Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

226results about "Pretreatment with acid reacting compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

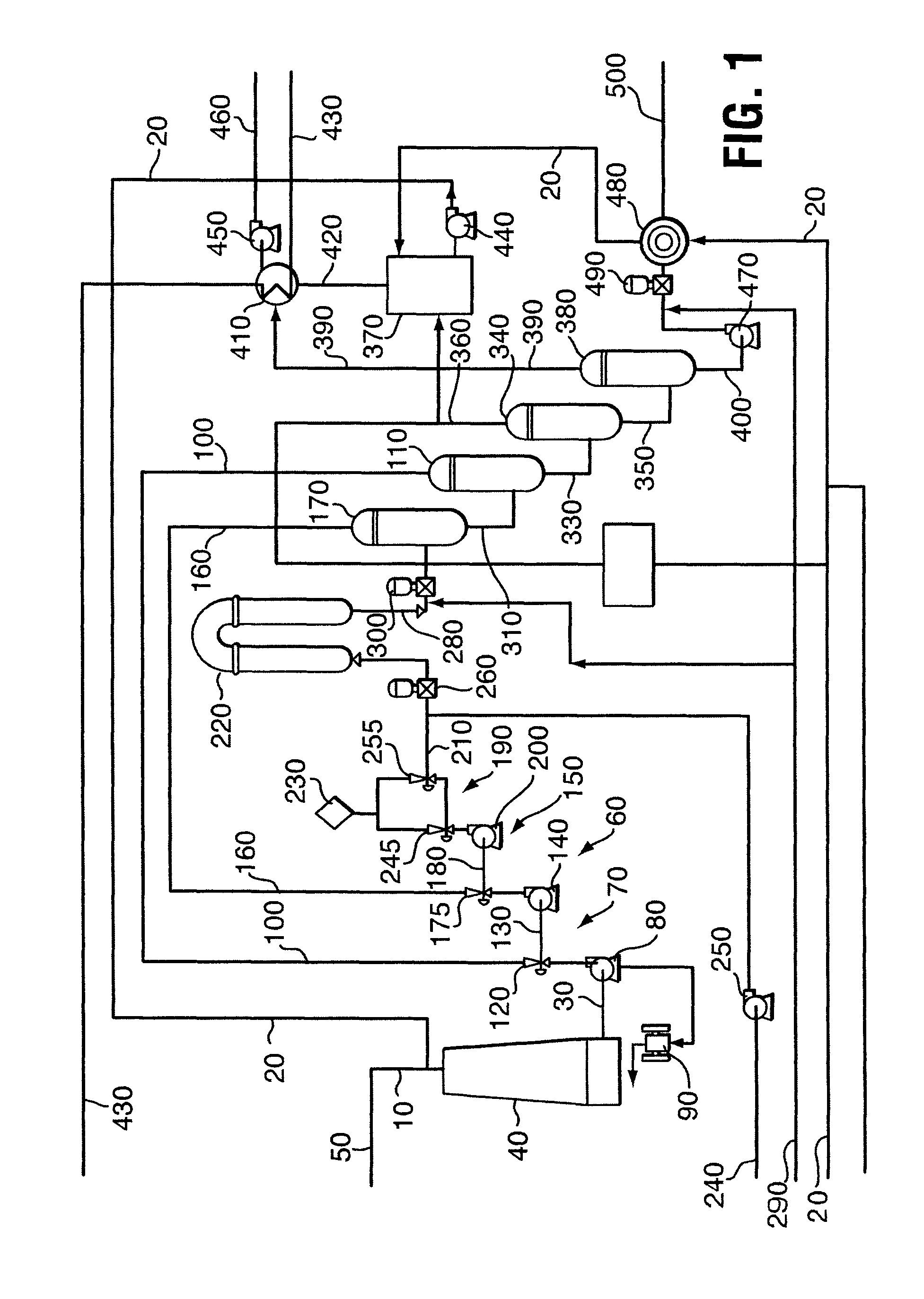

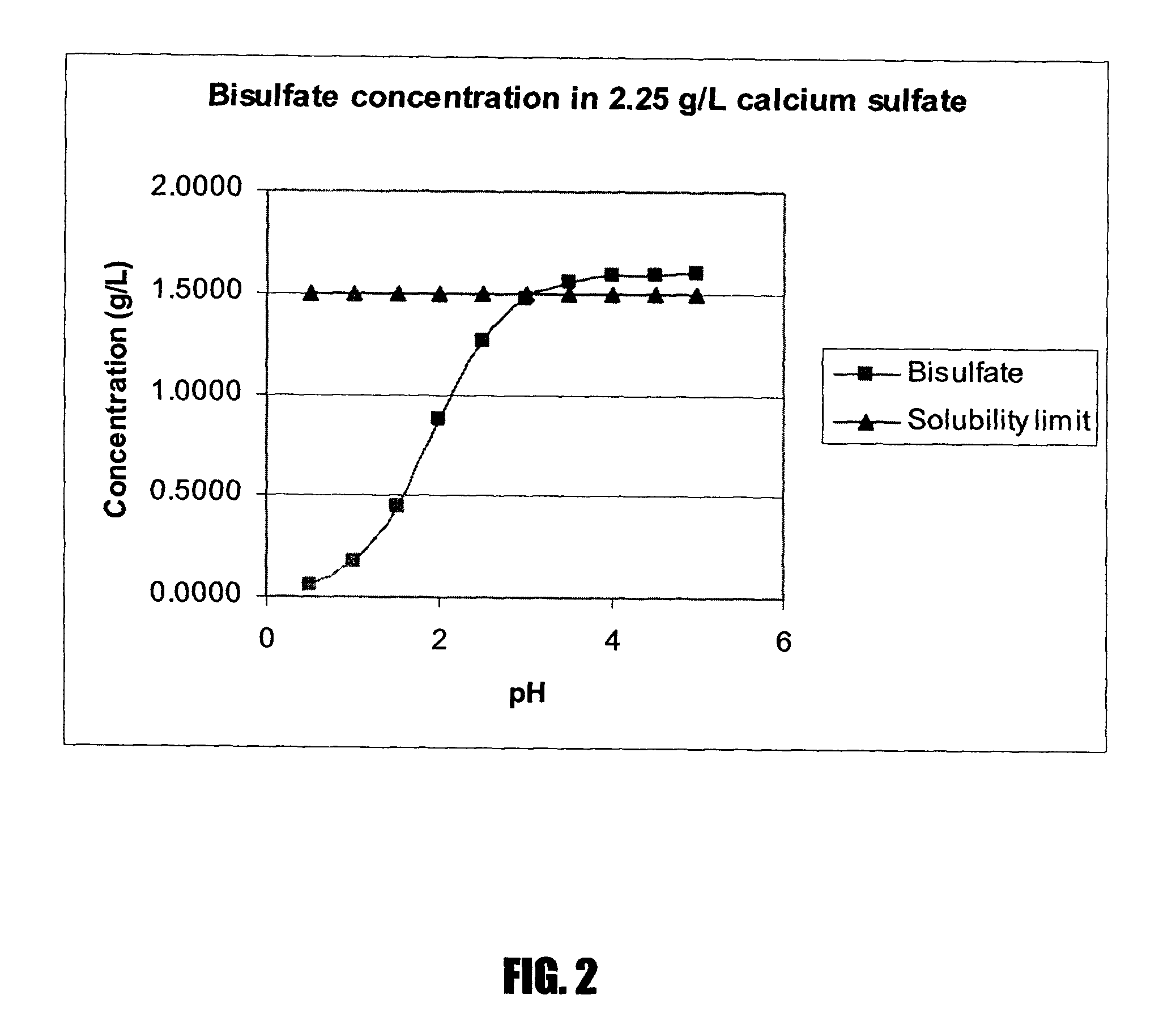

Method for producing ethanol and co-products from cellulosic biomass

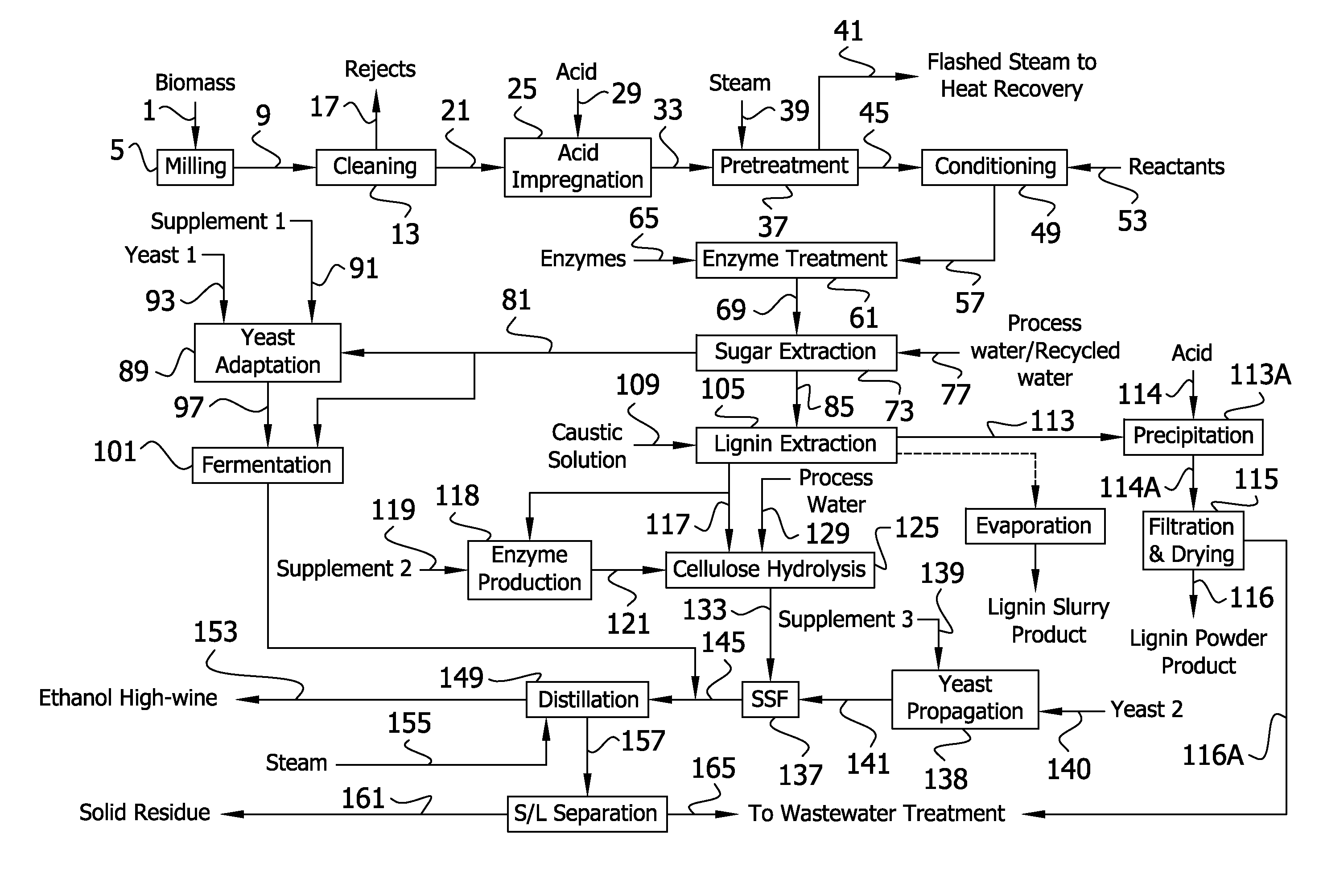

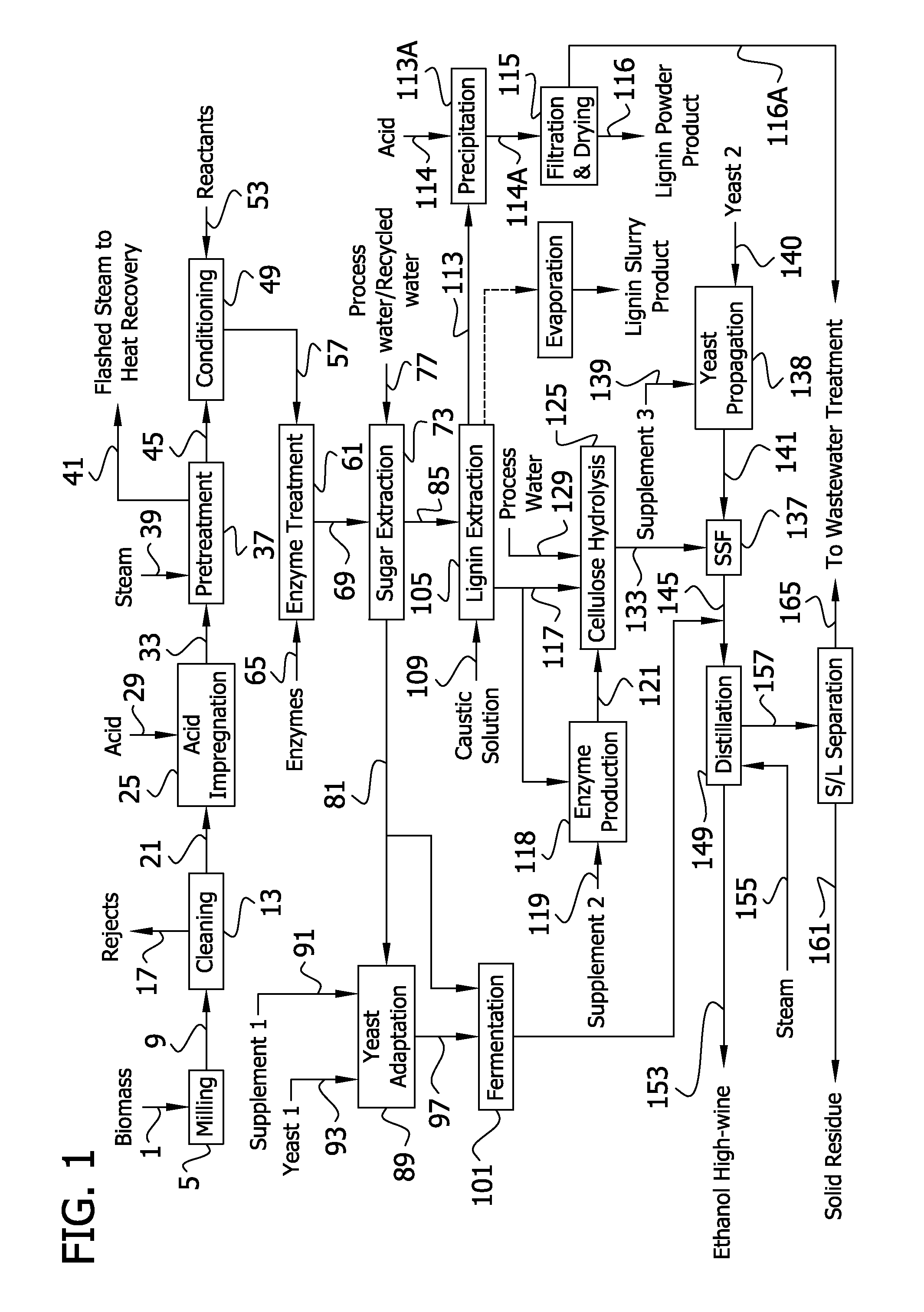

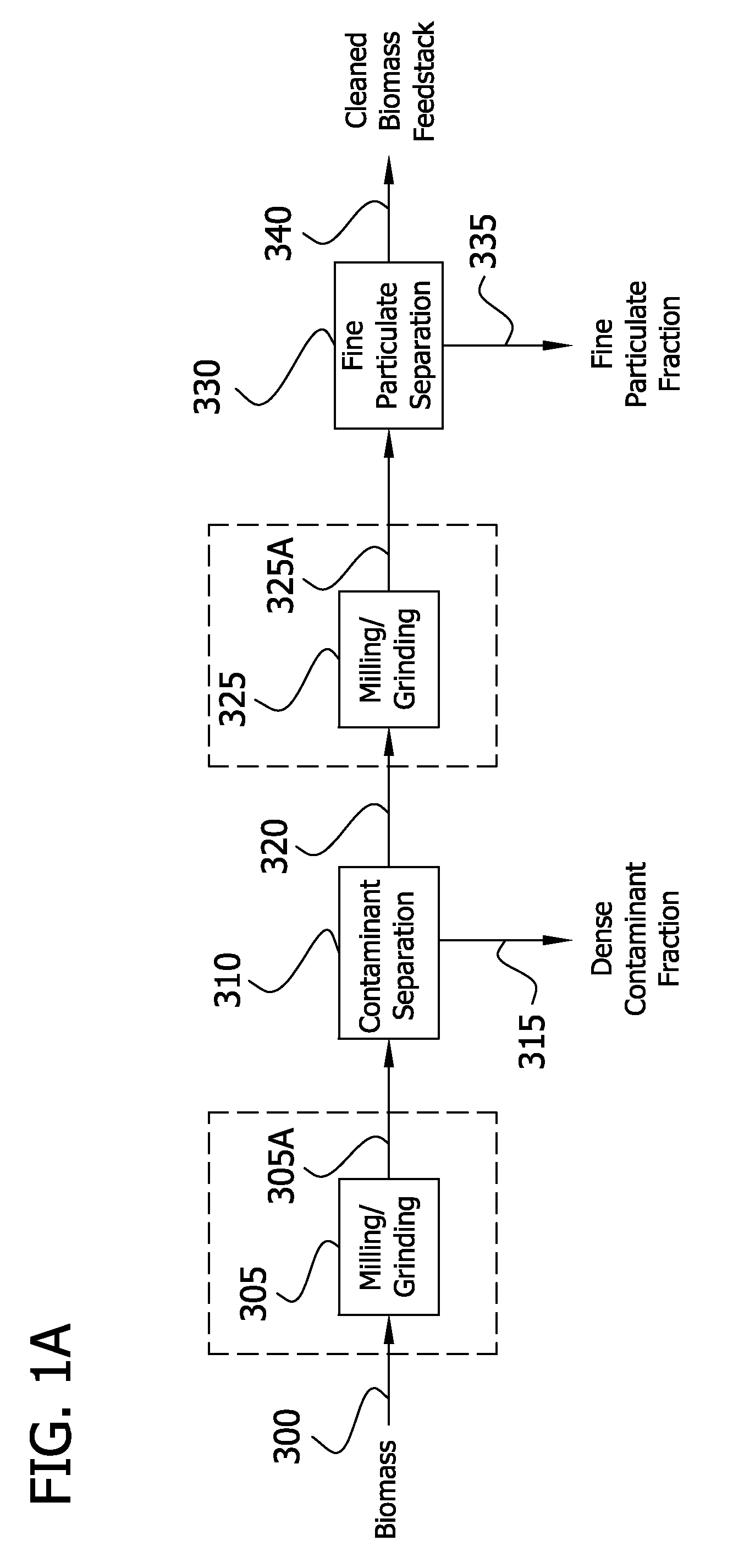

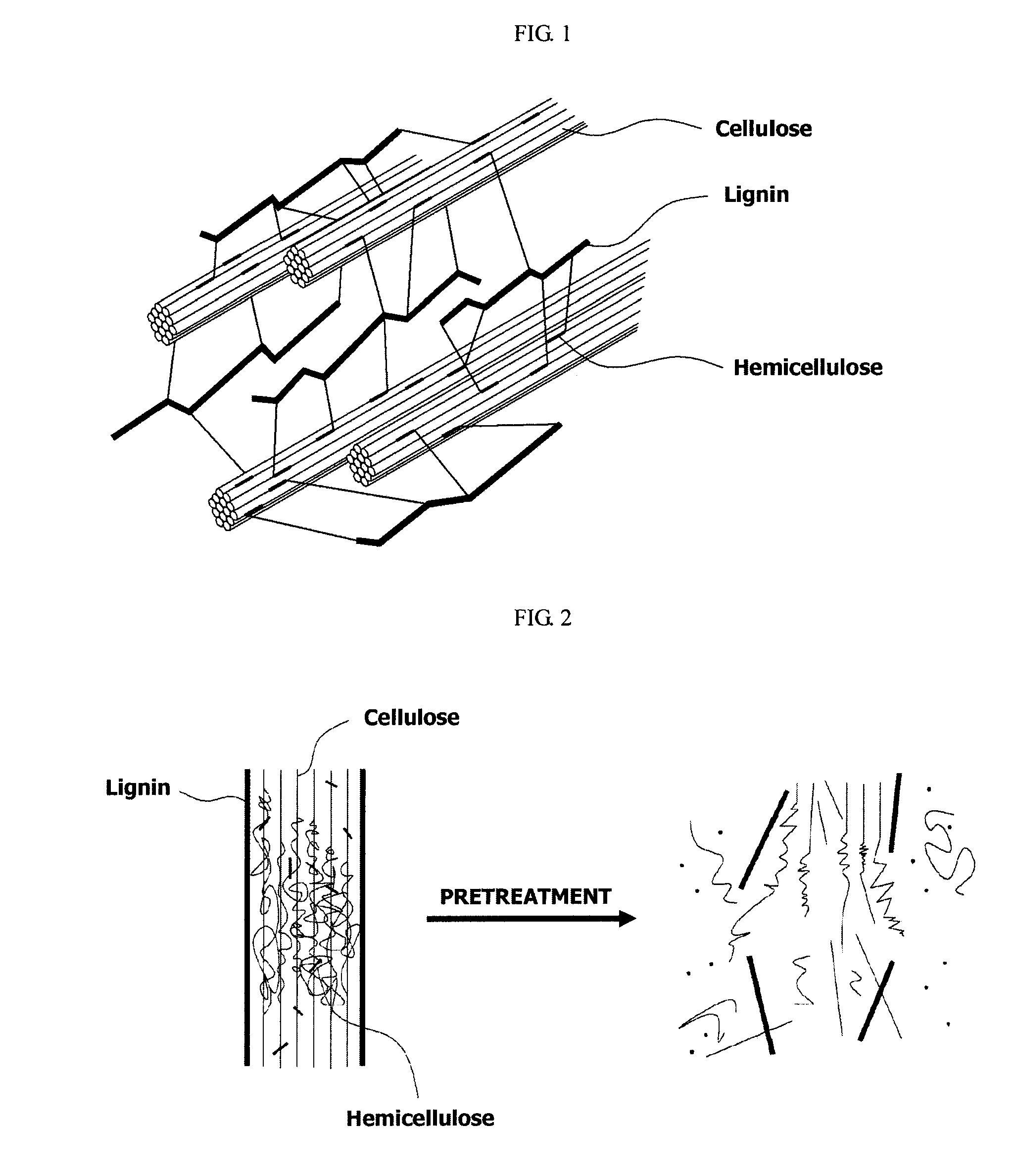

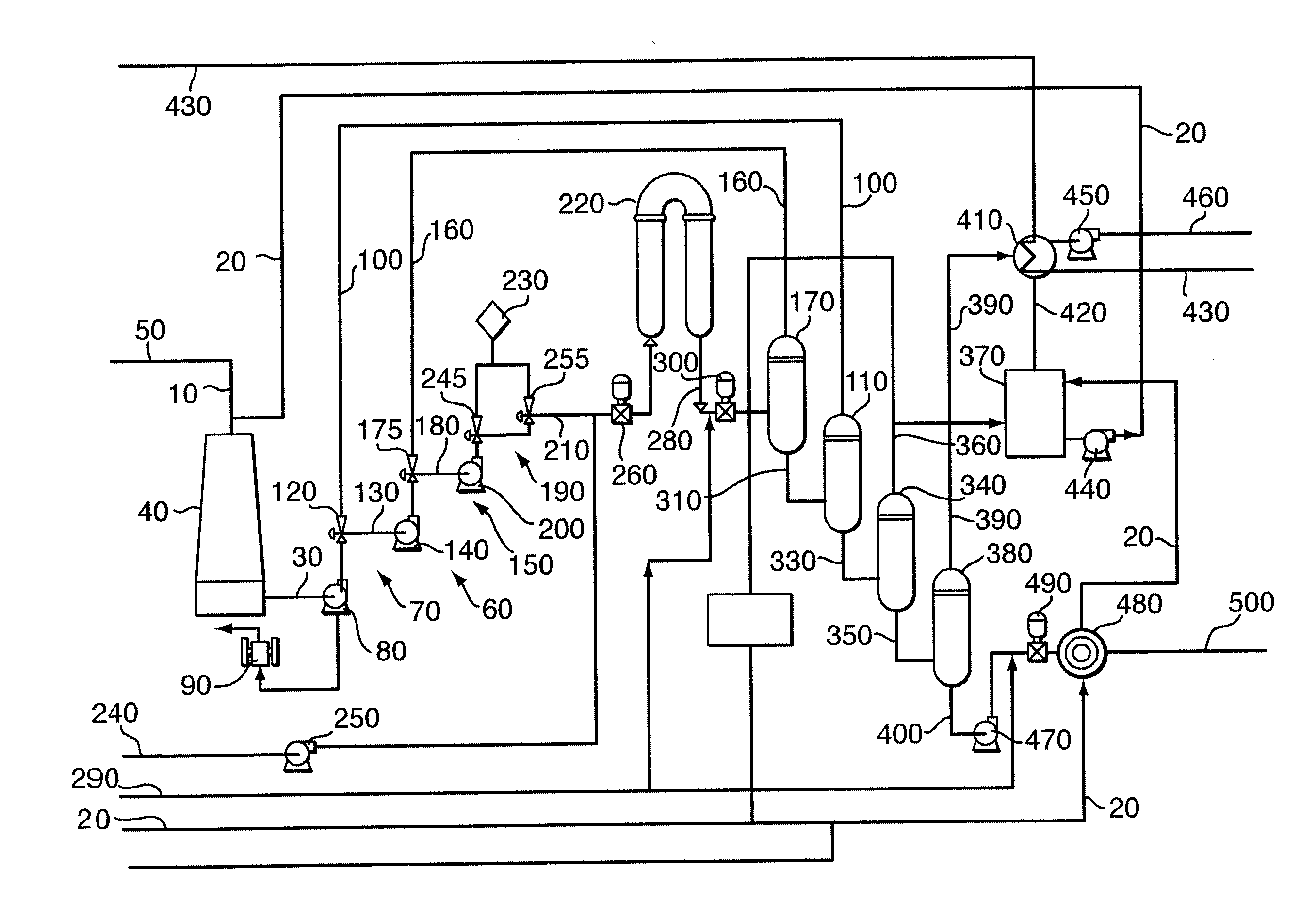

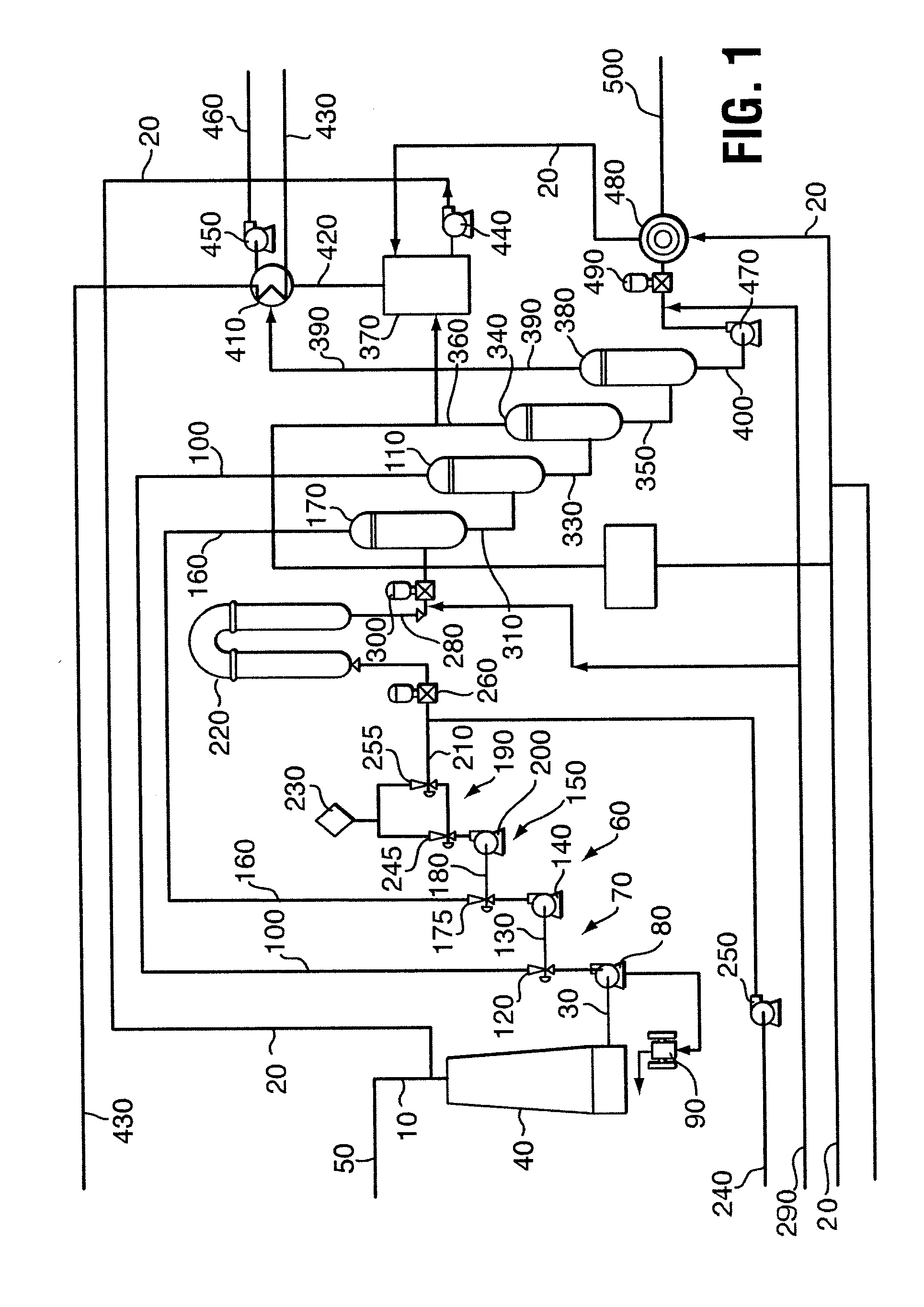

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

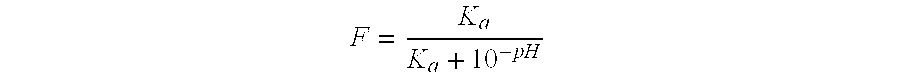

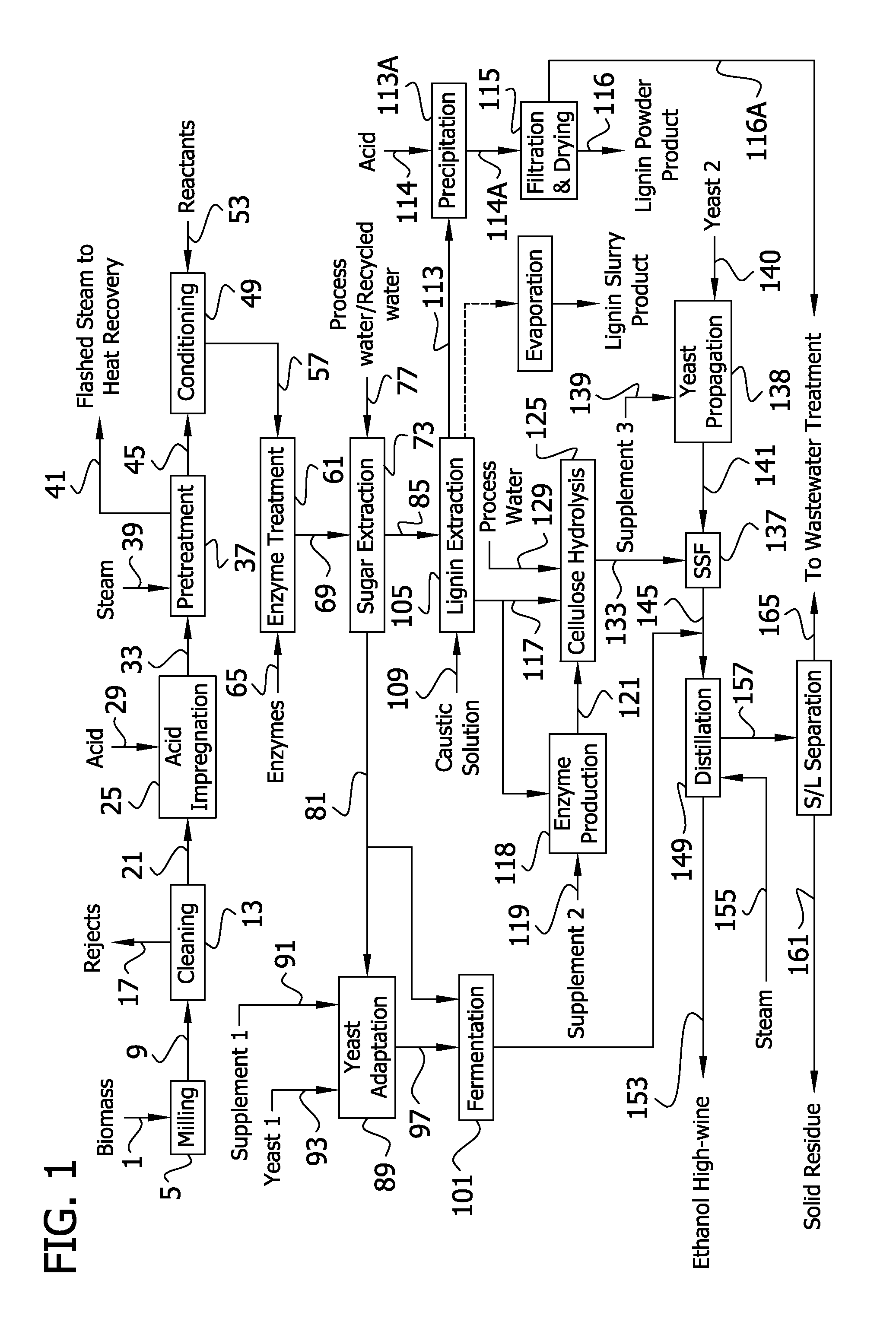

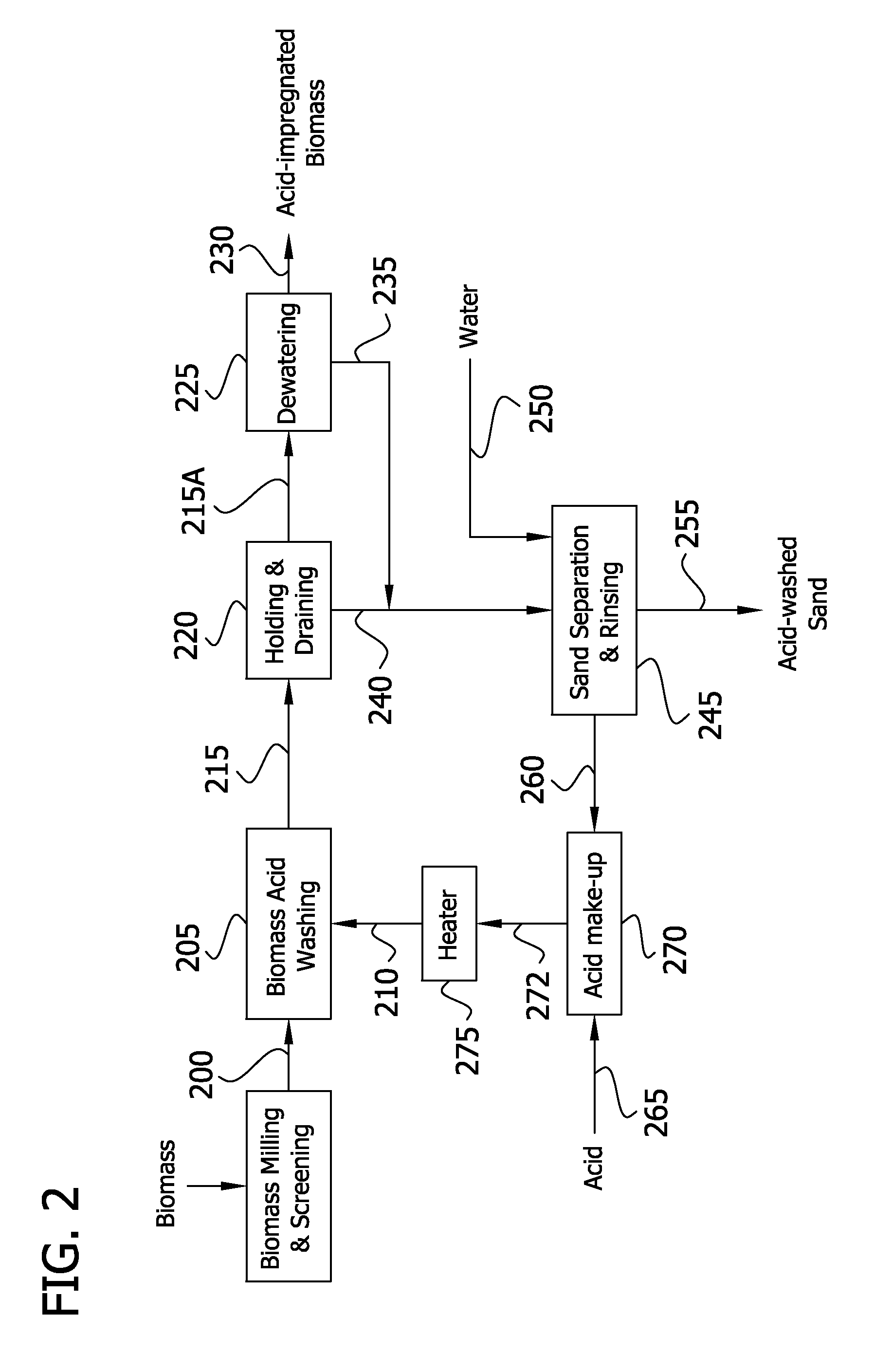

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

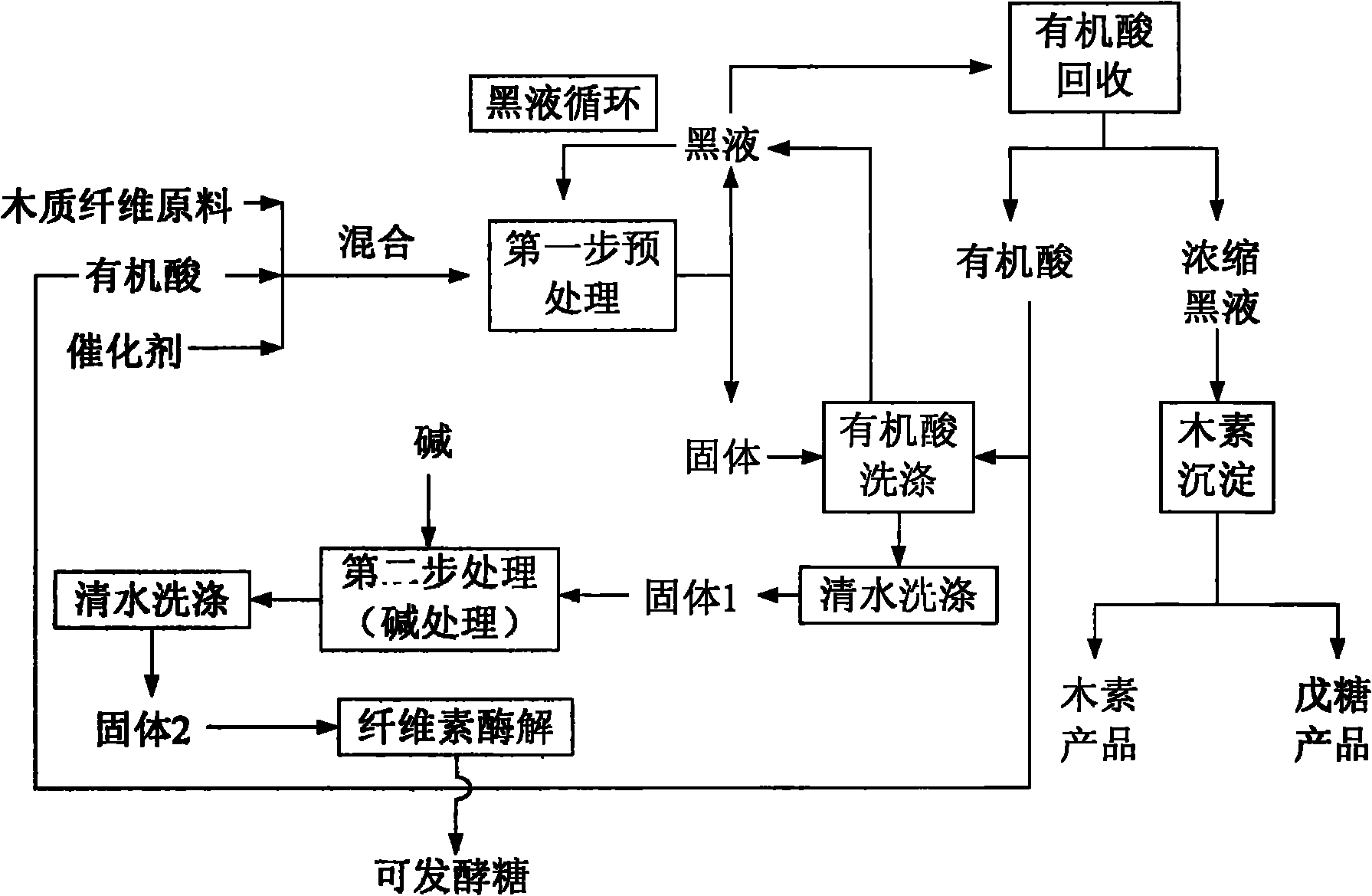

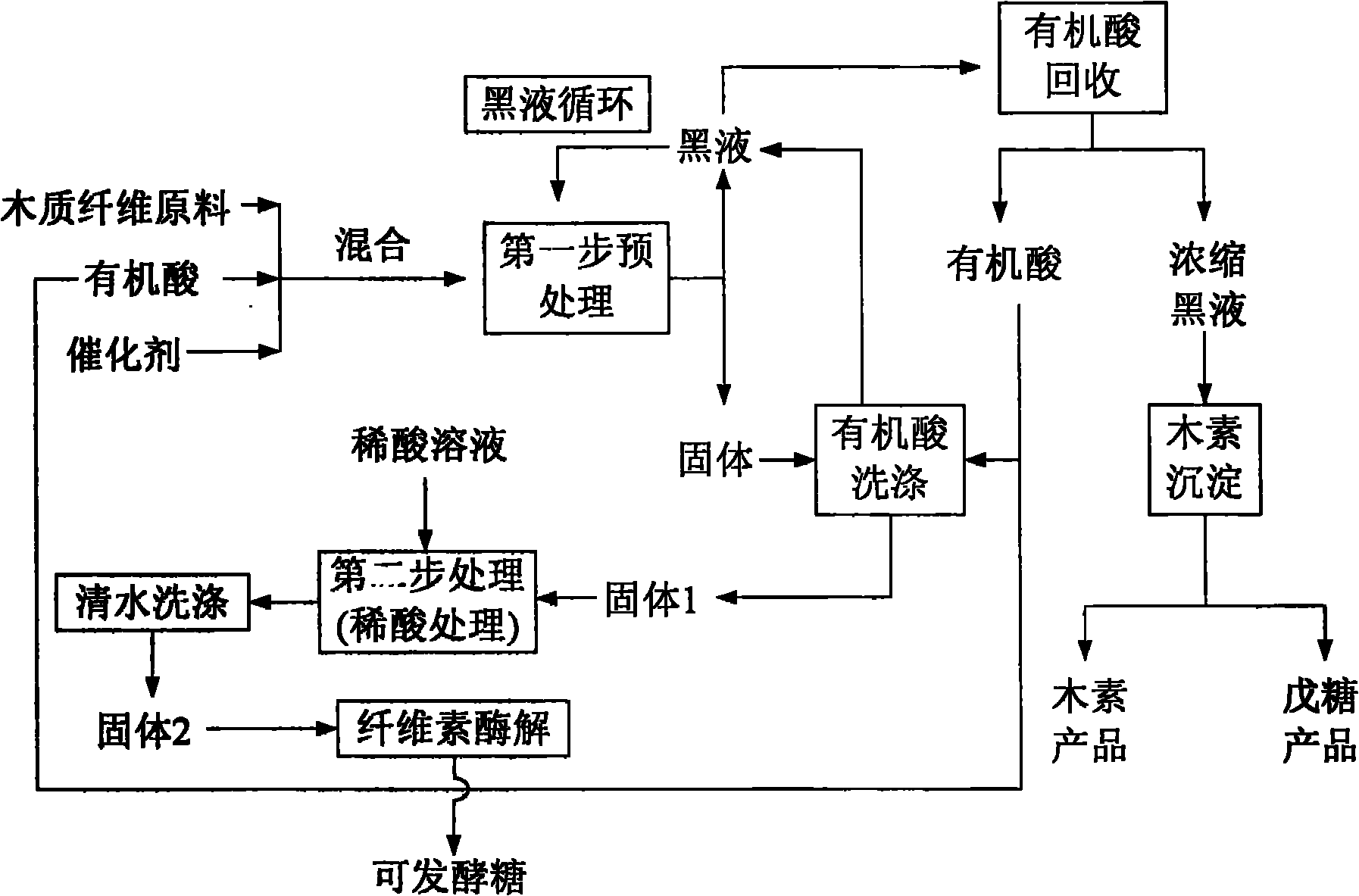

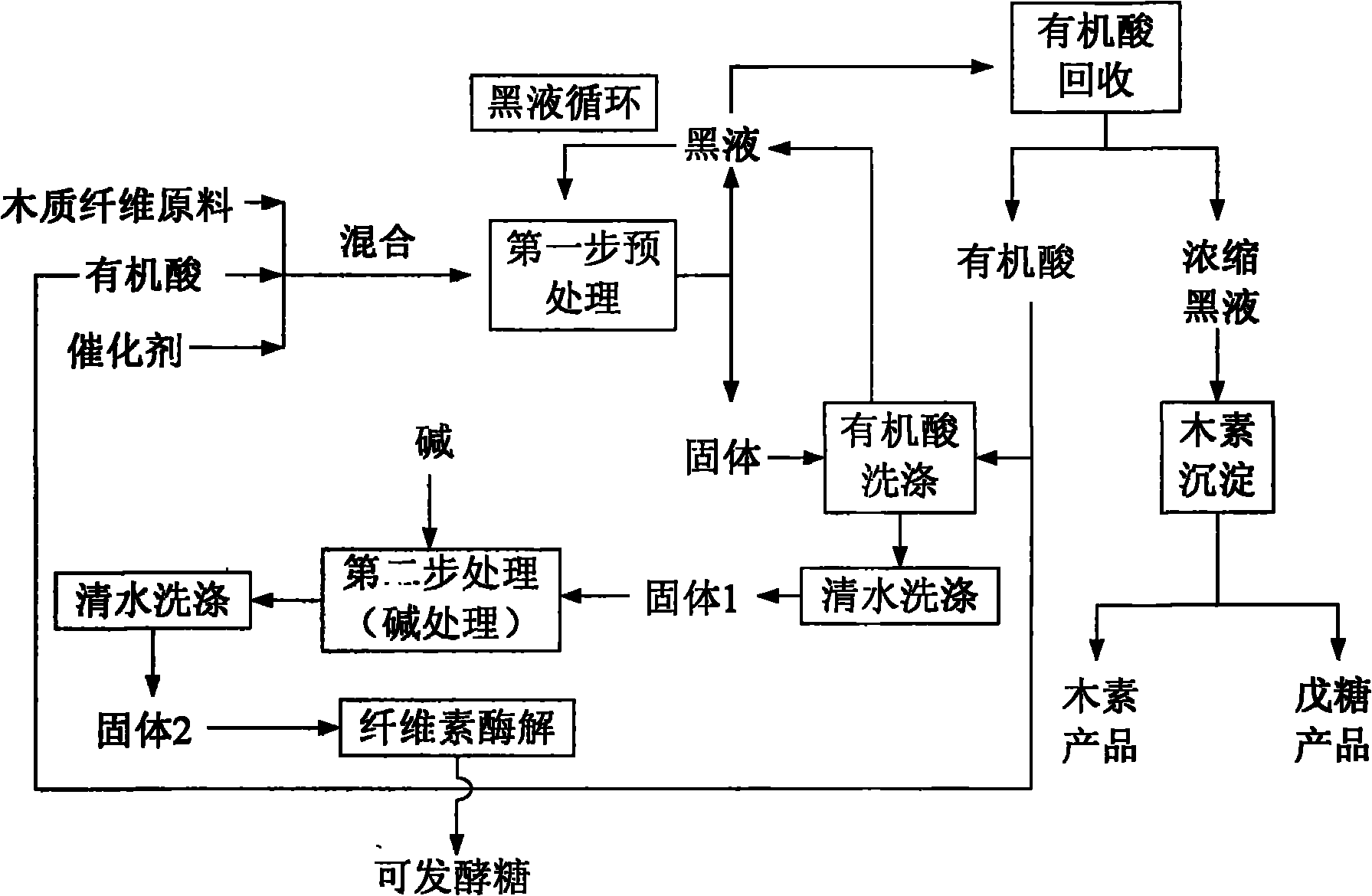

Pretreatment method of wood fiber raw materials

InactiveCN101864683ARealize comprehensive utilizationRealize full-price developmentPretreatment with acid reacting compoundsCelluloseFiber

The invention relates to a pretreatment method of wood fiber raw materials, which belongs to the technical field of biomass chemical engineering. The process comprises the following steps: carrying out the first-step treatment after the wood fiber raw materials are mixed with mixed liquid of an organic acid solution and catalysts to obtain a liquid-solid mixture; separating the obtained liquid-solid mixture to obtain pretreatment black liquid and cellulose solids; washing the obtained cellulose solids by the organic acid solution to obtain washing black liquid and cellulose solids; adopting diluted acid or alkali for carrying out the second-step treatment on the obtained cellulose solids; mixing the obtained pretreatment black liquid and the obtained black liquid to obtain mixed black liquid; circularly using the mixed black liquid in the first-step treatment process; and recovering organic acids, lignin products and syrup solutions from the black liquid in the cyclic use for at least three times. The invention has the advantages that the full-rate development of raw materials can be realized, in addition, the environment-friendly effect can be realized, and the invention conforms to the requirement of modern biorefinery development.

