Rapid production method of pickled chicken claws

A production method, the technology of soaking chicken feet, applied in the field of rapid production of soaking chicken feet, can solve food safety hazards, affect consumer trust and other problems, achieve the effects of shortening soaking time, reducing the chance of microbial contamination, and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

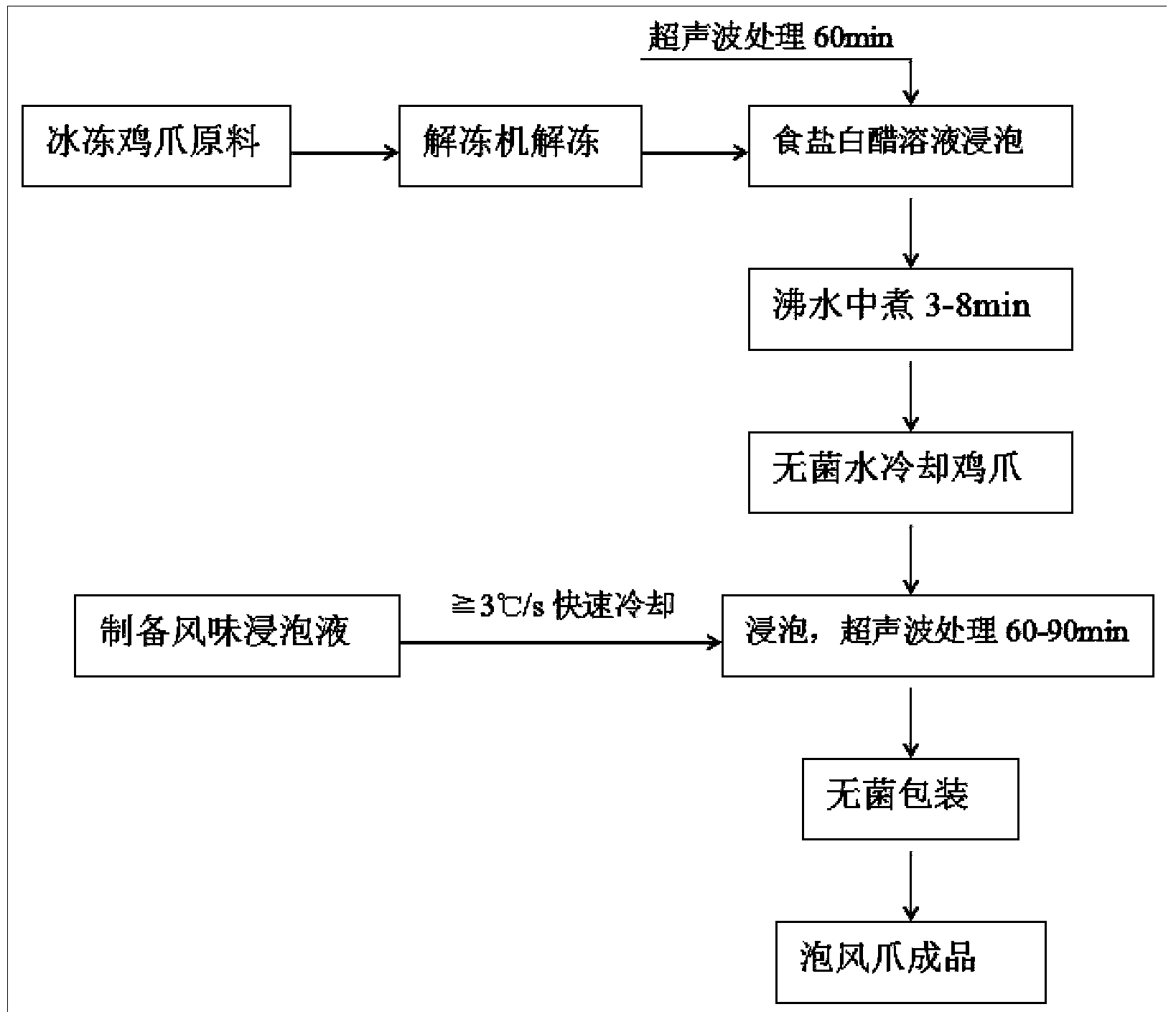

[0043] The brewing steps of split chicken feet:

[0044] (1) Thaw and clean the chicken feet first;

[0045] (2) Ultrasonic treatment of the divided chicken feet for 60 minutes under the condition of frequency 40-60KHz and power 500-600W can make the chicken feet sterilize and whiten;

[0046] (3) The treated chicken feet do not need to be cleaned again, and boiled in a solution of 1-2% salt and 3-4% white vinegar for 5-8 minutes (the mass ratio of water to chicken feet is 1.5:1);

[0047] (4) Add 2-3% white vinegar to the cooling water to cool the chicken feet for 10-20 minutes;

[0048] (5) Add 1% biological preservatives or vegetable alcohol extracts to the flavor soaking liquid, use ultrasonic waves at a frequency of 40-60KHz and a power of 500-600W for 60 minutes to taste;

[0049] (6) The soaked chicken feet are vacuum-packed to get the finished product.

[0050] The thawing method in the step (1) needs to be thawed with a thawing machine for 3-5 minutes, and the time...

Embodiment 2

[0057] The brewing steps of the whole chicken feet:

[0058] (1) First thaw and clean the chicken feet, (2) The cleaned chicken feet are treated with ultrasonic waves at a frequency of 40-60KHz and a power of 500-600W for 60 minutes, so that the chicken feet can be sterilized and whitened, ( 3) The processed chicken feet do not need to be cleaned again. Boil them in a solution of 1-2% salt and 3-4% white vinegar for 5-8 minutes (the ratio of water to water is 1.5:1 claws), (4) add 2 - Cool the chicken feet with 3% white vinegar cooling water for 10-20 minutes, (5) use ultrasonic waves at a frequency of 40-60KHz and a power of 500-600W in the flavor soaking solution added with 1% vegetable alcohol extract for 90 minutes to taste, (6) The soaked chicken feet are vacuum-packed to get the finished product.

[0059] The thawing method in the step (1) needs to be thawed by a thawing machine for 3-5 minutes, and the natural thawing time of tap water is 8-12 hours.

[0060] In the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com