Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3561 results about "Basalt fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

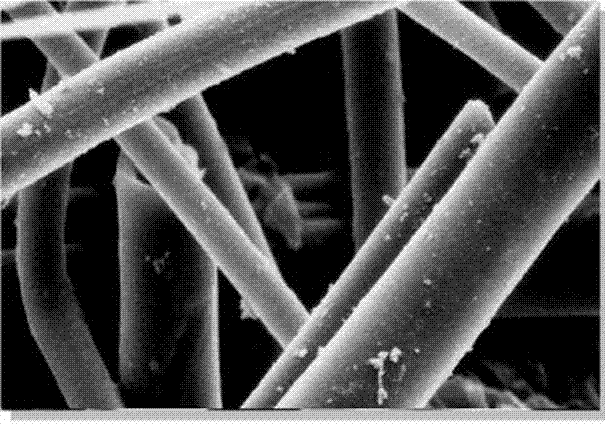

Basalt fiber is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase, pyroxene, and olivine. It is similar to fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries and can also be used as a composite to produce products such as camera tripods.

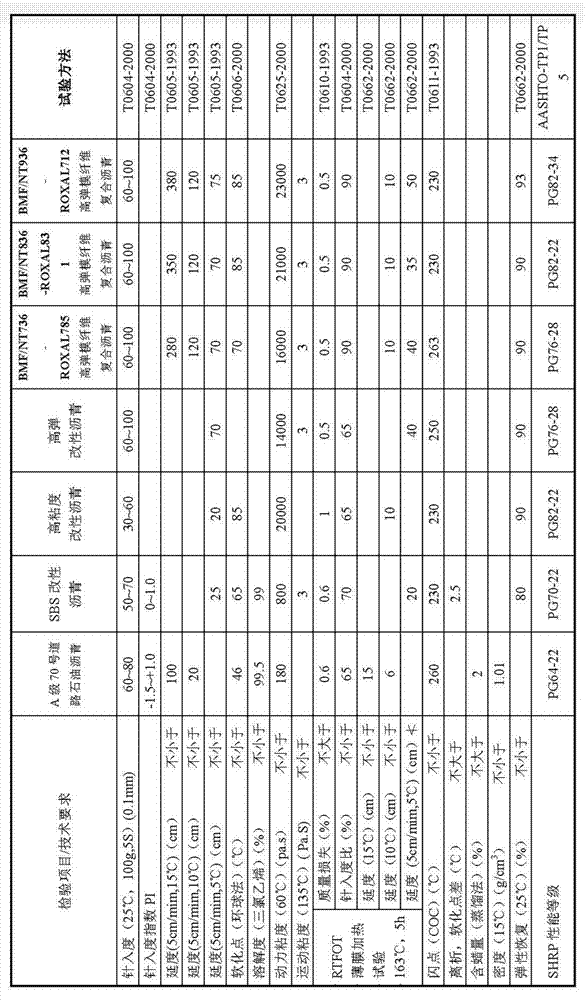

Composite material containing modified basalt fiber and polymer and preparation method thereof

The invention provides composite material containing a modified basalt and a polymer and a preparation method thereof, wherein the main components of the composite material contains: 1200-1300 parts of polymer, 700-800 parts of modified basalt fiber, and 5-50 parts of surfactant coupling agent. The method, by means of the mechanical force, supersonic wave and electromagnetic force synthetic effect of the surfactant or coupling agent, comprises: uniformly dispersing the polymer and the modified basalt fiber into a solvent to prepare a uniform and stabile mixture, adding another solvent into the mixture, implementing the cladding or wrapping to the modified basalt fiber while precipitating the polymer from the mixture, and then forming the composite material of the modified basalt fiber containing polymer. The composite material can be used for preparing asphalt with excellent performances, the method has the advantages of low cost, simple operation and easy enlargement, and the method makes it easy for the modified basalt fiber to be uniformly dispersed in the polymer.

Owner:长沙北美孚新材料科技有限公司

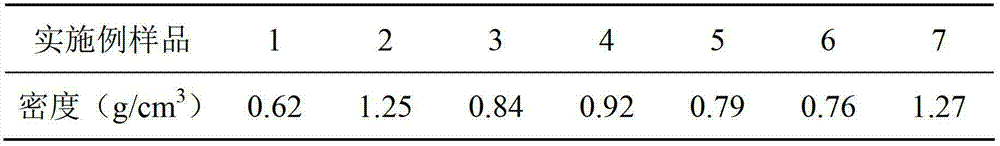

Light composite material

InactiveCN103087463ASolve the insulation performanceSolve the sound insulationGlass fiberCarbon fibers

The invention relates to a light composite material, and in particular relates to a hollow microspheres and fiber body composite material. The light composite material consists of a base material, the fiber body and hollow microspheres which are uniformly distributed. The proportion of the total volume of the fiber body and hollow microspheres and the base material is (1:5)-(1:1). The base material is thermoplastic or thermosetting resin. The fiber body is at least one of fibrilia, carbon fiber, glass fiber, polypropylene fiber, aramid fiber and basalt fiber. The hollow microspheres are at least one of hollow glass microspheres and hollow ceramic microspheres. The volume ratio of the fiber body and the hollow microspheres is (1:5)-(1:1). The fiber body and the hollow microspheres are bonded together through the base material. According to the light composite material provided by the invention, the problem that current composite material is unsatisfactory in heat insulation, sound insulation, shock absorption and the like because the inner structure is almost a solid structure can be solved.

Owner:CHERY AUTOMOBILE CO LTD

Basalt fiber surface modification impregnating compound and preparation method thereof

The invention discloses a basalt fiber surface modification impregnating compound and a preparation method thereof, and belongs to a basalt fiber impregnating compound. The impregnating compound comprises the following components in percentage by weight: 0.2-0.6% of organic silane coupling agent, 0.05-0.3% of pH (potential of hydrogen) conditioning agent, 3.0-10.0% of polyvinyl acetate emulsion, 0.2-2.0% of polyurethane emulsion, 0.5-3.0% of water-borne epoxy resin film forming matter, 1.0-5.0% of polyolefin emulsion, 0.1-1.0% of organic silicon emulsion, 0.1-1.0% of antistatic agent and the balance of water. The basalt fiber surface modification impregnating compound prepared according to the rated mass ratio is directly coated on the surface of basalt fiber in the basalt producing and wiredrawing process, and the surface modification is finished after the basalt fiber surface modification impregnating compound is dried, thereby being convenient to use. Meanwhile, the preparation method for the basalt fiber surface modification impregnating compound, which is disclosed by the invention, is simple, is suitable for industrial production and is easy for popularizing.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

