Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2272 results about "Low permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Low permeability material. Low permeability material means a geological unit of unconsolidated material (usually clay or till) or bedrock (usually shale) that is all or partially saturated, and having permeability low enough (10-7 cm/sec) to give water in the aquifer artesian head.

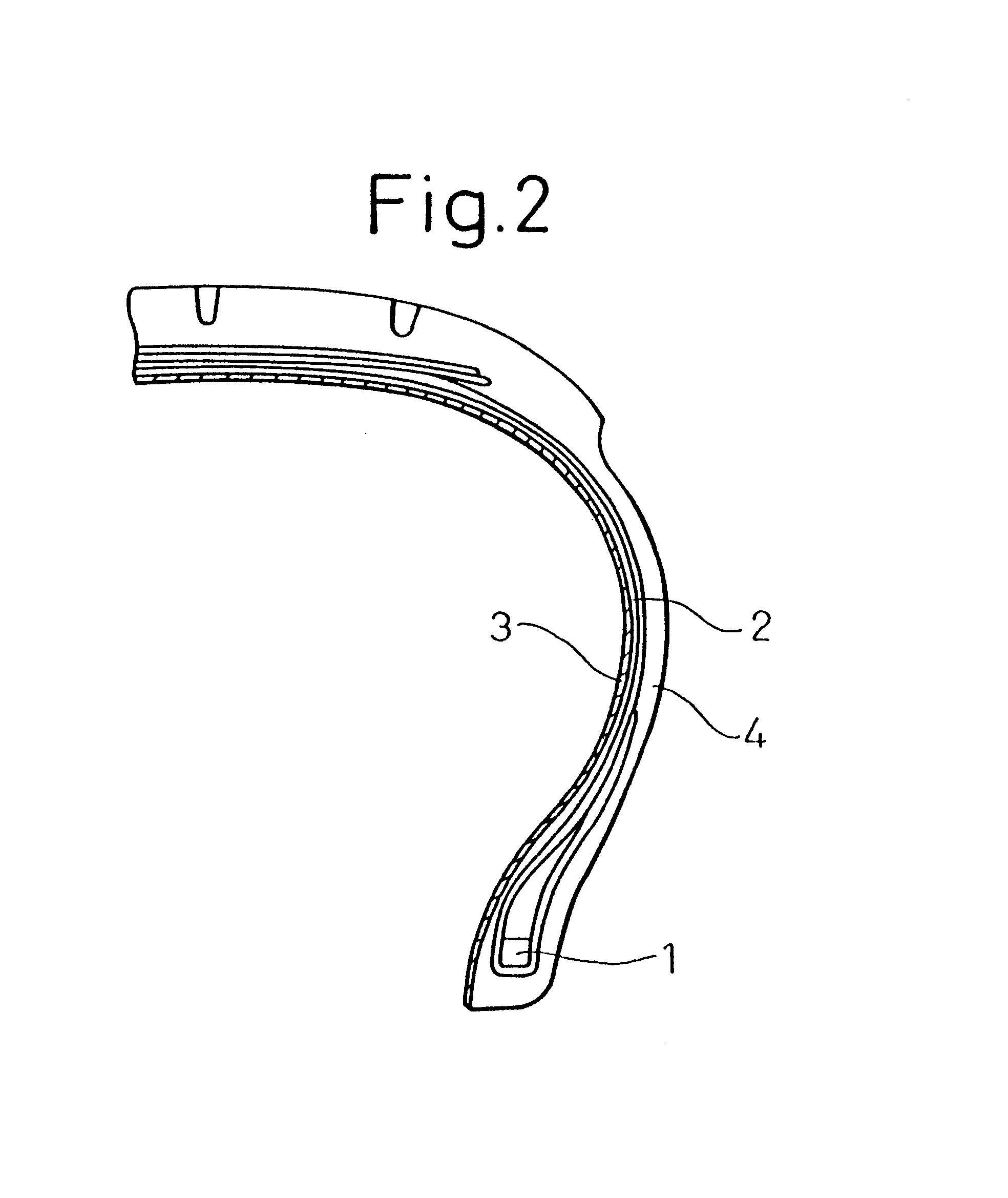

Closed system artificial intervertebral disc

An artificial intervertebral disc and disc nucleus are described herein having chambers and dampening members. The dampening members may be within or outside of the main body of the device. The chambers may be filled with a suitable liquid, gas, or both, and separated by valves to regulate flow of fluid between chambers, within a dampening member, between the main body and dampening member, or all of the above. Chambers may be filled with responsive hydrogels, EPAM, or other suitable materials, and the device may have activation plates or members, a strain gauge, a pressure sensor, or other means for detecting changes in the materials and / or triggering desired changes in the materials in order to mimic the behavior of a healthy native disc or disc nucleus. A control system may be in communication with the device for receiving feedback and delivering stimuli to initiate desired changes in the fluids or other materials. Membranes may be of variable permeability and may be metallized to ensure as low permeability as possible. Dampening members may be filled during manufacture with carbon dioxide or other suitable gas which may be in a supercritical state and allowed to return to ambient temperature and gaseous state or by other means. Methods of manufacture, delivery of the artificial disc and related structures, and methods of treatment are also described.

Owner:SYNECOR LLC

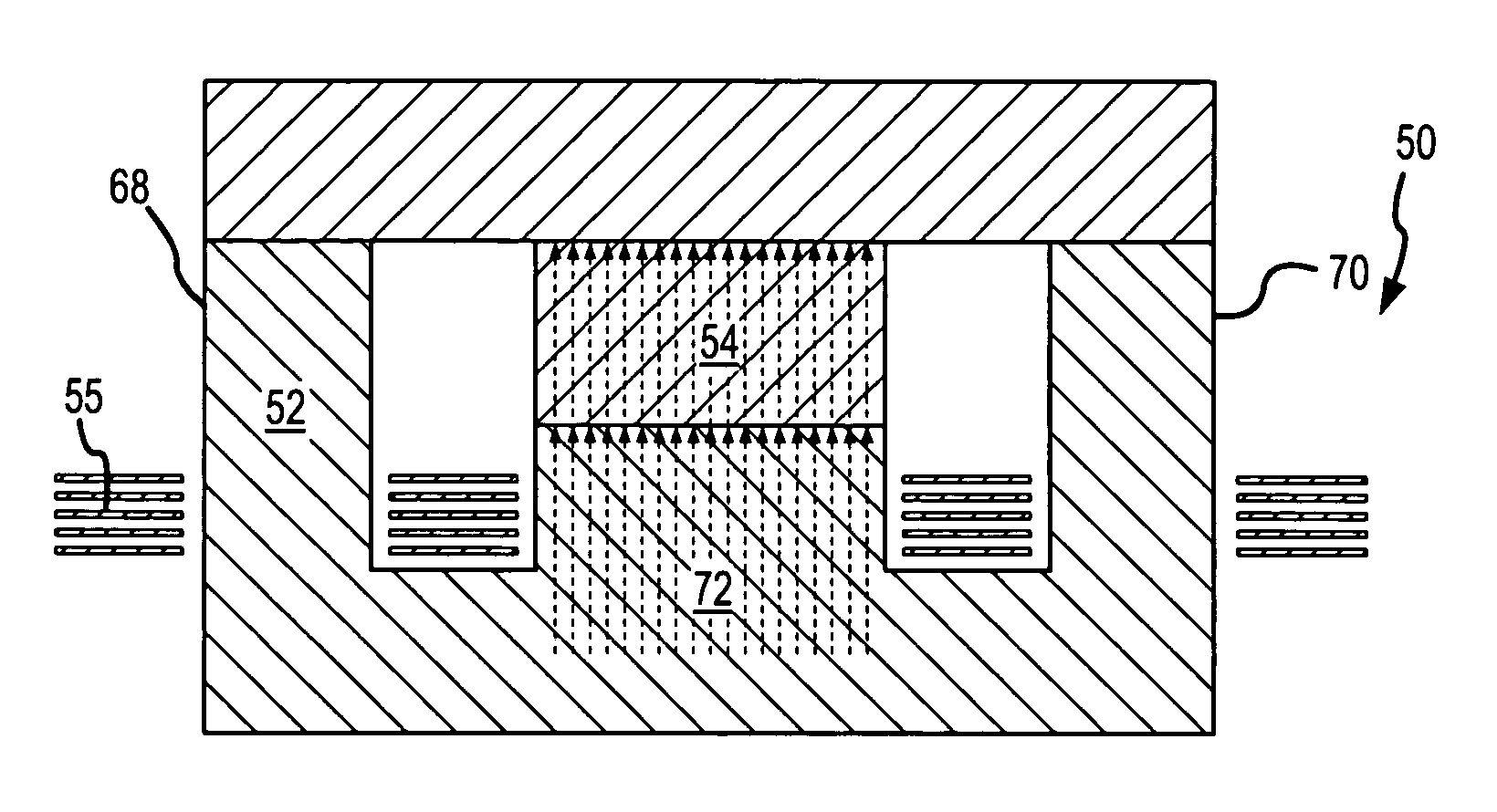

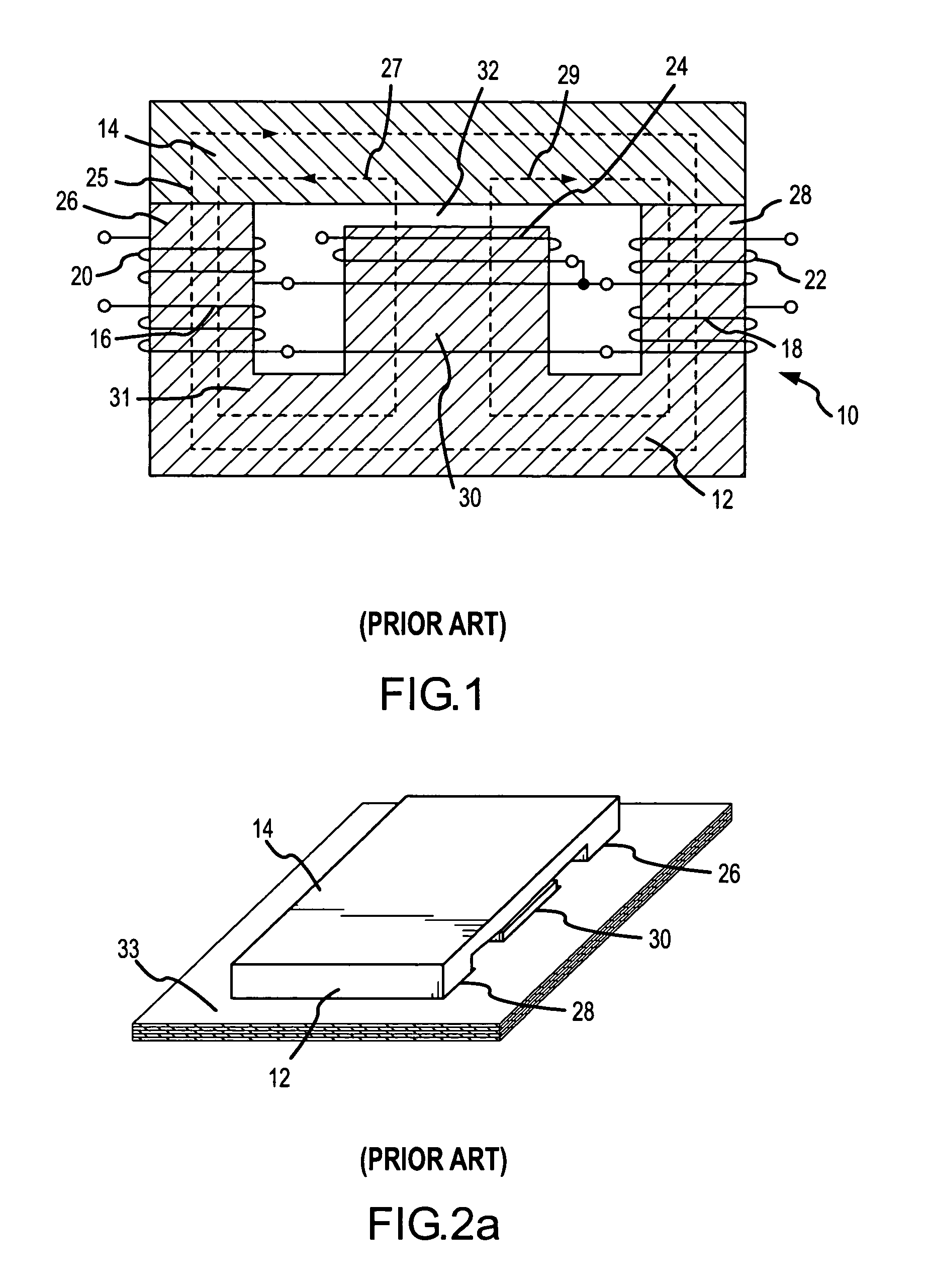

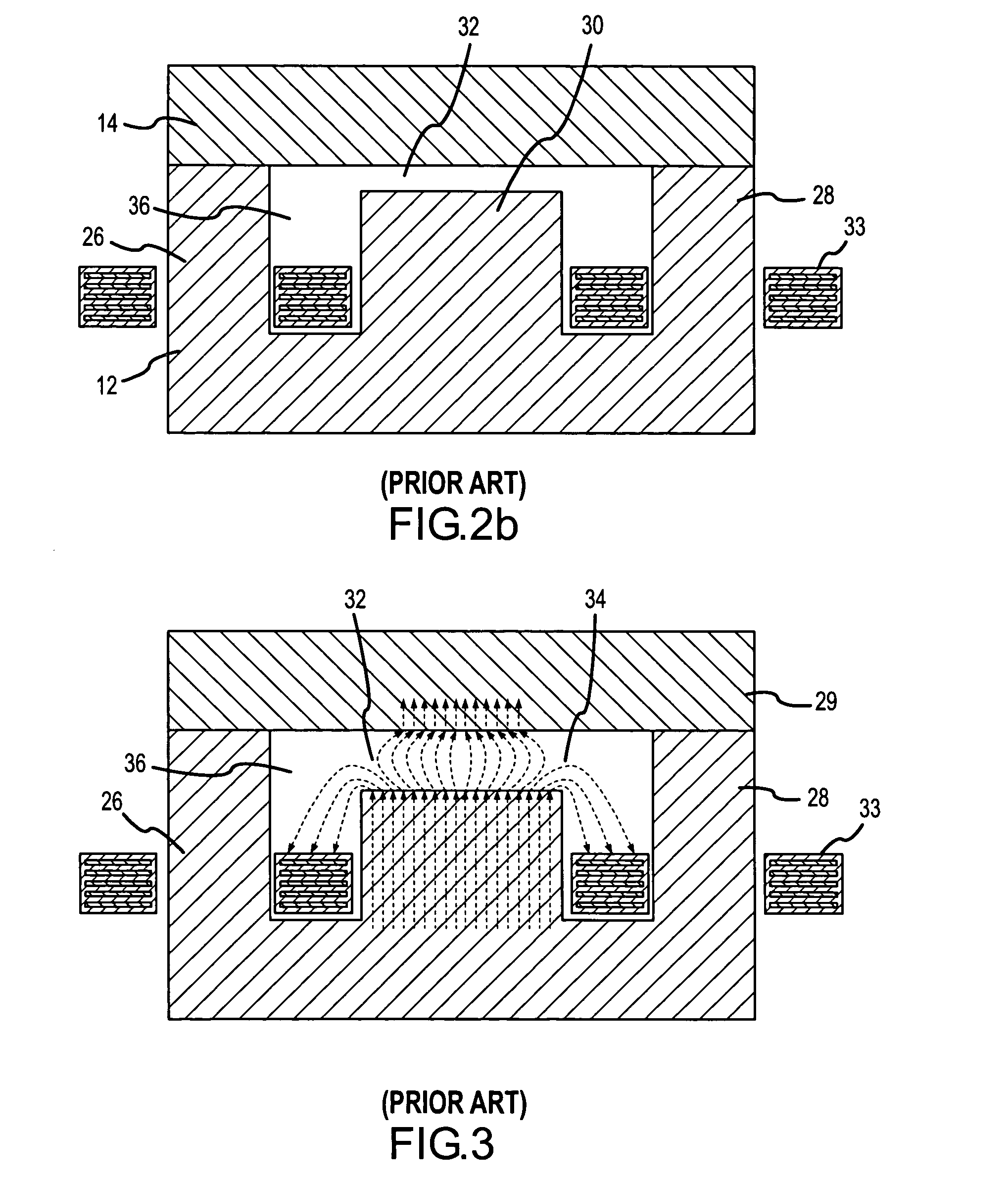

Composite magnetic core for switch-mode power converters

ActiveUS6980077B1Avoid Core SaturationLower average currentTransformers/inductances magnetic coresCores/yokesEddy currentConductor Coil

A composite magnetic core formed of a high permeability material and a lower permeability, high saturation flux density material prevents core saturation without an air gap and reduces eddy current losses and loss of inductance. The composite core is configured such that the low permeability, high saturation material is located where the flux accumulates from the high permeability sections. The presence of magnetic material having a relatively high permeability keeps the flux confined within the core thereby preventing fringing flux from spilling out into the winding arrangement. This composite core configuration balances the requirements of preventing core saturation and minimizing eddy current losses without increasing either the height or width of the core or the number of windings.

Owner:MYPAQ HLDG LTD

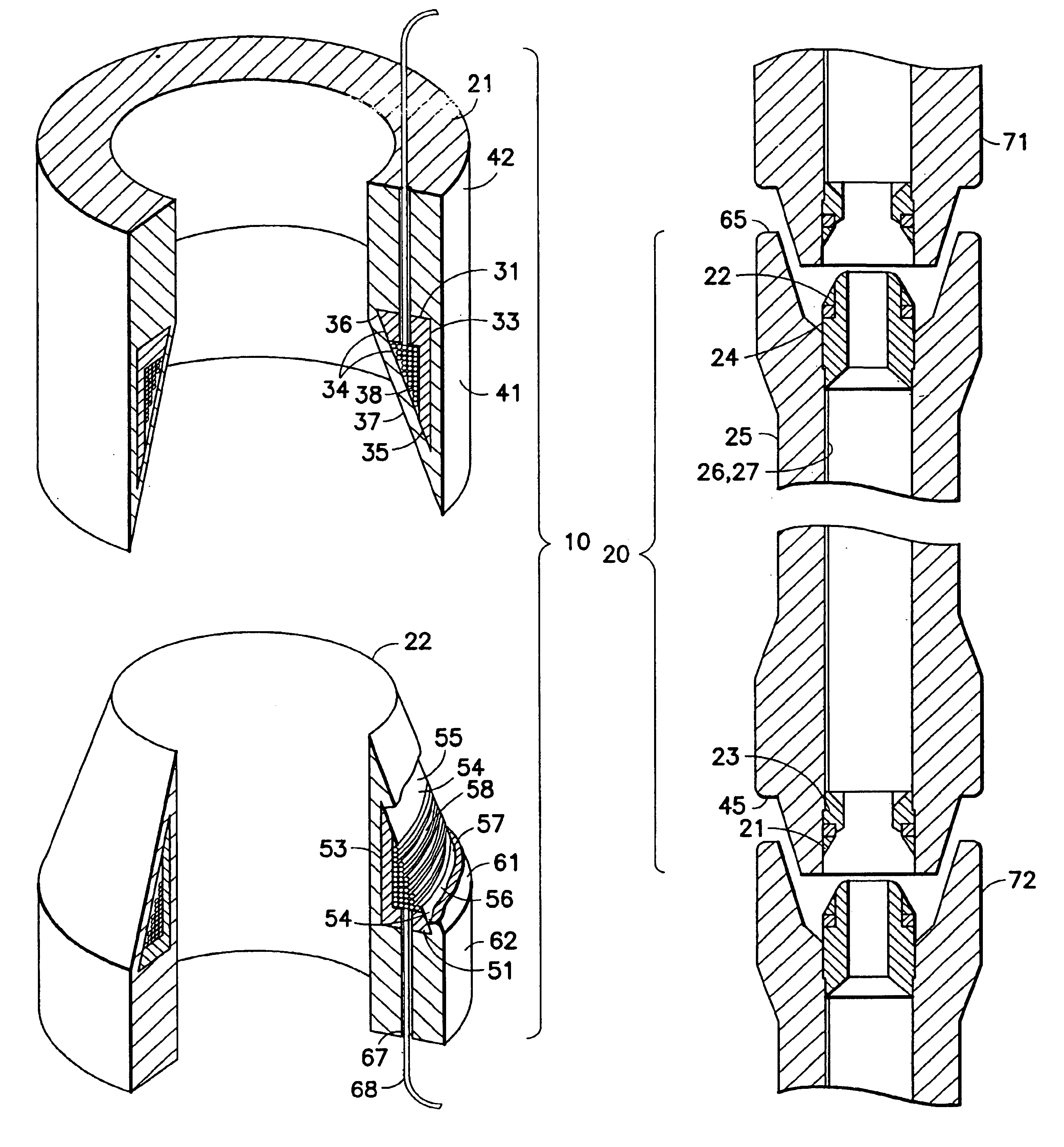

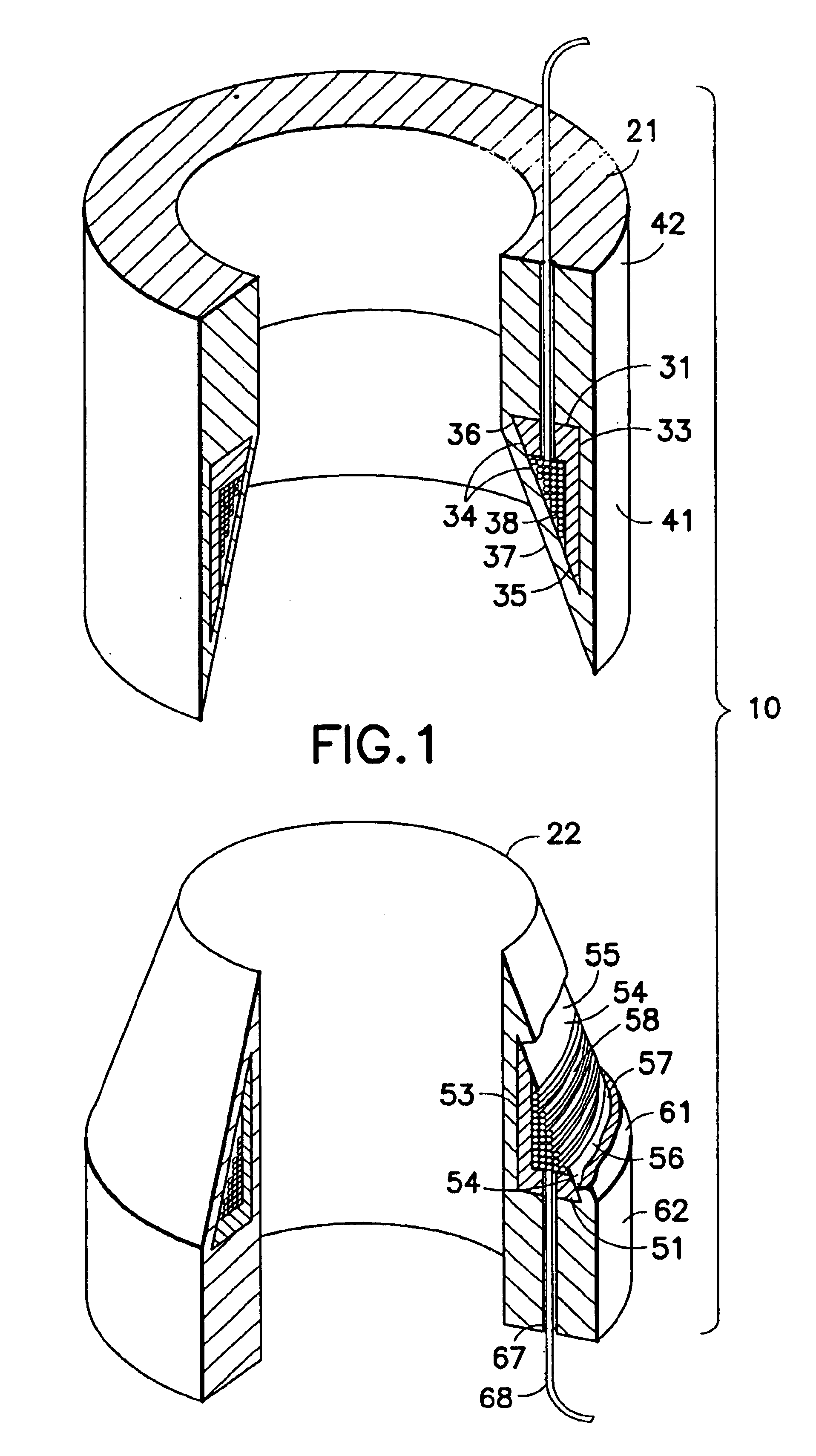

Low-loss inductive couplers for use in wired pipe strings

A first flux-loop inductive coupler element electrically couples with a second flux-loop inductive coupler element. The first flux-loop inductive coupler element comprises a first ring-like core having high magnetic permeability and a conical-section annular first face transverse to the plane of the first core. The first face has a first annular groove separating a first conical-section larger-diameter face and a first conical-section smaller-diameter face. A first coil is wound within the annular groove. The first and second cores form a low-reluctance closed magnetic path around the first coil and a second coil of the second flux-loop inductive coupler element.A first current-loop inductive coupler element electrically couples with a second current-loop inductive coupler element. The first current-loop inductive coupler element has a first high-conductivity, low-permeability shaped belt of a first end of a first pipe joint, a first ring-like core located at the first end, and a first electrically conductive coil wound about the first ring-like core. The first high-conductivity, low-permeability shaped belt partially encloses the first coil. It is shaped to cooperate with the second high-conductivity, low-permeability shaped belt of an adjacent second pipe joint having a second electrically conductive coil and a second high-conductivity, low-permeability shaped belt to create a closed toroidal electrical conducting path. The closed toroidal electrical conducting path encloses the first coil and the second coil when the first and second pipe joints are mated.

