Method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process and product thereof

A technology of dissolving pulp and pre-hydrolysis, which is applied in pulping with inorganic alkali, pretreatment with acidic compounds, non-woody plant/crop pulp, etc., can solve the problems of process shortening and waste of resources, and achieve the reduction of processing costs and comprehensive The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

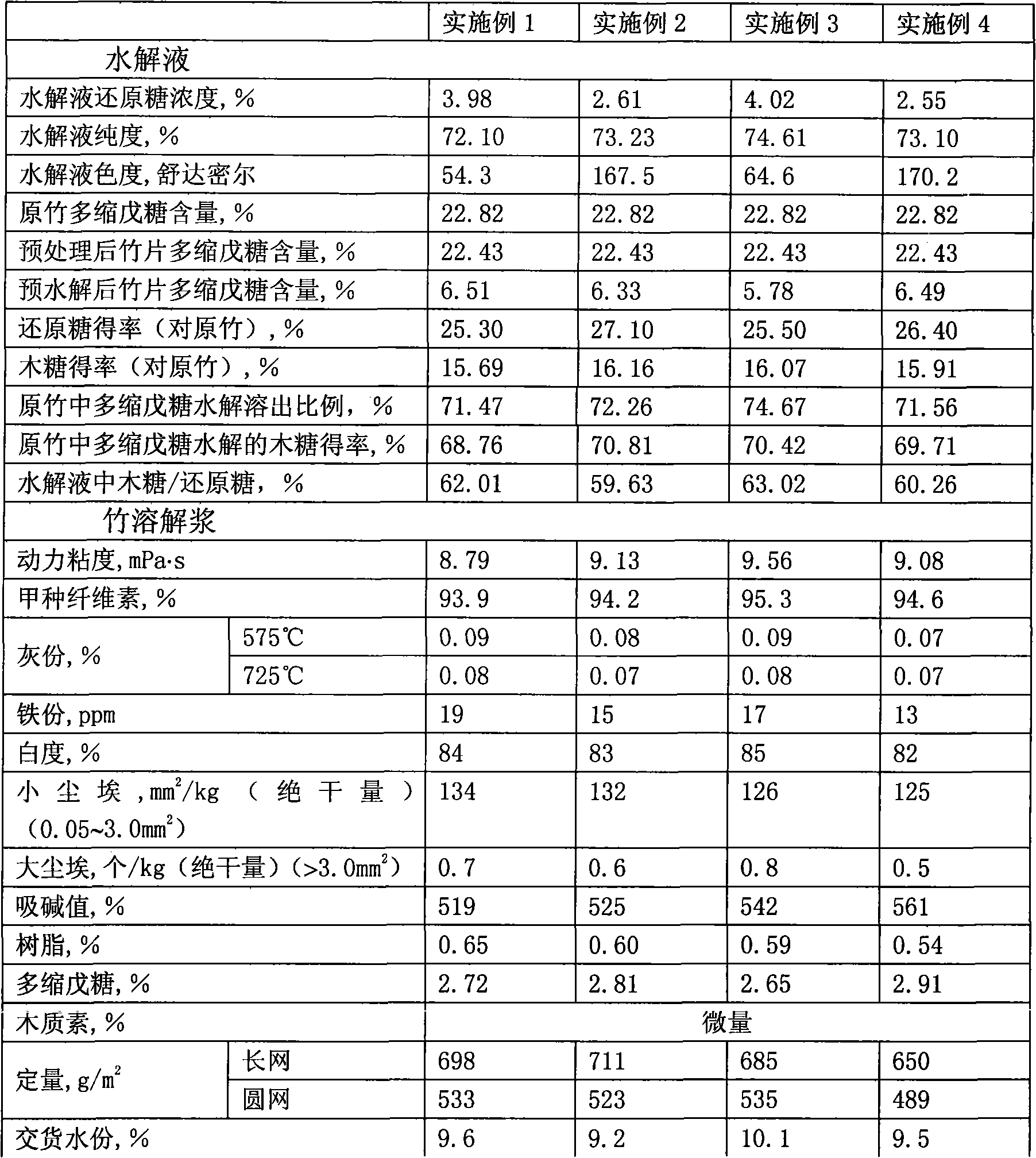

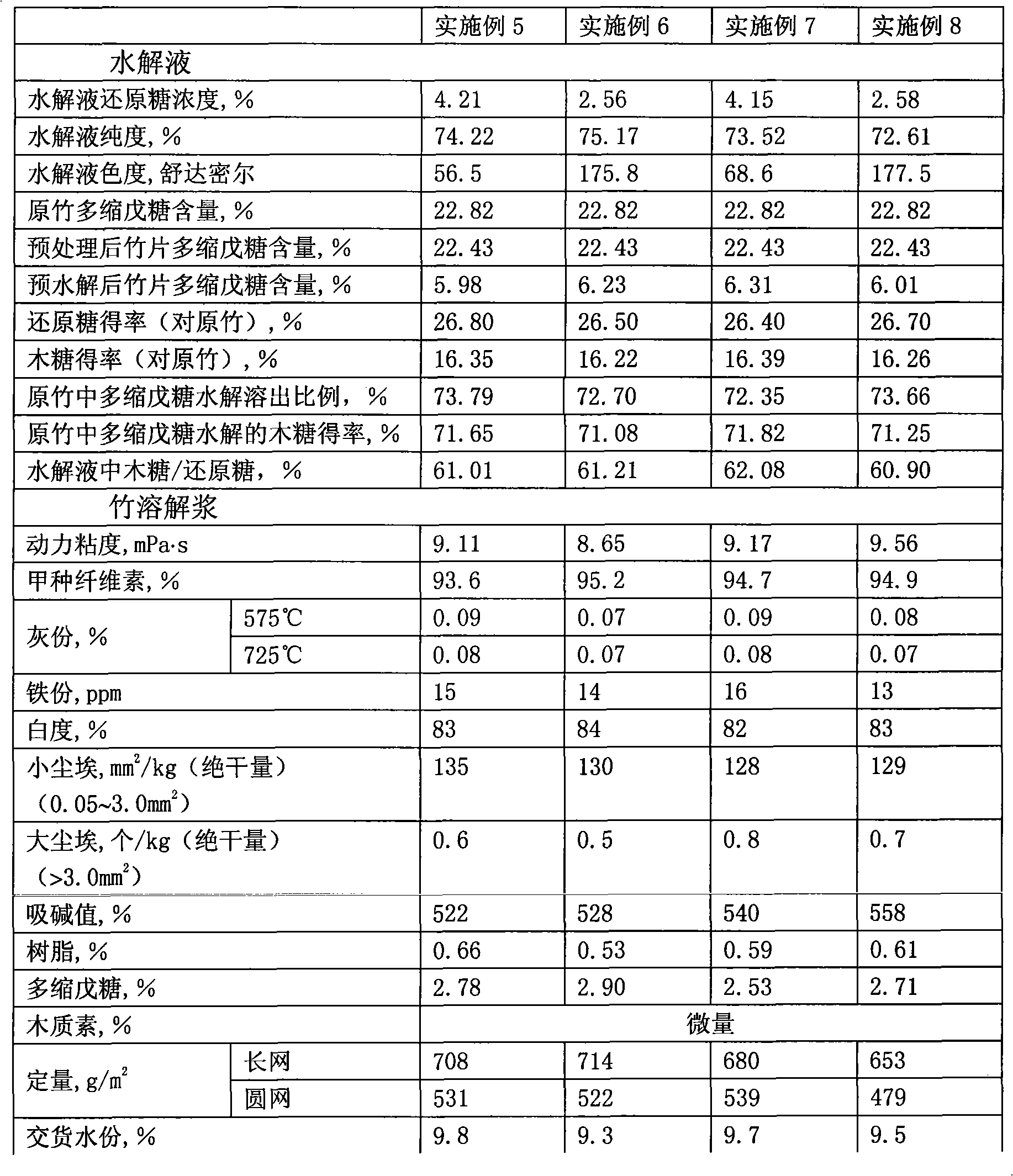

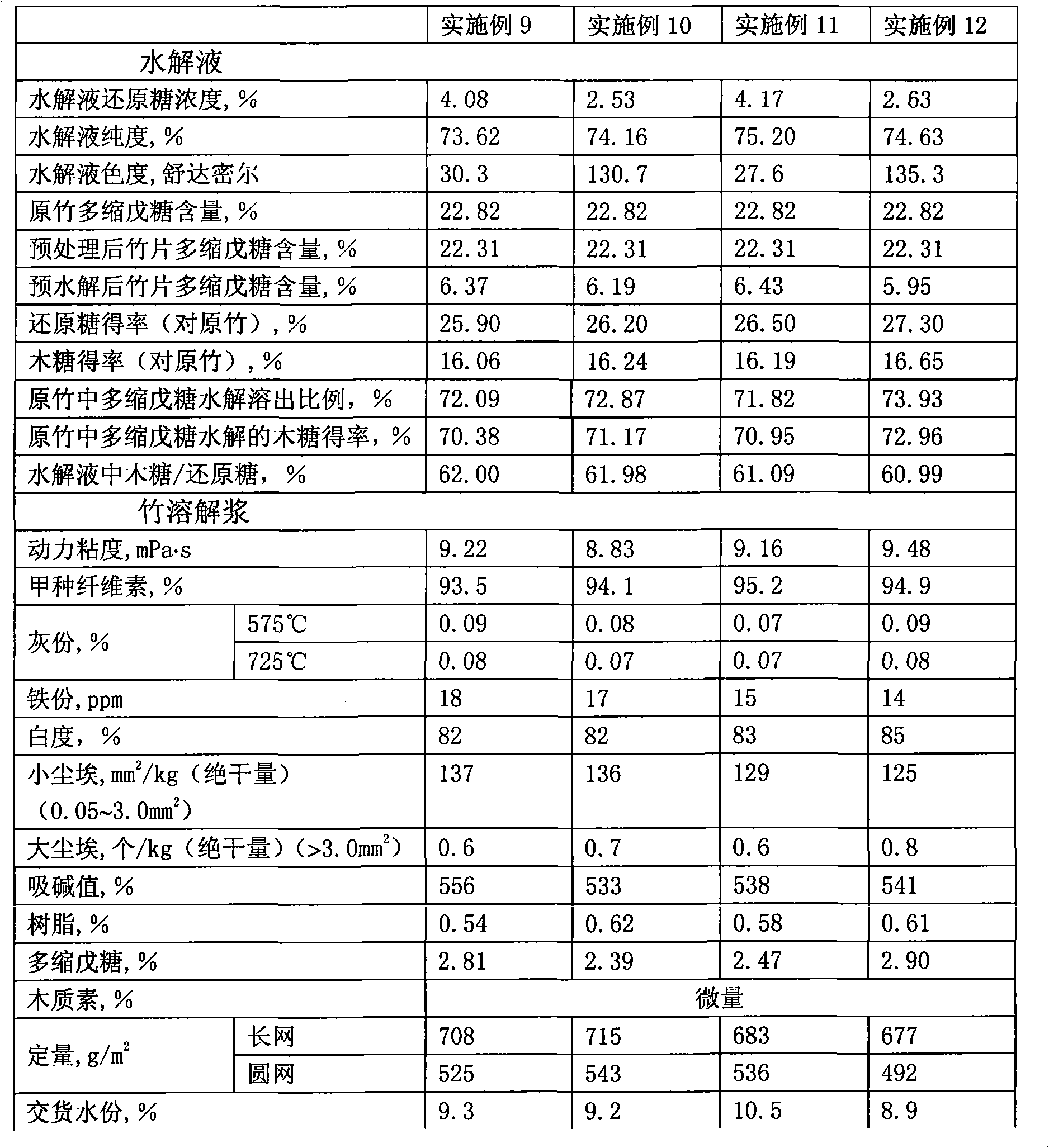

Examples

Embodiment 1

[0066] Provide a kind of method that the improved pre-hydrolysis alkali method manufactures bamboo dissolving pulp, comprises the steps:

[0067] (1) Bamboo material preparation: cut two to three-year-old bamboo into bamboo chips with a length of 15-30mm, a width of 10-20mm, and a thickness of 3-8mm through a slicer, screen through a high-frequency vibrating screen, and spray and wash with high-pressure water , remove impurities and dust;

