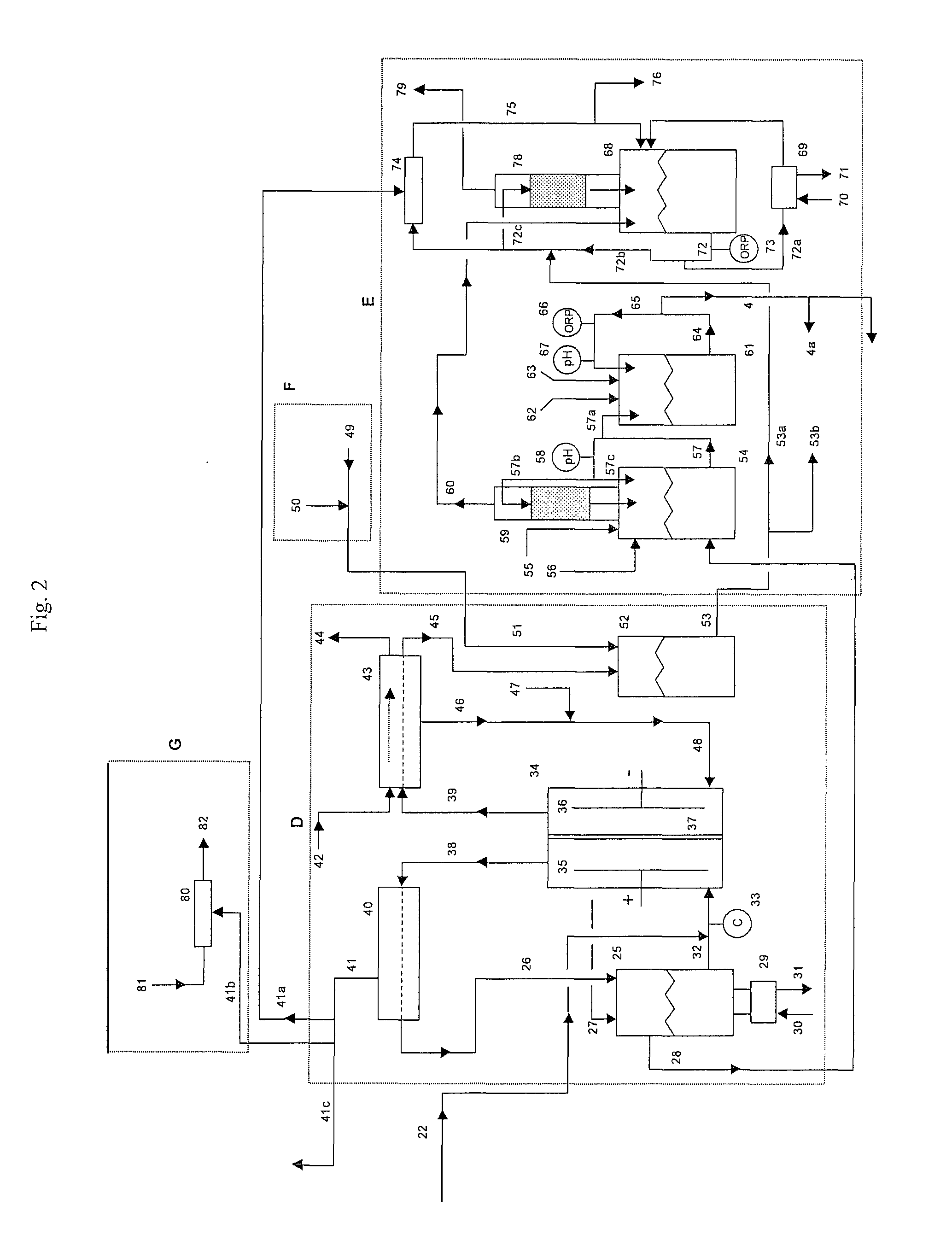

Process for the on-site production of chlorine and high strength sodium hypochlorite

ActiveUS20070251831A1Reduce hardnessGuaranteed uptimeCellsPhotography auxillary processesElectrolysisBleach

The present invention relates to a novel economical on-site electrochemical based membrane cell based process with the capability of producing high strength sodium hypochlorite and / or elemental chlorine gas in any ratio as required by the needs of a water or wastewater treatment plant. The system is compact and modular, using membrane cell based electrolyzers and utilizing novel process modifications and sensors to allow for the unattended control and safe operation of the process. The process allows the operator to produce elemental chlorine gas and sodium hypochlorite in any product ratio, such that 5% to 100% of the total chlorine produced by the process can be converted to high strength bleach. The process has the flexibility to produce stable high quality, low to high strength sodium hypochlorite solutions in concentrations ranging from about 2 to 15% trade as NaOCl.