Owner:SCHLUMBERGER TECH CORP

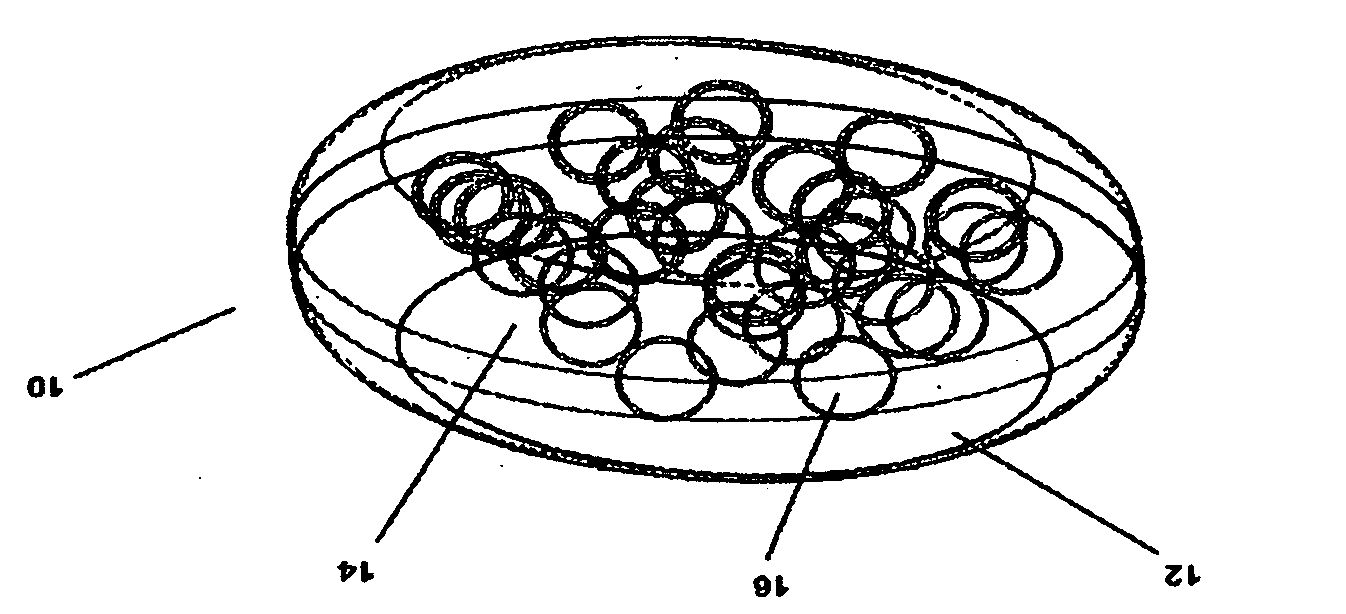

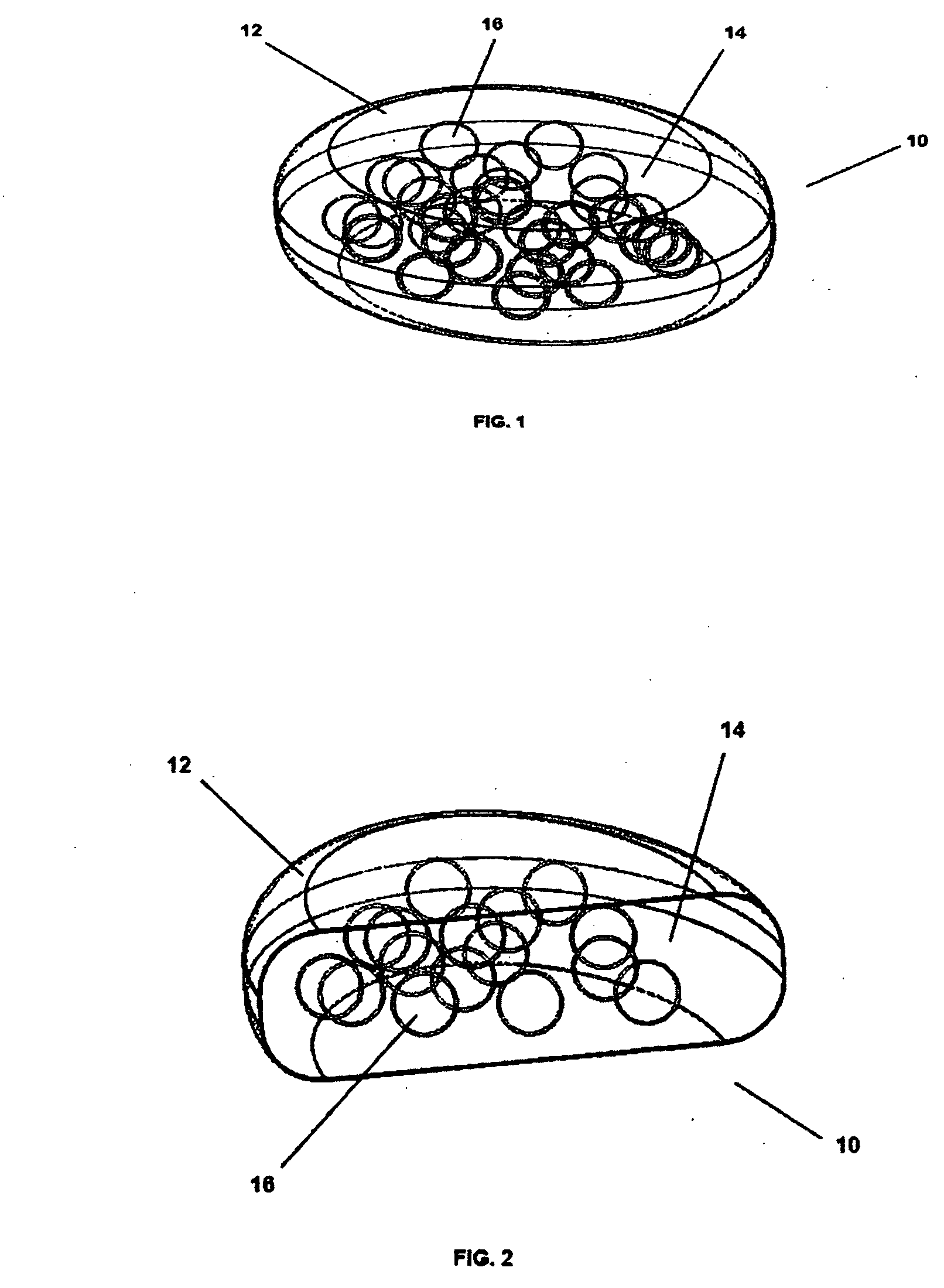

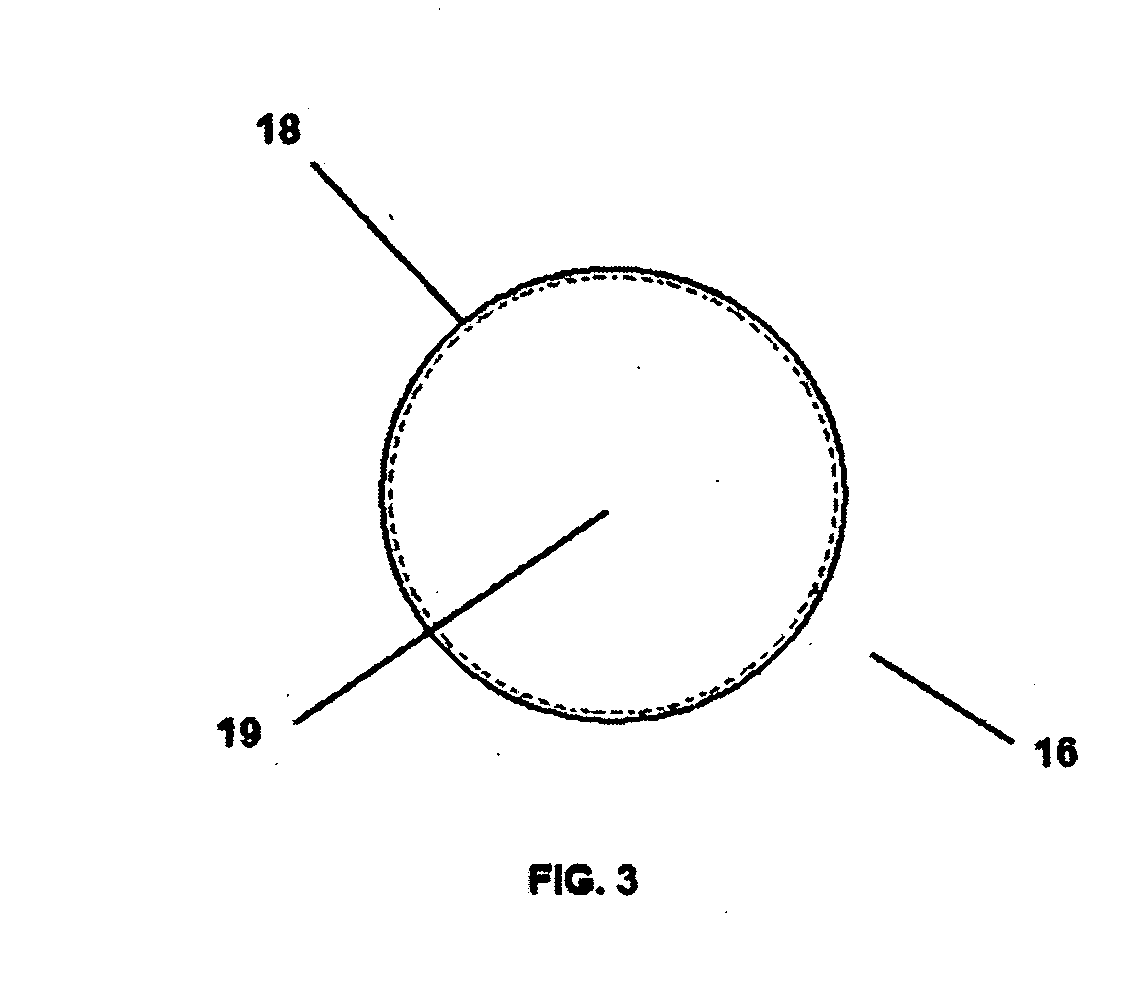

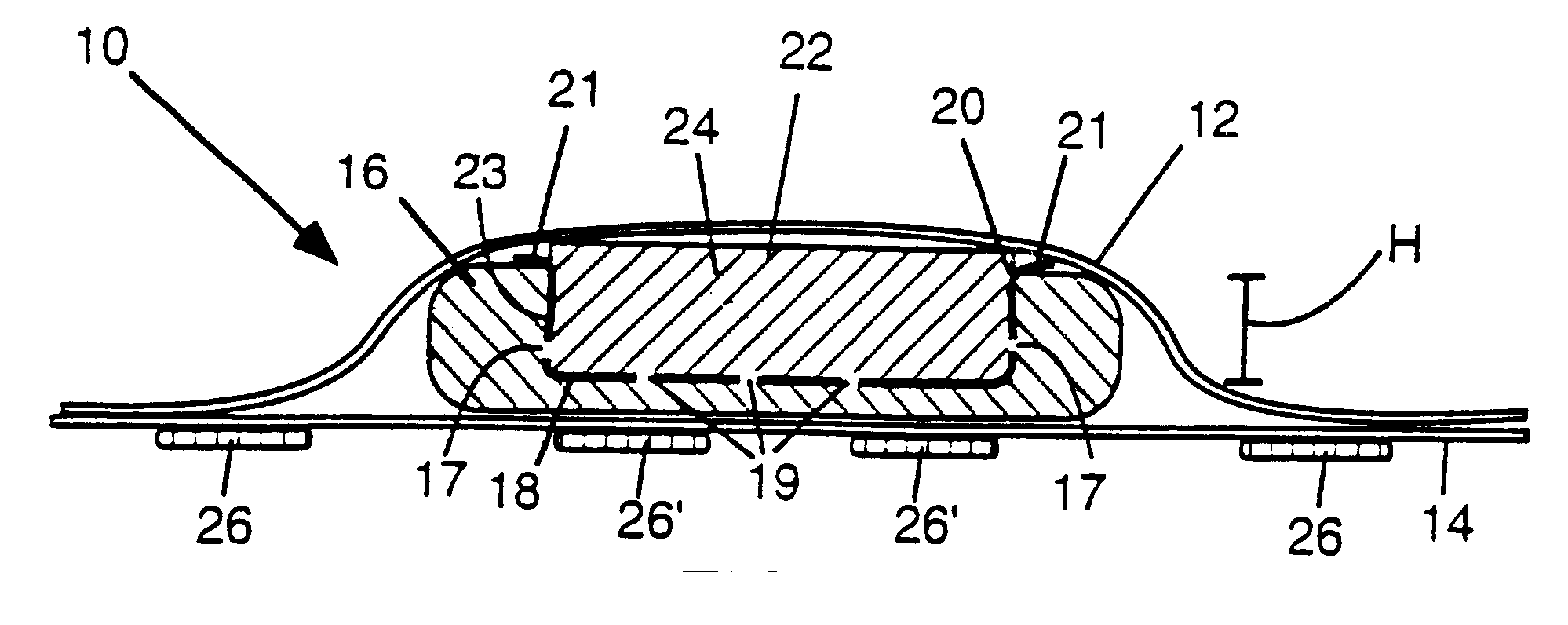

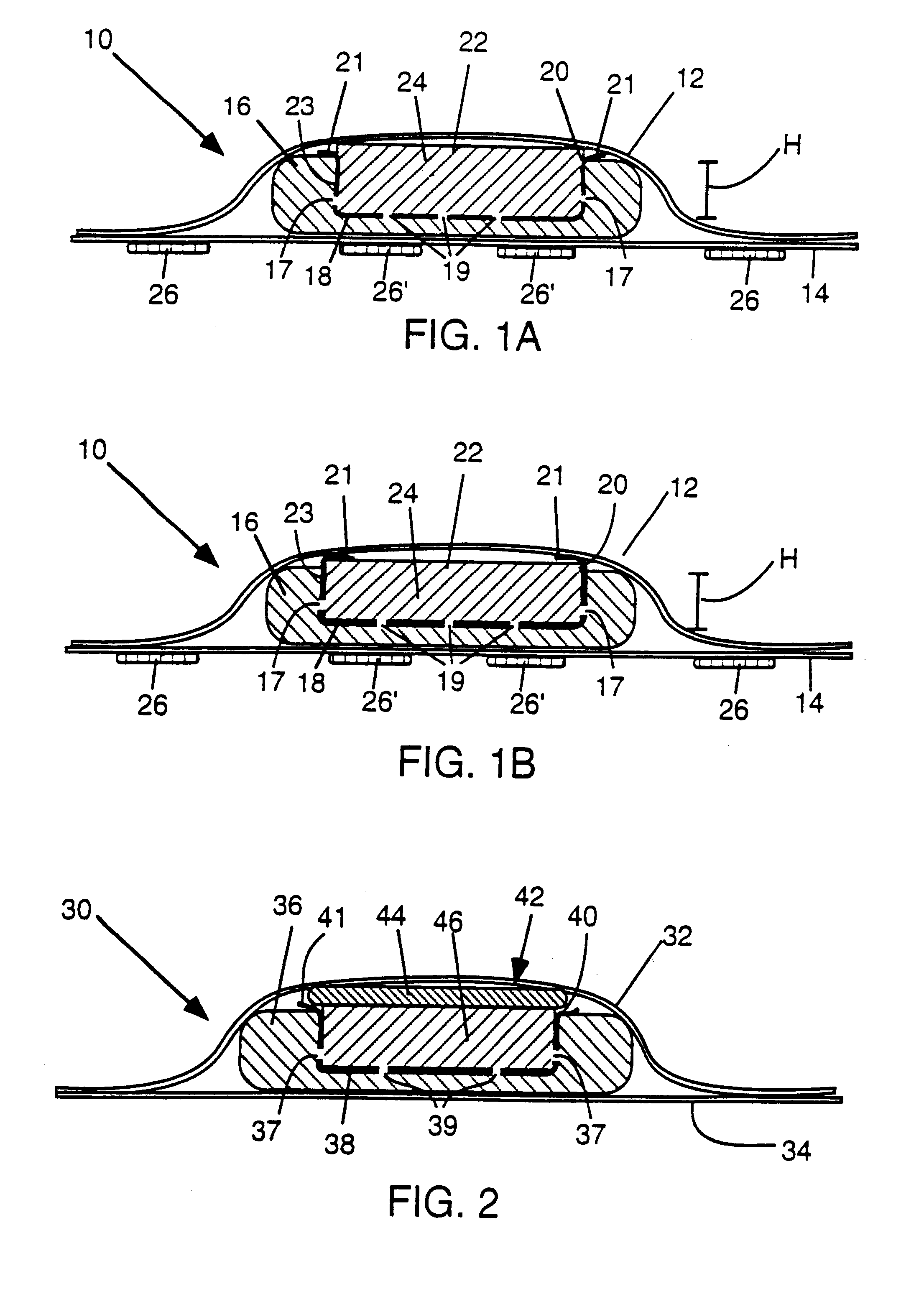

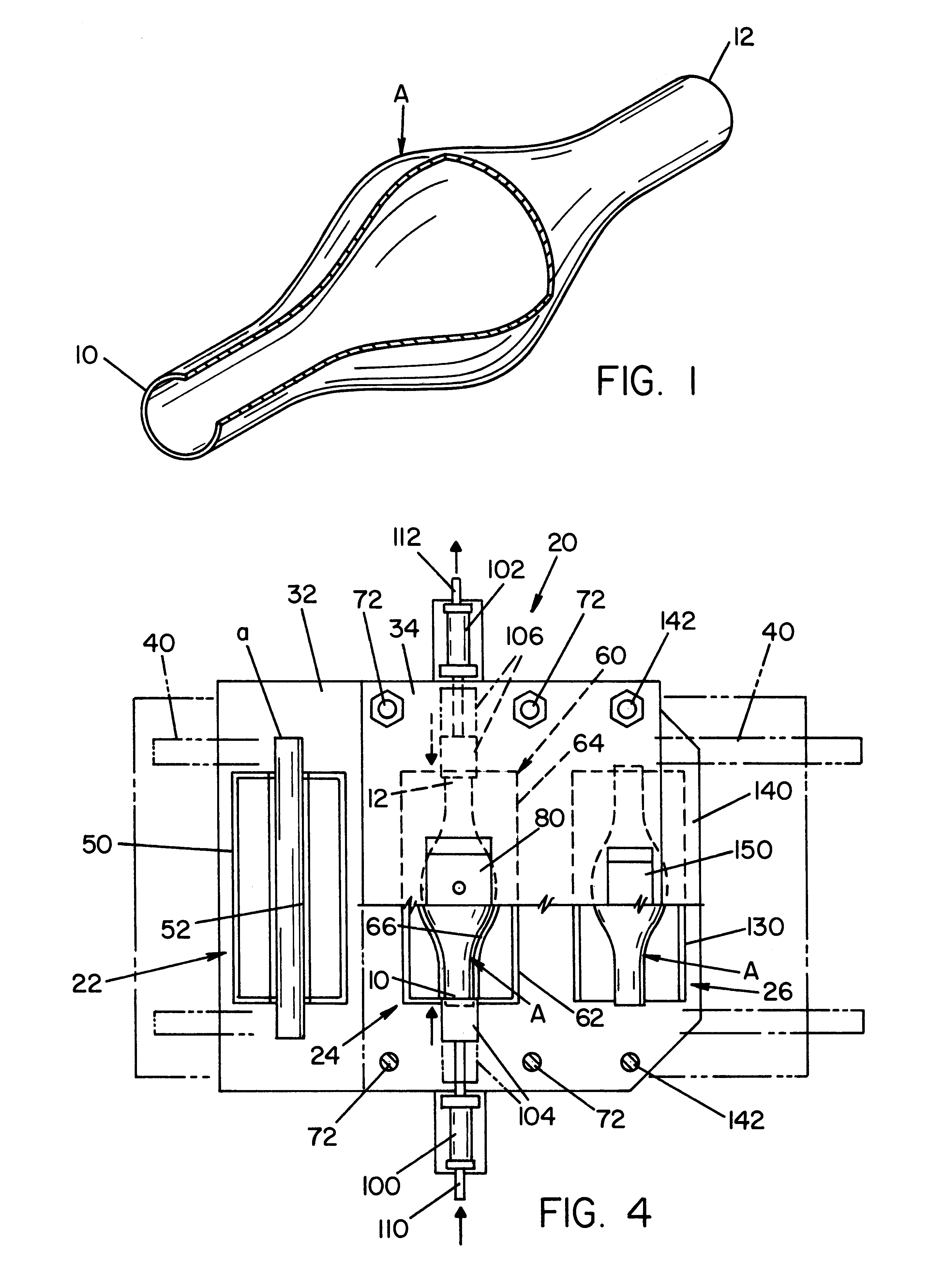

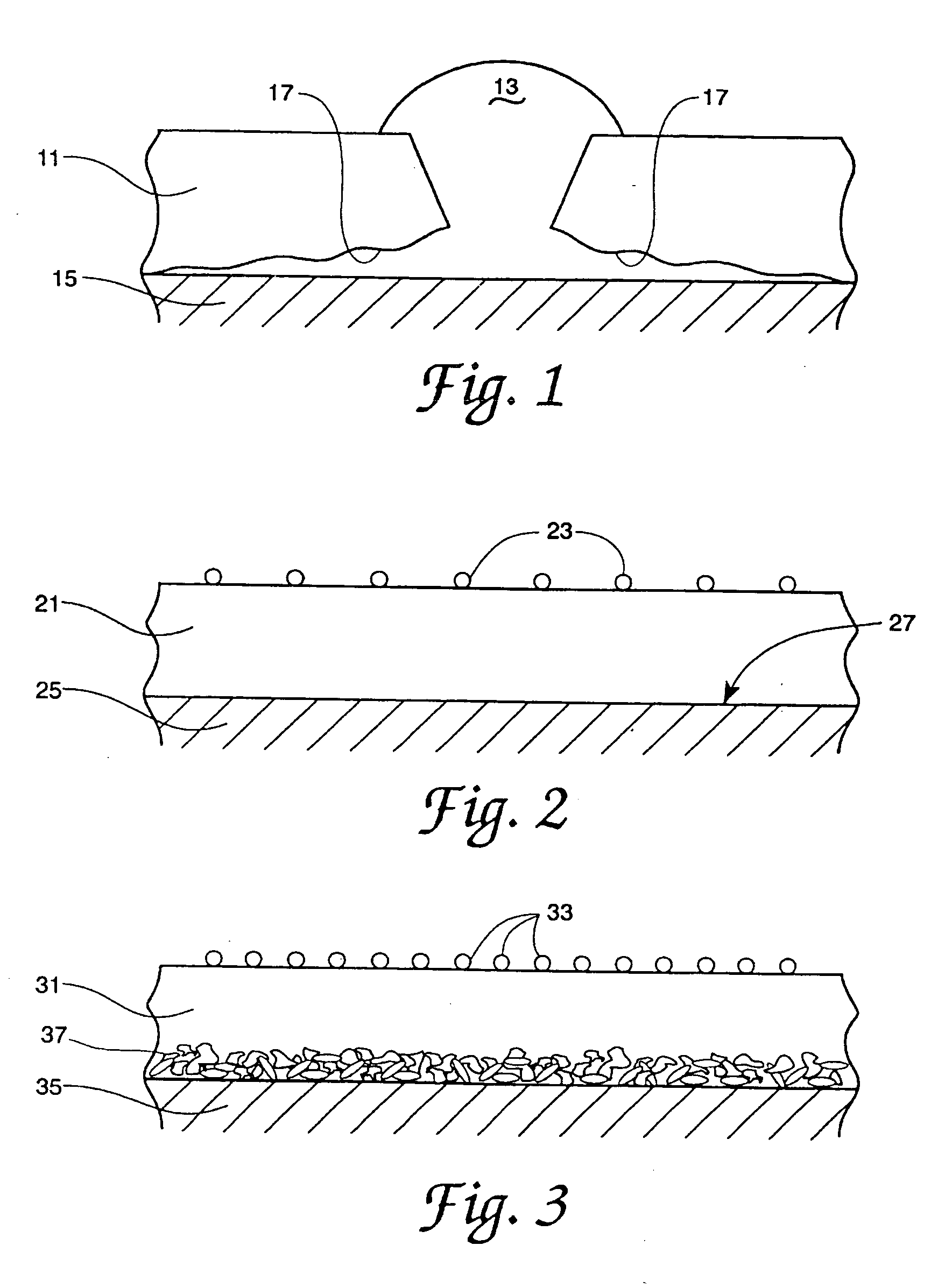

Absorbent article with center fill performance

InactiveUS6673982B1Reduce the possibilitySanitary towelsBaby linensAbsorbent materialMechanical engineering

An absorbent article comprising a central absorbent member and a lateral wicking barrier for inhibition of wicking from the central regions of the article to an outlying outer absorbent member. The wicking barrier has a vertical component for prevention of radial wicking in the plane of the article and thus promotes center filling of the article with fluid and reduces the likelihood of leaks from the sides of the article. The wicking barrier can also have a horizontal component to prevent leakage, redirect fluid flow, and improve fit and performance of the article. In one embodiment, the central absorbent member is a concentric absorbent structure having alternating rings of barrier material and absorbent material, including a spiral wound composite formed from a layer of barrier material wound with a layer of absorbent material and then sliced to provide a thin absorbent layer having high permeability in the thickness direction but low permeability in the plane due to the barrier material.

Owner:KIMBERLY-CLARK WORLDWIDE INC

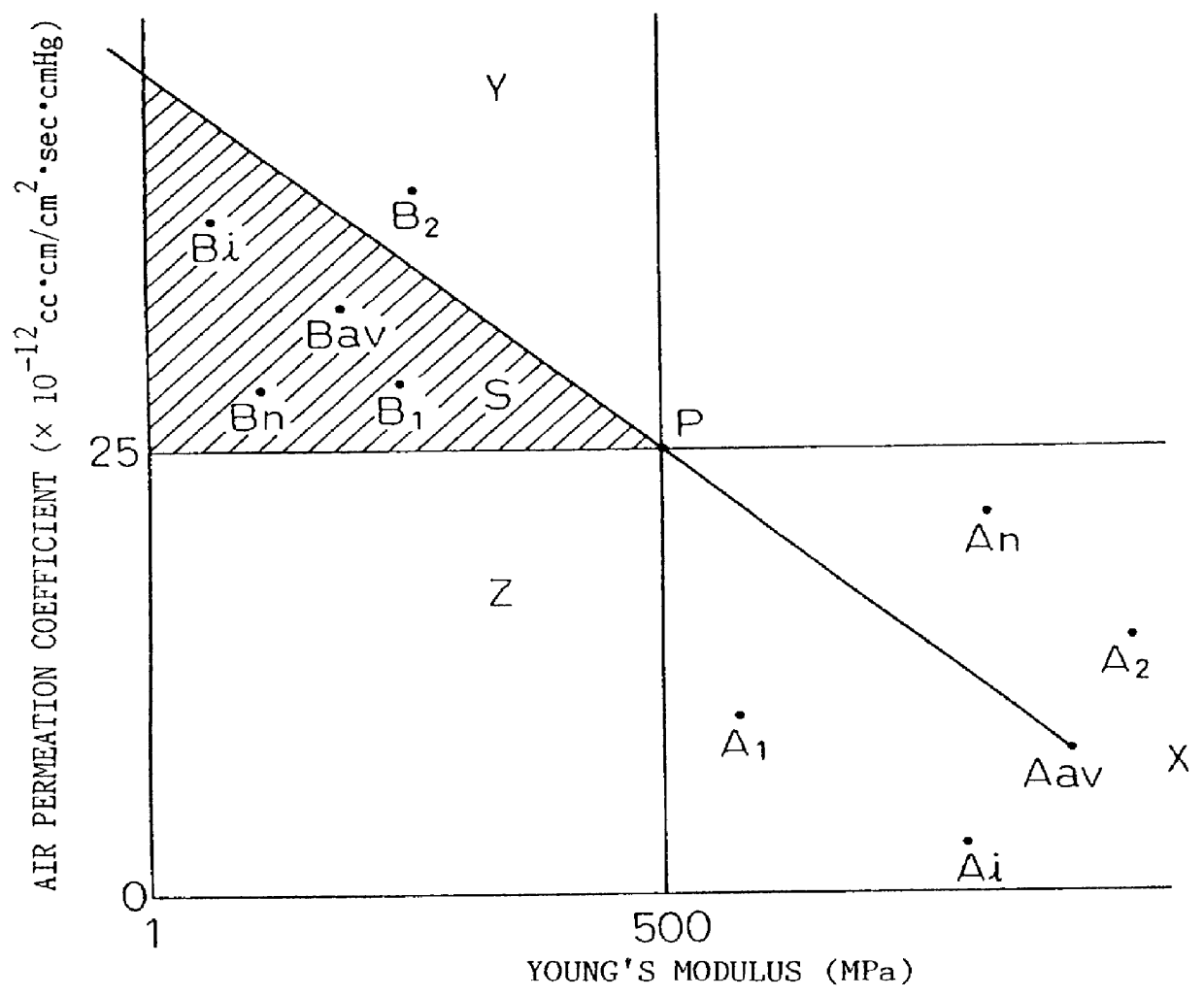

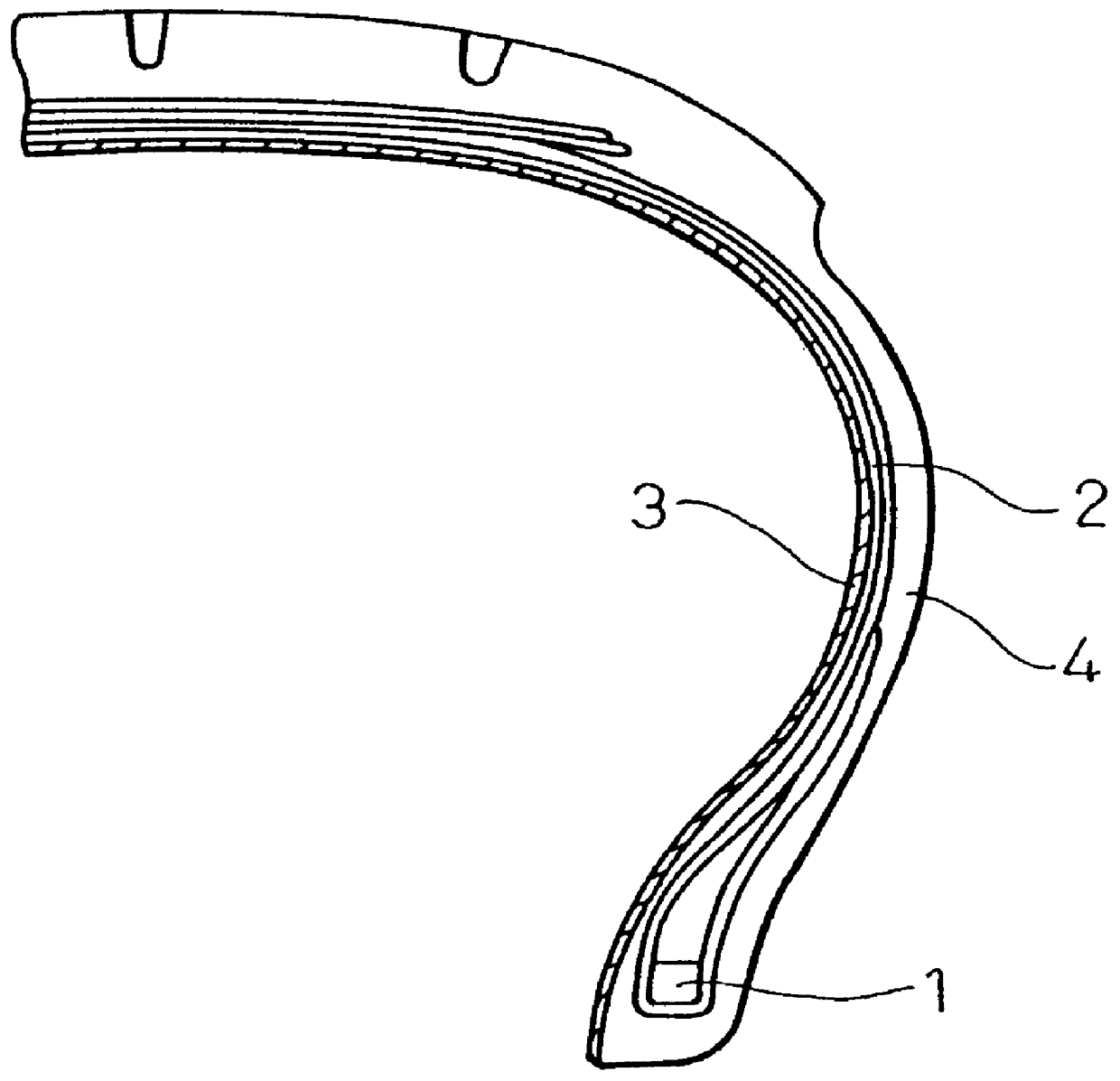

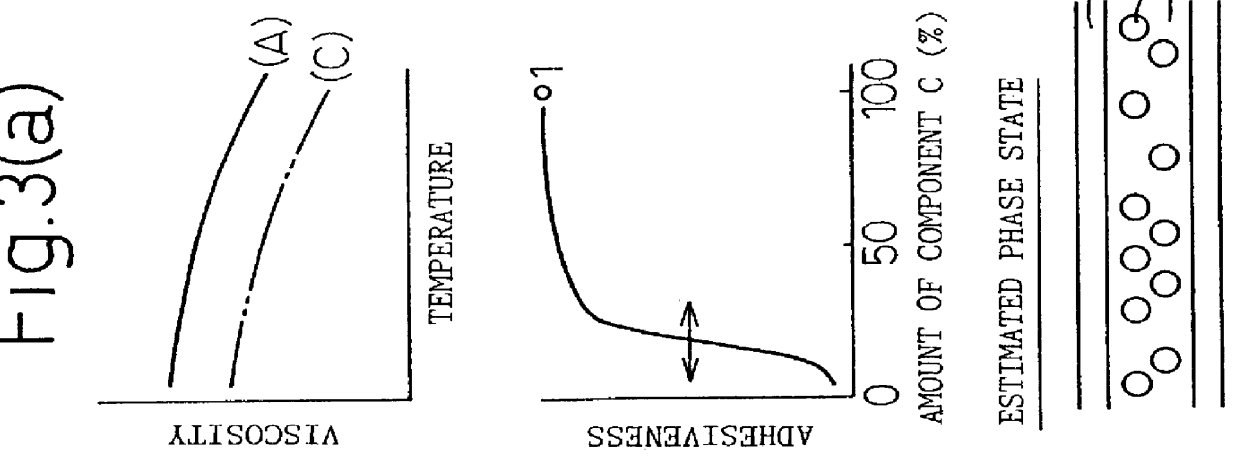

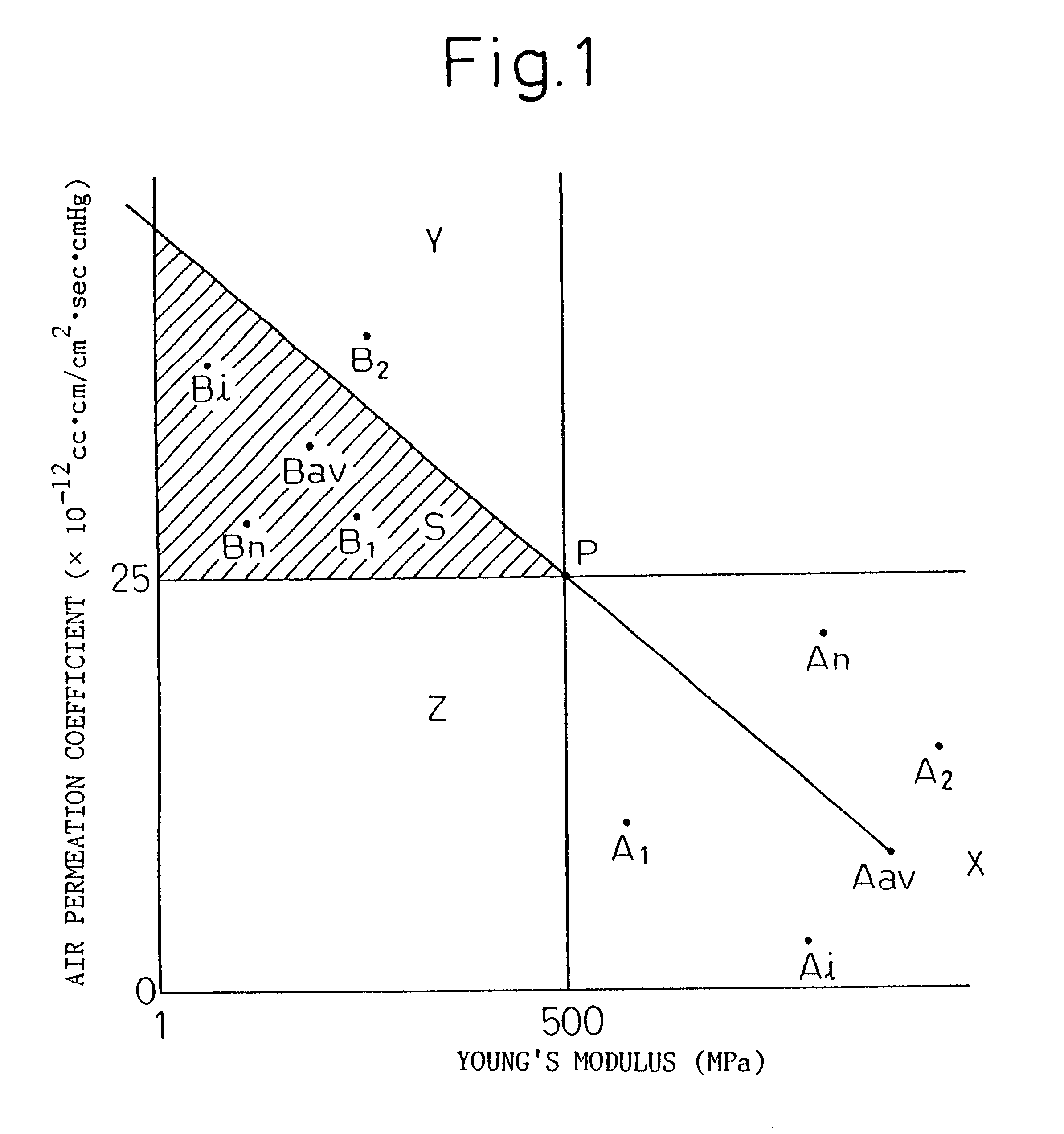

Pneumatic tire made by using lowly permeable thermoplastic elastomer composition in gas-barrier layer and thermoplastic elastomer composition for use therein

InactiveUS6062283AHigh elastomer ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

PCT No. PCT / JP97 / 01514 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 45489 PCT Pub. Date Dec. 4, 1997A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:YOKOHAMA RUBBER CO LTD

