Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2664 results about "Viscose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscose is a term often used to represent the viscose fiber that is made from natural sources such as wood and agricultural products that are regenerated as cellulose fiber. The molecular structure of natural cellulose is preserved in the process. The many types and grades of viscose fibers can imitate the feel and texture of natural fibers such as silk, wool, cotton, and linen. The types that resemble silk are often called artificial silk. The fibre is used to make textiles for clothing and other purposes.

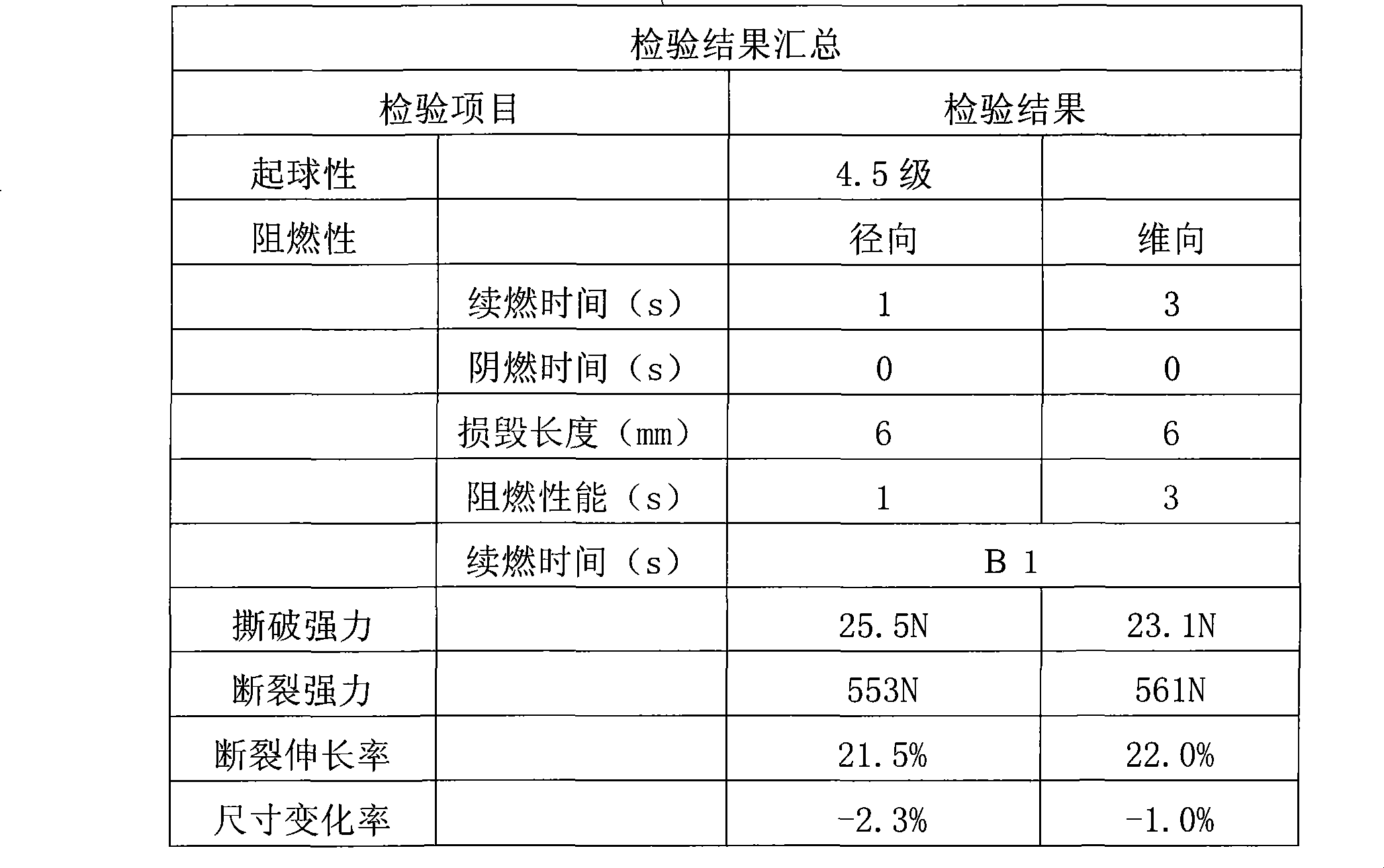

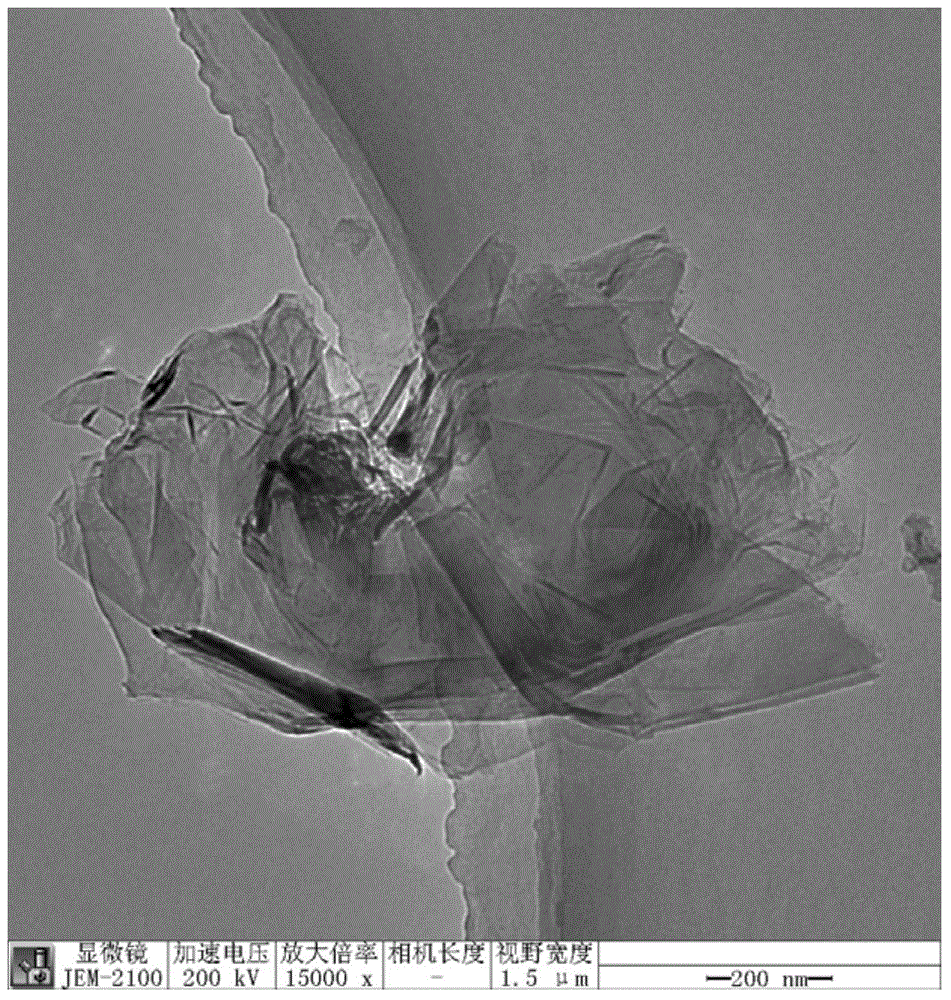

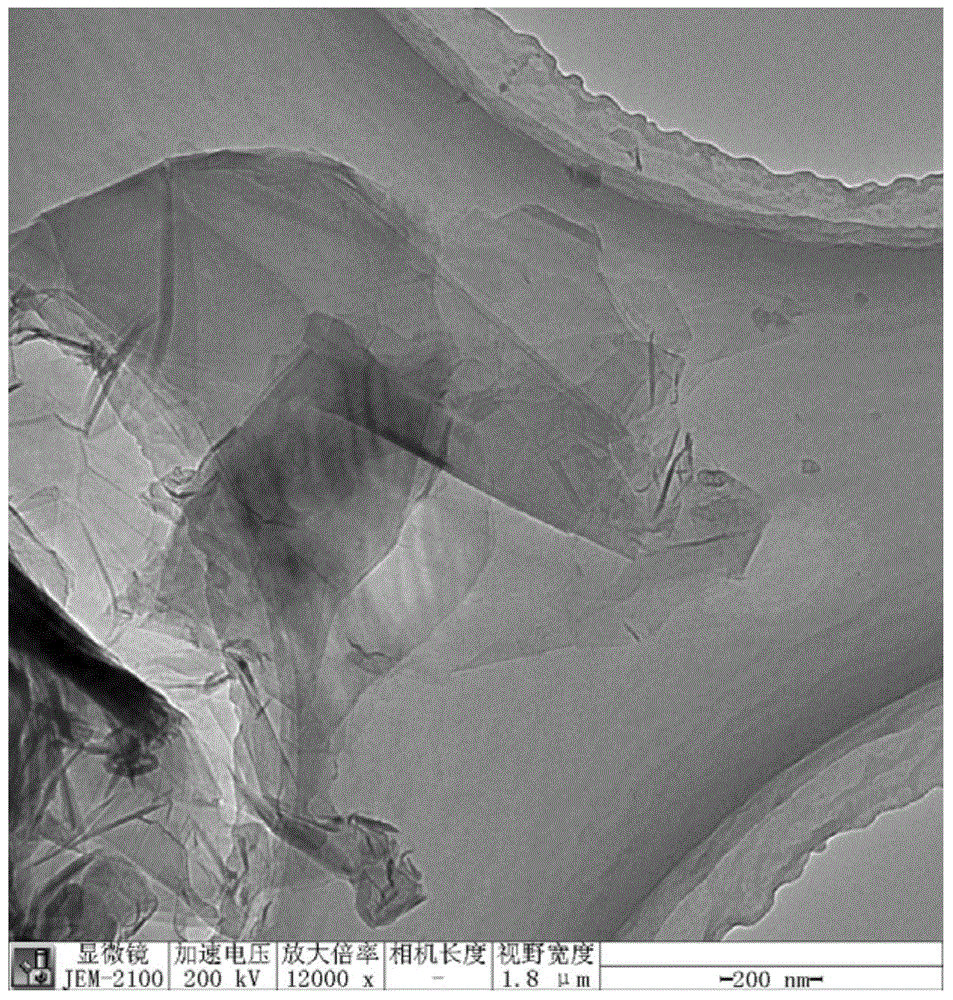

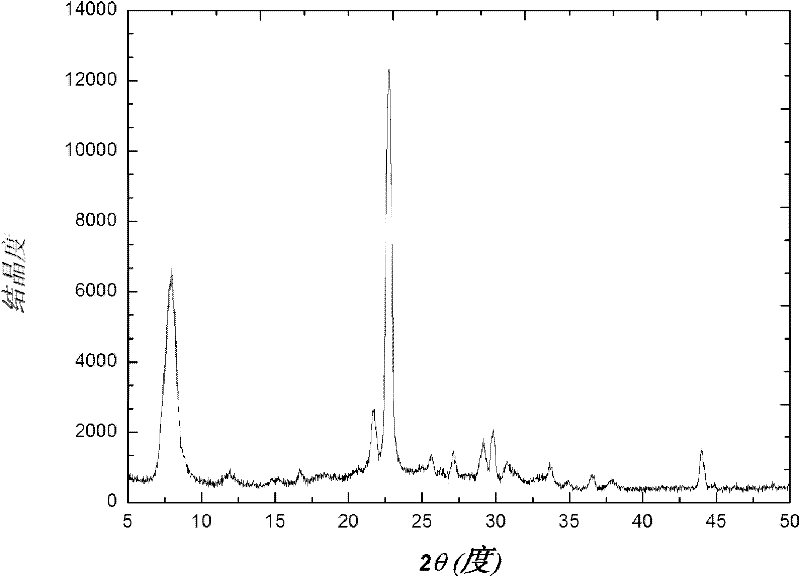

Grapheme-containing viscose fiber and preparation method thereof

ActiveCN104328523AHigh breaking strengthGrapheneArtificial filaments from viscoseViscoseUltimate tensile strength

The invention relates to a graphene-containing viscose fiber and a preparation method thereof. Graphene is non-oxidized graphene with a layer number not more than 10. The preparation method comprises the step of introducing the graphene into viscose before spinning. The viscose fiber obtained through the preparation method disclosed by the invention outstandingly enhances the fracture strength.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