Owner:TSINGHUA UNIV

Method of continuous processing of lignocellulosic feedstock

InactiveUS7754457B2Quantity minimizationEasier to dispense evenlyPretreatment with water/steamSugar derivativesCelluloseChemistry

Owner:IOGEN ENERGY CORP

Organic biomass fractionation process

InactiveUS20030041982A1Economical and efficientLow costPretreatment with acid reacting compoundsWaste based fuelFractionationNitration

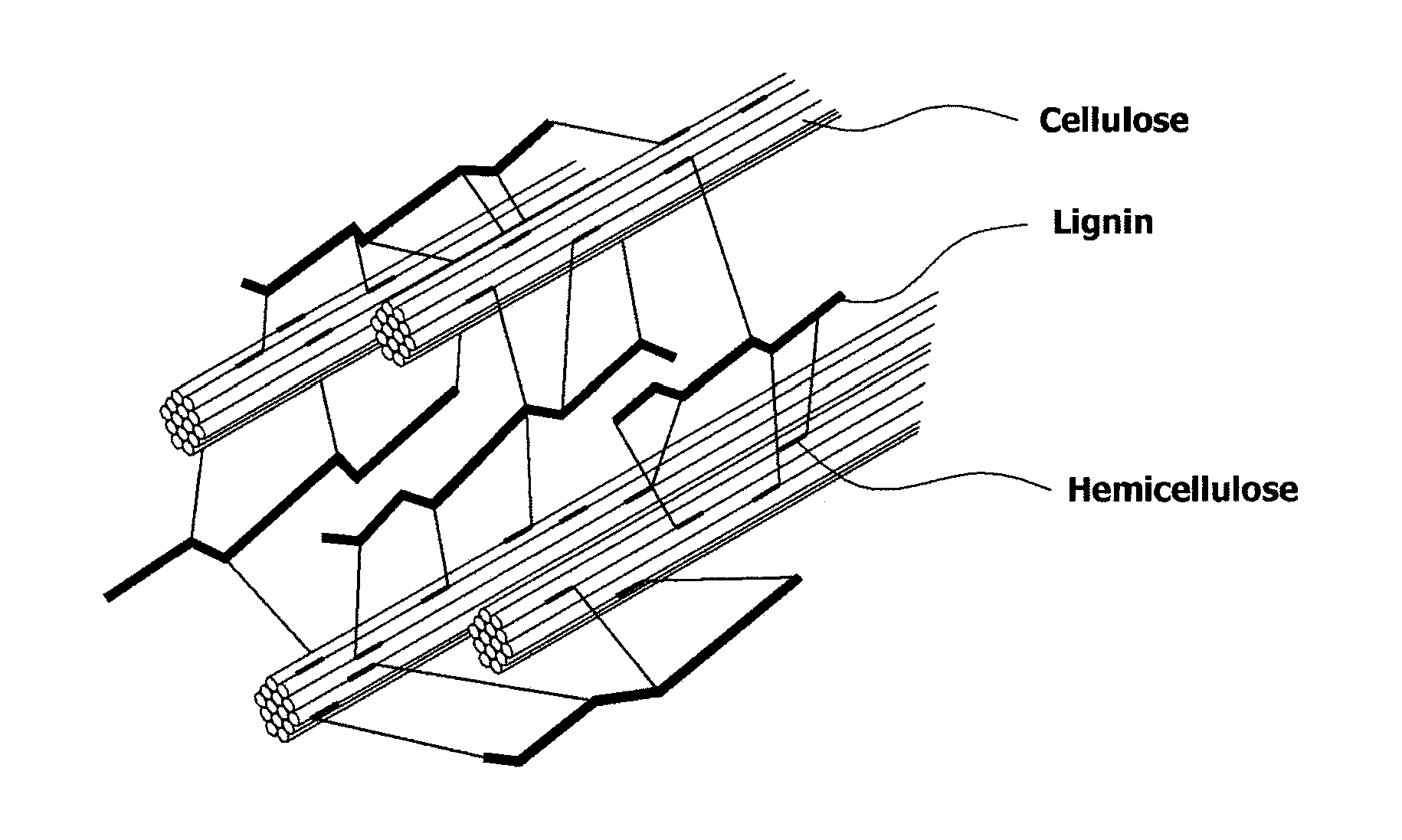

A method for fractionating fibrous biomass comprising cellulose, hemicellulose and lignin components to separate said lignin, cellulose and hemicellulose from one another comprises: (a) shredding said fibrous biomass; (b) concurrently with or subsequent to said shredding, contacting said biomass with an aqueous solution of a nitrate ion source at a concentration of about 0.1-0.3% at a temperature in the range of about 60° to about 80° C. to initiate nitration of the lignin component of said biomass; (c) submerging said partially nitrated biomass in an aqueous solution of a nitrate ion source in the presence of an aluminum compound at a temperature within the range of about 75-100° C. for a time sufficient to complete the nitration of said lignin component; (d) contacting the nitrated biomass produced in step (c) with an alkaline extraction liquor comprising NH4OH at an initial concentration sufficient to solubilize said nitrated lignin component and said hemicellulose component from said cellulose component of said biomass; e) recovering said cellulose from said extraction liquor containing said solubilized nitrated lignin and hemicellulose components, wherein said cellulose comprises at least about 88% alpha cellulose; (f) treating said extraction liquor with an acid to precipitate lignin contained therein, and (g) separating said lignin from soluble hemicellulose in said extraction liquor. The recovered cellulose component comprises at least 88% alpha cellulose and is useful as a starting material for the production of ethanol.

Owner:PRIOR ERIC S

Method for producing pulp and lignin

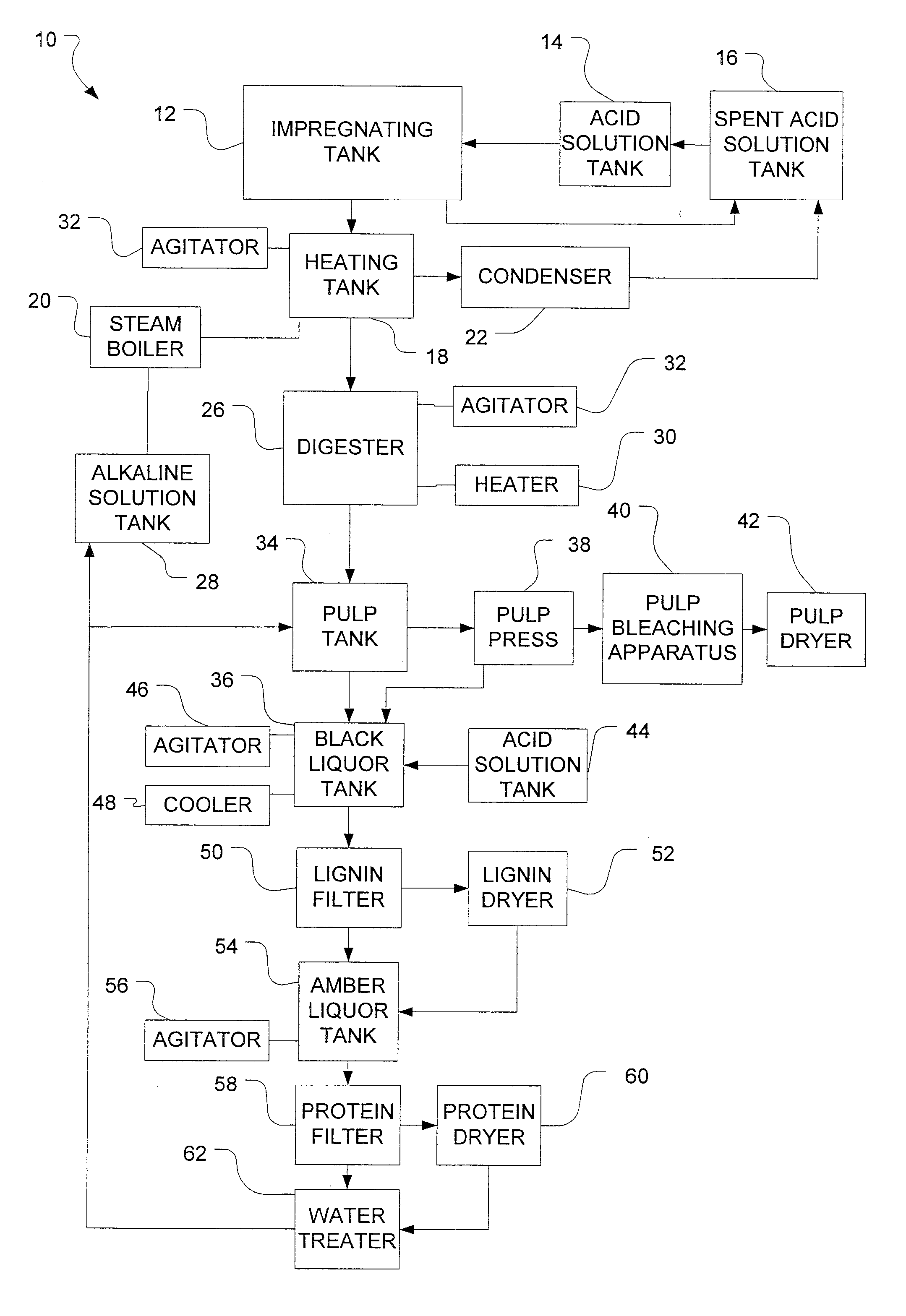

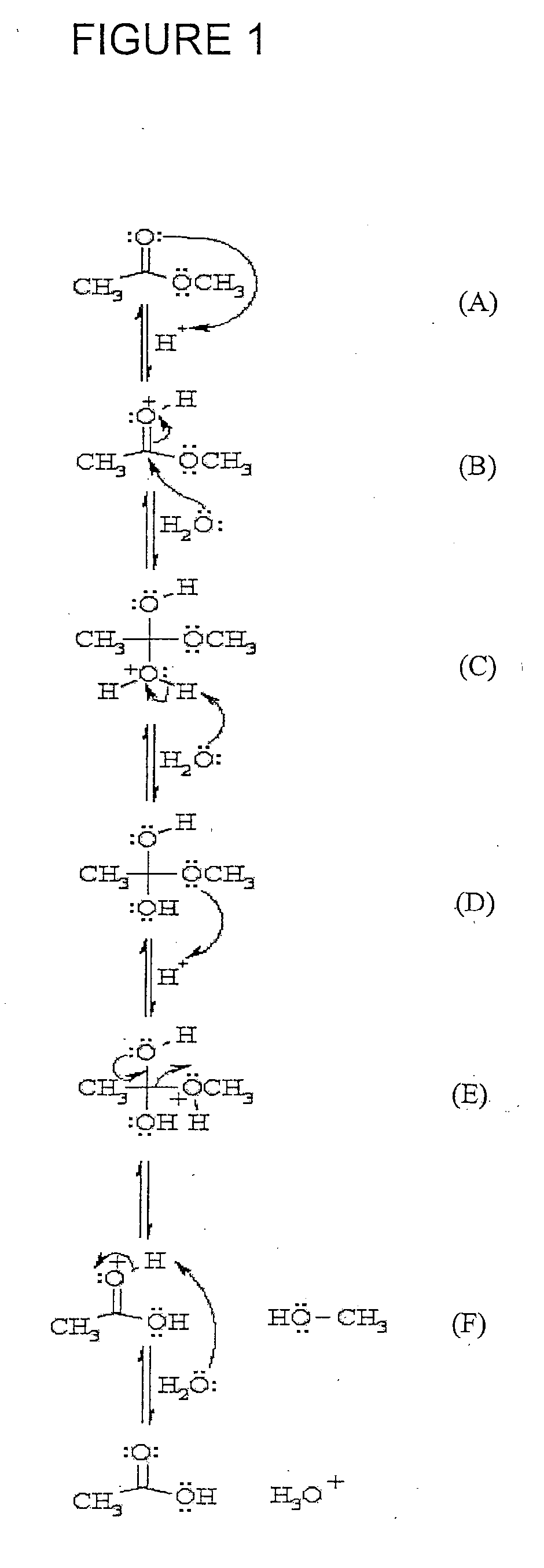

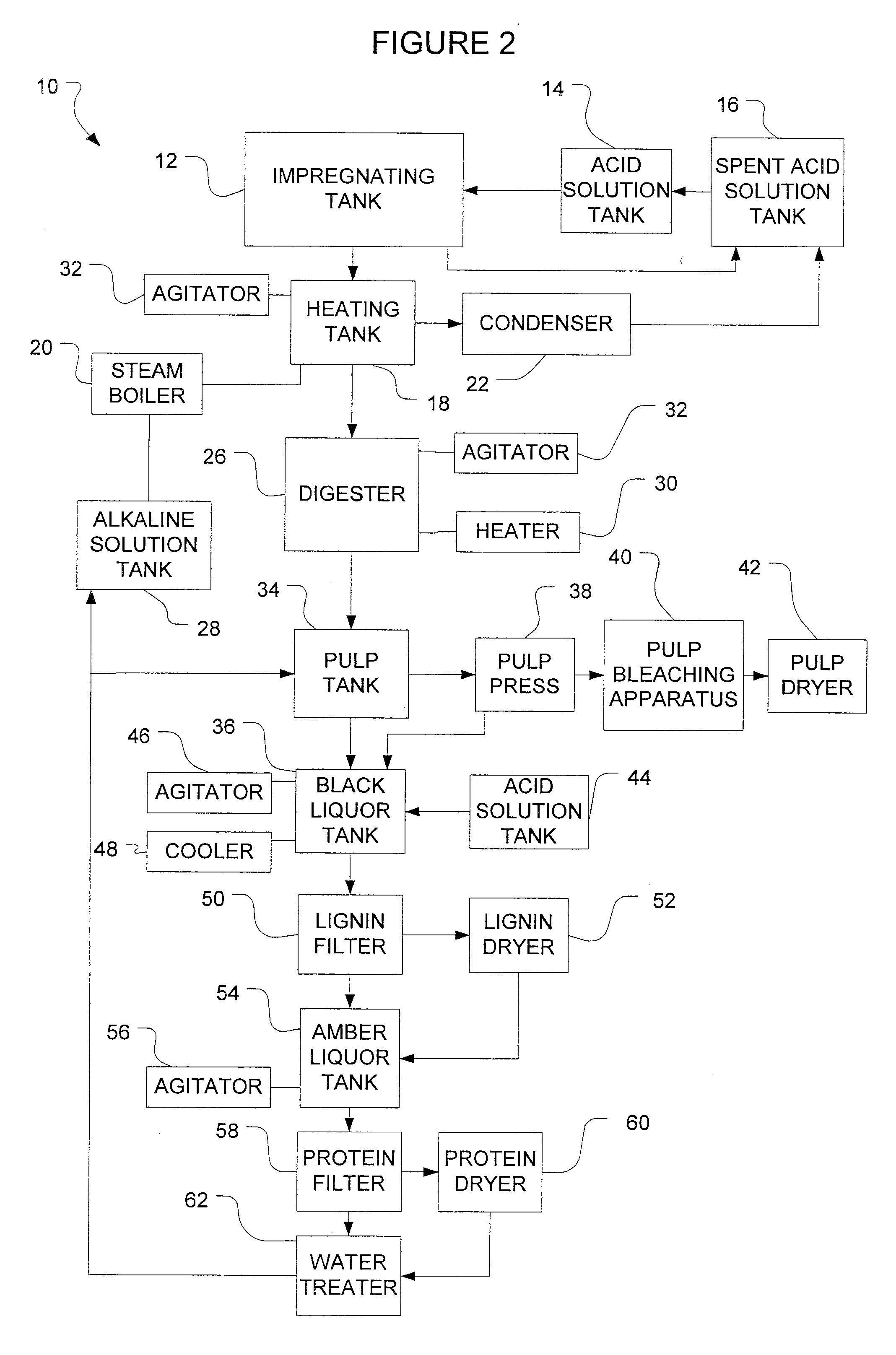

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

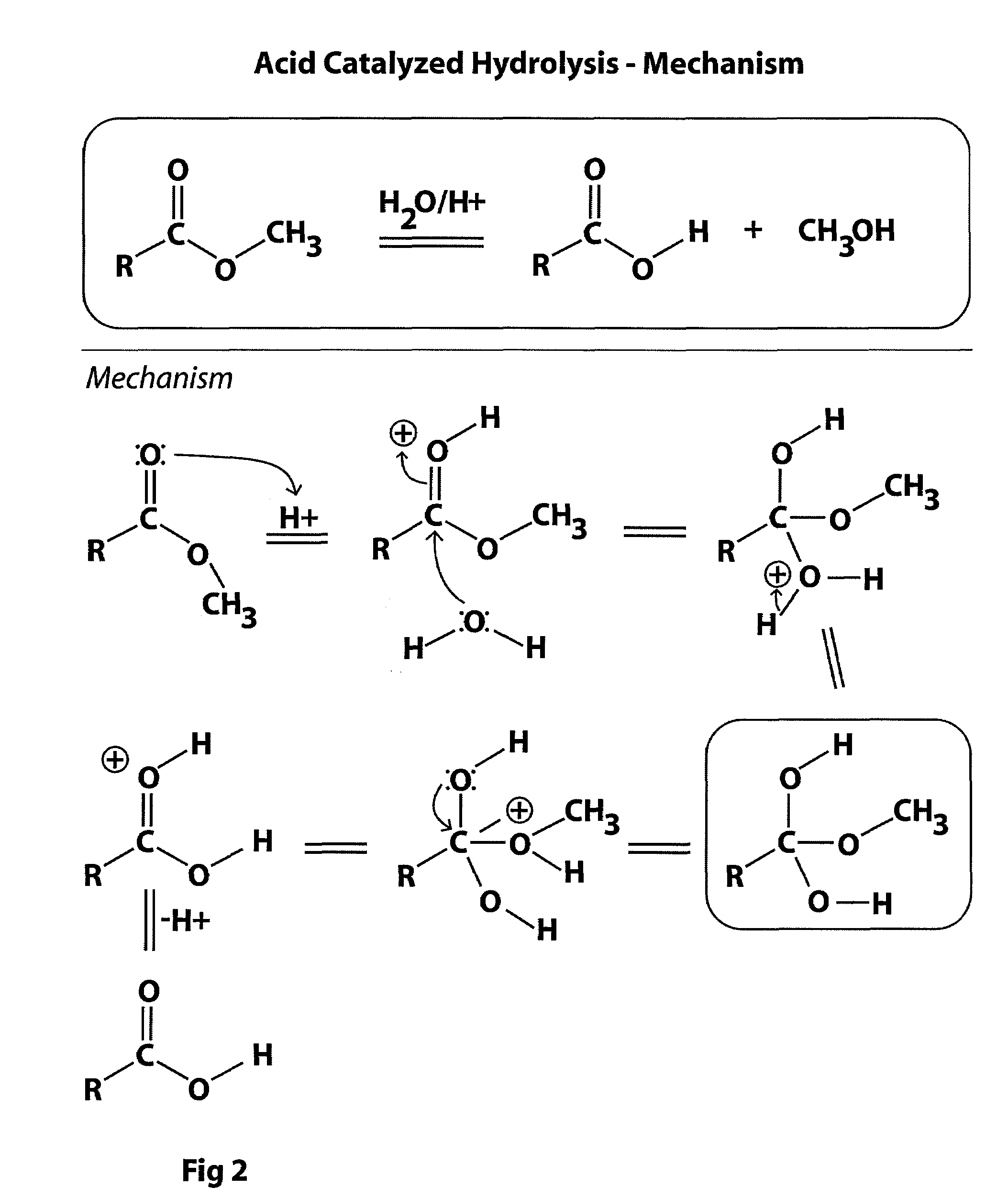

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Method and apparatus for fractionating lignocellulose-based biomass

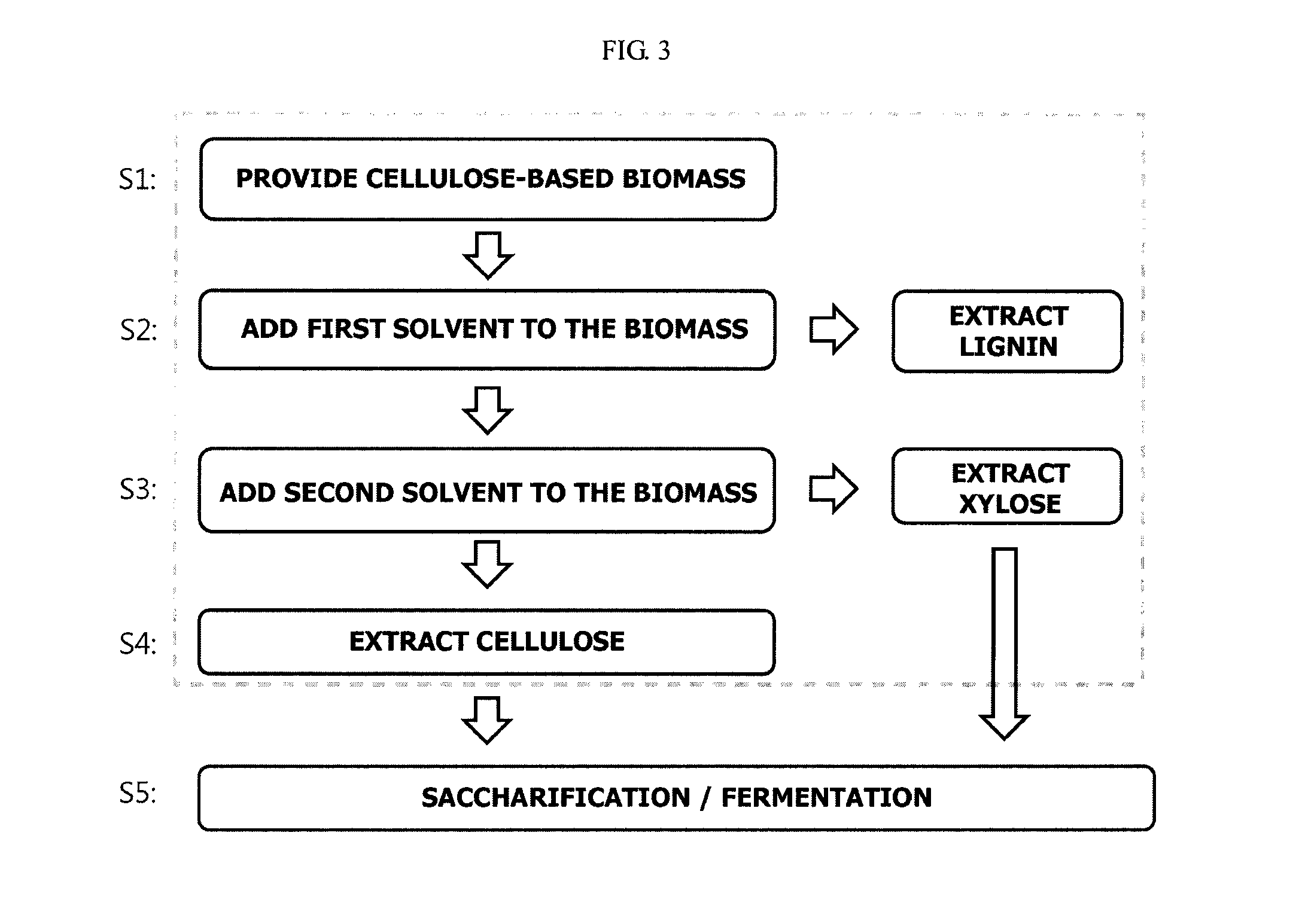

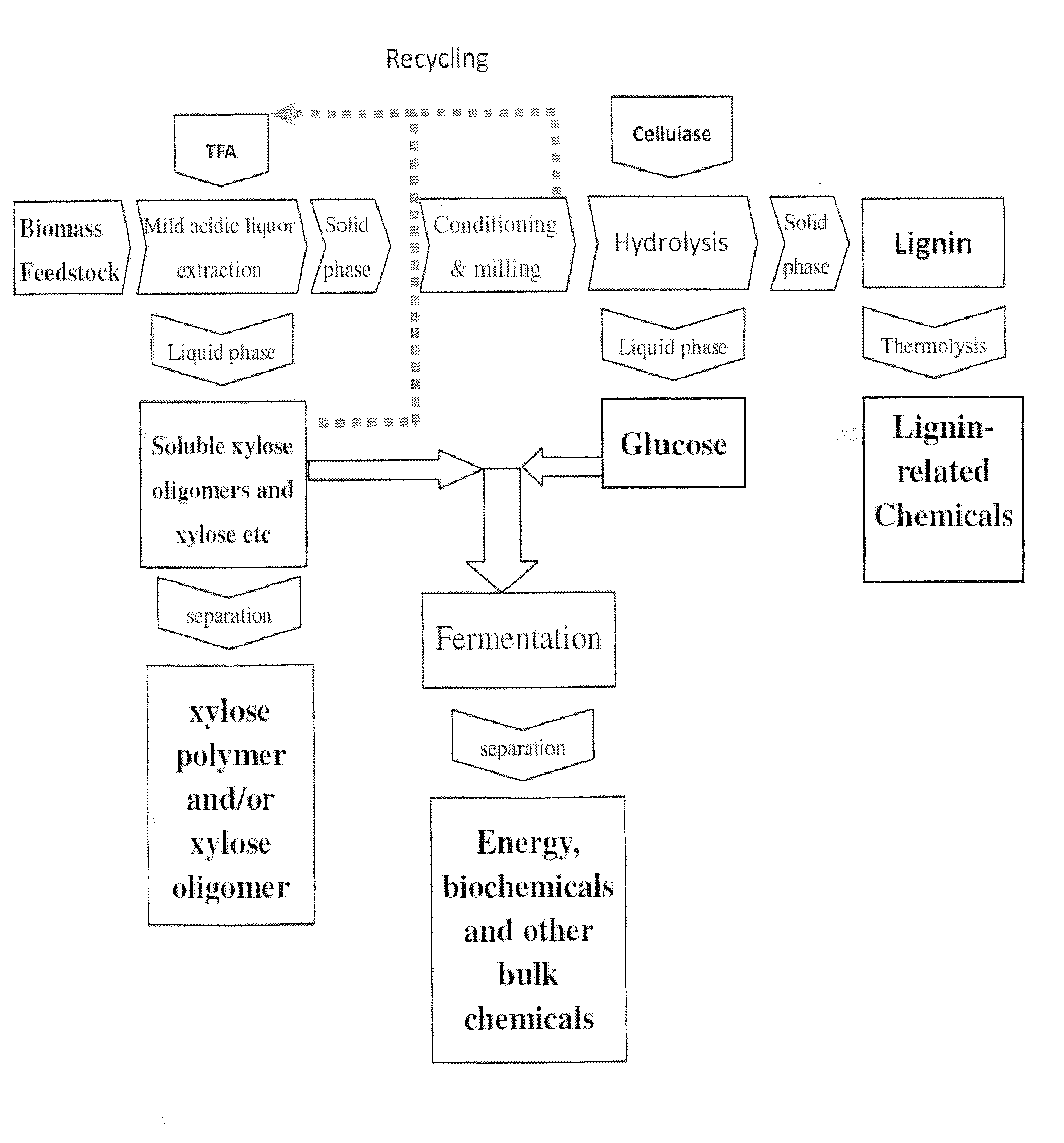

ActiveUS20100203605A1Improve processing efficiencyEnhanced interactionPressurized chemical processBiological substance pretreatmentsCelluloseLignin degradation

A method and apparatus for fractionating a lignocellulose-based biomass are provided. The method includes providing a lignocellulose-based biomass, extracting lignin from the biomass by adding a first solvent capable of dissolving the lignin, extracting xylose by adding a second solvent capable of dissolving hemicellulose to the biomass treated with the first solvent, and extracting the cellulose remaining in the biomass. In this method, a continuous process can be performed instead of a low efficiency batch-type process and components of the biomass can be obtained at high yield.

