Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Texture design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

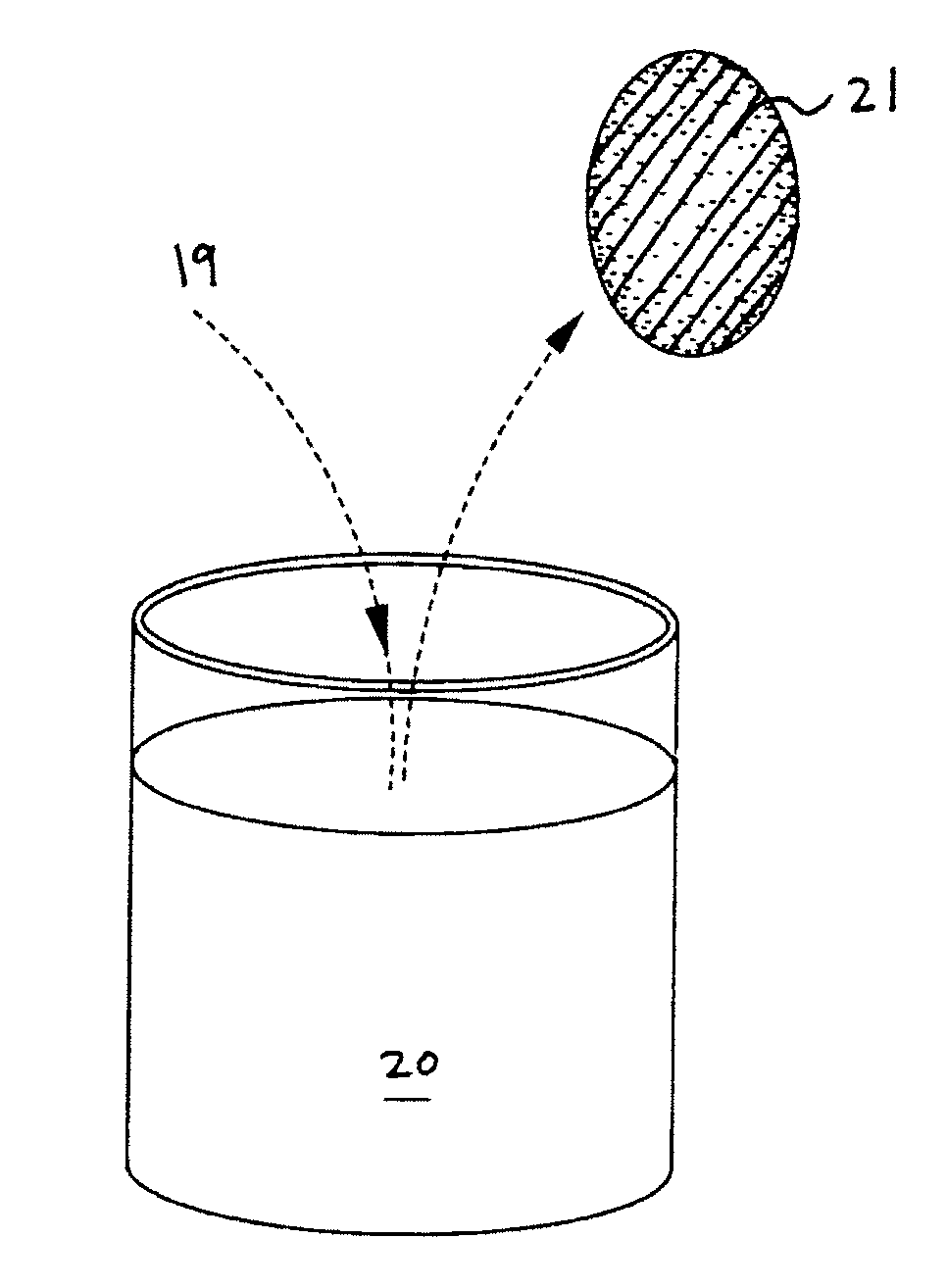

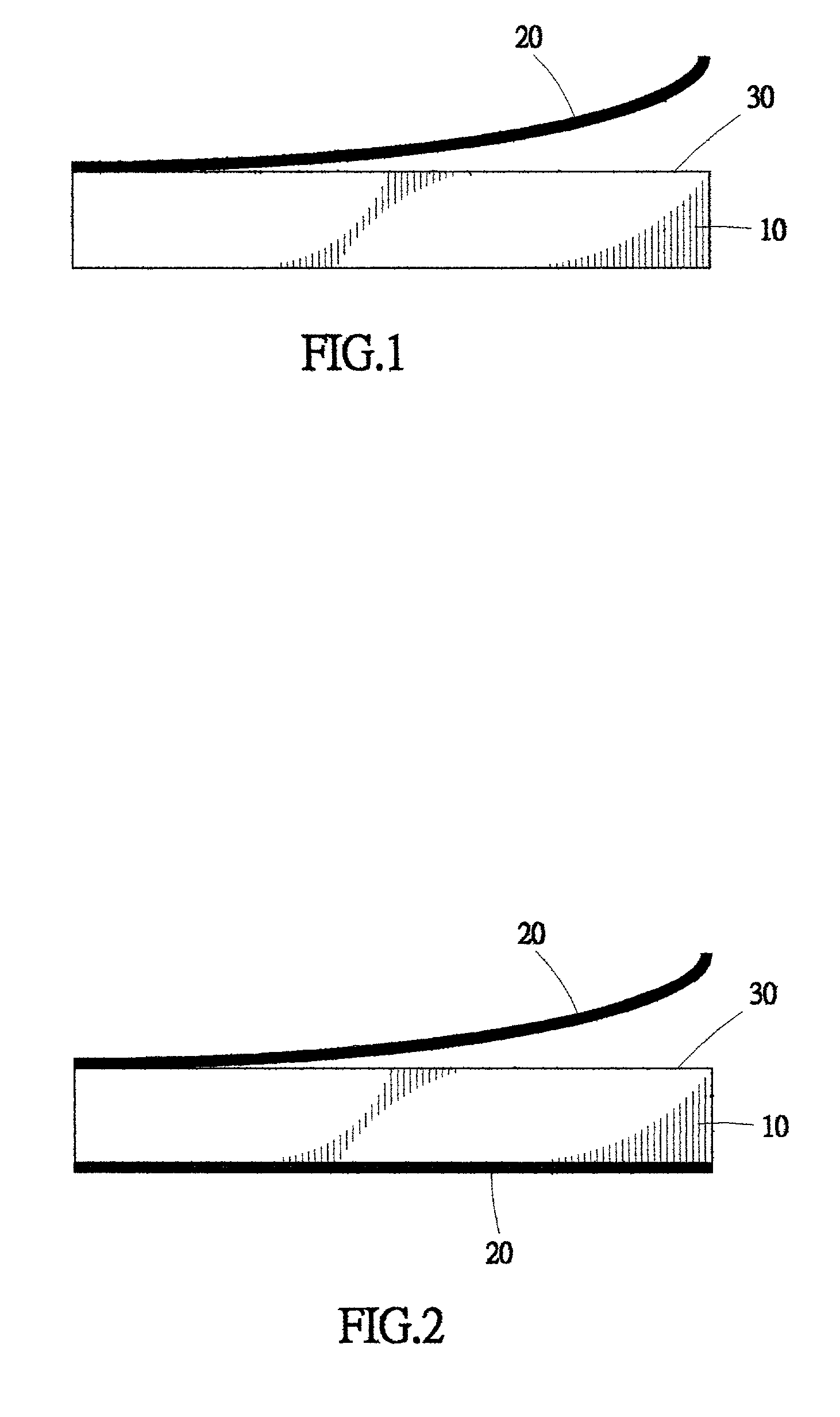

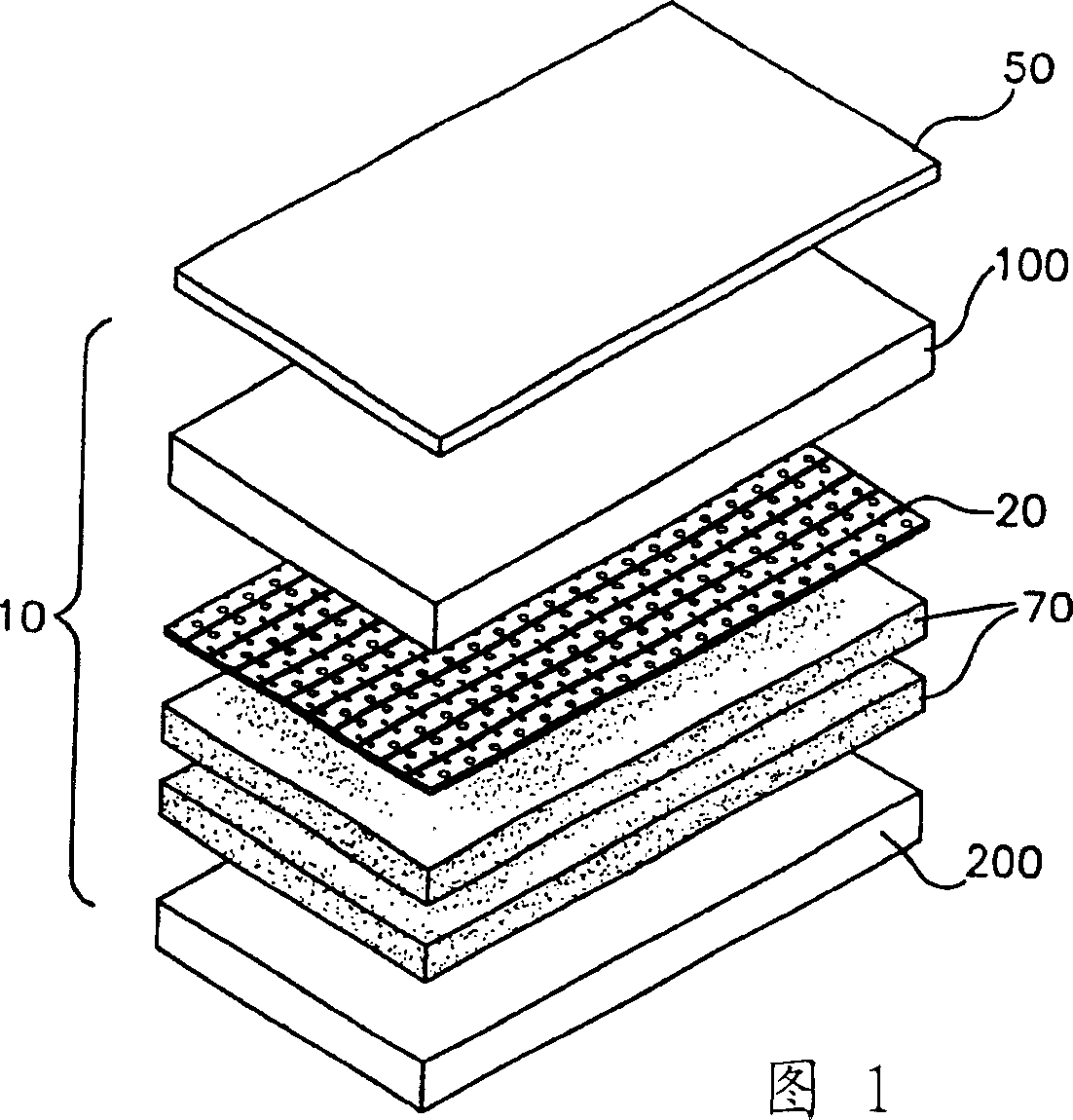

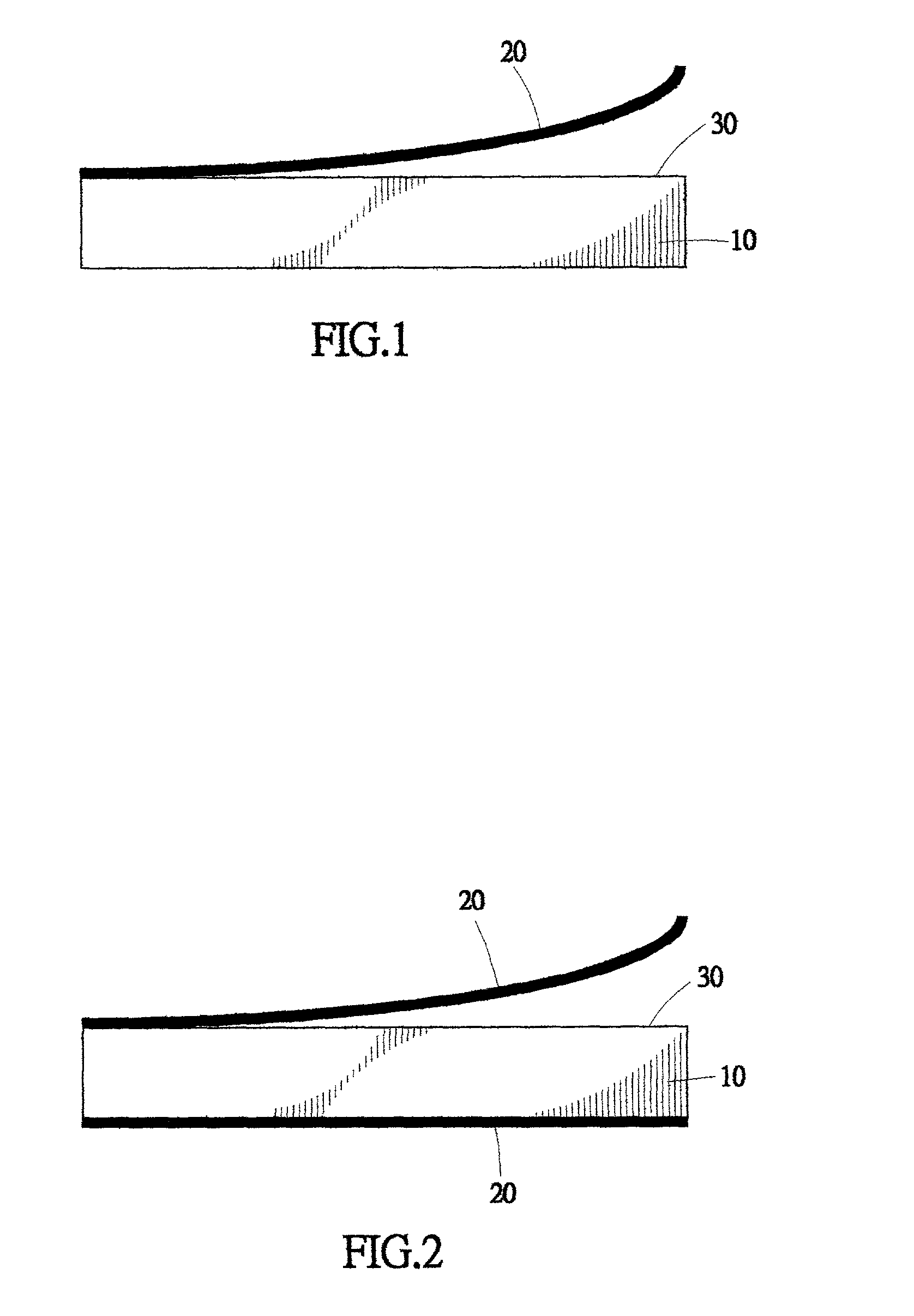

Implants and methdos for manufacturing same

InactiveUS20110093069A1Easy to fixDiscourages organizationMammary implantsPretreated surfacesParticulatesTexture design

Implantable prosthesis, components of prosthesis, and methods of making same are provided. The methods generally include the steps of providing an implant shell, applying a curable fluid composition to the shell to form a coating thereon and applying a particulate component to the composition. The composition is a mixture, for example, an emulsion, containing a silicone-based elastomer dispersion and droplets of a suspended leachable agent. After the elastomer is stabilized and cured, the particulate component and leachable agent are removed, resulting in an implantable member having a porous, open-cell surface texture designed to be effective in reducing incidence of capsular formation or contraction.

