Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about "Leno shedding mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6698458B1Beneficial and long-term low permeabilityExcellent long-term storage stabilityLeno shedding mechanismPreformed elementsNeopreneEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds wherein the film is present on the surface in an amount of at most 3.0 ounces per square yard of the fabric.

Owner:MILLIKEN & CO

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6701971B1Reduced packaging volumeLong leak-downLeno shedding mechanismPreformed elementsElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 7 seconds. All coatings, in particular elastomeric, non-silicon coatings, and coated airbags, meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

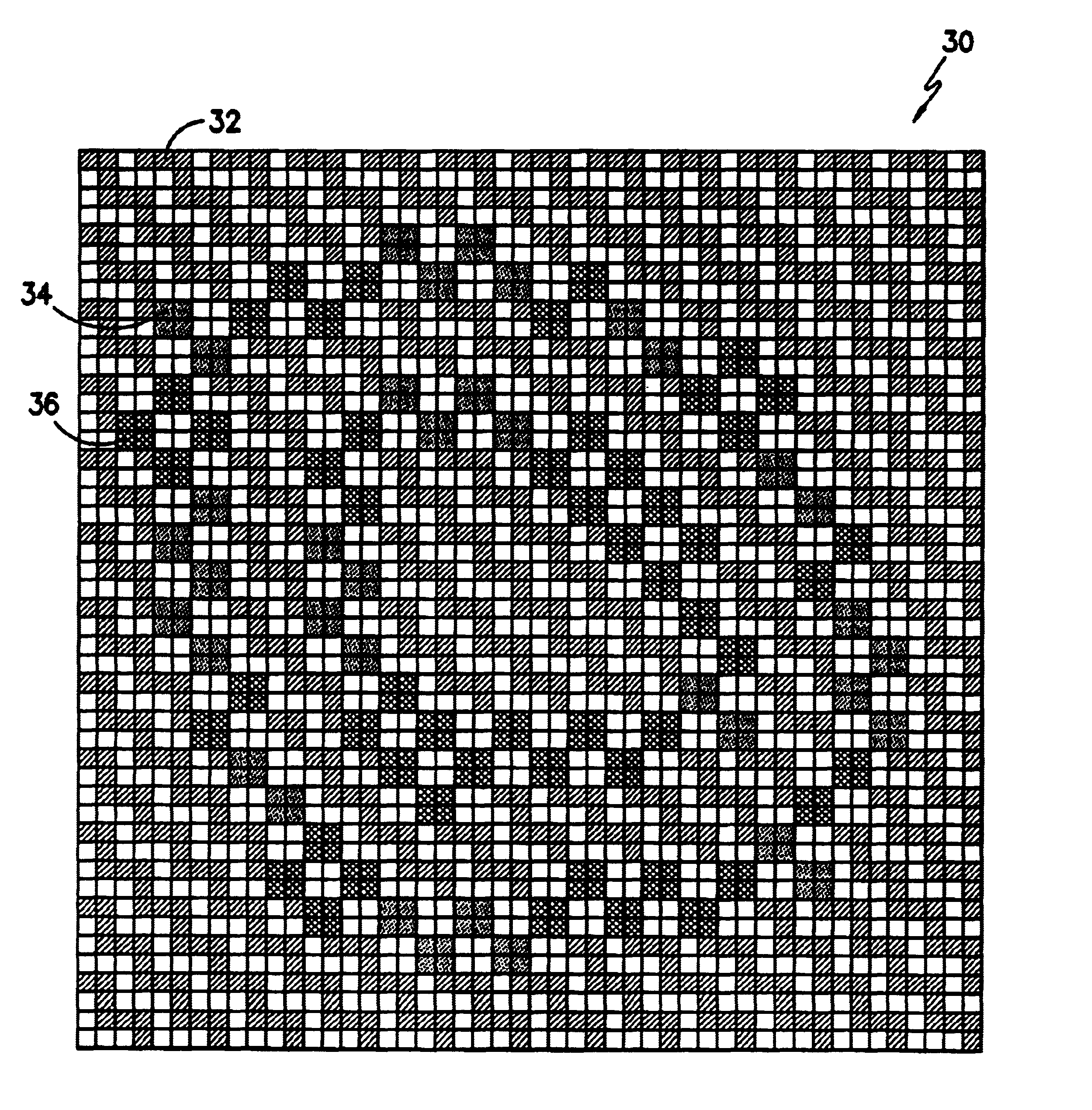

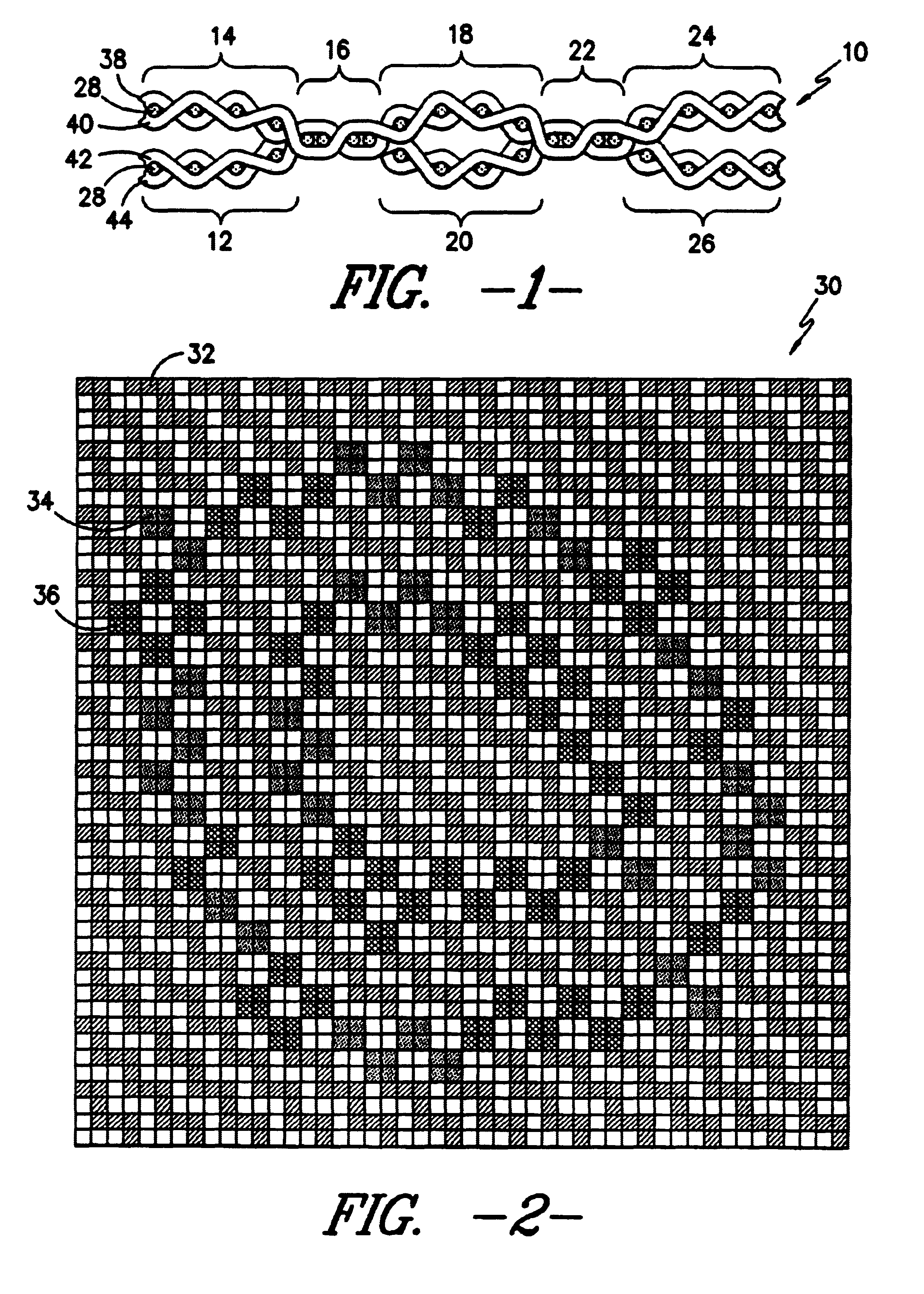

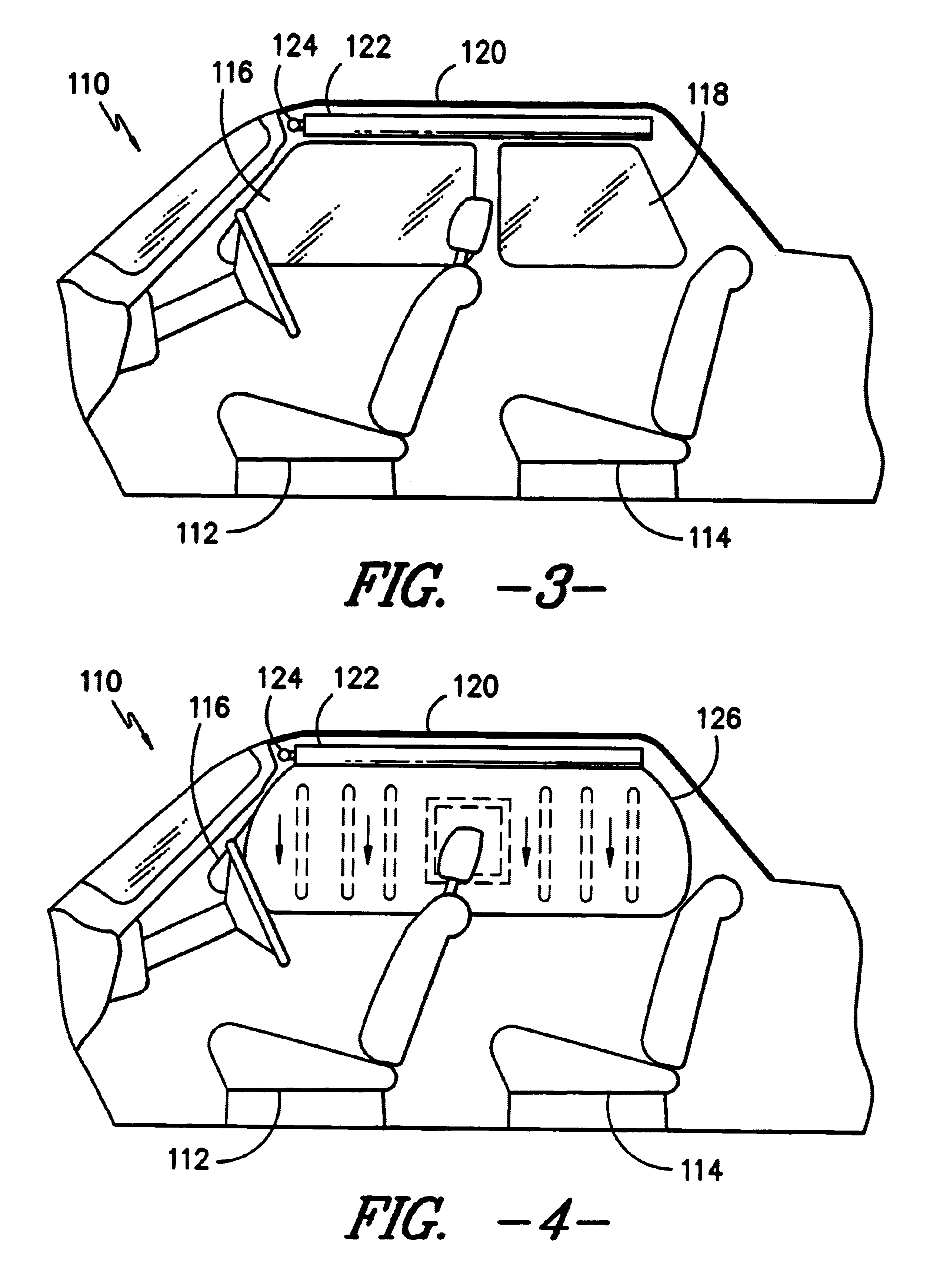

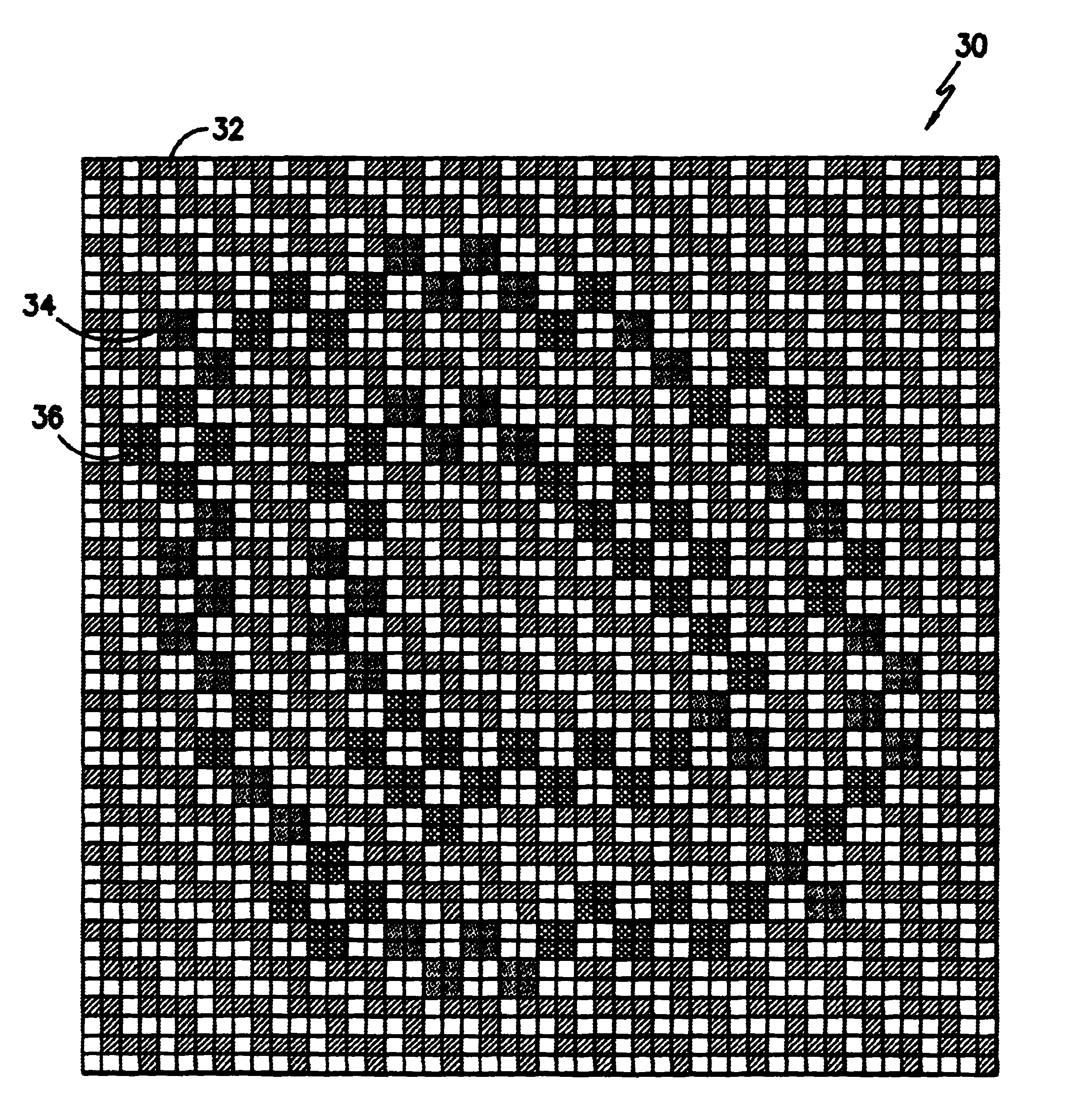

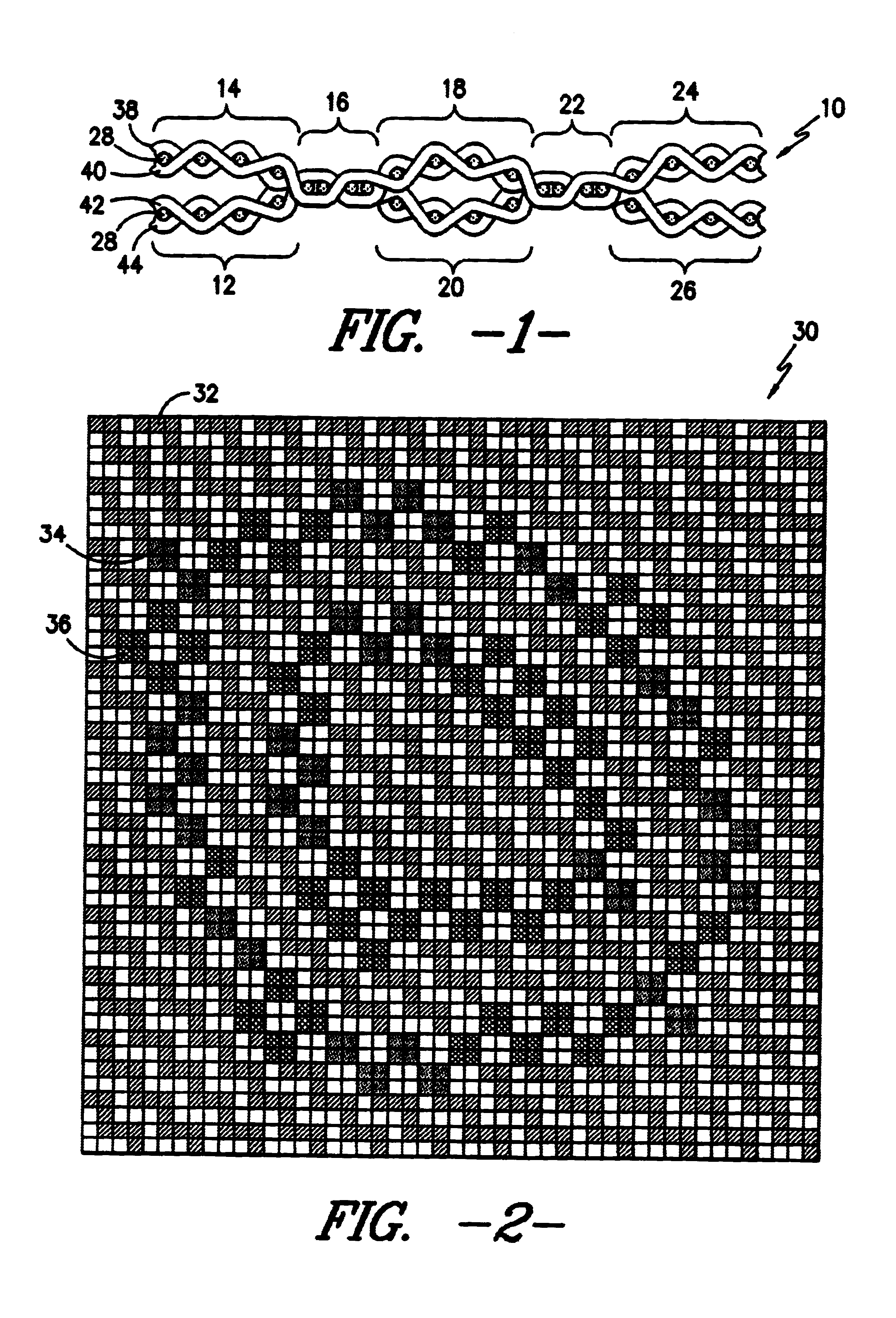

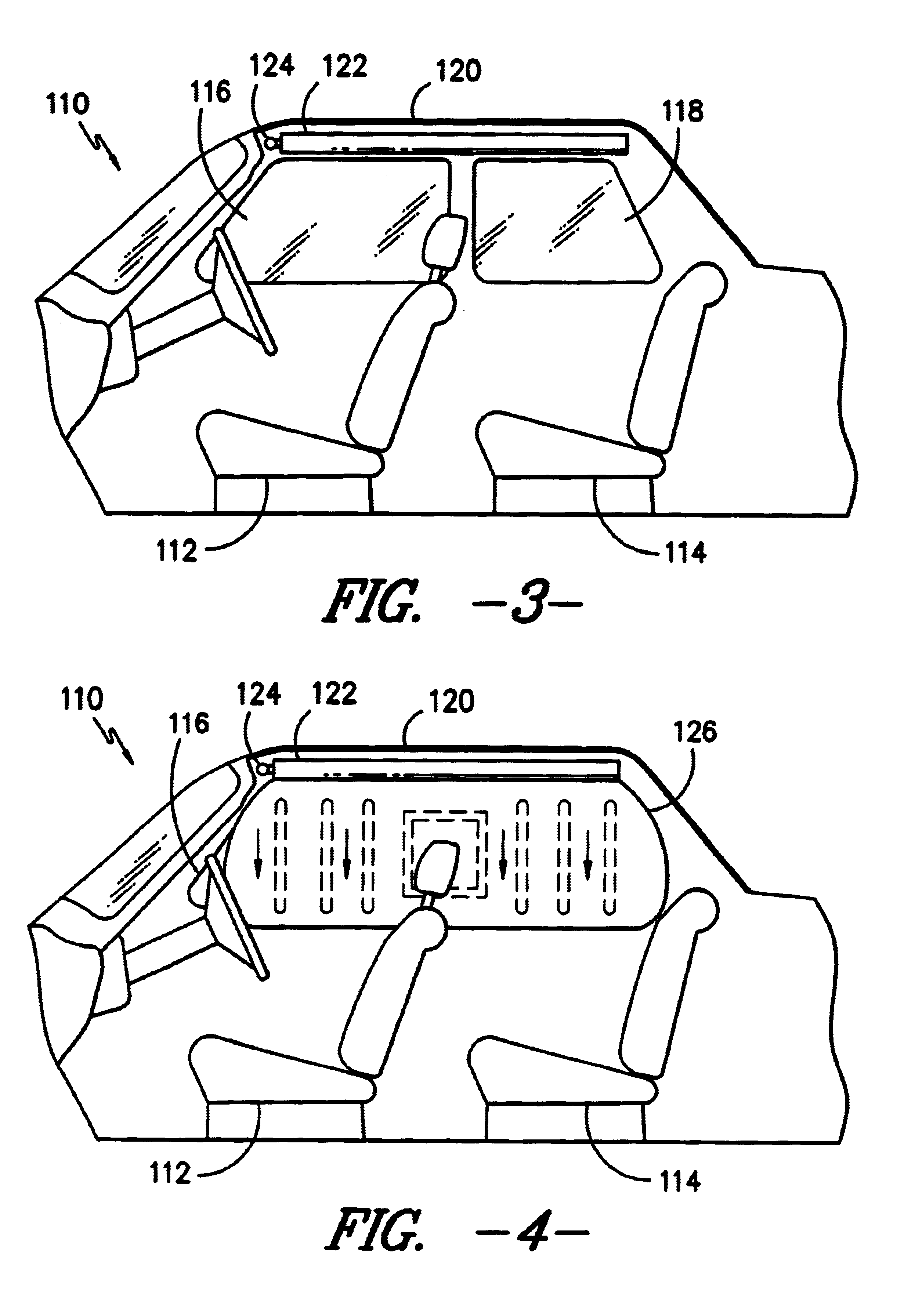

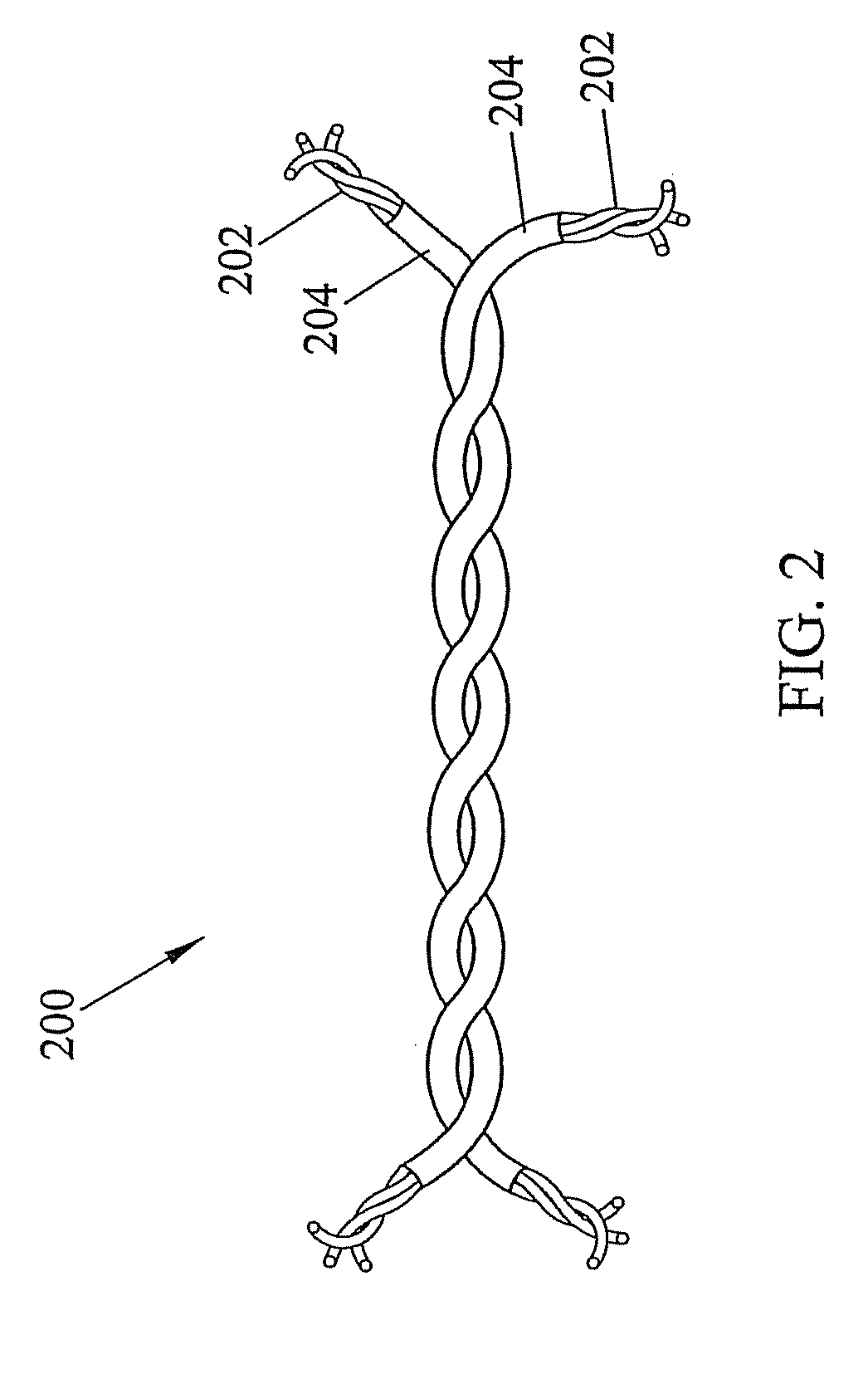

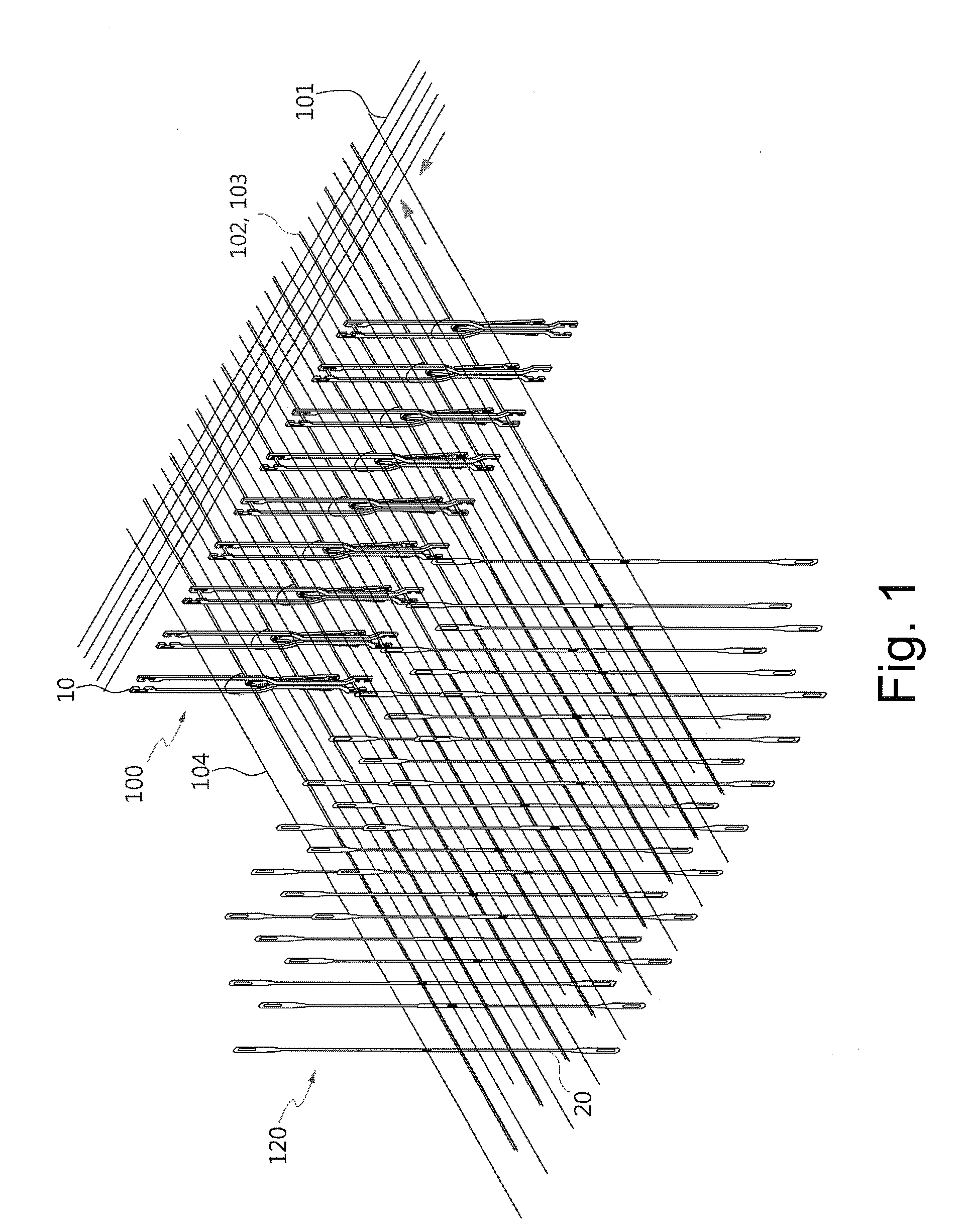

Fabric and yarn structures for improving signal integrity in fabric-based electrical circuits

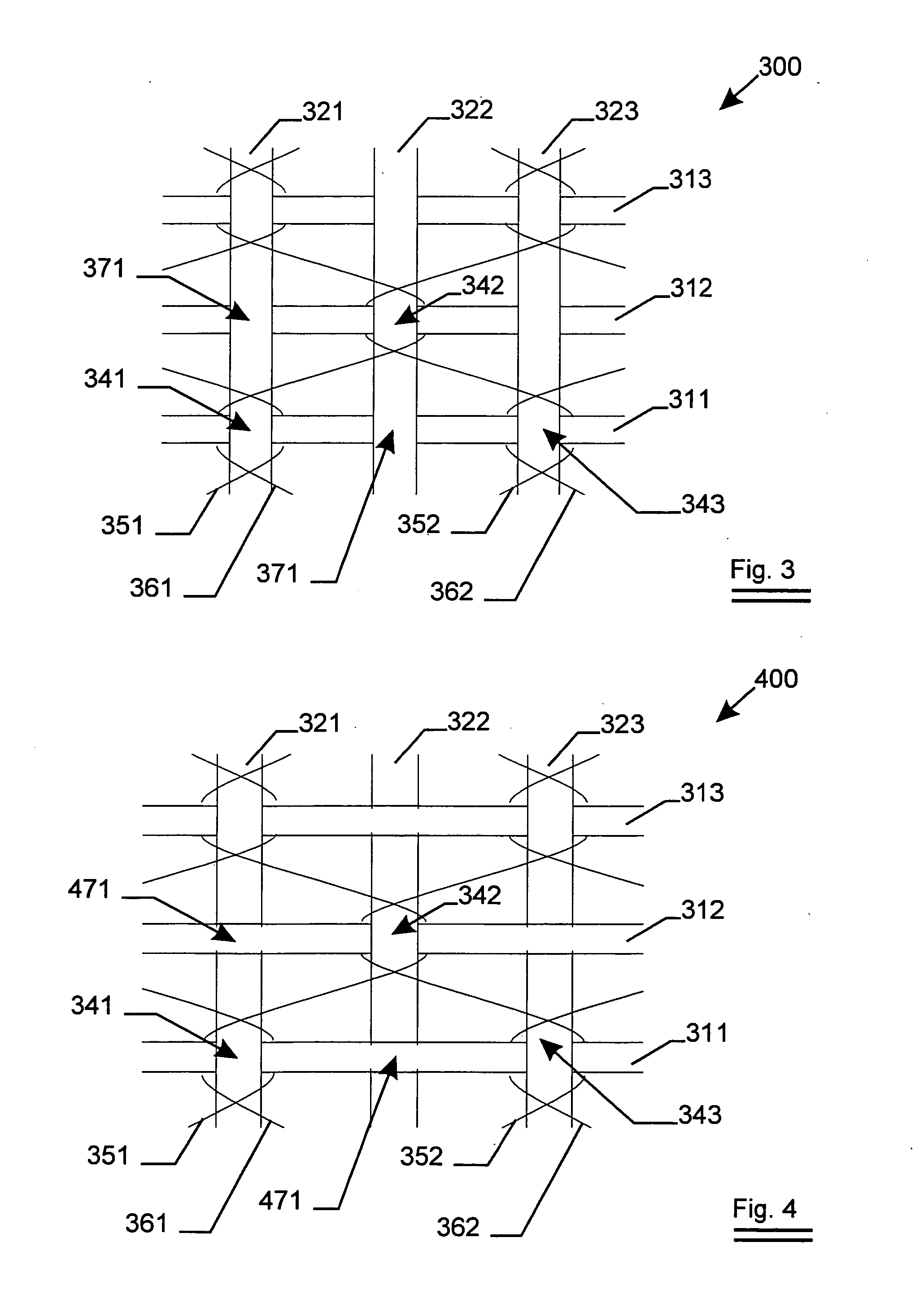

InactiveUS20080287022A1Reduce crosstalkImprove the immunityJacquardsLeno shedding mechanismPower gridTwisted pair

Coaxial and twisted pair conductive yarn structures reduce signal crosstalk between adjacent lines in woven electrical networks. A coaxial conductive yarn structure includes an inner conductive yarn having a plurality of conductive strands twisted together. An outer conductive yarn is wrapped around the inner conductive yarn. An insulating layer separates the inner and outer yarns. A twisted pair conductive yarn structure includes first and second conductive yarns, each including a plurality of conductive strands being twisted together. The first and second conductive yarns are twisted together to form a helical structure. In a woven electrical network, at least one conductor of adjacent conductive yarn structures is connected to ground to reduce signal crosstalk. Coaxial and twisted pair yarn structures may also be formed simultaneously with weaving or knitting the threads that make up the structures into a fabric.