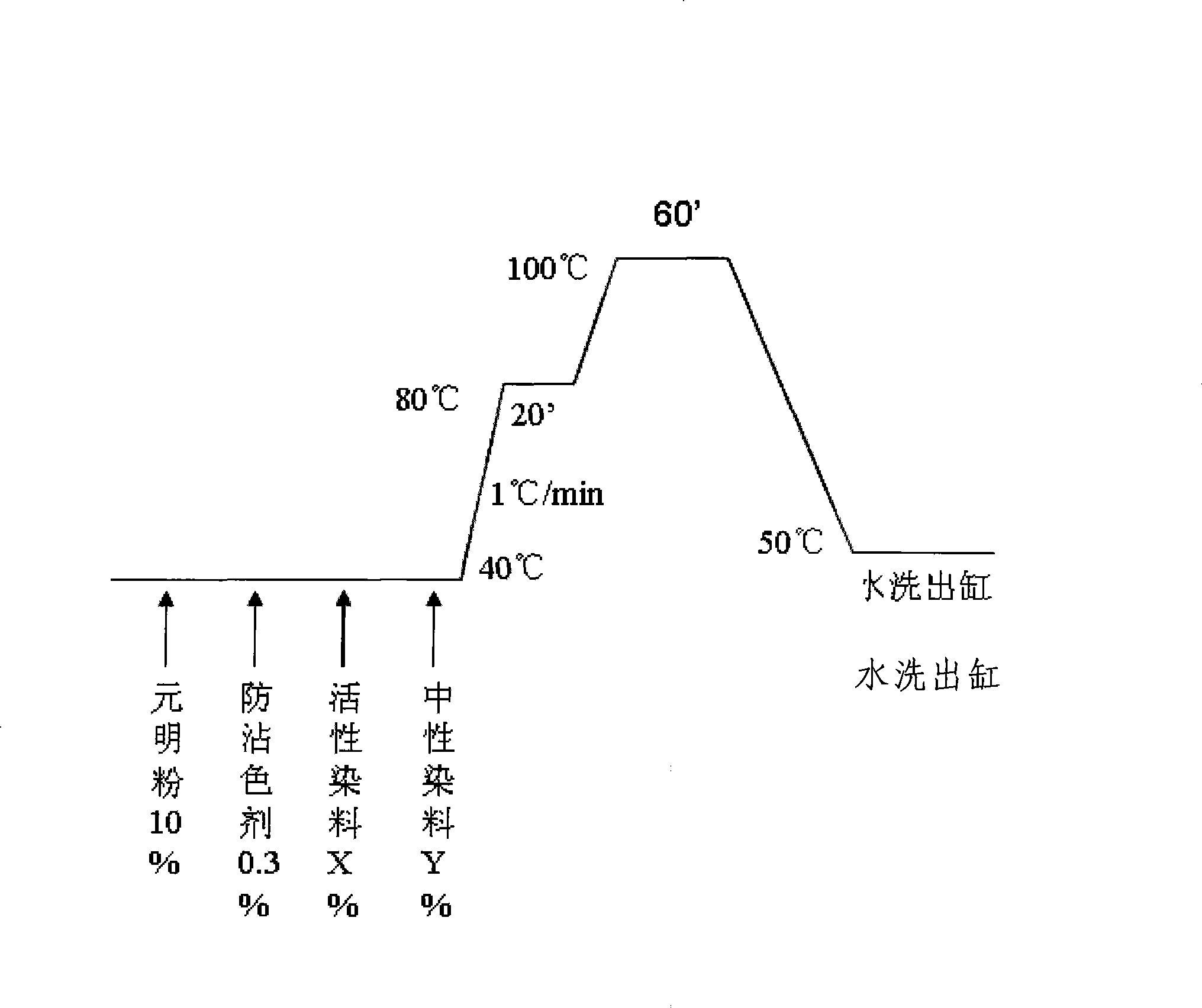

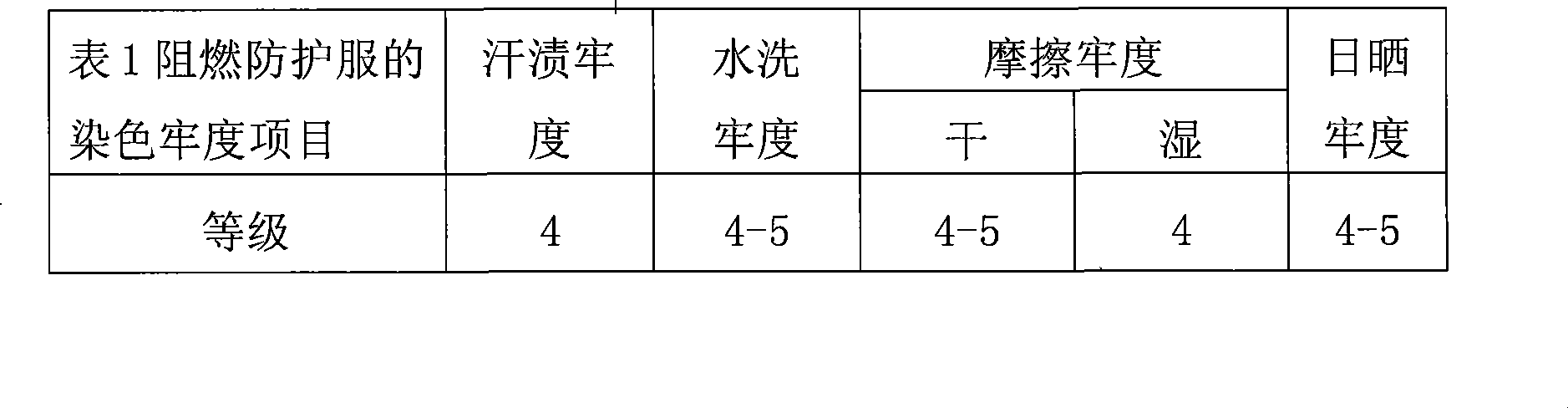

Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

The invention relates to an industrial anti-flaming exposure suit fabric and a manufacturing method and an exposure suit thereof. Yarns used in the industrial anti-flaming exposure suit fabric are formed by the blending of anti-flaming viscose, wool fibers and nylon fibers. The blending proportions (weight percentage) of the anti-flaming viscose, the wool fibers and the nylon fibers are respectively 45 percent to 55 percent, 35 percent to 45 percent and 5 percent to 15 percent. The industrial anti-flaming exposure suit fabric used in front of electric welding and metallurgy smelting furnaces has the functions of permanent anti-flaming performance, high temperature resistance, heat convection resistance, molten metal splashing resistance, and the like. The fabric is not only suitable for firefighter uniforms, flying protective clothing, and the like, realizes permanent anti-flaming performance and high temperature resistance, but also meets the requirements of the anti-flaming exposure suit fabric used in front of the electric welding and metallurgy smelting furnaces for the functions of heat convection resistance, molten metal splashing resistance, and the like.

Owner:SHANGHAI IBENA TEXTILE PROD

Production process of high-quality ecological antibacterial health-care sock

ActiveCN103815555AGood health effectImprove antibacterial propertiesLiquid/gas/vapor article treatmentPanty-hoseYarnEscherichia coli

The invention discloses a production process of a high-quality ecological antibacterial health-care sock. The production process of the high-quality ecological antibacterial health-care sock comprises the following steps of yarn manufacturing, sock weaving, seam allowance processing, reinforcing, setting, pre-drying, water bathing, drying and package detection. The production process of the high-quality ecological antibacterial health-care sock adopts the method that natural cotton fibers, aloe fibers and modal fibers are interlaced and makes full use of the good antibacterial effect of the aloe fibers, and the bottom of the sock adopts a flat structure, so that the fabric can meet the requirements for high air permeability and comfort. The aloe fibers are used for replacing traditional common viscose, and aloe isocitric acid calcium and other matter have the functions of improving the constitution, strengthening the heart, promoting blood circulation, softening hardened arteries, lowering the cholesterol content and expanding the blood capillaries, and have a certain inhibition effect on escherichia coli and staphylococcus aureus. Compared with the prior art, the high-quality ecological antibacterial health-care sock has good health-care performance and antibacterial performance.

Owner:浙江丰悦针纺有限公司

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

Multifunctional viscose and preparation method thereof

ActiveCN104831389AGood far infraredImproves UV resistanceGrapheneArtificial filaments from viscoseViscoseAntibacterial activity

The invention provides multifunctional viscose. The multifunctional viscose comprises viscose, graphene and nano-silver, wherein nano-silver is loaded to a graphene slice layer in situ. The invention further provides a preparation method of the multifunctional viscose. The preparation method is characterized by comprising the following steps: (a) dispersing graphene in a water solution, so as to obtain a graphene dispersion liquid; (b) dissolving silver salt into the graphene dispersion liquid, adding a reducing agent, and carrying out reduction reaction, so as to obtain nano-silver-loaded graphene dispersion liquid; and (c) uniformly mixing the nano-silver-loaded graphene dispersion liquid with viscose liquid, and carrying out spinning, so as to obtain the multifunctional viscose. An experimental result shows that compared with viscose which is not added with nano-silver-loaded graphene, the multifunctional viscose has the advantages that the far infrared temperature increase performance is increased by not less than 100%, the ultraviolet protecting coefficient is increased by not less than 70%, and the antibacterial activity reaches 99.9% and is increased by not less than 100%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Fabric capable of preventing electromagnetic radiation

InactiveCN101942729AElastic fit and comfortableHarm reductionWeft knittingWarp knittingYarnSilver plate

The invention relates to a fabric capable of preventing electromagnetic radiation, which is knitted or weaved. The warp and the abb of the fabric comprise covering yarn. The covering yarn takes one of silver plating fiber, carbon fiber and carbon black organic fiber as core yarn and takes comfortable fiber as skin yarn; the silver plating fiber is formed by carrying out silver plating on synthetic fiber; the weight ratio of the corn yarn to the skin yarn is 10-70:30-90; and the comfortable fiber is one of cotton, wool, silk, hemp, viscose, bamboo fiber, bamboo carbon fiber, soybean fiber, PLA fiber, alginate fibre, milk fiber and pearl fiber. The invention can shield electromagnetic wave, and the shield effect is above 99%. The skin yarn in the covering yarn adopts natural fiber, and the natural fiber on the outer layer has the characteristics of moisture absorption, ventilation and comfort.