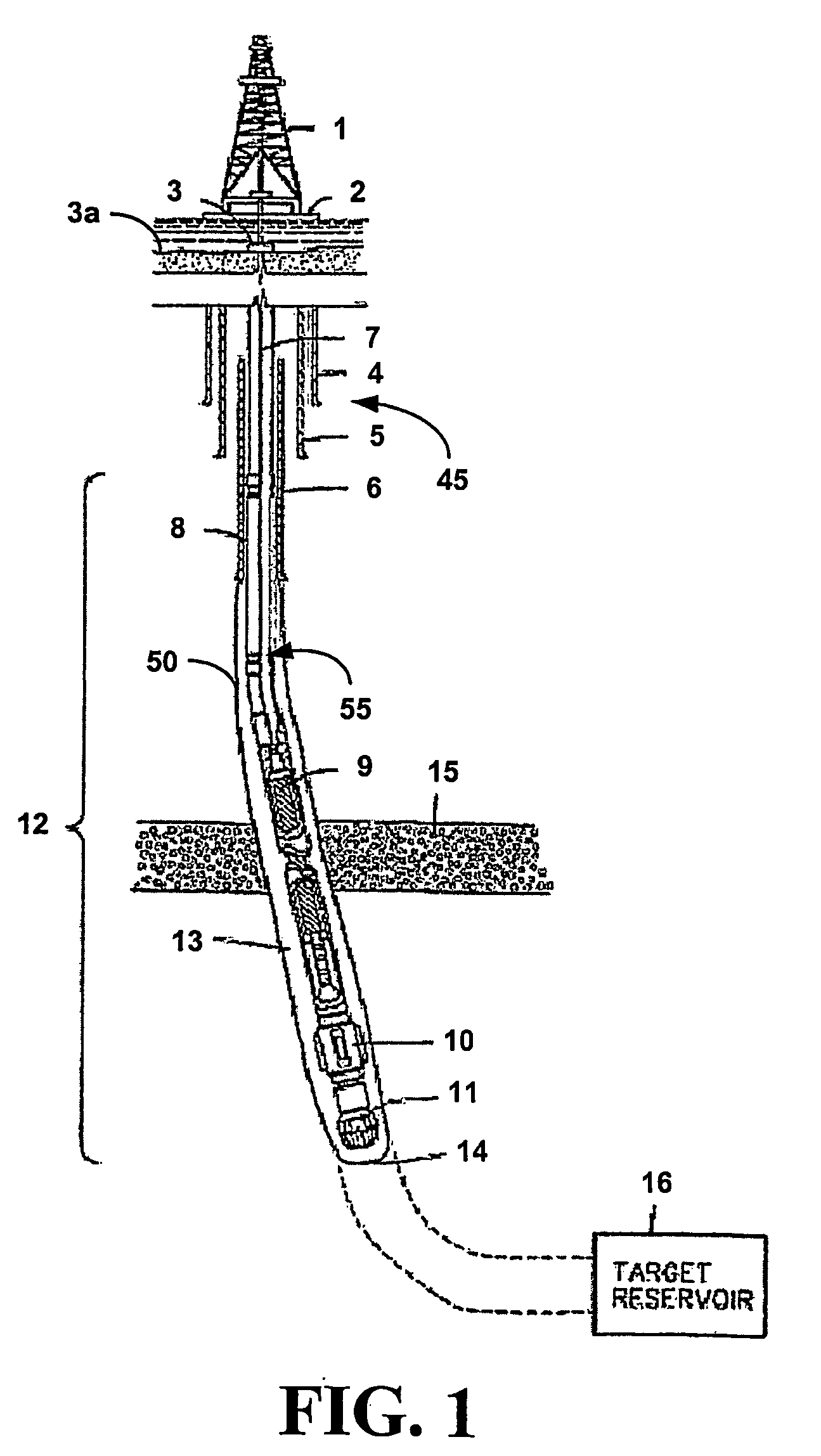

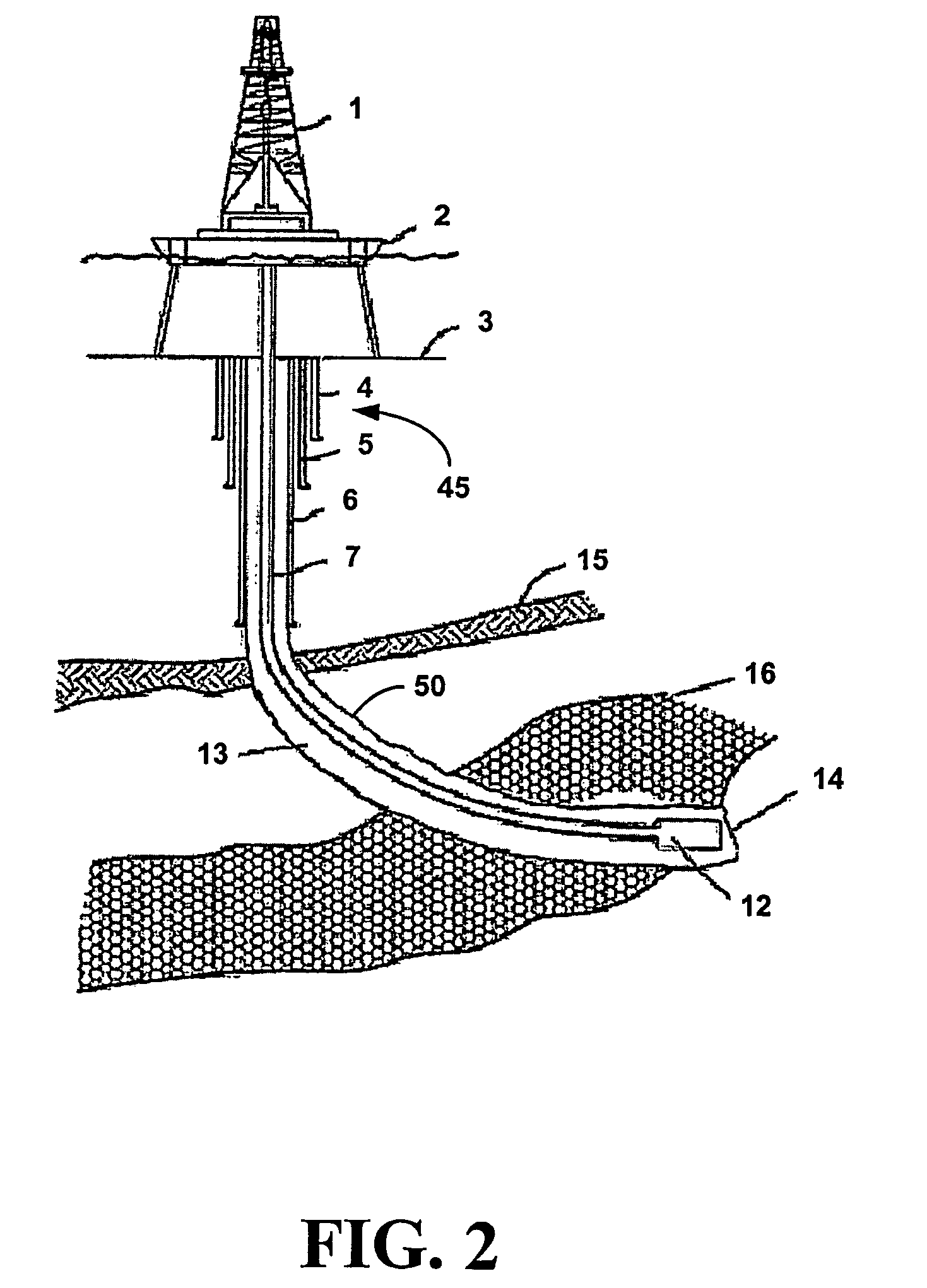

Drilling method for maintaining productivity while eliminating perforating and gravel packing

InactiveUS20060108114A1Improved formation productivityImprove productivityFluid removalProduction rateWell drilling

A method for well construction and completion is disclosed. First, a productive section of a well is drilled in the presence of a fluid system that controls fluid losses, is substantially non-damaging to the formation and includes particles in a particle size distribution sufficient to form a low permeability filter cake on a formation face and to allow the majority of the filter cake particles to flow back into the borehole after well completion. after drilling, a casing includes at least one and preferably a plurality of extendable permeable elements or member is run in the well so that the elements are positioned and aligned with sites in the producing formation and once extended form production conduits between the formation and an interior of the casing. A completed borehole is also disclosed including a casing having production conduits formed from the extendable members or elements.

Owner:BAKER HUGHES INC

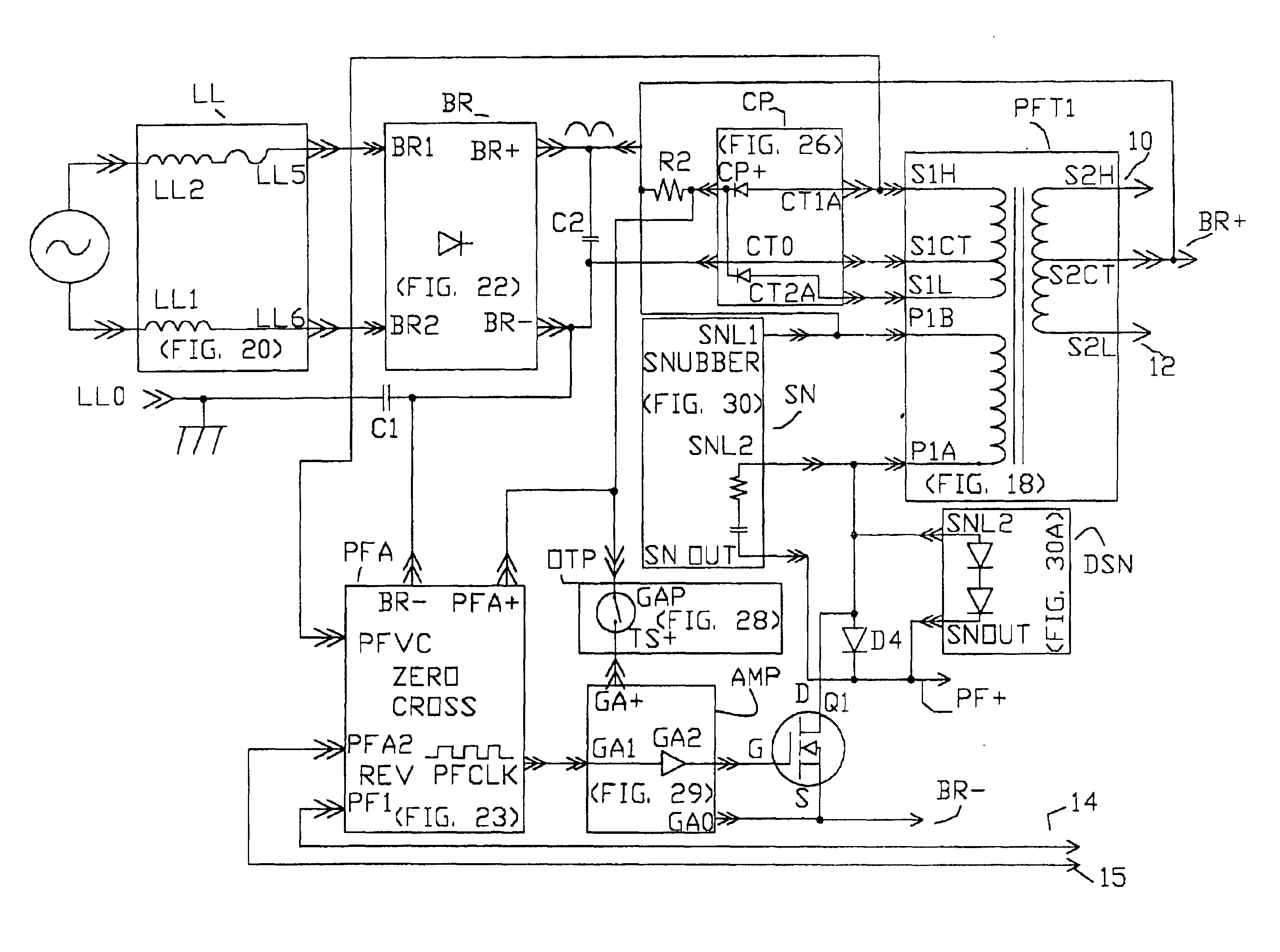

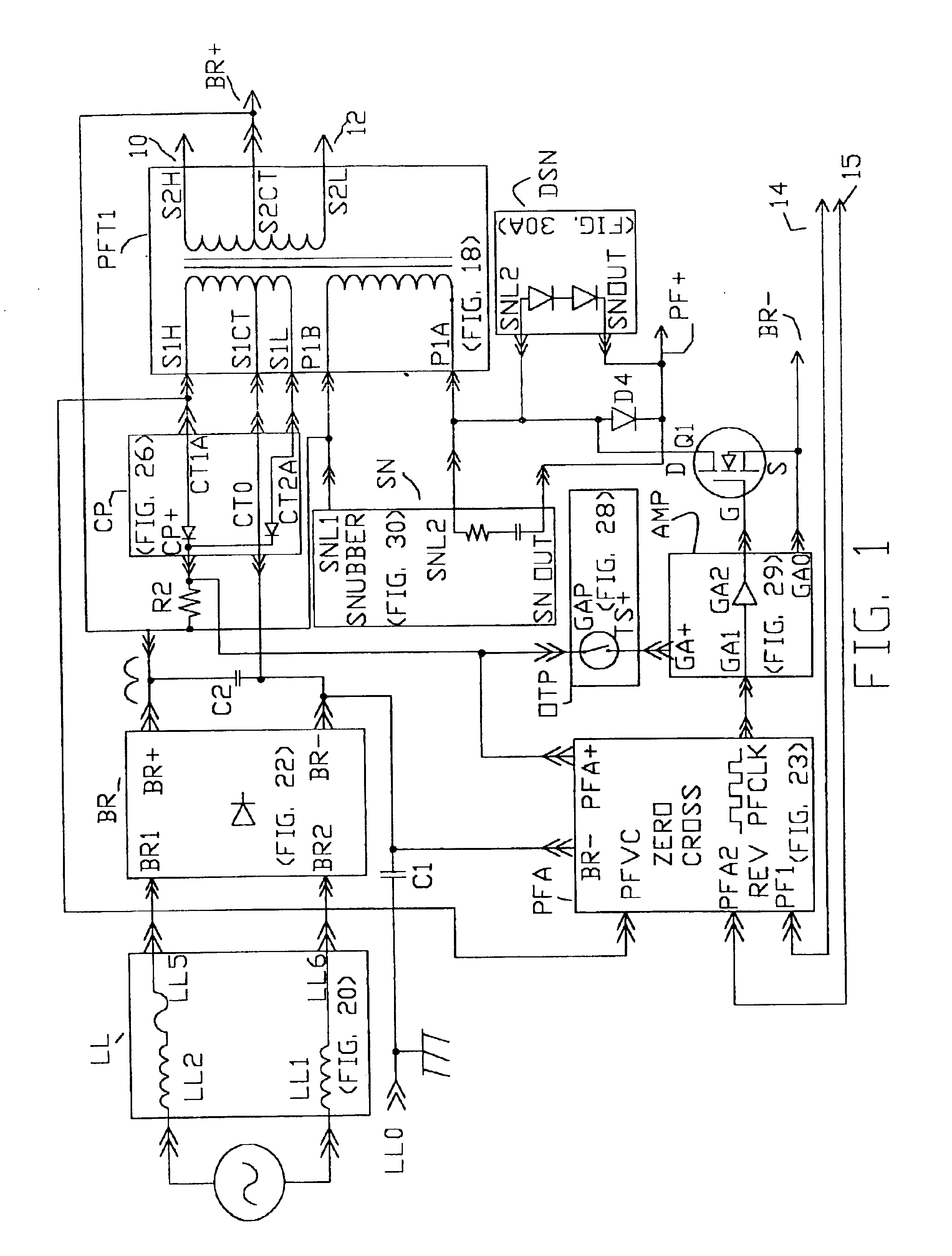

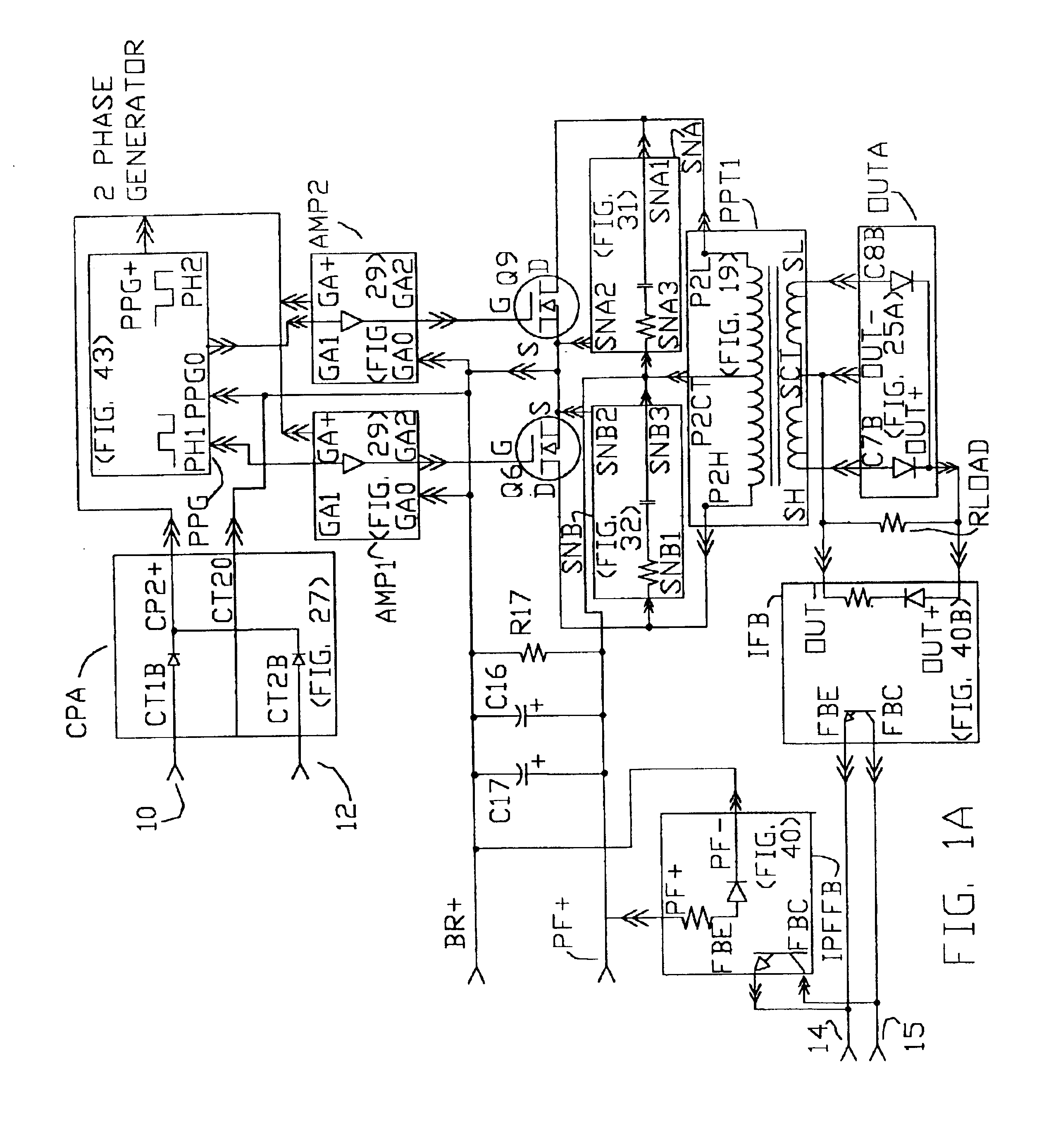

Two-stage converter using low permeability magnetics

InactiveUS6952355B2Improve power factorProvide protectionEfficient power electronics conversionDc-dc conversionDesign strategyPower density

The use of low permeability magnetic material (NSME) with the disclosed design strategies form a two-stage isolated output converter system with the distinct advantages of superior density, efficiency, thermal operating bandwidth, service life, transient survival, and form factor flexibility over the prior art. These improvements are realized by, optimized application of NSME, efficient rectifying flyback management techniques, inclusion of switching buffers that substantially reduce switching losses. The instant invention provides power factor correction, output regulation, inrush limiting, over voltage, over current, over temperature, and transient protection, multi-converter load sharing, hot swapability, and fault signals.The disclosed system is designed, specified, and certified to function from −40 deg. C. to +65 deg. C. from a 180 vac to 264 vac 50 / 60 Hz input line and supports 1000 watts of output or 600 watts from 90 vac to 120 vac 50 / 60 Hz line input at greater then 0.95 power factor and features a packaged power density of 14 watts per cu. in. at high line.

Owner:SATURN ELECTRONICS & ENG

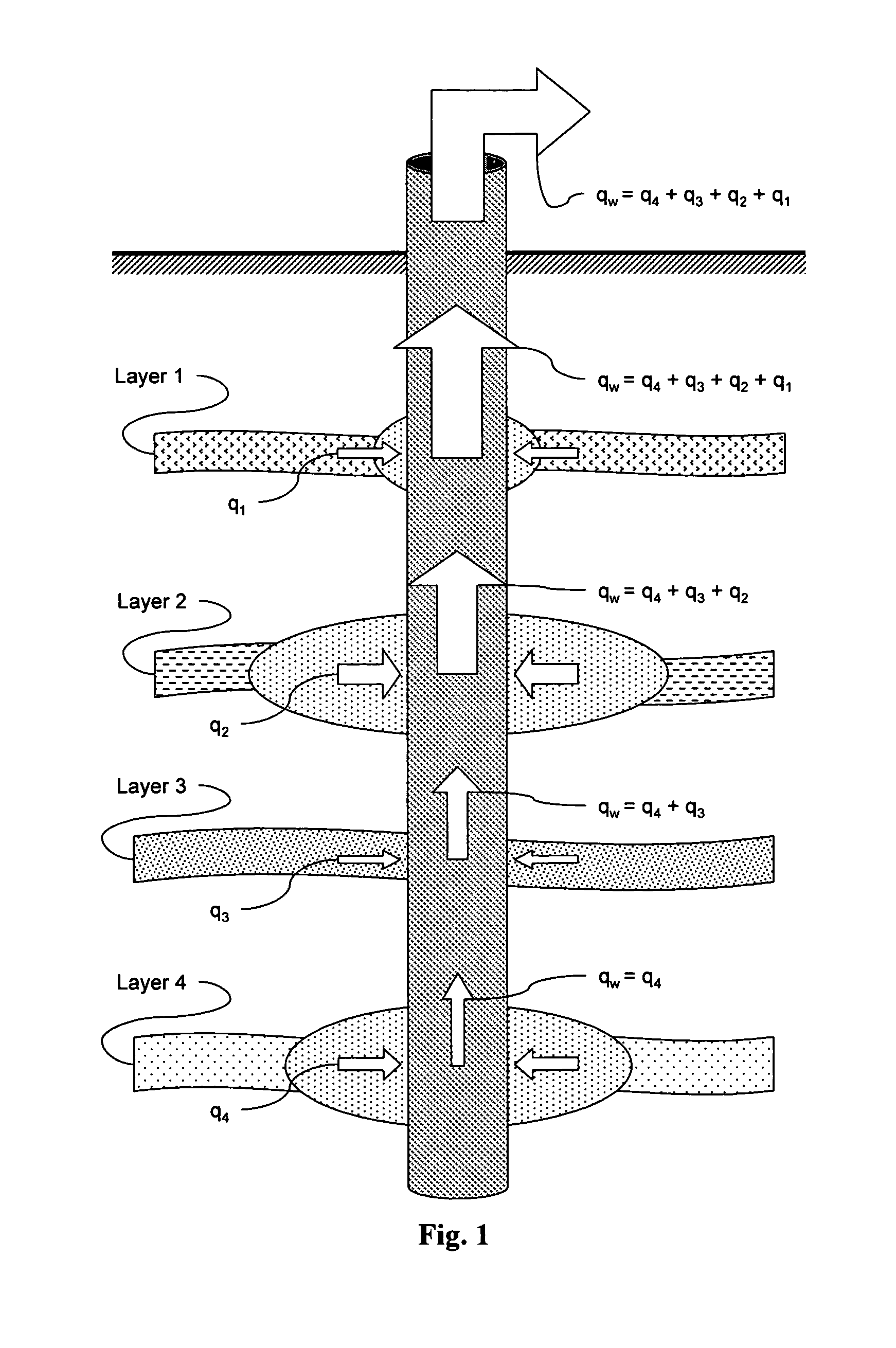

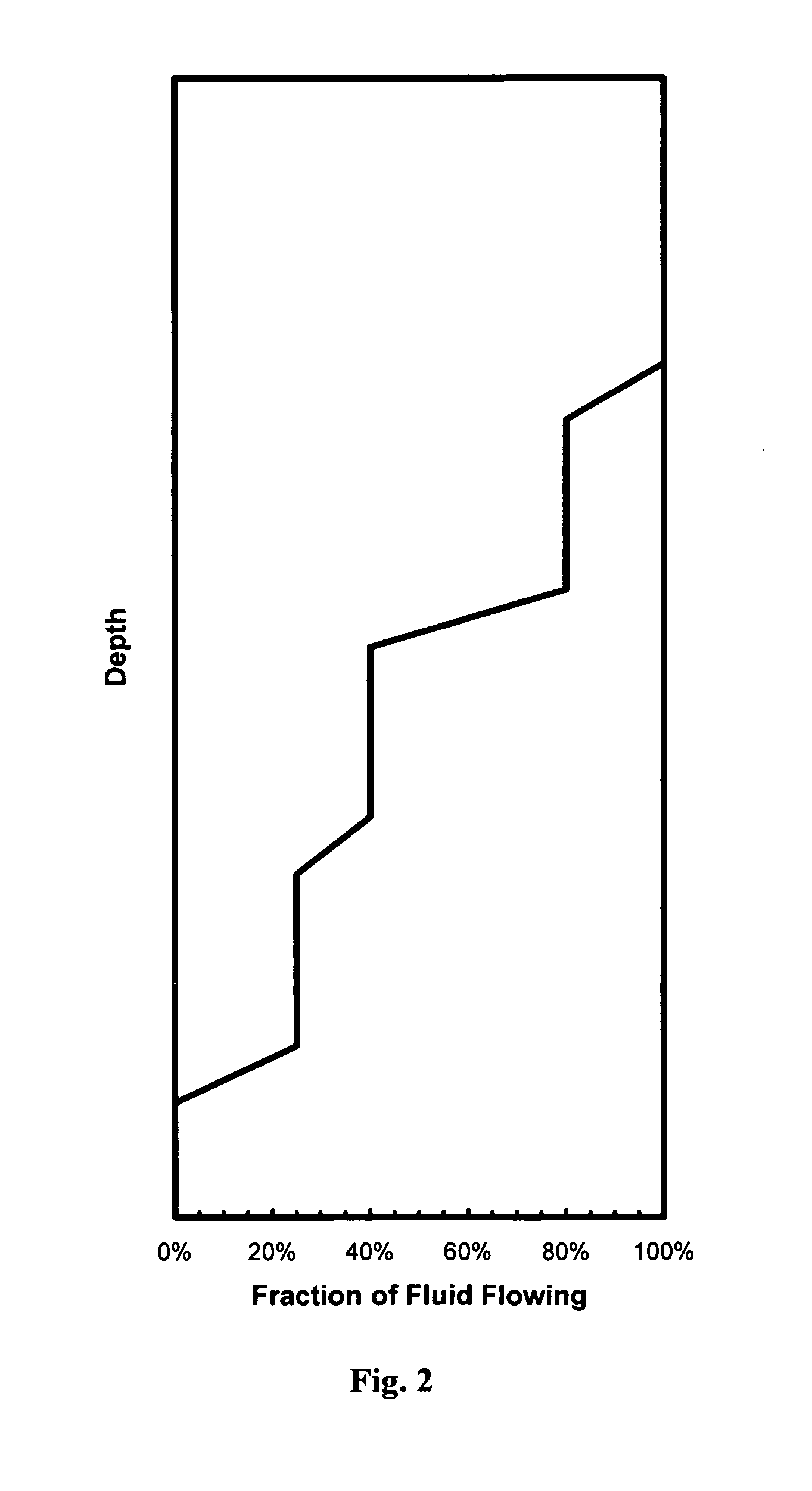

Method for characterizing and forecasting performance of wells in multilayer reservoirs having commingled production

InactiveUS7369979B1Electric/magnetic detection for well-loggingFluid removalSkin factorPredictive methods

A method for forecasting performance for and characterizing the properties of a multilayer low permeability gas reservoir. The method includes a coupled well / reservoir predictive model that accounts for pressure drop between layers, allowing accurate, rigorous, and rapid forecasting of reservoir performance. The method provides estimates of individual layer properties such as in-situ permeability, skin factor, fracture half-length, fracture conductivity, drainage area, etc. by simultaneously history matching production data and production log data using the coupled well / reservoir predictive model.

