Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281results about How to "Improve vertical bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

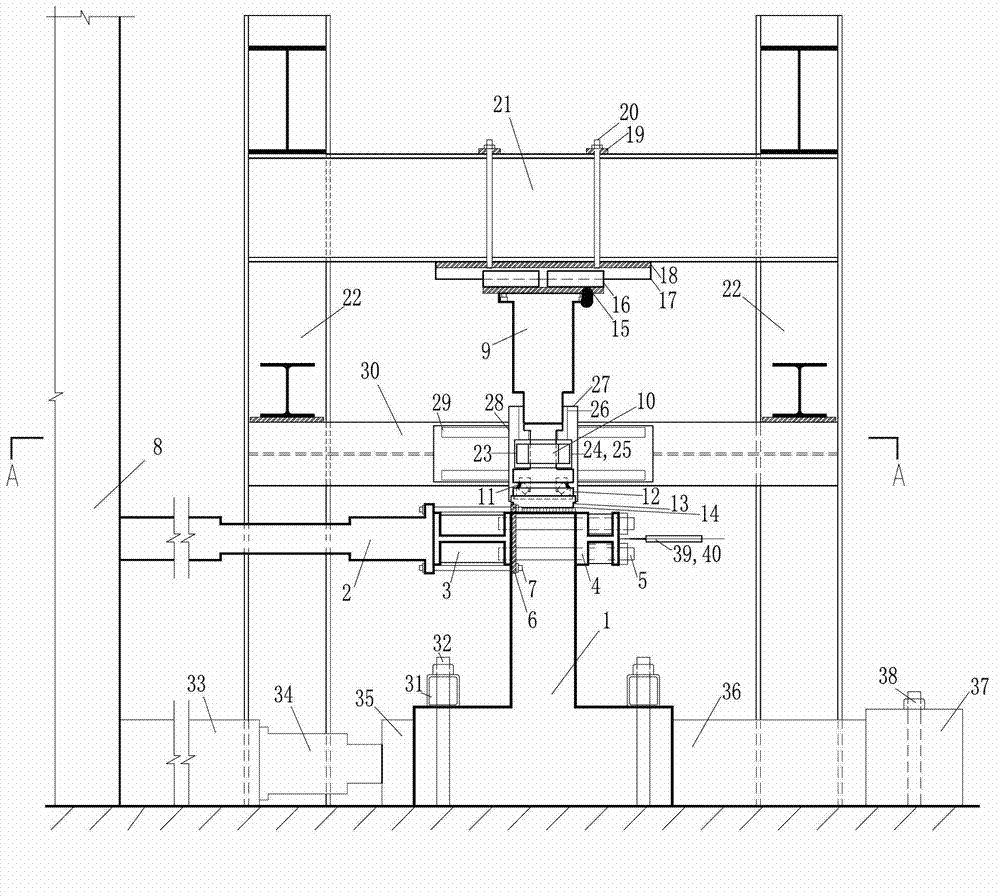

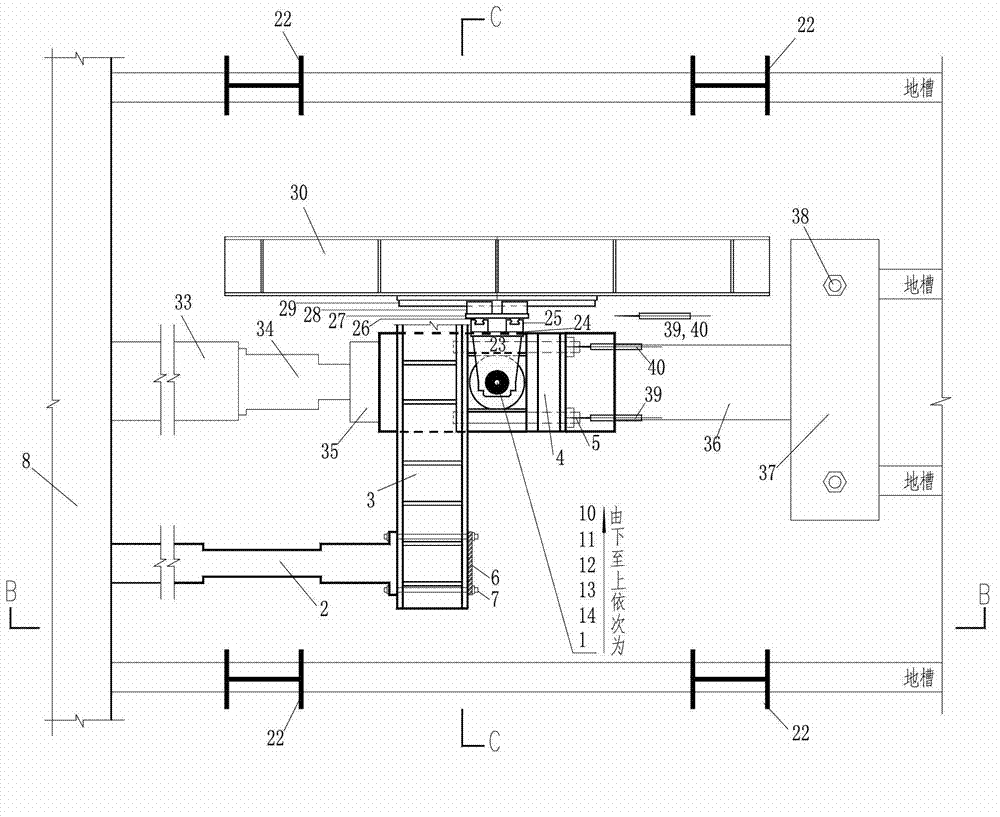

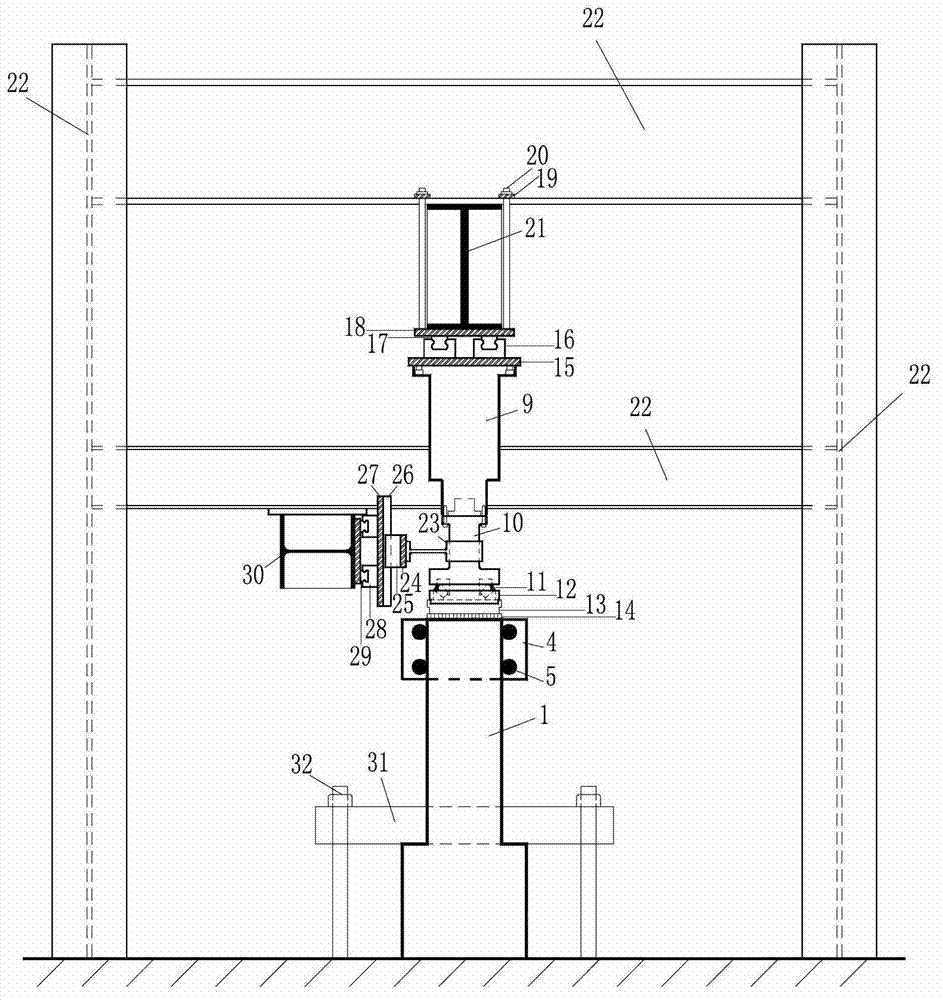

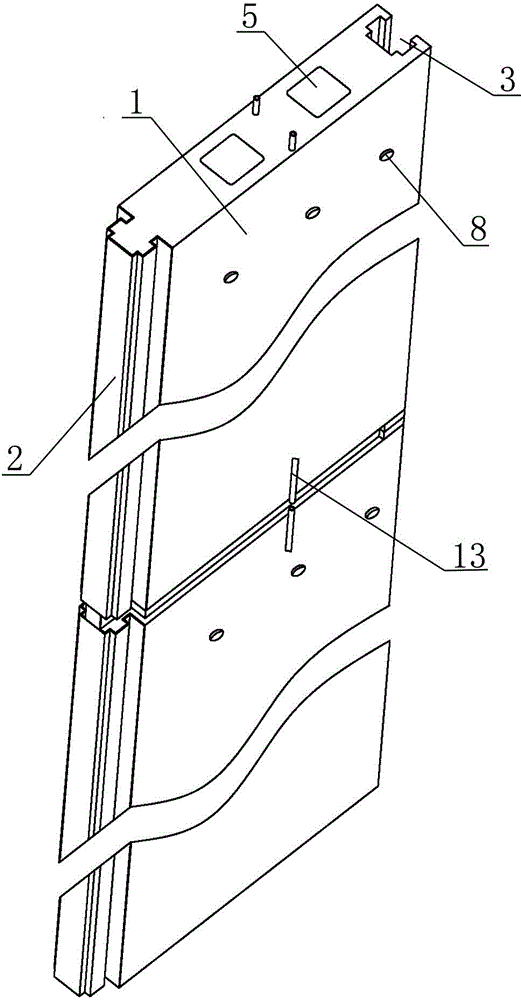

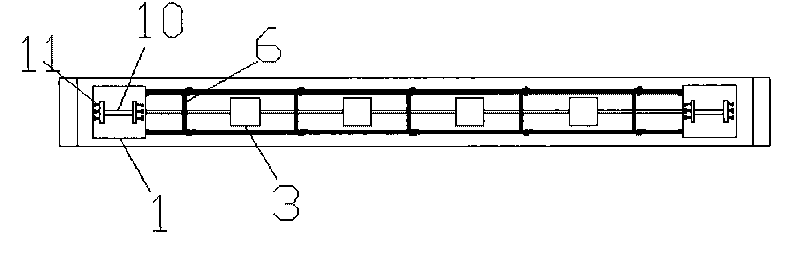

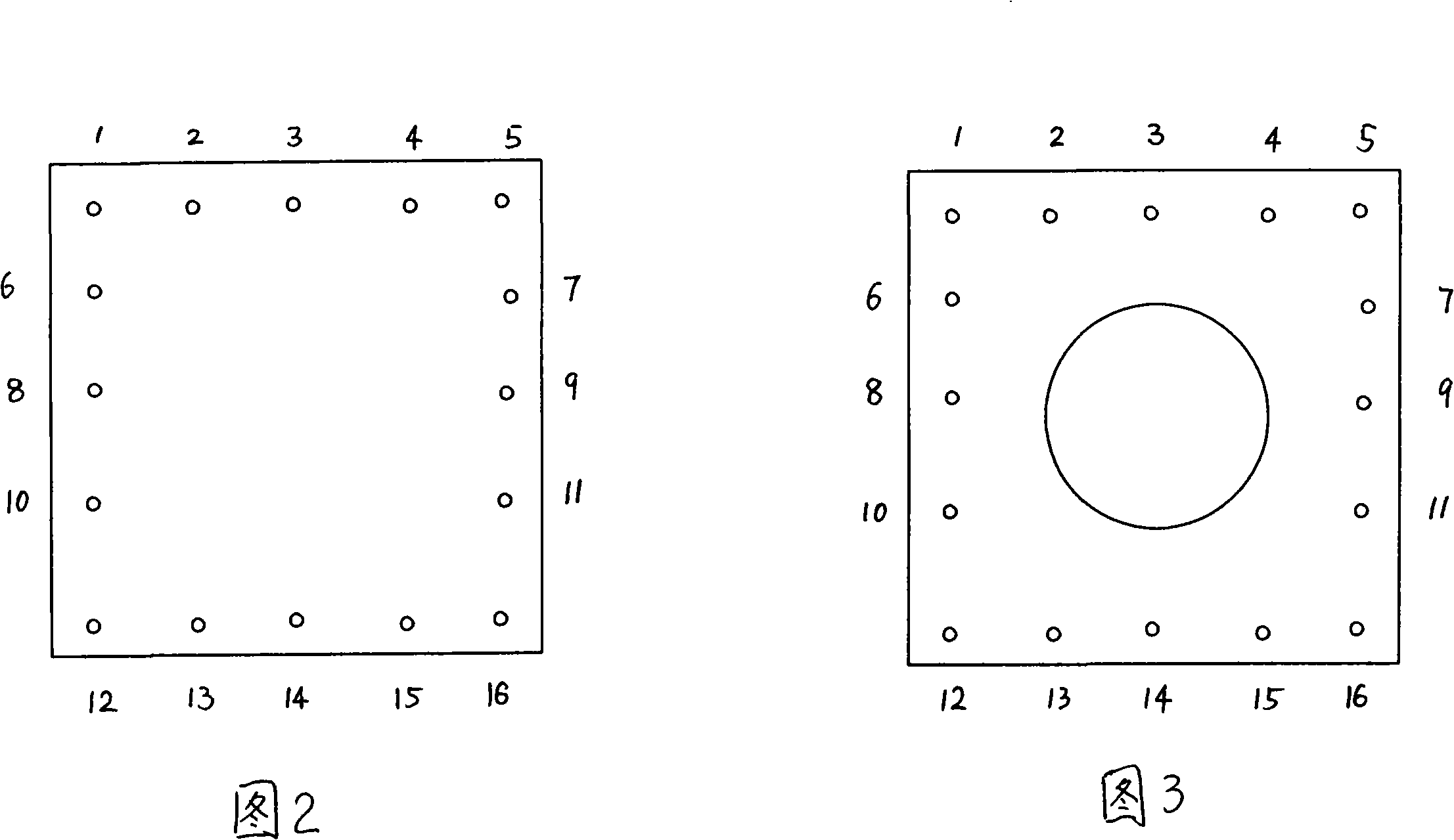

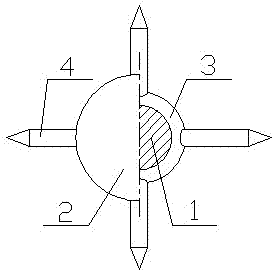

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

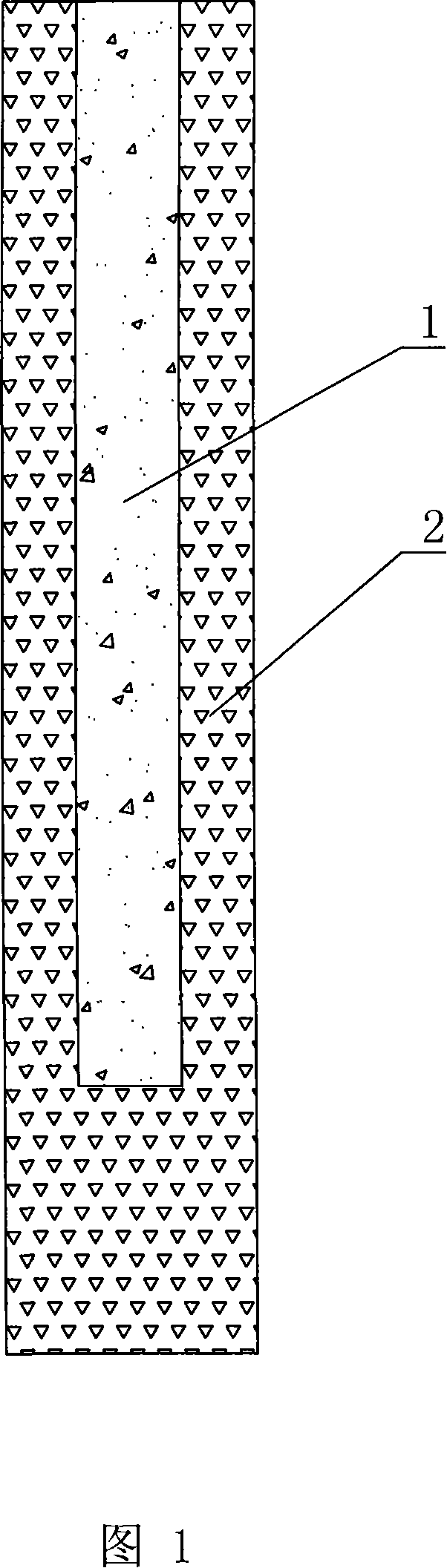

Assembled embedded type prefabricated hollow underground continuous wall and construction method thereof

InactiveCN103334422AEnsure safetyGuaranteed reliabilityArtificial islandsUnderwater structuresConvex sideHollow core

The invention relates to an assembled embedded type prefabricated hollow underground continuous wall. The assembled embedded type prefabricated hollow underground continuous wall is formed by splicing a plurality of wall body units; each wall body unit comprises a wall body unit body, an upper connecting assembly and a lower connecting assembly; the wall body unit body is a hollow block body; the left side face of the wall body unit body is provided with a tenon; the transverse end surface of the tenon is a rectangle provided with an externally convex side wall, and the right side face of the tenon is a groove; the upper connecting assembly is formed by a right side opening groove body which is the same as the transverse end surface of the wall body unit body, a base plate and two L-type connecting blocks; the opening groove body is encircled by a connecting steel plate with a keyhole; an opening of the opening groove body is in inserting connection with the two L-type connecting blocks; the height of each L-type connecting block is half that of the connecting steel plate; the base plate is arranged at the top surface of the connecting steel plate, and is projected out of the outer edge of the connecting steel plate; wall body main ribs are welded on the base plate; the structures and shapes of the upper connecting assembly and the lower connecting assembly are completely the same; and the up-and-down splicing of the wall body unit is realized through bolts after the upper connecting assembly and the lower connecting assembly are in inserting connection. The assembled embedded type prefabricated hollow underground continuous wall has the advantages of shortening the construction period, improving the construction quality, reducing the probability of construction accidents, and the like.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