Owner:SAMSUNG ELECTRONICS CO LTD

Biomass pretreatment process

ActiveUS8168840B2Pressurized chemical processPretreatment with alkaline reacting compoundsCelluloseLignocellulosic biomass

A process is described for pretreating lignocellulosic biomass. The process comprises swelling the lignocellulosic biomass with an aqueous liquid. The pretreated lignocellulosic biomass may be used as a feedstock for the enzymatic conversion to ethanol, or in a thermal conversion. process to produce bio-oil. The pretreatment results in a greater yield and, in the case of a thermal conversion process, a better quality of the bio-oil. The pretreatment process may be used to adjust the composition and amount of inorganic material present in the lignocellulosic biomass material.

Owner:MARD INC

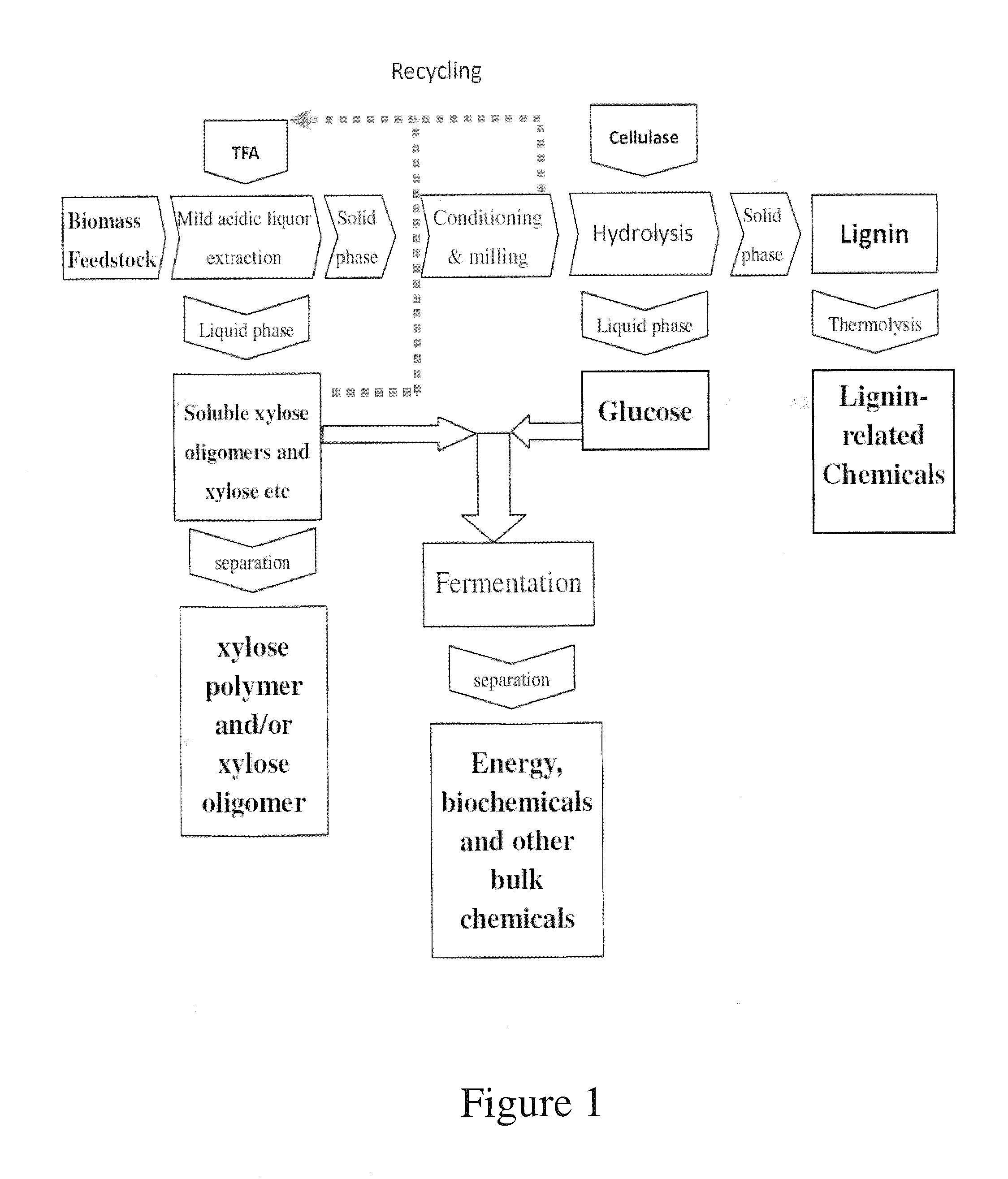

Process for biomass conversion

InactiveUS20100297704A1Easy to GrindIncrease ratingsSugar productsPretreatment with acid reacting compoundsPolymer scienceEnergy products

The present invention relates to a clean process of preparing high grade biomass products, and their use in the production of health care products, bio-energy products, biochemicals, bio-originated chemicals and biodegradable plastics.

Owner:LI RONGXIU

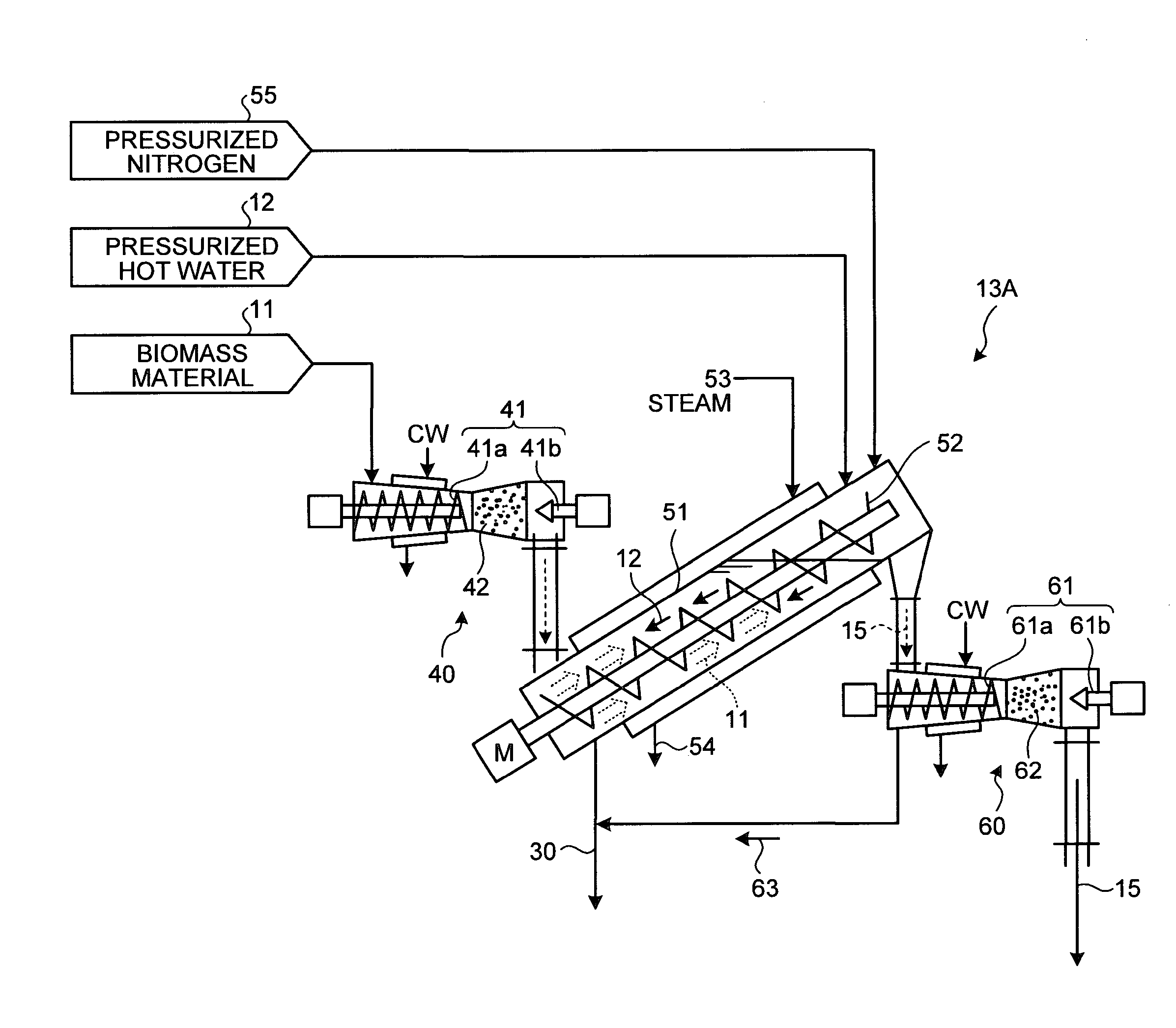

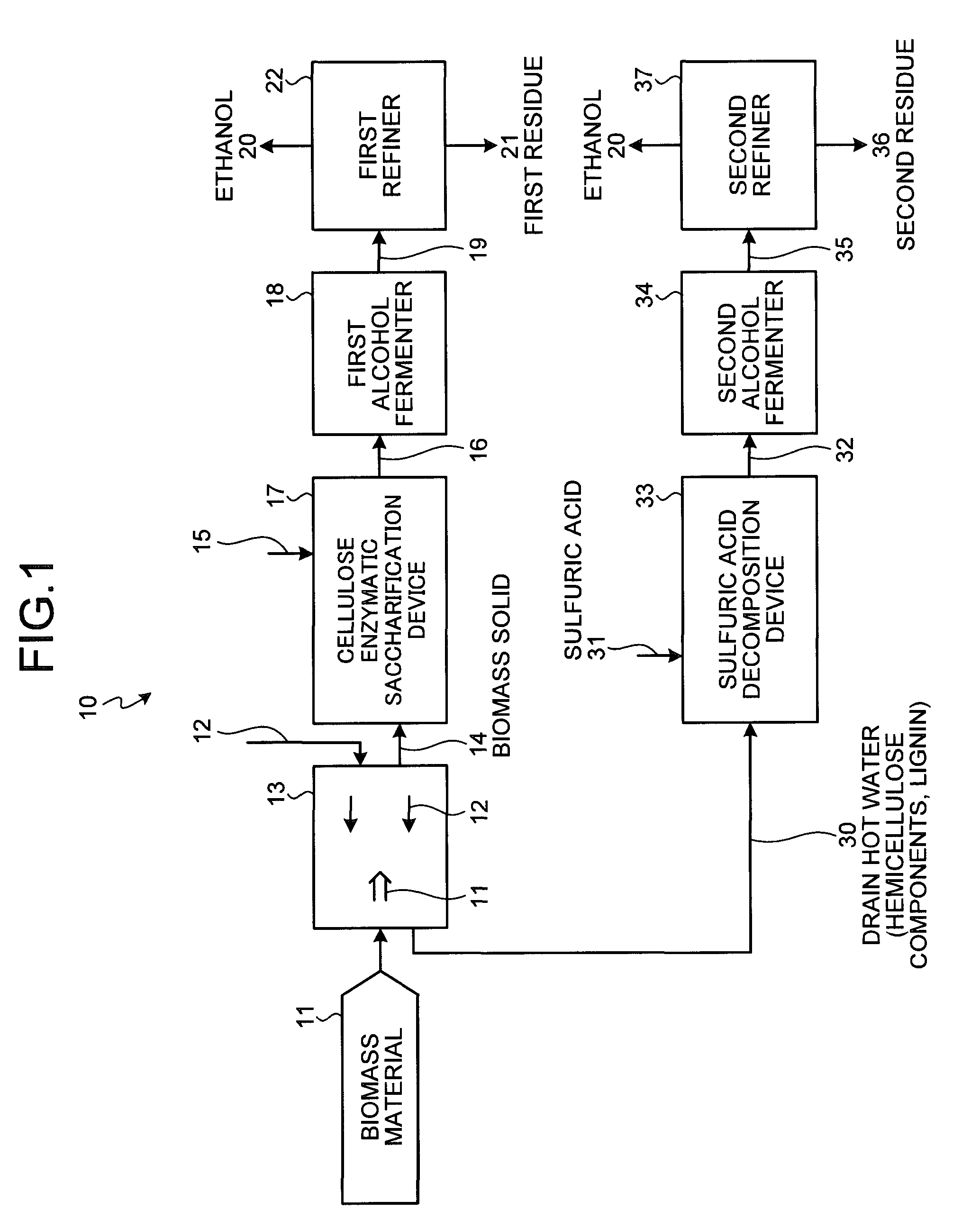

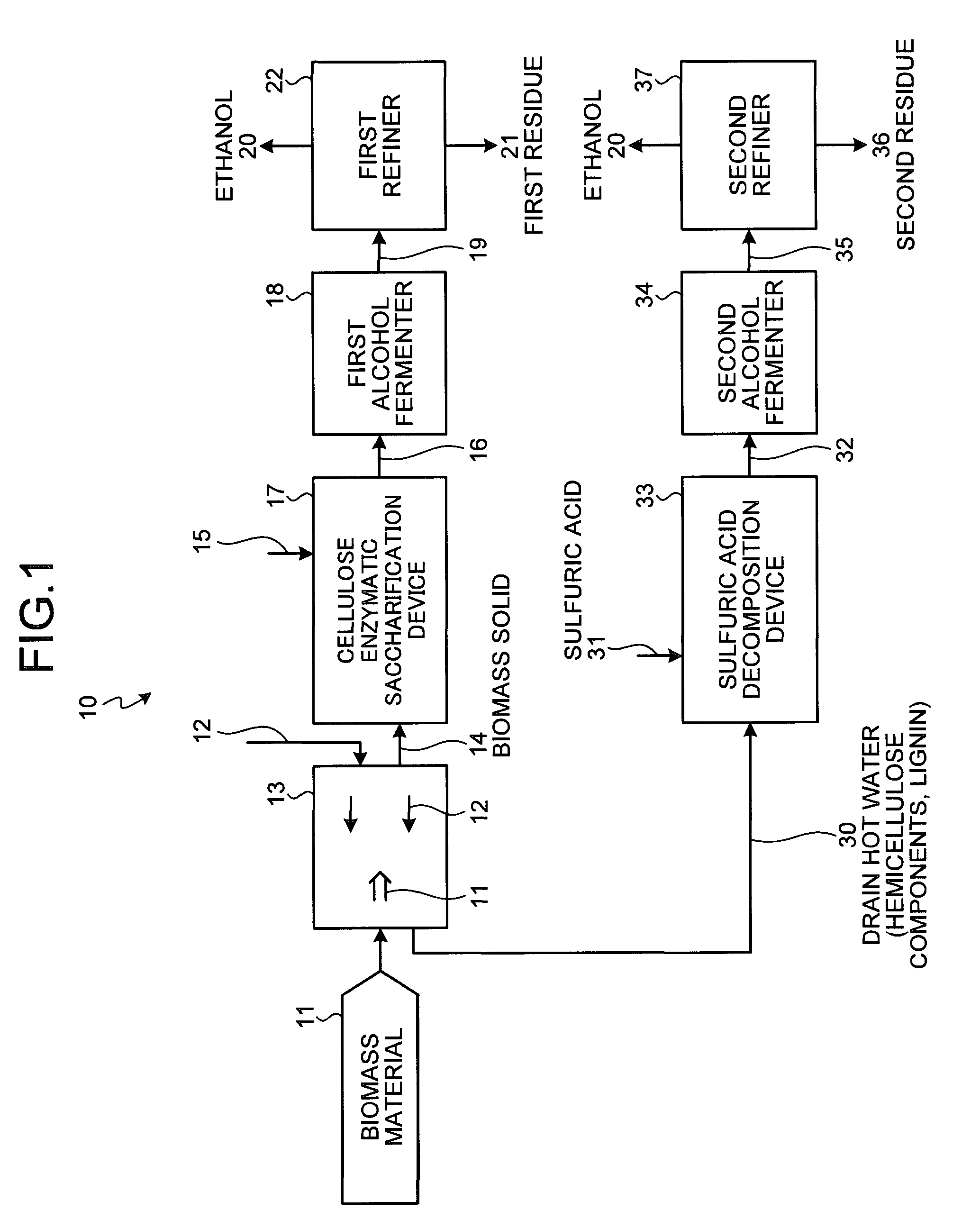

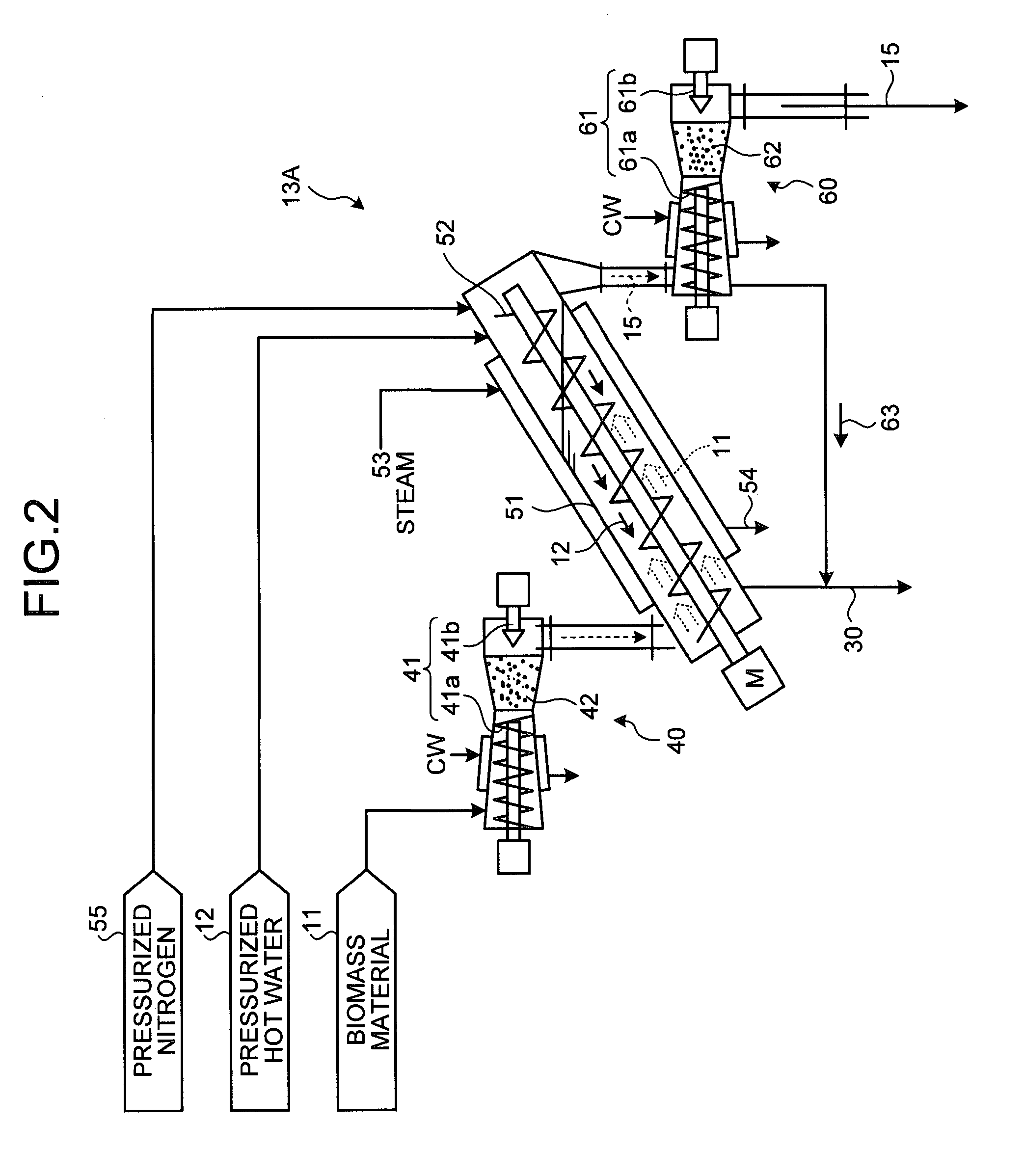

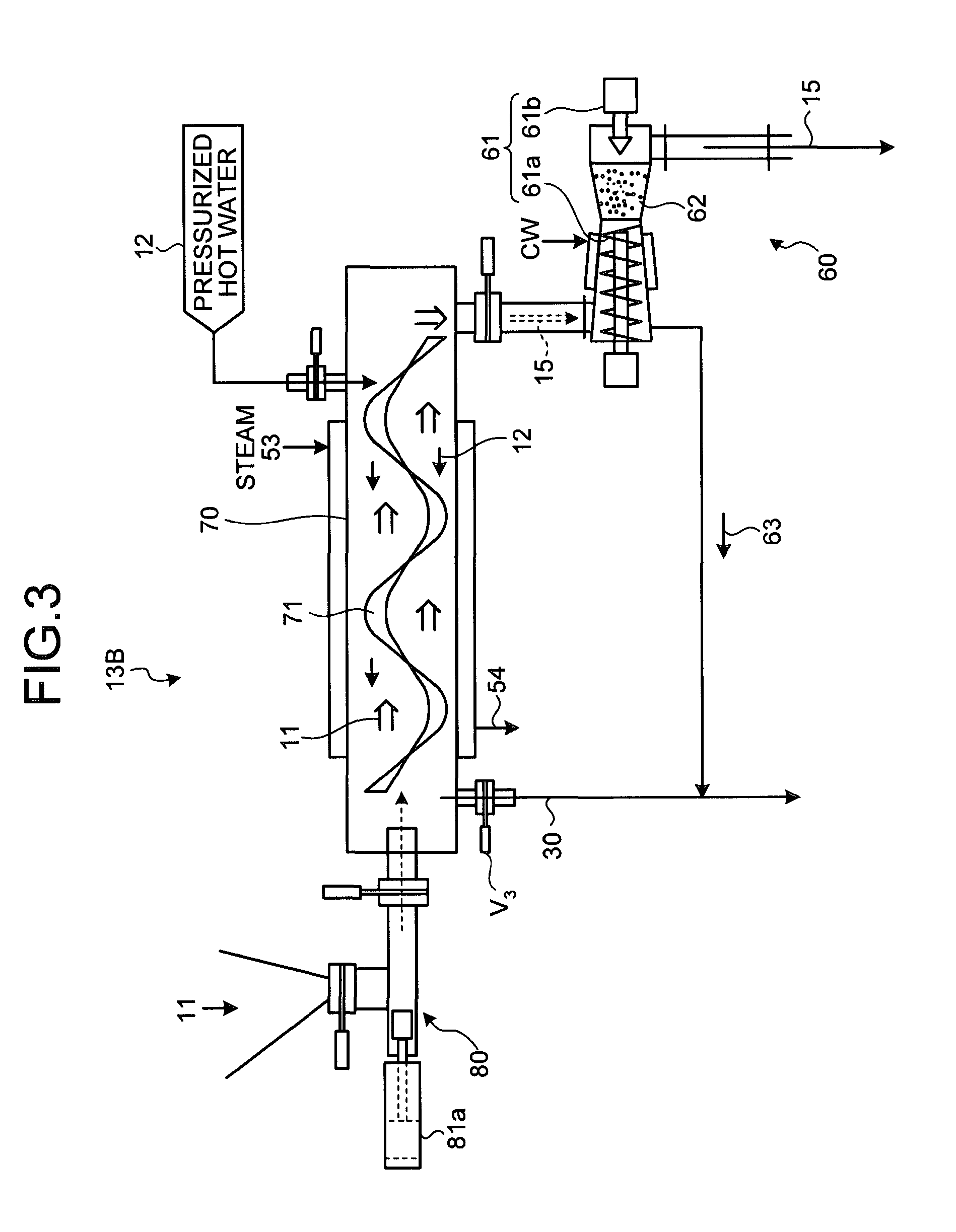

Organic material production system using biomass material and method

ActiveUS20110124057A1Efficiently saccharifyingImprove efficiencyPretreatment with water/steamBioreactor/fermenter combinationsAlcoholDecomposition

An organic material production system using biomass material includes: a hydrothermal decomposition apparatus (13) that causes the biomass material (11) and hot compressed water (12) to countercurrently contact with each other and undergo hydrothermal decomposition, and that transfers a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from a biomass solid residue; a cellulose enzymatic saccharification device (17) that treats, with an enzyme, cellulose in the biomass solid residue, so as to enzymatically saccharify the cellulose to a first sugar solution containing hexose; an alcohol fermenter (18) that produces alcohols by fermentation using the obtained first sugar solution; a sulfuric acid decomposition device (33) that decomposes, with sulfuric acid, the hemicellulose component in hot water (30) discharged from the hydrothermal decomposition apparatus, which contains the eluted lignin component and the eluted hemicellulose component, so as to decompose the hemicellulose component to a second sugar solution containing pentose; and a second alcohol fermenter (34) that produces, using the second sugar solution containing pentose, alcohols by fermentation.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

Short linen viscose fiber and preparation method thereof

ActiveCN102181956ARetain bacteriostasisHigh whitenessPretreatment with acid reacting compoundsPulp de-wateringPre treatmentUltimate tensile strength

The invention discloses short linen viscose fiber and a preparation method thereof. The viscose fiber is produced by preparing linen pulp from linen and then using the linen pulp. The preparation method comprises the following steps of: pre-processing, washing, digesting, washing, pulping, degritting, concentrating, alkali refining, whitening, performing acid treatment, washing, finely selecting, degritting, concentrating, papermaking, soaking, squeezing, smashing, aging, yellowing, grinding, dissolving, filtering, defoaming, filtering, spinning, drafting, cutting off, performing post treatment, drying, packaging and the like. The preparation method has the advantages that: the performance of bacterial resistance and bacterial resistance of the linen fiber can be kept better, a finished product has high whiteness, the production period is short, the problems of large digesting intensity, complicated digesting process and the like are solved, and the pollution generated during production is low.

