Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1841results about "Pulp bleaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lyocell nonwoven fabric

InactiveUS7067444B2Powerful solventLow tendency to fibrillatePulp properties modificationMonocomponent cellulose artificial filamentMelt blowingNonwoven fabric

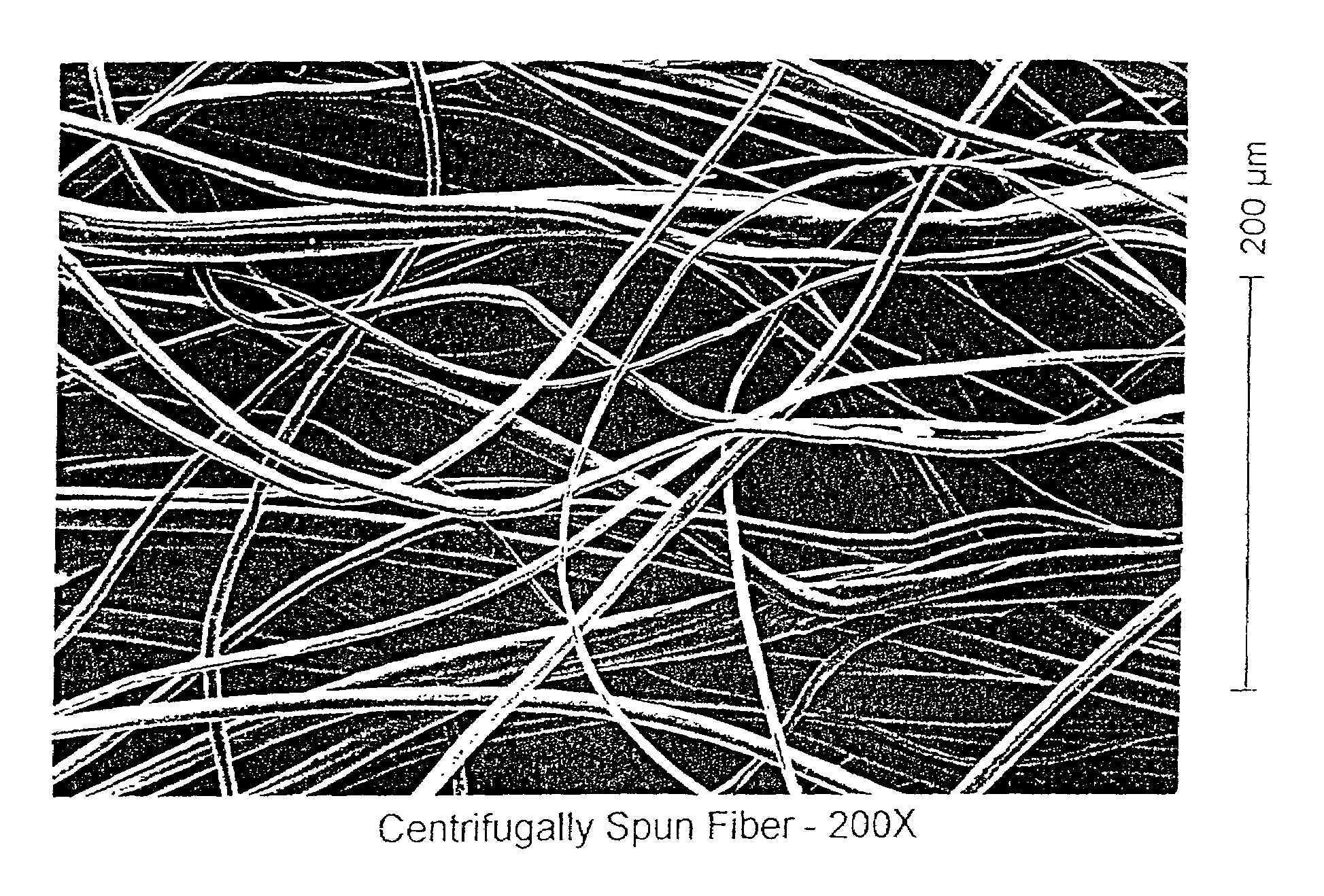

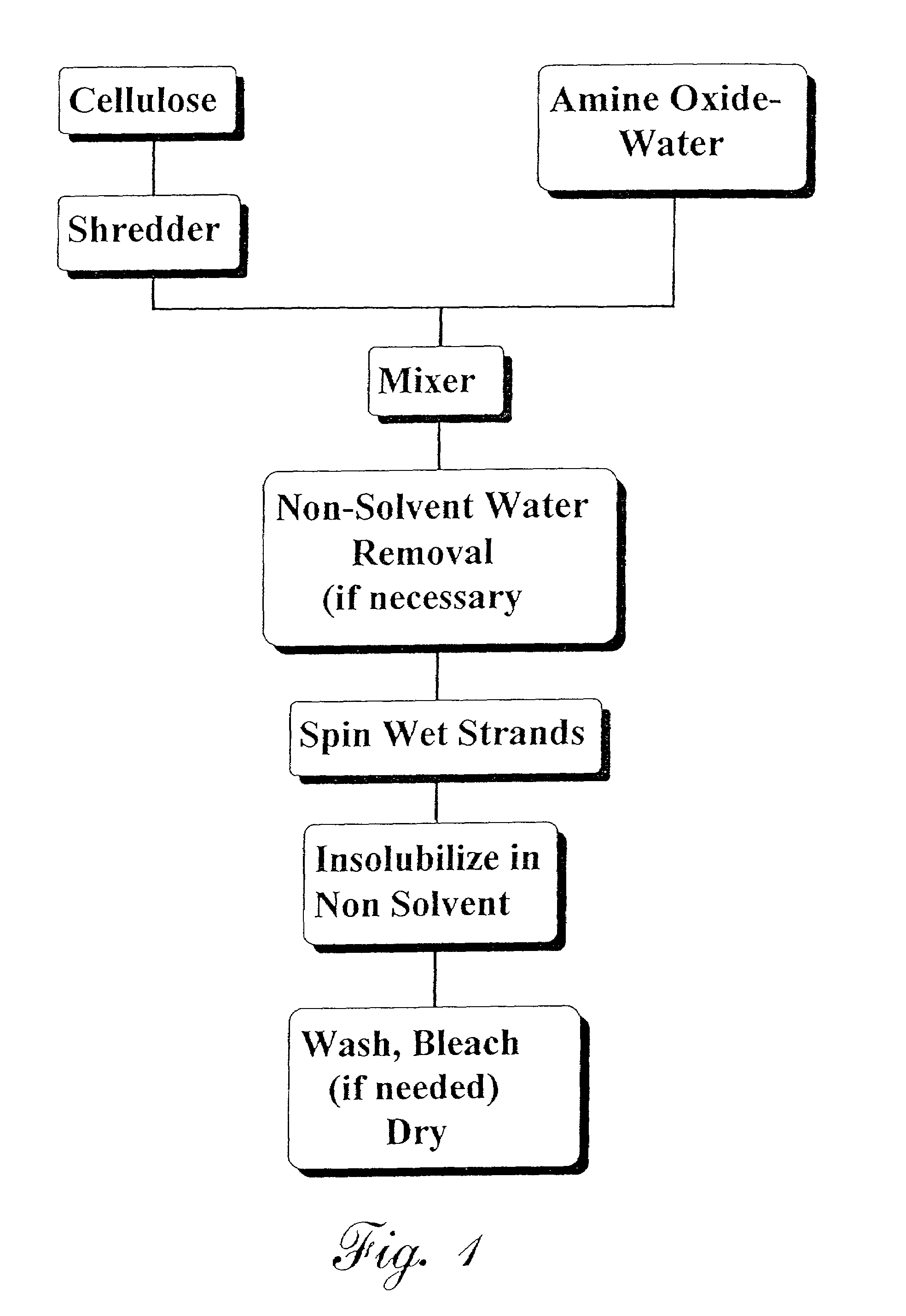

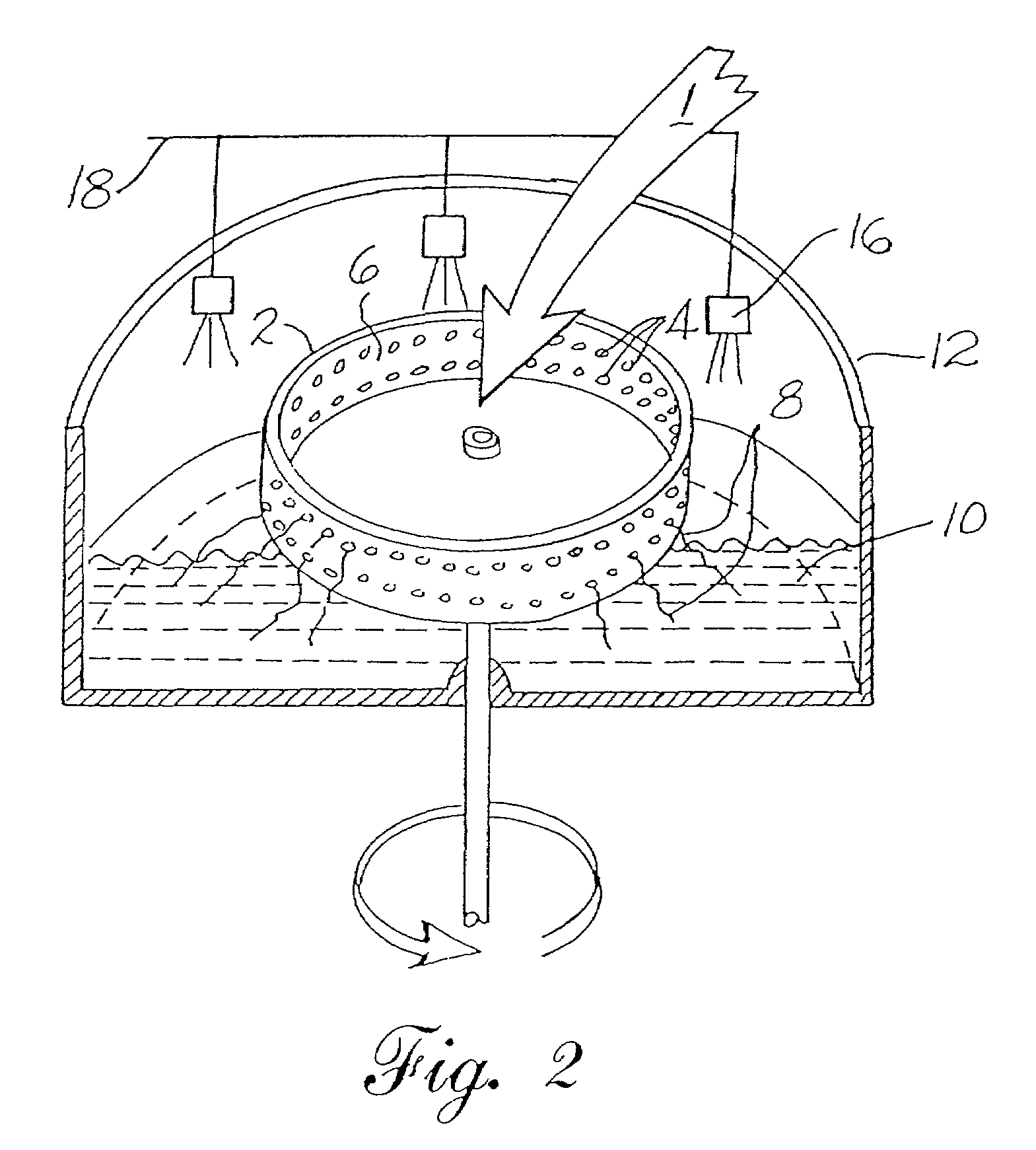

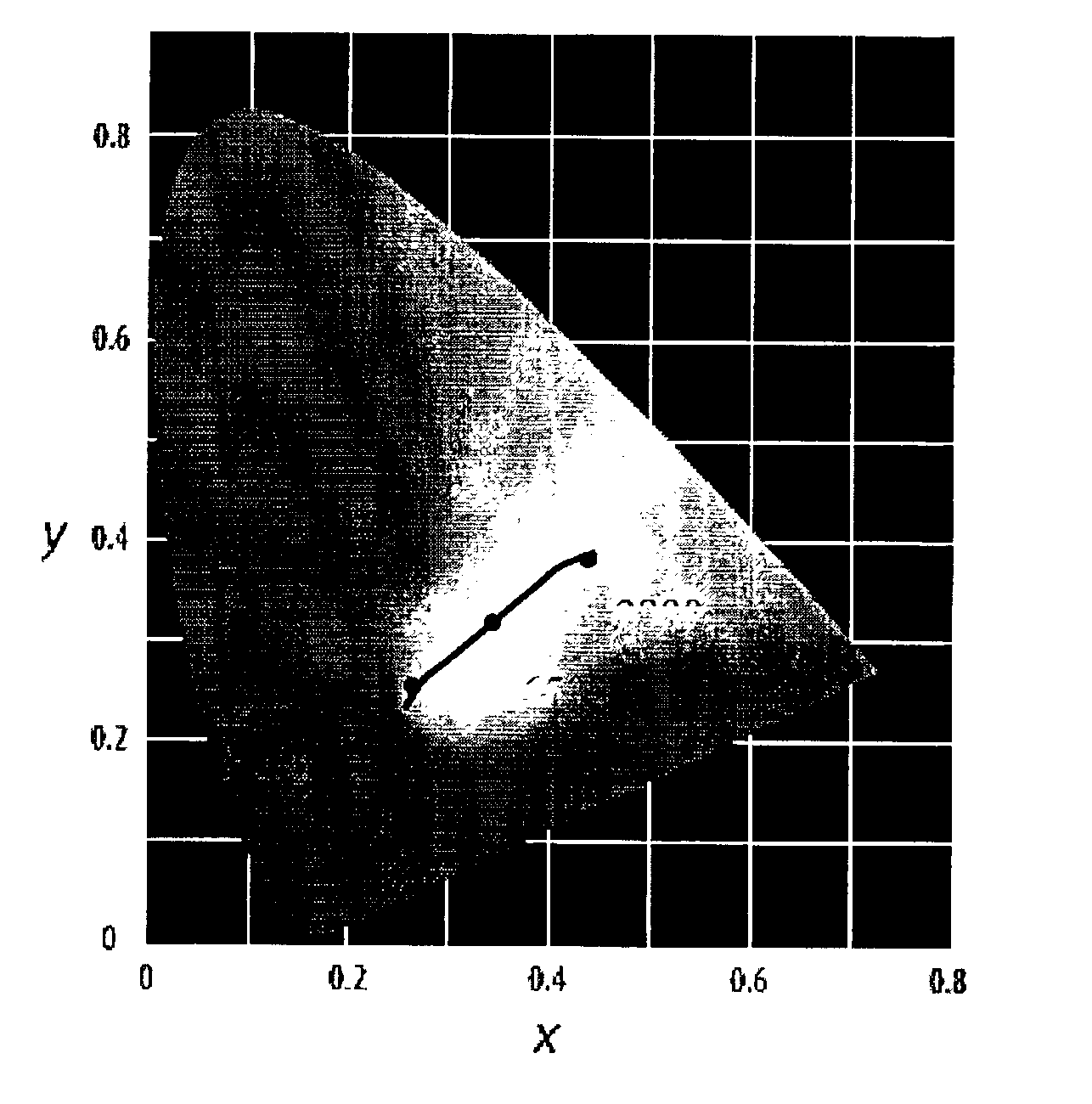

A lyocell nonwoven fabric having fibers characterized by pebbled surfaces and variable cross sections and diameters along the fibers and from fiber to fiber, is disclosed. The lyocell nonwoven fabric is produced by centrifugal spinning, melt blowing or spunbonding. The lyocell nonwoven fabric has fibers that can be made in the microdenier range with average weights as low as one denier or less. The lyocell nonwoven fabric has fibers with low gloss, a reduced tendency to fibrillate and have enhanced dye receptivity.