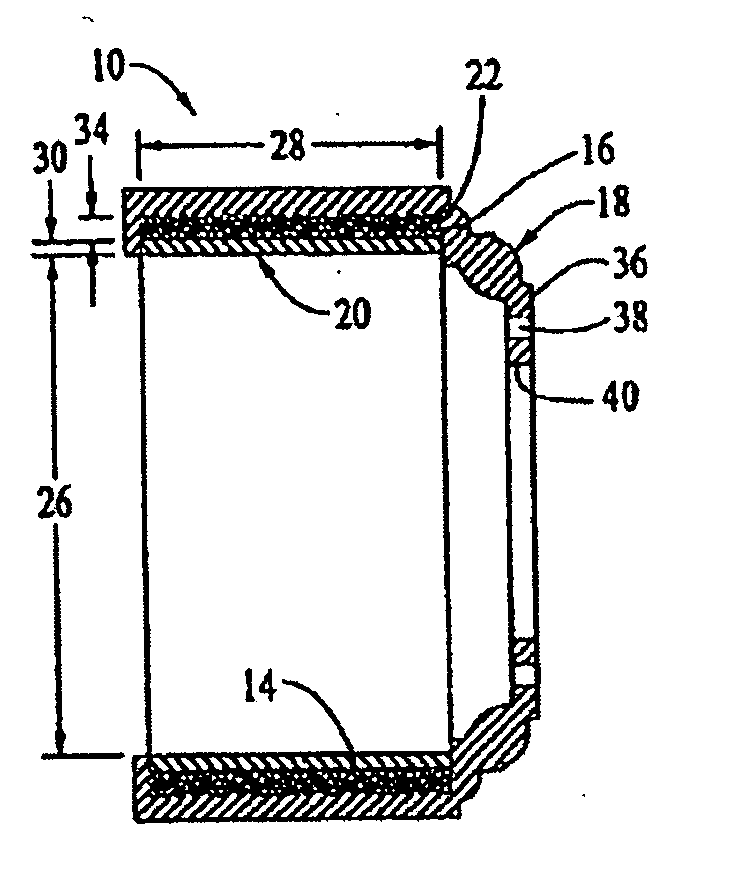

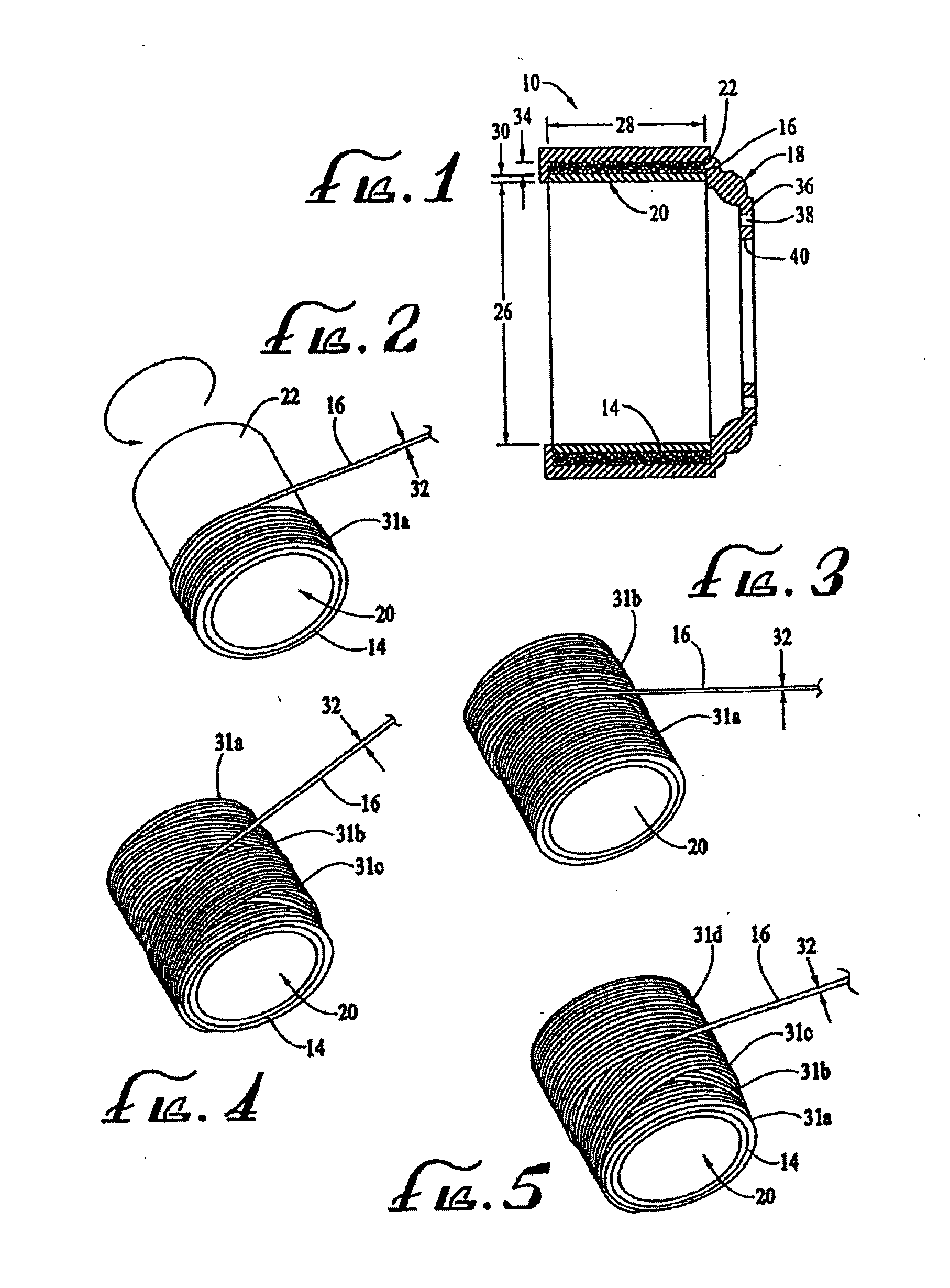

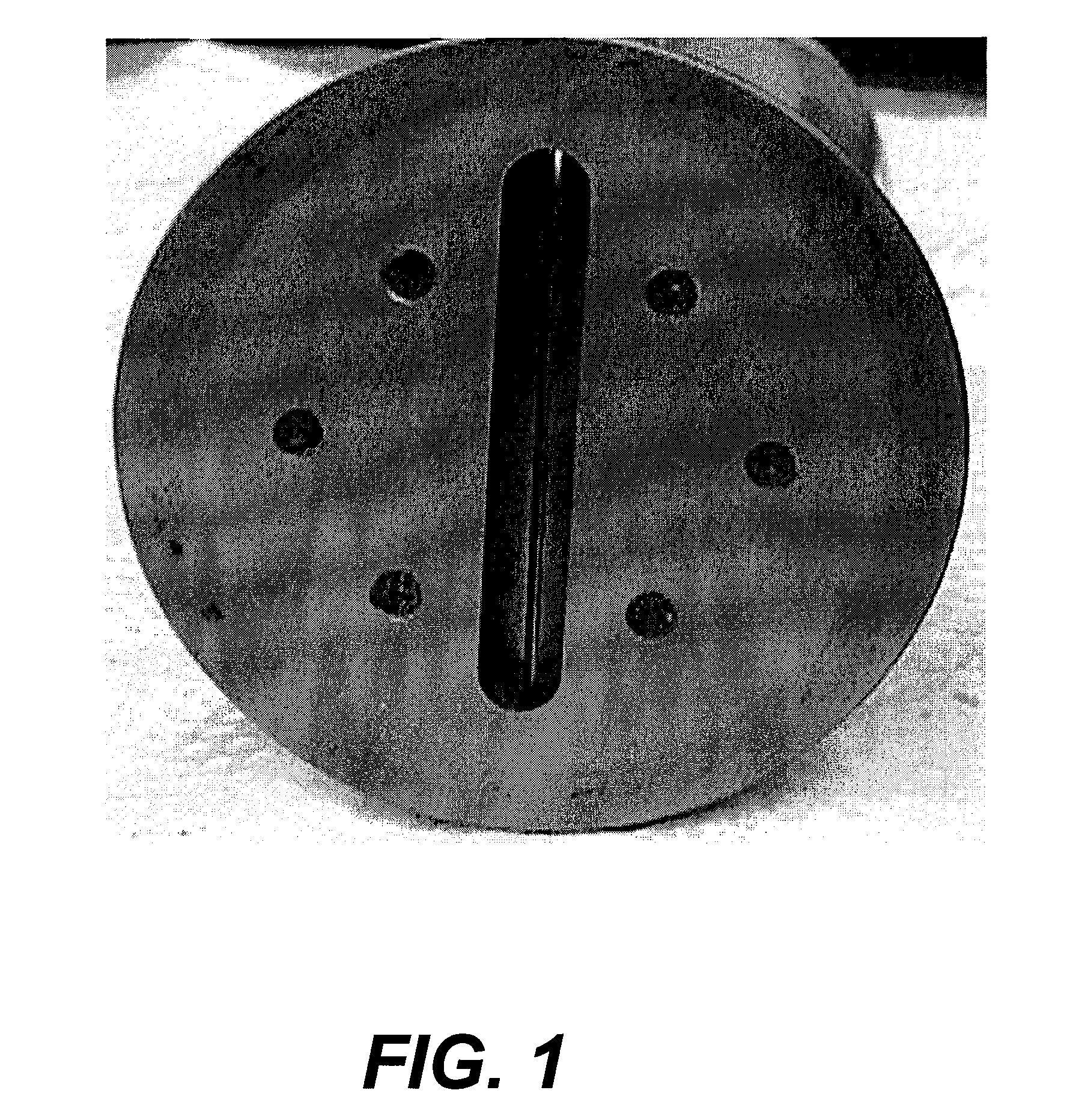

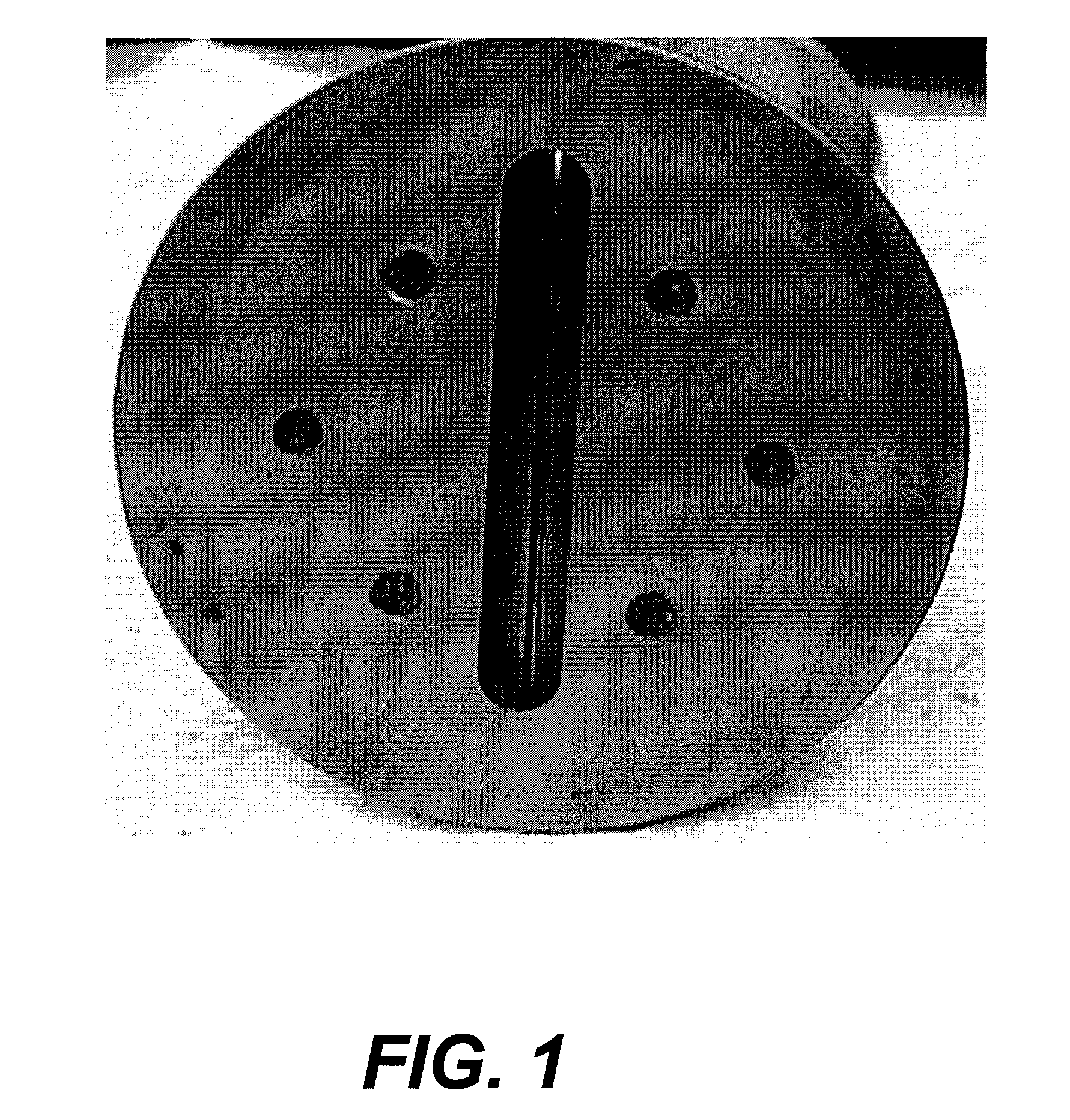

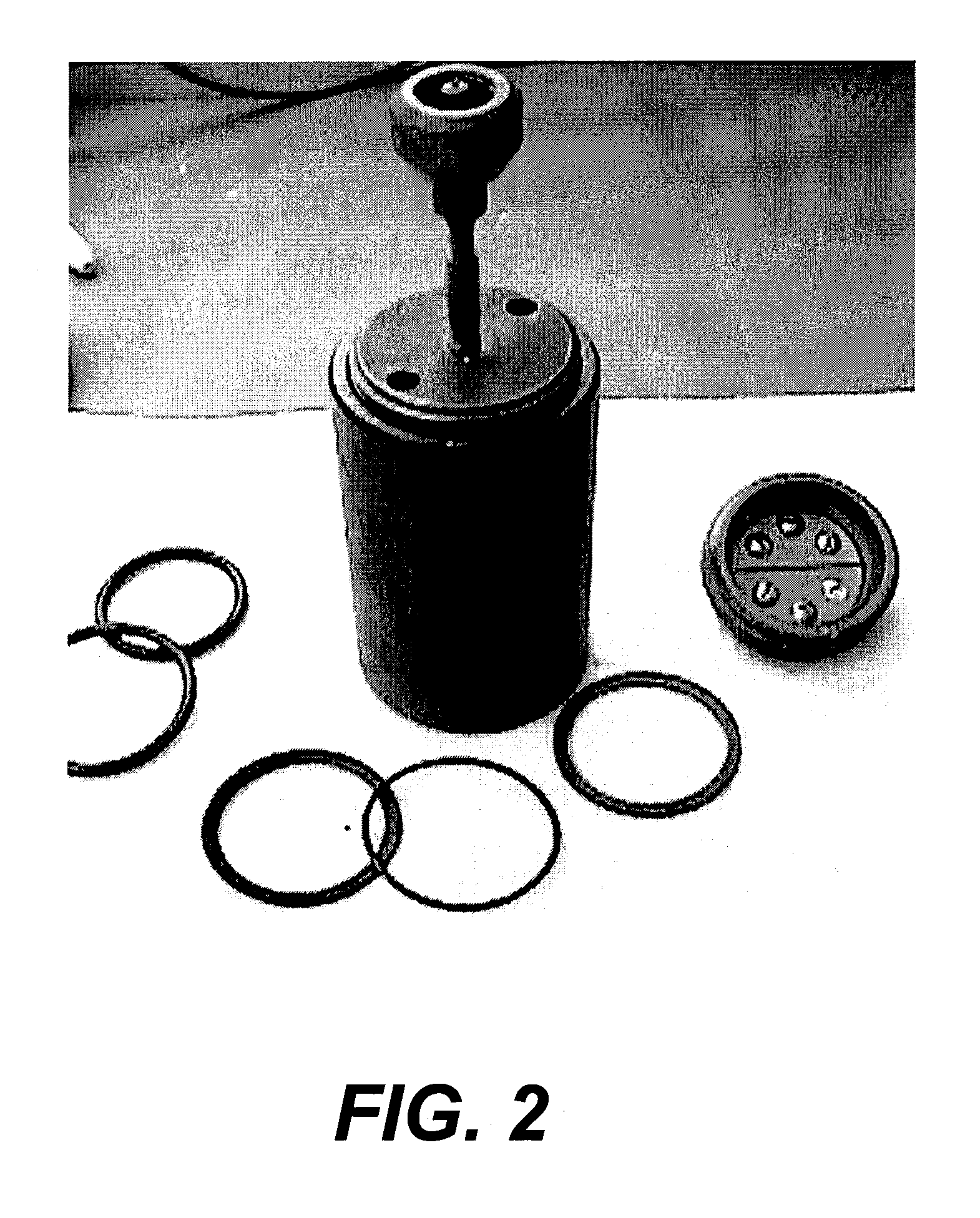

Lightweight reinforced brake drum and method for making same

InactiveUS20050217950A1Reduce manufacturing costAdd supportBraking drumsCoatingsCarbon graphiteEngineering

The invention provides a lightweight brake drum (10) comprising a lightweight, tubular inner member (14) having a reinforcement wrapping retention pattern (e.g., groove) cast in the exterior surface thereof, a length of reinforcement material (e.g., wrapped wire, cable, mesh, fibers, etc.) (16) in communication with a reinforcement retention pattern (e.g., a groove around the inner member) (14), the drum including an outer shell (18). The inner member (14) and the outer shell (18) are made of lightweight materials. Single, or multiple layers of reinforcement material (e.g. wrapping) are applied (e.g., wrapped) around the inner member (14) to support and inhibit expansion of the inner member (14). Because the reinforcement material (16) provides support against expansion, the inner member (14) and the outer shell (18) can be made of lightweight materials. In preferred embodiments, a bonding layer (66) is applied to the exterior surface of the inner member prior to application of the reinforcement material thereon. In preferred embodiments the reinforcement material comprises a low-impedance material such as copper along with another material that has good tensile strength characteristics (e.g., steel, composite fibers, Basalt-fibers, etc.). Preferably, the inner member comprises at least one material selected from the group consisting of a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, ceramic matrix composite (CMC), and carbon graphite foam.

