Preparation method of thermoplastic polyurethane beads and bead molding technology

A thermoplastic polyurethane and bead technology, which is applied in the field of high-foaming thermoplastic polyurethane beads and foamed bead moldings, can solve the problem that TPU foamed materials cannot be recycled, the cells of TPU foamed beads are not uniform, and the TPU foamed beads cannot be recycled. The performance of the foam material is reduced, so as to avoid the melt viscosity being too high, shorten the immersion time, and improve the processing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

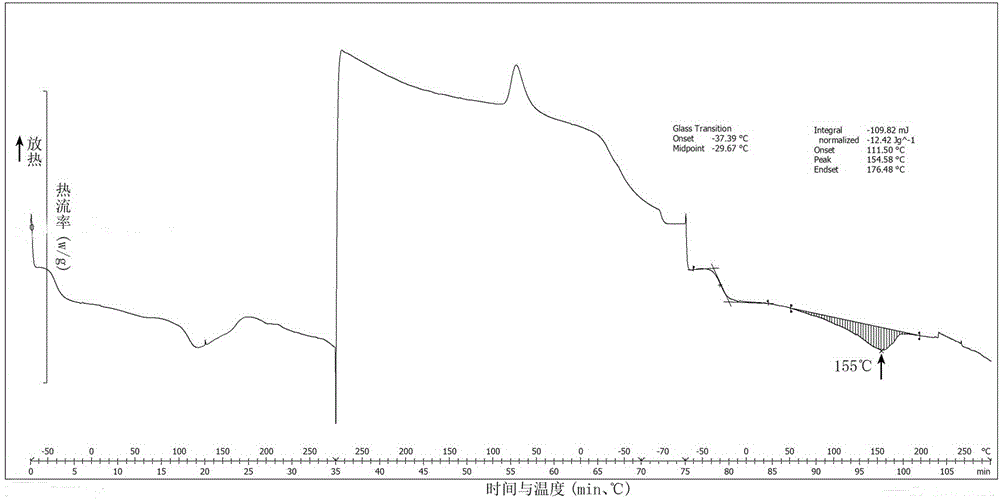

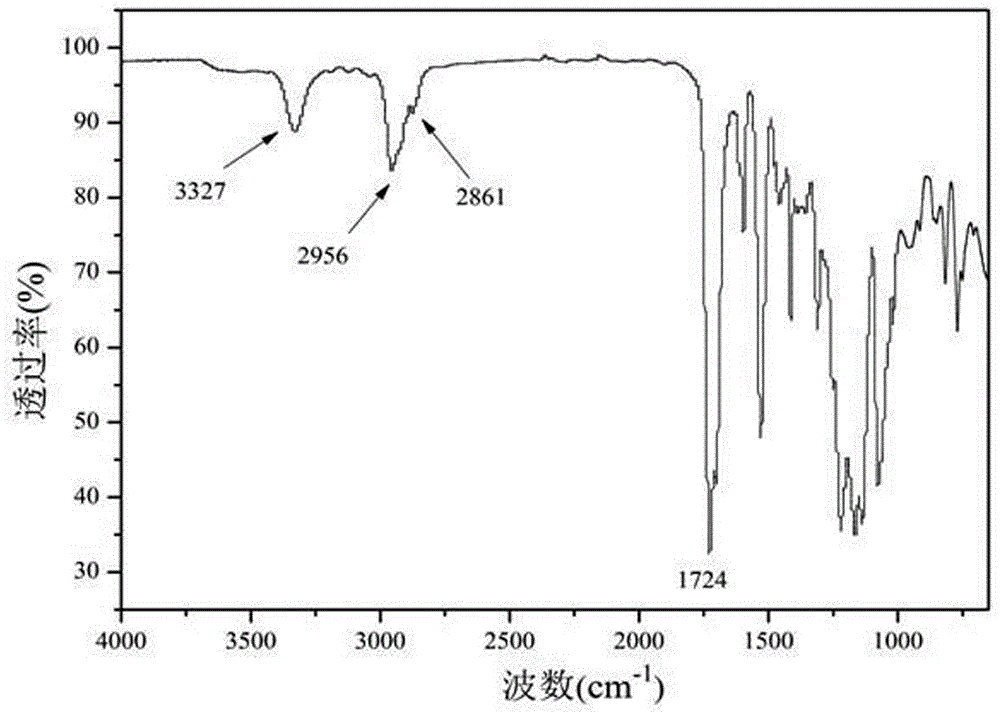

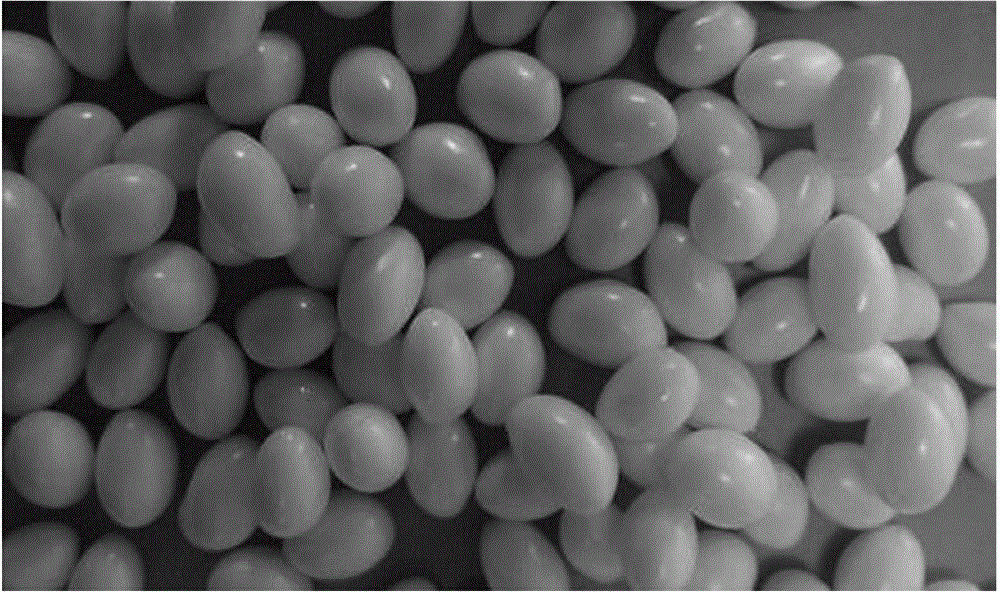

[0046] 100kg TPU particles in Table 1, 15Kg EVA melt viscosity modifier, 10kg calcium carbonate and 1.2kg anti-aging agent were premixed in a high-speed mixer, and the length was 1.3 mm and long Elliptical TPU blend particle G1 with diameter ratio of 1.2. The DSC curve of thermoplastic polyurethane elastomer blend particles is attached figure 1 As shown, this curve is a secondary heating curve, which is to eliminate the thermal history. From the curve, it can be seen that the glass transition temperature of TPU is -37.39°C, and the melting range is 111.5-176.4°C. It can be inferred that the optimum foaming temperature of this TPU is generally The melting range peak was determined as the optimum foaming temperature. The infrared spectrum of thermoplastic polyurethane elastomer blend particles is attached figure 2 As shown, 3327cm -1 It is the imino infrared absorption peak in carbamate, 2956 and 2861cm -1 Infrared absorption peaks for methyl and methylene, strong 1724cm -...

Embodiment 2

[0050] Premix 100kg TPU particles, 15Kg LDPE melt viscosity regulator, 13kg talcum powder and 1kg anti-aging agent in Table 1 in a high-speed mixer, and melt and blend underwater pellets through an extruder to make a length of 1.5 mm and a long diameter Round TPU blend particle G2 with a ratio of 1.