Owner:SPIVEY JOHN PAUL

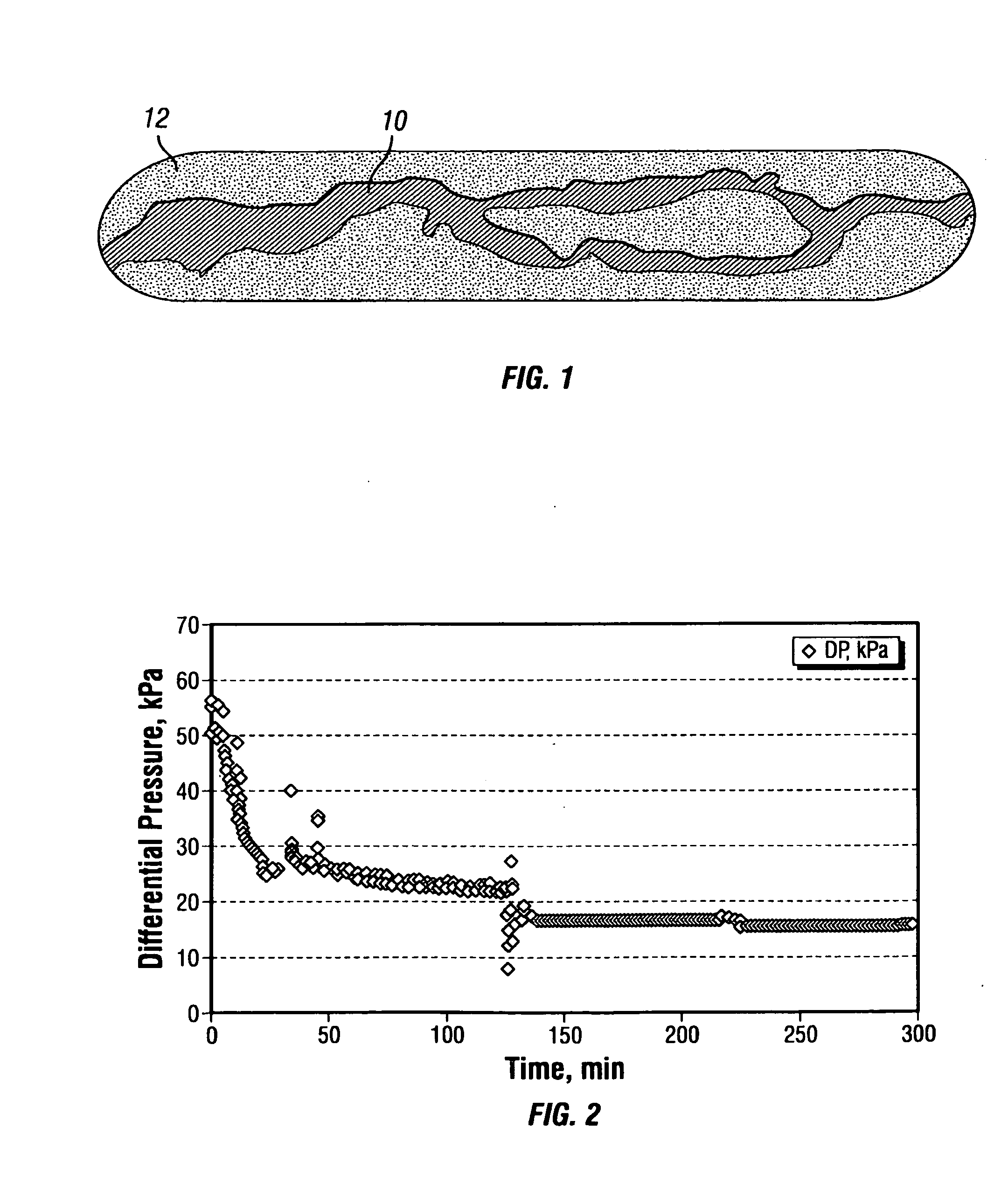

Proppant placement

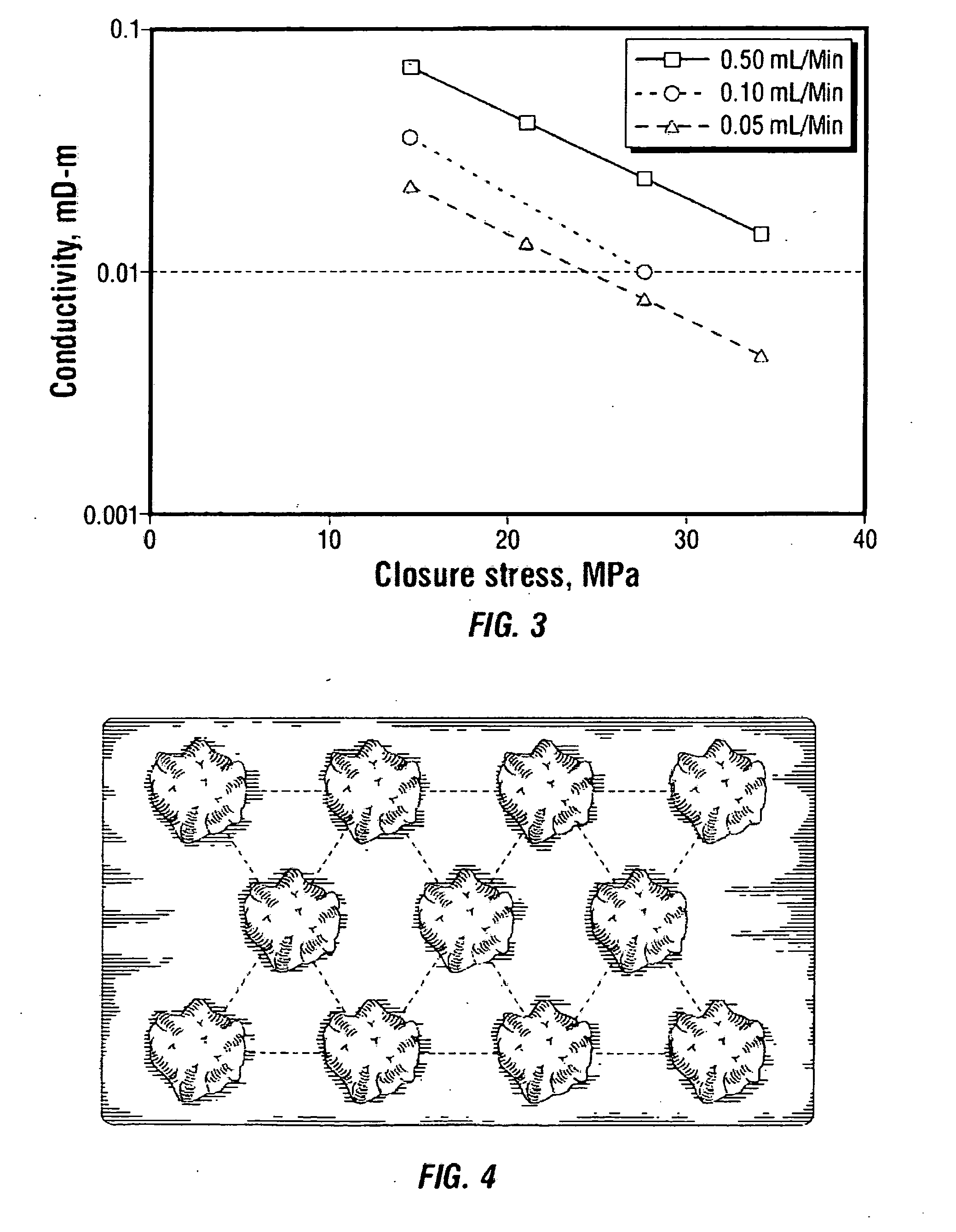

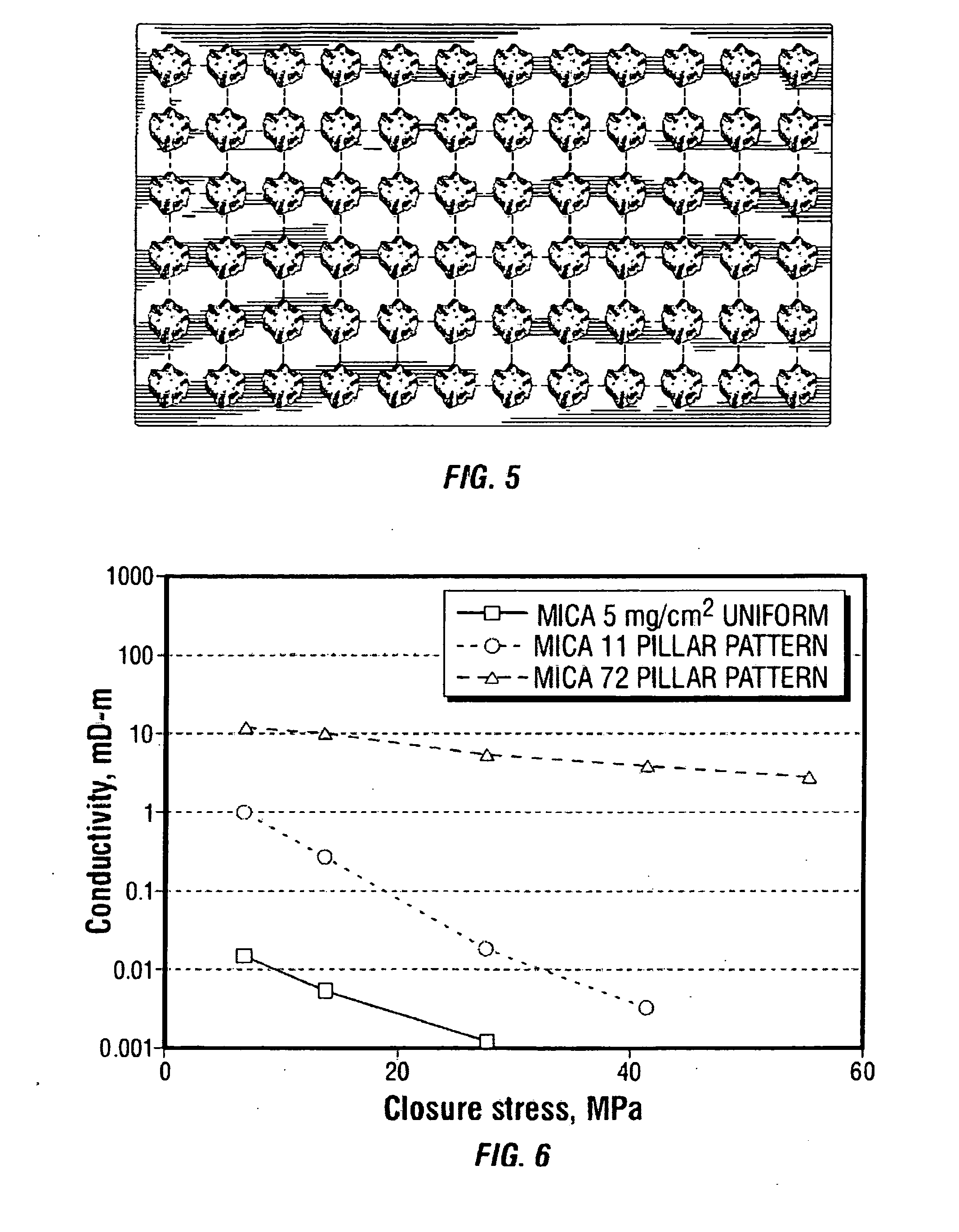

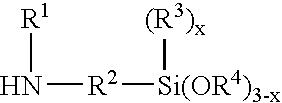

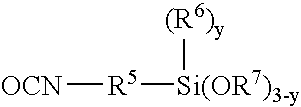

InactiveUS20130161003A1Induce and enhance non-uniformityImprove conductivityFluid removalDrilling compositionFlocculationEngineering

Embodiments of hydraulic fracturing methods disclosed herein use fine mesh proppant. In one embodiment the method is used to fracture a low permeability formation. In one embodiment the method uses flocculation to improve conductivity of a fracture. In one embodiment fluid flow through the fine mesh proppant in the fracture creates a network of connected channels to improve the fracture conductivity.

Owner:SCHLUMBERGER TECH CORP

Sealant composition having reduced permeability to gas

This invention relates to a moisture-curable silylated resin-containing composition containing, inter alia, moisture-curable silylated resin, the cured composition exhibiting low permeability to gas(es).

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

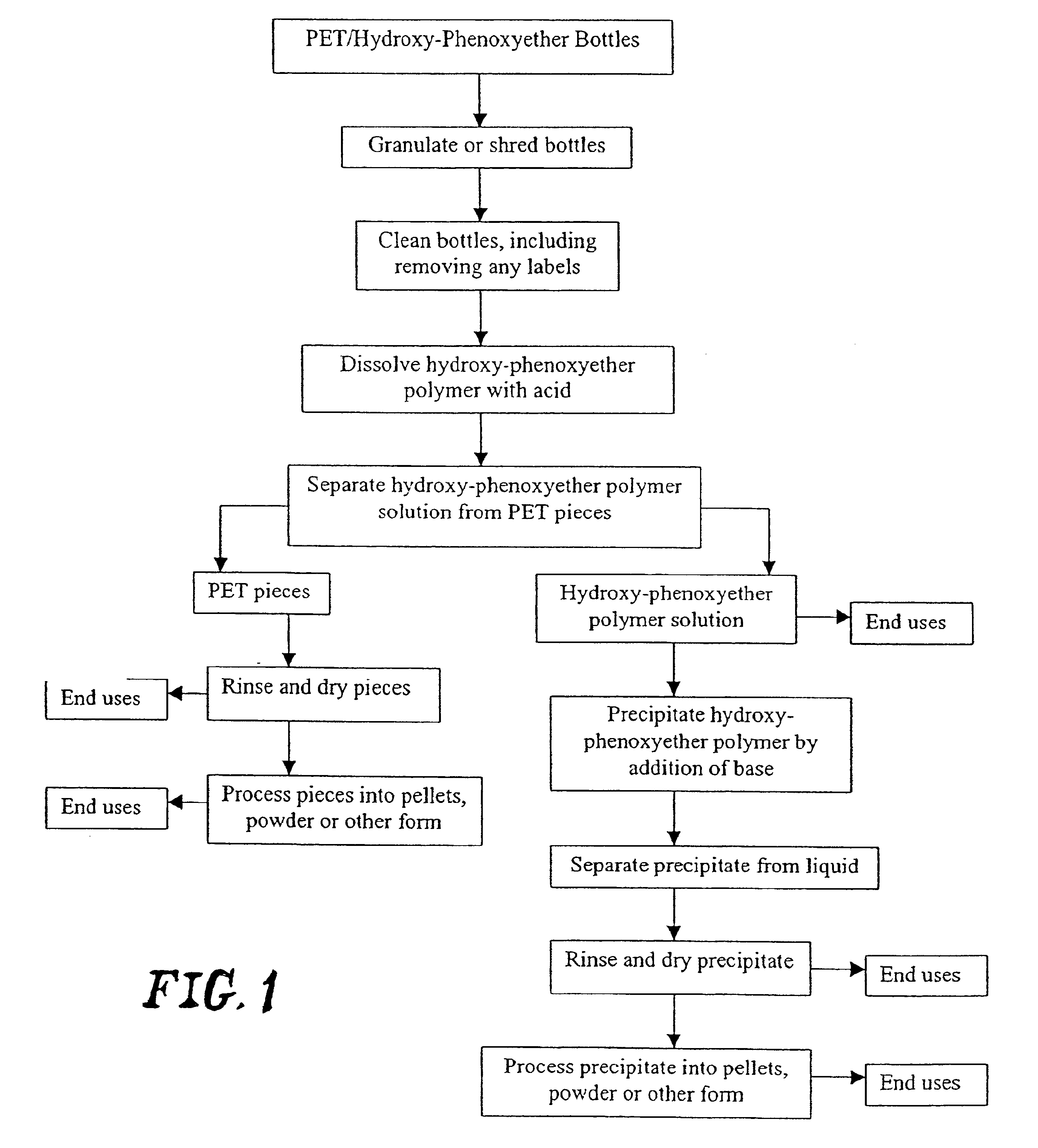

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS6808820B2Reduce the amount requiredMaintain good propertiesSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

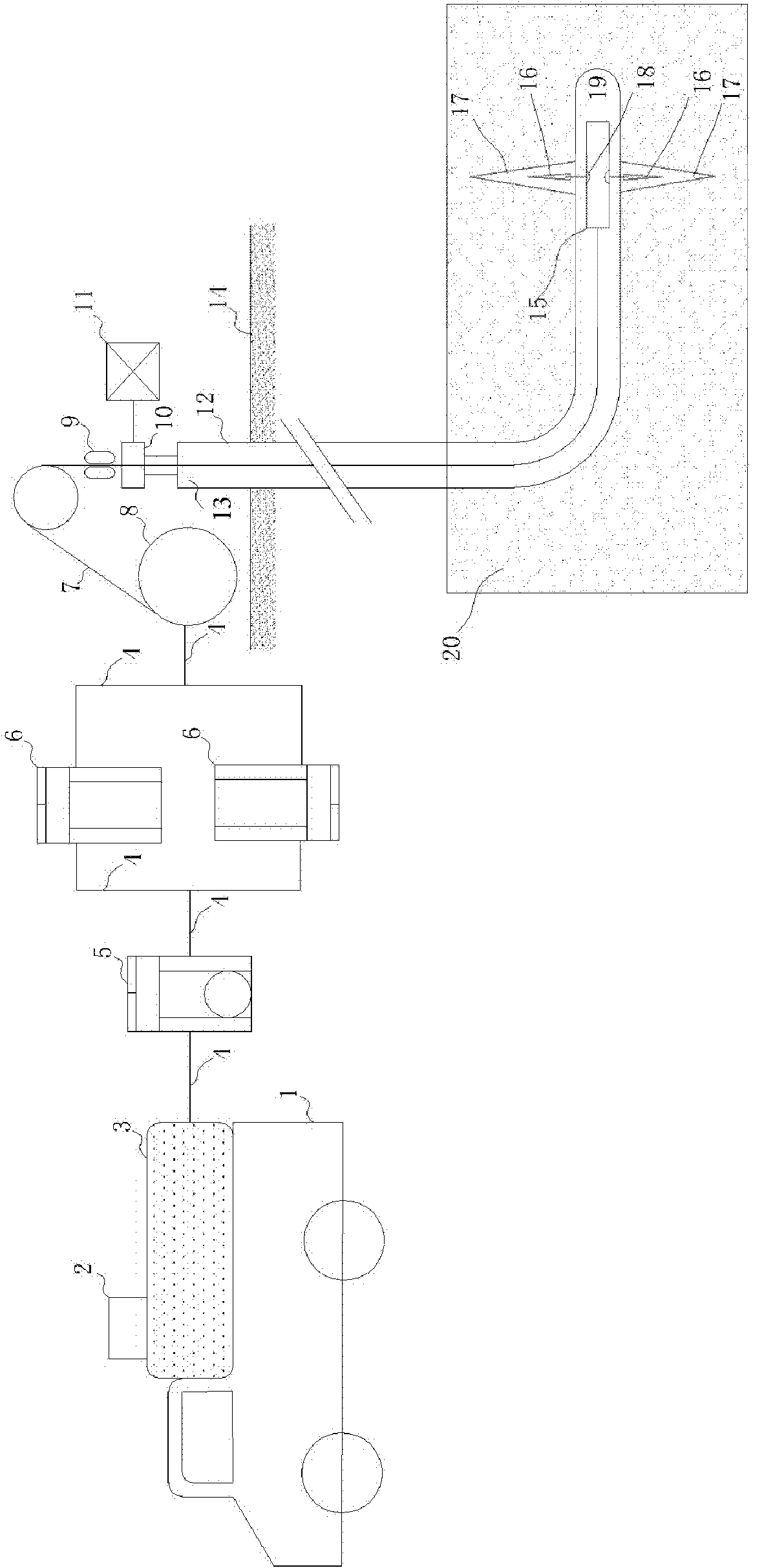

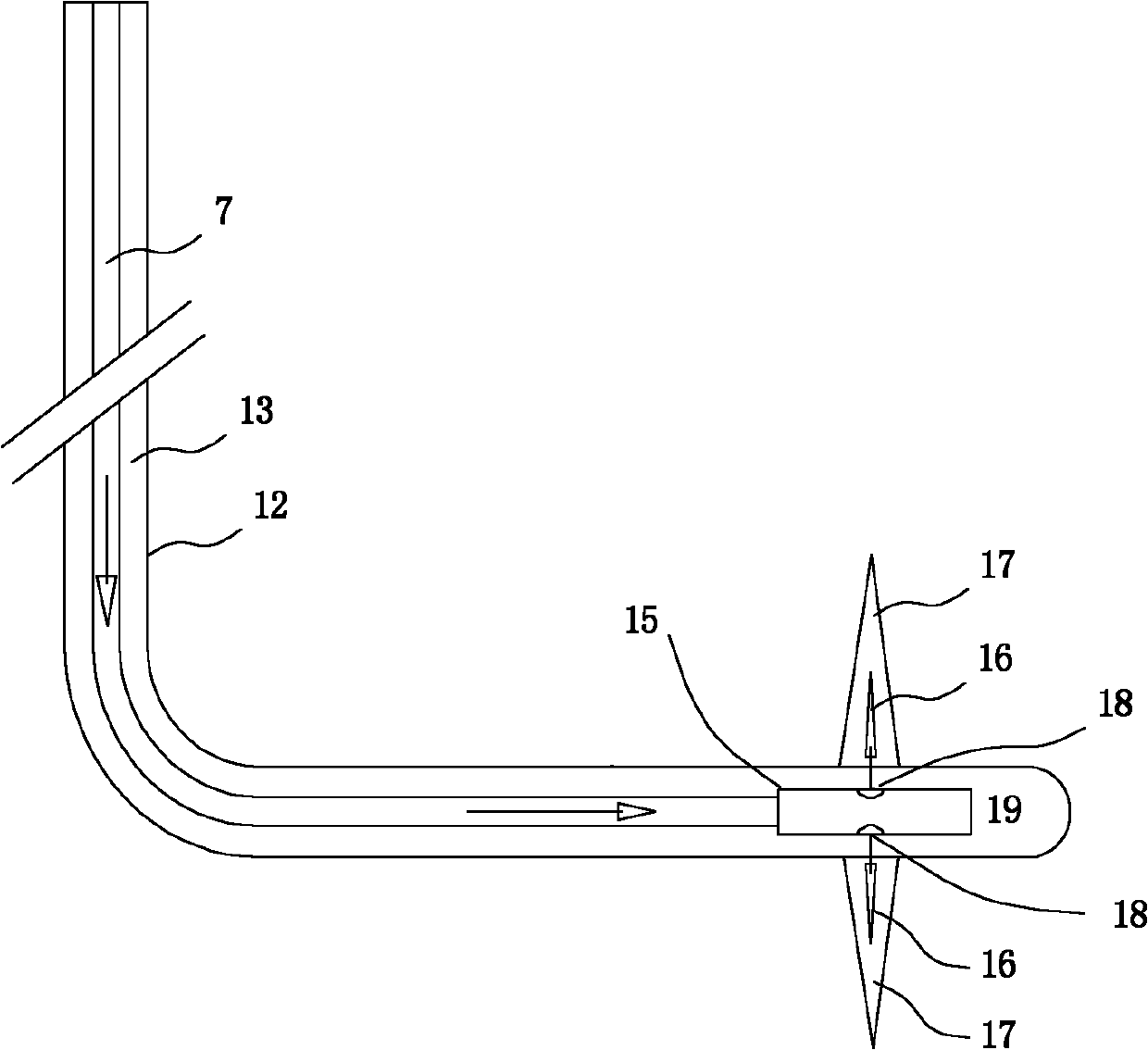

Coiled tubing supercritical CO2 jet fracturing method

ActiveCN102168545AJet rock breaking efficiency is highRock breaking threshold pressure is lowLiquid/gas jet drillingFluid removalWater basedFracturing fluid

The invention relates to a coiled tubing supercritical CO2 jet fracturing method. The method is used for performing jet fracturing on oil well reservoirs by taking supercritical CO2 as fracturing fluid. By the method, a supercritical CO2 fluid is used as the fracturing fluid to perform the jet fracturing; a supercritical CO2 sand jet perforating hole can reduce system pressure; the pressure needed by fissure extension can be further reduced by the characteristics of low viscosity and high dispersion performance of the supercritical CO2 fluid; most importantly, the supercritical CO2 jet fracturing does not pollute the reservoirs, but the supercritical CO2 can further improve the oil and gas recovery ratio after entering the reservoirs; the return discharge is not needed after the fracturing is completed; when the stage-by-stage jet fracturing is performed by using the coiled tubing, a tube pillar can be lifted or put down without mineshaft pressure relieving, the operation process is reduced and the operation cost is reduced, so that the method is extremely suitable for fracturing modification of unconventional oil-gas reservoirs such as thick oil reservoirs, low permeability and super-low permeability oil-gas reservoirs, shale gas reservoirs, coal bed methane reservoirs and the like of which the effects are low by using the conventional water-based fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

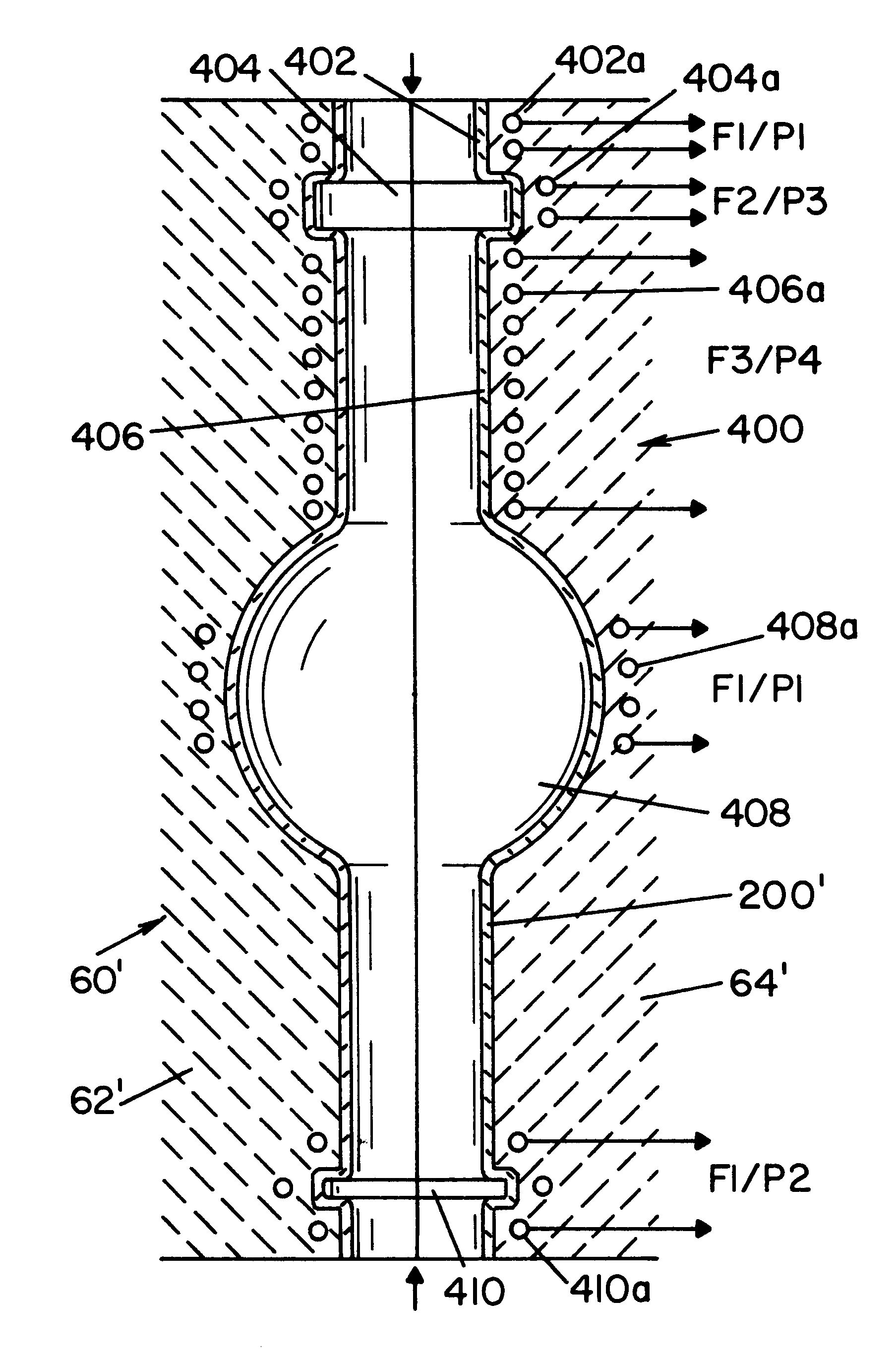

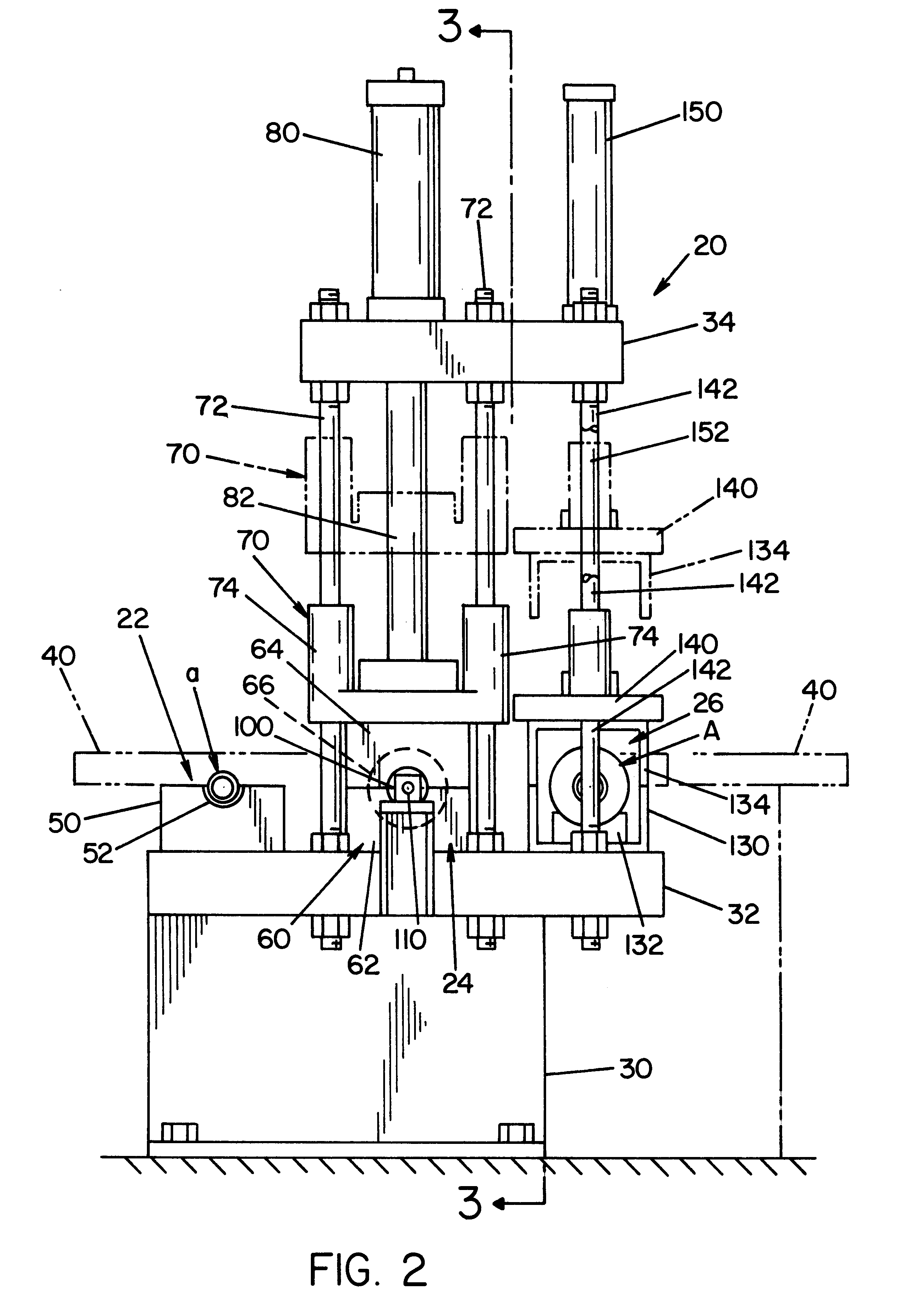

Method of forming a tubular blank into a structural component and die therefor

InactiveUS6322645B1Quick upgradeImprove mechanical propertiesShaping toolsFurnace typesElectrical conductorEngineering

A method of forming an elongated tubular blank into a tubular structural component having a predetermined outer configuration, the method comprising: providing a shape imparting shell formed from a low permeability, rigid material which includes an inner surface defining the predetermined shape, plugging the open ends of the tubular blank, placing the plugged blank into the shell, and forming the tubular blank into the tubular component by inductively heating axial portions of the blank by axially spaced conductors adjacent the shell while or before forcing gas at a high pressure into the plugged blank until the blank conforms to at least a portion of the inner surface of the shell to form the structural component.

Owner:TEMPER IP

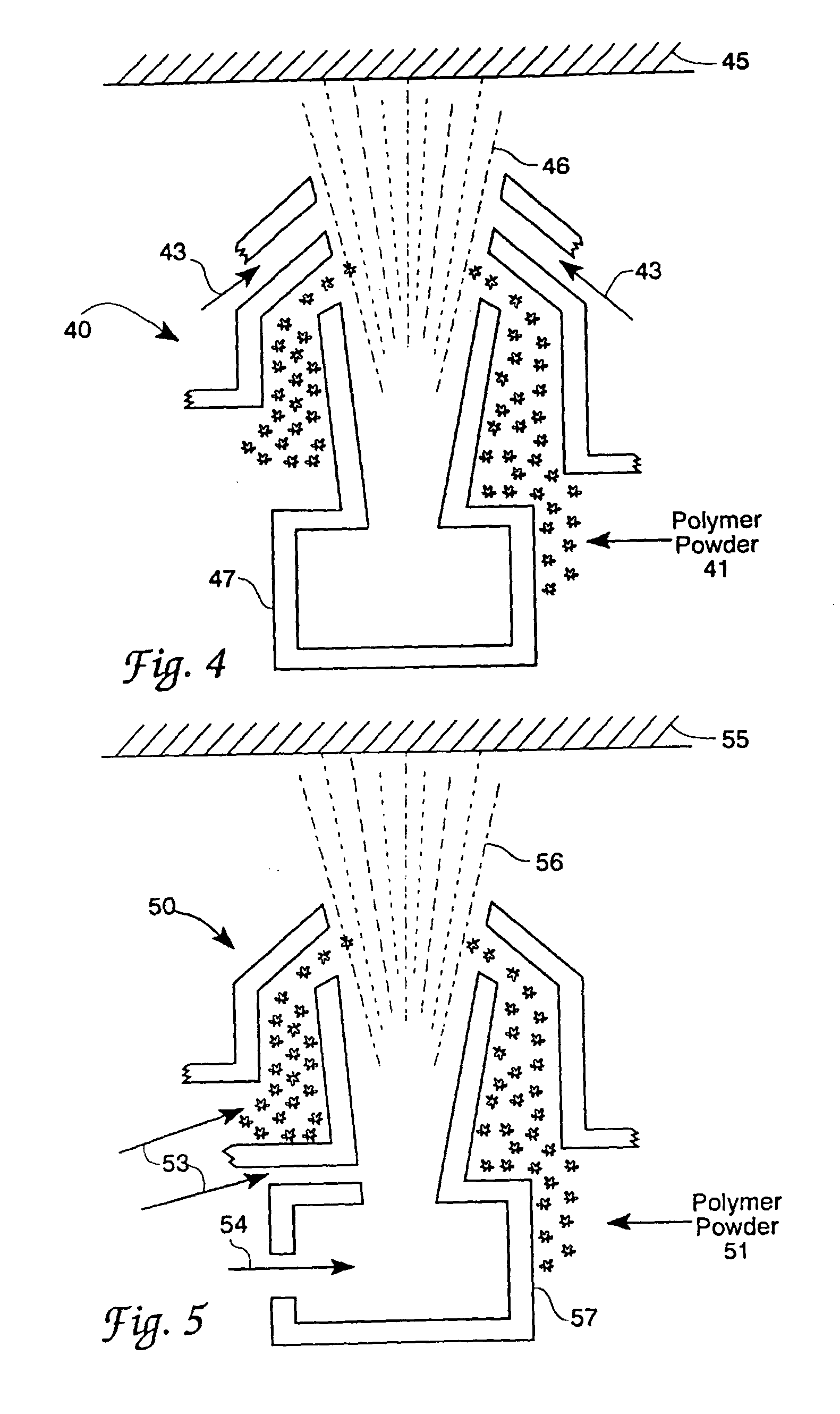

Process for coating substrates with polymeric compositions

InactiveUS20050048218A1Eliminate the problemElimination of free volumeLiquid surface applicatorsMolten spray coatingMetallurgyFuel tank

Corrosion resistant non-polar polymer coatings and methods for applying the coatings to substrates are described, wherein a source of non-polar polymer powder is deposited as a coating onto the surface of a substrate by high temperature thermal spray. The non-polar character of the powder and any additives thereto is substantially preserved during the high temperature thermal spray process by the use, at one or more locations along the thermal spray route, of at least one non-oxidizing shielding gas, at least one reducing gas, or a combination of the two types of gases to displace or react with ambient oxygen. High velocity impact force (HVIF) spraying techniques are preferred. Similarly processes and materials for low permeability and non-corrosive HVIF coatings for steel fuel tanks are disclosed.

