Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Card-punching apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

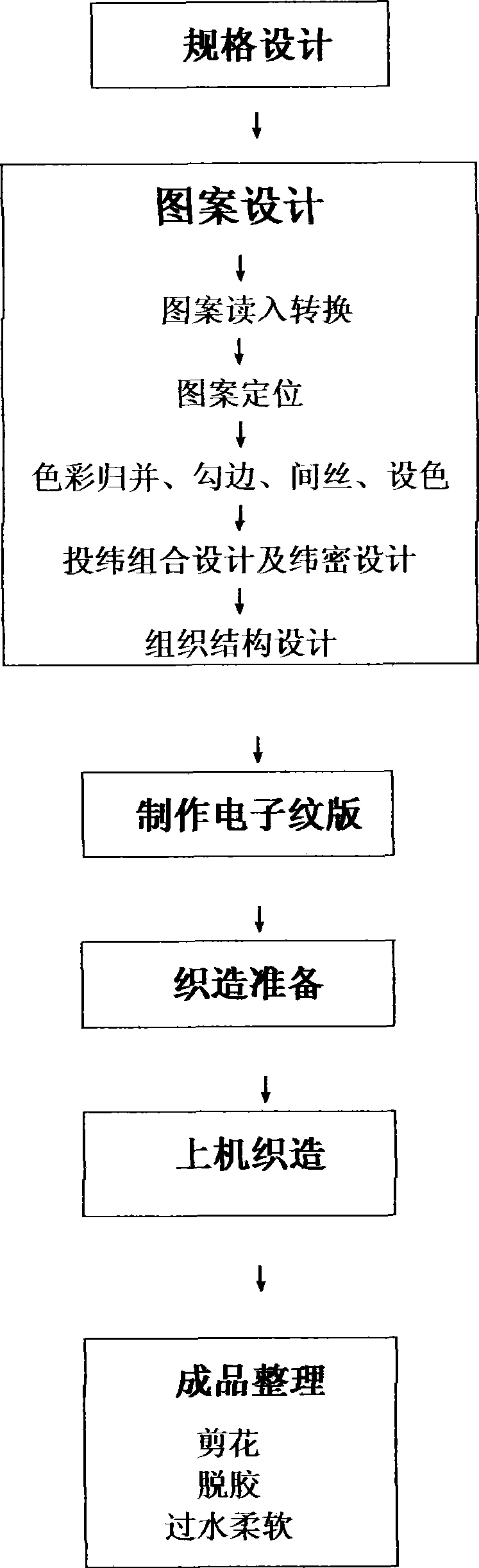

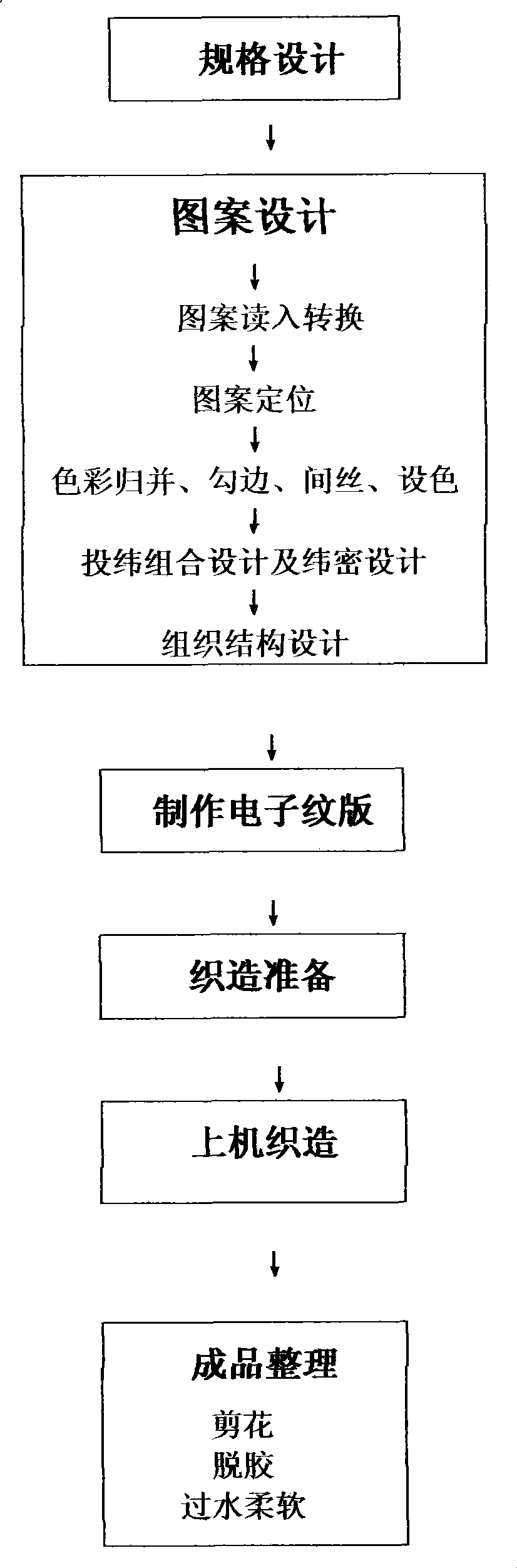

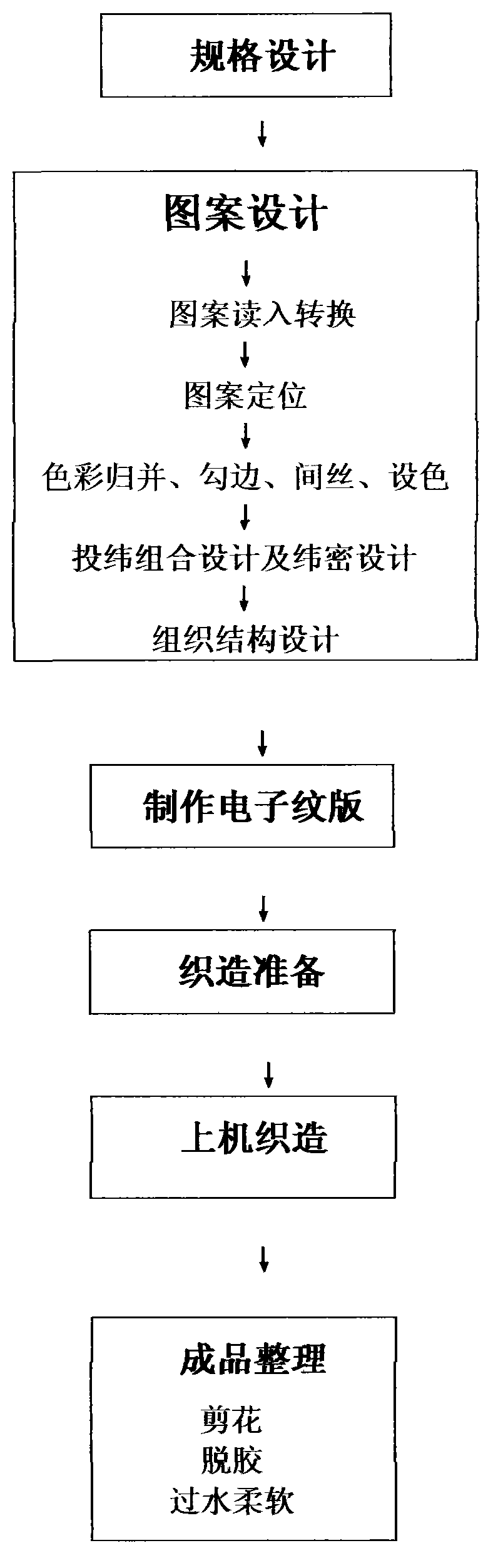

Production method of figured cloth different from embroidery characteristics

ActiveCN101423998AFeel goodStrong three-dimensional senseCard-punching apparatusSwivel-woven fabricsWork in processVolumetric Mass Density

The invention discloses a method for manufacturing jacquard fabrics different from embroidering properties, which comprises the following steps of specification design, pattern design, weaving preparation, weaving on a machine, and sorting of finished products, wherein the step of pattern design is to read target patterns of the jacquard fabrics to be manufactured into a computer, to adjust and position the position of the patterns on the fabrics according to the dimension of the finished products, to set a plurality of colors for the patterns, to merge the colors, and to manufacture an electronic pattern card through picking combinational design, longitude and latitude density design and weave construction design; and the step of sorting of the finished products is to perform trimming on the floating length of weft threads on the reverse side of semifinished products which are off the machine. The jacquard fabrics produced by the method have good hand feeling, strong third dimension, high ornamental value, and distinct contrast between rugged figured pattern and refined bottom plates, achieve the embroidering style after being subjected to two procedures of jacquard weaving and jacquard trimming, is accurate to position the patterns, are more suitable to be used as family spinning fabrics such as curtains and back cushions compared with the prior jacquard fabrics, and have the characteristics of short manufacturing time and low production cost.

Owner:DALI SILK ZHEJIANG

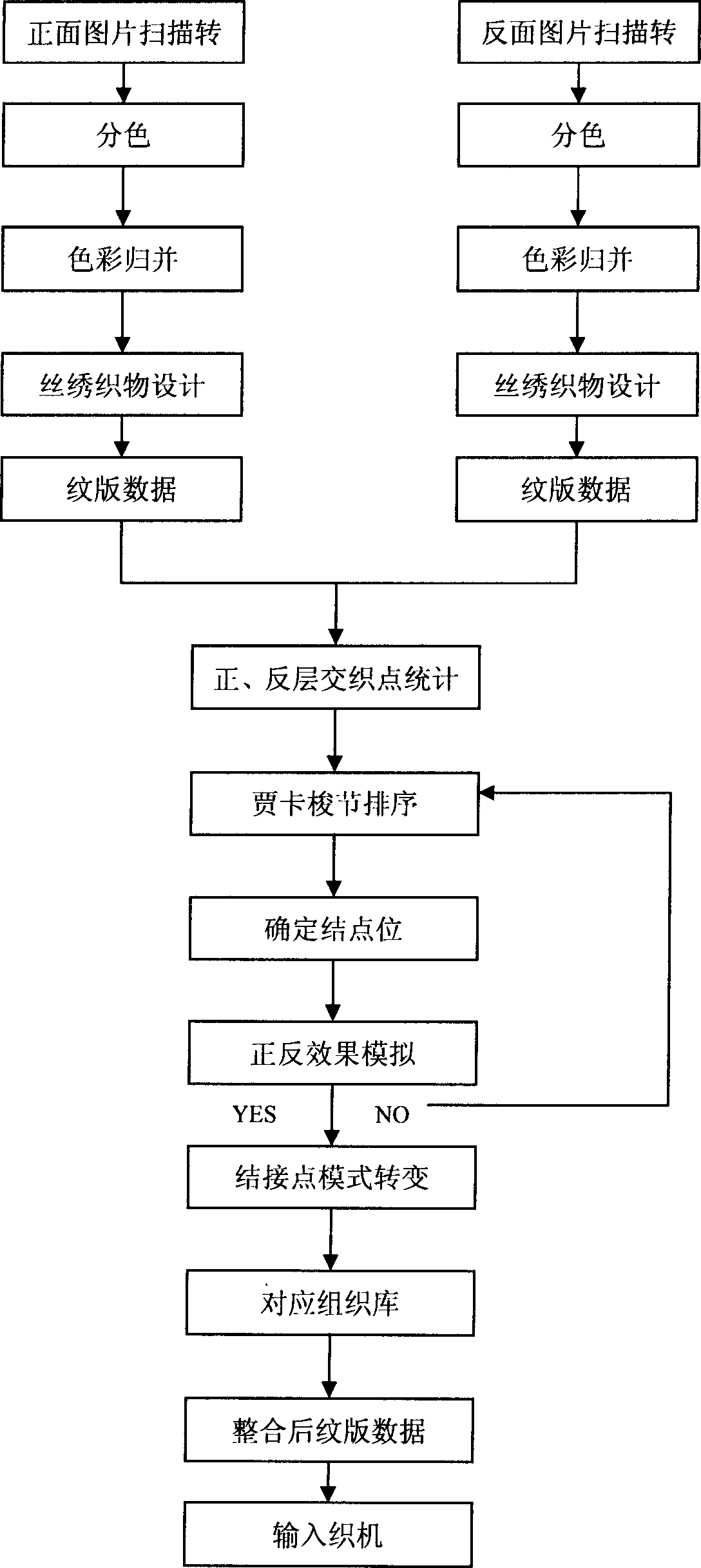

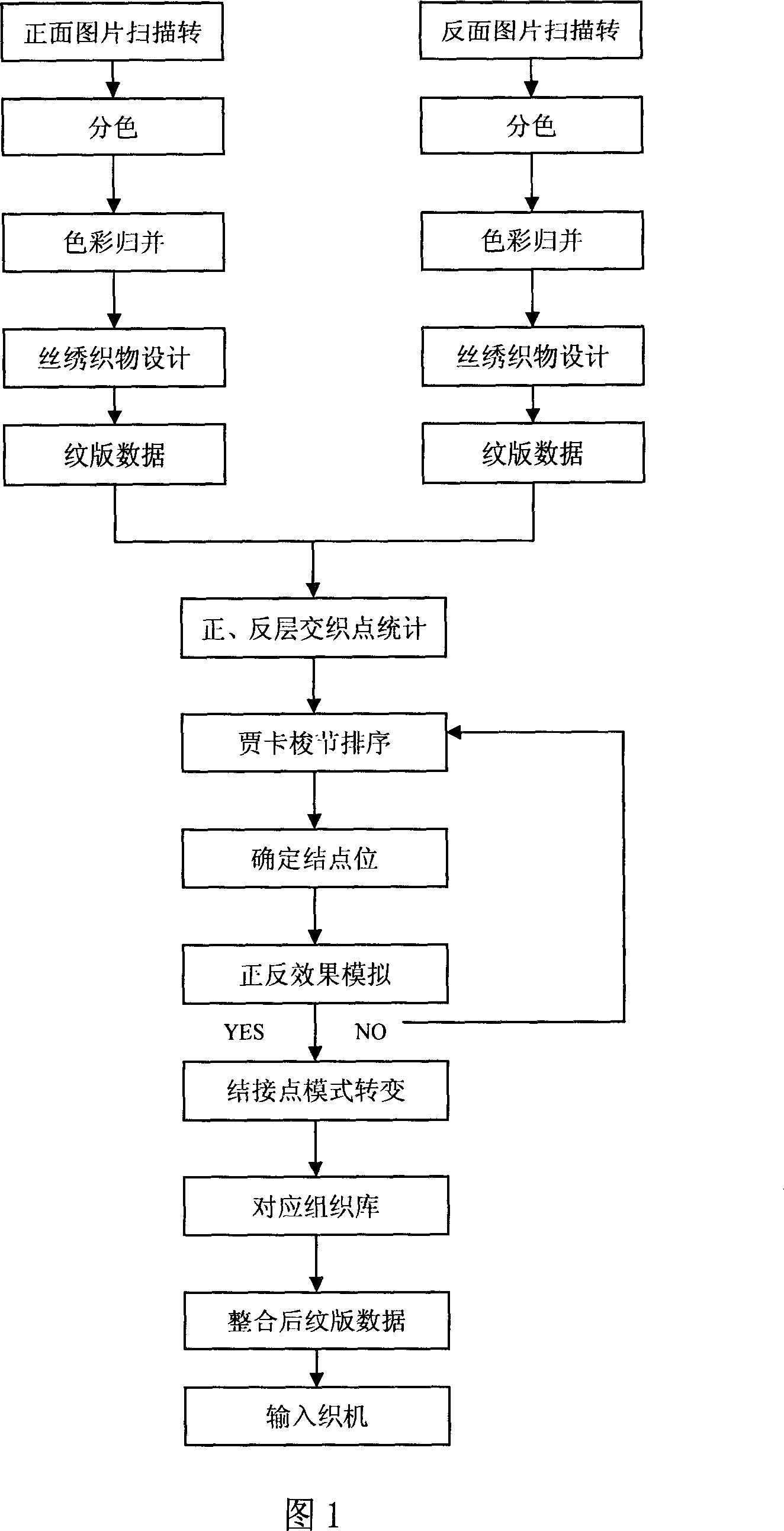

Digitel code manufacturing method jacquard weave double surface beautiful and glorious

InactiveCN1786308AMeet individual needsWide range of materialsPattern making devicesCard-punching apparatusTexture designPersonalization

The invention belongs to silk weaving picture-scenery technique development field, especially relates to a digital pattern two side beautiful brocade manufacturing method. The method includes the following steps: scanning, changing, color separating to set color bank; adding up crossing point according to electron lag; doing knitted texture design and confirming crunode position; inputting electron lag into loom control system. Materials drawing of the invention are very wide. And the product can satisfy consumerí»s individuation demand.

Owner:韩容

Method for manufacturing jacquard fabric with different material quality and style

InactiveCN101109121AExpress the verve of pen and inkImprove weaving methodJacquardsCard-punching apparatusGraphicsJacquard loom

The invention relates to a preparing way for a jacquard fabric, in particular to a preparing way for a jacquard fabric of different materials and styles, which comprises the treating of several graphic images of different styles, designing texture boards for fabrics, combining the texture boards, creating a complete texture-board document, sending the texture boards for an electronic jacquard loom to weave; also placing a warp of one or more materials and a weft of at least 2 materials on the loom; and turning on the loom to make the fabric. The invention uses different materials to express the artistic effect of color jacquard fabric of different styles of the same picture. The textures in the fabric run smoothly, the joining sites are smooth and natural; the color and brightness of the whole fabric are harmonic, and the topic is clear, which expresses better the romantic charm in original artistic works.

