Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

736results about "Jacquards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

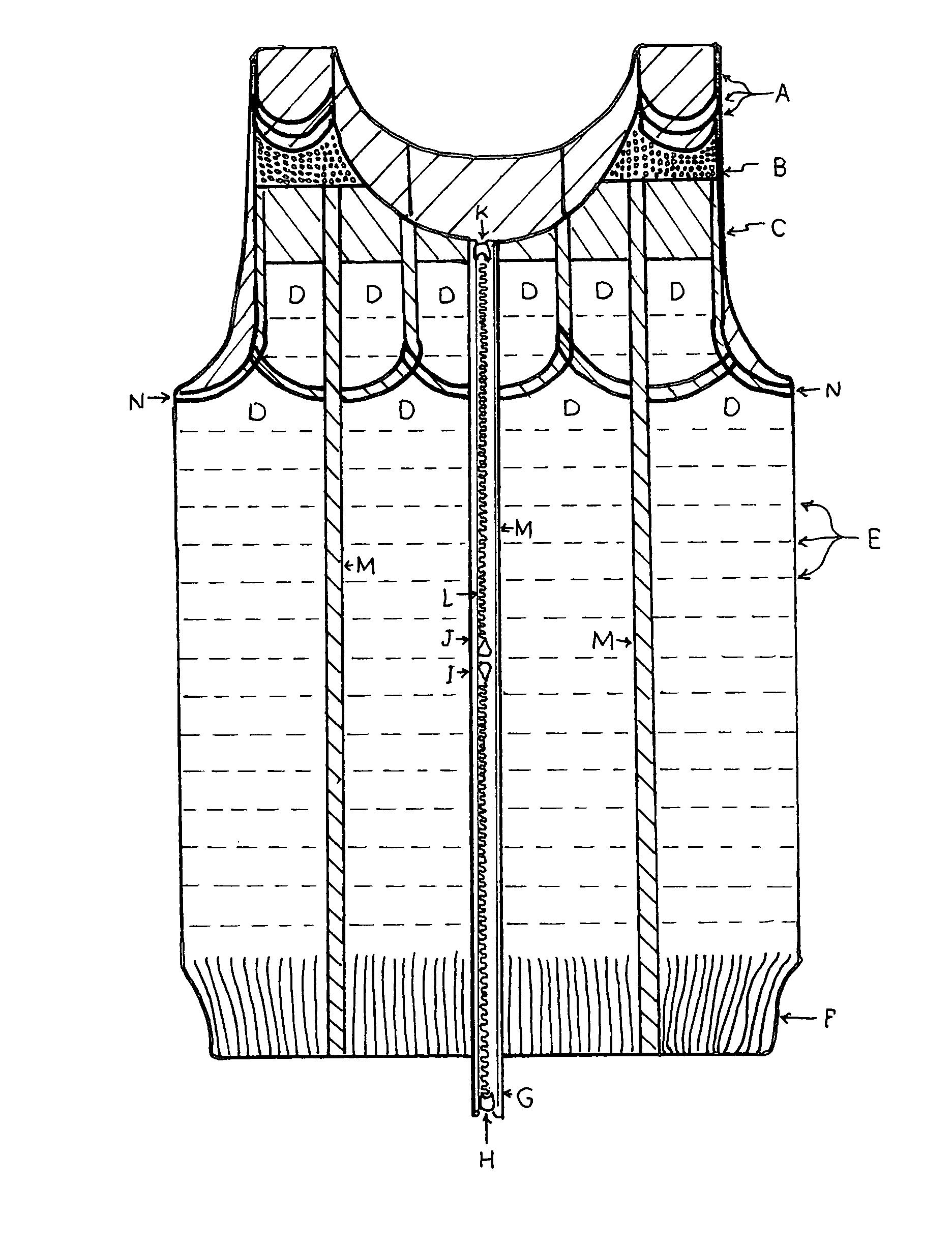

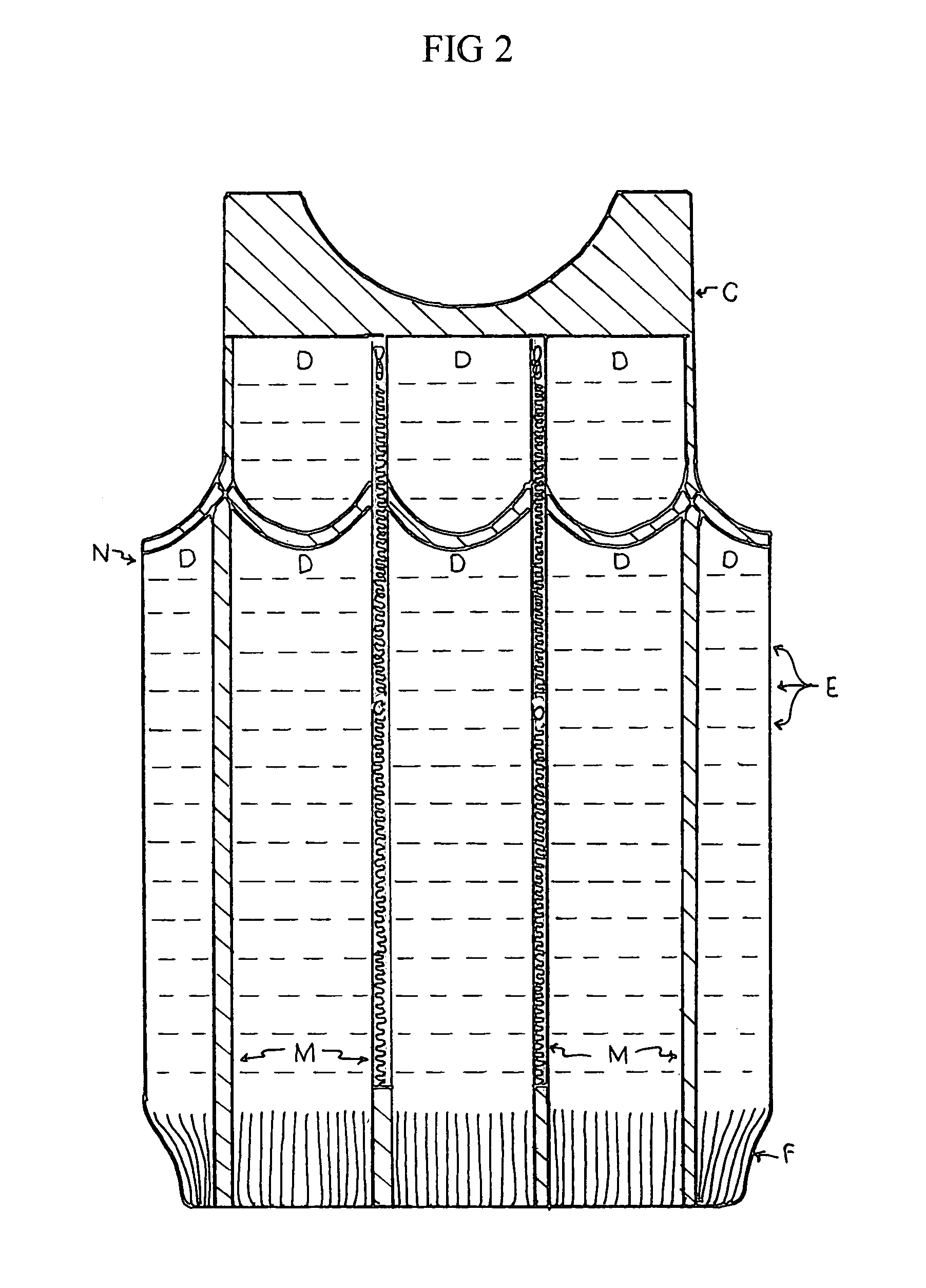

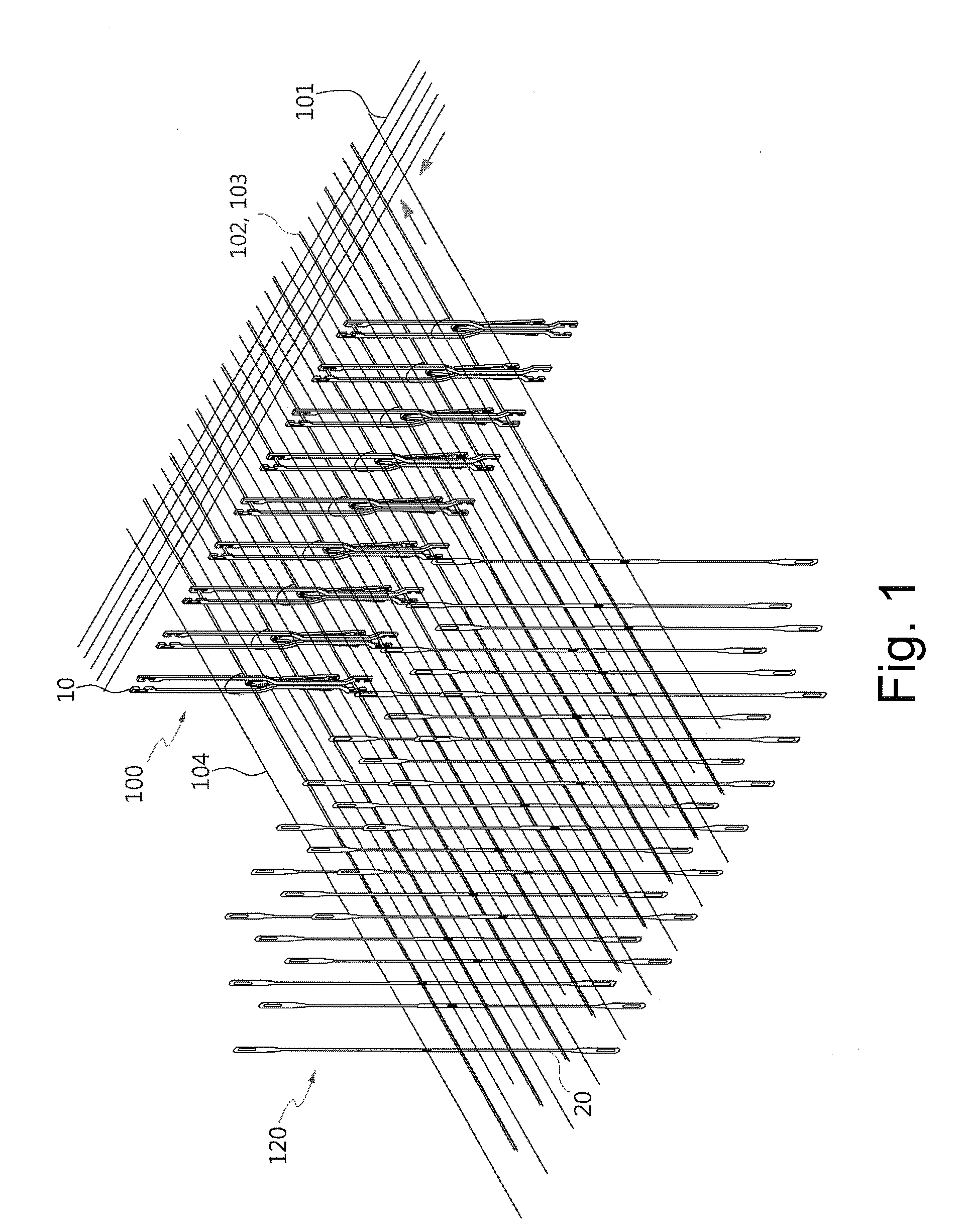

Weaving process for production of a full fashioned woven stretch garment with load carriage capability

InactiveUS7841369B1Easy to useHigher compressive forceJacquardsLoomsPulp and paper industryLoad carriage

A weaving process for constructing weft stretch full fashioned utility garments using a jacquard machine, an electronic loom and highly stretchable elastomeric fill yarns.

Owner:V PARADOX

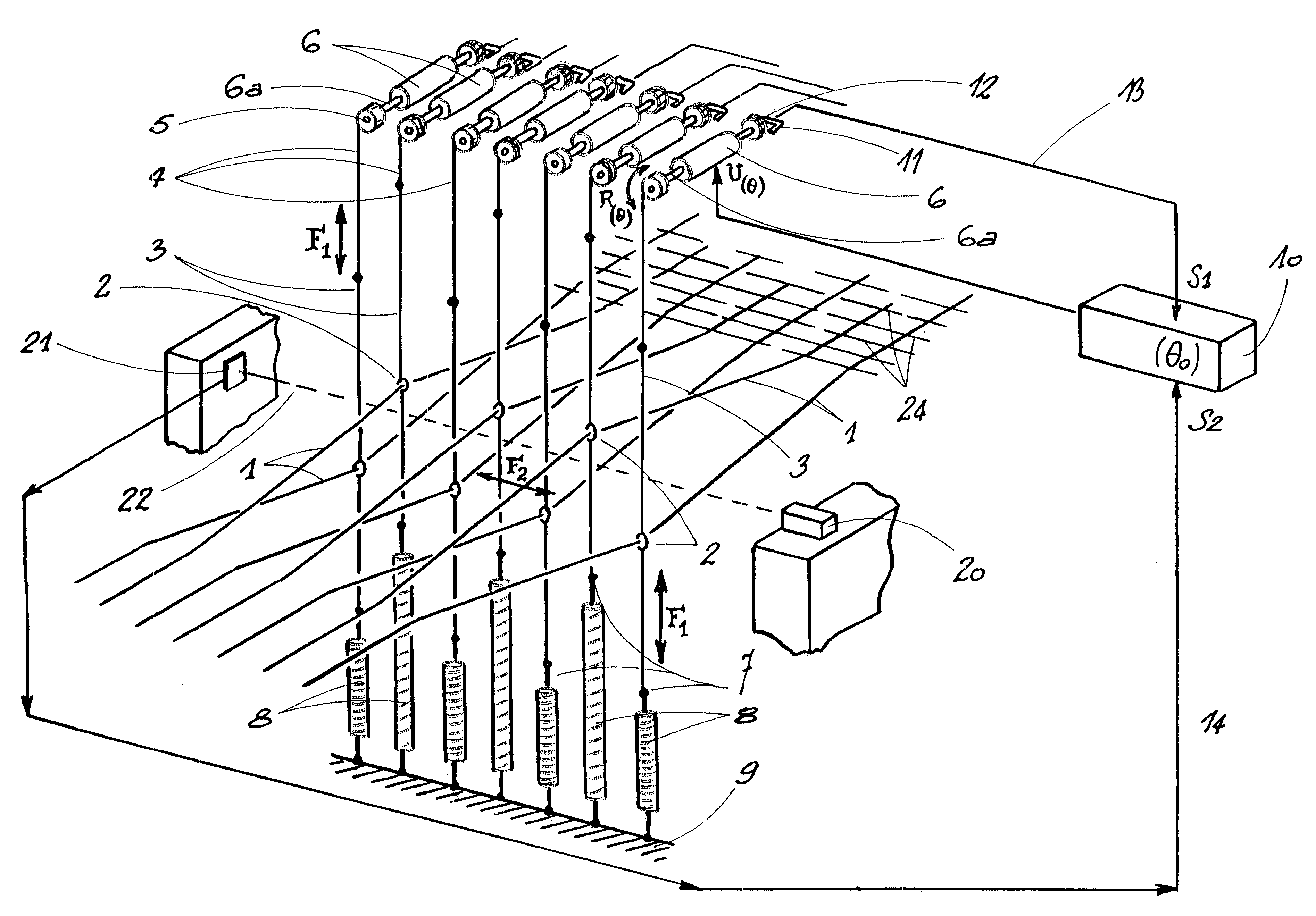

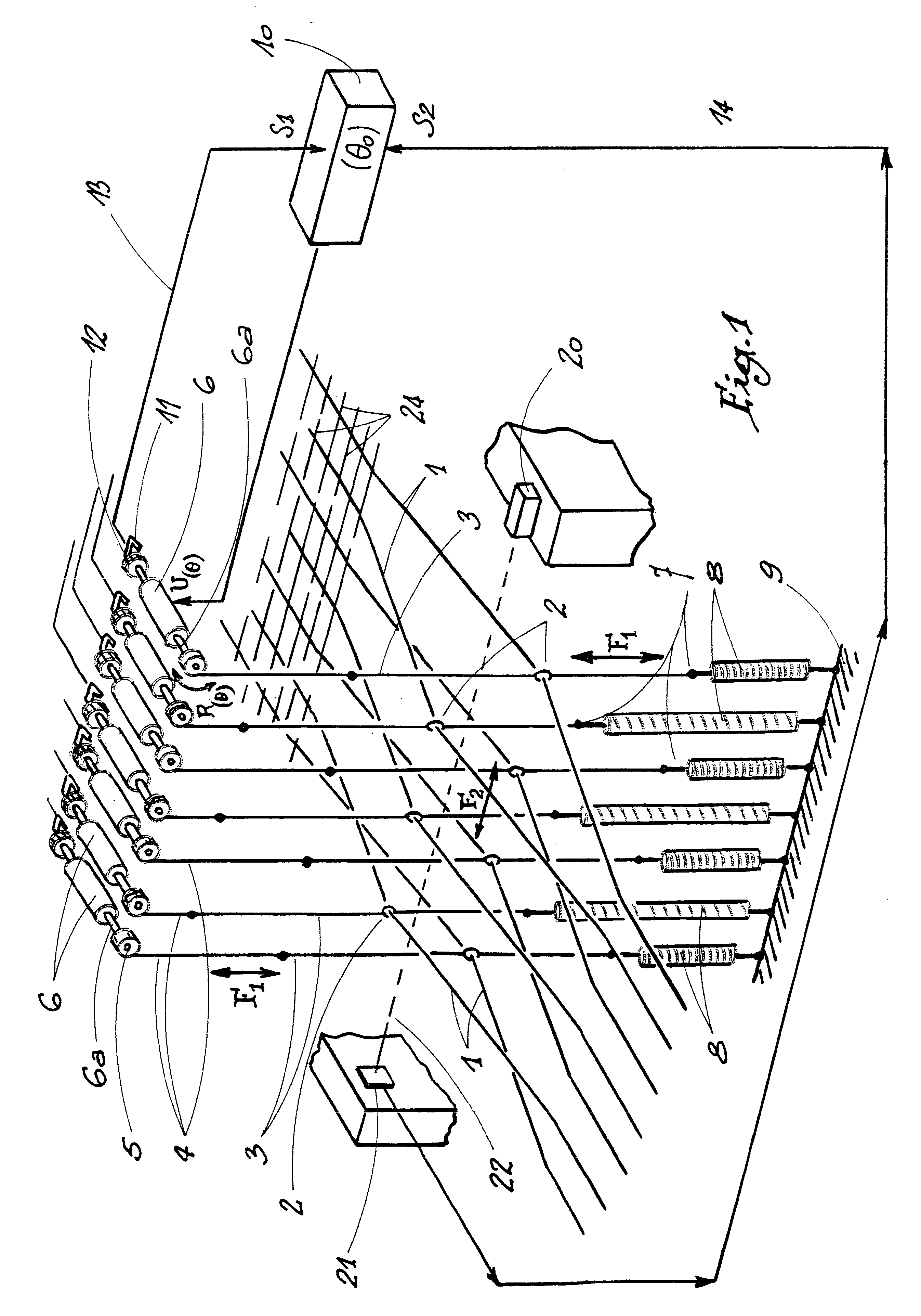

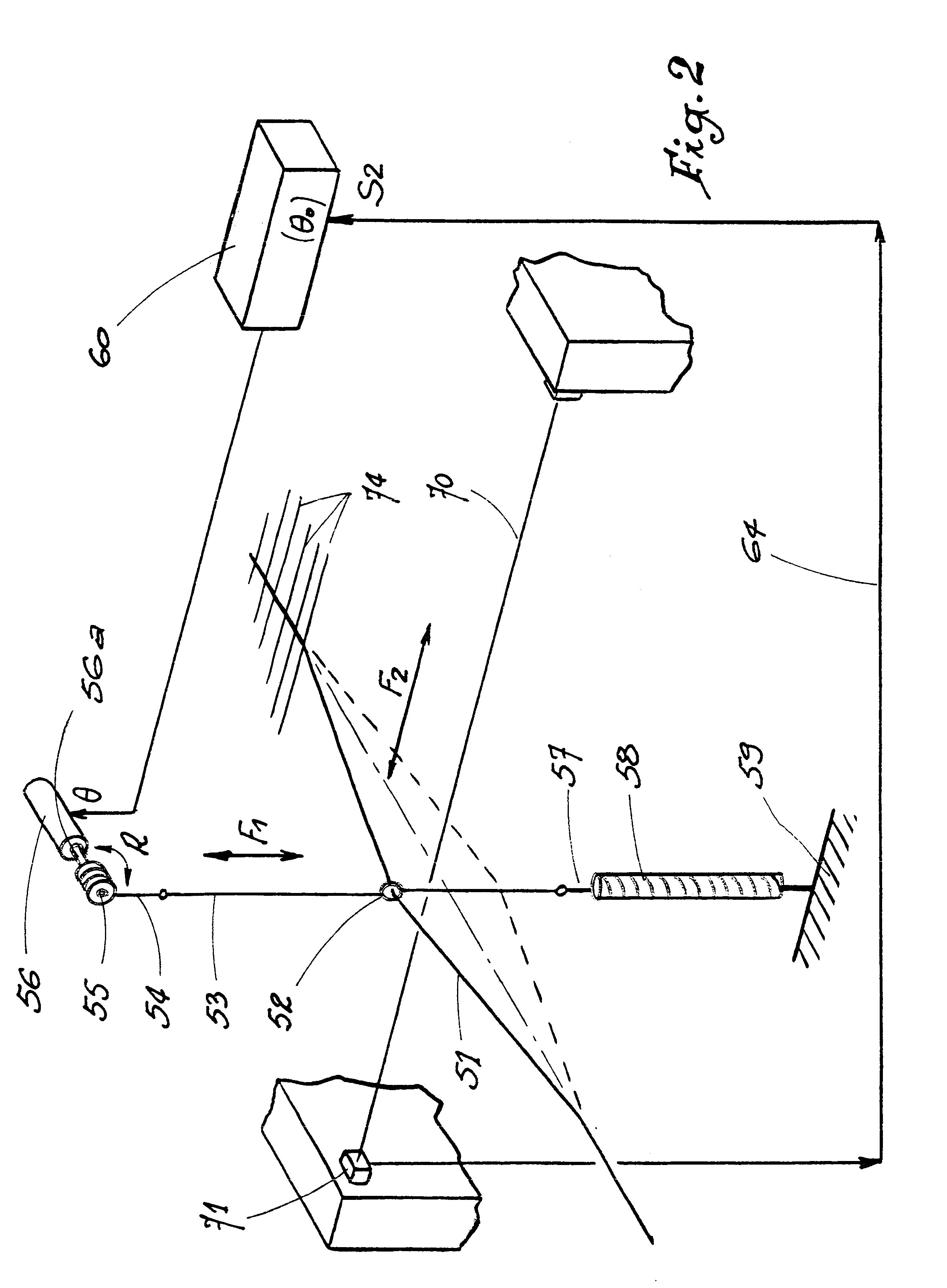

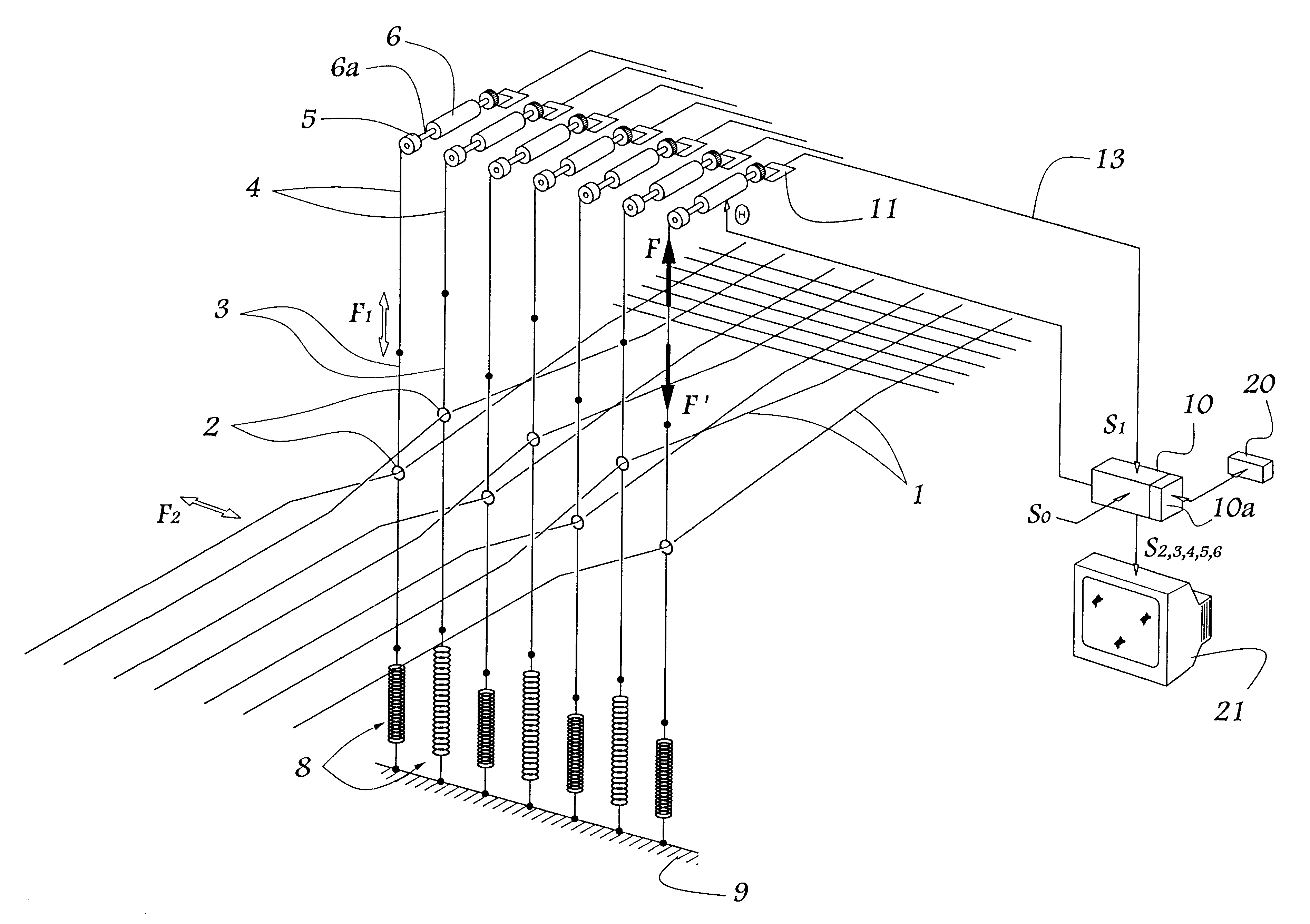

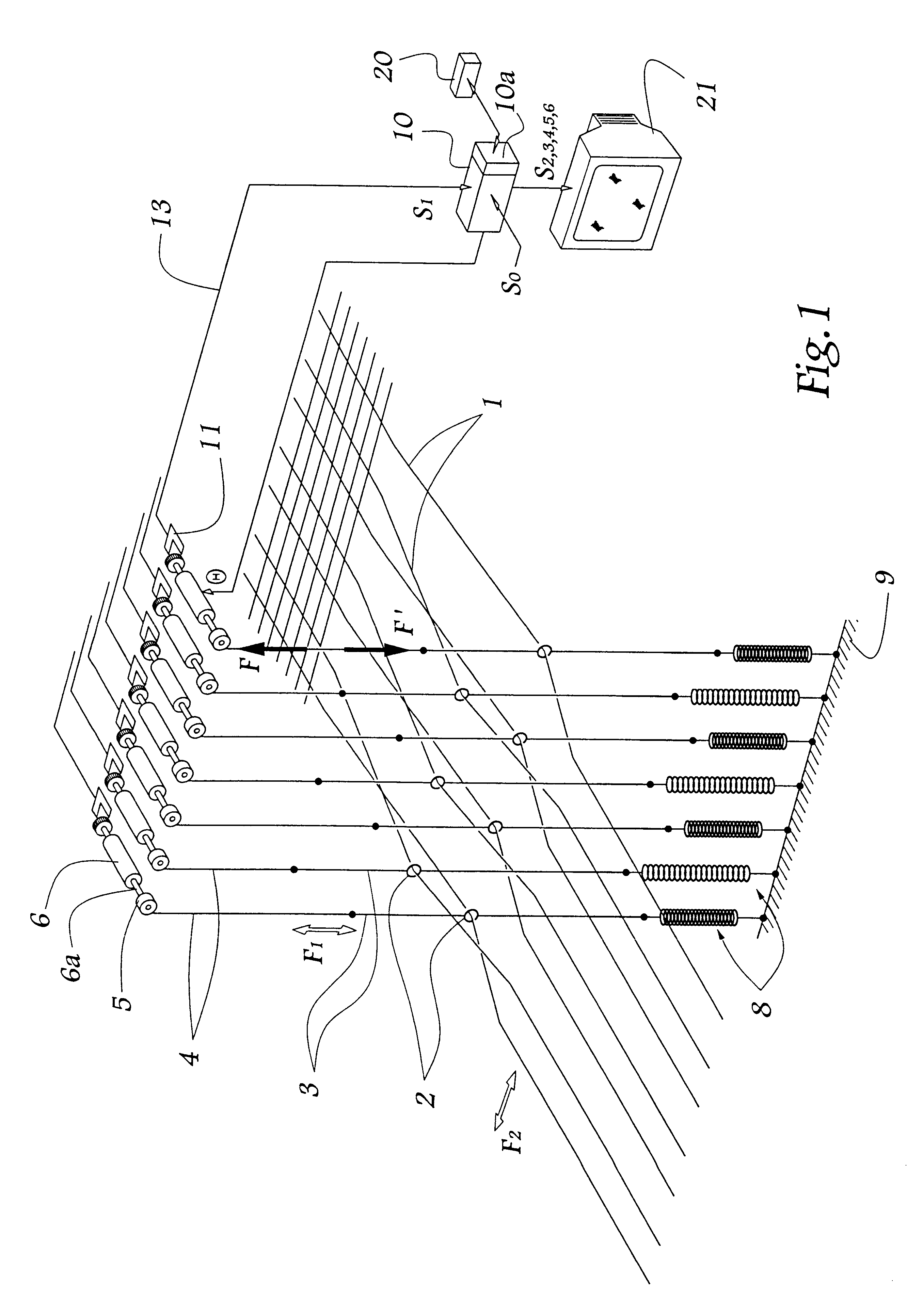

Process and device for positioning weaving loom warp yarns

InactiveUS6293315B1Adjustable strokePrecise positioningJacquardsOther shedding mechanismYarnEngineering

A device for positioning warp yarns of a weaving loom which are controlled by electrical actuators for forming a shed which includes a first detector common to the warp yarns driven by a plurality of different actuators for detecting the passage of at least one warp yarn into a predetermined position, and a second device for determining a value of a control parameter of an actuator for controlling movement of the at least one warp yarn upon passage into the predetermined position. The process consists in displacing a warp yarn and detecting its passage into a predetermined position and selecting a value of a control parameter of an actuator for the warp yarn upon passage of the warp yarn into the predetermined position and in using the selected value as a control point for controlling an actuator for the warp yarn.