Owner:BENMAXX

Composite core for power grid transmission line wire and preparation method thereof

The invention provides a composite core for a power grid transmission line wire and a preparation method thereof. The composite core has high strength, high toughness, high glass-transition temperature and surface cleanness. Materials of the composite core comprise a resin material and a strengthening material. The resin material comprises a thermosetting resin, a curing agent, an accelerating agent, a releasing agent, a flexibilizer and nanometer particles. The strengthening material is one kind or a plurality of kinds of carbon fiber, glass fiber, basalt fiber, boron fiber, aramid fiber, silicon carbonate fiber and protein bound iodine (PBI) fiber. The content of composite core fiber Vf=50-80%, tensile strength of the composite core is not lower than 2100MPa, and glass transition temperature of the composite core is not lower than 180 DEG C. The toughness of the composite core is remarkably improved, and breakage and cracking probability caused by brittleness factors in production, transportation and wire hanging construction processes are reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

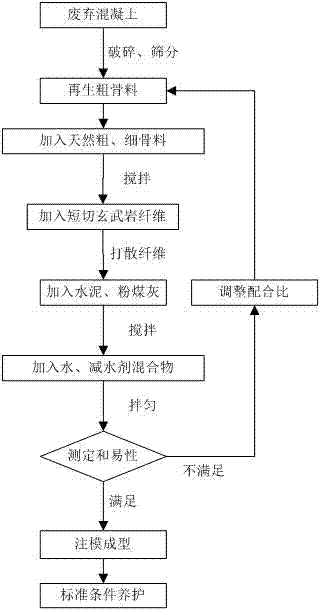

Recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate

The invention belongs to the field of building materials and in particular relates to recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate. The recycled concrete is prepared from the following raw materials in parts by weight: 100-300 parts of water, 300-500 parts of ordinary Portland cement, 500-700 parts of medium sand, 500-650 parts of natural gravels, 500-650 parts of recycled coarse aggregate, 30-50 parts of fly ash, 1-5 parts of a water reducing agent and 1-6 parts of short-cut basalt fibers. The recycled concrete provided by the invention is low in preparation cost, and the obtained concrete has high temperature resistance, corrosion resistance, tensile strength, crack resistance and better durability property.

Owner:FUZHOU UNIV

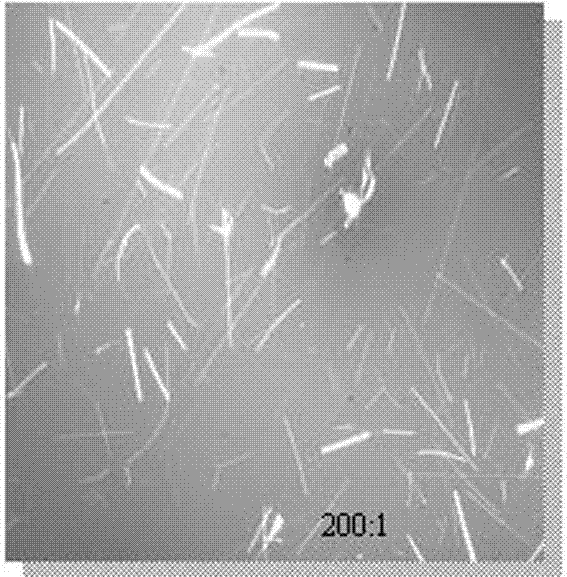

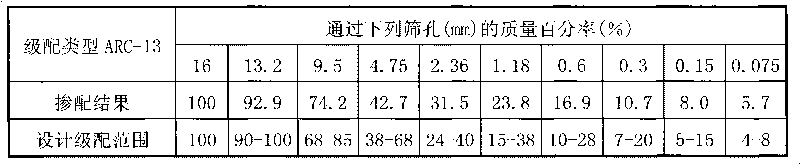

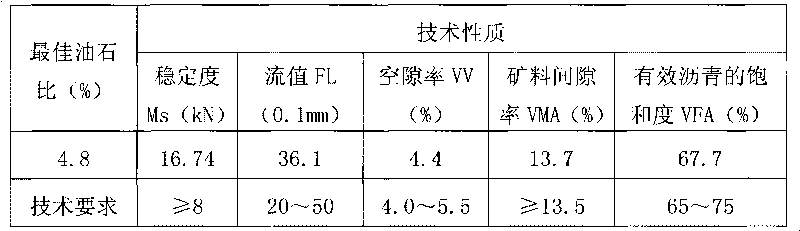

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

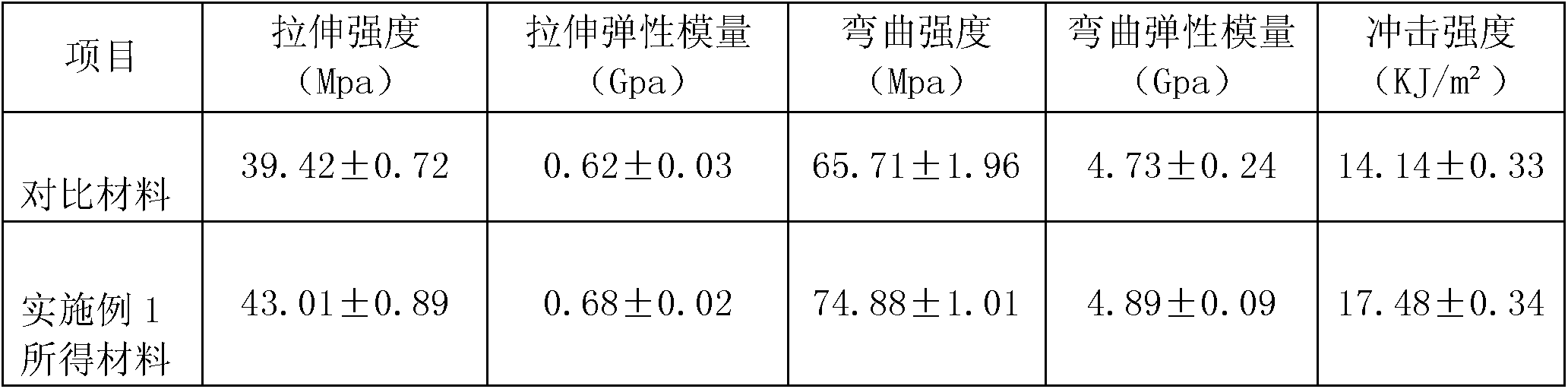

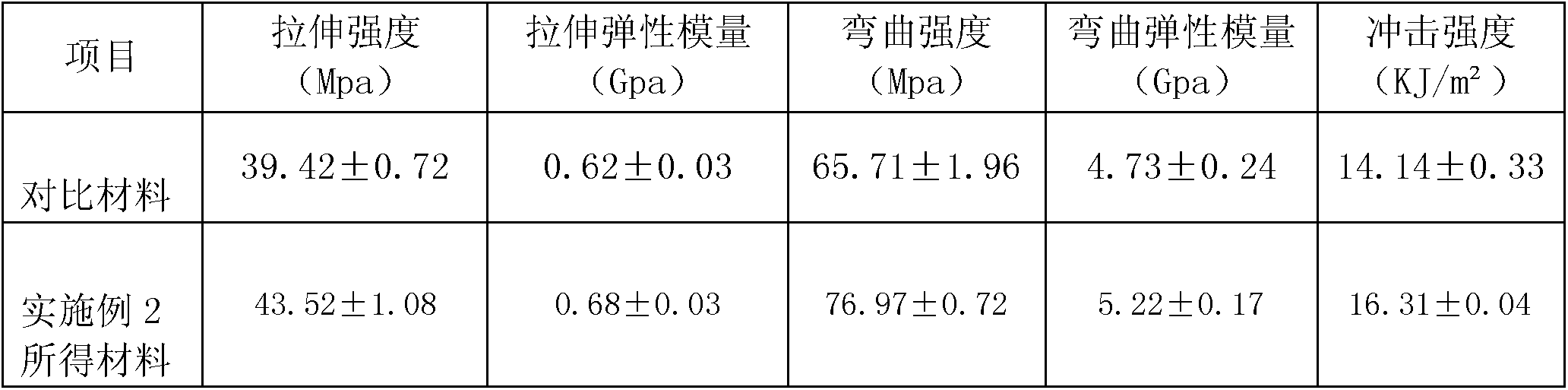

Basalt fiber reinforced wood-plastic composite material and preparation method thereof

The invention discloses a basalt fiber reinforced wood-plastic composite material and a preparation method thereof, and relates to a wood-plastic composite material and the preparation method thereof. The problem of bad comprehensive mechanical property of the current wood-plastic composite material is solved. The material is prepared from thermoplastic plastic, a wood fiber material, modified basalt fibers, a bulking agent and a lubricant. The preparation method comprises the following steps: 1. pre-treating the wood fiber material; 2. sequentially putting the raw materials in a high-speed mixer to be stirred, discharging the materials into a low-speed cold mixer to be stirred, and cooling the materials to obtain premix; and 3. carrying out extrusion forming on the premix. Beside keeping the advantages of good weather fastness, thermal insulation, water resistance, corrosion resistance, and the like, the basalt fiber reinforced wood-plastic composite material provided by the invention has the advantages that the mechanical property is greatly improved compared with common wood-plastic composite materials, and the problems of low mechanical strength and large brittleness of traditional wood-plastic composite material products are well solved. Leftover materials generated in the production process of the basalt fiber reinforced wood-plastic composite material provided by the invention can be entirely recycled, few additives are added, and the basalt fiber reinforced wood-plastic composite material is environment-friendly, thereby being a typical environment-friendly material.