Owner:WEIDMAN LARRY G

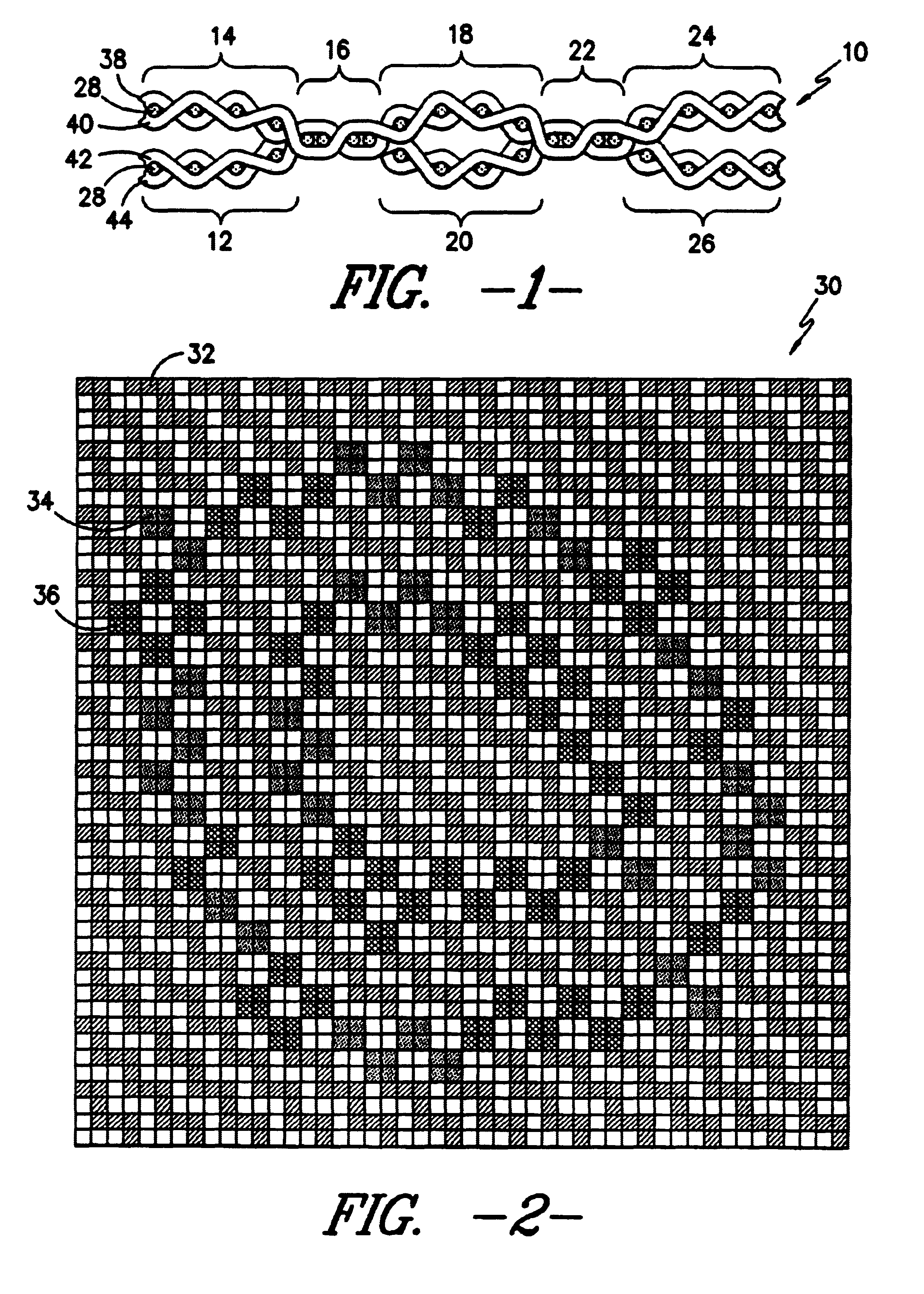

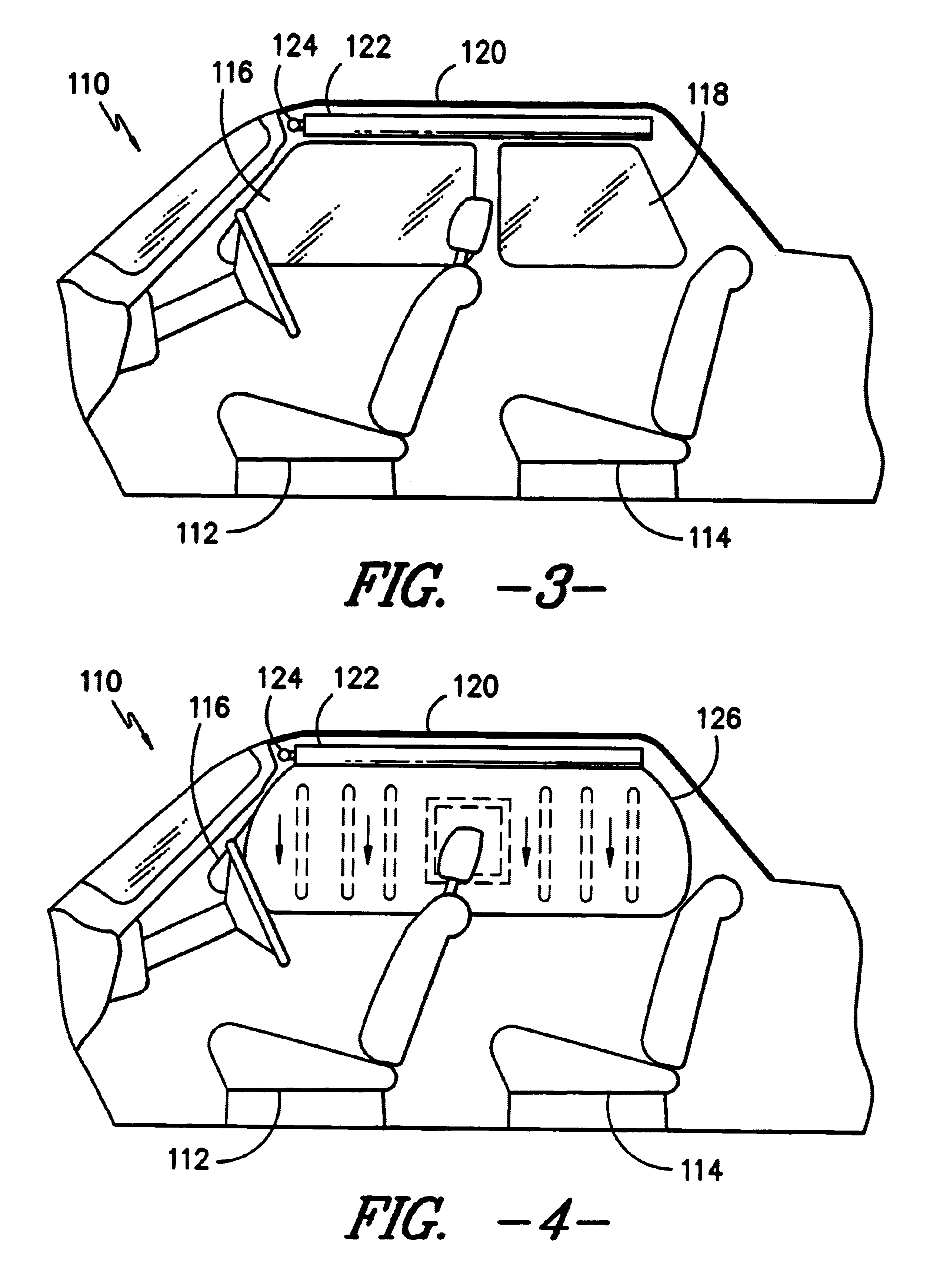

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6698458B1Beneficial and long-term low permeabilityExcellent long-term storage stabilityLeno shedding mechanismPreformed elementsNeopreneEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds wherein the film is present on the surface in an amount of at most 3.0 ounces per square yard of the fabric.

Owner:MILLIKEN & CO

Pneumatic tire with colored thermoplastic elastomer layer adjacent a black-concealing layer

InactiveUS6397912B1Raise the ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:THE YOKOHAMA RUBBER CO LTD