Owner:韩容

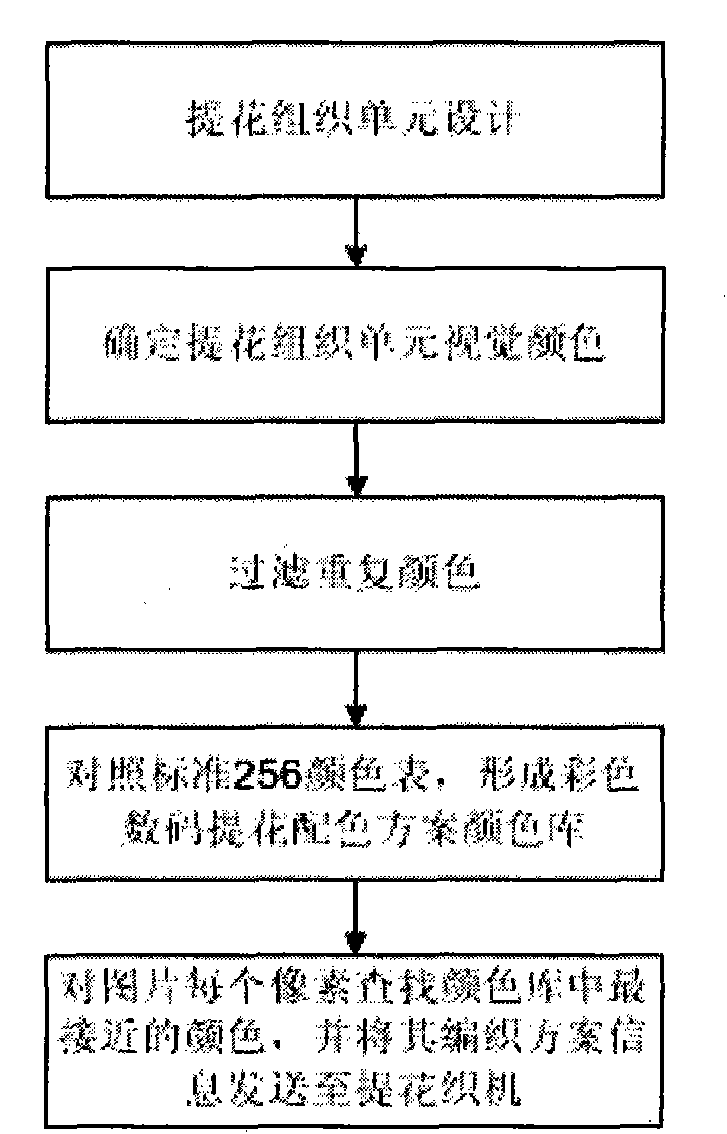

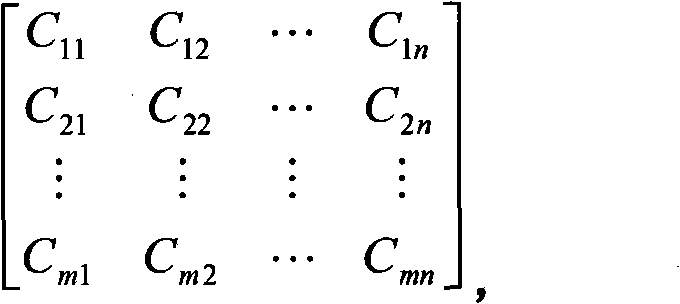

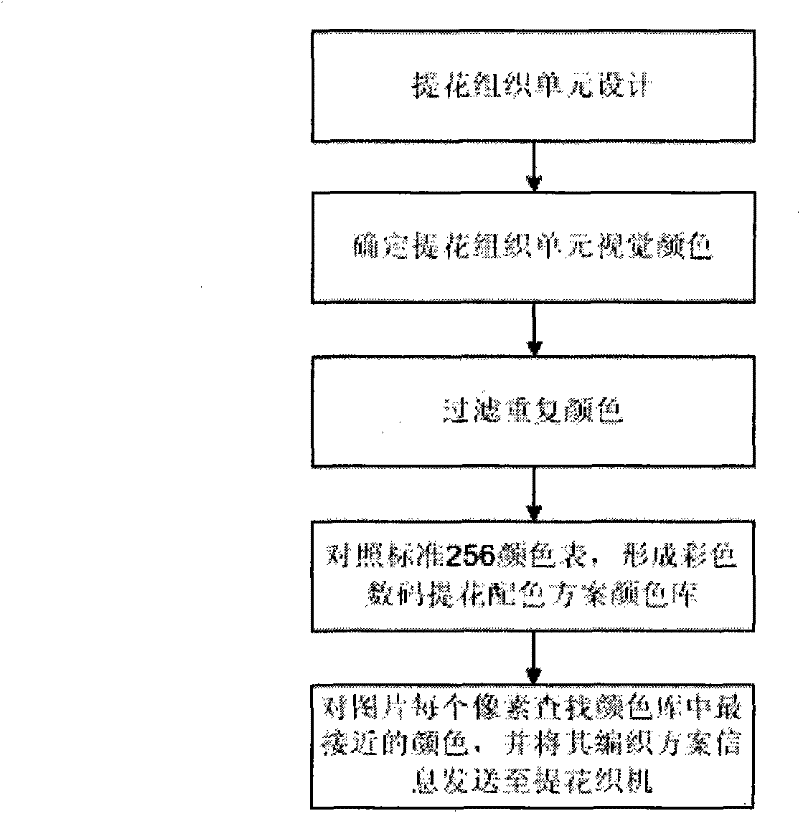

Method for controlling digital jacquard-woven colored patterns

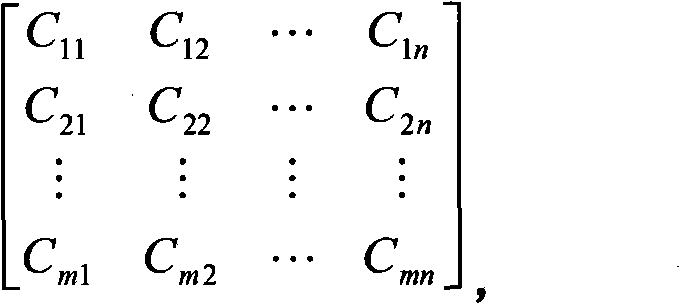

The invention discloses a method for controlling digital jacquard-woven colored patterns. The method comprises the following steps of: determining the parameters of a jacquard weave unit and obtaining the visual colour value corresponding to each intersecting point in the jacquard weave unit by a colour space hybrid colour processing method; and removing the same visual colour data, keeping the visual colour data of an interweaving way, after filtering the data by contrasting a standard 256 colour list by a colour difference computing method, comparing the colour of each pixel point of the colored patterns input into a computer with the visual colours of the jacquard weave unit to obtain the colours with the maximum colour similarity, forming a program, and controlling the digital jacquard to weave colored patterns. All the similar colours in the standard 256 colour can be prepared from yarns with fixed colours without manually selecting the colours of yarns; and the back of a provided jacquard product is relatively flat, so the quality and added value of the product are improved.

Owner:SUZHOU UNIV +1

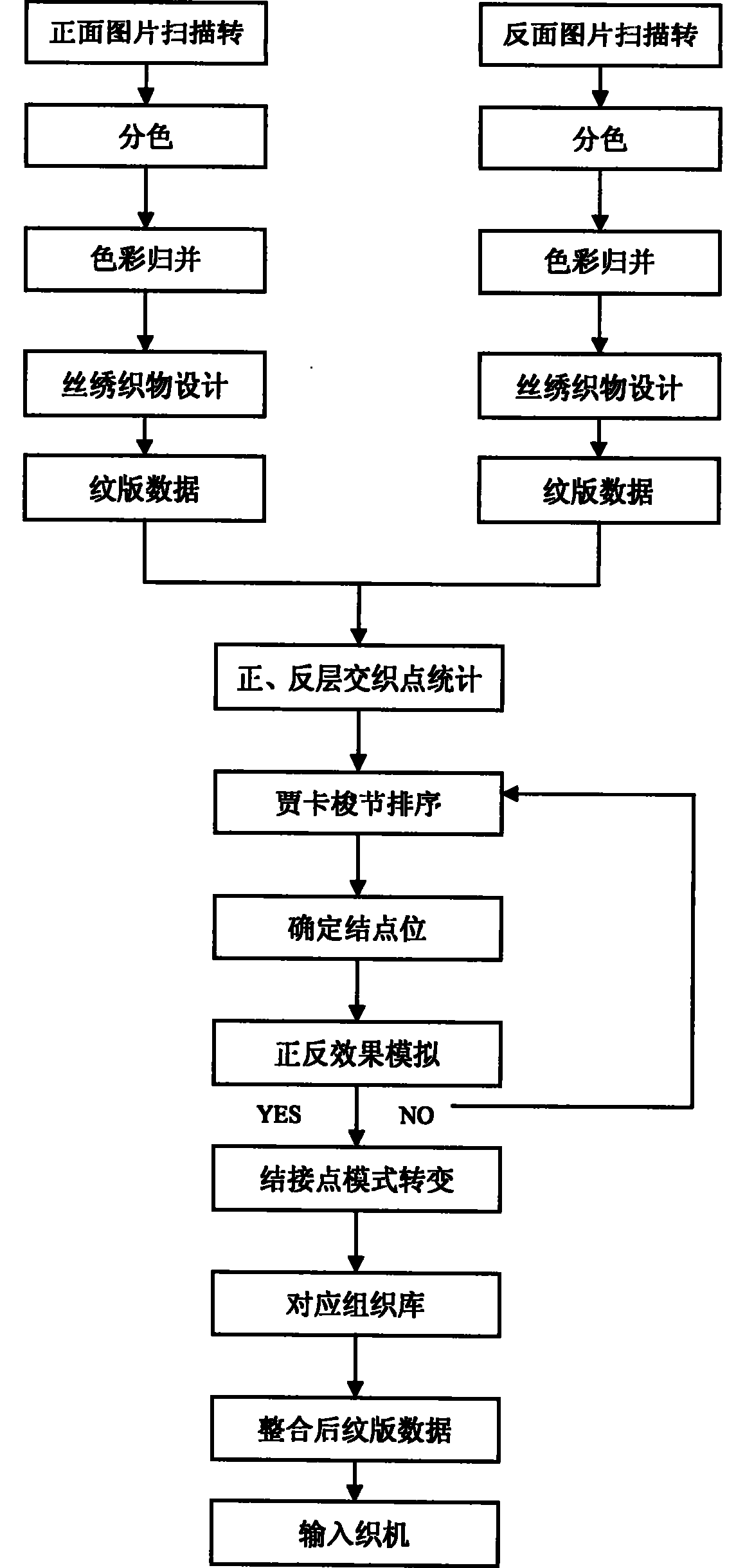

Design method of two-sided different effect digital jacquard dress fabric

InactiveCN101457433ARich varietyProtection precisionPattern making devicesCard-punching apparatusPunchingEngineering

The invention discloses a design method for double-faced different-effect digital jacquard weave garment material. The design method for the double-faced different-effect digital jacquard weave garment material is characterized in that the method comprises the steps as follows: (1) the front face effect design is carried out on the fabric to obtain a front pattern and the back face effect design is carried out on the fabric to obtain a back pattern; (2) the front pattern and the back pattern are superimposed to be displayed in one plan of weave, and then picking design, composite weave design, scale design, major weave needle-punching introduction and accessorial needle-punching introduction are carried out; (3) a composite digital weave plate is generated. The method is applicable to garment material development to weave double-faced different-effect digital jacquard weave garment material with different colors, patterns and stylistic characteristics on the front and back faces.

Owner:JIAXING YUELONG JACQUARD & WEAVING +1

Preparation technique of yarn-dyed jacquard fabric with printing texture characteristic

The invention discloses a preparation technique of a yarn-dyed jacquard fabric with printing texture characteristic. The preparation technique comprises the following steps of: (1) designing patterns, and selecting and layering colors; (2) designing and manufacturing a fabric texture board; (3) preparing weaving and knitting; (4) weaving and knitting on a machine; and (5) producing a finished product. The types of multicolor jacquard fabric products can be enriched by adopting the weaving and knitting method, the jacquard fabric not only can be kept with bright color, rich gradient layout and strong stereoscopic impression, but also has fine and smooth patterns of printing products, and the patterns are diversified and strong in stereoscopic impression. The disadvantages of the jacquard fabric on the expressing methods of patterns with real flowers, characters and scenes can be made up for.