Owner:STAUBLI FAVERGES SA

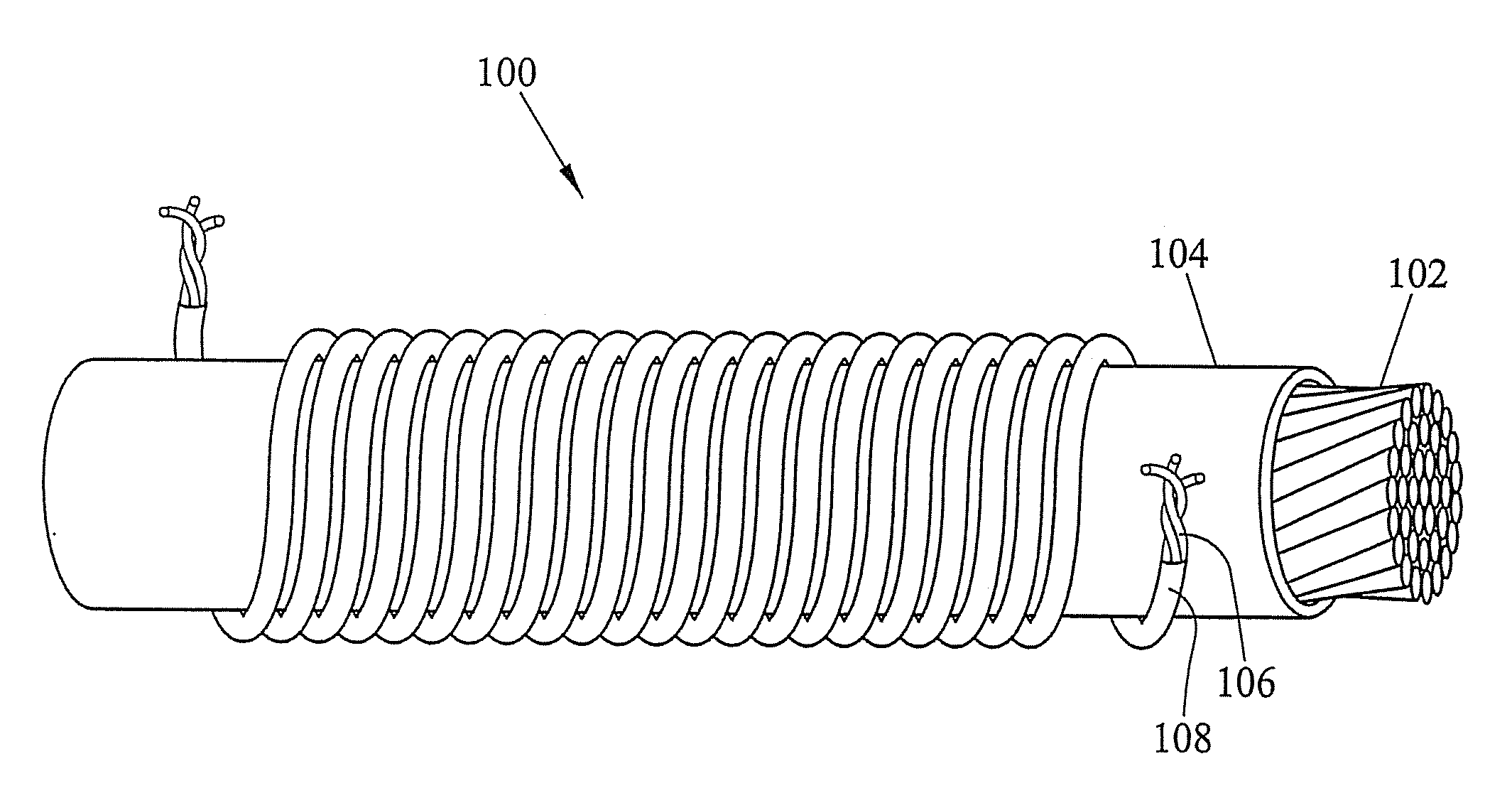

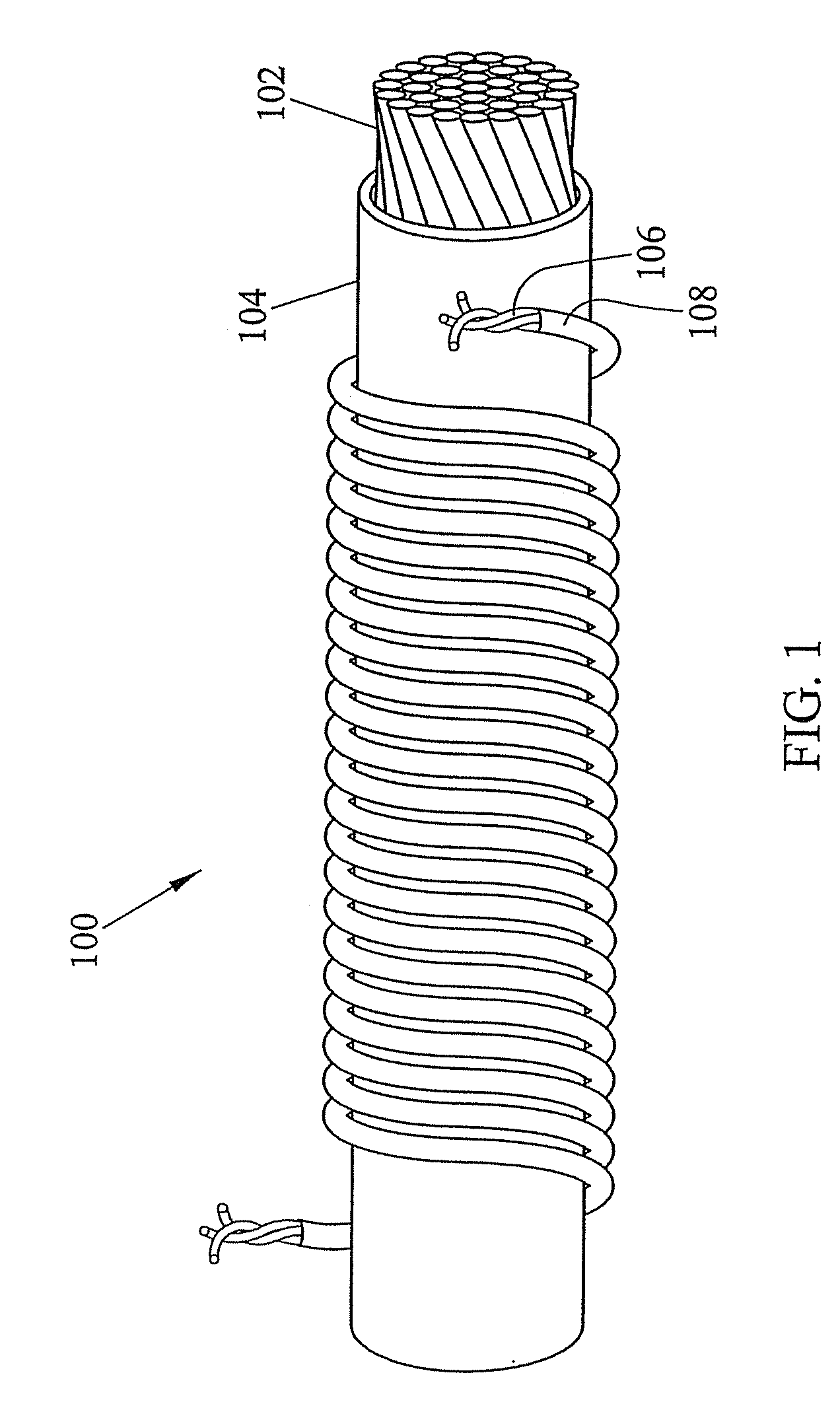

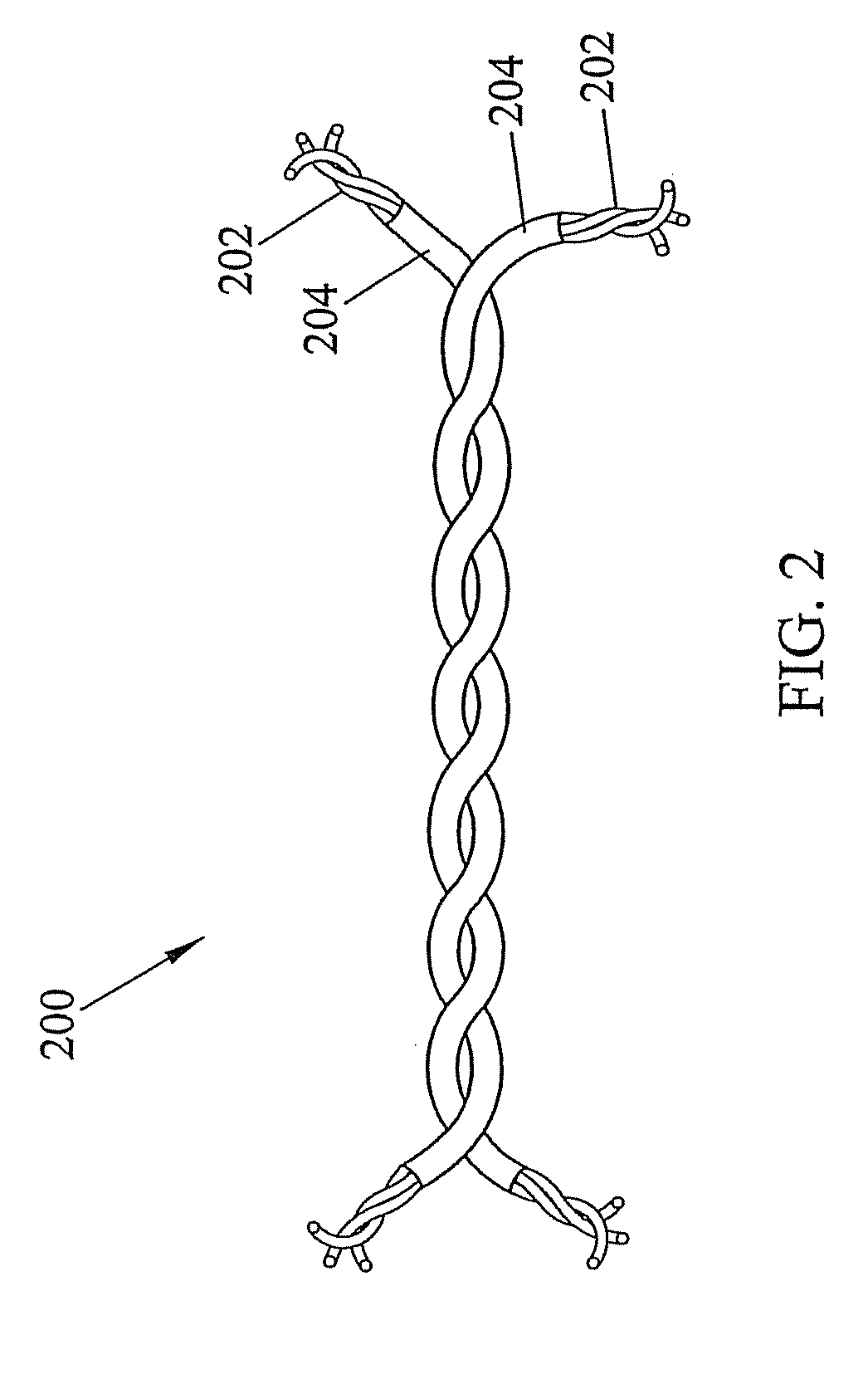

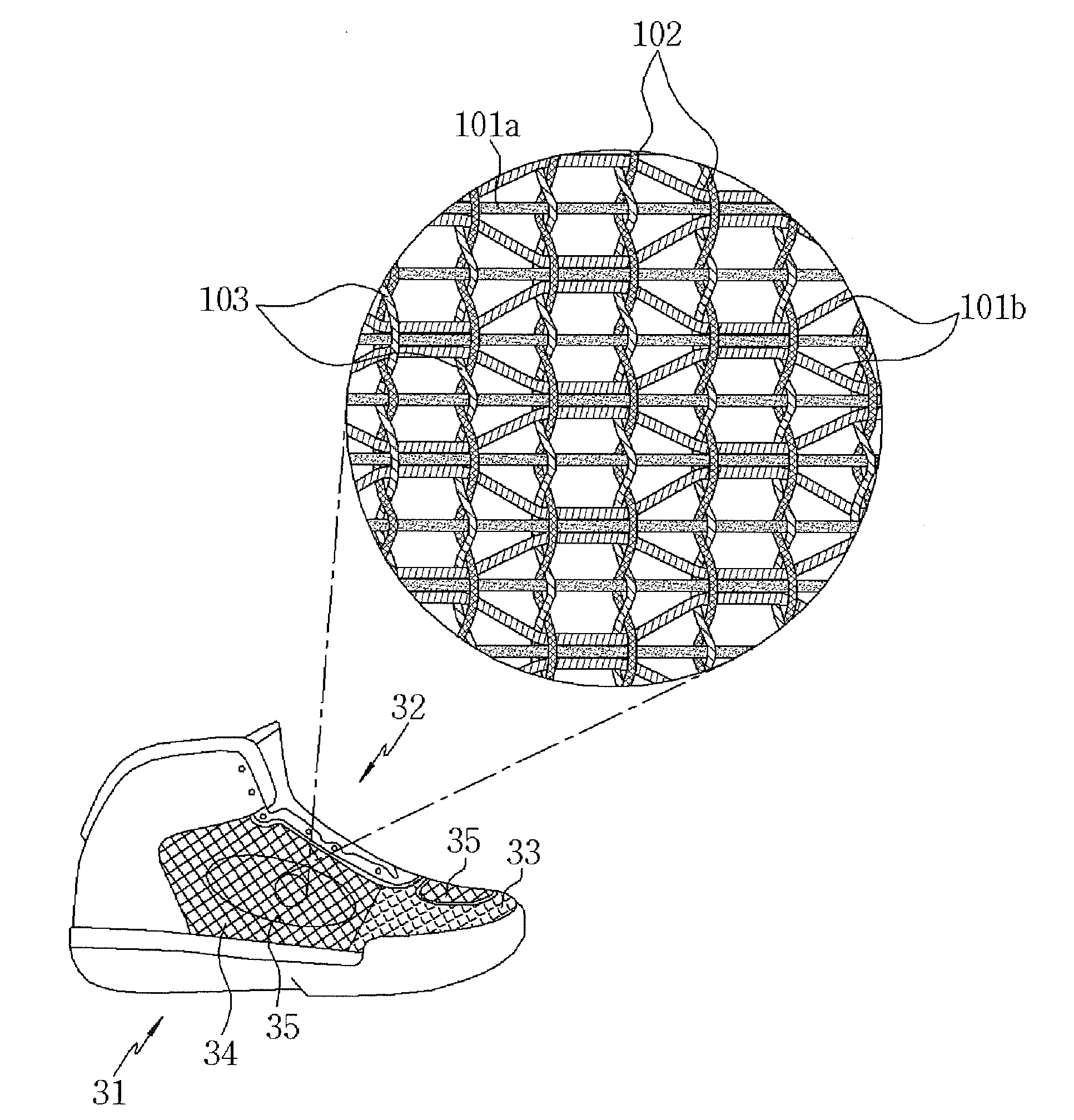

Fabric and yarn structures for improving signal integrity in fabric-based electrical circuits

InactiveUS20080287022A1Reduce crosstalkImprove the immunityJacquardsLeno shedding mechanismPower gridTwisted pair

Coaxial and twisted pair conductive yarn structures reduce signal crosstalk between adjacent lines in woven electrical networks. A coaxial conductive yarn structure includes an inner conductive yarn having a plurality of conductive strands twisted together. An outer conductive yarn is wrapped around the inner conductive yarn. An insulating layer separates the inner and outer yarns. A twisted pair conductive yarn structure includes first and second conductive yarns, each including a plurality of conductive strands being twisted together. The first and second conductive yarns are twisted together to form a helical structure. In a woven electrical network, at least one conductor of adjacent conductive yarn structures is connected to ground to reduce signal crosstalk. Coaxial and twisted pair yarn structures may also be formed simultaneously with weaving or knitting the threads that make up the structures into a fabric.

Owner:NORTH CAROLINA STATE UNIV

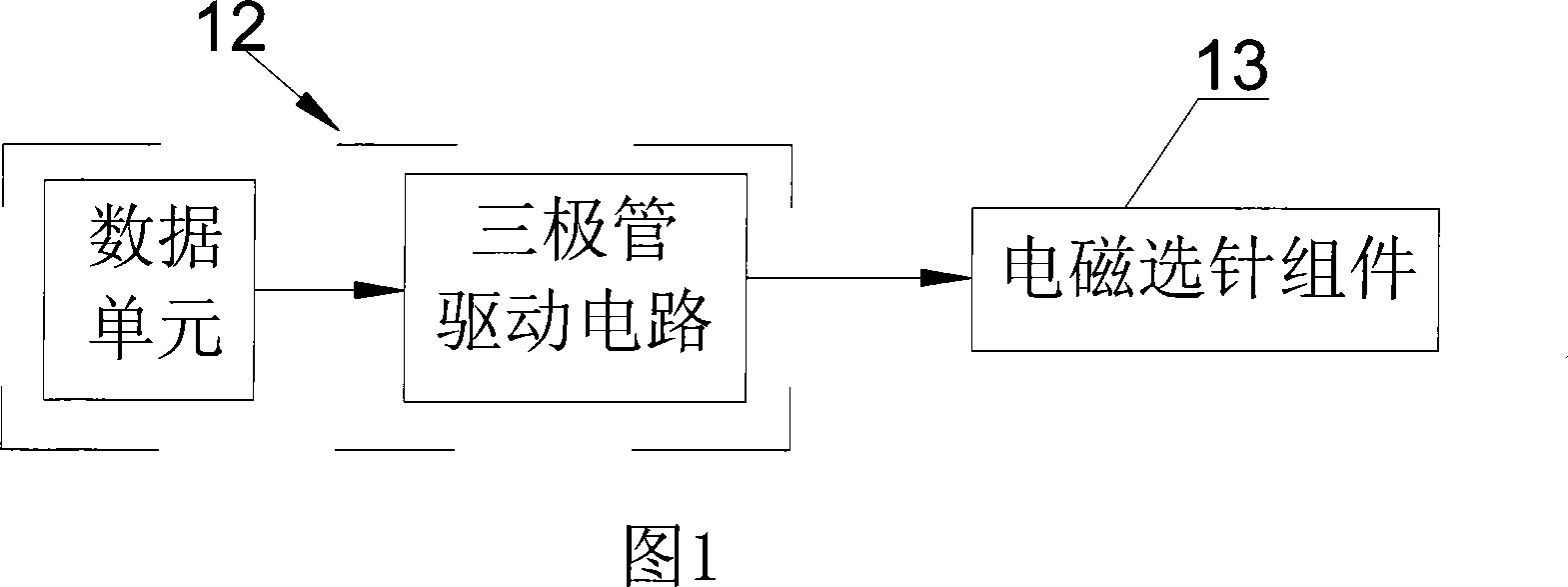

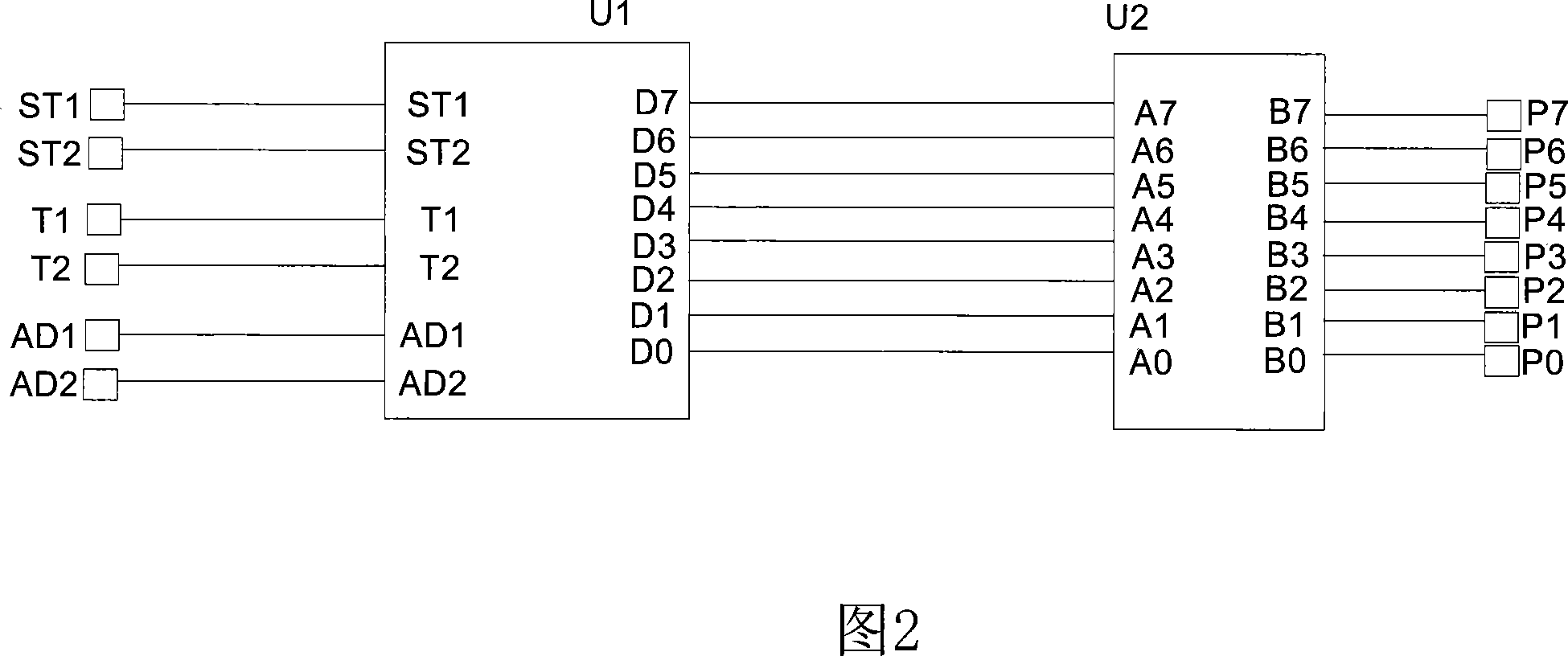

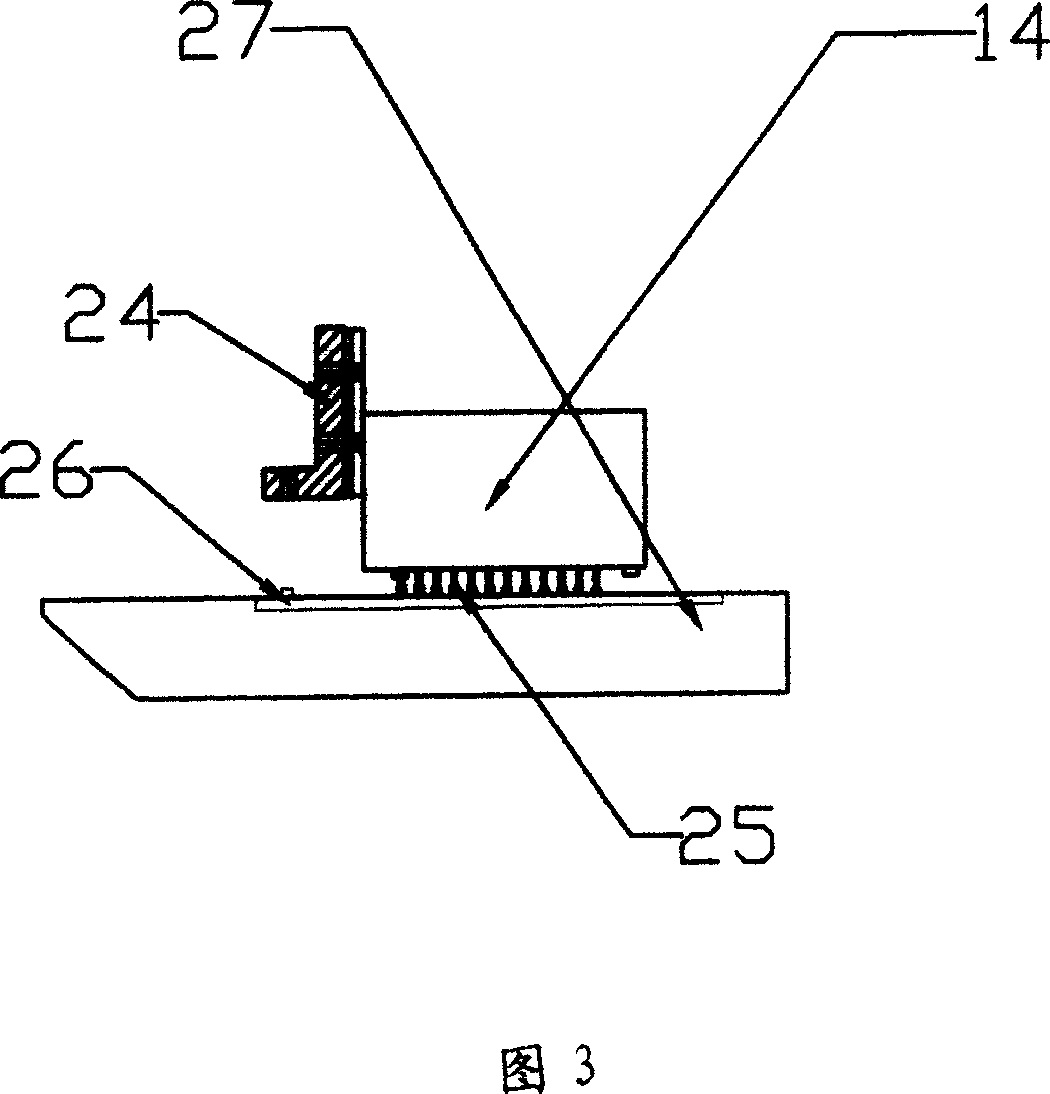

Electromagnetism needle selector drive plate and electronic jacquard machine control system using the same

