Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4915 results about "Thermoplastic polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

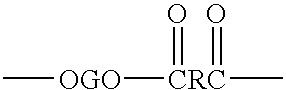

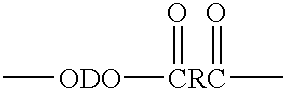

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease and abrasion. Technically, they are thermoplastic elastomers consisting of linear segmented block copolymers composed of hard and soft segments.

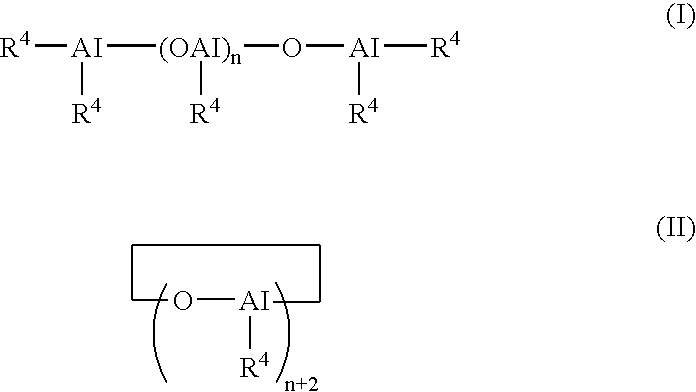

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

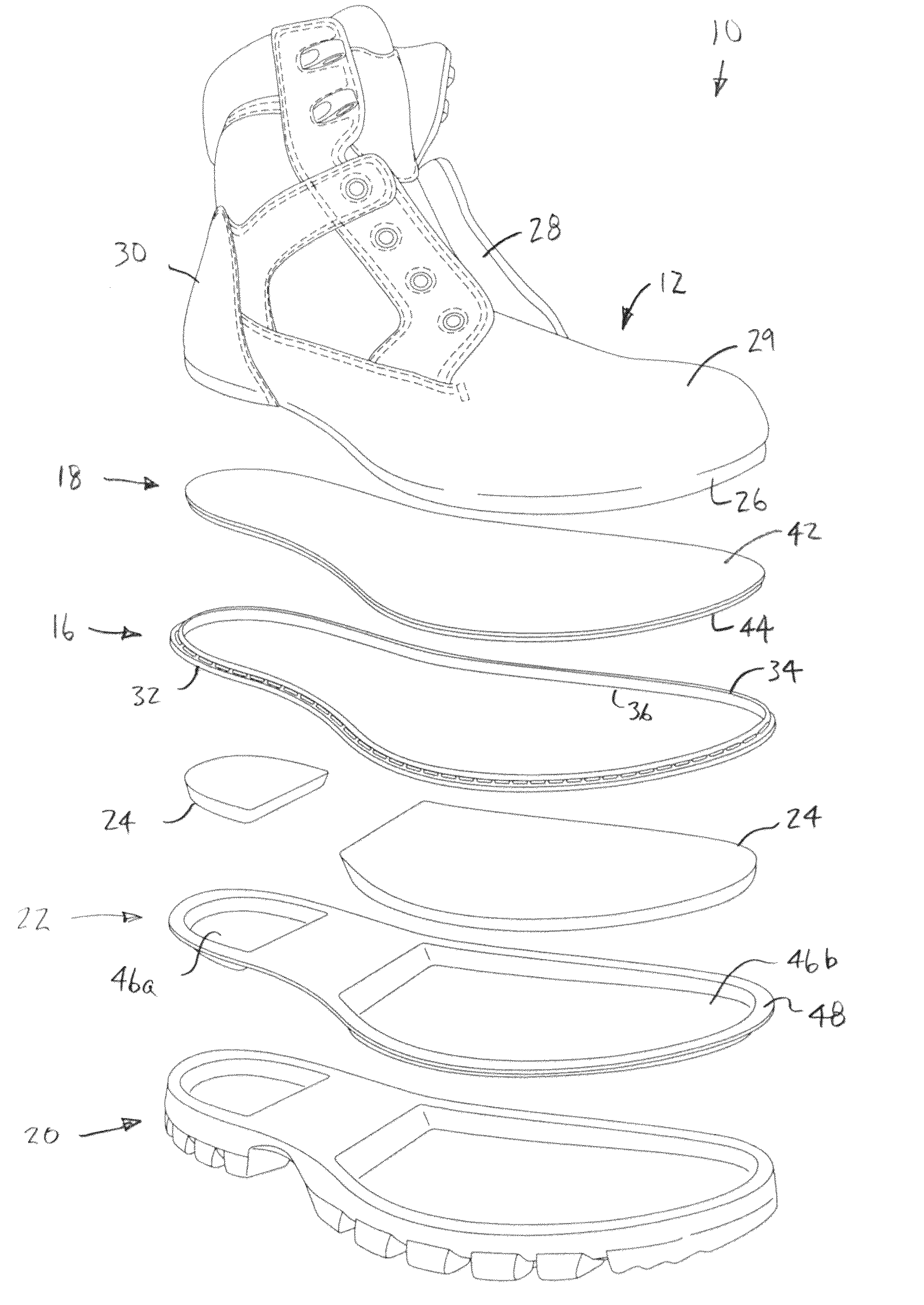

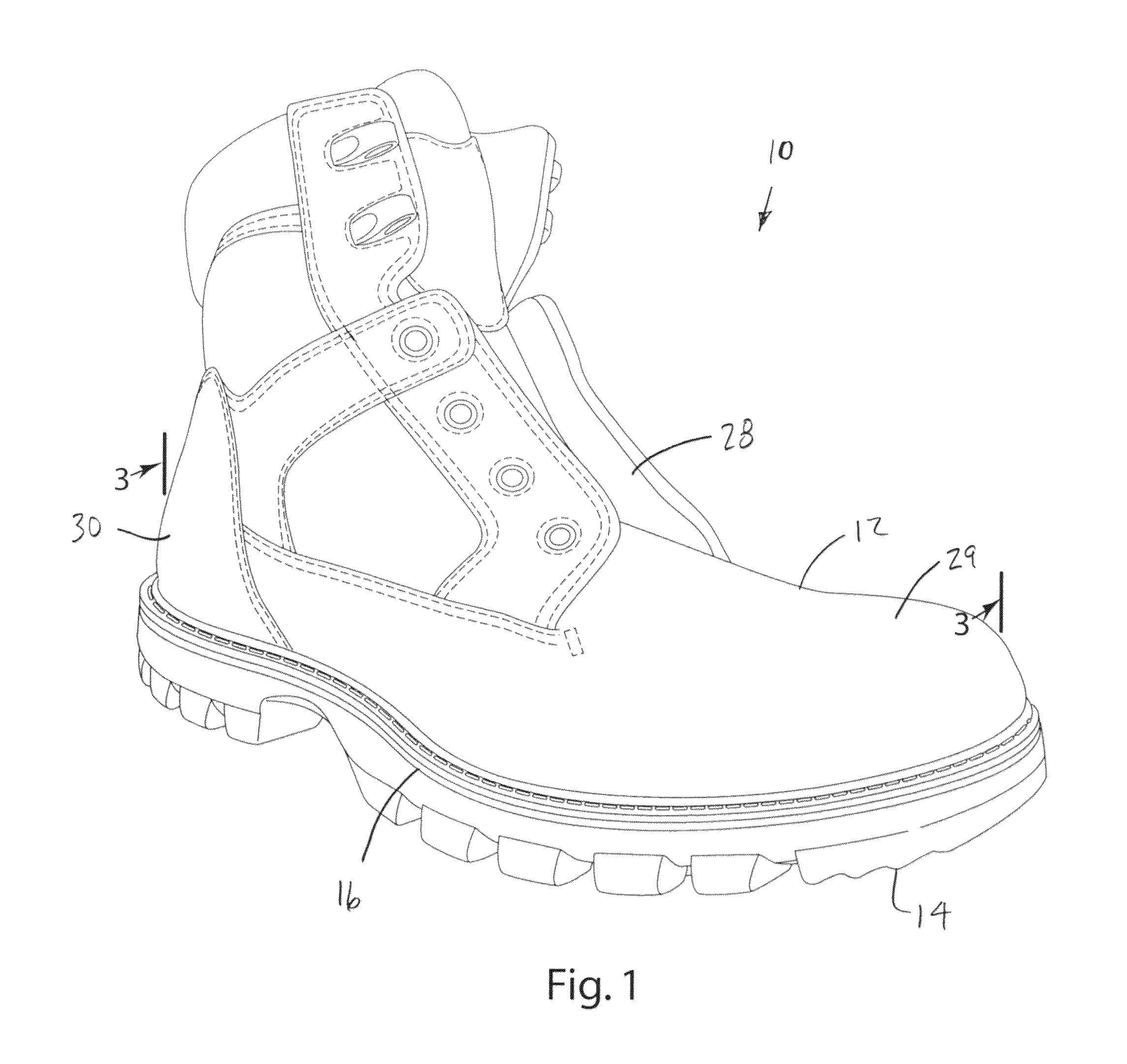

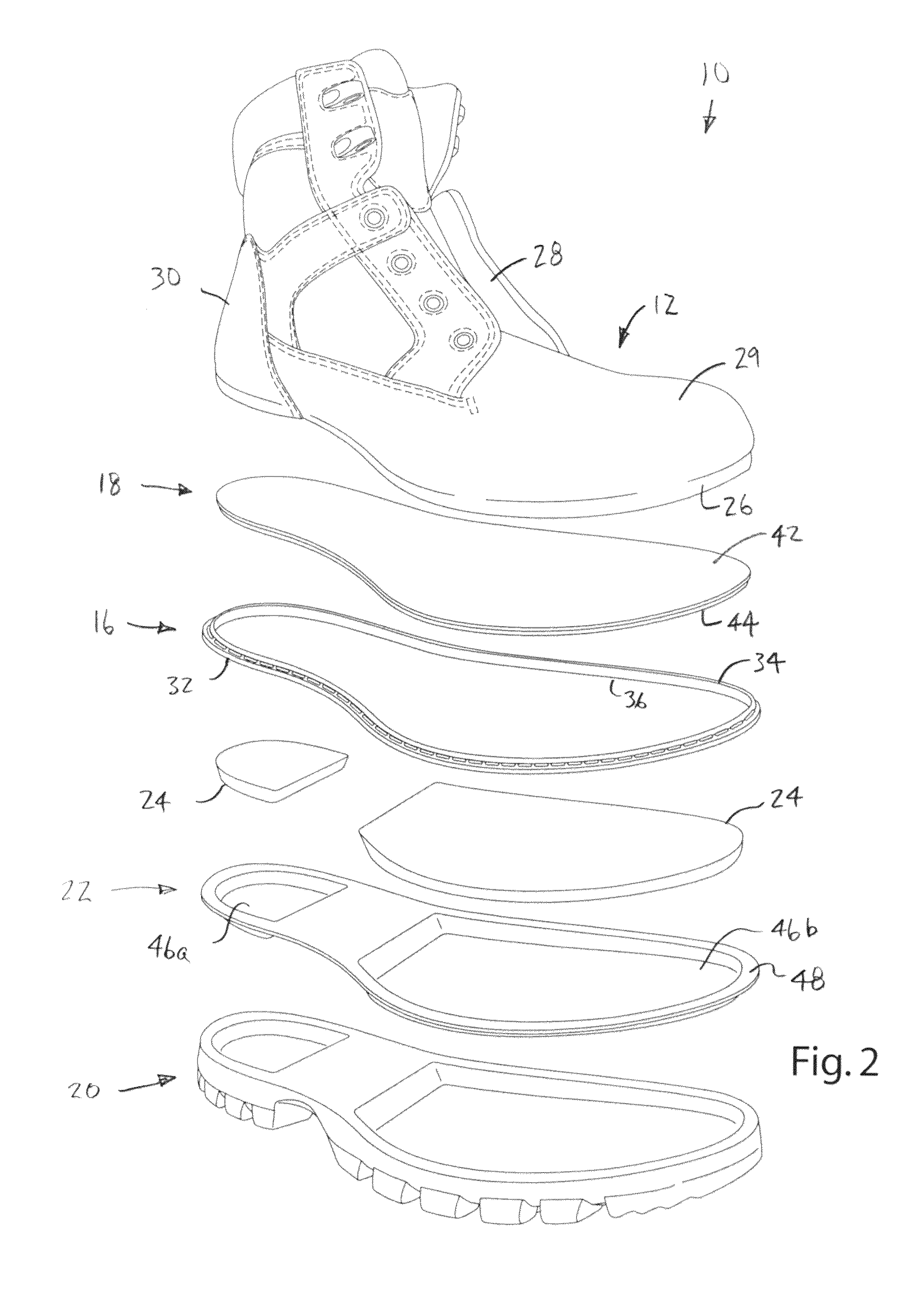

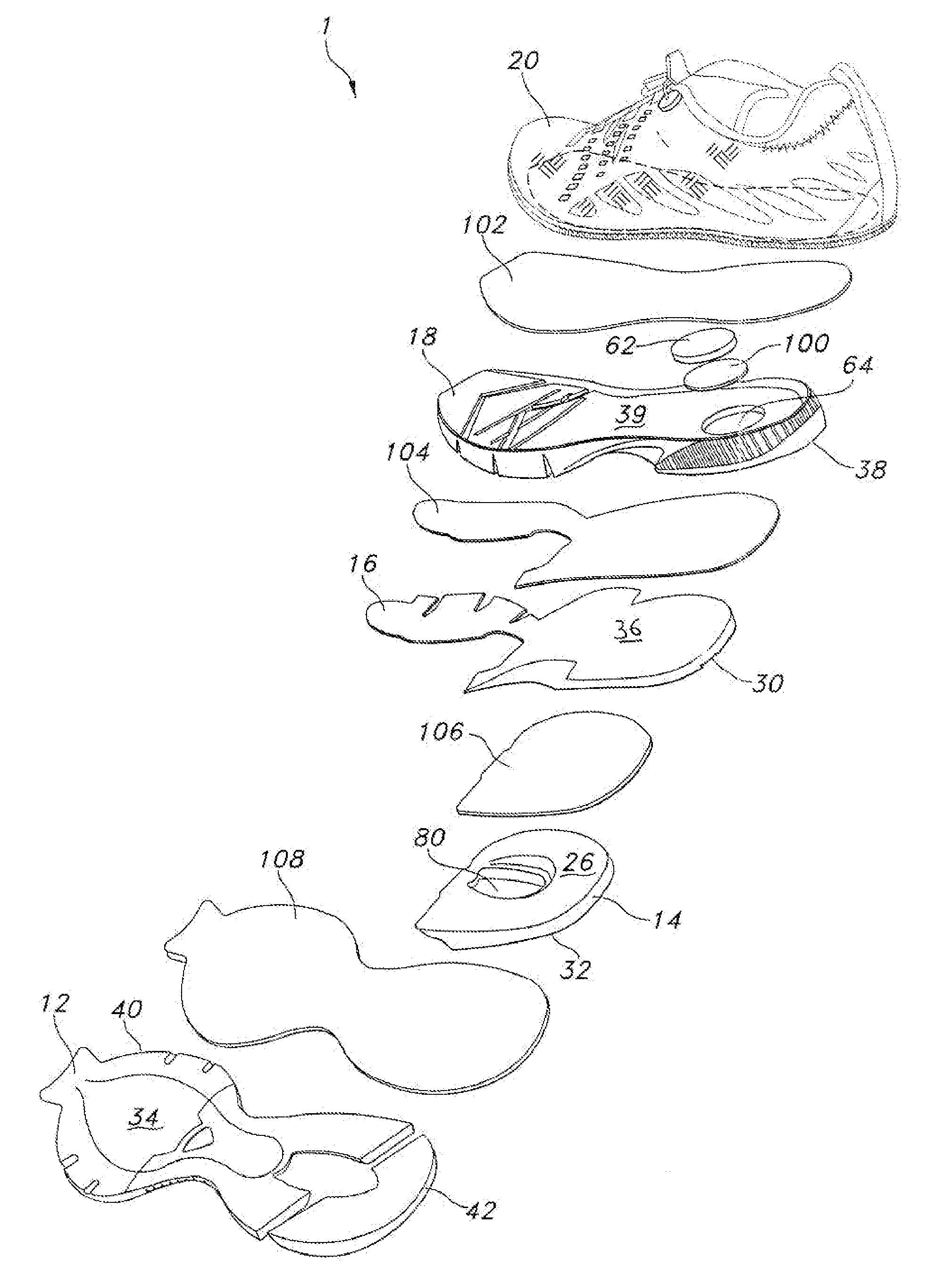

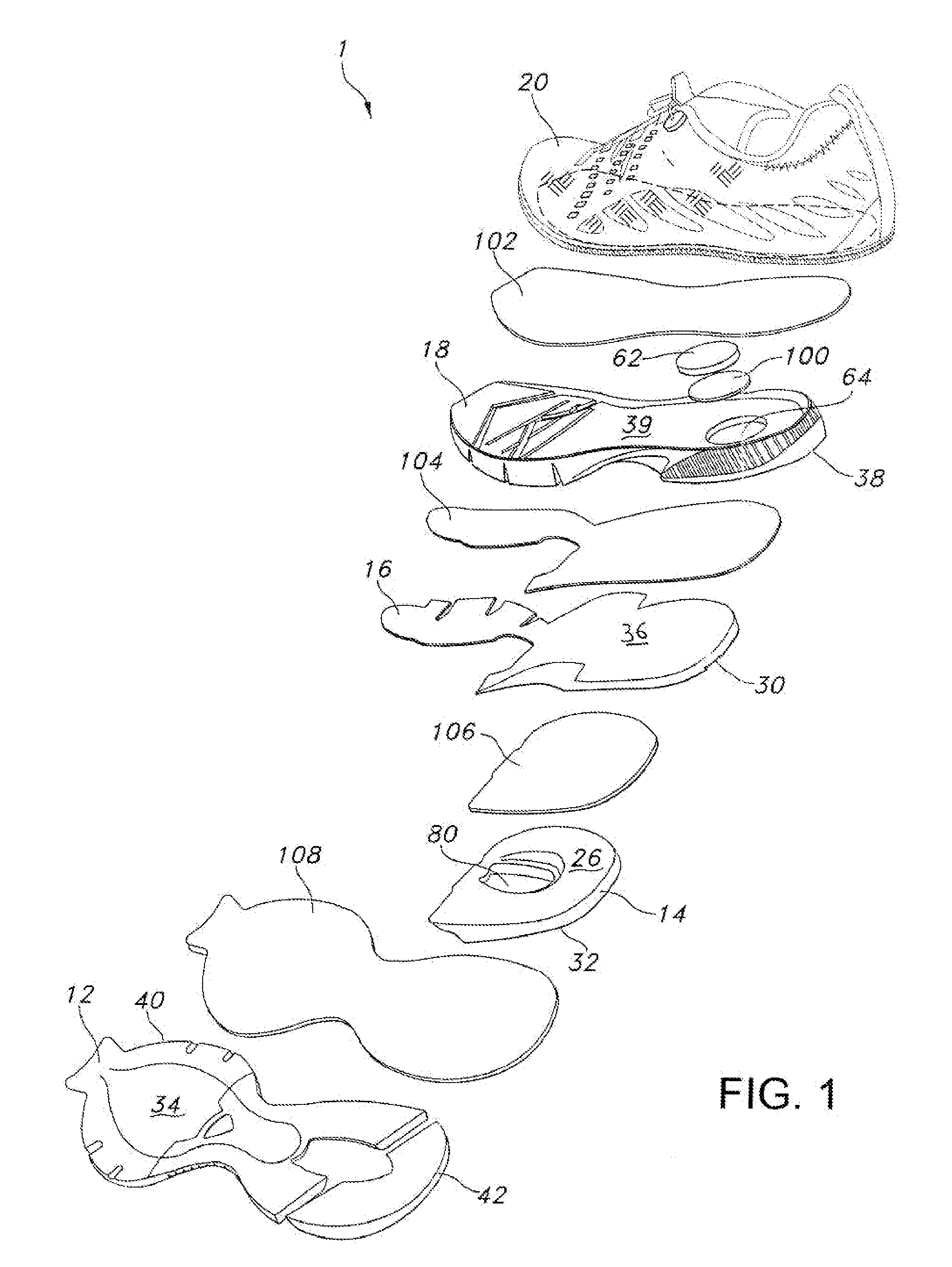

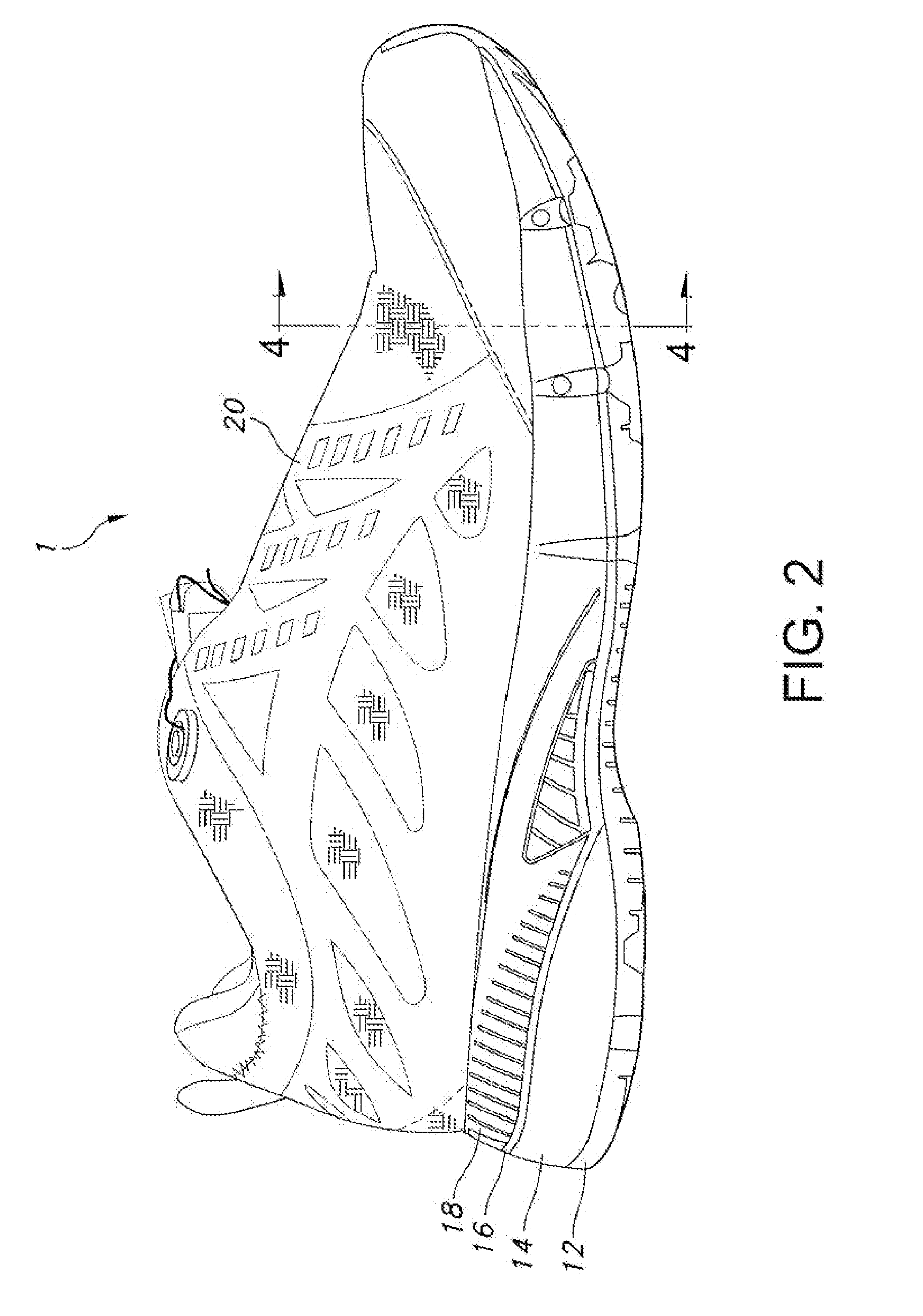

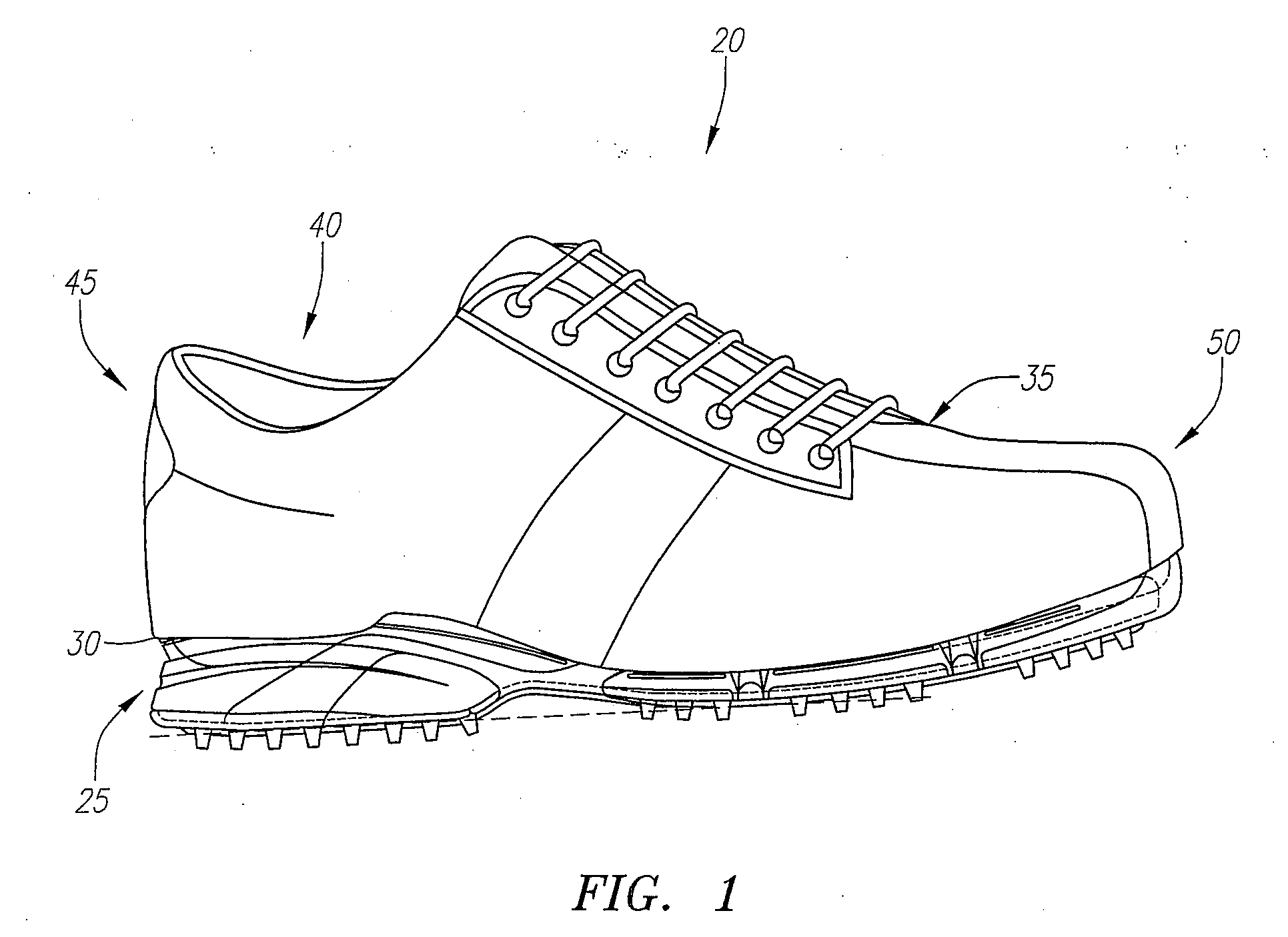

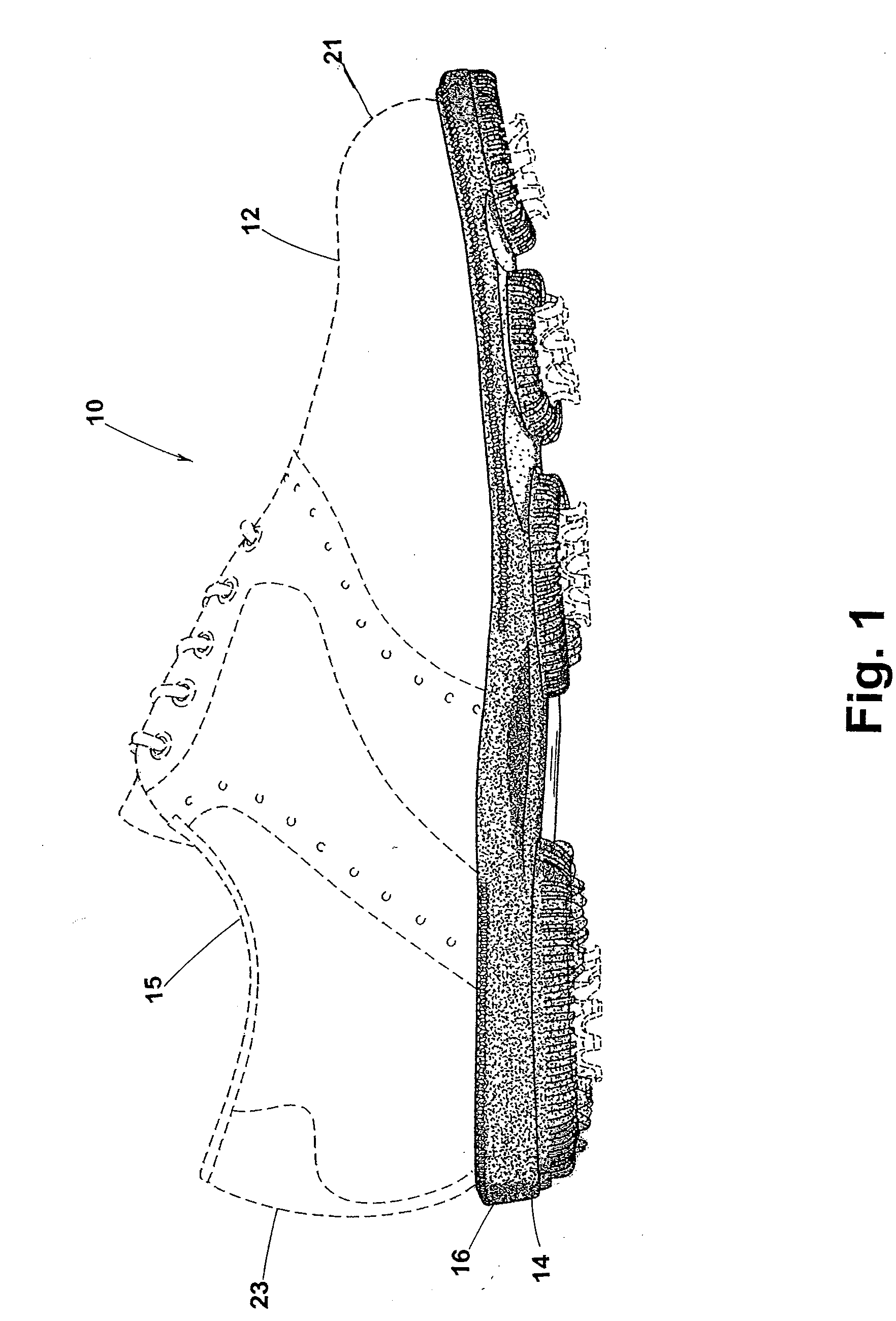

Footwear construction

A welted footwear construction with a direct-attach outsole and an internal tray containing a low density cushioning material. The welt may be secured to the upper and insole by one line of stitching and to the tray by a second line of stitching. The tray may include separate heel and forefoot cavities, each containing a low density cushioning material. The tray may be manufactured from thermoplastic urethane (“TPU”) and may contain low-density polyurethane (“PU”). The low-density PU may be molded in place within the cavities in the tray. The outsole may be directly attached to the undersurface of the tray, and may be manufactured from high-density PU.

Owner:WOLVERINE OUTDOORS

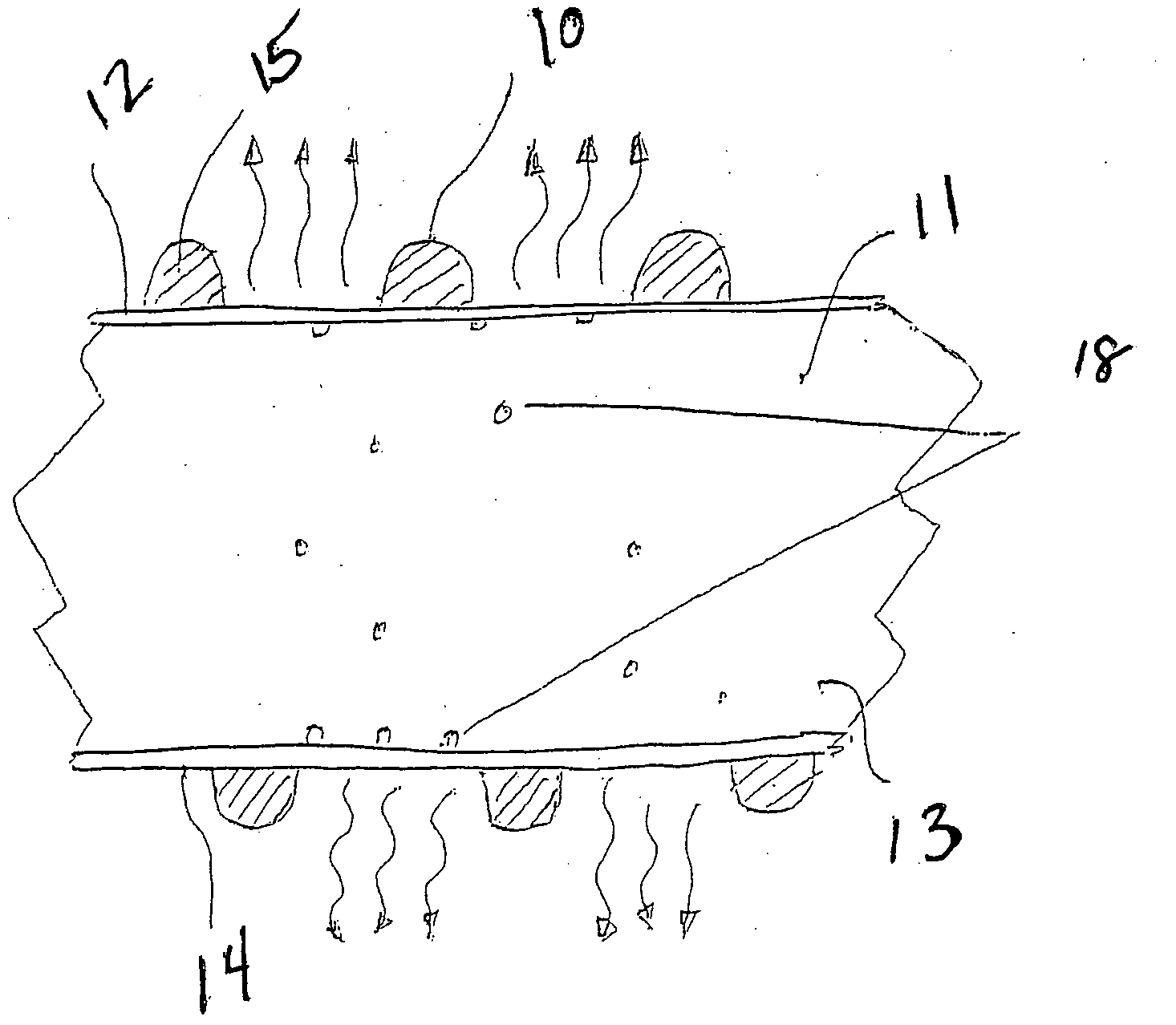

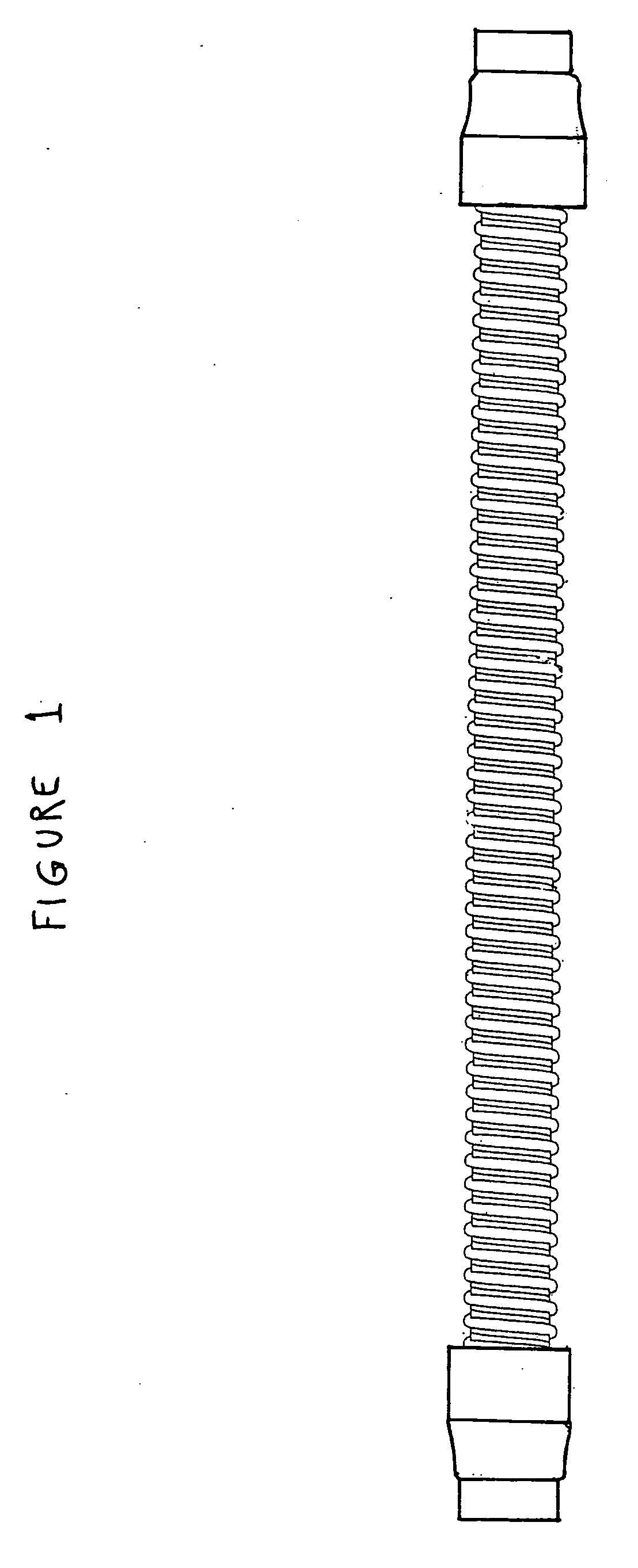

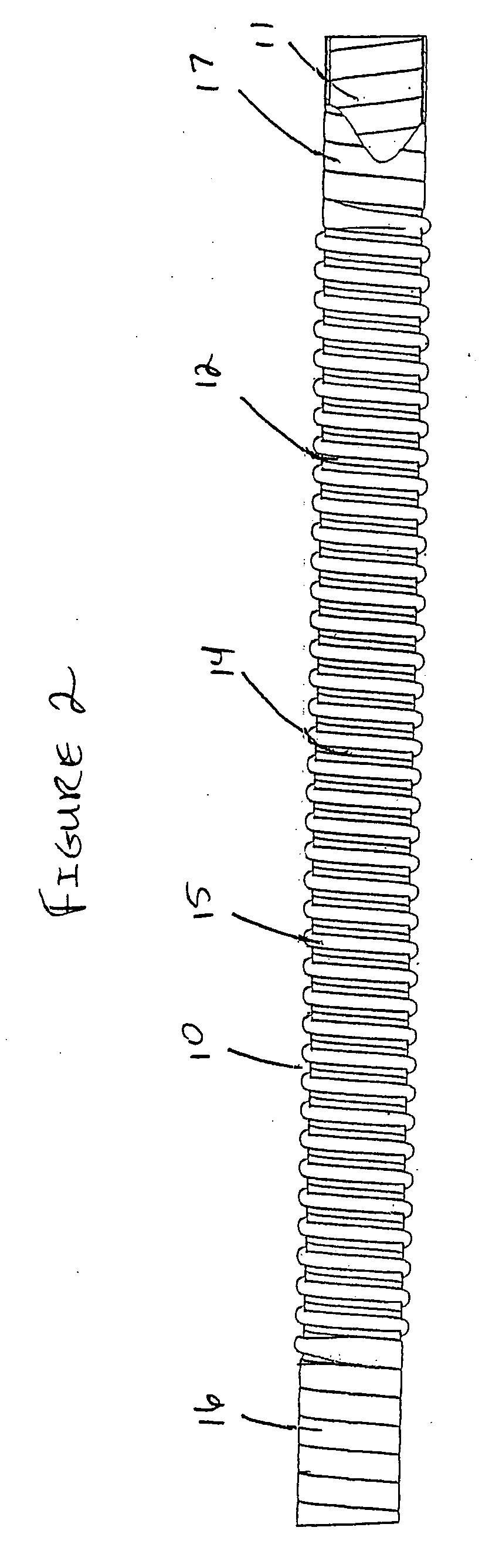

System for removal of water from a hose and the hygroscopic hose utilized

InactiveUS20090025724A1Prevent moistureRespiratorsMedical devicesRespiratorThermoplastic polyurethane

A respirator system and hygroscopic hose used in the system is disclosed. The system includes a means for generating a flow of air, a hose connected to the generating means and a mask adapted to be secured to a patient. The mask connected to the hose such that air generated by the generating means passes through the hose to the mask. The hose is a hygroscopic hose made up of a thermoplastic polyurethane. The thermoplastic polyurethane permits water formed by the respiration of the patient to permeate through a sidewall of said hose from an inner surface of the hose to an outer surface of the hose. The sidewall of the hose does not permit air generated by the generating means to pass through the sidewall.