Owner:汕头市奥山服饰有限公司

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

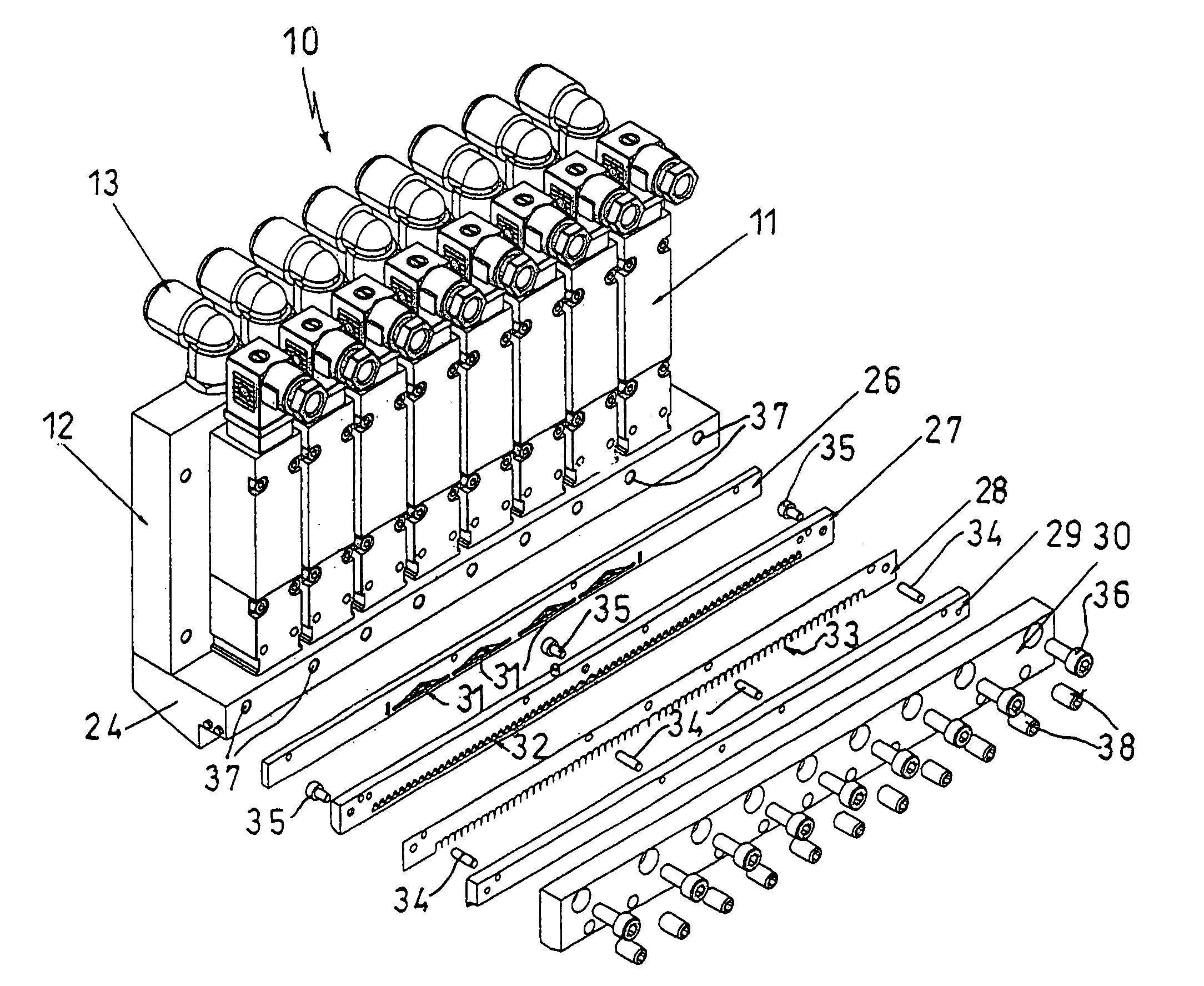

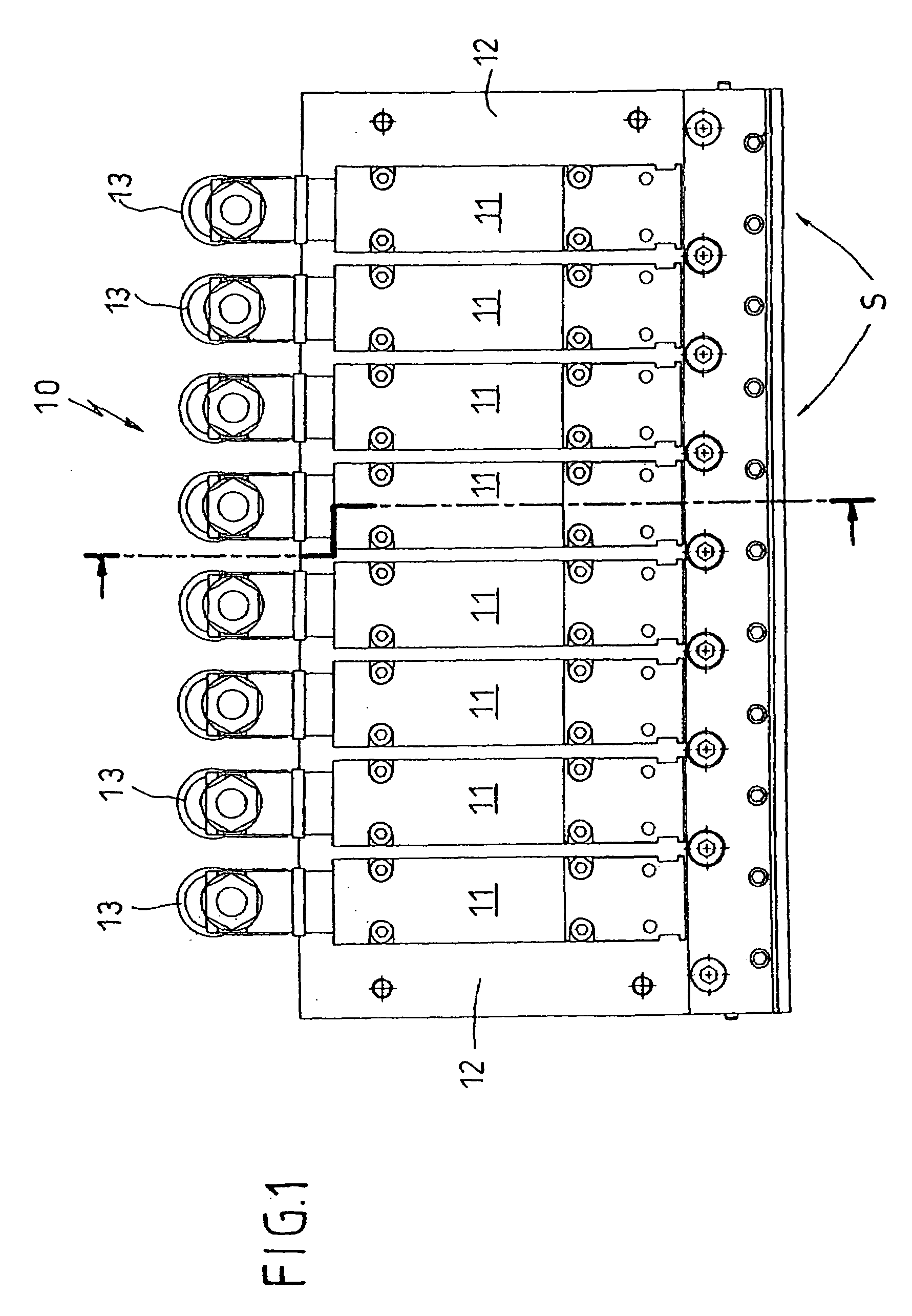

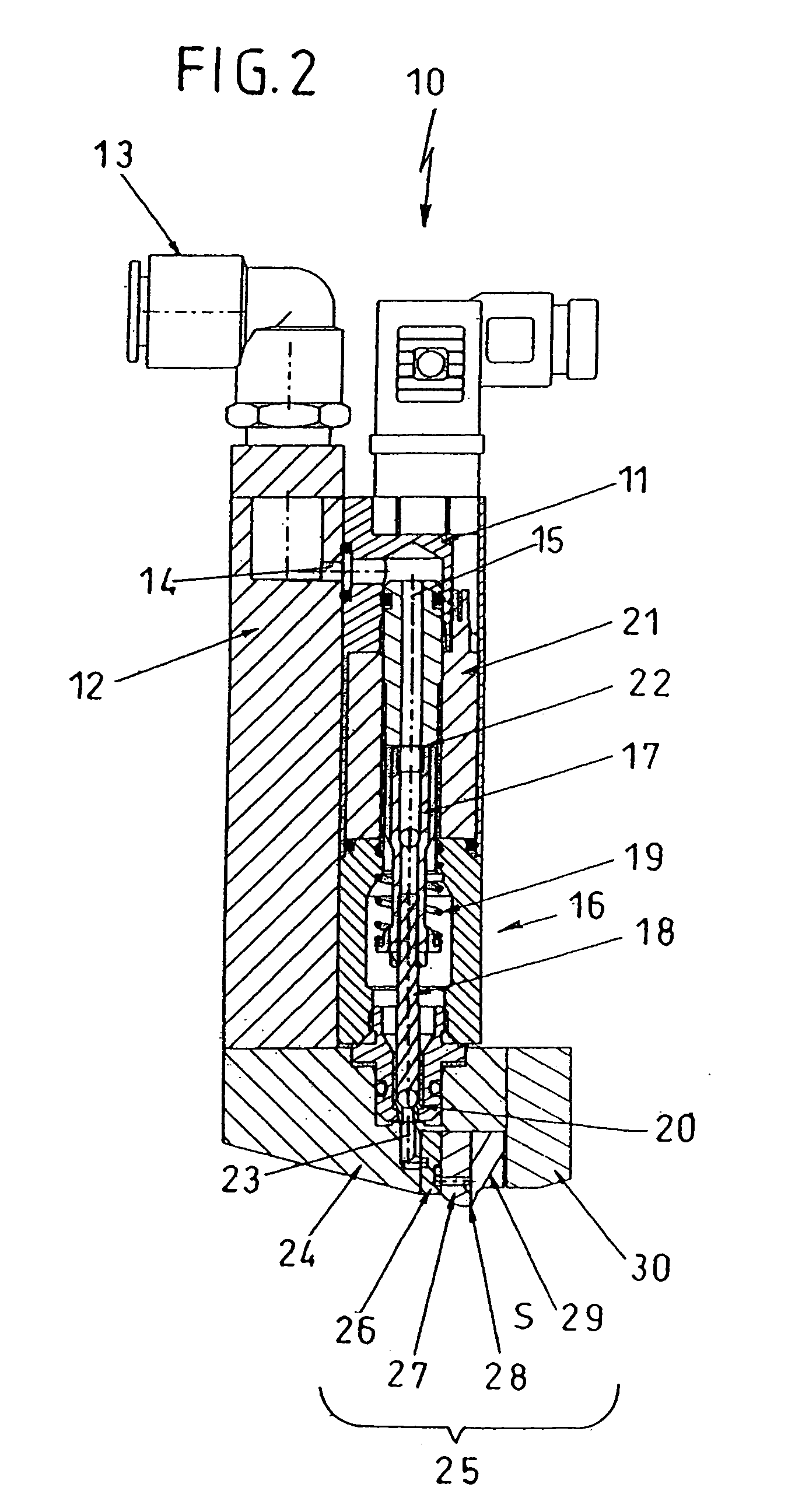

Device for surface coating of viscose media

InactiveUS7056386B2Faster andCost-effective can be replacedLiquid surface applicatorsSpray nozzlesAdhesiveApplication module

A mechanism for the application of viscous substances, particularly of dispersion adhesives, onto a moving substrate, includes a jet body, upon which a variety of application modules are aligned, which are supplied with substances by means of at least one supply unit, and a slot jet configuration, with which the substance can be applied to the moving substrate in the form of a defined application pattern. The slot jet configuration may be exchanged for the purpose of altering the application pattern. The slot jet configuration is formed by a jet strip system, which is useable for any application pattern, and a distribution plate, which is replaceable regardless of application pattern and which is upstream of the jet strip system in terms of flow.

Owner:ITW DYNATEC

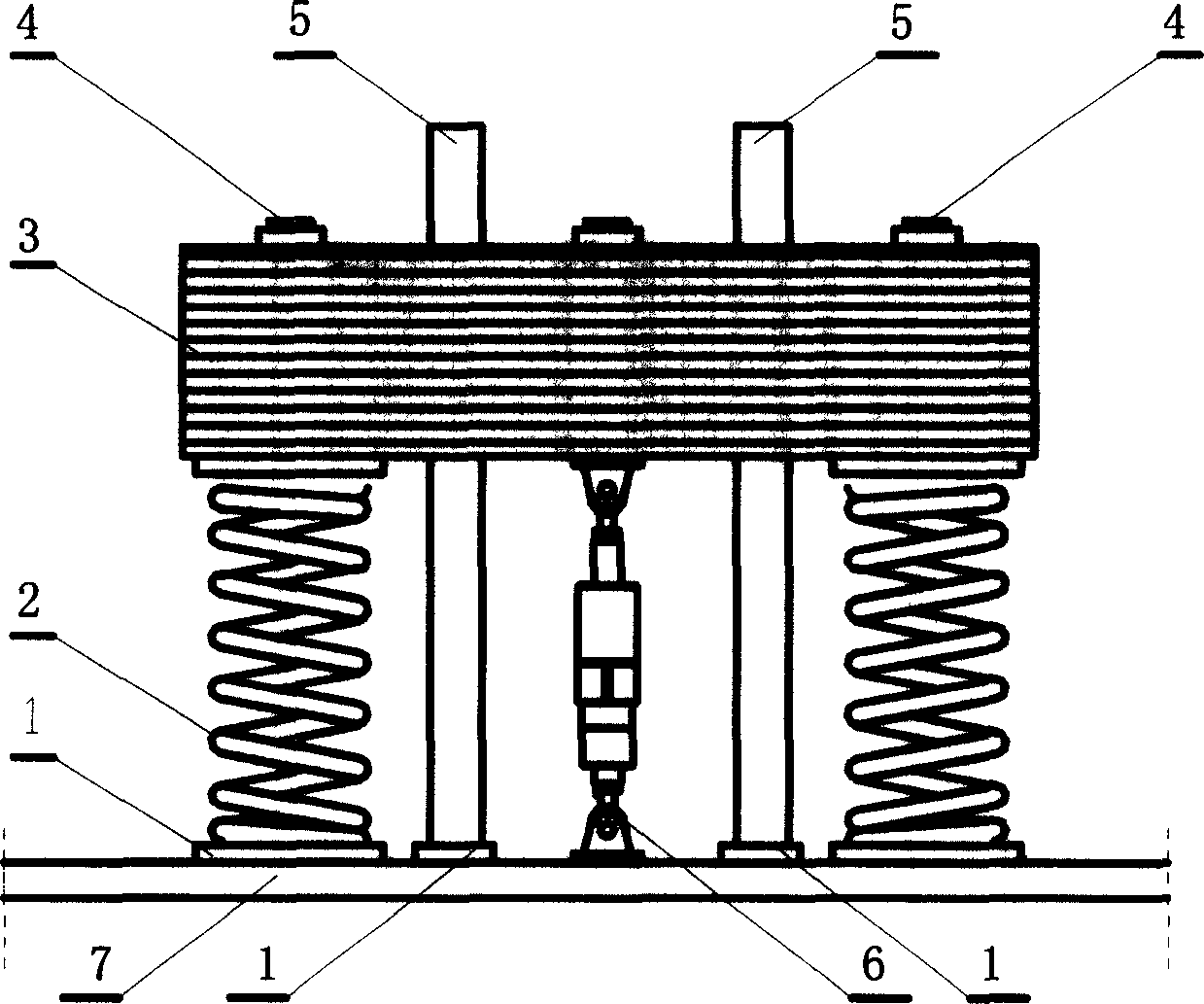

Oriented vertical adjustable tuning mass bumper

InactiveCN1614148AReduce resonanceEnsure safetyBridge structural detailsShock proofingSheet steelResonance

A vibration-damping control unit for the pedestrian bridge over street, landing bridge of port and other similar structures in order to reduce the resonance caused by load features that mass block is made up of the steel plates through stacking them together and fixing by screw bolts, and two vertical guide rods are arranged at both sides of viscose oil damper for preventing its lateral swinging. Said mass block is regulatable.

