Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2662results about How to "Fast forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

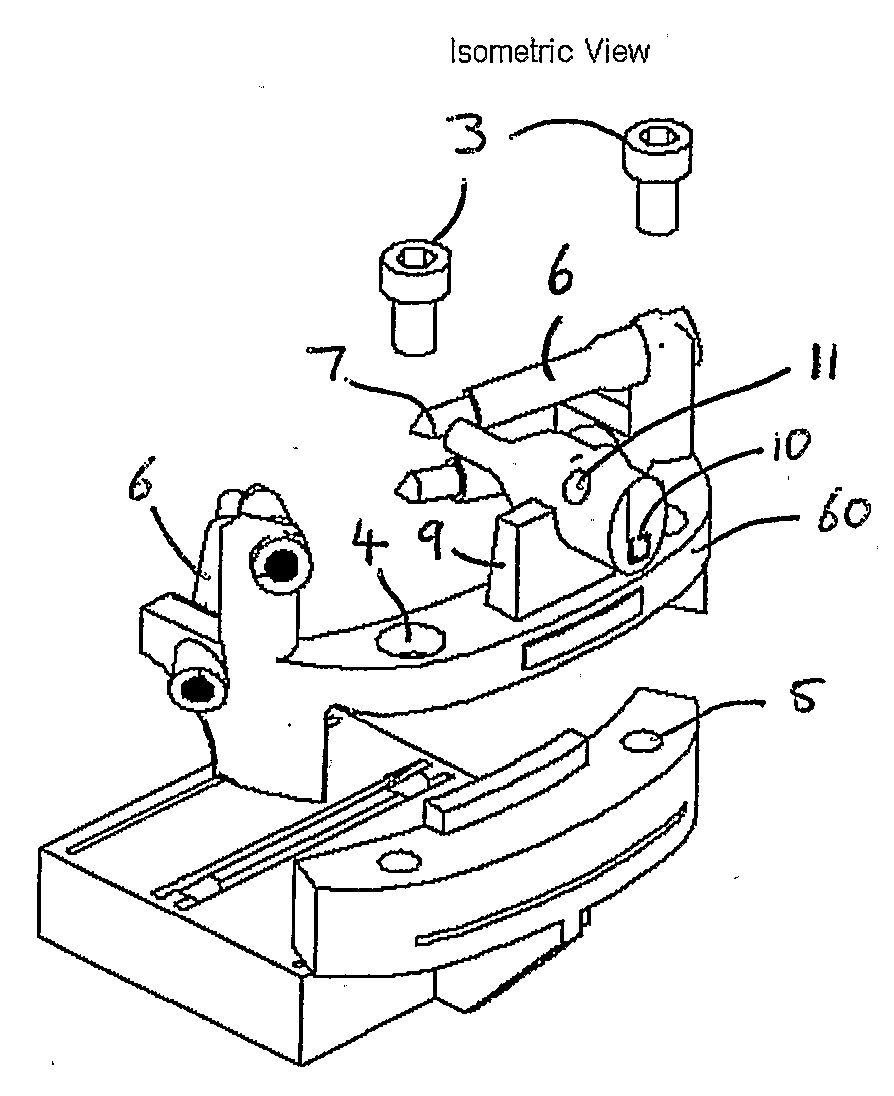

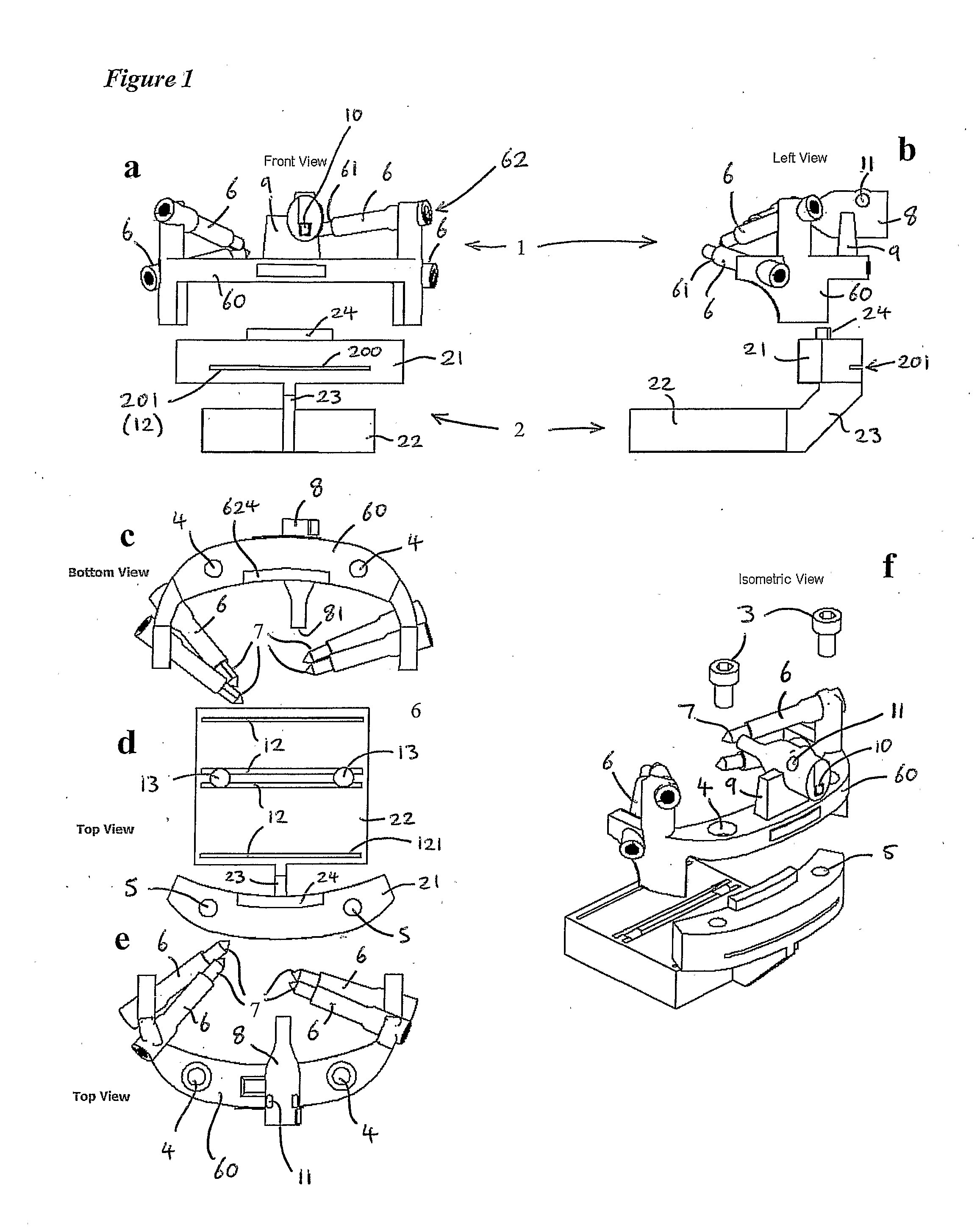

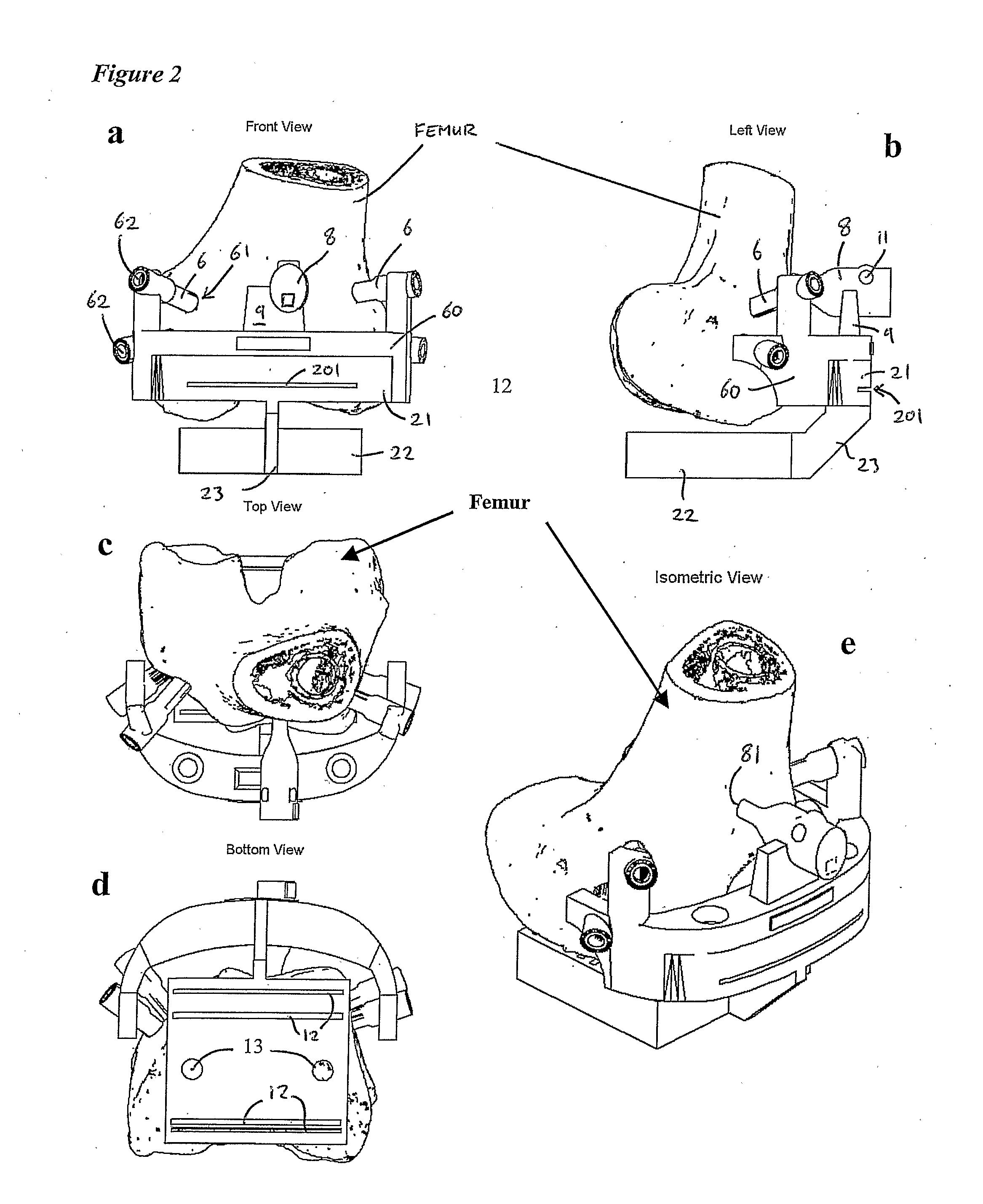

Surgical templates

ActiveUS20100191244A1Quick checkShort timeAdditive manufacturing apparatusDiagnosticsProsthesisSurgical template

A surgical template system for use in working on a bone comprises: a tool guide block comprising at least one guide aperture for receiving and guiding a tool to work on a bone; locating means comprising a plurality of locating members, each member having a respective end surface for positioning against a surface of the bone; and attachment means for non-adjustably attaching the tool guide block to the locating means such that, when attached, the member end surfaces are secured in fixed position with, respect to each other, for engaging different respective portions of the surface of the bone, and the at least one guide aperture is secured in a fixed position with respect to the end surfaces. Corresponding methods of manufacturing a surgical template system, methods of manufacturing locating means for a surgical template system, methods of fitting a prosthesis to a bone, surgical methods, and surgical apparatus are described.