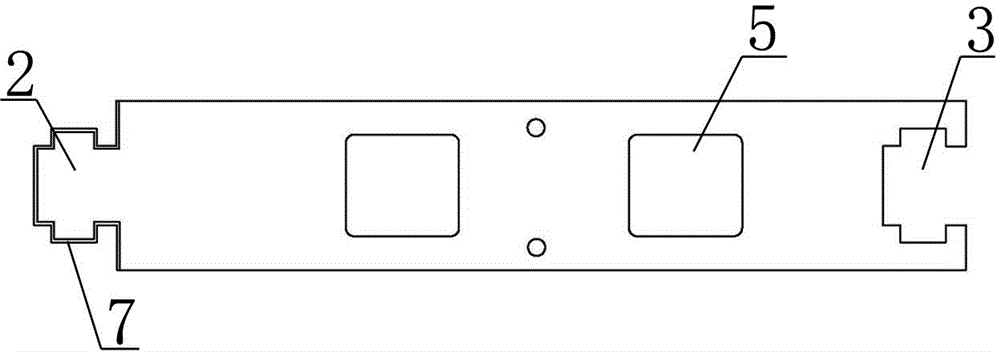

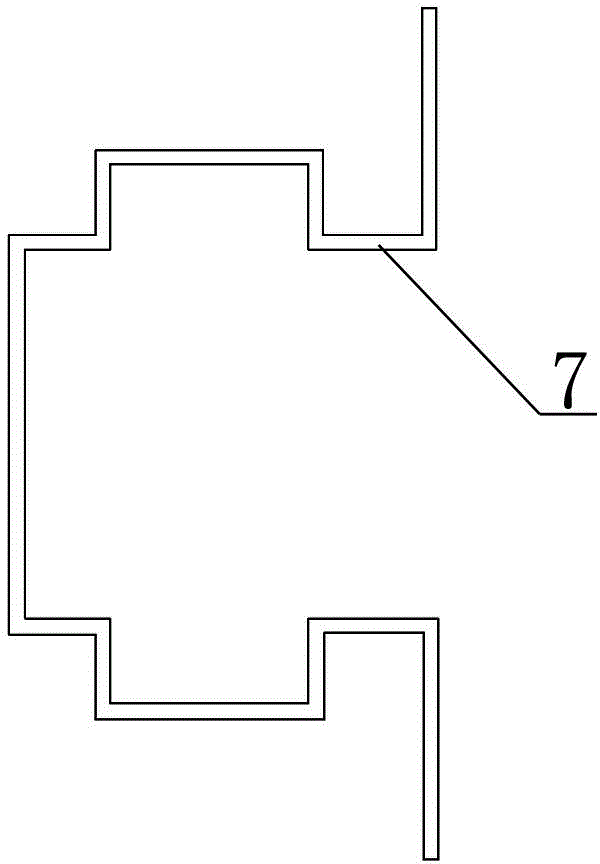

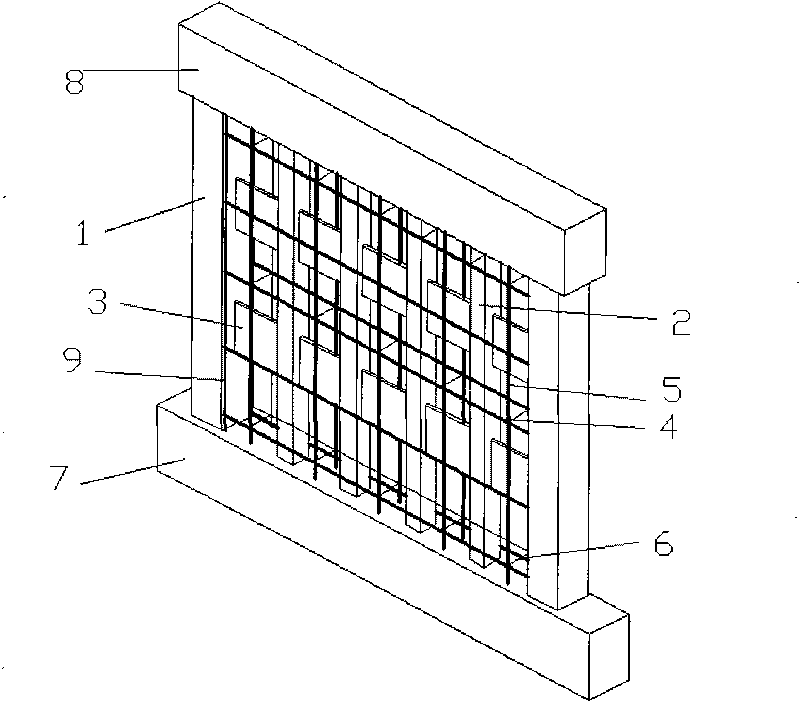

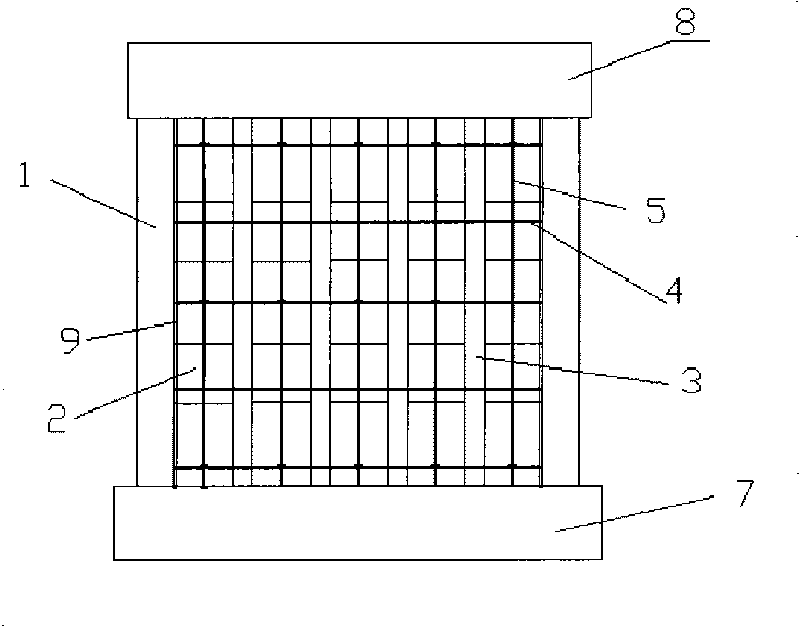

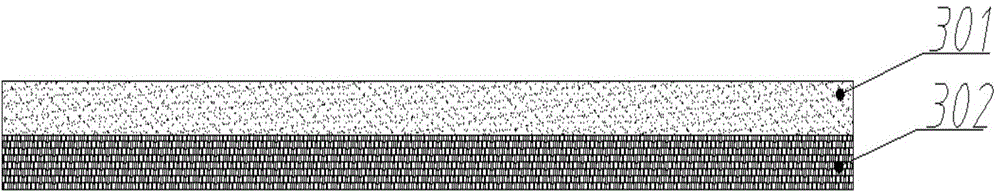

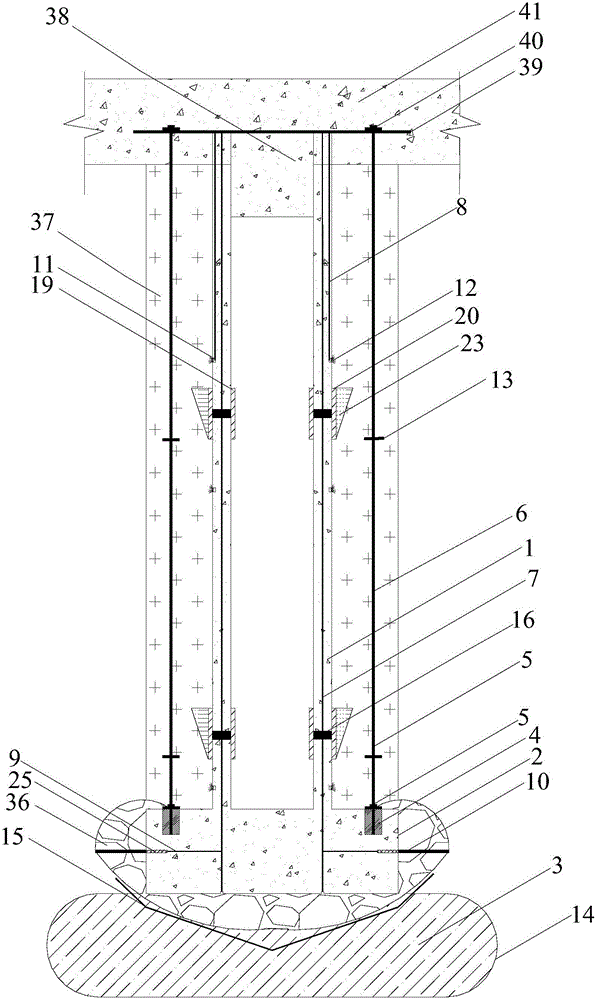

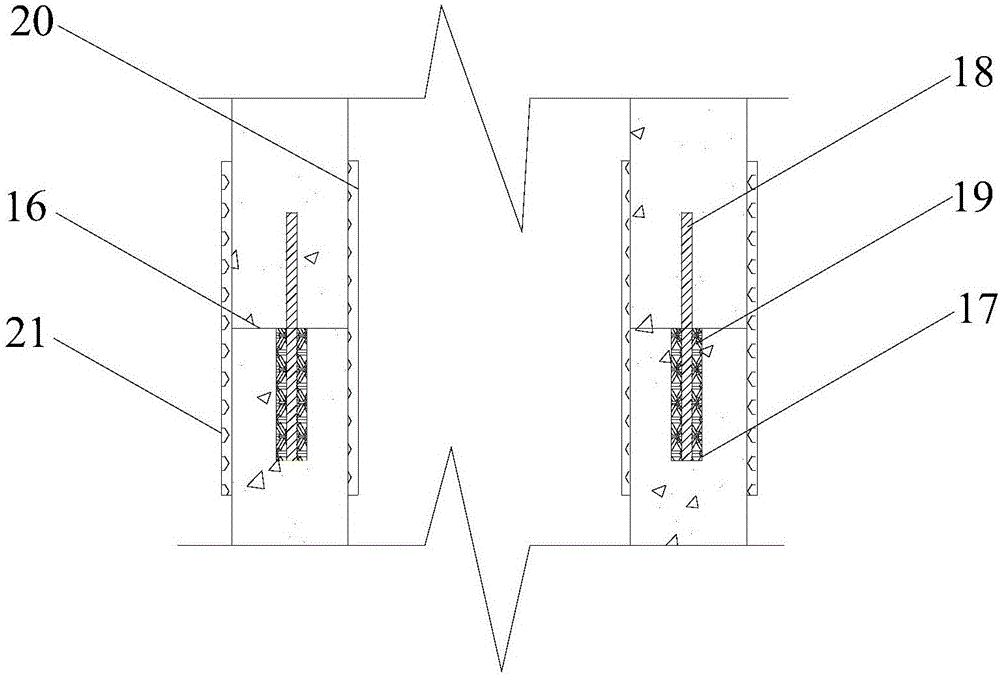

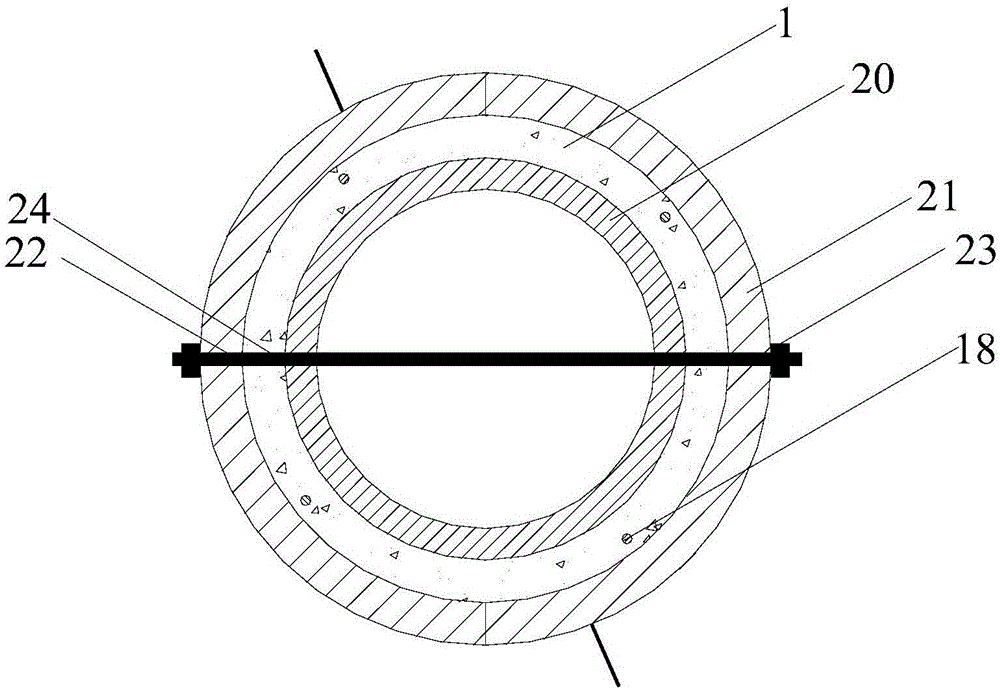

Shear wall with inbuilt continuous-row steel tube concrete core column and soft steel energy consumption bond and manufacturing method thereof

InactiveCN101761154ASuppression of out-of-plane instability problemsImprove vertical bearing capacityWallsBuilding material handlingRebarUltimate tensile strength

The invention discloses a shear wall with an inbuilt continuous-row steel tube concrete core column and a soft steel energy consumption bond and a manufacturing method thereof, belonging to the field of steel tube concrete combined shear wall. The shear wall comprises a combined steel tube concrete frame and a shear wall body, wherein the shear wall body comprises a steel tube concrete core column and a soft steel energy consumption bond, and the left end and the right end of the steel plate energy consumption bond are fixedly connected with the core column and the steel tube concrete frame; two sides of the continuous-row core column are provided with longitudinal and transverse mat reinforcements, and reinforcements on two sides are connected by binding rebars; soft steel energy consumption short steel plates the strength of which is smaller than that of the steel plate are arranged between the core columns and between the core column and a frame column, thus greatly improving the ductility and the flexural rigidity of the shear wall; meanwhile, because the short steel plate is equivalent to a connecting beam, the effect of invisible 'strong column and week beam' can be realized; and the soft steel energy consumption bond, the concrete wall body, the frame column and the core column jointly form three defensive lines of a lateral force resisting system. The invention adopts the steel tube concrete core column and the soft steel energy consumption bond as the lateral force resisting system, improves the vertical rigidity and the bearing capacity of the shear wall, has the advantages of convenient construction and shortened construction period and is more economical.

Owner:BEIJING UNIV OF TECH

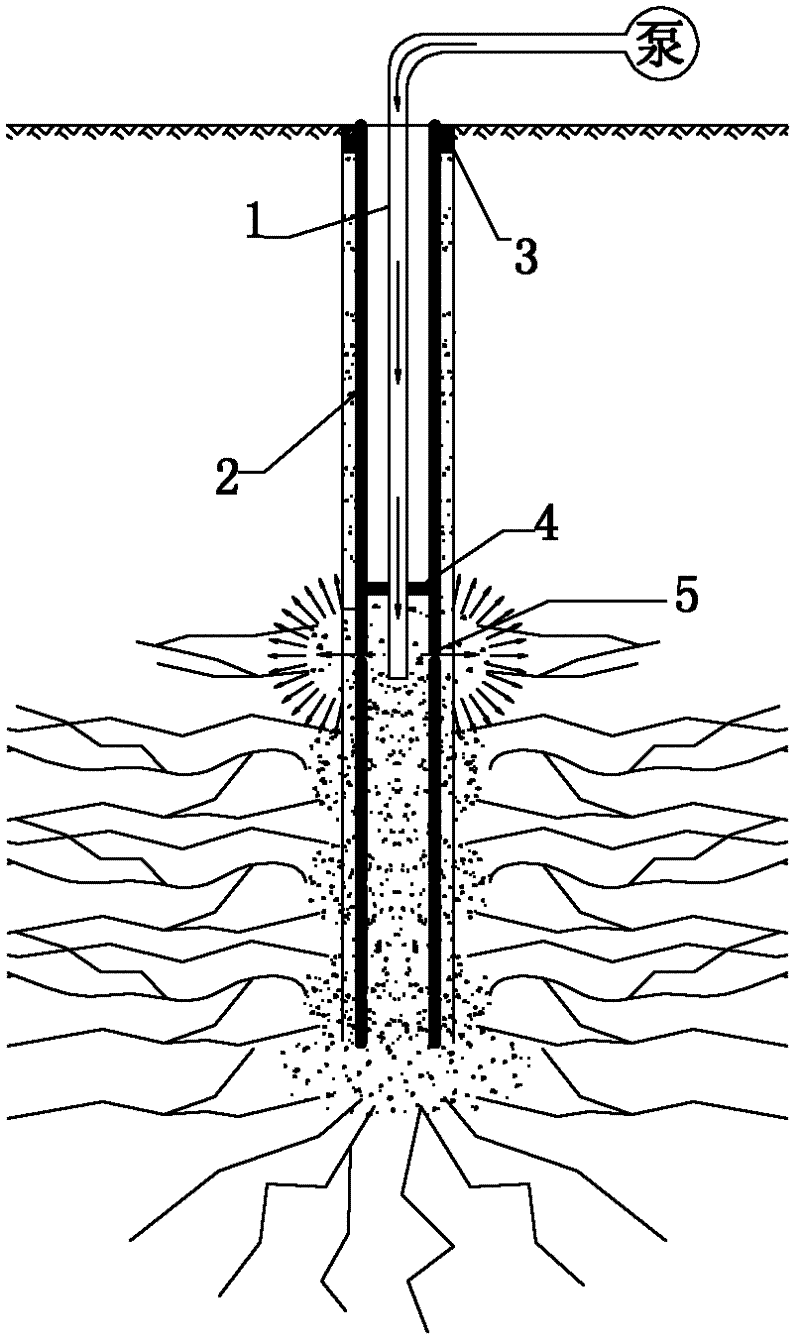

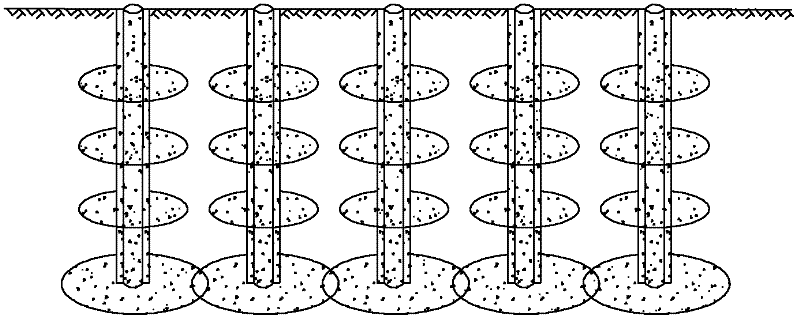

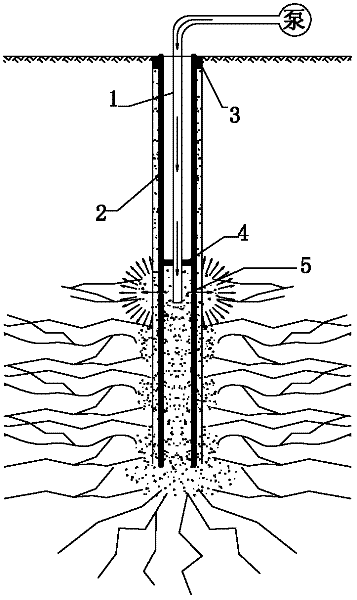

Grouting-type micro steel pipe pile and grouting reinforcement method

InactiveCN102493437AIncrease stressIncreased shear strengthExcavationsBulkheads/pilesSlurryPollution

The invention relates to a grouting-type micro steel pipe pile, comprising a steel pipe, wherein a plurality of spaced slurry outlet groups are formed in the side wall of the steel pipe along an axial direction, and a closed rubber loop is sleeved outside each slurry outlet group. Each slurry outlet group is composed of a plurality of slurry outlets uniformly distributed on a same horizontal plane. The invention further discloses a grouting reinforcement method of the steel pipe pile. According to the invention, a reinforcement effect is obvious, the vertical bearing capacity and the slope stability of a body to be reinforced can be increased from multiple aspects, nonuniform sedimentation can be effectively reduced, and the characteristics of small construction interferences, no pollution, simple construction process, low manufacture cost and the like are achieved at the same time.

