Manufacturing method for filament non-woven fabric

A filament non-woven fabric and a manufacturing method technology, applied in textiles, papermaking, non-woven fabrics and other directions, can solve the problems of limited application range and production speed, poor dimensional stability, low production speed, etc., to achieve convenient reinforcement process, uniformity The effect of good performance and fast network speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Manufacture of glass filament fiber spunlace felt for high temperature filtration, weight 700g / m 2 .

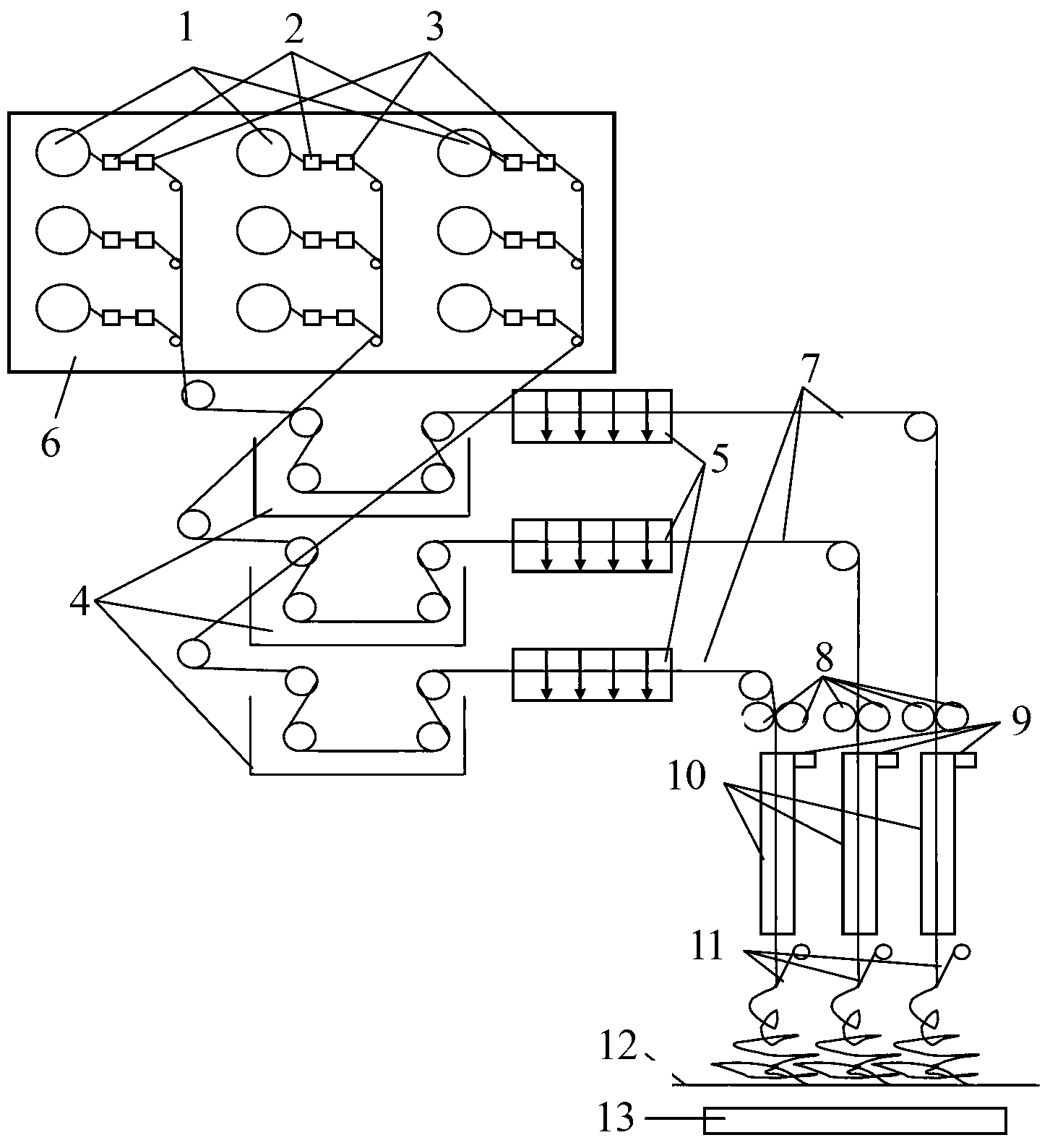

[0031] The process flow of the glass filament fiber spunlace felt for high temperature filtration of the present embodiment (see figure 2 ), and its specific implementation steps:

[0032] Unwinding: Place the yarn bobbin 1 wound with untwisted glass filament fiber 7 on the creel 6, after which the glass filament fiber passes through the tensioner 2 and the infrared short-line self-stop device 3, and the spinning speed of the bobbin is set at 12000r / min.

[0033] Cleaning: the glass filament fiber 7 after unwinding passes through the ultrasonic cleaning pool 4, the power of the ultrasonic cleaning machine is 3000W, the working frequency is 40KHZ, the washing temperature is 60°C, and the water-soluble ultrasonic cleaning agent is selected.

[0034] Drying: the glass filament fiber 7 passes through the single fiber drying device 5, and the hot air temperature is set a...