Owner:XIROS

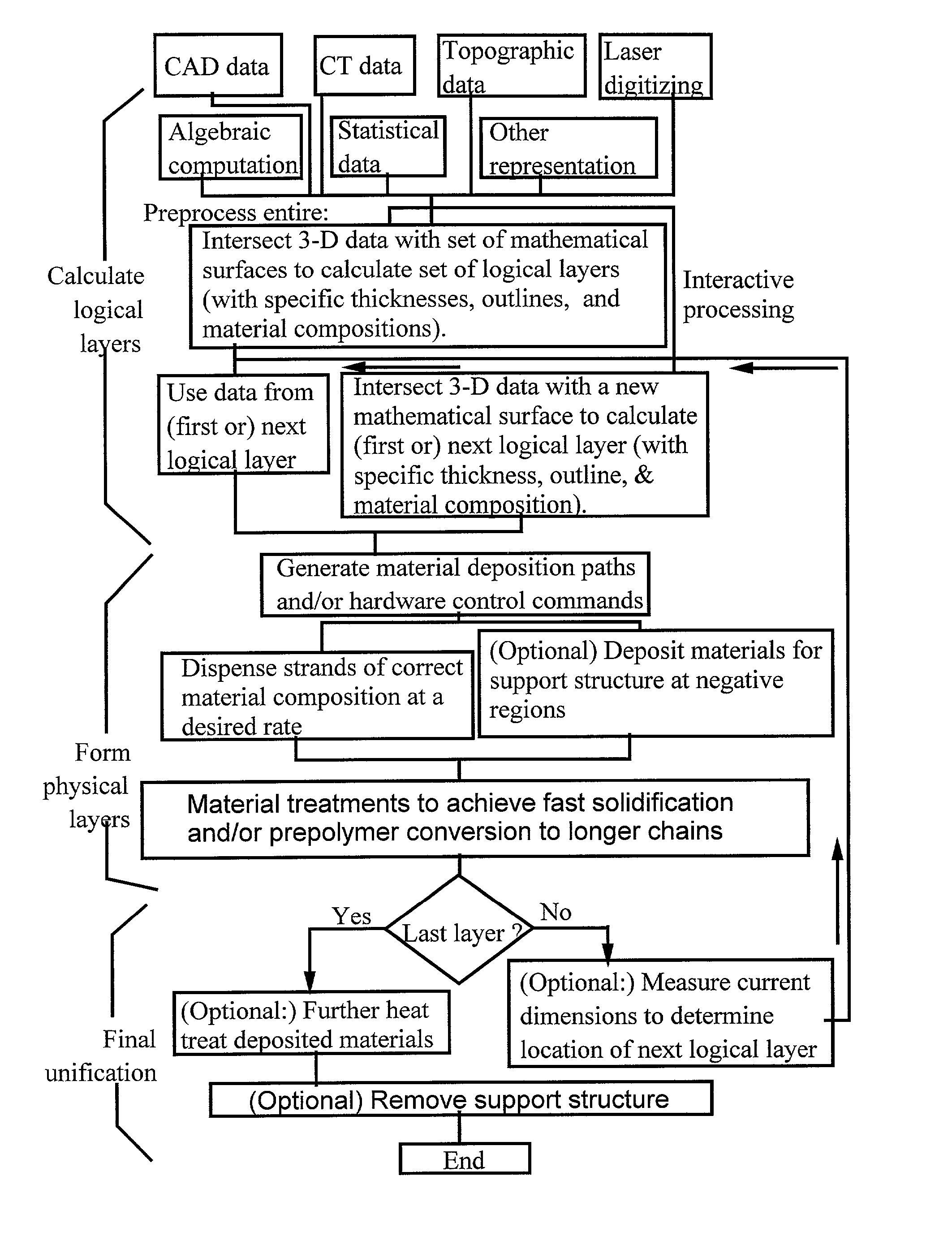

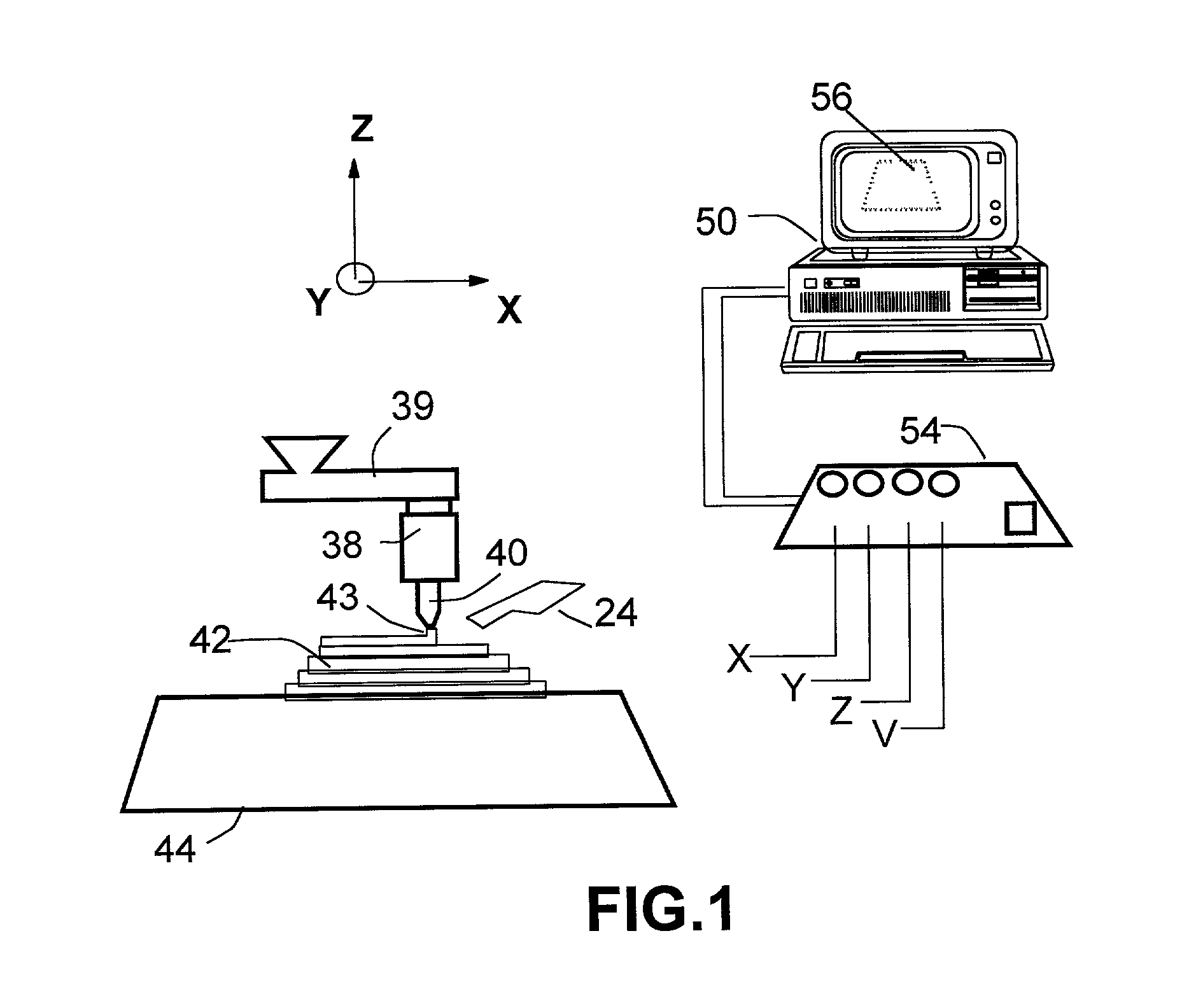

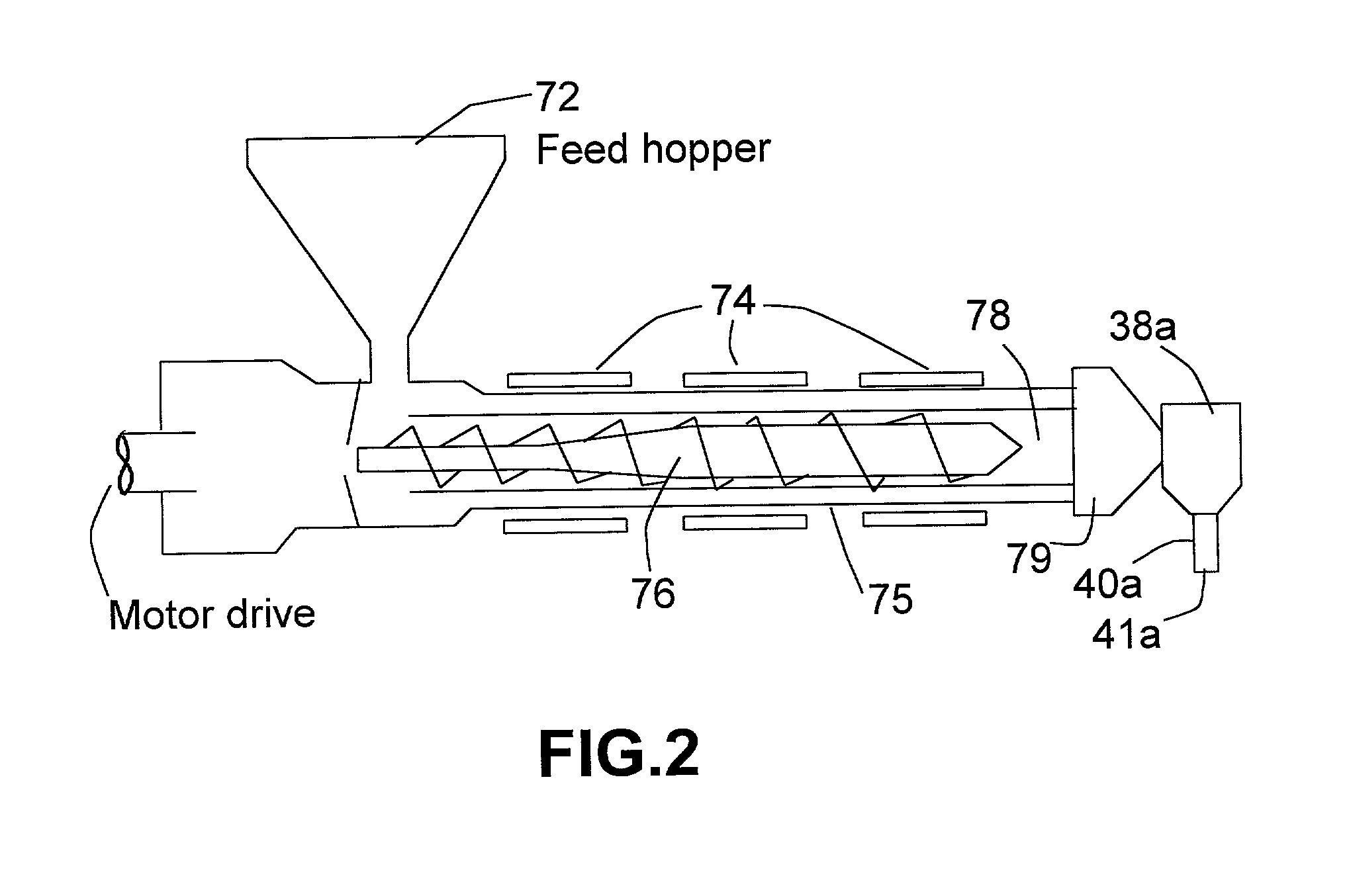

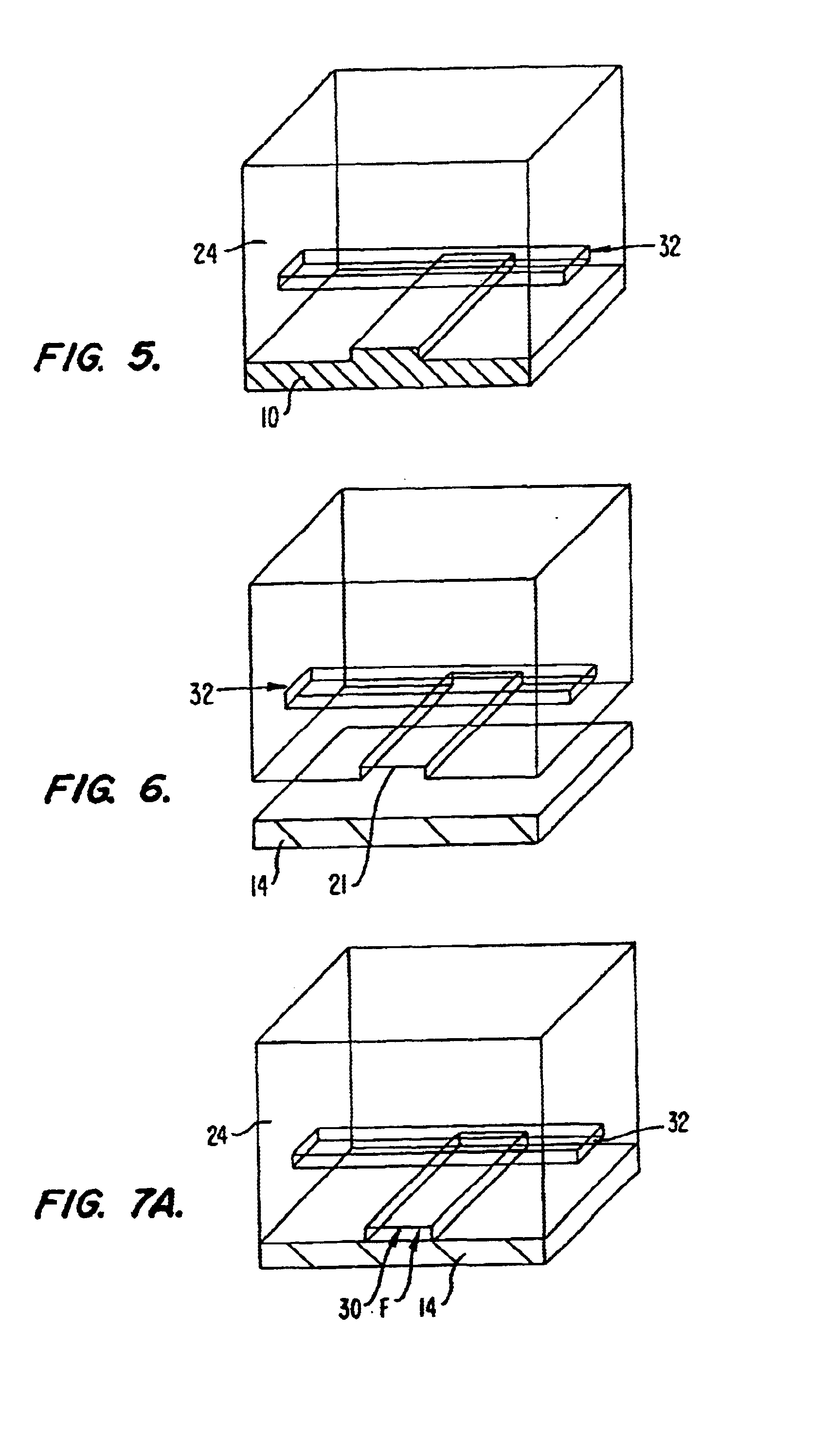

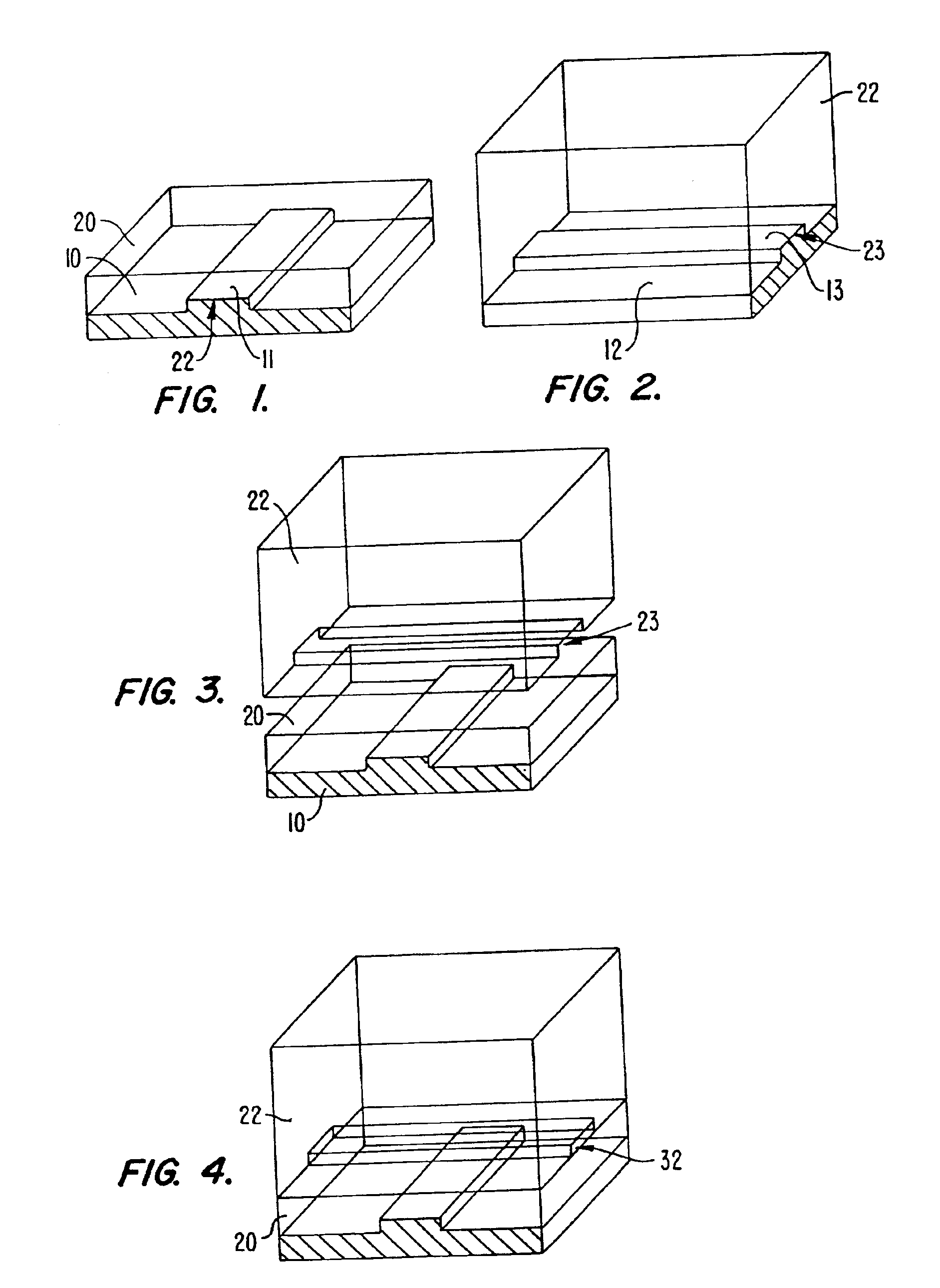

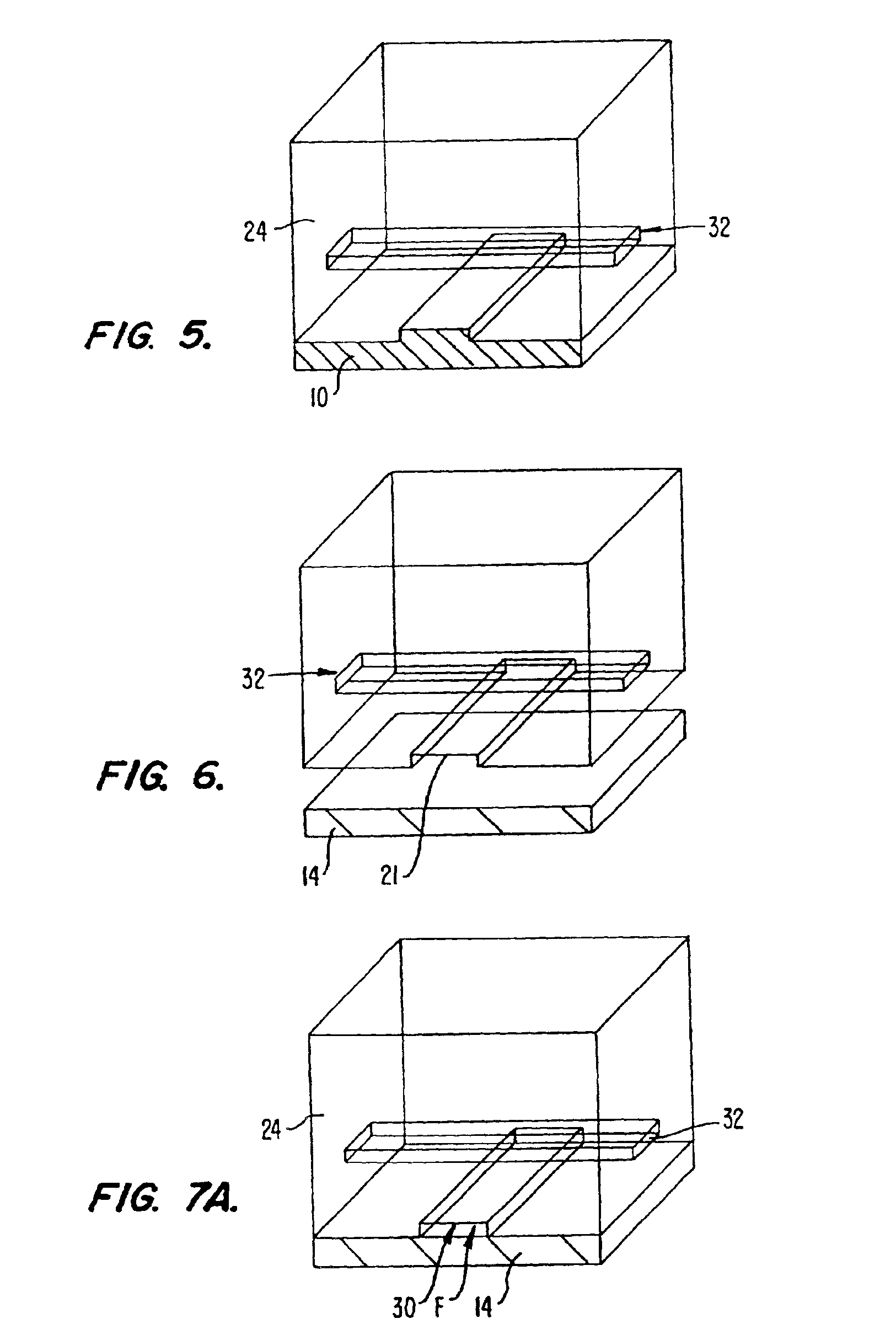

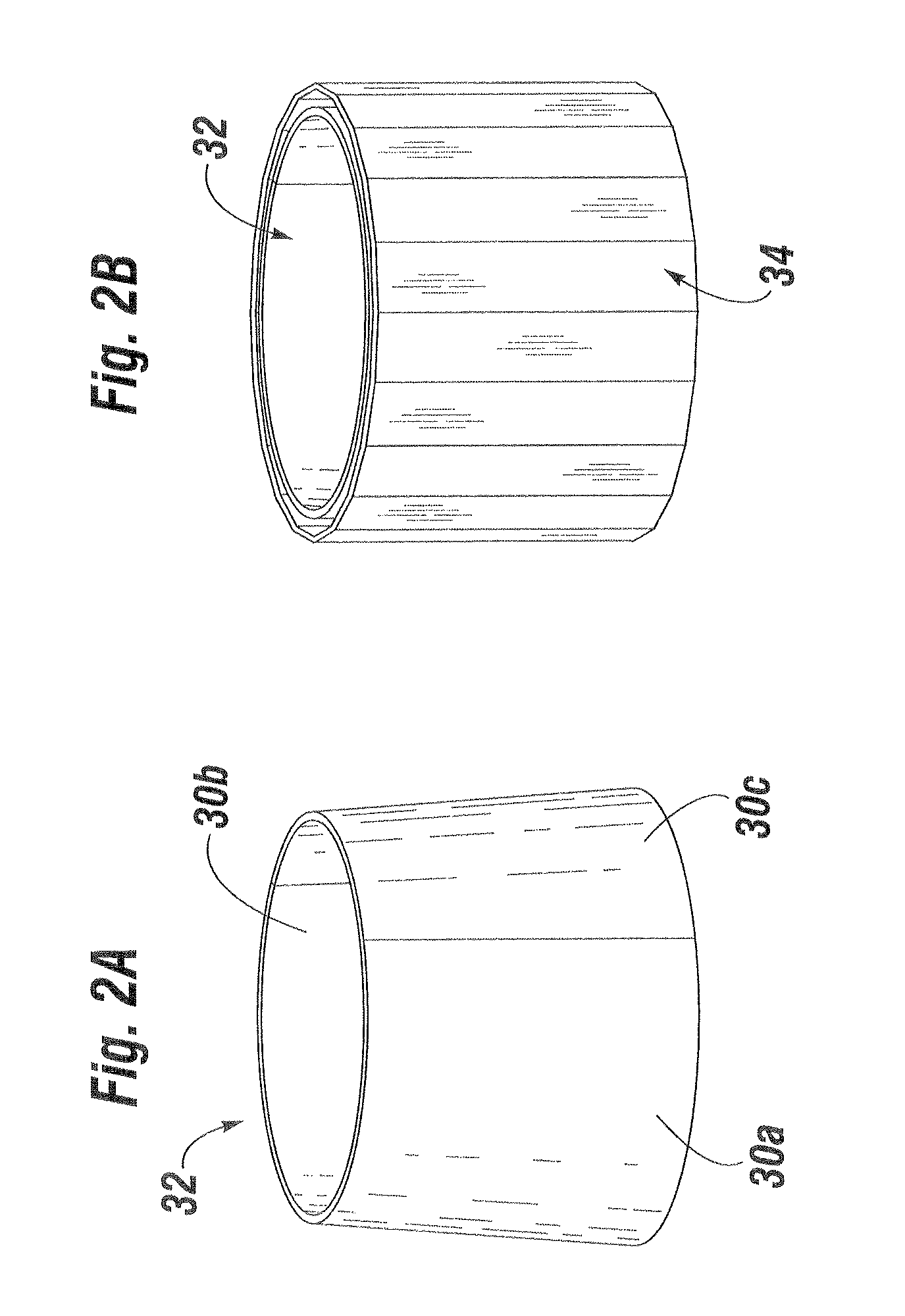

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

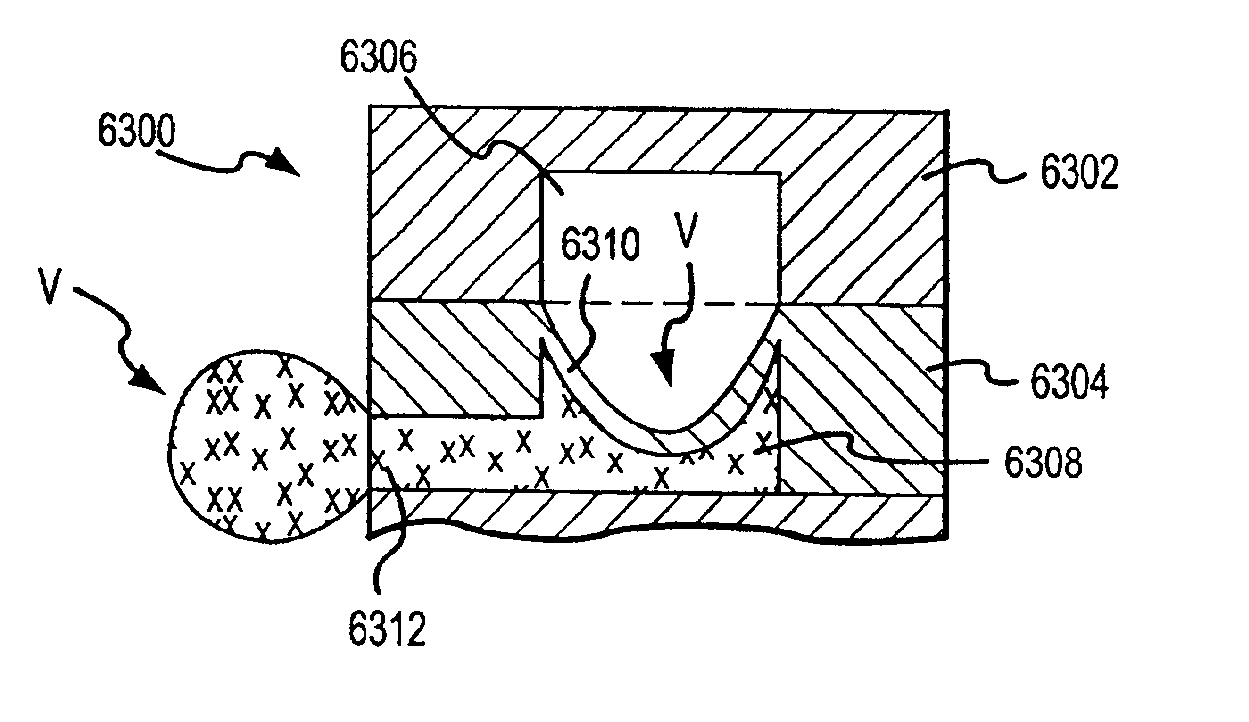

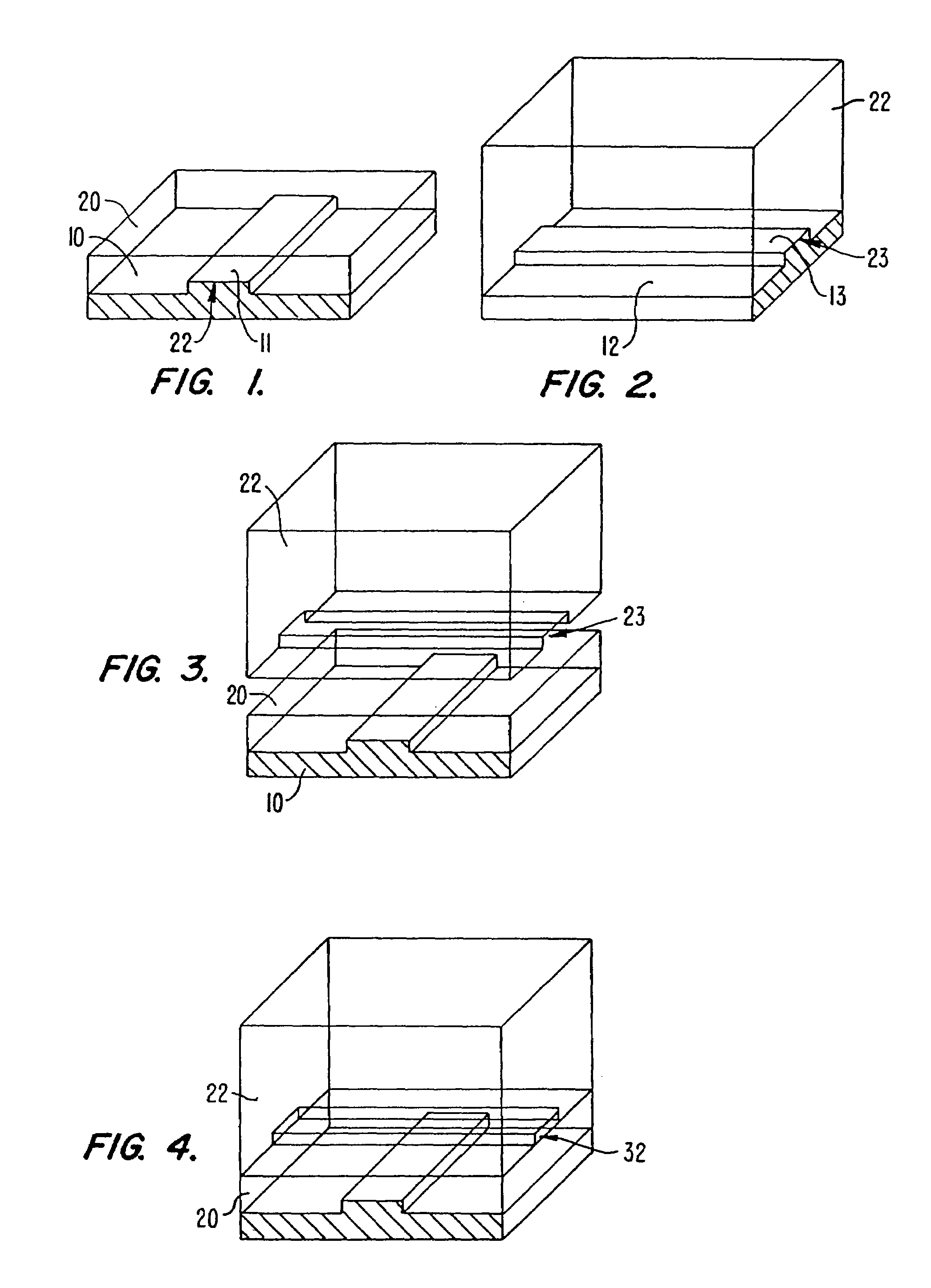

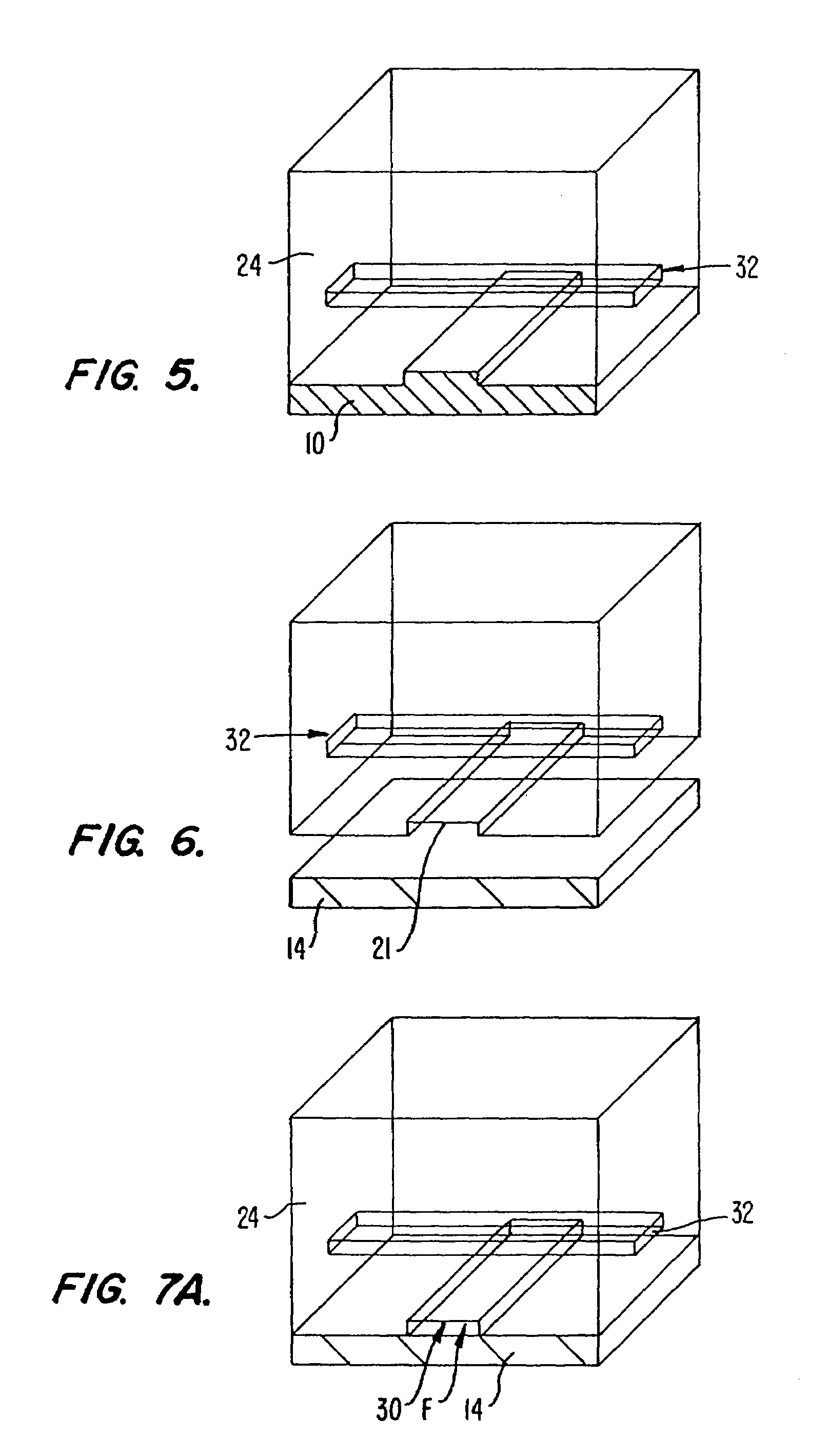

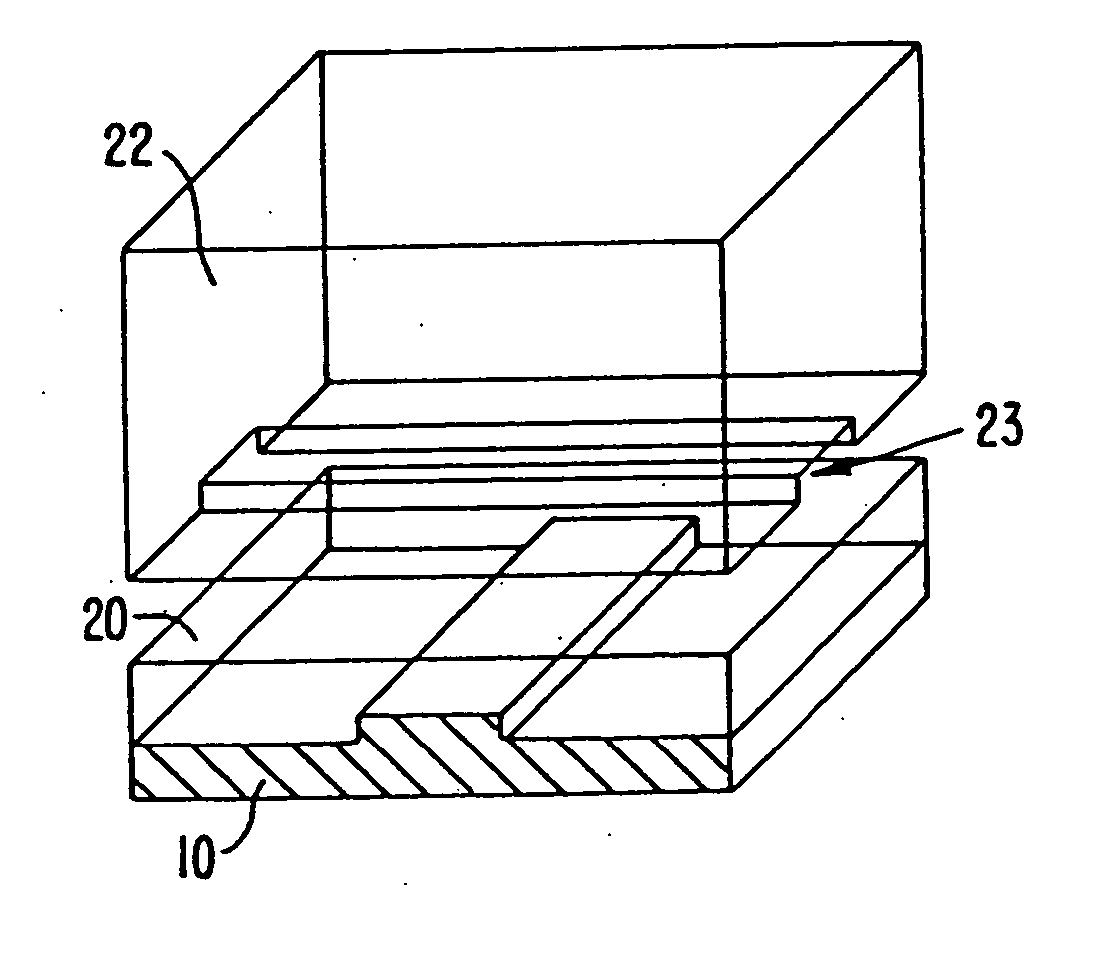

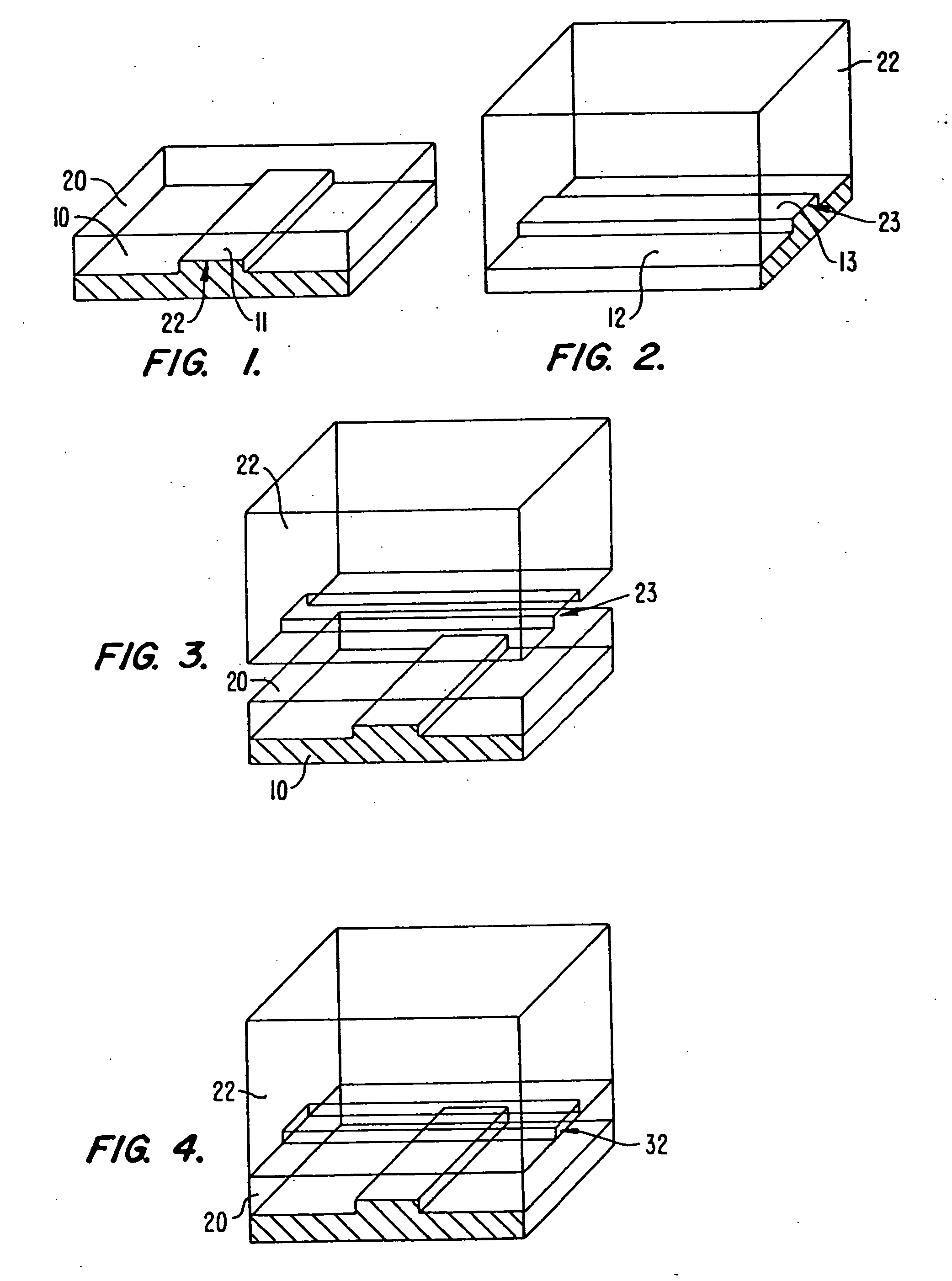

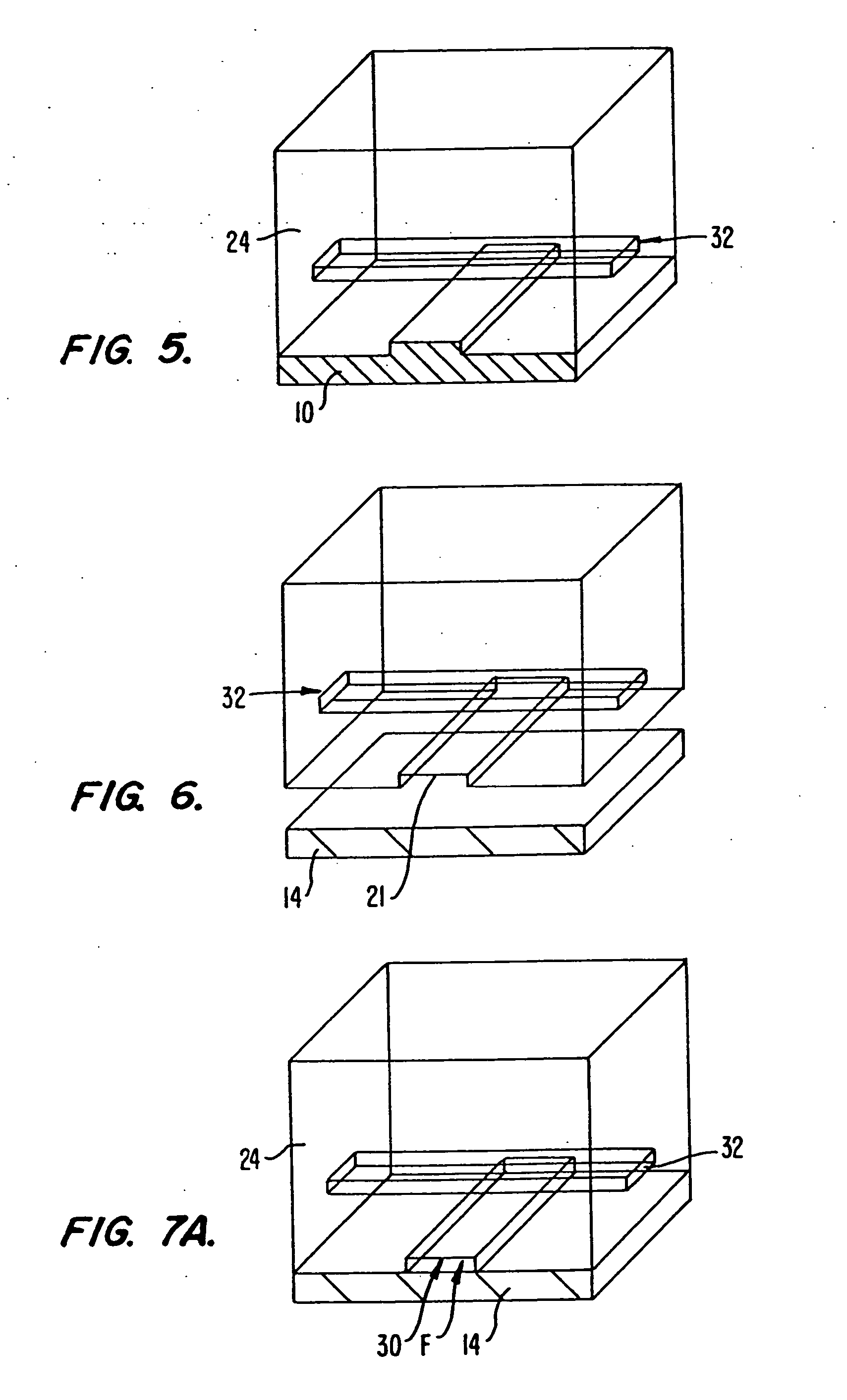

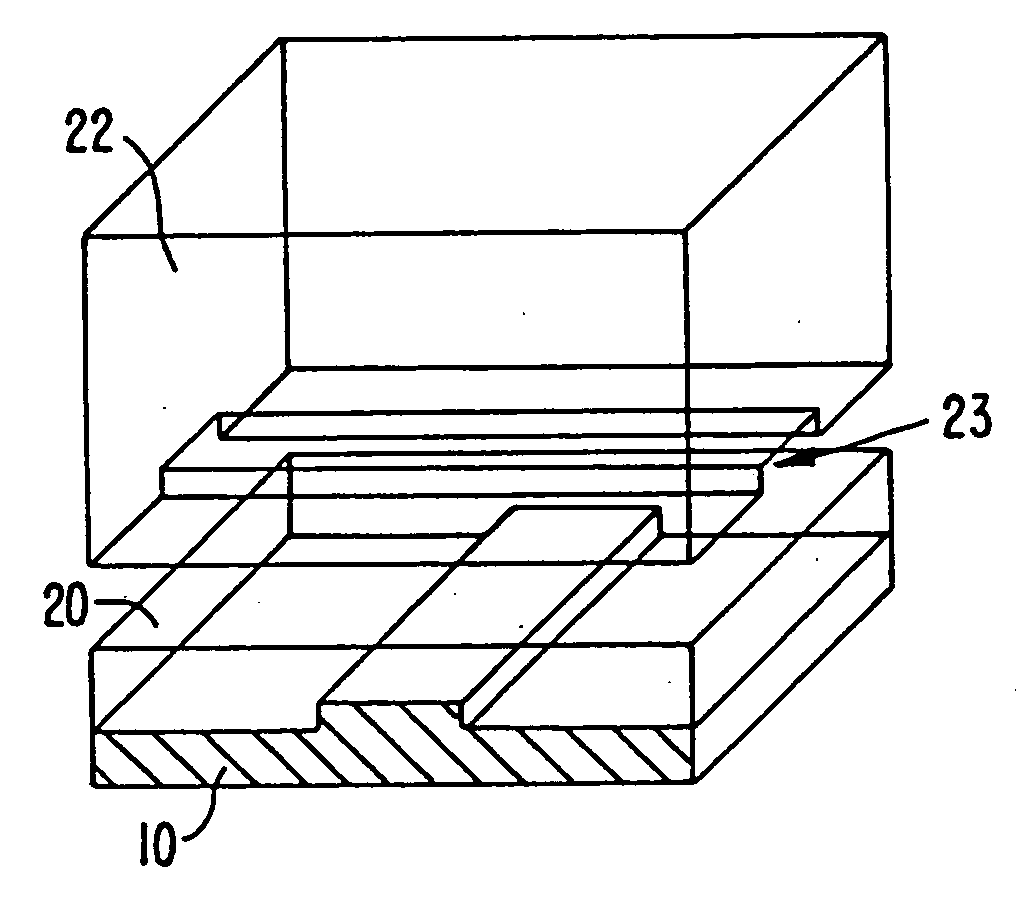

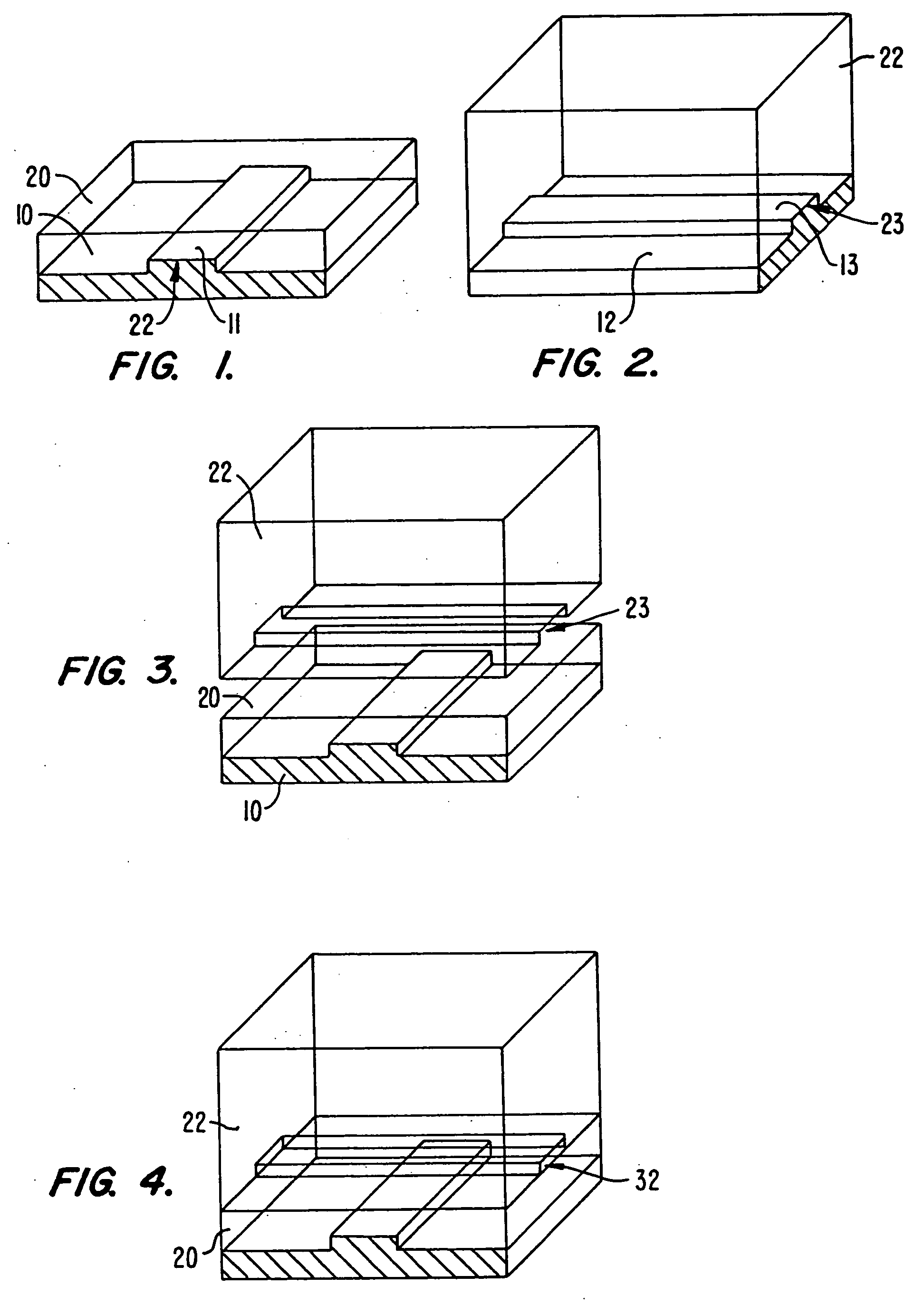

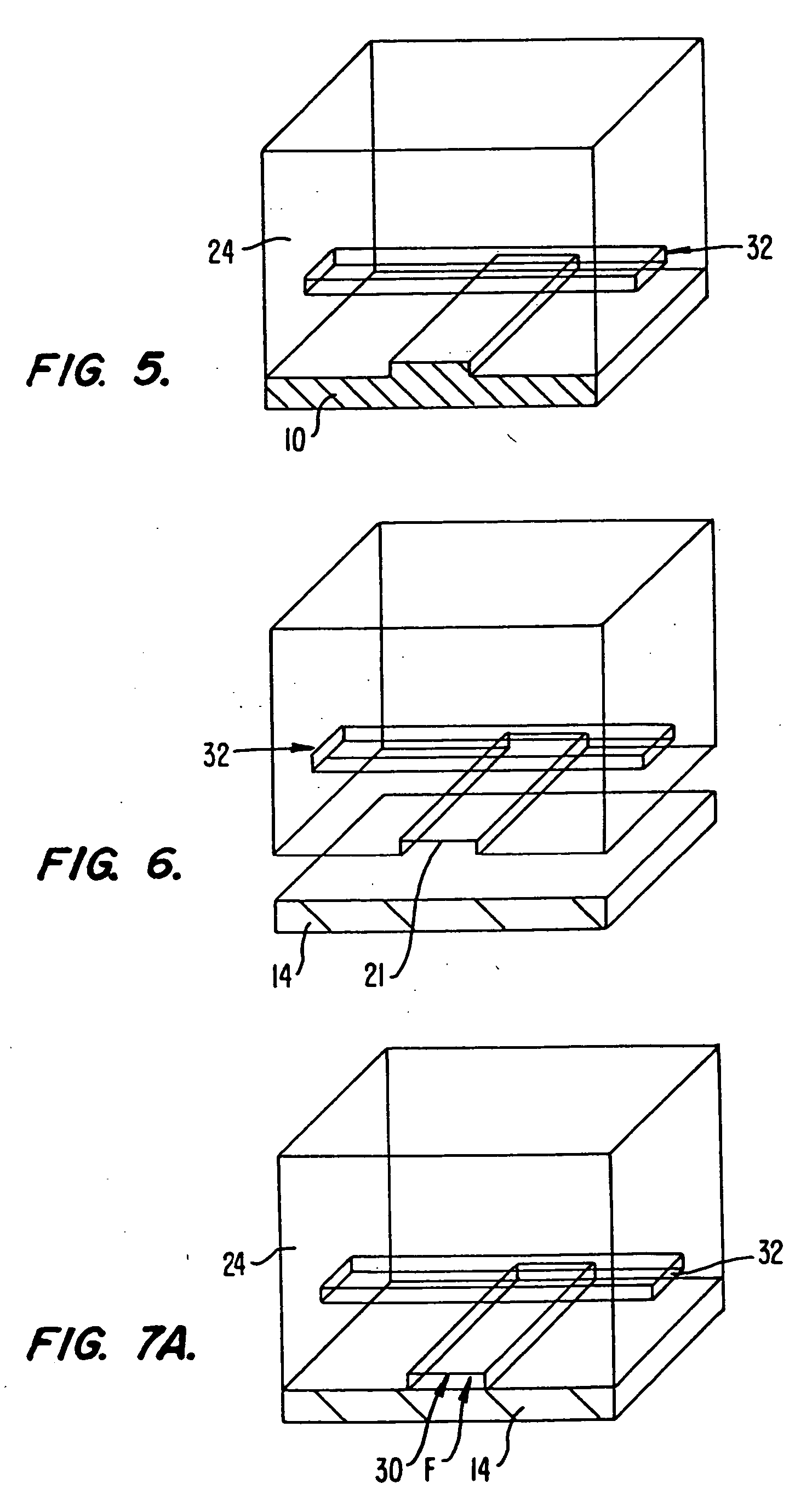

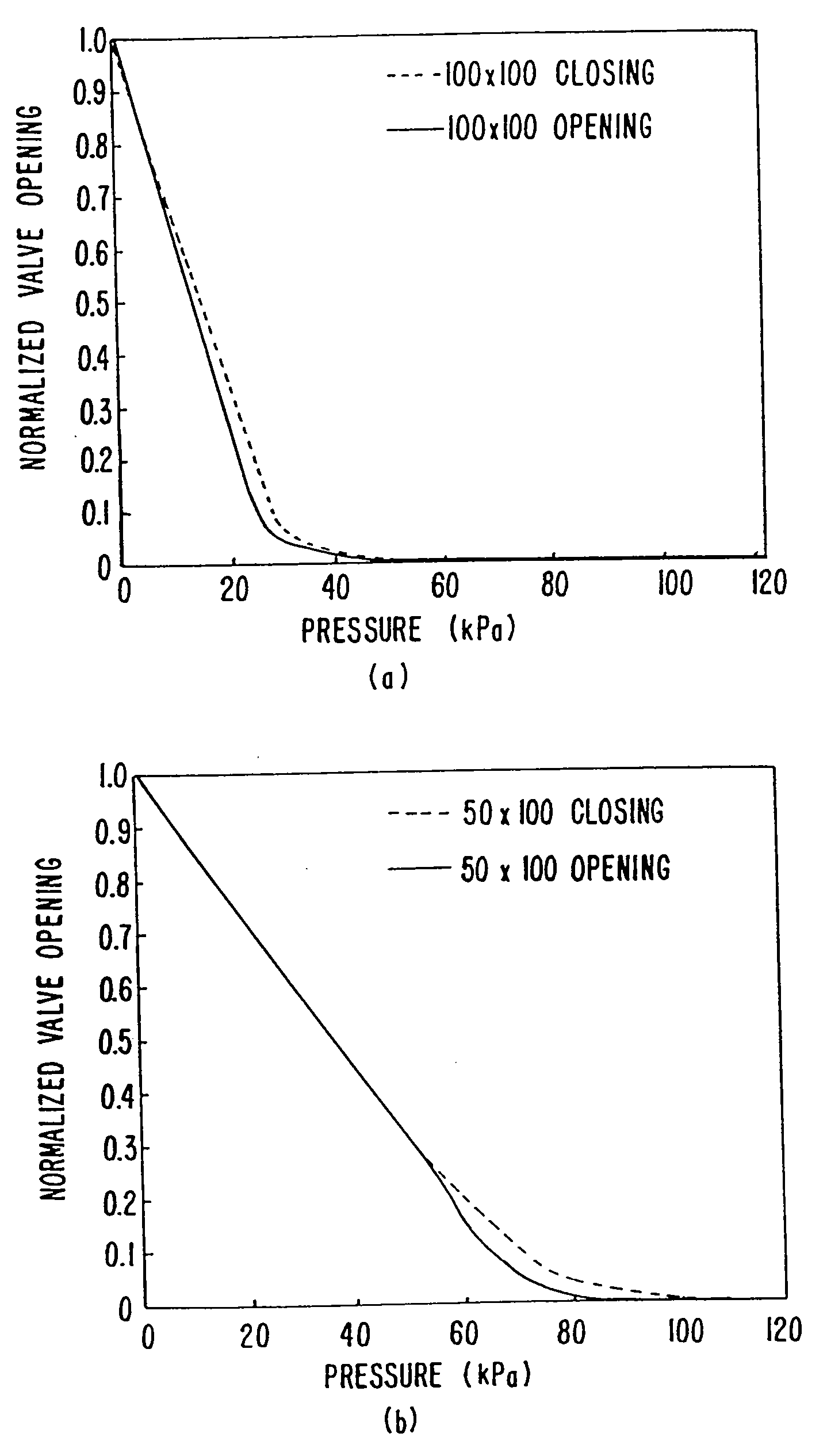

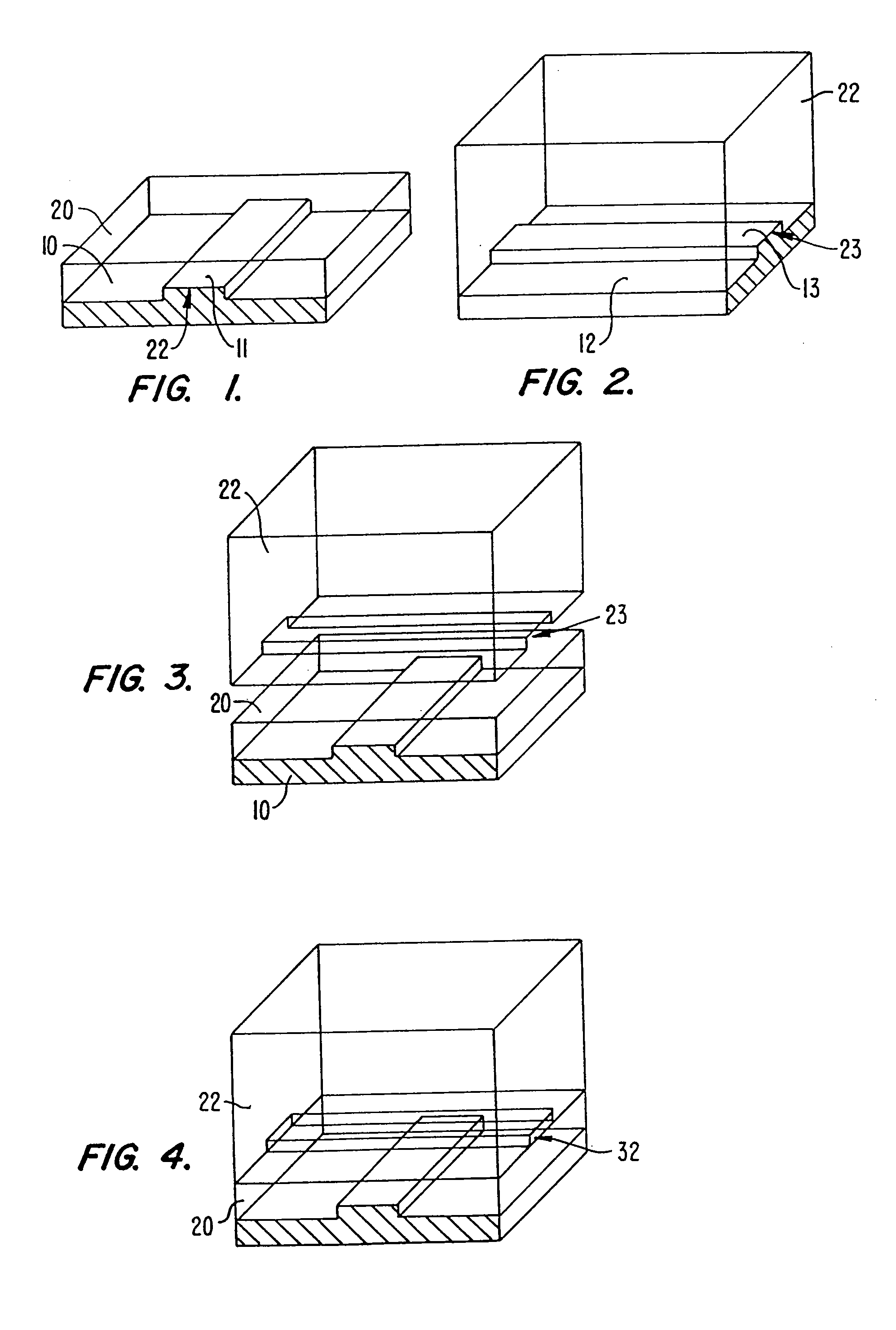

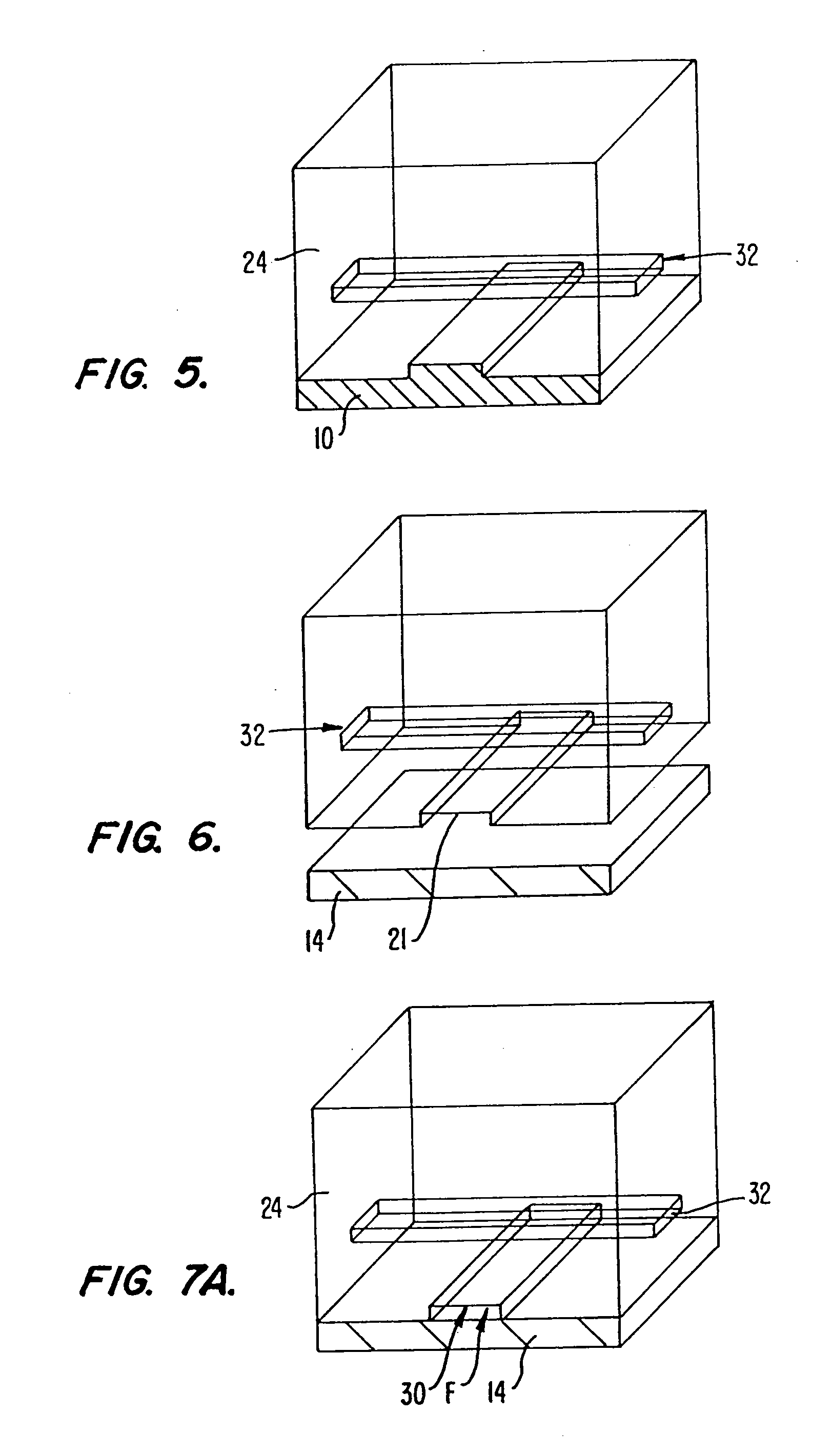

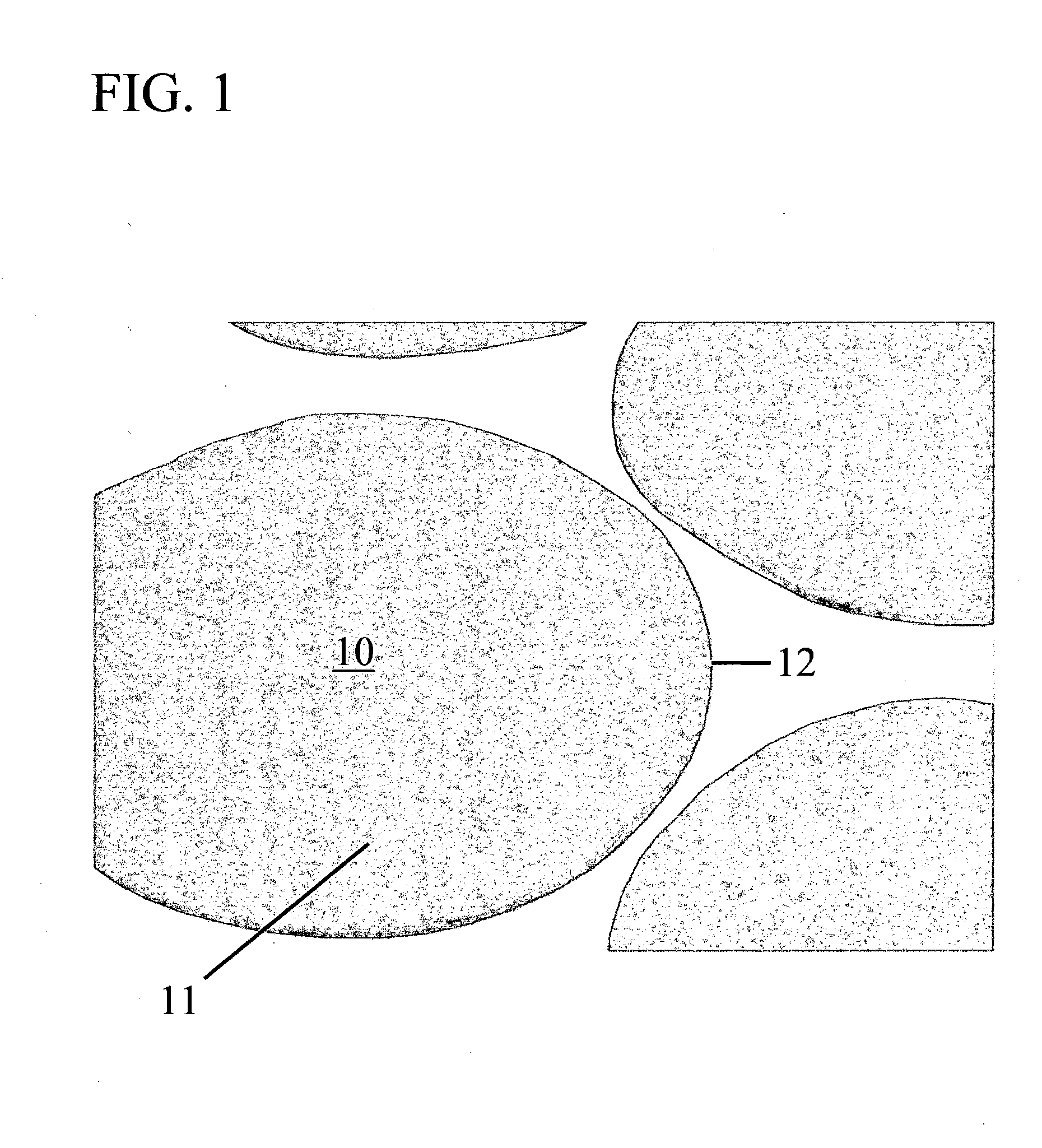

Microfabricated elastomeric valve and pump systems

InactiveUS6929030B2High speedSmall sizeFixed microstructural devicesVolume/mass flow measurementEngineeringPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

Microfabricated elastomeric valve and pump systems

InactiveUS6899137B2Increase speedSmall sizeFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

Microfabricated elastomeric valve and pump systems

InactiveUS7144616B1High speedSmall sizeEngine diaphragmsFixed microstructural devicesPlanar substrateMechanical engineering