Owner:SHANDONG UNIV

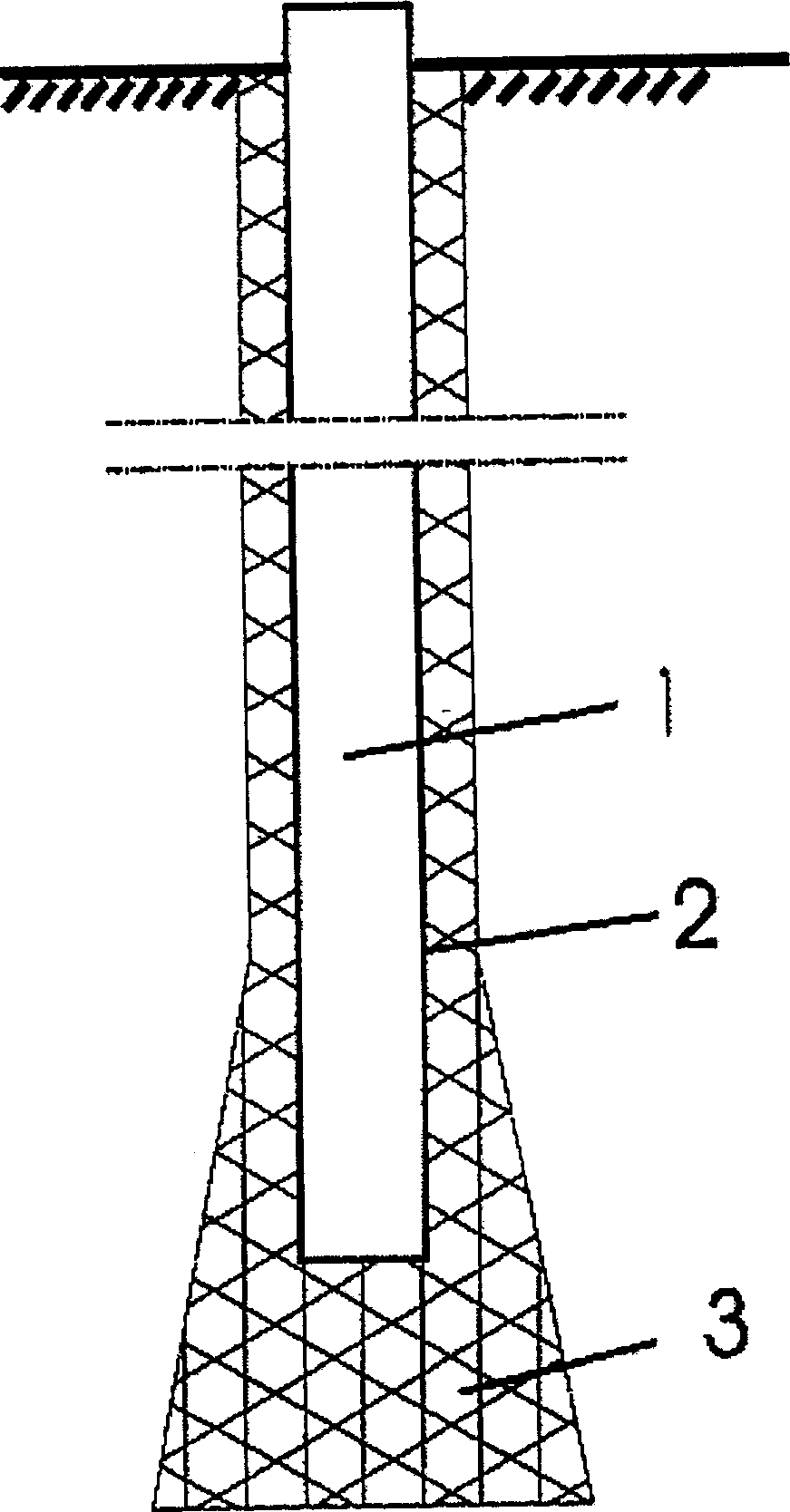

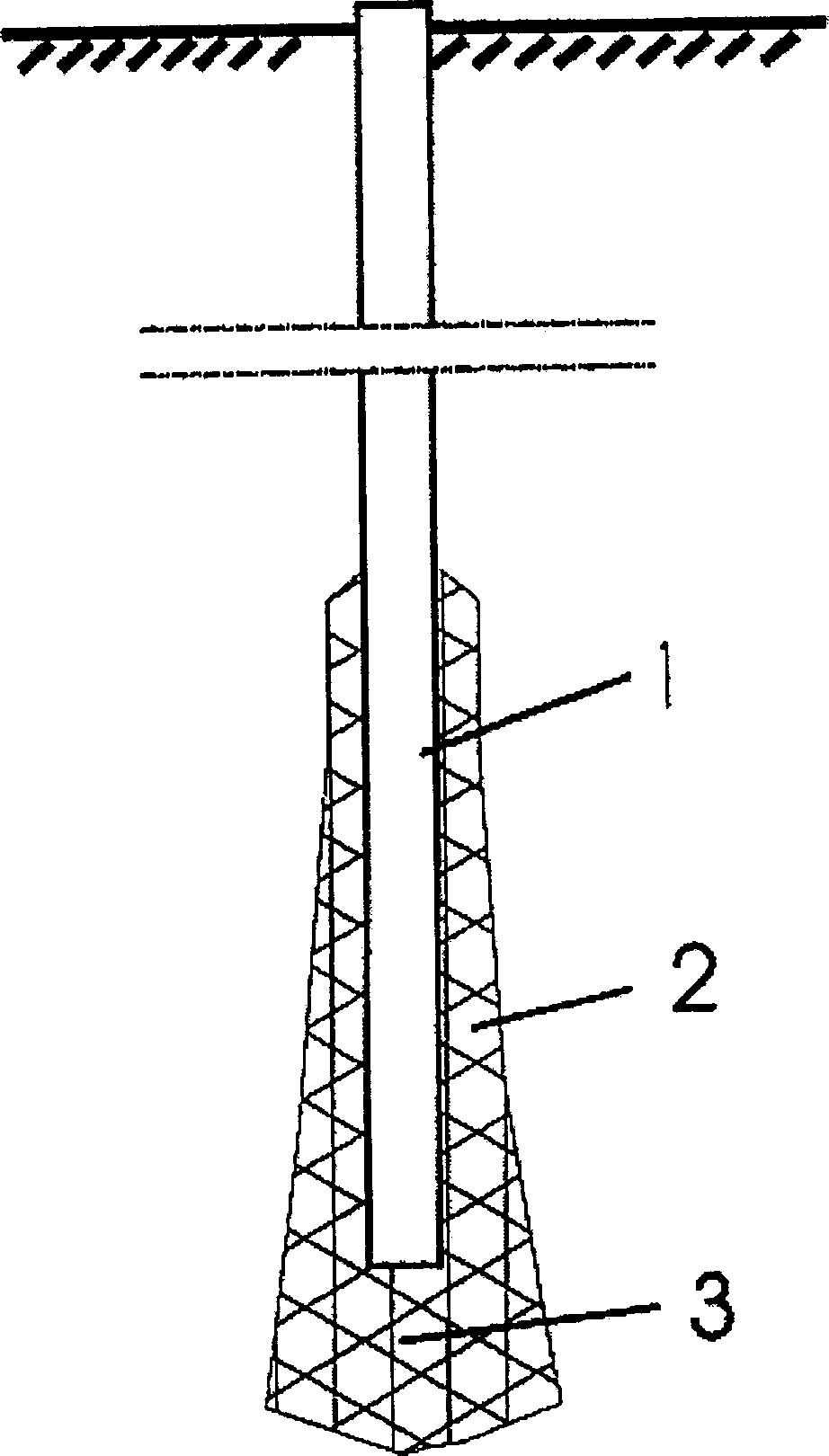

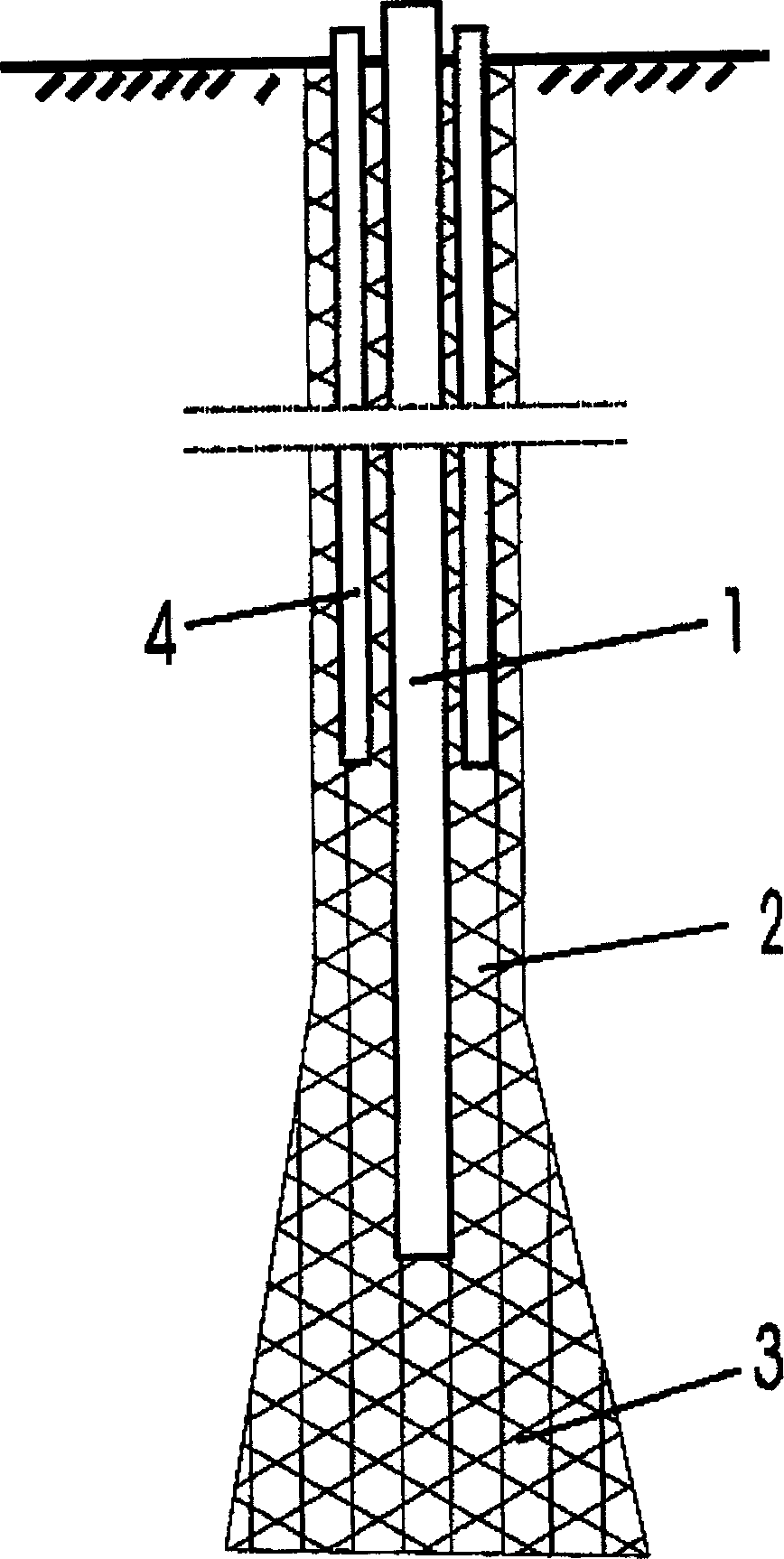

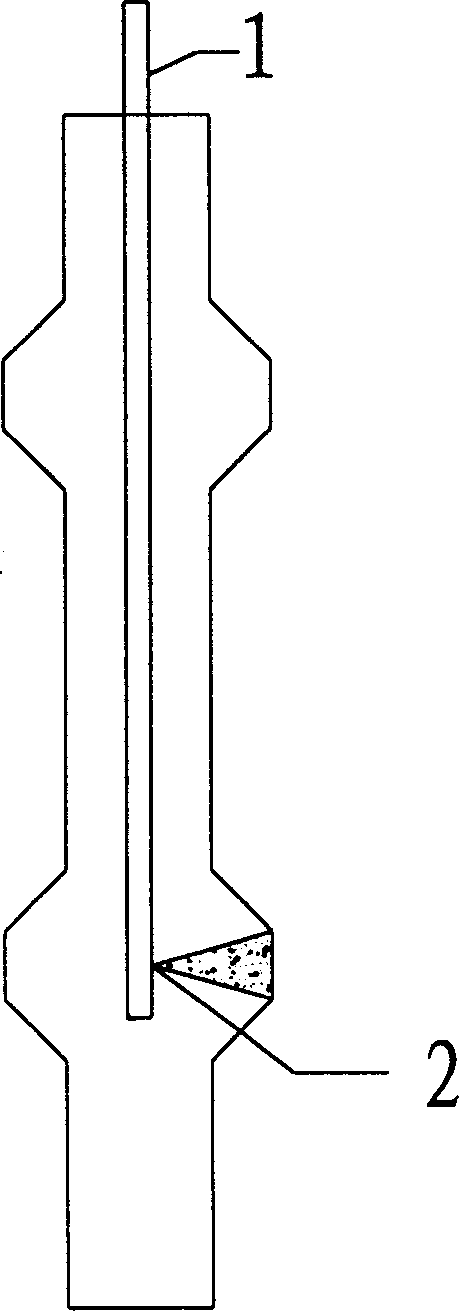

High-pressure rotary spraying and core inserting process to form pedestal pile

InactiveCN1441124AHigh strengthIncrease loading capacityBulkheads/pilesBridge engineeringReinforced concrete

The present invention relates to high-pressure rotary spraying and core inserting process to form pedestal pipe. The pedestal pile consists of core pile, column and pile depestal. The cylindrical or turned frustum-shaped core pile may be prefabricated reinforced concrete pile, in-situ deposited pile or other pile in different cross section shapes. The pile pedestal below the core pile has diameter greater than that of the core pile. The column has circular, semi-circular of fan-shaped cross section. There may be several auxiliary core piles around the main solid or hollow core pile and several rings in relatively great diameter around the column. The present invention has reasonable design, compact structure, high friction resistance, and wide application in building engineering, bridge engineering, civil engineering, water engineering, etc.

Owner:雷玉华

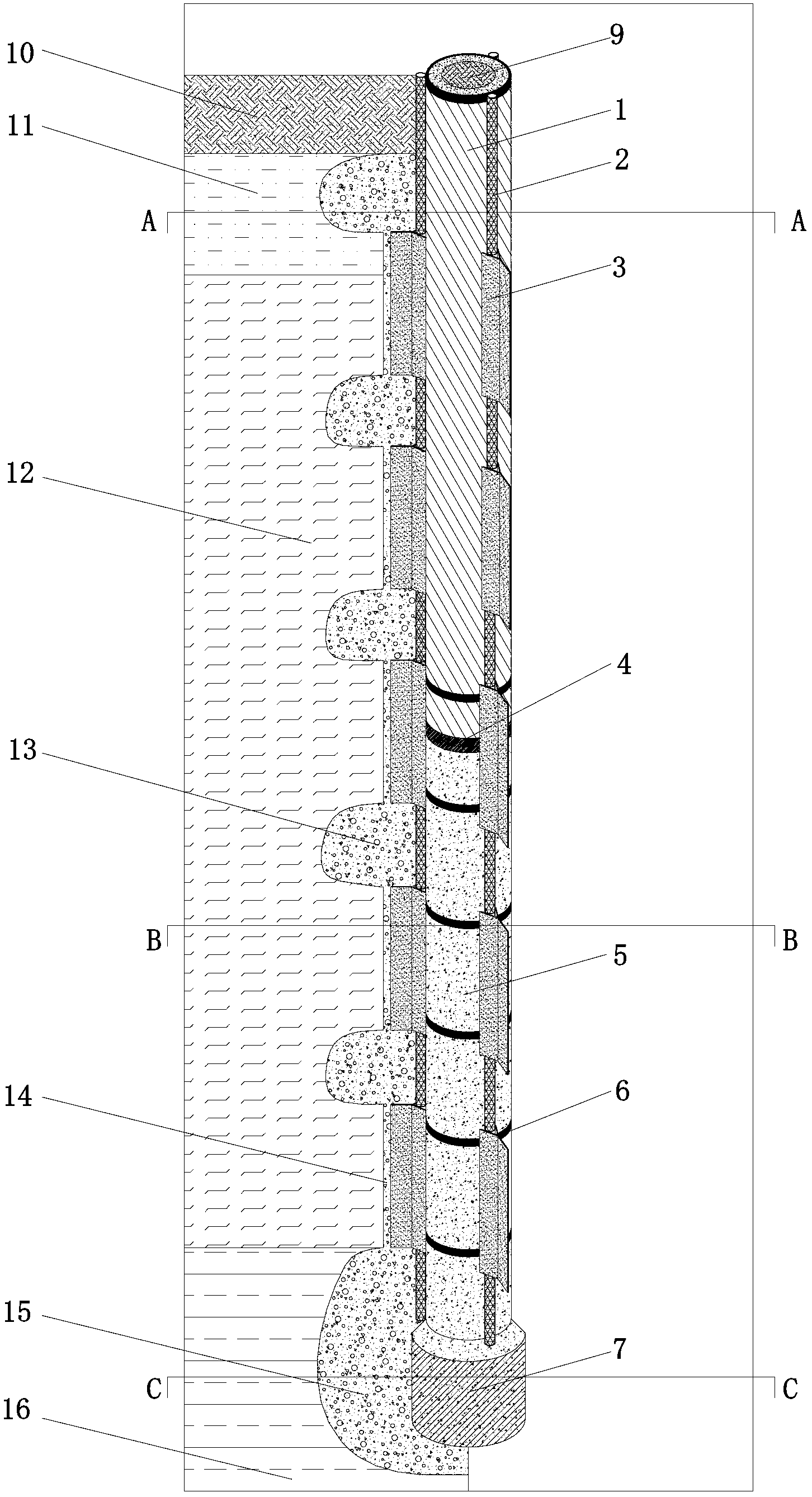

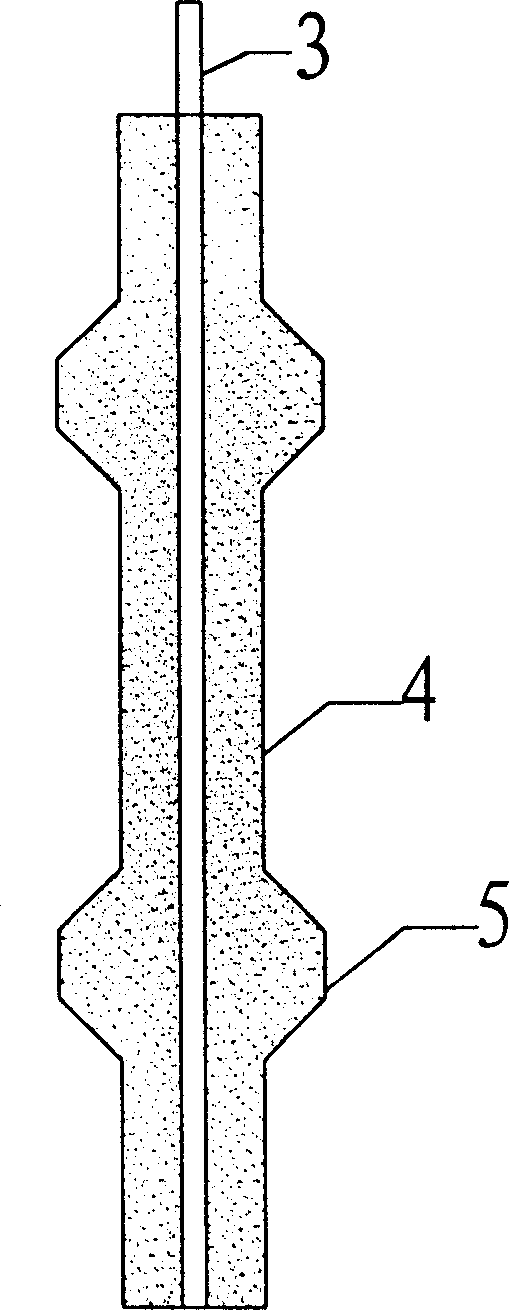

Implanted and grouted compound pile and construction method

ActiveCN103184734AReduce the crowding effectImprove integrityBulkheads/pilesDrill holeBearing capacity

The invention relates to an implanted and grouted compound pile which mainly comprises a precast tubular pile, Y-shaped wing plates, solidified backfill soil, pile side grouting reinforcing bodies, high pressure grouting squeezing bodies, a pile bottom precast enlarged head and a pile bottom high pressure grouting enlarged head. The precast tubular pile is formed by combining and connecting a plurality of sections of tubular piles with one or various pile diameters; the bottom of the precast tubular pile is provided with the precast enlarged head; the Y-shaped wing plates are uniformly distributed outside the tubular pile in the ring direction; high pressure grouting tubes pass through cavities between the Y-shaped wing plates and the tubular pile and the positions of grouting tube orifices are adjustable; the high pressure grouting squeezing bodies are formed by continuously grouting at the designed positions at high pressure; and the solidified backfill soil is back filled into a cavity inside the precast tubular pile and the residual solidified soil is paved on the construction site. According to the invention, the enlarged pile head is formed at the bottom of the tubular pile and the grouting reinforcing bodies and the high pressure grouting squeezing bodies are formed outside the tubular pile, so that bearing capacity of the soil in different positions around the pile can be sufficiently played; and a drilling and earth borrowing technology is adopted to form a hole, and a soil compaction effect is small. Moreover, the invention further discloses a construction method of the implanted and grouted compound pile.

Owner:ZHEJIANG TIANRUN CONSTR

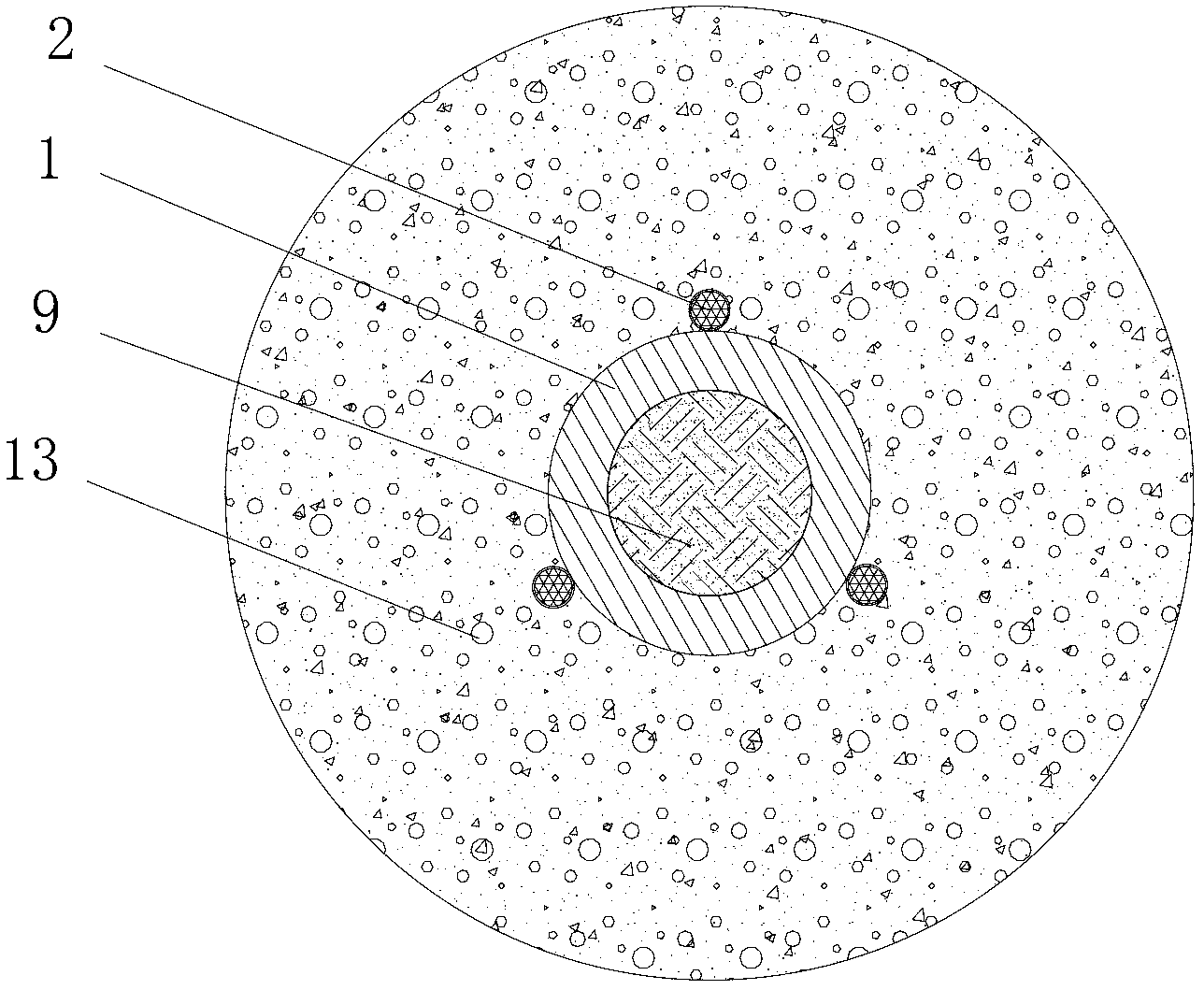

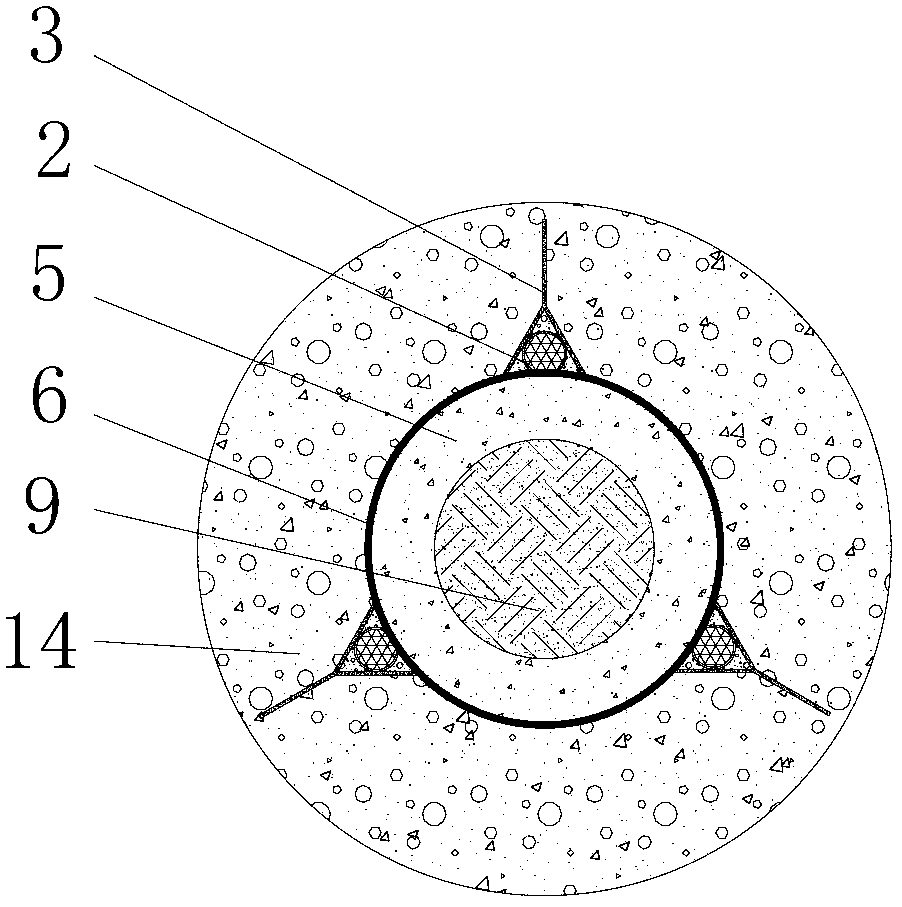

Construction machinery used for large diameter hollow pile and its construction method and use

InactiveCN101215836AReduce side frictionIncreased vertical bearing capacity of single pileBulkheads/pilesDrilling machines and methodsHigh pressureHigh load

The invention discloses a construction machine for hollow piles with large diameter and the construction method and usage, which comprises a drilling system, a pile pounding system, a drainage system which are integrated into one part. The pile forming method comprises: a high-spray drilling bit is arranged on a steel tube (a protection cylinder) or on the bottom of an inner hole of a pre-made tube pile for hole drilling and mud making; the mud is drained from a water joint or a drainage pipe; the protection cylinder or tube pile is pressed asynchronously or synchronously along with the drilling bit; during pile-sinking process, water mud is sprayed to the outer soil of the hole to solidify the surrounding soil of the pile and fill the gaps between the pile and surrounding soil of the pile; after the drilling bit reaches certain depth, the water mud is again sprayed to solidify surrounding soil of the pile; lifting the drilling bit; putting down reinforcement cage; casting concrete for piling. The invention is a construction method for foundation piles and drilling with large diameter, super long and high load, which especially provides convenient, labor-saving, rapid and economical equipment and method for marine pile driving.