Owner:NORTH CAROLINA STATE UNIV

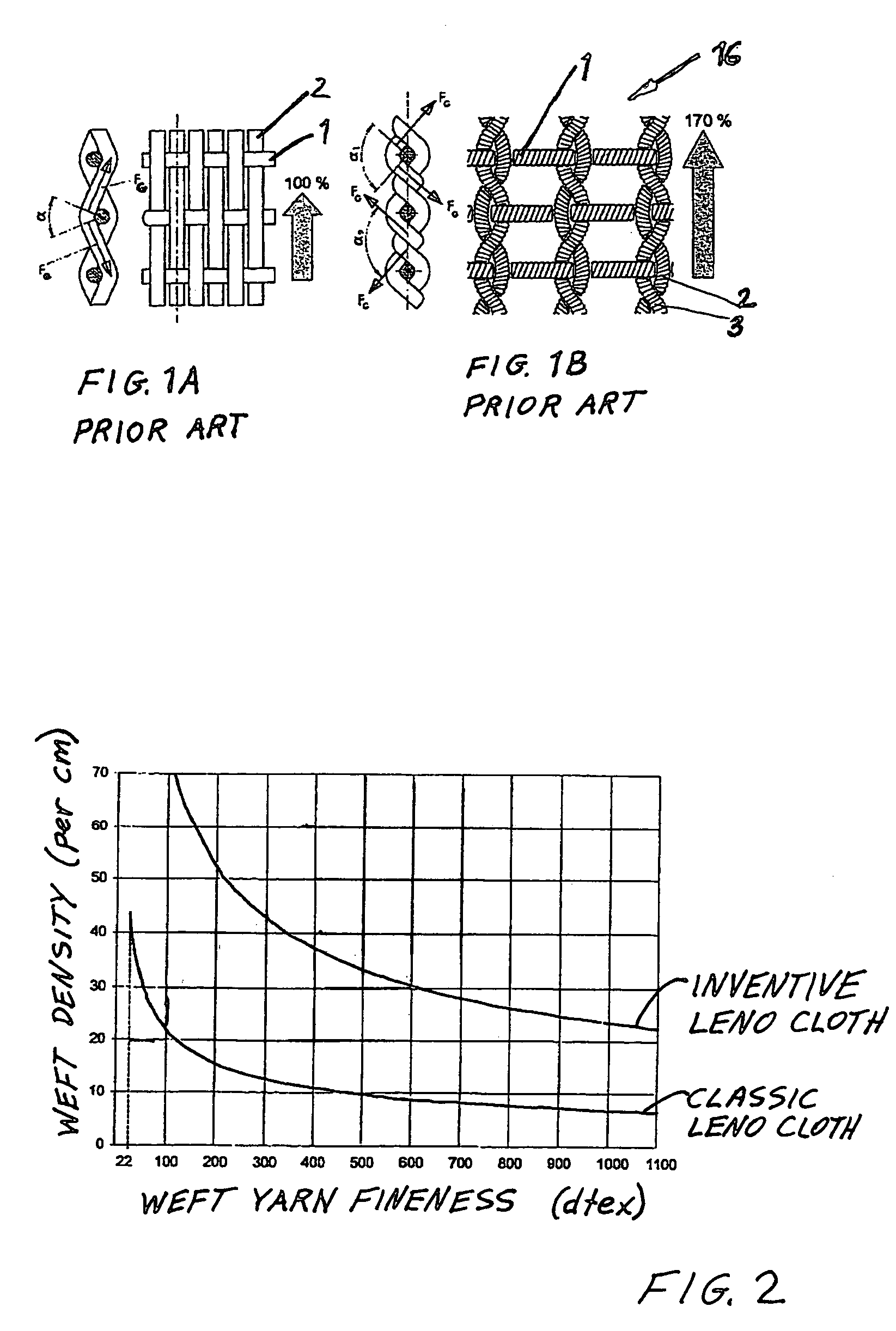

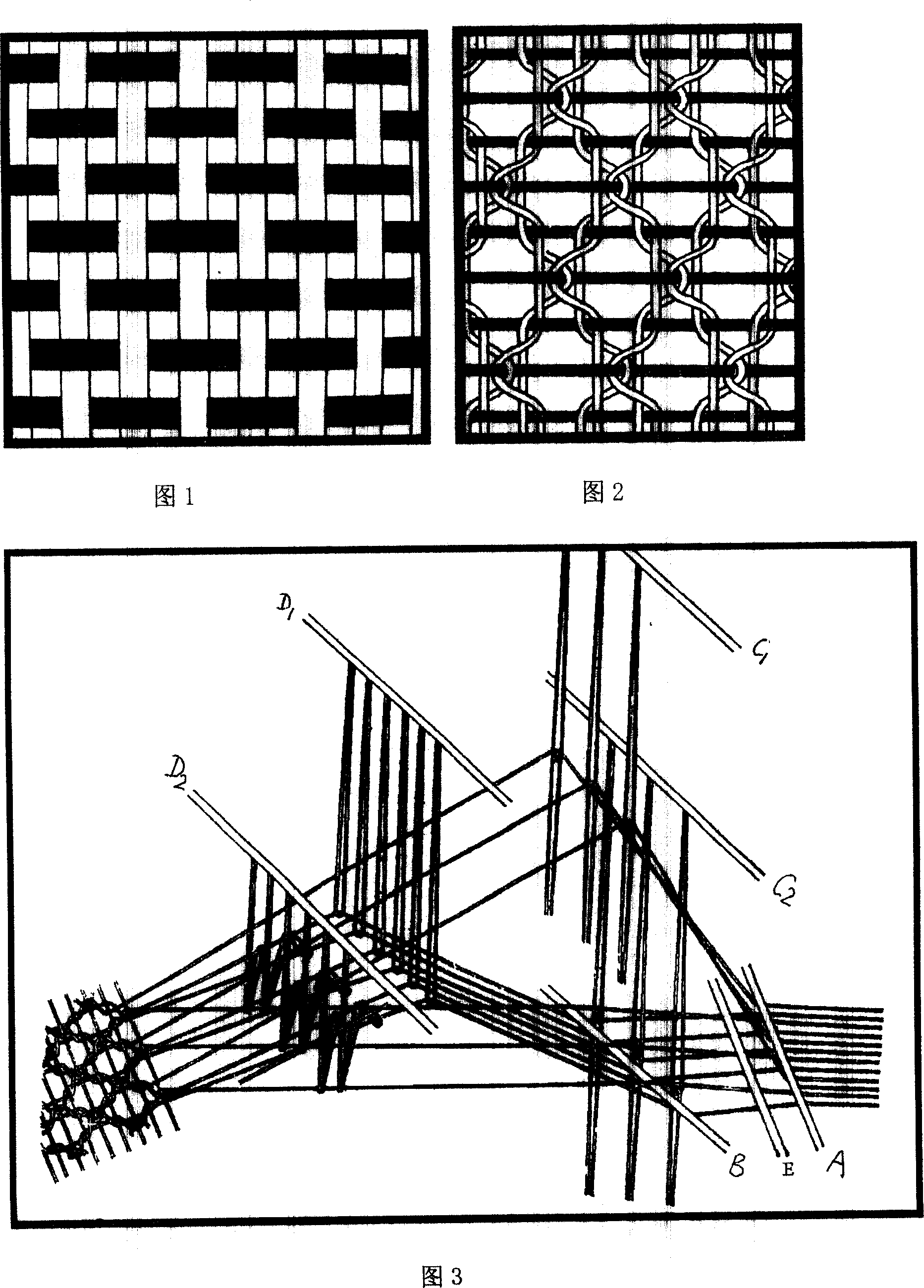

Leno cloth as well as method and weaving machine for production thereof

InactiveUS7287553B2Reduce tensionStronger working-in insertion or take-upOrnamental textile articlesLeno shedding mechanismYarnEngineering

A leno cloth is prepared, which comprises at least ground warp threads 1, leno warp threads 3 and weft threads 2, and in which the weft threads 2 and the ground warp threads 1 are arranged essentially interspace free. The weft threads are bound-off by means of the leno warp threads 3, which comprise a clearly lower titer relative to the ground warp threads 1, with such a lower tension relative to the ground warp threads, so that the crossings of the leno warp threads 3 with the ground warp threads 1 that are present due to the binding are arranged in a plane parallel to the plane of the maximum thickness of the weft threads. The leno warp threads 3 comprise a higher working-in or take-up into the woven cloth than the ground warp threads 1. According to a further aspect of the invention, a method for the production of a leno cloth as well as a loom for the carrying out of the method for the production of a leno cloth are described.

Owner:LINDAUER DORNIER GMBH

Woven fabric comprising leno weave bound metal

InactiveUS20070235595A1Avoid possibilityOut of alignmentLeno shedding mechanismWire networkEngineeringWoven fabric

A woven fabric in which warp elements are provided out of metal. The fabric further comprising at least a first set of substantially parallel binding elements present in warp direction of the fabric. This first set of binding elements bind the warp elements to the weft elements by means of a leno weave at at least a part of the intersection points of warp and weft elements. The fabric as subject of the invention is characterized in that each binding element of the first set of binding elements crosses more than one warp element between consecutive intersection points bound by this binding element.

Owner:NV BEKAERT SA

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

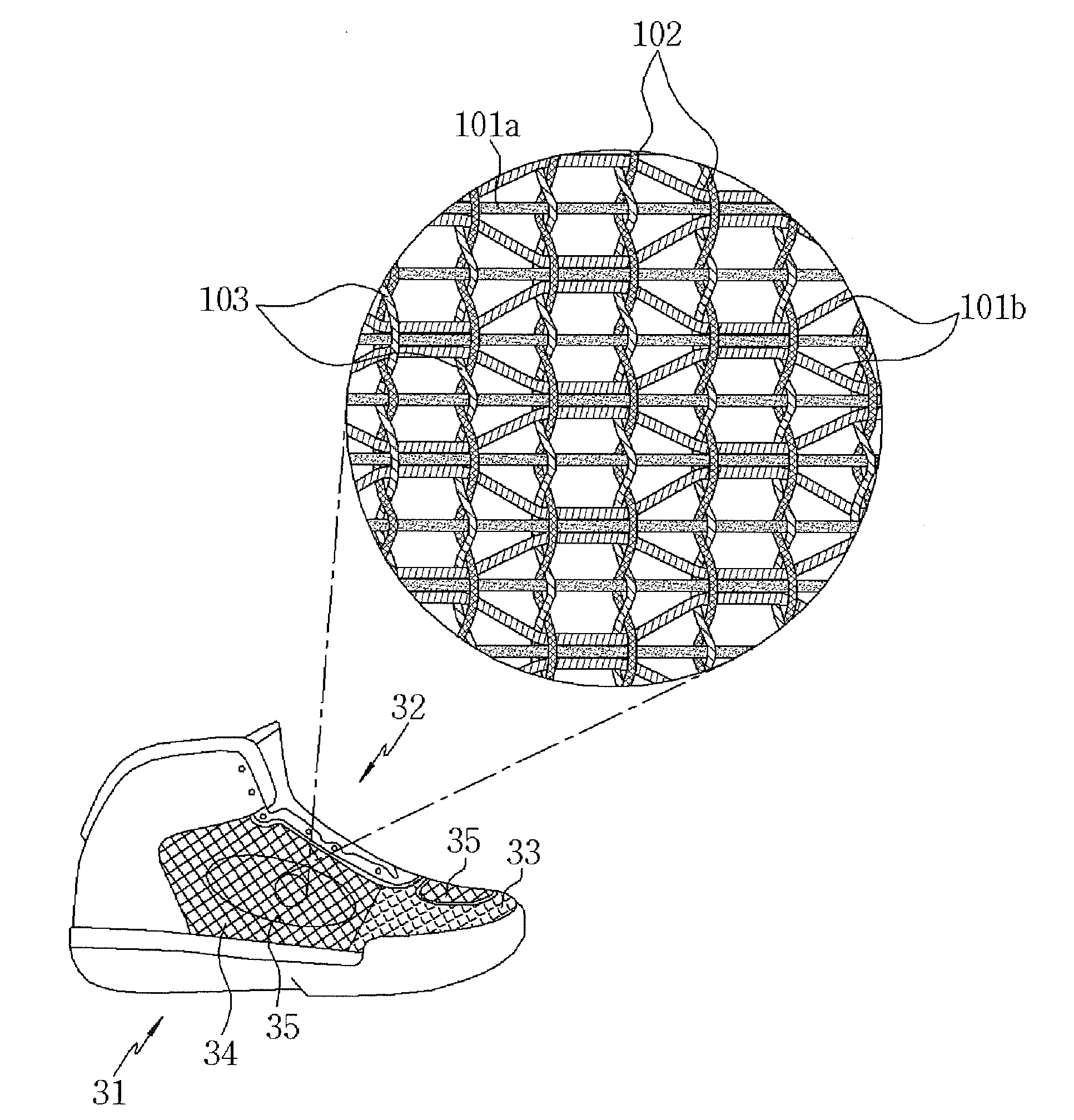

Loom for weaving fabric with two types of tissue, shoe upper woven using the same, and shoe

ActiveUS20160309843A1Improve productivityReduce processJacquardsLeno shedding mechanismEngineeringWoven fabric