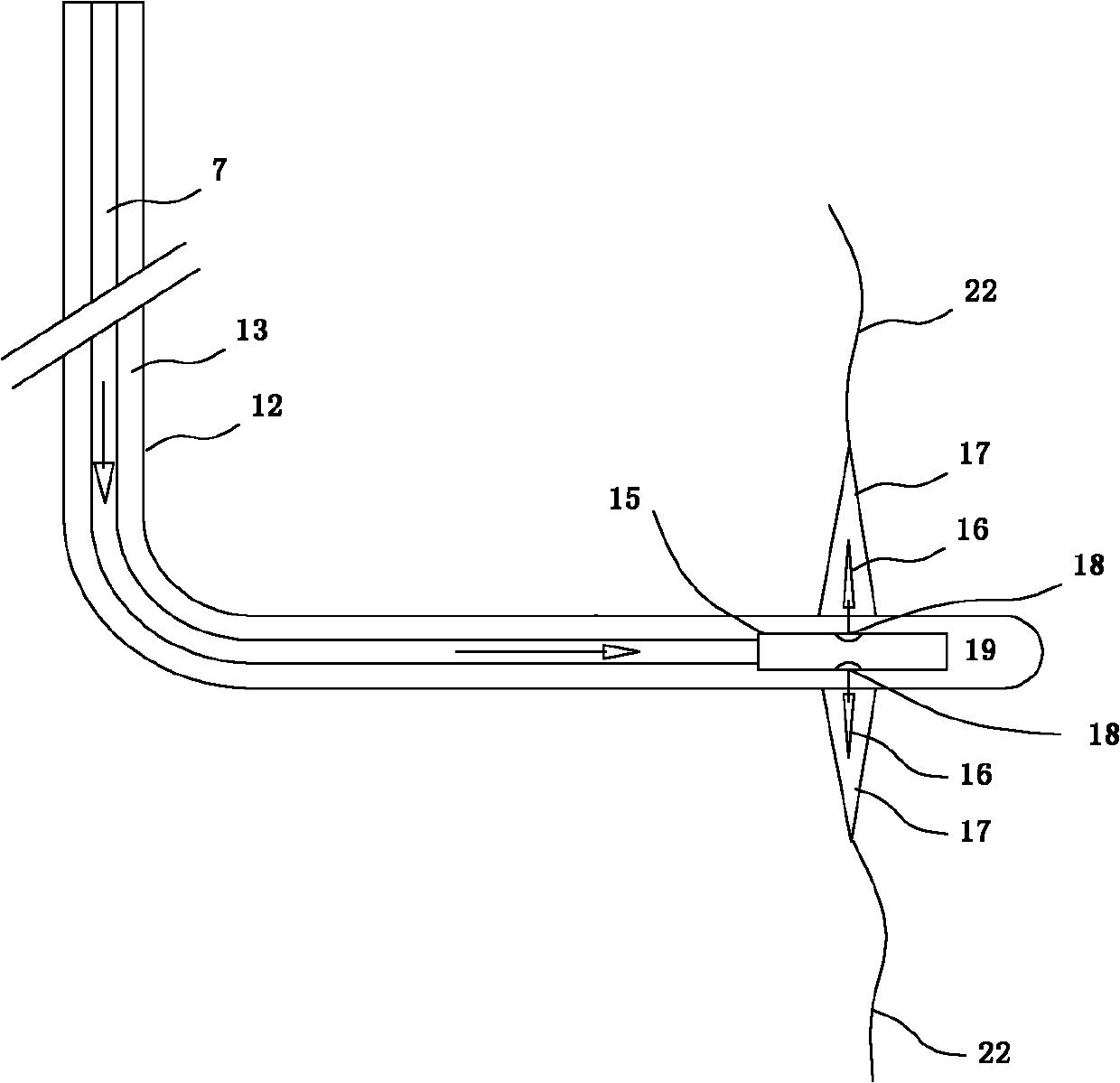

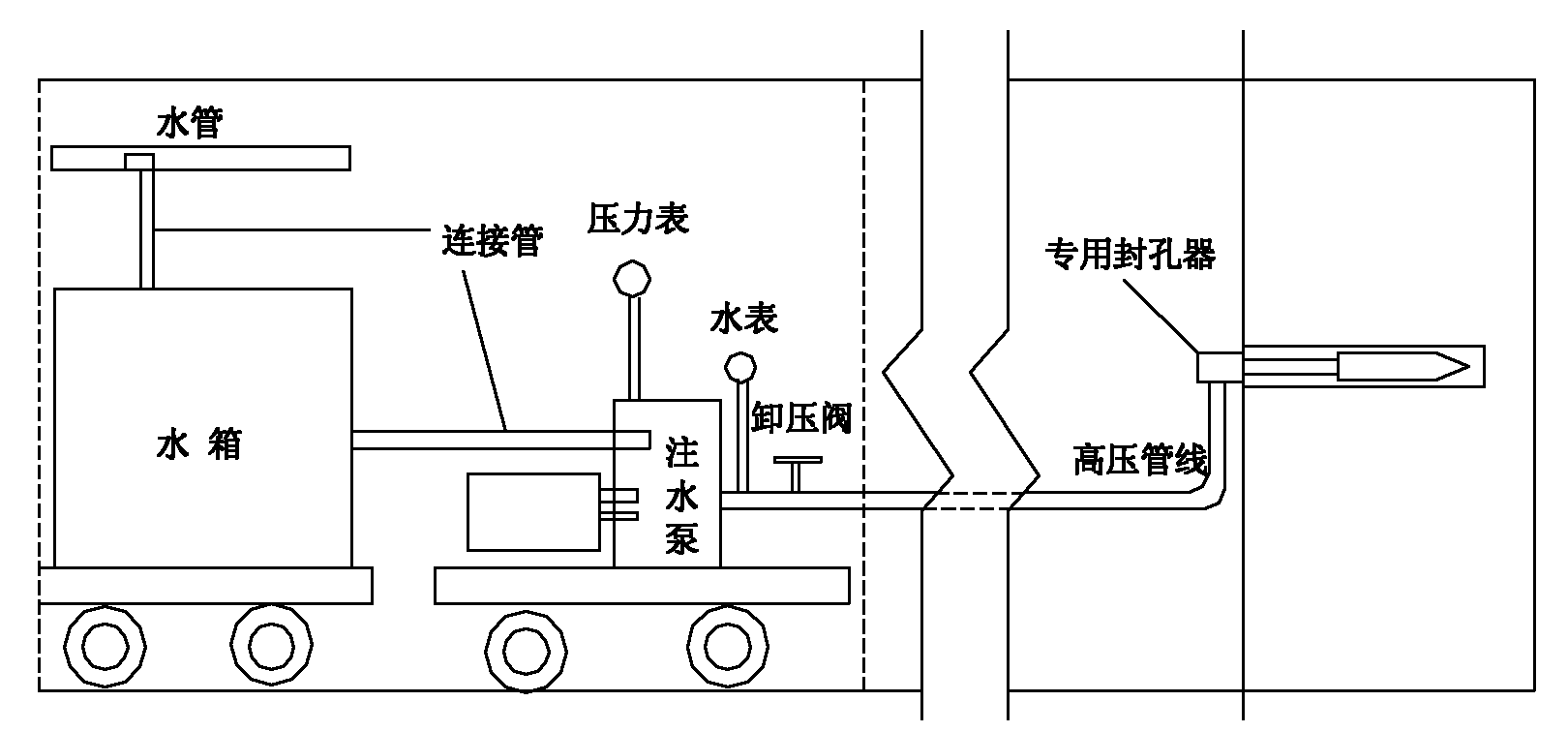

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

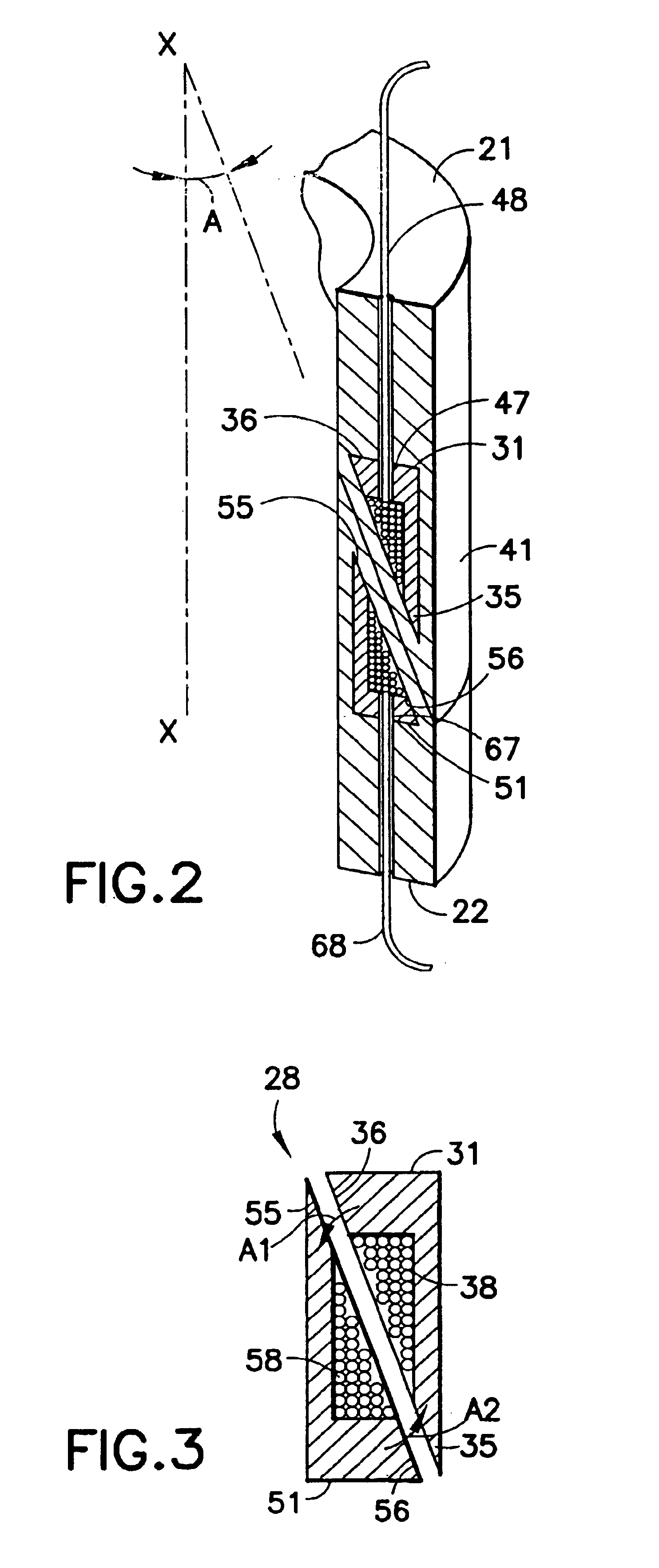

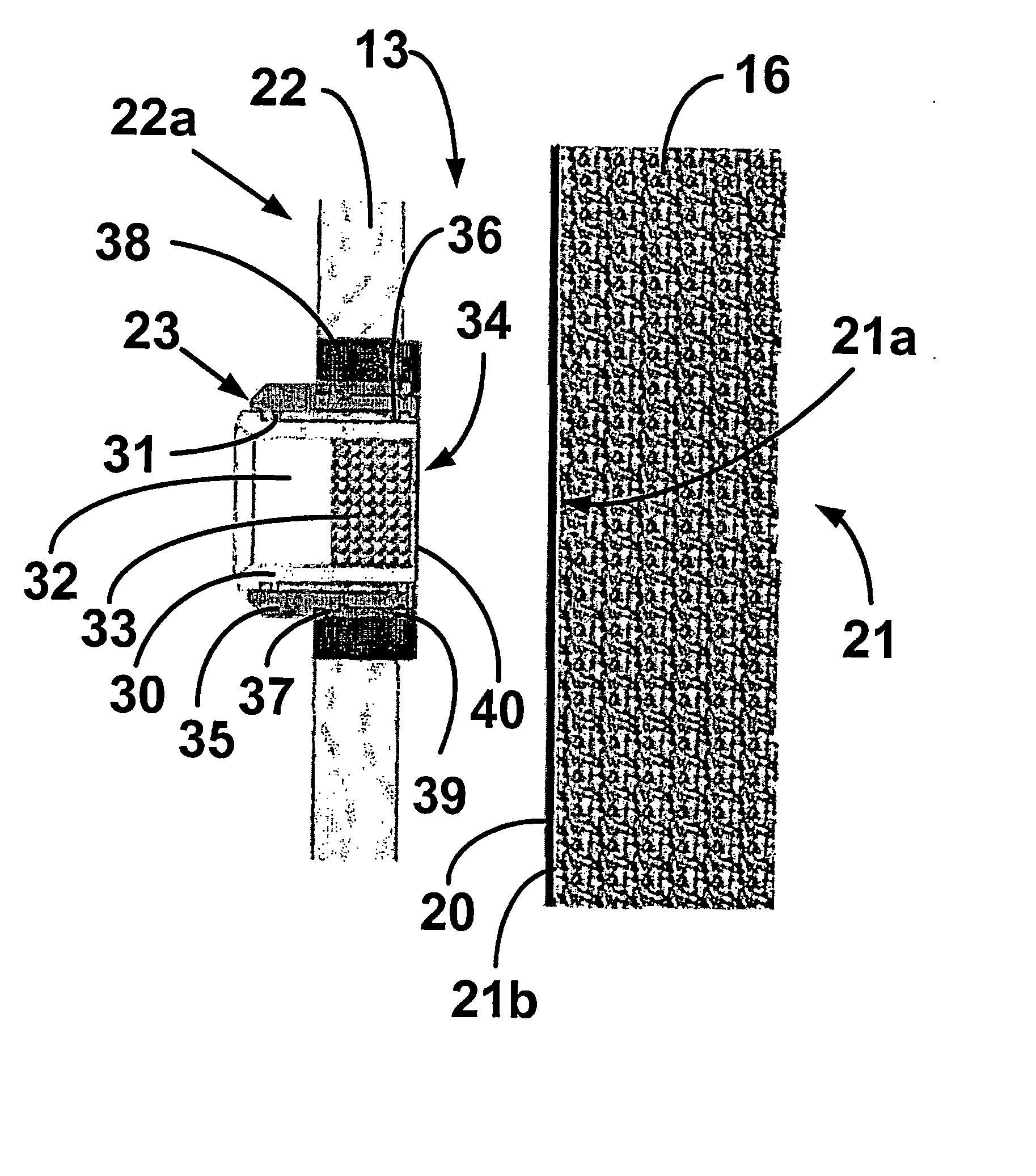

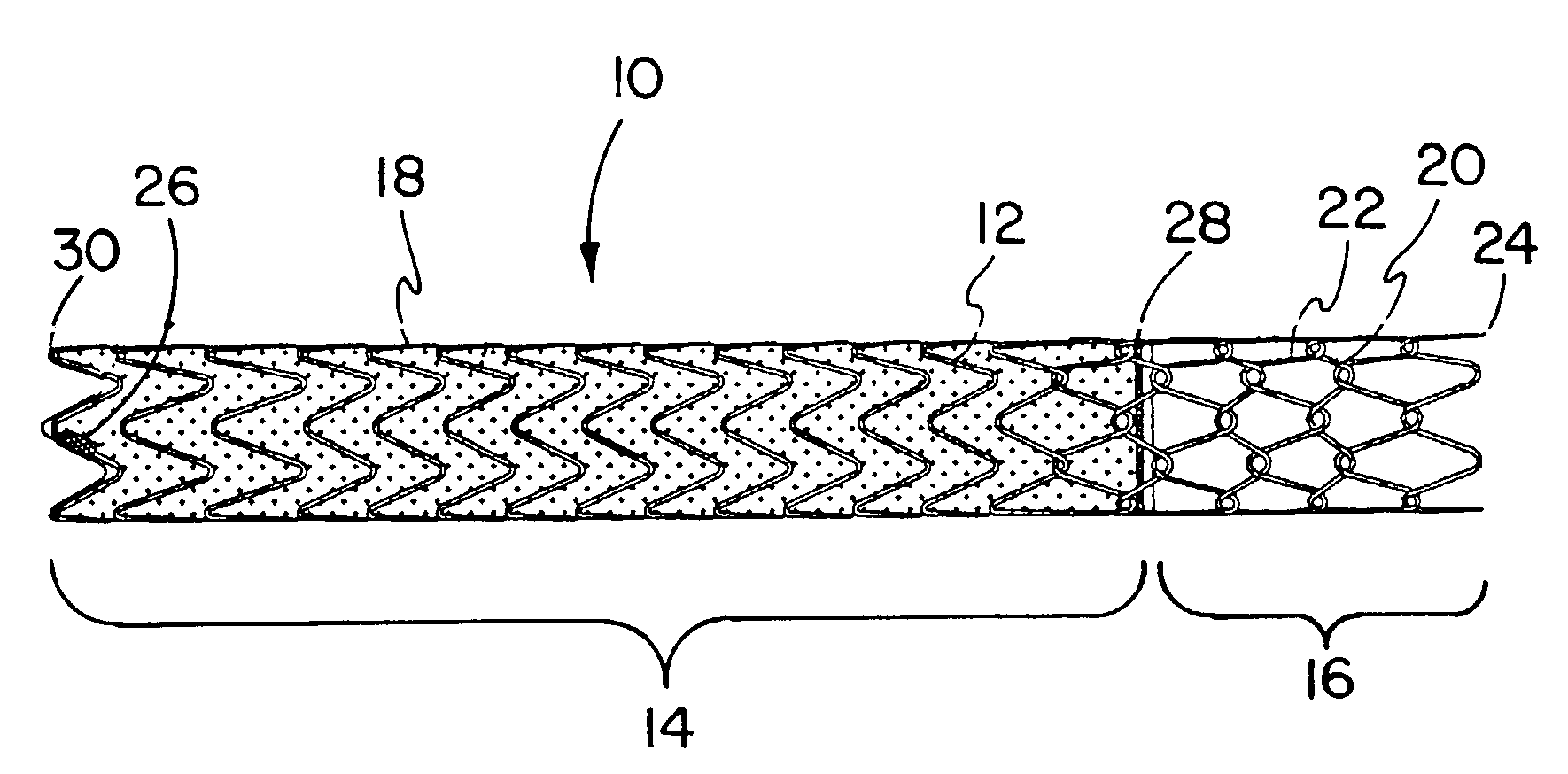

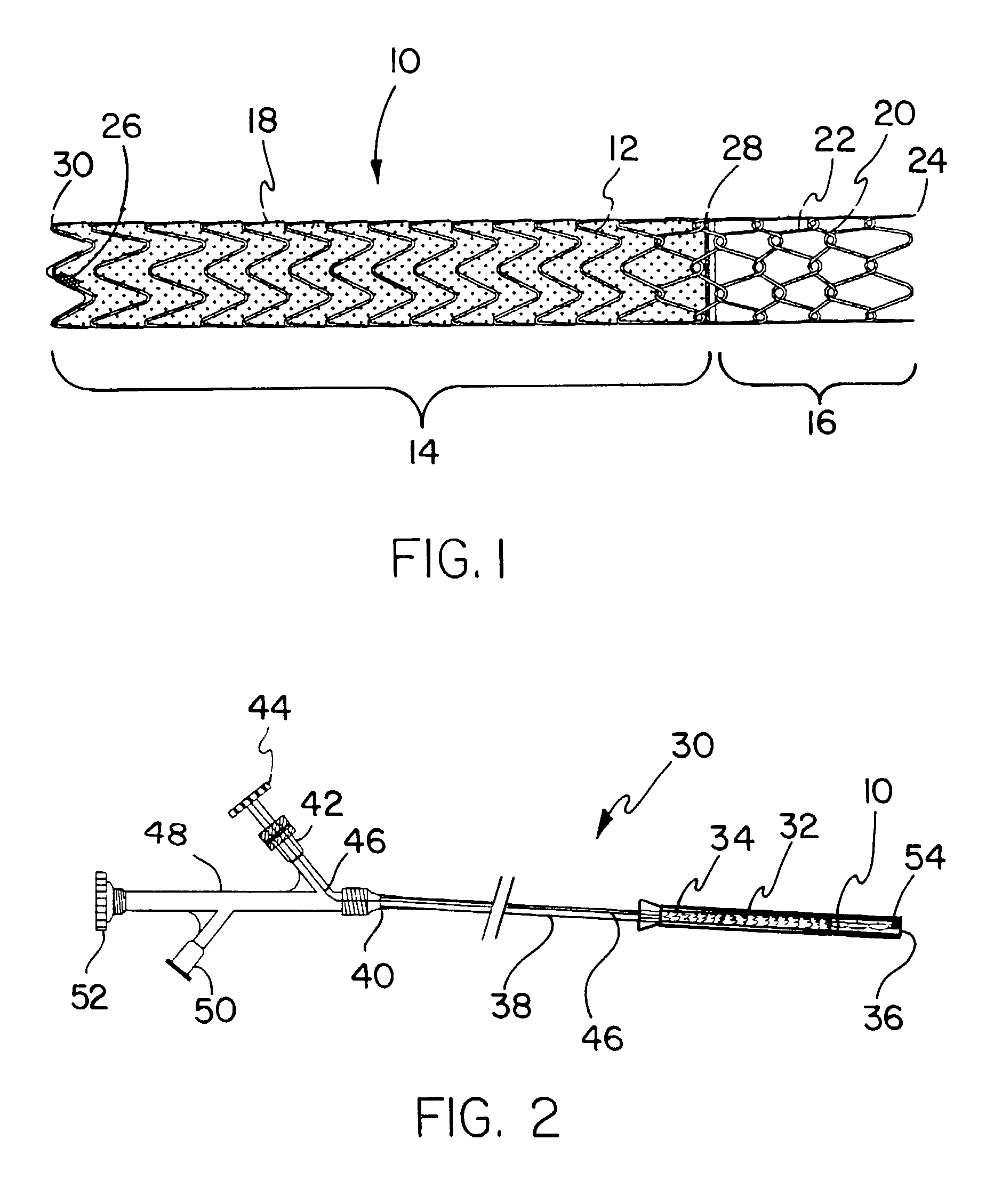

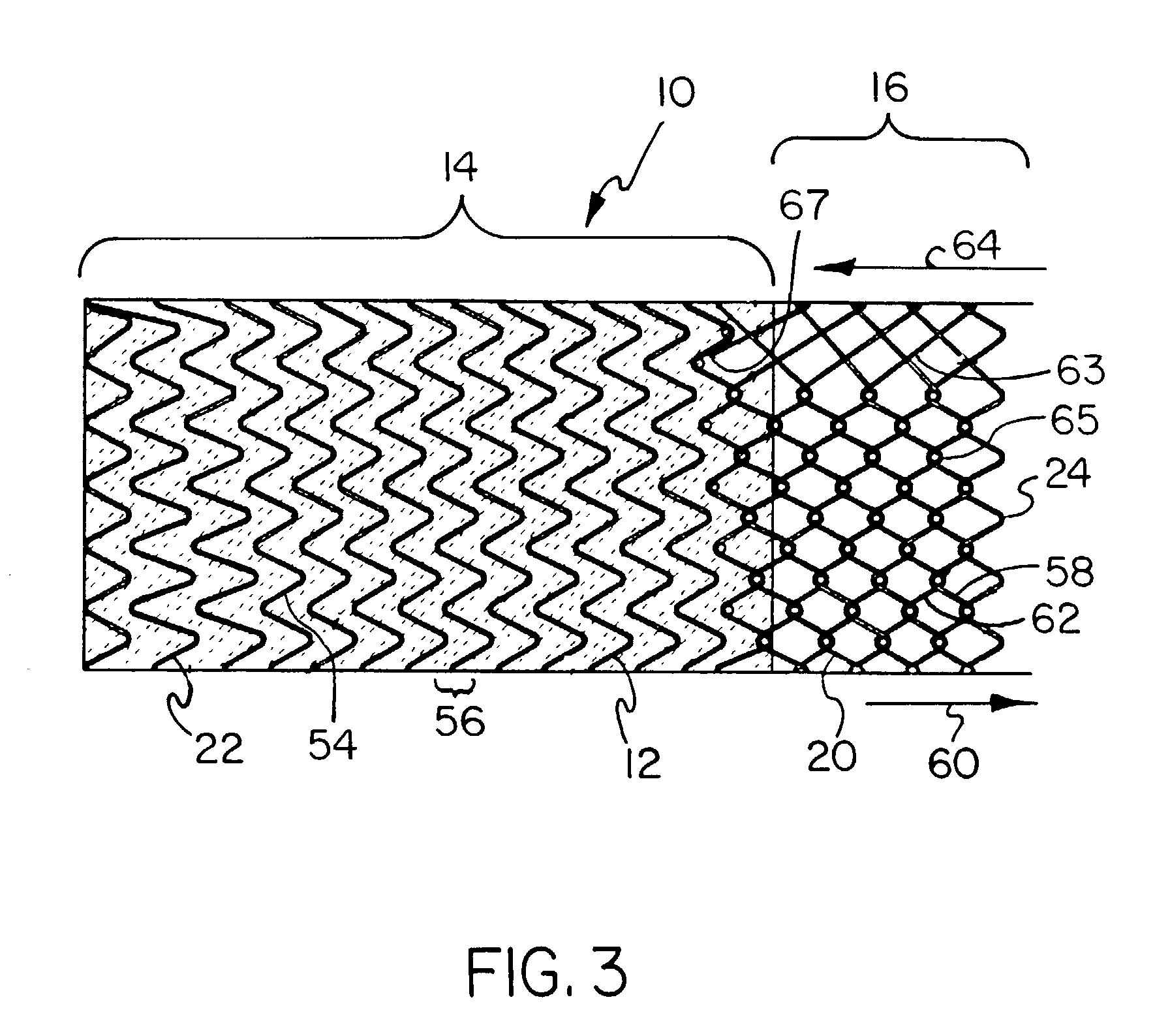

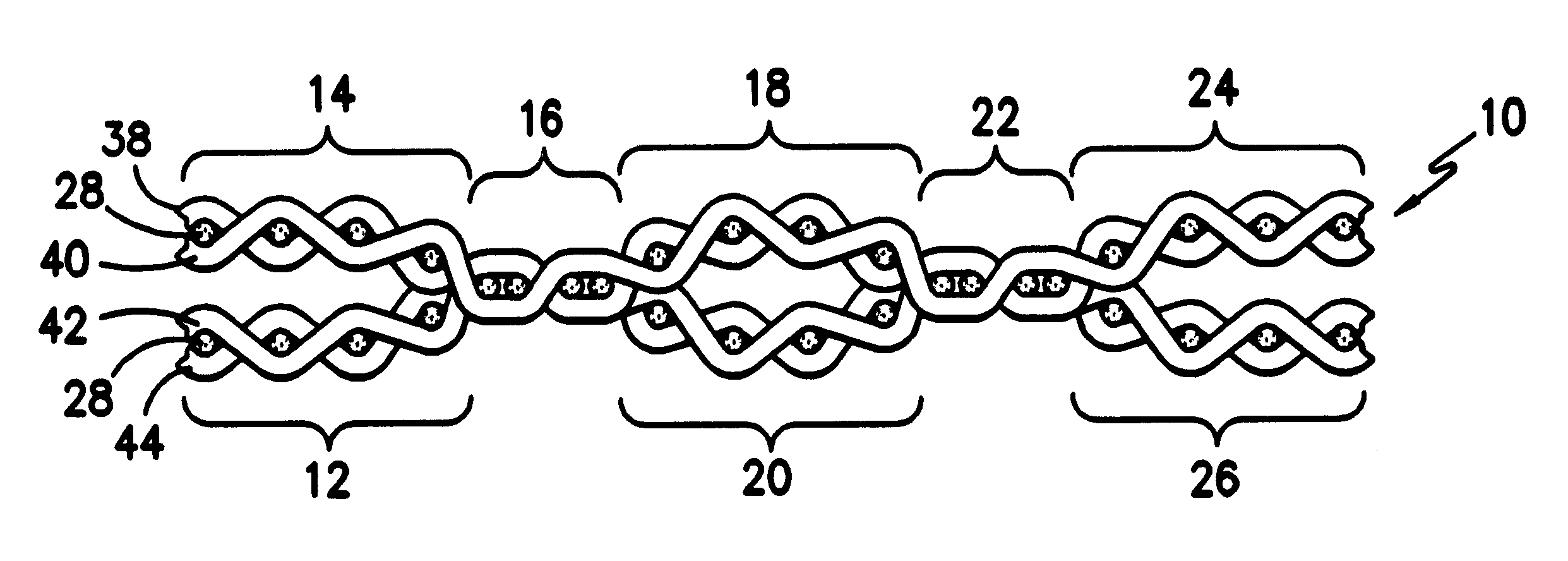

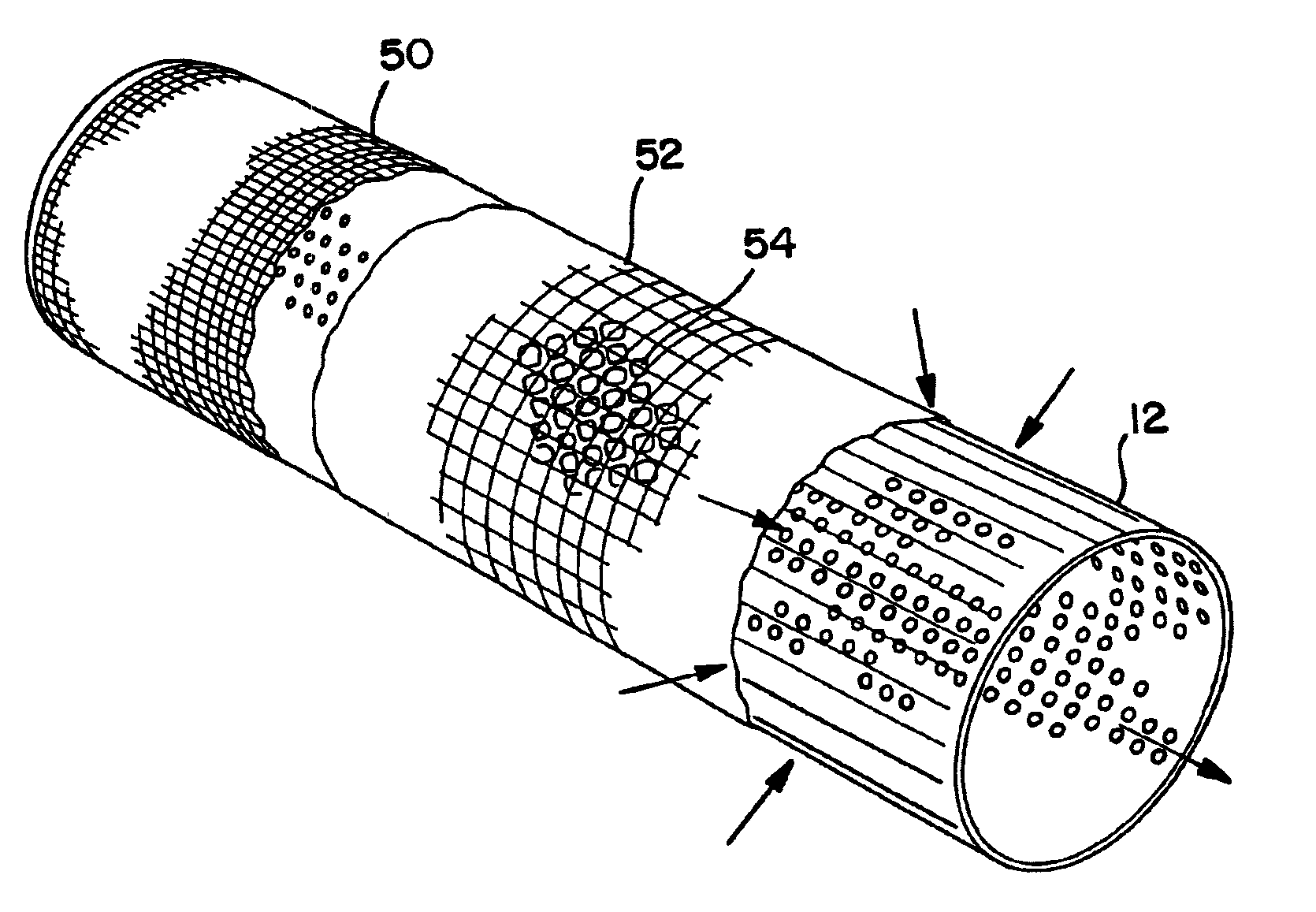

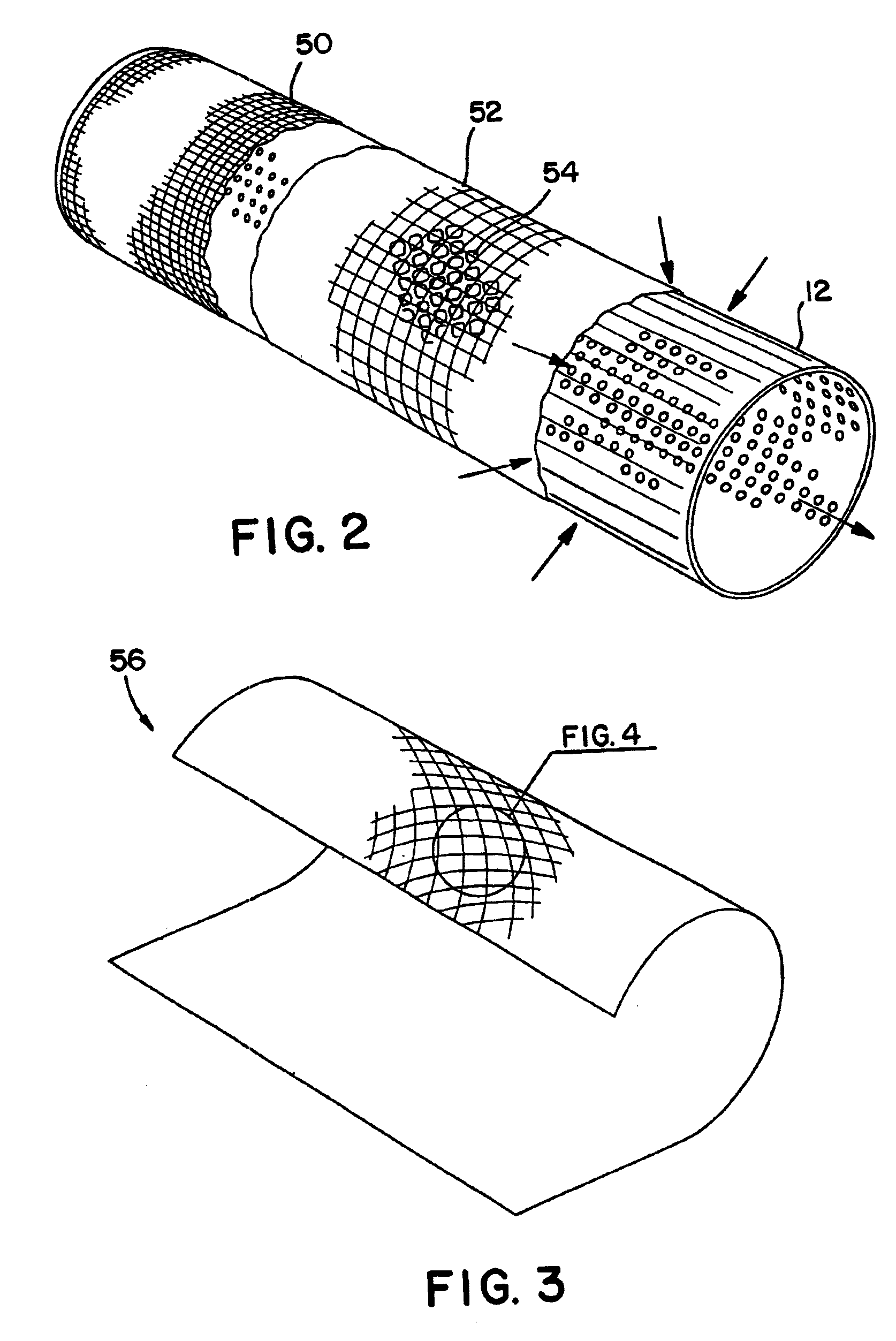

Covered endoprosthesis and delivery system

InactiveUS7056336B2Easily and accurately placed within intrahepatic tractEasy to manufactureStentsBlood vesselsVeinStent grafting

The present invention is an improved endovascular device particularly useful for use in transjugular intrahepatic portosystemic shunt (TIPS) procedures. The device employs a two-part stent-graft construction that provides a low permeability membrane to line the shunt and an uncovered stent portion designed to reside in the portal vein. The device provides numerous benefits over previous stents and stent-grafts used in TIPS procedures, including being more compact to deliver, being easier to accurately deploy, a controlled compacted surface with tucked apices, an improved stent winding pattern, and being more flexible in delivery and use.

Owner:WL GORE & ASSOC INC

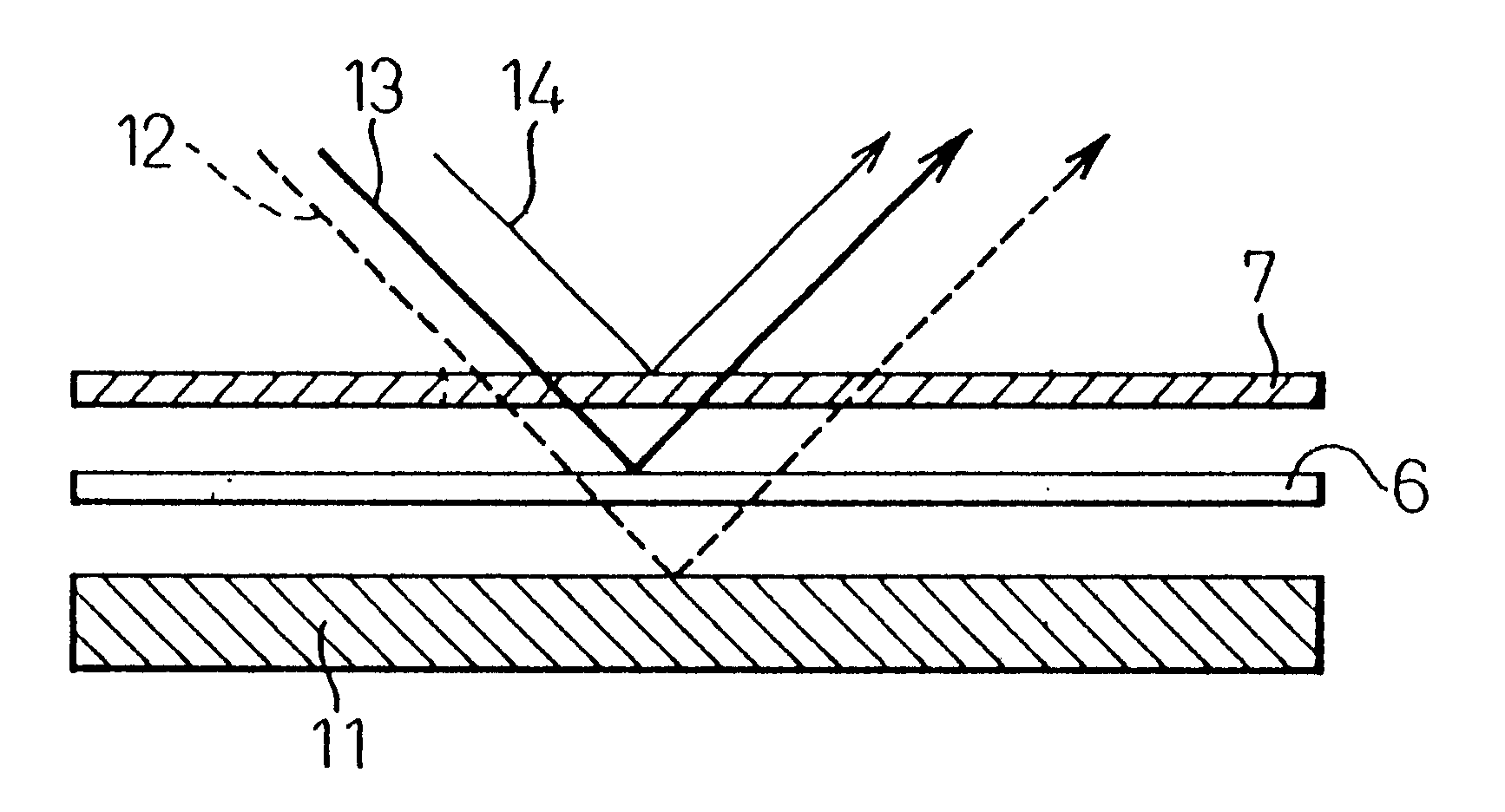

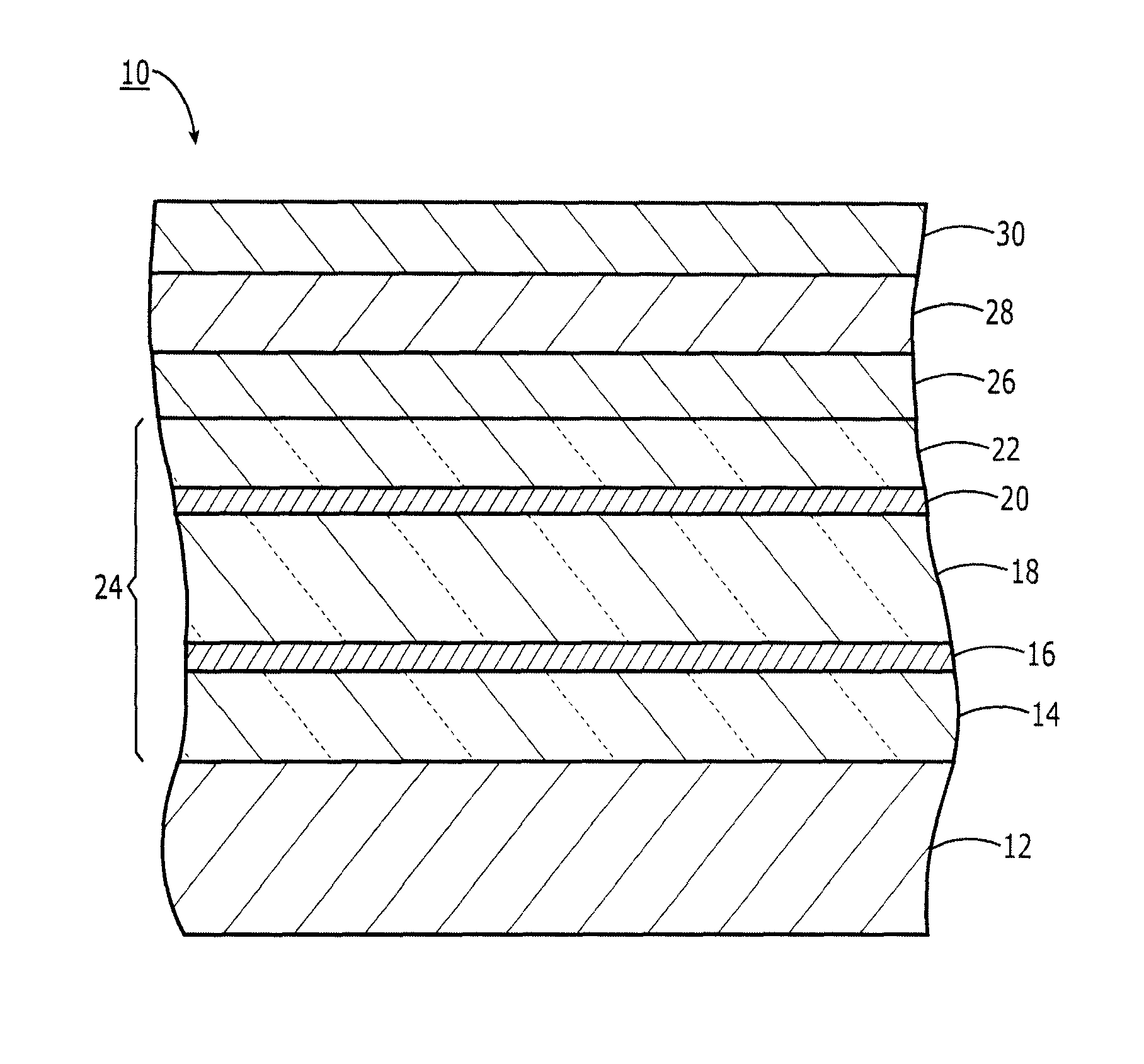

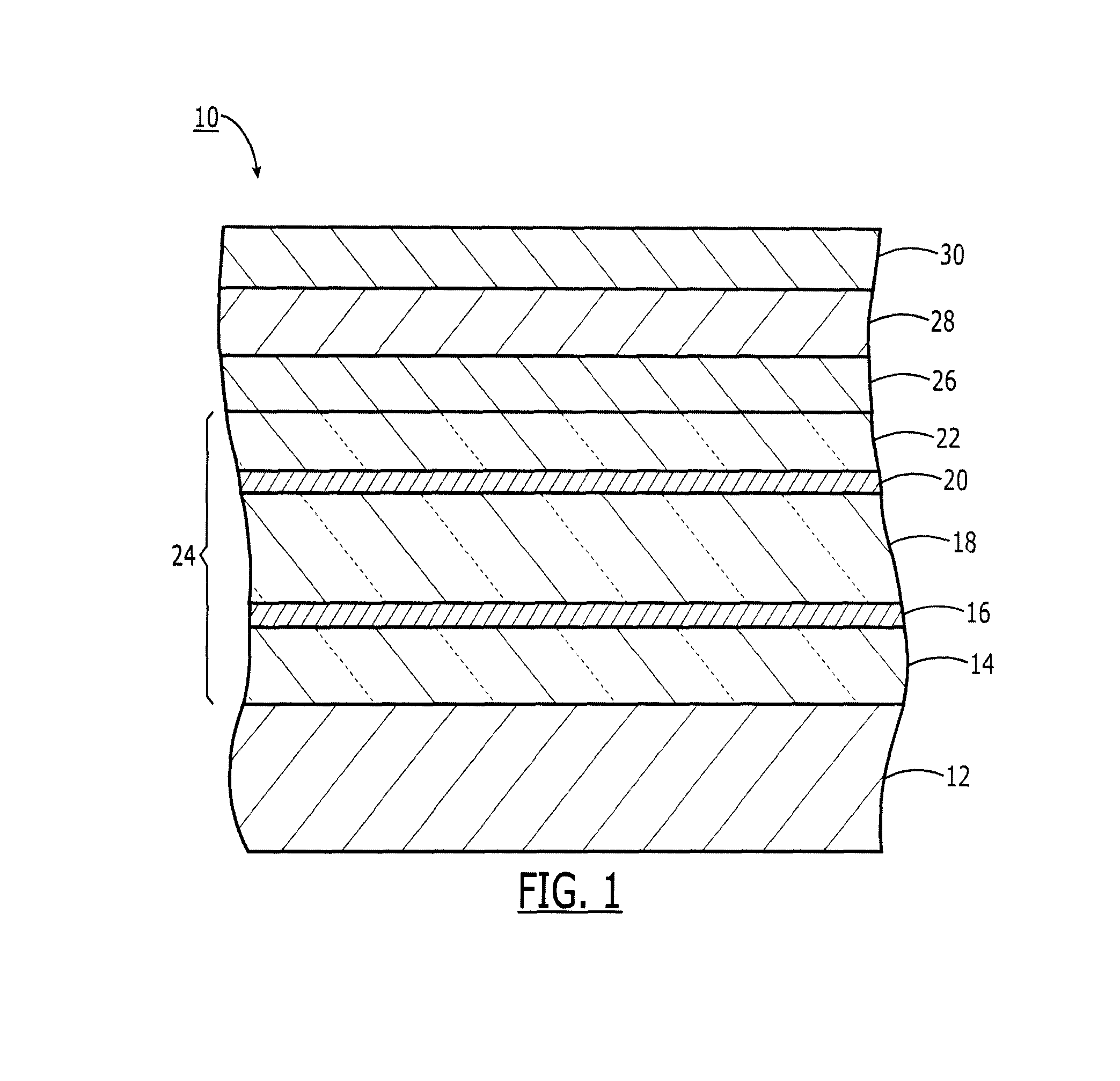

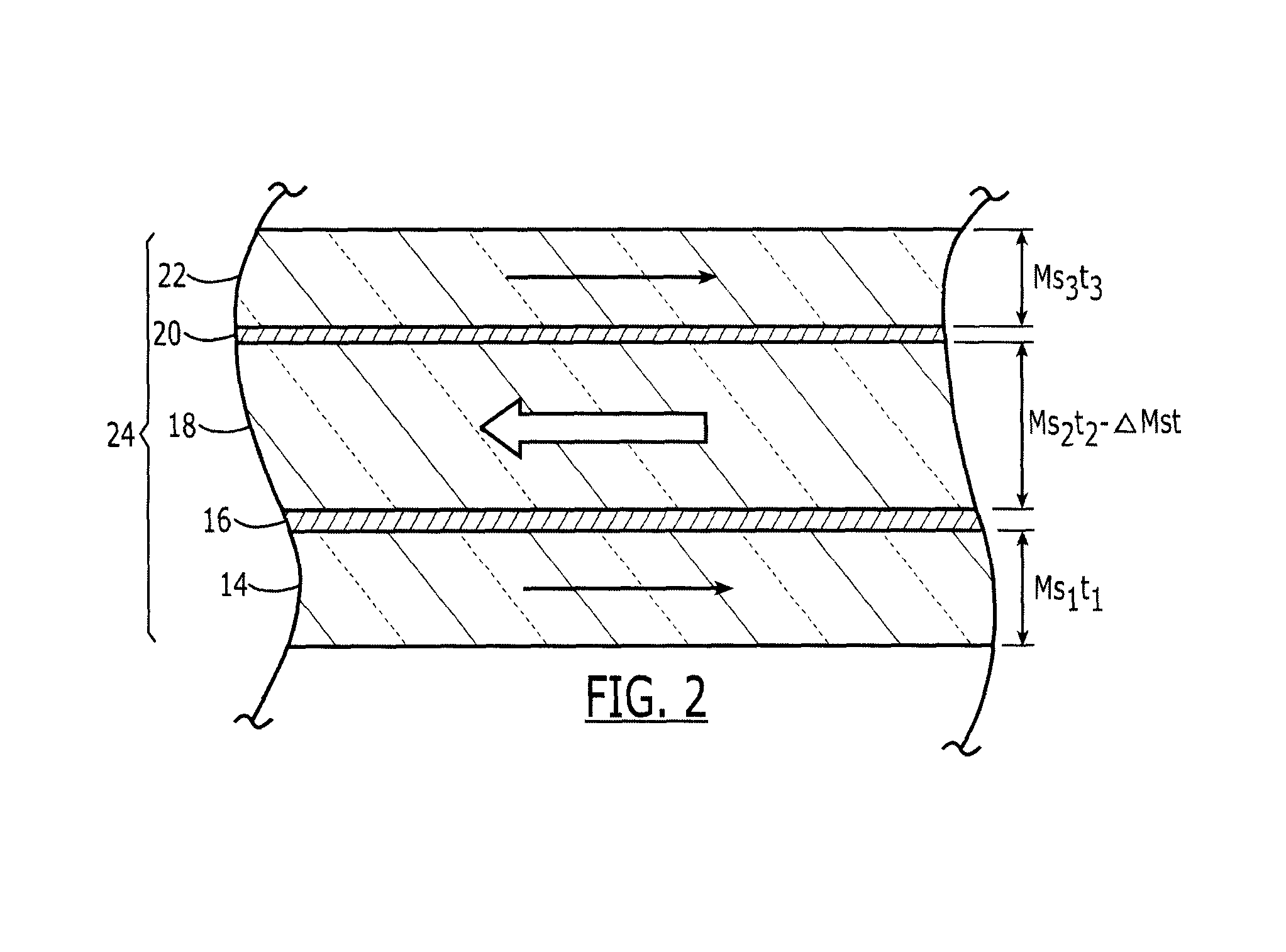

Perpendicular magnetic recording medium with single domain exchange-coupled soft magnetic underlayer and device incorporating same

InactiveUS8597723B1Improve performanceRobustnessMagnetic field orientationRecord information storageMagnetizationRadial field

A perpendicular magnetic recording disk having a single domain exchange-coupled laminated soft magnetic underlayer (SUL) is disclosed. The SUL is a combination synthetic anti-parallel coupled SUL structure, which has the product (Mst) of saturation magnetization and film thickness of the middle ferromagnetic layer less than the sum of the Mst of the bottom and top ferromagnetic layers. Subjected to a post radial field reset process, this SUL provides single domain state. Moreover, both robustness of stray fields and low permeability are obtained while keeping excellent corrosion resistance and cost effective manufacturability.

Owner:WD MEDIA

Tight formation water shut off method with silica gel

A delayed gelling system useful in conformance control in the production of petroleum from subterranean formations, especially low permeability formations, is disclosed. The gelling system comprises a basic silica sol, an activator comprising a hydroxyl donor, and an optional syneresis inhibitor. In the disclosed method of using the gelling system, the gelling system may be pumped into formations with excessive water and / or gas production and thermally activated in the formation at downhole conditions to form a hard gel to reduce water and / or gas production.

Owner:SCHLUMBERGER TECH CORP

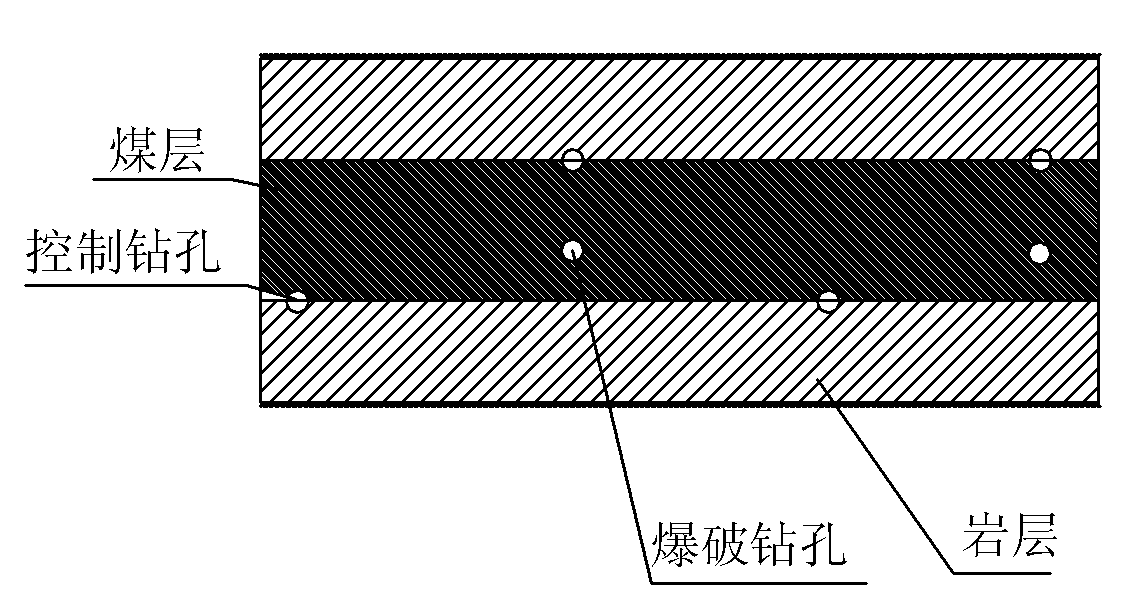

Method for integrated comprehensive management of gas in low-permeability single coal bed

InactiveCN102121395AReduce outstanding riskImprove breathabilityDrilling rodsFluid removalSocial benefitsHydraulic fracturing

The invention relates to a method for integrated comprehensive management of gas in a low-permeability single coal bed, which can effectively solve the problem of comprehensive management and utilization of the gas. A technical scheme of the method comprises the following steps of: firstly, drilling holes, wherein a high-torque drilling machine and a rifle or a trihedral drill stem are used for solving the phenomenon of clamping the drill stem caused by collapsing and jetting of the holes in the hole drilling process; and then, performing hydraulic fracturing permeability improvement on the coal body, drilling holes for pre-split blasting, performing gas drainage, and recycling the drained gas, thereby implementing the integrated management of the gas. With the method provided by the invention, the permeability of the coal body is improved, a pre-draining rate of the gas is improved, and the drained gas is recycled, so that the drilled holes are radically prevented from being blocked in the construction process, the problem of difficulties in draining the gas in the low-permeability coal bed with a drilling tool having insufficient capability in the drilling construction is solved, consequently, outburst risk of the coal and the gas is reduced, outburst accidents of the coal and the gas are reduced and even avoided, and mine production safety and lives of coal mine workers are ensured, so that the method brings great economic and social benefits.