Owner:ALLERGAN INC

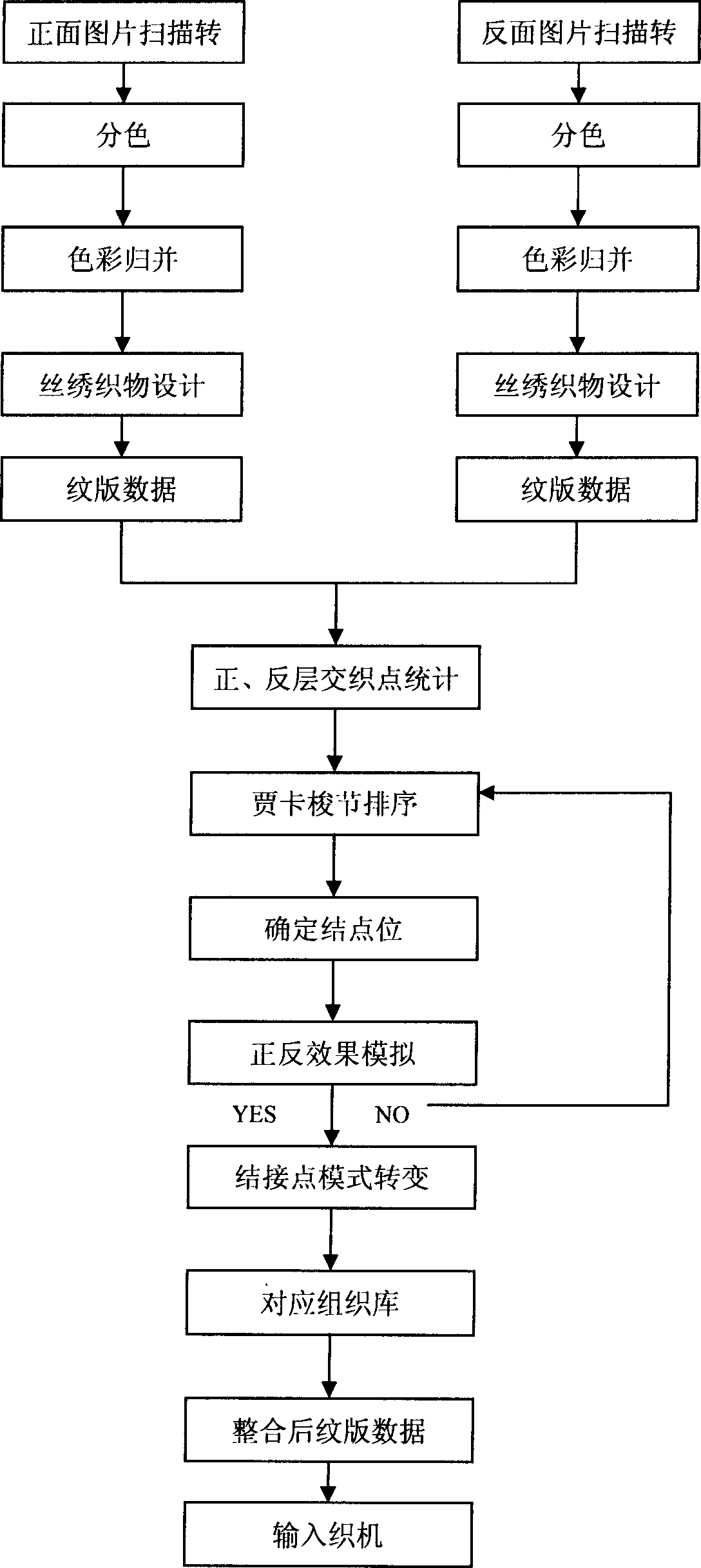

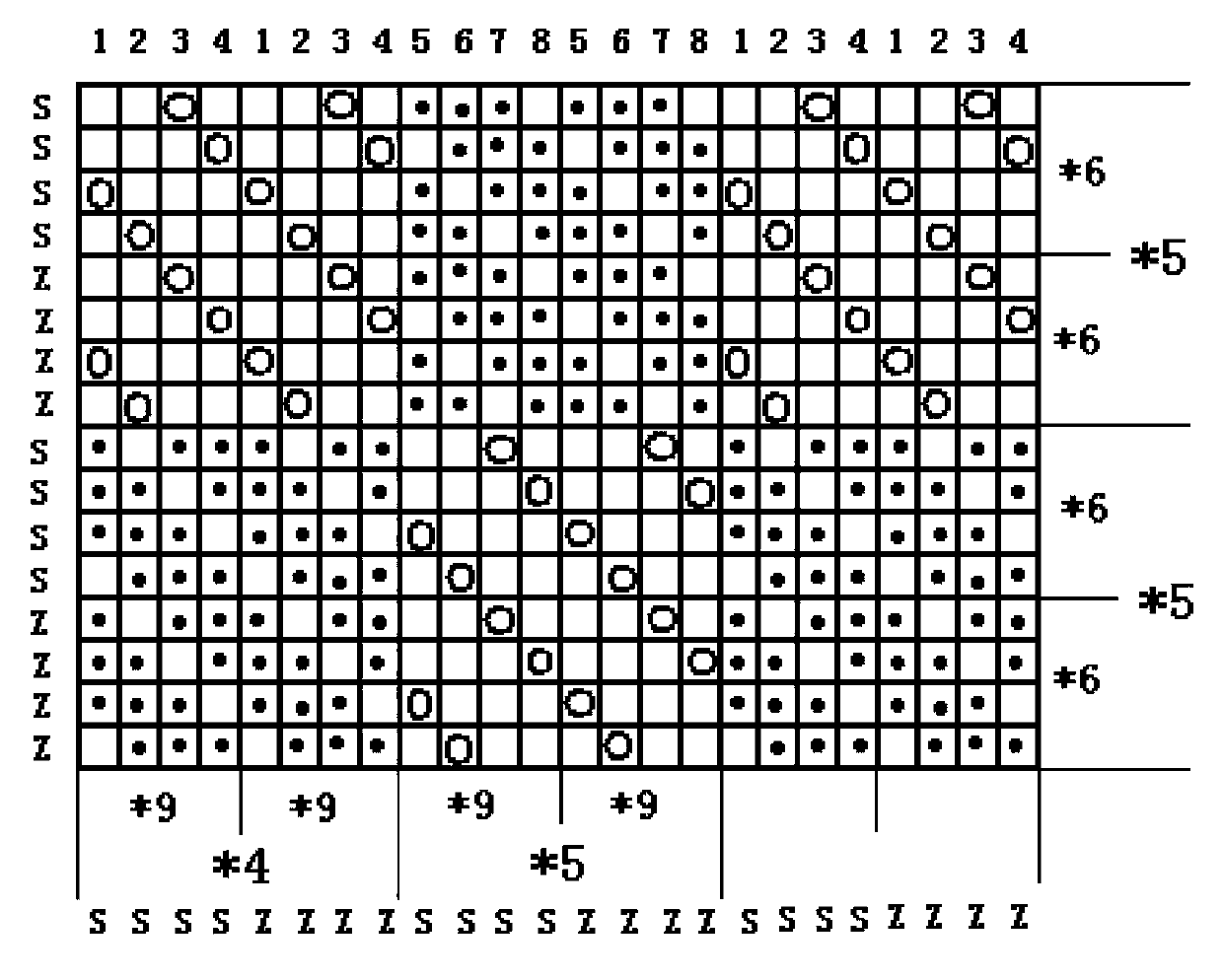

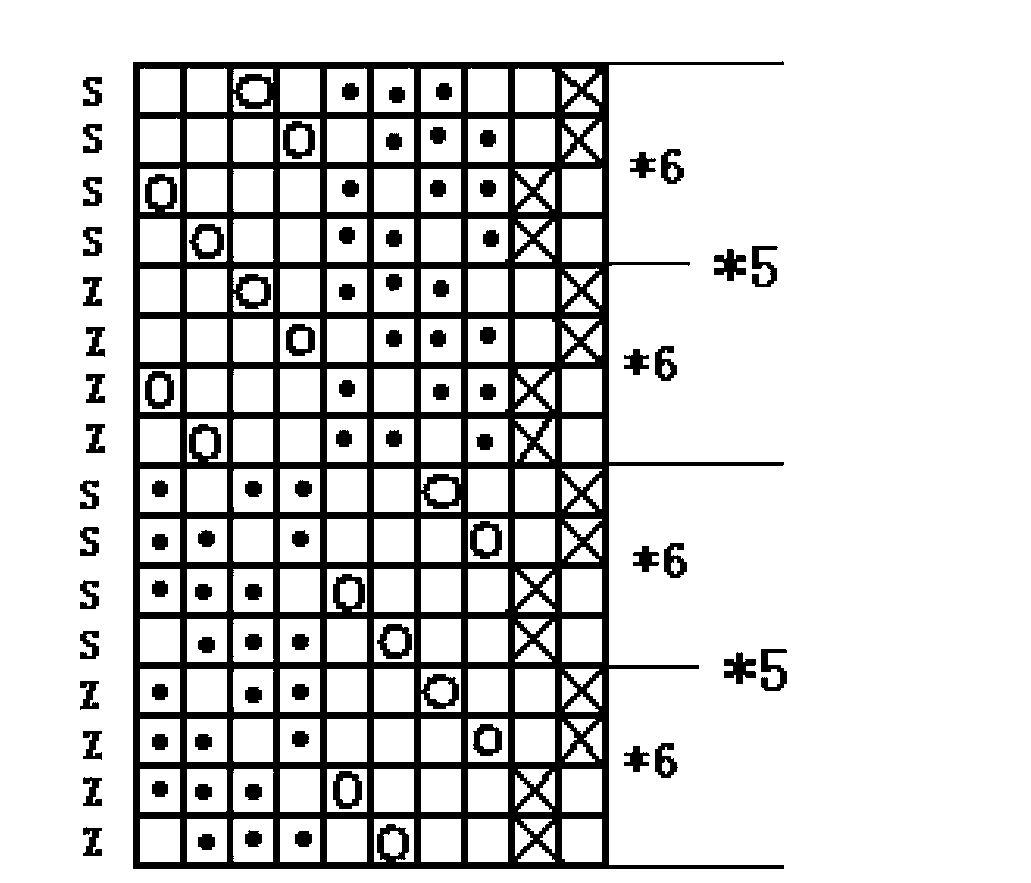

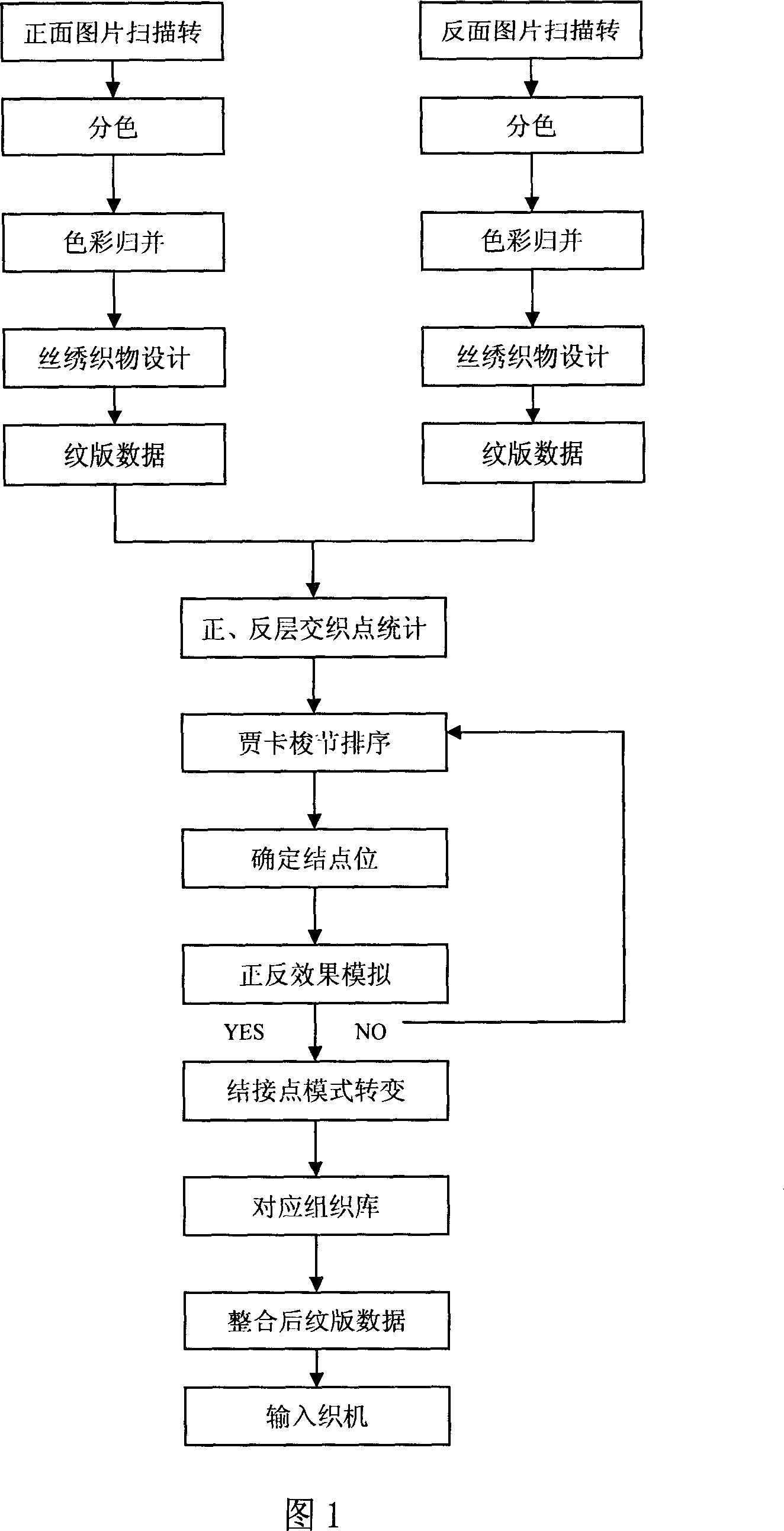

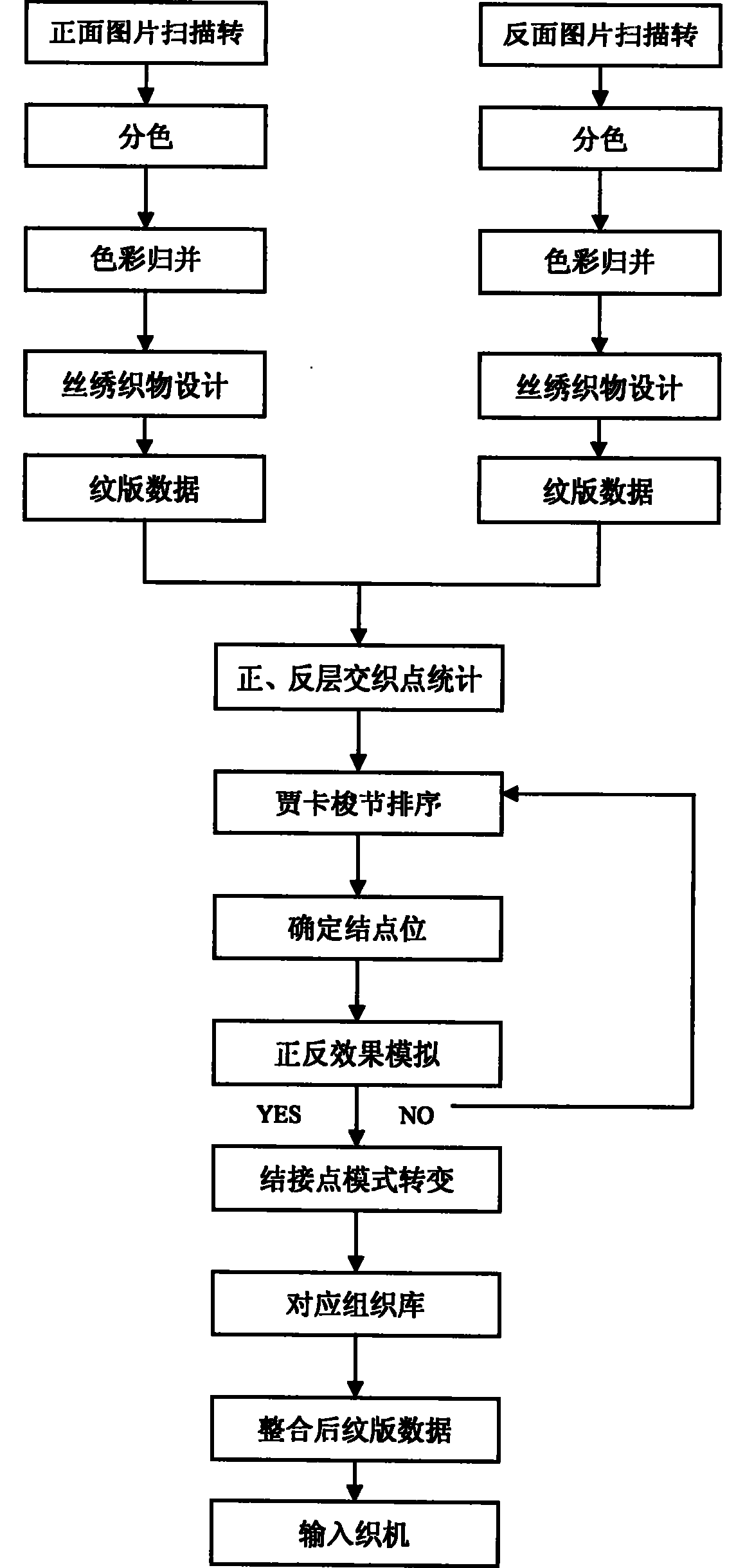

Digitel code manufacturing method jacquard weave double surface beautiful and glorious

InactiveCN1786308AMeet individual needsWide range of materialsPattern making devicesCard-punching apparatusTexture designPersonalization

The invention belongs to silk weaving picture-scenery technique development field, especially relates to a digital pattern two side beautiful brocade manufacturing method. The method includes the following steps: scanning, changing, color separating to set color bank; adding up crossing point according to electron lag; doing knitted texture design and confirming crunode position; inputting electron lag into loom control system. Materials drawing of the invention are very wide. And the product can satisfy consumerí»s individuation demand.

Owner:韩容

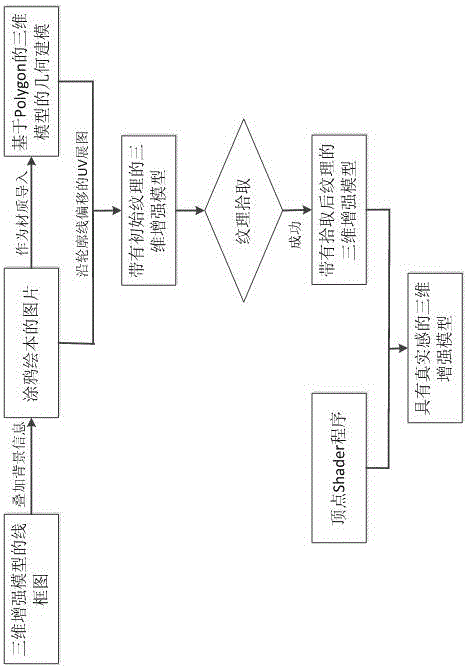

Photorealistic sense generation method of mobile augmented reality type doodle picture book

ActiveCN106127859AReduce material selection restrictionsImprove lighting effectsImage data processingTexture designComputer graphics (images)

The invention belongs to the technical field of mobile augmented reality, and provides a photorealistic sense generation method of a mobile augmented reality type doodle picture book. The photorealistic sense generation method comprises the steps of: (1) texture design, which is used for designing textures displayed by a three-dimensional augmented model before and after pickup; (2) three-dimensional augmented model design, which is used for designing a geometric model of a role model of a doodle object and drawing a UV plot map of the role model; (3) and vertex Shader design, wherein picture book images in an image sequence acquired by a camera are subjected to a series of processing steps such as projection, conversion and rasterization by means of a Shader program, so that the display of the model after pickup is more realistic. The photorealistic sense generation method can expand