Owner:雷玉华

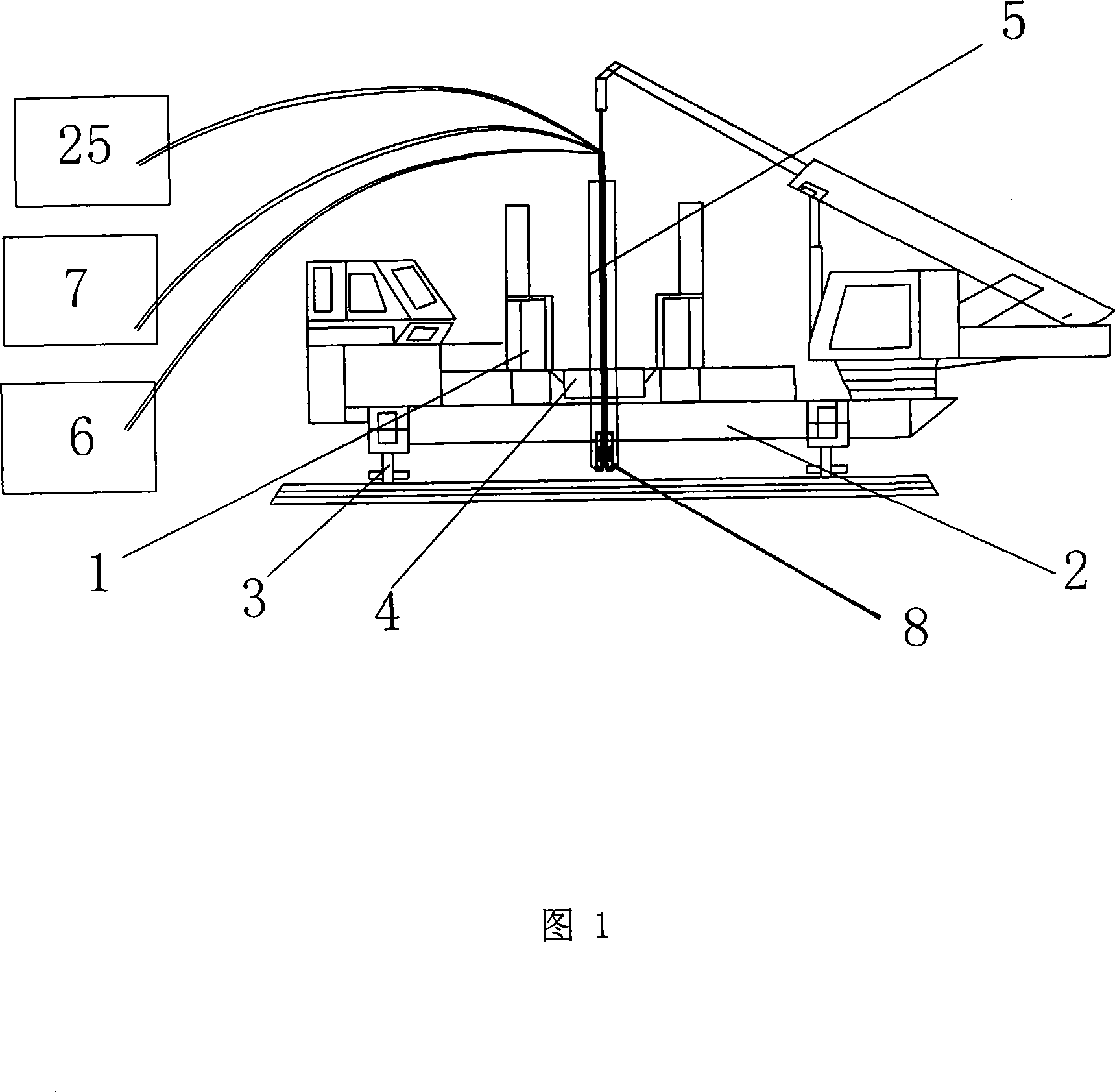

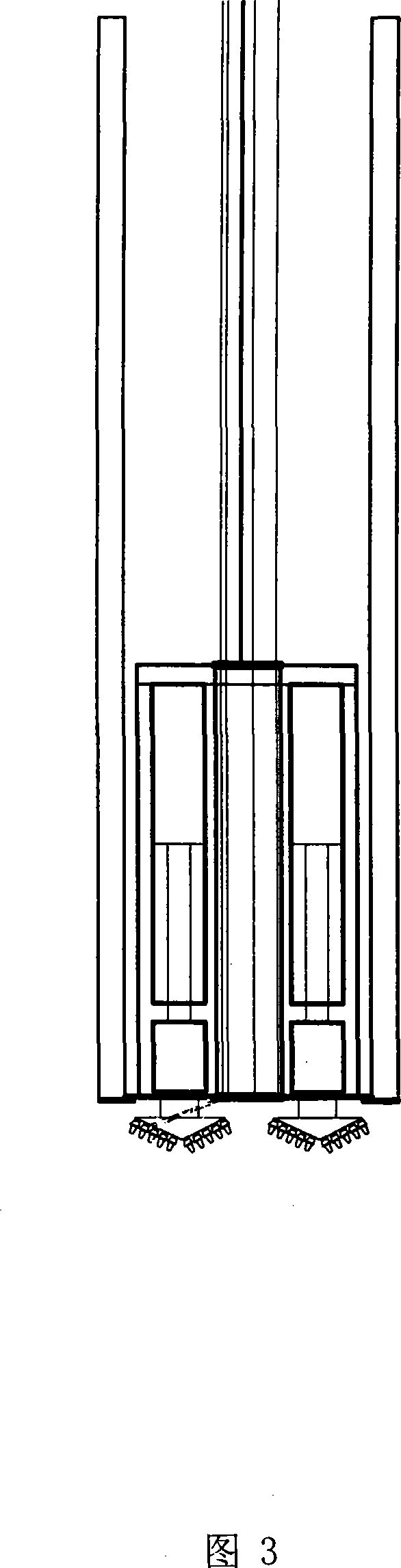

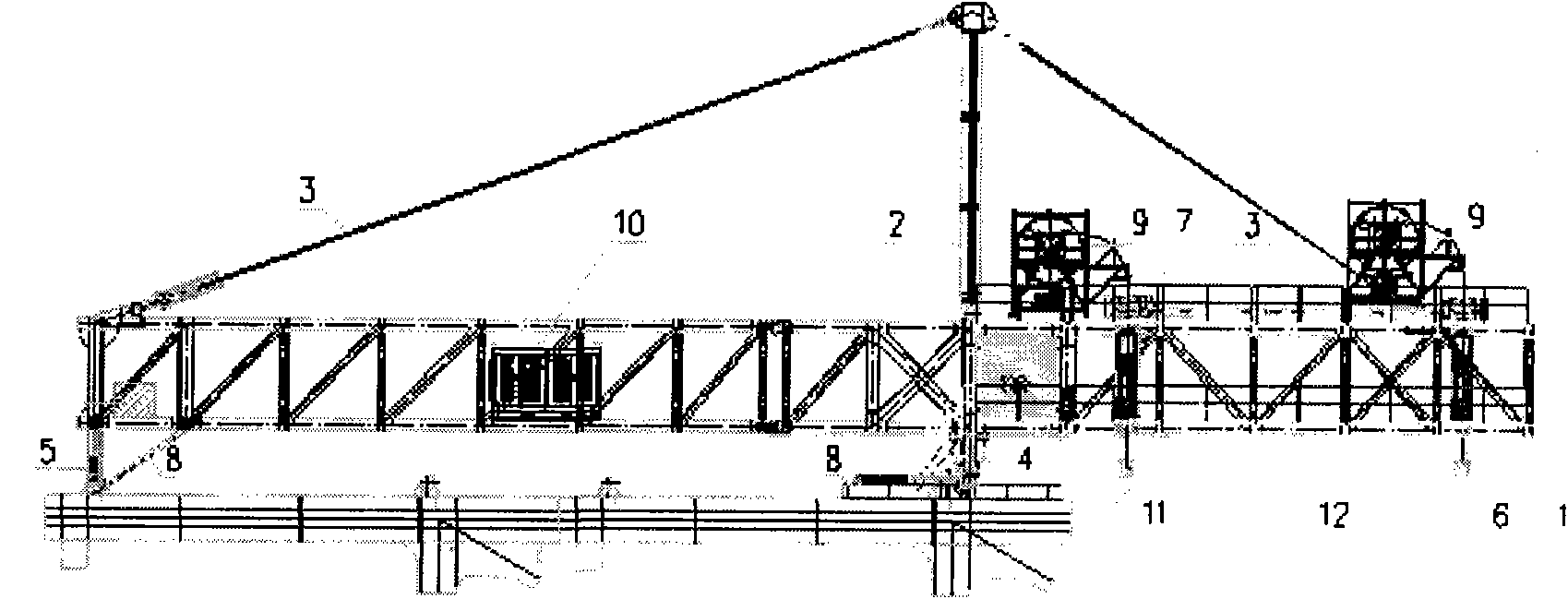

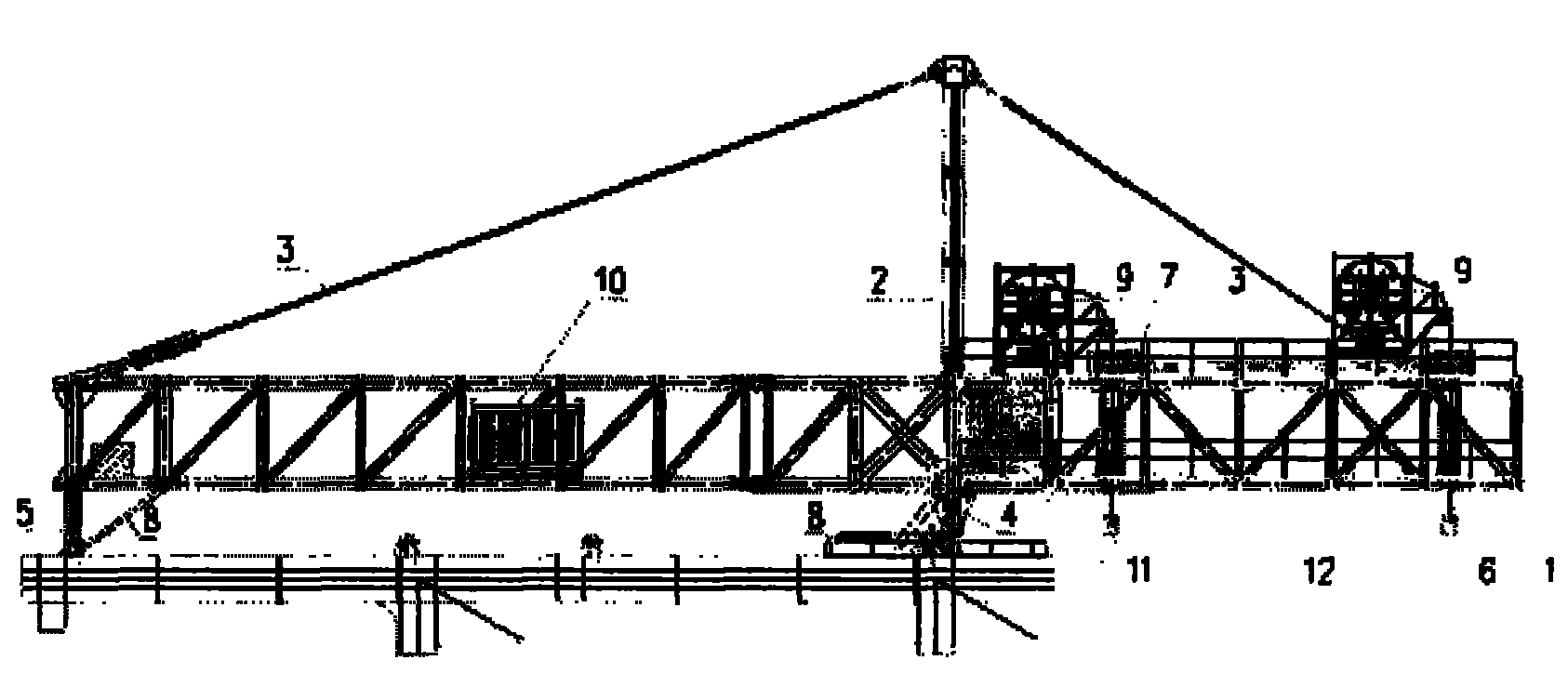

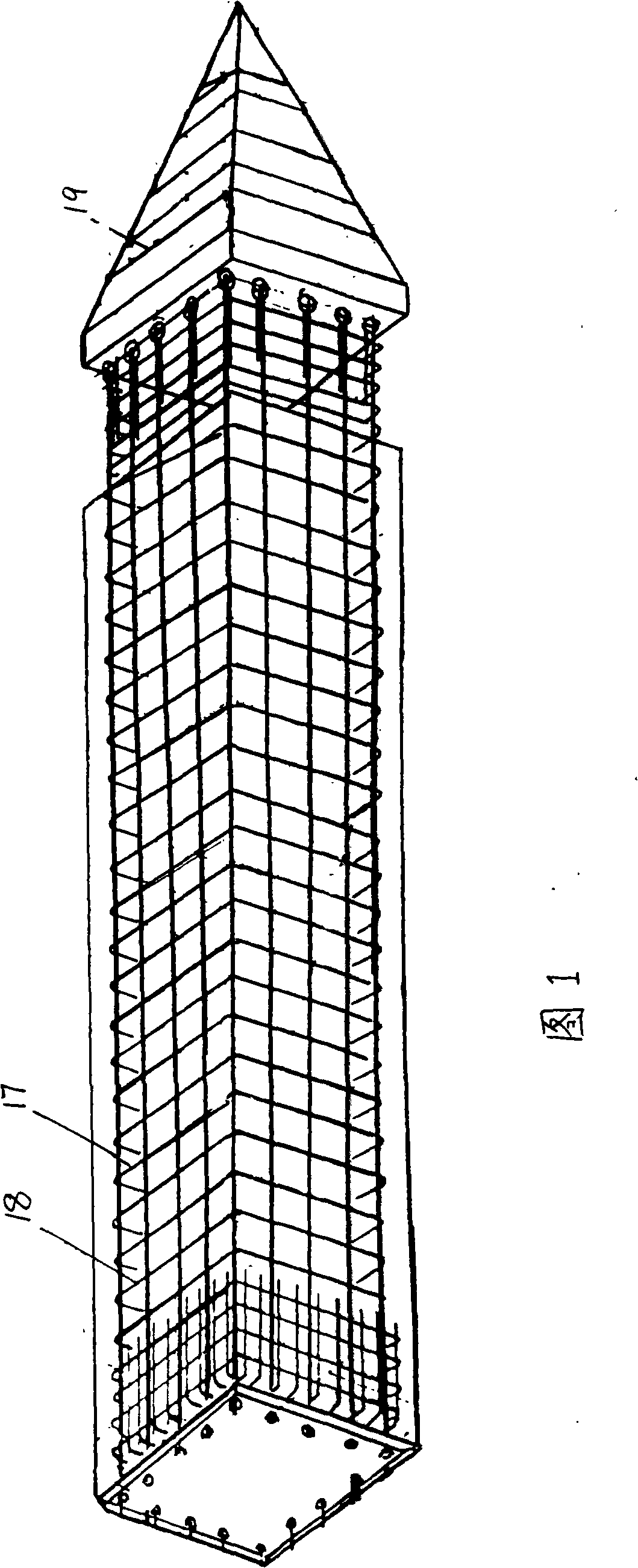

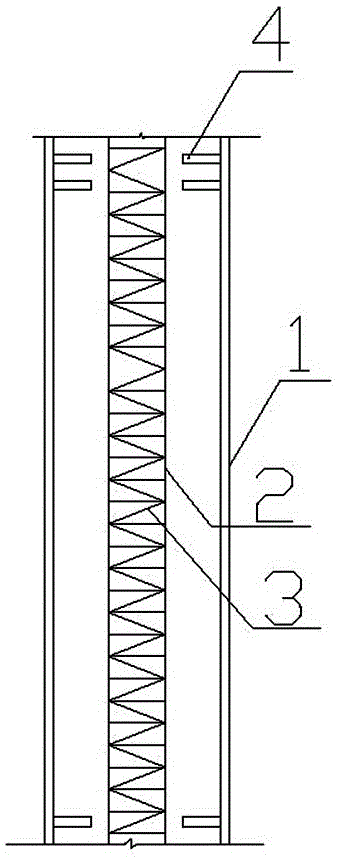

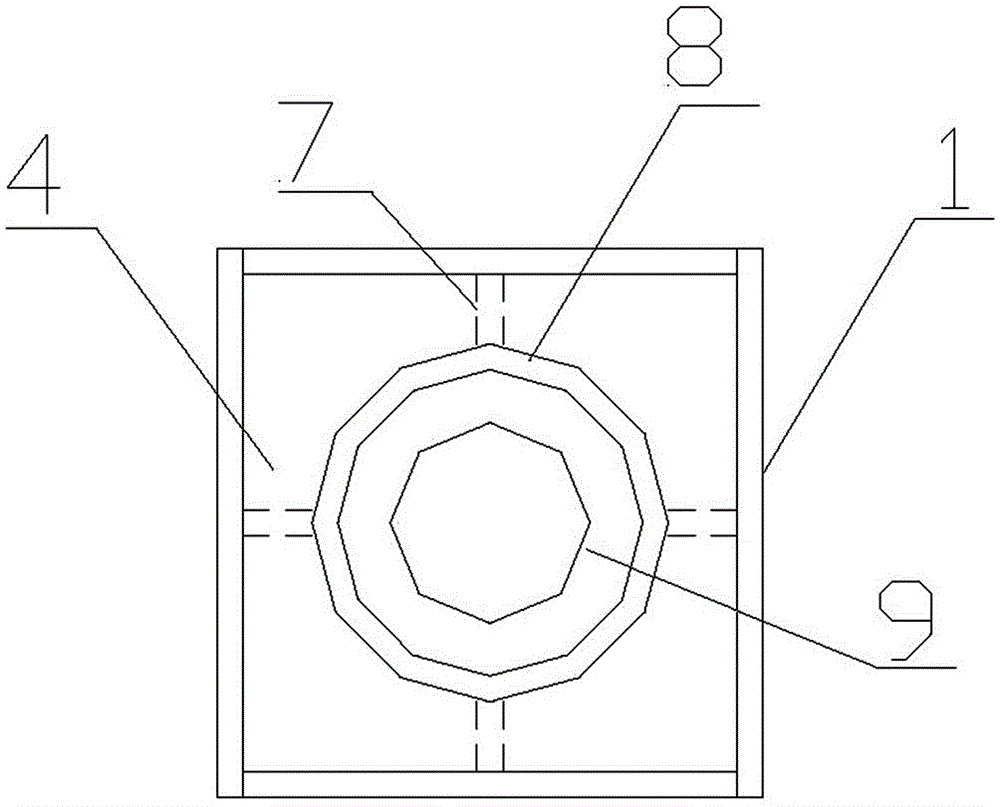

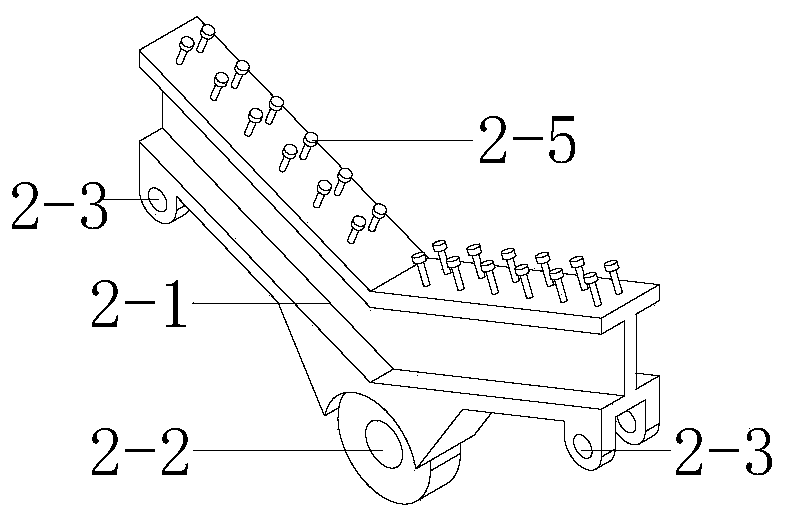

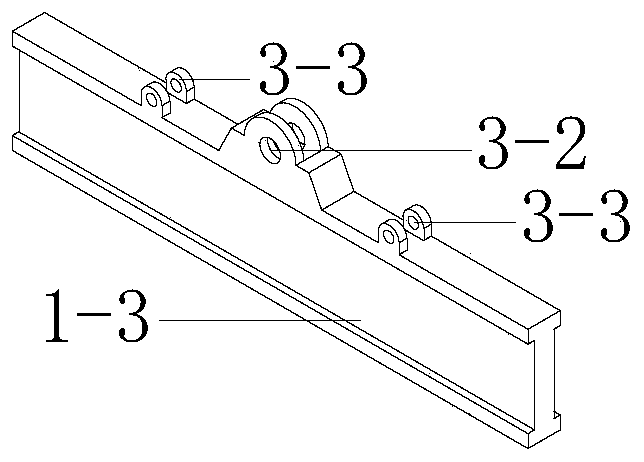

Separable large-section truss girder hydraulic lifting device

ActiveCN102094389AImprove vertical bearing capacityReduce the amount of structural steel usedLifting devicesBridge erection/assemblyPre stressPre stressing

The invention relates to a separable large-section truss girder hydraulic lifting device. The separable large-section truss girder hydraulic lifting device comprises a main bearing structure, a positioning and anchoring system, a main lifting system, a running system, a hydraulic pump station power system, and a computer control and operation system, wherein the main bearing structure consists ofa main bearing truss, a steel tower and a pulling rope, and is a tower, rope and girder combined system; the main bearing truss is a main girder; the steel tower is in a lattice form; a steel anchor girder is arranged on the top of the steel tower; the pulling rope is anchored on the bearing truss and the steel tower respectively; the two ends of a front rope are fixed, and one end of a rear ropeis fixed and the other end of the rear rope is tensioned; and the whole main bearing structure is triangular. In the main bearing structure of the separable large-section truss girder hydraulic lifting device, the structural bearing capacity is improved by a method of pre-stressing the main bearing truss by using parallel steel ropes, so the structural gravity is reduced. By a technology of controlling hydraulic lifting by using a computer, precise control, such as synchronous lifting control, single top lifting control, longitudinal movement adjusting control and the like, can be realized under the condition of a large deviation between a front lifting load and a rear lifting load, and the precision is up to 1 millimeter.

