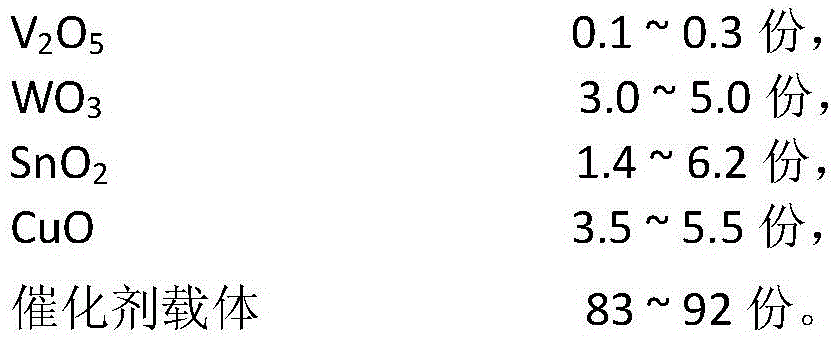

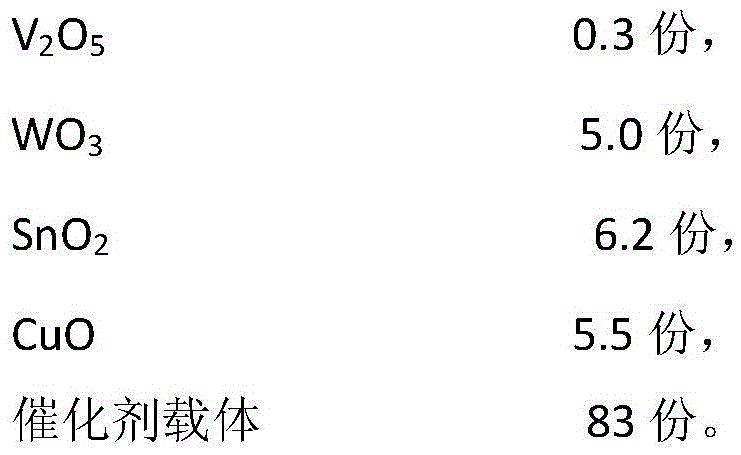

Low-cost SCR denitration catalyst and preparation method thereof

A denitrification catalyst, low-cost technology, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the complex and harsh preparation steps, produce a large amount of waste liquid and waste residue, etc., achieve low raw material cost and reduce hazards , high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the low-cost SCR denitration catalyst of the present embodiment is achieved through the following steps:

[0035] Step 1 Crush the low titanium slag (the components are shown in Table 1.1), sieve out 150g of 20-40 mesh titanium slag, dissolve it in 500mL of sodium hydroxide solution with a mass concentration of 15wt%, and place it in a hydrothermal kettle at 70°C. Then, the titanium slag was filtered and washed to neutrality, then dried at 105°C for 10h, and finally calcined at 400°C for 5h to obtain the catalyst carrier;

[0036] Step 2 Weigh 0.064g of ammonium metavanadate, 1.640g of ammonium tungstate and 1.704g of oxalic acid, respectively, and dissolve them in 100mL of deionized water, stir at room temperature for 30min, and then add 4.126g of copper nitrate and 0.997g of stannous sulfate to continue stirring. 90min, the substances in the solution are fully mixed and dissolved;

[0037] Step 3 Place 46g of the catalyst carrier prepared in...

Embodiment 2

[0042] The preparation method of the low-cost SCR denitration catalyst of this embodiment is realized through the following steps:

[0043] Step 1: Break the high-titanium slag (the composition is shown in Table 1.2), screen out 150g of 20-40 mesh titanium slag, dissolve it in 500mL of sodium hydroxide solution with a mass concentration of 15wt%, and place it in a hydrothermal kettle at 90°C neutralize for 3 hours, then filter and wash the titanium slag until it becomes neutral, then dry it at 120°C for 5 hours, and finally roast it at 400°C for 5 hours to obtain a catalyst carrier;

[0044] Step 2 Weigh 0.193g of ammonium metavanadate, 3.557g of sodium tungstate and 3.75g of oxalic acid and dissolve them in 100mL of deionized water, stir at room temperature for 30min, then add 5.894g of copper nitrate and 5.358g of tin tetrachloride to it Continue to stir for 90 minutes to fully mix and dissolve the substances in the solution;

[0045] Step 3 Place the 41.5g catalyst carrier...

Embodiment 3

[0049] The preparation method of the low-cost SCR denitration catalyst of this embodiment is realized through the following steps:

[0050] Step 1: Break the high-titanium slag (the composition is shown in Table 1.2), screen out 150g of 20-40 mesh titanium slag, dissolve it in 500mL of sodium hydroxide solution with a mass concentration of 15wt%, and place it in a hydrothermal kettle at 80°C After neutralizing for 4 hours, filter and wash the titanium slag until it becomes neutral, then dry it at 110°C for 4 hours, and finally roast it at 400°C for 5 hours to obtain a catalyst carrier;

[0051] Step 2 Weigh 0.129g of ammonium metavanadate, 2.187g of ammonium tungstate and 2.316g of oxalic acid and dissolve them in 100mL of deionized water, stir at room temperature for 30min, then add 4.822g of copper chloride and 2.852g of tetrachloride to it Tin continued to stir for 90 minutes to fully mix and dissolve the substances in the solution;

[0052] Step 3 Place the 41.5g catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com