Owner:INT PAPER CO

Whitened fluff pulp

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

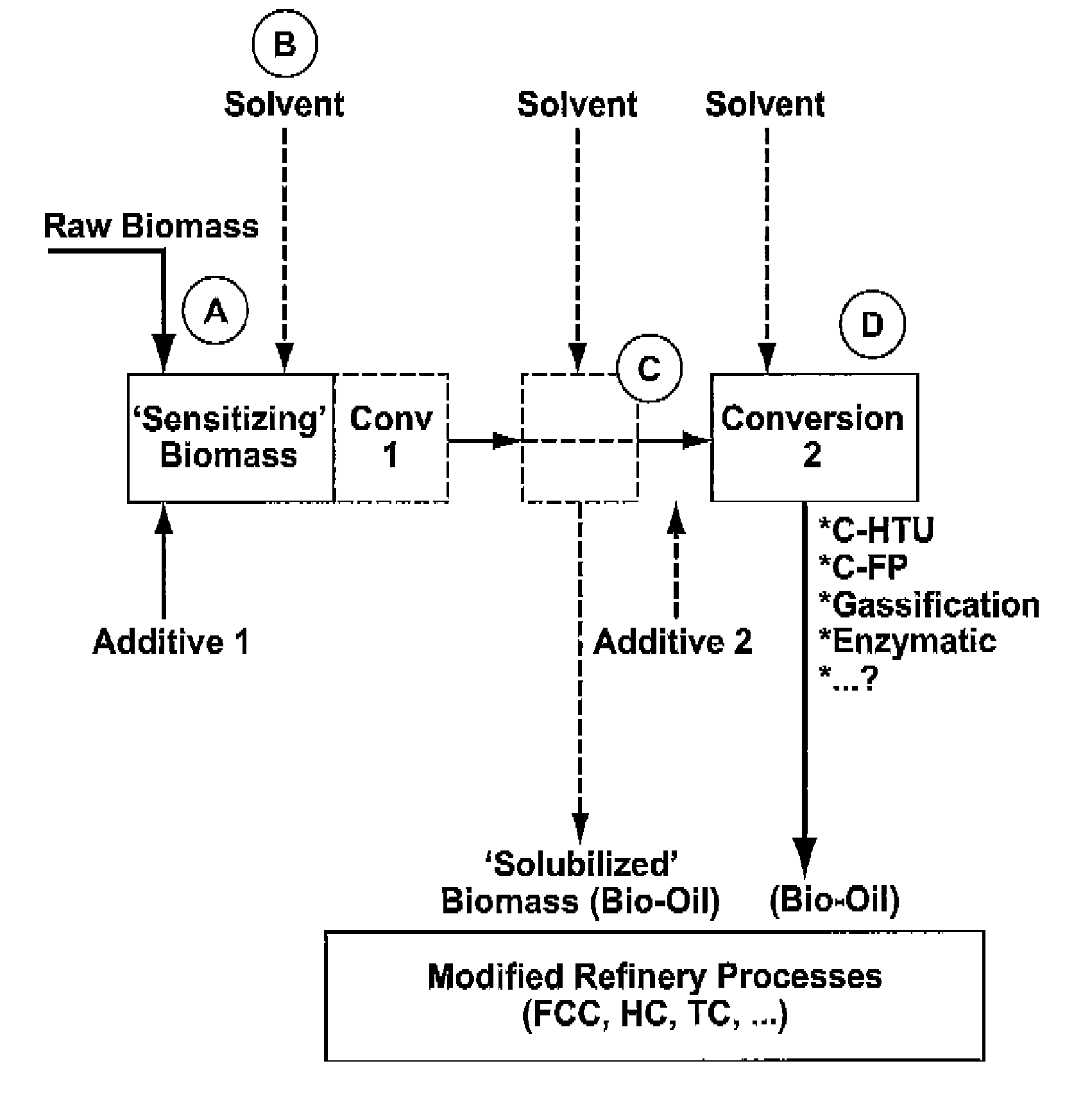

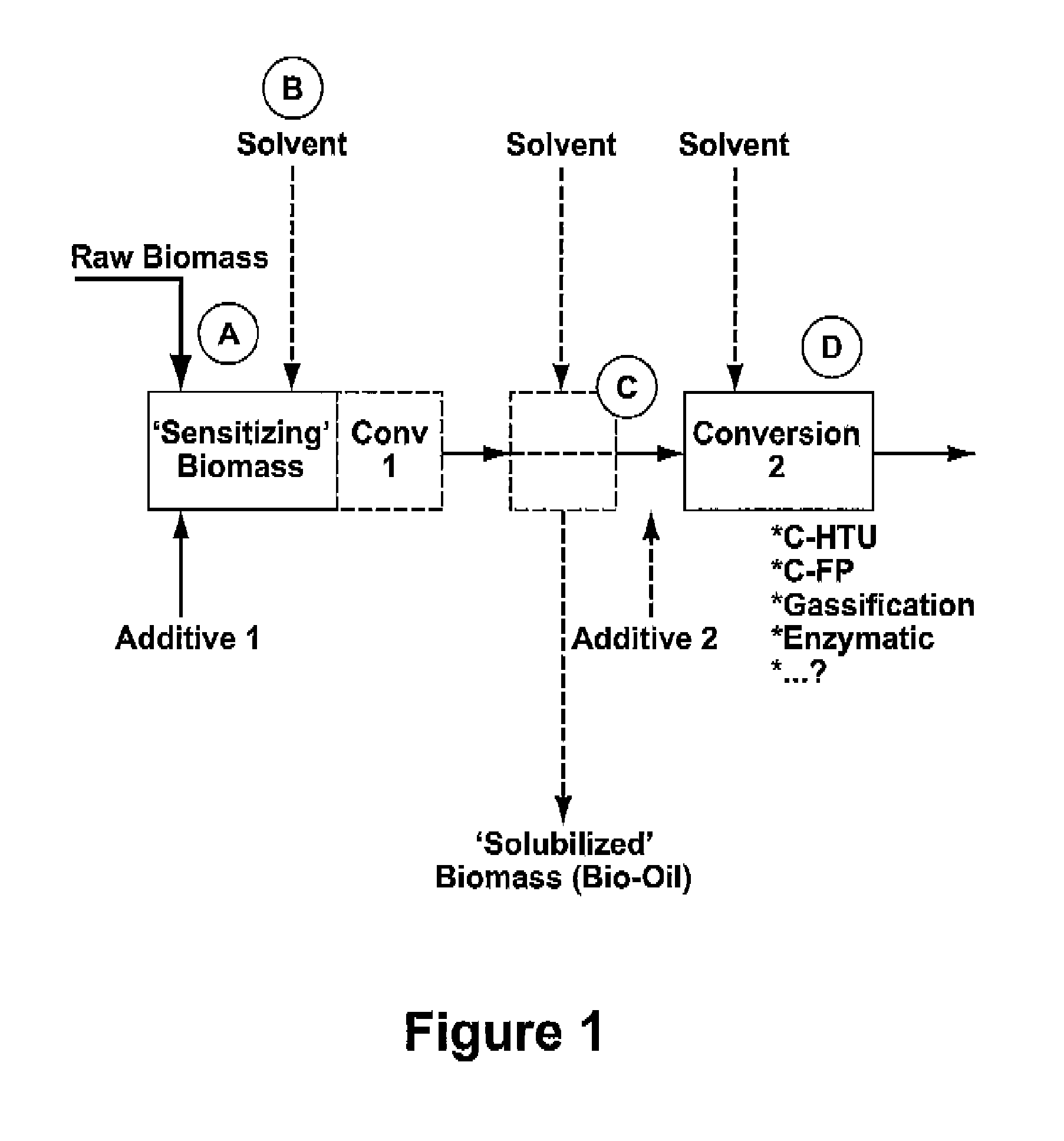

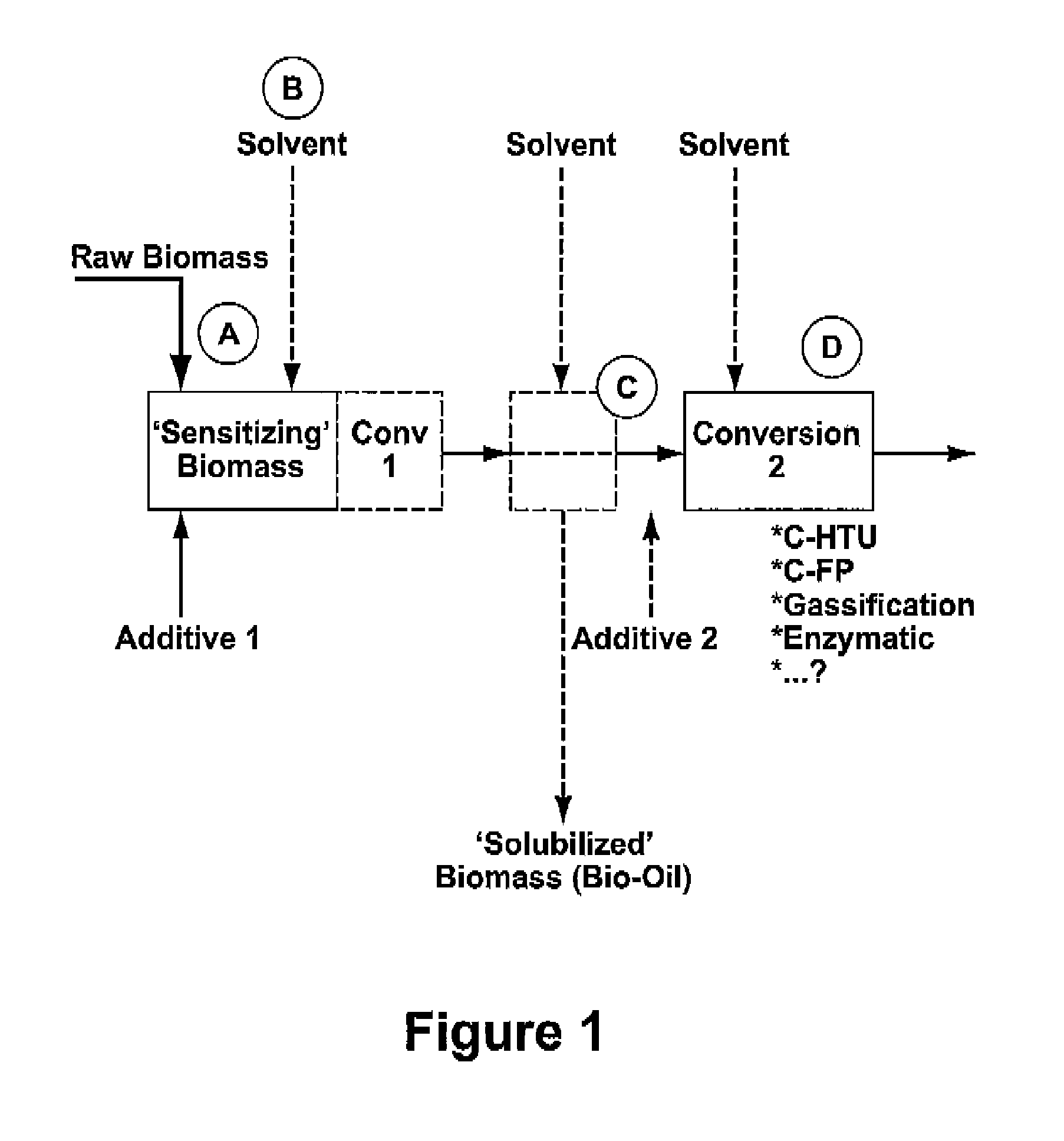

Process for the conversion of biomass to liquid fuels and specialty chemicals

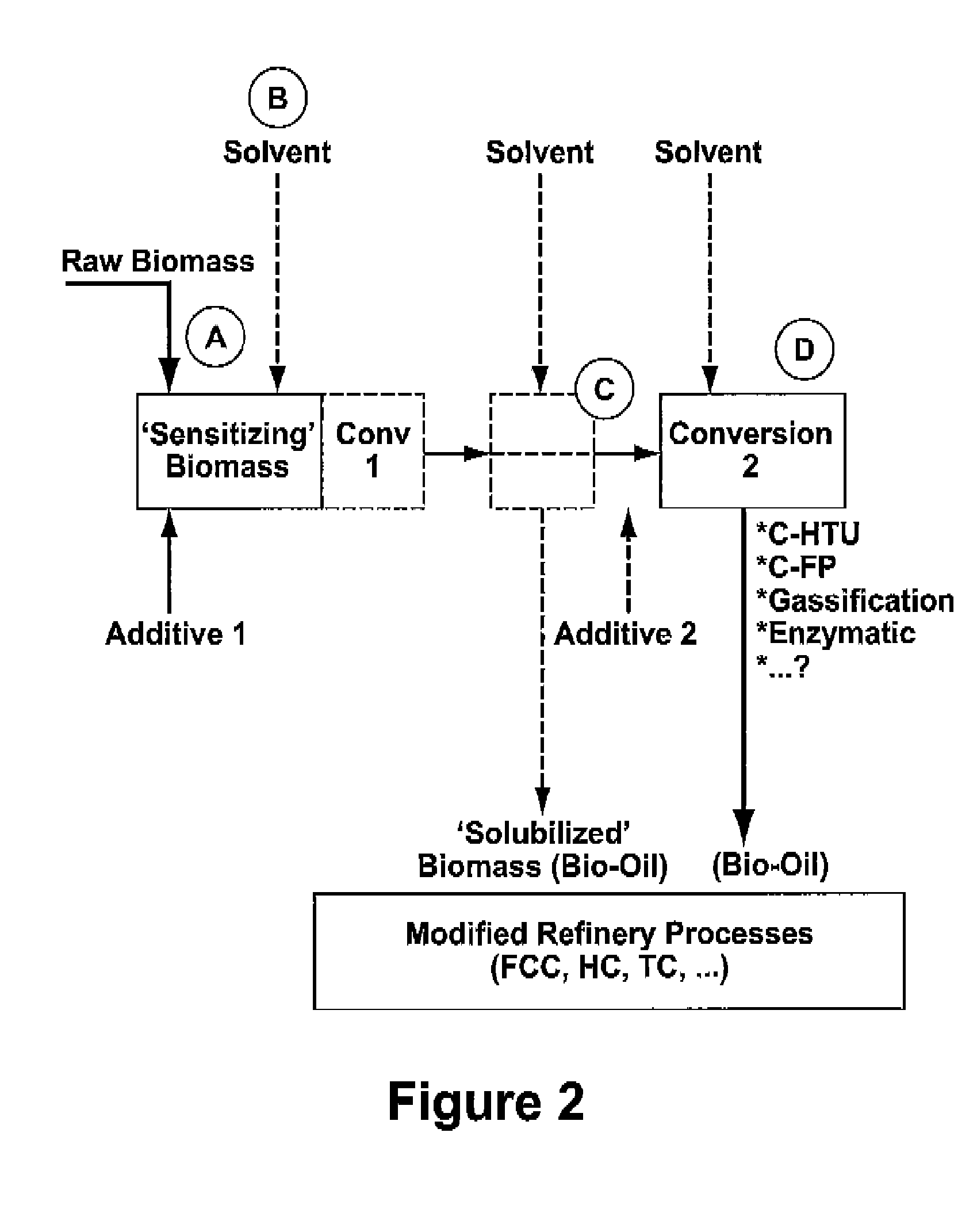

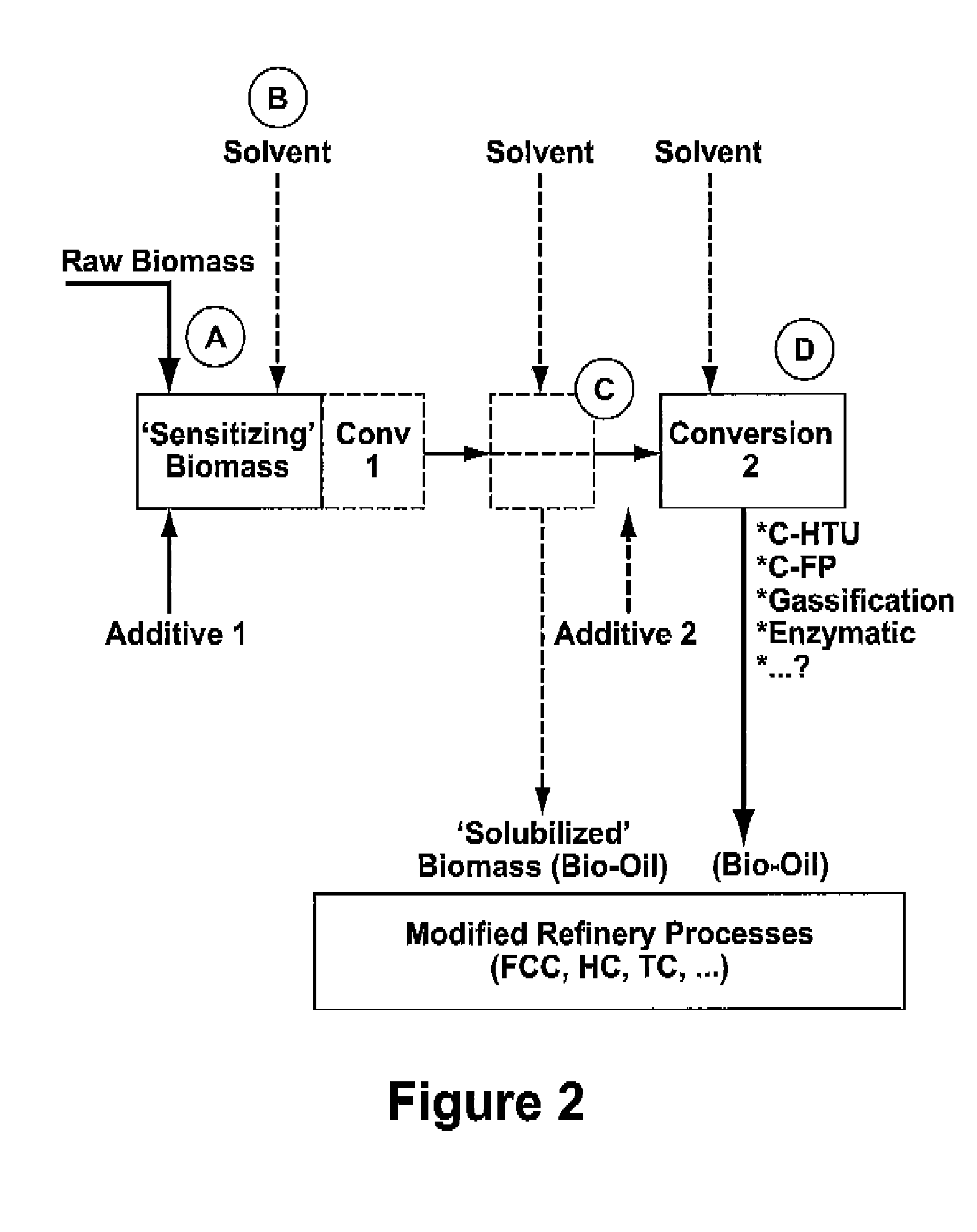

Disclosed is a hydrothermal treatment process for conversion of a carbon-based energy carrier material. The process comprises a step for sensitizing or activating the carbon based energy carrier material to increase its susceptibility to hydrothermal conversion. As a result of the sensitization step, the hydrothermal conversion step itself may be carried out under relatively mild conditions.The process comprises the steps of sensitizing the carbon-based energy carrier material to increase its susceptibility to hydrothermal conversion; and subjecting the sensitized carbon-based energy carrier material to hydrothermal conversion at a temperature of less than 300 degrees centigrade in a hydrothermal treatment reactor.

Owner:MARD INC

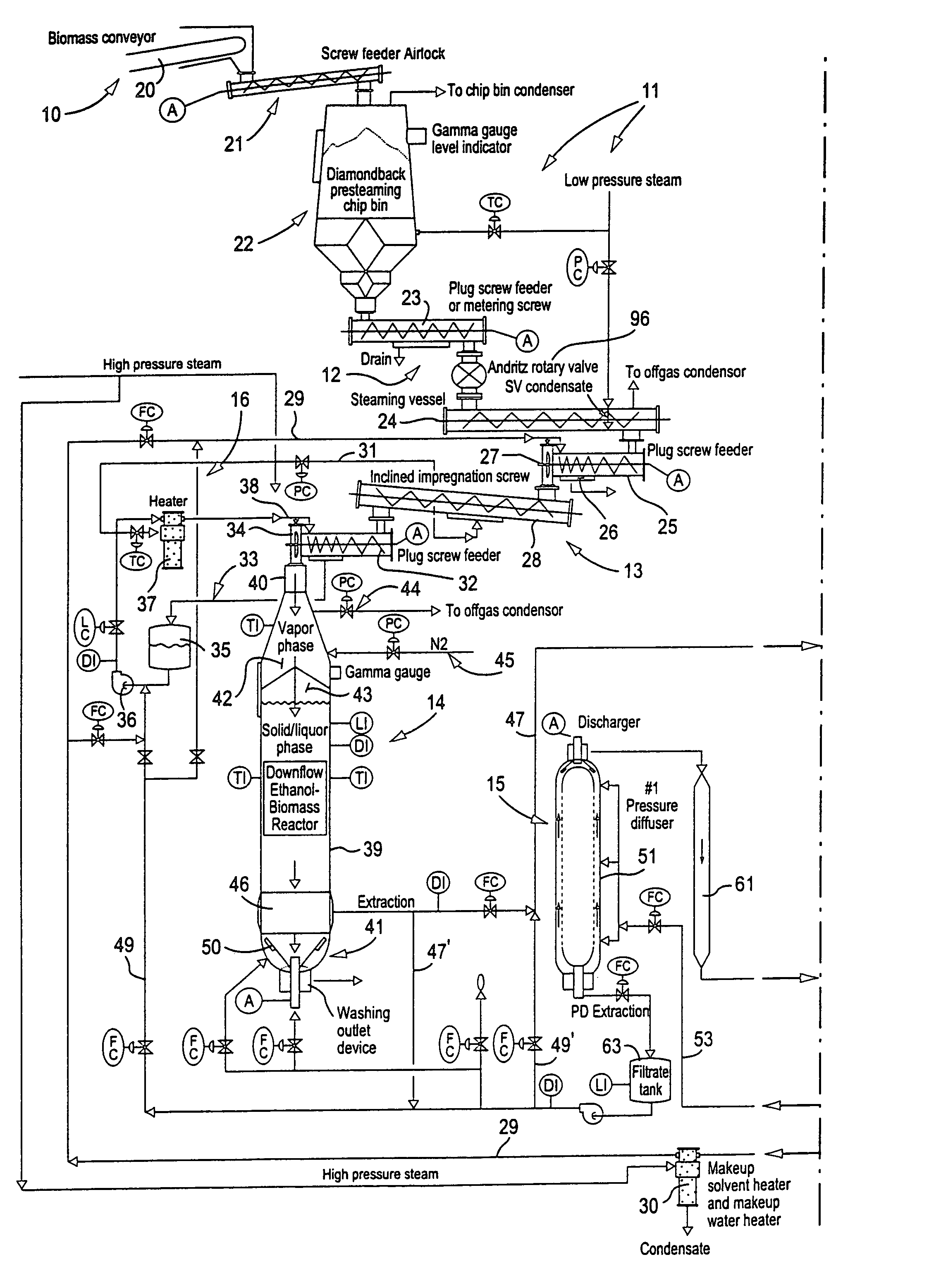

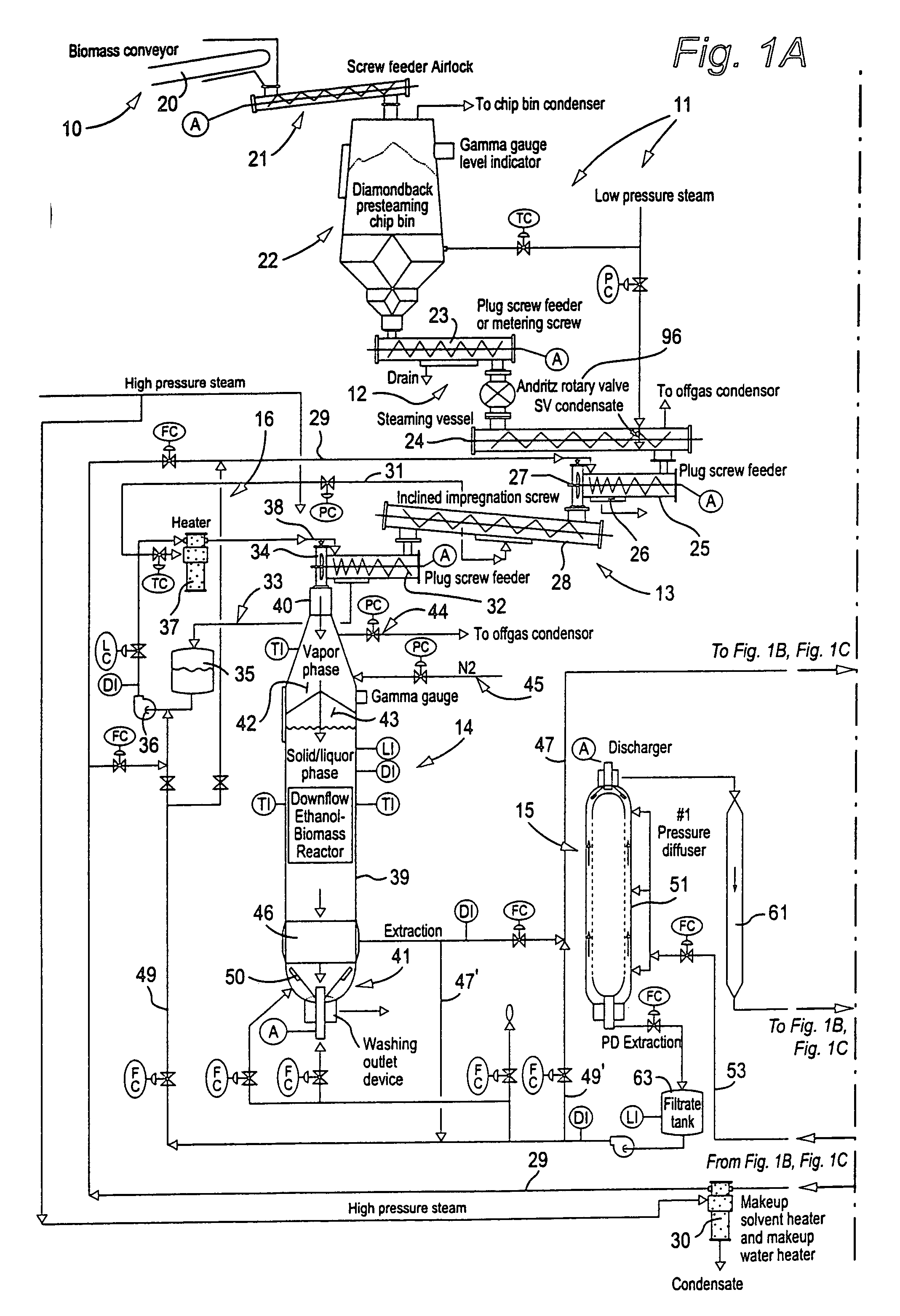

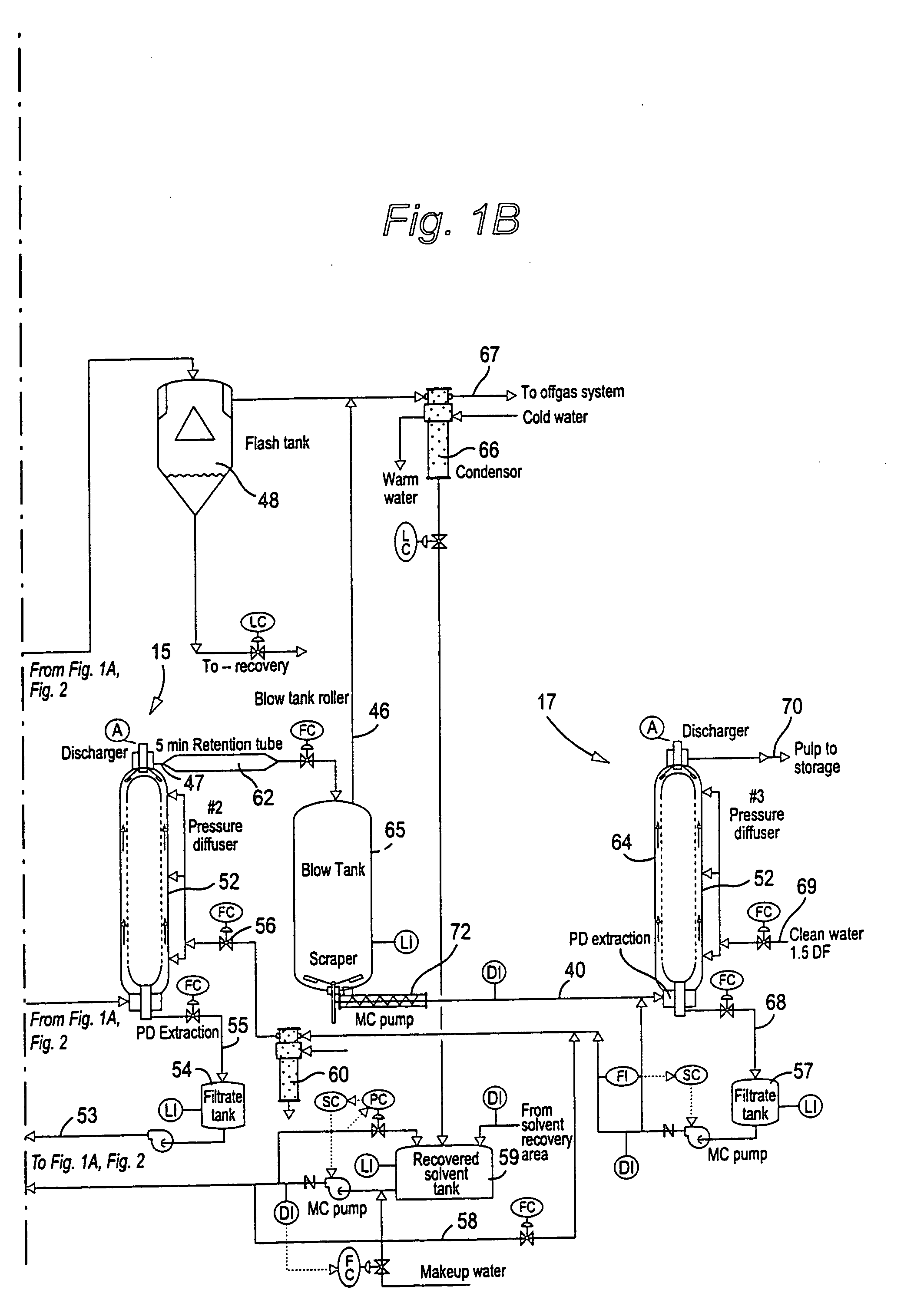

Solvent pulping of biomass

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

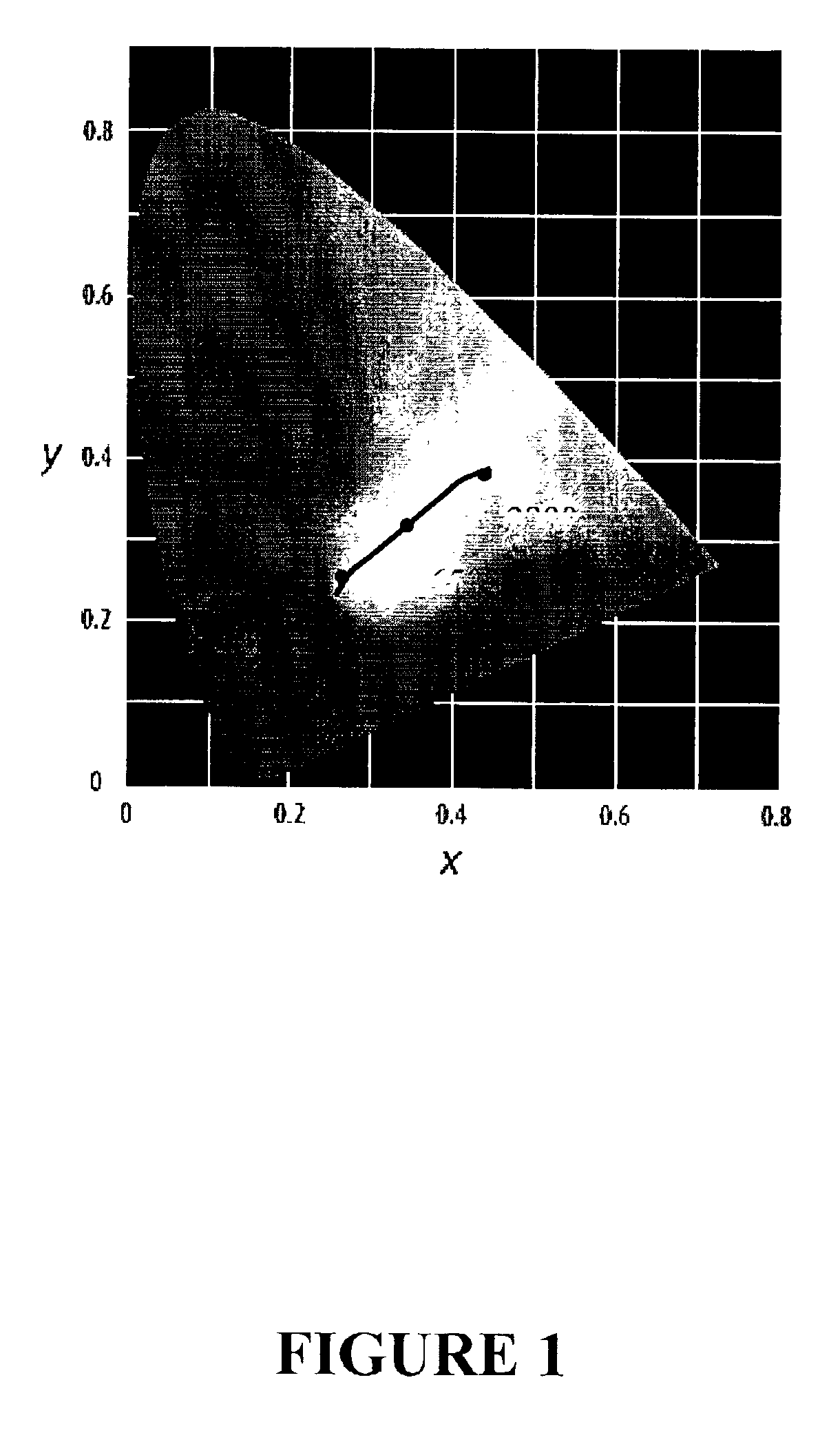

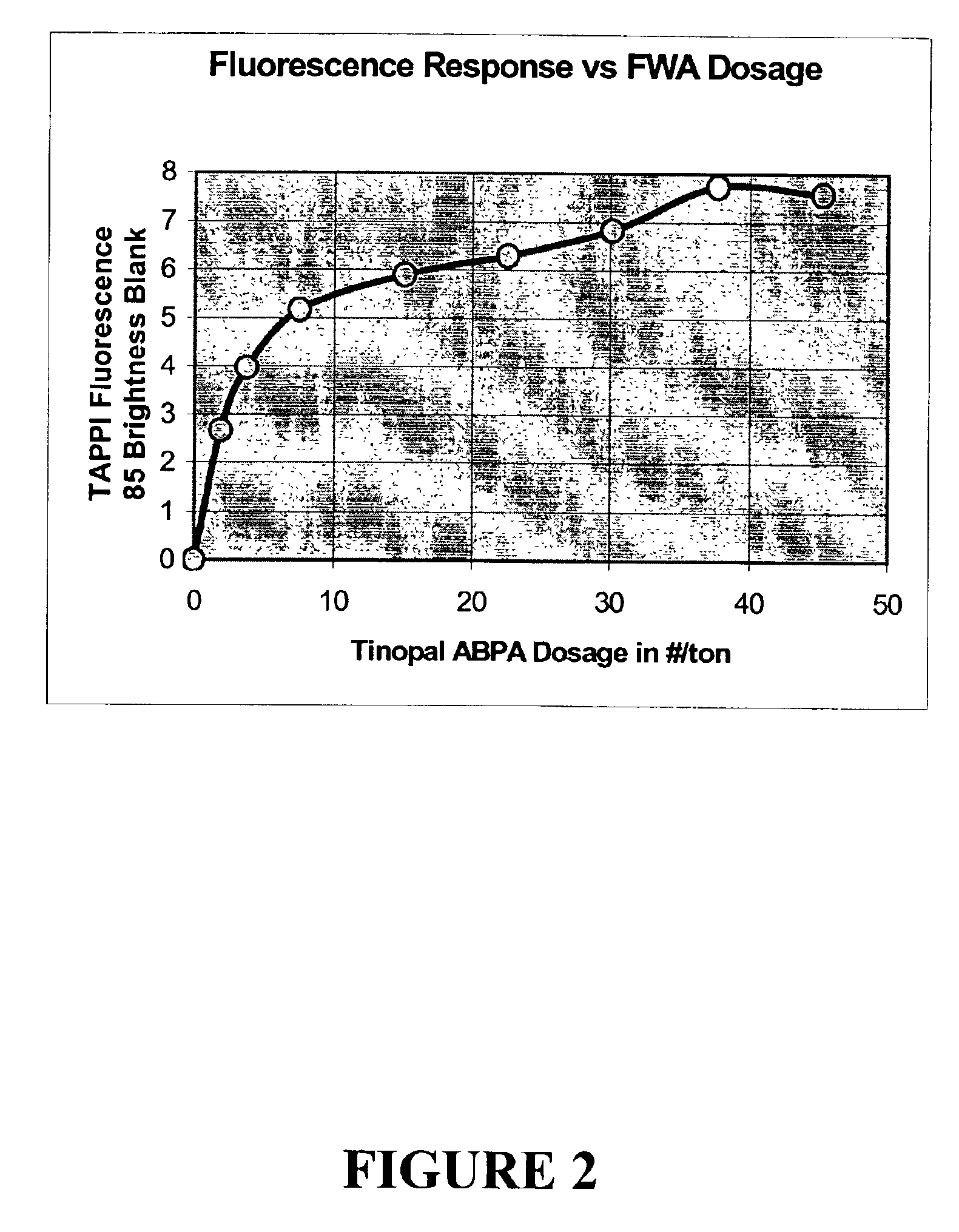

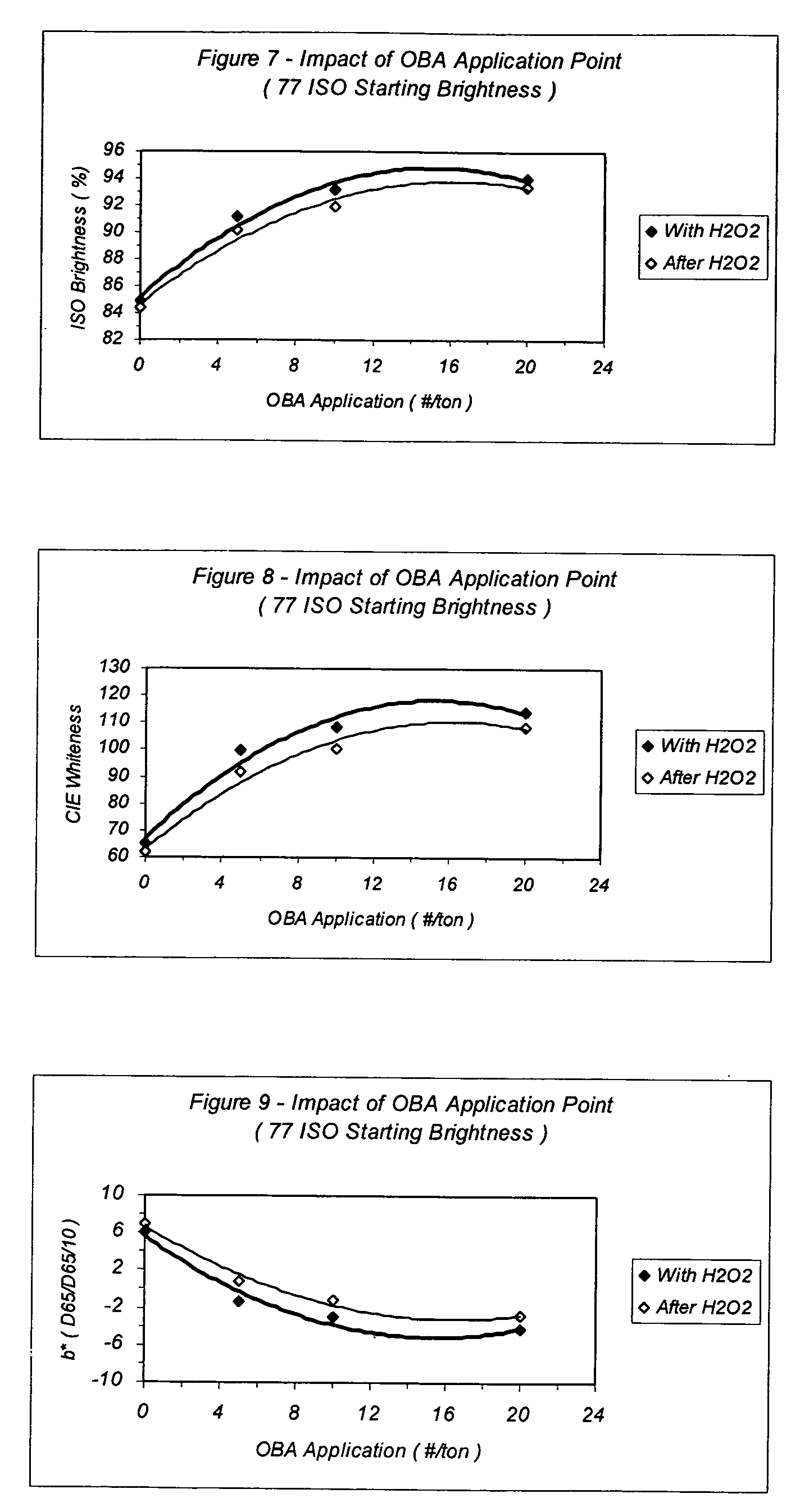

Pulp and paper having increased brightness

InactiveUS20070193707A1Natural cellulose pulp/paperSpecial paperPulp and paper industryBrightness perception

