Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1273 results about "Isolation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The von Restorff effect, also known as the "isolation effect", predicts that when multiple homogeneous stimuli are presented, the stimulus that differs from the rest is more likely to be remembered.

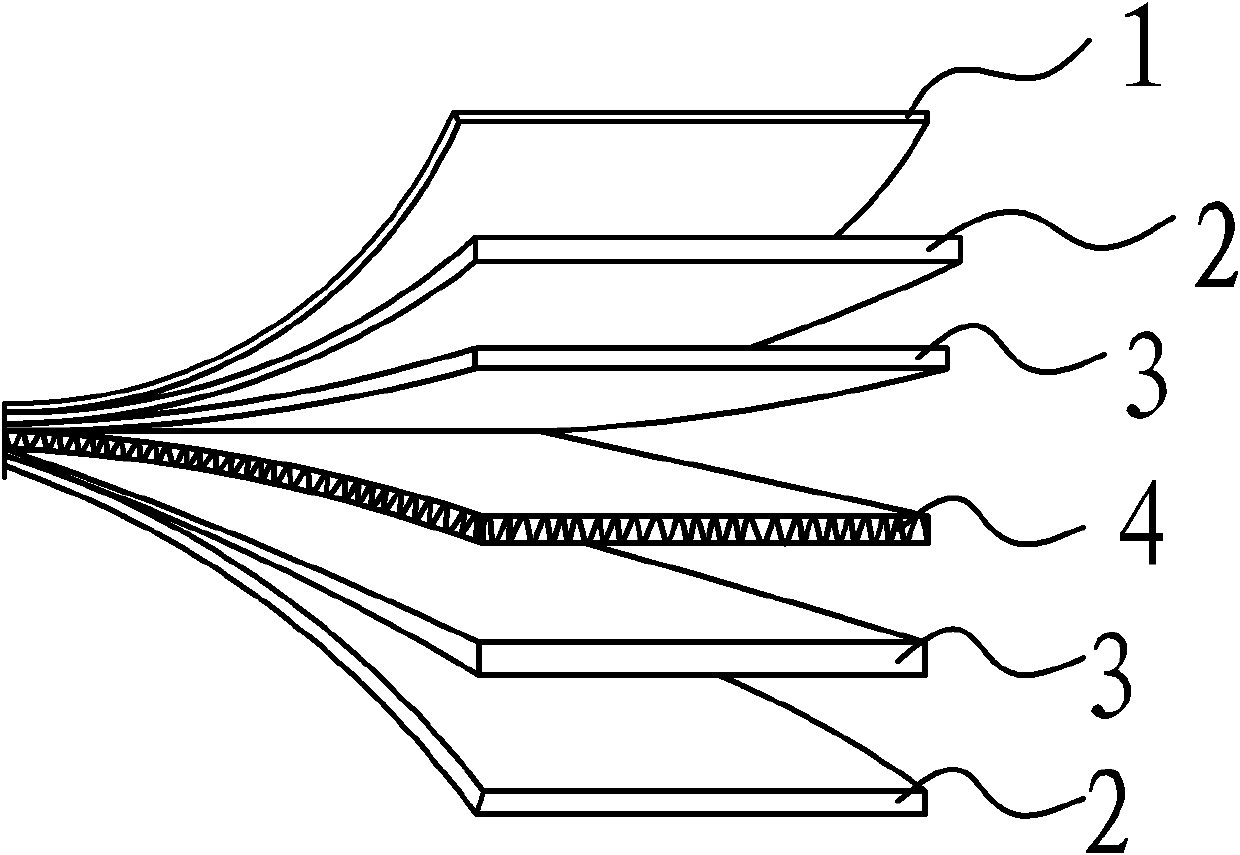

Broadband double polarization omnidirectional antenna and feed method

ActiveCN102447163AImprove balanceEffective coverageRadiating elements structural formsPolarised antenna unit combinationsOmnidirectional antennaIsolation effect

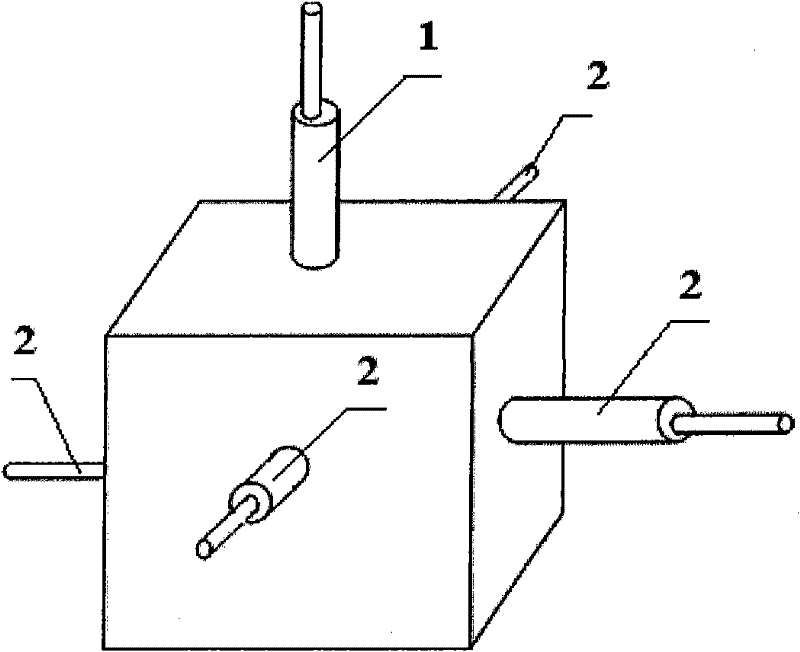

The invention provides a broadband double polarization omnidirectional antenna and a feed method. The feed method concretely comprises the following steps that with the adoption of coaxial arrangement of a horizontal polarization antenna and a vertical polarization antenna, the horizontal polarization antenna are respectively adhered to the upper surface and the lower surface of an adhesion platethrough two vibration arms of a folded dipole; in addition, the two vibration arms are respectively connected with the structures of a feeder inner conductor and a feeder outer conductor, so that thedouble polarization antenna has wider working frequency band width; and meanwhile, the double polarization ceiling antenna has good polarization isolation effect and covering balance, can effectivelyexert the performance of an MIMO antenna in LTE and WLAN systems and can be effectively applied to a 2G network and a 3G network so that the data transmission rate is increased.

Owner:CHINA MOBILE GROUP DESIGN INST

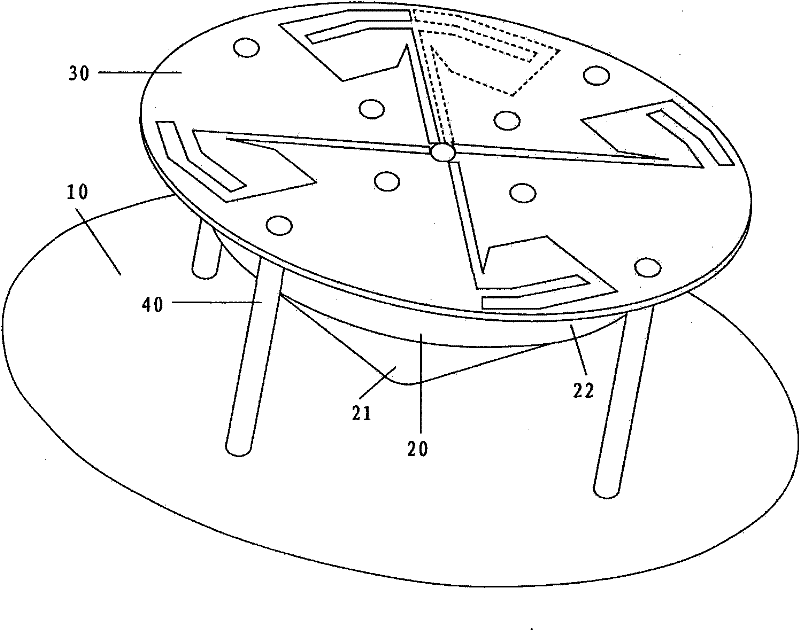

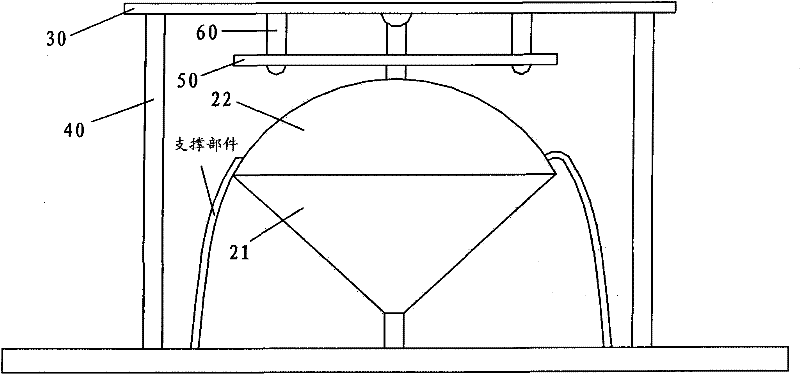

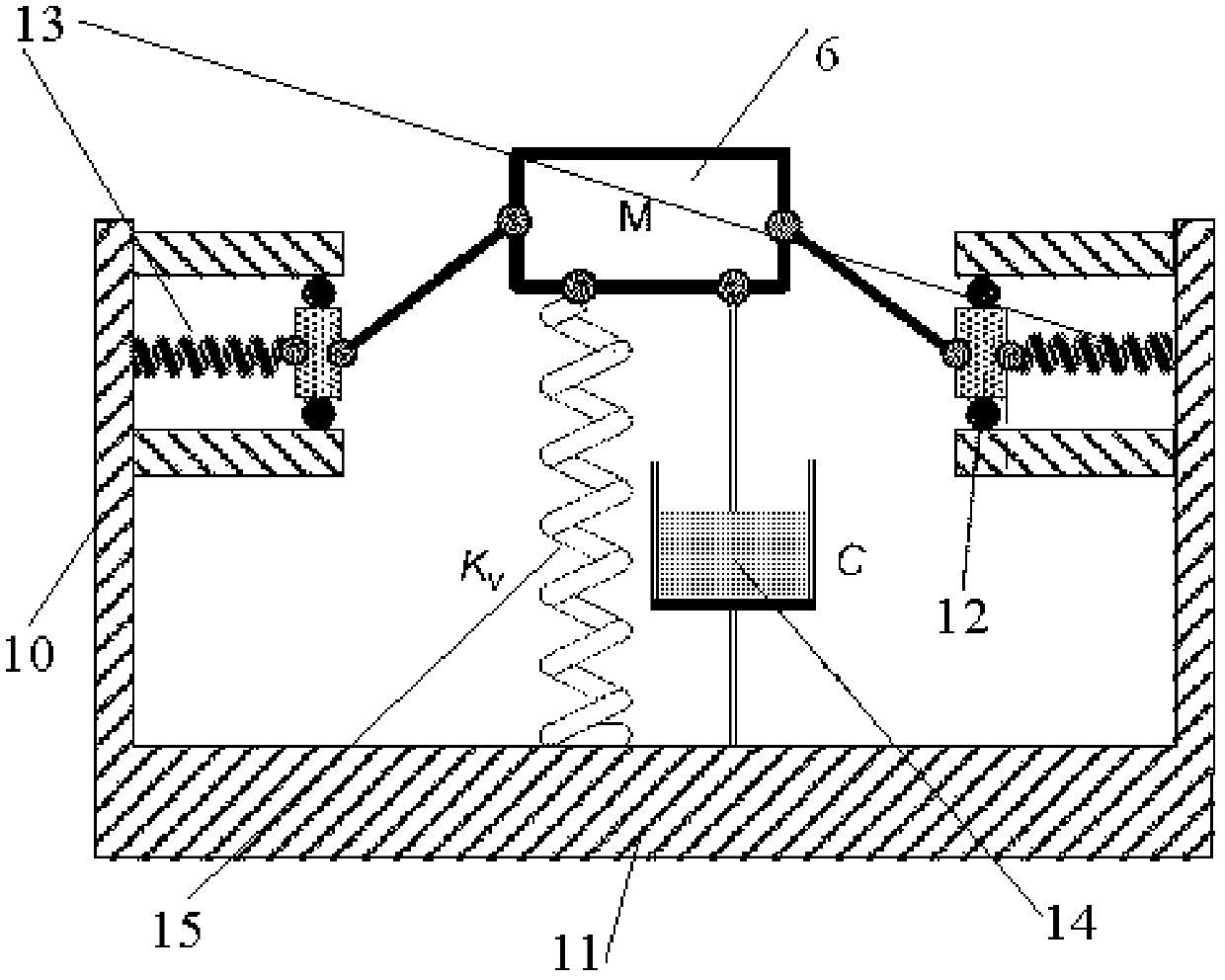

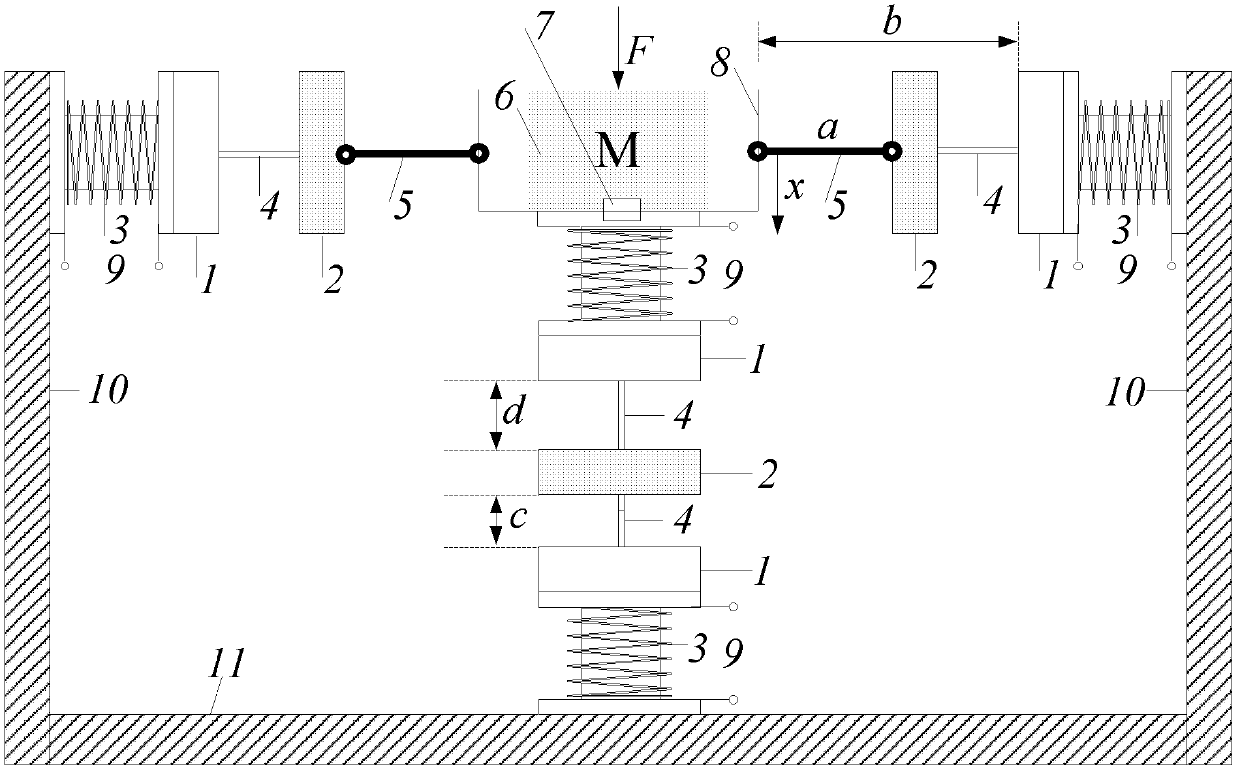

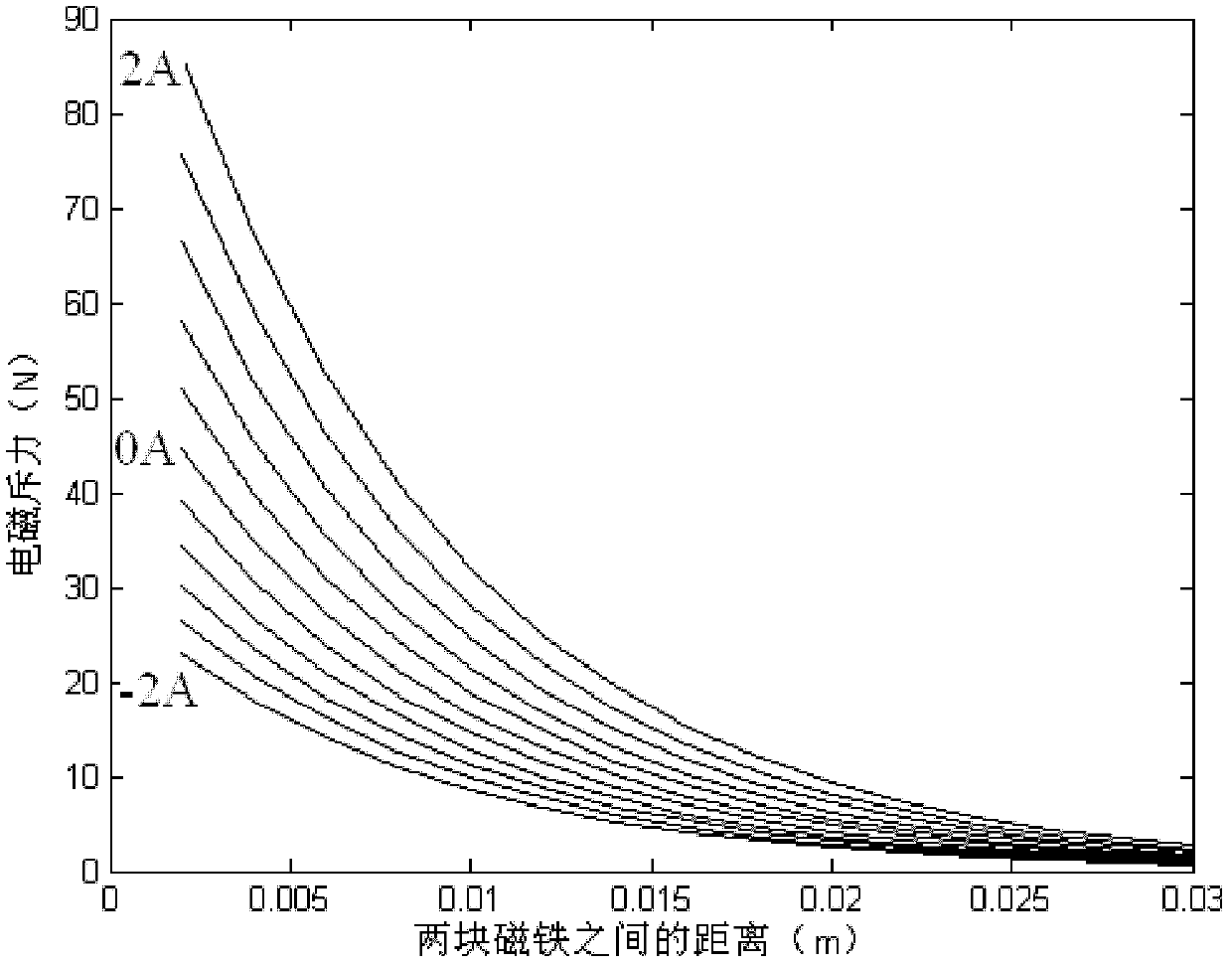

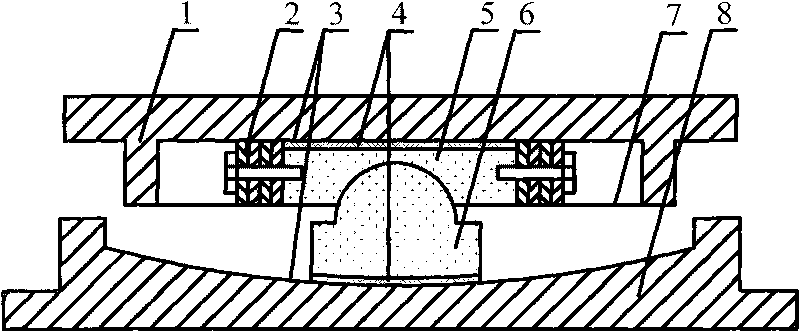

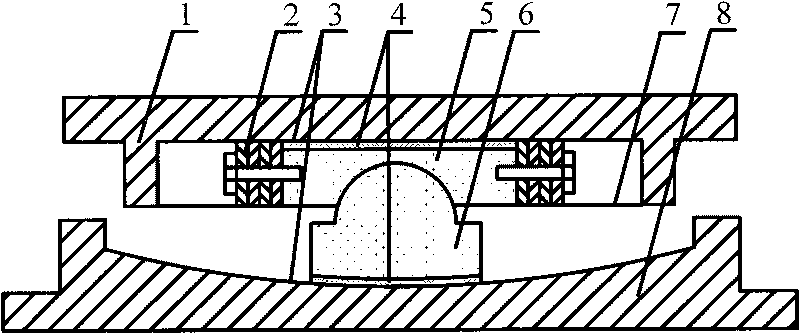

Load-bearing adjustable zero-stiffness electromagnetic vibration isolator and control method thereof