Owner:ELECTROLYTIC TECH CORP

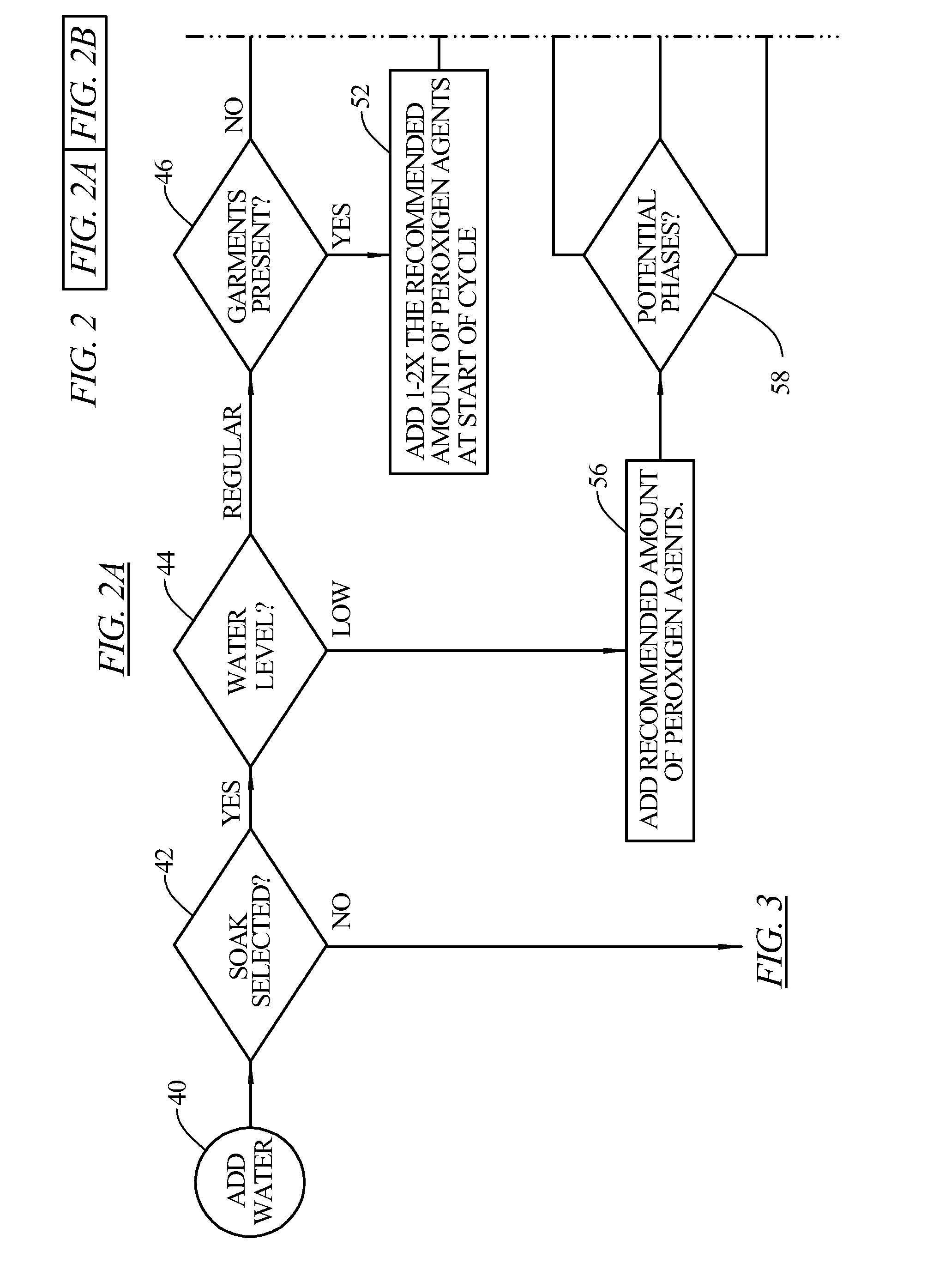

Washer and washer control with cycles for laundry additives and color safe bleaches/in-wash stain removers

A washer and a control for an automatic washer to operate the washer through a wash cycle selected based upon a range of conditions of a fabric load to be washed. The control has a plurality of selectable stain type entrées, each with a particular dedicated wash cycle. The control also has dispensing control over at least two wash liquor additives, one being a detergent and the other being an oxidizing agent. The control operates the dedicated wash cycles, as selected, using both the detergent and the oxidizing agent, however, the detergent and the oxidizing agent may be dispensed in different orders and at different times and in different amounts, depending on the stain type selected.