Owner:JILIN HABOD NEW MATERIALS TECH

Compositions comprising melt-processed inorganic fibers and methods of using such compositions

Improved lost circulation compositions that include melt-processed inorganic fibers and methods for using such compositions in subterranean formations are provided. An example of a method of the present invention is a method comprising providing a drilling mud comprising a plurality of melt-processed inorganic fibers, wherein the melt-processed inorganic fibers have a length of less than about 10 millimeters, and comprise at least one melt-processed inorganic fiber selected from the group consisting of: a basalt fiber, a wollastonite fiber, and a ceramic fiber; and circulating the drilling mud in the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

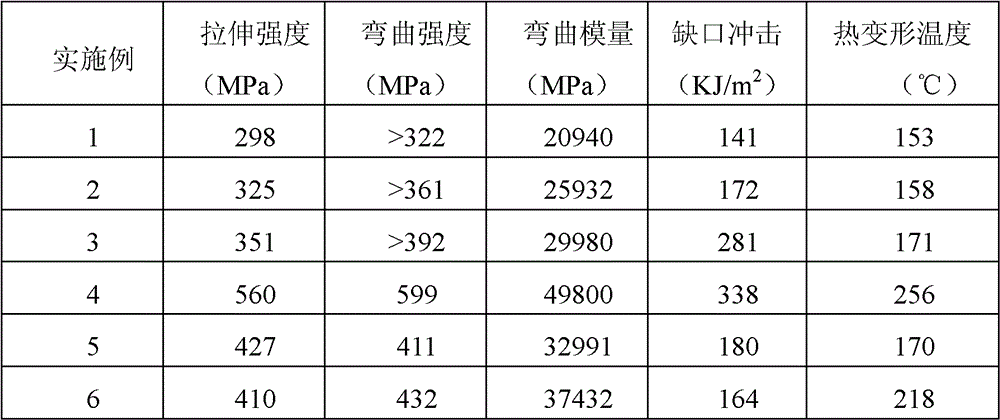

High-strength basalt fibre reinforced nylon composition and preparation method thereof

The invention discloses high strength basalt fiber reinforcing nylon composition, which comprises the following components and contents (parts by weight): 50-70 percent of nylon, 20-40 percent of basalt fiber, 3-12 percent of toughening agent, 1-5 percent of antioxidant, 0.3-1 percent of coupling agent and 0-15 percent of other accessory ingredient. Compared with the common glass fiber reinforcing nylon composition in the present market, the high strength basalt fiber reinforcing nylon composition has the advantages of high intensity, high impact strength and good temperature resistance, etc.

Owner:SHENZHEN KEJU NEW MATERIAL

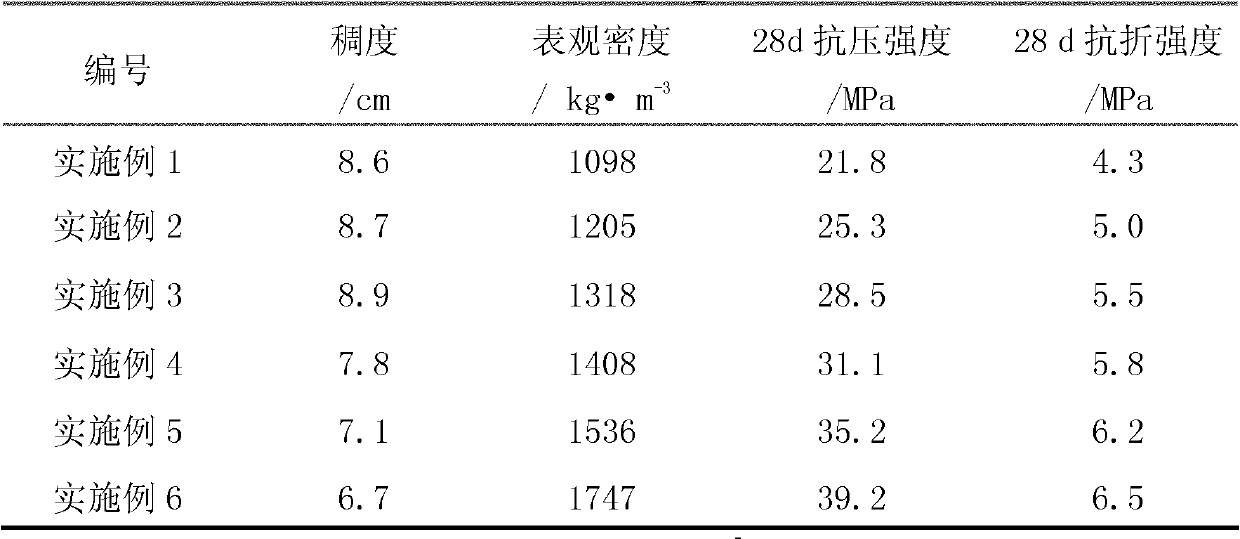

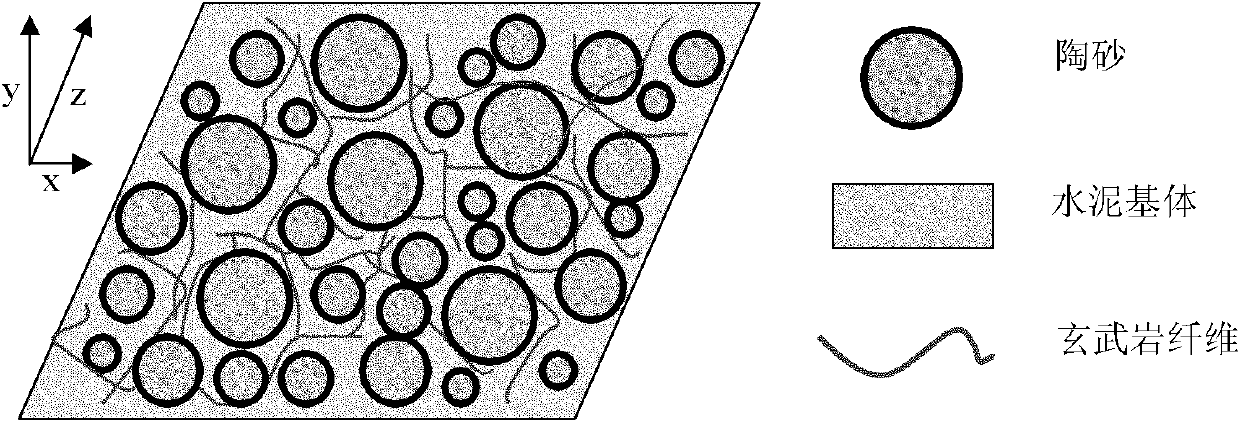

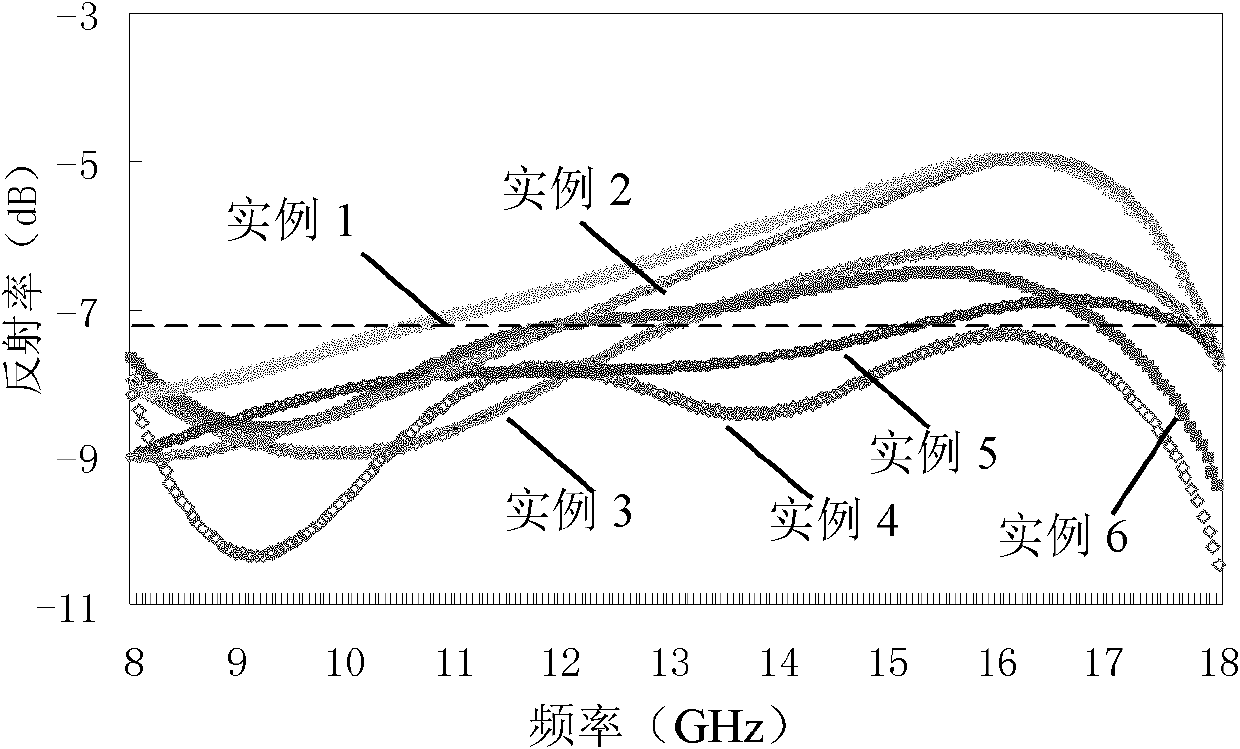

High-iron ground steel slag lightweight high-toughness wave absorption concrete and preparation method thereof

The invention relates to wave absorption concrete and a preparation method thereof. High-iron ground steel slag lightweight high-toughness wave absorption concrete is characterized in that the concrete is prepared from powder, aggregate and admixture, wherein the powder consists of silicate cement, fly ash and high-iron ground steel slag; the aggregate is ceramic sand; the admixture consists of efficient water reducing agent, basalt fiber and water; and the concrete comprises the following raw materials in a ratio (kg / m<3>): 110 to 300 kg / m<3> of silicate cement, 80 to 120 kg / m<3> of fly ash, 70 to 140 kg / m<3> of high-iron ground steel slag, 600 to 1,500 kg / m<3> of ceramic sand, 3.0 to 4.5 kg / m<3> of efficient water reducing agent, 30 to 50 kg / m<3> of basalt fiber and 150 to 180 kg / m<3> of water. The wave absorption concrete has the characteristics of energy conservation, environmental protection and low price.