Owner:DALIAN UNIV OF TECH

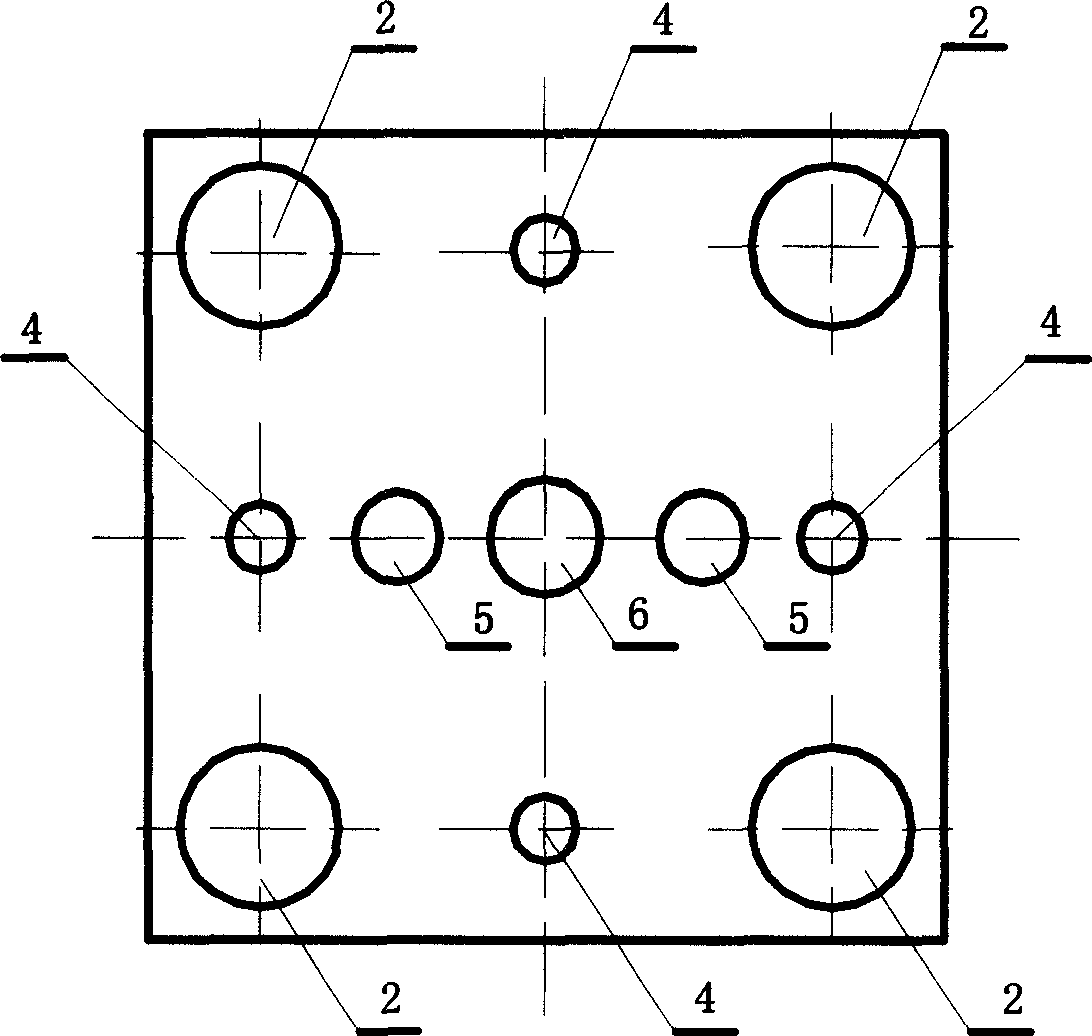

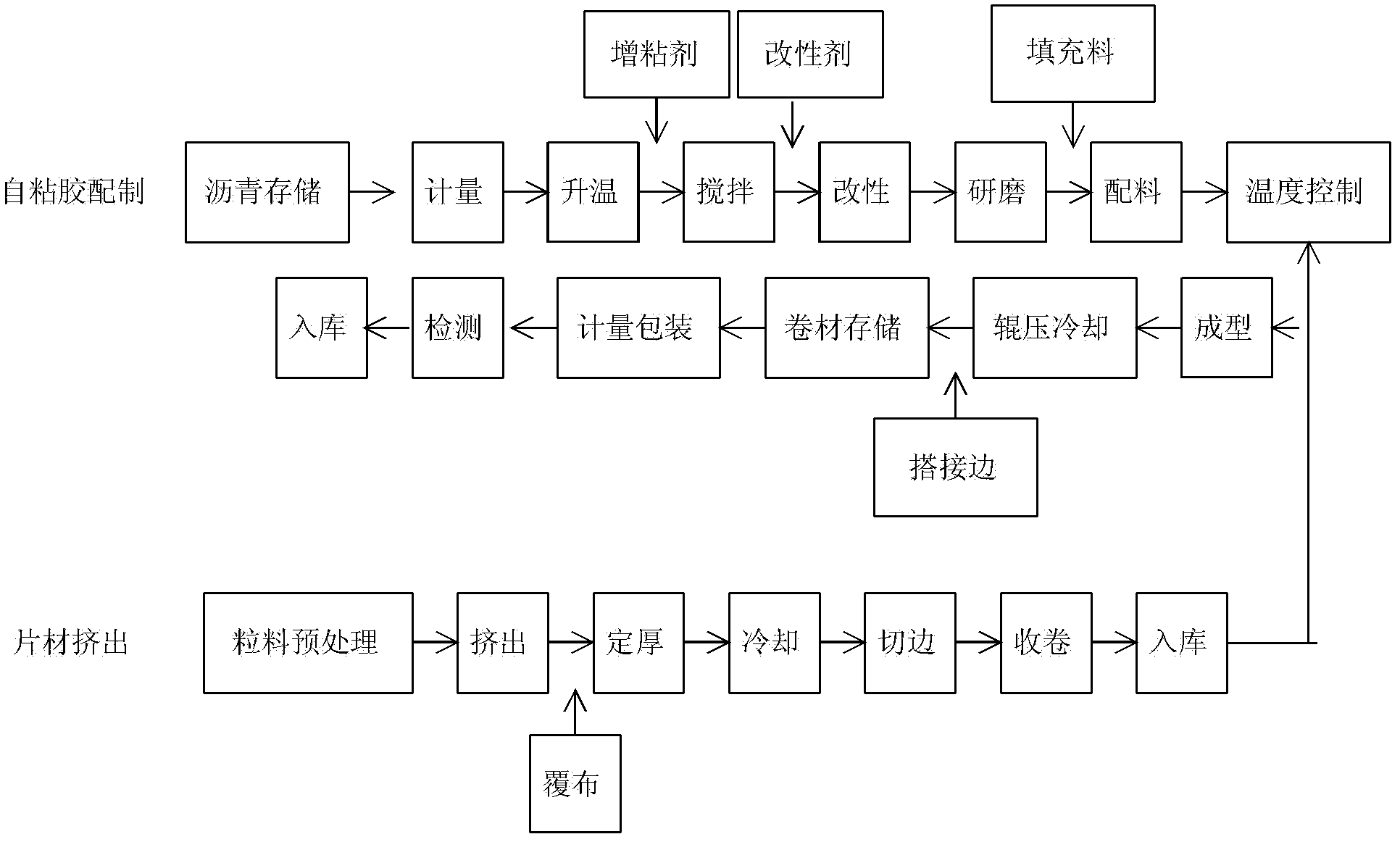

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

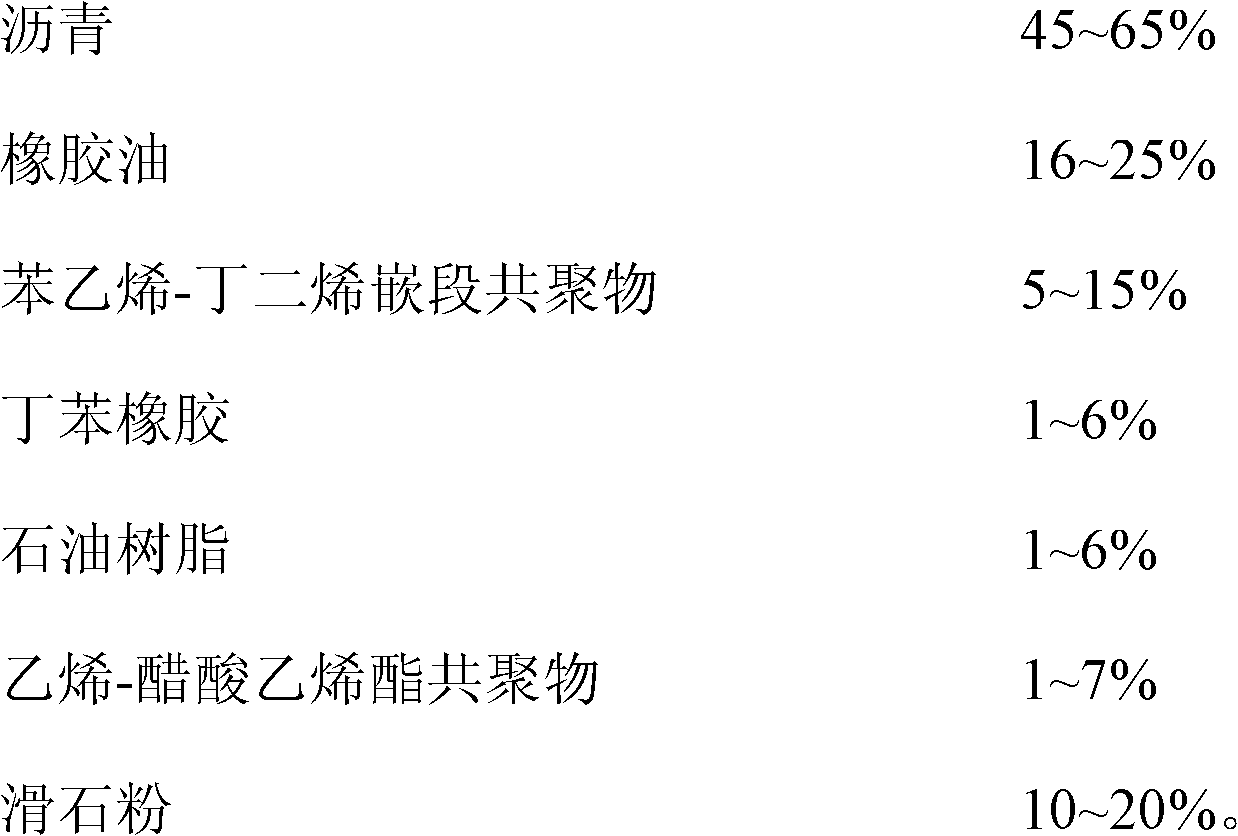

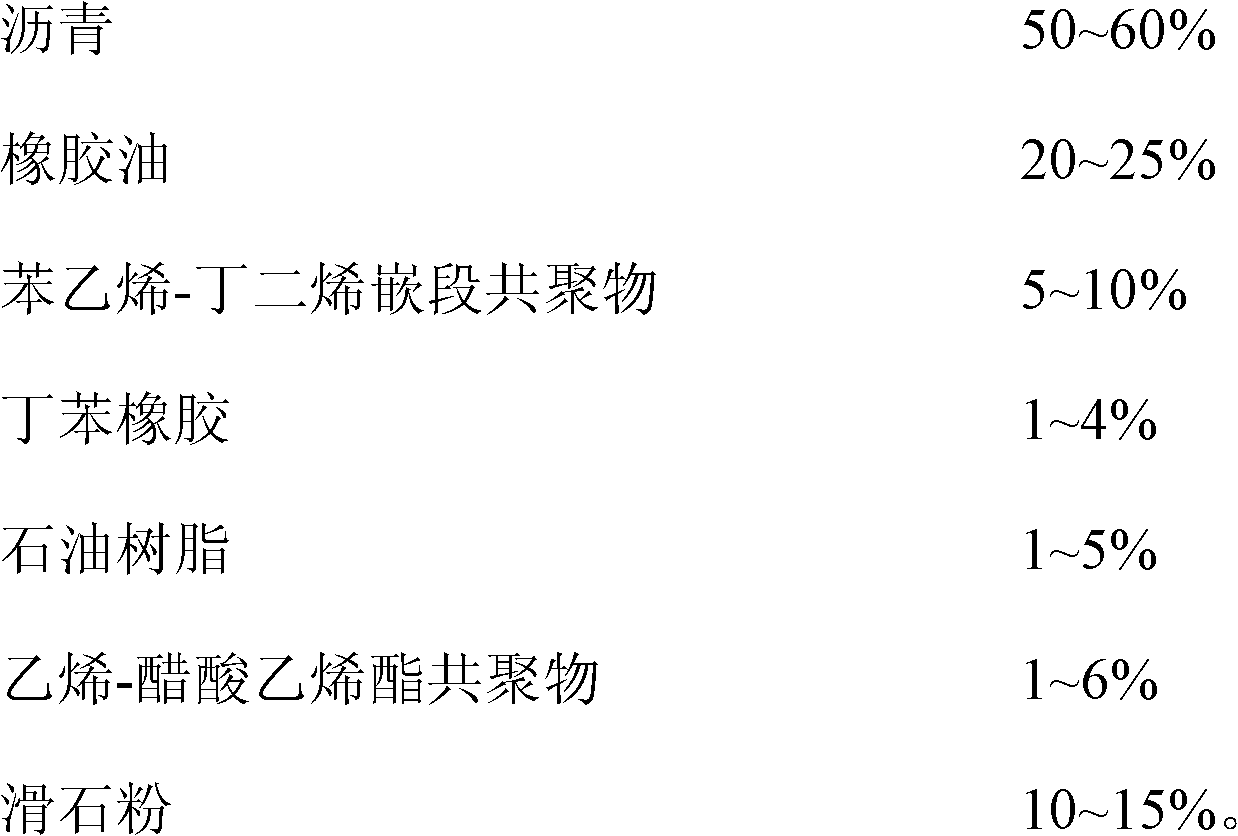

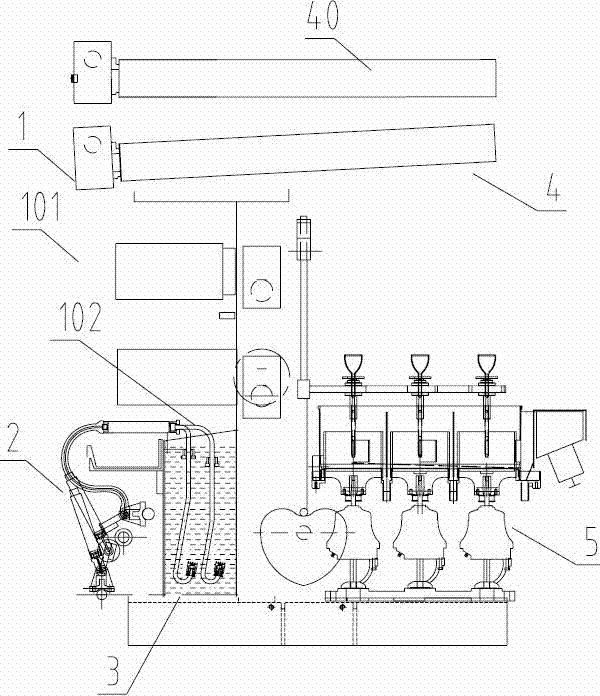

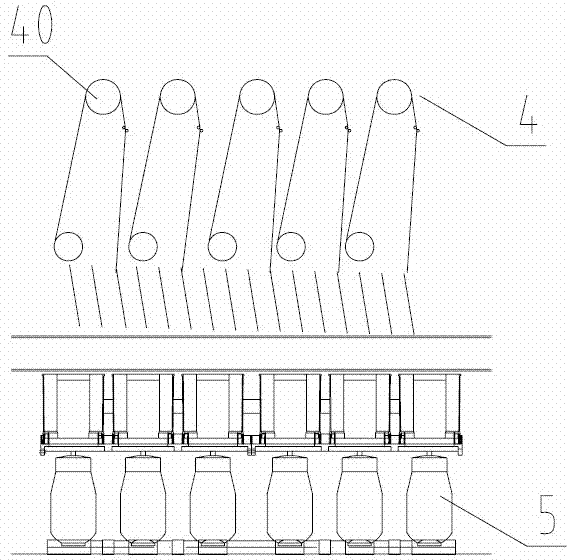

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

Flame-retardant and fireproof fabric, and processing technology and textile thereof

ActiveCN103352293AImprove flame retardant performanceHigh metabolismWeft knittingFibre treatmentPolyesterPolymer science

The invention relates to flame-retardant and fireproof fabric, and a processing technology and textile thereof. Warp yarns adopt wool tops formed by blending flame-retardant acrylic, flame viscose, fine-denier polyester and aramid fiber 1313 fiber; weft yarns adopt wool tops formed by blending alginate fiber, polyphenylene sulfide, polysulfonamide and phenolic fiber; then the warp yarns and the weft yarns form the flame-retardant and fireproof fabric through steps of dyeing, fixation, rinsing, sizing, weaving, desizing, rinsing, drying, baking, full decatizing and the like. The fabric has the characteristics of simple processing technology, good flame-retardant effect and the like, and can be applied to apparel, home textile, sports goods, medical care and fireproof fabric.

Owner:SHANGHAI ZANRAY IND

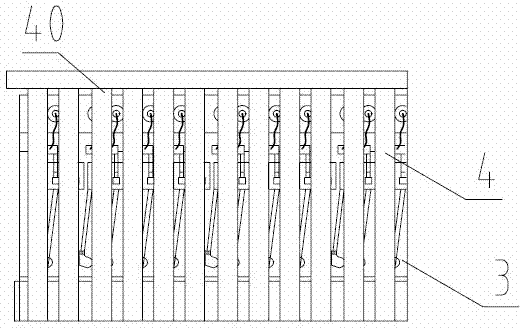

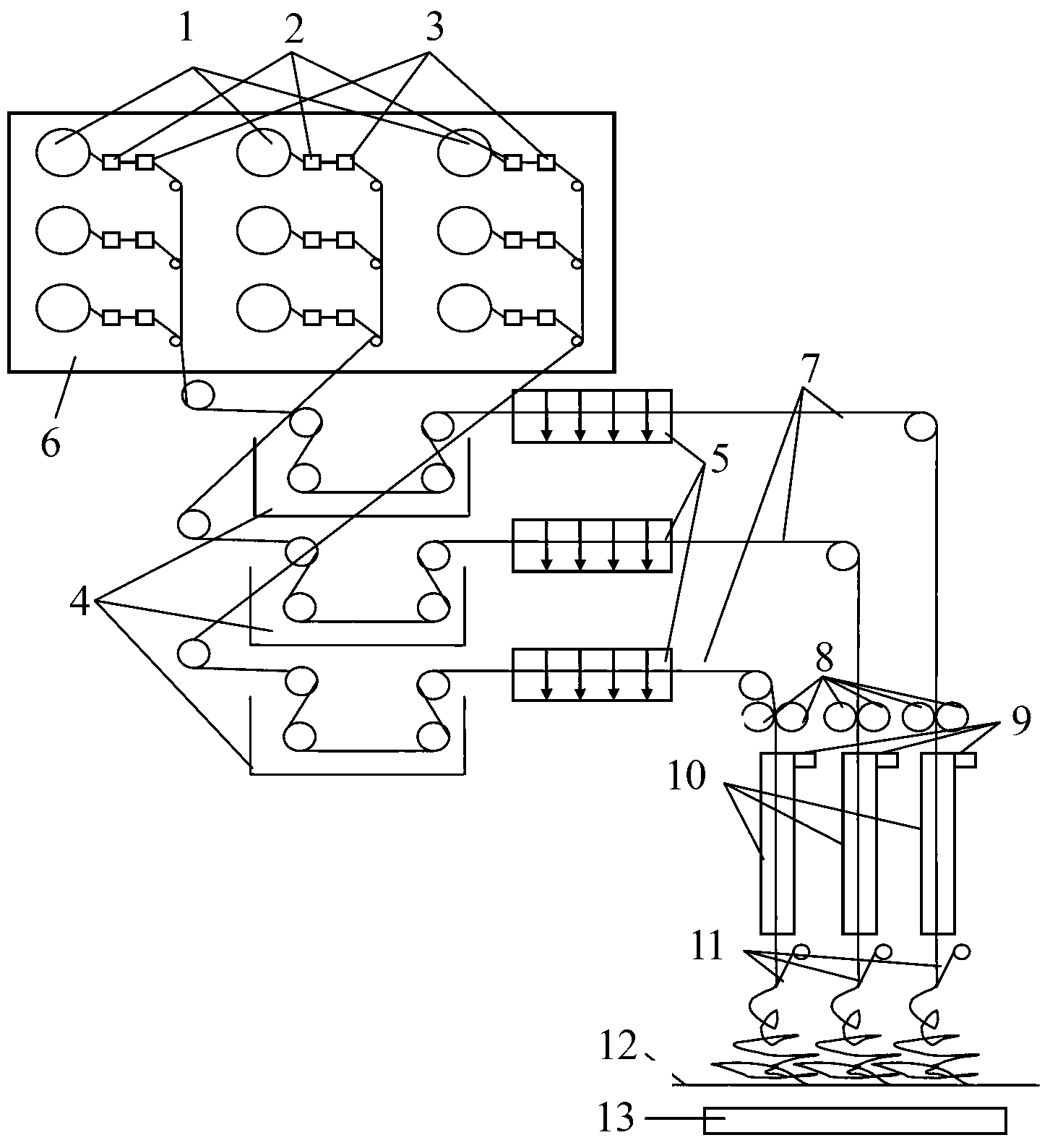

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

Coolmax fiber/pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions

InactiveCN101608378AMaintain sweat-wicking and quick-drying propertiesSmooth textureWeft knittingWarp knittingYarnPerspiration