the material selection range of the doodle picture book, can creatively solve the problem of normal illumination and visual effect of a three-dimensional augmented model provided with a narrow component, and establishes the method for generating photorealistic sense of the mobile augmented reality type doodle picture book.

Owner:HUAZHONG NORMAL UNIV

Implants and methods for manufacturing same

ActiveUS20130302511A1Easy to fixDiscourages organizationMammary implantsPharmaceutical containersParticulatesElastomer

Implantable prosthesis, components of prosthesis, and methods of making same are provided. The methods generally include the steps of providing an implant shell, applying a curable fluid composition to the shell to form a coating thereon and applying a particulate component to the composition. The composition is a mixture, for example, an emulsion, containing a silicone-based elastomer dispersion and droplets of a suspended leachable agent. After the elastomer is stabilized and cured, the particulate component and leachable agent are removed, resulting in an implantable member having a porous, open-cell surface texture designed to be effective in reducing incidence of capsular formation or contraction.

Owner:ALLERGAN INC

Glaze of brunet ceramic and preparation method of glaze

The invention discloses glaze of brunet ceramic. The glaze is prepared from, by weight, 88-92% of ground glaze and 8-12% of transparent glaze; the ground glaze is prepared from, by weight, 2-5 parts of super white zirconium silicate, 18-22 parts of feldspar powder, 23-27 parts of albite, 3-5 parts of aluminum oxide, 8-10 parts of kaolin and 5-7 parts of calcined kaolin; the transparent glaze is prepared from, by weight, 3-7 parts of burned zinc oxide, 6-10 parts of barium carbonate, 28-32 parts of feldspar powder or 28-32 parts of albite, 0-3 parts of calcined alumina, 11-14 parts of calcinedtalc, 8-12 parts of calcite, 4-6 parts of quartz, 8-10 parts of kaolin and 7-14 parts of calcined kaolin. By means of the method, a product is rich in texture design and pattern, good in texture and soft, vivid, stable in performance, free of corrosion and free of crack.