Owner:HAINING ZHIDA TEXTILE WEAVING

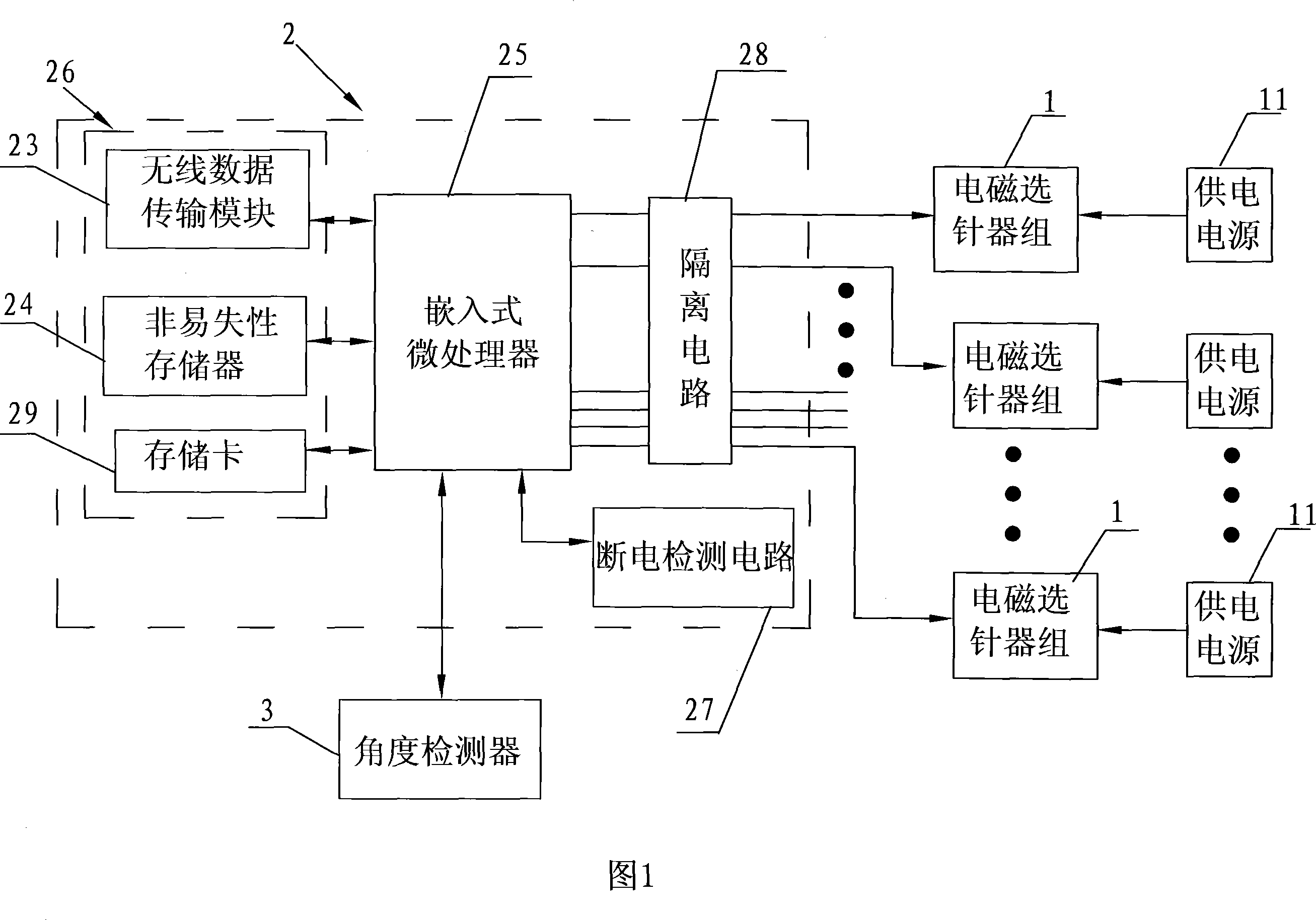

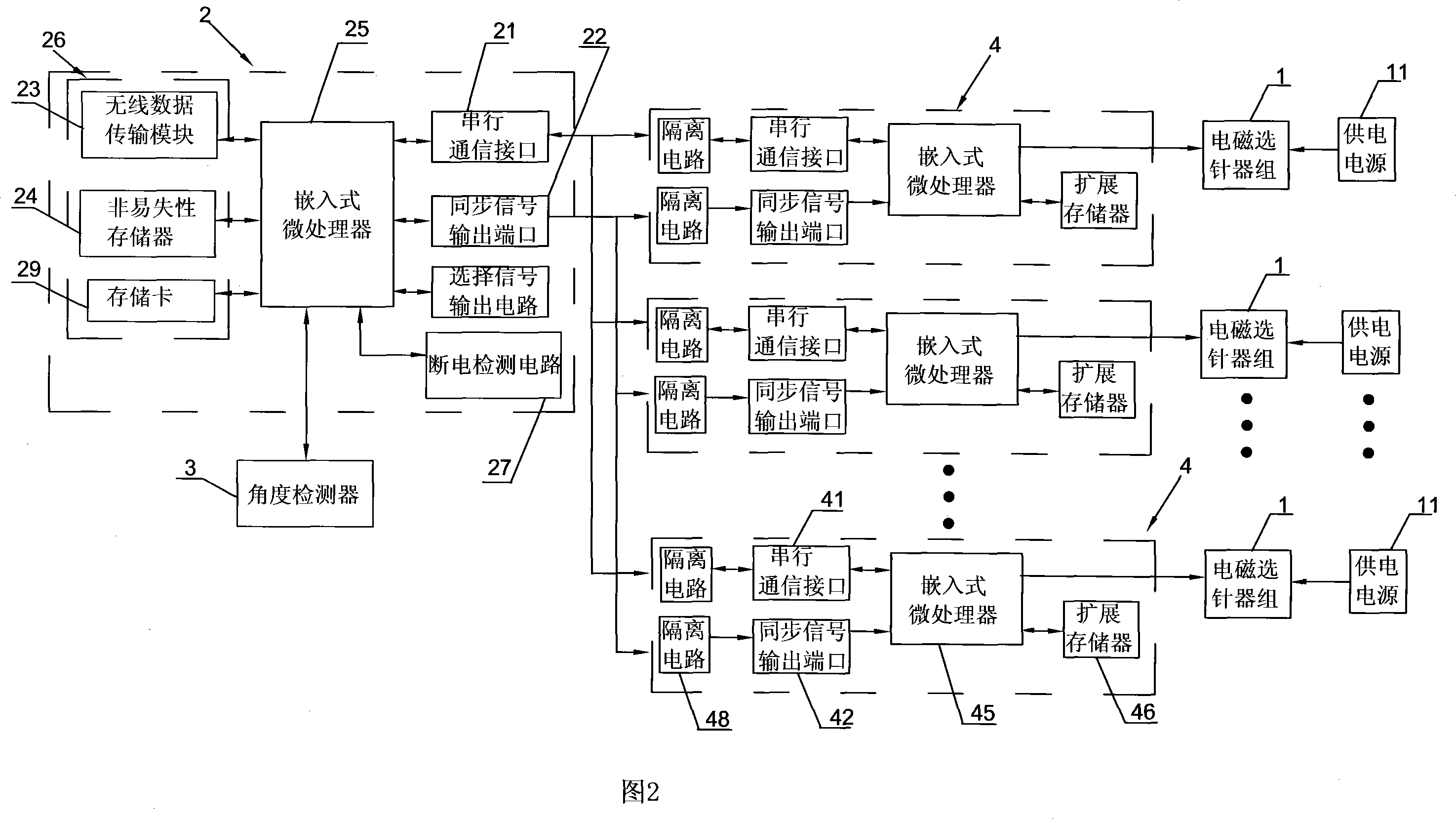

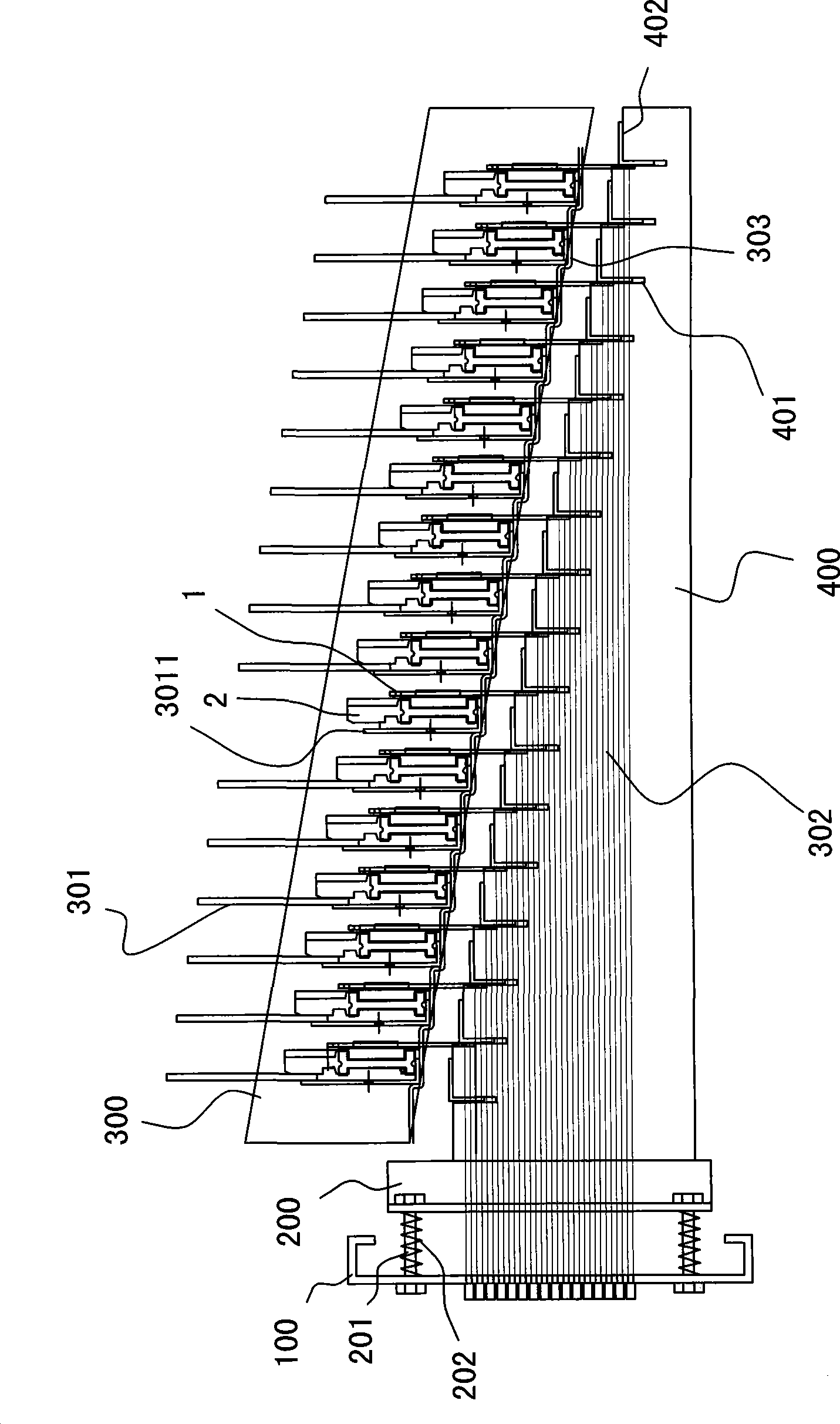

Control system for electronic jacquard machine

InactiveCN101054752AWork reliablyImprove anti-interference abilityJacquardsElectric programme controlControl systemData transmission

The invention relates to a control system of electronic jacquard machine including a plurality of electromagnetic needle selector, which at least divided to two separate electromagnetic needle selector sets, and each electromagnetic needle selector set is supplied by separate power supply; a main controller, which contains a embedding type microprocessor, a storage mechanism for storing pattern data, Wherein, data input end of the embedding type microprocessor is connected with each electromagnetic needle selector set. Before spinning, the main controller reads spinning pattern data in the storage mechanism and carries format conversion, storage and grouping of data, when the jacquard machine working, the embedding type microprocessor outputs each group of spinning pattern data to the corresponding electromagnetic needle selector set for carrying pattern operation. Due to directly driving the electromagnetic needle selector set by the main controller, the electromagnetic needle selector can work reliably, contradiction of high data transportation speed and cable length is solved, and due to avoiding using longer cable to transport data, immunity of the control system is greatly increased.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

Manufacturing method of large jacquard embroidery electronic card for loom control system

InactiveCN1955350ARich layersHigh interweave densityCard-punching apparatusGraphicsImaging processing

An electronic pattern card of jacquard embroidery for loom control system is prepared through graphics and image processing, and design of jacquard weaving.

Owner:韩容

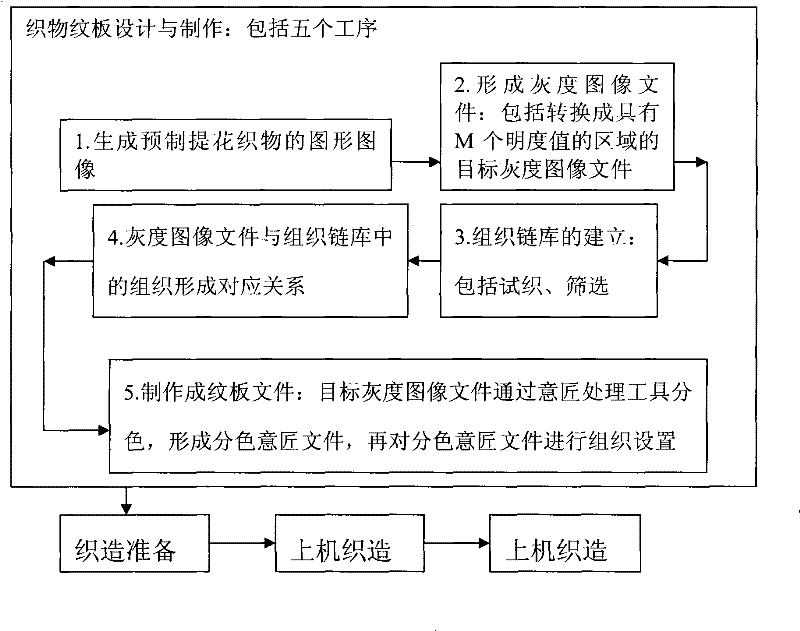

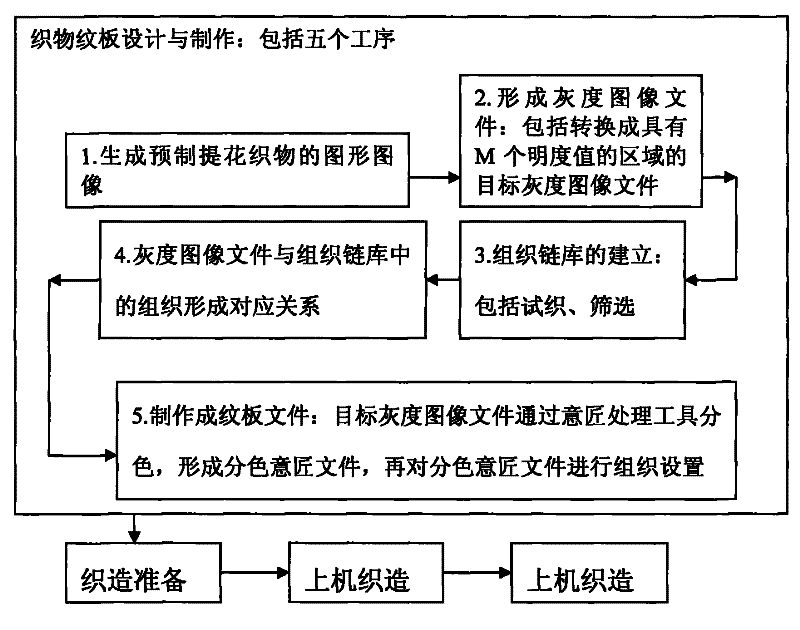

Preparation process of monochrome graded display jacquard fabric

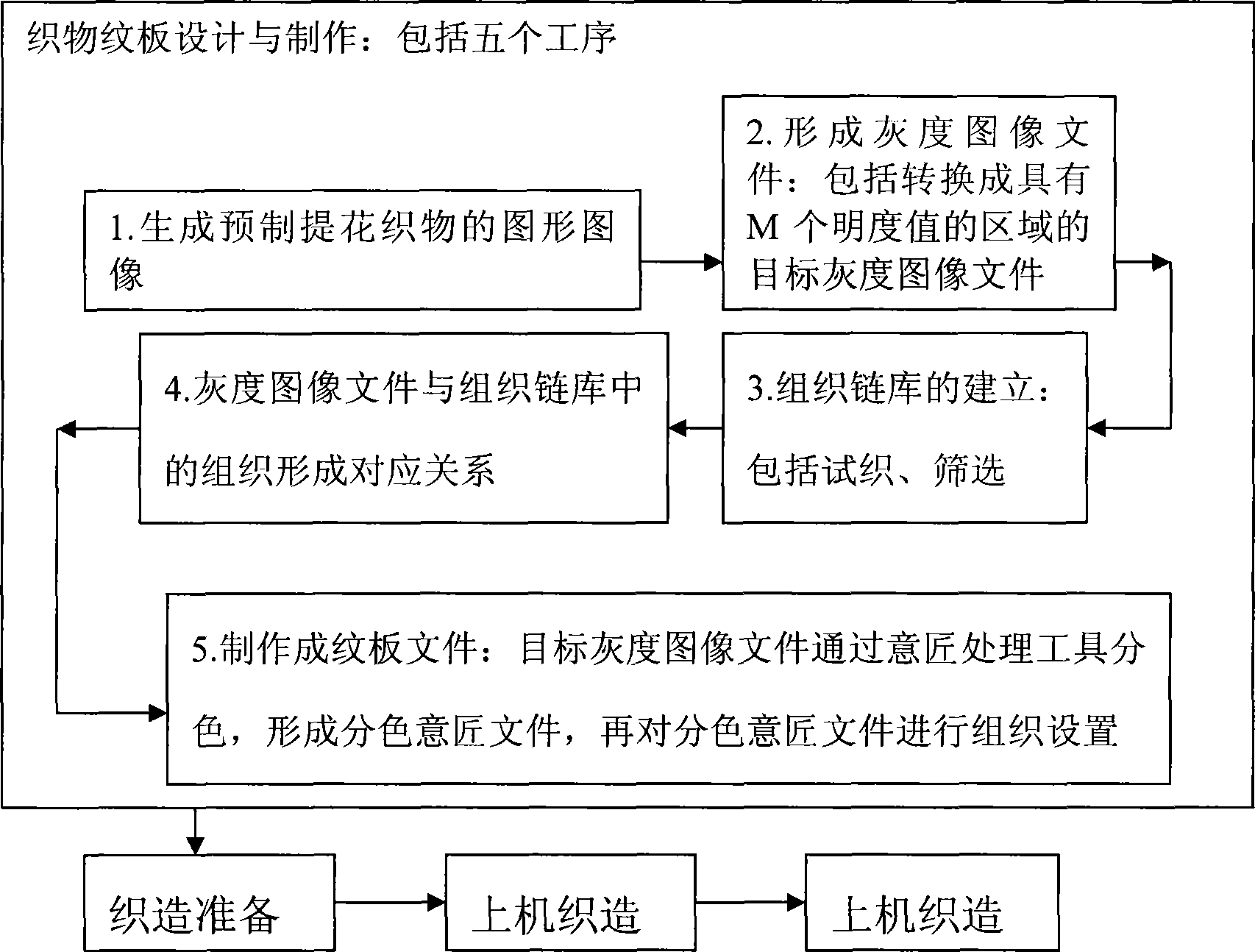

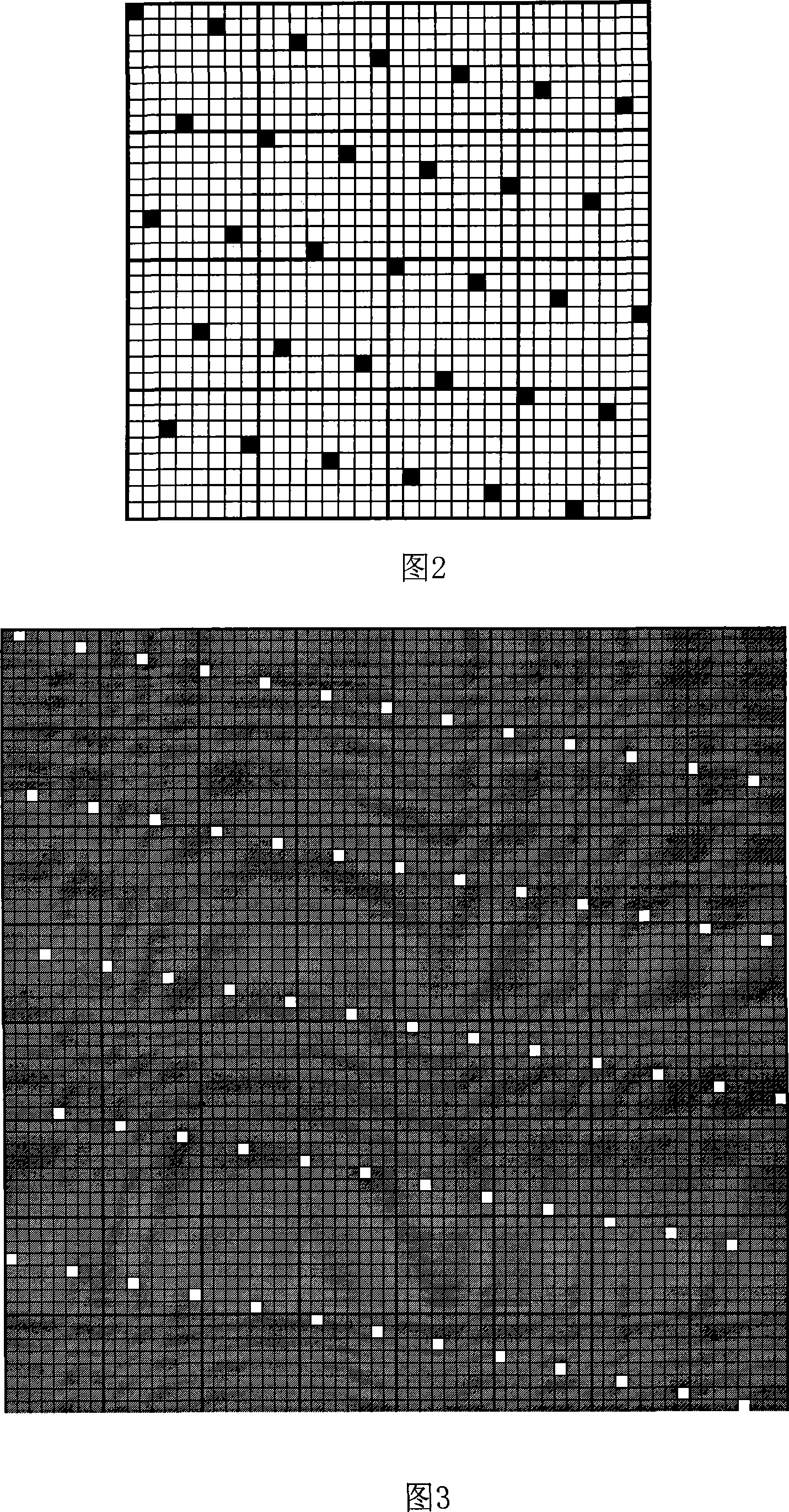

InactiveCN101445988AAccurate configurationRich layersCard-punching apparatusSwivel-woven fabricsYarnDigital image

The invention relates to a preparation process of monochrome graded display jacquard fabric. The preparation process comprises the following steps: (1) designing and manufacturing a fabric card; (2) preparing for weaving; (3) looming and weaving; and (4) manufacturing a finished product. The preparation process is characterized in that the designing and manufacturing the fabric card is as follows: (1) generating a digital image of prefabricated jacquard fabric; (2) forming the digital image into a gray scale image file; (3) creating a tissue link library with different lightness values; (4) causing the gray scale image file and tissues in the tissue link library to form a corresponding relation; and (5) manufacturing a fabric card file. The significant substantial effects of the preparation process are as follows: 1. processing warp and weft with uniform dyeing and applying the creation of a tissue model, thus ensuring precision configuration, abundant hierarchy and exquisite variation of the fabric texture; 2. having simple production process and little limitation and reducing the cost of raw materials; and 3. being capable of dyeing after weaving gray warp and weft, thus process is simple and dye is saved.

Owner:ZHEJIANG SCI-TECH UNIV

Latitudinal spacing color mixed jacquard fabric surface staining method

InactiveCN101158078ARich artistic expressionThe change effect is obviousCard-punching apparatusWoven fabricsColor effectColor changes

The invention discloses a surface color method of a zonal spatial color mixing jacquard fabric. Jacquard design color band series maps that meet a zonal ratio relationship are drown in a jacquard CAD. Groups of mixing color woofs that are corresponding to the jacquard design color are arranged. Then jacquard design color with different color numbers is changed to the jacquard design color bands in the series maps in the jacquard with a color change function. A framework between threads that meets the requirement for cutting the float length of the color woof is provided. A backing framework is provided for a concreting colorless woof. Colors of the jacquard design color bands are corresponding to the framework between threads and the backing framework in a structure list of the jacquard CAD one by one. The fabric that uses the color method can meet the requirement of colorful design patterns, besides, as the woof floating length used has less connection with warp threads, the pattern is protruded and rich, thus showing a relief-shaped stereoscopic sense and enriching the color effect of jacquard.