ActiveCN101054749AImprove reliabilityShorten the data transfer pathJacquardsProgramme control in sequence/logic controllersMicrocontrollerMachine control

The invention relates to an electromagnetic needle selector drive plate and an electronic jacquard machine control system using the same. The drive plate includes a data unit, a base and a triode drive circuit connected with output end of the data unit, wherein the data unit is a singlechip, signal output port of the singlechip is electrically connected with the base of the triode drive circuit; the control system includes a plurality of electromagnetic needle selectors and controller for driving the electromagnetic needle selectors, wherein each electromagnetic needle selector includes a electromagnetic needle selecting component and a electromagnetic needle selector drive plate. Because the data unit of the electromagnetic needle selector drive plate employs singlechip, pattern data is stored in the singlechip before spinning, when spinning, the singlechip can drives the electromagnetic needle selector component directly by the triode drive circuit, thereby, the electromagnetic needle selector drive plate and the electronic jacquard machine control system using the same has no path problem of data transmission, and reliability and immunity of the control system is increased.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

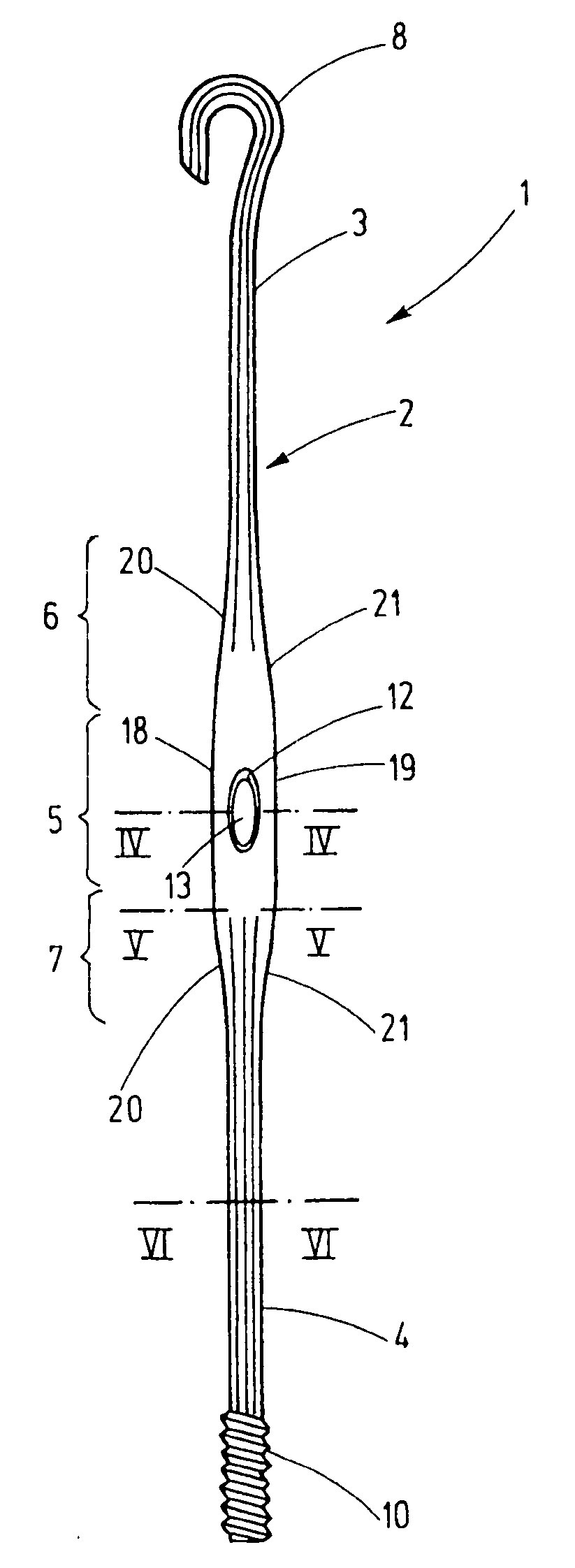

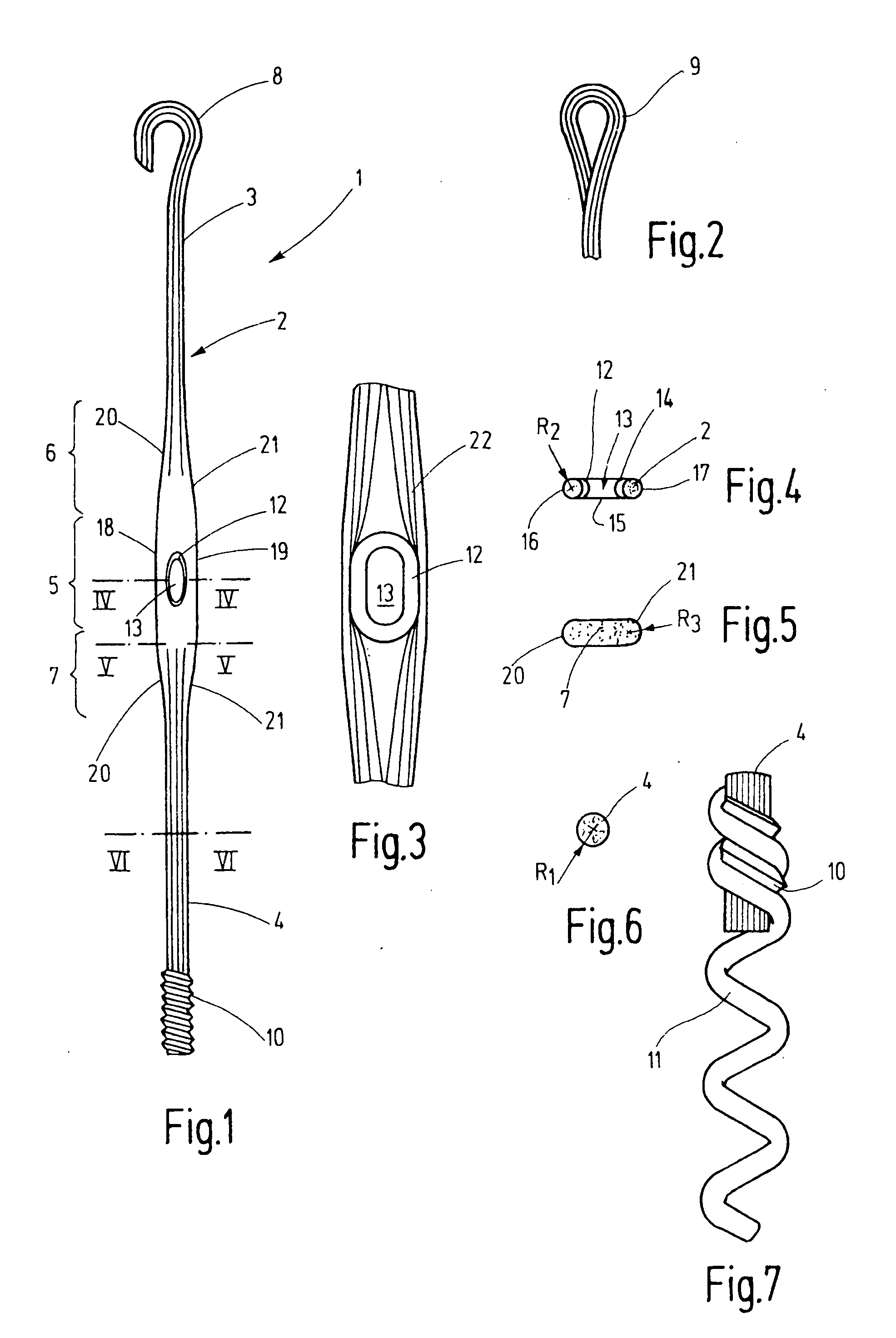

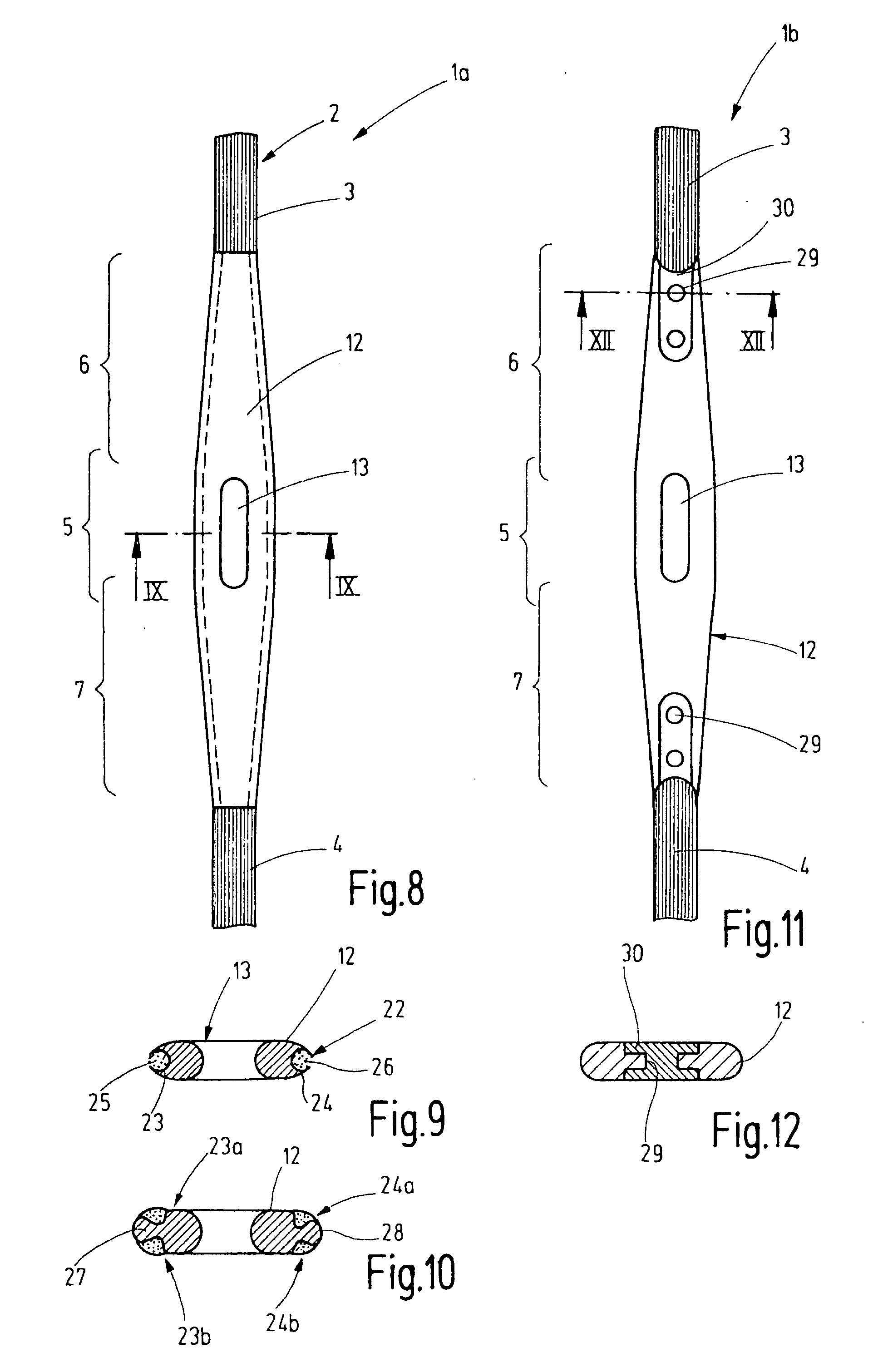

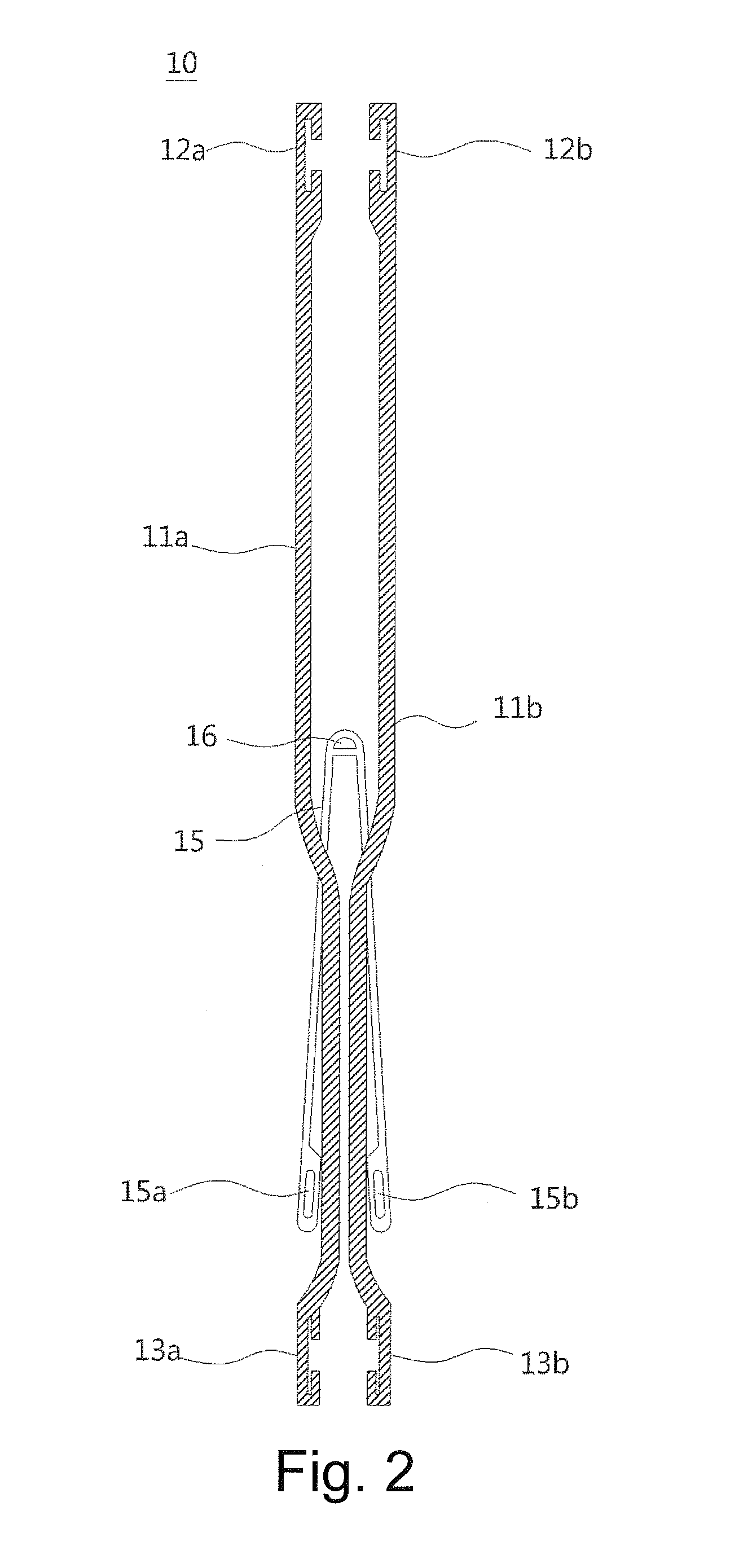

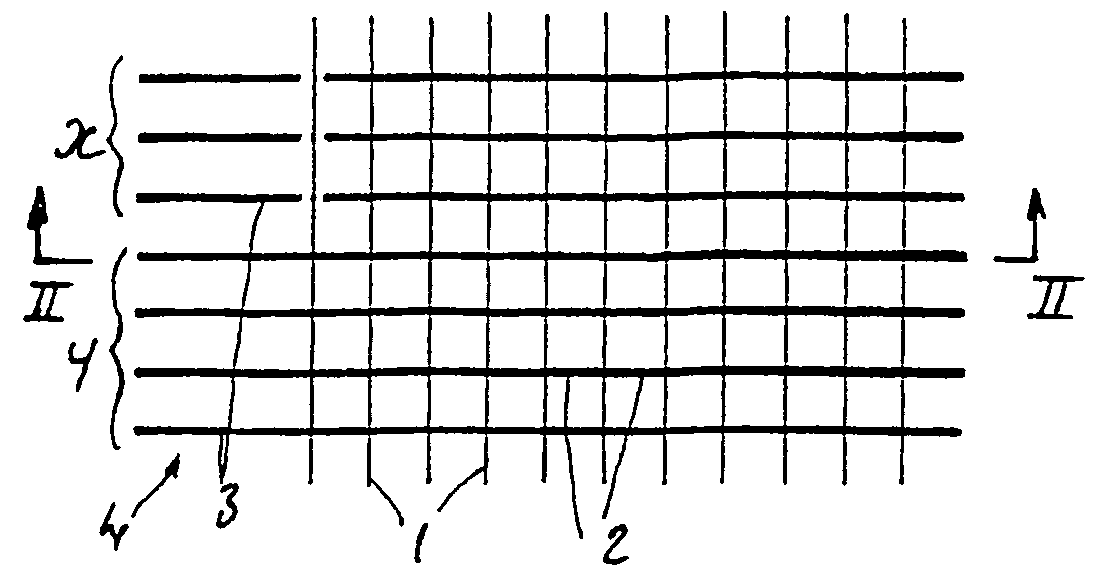

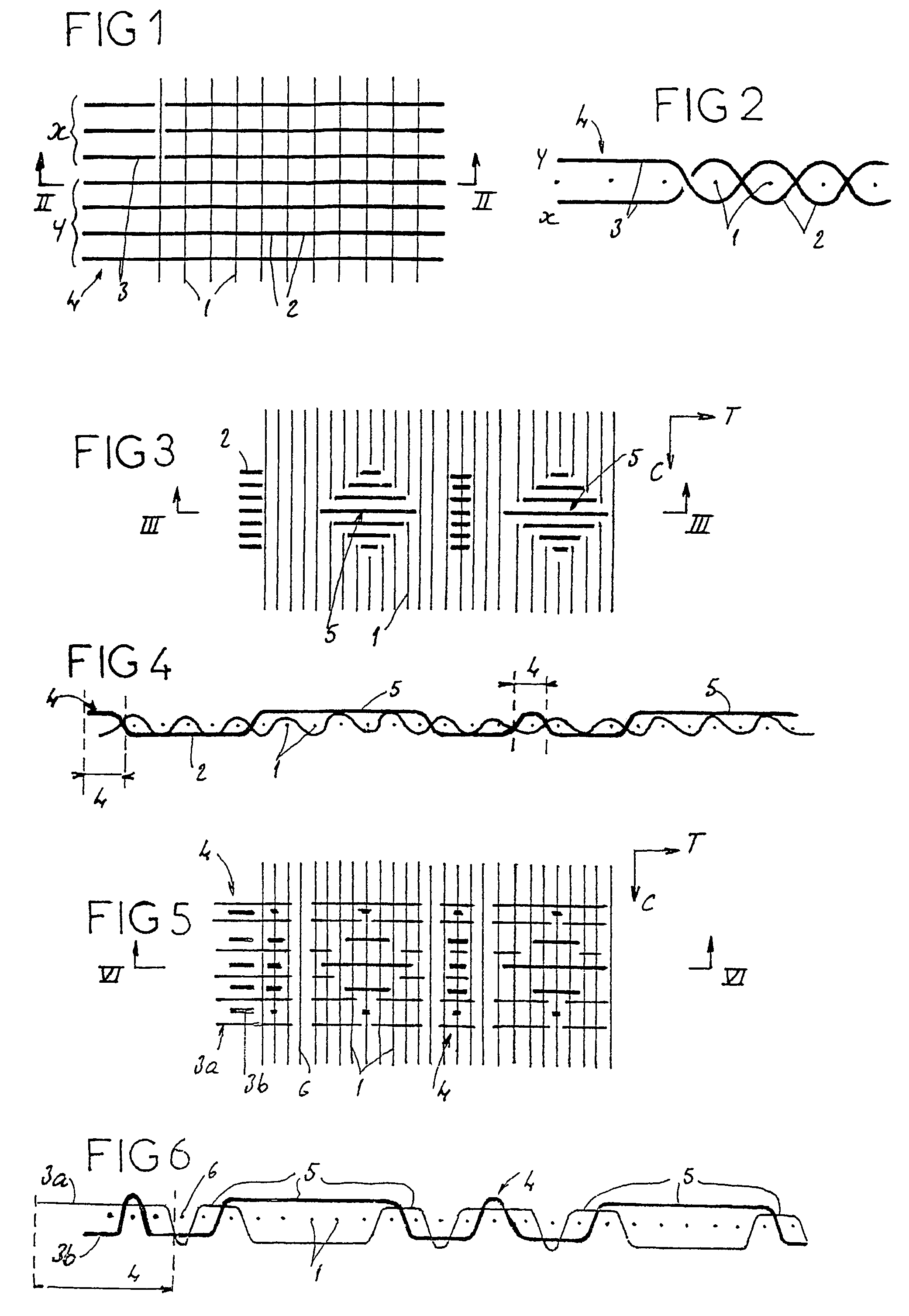

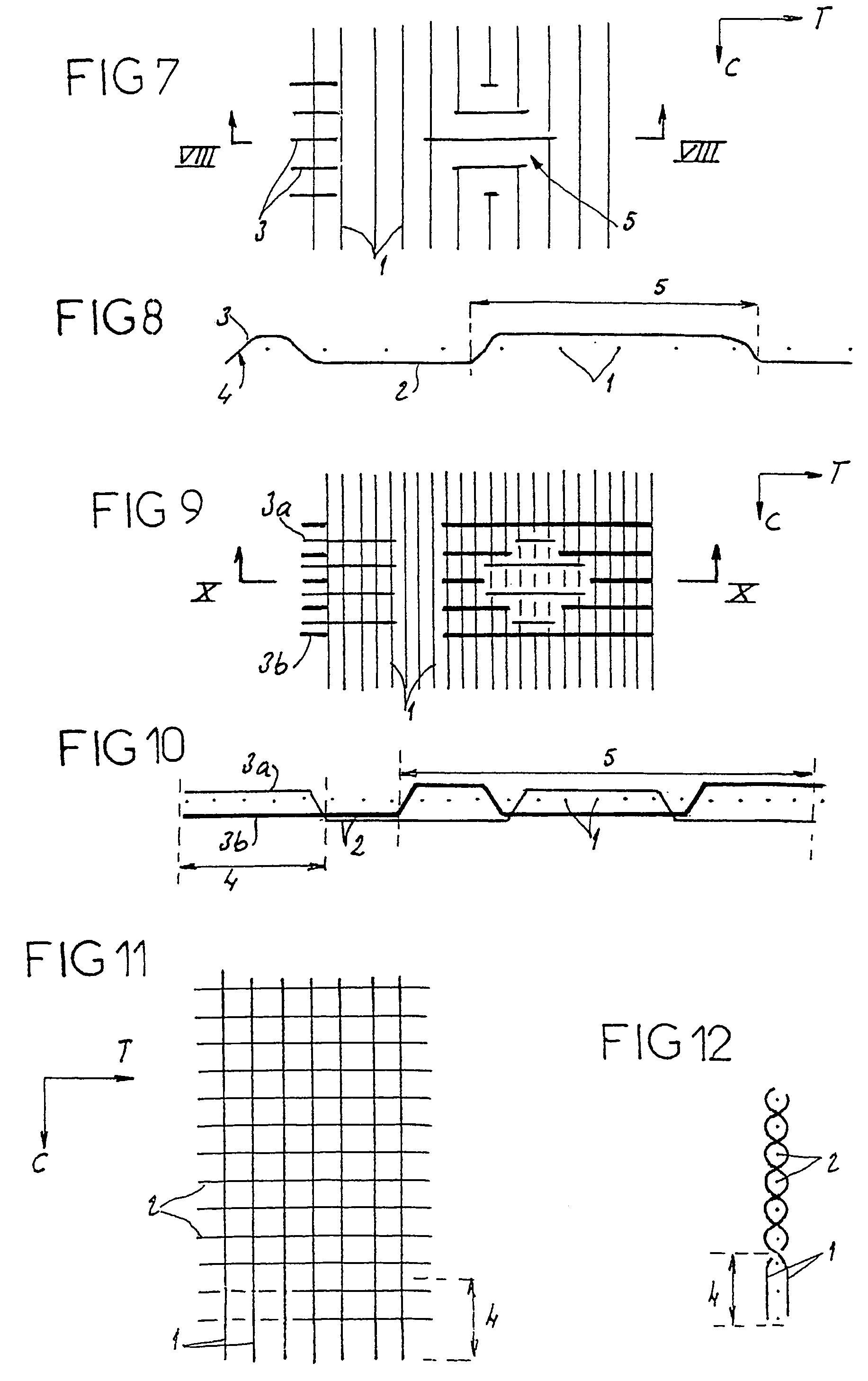

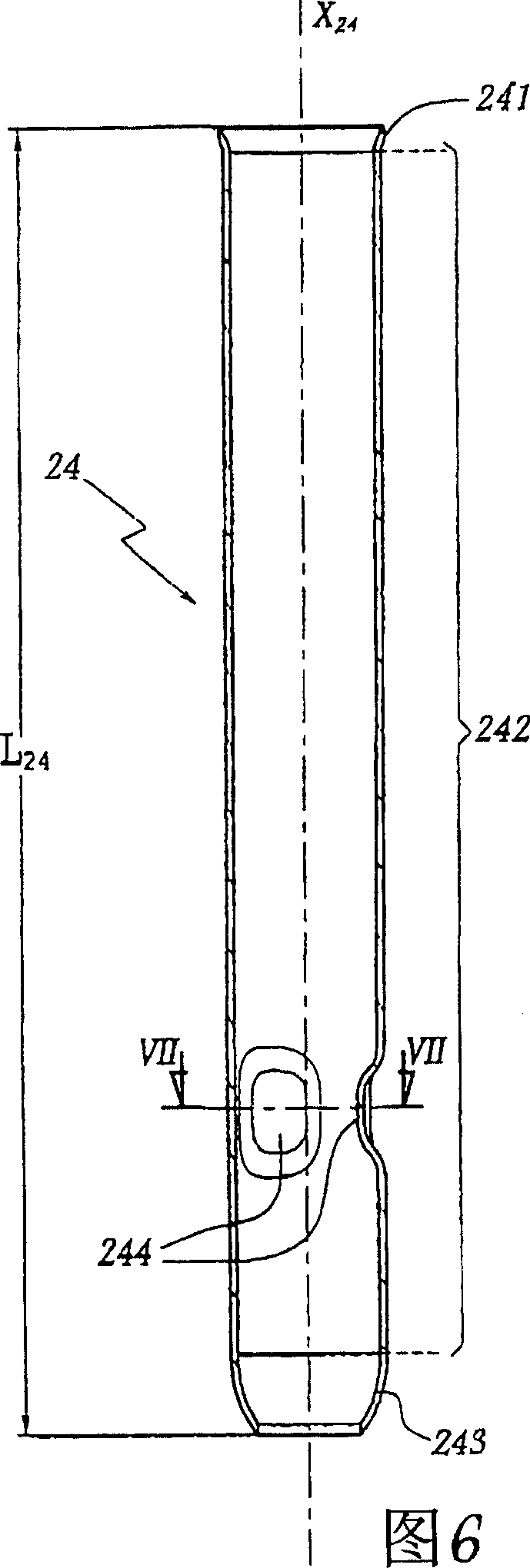

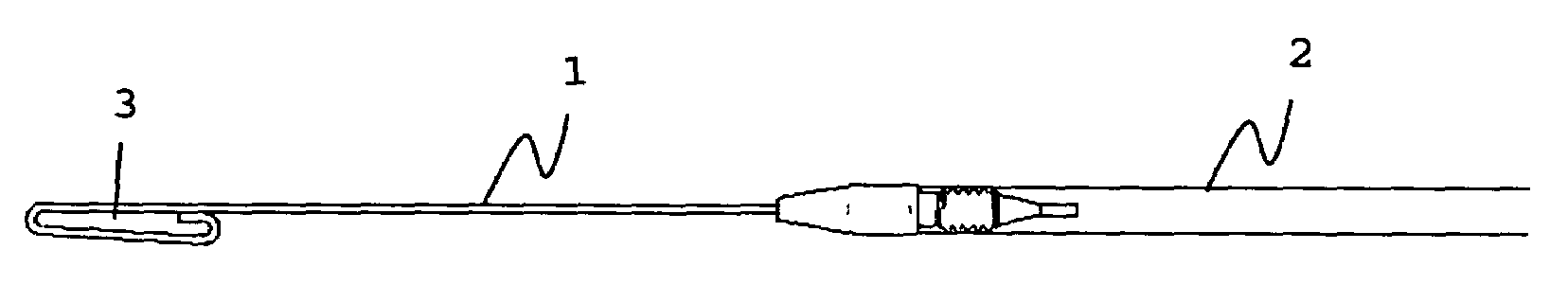

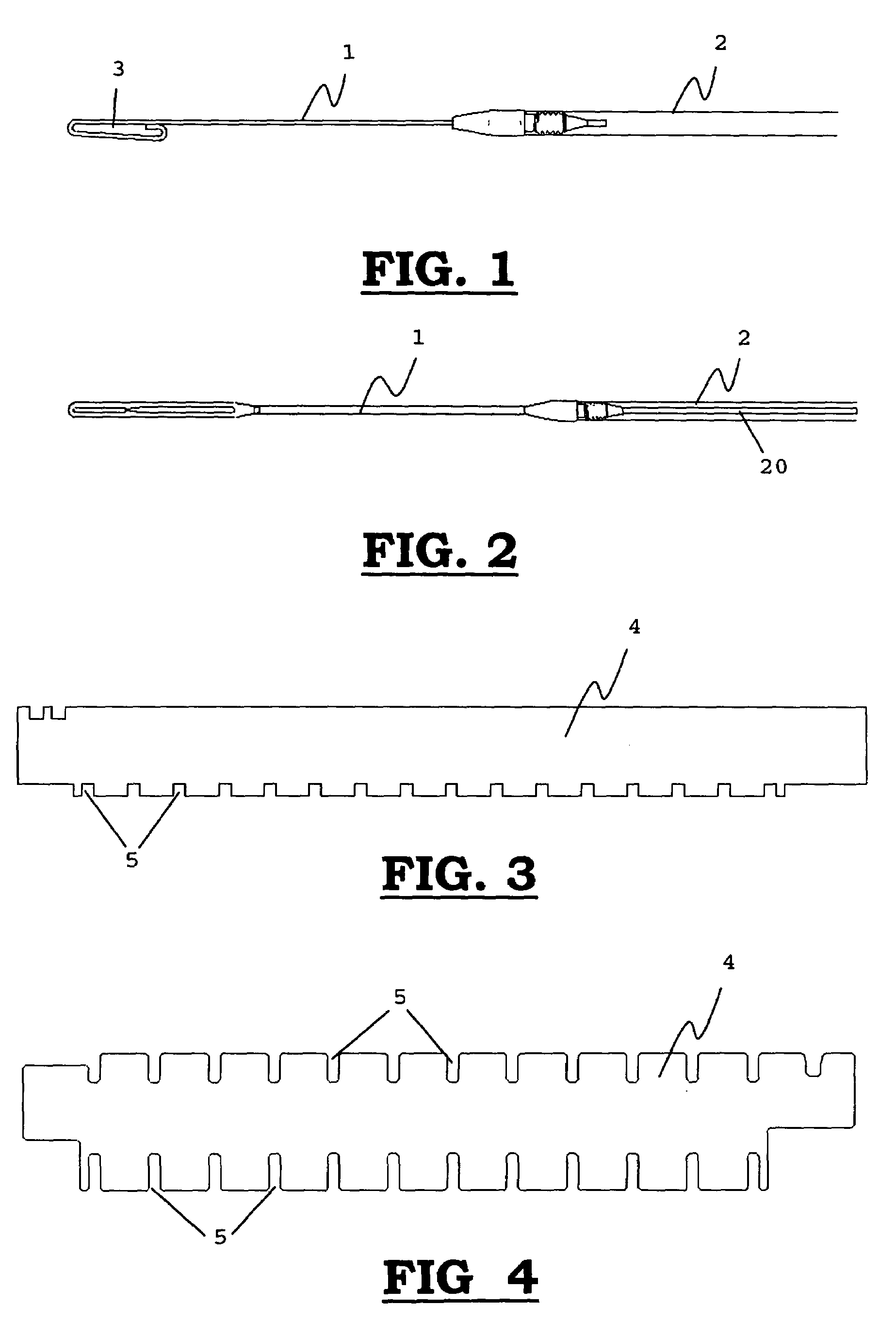

Weaving heddle for jacquard weaving machine

An inventive heddle for jacquard machines essentially consists of fiber-reinforced plastic material, whereby the thread eye is formed by a mail (12). The heddle body comprises two legs (3, 4). Between the relatively wide thread eye region (5) and the legs (3, 4), ramp sections (6, ) are provided, which sections have a length that is greater than the length of the thread eye (1). Preferably, the length is greater than twice the longitudinal extension of the thread eye. In most cases, said length is between 10 and 30 mm. As a result of this measure, the wear of the plastic material in the vicinity of the thread eye (13) is kept minimal enough that neither any damage to the stiffening fibers (22) in the body of plastic material nor any damage to the warp threads needs to be feared.

Owner:GROZ BECKERT KG

Method for manufacturing jacquard fabric with different material quality and style

InactiveCN101109121AExpress the verve of pen and inkImprove weaving methodJacquardsCard-punching apparatusGraphicsJacquard loom

The invention relates to a preparing way for a jacquard fabric, in particular to a preparing way for a jacquard fabric of different materials and styles, which comprises the treating of several graphic images of different styles, designing texture boards for fabrics, combining the texture boards, creating a complete texture-board document, sending the texture boards for an electronic jacquard loom to weave; also placing a warp of one or more materials and a weft of at least 2 materials on the loom; and turning on the loom to make the fabric. The invention uses different materials to express the artistic effect of color jacquard fabric of different styles of the same picture. The textures in the fabric run smoothly, the joining sites are smooth and natural; the color and brightness of the whole fabric are harmonic, and the topic is clear, which expresses better the romantic charm in original artistic works.

Owner:韩容

Loom for weaving fabric with two types of tissue, shoe upper woven using the same, and shoe

ActiveUS20160309843A1Improve productivityReduce processJacquardsLeno shedding mechanismEngineeringWoven fabric

Owner:SONG SOO BOK

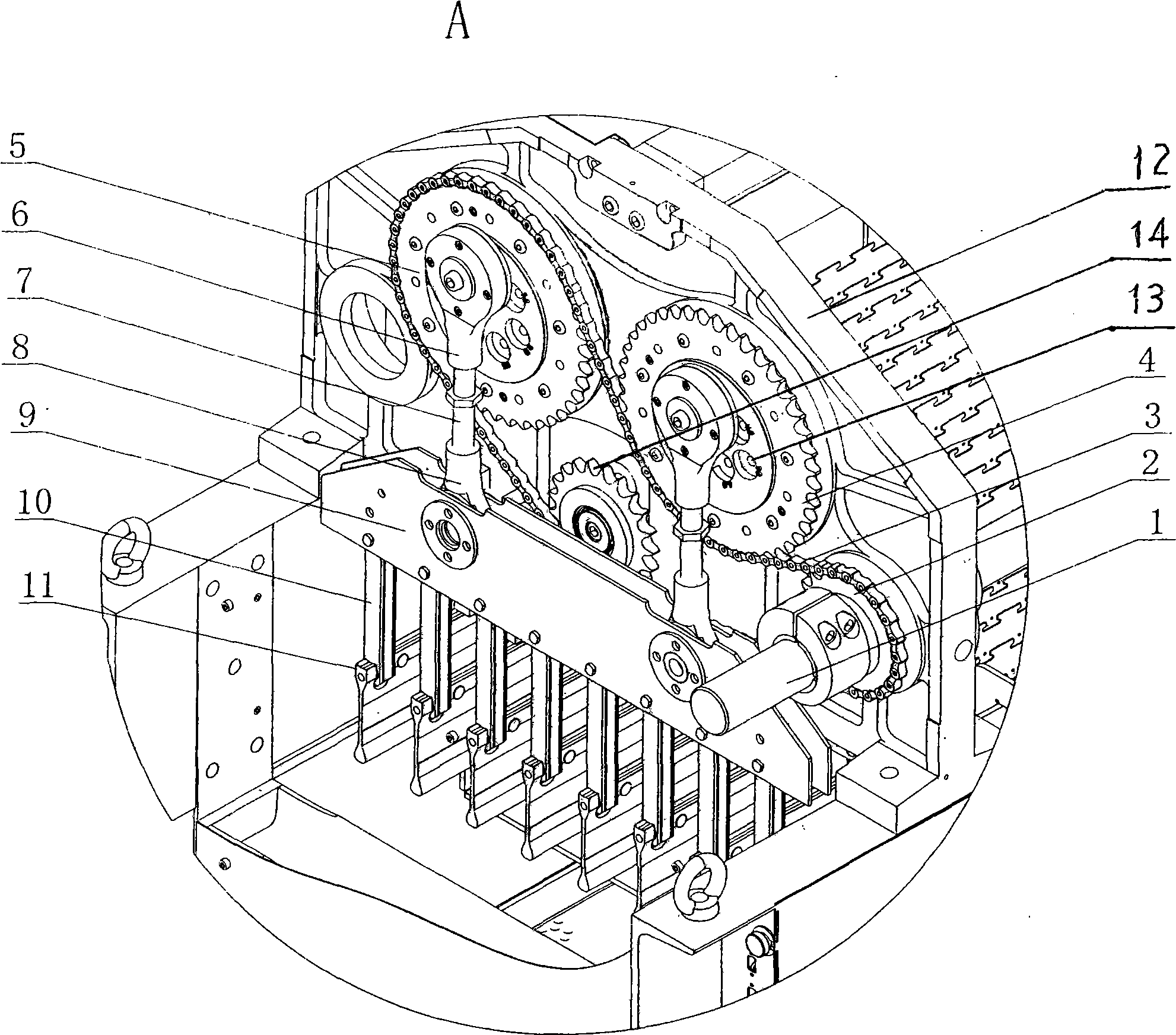

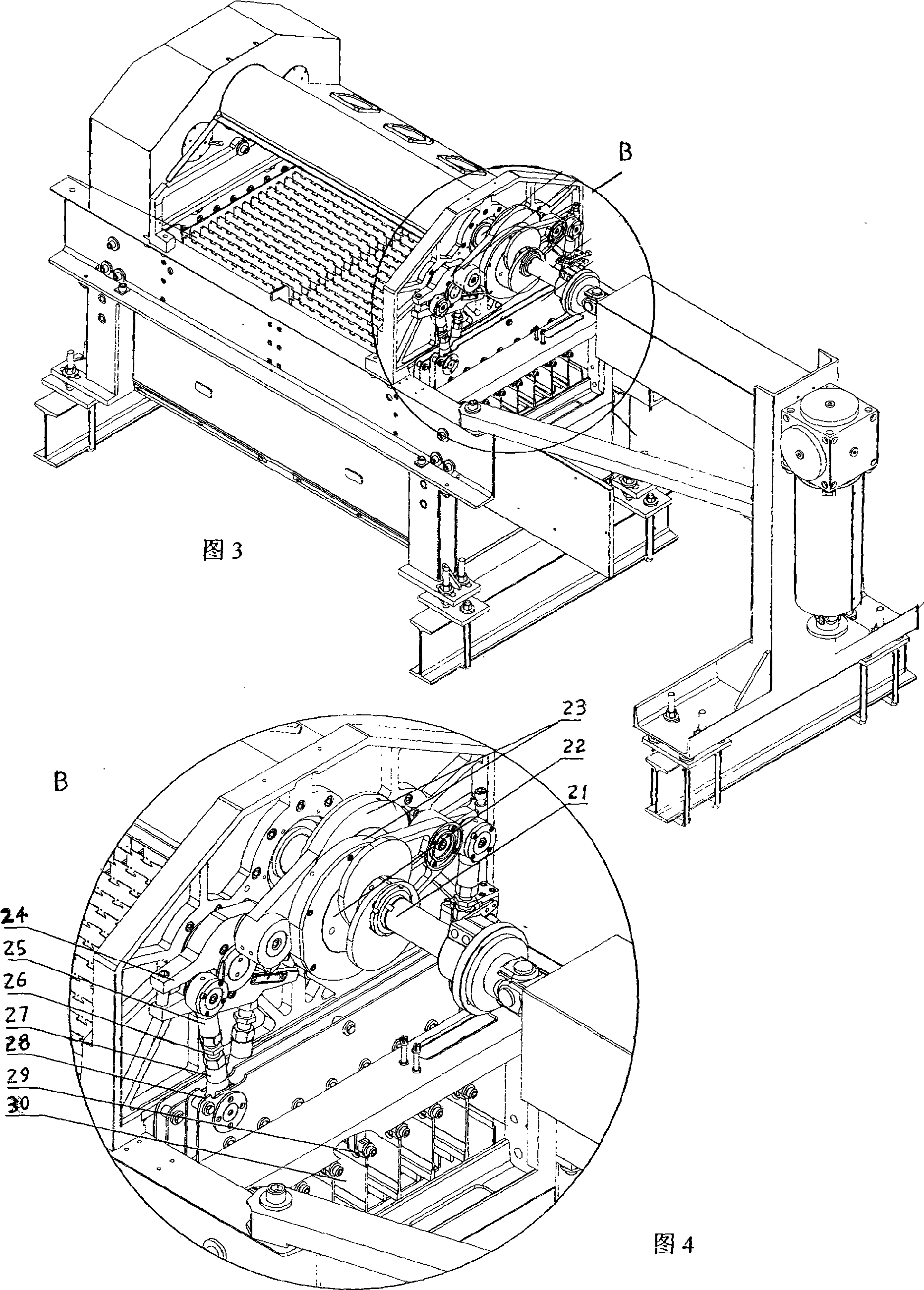

Chain jacquard