Owner:SONG SOO BOK

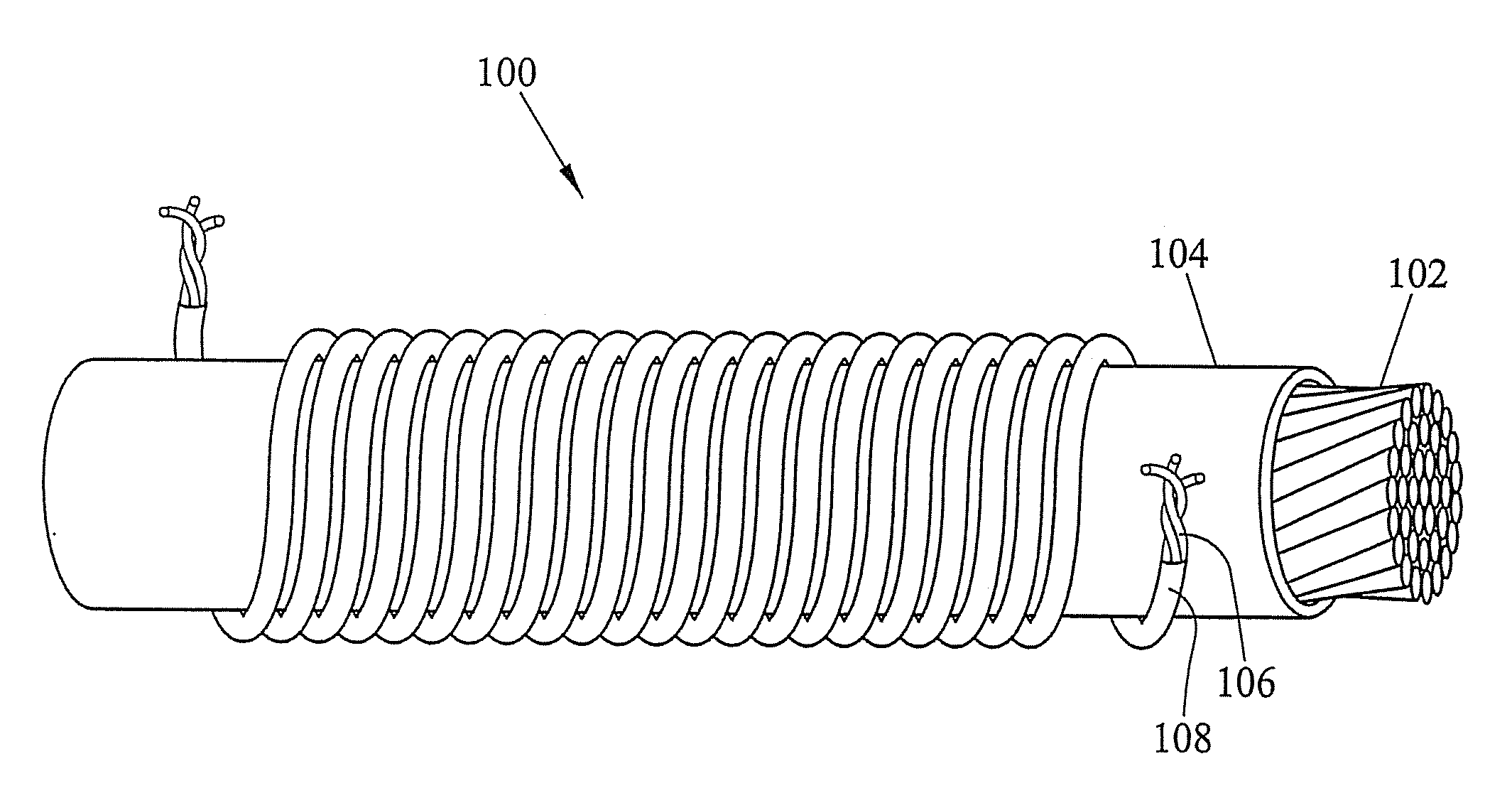

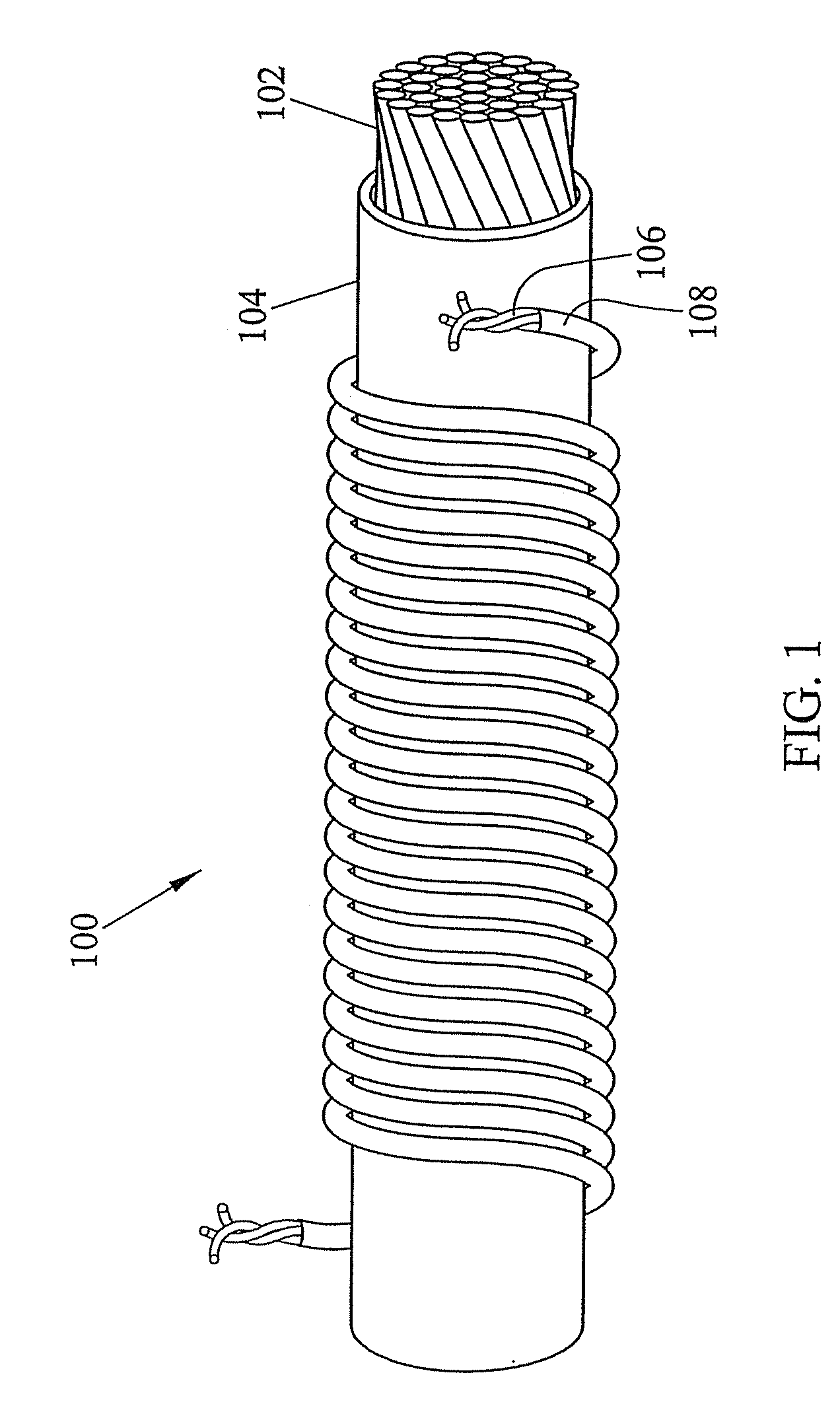

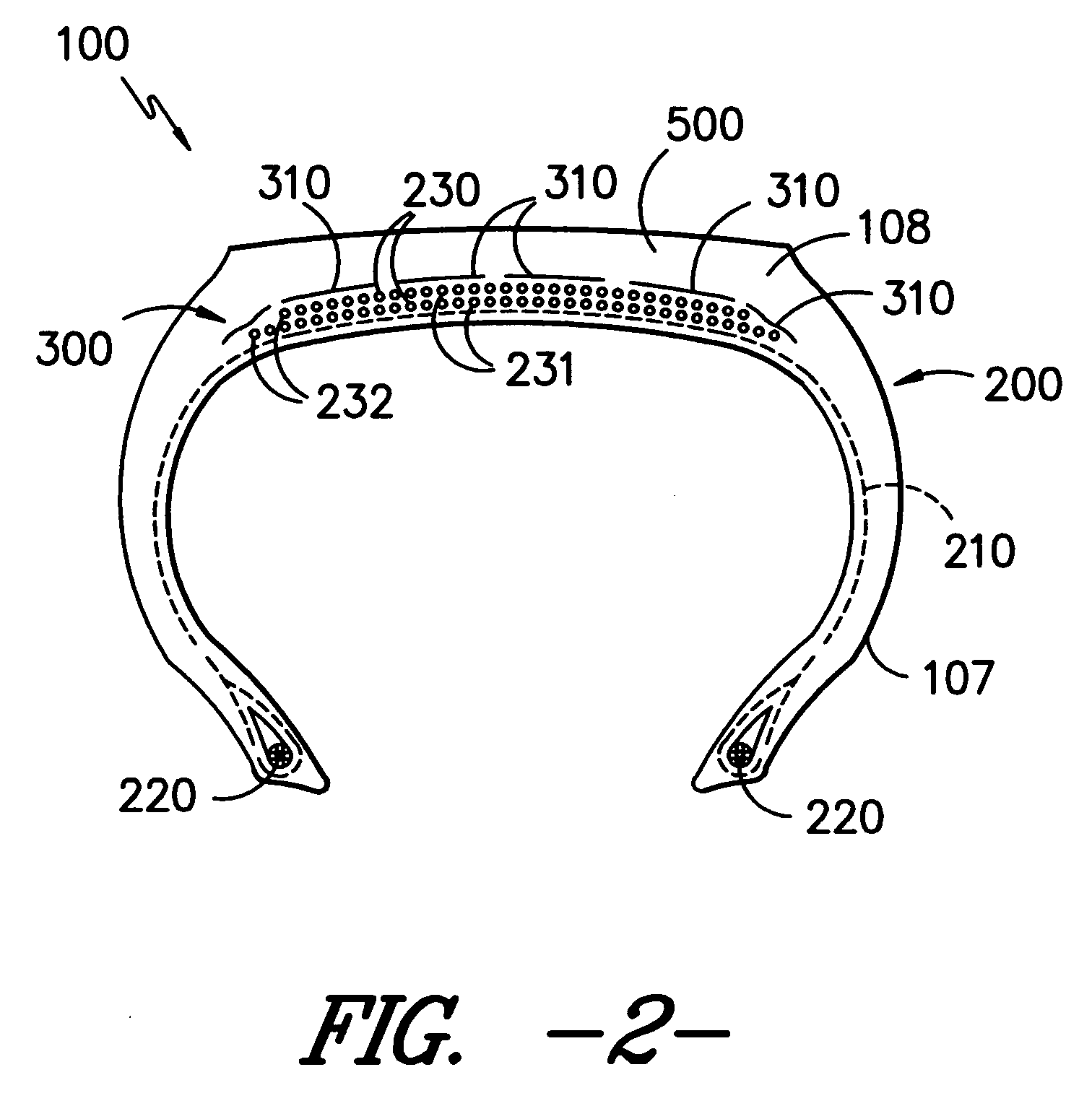

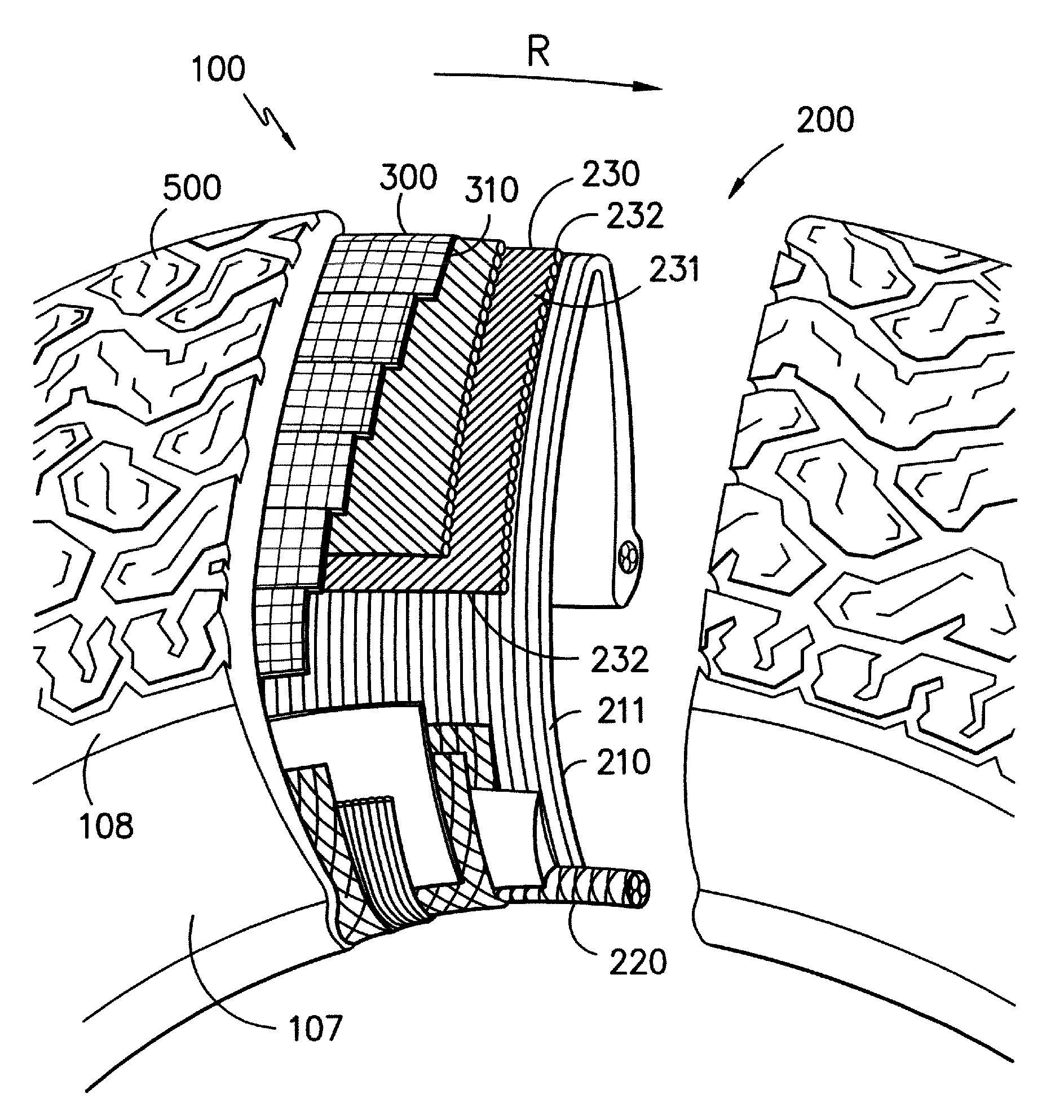

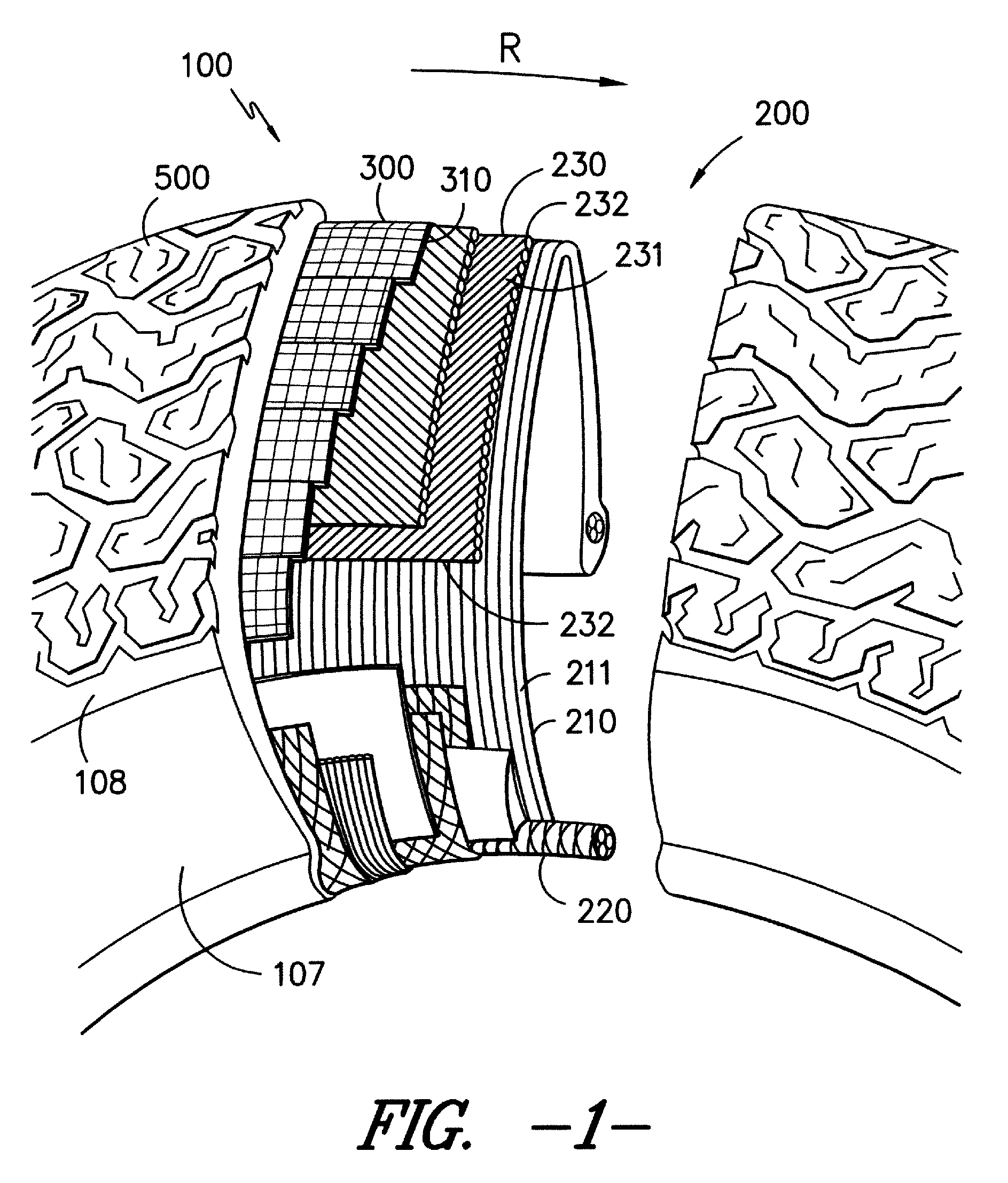

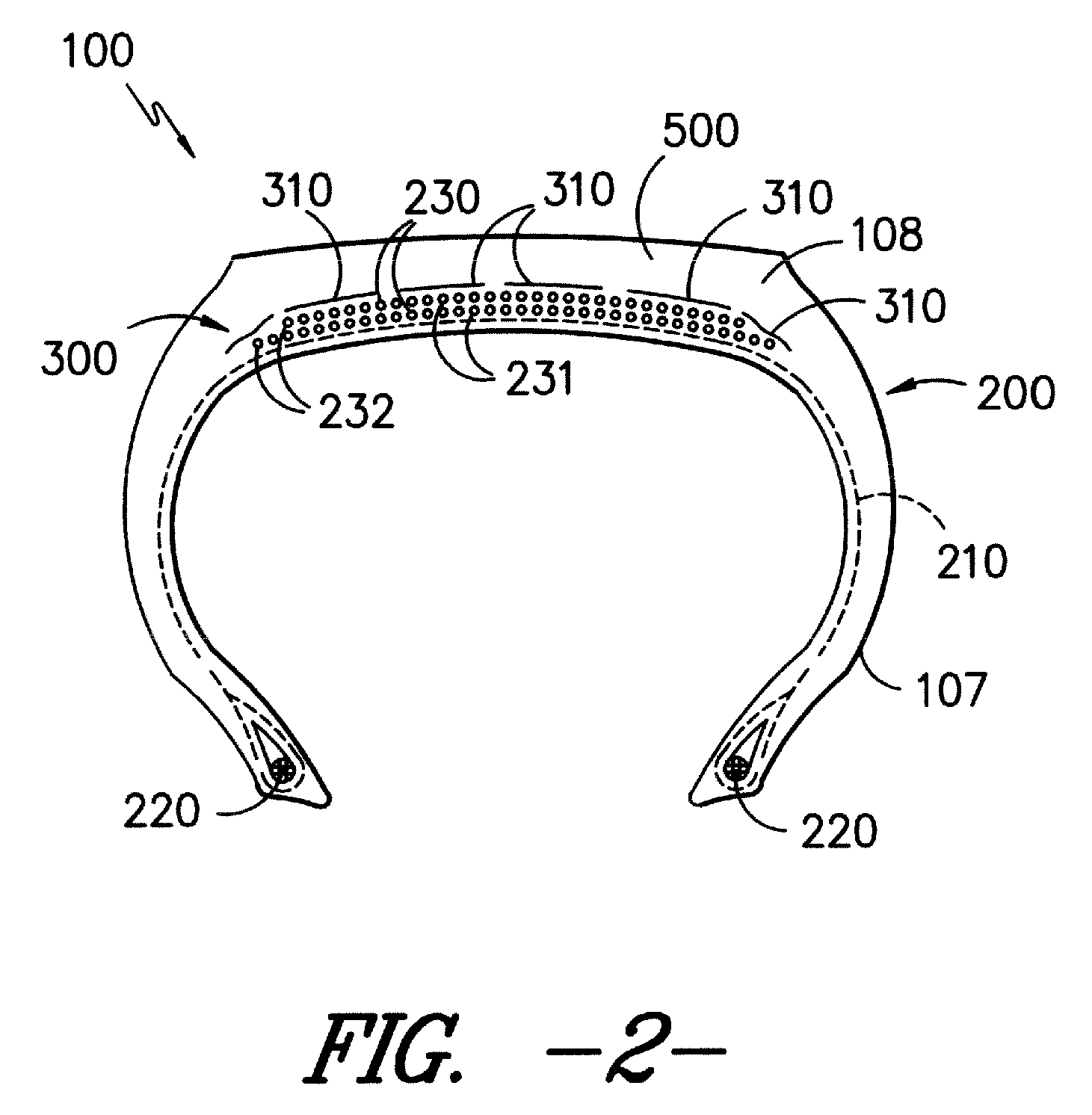

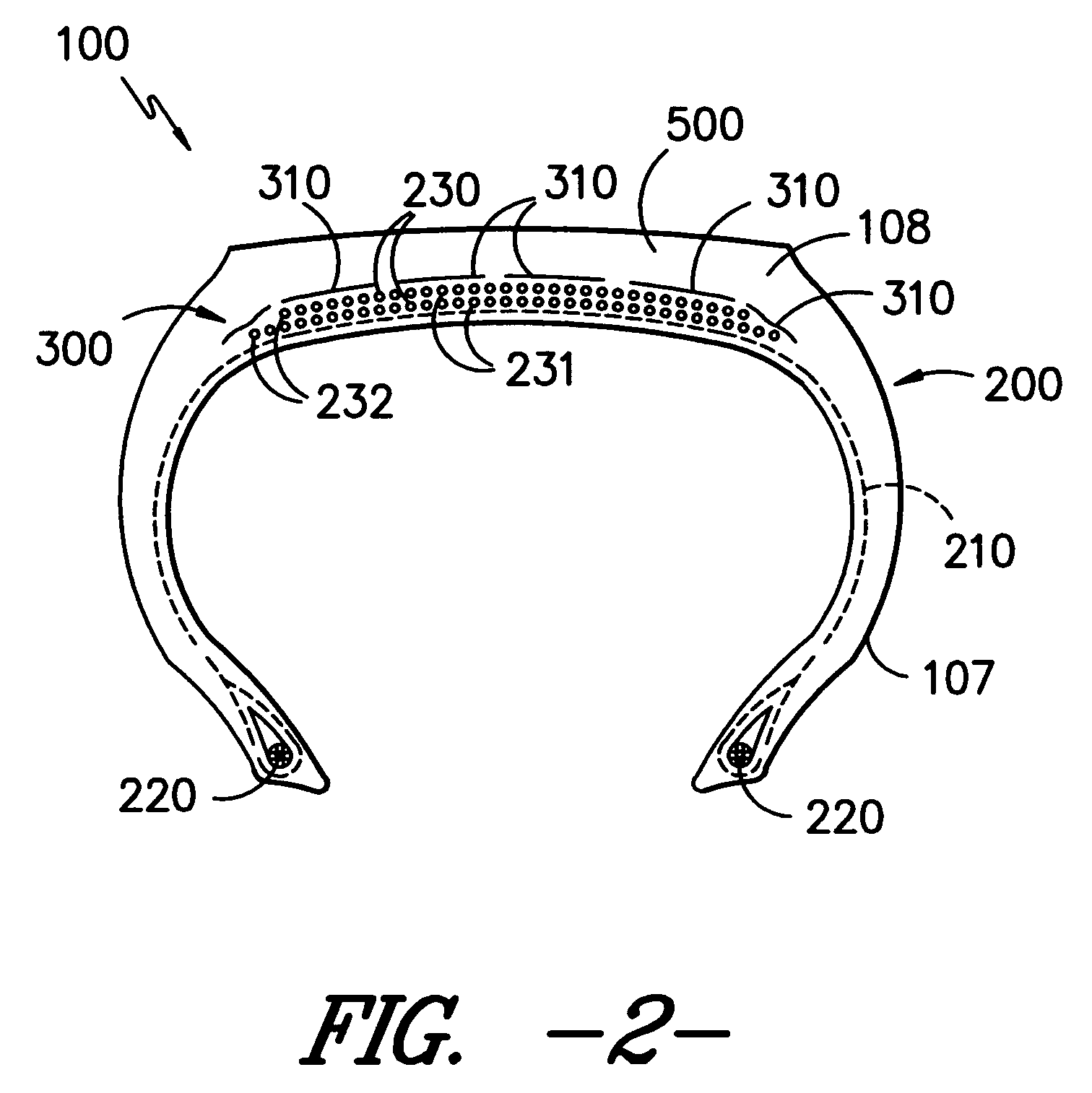

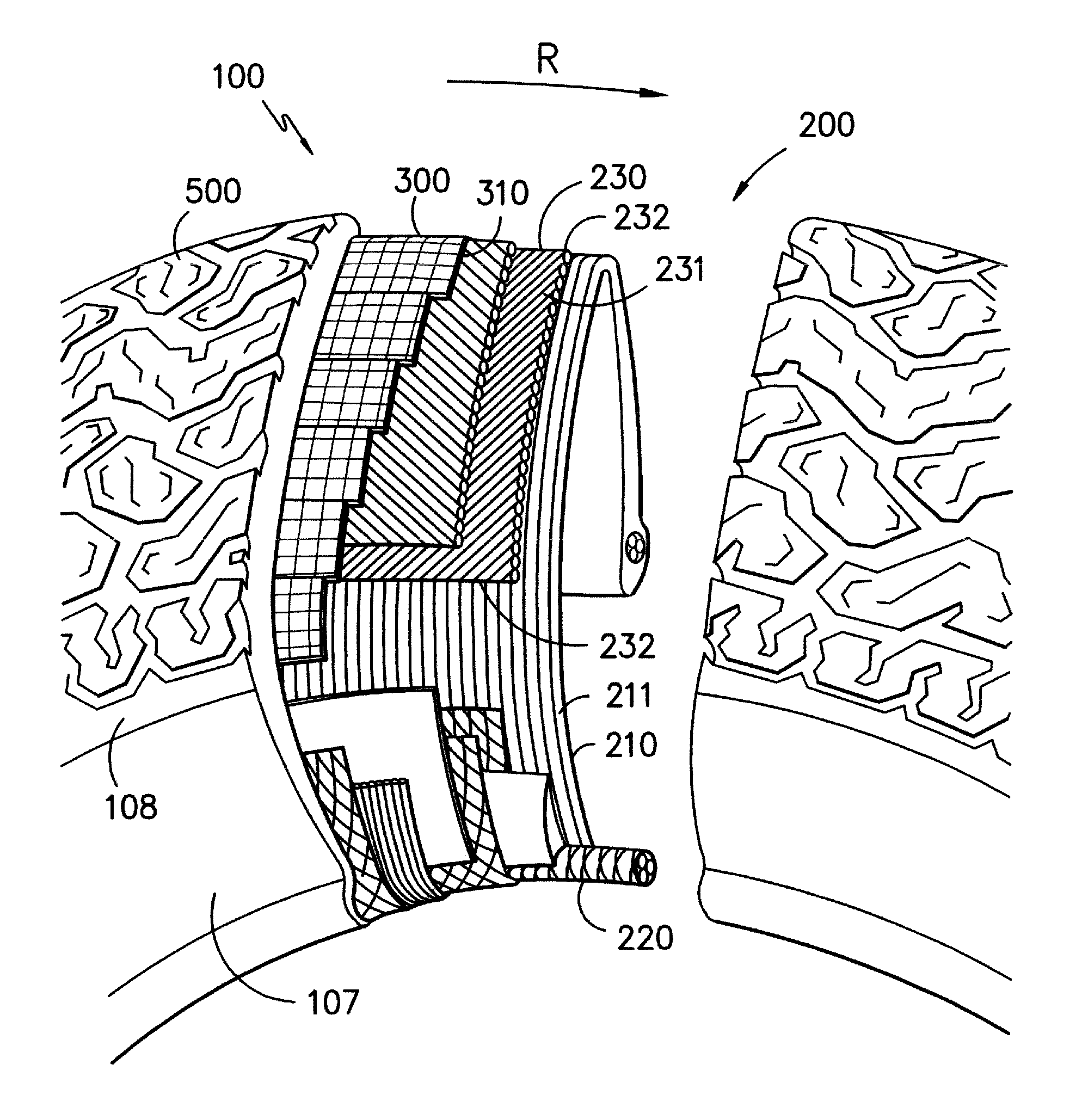

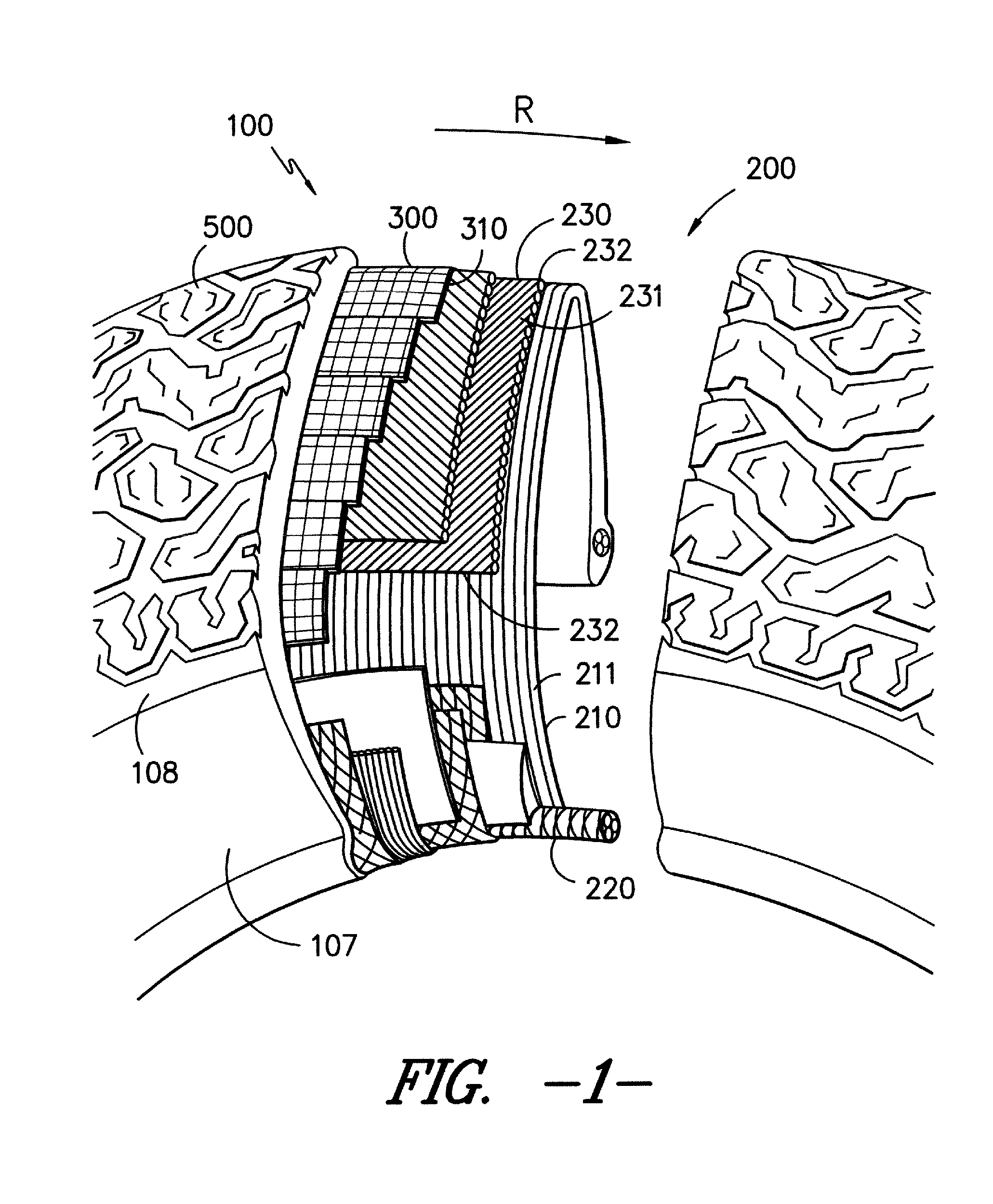

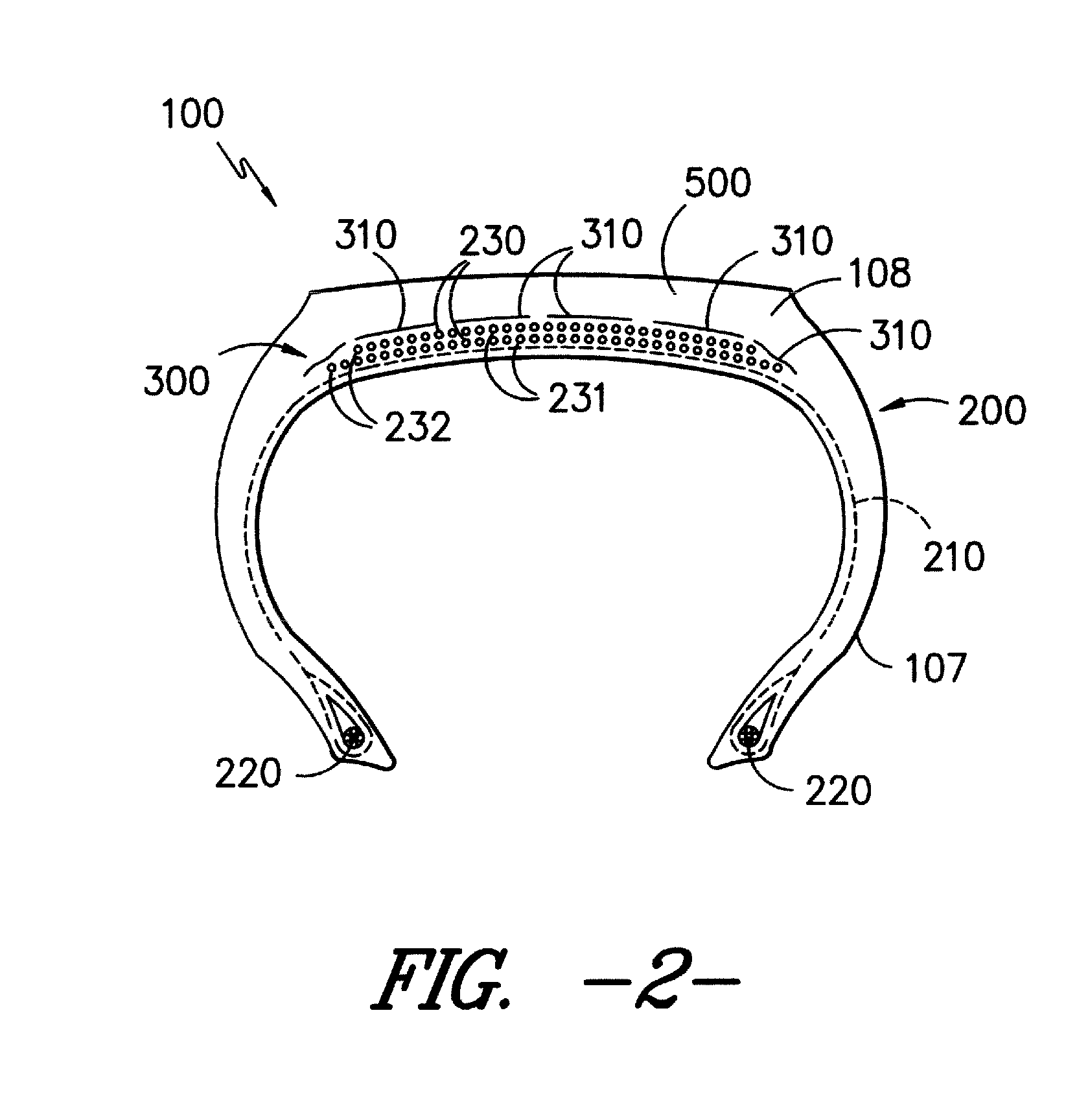

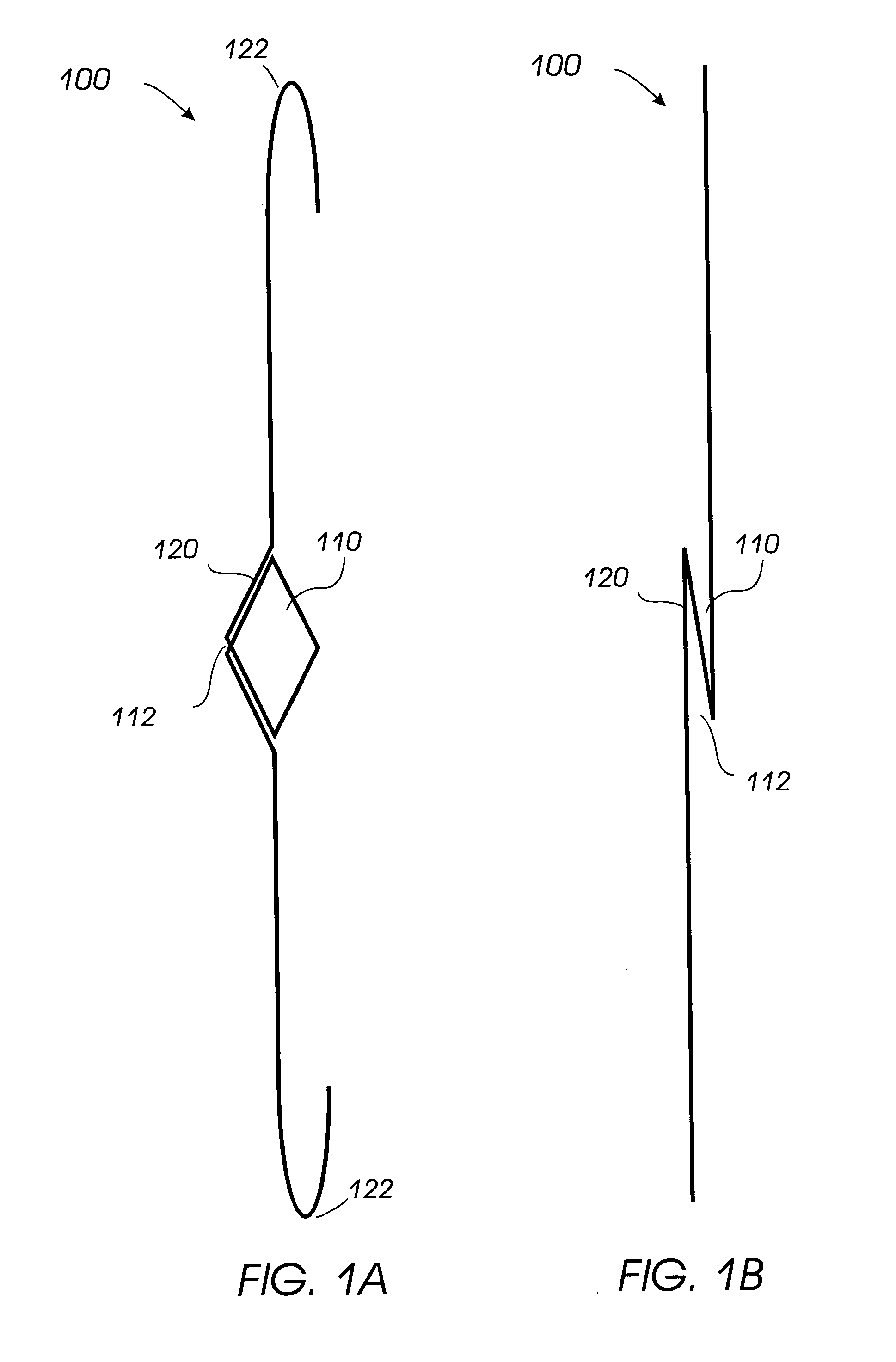

Leno cap ply for pneumatic tire

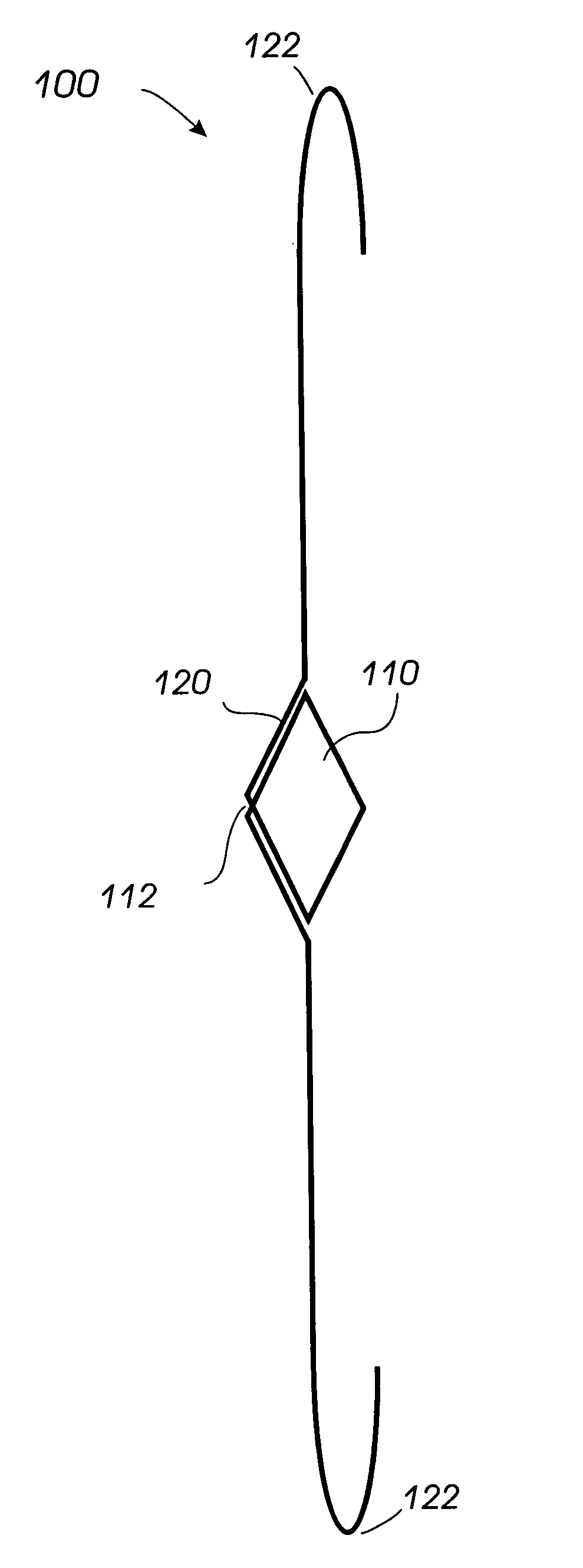

A pneumatic tire containing a tread, a carcass having at least one belt ply disposed below the tread, and a cap ply located between the carcass and the tread. The cap ply comprises at least one layer of an open construction leno weave tape having a pair of warp yarns in the longitudinal direction and a weft yarn in the weft direction. The pair of warp yarns comprises a first warp yarn and a second warp yarn, where the second warp yarn has a force of elongation of between about 1 and 40% the force of elongation of the first warp yarn, where the second warp yarn is in tension, and where the second warp yarn has an elongation at break of greater than 2%. The leno weave tape is disposed in a flat pattern around the circumference of the carcass in the area of the belt ply. A method of making a pneumatic tire is also disclosed.

Owner:MILLIKEN & CO

Process for Forming Pneumatic Tire with Leno Cap Ply

A pneumatic tire containing a tread, a carcass having at least one belt ply disposed below the tread, and a cap ply located between the carcass and the tread. The cap ply comprises at least one layer of an open construction leno weave tape having a pair of warp yarns in the longitudinal direction and a weft yarn in the weft direction. The pair of warp yarns comprises a first warp yarn and a second warp yarn, where the second warp yarn has a force of elongation of between about 1 and 40% the force of elongation of the first warp yarn, where the second warp yarn is in tension, and where the second warp yarn has an elongation at break of greater than 2%. The leno weave tape is disposed in a flat pattern around the circumference of the carcass in the area of the belt ply. A method of making a pneumatic tire is also disclosed.

Owner:MILLIKEN & CO

Method and weaving loom for producing a leno ground fabric

Owner:LINDAUER DORNIER GMBH

Apparatus for forming a leno weave

Owner:SULZER TEXTIL AG

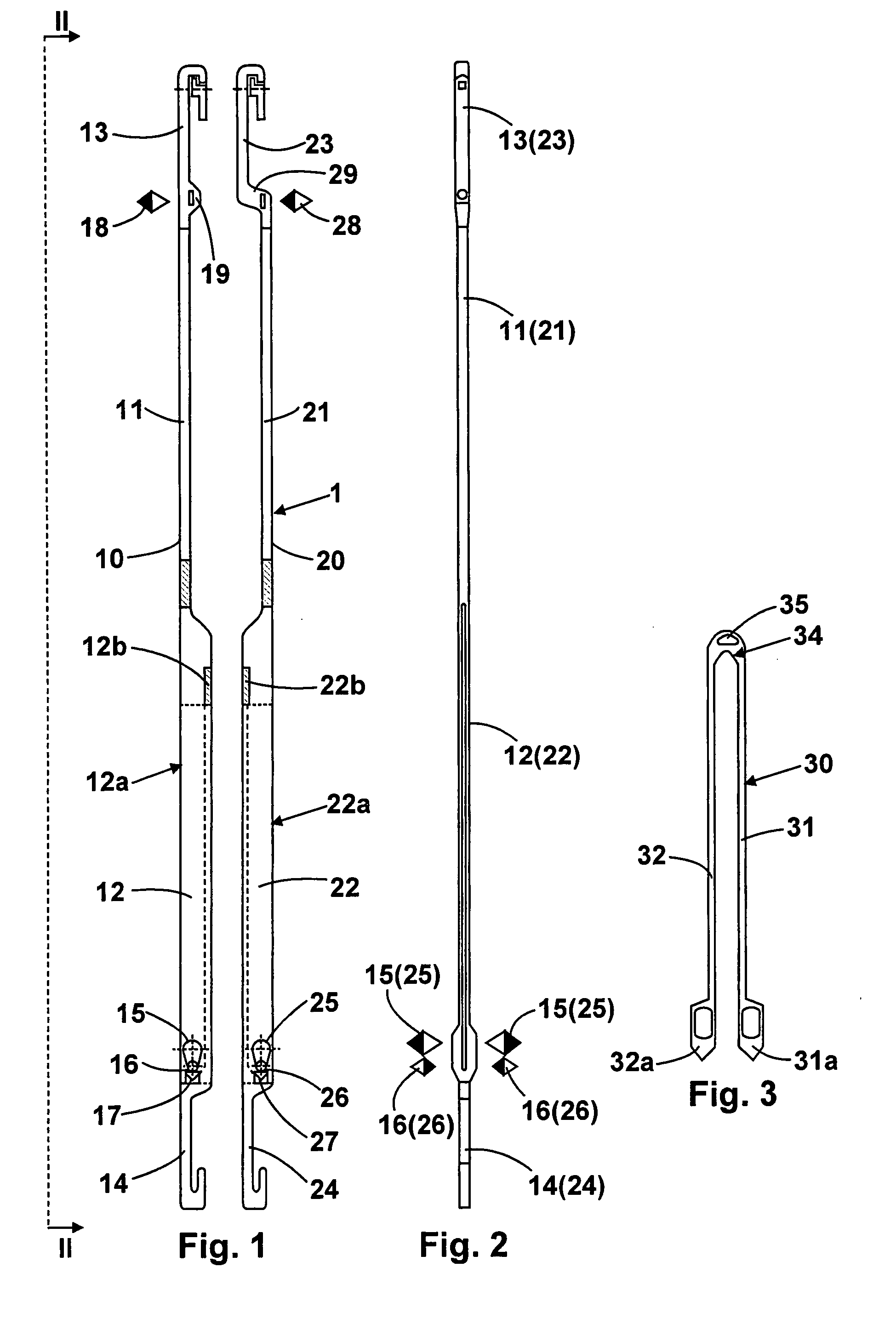

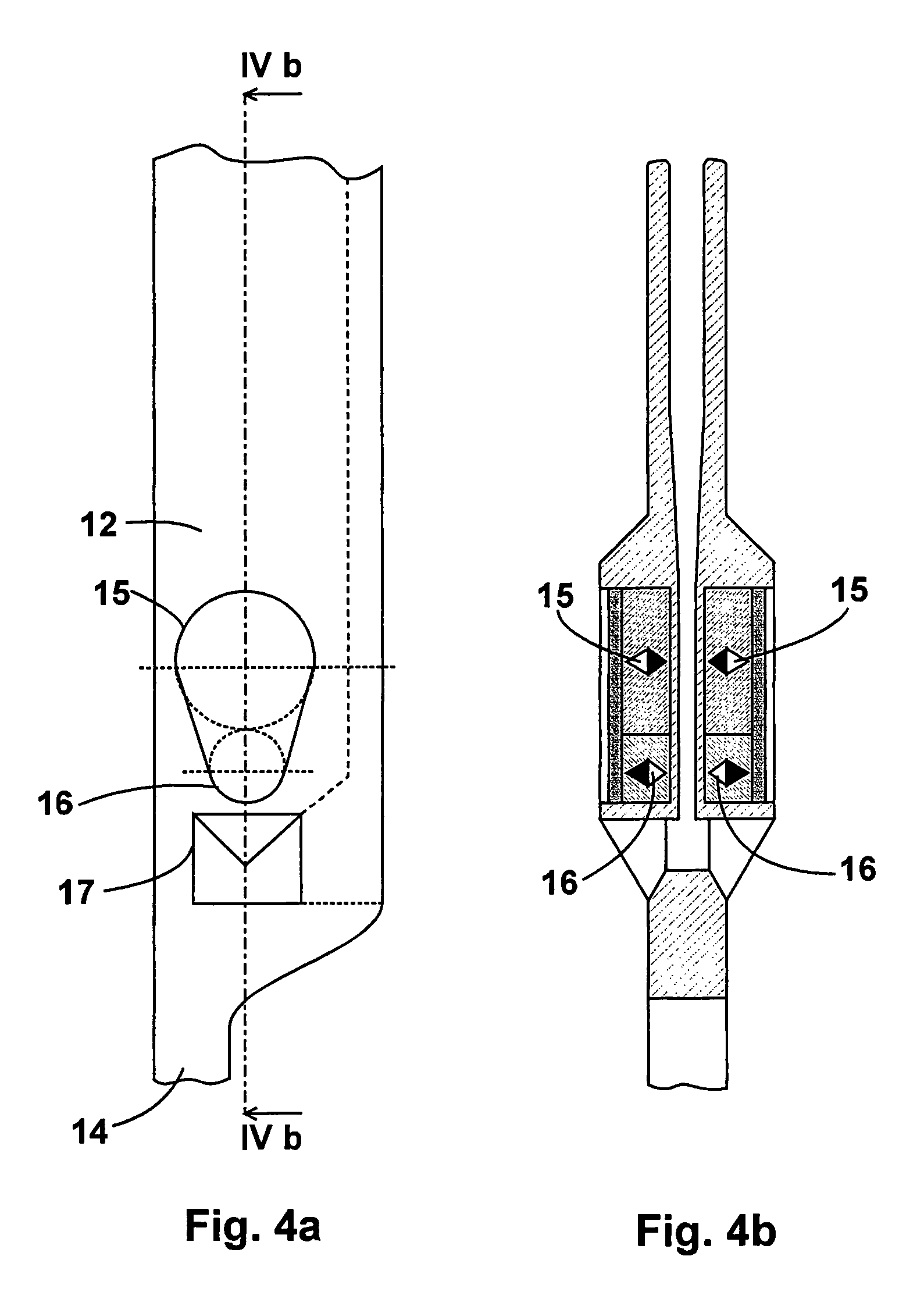

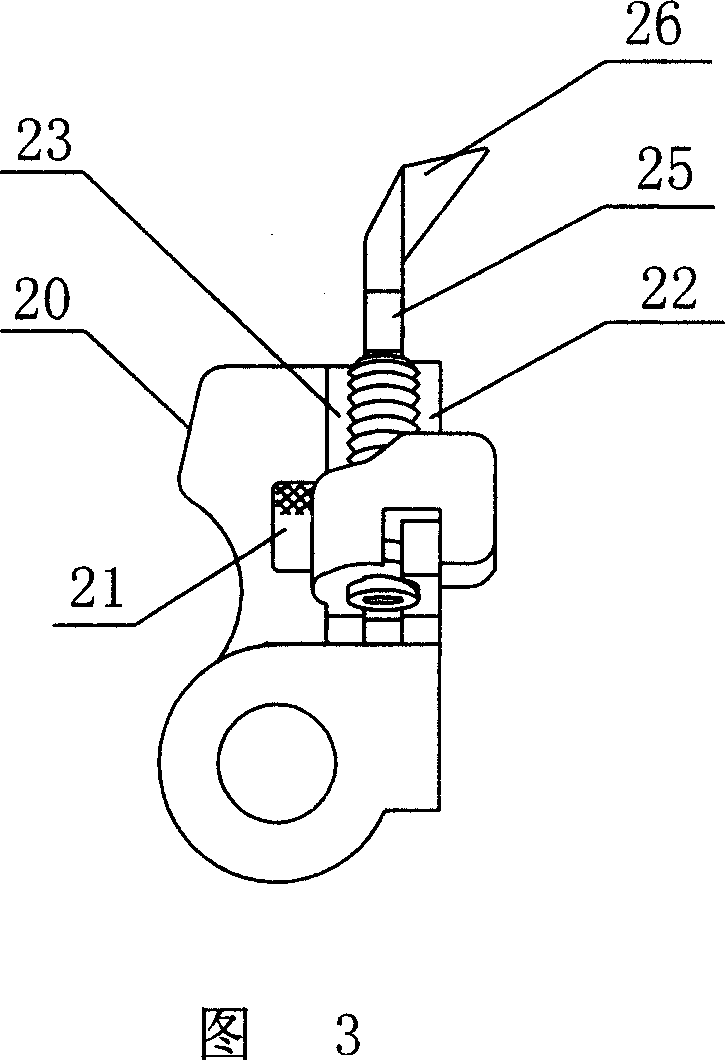

Lifting heald

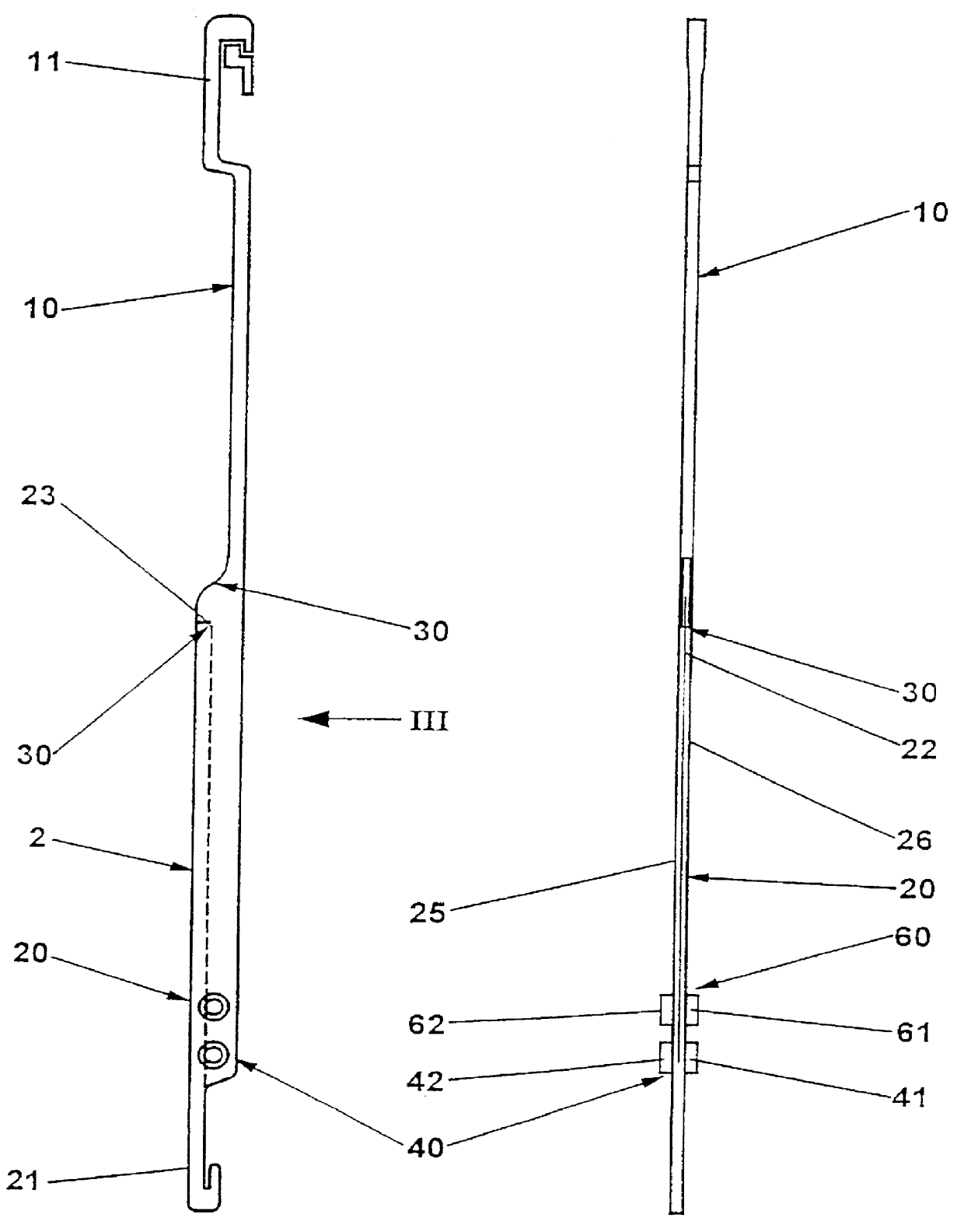

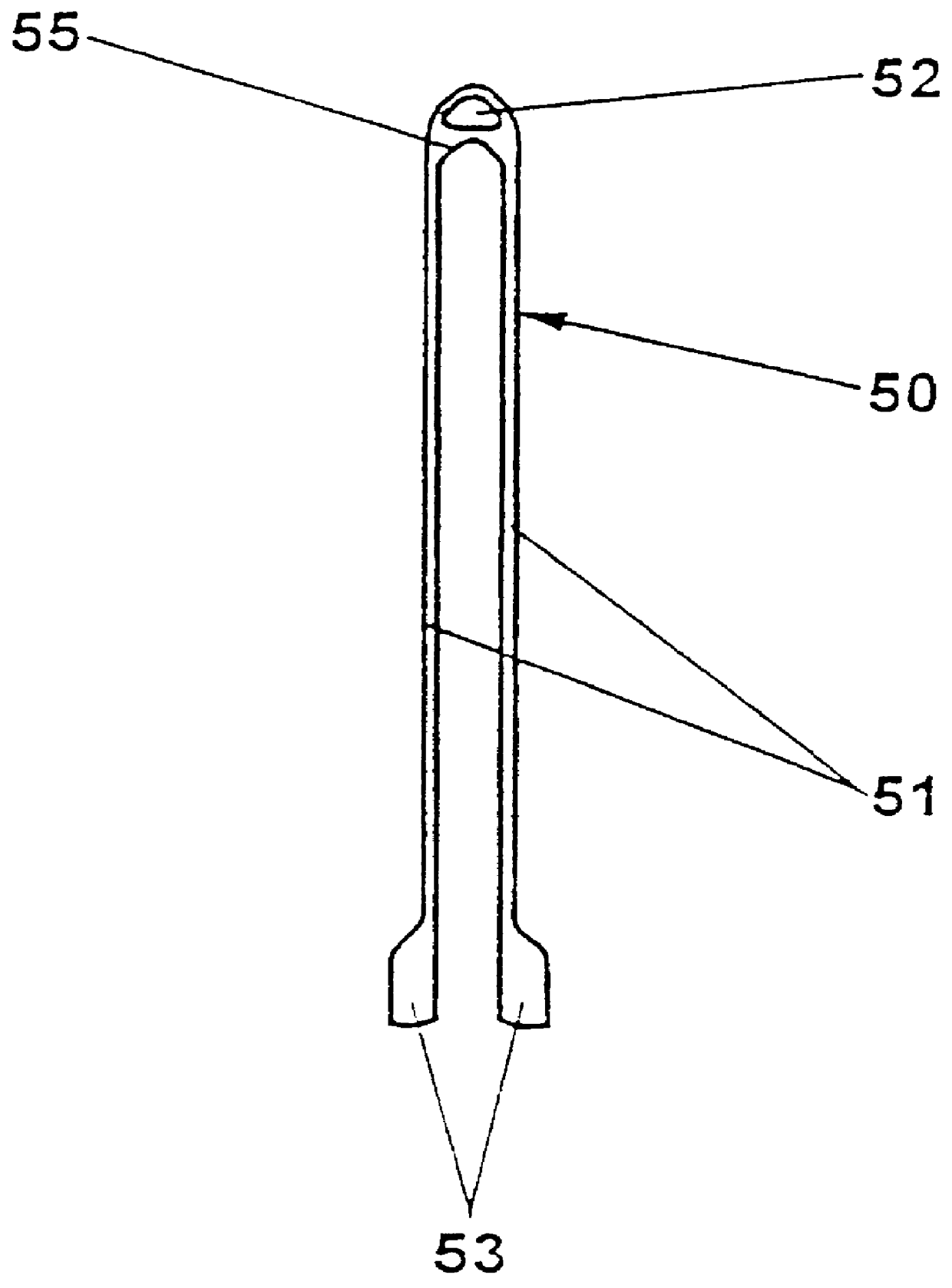

A lifting heald assembly is used in a device which forms a leno selvedge on a fabric or hosiery. The heald assembly comprises two lifting healds and one half heald alternately taken along by the lifting healds. Each lifting heald has, in the area of one end, at least one first magnet for guiding the half heald and has a web for taking along the half heald. The spacing between the web and the magnet corresponds approximately to the length of the half heald's legs and the lifting heald (2, 3) is provided with at least one second magnet (61, 62) that is arranged in or on the lifting heald (2, 3) and longitudinally spaced from the first magnet (41, 42) in the direction of the web (23).

Owner:GEBR KLOCKER

Woven fabric comprising leno weave bound metal

InactiveUS7341076B2Dimensionally stableNot show tendencyLeno shedding mechanismWire networkEngineeringMetal

A woven fabric in which warp elements are provided out of metal. The fabric further comprising at least a first set of substantially parallel binding elements present in warp direction of the fabric. This first set of binding elements bind the warp elements to the weft elements by means of a leon weave at at least a part of the intersection points of warp and weft elements. The fabric as subject of the invention is characterized in that each binding element of the first set of binding elements crosses more than one warp element between consecutive intersection points bound by this binding element.