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

Tricalcium phosphates, their composites, implants incorporating them, and method for their production

InactiveUS20050031704A1Easily controlEnhance packing and densificationBiocideHeavy metal active ingredientsChemistryProsthetic implants

Methods for the synthesis of tricalcium phosphates are presented, as well as a series of specific reaction parameters that can be adjusted to tailor, in specific ways, properties in the tricalcium phosphate precursor precipitate. Particulate tricalcium phosphate compositions having an average crystal size of about 250 nm or less are provided. Compositions of the invention can be used as prosthetic implants and coatings for prosthetic implants.

Owner:PIONEER SURGICAL TECH INC

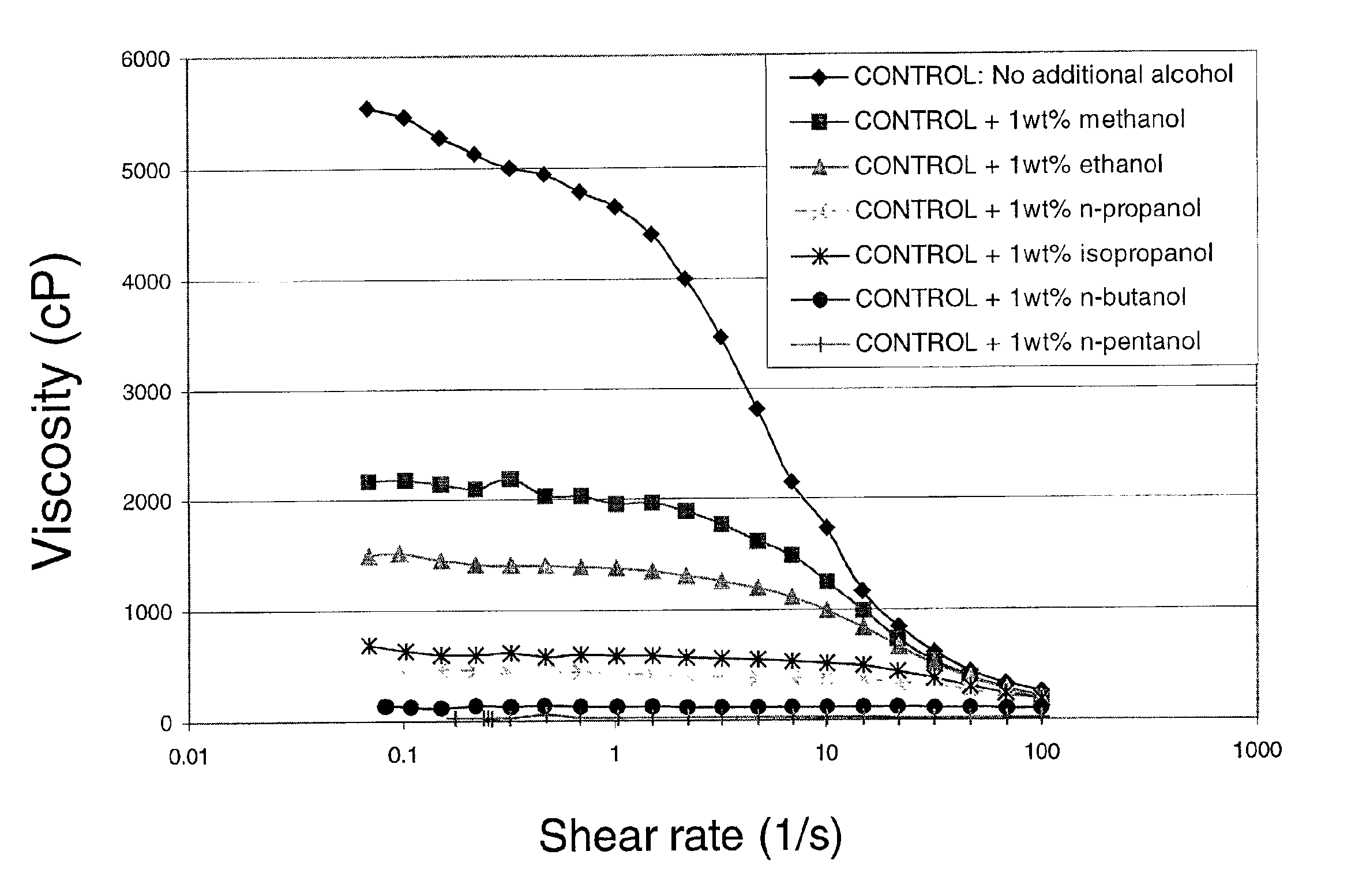

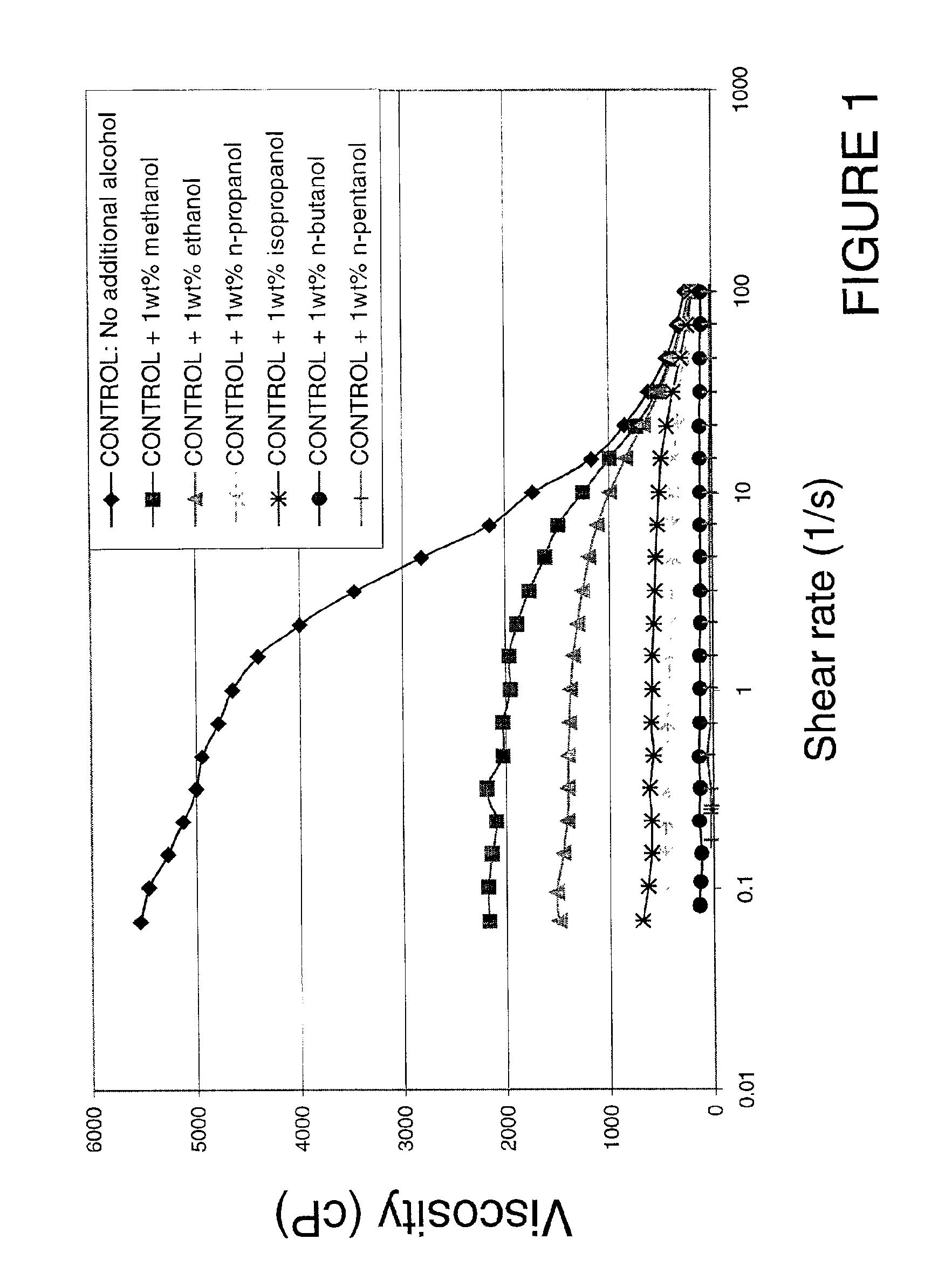

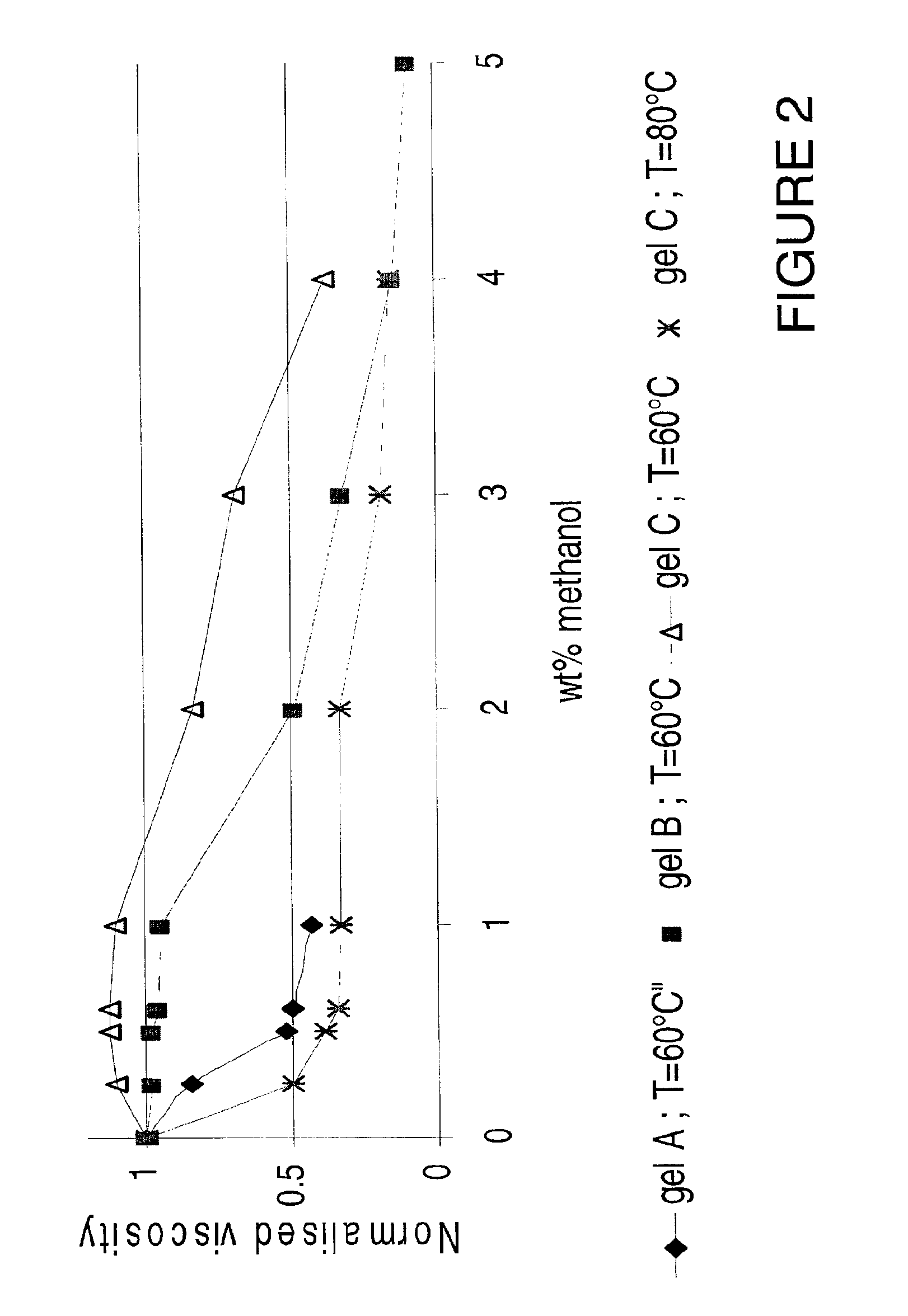

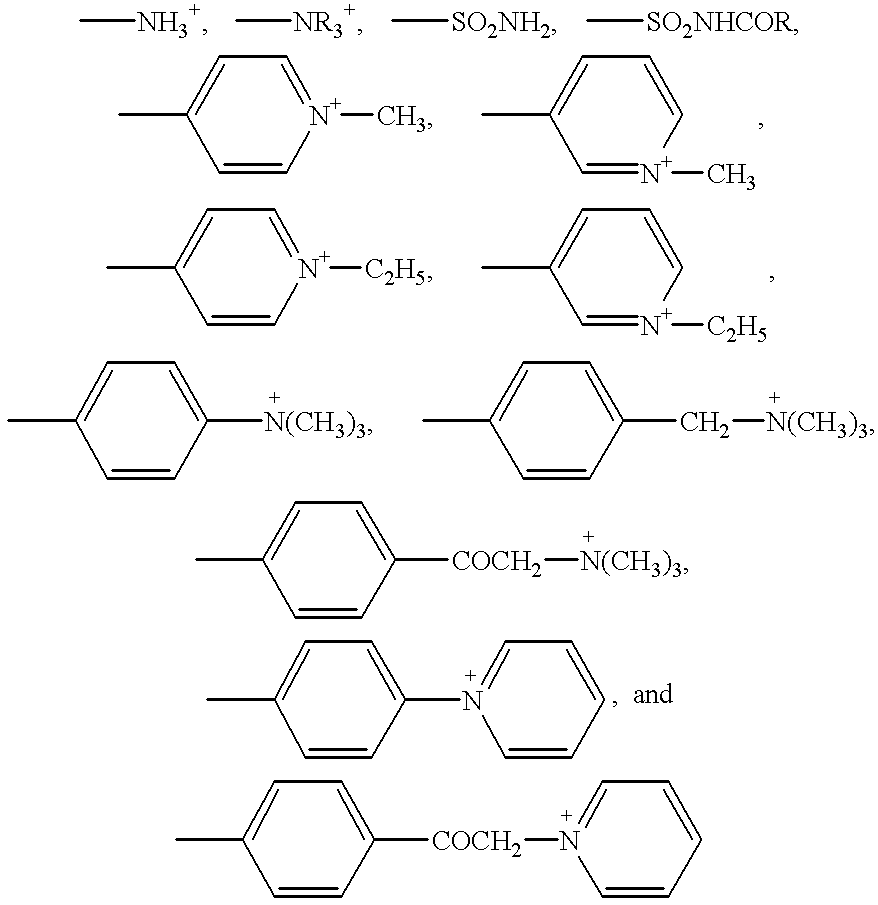

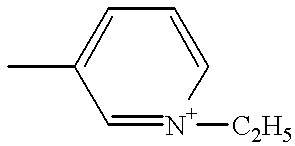

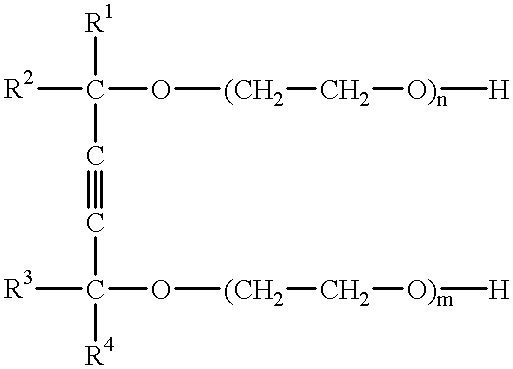

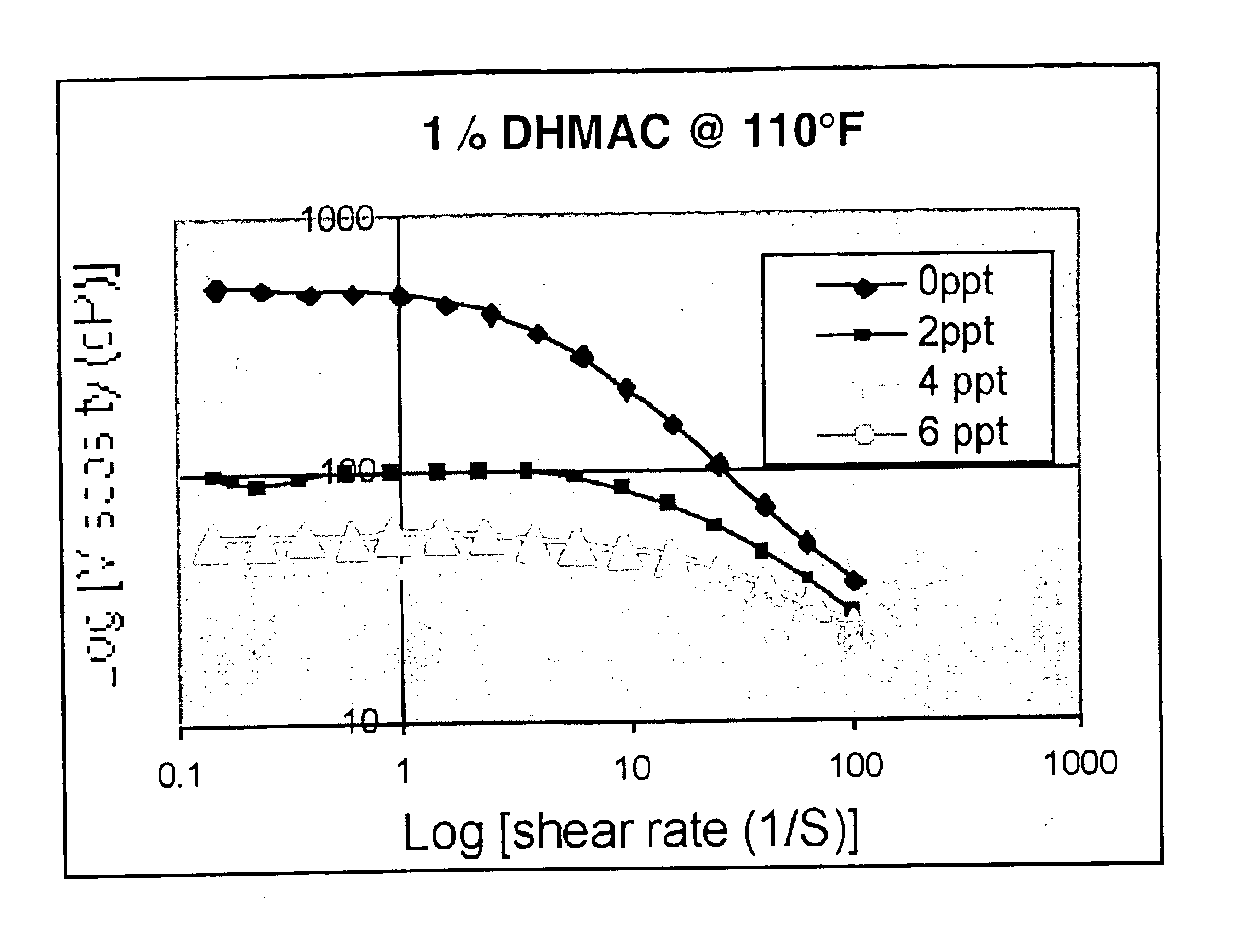

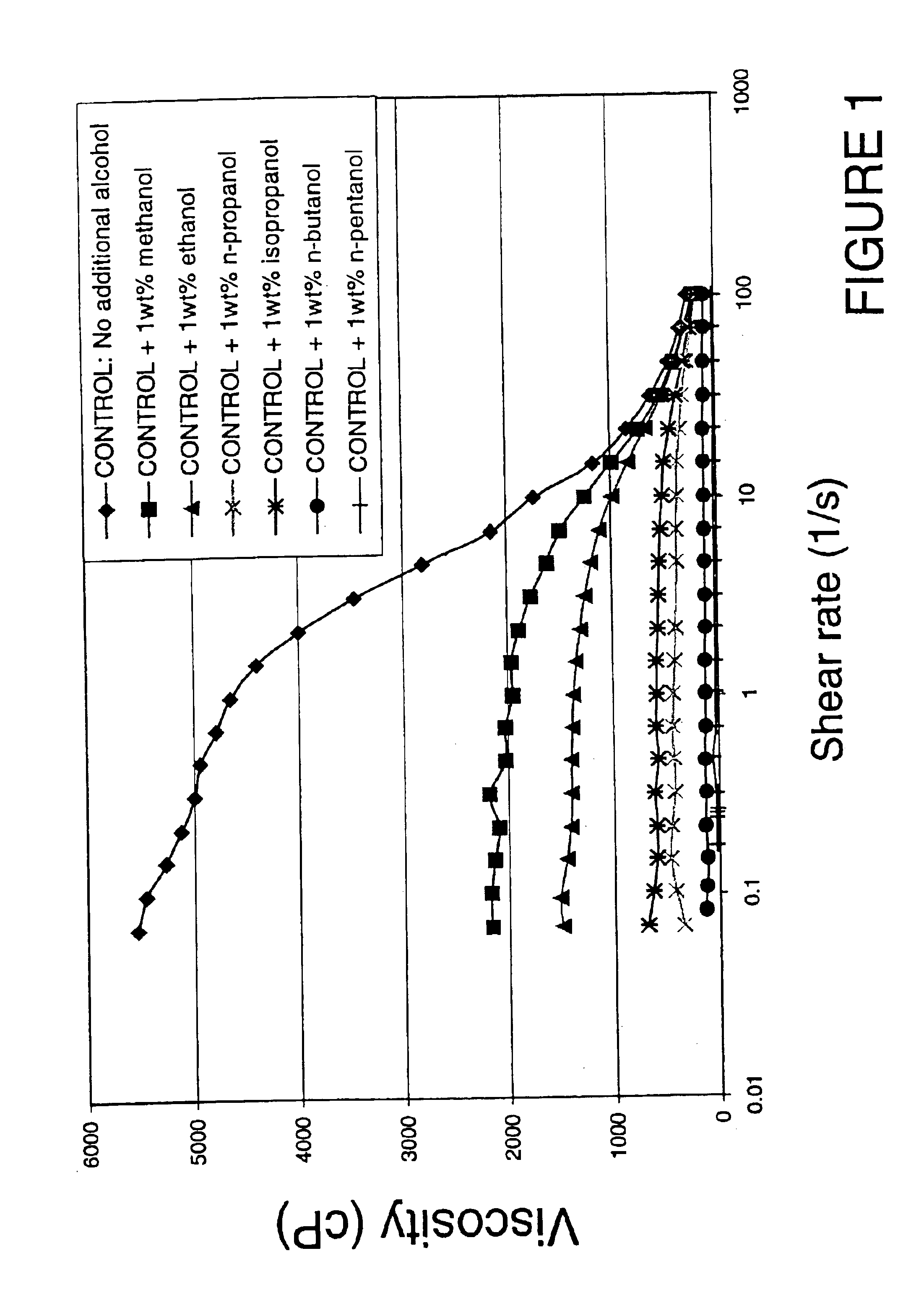

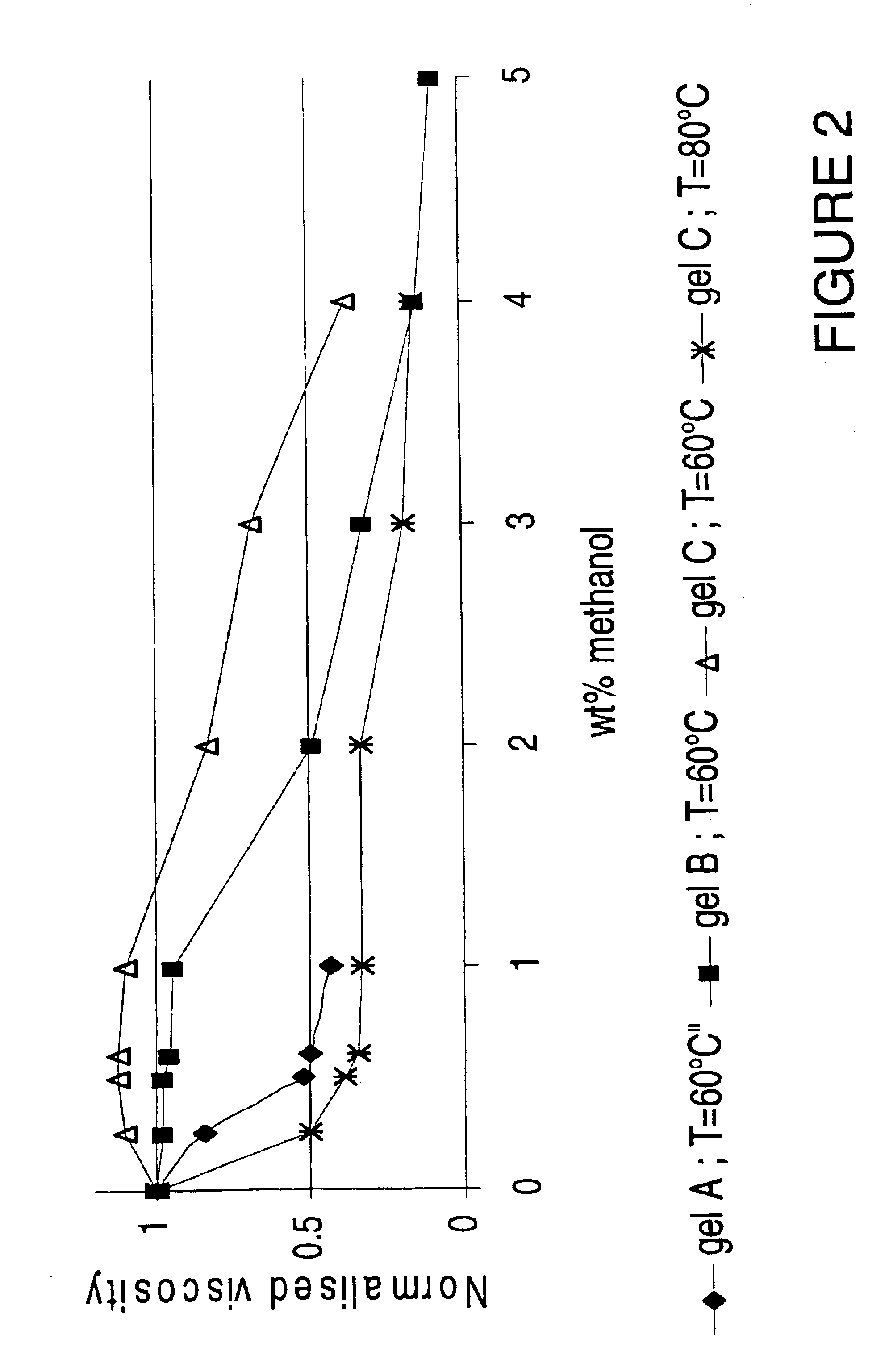

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6881709B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

Microfabricated elastomeric valve and pump systems

InactiveUS20050226742A1Fast formingEasy to manufactureFunctional valve typesEngine diaphragmsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