The invention provides a chain jacquard machine which includes a frame, a wallboard, a scraping out cutter mechanism and a transmission mechanism. The scraping out cutter mechanism includes an adjusting screw rod, a down base, a scraping out cutter frame plate, a small pull rod and a scraping out cutter, the transmission mechanism includes a drive sprocket, a first adjusting sprocket with two sheds, a tension sprocket and a closed chain, the closed chain external connects with sprocket of the first shed adjusting sprocket, and inner connects with sprockets of the second shed adjusting sprocket, the tension sprocket and the drive sprocket, some eccentric locating holes are distributed on the first and second shed adjusting sprocket, upper end of the adjusting screw rod hinge joints with an eccentric locating hole. The chain jacquard machine provided by the invention has advantages that running of the machine is stability with little impact and lower noise, speed of mainshaft is increased, torquemoment is reduced for applicable to over loading woof and high speed loom, structure of the machine is simple by reducing some components, trouble point and trouble rate are reduced greatly, maintainability of the machine is simple, so the machine is low in price and has lower maintain cost, producting efficiency is increased.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

Method for producing an optical-fibre based fabric

The invention relates to a method for weaving a fabric containing, at least partly, glass-fibres as warp threads and / or weft threads, which are treated in such a way that they enable light to be diffused in a substantially perpendicular direction with respect to the longitudinal axis of the threads. The method includes a weaving of a Jacquard pattern forming a matrix for separating and identifying the feeding ends of a predetermined number of glass fibres, which are to be rearranged in bundles and connected to the same light source. The fabric produced according said method is also disclosed.

Owner:BROCHIER TECH

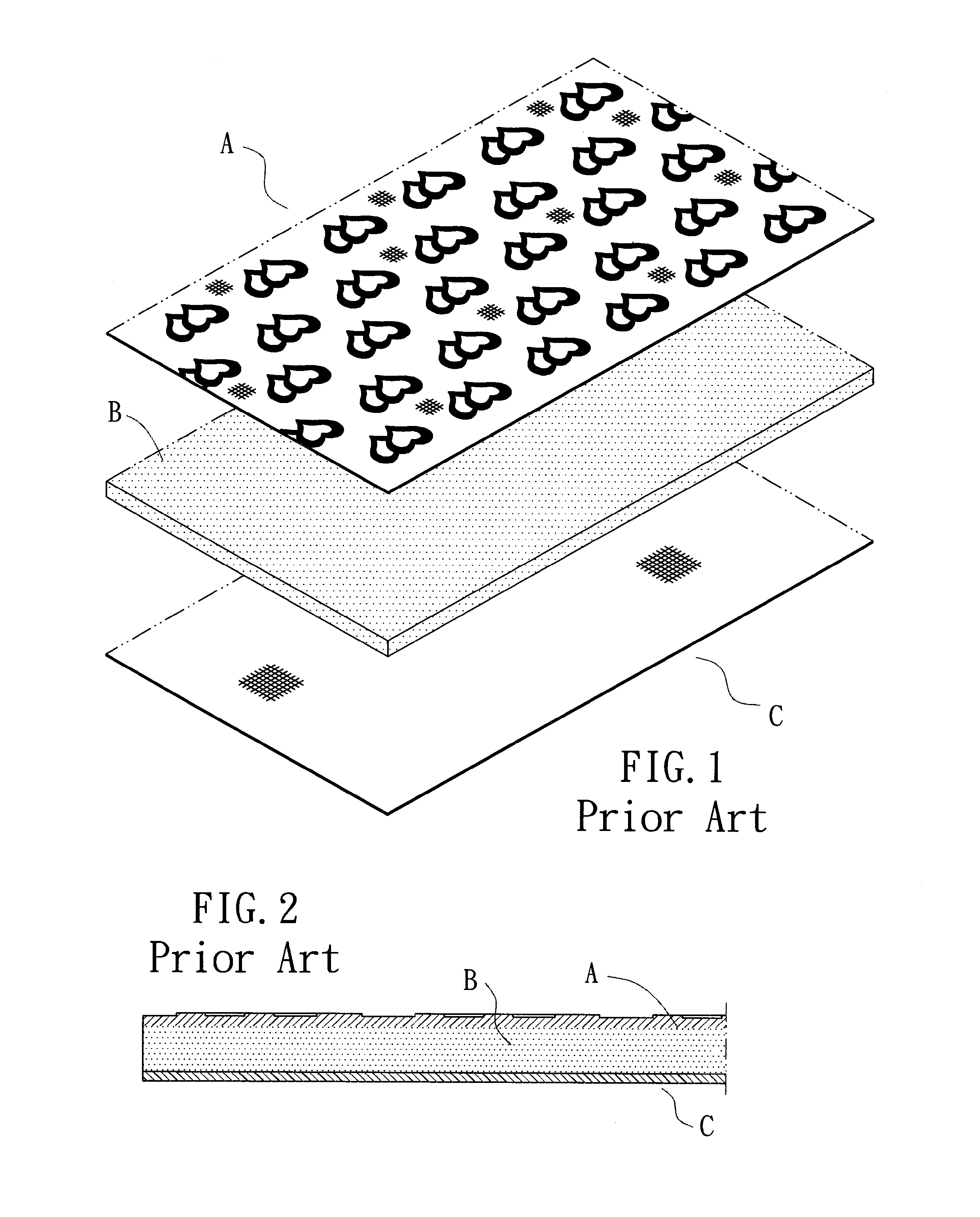

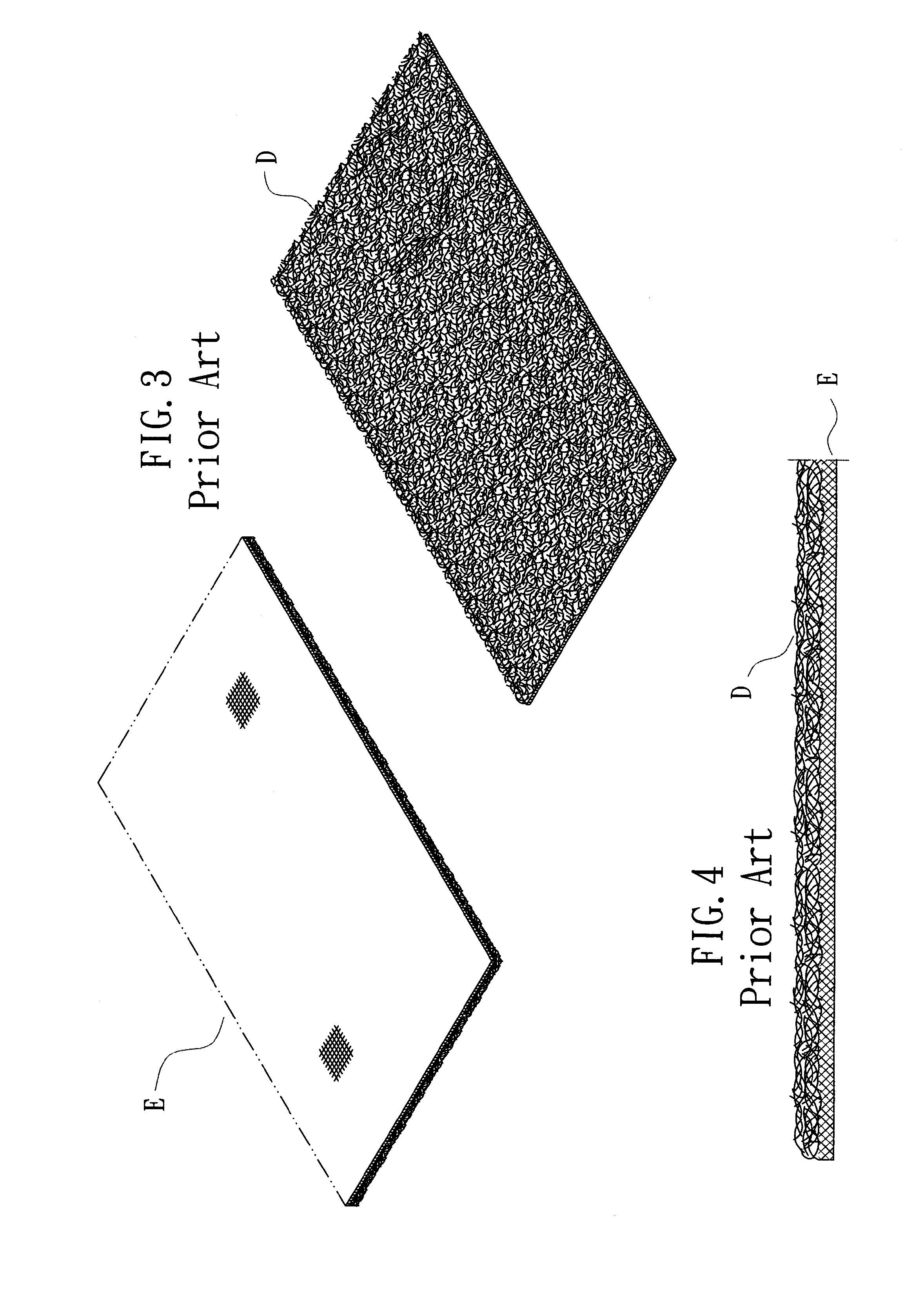

Textile having an integral underlying layer of hook and loop fabric

A textile is provided with an underlying layer of hook and loop fabric; and a jacquard surface layer formed integrally with the underlying layer of hook and loop fabric. No adhesive is used in the manufacturing processes so as to minimize impact to the environment. The textile is particularly for the manufacturing of shoes and head covering.

Owner:YANG SUNG YUN

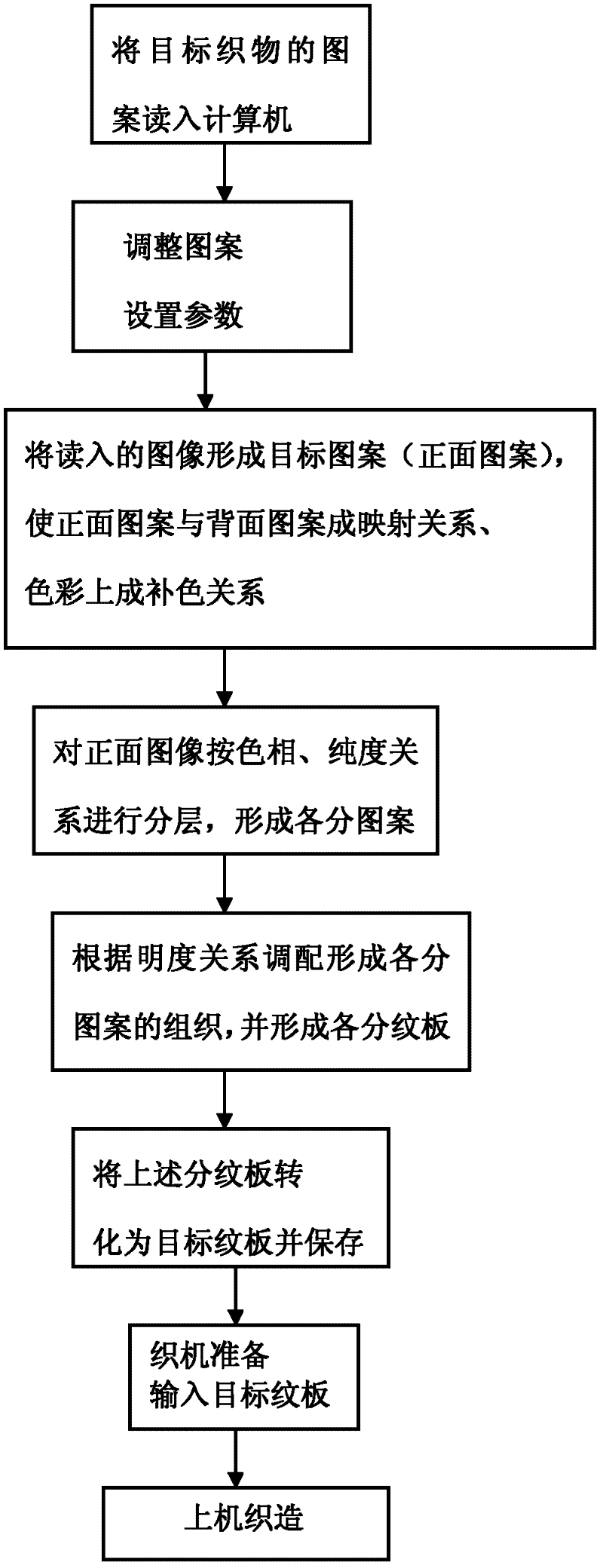

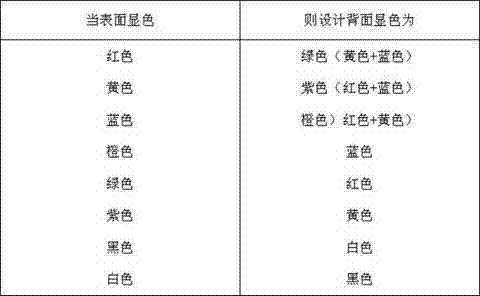

Method for designing and manufacturing double-side colored jacquard fabrics by adopting complementary color principle

ActiveCN102505243AReduce the number of picksLayeredJacquardsWoven fabricsComputer Aided DesignSurface pattern

The invention relates to a method for designing and manufacturing double-side colored jacquard fabrics by adopting the complementary color principle. The method comprises the steps of pattern plate design and manufacture work procedures and is characterized in that the work procedures comprise the following processes of: A, reading images of jacquard fabrics to be woven into a computer; B, regulating read images, setting parameters and giving out pixel value, wherein the pixel value corresponds to the number of warps and wefts; C, carrying out image modification design and regulation; and D, designing processed images into target patterns and carrying out pattern plate manufacture by using a jacquard fabric computer aided design system. The method has the prominent substantial characteristics that the method adopts the complementary color principle, back side patterns are woven by wefts which are not used by surface patterns, the complementary color relationship is shown, and in addition, the brightness change is shown, so the fabric patterns have the stereovision, in addition, the weft insertion quantity is small, the woven fabrics are in a single-layer structure, the thickness and the heavy weight are avoided, the color is improved, and the patterns are exquisite and elegant.