Owner:GUANGDONG JIA MEI CERAMIC

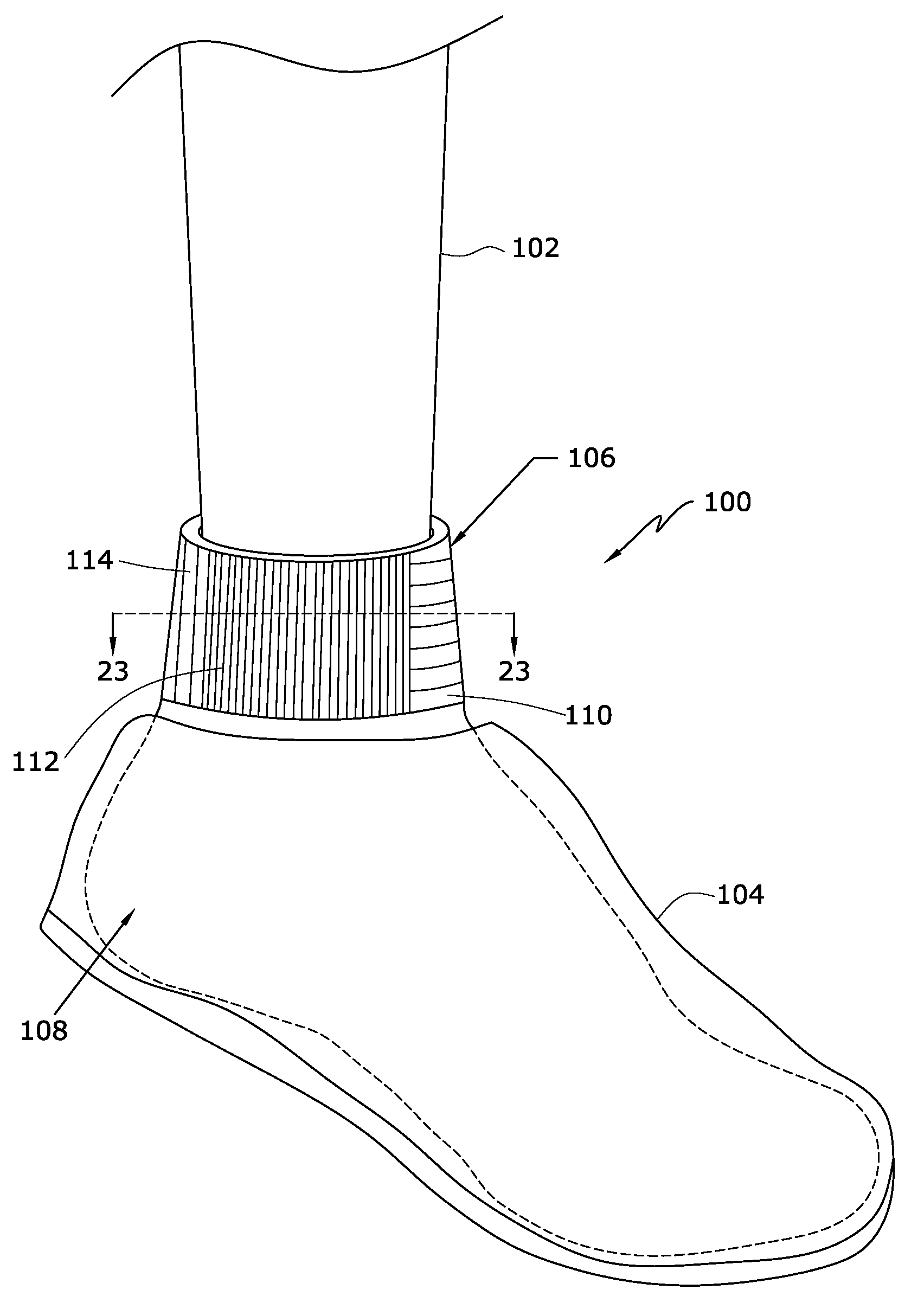

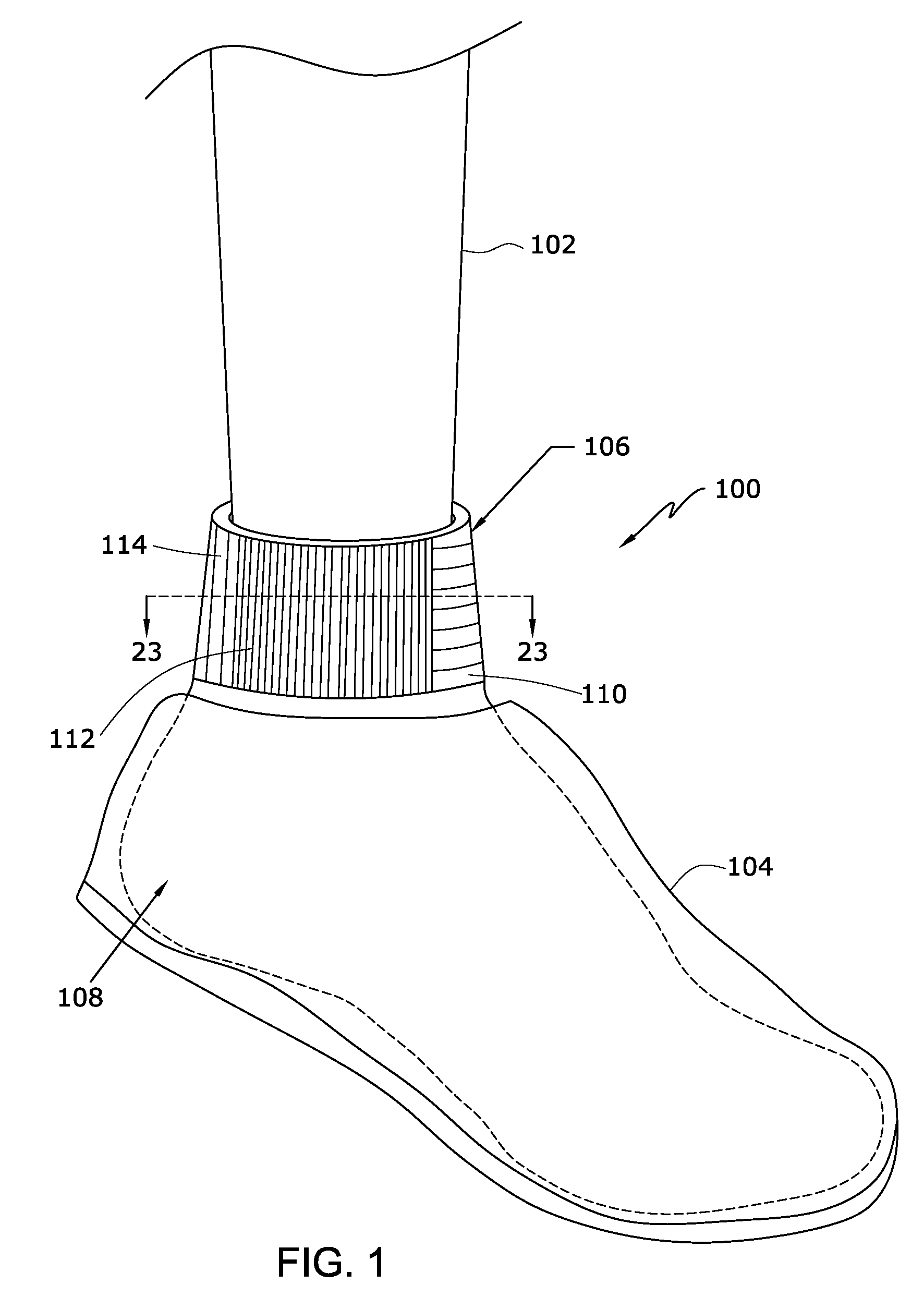

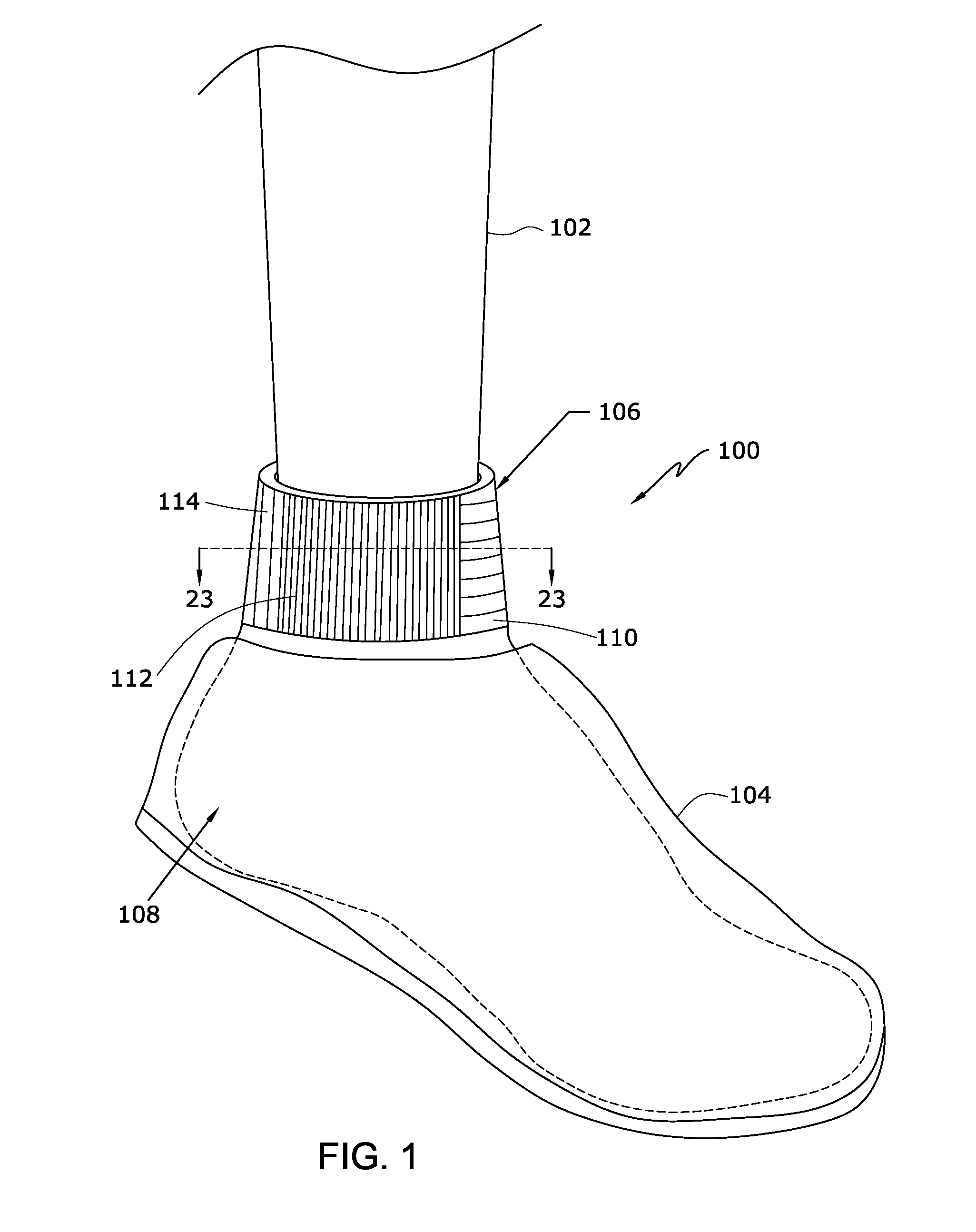

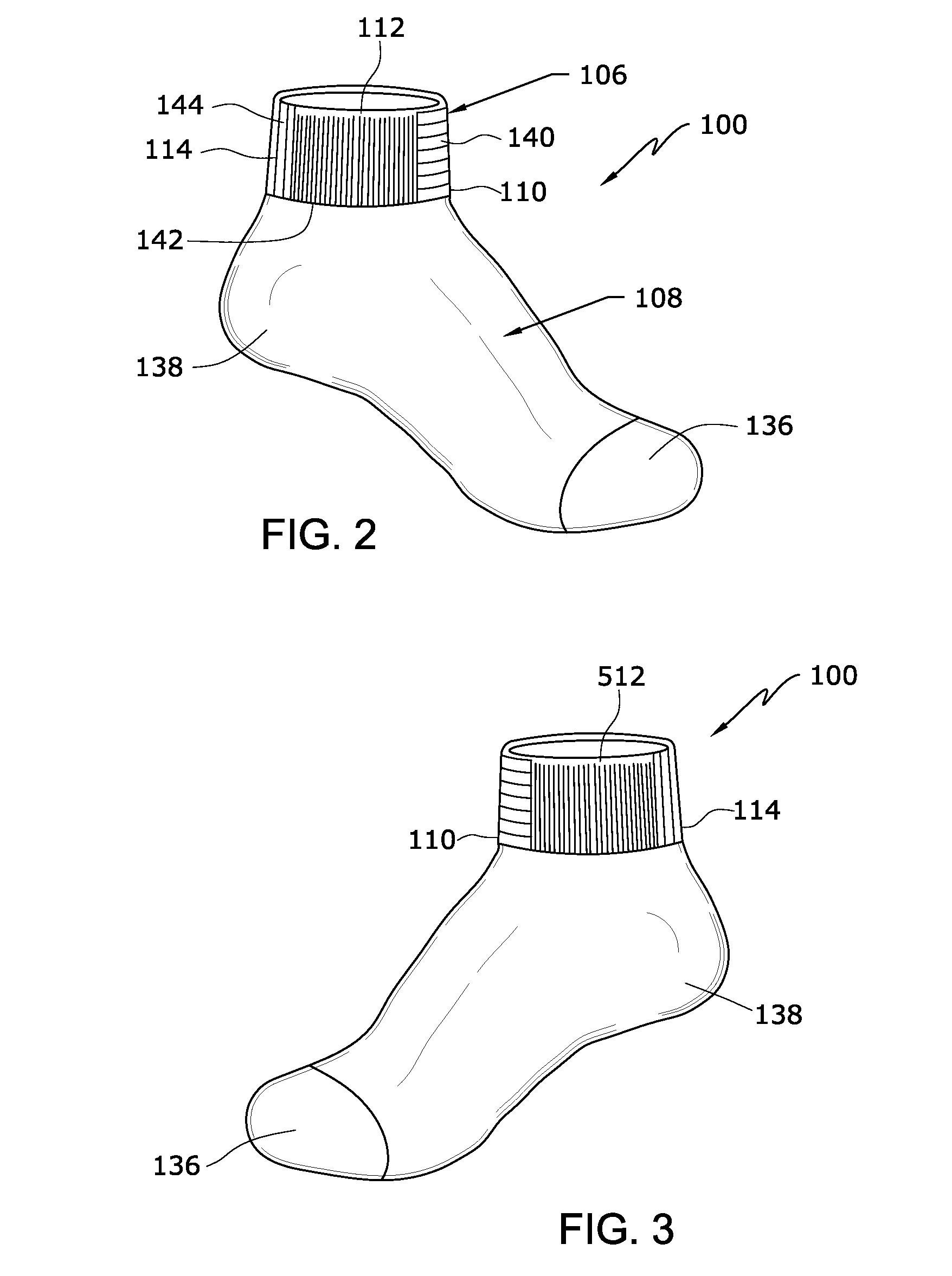

Apparel with reduced drag coefficient

Owner:NIKE INC

Apparel with Reduced Drag Coefficient

ActiveUS20080189825A1Reduce resistanceGarment special featuresProtective garmentLeading edgeTexture design

An athletic garment including a panel designed to reduce frictional and pressure drag around an appendage of an athlete competing in a high-speed event, such as running and cycling. The panel is positioned to encircle the appendage, and is provided with regions having different surface texture roughnesses. The leading edge of the panel includes texture designed to enhance the laminar boundary layer, while the adjacent portion of the panel includes texture intended to trip the boundary layer to turbulent flow. The drag-reducing panel may be the cuff of a sock, a sleeve, wristband, a headband, or the like.