Owner:FLEXIBLE TECH INC

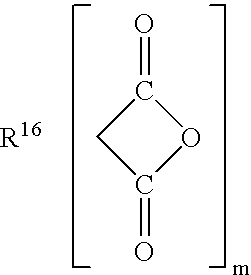

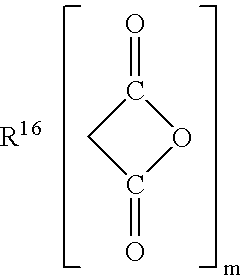

Biodegradable polyurethane and polyurethane ureas

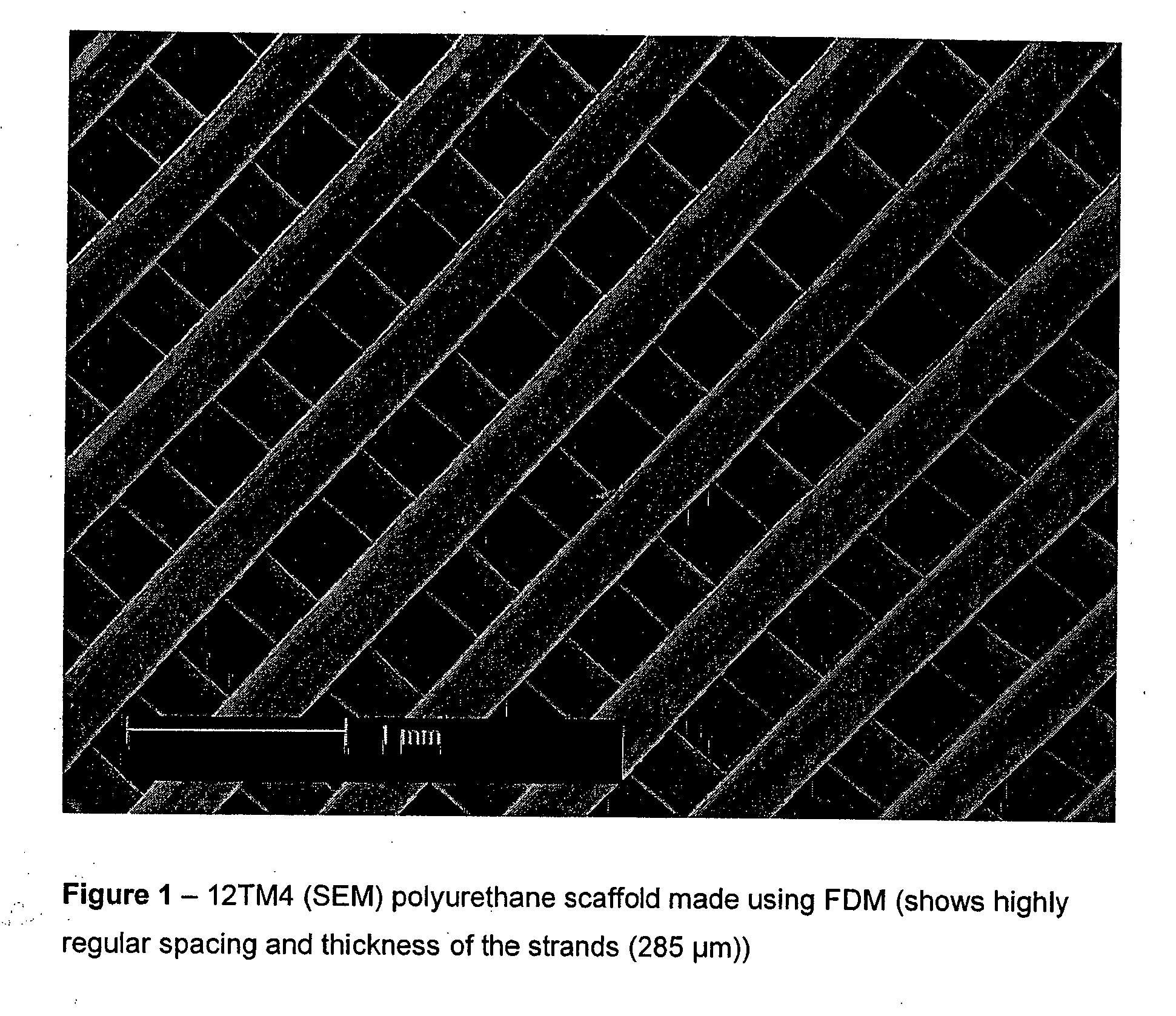

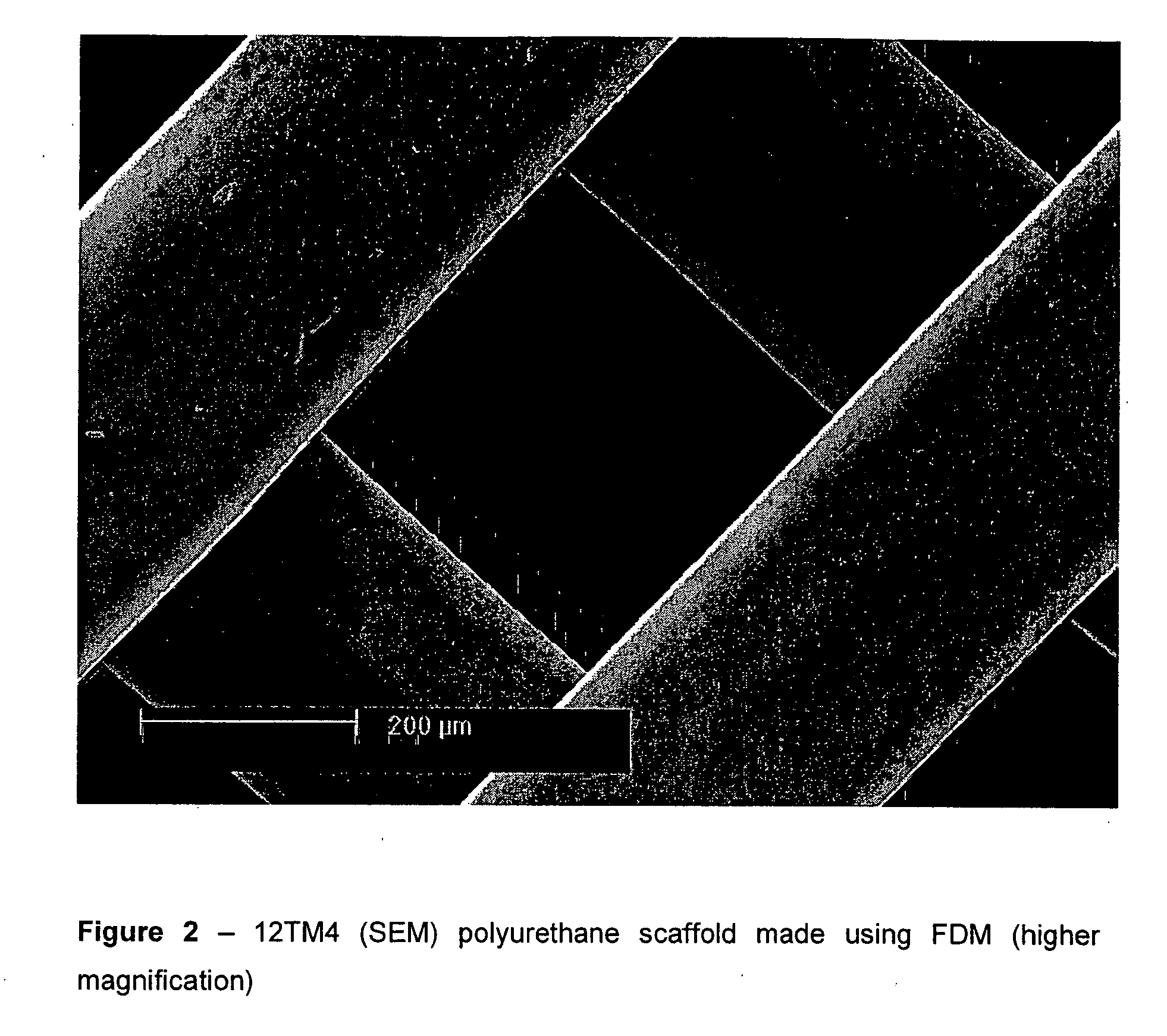

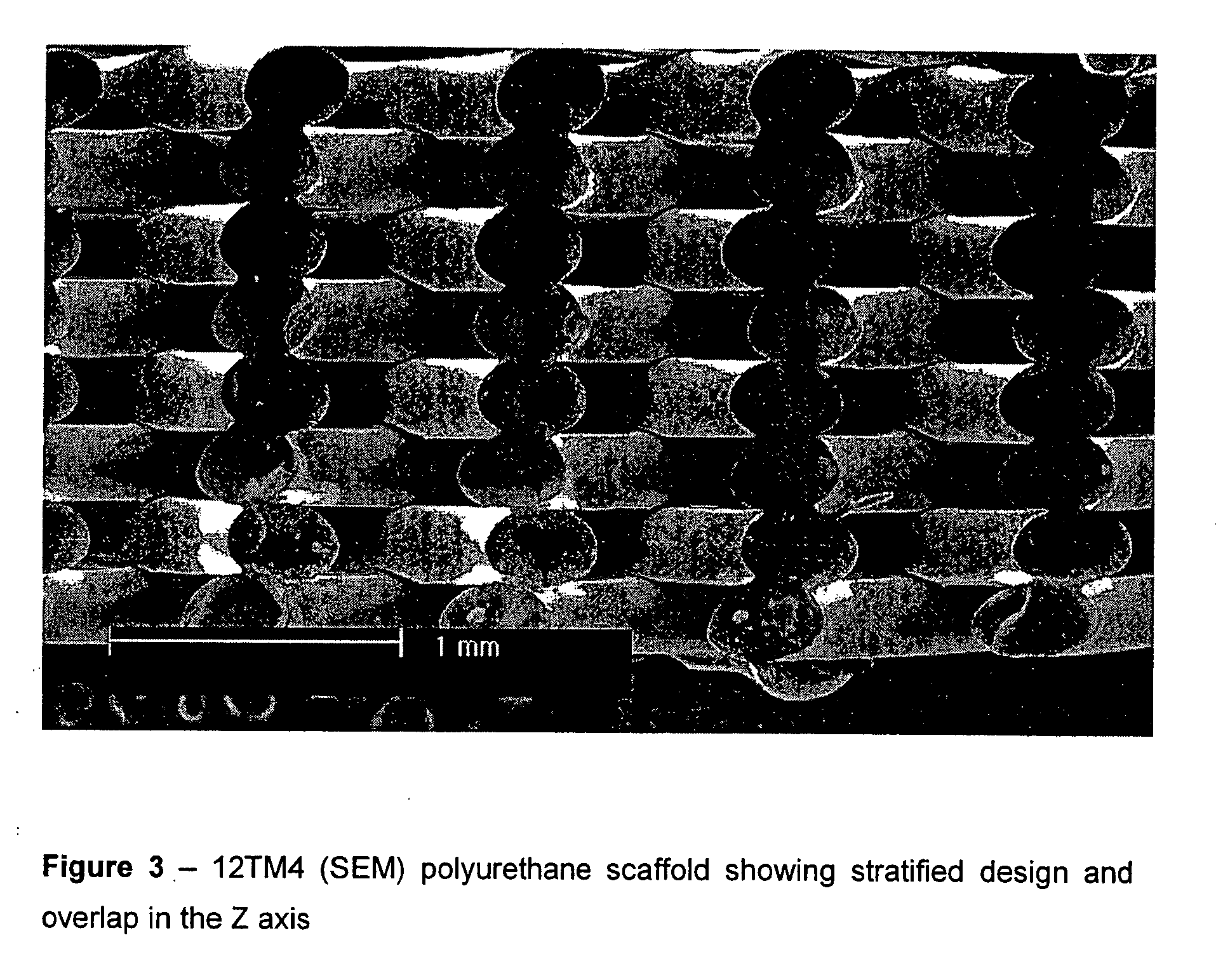

ActiveUS20060051394A1Fast formingEasily degradableOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Footwear sole construction

InactiveUS20070295451A1Less waiting timeEnsure even distributionSolesUpperAdhesiveThermoplastic polyurethane

A footwear adhesion system including a thermoplastic film, a sole component, and a footwear component. In one embodiment, the thermoplastic film is a thermoplastic polyurethane (“TPU”) film. The film is sandwiched between the sole component and the footwear component. The film may be activated, for example, by high frequency welding, to form a bond between the sole component and the footwear component without releasing the amount of volatile organic compound emissions typical with conventional adhesives. Use of the film reduces or eliminates the need for conventional environmentally unfriendly cement in footwear construction.

Owner:WOLVERINE WORLD WIDE

Solid golf ball

InactiveUS20080312008A1Improve spin performanceIncrease distanceGolf ballsSolid ballsOrganosulphur compoundPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a thermoplastic polyurethane and (B) a polyisocyanate compound, which resin blend contains a polyisocyanate compound in at least some portion of which all the isocyanate groups on the molecule remain in an unreacted state, and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

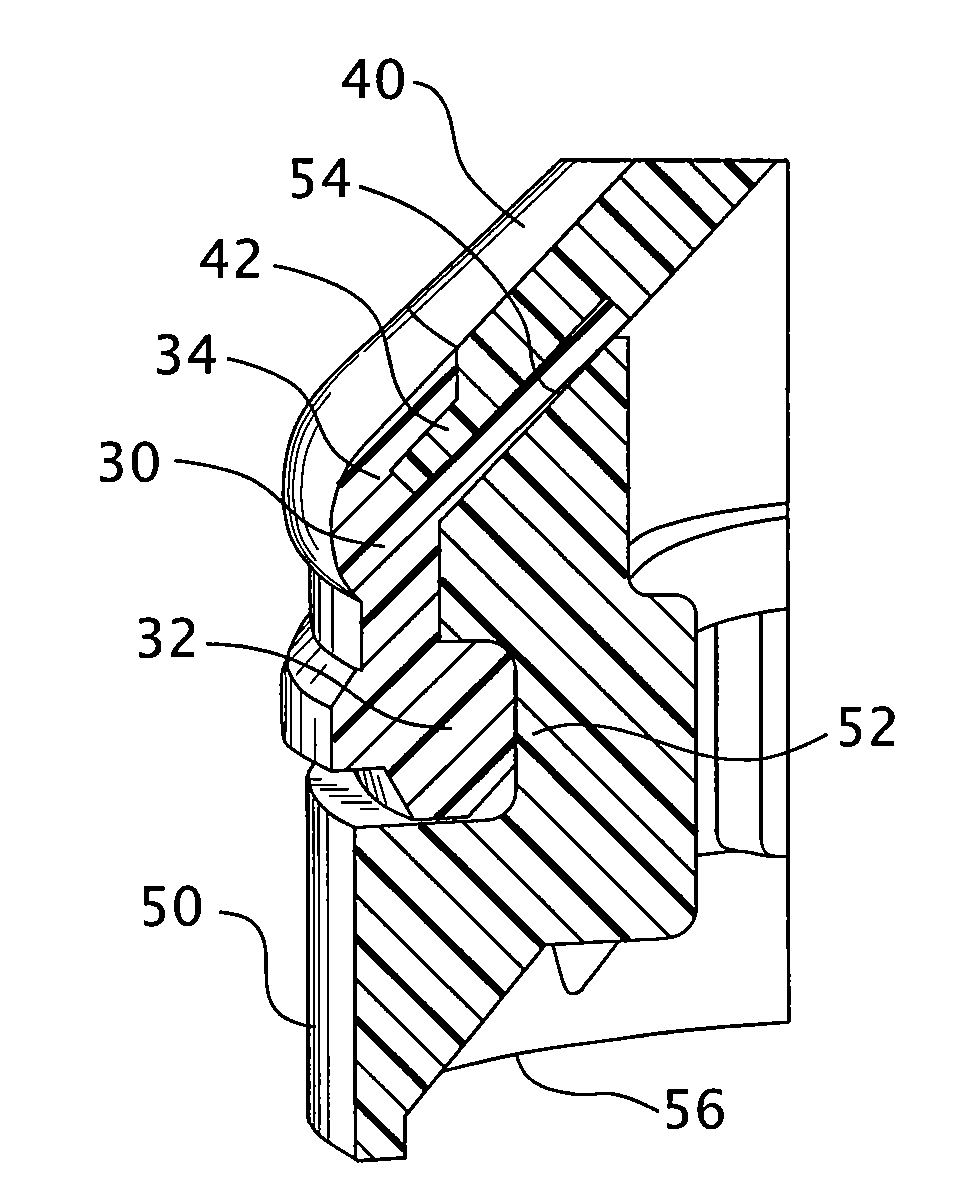

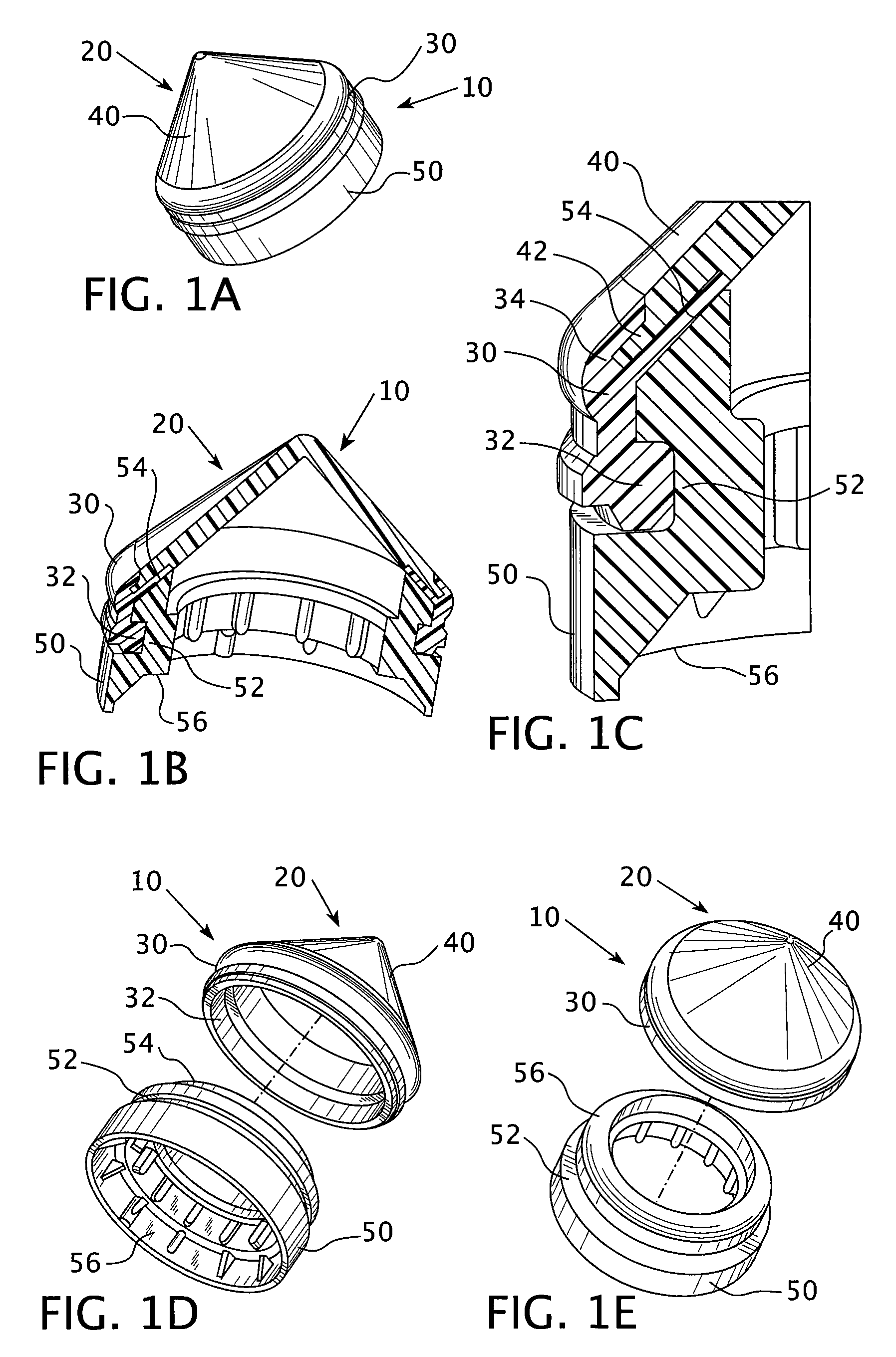

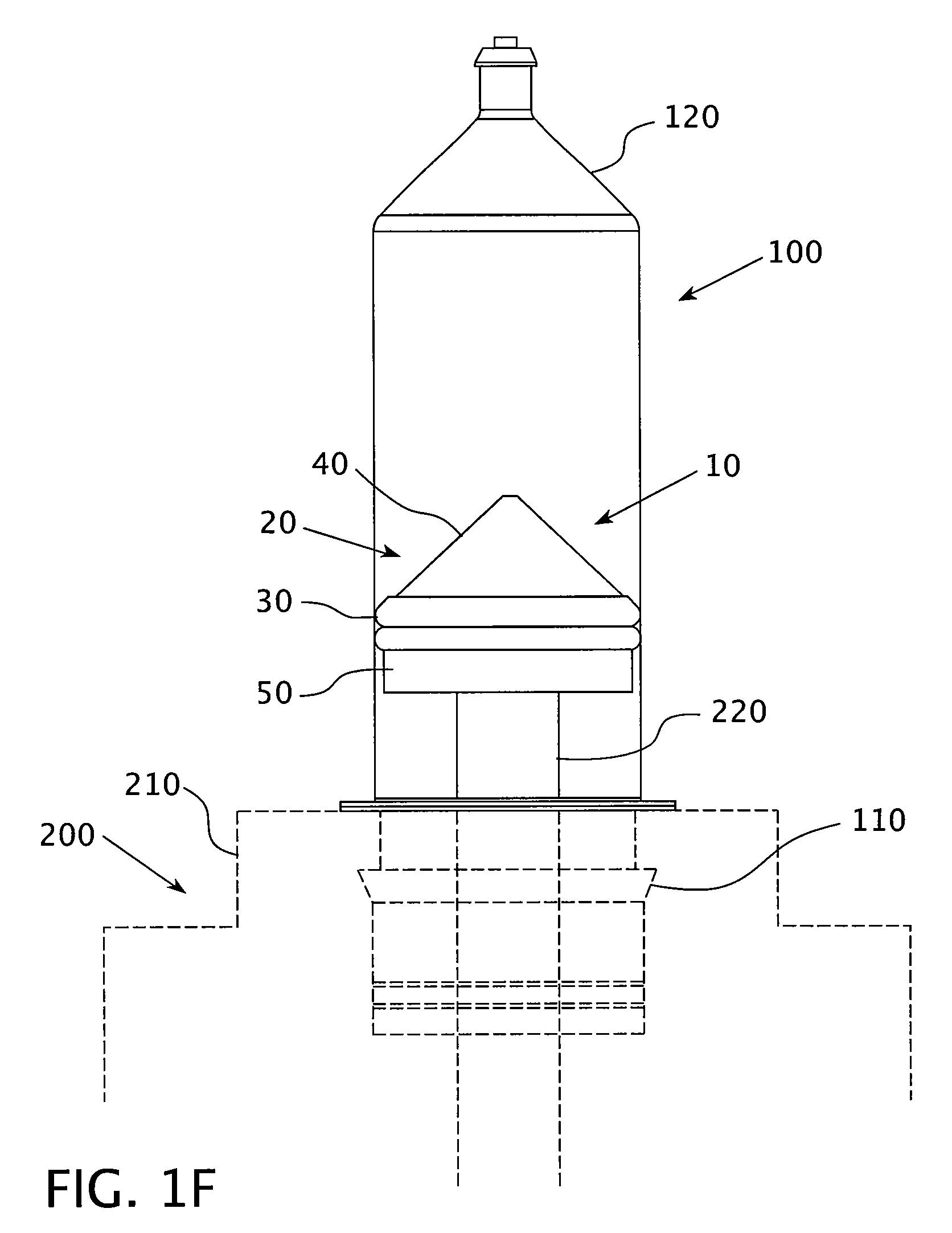

Plunger Covers and Plungers for Use in Syringes and Methods of Fabricating Plunger Covers and Plungers for Use in Syringes

A plunger cover for use with a syringe includes a sealing portion adapted to form a seal with the syringe and a central portion adapted to contact fluid within the syringe. The central portion can, for example, be more rigid than the sealing portion. The sealing portion and the central portion are connected in an overmolding process. The sealing portion can, for example, be formed from a thermoplastic elastomer or a thermoplastic polyurethane. The central portion can, for example, be formed from polypropylene, acrylonitrile butadiene styrene, polycarbonate or copolymers thereof.