InactiveCN102606673ALower natural frequencyAchieving vibration isolation over a wide range of frequenciesNon-rotating vibration suppressionIsolation effectEngineering

The invention discloses a load-bearing adjustable zero-stiffness electromagnetic vibration isolator and a control method thereof. An electromagnetic spring of the vibration isolator in the perpendicular direction is composed of three permanent magnets and two groups of controllable direct current electromagnets, two magnets have opposite polarity and generate repulsive force, and stiffness of theelectromagnetic spring can be adjusted by changing and controlling current. An electromagnetic spring of the vibration isolator in the horizontal direction is composed of two groups of symmetrically distributed electromagnetic springs, and stiffness of the electromagnetic spring can be adjusted by changing and controlling current. When the system load-bearing weight is changed, the stiffness of the perpendicular electromagnetic spring and the stiffness of the horizontal electromagnetic spring are led to meet a certain proportional relationship by adjusting and controlling current so that stiffness of the system at the balance position can be zero. When a vibration isolation device is in small vibration near the balance position, dynamic stiffness is very small, and natural frequency of the whole system is very low so that the vibration isolator can achieve wide-range frequency vibration isolation and has good low frequency vibration isolation effect. In addition, the vibration isolator is compact in structure, light in weight and convenient to control.

Owner:HUNAN UNIV

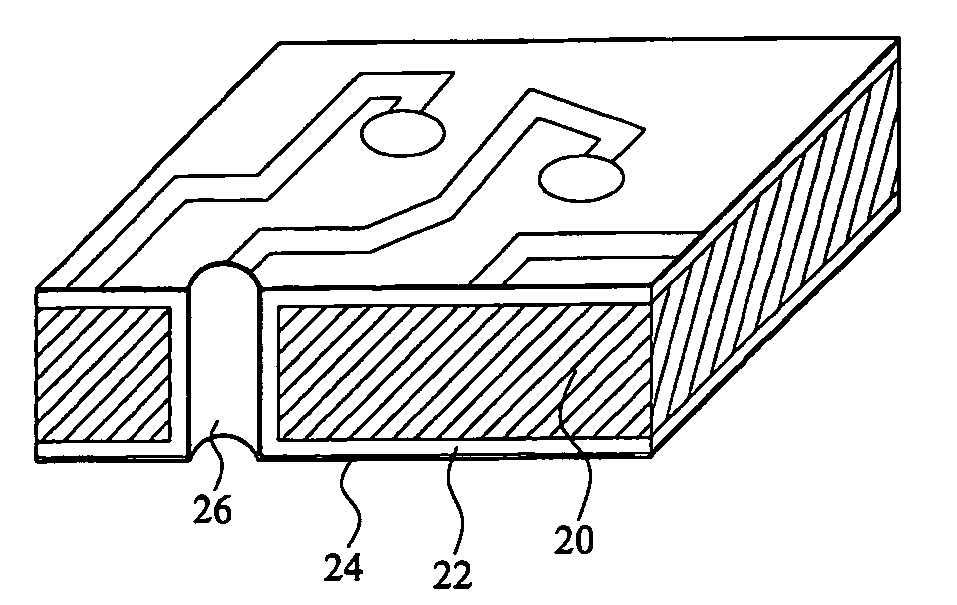

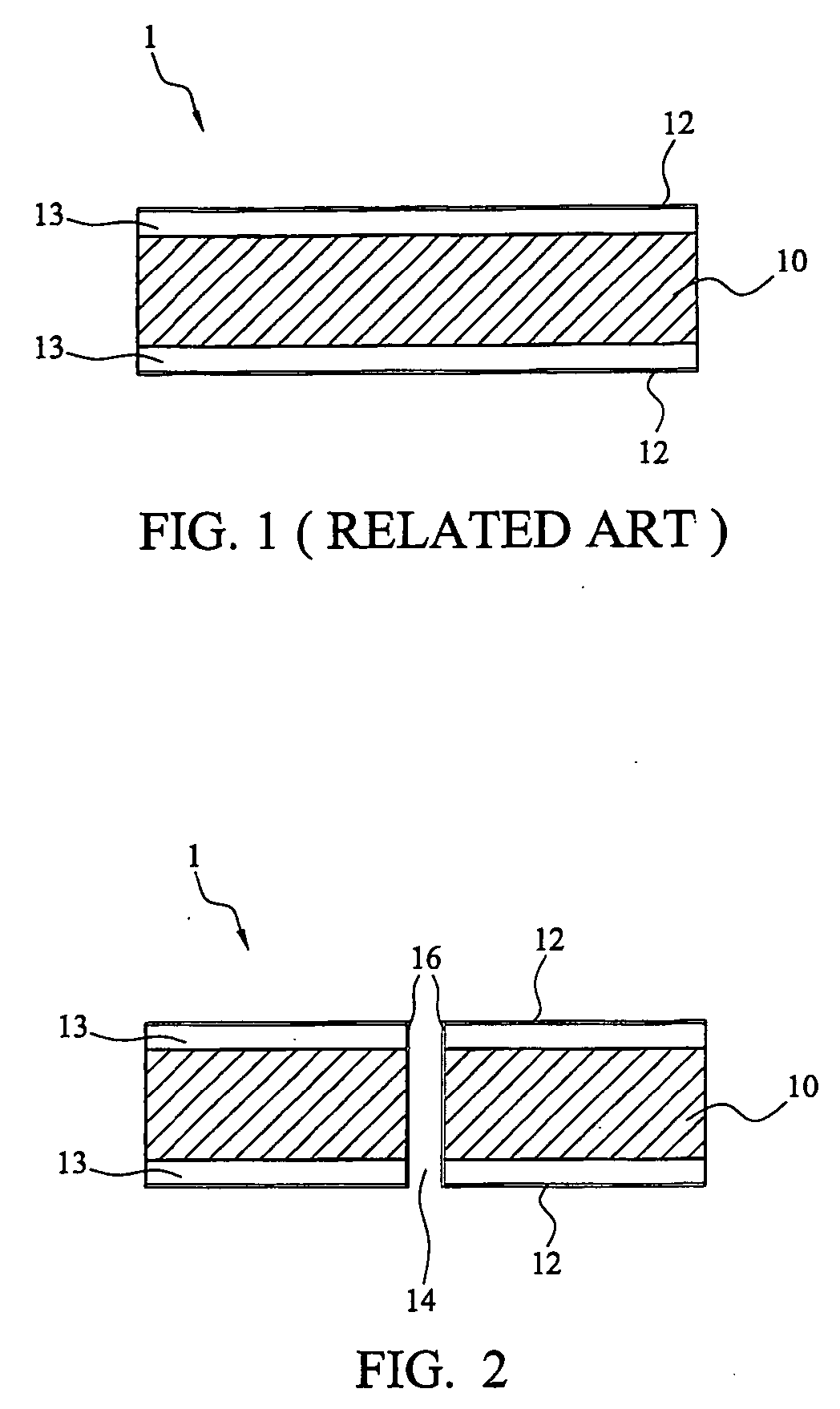

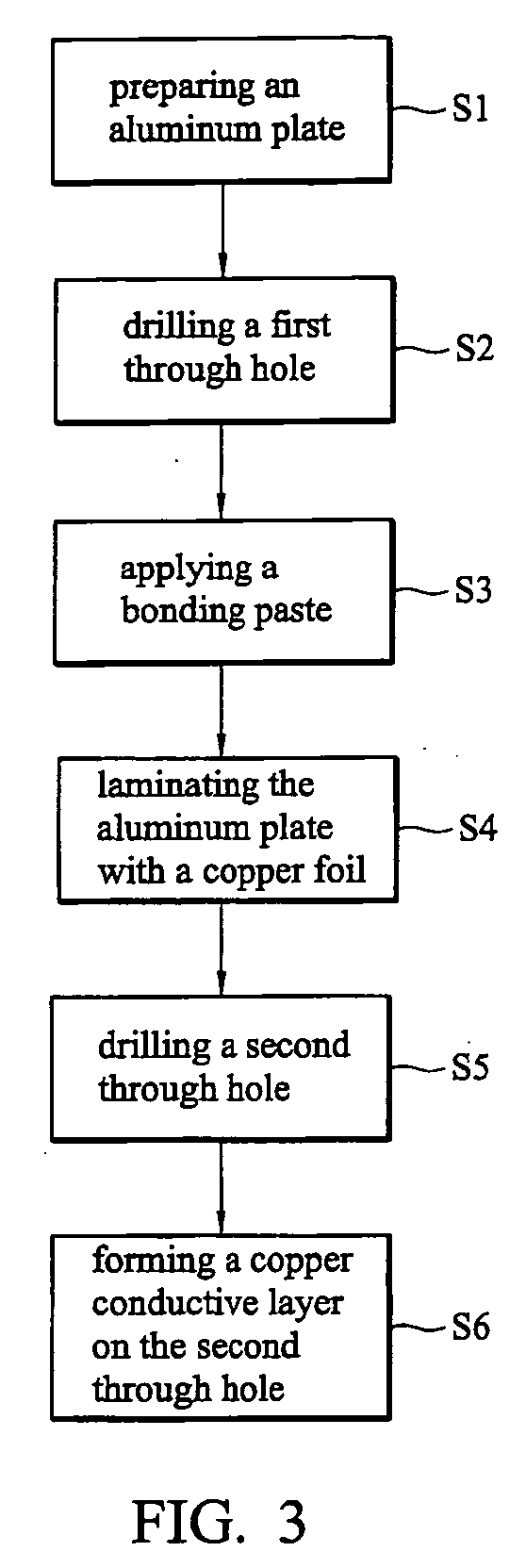

Circuit board with a through hole wire and manufacturing method thereof

InactiveUS20070010086A1Improve thermal conductivityImprove cooling effectPrinted circuit aspectsSemiconductor/solid-state device manufacturingIsolation effectCopper foil

An aluminum substrate is drilled to form a first through hole, and is then laminated with copper foils on upper and lower surfaces of the aluminum substrate via a binder. Due to the pressure of the lamination, the binder is partially forced to flow into and fill the first through hole, and the binder is then solidified. Concentric with the first through hole, a second through hole having a smaller aperture than the first through hole is drilled. By a non-electrical and electrical plating method, a copper conductive layer is formed on the side wall of the second through hole to complete the through hole wire. Because of the isolation effect of the binder, the aluminum substrate is not electrically connected to the copper foils and the copper conductive layer.

Owner:DELTA ELECTRONICS INC

Foamed concrete and preparation method thereof

ActiveCN103304200AReduce voidsImprove waterproof performanceCeramicwareIsolation effectFoam concrete

The invention provides foamed concrete and a preparation method thereof, and belongs to the technical field of building materials. The foamed concrete provided by the invention consists of the following components in percentage by mass: 25-55 percent of a gel material, 18-50 parts of light aggregate, 13-36 parts of water, 0.5-5 parts of a foaming agent, 0.03-0.5 part of a thickening agent and 0.03-0.5 part of enhanced fiber, wherein the gel material consists of cement and coal ash or superfine slag powder; the light aggregate consists of coarse light aggregates and fine light aggregates; the foaming agent is a hydrogen peroxide solution or an ammonium hydrogen carbonate; the thickening agent is powdered carboxymethylcellulose; the enhanced fiber is a lignin fiber or a polypropylene fiber or an alkali resistance glass fiber which is 5-20 mm long. The water prevention, sound isolation and heat isolation effects of the foamed concrete prepared by the invention are better than those of the existing foamed concrete. According to the method, the foaming process of processing various batches and scales of foamed concrete can be precisely controlled by in-situ foaming; the method can be suitable for large-scale production of high-quality foamed concrete.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

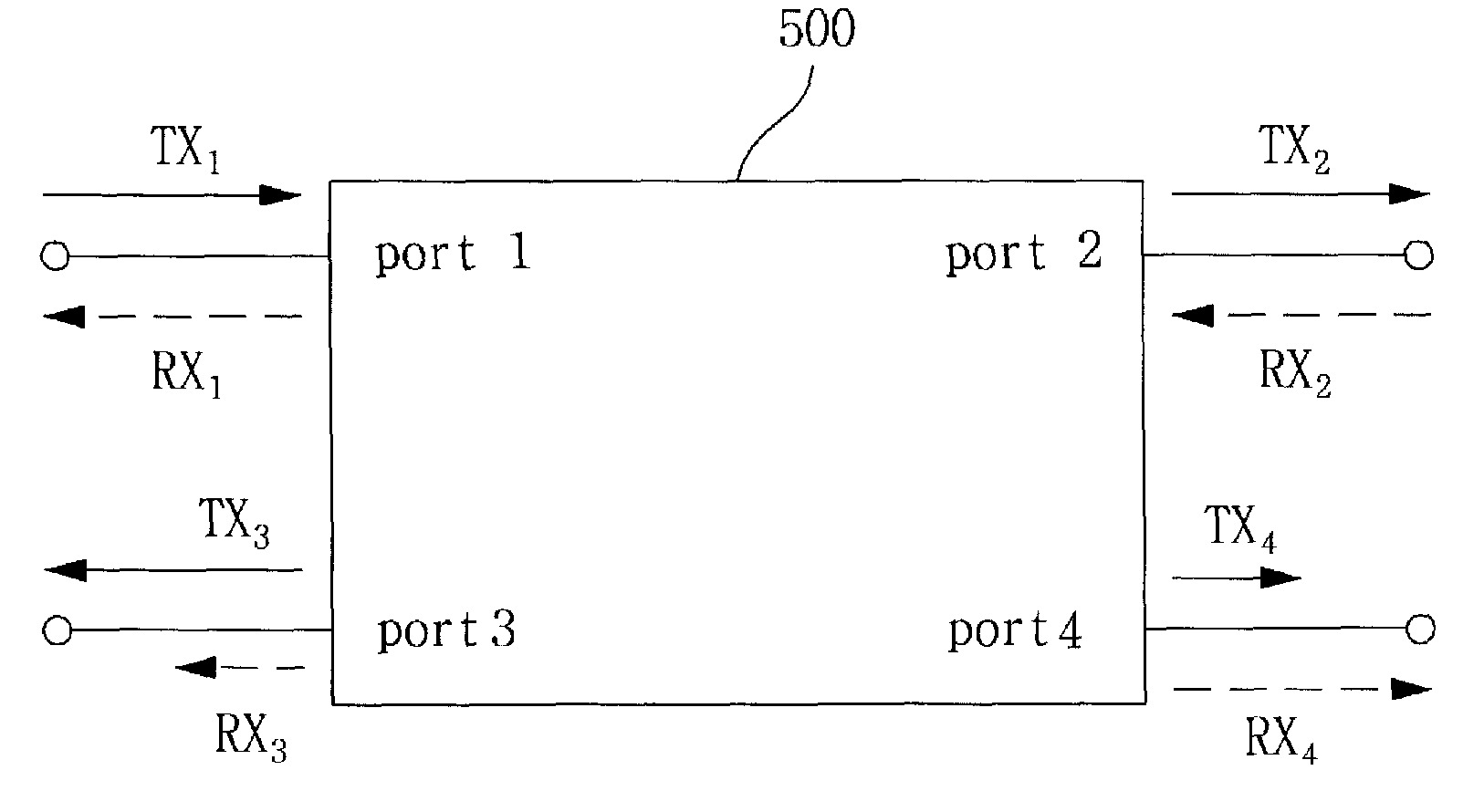

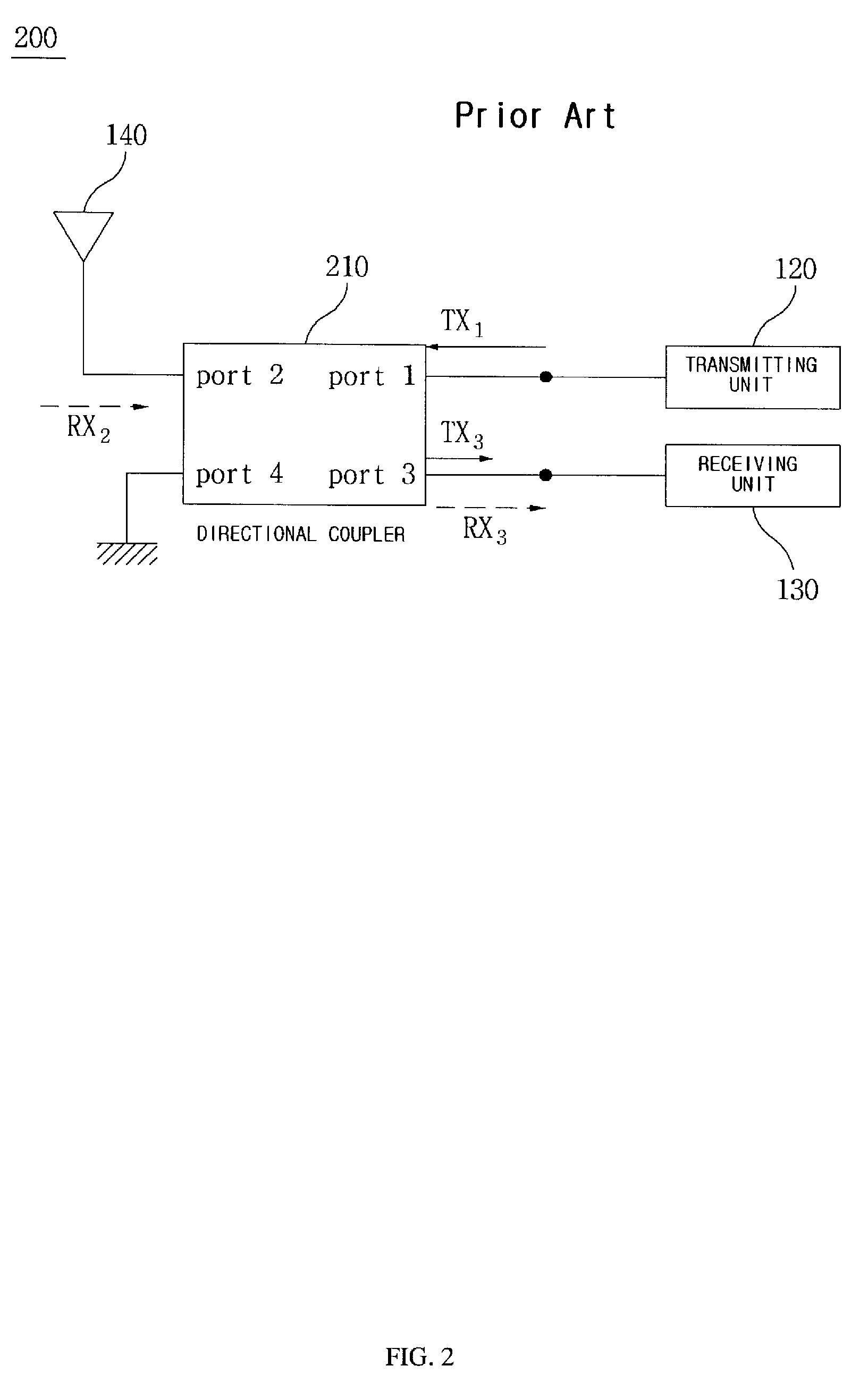

Coupling apparatus for dividing receiving and transmitting signals and control method thereof