Owner:潍坊欣龙生物材料有限公司

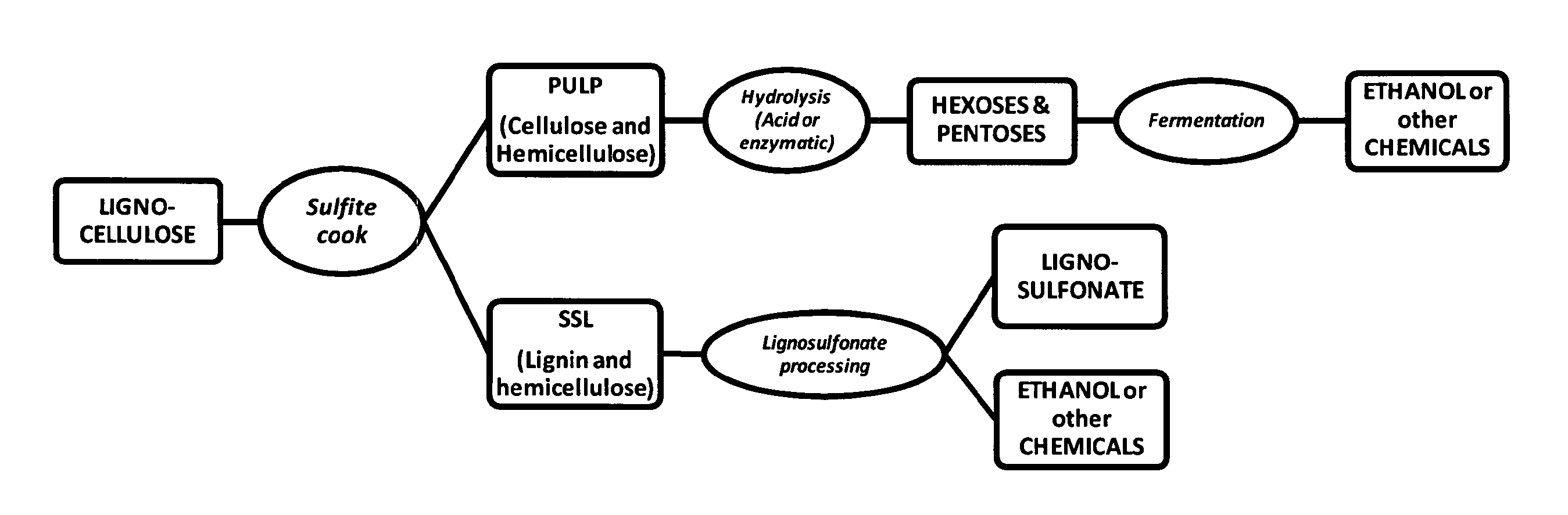

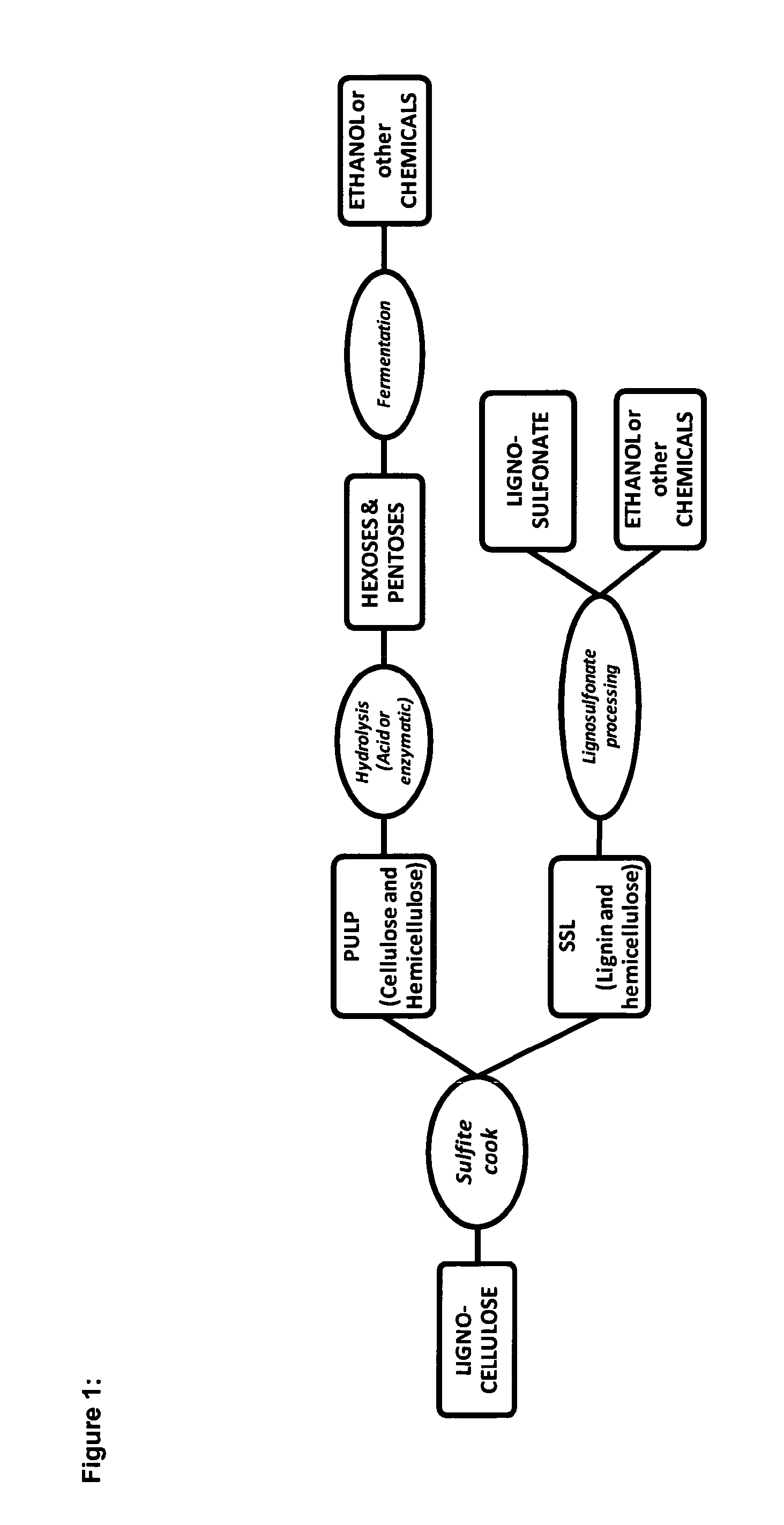

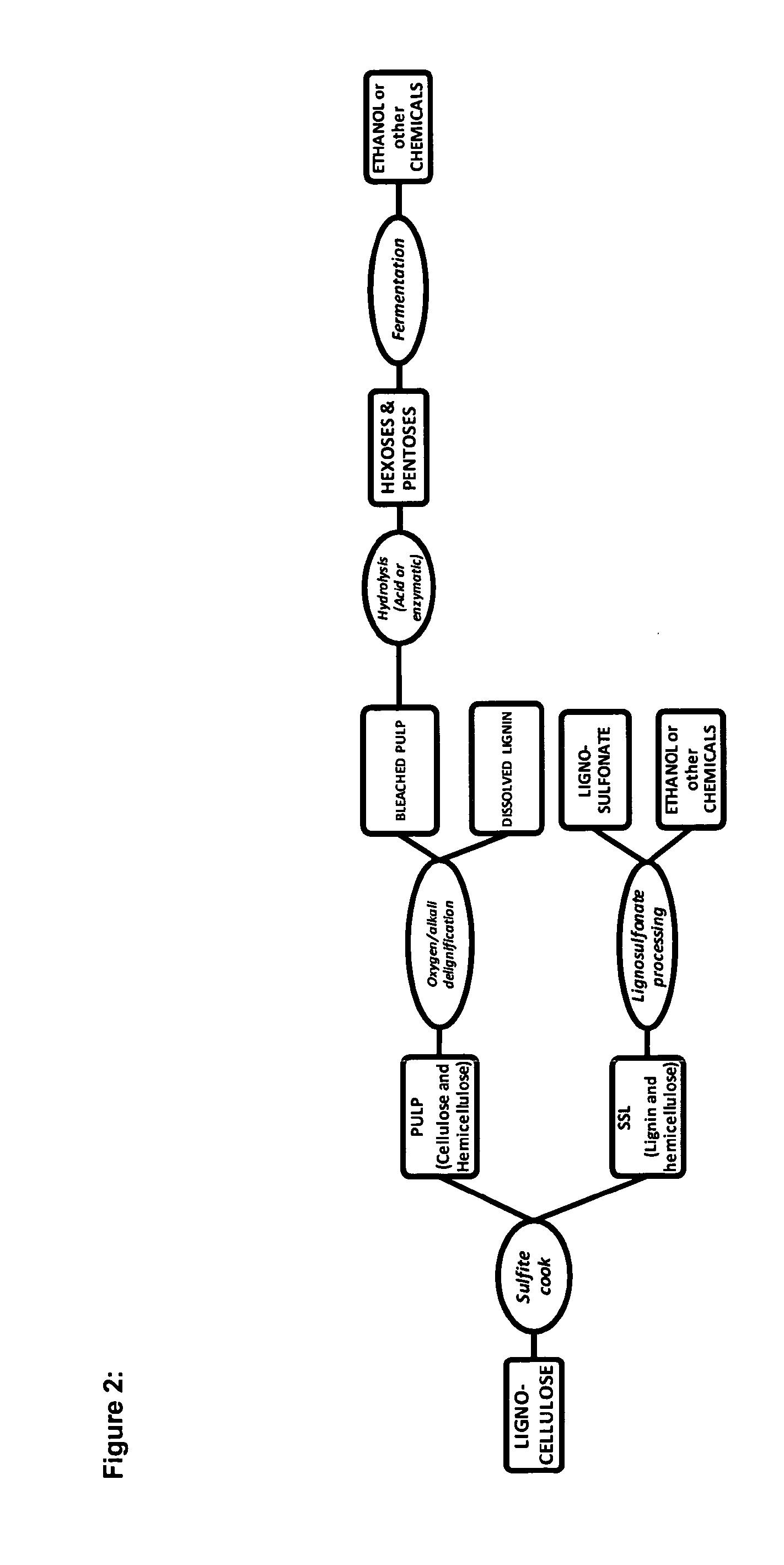

Lignocellulosic biomass conversion

ActiveUS20110250638A1Easy to separateMaintain good propertiesSugar derivativesPretreatment with alkaline reacting compoundsCelluloseSingle-cell protein

The present invention relates to a process for the production of second generation biofuels and / or sugar based chemicals—for example ethanol, butanol etc—and / or materials—for example plastics, single cell proteins etc.—together with sulfonated lignin from lignocellulosic biomass, in particular from lignocellulosic biomass comprising, among others, annual plants, agricultural waste, or wood. In particular, the present invention relates to a process for the production of sugar based chemicals, biofuels or materials together with sulfonated lignin from lignocellulosic biomass comprising the pretreatment of a lignocellulosic biomass in a sulfite cooking step.

Owner:BORREGAARD INDS

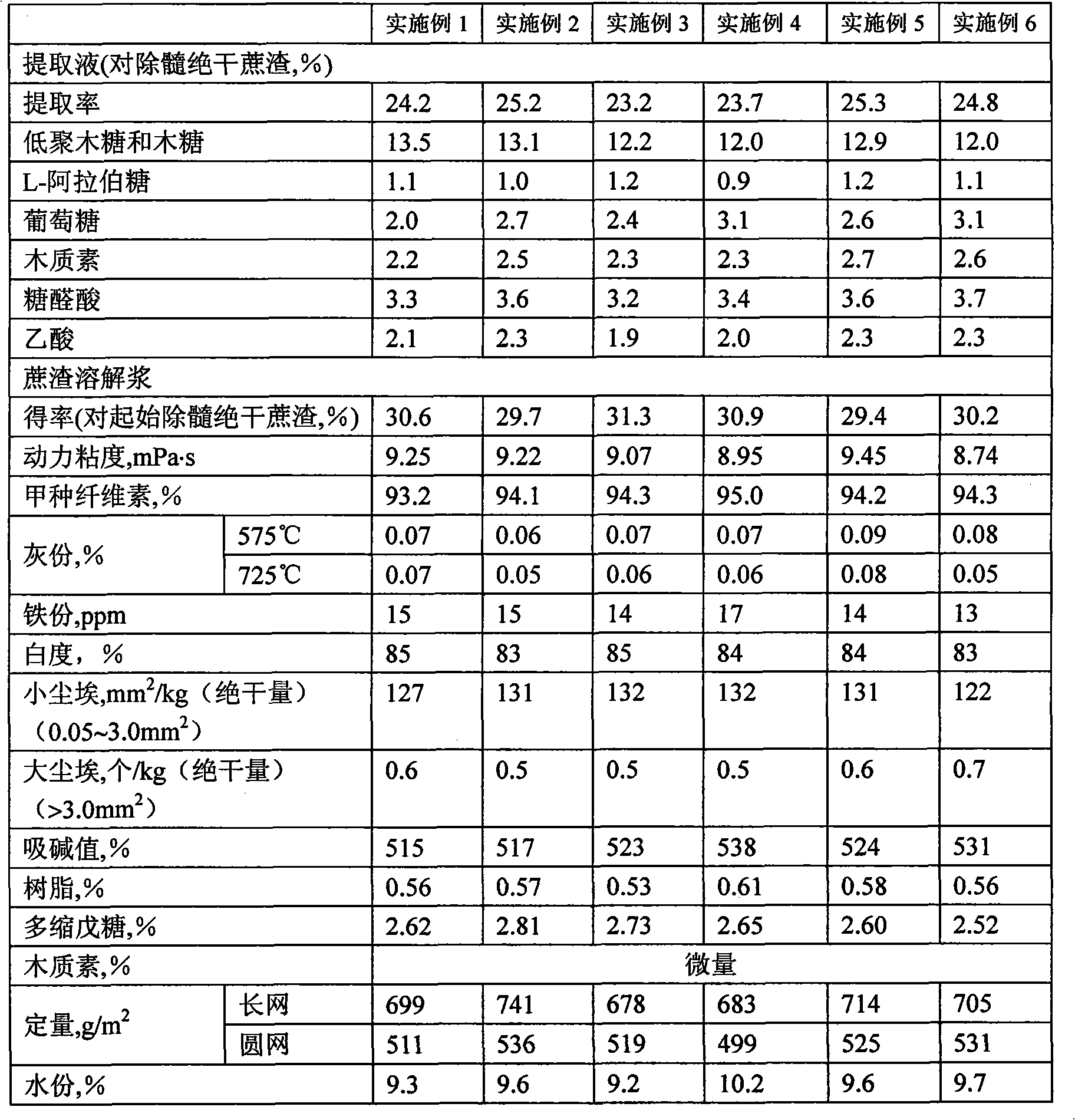

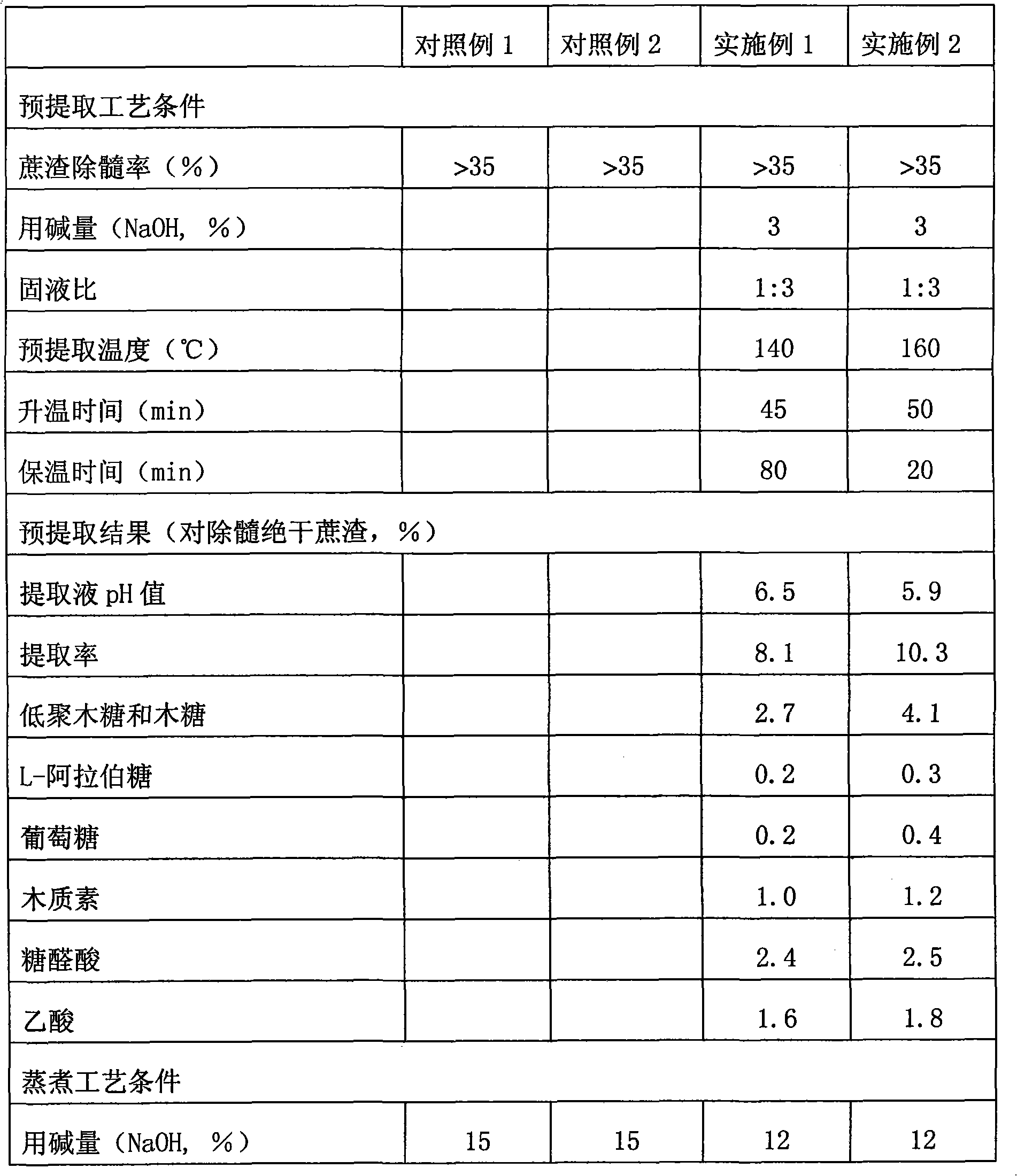

Method for preparing bagasse dissolving pulp and pre-extracting hemicellulose and product thereof

InactiveCN101613970AHigh extraction rateReduce the content of non-sugar organic debrisSugar derivativesPretreatment with acid reacting compoundsLiquid ratioDissolving pulp

The invention relates to a method for preparing bagasse dissolving pulp and pre-extracting hemicellulose and products thereof; the method comprises the following steps: bagasse preparation which comprises the steps of depithing and washing; prehydrolysis which is carried out in a globe digester or a hydrolysis boiler; wherein, the process conditions are as follows: in the process for depithing and oven-drying bagasse, the solid-to-liquid ratio is 1:0.4-8.0, the hydrolysis temperature is 100-200 DEG C, the hydrolysis time is 15-240min, the pH value of the end point of hydrolysis is 2-5; in the process of the solid-to-liquid separation and washing, the filtrate is collected to prepare extracting solution; dissolving pulp is prepared by residue alkali method. By adopting the method, bagasse dissolving pulp and bagasse extracting solution which is used to prepare oligosaccharides are obtained. Most of pentosan in bagasse can be extracted by controlling the process conditions of the prehydrolysis, the technical route and the process conditions have strong pertinence so that the reactivity and the uniformity of bagasse dissolving pulp can be improved; by improving the traditional dissolving pulp alkali method for pulping, bagasse biorefinery based on dissolving pulp pulping can be realized in engineering so that the production costs for preparing bagasse dissolving pulp and pre-extracting hemicellulose are reduced.