Owner:BAYER HEALTHCARE LLC

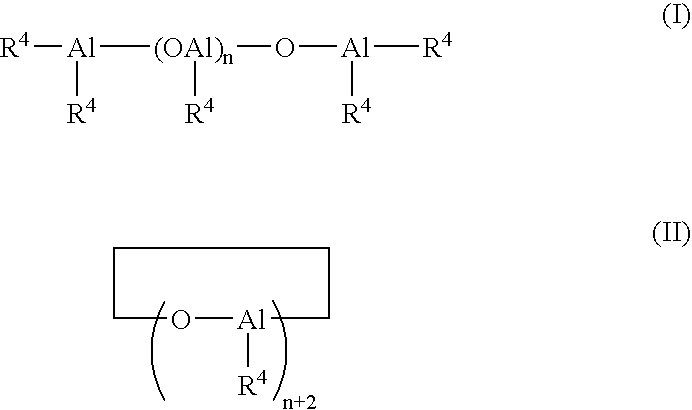

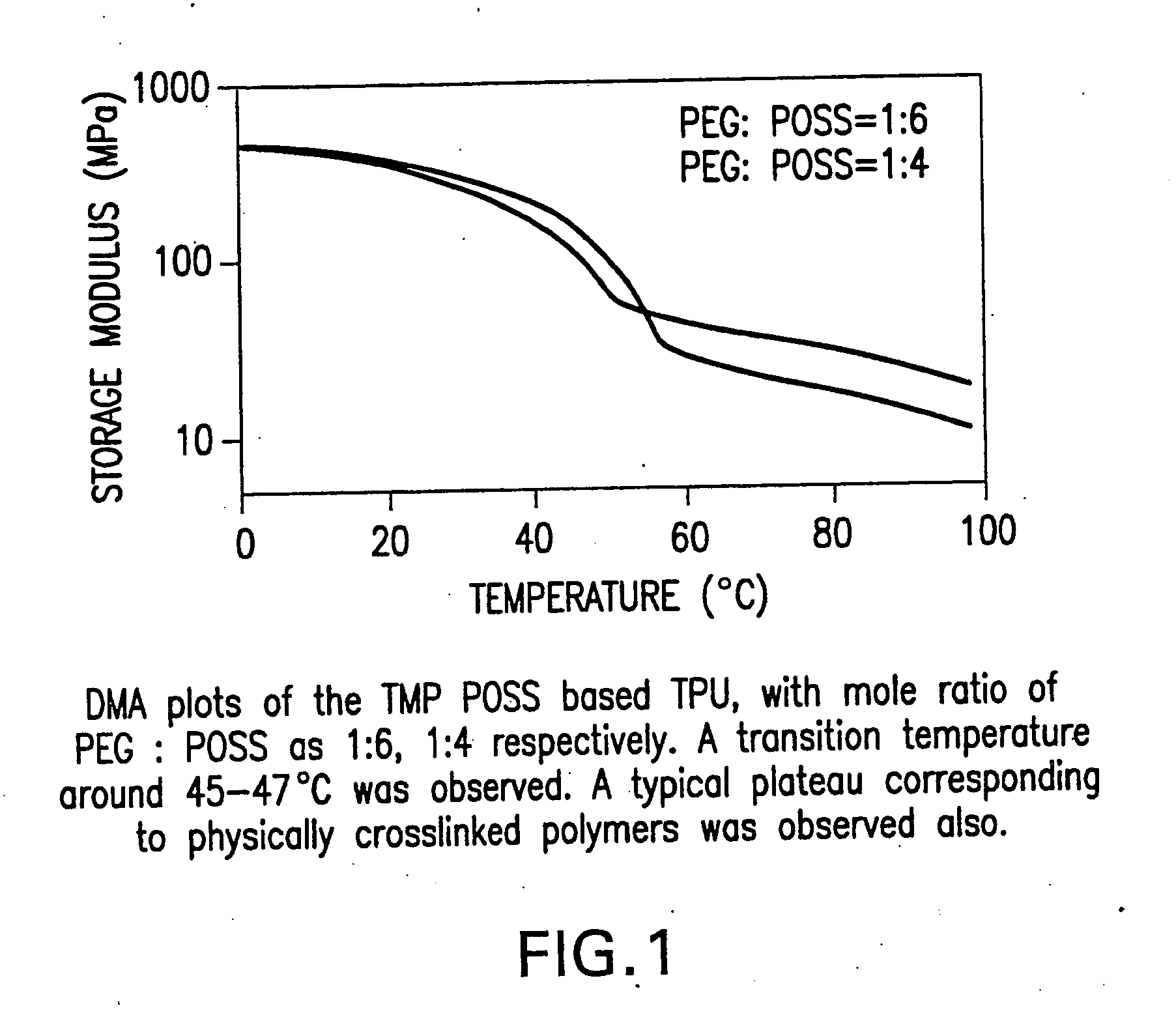

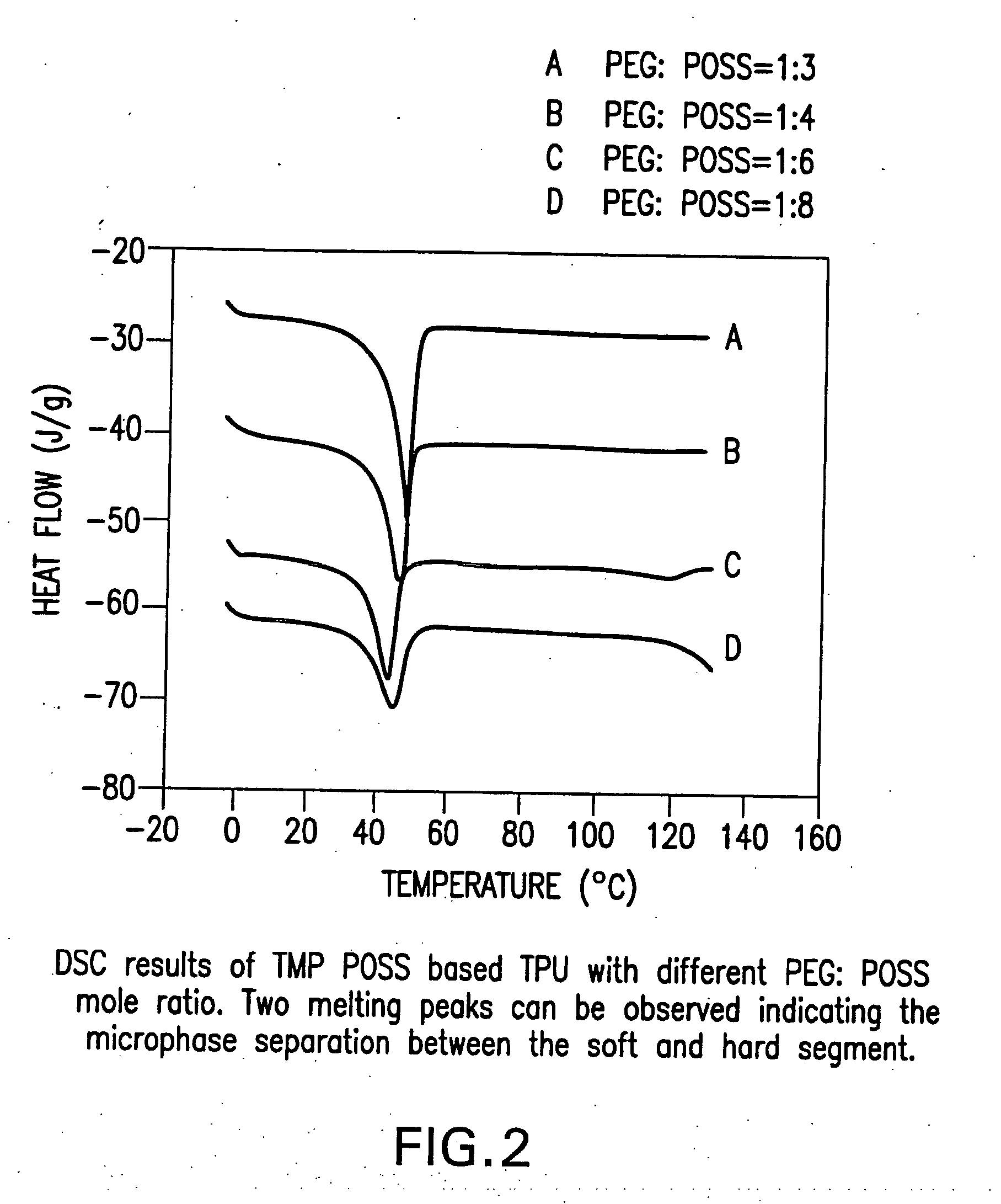

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

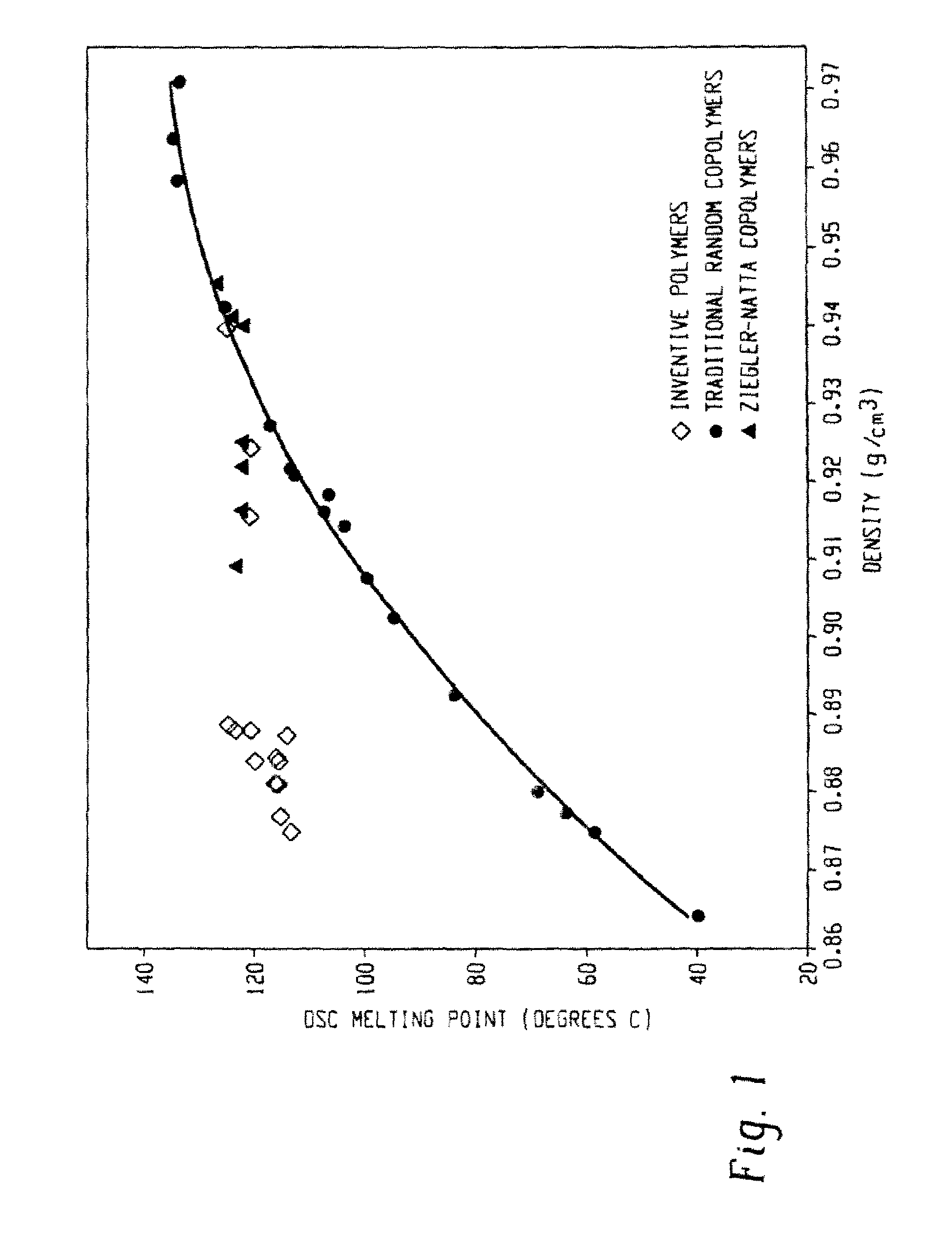

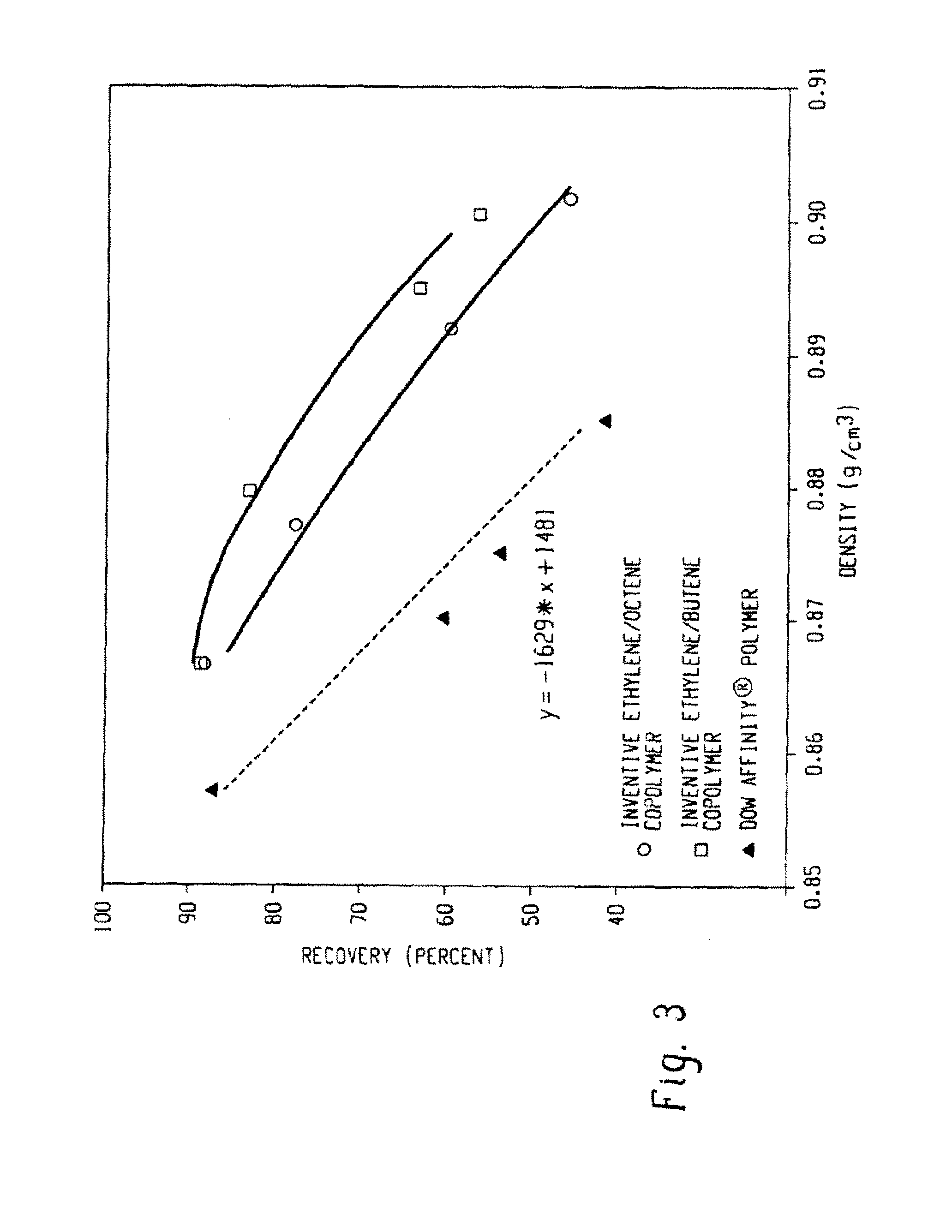

Polyolefin compositions and articles prepared therefrom, and methods for making the same

ActiveUS20100029827A1Film/foil adhesivesSynthetic resin layered productsPolyolefinThermoplastic polyurethane

The invention provides a composition comprising at least one olefin multi-block interpolymer; at least one functionalized olefin-based polymer; and optionally at least one thermoplastic polyurethane. The invention also provides for articles prepared from the inventive compositions and for methods for making the same.

Owner:DOW GLOBAL TECH LLC

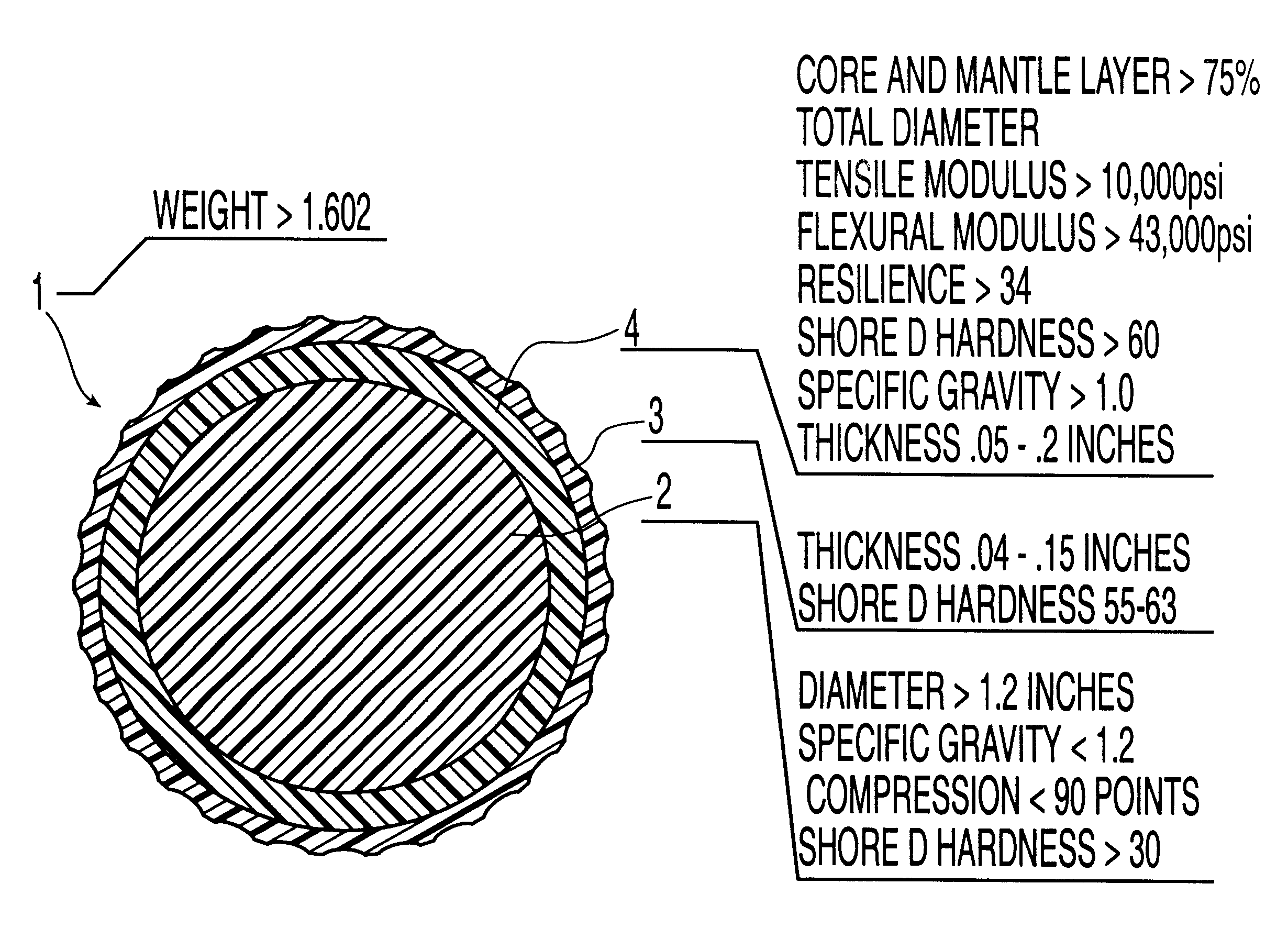

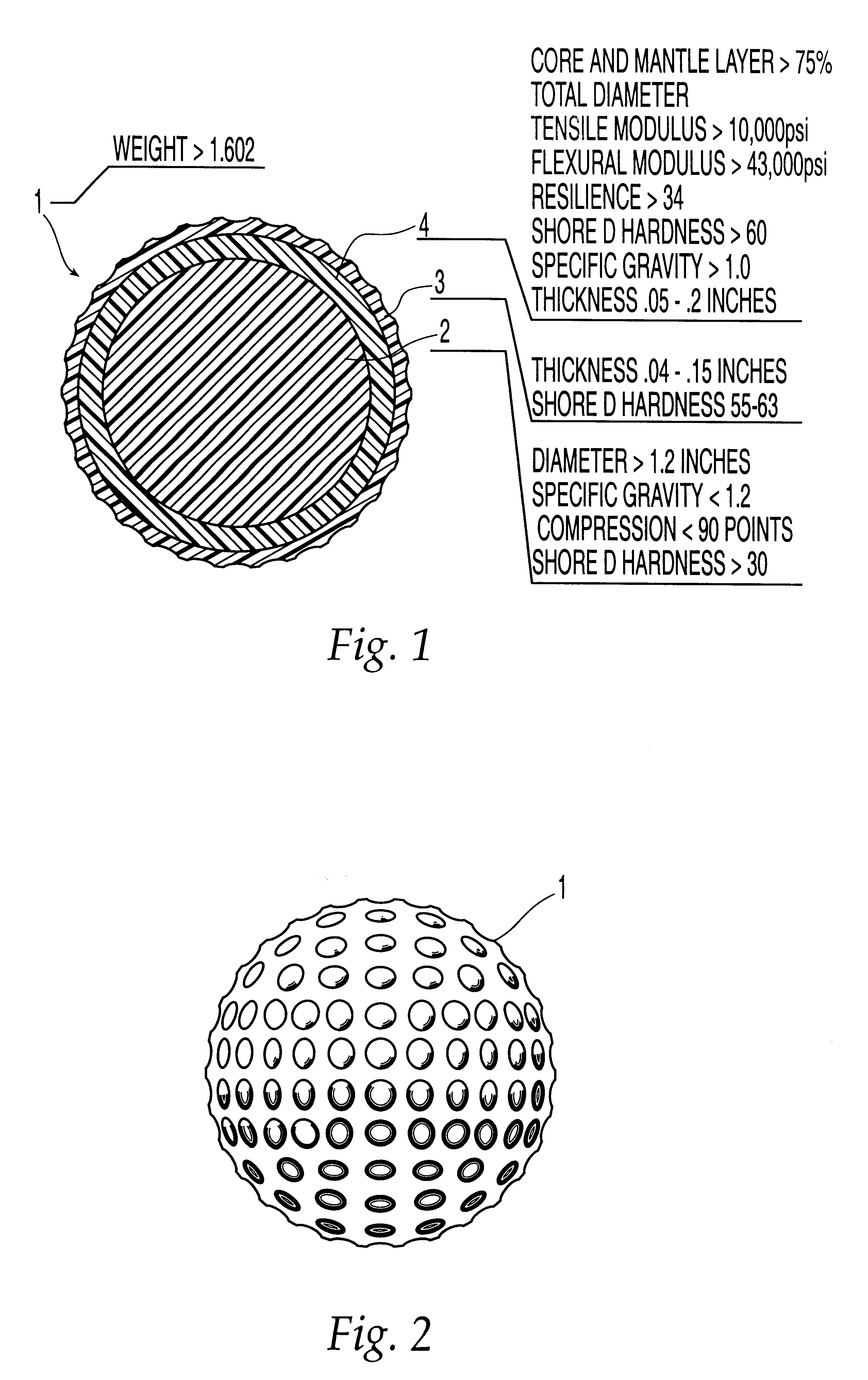

Multilayer golf ball

InactiveUS6315680B1Synthetic resin layered productsGolf ballsThermoplastic elastomerThermoplastic polyurethane