The invention relates to a Coolmax fiber / pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions, the fabric is knitted by blending yarns containing pearl fiber, the blending yarns are one or more than one of tencel fiber, modal fiber and viscose, the mass ratio of pearl fiber in the blending yarns is 15-50%, the blending yarns are spun to be 16-60. The fabric of the invention has the health care efficacies of promoting microcirculation of human body blood, preventing ultraviolet rays and protecting skin, keeps the feature of fast perspiration and simultaneously has the advantages of smooth texture, good wearability and comfort wearing.

Owner:DONGHUA UNIV +1

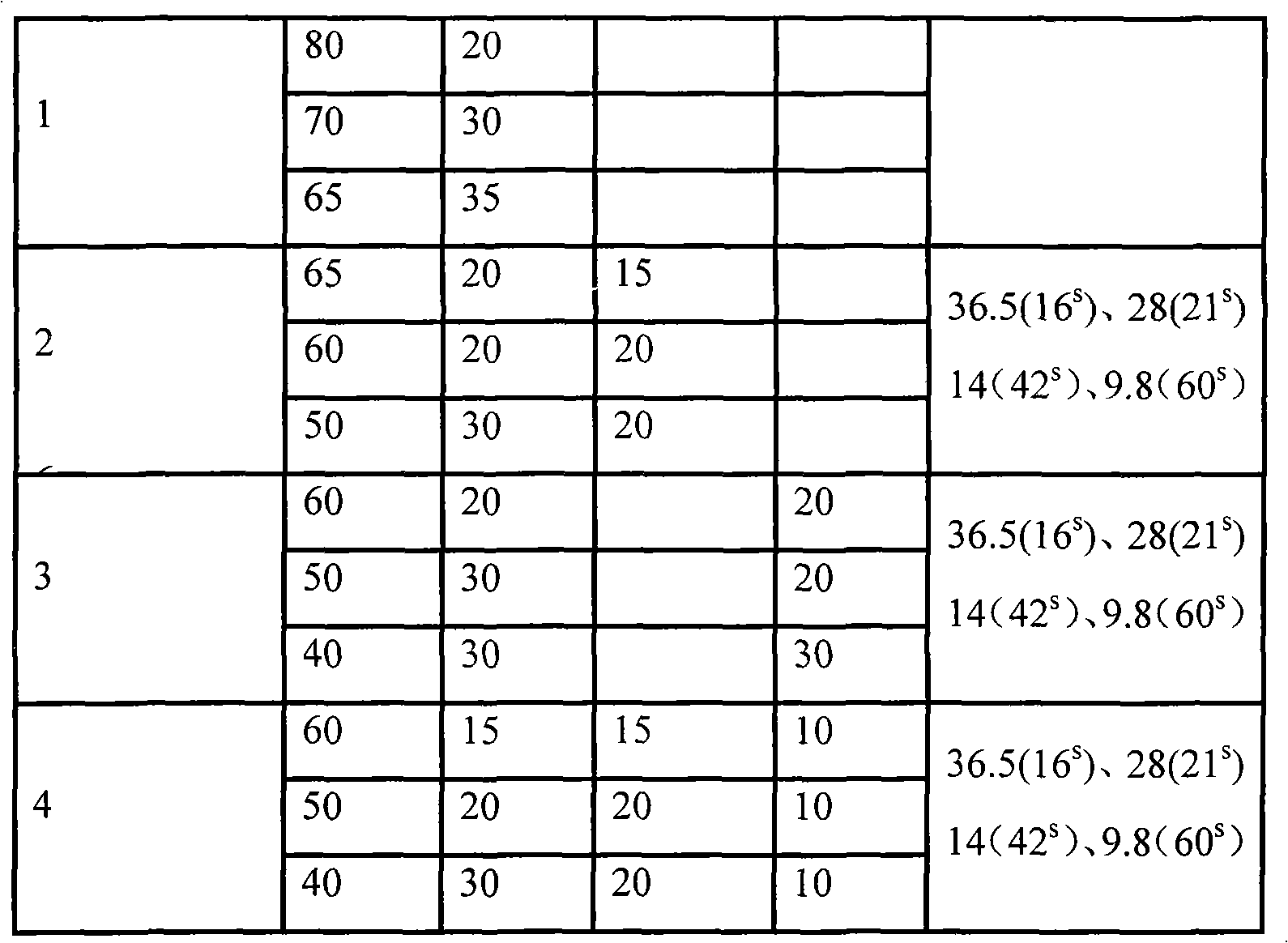

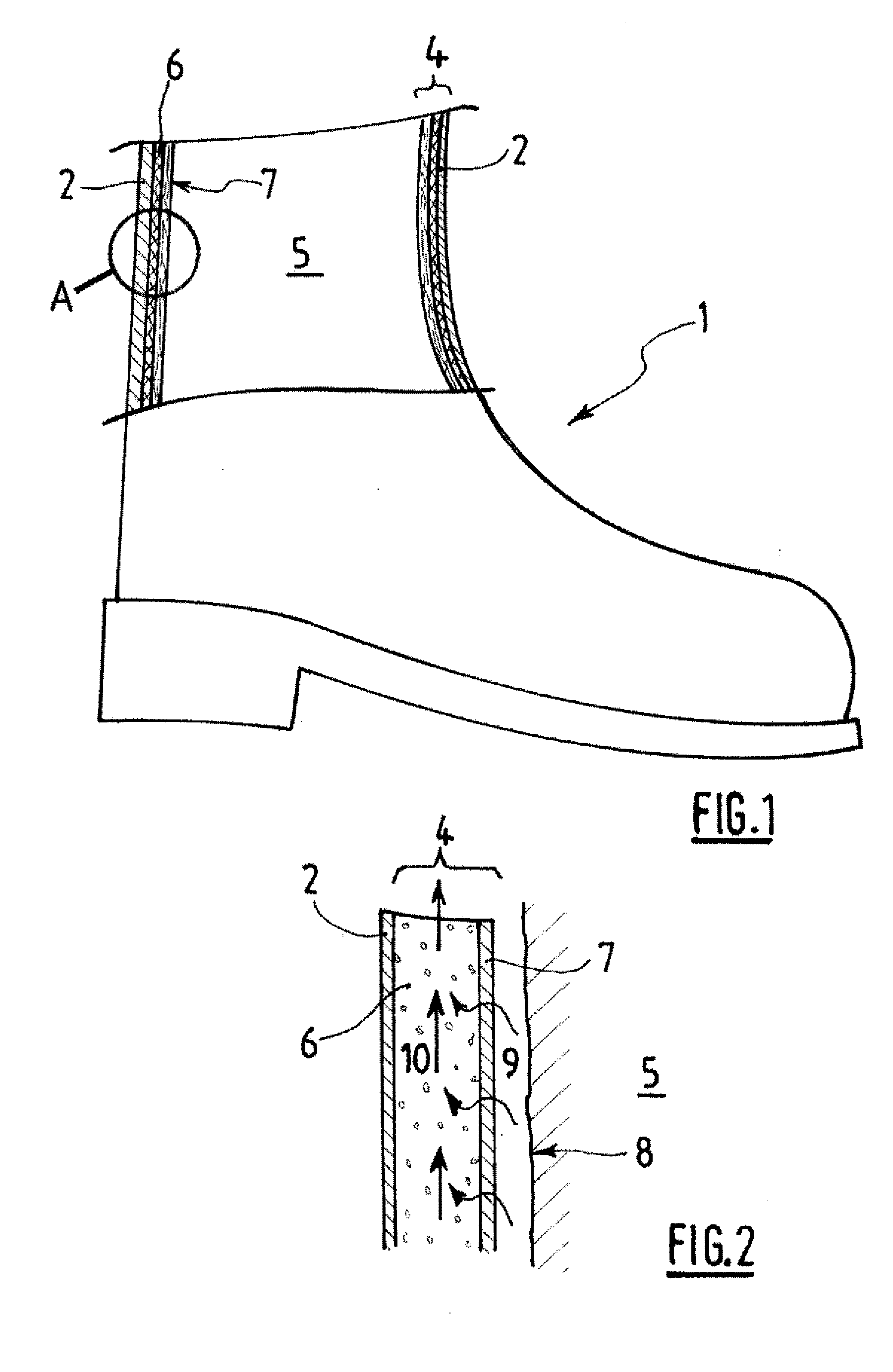

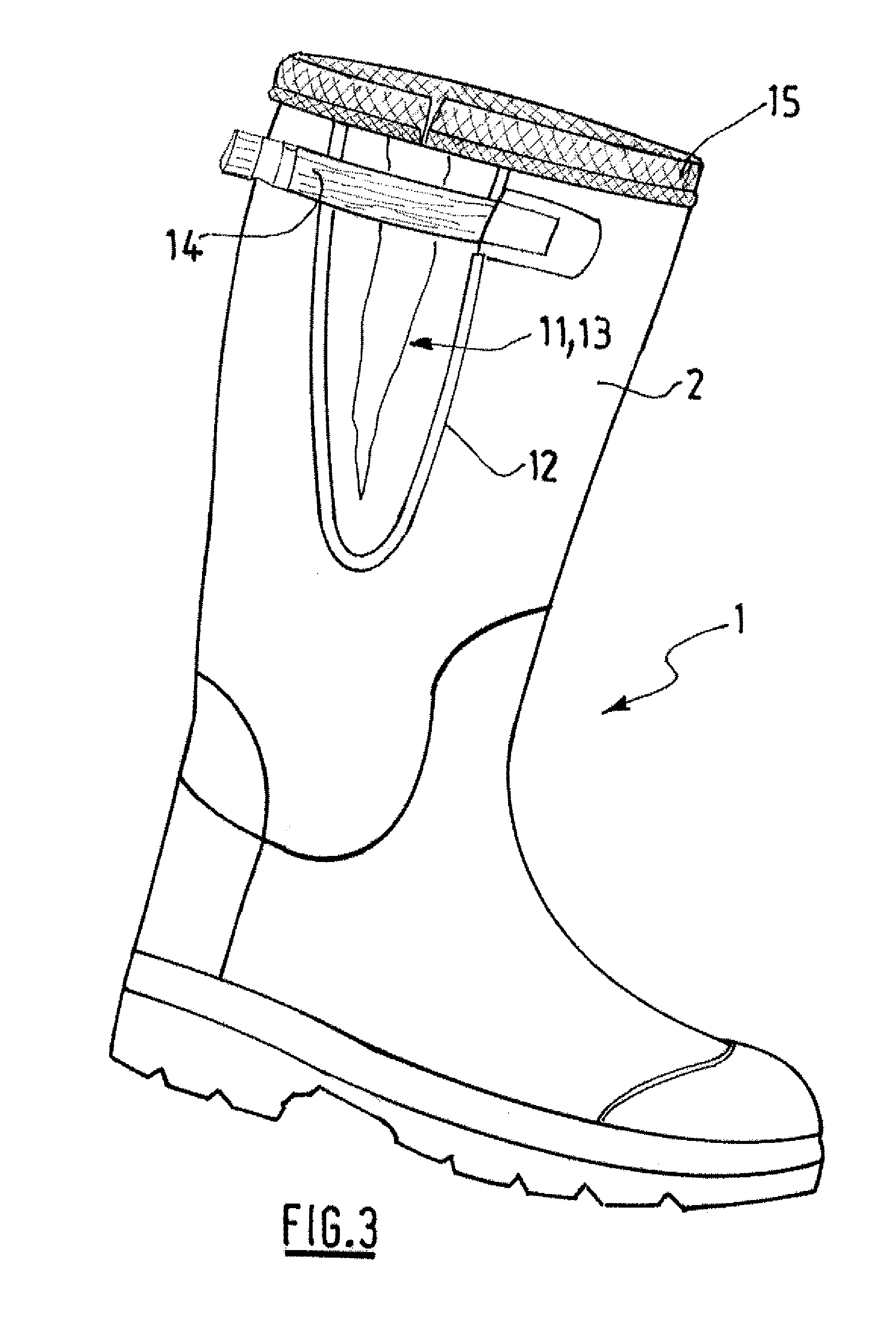

Boot

The invention relates to a boot (1) comprising a leg (2) in rubber combined with a textile lining (4), the lining (4) comprising a first textile layer (6) able to evacuate moisture (10) and a second textile layer (7) intended to be in contact with the foot (5) of a user, forming a layer to protect the foot against moisture. The first textile layer (6) is made by using a resilient fabric with a thickness greater than 3 mm, and the second textile layer (7) is bamboo viscose based.