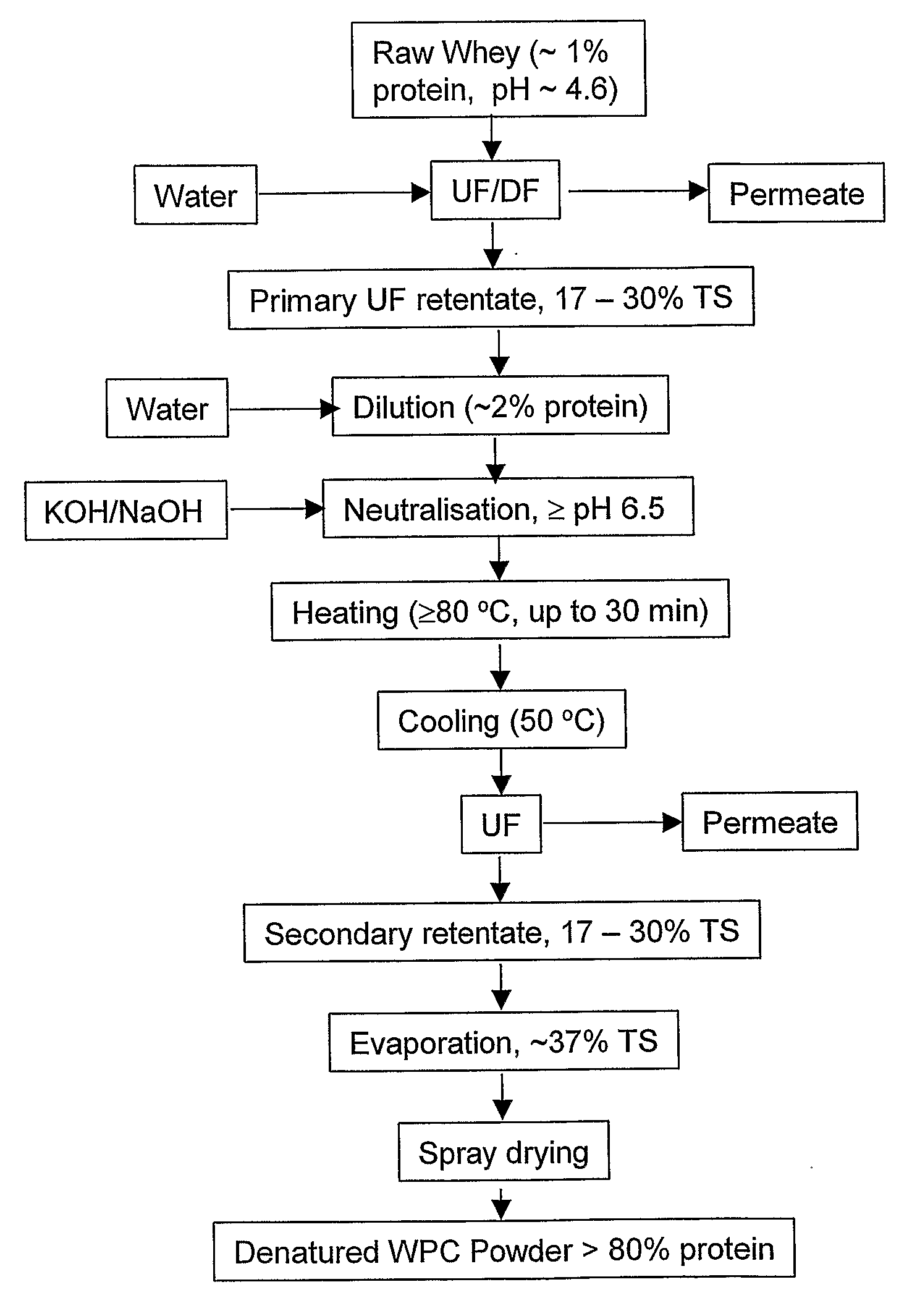

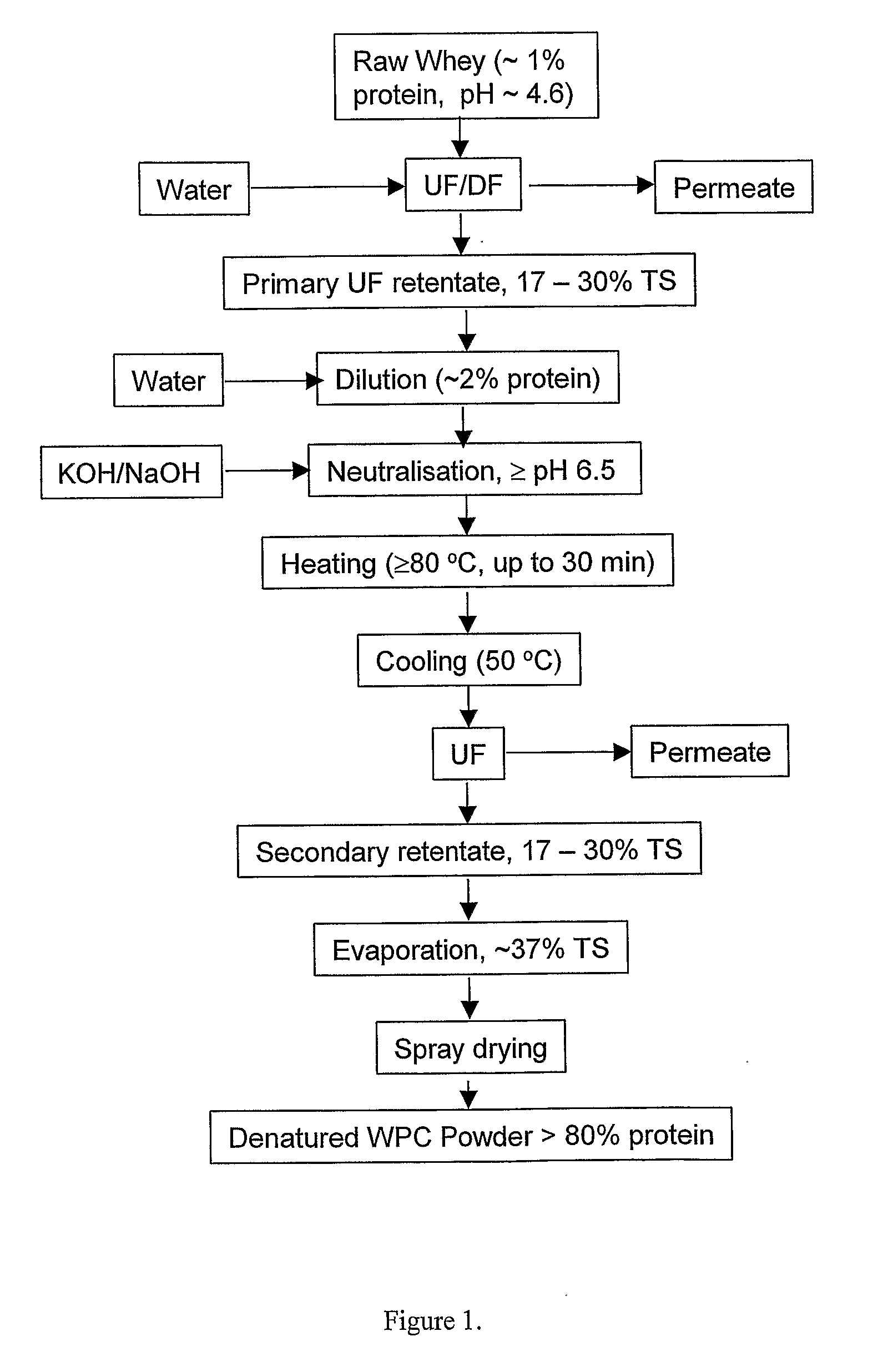

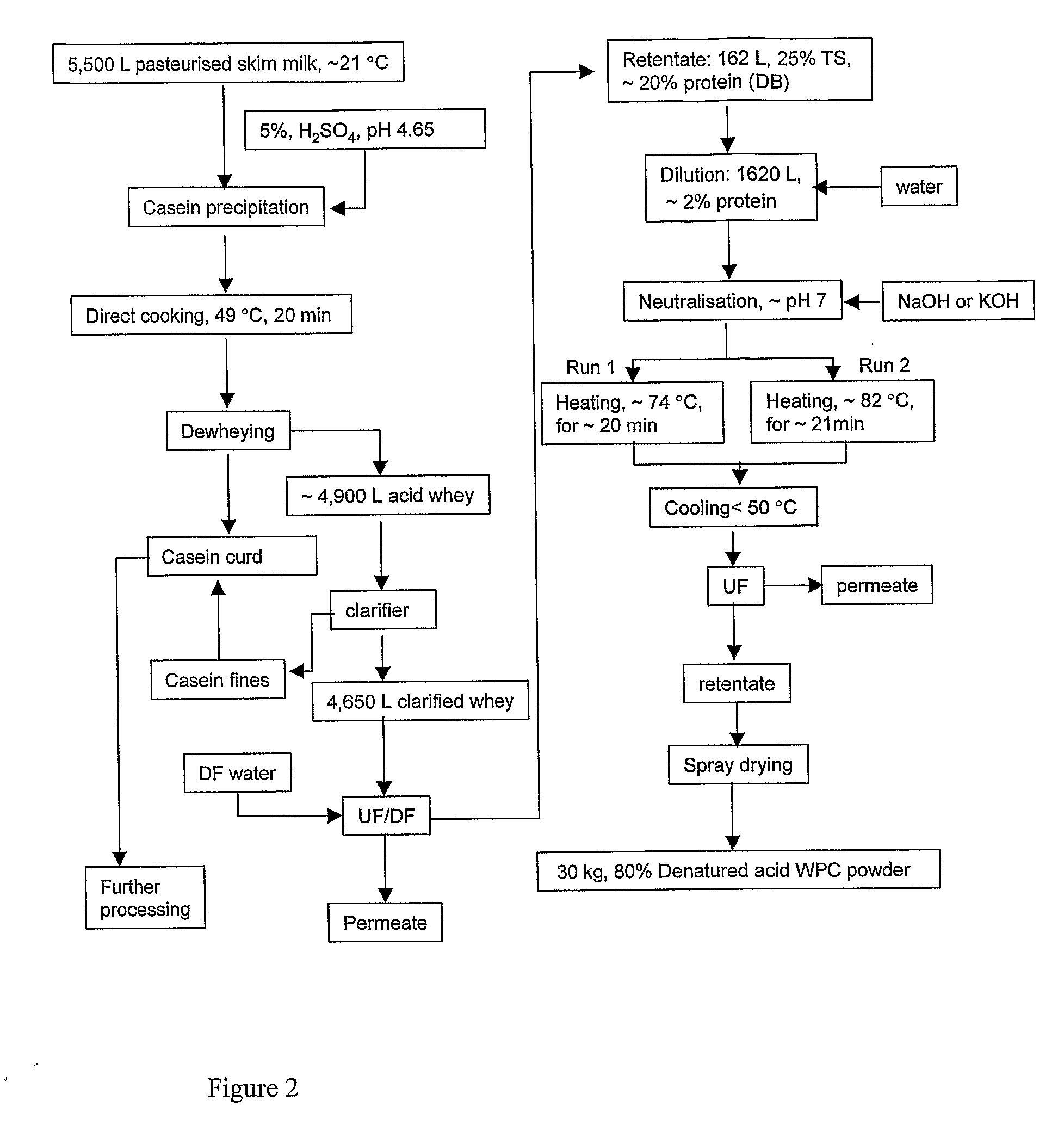

Whey Product and Process

InactiveUS20080305235A1High viscosityHigh in proteinMilk preparationFood ingredient as viscosity modification agentWhey proteinSurface heat

The invention provides a process for preparing a dried modified whey protein concentrate. A whey protein solution is used having less than 5% total solids and a combined calcium and magnesium concentration of less than 70 mmol / kg on a dry basis and a pH of 6.0-7.5. It is heated to greater than 70° C. for up to 60 minutes to denature the whey protein. The solution is then cooled to 40° C.-60° C.; and subsequently spray dried. Alternatively a higher initial concentration of total solids may be used in an embodiment where the heating is carried out on a scraped surface heat exchanger.

Owner:FONTERRA COOP GRP LTD

Ink, ink-jet recording process, recording unit, ink cartridge and ink-jet recording apparatus

InactiveUS6375317B1Stable formationQuality improvementMeasurement apparatus componentsInksPolymer scienceAqueous medium

An ink comprising particles of self-dispersing carbon black having at least one hydrophilic group at the surface thereof, and calcium in an aqueous medium. The ink can form images excellent in fastness properties such as water fastness and light fastness and character quality, and can be stably ejected from a recording head irrespective of printing environment.

Owner:CANON KK

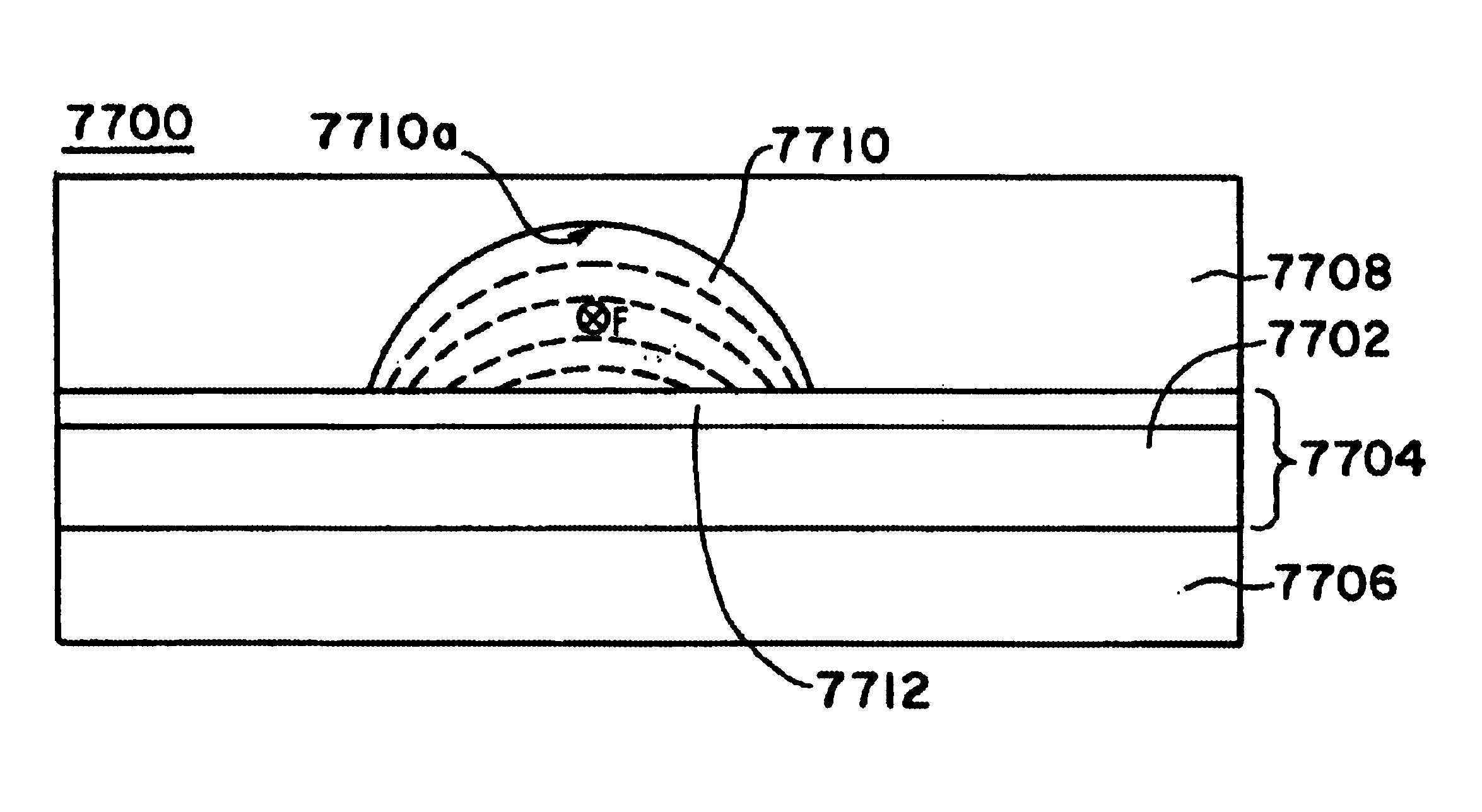

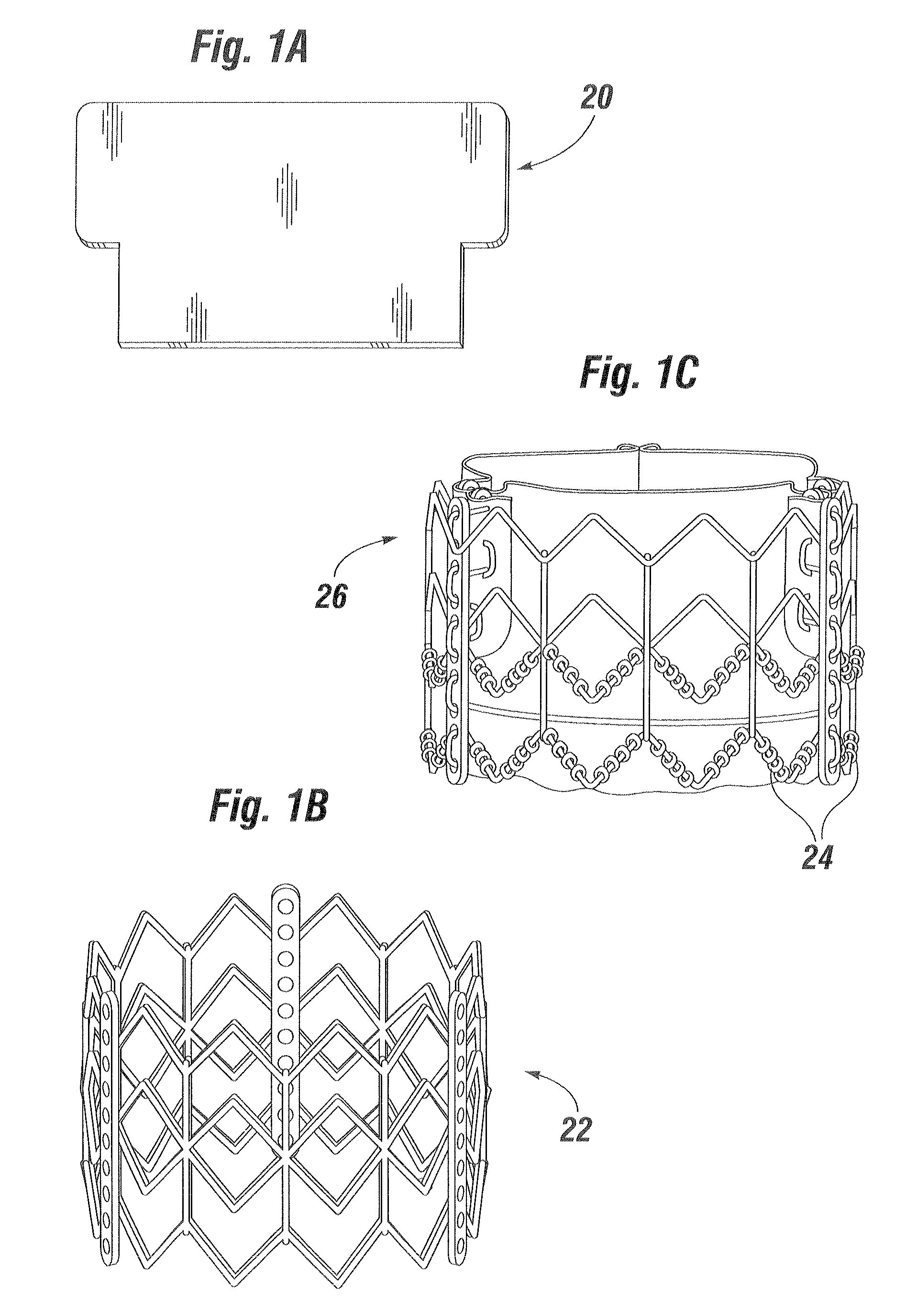

Virtual heart valve

ActiveUS8219229B2Accurate measurementFast formingHeart valvesAnalogue computers for chemical processesStress levelStructural engineering

Owner:EDWARDS LIFESCIENCES CORP

Materials and Process Using a Three Dimensional Printer to Fabricate Sintered Powder Metal Components

InactiveUS20150125334A1Fast formingAdditive manufacturingIncreasing energy efficiencyGreen state3D printing