The present invention is directed towards a high-spin multi-layer golf ball which comprises a core with a Shore D hardness of preferably greater than about 30, and a mantle layer disposed between the core and a cover layer, wherein the mantle layer has a Shore D hardness greater than 60 and a resilience of greater than 34. Preferably, the mantle layer is comprised essentially of dynamically vulcanized thermoplastic elastomer, functionalized styrene-butadiene elastomer, thermoplastic polyurethane, metallocene polymer, thermoset materials or blends thereof. Preferably, the mantle layer has a specific gravity of greater than 1, and the core has a specific gravity of less than 1.2.

Owner:ACUSHNET CO

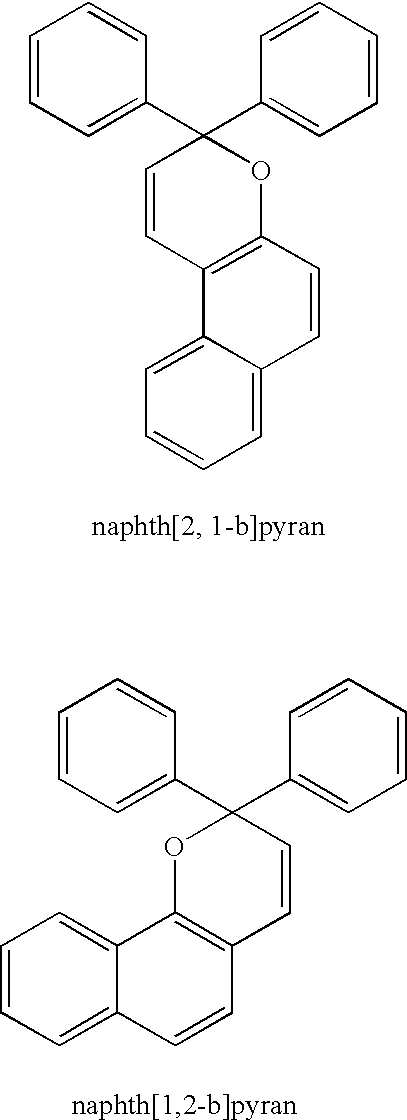

Photochromic polyurethane laminate

ActiveUS20050233153A1Improve fatigue resistanceGood dimensional stabilityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

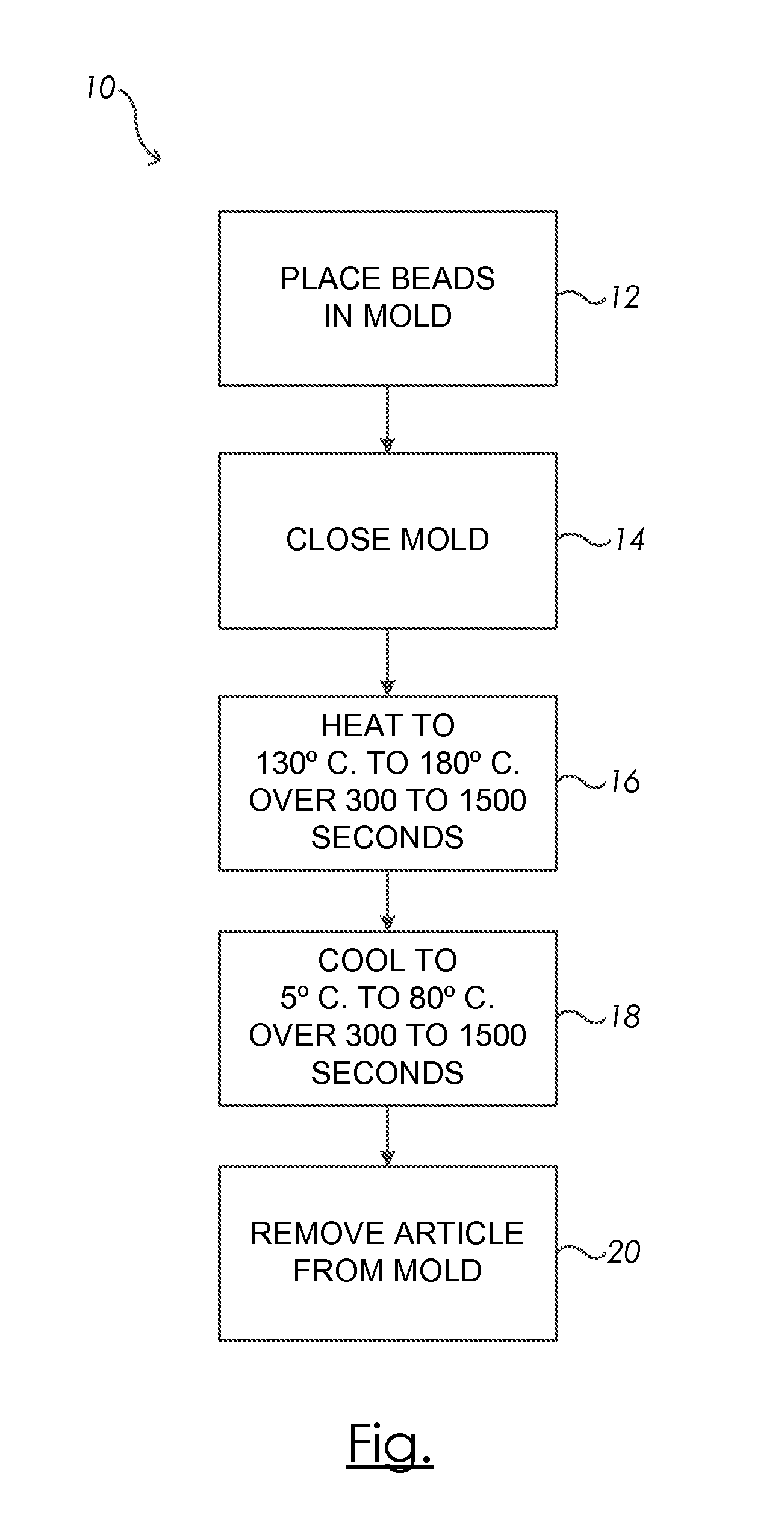

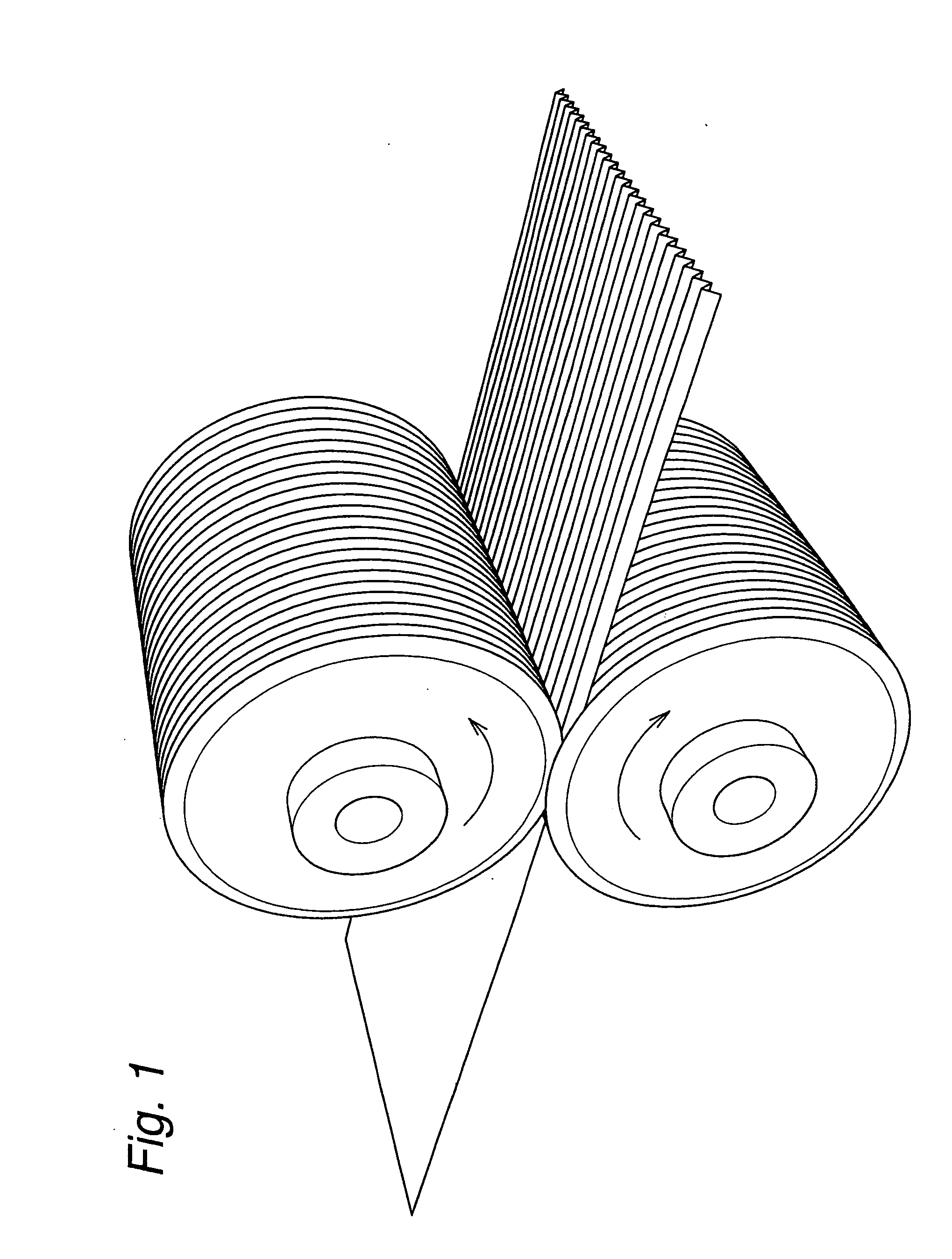

Bead Foam Compression Molding Method for Low Density Product

ActiveUS20140017450A1Low densityOptimization definitionSolesLayered productsCompression moldingThermoplastic polyurethane

Disclosed is a method for molding a foamed article, such as a midsole or outsole for footwear, in which a desired amount of thermoplastic polyurethane foam beads are placed in a compression mold in the shape of the article and the mold is brought to a peak temperature of from about 130° C. to about 180° C. over a period of from about 300 to about 1500 seconds, then cooled to from about 5° C. to about 80° C. over a period of from about 300 to about 1500 seconds within about 30 seconds after the peak temperature is reached. The foamed article made by the method has a density of from about 0.1 to about 0.45 g / cm3.

Owner:NIKE INTERNATIONAL LTD

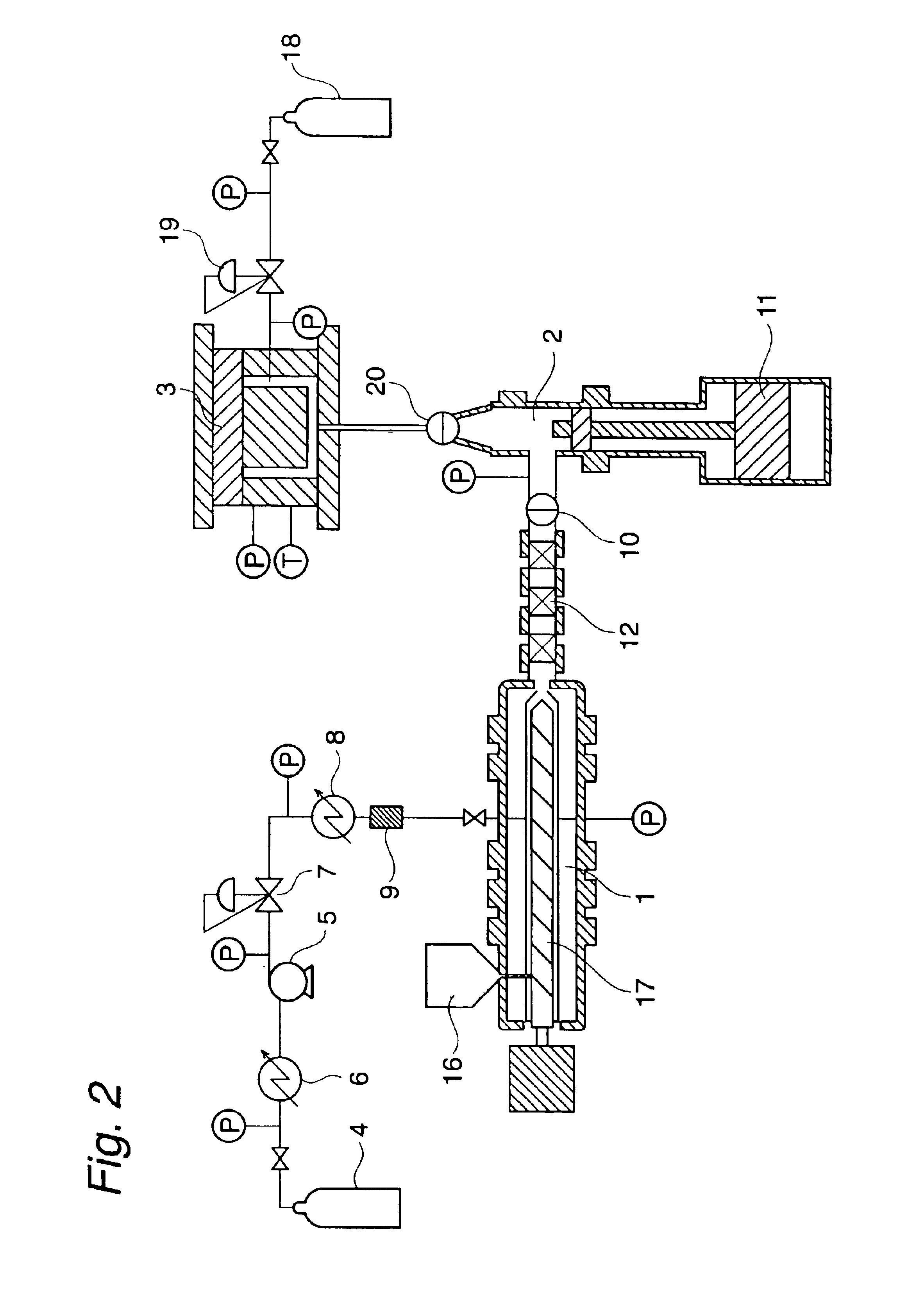

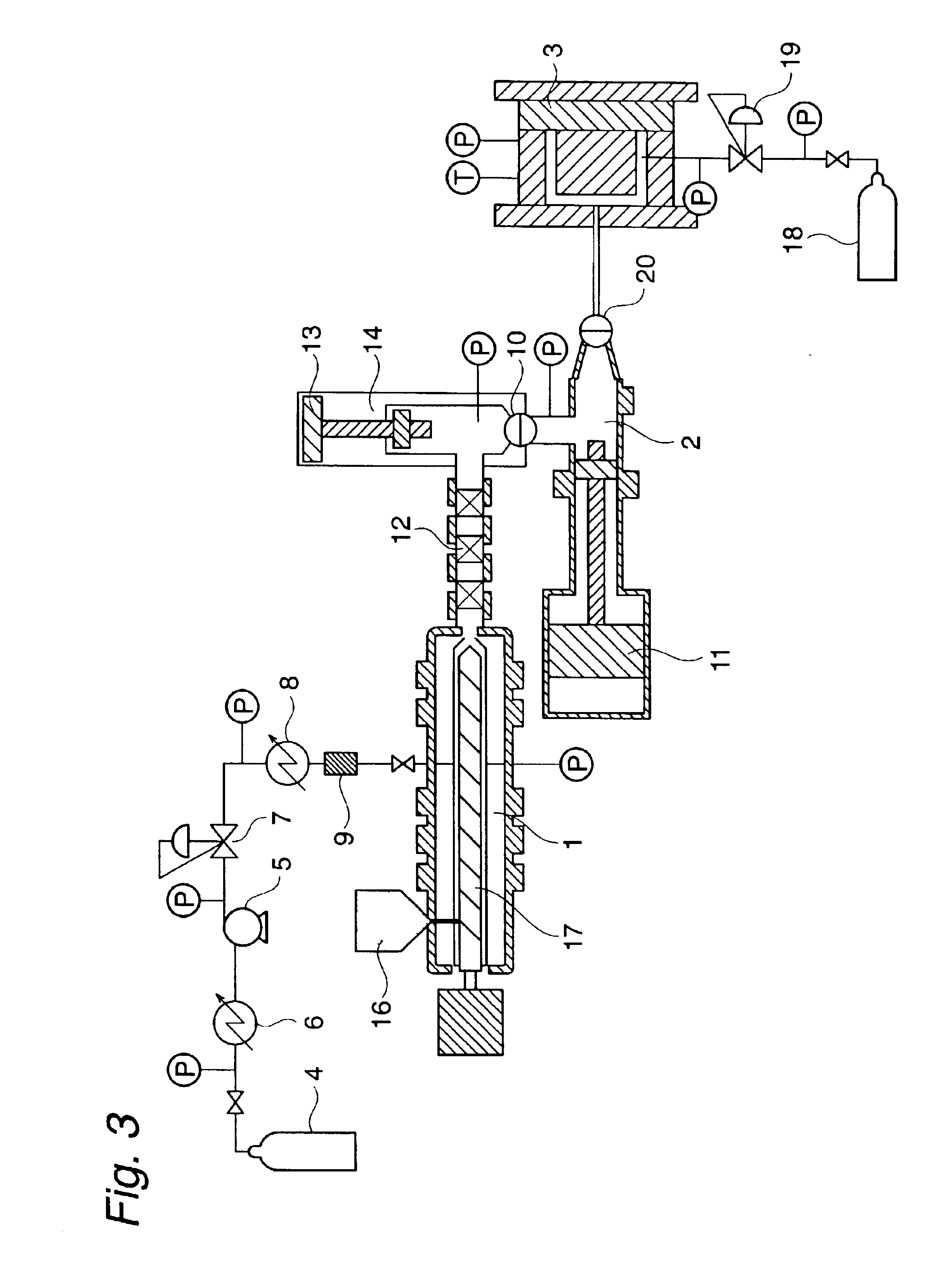

Foam of thermoplastic urethane elastomer composition and process for producing the foam