Owner:ZHEJIANG SCI-TECH UNIV

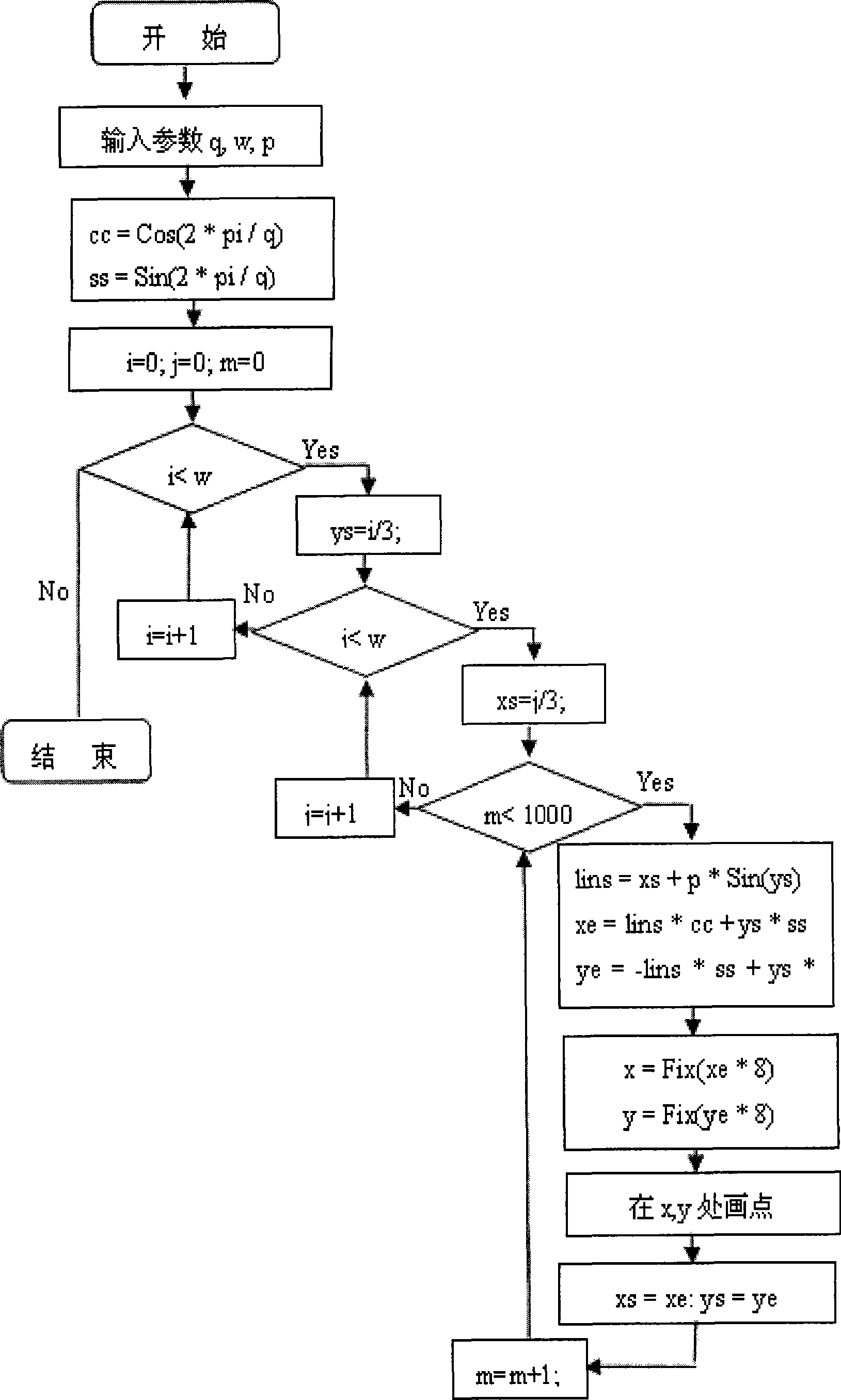

Method for preparing digital line crepe

InactiveCN101445981ANew pattern designNew production processPattern making devicesCard-punching apparatusInformation controlBitmap

The invention relates to a method for preparing a digital line crepe, comprising the following steps: uniform stochastic web graphics are generated and fabric pattern types are generated; line uniform stochastic web graphics are obtained through the regulation of parameters; parts of the selected generated line uniform stochastic web graphics are intercepted; the obtained local graphics of the uniform stochastic web are sheared, stacked, rotated and distorted to design satisfied line decorative pattern effect and are stored as bitmap files; a jacquard weaving CAD method is used for decorative pattern color separation and drafting treatment to generate files; an electronic jacquard information control system or an automatic rolling jacquard card system is used for the plate making; jacquard weaving is adopted for forming fabrics. The method for preparing the digital line crepe has the beneficial effects of new pattern design mode, new production process and new fabric effect. Due to the digital processing on the patterns, a specific line crepe weaving effect is formed.

Owner:ZHEJIANG SCI-TECH UNIV

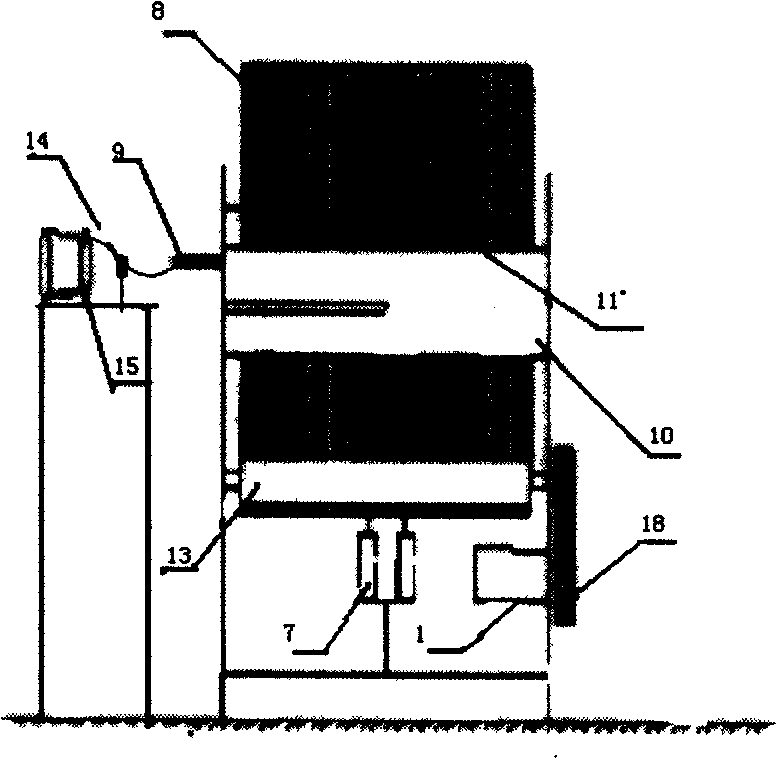

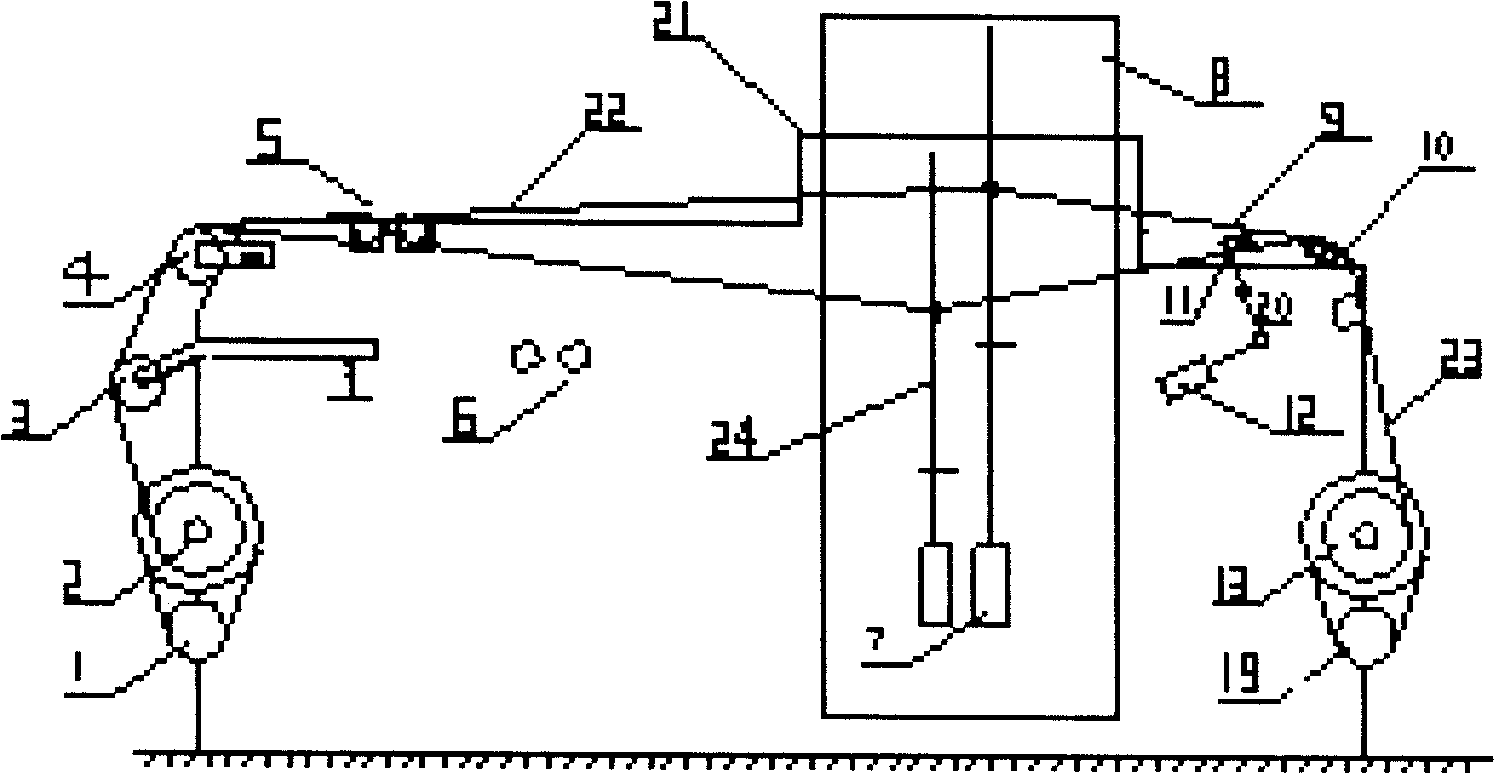

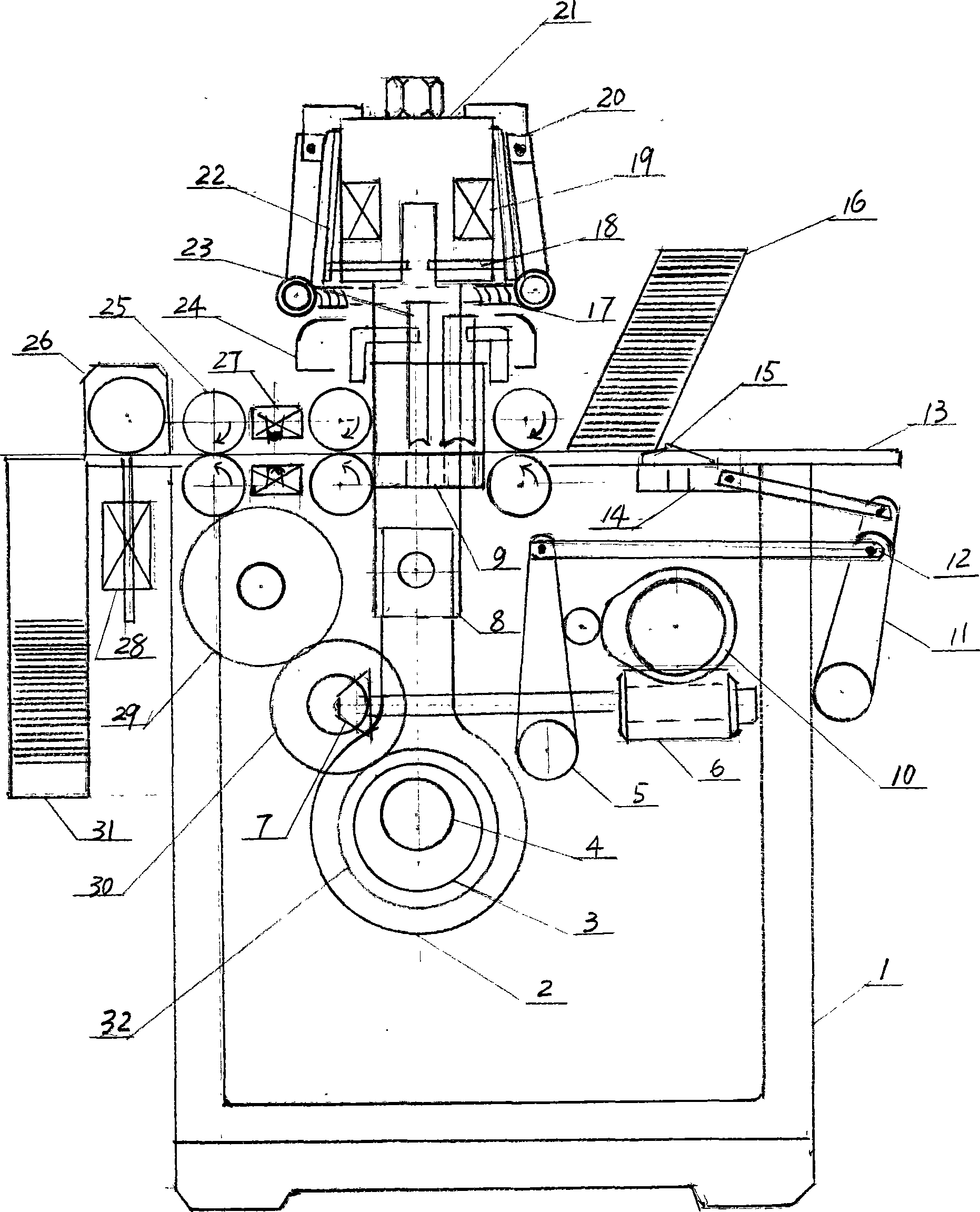

Full-automatic air injection proofing press

InactiveCN101314882AVersatileMeet design needsLoomsCard-punching apparatusDesign softwareEngineering

The invention discloses a full-automatic jet sample loom which adopts computer control to realize the full-automatic operations of weft inserting, color selecting, weft cutting, heald raising, beating-up, let-off warping, coiling, etc. according to the design requirements of a chain draft. In the structure, a weft inserting device is arranged at the front part of the sample loom; the middle part divides a wrap into two layers so as to form a shed through a heald frame moving device; a weft color selecting system and a weft inserting device are arranged at the side part; and a let-off warping device, etc. are arranged at the rear part. In the control, ten functional buttons are used for finishing the selection. In the operation, the design and the correction to a chain draft as well as the control to the sample loom can be carried out through clicking the related display icons by a mouse according to the explanatory note displayed on a design software screen. The sample loom has the advantages that the sample weaving operation can be conveniently, easily, fast and accurately finished; and the sample quality can reach the standard of the actual woven fabric.

Owner:JIANGNAN UNIV

Electronic needle selection mechanism for jacquard machine

ActiveCN101509165AOvercome the flaw of damageEasily brokenJacquardsCard-punching apparatusReciprocating motionElectromagnetic valve

The invention discloses an electronic cylinder provided with a valve seat frame and a push pin frame, all electromagnetic valve plates for fixing electromagnetic valves are arranged in the valve seat frame, the push pin frame is positioned below the valve seat frame and constructed by a stair descending plate and a push pin frame, the stair descending plate is provided with plural rows of push pin baffle plates, and the push pin frame and the restoring plate are integrated as a whole. Relative to the push pins, the valve seat frame can move to and fro in the horizontal direction and the vertical direction, and the push pin frame can move to and fro in the horizontal direction. Each electromagnetic valve is provided with two armature pins, porose or aporate situation is shaped by whether the armature pins cover the push pin baffle plate through pores, and the work is done. The invention replaces the restoring coils or permanent magnet with the mechanical restoring mode, thus, on the one hand, eliminating residual magnetism and resolving the problem of electromagnetic valve damage caused by easy breakage of the connecting wires of the working coils; on the other hand, resolving the problem of likely tremble of the hanging push pins under the combined action of the push pin frame and the push pin baffle plate after adopting the integral push pin structure, to enhance the adaptability of the push pins and the transverse pins.

Owner:浙江新辉纺织机械有限公司

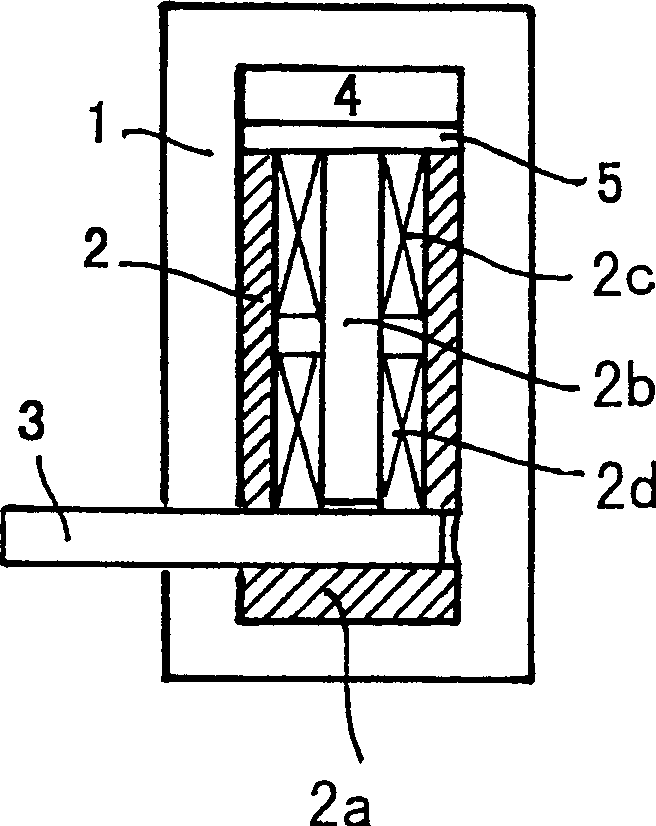

Electronic board of jacquard weave

InactiveCN1431347ALow calorific valueWork reliablyCard-punching apparatusPattern cardsPower flowEngineering

An electronic jacquard plate features that a permanent magnet and an insulating layer and arranged on the top of electromagnet to decrease the time and amplitude of current flowing in the winding of electromagnet, resulting in less heat generation, high reliability and long service life.