ActiveUS20110053525A1Maximize the effectReduce the valueElectric signal transmission systemsMemory record carrier reading problemsIsolation effectUltrasound attenuation

The present invention is directed to reducing leakage of a transmitting signal to a receiving unit in a wireless communication system with a transmitting unit and the receiving unit sharing an antenna. A coupling apparatus for dividing a radio frequency (RF) transmitting signal and an RF receiving signal in a transceiver with a transmitting unit and a receiving unit sharing an antenna, includes: a four-port circuit having port 1, port 2, port 3, and port 4, a through path being formed between the port 1 and the port 2, a first signal input to the port 1 being coupled to the port 4, a second signal input to the port 2 being coupled to the port 3, and an isolation path being formed between the port 1 and the port 4 and between the port 2 and the port 3; and an attenuator attenuating and outputting a signal output from the port 3 of the four-port circuit, and the RF transmitting signal is input to the port 1 of the four-port circuit, the RF receiving signal is input to the port 2 of the four-port circuit, and outputs of the attenuator and the port 4 of the four-port circuit are provided the receiving unit. Leakage of a transmitting signal of a transmitting unit to a receiving unit in a communication system sharing an antenna can be isolated. Furthermore, an isolation effect of a leakage signal of a transmitting unit to a receiving unit can be maximized while adaptively changing an attenuation value of a variable attenuator.

Owner:INTELLECTUAL DISCOVERY CO LTD

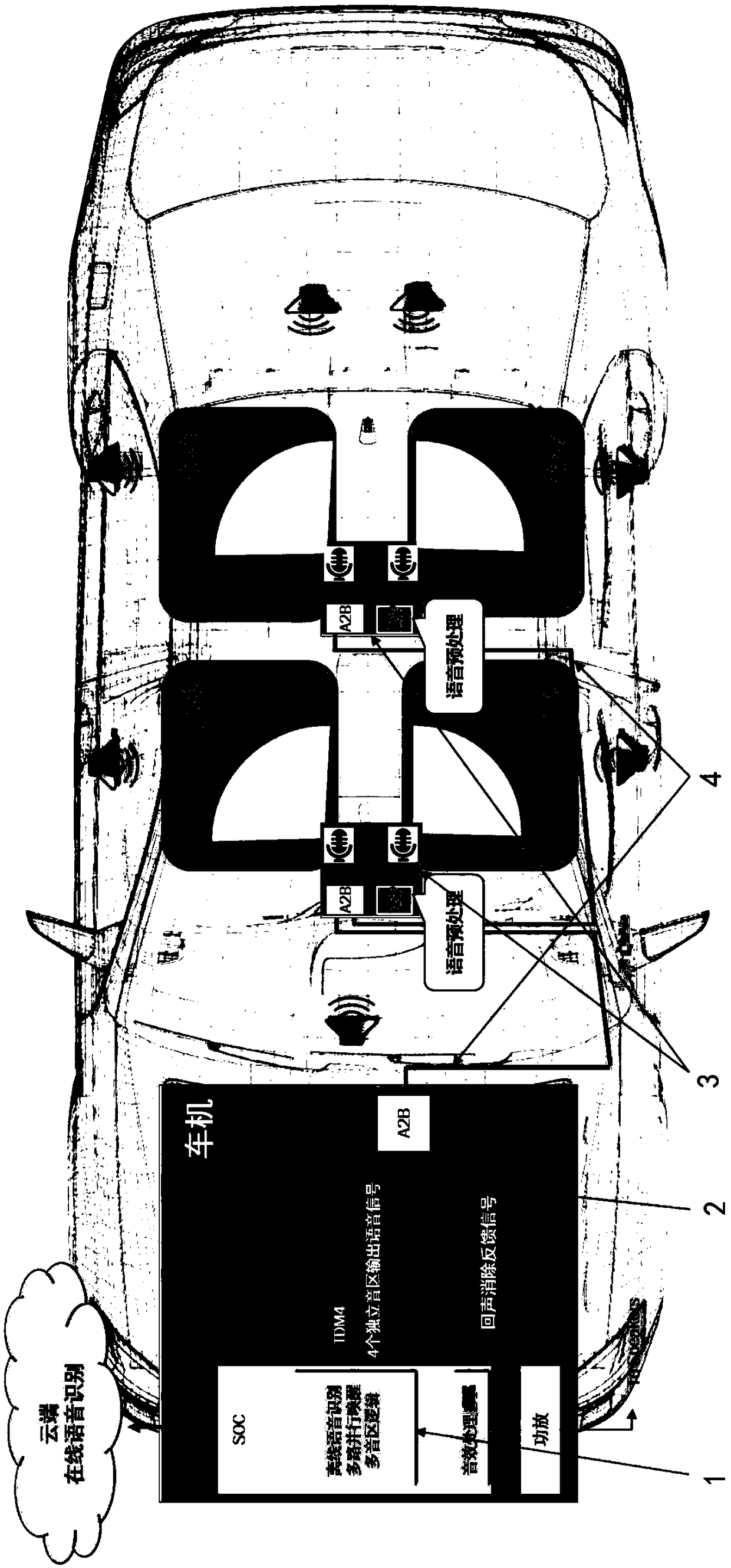

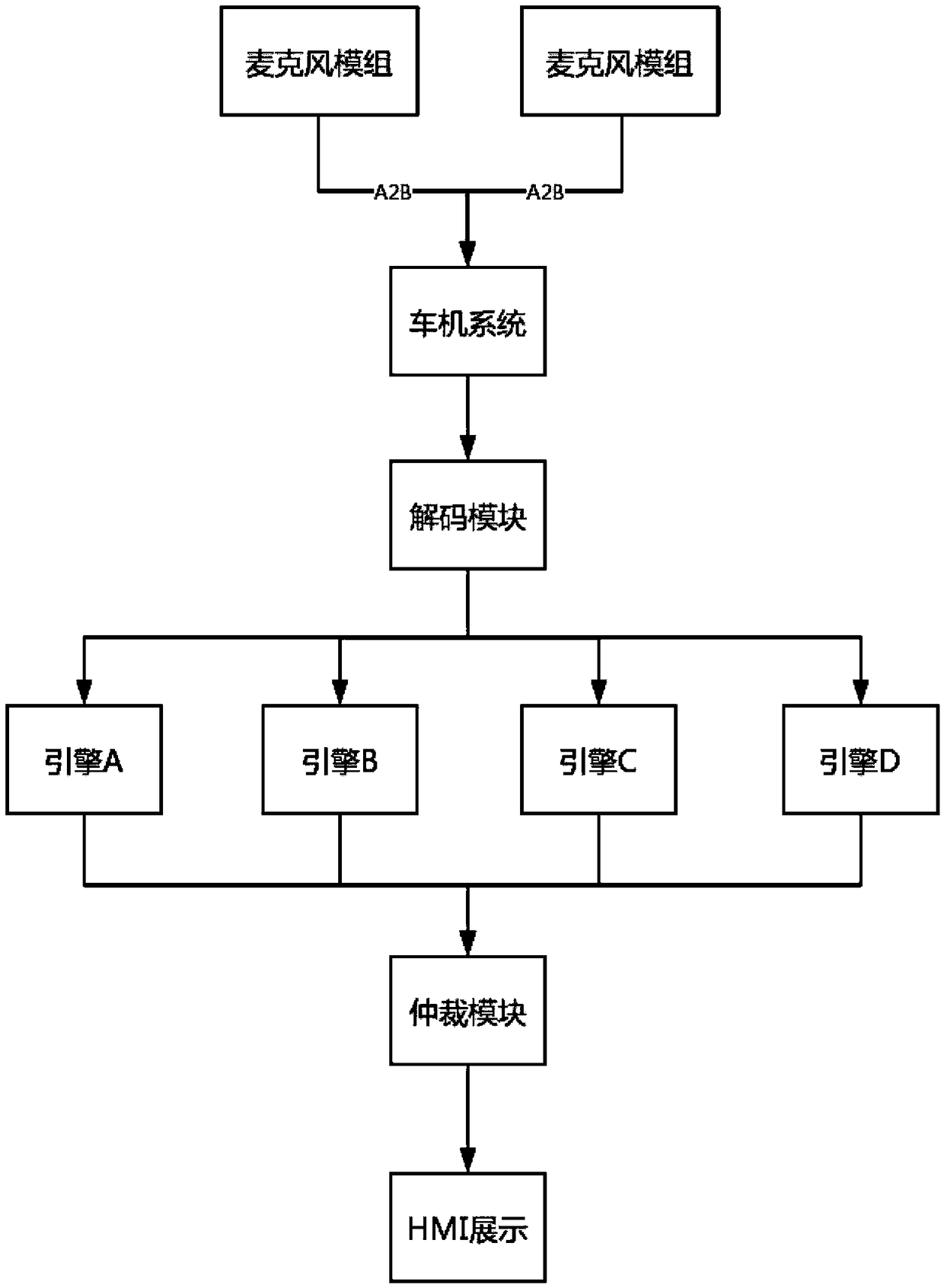

Multi-tone area speech recognition method and device, and storage medium

ActiveCN109192203AImprove isolationEasy to understand implementationSpeech recognitionIsolation effectSpeech identification

The embodiment of the invention provides a multi-tone area speech recognition method and device, and a computer-readable storage medium. The multi-tone area speech recognition method comprises the steps: collecting speech in a speech acquisition environment using a microphone module, wherein a target tone area is set for each microphone in the microphone module in advance, the target tone area being one of a plurality of independent tone areas in the speech acquisition environment set in advance; Judging whether the speech is from a target sound region; Suppressing speech from a sound region other than the target sound region; the suppressed speech is recognized. As the embodiment of the invention use a microphone module to isolate different sound regions, the voice use by all the staff inthe voice acquisition environment is realized by isolating a plurality of sound regions, and the isolation degree of each sound region can reach 15-20dB, the ideal isolation effect is achieved.