Owner:李加林

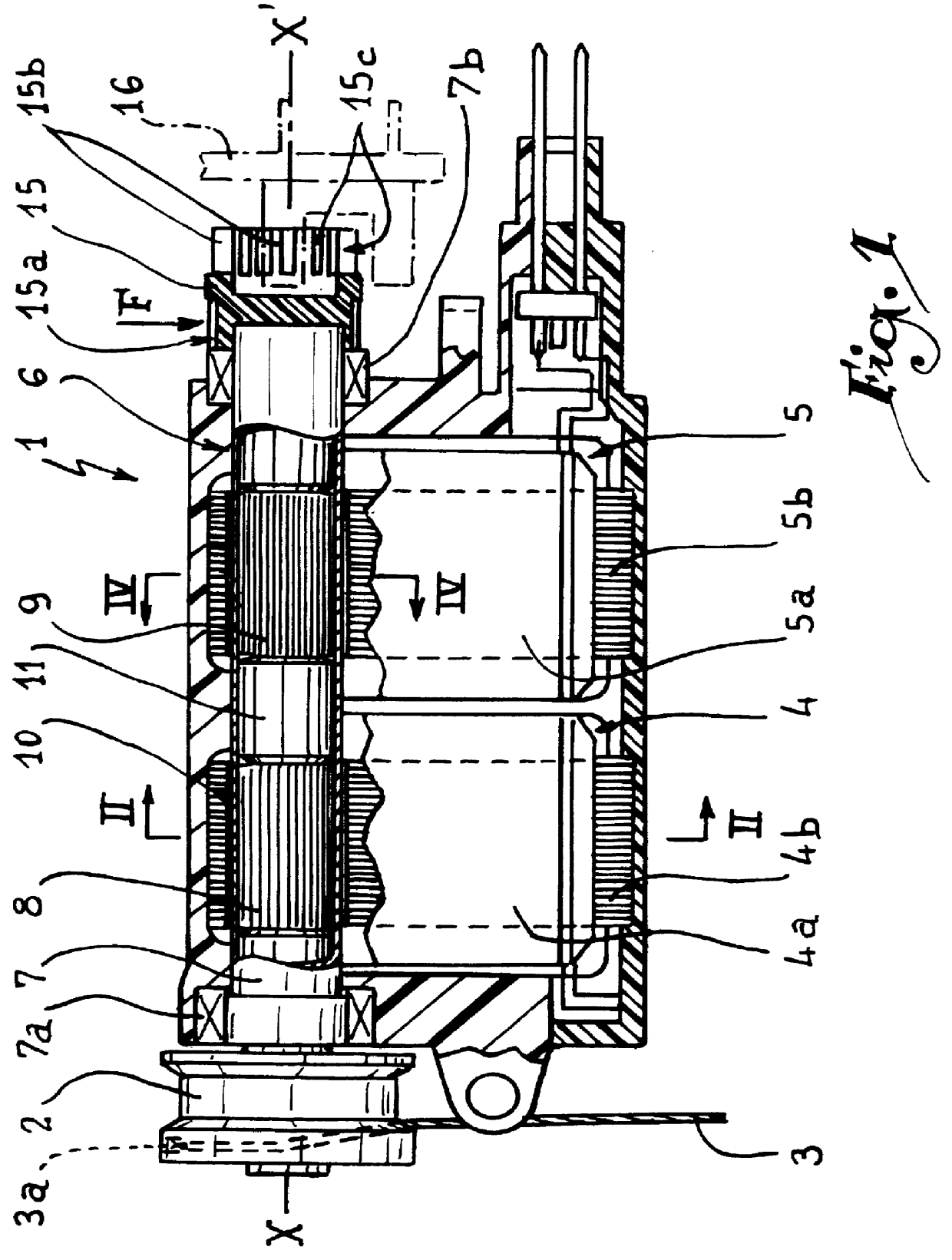

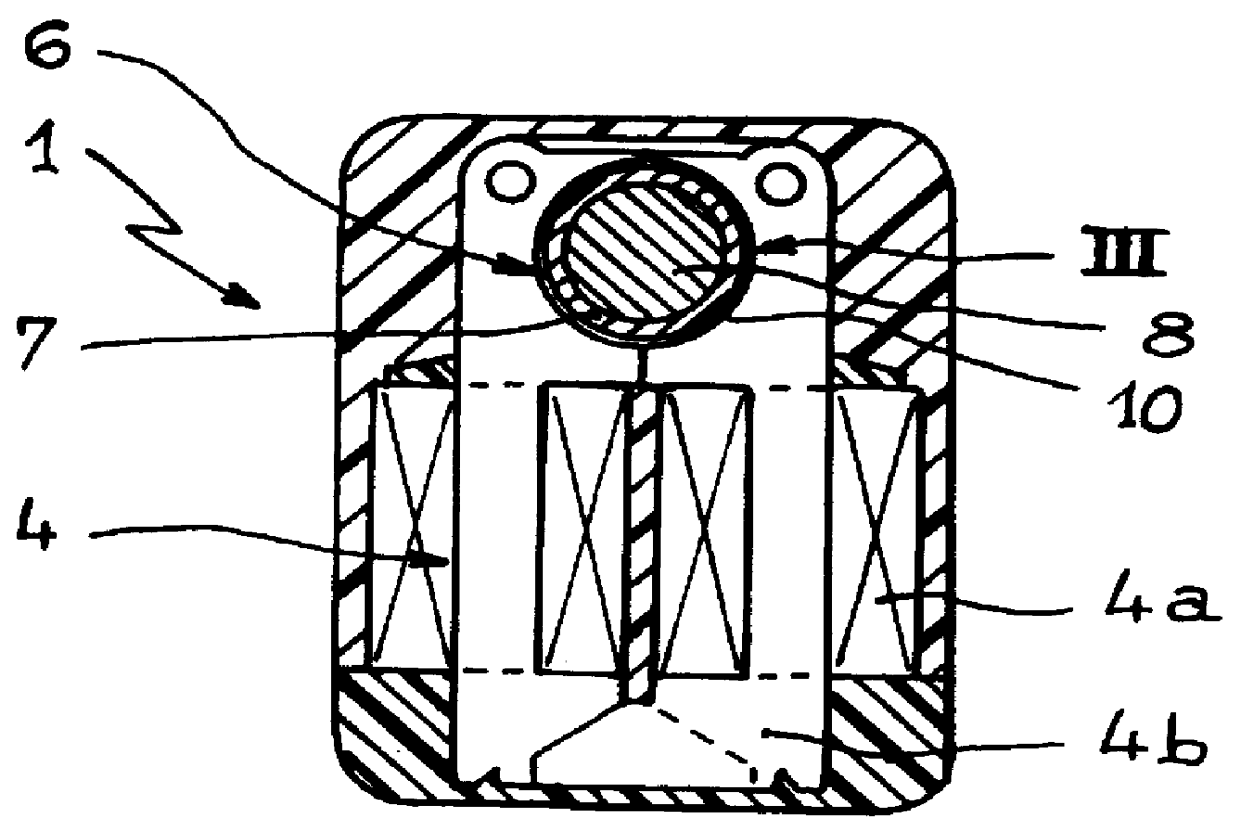

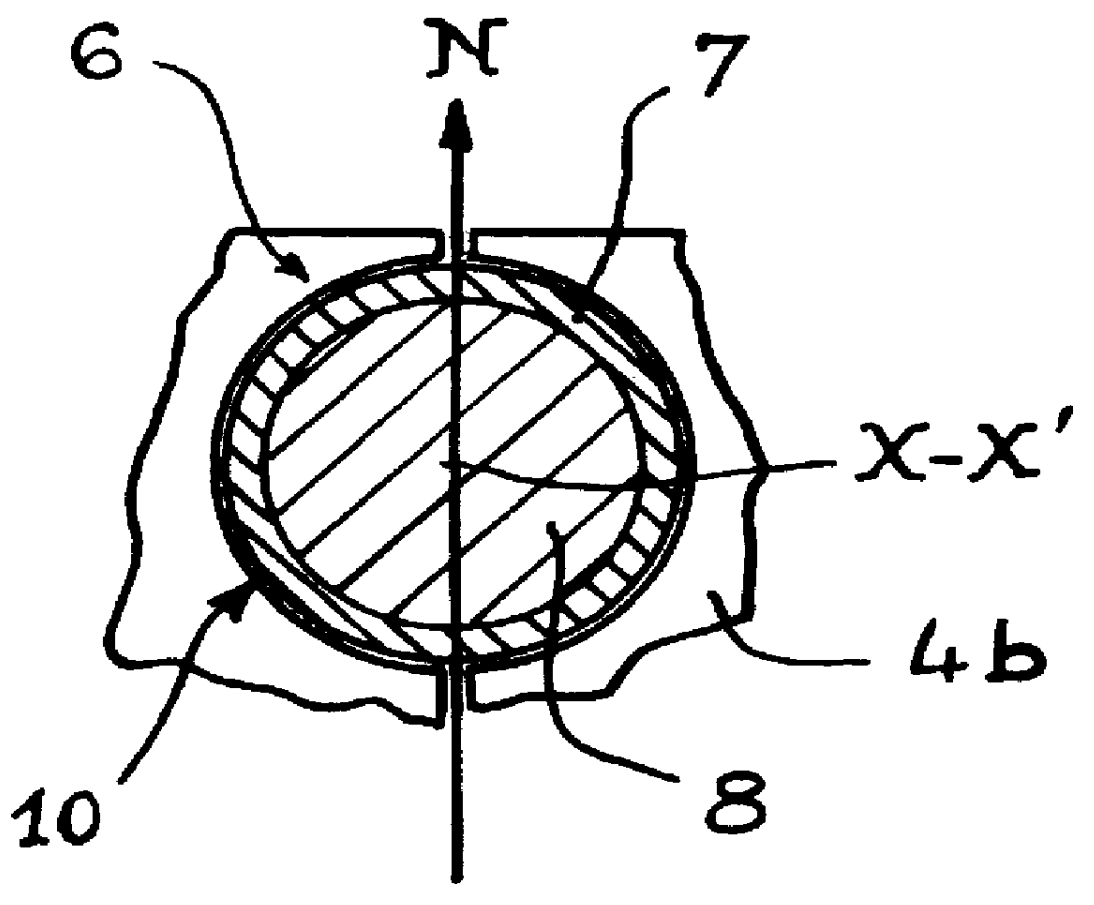

Electrical rotating actuator for forming a weaving loom shed

InactiveUS6105630AEasy to manufactureReduce the overall diameterJacquardsDobbiesElectrical polarityEngineering

An electrical rotating apparatus for controlling a harness cord associated with the shed of a weaving loom which includes an actuator including a rotor and a stator. The rotor is formed of at least two permanent magnets which are mounted within a tube so as to be spaced axially with respect to one another and wherein a plurality of stator elements are also provided offset axially relative to an axis of rotation of the rotor such that each of the plurality of rotors corresponds with a separate one of the plurality of stators. The polarities of one or the other of the permanent magnets or the stator elements are offset angularly relative to the axis of rotation.

Owner:STAUBLI FAVERGES SA

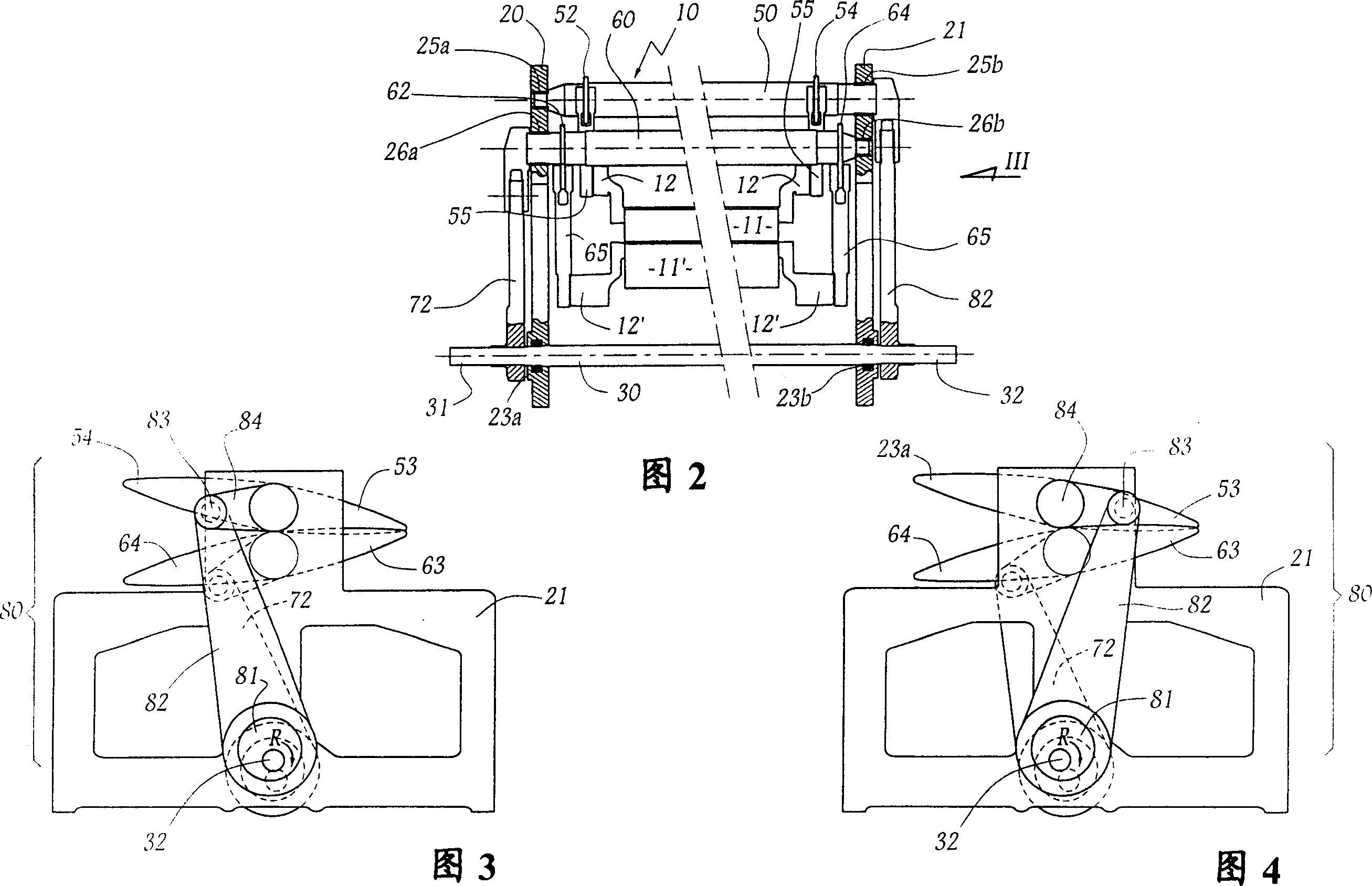

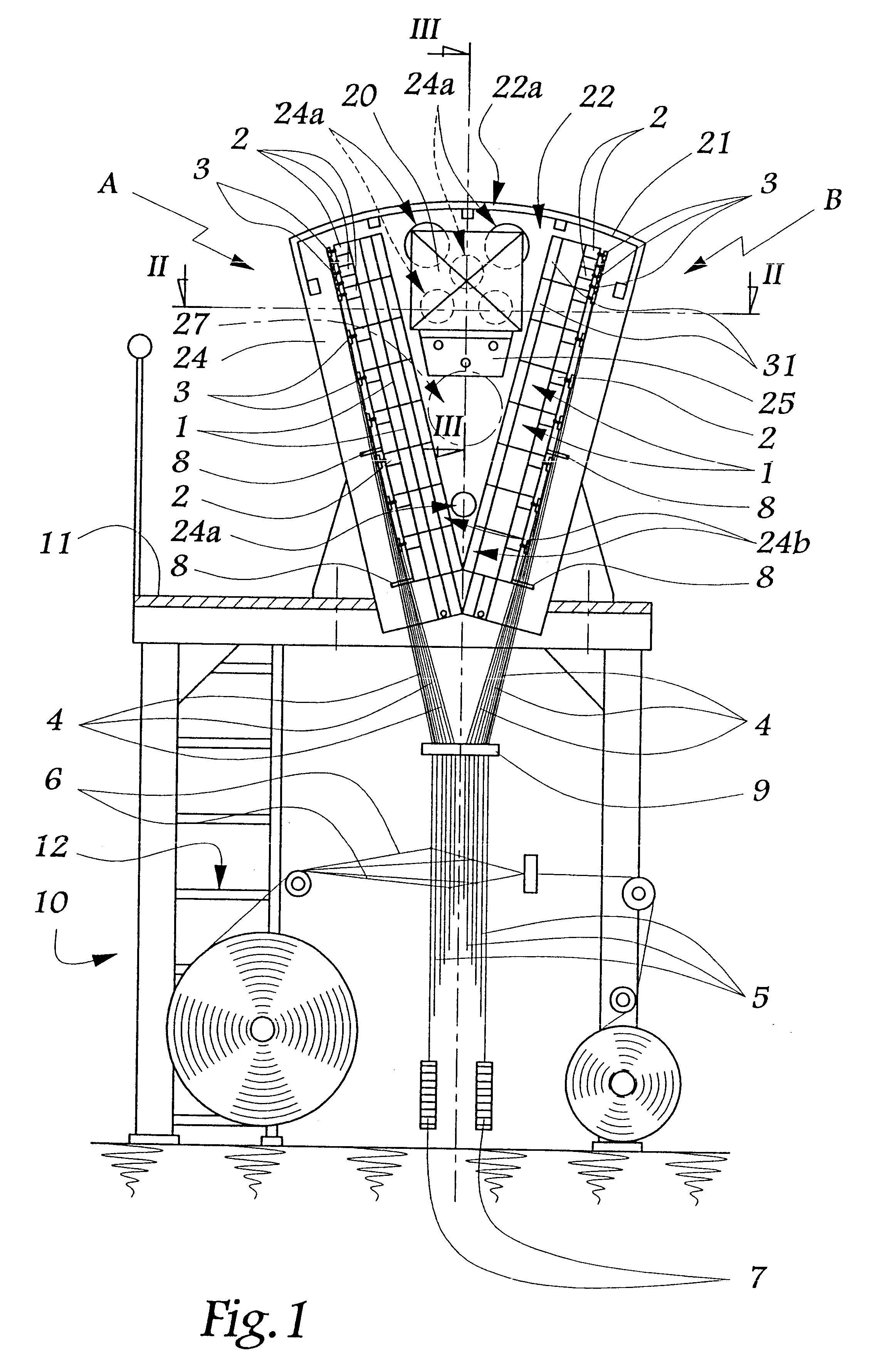

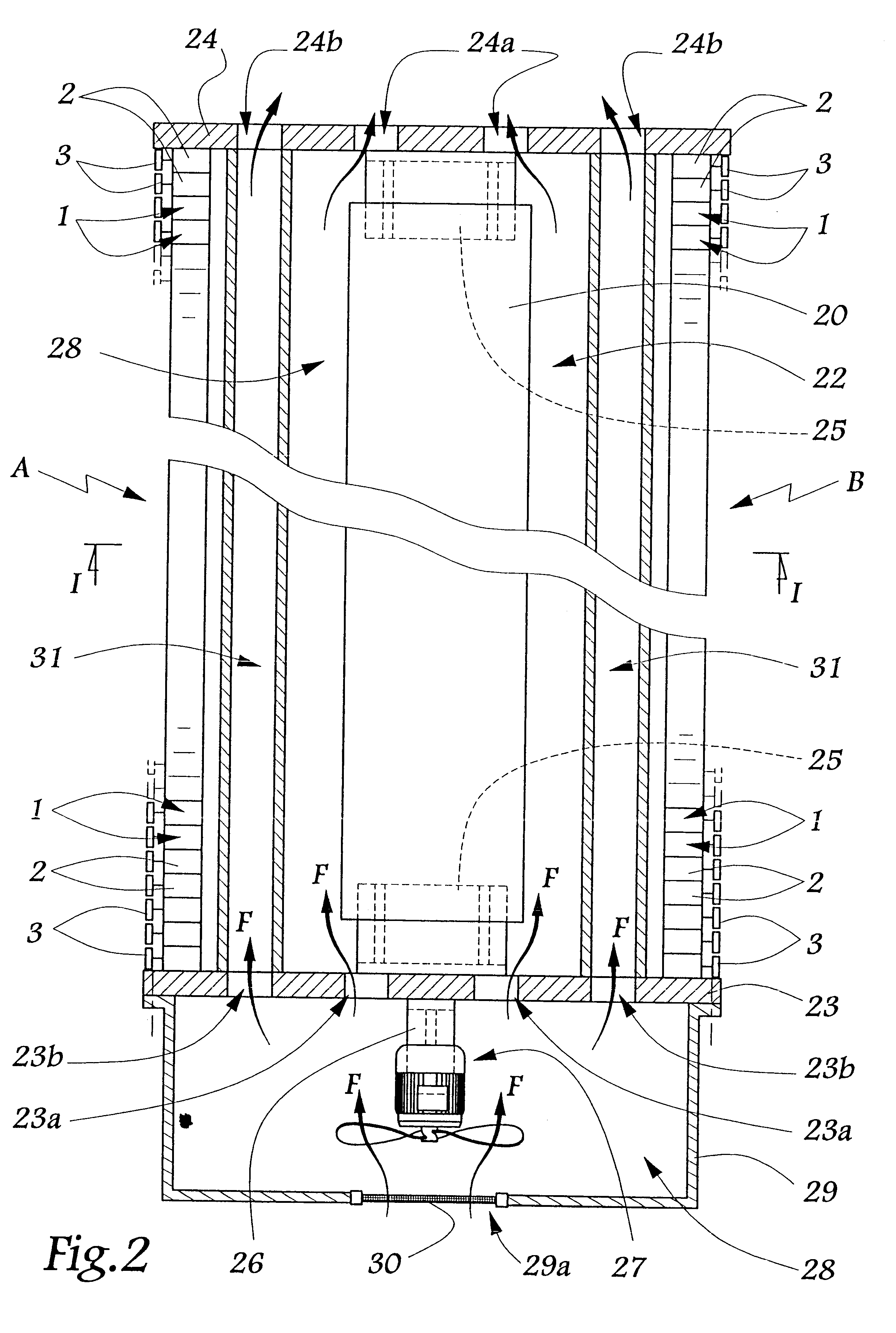

Shed forming device and weaving loom of the jacquard type equipped with such a device

ActiveCN1550592ARealize one-way controlEfficient driveJacquardsCam shedding mechanismJacquard loomStructural engineering