Owner:上海士林纤维材料有限公司

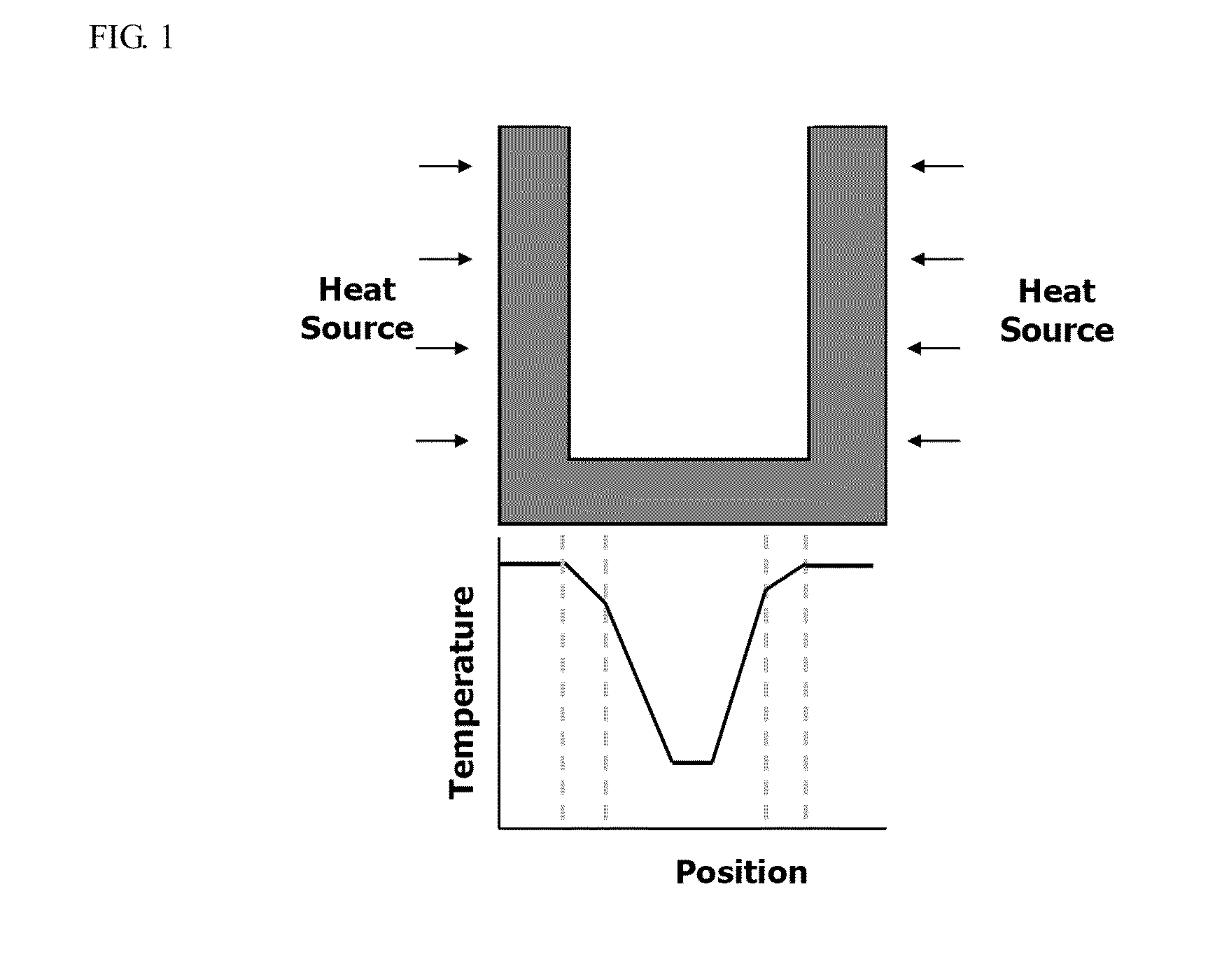

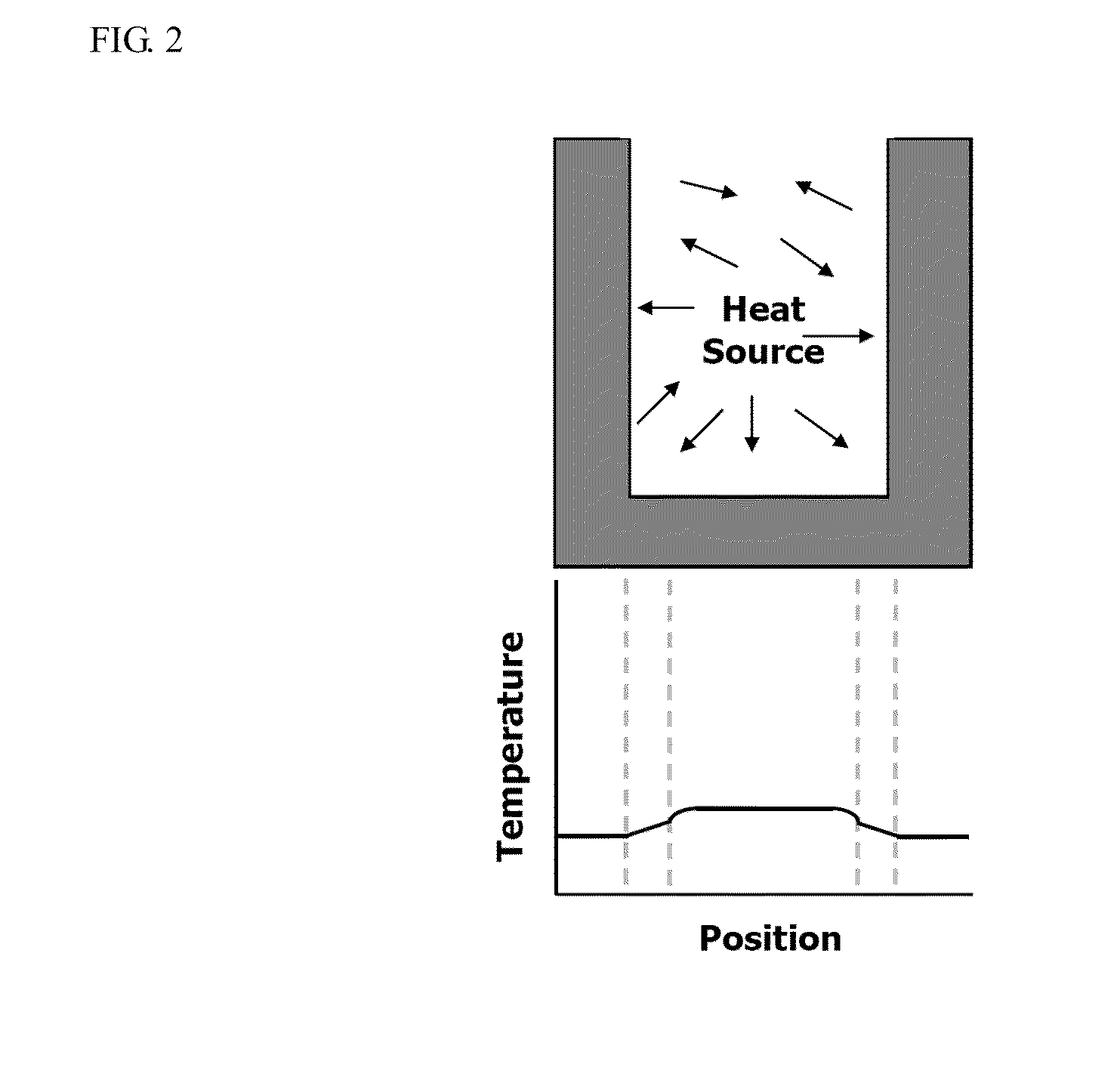

Method and apparatus for pretreating biomass using internal heat

ActiveUS20110143412A1Bioreactor/fermenter combinationsPretreatment with water/steamWater-reactiveProcess engineering

A method for pretreating a biomass, in which a water-reactive anhydride contacts a biomass, is disclosed. The biomass is pretreated using internal heating by an exothermic reaction. Further, an apparatus for pretreating a biomass having a reaction part including an inlet part and an outlet part for the water-reactive anhydride is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

Removal of inorganic elements from wood chips

InactiveUS20050034823A1Less energy consumptionIncrease moisture contentWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsProduction linePregnant leach solution

In a process of treating wood chips for reduction of the concentration of undesirable inorganic elements prior to cooking in a production line for chemical pulp, the wood chips, having entrapped air, are treated with an aqueous leaching liquor at elevated temperature and pressure, followed by draining at atmospheric pressure or below atmospheric pressure, the pressures being controlled to yield a moisture content in the wood chips as low as possible for adequate leaching result and behavior of the chips in a subsequent digester. The aqueous leaching liquor is e.g. pulp mill process water with a low content of undesirable inorganic components, such as bleach plant spent liquor or condensate. The aqueous leaching liquor drained from the treated wood chips may be purified and recycled back to the process.

Owner:STFI

Method for producing pulp and lignin

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

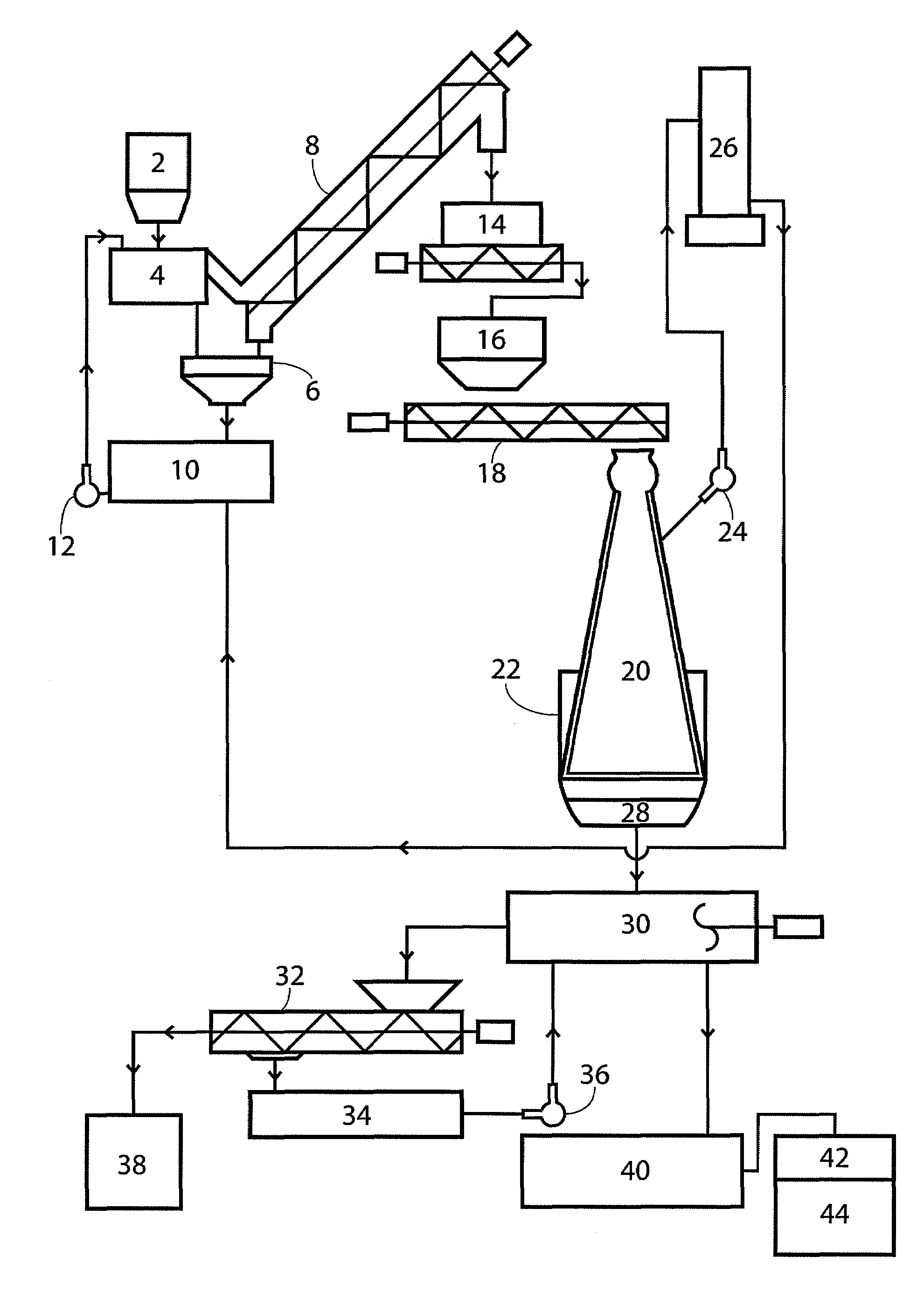

Catalytic reactor process for the production of commercial grade pulp, native lignin and unicellular protein

ActiveUS7396434B2Pulp liquor regenerationWashing/displacing pulp-treating liquorsCelluloseChemical solution

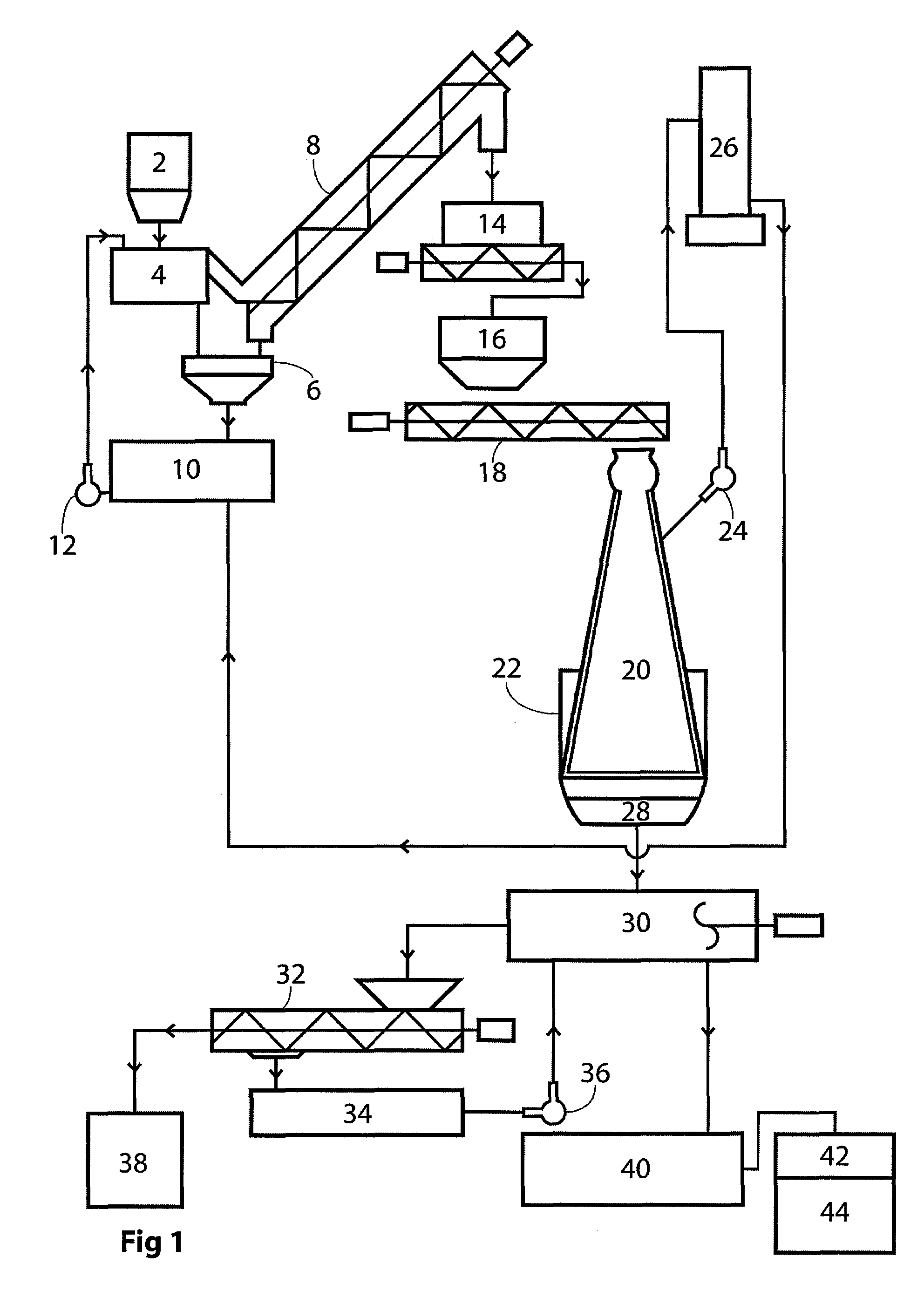

A continuous and batch system to produce cellulose, native lignin and unicellular protein from any form of vegetation in a closed process. The biomass is mixed in the impregnate solution of nitric acid and / or ammonium hydroxide and water. After a period of time at room temperature and atmospheric pressure the chemical solution is recycled. The biomass is moved to the reactor and heated. Evaporated impregnate is recovered via absorption tower and recycled back to chemical solution. The biomass is moved to an alkaline solution, then cooled to separate pulp from black liquor. The black liquor is pumped to a separation tank and is treated to precipitate lignin. The solution is filtered to separate sweet liquor and lignin. The lignin is dried and the sweet liquor is fermented to produce unicellular protein.

Owner:PURE LIGNIN ENVIRONMENTAL TECH

Method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process and product thereof

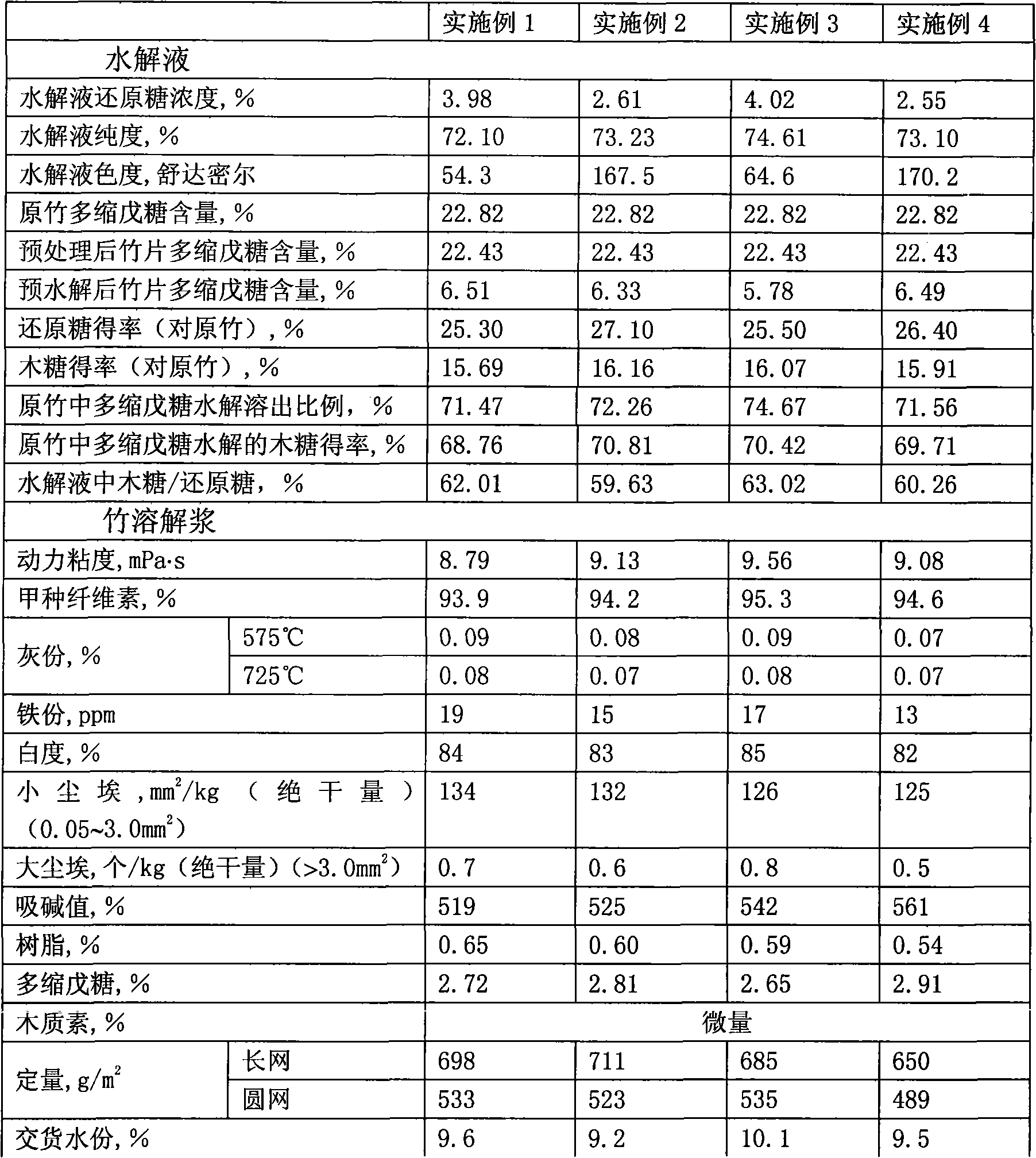

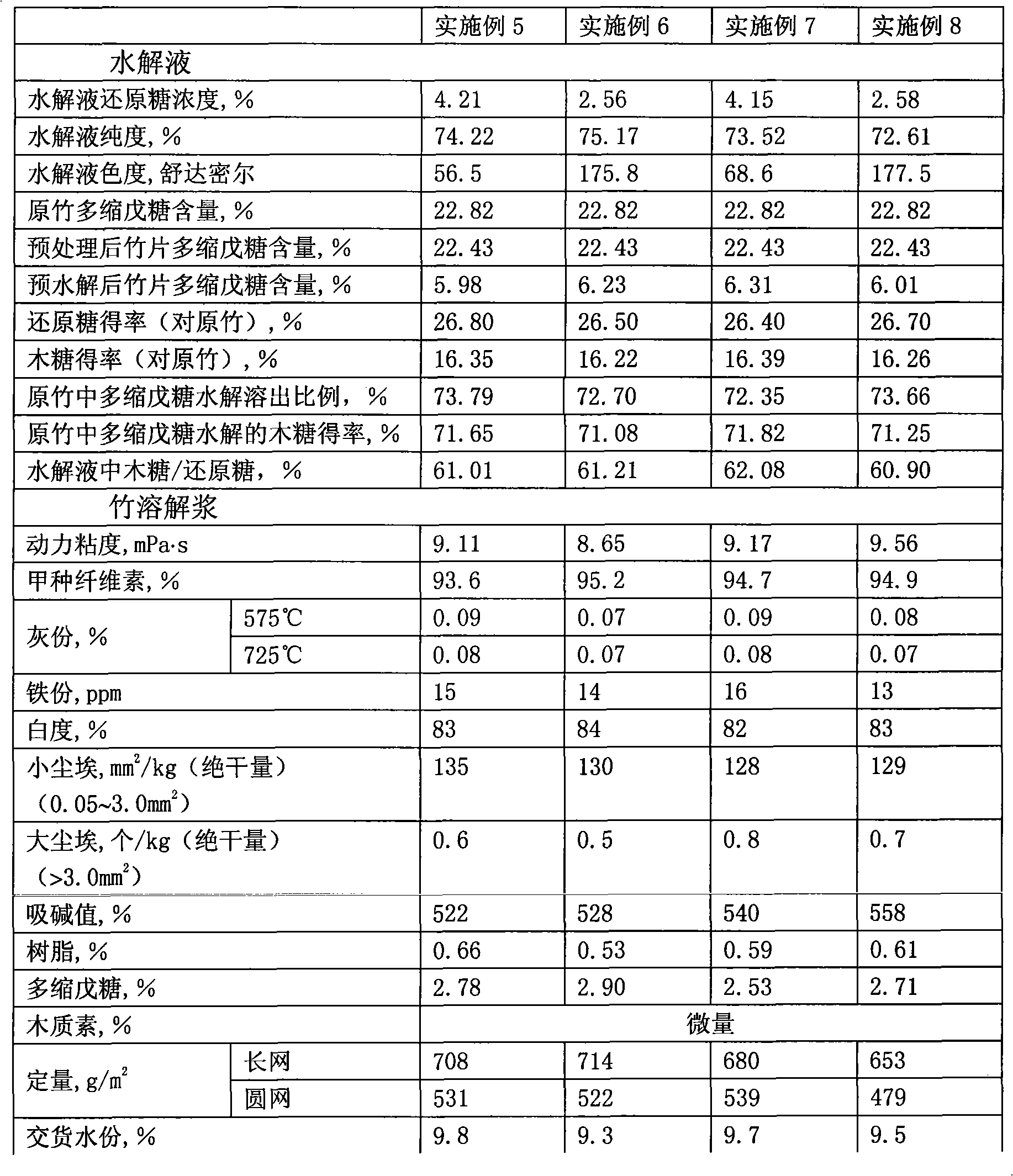

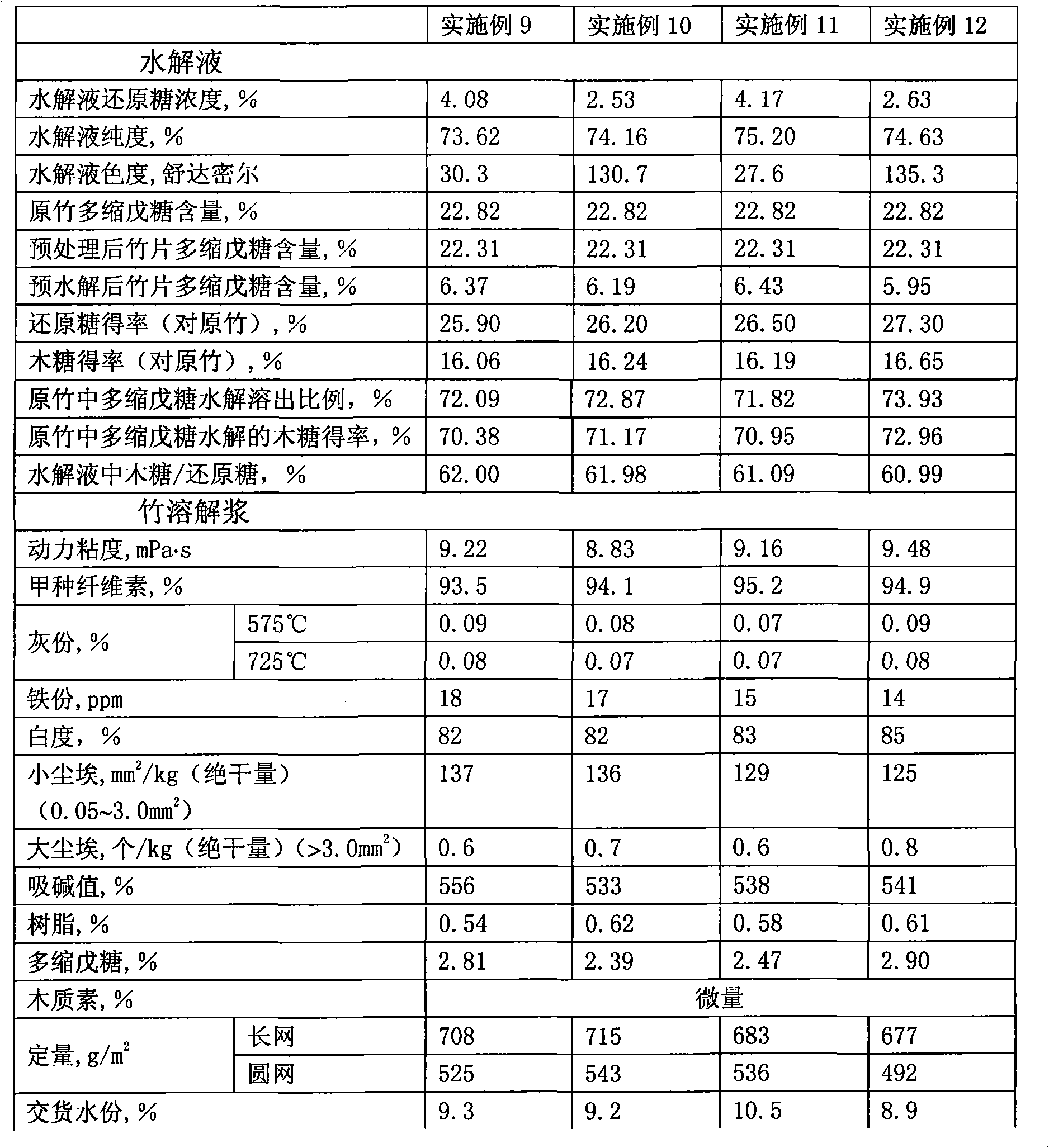

InactiveCN101514529AReasonable range of hydrolyzed reducing sugar concentrationReasonable range of purityPretreatment with acid reacting compoundsPulping with inorganic basesHydrolysatePerformance index

The invention relates to a method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process, which comprises the following steps of: bamboo material preparation, in which bamboo is made into bamboo sheets and bamboo threads, the bamboo sheets and threads are washed to remove impurities and dust; pretreatment, which is for removing more organic and nonorganic impurities, and in which the loss of pentosan is less than 2 percent; prehydrolysis, which is carried out at an acid concentration of sulphuric acid and hydrochloric acid of 0.1 to 10.0 weight percent, a temperature of between 80 and 14 DEG C and a liquor ratio of 1:4-15 for 30 to 400 minutes; and alkaline process. The method has the advantages that: the performance index of the bamboo dissolving pulp meets the requirements of viscose fibre pulp and the like; the improved prehydrolysis process allows the major part of pentosan in the bamboo to be hydrolyzed; the hydrolysate can be used as a raw material for xylose, xylitol, L-Arabinitol, ethanol and other products; the improved prehydrolysis process lays a good foundation for cooking and improving the reaction performance of the dissolving pulp; little production cost is added, the treatment load and cost of waste are reduced with the recovery of the products of the prehydrolysis, and the comprehensive cost is the lowest; and the comprehensive utilization of the components of biomass is realized during the pulping process of the dissolving pump.