Owner:APOLLO INTELLIGENT CONNECTIVITY (BEIJING) TECH CO LTD

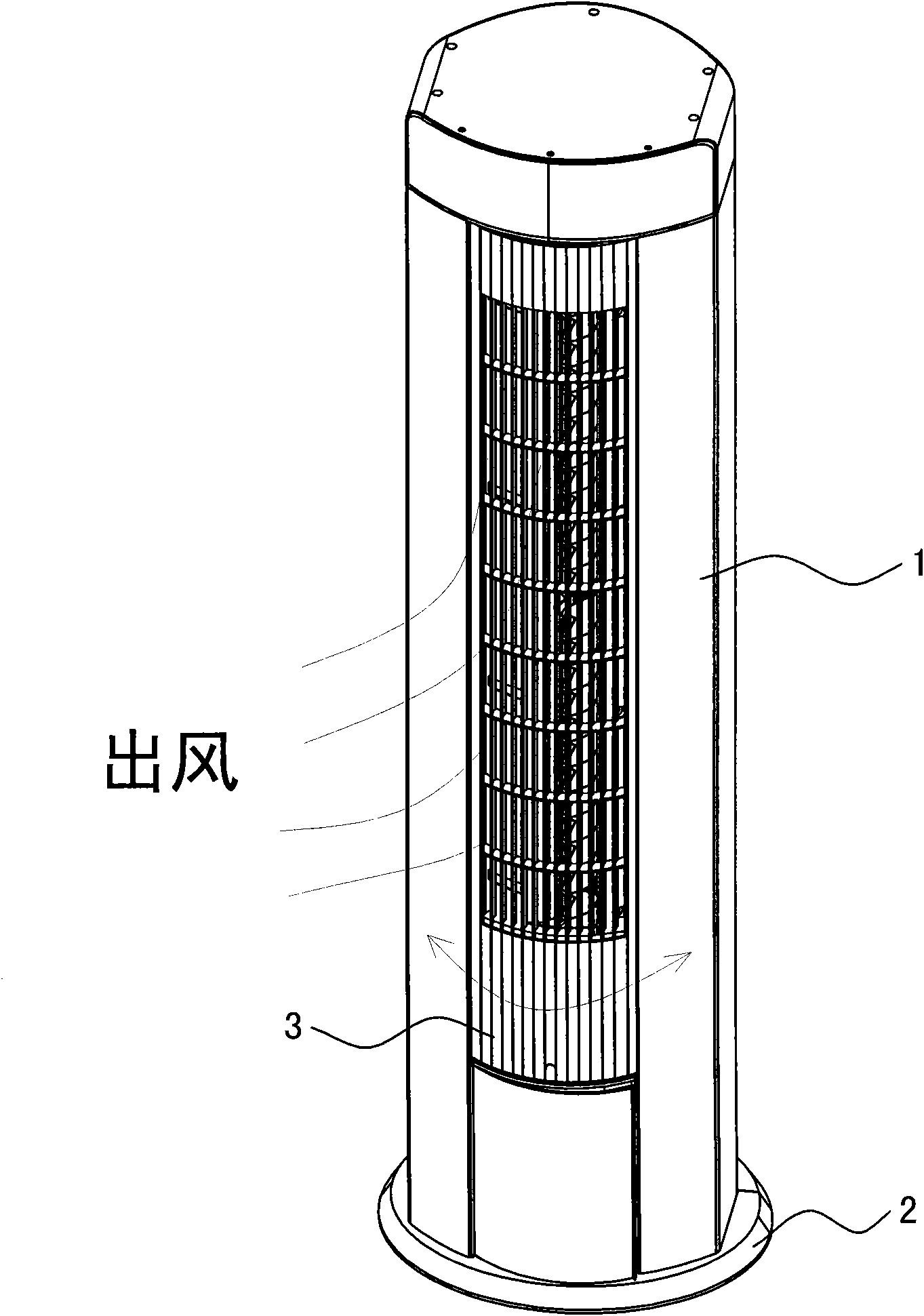

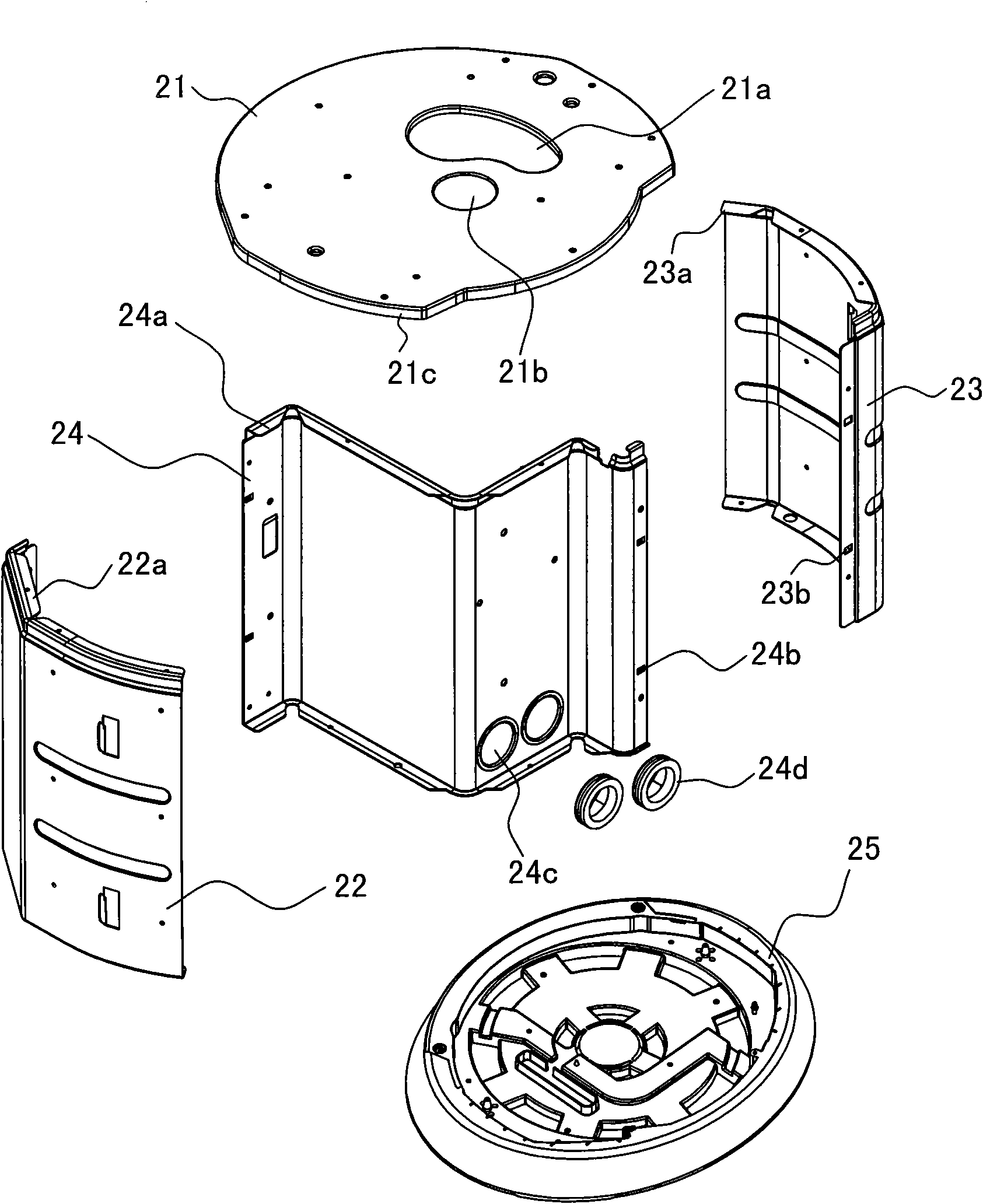

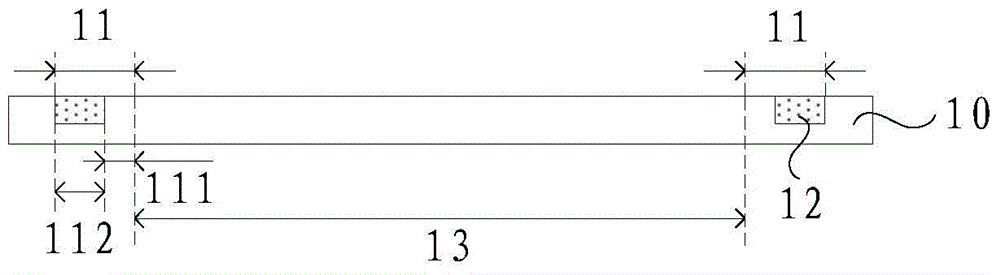

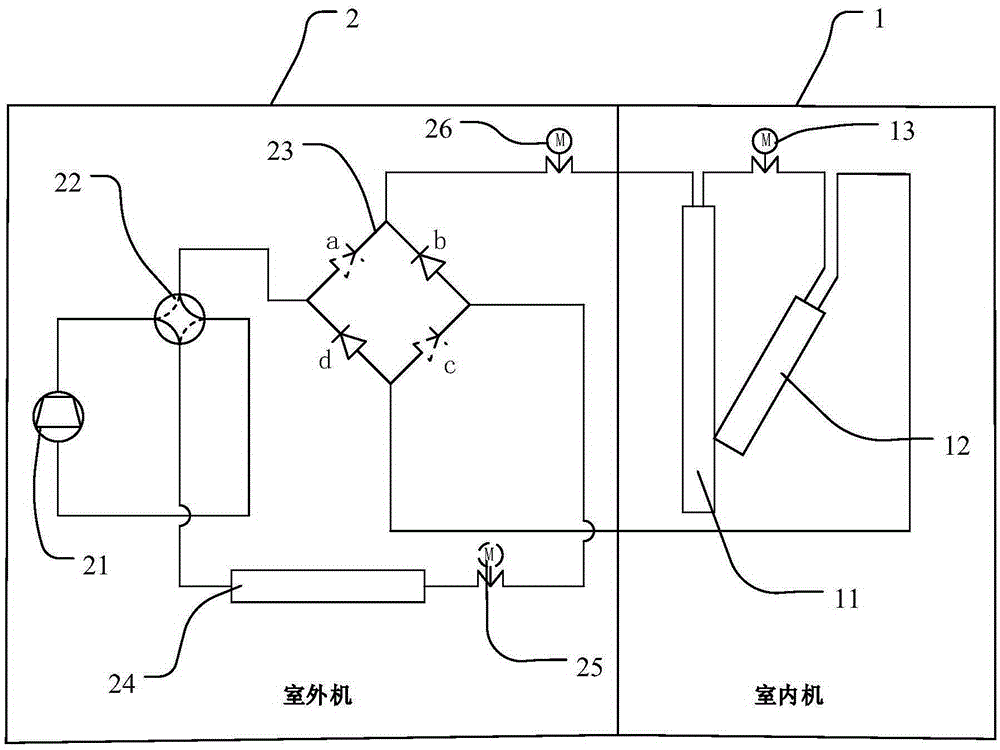

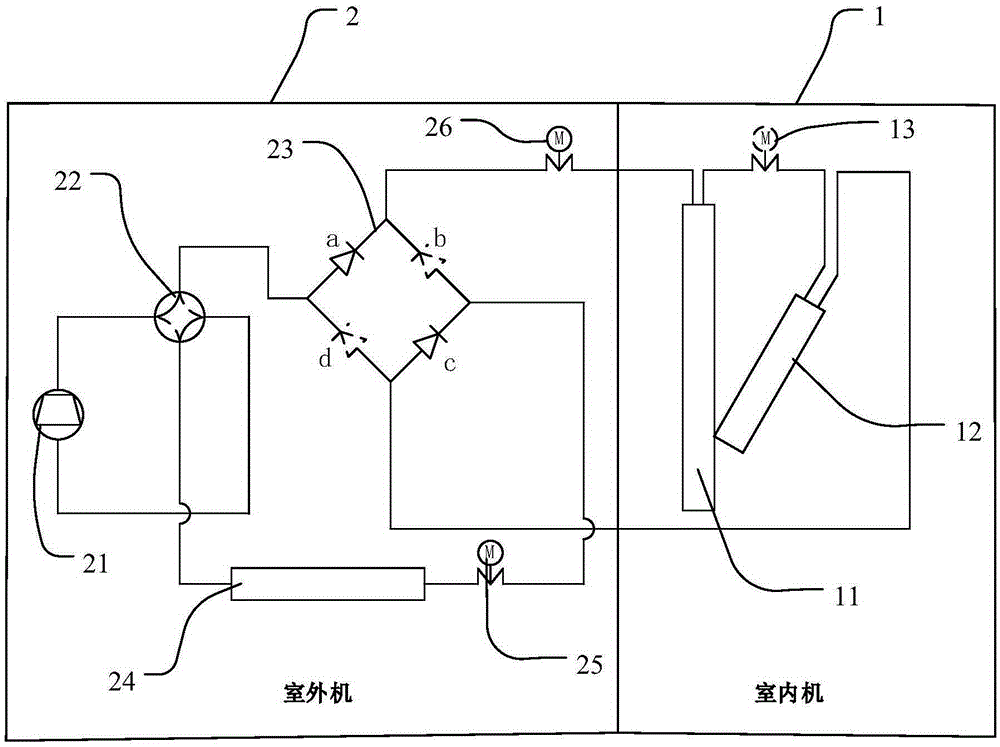

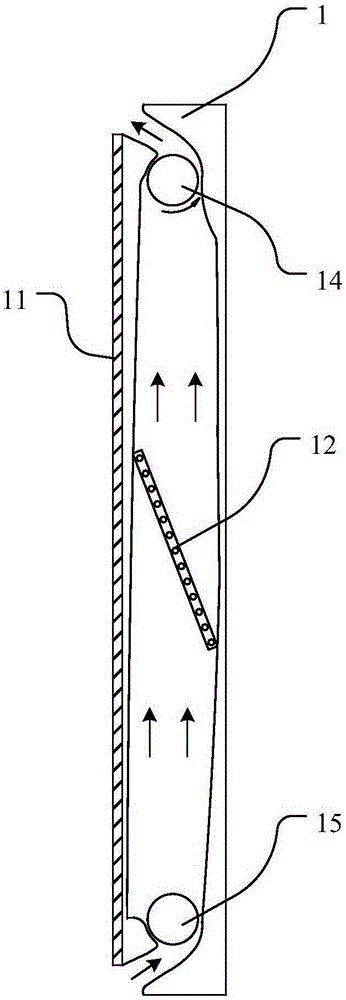

Vertical air conditioner

ActiveCN102466314AImprove the effect of water and electricity isolationImprove securityLighting and heating apparatusHeating and ventilation casings/coversElectricityIsolation effect

The invention discloses a vertical air conditioner, which comprises a base part, an outer shell, an inner shell, a driving mechanism, an air channel component and an electric appliance box, wherein the outer shell is arranged on the base part and is provided with a first opening; the air channel component is arranged on the base part in the outer shell, and comprises an air inlet, an air outlet, a connecting pipe, a water discharge pipe and a connecting lead wire; the air inlet and the air outlet are opposite to the first opening; the connecting lead wire is connected with the electric appliance box; a first cavity and a second cavity are formed in the base part; the electric appliance box is arranged in the first cavity; and the connecting pipe and the water discharge pipe extend into the second cavity. Two cavities are formed at the bottom of the shell, and the electric appliance box and the water discharge pipe are arranged in the two cavities, so that the electric appliance box is directly isolated from the water discharge pipe, and the water and electricity isolation effect is enhanced; furthermore, the electric appliance box is far away from a refrigeration system, and condensed water cannot be generated in the vertical air conditioner, so that the safety is high.

Owner:GREE ELECTRIC APPLIANCES INC

Method for recycling platinum and rhodium from binary aqua regia insoluble slag

InactiveCN101476044AEmission reductionImprove protectionProcess efficiency improvementIsolation effectRecovery method

The invention relates to a precious-metal recovery method, specifically relates to a method of recovering platinum / rhodium from insoluble residue of dualistic royal water for solving problems of the existing platinum / rhodium recovering method that the process flow is lengthy and complicated, operational process is dangerous, the isolation effect is bad, and the like. The method comprises steps of preprocessing the insoluble residue of royal water by using barium superoxide, oxidizing the platinum and rhodium thereof, dissolving the oxidized platinum and rhodium in hydrochloric acid; using ammonium chloride to deposit platinum after being converted to a sodium type, adding hydrazine hydrate for recovering the spongy platinum, complexing by adding sodium nitrite into the filter liquor after platinum deposition, depositing rhodium by using ammonium chloride, adding hydrochloric acid for dissolving and sodium type conversion, eliminating base metal in the liquid by using ion exchange resin, finally using hydrazine hydrate and hydrogen gas flame for recovering rhodium powder. The method is a precious-metal-resource secondary recovery utilization and purification method, and has advantages of simple technique, short purification period, convenient operations, high coefficient of recovery, little discharging of waste gas and waste matter, and environment protection, and the like.

Owner:CNOOC TAIYUAN PRECIOUS METALS

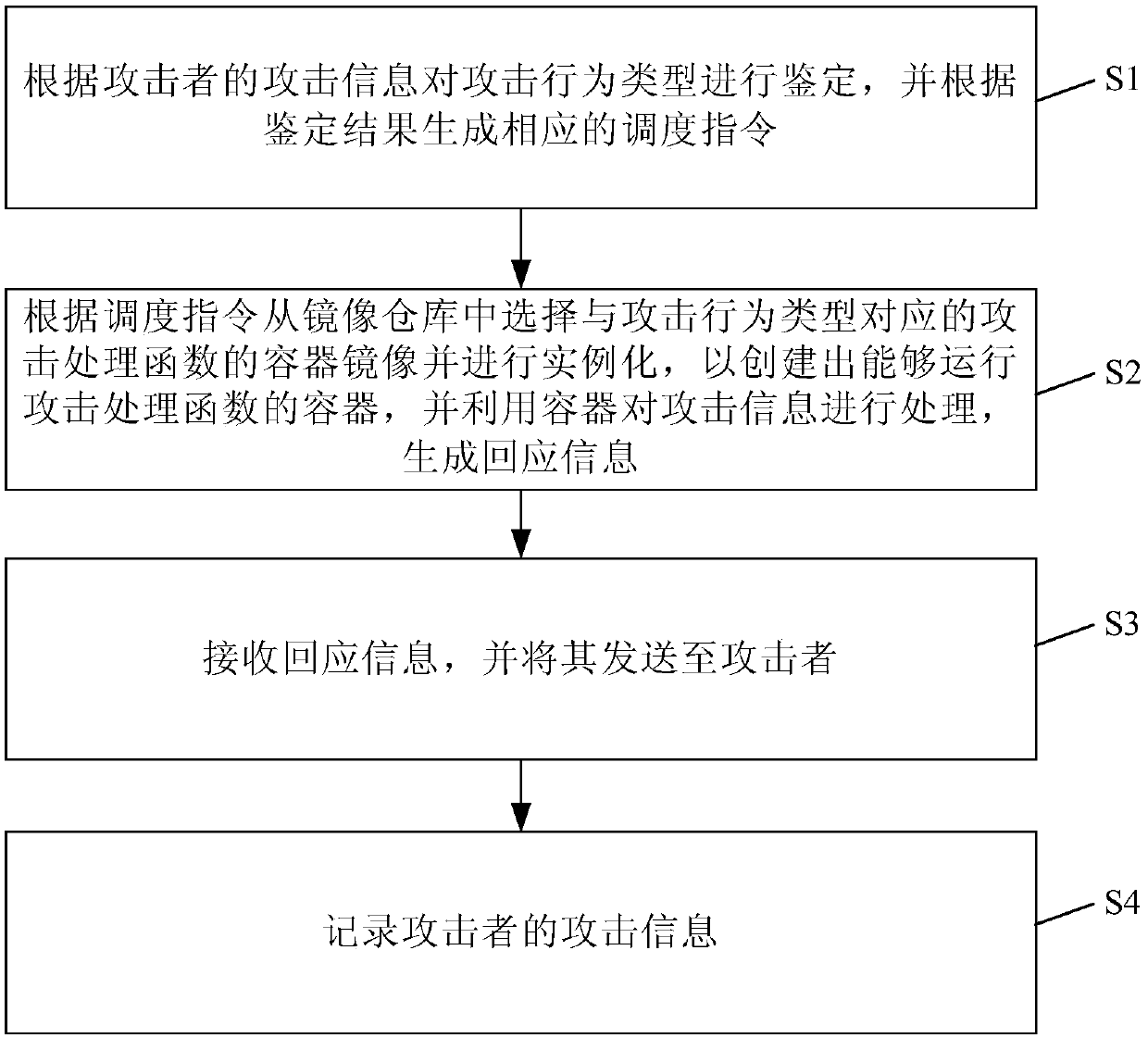

Honey pot active defense method and honey pot active defense system based on Serverless framework

The invention discloses a honey pot active defense method and a honey pot active defense system based on a Serverless framework. The honey pot active defense method comprises the steps: identifying anattack behavior type according to attack information of an attacker and generating a corresponding dispatching instruction according to an identifying result; choosing a container mirror image of anattach processing function corresponding to the attach behavior type from a mirror image warehouse according to the dispatching instruction, performing instantiation to establish a container which canoperate the attack processing function and utilizing the container to process of the attach information to generate response information; receiving the response information and sending the response information to the attacker. By means of the honey pot active defense method disclosed by the technical scheme of the invention, different types of attacks can be quickly responded; in addition, a honey pot is achieved by the container, a better environmental isolation effect is achieved, and that the attacker threatens the whole network environment through the honey pot environment is prevented tothe maximum extent.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