Owner:LE CHAMEAU

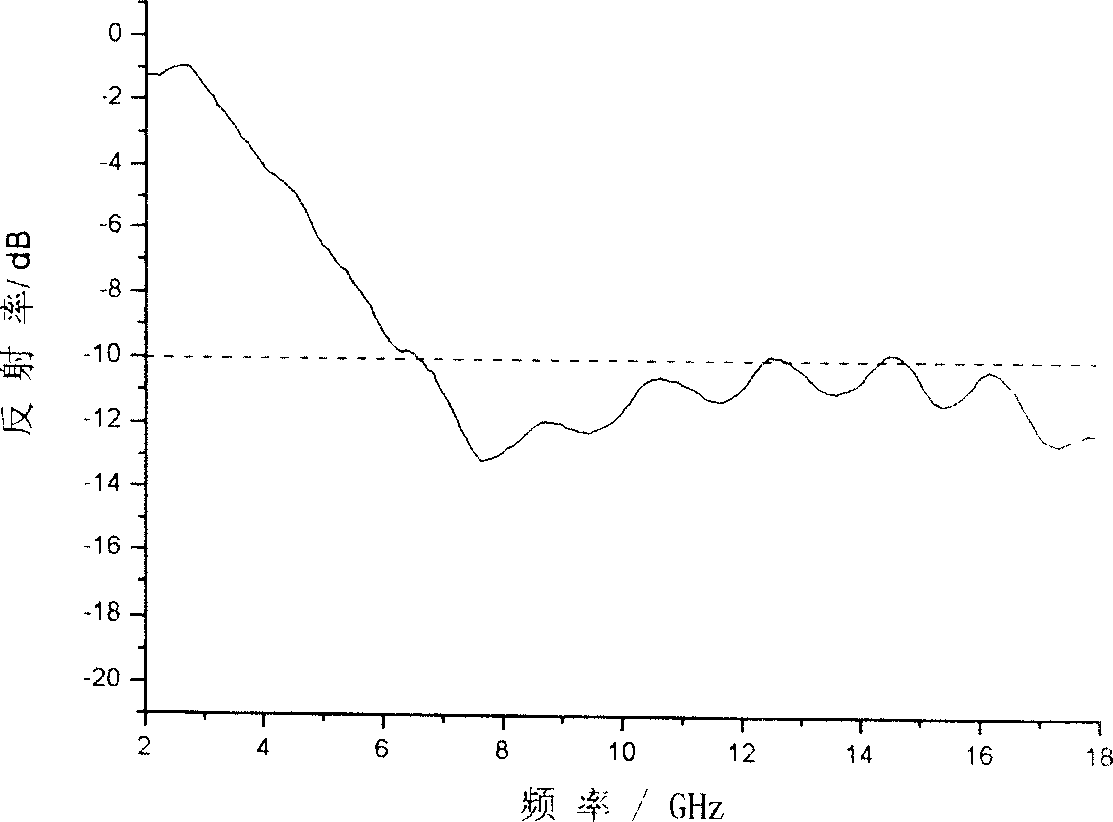

Novel light-wave absorbing carbon fiber composite material preparation method

InactiveCN1730555ASimple processLow processing and manufacturing costsArtificial filament chemical after-treatmentCelluloseMaterials preparation

The invention discloses a novel light-wave absorbing carbon fiber composite material preparation method which comprises, subjecting cellulose viscose to carbonization and activation, obtaining active adhesive based carbon fiber, making the active carbon fiber to 5-50mm short carbon fiber, charging into bisphenol type A epoxy resin, mixing homogeneously, mixing with low-molecular-weight polyamide curing agent, finally agitating homogeneously and hot-setting.

Owner:TIANJIN UNIV

Flame-retardant covering yarn fabric and application thereof

InactiveCN102181993AAchieving Flame RetardancyRealize high-strength functionsWoven fabricsYarnPolyesterYarn

The invention discloses a flame-retardant covering yarn fabric and application thereof. The product is made from covering yarns, wherein the covering yarns are subjected to the processing of flame-retardant after finishing; the core yarns of the covering yarns are polyester, nylon, spandex, vinylon, polyethylene or composite yarns thereof; and the cladding material of the covering yarns are cotton fibers, viscose fibers or composite fiber materials thereof. The flame-retardant covering yarn fabric can be applied to the manufacturing of protective clothing, military clothing or military coverlets. The flame-retardant covering yarn fabric provided by the invention can keep higher physical mechanical strength and has a flame-retardant effect.