[0051] Weigh 15kg of TPU blend particles G2 into the autoclave, raise the temperature of the autoclave to 180°C, and inject high-pressure CO 2 and N 2 The fluid made the pressure of the autoclave reach 20 MPa. In order to make the impregnation and heating of the TPU blend particles G2 more uniform, the autoclave was turned on with low-speed stirring, and the impregnation time was 1 h. After the high-pressure fluid reaches the dissolution equilibrium in the TPU resin, the pressure is released gradually, and the pressure release time is 10s to obtain pre-expanded TPU particles Y2. Move the above-mentioned pre-expanded particles Y2 into the secondary foaming autoclave, feed 0.6 MP...

Embodiment 3

[0054] Premix 100kg of TPU particles, 12Kg of ABS melt viscosity regulator, 12kg of clay and 2kg of anti-aging agent in Table 1 in a high-speed mixer, melt and blend underwater granulation through an extruder to make a length of 3 mm, aspect ratio The elliptical TPU blend particle G3 is 1.7.

[0055] Weigh 14kg of TPU blend particles G3 into the autoclave, raise the temperature of the autoclave to 130 °C, and feed high-pressure CO 2 and N 2 The fluid made the pressure of the autoclave reach 19 MPa. In order to make the impregnation and heating of the TPU blend particles G3 more uniform, the autoclave was started to stir at a low speed, and the impregnation time was 1.5 h. After the high-pressure fluid reaches the dissolution equilibrium in the TPU resin, the pressure is gradually released. The pressure release time is 13s, and the pre-expanded TPU particles Y3 are obtained. Move the above-mentioned pre-expanded particles Y3 into the secondary foaming autoclave, feed 0.4 MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com