Fiber-steel plate-rubber combined seismic-insulation support

A technology of seismic isolation bearing and rubber combination, which is applied in the field of building isolation, can solve the problems of heavy bearing, inconvenient construction, unsuitable for seismic isolation, etc., and achieve the effects of convenient construction, weight reduction and installation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

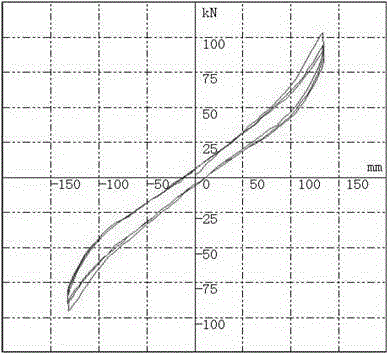

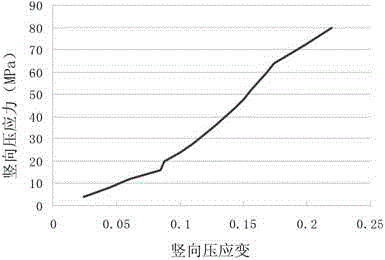

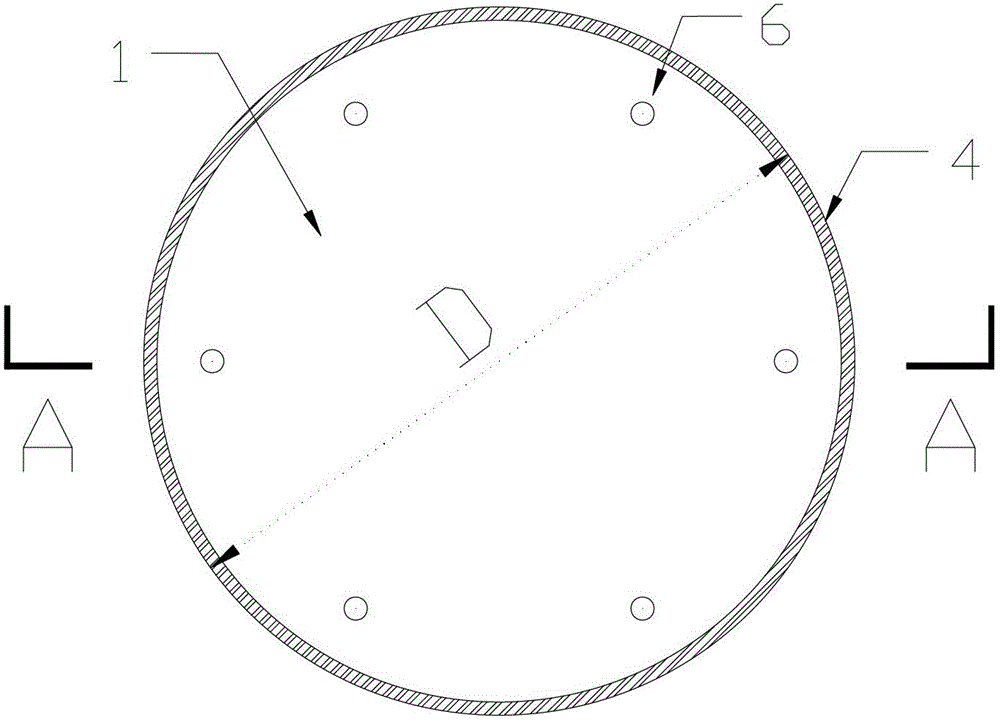

[0019] Such as figure 1 and image 3 As shown, a cylindrical fiber-steel plate rubber composite shock-isolation bearing is composed of a fiber cloth layer 3, a rubber layer 2 and a steel plate layer 5, and the three are stacked alternately, and the stacking sequence is as follows: rubber layer 2, The fiber cloth layer 3, the rubber layer 2, the steel plate layer 5, and the rubber layer 2 are superimposed in this way to form a composite body, and an end steel plate 1 is added to the upper and lower end faces of the composite body, and a rubber protective layer 4 is added around the side of the composite body, and finally Bonded by vulcanization.

[0020] The diameter D of the vibration isolation support in this embodiment is 320mm, the height is 110mm, and there are 35 layers laminated together, of which the thickness of the rubber layer is 3.1mm, the thickness of the steel plate layer and the fiber cloth layer are both 2mm, the thickness of the end steel plate is 10mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com