Embodiment 2

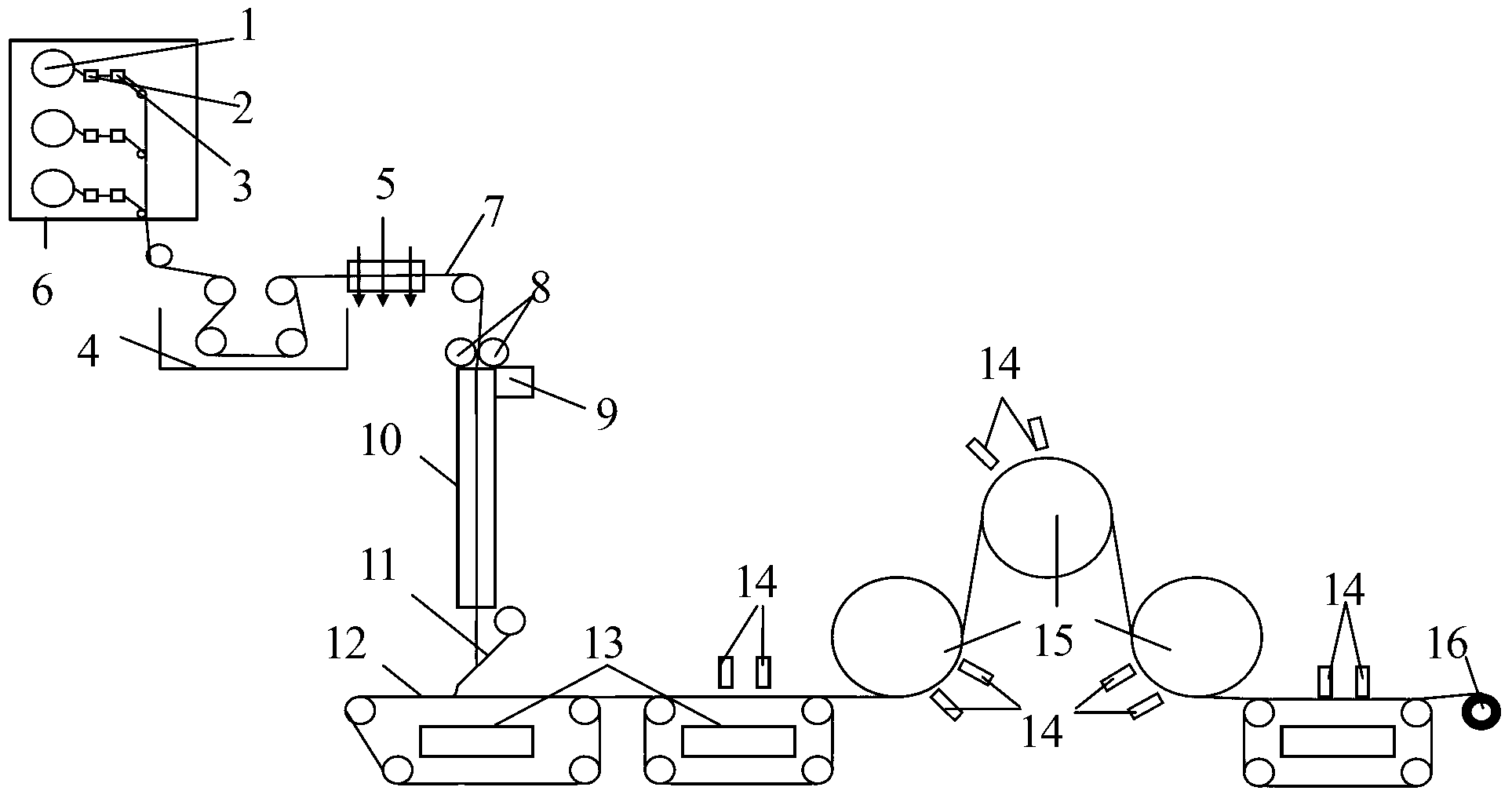

[0038]Manufacture of PTFE filament needle felt for high temperature filtration, weight 500g / m 2

[0039] The process flow of the long needle-punched PTFE felt used for high-temperature filtration of this embodiment can be found in image 3 , and its specific implementation steps are as follows:

[0040] The PTFE fiber web forming steps (comprising unwinding, cleaning, drying and filament forming) are the same as in Example 1. The process conditions are specifically set as follows: the drafting air pressure is 0.45Mpa, the speed of the supporting net curtain 7 is 15m / min, and the step of fixing the net is that the supporting net curtain 12 sends the uniformly dispersed PTFE filament fiber web into the pre-acupuncture machine through The pre-acupuncture head 17 is pre-acupunctured, and then consolidated into a PTFE filament needle-punched felt after passing through three main acupuncture heads 18 for main acupuncture. The pre-acupuncture frequency was set to 600r / min, and the...

Embodiment 3

[0042] Manufacture viscose filament spunlace cloth, weight 100g / m 2 .

[0043] This embodiment manufactures the technological process of viscose filament spunlaced cloth (see figure 2 ) The specific implementation steps are the same as in Example 1. The process conditions are specifically set as follows: drying temperature 100°C, drafting airflow pressure 0.45Mpa, support screen curtain 7 speed 20m / min; water thorn head pressure set to 40bar, 60bar, 80bar, 80bar, 110bar in sequence from front to back , 110bar, 160bar, 160bar, 80bar, 80bar. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com