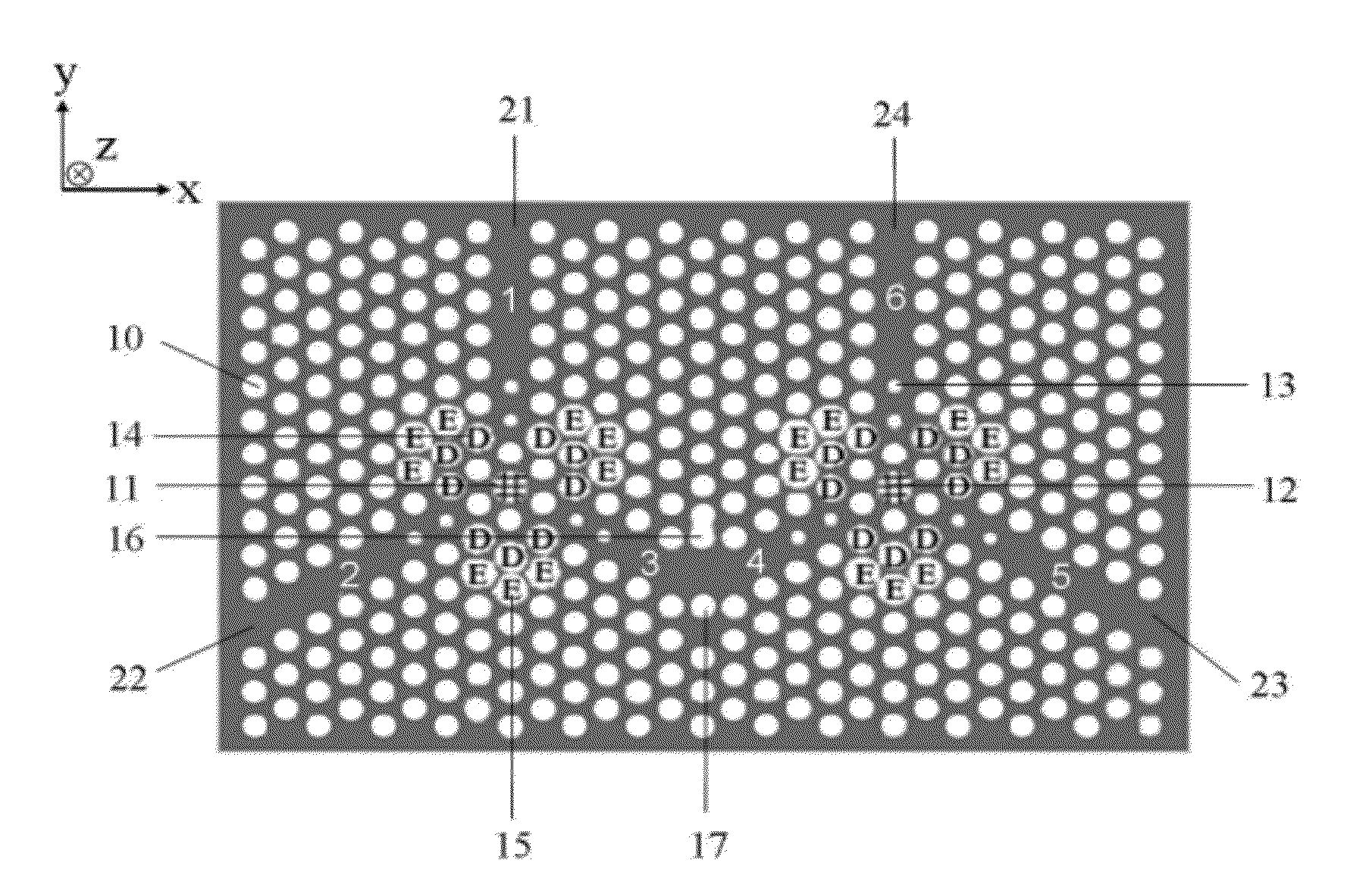

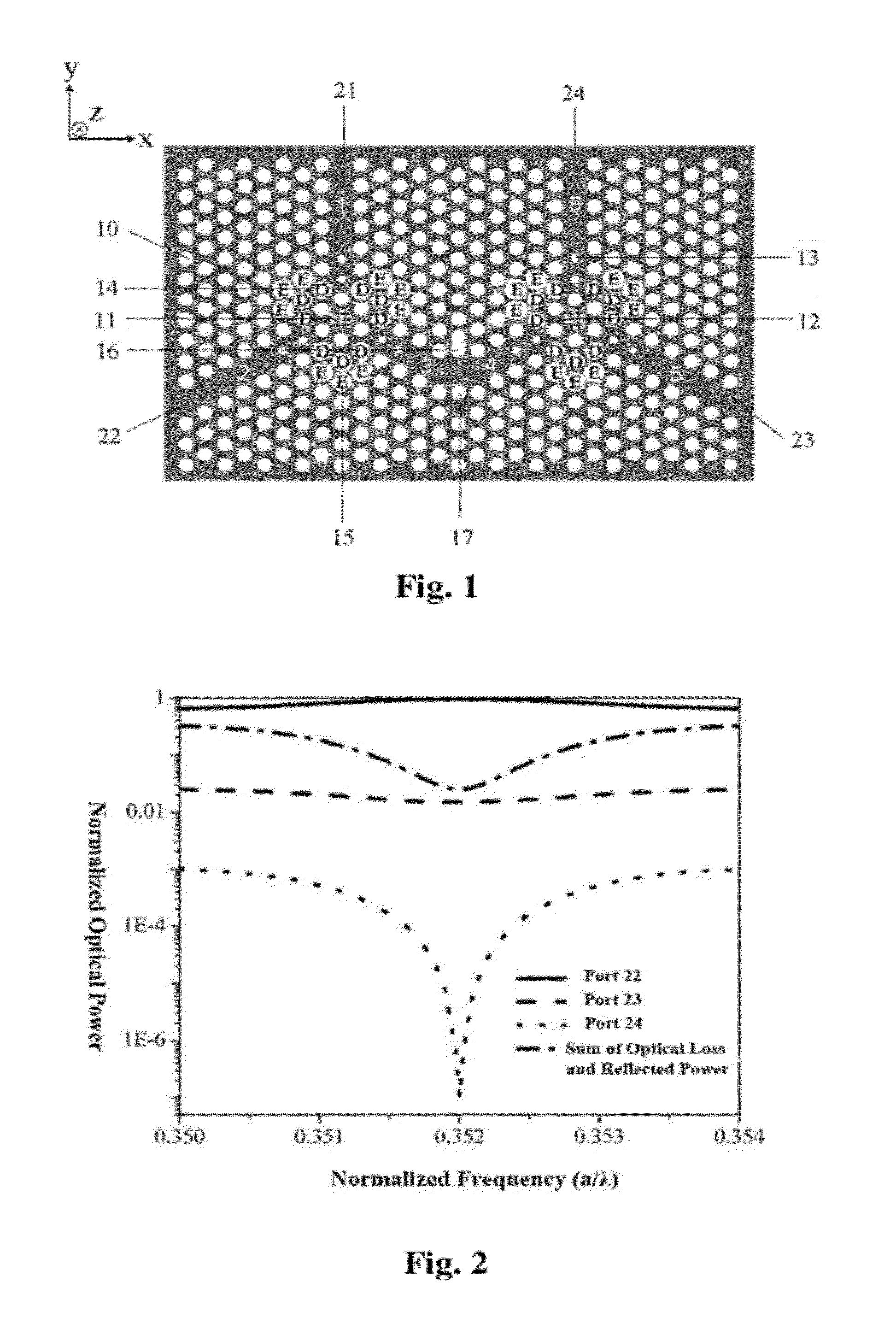

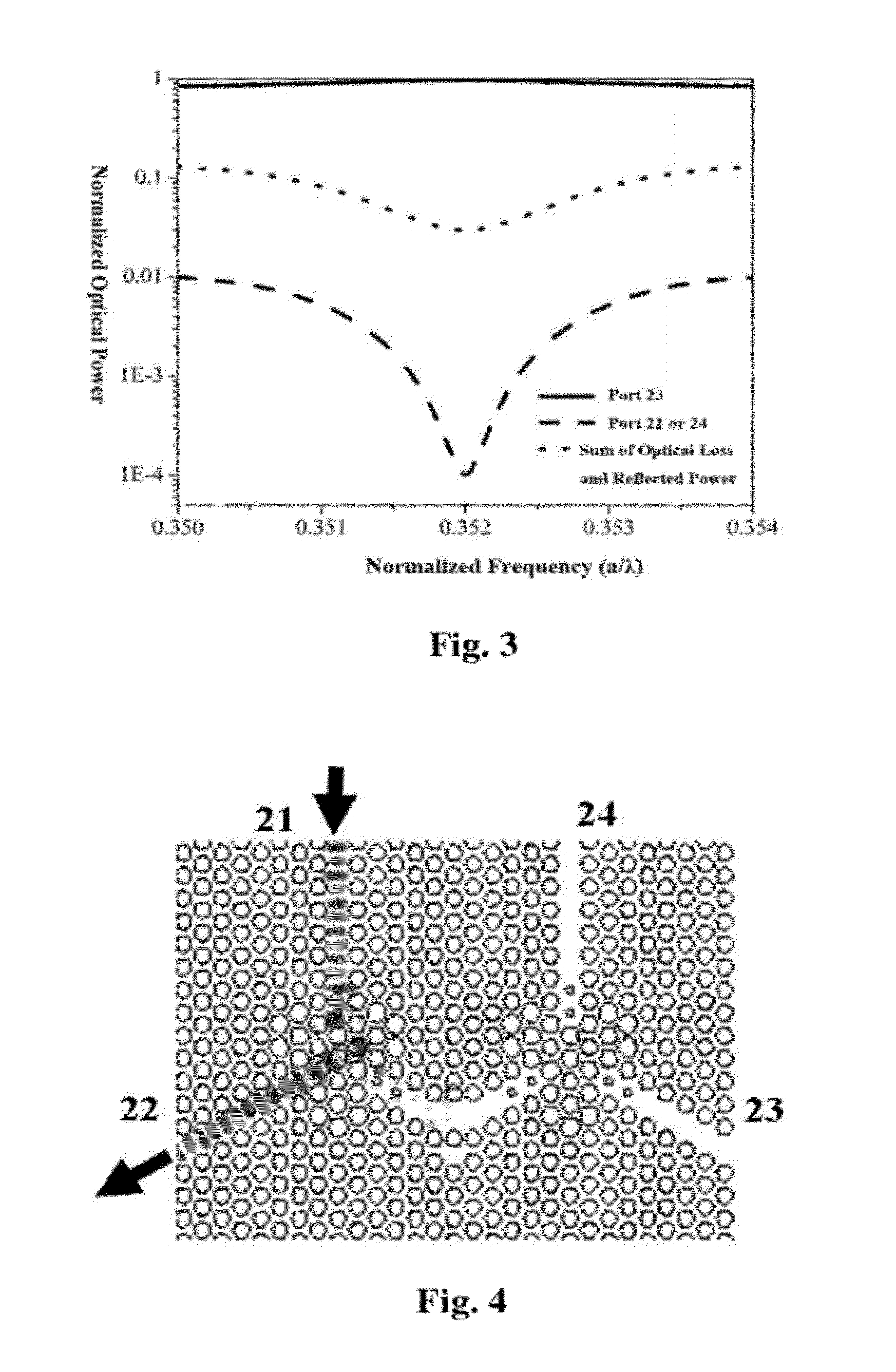

Photonic Crystal Four-Port Circulator Based on Coupling of Magneto-Optical Cavities

InactiveUS20120251048A1Compact structureEasy to integrateNanoopticsCoupling light guidesIsolation effectPhotonic crystal

The invention relates to a photonic crystal four-port circulator based on the coupling of magneto-optical cavities, which comprises two same magneto-optical cavities and three waveguides which are symmetrically distributed on the periphery of each magneto-optical cavity, wherein two waveguides connected with the magneto-optical cavities respectively are in a “v-shaped” arrangement, thereby guaranteeing that waveguides which are connected with the left sides of the two magneto-optical cavities are parallel to each other and waveguides which are connected with the right sides of the two magneto-optical cavities are parallel to each other as well and achieving the high-efficiency transmission in the case of the coupling of the magneto-optical cavities. The circulator provided by the invention utilizes the optical activity of the magneto-optical cavities to realize the rotation of the mode pattern of electromagnetic fields in the cavities, achieves the light transmission and isolation effects on different waveguides.

Owner:SHENZHEN UNIV

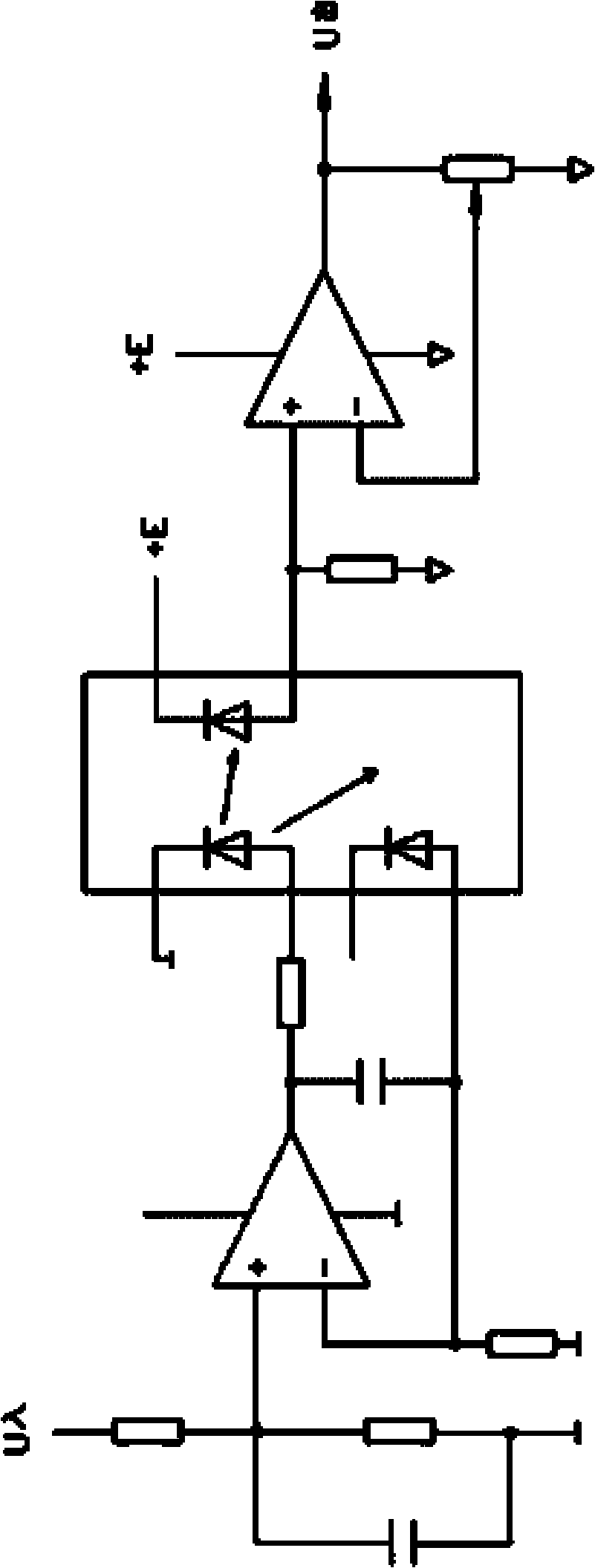

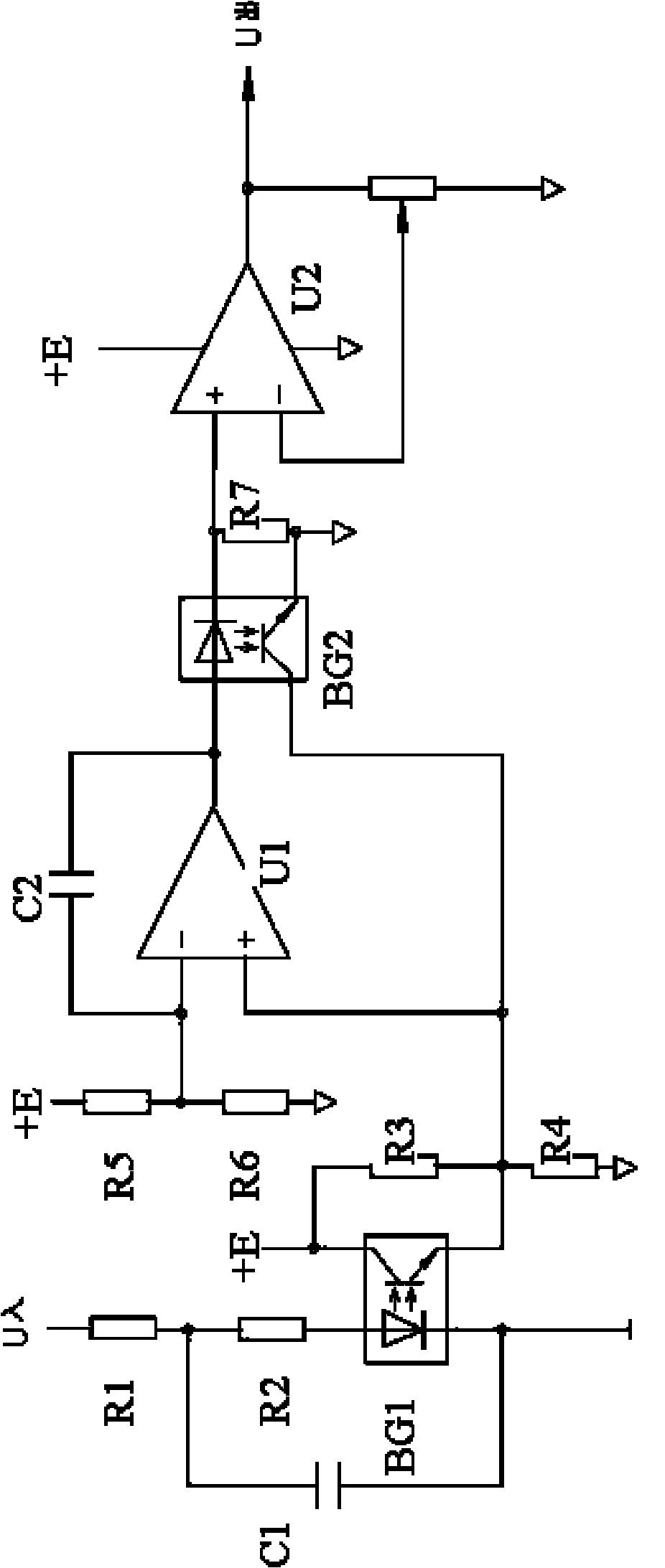

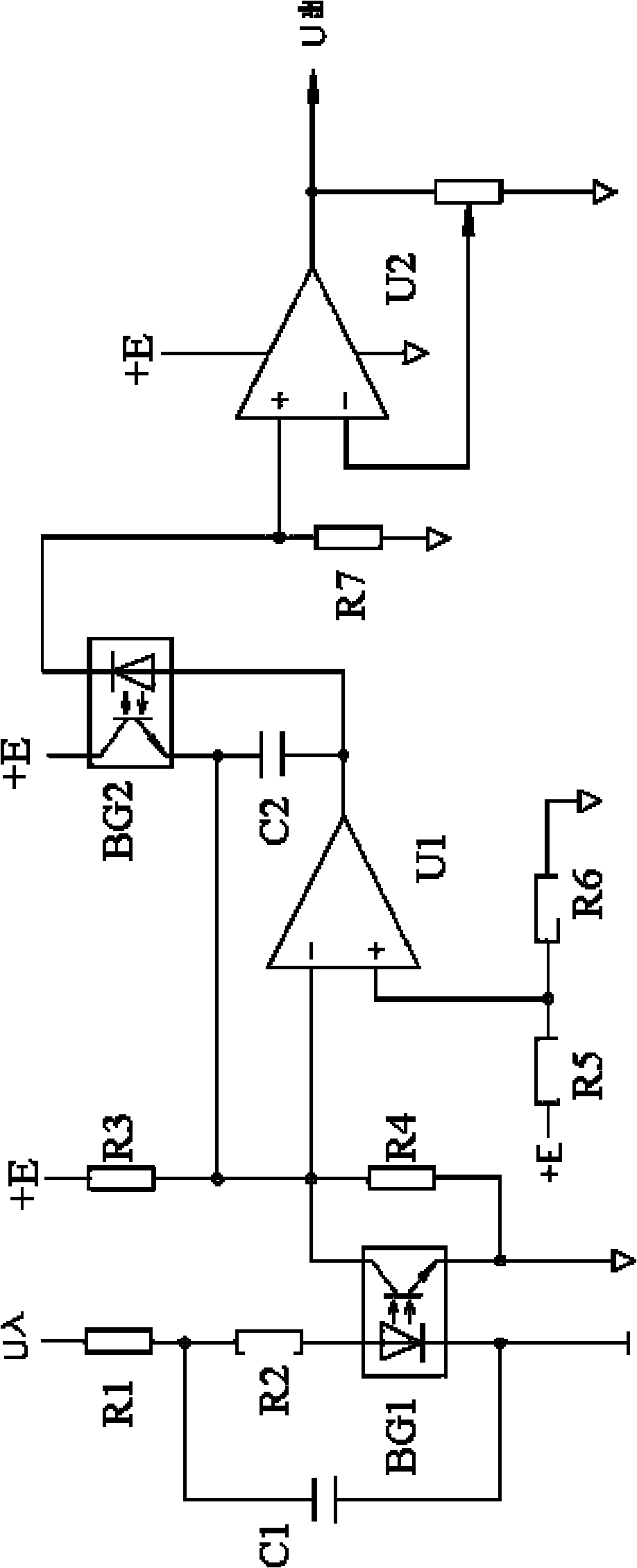

Isolation detection circuit of DC bus voltage

InactiveCN101923111ALow costHigh measurement accuracyCurrent/voltage measurementVoltage/current isolationIsolation effectLow voltage

The invention discloses an isolation detection circuit of DC bus voltage, which comprises optical coupling elements and single-power dual-operational amplifiers. The output phototriodes of the two optical coupling elements BG1 and BG2 are connected in series, and the connection point is connected with the in-phase or out-phase input end of the first operational amplifier U1 to supply power at a low-voltage side through a DC power supply +E; one of the optical coupling elements is a detection optocoupler BG1, and the LED thereof is serially connected with a high-voltage resistor R1 to detect the DC bus voltage; the other one of the optical coupling elements is a feedback control optocoupler BG2; the two input ends of the operational amplifier U1 are connected with the opposite angles of the electrical bridge of equal-arm resistors R3, R4, R5 and R6 powered by the DC power supply, and the output of the operational amplifier U1 is serially connected with the LED of the feedback optocoupler; and the input current of the feedback optocoupler is converted into voltage through a resistor R7 and subjected to in-phase amplification by the operational amplifier U2 before output. The invention provides a new method for detecting a DC bus, which has the advantages of simple circuit, low cost, high measurement precision, good isolation effect and broad popularization and application prospect.

Owner:NIDEC BEIJING DRIVE TECH CO LTD

Solid medical ultrasound coupling patch and preparing method thereof

ActiveCN105536005AAvoid breakingAvoid sexual cross-infectionEchographic/ultrasound-imaging preparationsIsolation effectUltrasonography

The invention discloses a solid medical ultrasound coupling patch and a preparing method thereof. The solid medical ultrasound coupling patch is prepared from a sodium alginate polymer, carrageenan, xanthan gum, hydroxymethyl cellulose, propylene glycol, glycerol, a preservative and deionized water. The preparing method comprises the steps that the sodium alginate polymer, glycerol, pure water andthe like are taken according to the mass ratio, mixed, heated and stirred evenly, and the mixture is discharged after heat-preservation defoaming is carried out, and then forms products of various specifications and shapes through filling. The solid medical ultrasound coupling patch is convenient to use and has excellent sound conduction and isolation effects; when medical personnel are in contact with infectious patients, the functions of preventing the risk of cross infection in a hospital and protecting the medical personnel are achieved after separation. The solid medical ultrasound coupling patch serves as a coupling medium, is specially applied to black and white ultrasonic equipment, color Doppler ultrasound equipment and the fields of ultrasound focusing and ultrasound treatment,and is suitable for the superficial surface, soft tissue, muscle bones, milk glands and thyroid glands of the human body and other parts where a liquid gel medium is difficult to use in ultrasound application.