Owner:NIKE INC

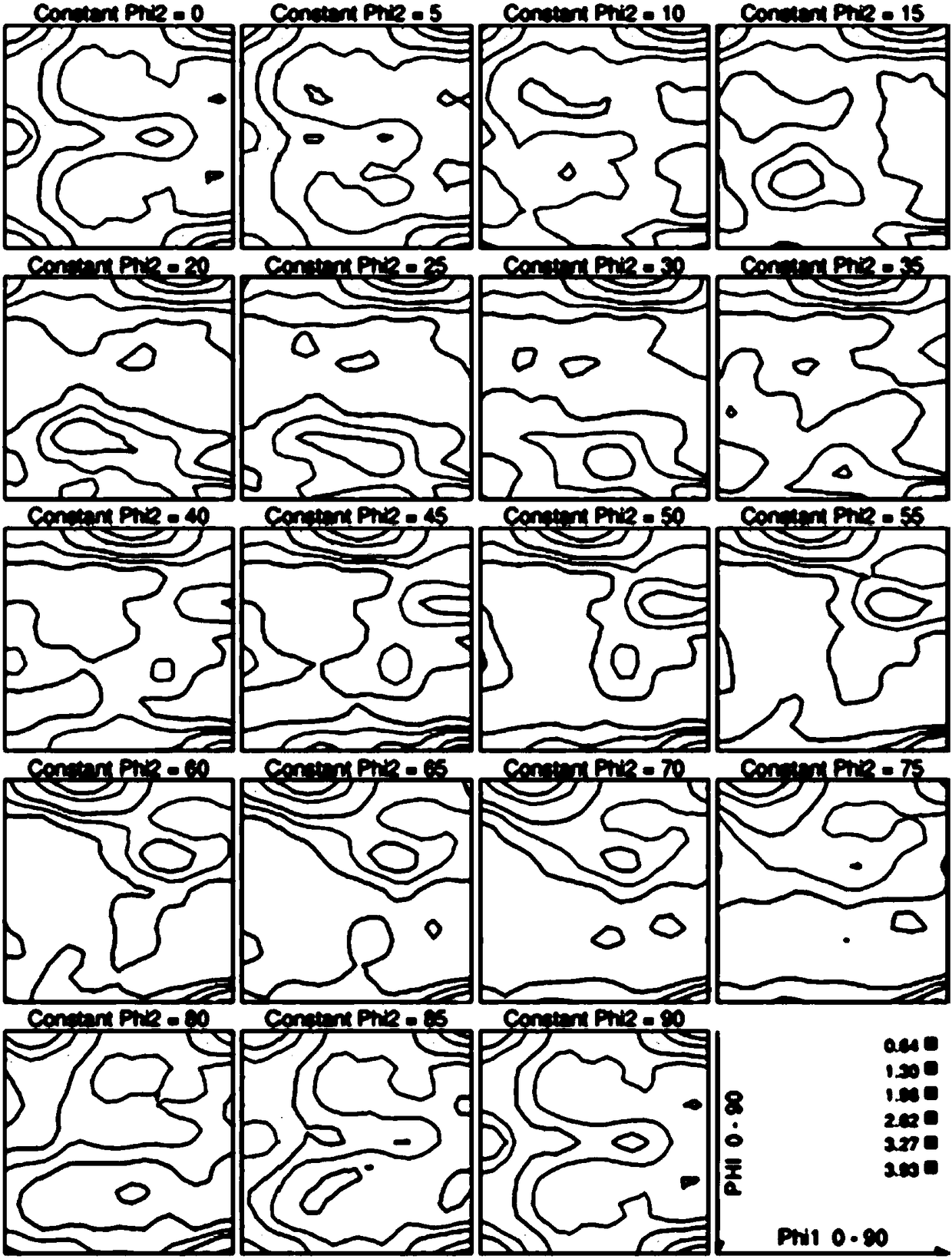

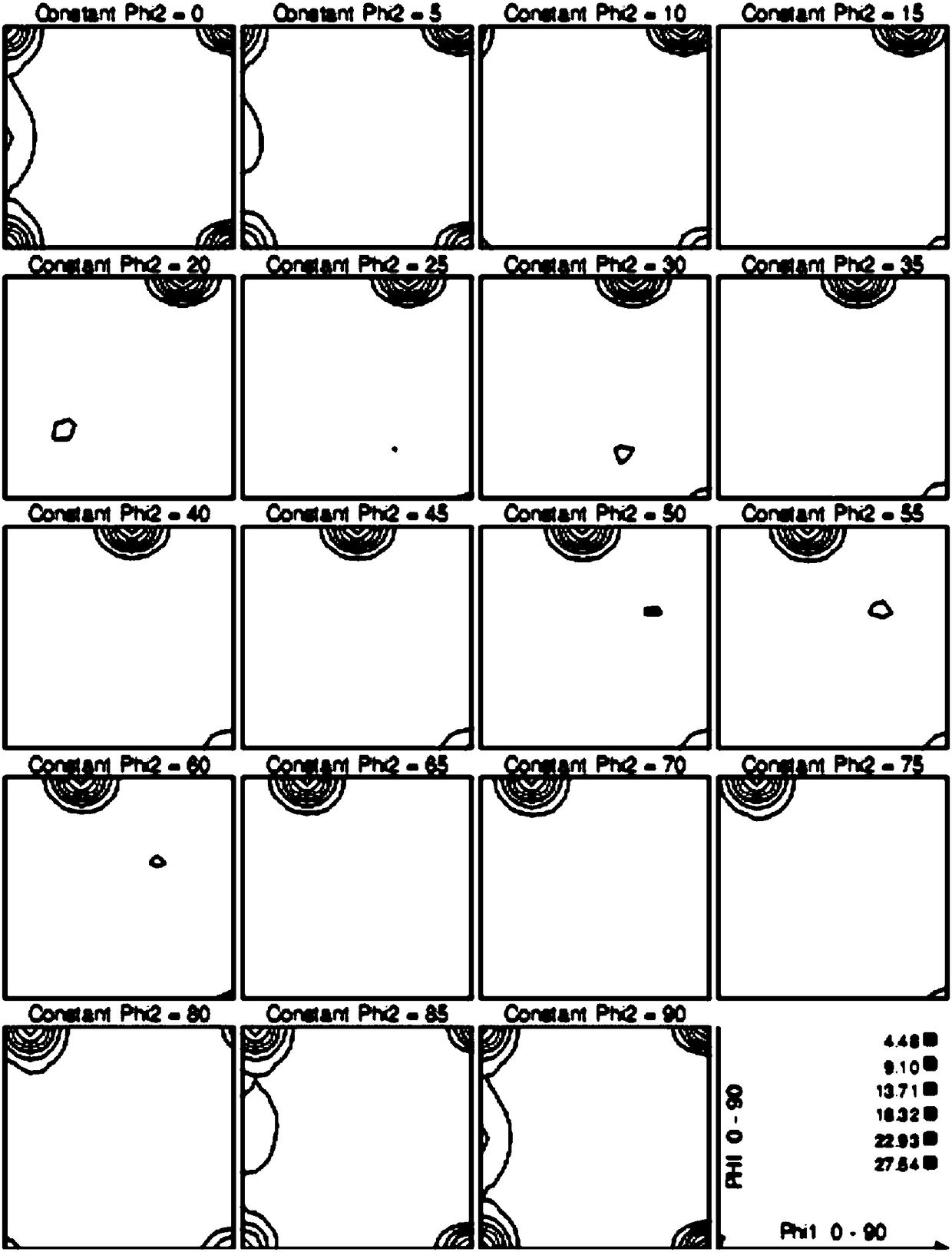

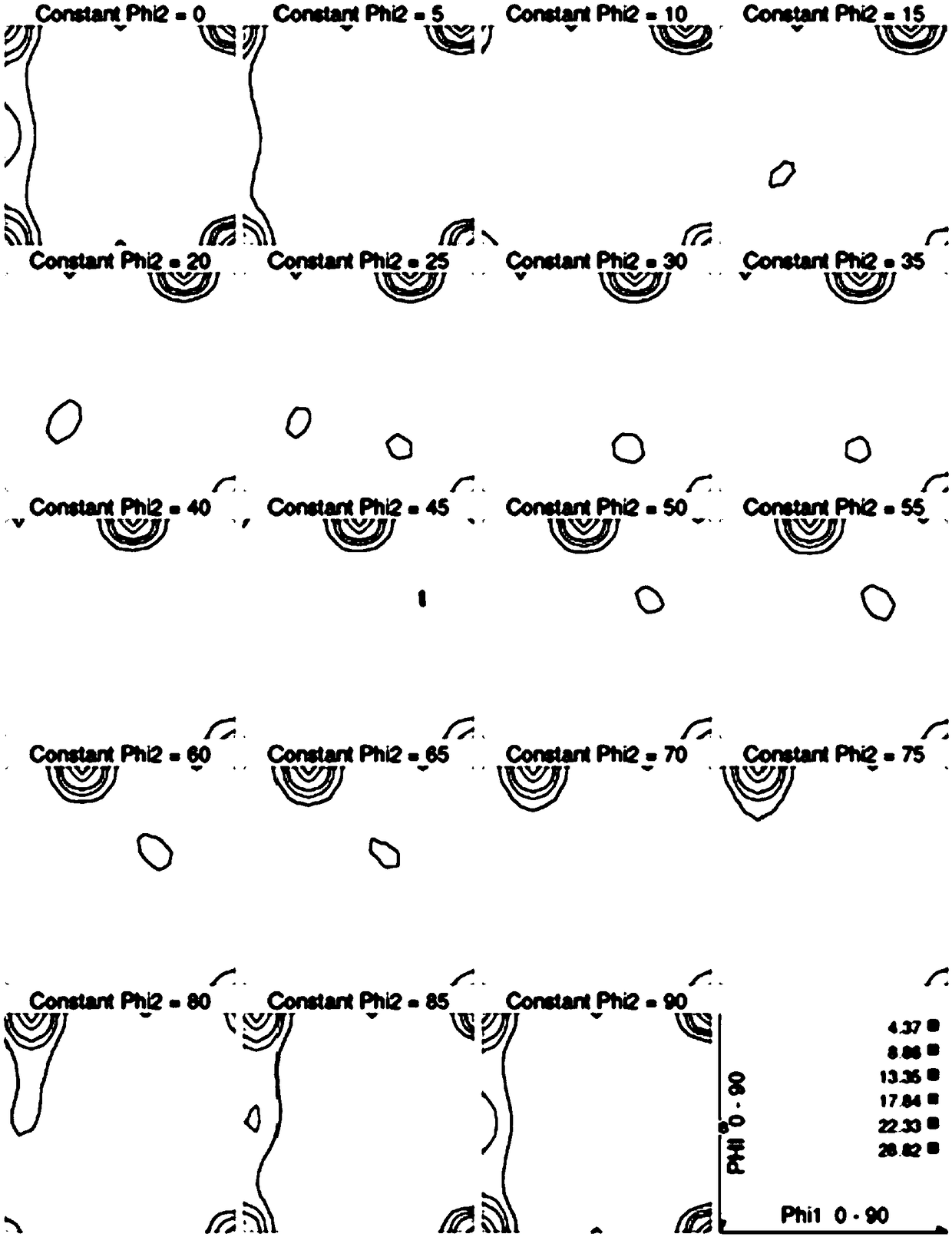

Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

Elastic polypropylene wet suit fabric

An elastic polypropylene wet suit fabric is made of fine count polypropylene fibers with fine denier counts. The elastic polypropylene wet suit fabric has a texture designed on the basis of elastic features and is woven with a high speed circular knitting machine and then treated in a finishing process. Such polypropylene wet suit fabric is laminated with an artificial rubber sponge in a laminating process and then made to be a polypropylene wet suit fabric piece with high elasticity, low modulus, better flushing capability and high dye fast grade at a special elasticity-processing stage. The laminated polypropylene wet suit fabric piece is suitable for the production of wet suits and other related products. The polypropylene wet suit fabric of the present invention is better in elasticity than conventional single-directional and low-elastic wet suit fabric, and capable to improve the comfort, flushing capability and dye fast grade of wet suits.

Owner:SHEI CHUNG HSIN IND

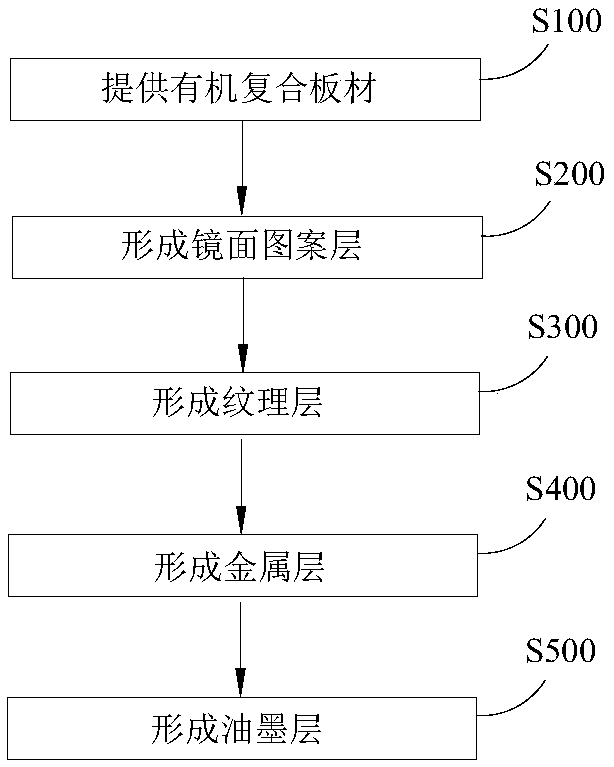

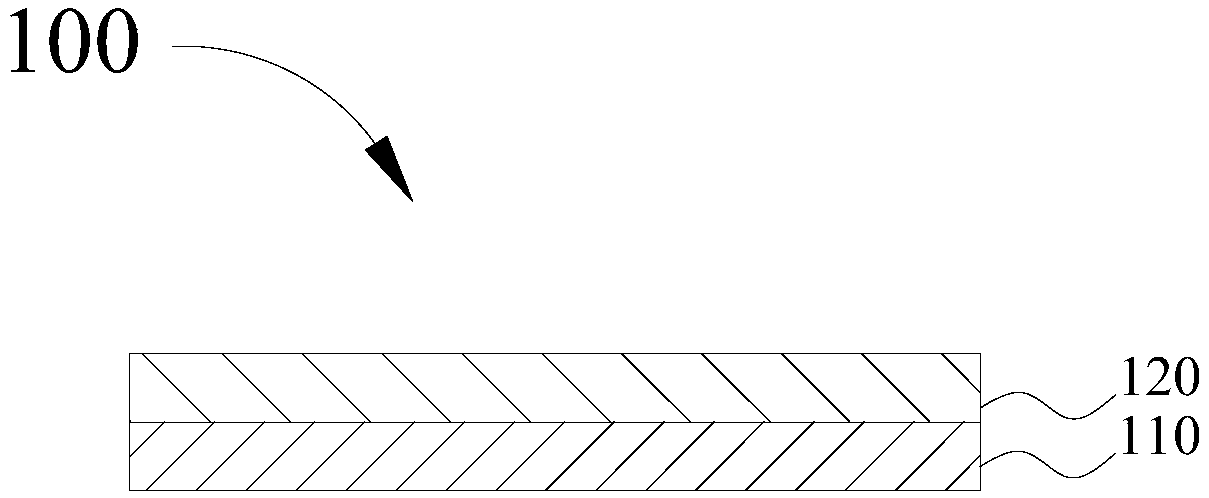

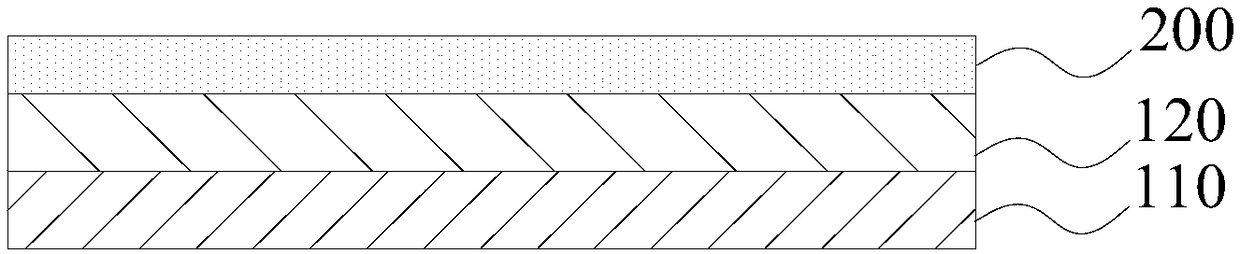

Shell and preparation method thereof and mobile terminal

ActiveCN108638729AShorten the production cycleIncrease productivityOrnamental structuresSpecial ornamental structuresTexture designSimple Organic Compounds

The invention discloses a shell and a preparation method thereof and a mobile terminal. The method of preparing the shell comprises the following steps: providing an organic compound panel which comprises a plurality of laminated sub layers; forming a mirror surface image pattern layer on the surface of one side of the organic compound plate; forming a texture layer on the side, far from the organic compound panel, of the mirror surface image pattern layer; forming a metal layer on the side, far from the mirror surface image pattern layer, of the texture layer; and forming a printing ink layeron the side, far from the grain layer, of the metal layer. Therefore, the shell prepared by the method is short in production period, easy to process, high in production efficiency, low in cost and difficult to crush; the integral brightness and the surface gloss effect of the shell are enhanced, and the appearance effect is improved obviously. According to the method, the mirror surface patterndesign and the texture design can be carried out on the shell, so that the shell is suitable for a personalized trend and the market competitiveness of the product is obviously improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Apparel with Reduced Drag Coefficient

An athletic garment including a panel designed to reduce frictional and pressure drag around an appendage of an athlete competing in a high-speed event, such as running and cycling. The panel is positioned to encircle the appendage, and is provided with regions having different surface texture roughnesses. The leading edge of the panel includes texture designed to enhance the laminar boundary layer, while the adjacent portion of the panel includes texture intended to trip the boundary layer to turbulent flow. The drag-reducing panel may be the cuff of a sock, a sleeve, wristband, a headband, or the like.