Owner:INT PAPER CO

Process for manufacturing pulp, paper and paperboard products

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

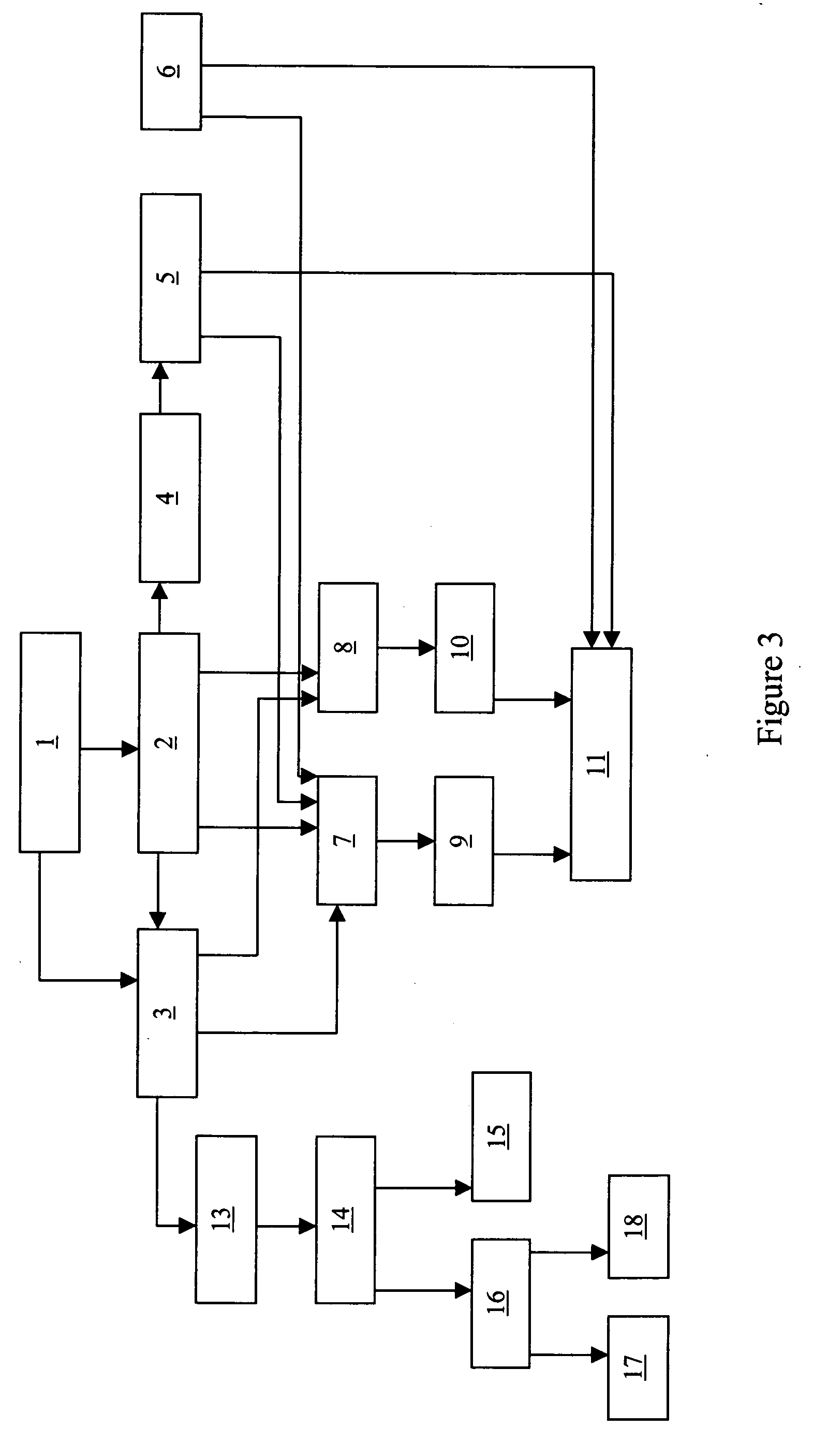

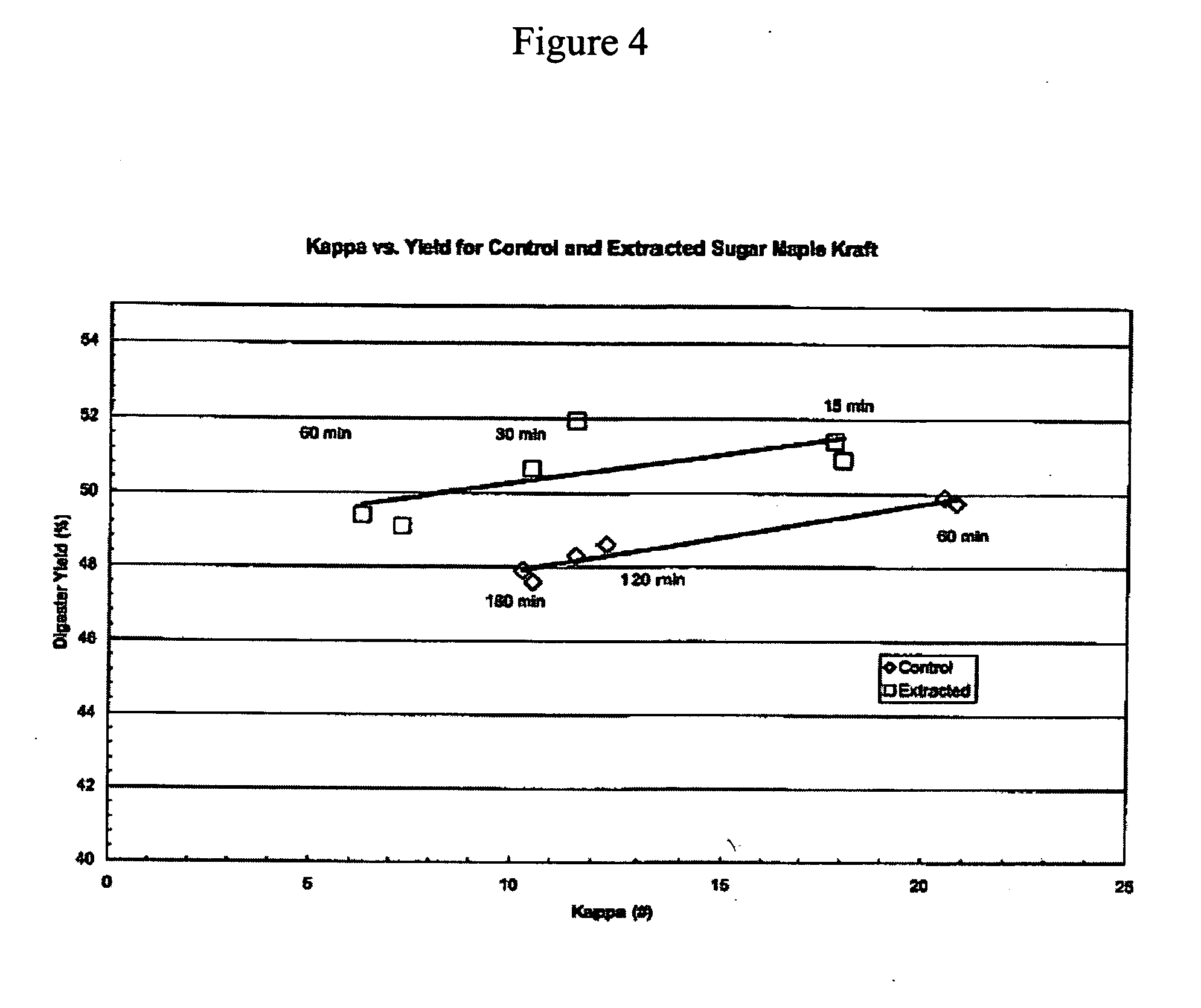

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

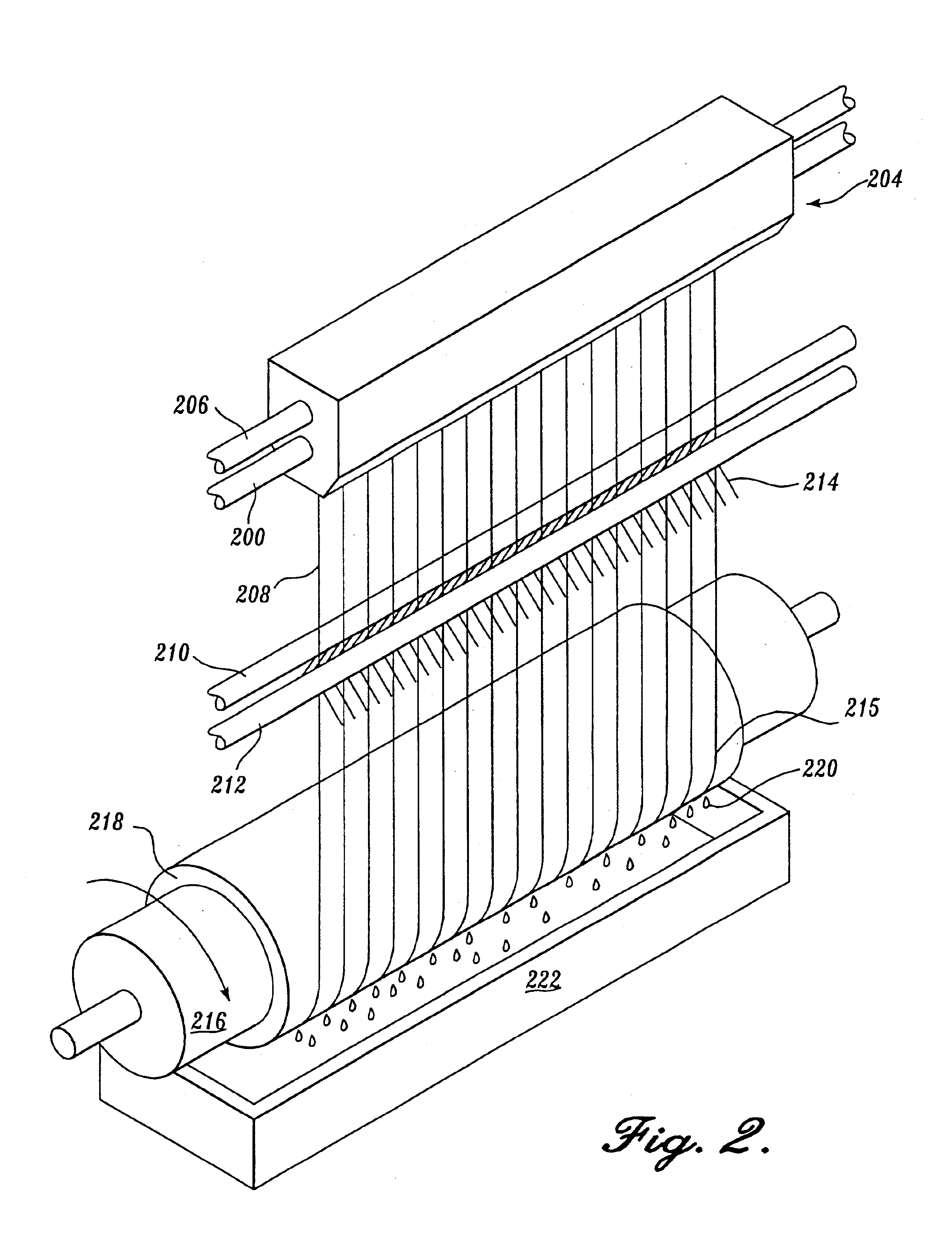

Meltblown process with mechanical attenuation

InactiveUS6773648B2High speed spinningImprove productivityPulp properties modificationArtificial filament physical treatmentCelluloseUltrasound attenuation