Owner:WUHAN HAIJIAN ENVIRONMENTAL PROTECTION MATERIALS CO LTD

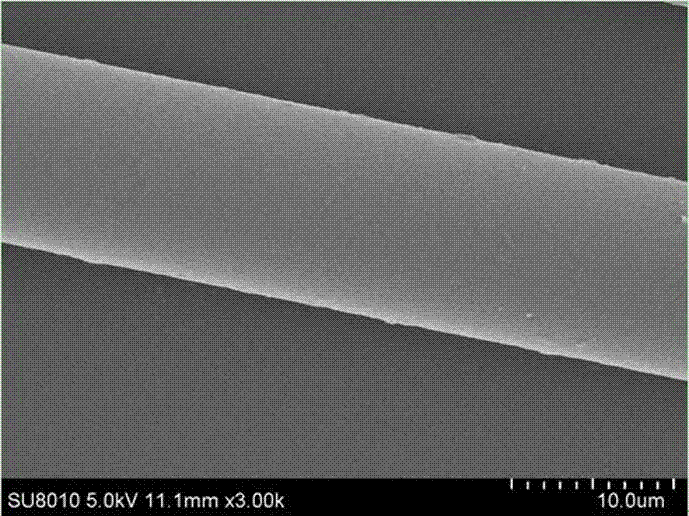

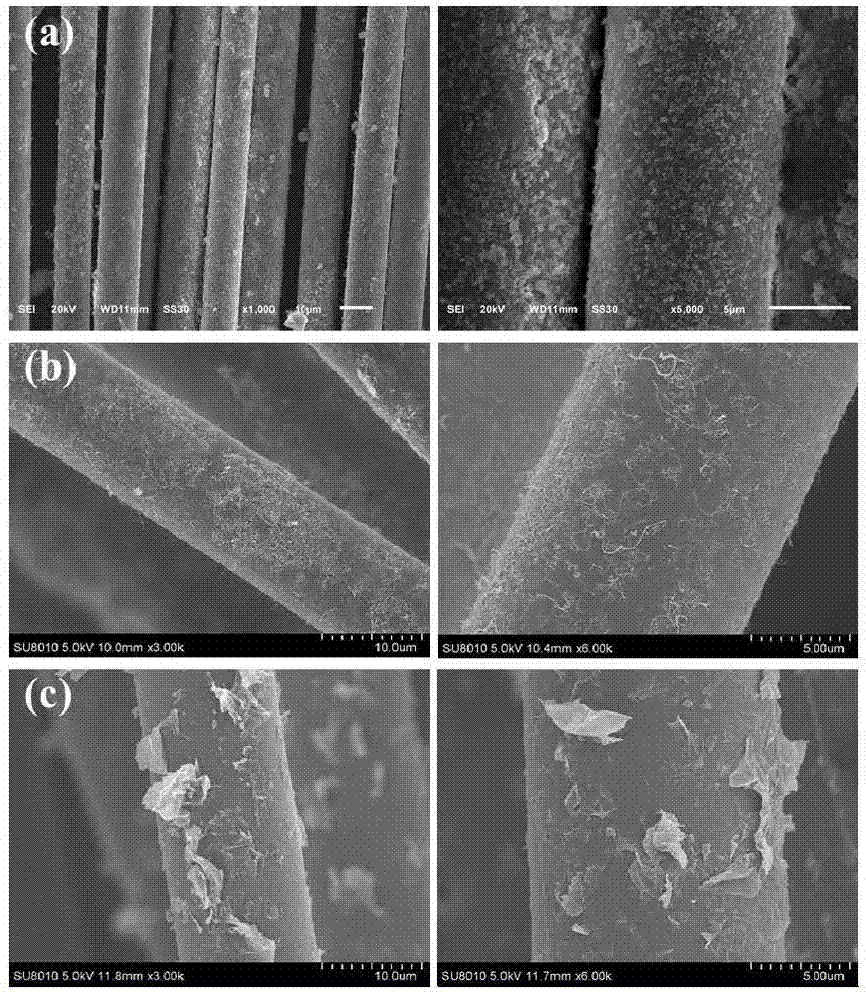

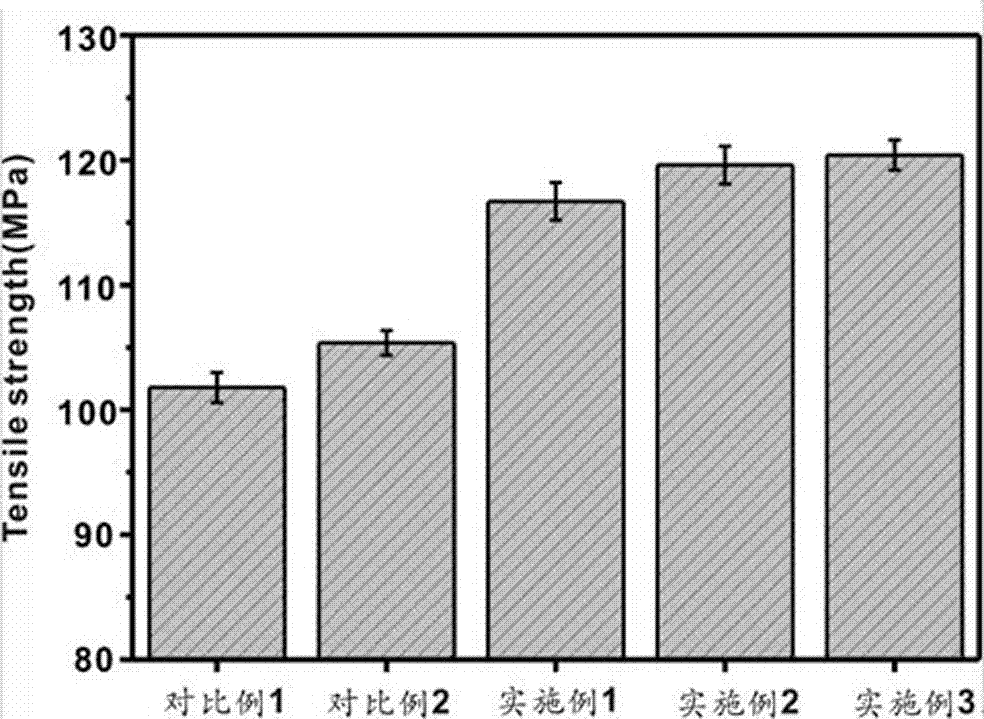

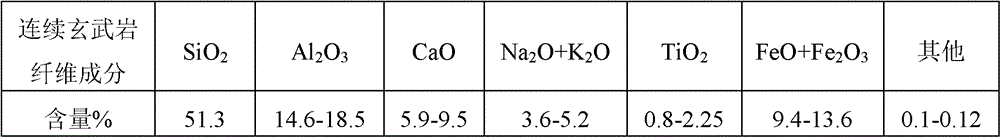

Preparation method and application of basalt fiber surface nano-coated multi-scale reinforcement

The invention belongs to the field of fiber-reinforced composite materials, and in particular relates to a preparation method and application of a basalt fiber surface nano-coated multi-scale reinforcement. According to the preparation method, functional nanoparticles are added into basalt fibers by using a surface coating method, and the basalt fibers are subjected to surface modification, so that the surfaces of the basalt fibers are successfully coated with the nanoparticles, and the multi-scale reinforcement having a nanoparticle and basalt fiber composite structure is further prepared. After the surfaces of the basalt fibers are coated with the nanoparticles, the wetting property of the basalt fibers is obviously improved, and the roughness of the basalt fibers is obviously increased, so that the interface compatibility between the basalt fibers and a matrix in a composite material is facilitated to be improved, stress concentration is effectively relieved, the interface damage to the composite material is inhibited, and the comprehensive performance of the composite material is further improved.

Owner:ZHONGBEI UNIV

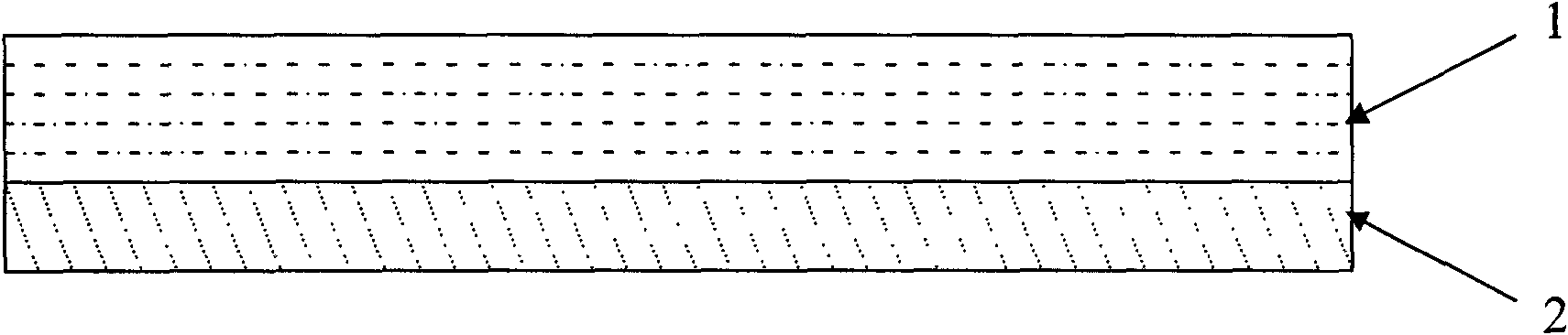

Bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet material and preparation method thereof

ActiveCN103059406AGood value for moneyImprove flame retardant performanceTemperature resistanceBasalt fiber

The invention belongs to the technical field of high polymer material, and discloses a bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet material and a preparation method thereof. The composite sheet material is prepared from the following components by weight: 40-60 parts of a thermoplastic resin, 40-60 parts of a continuous basalt fiber and 0.2-0.5 part of a titanate coupling agent. The invention also discloses a preparation method of the bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet material. The bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet material provided by the invention has good flame resistance, high temperature resistance, comprehensive performance and a low price.

Owner:LIAONING LIAOJIE SCI & TECH

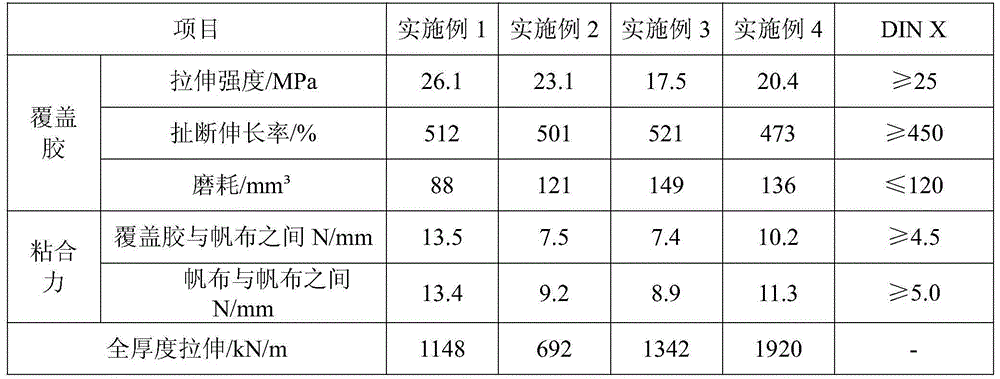

Preparation method for basalt fiber conveying belt

ActiveCN104692027AReduce weightReduce energy consumptionNatural rubber adhesivesConveyorsPolymer scienceAdhesive

The invention relates to a preparation method for a basalt fiber conveying belt, and belongs to the technical field of rubber products. The preparation method comprises the following steps: performing hydrochloric acid treatment, coupling agent treatment and plasma grafting and impregnation treatment on basalt fiber cloth; mixing natural rubber, synthesized rubber, an activating agent, an anti-aging agent, a reinforcement agent and a plasticizer to obtain a first section of mixed rubber; adding a promoter and a vulcanizer for mixing to obtain a second section of mixed rubber, and extruding the second section of mixed rubber to obtain a coverage rubber sheet; mixing the natural rubber, the synthesized rubber, the activating agent, the anti-aging agent, an adhesive, the reinforcement agent and the plasticizer to obtain a first section of mixed rubber; then adding the promoter, the vulcanizer and an adhesive RA for mixing to obtain a second section of mixed rubber, freshening after the second section of mixed rubber is stewed, and attaching the second section of mixed rubber and the basalt fiber cloth to obtain rubberized canvas; attaching the basalt fiber rubberized canvas layer by layer to obtain a framework, attaching the coverage rubber sheets to the upper surface and the lower surface of the framework to obtain a belt blank, and vulcanizing the belt blank to obtain the basalt fiber conveying belt. The conveying belt prepared by the preparation method is low in cost, light in mass, high in intensity, fatigue-resistant and long in service life; the conveying energy consumption can be greatly reduced.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