Owner:NIKE INC

Design method of micro texture having flat wall surface drag reduction function

PendingCN111460699AReduce size design rangeLow flow resistanceDesign optimisation/simulationSustainable transportationWall shearTexture design

The invention discloses a design method of a micro texture having a flat wall surface drag reduction function, and belongs to the field of surface texture design. According to the gas flow rate, an area, namely a buffer layer between a viscous bottom layer and a logarithmic law layer, where the wall shear stress is generated is determined by combining a boundary layer theory. Dimensionless treatment is performed on the size, and the thickness of the buffer layer is calculated so as to determine the height range of the micro texture. According to a Reynolds formula, the critical point of the fluid flowing from the laminar flow to the turbulent flow is calculated, and the arrangement area range of the micro texture is obtained. According to the two data, resistance reduction micro texture design is carried out, CREO software modeling is utilized, simulation is carried out through flow field simulation software FLUENT, the micro texture resistance reduction situation is analyzed, characteristic parameters of the micro texture are optimized, and the design of the flat-wall resistance reduction micro texture with the resistance reduction effect is achieved. The boundary layer theory isadopted, micro texture parameter design is conducted through layering and positioning of the turbulence area, the size design range of the drag reduction micro texture can be effectively narrowed, thesimulation amount is reduced, and the resource cost is saved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

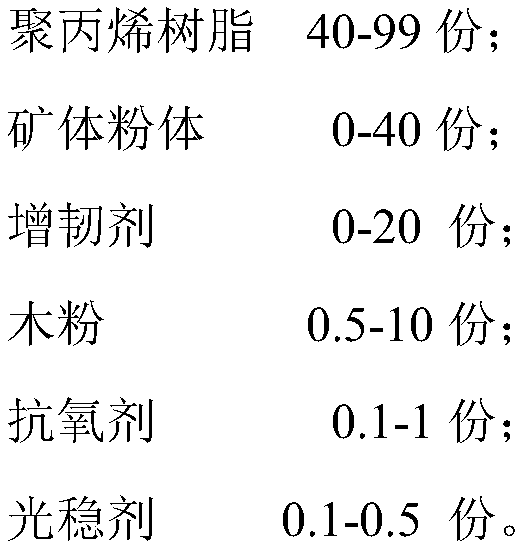

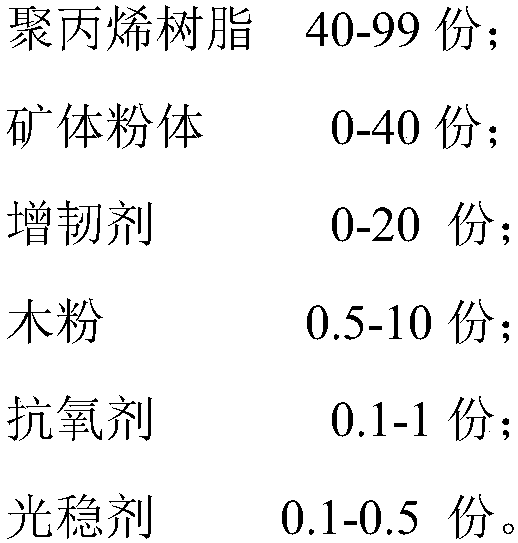

Wood flour-filled modified polypropylene material with low odor and imitation flocking effect, and preparation method thereof

InactiveCN108148261AReduce manufacturing costWith imitation flocking effectTexture designMaterial physics

The invention discloses a wood flour-filled modified polypropylene material with low odor and an imitation flocking effect, and a preparation method thereof. The wood flour-filled modified polypropylene material is prepared from the following components in percentage by weight: 40 to 99 parts of polypropylene resin, 0 to 40 parts of ore body powder, 0 to 20 parts of flexibilizer, 0.5 to 10 parts of wood flour, 0.1 to 1 part of antioxidant, and 0.1 to 0.5 part of light stabilizer. Compared with the prior art, the wood flour-filled modified polypropylene material provided by the invention has the following positive effects that (1) the wood flour is adopted to replace chemical staple so as to be added into the light-colored modified polypropylene material, a texture design is combined to have the imitation flocking effect, and a wood flour grid or a hollow structure can adsorb odor, so that not only is the material odor reduced, but also a light wooden fragrance can be produced. The material can replace an interior trim part product coated with textile fabrics, so that not only is the production cost of auto parts manufacturers saved, but also the high requirements of consumers on smell and vision effects of automotive interior trims are greatly met. (2) Less wood flour is added, so that the wood flour is not easy to precipitate out and has no influence on a physical performanceof the material.

Owner:SHANGHAI PRET COMPOSITES +4

High-elasticity wet suit fabric

InactiveUS6708528B2High elongationPromote recoveryWeft knittingProtective garmentTexture designFiber

A high-elasticity wet suit fabric is made of fine count artificial fibers with fine denier counts and elastic yams with high elongation and recovery capabilities, having a texture designed on the basis of elastic features, knitted with a high-speed circular knitting machine and treated in a dyeing and finishing process. Such a high-elasticity wet suit fabric is laminated with an artificial rubber sponge in a laminating process to form a high-elastic wet suit fabric piece. The high-elasticity wet suit fabric of the present invention is better in elasticity than the conventional single-directional and low-elastic wet suit fabric, and capable to improve the comfort, flexibility and elongation of wet suits.

Owner:SHEI CHUNG HSIN IND

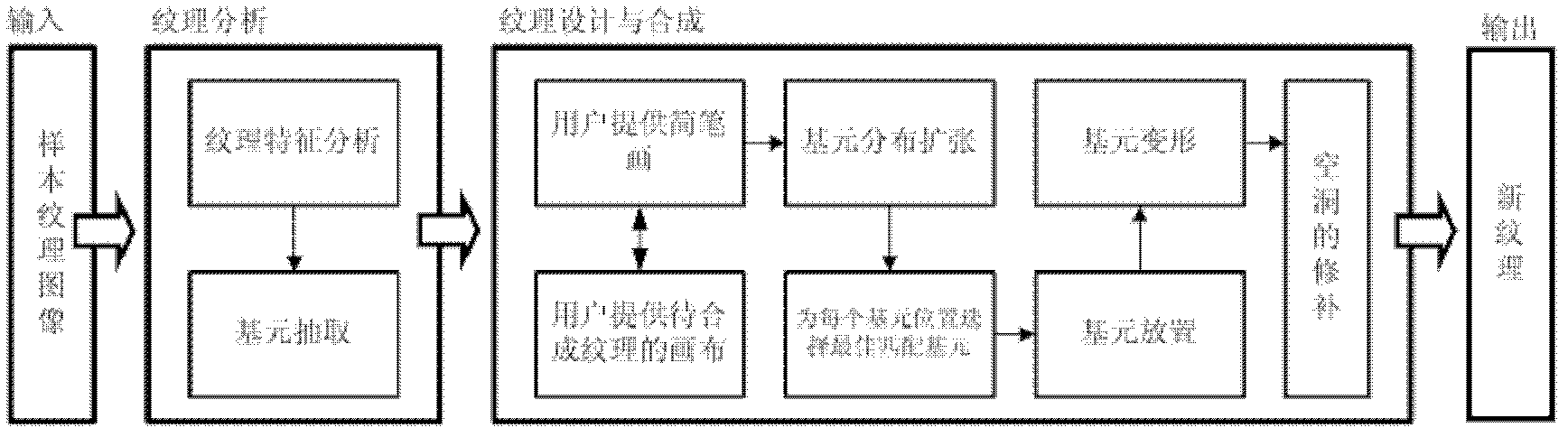

Texture design and synthesis method based on element reorganization

InactiveCN102426708AAddresses issues requiring reference to sample texturesFix issues with referencing sample texturesDrawing from basic elementsPattern recognitionTexture design

The invention relates to a texture design and synthesis method based on element reorganization, comprising the steps of: (1) element extraction; (2) element classification; (3) element distribution and generation; (4) element placement and deformation; and (5) post-treatment. Compared with the prior art, the invention well solves the problem that sample texture needs to be referred to in a texture synthesis process, and an existing synthesis method based on sample texture is improved through a treatment method controlled by a user.

Owner:SHANGHAI JIAO TONG UNIV

Low-odor and flocking-effect-imitating plant straw powder filled modified polypropylene material and preparation method thereof

The invention discloses a low-odor and flocking-effect-imitating plant straw powder filled modified polypropylene material and a preparation method thereof. The low-odor and flocking-effect-imitatingplant straw powder filled modified polypropylene material is prepared from the following components in percentage by weight: 40 to 99 parts of polypropylene resin, 0 to 40 parts of ore body powder, 0to 20 parts of a toughening agent, 0.5 to 10 parts of plant straw powder, 0.1 to 1 part of an antioxidant and 0.1 to 0.5 part of a light stabilizer. The low-odor and flocking-effect-imitating plant straw powder filled modified polypropylene material disclosed by the invention has the following positive effects that 1, chemical staple fibers are replaced with the plant straw powder; the plant strawpowder is added into the light-color modified polypropylene material, and a texture design is combined, so that the material has a flocking-effect-imitating effect; a hollow structure of the straw powder has an adsorption effect on odor so that the odor of the material is reduced and a slight wheat aroma also can be generated. The material disclosed by the invention can be used for replacing a textile fabric covered interior part product; the production cost of automobile part manufacturers is saved and high requirements of consumers on smell sense and vision of automobile interior parts aregreatly met; 2, the amount of the added plant straw powder is relatively small and the plant straw powder does not easily separate out, so that the plant straw powder has no influence on physical performance of the material.

Owner:SHANGHAI PRET COMPOSITES +4

Hand-weaved style fabric and processing technology thereof

InactiveCN103866457ASubtle EffectAchieve satisfactory goalsSwivel-woven fabricsLappet-woven fabricsTexture designYarn

The invention relates to a hand-weaved style fabric and a processing technology thereof. Warps of the fabric adopt CJ9.7tex / S twist directions and Z twist directions, wefts adopt 1950 twists per meter in the CJ9.7tex / S twist directions and Z twist directions, and a fabric texture is a 3 / 1+1 / 3 change square texture which is subjected to flower type arrangement; the ratio of the warps in the S twist directions and the Z twist directions is 36: 36, and the ratio of the wefts in the S twist directions and the Z twist directions is 24: 24. According to the processing technology, special craft technologies are used in processes of warping, slashing, weaving, dyeing and finishing, and the like. The hand-weaved style fabric and the processing technology thereof have the advantages that texture designs are matched with yarn twist directions, twist degree changes and positioning applications to weave the novel hand-weaved style fabric; conventional pure cotton raw materials are applied, and matching of twist directions, twist degrees, and textures of the yarn is used for novel design, so that the fabric obtains a subtle square effect, a hand-weaved style is achieved, and purposes of market acceptance and customer satisfaction are achieved.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Production method for improving anti-crease effect of pure-cotton popline dyed fabric

ActiveCN103541103AReduce the densityReduce weft densityMercerising of indefinite length fabricsWoven fabricsTexture designEngineering

The invention relates to a production method for improving anti-crease effect of pure-cotton popline dyed fabric. Sample cloth is the pure-cotton popline dyed fabric, and the texture specifications of the pure-cotton popline dyed fabric include that the fabric texture is formed by 1 / 1 plain lines, 2 / 1 slope lines, 2 / 2 slope lines, 3 / 1 slope lines, 1 / 1 plain back plus 2 / 1 slope lines or 1 / 1 plain back plus 3 / 1 slope line texture, yarn count is 40-90 British count sub-thread yarns or 80-180 British count double-thread yarns, warp density is 120-230 thread / inch, weft density is 70-130 thread / inch, weaving difficulty coefficient is 28-37, and the ratio of the warp density to the weft density is 1.5 to 1.9. The production method is characterized by including steps of modifying pattern texture design, spinning raw cotton, dyeing, weaving, burning, mercerizing, tentering, preshrinking and obtaining a finished product. The finished fabric is ecological and environment-friendly after being processed without adding any resin and catalyst by the production method. Since the warp density and the weft density are lowered, cost is reduced, the finished fabric is light and thin, moisture absorbing permeability is improved by more than 30%, and wearing performance is good.