Owner:WEYERHAEUSER NR CO

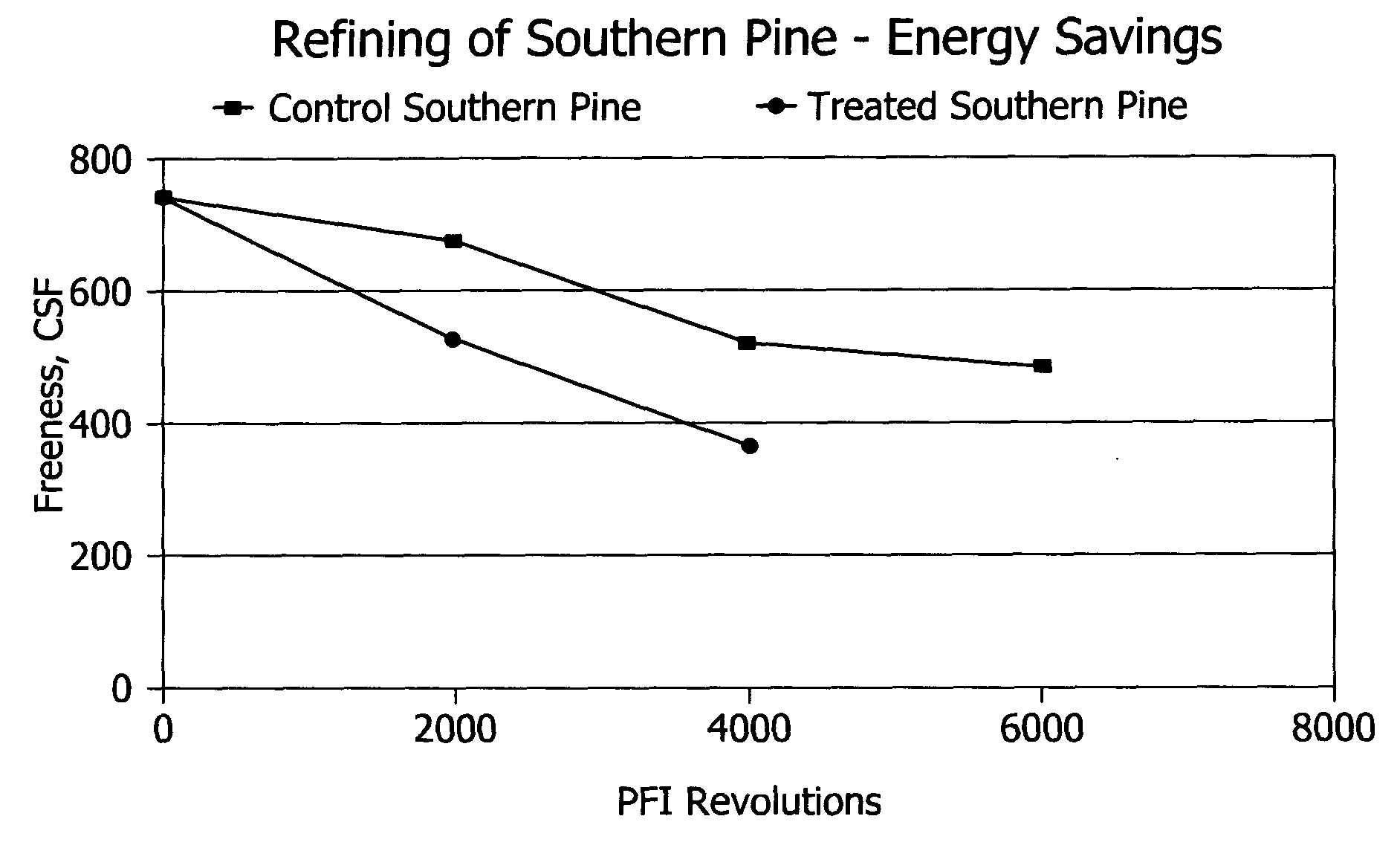

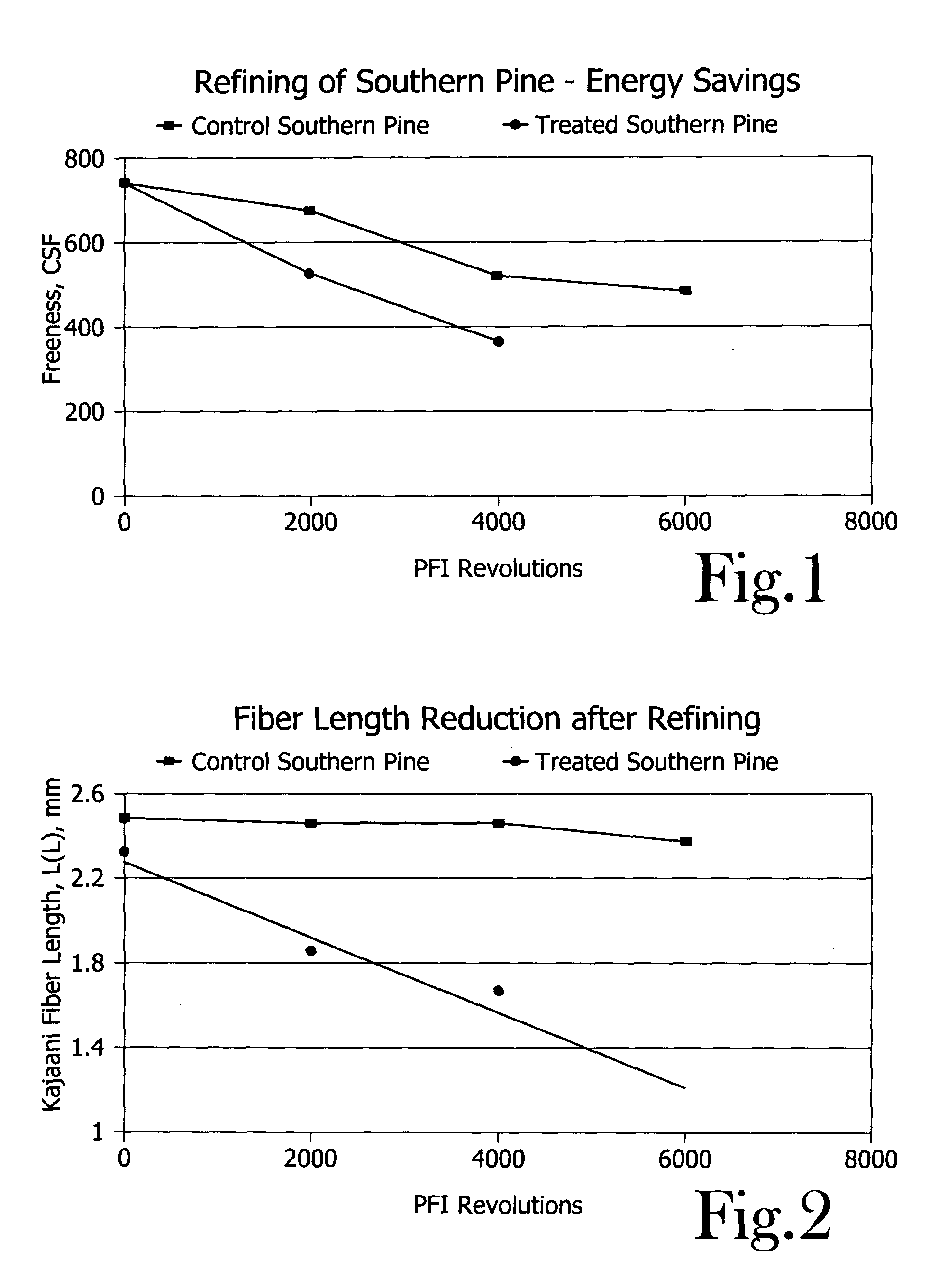

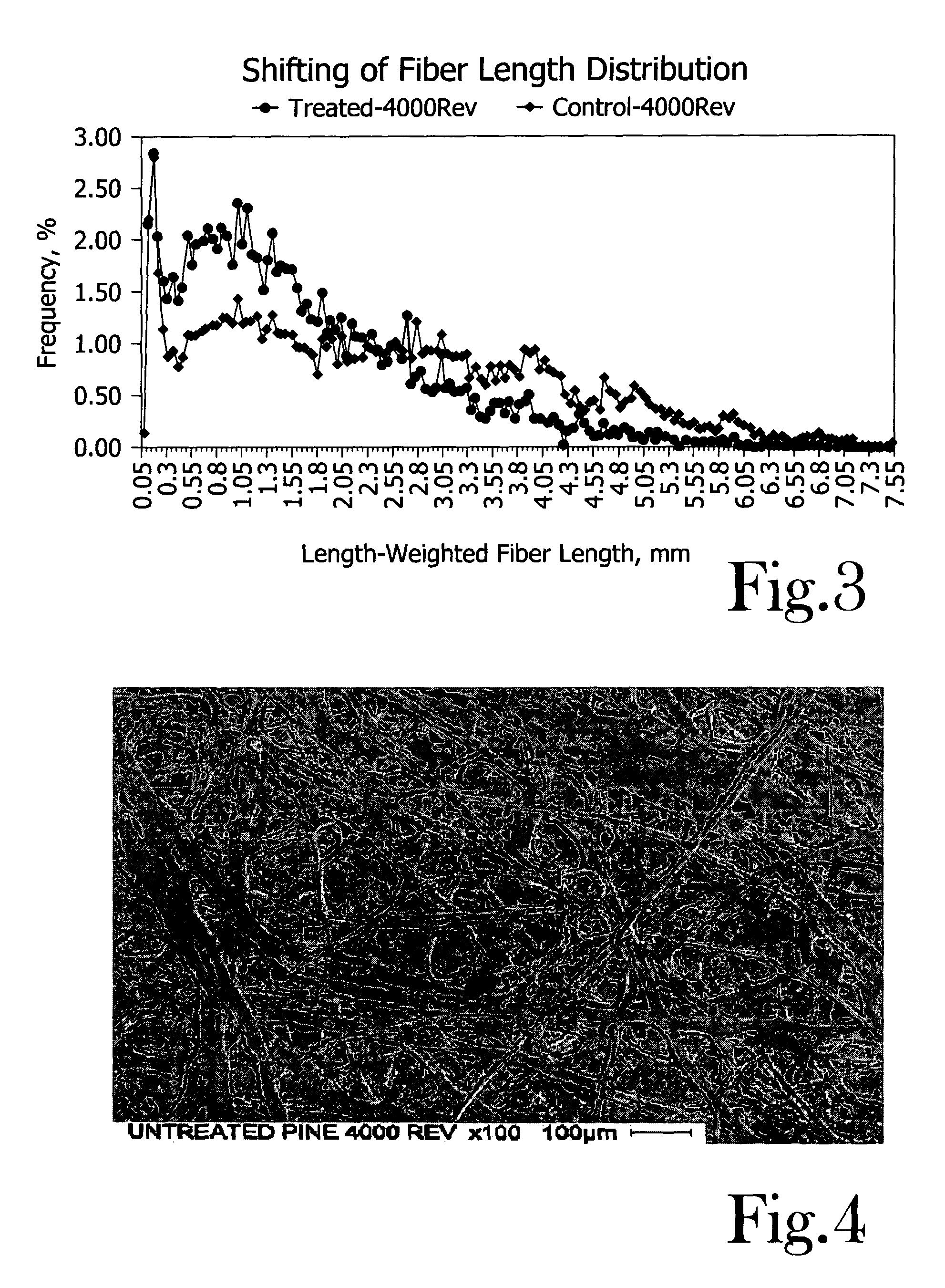

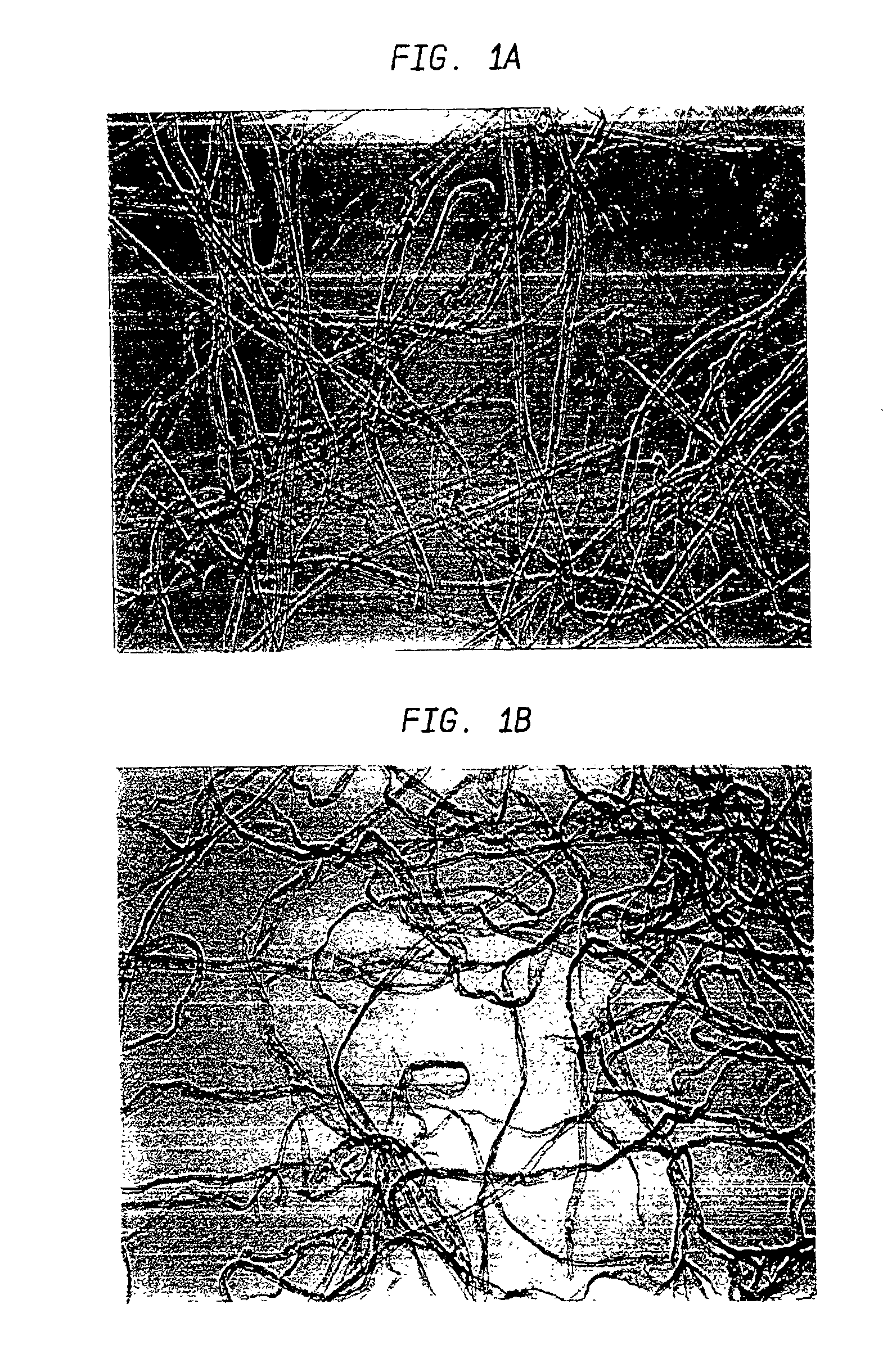

Chemical activation and refining of southern pine kraft fibers

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

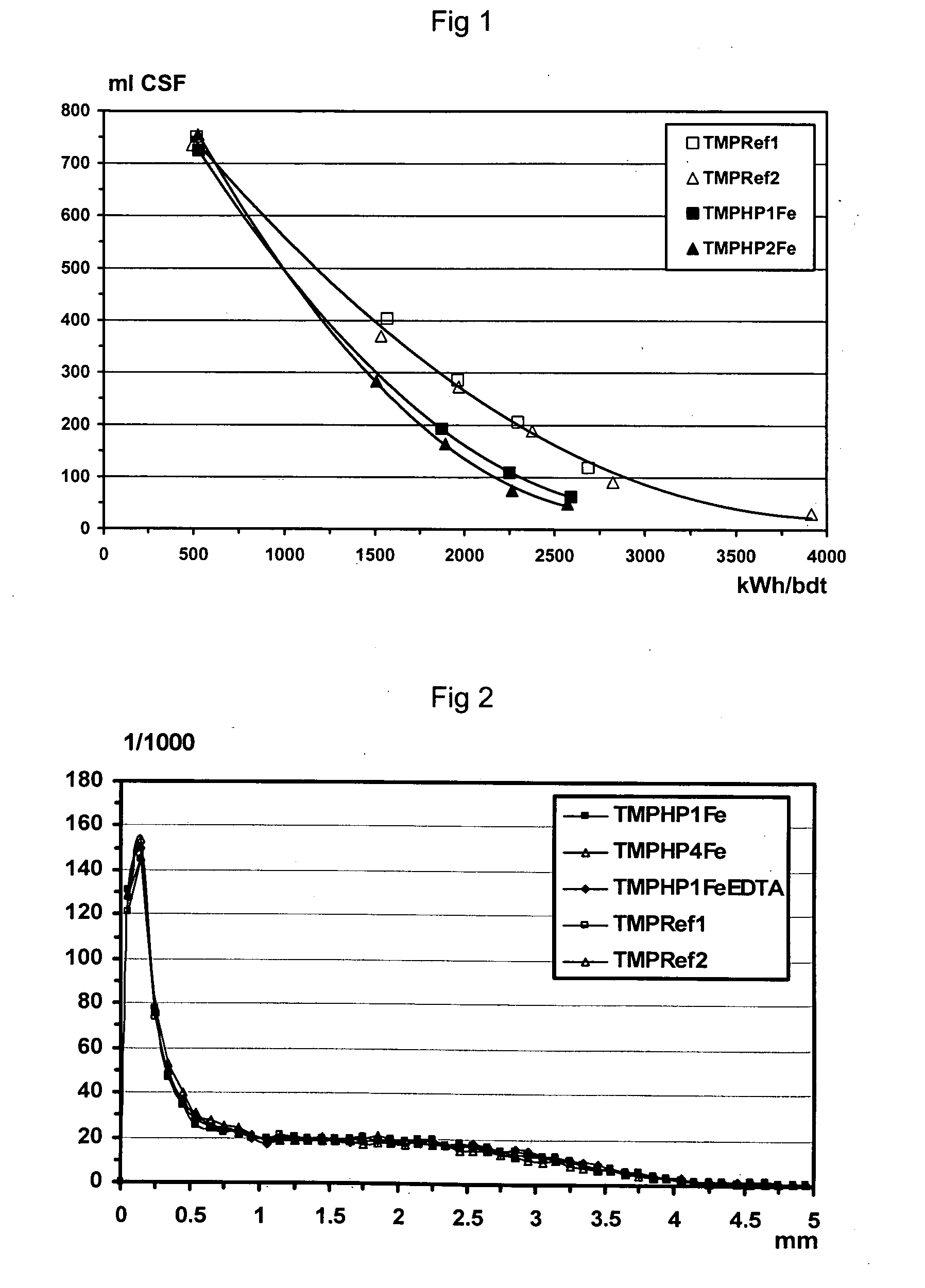

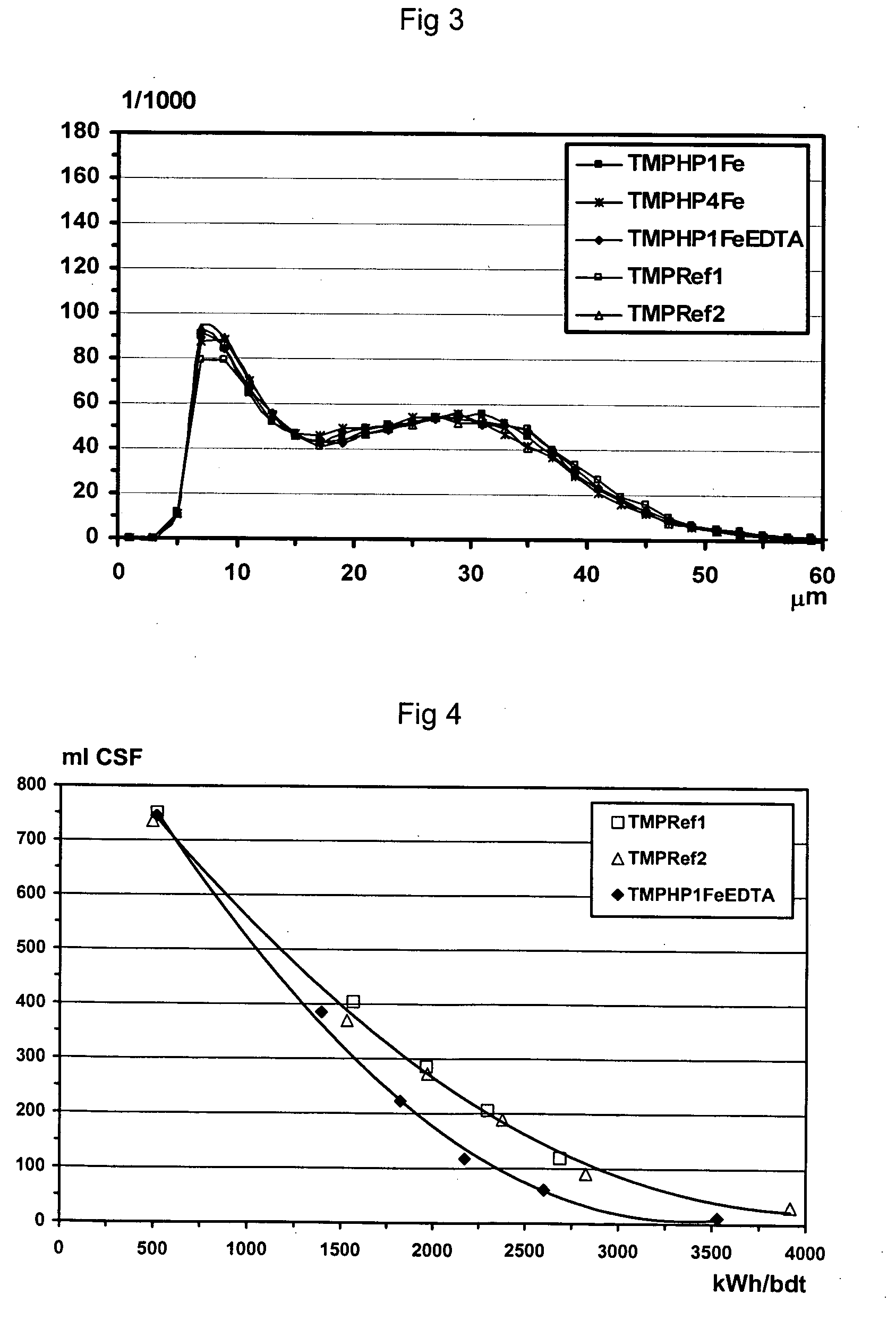

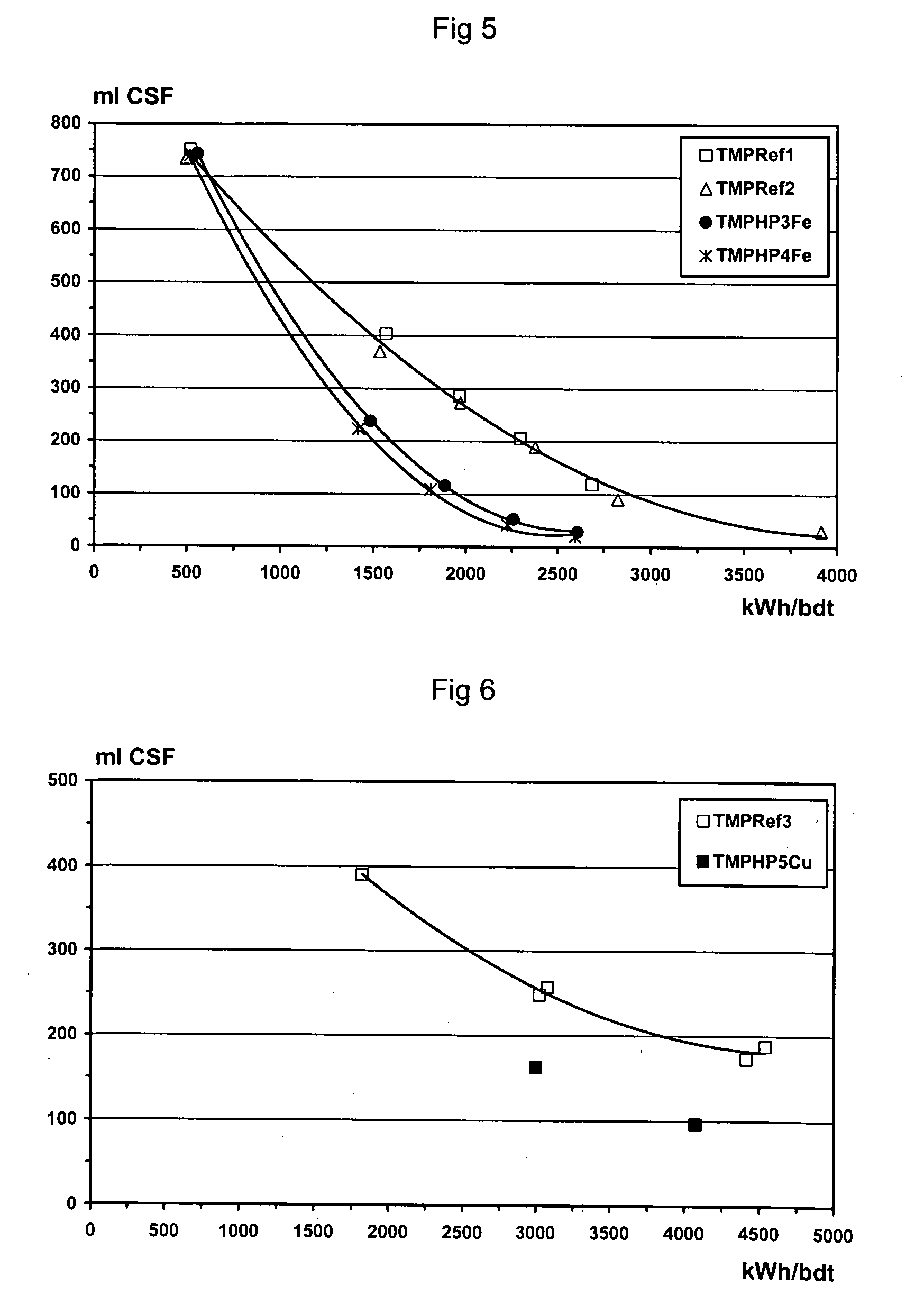

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

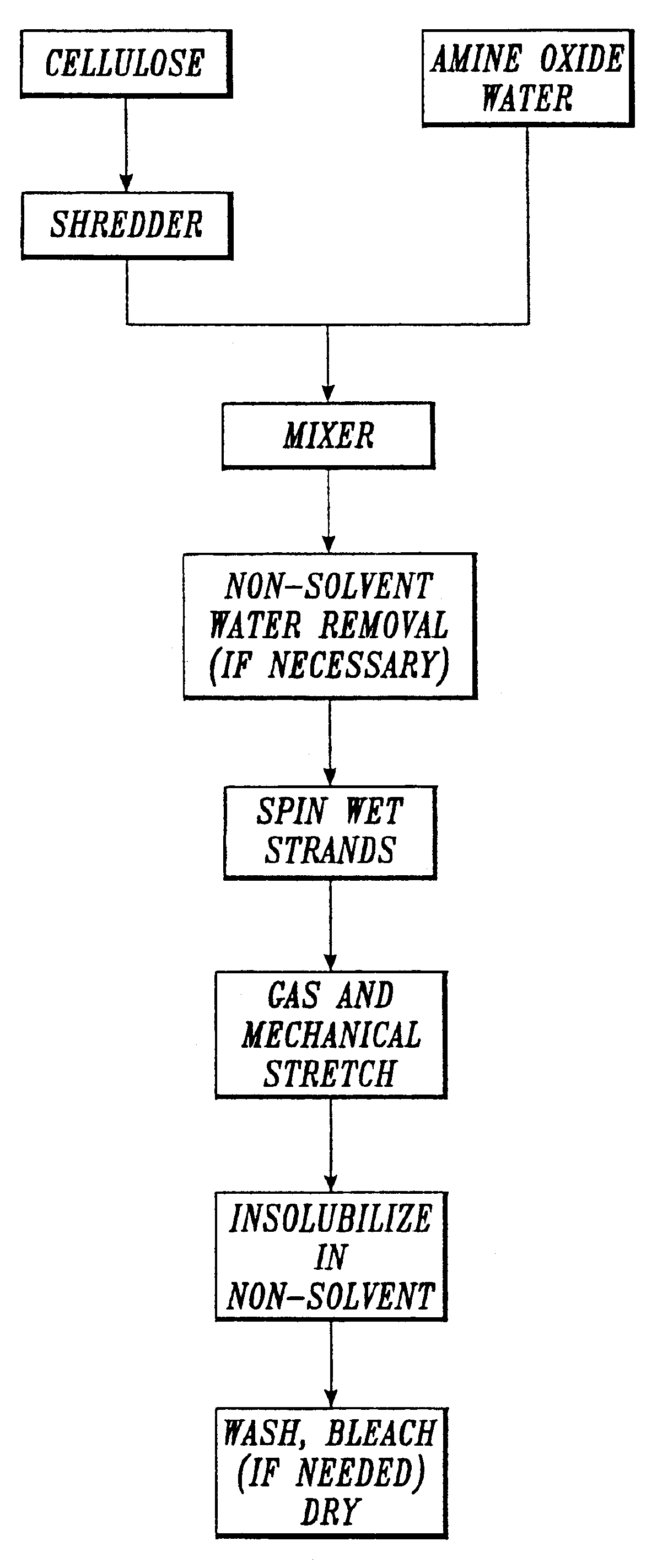

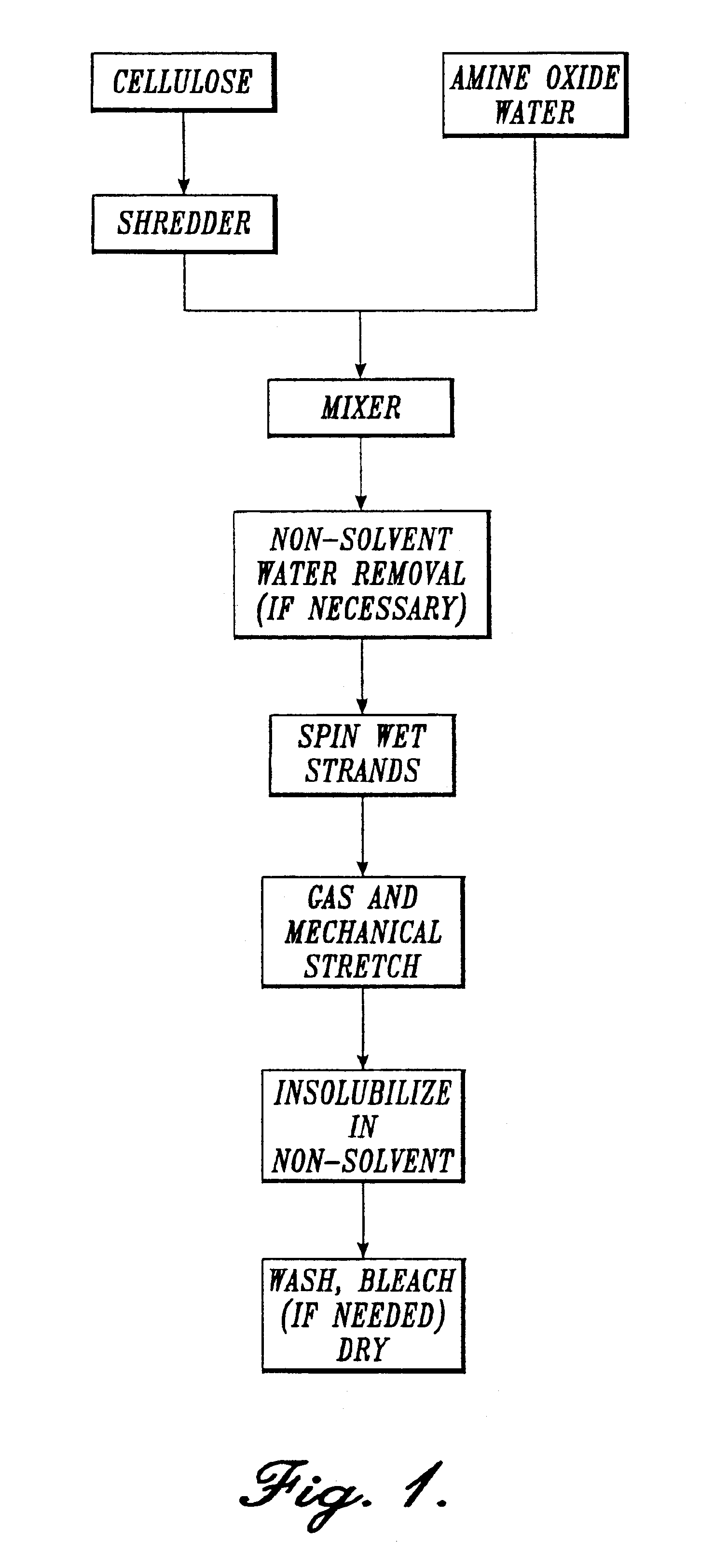

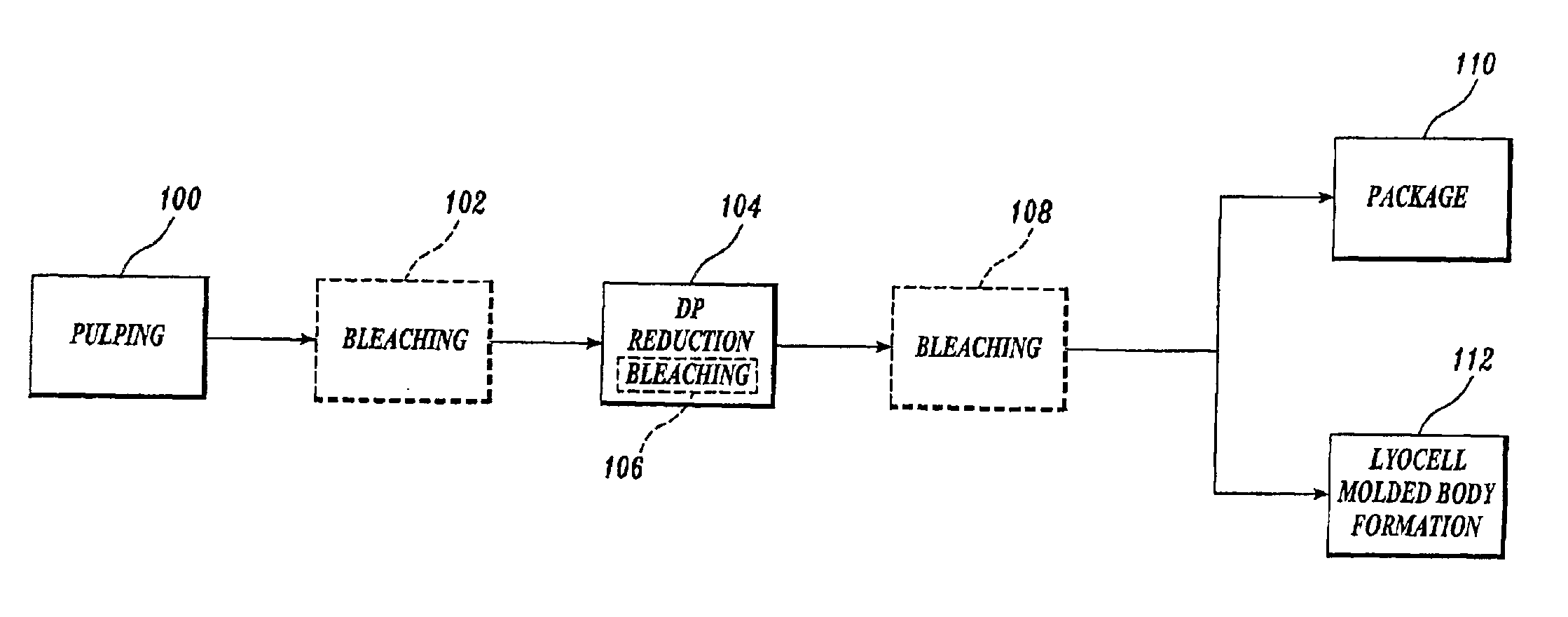

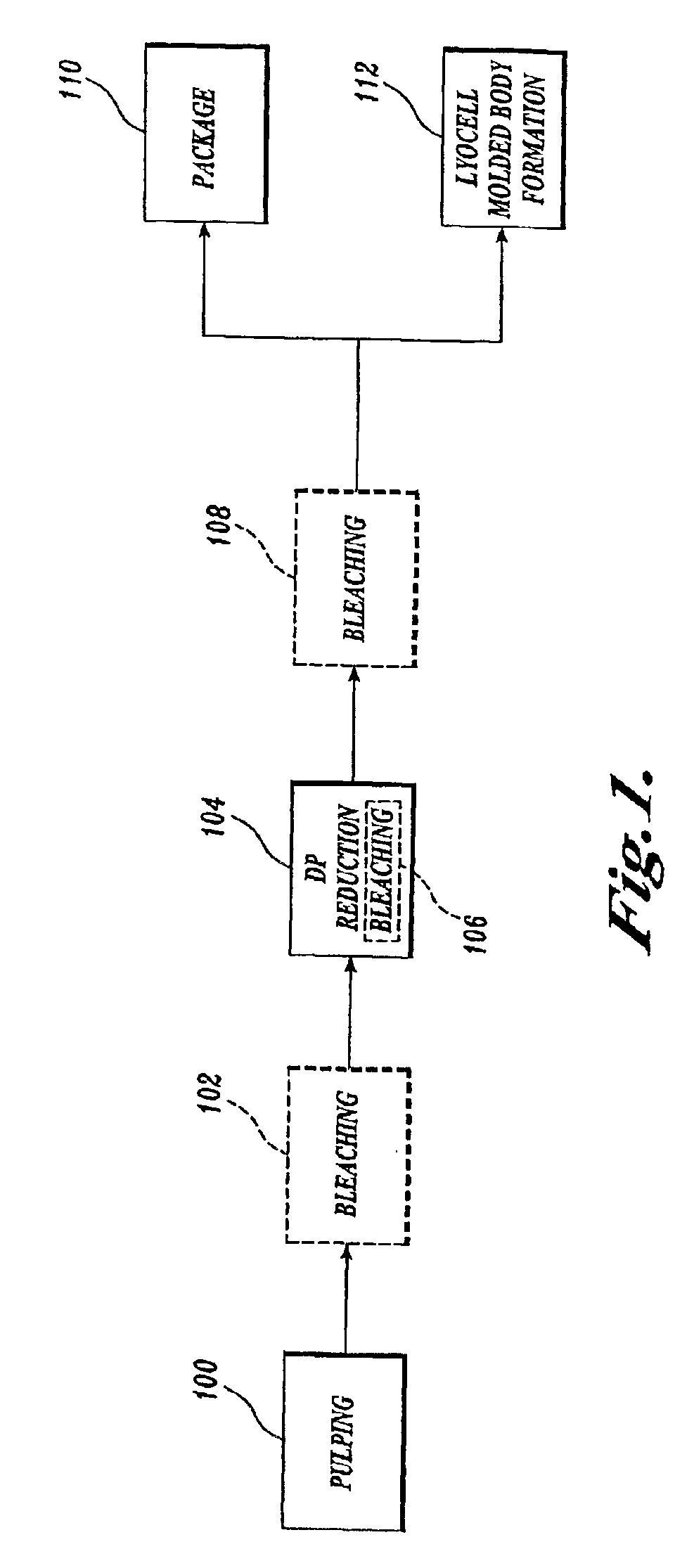

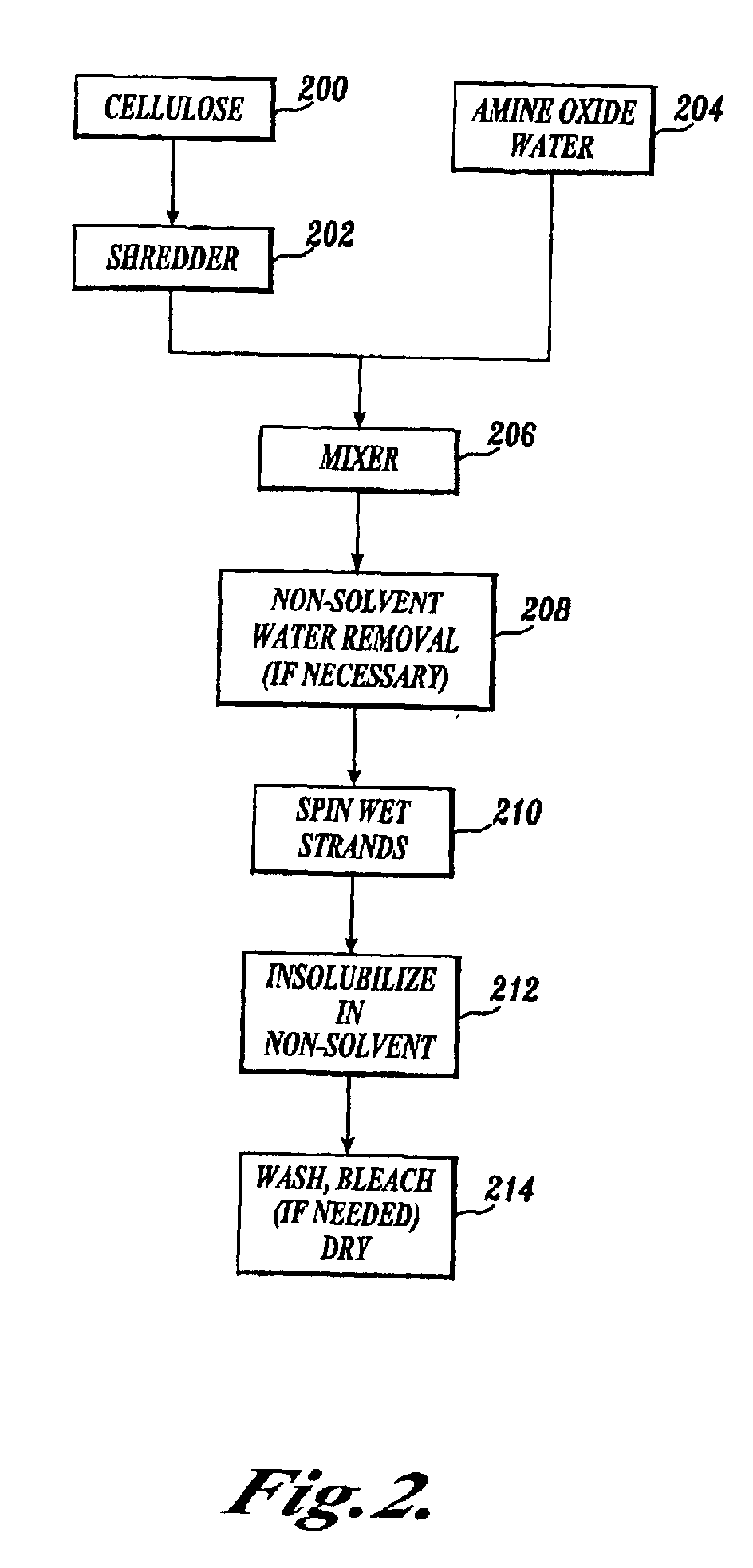

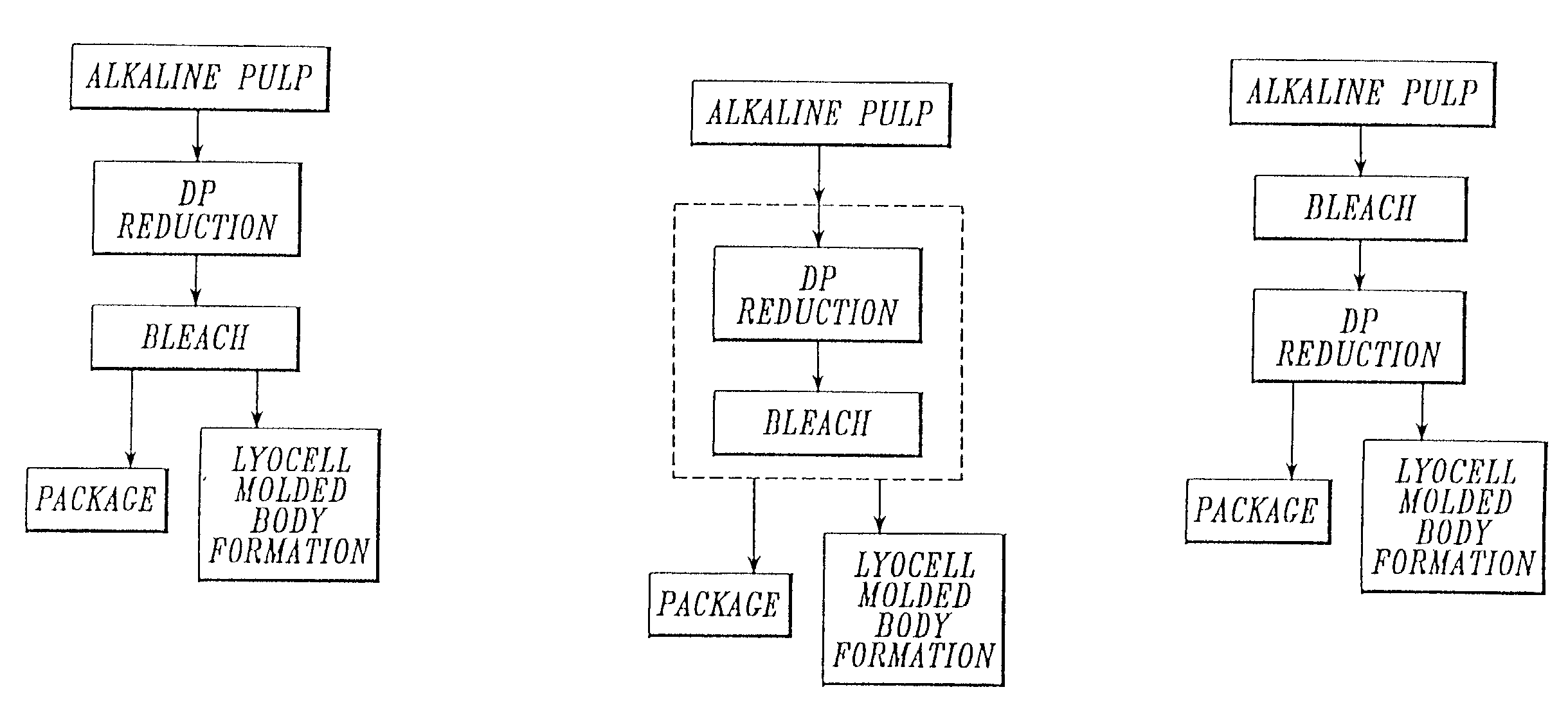

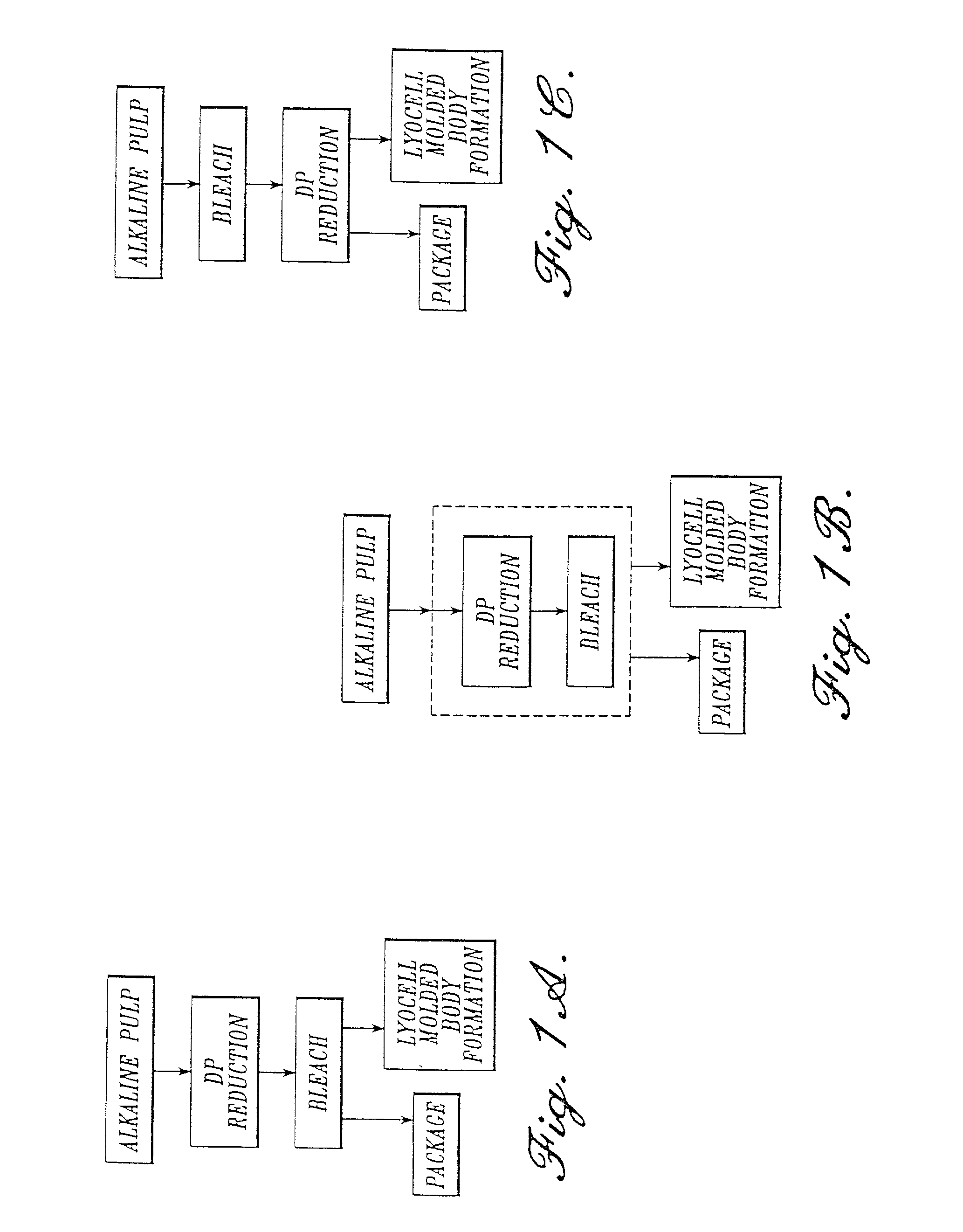

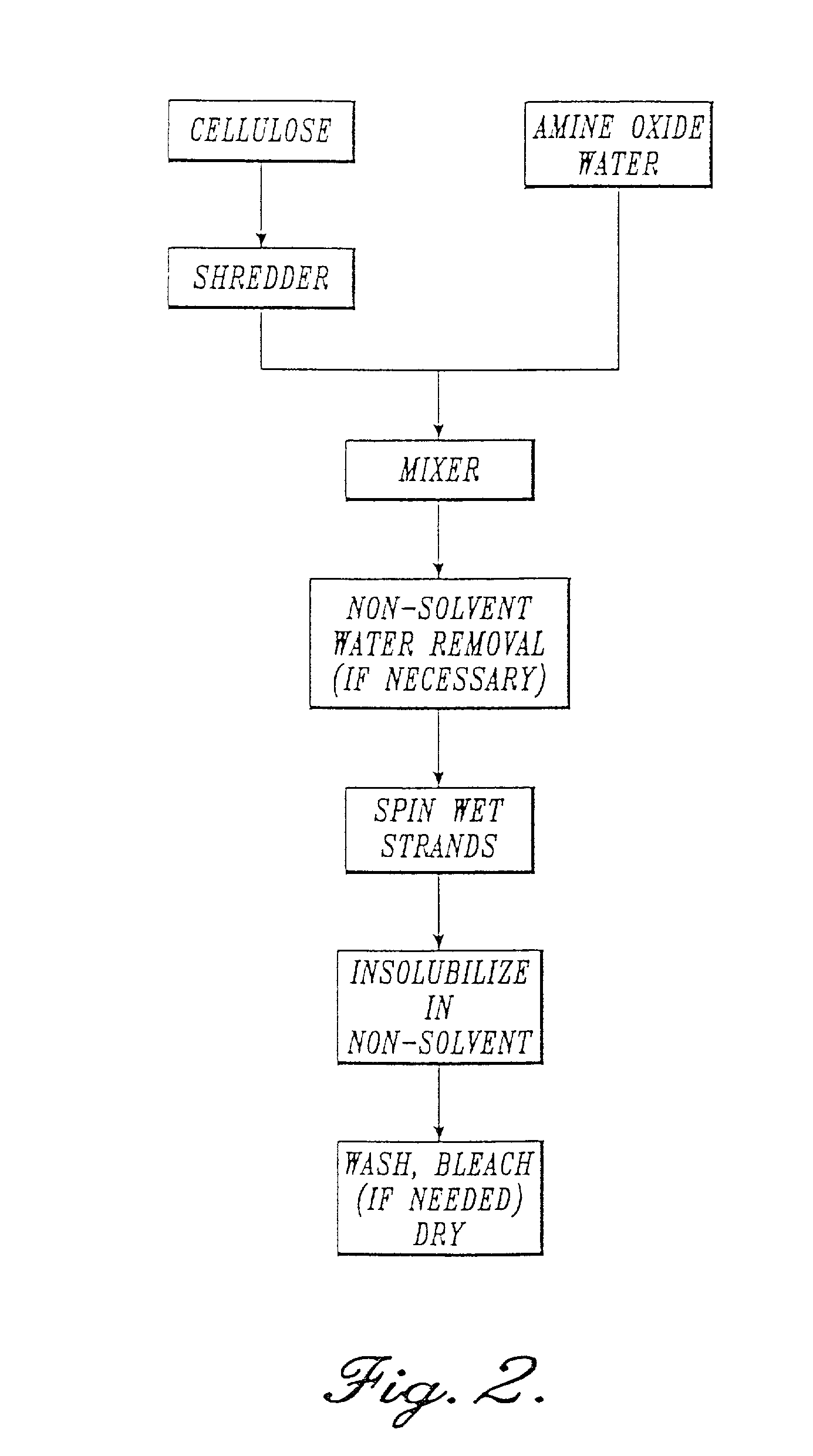

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

Process for making a composition for conversion to lyocell fiber from an alkaline pulp having low average degree of polymerization values

InactiveUS7083704B2Reducing hemicellulose contentIncreasing copper numberPulp properties modificationMonocomponent cellulose artificial filamentHemicelluloseLyocell

The present invention provides compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization (D.P.) and a narrow molecular weight distribution. Further, the present invention provides processes for making compositions, useful for making lyocell fibers, by contacting an alkaline pulp having a high hemicellulose content of at least about 7% with an oxidant sufficient to reduce the average degree of polymerization to about 200 to 1100 without substantially reducing the hemicellulose content or increasing the copper number of the pulp.

Owner:INT PAPER CO

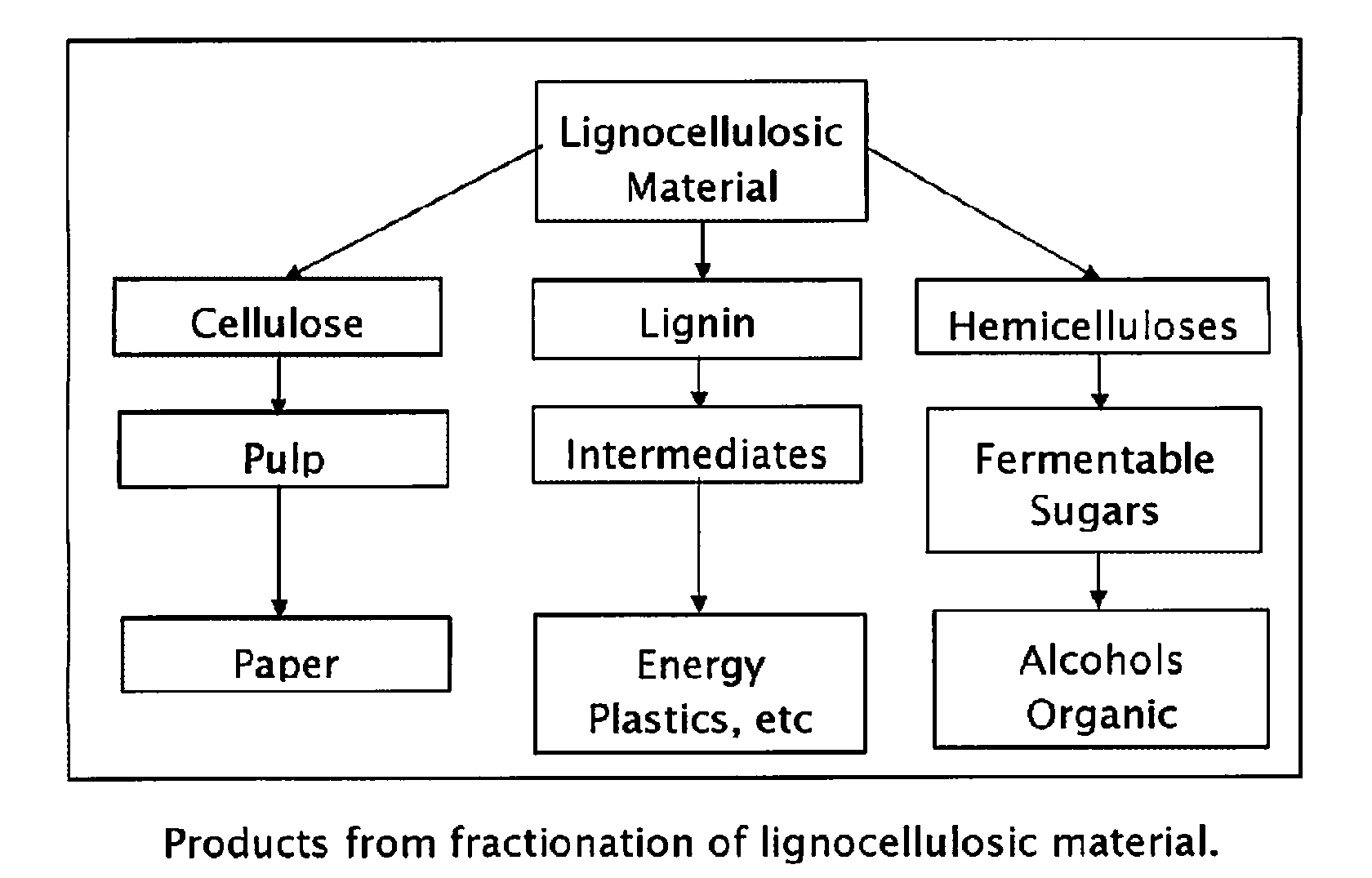

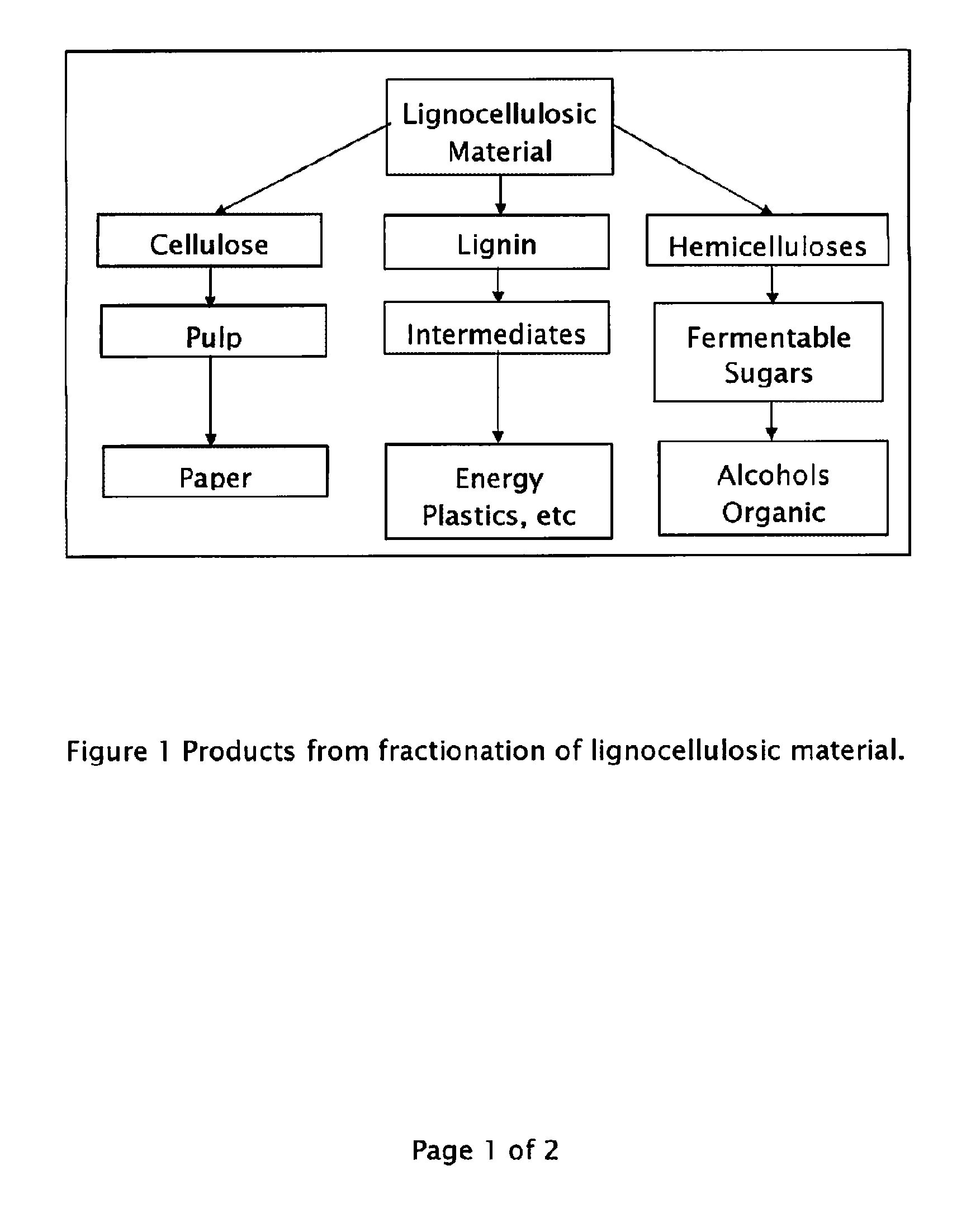

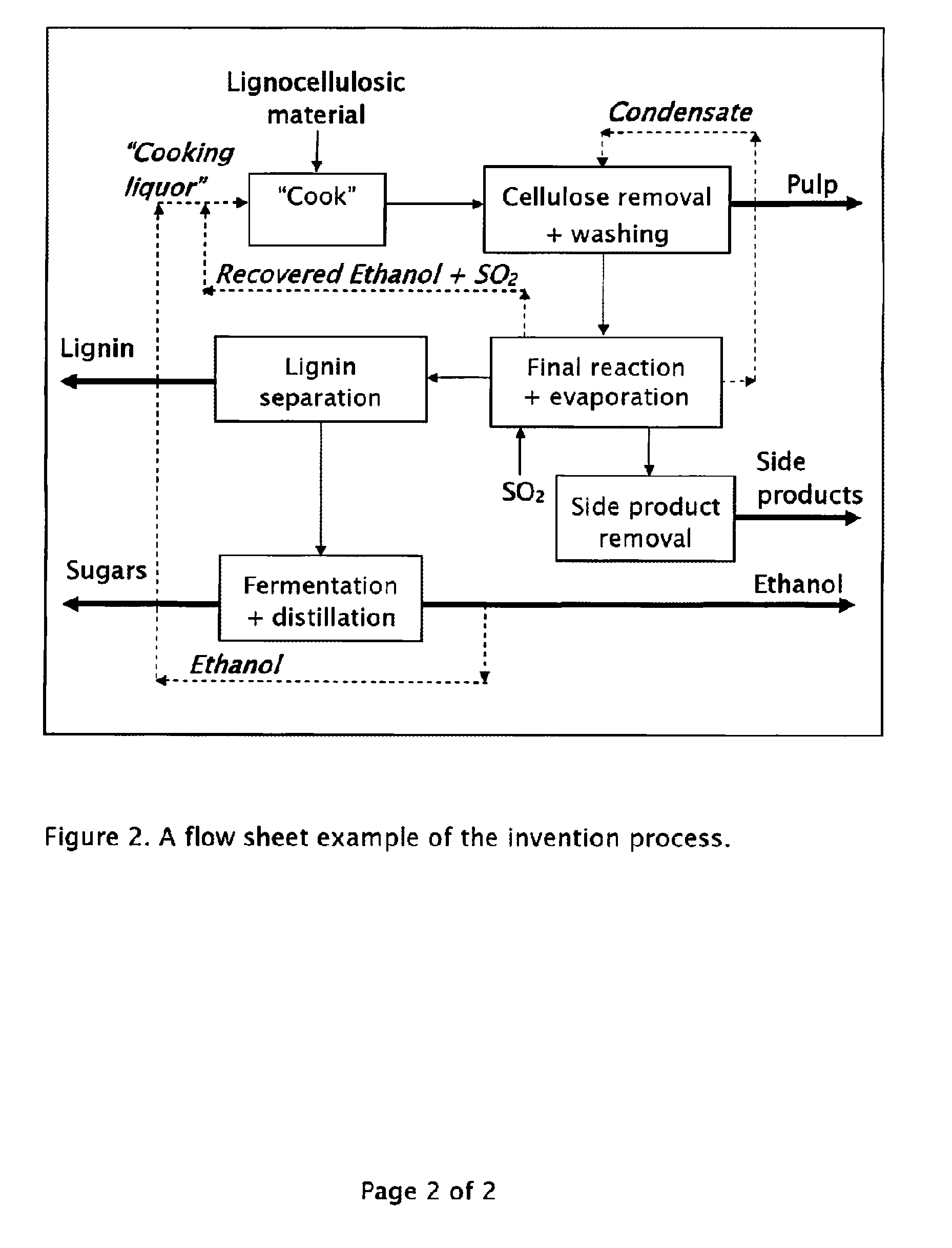

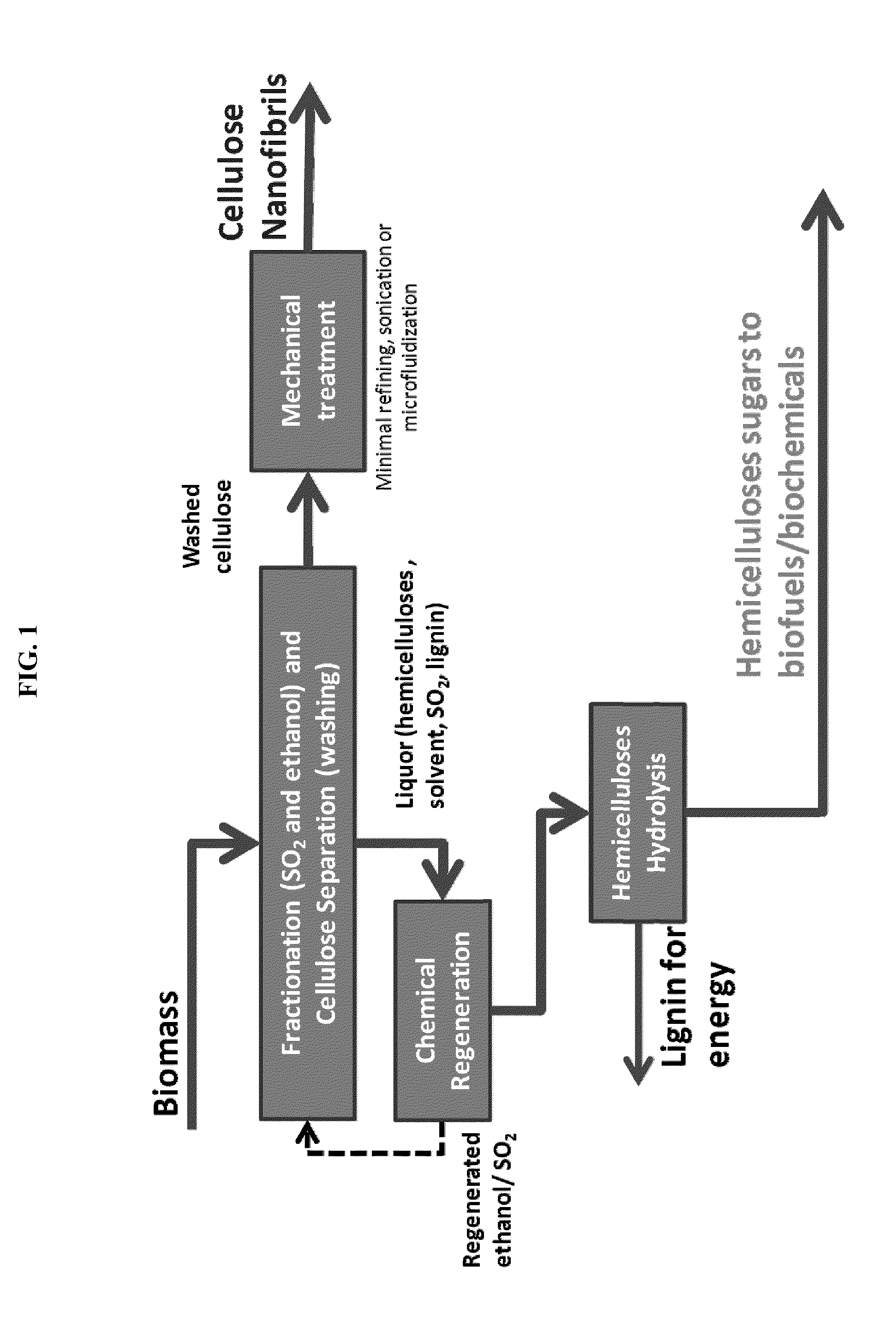

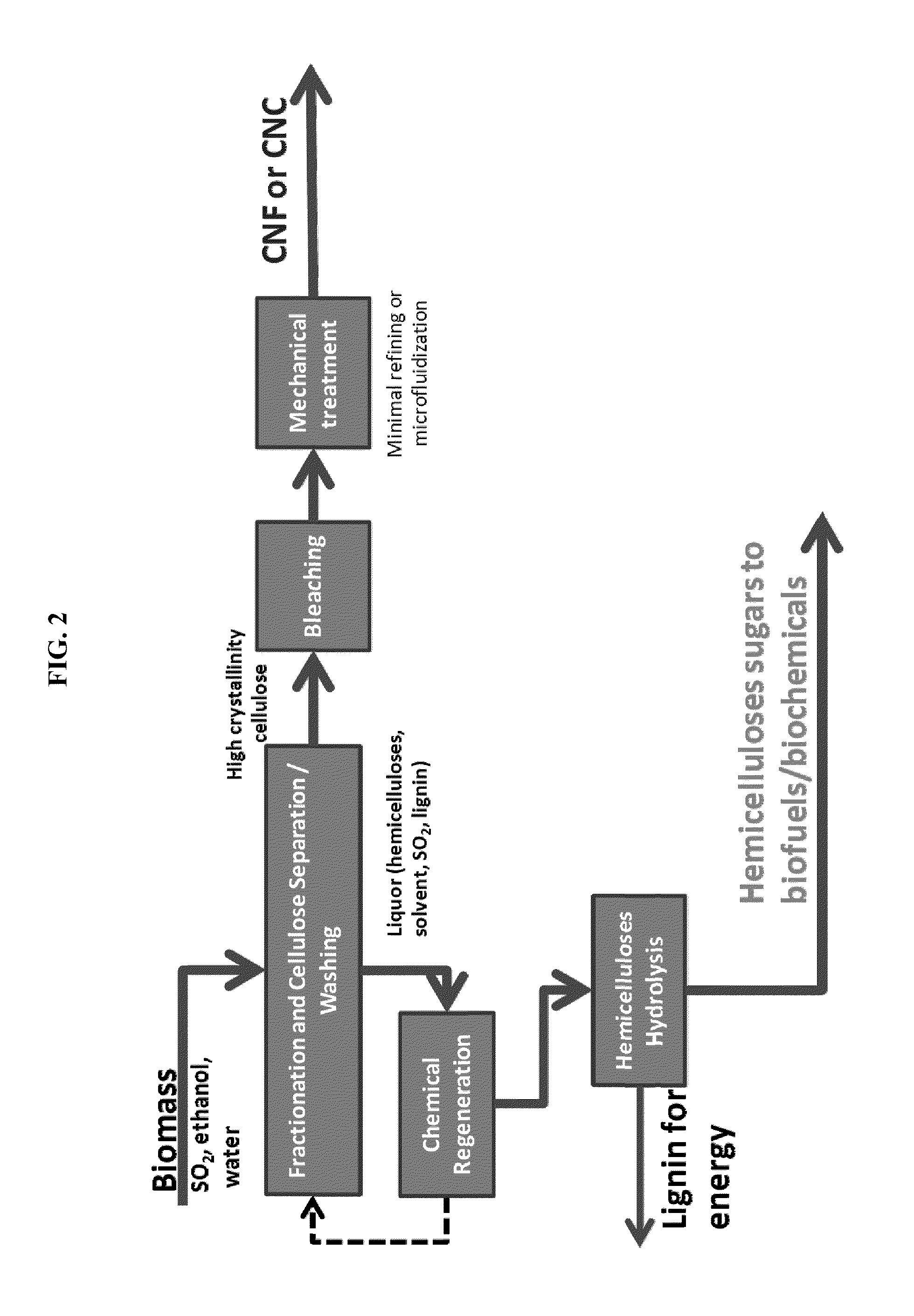