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

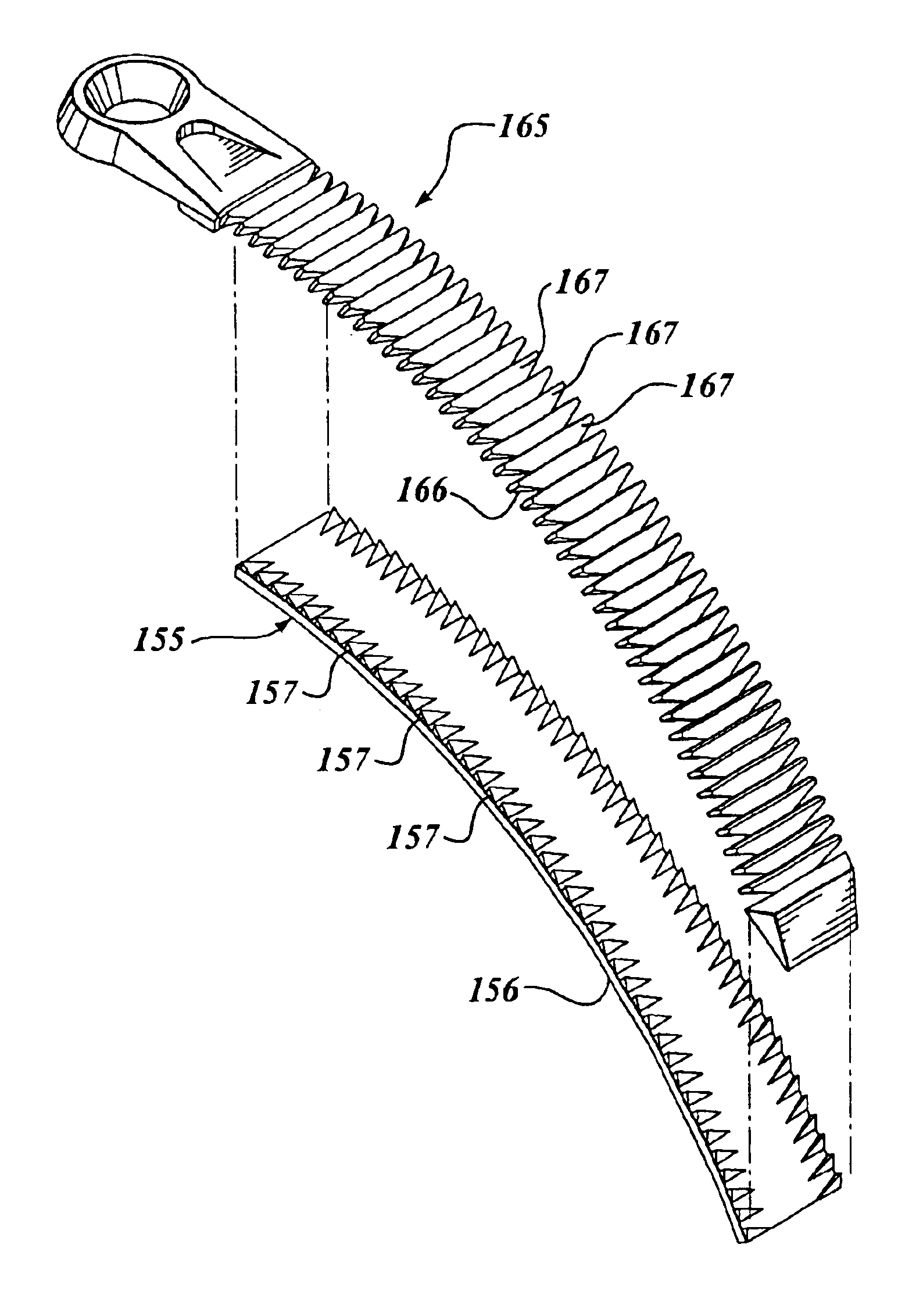

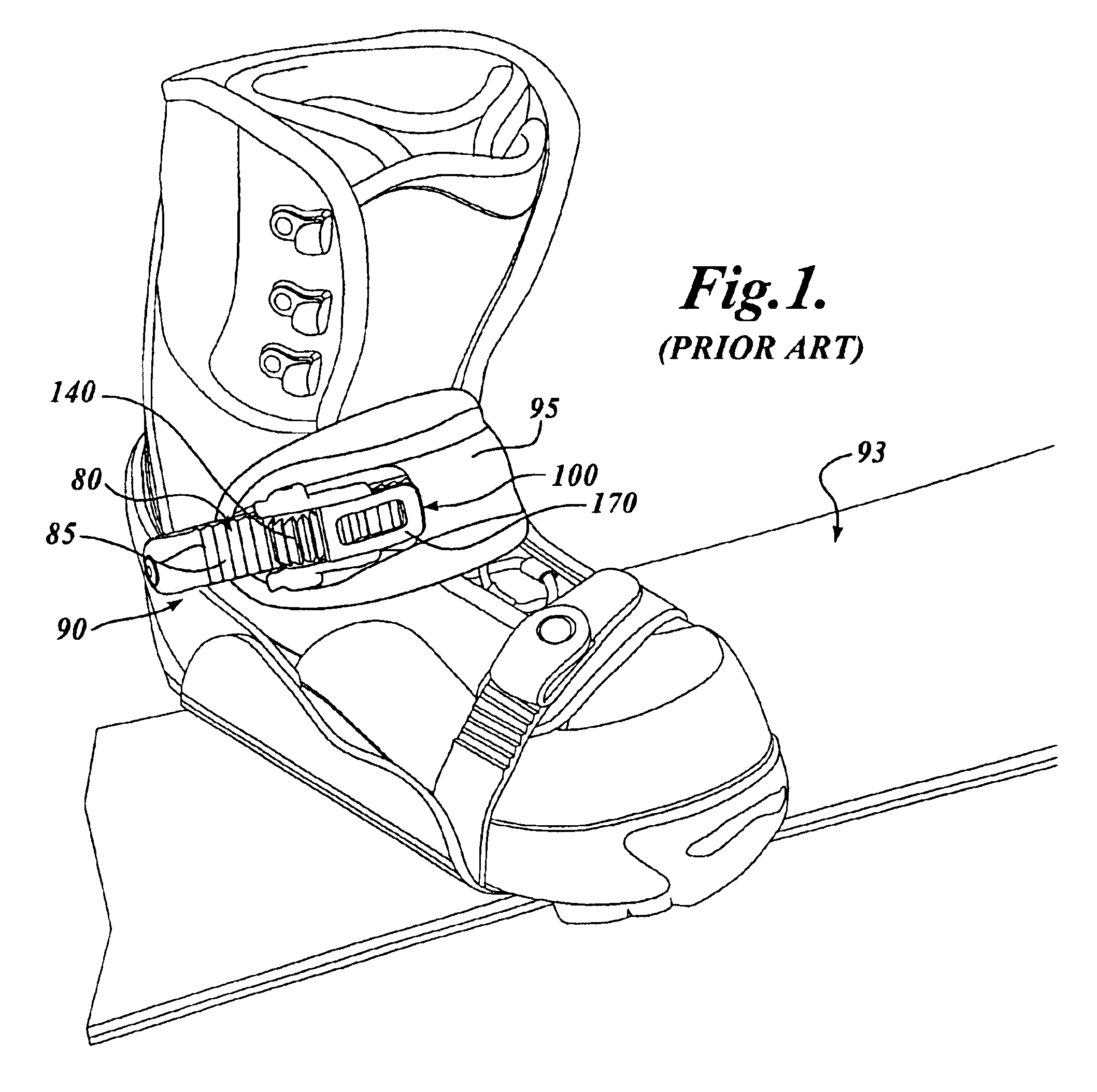

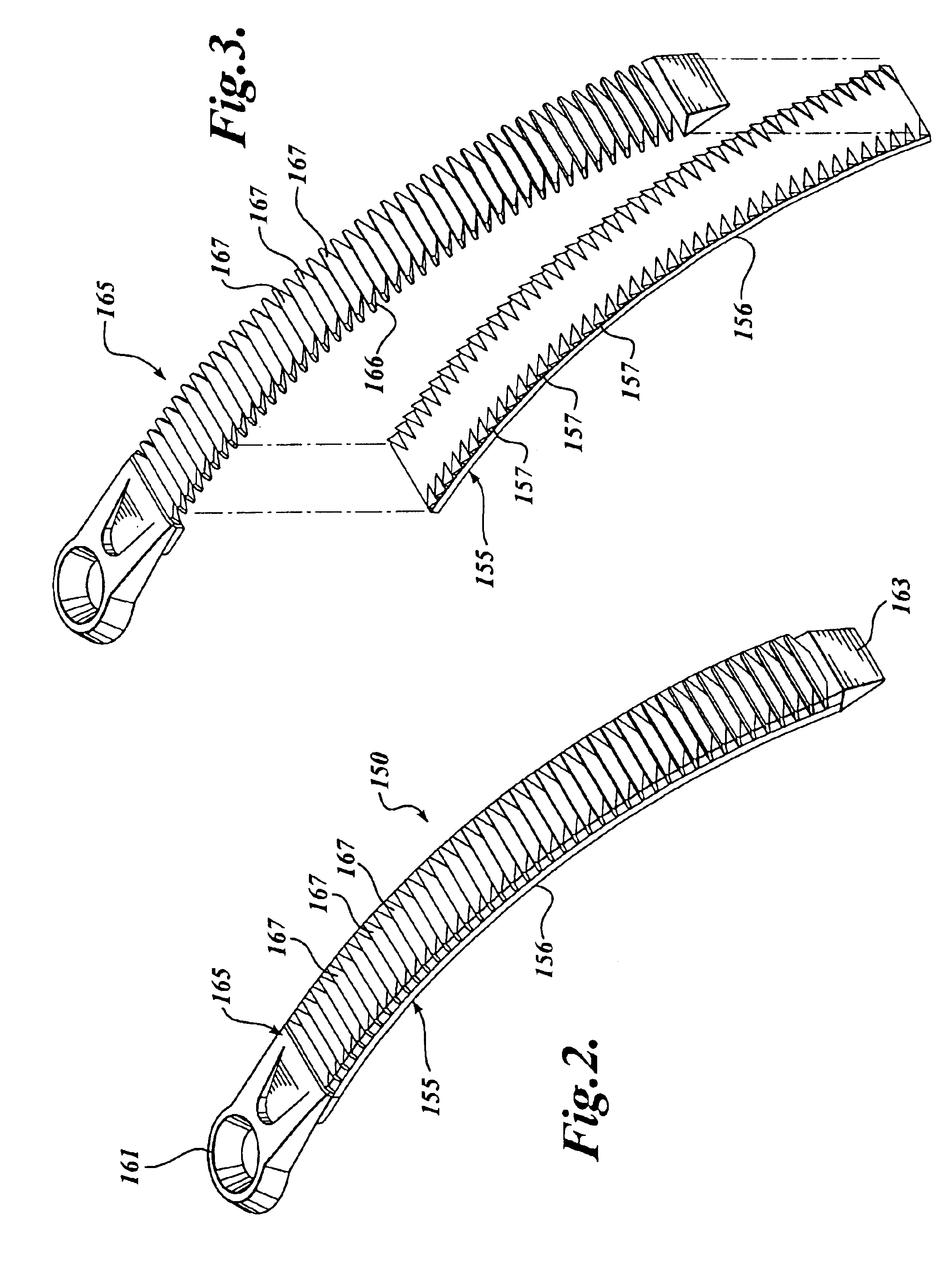

Co-molded ladder strap

InactiveUS6898826B2Desired flexibilityDesired hardness characteristicSnap fastenersSki bindingsShell moldingThermoplastic polyurethane

A ladder strap (150) is made by joining—for example, by co-molding—a first, relatively supple material, defining a lower strap portion (155) with a second, relatively hard material defining an upper strap portion (165). The teeth (167) of the ladder strap are comprises substantially of the harder, second material. In a preferred embodiment, the first and second materials are thermoplastic urethanes, and the co-molding is done using an injection molding process. The co-molding process may be accomplished with co-injection, wherein the two materials are injected at about the same time, or the first material may be injected into a first mold cavity and allowed to partially set, after which the cavity is modified to accommodate the second material.

Owner:K 2 CORP

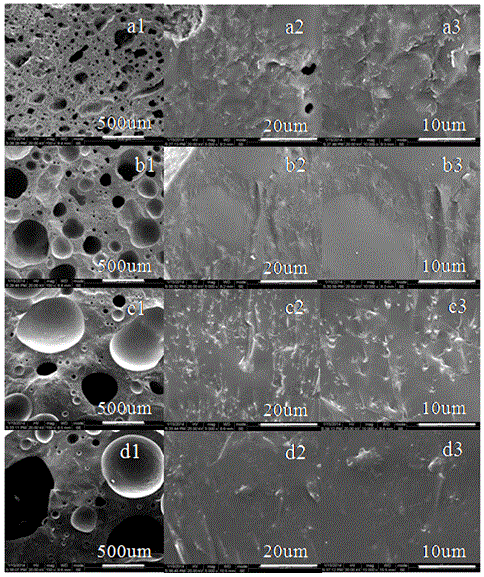

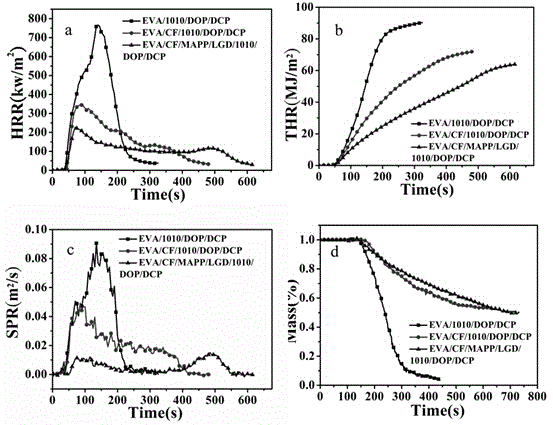

Low-smoke halogen-free flame retardant thermoplastic elastomer alloy for flexible wire rod and preparation method thereof

InactiveCN101225224AHigh tensile strengthHigh elongationInsulated cablesInsulated conductorsLow voltageAntioxidant

The invention discloses a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires and a preparation method of the alloy, which is characterized in that: the material comprises thermoplastic polyurethane elastomer, thermoplastic styrene elastomer, compatilizer, phosphorus-nitrogen compound flame retardant, flame-retarding potentiating agent, lubricant, antioxidant and colorant; the weight ratio of the thermoplastic polyurethane elastomer, the thermoplastic styrene elastomer, the compatilizer, the phosphor-nitrogen compound flame retardant, the flame-retarding potentiating agent, the lubricant, the antioxidant and the colorant is 40 to 55 : 5 to 25 : 5 to 10 : 20 to 25 : 3 to 10 : 1.5 : 0.25 : 0.25; the preparation method is that the all components are evenly mixed in a high-speed mixer, and then extruded, drew and granulated at 170 to 210 degree centigrade, and then a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires is obtained. The low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires has the advantages of achieving distinct flame-retarding effect at a small quantity of flame retardant dosage, satisfying the flame-retarding requirement of low-voltage wires, adjusting the Shore durometer number of the material between 80 to 95, good pliability, high physical mechanical property and according with the halogen-free and environment-friendly requirement.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Foamed thermoplastic polyurethanes

InactiveUS7202284B1Improve cell structureExcellent surface appearanceCoatingsPolymer scienceMicrosphere

Process for the preparation of foamed thermoplastic polyurethanes characterized in that the foaming of the thermoplastic polyurethane is carried out in the presence of thermally expandable microspheres.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

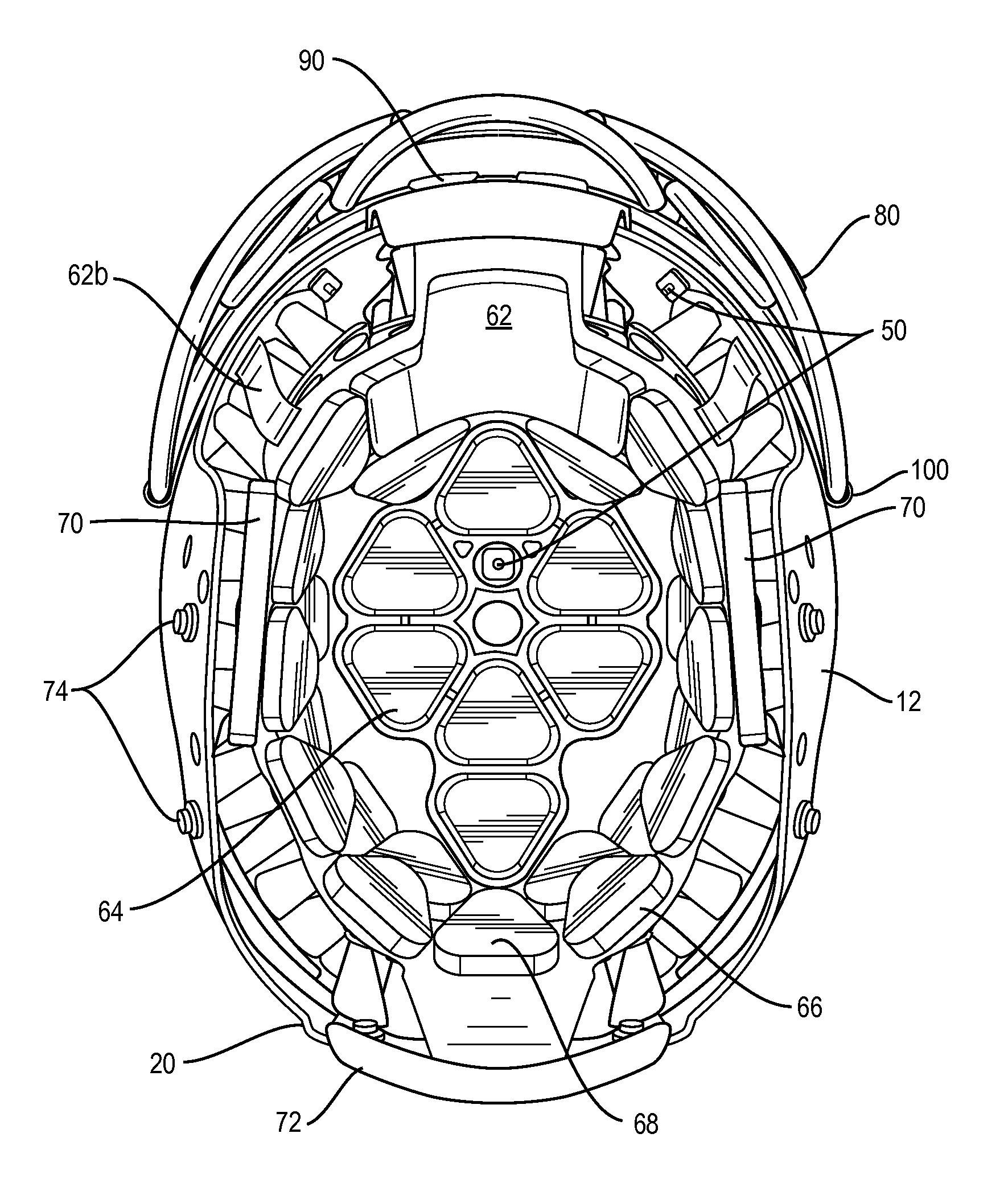

Football helmet

A football helmet with shell, faceguard, padding and comfort liner system, has replaceable nose bumpers for connecting a top center of the faceguard to the shell, button and keyhole connectors connecting the liner to an inner surface of the padding and T-nut connectors for connecting the padding to an inner surface of the shell. Front portions of the comfort liner have harder foam cushions than other portions of the liner to improve impact absorption. Selected areas of the padding system contain pads with inner and outer molded thermoplastic urethane parts of different durometer, each including a sheet with plural alternating hollow protrusions. The faceguard has an upper bar with raised ends above a lower edge of the front portion of the shell that form a face opening and on either side of the nose bumper.