Owner:LUTAI TEXTILE

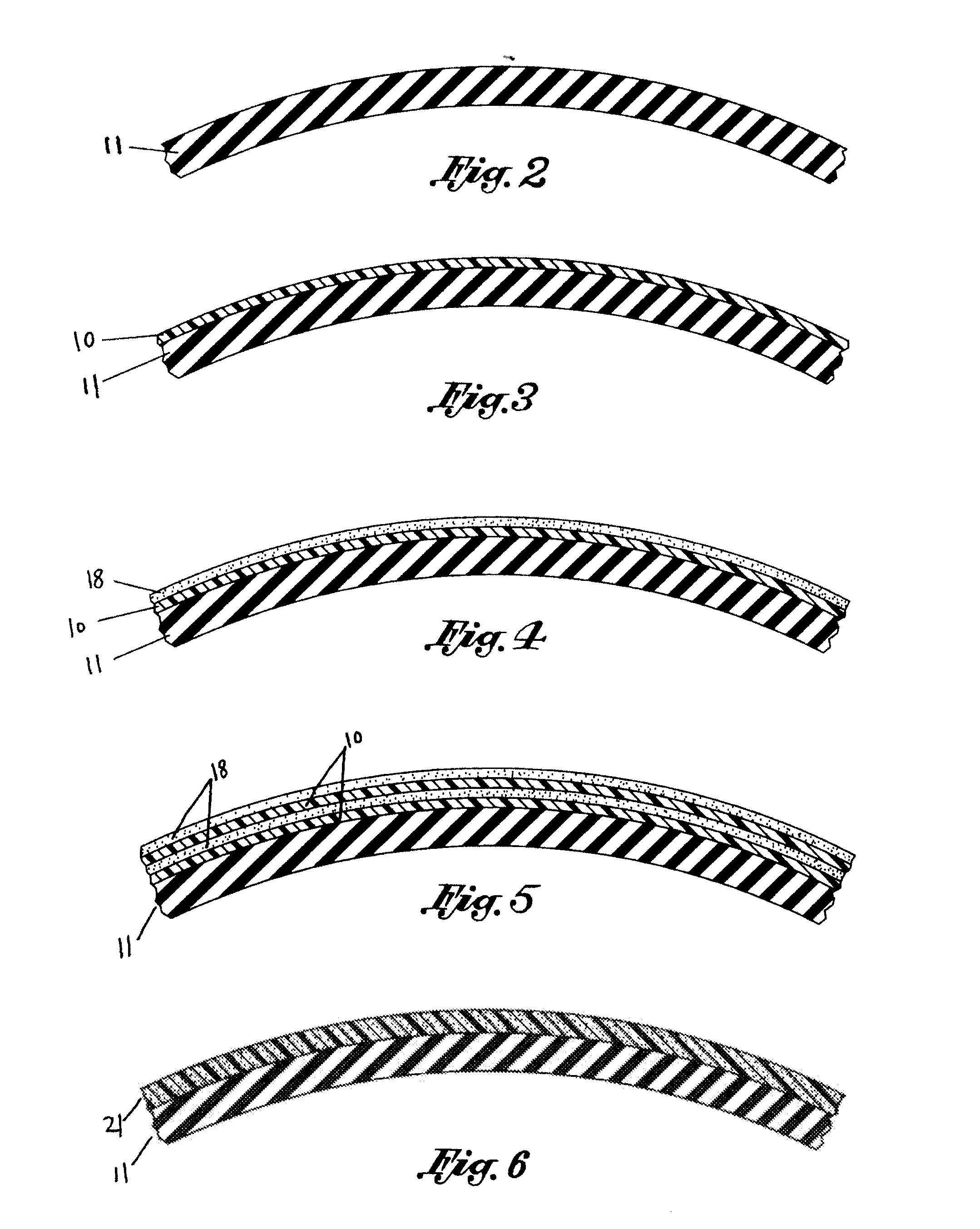

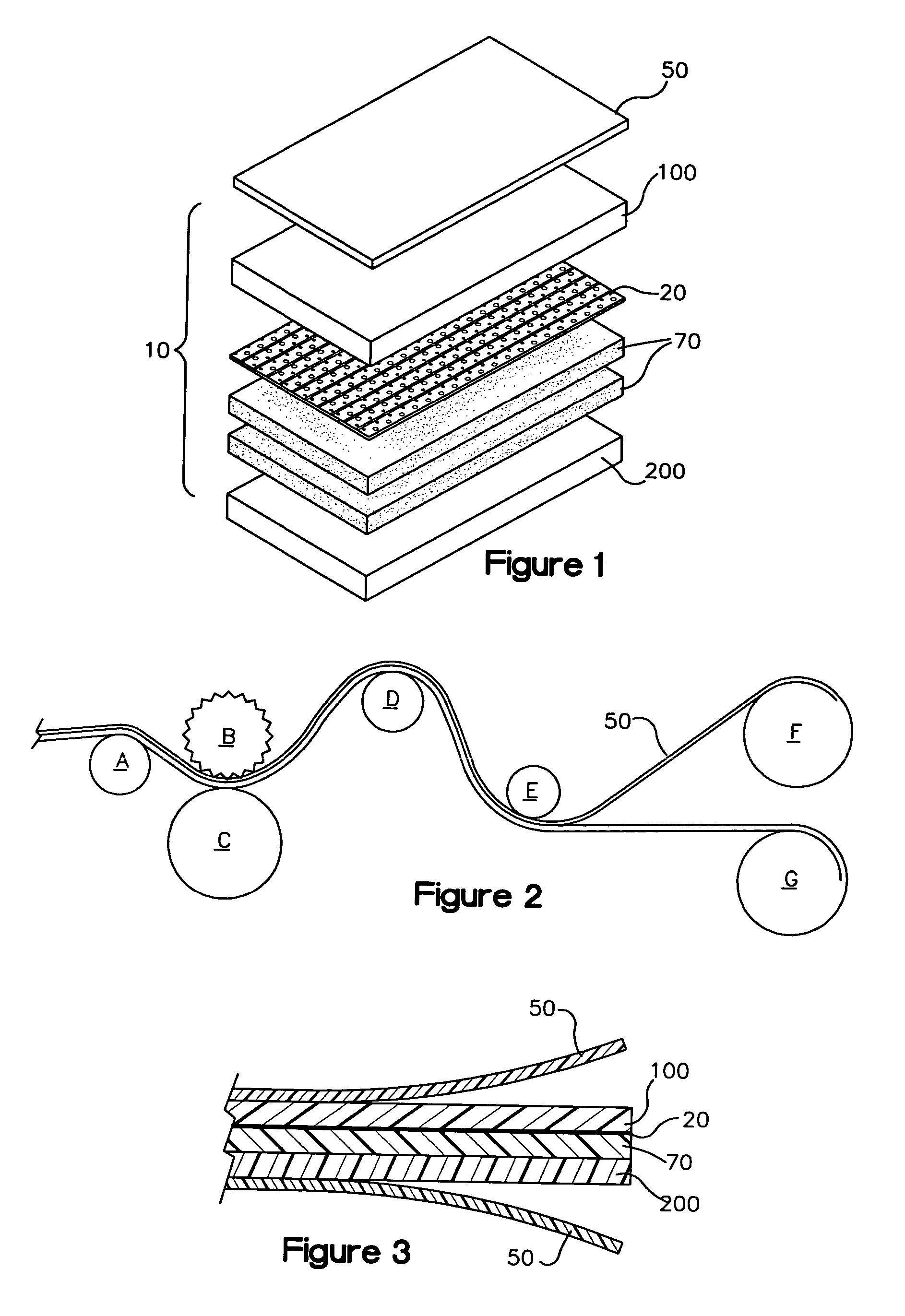

Dimensionally stable laminate with removable web carrier and method of manufacture

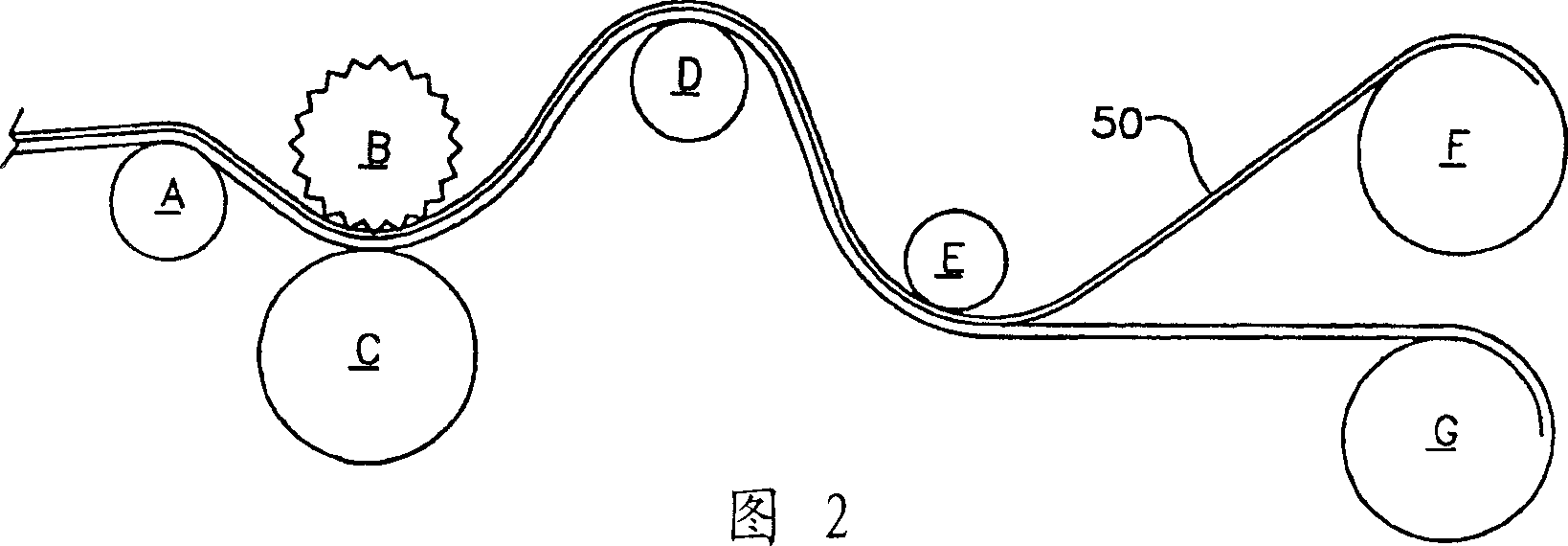

ActiveUS7052761B2Reduce distortion problemsMinimize distortionMechanical working/deformationLamination ancillary operationsTexture designRoll forming

A balanced dimensionally stable laminate uses a web carrier which is removably attached to a layer of the laminate during lamination and processing. The web carrier maintains dimensional stability of the layers of the laminate during lamination and processing and after removal of the web carrier. The web carrier is removed if at all only after the laminate is formed and processed. The bonding force of the web carrier with at least one of the polymers layer resists forces which would otherwise dimensionally distort the layers of the laminate or design features thereof during lamination, particularly in thermal roll-forming lamination. The layers of the laminate, which may include print and texture design features, remain dimensionally stable after removal of the web carrier. The web carrier can be removed at any time prior to or after final application of the laminate to a substrate.

Owner:SCHNELLER

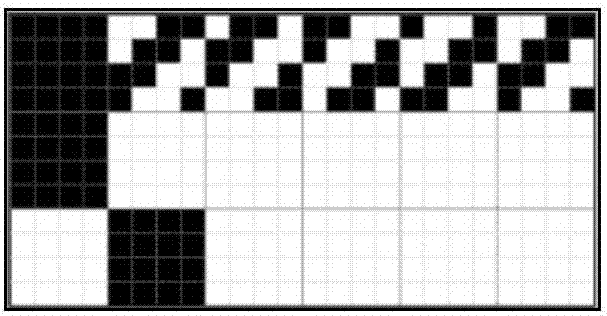

Full-color warp coloring jacquard fabric weaving and designing method

InactiveCN107059214AColorful color effectsReduce selectionSwivel-woven fabricsLappet-woven fabricsTexture designEngineering

The invention relates to the technical field of fabric weaving, particularly to a full-color warp coloring jacquard fabric weaving and designing method. The full-color warp coloring jacquard fabric weaving and designing method specifically comprises the following steps of warp and weft determination, primary color texture design, primary color palette design, pattern adjustment, pattern color separation, texture laying and fabric weaving. According to the full-color warp coloring jacquard fabric weaving and designing method with color mixing prior to texture configuration, color expression for any pattern can be achieved only through 10 primary color textures, so that the design efficiency can be improved, and meanwhile, fabric color richness can be greatly enhanced, and accuracy of weaved color gradation can be ensured.

Owner:ZHEJIANG SCI-TECH UNIV

Method for producing vertical bar flat cut towel product

ActiveCN101818402AReduce manufacturing costImprove weaving processWoven fabricsVertical barTexture design

The invention discloses a method for producing a vertical bar flat cut towel product, which comprises the following steps of: 1) spinning, namely performing spinning by adopting ply yarns as towel yarns, wherein the yarn count of single yarns is British 8 to 10s and the twist of the ply yarns is 28 to 35 twists per 10 centimeters; and 2) weaving, namely weaving the yarns to obtain towel gray fabric, wherein during weaving, the warp density is more than or equal to No. 56 in portie, and the weft density is more than or equal to 200 yarns per 10 centimeters. The method effectively improves the conventional weaving process, obtains the vertical bar flat cut towel product by changing the towel texture design, and breaks through the appearance limitation of the primary cut pile products. Compared with the primary cut pile products, the obtained product has the advantages that: the hairiness amount is relatively reduced, and the appearance of the obtained product is obviously improved afterwashing and is unique.

Owner:LOFTEX CHINA LTD

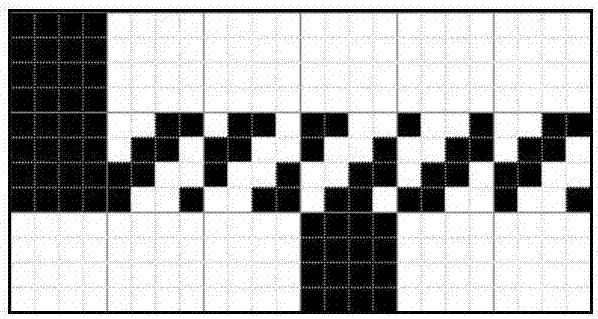

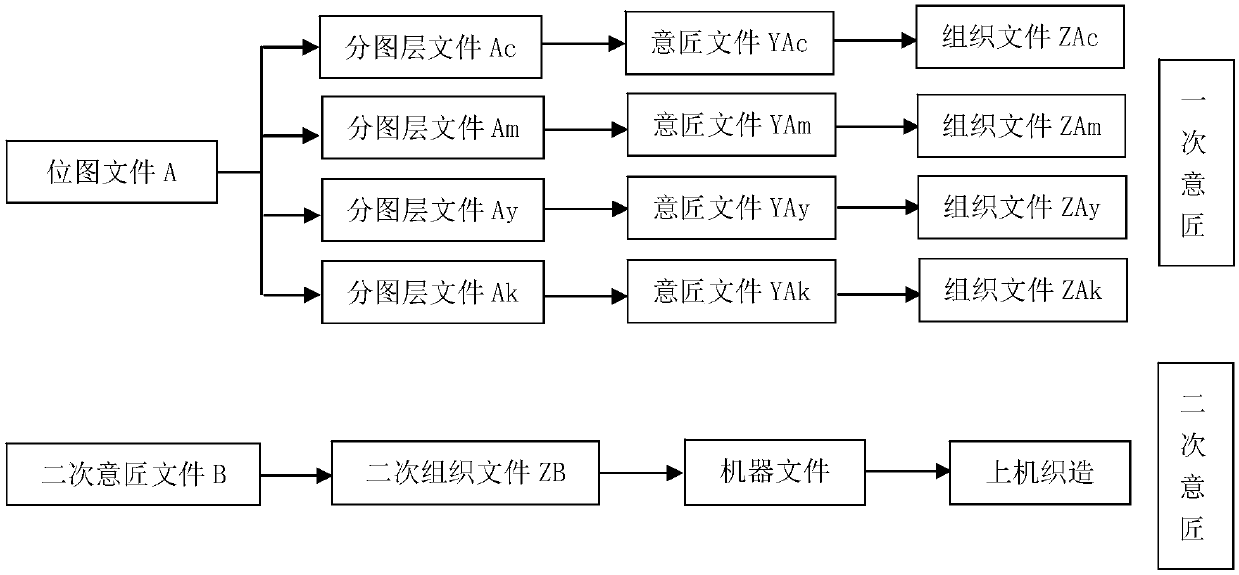

Method for producing true-color jacquard fabrics through double-design method

InactiveCN107557968ASimple designRealize secondary transformationPattern making devicesSwivel-woven fabricsTexture designGraphics

The invention discloses a method for producing true-color jacquard fabrics through a double-design method. The method for producing the true-color jacquard fabrics through the double-design method applies the double-design method to complete color pattern design and loom weaving of fabrics and comprises the following steps of 1) selecting and setting a bitmap file as a bitmap file A with a heightof M, a width of N, a warp density (Pj) of P, a weft density (Pw) of Q, a warp number of N*P and a weft number of M*Q; 2) performing first design; 3) performing second design. The method for producingthe true-color jacquard fabrics through the double-design method breaks through the design steps of traditional pattern weaving, skillfully combines artistic retouching and technological design, corresponds well to computer color modes, embodies fabric color, facilitates texture design, achieves secondary transformation of design, separates design from patterns and totally breaks traditional design concepts. Besides, the method for producing the true-color jacquard fabrics through the double-design method is simple and intuitive in design, greatly reduces the workload of design processes, improves the production efficiency, reduces the production costs and enables design ideas to turn into real woven products rapidly, thereby being an important innovative achievement.