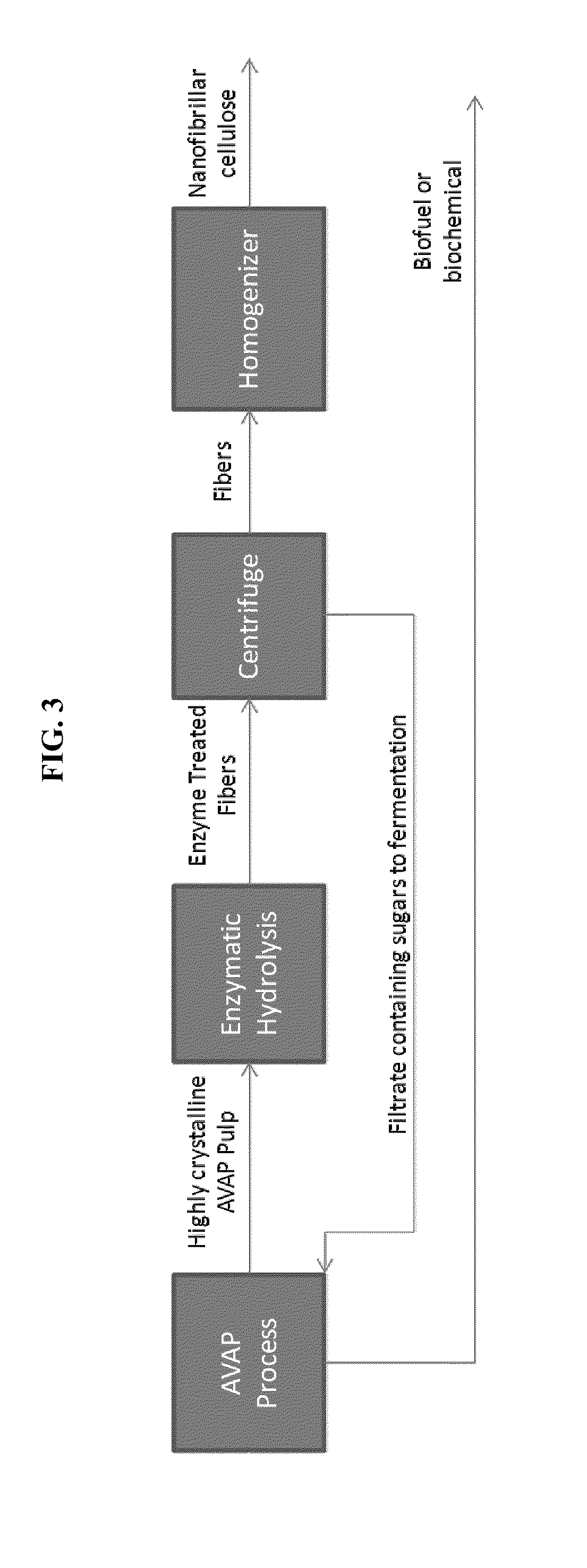

Method for the production of fermentable sugars and cellulose from lignocellulosic material

ActiveUS8030039B1High yieldIncreased ethanol yieldFats/resins/pitch/waxes removal in pulpPulping with organic compoundsOrganic acidAlcohol

A method for the production of fermentable sugars and high viscosity cellulose from lignocellulosic material in a batch or continuous process is provided. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals can be reused, lignin is separated for the production of process energy, and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Recyclable buffer for the hydrothermal hydrocatalytic treatment of biomass

InactiveUS20140166221A1Minimal lossMaintain activityPulp bleachingLiquid hydrocarbon mixture productionCelluloseHydrogen

A method of hydrothermal hydrocatalytic treating biomass is provided. Lignocellulosic biomass solids is provided to a hydrothermal digestion unit in the presence of a digestive solvent, at least one of ammonia or a source of ammonia, and a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co, Ni or mixture thereof, incorporated into a suitable support. The lignocellulosic biomass solids and digestive solvent are heated in the presence of hydrogen, supported hydrogenolysis catalyst and the at least one of ammonia or a source of ammonia forming a product solution containing plurality of oxygenated hydrocarbons and ammonia. At least a portion of ammonia is separated and recycled to the hydrothermal digestion unit.

Owner:SHELL OIL CO

Conversion of Lignocellulosic Biomass to Chemicals and Fuels

InactiveUS20080312346A1Pulp liquor regenerationOther chemical processesCelluloseLignocellulosic biomass

A method for preparing biomass for slurry processing. The method includes solubilizing the solid material into either a dissolved state or a suspended solid in a liquid phase, and treating the liquid phase to produce chemicals and fuels.

