Light composite material

A composite material and lightweight technology, applied in the field of lightweight composite materials, can solve problems such as heat insulation, sound insulation, and unsatisfactory shock absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

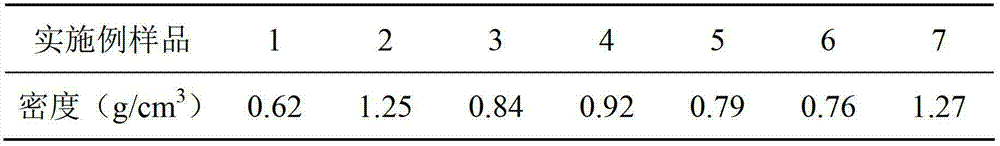

Examples

Embodiment 1

[0017] Embodiment 1 A kind of lightweight composite material

[0018] A kind of lightweight composite material, by volume ratio is the phenolic resin of 2:1:1, the hemp fiber that average fiber length is 5.1mm and hollow glass microsphere composition; Described hollow glass microsphere density is 1g / cm 3 , hollow microsphere diameter 500um. After the hollow glass microspheres and hemp fibers are oscillated by an oscillator, the phenolic resin is added and stirred evenly, and finally hot-extruded to obtain a lightweight composite material of the phenolic resin, hemp fibers and hollow glass microspheres.

Embodiment 2

[0019] Embodiment 2 A kind of lightweight composite material

[0020] A kind of lightweight composite material, be the polyimide of 10:1:1 by volume, the carbon fiber that average fiber length is 7.8mm and hollow glass microsphere composition; Described hollow glass microsphere density is 0.1g / cm 3 , hollow microsphere diameter 50um. After the hollow glass microspheres and carbon fibers are oscillated by an oscillator, polyimide is added and stirred evenly, and finally hot-extruded to obtain a lightweight composite material of polyimide, carbon fibers and hollow glass microspheres.

Embodiment 3

[0021] Embodiment 3 A kind of lightweight composite material

[0022] A lightweight composite material, 4 parts by volume of a mixture of urea-formaldehyde resin and melamine-formaldehyde resin, 2 parts of a mixture of glass fibers and polypropylene fibers with an average fiber length of 8mm, and 1 part of hollow glass microspheres and hollow ceramic microspheres The composition of the mixture of balls; the ratio of materials in the mixture is 1:1. The mixture of the hollow glass microspheres and hollow ceramic microspheres 0.5g / cm 3 , The average diameter of hollow glass microspheres and hollow ceramic microspheres is 50um. 2 parts of a mixture of glass fiber and polypropylene fiber and 1 part of a mixture of hollow glass microspheres and hollow ceramic microspheres are shaken by an oscillator, then add 4 parts of a mixture of urea-formaldehyde resin and melamine-formaldehyde resin and stir evenly, and finally hot extrusion Compression molding results in lightweight composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com