Owner:杭州经纬计算机系统工程有限公司

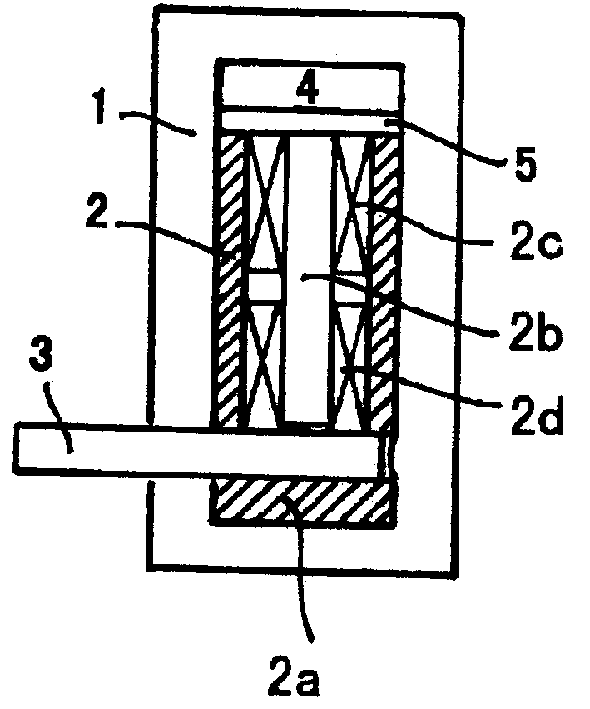

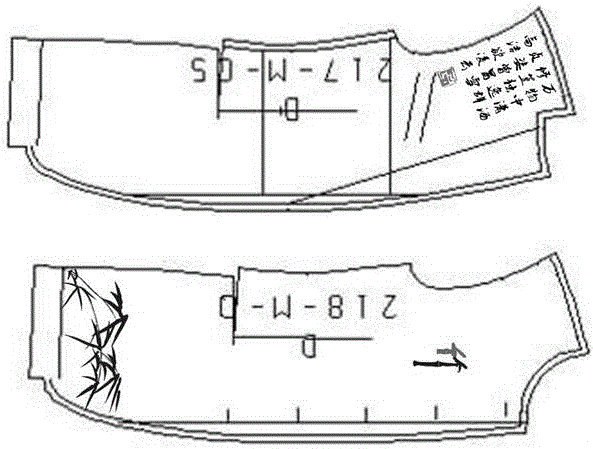

Method for weaving garment fabric which can exhibit the personalized pattern at any position of garment

ActiveCN106222832AImprove operational efficiencyNo wasteCard-punching apparatusPersonalizationState of art

The invention discloses a method for weaving the garment fabric which can exhibit the personalized pattern at any position of the garment, and belongs to the field of weaving fabric. The method comprises the following steps: a, carrying out the clothing layout design and establishing the layout chart; b, locating the individualized pattern position according to the clothing version and the position of the personalization pattern on the clothing, locating the personalization pattern of the fabric on the layout chart to complete the design of the positioning version; c, weaving the fabric. Compared with the prior art, the weaving method of the invention firstly forms the positioning jacquard or printing plate of the garment, and realizes the fabric, and has higher operation efficiency in the personalized garment production, and the product has good and high quality, and has good promotion and application value.

Owner:山东如意毛纺服装集团股份有限公司

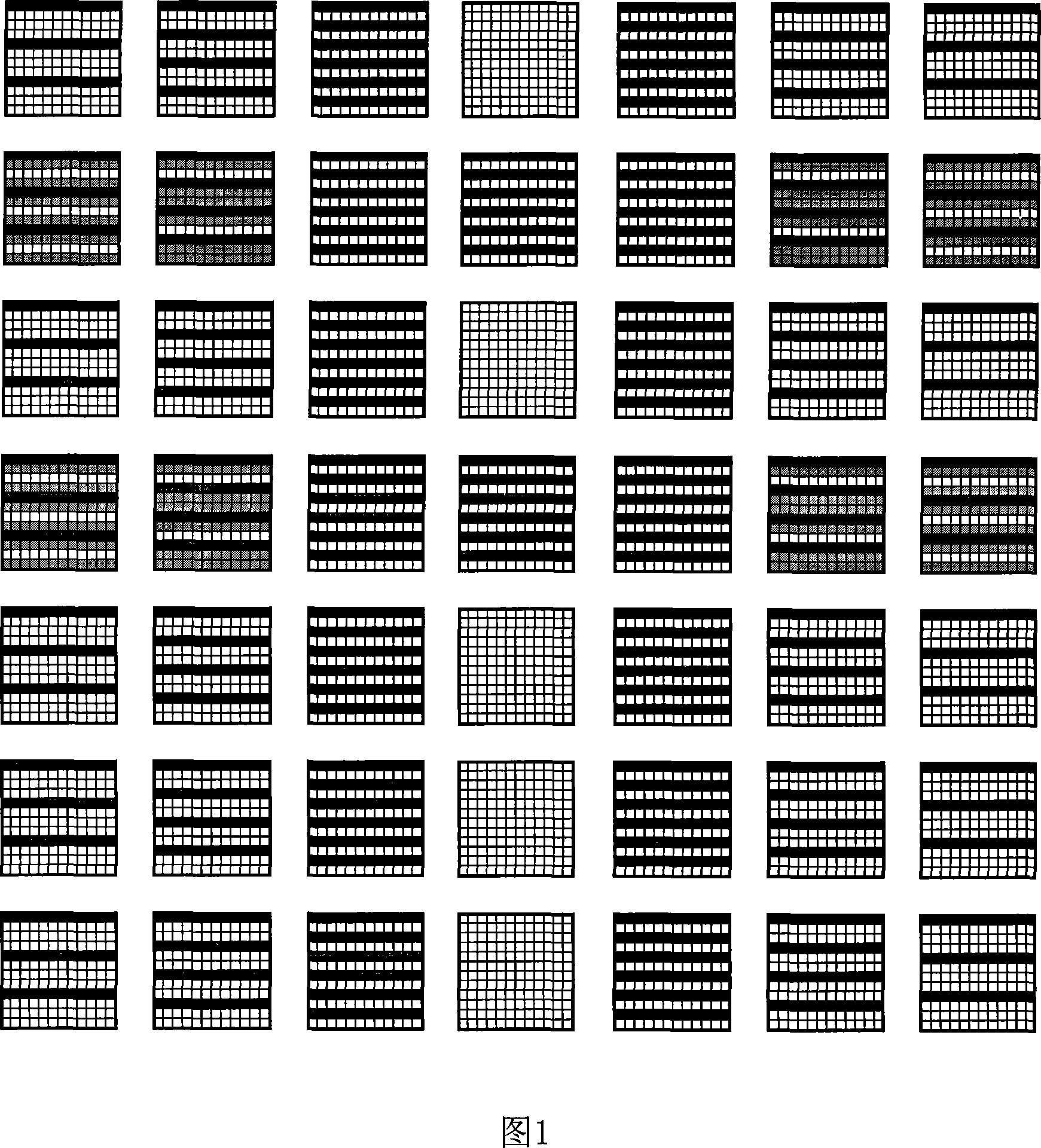

Decomposition and intelligent jacquard weaving preparation technology for patterns with scattered-point layout

InactiveCN105155079AInfinite permutations and combinationsReasonable designCard-punching apparatusPattern recognitionPersonalization

The invention discloses a decomposition and intelligent jacquard weaving preparation technology for patterns with scattered-point layout. The technology comprises the following steps: 1), the patterns with the scattered-point layout are selected; 2), the patterns with scattered-point layout are subjected to pattern unit decomposition and extraction; 3), five large flowers, five small flower and one blank space are taken as a basic unit for intelligent permutation and combination, and a multi-pattern cycle-free jacquard pattern drawing is formed; 4), technological parameters of fabric texture are determined; 5), a jacquard design drawing is generated through CAD (computer aided design) processing, and cycle-free jacquard weaving is performed. The decomposition and intelligent jacquard weaving preparation technology is reasonable in design, one kind of jacquard patterns having relatively independent pattern units and scattered-point layout characteristic are divided into equal parts, different pattern units are formed, intelligent and reasonable layout is performed by the aid of a neural network method, and the basic concept of forming reasonable picture composition variations as many as possible with materials as few as possible is realized; the obtained fabric has the obvious characteristics of endless permutation and combination variations of the patterns, difficulty in imitating and high personalization.

Owner:ZHEJIANG SCI-TECH UNIV

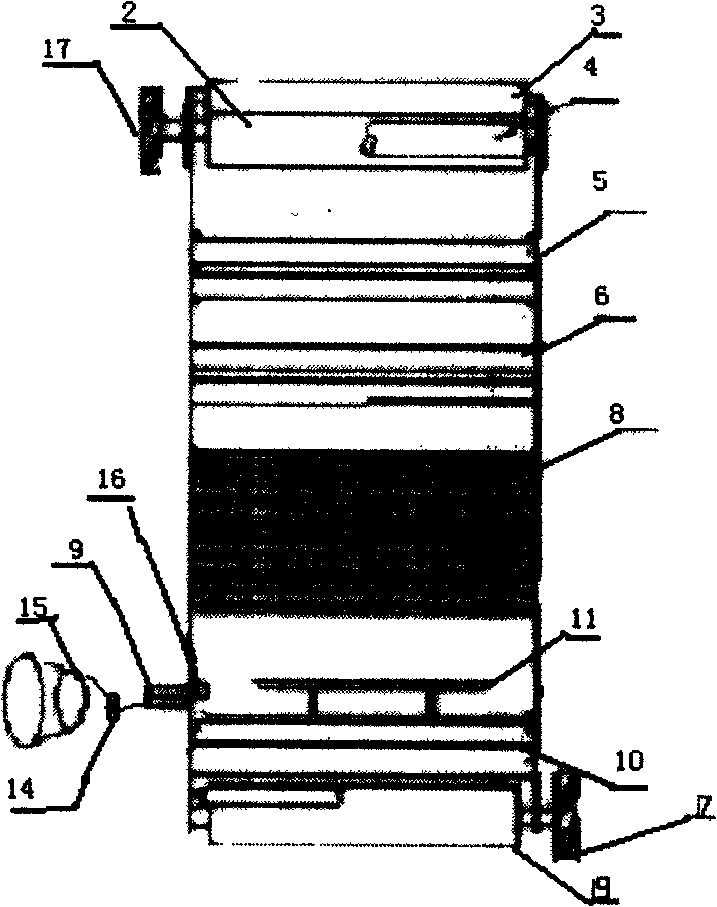

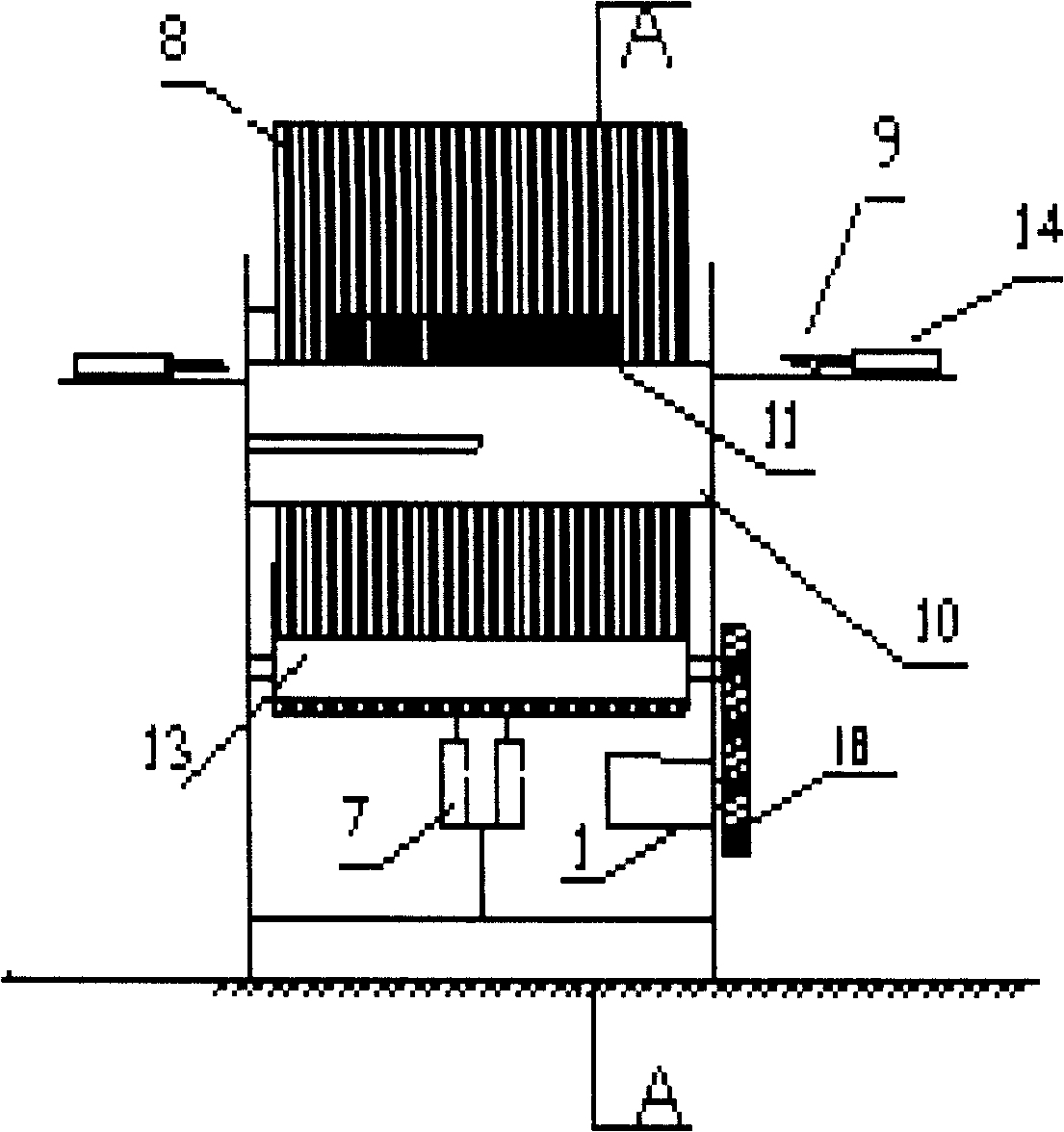

Full-automatic pattern loom with shuttle

InactiveCN101314880AVersatileReasonable functionSmallware loomsCard-punching apparatusDesign softwareEngineering

The invention discloses a full-automatic sample shuttle-loom which adopts computer control to realize the full-automatic operations of heald raising, shuttle picking, beating-up, let-off warping, coiling, etc. according to the design requirements of a chain draft. In the structure, a picking device is arranged at the front part of the sample loom; the middle part divides a wrap into two layers for forming a shed through a heald frame moving device; a shuttle-picking device is arranged at the side part; and a let-off warping device, etc. are arranged at the rear part. In the control, ten functional buttons are used for finishing the selection. In the operation, the design and the correction to the chain draft as well as the control to the sample loom can be carried out through clicking the related display icons by a mouse according to the explanatory note displayed on a design software screen. The sample loom has the advantages that the sample weaving operation can be conveniently, easily, fast and accurately finished; and the sample quality can reach the standard of the actual woven fabric.