Owner:JIANGSU TANGWEAR IND

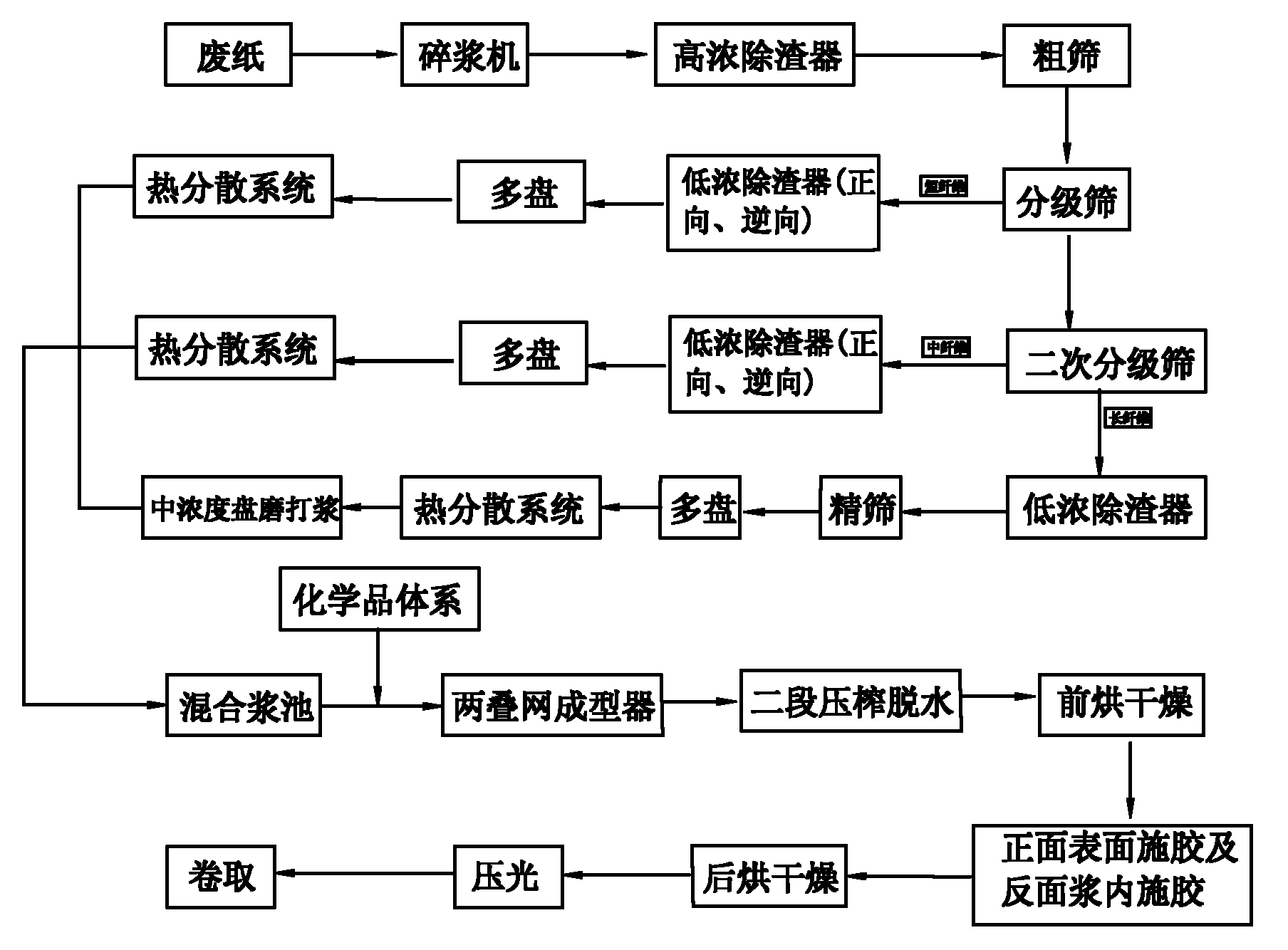

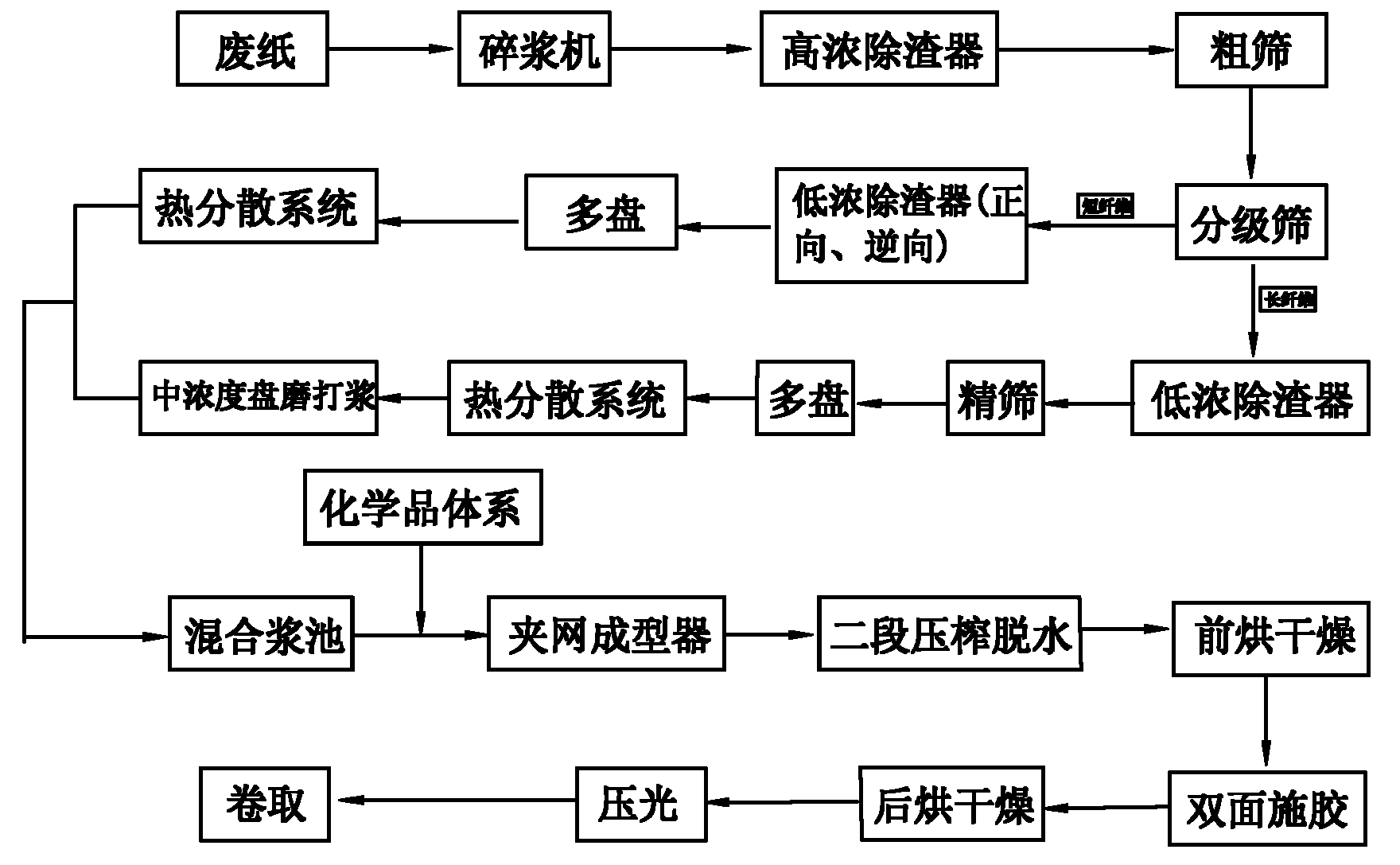

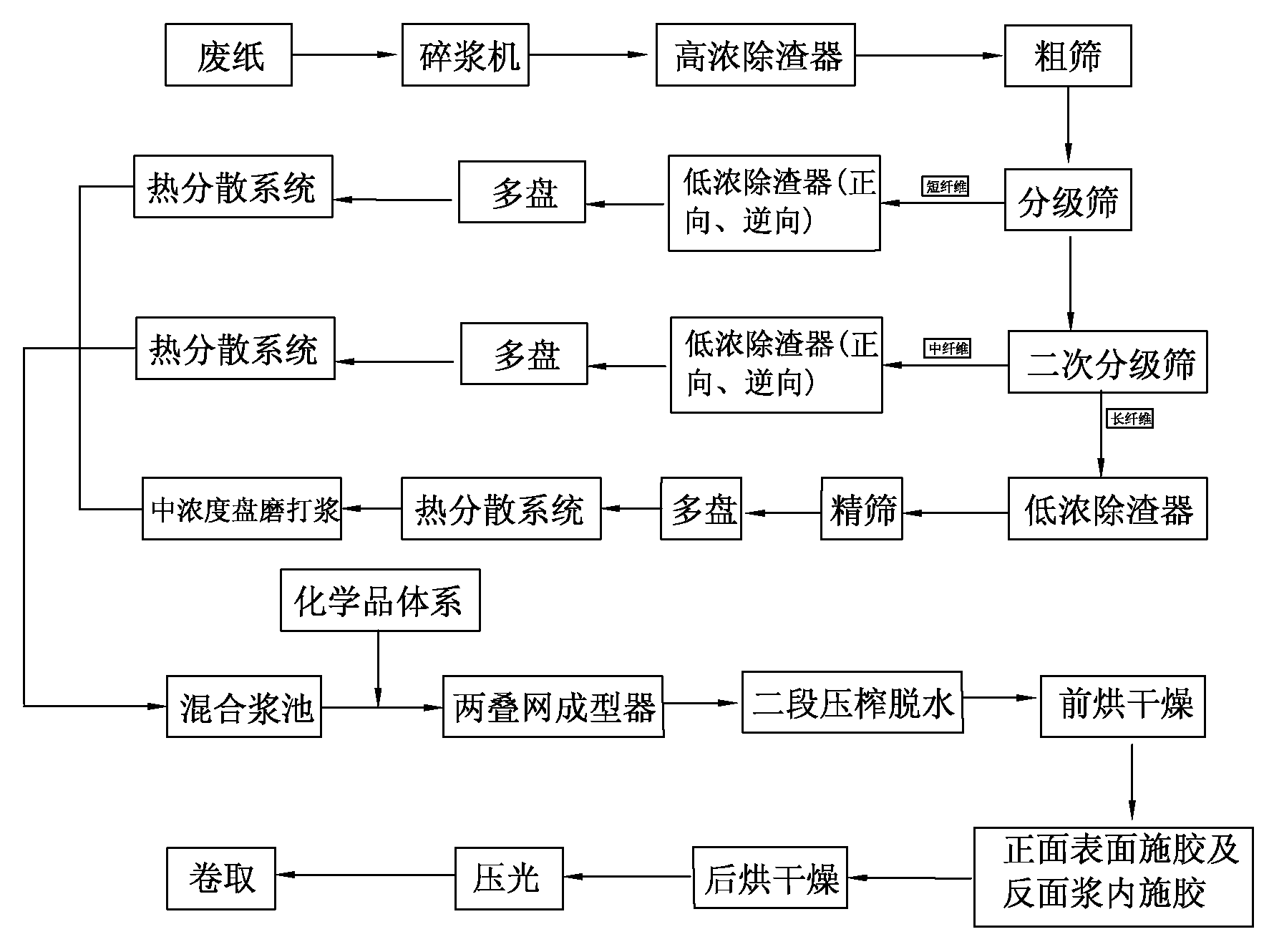

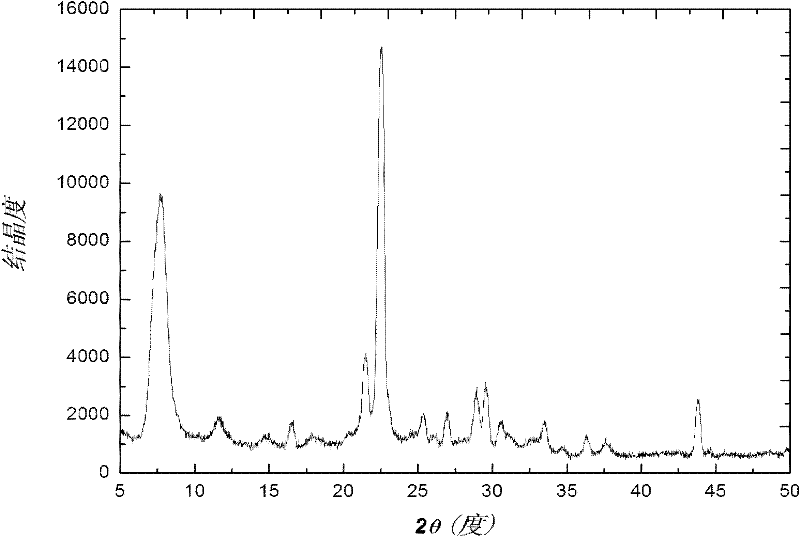

Production method of kraft cardboard with ultra low gram weight

ActiveCN102493261AHigh strengthReduce dosagePaper recyclingSecondary cellulose fibresCardboardViscose

The invention relates to the technical field of papermaking methods, especially to a production method of a kraft cardboard with an ultra low gram weight. The method comprises the following technological steps of: conducting batching; adding water for disintegrating so as to obtain a slurry; carrying out combined purification treatment to the slurry; performing moderate concentration beating; adding a chemical system into the combined slurry; papermaking; molding filtration water for papermaking; implementing two-stage squeezing dewatering; conducting primary baking for drying; carrying out sizing; performing further baking for drying; implementing calendering; and conducting coiling. The invention effectively solves the problems of low grade, poor strength, high pollution load of discharged sewage, large gram weight, incomplete treatment to viscose materials and hot melt materials in waste paper, large process investment and other problems in existing kraft cardboards. The production method of a kraft cardboard with an ultra low gram weight in the invention makes use of a combined technology of pulping and papermaking, and fully utilizes secondary fibers to prepare a kraft cardboard with an ultra low gram weight through papermaking, so that the fiber consumption is reduced. And the prepared kraft cardboard has high strength and a gram weight of 90g / m<2>. The method provided in the invention has high vehicle operation speed, reduces production cost and energy consumption, decreases pollutant discharge, and enhances economic benefits.

Owner:DONGGUAN NINE DRAGONS PAPER IND

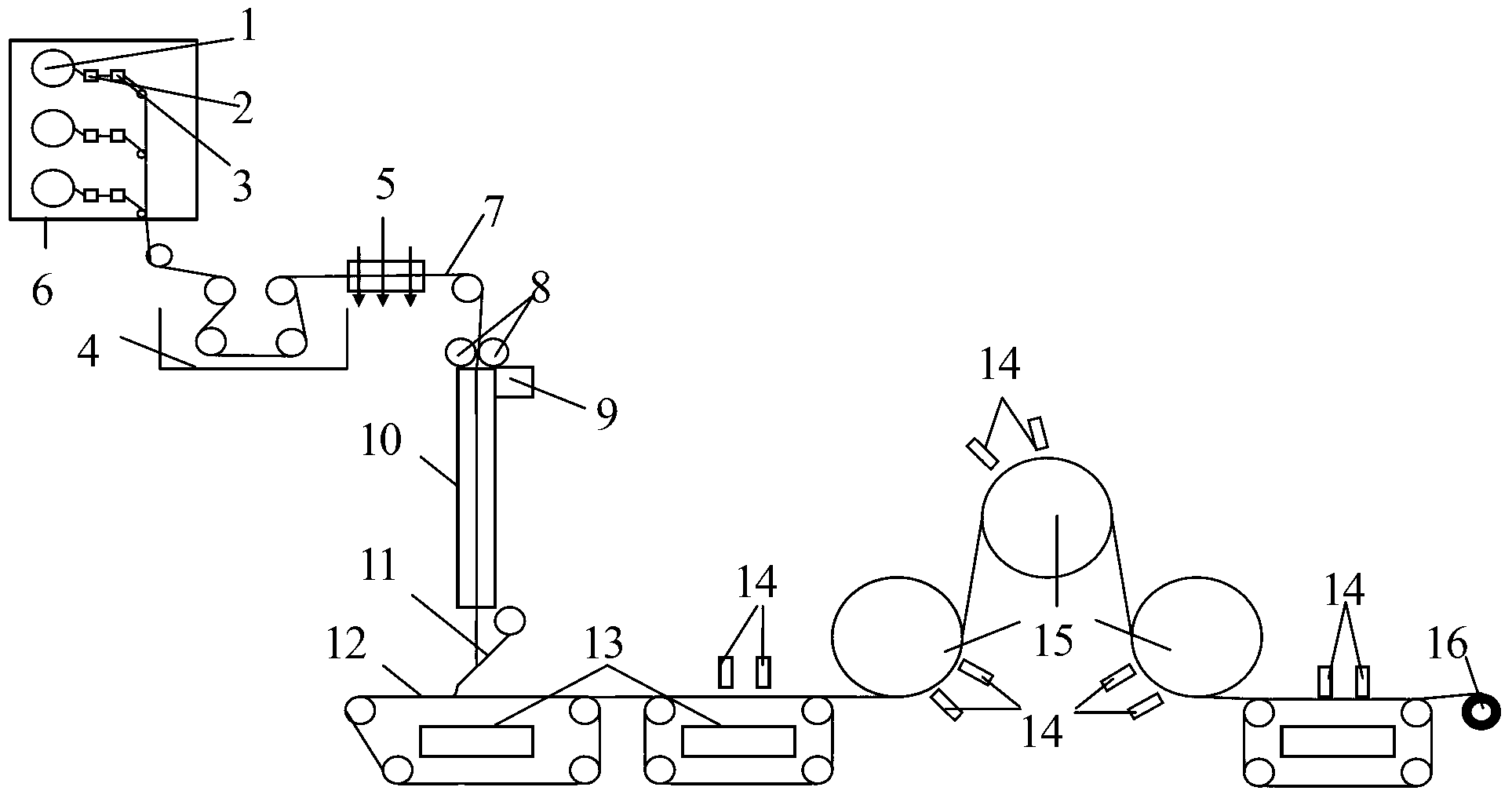

Dimensionality-stable regenerated cellulose fiber and preparation method thereof

ActiveCN102586919AImprove filtering effectImprove wet modulusArtificial filaments from viscoseViscoseWet strength

The invention relates to a preparation method of a dimensionality-stable regenerated cellulose fiber. The preparation method comprises the following steps: carrying out dipping, squeezing, crushing, ageing, yellowing, continuous dissolving, filtering, and deaeration operations on a cellulose raw material to prepare a spinning viscose glue; and spinning to prepare the dimensionality-stable regenerated cellulose fiber, wherein a mixture comprising one or more of a denaturant and a crosslinking agent is added in the continuous dissolving step of the spinning viscose glue operation or before the spinning step. The dimensionality, the dry strength, the wet strength and the dry extension of the dimensionality-stable regenerated cellulose fiber are 1.4-1.72dtex, 1.6-3.0CN / dtex, 1.2-2.8CN / dtex and 10-20% respectively. The dimensionality-stable regenerated cellulose fiber prepared by adopting the method of the invention overcomes disadvantages of low fabric preparation rate and bad dimensional stability caused by the overhigh hygroscopic expansion rate and large wet tensile elongation of common viscose fibers, and has the advantages of stable transverse section and vertical dimensionality, and strong weaving strength.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Composite antibiotic finishing agent and preparation method and finishing process thereof for application to mucilage glue and cotton fiber interweaved jacquard fabric

The invention discloses a composite antibiotic finishing agent which comprises an organic antibacterial active component, an inorganic antibacterial active component, a penetrating agent, an adhesive, a softening agent, a suspending agent and the balance of water, wherein a non-dissolution type polymer antibacterial agent is selected as the organic antibacterial active component, and silver-loaded nanometer titanium dioxide is selected as the inorganic antibacterial active component. The invention also discloses a method for preparing the composite antibiotic finishing agent and a process used for finishing a mucilage glue and cotton fiber interweaved jacquard fabric. The main material of the composite antibiotic finishing agent for textiles is formed by the organic antibacterial active component and the inorganic antibacterial active component, thus the composite antibiotic finishing agent has a high-efficiency inhibiting capacity of more than 20 kinds of harmful bacteria such as escherichia coli, staphylococcus aureus, gonococcus and the like; the bacteria inhibiting rate is higher than 99 percent; the repelling and preventing rate of dust mites, gamasid mites and chigger is higher than 99 percent; the repelling and preventing rate of dust mites, gamasid mites and chigger is higher than 95 percent, and the killing rate is higher than 90 percent after the mucilage glue and cotton fiber interweaved jacquard fabric is washed for 50 times; and the gonococcus, escherichia coli, staphylococcus aureus and the like do not grow on the fabric which is not washed for 30 times, 50 times or 100 times, and the bacteria inhibiting rate is higher than 99 percent.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Bamboo dissolved pulp manufacturing technique

InactiveCN101158122AHigh strengthAvoid degradationDigestersPulp bleachingAcetic acidCellulose acetate

The invention discloses a manufacturing technique of bamboo dissolving pulp. The manufacturing technique sequentially comprises cropping, screening and removing ashes, washing under standard temperature, sulfate cooking, serosity separation, scrubbing purification, chlorination treatment, alkali treatment, acetic acid bleaching +H2O2 oxidation organic bleaching, acid complex treatment and runnability. The invention effectively shortens the production process and enhances production efficiency of producing bamboo dissolving pulp by bamboo. The dissolving pulp can be used in rayon dissolving pulp, nitrocellulose dissolving pulp, cellulose acetate dissolving pulp and cellulose dissolving pulp. At the same time, the invention enhances the harvesting rate of making bamboo dissolving pulp by bamboo.

Owner:宜宾纸业股份有限公司

Textile size and preparation method thereof

The invention discloses a high-performance and environment-friendly textile size and a preparation method thereof. By using the reactivity of activated polyethylene glycol, textile size is modified by animal glue and the modified animal glue is compounded with high-performance starch and a sizing assistant to develop the novel high-performance size capable of replacing dirty size polyethylene glycol size in the yarn sizing and weaving of cotton, viscose and blended yarn thereof. The size comprises the following components in percentage by weight: 5-10 percent of polyethylene glycol modified animal glue, 70-90 percent of modified starch and 5-25 percent of high-efficiency assistant. In addition, the size has excellent sizing fluid and sizing film performance and sizing performance.

Owner:YIXING JUNDA SLURRY TECH

Anti-bacterial fabric

InactiveCN105568491AImprove antibacterial propertiesLong lasting antibacterialWeft knittingWarp knittingPolyesterViscose

The invention discloses anti-bacterial fabric. The anti-bacterial fabric is prepared from following fibers in parts by weight through blending: 10-20 parts of polyester fibers, 5-15 parts of flax fibers, 25-35 parts of cotton fibers, 5-8 parts of viscose fibers, 15-25 parts of bamboo charcoal fibers, 3-8 parts of chitin fibers and 5-12 parts of nano silver ion fibers, and the fibers are impregnated in an organosilicon quaternary ammonium salt antibacterial agent for 10-15 min. The anti-bacterial fabric has the high anti-bacterial capacity and is non-toxic and harmless to human bodies and high in antibacterial endurance.

Owner:江苏新凯奇纺织实业有限公司

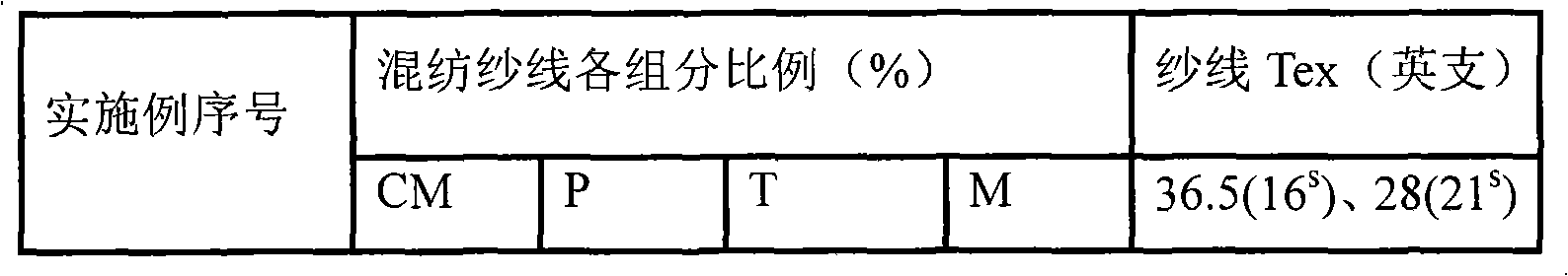

Wool, pearl fibre, modal, viscose blended yarn and method of processing the same

The invention relates to blended yarn which contains wool, pearl fiber, modal fibre and viscose, and a machining method thereof. The blended yarn is composed of wool, pearl fiber, modal fibre and viscose with the mass ratio as the following: wool 10-15%, pearl fiber 20-30%, modal fibre 30-35% and viscose 25-30%. The blended yarn can be in pure white, bleached to be white, gray, apricot, pinkish purple, or in other colors. The performance index meets the requirements that the single yarn rupture strength is 12.5-19.5cN / tex, the CV value of single yarn rupture strength is less than or equal to 6.0% and the CV value of yarn evenness variation coefficient is less than or equal to 15%. The processing method includes the following steps: dyeing according to the tinctorial pattern of a matching card (used for producing colored yarn), manually mixing the cotton and baling; grabbing the cotton through a disc, blending and opening the cotton, opening the cotton through carding pins, feeding cotton in the vibrating mode, single beater scutching, combing the cotton, drawing, roving, spinning, winding and packing.