Owner:施托布利里昂公司

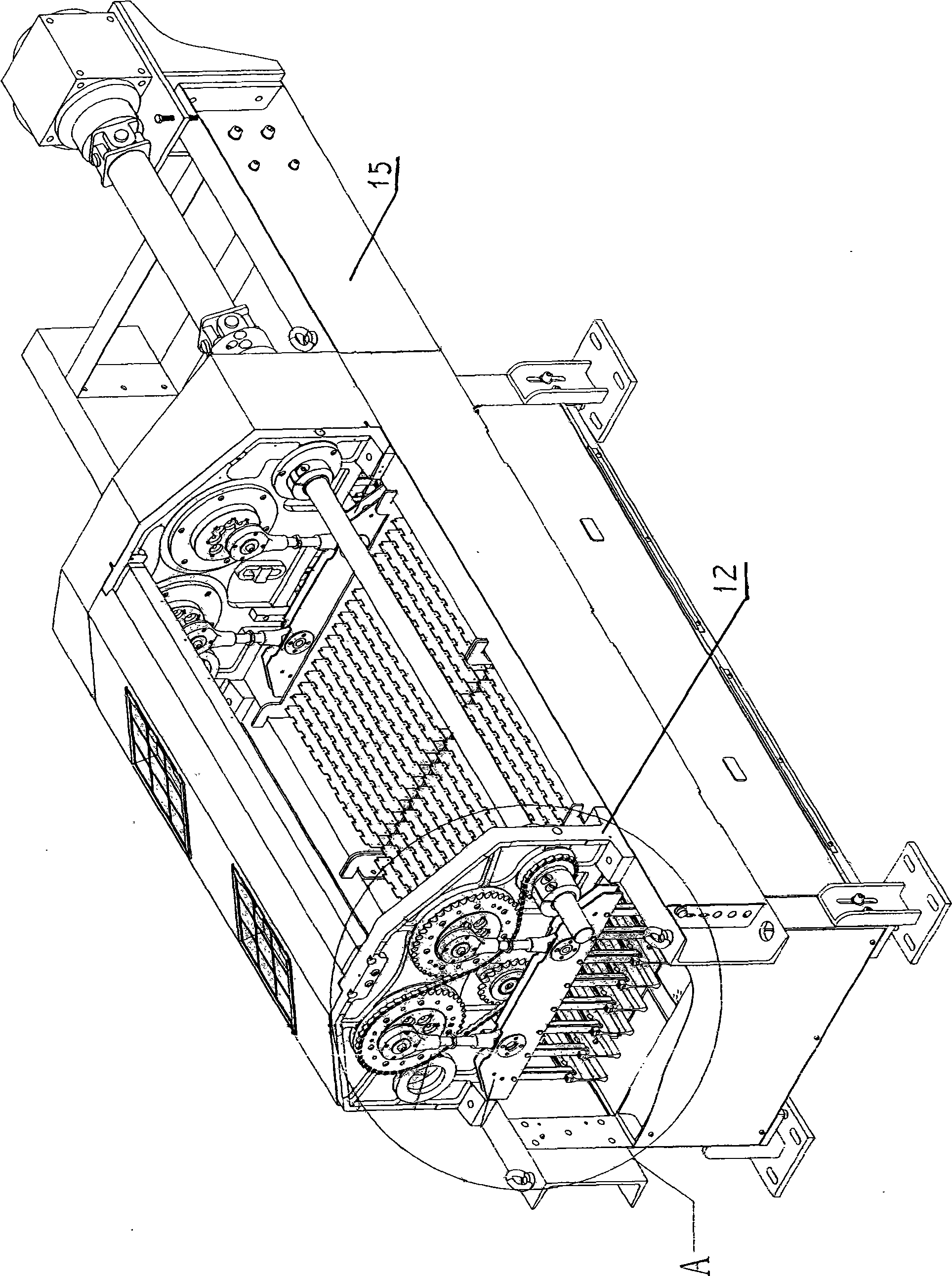

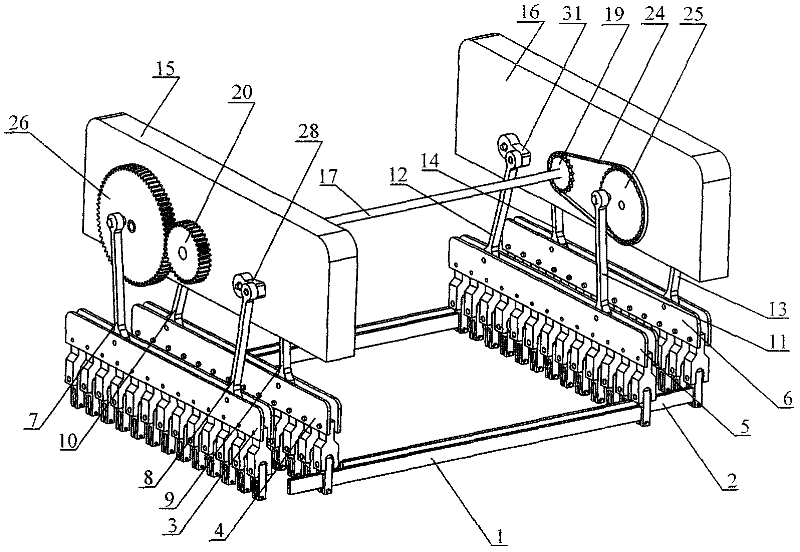

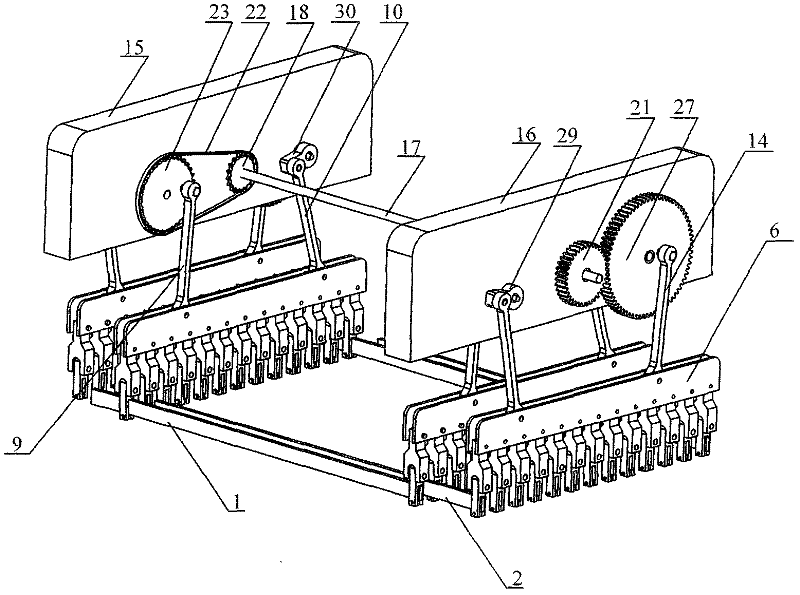

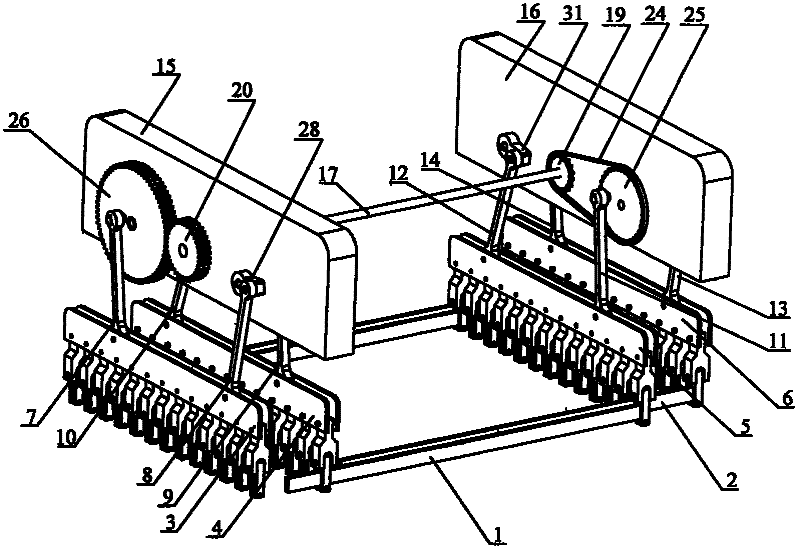

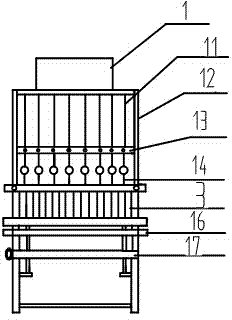

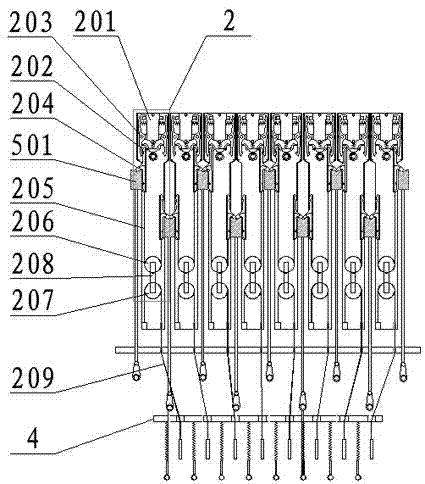

Griffe transmission mechanism of electronic jacquard machine

The invention discloses a griffe transmission mechanism of an electronic jacquard machine. The griffe transmission mechanism comprises a griffe on the lower end of a frame, a plurality of needle lifting arms on two sides of the frame for lifting the griffe, a plurality of links for connecting the needle lifting arms, and a transmission spindle installed by means of fixing plates at two sides of the upper end of the frame, wherein the transmission spindle is provided with driving chain wheels on the inner sides of the fixing plates; the outer sides of the fixing plates are provided with driving gears; the driving chain wheels are connected with eccentric driven chain wheels by chains; the driving gears are engaged with eccentric gears; and the outer sides of the fixing plates are provided with outer side cranks coaxial with the eccentric driven chain wheels while the inner sides of the fixing plates are provided with inner side cranks coaxial with the eccentric gears. According to the griffe transmission mechanism of the electronic jacquard machine in the invention, one transmission spindle is used to drive the eccentric driven chain wheels and the eccentric gears at two sides of the frame as well as the outer side cranks and the inner side cranks to stagger by 180 degrees in order to lift or drop four needle lifting arms connected with a loom, and to drive the griffe to synchronously lift jacquard needles to sequentially move upwards to form a scissors-like warp thread opening; and the whole transmission mechanism is simple in structure, skilful in design and smooth in operation.

Owner:浙江奇汇电子提花机有限公司

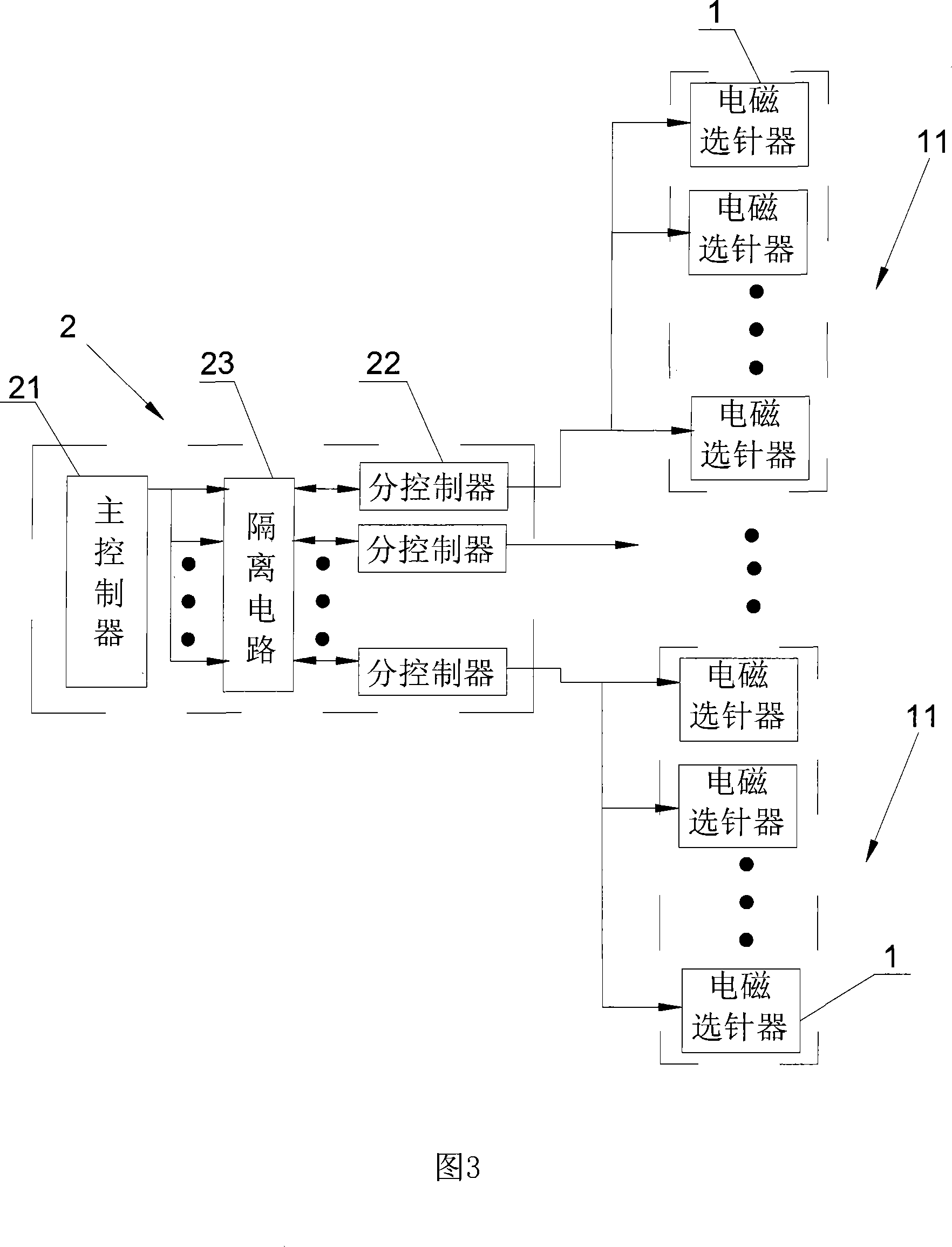

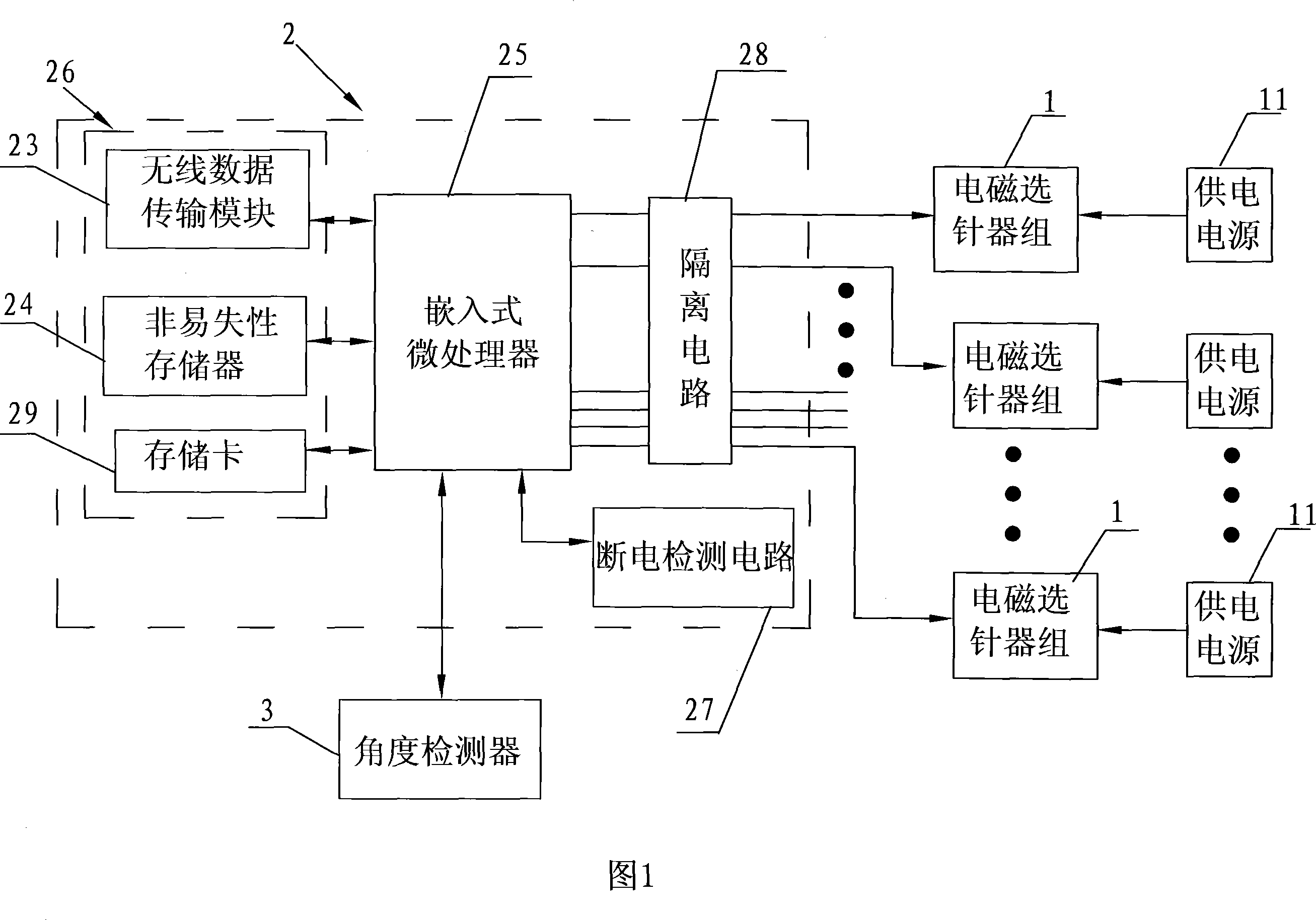

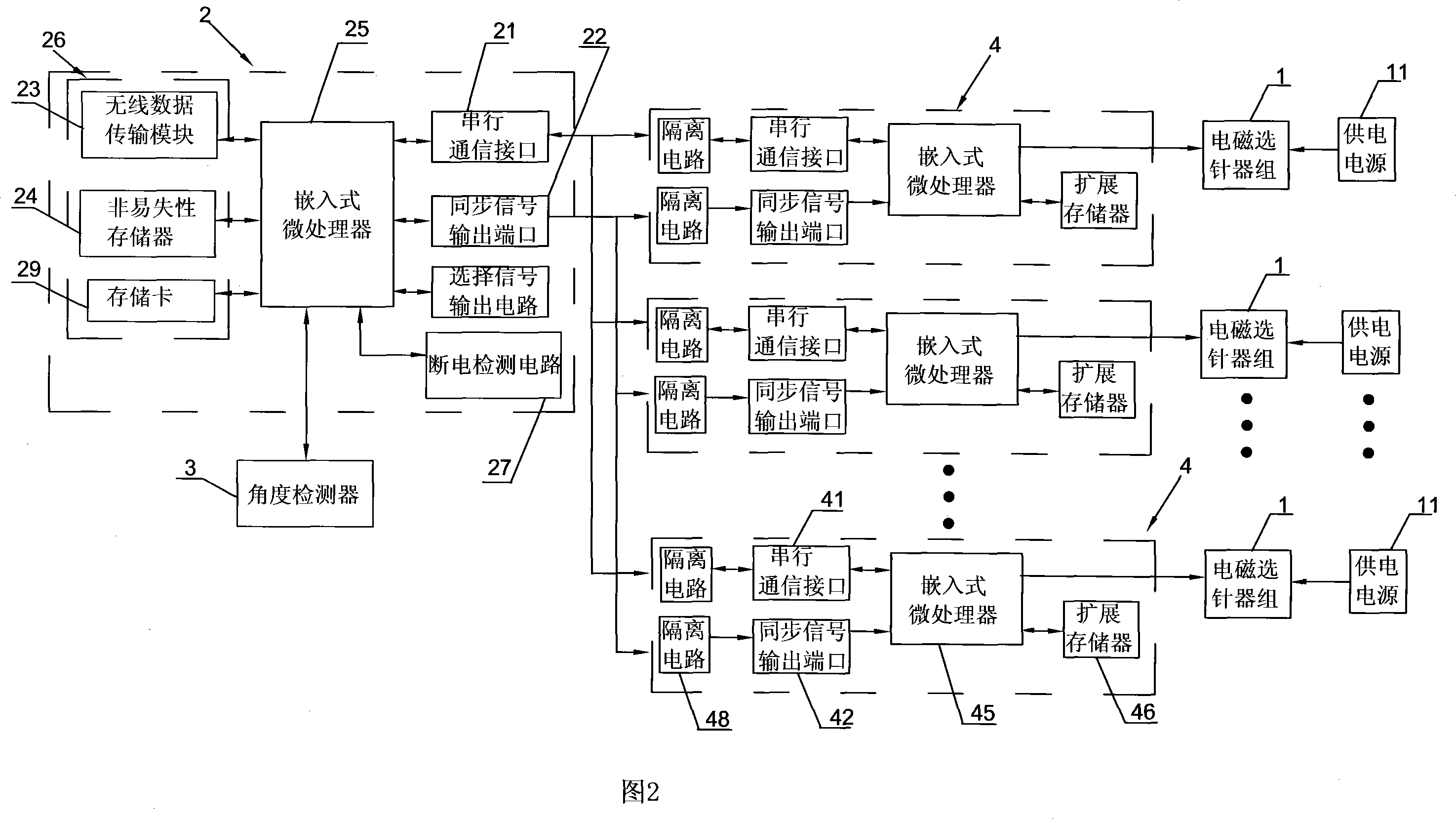

Control system for electronic jacquard machine

InactiveCN101054752AWork reliablyImprove anti-interference abilityJacquardsElectric programme controlControl systemData transmission

The invention relates to a control system of electronic jacquard machine including a plurality of electromagnetic needle selector, which at least divided to two separate electromagnetic needle selector sets, and each electromagnetic needle selector set is supplied by separate power supply; a main controller, which contains a embedding type microprocessor, a storage mechanism for storing pattern data, Wherein, data input end of the embedding type microprocessor is connected with each electromagnetic needle selector set. Before spinning, the main controller reads spinning pattern data in the storage mechanism and carries format conversion, storage and grouping of data, when the jacquard machine working, the embedding type microprocessor outputs each group of spinning pattern data to the corresponding electromagnetic needle selector set for carrying pattern operation. Due to directly driving the electromagnetic needle selector set by the main controller, the electromagnetic needle selector can work reliably, contradiction of high data transportation speed and cable length is solved, and due to avoiding using longer cable to transport data, immunity of the control system is greatly increased.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

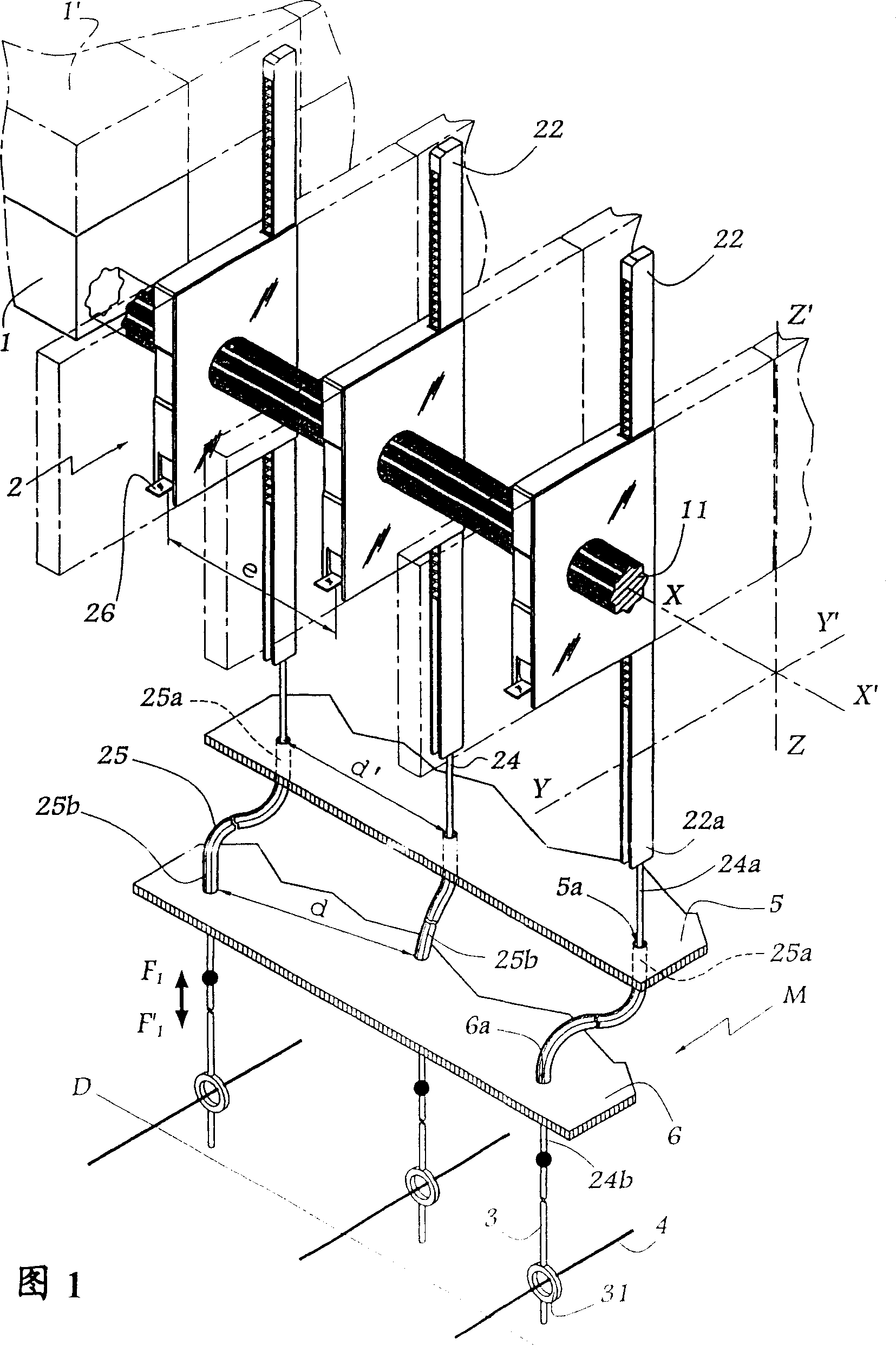

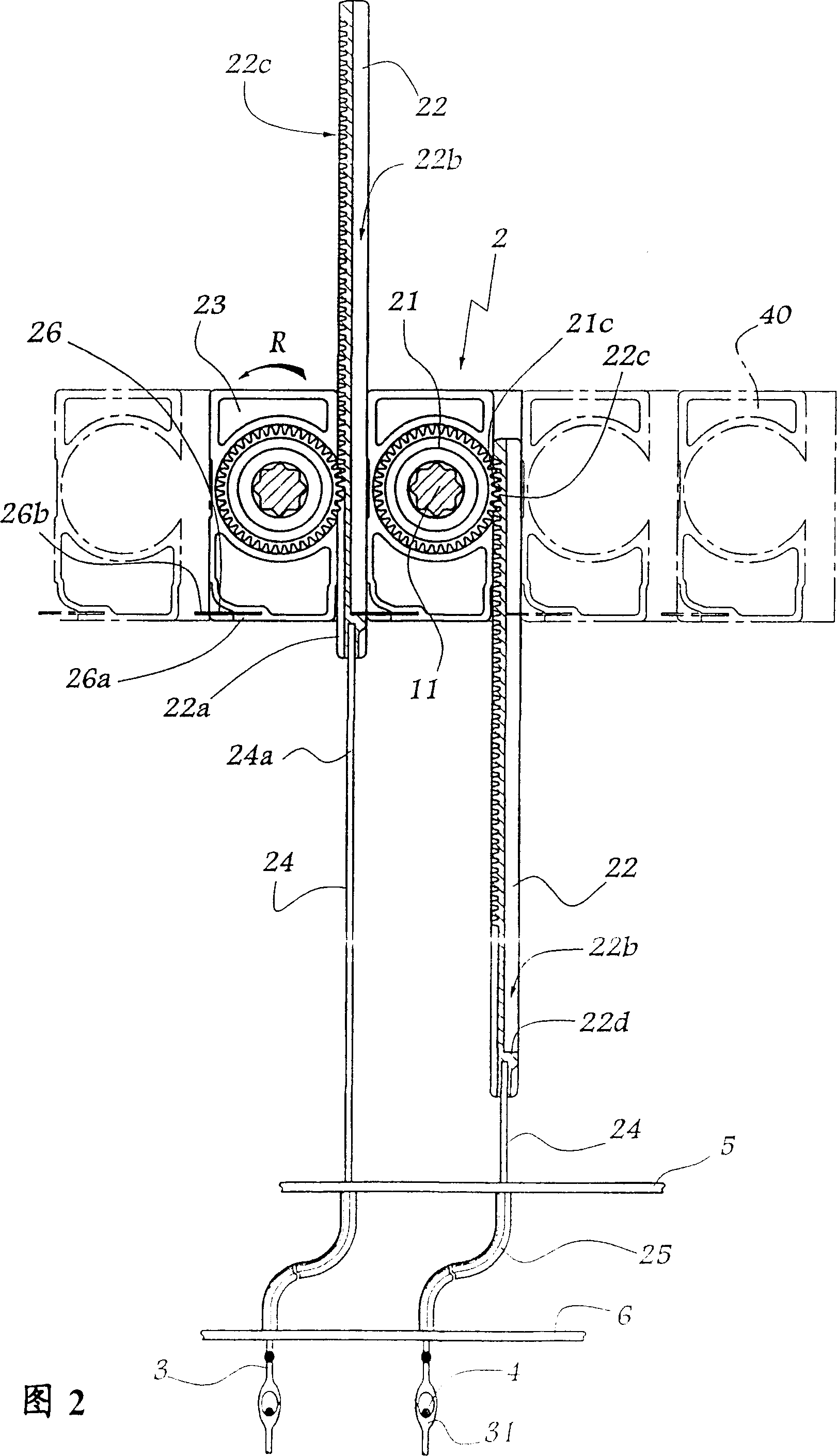

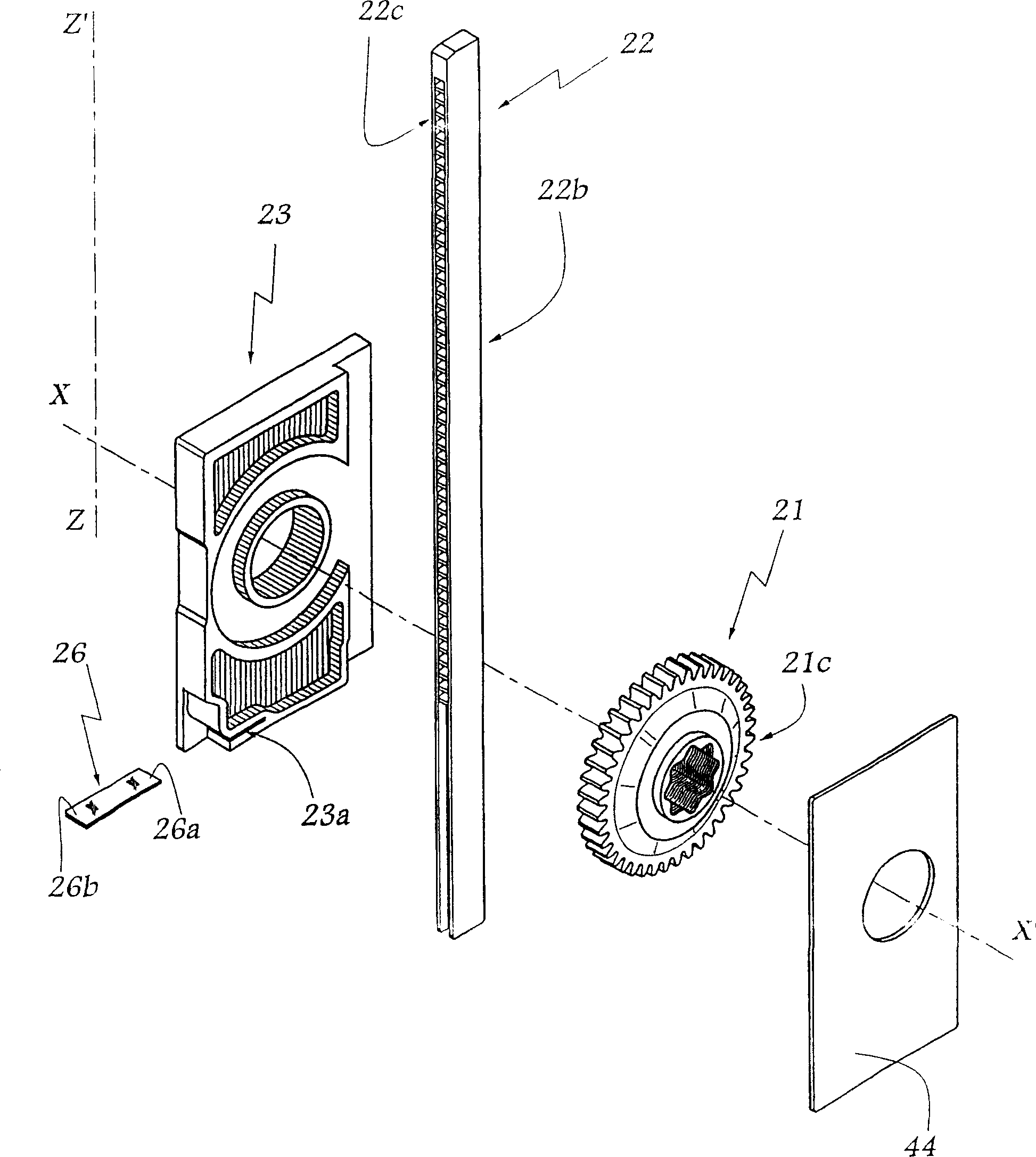

Device for forming shed in weaving loom of jacquard type

InactiveCN1520475ASave spaceAlignment is quick and accurateJacquardsOther shedding mechanismEngineeringRotary actuator

The invention relates to a shedding device comprising at least one electric rotary actuator having an output shaft ( 11 ) that is designed to rotate a pinion ( 21 ) which is engaged with a rack ( 22 ), said rack being connected to a control heald ( 3 ) of a warp end ( 4 ) by means of a load transfer element ( 24 ).