Owner:JIANGNAN UNIV

Intelligent control board for electronic dobby device

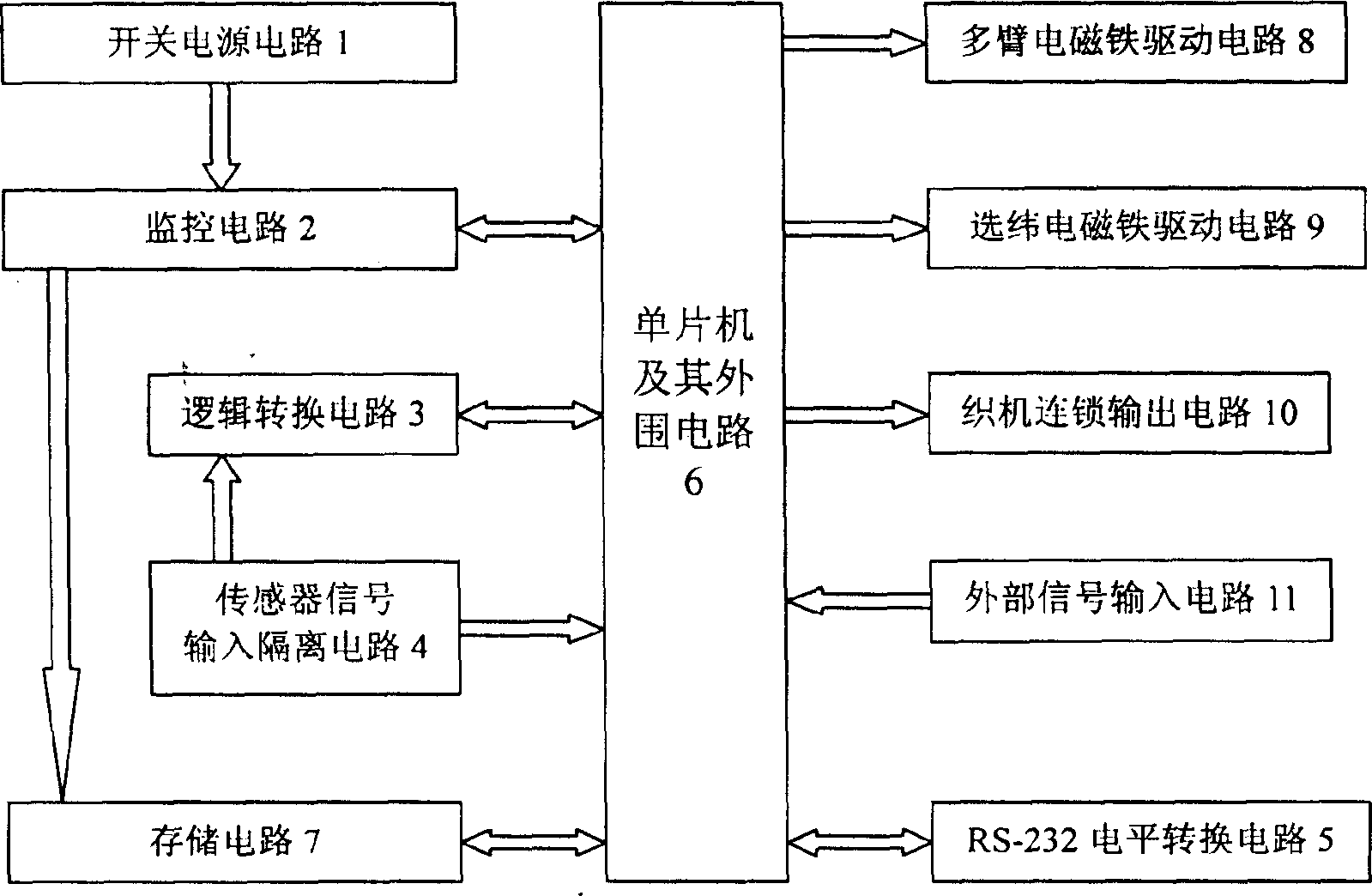

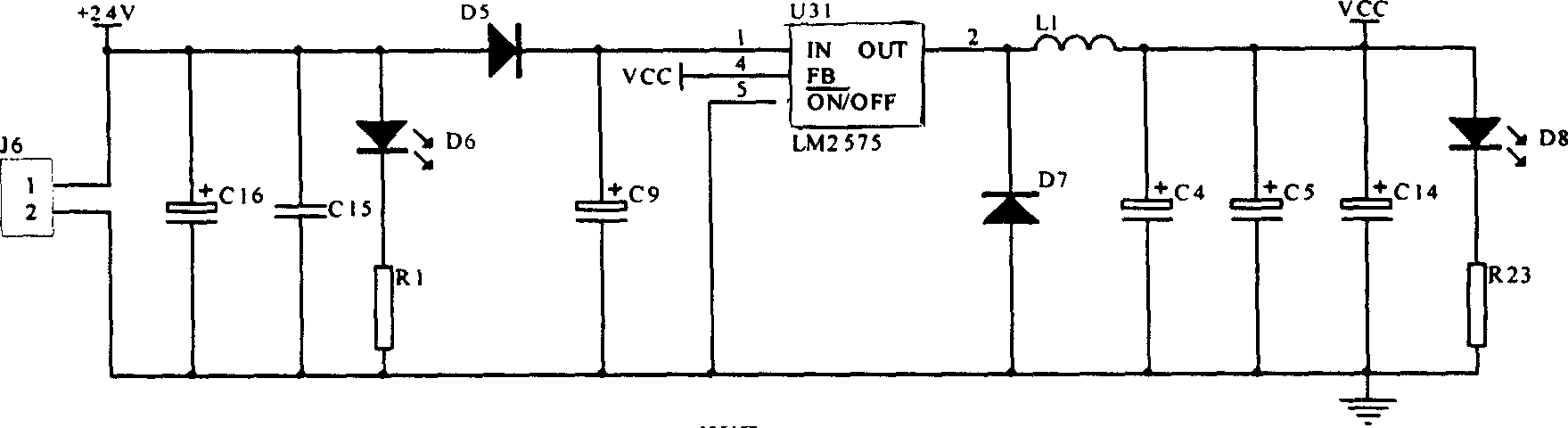

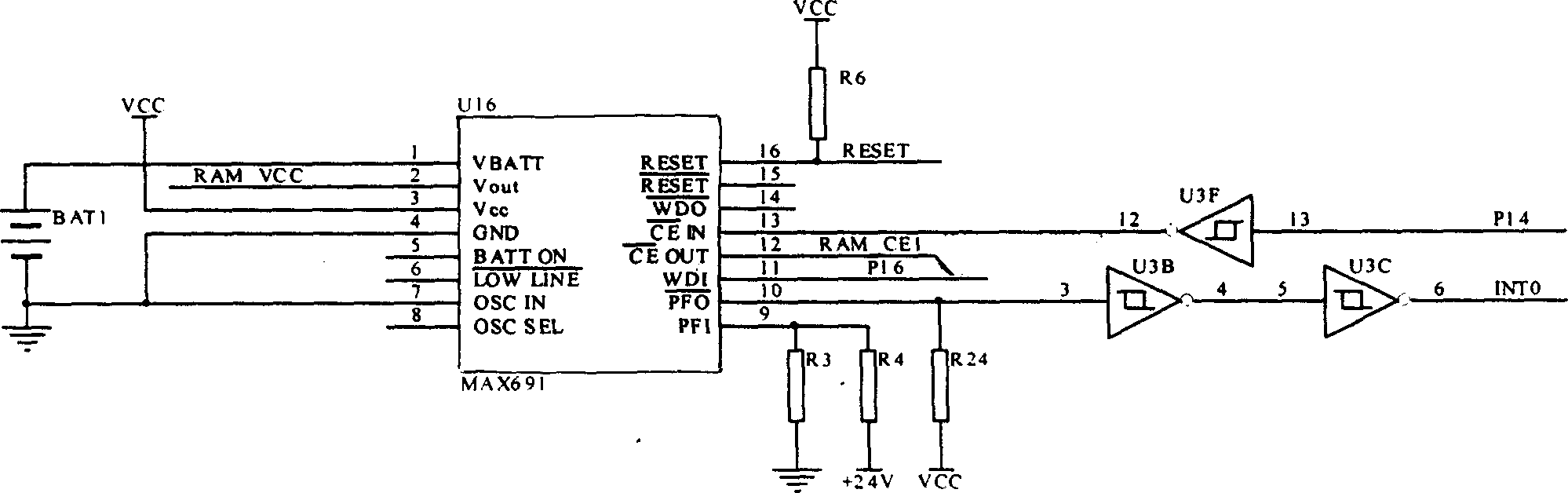

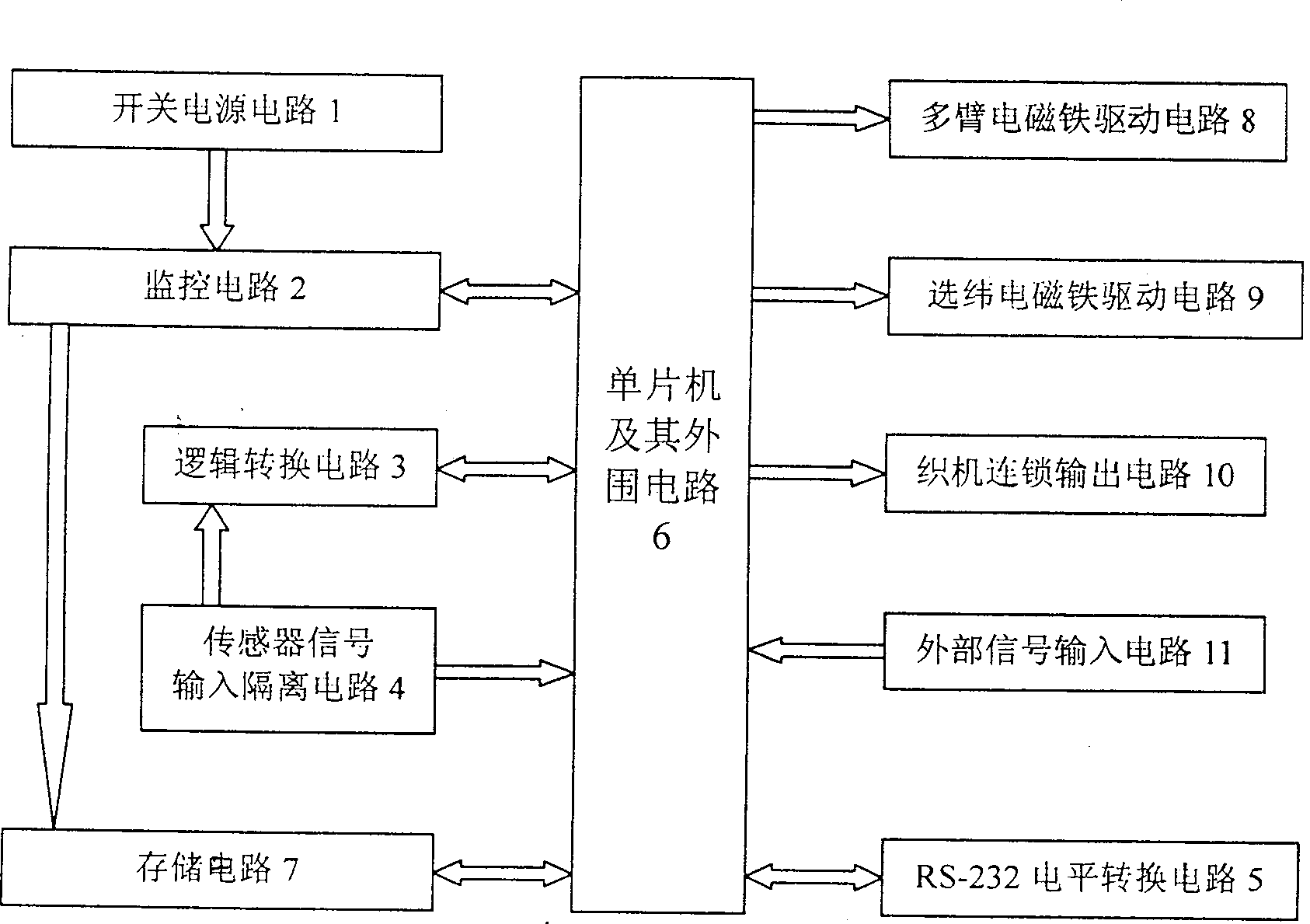

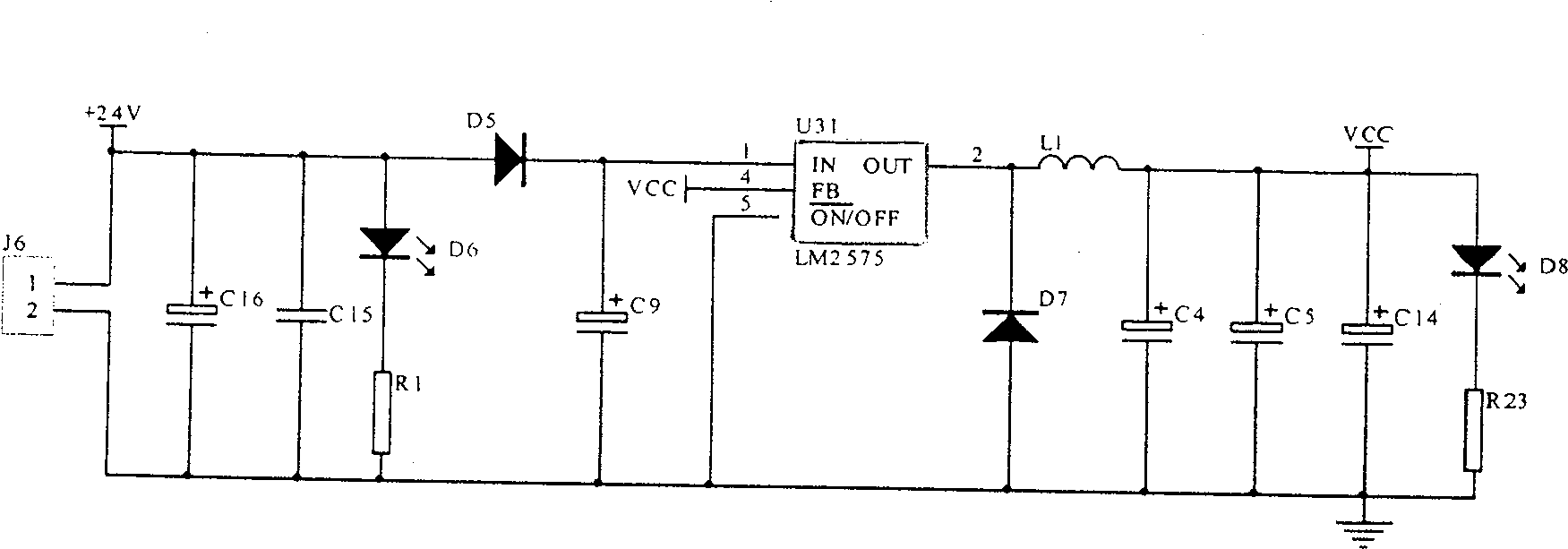

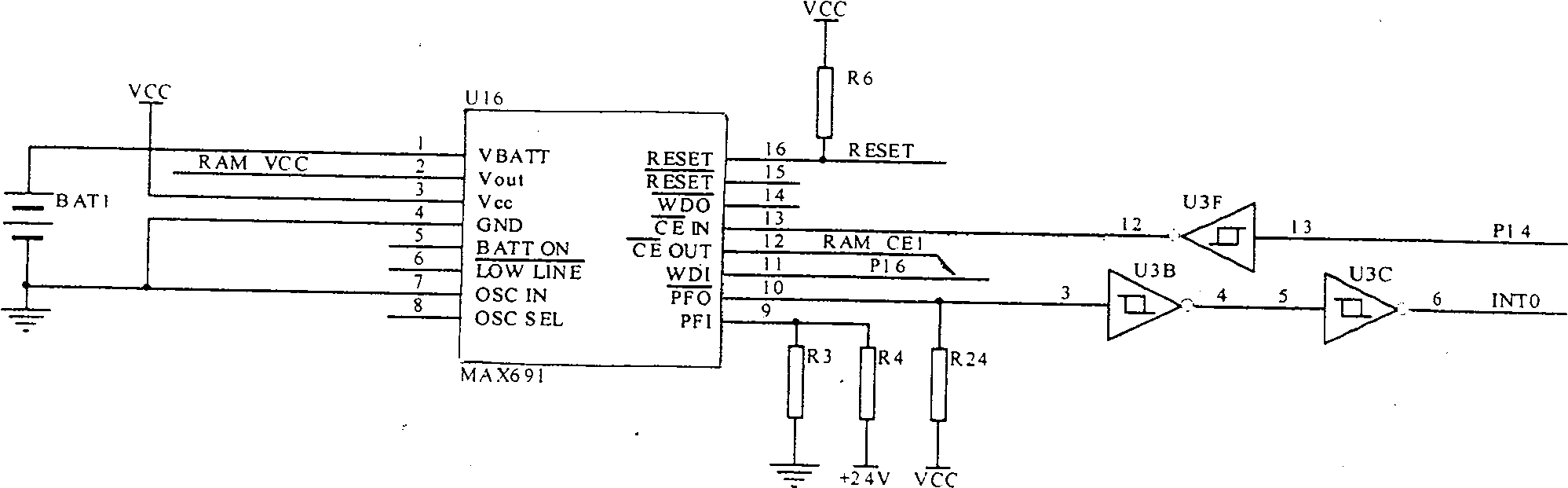

ActiveCN1811031ASafe storageReliable transmissionDobbiesCard-punching apparatusMicrocontrollerEngineering

The intelligent control board for electronic dobby device is one control circuit for various kinds of shuttle loom in textile. It includes a switching power source circuit, a monitoring circuit, a sensor signal input isolating circuit, an RS-232 level converting circuit, a monolithic computer with peripheral circuit, a dobby electromagnet driving circuit, a weft selecting electromagnet driving circuit and an outer signal input circuit. It features a logic converting circuit connected between the sensor signal input isolating circuit and the monolithic computer with peripheral circuit, a memory circuit set between the monitoring circuit and the monolithic computer with peripheral circuit, and a loom interlinking output circuit connected to the monolithic computer with peripheral circuit. The present invention has the advantages of accurate control, reliable data storing, and reliable data transmission to avoid malfunction of loom.

Owner:常熟纺织机械厂有限公司

Silk-weaving forming process for color image

InactiveCN1804173AMake up for not being able to saveMake up for cleaningPattern making devicesCard-punching apparatusPattern recognitionColor image

Owner:JIHUA 3522 APPLIANCES & DECORATIONS

Technique for preparing digital kernel fabric

InactiveCN101210356ADelicate and rich decoration effectUniqueCard-punching apparatusPattern cardsEngineeringL-system

The invention relates to the preparation process of a digital wheat grain fabric capable of accurately drawing weave diagram and coloring, comprises (1) design and fabrication of a pattern card; (2) preparation of a loom; and (3) weaving by the loom. The process is characterized in that the design and fabrication of the pattern card includes the following steps of (1) designing a basic weave diagram of a fabric to form a circular fractal weave diagram by a computer based on L-system theory; (2) designing a superposed weave diagram superposing the fractal weave diagram; (3) superposing the superposed weave diagram and the fractal weave diagram by the computer to generate a digital wheat grain weave diagram; and (4) designing the digital wheat grain weave diagram, forming the pattern card and storing. The invention has the advantages that (1) less workloads are needed for drawing and coloring to prevent the occurrence of error, and the entire process has characteristics of fast, accurate, convenient, etc.; (2) the fractal weave diagram is superposed with the superposed weave diagram to generate the weave diagram of a target fabric, thus controlling the float length and ensuring fabric quality.

Owner:ZHEJIANG SCI-TECH UNIV

Production method of figured cloth different from embroidery characteristics

ActiveCN101423998BFeel goodStrong three-dimensional senseCard-punching apparatusSwivel-woven fabricsEngineeringWork in process

The invention discloses a method for manufacturing jacquard fabrics different from embroidering properties, which comprises the following steps of specification design, pattern design, weaving preparation, weaving on a machine, and sorting of finished products, wherein the step of pattern design is to read target patterns of the jacquard fabrics to be manufactured into a computer, to adjust and position the position of the patterns on the fabrics according to the dimension of the finished products, to set a plurality of colors for the patterns, to merge the colors, and to manufacture an electronic pattern card through picking combinational design, longitude and latitude density design and weave construction design; and the step of sorting of the finished products is to perform trimming onthe floating length of weft threads on the reverse side of semifinished products which are off the machine. The jacquard fabrics produced by the method have good hand feeling, strong third dimension,high ornamental value, and distinct contrast between rugged figured pattern and refined bottom plates, achieve the embroidering style after being subjected to two procedures of jacquard weaving and jacquard trimming, is accurate to position the patterns, are more suitable to be used as family spinning fabrics such as curtains and back cushions compared with the prior jacquard fabrics, and have the characteristics of short manufacturing time and low production cost.