Owner:SCHUTT SPORTS IP LLC

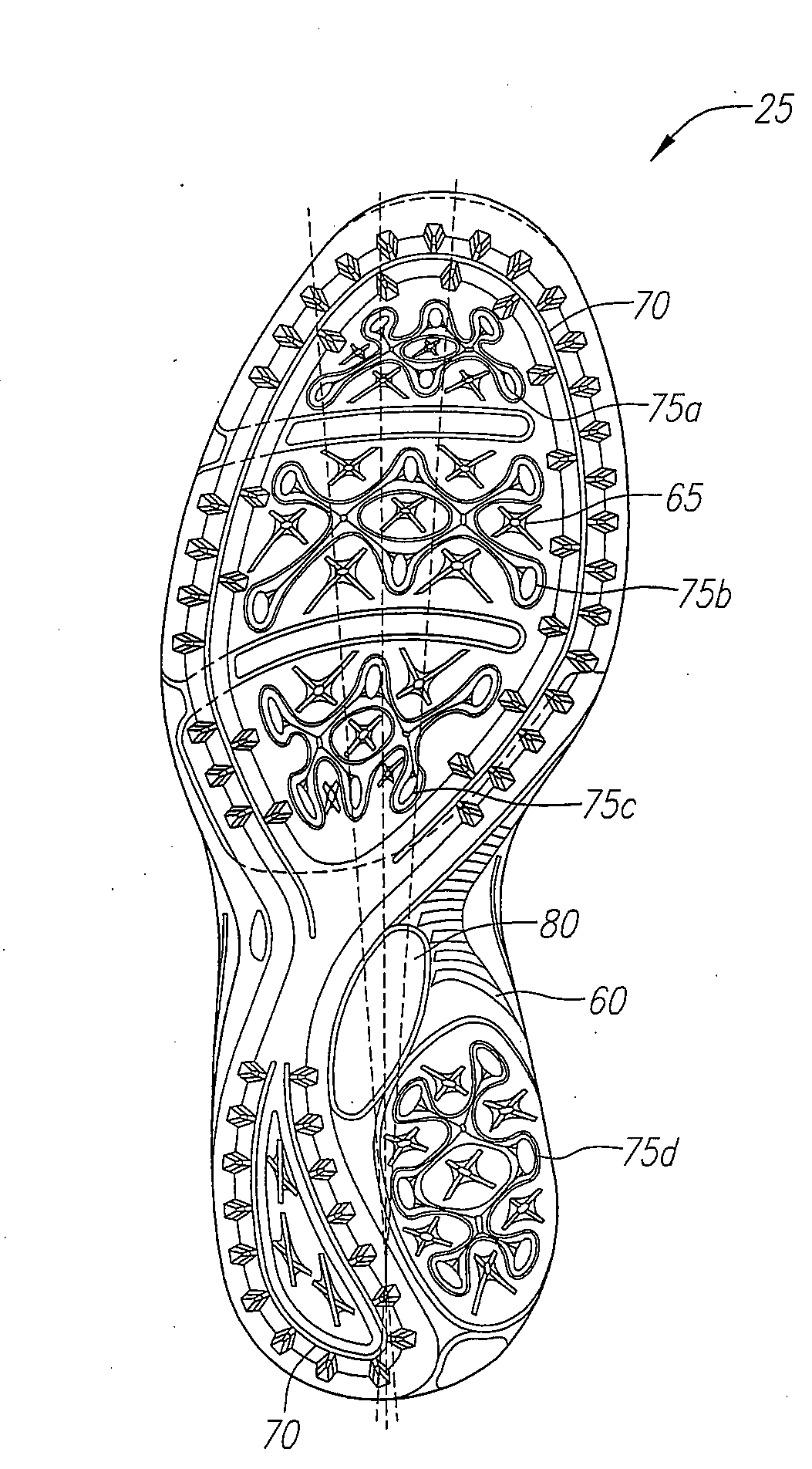

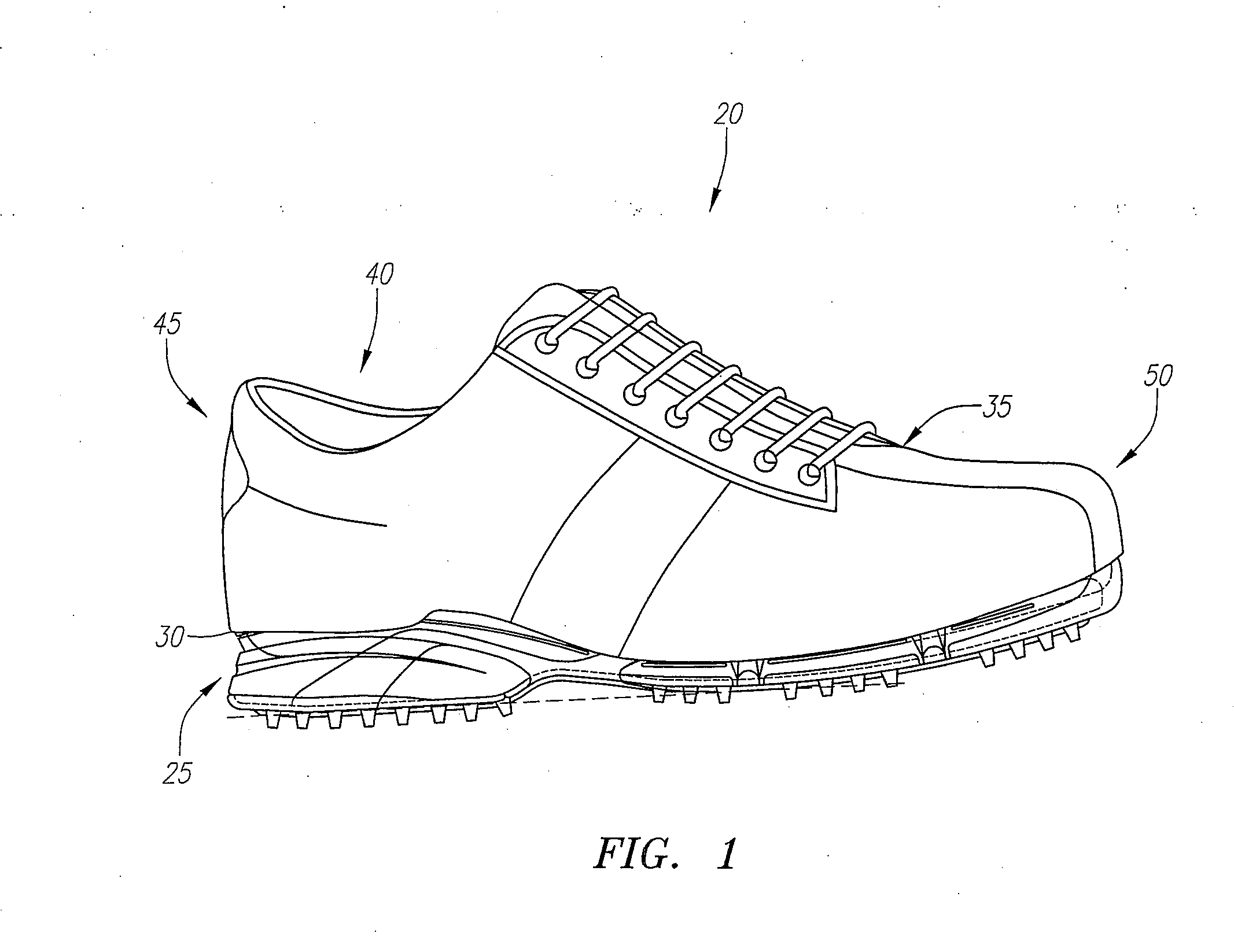

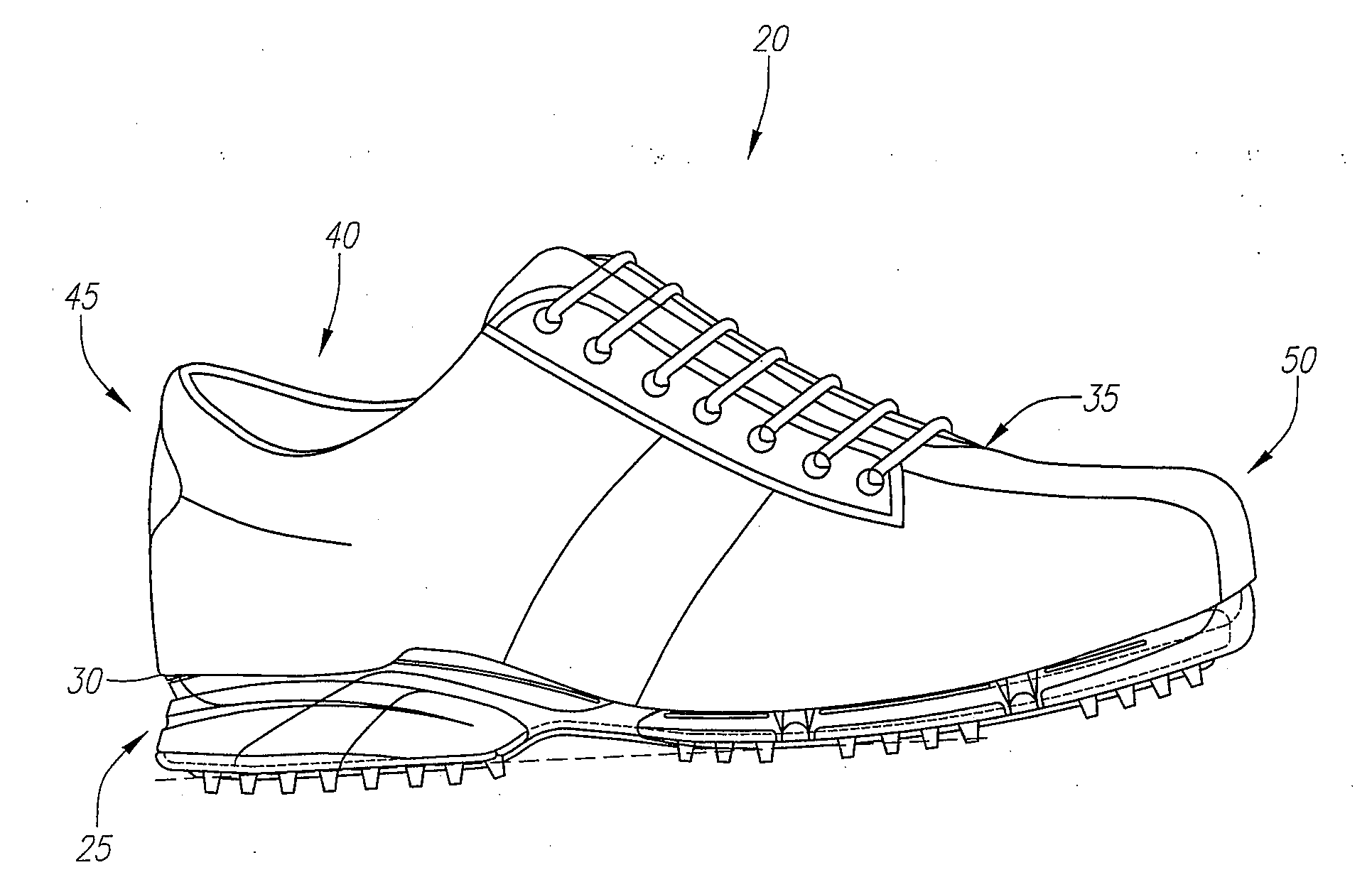

Chemically-treated Outsole Assembly for a Golf Shoe

ActiveUS20080282579A1Increased durabilityGood dynamic flexibilitySolesThermoplastic polyurethaneEngineering

An out-sole assembly for a golf shoe. The outsole assembly includes an internal base member composed of EVA, an inner frame member composed thermoplastic polyurethane subjected to an isocyanate solution, an external base member composed of a thermoplastic polyurethane, a dual looping frame composed of a thermoplastic polyurethane, and a plurality of spike members.

Owner:CALLAWAY GOLF CO

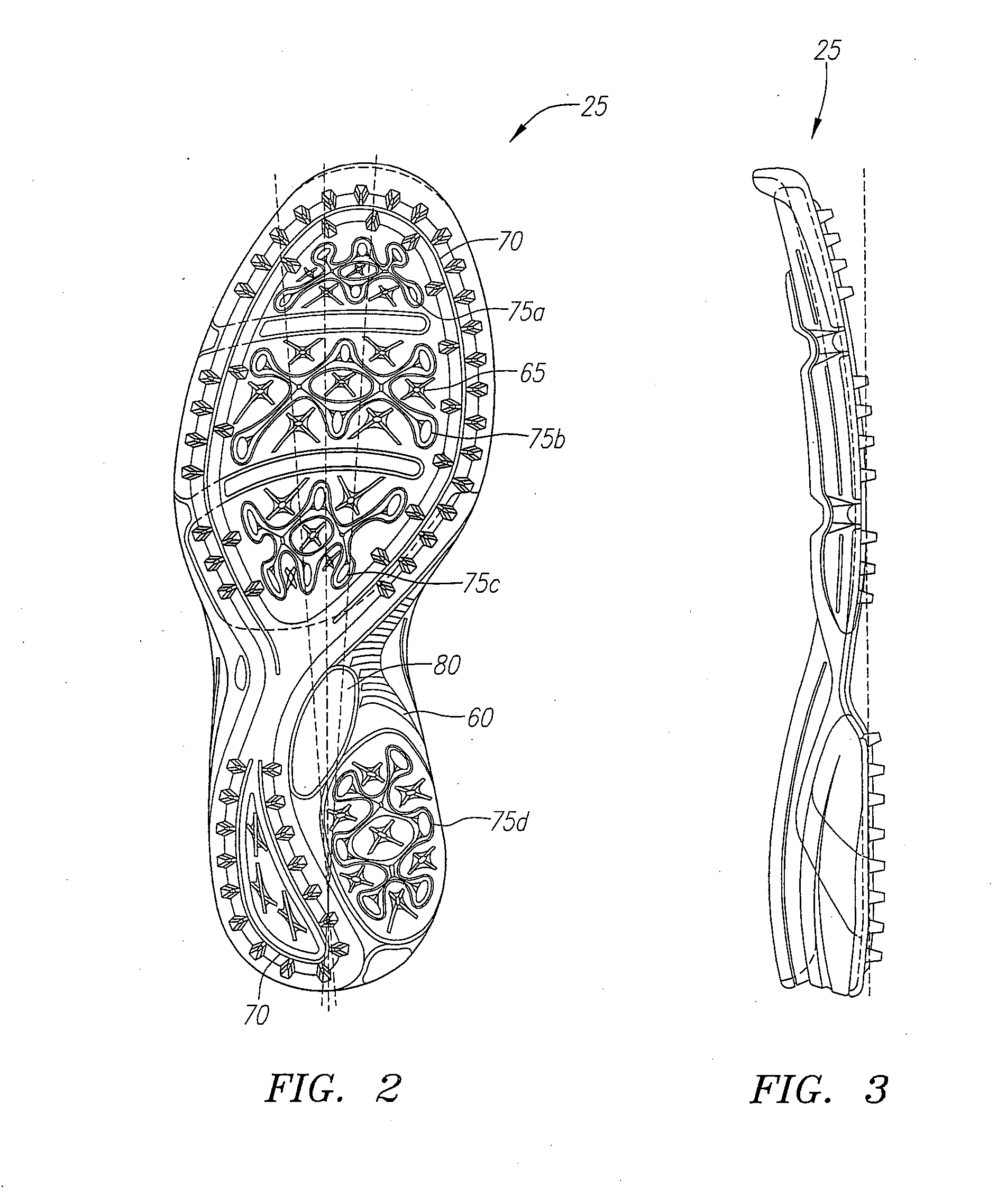

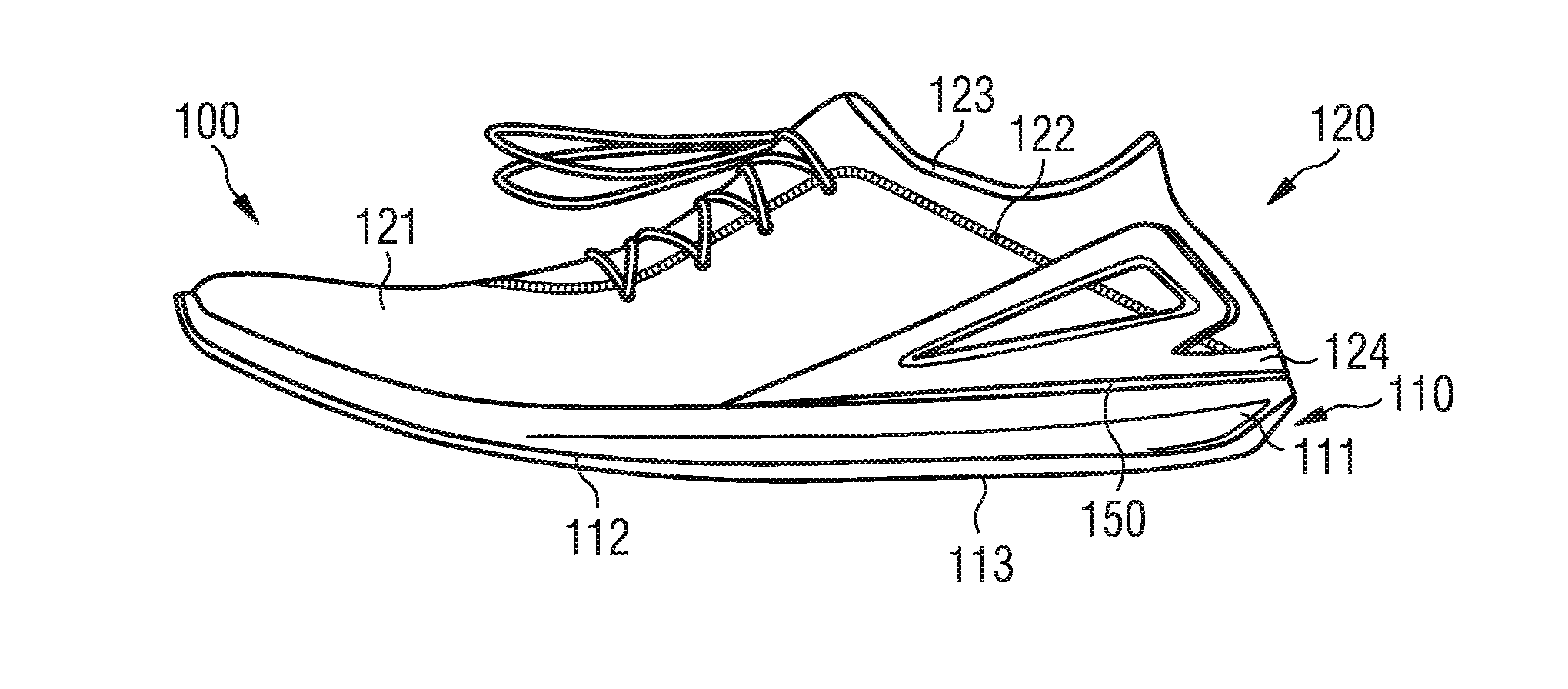

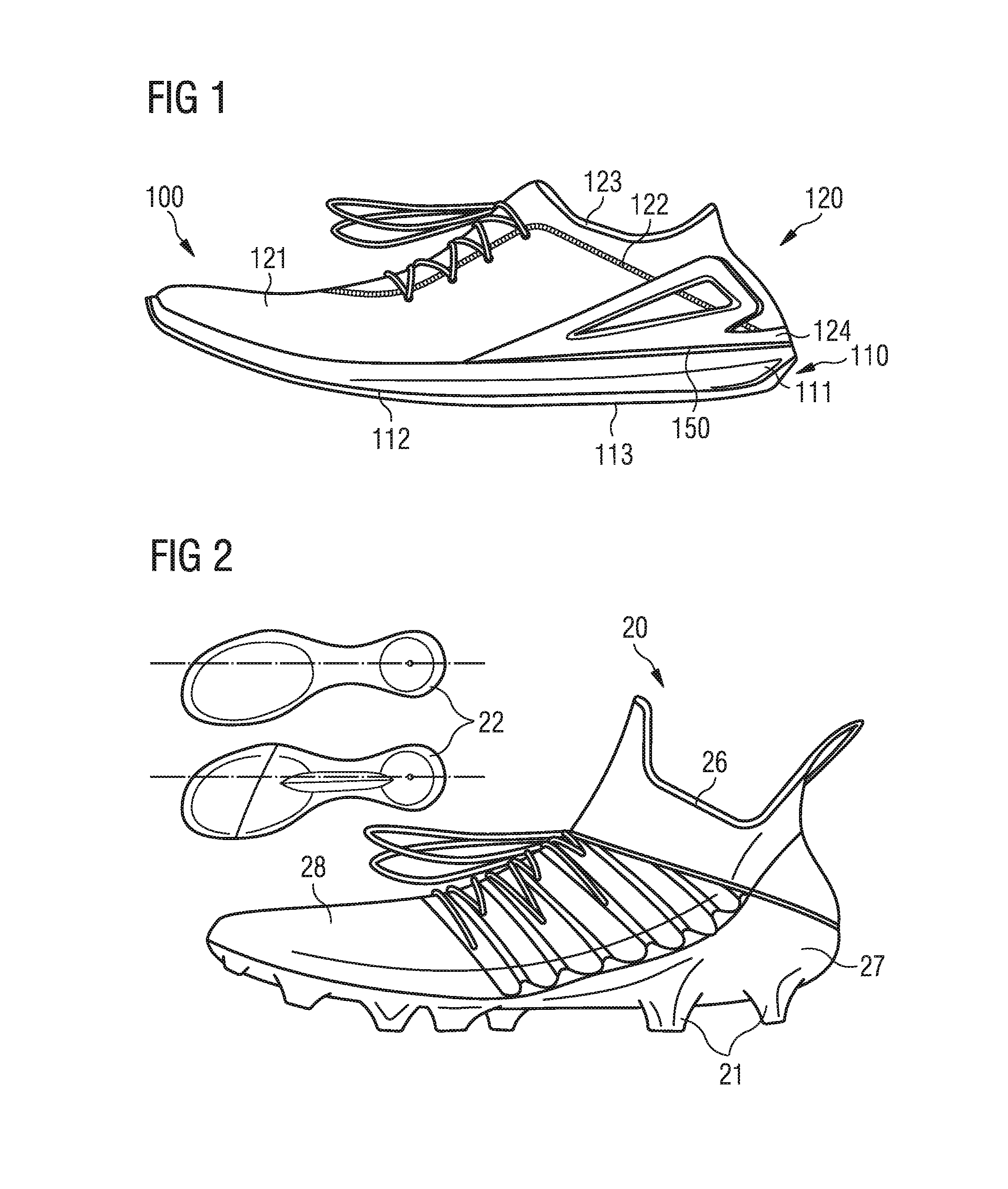

Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

InactiveUS20160302508A1Easy to identifySolesInsolesPolyethylene terephthalatePolyethylene terephthalate glycol

A sports shoe includes an upper wherein a majority by weight of the upper is made from a thermoplastic base material and a sole wherein a majority by weight of the sole is made from the same thermoplastic base material. The sole and the upper are individually fabricated and joined to each other. The thermoplastic base material includes at least one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

Owner:ADIDAS

Articles Comprising Nonpolar Polyolefin and Polyurethane, and Methods for Their Preparation and Use

ActiveUS20090275690A1Improve adhesionSynthetic resin layered productsCoatingsPolyesterPolymer science

The adhesion between a low surface energy (i.e., nonpolar) material, e.g., a polyolefin such as polyethylene, and a high surface energy (i.e., polar) material, e.g., a polyester, polyurethane, polycarbonate or polylactic acid, is promoted by blending with the nonpolar material typically from 15 to less than 50 wt % of a diol-based thermoplastic polyurethane (d-TPU), e.g., a polydiene diol-based TPU, based on the combined weight of the nonpolar material and the d-TPU. The promoted adhesion allows for the effective painting, printing, over-molding or HF-welding of a nonpolar substrate, e.g., a polyolefin film, with a polar coating, e.g., a paint, ink, etc. Aqueous dispersions can also be made from the blend of nonpolar material and d-TPU.