Owner:NV BEKAERT SA

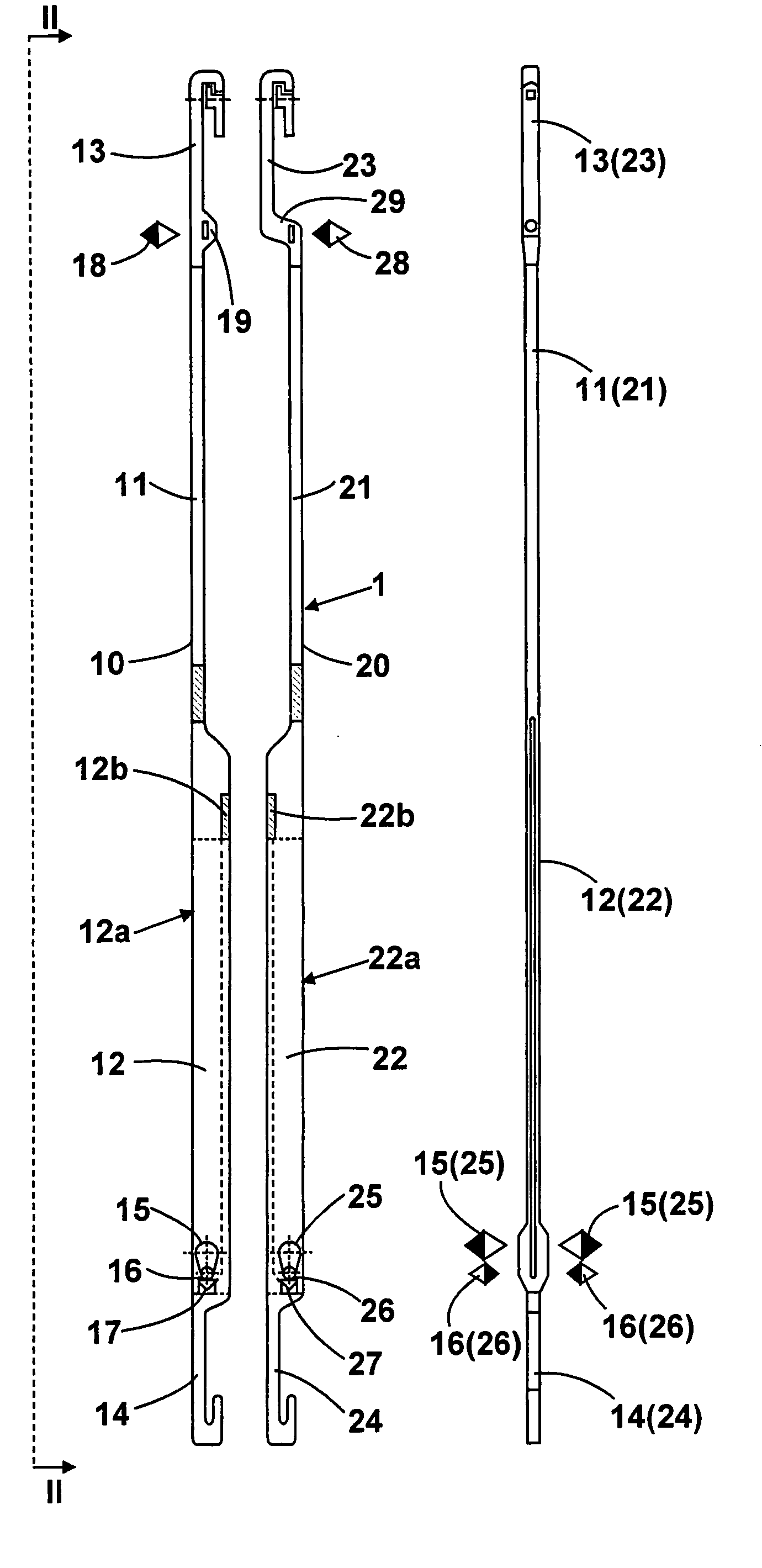

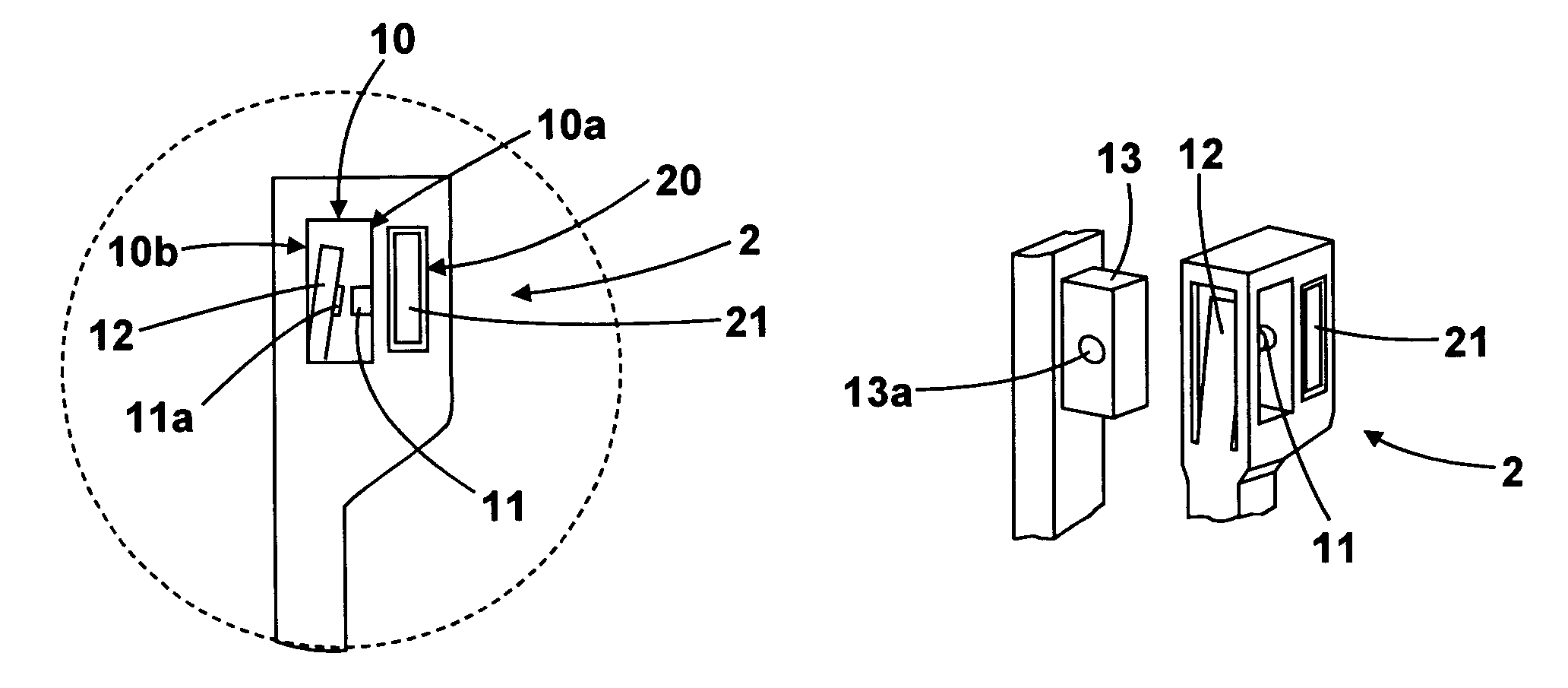

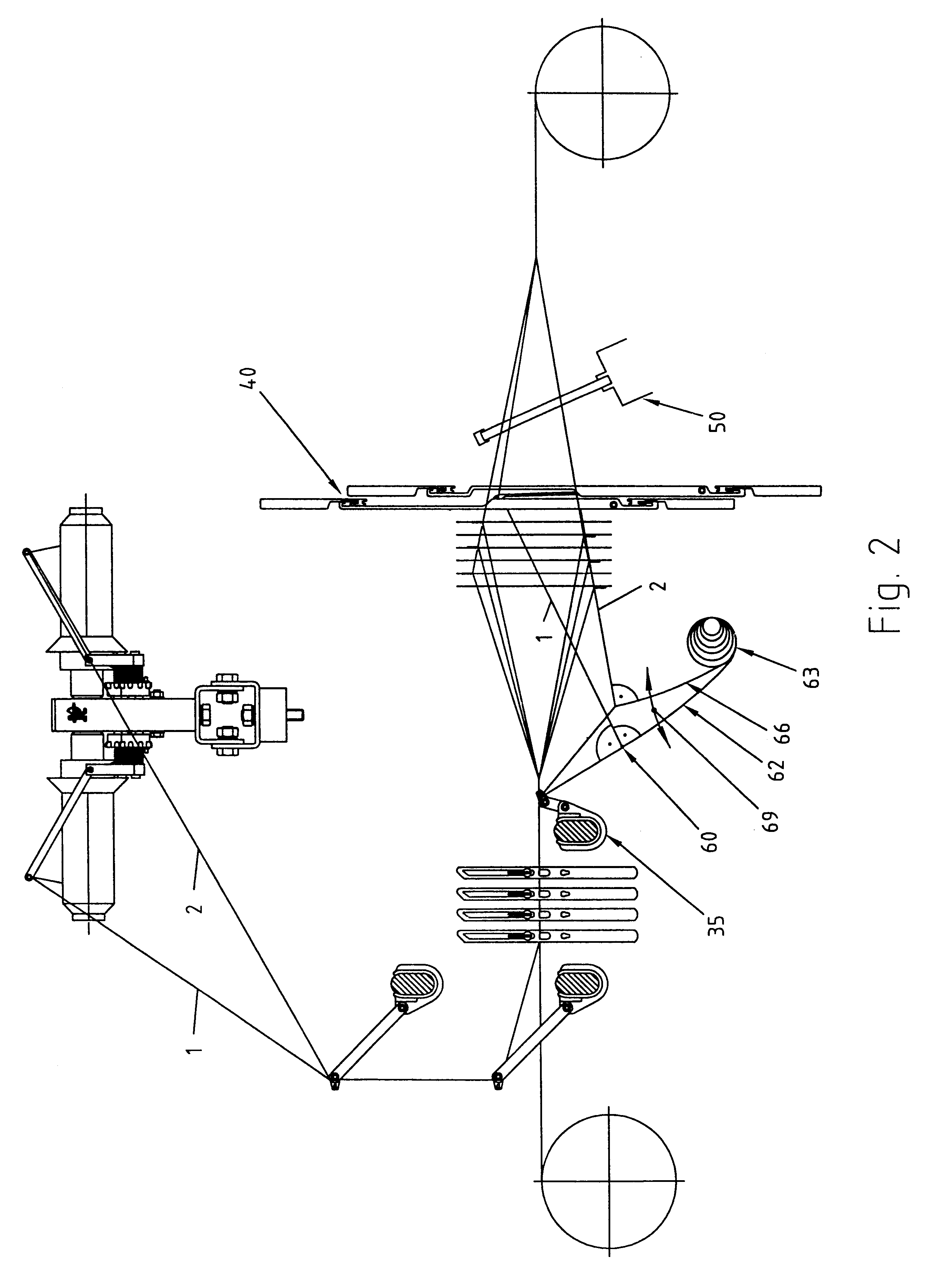

Device for forming a leno selvedge

A device (1) for forming a leno selvedge, said device having two lifting healds (10, 20) and one half heald (30), the lifting healds (10, 20) having a securing element (13, 23; 14, 24) provided respectively at the upper and lower end thereof, said lifting healds (10,20) having, in the region of the lower end, at least one magnet for the foot (31a, 32a) of the half heald (30), each lifting heald (10, 20) having at least one magnet (18, 28) in the region of its upper end, the magnets (18, 28) of the two lifting healds (10, 20) of a leno selvedge device being polarized such that the healds attract each other.

Owner:GEBR KLOCKER

Device and method for weaving four-and-complexgauze

InactiveCN101016670AConducive to carry forwardImprove protectionLeno shedding mechanismGauze-woven fabricsGround rollerEngineering

The invention discloses a method for producing four-warp winder, characterized in that the invention comprises following steps that preparing half heald roller, using two half heald rollers and two ground rollers to form an integral spinning device, using half heald roller as opening device, the invention can avoid weft blade in weaving and use four wraps as one group, while one shuttle is two-wrap winder, one shuttle is four-wrap winder, and four shuttles as one circle, to obtain the four-wrap winded fabric.

Owner:NANJING YUNJIN RES INST

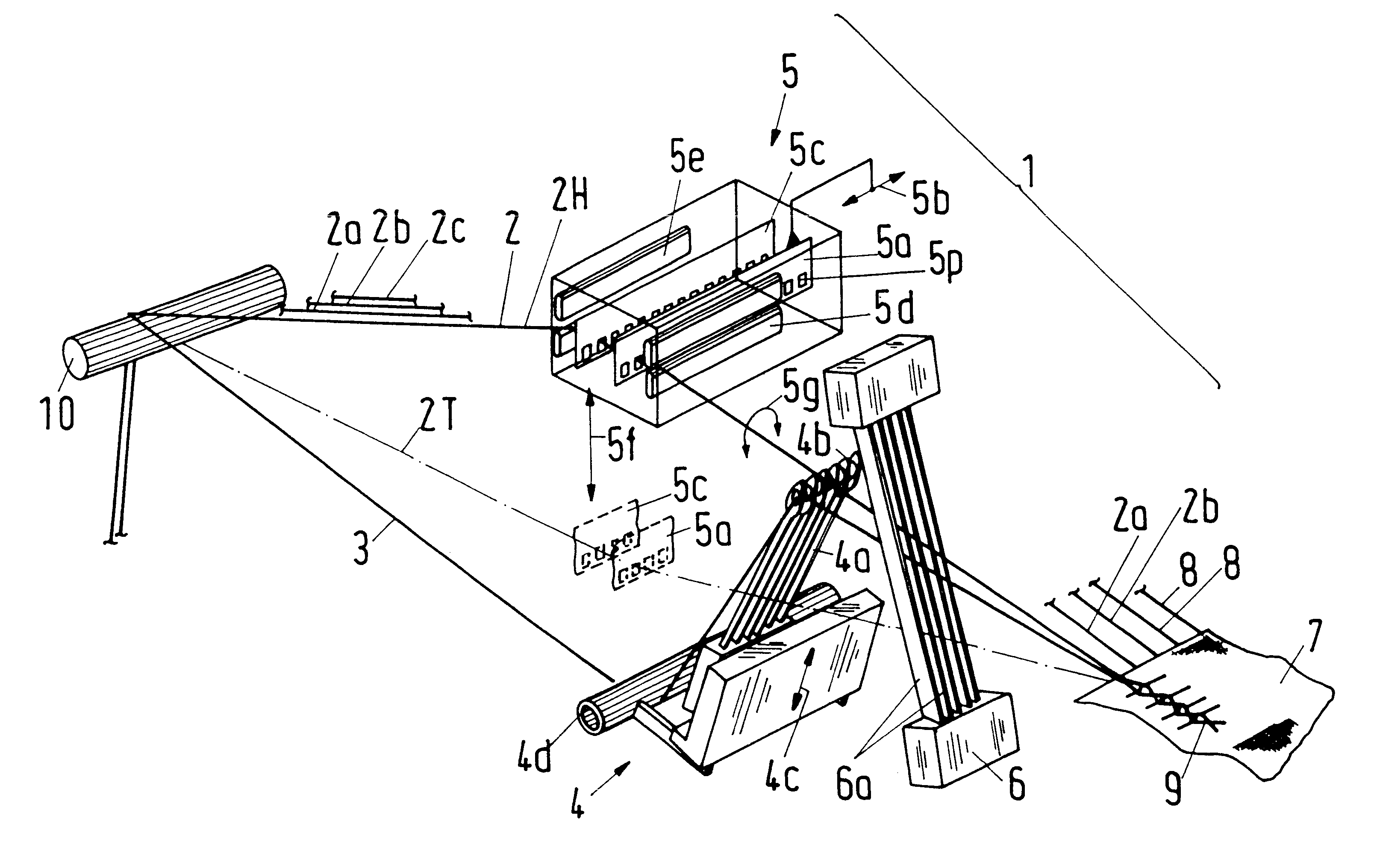

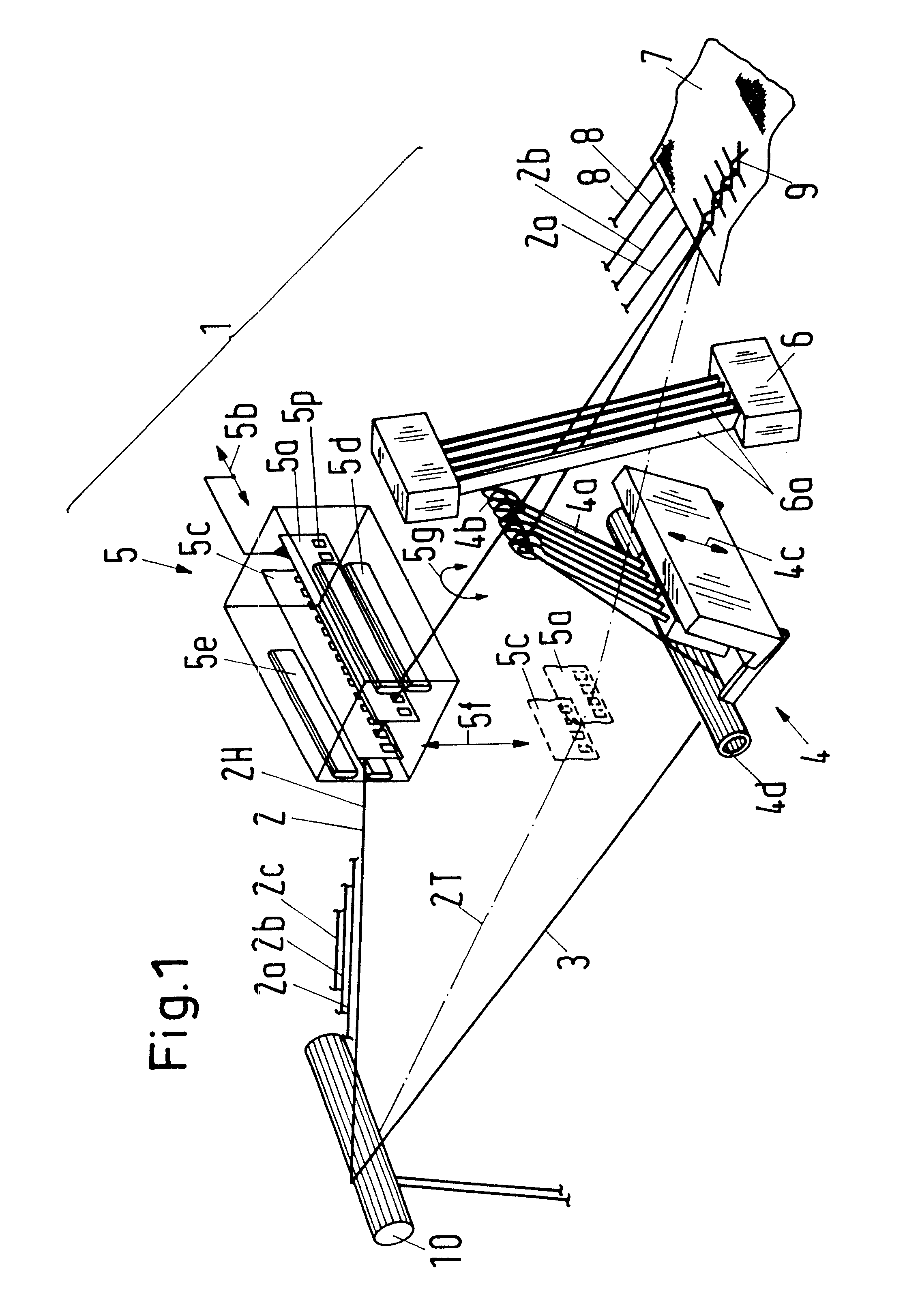

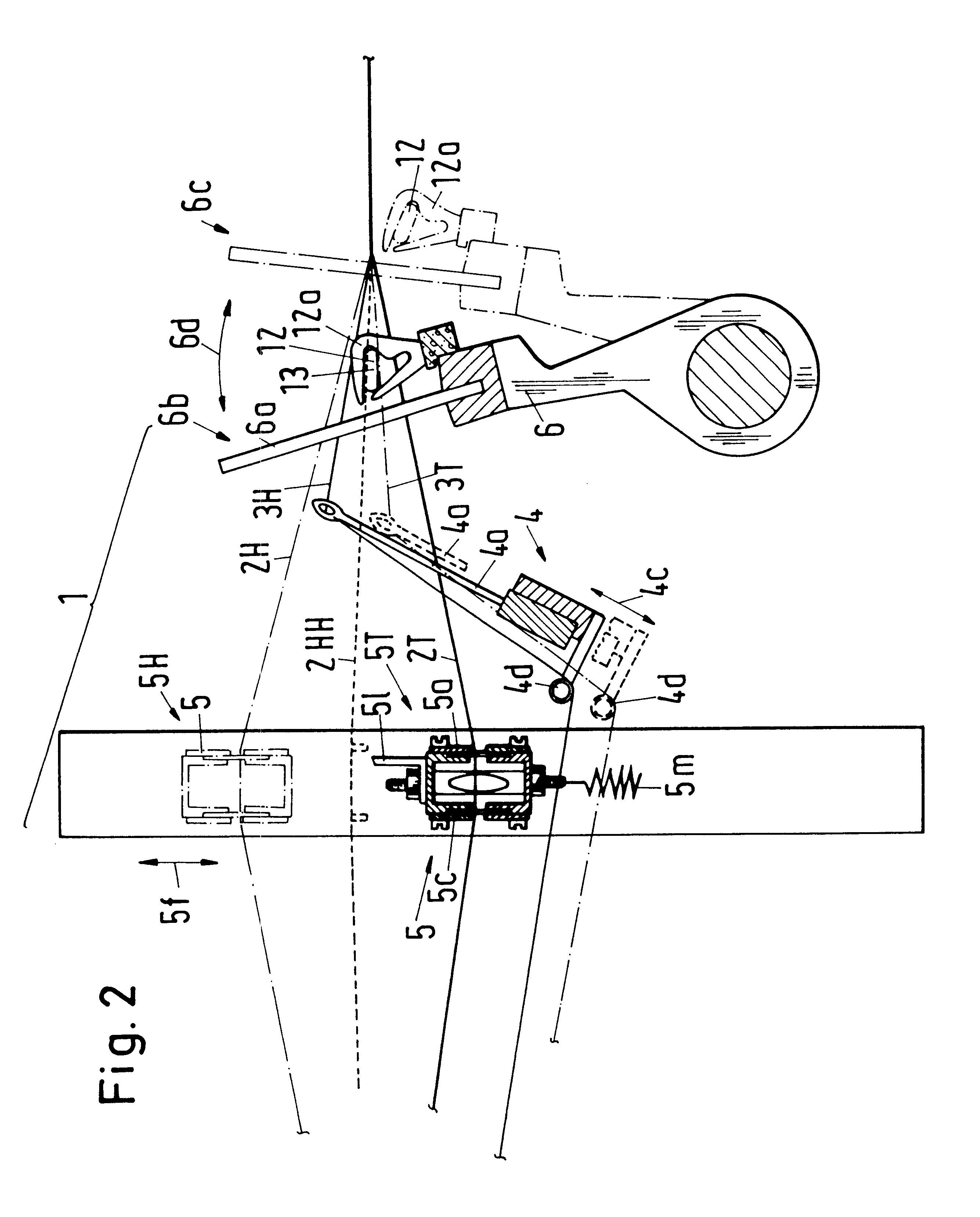

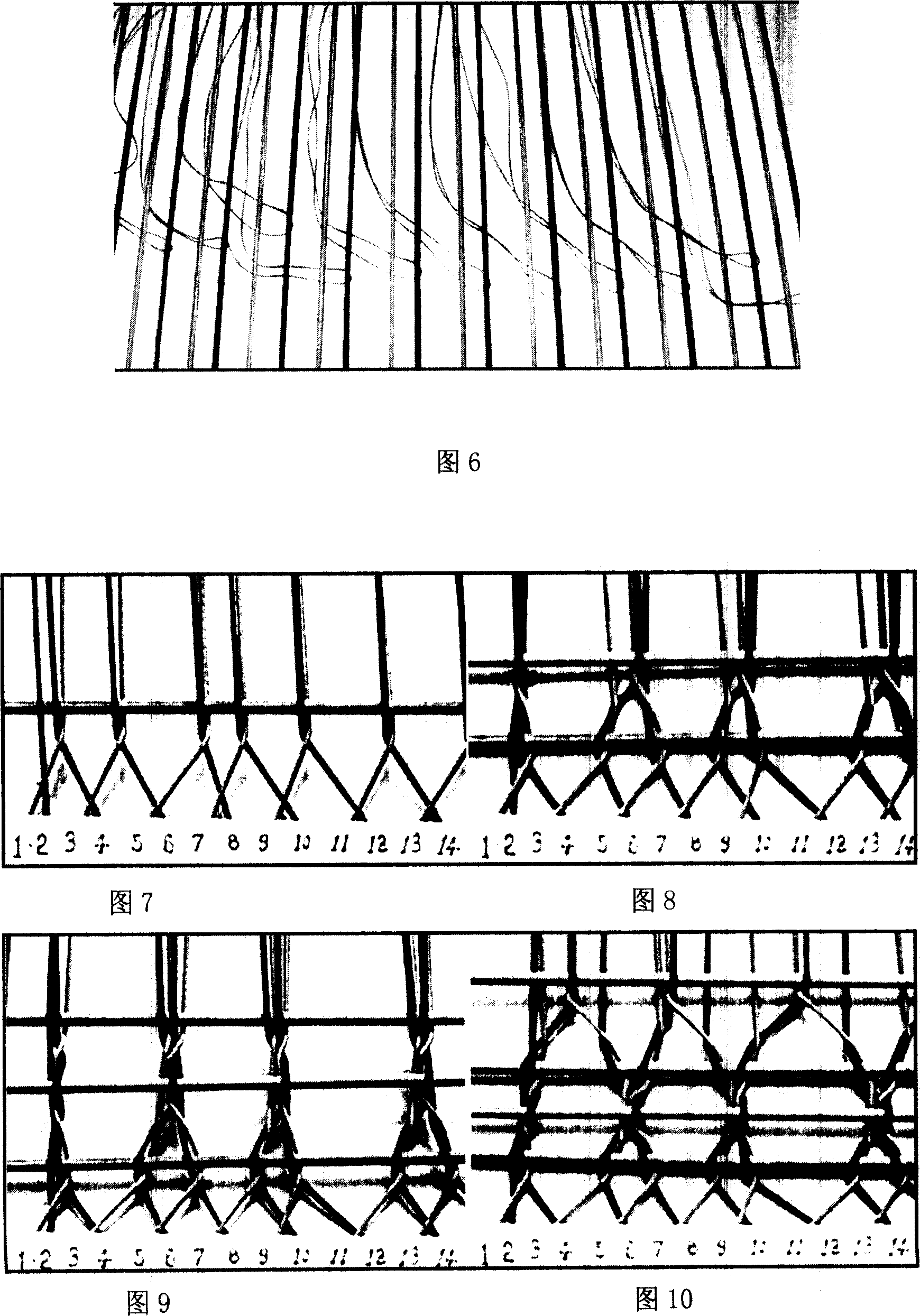

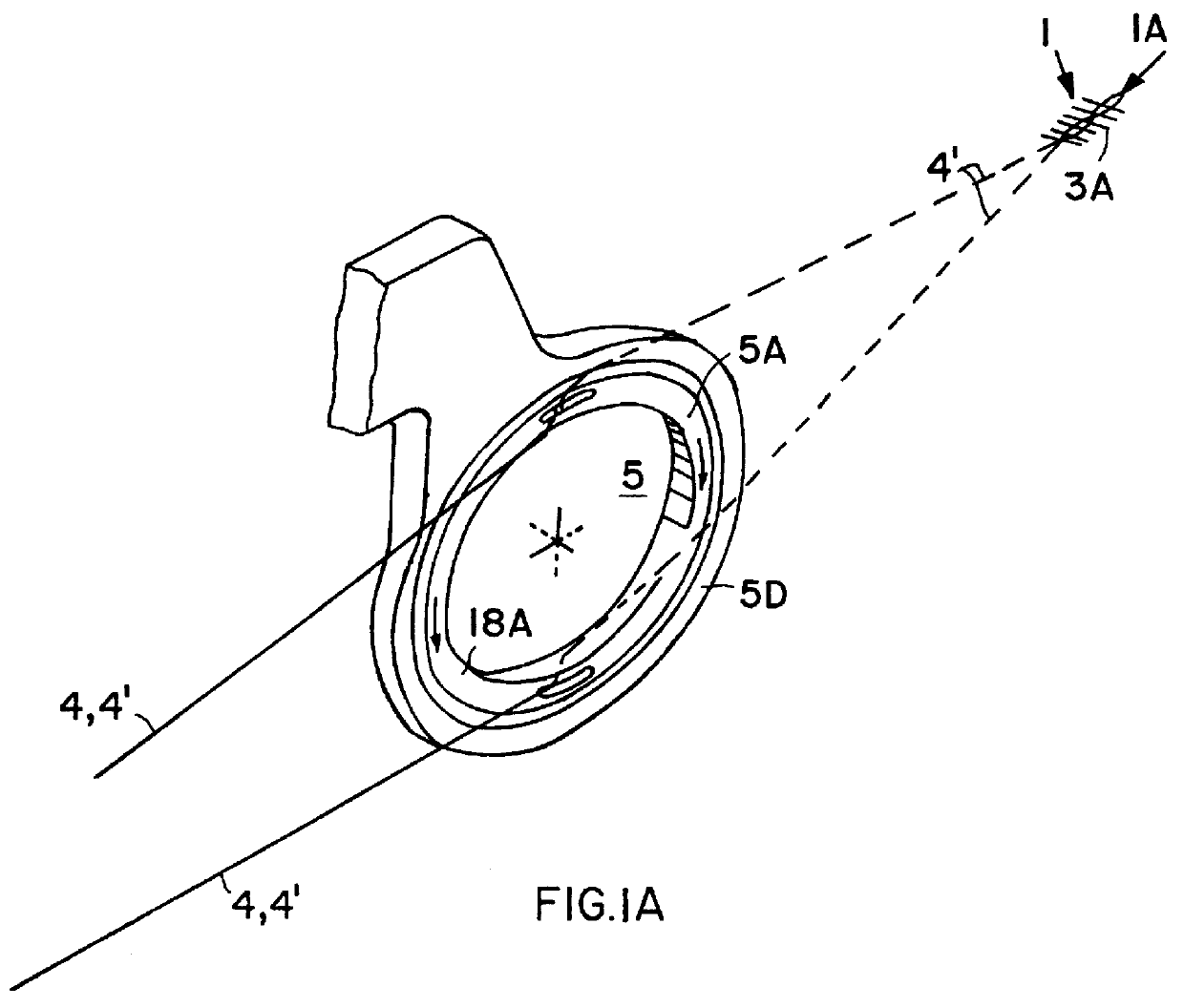

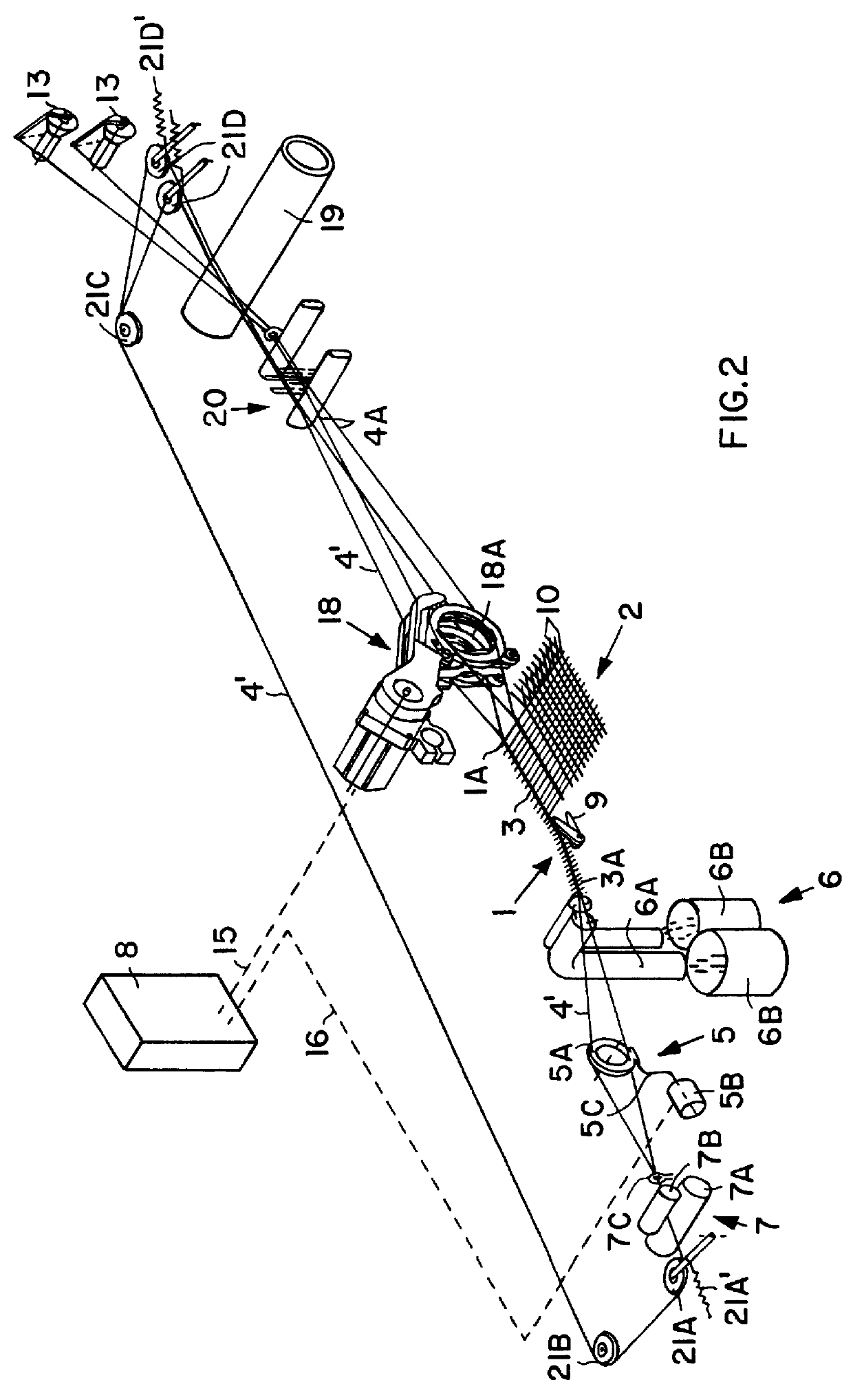

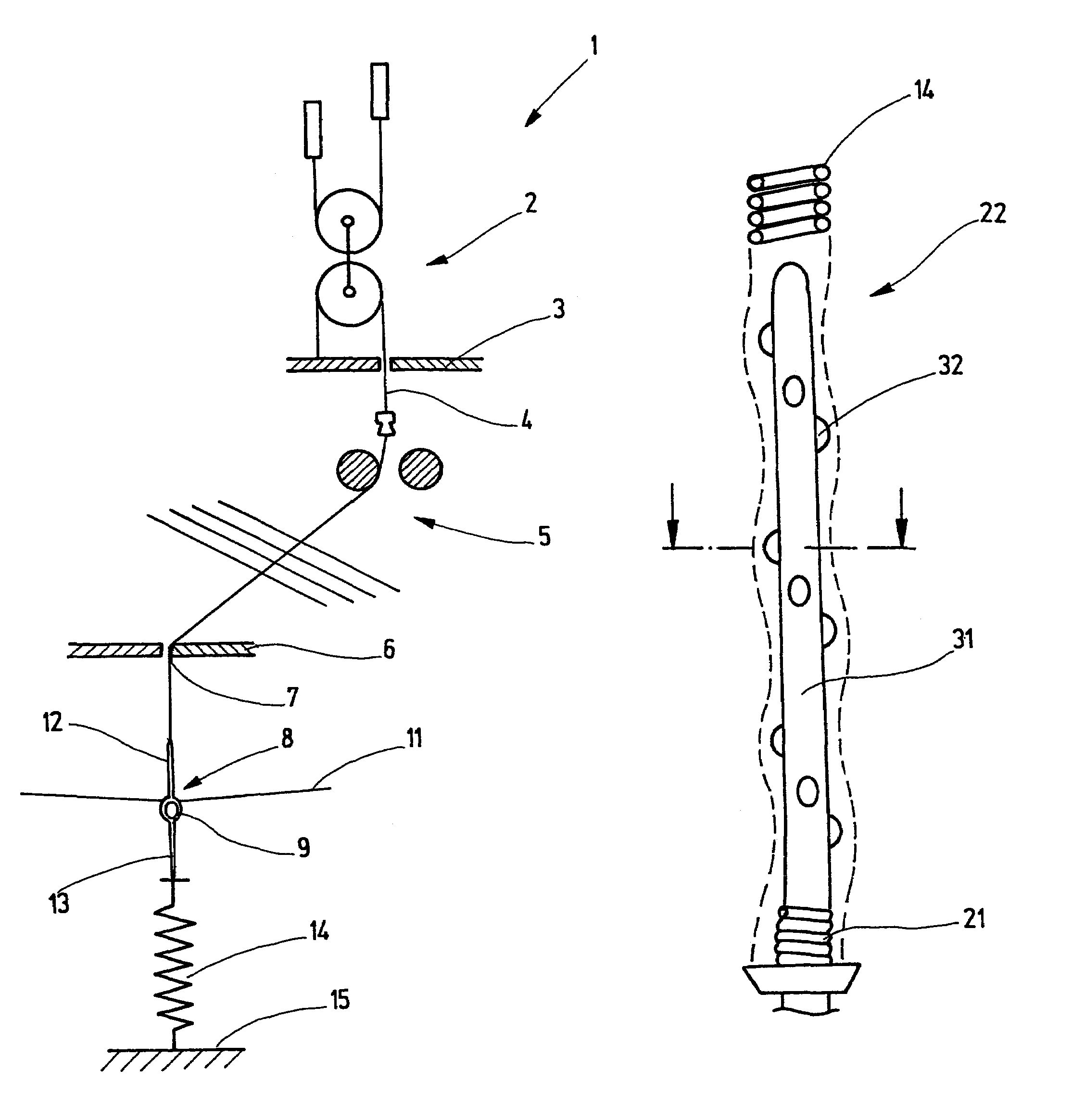

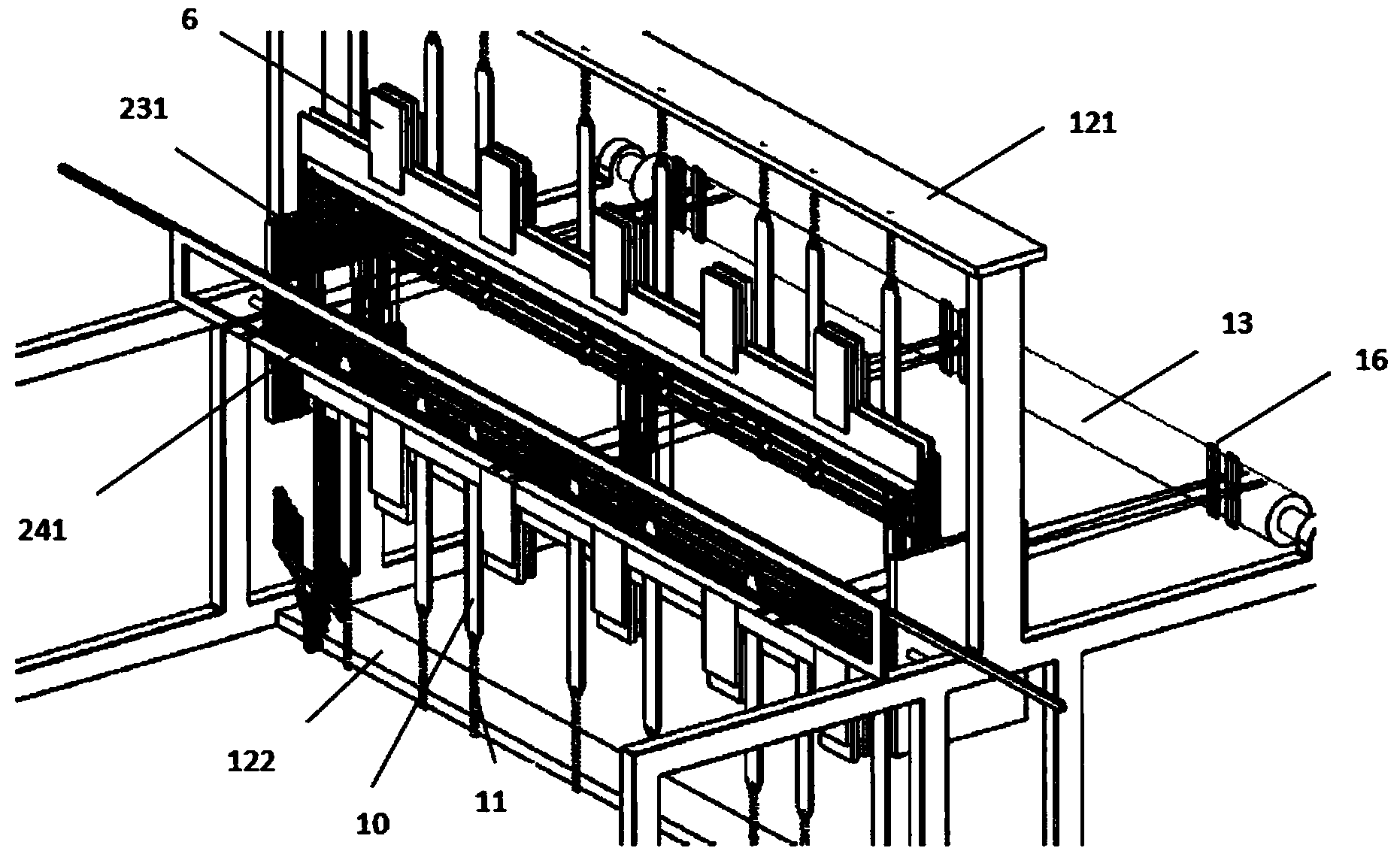

Separating weft thread waste of a single uncontaminated material from untwisted leno binding threads in trimmed catch selvages

A method and an apparatus serve to process a catch selvage that has been trimmed from a web being woven on a loom, so as to separate weft thread ends and leno threads from the catch selvage to produce a type-pure weft thread waste and a type-pure leno thread waste or reusable leno threads. The term "type-pure" refers to a waste material containing a single uncontaminated type or color of thread material, e.g. wool vs. synthetic or blue vs. red. After the catch selvage (1) has been trimmed from the edge (11) of the woven web (2), the leno threads (4, 4') are untwisted from each other by being rotated by an untwisting apparatus (5) in a direction opposite the binding twist applied by the leno device (18). Thereby, the full leno binding (1A) is completely unbound and opened, so as to release the weft thread ends (3A), which are then sucked into a proper one of weft waste collection containers (6B) by a suction pipe (6A), so that only a single type-pure and / or color of weft thread end is collected in each container (6B). The unbound leno threads (4) are collected as a type-pure waste or are rewound on spools to be reused. Alternatively, by using endless closed-loop leno threads (4'), the leno threads (4') are continuously recirculated back to the leno device (18), without intermediately being wound onto spools.