Owner:DALI SILK ZHEJIANG

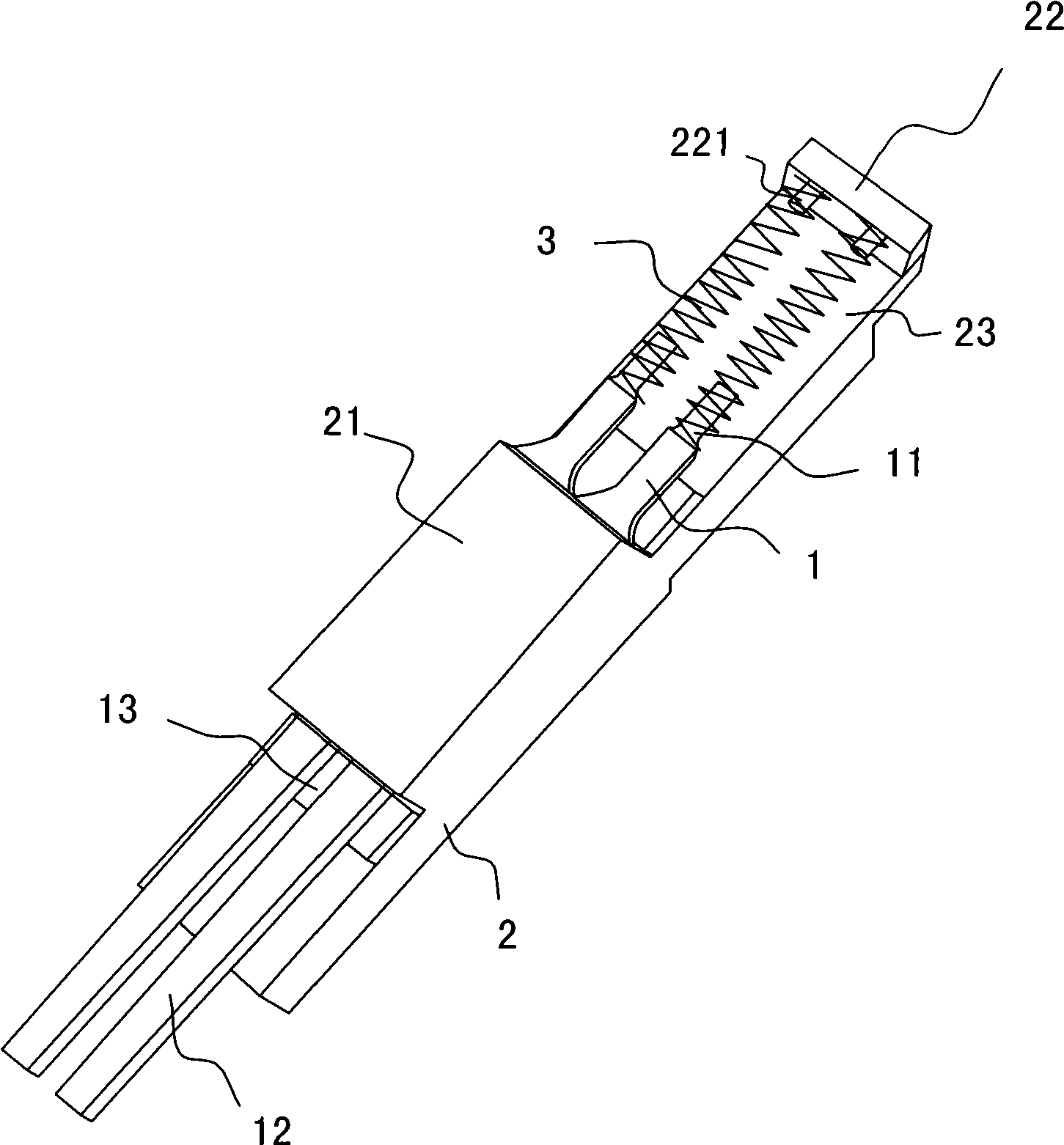

Method for fast converting and producing name selvedge double-width and single-width jacquard fabrics

InactiveCN101538756ARealize free conversionEasy to operateJacquardsCard-punching apparatusJacquard loomEngineering

The invention relates to a method for fast converting and producing name selvedge double-width and single-width jacquard fabrics, including the following steps: (1) establishing double-width harness cord pattern files and single-width harness cord pattern files on an electronic jacquard machine; (2) setting the restoring force of warp threads; (3) setting the parameter of the restoring force of a return spring; (4) arranging components used for a selvedge structure and a name selvedge structure; (5) ensuring the number of the warp threads of a cloth structure; and (6) changing settings according to requirements so as to accomplish the mutual double-width and single-width conversion. The method combines the electronic function of the advanced electronic jacquard machine with the jacquard production technology, just takes 10 minutes in realizing the mutual double-width and single-width conversion, fills the gap of fast double-width and single-width conversion of a broad-width jacquard loom, is easy to operate, increases the production efficiency, is especially suitable for producing the jacquard fabrics and can also be used for weaving other types of shell fabrics.

Owner:NINGBO RENFENG HOME TEXTILE

Digital code manufacturing method for jacquard weave double surface embroidery

InactiveCN1786308BMeet individual needsWide range of materialsPattern making devicesCard-punching apparatusPersonalizationTexture design

Owner:韩容

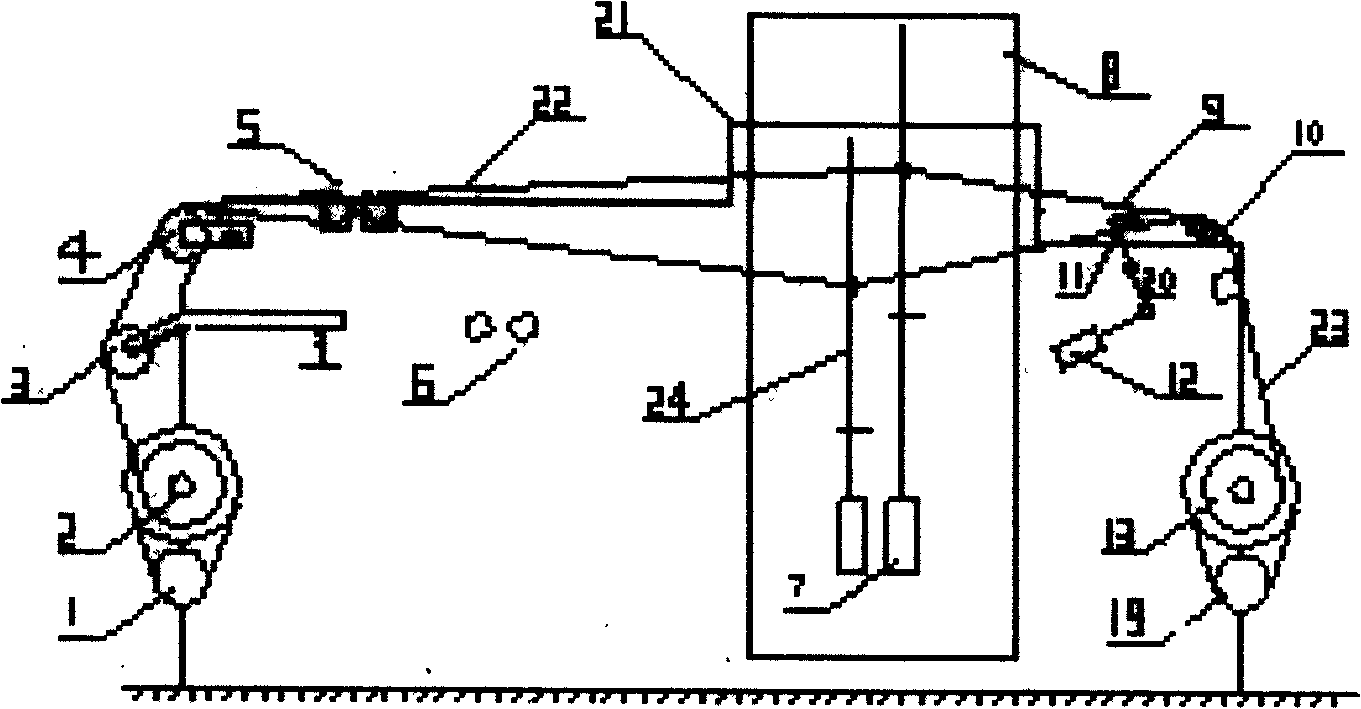

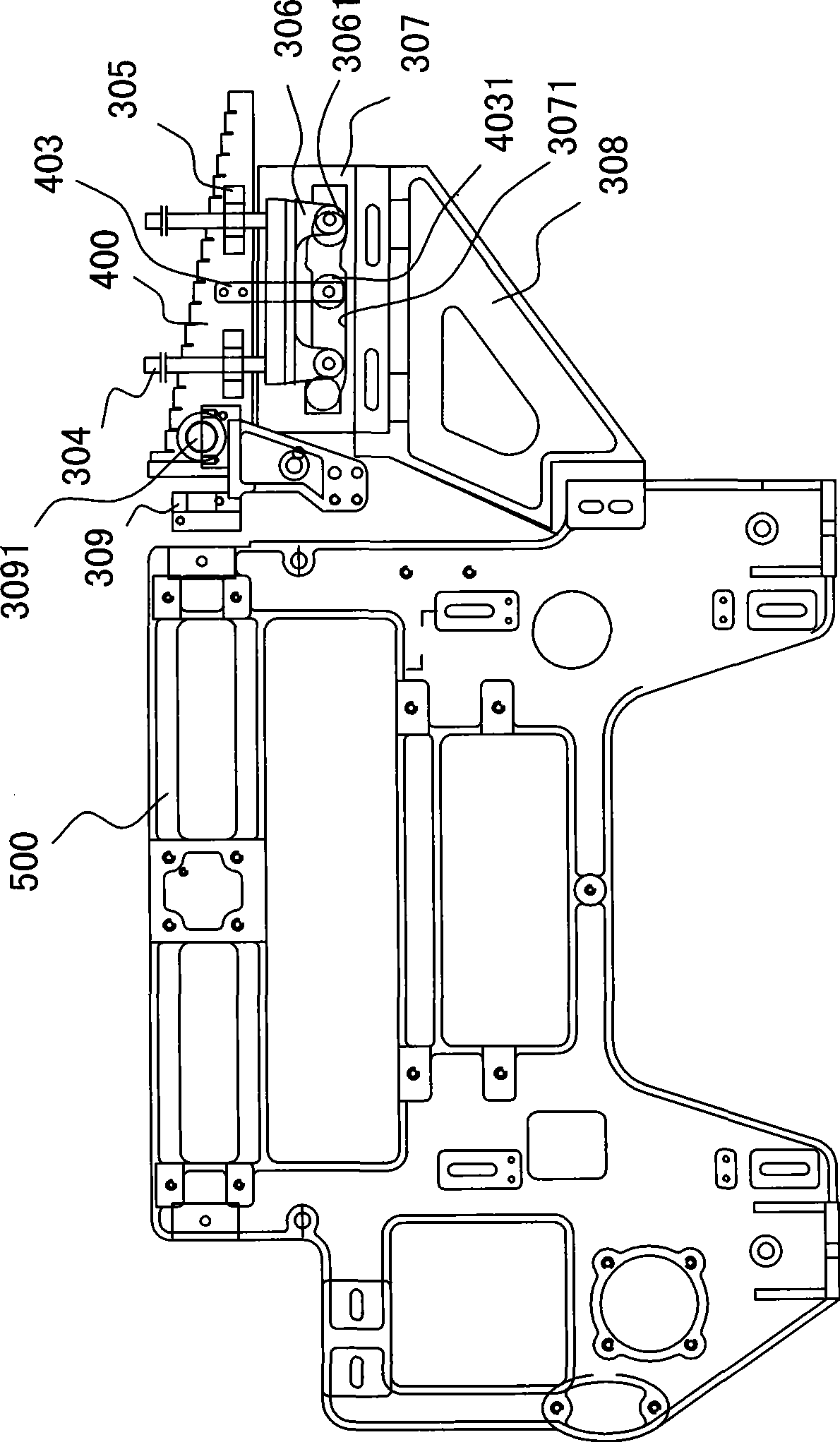

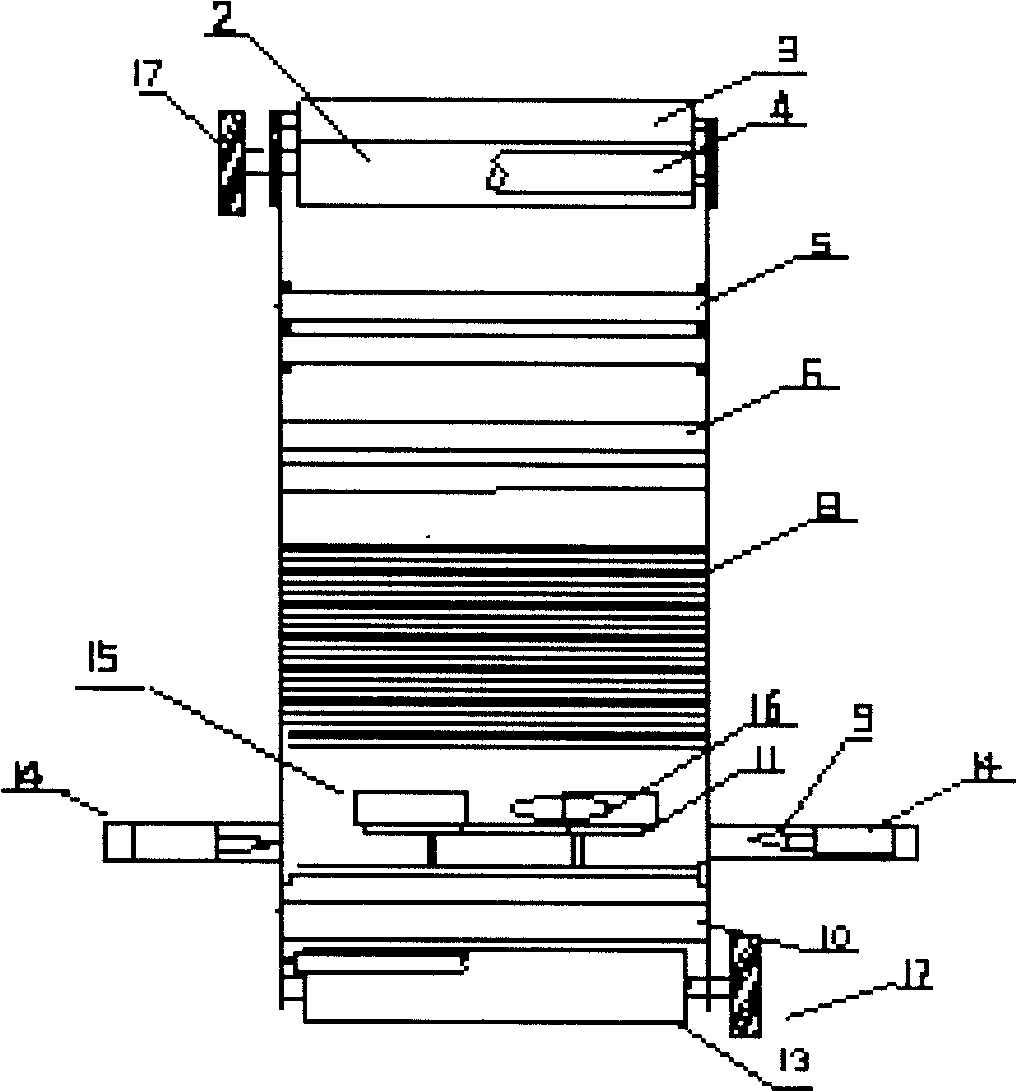

Multifunctional high speed automatic punch machine for pattern card

InactiveCN101463520AImprove punching efficiencyHigh degree of automationCard-punching apparatusArticle feedersPunchingAutomation

The invention provides a multifunctional high speed figure sheet automatic perforating press which has the technical key points that a push pawl automatic paper feeder is arranged behind a rolling stepping transmission device that is arranged in front of a horizontal type punch die hole punched device, an electronic detecting device is arranged at back of the horizontal type punch die hole punched device, an automatic numbering machine is positioned behind the electronic detecting device, a plurality of rolling shafts are arranged among the devices that are transmitted by the rolling shafts in a stepping way. The multifunctional high speed figure sheet automatic perforating press is provided with the push pawl automatic paper feeder, the rolling stepping transmission device and the automatic numbering machine, and integrates the functions of punching, detecting and number printing, so as to have the characteristics of good quality of figure sheet punched hole, high efficiency, high degree of automation, etc.

Owner:沈尧生 +1

Intelligent control board for electronic dobby device

ActiveCN100513661CSafe storageReliable transmissionDobbiesCard-punching apparatusMicrocontrollerLogical combination

The utility model relates to an intelligent control board for an electronic dobby device, which belongs to a control circuit and is used for various shuttleless looms in the textile field. Including switching power supply circuit, monitoring circuit, sensor signal input isolation circuit, RS-232 level conversion circuit, single-chip microcomputer and its peripheral circuit, multi-arm electromagnet drive circuit, weft selection electromagnet drive circuit and external signal input circuit, features: in A logic conversion circuit is connected between the sensor signal input isolation circuit and the single-chip microcomputer and its peripheral circuits; a storage circuit is connected between the monitoring circuit and the single-chip microcomputer and its peripheral circuits; the single-chip computer and its peripheral circuits are connected with a loom chain output circuit. Advantages: The logic conversion circuit can generate interrupts in real time according to the changes of sensor signals, and obtain corresponding strobe signals through logical combination, making the control more accurate; the storage circuit can reliably store a large amount of data, and under the protection of the backup battery, even The data will not be lost even when the power is off; the interlocking output circuit of the loom can transmit data reliably, and the misoperation of the loom is effectively prevented through the interlock mechanism.

Owner:常熟纺织机械厂有限公司

Method for controlling digital jacquard-woven colored patterns

The invention discloses a method for controlling digital jacquard-woven colored patterns. The method comprises the following steps of: determining the parameters of a jacquard weave unit and obtaining the visual colour value corresponding to each intersecting point in the jacquard weave unit by a colour space hybrid colour processing method; and removing the same visual colour data, keeping the visual colour data of an interweaving way, after filtering the data by contrasting a standard 256 colour list by a colour difference computing method, comparing the colour of each pixel point of the colored patterns input into a computer with the visual colours of the jacquard weave unit to obtain the colours with the maximum colour similarity, forming a program, and controlling the digital jacquard to weave colored patterns. All the similar colours in the standard 256 colour can be prepared from yarns with fixed colours without manually selecting the colours of yarns; and the back of a provided jacquard product is relatively flat, so the quality and added value of the product are improved.

Owner:SUZHOU UNIV +1

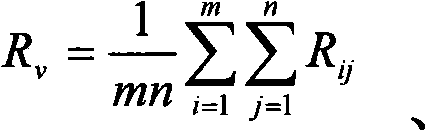

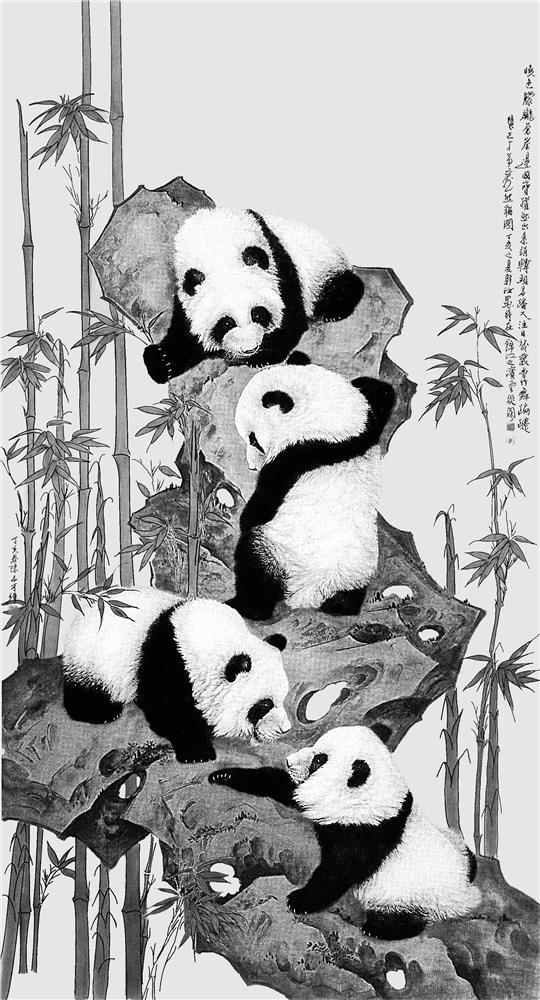

Shu brocade decorative painting fabric with realistic hairiness effect and design method thereof

ActiveCN110588232BSpecial ornamental structuresCard-punching apparatusComputer graphics (images)Industrial engineering

The invention discloses a Shu brocade decorative painting fabric with realistic hairiness effect and its design method. The conventional area on the painted fabric is woven according to the ordinary Shu brocade technique; the hairy area is woven with free interfilament tissue, and the hairy area is superimposed on the conventional area where the animal pattern is located; the design method includes the following steps: The conventional area is processed according to the conventional Shu brocade pattern to generate the corresponding pattern file EP1; the hairiness area is processed and the corresponding pattern file EP2 is generated; the pattern file EP1 and the pattern file EP2 are synthesized to generate the final pattern file EP3; Weaving on the machine; the Shu brocade decorative painting fabric and its design method can display the image of animals three-dimensionally and realistically, so that the viewer has a brand-new sense in terms of touch and vision, and perfectly presents the art of Shu brocade craft painting value and economic value.