Owner:DOW GLOBAL TECH LLC

Multi-piece solid golf ball

InactiveUS6142888AImprove performanceIncrease elasticityGolf ballsSolid ballsProduction rateMass scale

Owner:BRIDGESTONE SPORTS

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7091297B2High modulusSufficient cross-linkingStentsOther chemical processesPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligomeric silsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated POSS and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Polyurethane Compositions and Articles Prepared Therefrom, and Methods for Making the Same

Owner:DOW GLOBAL TECH LLC

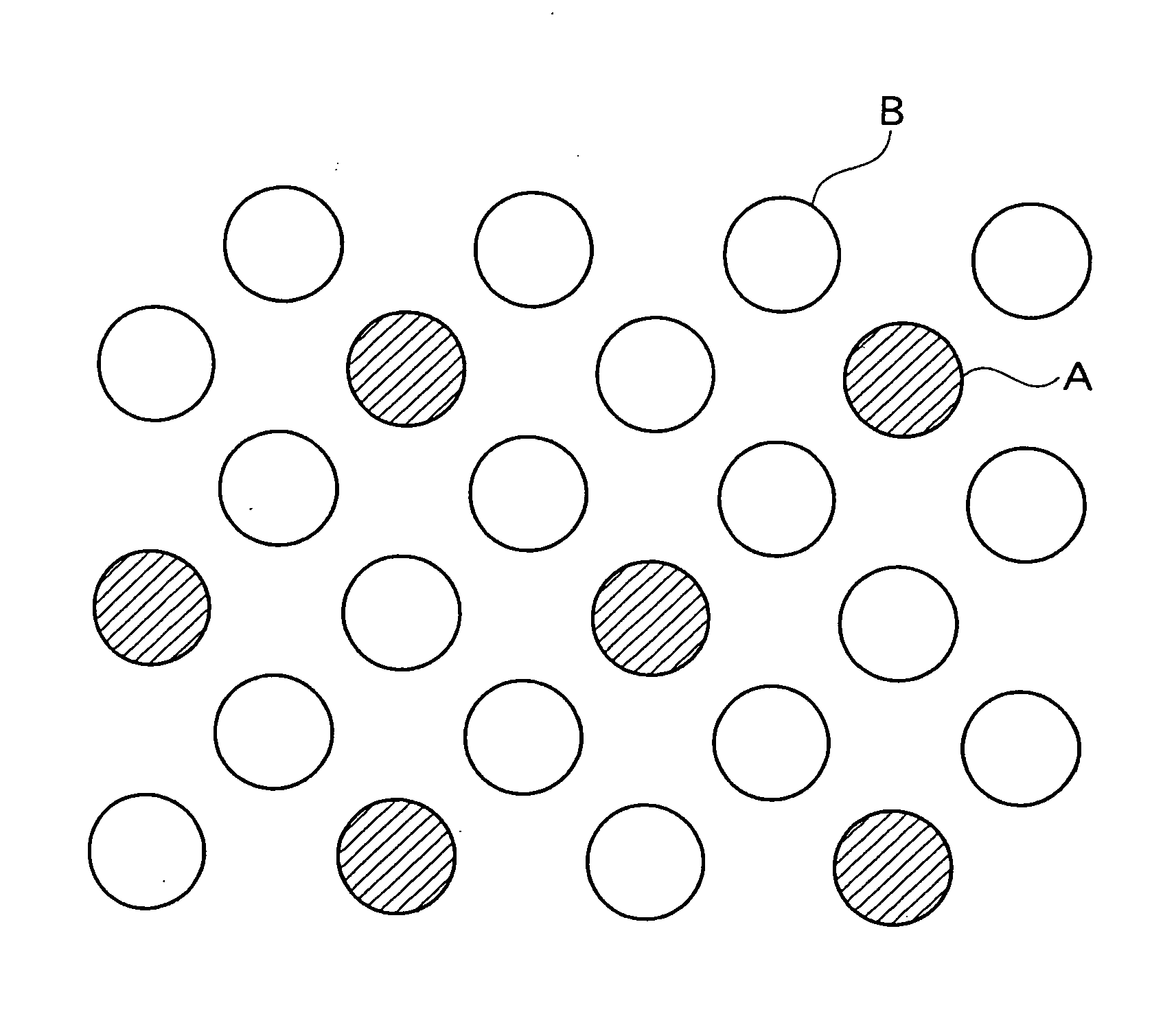

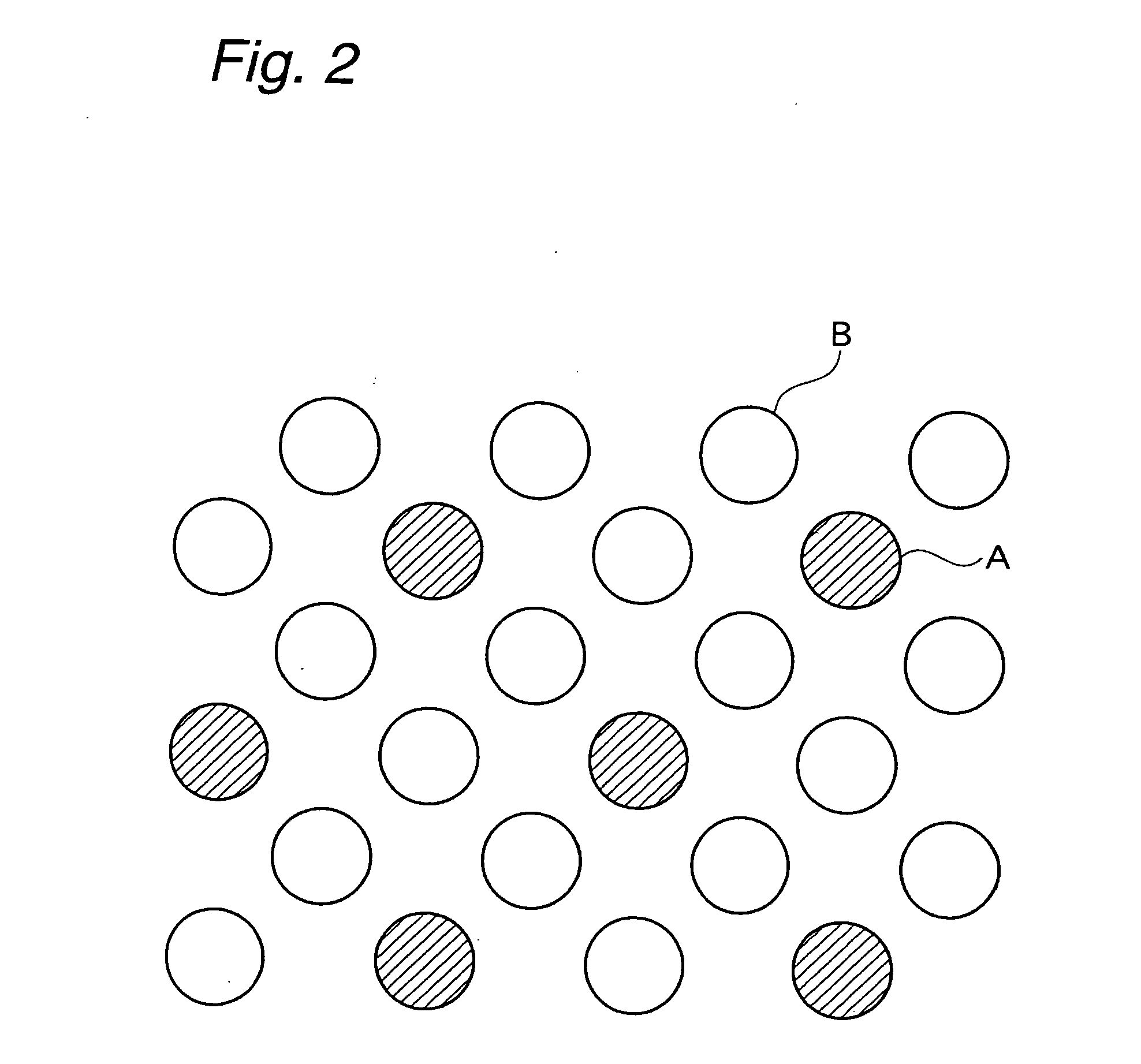

Mixed fiber and, stretch nonwoven fabric comprising said mixed fiber and method for manufacture thereof

ActiveUS20060121812A1Excellent touch and heat sealing property and productivityLow residual strainWoven fabricsNon-woven fabricsPolymer scienceThermoplastic polyurethane

A fiber mixture according to the invention comprises fibers A comprising a polymer A containing a thermoplastic polyurethane elastomer and fibers B comprising a thermoplastic polymer B other than the thermoplastic polyurethane elastomer, said thermoplastic polyurethane elastomer having a solidifying point of 65° C. or above as measured by a differential scanning calorimeter (DSC) and containing 3.00×106 or less polar-solvent-insoluble particles per g counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 μm in diameter. An elastic nonwoven fabric comprises the fiber mixture.

Owner:MITSUI CHEM INC

Golf ball cover stocks and golf balls

Owner:BRIDGESTONE SPORTS

Chemically-treated Outsole Assembly for a Golf Shoe

ActiveUS20110072687A1Increased durabilityDynamic flexibilitySolesThermoplastic polyurethaneGolf Ball

An out-sole assembly for a golf shoe. The outsole assembly includes an internal base member composed of EVA, an inner frame member composed thermoplastic polyurethane subjected to an isocyanate solution, an external base member composed of a thermoplastic polyurethane, a dual looping frame composed of a thermoplastic polyurethane, and a plurality of spike members.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Multi-piece solid golf ball

ActiveUS20050075196A1High reboundImprove flight performanceGolf ballsSolid ballsRare earthCarboxylic acid

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

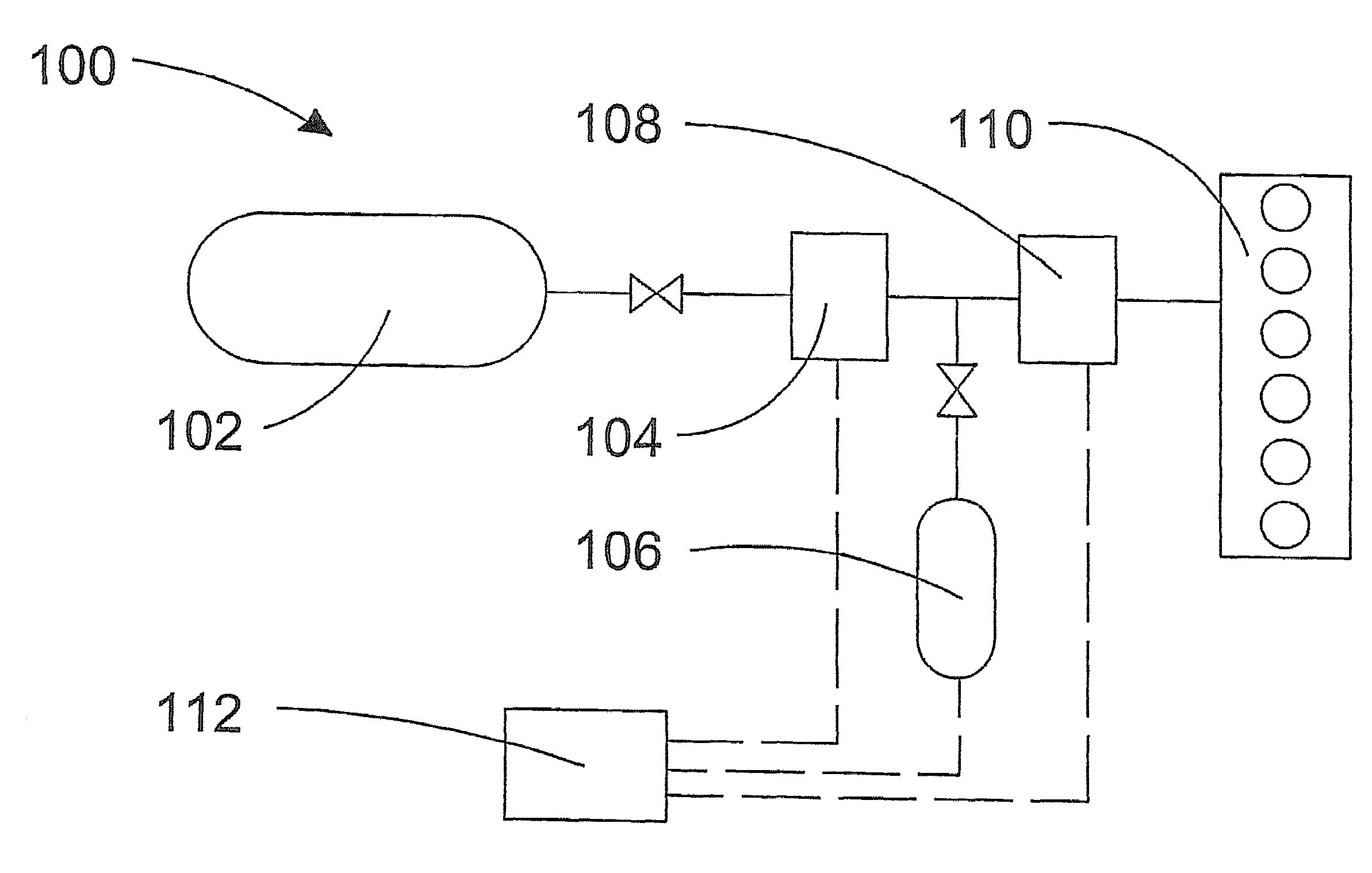

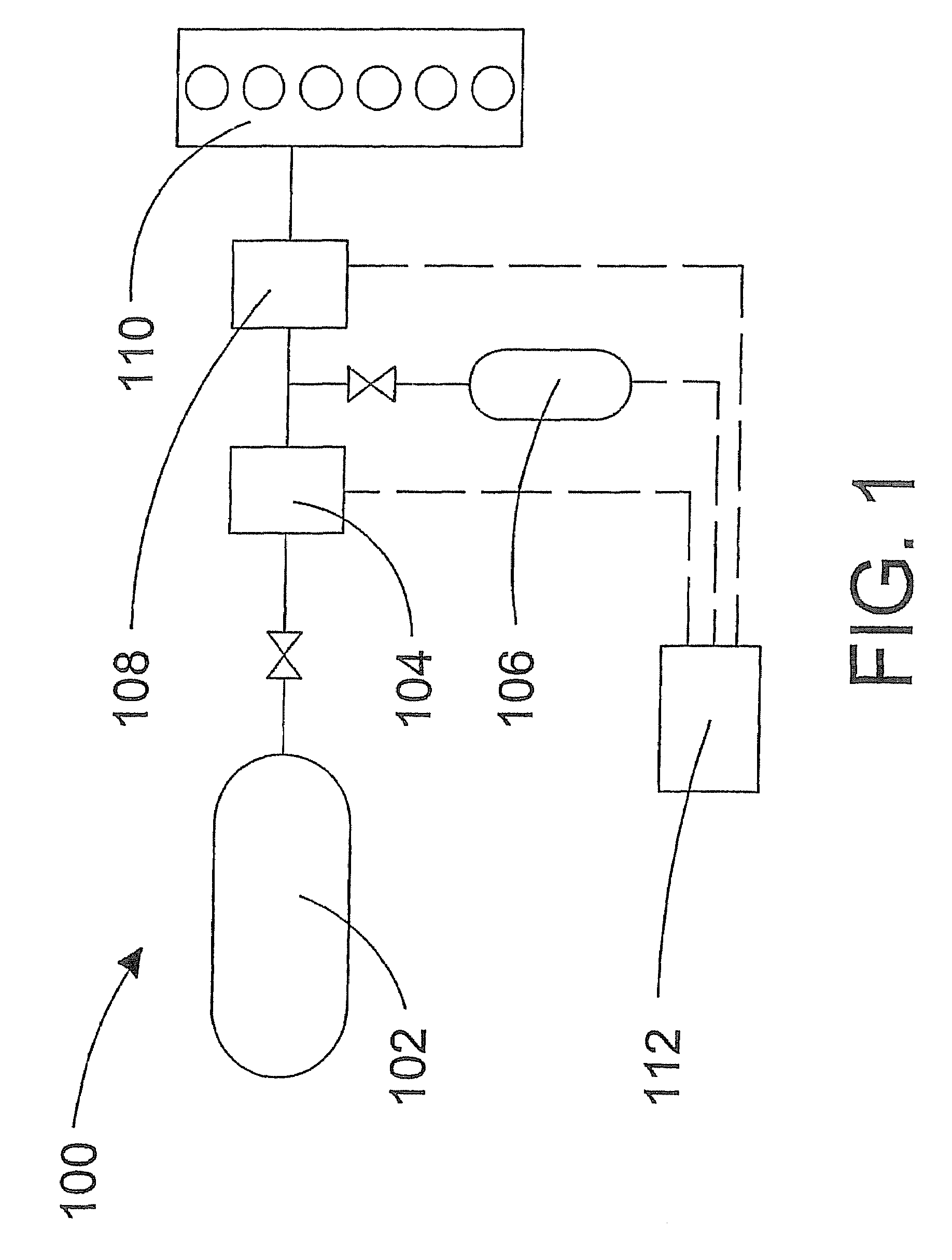

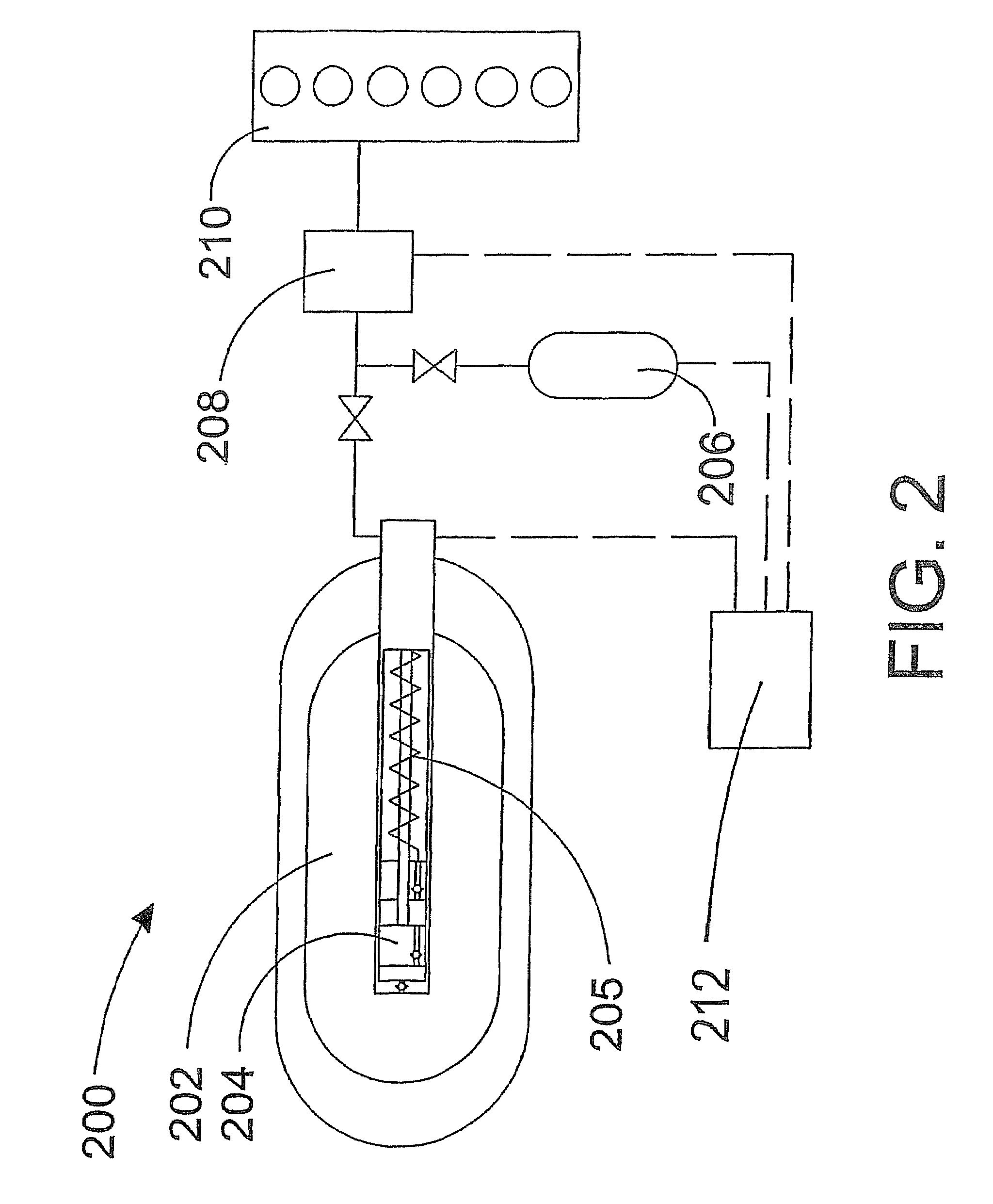

High pressure gaseous fuel supply system for an internal combustion engine and a method of sealing connections between components to prevent leakage of a high pressure gaseous fuel

InactiveUS7308889B2High strengthEasy to shapeInternal combustion piston enginesFuel supply apparatusPresent methodCombustion

A high-pressure fuel system supplies gaseous fuel to an internal combustion engine. Gaseous fuel pressure within the system is at least 17 MPa during normal operation. The system comprises a number of components and conduits and at least one resilient member for sealing at an interface between two components. The resilient member consists essentially of thermoplastic polyurethane. A corresponding method provides sealing between components containing gaseous fluids at pressures that can be above 17 MPa, in which the gaseous fluids routinely undergo rapid reductions in pressure. The method comprises disposing a resilient member, which consists essentially of thermoplastic polyurethane, at an interface between the components. Gas pressure fluctuations can occur during operation of the components or when the high-pressure gas is vented from the components upon shut down of the high-pressure system. A particularly suitable application for the present method is high-pressure gaseous fuel supply systems for internal combustion engines.

Owner:WESTPORT POWER

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Golf shoe outsole

The present invention is further directed towards a golf shoe having an outsole comprising of forward and rear base sections that are connected and molded together with an arch support shank. The base sections are relatively soft and made from thermoplastic polyurethane having a maximum Shore A hardness of between 75 to 85. The shank is also made of thermoplastic polyurethane having a minimum hardness of at least 95 Shore A hardness. Each base section has a plurality of openings, wherein a corresponding plurality of relatively hard pods are molded, each pod of a size and configuration to fit within a corresponding opening and extend at least 6.3 mm from the bottom surfaces of the base sections. The shoe provides flexibility both across the metatarsal area and longitudinally at approximately the metatarsal area thereby providing the golfer with improved traction and balance, especially when the golfer executes a golf shot.

Owner:ACUSHNET CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com