Owner:LINDAUER DORNIER GMBH

Pneumatic tire with leno cap ply and method of making same

A pneumatic tire containing a tread, a carcass having at least one belt ply disposed below the tread, and a cap ply located between the carcass and the tread. The cap ply comprises at least one layer of an open construction leno weave tape having a pair of warp yarns in the longitudinal direction and a weft yarn in the weft direction. The pair of warp yarns comprises a first warp yarn and a second warp yarn, where the second warp yarn has a force of elongation of between about 1 and 40% the force of elongation of the first warp yarn, where the second warp yarn is in tension, and where the second warp yarn has an elongation at break of greater than 2%. The leno weave tape is disposed in a flat pattern around the circumference of the carcass in the area of the belt ply. A method of making a pneumatic tire is also disclosed.

Owner:MILLIKEN & CO

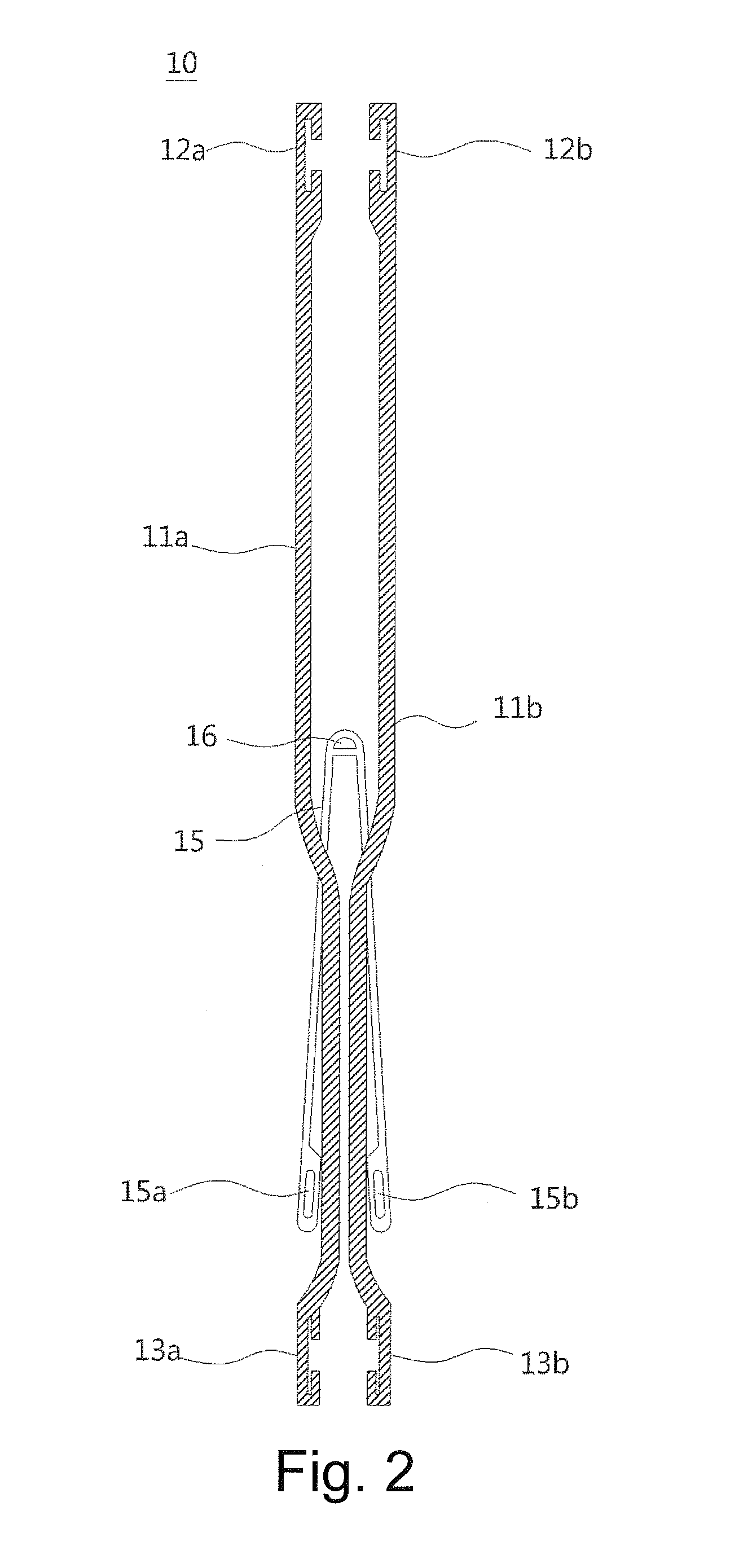

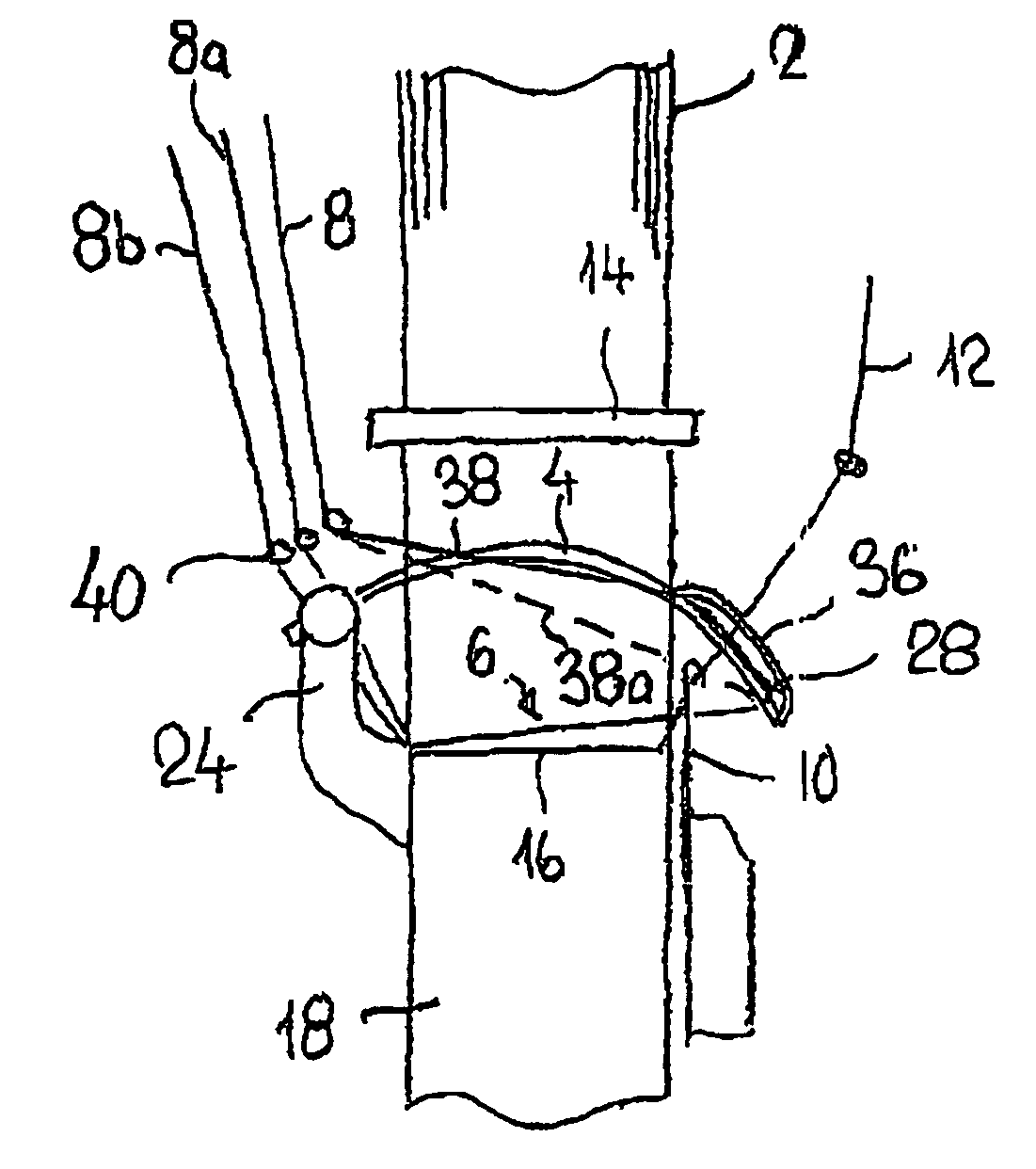

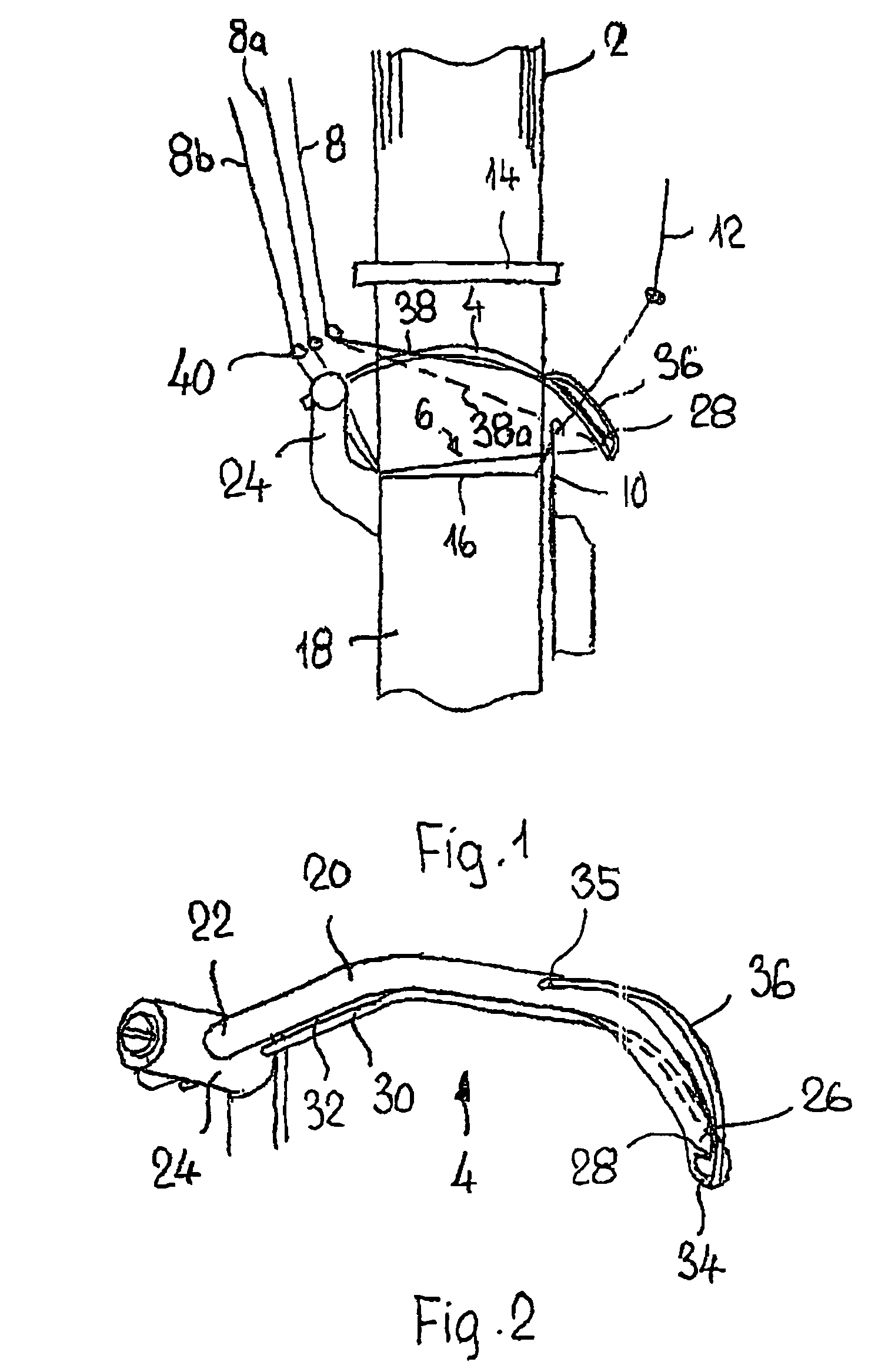

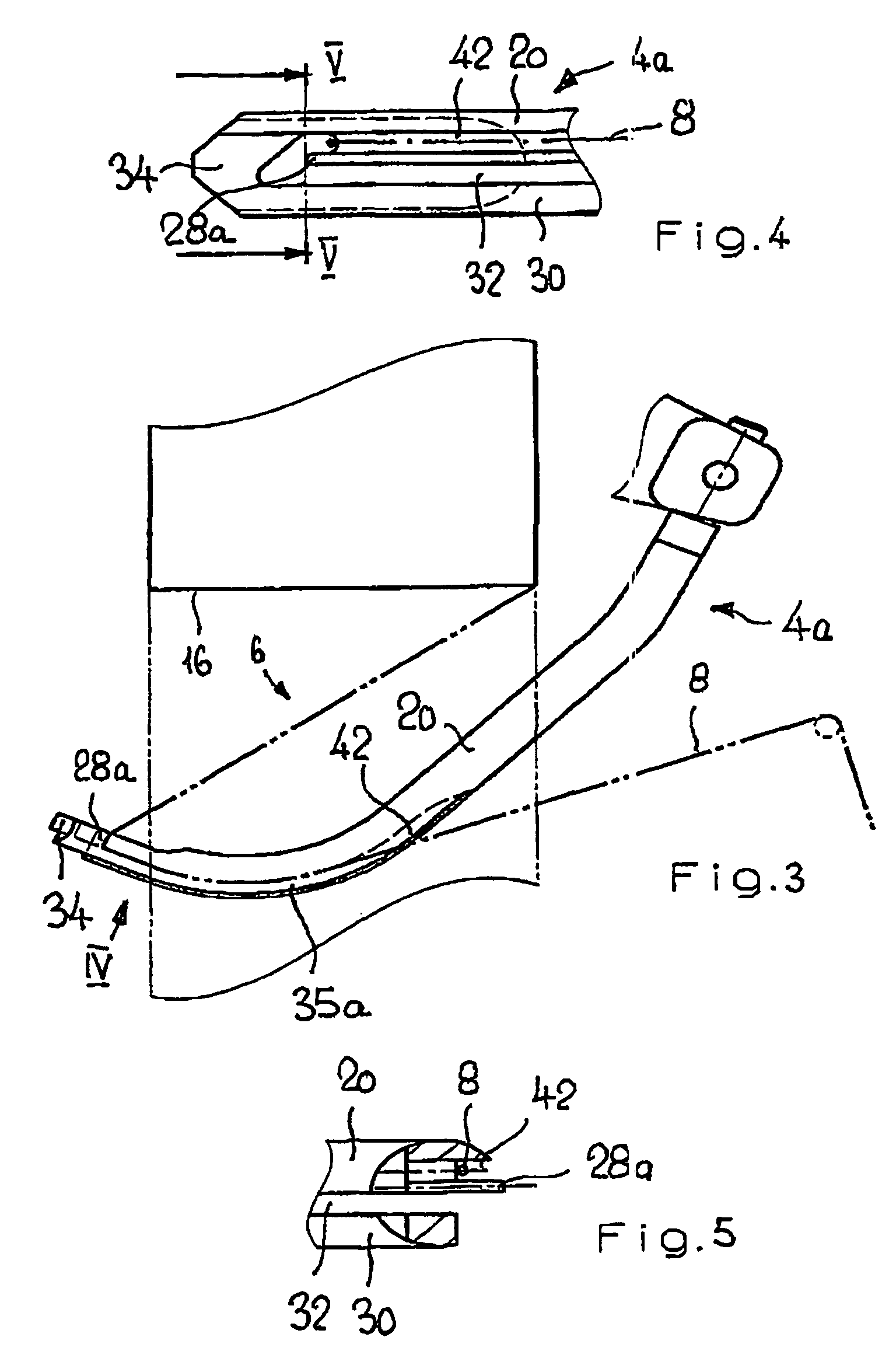

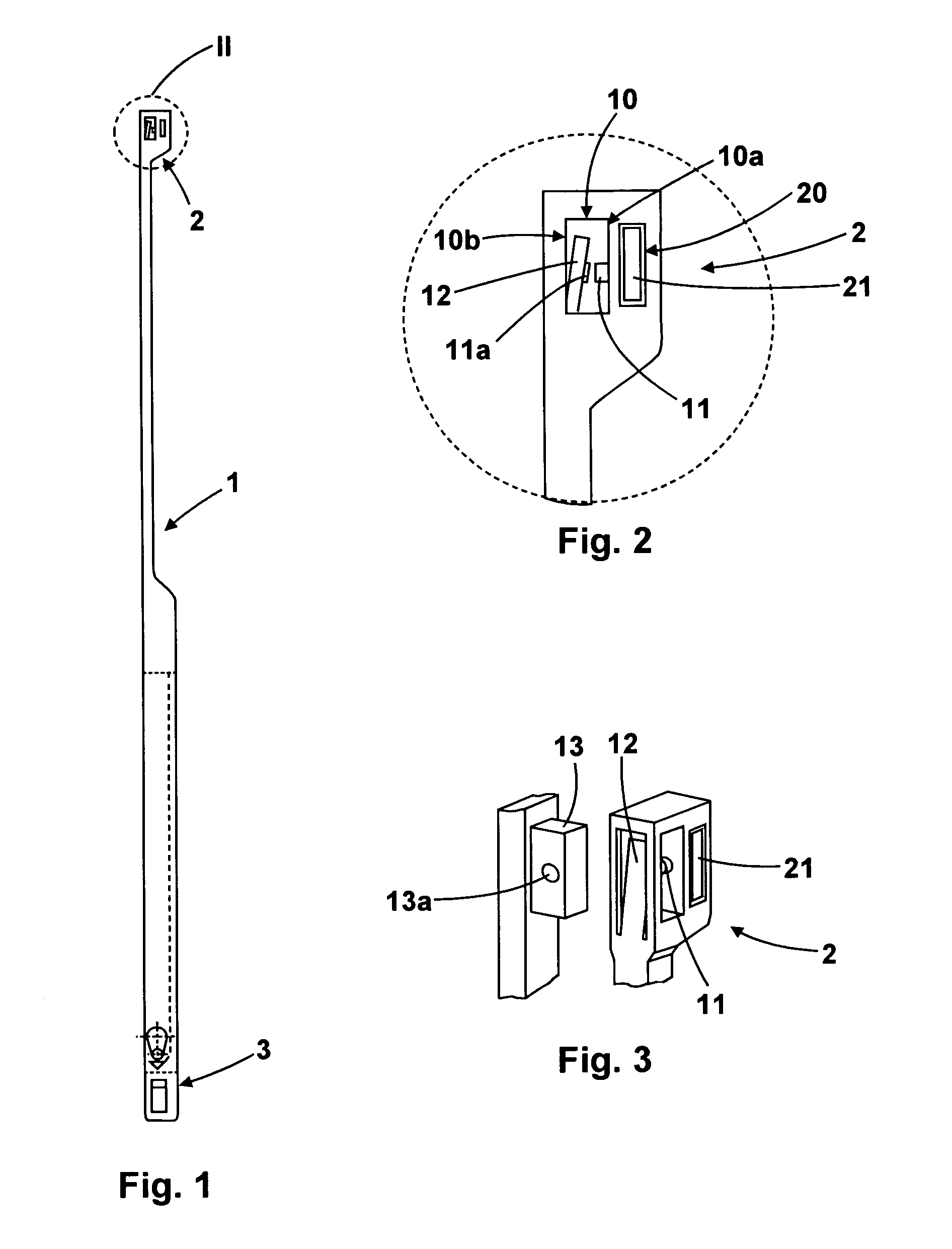

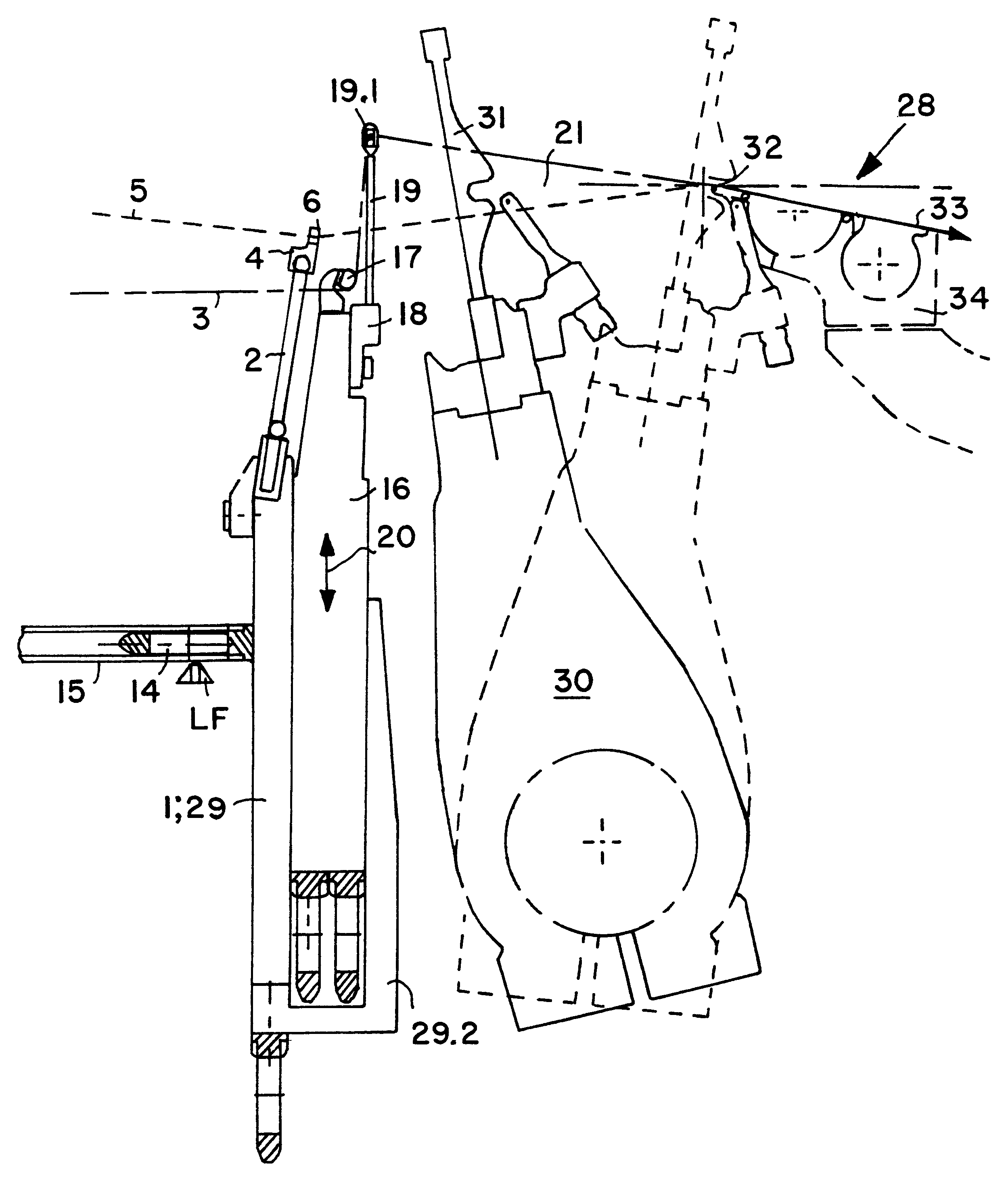

Weft introduction needle for a ribbon needle loom

The weft introduction needle for a ribbon needle loom comprises a bent arm (20), which may be fixed at one end (22) to a drive element (24) of a ribbon needle loom and comprises a hook (28) at the other end (26), for registering an exposed thread loop. The arm (20) is provided with a guide piece (30) essentially over the whole length thereof, forming a longitudinal slot (32) with the arm (20) for accommodating at least one weft thread. At the end away from the hook (28), the guide piece is connected to the arm (20), by means of a connector piece (34). A guidance element (36) is arranged on the side of the arm (20) facing away from the guide piece (30) in order to improve the guiding of a weft thread loop, extending over only a section of the length of the arm, starting from the vicinity of the hook (28), whereby the guidance element (36) forms a diverter point (35) in the region away from the hook (28), for diverting the free flare (38) of the weft thread loop (6).

Owner:TEXTILMA AG

Leno Cap Ply for Pneumatic Tire

A pneumatic tire containing a tread, a carcass having at least one belt ply disposed below the tread, and a cap ply located between the carcass and the tread. The cap ply comprises at least one layer of an open construction leno weave tape having a pair of warp yarns in the longitudinal direction and a weft yarn in the weft direction. The pair of warp yarns comprises a first warp yarn and a second warp yarn, where the second warp yarn has a force of elongation of between about 1 and 40% the force of elongation of the first warp yarn, where the second warp yarn is in tension, and where the second warp yarn has an elongation at break of greater than 2%. The leno weave tape is disposed in a flat pattern around the circumference of the carcass in the area of the belt ply. A method of making a pneumatic tire is also disclosed.

Owner:MILLIKEN & CO

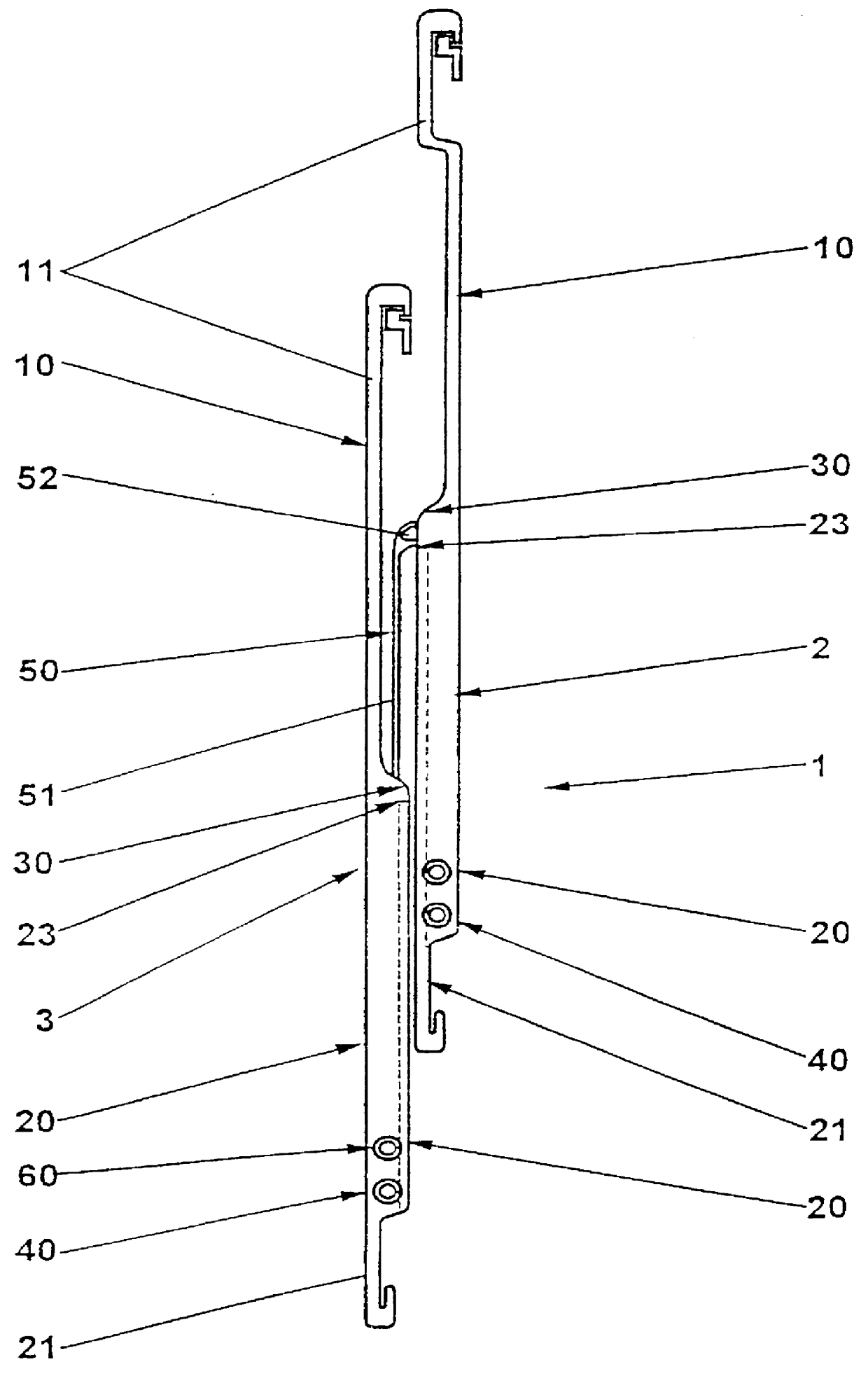

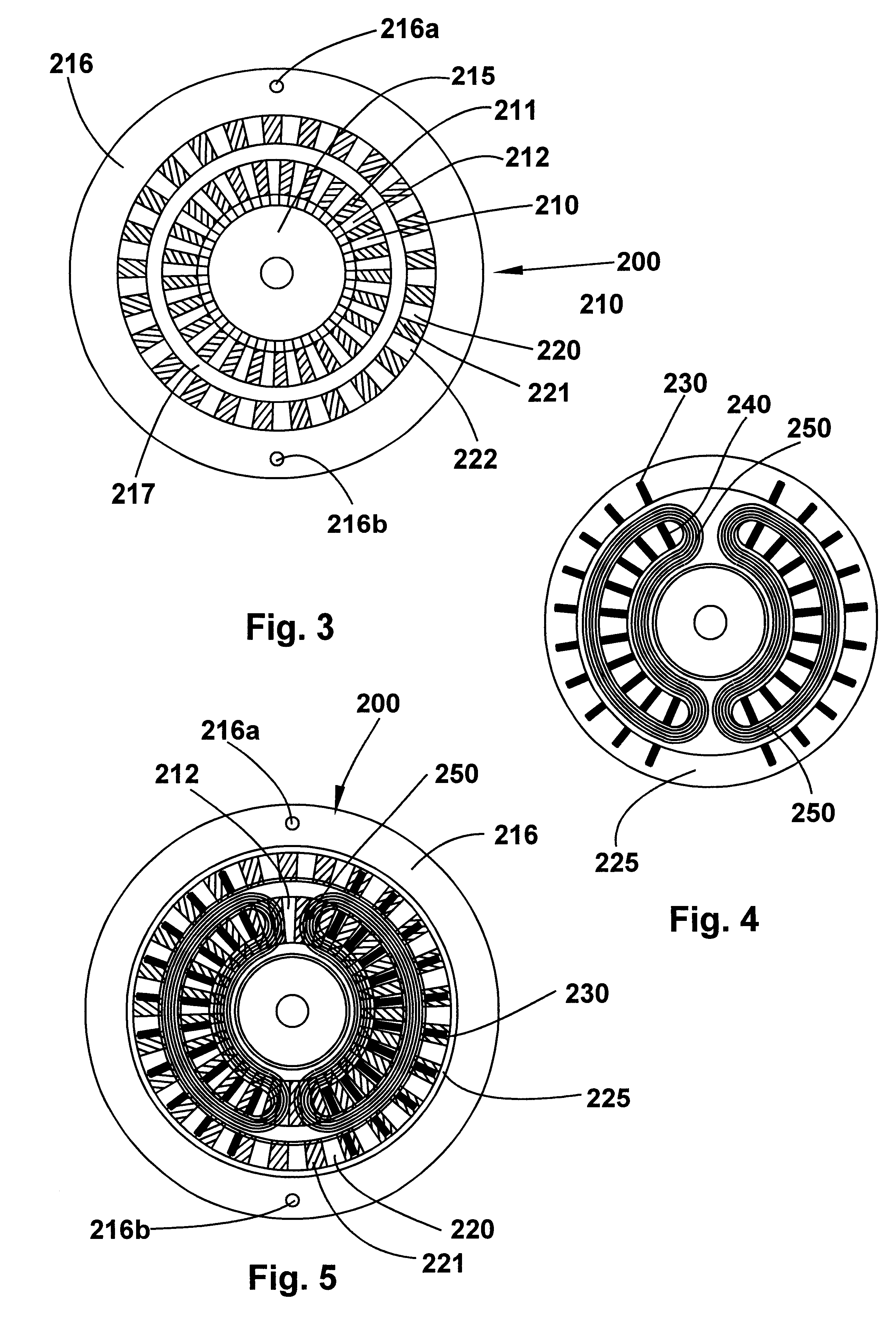

Heddle, especially lifting heddle

The subject matter of the invention is a heddle (1), more specifically a lifting heddle as part of a leno selvedge device, the heddle comprising a head portion and a base portion with a closed or an open eyelet for mounting to a heddle frame or to a heddle ridge bar (13), the head portion and / or base portion (2, 3) being adapted to be secured stationarily to the heddle frame or the heddle ridge bar (13), with the head portion (2) and / or the base portion (3) being adapted to be interlockingly and non-slidably fixed to the heddle frame or to the heddle ridge bar (13) by means of a detent system (11, 12, 13a).