Owner:平顶山天安煤业股份有限公司十矿

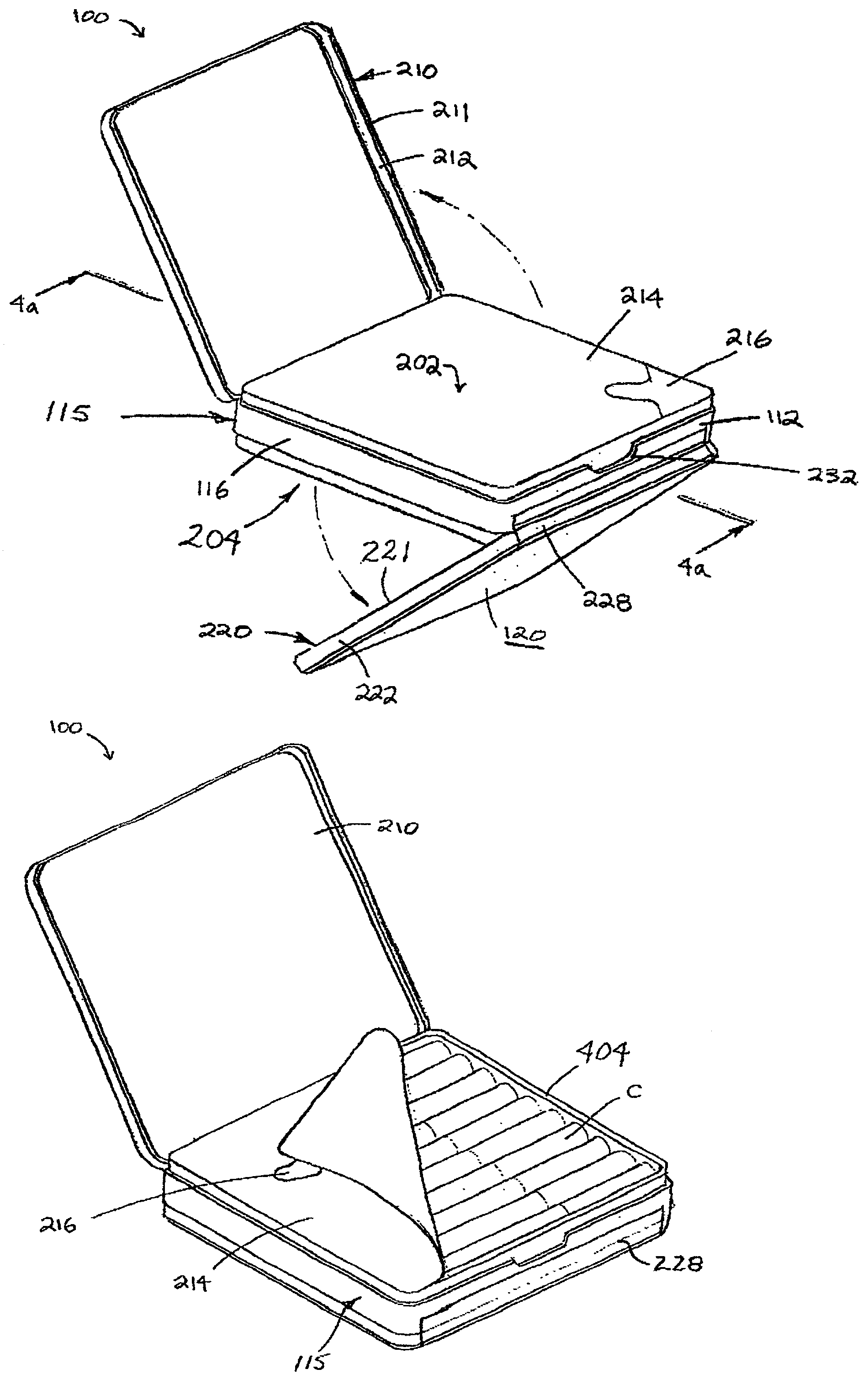

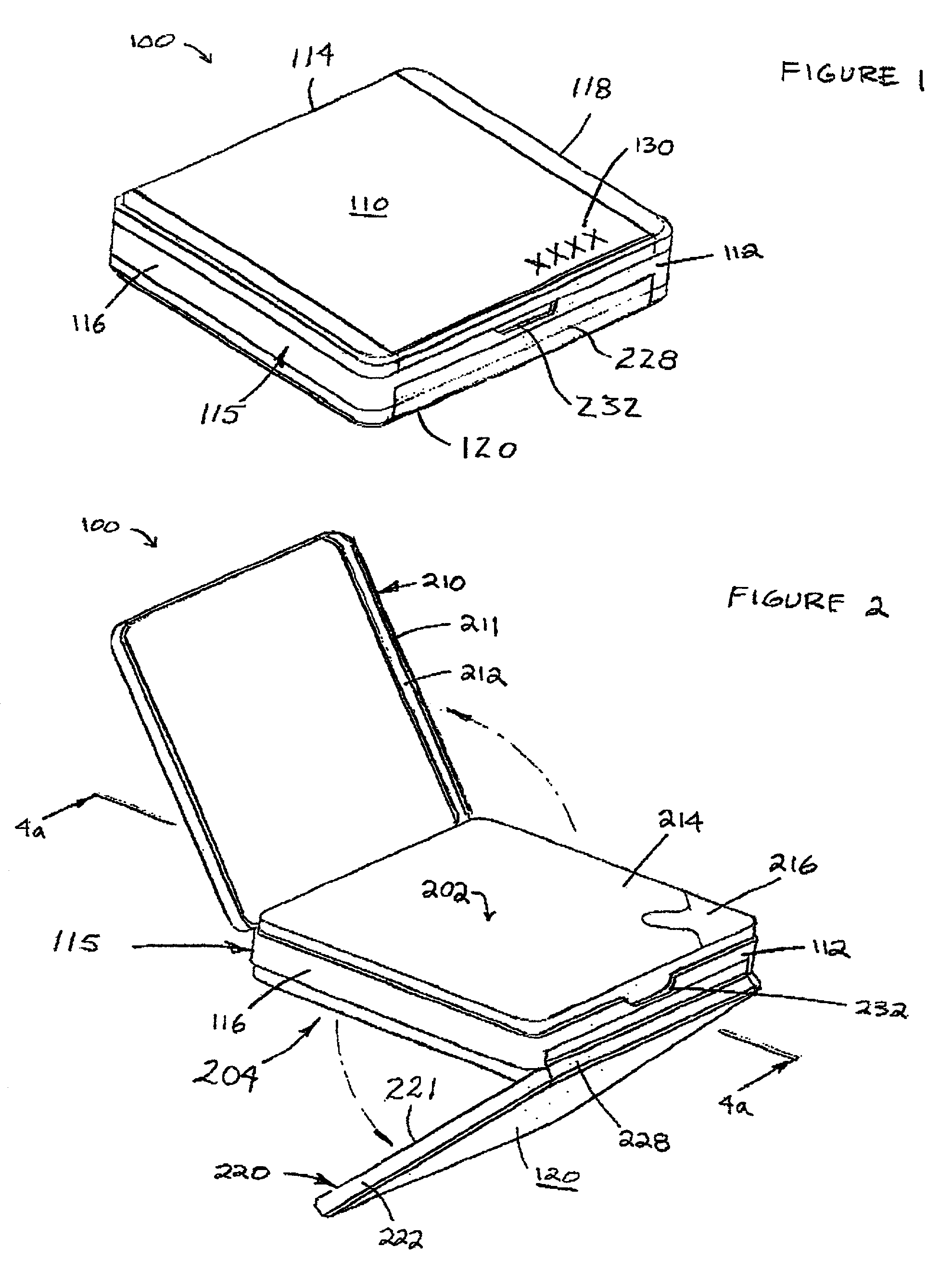

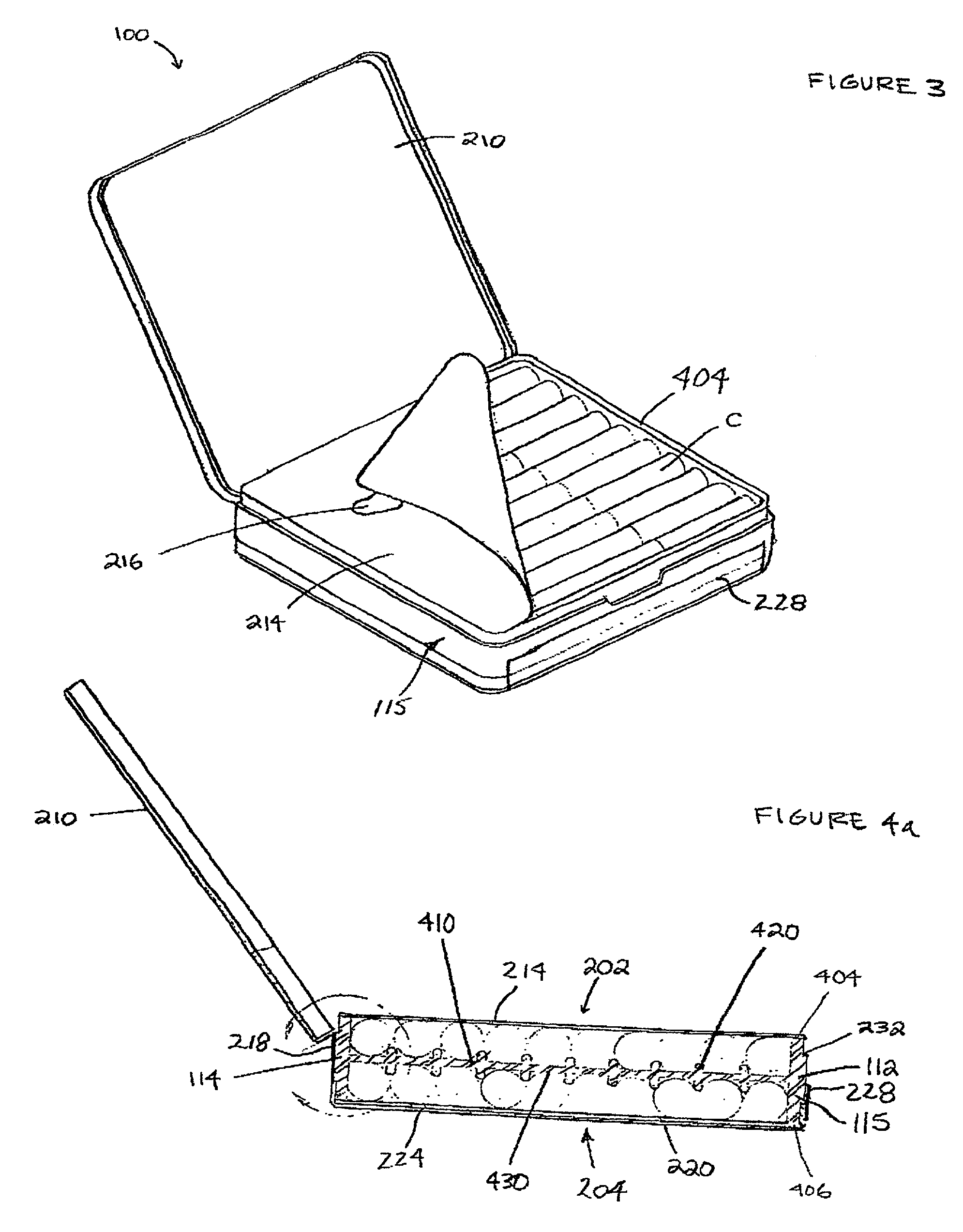

Dual-lid cigarette container and method of packaging cigarettes

InactiveUS7124883B1Increasing product identificationAvoid high pressureCigar manufacturePackaging cigaretteThin membranePaper sheet

A package or container for holding two or more types or brands of smoking articles, such as cigarettes, having a generally rectangular shape with two openings on opposite sides of the container and a method of making the same is disclosed. The container has two lids, a body, and a separation member that divides the container into two or more compartments, each filled with smoking articles. The lids are made of metal and are hinged to the body on opposite ends of the container using strap hinges made of a paper or foil laminate, and contain printed information such as text and logos. The separation member includes raised portions to hold the smoking articles securely within the compartments and each compartment is sealed with a layer of film that may be pulled up and off of the container compartment using a tab attached to the sealing layer. The freshness and diffusion of aromas from the different types or brands of smoking articles is prevented from migrating between the separate compartments by use of low permeability materials including various plastics and metals.

Owner:R J REYNOLDS TOBACCO COMPANY

Low-permeability connecting device

InactiveUS6997486B2Reduce couplingLess tendencyFluid pressure sealed jointsJoints with sealing surfacesEngineeringMechanical engineering

Owner:NOBEL PLASTIQUES

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6429155B1High leak-down timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementEngineeringNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds as well as a very low packing volume (for more efficient use of storage space within a vehicle) for the target side curtain airbag.

Owner:MILLIKEN & CO

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS20020090473A1Reduce the amount requiredMaintain good propertiesMouldsConfectioneryPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

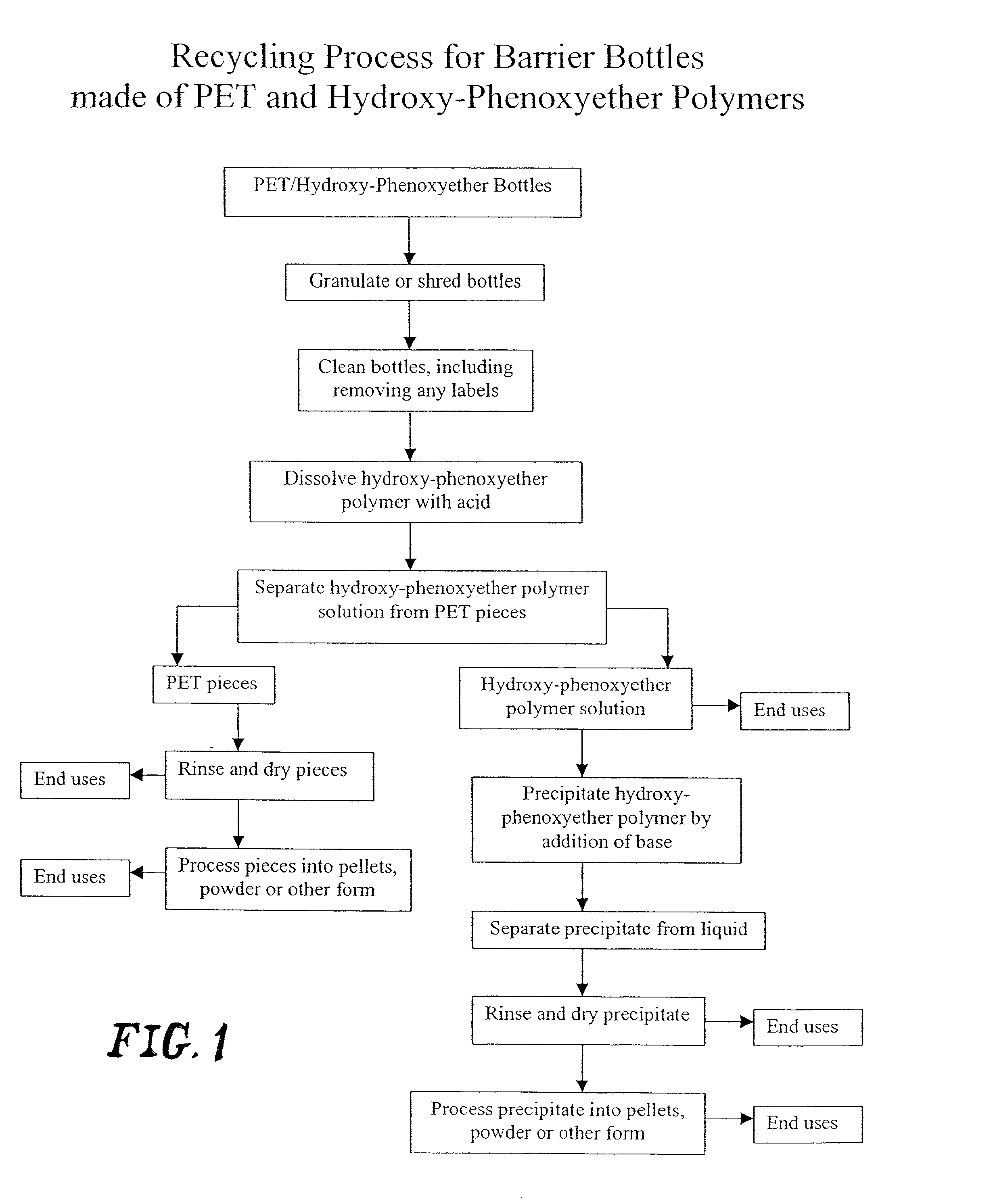

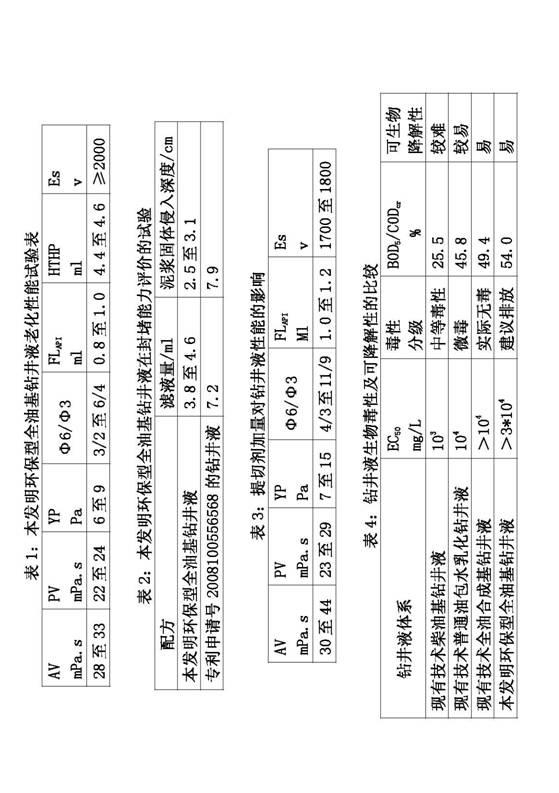

Environmental-friendly type oil-based drilling fluid and preparation method thereof

ActiveCN102304353AAvoid damageImprove the blocking effectDrilling compositionHorizontal wellsPetroleum

The invention relates to the technical field of an oil-based drilling fluid for petroleum drilling, in particular to an environmental-friendly type oil-based drilling fluid and a preparation method therefore. The environmental-friendly type oil-based drilling fluid is prepared from the following raw materials: base liquid white oil, calcium chloride water solution, an emulsifying agent, a wetting agent, organic oil for drilling fluid, a composite plugging agent, a shear strength improving agent, a basicity regulating agent and a fluid loss additive; and a weighting agent is added into a mixture of the raw materials. The oil-based drilling fluid has the following advantages of: good plugging property, high shear viscosity and strong rock carrying capability; the EC 50 (median effect concentration) of the drilling fluid is larger than 3*104mg / L; the drilling fluid has good environmental safety; the return permeability of the drilling fluid can reach 90%-98%; the drilling fluid has little damage to reservoirs; the preparation process of the drilling fluid is simple; the drilling fluid is mainly applied to a special construction technology such as underbalance, horizontal wells and the like, water sensitivity reservoirs and low-pressure low permeability gas wells.

Owner:克拉玛依市金鑫科技有限公司

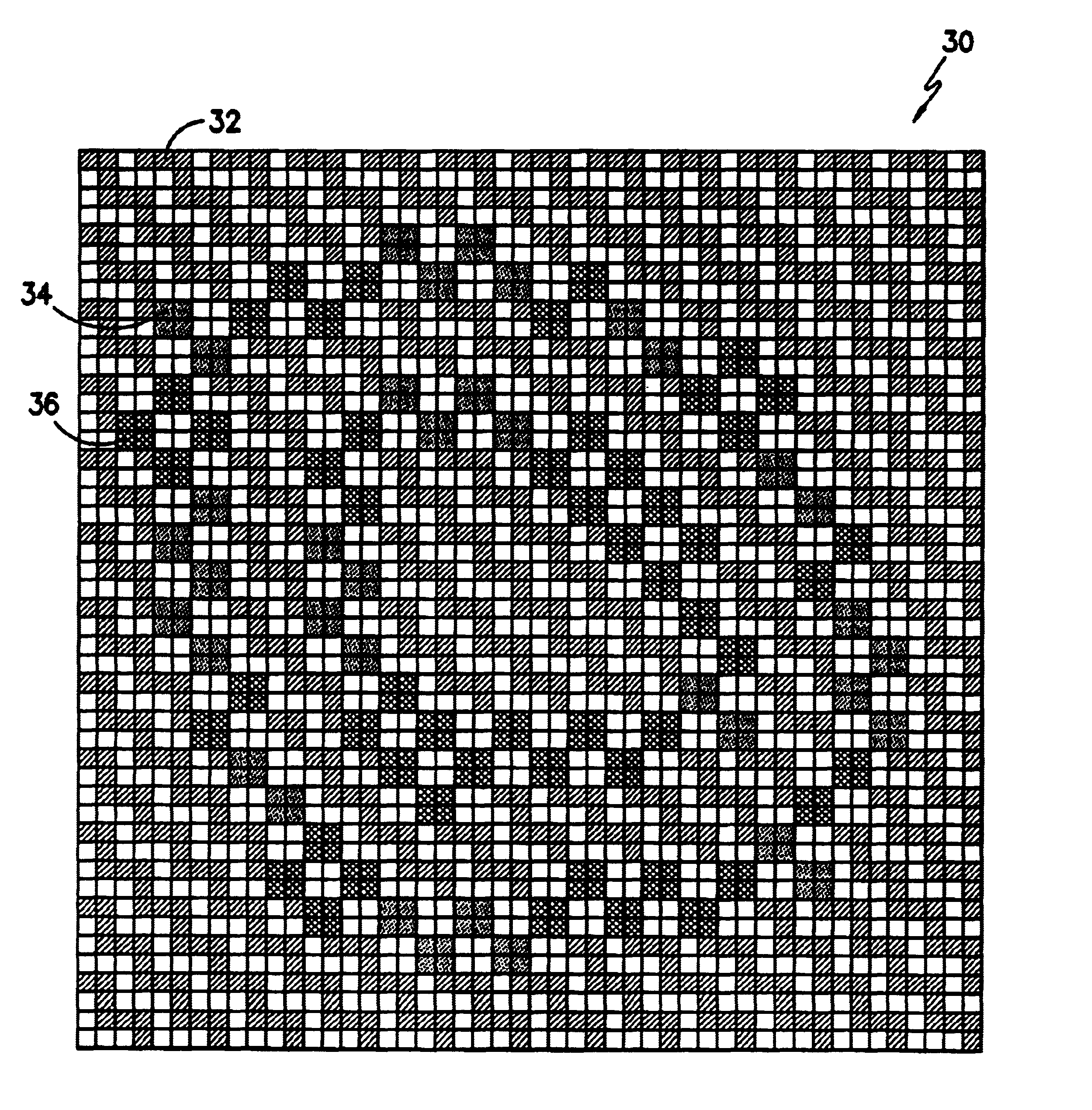

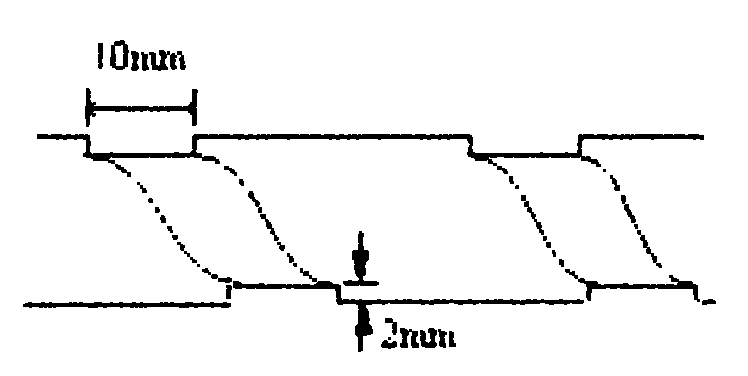

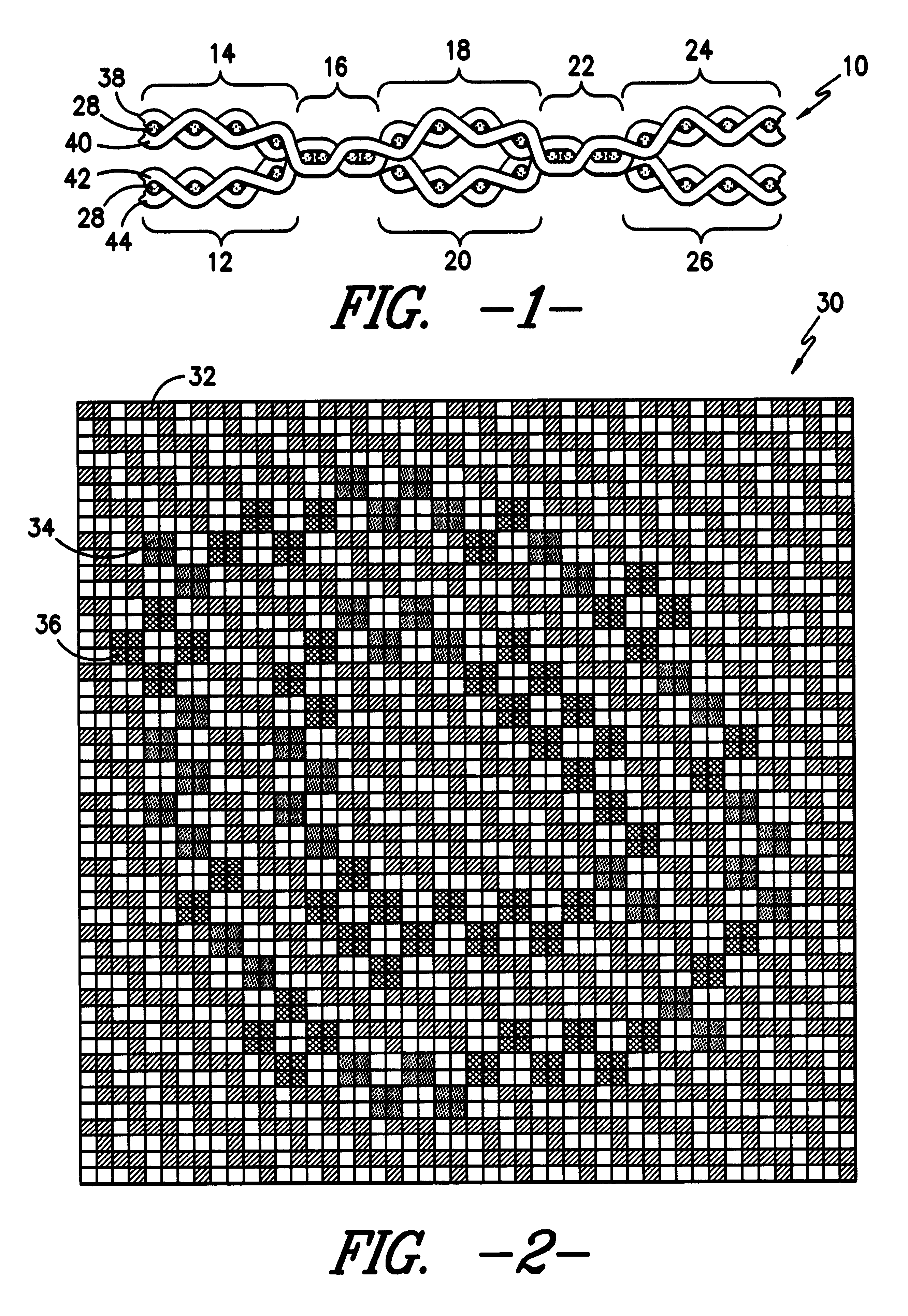

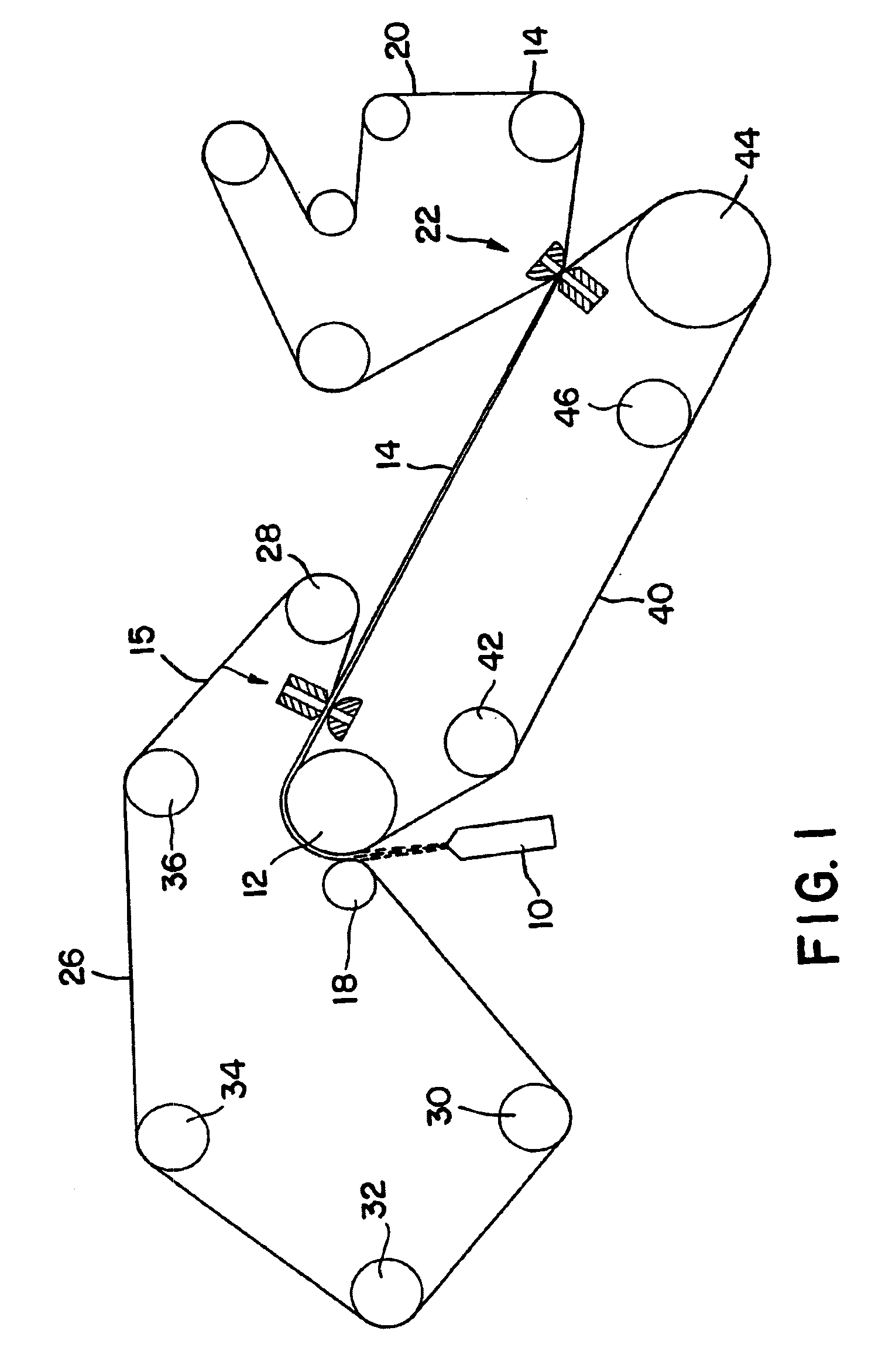

Paper webs having a watermark pattern

InactiveUS7070678B2Gram weight highReduce basis weightNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing paper webs having a pattern formed into the web is disclosed. The pattern is formed during formation of the web and is made by varying the basis weight of the web. The paper web is produced by depositing an aqueous suspension of fibers between two forming surfaces. One or both of the forming surfaces include lower permeability areas that create lower basis weight areas in the web. The lower permeability areas are contained in the forming surface according to a particular pattern. For instance, the lower permeability areas can be formed into a drainage roll sleeve contained on a drainage roll which contacts a forming surface. The drainage roll can be a forming roll or a breast roll.