Owner:SHENZHEN MINHAO TECH CO LTD

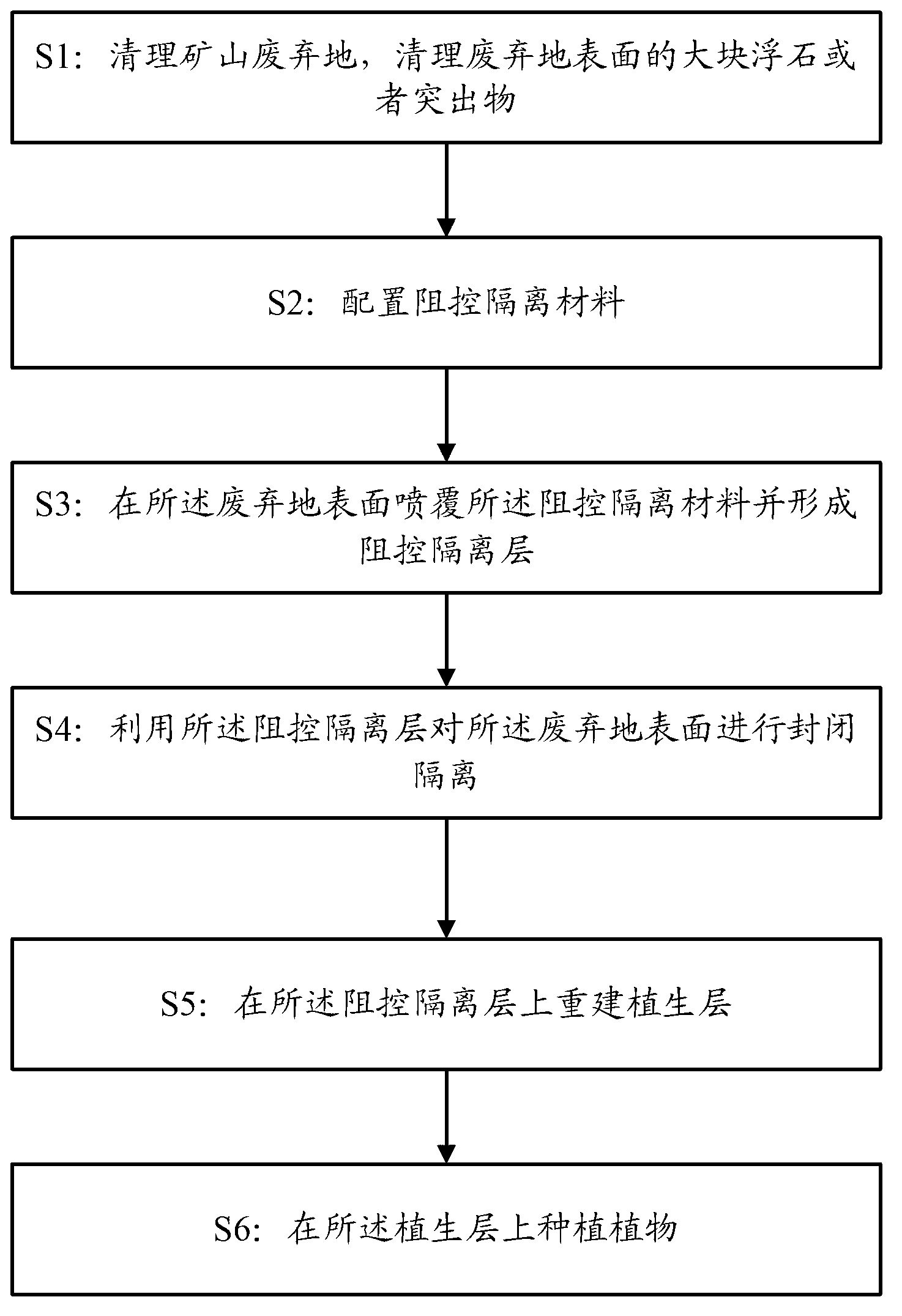

Treatment method for recovering mine polluted land vegetation

ActiveCN103299799AExcellent physical and chemical propertiesAvoid re-acidificationSoil lifting machinesExcavationsIsolation effectFiber

The invention is applicable to the field of ecological remediation and provides a treatment method for recovering mine polluted land vegetation. The method comprises the following steps of eliminating large pumice stone or protrusion on the surface of a mine polluted land; preparing an obstruction, control and isolation material; spraying the obstruction, control and isolation material on the surface of the polluted land to form an obstruction, control and isolation layer; sealing and isolating the surface of the polluted land by use of the obstruction, control and isolation layer; reestablishing a vegetation layer on the obstruction, control and isolation layer by use of a fiber soil fixation and slope protection vegetation technology; planting plants on the vegetation layer so as to realize vegetation recovery. According to the treatment method, the obstruction, control and isolation layer is formed on the surface of a mine so as to achieve a physical and chemical sealing and isolation effect, acidic and heavy metal ions which are likely to be reversely permeated in the deep layer of the mine are prevented from being reversely permeated to the surface layer of the mine due to the soil capillary action, and the vegetation layer is reestablished on the obstruction, control and isolation layer, so that a mine soil environment with favorable physical and chemical properties can be provided for the growth and development of the plants, and thus the purposes of recovering the vegetation and conserving water and soil can be achieved.

Owner:深圳市如茵生态环境建设有限公司

Method for controlling solidification and cooling of heavy castings

A method for controlling solidification and cooling of heavy castings improves a traditional chilling block, and a cooling channel is arranged inside the chilling block. A flowing cooling medium is led to the cooling channel inside the chilling block after the heavy castings are poured, so that cooling capacity of the chilling block cannot achieve saturation, and the chilling block can continuously have cooling effects. If the cooling medium is led to the cooling channel inside the chilling block, the hollow chilling block hinders heat of the castings from delivering from the chilling block to outside due to air-isolation effects. The method changes effects of the traditional chilling block, enables the chilling block to serve as a carrier for heat transferring and cooling, enables the cooling medium to continuously and indirectly cool the heavy castings, can quicken solidification and cooling of partial areas, better achieves progressive solidification, and improves feeding of the castings. After the heavy castings are solidified, the cooling capacity of the chilling block in different time can be adjusted by controlling the flow of the cooling medium, cooling with the castings is evenly quickened, and residual stress of the castings is reduced. The method is simple in chilling block manufacture, simple and convenient in operation and low in cost.

Owner:北京新方尊铸造科技有限责任公司

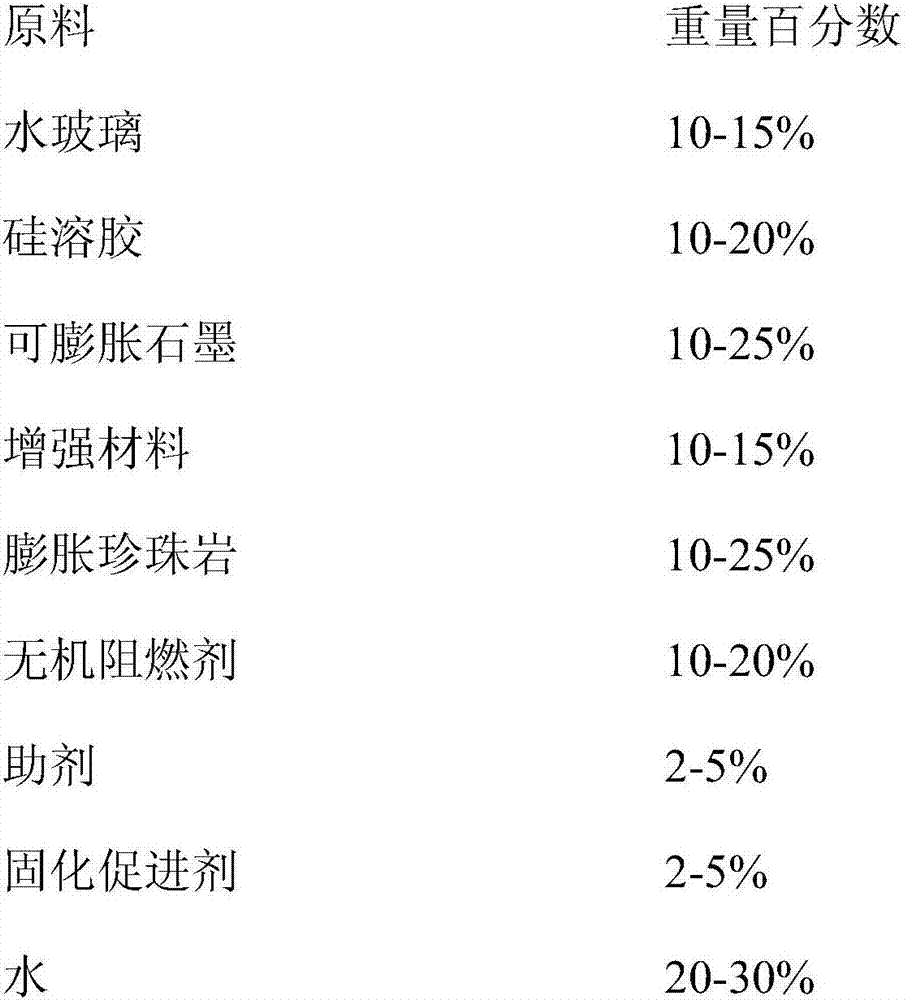

Inorganic expanded fireproof coating and preparation method

InactiveCN107216693AHarm reductionTo achieve the effect of flame retardant and heat insulationFireproof paintsIsolation effectFiber

The invention relates to a smoke-free inorganic ultrathin expanded fireproof coating and a preparation method thereof. The smoke-free inorganic ultrathin expanded fireproof coating is prepared from water glass, silica gel, expanded graphite, enhanced fiber, expanded perlite, an inorganic flame-retardant agent, an additive, a curing accelerator and water. The smoke-free inorganic ultrathin expanded fireproof coating has the advantages that the physical foaming technique is adopted, the flame-retardant and heat-isolation effects are realized by the inorganic flame-retardant agent and the inorganic foaming agent, the dry film thickness of the fireproof coating layer is 1 to 2mm, and the fire-resistant protection is provided for the substrate for at least 60min; in the construction process, the emission of VOC (volatile organic compound) is avoided, the toxic and harmful gas and smoke are not produced in the fire protection process, and a safe and environment-friendly green functional coating is provided.

Owner:MARINE CHEM RES INST

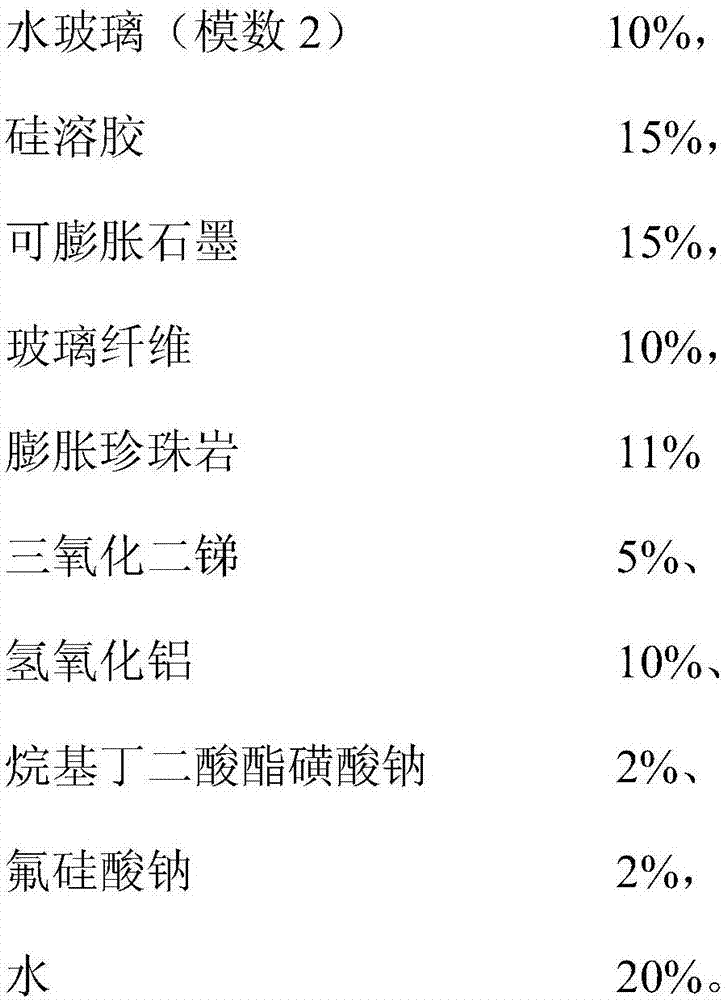

Multi-channel plant root exudate collection system and collection method thereof

InactiveCN102636373AImprove accuracyImprove collection efficiencyWithdrawing sample devicesIsolation effectPeristaltic pump

The invention discloses a multi-channel plant root exudate collection system and a collection method thereof. The system consists of a plurality of same collection devices and a multi-channel peristaltic pump, wherein the top end of a plant culture tank in each collection device is provided with a cover plate; a water outlet at the bottom end of the plant culture tank is connected with a filtering device; the filtering device is then connected with a root exudate adsorption device through the multi-channel peristaltic pump; and the root exudate adsorption device is then connected to the plant culture tank through a pipeline for recovering nutrient solution. The collection method comprises the following steps of performing water culture or quartz sand culture in the plant culture tank to culture plants; and flowing the nutrient solution from the plant culture tank into the adsorption device holding resin through the filtering device along a pipeline under the driving of the peristaltic pump, wherein the nutrient solution flows back into the plant culture tank after the root exudate is adsorbed by the resin. The collection system and the collection method can be used for simultaneously collecting a plurality of sets of plant root exudates, so that the cost, the time and the space are saved; and the system has a good isolation effect from the exterior, so that the accuracy for collecting the root exudates is improved.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

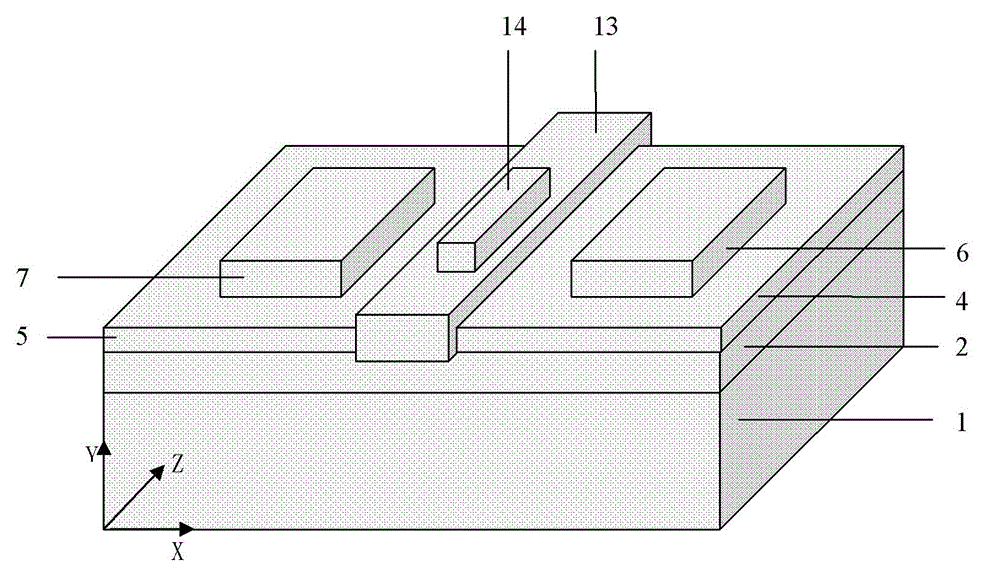

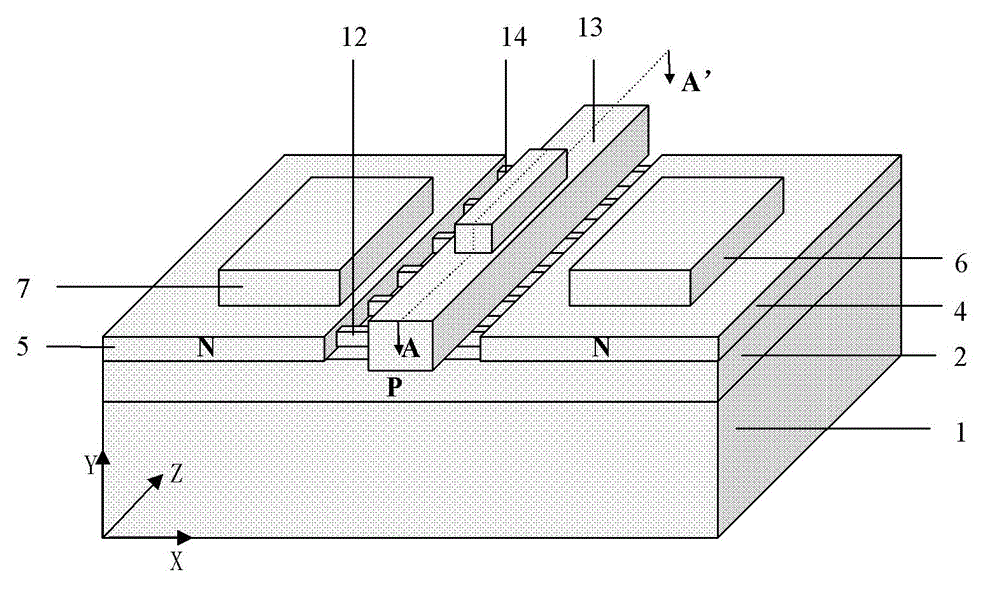

Junctionless silicon nanowire transistor based on bulk-silicon material and method for manufacturing junctionless silicon nanowire transistor

InactiveCN102916048AReduce manufacturing costImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation effectSilicon nanowires

The invention discloses a junctionless silicon nanowire transistor based on a bulk-silicon material and a method for manufacturing the junctionless silicon nanowire transistor. The junctionless silicon nanowire transistor comprises a bulk-silicon substrate, a polycrystalline grid, a drain electrode, a source electrode and a grid electrode, a P-type doped layer or an N-type doped layer is manufactured on the bulk-silicon substrate, an N-type doped layer or a P-type doped layer with a doping type opposite to the first P-type doped layer or first the N-type doped layer is manufactured on the first P-type doped layer or the first N-type doped layer, and a PN junction is formed by the different types of doped layers and realizes an electric isolation effect; a source region, a drain region and a silicon nanowire are manufactured on the second N-type doped layer or the second P-type doped layer, and the source region and the drain region are connected with each other by the silicon nanowire to form conducting channels; an insulating dielectric layer is manufactured on the surface of the integral silicon nanowire, the surface of the source region and the surface of the drain region; the polycrystalline grid is manufactured between the source region and the drain region and completely wraps the silicon nanowire; the drain electrode is manufactured on the drain region of silicon; the source electrode is manufactured on the source region of the silicon; and the grid electrode is manufactured on the polycrystalline grid. The junctionless silicon nanowire transistor and the method have the advantage that the junctionless silicon nanowire transistor can be manufactured on the bulk-silicon substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Light-weight and heat-isolation mullite bricks and preparation method thereof

The invention particularly relates to light-weight and heat-isolation mullite bricks and a preparation method thereof. The technical scheme is that the light-weight and heat-isolation mullite bricks are prepared from the following raw materials in percentage by weight: 40 to 48 percent of flint clay, 14 to 38 percent of kyanite, 6 to 16 percent of clay and 14 to 24 percent of alpha-Al2O3 fine powder, wherein a bonding agent is 15 to 20 percent by weight of the raw materials, and a pore-forming agent is 45 to 60 percent by weight of the raw materials. The preparation method comprises the following steps of firstly mixing the alpha-Al2O3 fine powder with the pore-forming agent, and carrying out wet grinding for 8 to 10 hours to obtain homogenized mud; uniformly stirring the homogenized mud, the flint clay, the kyanite, the clay and the bonding agent; carrying out aging, forming and baking; and preserving the heat at 1,325 to 1,450 DEG C for 3 to 5 hours to obtain the light-weight and heat-isolation mullite bricks. The light-weight and heat-isolation mullite bricks and the preparation method thereof have the advantages of saving resources, being simple in process, and being environmentally-friendly; and the prepared light-weight and heat-isolation mullite bricks are high in heat stability, low in heat conduction coefficient, low in volume density, low in after-burning linear shrinkage ratio, high in compression strength and good in heat insulation and isolation effect.