Owner:GEBR KLOCKER

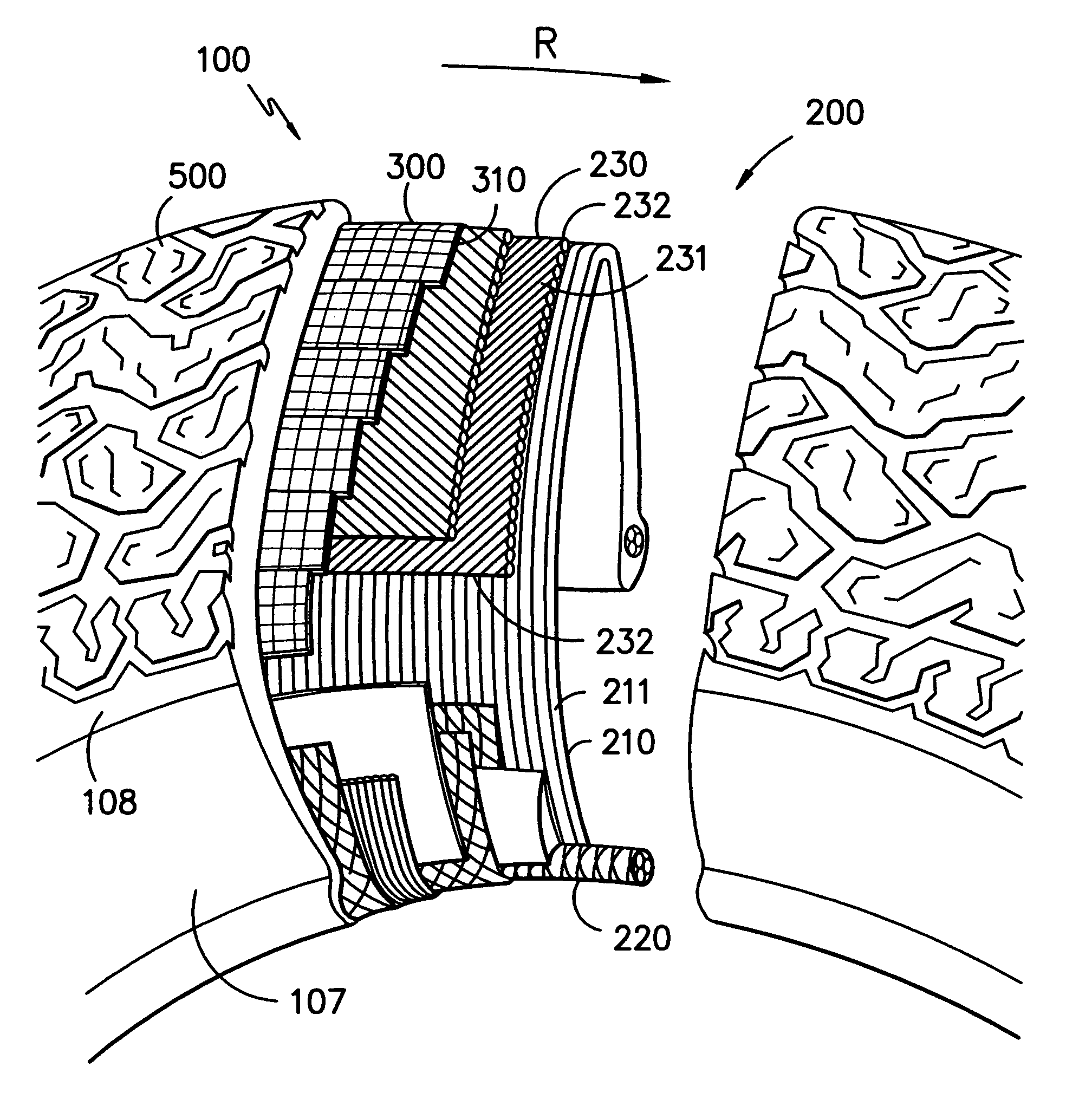

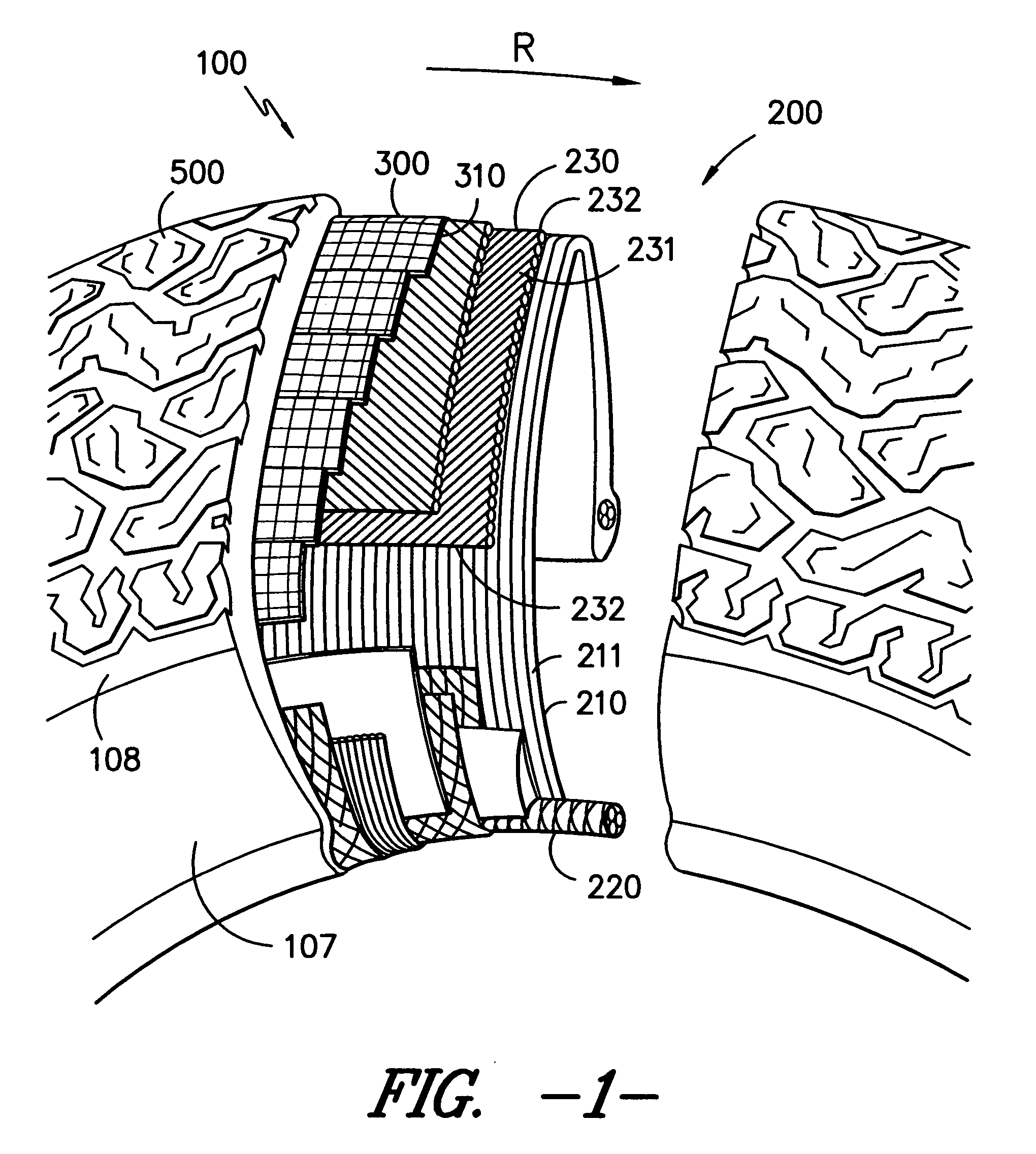

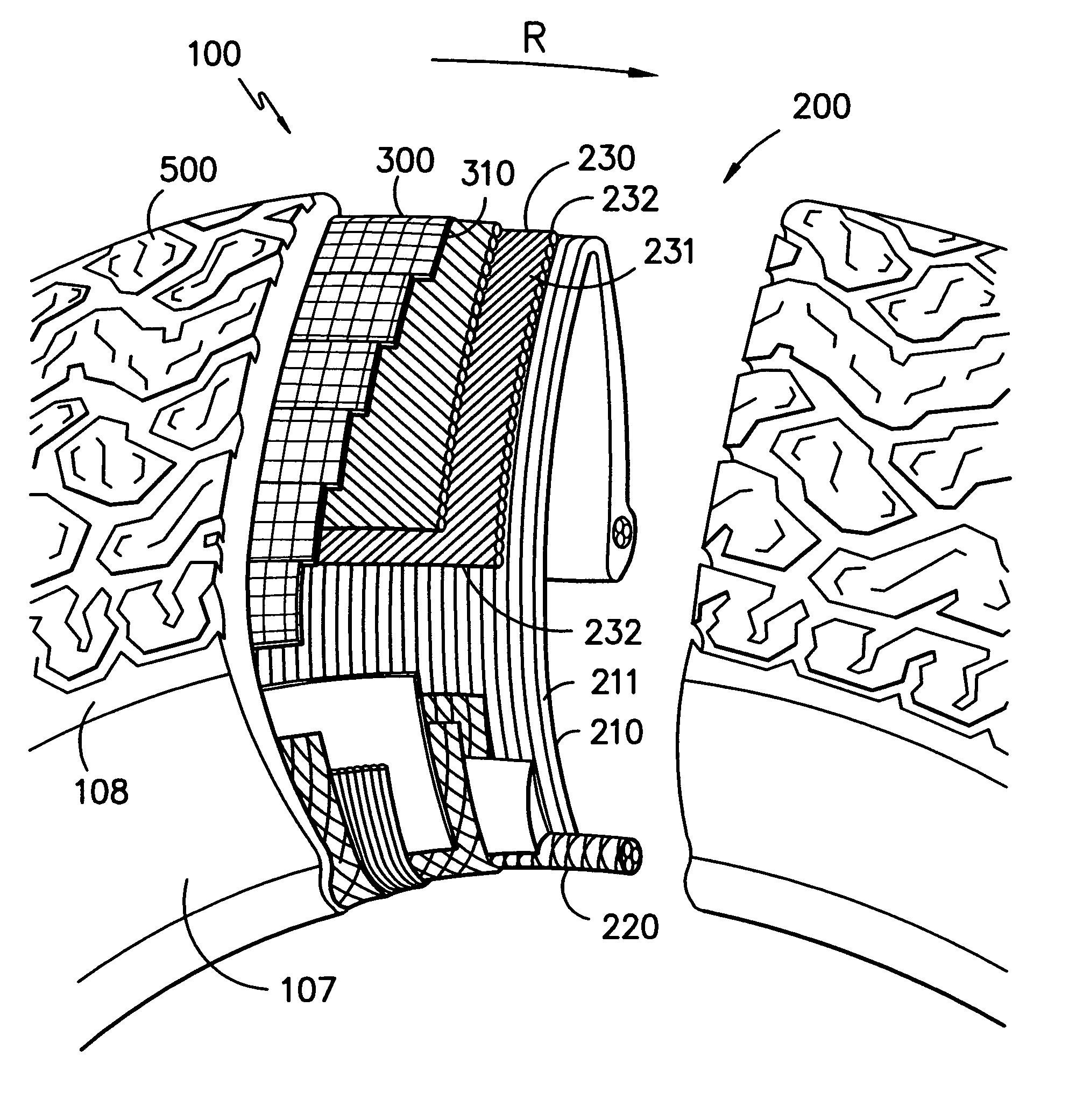

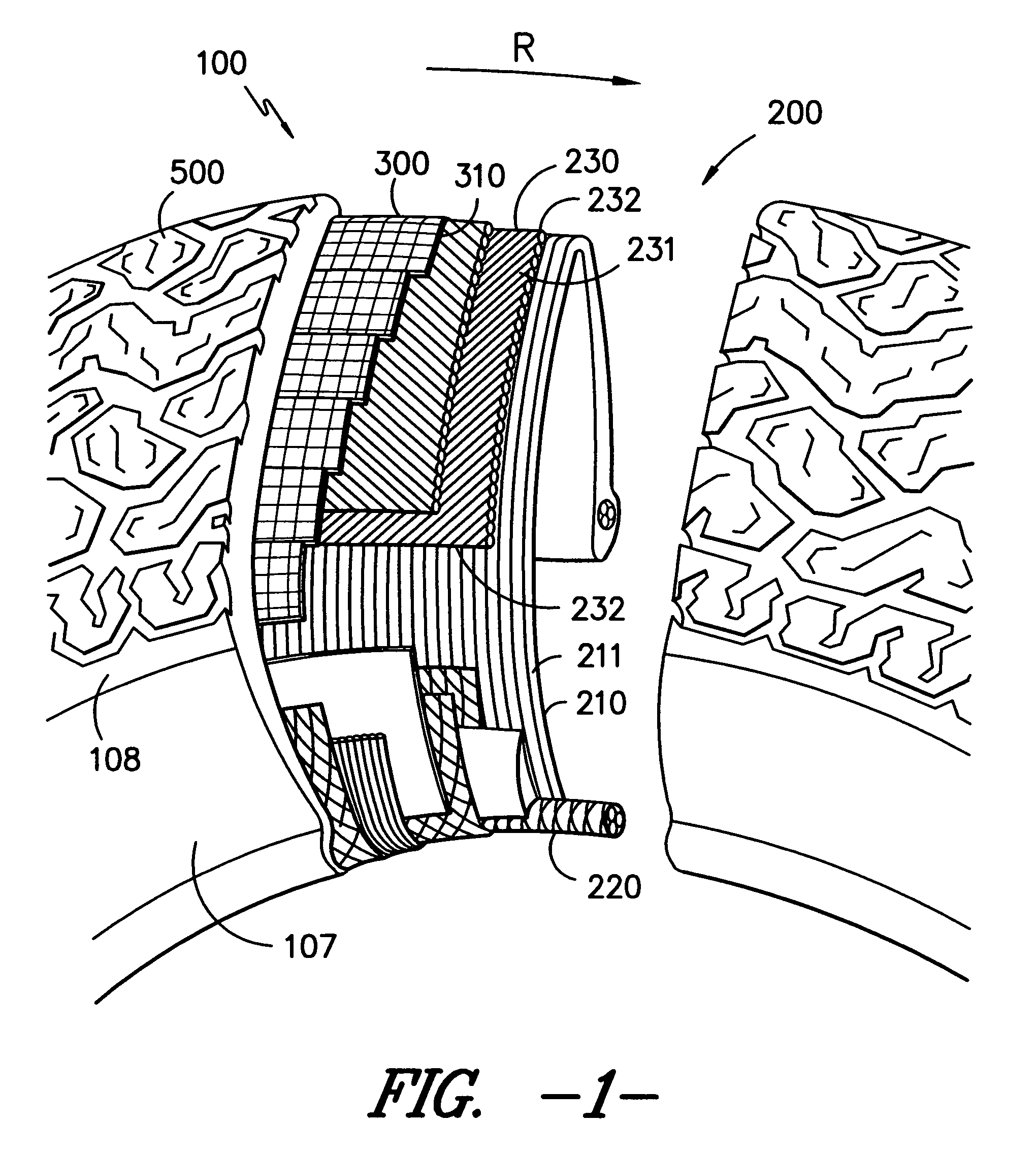

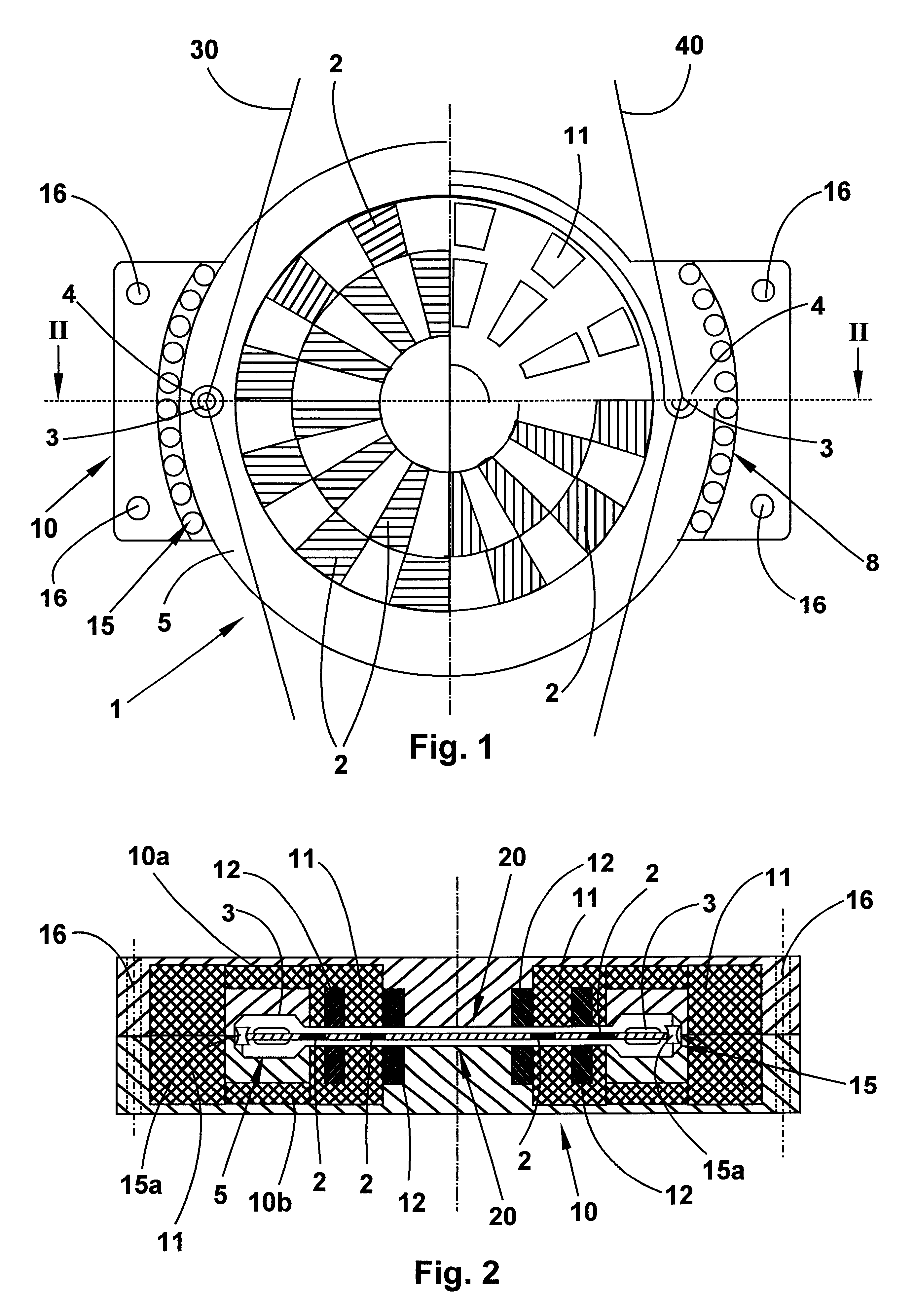

Device for forming a leno selvedge with an electric motor comprising a rotor and a stator accomodating the rotor

InactiveUS6246147B1Improve power densityFast inversionMagnetic circuit rotating partsLeno shedding mechanismMagnetic polesEngineering

Device for forming a leno selvedge with an electric motor comprising a rotor (1; 200) and a stator casing (10) accommodating the rotor, whereas the rotor is provided with at least two guiding apertures (3; 216, 216b) for the doup ends and whereas the rotor (1, 200) is provided with several magnetic poles oriented in axial direction, the rotor (1; 200) being provided with two spaced magnetic rings (210, 220) arranged in radial direction, the magnetic rings (210, 220) being provided with several magnet segments (2; 211, 212; 221, 222) each, the magnet segments (2; 211, 212) of the one magnetic ring (2; 210) being locally offset relative to those of the other magnetic ring (2; 210, 220), whereas the rotor (1; 100) is received on both sides in axial direction by the stator casing (10; 225), whereas the stator casing (10; 225) is provided with iron cores (11; 230, 240) with appropriate windings (12; 250), the ends of which being oriented toward the magnetic poles of the rotor.

Owner:GEBR KLOCKER

A method for making jacquard fabric with simulated color effect

InactiveCN102277674ALifelikeQuality improvementLeno shedding mechanismImage data processing detailsText fileSoftware

The invention discloses a method for making a jacquard fabric with simulated color effects. Firstly, the image file is processed, and the artwork is scanned into a computer, adjusted with Photoshop image processing software, and four color separations are performed to separate four colors into blue and blue respectively. , red, yellow, and black pictures; and then weaving electronic pattern file production, using the jacquard fabric system to carry out the latitude and longitude gradient organization of the blue, red, yellow, and black pictures into a pattern file, and then four The individual version files are combined into a four-color weaving version file; finally, the weaving version file is input into the electronic jacquard machine, and white warp yarns and four-color weft yarns are used to weave fabrics through electronic pattern file control. The method of the invention is novel, and can weave jacquard fabrics with rich colors, high quality and high quality.

Owner:LUOLAI LIFESTYLE TECH CO LTD

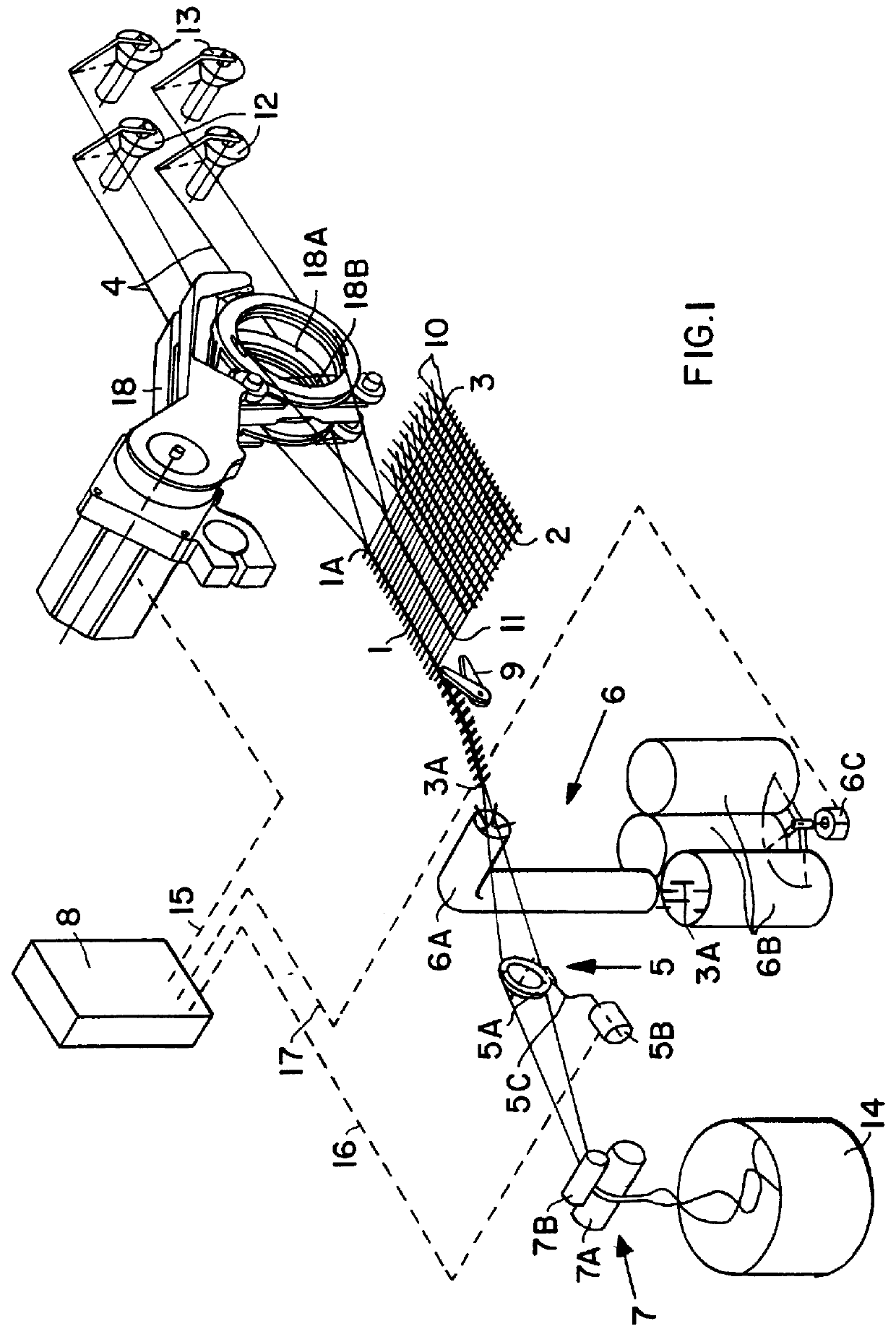

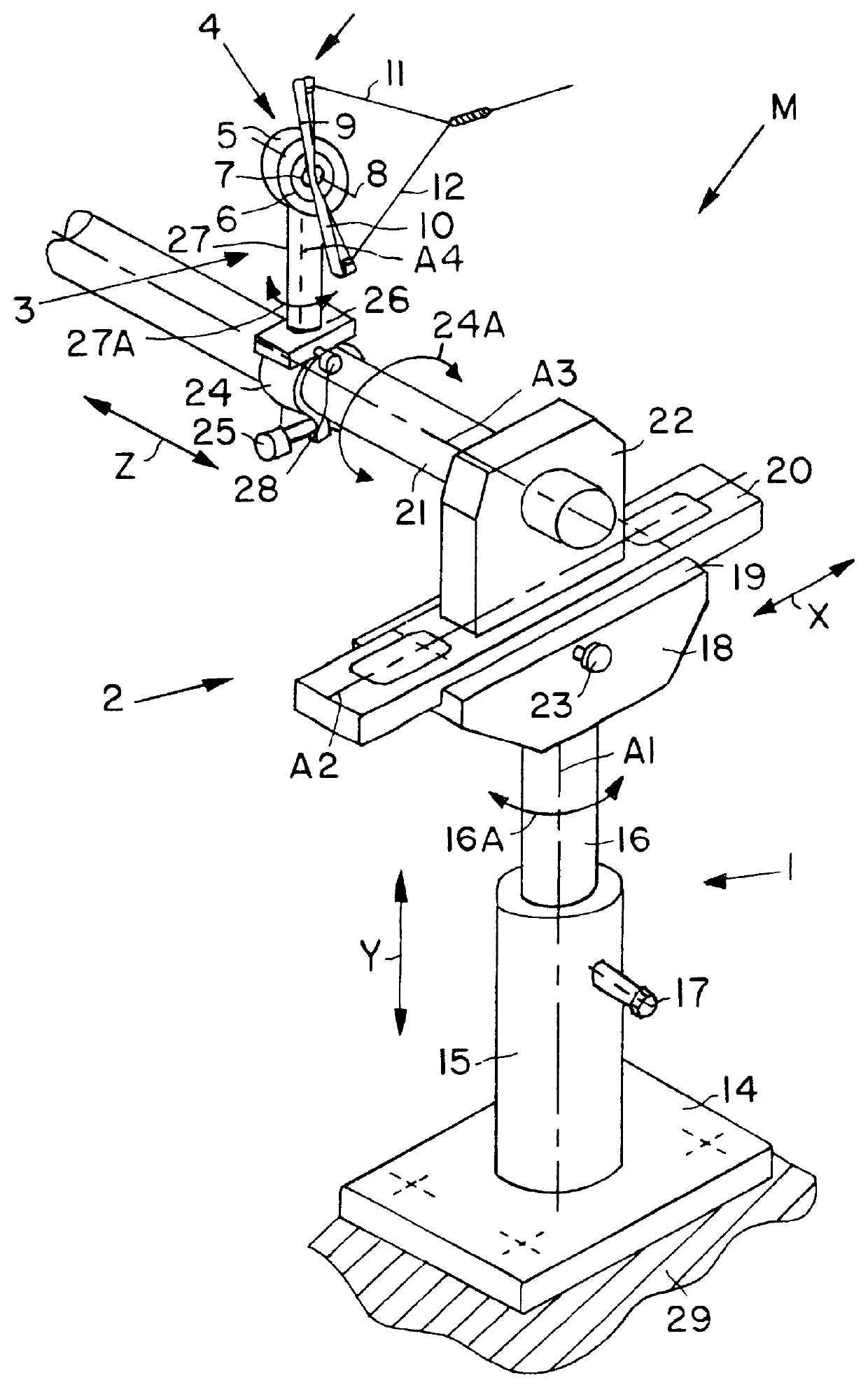

Mounting and positioning apparatus for a leno selvage former

A leno selvage former is supported by a mounting for position adjustments in the three directions of a three-dimensional rectangular coordinate system and preferably also for an angular position adjustment about at least one rotational axis. For this purpose the mounting has three sections. A first section carries a second section which carries a third section. The first section is, for example adjustable in the Y-direction, while the second section is adjustable in the X-direction and the third section is adjustable in the Z-direction of the rectangular coordinate system. At least one of the three sections is preferably also angularly adjustable. At least one lock such as a screw is provided for locking-in an adjusted position.

Owner:LINDAUER DORNIER GMBH

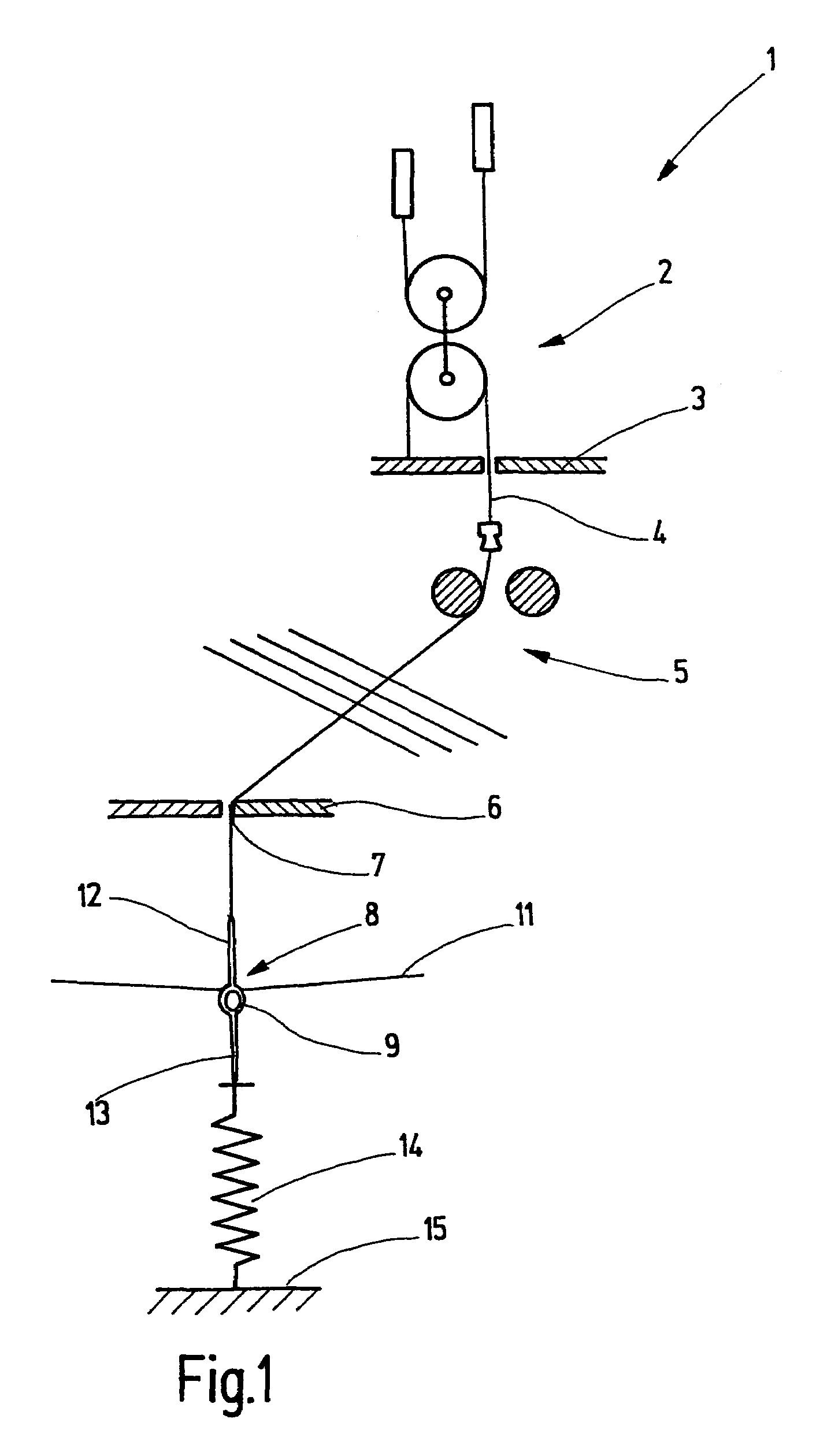

Spring dampened shedding device

InactiveUS7036532B2Effectively dampens undesirable resonating propagationAccurate pressureJacquardsLeno shedding mechanismJacquard loomResonance

A shedding device in a jacquard loom, having a heddle with a retracting spring rigidly anchored in the loom or to the floor for urging the heddle to a lower shed forming position. To suppress the development of resonance in the spring, a core element is provided, which contacts the inside of the spring at points spaced apart from one another and forces the spring to take a course which deviates from the rectilinear. As a result, friction forces that contribute to damping the spring motion are created between the spring and the core element.