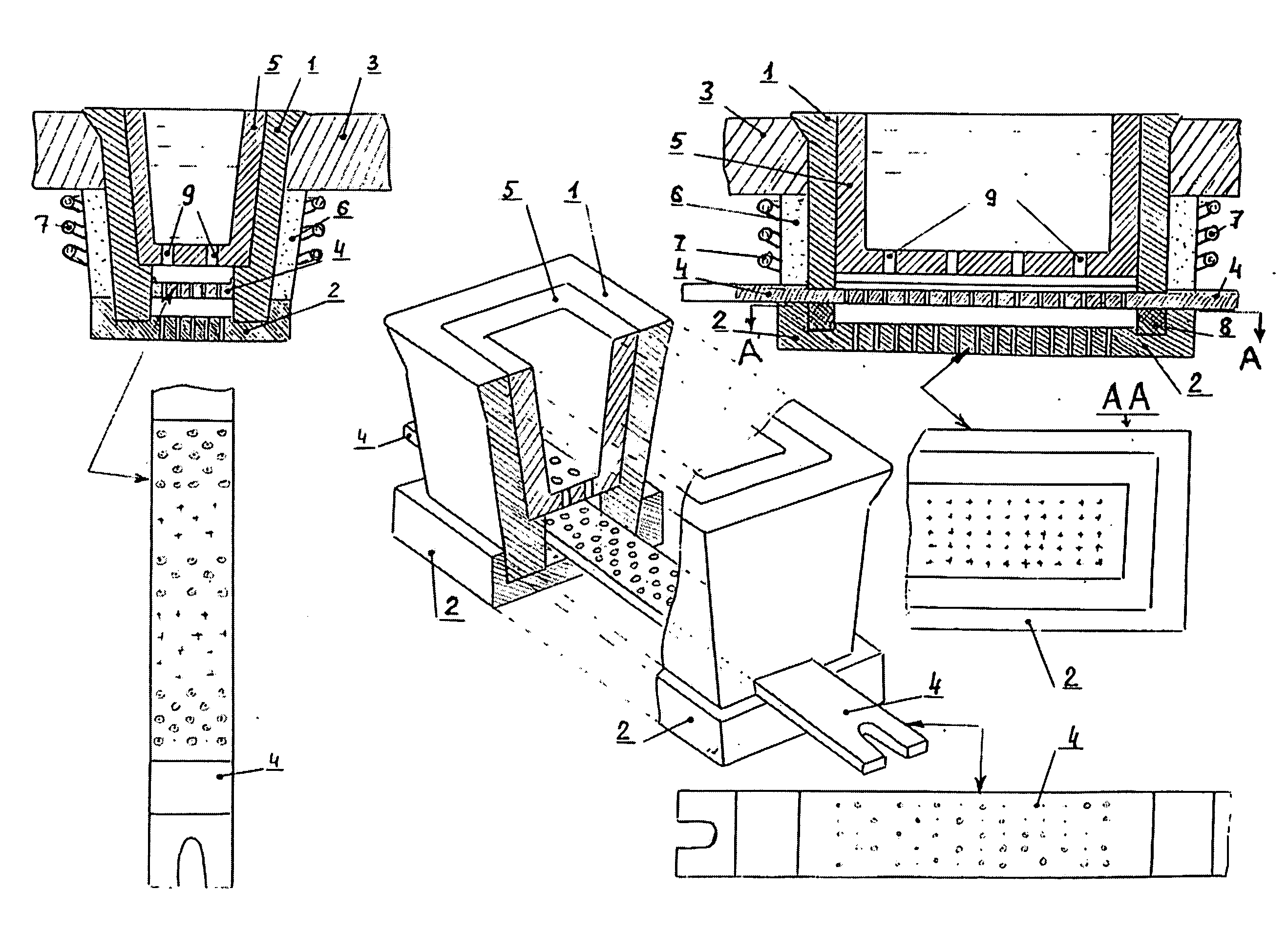

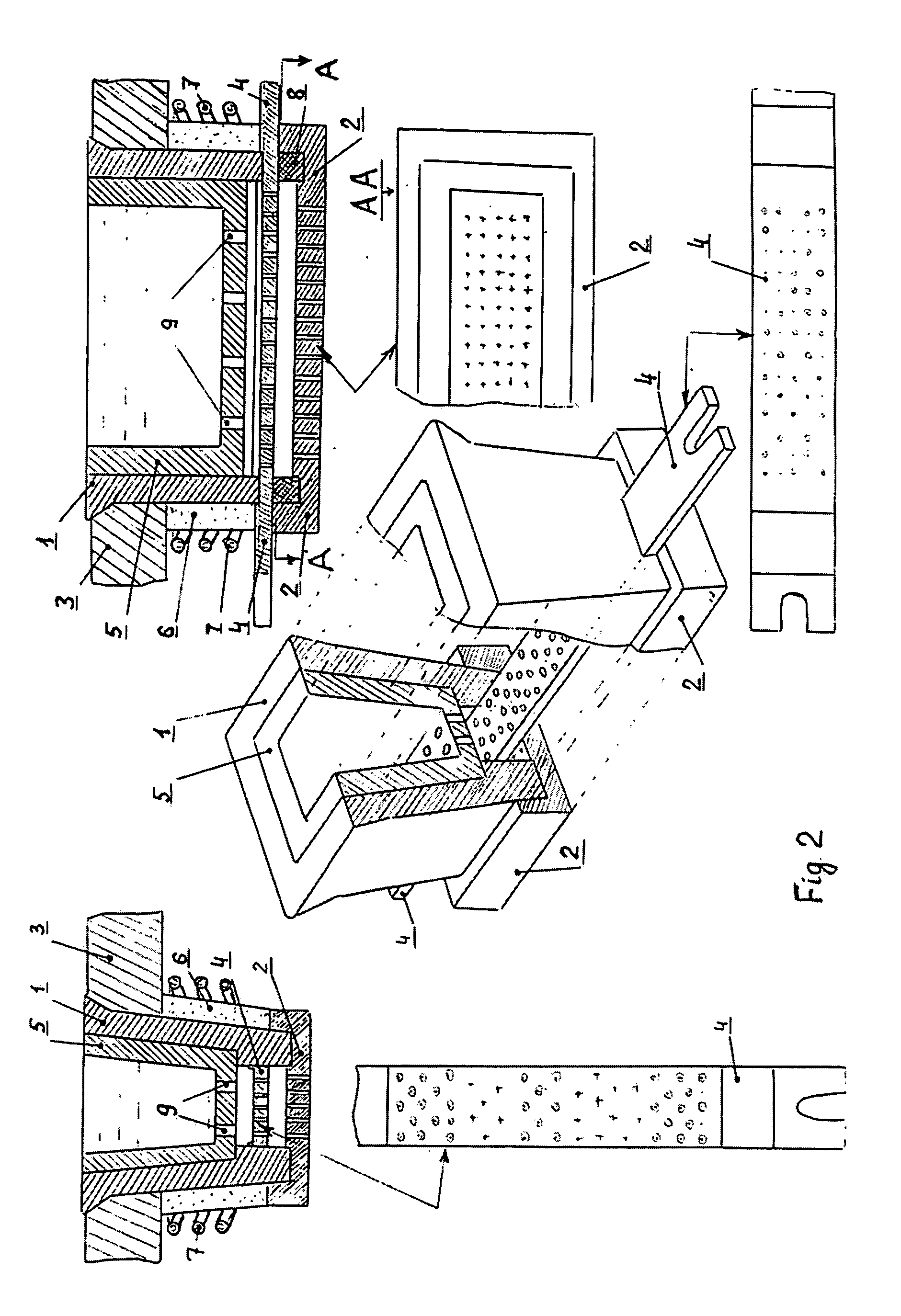

Apparatus integrated with ceramic bushing for manufacturing mineral/basalt fibers

ActiveUS20060218972A1Low costImprove stabilityGlass furnace apparatusRotary drum furnacesComposite applicationMicrometer

The apparatus integrated with ceramic bushing / s for manufacturing mineral / basalt fibers from natural basalt rocks is disclosed. The apparatus and the ceramic bushing / s are integrated into one unit capable provide all operations which are needed: melt basalt rock materials, homogenize basalt glass body suitable for forming fibers to be drawn / attenuated into continuous fibers and gathered into a strand of elemental fibers from 7 to 20 micrometers (μm) in diameter. Also the coarse fibers at the diameters from 20 μm to 100 micrometers (μm) having amorphous structural state which exhibit ductile / flexible properties. The ceramic bushing / s are designed to eliminate precious Pt, Rd metals using instead corrosion resistant ceramic materials to reduce basalt fiber products cost and to increase its commercial compatibility when compared to the other fibers currently been on the market in reinforced concrete / composite applications, including Three Dimension Fiber Reinforced Concrete-3D FRC.