Owner:上海士林纤维材料有限公司

Method of Continuous Processing of Lignocellulosic Feedstock

InactiveUS20080293114A1Improve distributionAvoids sugar degradationPretreatment with water/steamSugar derivativesCellulosePre treatment

Owner:IOGEN ENERGY CORP

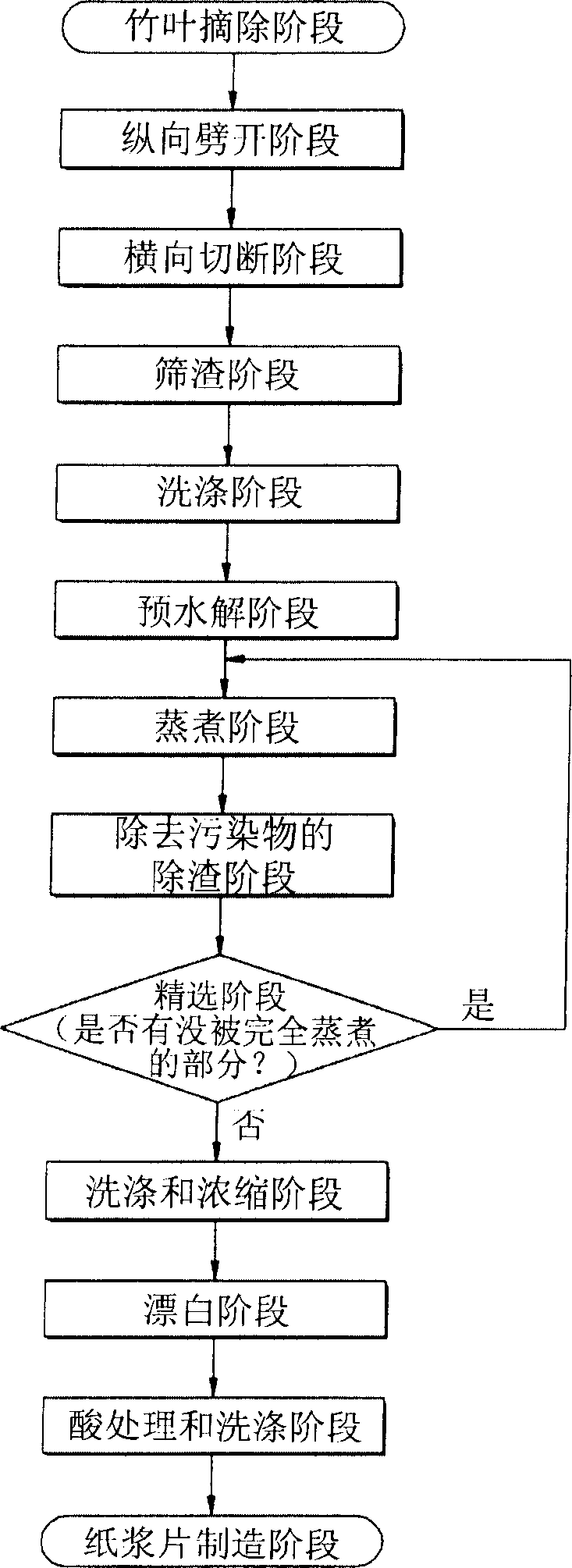

The production method and pulp maked bamboos

InactiveCN1854388AHigh yieldPretreatment with water/steamWashing/displacing pulp-treating liquorsPulp and paper industryCellulose pulp

The present invention relates to a kind of method that utilizes bamboo to make paper pulp, relate to firstly splitting bamboo vertically and transversely and then going through the process of screening and washing to reduce the consumption of medicines in the process of prehydrolysis and pulping and make it easy to react, thereby A method of making pulp from bamboo and its pulp that can produce better-quality, higher-yield dissolving pulp, and that can prevent the generation of dioxins by using the bleaching method of ECF or TCF. Since the anthraquinone caustic soda method using anthraquinone as a catalyst is used in the cooking process, the effects of improving delignification and pulp quality and increasing pulp yield are obtained. Also, the content and degree of polymerization of α-cellulose can be arbitrarily adjusted according to the characteristics of the man-made fibers produced as desired by adjusting the conditions of prehydrolysis, cooking and bleaching. At the same time, by recovering xylose produced in the dissolving pulp manufacturing process, it is used to manufacture xylitol, seasoning, furfural, etc., thereby contributing to the improvement of resource utilization and economic efficiency of waste.

Owner:李权革

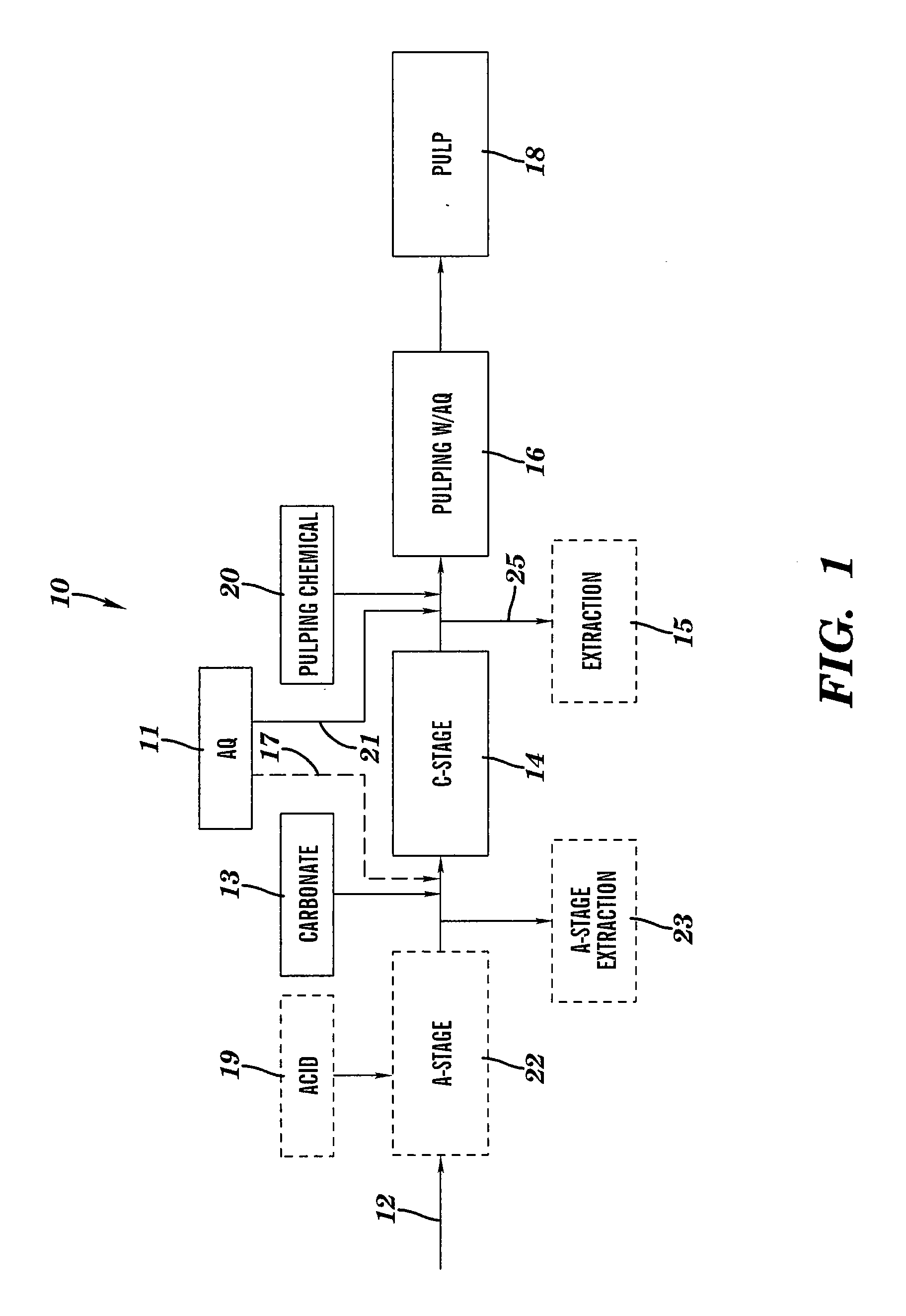

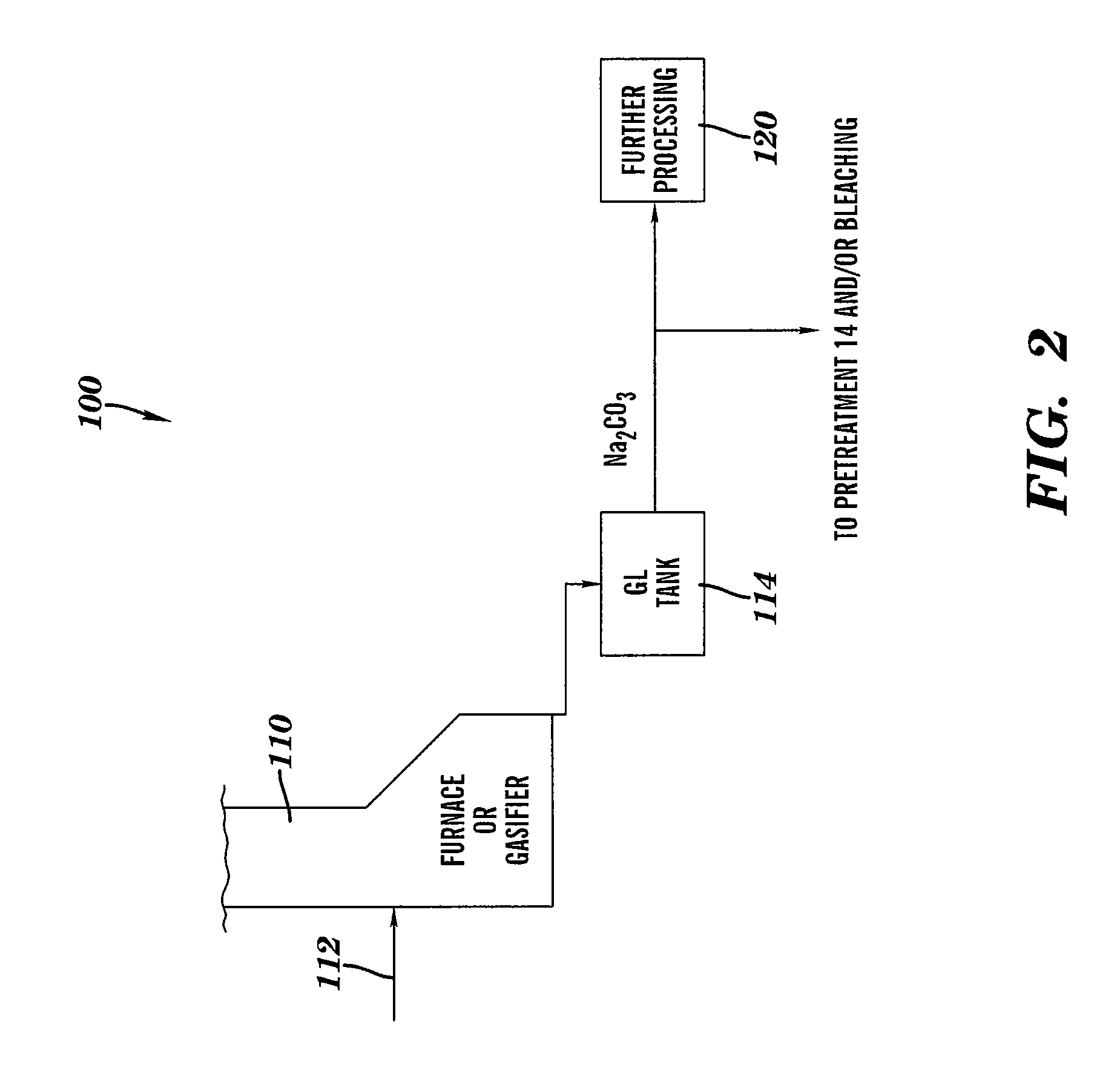

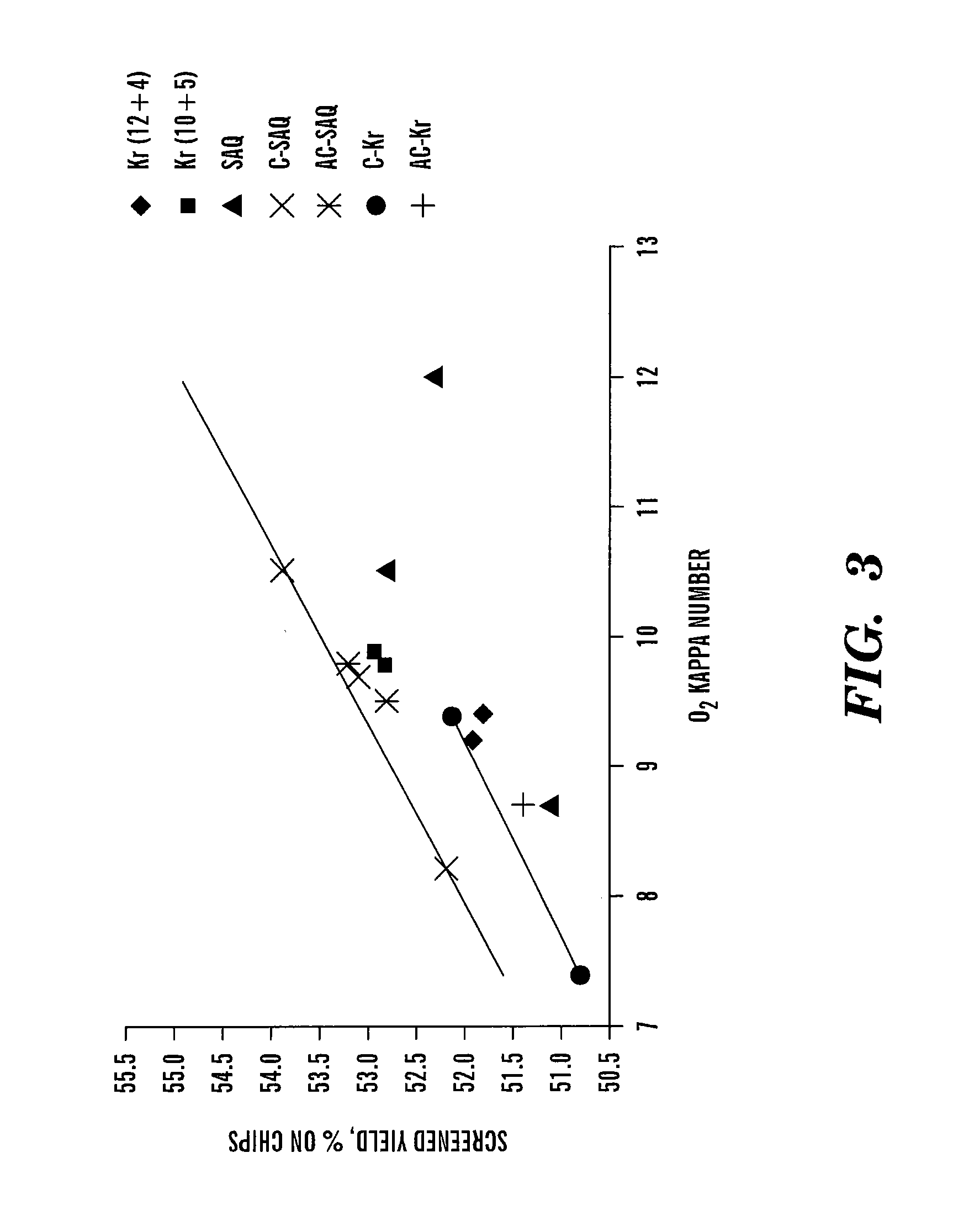

Methods for carbonate pretreatment and pulping of cellulosic material

InactiveUS20070284068A1Pulp liquor regenerationPretreatment with acid reacting compoundsFiberCarbonate

A method of pretreating comminuted fibrous material with sodium carbonate and then cooking the pretreated material in the presence of anthraquinone (AQ) is provided. The resulting pulp produced has a higher yield, enhanced strength, and better bleachability compared to pulp produced by prior art methods. AQ may also be introduced to the carbonate pretreatment stage. The method may further include an acid pretreatment providing further enhanced properties to the pulp produced.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Biomass pretreatment process

ActiveUS20110114876A1Pressurized chemical processPretreatment with alkaline reacting compoundsCelluloseLignocellulosic biomass

A process is disclosed for pretreating lignocellulosic biomass. The process comprises swelling the lignocellulosic biomass with an aqueous liquid. The pretreated lignocellulosic biomass may be used as a feedstock for the enzymatic conversion to ethanol, or in a thermal conversion process to produce bio-oil. The pretreatment results in a greater yield and, in the case of a thermal conversion process, a better quality of the bio-oil.The pretreatment process may be used to adjust the composition and amount of inorganic material present in the lignocellulosic biomass material.