Owner:江阴市茂达棉纺厂有限公司

Method for synthesizing heteroatom Sn-beta zeolite

InactiveCN102249258AEfficient catalytic effectLow viscosityMolecular sieve catalystsCatalyst activation/preparationSolventWater content

The invention belongs to the technical field of catalytic chemistry, and relates to a method for preparing a heteroatom Sn-beta zeolite molecular sieve. The method is characterized by comprising the following steps of: stirring a silicon source, tetraethyl ammonium hydroxide, a tin source, water and ethanol serving as a solvent in a ratio to form initial gel; adding fluoride serving as a mineralizing agent to form a viscose system, and crystallizing at the temperature of between 100 and 180 DEG C for 3 to 10 days to hydrothermally synthesize a Sn-heteroatom molecular sieve with a beta structure. The molecular sieve is synthesized in a neutral or subacid synthesis system under the conditions that a crystal seed is not added, relatively cheap white carbon black is taken as the silicon source, and ammonium fluoride meeting the environment-friendly requirement is taken as the mineralizing agent. The synthesis system has low water content, absolute ethanol serving as an auxiliary agent is added to reduce the viscosity of the synthesis system, convenience is provided for stirring, and the requirement on large-scale industrial production is well met. The method is low in cost, environment-friendly, simple, and easy to industrialize.

Owner:DALIAN UNIV OF TECH

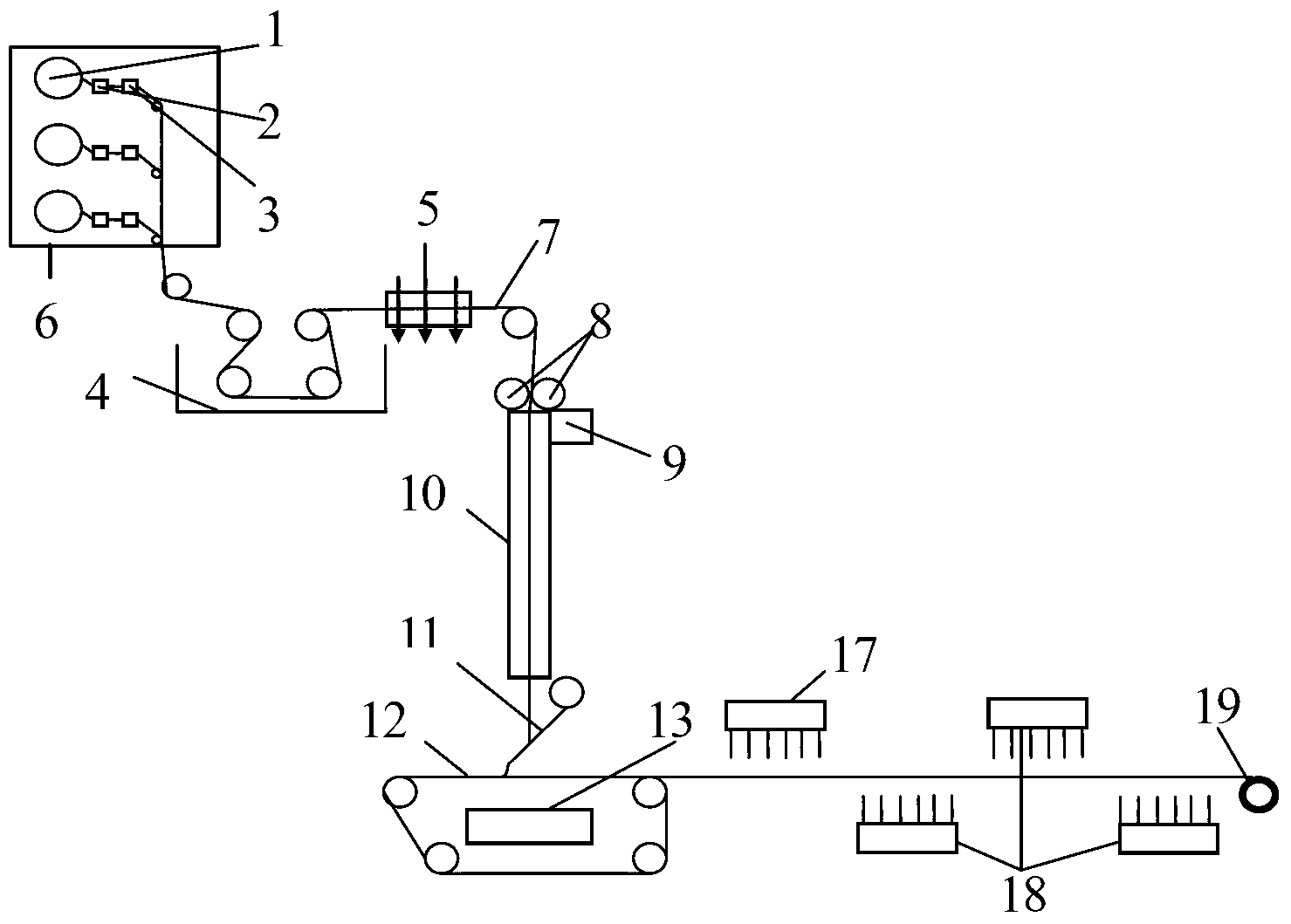

Manufacturing method for filament non-woven fabric

The invention discloses a manufacturing method for filament non-woven fabric. The manufacturing method for the filament non-woven fabric comprises the following technological steps that (1) a creel is used for unwinding filament fibers, wherein the filament fibers comprise polyphenylene sulfide fibers, aramid fibers, Teflon fibers, viscose fibers, polyimide fibers or polyacrylonitrile fibers, carbon fibers, and glass fibers or basalt fibers, and the filament fibers are zero-twist continuous filaments, and the fineness of the filament fibers is 1micron to 200 microns; (2) ultrasonic waves are used for washing the filament fibers; (3) sigle-fiber drying devices are used for drying the filament fibers; (4) the filament fibers are fed into a tubular drafting device to carry out drafting acceleration through speed adjusting rollers and tensioners, and the filament fibers are evenly dispersed through silk placement devices, and are laid on a net forming curtain to form a filament fiber net; (5) the filament fiber net is manufactured into the filament non-woven fabric through a needled processing method of the non-woven fabric or a spunlace processing method of the non-woven fabric or a hot-rolling processing method of the non-woven fabric.

Owner:TIANJIN POLYTECHNIC UNIV

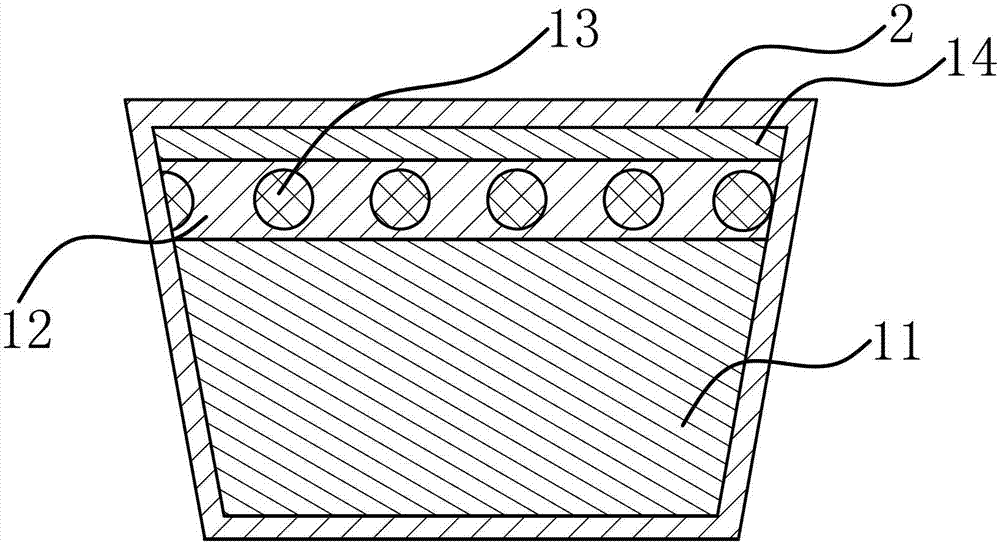

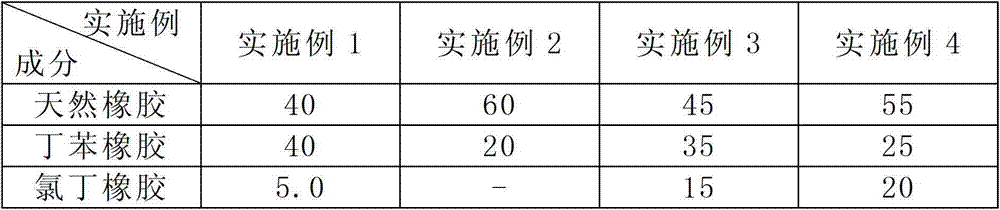

Wrapping cloth V belt and manufacture method thereof

The invention relates to a wrapping cloth V belt and a manufacture method of the wrapping cloth V belt and belongs to the technical field of mechanical transmission devices and materials. The wrapping cloth V belt comprises a core layer and a wrapping cloth layer covered on the outer surface of the core layer. The core layer sequentially comprises a base glue layer made of fiber glue pieces, a viscose layer, a polyester hard line rope and a buffering glue layer from bottom to top. The fiber glue pieces comprise natural rubber, butadiene styrene rubber, chloroprene rubber, reclaimed rubber, anti-aging agents, stearic acid, magnesium oxide, carbon black, softening agents, short fibers, zinc oxide, padding, and accelerating agents. The fiber glue pieces manufactured by mixed refining undergo horizontal cutting and splicing, and therefore short fibers in the fiber glue pieces are horizontally arranged. The finished wrapping cloth V belt is obtained through treatment of forming, cutting, cloth wrapping, vulcanization and demolding. Components in the rubber pieces are reasonable in ratio, and the wrapping cloth V belt has the advantages of being high in intensity, not prone to horizontal deformation, and long in service life. The manufacture method of the wrapping cloth V belt is simple in technology and easy to operate.

Owner:台州市格茂橡塑制品有限公司

Moisture-absorbing and bacteriostatic base cloth of beauty mask made of spunlace non-woven fabric and preparation method thereof

ActiveCN108166157AImprove the problem of viscosity instabilityGood viscosity stabilityNon-woven fabricsArtifical filament manufactureYarnViscose

The invention discloses moisture-absorbing and bacteriostatic base cloth of a beauty mask made of spunlace non-woven fabric and a preparation method thereof, relating to the technical field of non-woven fabrics. The moisture-absorbing and bacteriostatic base cloth is composed of following fibers, by weight, 40-60% of sodium alginate viscose fibers and 40%-60% of chitosan viscose fibers. The preparation method comprises the following steps: firstly preparing the sodium alginate viscose fibers and the chitosan viscose fibers; next, respectively opening and carding the chitosan viscose fibers; then, netting in an intersected manner; reinforcing a fiber net that is laid well by spunlace, drying the fiber net so as to obtain the base cloth. Sodium alginate and chitosan are respectively added into viscose primary liquid to spin viscose yarns. Epichlorohydrin is utilized such that sodium alginate and chitosan are closely combined with viscose. Sodium alginate viscose fibers and chitosan viscose fibers produced show great air permeability, water retention and moisture absorption capabilities and are capable of eliminating bacteria and inhibiting bacteria. Then, non-woven fabric made by intersecting netting and spunlace reinforcement can be used for material of base piece of the mask. The moisture-absorbing and bacteriostatic base cloth is comfortable and skin-friendly and capable of diminishing inflammation and inhibiting bacteria. Skin can be cleaned and effectively protected. The damage of cosmetics to the skin is minimized.

Owner:HEFEI C&P NONWOVEN PROD

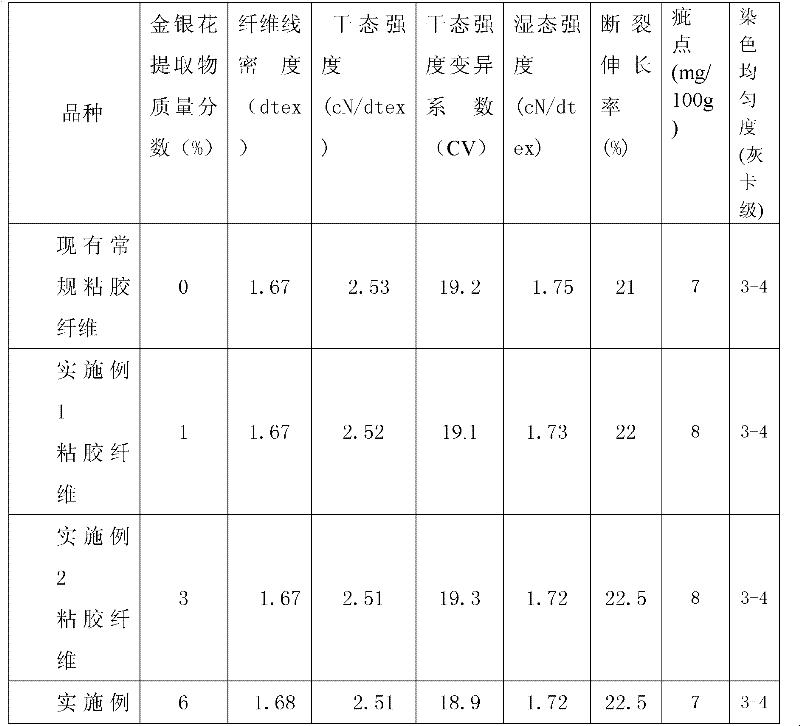

Natural antimicrobial contained viscose fiber and preparation method thereof

InactiveCN102505171AImprove antibacterial functionNo side effectsArtificial filaments from viscoseWet spinning methodsSocial benefitsViscose

The invention provides a natural antimicrobial contained viscose fiber and a preparation method thereof. The natural antimicrobial contained viscose fiber comprises a viscose fiber and antimicrobial contained therein, and is characterized in that the antimicrobial is made of powder of natural honeysuckle extract, solution of the natural honeysuckle extract powder is added into viscose spinning dope, and the solution of the natural honeysuckle extract powder contains honeysuckle extract particles which, by weight, accounts for 1%-6% of the viscose spinning dope. The natural honeysuckle extract is used as the antimicrobial evenly distributed in the fiber, the antibacterial function lasts long, and the antimicrobial has no side effects on human bodies. The viscose fiber with the antibacterial function of honeysuckle is suitable for being made into underwear, other clothes and bedding textiles, is wide in application and has great economic and social benefits. The preparation method is reasonable and simple in process and suitable for industrial production.

Owner:山东省纺织科学研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com