Owner:KIMBERLY-CLARK WORLDWIDE INC

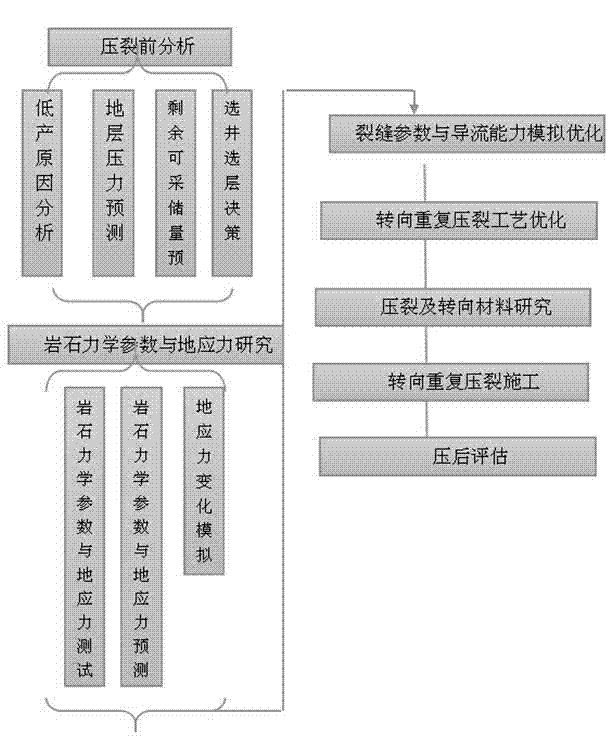

Low permeability gas reservoir turning repeated fracturing technological method

ActiveCN104727798ARealize integrationOptimum Fracturing Construction Pumping ProcedureFluid removalSealing/packingIntegrated designReservoir evaluation

The invention provides a low permeability gas reservoir turning repeated fracturing technological method. The specific technological method comprises the following steps of gas well initial fracturing failure or low-efficiency reason analyzing, reservoir stratum evaluating conducted before turning repeated fracturing, turning repeated fracturing well selection and stratum selection decision making, rock mechanical parameter and ground stress testing, turning repeated fracturing ground stress field changing simulating, fracture geometrical parameter and flow conductivity optimizing, turning repeated fracturing technology optimizing, fracturing liquid and turning agent studying, repeated fracturing constructing and evaluating conducted after repeated fracturing. The well selection and stratum selection decision making and residual gas detecting serve as verification systems of each other, fracturing design and fracture detecting serve as verification systems of each other, and a novel fracture turning agent is used in the low permeability gas reservoir turning repeated fracturing technological method. The integrated design of the low permeability gas reservoir turning repeated fracturing is achieved, and the low permeability gas reservoir turning repeated fracturing technological method has the advantages that the design links are macroscopically integrated, local innovation is achieved, linkage is close, mutual verification is achieved, the design is advanced, and the technological advantage is obvious.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

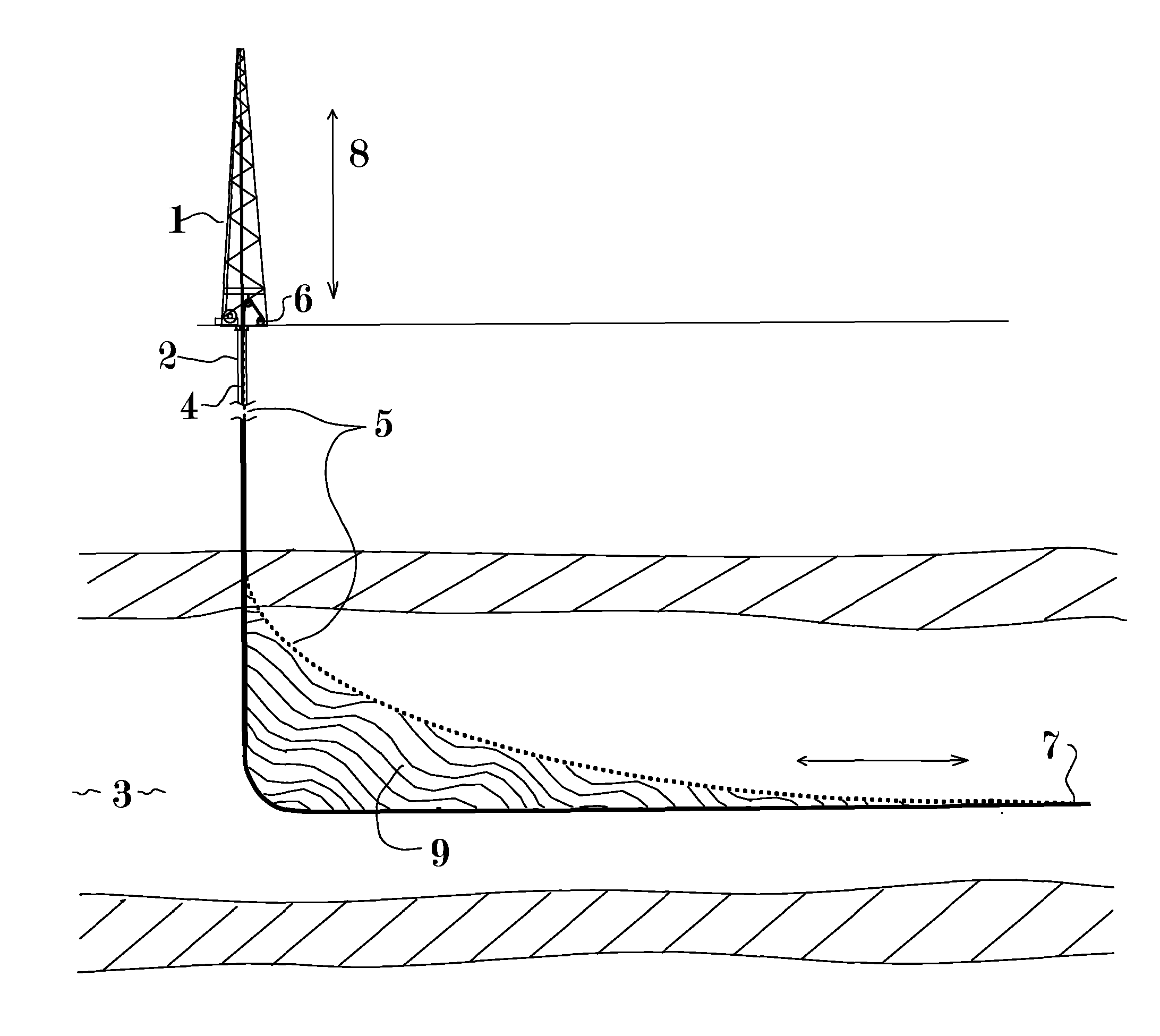

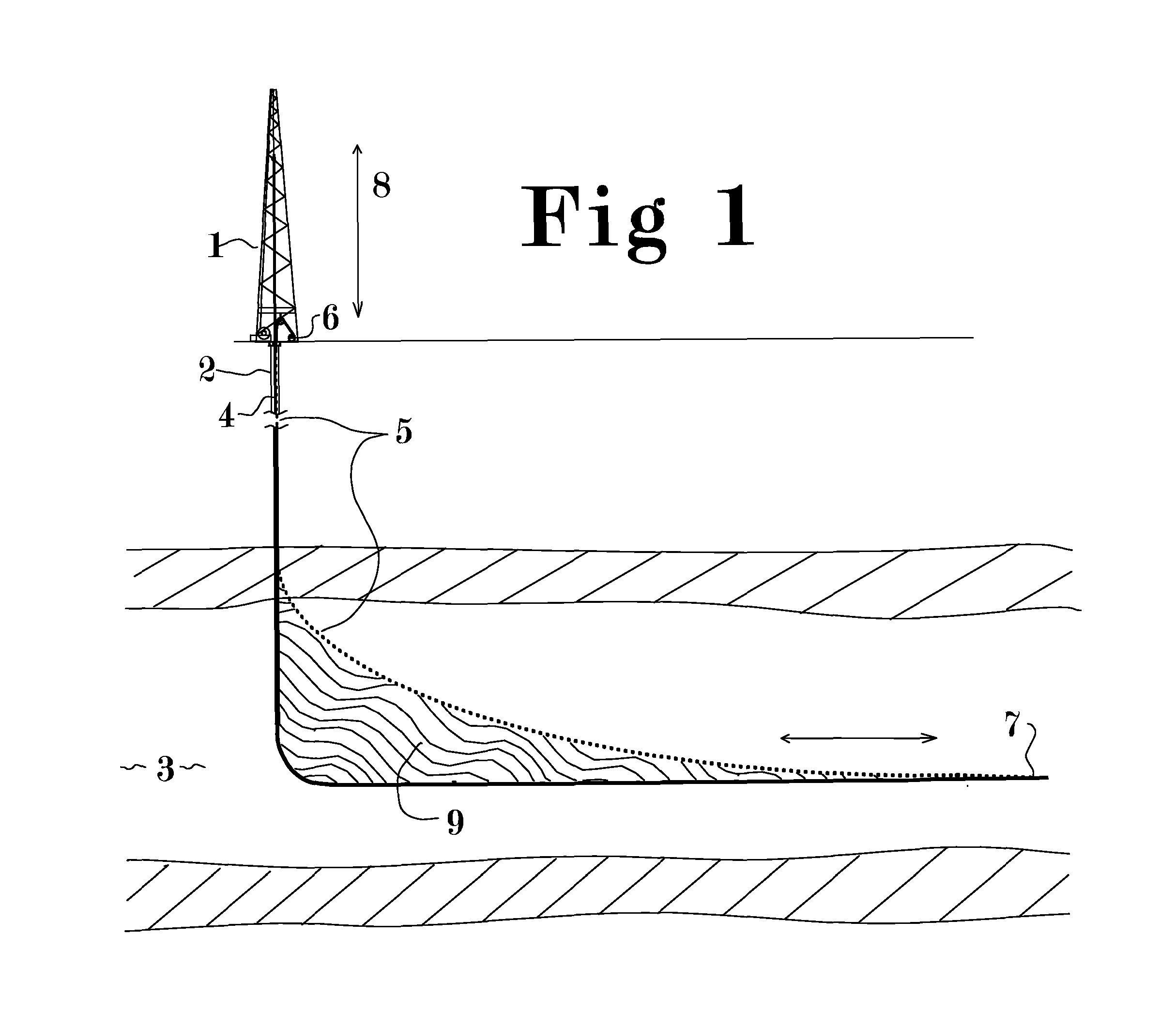

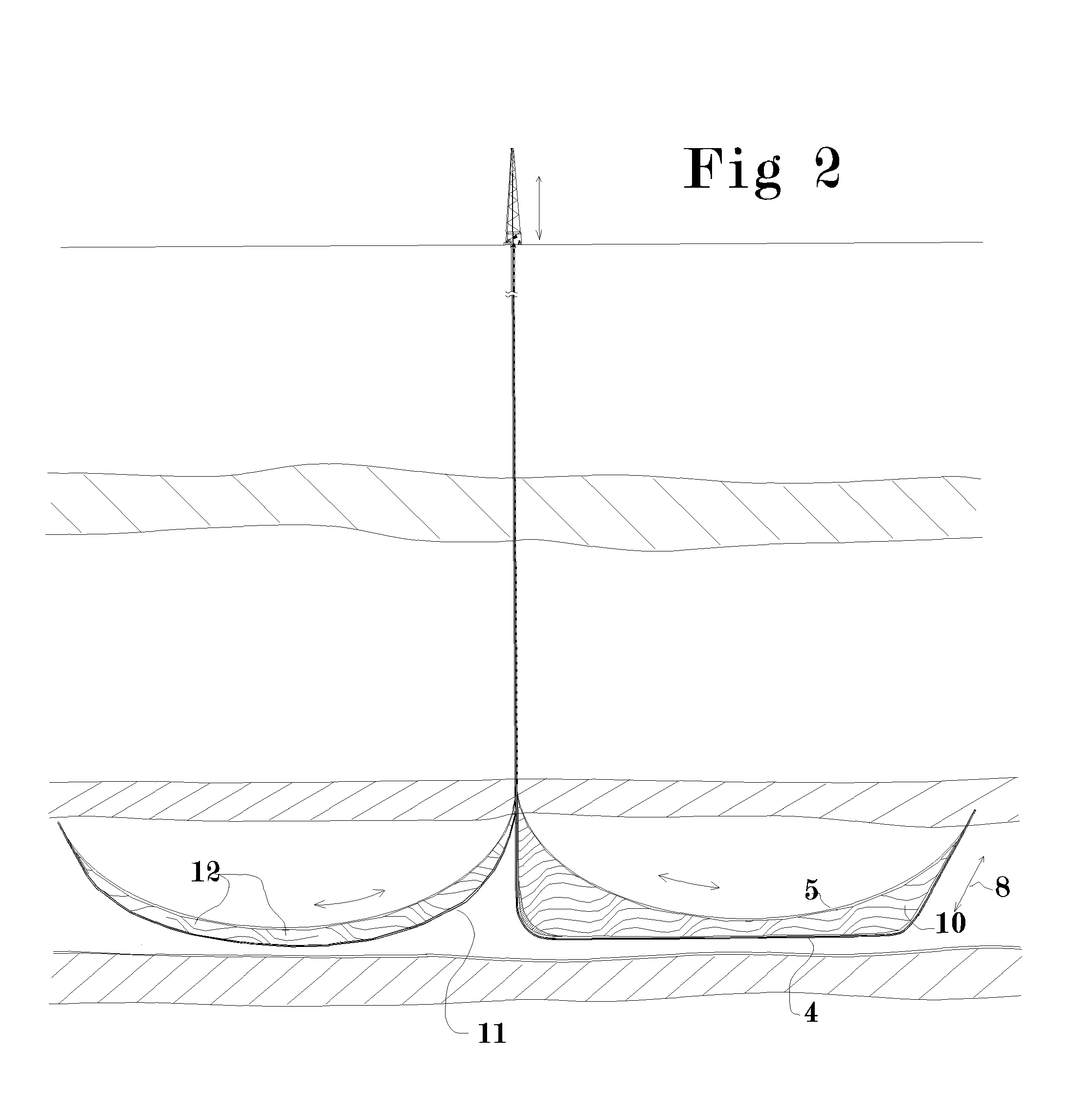

Method and Apparatus for Increasing Well Productivity

InactiveUS20110247816A1Increase productivityRate of flow of resources between the formation and the well is substantially increasedEarth drilling toolsFluid removalEnvironmental issueFlow limitation

This patent application discloses method and apparatus to cut an extended slot connecting a well to a substantial cross section of a desired producing formation whereby material can flow freely between the formation and the wellbore and at least partially overcome the flow limitations of low permeability formations without the environmental issues associated with hydraulic fracturing. It is further disclosed that the connection between said slot and the formation may be further enhanced by explosive or combustive processes that rapidly generate gas pressure within the large surface area of the slot, thereby changing its characteristics and forcing open additional fractures into the cross section of formation exposed to the slot. The method may significantly increase the recoverable percentage of natural gas from low permeability deposits such as shale and coal.

Owner:CARTER JR ERNEST E

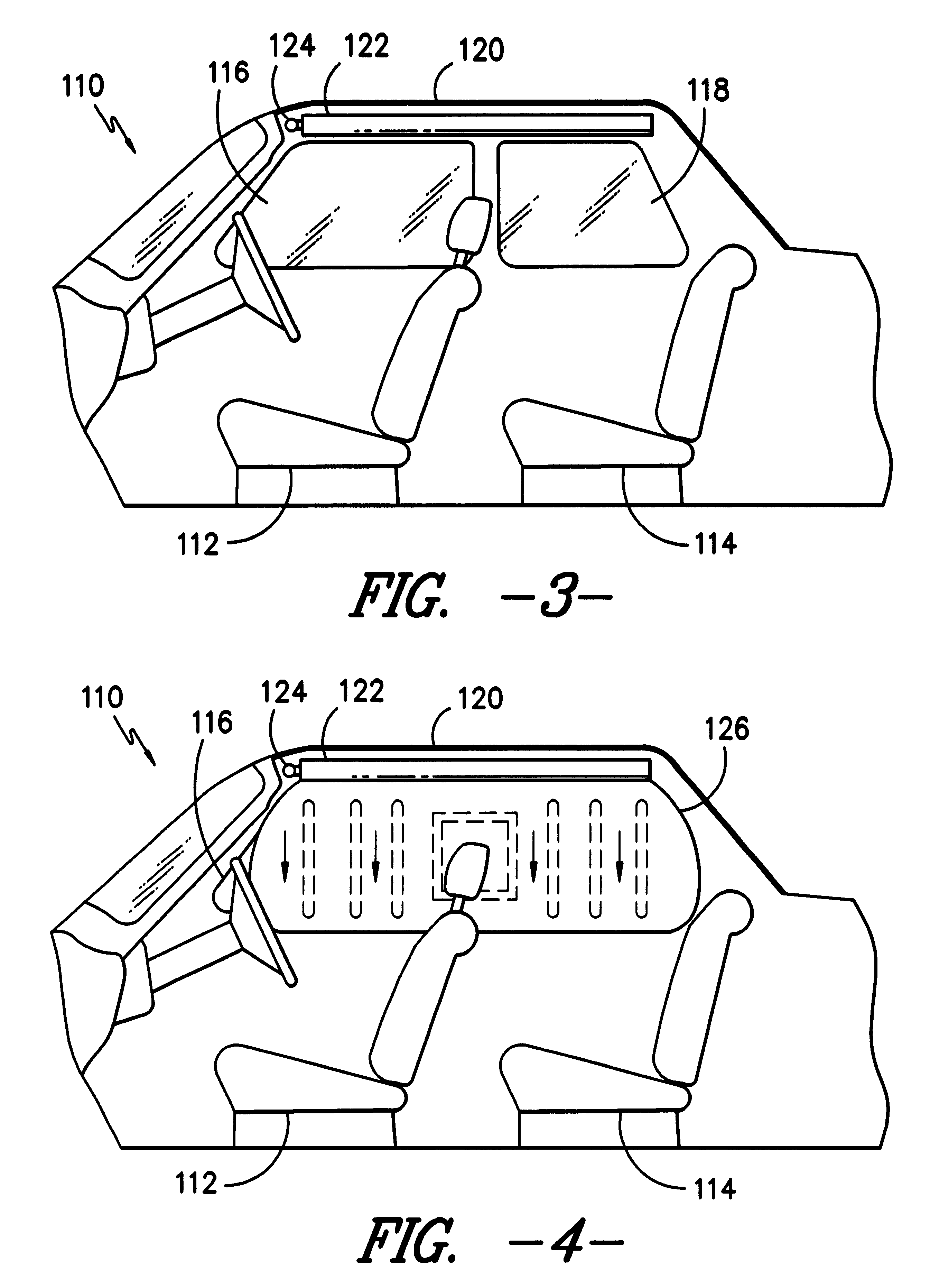

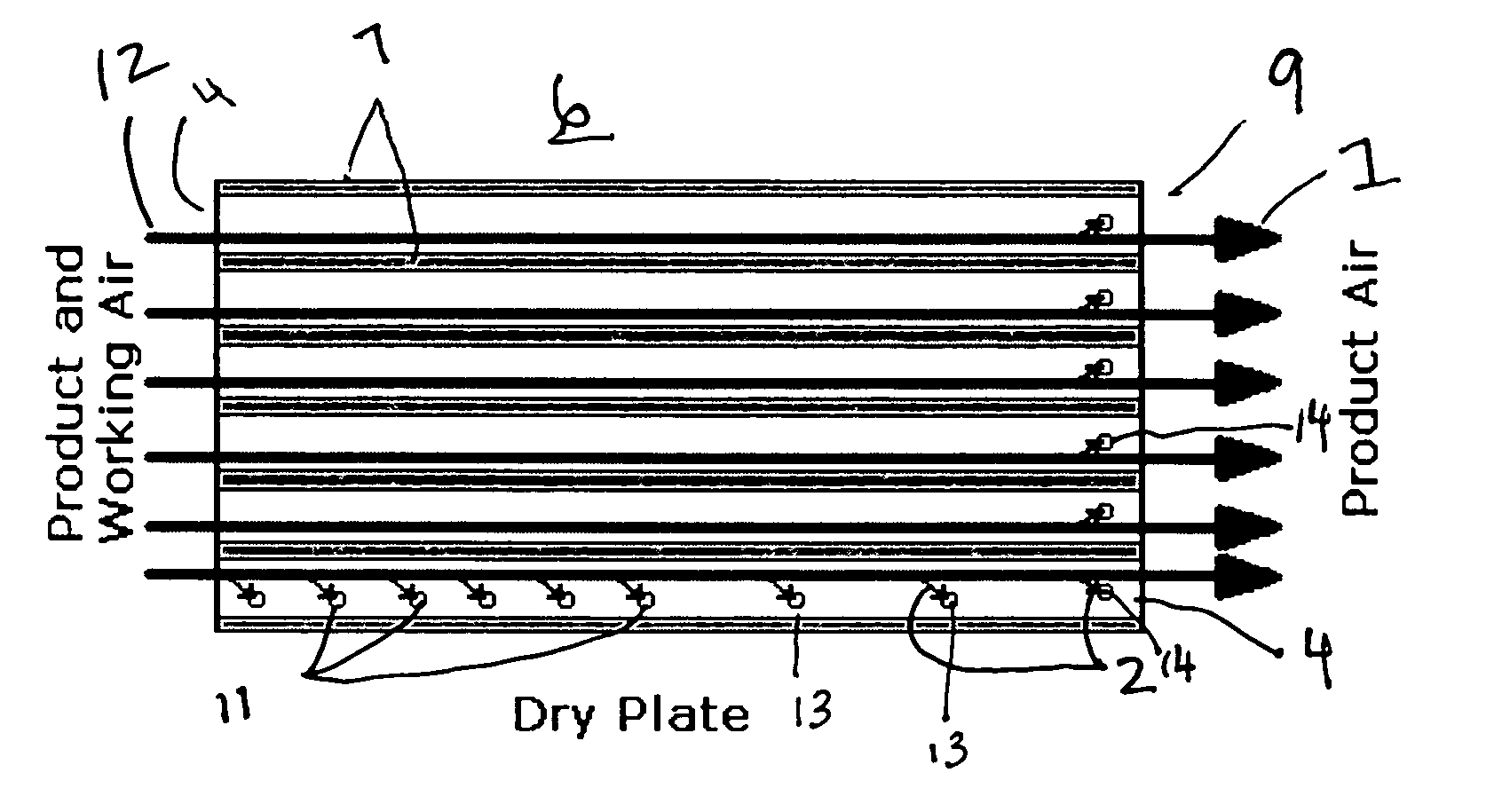

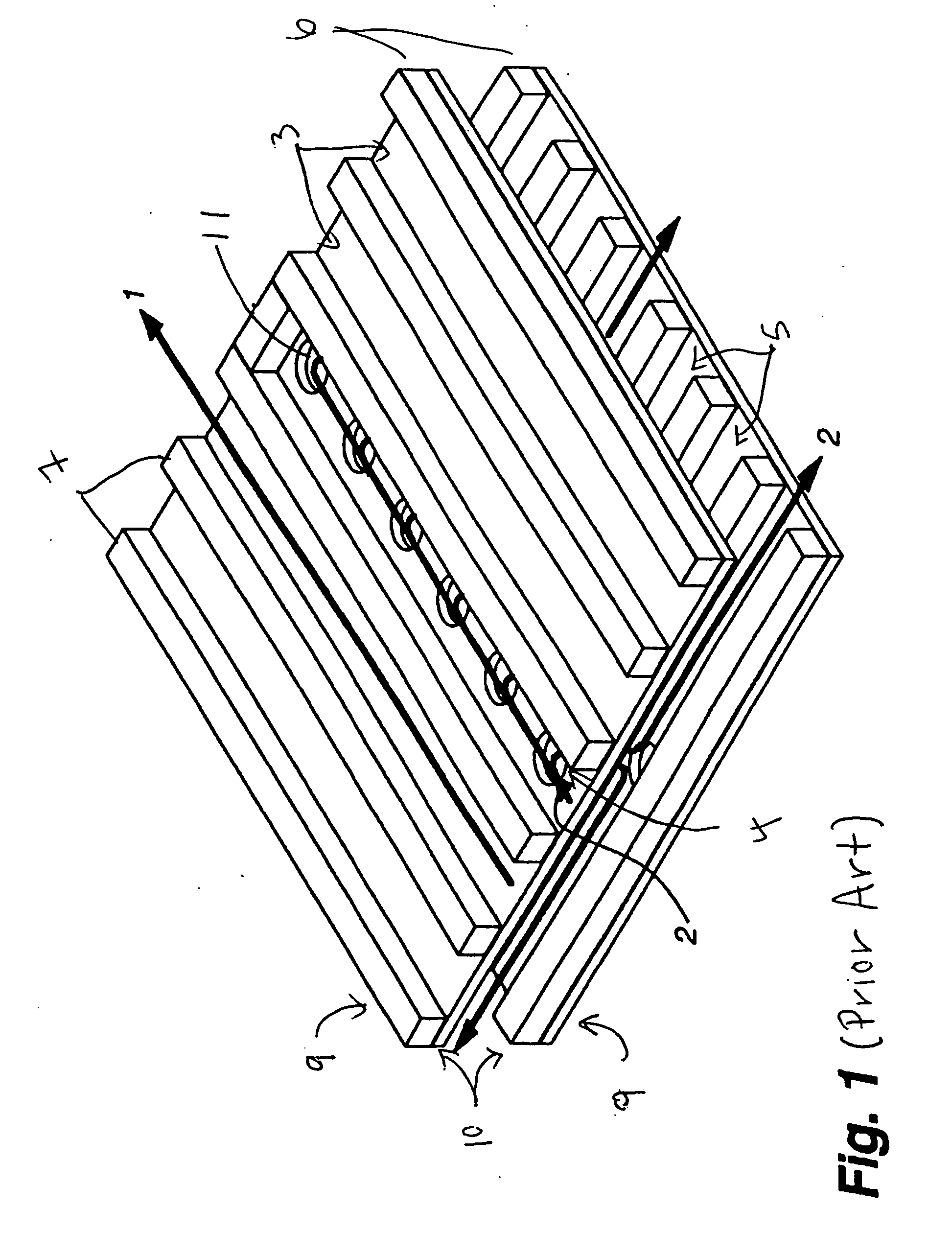

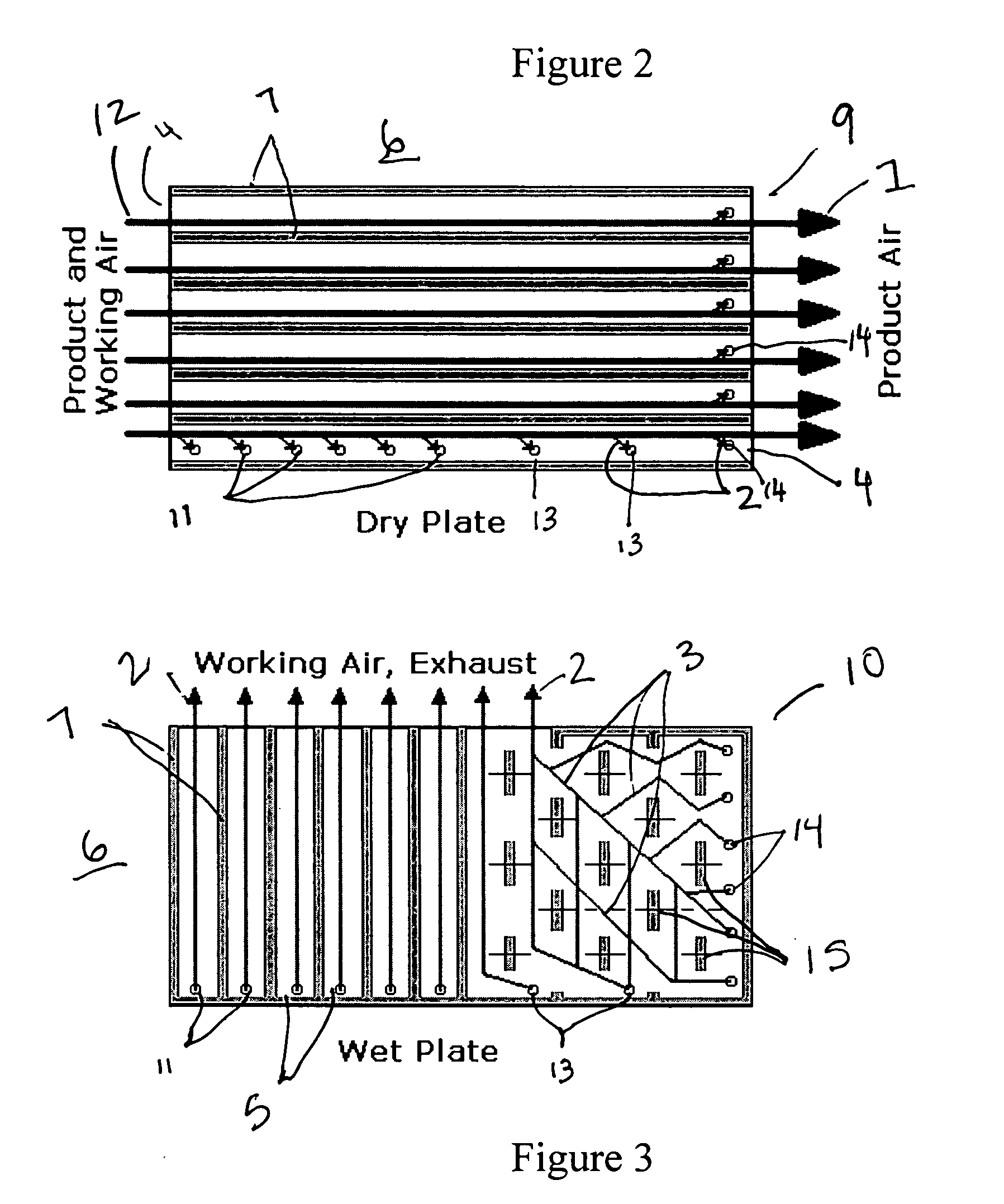

Indirect evaporative cooling of a gas using common product and working gas in a partial counterflow configuration

InactiveUS20050210907A1Increase heat loadLess working airFree-cooling systemsStationary conduit assembliesEvaporative coolerEngineering

An indirect evaporative cooler includes a number of heat transfer plates. Each plate has a wet side and a dry side, and the dry sides of adjacent plates face each other. The plate dry sides have low permeability to an evaporative liquid. Input air flows over the dry sides from an input end to an output end. Part of the input air becomes product air and exits at the output end. The rest of the input air passes through perforations in the plates to the other side of the plates to become working air. The other side of each plate is a wet side, which is wet by an evaporative liquid. Working gas flows over the wet side, evaporating the evaporative liquid and cooling the evaporative liquid, the plate, and finally the product gas by heat transfer. The perforations are formed both toward the input end of the plate and toward the output end of the plate. Part of the wet side of the plate, toward the output end of the plate, has a plurality of barriers placed to cause the working gas at that end of the plate to flow in a direction generally counter to the input air.

Owner:IDALEX TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com