[0068] (2) Pretreatment: carried out in a hydrolysis pot, the treatment agent is sulfuric acid, and the process conditions are: the sulfuric acid concentration is 0.1wt%, the temperature is 110 ° C, the liquid ratio is 1: 10, the treatment time is 60 minutes, and the treatment is discharged after the pretreatment liquid, and washing material;

[0069] (3) Pre-hydrolysis: carried out in a hydrolysis pot, the hydrolysis catalyst is sulfuric acid, and the process conditions are: the concentration of sulfuric acid is 0.7wt%, the temperature is...

Embodiment 2

[0081] Provide another kind of improved prehydrolysis alkali method to manufacture the method for bamboo dissolving pulp, comprise the steps:

[0082] (1) Bamboo material preparation: with embodiment 1, two to three-year-old bamboo materials are cut into long 15~30mm, wide 10~20mm, thick 3~8mm bamboo slices by slicer, screened by high-frequency vibrating sieve, and use high-pressure Spray washing with water to remove impurities and dust;

[0083] (2) pretreatment: with embodiment 1, carry out in hydrolysis pot, treatment agent is sulfuric acid, and process condition is: sulfuric acid concentration is 0.1wt%, and temperature is 110 ℃, and liquid ratio is 1: 10, and treatment time is 60 minutes, After pretreatment, the treatment liquid is discharged and the material is washed;

[0084] (3) Pre-hydrolysis: carried out in a hydrolysis pot, the hydrolysis catalyst is sulfuric acid, the process conditions are: the acid concentration is 1.5wt%, the temperature is 125 ° C, the liquid...

Embodiment 3

[0087] Provide another kind of improved prehydrolysis alkali method to manufacture the method for bamboo dissolving pulp, comprise the steps:

[0088] (1) Bamboo material preparation: with embodiment 1, two to three-year-old bamboo materials are cut into long 15~30mm, wide 10~20mm, thick 3~8mm bamboo slices by slicer, screened by high-frequency vibrating sieve, and use high-pressure Spray washing with water to remove impurities and dust;

[0089] (2) pretreatment: with embodiment 1, carry out in hydrolysis pot, treatment agent is sulfuric acid, and technological condition is: sulfuric acid concentration is 0.1wt%, and temperature is 110 ℃, and liquid ratio is 1: 10, and treatment time is 60 minutes, After pretreatment, the treatment liquid is discharged and the material is washed;

[0090] (3) pre-hydrolysis: with embodiment 1, carry out in hydrolysis pot, hydrolysis catalyst is sulfuric acid, and process condition is: sulfuric acid concentration is 0.7wt%, and temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com