Owner:WHIRLPOOL CORP

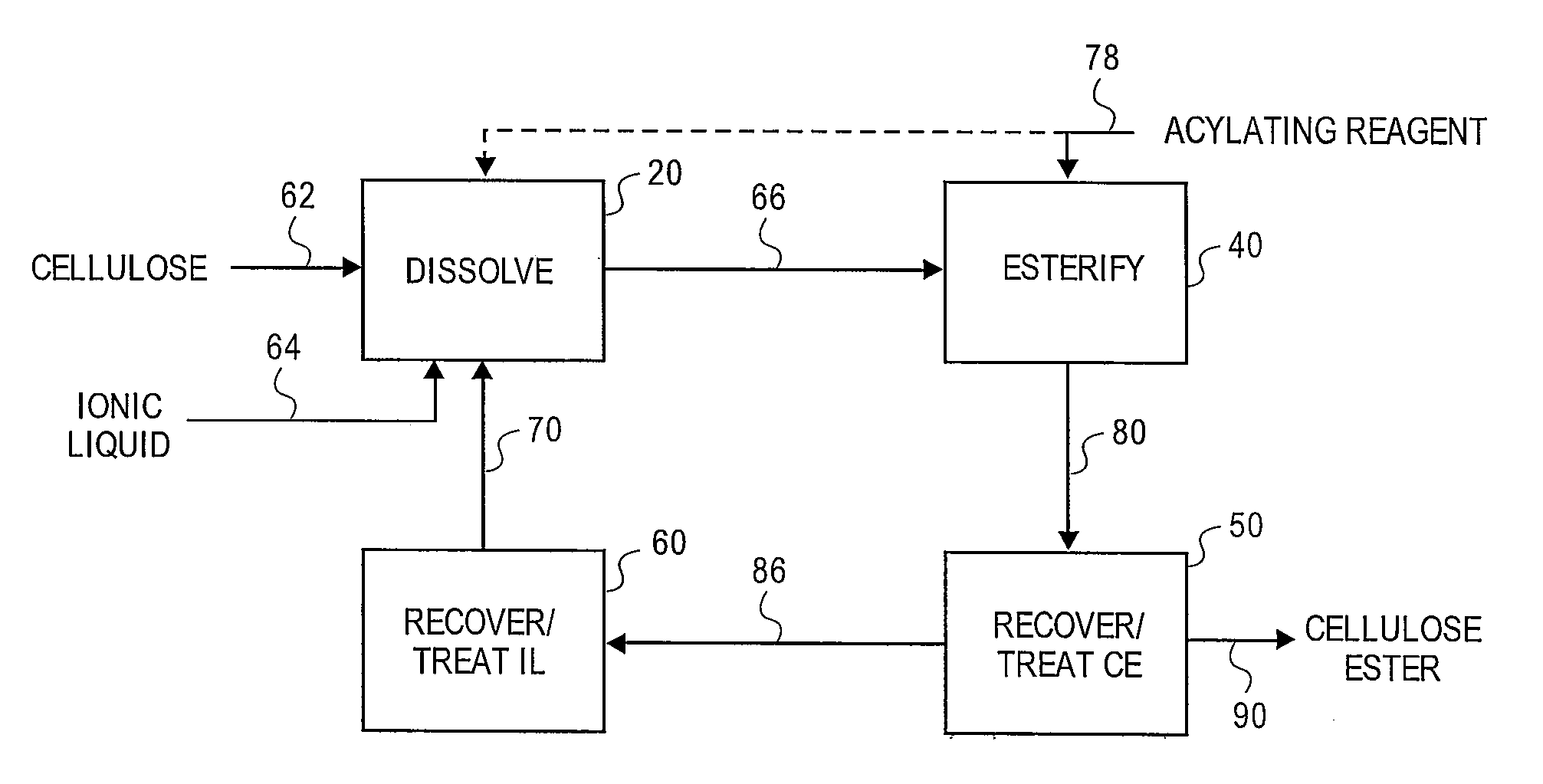

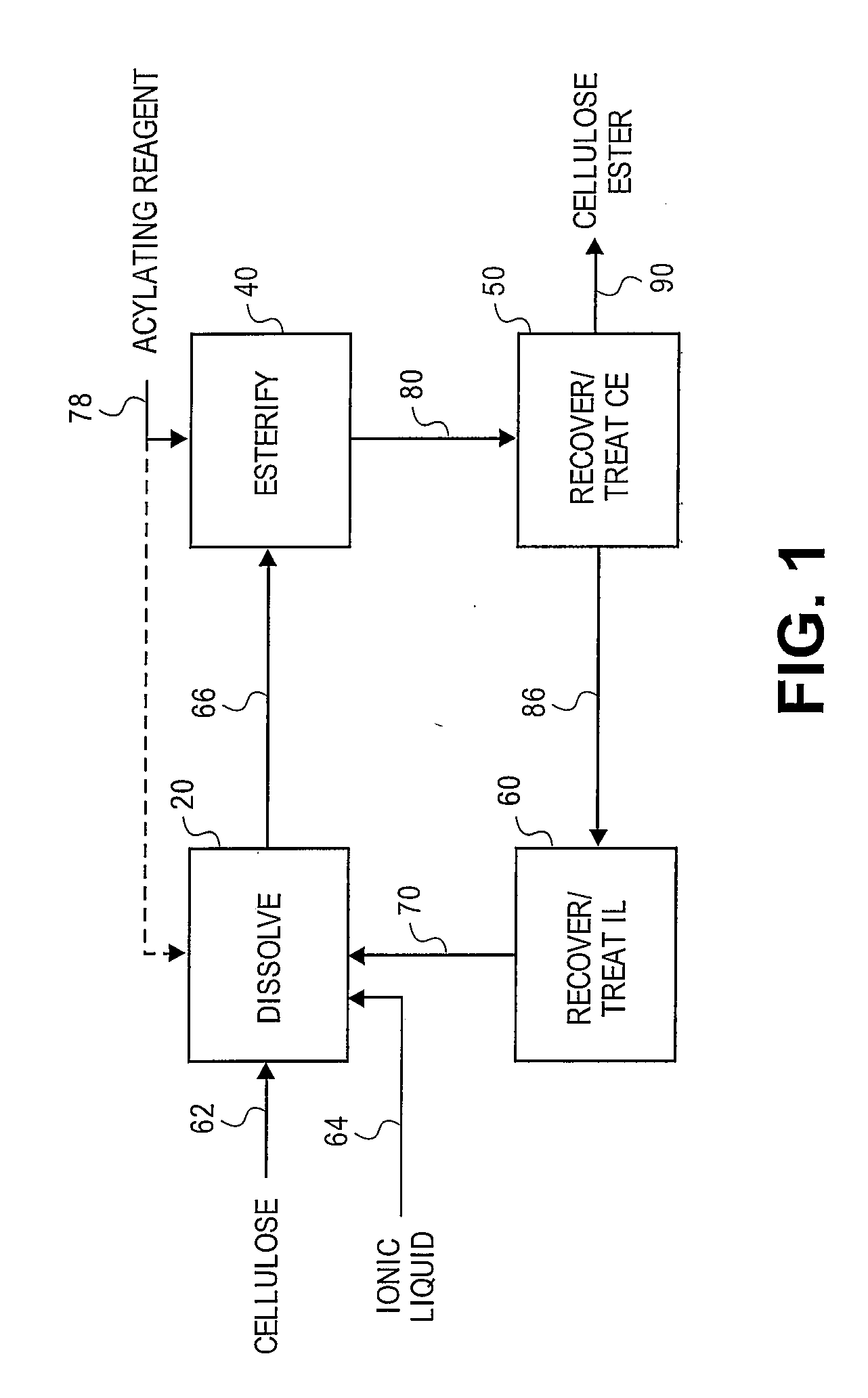

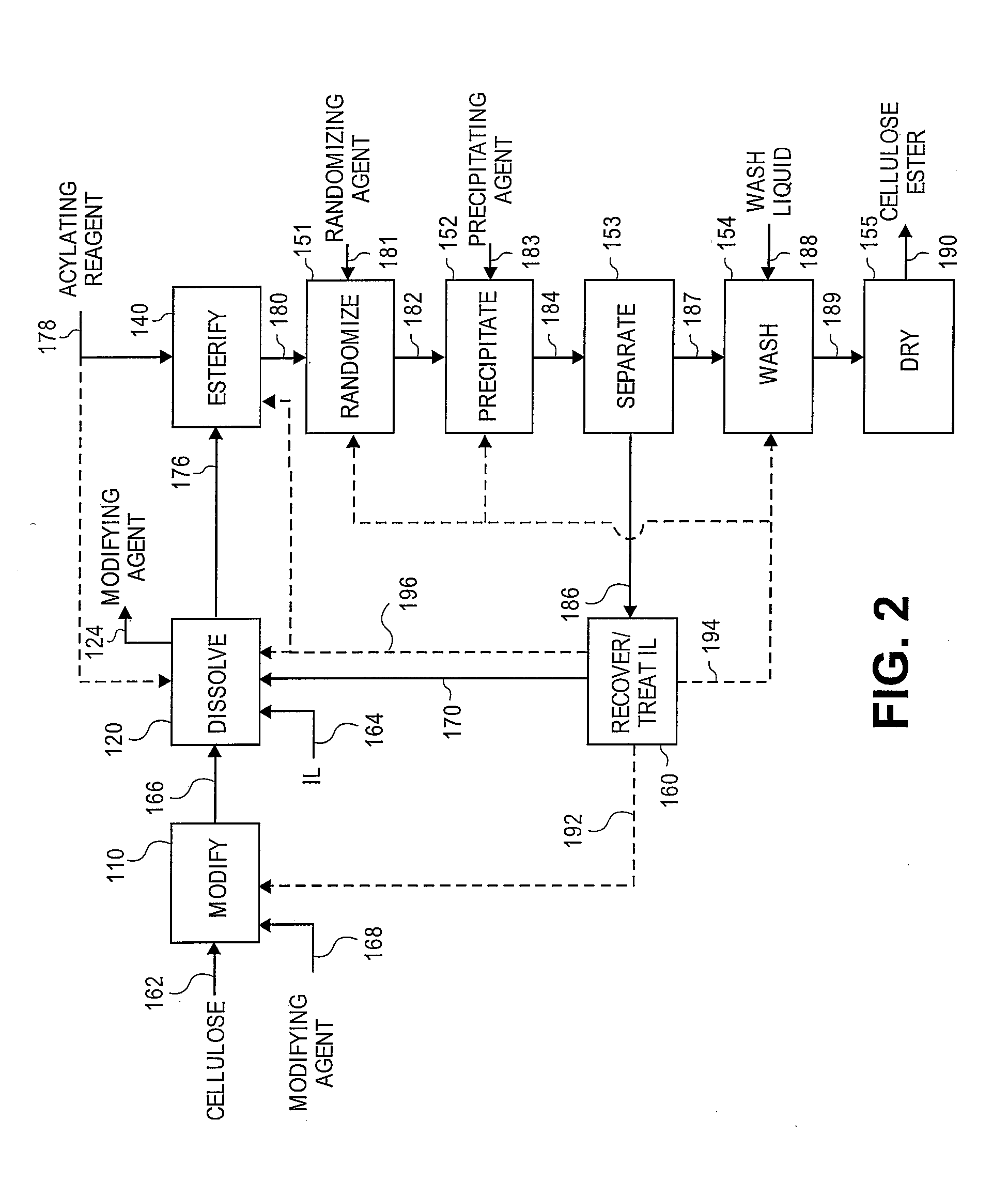

Treatment of cellulose esters

Ionic liquids and cellulose ester compositions and processes for producing ionic liquids and cellulose esters. Cellulose esters can be produced by esterifying cellulose in a reaction medium comprising one or more ionic liquids. Cellulose esters prepared via the methods of the present invention can be contacted with at least one bleaching agent to produce bleached cellulose esters having a ΔE value of less than 30.

Owner:EASTMAN CHEM CO

Non-phosphate, agglomerated laundry booster

InactiveUS6022843AGood lookingImprove performanceInorganic/elemental detergent compounding agentsSurface-active non-soap compounds and soap mixture detergentsPhosphateBleach

The invention is an improved, non-phosphate, non-bleach, agglomerated laundry booster which has a) a solids portion with i) at least 5% by weight of a first builder selected from the group consisting of alkali metal carbonate, alkali metal bicarbonate, alkali metal sesquicarbonate, and mixtures thereof; and ii) a second builder of at least 25% by weight alkali metal tetraborate pentahydrate; and b) i) a first liquid which comprises an anionic, acidic surfactant, in an amount no greater than about 10% by weight; and ii) a second liquid which comprises an agglomerating agent. The first liquid is neutralized by the first builder of a)i) to form a first set of particles, the second builder forms a second set of particles, and the second liquid co-agglomerates both the first and second sets of particles. The invention also provides a method for preparing this laundry booster.

Owner:THE CLOROX CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com