Owner:AMERICAN HAKKO PRODS

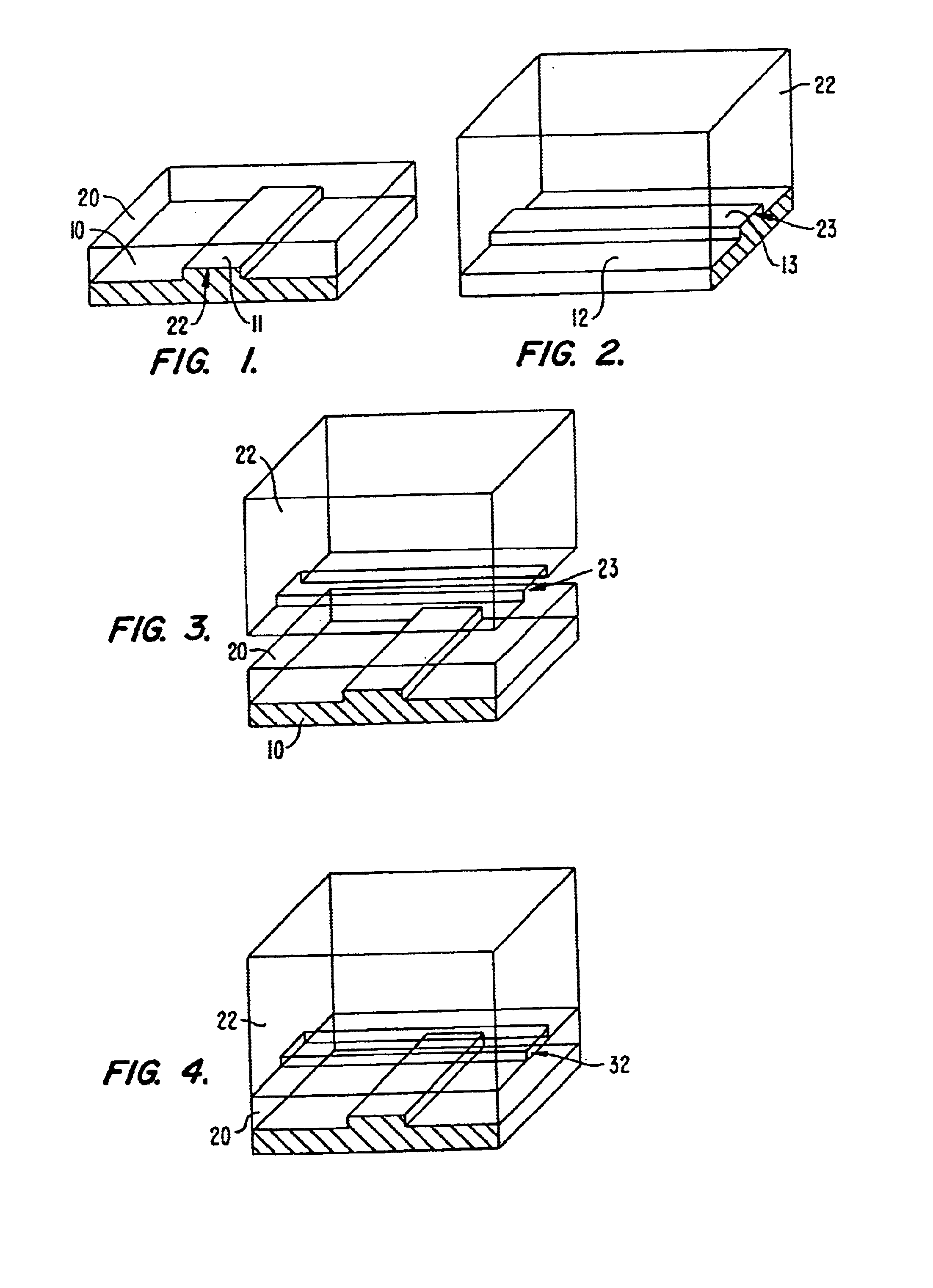

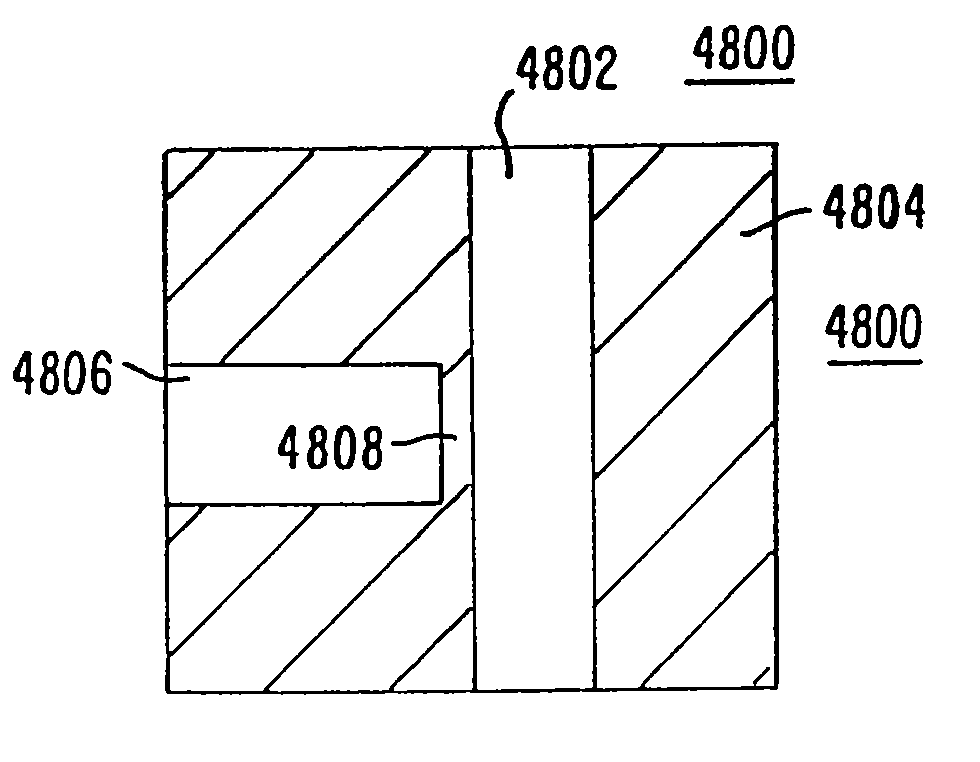

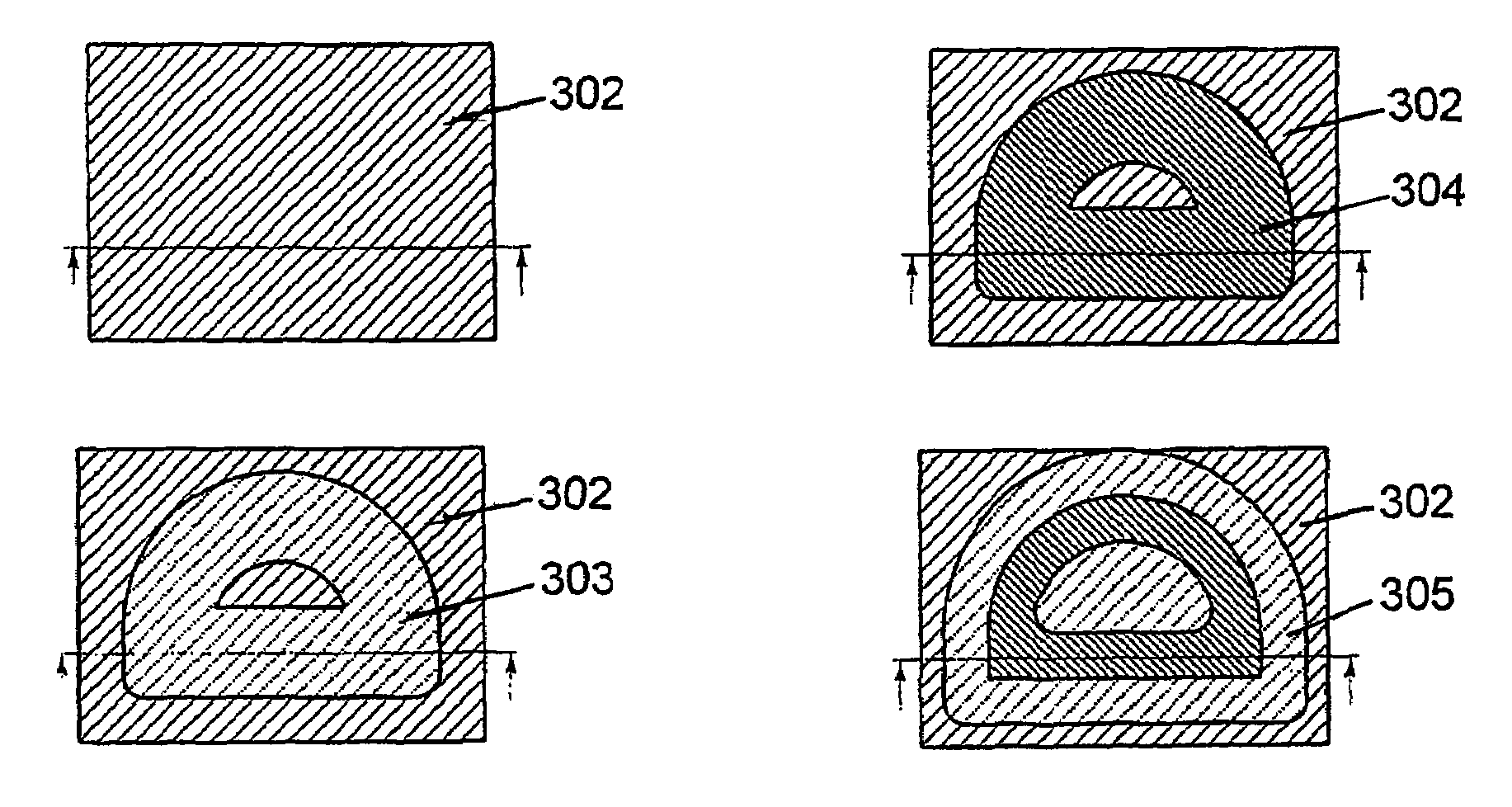

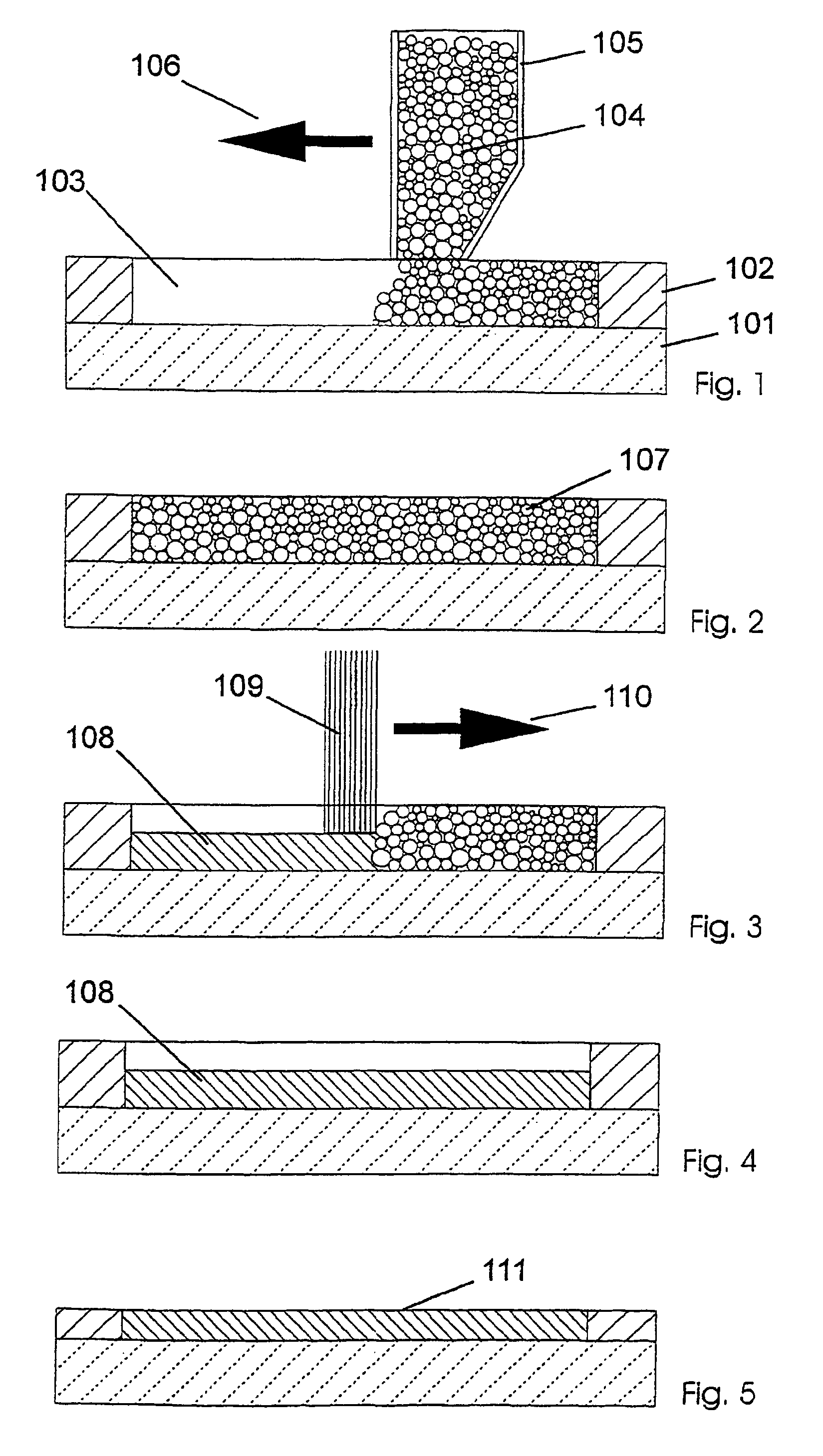

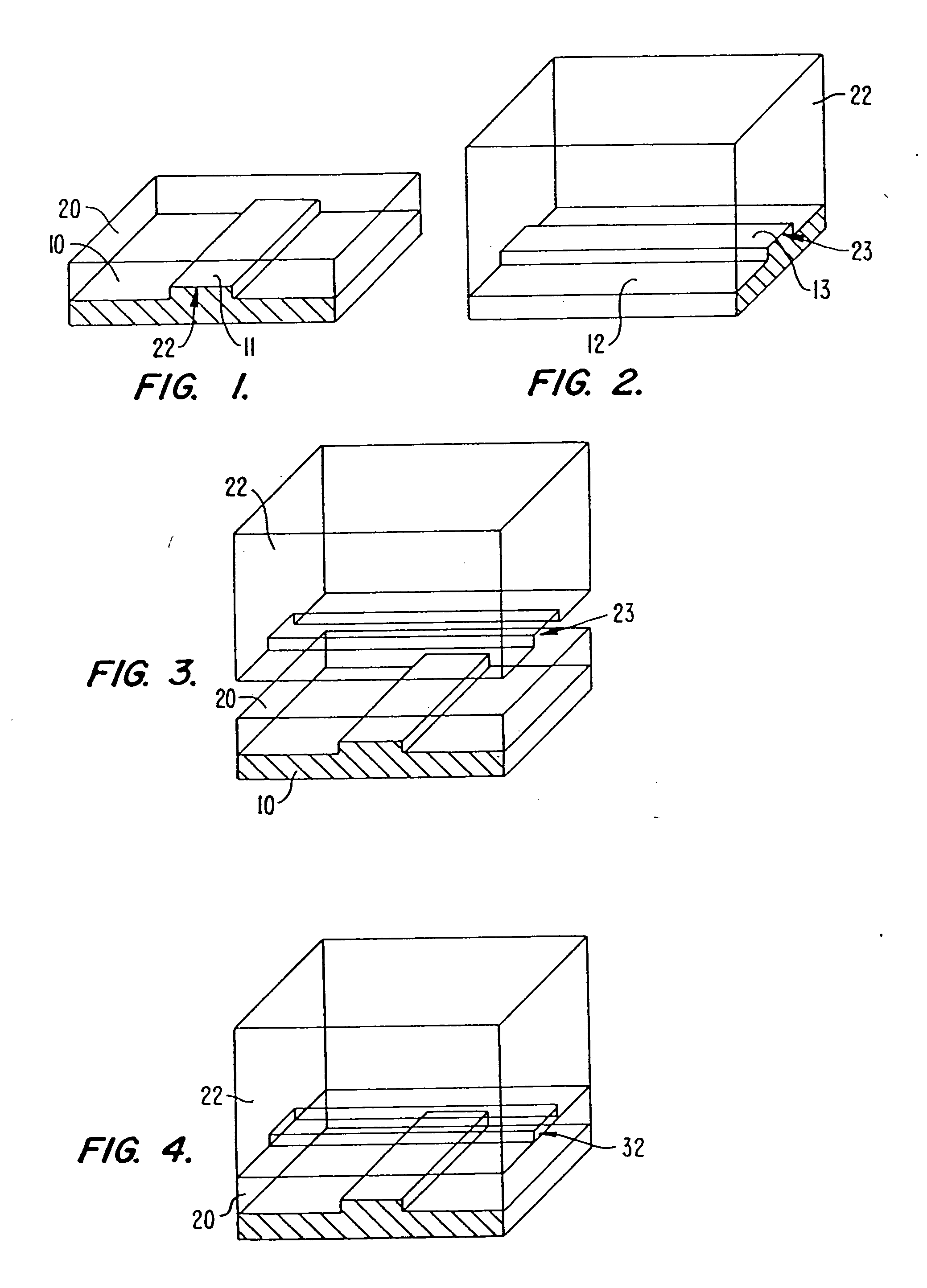

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

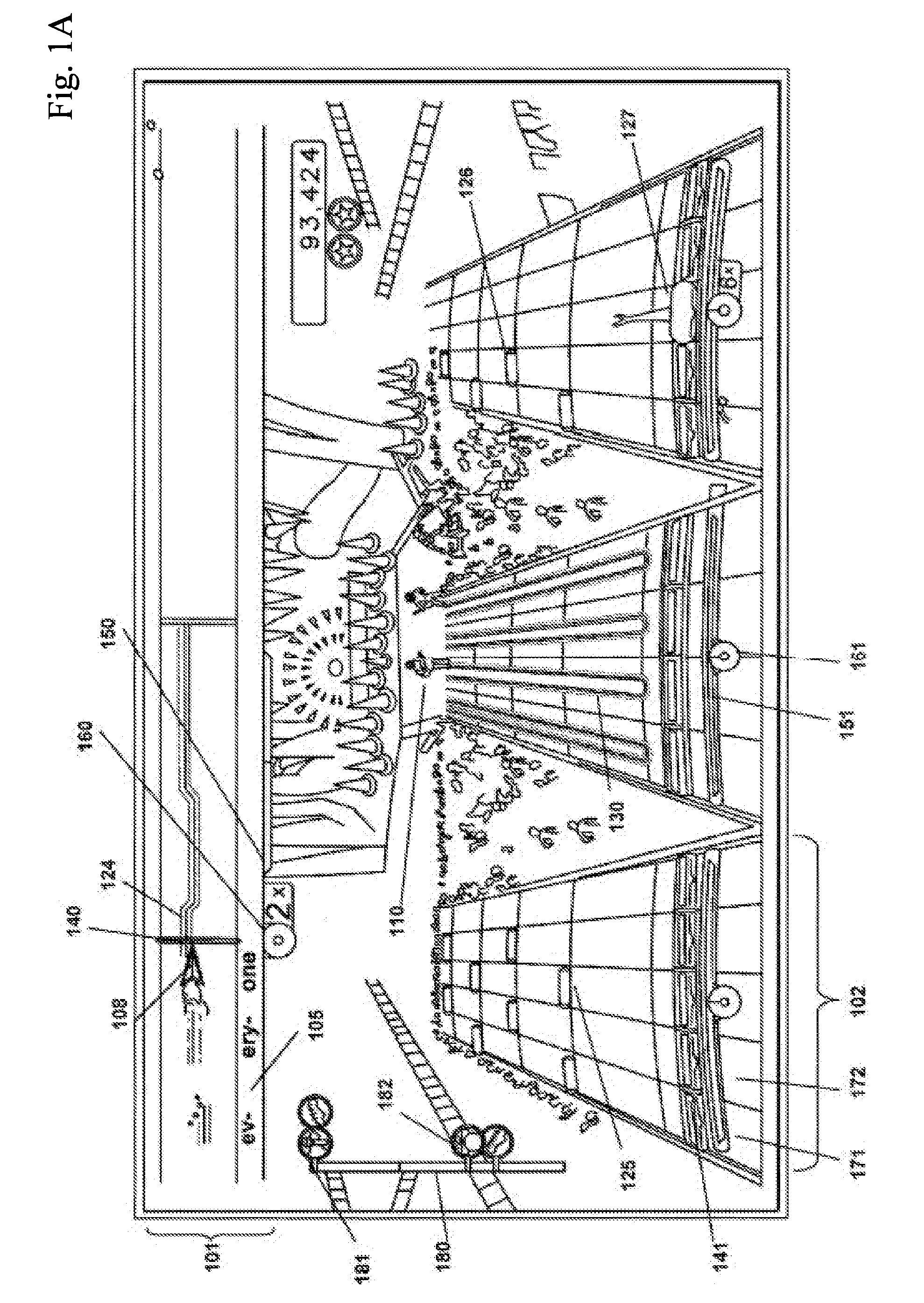

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

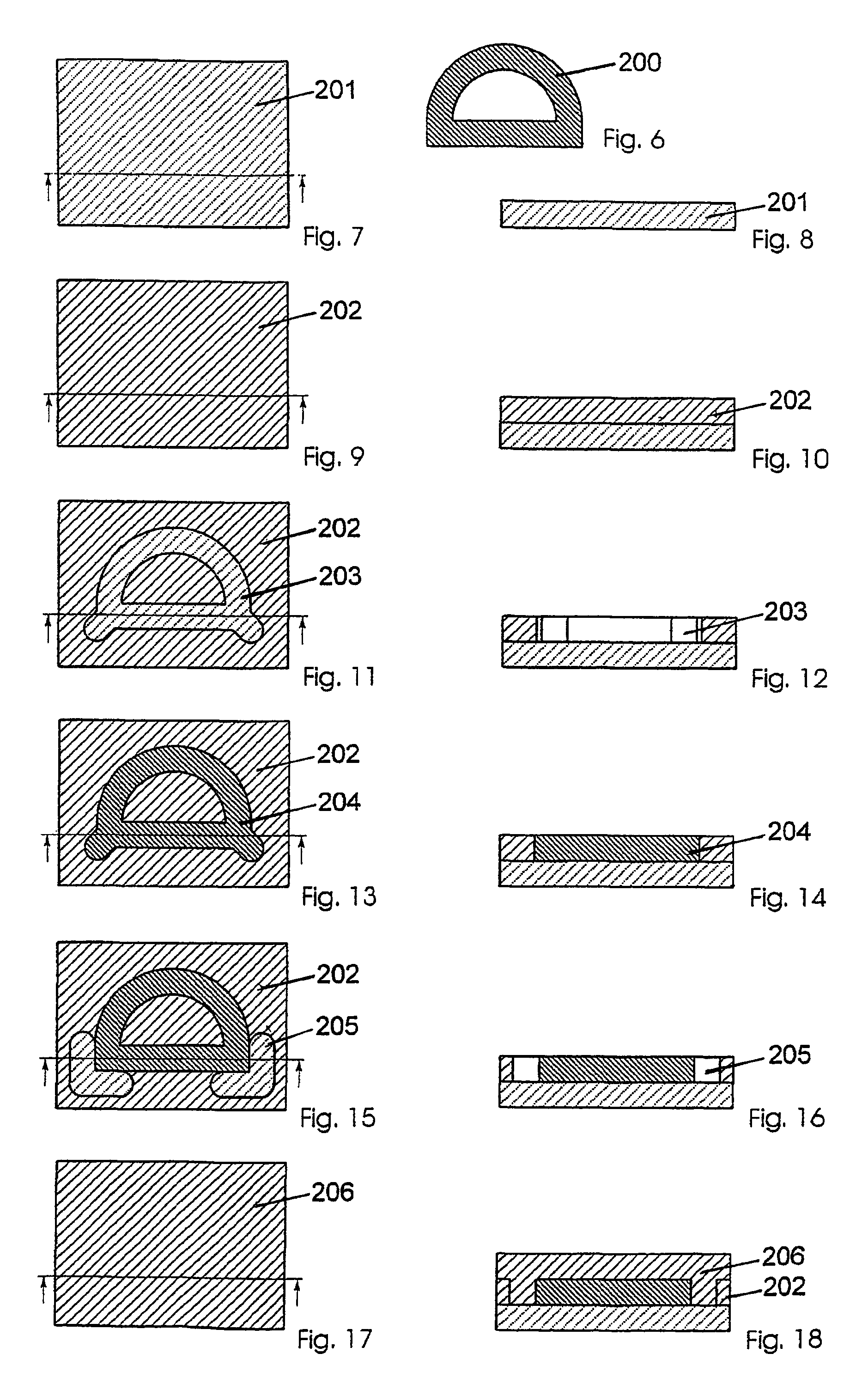

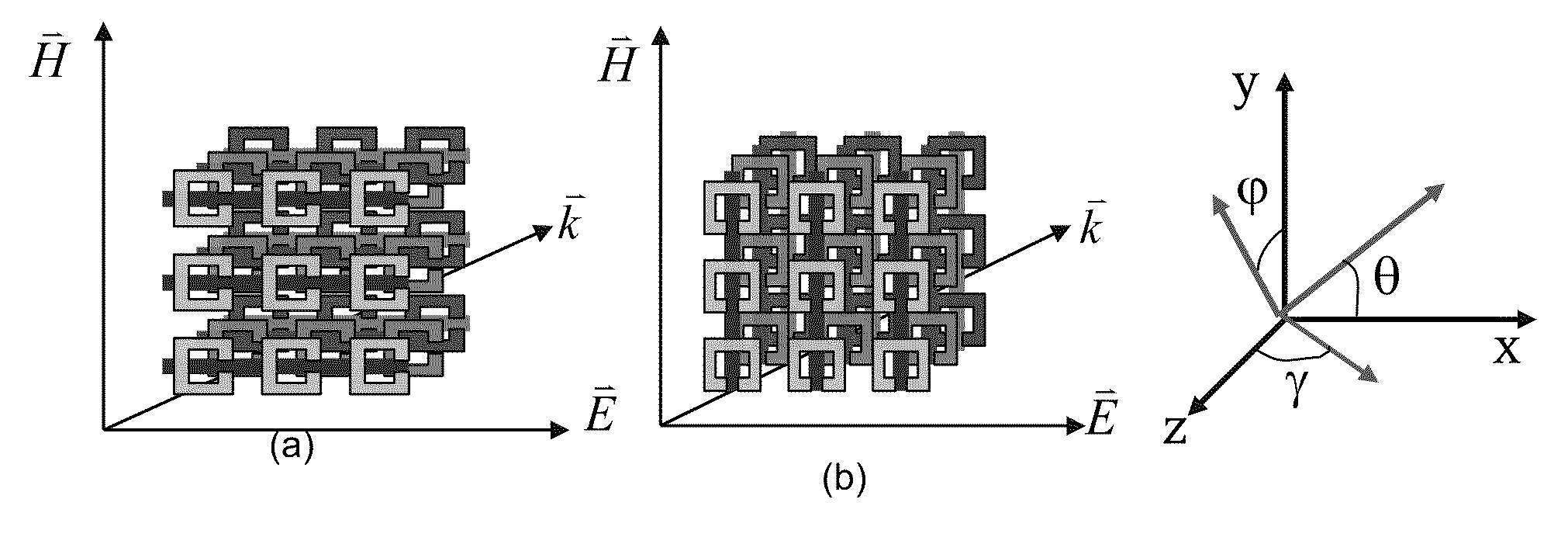

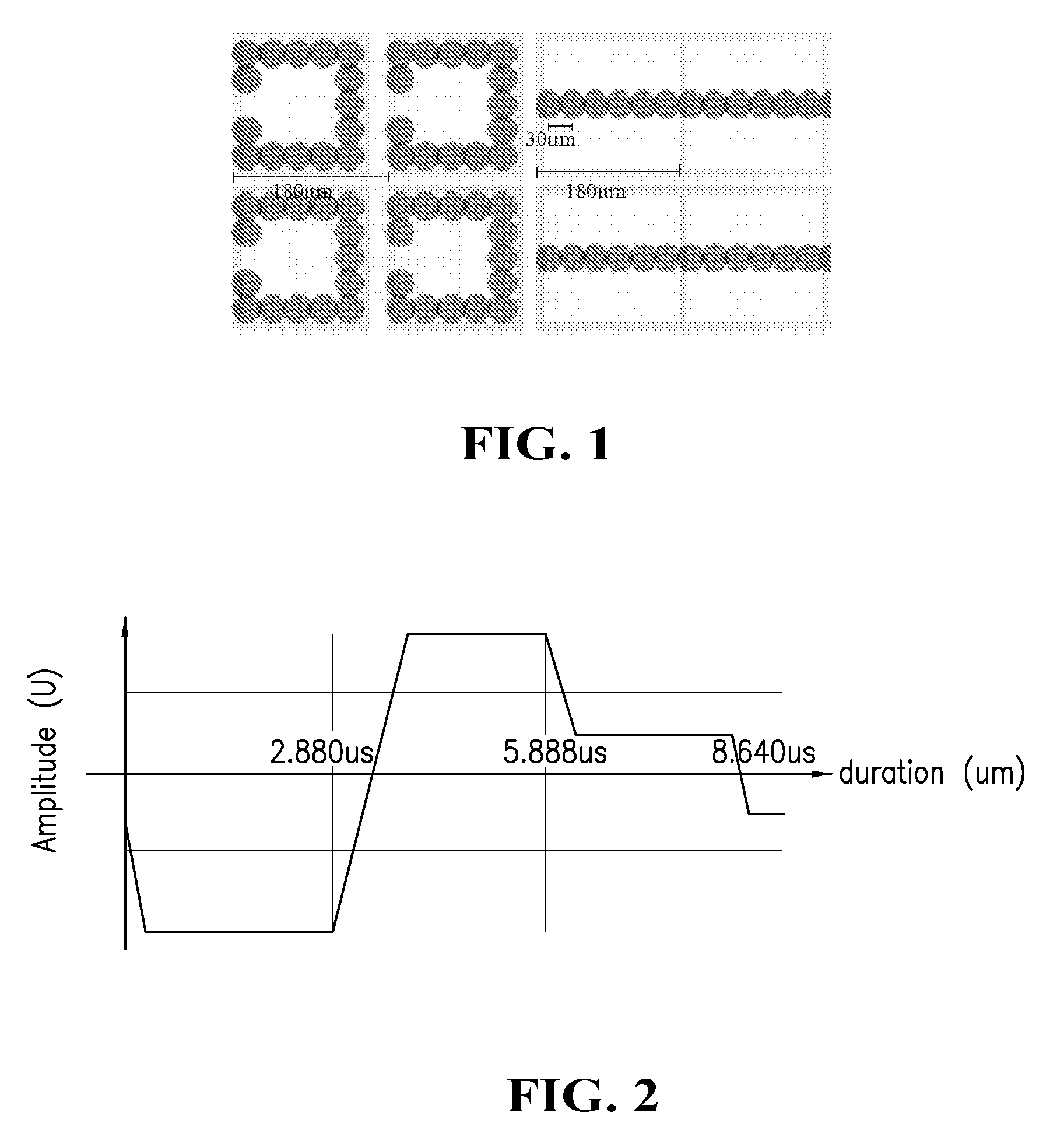

Metamaterials with terahertz response and methods of making same

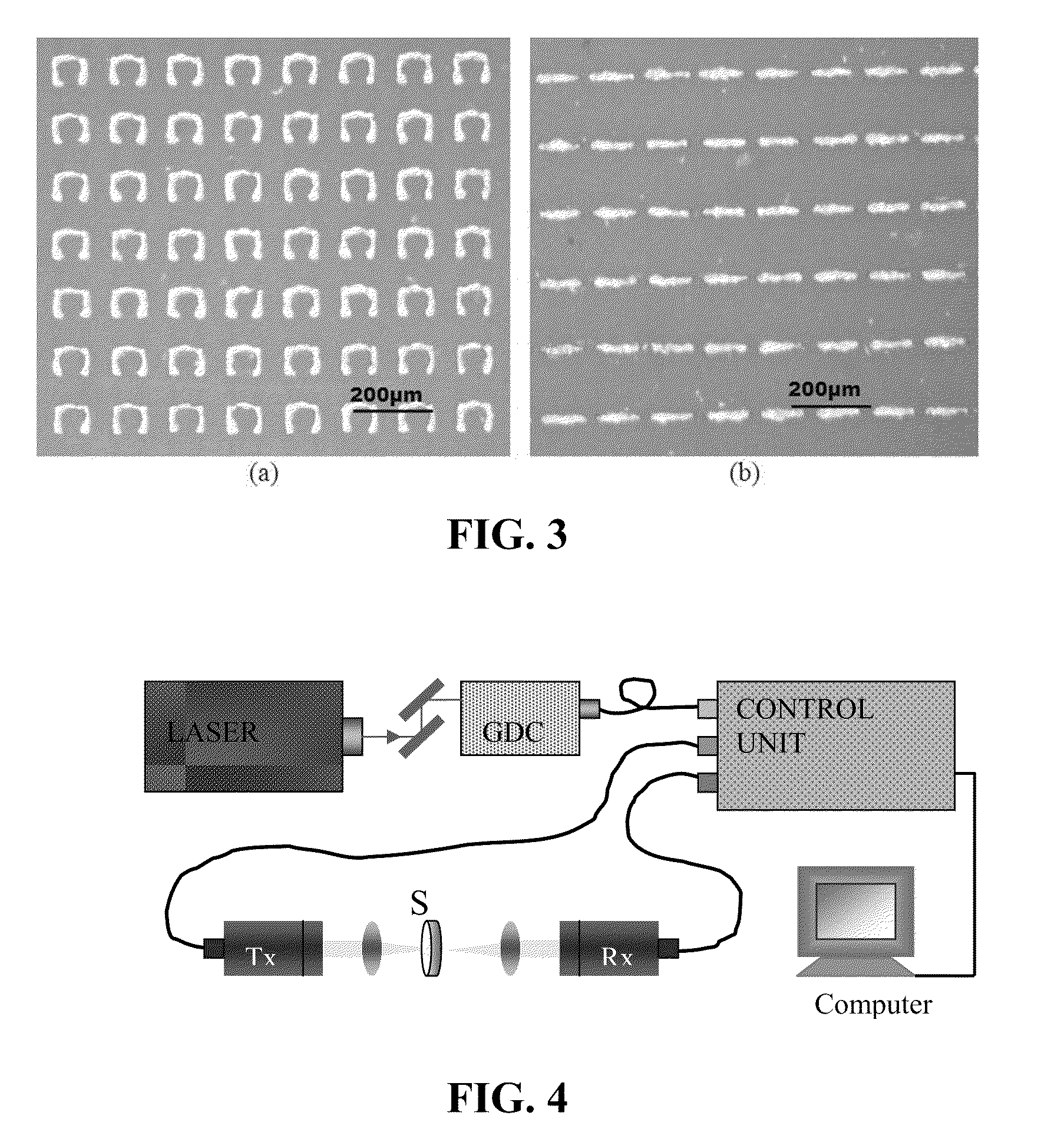

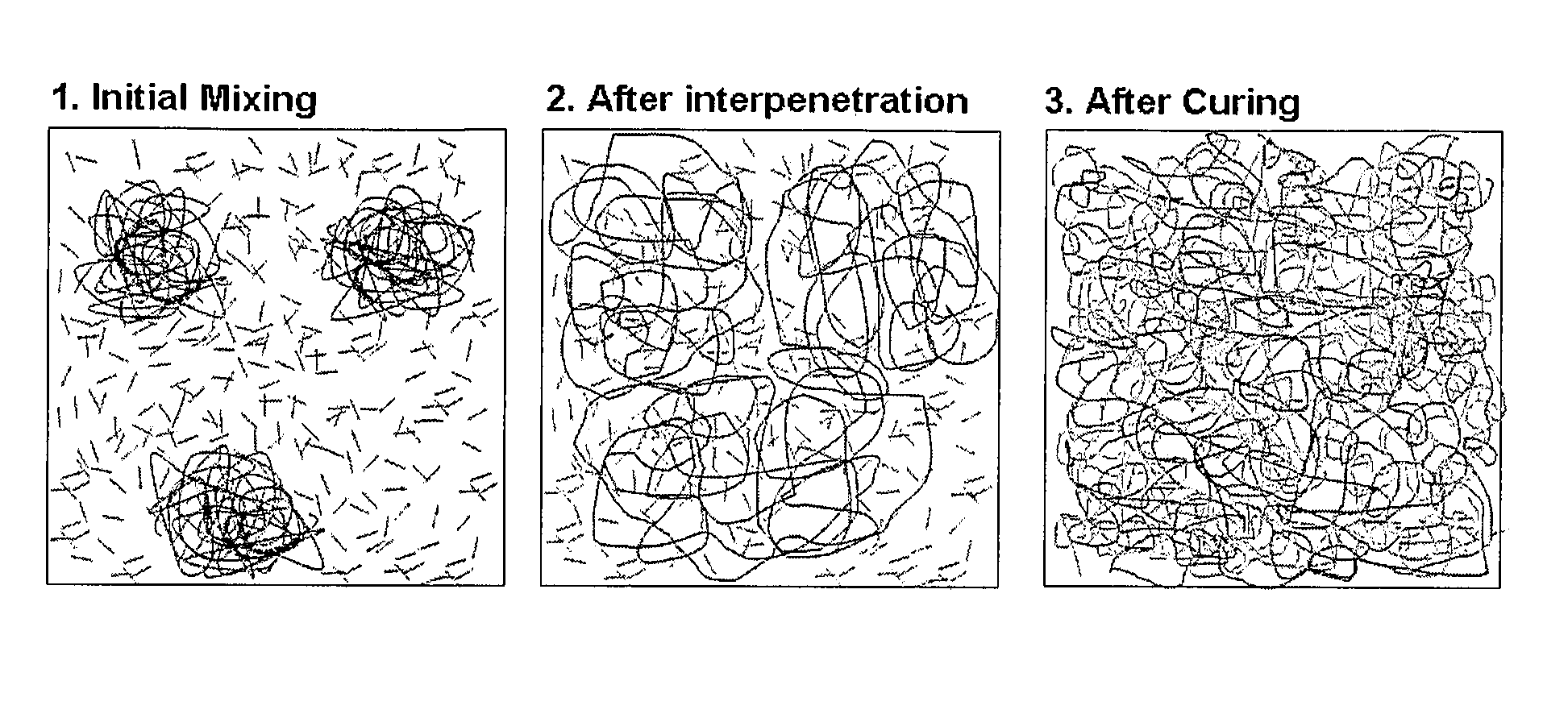

InactiveUS20100271692A1Minimize risk of contaminationReduce manufacturing costMaterial analysis by optical meansResonatorsEngineeringLeft handed

Flexible metamaterials and three-dimensional metamaterials operable in the terahertz range are disclosed. Methods are disclosed for fabricating terahertz response metamaterials using microfluidic-jetted techniques. Layers of material including substrate and deposited material are stacked to form three dimensional bulk metamaterials. The fabricated metamaterials act as left-handed metamaterials in the range 0.1 to 3.0 THz.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

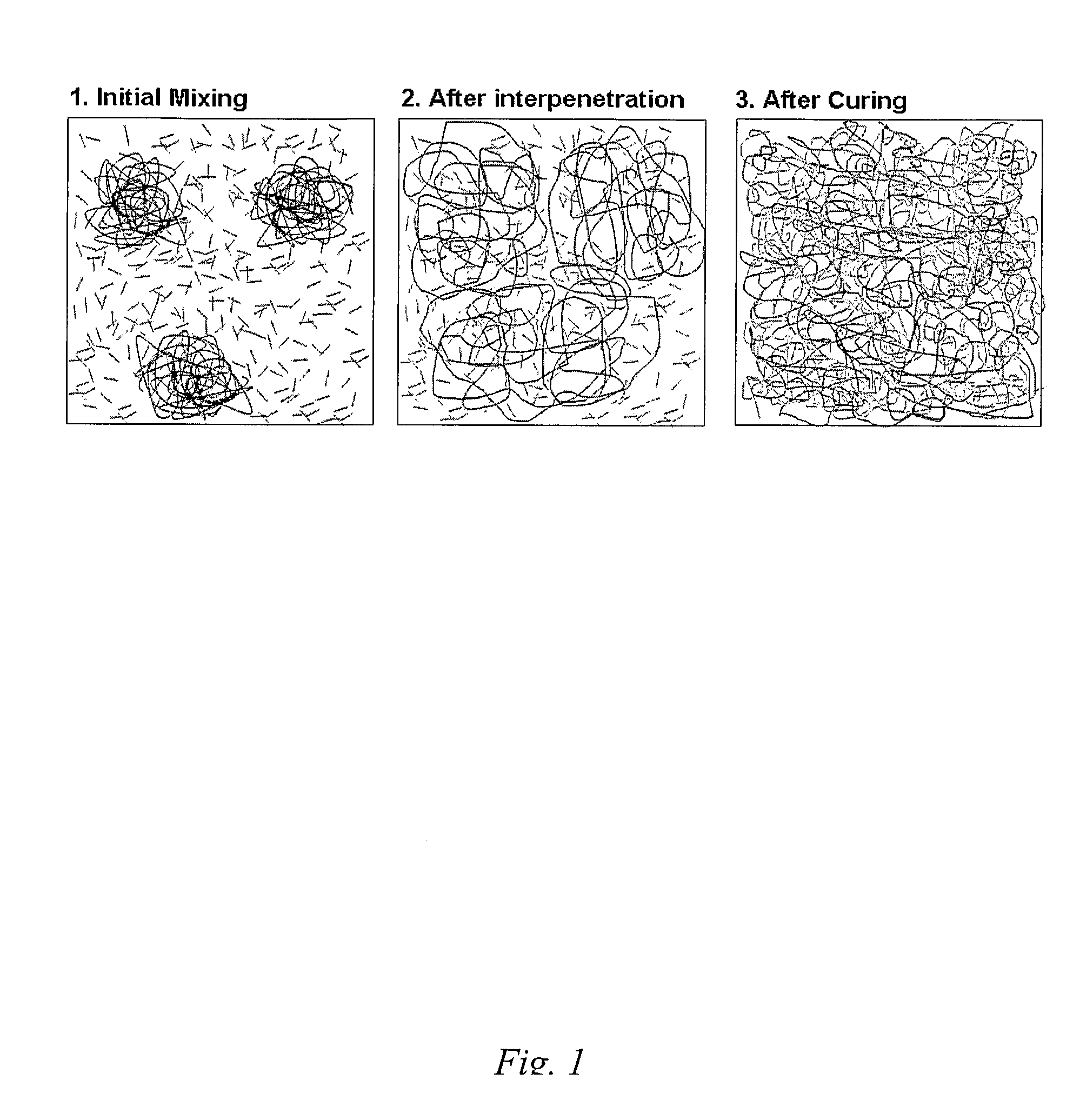

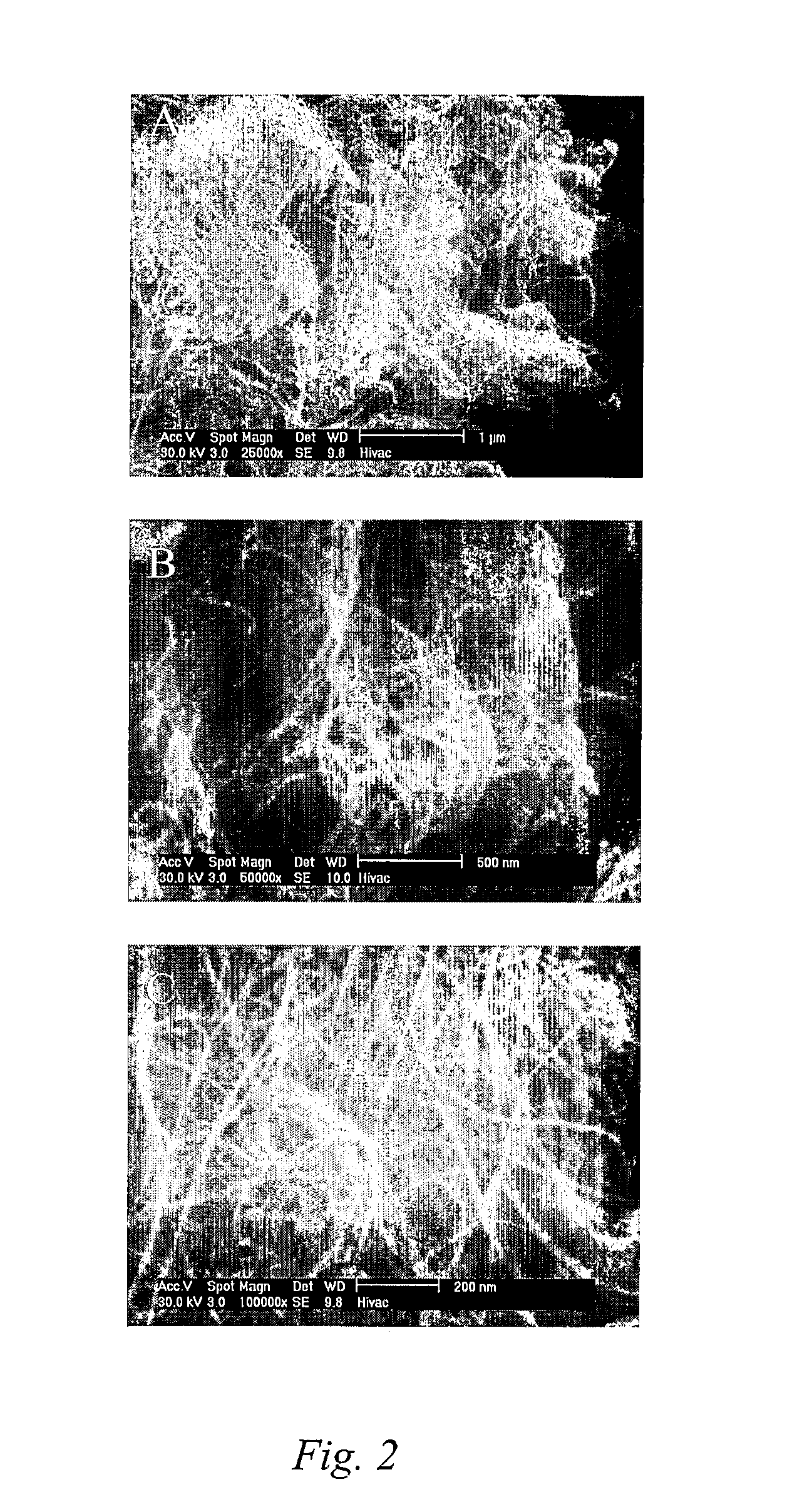

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

Viscosity reduction of viscoelastic surfactant based fluids

InactiveUS6908888B2Improve efficiencyImproves and optimizes conditionOther chemical processesFluid removalAlcoholSolid particle

Methods and compositions are disclosed for controlled addition of components that decrease the viscosity of the viscoelastic surfactant fluids or for controlled changes in the electrolyte concentration or composition of the viscoelastic surfactant fluids. One aspect of the invention relates to the use of internal breakers with a delayed activation. Another aspect of the invention relates to the use of precursors that release a breaking system such as alcohol by a process such as melting, slow dissolution, reaction with a compound present in the fluid or added to the fluid during or after the step of injecting, rupture of an encapsulating coating and de-adsorption of a breaking agent absorbed into solid particles. In another aspect of the invention, alcohols are included in a pad to reduce the low-shear viscosity and reduce the resistance to flow of the treatment fluids during a desired phase of the treatment.

Owner:SCHLUMBERGER TECH CORP

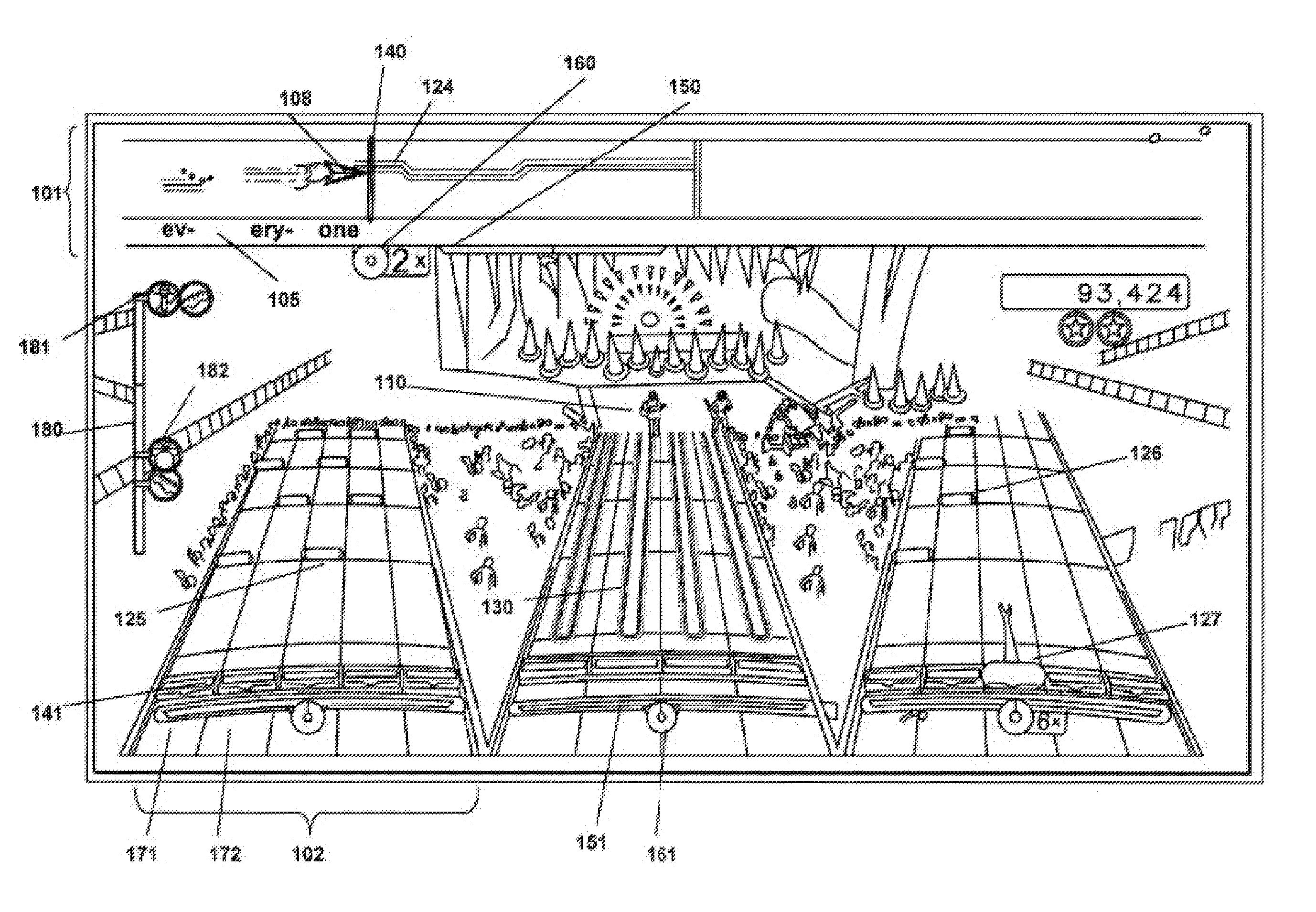

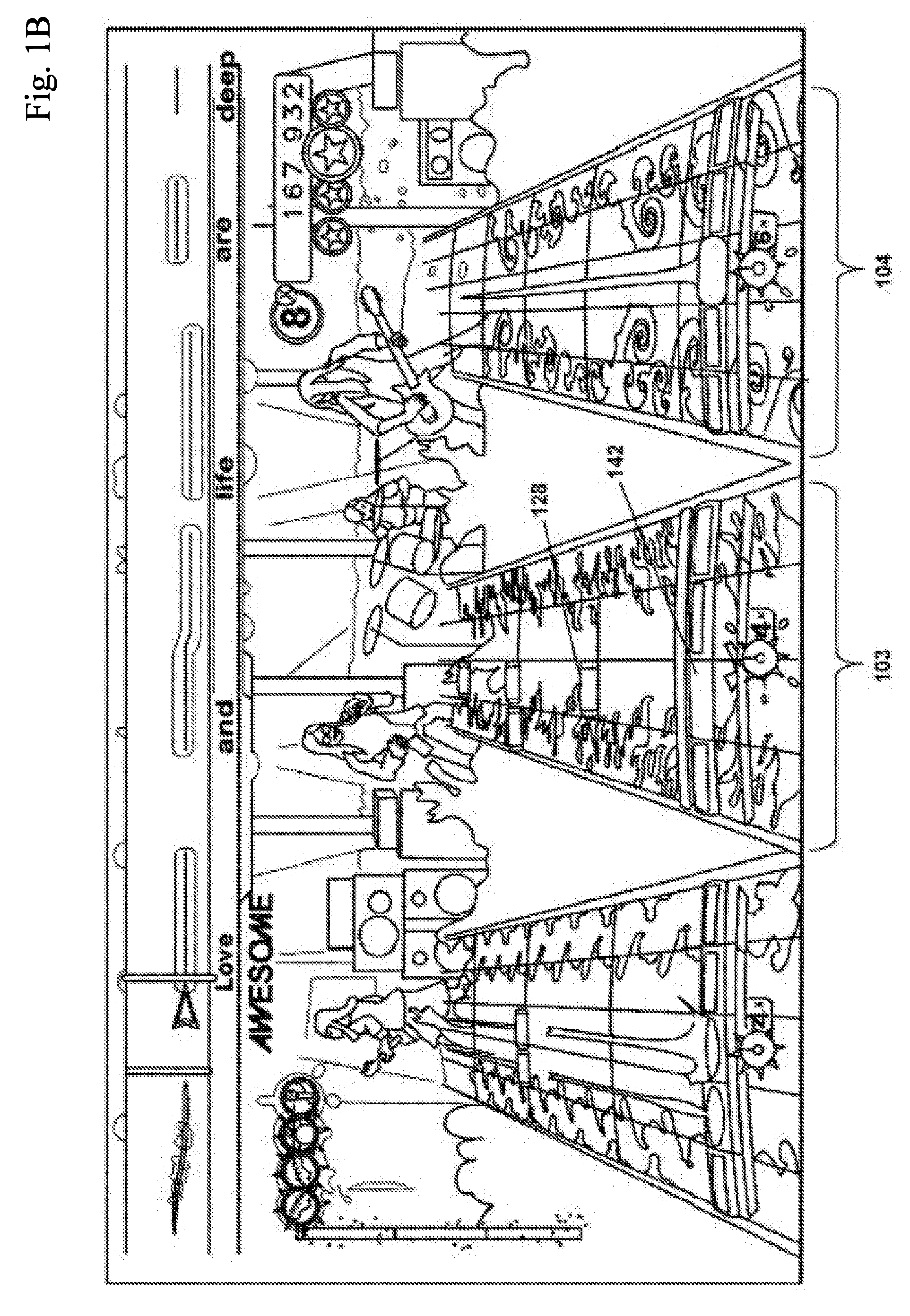

Systems and methods for asynchronous band interaction in a rhythm action game

ActiveUS20100029386A1Valid matchFast formingElectrophonic musical instrumentsVideo gamesFrequency bandAction game

Provided are methods and systems and computer readable media for providing interaction between remote players and one or more local players of a rhythm-action game executed on a game platform. One or more local players is identified to participate in a networked session of a rhythm action game corresponding to a predetermined band template, each local player associated with a type of simulated musical instrument. A first type of simulated musical instrument, represented in the predetermined band template and not associated with any of the one or more local players, may then be identified, along with a remote player associated with the first type of simulated musical instrument. Then, game platforms of the local and remote players communicate to establish a networked session of the rhythm action game with the one or more local players and the identified remote player before initiating a game session where the players play the game.