Owner:ZHEJIANG SCI-TECH UNIV

Viscose twisted yarn and modal/cotton interwoven jacquard home textile fabric production method

InactiveCN106811854ASame starting pointRaise the gradeSingeingHeating/cooling textile fabricsTexture designYarn

The invention relates to a viscose twisted yarn and modal / cotton interwoven jacquard home textile fabric production method. The production method includes the following steps: (1) raw material preparation; (2) sectional beaming; (3) pattern and texture design; (4) weaving; and (5) after-finishing. The viscose imitated silk jacquard home textile fabric is soft and smooth, has a gloss of silk, can show the silk style of the fabric, has wear performance such as excellent moisture absorption performance and air permeability, is practical, comfort and beautiful, and can meet the demand of people for high grade high-quality home textile fabric.

Owner:JIANGSU YUEDA HOME TEXTILE

Dimensionally stable laminate with removable web carrier and method of manufacture

InactiveCN1735506AResistance to distortionLamination ancillary operationsSynthetic resin layered productsTexture designRoll forming

A balanced dimensionally stable laminate uses a web carrier which is removably attached to a layer of the laminate during lamination and processing. The web carrier maintains dimensional stability of the layers of the laminate during lamination and processing and after removal of the web carrier. The web carrier is removed if at all only after the laminate is formed and processed. The bonding force of the web carrier with at least one of the polymers layer resists forces which would otherwise dimensionally distort the layers of the laminate or design features thereof during lamination, particularly in thermal roll-forming lamination. The layers of the laminate, which may include print and texture design features, remain dimensionally stable after removal of the web carrier. The web carrier can be removed at any time prior or after final application of the laminate to a substrate.

Owner:SCHNELLER

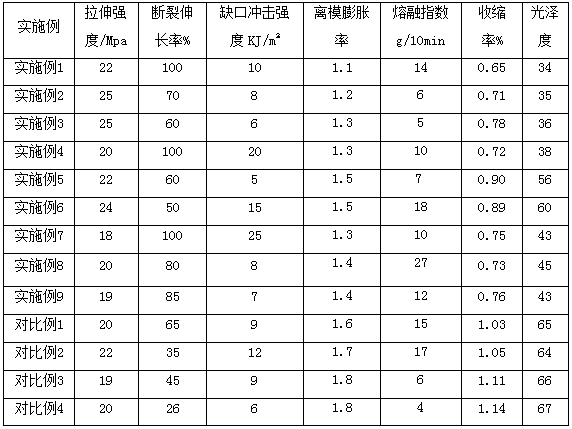

Polypropylene composite material and preparation method thereof, sheet or irregular section prepared thereby and application thereof

The invention discloses a polypropylene composite material and a preparation method thereof, a sheet or an irregular section prepared thereby and application thereof. The composite material comprises50-80 parts of polypropylene, 5-20 parts of a skin texture copying agent, and 10-30 parts of a size stabilizing agent; the width of half peak of a crystallization peak of the polypropylene is 3-7 DEGC; the peak temperature of the crystallization peak of the polypropylene is 113-120 DEG C; the peak temperature of the crystallization peak of the skin and texture copying agent is 90-100 DEG C. According to the polypropylene composite material, the mold releasing expansion rate and the glossiness of the composite material are reduced, and meanwhile, the material is high in shrinkage rate; the material is low in mold releasing expansion rate, so that injection molding defects such as bright shadow, waveform and white spots in skin and texture copying can be effectively avoided; material support is supplied to nice skin and texture design; the structural design can integrate more aesthetic effects.

Owner:GUANGDONG KINGFA TECH CO LTD

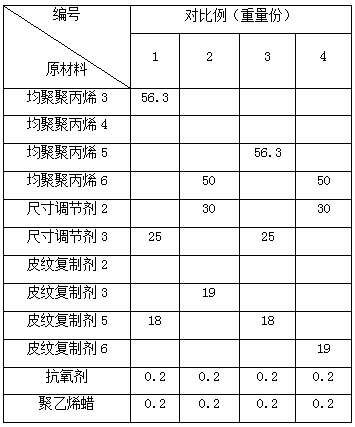

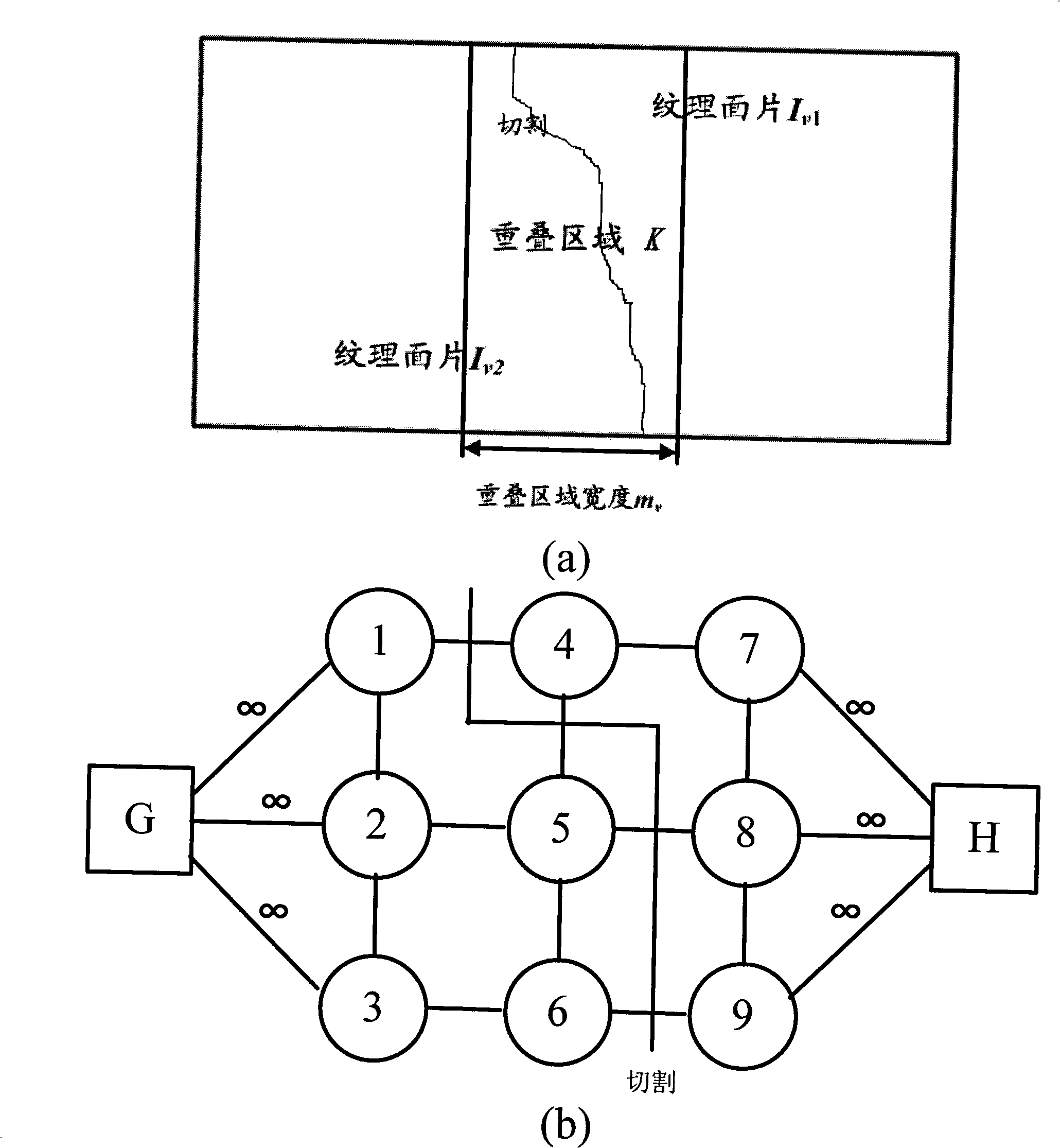

Loop vein design method based on vein pattern

InactiveCN101308580AThe method is simpleLow costImage enhancement3D-image renderingPattern recognitionVein

The invention discloses a cycling texture design method based on texture master drawing; the method comprises the following steps: (1) inputting a texture master drawing, and folding the texture master drawing from head to tail in the horizontal direction; finding the best seam line through image cutting in the horizontally overlapped area so as to obtain the cycling texture in the horizontal direction; (2) folding the cycling texture in the horizontal direction from head to tail from the vertical direction, and finding the best seam line through image cutting in the vertically overlapped area so as to obtain the final cycling texture. The method of the invention is simple and convenient, which has low cost and precise control; the user can design the size of the cycling texture based on needs to achieve the purpose of designing cycling texture directly through texture master drawing.

Owner:ZHEJIANG UNIV

Structure of double-layer yarn-dyed anti-raveling knitted fabric

InactiveCN102534969AGood anti-scattering performanceFeel plumpFlat-bed knitting machinesTexture designYarn

The invention discloses a weaving method of fabric, aiming at providing the weaving method of double-layer yarn-dyed anti-raveling knitted fabric. The weaving method is characterized in that, in addition to pretreatment of yarn, the weaving method further comprises the following steps of: performing texture design on an upper layer and a lower layer of the fabric; performing weave design on the fabric; synthesizing texture plate files of the upper layer and the lower layer of the fabric by utilizing a computer-assisted design system; and inputting the texture plate file of the double-layer yarn-dyed fabric into a computerized flat knitter, performing circulating movement through a needle bed, and adjusting the tension state of the yarn and the looping state of weave to produce the double-layer yarn-dyed anti-raveling knitted fabric. The weaving method disclosed by the invention has the benefits that the artistic appearance effect of the double-layer yarn-dyed weft-knitted fabric with good anti-raveling performance, plump hand feeling and unique appearance is formed; personalized feature of being vivid, fashionable, plentiful and colorful of the fabric is increased, and a mysterious artistic effect is given to people; the weave of the fabric is smooth in trend, and smooth and natural in conjunction; and the color and the tone are alternate in brightness and darkness and harmonious, and an unique charm of the weave of the fabric is further shown.

Owner:JIANGNAN UNIV

High-elasticity wet suit fabric

InactiveUS20030172685A1High elongationPromote recoveryWeft knittingProtective garmentFiberTexture design

A high-elasticity wet suit fabric is made of fine count artificial fibers with fine denier counts and elastic yarns with high elongation and recovery capabilities, having a texture designed on the basis of elastic features, woven with a high-speed circular knitting machine and treated in a dyeing and finishing process. Such a high-elasticity wet suit fabric is laminated with an artificial rubber sponge in a laminating process to form a high-elastic wet suit fabric piece. The high-elasticity wet suit fabric of the present invention is better in elasticity than the conventional single-directional and low-elastic wet suit fabric, and capable to improve the comfort, flexibility and elongation of wet suits.

Owner:SHEI CHUNG HSIN IND

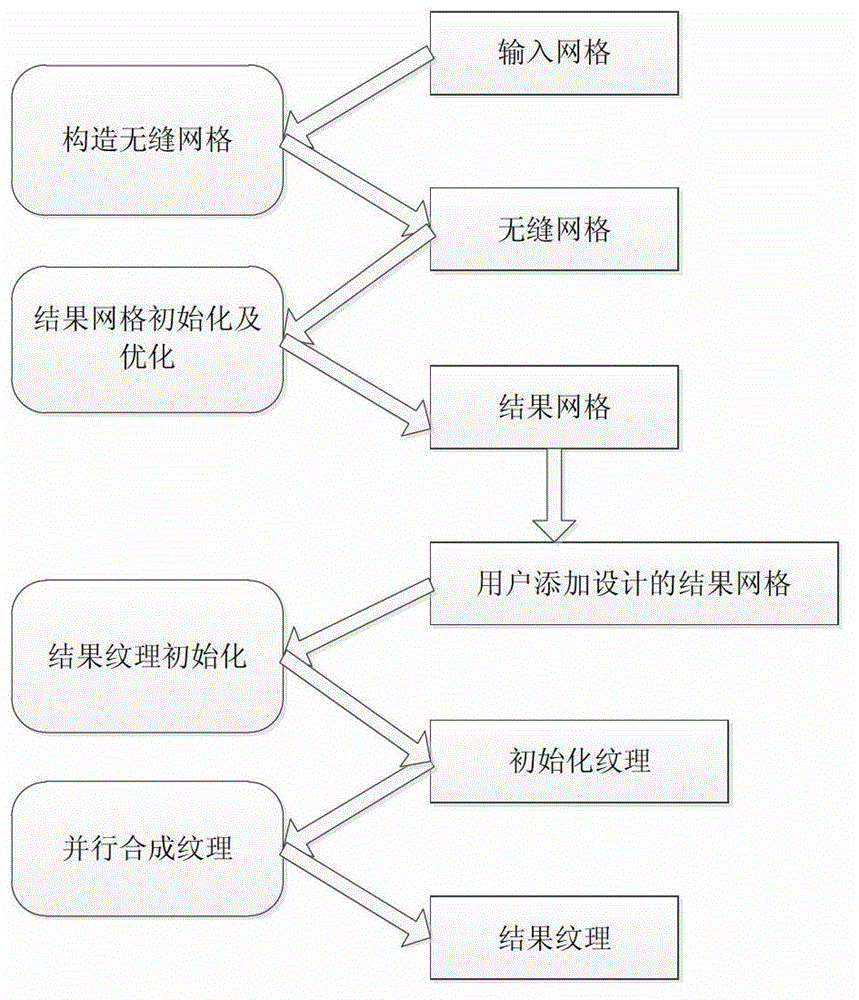

User interactive structural texture synthesis method

InactiveCN102867317ABest synthesis resultImprove practicality2D-image generationTexture designComputer graphics (images)

The invention provides a user interactive structural texture synthesis method. The method comprises the following steps of: firstly generating a target grid which is the same with the mode of a sample image and has the ideal size according to a grid which is input by a user or the grid extracted from the sample image, further performing texture design by adding various synthesis modes by the user, then performing initialization on the target grid according to a feature distance concept provided by the invention and finally synthesizing result texture in a parallel manner by combining with the pixel direction feature provided by the invention. According to the method disclosed by the invention, the synthesis effect against the structural texture is good, and interactive texture design and synthesis can be realized by utilizing the parallelism of a GPU (graphic processing unit) on frame rate.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com