Owner:DEUTE INST FUR TEXTIL & FASERFORSCHUNG STUTTGART

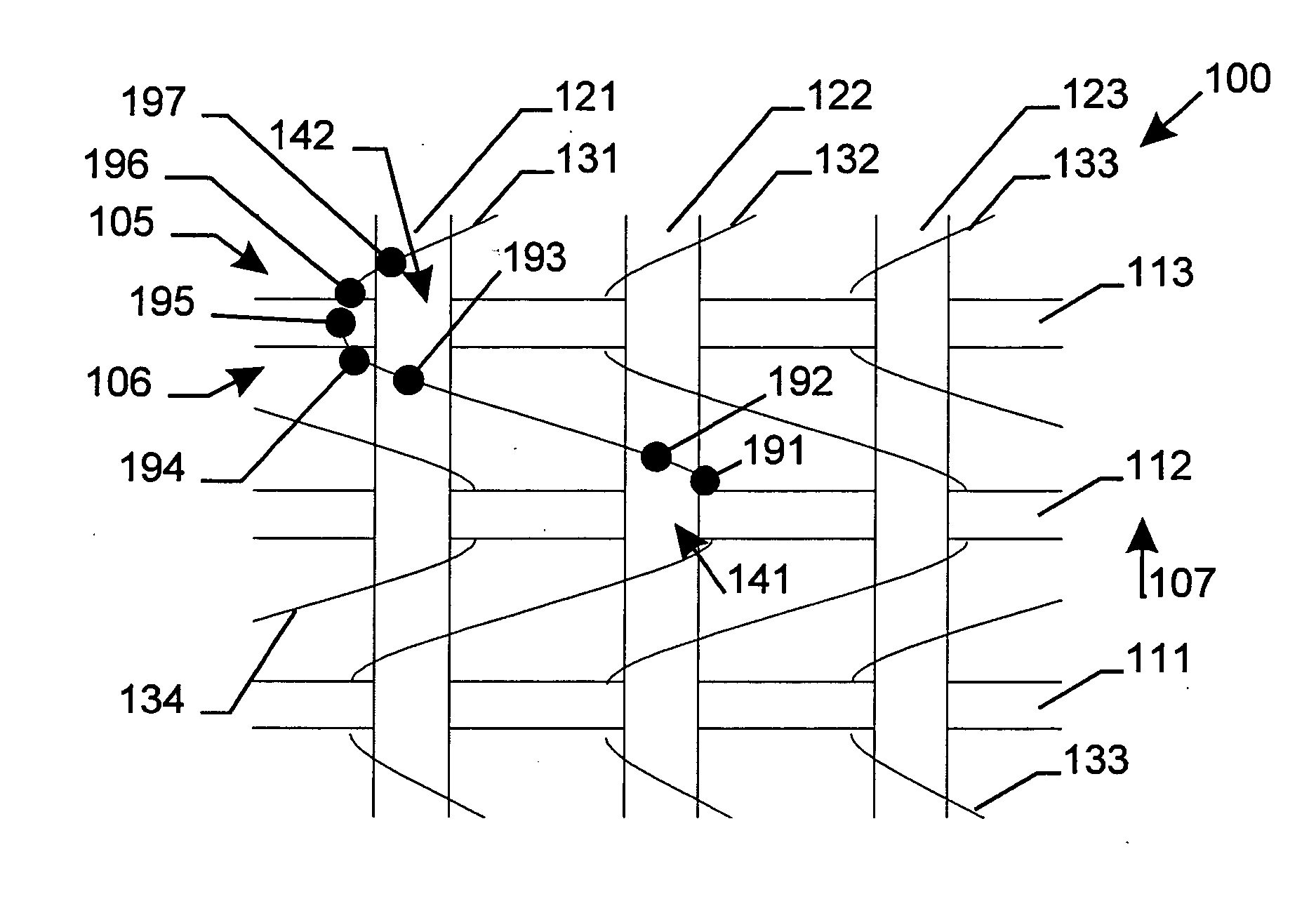

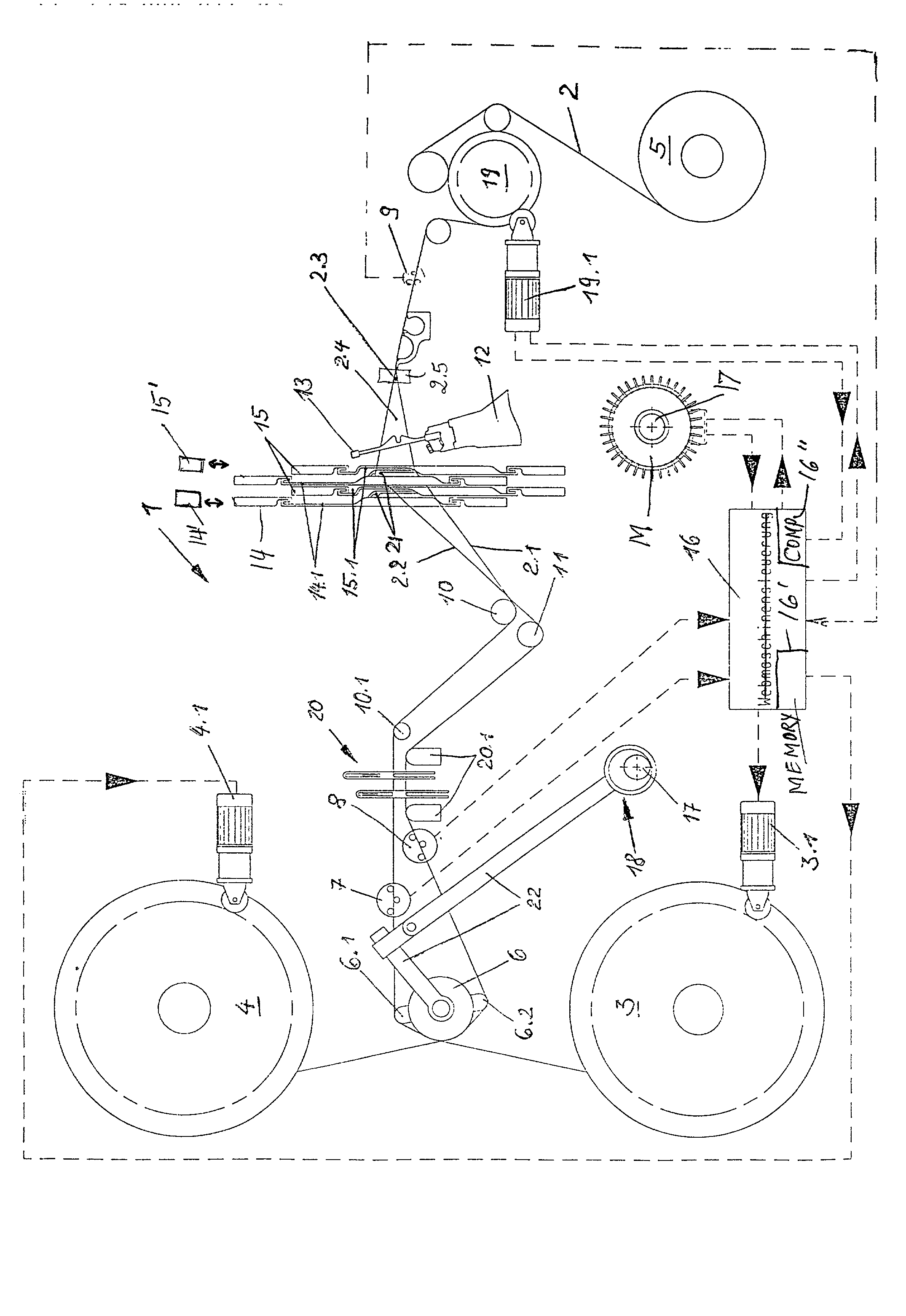

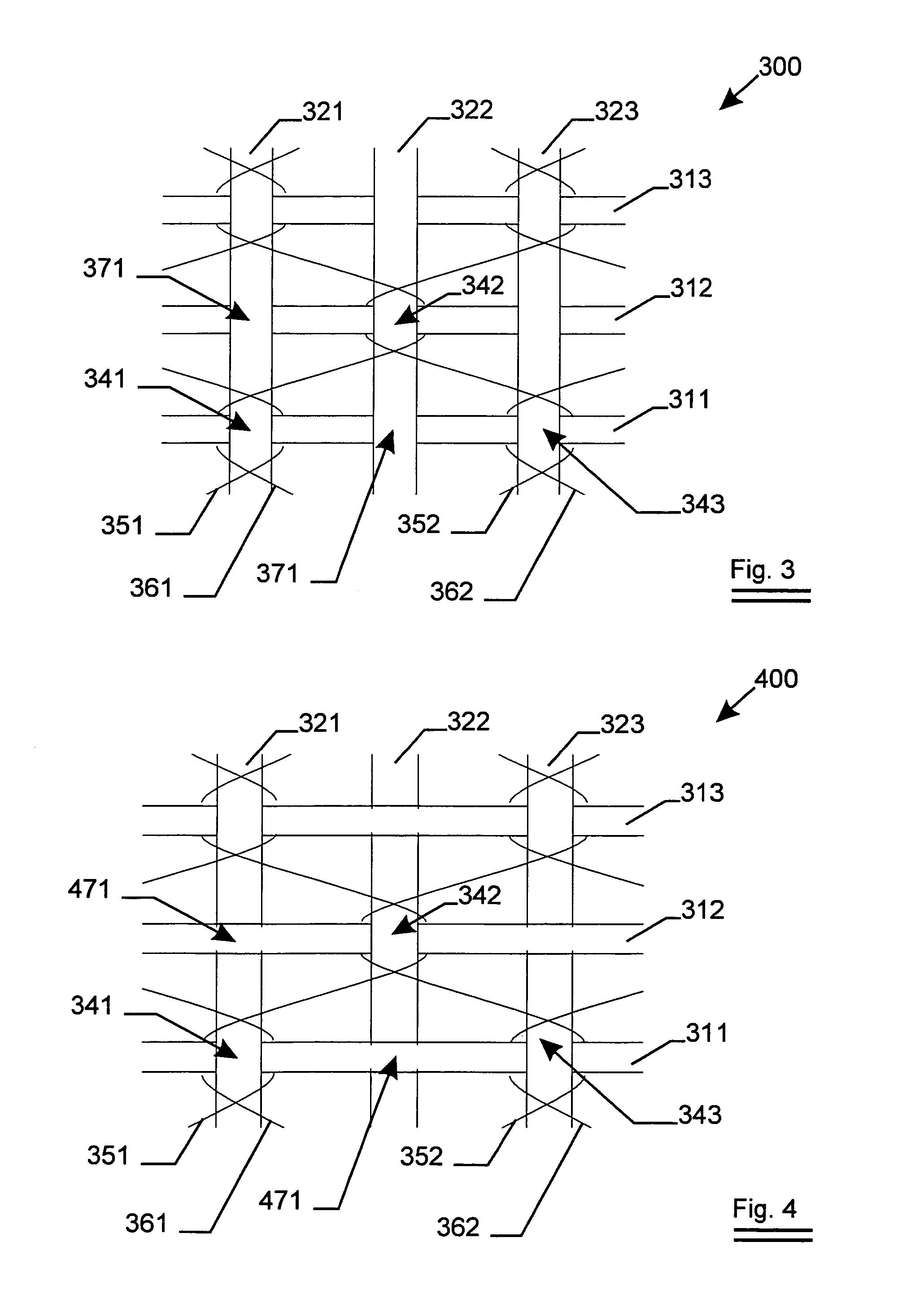

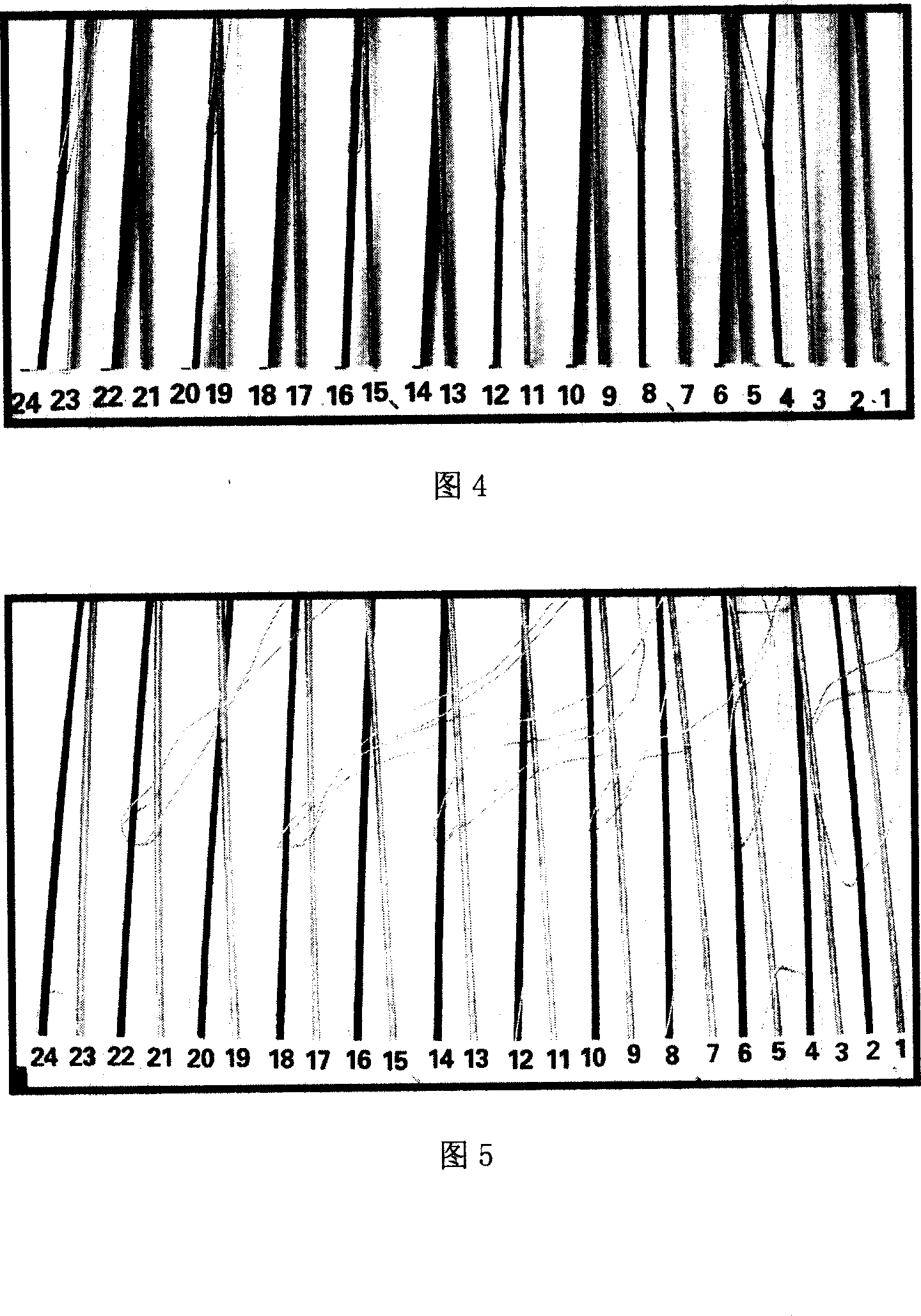

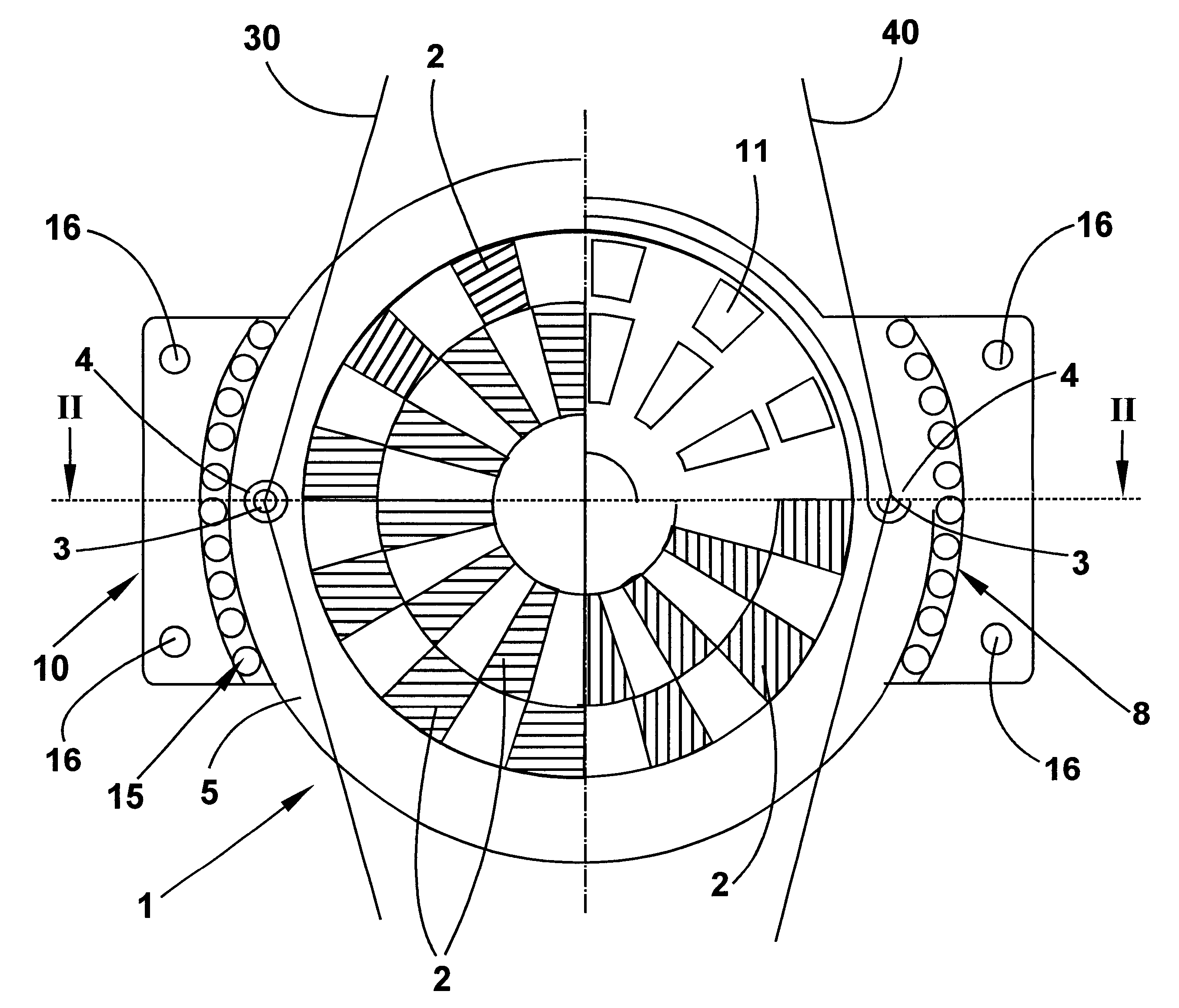

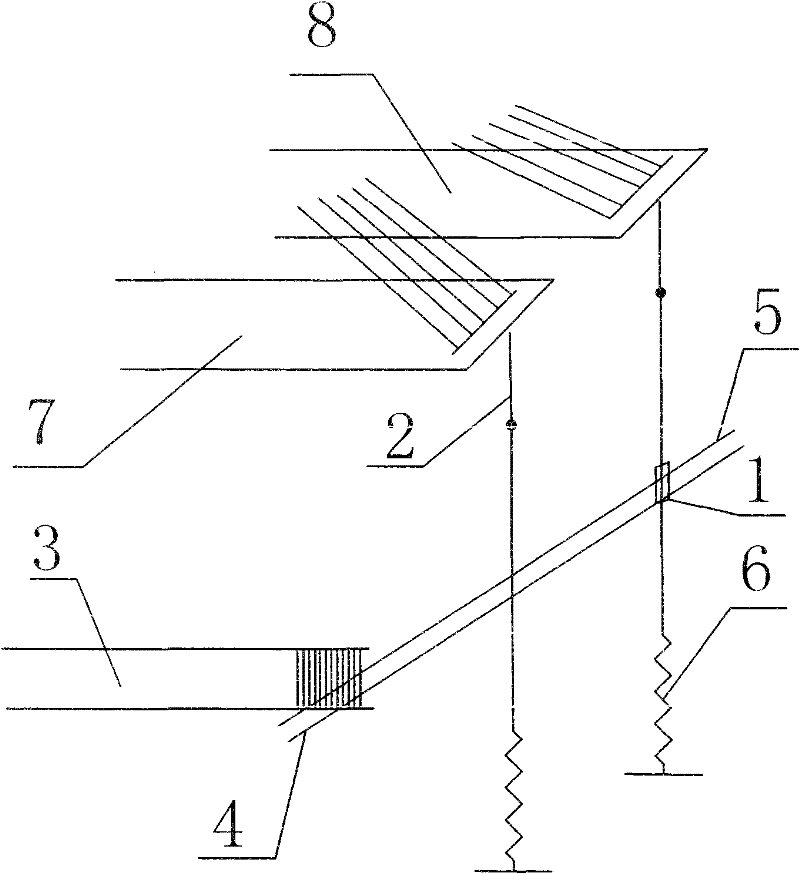

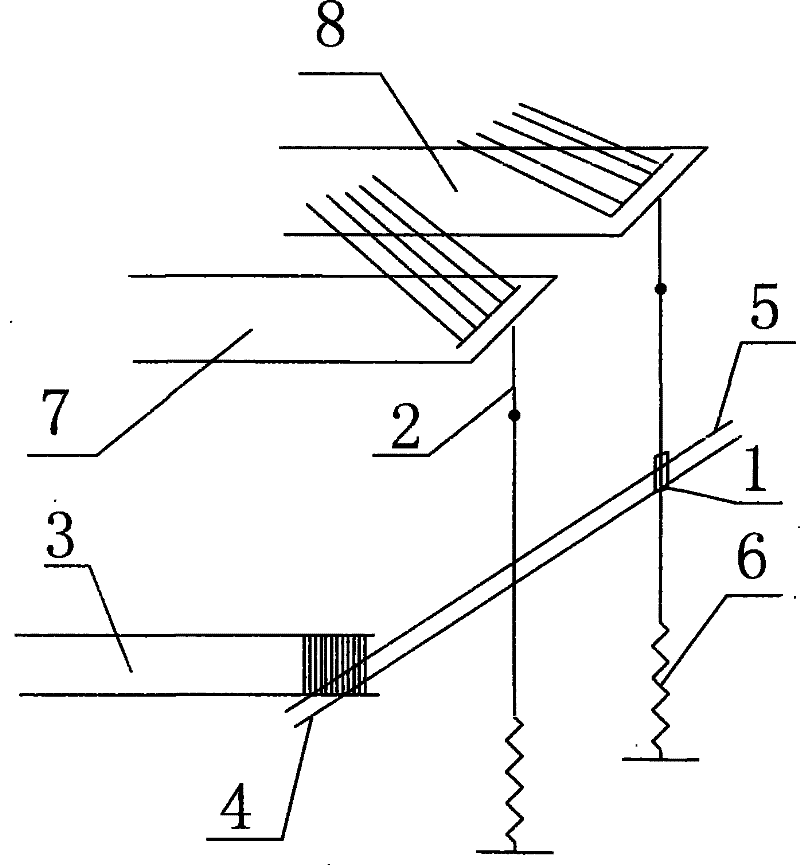

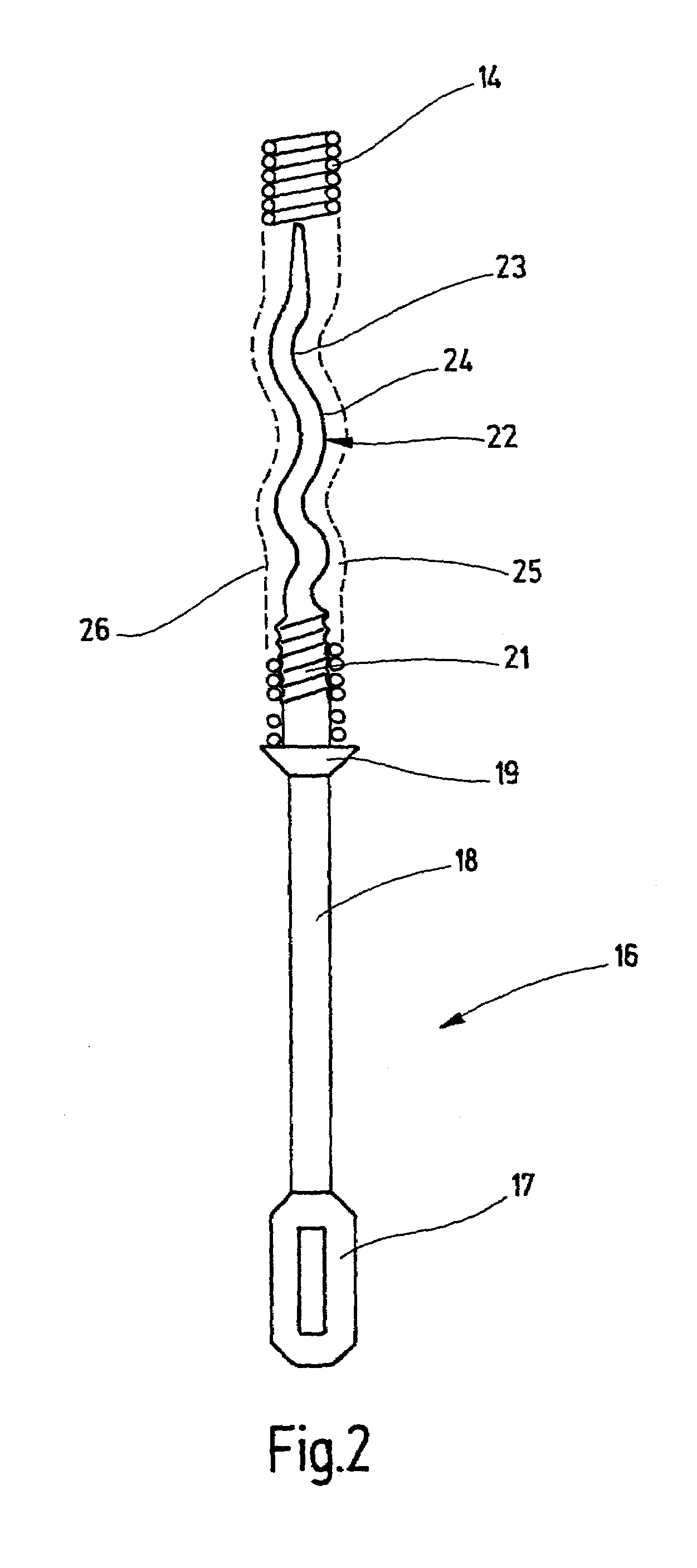

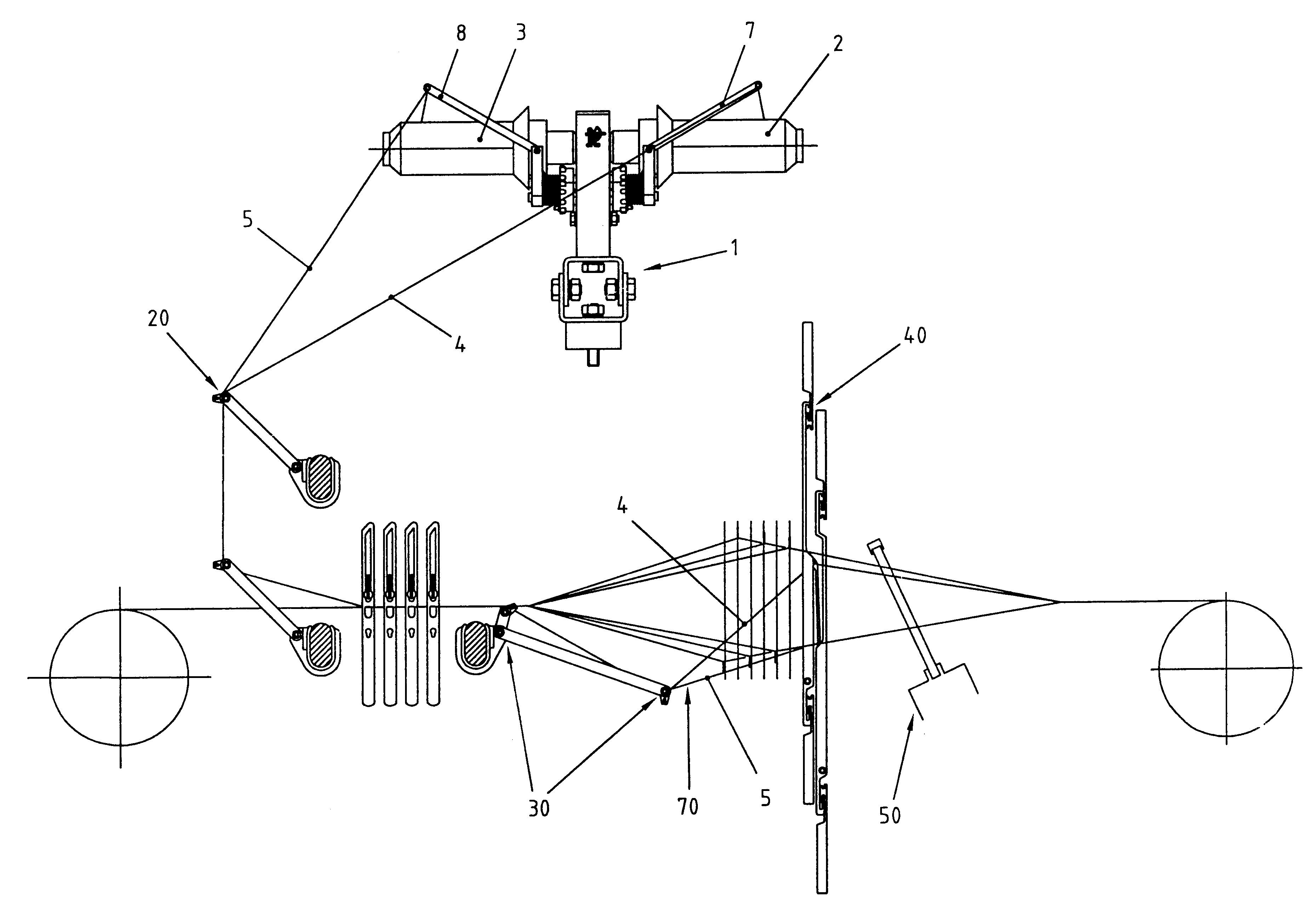

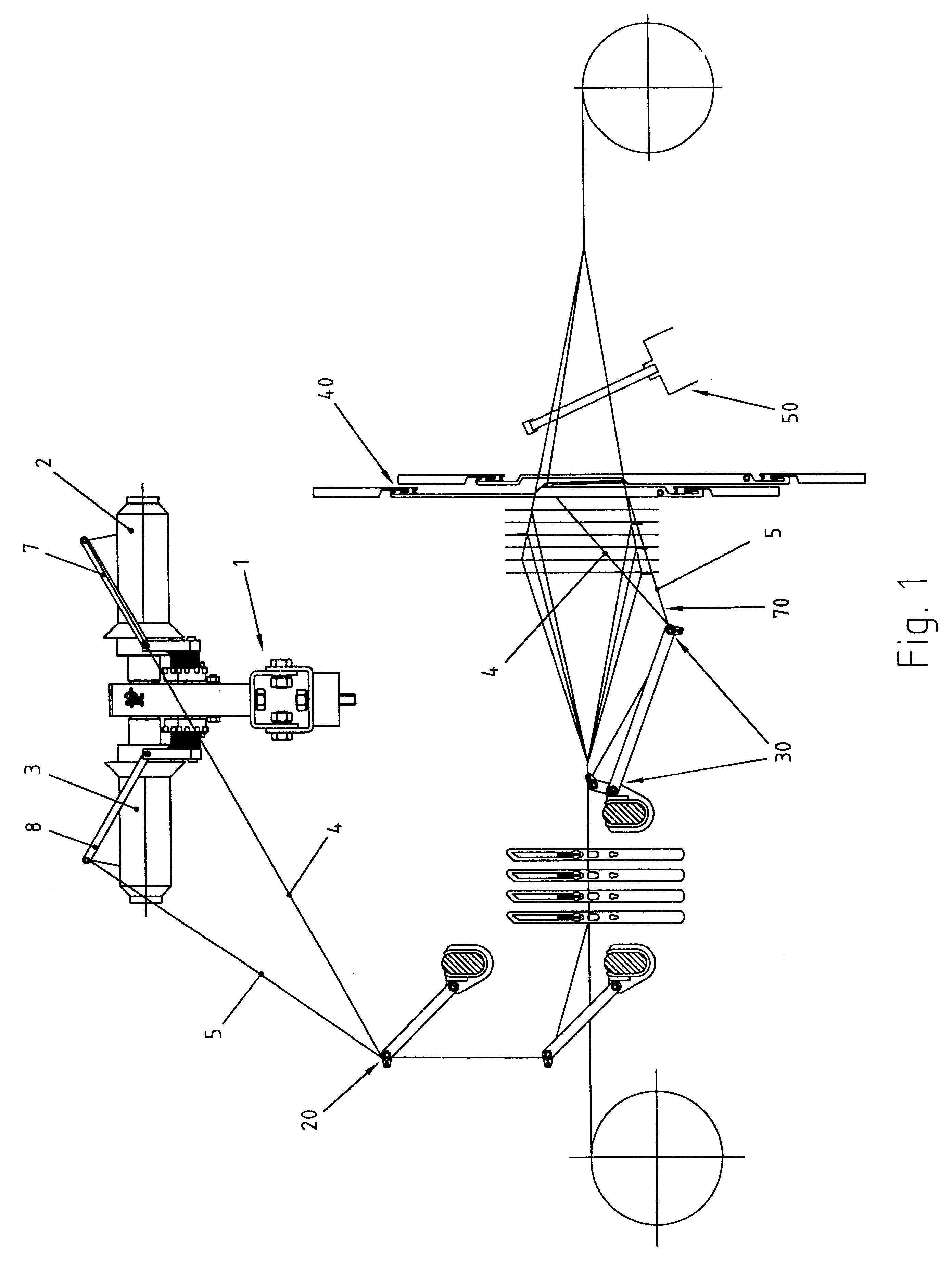

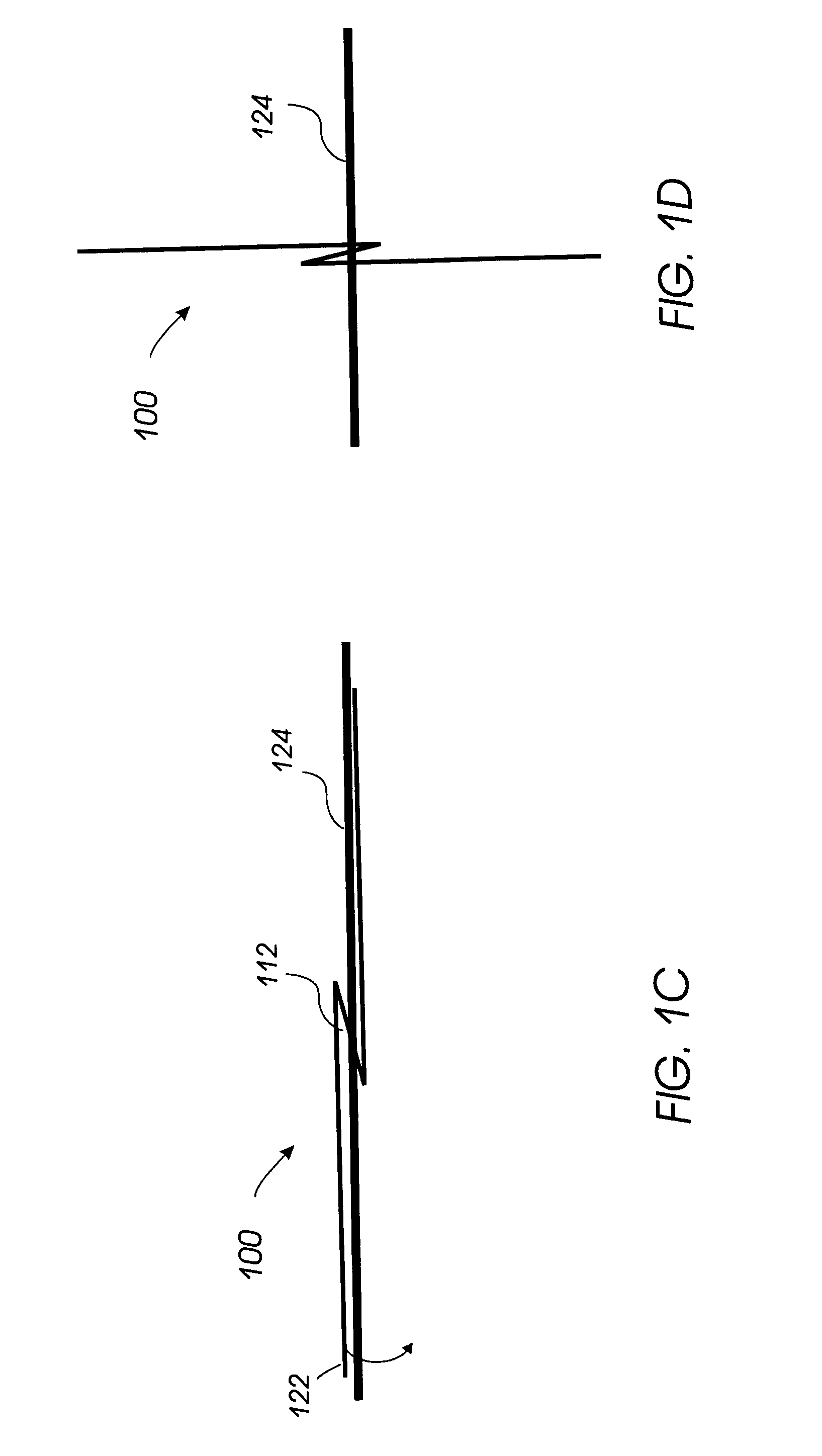

Weaving loom for producing a leno fabric

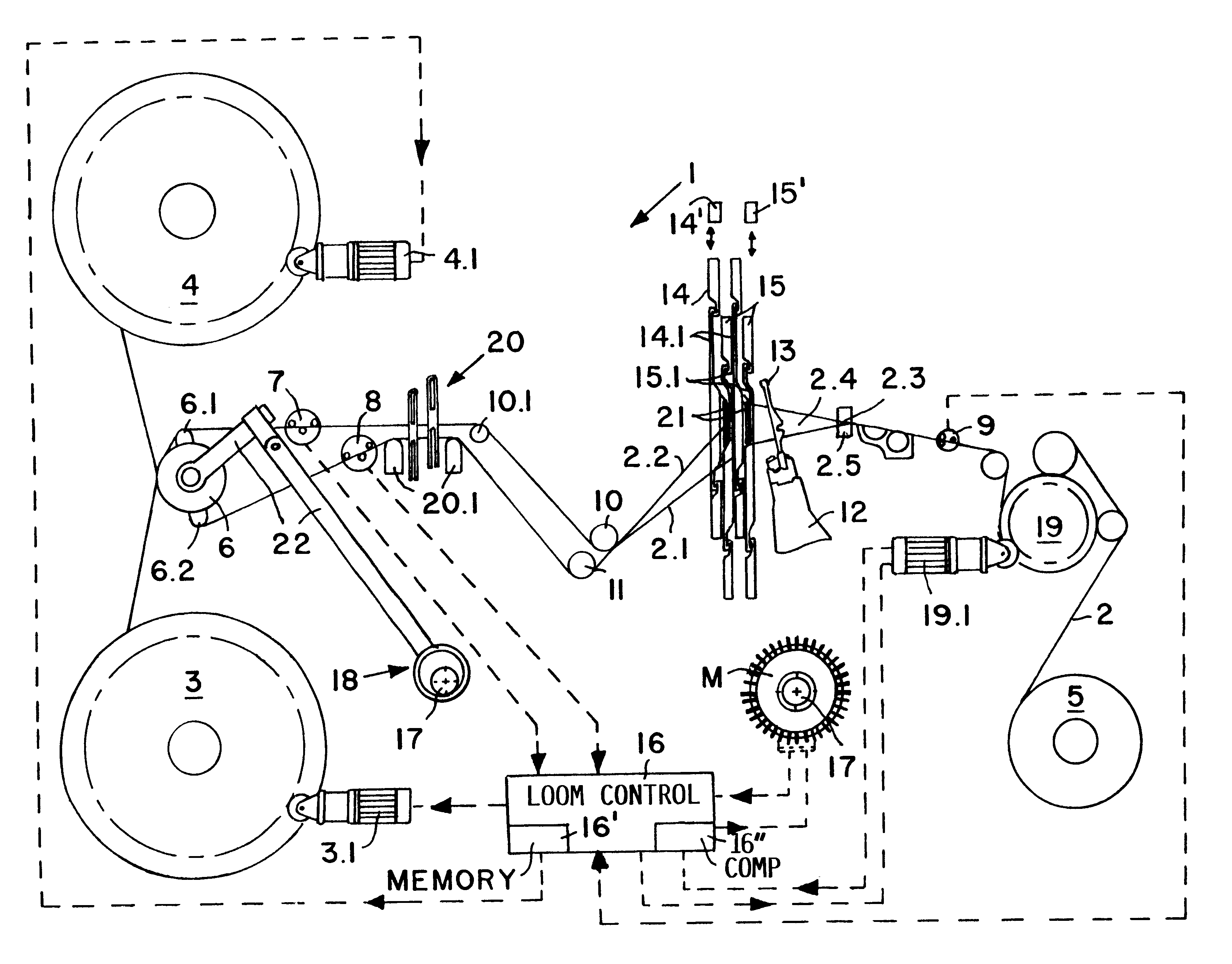

InactiveUS6315008B2Reduce in quantityAvoiding bending momentsLeno shedding mechanismLoomsYarnControl system