Owner:HARMONIX MUSIC SYSTEMS

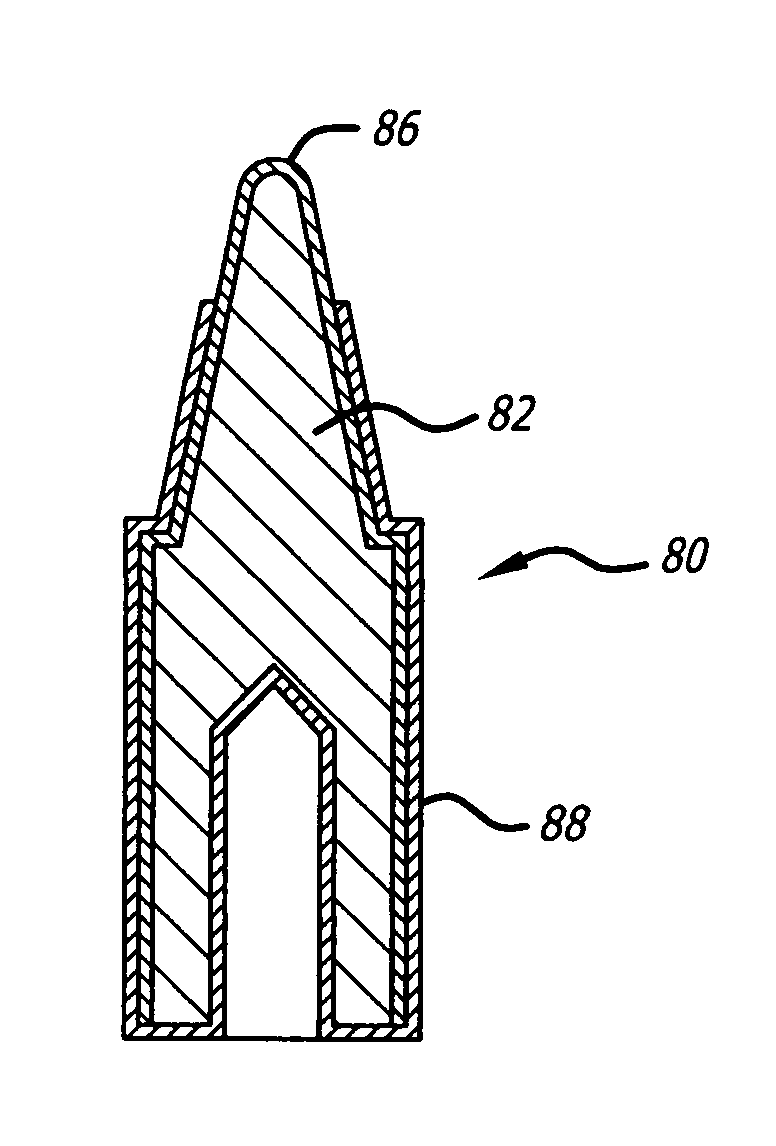

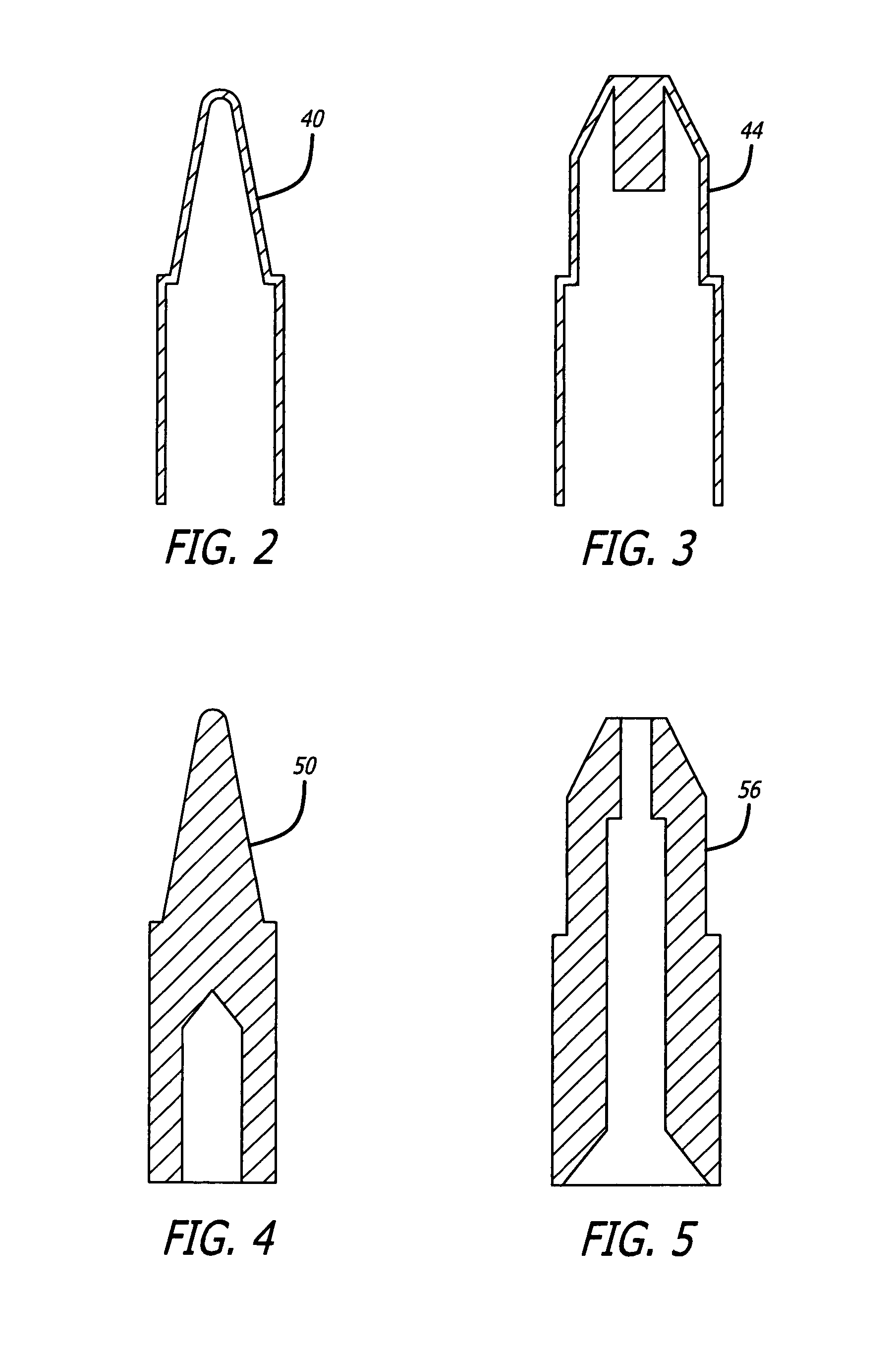

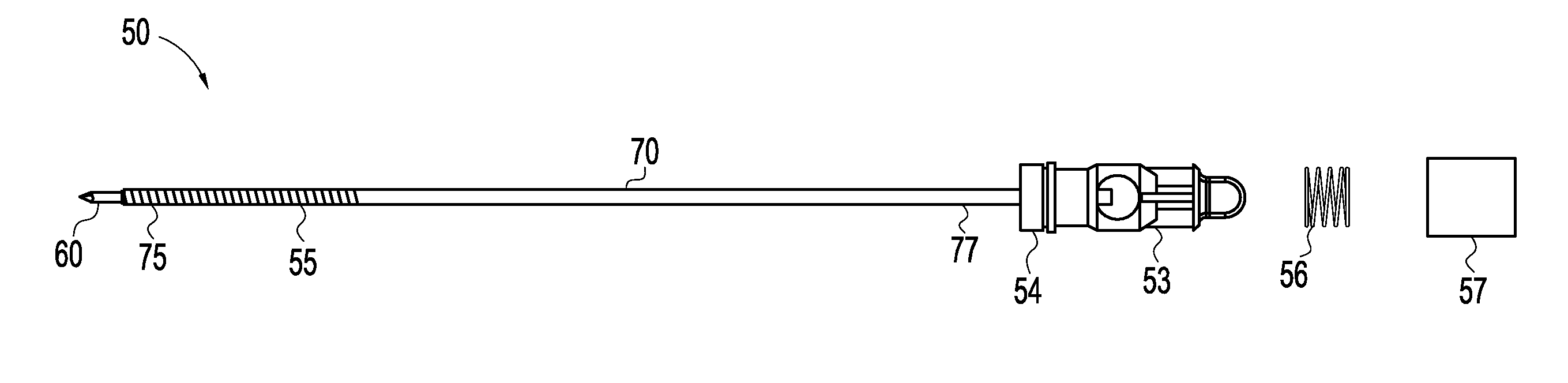

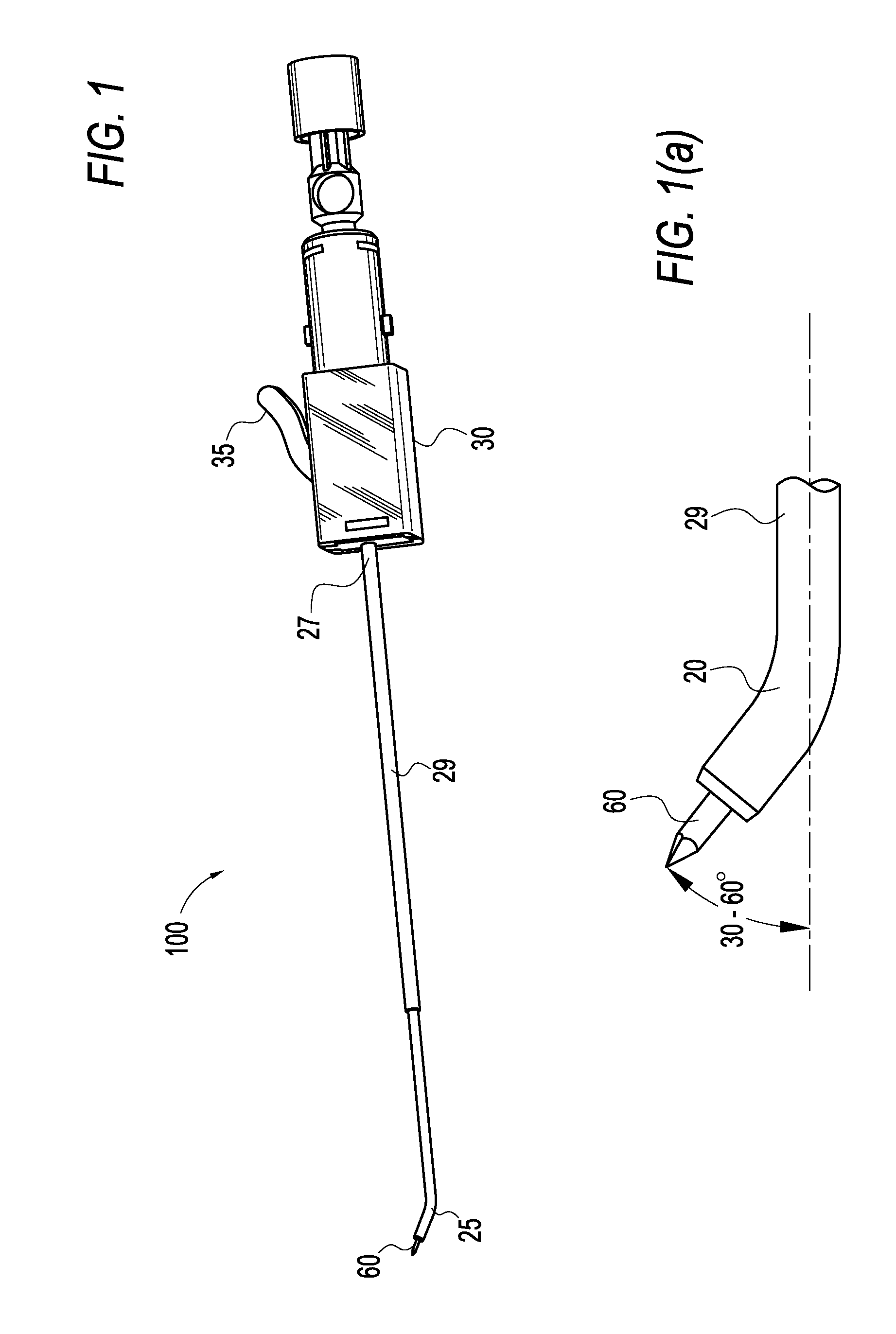

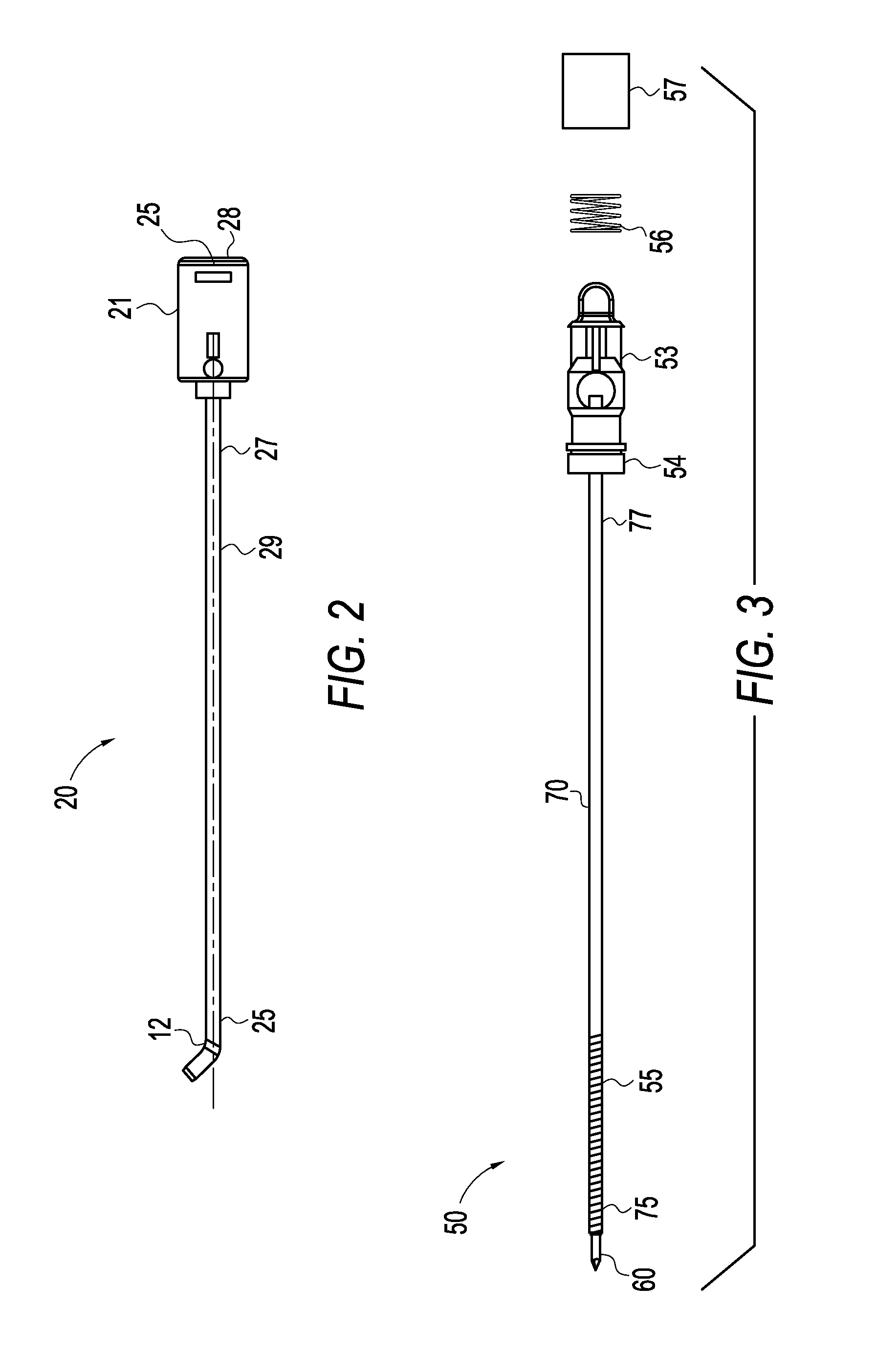

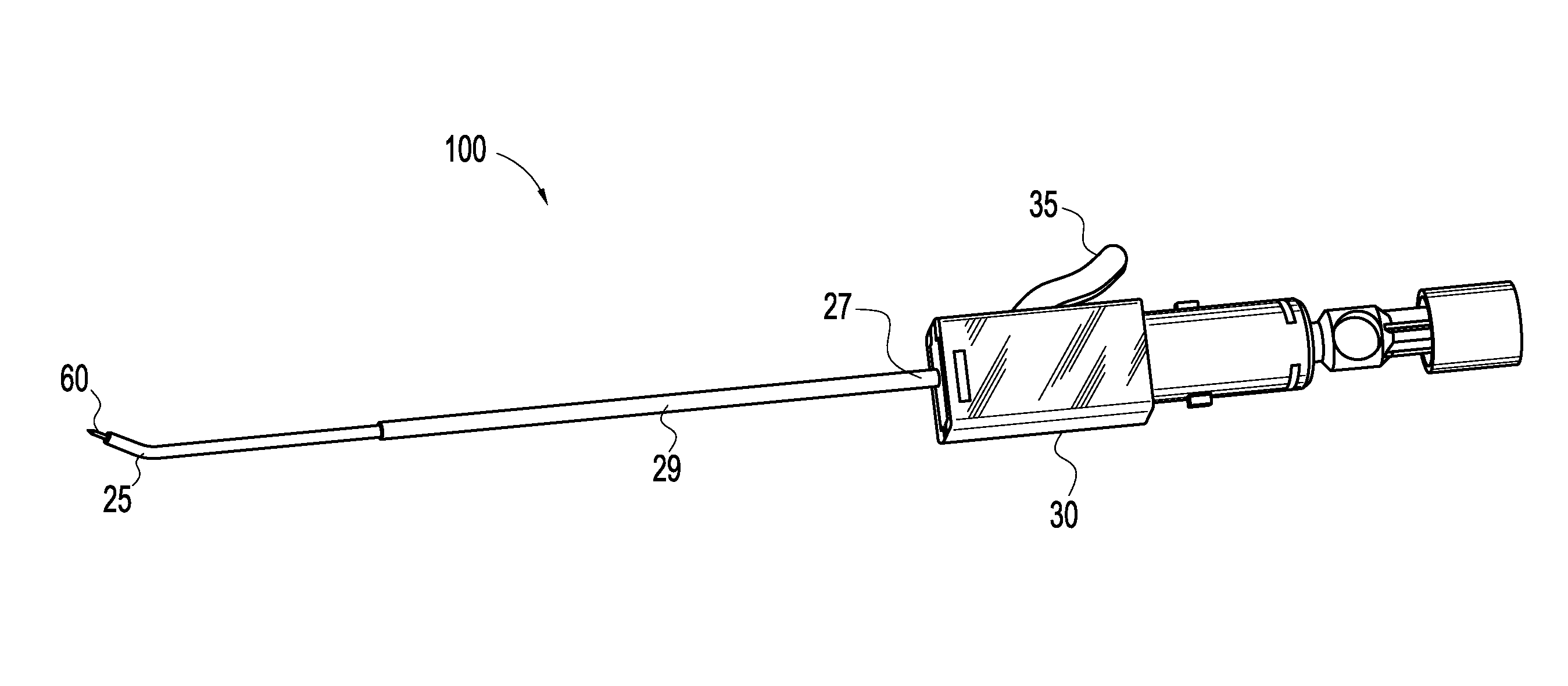

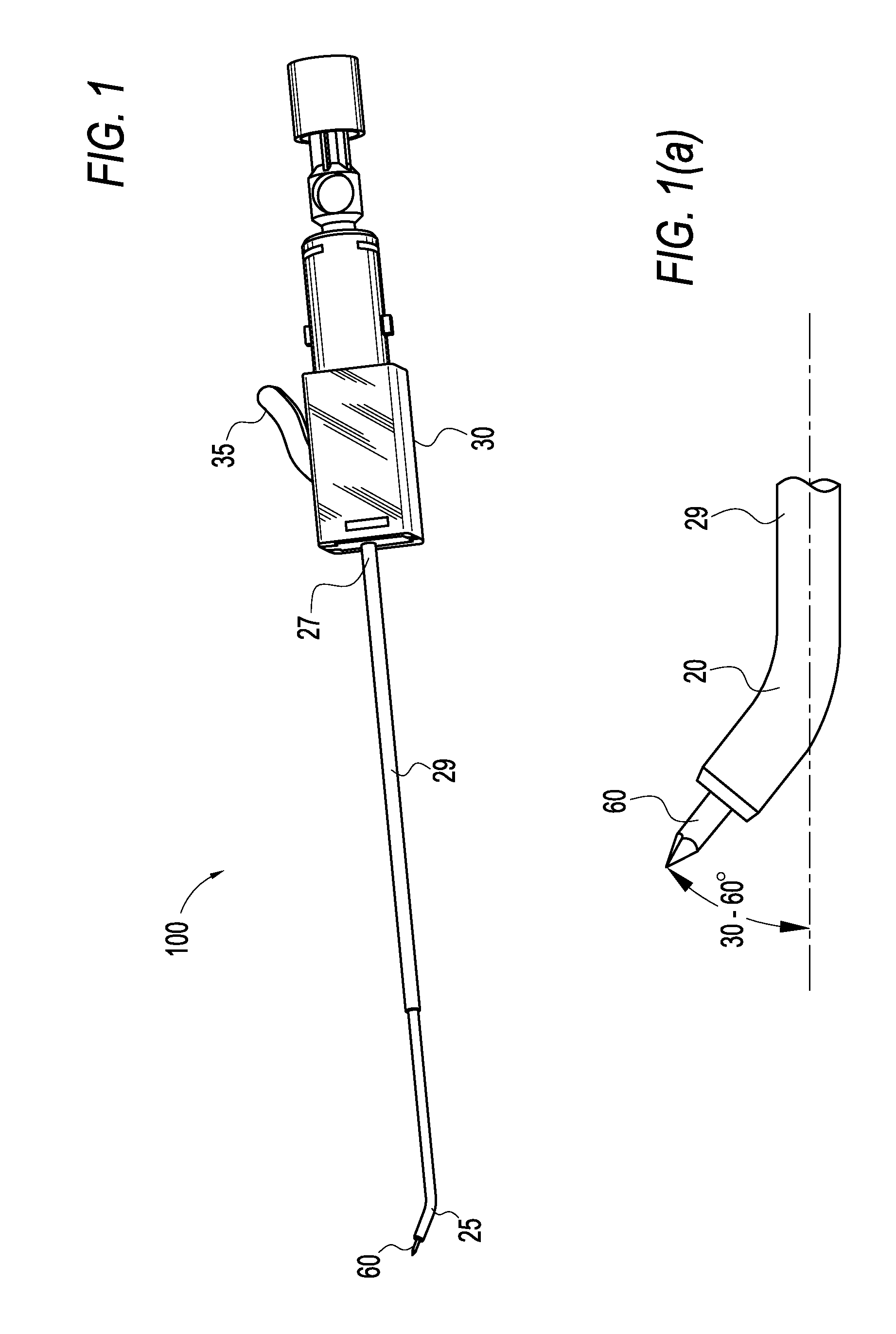

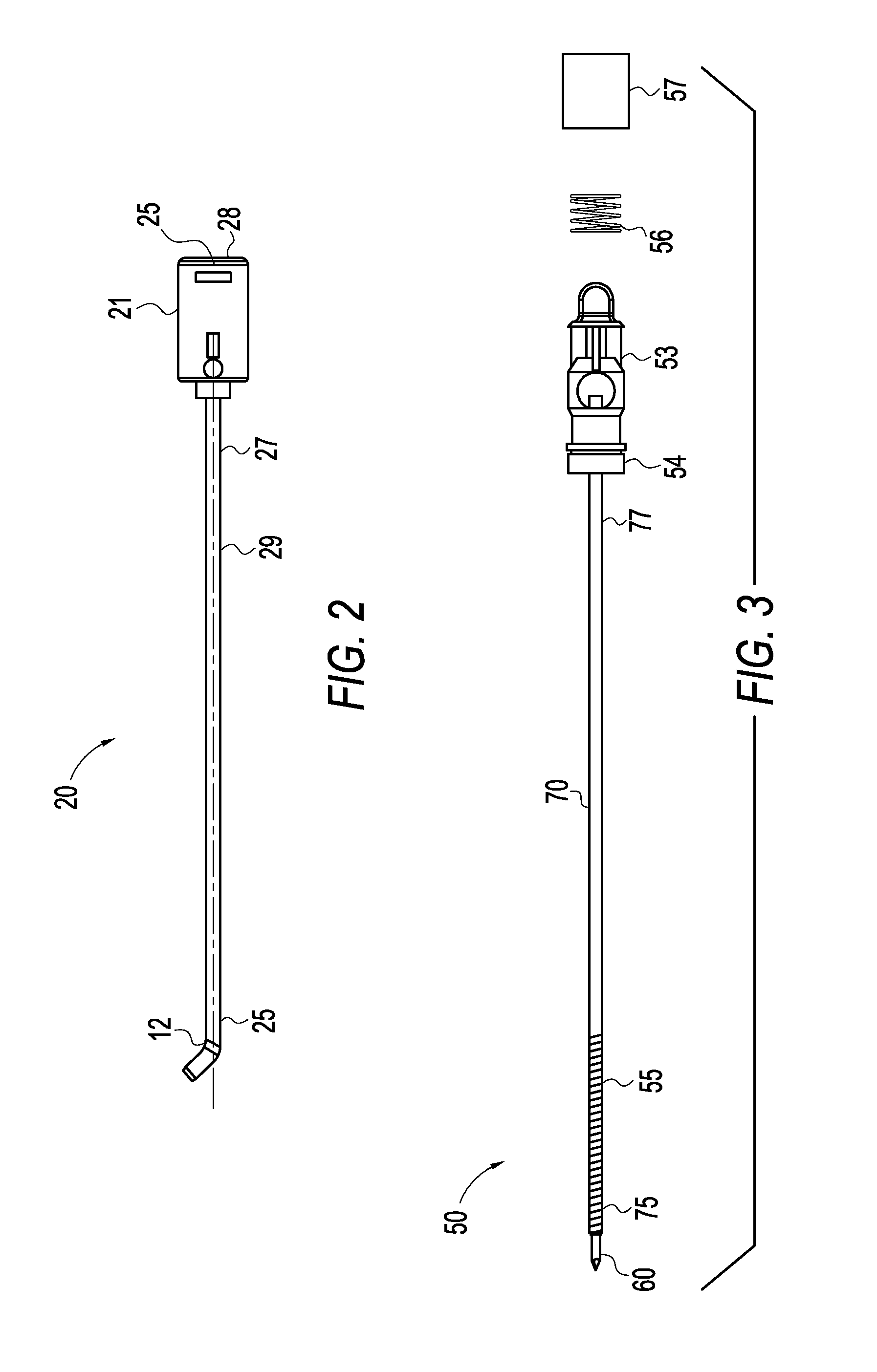

Microfracture instrument

ActiveUS20100249786A1Less timeSmall diameterEndoscopic cutting instrumentsProsthesisEngineeringActuator

A bone drill that includes a shaft with a flexible portion having a proximal end and a distal end and a drill tip coupled to the distal end of the shaft. The bone drill also includes a cannulated sheath with a proximal end and a distal end, the sheath housing a portion of the shaft and having a curved portion at the distal end. The drill tip may also be housed within the curved portion of the sheath. The bone drill may also include a hub with an actuator mechanism, the hub being coupled to the sheath, wherein the actuator mechanism retracts the sheath to cause the drill tip to extend beyond the distal end of the sheath.

Owner:ARTHREX

Microfabricated elastomeric valve and pump systems

InactiveUS20050112882A1Fast formingEasy to manufactureFunctional valve typesEngine diaphragmsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

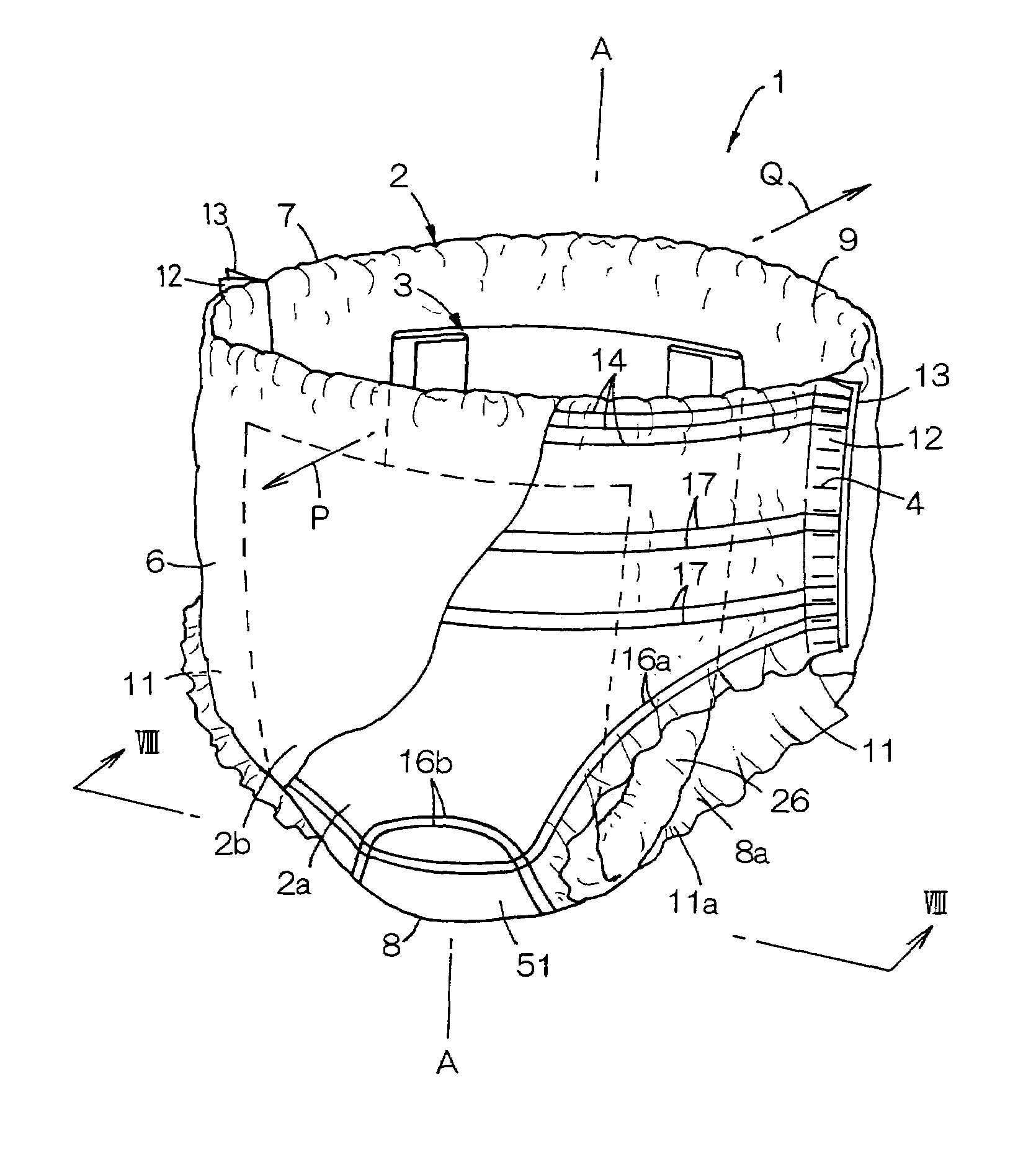

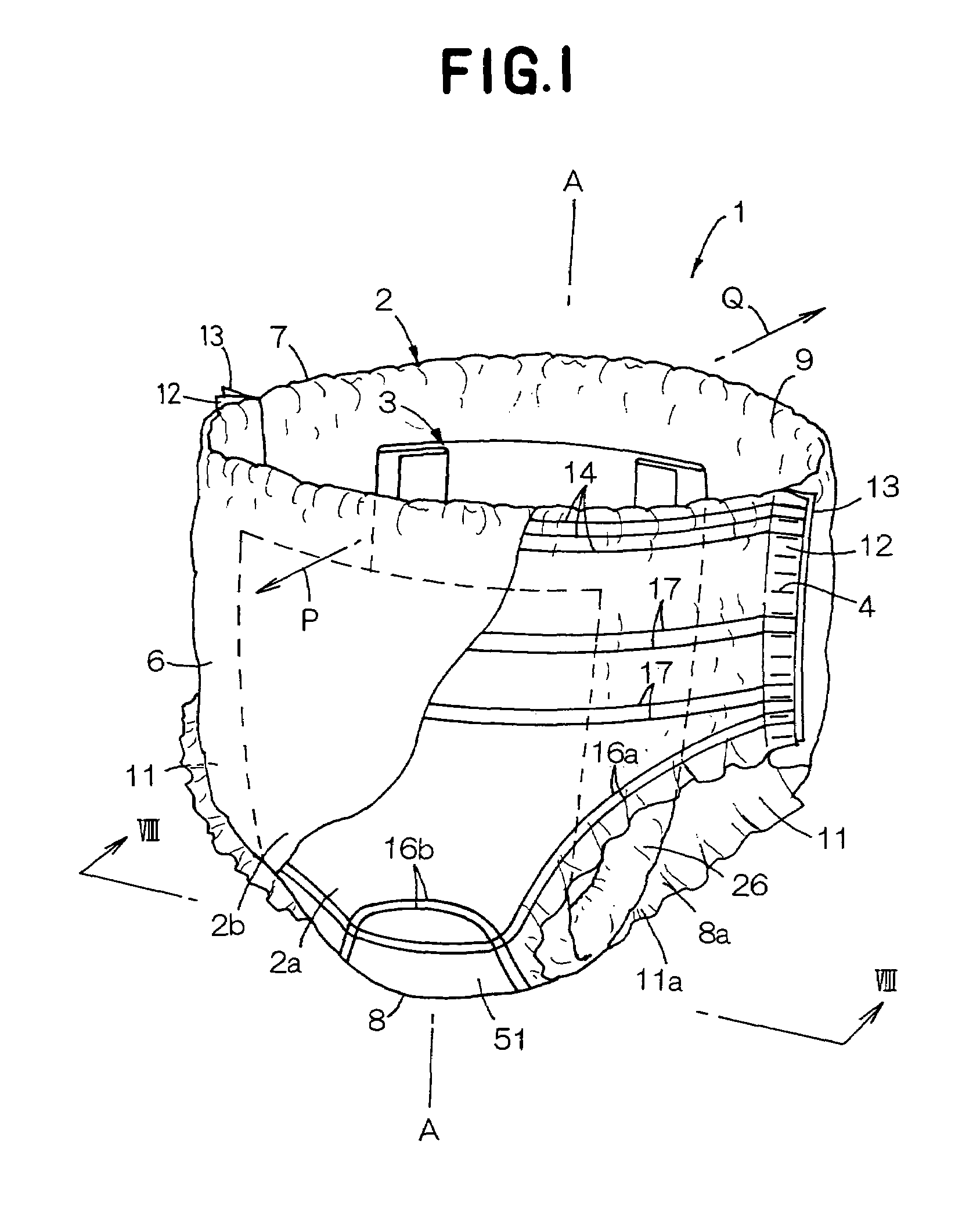

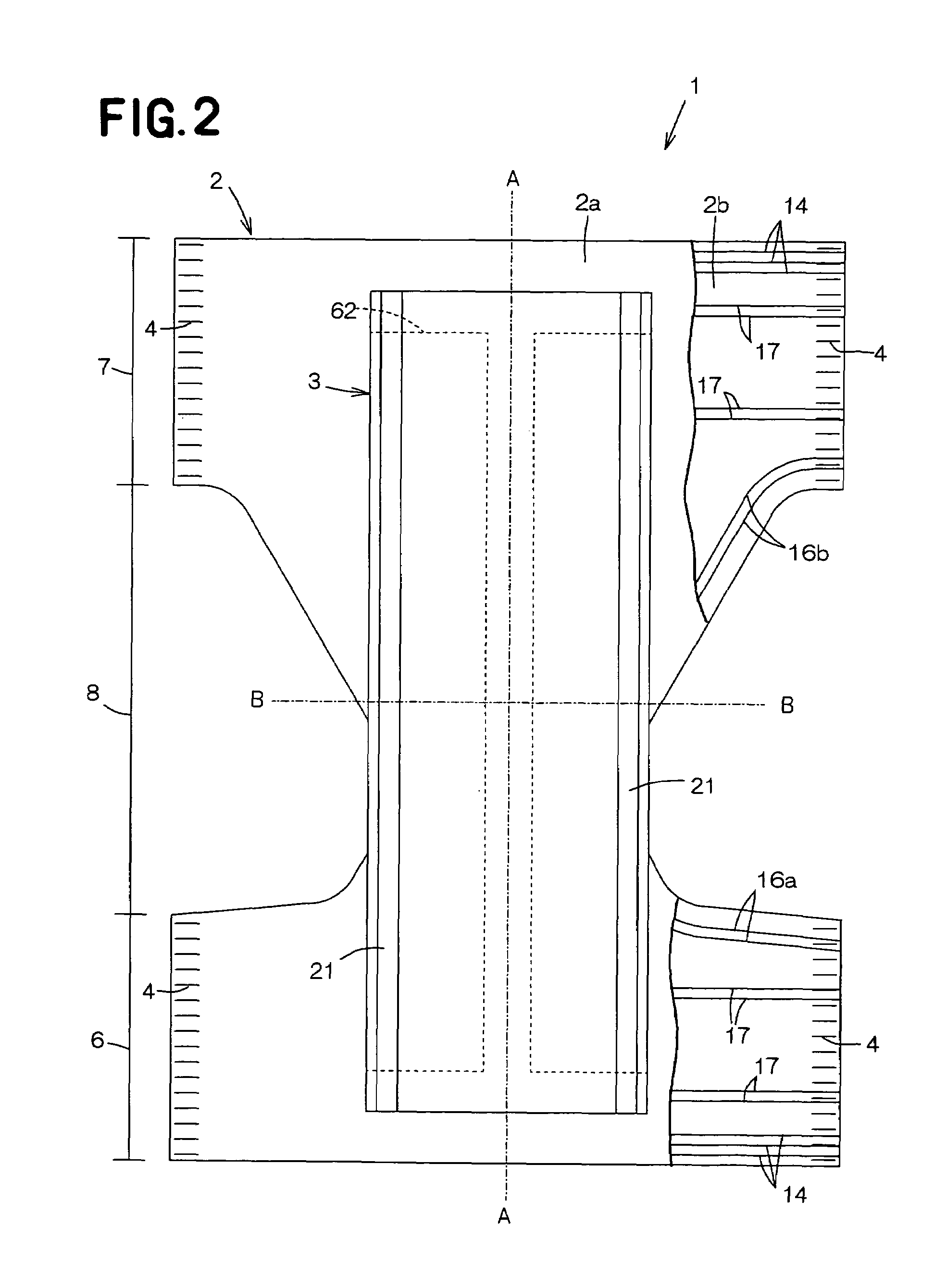

Disposable wearing article having multilayered core comprising convex gaps and v-shaped cutouts