Owner:WUHAN UNIV OF SCI & TECH

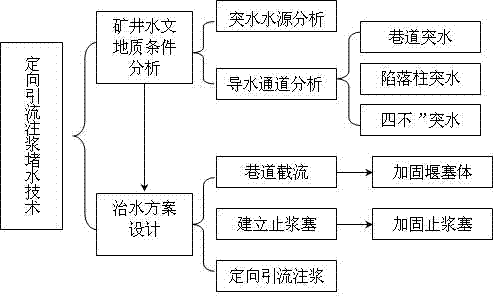

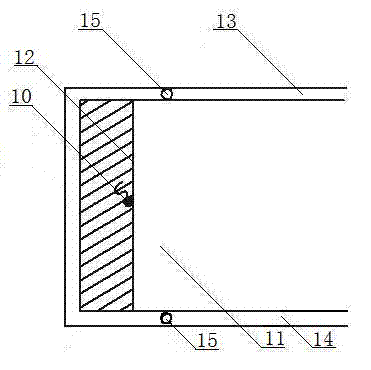

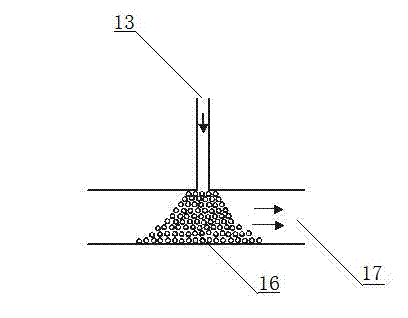

Technology for plugging water bursting in mine by directional diversion grouting

ActiveCN102705005AImprove the purpose of grouting to block water inrushUnderground chambersDrainageIsolation effectWater discharge

The invention provides a technology for plugging water bursting in mine by directional diversion grouting which can be used for plugging individual large fractures and quite a number of narrow fractures or weak zones which still exist and improving the effect in plugging water bursting in mine on the basis of ordinary grouting. Directional diversion water discharge is carried out near a water bursting point, so that the static water condition is changed as micro dynamic water condition; fine aggregates and slurries are guided to flow through a water channel to plug the water channel gradually, so that the purpose of grouting for water plugging can be achieved; and the problems of slurry waste because the slurry diffuses towards the far direction along the channel having larger fractures or the problem that new fractured gaps are formed along narrow fractures or weak zones so that the water isolation effect formed previously is damaged are overcome.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Arc-shaped steel spring plate vibration isolation support of friction pendulum

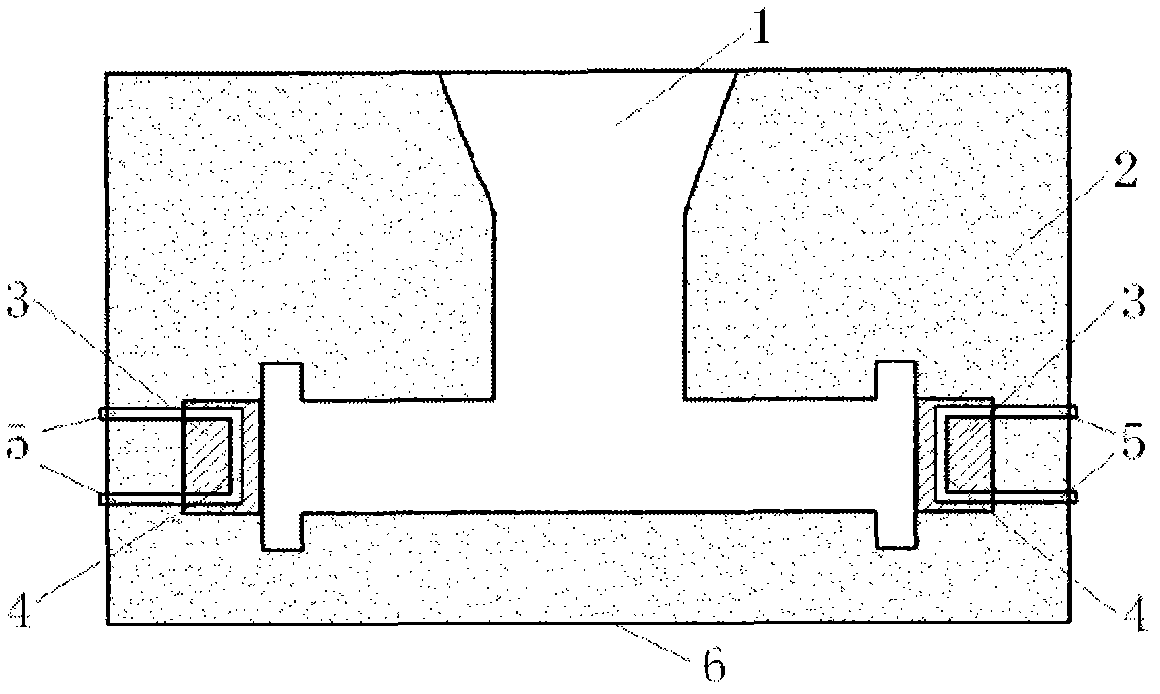

InactiveCN101701477ASimple structureImprove vertical bearing capacityBridge structural detailsShock proofingIsolation effectEngineering

The invention relates to an arc-shaped steel spring plate vibration isolation support of a friction pendulum in the field of buildings, bridges and sluices engineering. The arc-shaped steel spring plate vibration isolation support comprises an upper support plate, a column upper sliding block, a column biconvex spherical lower sliding block and a lower support plate, wherein the lower part of the upper support plate is provided with a circular sealing plate, the outer wall of the lower part of the upper support plate is connected with the upper surface of the column upper sliding block, an arc-shaped steel spring plate elastic assembly connected with the column upper sliding block is arranged between the column upper sliding block on the outer wall of the lower part of the upper support plate and the circular sealing plate, a concave spherical surface of the column upper sliding block is connected with an upper convex spherical surface of the column biconvex spherical lower sliding block, and a lower convex spherical surface of the column biconvex spherical lower sliding block is positioned in a concave spherical surface of the lower support plate. The vibration isolation support has simple structure, large vertical loading capacity, good durability and remarkable vibration reduction and isolation effects, can freely rotate in various directions, and is suitable for buildings, bridges, sluices and other structures in a strong earthquake region.

Owner:BEIJING UNIV OF TECH

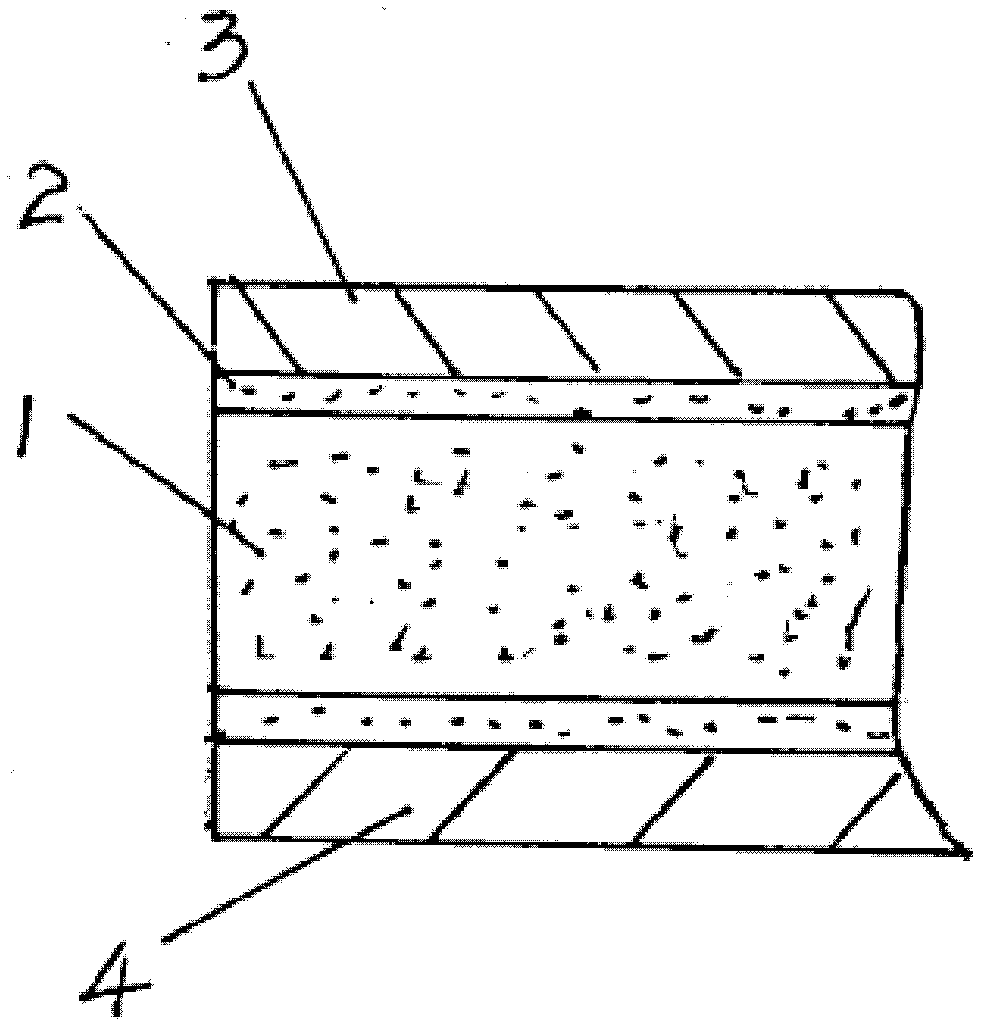

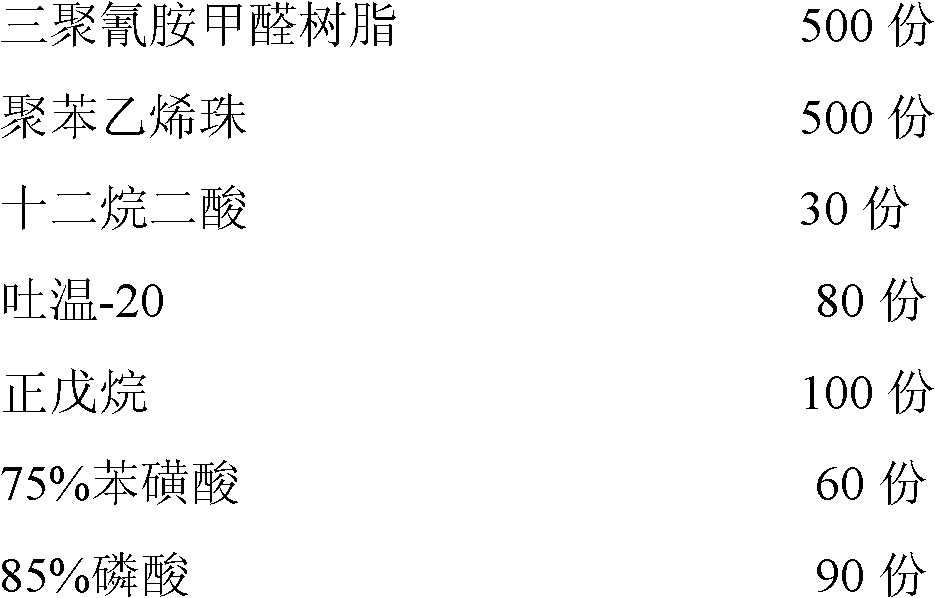

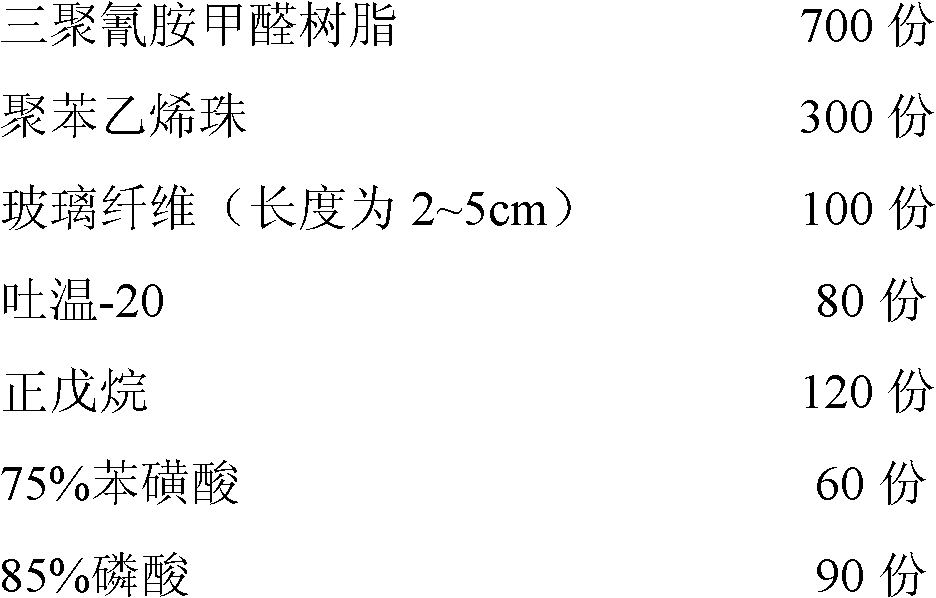

Macromolecular composite foam material as well as preparation method and application thereof

ActiveCN103374200AImprove flame retardant performanceImprove sound absorptionSynthetic resin layered productsIsolation effectFoaming agent

The invention belongs to the technical field of macromolecular materials and discloses a macromolecular composite foam material as well as a preparation method and application thereof. The material is formed by the following components in parts by weight: 50-500 parts of polystyrene bead, 500-950 parts of melamine formaldehyde resin, 100-200 parts of a foaming agent, 100-200 parts of a curing agent, 0-200 parts of a surface active agent, 0-150 parts of a flexibilizer and 0-200 parts of an additive. The preparation method comprises the following steps of: stirring 50-500 parts of polystyrene bead, 500-950 parts of melamine formaldehyde resin, 100-200 parts of foaming agent, 0-200 parts of surface active agent, 0-150 parts of flexibilizer and 0-200 parts of additive for 4-6 minutes, preheating the components for 5-10 min so that the temperature of a mixture is 30-40 DEG C, then adding 100-200 parts of curing agent, stirring for 1-2 minutes, pouring a second mixture into a preheated die for foaming and curing for 2-3 hours, thereby obtaining the macromolecular composite foam material. The invention also discloses application of the macromolecular composite foam material in serving as an insulation plate. The macromolecular composite foam material provided by the invention has high anti-flaming property and a good sound isolation effect.

Owner:HEFEI GENIUS NEW MATERIALS

Coating sunshade composite material with high reflectivity and preparation method thereof

ActiveCN102582170AImprove reflective effectImprove reflectivitySynthetic resin layered productsReflecting/signal paintsPolyesterIsolation effect

The invention provides a coating sunshade composite material with high reflectivity. The composite material comprises a polyester base material layer, wherein the two side surfaces of the polyester base material layer are coated with a polyvinyl chloride (PVC) thin film layer respectively; a reflecting layer is coated on one side surface of each PVC thin film layer and comprises a PVC base coating layer and a PVC top coating layer; and the aperture rate of the composite material is 2 to 6 percent. The invention also provides a preparation method for the composite material. The composite material has good sunshade and heat-isolation effects.

Owner:NINGBO XIANFENG NEW MATERIAL

Separated thermal cycle sludge dry method and device thereof

InactiveCN102311216AReduce energy consumptionGuaranteed uptimeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningIsolation effectWorking fluid

The invention relates to a treatment technique of sludge produced by sewage treatment, in particular to a separated thermal cycle sludge dry method and a device thereof. The method comprises the following steps: putting wet sludge in a drying tank for drying, leading out the steam produced by drying through a fan, letting the steam enter an evaporator be condensed into water, letting the peripheral water of tubes as working fluid be subject to evaporation to generate secondary steam, compressing the secondary steam by a vapor compressor to heat, then putting the secondary steam processed by heating as an outer heating source of the drying tank in a heat transfer of the drying tank; supplying heat to sludge indirectly, letting the steam after the heat supply be condensed into water, letting the water enter the evaporator through the heat absorption of the tubes of the combustion furnace to form a closed cycle of the working fluid. According to the invention, evaporation latent heat of water and heat value of non-condensable gas are fully recycled, to that the energy consumption is minimized; and because of the isolation effect of the evaporator, the vapor compressor is separated from the products formed by anhydration of the sludge, so that the system can stably run in long-term, and the investment cost is greatly reduced.

Owner:郭少仪 +1

Broadband dual-polarized OMNI-directional antenna and feeding method using the same

ActiveUS20130215832A1Good polarization isolation effectImprove data transfer ratePolarised antenna unit combinationsWireless commuication servicesIsolation effectElectrical conductor

A broadband dual-polarized omni-directional antenna and a feeding method using the same are provided. By setting a vertically polarized antenna and a horizontally polarized antenna each in co-axial, the horizontally polarized antenna is attached to an upper surface and a lower surface of the attaching plate respectively by two arms of a folded dipole and the two arms connect to an inner conductor and an outer conductor of a feed line so that the dual-polarized antenna may have a comparatively broad bandwidth. At the same time, since the dual-polarized ceiling antenna has a good isolation effect and coverage balance, it may work as the MIMO antenna in the LTE and WLAN systems effectively and may be used in the 2G and 3G networks to improve the data transmission rate.