Owner:BLACKBULL IND INC +1

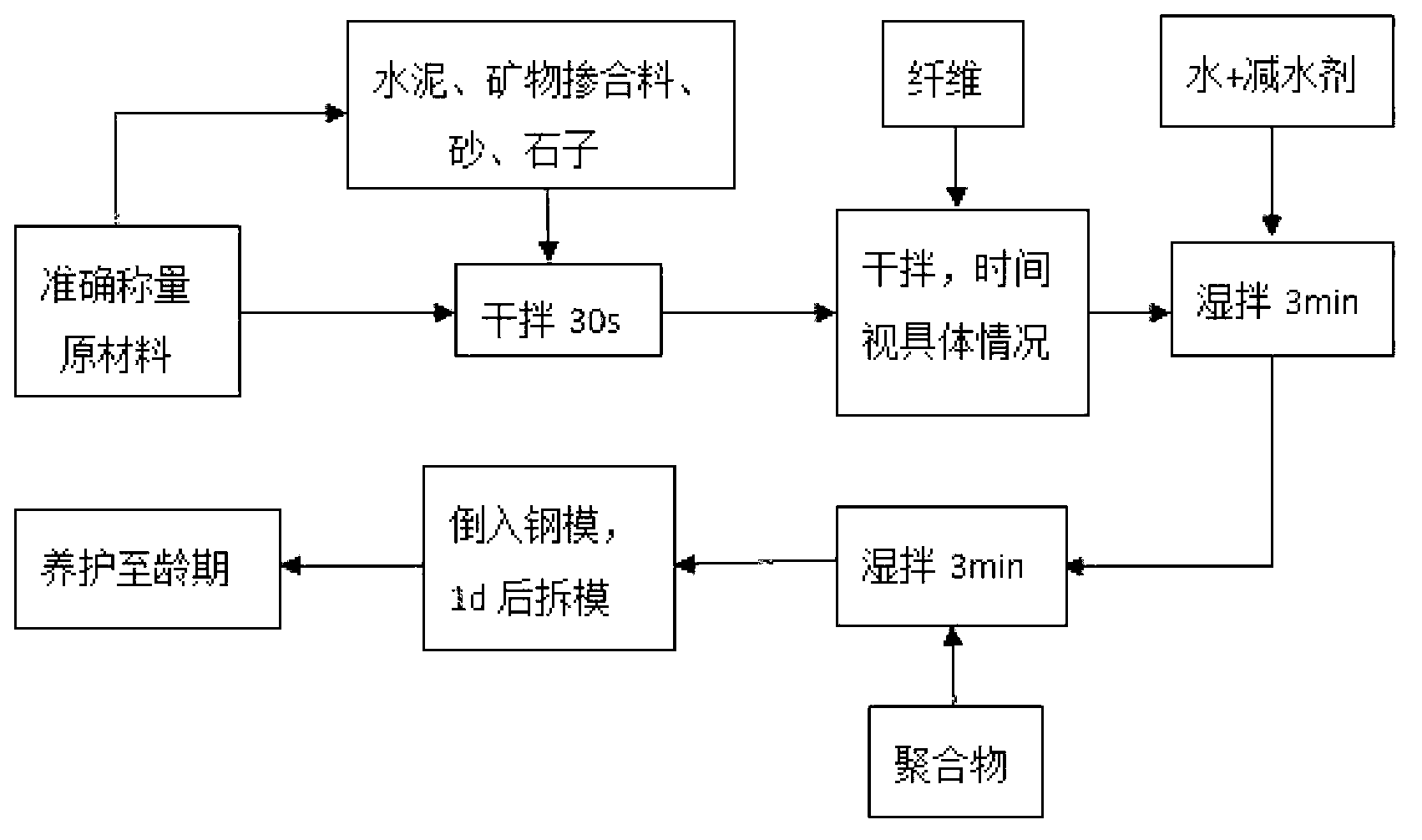

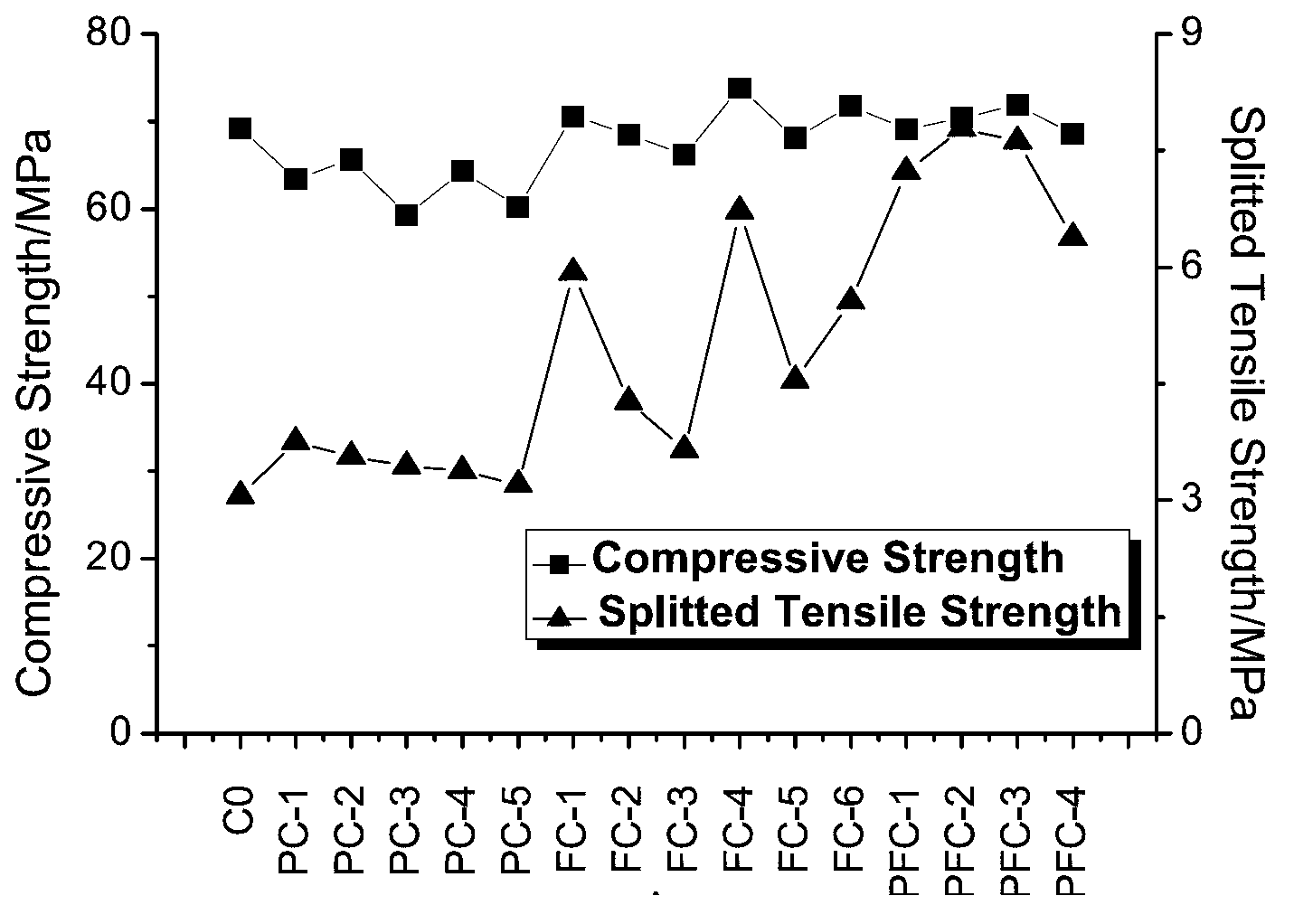

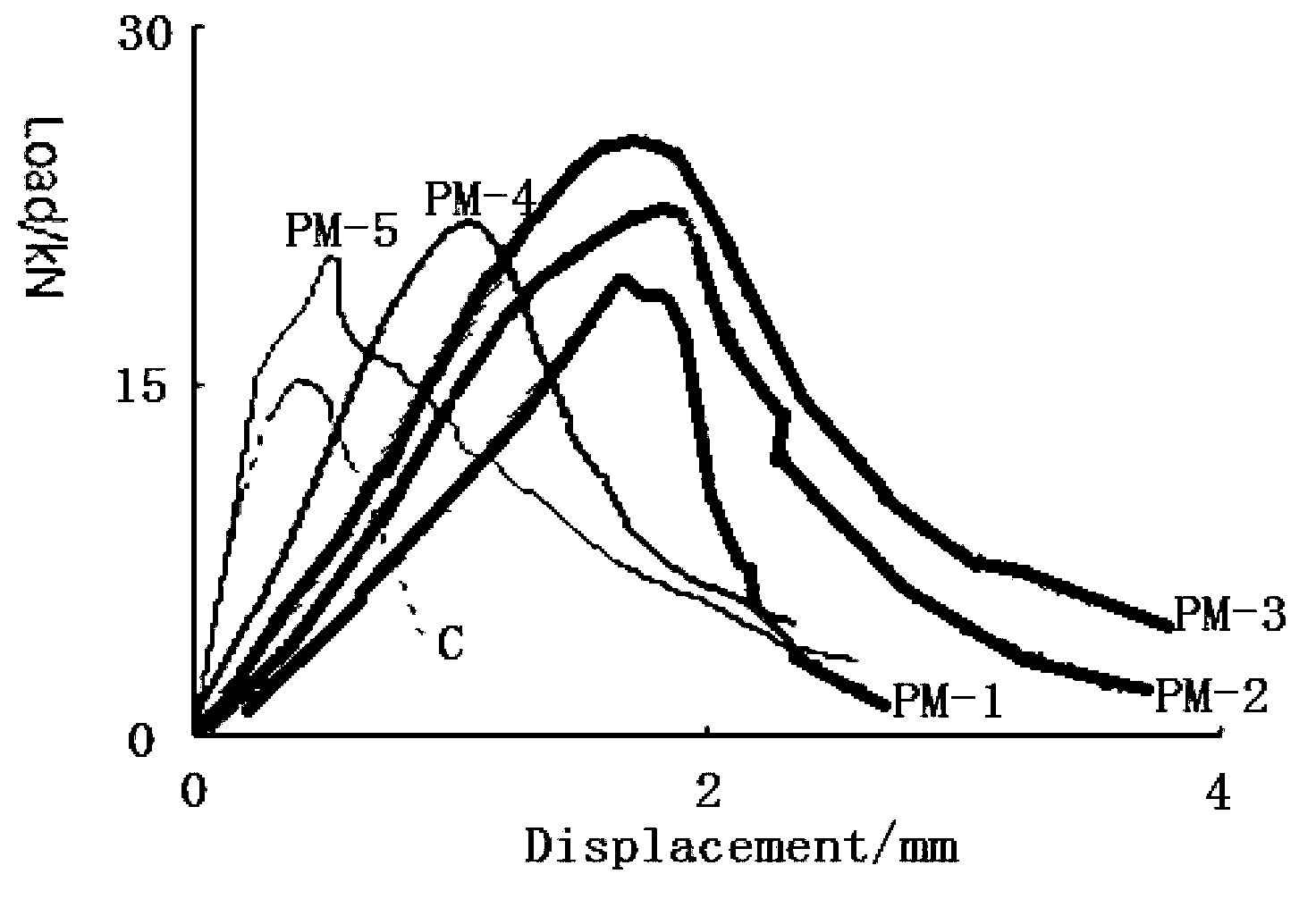

Fibre-polymer compound toughened concrete and preparation method for same

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

Rubber elastic self-compaction concrete for plate-type ballastless tracks

InactiveCN104030638AHigh compressive strengthImprove impact resistancePolyvinyl alcoholUltimate tensile strength

The invention relates to a rubber elastic self-compaction concrete for plate-type ballastless tracks, which is used for obviously enhancing the compression strength of the self-compaction concrete and enabling the self-compaction concrete to have favorable shock absorption and damping capacities. The rubber elastic self-compaction concrete for plate-type ballastless tracks can be used as a filler between the track plate and the bottom plate in a CRTS III plate-type ballastless track structure, and can also be used as a filler between a switch plate and the bottom plate in a switch structure. The self-compaction concrete is composed of the following components in parts by weight: 100 parts of cement, 4-10 parts of rubber powder, 30-60 parts of mineral admixture, 250-300 parts of fine aggregate, 250-300 parts of coarse aggregate, 1-2 parts of basalt fiber, 5-15 parts of expanding agent, 1.0-2.0 parts of water reducing agent, 0.01-0.05 part of rheologic assistant, 0.001 part of defoaming agent and 40-60 parts of water. The grain fineness of the rubber is 30-50 meshes, and the surface of the rubber is previously treated with polyvinyl alcohol and a silane coupling agent.

Owner:SOUTHWEST JIAOTONG UNIV +1

Preparation method of continuous basalt fibers

ActiveCN105837024ASolve the defect that is easy to breakImprove toughness and strengthGlass making apparatusPolymer scienceBasalt fiber

The invention discloses a preparation method of continuous basalt fibers. A modifier in basalt can fast transfer heat so that heat in the basalt fibers is easily transferred to the fiber surfaces, cooling curing rates inside and outside the fibers are the same, fiber toughness and strength are improved, and basalt fibers bear uniform load in stretching and are not easily broken so that the continuous basalt fibers are prepared. The preparation method has simple processes and substantial effects, is suitable for large scale industrial production and has a wide market application prospect.

Owner:江苏狮腾工程材料有限公司

High temperature resistance basalt fiber composite filter material and preparation method thereof

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

Ultra-high performance concrete mixed with hybrid fibers

The invention belongs to the technical field of building materials, and particularly relates to ultra-high performance concrete mixed with hybrid fibers. The concrete is prepared from ordinary Portland cement, silica fume, floating bead fly ash, slag powder, HP-CSA, quartz sand, limonite ore, titanium alloy sand, water reducing agent, defoaming agent, steel fiber, basalt fiber, cellulosic fiber and water. The ultra-high performance concrete mixed with the hybrid fibers has the advantages that the problems that the water-binder ratio is low, the usage amount of cementing material is large, andthe incorporation of the high-performance water reducing agent increases the shrinkage of the concrete can be solved, the constraint problem caused by the shrinkage on the application of the ultra-high performance concrete fabricated precast unit can be overcome, and the toughness of products is drastically improved. The ultra-high performance concrete mixed with the hybrid fibers is applicable tovarious concrete projects with special structures such as long span and super high-rise, and is suitable for various types of fabricated buildings.

Owner:TONGJI UNIV

Concrete with functions of crack resistance and infiltration resistance

InactiveCN104386959AReduce porosityImprove pore structureSolid waste managementCrack resistanceDiethylenetriamine

The invention discloses concrete with the functions of crack resistance and infiltration resistance. The concrete comprises the following raw materials in part by weight: 70-100 parts of cement, 400-500 parts of macadam, 50-70 parts of river sand, 40-50 parts of fly ash, 30-60 parts of mine residues, 5-20 parts of coal slack, 20-50 parts of basalt fibers, 5-15 parts of polypropylene fibers, 5-20 parts of glass fibers, 6-13 parts of expanded perlite, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nano calcium carbonate, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zinc stearate, 2-5 parts of zinc borate, 3-7 parts of sodium citrate, 0.5-1.4 parts of acetyl tributyl citrate, 0.7-1.3 parts of diethylenetriamine, 3-10 parts of a water reducing agent, and 80-100 parts of water. The concrete disclosed by the invention has the advantages of good crack resistance, excellent infiltration resistance and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

Fiber concrete

InactiveCN104030642AImprove impermeabilityLow bleeding rateSolid waste managementSuperplasticizerCarboxylic acid

The invention discloses fiber concrete comprising the following components in parts by weight: 170-180 parts of water, 335-345 parts of cement, 60-70 parts of coal ash, 13-19 parts of silicon ash, 1755-1775 parts of aggregates, 2.8-3.5 parts of basalt fiber, 3-5 parts of polycarboxylate superplasticizer and 30-34 parts of light silica fiber anti-crack reinforcer. Basalt fiber is not only good in stability, but also has various excellent performances such as electric insulation property, corrosion resistance, combustion resistance, high temperature resistance and the like. Due to the doping of the light silica fiber anti-crack reinforcer, the separation tendency of the concrete can be effectively avoided and inhibited, and cracks generated after the concrete is poured can be remarkably reduced and even completely eliminated, so that the concrete has the advantages of high compactness, high strength, good durability, low bleeding rate, high anti-crack coefficient and the like. Due to the doping of the coal ash, the silicon ash and the polycarboxylate superplasticizer, the performance of the concrete is improved, the generation of cracks is controlled effectively, and the positive significance for the durability of the concrete is taken.