Owner:UOP LLC +1

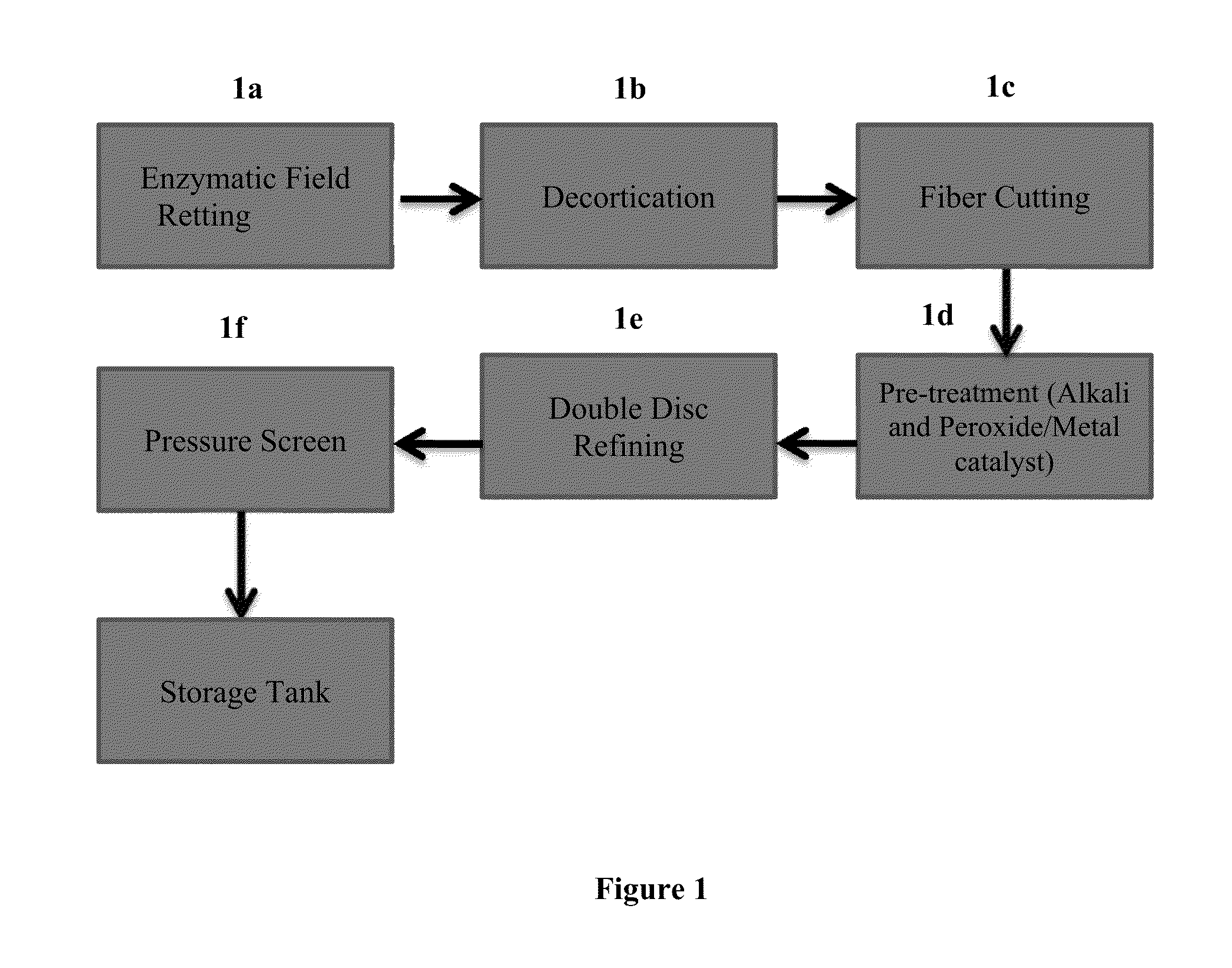

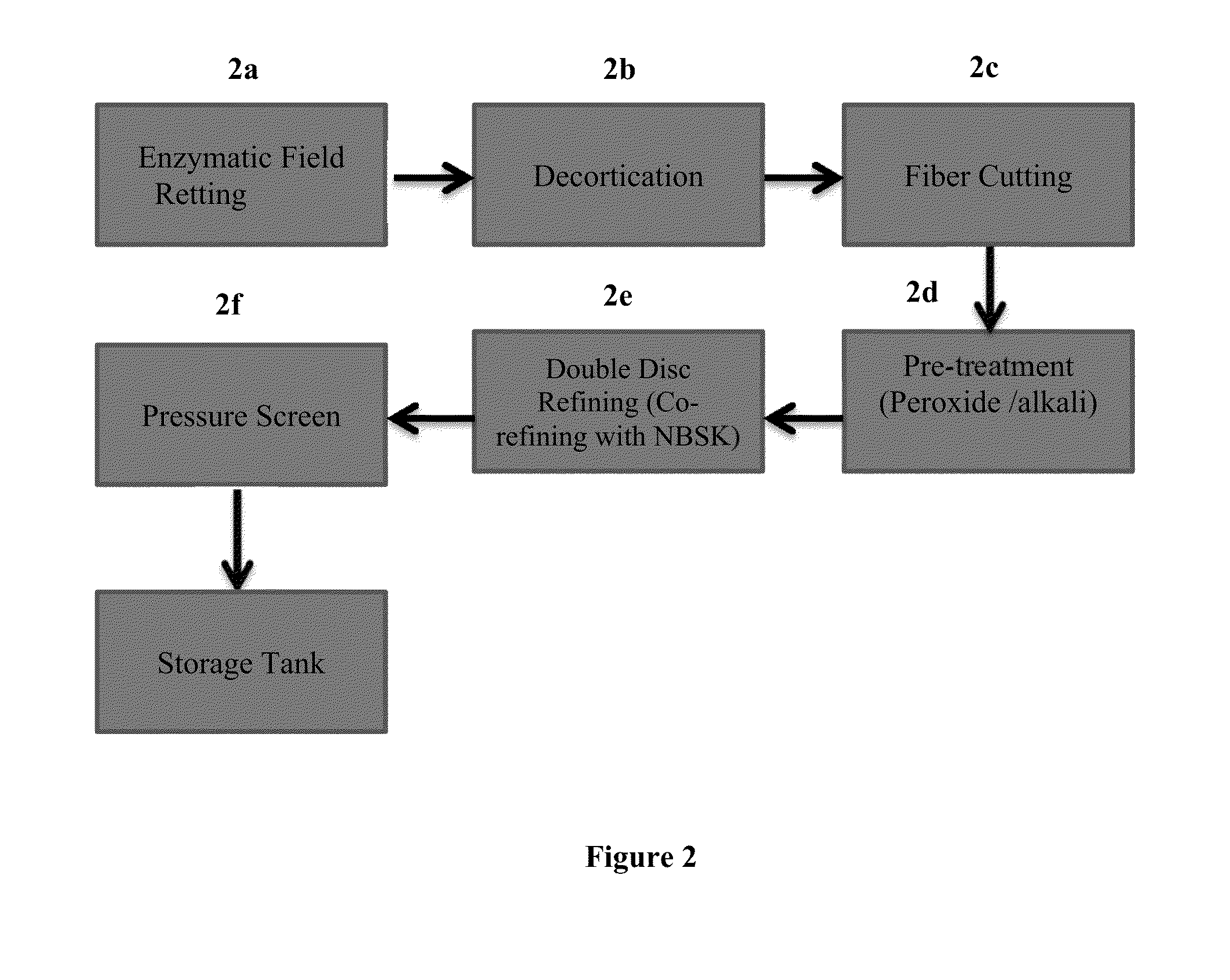

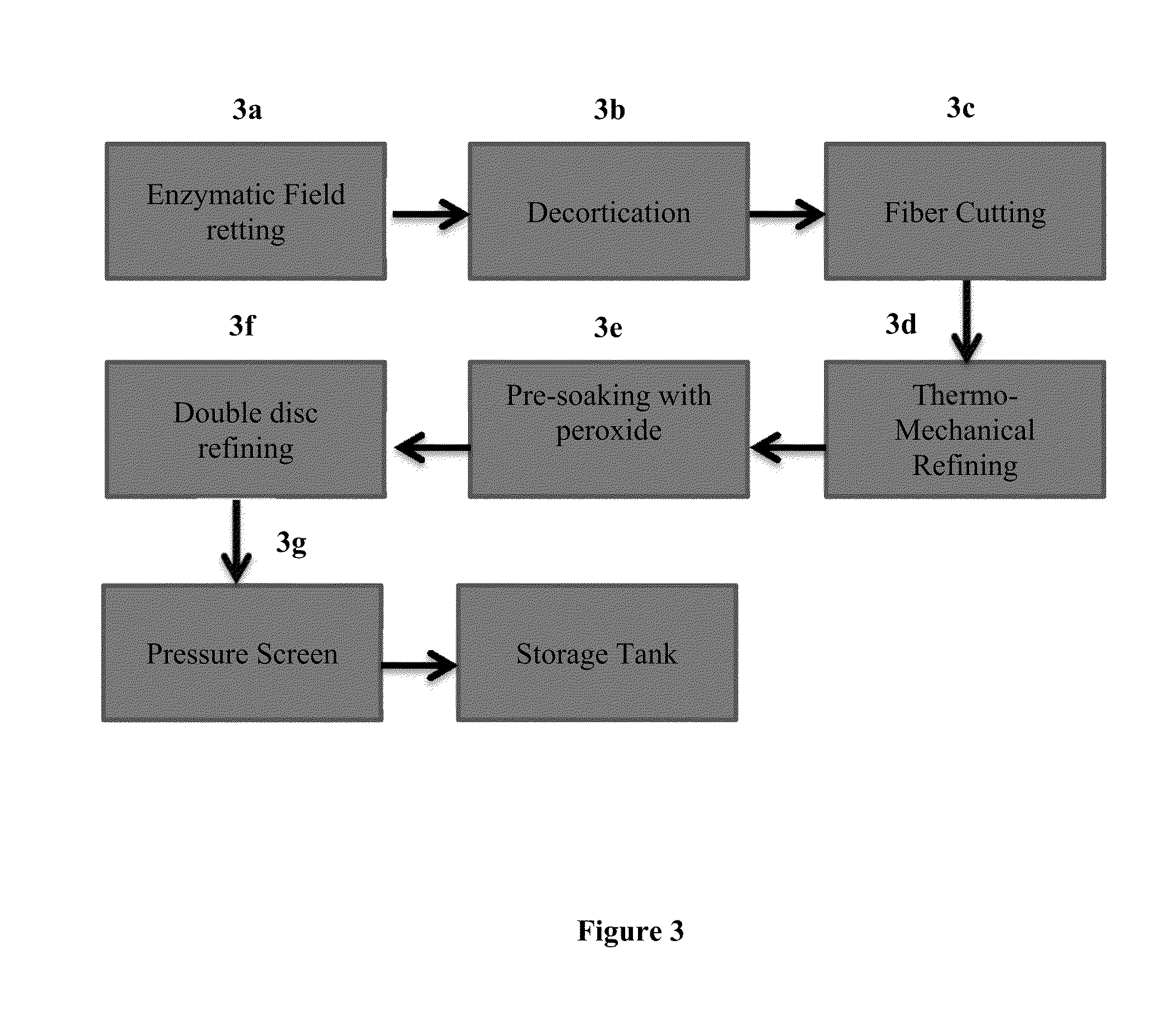

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS20160130762A1Reduce manufacturing costLose weightNon-fibrous pulp additionPaper after-treatmentCelluloseBleach

A method to prepare, pulp, and bleach cannabis bast and hurd fibers to allow for the fiber to be incorporated into absorbent cellulosic structures on a wet-laid paper machine while keeping the pectin within the fibers. The wet laid paper machine can use the ATMOS, NTT, ETAD, TAD, or UCTAD method to produce the absorbent cellulosic structure. Absorbent cellulosic structures are produced with the cannabis bast and hurd fibers or with the bast fibers alone with the hurd fibers being combined with paper mill sludge or dust to form a fuel pellet.

Owner:FIRST QUALITY TISSUE

Process for the conversion of biomass to liquid fuels and specialty chemicals

The present invention relates to the conversion of solid biomass to liquid fuels and specialty chemicals. The process utilizes an activating step to make the biomass more susceptible to conversion, that is the biomass is broken down such that the components of the biomass are dissociated. Subsequently, the activated biomass undergoes a reaction to convert it to a bio-oil.

Owner:MARD INC

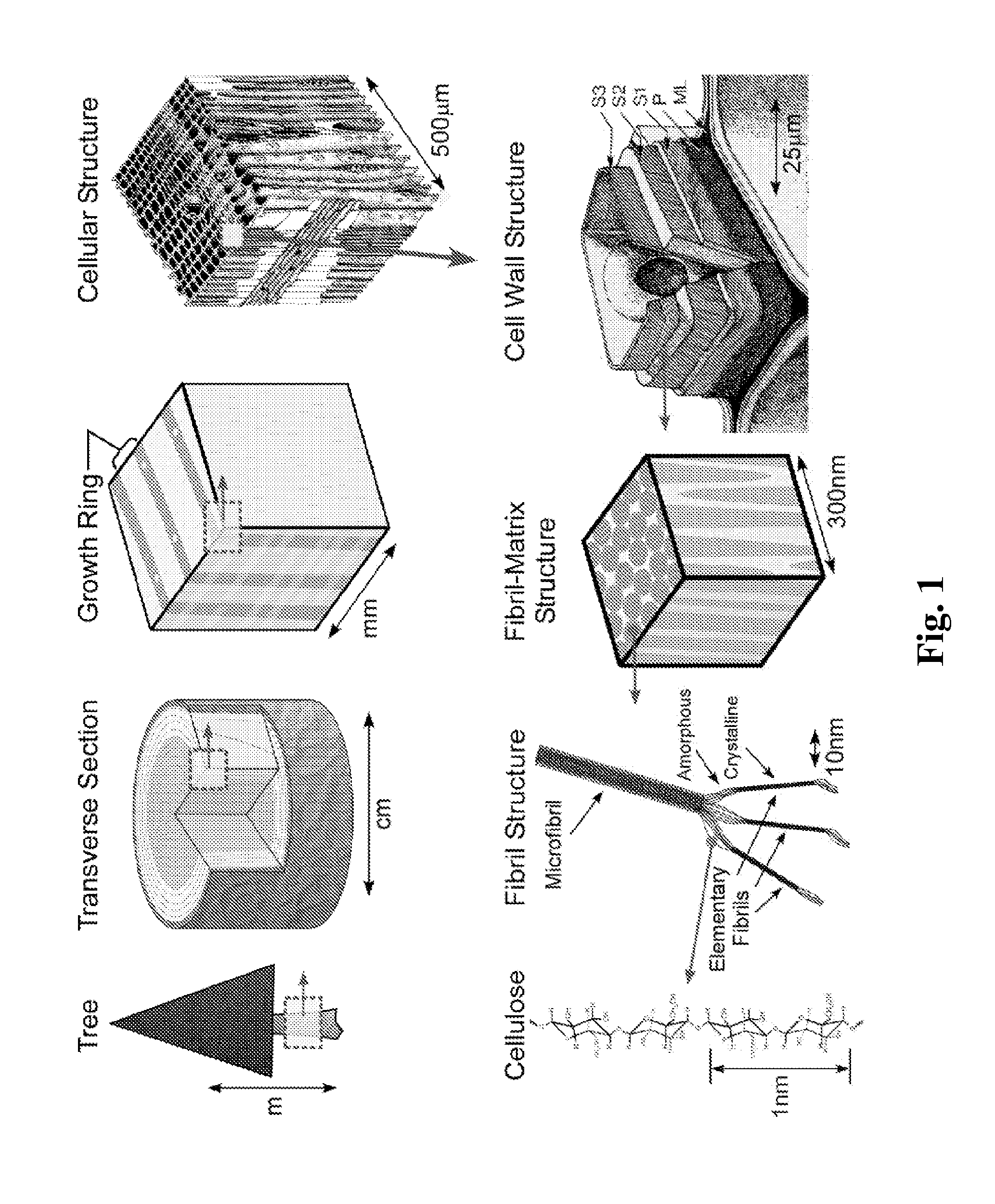

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

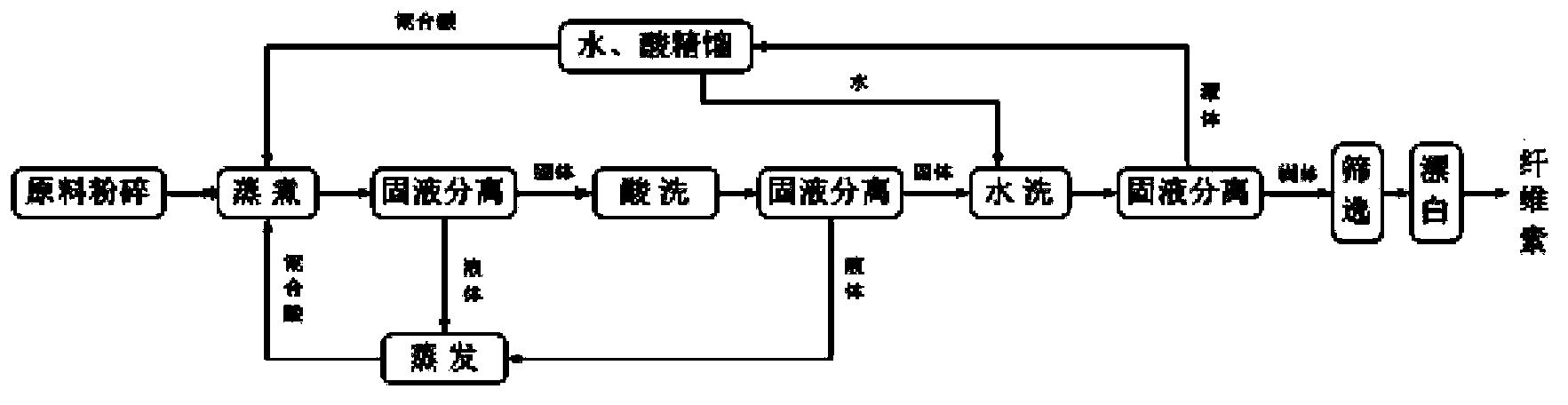

Technology for extracting cellulose from biomass raw materials

ActiveCN103898782AHigh purityReduce cooking timePulp bleachingPulping with acid salts/anhydridesAcetic acidOrganic acid

The invention relates to a cellulose extracting technology, and specifically relates to a technology that utilizes organic acids to extract cellulose from biomass raw materials in the presence of a hydrogen peroxide catalyst. The technology comprises the following steps: in the presence of a hydrogen peroxide catalyst, utilizing an organic acid to cook biomass raw materials, wherein the organic acid is composed of formic acid with a concentration of 70 to 95 wt% and acetic acid with a concentration of 70 to 95 wt%; extracting and screening so as to obtain screened cellulose pulp; and further bleaching the screened pulp so as to obtain the target cellulose; wherein the cellulose is dissolving pulp or industrial cellulose. The alpha-cellulose content of the cellulose obtained by the method provided by the invention is more than 90 wt%. The technology has the advantages of simple route and low energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

