Polypropylene composite material and preparation method thereof, sheet or irregular section prepared thereby and application thereof

A composite material, polypropylene technology, applied in the field of polymer composite materials, can solve the problems of not being able to produce parts containing skin texture, low shrinkage rate, sensitive skin allergies, etc., to reduce mold expansion rate and gloss. , The effect of low shrinkage rate and low mold release expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9 and comparative example 1-4

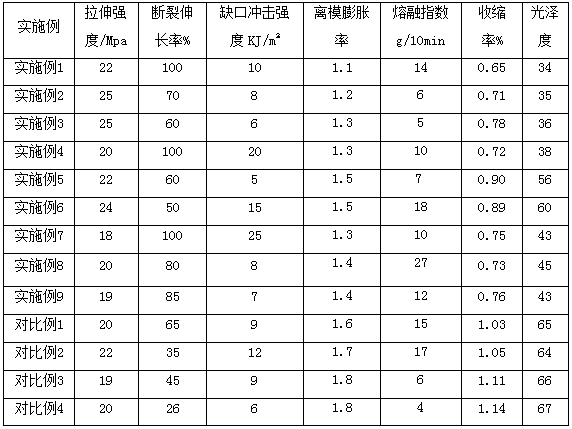

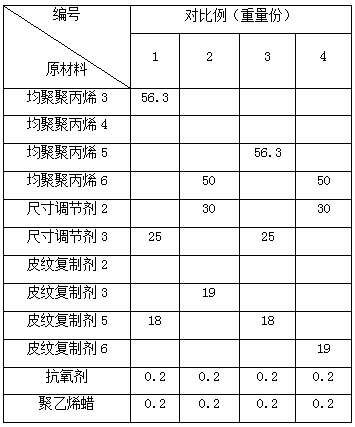

[0056] Weigh the components according to the parts by weight shown in Table 1, first mix the polypropylene, skin texture replicating agent, and size regulator in a high mixer for 3 minutes, then add antioxidant and lubricant, and mix for 2 minutes again, the speed The premix is obtained at 2000 rpm; the premix is melted and extruded by a twin-screw extruder, and the temperature of each zone of the screw is maintained at 190-230°C, extruded and granulated to obtain a polypropylene composite material, which is prepared according to the standard The test specimens were tested, and their mechanical properties were determined, and the specific values are listed in Table 3.

[0057] Table 1 Composition and properties of polypropylene composites in Examples and Comparative Examples

[0058]

[0059] Continuation of Table 1:

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com