Owner:HUNAN CONSTR ENG GRP COR +1

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

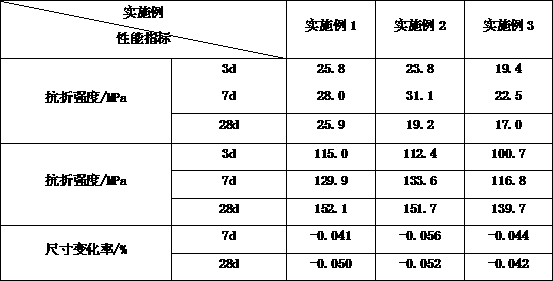

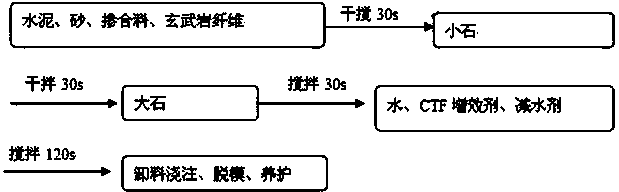

Basalt fiber concrete and preparation method thereof

The invention discloses basalt fiber concrete and a preparation method thereof, and belongs to concrete. The concrete consists of the following components in percentage by weight: 14-19 parts of cement, 29-39 parts of sand, 35-44 parts of stones, 1-4 parts of active admixture, 0.05-0.8 part of basalt short fiber, 0.05-1 part of other short fiber, 6-8.5 parts of water, 0.05-0.15 part of CTF synergist and 0.05-0.2 part of a water reducing agent. Through the addition of the basalt fiber that is in net-form distribution to the concrete, both toughness and anti-cracking performance of the concrete are effectively improved; the concrete, which is prepared depending on the proportions and by the preparation method, has the advantages that the maximum crack width is reduced by 44.8-89.7%, the average cracking area is reduced by 19.7-92.6%, the crack quantity in unit area is reduced by 22.7-25.2%, the total cracking area in the unit area is reduced by 1.7-94.5%, the frost resistance is enhanced by 37-50% and the shock resistance is improved by more than twice; the concrete can be used for effectively avoiding various defects of existing conventional concrete.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

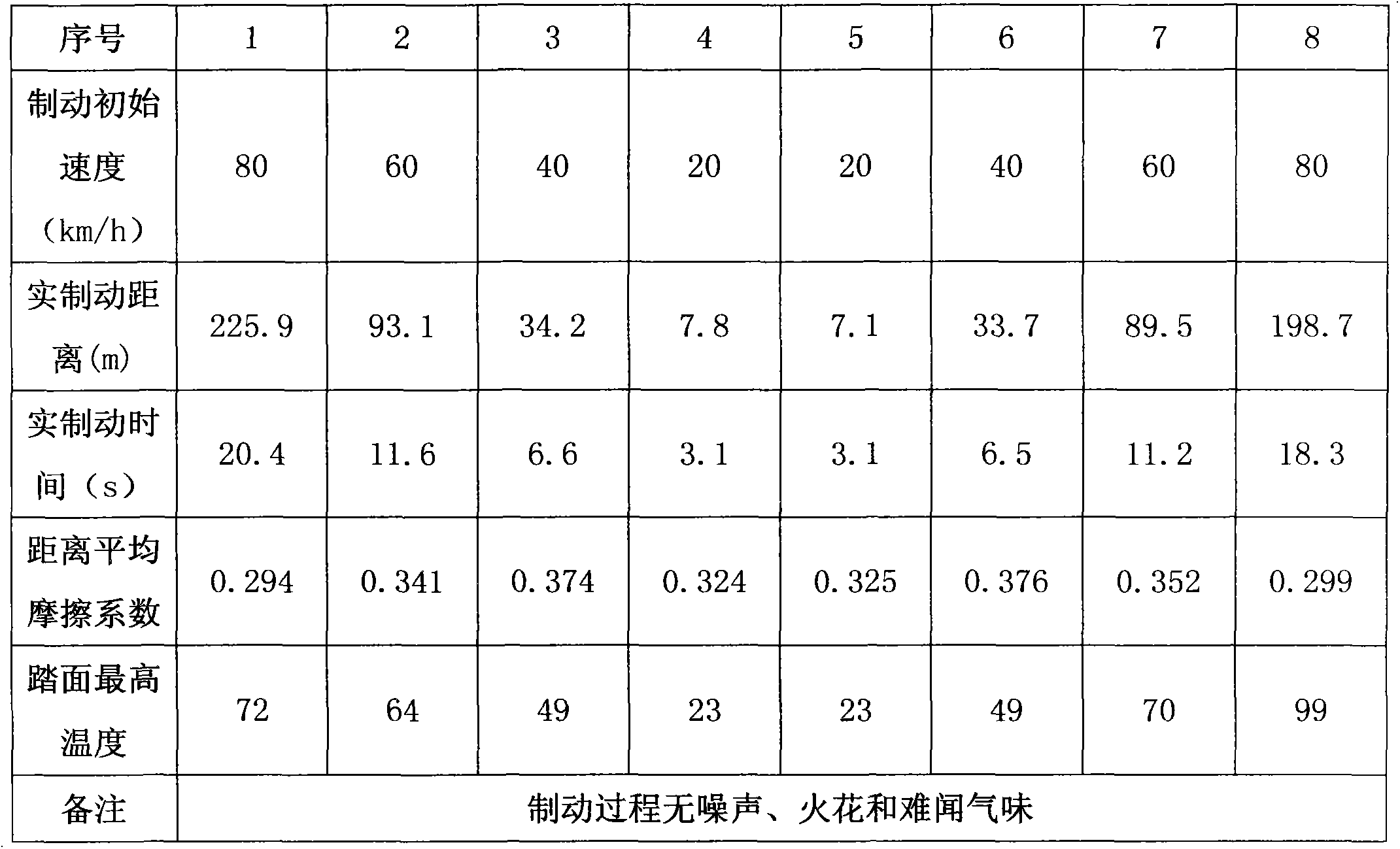

Composition brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893AImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

The invention relates to a composition brake shoe for an urban rail vehicle and a manufacturing method of the composition brake shoe for the urban rail vehicle. The composition brake shoe comprises the following components of, by weight, 10-15 parts of butadiene-acrylonitrile rubber, 10-20 parts of cashew nut shell oil modified phenolic resin, 6-10 parts of basalt fibers, 4-8 parts of carbon fibers, 8-15 parts of steel fibers, 5-8 parts of sepiolite fibers, 2-6 parts of hexamethylenetetramine, 5-8 parts of iron oxide powder, 5-7 parts of crystalline flake graphite, 5-7 parts of chromite, 6-9 parts of barium sulfate, 3-6 parts of potassium feldspar and 5-8 parts of frictional powder. The manufacturing method of the composition brake shoe is a dry method production technology, and comprises the steps of steel back production, abrasive blasting processing, shaping, burdening, mixing, hot compacting, heat processing, subsequent processing, finished product forming and inspection. The manufactured composition brake shoe is inspected through the 1:1 rack test, is excellent in friction and abrasion resisting performance, stable in brake performance, safe and environmentally friendly, and solves the problem that the friction coefficient drops too fast under the conditions of damascene of the composition brake shoe for the urban rail vehicle, hot cracks, hot spots and rain and snow weather.

Owner:GUANGXI UNIV FOR NATITIES

Surface treatment method for basalt fibre

InactiveCN101125738ANot easy to cause pollutionComposite improvementTreatment effectPlasma generator

The invention discloses a treatment method for treating the surface of basalt fiber with simple technique, good treatment effect and low cost and is characterized in that a discharge electrode in a plasma generator device is caused to generate plasma and then basalt fiber goes through the plasma, thereby, the surface of the basalt fiber is modified. The composition performance of the basalt fiber after being treated through the method of the invention with organic substrate materials is greatly improved.

Owner:ZHANGJIAGANG ZHONGLIAN TECH +1

Compositions Comprising Melt-Processed Inorganic Fibers and Methods of Using Such Compositions

Improved lost circulation compositions that include melt-processed inorganic fibers and methods for using such compositions in subterranean formations are provided. An example of a method of the present invention is a method comprising providing a drilling mud comprising a plurality of melt-processed inorganic fibers, wherein the melt-processed inorganic fibers have a length of less than about 10 millimeters, and comprise at least one melt-processed inorganic fiber selected from the group consisting of: a basalt fiber, a wollastonite fiber, and a ceramic fiber; and circulating the drilling mud in the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

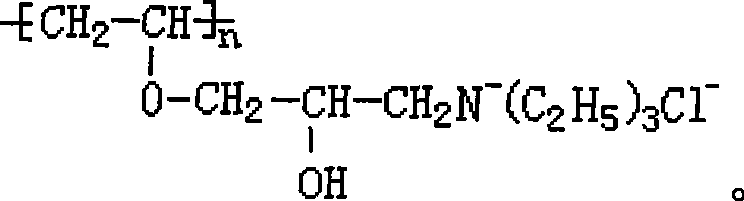

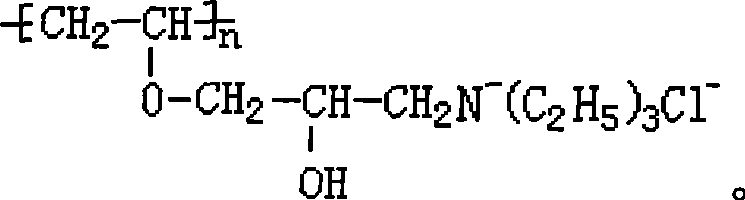

Inorfil softening intensifier and preparation thereof

InactiveCN101503280AGood flexibilityHigh strengthInorganic fibres/flakesGlass fiberPolyvinyl alcohol

The invention relates to an inorganic fiber softening reinforcing agent and a preparation method thereof. The method is to lead H2O2, polyvinyl alcohol and potassium hydroxide to react for 2 to 4 hours at a temperature between 50 and 60 DEG C, adds an etherifying agent after the reaction to react for 4 to 8 hours at a temperature between 50 and 70 DEG C, and regulates the pH value of the solution to 7 to 8 so as to obtain the inorganic fiber softening reinforcing agent. The softening reinforcing agent is applicable to various inorganic fiber materials produced by physical or hot melt method, including basalt fibers, aedelforsite fibers, meerschaum fibers, gypsum fibers, flyash fibers and glass fibers. The softening reinforcing agent can improve the softness and strength of inorganic fibers, improve the defect of easy fracture of the inorganic fibers in processes of pulping, dispersing and transporting, change the charge property of the inorganic fiber surface, reinforce the bonding force of the inorganic fibers and plant fibers, and greatly improve application performance of the inorganic fibers in making paper, insulating wool boards and the like by wet method.

Owner:鹤壁洁联新材料科技有限公司

High toughness cement-based material-nonmetal fiber rib composite structure as well as application and application method thereof

InactiveCN103938803AImprove carrying capacityIncreased durabilityBuilding repairsGirdersCarbon fibersPolyvinyl alcohol

The invention discloses a high toughness cement-based material-nonmetal fiber rib composite structure. According to the structure, a high toughness cement-based material is adopted as a base material, nonmetal fiber rib is adopted as directional reinforcing rib; the high toughness cement-based material comprises the following components in percentage by weight: 35% of cement, 45-55% of fly ash, 5-10 % of silicon ash and 5-10% of metakaolin; high-strength short fiber is one or more out of polyvinyl alcohol fiber, polyethylene fiber, carbon fiber and aramid fiber; the nonmetal fiber rib is carbon fiber reinforced plastic rib, aramid fiber reinforced plastic rib, glass fiber reinforced plastic rib or basalt fiber reinforced plastic rib. The invention further discloses applications and an application method of the high toughness cement-based material-nonmetal fiber rib composite structure. The high toughness cement-based material and the nonmetal fiber rib are utilized to reinforce the reinforced concrete structure, so that the bearing capacity and the durability of the structure are increased and the aging speed of the structure is reduced.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com