Large load composite pile and construction method thereof

A technology of composite piles and large loads, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as poor vertical load bearing capacity, and achieve large vertical bearing capacity of single piles, small environmental impact, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

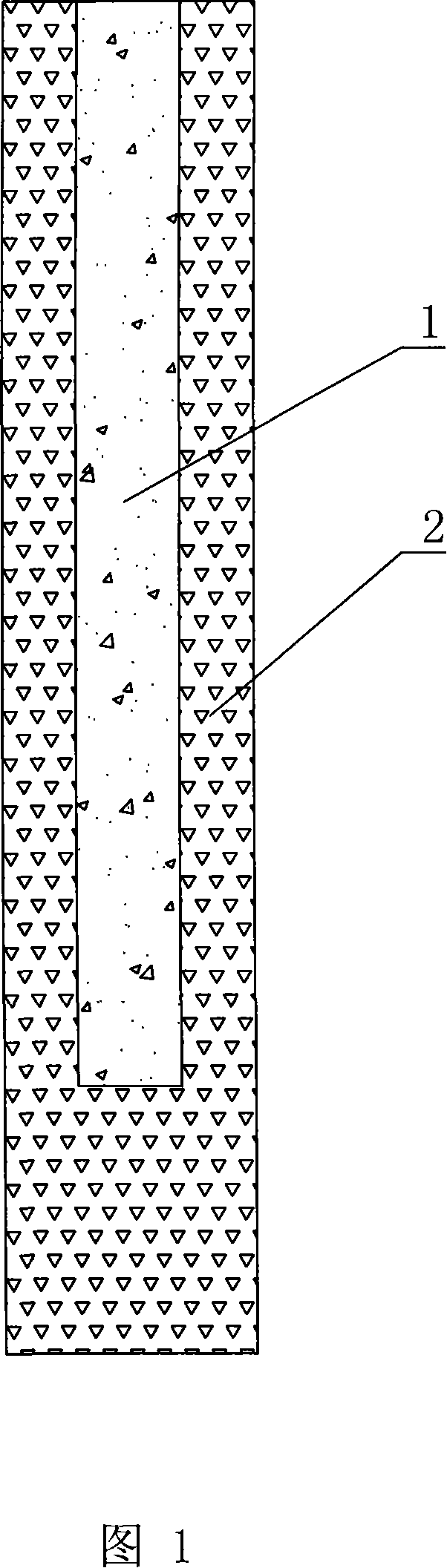

[0015] A large-load composite pile as shown in Figure 1 includes a pile core 1 and an outer layer pile 2 wrapped outside the pile core 1. The pile core 1 is made of multi-section high-strength prestressed concrete pipe piles, and the outer layer pile 2 It is a plain concrete pile, which can be poured on site.

[0016] Above-mentioned composite pile can adopt following method to make:

[0017] The method comprises the following steps: a. using the long auger drill hole pumping concrete construction method to cast plain concrete on site to form piles; Pile top elevation. When the length of a single pipe pile is not enough, piles can be connected.

[0018] The composite pile can be produced with reference to the parameters in the table below:

[0019] Composite pile

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com