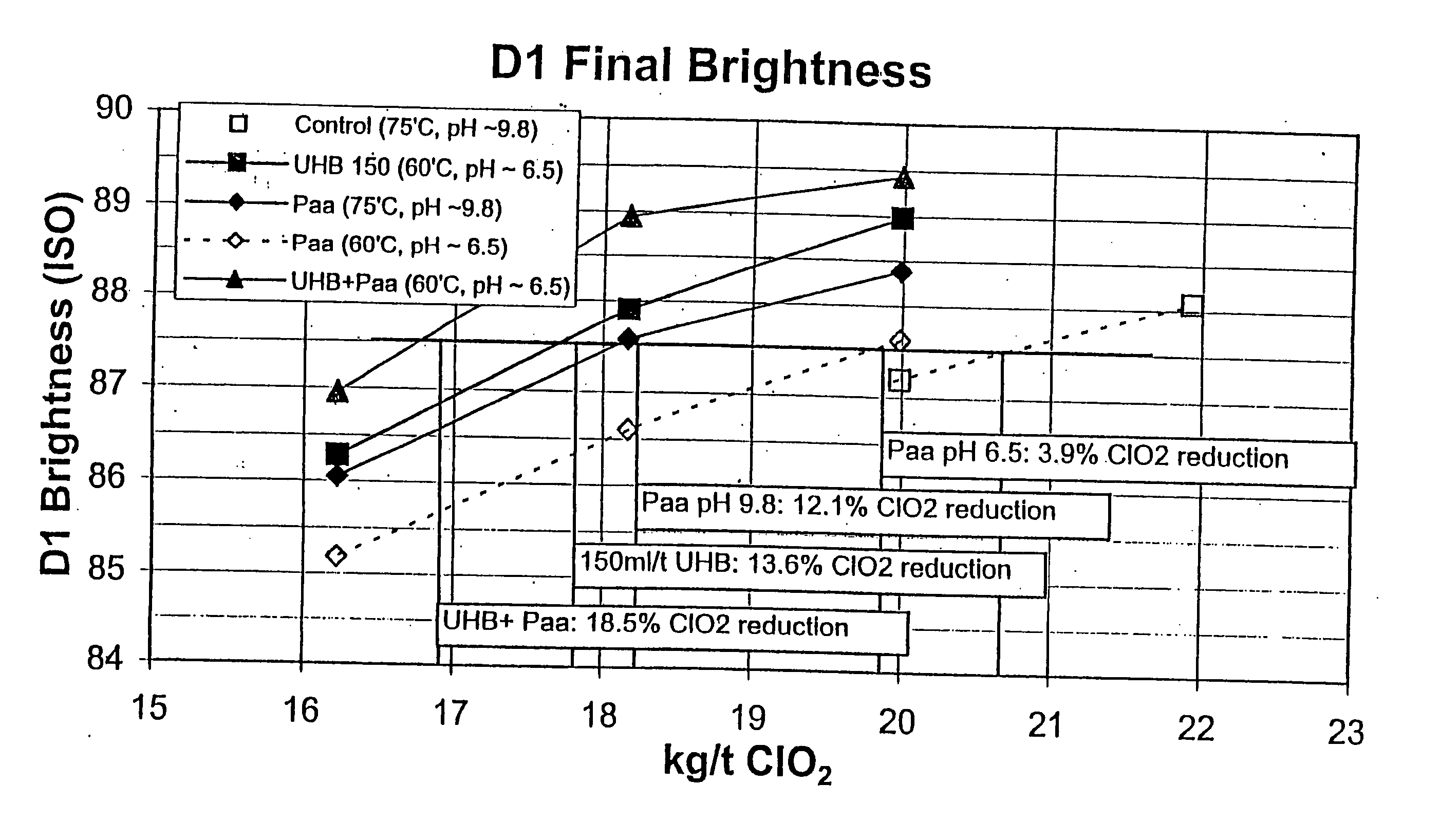

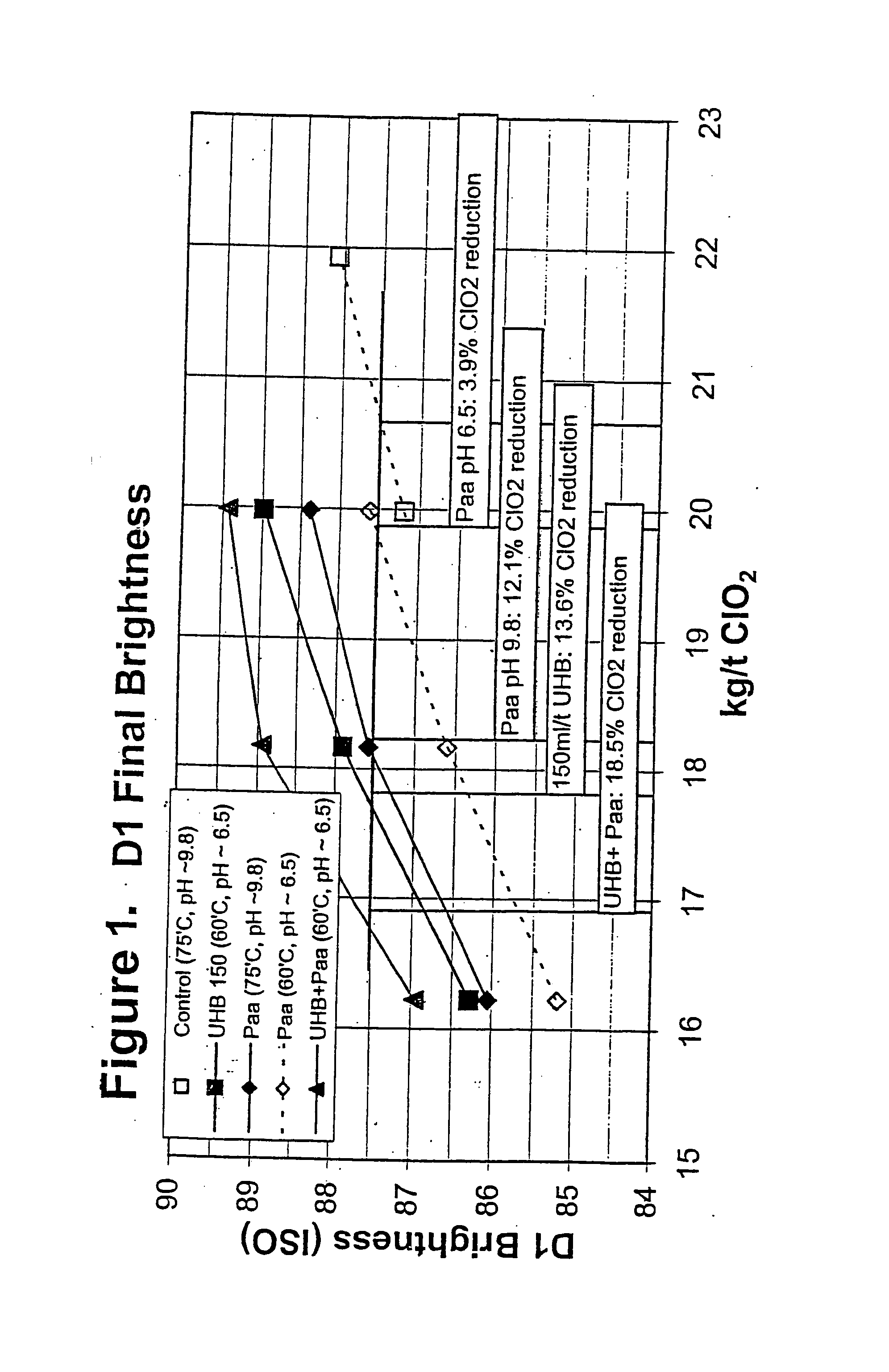

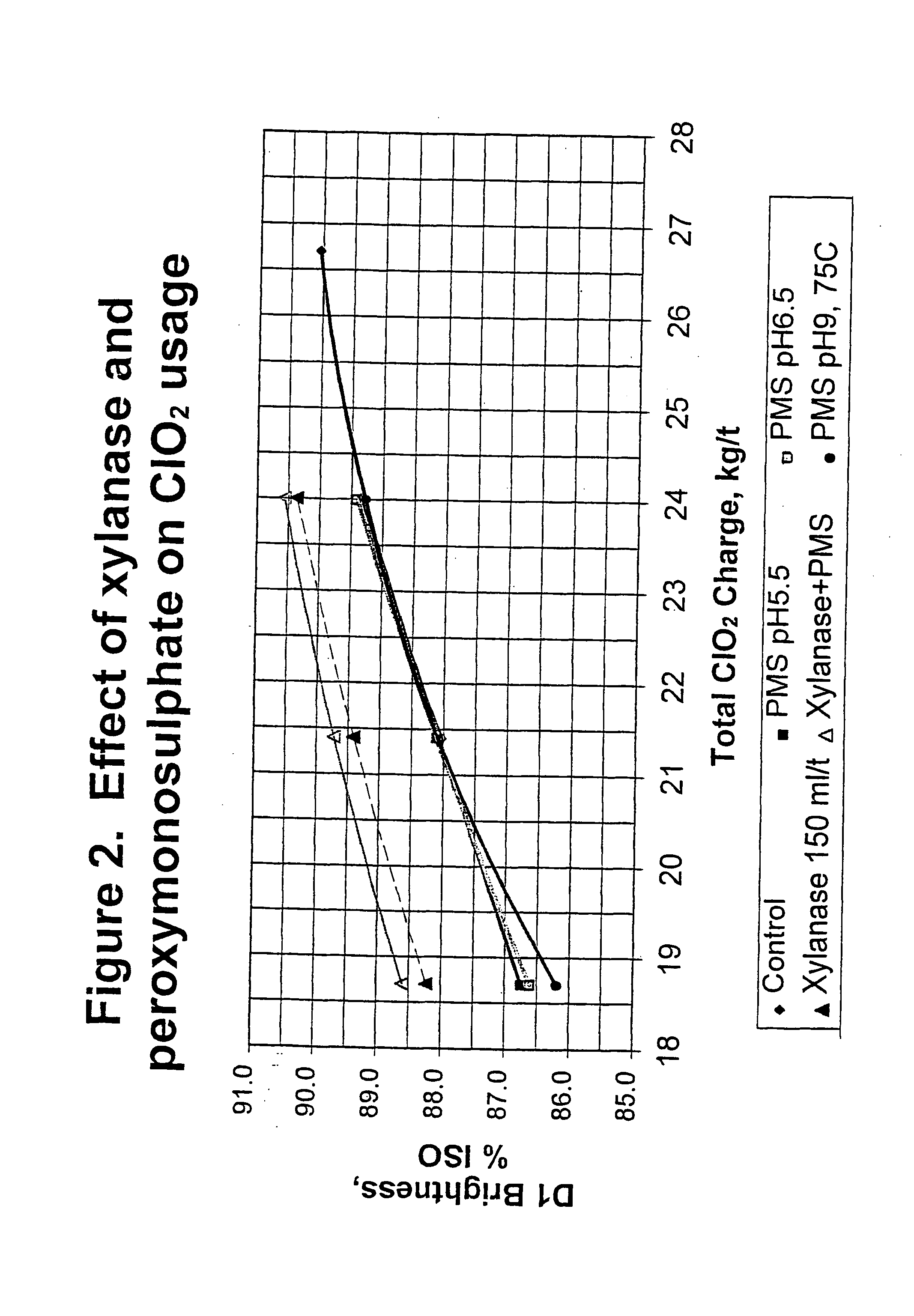

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

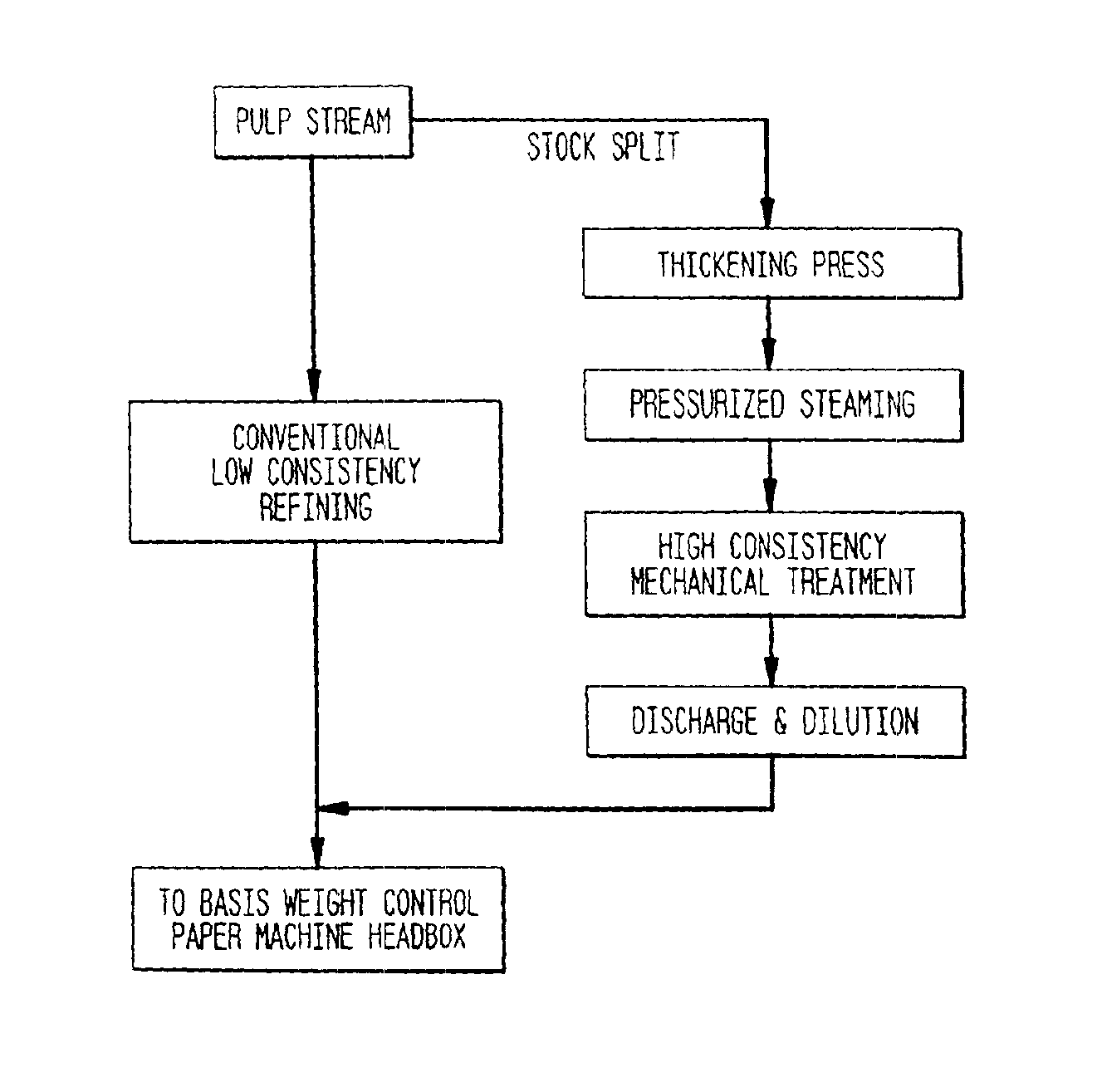

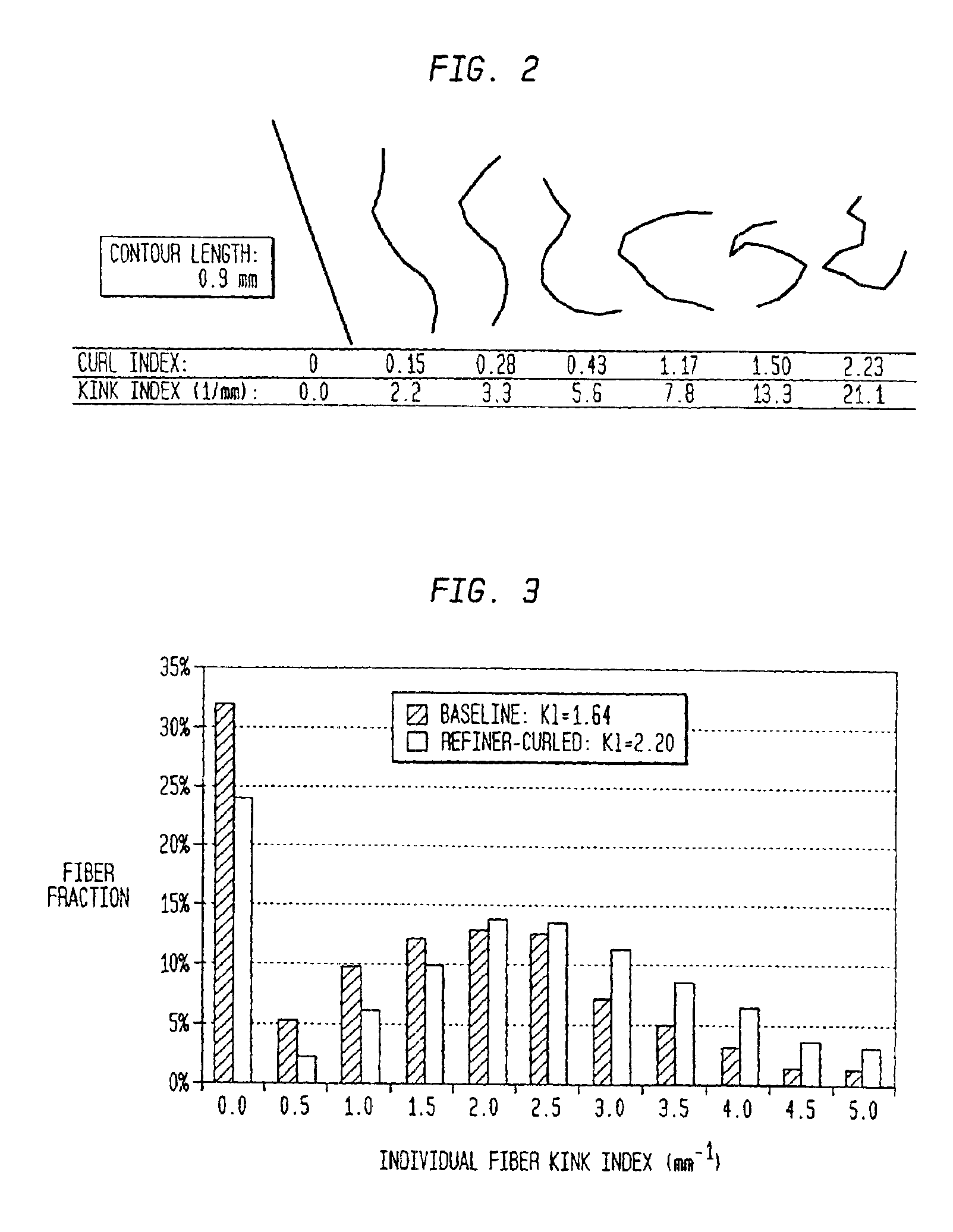

Method of providing papermaking fibers with durable curl

A process for producing high bulk cellulosic fiber exhibiting a durable elevated curl index includes: (a) concurrently heat treating and convolving cellulosic fiber pulp at elevated temperature and pressure at high consistency under conditions selected so as to preclude substantial fibrillation and attendant paper strength and fiber bonding development; and (b) recovering the pulp wherein the length weighted curl index of the treated fiber is at least about 20% higher than the length weighted curl index of the fiber prior to the heat treatment and convolving thereof. The curl imparted to the fiber persists upon treatment for 30 minutes in a laboratory disintegrator at 3000 rpm at 1% consistency at a temperature of 125° F. Moreover, the curl may be imparted to the fiber in a disk refiner at very short residence times, on the order of several seconds or less. In general, the process is carried out in the presence of saturated steam at a pressure of from about 5 to about 150 psig.

Owner:GPCP IP HLDG LLC

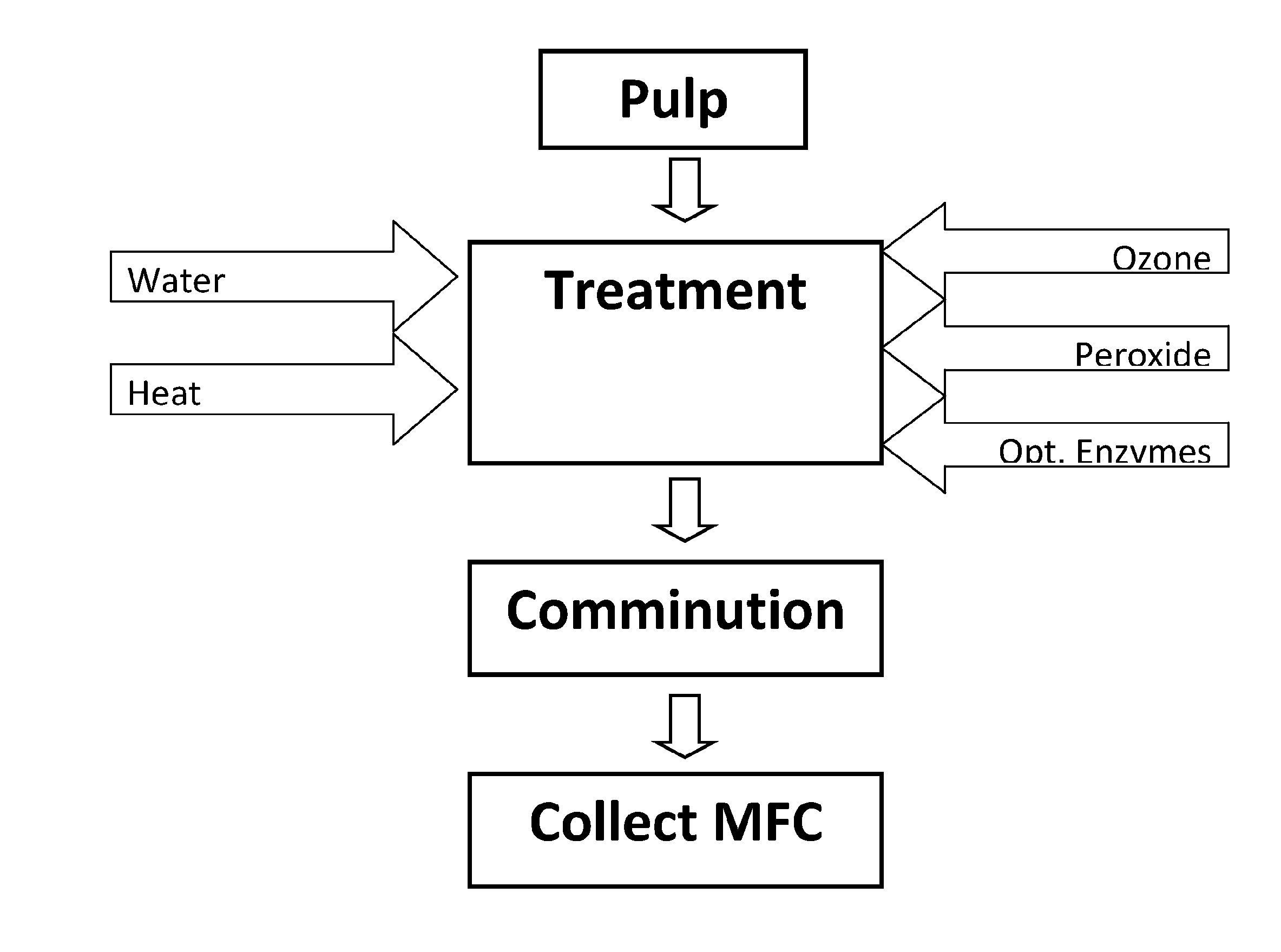

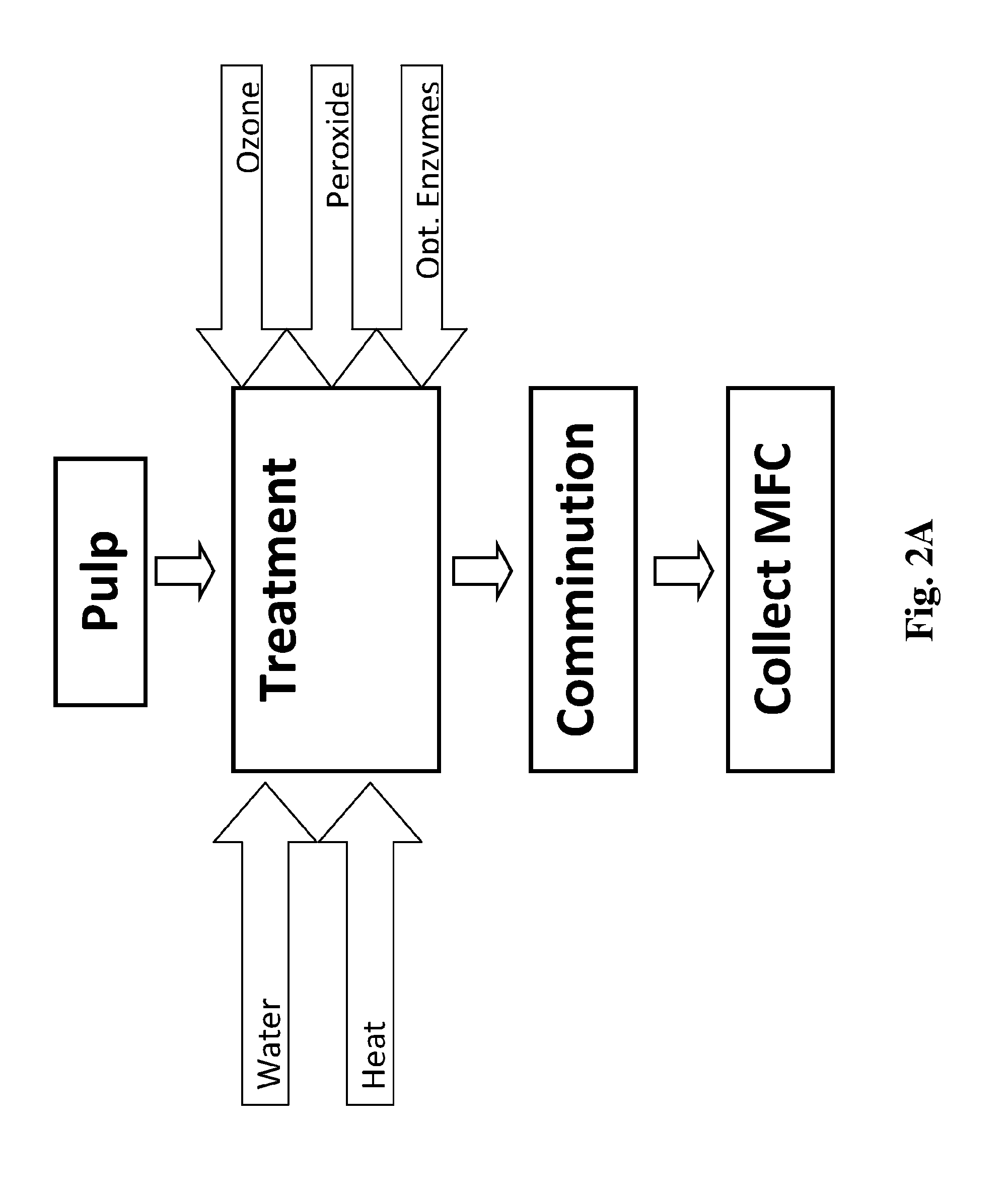

Energy Efficient Process for Preparing Nanocellulose Fibers

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

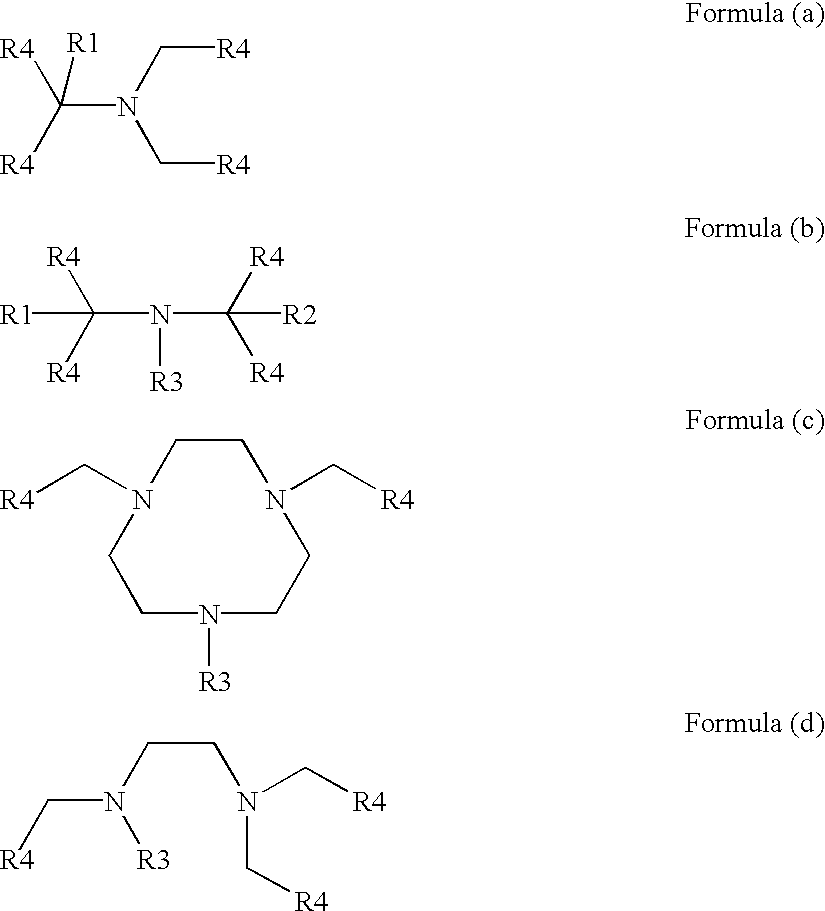

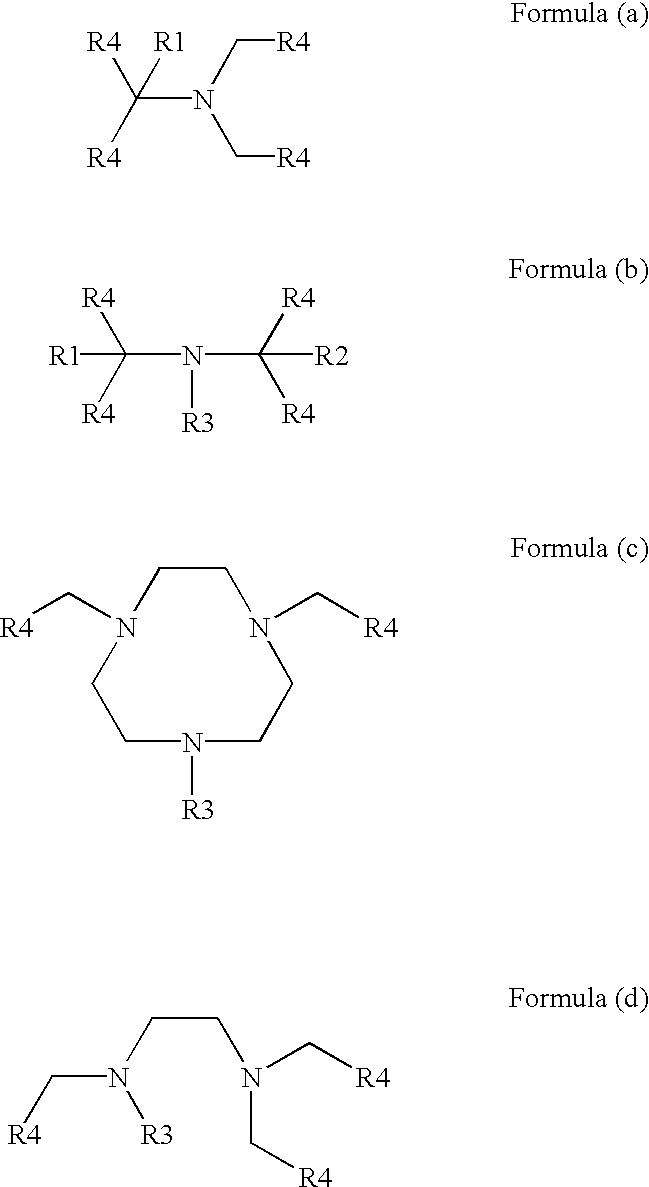

Transition metal complexes with polydentate ligands for enhancing the bleaching and delignifying effect of peroxo compounds

InactiveUS20020066542A1Surpass delignifyingSurpass bleachingPulp bleachingPulping with organic solventsAqueous solutionCobalt

Transition metal complex compounds of polydentate ligands with improved delignifying and bleaching performance. These polydentate ligands are organic ligands which, in aqueous solution and in the presence of atmospheric oxygen, or hydrogen peroxide, form a complex with a transition metal, in particular cobalt. The complexes are mono- or polynuclear and they have, when peroxo compounds are used, better delignifying and bleaching performances than conventional transition metal complex compounds. A delignifying and bleaching method, in which these transition metal complex compounds with polydentate ligands having improved delignifying and bleaching performance are used as catalysts, is also described.

Owner:DEGUSSA AG

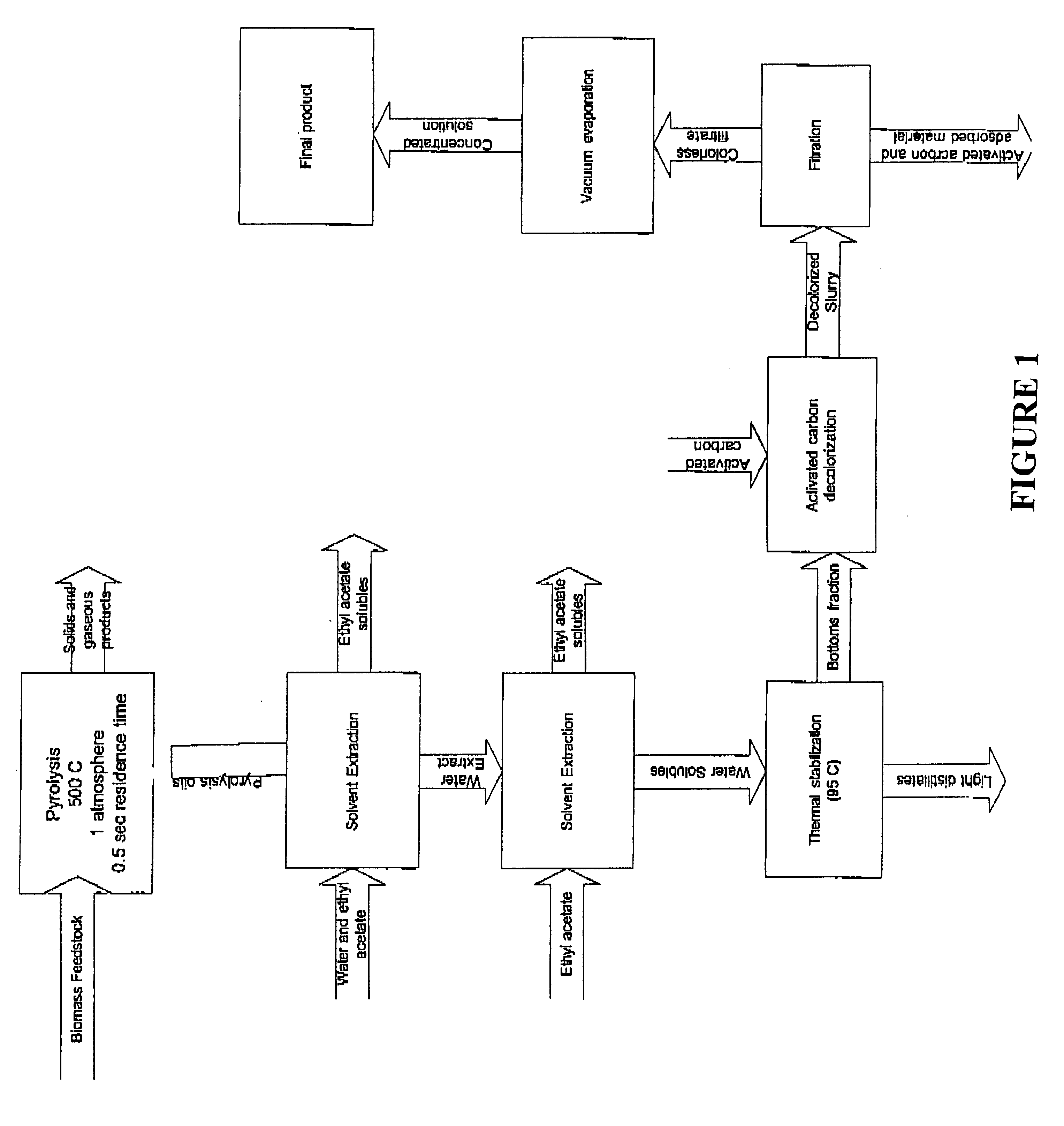

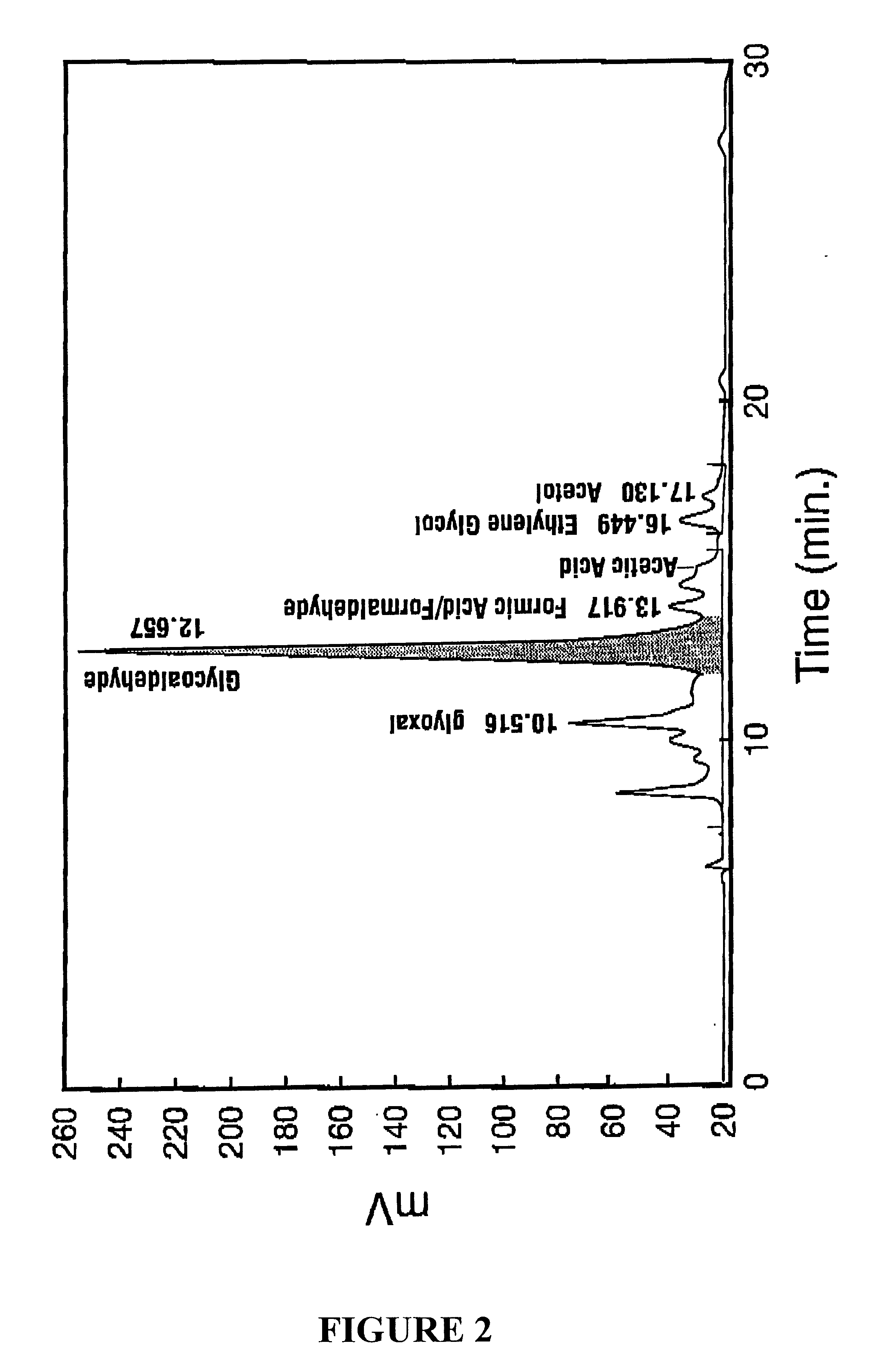

Preparation of brightness stabilization agent for lignin containing pulp from biomass pyrolysis oils

A process for producing a brightness stabilization mixture of water-soluble organic compounds from biomass pyrolysis oils comprising:a) size-reducing biomass material and pyrolyzing the size-reduced biomass material in a fluidized bed reactor;b) separating a char / ash component while maintaining char-pot temperatures to avoid condensation of pyrolysis vapors;c) condensing pyrolysis gases and vapors, and recovering pyrolysis oils by mixing the oils with acetone to obtain an oil-acetone mixture;d) evaporating acetone and recovering pyrolysis oils;e) extracting the pyrolysis oils with water to obtain a water extract;f) slurrying the water extract with carbon while stirring, and filtering the slurry to obtain a colorless filtrate;g) cooling the solution and stabilizing the solution against thermally-induced gelling and solidification by extraction with ethyl acetate to form an aqueous phase lower layer and an organic phase upper layer;h) discarding the upper organic layer and extracting the aqueous layer with ethyl acetate, and discarding the ethyl acetate fraction to obtain a brown-colored solution not susceptible to gelling or solidification upon heating;i) heating the solution to distill off water and other light components and concentrating a bottoms fraction comprising hydroxyacetaldehyde and other non-volatile components having high boiling points; andj) decolorizing the stabilized brown solution with activated carbon to obtain a colorless solution.