Owner:UNI CHARM CORP

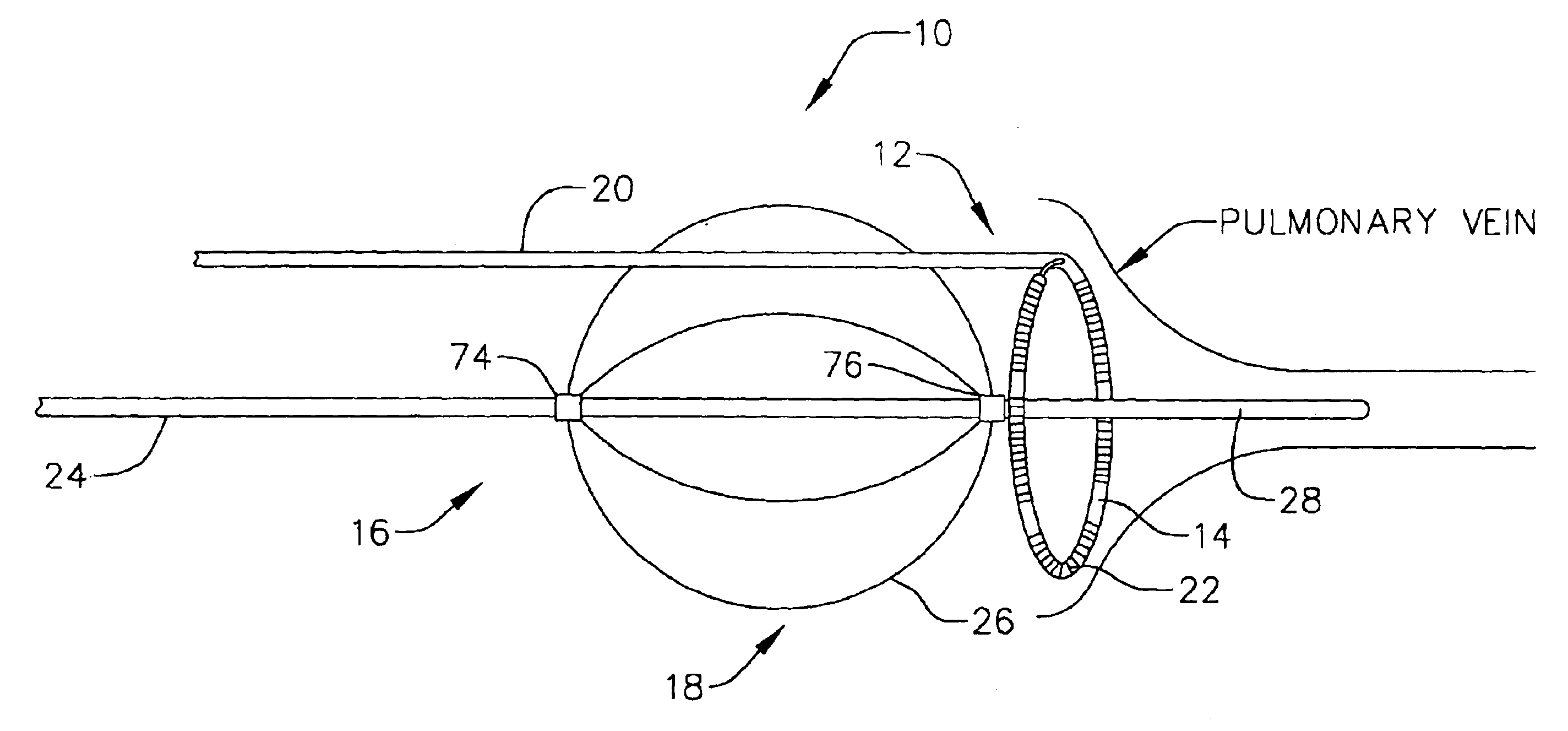

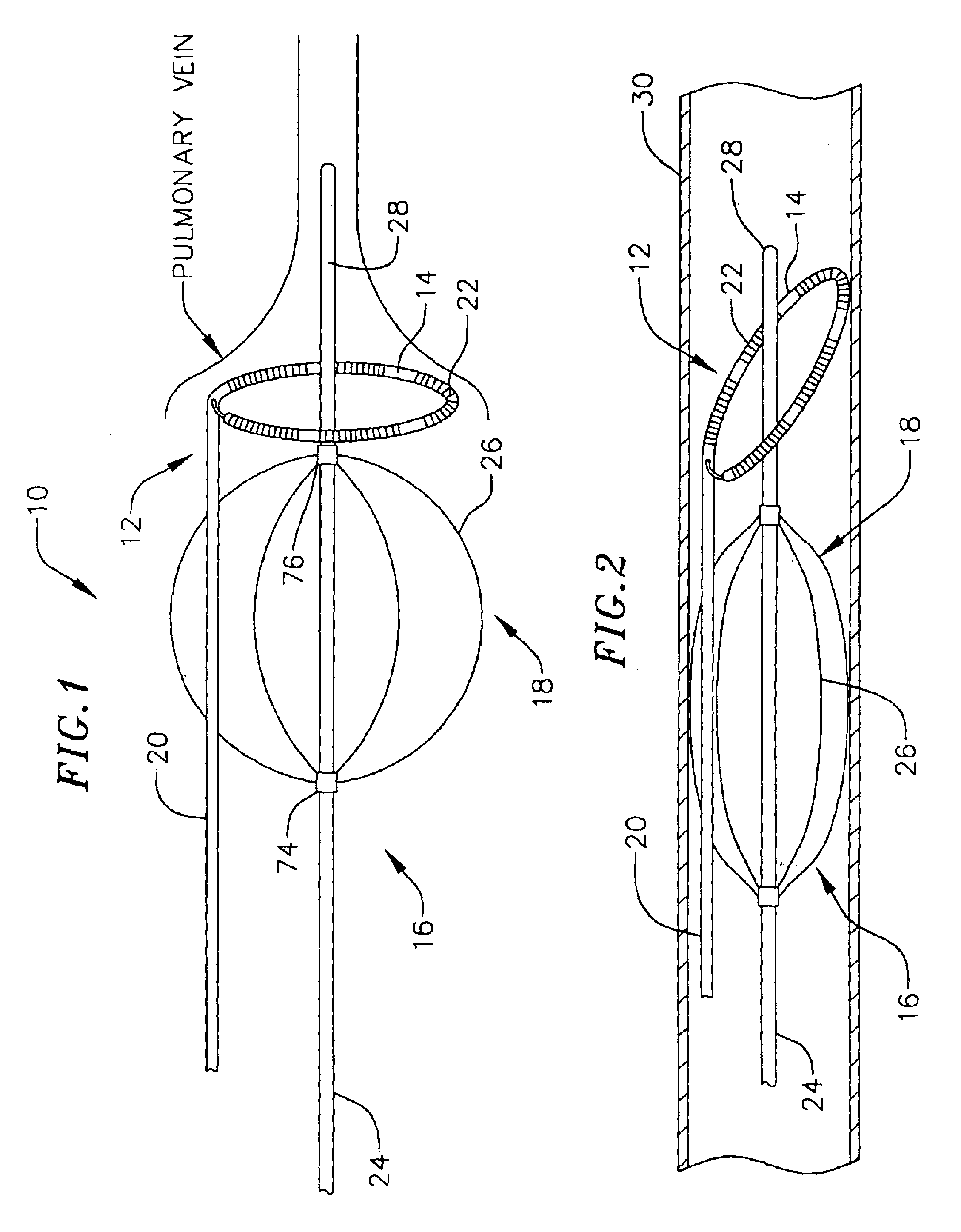

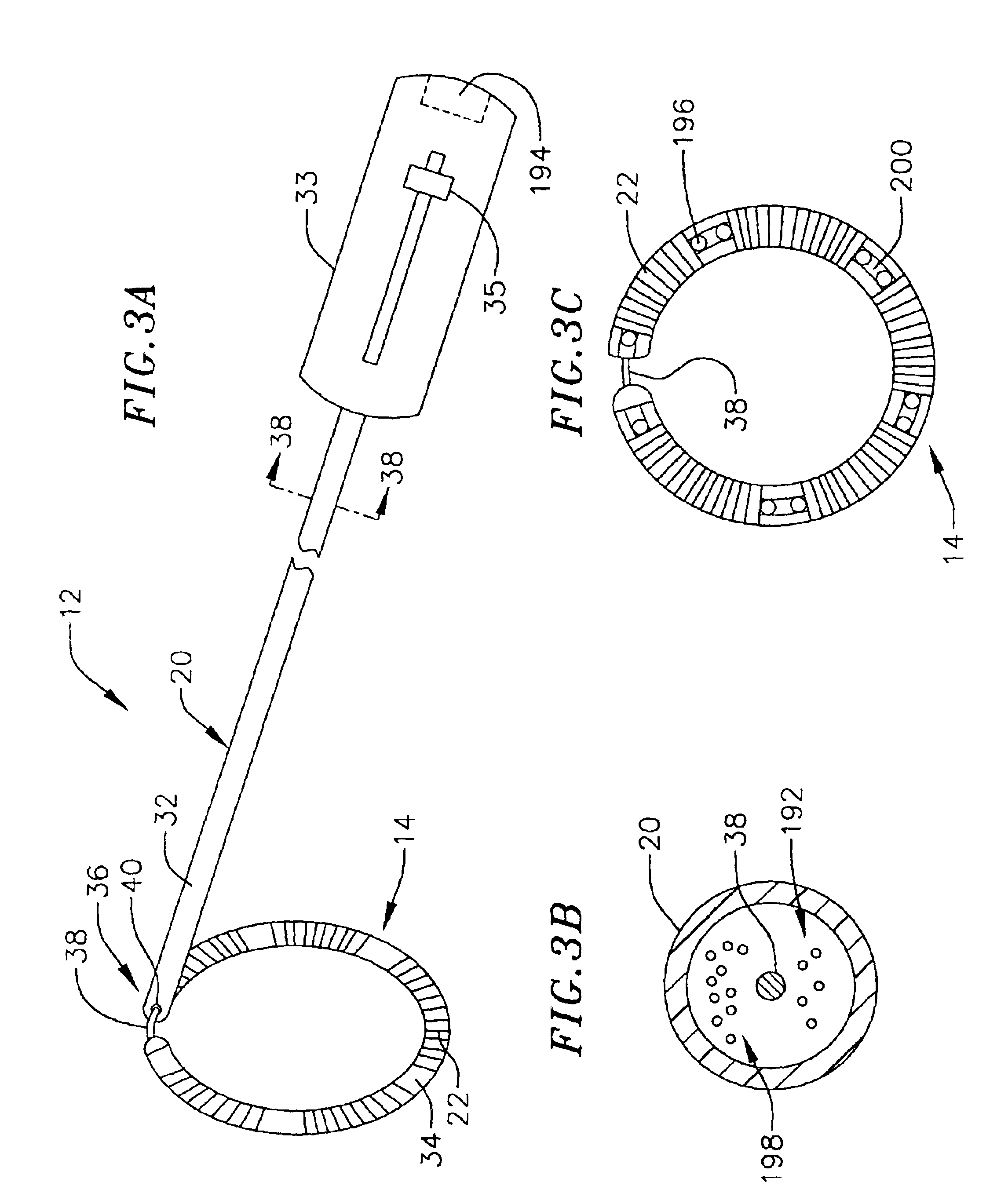

Loop structures for supporting diagnostic and therapeutic elements in contact with body tissue and expandable push devices for use with same

InactiveUS6908464B2Improve the level ofCreate efficientlyCatheterSurgical instruments for heatingBody tissueLesion

An apparatus that facilitates the creation of circumferential lesions in body tissue. The apparatus includes a first probe having a loop structure that supports electrodes or other operative elements against the body tissue and a second probe with an expandable push structure that may be used to urge the loop structure against body tissue.

Owner:BOSTON SCI SCIMED INC

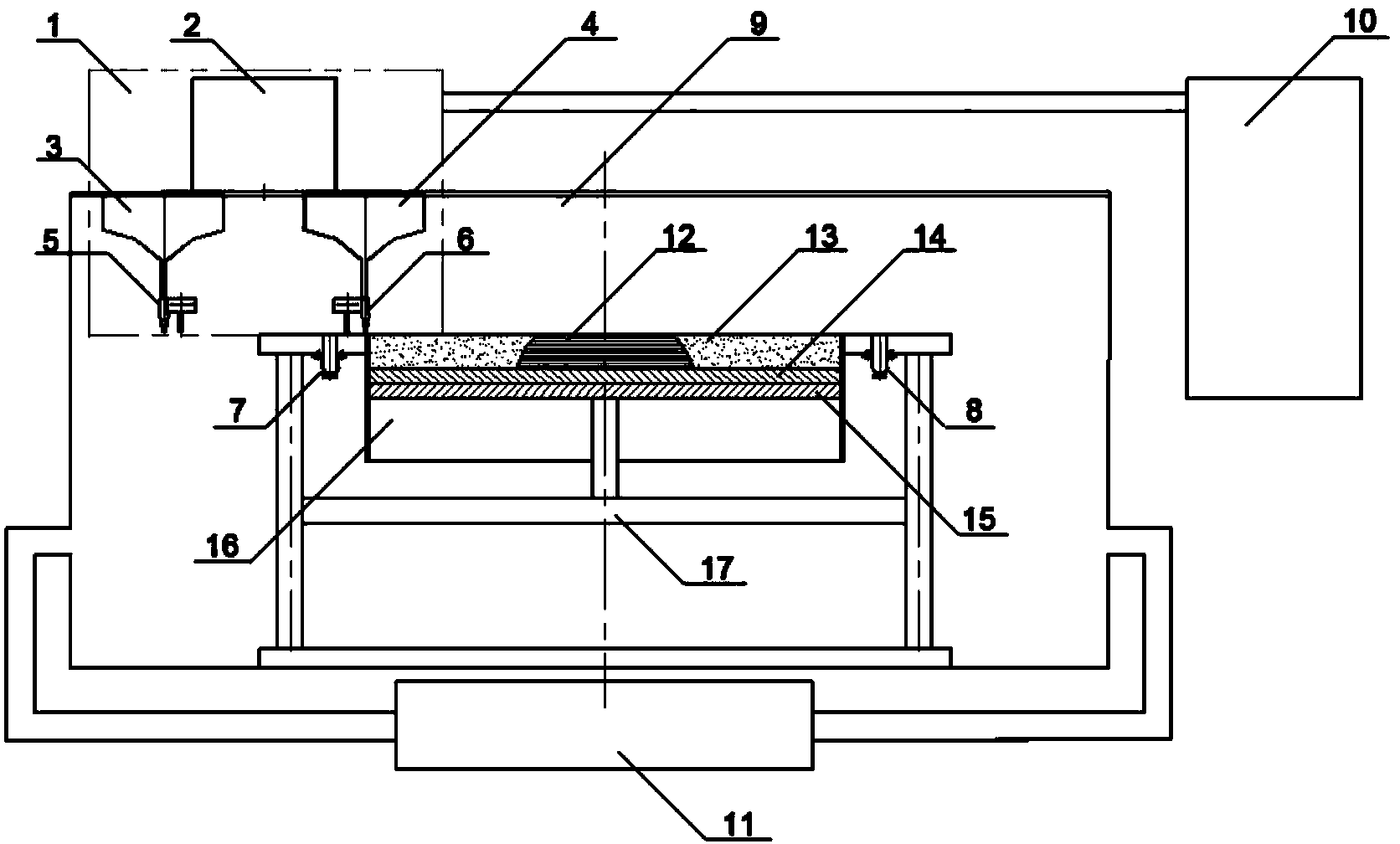

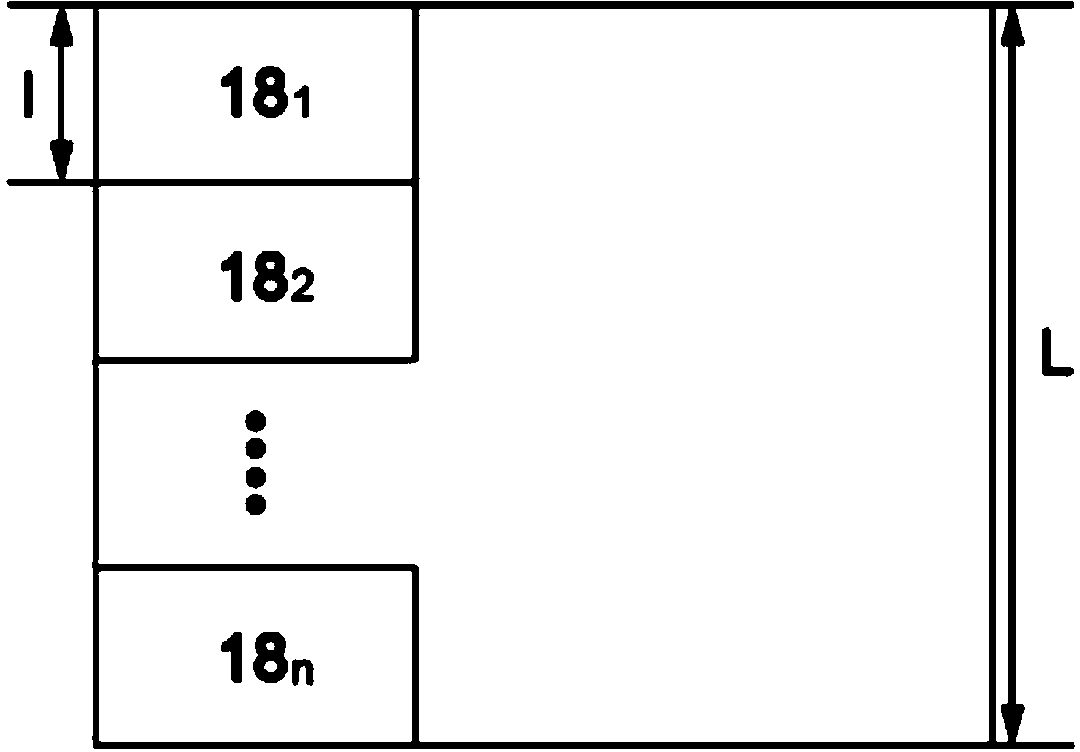

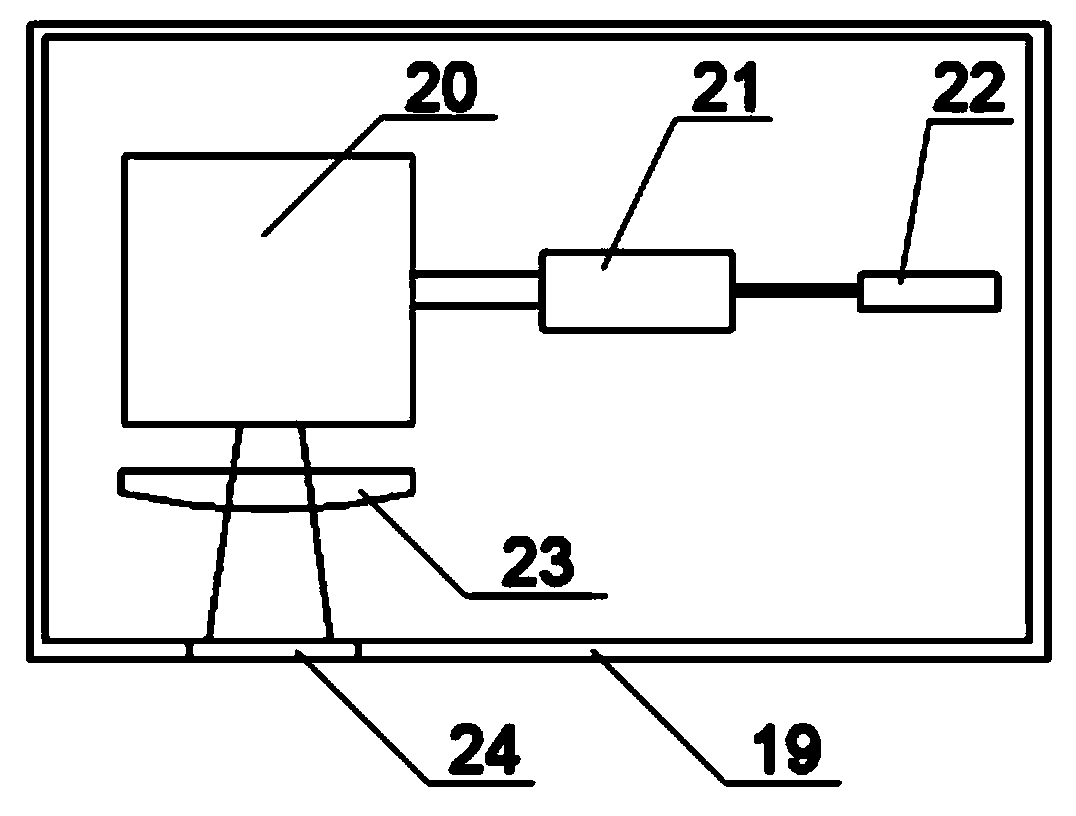

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

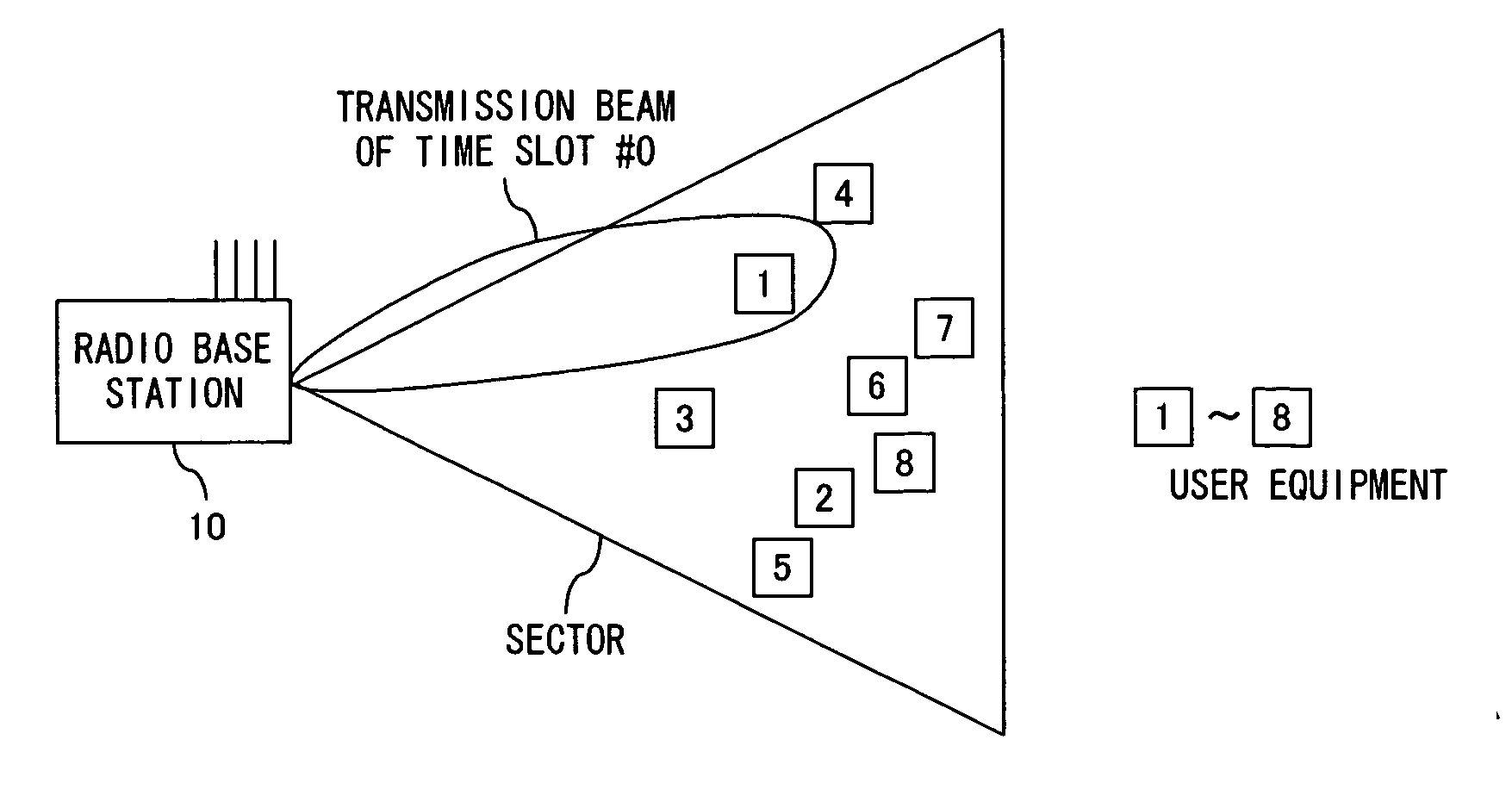

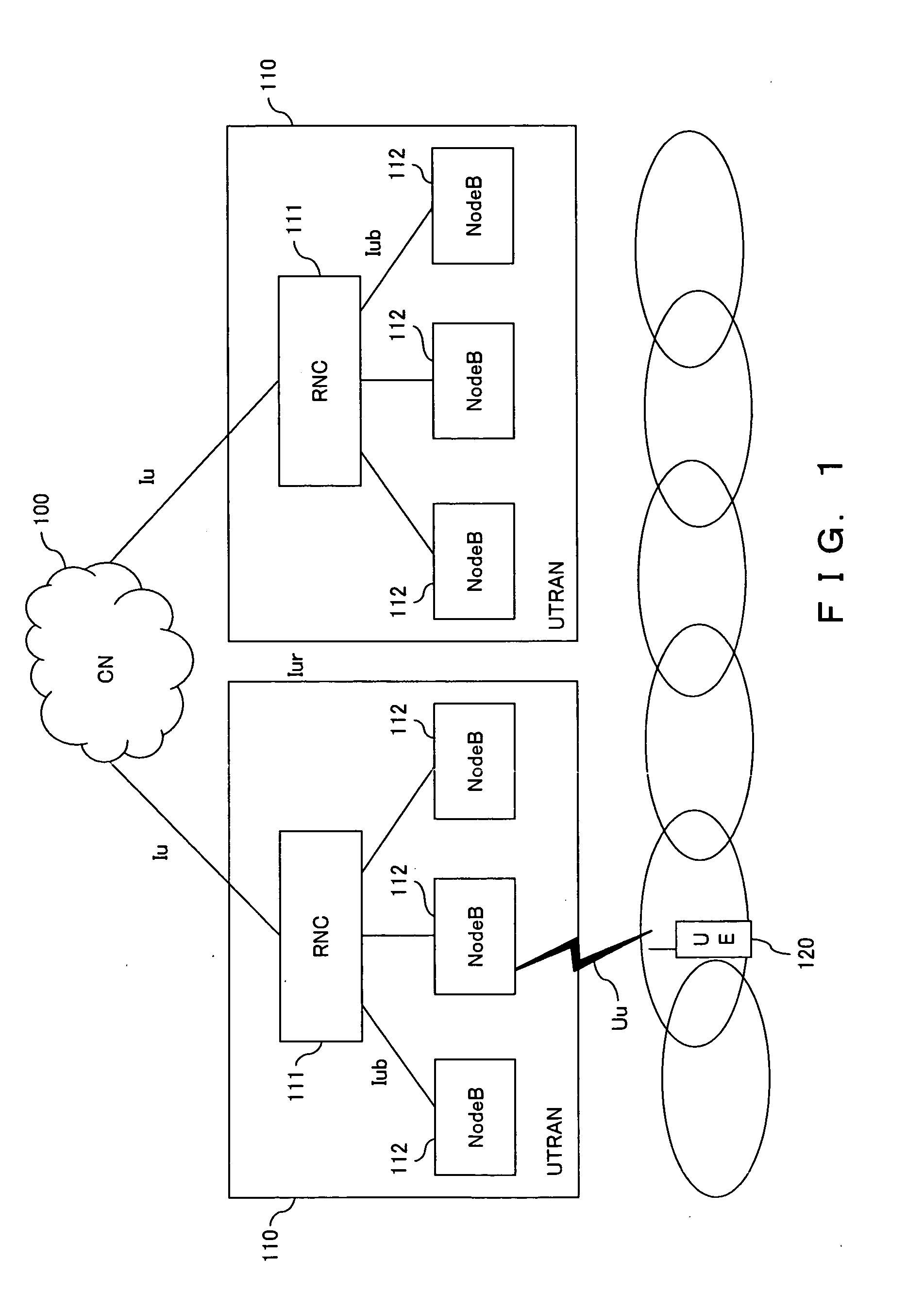

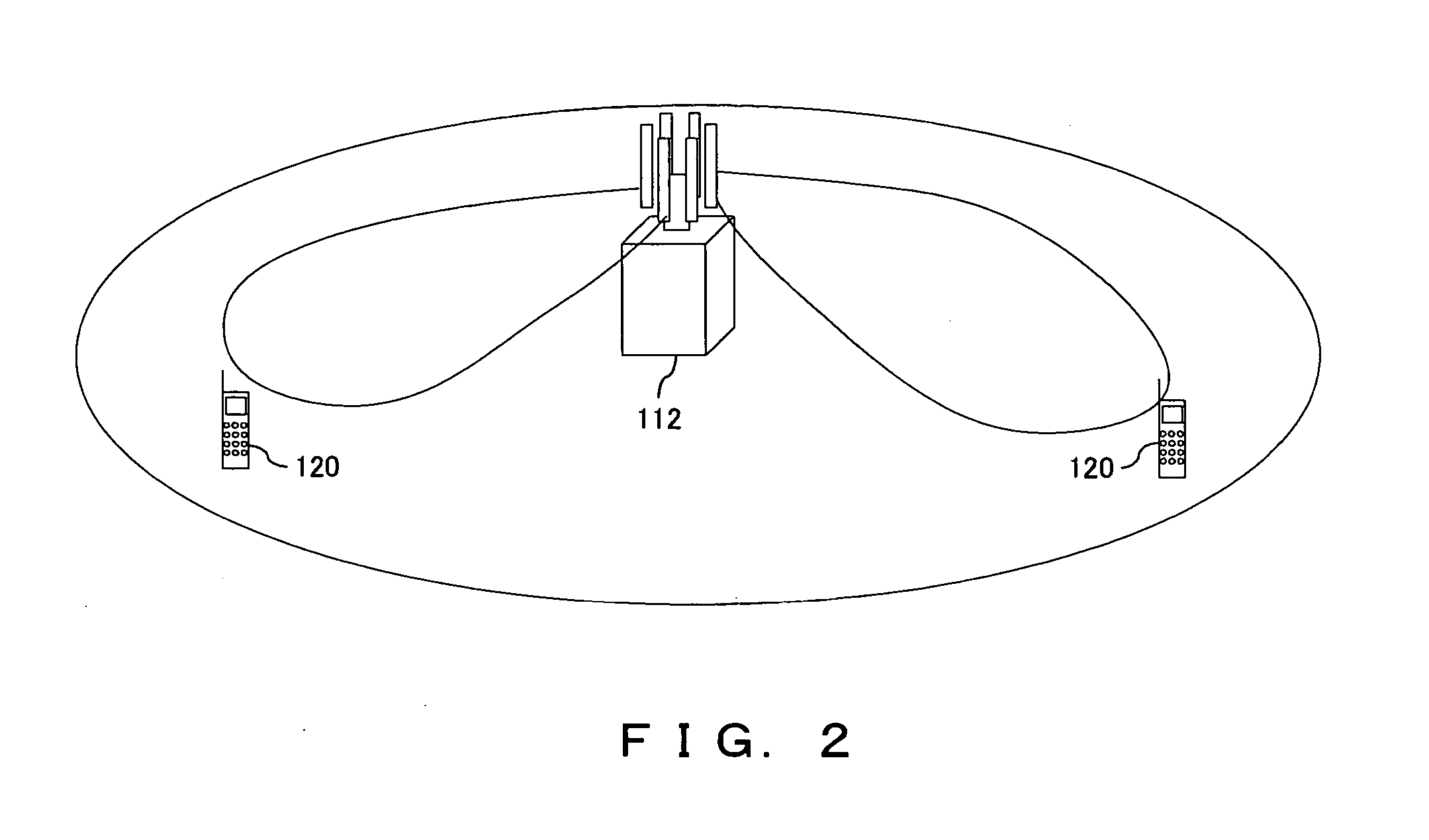

Radio base station apparatus and radio communication method

InactiveUS20050266799A1Fast formingSuppress interferenceSpatial transmit diversityCode division multiplexDirectivityRadio Base Station

Owner:FUJITSU LTD

Microfabricated elastomeric valve and pump systems

InactiveUS20080289710A1Increase speedSmall sizeButtonsServomotor componentsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