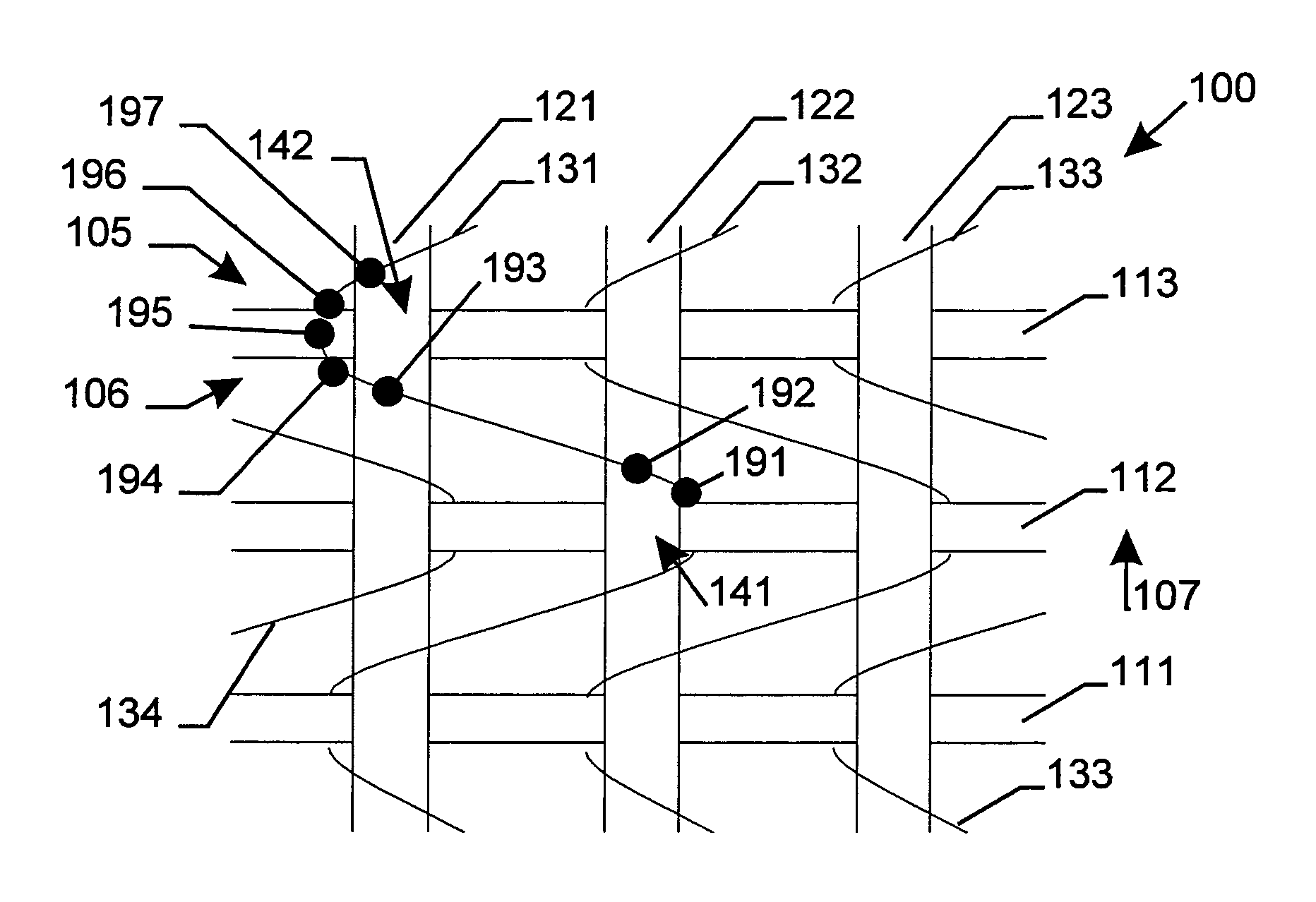

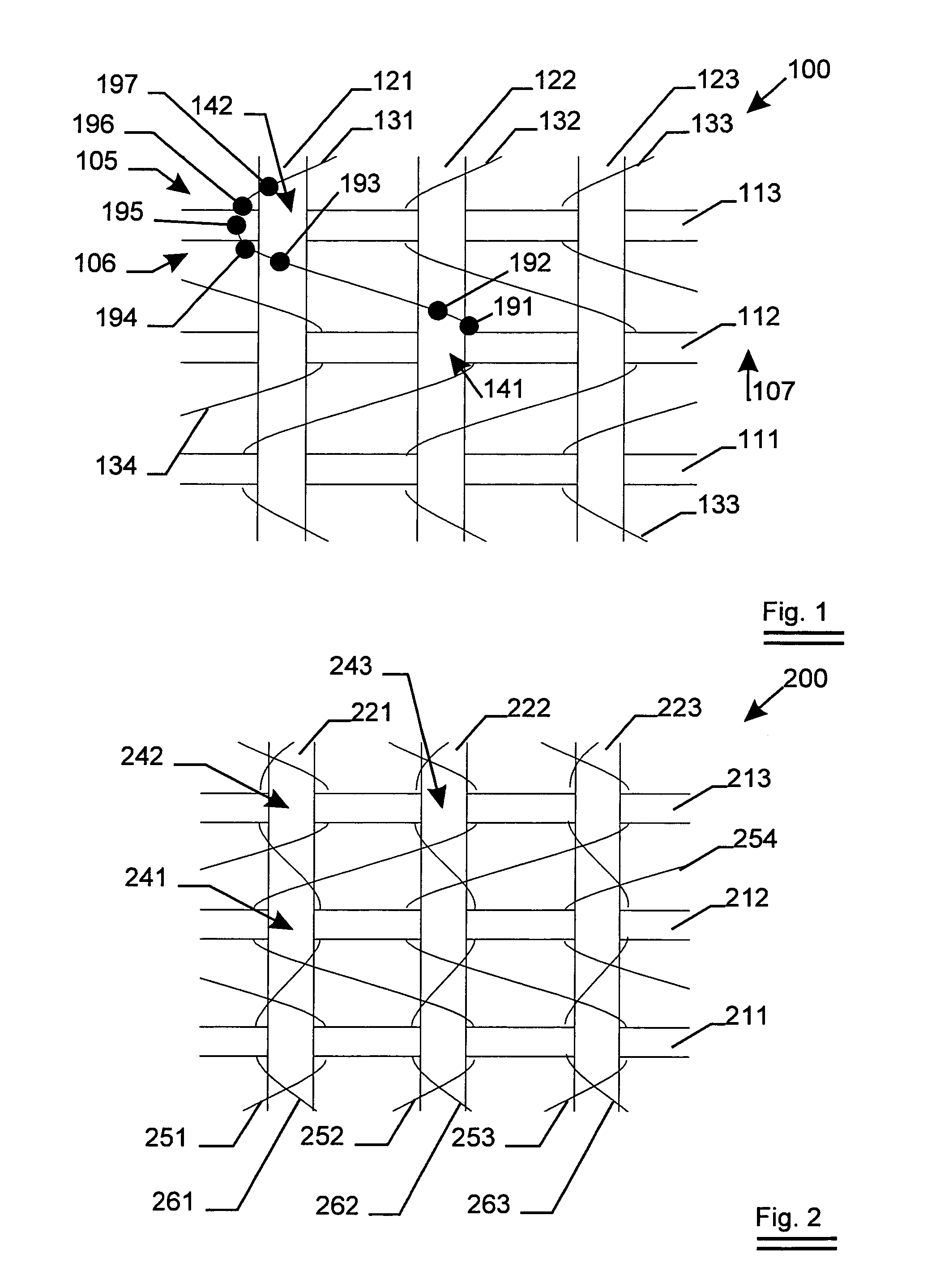

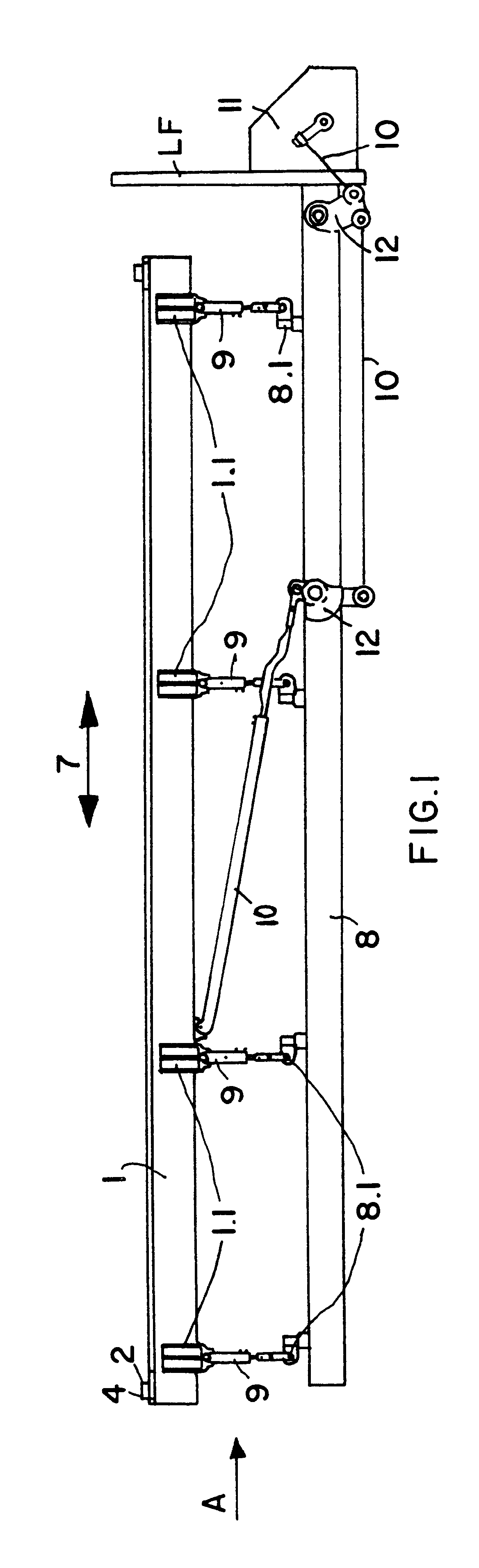

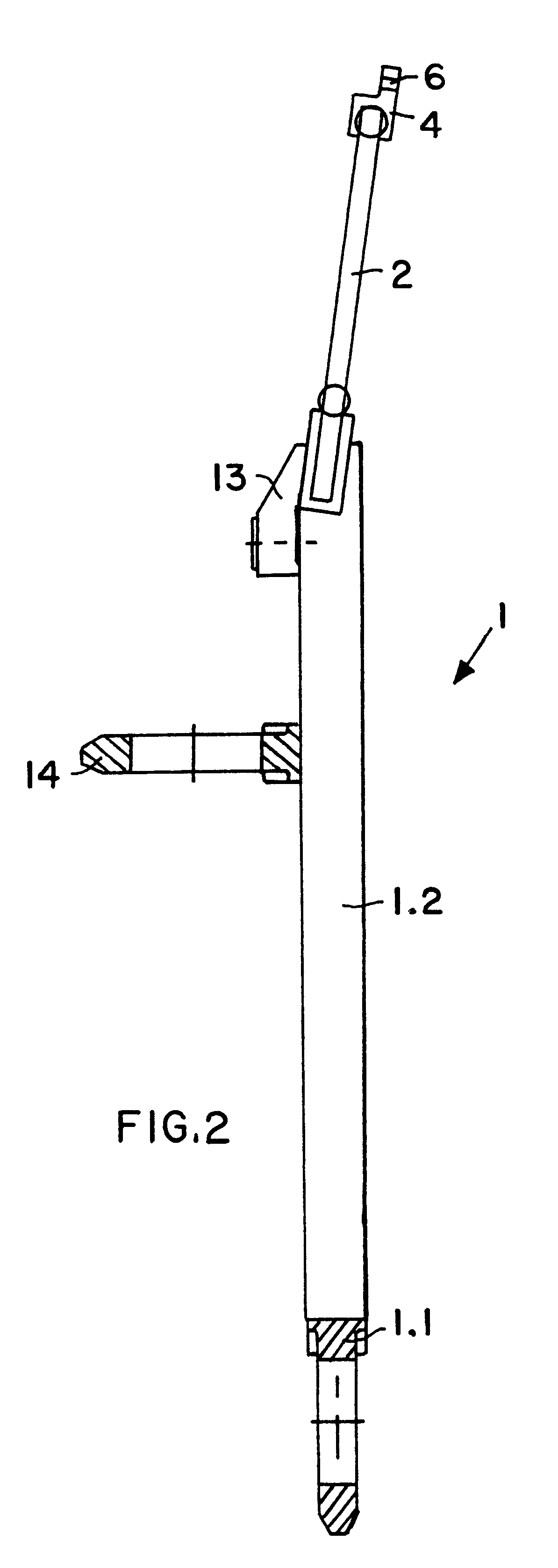

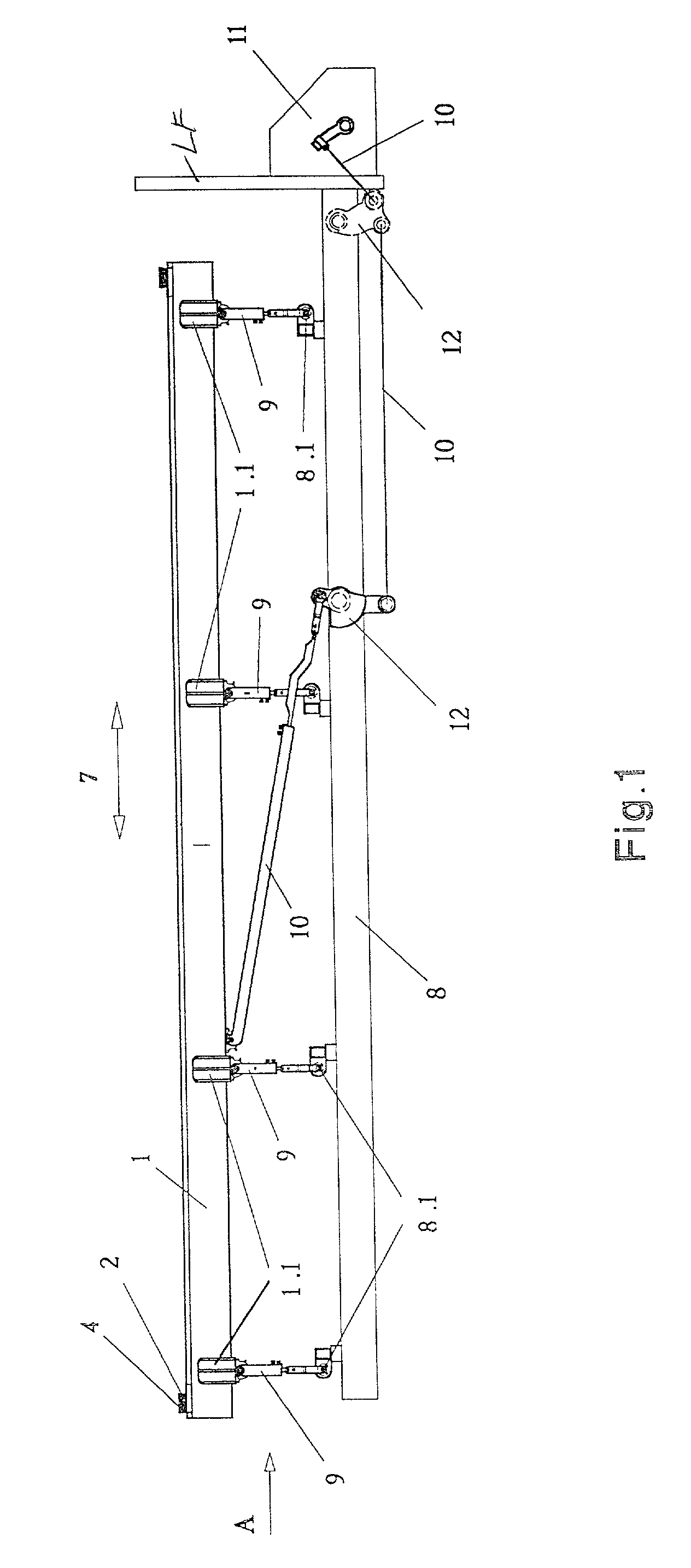

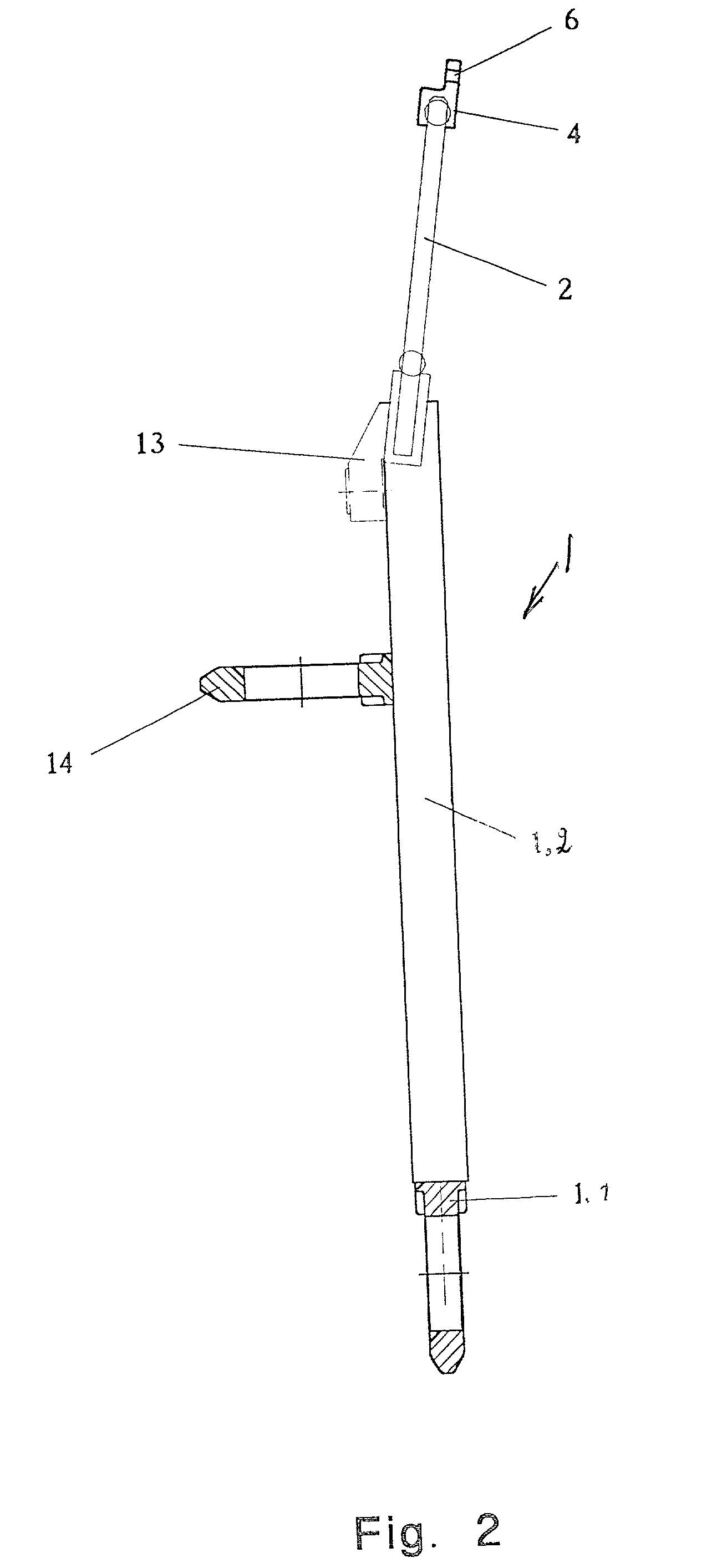

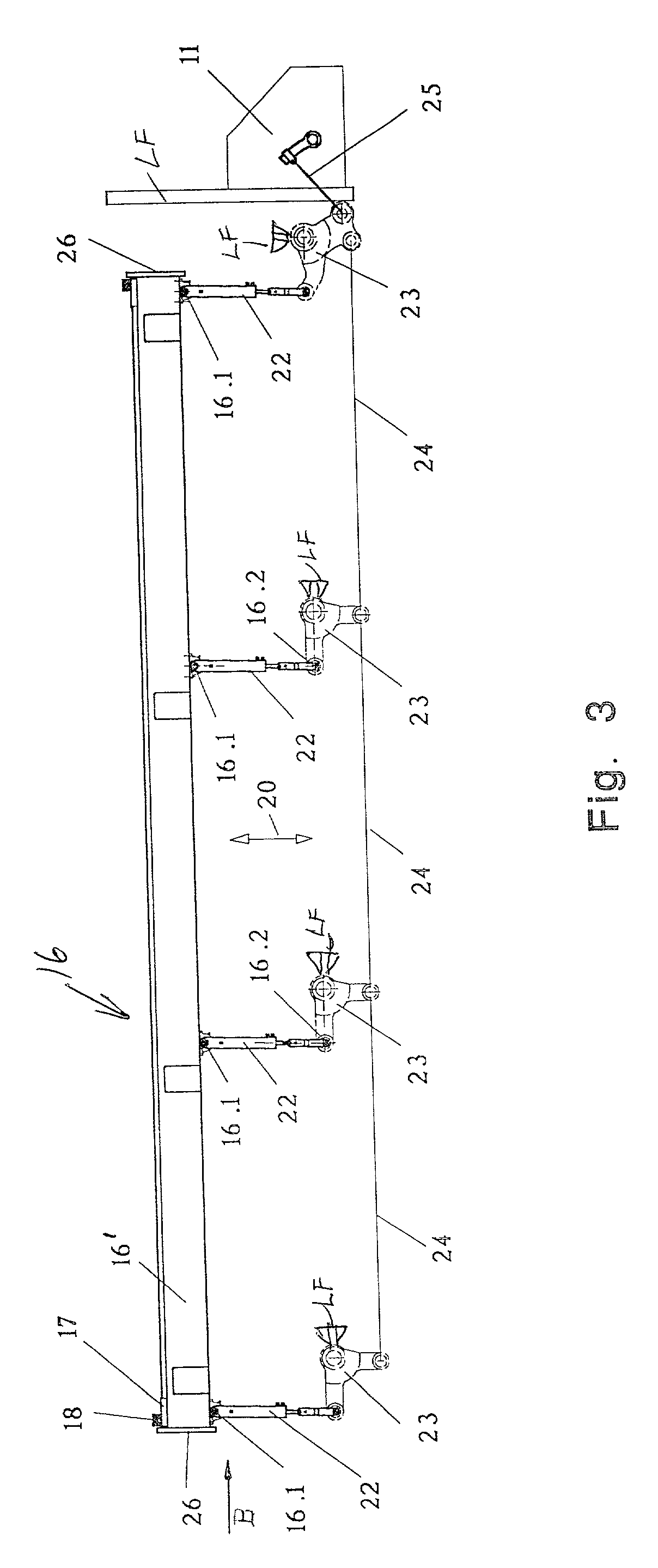

A warp thread control system for forming the loom shed as a first control section (1) and a second warp control section (16). The first section is equipped with at least one guide element (2) for guiding the leno threads (3) and a guide rod (4) carrying a multitude of passages 6 arranged and parallel to one another for guiding the ground threads (5). The second warp control section (16) includes a thread detour element (17) for detouring the leno threads (3) and a needle bar (18) carrying a multitude of needles (19) with needle eyes (19.1) for guiding the leno threads (3). Both the first warp control section (1) and the second warp control section (16) are positioned on the side of the reed facing the warp threads whereby the positioning may differ either above or below a weaving plane (28) or partially above and partially below the weaving plane (28). Preferably but not necessarily both warp control sections are driven by a common drive (11).

Owner:LINDAUER DORNIER GMBH

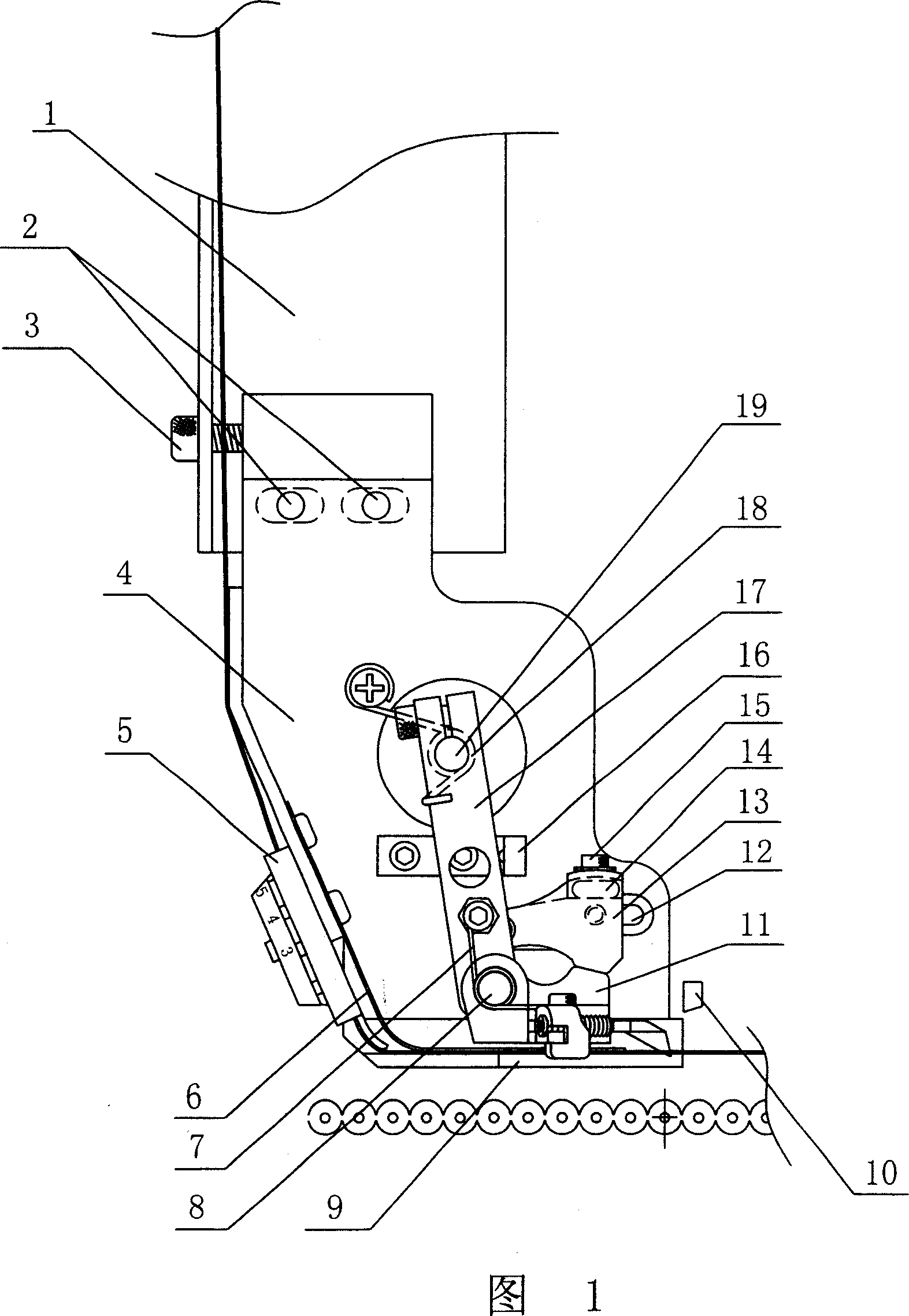

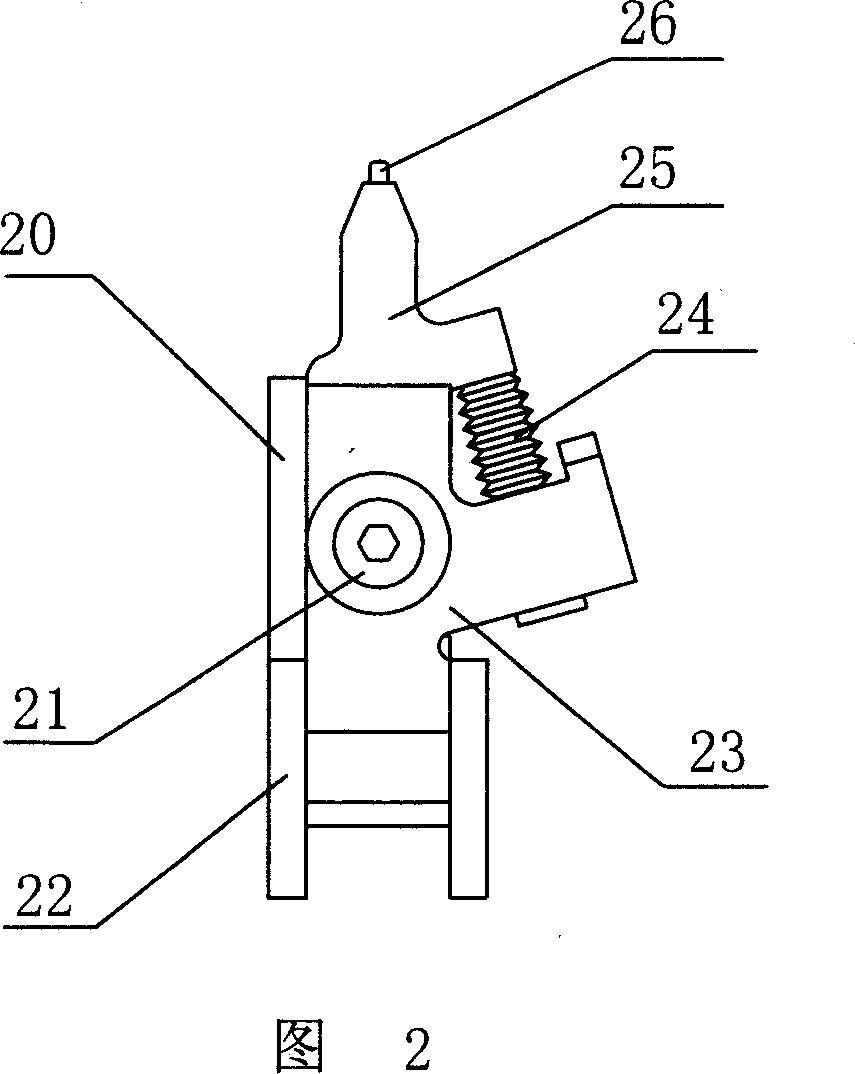

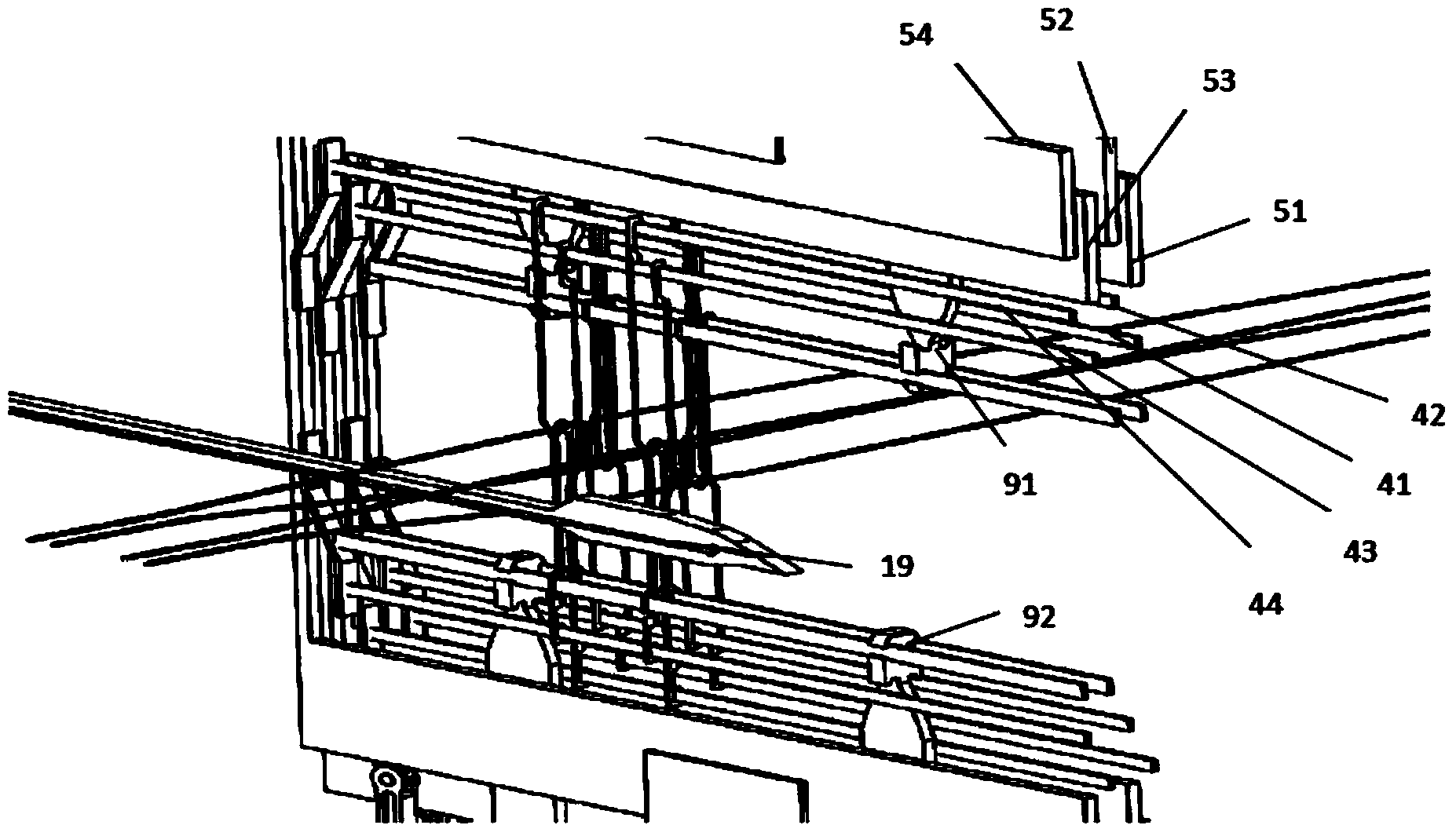

Sequin driving regulating mechanism

InactiveCN1948577AStable structureEasy to debugLeno shedding mechanismOther shedding mechanismElectric machineryEngineering

The invention is driving and adapting mechanism for bead chip, which belongs to field of bead chip machine. It contains bead chip framework and conterminal electric motor. Upper end of deflector connects with motor shaft and lower end adapts to front fulcrum device. Corresponding position-setting seat and rackwork of deflector are set on bead chip framework. It is characterized in that the front fulcrum device contains front fulcrum seat and front fulcrum wiper. Set position-setting cant and oblique arm on two sides of front fulcrum seat, guide pore on center of front fulcrum wiper, bead chip driving fulcrum on front end and wiper oblique arm on brink. Front fulcrum passing guide pore is connected with front fulcrum seat for adapting by fix screw. Oblique arm of front fulcrum seat is crested to wiper oblique arm for adapting by fix screw. Positioning base of rackwork is fixed on bead chip framework. Positioning chip and positioning base adapt by elastic rotation. Positioning cant of positioning chip contacts positioning cant for adapting. The adapting mechanism is simple and fast, which can improve worked efficiency effectively. Its products have high percent of pass.

Owner:李龙洙

Doup end tension regulating device for a selvedge former

Owner:GEBR KLOCKER

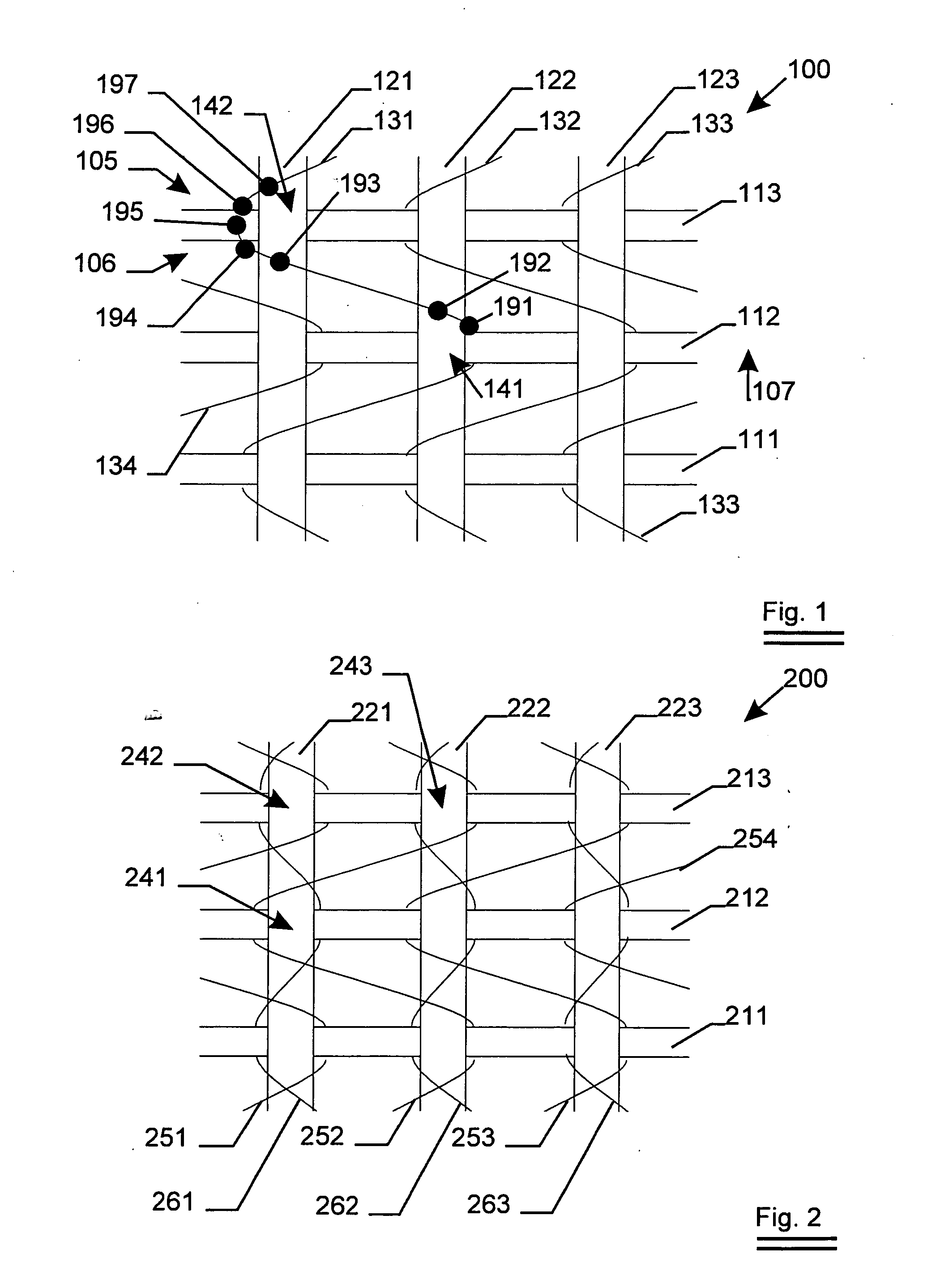

Weaving loom for producing a leno fabric

InactiveUS20010015235A1Reduce in quantityAvoiding bending momentsLeno shedding mechanismLoomsYarnControl system

A warp thread control system for forming the loom shed as a first control section (1) and a second warp control section (16). The first section is equipped with at least one guide element (2) for guiding the leno threads (3) and a guide rod (4) carrying a multitude of passages 6 arranged and parallel to one another for guiding the ground threads (5). The second warp control section (16) includes a thread detour element (17) for detouring the leno threads (3) and a needle bar (18) carrying a multitude of needles (19) with needle eyes (19.1) for guiding the leno threads (3). Both the first warp control section (1) and the second warp control section (16) are positioned on the side of the reed facing the warp threads whereby the positioning may differ either above or below a weaving plane (28) or partially above and partially below the weaving plane (28). Preferably but not necessarily both warp control sections are driven by a common drive (11).

Owner:LINDAUER DORNIER GMBH

Apparatus and method for warping a loom

InactiveUS20050061384A1Quick SetupFast threadingLeno shedding mechanismAuxillary apparatusEngineering

An apparatus and method for warping a loom includes a heddle with an open or openable break in the circumference of its eyelet that allows insertion and removal of warp thread with simple motions through the break while both ends of the warp threads are fastened to the loom. A warp beam includes a plurality of retaining members that retain parallel strands of warp thread in a spaced relationship to one another. A length of warp thread is wound in consecutive parallel lines between two spaced apart warp beams. The combination of openable heddles and warp beams with warp thread retaining members allow a loom or knitting device to be rapidly set-up, allow for easy correction of mistakes, and for the removal and reloading of the heddles or a weaving project in mid-production.

Owner:HOLLY DAVID A

Device and method for controlling warp yarns of gauze cloth on loom

The invention discloses a device and a method for controlling warp yarns of gauze cloth on a loom, and belongs to the technical field of braiding equipments in the textile industry. The device comprises a plurality of heald frames, brackets, first healds, second healds, two-way brackets, linkages and multi-arm mechanisms, wherein the first healds and the second healds are mounted on the brackets front and back in pairs; the brackets are arranged in parallel side by side, and are connected with the heald frames; upper cross beams and lower cross beams of the brackets are respectively connected with a plurality of wooden frames; the heald frames are mounted in baffles on the two sides of the loom; the heald frames are connected with the linkages; the linkages are connected with the multi-arm mechanisms; the two-way brackets are arranged between the adjacent heald frames; the first healds and the second healds respectively pass through the two-way brackets; the two-way brackets are respectively connected with the upper cross beam and the lower cross beam of the loom through nylon pieces and springs. The invention further provides the method for controlling the warp yarns of the gauze cloth. The device and the method have the advantages that the device is suitable for the high-speed weaving of thick yarns, the opening is clear, the friction of yarns is avoided, and the structural design is simple and reasonable.

Owner:北京燕阳新材料技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com