Owner:SHANGHAI FOUND ENG GRP

Production method of pretensioning prestressed concrete dynamic load piles

ActiveCN102166788AImprove performanceImprove the bending capacityCeramic shaping apparatusBulkheads/pilesPre stressPre stressing

The invention discloses a production method of pretensioning prestressed concrete dynamic load piles, comprising the following steps: arranging a welded non-prestressed steel reinforcement framework cage in a prestressed steel reinforcement cage; cleaning a corresponding steel die; coating a separant; suspending the double-layer steel reinforcement framework cage in a lower die body of the steel die; respectively arranging the end plates of a connected hooping plate at the two ends of the double-layer steel reinforcement framework cage; casting concrete material to the lower die body of the steel die; carrying out die assembly and pre-stressed tensioning; performing centrifugal shaping; pouring out the surplus starch solution on the inner wall; and carrying out steam curing and secondary steam curing. The production method provided by the invention aims to overcome the shortages in the prior art. The invention provides a method for producing a pretensioning prestressed concrete dynamic load dynamic load pile with horizontal anti-bending bearing capacity, high shearing resistance, high bearing capacity of a single pile, and strong shock resistance.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Method for processing soft foundation by net bag method

ActiveCN101476315AHigh strengthImprove bearing capacitySoil preservationHigh integrityBuilding design

The invention provides a method for treating weak foundation by mesh bag method, which comprises: weaving mesh bags by macromolecular engineering materials, filling the mesh bags with sandstones as aggregate; planting into the holes drilled in the foundation and filling the holes with sandstone aggregate to form mesh bag sandstone piles; laying the mesh pieces woven by macromolecular engineering material and pad layer consisted of sandstone aggregate on the top surface of the pile and foundation; connecting the mesh open on the top of the mesh bag broken stone pile with the mesh pieces thereon; thus, the mesh and the mesh bags are connected into a complete reinforcing body in the foundation, and the reinforcing body and the original foundation together form a composite foundation. The invention is a simple and easy method, uses the polyethylene and polypropylene macromolecular engineering material with the advantages of high strength, acid-base resistance, anti-aging and anticorrosion; is more suitable for foundation treatment in salinized soil region with high corrosion to concrete and steel; achieves higher integrity of reinforcing body, can greatly increase the foundation bearing capacity and reduce settlement amount to reach the building design requirement.

Owner:陕西长嘉建设工程有限公司

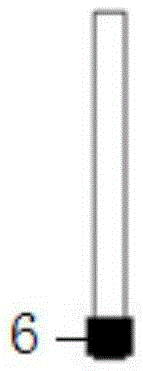

Method for processing prestress square pile

InactiveCN101302758AImprove vertical bearing capacityImprove crack resistanceBulkheads/pilesPre stressArchitectural engineering

The invention relates to the construction field. The processing method of a pre-stress square pile includes the steps that: firstly, bar sheathing, wherein, a main octagonal reinforced bar is sheathed in an inner octagonal spiral hoop bar according to a hole position and then a main tetragonal reinforced bar is sheathed in a tetragonal position in a tetragonal hoop bar and the two ends are locked tightly by anchorages; secondly, tensioning, wherein, the main reinforced bar is tensioned by sections in a tensioning platform to 105 percent of the tension and then anchoring is carried out; thirdly, casting, wherein, the concrete casting is conducted in compound die after the inspection of tension and when the strength of the concrete meets the requirements, the reinforced bar is released and the unwanted main reinforced bar is cut; fourthly, finishing operation is carried out. Compared with the similar processing method, the method of the invention does not need pre-cast reinforced cage, and the bar sheathing can be directly conducted in the tensioning platform; the hoop bar is a spiral bar, thus having convenient installation but no breaking end, saving time and labor and having no need for wielding. The processing method of the invention can be used for pre-making solid pile or hollow pile in various sizes, thus increasing the anti-cracking strength and the limit bending moment of the pile body and prolonging the service life to 50 to 100 years.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

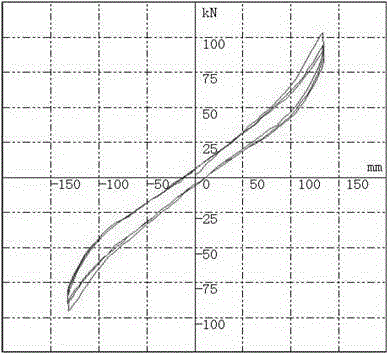

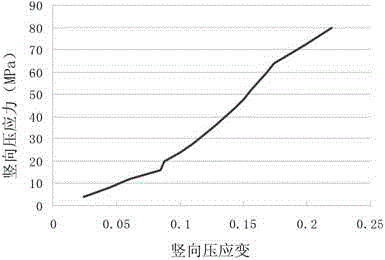

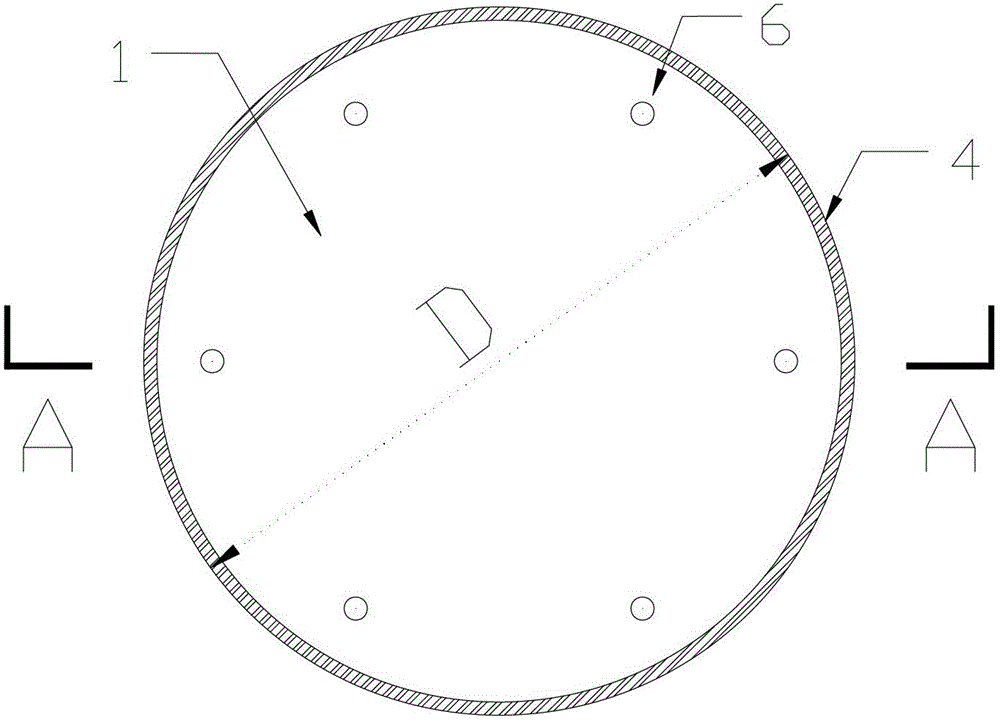

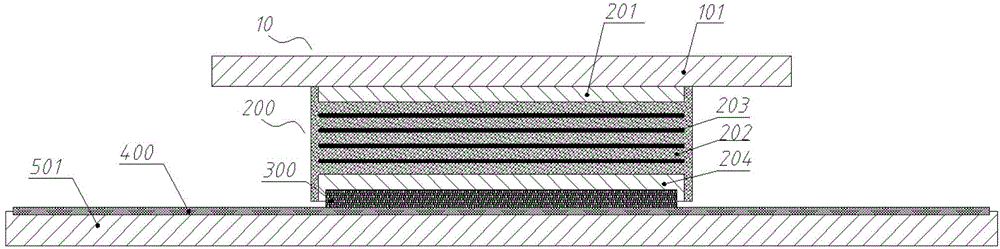

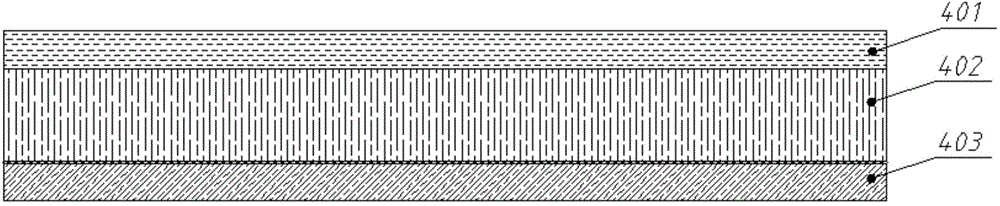

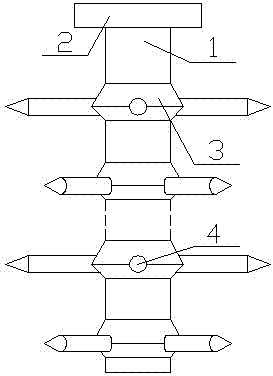

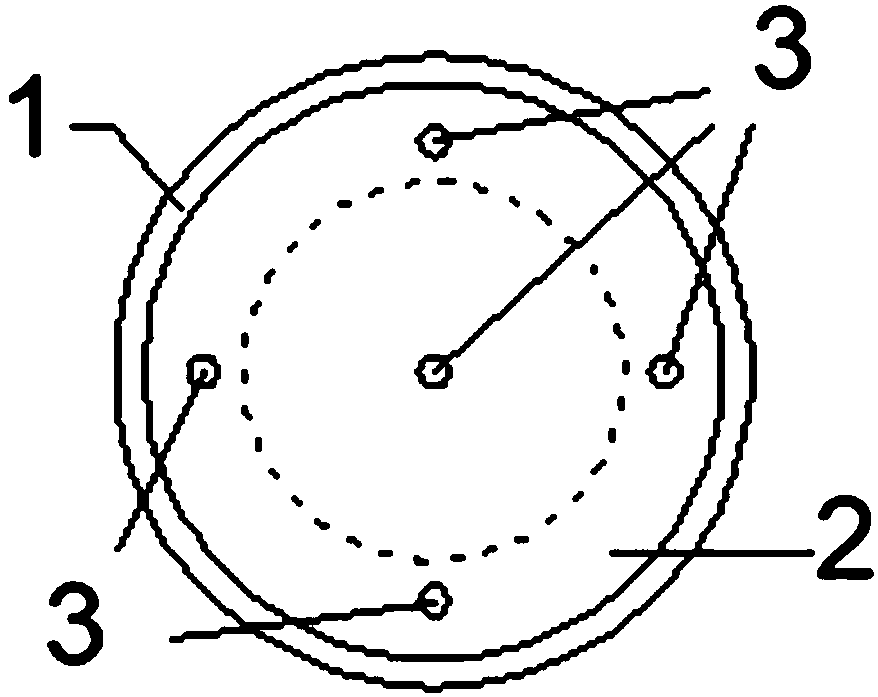

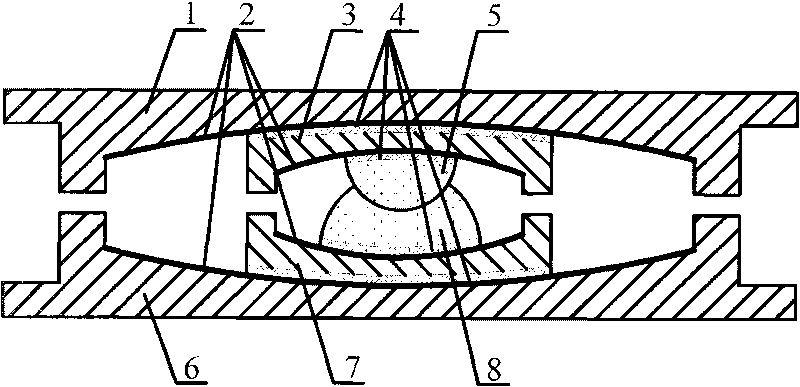

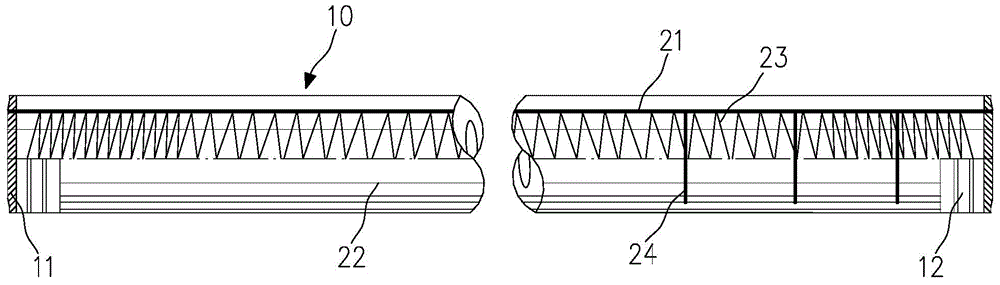

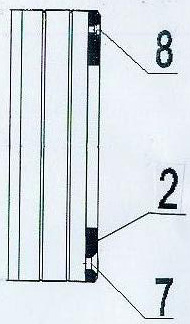

Fiber-steel plate-rubber combined seismic-insulation support

InactiveCN102720270AGood performance of shock isolation and energy consumptionReduce weightShock proofingFiberEngineering

The invention relates to a fiber-steel plate rubber combined seismic-insulation support which belongs to the field of seismic insulation of housing construction. The seismic-insulation support comprises a fiber fabric layer, rubber layers and a steel plate layer which are overlapped to form an overlapped body in a staggered manner and in the overlapping sequence of one rubber layer, the fiber fabric layer, one rubber layer, the steel plate layer and one rubber layer. End steel plates additionally arranged on the upper end face and the lower end face of the overlapped body and rubber protective layers arranged on sides of the overlapped body are finally adhered by vulcanizing. The fiber-steel plate-rubber combined seismic-insulation support is light in dead weight and has better damping characteristics on the aspects of seismic-insulation and energy dissipation, and construction and mounting cost can be saved.

Owner:BEIJING UNIV OF TECH

Hole drilling mudjack pile construction method

ActiveCN101215835ATightly boundImprove vertical bearing capacityBulkheads/pilesEngineeringHigh pressure

A high pressure bored pile construction method of the invention belongs to the foundation piling technical field, which comprises: a drilling rig is positioned to drill a hole downward and mud protection is provided; after drilling to a required depth, using clear water for cleaning the hole; lifting a drill rod and dissembling the drill bit and inserting a reinforcement cage as soon as possible and lengthening the drill rod to the end of the hole for first hole bottom grouting; after the grouting, continuously throwing stones while in the drilling status of the drill rod; after stones are thrown in, processing the secondary hole bottom grouting and adopting concrete insertion type vibration rod for pounding to 0.6 to 1.2 m under the hole edge to ensure a dense pile top. The pile body of the invention is of concrete with no sand, has high vertical bearing ability and lateral force resistance ability. The method needs relative small construction equipment and has little construction vibration and noise, needs small construction field, can convert the foundation extension construction into the foundation extension pile construction, greatly improves vertical bearing ability of each pile, and also can process the inclined pile construction.

Owner:ZHEJIANG YIJIAN CONSTR GROUP +1

High-strength concrete prefabricated pile doped with fiber-reinforced plastic bar

The invention discloses a high-strength concrete prefabricated pile doped with a fiber-reinforced plastic bar, which comprises a steel reinforcement cage framework. The high-strength concrete prefabricated pile is characterized in the fiber-reinforced plastic bar is arranged in the steel reinforcement cage framework; end plates are respectively arranged at two ends of the steel reinforcement cage framework; concrete is cast on the steel reinforcement cage framework and the fiber-reinforced plastic bar, so that the steel reinforcement cage framework, the fiber-reinforced plastic bar and the end plates are integrated; and a central round hole penetrating through the whole pipe body is formed in the middle of the integrated pile body. The invention aims at overcoming the defects in the prior art and providing the high-strength concrete prefabricated pile doped with the fiber-reinforced plastic bar, which has the advantages of favorable horizontal bending resistant bearing capacity, high pullout-resistant bearing capacity, high single-pile vertical bearing capacity, strong anti-seismic capability and suitability for projects having higher requirements for bending resistance and pullout resistance.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

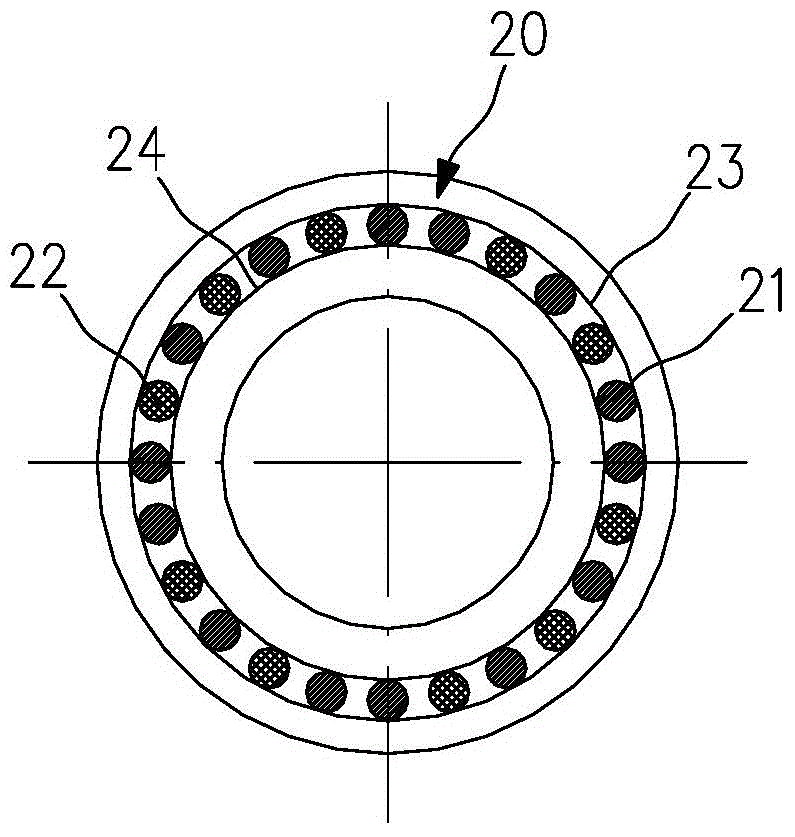

Electromagnetic damping composite sliding plate support

ActiveCN104929246AControllable Damping Energy DissipationImprove vertical bearing capacityProtective foundationShock proofingWeather resistanceReciprocating motion

The invention discloses an electromagnetic damping composite sliding plate support which is composed of an upper connecting plate, an elastic support part, a permanent magnetic type sliding body, an eddy current sliding compound plate and a lower connecting plate. The elastic support part is composed of an upper sealing plate, a lower sealing plate, an elastic body and a stiffening plate, wherein the elastic body and the stiffening plate are arranged between the upper sealing plate and the lower sealing plate in an alternate overlapped mode. The permanent magnetic type sliding body is formed by overlapping a permanent magnet and a sliding material and is fixed to the lower portion of the elastic support part in an embedded mode. The eddy current sliding compound plate is formed by sequentially overlapping a sliding panel, an eddy current plate and a magnetic conduction plate. The permanent magnetic type sliding body and the eddy current sliding compound plate form a friction pair. When the electromagnetic damping composite sliding plate support is subjected to horizontal power loads, the upper portion and the lower portion of the support slide relatively, and electromagnetic damping is generated through reciprocating motion. Compared with the prior art, the electromagnetic damping composite sliding plate support can provide controllable damping dissipation energy and has the advantages of being high in vertical loading force, free of maintenance, low in manufacturing cost, superior in weather resistance and the like.

Owner:GUANGZHOU UNIVERSITY

Large load composite pile and construction method thereof

InactiveCN101148876AIncrease ultimate bearing capacityReduce dosageBulkheads/pilesPre stressPre stressing

The present invention discloses one kind of heavy load composite pile comprising one pile core of high strength pre-stressed concrete pipe and one outer layer pile of plain concrete coating the pile core and its construction process. The construction process includes the following steps: 1. long auger boring and pump pressurizing concrete to form the in-situ deposited plain concrete pile; and 2. hoisting the high strength pre-stressed concrete pipe pile and inserting or pressurizing into the center of the plain concrete pile until reaching the designed depth. The composite pile has the vertical load borne by the high strength pre-stressed concrete pipe pile and the plain concrete pile, the side friction force increased by the plain concrete pile with relatively great cross section. It has great limit bearing capacity from the high strength pre-stressed concrete pipe pile.