Owner:MARD INC

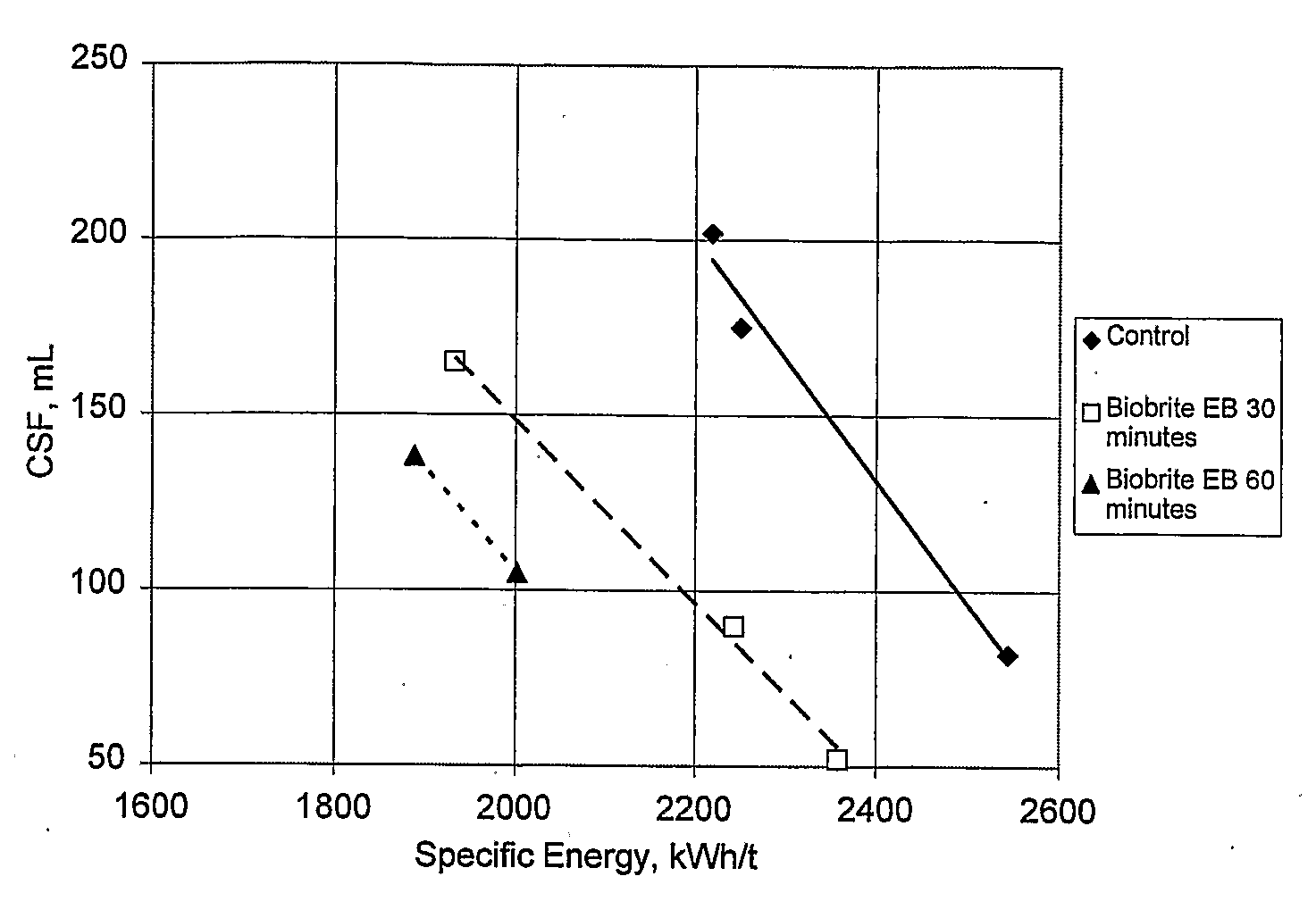

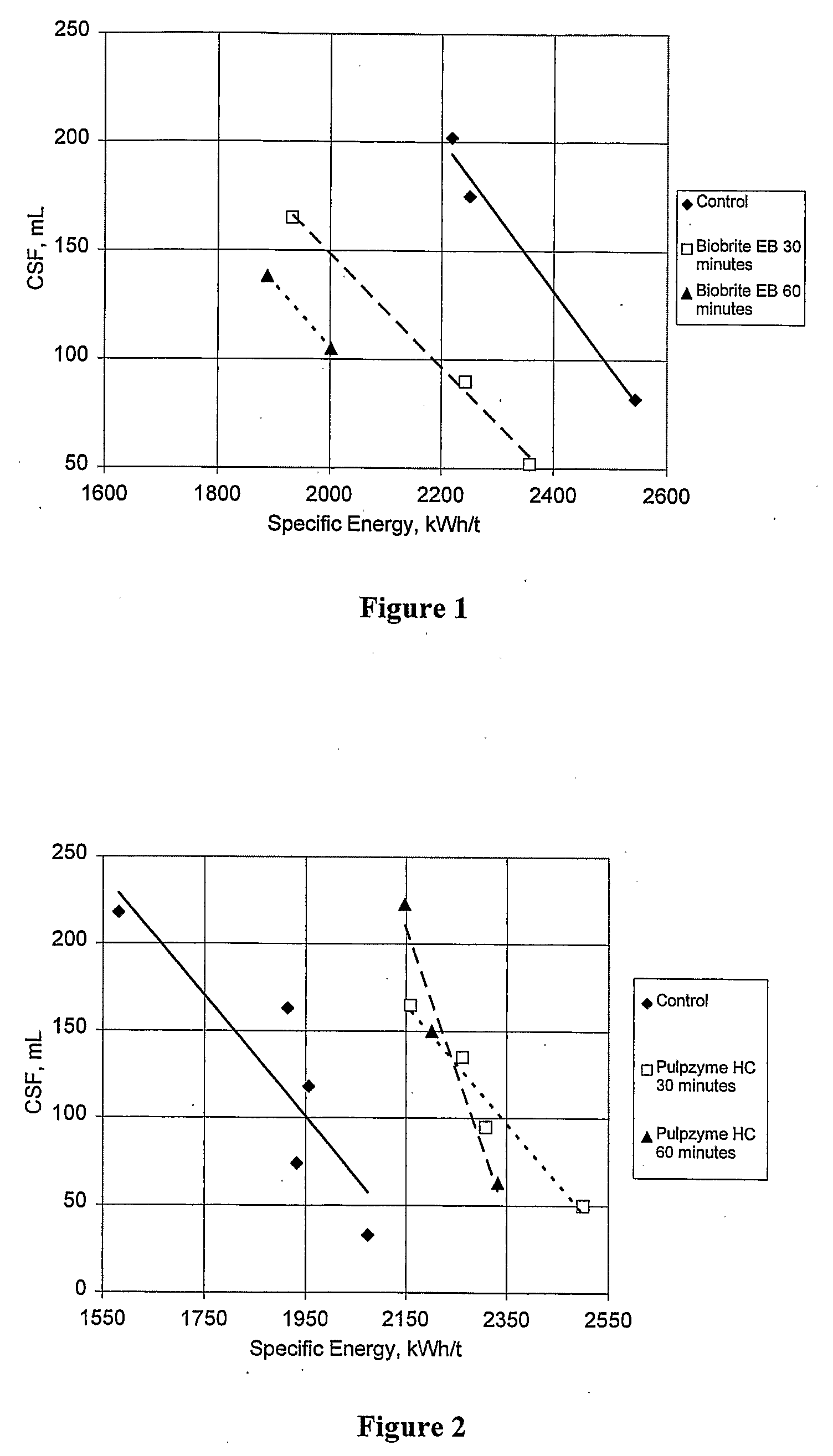

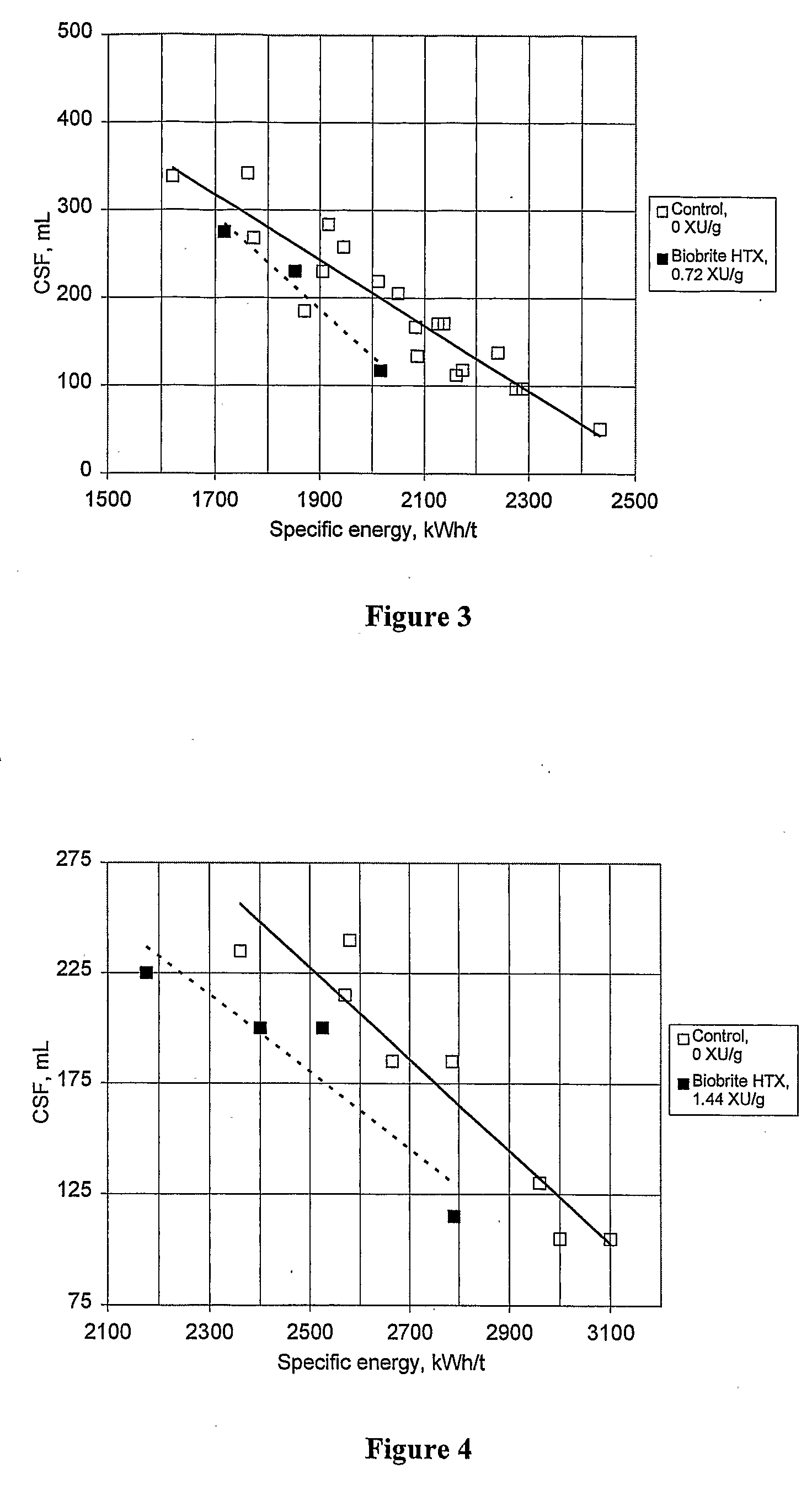

Method For Mechanical Pulp Production

InactiveUS20090107643A1Reduce refiner energyHigh energyPretreatment with water/steamPretreatment with acid reacting compoundsPulp and paper industryOxidative enzyme

A method of producing hardwood pulp is provided. This method comprises treating hardwood chips with one or more than one Family 11 xylanase enzyme in the absence of adding an oxidizing enzyme for about 5 minutes to about 120 minutes, to produce a treated chip mixture. The treated chip mixture is then mechanically refined to produce the hardwood pulp.

Owner:CENT TECHN IND DIT CENT TECHN

Method for producing bamboo pomace

ActiveCN1974921AIncreased surface area per unit weightPenetrate fastWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsPomaceViscose fiber

The present invention provides a preparation method of bamboo pulp, belonging to the field of chemical fiber technology. Said method includes the following steps: obliquely cutting bamboo strip material into the form of horseshoe, the chip cross-section spacing distance is 20-40 mm, then prehydrolyzing the prepared bamboo strip, adding alkali and cooking, removing sand, making one-stage or two-stage bleaching treatment, making the bleached pulp material undergo the processes of acid treatment, concentration and pulping so as to obtain the invented bamboo pulp. Said bamboo pulp can be used for producing viscose fibre.

Owner:吉林化纤股份有限公司

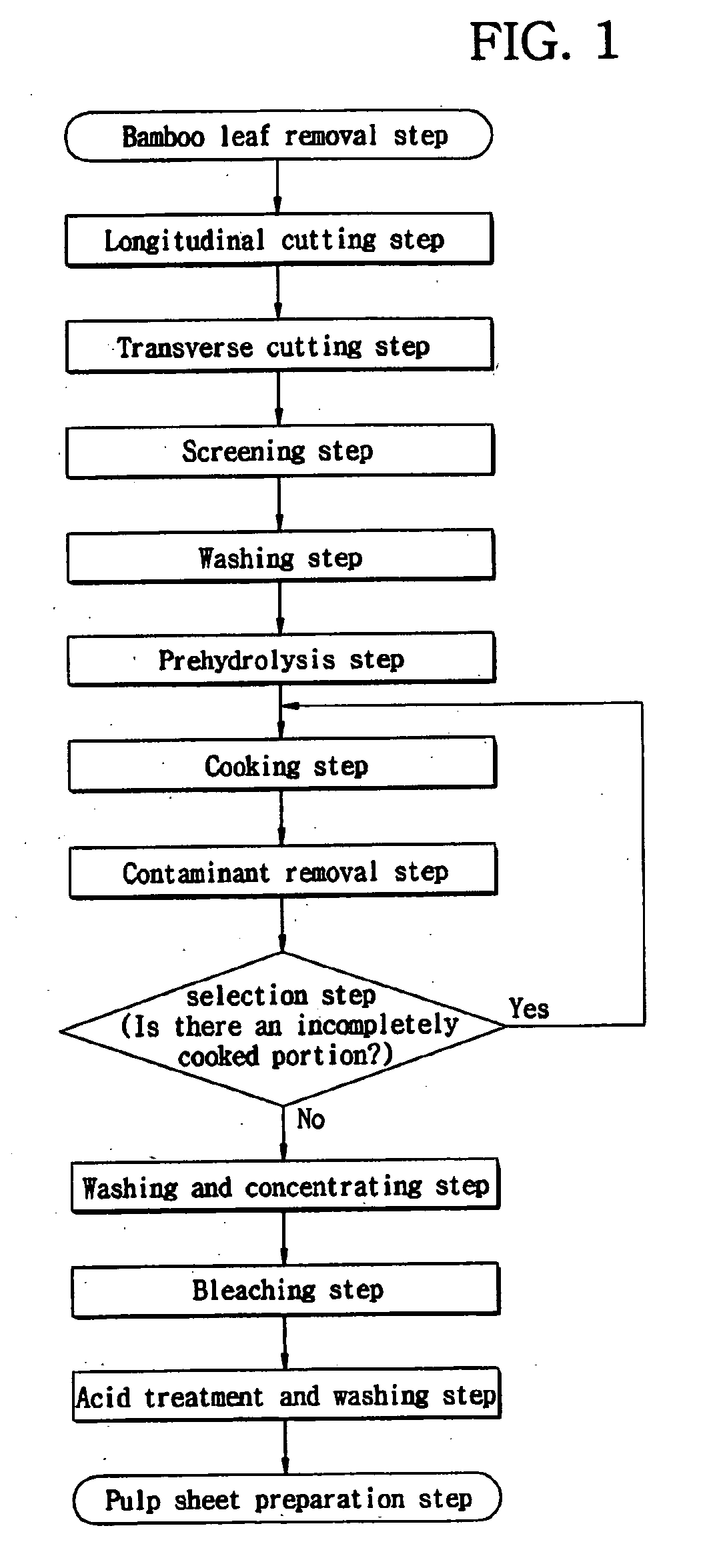

Process for Producing Fiber Pulp Utilizing Bamboo and Pulp Produced Using the Same

InactiveUS20080295982A1Low environmental pollutionPretreatment with water/steamWashing/displacing pulp-treating liquorsFiberPulp and paper industry

Disclosed is a process for producing pulp utilizing bamboo, comprising finely cutting the bamboo into short segments and subjecting the cut bamboo to screening and washing processes to thereby produce dissolving pulp capable of achieving reduced consumption of chemical agents used during pre-hydrolysis and pulping processes and case of reaction, and having superior quality and high yield. Further, provided are also a process for producing fiber (dissolving) pulp utilizing bamboo, capable of preventing generation of dioxin by bleaching the pulp via ECF or TCF bleaching, and a pulp produced using the same.

Owner:LEE KWON HYOK +1

Organic material production system using biomass material and method

ActiveUS8163517B2Efficiently saccharifyingImprove efficiencyBioreactor/fermenter combinationsPretreatment with water/steamAlcoholDecomposition

An organic material production system using biomass material includes: a hydrothermal decomposition apparatus (13) that causes the biomass material (11) and hot compressed water (12) to countercurrently contact with each other and undergo hydrothermal decomposition, and that transfers a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from a biomass solid residue; a cellulose enzymatic saccharification device (17) that treats, with an enzyme, cellulose in the biomass solid residue, so as to enzymatically saccharify the cellulose to a first sugar solution containing hexose; an alcohol fermenter (18) that produces alcohols by fermentation using the obtained first sugar solution; a sulfuric acid decomposition device (33) that decomposes, with sulfuric acid, the hemicellulose component in hot water (30) discharged from the hydrothermal decomposition apparatus, which contains the eluted lignin component and the eluted hemicellulose component, so as to decompose the hemicellulose component to a second sugar solution containing pentose; and a second alcohol fermenter (34) that produces, using the second sugar solution containing pentose, alcohols by fermentation.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

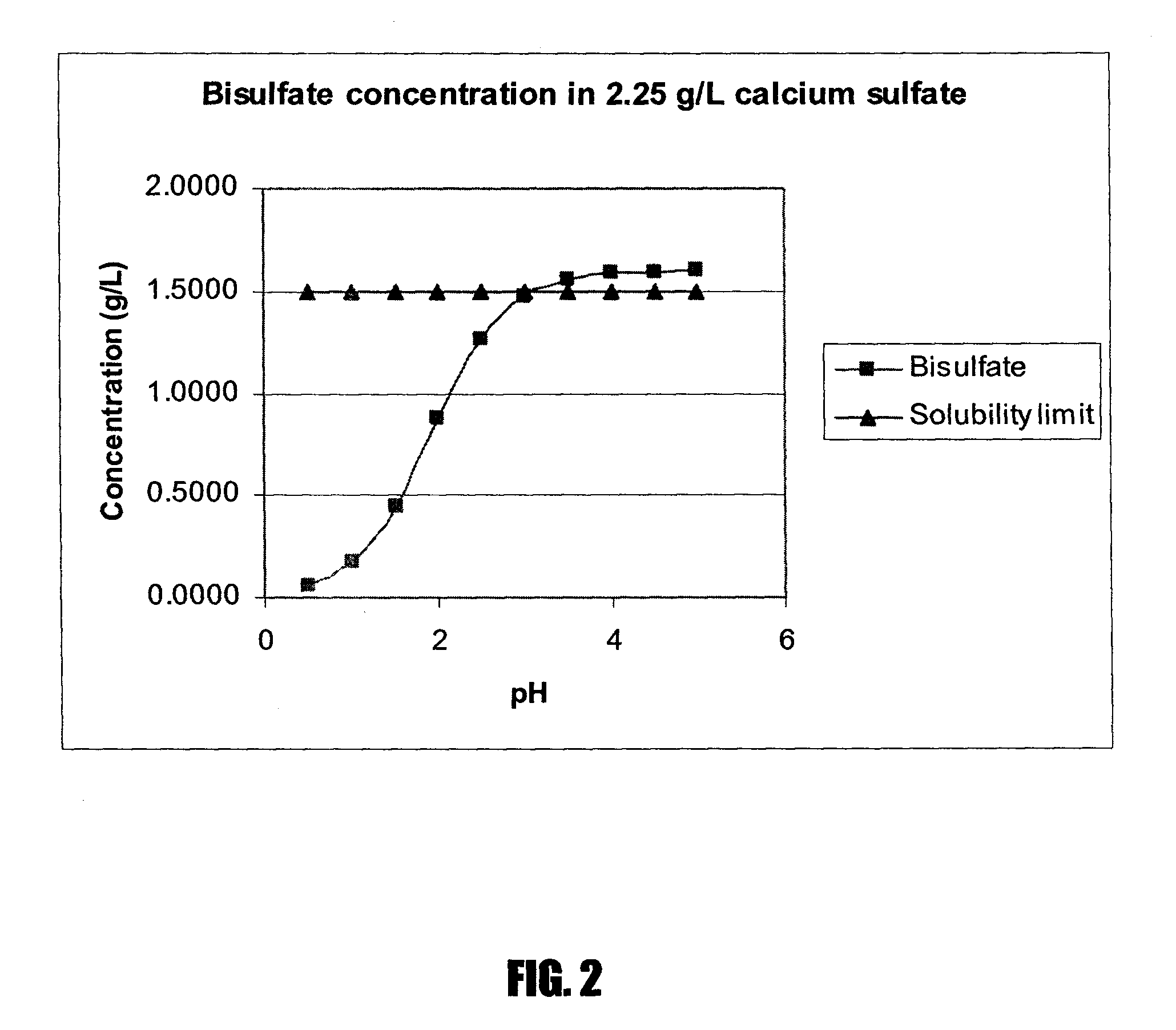

Biomass treatment for hydrothermal hydrocatalytic conversion

InactiveUS20150167238A1Reduced effectivenessMinimize amount of waterPretreatment with water/steamPretreatment with alkaline reacting compoundsCatalytic transformationHydrodeoxygenation

A selective removal of metal and its anion species that are detrimental to subsequent hydrothermal hydrocatalytic conversion from the biomass feed prior to carrying out catalytic hydrogenation / hydrogenolysis / hydrodeoxygenation of the biomass in a manner that does not reduce the effectiveness of the hydrothermal hydrocatalytic treatment while minimizing the amount of water used in the process is provided.

Owner:SHELL OIL CO

Process for treating biomass

ActiveUS20130289268A1Promote digestionIncrease enzyme digestibilityPretreatment with water/steamSugar derivativesMarine engineeringWater content

This invention is directed to a process for treating biomass. The biomass is treated with a biomass swelling agent within the vessel to swell or rupture at least a portion of the biomass. A portion of the swelling agent is removed from a first end of the vessel following the treatment. Then steam is introduced into a second end of the vessel different from the first end to further remove swelling agent from the vessel in such a manner that the swelling agent exits the vessel at a relatively low water content.

Owner:MICHIGAN BIOTECH INST

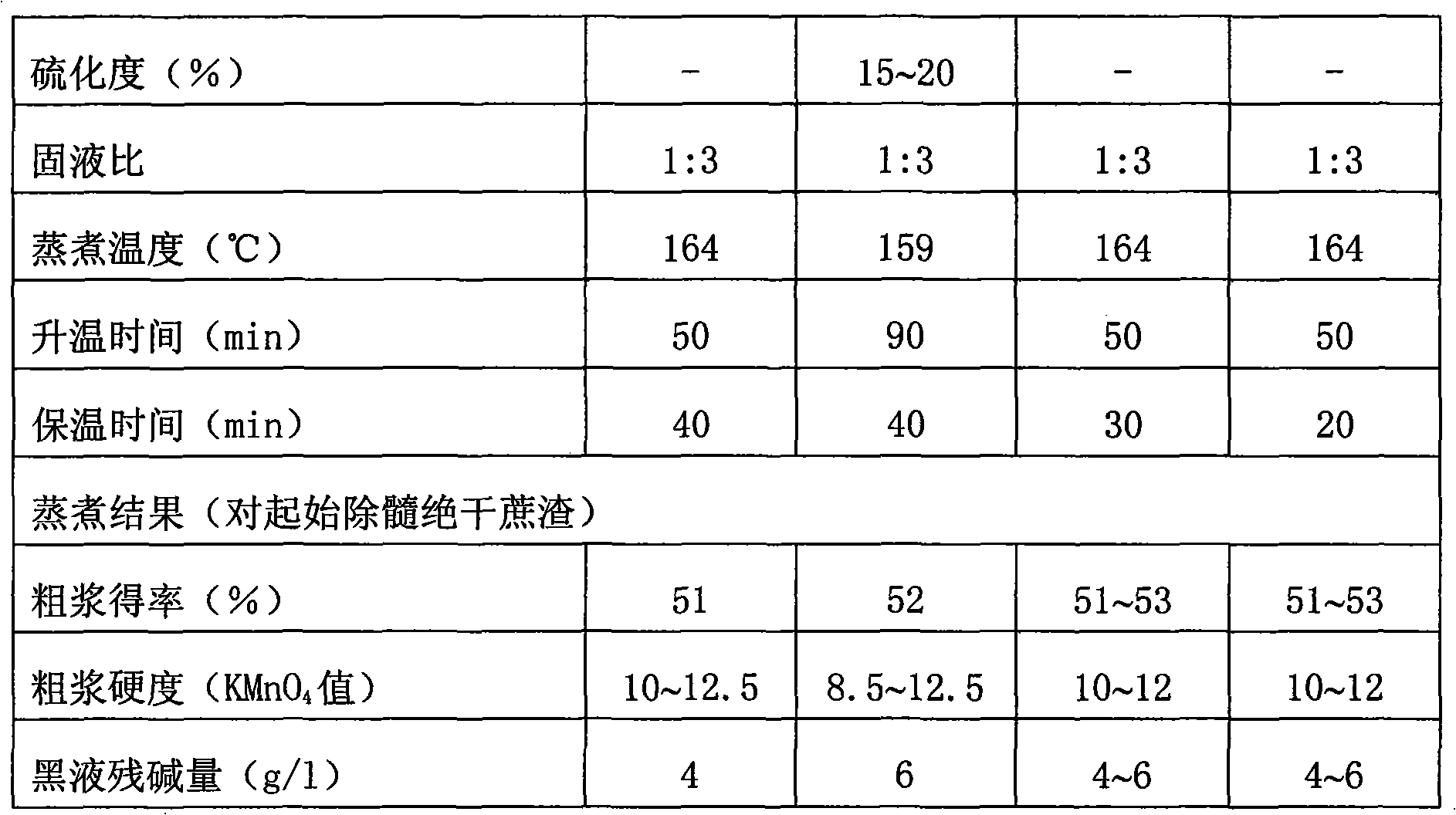

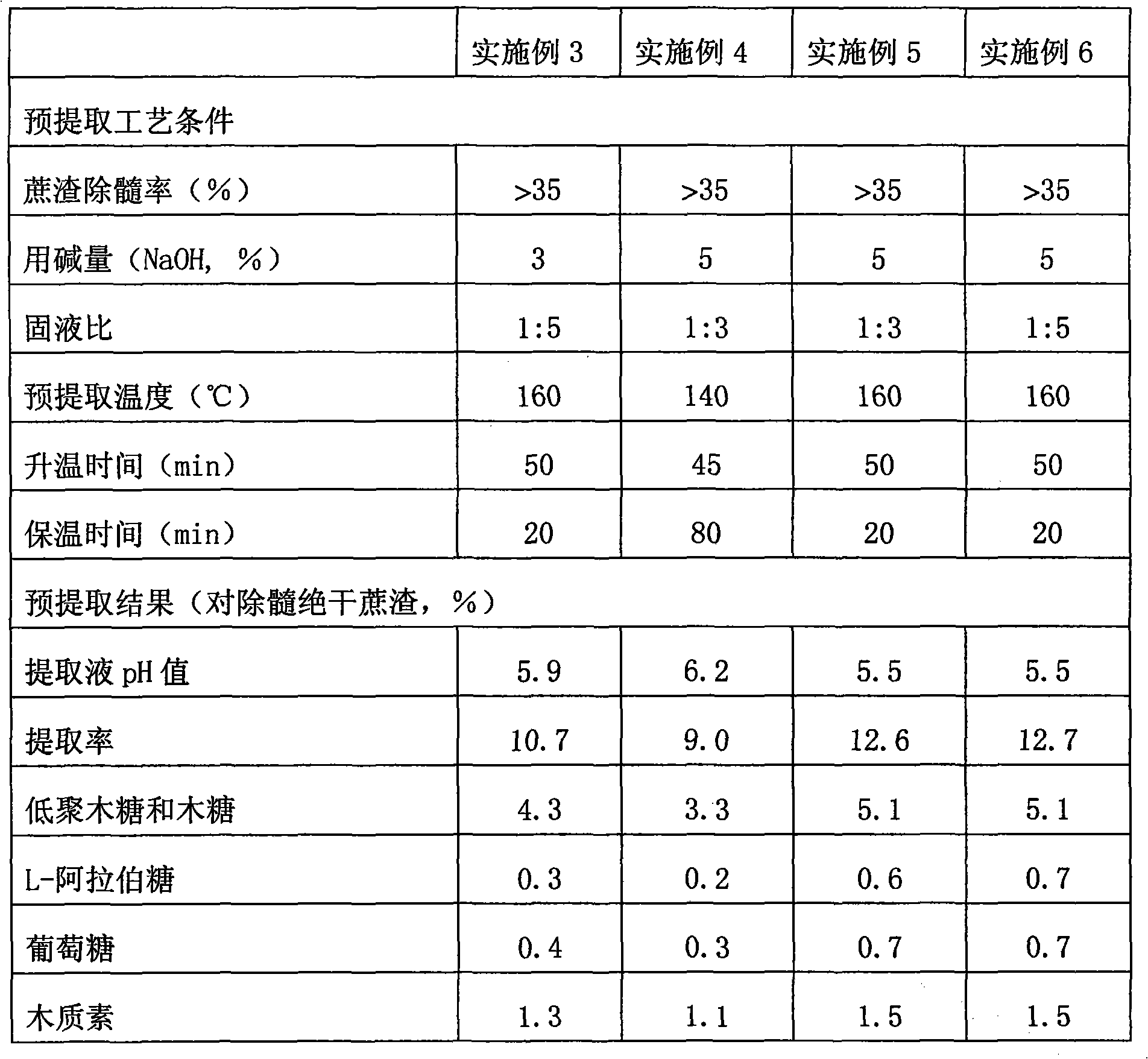

Bagasse alkaline pulping method by pre-extracting hemicellulose and product thereof

InactiveCN101565907ALess investmentReduce manufacturing costSugar derivativesPretreatment with acid reacting compoundsSteam pressureSolvent

The invention relates to a bagasse alkaline pulping method by pre-extracting hemicellulose and a product thereof; the method includes the following steps of: preparing bagasse: depithing and washing the bagasse; pre-extraction, in which the extracted solvent is sodium hydroxide solution and the technical condition comprises an alkaline content of 1-8percent, a solid-to-liquid ratio of 1:2.5-8.0, extraction temperature of 80-180 DEG C, heating-up time of 10-120 minutes, holding time of 0-120 minutes, a pH value of 4.5-6.9 at a reaction end point, and the pressure of saturated steam pressure at corresponding temperature; liquid solid separation and washing: collecting filtrate to produce extract; and preparing the pulp by residue alkaline process. In the invention, bagasse extract capable of extracting xyio-oligosacchandes, and the like and bagasse rough pulp for preparing whitened chemical pulp can be obtained; with a pre-extraction procedure added before stewing, the unscreened yield and hardness of bagasse are equivalent to that of pure pulping without pre-extraction by controlling the pre-extraction and stewing technical condition; bagasse biological refining on a pulping basis is realized; and the cost for pulping and pre-extracting hemicellulose is reduced, thereby saving resources.

Owner:上海士林纤维材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com