Owner:施托布利里昂公司

Device for hooking between elements of a shed forming device, method for manufacturing and using the same

ActiveCN1928176AImprove accessibilityLimit the risk of wear and tearJacquardsStructural engineeringCentripetal force

Owner:施托布利里昂公司

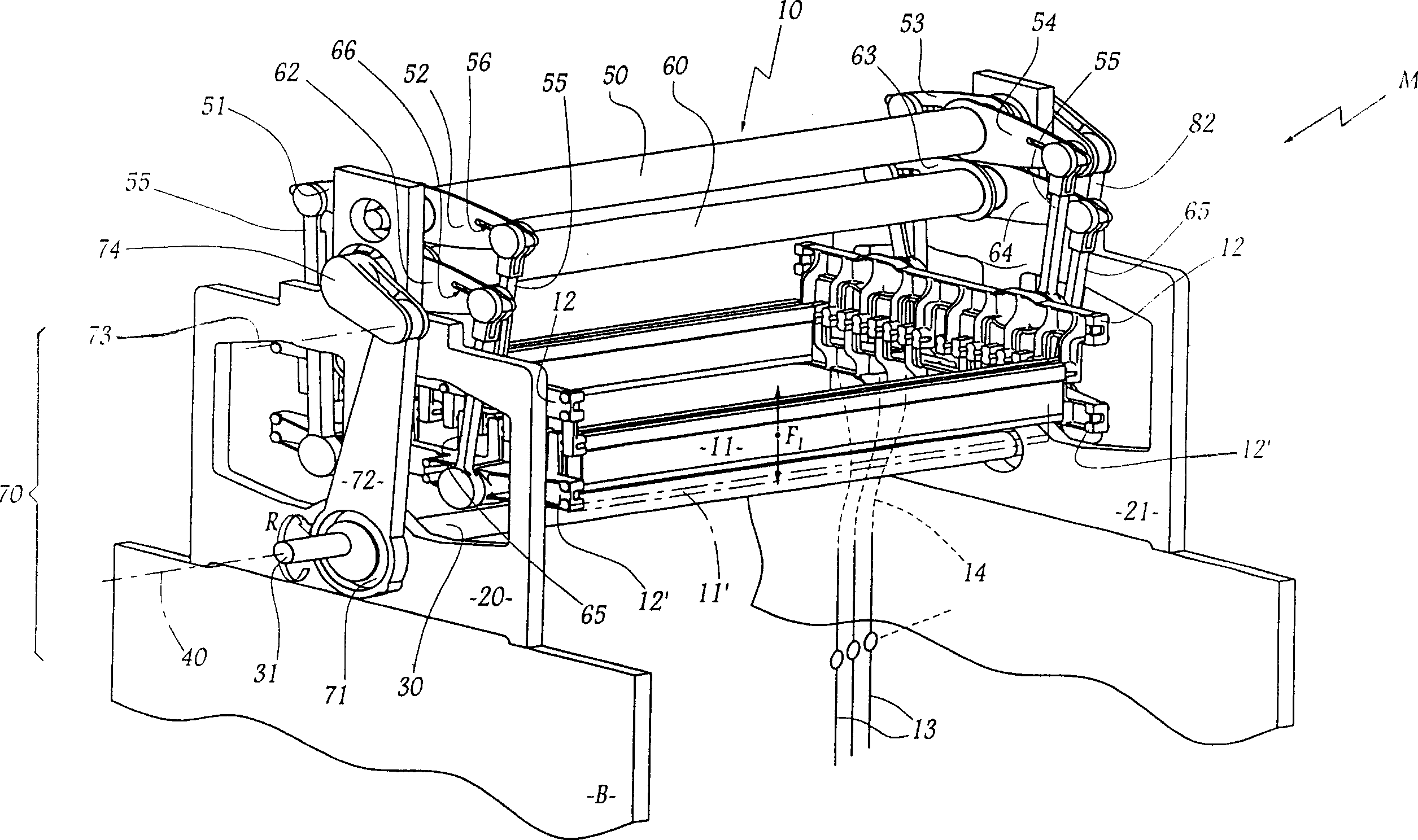

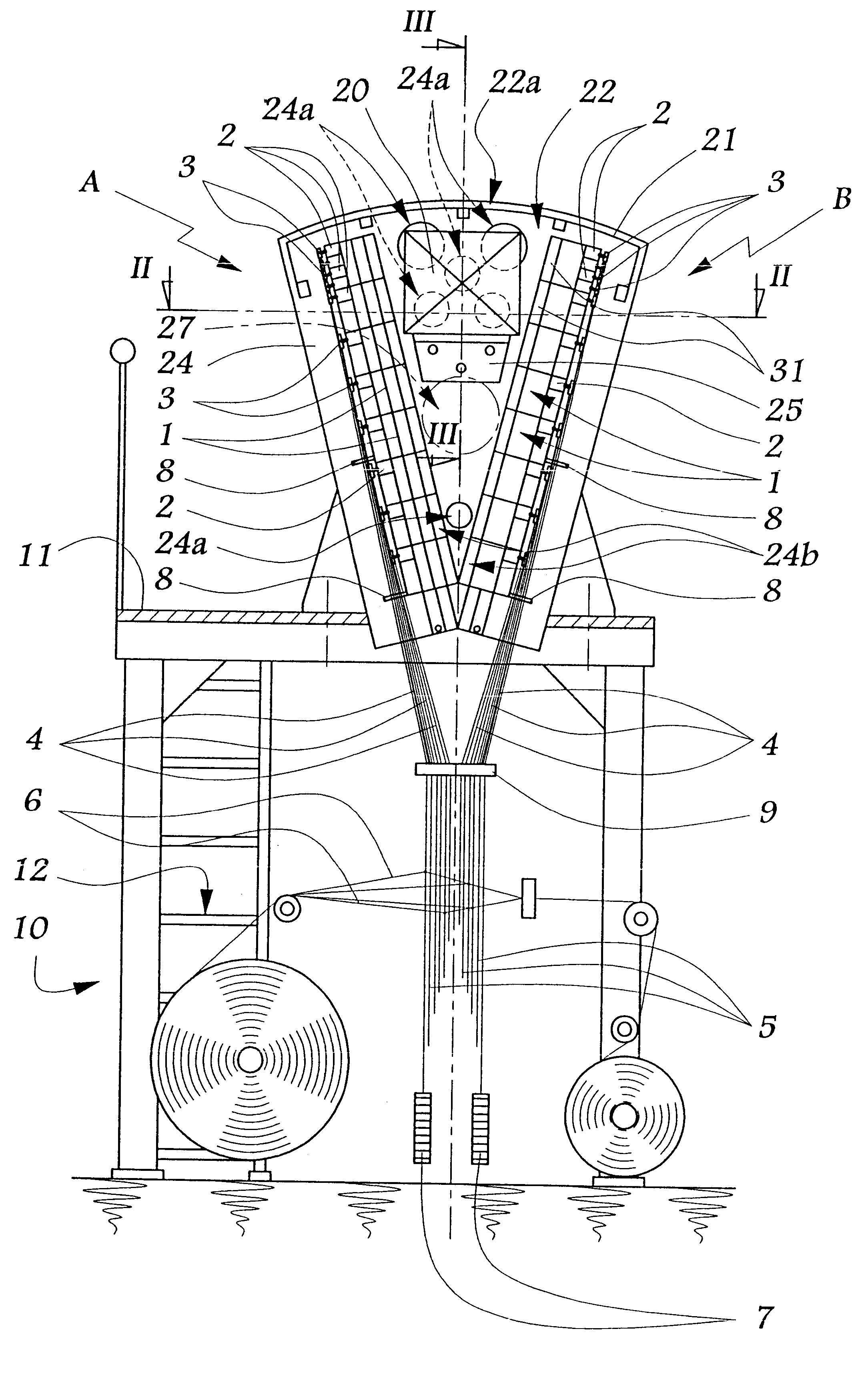

Weaving loom panel support structure for jacquard selectors

A loom and a weaving mechanism of the Jacquard type for forming the shed in the loom wherein the weaving mechanism is associated with a harness including harness cords secured to heddles. The harness cords are controlled by electric actuators mounted to two panels extending above the heddles and between which a compartment is formed in which a control unit for supplying and monitoring the operation of the actuators is housed.

Owner:STAUBLI FAVERGES SA

Method for preparing polyester heddle twine for jacquard loom

The present invention relates to a production method of jacquard polyester heddle twine. Said invention utilizes selection of industrial polyester multifilament and uses it as new material for makingheddle twine on the lay-over arrangement of jacquard loom, and adopts the processes of improved cabling, sizing and infrared drying so as to obtain the invented product jacquard polyester heddle twine. As compared with existent jacquard polyester heddle twine its tensile breaking strength is raised by once, under the identical test condition its expand and contract amount of reduced by 20-95% andits cost also is reduced by 30%.

Owner:SHANGHAI UNIV OF ENG SCI +1

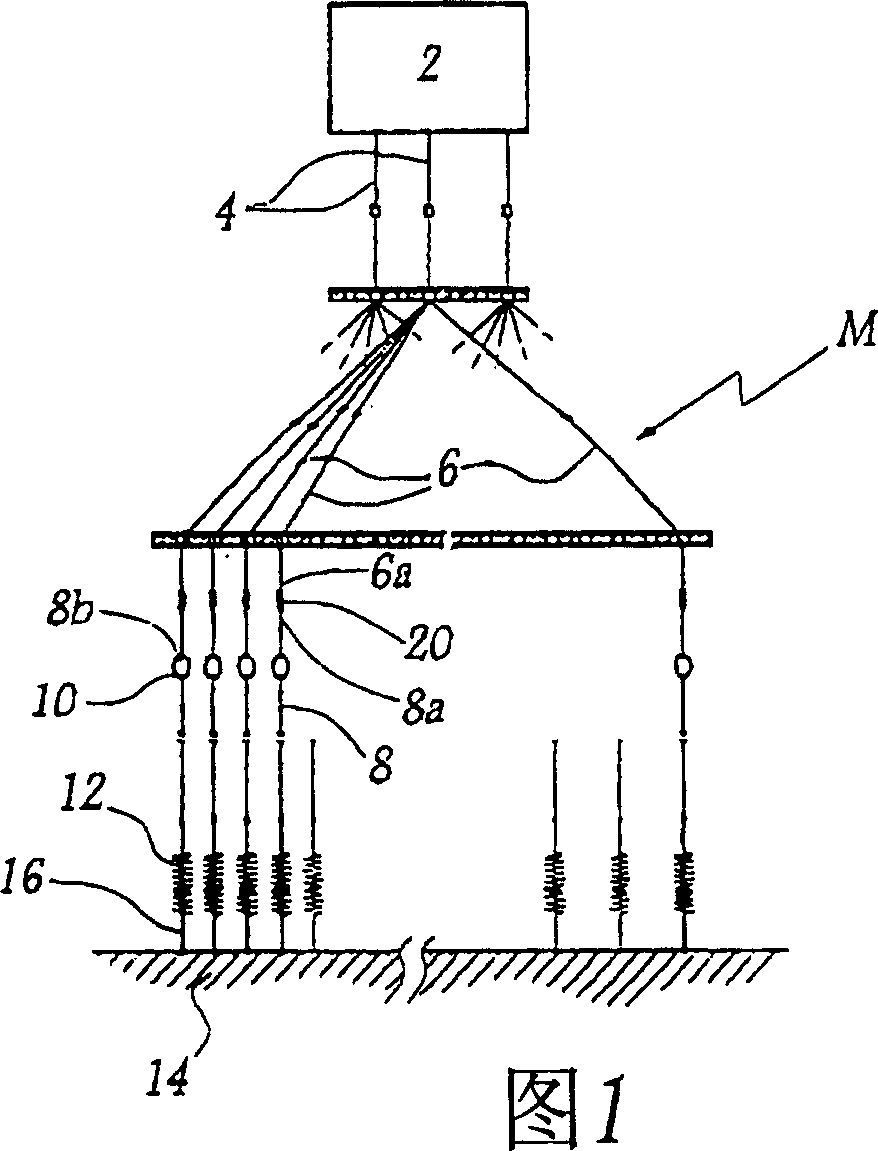

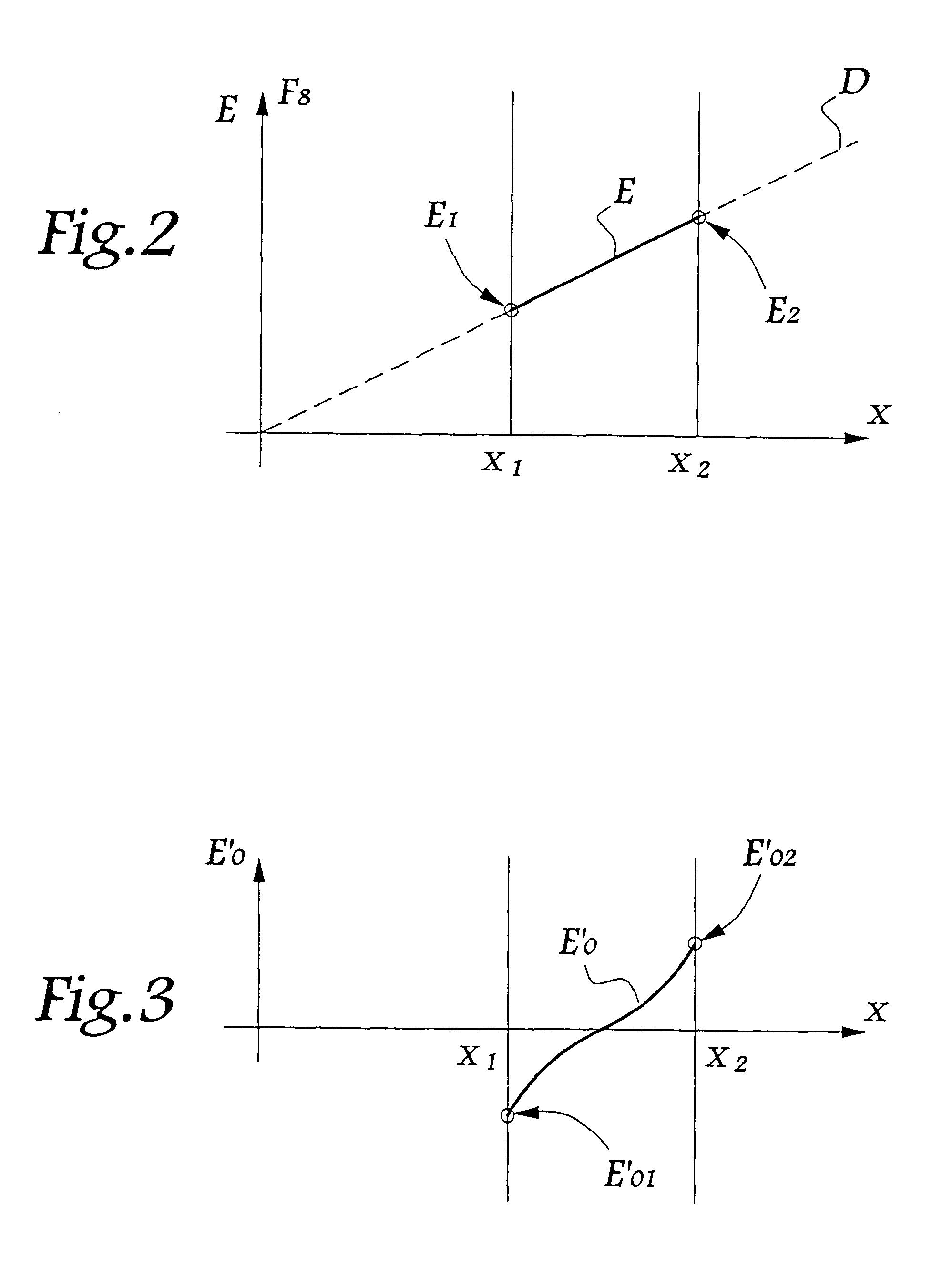

Method and device for detecting jacquard shed anomalies

InactiveUS6357486B2Reduce operating costsQuick and accurate identificationJacquardsLoomsYarnEngineering

In a weaving loom of the Jacquard type comprising electrical actuators for displacing heddles controlling the position of the warp yarns, the following steps are carried out:a so-called "normal effort" is determined, exerted by at least one actuator on at least one harness cord in order to displace, between two positions of its normal stroke, at least one heddle connected to a normally taut warp yam;from this normal effort, at least one threshold value representative of a limit of a range of values of normal weaving effort is determined;while the loom is in operation, a so-called "operational effort" exerted by this actuator on the harness cord is determined;at least one value representative of this operational effort is compared with the threshold value, anda first, so-called "anomaly signal" is generated when the value representative of the operational effort is outside the afore-mentioned range.The device comprises a logic unit incorporating a comparator and associated with a memory and a display means.

Owner:STAUBLI FAVERGES SA

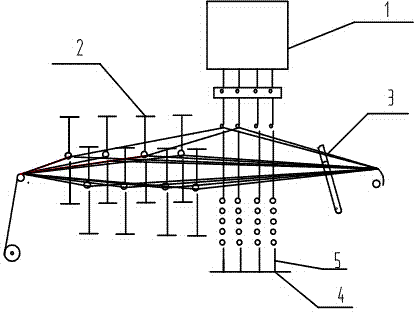

Tapestry weaving semi-automatic sample weaving machine

ActiveCN104727001AIncrease productivityReduce labor intensityJacquardsSmallware loomsSemi automaticUltimate tensile strength

The invention designs a tapestry weaving semi-automatic sample weaving machine. The semi-automatic sample weaving machine comprises a weft insertion device, a beating-up device, a let-off device and a take-up device and is characterized by further comprising a pneumatic opening device and an electronic jacquard opening device. The electronic jacquard opening device is fixed between the let-off device and the take-up device. The pneumatic opening device is fixed in front of the electronic jacquard opening device. The semi-automatic sample weaving machine has the advantages that the pneumatic opening device and the electronic jacquard opening device are effectively combined with a traditional sample weaving machine, a traditional purely-manual tapestry weaving machine is changed into the semi-automatic tapestry weaving machine, equipment automation level is further increased, labor intensity of operators is relieved, and production efficiency is increased effectively.

Owner:IANGSU COLLEGE OF ENG & TECH

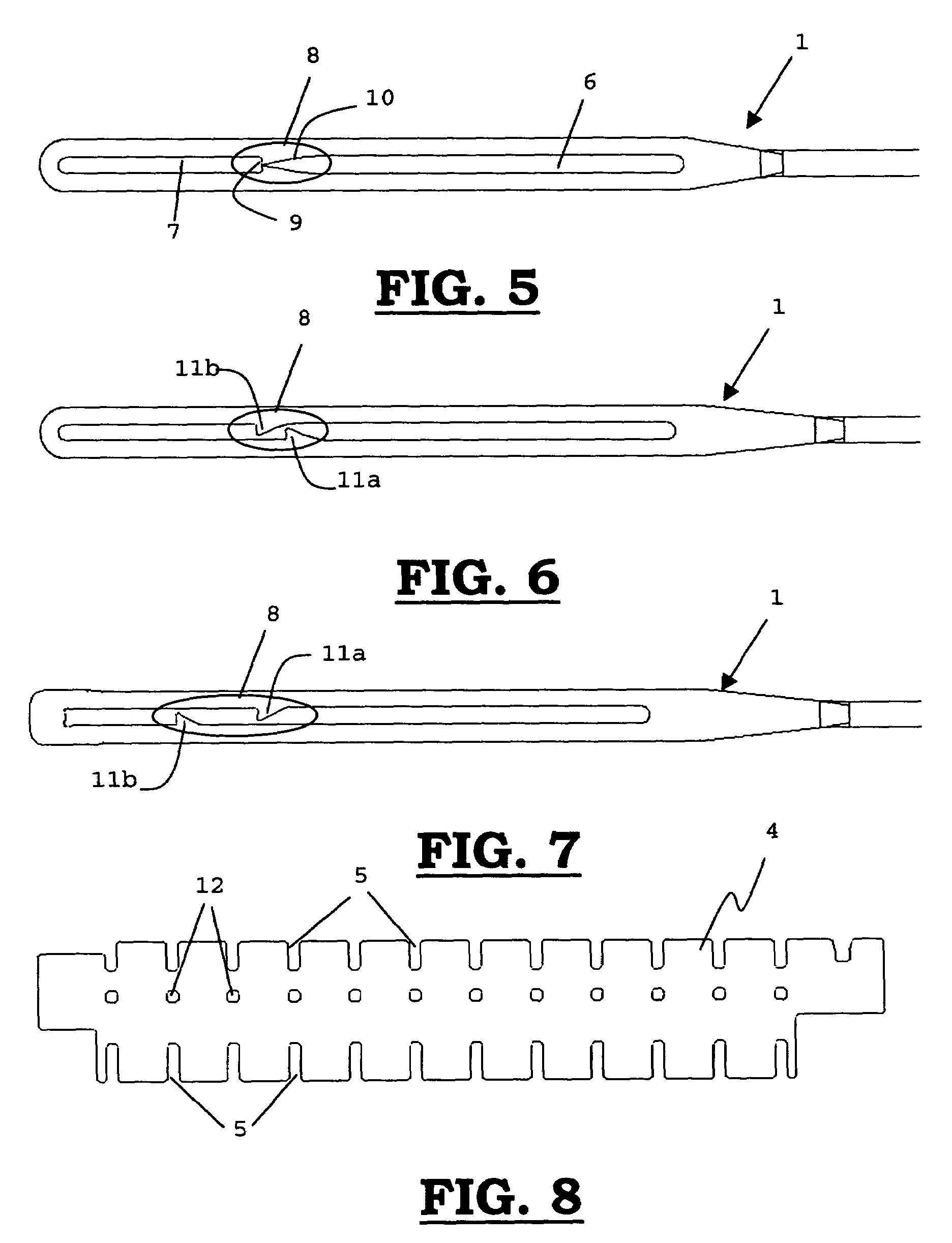

Device for attaching return springs in a harness of a Jacquard weaving machine

On the one hand, the invention relates to a device for exerting a return force on at least one harness element of the harness of a Jacquard weaving machine, comprising at least one return spring (2) provided with means of attachment (1) for attaching the return spring (2) to retaining means (4) being immovably provided, said means of attachment (1) being provided with a positioning opening (6) for positioning the means of attachment (1) with respect to the retaining means (4), and a fixing opening (7) for fixing the means of attachment (1) to the retaining means (4), a spring connection (8) being provided between the positioning opening (6) and the fixing opening (7), in such a manner that the means of attachment (1) are able to move from positioning opening (6) to the fixing opening (7) with respect to the retaining means (4), but after having been fixed will be unable to move back from the fixing opening (7) to the positioning opening (6) with respect to the retaining means during operation or transport of the Jacquard machine.On the other hand, the invention relates to a device for immovably installing the retaining means (4) of one or several return springs (2) of a Jacquard weaving machine, the device being provided with at least two fixed installing elements (13) for installing the retaining means (4), the said installing elements (13) being provided with one or several recesses to apply the retaining means (4).

Owner:N V MICHEL VAN DE WIELE

Multifunctional electronic jacquard double-sided circular weft braiding machine controlled by computer

InactiveCN101074514AIncrease color varietiesLow costJacquardsCircular knitting machinesFrequency changerTorque motor

This invention discloses one double round weft electronic jacquard machine under computer control. It includes Rack, the main motor, yarn planes, vol cloth planes, the syringes, needles under the automatic lane changing air pressure scissors, needle for the next election, the Department of weaving, fabric density regulating agencies, fault alarm device, frequency converter, the host computer, needle-election above, stepper motor and torque motor. The trouble alarm device, automatic lane changing air pressure scissors, needle-election in both above and below connect with the host computer, volume cloth connect with the computer by the torque Motor installed in the volume cloth, the needle-election above is installed above the needle-election below. This invention has the advantages of rational structure, high degree of automation, electronic jacquard in double-sides, high-productivity, low cost of raw materials and various fabrics with high grade available.