Owner:MIDWEST RES INST

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

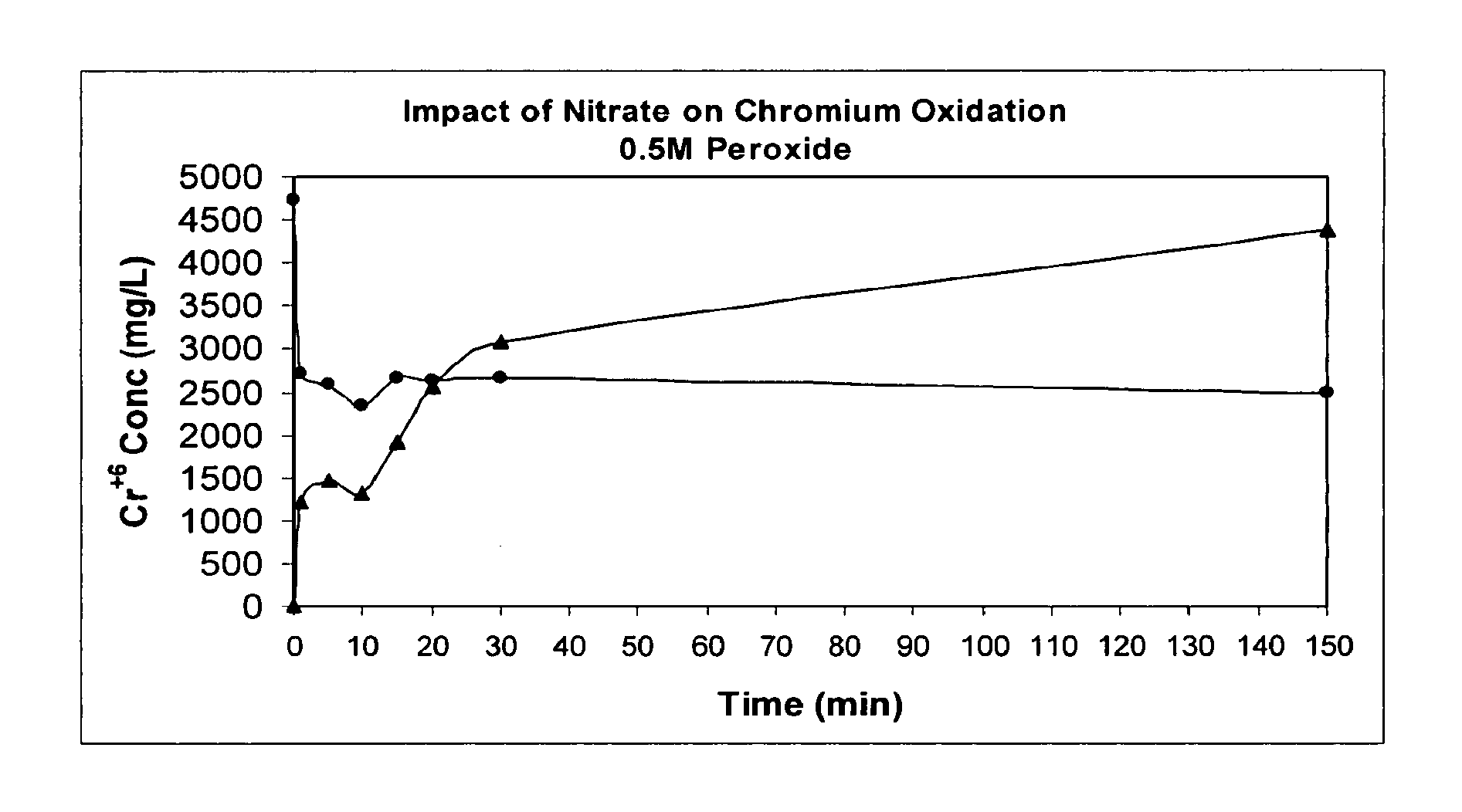

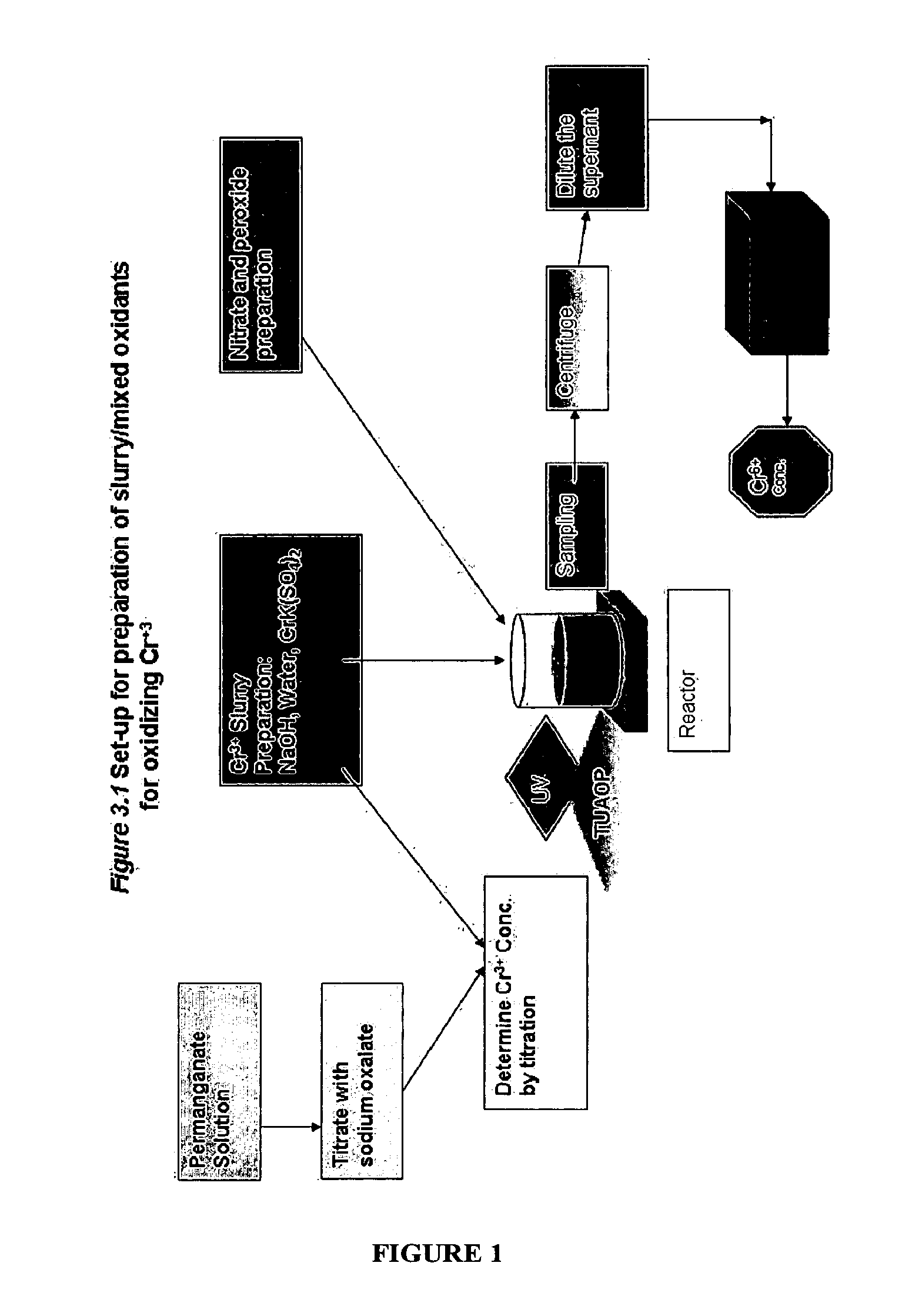

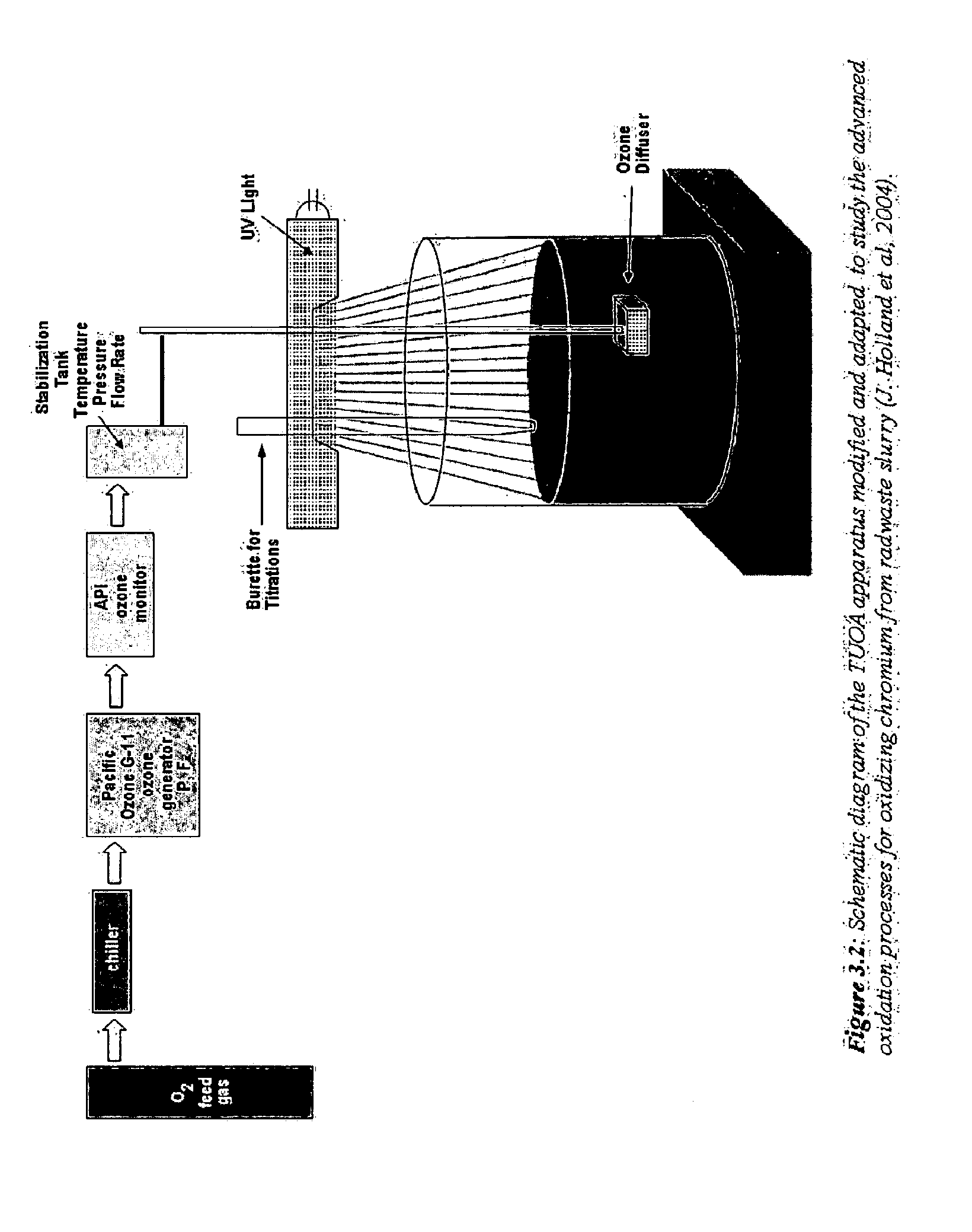

Oxidative Treatment Method

InactiveUS20100320156A1Quickly and efficiently decomposeEffective treatmentWater/sewage treatment by irradiationDecorative surface effectsElectrolysisWaste stream

The present invention provides a method for oxidizing a substance (e.g., in a waste stream, drinking water, a paper pulp slurry, or on a surface), which uses free radicals and reactive species generated from multiple oxidants. The method comprises combining peroxynitrite or peroxynitrous acid and at least one additional oxidizing agent for a period of time sufficient to oxidize the substance of interest. The peroxynitrite or peroxynitrous acid preferably is formed by irradiation of nitrate ion and / or nitric acid (e.g., with UV or gamma rays). The yield of free radicals and reactive species, which are the intermediate species that perform the oxidation may be increased by addition of a catalysts, electromagnetic radiation, sonic waves, and / or electrolysis.

Owner:TULANE EDUCATIONAL FUND

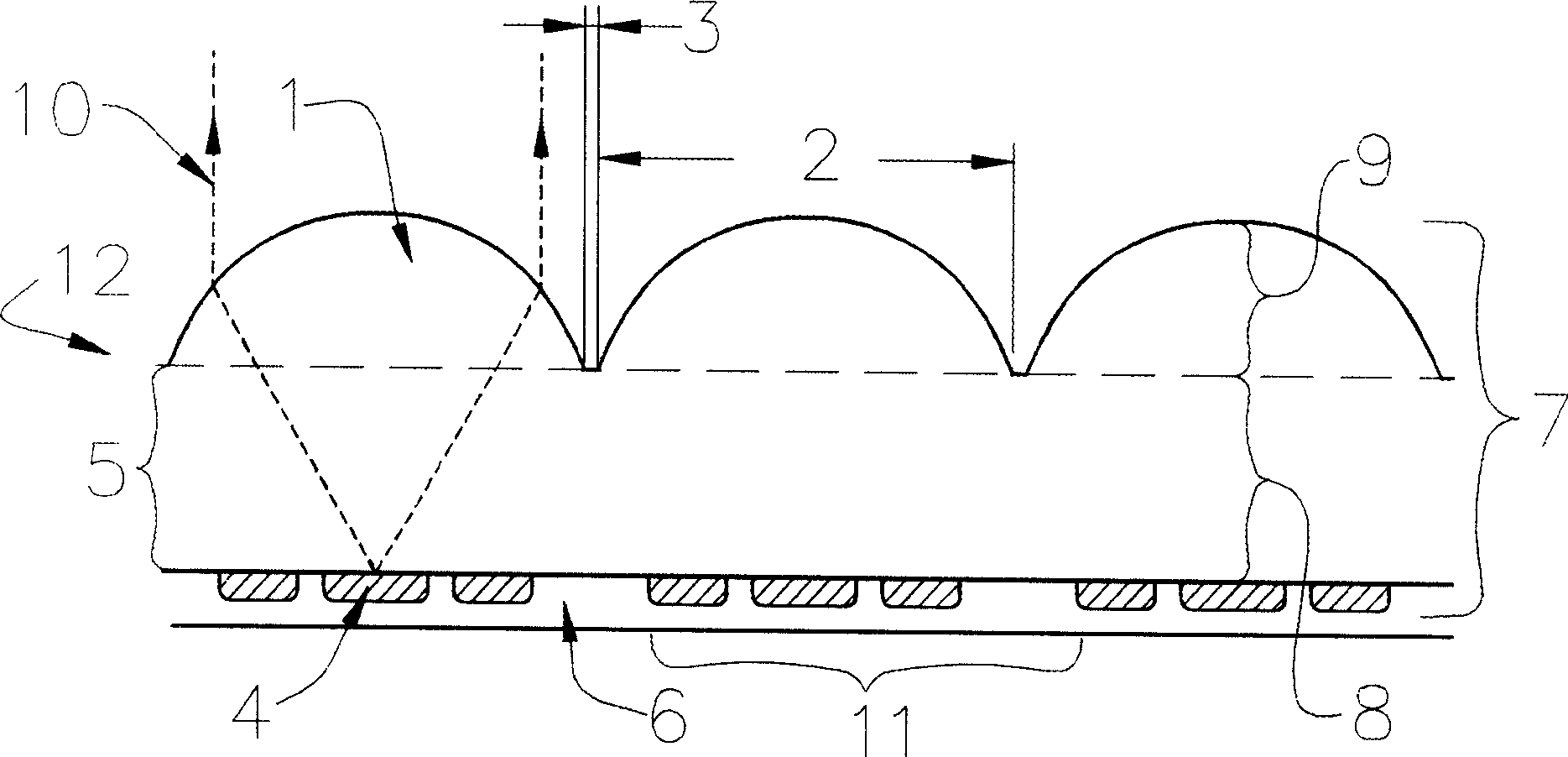

Image presentation and micro-optic security system

Am image presentation system employing microstructured icon elements to form an image. In one form a synthetic optical image system is provided that includes an array of focusing elements, and an image system that includes or is formed from an array or pattern of microstructured icon elements, such as those described below, wherein the microstructured icon elements are designed to collectively form an image or certain desired information, and wherein the array of focusing elements and the image system cooperate, for example through optical coupling, to form a synthetic optical image which image may optionally be magnified. In another form an image presentation system is provided that includes or is formed from an array or pattern of microstructured icon elements, such as those described below, wherein the microstructured icon elements are designed to collectively form an image or certain selected information, and wherein the image system is designed to stand alone and be the image viewed or the information read by use of a magnifying device, such as a magnifying glass or microscope, that is provided separately from the image system.

Owner:VISUAL PHYSICS LLC (US)

Chemical method for lignin depolymerization

InactiveUS6214976B1Improve efficiencyWithout major damage to cellulosePulp bleachingLignin derivativesDepolymerizationAqueous solution

A process for depolymerizing and / or chemically modifying lignin or lignin-like compounds in which a solution of copper and peroxide acts on lignin and / or lignin-like substance at a temperature of less than 100° C., characterized in that the solution is an aqueous solution containing copper or a copper complex, a coordination compound and peroxide and wherein the concentration of the copper or copper complex is between 0.001% and 5%, and wherein the concentration of the coordination compound is lower than 20% and wherein the concentration of peroxide is between 0.01% and 20%.

Owner:ANNIKKI GMBH +1

Process of producing high-yield pulp

The present invention relates to a process for preparing a high-yield pulp comprising a) treating a lignocellulose containing material chemically by means of an oxidising system comprising at least one non-enzymatic oxidant substantially free from ozone and chlorine dioxide and an activator at a pH from about 2 to about 6.5; and b) treating the lignocellulose containing material mechanically for a time sufficient to produce a high-yield pulp, wherein the lignocellulose containing material is chemically treated prior to and / or during any mechanical treatment stage, and wherein the lignocellulose containing material is not chemically treated at a pH from about 11.5 to about 14 between stages a) and b).

Owner:AKZO NOBEL CHEM INT BV

Compositions and processes for paper production

ActiveUS20080017337A1Avoid brightness lossIncrease brightnessNatural cellulose pulp/paperSpecial paperPaper productionPapermaking

Oxidative compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The oxidative composition and method maintains and / or enhances brightness, prevents yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the oxidative agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

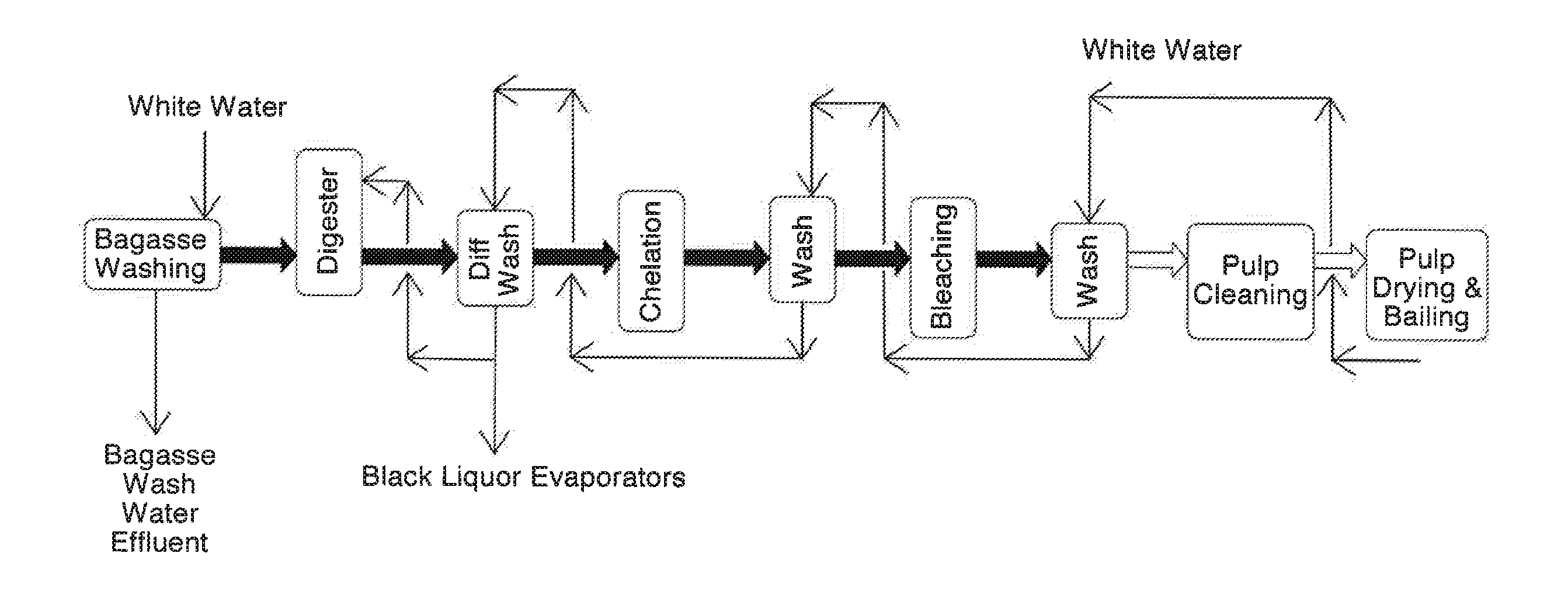

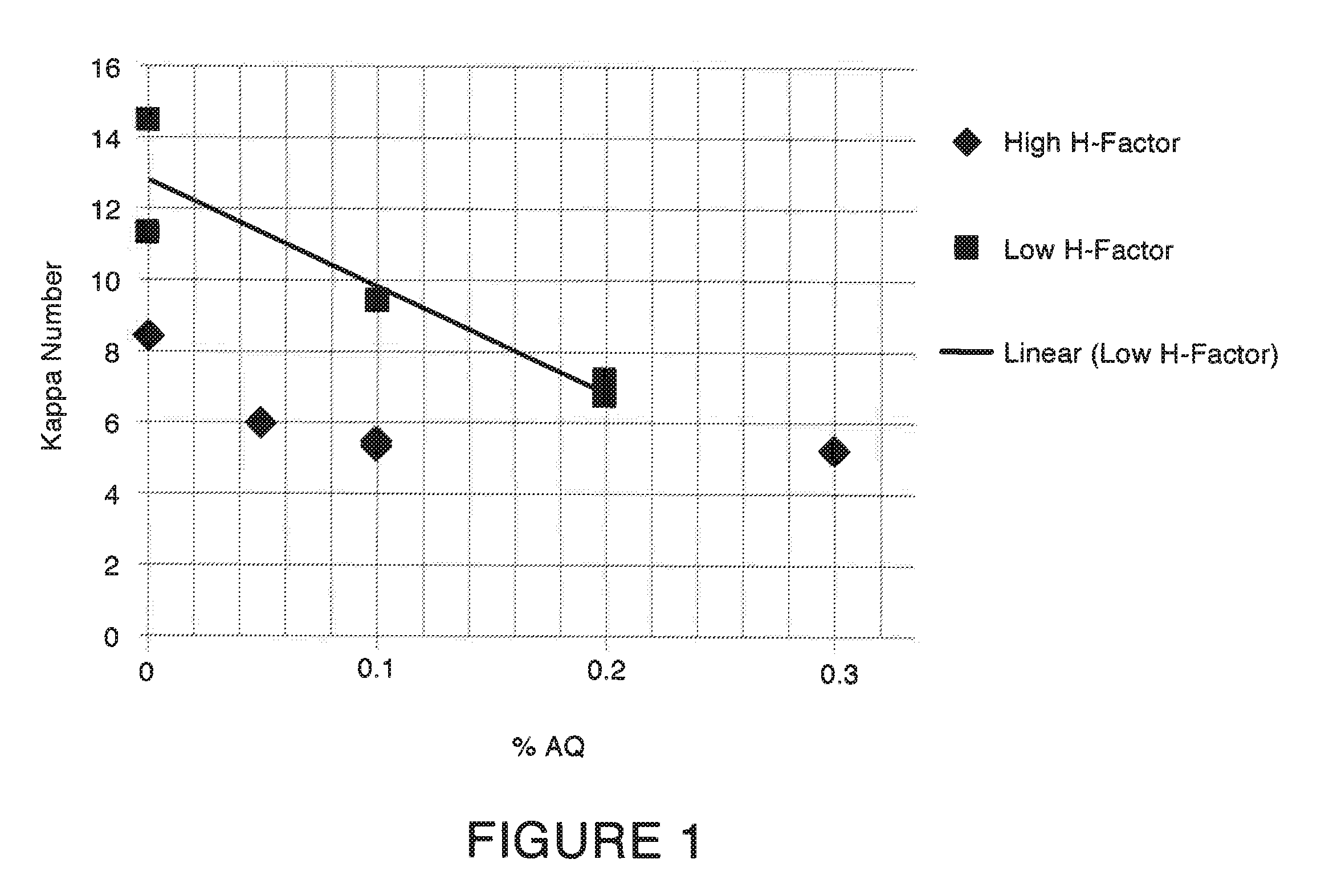

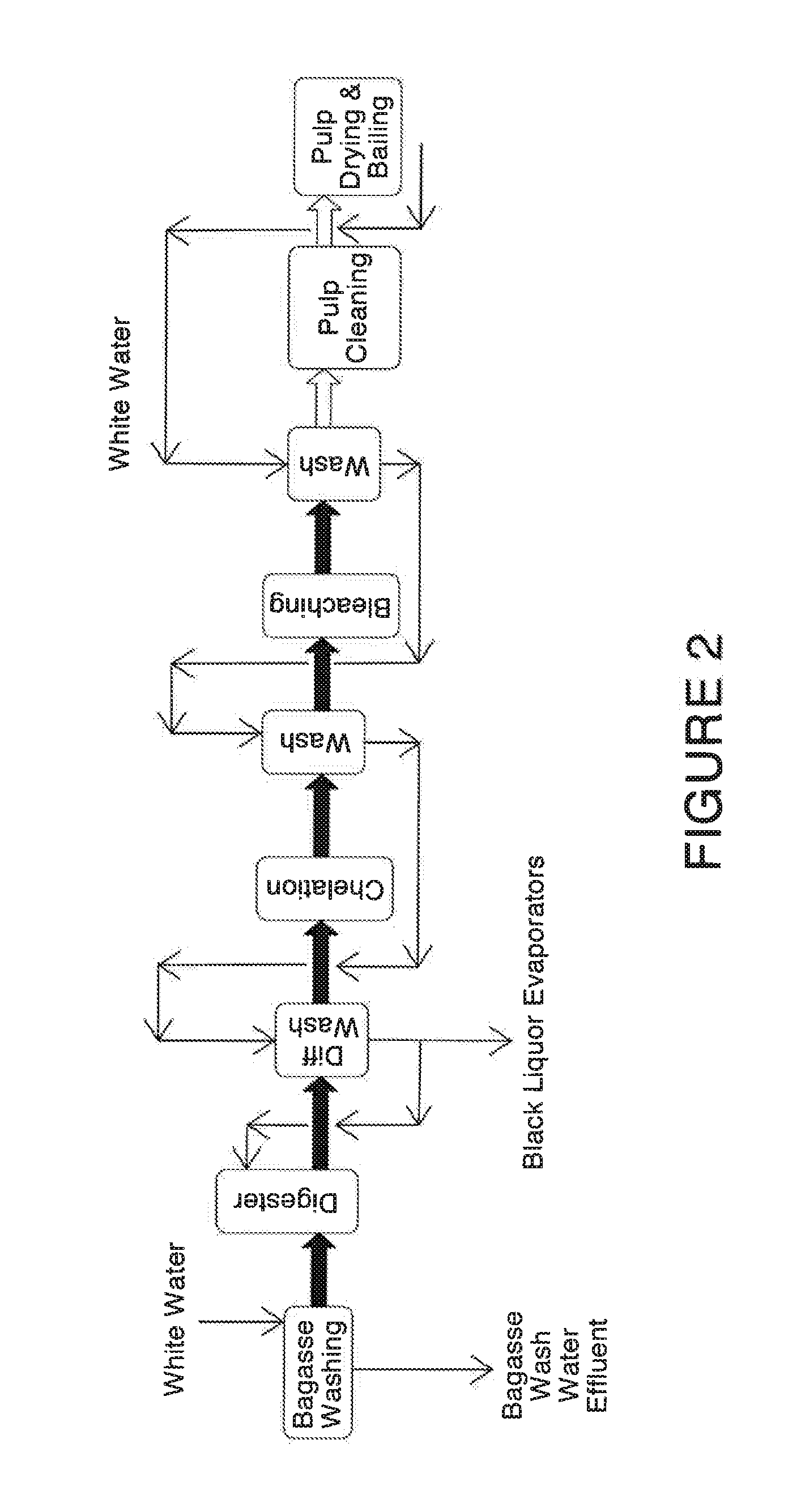

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com