Owner:山东省机械施工有限公司

Root pressure grouting pile and construction method thereof

InactiveCN103205965AIncrease side frictionIncrease the bearing areaBulkheads/pilesRoot pressureSupporting wall

The invention discloses a root pressure grouting pile comprising a cylindrical pile foundation, wherein the root pressure grouting pile further comprises a bearing platform surface arranged on the top of the cylindrical pile foundation, and a plurality of root keys are arranged on the cylindrical surface of the pile foundation; or concentrically projecting support disks are arranged on the cylindrical surface of the pile foundation, and the plurality of root keys are connected with the support disks. The construction method comprises the following steps of: firstly, digging the earthwork of a first segment of pile hole, and extruding the holes of the support disks after forming the first segment of pile hole; horizontally knocking the root keys out of the holes of the support disks, respectively, and reserving the inner ends of the root keys in the pile hole; building a supporting wall template along the side wall of the pile hole, and pouring supporting wall concrete; repeating the steps, circularly working downwards segment by segment until the depth of the pile hole reaches a required demand; and hanging a preformed pile foundation reinforcement cage in a supporting wall hole, and pouring the pile body of the pile foundation. Therefore, in the pile structure built by the invention, the stress area of the pile foundation is increased, the bearing pressure of the pile foundation is improved, the construction materials are few, the construction is convenient, and the construction cost is lowered.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

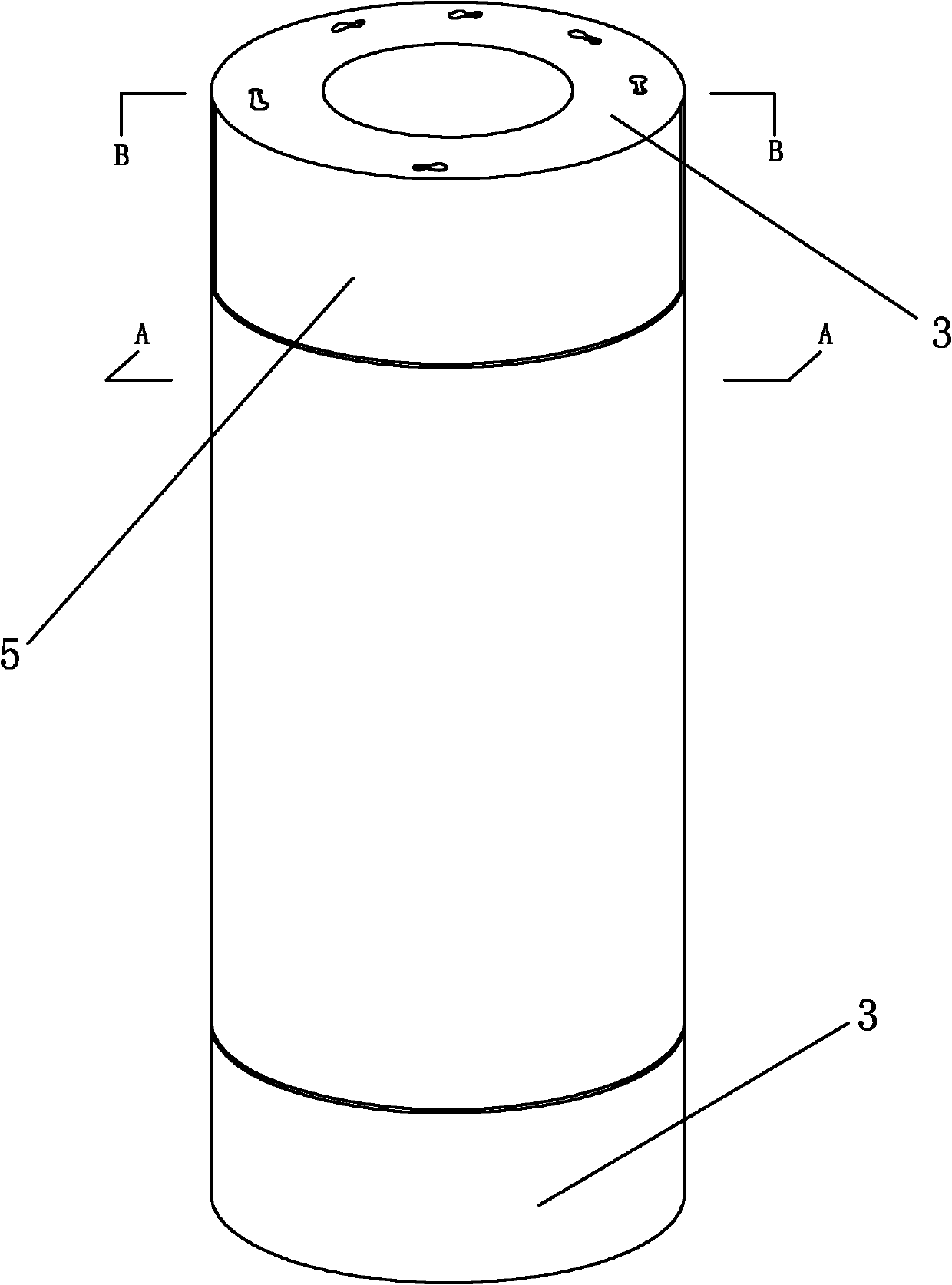

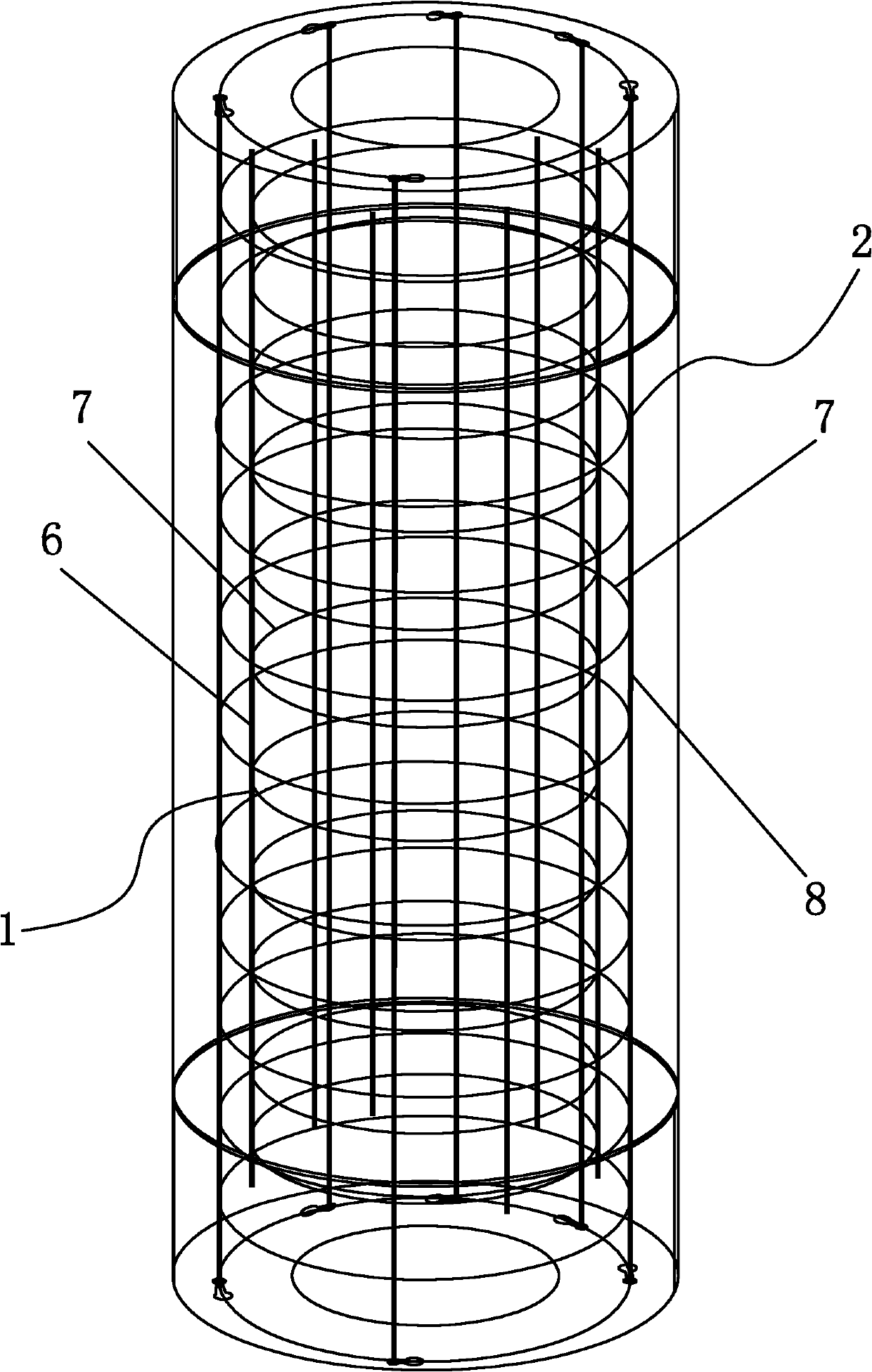

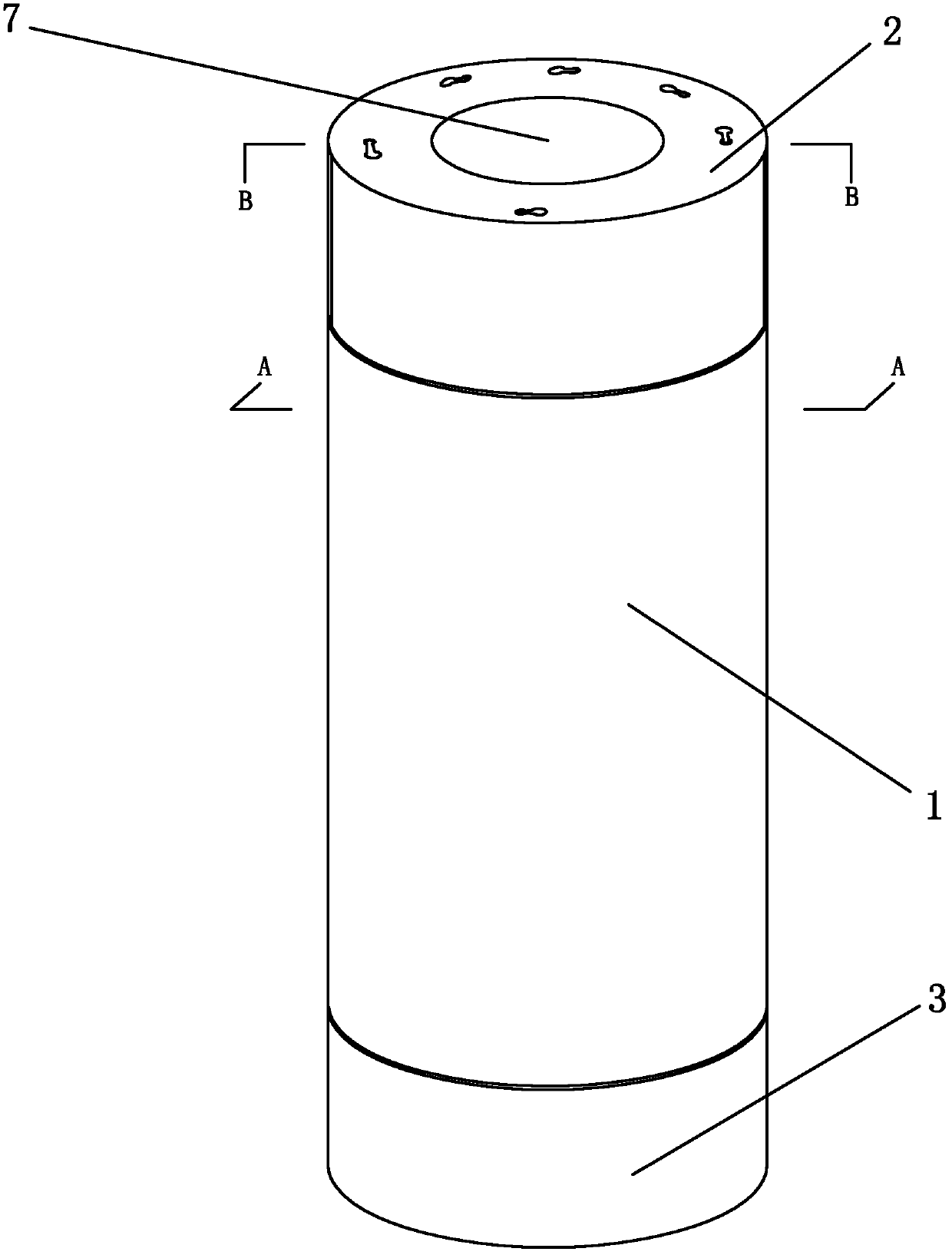

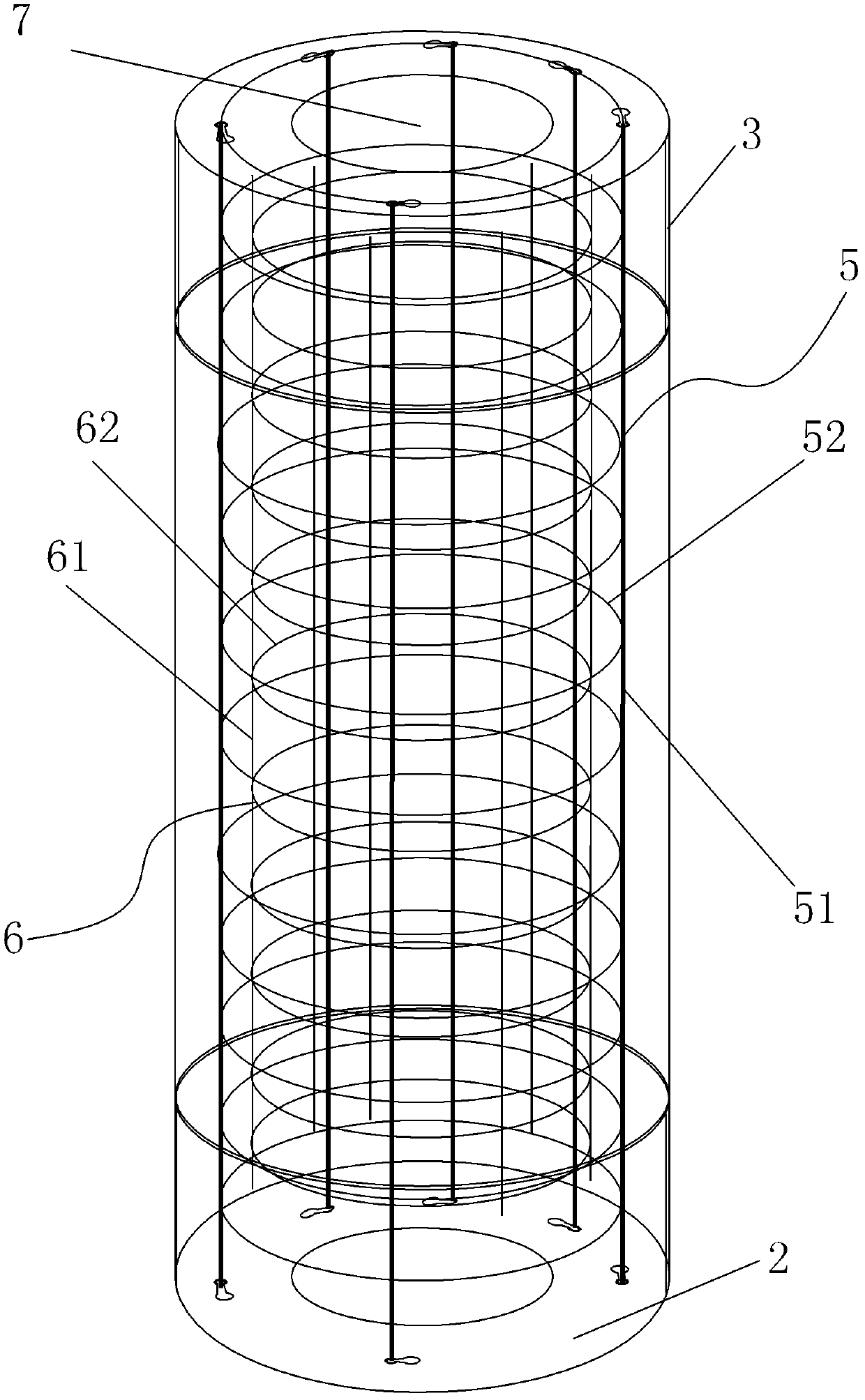

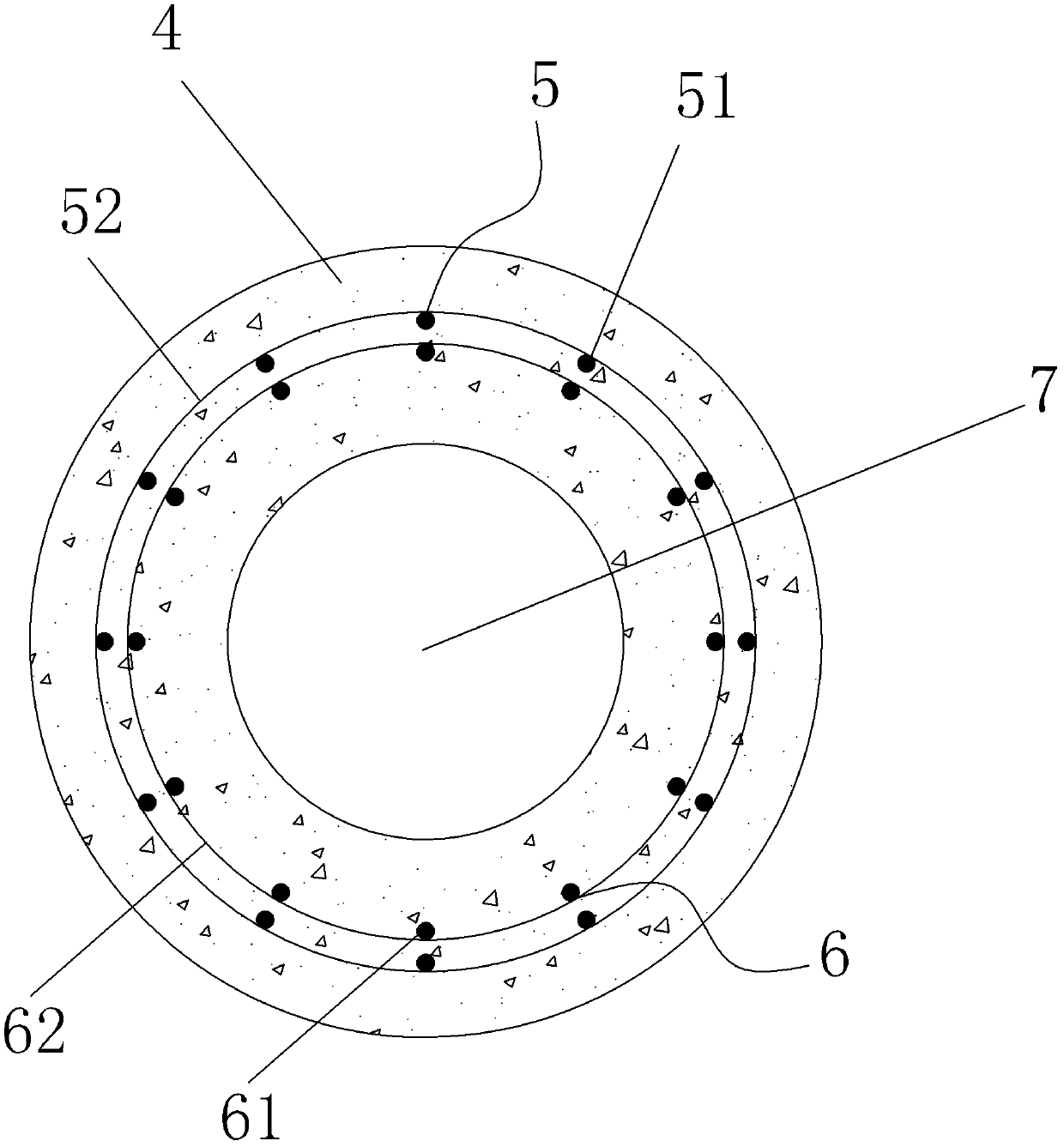

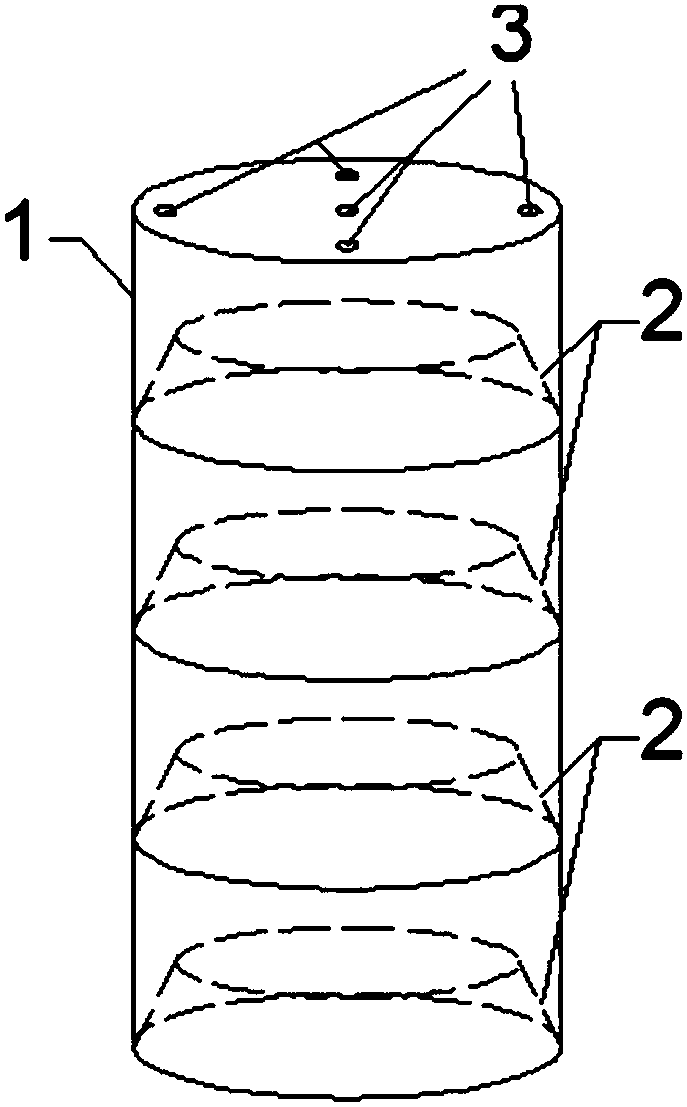

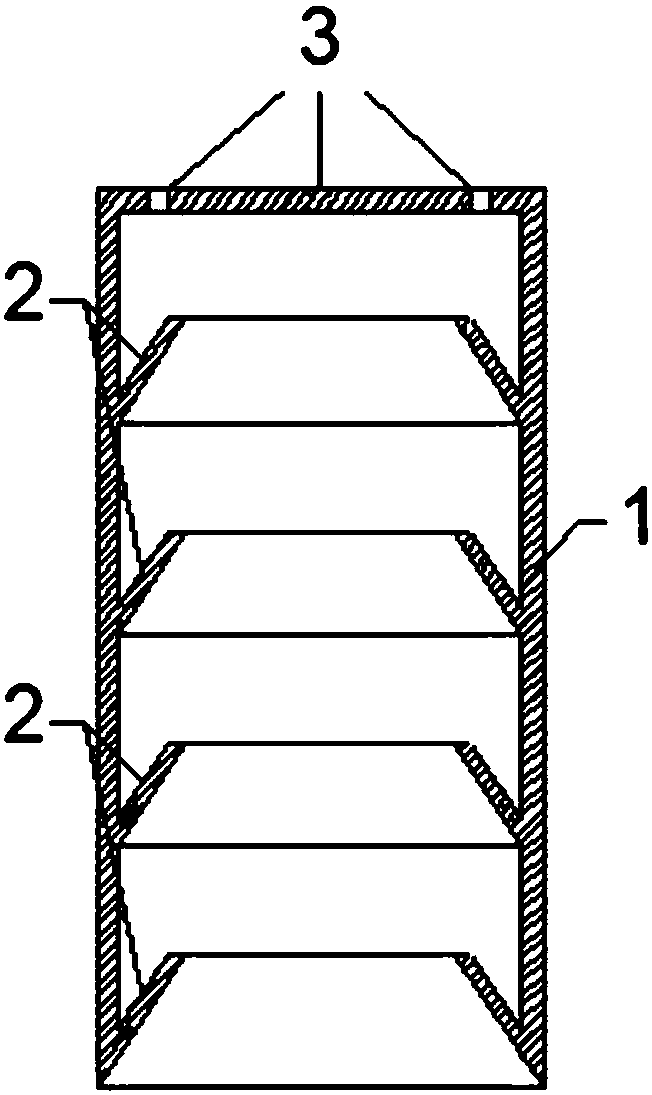

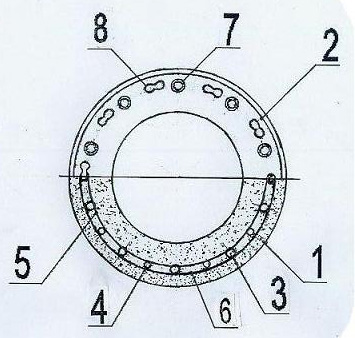

Inner ring type seabed suction anchor for deep sea and installation method thereof

ActiveCN108425379AReduce resistanceReduce construction costsFoundation engineeringSuction stressSea waves

The invention discloses an inner ring type seabed suction anchor for deep sea and an installation method thereof. The suction anchor comprises a suction main barrel, the suction main barrel is of a barrel type structure of which the bottom is opened and the top end is closed, the inner wall of the suction main barrel is provided with a plurality of hollow annular bulges at equal intervals along anaxial direction, the inner wall of the suction main barrel and the side walls of the hollow annular bulges form a barb-shaped structure, and the center and the edges of the top of the suction main barrel are provided with drainage holes. The suction anchor can more smoothly sink and penetrate into the soil, can sink to the preset design depth, reduces the disturbance to the soil outside the barrel to the maximum extent under the effect of increasing side friction resistance, and reduces the erosion of sea waves on existing foundations; the vertical bearing capacity and the ultimate pull-out resistance bearing capacity of the suction anchor can be greatly improved under various working conditions; and under the condition of realizing the functions, the convenience of recycling the suctionanchor can also be ensured.