Owner:陈国标

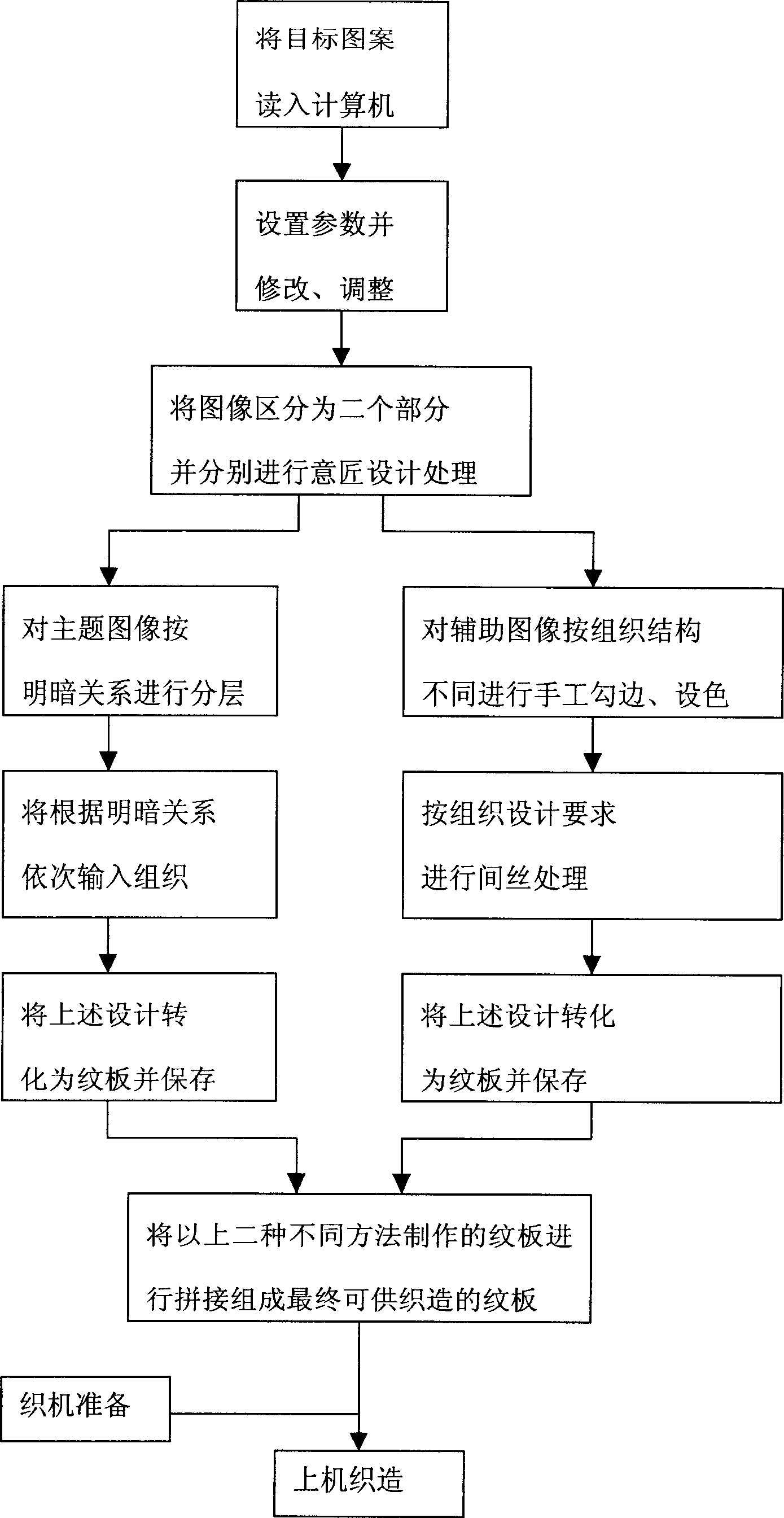

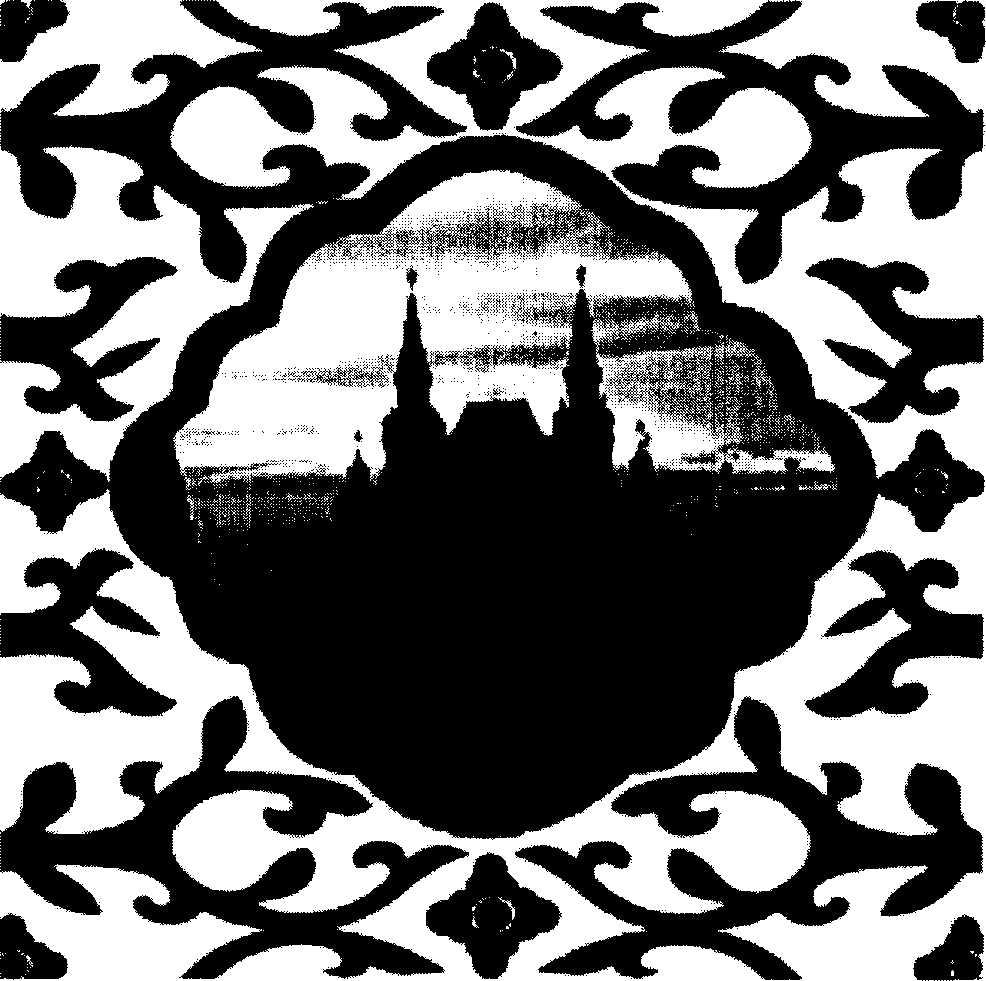

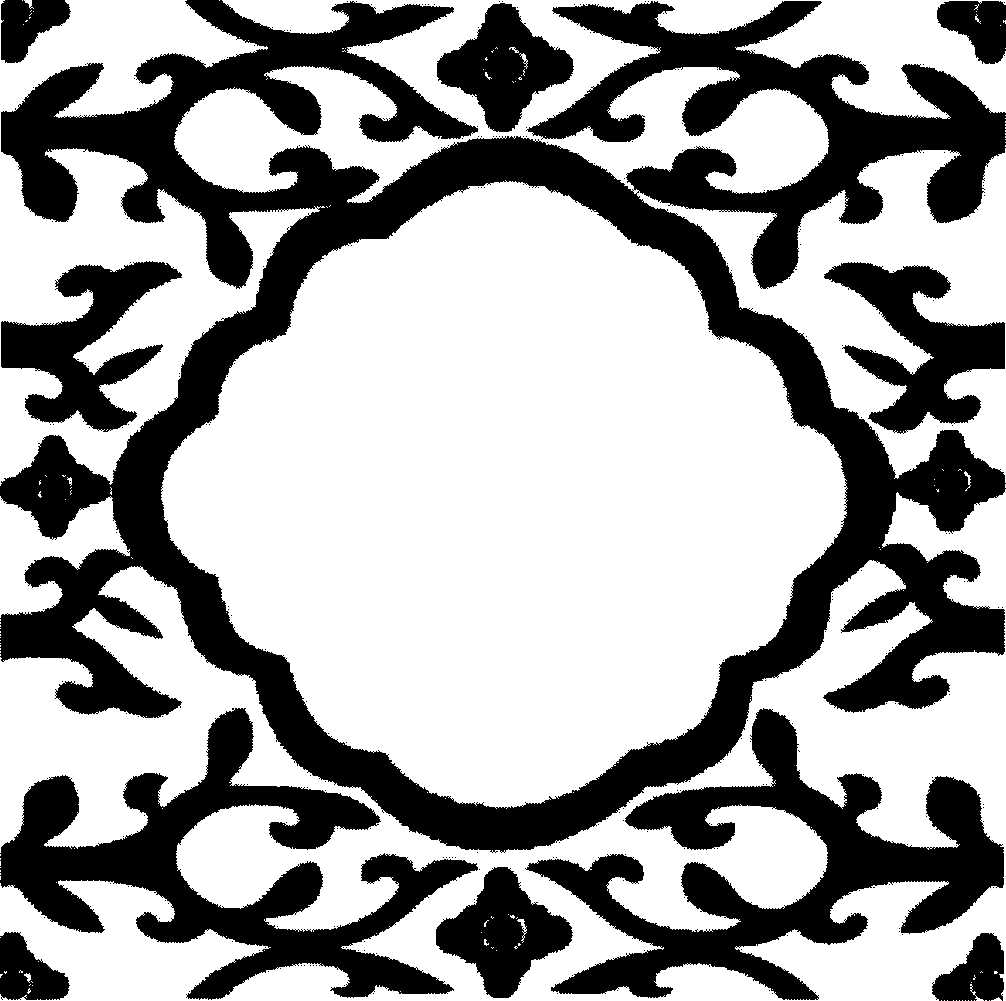

Making process of color jacquard fabric with different speciality

InactiveCN1847489AIngenious combinationRich interweaving color effectJacquardsPattern making devicesSubject matterComputer software

The present invention discloses the making process of color jacquard fabric possessing different speciality. The making process includes the steps of card design and making, loom preparation, and weaving. The step of card design and making includes reading the target image of the jacquard into the computer, regulating the read image and setting parameters, giving image pixel number corresponding to the image sizes, frame modifying design and regulation of the read image, separating the processed target image into subject image part and auxiliary pattern parts and separated image and pattern design and card design with the jacquard computer software, superposing the two designed cards to form one image and pattern card and saving. The said making process can obtain jacquard fabric with vivid picture, rich color representation and patter well combined together.

Owner:李加林

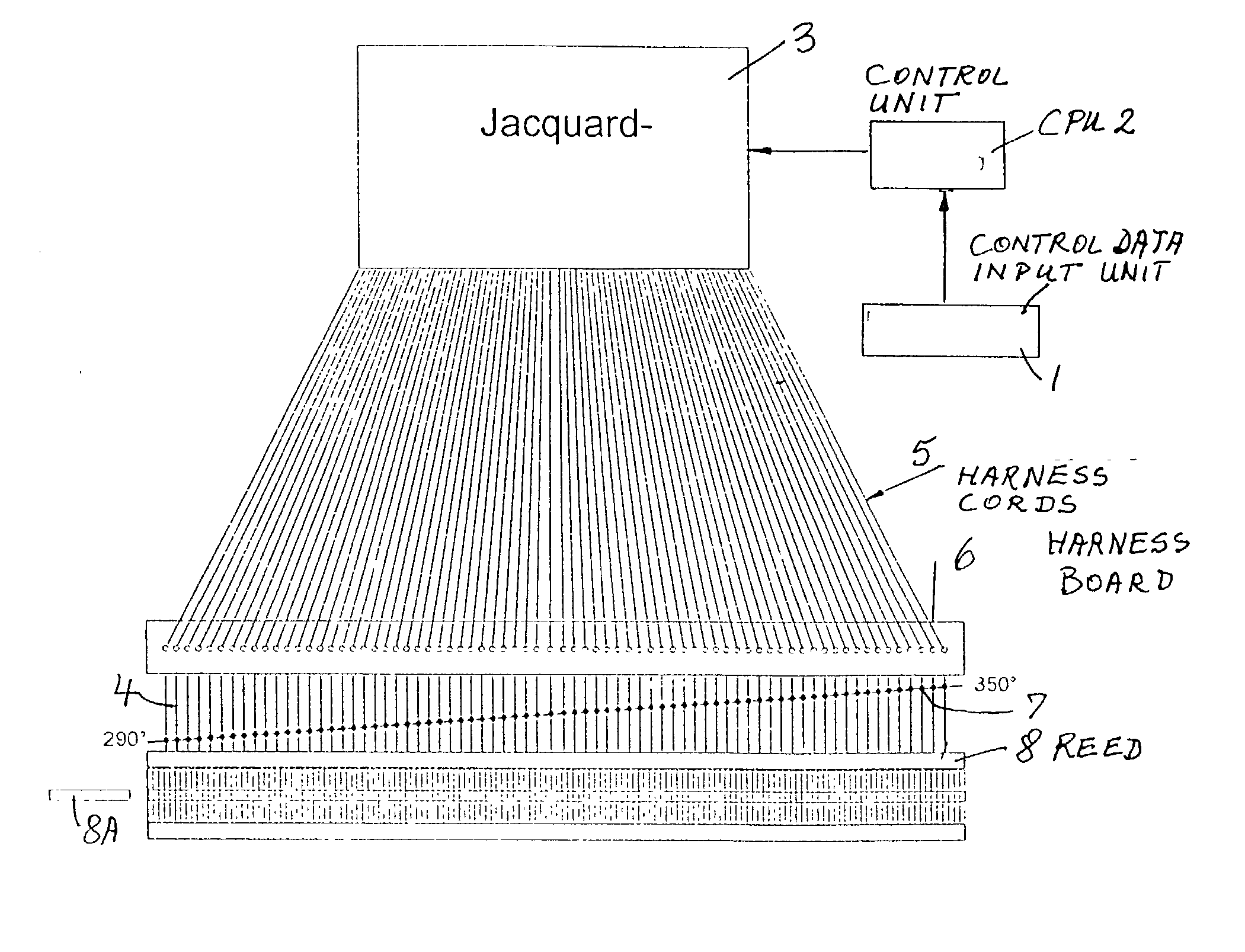

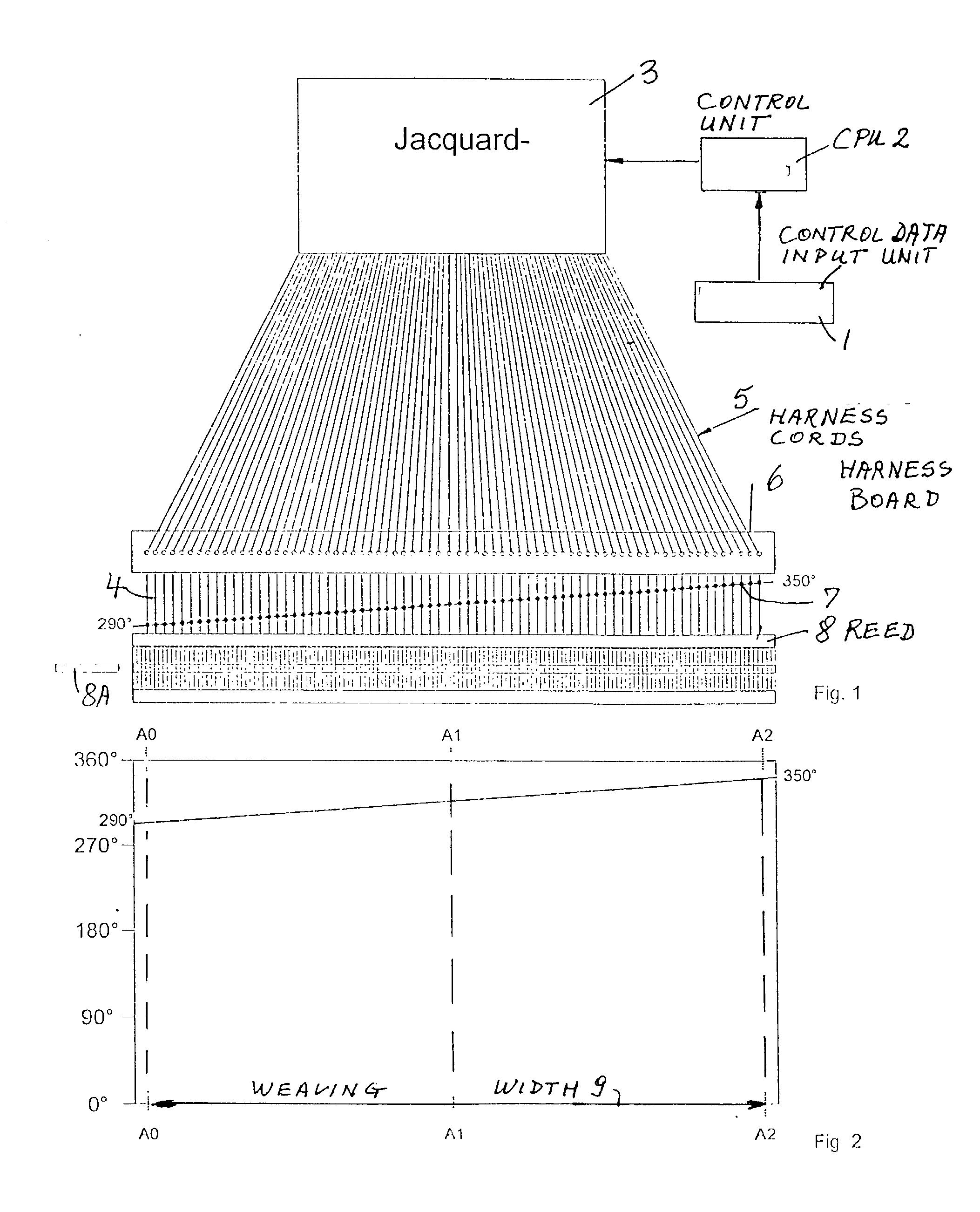

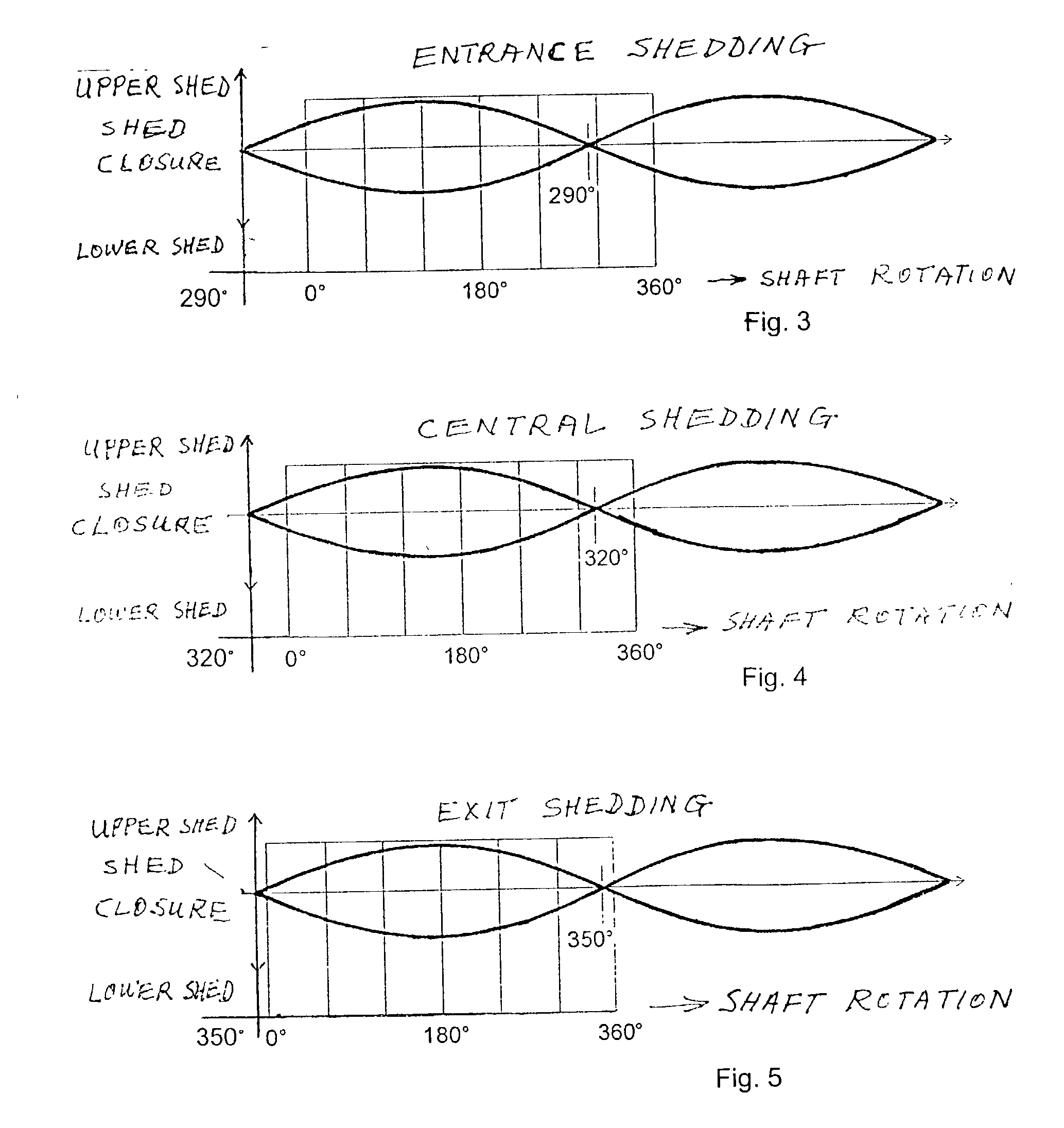

Method for controlling the shed in a loom with fluidic weft insertion

InactiveUS20030070721A1Operational securityExtended time intervalJacquardsLoomsHelical lineEngineering

The shed of a fluidic weaving loom is not changed simultaneously for all warp threads, but rather continuously starting at the weft entrance and continuing helically, so to speak, to the exit of the warp shed. This sequential shed closure takes place with a so-called domino effect along a helical line curved in space, whereby additional time is gained for stretching the inserted weft thread and temporarily stopping the shed formation or shedding is avoided.

Owner:STAUBLI FAVERGES SA

Jacquard vinylon polyester oil mounting thread and its manufacturing method

The invention relates to a method of jacquard loom, through choosing polyester multifilament with high strength and low expansion for industry and comeandgo for producing the material of thread of the jacquard loom shedding motion, and by using the advanced processing techniques like cabling, filling and then wax oil, making the tensile break strength of jacquard loom / be increased 40-50N / one than the present one and the distortion value is decreased by 95-115%, meanwhile, its abrasive resistance is one time higher than the vinylon.

Owner:倪轮官

Extra fine, high density, extra broad jacquard bedclothes face fabric and producing method thereof

An extra-wide jacquard bedding fabric with extra-high count and high density is characterized in that cotton yarn with the specification of J14.5tex or below or blended yarn with cotton content of over 20 percent is adopted as warp-wise or across warp raw materials. Warp-wise density is 748piece / 10cm to 807piece / 10cm and across warp density is 374piece / 10cm to 2750piece / 10cm. With adopting a special method, a shed is provided with 1 to 6 pieces of weft yarn. The manufacturing method of the invention is as follows: the preparation of the raw materials, warping, slashing, the preparation of mounting, drawing-in, pattern design, looming and inspection and packing. The extra-wide jacquard bedding fabric with extra-high count and high density has the textile fabric of special style and the pattern of strong stereo perception, so the high-grade jacquard bedding fabric is light and soft and has good permeability, thus meeting the requirements of consumers. In addition, the technical proposal is more reasonable and effective.

Owner:VEKEN HLDG GROUP

Single-layer portrait tapestry possessing different speciality and its making process

InactiveCN1847488AImprove the three-dimensional effectVivid and flexibleJacquardsPattern cardsComputer graphics (images)Subject matter

The present invention discloses one kind of single-layer portrait tapestry possessing different speciality and its making process. The making process includes the steps of card design and making, loom preparation, and weaving. The step of card design and making includes reading the target image of the jacquard into the computer, regulating the read image and setting parameters, giving image pixel number corresponding to the image sizes, frame modifying design and regulation of the read image, separating the processed target image into subject image part and auxiliary pattern parts and separated image and pattern design and card design with the jacquard computer software, superposing the two designed cards to form one image and pattern card and saving. The said making process can obtain jacquard with rich image layers and beautiful patterns and speciality.

Owner:李加林

Polyvinyl alcohol fiber oil pattern harness cord thread and its preparing method

The present invention relates to a kind of oiled polyvinyl harness flex for jacquard and its production process. The oiled polyvinyl harness flex is produced with light yellow polyvinyl yarn and white filtering polyvinyl yarn as material and through twisting, sizing and wax oil soaking. The produced oiled polyvinyl harness flex has yellow and white pattern, modulus 10-20 % higher than that of available one, small extension and less moisture influence.

Owner:倪轮官 +1

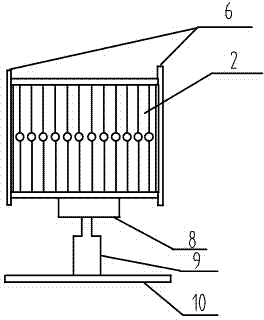

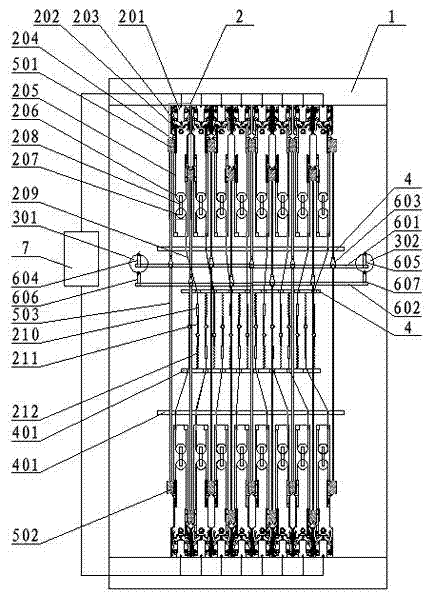

Novel electronic jacquard machine

ActiveCN102733034AFront and rear width shortenedEasy to debugJacquardsMaterial resourcesSpace requirements

The invention relates to a novel electronic jacquard machine, which comprises a control electric box, a rack, an upper electromagnetic selection execution component, a lower electromagnetic selection execution components, a synchronous reciprocating movement mechanism, a vertical griffe assembly, a suspension wire, a harness wire with a hole, a return spring and a fixed plate, wherein all electromagnetic selection execution components above the cloth fell of the electronic jacquard machine at present are evenly distributed above and below the cloth fell; a connecting rod is driven by the synchronous reciprocating movement mechanism to link the griffe of the corresponding upper and lower electromagnetic selection execution components; and when the suspension wire passes through a fixed plate hole, an inclined angle formed between the suspension wire and the fixed plate is controlled to be within an allowable range. The novel electronic jacquard machine can be directly installed in a weaving machine and has the advantages of reasonable structure and stable operation, and the periods for producing, installing and debugging the electronic jacquard machine are greatly shortened, the use space requirement on a user is lowered, more convenience is brought for transferring the electronic jacquard machine, and a great quantity of manpower, material resources and financial resources can be saved.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com