Owner:SICHUAN RES INST OF SILK SCI

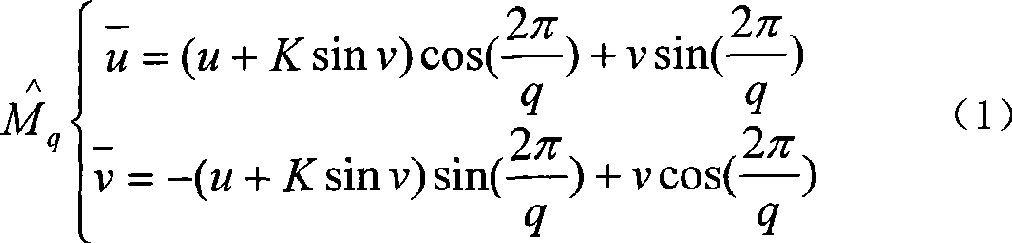

Preparation technology of composite digital crepe

InactiveCN104032440BMeet diverse needsReasonable designJacquardsCard-punching apparatusYarnRegular pattern

The invention discloses a preparation process for compound digital crepe. The preparation process comprises the specific steps: carrying out Hamiltonian conversion to obtain a quasi-regular pattern; treating by a set of trigonometric functions to obtain a change pattern of the quasi-regular pattern; then, carrying out ultra-micro treatment, tissue selection, yarn construction and design pattern generation on an obtained fabric pattern through a specific fabric pattern; knitting to finally obtain a pattern of the compound digital crepe. The method is reasonable in design; two types of crepe fabrics including the digital crepe and a traditional crepe figured silk fabric, which have complete different characteristics, are combined together so that the compound digital crepe has decorative pattern features of digital graphic processing and also has the line characteristics of the traditional crepe figured silk fabric; the advantage complementation of the digital crepe and the traditional crepe figured silk fabric is realized; a silk fabric with brand new hand feeling and impression is designed so as to meet the diversified demands of market consumption.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation process of monochrome graded display jacquard fabric

InactiveCN101445988BAccurate configurationRich layersCard-punching apparatusSwivel-woven fabricsYarnDigital image

The invention relates to a preparation process of monochrome graded display jacquard fabric. The preparation process comprises the following steps: (1) designing and manufacturing a fabric card; (2) preparing for weaving; (3) looming and weaving; and (4) manufacturing a finished product. The preparation process is characterized in that the designing and manufacturing the fabric card is as follows: (1) generating a digital image of prefabricated jacquard fabric; (2) forming the digital image into a gray scale image file; (3) creating a tissue link library with different lightness values; (4) causing the gray scale image file and tissues in the tissue link library to form a corresponding relation; and (5) manufacturing a fabric card file. The significant substantial effects of the preparation process are as follows: 1. processing warp and weft with uniform dyeing and applying the creation of a tissue model, thus ensuring precision configuration, abundant hierarchy and exquisite variation of the fabric texture; 2. having simple production process and little limitation and reducing the cost of raw materials; and 3. being capable of dyeing after weaving gray warp and weft, thus processis simple and dye is saved.

Owner:ZHEJIANG SCI-TECH UNIV

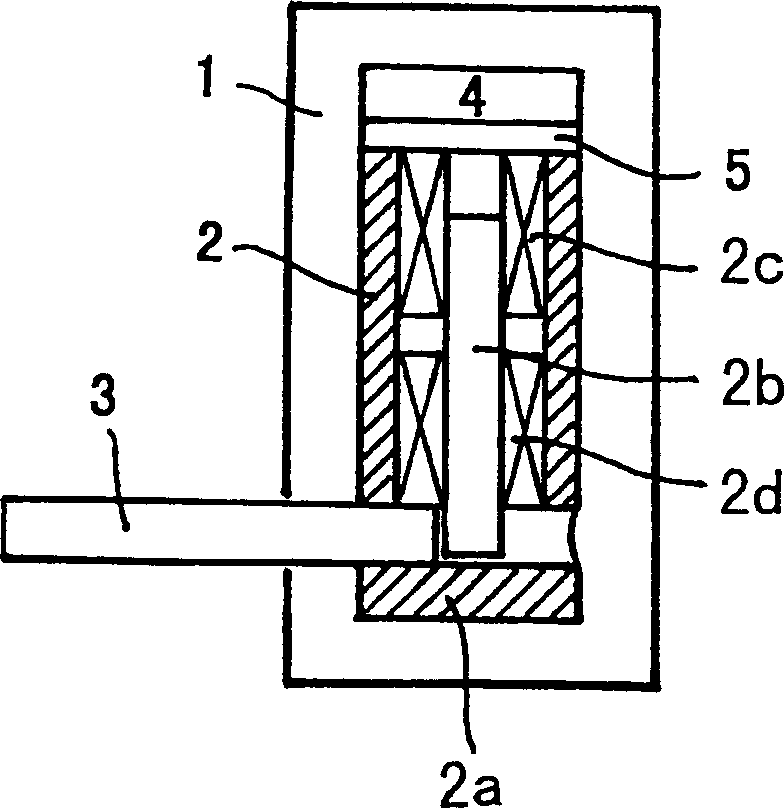

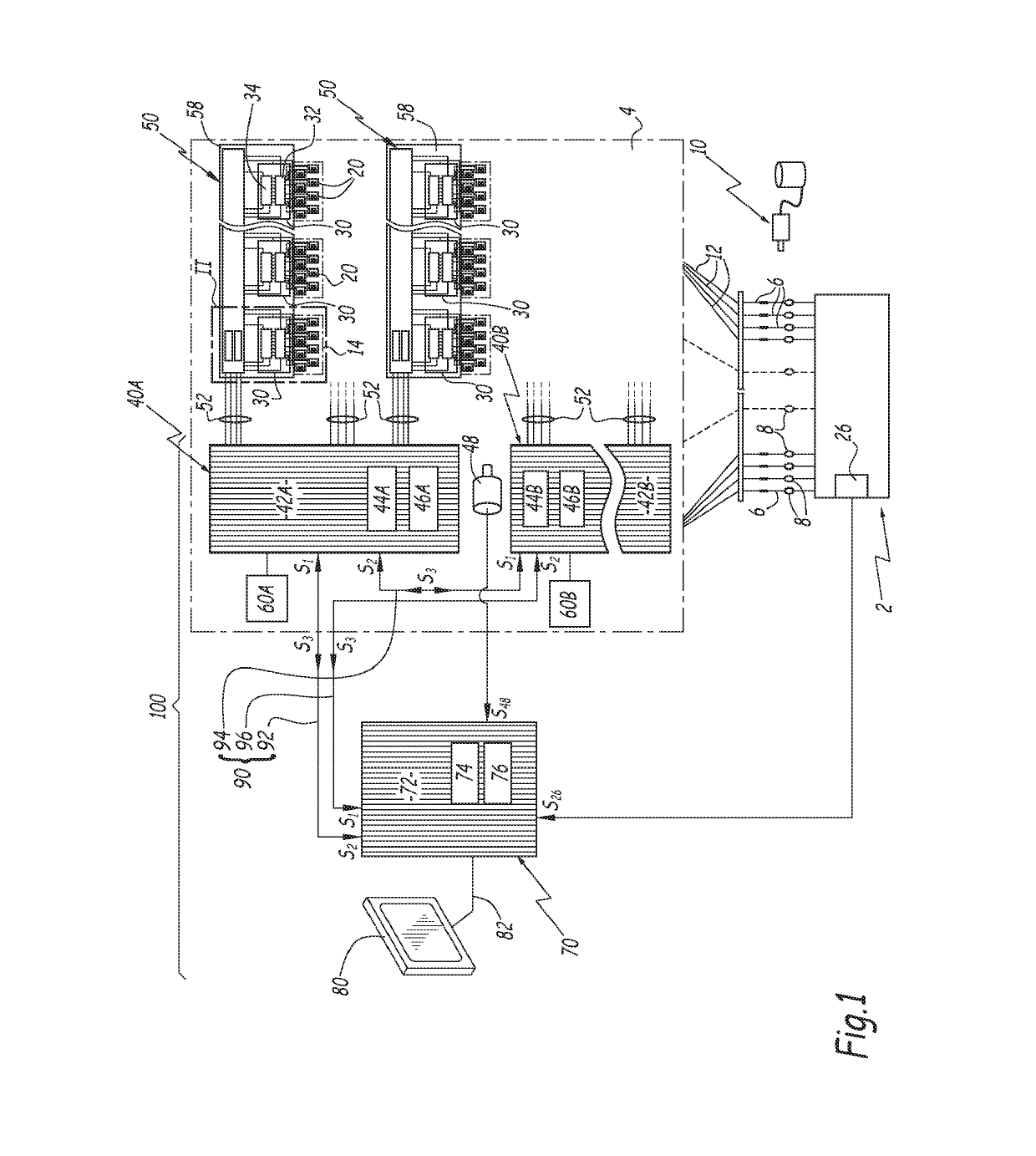

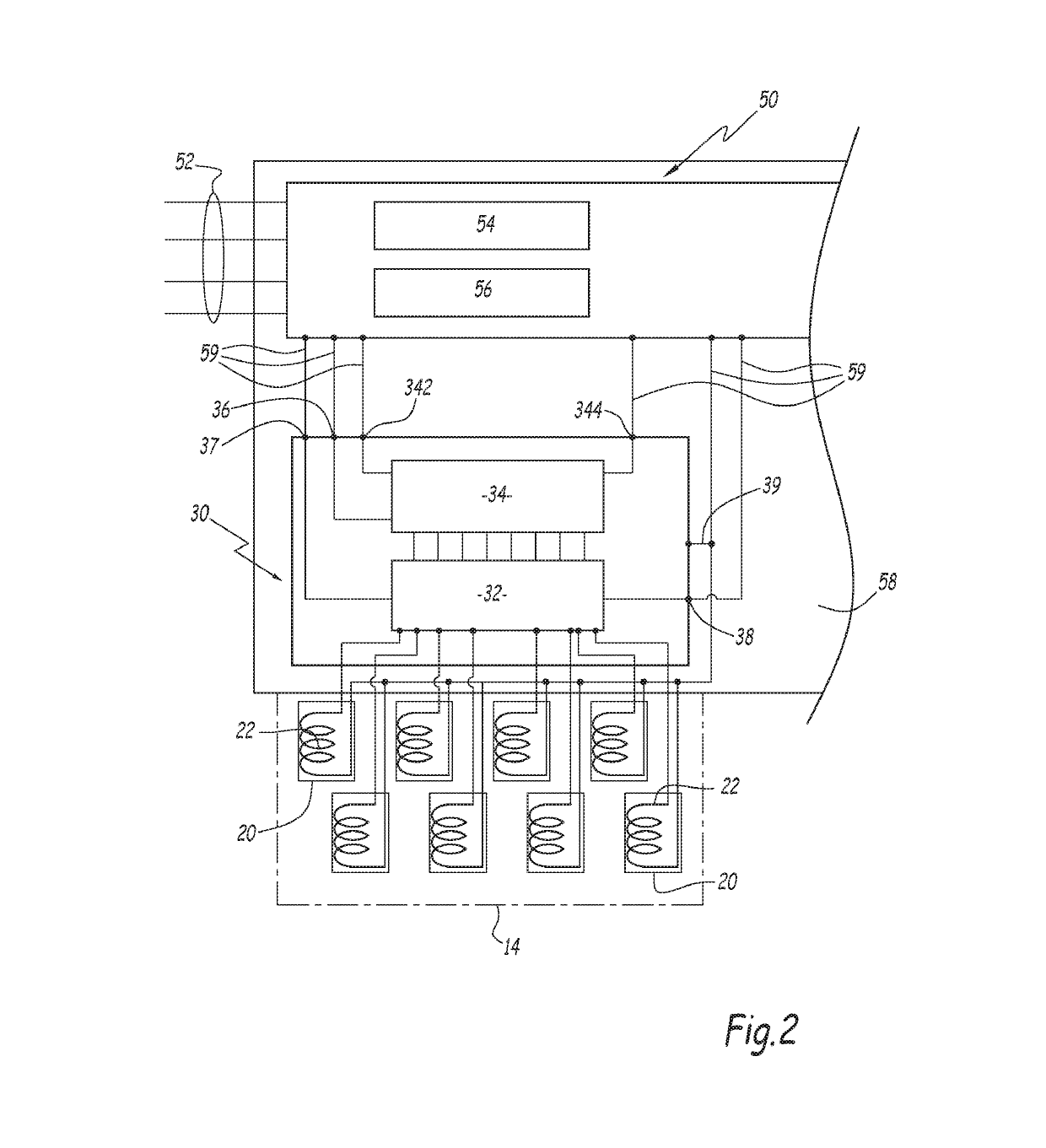

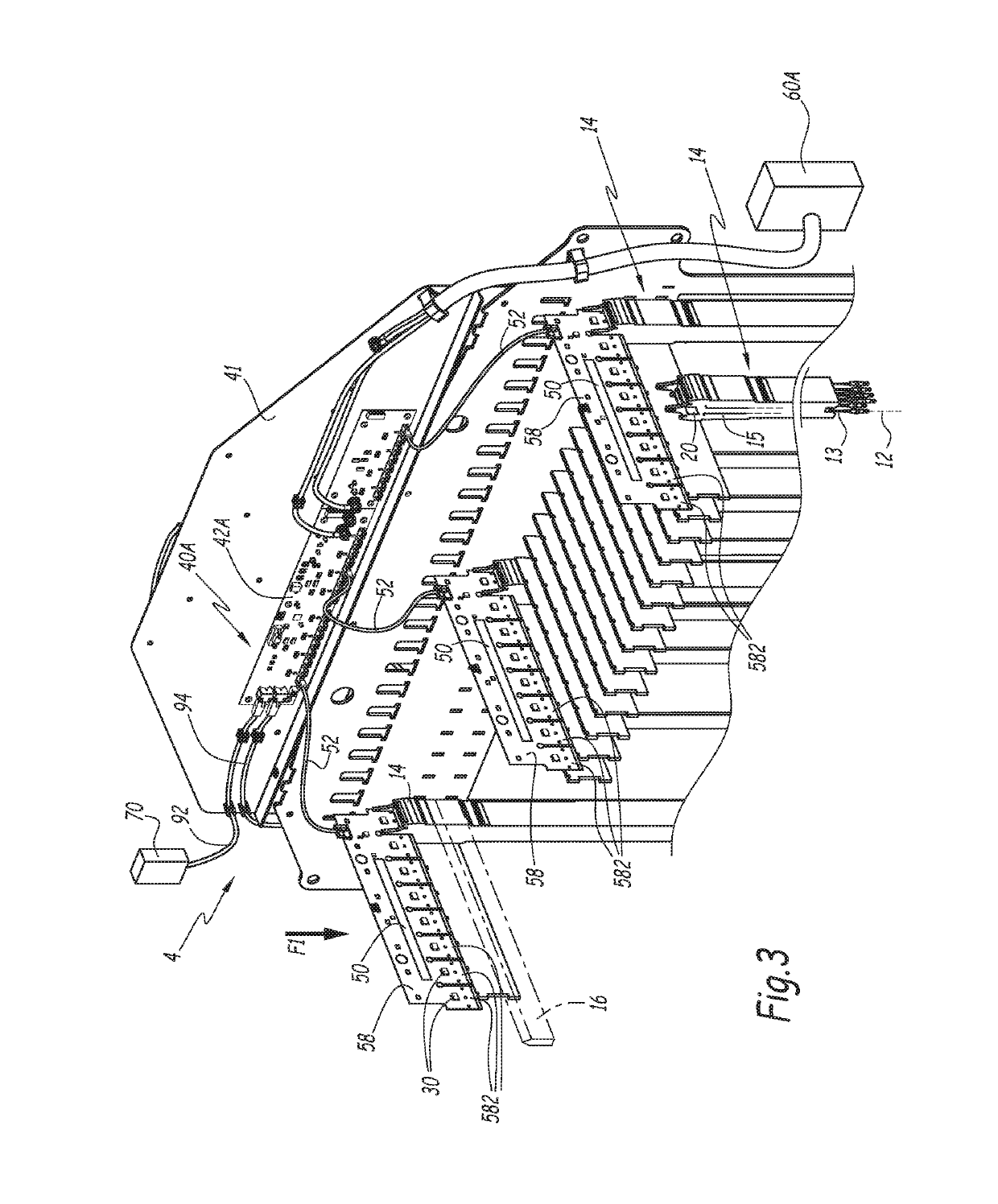

Control system for a jacquard mechanism, jacquard mechanism and weaving machine equipped with such a system

This control system (100) for at least one Jacquard mechanism (4) for forming shed has electromechanical selection devices (20) including magnets, a primary controller (70) intended to communicate with a weaving machine (2) and including at least one memory (76) to store weave pattern data and at least one computer (74). This system also includes at least two secondary controllers (40A, 40B), each electrically connected to the primary controller (70) and each able to control a group of electromechanical selection devices (20), each secondary controller having at least one memory (46A, 46B) for storing weave pattern data, at least one computer (44A, 44B), and control units (30) for the electromagnets belonging to the electromechanical selection devices (20). This system further includes at least one intermediate controller (50) in direct electrical connection, with one of the secondary controllers (40A, 40B) and with at least two electromagnet control units (30).

Owner:STAUBLI LYON

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com