Owner:ZHEJIANG UNIV

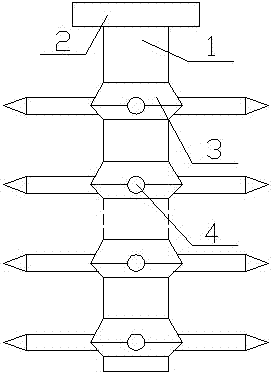

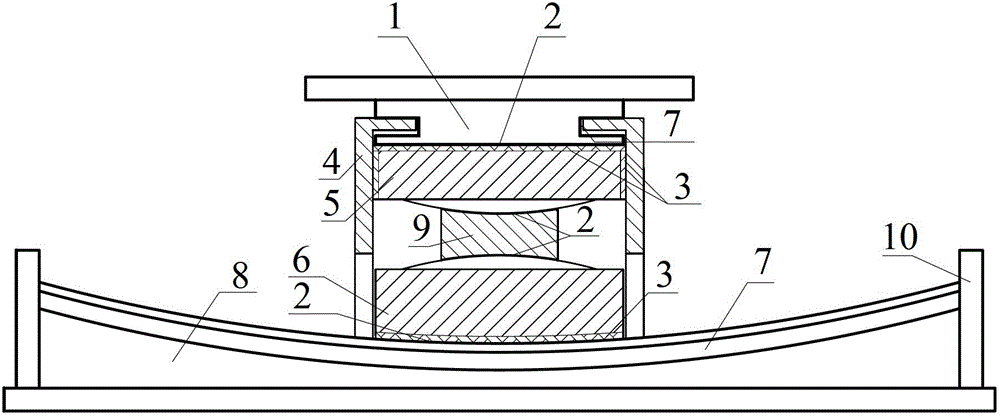

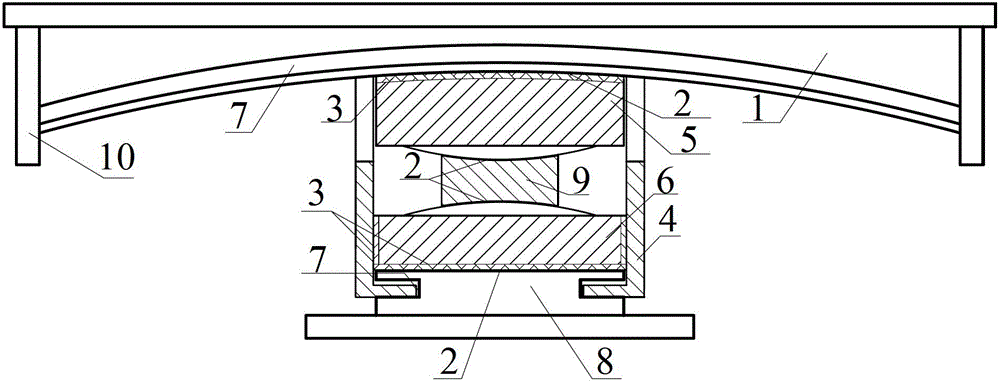

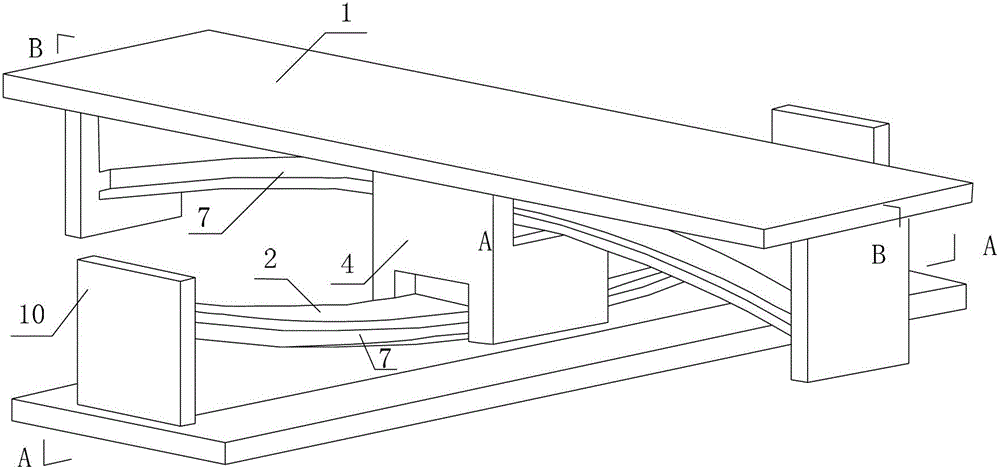

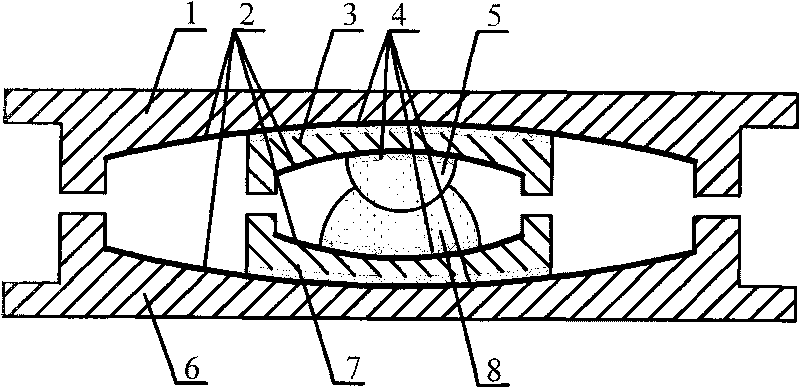

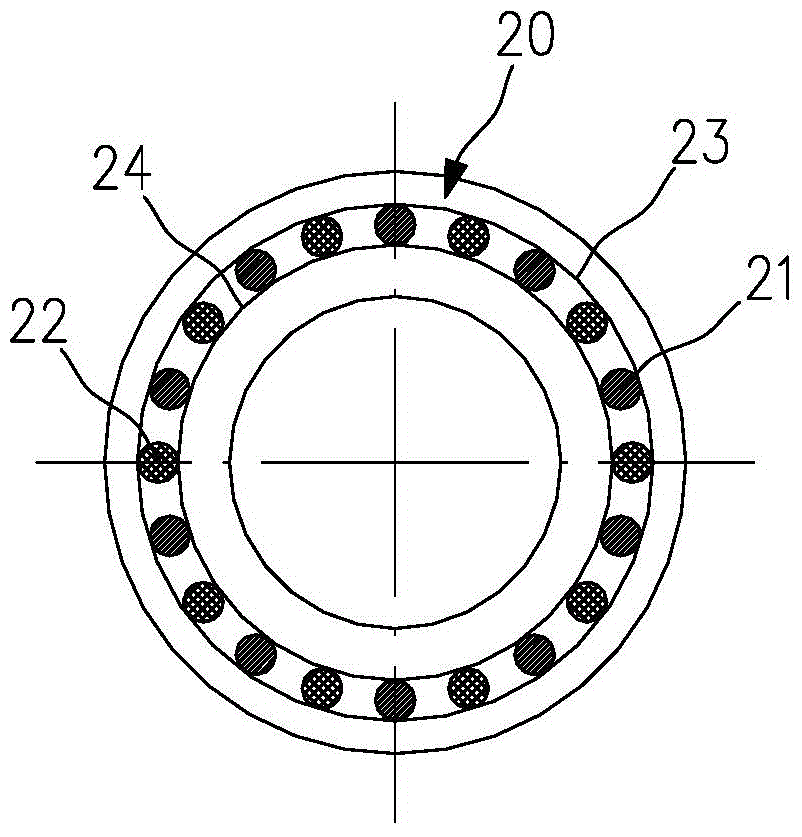

Pulling-resistant friction isolation bearing for bridge

ActiveCN103147393ASimple structureImprove vertical bearing capacityBridge structural detailsBridge materialsNormal loadFortification

The invention relates to a pulling-resistant friction isolation bearing for a bridge. The pulling-resistant friction isolation bearing comprises upper and lower bearing plates, upper and lower sliding bodies, a slider and a pulling-resistant housing, wherein the concave curved surface of the upper bearing plate is connected with the upper convex curved surface of the upper sliding body; a metal plate is arranged on the concave curved surface of the lower bearing plate; the concave curved surface of the lower bearing plate is connected with the lower convex curved surface of the lower sliding body; the upper sliding body is connected with the lower sliding body through the slider in the middle; the upper sliding body, the slider and the lower sliding body are arranged in the pulling-resistant housing; and the two side surfaces of the upper sliding body and the lower sliding body are connected with the inner wall of the pulling-resistant housing. The pulling-resistant friction isolation bearing adapts to deformation of the bridge under the action of a normal load, has the characteristics of rigidity and damping adaptivity, is strong in vertical pulling-resistant capability, meets the seismic performance requirements of the bridge under different fortification levels, is simpler in structure, high in vertical bearing capacity, large in horizontal displacement and good in durability and pulling resistance, and is suitable for the bridge with high seismic performance requirements.

Owner:BEIJING UNIV OF TECH

Non-autoclaved prestressed high-strength centrifuge pipe pile and preparation method thereof

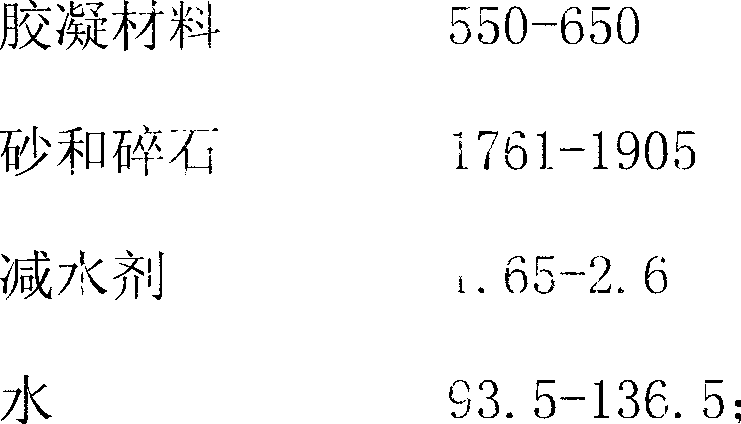

ActiveCN103030342BImprove protectionReduce energy consumptionShaping reinforcementsBulkheads/pilesLow speedPre stress

The invention discloses a non-autoclaved prestressed high-strength centrifuge pipe pile and a preparation method thereof. The concrete used by the pipe pile comprises the following components in parts by weight: 550-650 parts of cement, 1761-1905 parts of sand and gravel, 1.65-2.6 parts of water reducing agent and 93.5-136.5 parts of water. The cement comprises the following components in percentage by weight: 70-90% of cement, 5-20% of microbead and 5-10% of silica fume. The method for preparing the pipe pile comprises the following steps:: A. proportionally adding water, sand, gravel and water reducing agent into cement to prepare concrete; B. distributing the concrete in a steel mold, closing the mold, stretching, and centrifugally forming a prestressed concrete pipe pile on a centrifugal machine, wherein the centrifugal forming technique comprises four stages, including low speed, medium speed, medium high speed and high speed; and C. carrying out primary atmospheric steam curing or water curing on the centrifugally formed prestressed concrete pipe pile while controlling the constant temperature at 75-95 DEG C, and naturally standing for 7 days. The strength level of the concrete satisfies C105 strength requirements.

Owner:GUANGDONG SANHE PILE CO LTD

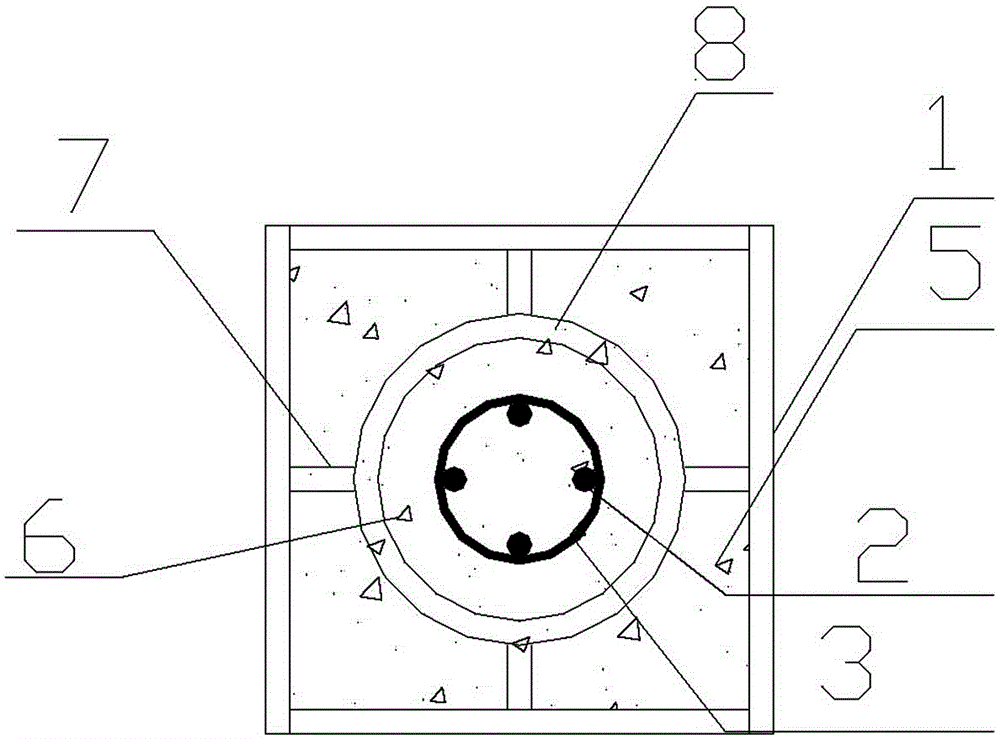

Self-adaptive multi-spherical face rubbing sliding vibration insulating support saddle

InactiveCN101701472AMinimize or isolate impactStrong Adaptive BehaviorBridge structural detailsShock proofingSelf adaptiveSpandrel

The invention provides a self-adaptive multi-spherical face rubbing sliding vibration insulating support saddle, relating to large buildings such as building and bridge and the like, comprising an upper support saddle plate, an upper sliding disc, a movable sliding block comprising an upper and a lower spherical gap, a lower sliding disc and a lower support saddle plate; the concave spherical face of the upper support saddle plate is internally connected with the upper sliding disc; the concave spherical face of the upper sliding disc is connected with the concave spherical face of the lower sliding disc by the movable sliding block composed of the upper and the lower spherical gaps; the convex spherical face of the lower sliding disc is connected with the concave spherical face of the lower support saddle plate; the upper spherical gap of the movable sliding block is positioned in the groove of the lower spherical gap; the upper and the lower spherical gaps are respectively provided with convex spherical faces. The support saddle in the invention has self-adaptive property for automatically adjusting rigidity and damping in countable and controllable displacement range based on different spherical faces with same or different curvature radii and friction coefficients; the support has simple structure, great upright bearing force, large level displacement, good service durability and clear vibration absorbing mechanism; the support saddle is applied to the large-span bridges and other large buildings with high requirement of vibration absorbing property.

Owner:BEIJING UNIV OF TECH

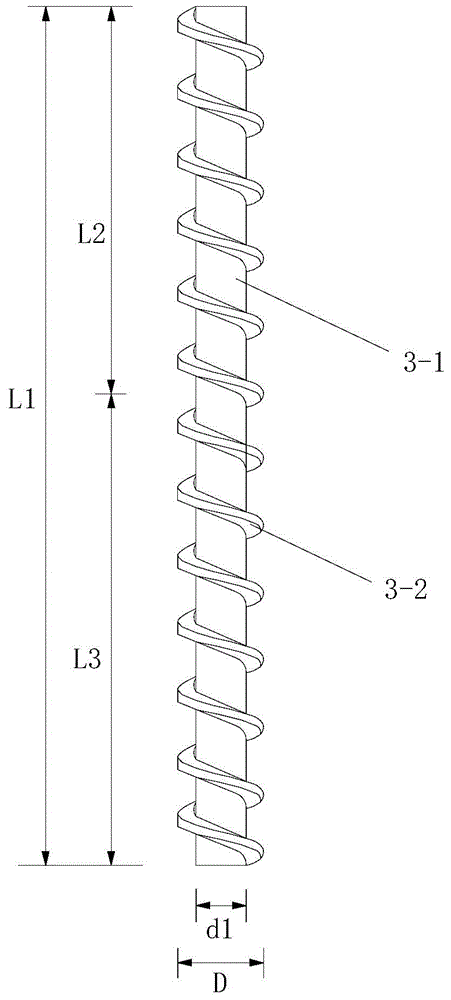

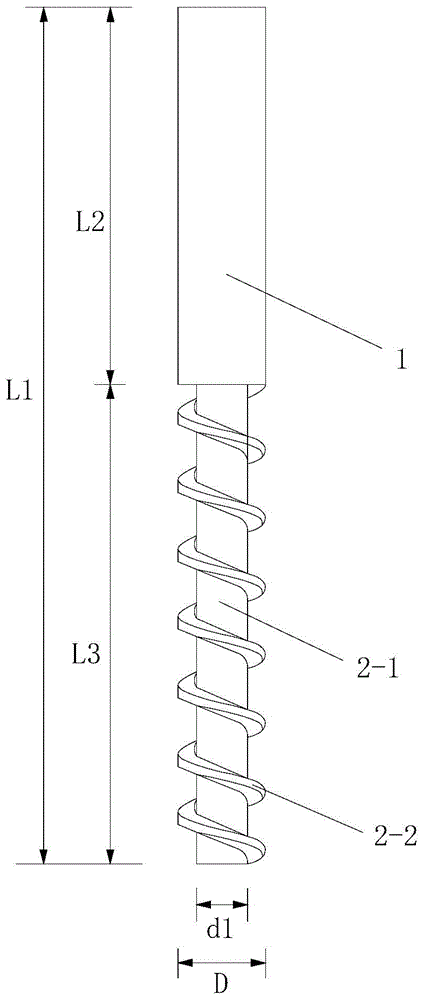

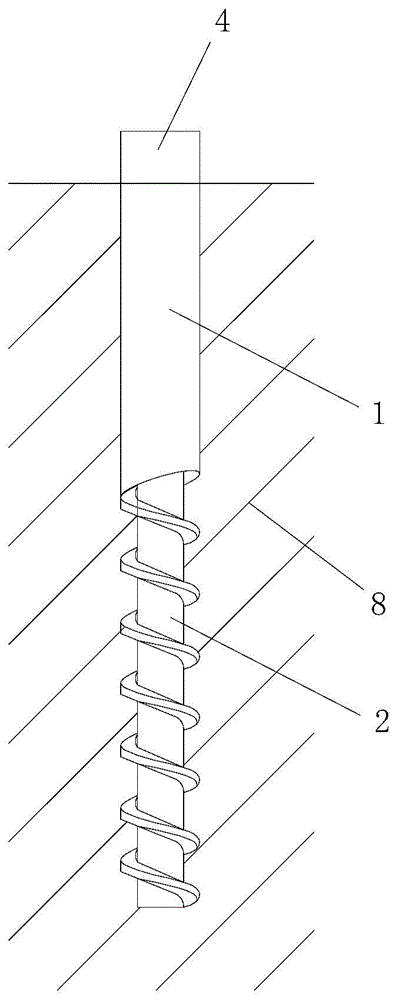

Reverse screw spike pile and construction method thereof

The invention discloses a reverse screw spike pile and a construction method thereof. The reverse screw spike pile comprises a pile body which is made of concrete, and the pile body is a full thread pile body or a partial thread pile body. The full thread pile body comprises a first pile core and a first external thread structure. The partial thread pile body comprises a straight rod section pile body part and a thread section pile body part, and the thread section pile body part comprises a second pile core and a second external thread structure. The first external thread structure and the second external thread structure are both provided with reverse threads. When a reinforcement cage is not arranged inside the pile body, the construction method comprises the following construction steps of enabling a drill rod of a pile machine to be located in place, drilling holes and conducting drill lifting and synchronous concrete pouring construction; when the reinforcement cage is arranged inside the pile body, the construction method comprises the following construction steps of enabling the drill rod of the pile machine to be located in place, drilling the holes, lifting a drill, tripping the reinforcement cage and pouring concrete. The reverse screw spike pile is reasonable in design, easy and convenient to construct, good in using effect, suitable for multiple stratum types, and capable of solving the problems that an existing long auger drilling pouring pile is poor in single-pile vertical bearing capacity, limited in application range, fast in construction progress and the like.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