Owner:CHINA MOBILE GROUP DESIGN INST

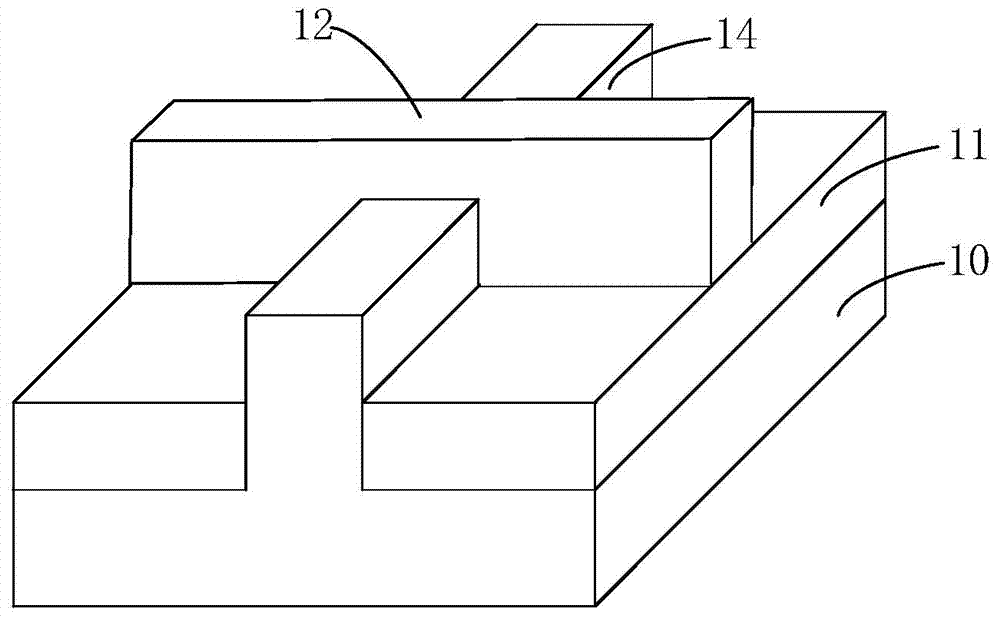

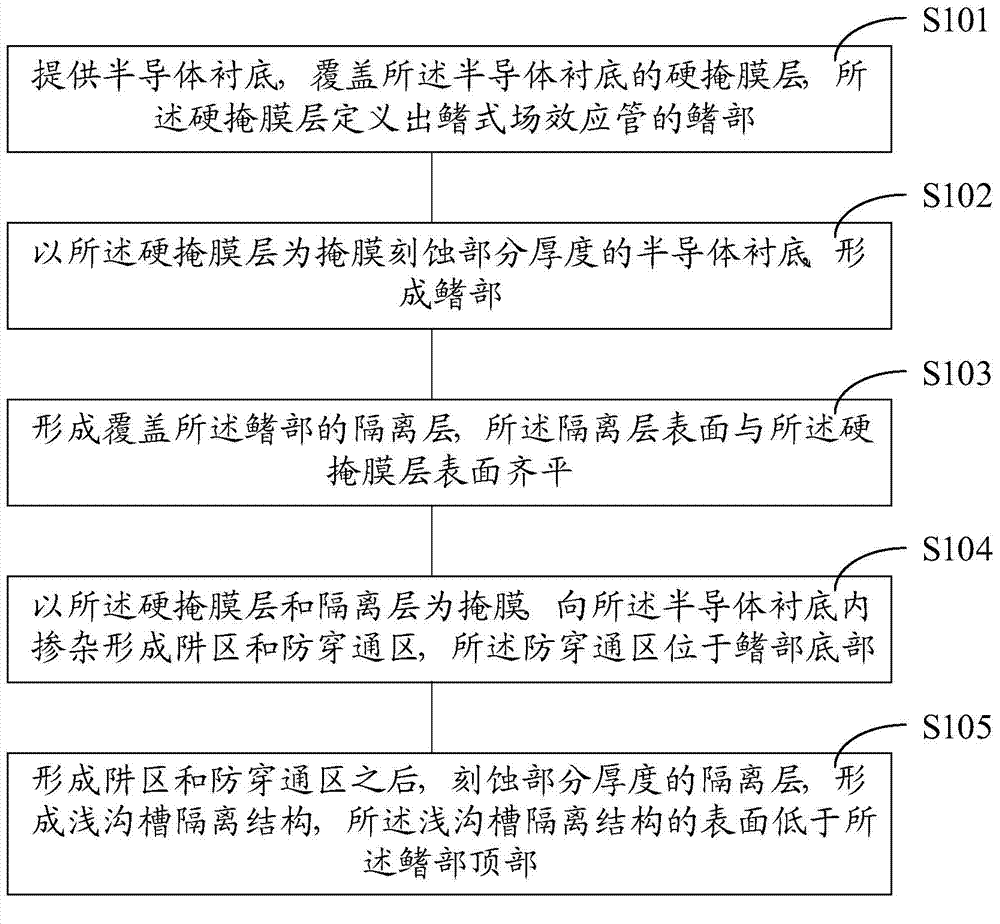

Fin type field-effect transistor forming method

ActiveCN104752214AQuality improvementQuality assuranceSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation effectIsolation layer

A fin type field-effect transistor forming method comprises the steps of providing a semiconductor substrate and a hard mask layer covering the semiconductor substrate, wherein the hard mask layer defines the fin portion of a fin type field-effect transistor; using the hard mask layer as a mask to etch a part of the semiconductor substrate to form the fin portion; forming an isolation layer covering the fin portion, wherein the surface of the isolation layer is flush with the surface of the hard mask layer; using the hard mask layer and the isolation layer as masks and forming a well region and a punchthrough-preventing region in the semiconductor substrate, wherein the punchthrough-preventing region is located at the bottom of the fin portion; etching a part of isolation layer after the well region and the punchthrough-preventing region are formed, forming a shallow-groove isolation structure, wherein the surface of the shallow-groove isolation structure is lower than the top of the fin portion. A formed fin type field-effect transistor is better in the punchthrough-preventing effect, the fin portion is better in quality, the isolation effect of the well region is better, and the performance stability of the fin type field-effect transistor is effectively improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

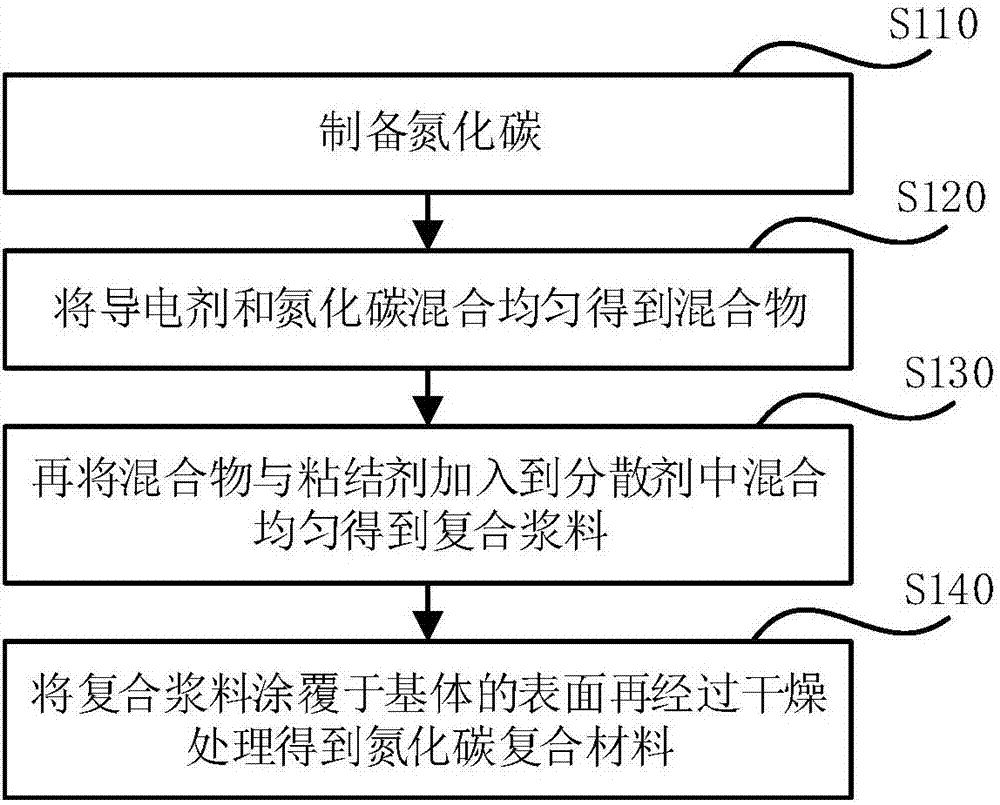

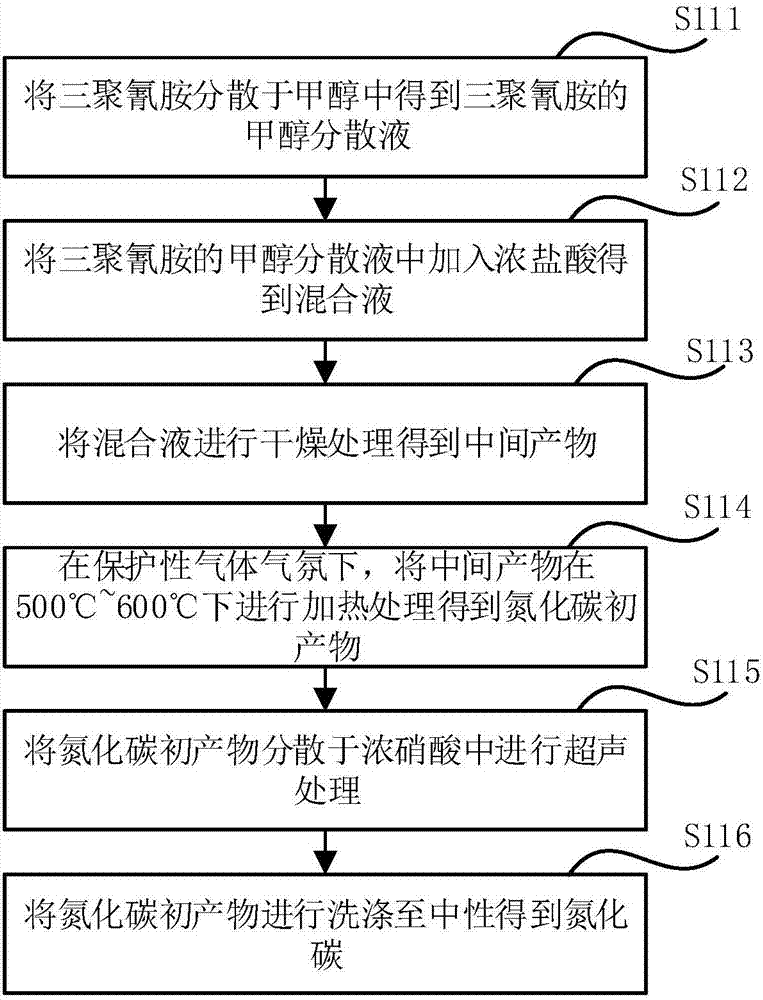

Carbon nitride composite material and preparation method and application thereof

InactiveCN107359302AGood physical barrierLarge specific surface areaLi-accumulatorsCell component detailsIsolation effectCarbon composites

The invention relates to a carbon nitride composite material and a preparation method and an application thereof. The carbon nitride composite material comprises a substrate and a composite coating layer for covering the surface of the substrate; the composite coating layer comprises carbon nitride, a conductive agent and a binder; the conductive agent is selected from at least one kind of active carbon, acetylene black, Ketjen black, graphite, graphene and carbon nanotubes. The carbon nitride composite material can be applied to a diaphragm of a lithium-sulfur battery; when a polysulfide exists, the conductive agent can transfer electrons generated in the charge-discharge process, so that an effect of a second current collector as well as an effect of physical isolation can be played; in addition, carbon nitride has relatively high physical isolation effect and large specific surface area; and due to existence of the nitrogen element, shuttling of the polysulfide can be suppressed by the dual chemical and physical absorption effects effectively, thereby enabling the lithium-sulfur battery to be relatively high in discharge specific capacity and cycling stability.

Owner:DONGGUAN UNIV OF TECH

Straw gypsum lightweight plate and preparation method thereof

InactiveCN101733832AStrong enoughReduce weightConstruction materialDischarging arrangementCelluloseIsolation effect

The invention discloses a straw gypsum lightweight plate, which comprises the following materials in part by weight: 90 to 100 parts of calcined gypsum, 20 to 40 parts of pulverized straw, 0.2 to 0.4 part of redispersible powder, 0.5 to 0.7 part of gypsum retarder, 0.2 to 0.4 part of polyvinyl alcohol (PVA) powder, 5 to 15 parts of white cement and 0.1 to 0.2 part of defoaming agent. The invention also discloses a method for preparing the straw gypsum lightweight plate, which comprises the following steps: firstly, pulverizing and putting straw in a reaction kettle for pretreatment; secondly, performing enzymolysis on the straw by adopting cellulose and centrifugalizing the straw to remove moisture: and thirdly, uniformly mixing in a stirring machine in a proportion of the raw material and water, paving mixture in a paving machine into a plate blank, performing fastening and cold compression on the plate blank to form the plate, and performing subsequent treatment to obtain the straw gypsum lightweight plate. The straw gypsum lightweight plate prepared by the method has the advantages of light weight, fireproofing, waterproofing, good sound isolation effect and good durability, is particularly suitable for an inner wall partition, a non-bearing wall and other building parts, and has good market prospect.

Owner:BEIJING UNIV OF TECH

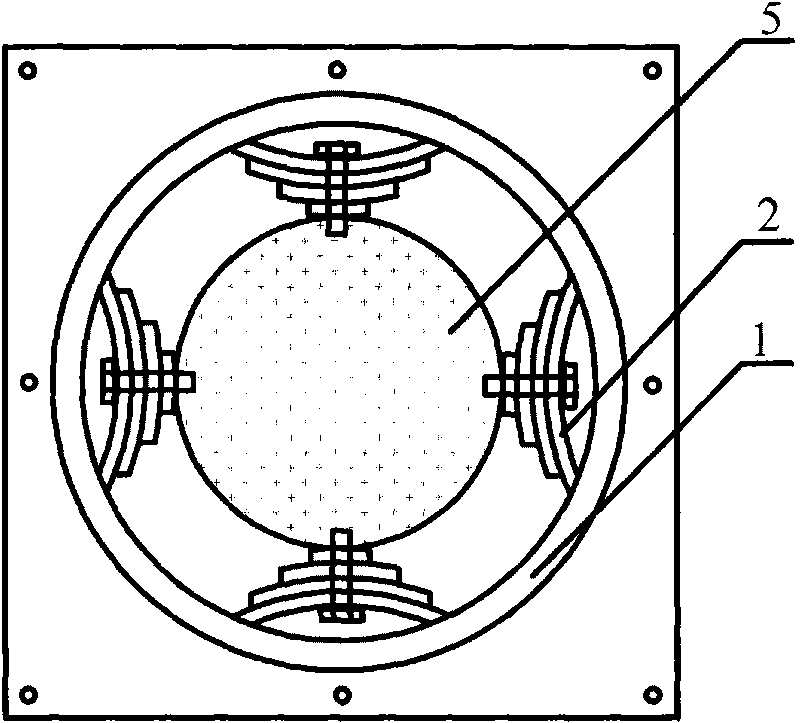

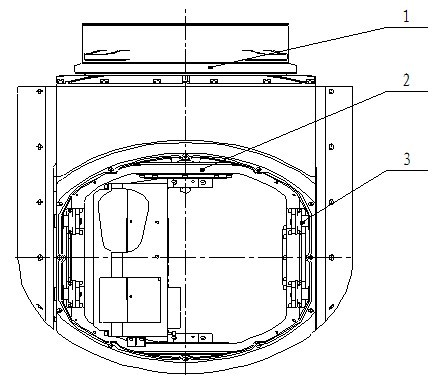

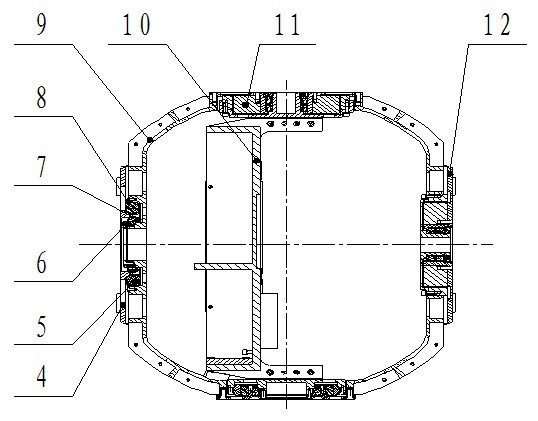

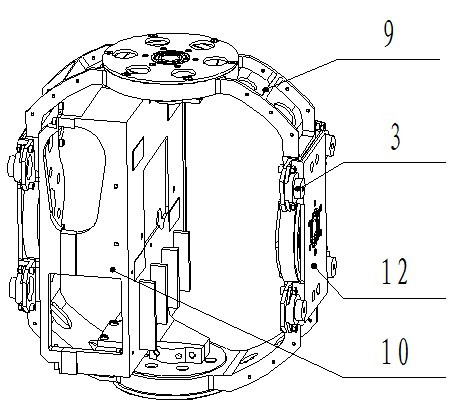

Photoelectric stable platform

InactiveCN102155517AOutstanding FeaturesHighlight significant effectNon-rotating vibration suppressionIsolation effectImaging quality

The invention relates to a photoelectric stable platform, which has a vibration-isolating inner ring and a plurality of frames. The photoelectric stable platform comprises an outer ring frame, an inner ring frame and an even number of vibration isolators of the same specifications, wherein various sensors are placed on the inner ring frame; and the vibration isolators are symmetrically installed relative to the centre of mass of the integration of the inner ring frame in which the various sensors which are installed. The invention has the advantages that: an isolation effect of the photoelectric stable platform on external interference is good; imaging quality and stabilization precision are high; the photoelectric stable platform is small in size, light in weight, large in bearing capacity, and convenient for assembly and disassembly; the weight of the platform can be reduced effectively; the assembly of the photoelectric stable platform can be adjusted quickly and conveniently according to requirements; and the photoelectric stable platform is characterized by simple structure, wide application range and the like.

Owner:武汉华中天经通视科技有限公司

Substrate for display and display device

InactiveCN104979373AImprove the effect of isolating water vaporExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesIsolation effectDisplay device

The present invention provides a substrate for display and a display device and relates to the technical field of display, aiming at solving the problem of an existing device that the steam isolation effect is poor. The substrate for display comprises an annular packaging region and a display region located on the inner side of the packaging region, wherein the packaging region comprises an annular sticking region and a groove region which is located on the inner side of the sticking region and / or the outer side of the sticking region; and a groove structure is formed in the groove region and a material for absorbing water is stored in the groove structure. The substrate is used for the display device.

Owner:BOE TECH GRP CO LTD +1

Air conditioner system, air conditioner and control system

ActiveCN105352214AEnable modular optional installationReduce noiseMechanical apparatusNoise suppressionIsolation effectControl system

The invention relates to an air conditioner control system. A radiant panel is arranged on an indoor unit. The indoor temperature can rapidly reach a set temperature point through the forced convection heat exchange of an indoor unit heat exchanger and air. When the indoor temperature reaches the set temperature, the indoor comfort degree is kept mainly through thermal radiation of a radiation device, an inner draught fan can be controlled to run in an ultra-silence manner or run at a low-wind gear or run in an intermittent manner or to completely stop running, and therefore the problem that the strong air blowing feeling exists during refrigerating running or heating running is solved, and meanwhile the running noise of the draught fan is reduced. The indoor unit discharges air upwards in the refrigerating process, and discharges air downwards in the heating process. Meanwhile, due to the fact that thermal radiation does not need to be spread through media and indoor air doest not have an isolation effect on thermal radiation, thermal radiation directly acts on human bodies and indoor facilities, and uniform indoor temperature gradient and comfort are ensured. Due to the fact that the radiation device bears parts of indoor loads, a radiation heat exchange panel can be produced in a modularized manner, and modularized selection installation of air conditioners is achieved according to sizes of rooms or magnitudes of loads.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com