Method for implanting steel bar to reinforce groove-type beam bridge face plate through UHPC thin layer

A technology for bridge decks and grooved girders, applied in bridge reinforcement, bridges, bridge parts, etc., can solve the problems of complex process, high cost, long maintenance time, etc., and achieve simple construction steps, short construction period, and save input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

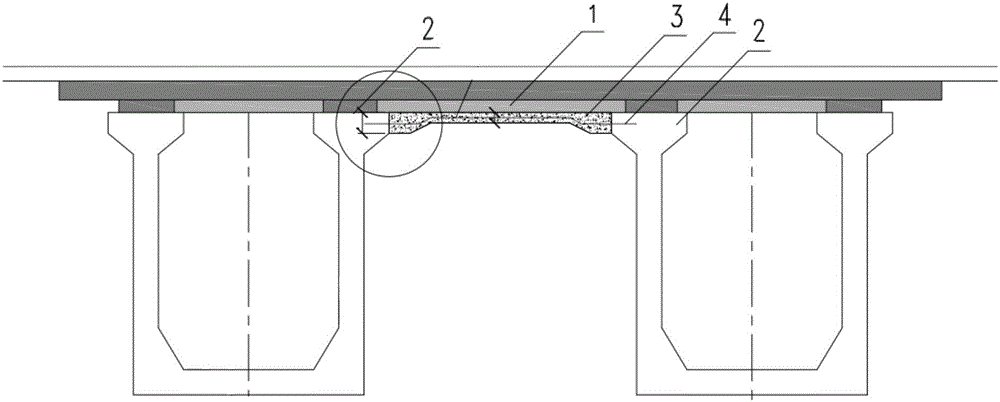

[0029] A method of using UHPC thin-layer reinforcement to strengthen channel girder bridge deck, refer to the attached Figure 1-3 , the concrete of the damaged part of the Type A bridge deck 1 of the channel girder is cleaned and chiseled off, and only the undamaged part is cleaned, and then the end beams 2 on both sides of the Type A bridge deck 1 are cleaned up on the side close to the bridge deck To facilitate the implantation of steel bars 4, fold the implanted steel bars 4 into the form shown in the figure and implant the implanted steel bars 4 into the end beams 2 of the channel beam along the transverse direction of the Type A bridge deck 1, with an anchorage depth greater than 15cm. Then the formwork is set up, and the ultra-high-performance concrete UHPC3 is poured in under pressure, and the self-compacting performance of the ultra-high-performance concrete is used for self-compacting, and the ultra-high-performance concrete UHPC3 is used for super bonding with steel ...

Embodiment 2

[0032] A method of using UHPC thin-layer reinforcement to strengthen channel girder bridge decks. The specific steps are: cutting and chiseling the damaged cement concrete at the parts of the bridge deck that need to be reinforced. The thickness of the cement concrete to be chiseled is determined according to the damaged parts. The damage can only be cleaned without chiseling, and the end beams of the channel girders on both sides of the bridge deck should be cleaned; the steel bars will be implanted in the joints on both sides along the transverse direction of the channel girder deck. cm, the longitudinal spacing of steel bars is 6cm, and the anchorage depth of the steel bars implanted at the joints on both sides is 15cm; UHPC is poured to the reinforcement part in the support form, and the UHPC adopts a compressive strength of more than 180Mpa, a tensile strength of more than 7Mpa, and no need for steam curing. When UHPC and UHPC are poured, the pouring thickness at both ends...

Embodiment 3

[0034] A method of using UHPC thin-layer reinforcement to strengthen channel girder bridge decks. The specific steps are: cutting and chiseling the damaged cement concrete at the parts of the bridge deck that need to be reinforced. The thickness of the cement concrete to be chiseled is determined according to the damaged parts. The damage can only be cleaned without chiseling, and the end beams of the channel girders on both sides of the bridge deck should be cleaned; the steel bars should be implanted in the joints on both sides along the transverse direction of the channel girder deck. , the longitudinal spacing of steel bars is 10cm, and the anchoring depth of steel bars implanted at the joints on both sides is 20cm; UHPC is poured to the reinforcement part in the support form, and the UHPC adopts UHPC with a compressive strength of more than 180Mpa, a tensile strength of more than 7Mpa, and no need for steam curing , when UHPC is poured, the pouring thickness at both ends o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com