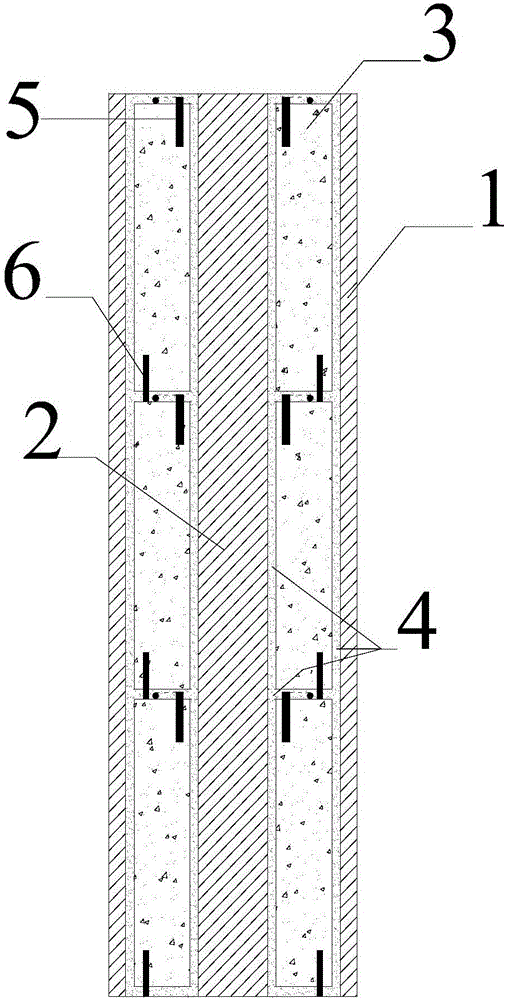

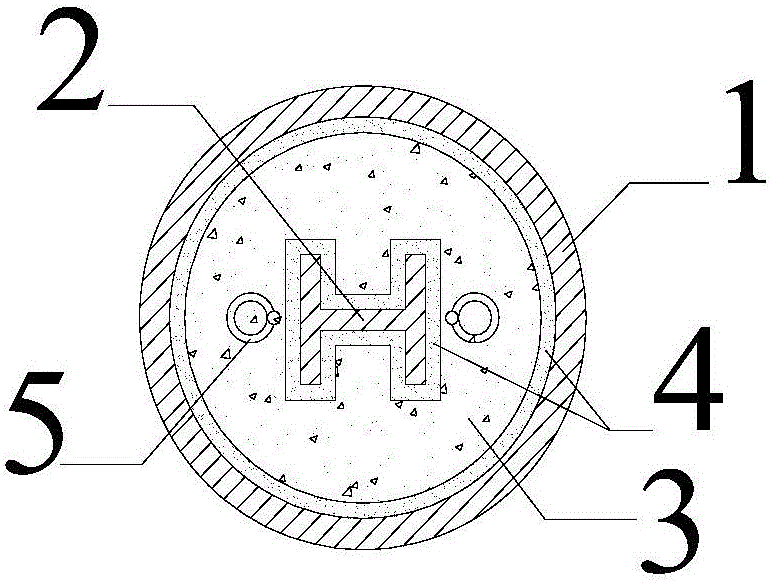

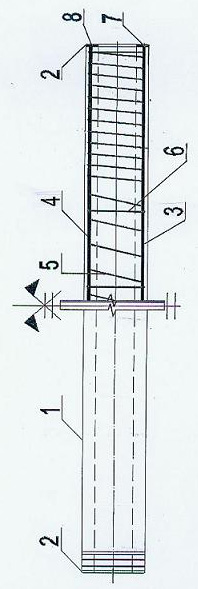

Semi-precast concrete filled steel tubular column with built-in high-strength structural steel and manufacturing method thereof

ActiveCN105926853AAvoid compression bucklingGive full play to the advantages of high strengthStrutsBuilding material handlingSocial benefitsPrecast concrete

The invention discloses a semi-precast concrete filled steel tubular column with built-in high-strength structural steel and a manufacturing method thereof. The semi-precast concrete filled steel tubular column comprises a steel pipe and a plurality of precast concrete segments sequentially arranged in the steel pipe at intervals in the vertical direction; gaps are reserved between the inner wall of the steel pipe and the outer walls of the precast concrete segments; a vertical through structural steel channel is reserved in the middle of each precast concrete segment and used for mounting the structural steel; gaps are reserved between the walls of the structural steel channels and the outer surface of the structural steel; grouting materials are poured in the steel pipe; and the gaps between the precast concrete segments, the gaps between the walls of the structural steel channels and the outer surface of the structural steel and the gaps between the outer walls of the precast concrete segments and the inner wall of the steel pipe are all fully filled with the grouting materials. According to the manufactured semi-precast concrete filled steel tubular column with the built-in high-strength structural steel, under the requirement for the same bearing capacity, the sectional dimension of the column can be remarkably reduced, and therefore the usable area of a building is enlarged, and good economic and social benefits are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Section bar inserting and high-pressure rotary jetting method for forming pile with expanded plates in sink area

InactiveCN1844588AReduce occupancyImprove vertical bearing capacityBulkheads/pilesLand resourcesEconomic benefits

The invention discloses a method for molding the high-pressure rotational spray expansion post in sink area. Wherein, forming a trapezium expansion disc on the post formed by rotational spraying slurry injection according to the segment pressure or the injection time; inserting section steel as anti-drawing material into the post. The invention can increase the upright bearing ability and improve the horizontal bearing ability; especially at the interface of soil, it can eliminate the effect of horizontal displacement, with lower cost, short time, easy construction, lower soil occupied and saved land resource. The invention can be used to strengthen the foundation in large distortion condition, to reduce cost and improve economic benefit, with wider application.

Owner:CHINA UNIV OF MINING & TECH

Construction method for non-prestressed centrifugal high-strength concrete pile planted pile

InactiveCN105421445AIncrease resistanceImprove pullout resistanceBulkheads/pilesHigh strength concreteSocial benefits

The invention provides a non-prestressed centrifugal high-strength concrete pile planted pile structure and a construction method thereof. The method comprises the construction steps that a pile planting machine is in place, the hole guiding operation is conducted, a bearing stratum is determined, base expansion is carried out, pile end cement paste is injected, pile periphery cement paste is injected and drill stems are pulled out, pile connection of pre-drilled holes is conducted, and non-prestressed centrifugal high-strength concrete piles are planted into pile holes. The pile planting construction method has the effects that damage to pile bodies is effectively reduced; the ductility of the pile bodies is improved more than 30%; the pile body cracking phenomenon is avoided; the whole performances of the pipe piles are improved more than 20%; the technique is simple, the cost is low and the cost performance is high; the centrifugal concrete piles which are high in vertical bearing capacity and horizontal pile foundation bearing capacity and capable of meeting the anti-seismic requirement can penetrate through a hard middle layer and a thick solidified layer and can be widely applied to foundation construction of various soil textures; it is ensured that the requirement of housing industrialization for quality is met; the pile planting construction method has good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

Concrete precast pile with mixed reinforcement of glass fiber-reinforced polymers and steel bars

The invention belongs to the technical field of concrete precast piles, and particularly relates to a concrete precast pile with mixed reinforcement glass fiber-reinforced polymers and steel bars. The concrete precast pile comprises a pile body with the two ends provided with anchor plates, wherein a reinforcement cage is arranged in the pile body and comprises prestressed reinforcements, the glass fiber-reinforced polymers and spiral stirrups, and the prestressed reinforcements and the glass fiber-reinforced polymers are distributed on the same cylindrical face with the central line of the pile body as the axis; the two ends of each prestressed reinforcement are fixedly connected with the anchor plates arranged at the two ends of the pile body respectively, the prestressed reinforcements and the spiral stirrups are welded together, and the glass fiber-reinforced polymers and the spiral stirrups are bound together. The concrete precast pile has the advantages of being high in bending resistance, good in durability, good in anti-seismic property and the like, and can be well applied to areas where the requirement for horizontal loads is high; meanwhile, the concrete precast pile is low in manufacturing cost, saves steel, and is convenient to construct and transport.

Owner:ANHUI INST OF BUILDING RES & DESIGN

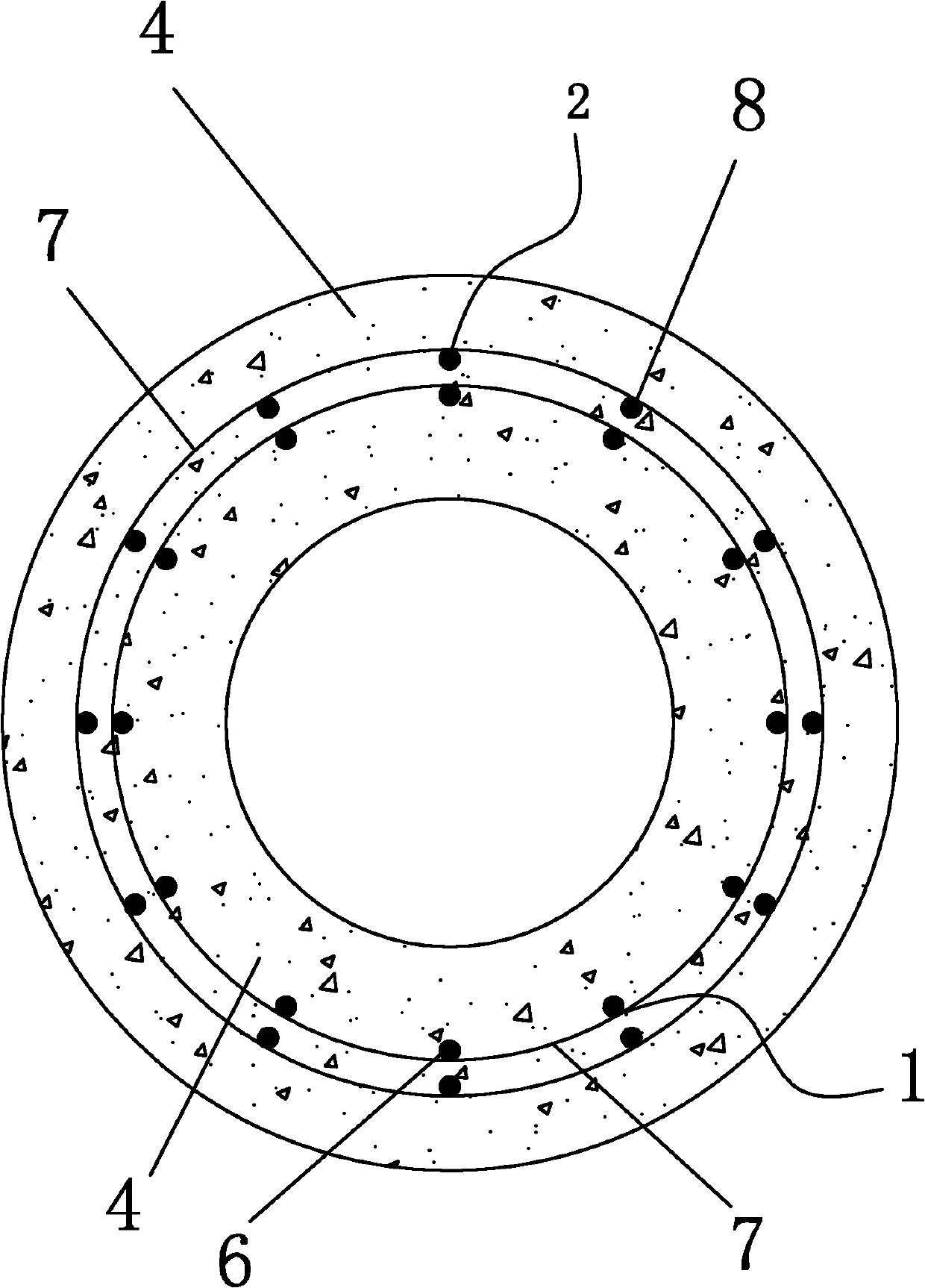

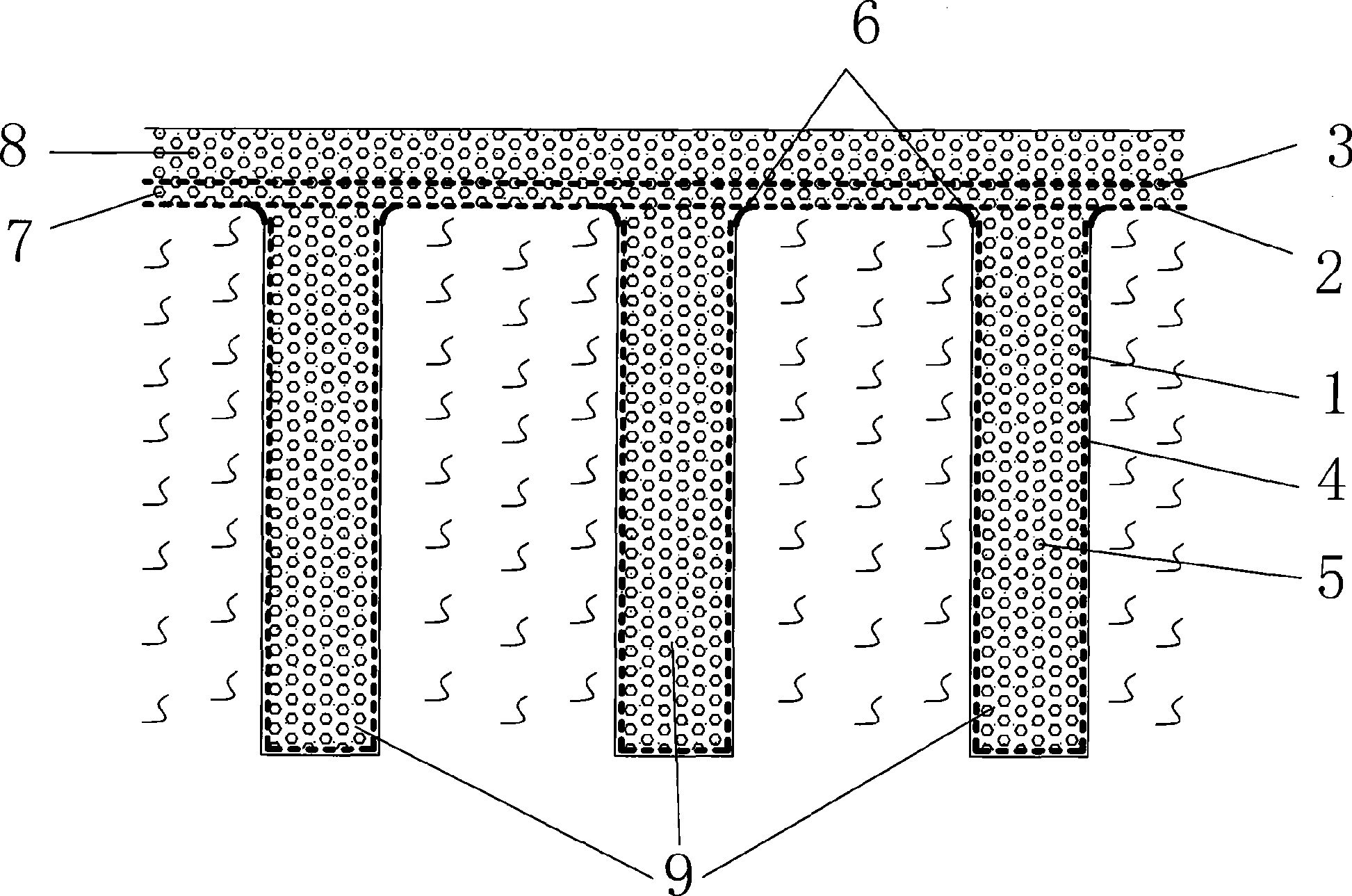

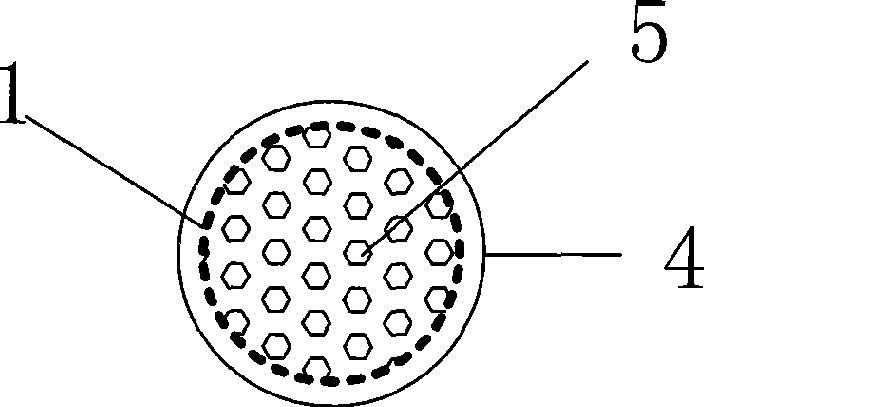

Space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and construction method

ActiveCN105133793AImprove mechanical performanceWide range of sizesStrutsBuilding material handlingRebarMaterials science

The invention relates to a space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and a construction method. A huge column comprises a core steel pipe concrete part and a steel-encased pipe concrete part. A core steel pipe forms an inner cavity. The inner cavity is filled with inner cavity concrete, and a steel bar frame is arranged through the middle part of the inner cavity. The core steel pipe and the steel-encased pipe form an outer cavity. The outer cavity is filled with outer cavity concrete, and at least a steel bar frame is arranged through the outer cavity. The core steel pipe and the steel-encased pipe are connected through a vertical connection plate and form a space steel pipe structure. The outer steel pipe of the huge column is connected with the inner steel pipe through the vertical connection plate, the space steel pipe structure is formed, and the force bearing performance of traditional steel pipe concrete can be raised effectively. The huge column has a strong anti-pressure capability, steel and concrete combined action performances are good under action of long-term load. The huge column has good earthquake resistant behavior, fireproof performance and construction convenience.

Owner:姚攀峰

Bottom-hinged-supporting low-damage self-reset shear wall

ActiveCN110005091ANo plastic damageSection internal force does not surgeWallsProtective buildings/sheltersReinforced concreteRebar

The invention relates to a bottom-hinged-supporting low-damage self-reset shear wall. The bottom-hinged-supporting low-damage self-resetting shear wall comprises a reinforced concrete wall plate, a self-reset wall bottom and a foundation beam; the reinforced concrete wall plate is connected with the upper end of the self-reset wall bottom, the foundation beam is connected with the lower end of theself-reset wall bottom, a connecting plate is arranged in the middle of the upper surface of the foundation beam and provided with a connecting beam hinged joint, and self-reset short support hingedjoints II are arranged on the two sides of the connecting beam hinged joint correspondingly; the self-reset wall bottom comprises a connecting beam and a self-reset short support; an anti-shear key isarranged on the upper surface of the connecting beam, a foundation beam hinged joint is arranged in the middle of the lower surface of the connecting beam, and self-reset short support hinged jointsI are arranged on the positions, corresponding to the two self-reset short support hinged joints II, of the two ends of the lower surface of the connecting beam; and the self-reset short support comprises an inner pipe, an outer pipe, a disc spring and baffles, the disc spring is arranged in the outer pipe, the baffles are arranged at the two ends of the disc spring, the inner pipe penetrates through an inner hole of the disc spring and the baffles at the two ends and are capped at the two ends of the inner pipe through a stop block, and self-reset short support hinged joints III are arrangedat the two ends of the self-reset short support.

Owner:BEIJING JIAOTONG UNIV

Vertical reinforcing rib reinforced bag grouting pile and construction method

ActiveCN106836179AReduce the crowding effectImprove integrityBulkheads/pilesSoil preservationTreatment effectEconomic benefits

The invention relates to a vertical reinforcing rib reinforced bag grouting pile and a construction method. The pile mainly comprises a prefabricated pipe pile, a prefabricated enlarged toe pile end with one part of the prefabricated pipe pile, a bottom filling enlarged toe pile end, a vertical reinforcing rib, a multi-section back expansion rib, a fixed disc, a bag, a steel plate pile tip, a pipe pile joint, a separate orifice positioning steel plate, a pile periphery reinforcing area, a grouting expanded bottom, a steel plate pile tip top pipe element, a top anchor plate and a foundation baseplate; pile connecting holes are respectively formed in the top and the bottom of the pipe pile; and an upper-section pile and a lower-section pile are connected through a pile connecting rod. An integral circular connecting inner sleeve and a separate arc connecting outer plate with a reverse triangular flange plate are sleeved in the pile connecting place by a stud and a nut. The technical method is convenient to construct, low in construction cost and low in technical requirements on engineering constructors, and can greatly improve the bend and shear resistance of the whole foundation pile. The method is simple in construction process, high in operability, convenient to control the quality, obvious in economic benefit and prominent in treatment effect.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

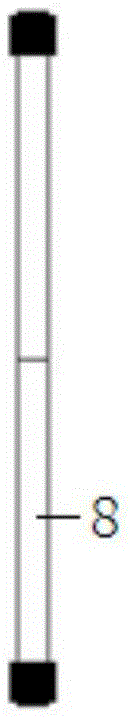

Toughening prestressed centrifugal concrete pile

InactiveCN102121246AImprove vertical bearing capacityImprove horizontal bearing capacityBulkheads/pilesRebarBearing capacity

The invention relates to a toughening prestressed centrifugal concrete pile which comprises a centrifugal concrete pile body, a prestressed main reinforcement, spiral hooping, two end plates and prestressed main reinforcement anchoring holes, and further comprises a non-prestressed main reinforcement and non-prestressed main reinforcement anchoring holes. Based on the reinforcement cage of the existing prestressed centrifugal concrete pile, the short anchoring reinforcements arranged on two end plates are changed into long non-prestressed main reinforcements capable of vertically passing through the whole frame so that the centrifugal concrete pile has the advantage of high bearing capacity because of the effect of the prestressed main reinforcement and the advantage of high horizontal bearing capacity because of the effect of the non-prestressed main reinforcement, therefore, the pile can replace the prefabricated solid square pile or on-site concreted pile used in area resisting eight-magnitude earthquake. Simultaneously, the structural design is reasonable, and the existing device and production method for producing the prestressed centrifugal concrete pile can be continue to use completely, therefore, the toughening prestressed centrifugal concrete pile is very easy for popularization, and a new variety is added for concrete piles.

Owner:宿迁市固丰管桩有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com