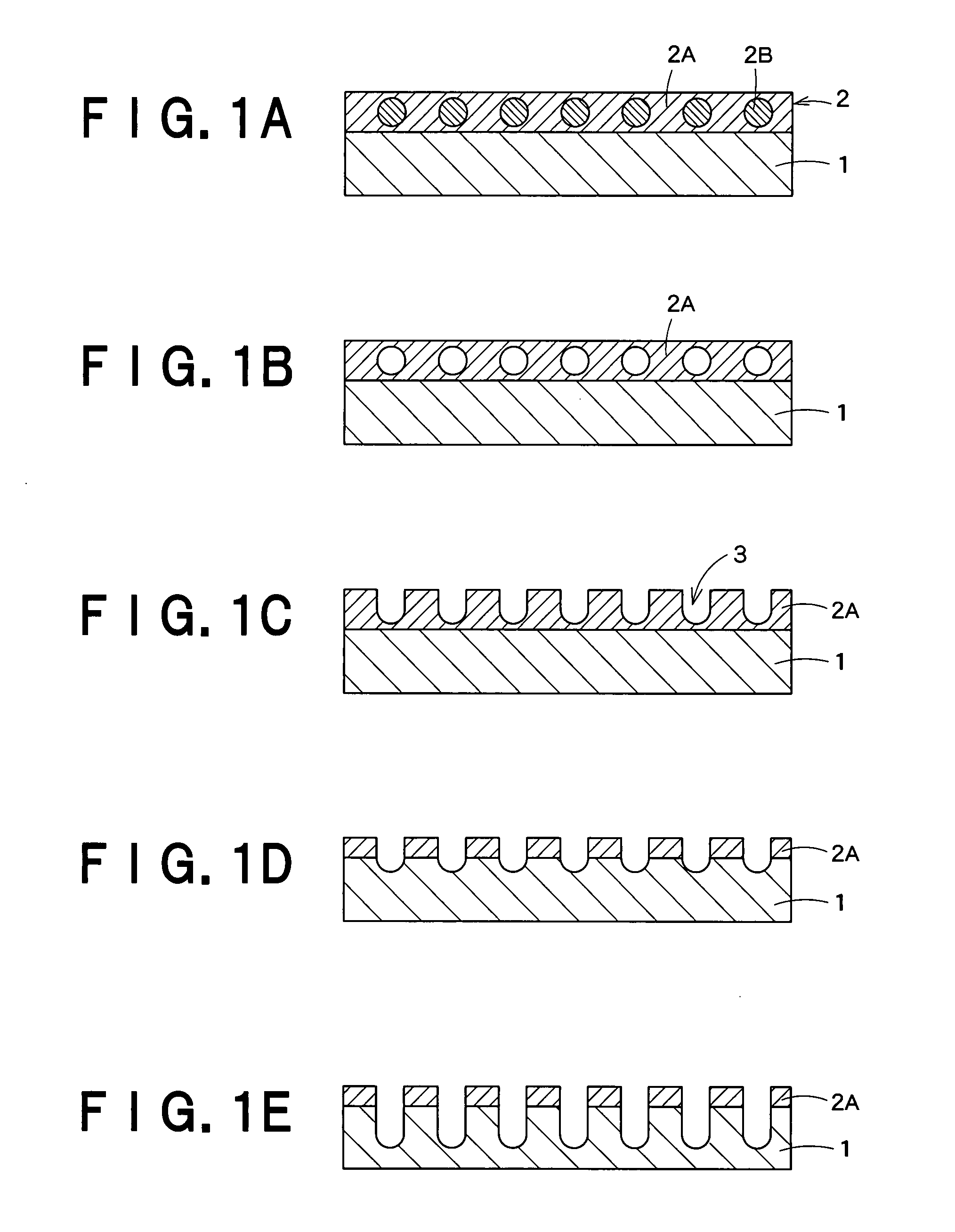

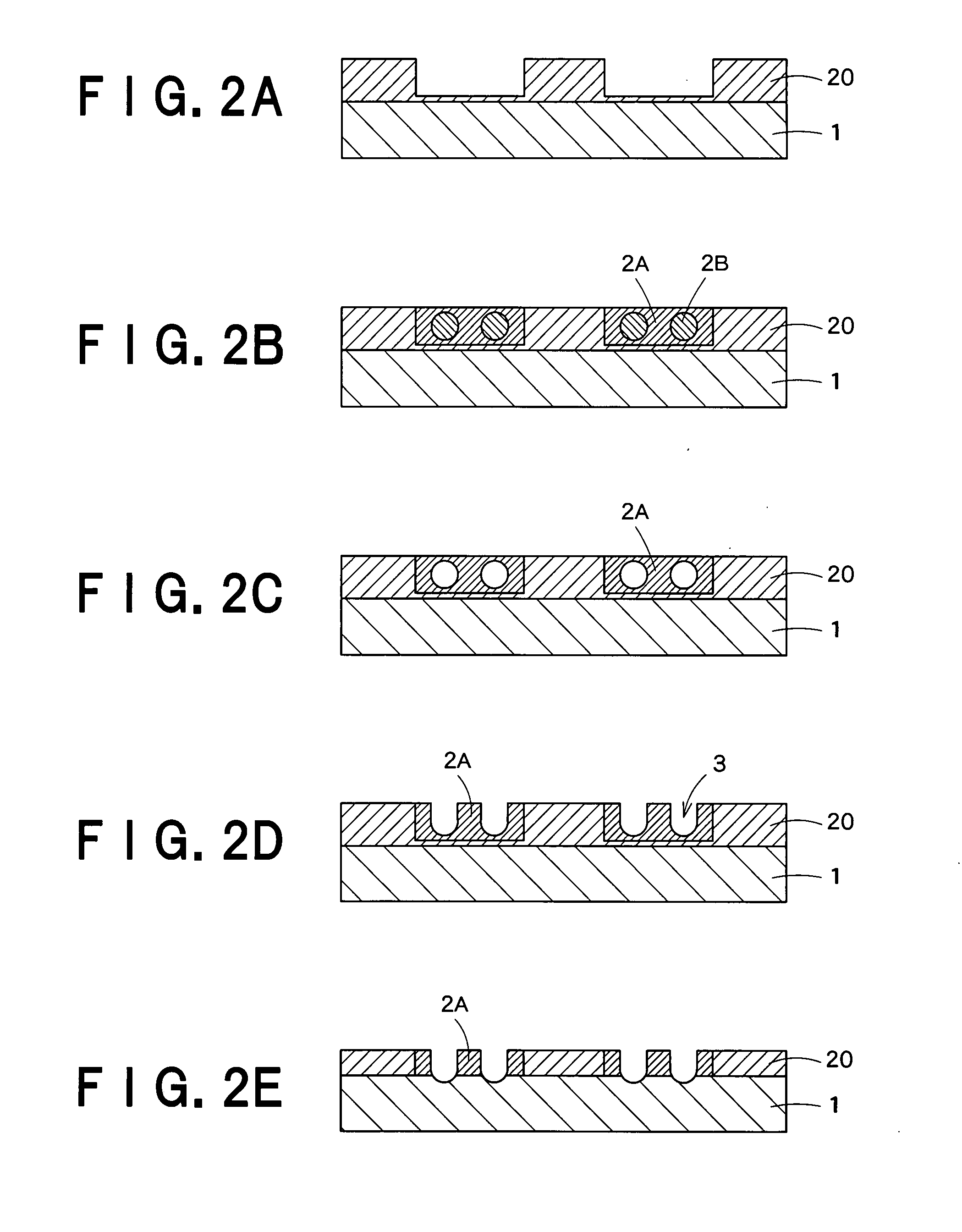

Method for pattern formation

InactiveUS20080041818A1Satisfactory etching resistanceHigh aspect ratioDecorative surface effectsNanoinformaticsOxygen plasmaSolvent

There is provided a method for pattern formation, including a step of coating a composition comprising a block copolymer, a silicon compound, and a solvent for dissolving these components onto an object to form a layer of the composition on the object, a step of subjecting the layer of the composition to self-organization of the block copolymer to cause phase separation into a first phase, in which the silicon compound is localized, having higher etching resistance by heat treatment or / and oxygen plasma treatment, and a second phase comprising a polymer phase and having lower etching resistance by heat treatment or / and oxygen plasma treatment, and thereby forming a pattern layer with a fine pattern, and a step of etching the object using as a mask the thus formed pattern layer.

Owner:KK TOSHIBA

Microfabricated elastomeric valve and pump systems

InactiveUS20050166980A1Fast formingEasy to manufactureFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

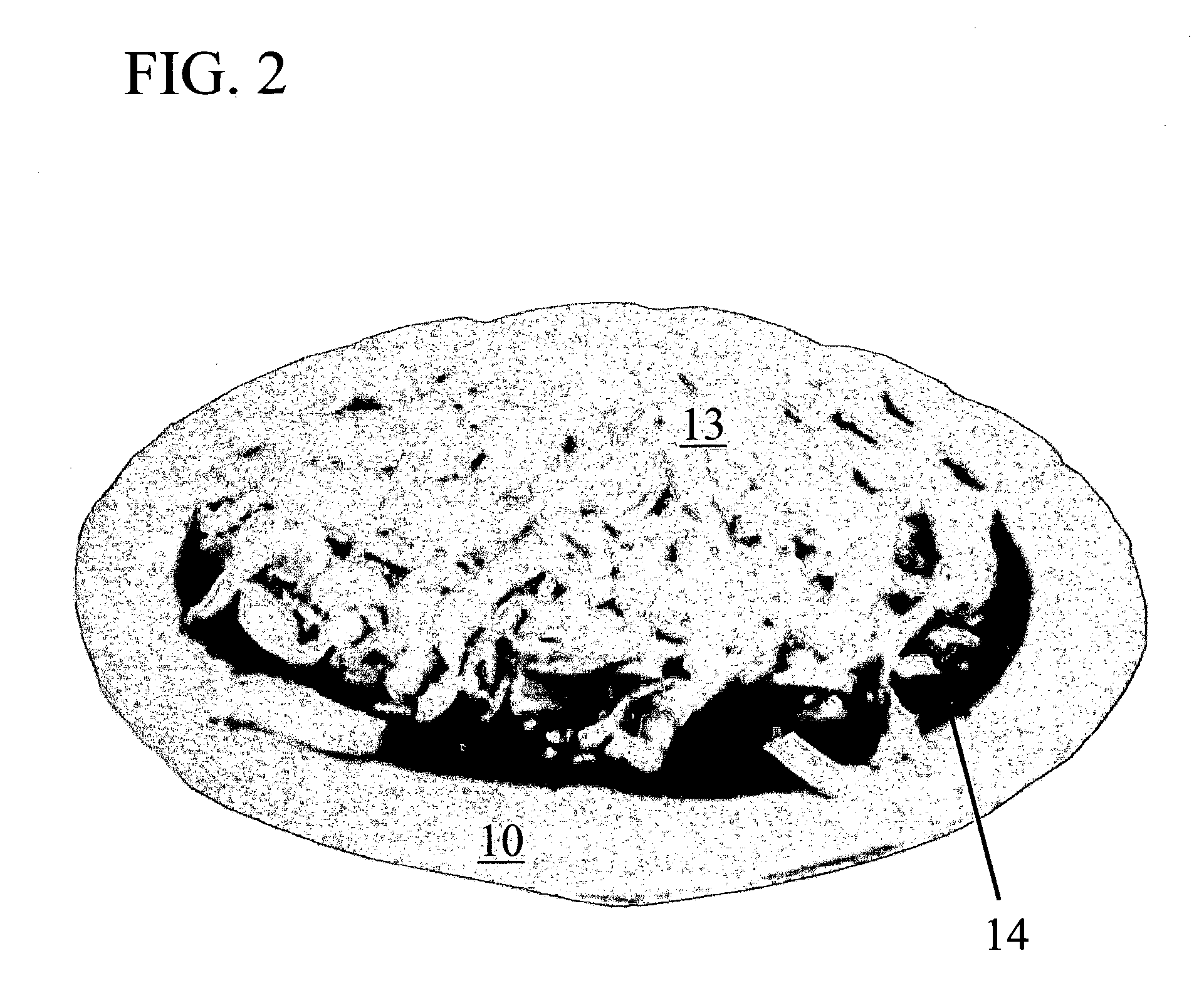

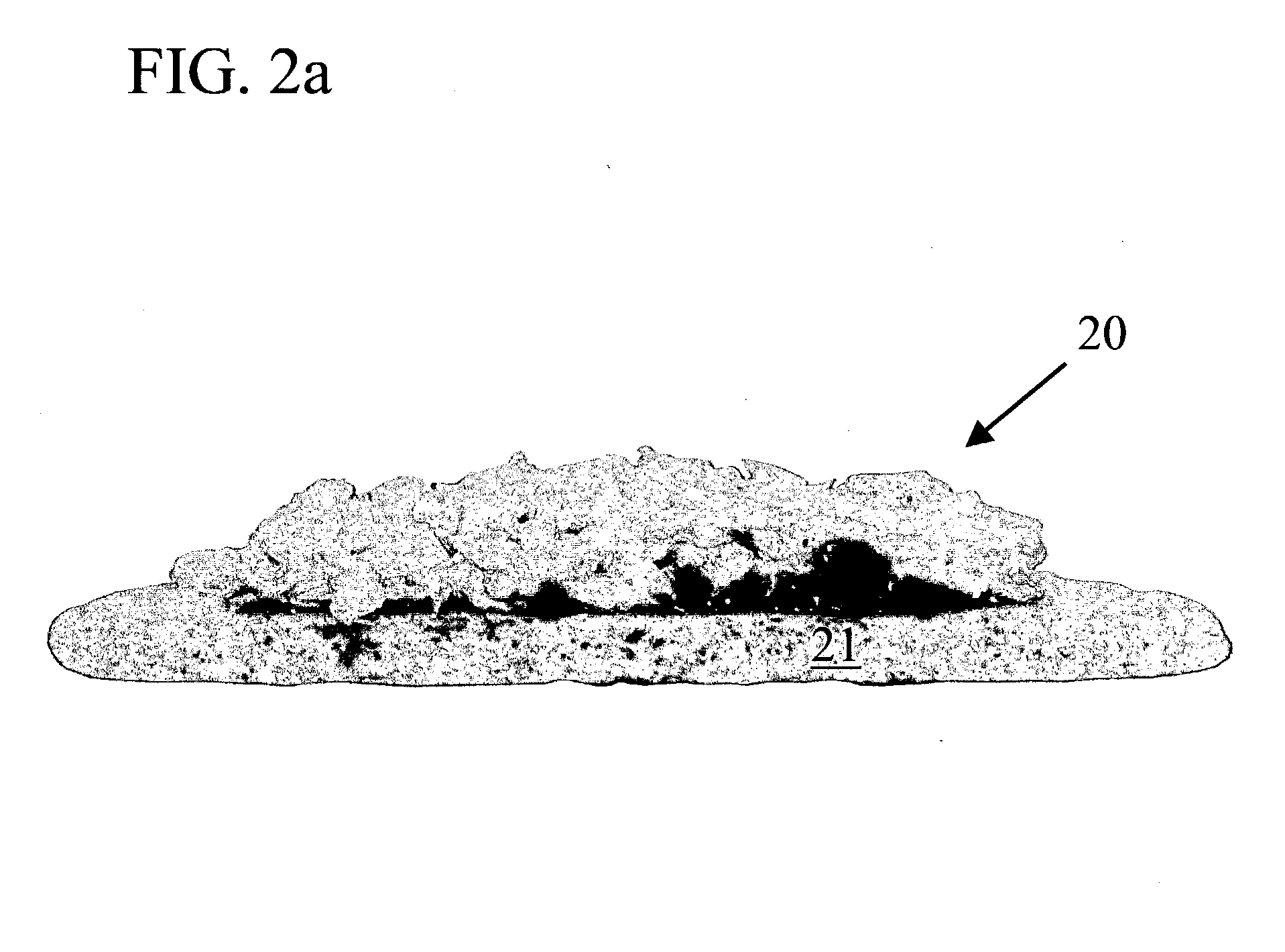

Dough that browns, raises and forms an oven tender bread crust under the influence of microwave incident energy

InactiveUS20040213883A1Increase moisture contentSoft bready characterReady-for-oven doughsBakery productsIncident energyConvection

A dough that can bake to form a bread product having a homebaked taste, aroma, freshness, attractive browned character and pleasing crispness of a homemade bread. The product can be obtained by baking the dough in a microwave oven without the time, bother and mess of preparing a leavened dough and baking the dough in a thermal or convection oven. The product can include bread products including breads rolls, etc. The invention relates to a crust that can be combined with a topping or filling to form a baked product. Such products include such items as a pizza, meat pie, fruit pie etc. suitable for baking in a microwave oven. The crust has a unique formulation that ensures a high quality product. Further, the unique formulation provides a crust that forms a well-raised, attractive browned crust even in combination with substantial quantities of fillings having large amounts of water and other components. The crust, combined with an appropriately sized susceptor layer, can be heated in a microwave to result in a crust containing food that is substantially equivalent to freshly made crusts.

Owner:SCHWANS GLOBAL SUPPLY CHAIN

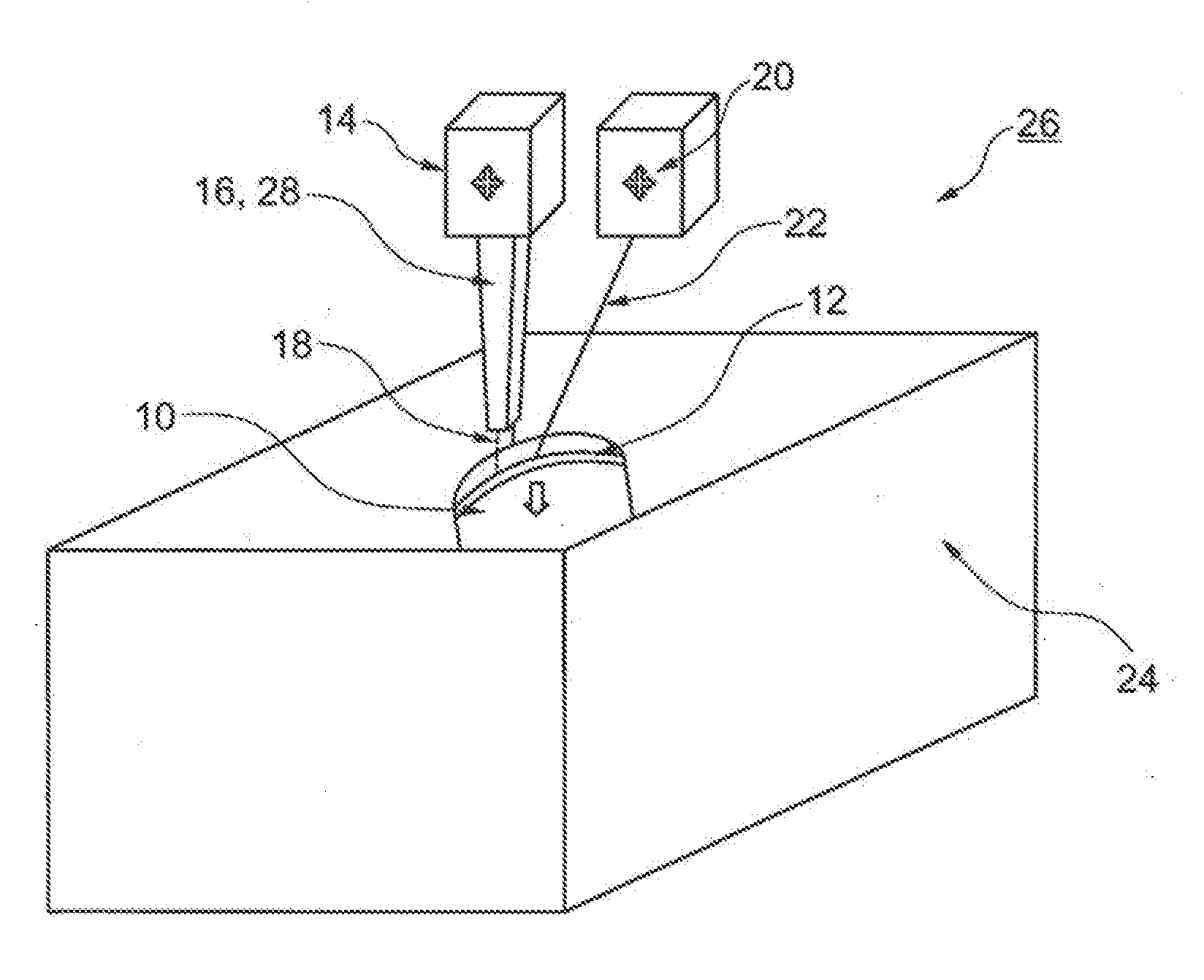

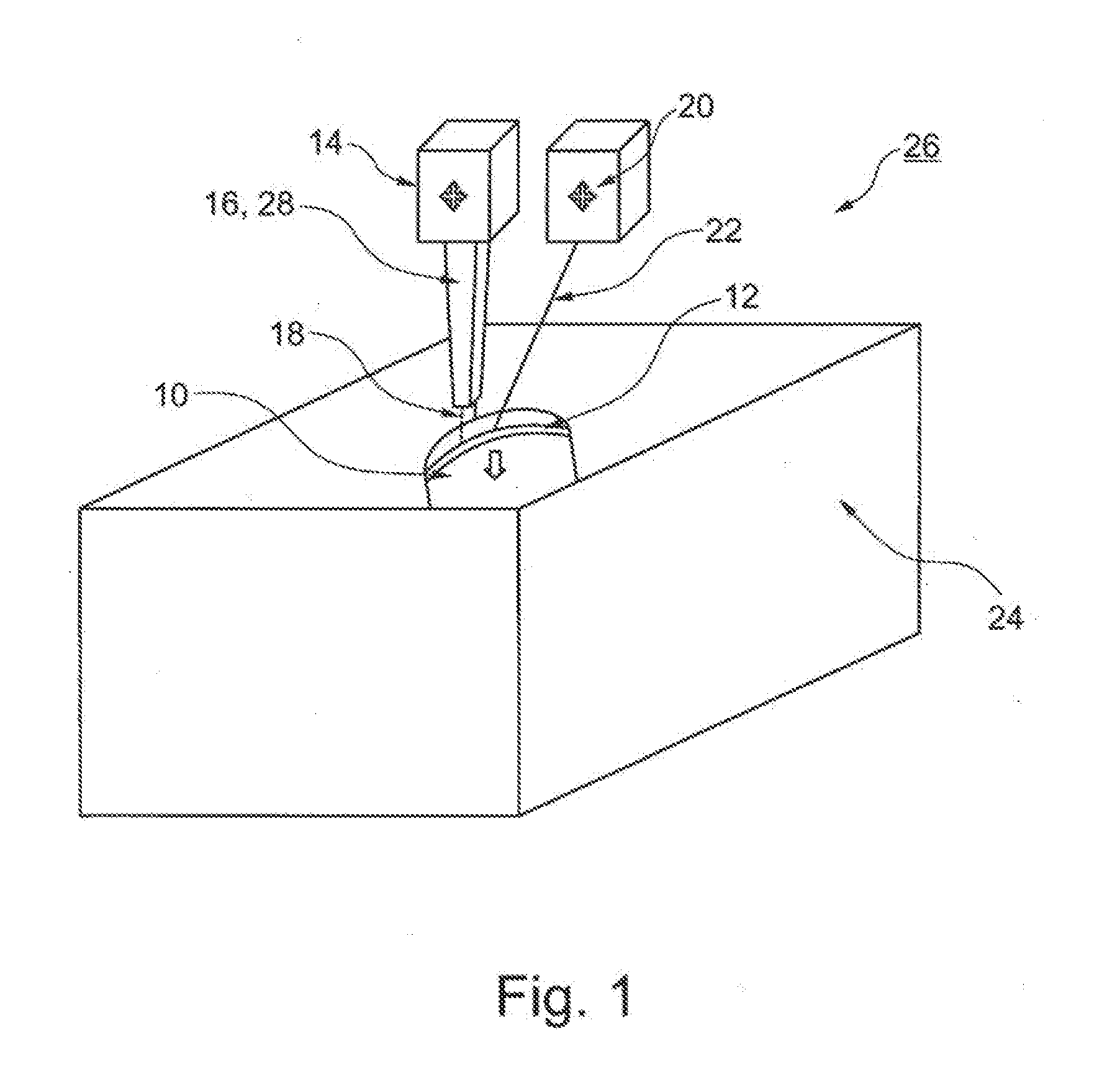

Method and device for producing a component of a turbomachine

InactiveUS20120217226A1High strengthAvoid poor resultsTurbinesAdditive manufacturing apparatusEngineeringTurbine

The invention relates to a method for producing a component (10) of a turbomachine, especially a structural part of a turbine or a compressor, the method being a generative production method for the layer-by-layer buildup of the component (10). After production of one or more successive component layers pressure is applied to at least sections of the surface of the most recently produced component layer (12), the pressure being induced by laser or plasma. The invention further relates to a device for producing a component (10) of a turbomachine, especially a structural part of a turbine or a compressor, the device (26) comprising at least one powder feed (28) for the deposition of at least one powder component material (16) onto a component platform, at least one radiation source (14) for a local layer-by-layer fusion or sintering of the component material (16) and at least one laser radiation source (20) or at least one plasma impulse source.

Owner:MTU AERO ENGINES GMBH

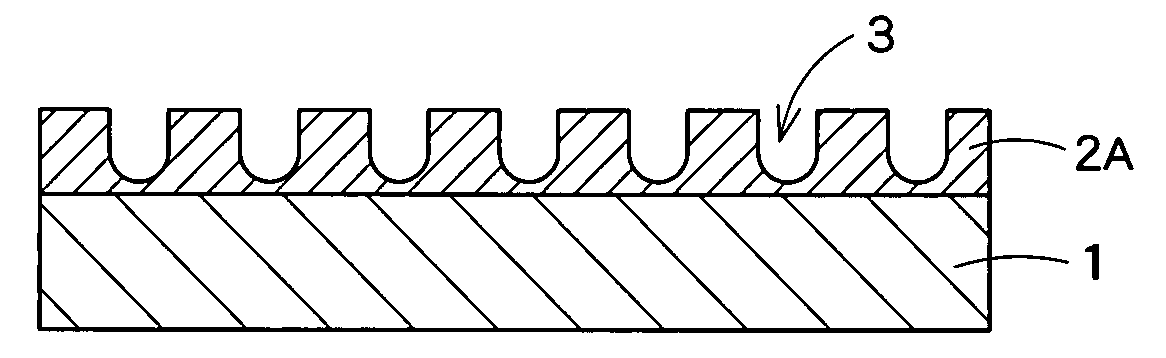

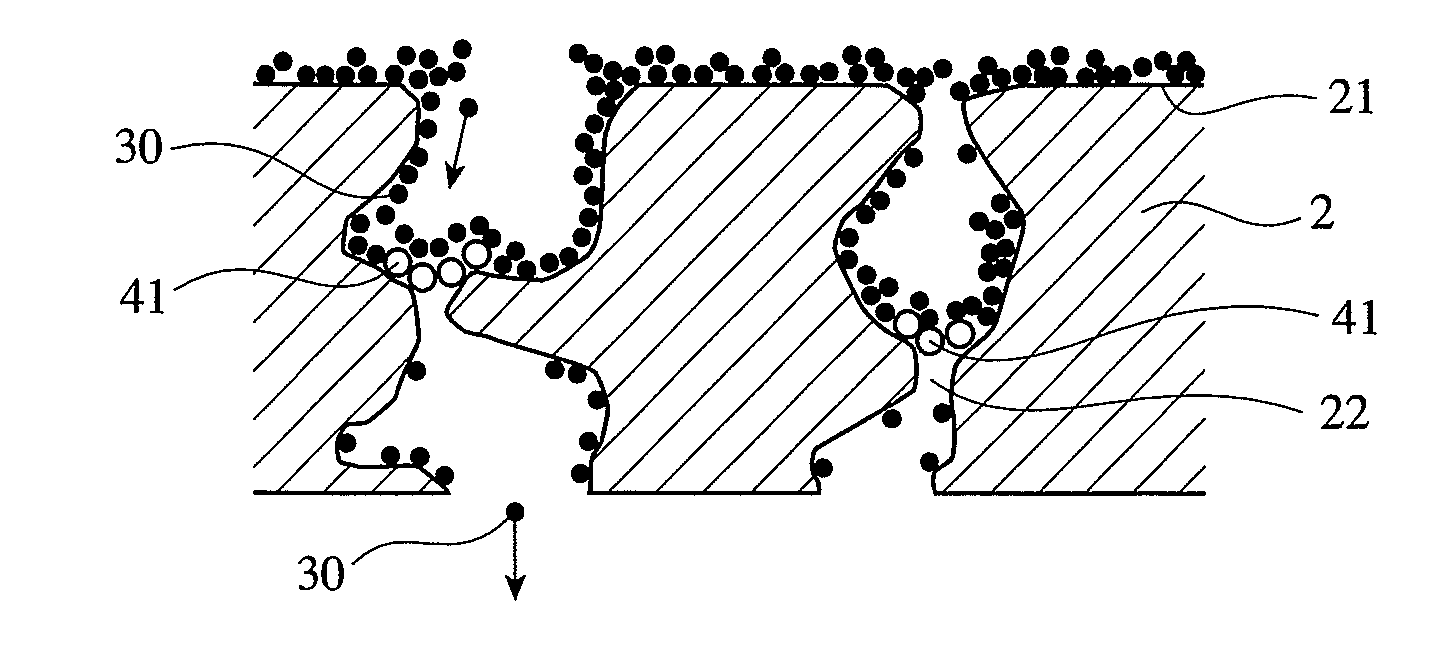

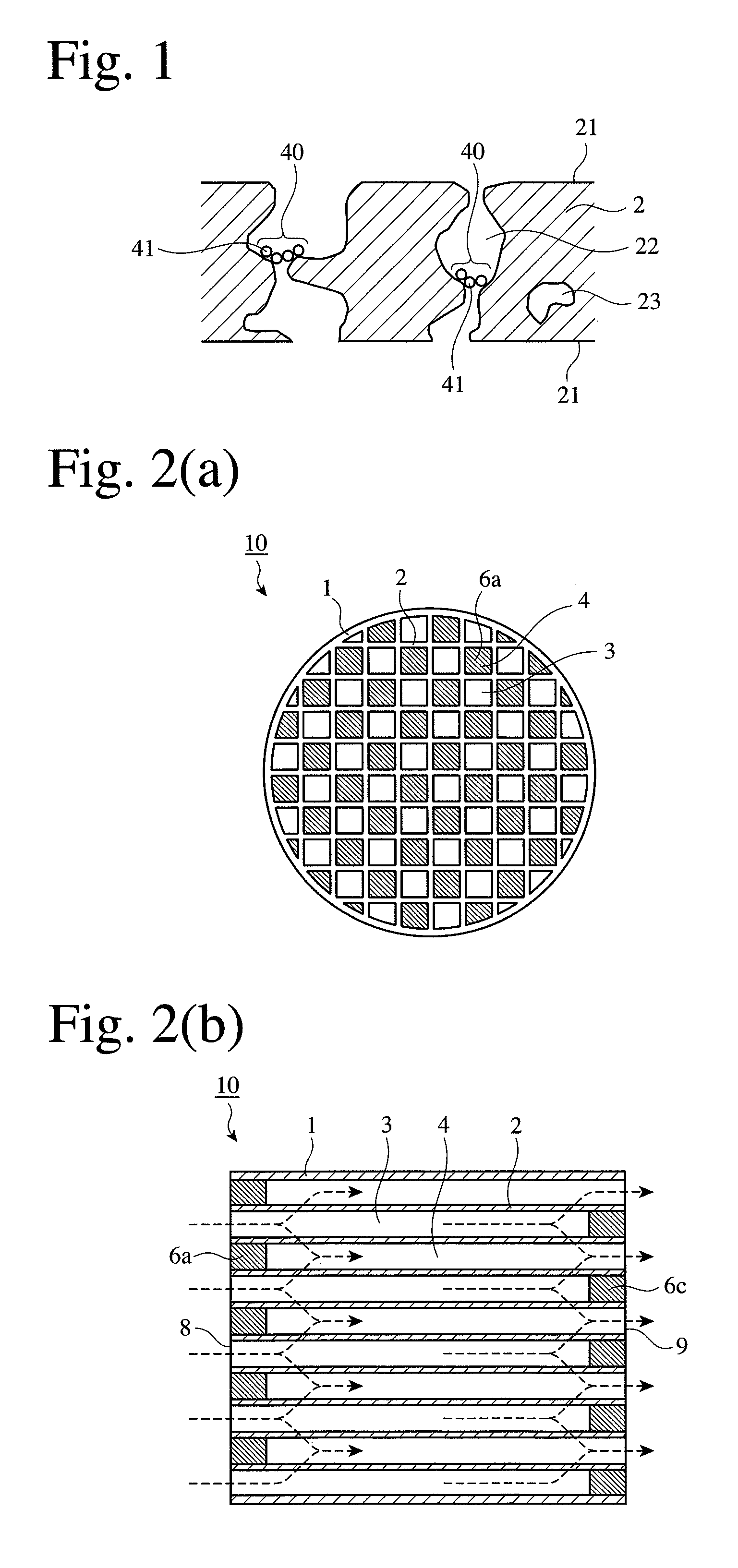

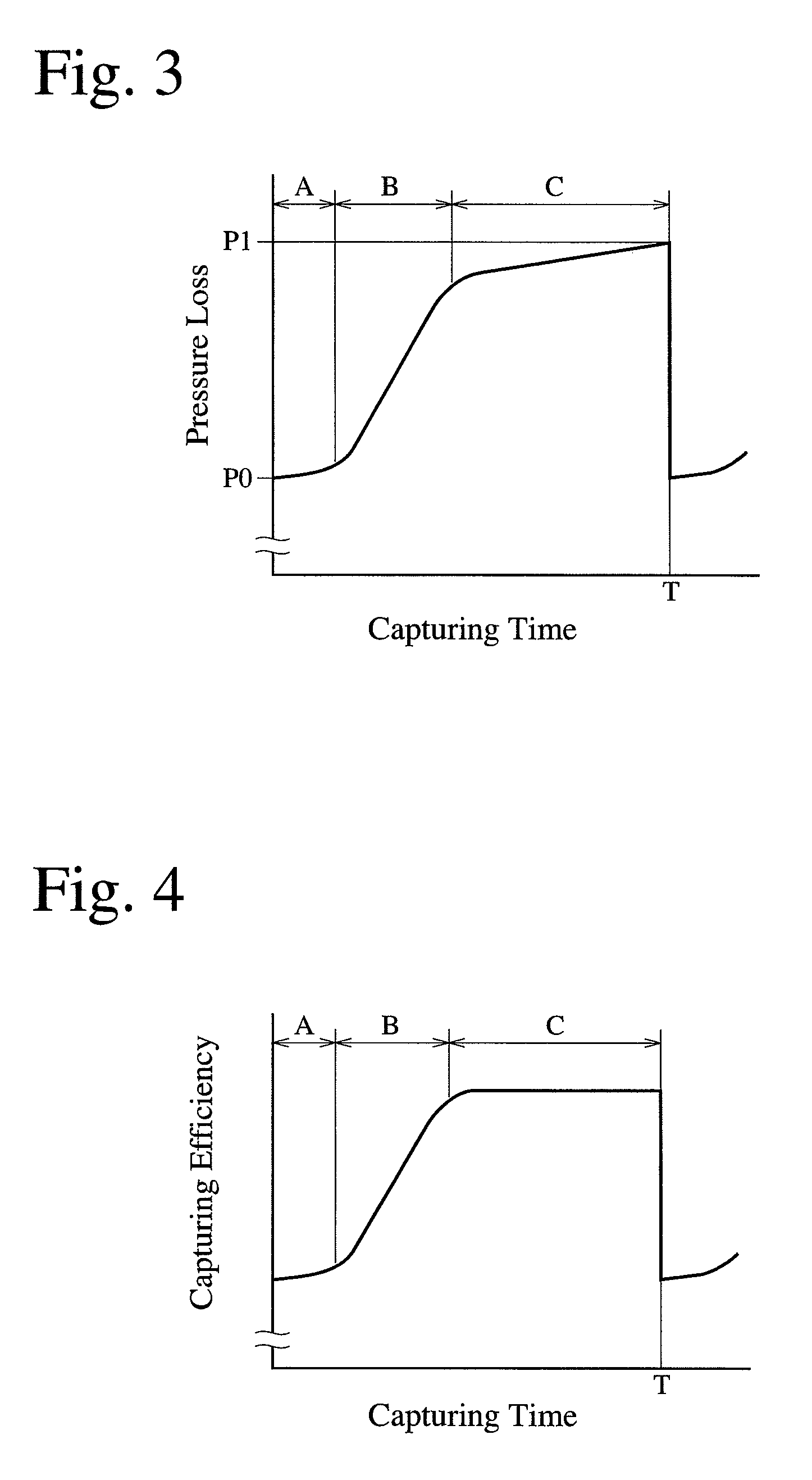

Ceramic honeycomb filter and its production method

ActiveUS8388721B2High PM-capturing efficiencyEasy to optimizeCombination devicesLiquid surface applicatorsCross-linkHoneycomb structure

A ceramic honeycomb filter comprising a honeycomb structure having large numbers of flow paths partitioned by porous cell walls, and plugs alternately formed in the flow paths on the exhaust-gas-inlet and outlet sides, the area ratio of pores opening at the cell wall surfaces being 20% or more, porous, cross-linked structures being formed by heat-resistant particles introduced together with a gas into penetrating holes constituted by communicating pores in the cell walls, such that they clog the penetrating holes, and the cross-linked structures being formed more on the exhaust-gas-outlet side of the ceramic honeycomb filter than on the exhaust-gas-inlet side.

Owner:HITACHI METALS LTD

Microfracture instrument

ActiveUS8852201B2Less timeQuick placementEndoscopic cutting instrumentsProsthesisEngineeringActuator

A bone drill that includes a shaft with a flexible portion having a proximal end and a distal end and a drill tip coupled to the distal end of the shaft. The bone drill also includes a cannulated sheath with a proximal end and a distal end, the sheath housing a portion of the shaft and having a curved portion at the distal end. The drill tip may also be housed within the curved portion of the sheath. The bone drill may also include a hub with an actuator mechanism, the hub being coupled to the sheath, wherein the actuator mechanism retracts the sheath to cause the drill tip to extend beyond the distal end of the sheath.

Owner:ARTHREX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com